Patents

Literature

80 results about "Kevlar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kevlar is a heat-resistant and strong synthetic fiber, related to other aramids such as Nomex and Technora. Developed by Stephanie Kwolek at DuPont in 1965, this high-strength material was first commercially used in the early 1970s as a replacement for steel in racing tires. Typically it is spun into ropes or fabric sheets that can be used as such or as an ingredient in composite material components.

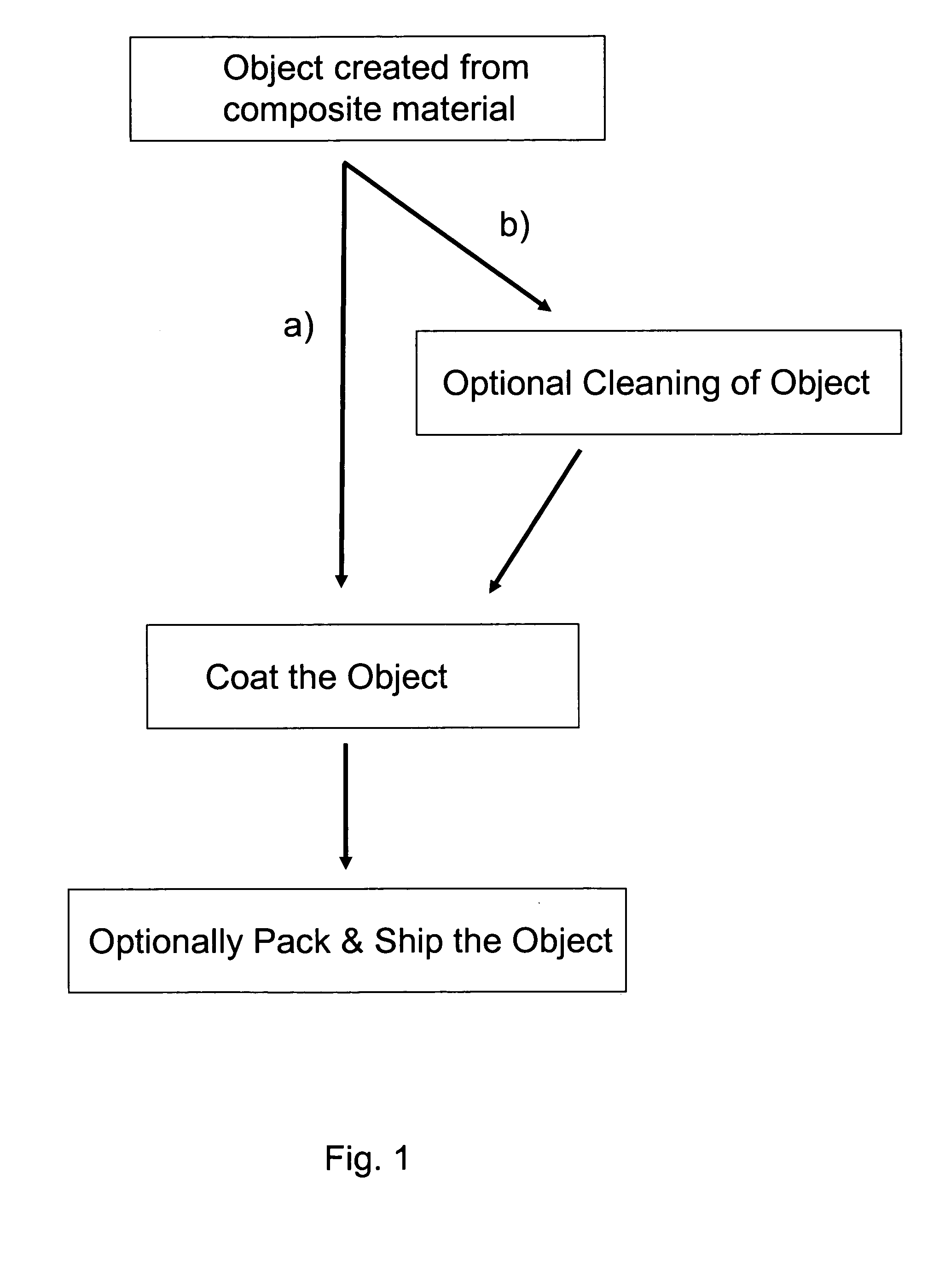

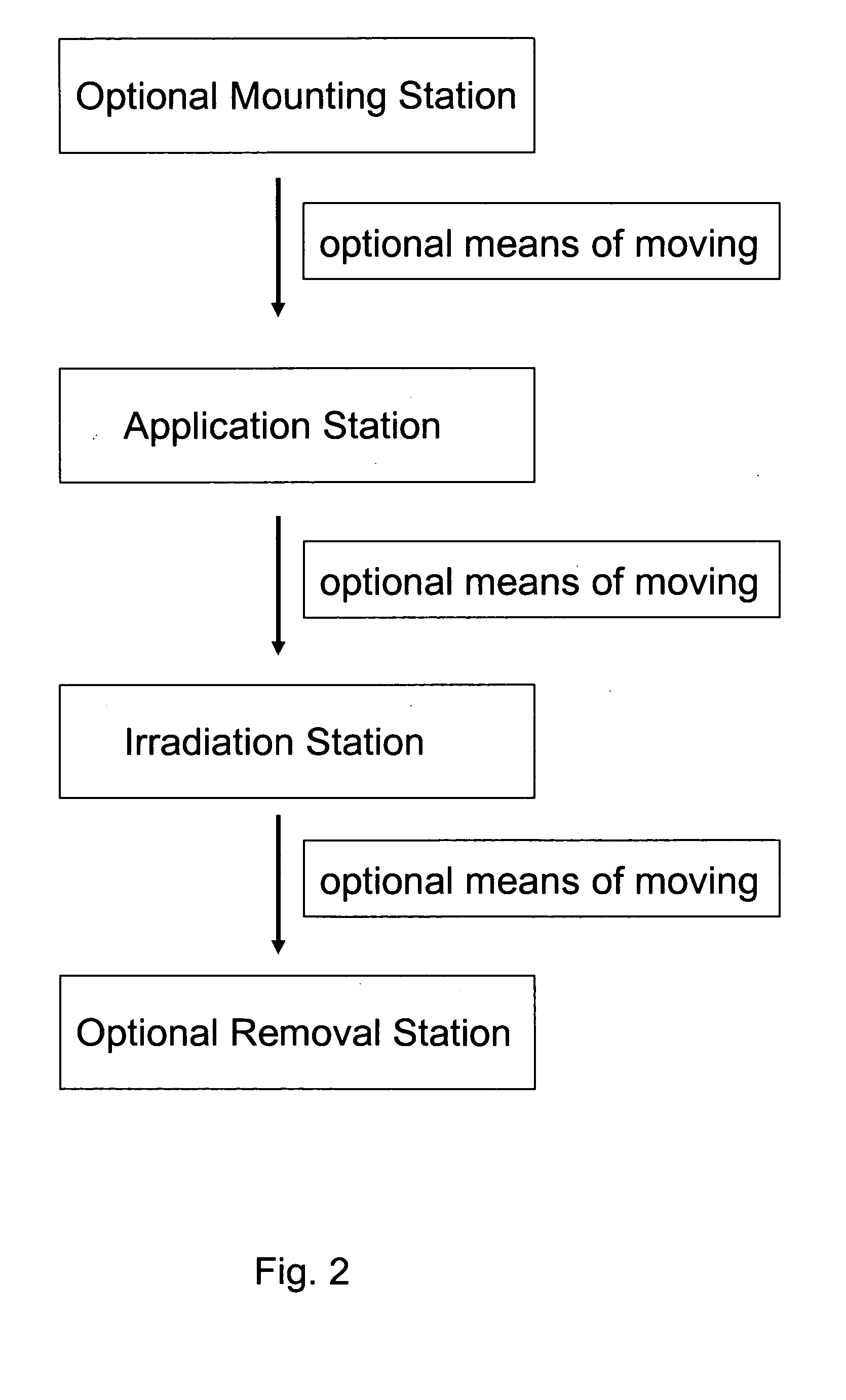

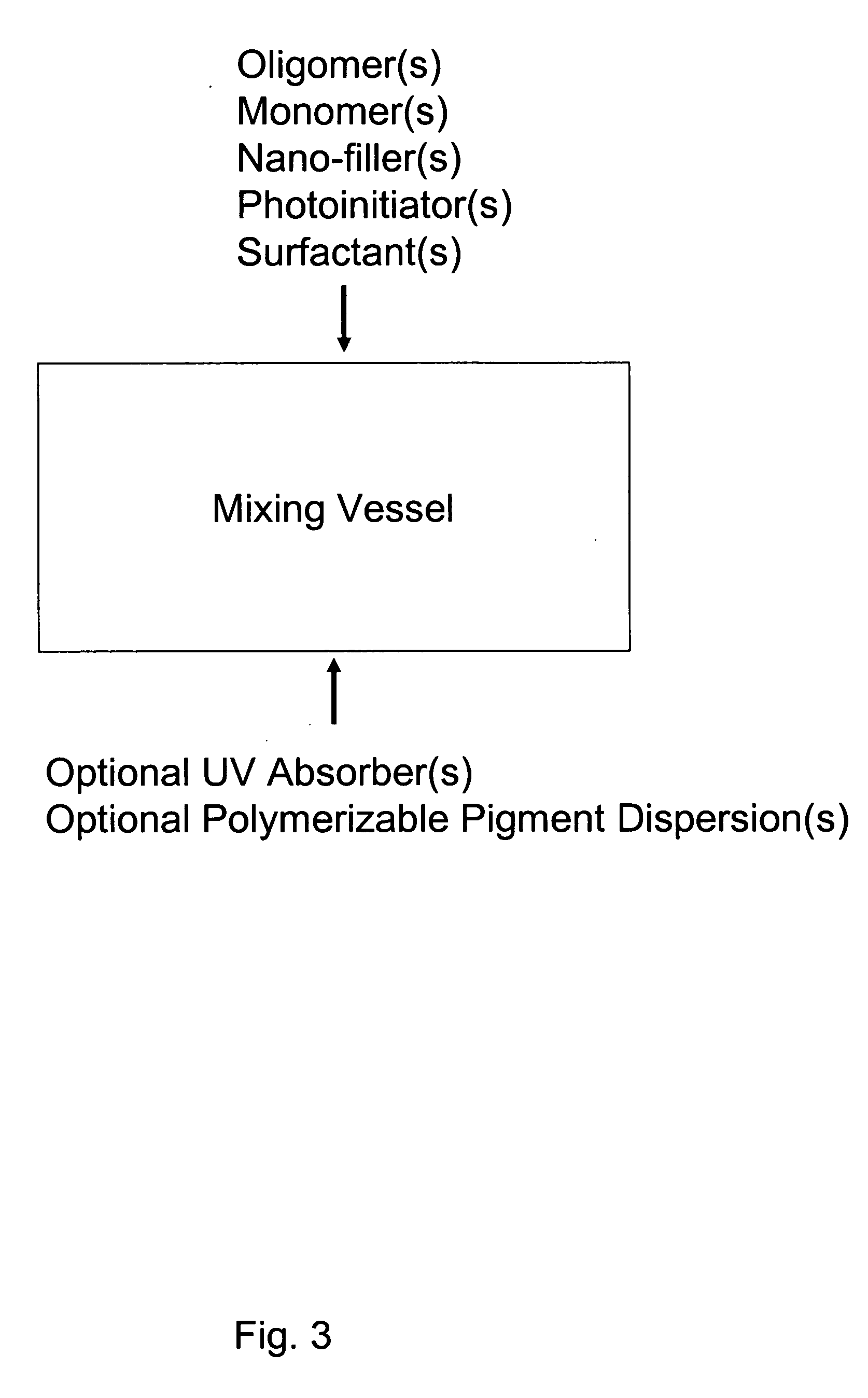

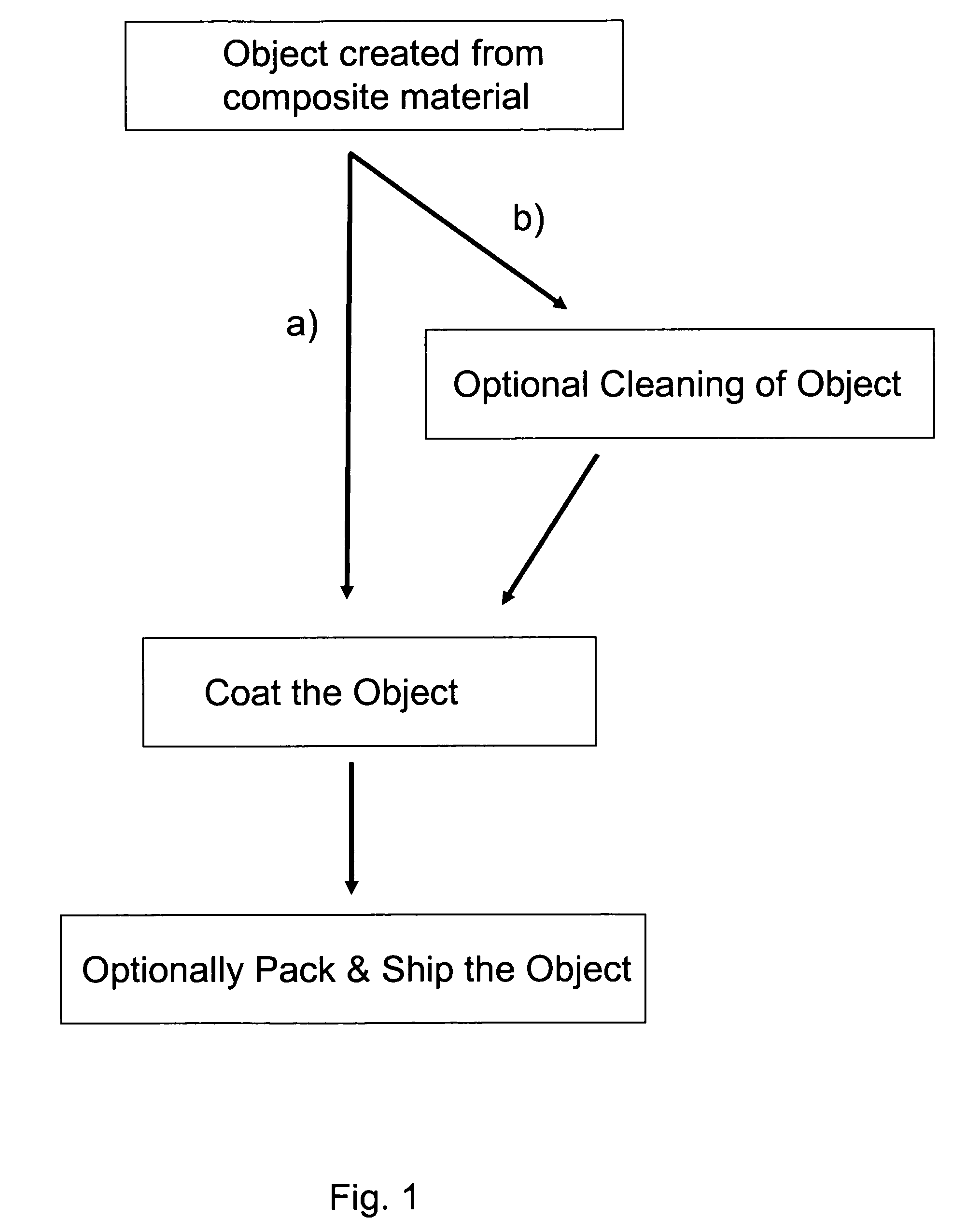

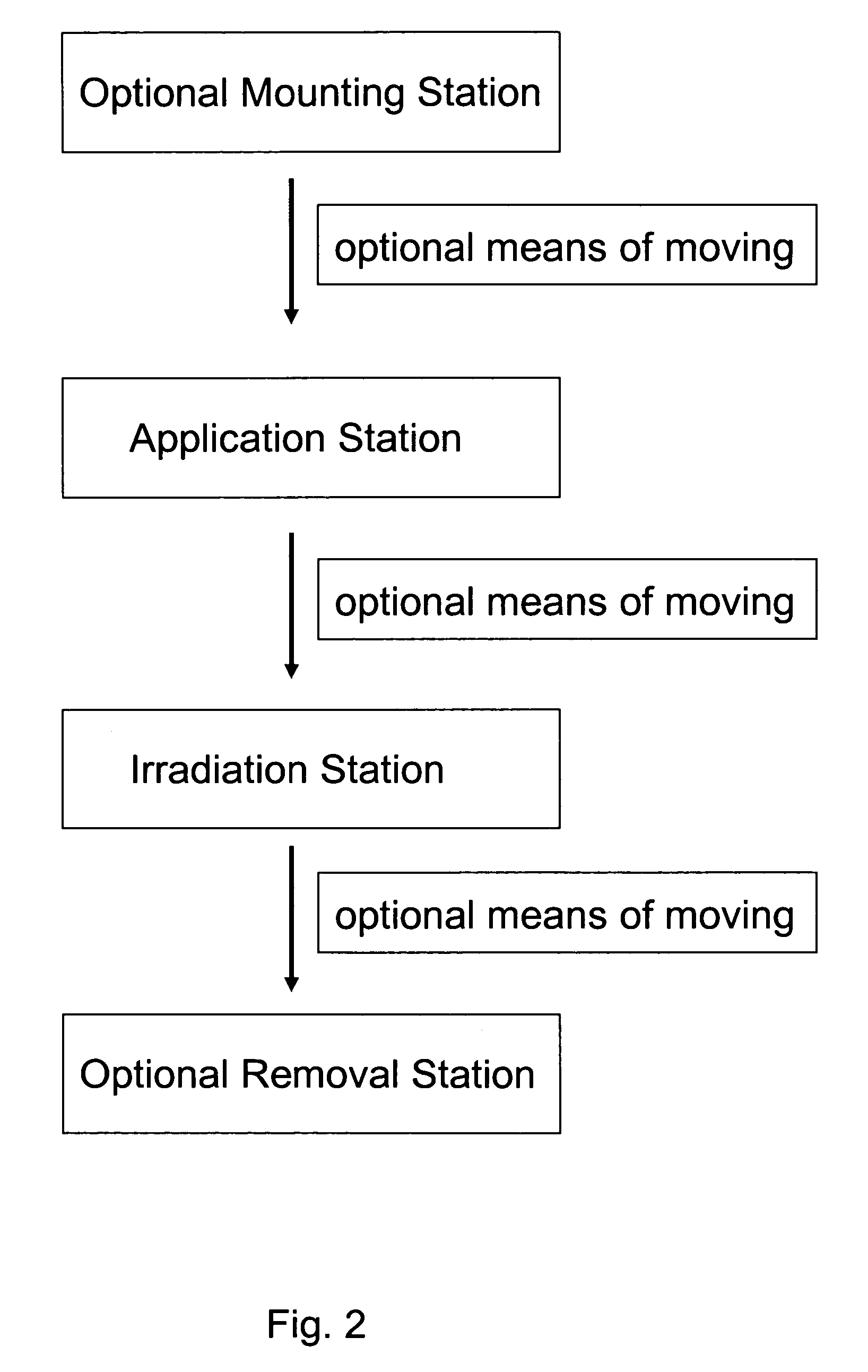

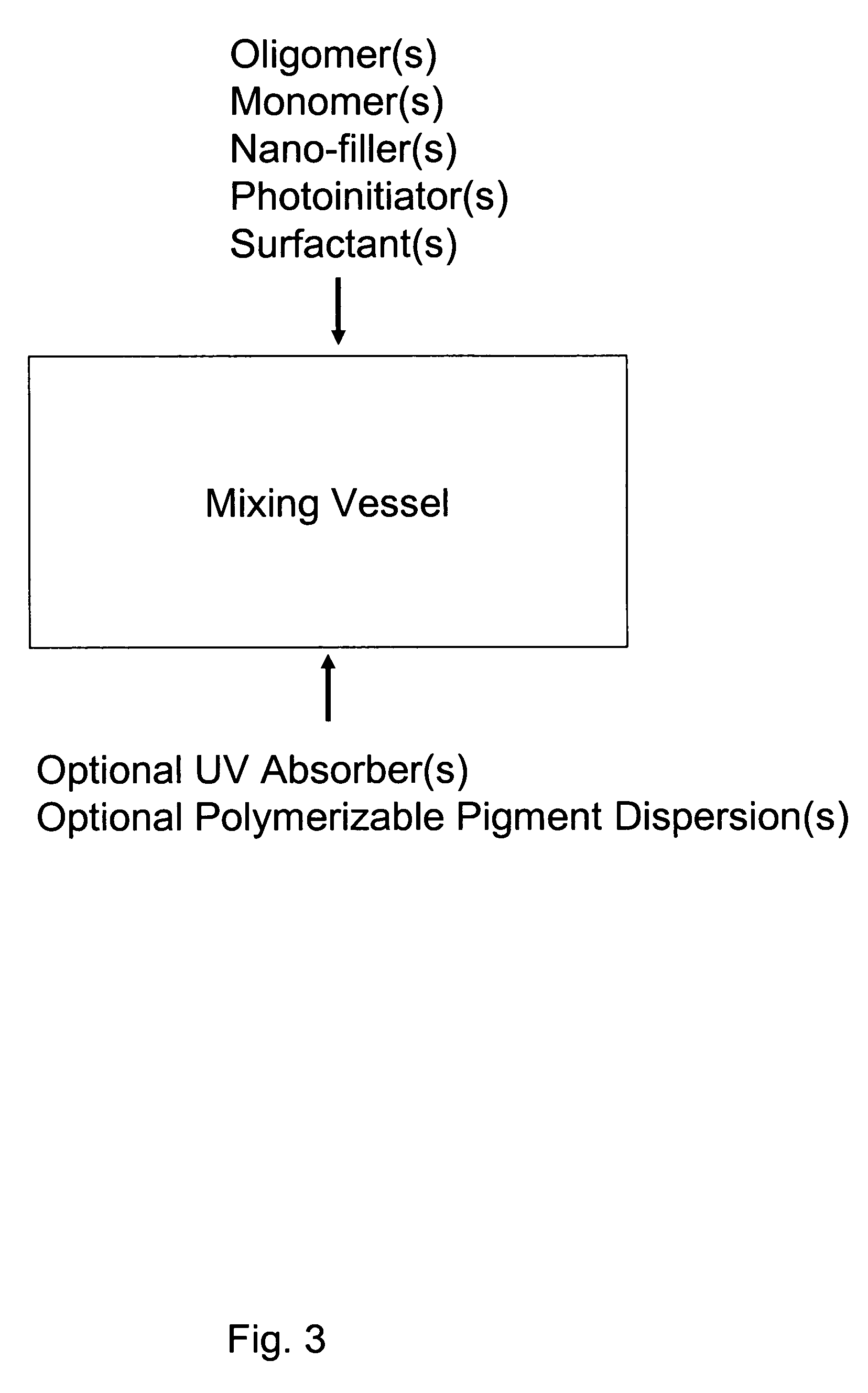

Environmentally friendly coating compositions for coating composites, coated composites therefrom, and methods, processes and assemblages for coating thereof

InactiveUS20050203202A1Exposure was also limitedSynthetic resin layered productsPolyurea/polyurethane coatingsGlass fiberCoated surface

Disclosed are environmentally friendly, substantially all solids coating compositions which are curable using ultraviolet and visible radiation. In addition, the disclosed coating compositions are suitable for coating composite objects and / or objects comprising composite materials, such as, but not limited to, fiberglass, fire retardant fiberglass, carbon fiber, fire retardant carbon fiber, Kevlar®, and fire retardant Kevlar®. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example composite architectural panels. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly, substantially all solids coating compositions curable using ultraviolet and visible radiation.

Owner:ECOLOGY COATING

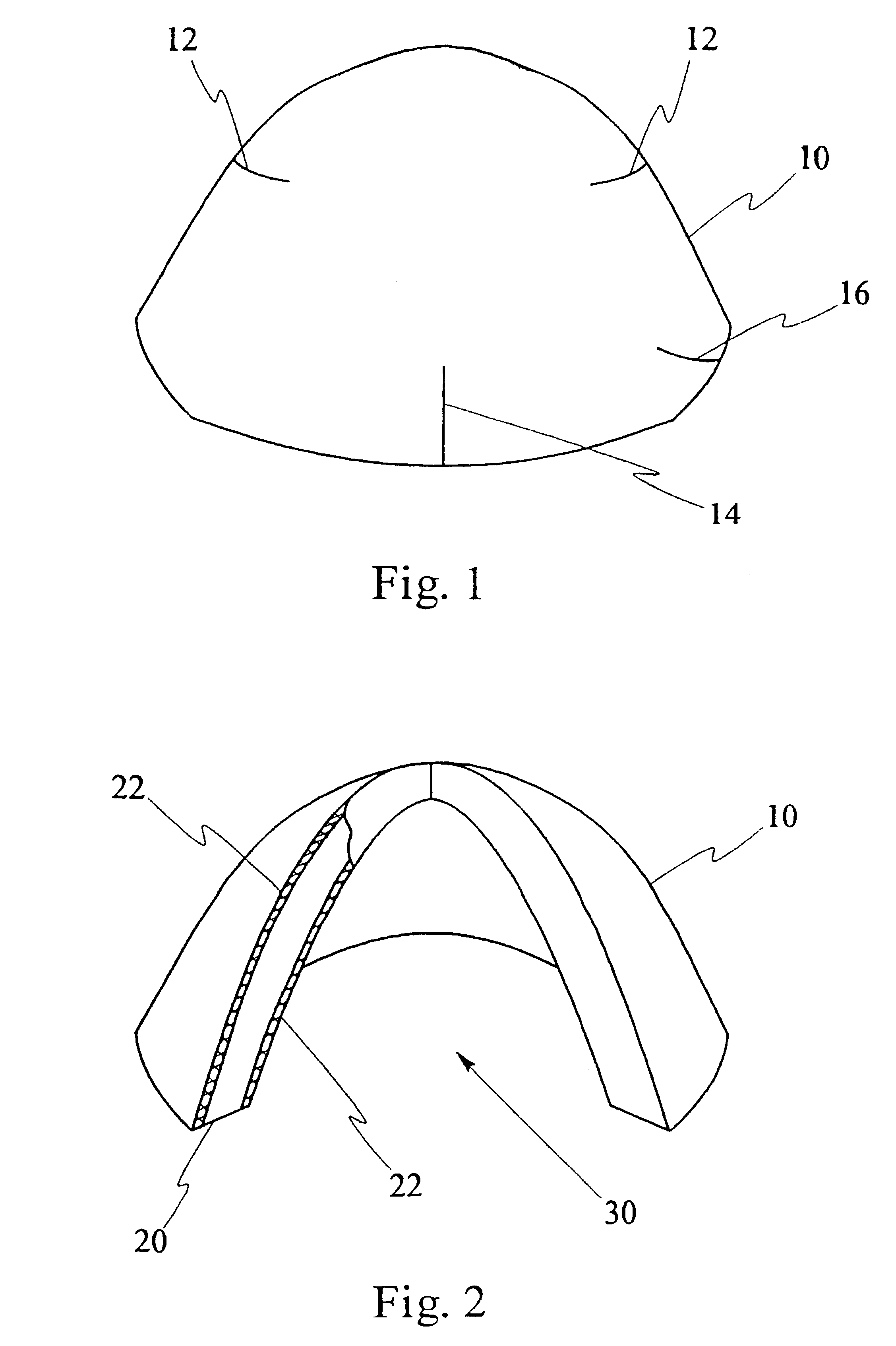

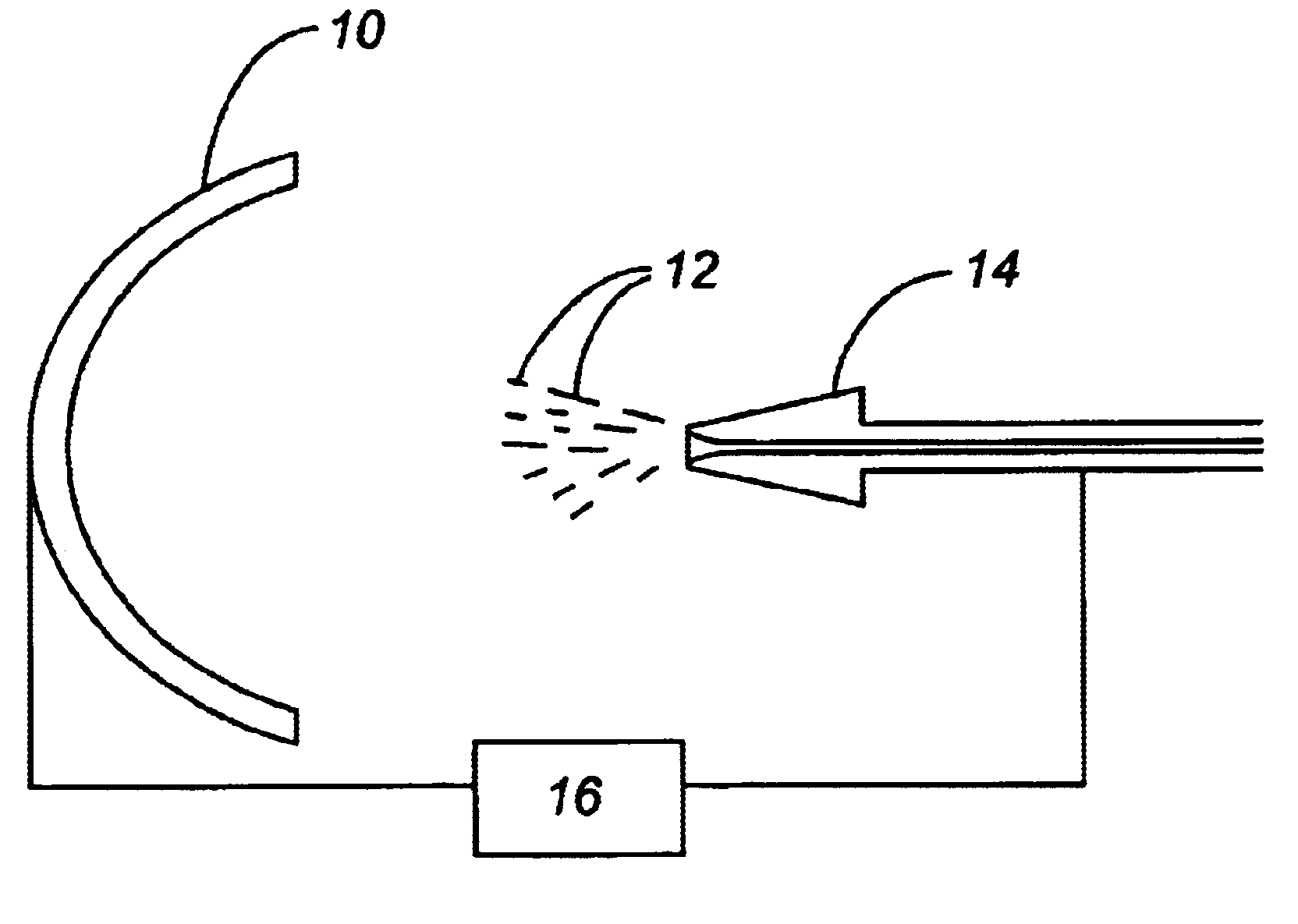

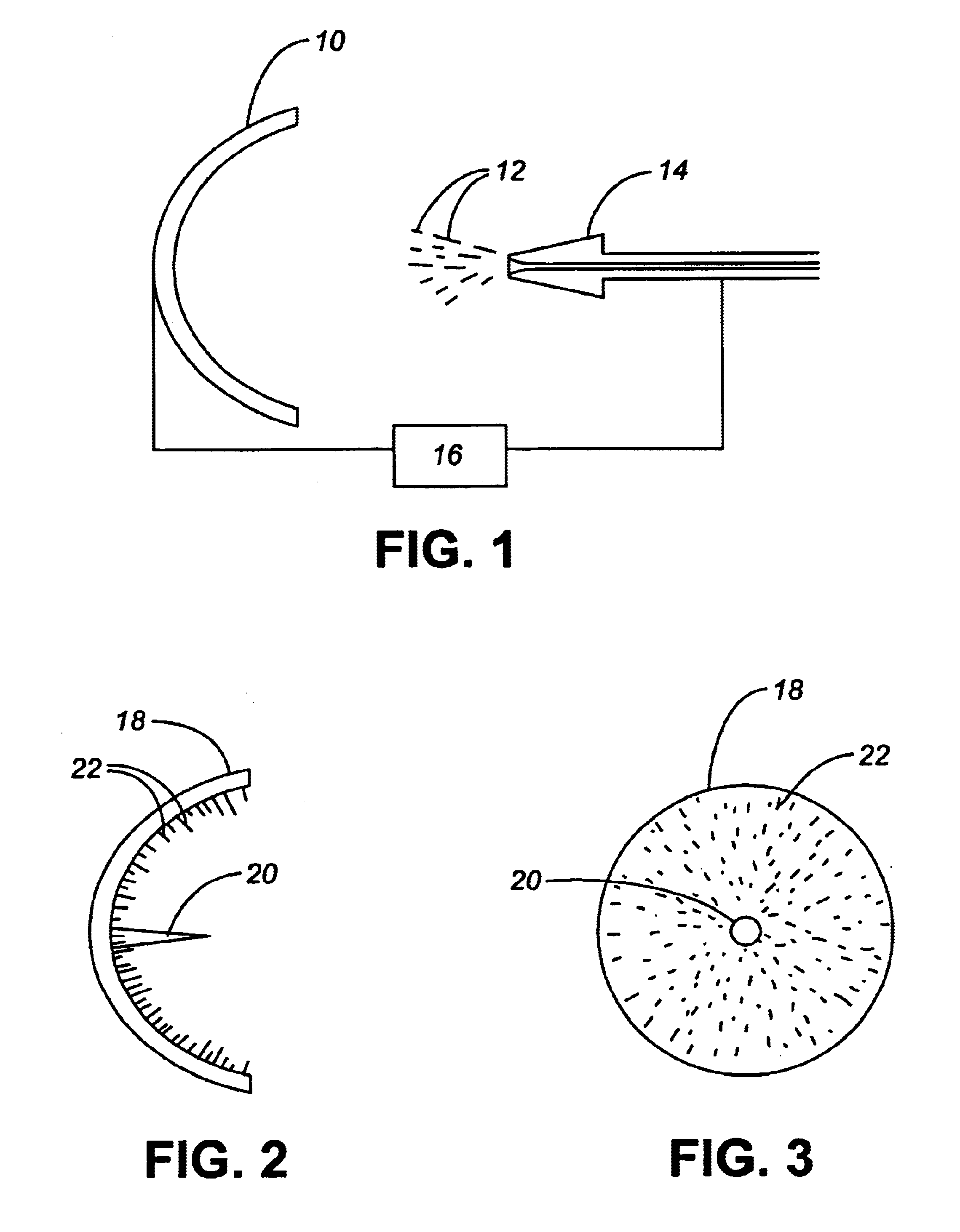

Apparatus and method for blast suppression

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE SOLICITOR GEN ACTING THROUGH THE COMMISSIONER OF THE ROYAL CANADIAN MOUNTED POLICE

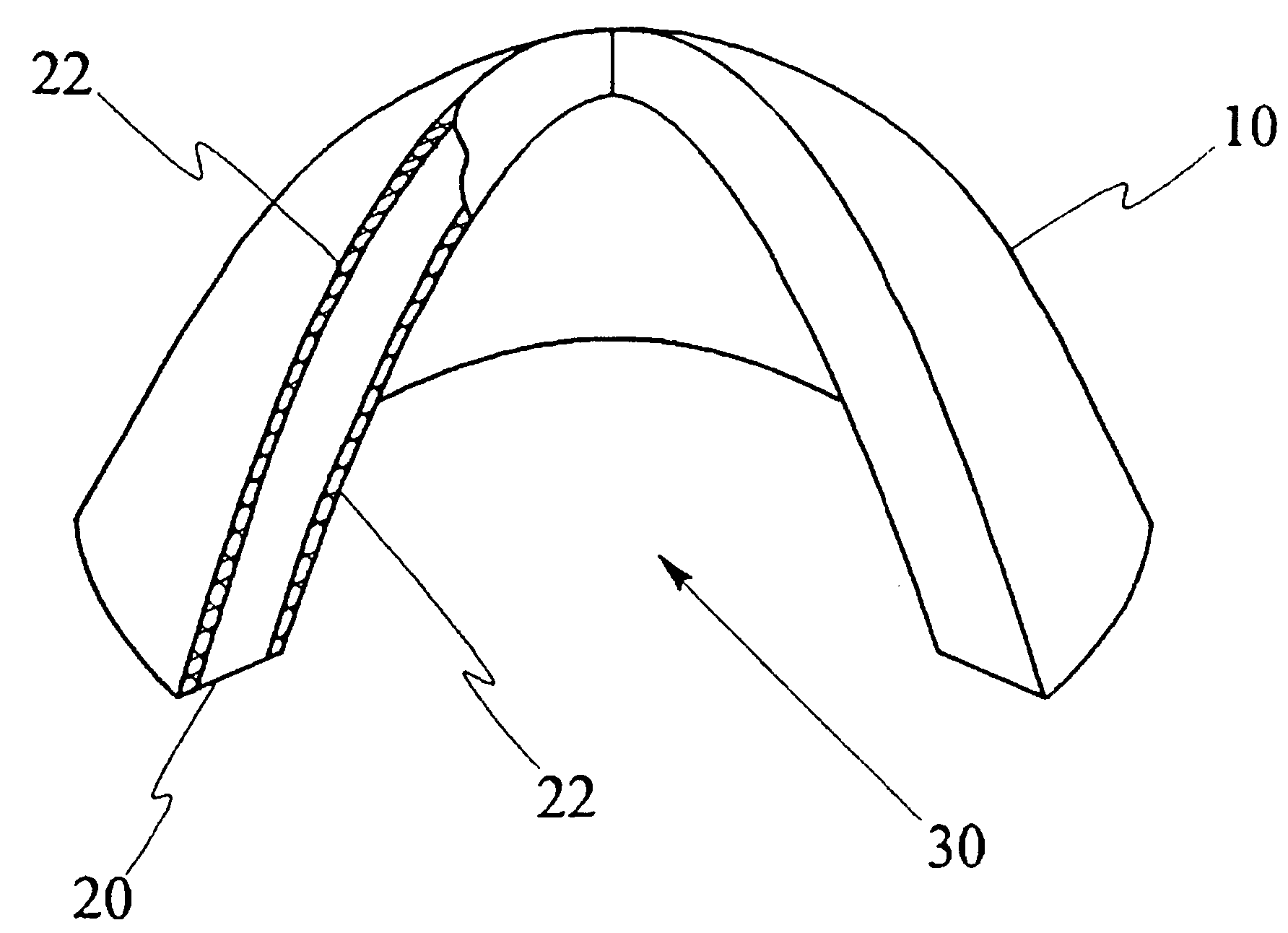

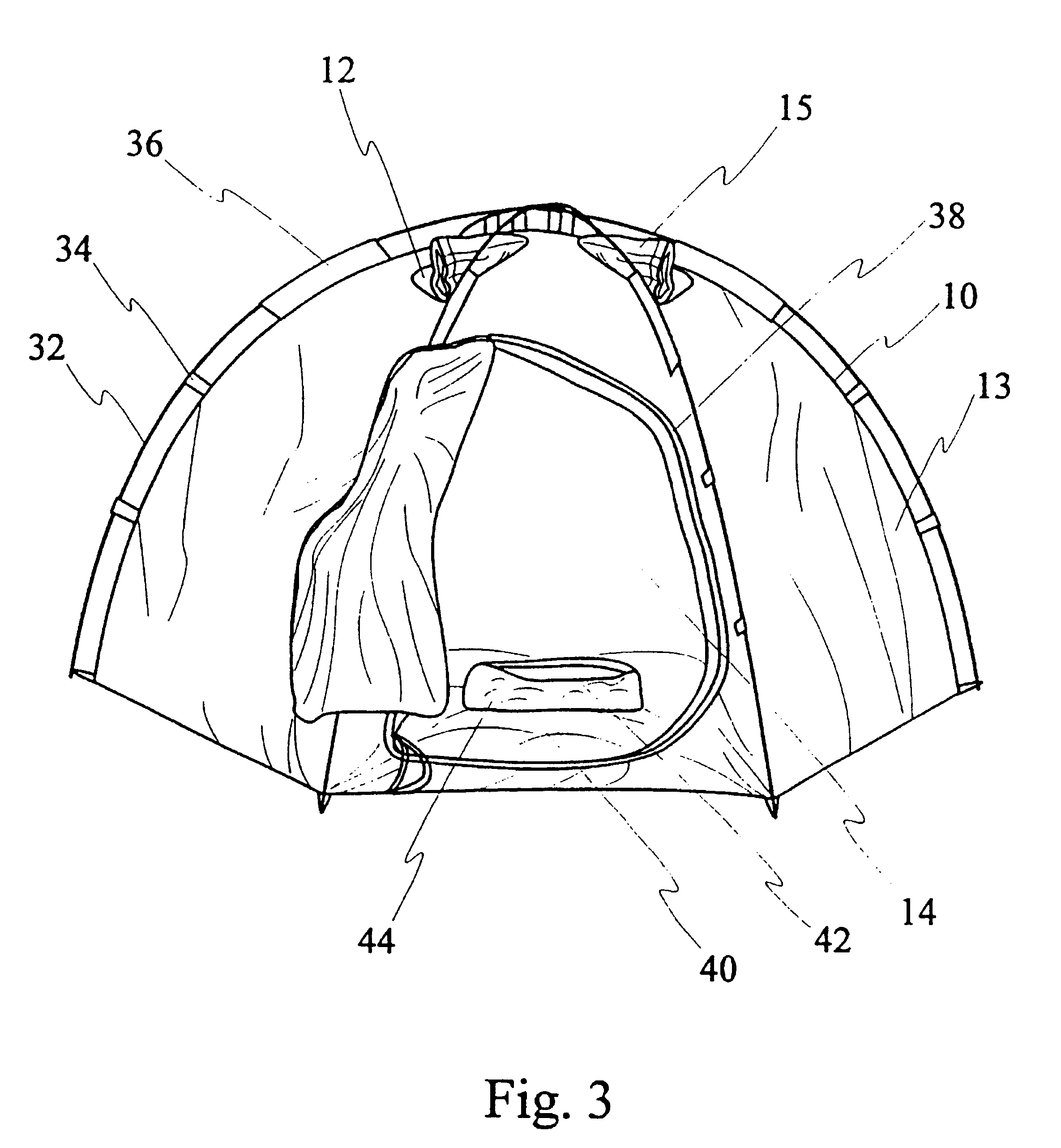

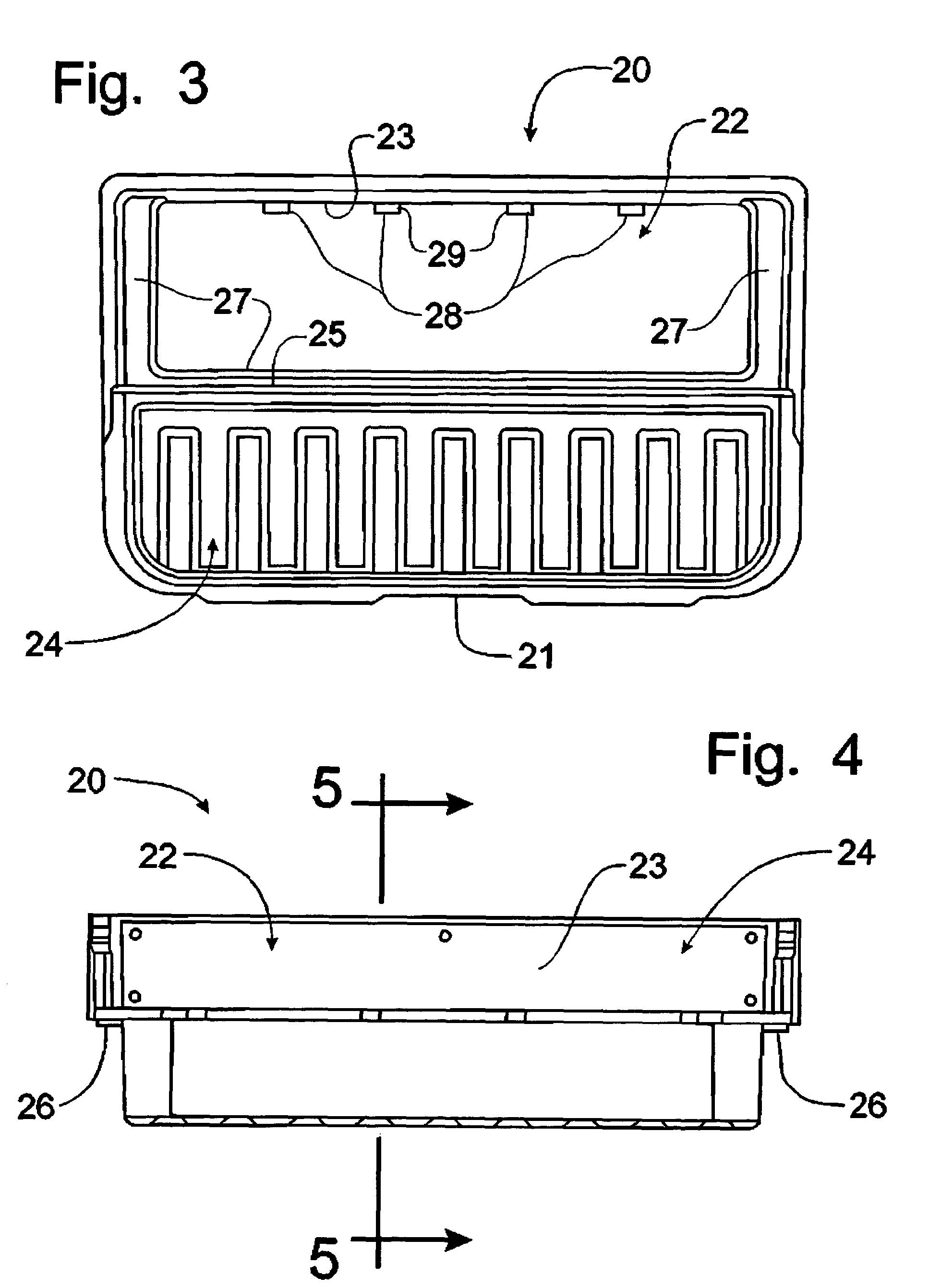

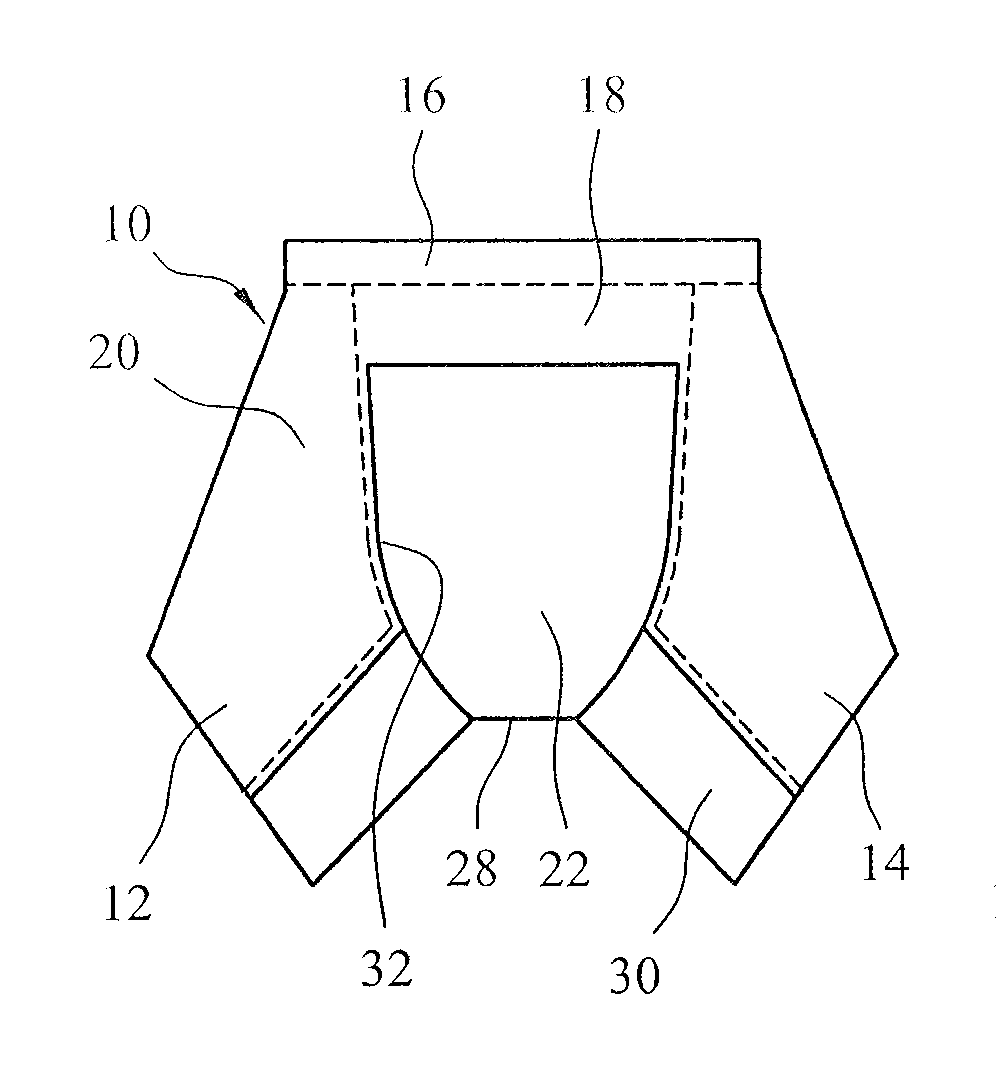

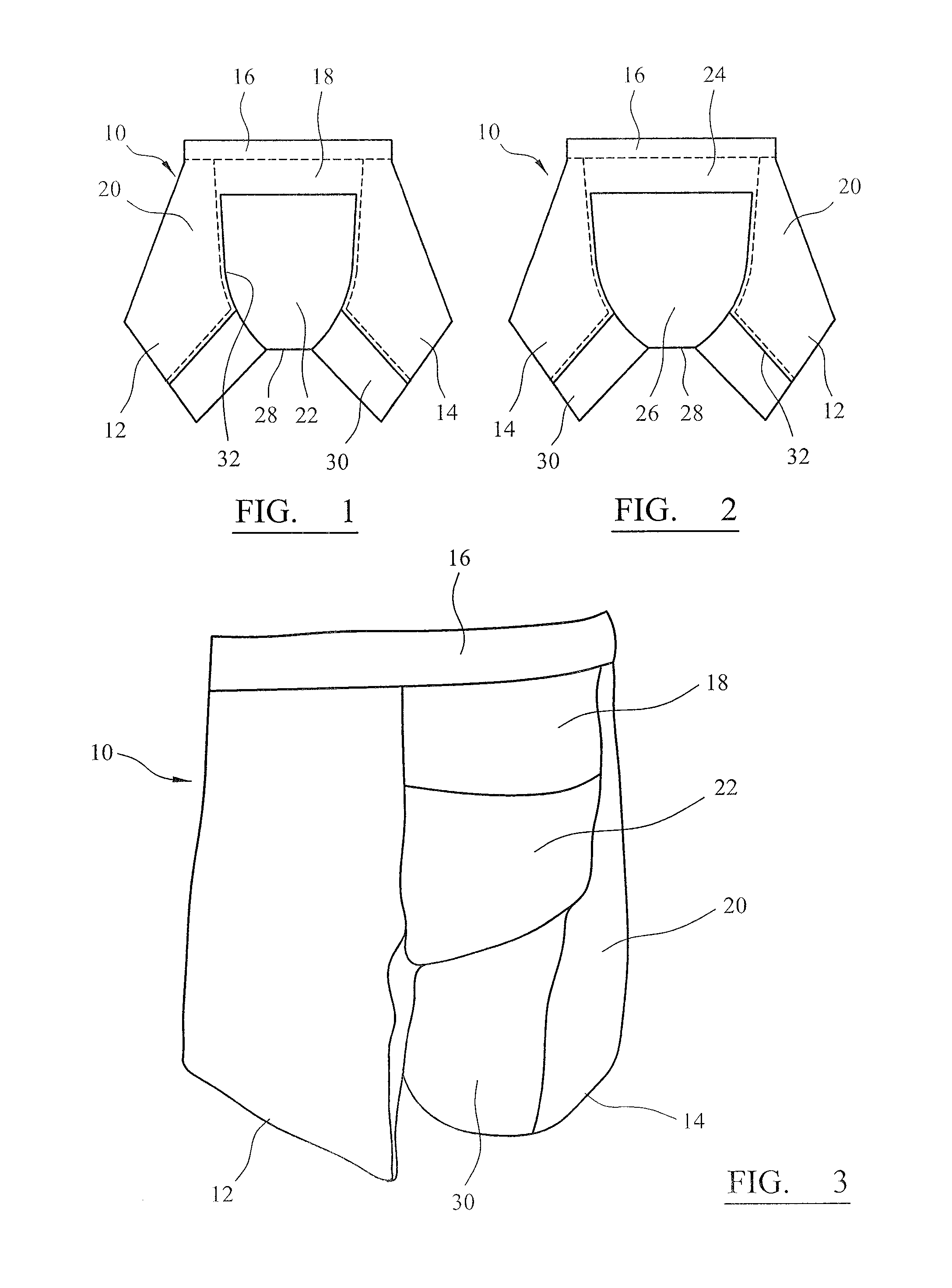

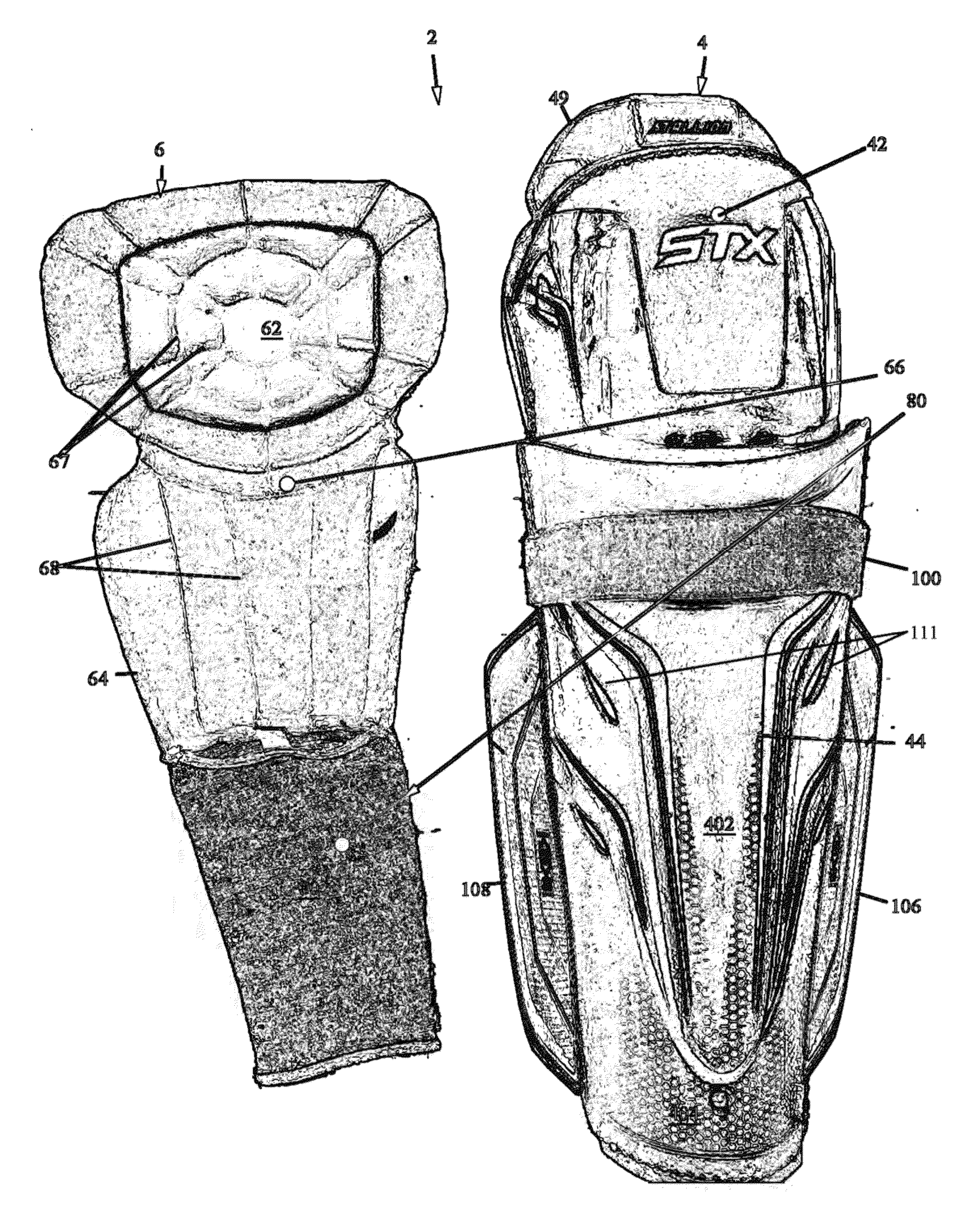

Multi-panelled protective undergarment

ActiveUS20120117700A1Good leg mobilityImprove protectionChemical protectionHeat protectionButtocksThigh

A protective undergarment (10), shown in the form of shorts, includes integrally formed protective panels (22, 26, 30) that exhibit slash-proof properties. The protective areas (22, 26, 30) are made from a flexible Kevlar® knit or the like, and extend to cover the groin, crotch, substantial areas of the buttocks and the inner thigh regions of both legs. The protective panels (22, 26, 30) are externally snitched to a low thermal burden material (18, 20), such as a polyester mesh, that provides elasticity and completes the structure of the shorts (10). The Kevlar® knit is flexible and preferably lies directly against the skin of a user to provide blast wave and ballistic fragment deflection whilst permitting mobility in a lightweight arrangement. Varying thickness of the Kevlar® knit can be used in the protective areas (22, 26, 30) selectively to enhance protection against blast wave and fragment penetration. The shorts (10) find particular application in battlefield theatres where military personnel are exposed to bomb threats.

Owner:BCB INT

Environmentally friendly coating compositions for coating composites, coated composites therefrom, and methods, processes and assemblages for coating thereof

InactiveUS7323248B2Synthetic resin layered productsPolyurea/polyurethane coatingsCoated surfaceGlass fiber

Disclosed are environmentally friendly, substantially all solids coating compositions which are curable using ultraviolet and visible radiation. In addition, the disclosed coating compositions are suitable for coating composite objects and / or objects comprising composite materials, such as, but not limited to, fiberglass, fire retardant fiberglass, carbon fiber, fire retardant carbon fiber, Kevlar®, and fire retardant Kevlar®. In addition, methods are disclosed for coating surfaces, or at least a portion of the surfaces, and curing of the coated surface to obtain partially or fully cured coated surfaces. Furthermore, articles of manufacture incorporating fully cured coated surfaces are disclosed, including, for example composite architectural panels. Also disclosed are methods, processes, production lines, articles of manufacture, and factories which incorporate these environmentally friendly, substantially all solids coating compositions curable using ultraviolet and visible radiation.

Owner:ECOLOGY COATING

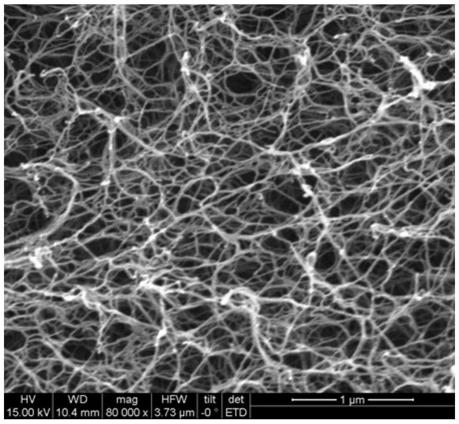

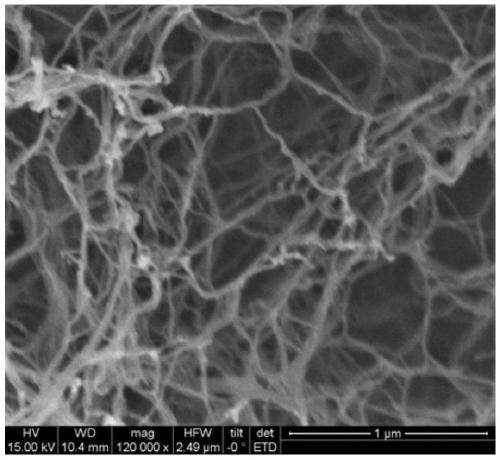

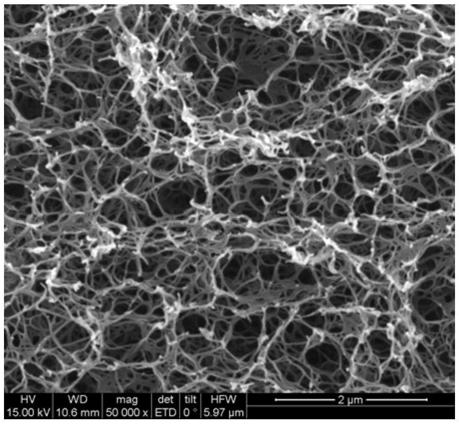

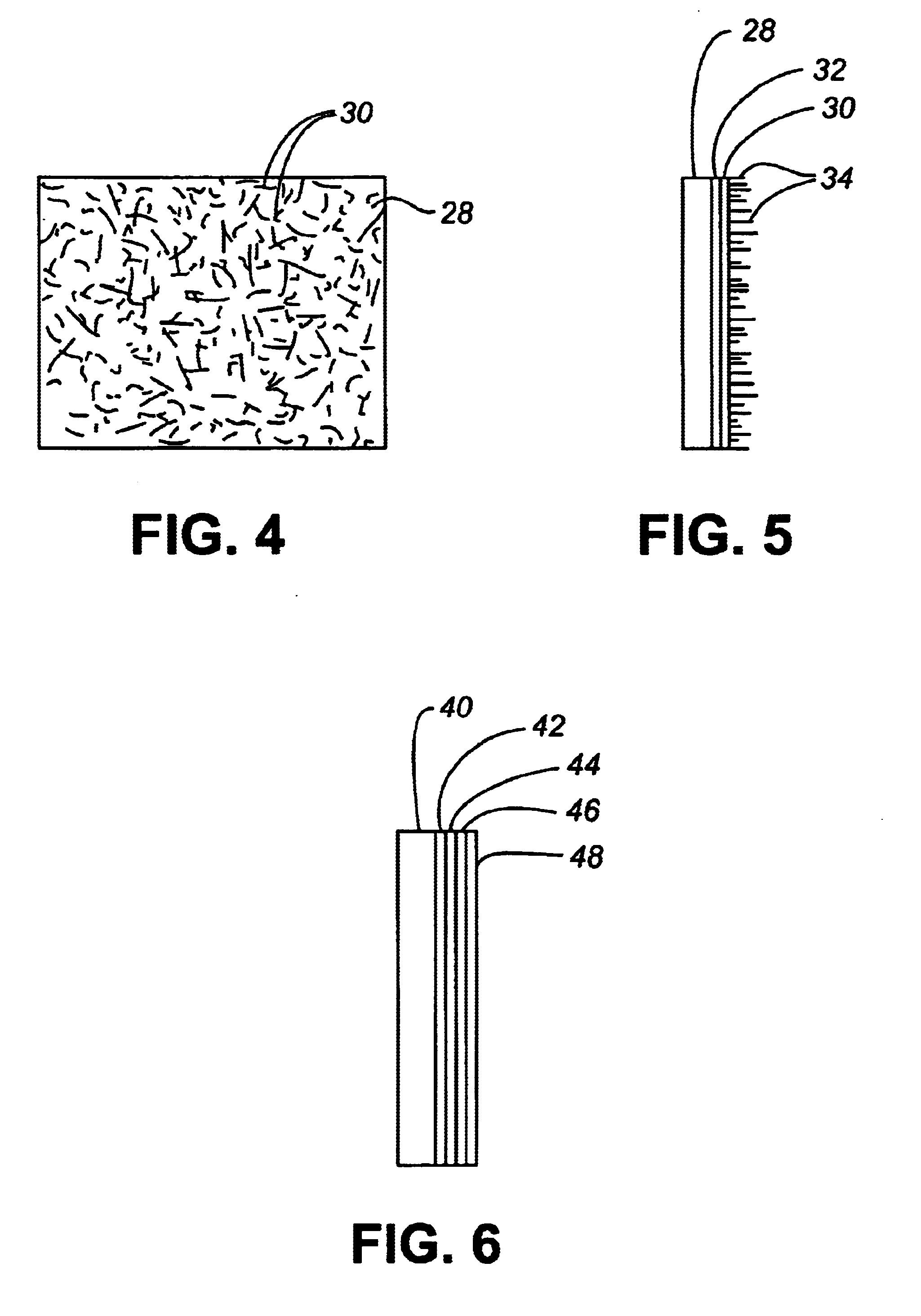

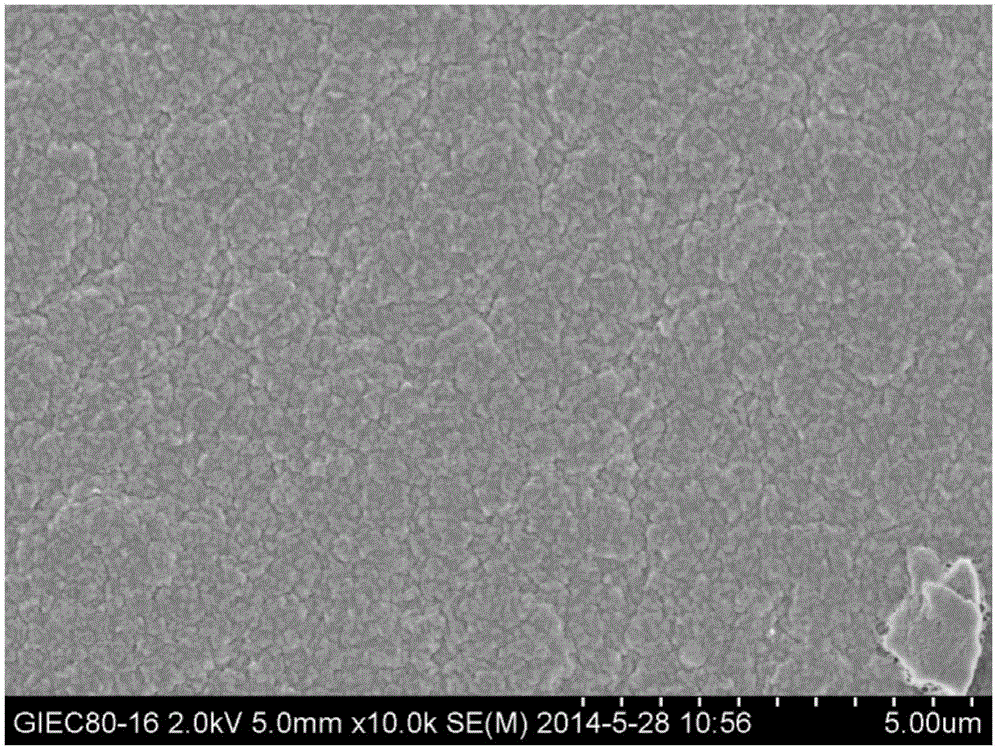

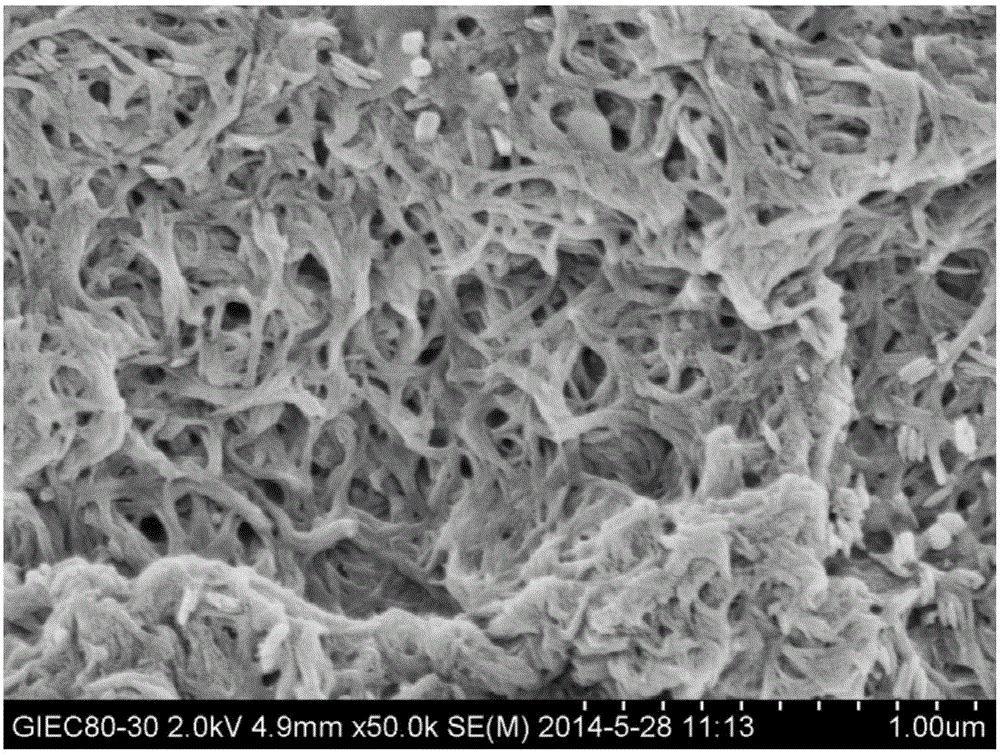

Kevlar aerogel film, and preparation method and application thereof

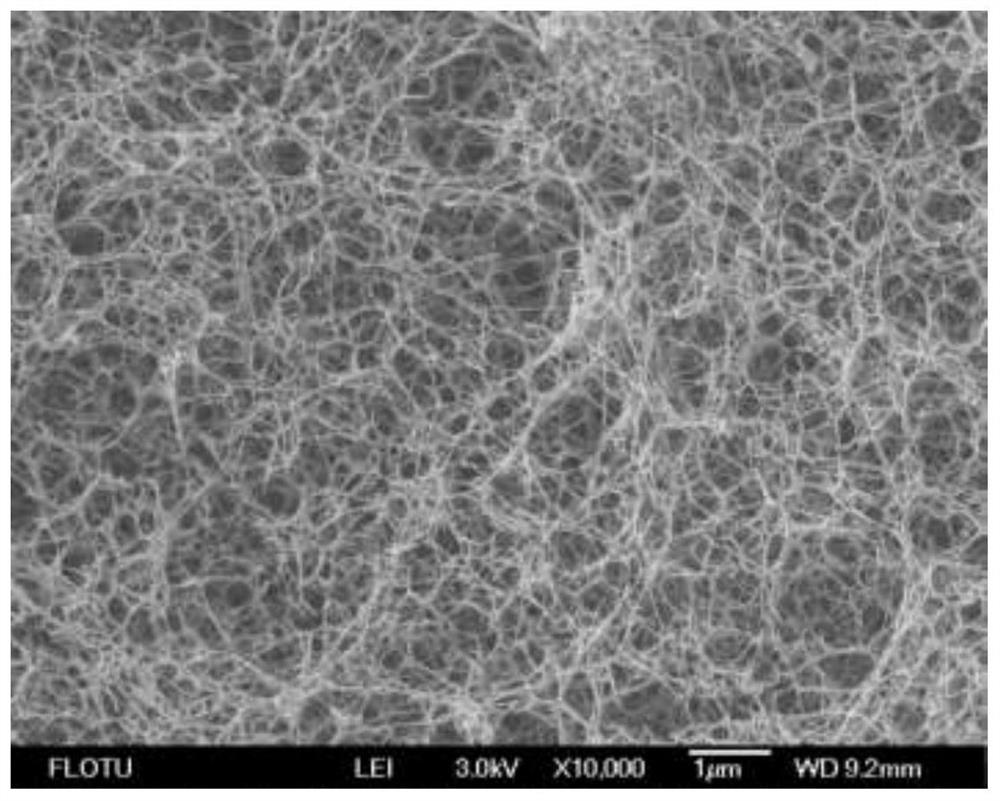

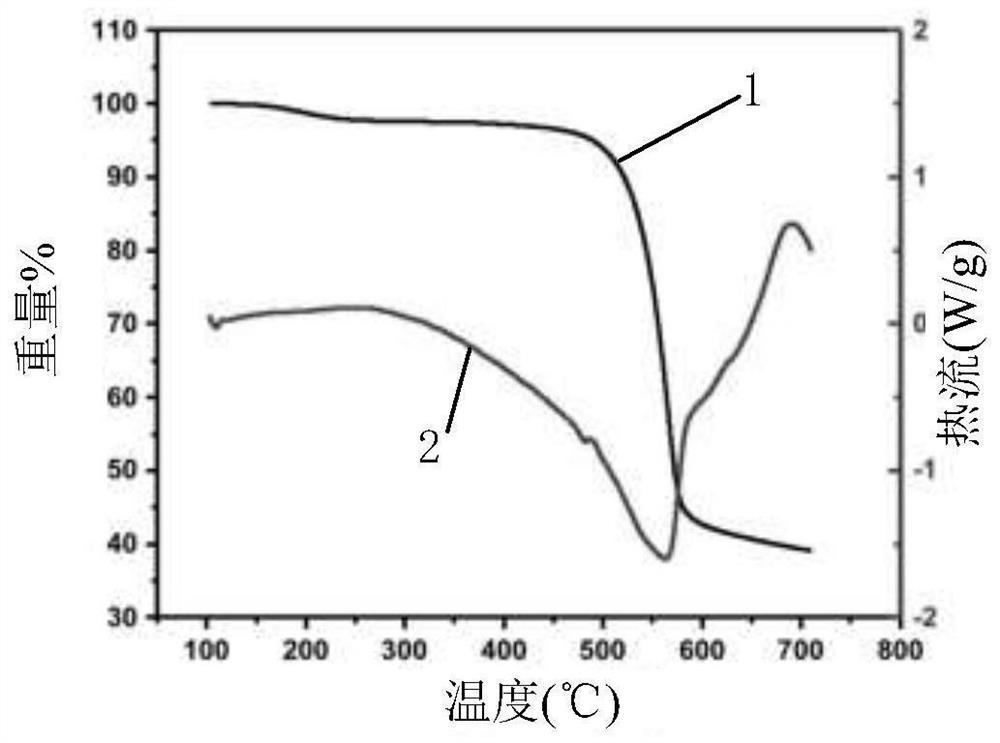

The invention discloses a Kevlar aerogel film, and a preparation method and application thereof. The Kevlar aerogel film has a communicating three-dimensional network-like porous structure formed by mutual overlapping of Kevlar nanofibers. The preparation method comprises: dissolving Kevlar fibers to form a Kevlar nanofiber sol; applying the Kevlar nanofiber sol to a substrate, and then transferring the substrate to a coagulation bath, and performing a sol-gel process and a subsequent solvent replacement process to form a Kevlar gel film; and finally, conducting drying to obtain the Kevlar aerogel film. The Kevlar aerogel film of the invention has high specific surface area and porosity, good flexibility, thermal stability and chemical stability, and the preparation process is simple, andis easy for continuous large-scale production. The Kevlar aerogel film can be directly used as a dielectric material, a sound insulation material, a heat insulation material, a filter film material, etc., and can also be used as a substrate of a flexible functional composite material.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Ultrasonic process for autocatalytic deposition of metal on microparticulate

InactiveUS6726964B1Eliminate the problemEliminates depletionHot-dipping/immersion processesLiquid surface applicatorsResonanceAramides

A process for depositing metal on microparticulate comprising immersing microparticulate in an autocatalytic plating bath comprising the metal; inducing ultrasonic vibration in the plating bath at a frequency corresponding to resonance frequency of the microparticulate; and inducing a turbulent vibration signal in the plating bath in a direction non-parallel to the ultrasonic vibration. This process results in the autocatalytic plating bath depositing the metal on the microparticulate with uniform thickness. The microparticulate can be spheres, flakes or microfibers, and can be made from a number of materials, such as synthetic polymers (nylon, Kevlar.TM., Zylon.TM., and aramid fibers) and biodegradable compounds. A method is disclosed for coating a surface with metallized microparticulate fibers with an orientation perpendicular to the surface.

Owner:THOMPSON G ALAN +1

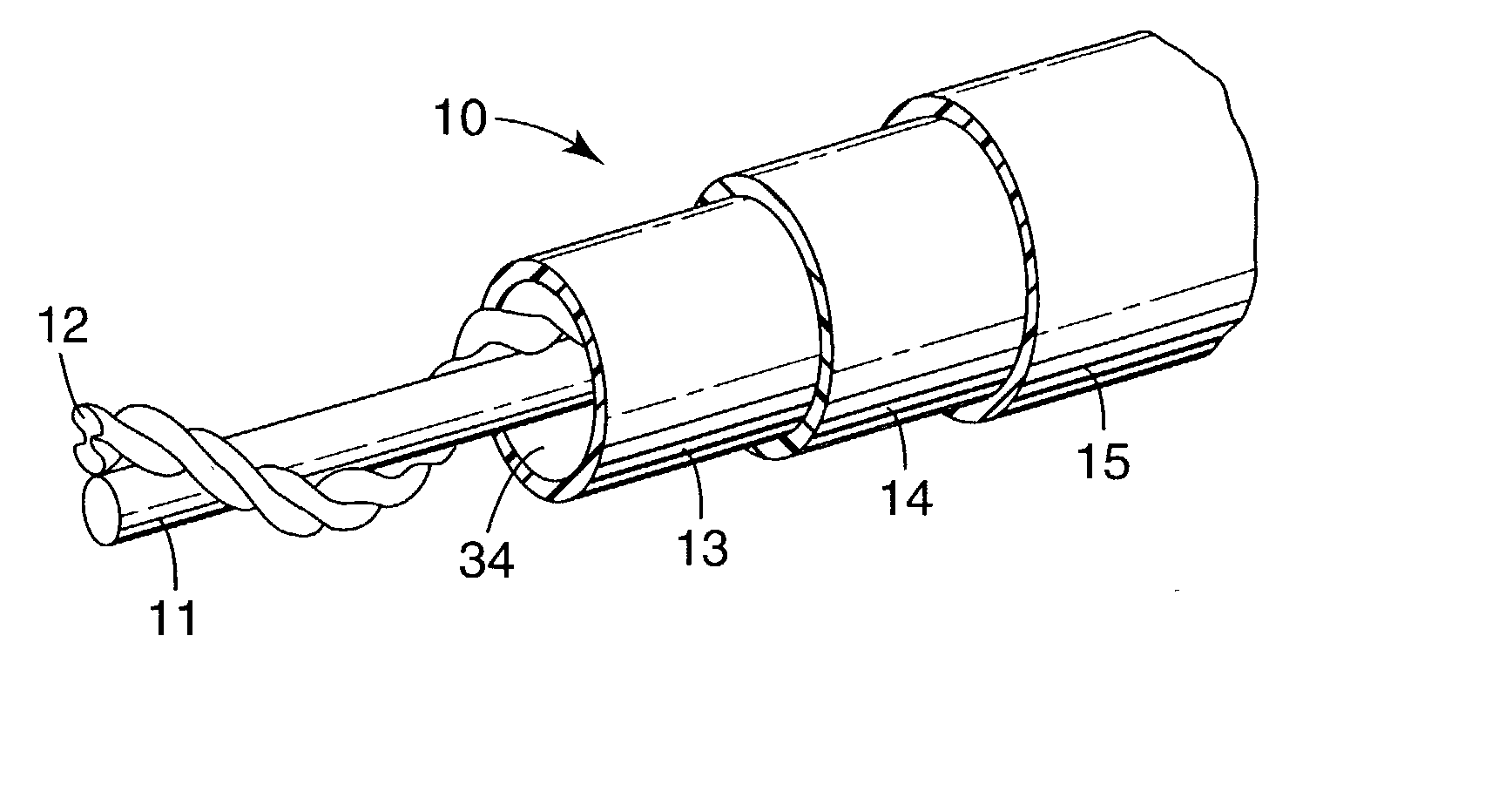

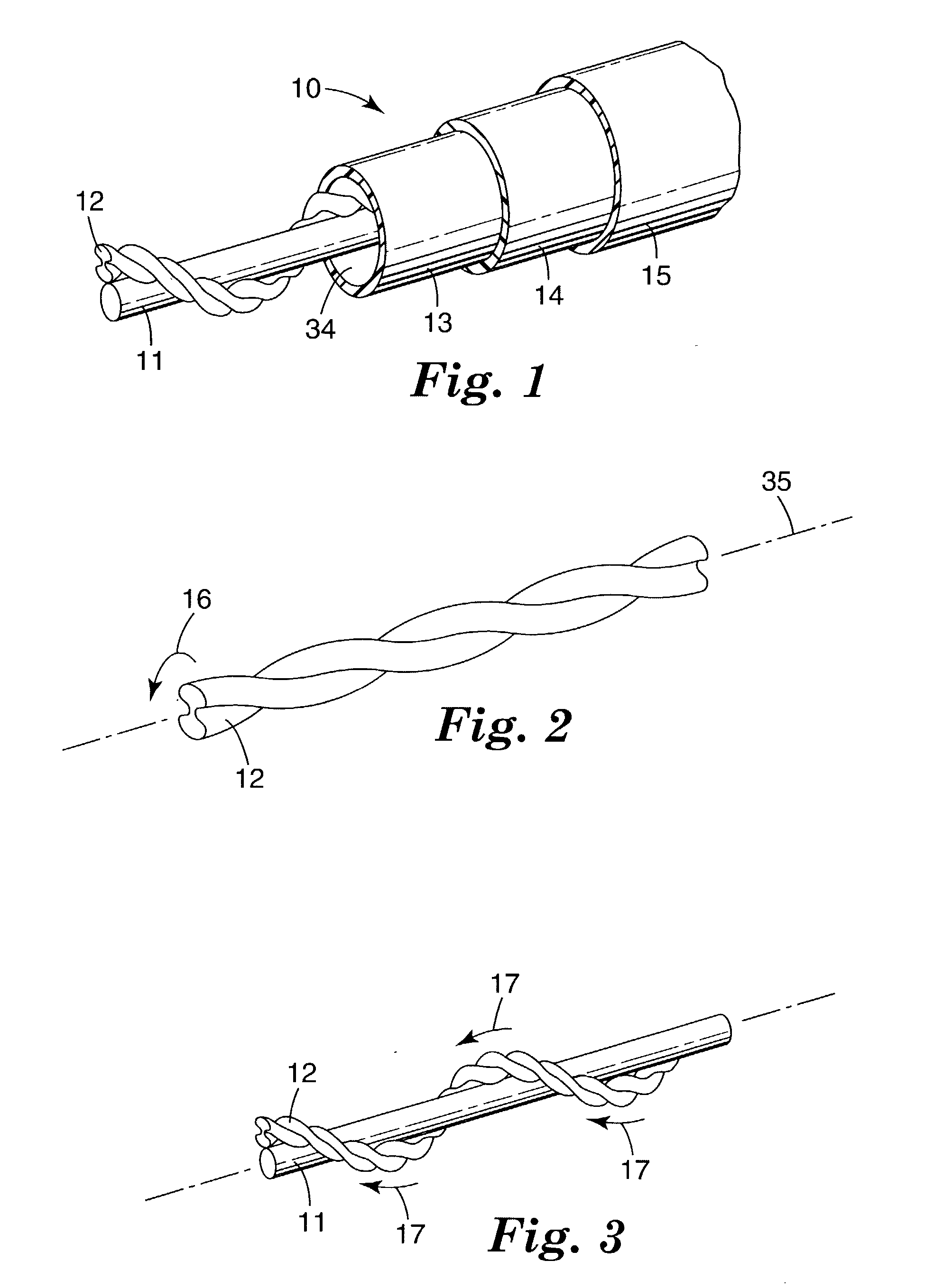

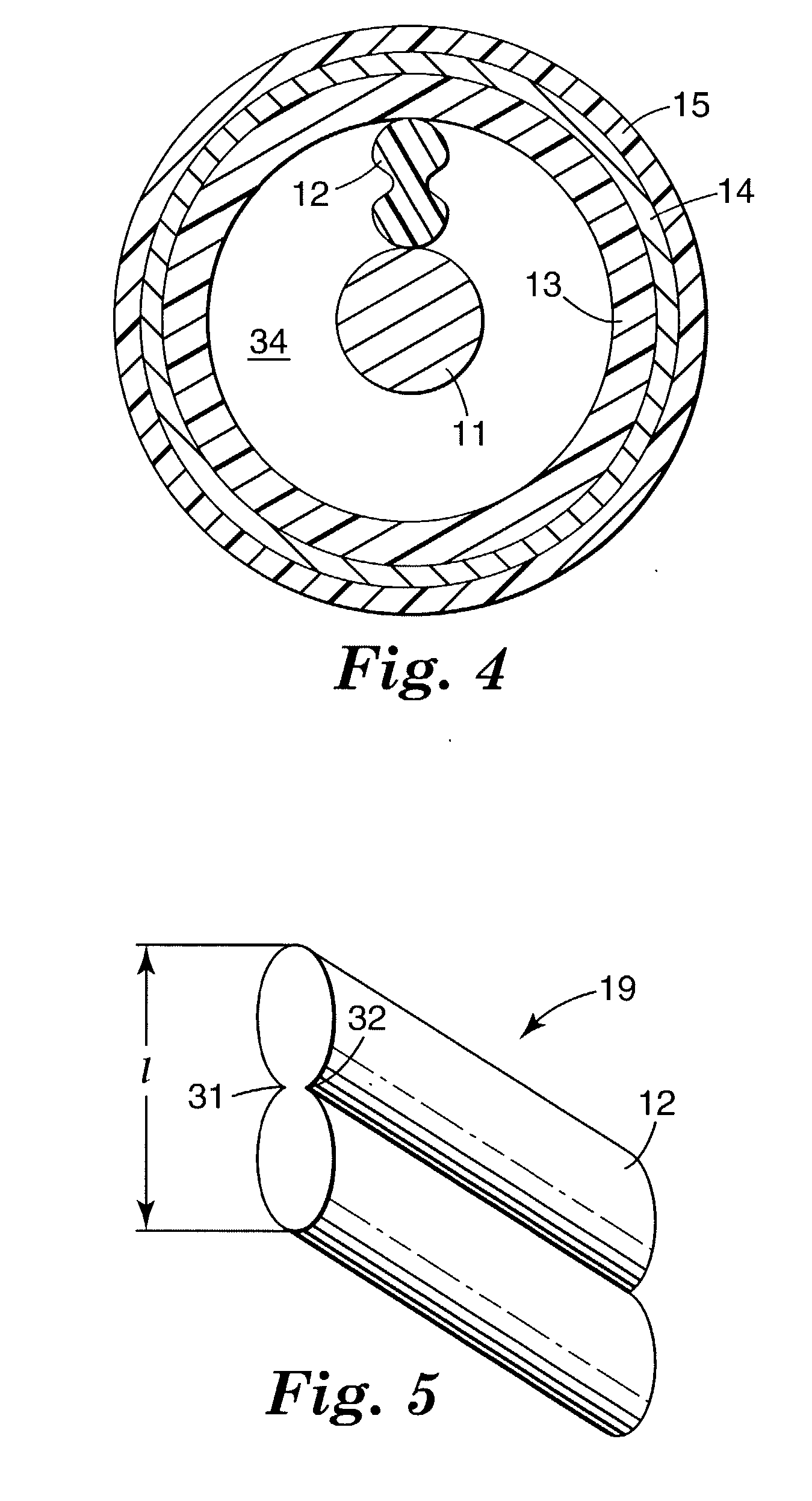

High propagation speed coaxial and twinaxial cable

The amount of air dielectric in air core coaxial and twinaxial cables is increased by spacer structures installed between the center conductor and the outer shield which have provision for air voids or pockets running lengthwise. The extra air space provides lower effective dielectric constant for the cable. In one embodiment, a single-element extruded spacer is formed with air cavities or voids that run continuously throughout the length of the spacer. Several spacer "profiles" or cross-sections are disclosed that place less solid dielectric mass in proximity to the center conductor. The result is a greater volume of air dielectric, and hence a lowered cable dielectric constant. In a further embodiment the spacer is a circular cross-sectioned element consisting of a central dielectric strength member surrounded with foamed material. Strength strands such as Kevlar(R) may be added to the spacer.

Owner:3M INNOVATIVE PROPERTIES CO

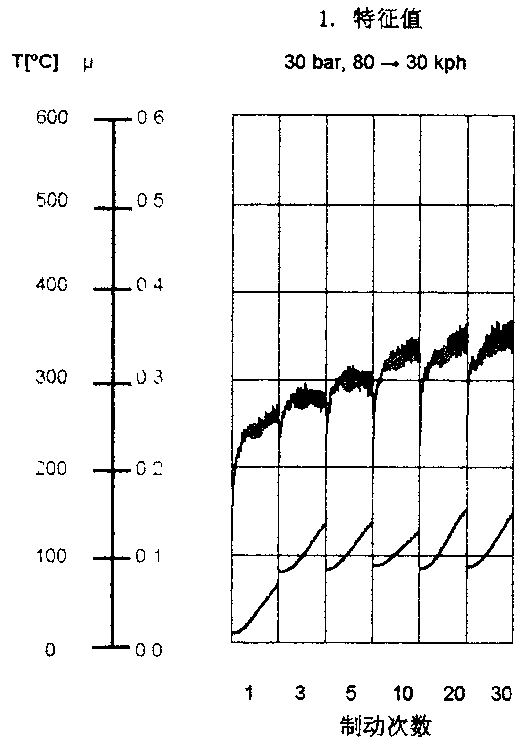

Environmental-protection high-speed car brake sheet and warm-pressing process of brake sheet

ActiveCN102141101ASmall recessionShorter braking distanceFriction liningVulcanizationMaterials science

The invention discloses an environmental-protection high-speed car brake sheet and a warm-pressing process of the brake sheet. A frictional material of the environmental-protection high-speed car brake sheet comprises the following components in parts by weight: 6-8 parts of phenolic resins, 2 parts of acrylonitrile rubber powder, 1-3 parts of Kevlar fibers, 5-7 parts of stannic sulfide, 5-7 parts of artificial graphite, 2 parts of polytetrafluoroethylene, 18-20 parts of steel fibers, 4-6 parts of red copper fibers, 2 parts of aluminum oxide, 3-5 parts of zirconium silicate, 5-7 parts of iron oxide black, 7-9 parts of titanium white, 6-8 parts of mineral fibers, 7-9 parts of white vermiculite, 8-10 parts of grammite and 5-9 parts of barium sulfate. The warm-pressing process of the environmental-protection high-speed car brake sheet comprises the steps of material burdening, material mixing, warm-pressing formation, thermal treatment, grinding and spraying. The high-speed car brake sheet has the advantages of safe and comfortable brake, no noise, low high-temperature and high-speed recession, stable frictional factor, environmental protection, long service life and the like; and the warm-pressing process of the environmental-protection high-speed car brake sheet has the advantages of high rate of finished products, high mechanical degree, high production efficiency and low energy consumption.

Owner:YANTAI WINHERE AUTO PART MFG

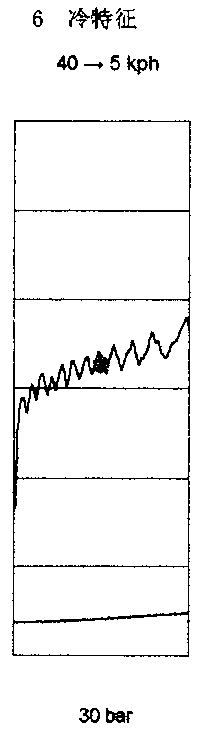

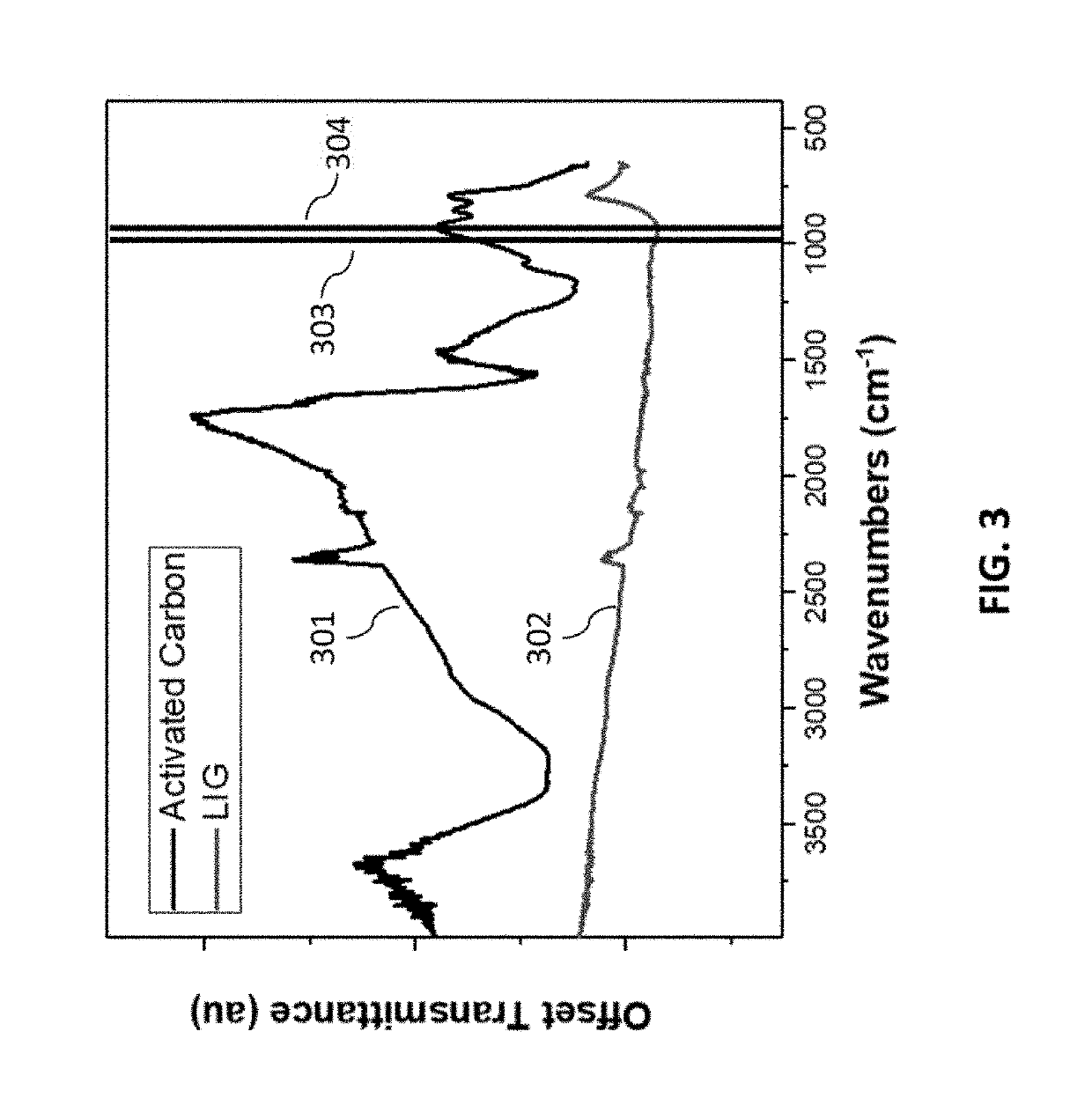

Methods of fabricating laser-induced graphene and compositions thereof

ActiveUS20190330064A1Improve electrical performanceQuality improvementSemi-permeable membranesMembranesFlexible electronicsMultiple pass

Methods that expand the properties of laser-induced graphene (LIG) and the resulting LIG having the expanded properties. Methods of fabricating laser-induced graphene from materials, which range from natural, renewable precursors (such as cloth or paper) to high performance polymers (like Kevlar). With multiple lasing, however, highly conductive PEI-based LIG could be obtained using both multiple pass and defocus methods. The resulting laser-induced graphene can be used, inter alia, in electronic devices, as antifouling surfaces, in water treatment technology, in membranes, and in electronics on paper and food Such methods include fabrication of LIG in controlled atmospheres, such that, for example, superhydrophobic and superhydrophilic LIG surfaces can be obtained. Such methods further include fabricating laser-induced graphene by multiple lasing of carbon precursors. Such methods further include direct 3D printing of graphene materials from carbon precurors. Application of such LIG include oil / water separation, liquid or gas separations using polymer membranes, anti-icing, microsupercapacitors, supercapacitors, water splitting catalysts, sensors, and flexible electronics.

Owner:B G NEGEV TECH & APPL LTD +1

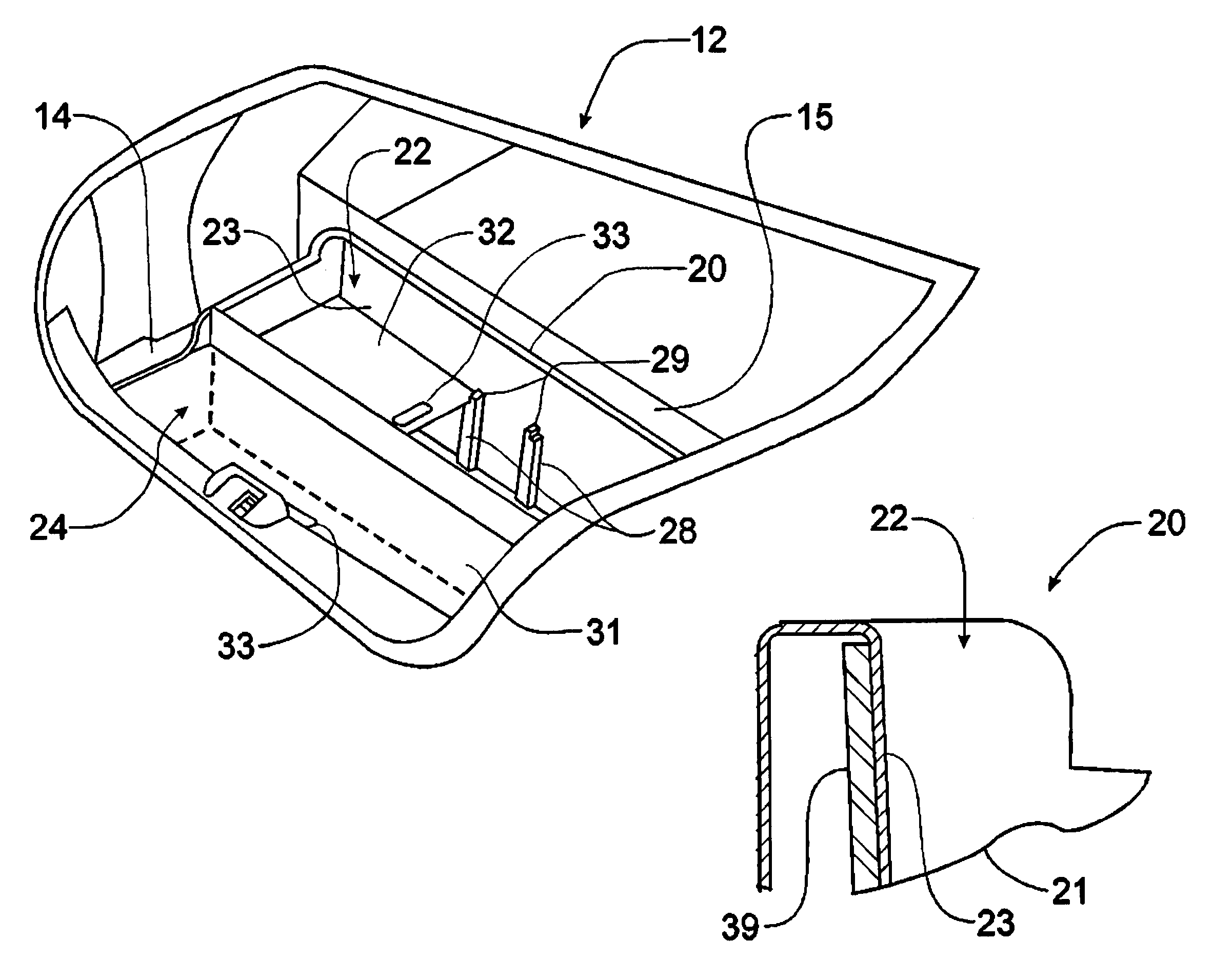

Penetration resistant trunk pack for police vehicles

ActiveUS7118017B1Easy to disassembleReduce the possibilityLuggage compartmentInternal framesFuel tankPolice vehicle

A trunk organizer for the trunk cavity of a police vehicle that forces the orientation of long, stiff items typically carried within the trunk cavity of police vehicles into a transversely extending orientation. The transverse orientation of these items typically found in police vehicle trunks reduces the likelihood of a high speed rear collision driving the items through the walls defining the trunk cavity, particularly the waterfall of the trunk cavity, into the fuel tank. The trunk organizer is preferably formed from high density polyethylene with a forward panel of Kevlar affixed to the front panel of the trunk organizer to provide further penetration resistance. Translucent lids provide a ready inspection of the items without requiring the opening of a compartment. The trunk organizer is sized and configured to fit snuggly within the trunk cavity of a conventional police vehicle and permits an easy removal therefrom.

Owner:FORD GLOBAL TECH LLC

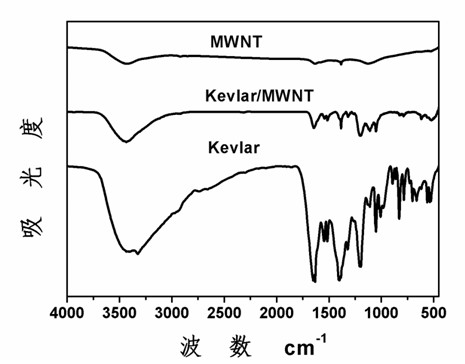

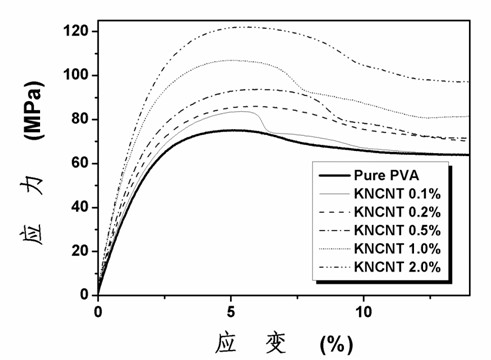

Preparation method of reinforced polyvinyl alcohol compound

The invention relates to a preparation method of a reinforced polyvinyl alcohol compound. The preparation method comprises the following steps: 1, dissolving Kevlar fibers in potassium hydroxide-containing dimethyl sulfoxide through a magnetic stirring method to obtain a stably-dispersed Kevlar nanofiber solution; 2, adding multi-walled carbon nanotubes to the Kevlar nanofiber solution, preparinga Kevlar non-covalently modified multi-walled carbon nanotube (Kevlar / MWNT) dispersion through an ultrasonic method, drying the solvent to obtain Kevlar / MWNT powder, and adding the Kevlar / MWNT powderto deionized water to prepare a Kevlar / MWNT water dispersion; and 3, adding polyvinyl alcohol, and carrying out heating stirring and vacuum drying sequentially to prepare polyvinyl alcohol compound reinforced by the the Kevlar nanofiber non-covalently modified multi-walled carbon nanotubes. According to the reinforced polyvinyl alcohol compound containing 2.0% of the Kevlar nanofiber non-covalently modified multi-walled carbon nanotubes synthesized in the invention, the fracture strength is 62.4% higher than that of a polyvinyl alcohol polymer, the Young modulus is improved by 61.3%, and excellent mechanical performances are performed.

Owner:SHANGHAI JIAO TONG UNIV

Aramid fiber blended yarn and preparation technology thereof

The invention relates to the field of textile production, in particular to aramid fiber blended yarn and a preparation technology thereof. The aramid fiber blended yarn is characterized in that 1414.Kevlar aramid fiber, 1313.T450 aramid fiber, flame retardant glue, modacrylic, combed cotton, conducting fiber, chinlon and tencel are adopted as raw materials, fineness degrees of the materials are respectively 1.7, 2.2 and 3 deniers, any four materials in the raw materials are selected as main raw materials, the length of the four materials selected as the main materials at will is 48-51 millimeters, the lengths of the remaining auxiliary raw materials are respectively 28 millimeters and 38 millimeters. Compared with the prior art, the processing technology is simple in process, produced products have good performance such as high strength, high modulus, high-temperature resistance, acid resistance, alkali resistance and light weight, are high in strength, and can solve the problem that a machine part is damaged easily. The development of the aramid fiber blended yarn and the success of matched military supplies can bring markets for enterprises and innovation conceptions. Meanwhile, firmness, flame-retarding performance and anti-static electricity capacity of the military supplies are changed in nature compared with prior fiber blended yarn.

Owner:SHANGHAI SHENAN TEXTILE

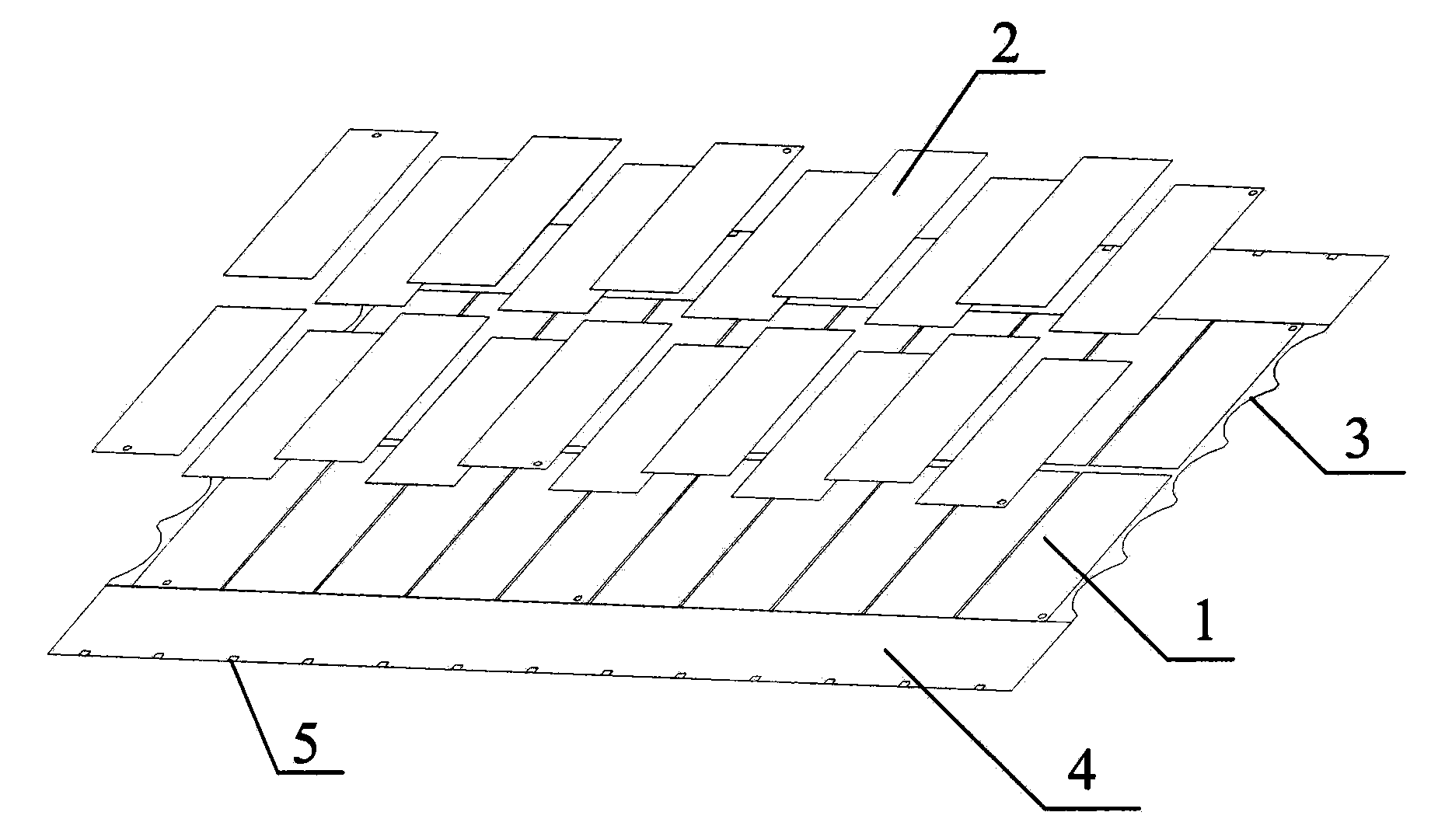

Thermal insulation/protection integrated space debris protection structure and application thereof

ActiveCN105109709ARealize three-dimensional comprehensive protectionPlay anti-heat insulation/protection functionCosmonautic thermal protectionThermal insulationKevlar

The invention discloses a thermal insulation / protection integrated space debris protection structure and an application thereof. The protection structure is formed by stacking a front plate and a filled layer, wherein the filled layer is formed by alternately stacking SiC fibre fabrics and ceramic fibre-reinforced SiO2 nanometre aerogel plates in pairs, and one side of each SiC fibre fabric is close to the front plate. The protection structure is applied to thermal insulation and debris protection for a spacecraft, the protection performance is obviously superior to the protection performance of a Nextel / Kevlar filled protection structure under the same surface density, puncture damages are avoided, the thermal insulation performance is good, and the thermal conductivity is not greater than 0.023W / m.K; the mass of the filled layer of the protection structure is not greater than 1.08kg, and the thermal insulation / protection integrated effect can be acted at a higher temperature in case of an equivalent mass compared with the traditional filled Whipple protection structure; and the different requirements of thermal insulation, debris protection and weight reduction can be met by changing the thickness of the filled layer, and the designability is high.

Owner:NAT UNIV OF DEFENSE TECH

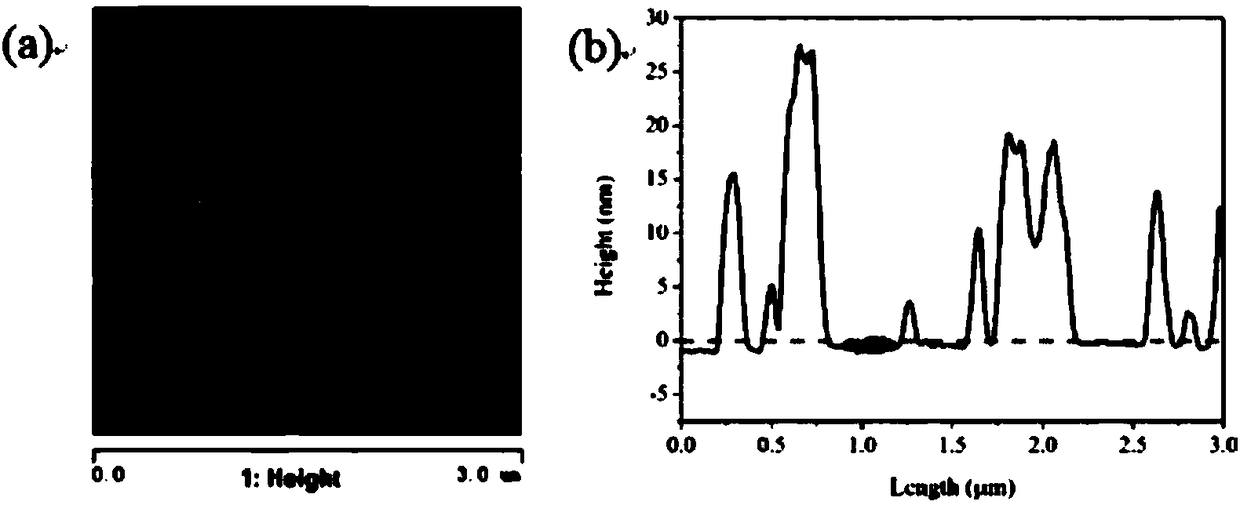

Method for preparing phosphoric acid doped high temperature proton exchange membrane with layer-by-layer assembly structure based on spin coating technique

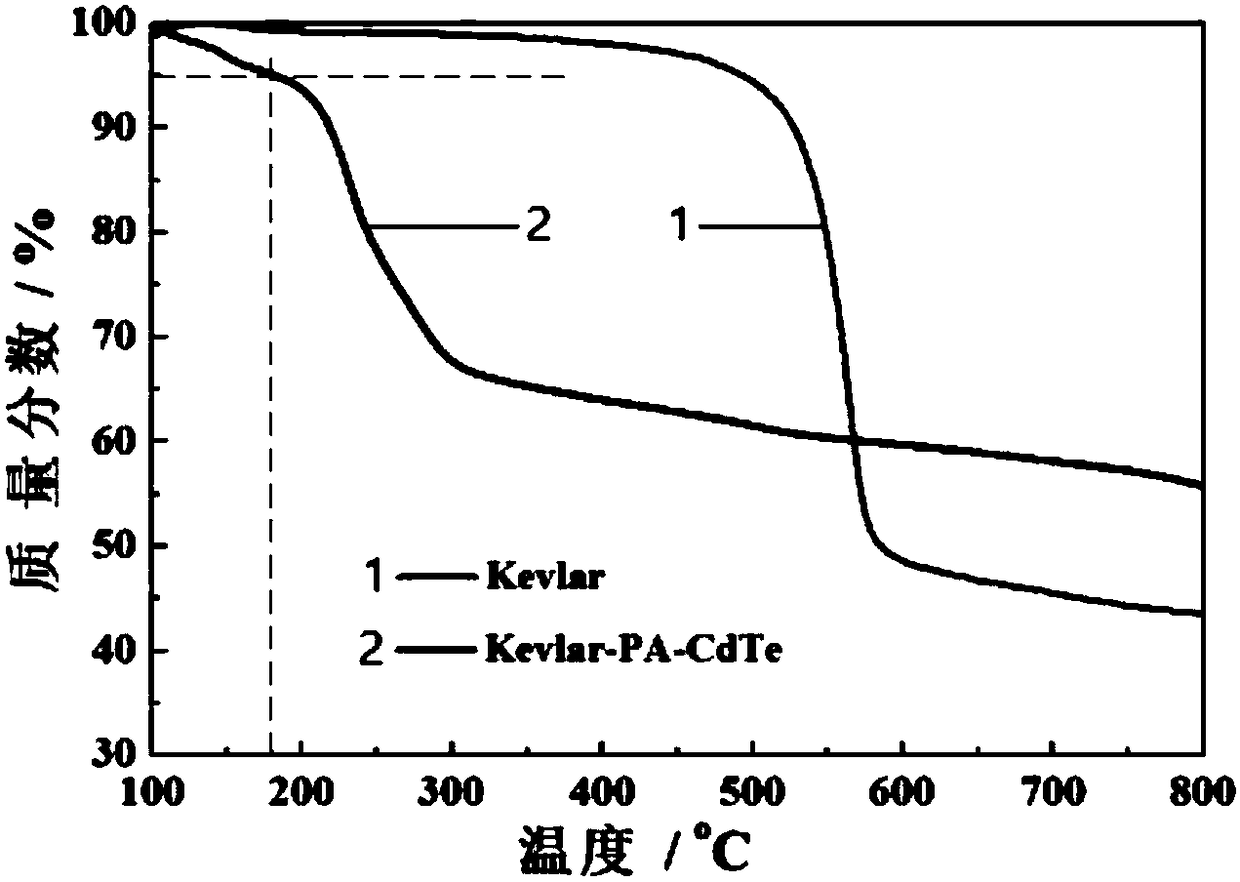

The invention belongs to the technical field of fuel cells, and relates to a preparation technology of a proton exchange membrane electrolyte, in particular to a method for preparing a phosphoric aciddoped, high temperature proton exchange membrane with a layer-by-layer assembly structure based on a spin coating technique. Kevlar nanofibers, cadmium telluride nanocrystals and phosphoric acid arespin-coated respectively to complete 2-5 layer assembly, and a 2-5 composite membrane with an ordered structure (Kevlar-CdTe-PA) is prepared; an oven-dried membrane is soaked in a phosphoric acid solution with a mass fraction of 40 to 85%, and the phosphoric acid doped (Kevlar-CdTe-PA) 2-5 / (40 to 85%) PA composite membrane based on the cadmium telluride nanocrystals is prepared. The method for preparing the phosphoric acid doped, high temperature proton exchange membrane with the layer-by-layer assembly structure based on the spin coating technique realizes the assembly of the Kevlar nanofibers and the cadmium telluride nanocrystals, and prepares the high-temperature proton exchange membrane with an ordered structure and good proton conductivity, and has potential application value in thefield of fuel cells. In addition, the method for preparing the phosphoric acid doped high temperature proton exchange membrane with the layer-by-layer assembly structure based on the spin coating technique provides a new research method and idea for preparing a novel composite membrane based on nanomaterials and the Kevlar nanofibers.

Owner:NORTHEASTERN UNIV

Kevlar nanofiber composite forward osmosis membrane, and preparation method and application thereof

InactiveCN104548968AHigh strengthIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSolventGlass sheet

The invention belongs to the technical field of membrane materials, and discloses a Kevlar nanofiber composite forward osmosis membrane, and a preparation method and application thereof. The preparation method comprises the following steps: stirring Kevlar fibers with an auxiliary agent, strong base and an organic solvent and dispersing to form a stable Kevlar nanofiber dispersion solution; adding a pore-foaming agent, and uniformly stirring to obtain a membrane casting solution; coating a glass plate with the membrane casting solution through blade coating to form a membrane, and soaking into a gel bath to form a gel membrane; soaking the gel membrane into an organic solution for solvent replacement to obtain a Kevlar nanofiber porous membrane; using the porous membrane as a substrate, diluting the Kevlar nanofiber dispersion solution, forming a membrane on the substrate through blade coating, soaking into the gel bath, taking out, and airing to obtain the Kevlar nanofiber composite forward osmosis membrane. The Kevlar nanofiber composite forward osmosis membrane has the advantages of high strength, high water flux and high salt intercepting rate, and is applicable to the field of water treatment.

Owner:广州粤禹环保科技有限公司

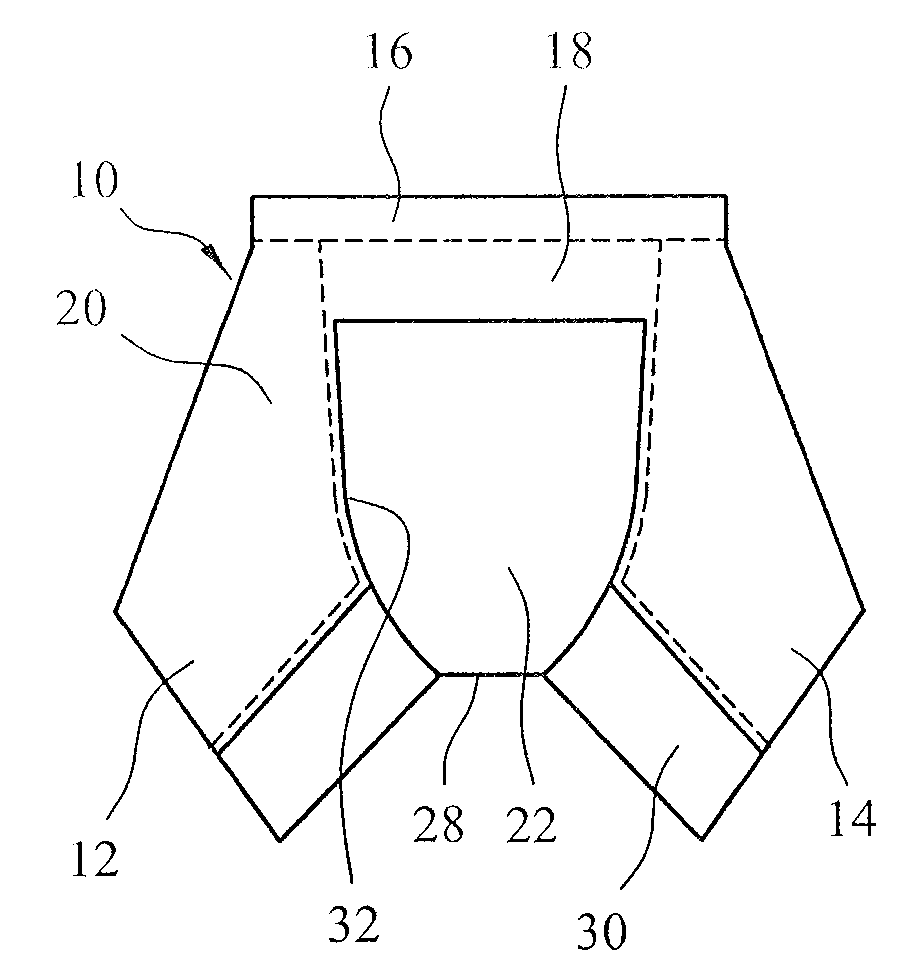

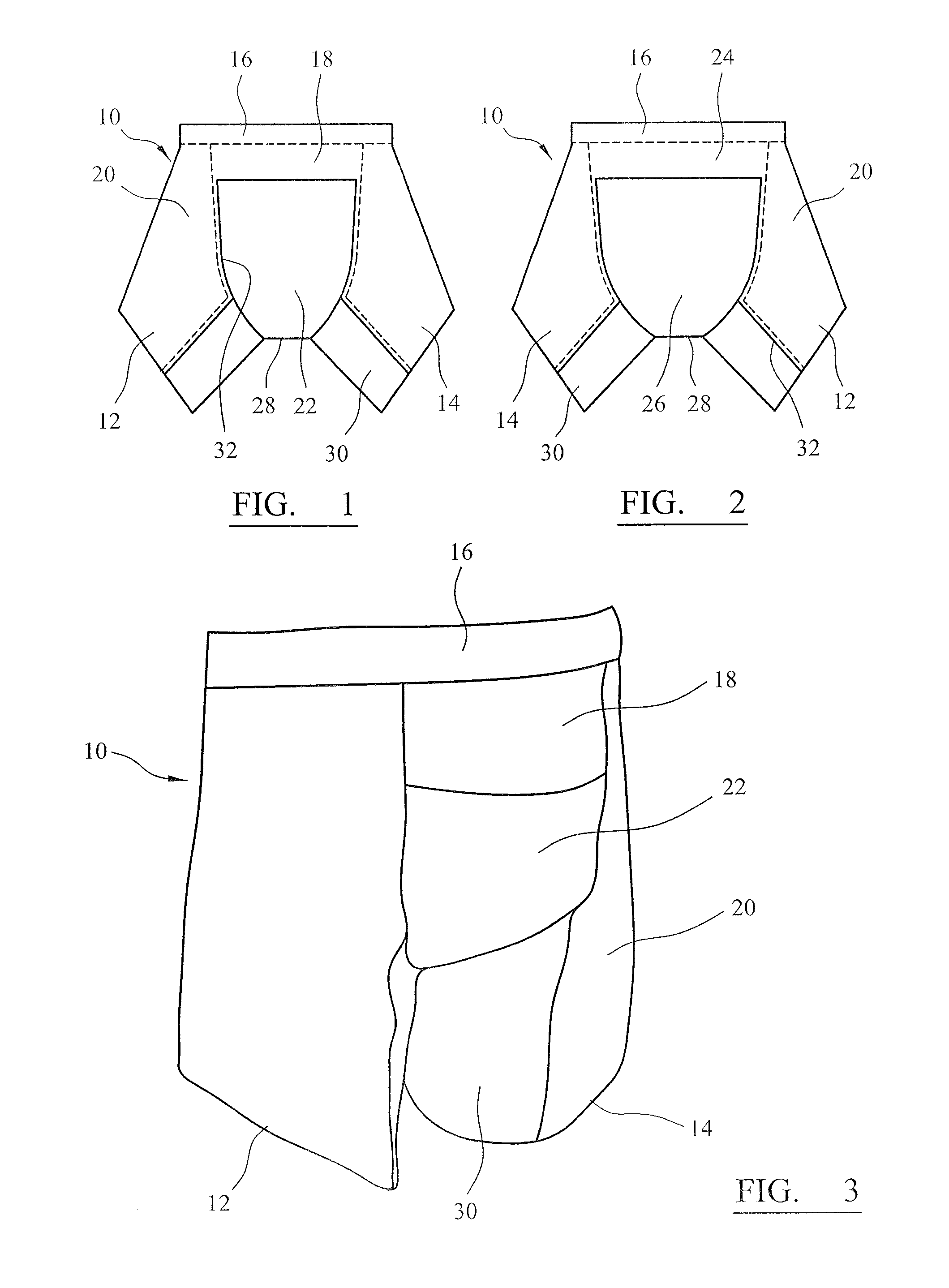

Multi-paneled protective undergarment

InactiveUS20130019365A1Improve mobilityImprove protectionPersonal protection gearProtective garmentThighButtocks

A protective undergarment (10), shown in the form of shorts, includes integrally formed protective panels (22, 26, 30) that exhibit slash-proof properties. The protective areas (22, 26, 30) are made from a flexible Kevlar® knit or the like, and extend to cover the groin, crotch, substantial areas of the buttocks and the inner thigh regions of both legs. The protective panels (22, 26, 30) are externally snitched to a low thermal burden material (18, 20), such as a polyester mesh, that provides elasticity and completes the structure of the shorts (10). The Kevlar® knit is flexible and preferably lies directly against the skin of a user to provide blast wave and ballistic fragment deflection whilst permitting mobility in a lightweight arrangement. Varying thickness of the Kevlar® knit can be used in the protective areas (22, 26, 30) selectively to enhance protection against blast wave and fragment penetration. The shorts (10) find particular application in battlefield theatres where military personnel are exposed to bomb threats.

Owner:BCB INT

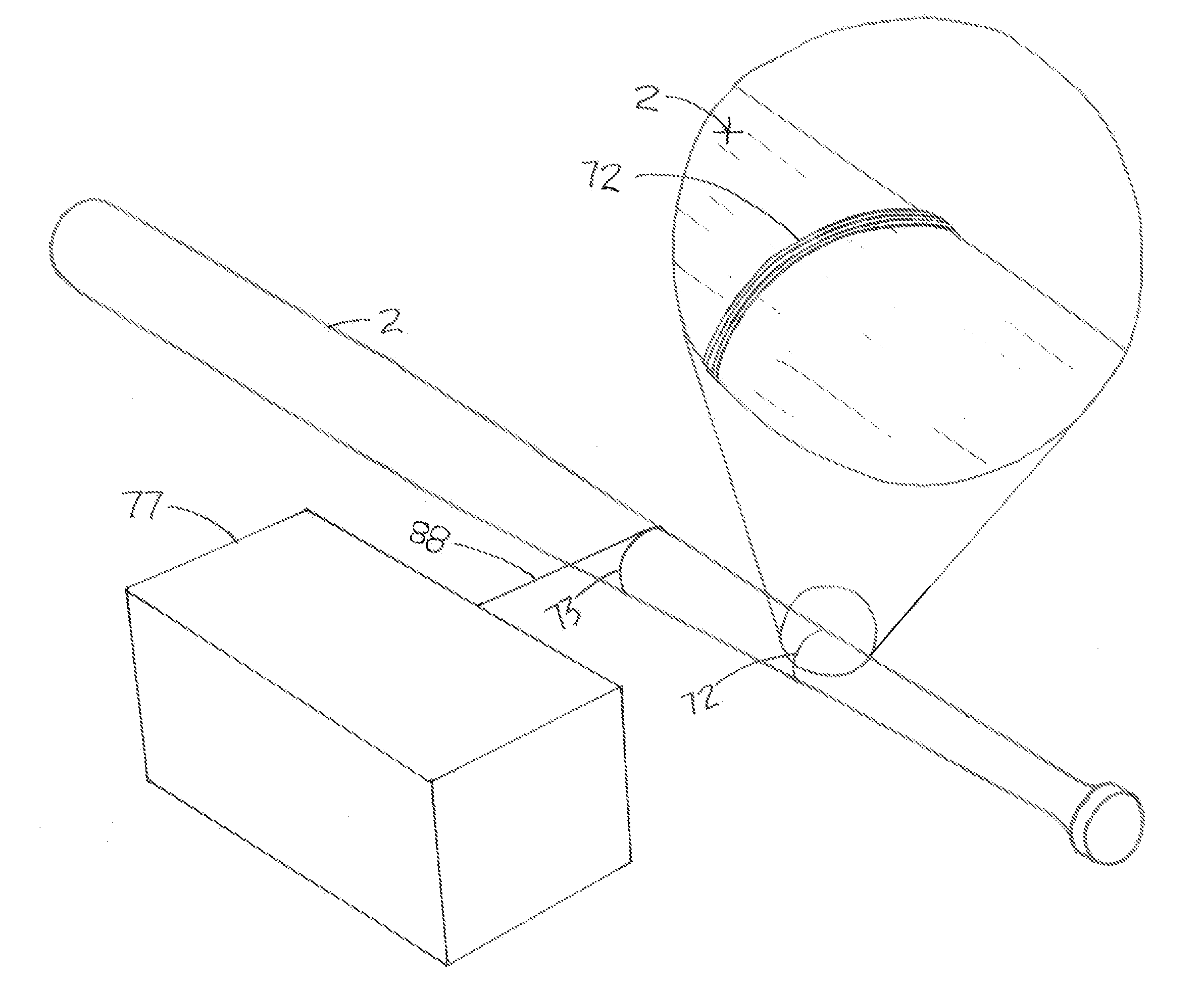

Reinforced Wooden Baseball Bat and Method

InactiveUS20130045823A1Small weightReduce breakageLaminationLamination apparatusMicrochiropteraKevlar

A reinforced wooden baseball bat is provided which includes a wooden bat body having a handle portion, a barrel portion, and a tapered portion in between, connecting the handle to the barrel, the handle diameter being smaller than the barrel diameter; this reinforced bat further includes one or more applications of wraps of high-strength and low weight threads of para-aramid fiber (Kevlar), carbon fiber thread or other high-strength and lightweight thread, wound, under tension, onto the circumference of said bat, with circumferential turns of said high-strength thread, applied and bonded to the wood bat, at locations along the length of the bat, where it is calculated that said bat will be made the strongest thereby. The location(s) along the bat, number of wraps, thread diameter, thread tension and the number of turns of thread per wrap, are calculated to maximally strengthen each individual bat, considering its characteristics.

Owner:SUBLETT SR ROBERT EARL

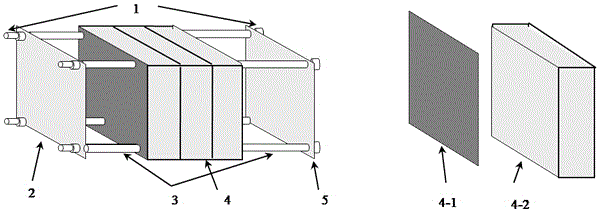

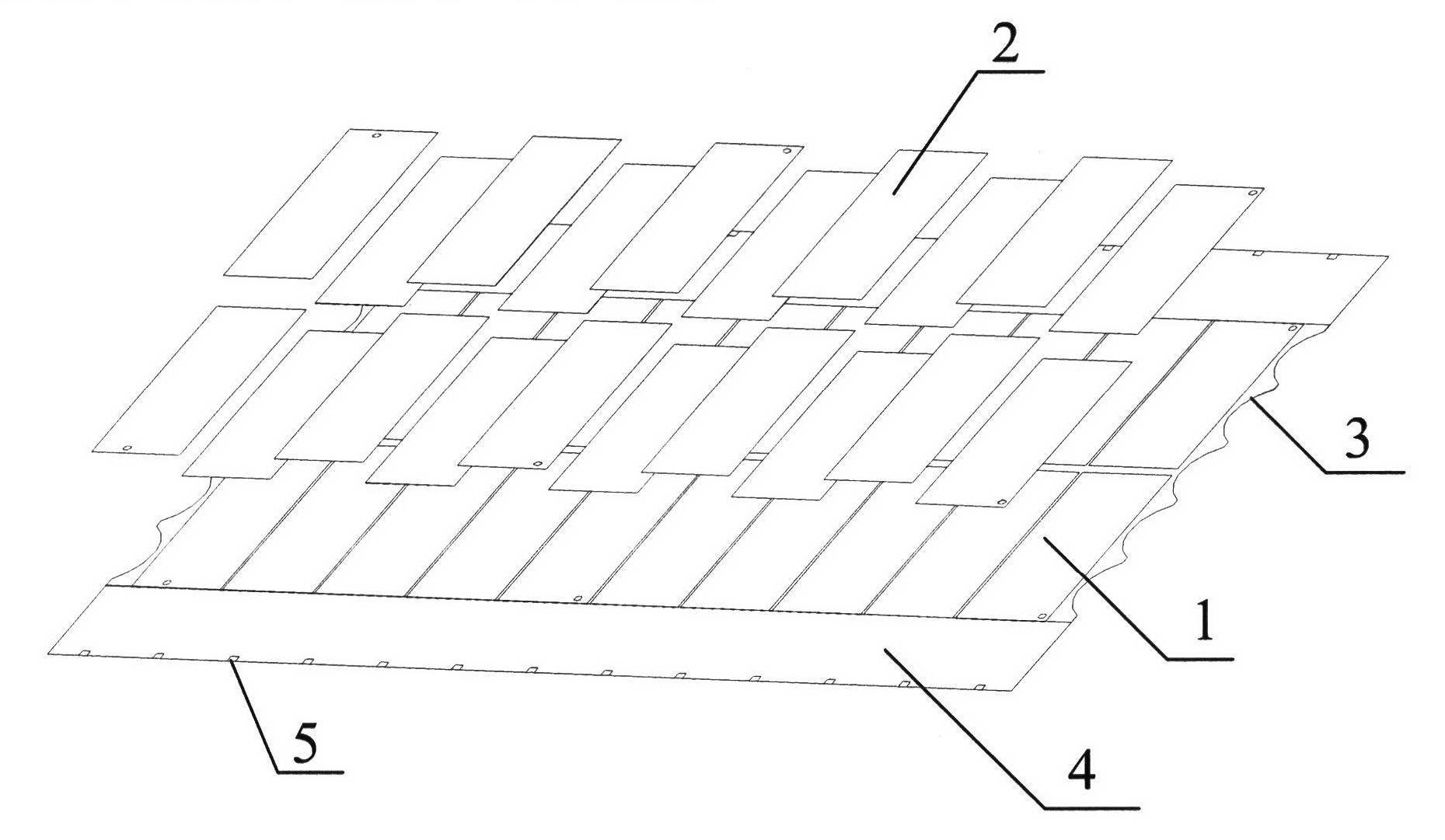

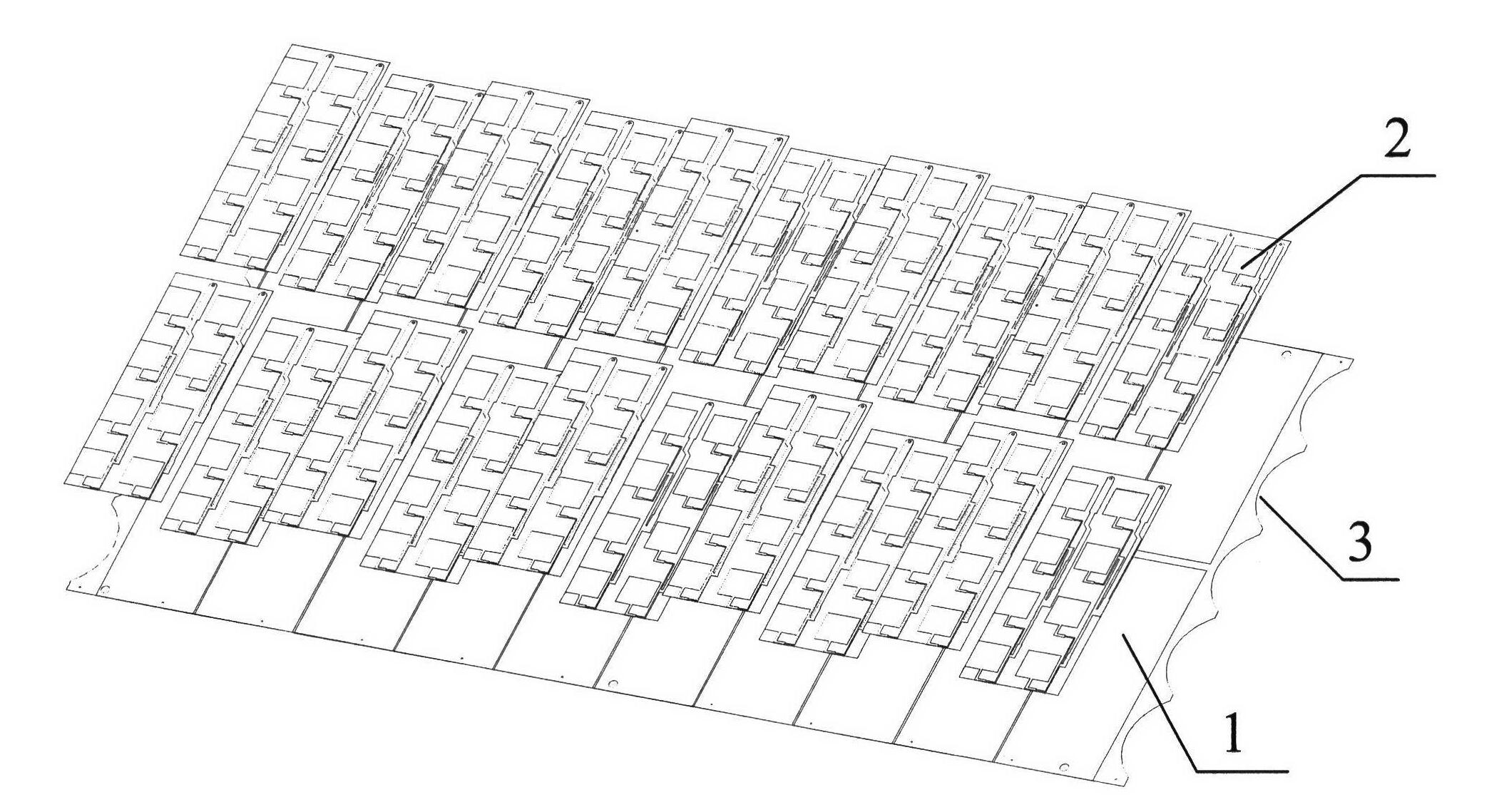

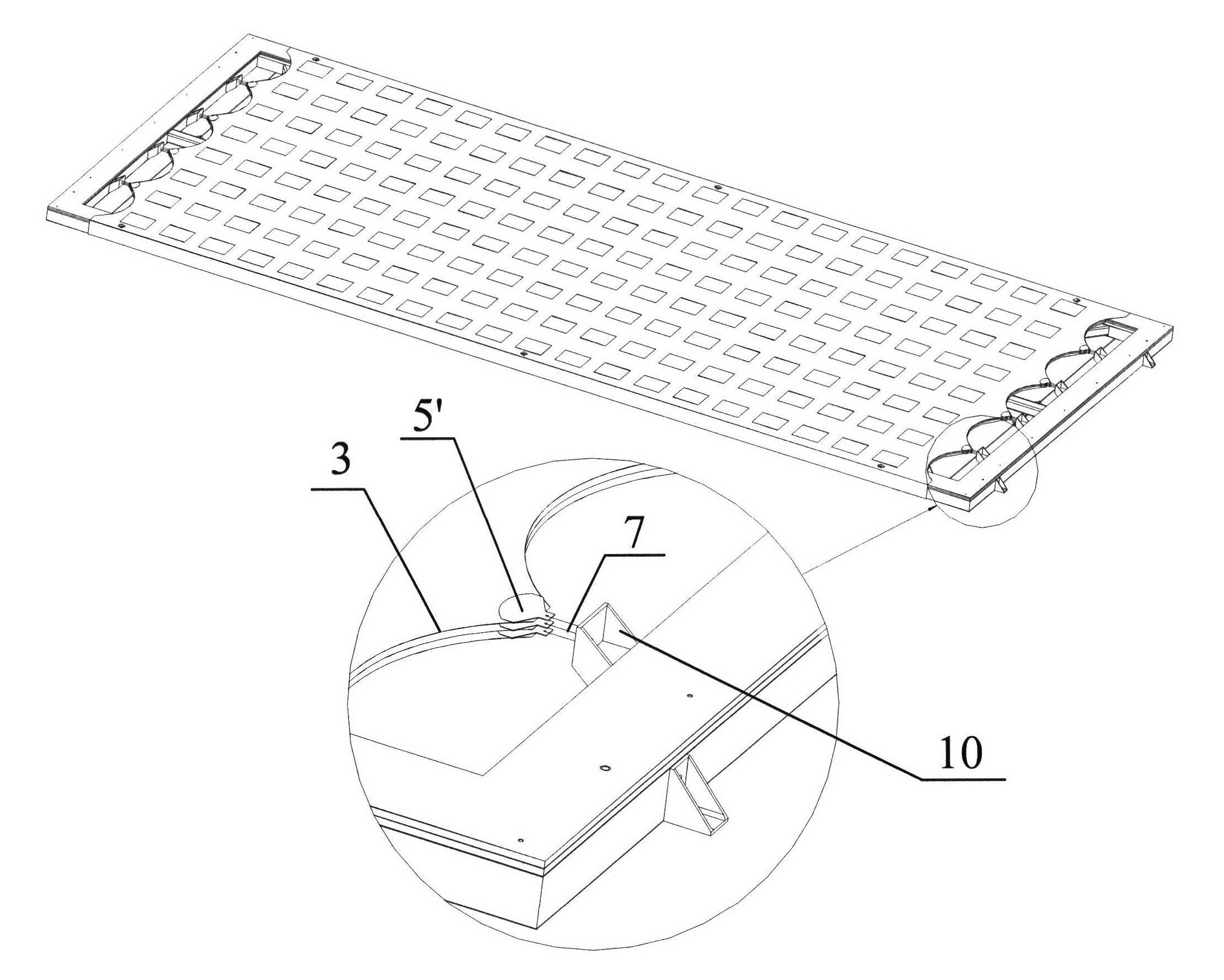

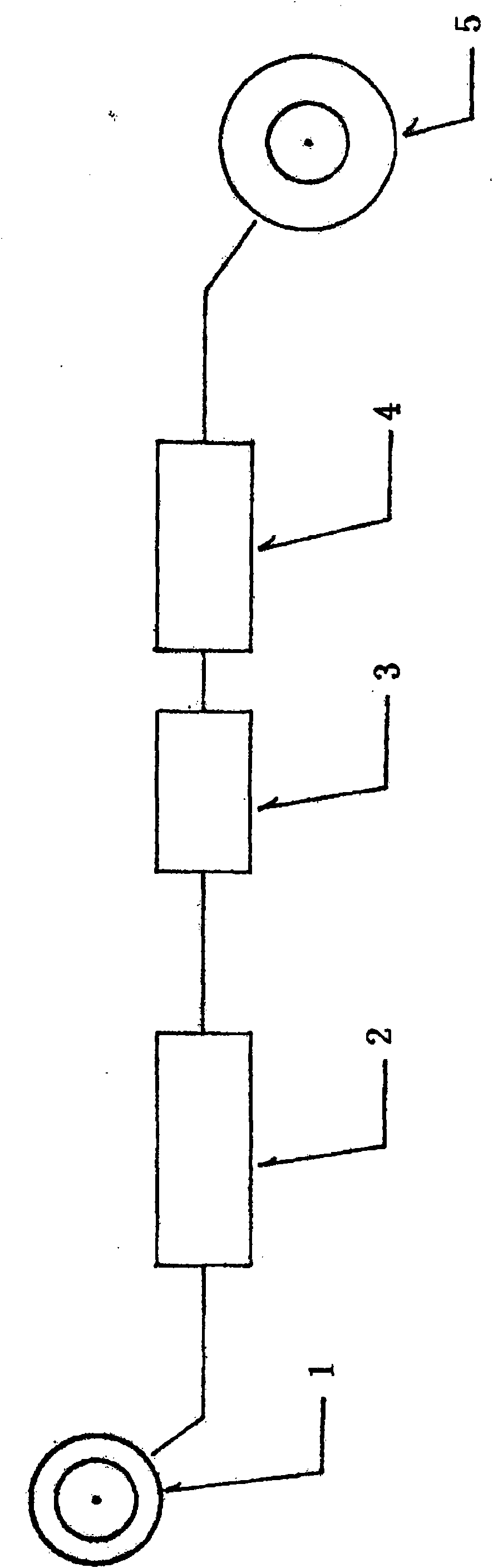

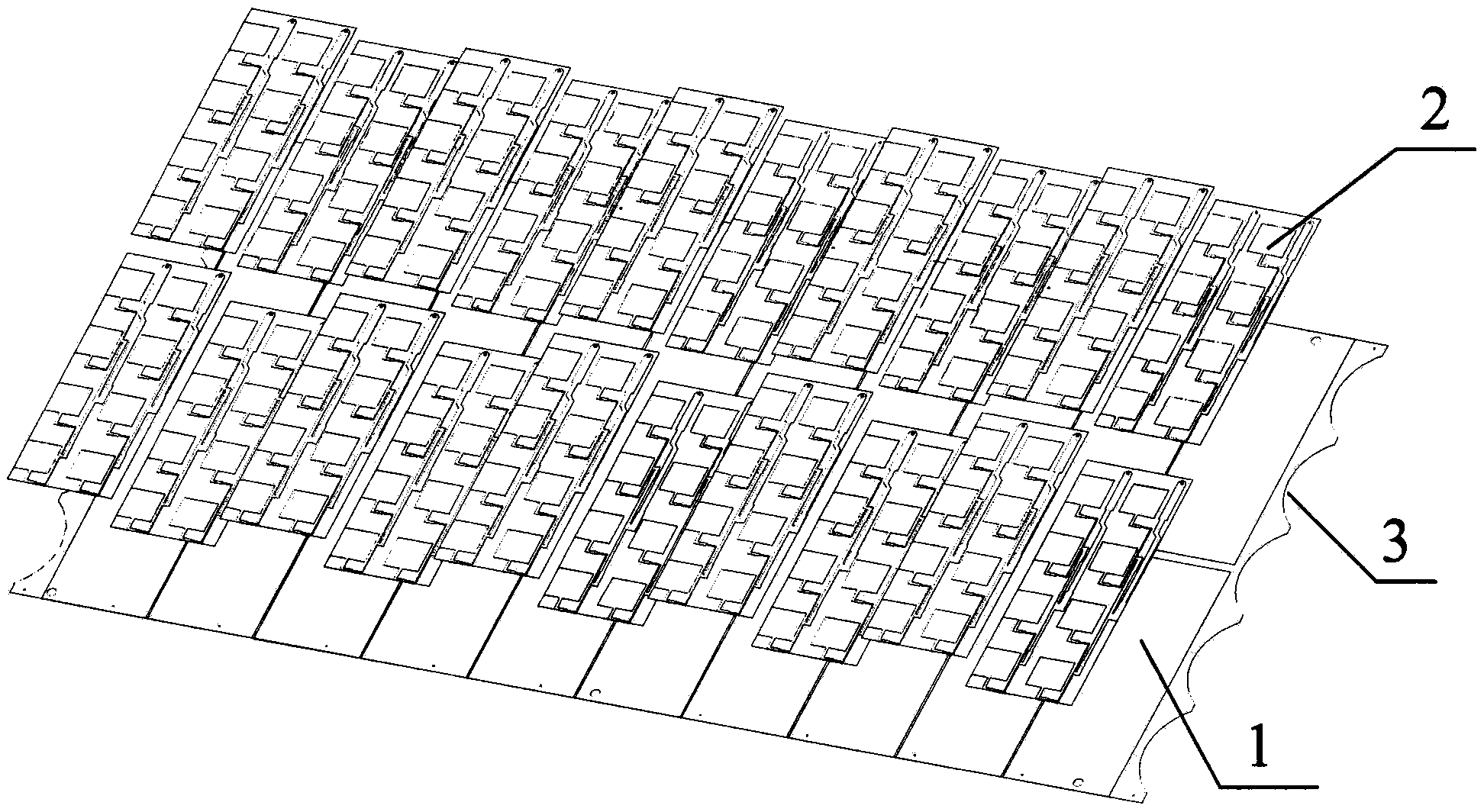

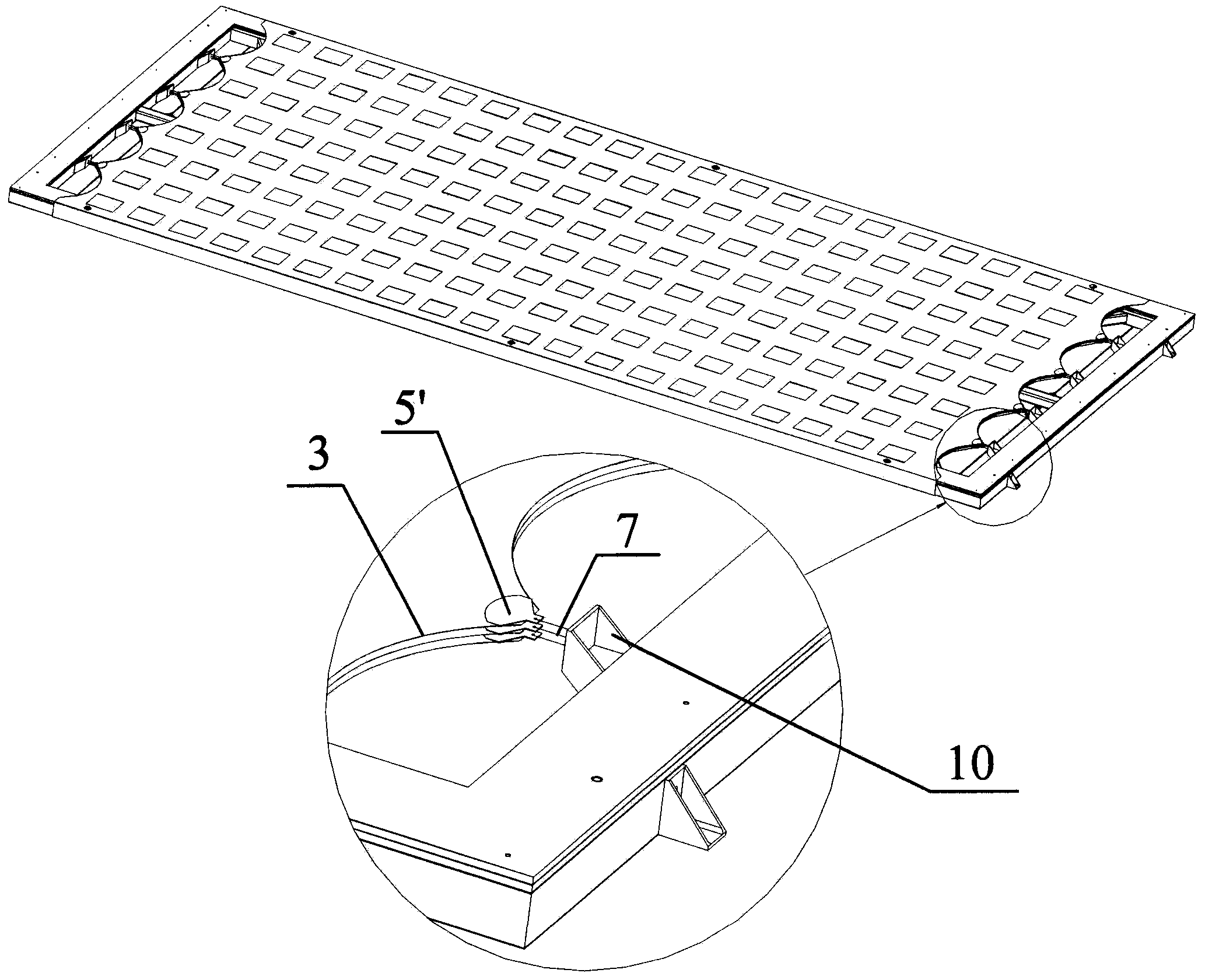

Method for preparing pre-tension membrane structure antenna

ActiveCN102593576ASolve size-constrained challengesGuaranteed fixed spacing requirementsAntenna arraysAntenna supports/mountingsNomex honeycombMembrane surface

The invention relates to a method for preparing a pre-tension membrane structure antenna. The method comprises the following steps: designing a membrane surface into a base membrane and electric membranes, splicing the base membrane and forming the electric membranes; marking out a bottom membrane according to a designed paste range, pasting the electric membranes; processing catenaries, splicing auxiliary strengthening plates, positioning the membrane surface by utilizing installation holes of a support framework of the membrane antenna and placing the first membrane surface on a corresponding position of the support framework; reversely loading pretightening force on the long side of the membrane surface by utilizing auxiliary loaded ropes and the support of the support framework, pre-tensioning tension ropes by an adjustment device and adjusting the tension ropes to designed positions for splicing and fixing; and installing a dielectric Kevlar / Nomex honeycomb panel so as to finally realize an antenna array surface. In the method, a phased-array antenna array surface is realized through a membrane structure; the weight of a traditional phased-array antenna structure is lightened; and the method provided by the invention has the characteristics that the pre-tension membrane structure antenna is capable of being continuous loaded; the membrane tension can be accurately controlled, the operation is convenient, a special membrane tying tool is not needed, and the like.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

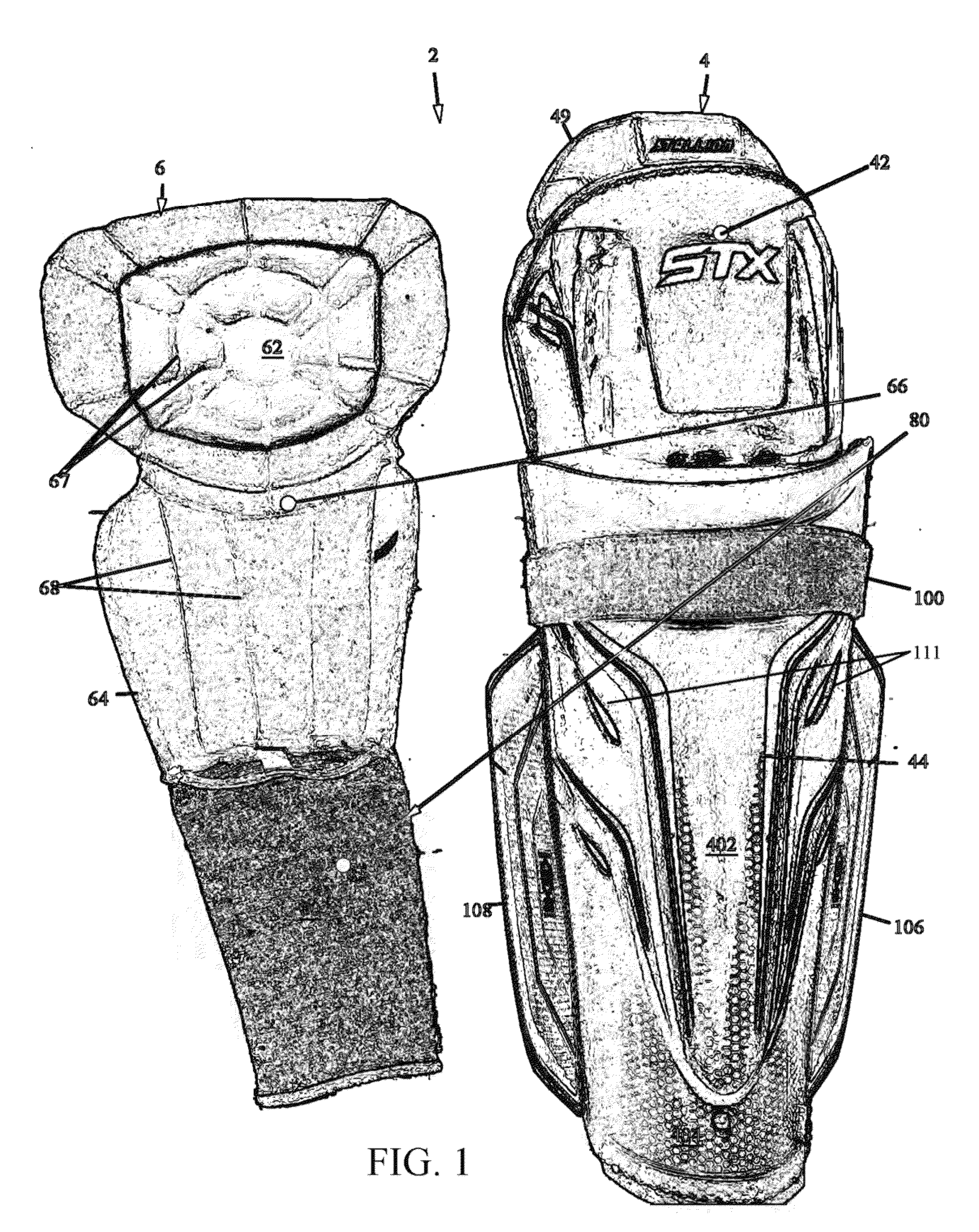

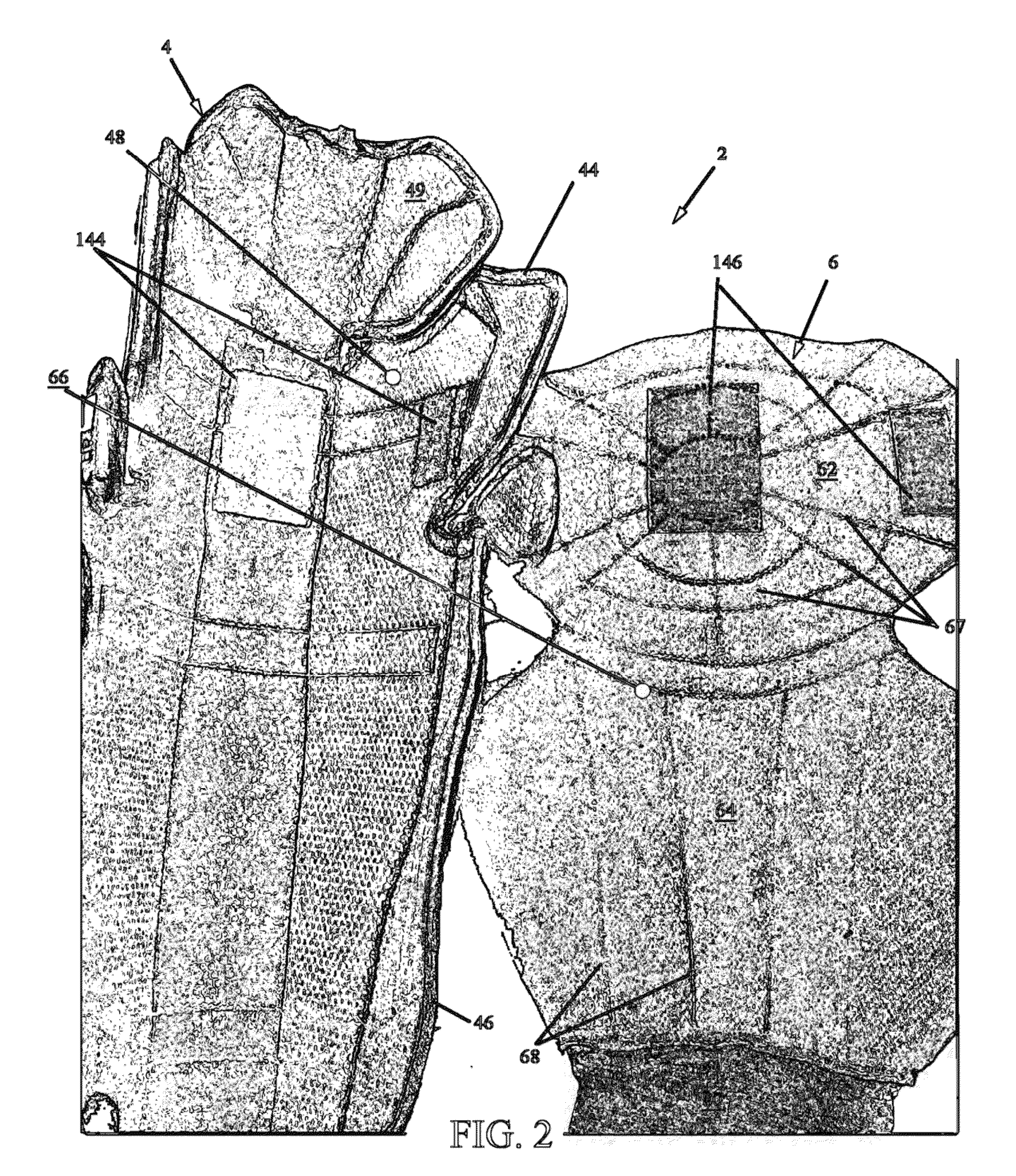

Sports shin guard with cut - resistant sleeve

A protective shin guard includes a floating knee section hingedly attached to a shin section, both sections being formed of one or more hard shell panels. The floating knee section is attached to the shin section by a main padding layer, and a liner is attached beneath the main padding layer. The liner includes an integral cut-resistant calf-sleeve attached along its bottom edge and extending downward. The cut-resistant calf-sleeve is an elastic tubular sleeve formed of a weave of elastic / cut-resistant fibers, e.g., Kevlar® and Spandex. The cut-resistant calf-sleeve is long enough to surround both the calf and the ankle. The cut-resistant calf-sleeve also provides a lower attachment feature that combines with an upper 360+ degree attachment strap to provide a better fit that will not shift or come loose during play.

Owner:WM T BURNETT IP

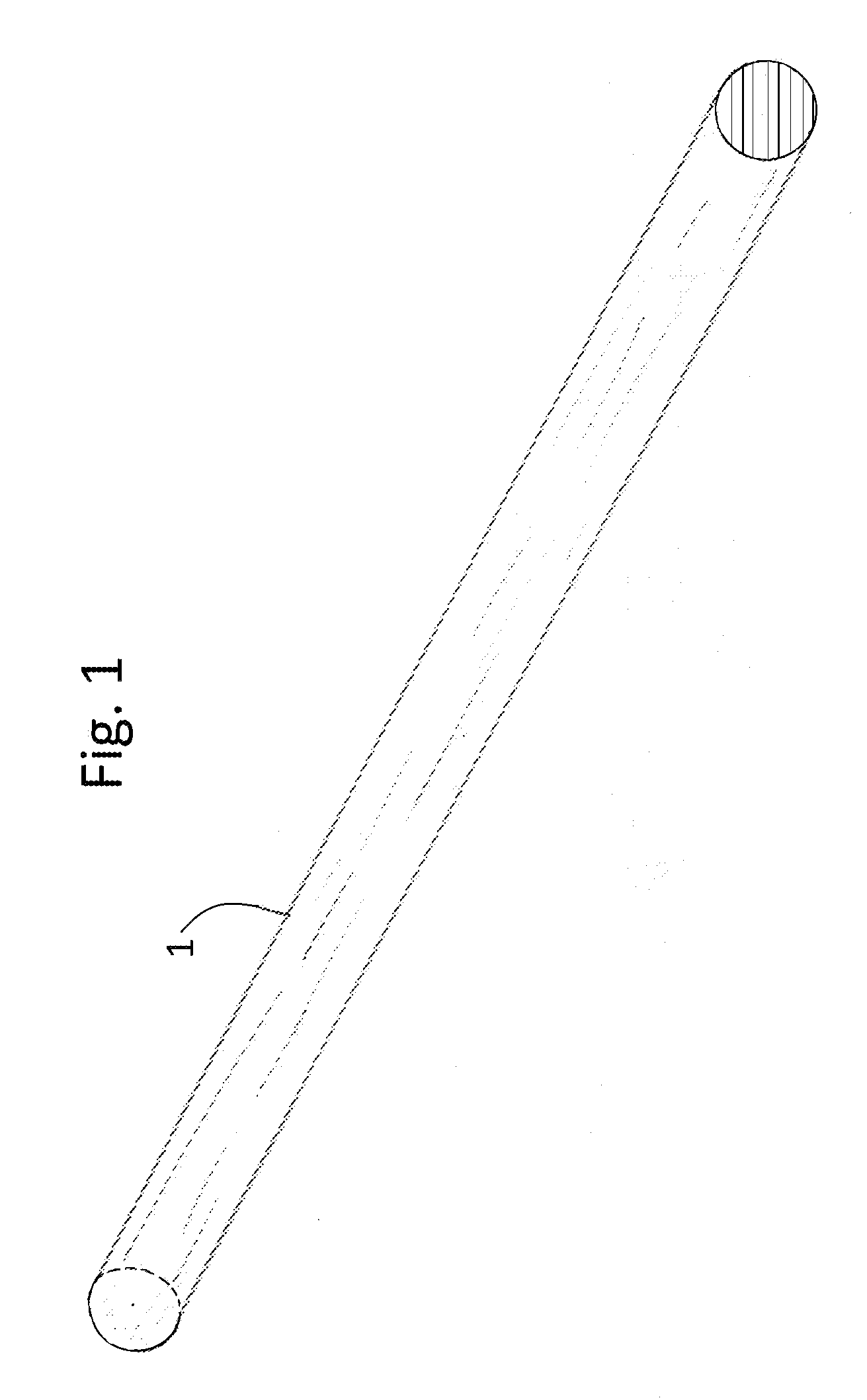

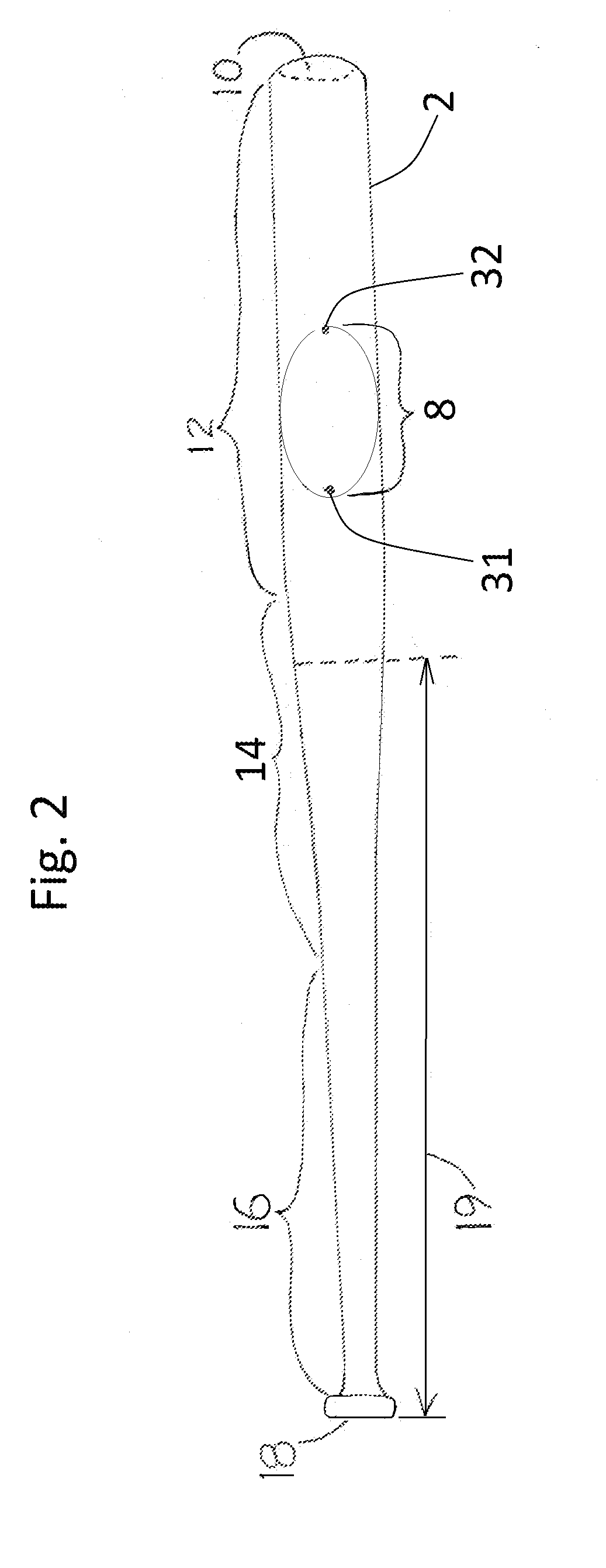

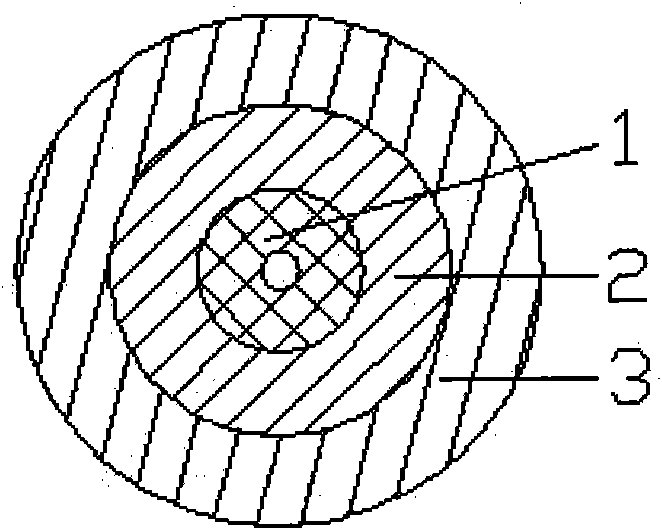

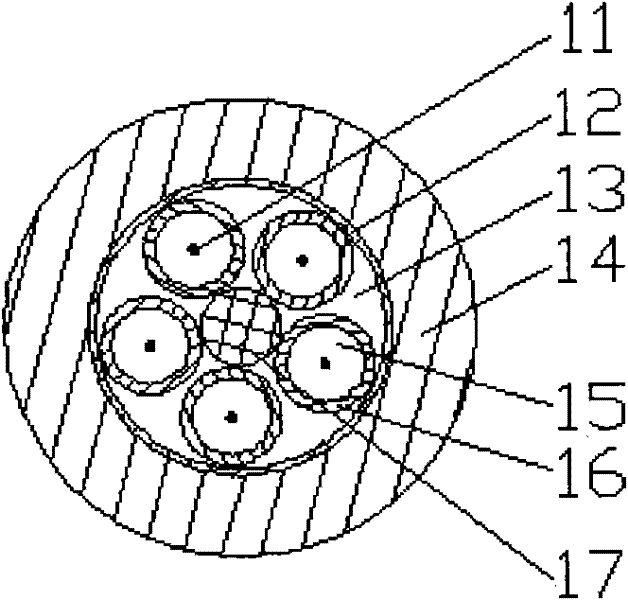

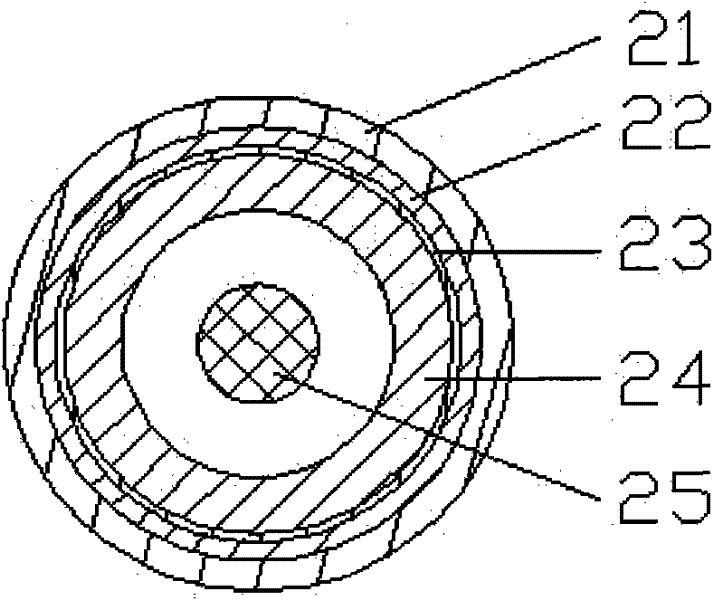

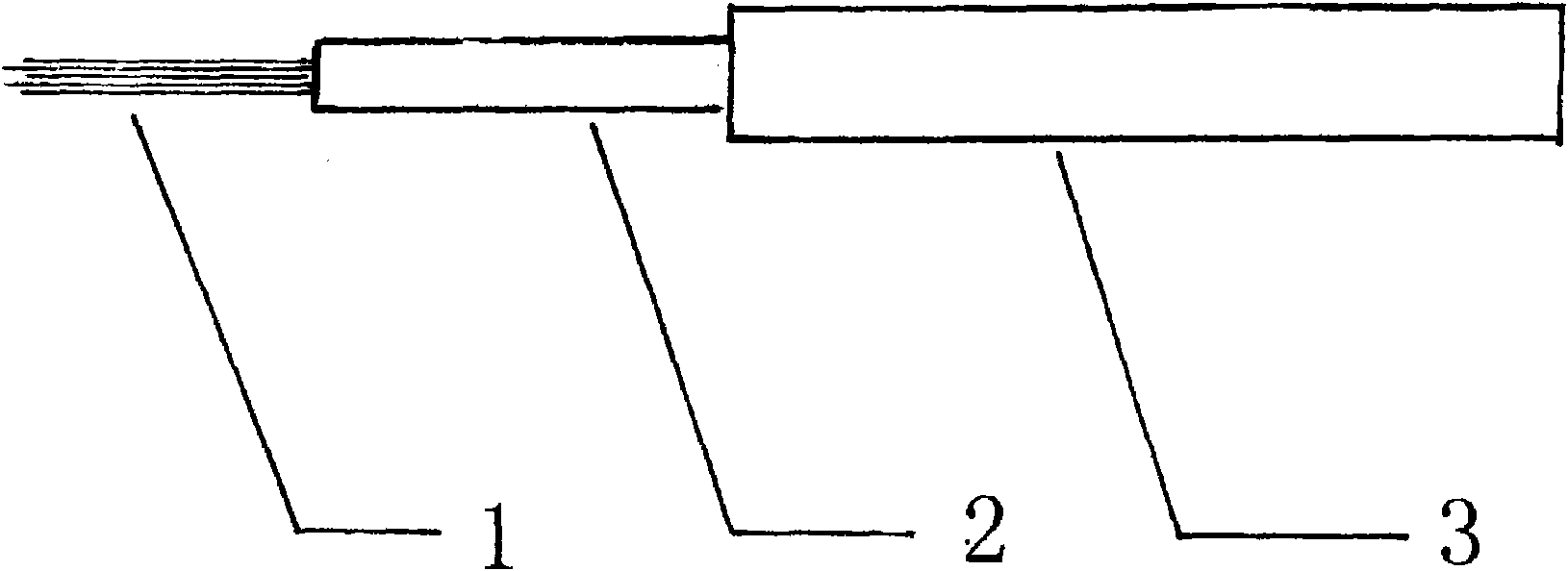

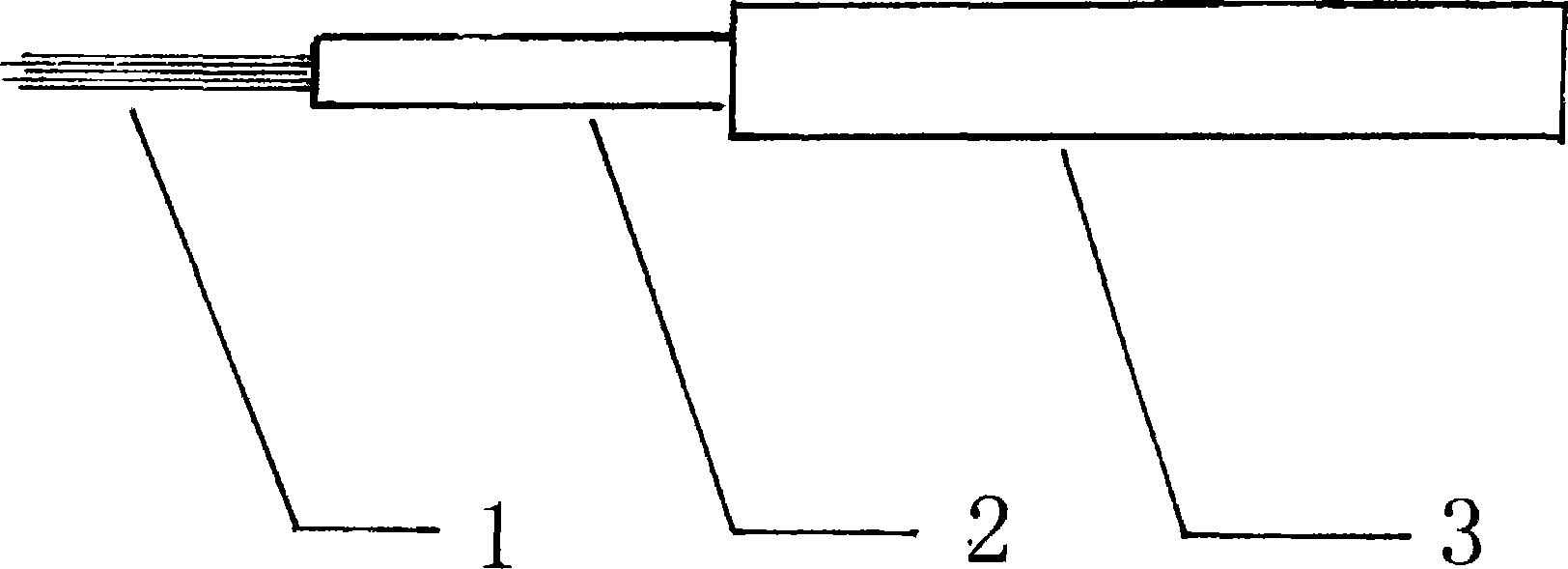

Armored sensing optical cable

InactiveCN102681114AImprove tensile propertiesImprove torsion resistanceThermometers using physical/chemical changesFibre mechanical structuresKevlarOptical fiber cable

The invention discloses an armored sensing optical cable, which comprises a tightly packaged fiber, a metal hose, a metal mesh grid and an outer jacket layer, wherein the tightly packaged fiber is wrapped by the metal hose; the metal mesh grid is coated out of the tightly packaged fiber; the outer jacket layer is coated on the metal mesh grid; when one tightly packaged fiber is provided, a laeyr of Kevlar is arranged between the metal hose and the metal mesh grid; when multiple tightly packaged fibers are provided, a layer of Kevlar and a flameproof inner jacket are arranged between the metal hose and the tightly packaged fiber in sequence. The armored sensing optical cable is armored by the small metal hose, the minimum outer diameter is only 0.9 mm after armored, and the minimum outer diameter of the optical cable is only 1.8 mm after the optical cable is formed. The interval between the tightly packaged fiber of the armored sensing optical cable and the external environment is small, the temperature measuring speed of the armored optical cable is quicker than that of the common optical cable, and the temperature measuring precision is accurate. The problems of complicated structure of a common outdoor optical cable structure, isolation of the optical fiber and the external environment and poor temperature measuring effect are solved.

Owner:东捷光电科技(苏州)有限公司

Fabric for protective clothing and protective clothing

Disclosed is a fabric for a protective clothing. The fabric is woven from weft and warp threads with different portion of a pigmented Para-Aramide i.e. Kevlar(RTM: para-aramid synthetic fiber). The fabric is woven with a one-sided interloop such that a large amount of the thread with a lower Para Aramide-portion is provided on an outer side of the fabric than the thread with a higher Para-Aramide-portion. It is suggested that a protective cloting is formed by weaving at least part of the fabric.

Owner:IBENA TEXTILWERKE

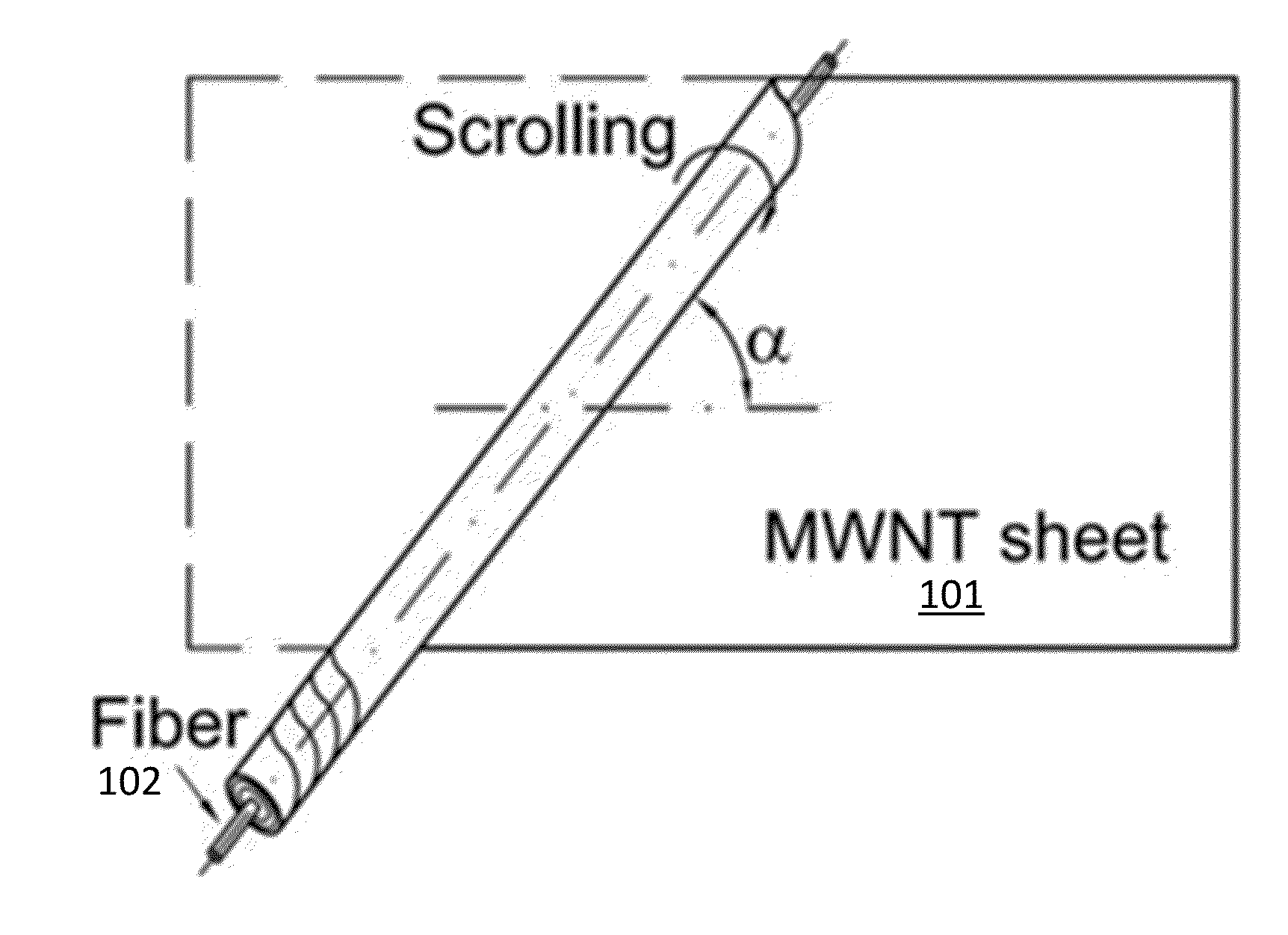

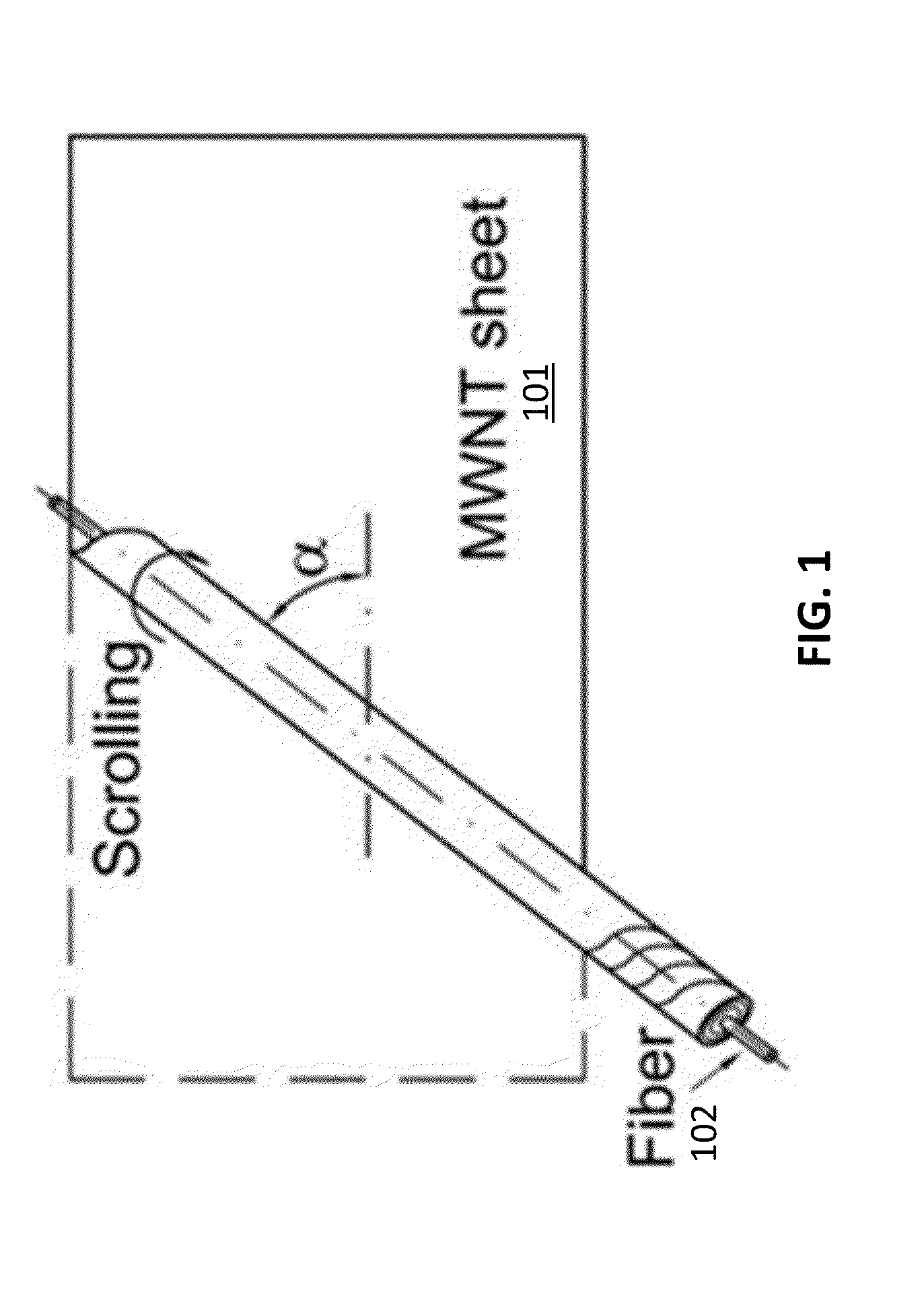

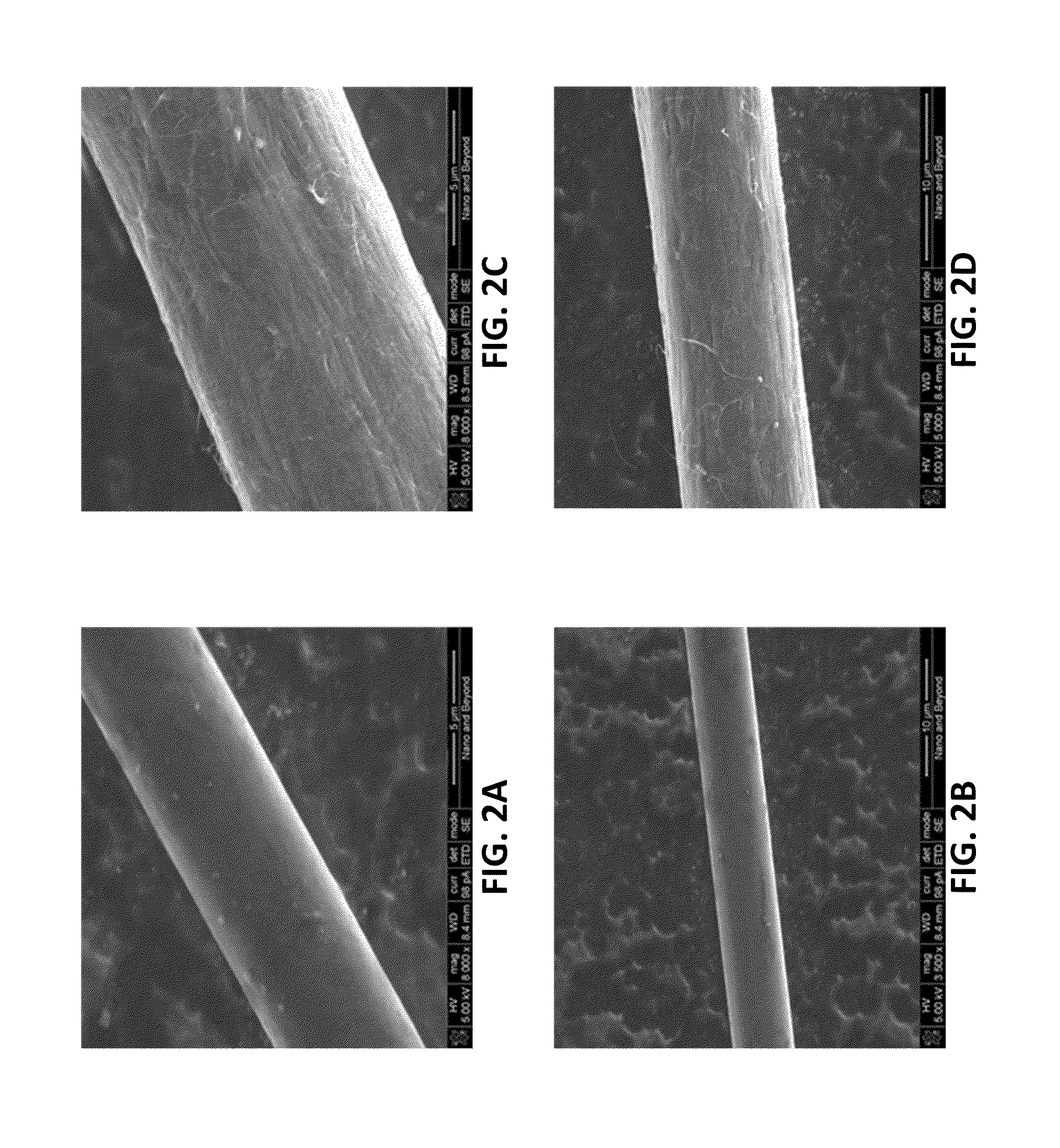

Method of fabricating carbon nanotube sheet scrolled fiber reinforced polymer composites and compositions and uses thereof

A novel method of fabricating carbon nanotube sheet scrolled fiber and fiber tows (carbon, graphite, glass, natural polymer, synthetic polymer, metallic, silicon carbide, Kevlar, etc.) in composites with improved interfacial shear strength, compressive strength, yield strength, stiffness and toughness has been reported. Single or multiple layers of carbon nanotube sheet, with a bias / wrapping angle of 0° and 90°, has been scrolled around single fiber and fibers tows to improve the above mentioned mechanical properties of the matrix surrounding the fiber. Other common methods of growing CNTs directly on the fibers actually damage the fiber surface during the required precursor deposition and CNTs growth process. This demonstrated solid-state method overcomes such known problems. The CNTs sheet scrolled fiber is embedded into the polymer matrix exhibits significant (80%) increase in interfacial shear strength, compressive strength and toughness.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

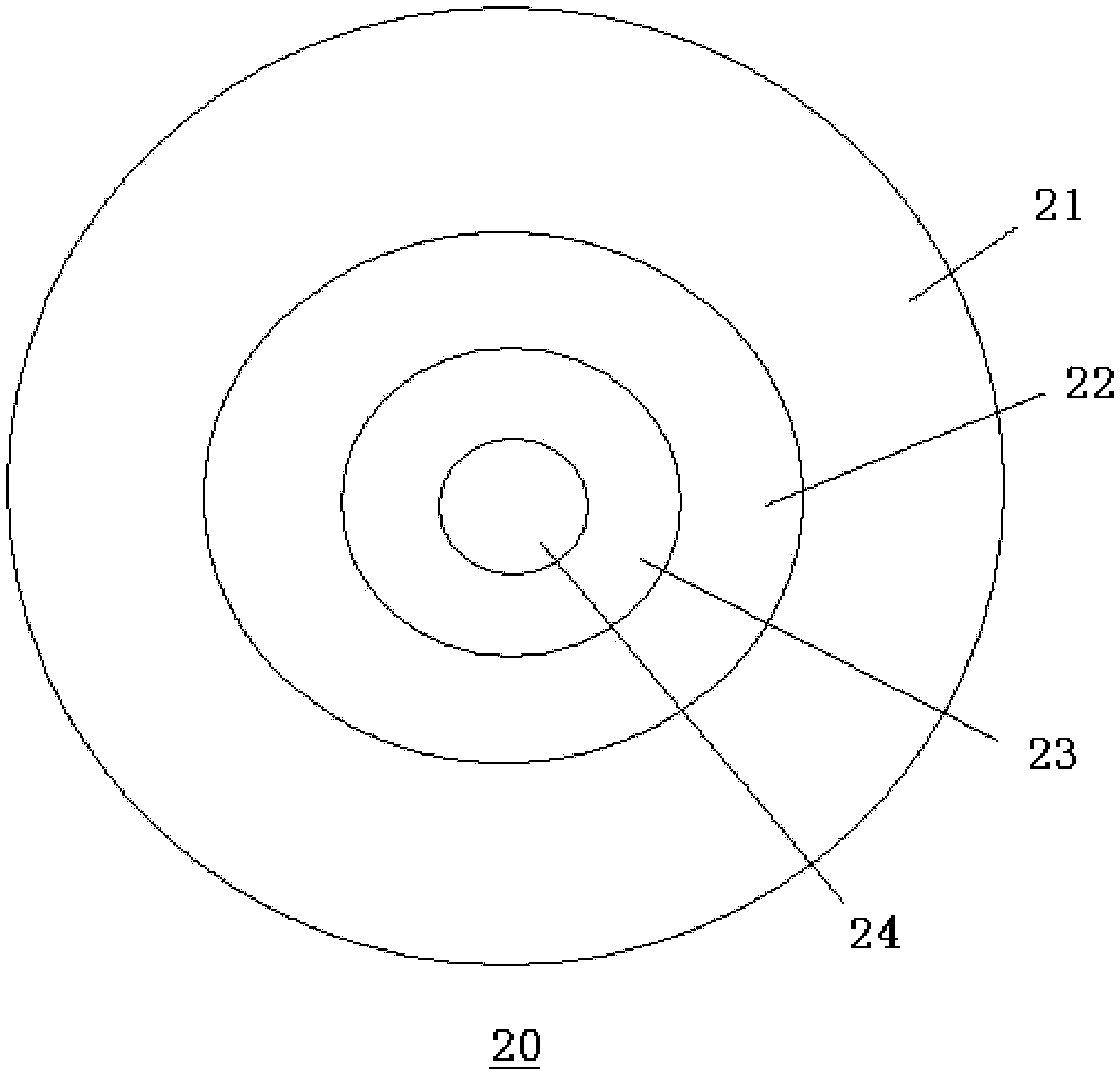

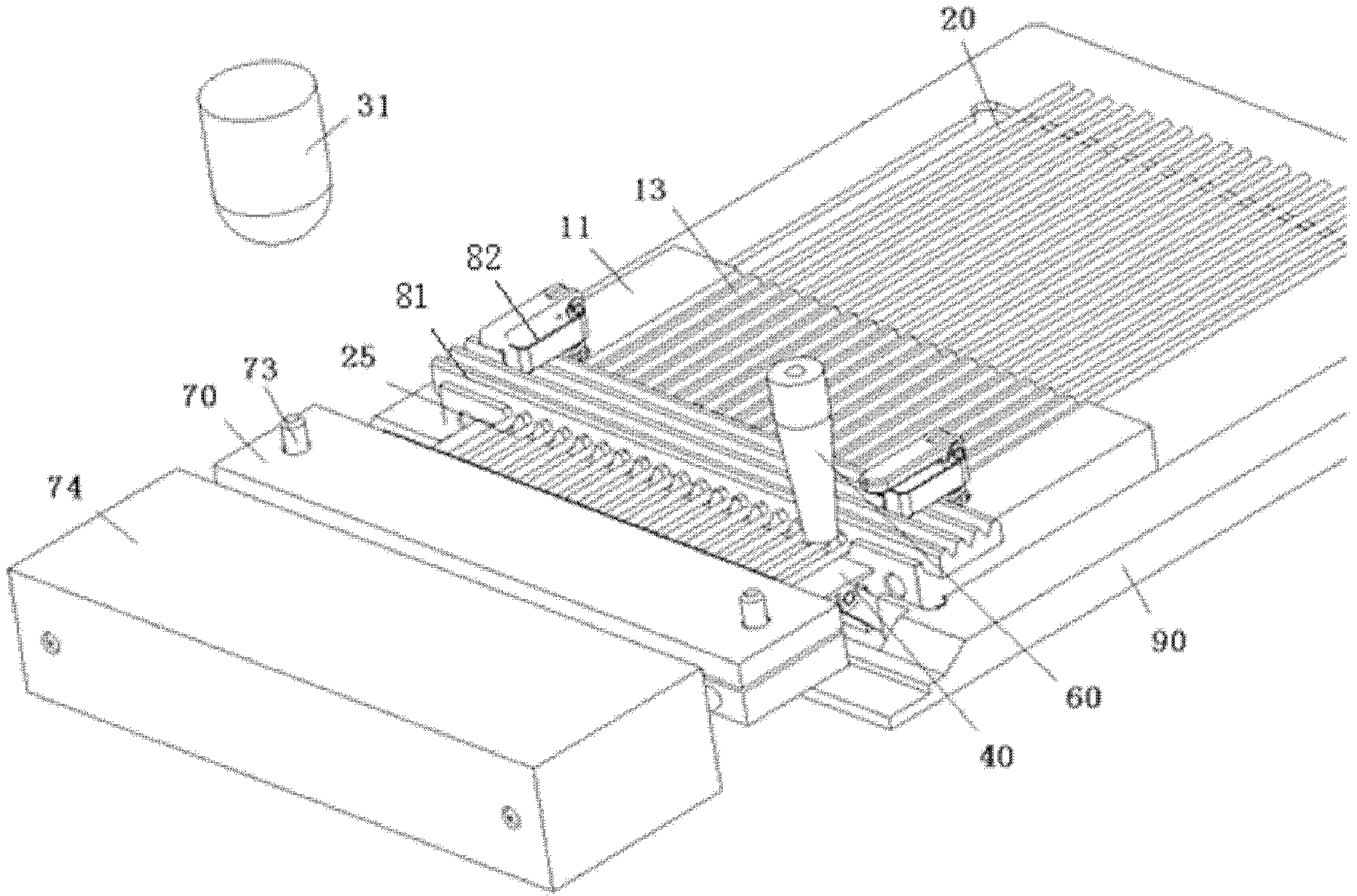

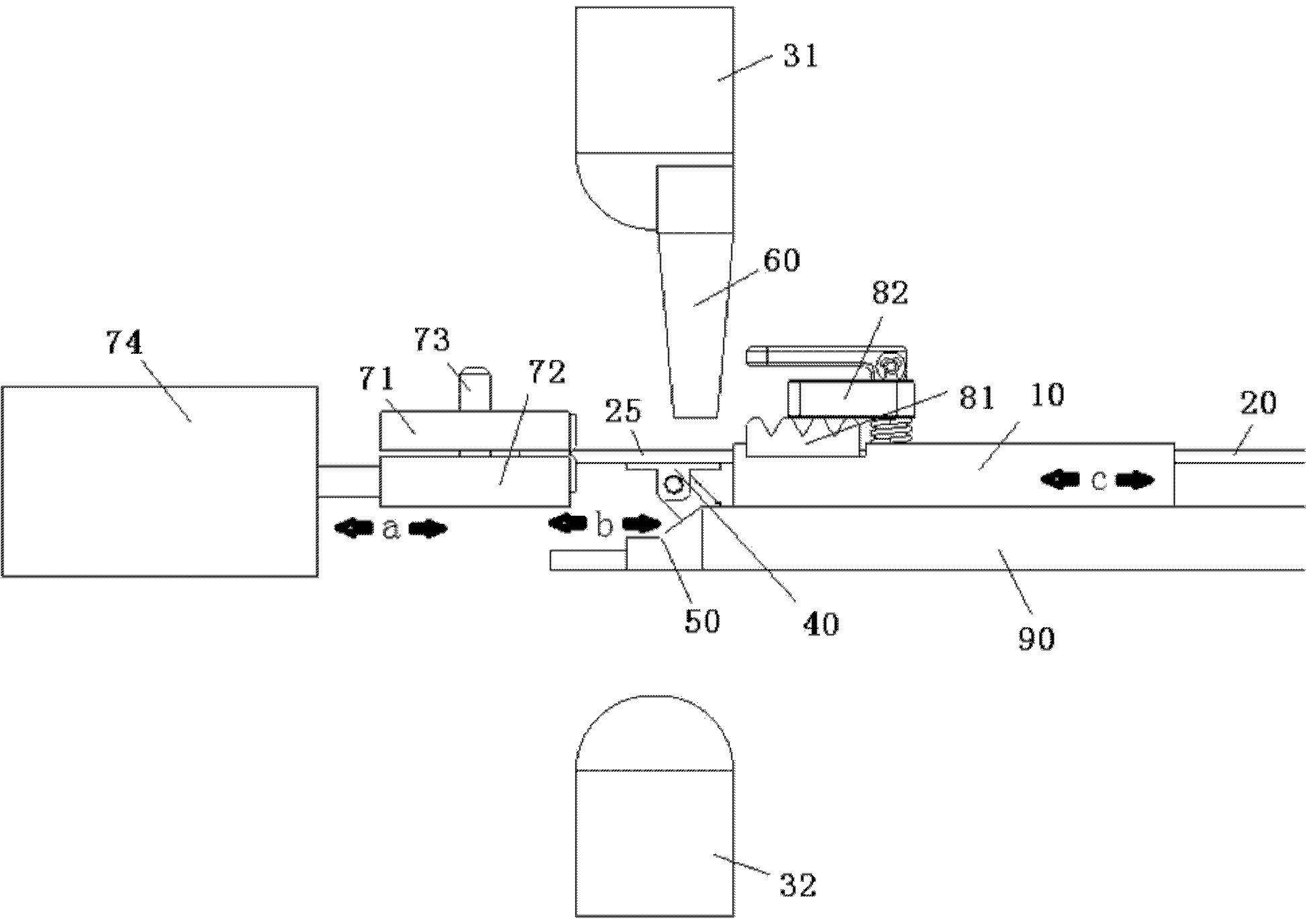

System and method for stripping optical cable

InactiveCN103777276AAchieve separationAvoid lossCoupling light guidesFibre mechanical structuresBare fiberKevlar

The invention relates to a system for stripping an optical cable. The optical cable (20) includes a bare fiber (24), a coverage layer (23) wrapping the bare fiber, a Kevlar layer (22) and an optical-fiber protective sleeve (21) from inside to outside. The system includes an optical-cable loading bench (10) provided with an end face (12) and an optical-cable loading face (11), wherein the optical-fiber loading face (11) is structured to be suitable for fixing the optical cable to be stripped on the loading face of the optical-cable loading bench and an to-be-stripped end of the optical cable extends out of the end face of the optical-cable loading bench; an air injection device (60) suitable for blowing air to the Kevlar exposed at the to-be-stripped end so as to make the Kevlar separate from the bare fiber; and a cutting device used for cutting the separated Kevlar. The invention also relates to an optical-cable stripping method.

Owner:ADC TELECOMM (SHANGHAI) DISTRIBUTION CO LTD

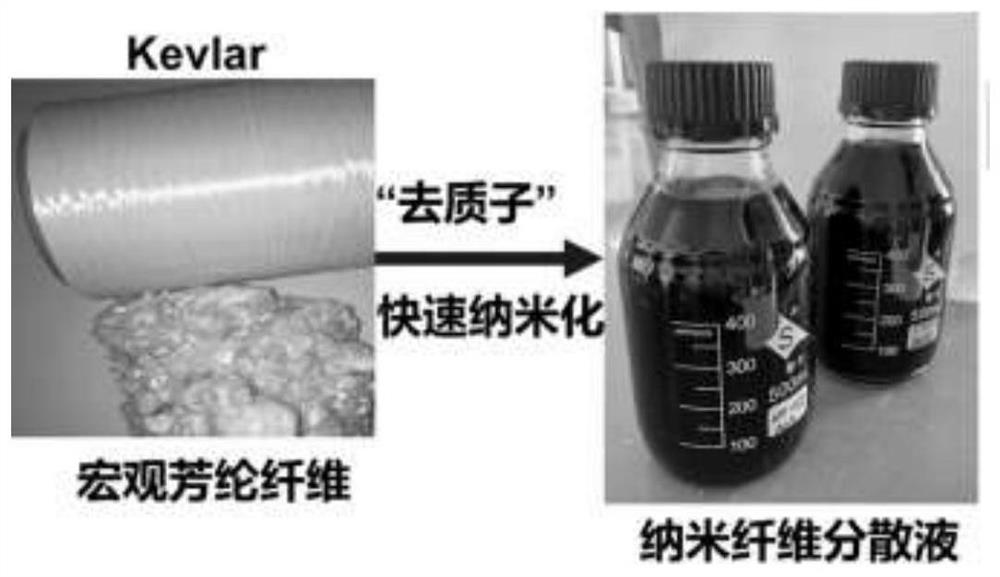

Method for preparing aramid nanofibers based on deprotonation of Kevlar and nanofiber prepared thereby

ActiveCN112878036AIncrease concentrationAccelerated destructionFibre typesBulk chemical productionPolymer scienceOrganic solvent

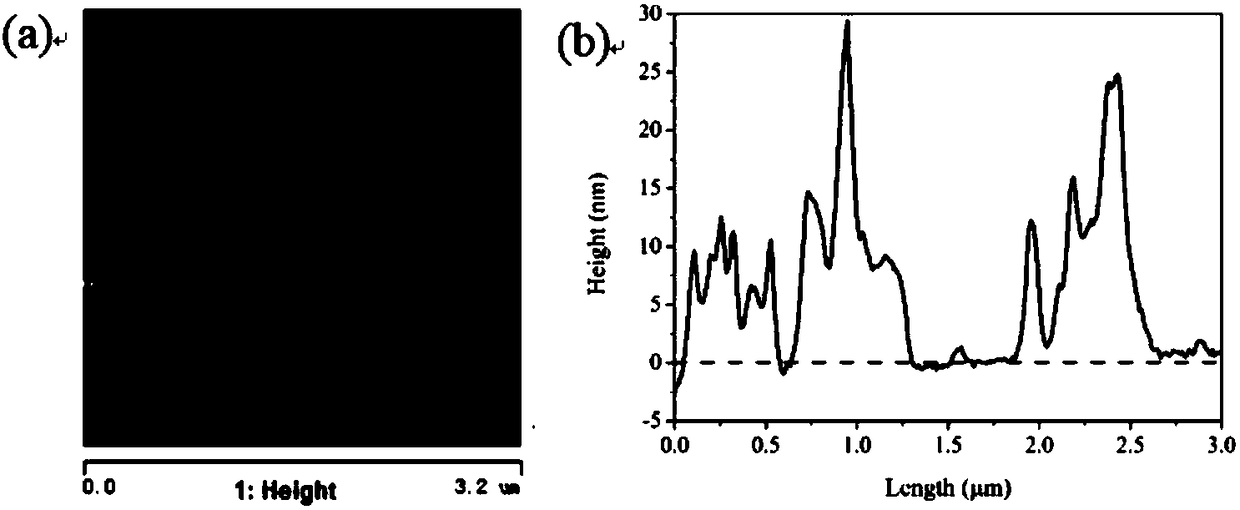

The invention provides a method for preparing aramid nanofibers based on Kevlar deprotonation. The method comprises the following steps: stirring and pretreating a mixed system of aramid fibers, an organic solvent and alkali to obtain an aramid fiber dispersion liquid; and adding a proton donor and / or an ionic reaction aid into the aramid fiber dispersion liquid to regulate and control the deprotonation degree so as to obtain an aramid nanofiber colloidal dispersion liquid. The invention further provides the aramid nanofiber colloidal dispersion liquid prepared by the method. According to the method, the nanocrystallization rate (within 1-4 hours) and the concentration (can reach 4 wt% or above) of a reaction system of the aramid fiber are increased, and the prepared aramid nanofibers are uniform in size, high in stability (the length is 5-20 microns and 5-30 nanometers), large in specific surface area and length-diameter ratio and excellent in high temperature resistance; and the method is simple in equipment and process and high in applicability, solves the problems of long preparation period, low reaction concentration, low production efficiency and the like, and has extremely high actual production and application values.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-performance rubber composite material containing Kevlar nano-fibers and preparation method thereof

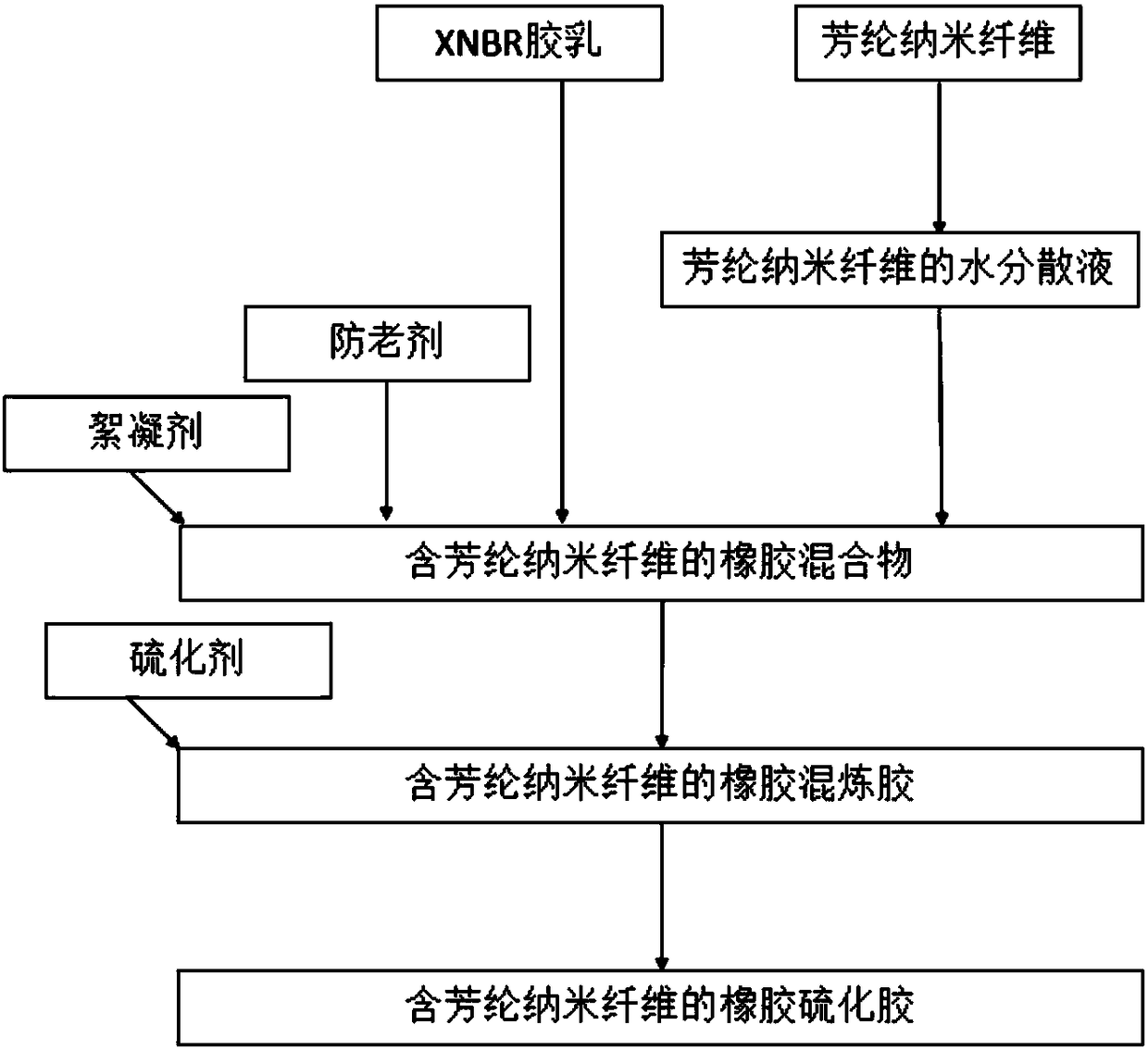

The invention discloses a high-performance rubber composite material containing Kevlar nano-fibers and a preparation method thereof. Kevlar nano-fiber aqueous dispersion is prepared by hydrothermal treatment of Kevlar fibers under a certain condition, then the dispersion is mixed with XNBR latex, the mixture is added into a flocculating agent, an XNBR mixture containing Kevlar nano-fibers is prepared by a co-agglomeration method, and an XNBR composite material with high mechanical properties and containing the Kevlar nano-fibers can be obtained through vulcanization processing by adding a vulcanizing agent. According to the high-performance rubber composite material containing Kevlar nano-fibers, provided by the invention, the Kevlar nano-fibers are added into rubber and well dispersed ina rubber matrix through a latex blending method, moreover, the mechanical properties of the rubber are improved. Therefore, the application range of XNBR rubber is expanded.

Owner:NANJING UNIV OF SCI & TECH

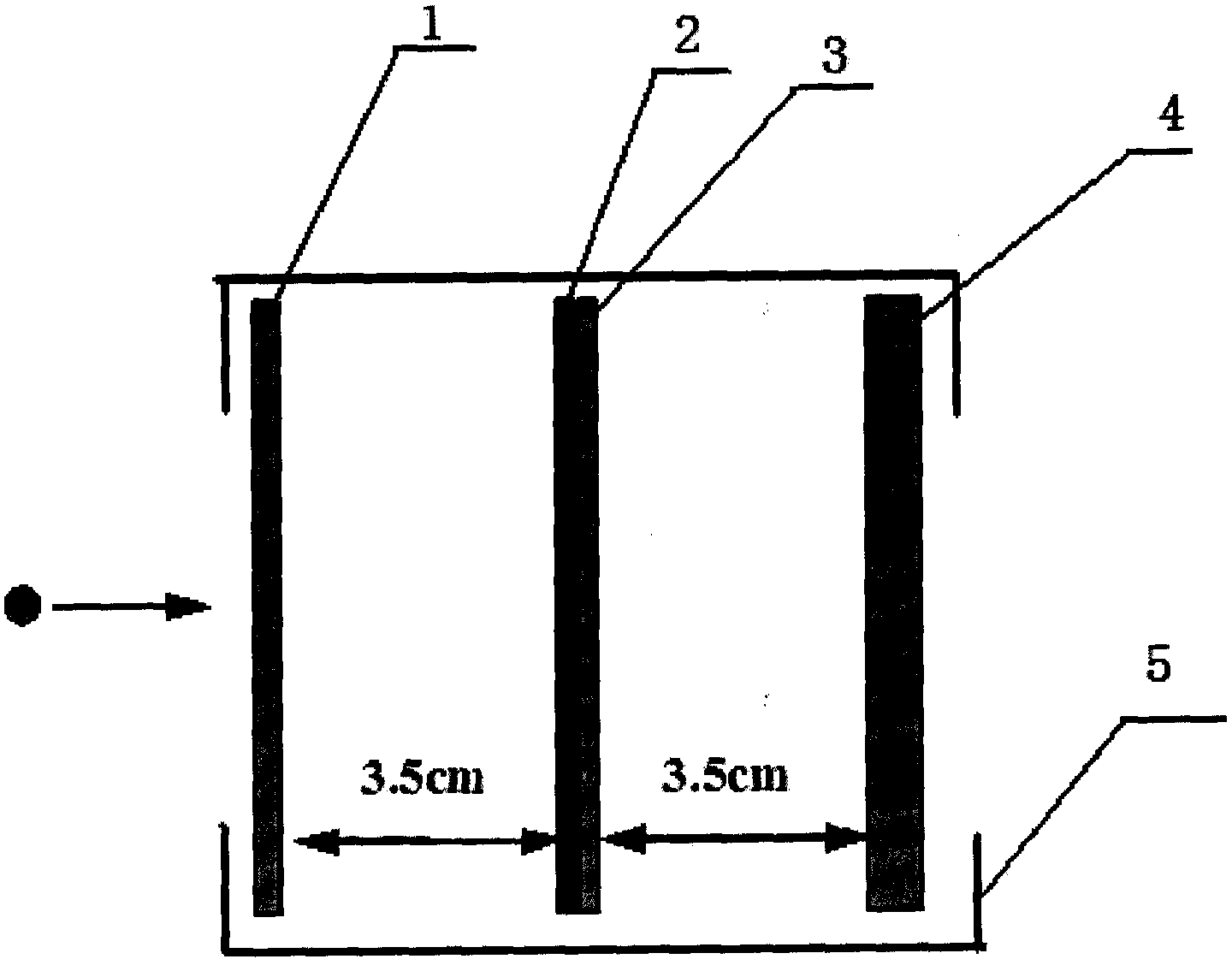

A filling type whipple protective structure based on basalt fiber fabric and its manufacturing method

ActiveCN105659753BAvoid damageStrong engineering application potentialLayered productsCosmonautic safety/emergency devicesKevlarBasalt fiber

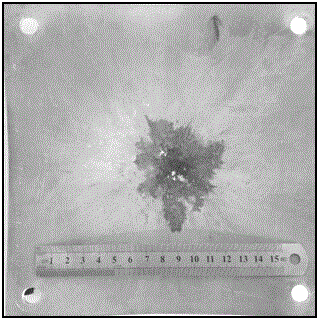

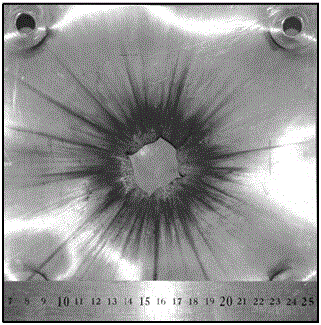

The invention discloses a filled Whipple protection structure based on basalt fiber fabric, which belongs to the field of passive protection research on space debris. The protective structure includes a buffer screen, a filling layer and a back wall, the filling layer is located between the buffer screen and the back wall, and the buffer screen, the filling layer and the back wall are fixed by a frame; the filling layer is divided into basalt fiber fabric and Kevlar fiber Two parts of the fabric, wherein the basalt fiber fabric is opposite to the buffer screen, and the Kevlar fiber fabric is opposite to the back wall, and the distance between the buffer screen and the filling layer, and between the filling layer and the back wall is 3 to 10 cm. The debris cloud formed by this protective structure itself is a powdery substance with a large diffusion range, and its damage effect on the aluminum back wall is much smaller than the debris cloud formed by the latter. engineering application potential.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

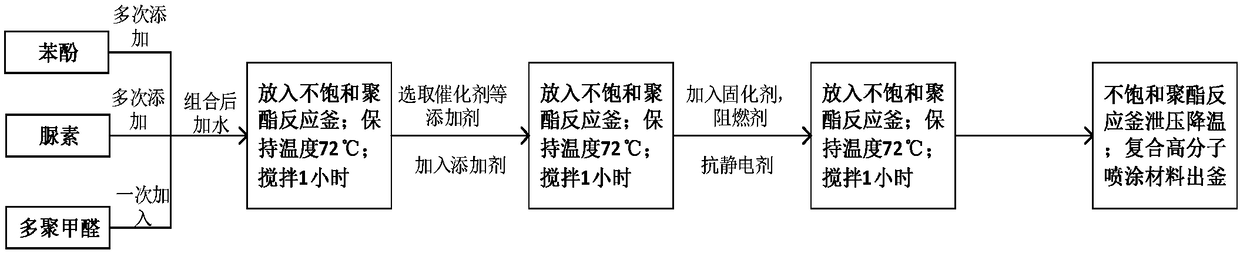

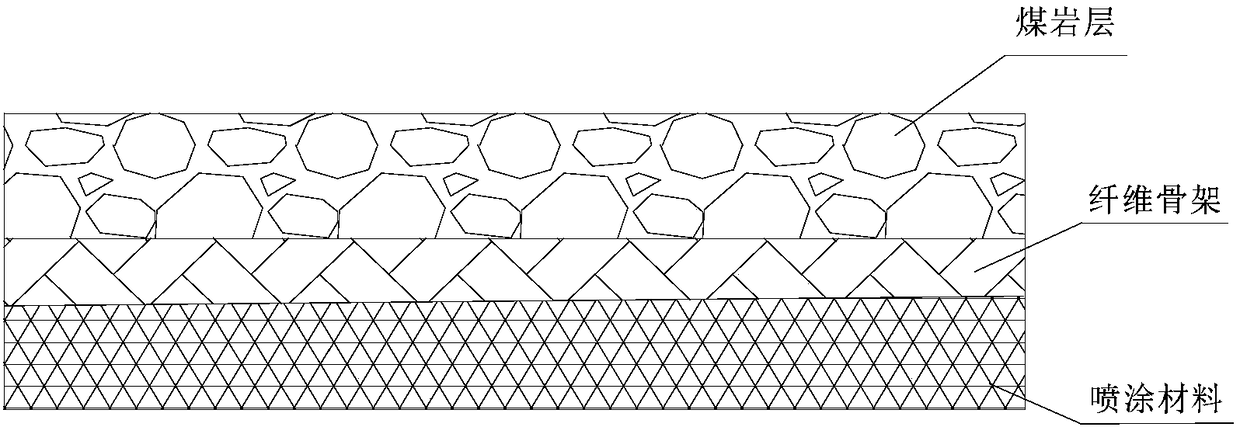

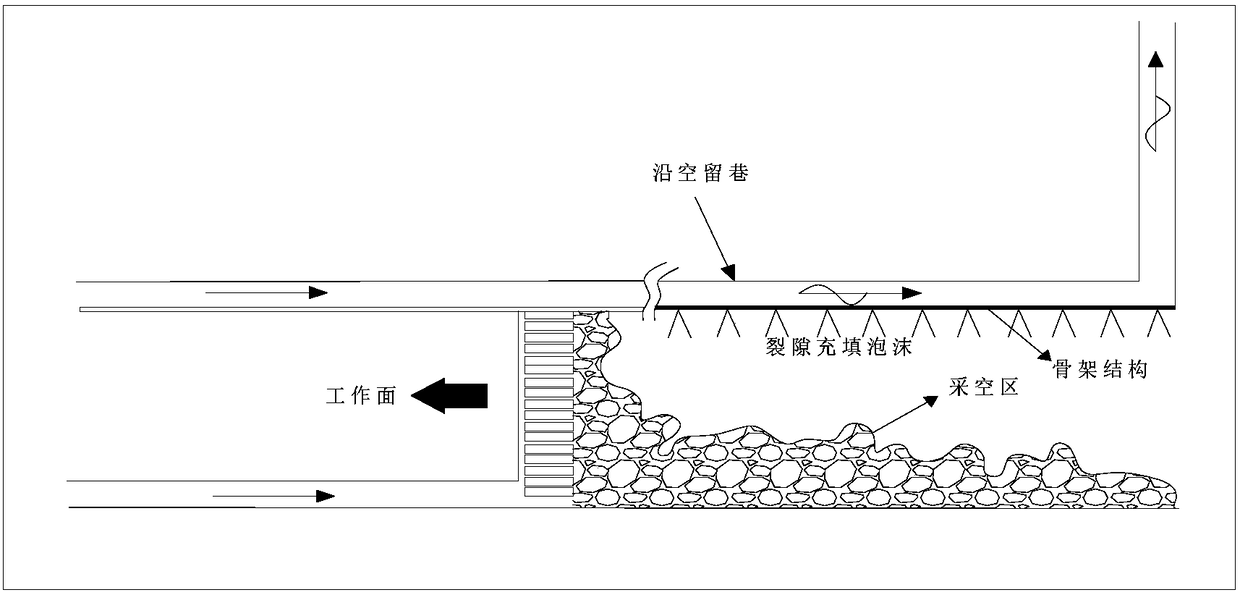

Composite spraying material and frame for downhole quick leaking stoppage and filling and implementing method thereof

InactiveCN108129943AImprove applicabilityImprove extraction efficiencyFireproof paintsProductsFoaming agentKevlar

The invention discloses a composite spraying material and frame for downhole quick leaking stoppage and filling and an implementing method thereof, and belongs to the composite spraying material and the sealing frame, and the implementing method thereof. A set reasonable proportion of phenolic foam, polyurethane foam and urea formaldehyde foam is selected, a base material of the spraying materialis synthesized, a proper flame retardant is added, and the properties of the base material are increased; an antistatic material, a catalyst, a curing agent, a surfactant, a foaming agent and other materials are added, and the flame-retardant and anti-static composite macromolecular spraying material is formed through specific technological process. Fiber-Kevlar is selected as a raw material to form the sealing frame and is used as a carrier of the spraying material, the structure deformation is flexible, and a whole for quick sealing and leaking stoppage is formed jointly. Through different embodiments, the composite spraying material is verified to have the characteristics of light mass, fast forming, strong sealing and good fire prevention and leaking stoppage effects, can effectively prevent downhole air leakage and harmful gas gushing and ensures the safety of workers.

Owner:CHINA UNIV OF MINING & TECH

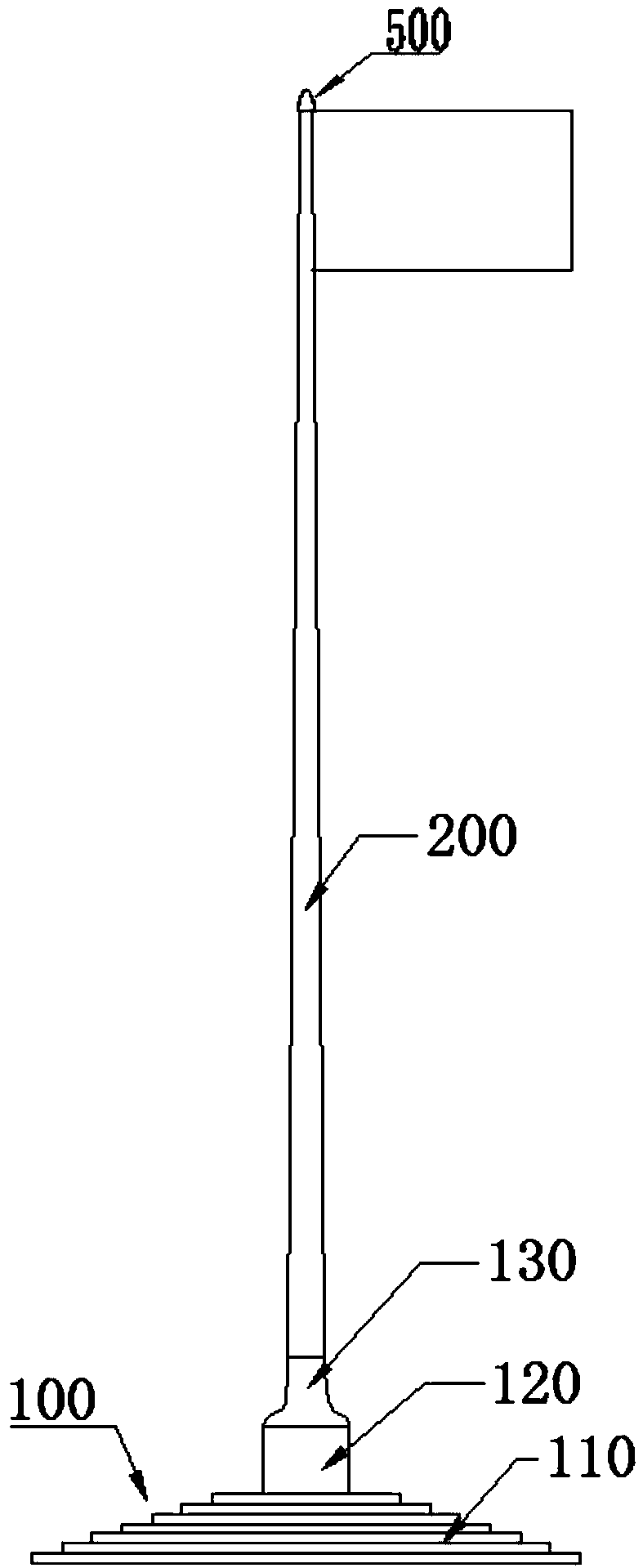

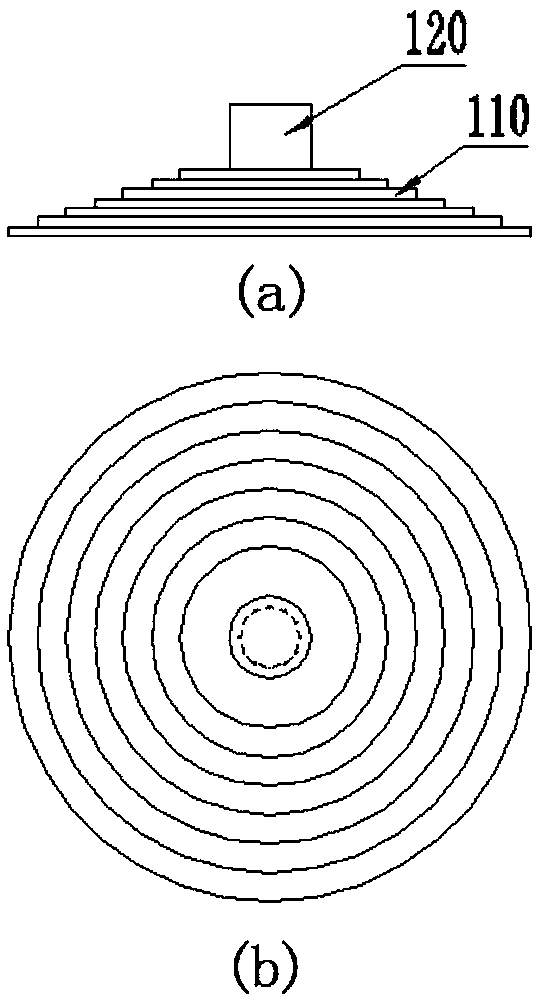

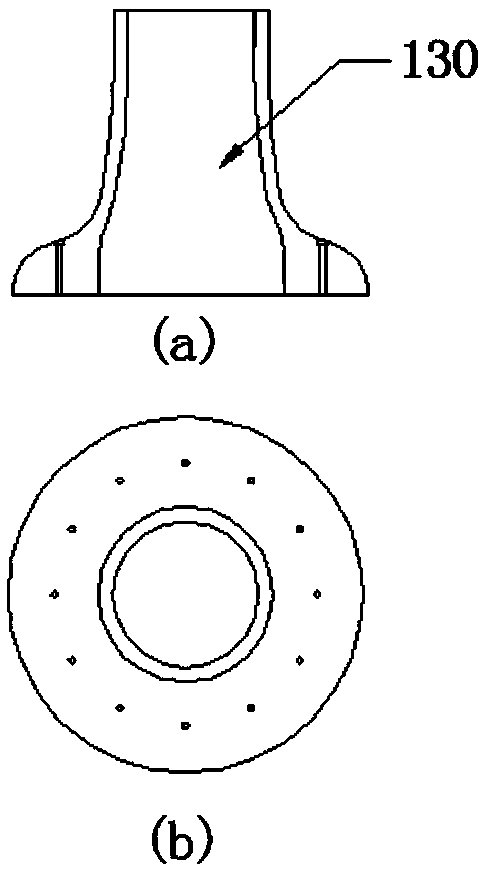

Innovative flagpole lifting device

The invention discloses an innovative flagpole lifting device. The innovative flagpole lifting device comprises a base, a flag column tube and a basement winch reel, wherein the flag column tube is arranged on the base, and the basement winch reel is arranged at the bottom of the base; the flag column tube is provided with a rectangular opening in the top, a Kevlar belt transition wheel is installed on the lower edge of the inner side of the rectangular opening, a Kevlar belt is connected with a flagpole frame outside the flag column tube, and the other end of the Kevlar belt penetrates through the rectangular opening, climbs over the Kevlar belt transition wheel, rotates by 360 degrees, passes through the hollow flag column tube and is wound around the reel. Electric soft iron is arrangedat the lower end of the flagpole frame, a horse shoe magnet is arranged on the inner wall of the top segment of the flag column tube, in the center line of the rectangular opening and at the positionof equal distance to the electric soft iron of the flagpole frame, and after a flag on the flagpole frame is lifted to the top of the flag column tube, the electric soft iron and the horse shoe magnet are right located at the same position to generate strong-magnetism attraction force for fixing. With the innovative flagpole lifting device, the three problems can be solved that after the flag islifted to the top, a rope, a column winding ring, hanging weight objects on the lower portion of a flagpole and others are arranged outside the flag column tube; when the flag encounters strong wind or due to the fact that compressed air is jetted and blown, the flag leaves from the column tube; the pull rope of the flag leaves from the top of the column tube under influencing of all kinds of factors. With the innovative flagpole lifting device, the solemnity and liberality of a flag-raising ceremony are kept, and the effects of attractiveness and vitality are realized.

Owner:黄劲鸣

Optical cable strengthening core and manufacture method thereof

InactiveCN101799575AHigh strengthHigh tensile strengthFibre mechanical structuresUV curingUltraviolet lights

The invention discloses a VU (ultraviolet light source) cured KEVLAR optical cable strengthening core. The strengthening element is prepared in such a way that the KEVLAR used as a base body enters a die hole to be extruded, stretched and cured into an elastic rod-shaped base body with the thickness of 0.3-5mm after being soaked by a UV curing agent, and a layer of special flexible epoxy resin with the thickness of 0.1-1mm, which is a bending resistant material, is cured on the elastic rod-shaped base body; the optical cable strengthening core is commonly applied in parallel and symmetrical sheath cable bodies; and one or more optical fibers all adopt insensitive optical fibers with the diameter of 250 microns. By synthesizing with the process technology, the optical cable adopting the strengthening core achieves the practical effects of high strength and folding resistance.

Owner:SHANGHAI GUOBIN CHEM

Method for preparing pre-tension membrane structure antenna

ActiveCN102593576BSolve size-constrained challengesGuaranteed fixed spacing requirementsAntenna arraysAntenna supports/mountingsNomex honeycombMembrane surface

The invention relates to a method for preparing a pre-tension membrane structure antenna. The method comprises the following steps: designing a membrane surface into a base membrane and electric membranes, splicing the base membrane and forming the electric membranes; marking out a bottom membrane according to a designed paste range, pasting the electric membranes; processing catenaries, splicing auxiliary strengthening plates, positioning the membrane surface by utilizing installation holes of a support framework of the membrane antenna and placing the first membrane surface on a corresponding position of the support framework; reversely loading pretightening force on the long side of the membrane surface by utilizing auxiliary loaded ropes and the support of the support framework, pre-tensioning tension ropes by an adjustment device and adjusting the tension ropes to designed positions for splicing and fixing; and installing a dielectric Kevlar / Nomex honeycomb panel so as to finally realize an antenna array surface. In the method, a phased-array antenna array surface is realized through a membrane structure; the weight of a traditional phased-array antenna structure is lightened; and the method provided by the invention has the characteristics that the pre-tension membrane structure antenna is capable of being continuous loaded; the membrane tension can be accurately controlled, the operation is convenient, a special membrane tying tool is not needed, and the like.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com