Thermal insulation/protection integrated space debris protection structure and application thereof

A technology for protective structure and space debris, which is applied in the directions of aerospace vehicle heat protection device, aerospace safety/emergency device, etc., and can solve the problems of increasing aircraft burden, large mass and volume, and poor heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

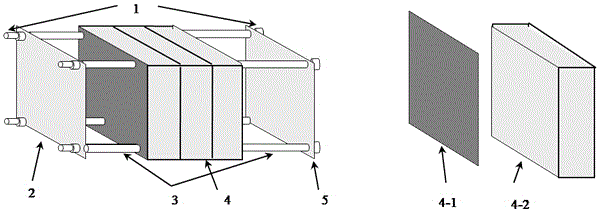

[0034] like figure 1 As shown, an anti-heat insulation / protection integrated space debris protection structure is formed by stacking a front plate 2 and a filling layer 4; the filling layer 4 is composed of three layers of SiC fiber fabric 4-1 and three layers of alumina ceramics fiber reinforced SiO 2 The nano-airgel plates 4-2 are stacked alternately in pairs, the thickness of the filling layer 4 is 60mm, and the SiC fiber fabric 4-1 is close to the front plate 2.

[0035] In order to facilitate the performance test, a back plate 5 is installed on the other side of the front plate 2 on the filling layer 4, the distance between the front plate 2 and the back plate 5 is 100 mm, and the filling layer 4 is connected to the front plate 2 and the back plate 5. The distances between the back plates 5 are all 20mm.

[0036] like figure 1 As shown, the assembly method of the protective structure test structure described in this embodiment is as follows: first, the front plate 2, t...

Embodiment 2

[0042] The difference between the anti-heat insulation / protection integrated space debris protection structure of this embodiment and embodiment 1 is that SiC fiber fabric 4-1 and alumina ceramic fiber reinforced SiO 2 The number of layers of the nano-airgel plate 4-2 is five, and the thickness of the filling layer 4 is 100mm; the distance between the filling layer 4 and the front plate 2 and the rear plate 5 is 0mm.

[0043] The difference between the assembling method of the protection structure described in this embodiment and that of Embodiment 1 is only that the filling layer 4 is not separated from the front plate 2 and the rear plate 5 by a sleeve 3 with a diameter greater than that of the drilled hole, and the screws on the screw rod 1 are screwed. Fasten with nuts and you're done.

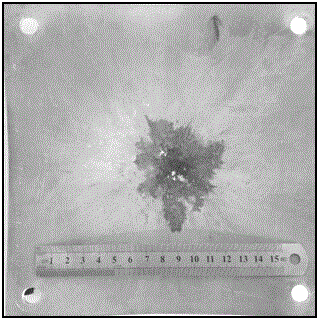

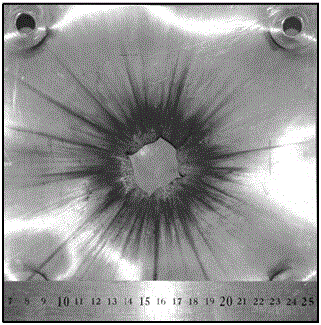

[0044] Under the conditions of impact velocity v≈6.8km / s and projectile diameter d=8.02mm, the anti-heat insulation / protection integrated space debris protection structure was used to cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com