Patents

Literature

7020 results about "Fiber reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforcement fibers are designed for specific and unique applications, ranging from micro synthetic fibers to reduce shrinkage and settlement cracking formed when concrete is still in the plastic state, to macro synthetic fibers as an alternative to traditional steel reinforcement for secondary reinforcement applicarions.

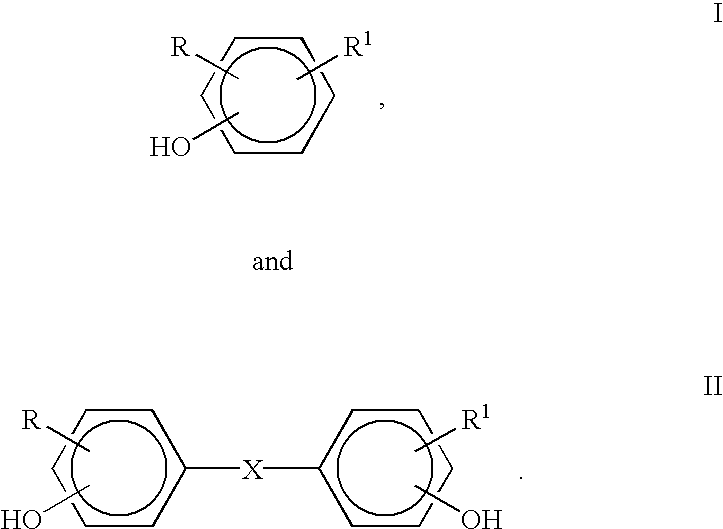

Proppants with fiber reinforced resin coatings

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

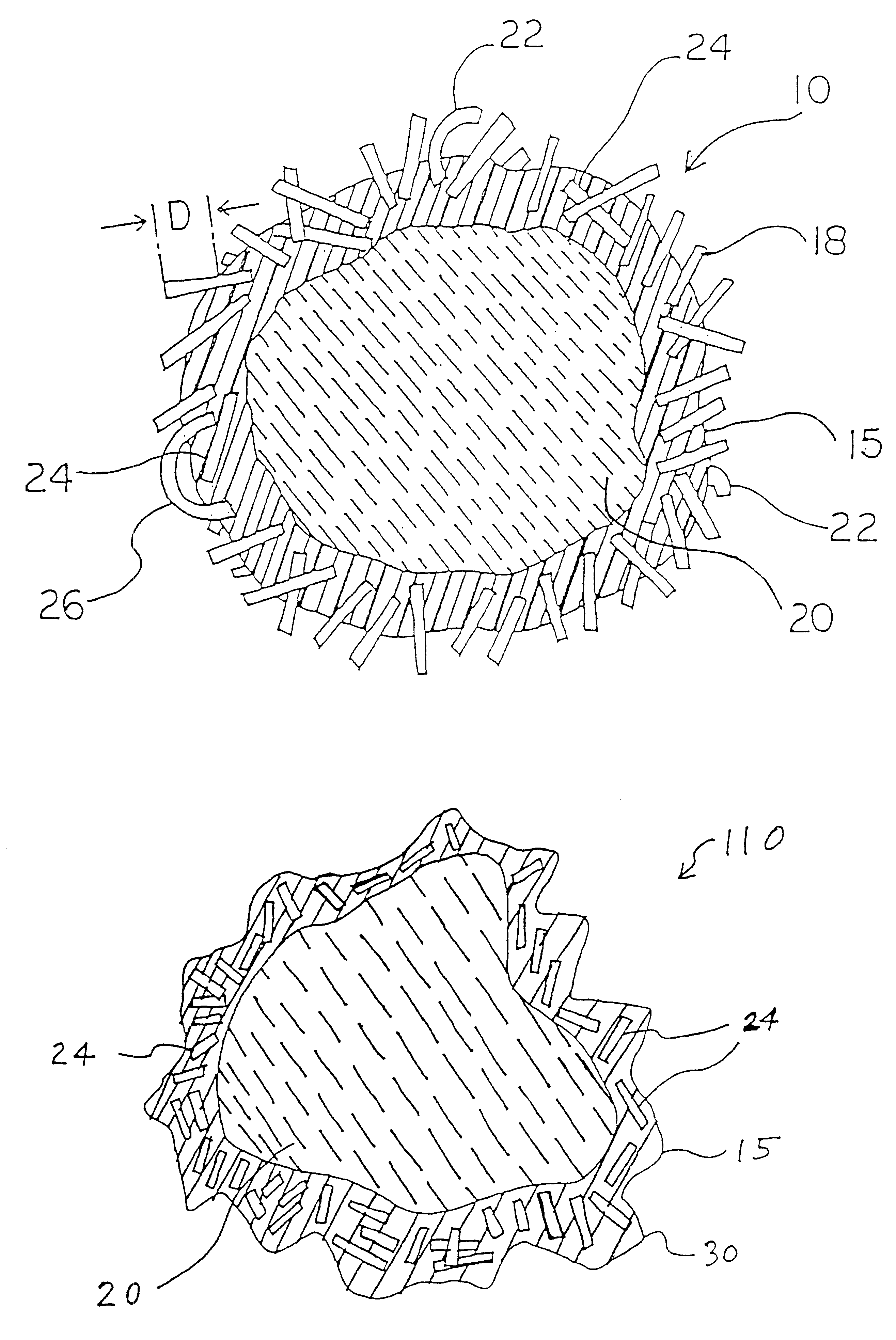

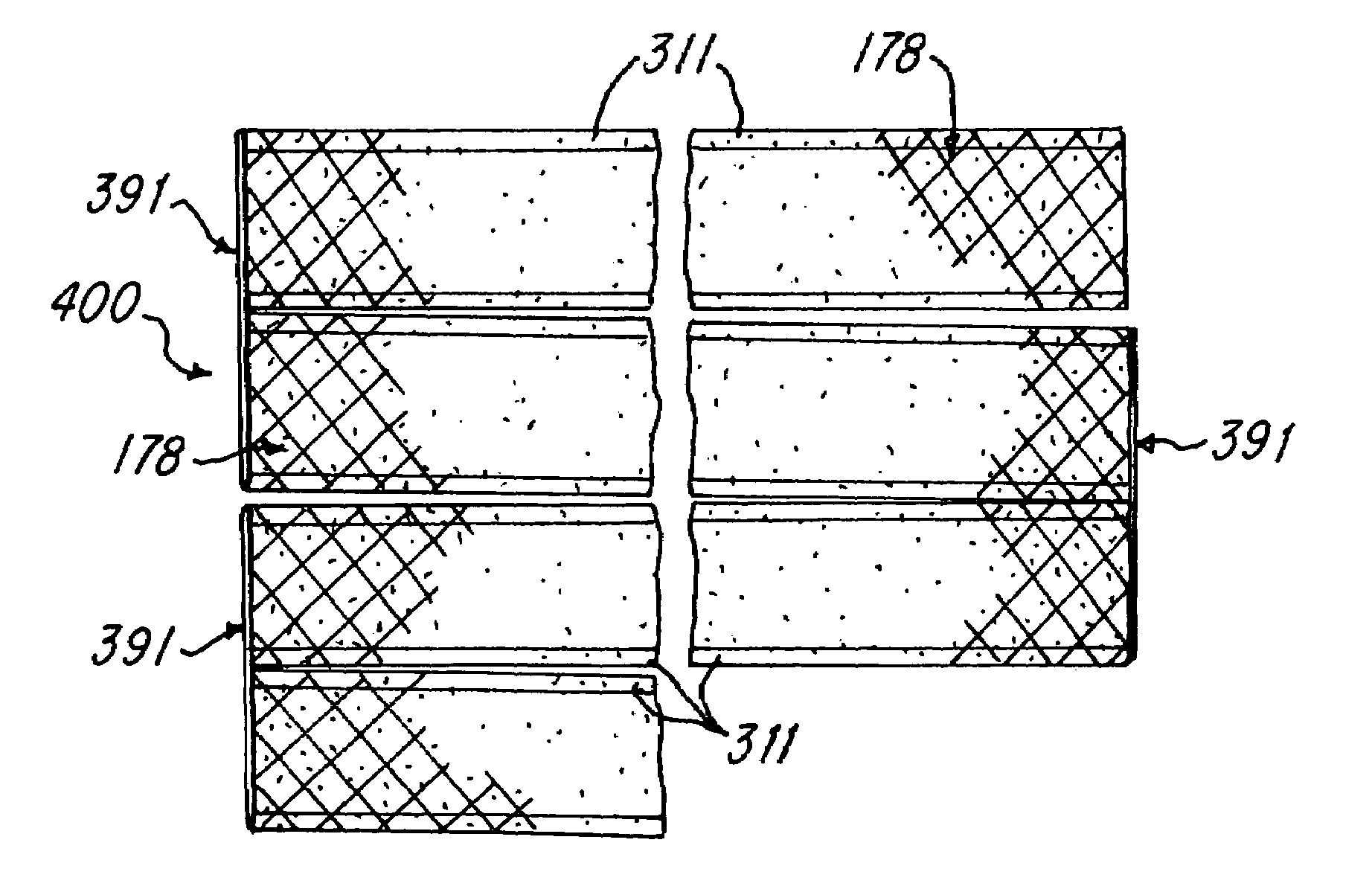

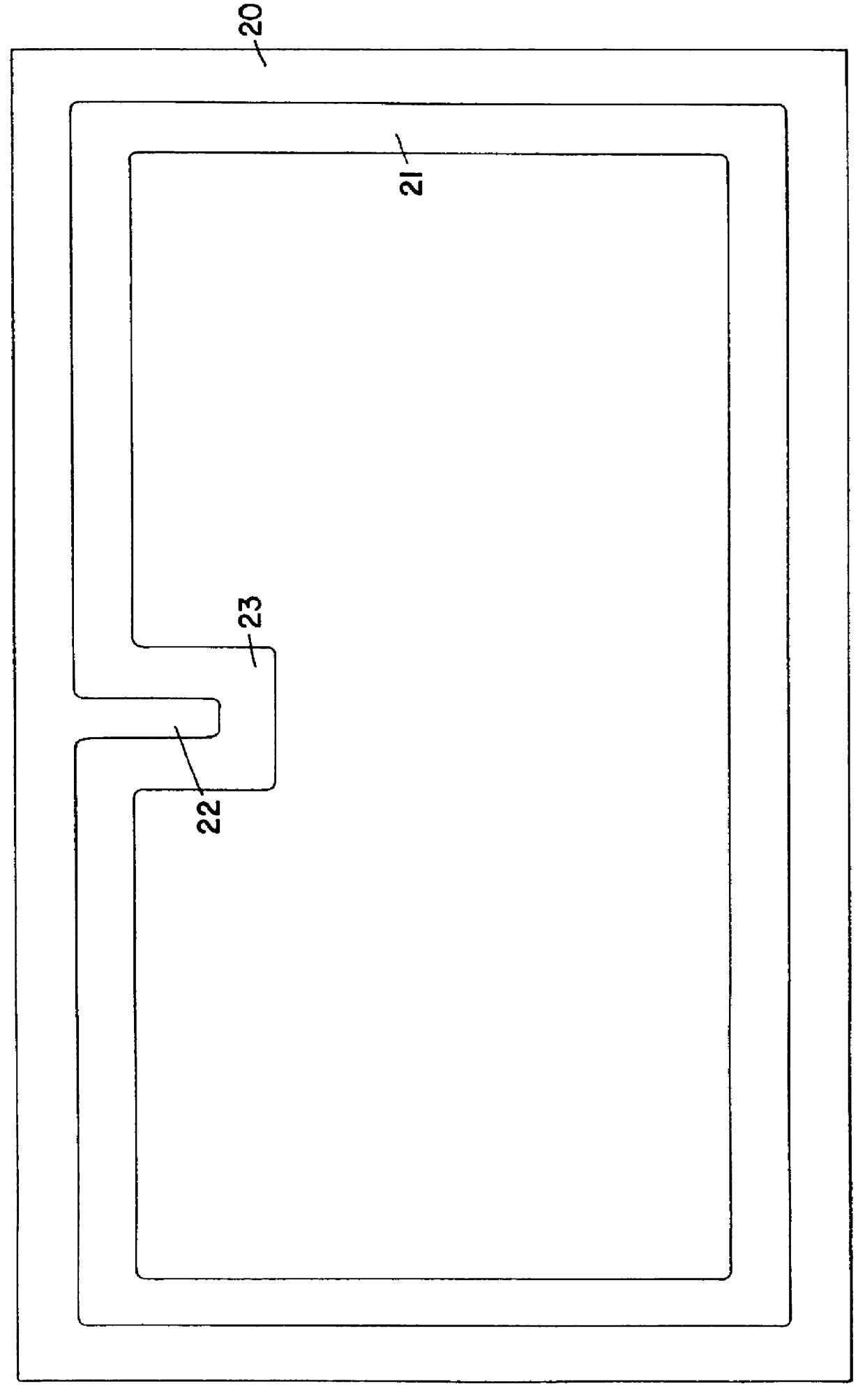

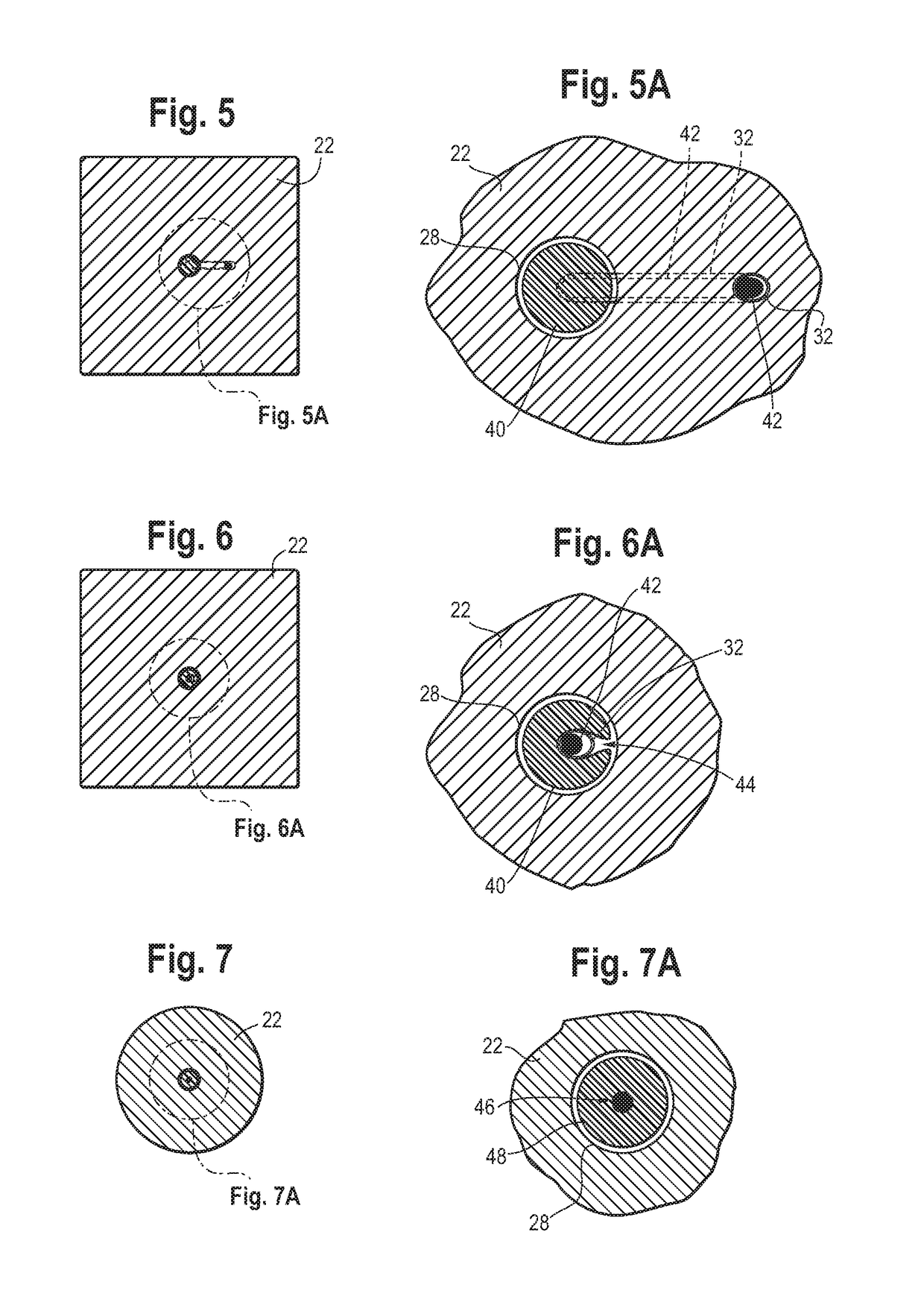

Implants for replacing hyaline cartilage, with hydrogel reinforced by three-dimensional fiber arrays

Implants with hydrogel layers reinforced by three-dimensional fiber arrays can replace hyaline cartilage. Such implants should replace an entire cartilage segment, rather than creating a crevice around a plug, so these implants must be thin and flat, they must cover large areas, the tips of any tufts or stitches must not reach the hydrogel surface, and they must be flexible, for arthroscopic insertion. The use of computerized stitching machines to create such arrays enables a redesigned and modified test sample to be made with no delays, and no overhead or startup costs. This provides researchers with improved tools for making and testing implants that will need to go through extensive in vitro, animal, and human testing before they can be approved for sale and use. Fiber-reinforced hydrogels also can be secured to strong shape-memory rims, for securing anchoring to bones.

Owner:FORMAE

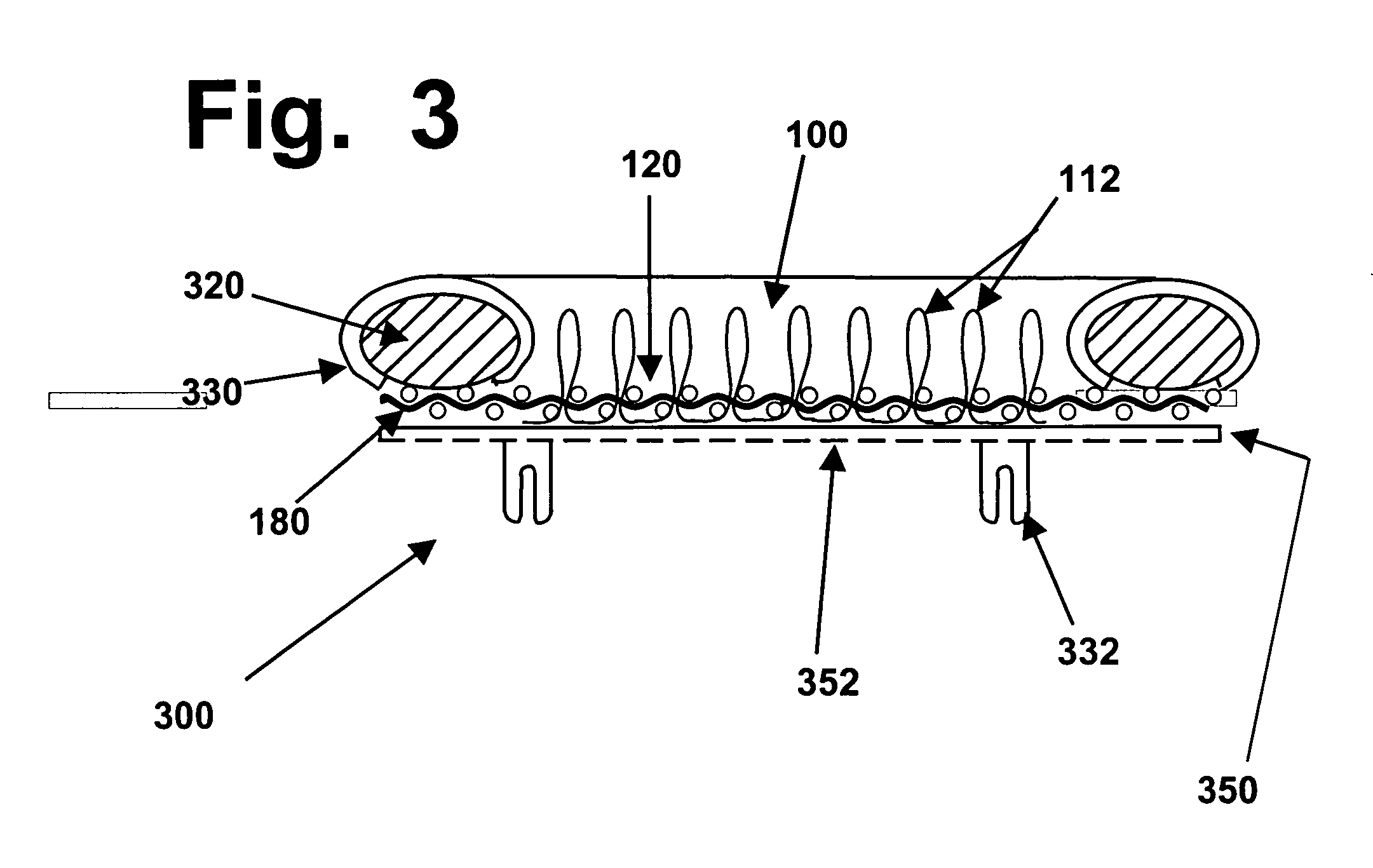

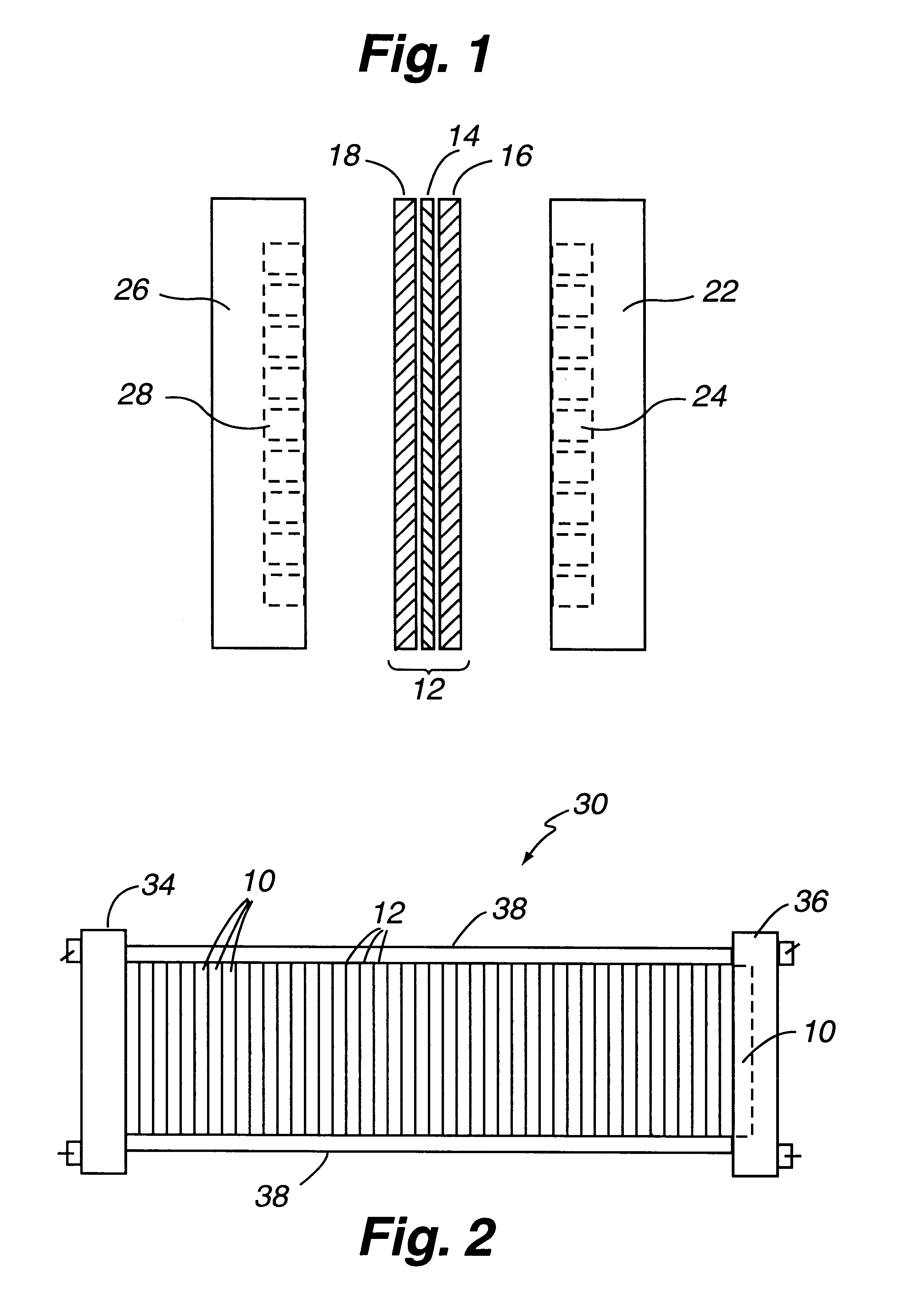

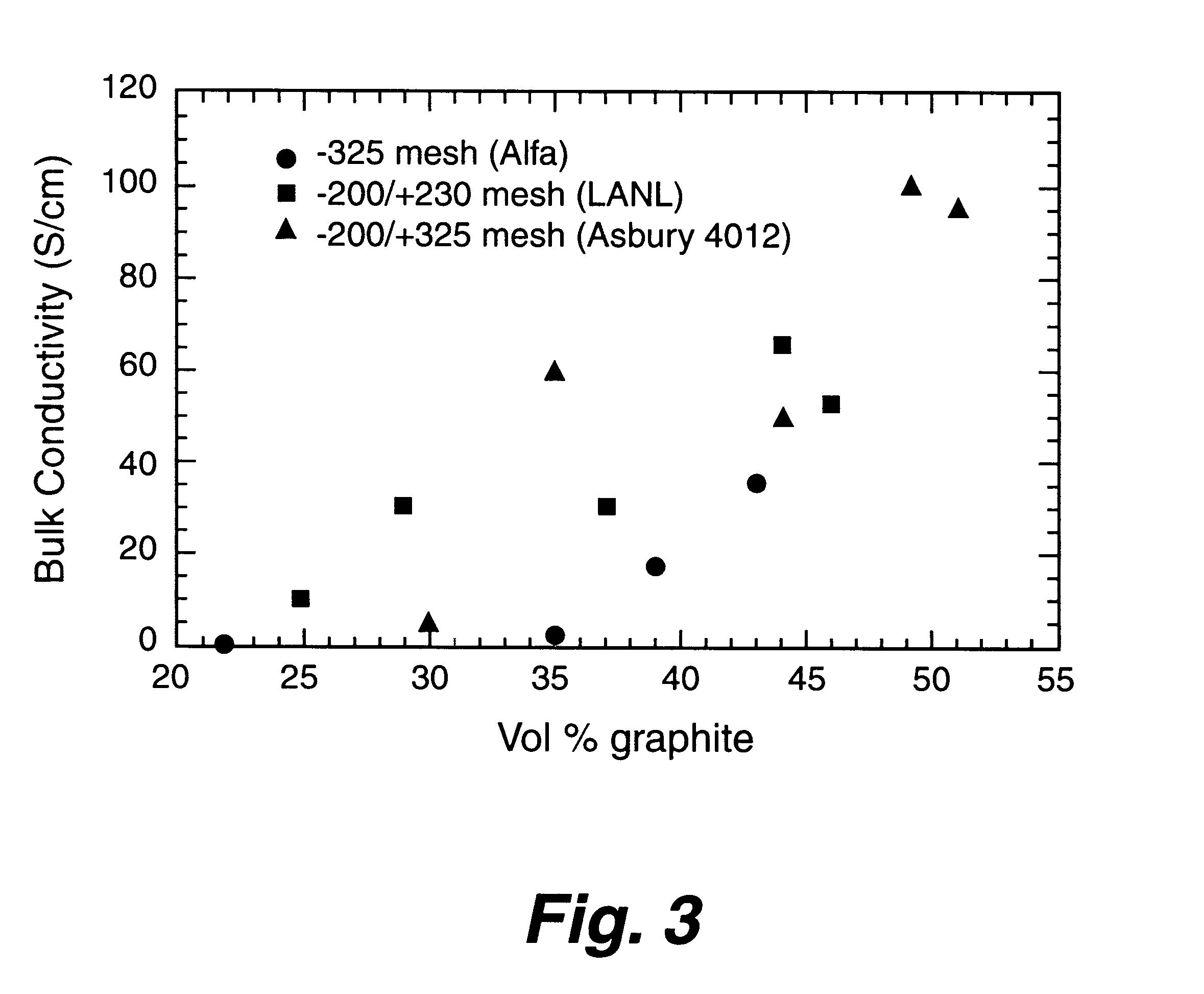

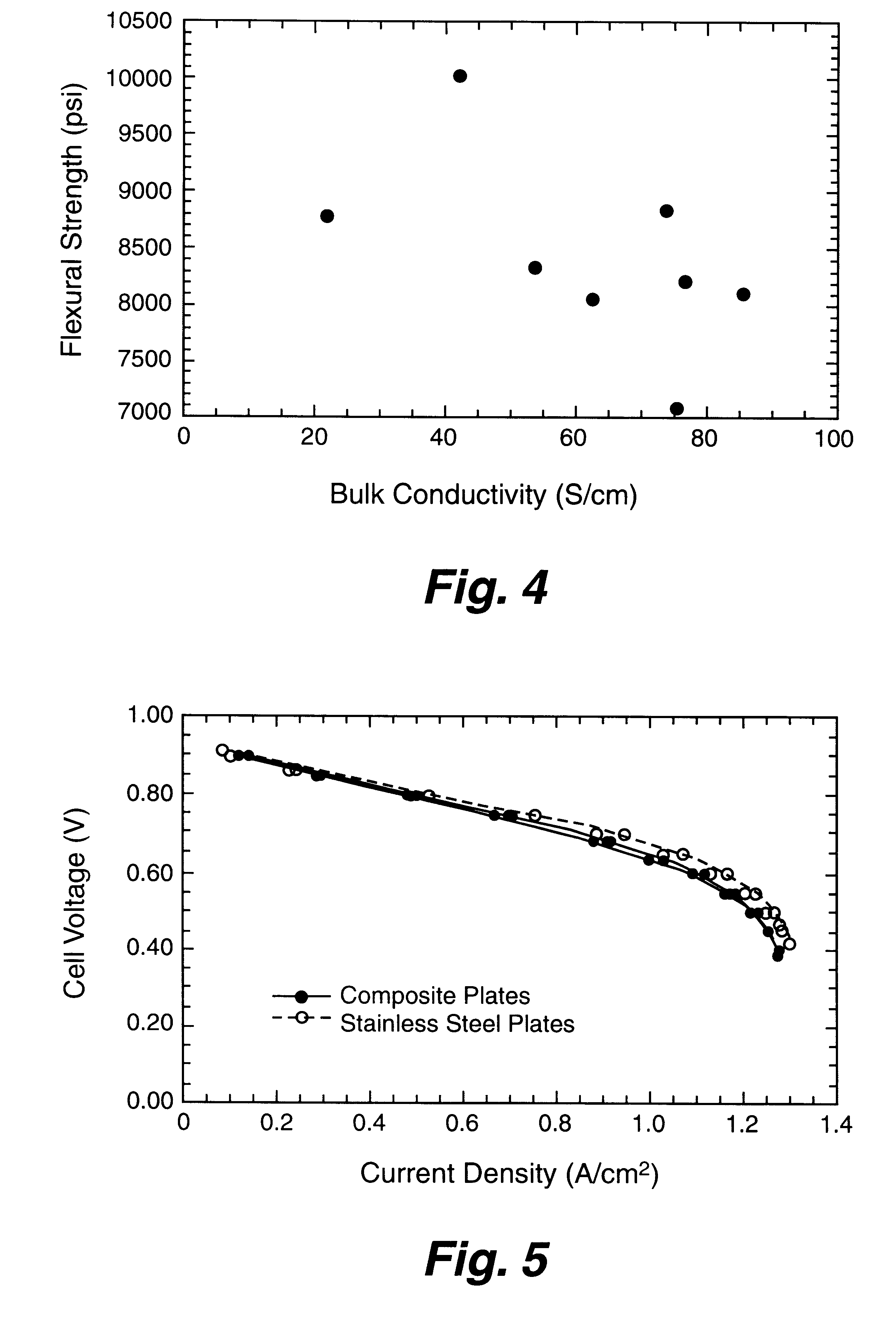

Composite bipolar plate for electrochemical cells

A bipolar separator plate for fuel cells consists of a molded mixture of a vinyl ester resin and graphite powder. The plate serves as a current collector and may contain fluid flow fields for the distribution of reactant gases. The material is inexpensive, electrically conductive, lightweight, strong, corrosion resistant, easily mass produced, and relatively impermeable to hydrogen gas. The addition of certain fiber reinforcements and other additives can improve the properties of the composite material without significantly increasing its overall cost.

Owner:TRIAD NAT SECURITY LLC

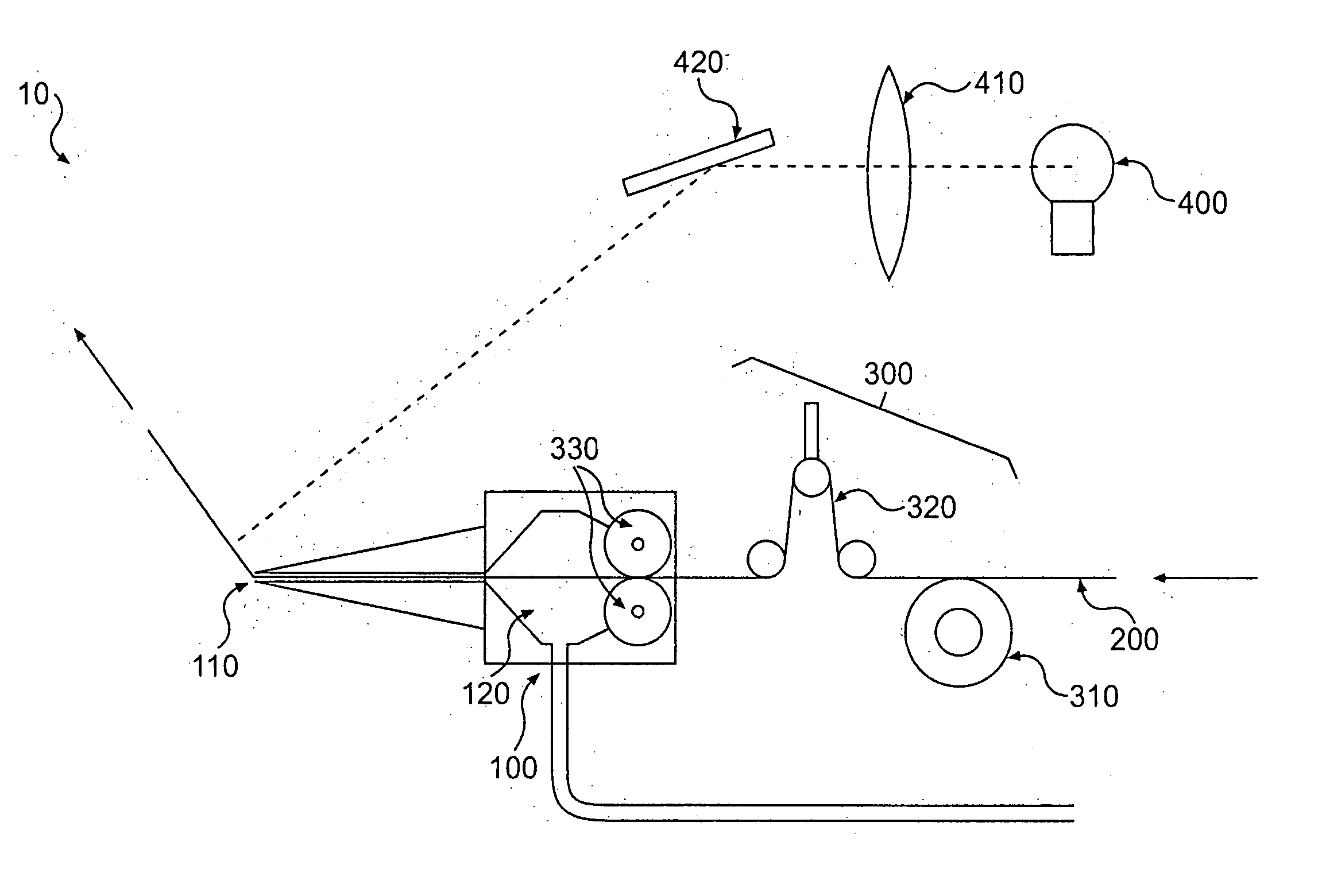

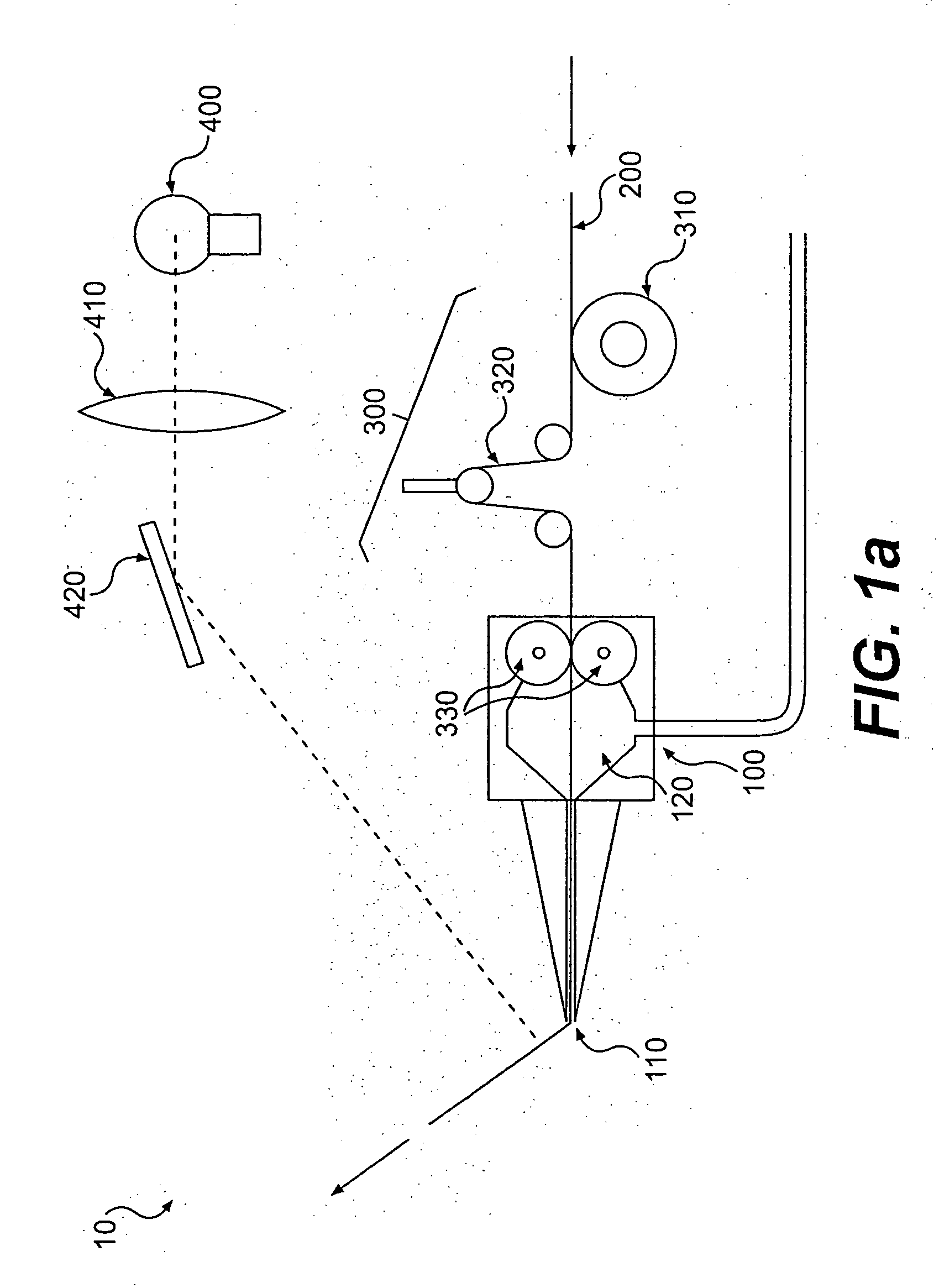

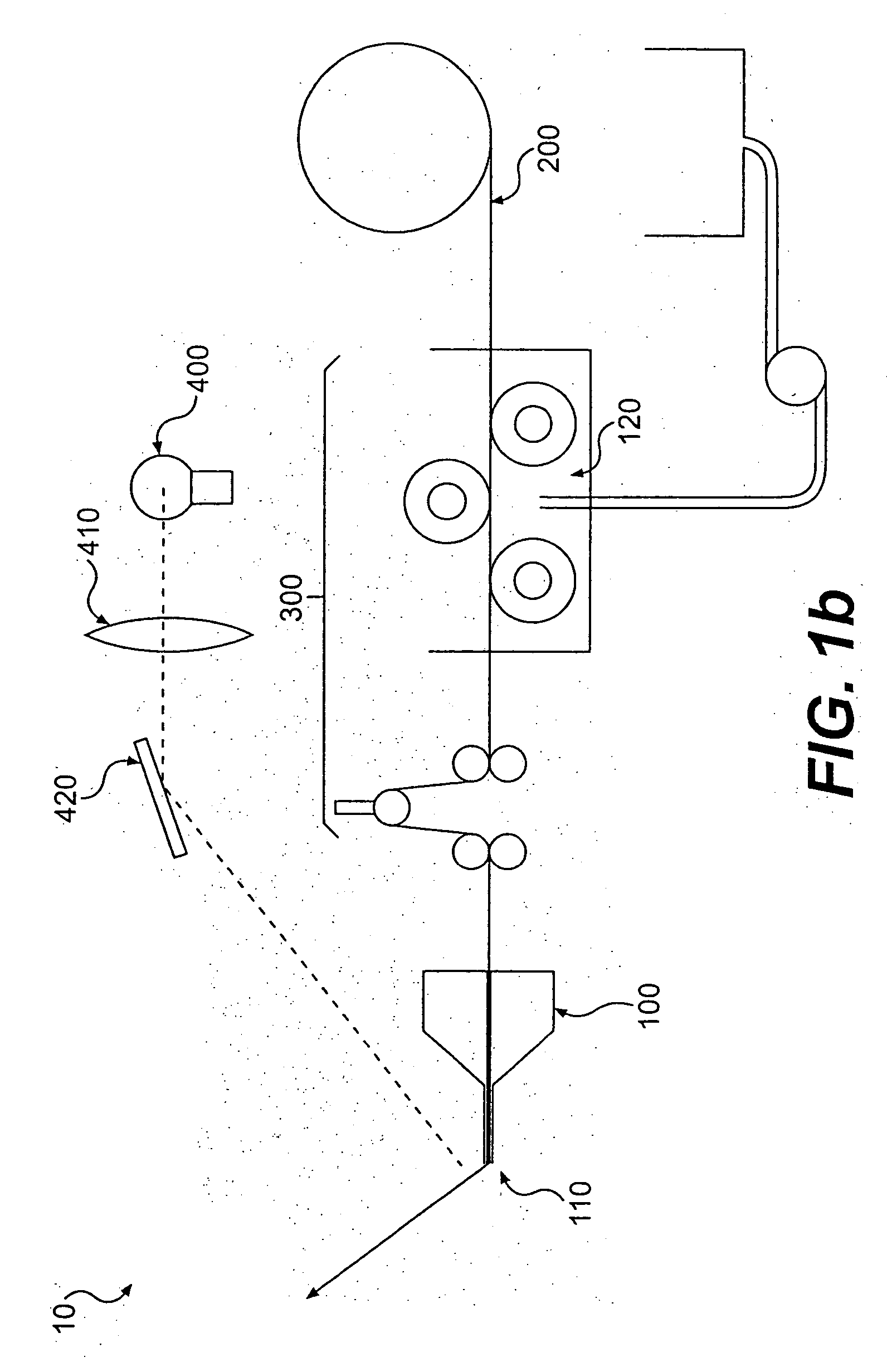

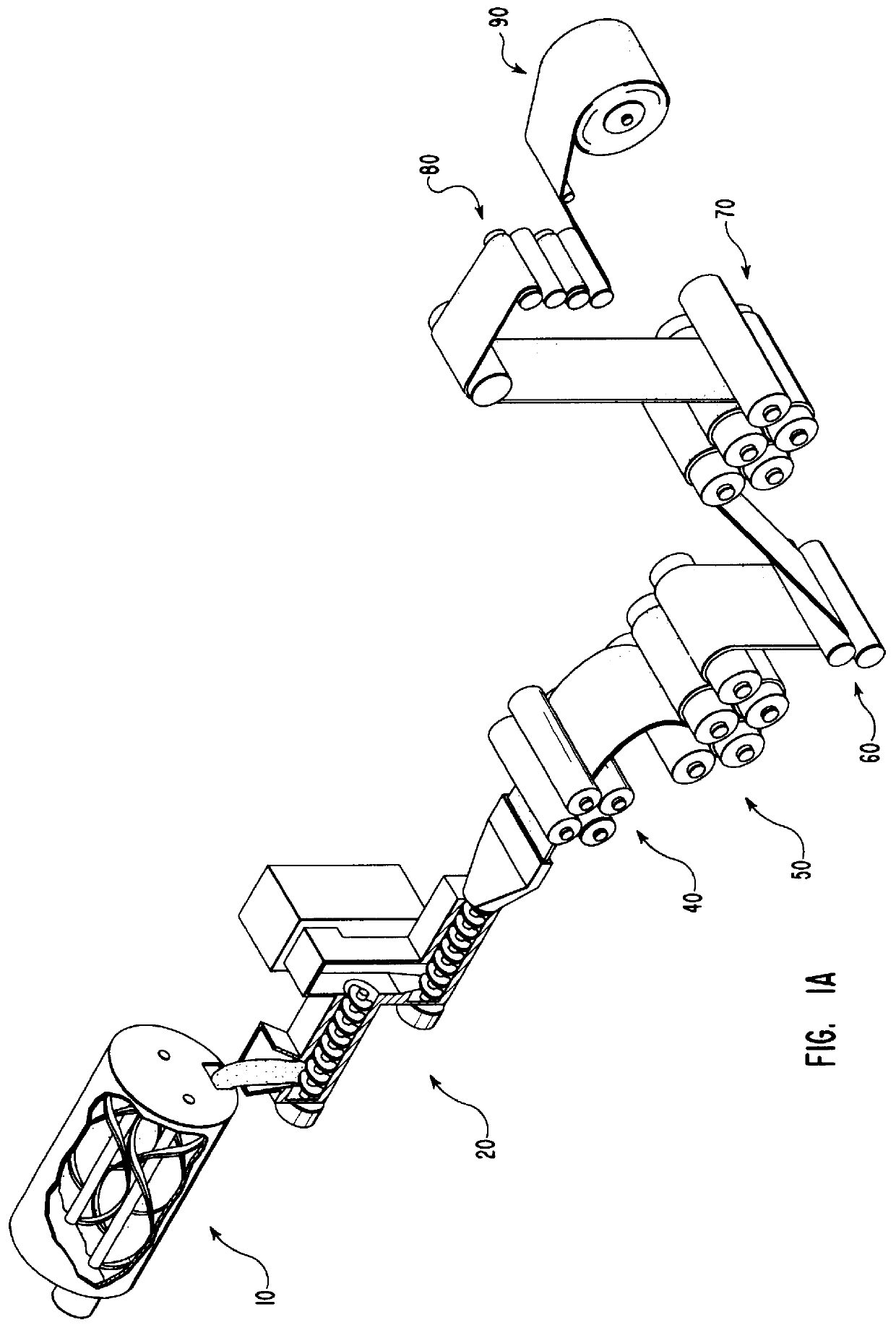

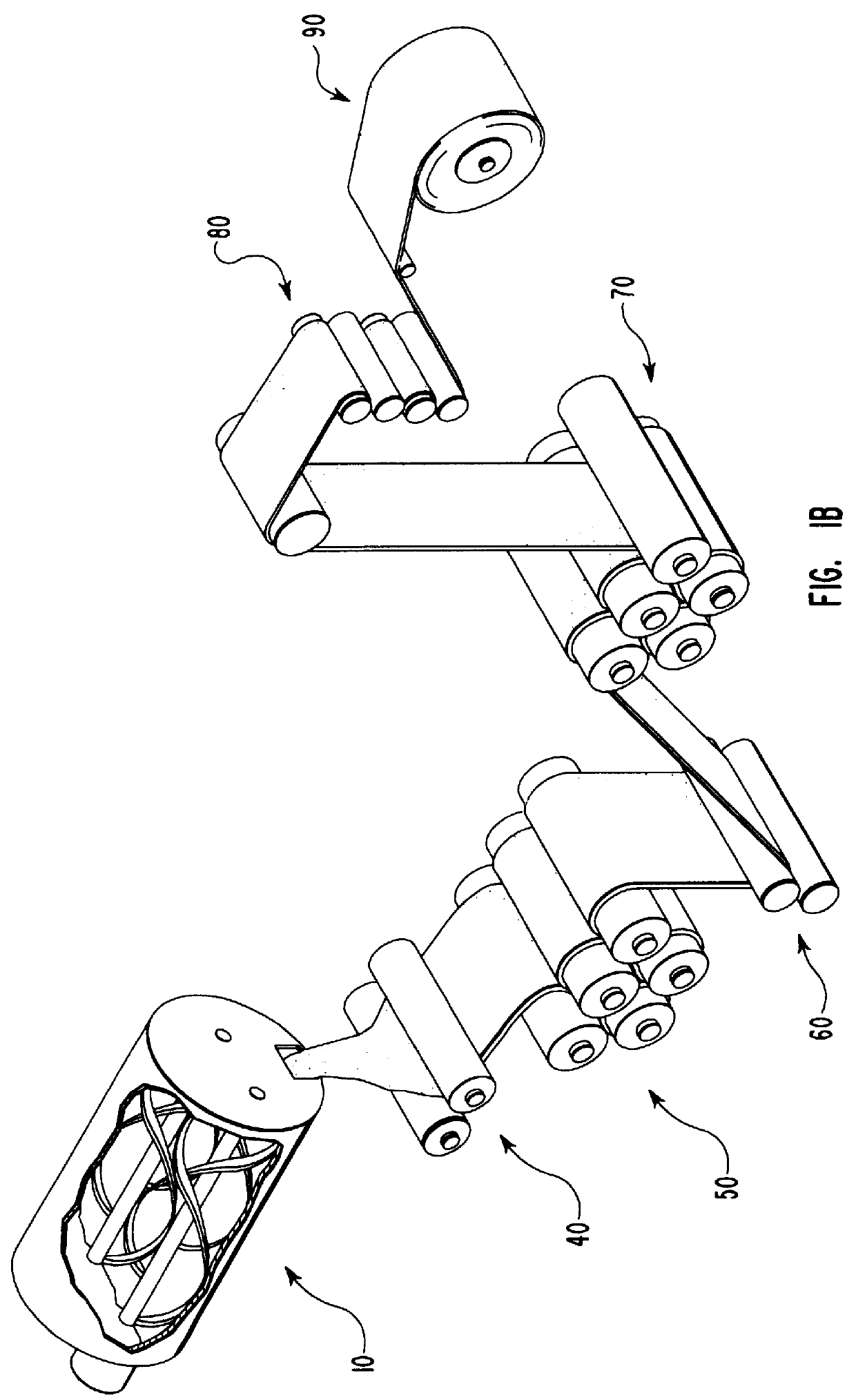

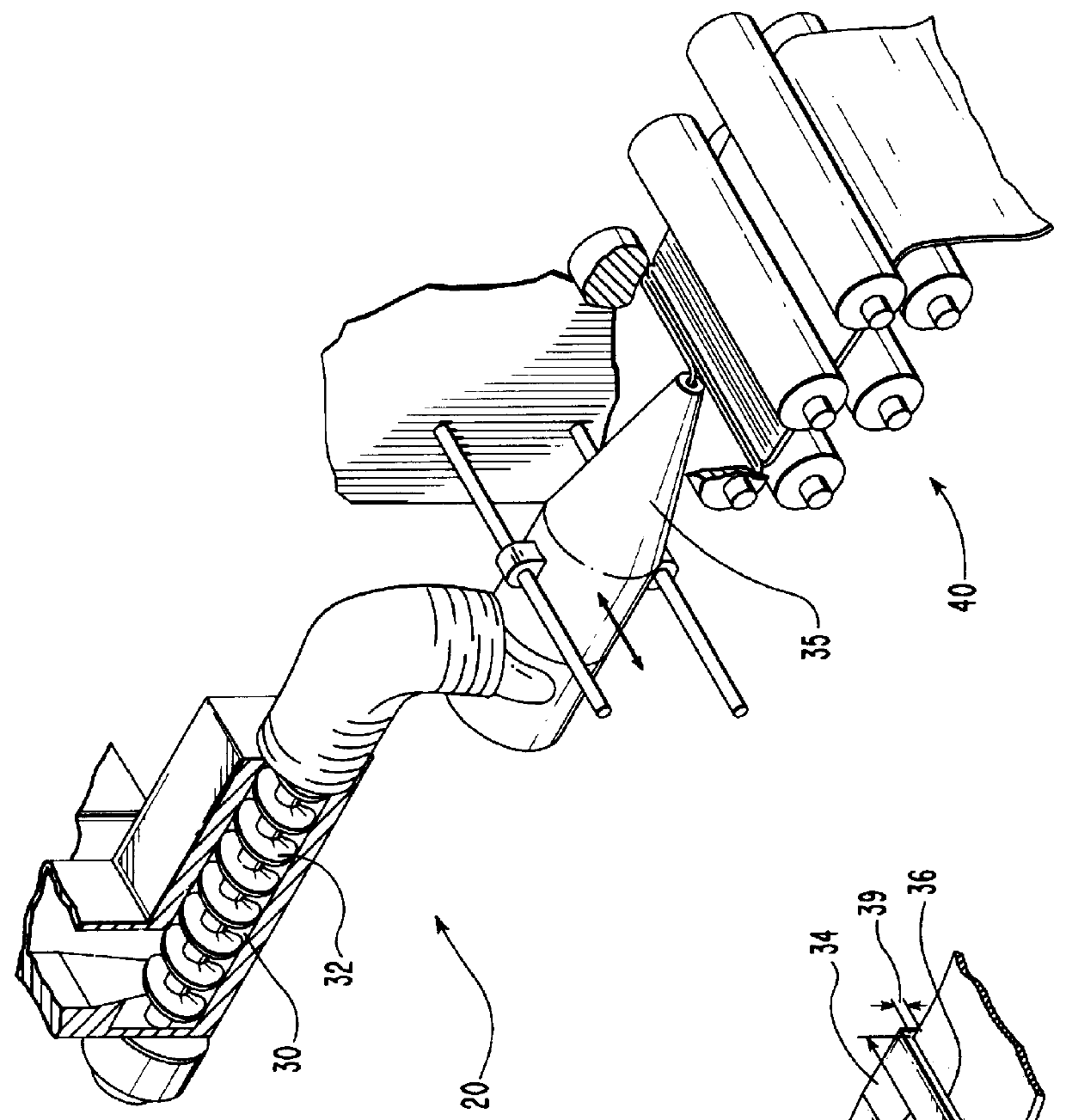

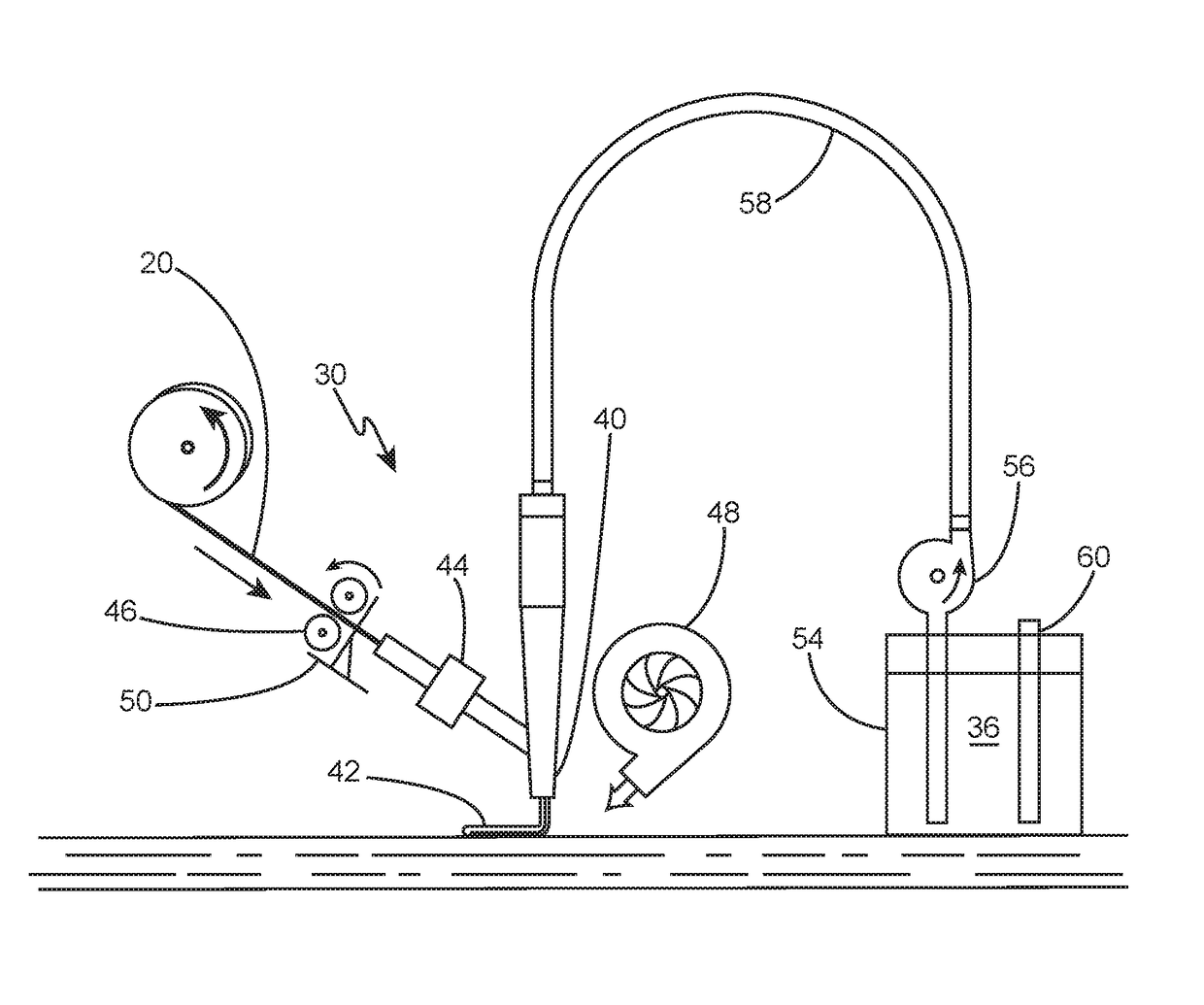

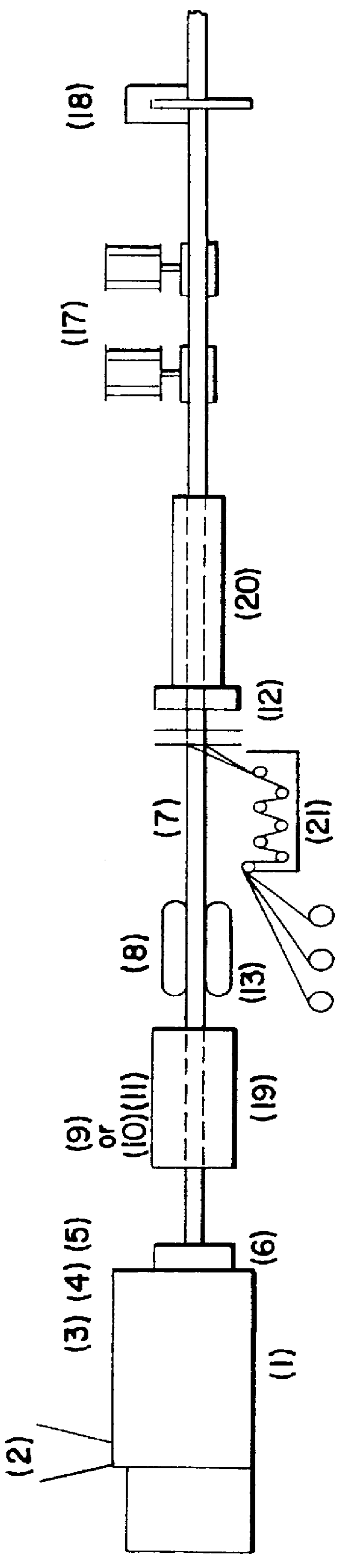

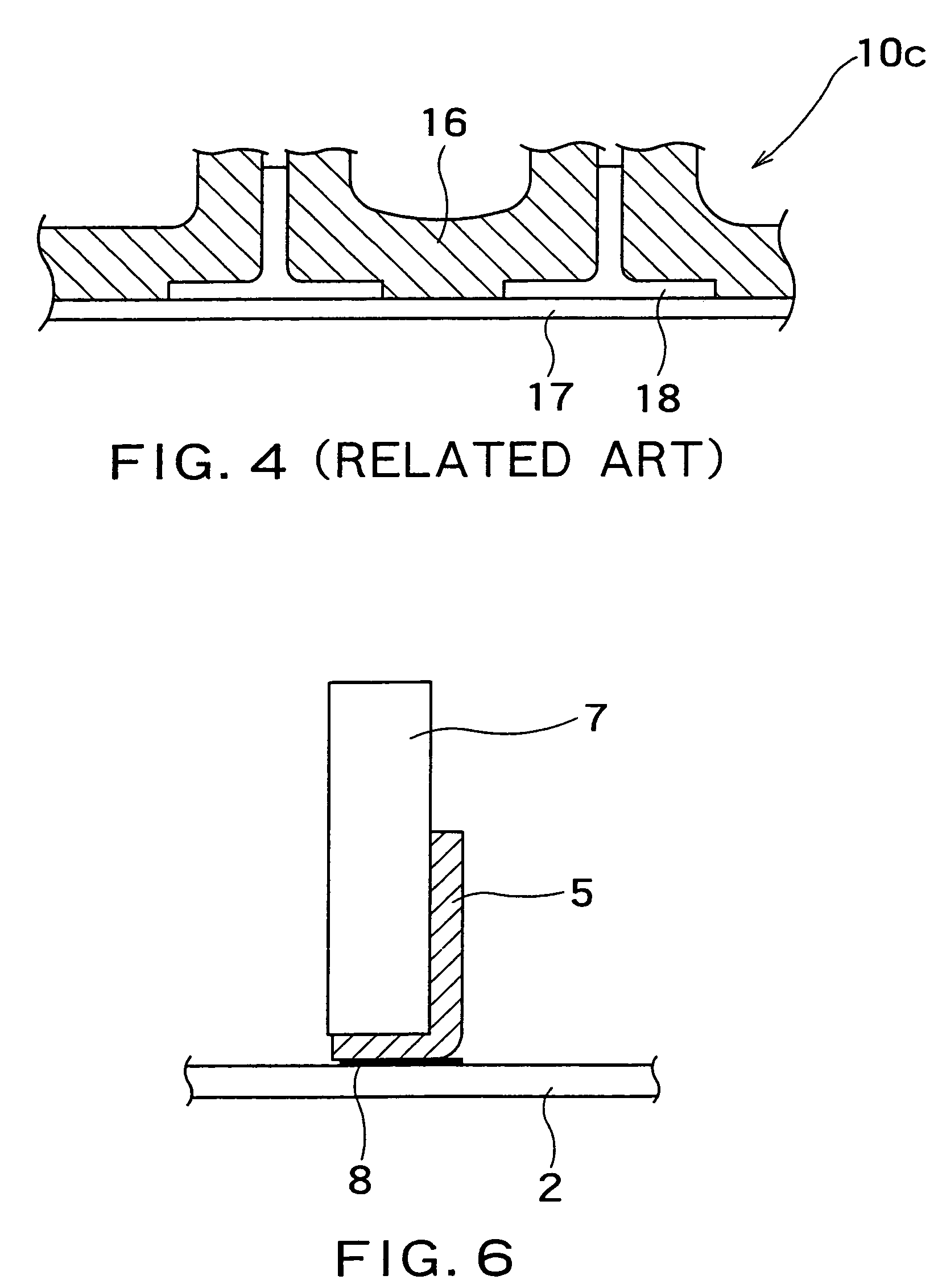

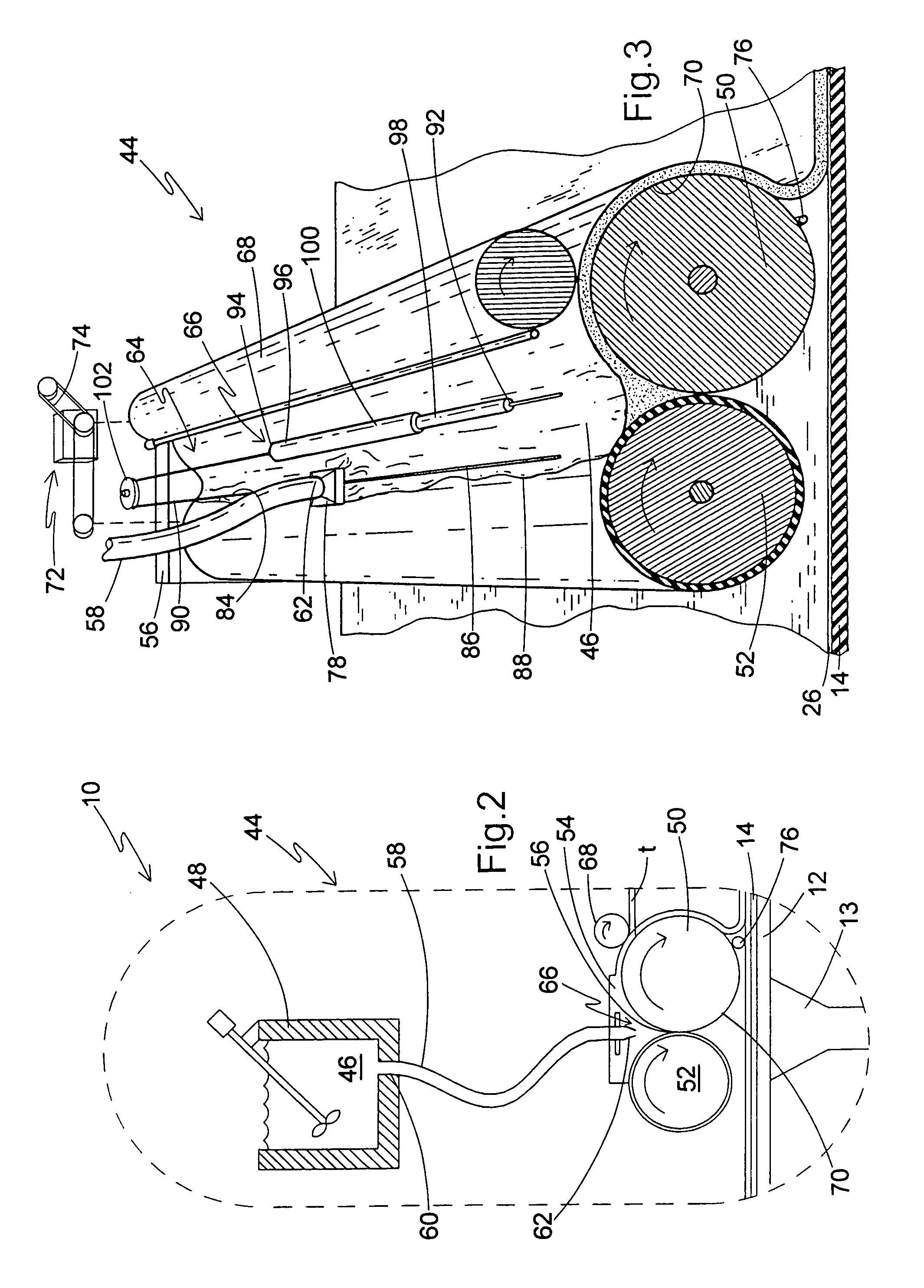

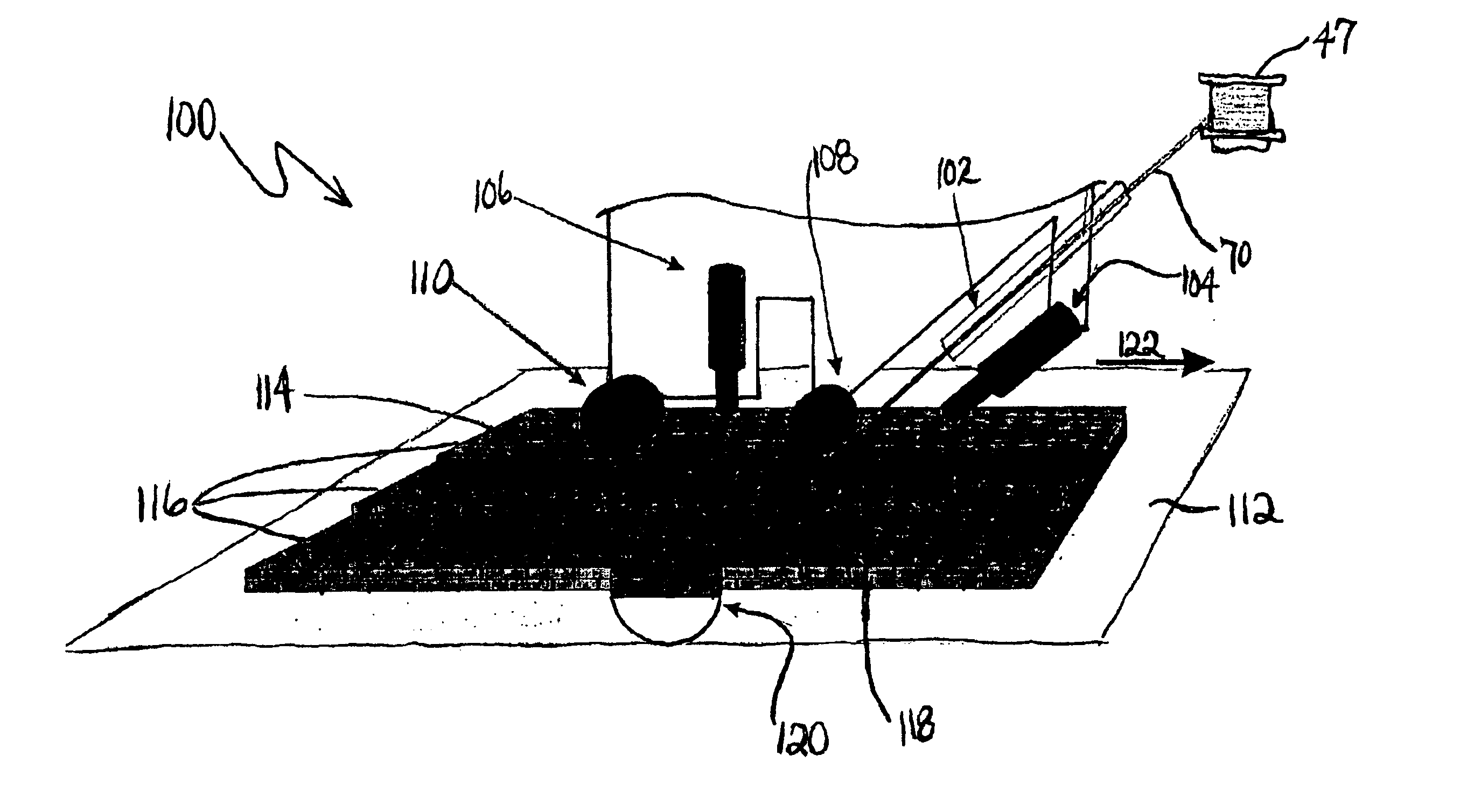

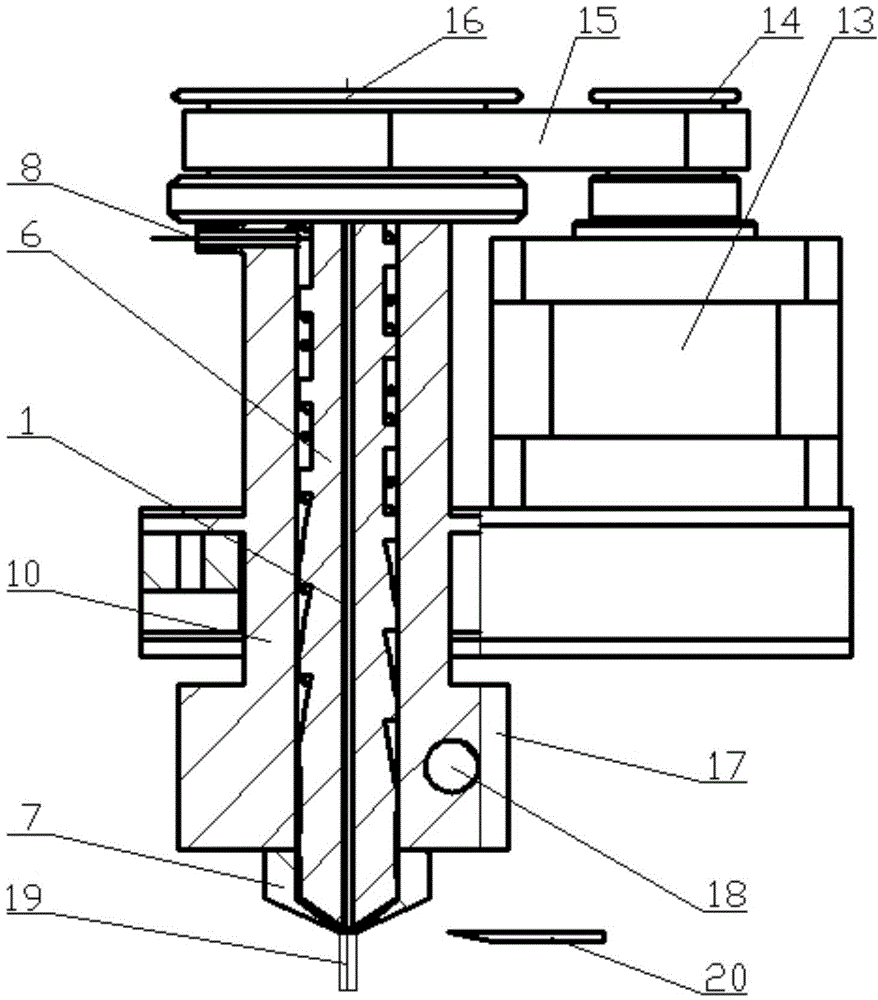

Apparatus for fabricating fiber reinforced plastic parts

InactiveUS20070003650A1Fast and cost-effectiveLow costAdditive manufacturing apparatusCeramic shaping apparatusEngineeringMechanical engineering

The invention relates to an apparatus and method for fabricating FRP parts. More specifically, the invention relates to a method for forming FRP parts without the use of forms or molds. According to a preferred embodiment of the present invention, the method for fabricating an FRP part comprises the steps of: programming a readable definition of a part into a machine, wherein the machine moves an extrusion head mounted to the machine in a controlled pattern; and wherein the machine regulates the speed of extrusion from the extrusion head; feeding a fiber reinforcement to the extrusion head of the machine; impregnating the fiber reinforcement with a radiation-initiated resin; extruding the impregnated fiber reinforcement from an orifice in the extrusion head; and exposing the extruded fiber reinforcement to curing radiation.

Owner:SCHROEDER ERNEST C

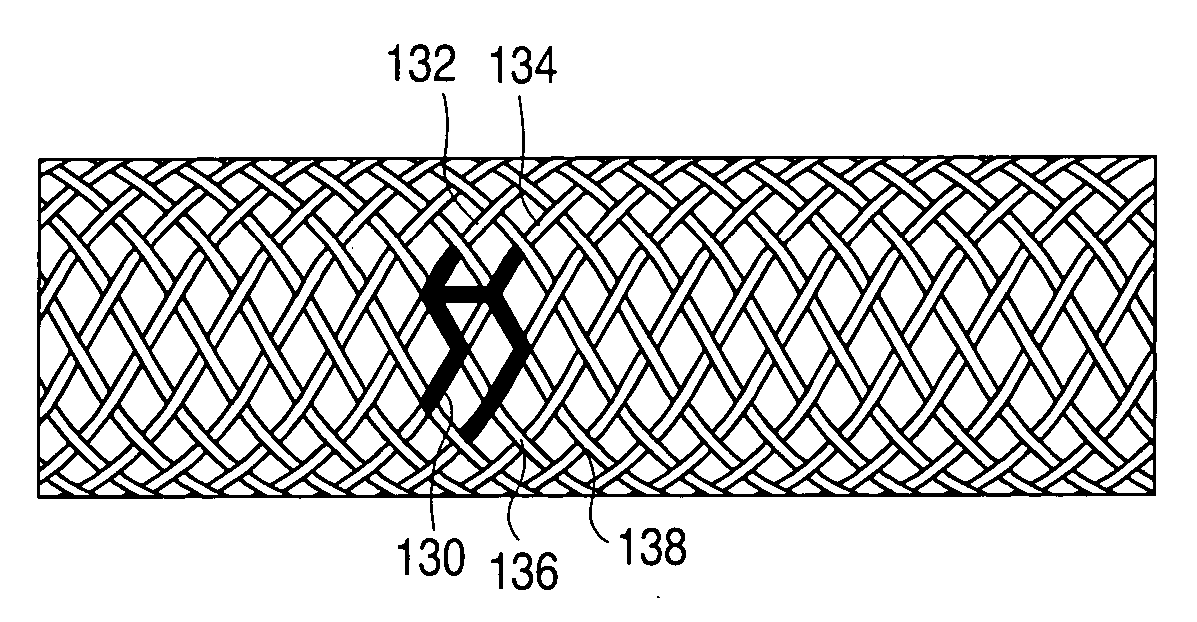

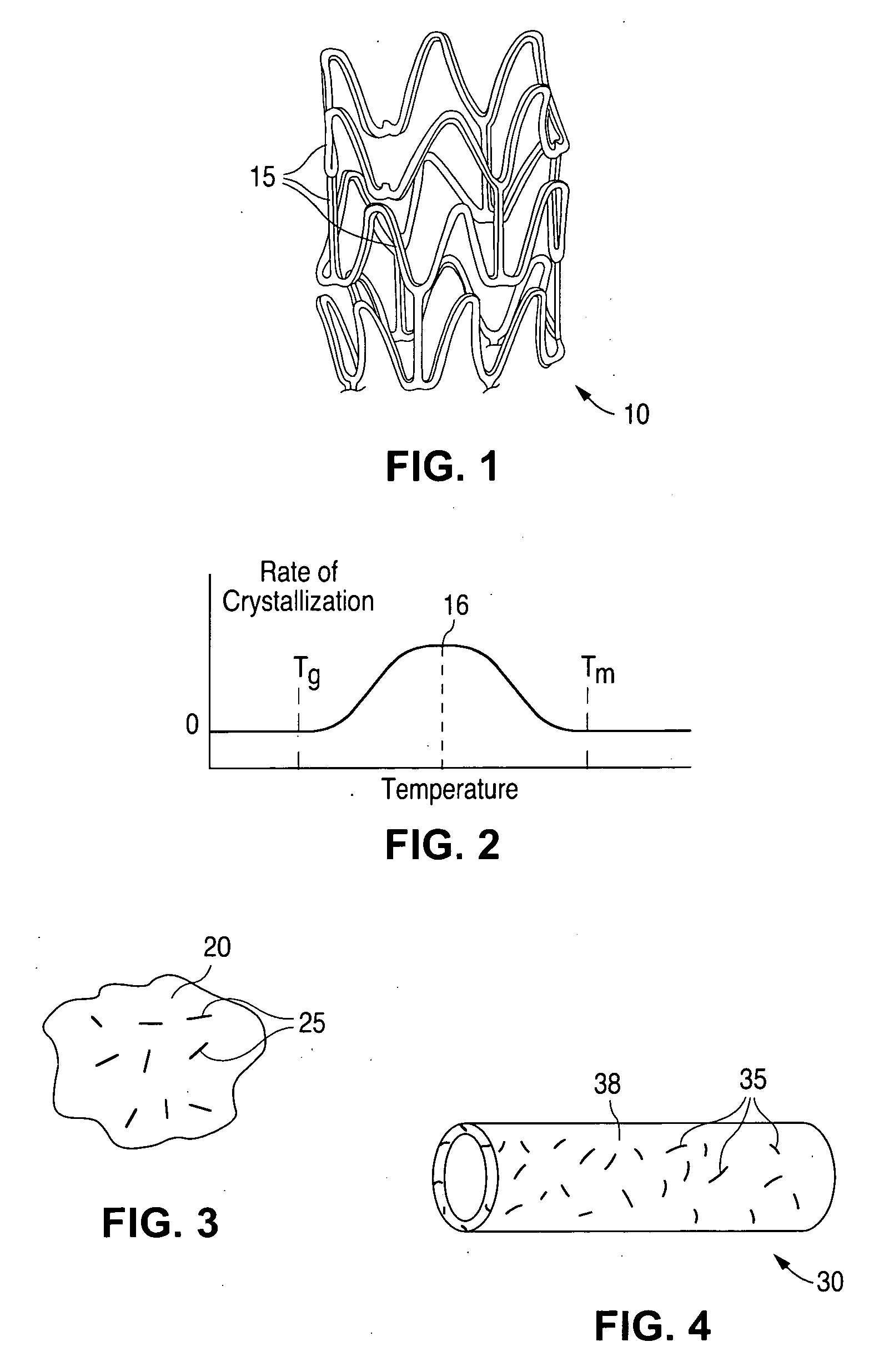

Fiber reinforced composite stents

InactiveUS20070038290A1Reduces radial profileLower softening temperatureStentsHollow filament manufactureInsertion stentFiber-reinforced composite

Owner:ABBOTT CARDIOVASCULAR

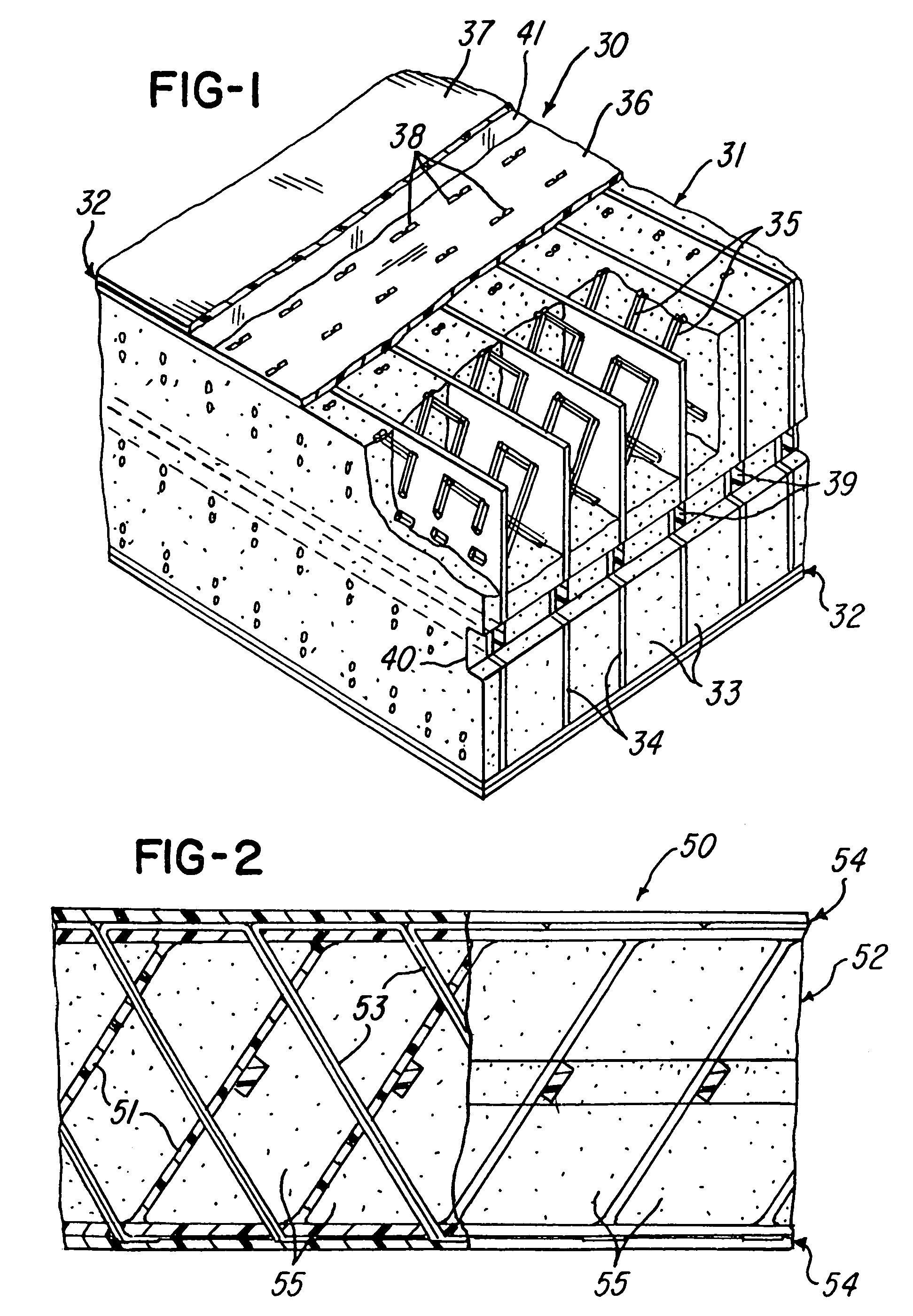

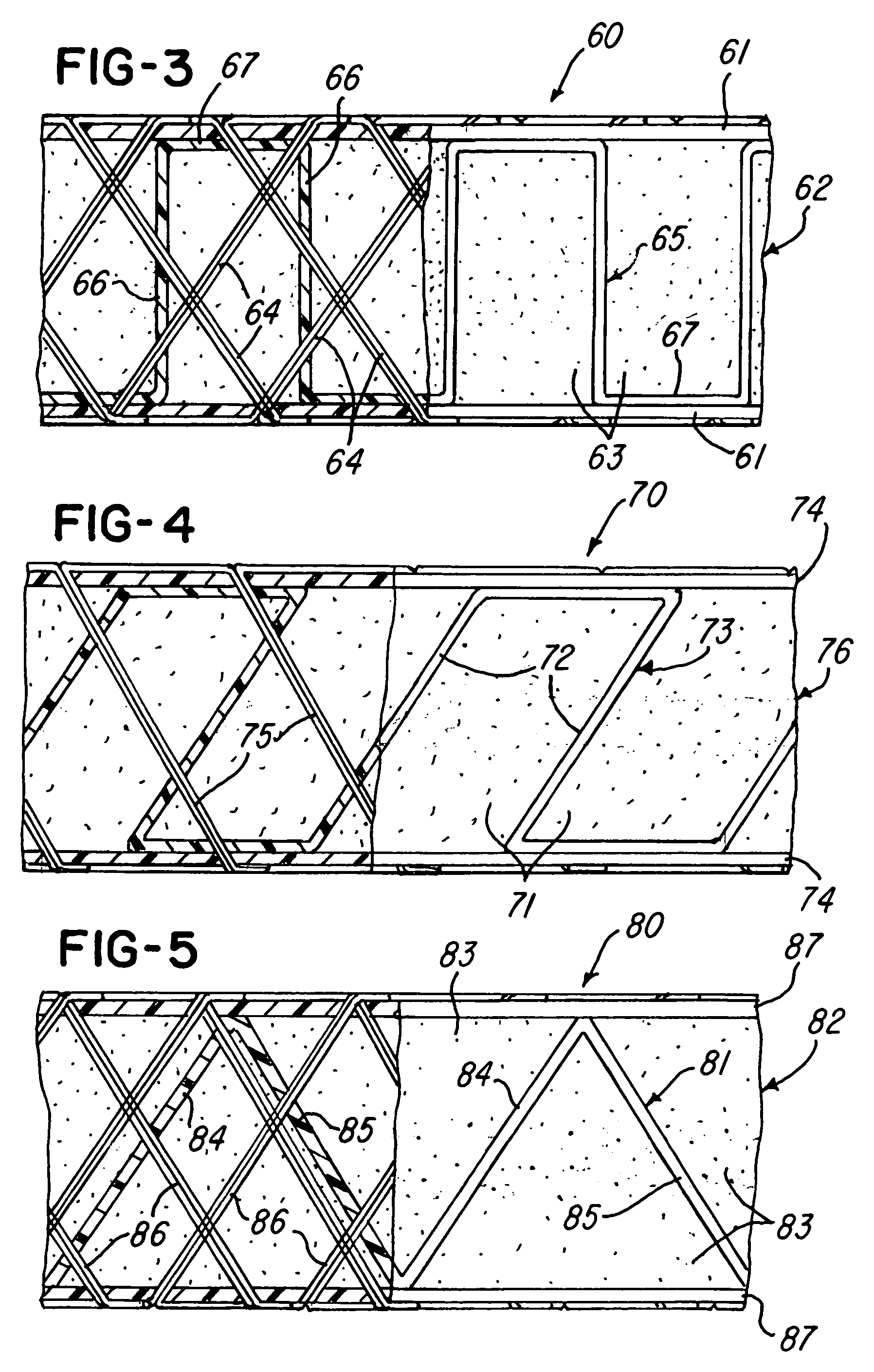

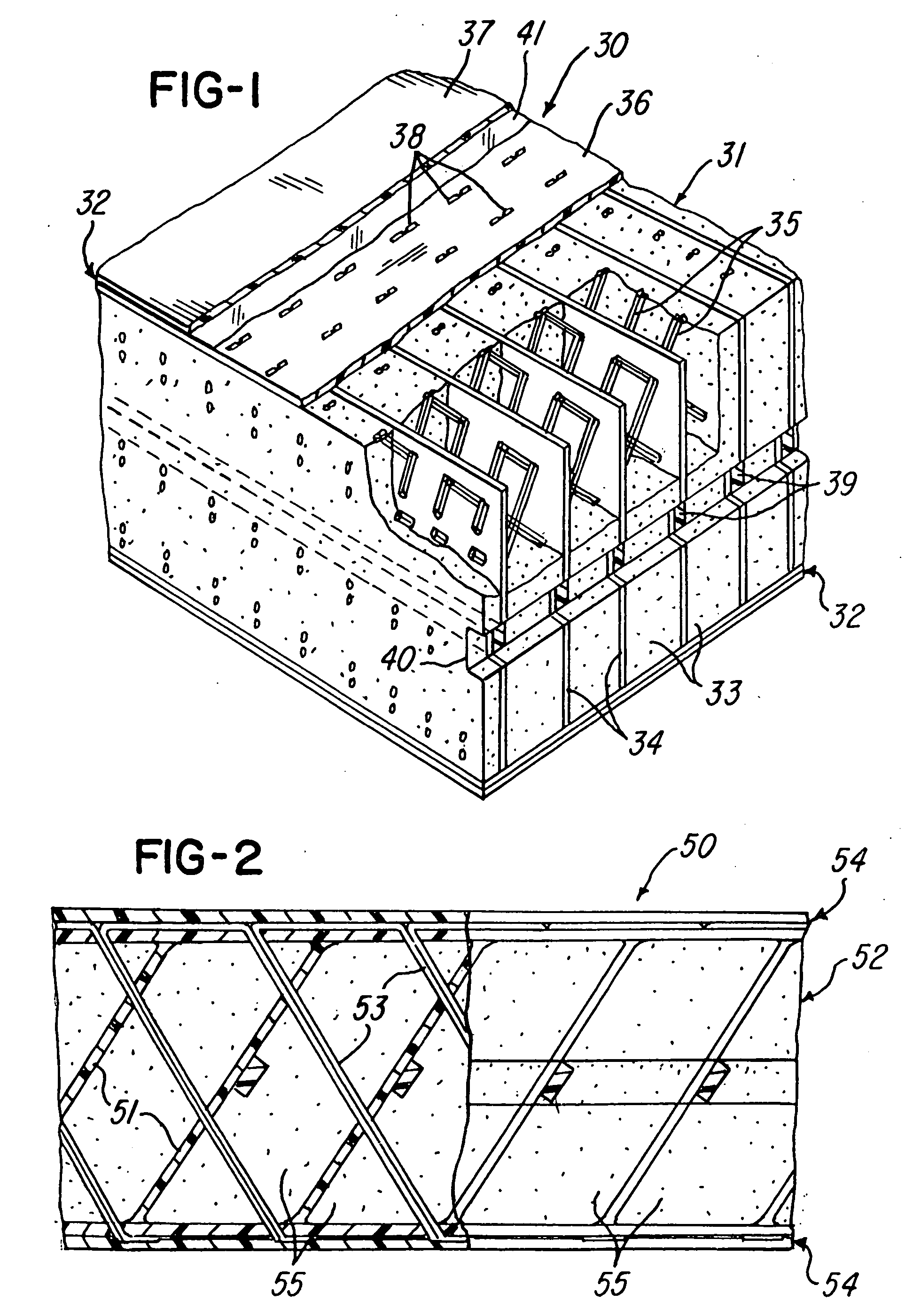

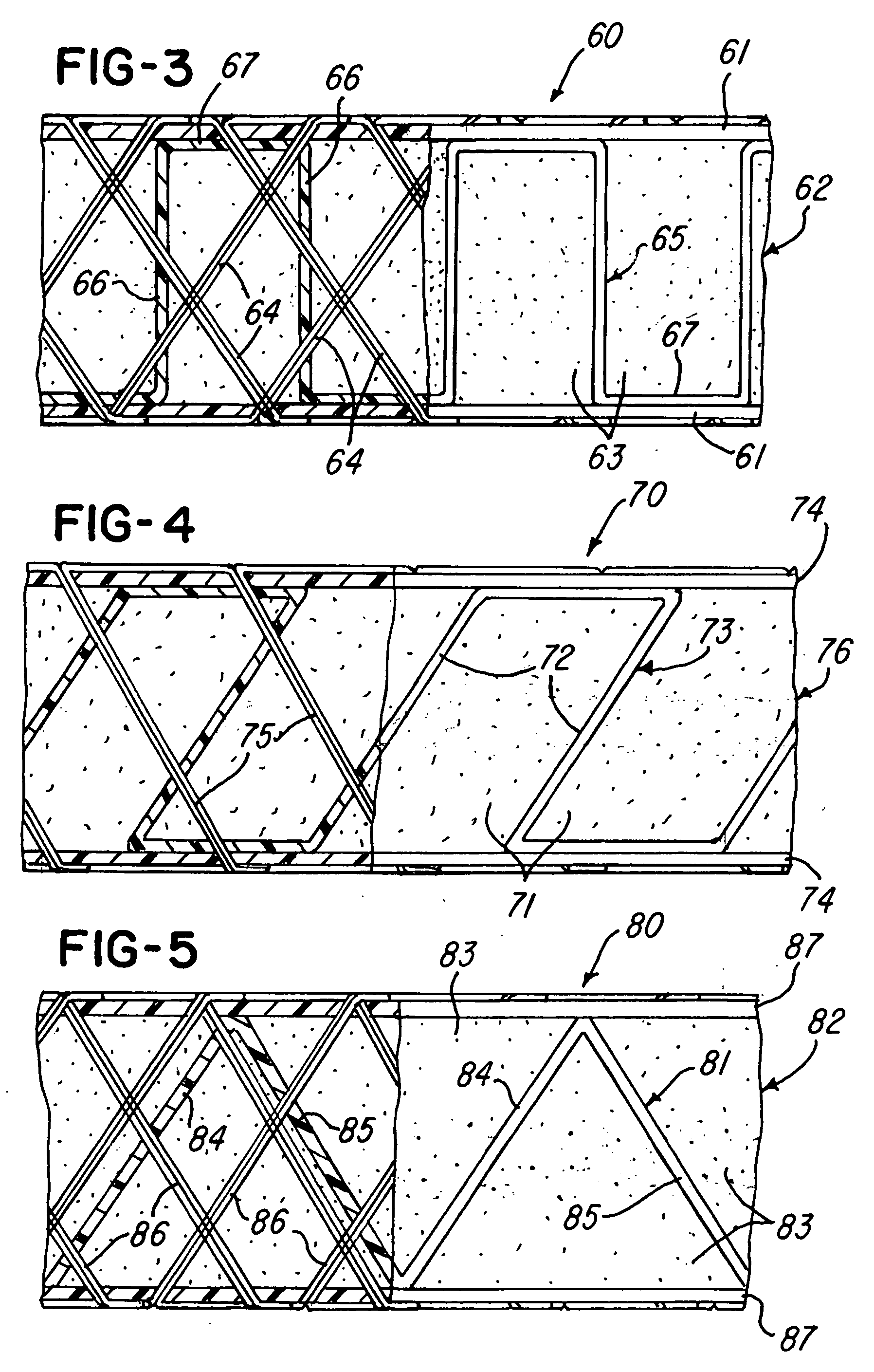

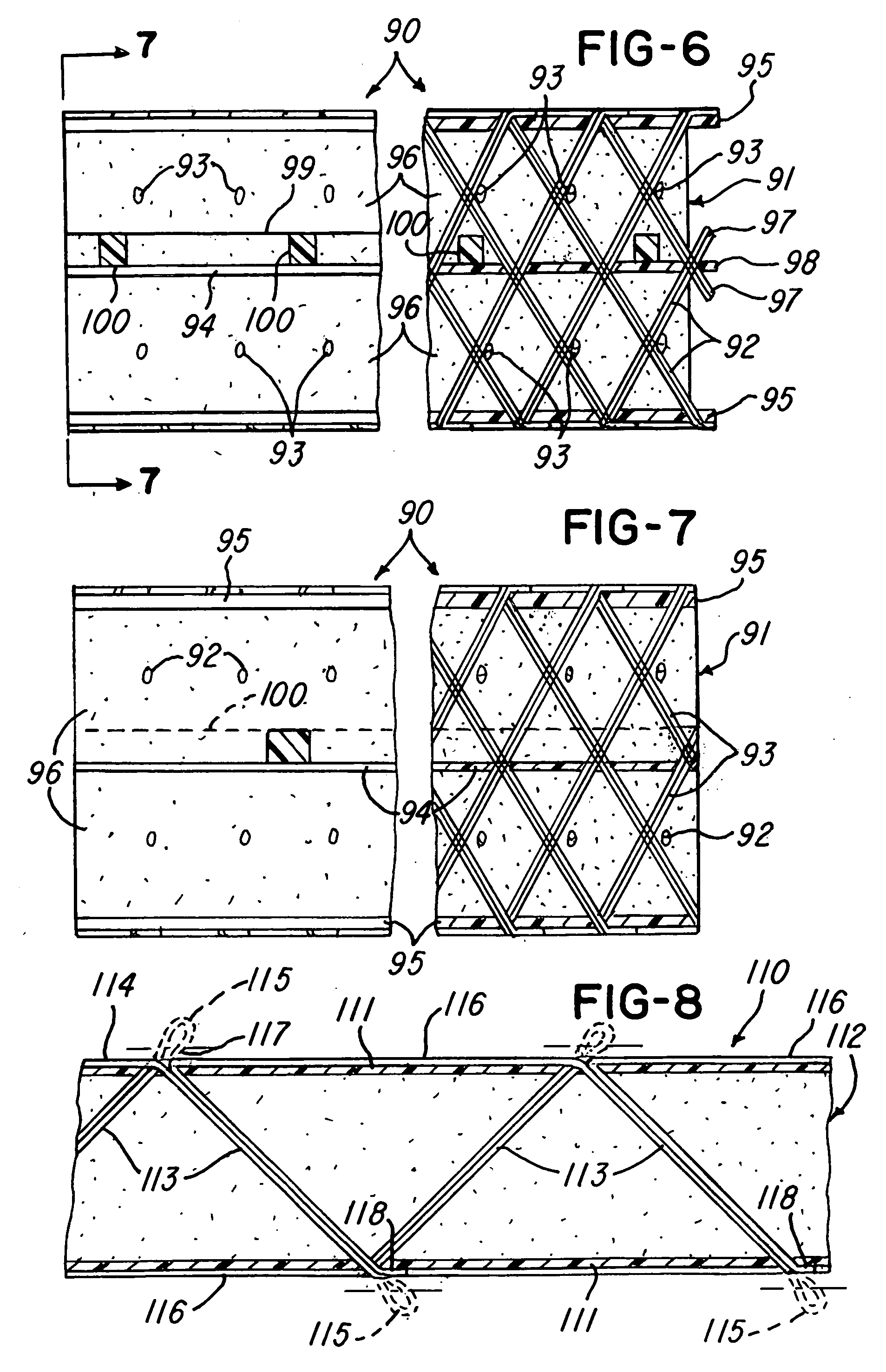

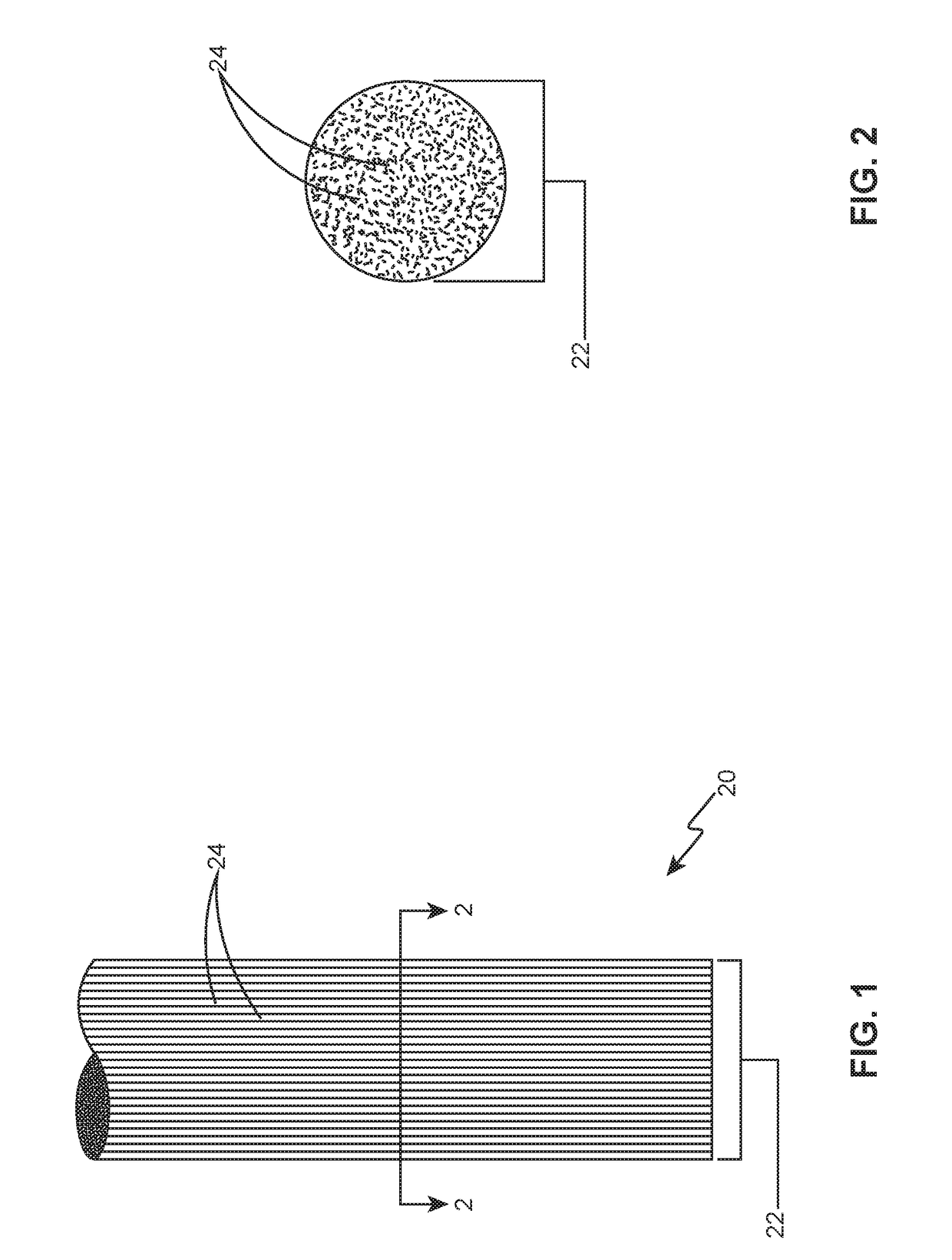

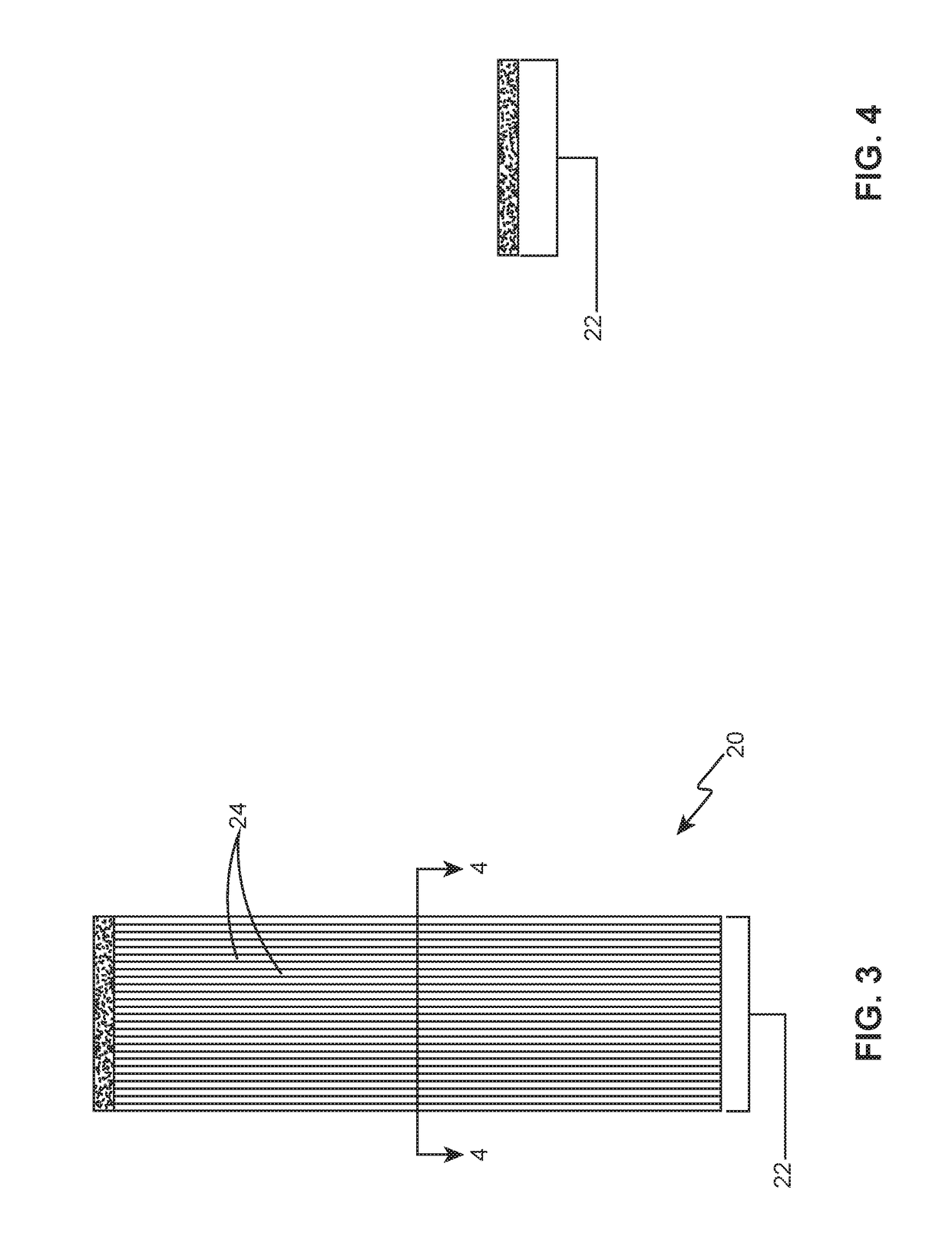

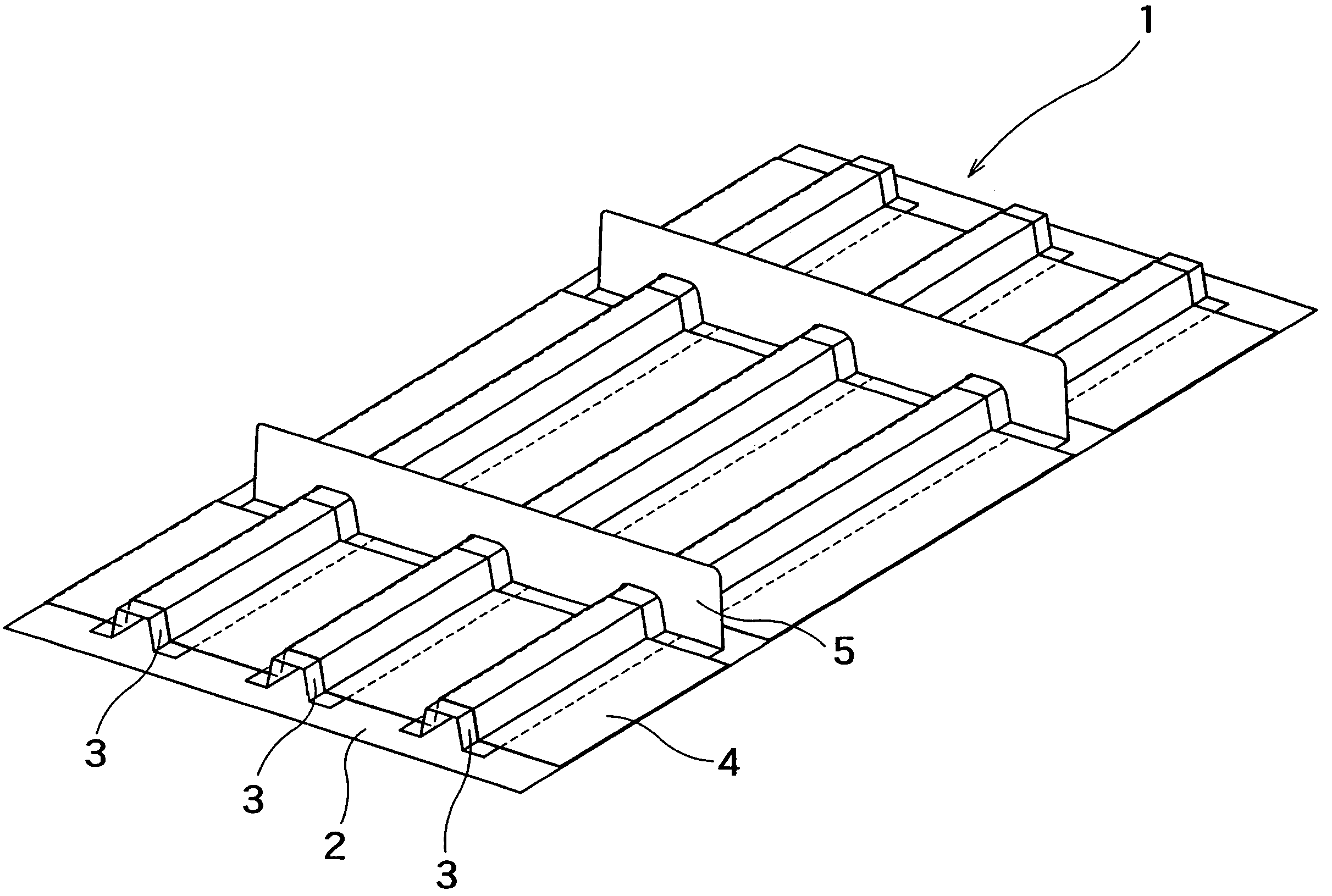

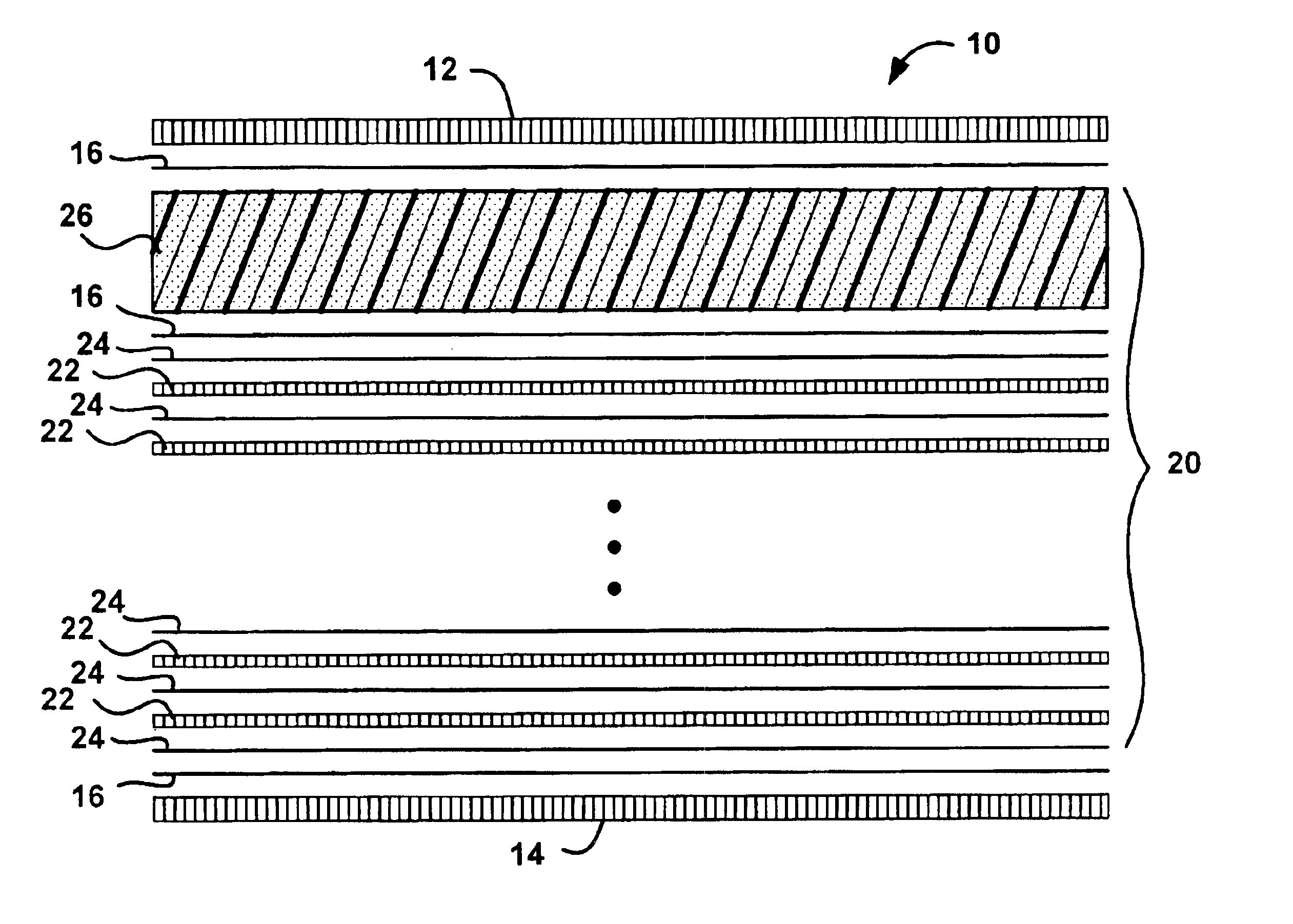

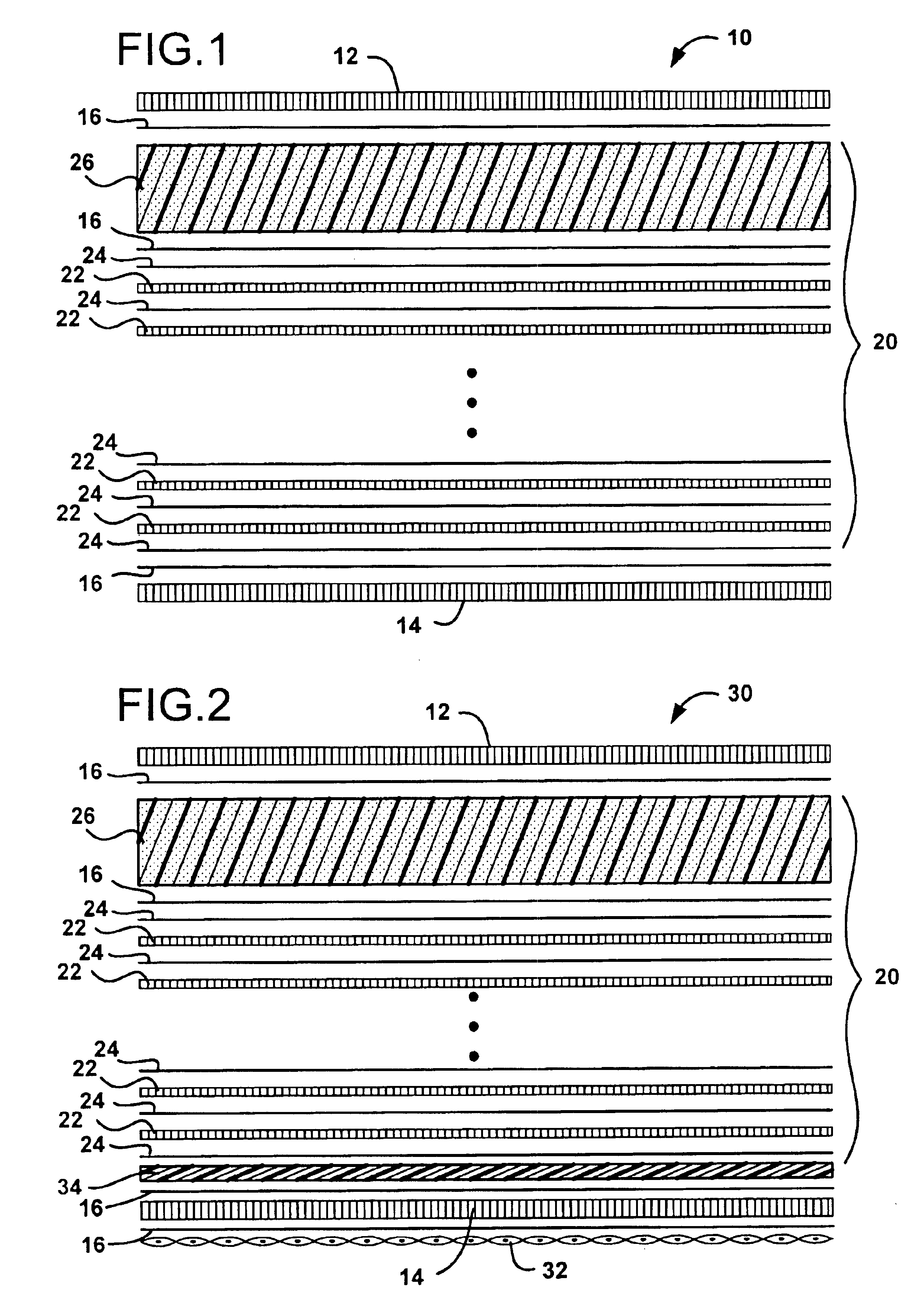

Fiber reinforced composite cores and panels

InactiveUS7393577B2Effective structureImprove impact resistanceSynthetic resin layered productsBuilding componentsEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

Owner:METYX USA INC

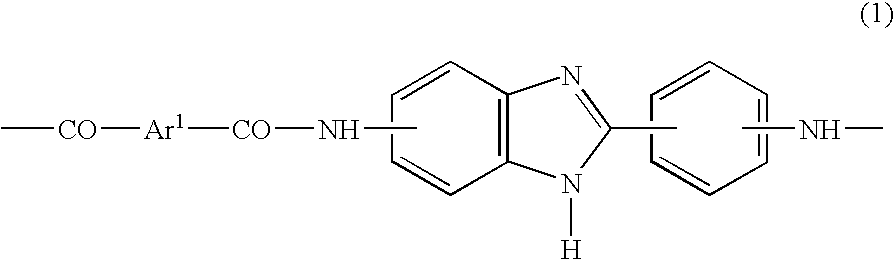

Heterocycle-containing aromatic polyamide fiber, method for producing the same, cloth constituted by the fiber, and fiber-reinforced composite material reinforced with the fiber

InactiveUS20100029159A1Improve balanceHigh strength holding ratioArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentAramidesFiber-reinforced composite

The heterocycle-containing aromatic polyamide fibers of the invention are excellent in balance among mechanical characteristics, particularly balance among tensile strength, initial modulus and strength in the direction perpendicular to the fiber axis, exhibit a high strength holding ratio under heat and humidity, and are excellent in flame retardancy, bulletproofness and cutting resistance, as compared to conventional aromatic polyamide fibers, and therefore can be favorably used in fields with severe mechanical characteristics and have stability to environmental variation. Accordingly, the heterocycle-containing aromatic polyamide fibers of the invention can be favorably used, for example, in fields including protective equipment, such as a helmet, a bulletproof vest and the like, a chassis for an automobile, a ship and the like, an electric insulating material, such as a printed circuit board and the like, and other various fields.

Owner:TEIJIN TECHNO PRODUCTS LTD

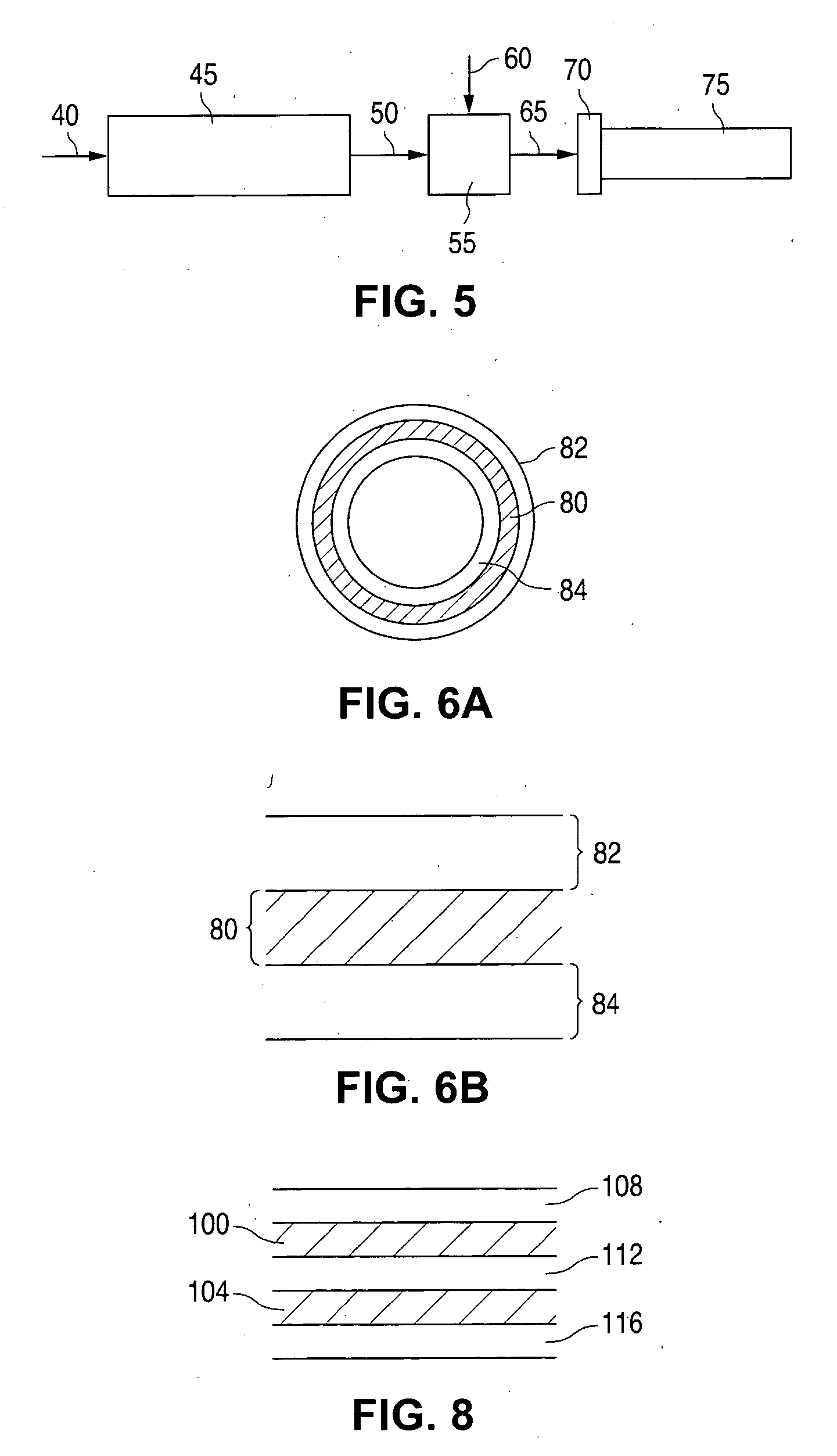

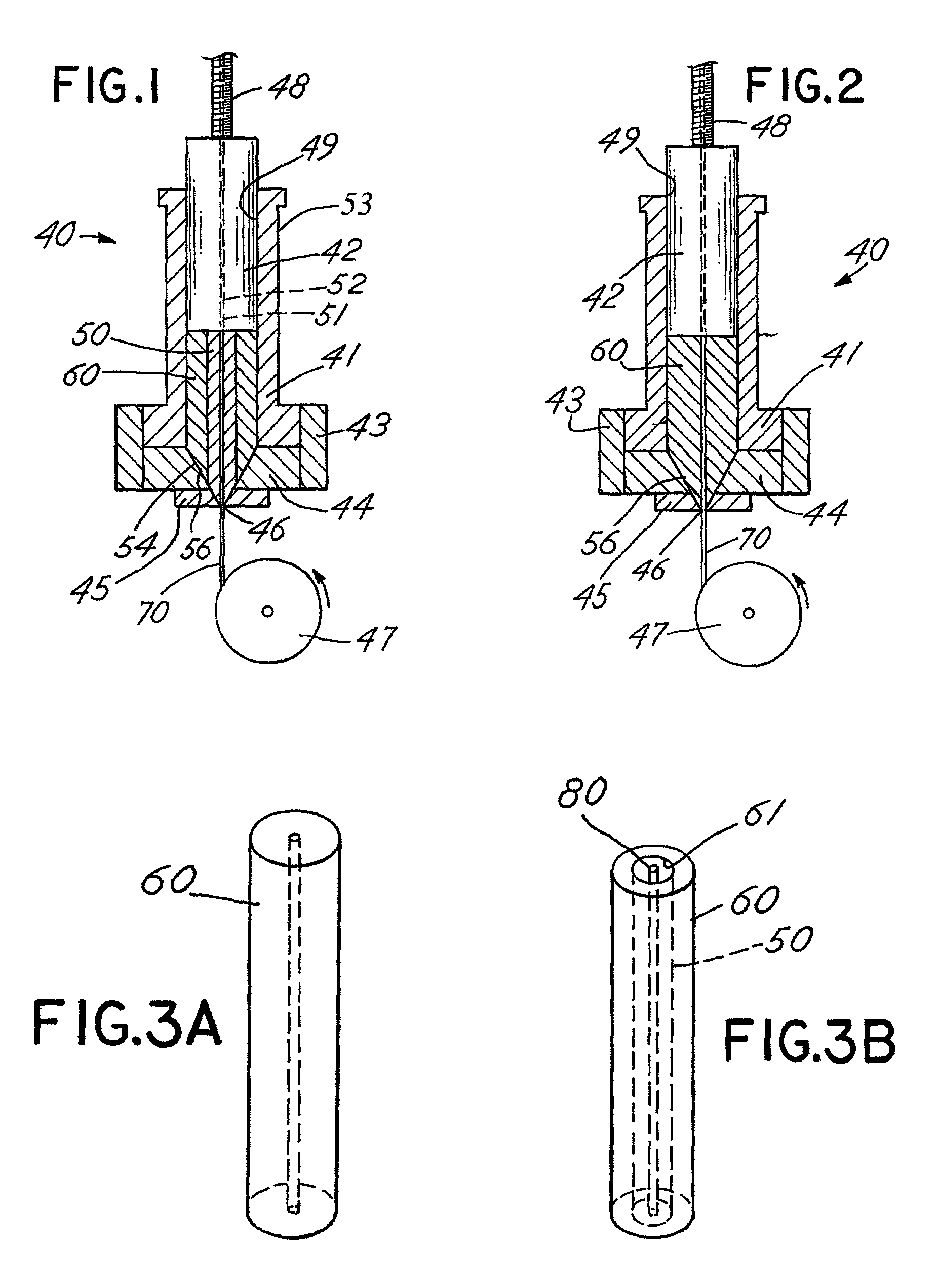

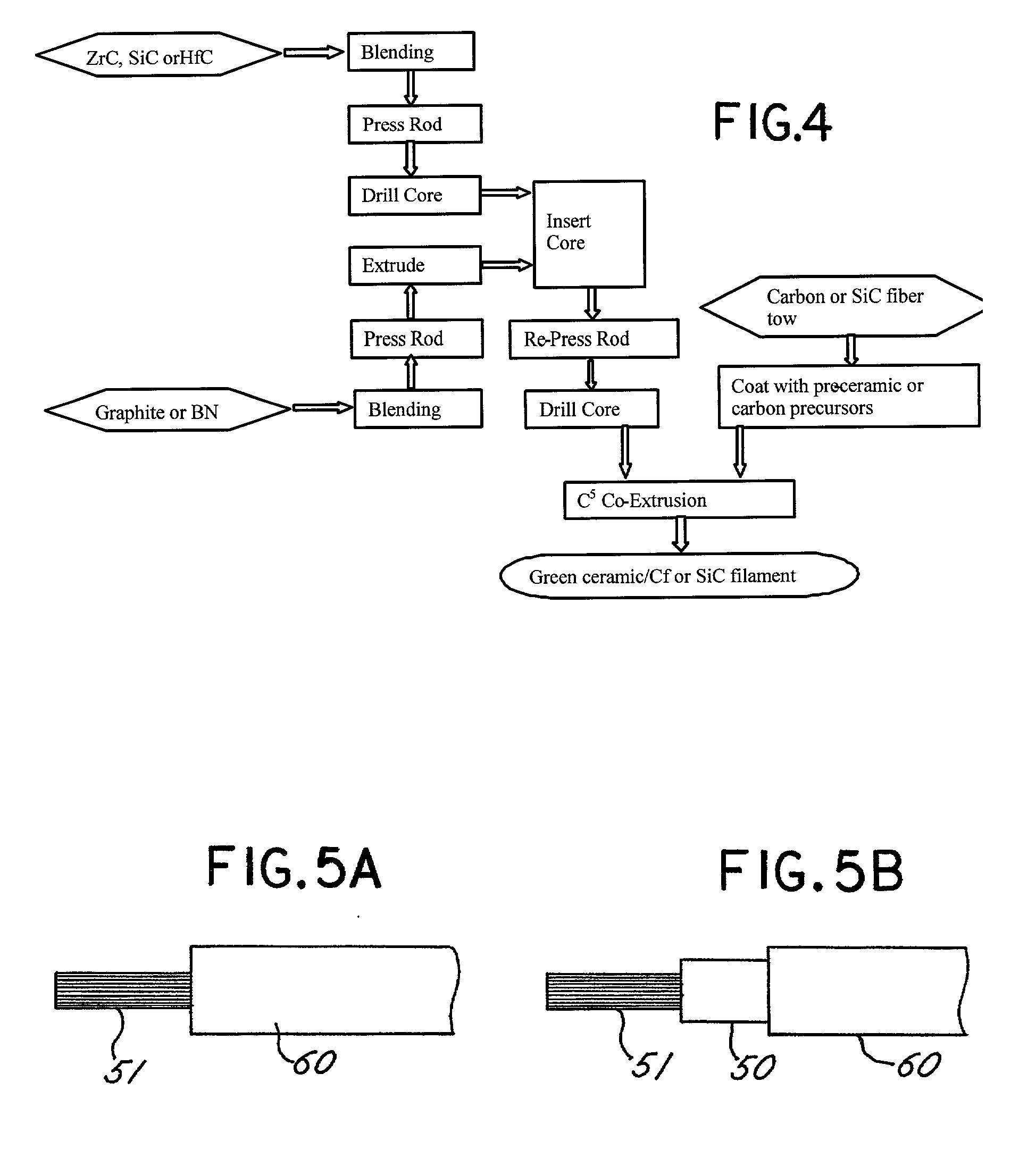

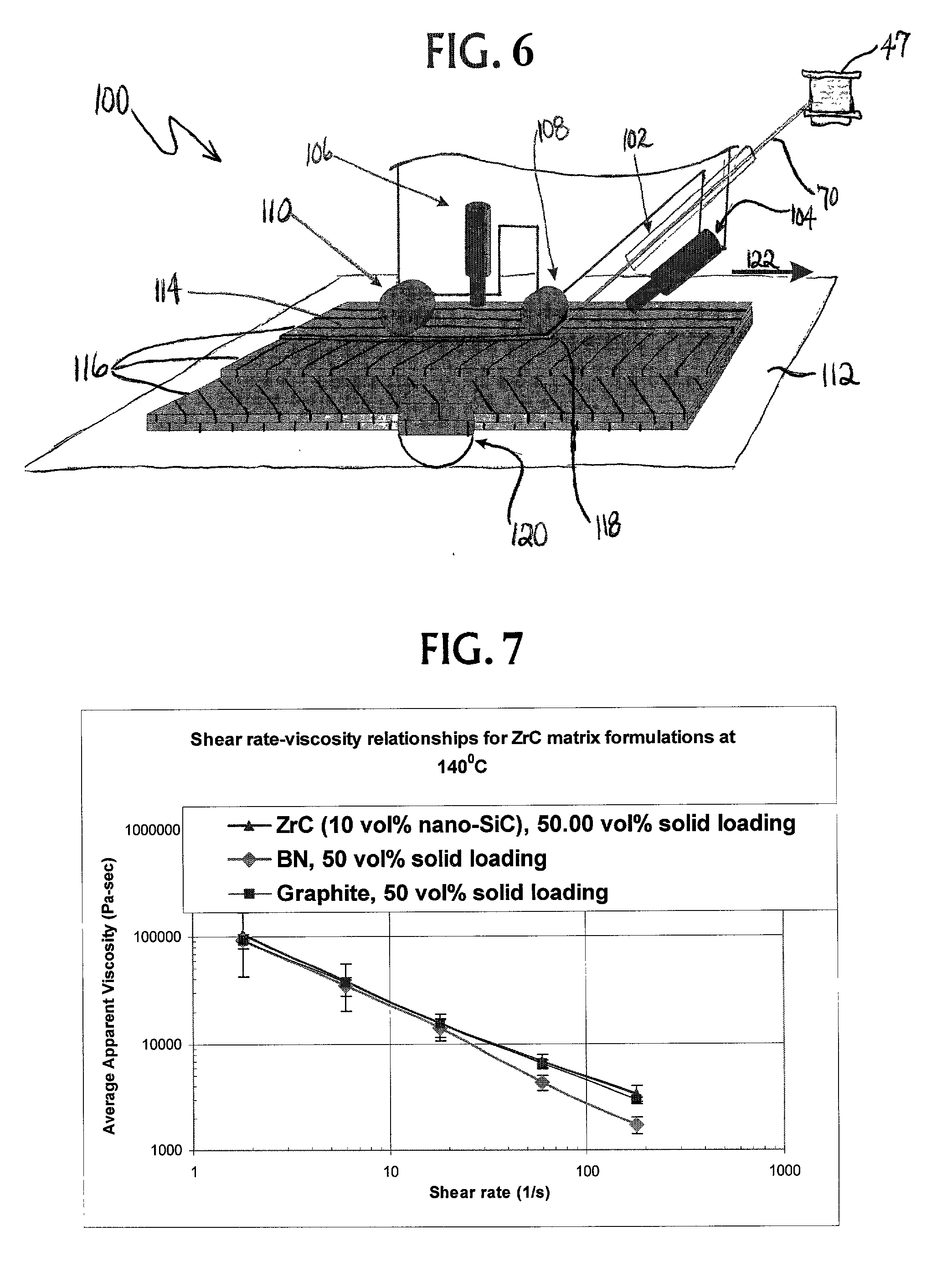

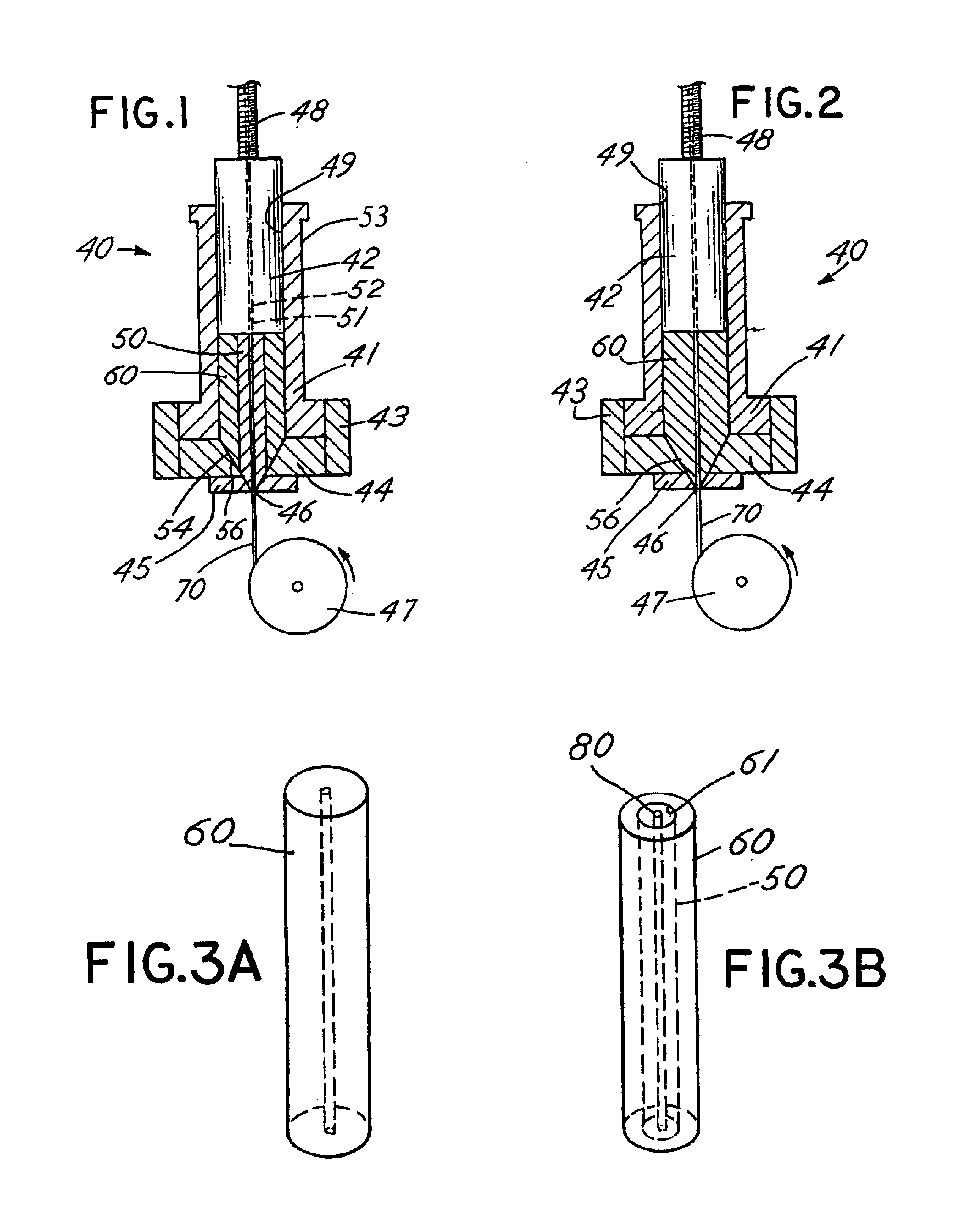

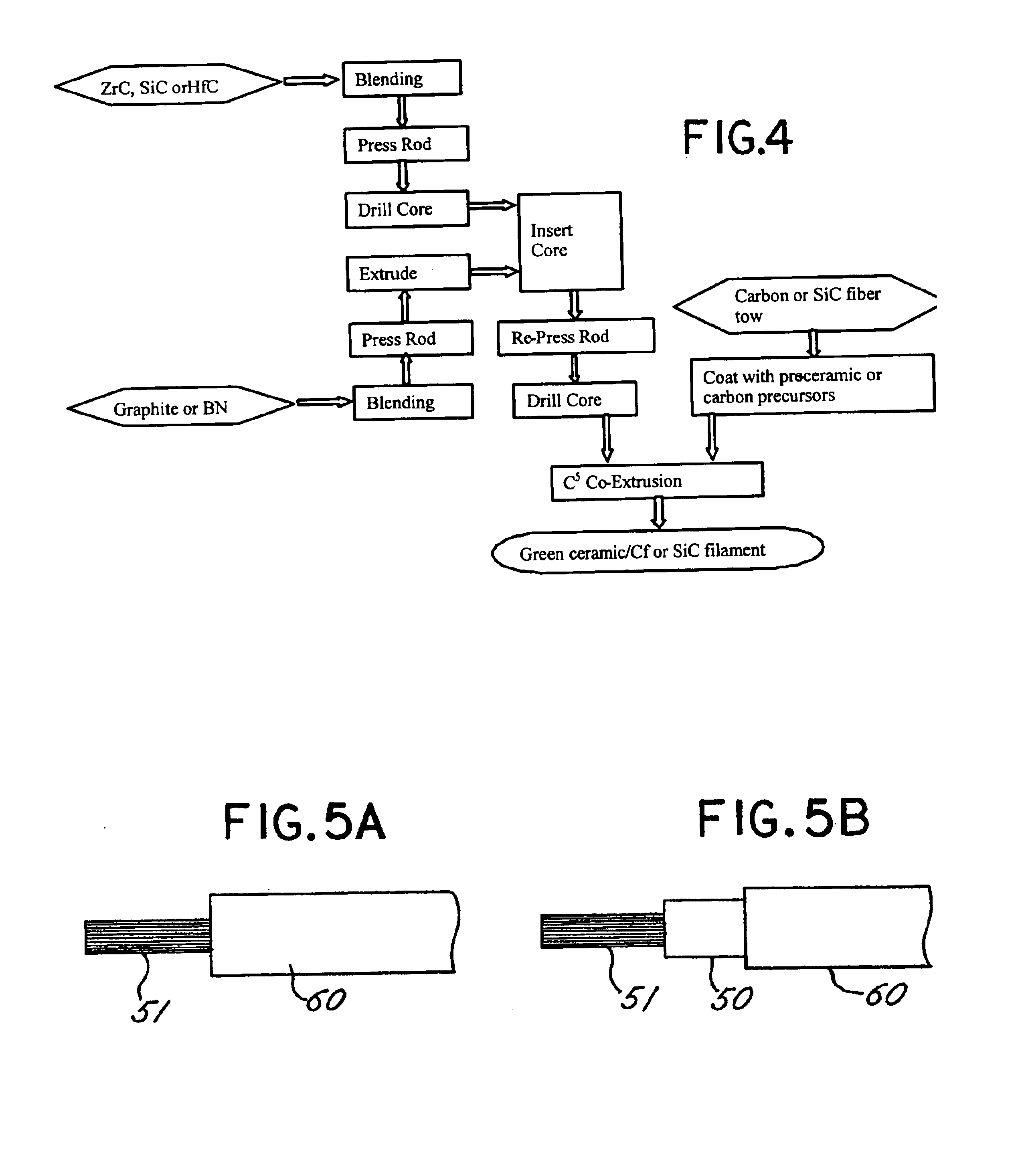

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

Fiber reinforced composite cores and panels

InactiveUS20050074593A1Effective structureImprove impact resistanceSynthetic resin layered productsBuilding componentsEngineeringFiber-reinforced composite

A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

Owner:METYX USA INC

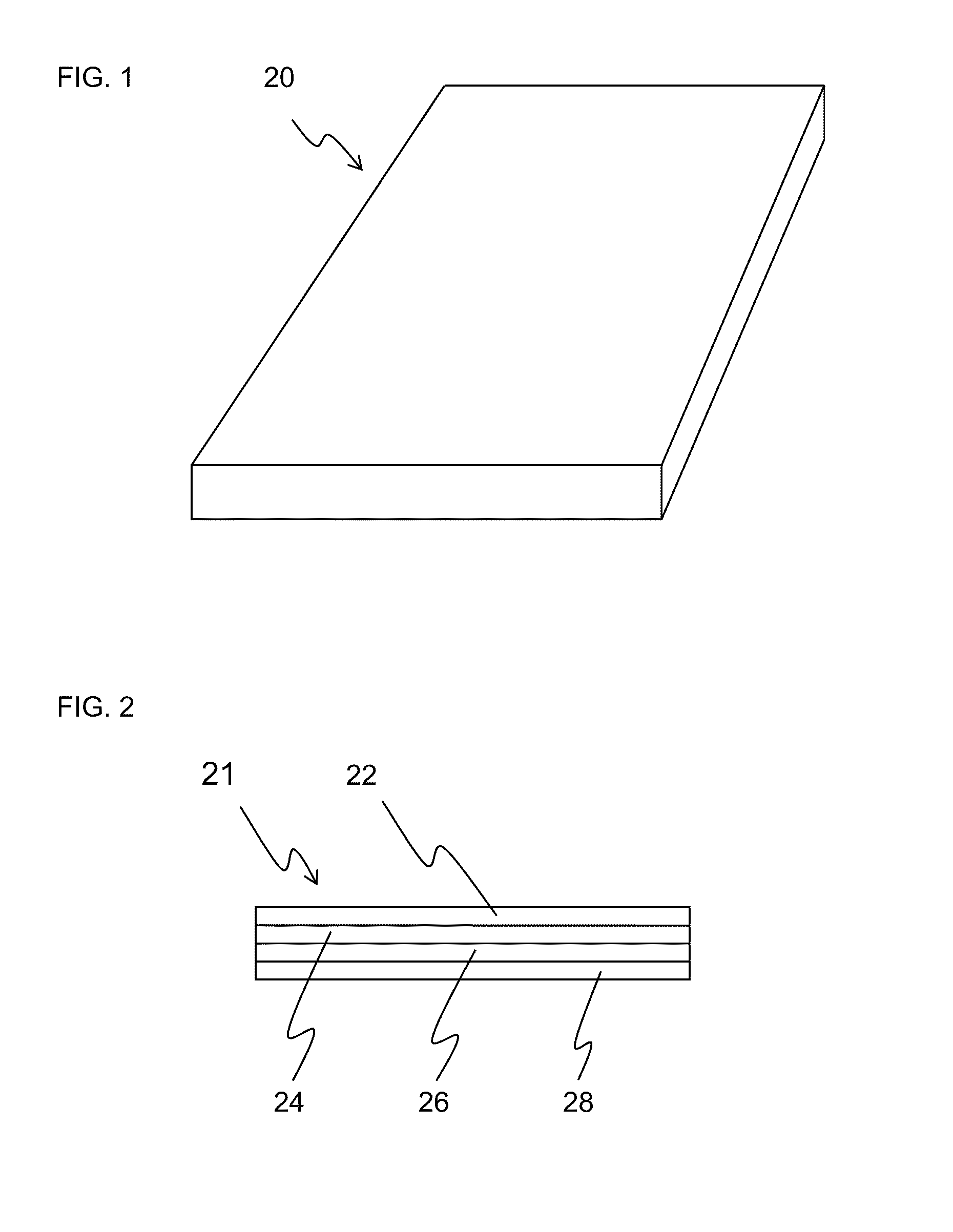

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

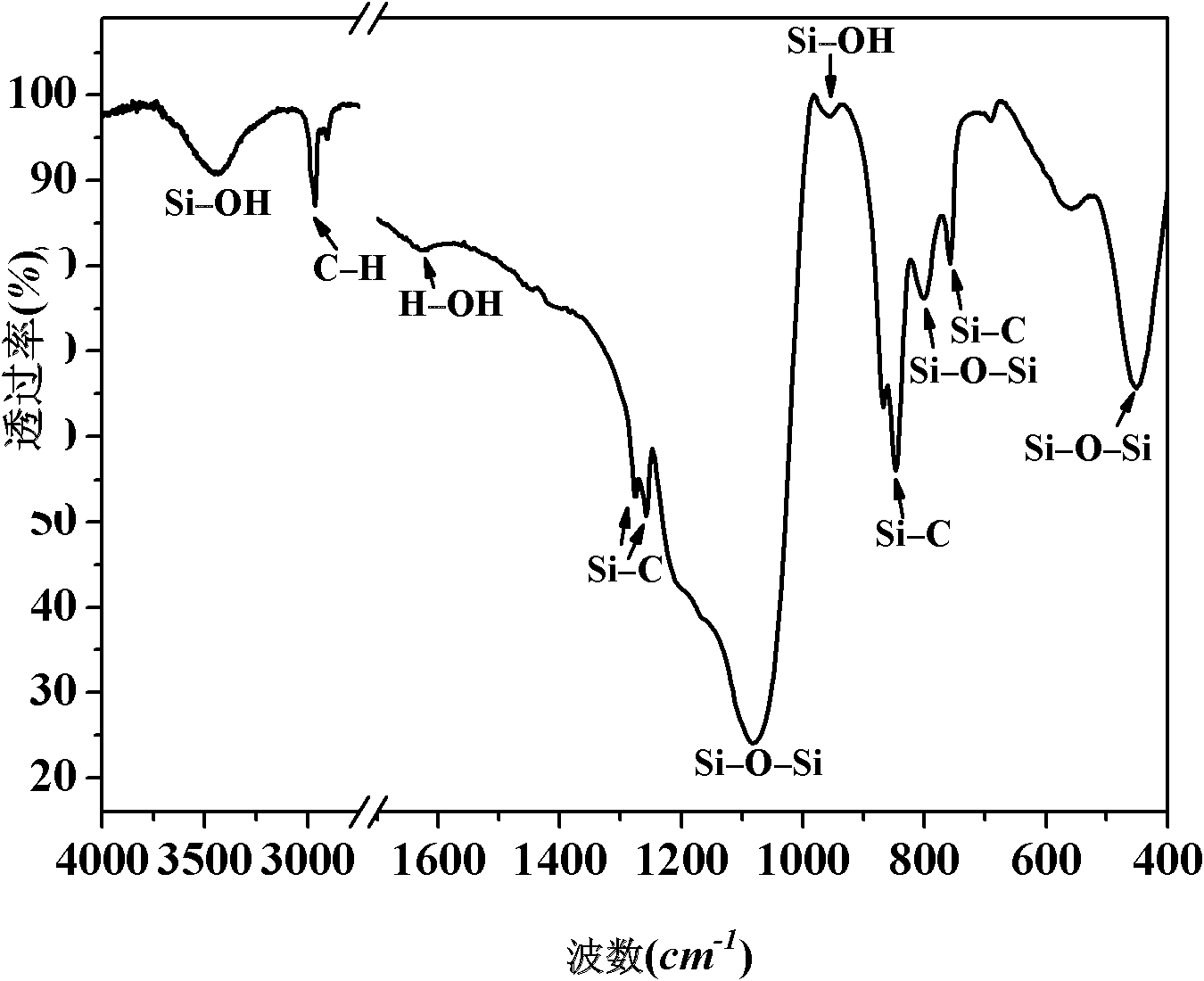

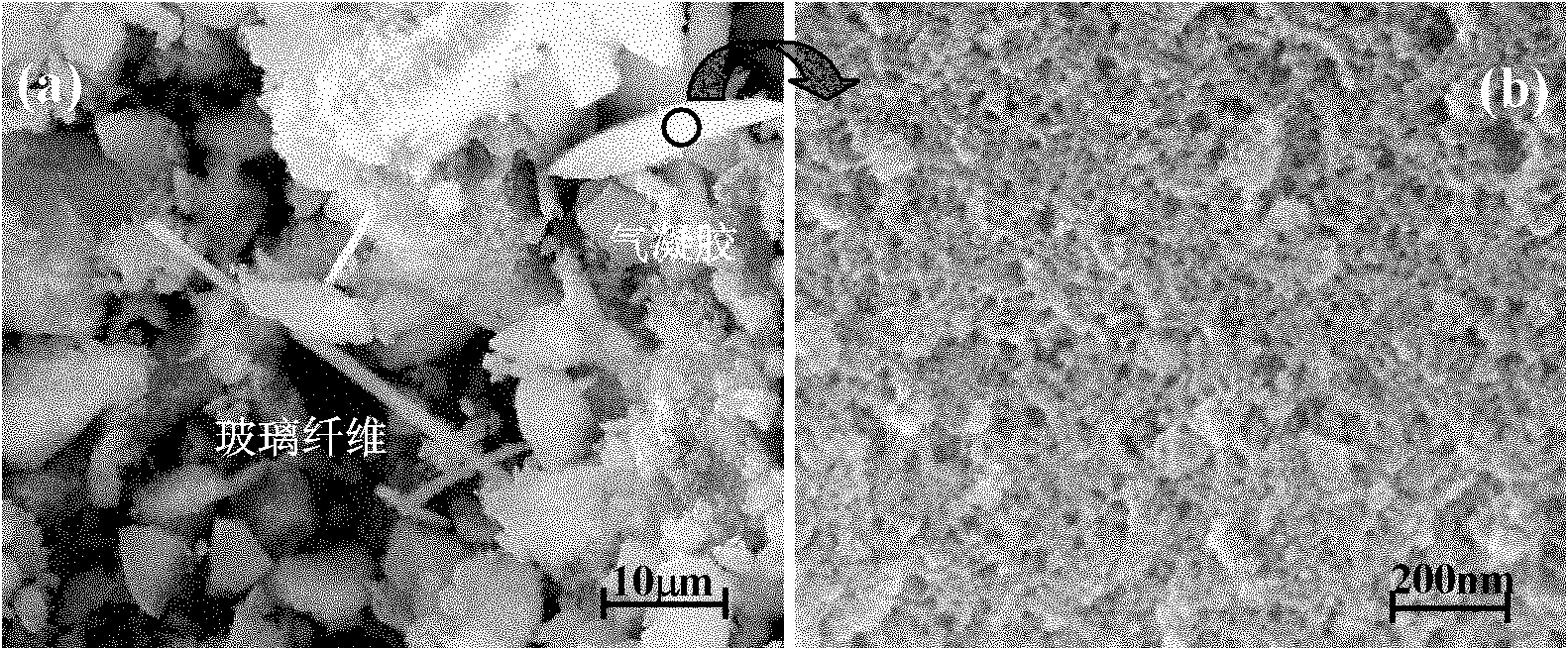

Glass fiber reinforced silicon dioxide aerogel composite material and preparation method thereof

The invention relates to an aerogel composite material, in particular to a glass fiber reinforced silicon dioxide aerogel composite material and a preparation method thereof. The excellent properties of aerogel are maintained, the mechanical properties of the aerogel are reinforced, and the glass fiber reinforced silicon dioxide aerogel composite material has good integrity and certain strength. The glass fiber reinforced silicon dioxide aerogel composite material is prepared by compounding glass fiber and silicon dioxide aerogel, wherein the glass fiber is a reinforcement, and the content ofthe glass fiber accounts for 1-15% total mass of a sample; the silicon dioxide aerogel is a matrix, tetraethoxysilane is a silicon source material, and methyltrimethoxysilane or methyltriethoxysilaneis used as a silicon source co-precursor. The preparation method comprises the following steps of: firstly, pretreating the glass fiber; then, preparing glass fiber reinforced silicon dioxide composite wet gel; and finally, aging, secondarily modifying and drying the silicon dioxide composite wet gel.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

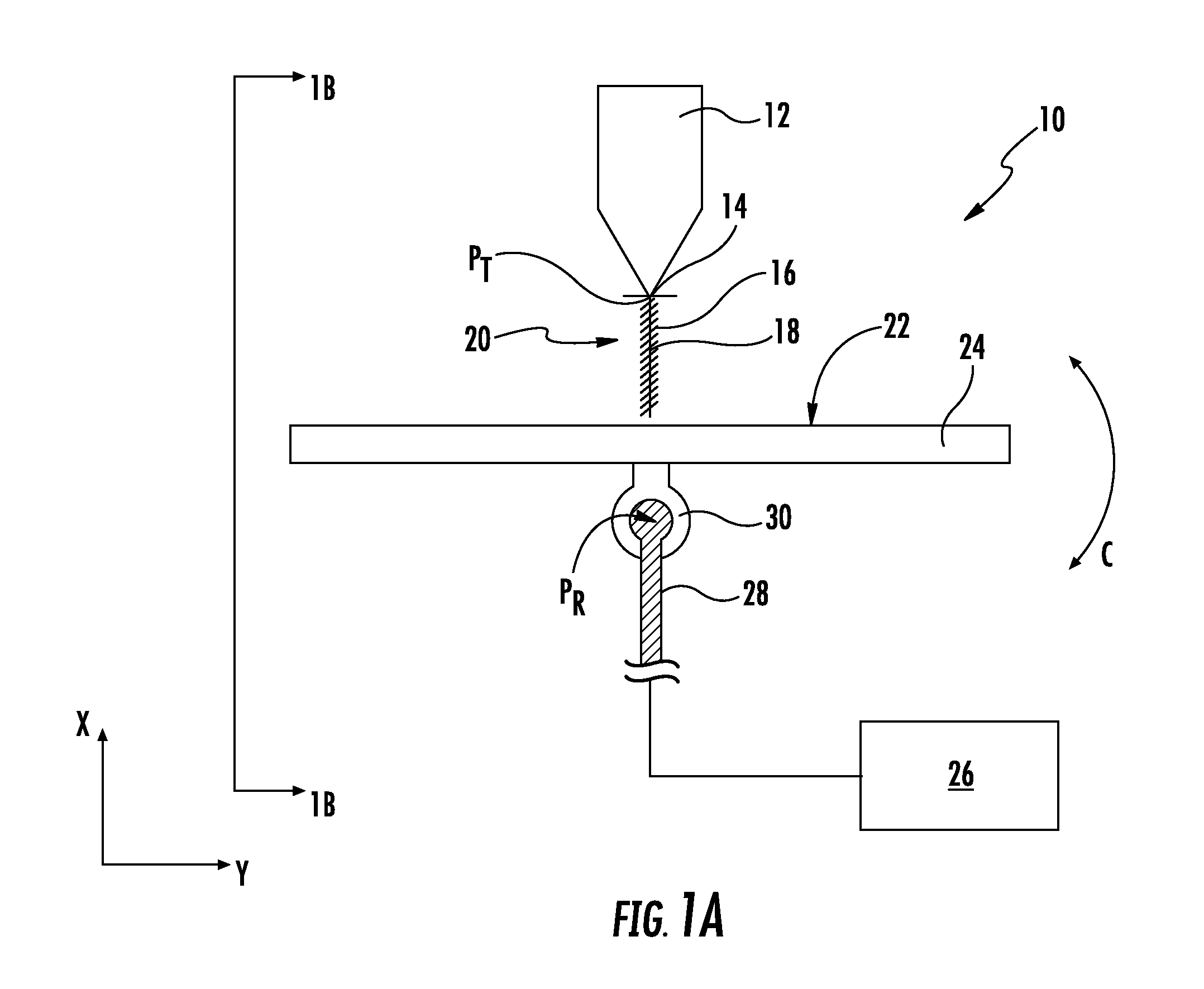

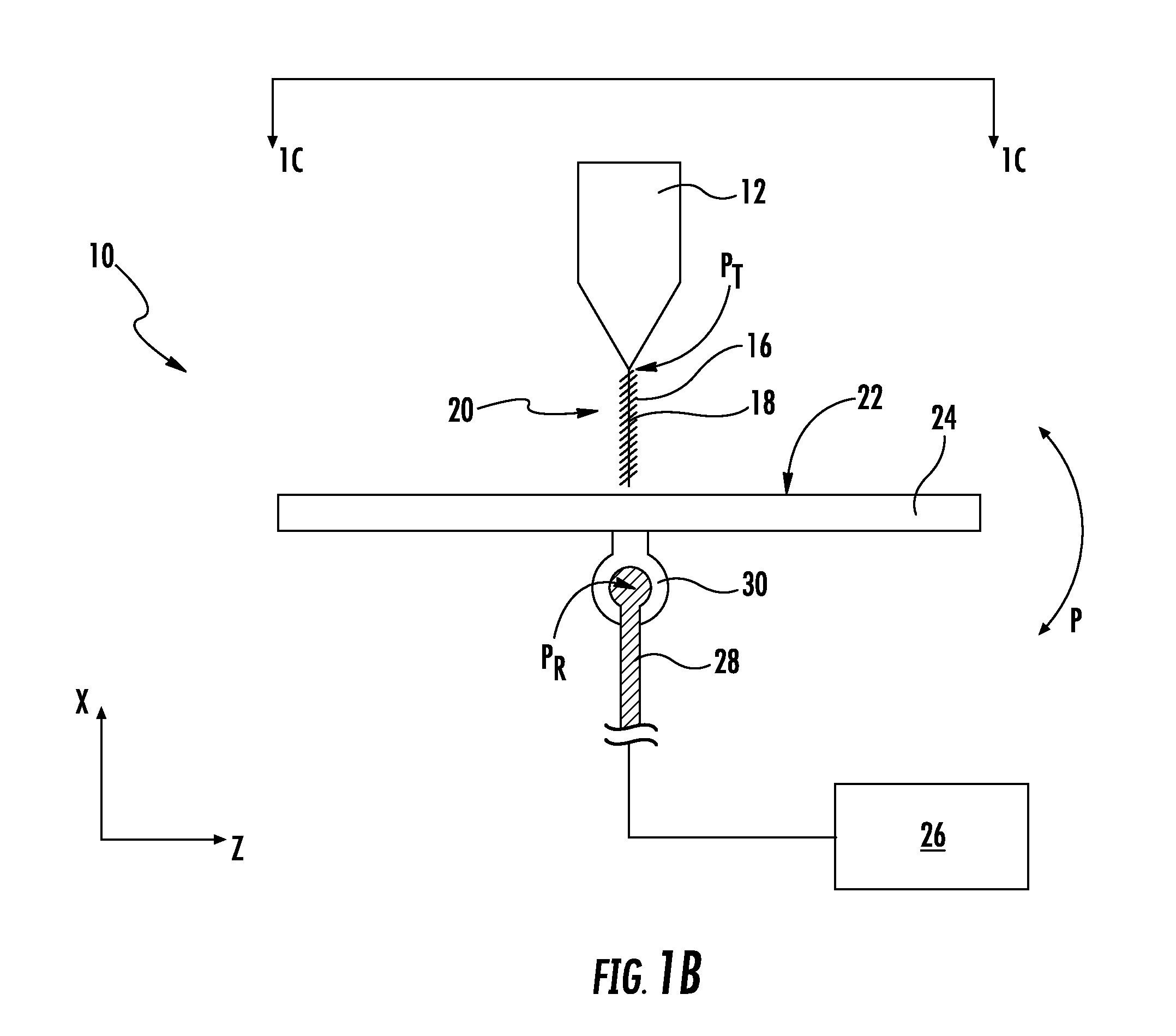

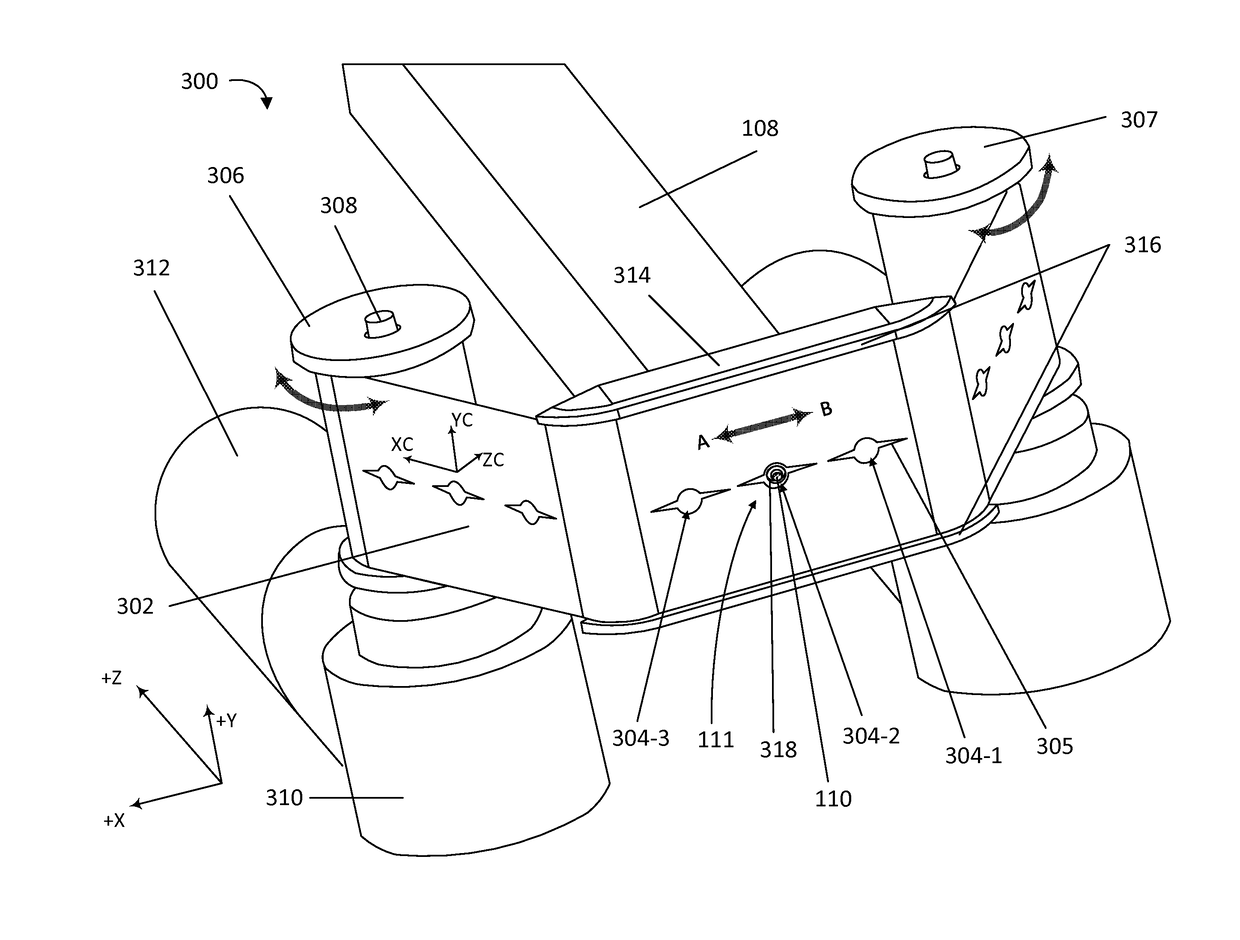

Machine and a Method for Additive Manufacturing with Continuous Fiber Reinforcements

InactiveUS20170151728A1Manufacturing heating elementsAdditive manufacturing with liquidsUltimate tensile strengthPolymer

Several examples of additive manufacturing machines and methods for depositing a bead of composite polymer material having continuous fiber reinforcement are disclosed. A length of fiber reinforcement is provided to a nozzle. The fiber reinforcement is embedded into a stream of a base polymer material at the nozzle and deposited as a bead of composite polymer material having fiber reinforcement. The fiber reinforcement may be dry or pre-impregnated with a reinforcing polymer. The additional strength of the composite polymer material having fiber reinforcement allows for true, three-dimensional printing of articles having unsupported regions.

Owner:UT BATTELLE LLC

Fiber thermoset reinforced thermoplastic structural member

InactiveUS6106944AHigh strengthImprove mechanical propertiesLayered productsSpecial ornamental structuresYoung's modulusEngineering

In the manufacture of a structural member comprising a thermoplastic composite core with an exterior reinforcing layer, the core member is initially extruded in the shape of a profile. The profile is then contacted with reinforcing fiber and resin to form the exterior reinforcing layer. The exterior thermosetting layer is cured to form a reinforcing layer. The structural member is preferably manufactured using a pultrusion method in which a tractor device is used to provide linear movement of the profile from the extrusion head to the exterior coating operation. The fiber-reinforced thermoset is coated on the entirety of the exterior of the profile or is applied only on a portion of the profile requiring reinforcement in a defined load-bearing direction. A preferred thermoplastic core comprises a polymer-fiber composite material. A structural member of the invention has significantly improved Young's modulus providing strength for applications such as telephone poles, electric poles, electric lighting poles, boat mast or keel applications, lumber replacements, structural members used in window and door manufacture, etc.

Owner:ANDERSEN CORPORATION

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS6986853B2Repaired quickly and efficientlySufficient protectionMaterial nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

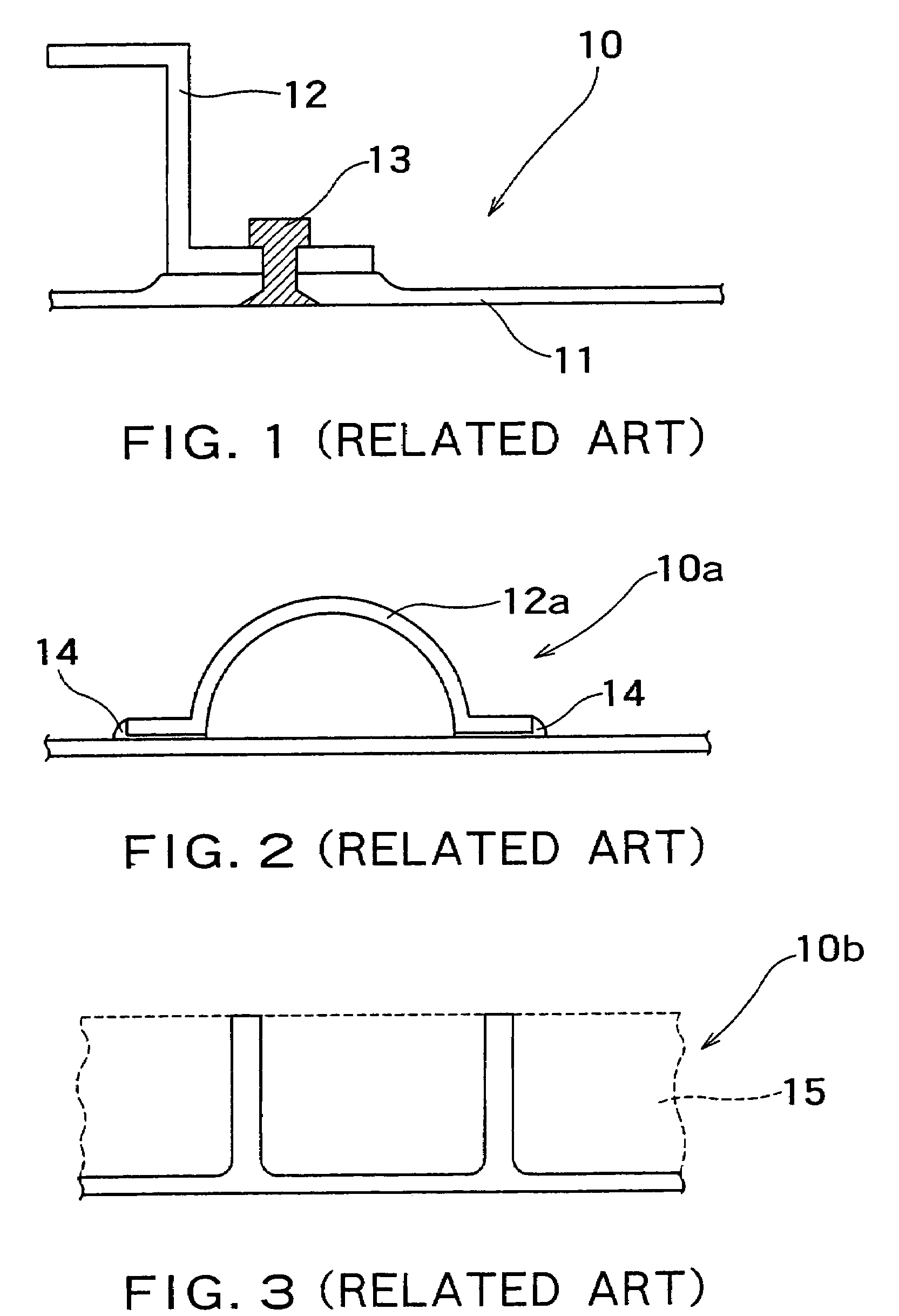

Composite material-stiffened panel and manufacturing method thereof

A composite material-stiffened panel has a skin obtained by molding a fiber-reinforced resin composite material into a flat skin, stiffeners arranged in rows on one surface of the skin, and a fiber-reinforced resin-composite material stitched on the skin covering the stiffeners. The composite material-stiffened panel can be manufactured as follows: A first fabric material is placed on a tool having a panel-shaped surface. Stiffeners are placed on the first fabric materials. A second fabric material is placed on the stiffeners to cover at least some of the stiffeners. The second fabric materials are reformed to match the shape of the stiffeners. The reformed second fabric material is stitched on the first fabric material along edges of the stiffeners. All the materials are covered with a bagging film for vacuum. Resin is infiltrated into the fabric materials by a RTM or a RFI method. The infiltrated resin is heated to be hardened.

Owner:SUBARU CORP

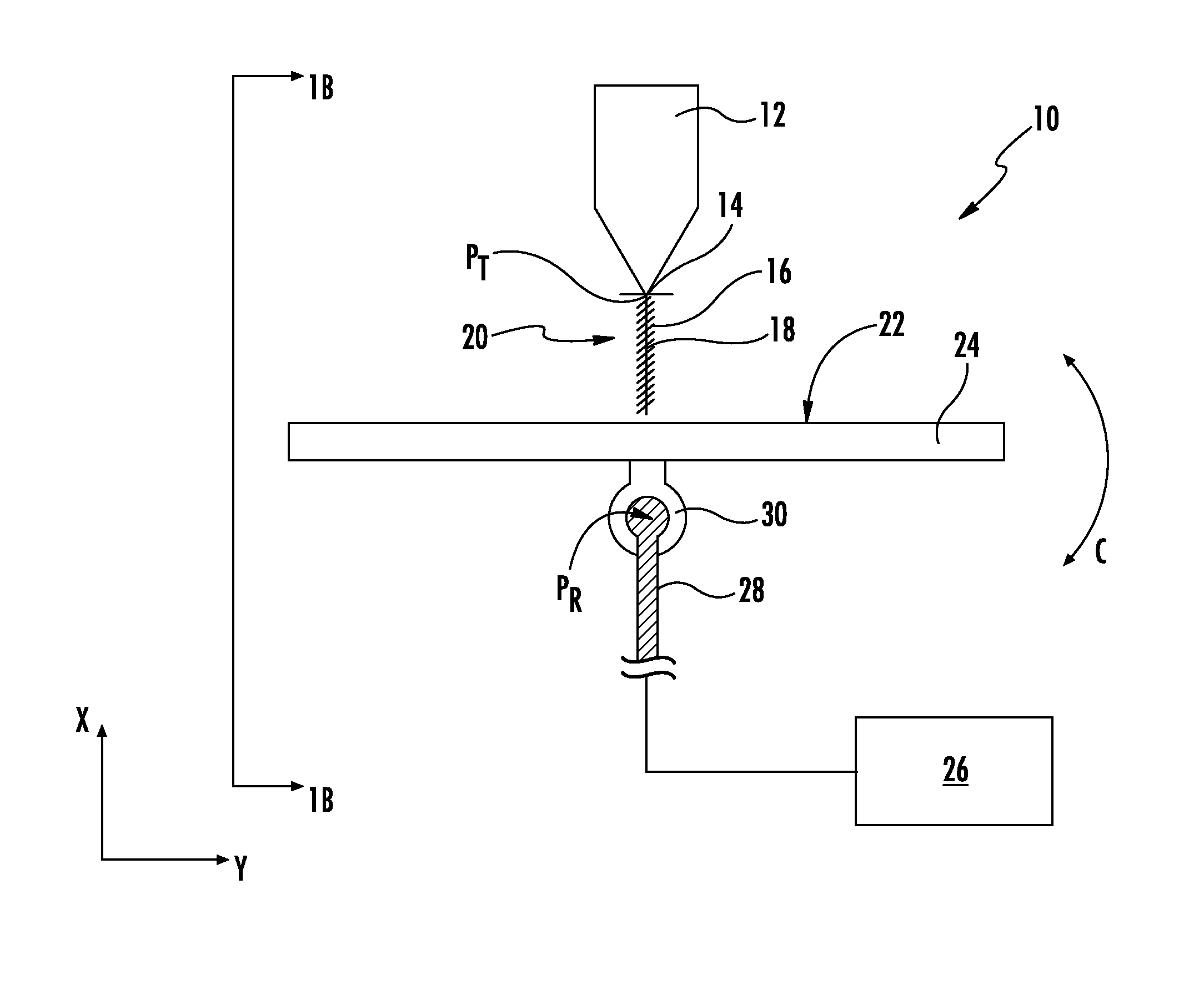

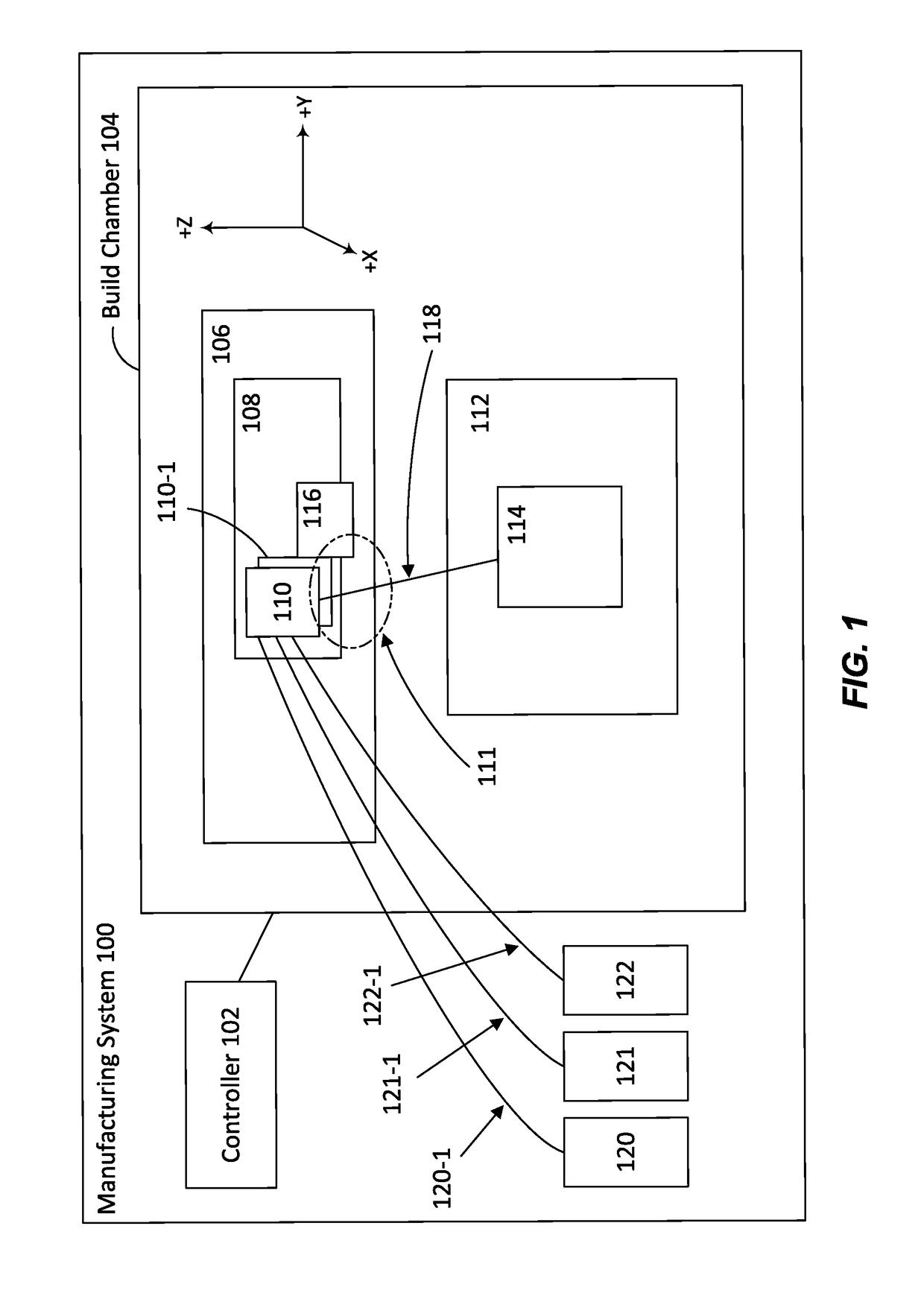

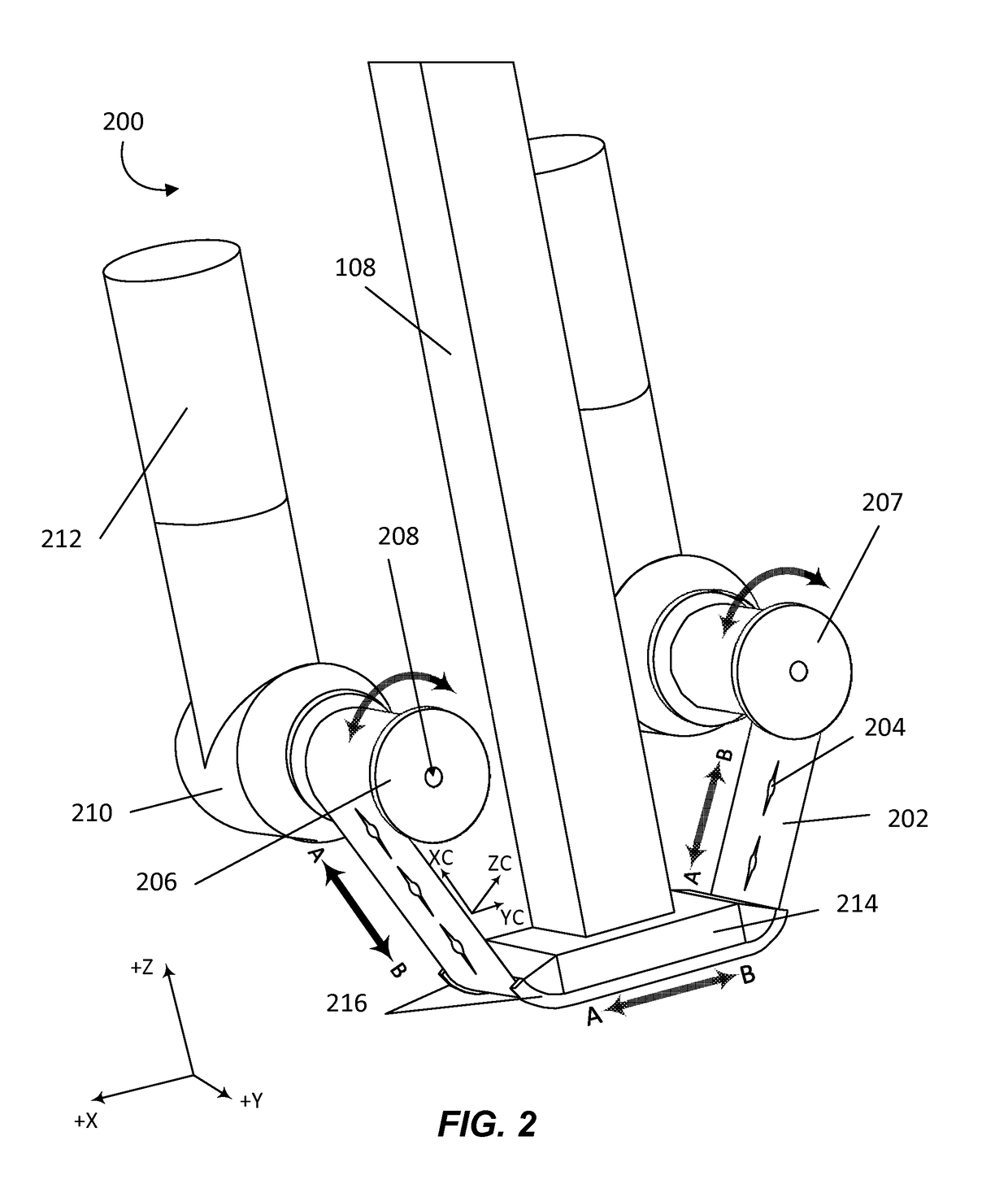

Integrated robotic 3D printing system for printing of fiber reinforced parts

ActiveUS20170057167A1Manufacturing platforms/substratesAdditive manufacturing with liquidsPrint mediaRobotics

A system for printing a three-dimensional object is provided. The system can include at least one print head configured to receive a continuous fiber and at least partially encase the continuous fiber with a formation material to create a composite material. The at least one print bed can be configured to move in at least six different degrees of freedom. The system can also include at least one print bed comprising a printing surface onto which the composite material may be selectively applied to form a work piece. The at least one print head can be positioned relative to the at least one print bed and configured to advance print media thereon.

Owner:UNIVERSITY OF SOUTH CAROLINA +1

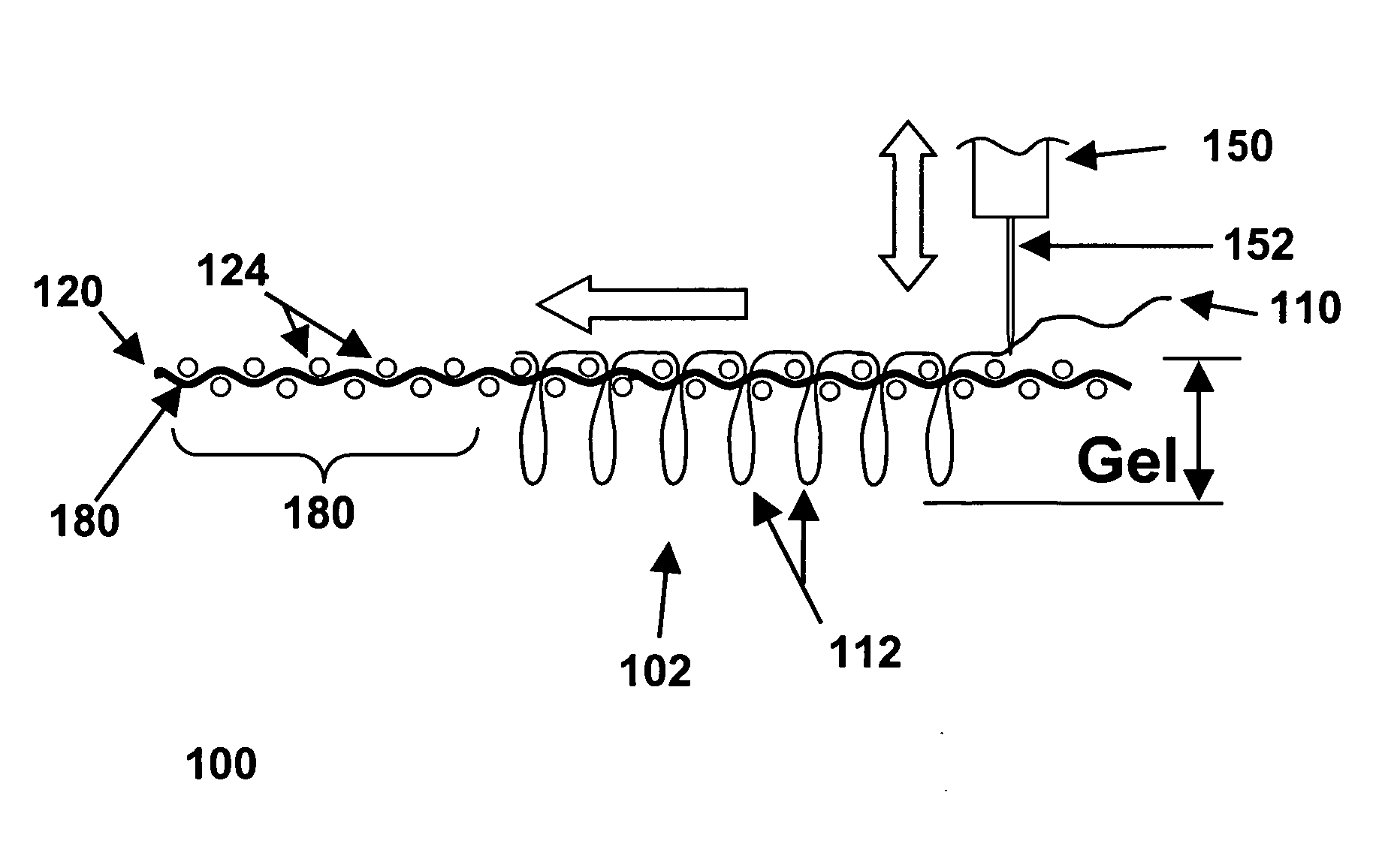

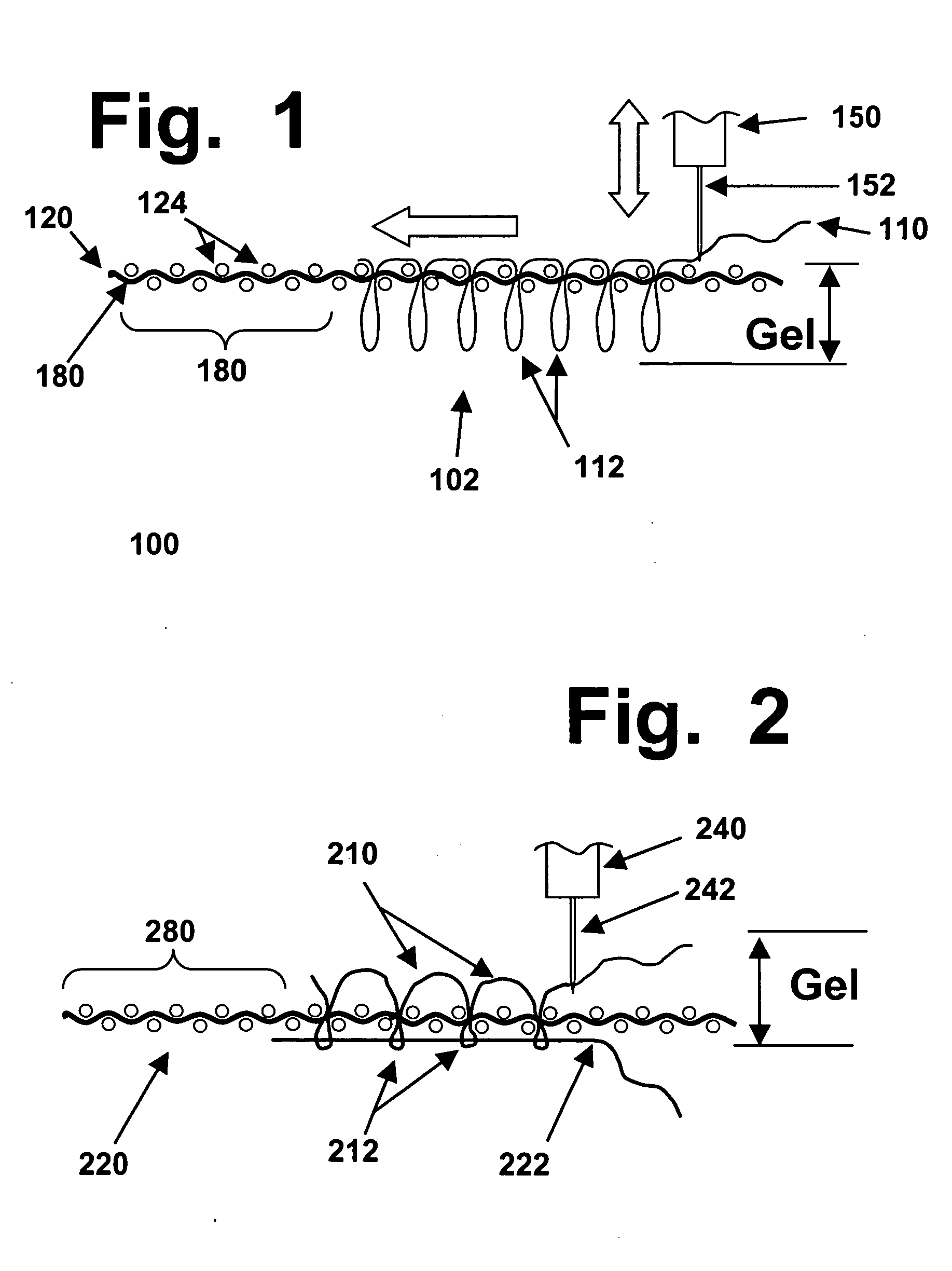

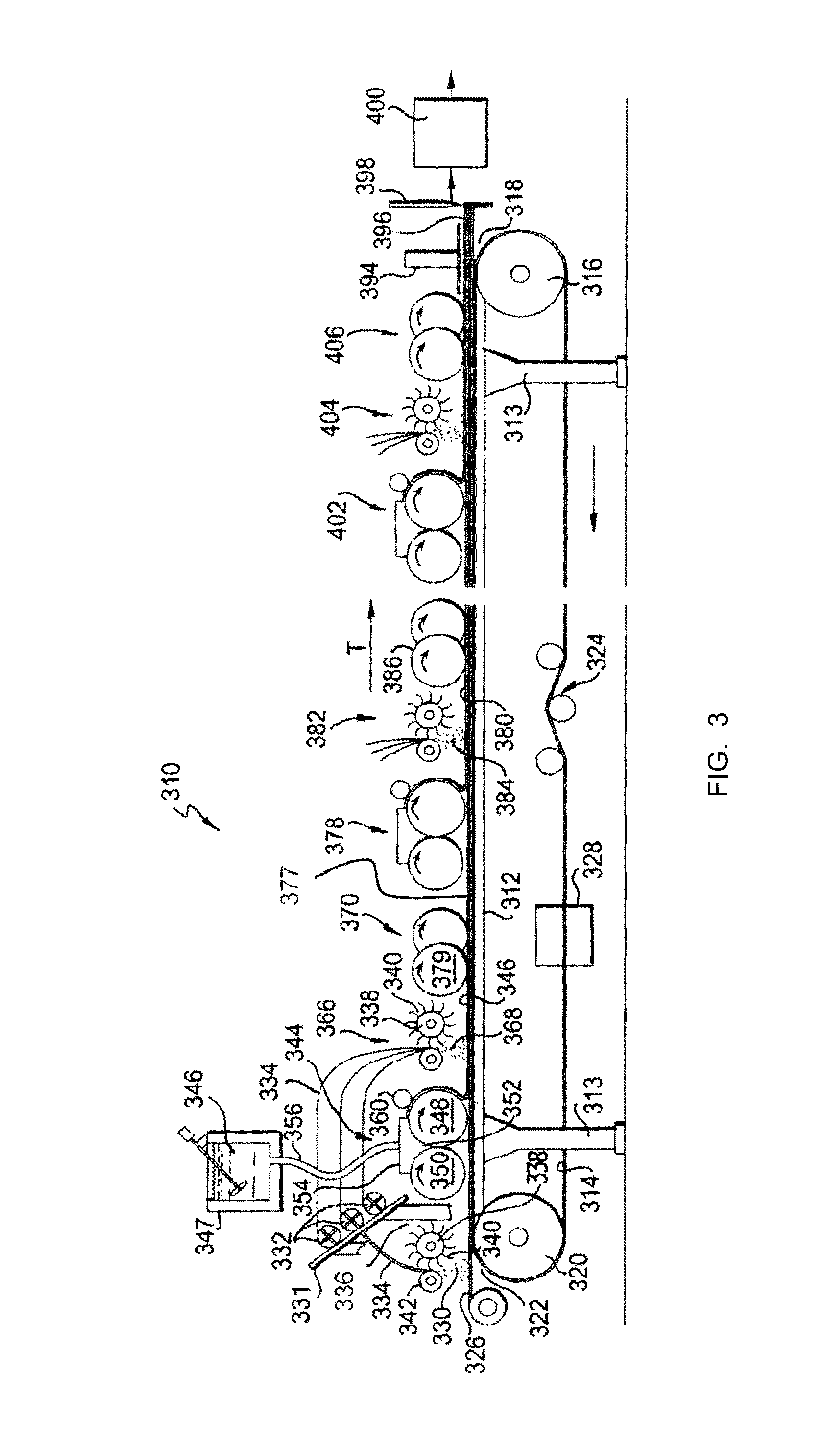

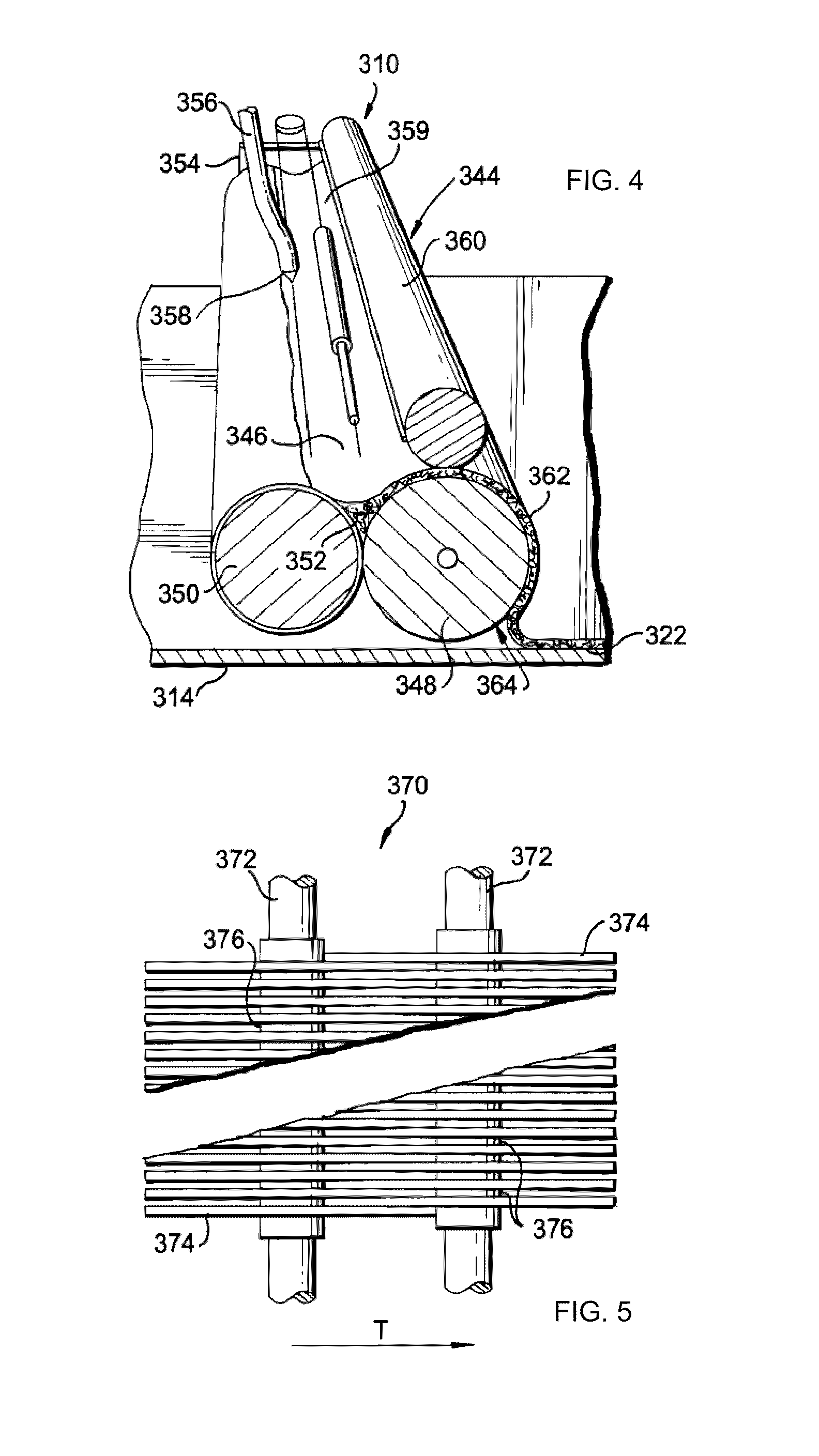

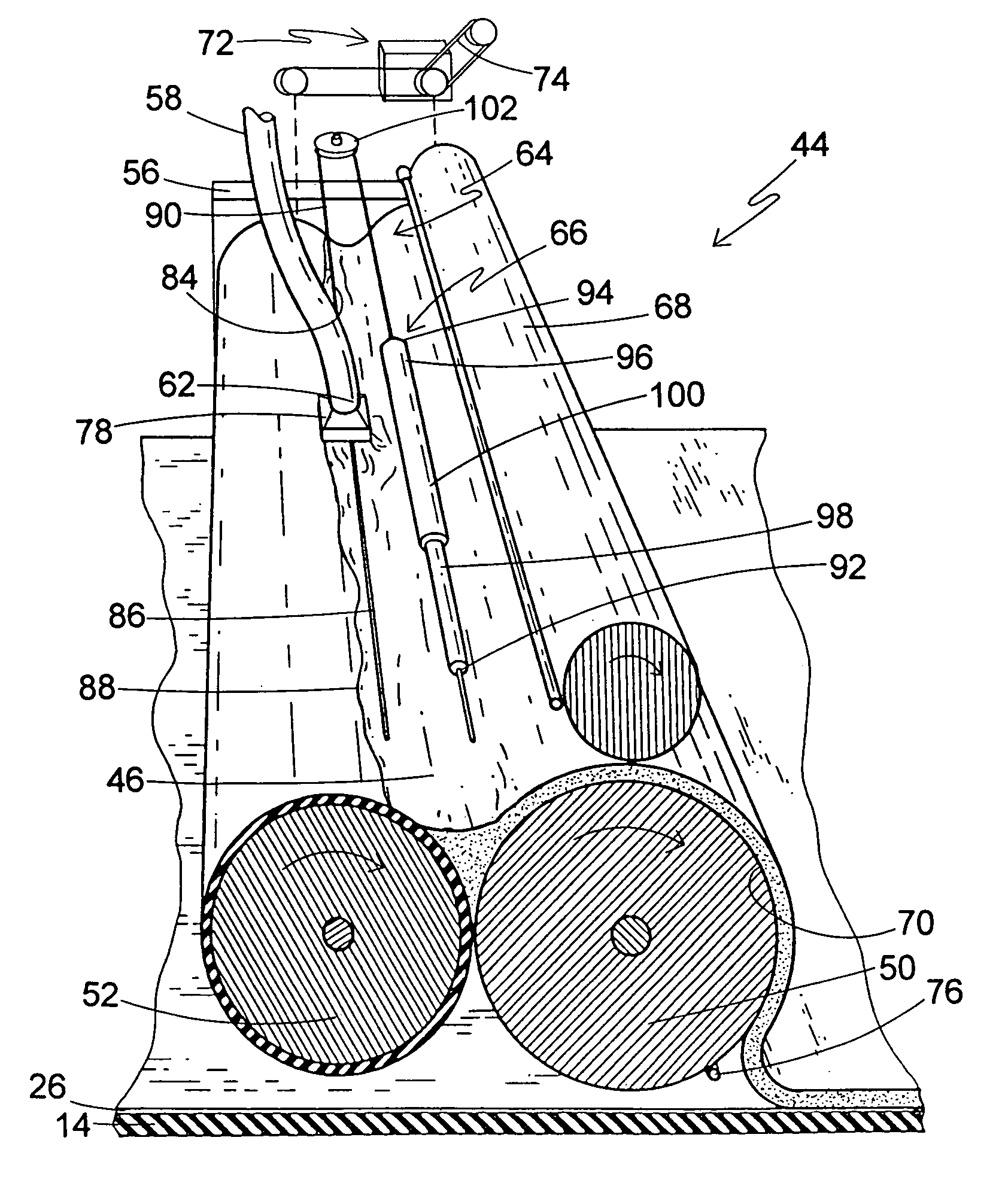

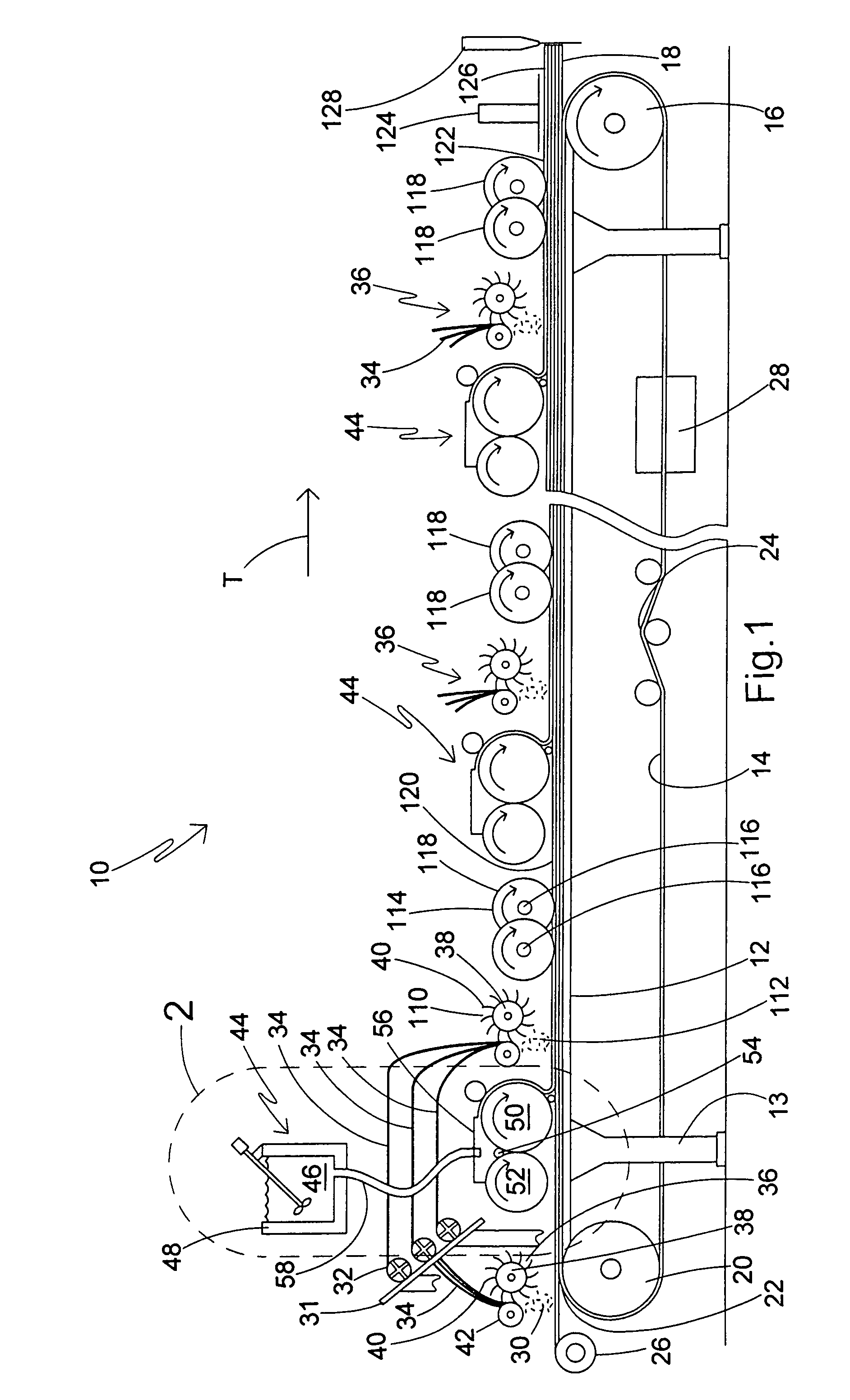

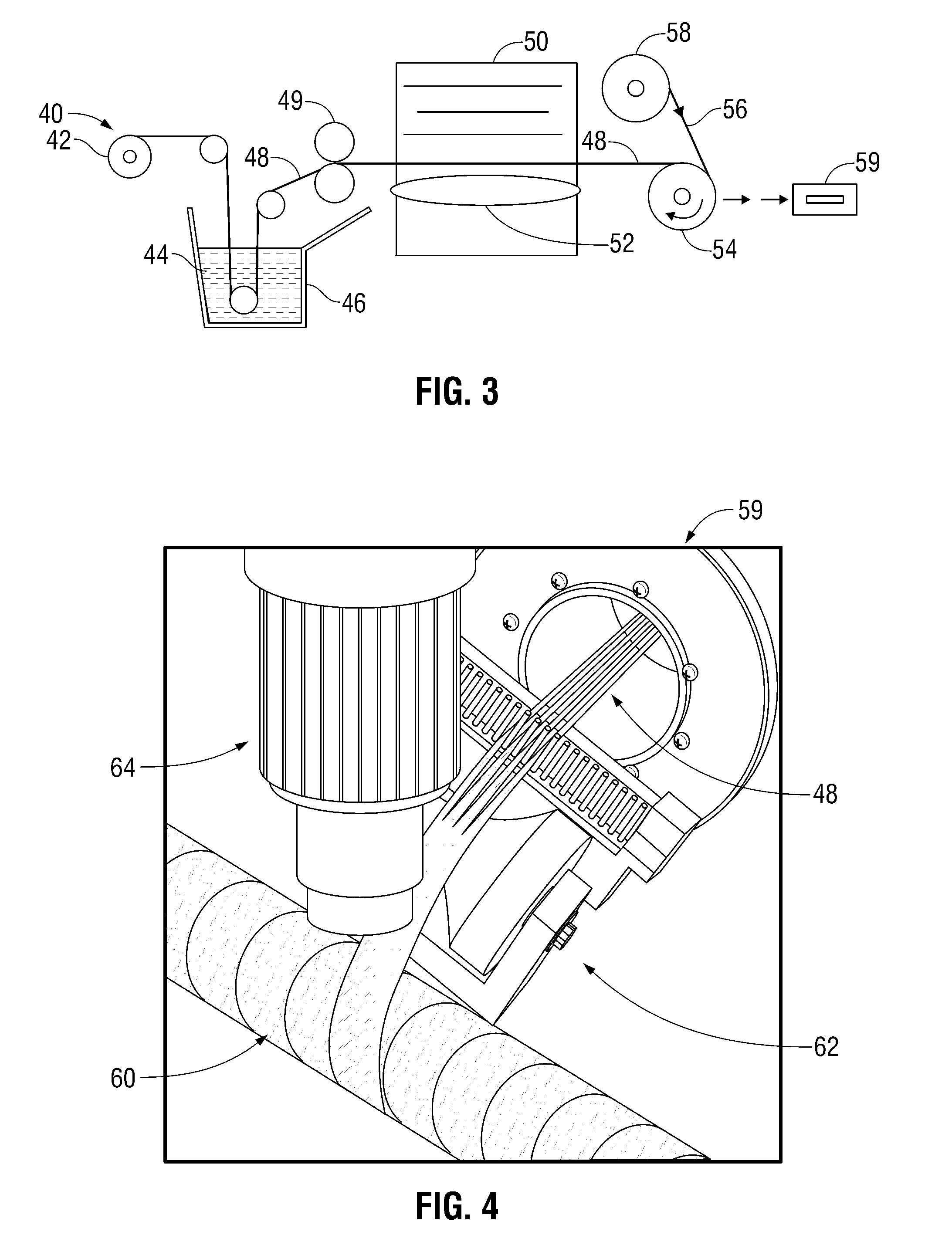

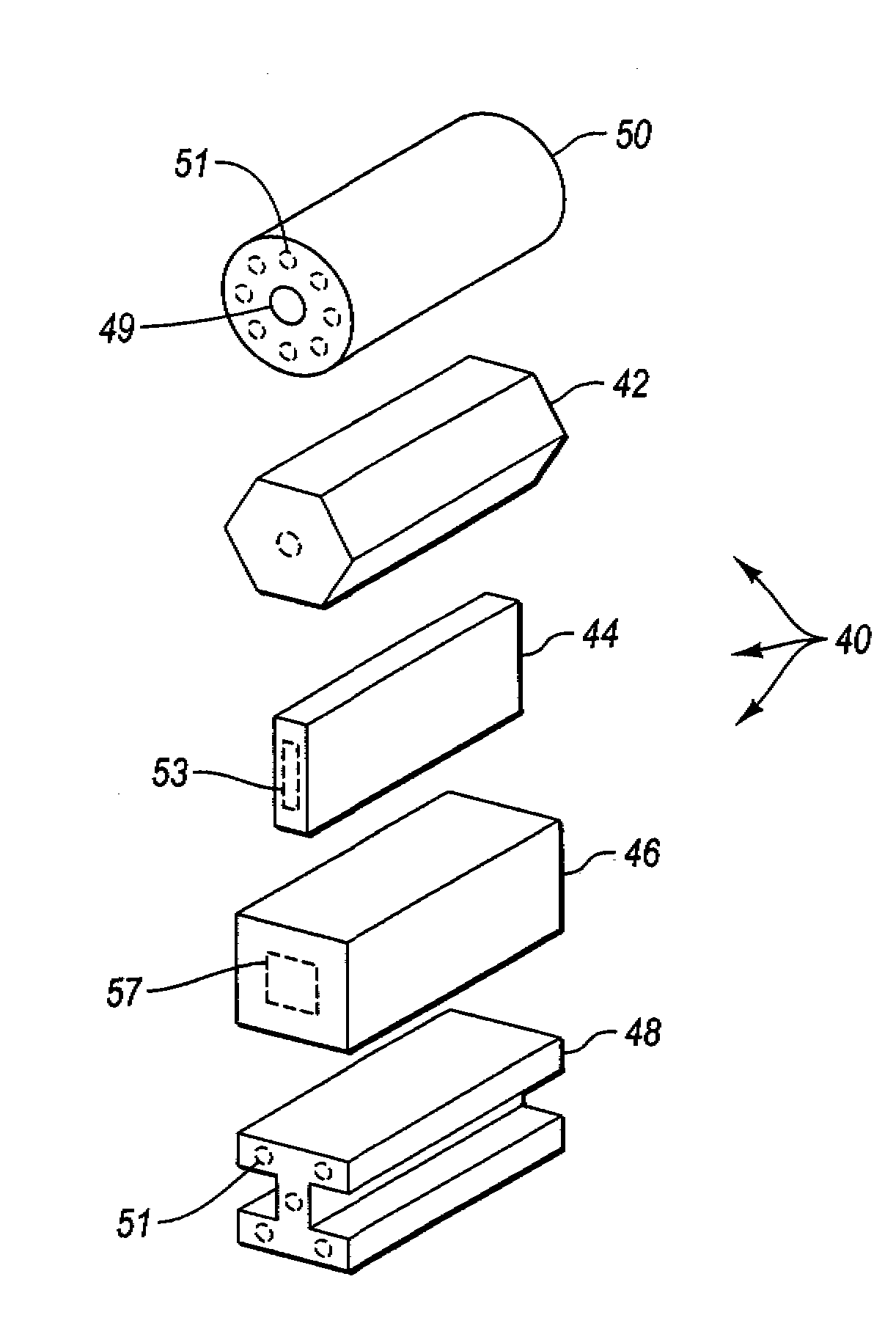

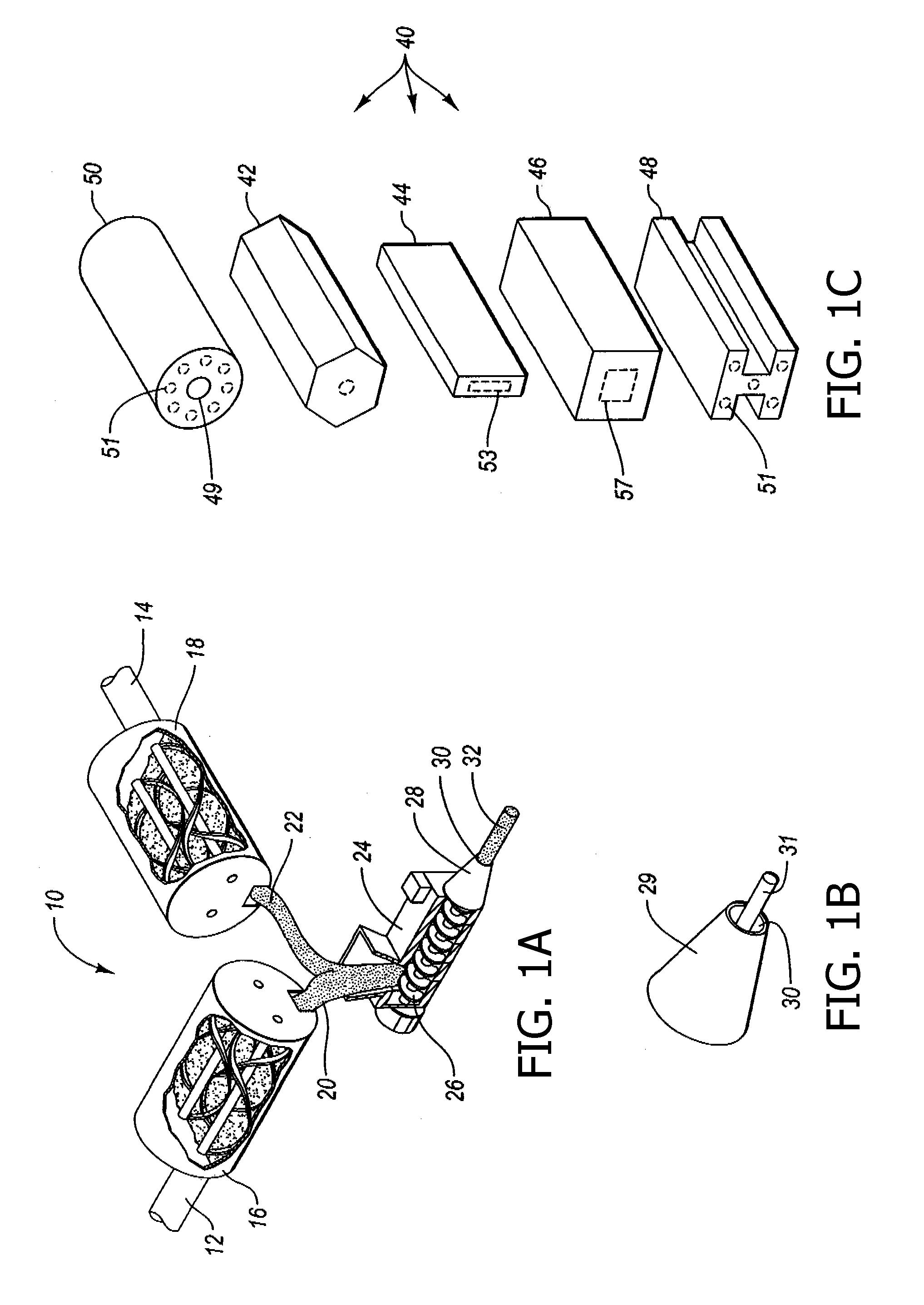

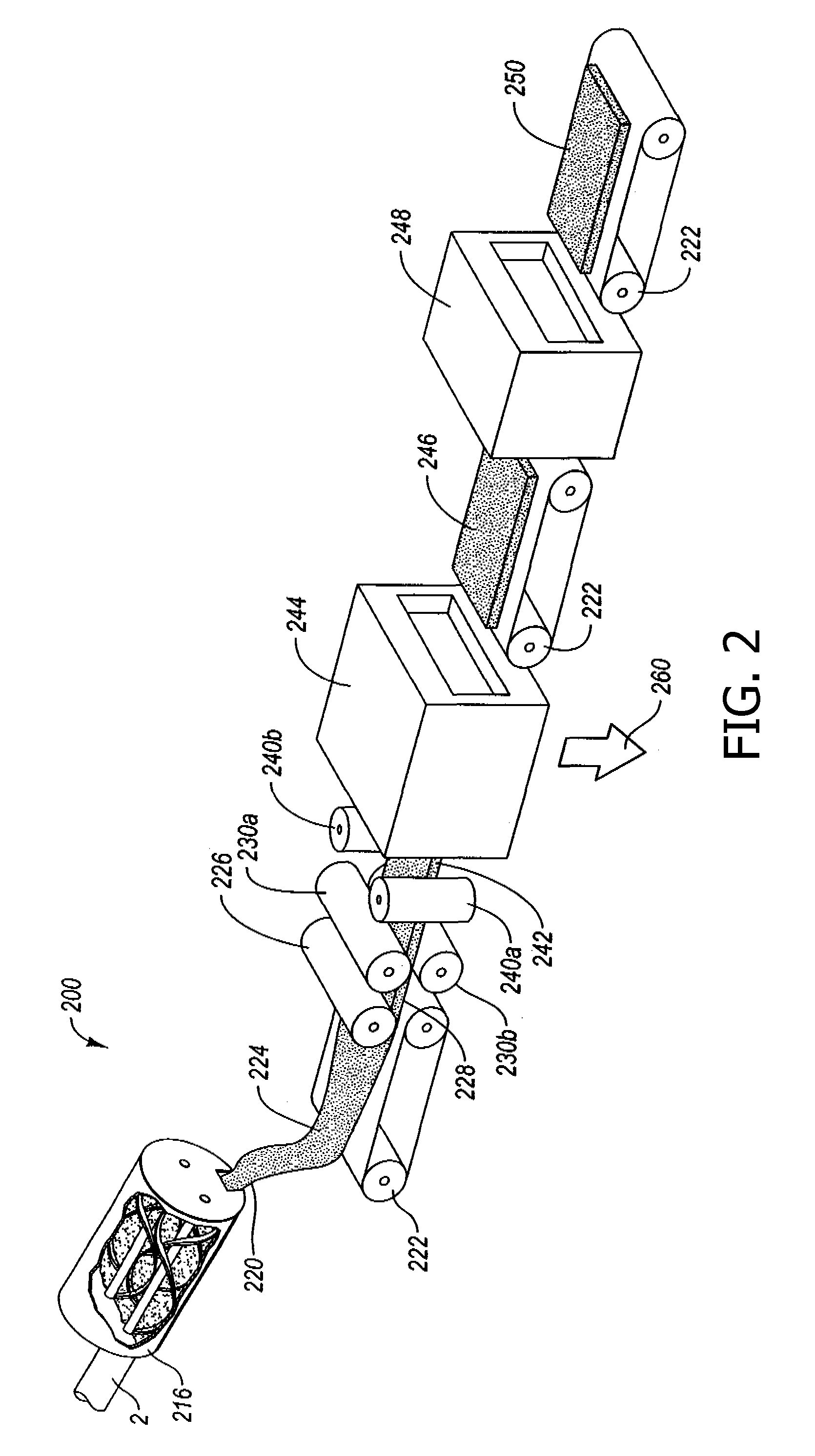

Slurry feed apparatus for fiber-reinforced structural cementitious panel production

Owner:UNITED STATES GYPSUM CO

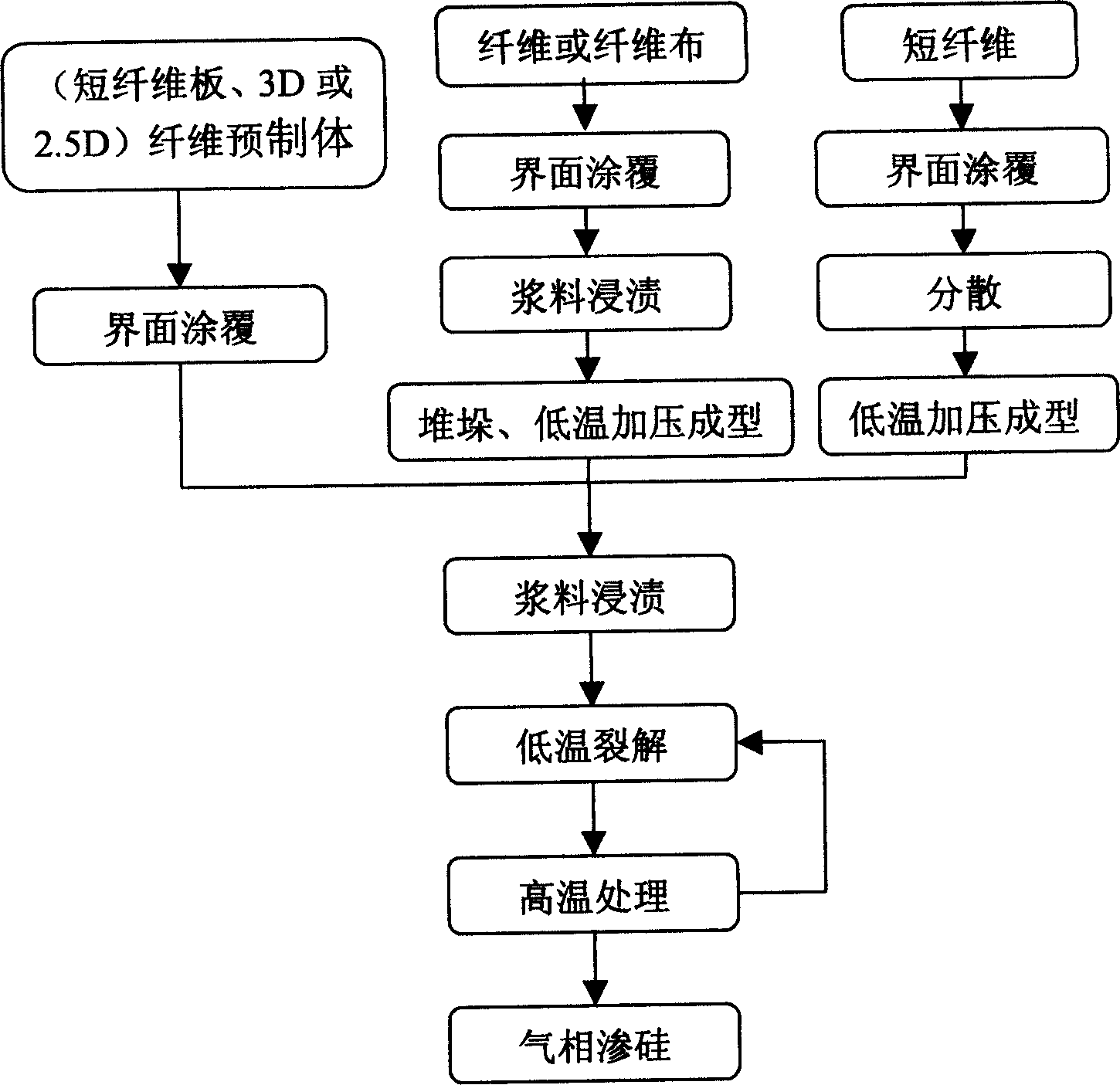

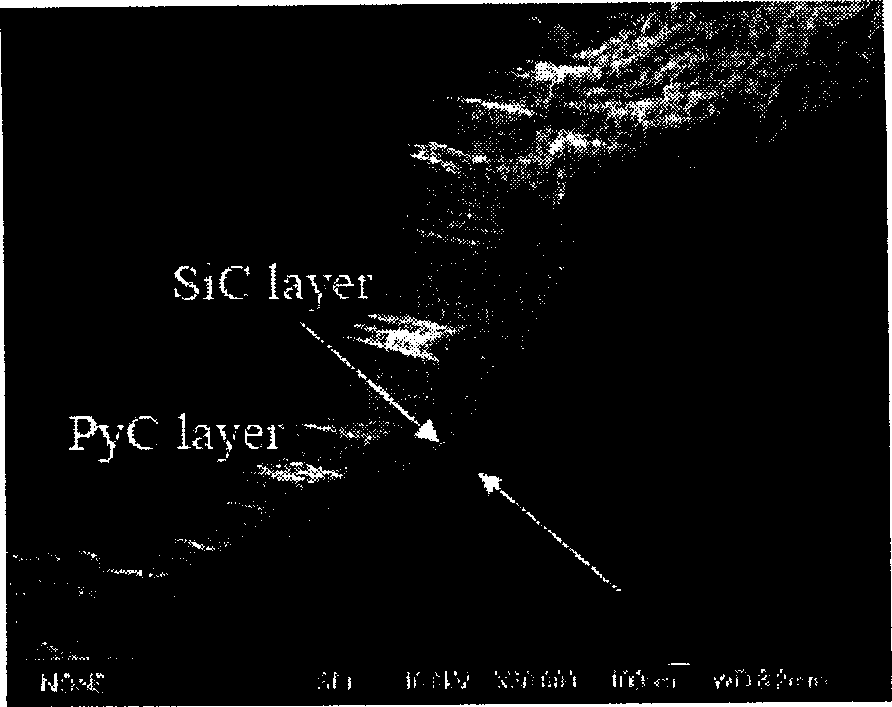

Method for preparing carbon-fiber reinforced silicon carbonate base composite by gas-phase siliconizing technology

This invention relates to preparation method gas phase siliconizing technique preparing high compact fiber reinforcement SiC group composite material. Protection layer interface is formed on fiber surface through gas phase or liquid phase, then they are dipped and cracked through nm SiC slime to make certain density precast body of fiber reinforcement SiC group. Carbon is added into the body through dipping and cracking way to form group body with certain pore, the group body penetrates inner part of the multi-hole body through gas phase silicon after it is high temperature treated, then it reacts with carbon and fills the pore to get compact basal body. The density of the material can reach 2.25-2.30g / cm3, open porosity is 3-6 percent; it is large more higher than traditional method of getting Cf / SiC material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

InactiveUS6899777B2Improved non-brittle failure characteristicFast preparationCeramic shaping apparatusCoatingsMetal fiberPolymer science

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

System and method for cutting material in continuous fiber reinforced additive manufacturing

ActiveUS20170144375A1Additive manufacturing with liquids3D object support structuresEngineeringKnife blades

Methods, apparatus, and systems for cutting material used in fused deposition modeling systems are provided, which comprise a ribbon including one or more perforations. Material is passed through at least one perforation and movement of the ribbon cuts the material. A further embodiment comprises a disk including one or more blade structures, each forming at least one cavity. Material is passed through at least one cavity and a rotational movement of the disk cuts the material. A further embodiment comprises a slider-crank mechanism including a slider coupled to a set of parallel rails of a guide shaft. The slider moves along a length of the rails to cut the material. Yet another embodiment comprises one or more rotatable blade structures coupled to at least one rod. The rotation of the blade structures causes the blade structures to intersect and cut extruded material during each rotation.

Owner:THE BOEING CO

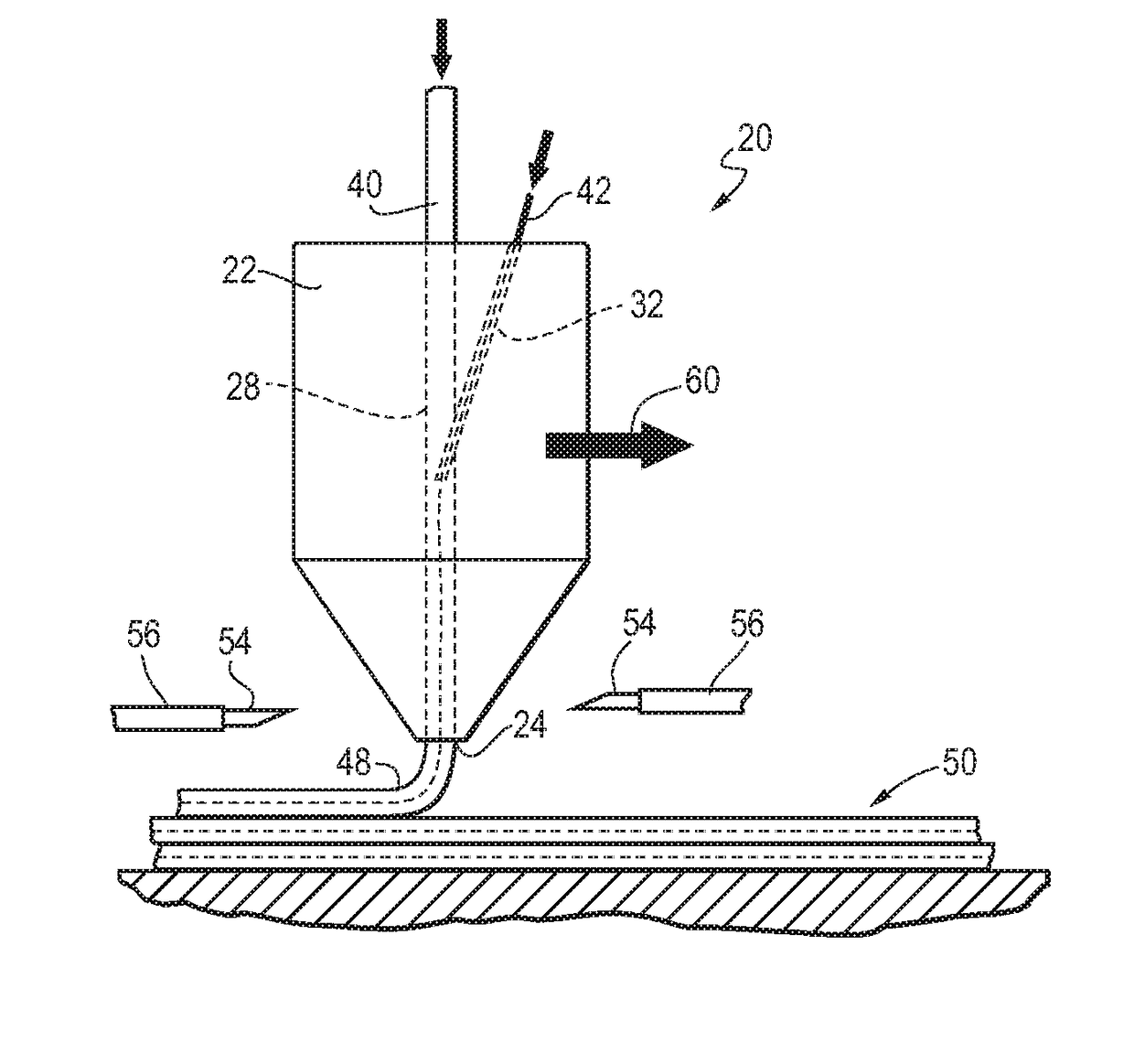

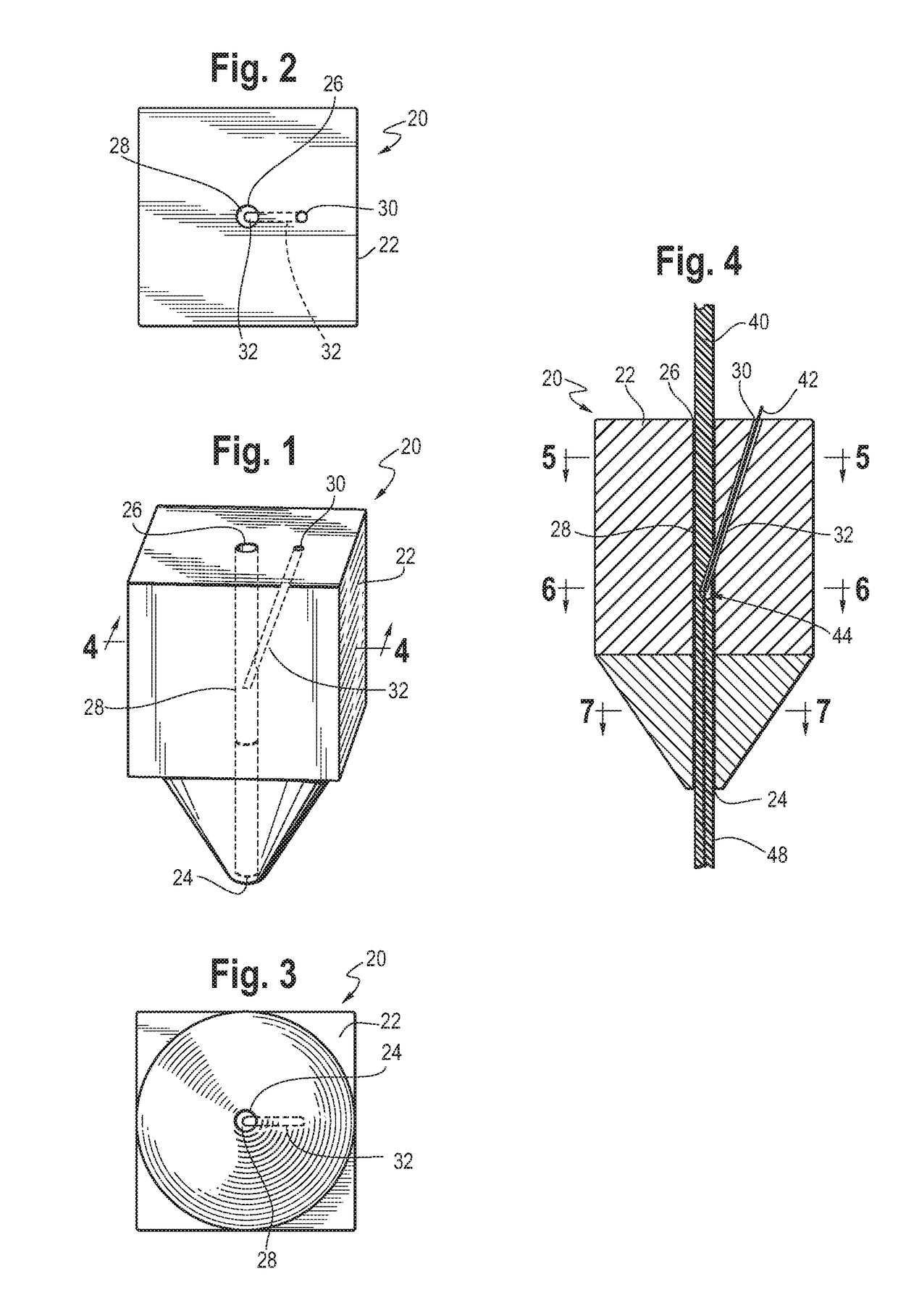

Device and method for 3D printing with long-fiber reinforcement

ActiveUS20170157851A1Eliminate point3D object support structuresAdditive mnaufacturing with solid and fluidAdvanced composite materialsPolymer

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

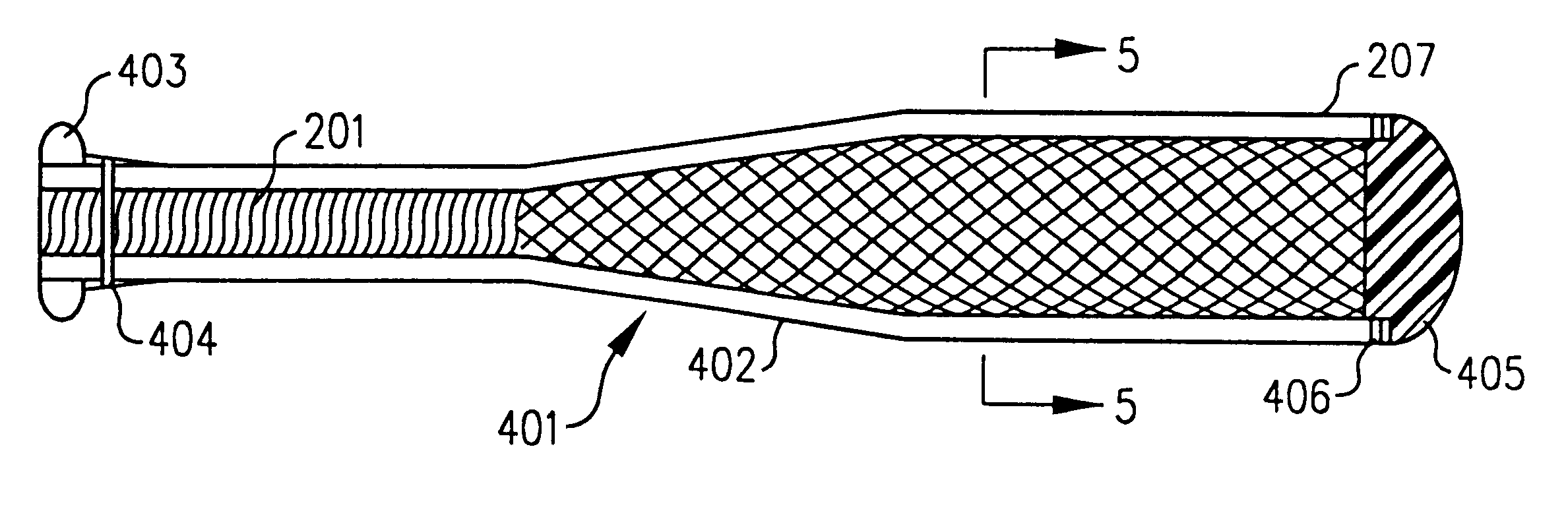

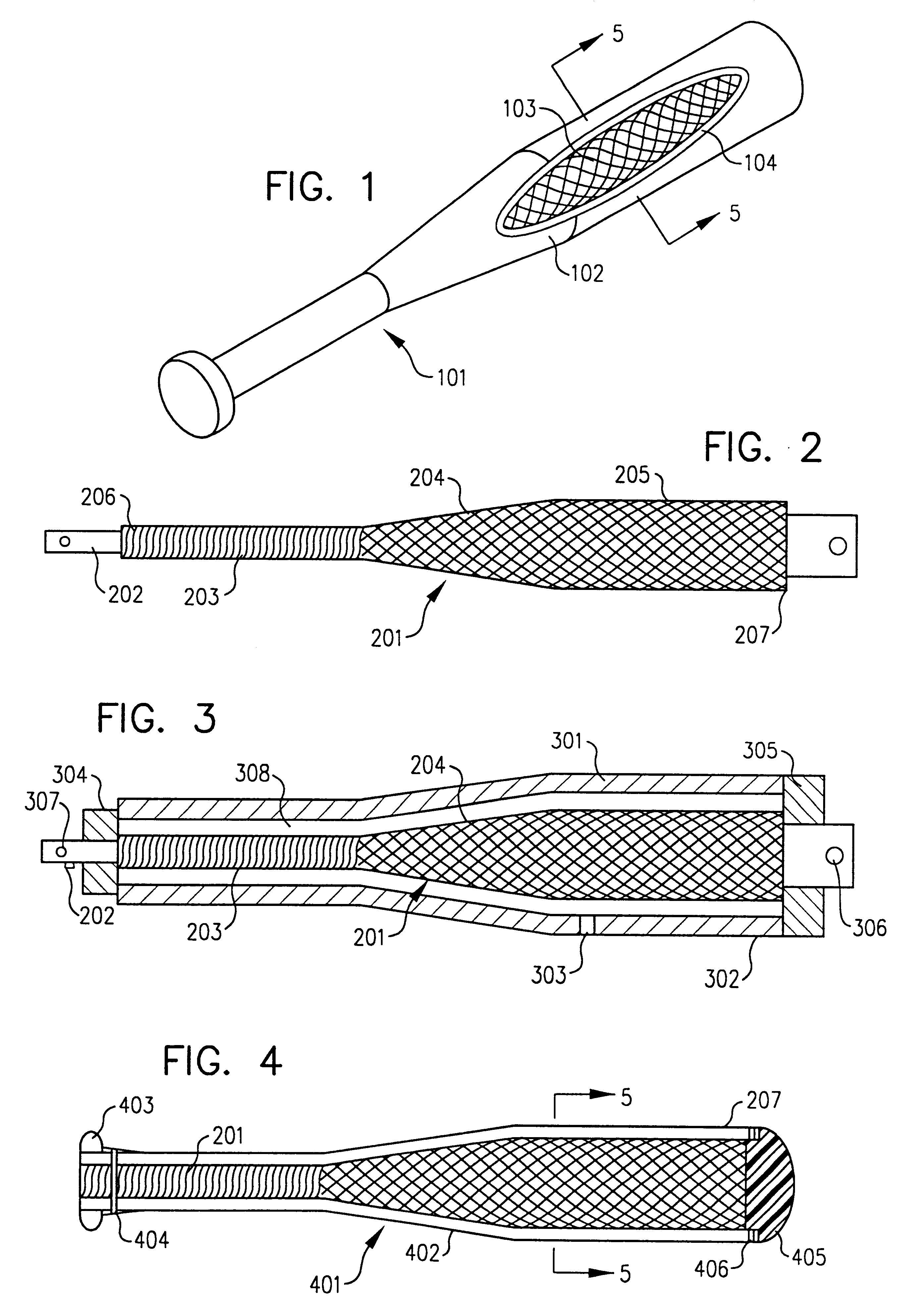

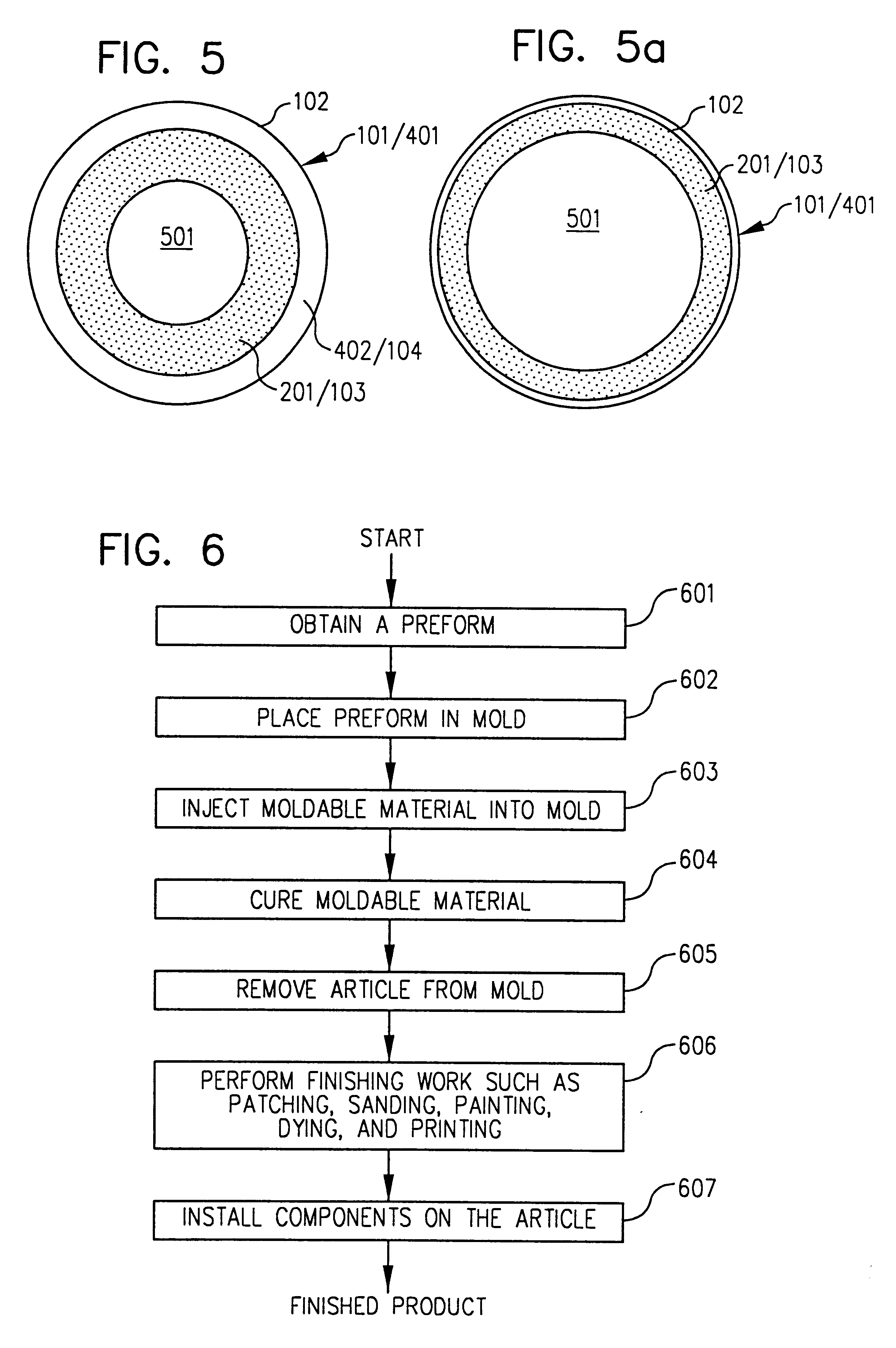

Fiber reinforced molded products and processes

A method for manufacturing elongate articles such as baseball bats, paddles, oars, hockey sticks, generic tubing and other articles and articles including molded material molded about a preform. The preferred method includes manufacturing a filament wound preform and reaction injection molding material about the preform to result in a finished article. The preferred baseball bat includes an elongate filament wound preform about which a quantity of urethane foam is molded.

Owner:ADVANCED COMPOSITES

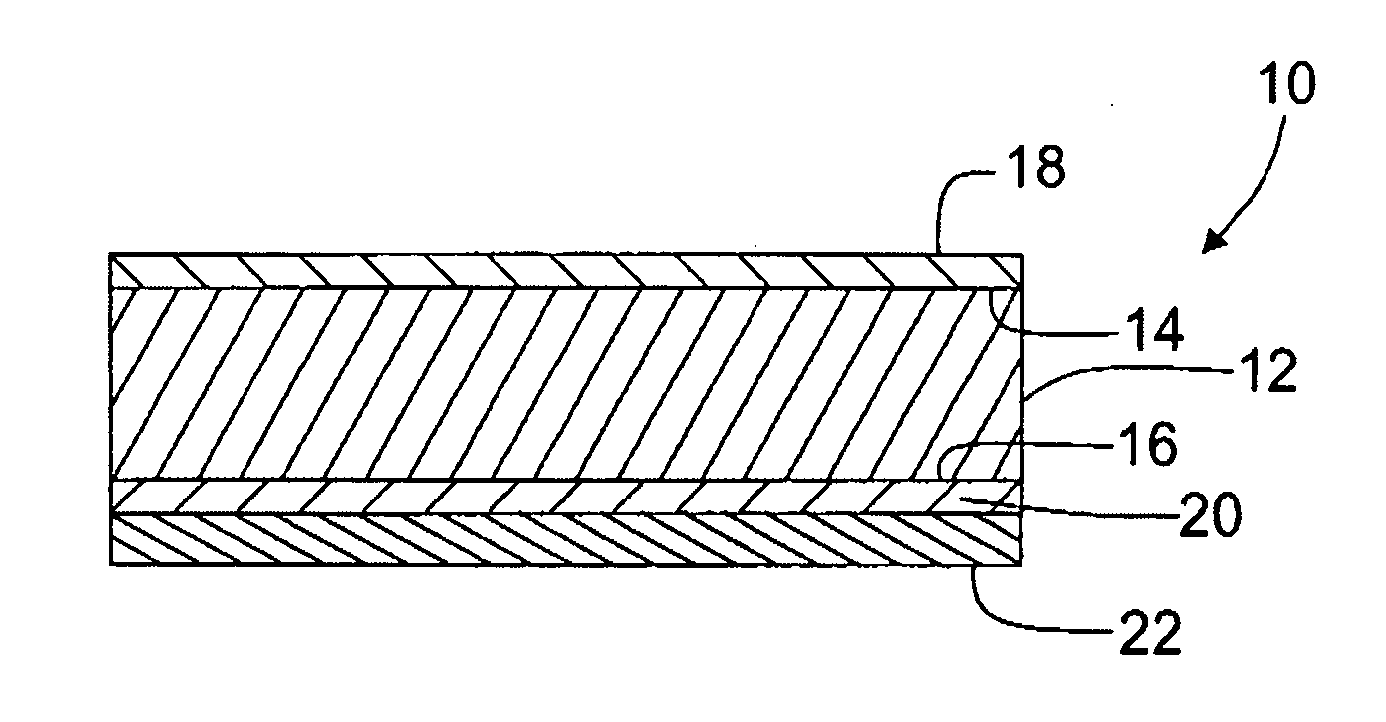

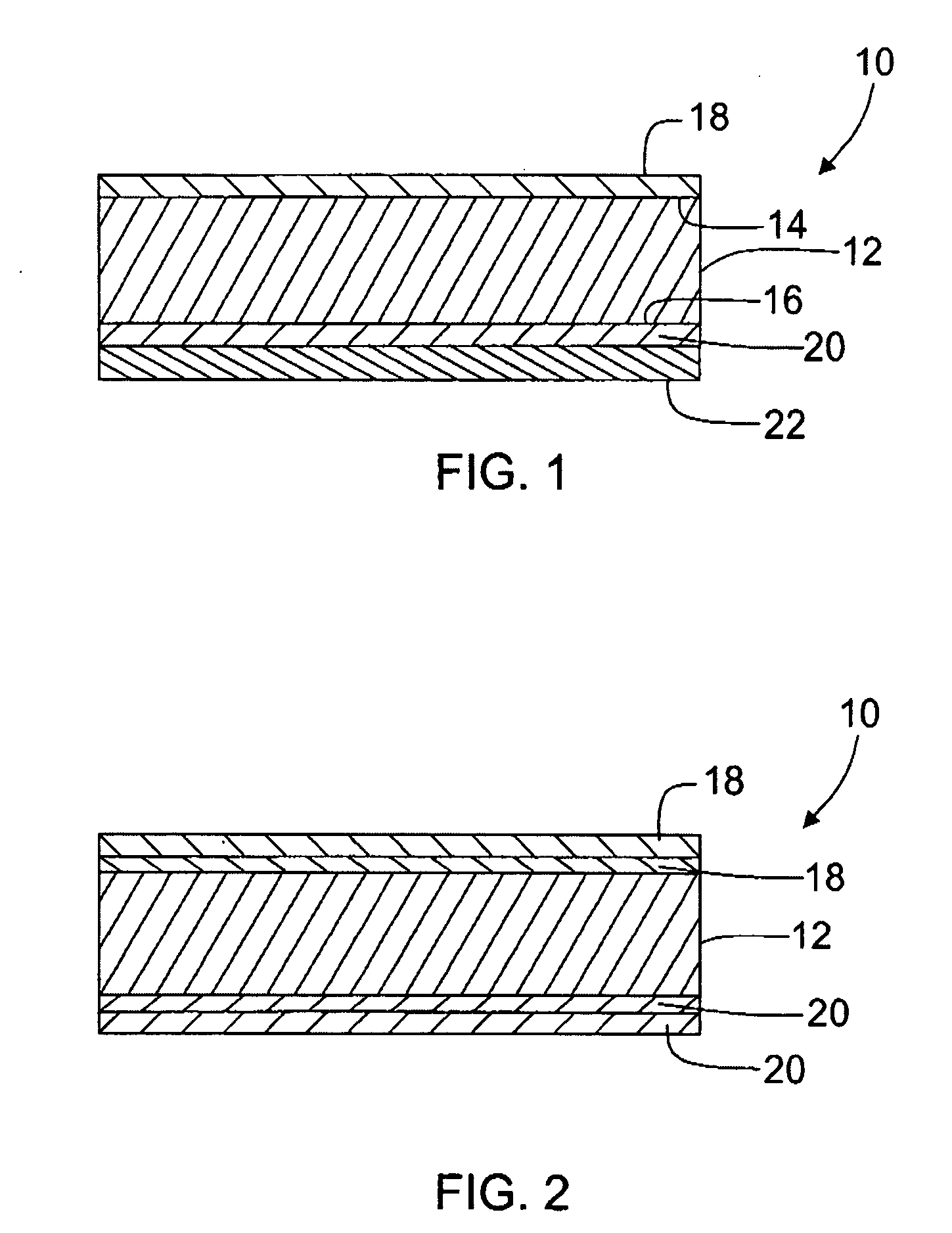

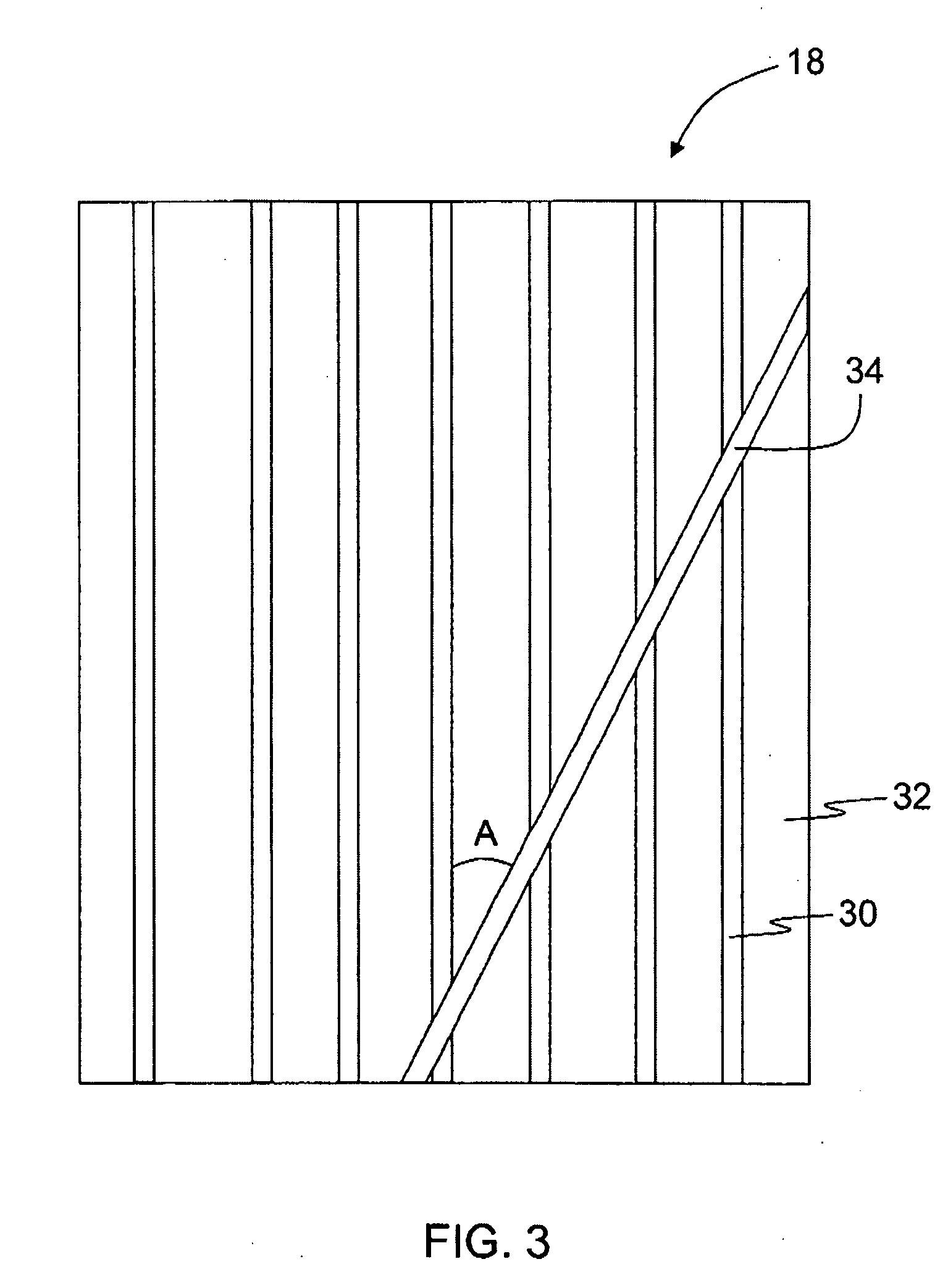

Lightweight thermoplastic composite including reinforcing skins

A lightweight fiber reinforced thermoplastic composite having an improved combination of surface roughness, flexural and shear characteristics. The composite generally comprises a fiber reinforced thermoplastic core containing reinforcing fibers bonded together with a first thermoplastic resin in which the core has a first surface and a second surface and at least one first skin applied to the first surface. The first skin comprises a plurality of fibers bonded together with a second thermoplastic resin, with the fibers in each first skin aligned in a unidirectional orientation within the first skin. The composite satisfies at least one of the conditions: an average surface roughness of the outer surface of the first skin is equal to or less than about 4.0 μm / 10 mm; the flexural modulus and strength are greater than about 10,000 MPa and greater than about 180 MPa, respectively; and the shear modulus and strength are greater than about 3,000 MPa and greater than about 100 MPa, respectively. In another embodiment, a fiber reinforced thermoplastic composite comprises a fiber reinforced thermoplastic core containing reinforcing fibers bonded together with a first thermoplastic resin, the core having a density of about 0.1 gm / cc to about 2.25 gm / cc and a porosity greater than about 0% by volume. The core has a first surface and a second surface and at least one first skin applied to the first surface, each of the first skins comprising fibers bonded together with a second thermoplastic resin. The first skin comprises a thermoplastic melt impregnated continuous fiber prepreg material, or commingled fiber rovings comprising reinforcing fibers and thermoplastic fibers, with the fibers in the first skin aligned in a unidirectional orientation within the first skin.

Owner:AZDEL INC

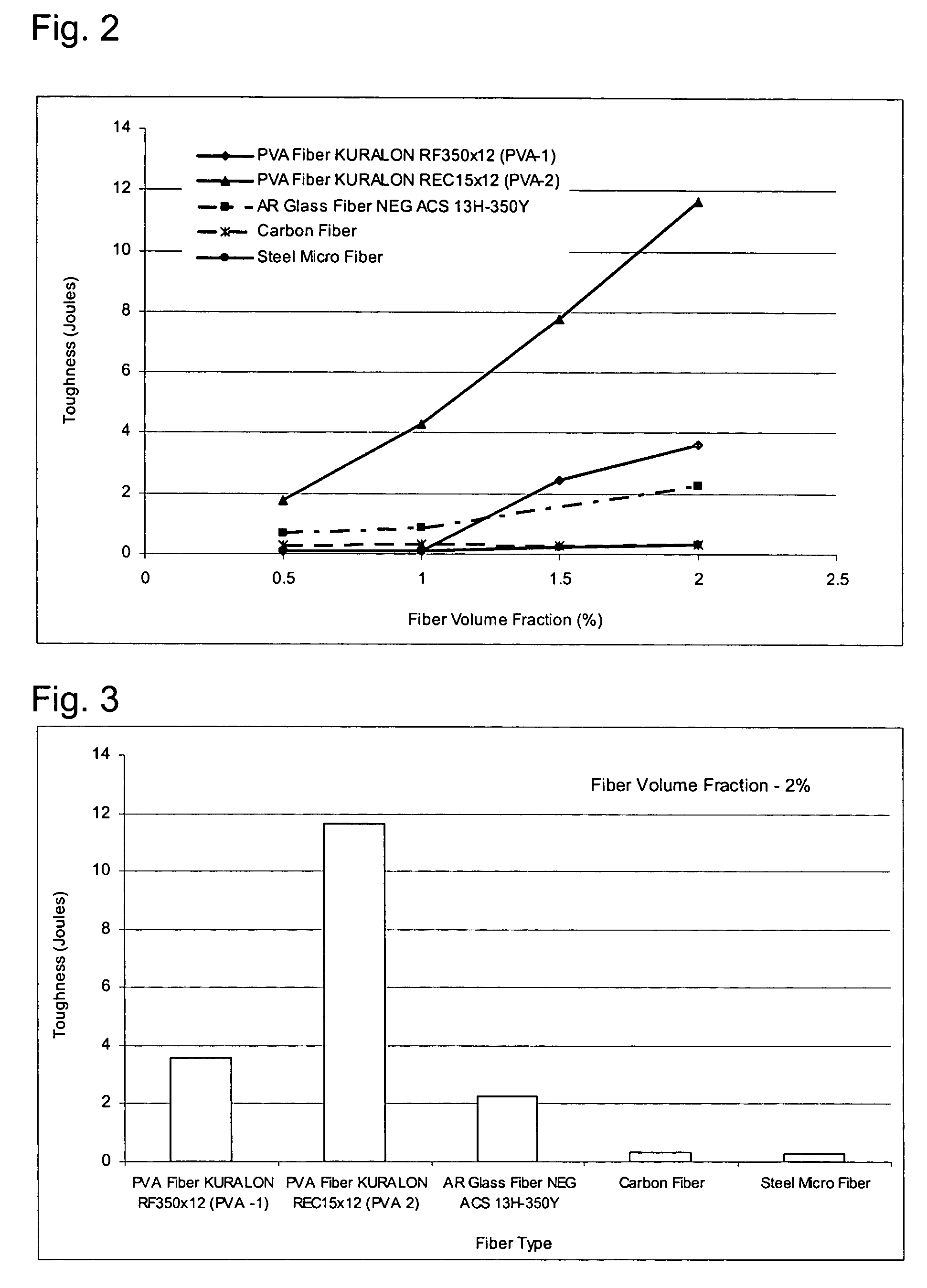

Lightweight, fiber-reinforced cementitious panels

ActiveUS20060147681A1Significant toughnessComposite goodConstruction materialCovering/liningsCement boardToughness

Lightweight, fiber reinforced, cementitious panels possessing exceptional toughness for use as building components in applications such as roofing elements, siding elements, framing and sheathing elements, and substrate elements for installation of floor finishes in residential and other building construction types. The panels employ a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, PVA fibers and lightweight filler. The inorganic binder may be, for example, hydraulic cement alone, or a combination of hydraulic cement and pozzolan / s, or a combination of hydraulic cement, alpha hemihydrate, active pozzolan and optionally lime. The PVA fibers reinforce the continuous phase and are randomly distributed throughout the composite. Typical panels of the invention have a density of 60-85 pcf.

Owner:UNITED STATES GYPSUM CO

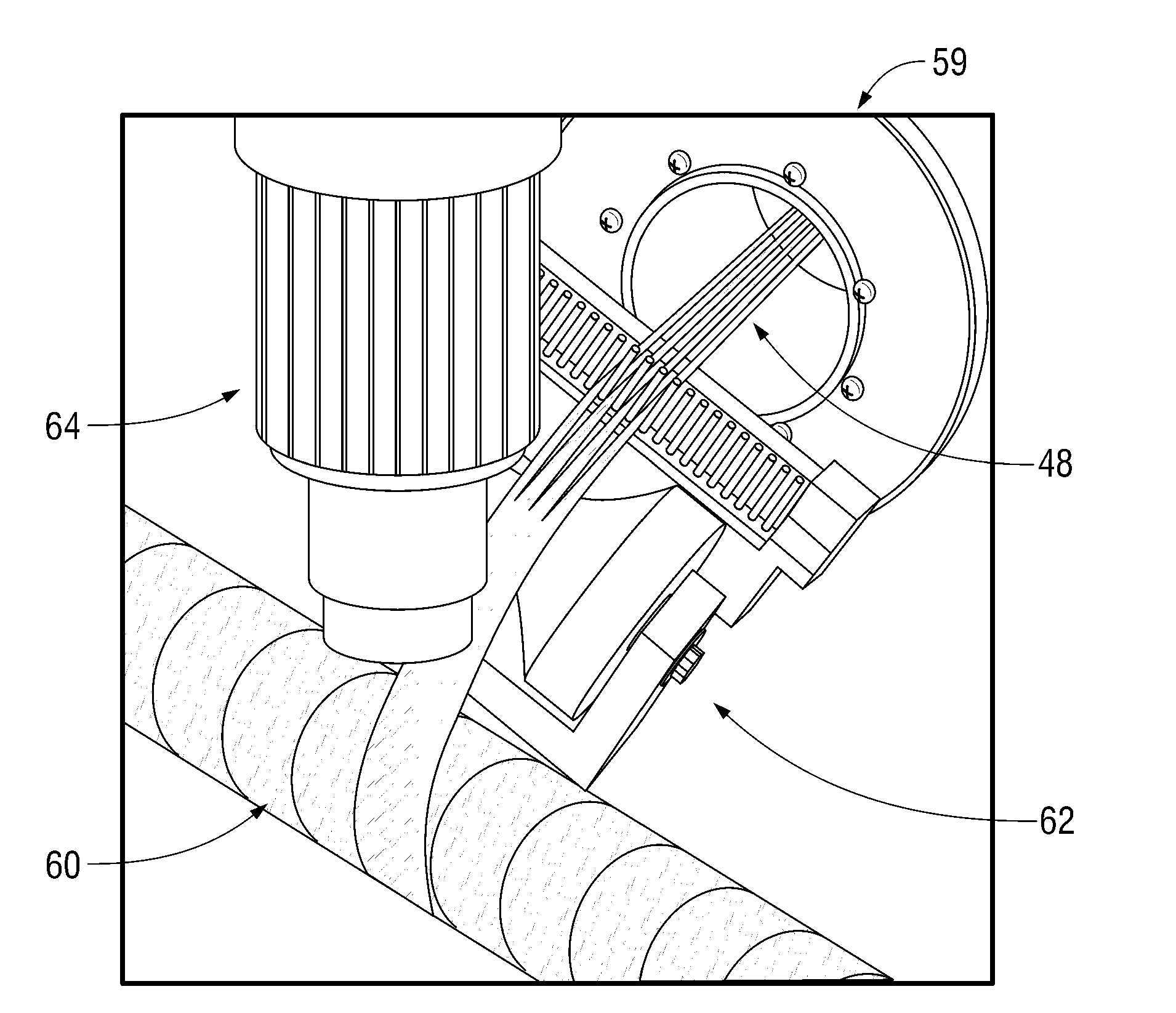

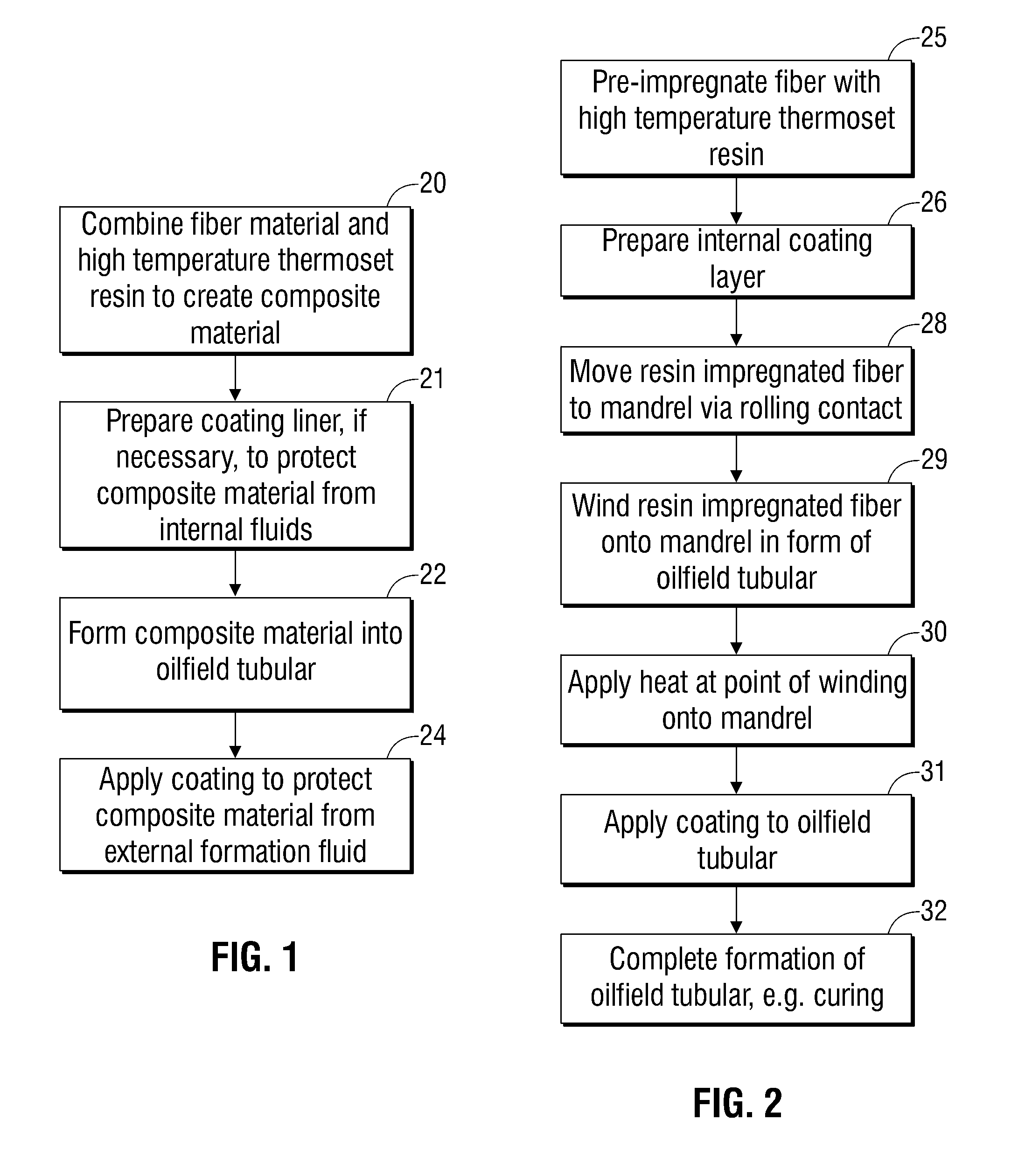

Fiber reinforced polymer oilfield tubulars and method of constructing same

InactiveUS20090236091A1High strengthImprove performanceDrilling rodsPaper/cardboard wound articlesHigh pressureProlonged exposure

A technique facilitates construction of high temperature fiber reinforced polymer oilfield tubulars. The technique comprises a method of combining a fiber material and a high temperature thermoset resin to create a high performance composite material. The composite material is formed into an oilfield tubular that can be used in a variety of downhole applications. The method of combining the high performance materials with low modulus, high temperature coating materials during the manufacturing process produces composite tubular products that can survive prolonged exposure to deleterious well fluids in high temperature and high pressure downhole environments.

Owner:SCHLUMBERGER TECH CORP

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Lightweight ballistic resistant rigid structural panel

InactiveUS6825137B2Without sacrificing ballistic resistanceImprove fatigueFuselage framesFuselage bulkheadsAdhesiveEngineering

A lightweight ballistic resistant rigid structural panel especially for use in aircraft interiors is disclosed. The rigid structural panel is made up of a core layer including a plurality of sheets of flexible, high-tensile strength fabric interleaved with a plurality of sheets of a thermal-fusible film adhesive, and a sheet of cushioning material adhered to the plurality of sheets of flexible, high-tensile strength fabric. Fiber-reinforced face skins are adhered to exterior surfaces of the panel core for structural strength and rigidity. The rigid structural panel is capable of resisting ballistic attack from handguns and like weapons, while maintaining a high degree of strength and rigidity.

Owner:NORDISK AVIATION PRODS A S

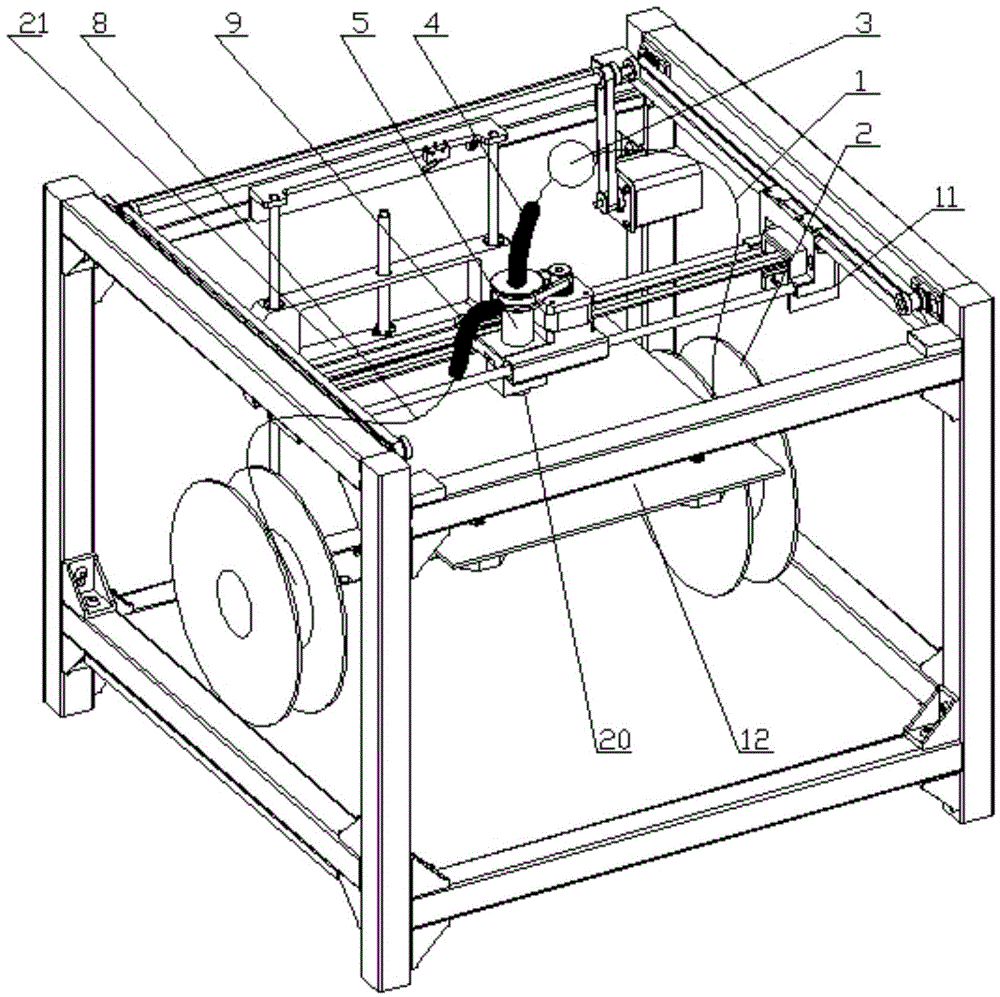

Continuous long-fiber reinforced-type composite material 3D printer and printing method thereof

The invention provides a continuous long-fiber reinforced-type composite material 3D printer and a printing method thereof. The 3D printer and the printing method are characterized in that the combination of the 3D printing technology and the composite material fiber placement technology achieves the 3D printing of a resin-based continuous long-fiber reinforced-type composite material, and the process does not need a die that is customized in advance and a pre-treated fiber pre-soaking belt, so that the cost is greatly decreased; meanwhile, the 3D printing method enables well and convenient control of the directions of the reinforced fibers in a manufactured part, and moreover, a composite material part with the customized mechanical property can be obtained easily, and the composite material part with a complex structure can be quickly manufactured; and compared with the original composite material fiber placement process, the printing method has the advantages that the application scope is wide, and the production efficiency is high.

Owner:XI AN JIAOTONG UNIV

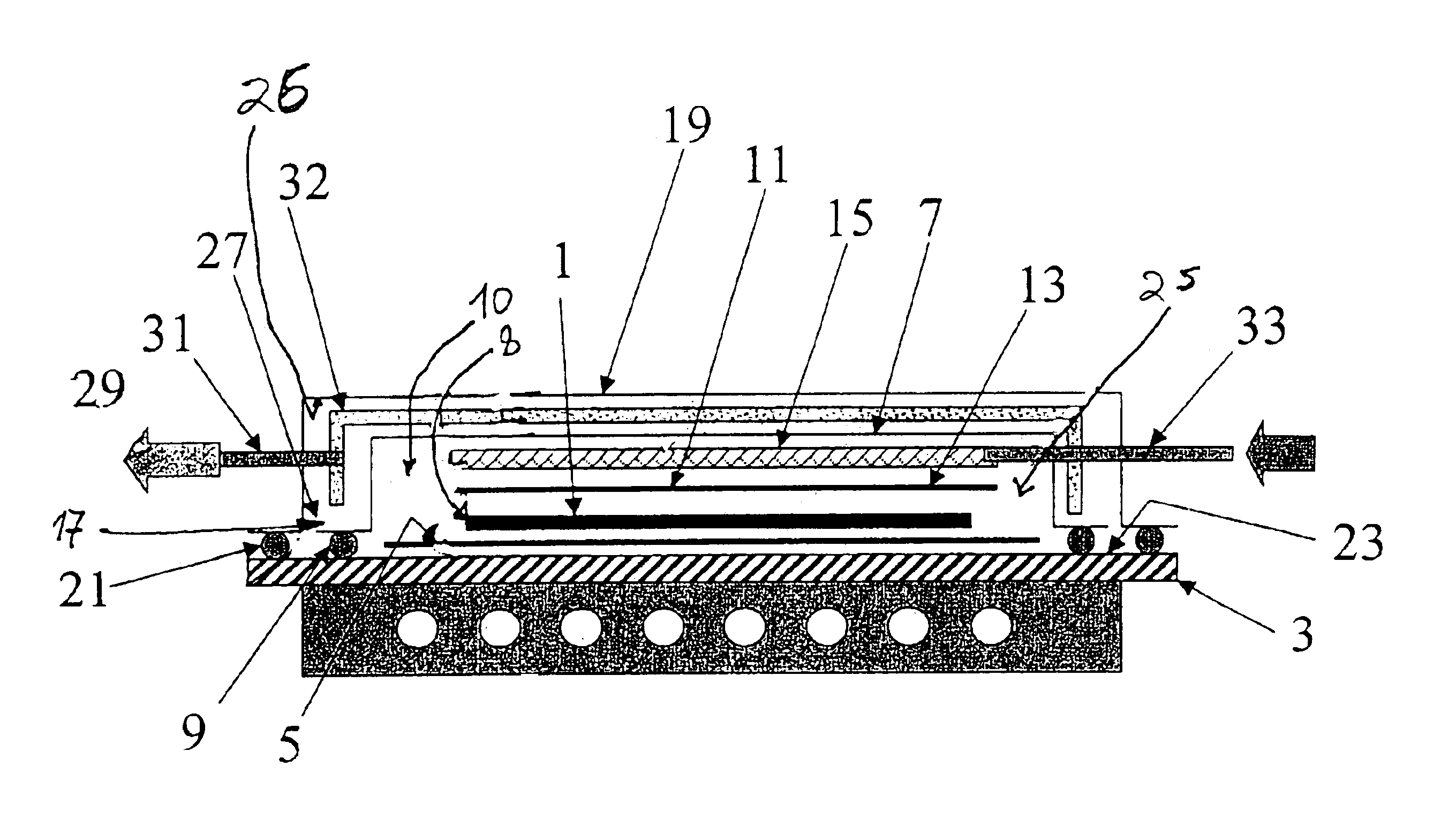

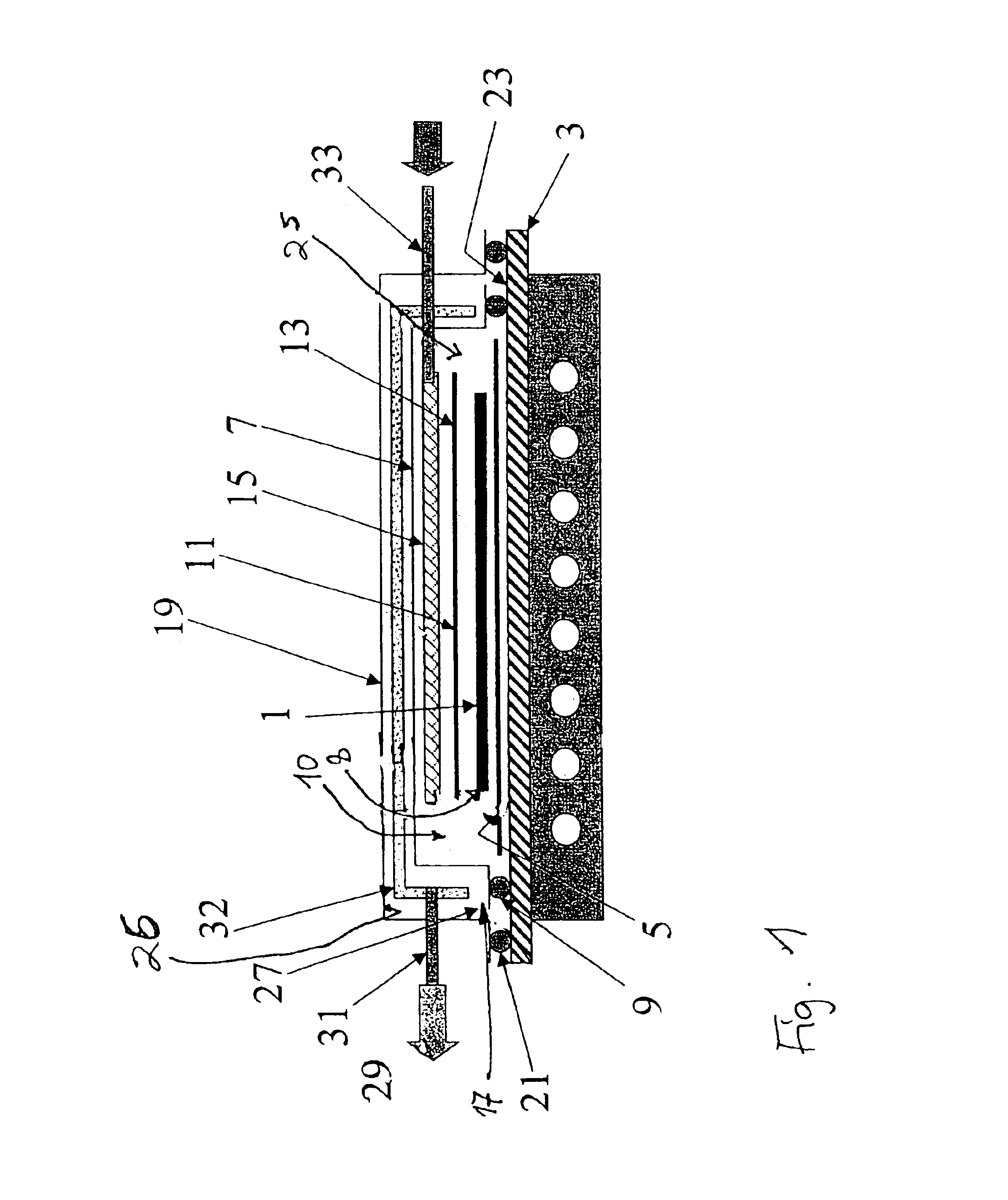

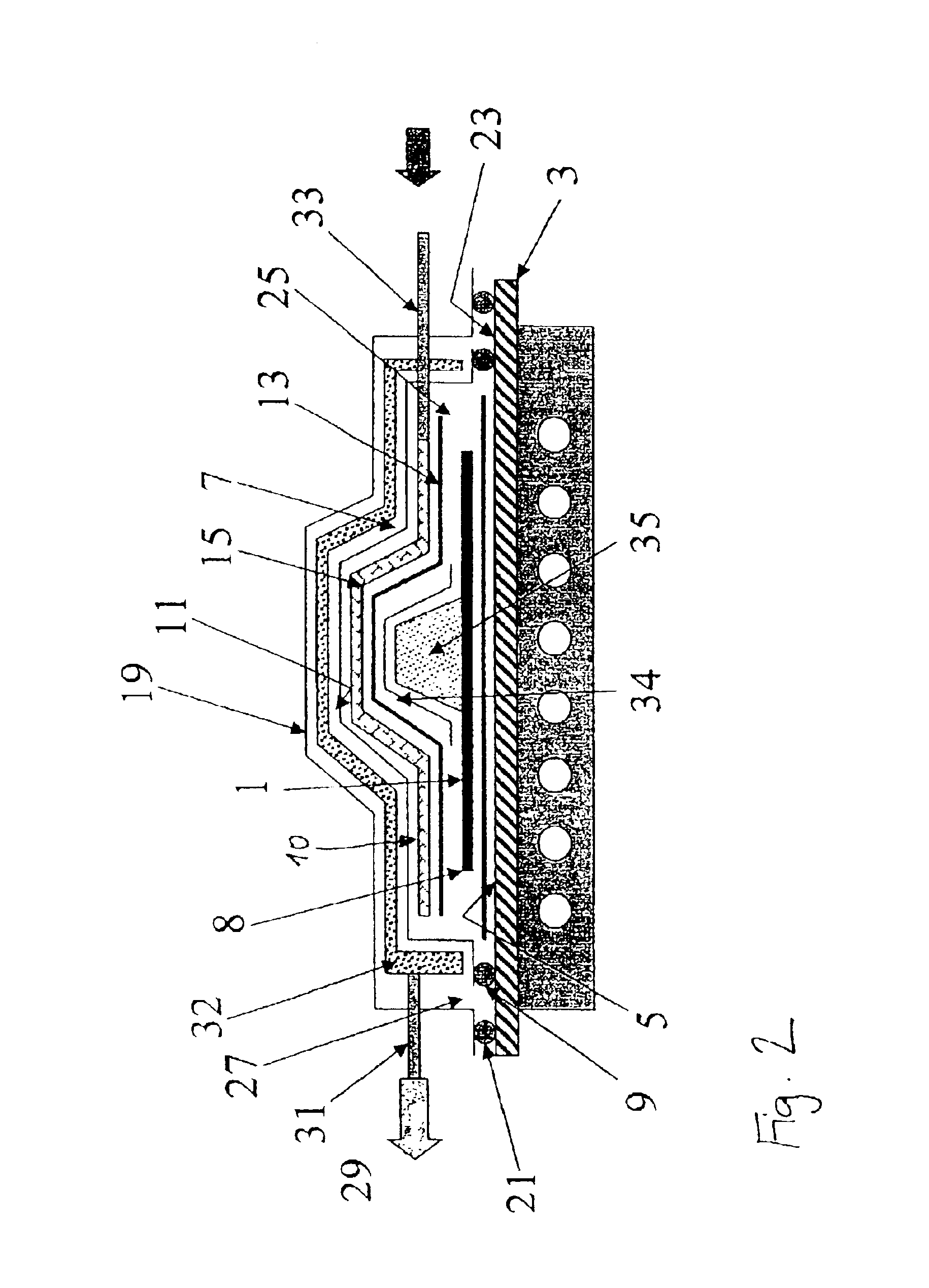

Method and device for producing fiber-reinforced components using an injection method

InactiveUS6843953B2Produced cost-effectivelyTop quality componentsConfectioneryWood working apparatusFibrous compositesMaterials science

In a method for producing fiber-reinforced plastic components made of dry fiber composite preforms by an injection method for injecting matrix material, the arrangement of the fiber composite preform on one surface of the preform resulting in a flow promoting device, on a tool, creates a first space by a gas-permeable and matrix-material-impermeable membrane surrounding the preforms. Formation of a second space arranged between the first space and the surroundings by a foil, which is impermeable to gaseous material and matrix material, is provided, with removal by suction, of air from the second space resulting in matrix material being sucked from a reservoir into the evacuated first space and with the flow promoting device causing distribution of the matrix material above the surface of the preform facing the flow promoting device, thus causing the matrix material to penetrate the preform vertically.

Owner:AIRBUS DEFENCE & SPACE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com