Method for preparing carbon-fiber reinforced silicon carbonate base composite by gas-phase siliconizing technology

A composite material and vapor-phase siliconizing technology are applied in the preparation of dense fiber-reinforced ceramic matrix composite materials, and the vapor-phase siliconizing process is used to prepare dense carbon fiber-reinforced SiC-based composite materials. and performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

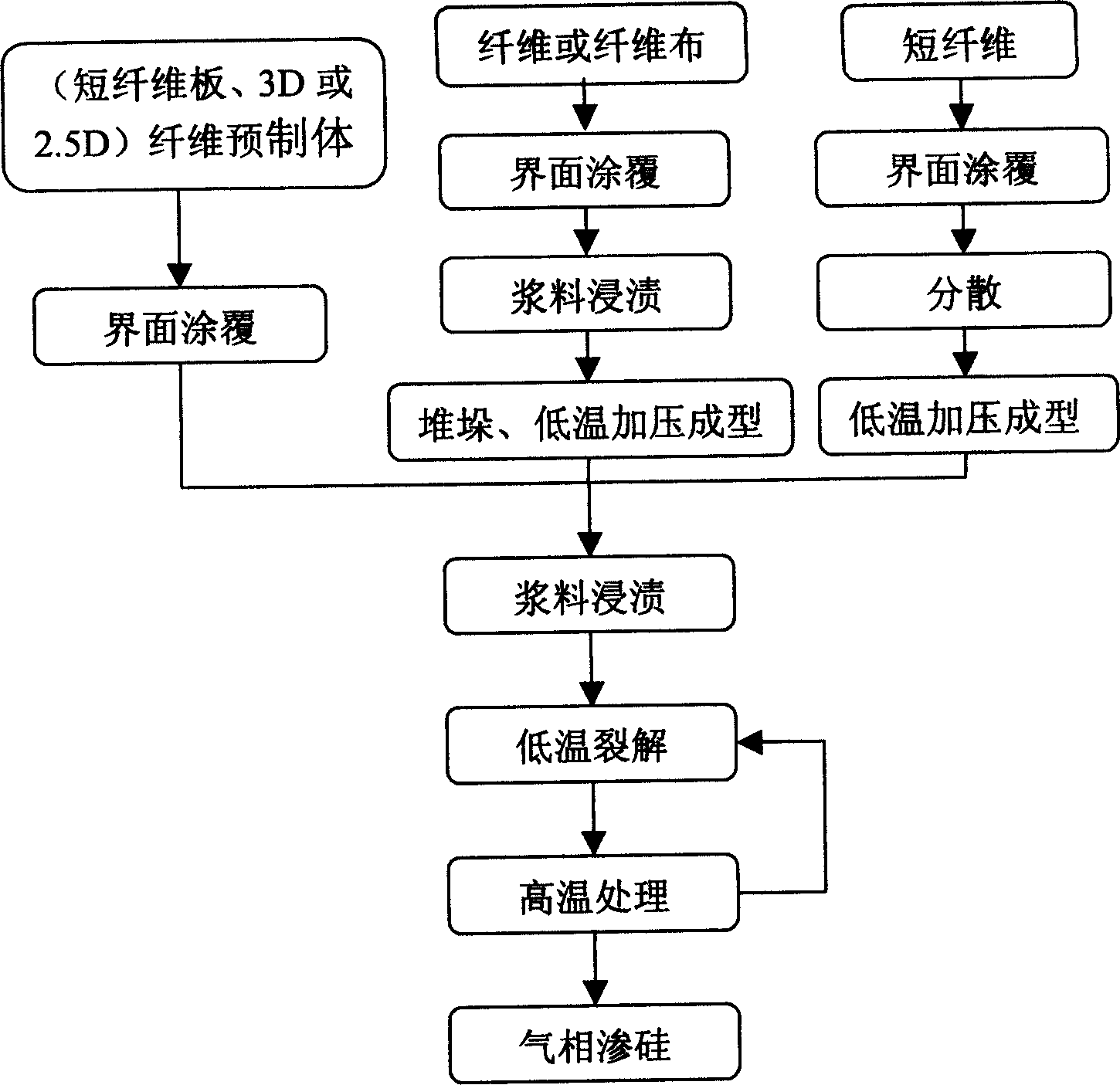

Method used

Image

Examples

Embodiment 1

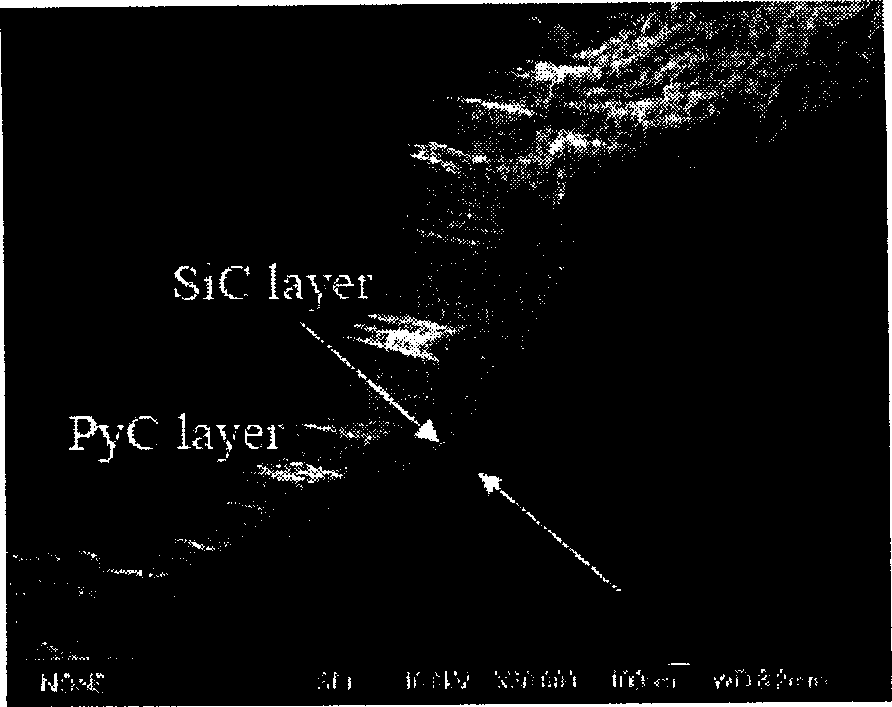

[0026] Example 1 3DC f / SiC composite material preparation

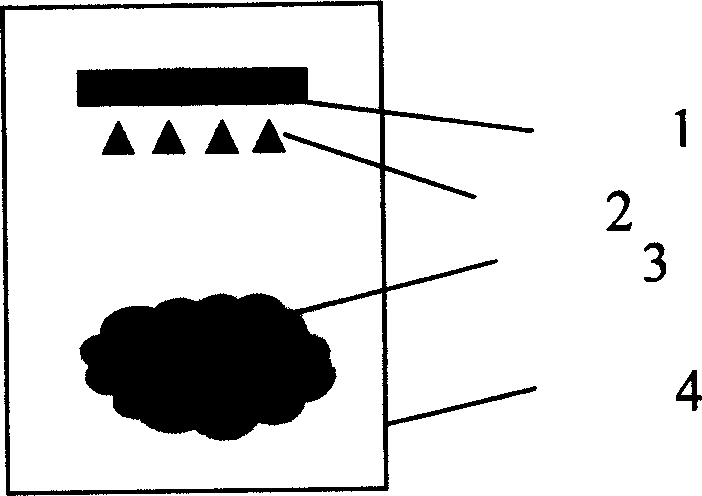

[0027] Weaving carbon fiber into 3D braided body, using pulsed CVI or forced pulsed CVI (another application), respectively using methane (CH 4 ) and MTS are the gaseous precursors, and the pyrolytic C / SiC bilayer interface is deposited on the surface of the C fiber with a thickness of ~150 and ~250nm, respectively (such as image 3 ). The pyrolysis temperature is 900-1200°C, and the pressure is several thousand Pa to tens of kilo Pa and the time is several seconds to tens of seconds. Then the resulting 3D braids with pyrolyzed C and bilayer interfaces were sequentially dipped in SiC / PCS slurries with SiC contents of 50 vol.%, 30 vol.% and 0 vol.%, and cracked at 1100 °C, and finally Phenolic resin impregnation, high temperature treatment at 1800°C to form a porous matrix. Its density is about 1.50g / cm 3 , The opening porosity is about 20%. according to figure 2 Place the sample and the graphite carbon tube f...

Embodiment 2

[0028] Embodiment 2 Unidirectional (UD)C f / SiC composite material preparation

[0029] With methane (CH 4 ) and MTS are vapor phase precursors, which are deposited on the surface of C fibers by pulsed CVI or forced pulsed CVI (C-SiC) 6 The multilayer interface has a thickness of about 100 nm. The fiber bundles are impregnated in nano-SiC / PCS slurry with SiC content of 50vol.%, wound into unidirectional sheets, stacked at 0°, pressurized at 200-300°C, and then impregnated with phenolic resin slurry , cracked at 1800°C to obtain a porous body with a density of about 1.47g / cm 3 , The opening porosity is about 21.6%. After sintering by vapor phase siliconizing reaction under vacuum condition at 1700℃, its density is 2.31g / cm 3 , the porosity is 3.1%, the three-point flexural strength is 220MPa, showing non-brittle fracture (such as Figure 6 ).

Embodiment 3

[0031] Preparation of SiC-based composites containing two-dimensional carbon fiber cloth.

[0032] Deposit BN / SiC multilayer interface on the surface of carbon fiber cloth, using BCl 3 -NH 3 Using MTS as a precursor, at 900-1200 ° C, using pulsed CVI or forced pulsed CVI process, the carbon fiber cloth is coated with a multi-layer (BN-SiC) interface. Then carry out in the mode of embodiment 1. SiC-based composite materials with similar properties are obtained.

[0033] The forced pulse CVI process involved in the above-mentioned embodiments is based on the pulsed CVI process, which is characterized in that the method of introducing forced pulse flow is used to improve the interface deposition rate while maintaining uniform deposition at the interface; the specific process is the upper opening of the graphite mold, The gas conduit is located at the bottom of the graphite mold. During the interface deposition process, the fiber, fiber braid or preform is placed on the upper p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com