Patents

Literature

405 results about "Basal body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A basal body (synonymous with basal granule, kinetosome, and in older cytological literature with blepharoplast) is a protein structure found at the base of a eukaryotic undulipodium (cilium or flagellum). It is formed from a centriole and several additional protein structures, and is, essentially, a modified centriole. The basal body serves as a nucleation site for the growth of the axoneme microtubules. Centrioles, from which basal bodies are derived, act as anchoring sites for proteins that in turn anchor microtubules, and are known as the microtubule organizing center (MTOC). These microtubules provide structure and facilitate movement of vesicles and organelles within many eukaryotic cells.

C/C and C/SiC composite material and metal connecting method

ActiveCN101143397AFirmly connectedSoldering apparatusWelding/soldering/cutting articlesParticulatesMetal fibers

The invention is a method of binding compound materials of the C / SiC and C / C, which belongs to the technology field of binding heterogeneous materials. The processing procedures are as following: 1. The surface of the e compound materials of the C / SiC and C / Cis pretreated, which comprise the surface of the connecting are grinding, cleaning, vacuum biscuit firing, preparation of double-layer metal film and microvacum heat treatment and so on. 2. The transition layer of the connecting area surface gradient of the compound materials of the C / SiC is coated and sintered. 3. The compound materials with the gradient transition layer as the felted phase is brazed with the metal in vacuum. The invention is characterized in that the gradient transition layer is directly used as the materials that bind the compound materials with the metal; the gradient transition layer is double-layered or multilayered (sub-layered) structure; from the inner basal body to the outer part of the compound materials, the melting points of active brazing alloy adopted by each sub-layer gradually lower, the coefficient of heat expansion that adjust volume percentage composition gradually lower and the coefficient of heat expansion of the sub-layers gradually rise. The brazing ceramic metal connecting piece of the invention has good strength, air tightness and wide application field, which is suitable for various non-metallic fibers, such as ceramics of SiC, Si3N4, Al2O3, AlN and so on and applicable for connecting the ceramic matrix compound materials with particulate reinforced with the metal.

Owner:GRIMAT ENG INST CO LTD

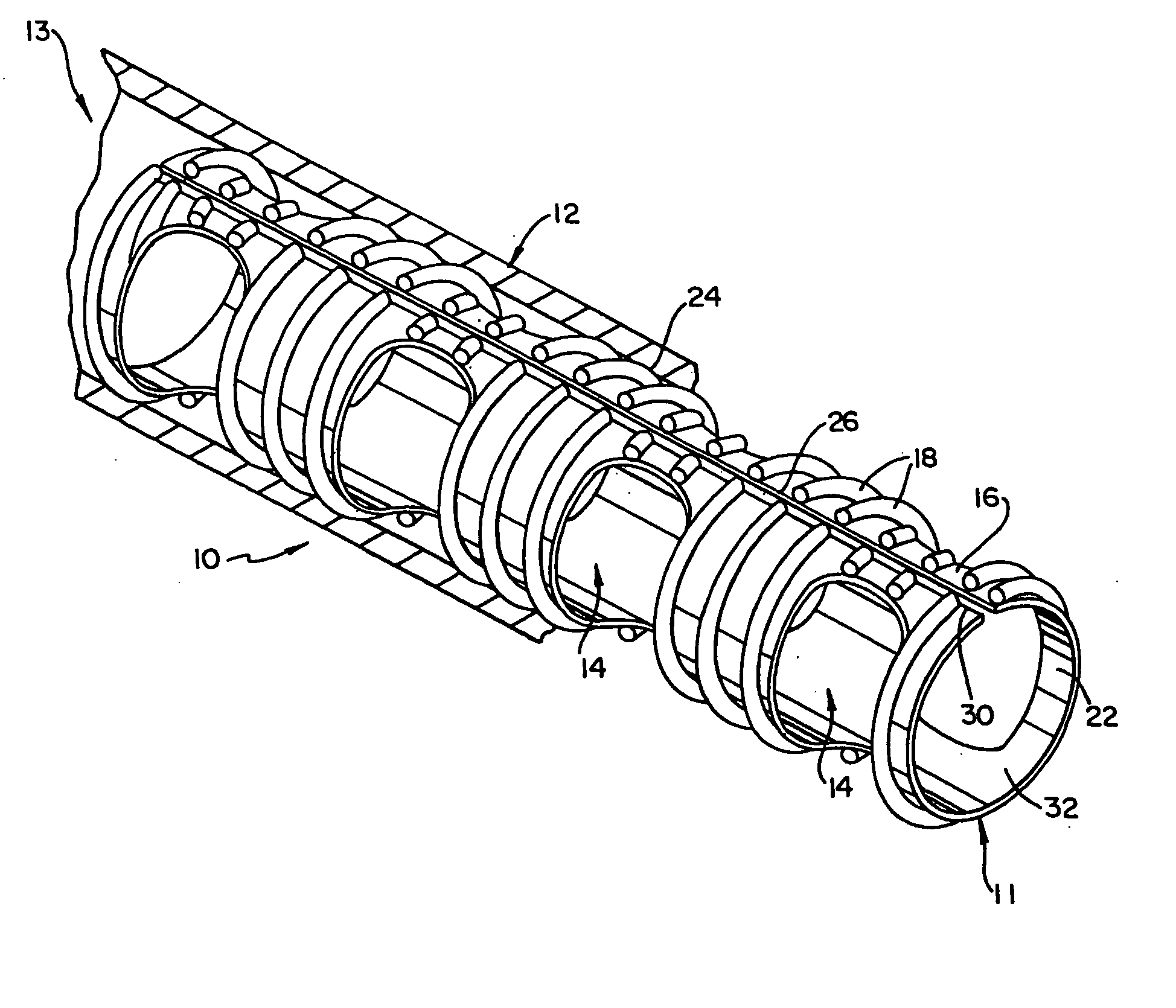

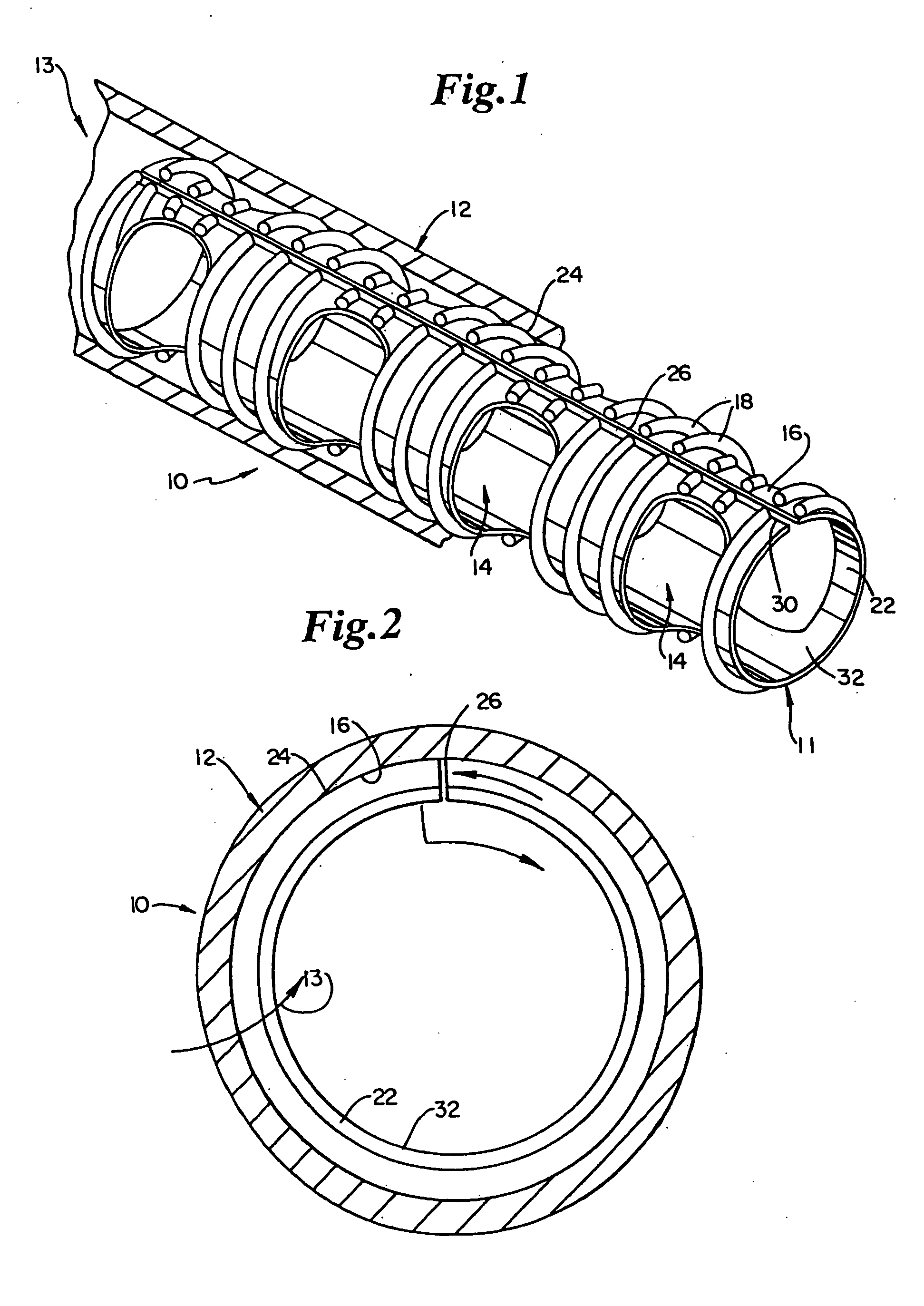

Biodegradable drug delivery vascular stent

A stent includes a main body of a generally tubular shape for insertion into a lumen of a vessel of a living being. The tubular main body includes a substantially biodegradable matrix having collagen IV and laminin that enclose voids within the matrix. The tubular main body also includes a biodegradable strengthening material in contact with the matrix to strengthen the matrix. The tubular main body is essentially saturated with drugs.

Owner:BOSTON SCI SCIMED INC

Olivine carbon bobbles composite material and use thereof

ActiveCN1889290AHigh magnificationImprove securityCell electrodesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCarbon nanotubeOlivine

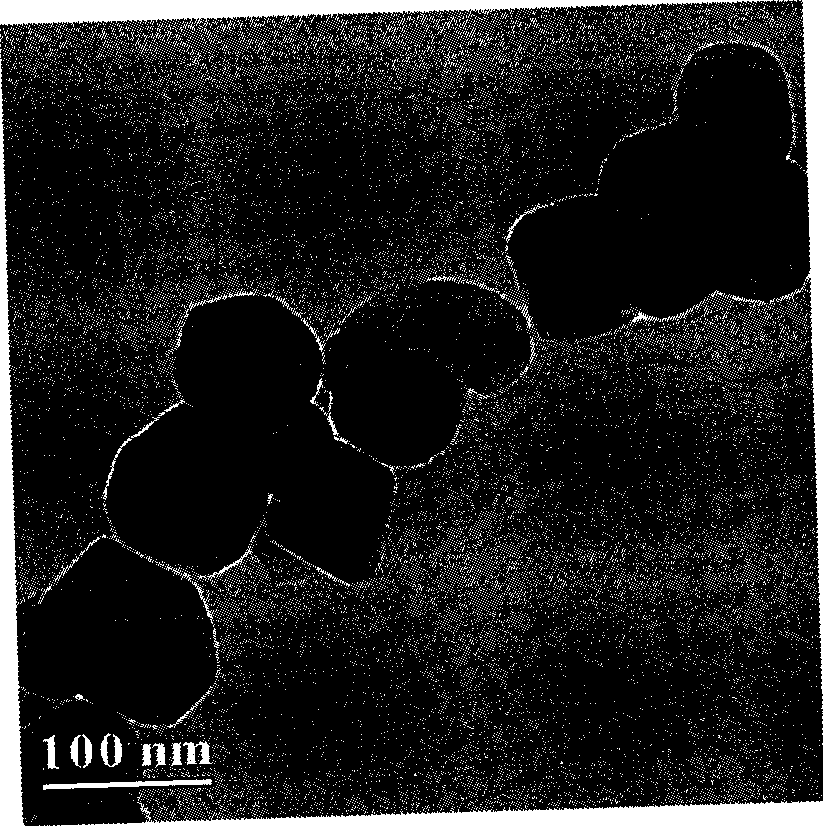

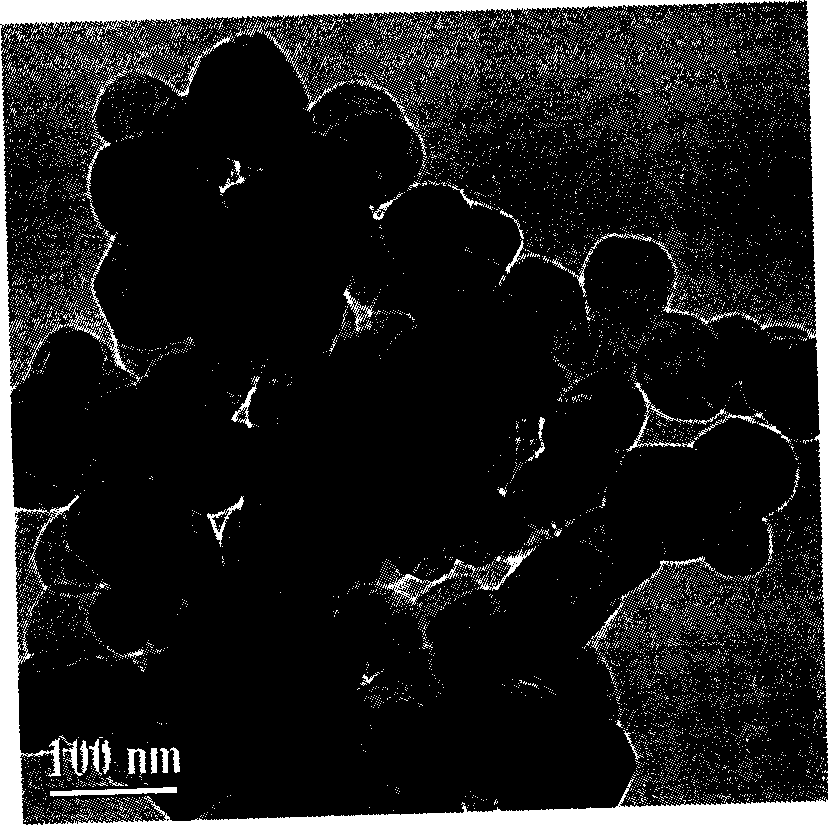

The present invention relates to a olivine carbon wool ball composite material. It one olivine basal body and wheresoever grown carbon nanotube or / and nano fiber, wherein the particle average diameter of said olivine basal body being 50 nm-50 micrometer, chemical constitution: LixAaMmBbPOzNn, said carbon nanotube or nano fiber diameter being 1-200 nm, length being 50 nm-100 um. Said composite material also includes olivine basal body surface covered single-layer carbon with thickeness 2-100 nm, carbon content being 1-20 wt per cent of basal body weight. Said composite material can directly be used as positive electrode active material in secondary lithium battery, also used as additive mixing use with existing positive electrode material. Said composite material can raise current positive electrode material and battery multiplying factor and safety feature. Secondary lithium battery Containing said olivine carbon wool composite material has large power density and high security etc advantages.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Soluble carbon nanometer pipe absocped with polyelectrolyte on surface and its preparation method

InactiveCN100999314AImprove machinabilitySimple and fast operationNanostructure manufacturePolyelectrolyteElectricity

This invention discloses a water-soluble carbon nanometer tube that superficially adsorbs polyelectrolyte and its preparation method. Process nanometer tube, make its surface have active group, display electro-negativity'alternatively adsorb electrolytic which has positive / negative charge by LBL, and make water-soluble carbon nanometer tube of superficial adsorbing single / multilayer polyelectrolyte. This invention is simple to operate, of no pollution; the product show good dissolving dispersibility in water, which can be used as superordinary aquosity additive, and provide excellent machinery, light, electricity, and magnetic function for water-soluble organic giant molecule basal body. And inlet different functional group through polyelectrolyte, make function pattern carbon nanometer tube. Thus, it has extensive application prospect in stuff science and organic medicine field of preparing nanometer ware, transmitter, and super electric capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

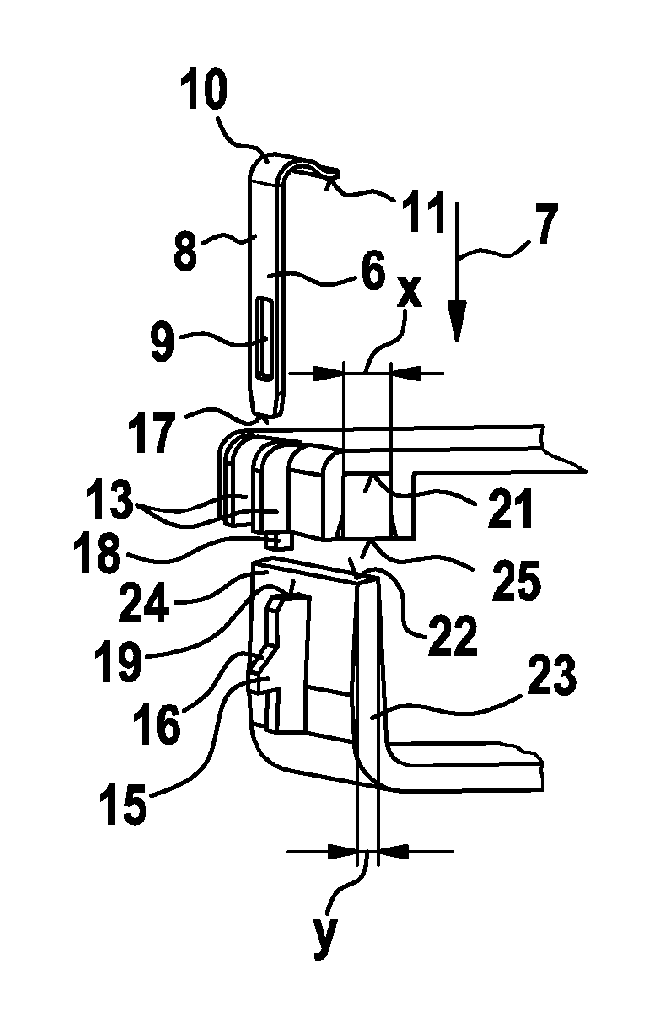

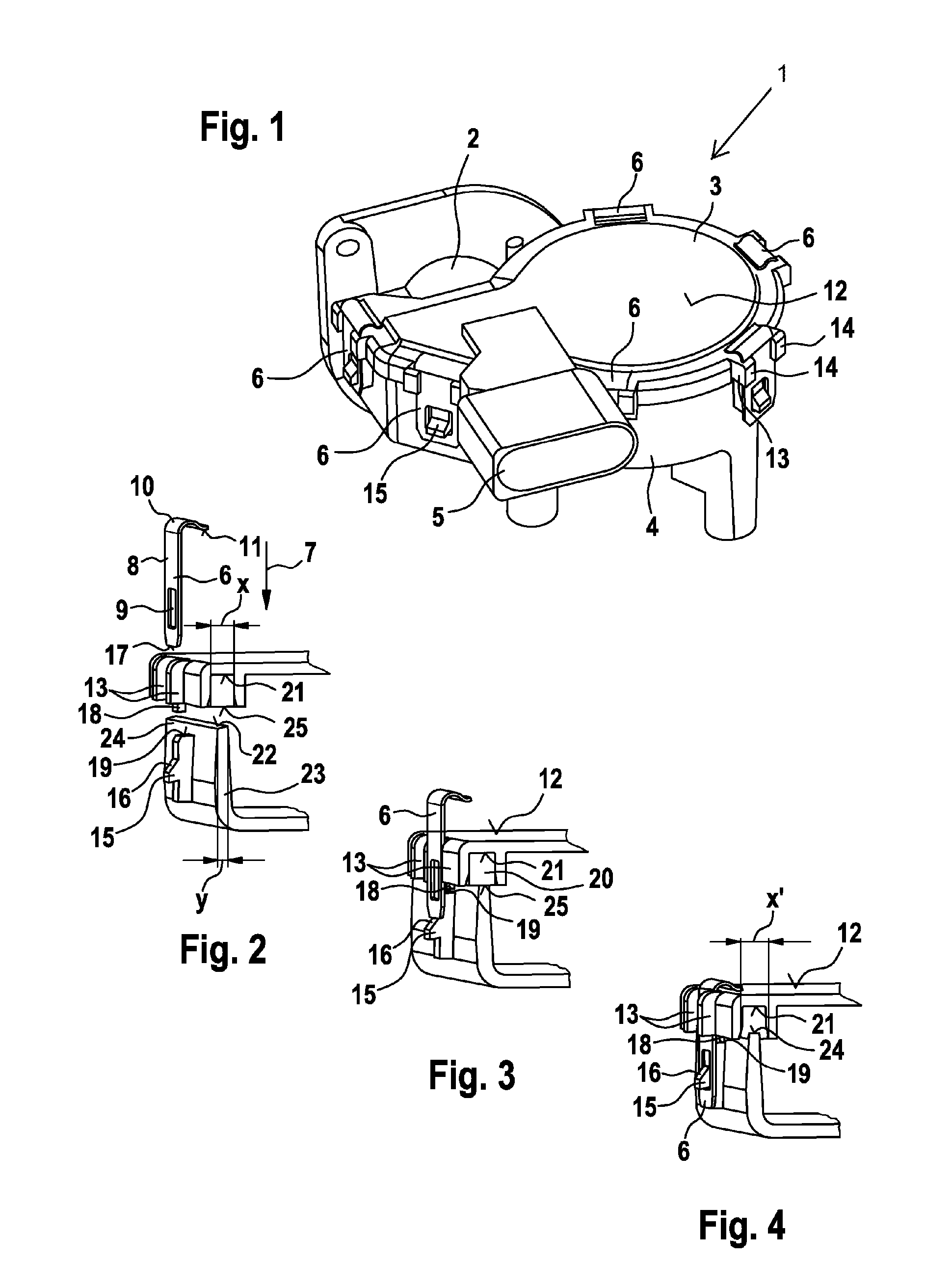

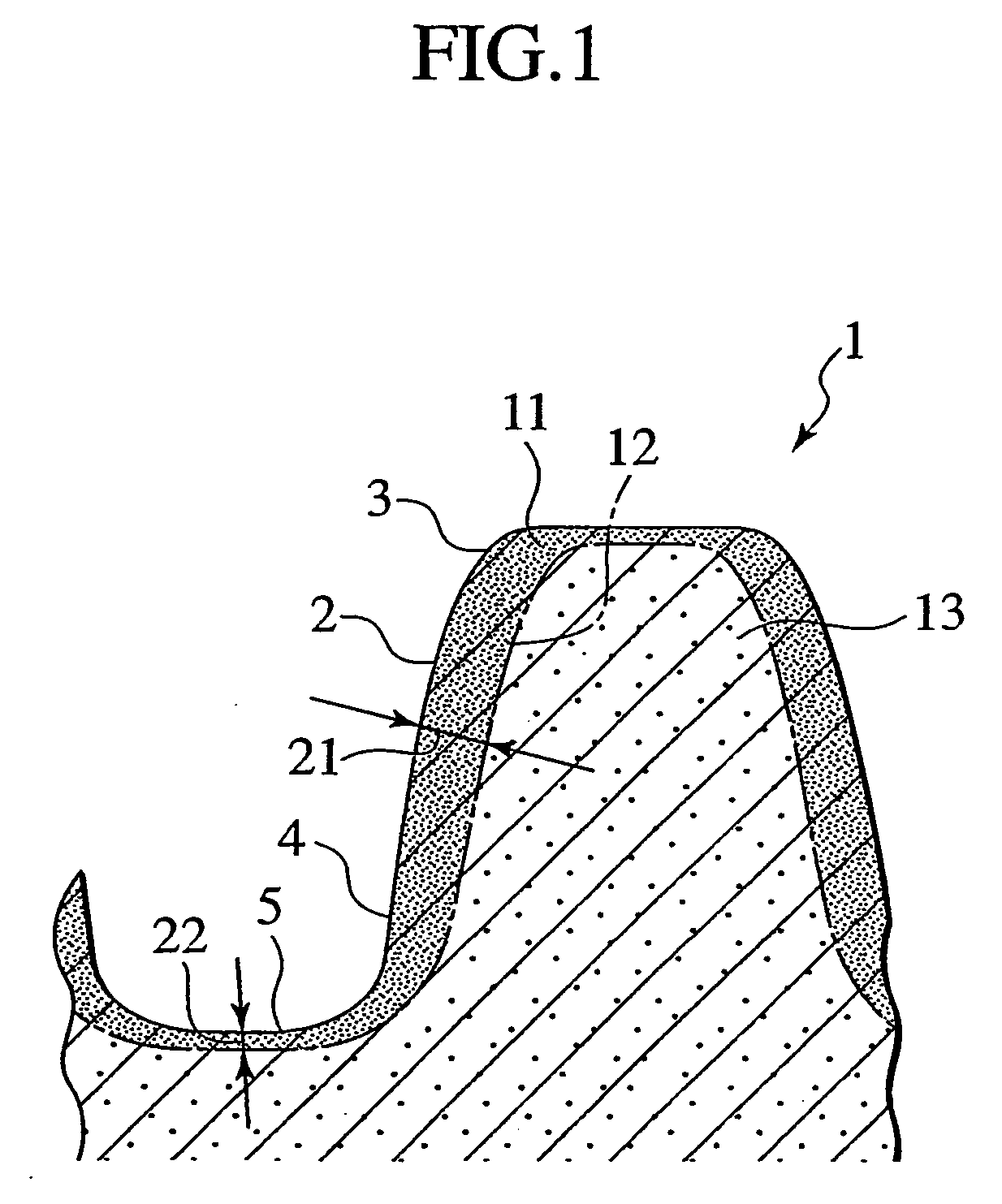

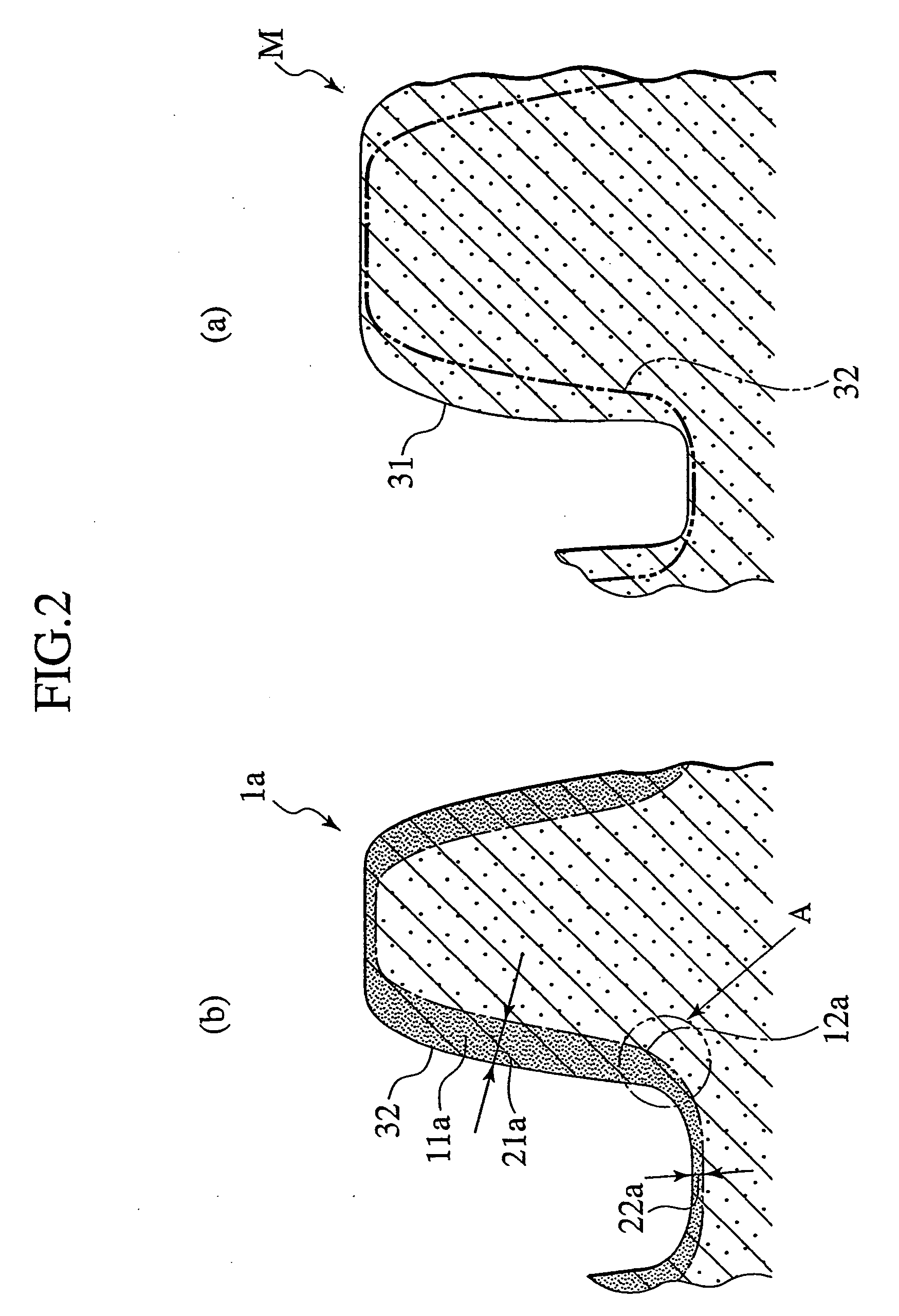

Gear housing

ActiveUS8286533B2Not easy to damageCost-effective manufacturingEngine sealsGearboxesEngineeringSpring steel

The invention relates to a gear housing (1) comprising a gear, particularly comprising a gear of a wiper device for motor vehicles, having a housing base body (4), having a housing cover (3) affixed at a distance to the housing base body (4) by means of a plurality of retaining clips (6) made of spring steel in circumferential direction, and having an annular seal (20) disposed between the housing base body (4) and the housing cover (3) and pressed against a support region (24) of the housing base body. The invention provides that the radial extension (y) of the support region is smaller than the radial extension (x, x′) of the annular seal.

Owner:ROBERT BOSCH GMBH

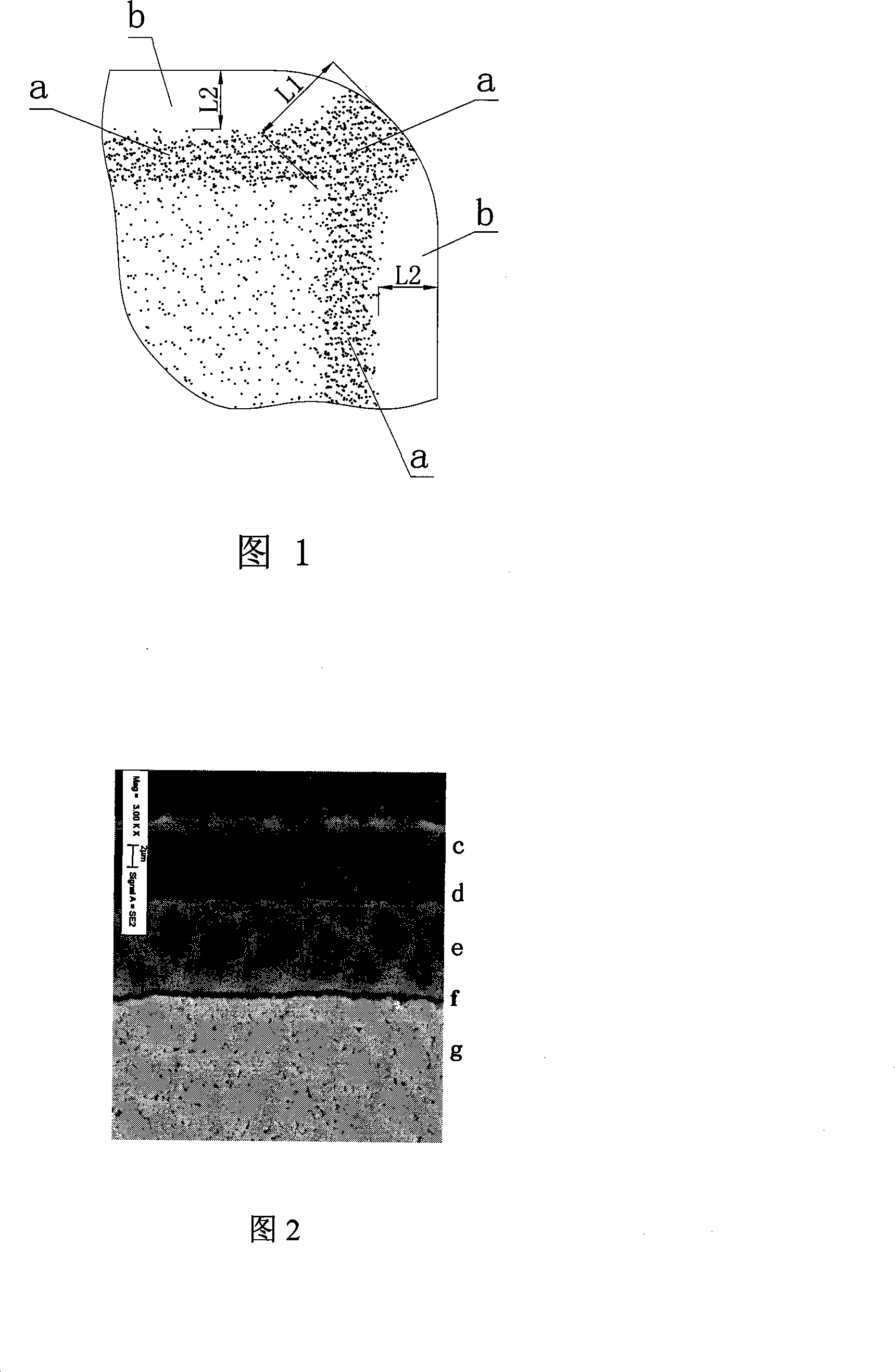

Bionic non smooth abrasion-proof gear wheel

InactiveCN1793700AImprove wear resistanceNot easy to losePortable liftingGearing elementsProject areaGear wheel

The invention relates to a design of wearable appearance of gear teeth and the manufacturing technique, for applying bionic nonsmooth theory to provide a bionic nonsmooth wearable gear able to effectively gear surface wearability. And it makes engaging friction surfaces of gear teeth into bionic nonsmooth surfaces, i.e. its teeth surfaces are distributed with ellipsoidal-pit, groove or grid nonsmooth unit bodies whose surfaces each have a 25 mum height difference from the surface of the basal body of the gear and whose distribution density is the ratio of geometric projected area on the surface of the basal body to the basal body area S=15í½30úÑ, and the hardness difference between the materials of the unit bodies and the basal body is 20-40 HRC, and these unit bodies the lubricated state of gear engaging and driving, thus improving gear wearability. The method is a more reasonable, effective, gear wearability-improving method.

Owner:JILIN UNIV

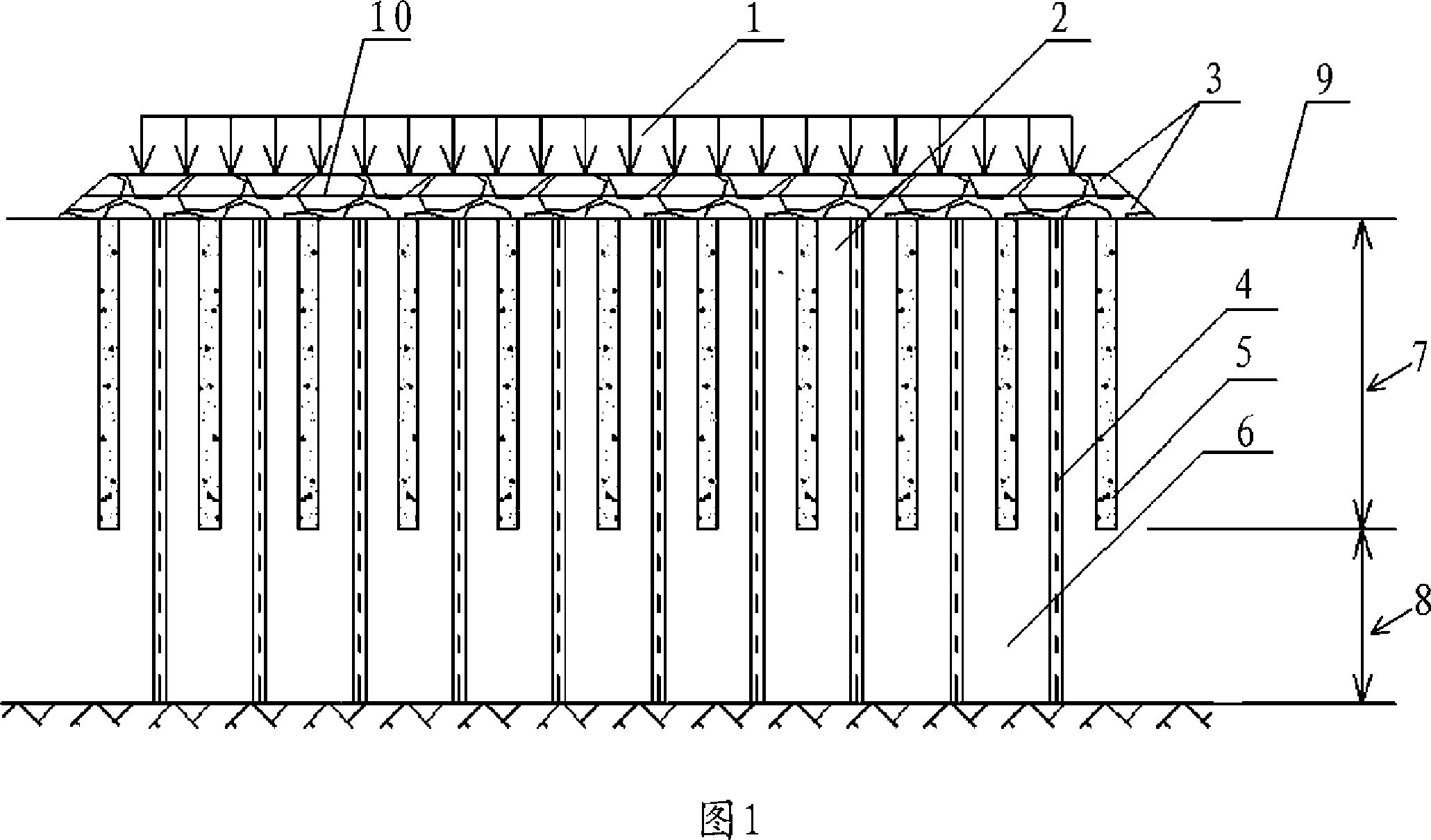

Foundation processing method

InactiveCN101024951AImprove reinforcement effectIncrease reinforcement depthBulkheads/pilesSoil preservationEarth surfaceCushion

The invention is a foundation processing method, comprising the steps of: 1. constructing vertical reinforcer in reinforced region basal body in the reinforced region from ground surface to underground; 2. after having constructed at least one vertical reinforcer, in the middle region between two vertical reinforcers, constructing a vertical drainage well which runs in order through the reinforced region basal body, and underlying layer basal body in the underlying layer from the ground surface; 3. when all or part of the vertical reinforcers and vertical drainage wells are finished, laying a drainage cushion on the ground surface on the reinforced region; horizontal drainage cushion and the vertical drainage wells are vertically and horizontally interconnected to compose a drainage system. And it raises the maximum valid reinforcing depth of the commonly-used composite foundation from generally less than 20 m to 30-40 m.

Owner:陈俊生

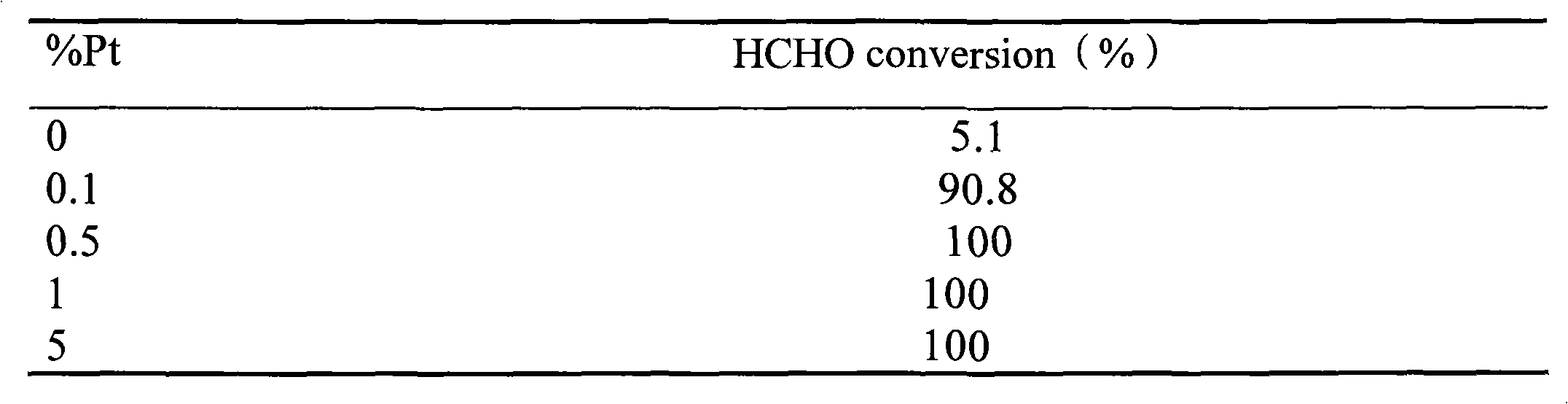

Catalyst for completely removing formaldehyde in indoor air at room temperature

InactiveCN102836712AGood removal effectImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPlatinumActive component

The invention provides a high-efficiency and humidity-resisting catalysis technology for removing formaldehyde at room temperature and relates to the field of catalysis and environmental protection. The catalysis technology is characterized in that honeycomb ceramic is used as a carrier, preloading mesoporous cerium dioxide (CeO2) is used as a basal body, and a back loading platinum (Pt) is used as an active component. The mesoporous CeO2 is characterized in that the diameter of every meso pore is 0.5-3nm. The weight ratio of the Pt to the CeO2 is 0-5 percent. The integral catalyst provided by the invention is high in efficiency and stability and has no side effects under a real environment with room temperature and normal humidity, and can be widely used for removing formaldehyde pollutants in various microenvironments.

Owner:SHANGHAI NIUYI NEW ENERGY TECH

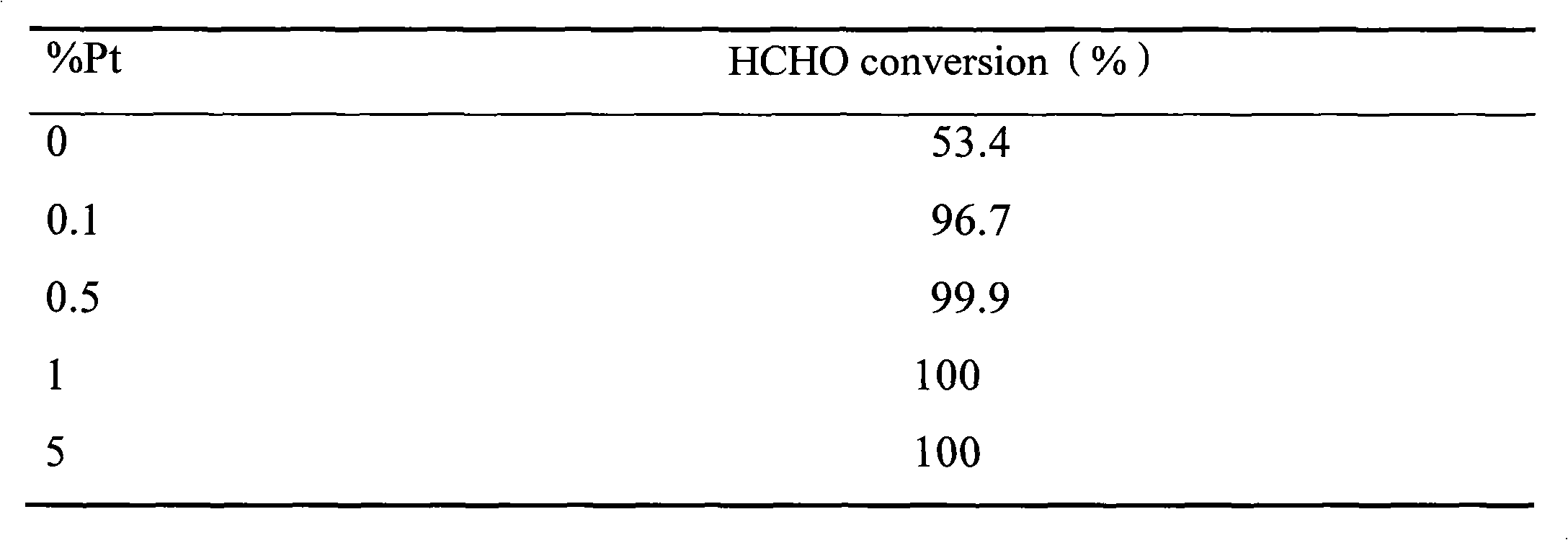

Sintered gear

Disclosed is a sintered gear composed of a sintered alloy having a metal matrix and pores. The tooth surface (2, 3, 4) of the tooth and the bottom land (5) have a densified layer (11) in which the porosity is reduced to 10% or less from the sintered alloy. The densified layer at the tooth surface is formed with a thickness of 300 to 1,000 microns, and the densified layer at the bottom land is formed with a thickness of 10 to 300 microns. The boundary surface of the densified layer is continuous from the tooth surface side to the bottom land side so as not to have a substantial level difference.

Owner:HITACHI POWDERED METALS COMPANY +1

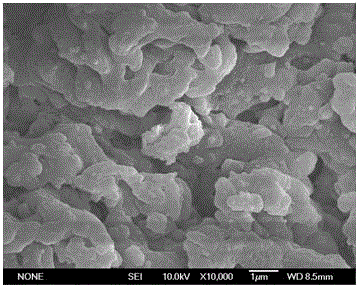

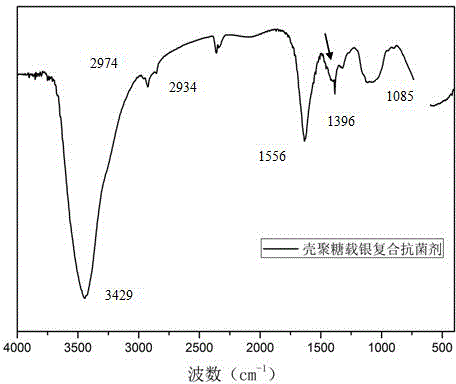

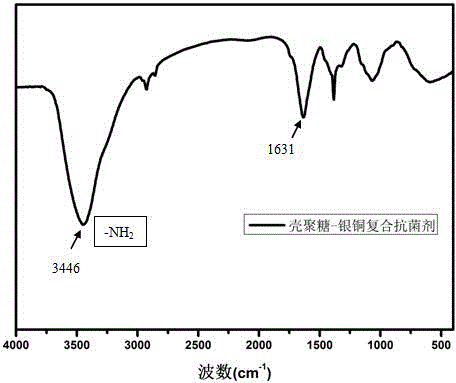

Method for preparing complex antimicrobial agent by blending chitosan and silver copper

InactiveCN104145993AReduce usageImprove antibacterial propertiesAntibacterial agentsOrganic active ingredientsEscherichia coliEnvironmental resistance

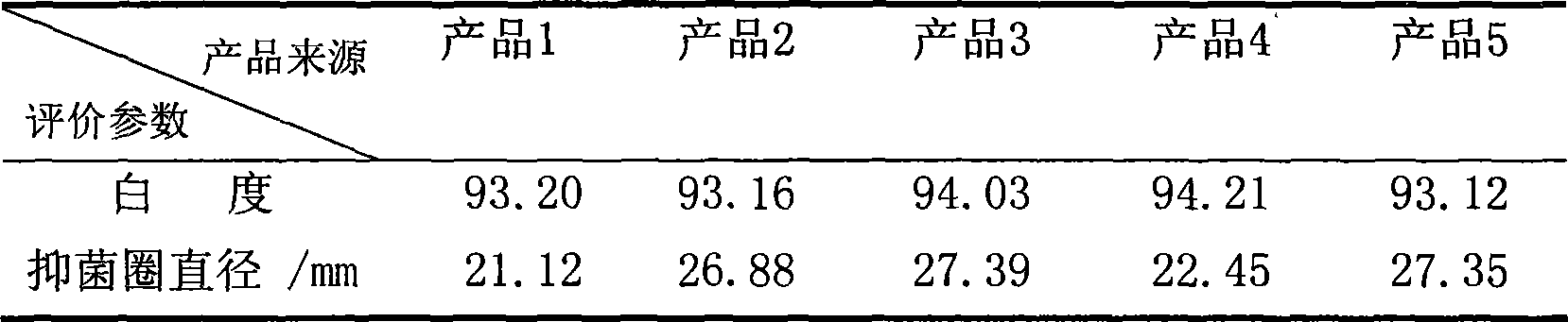

The invention relates to a method for preparing a complex antimicrobial agent by blending chitosan and silver copper. The method comprises the following steps: silver nitrate and cupric nitrate are blended according to the concentration ratio of 1:30 to 1:80, and then are blended with chitosan. Therefore, a light blue antibacterial agent powder is prepared. According to the method provided by the invention, the usage amount of silver is reduced, the chitosan is also used as a reducing agent, chemical reagents are no longer added, and the toxicity of an antibacterial agent is reduced. Due to the change of technological conditions, the oxidation-reduction reaction of the chitosan and the cupric nitrate can be performed sufficiently, an aldehyde group (-CHO) is generated in the reaction, Ag<+> is enabled to be completely reduced to elemental silver, Cu<2+> is hibernated in a chitosan basal body, so as to play a synergistic antibacterial effect, a remarkable inhibiting effect on escherichia coli and staphylococcus aureus is detected through an inhibition ring test, an inhibition ring which is equal to or greater than 10 mm is formed under a culture condition of 37 DEG C, a remarkable bacteriostatic effect is played, materials used cause no harm to human body, the price is low, and the novel complex antimicrobial agent is green and environment-friendly.

Owner:TAIYUAN UNIV OF TECH +1

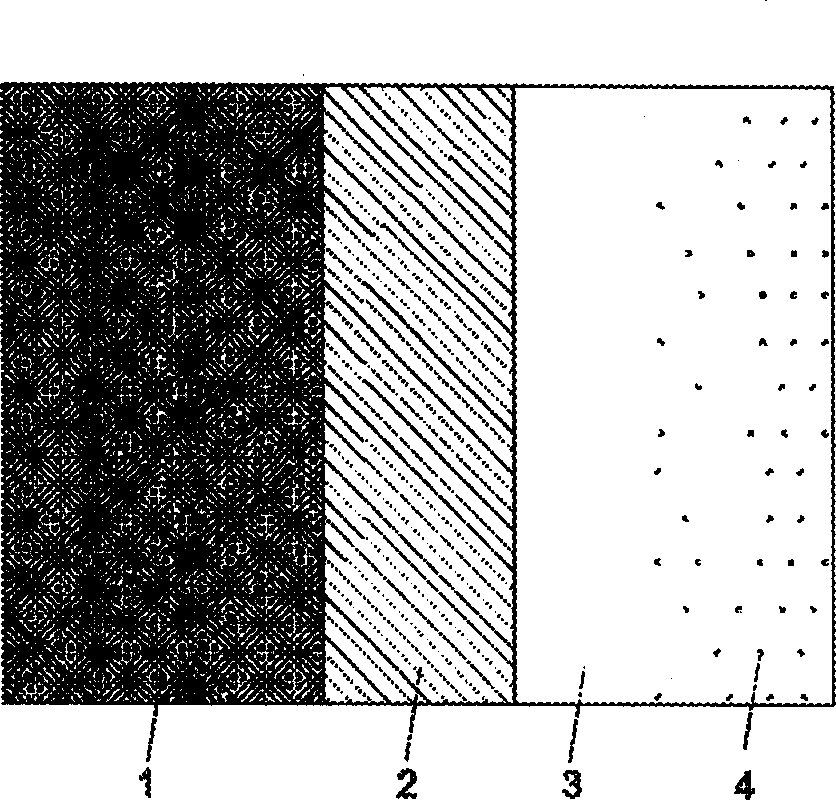

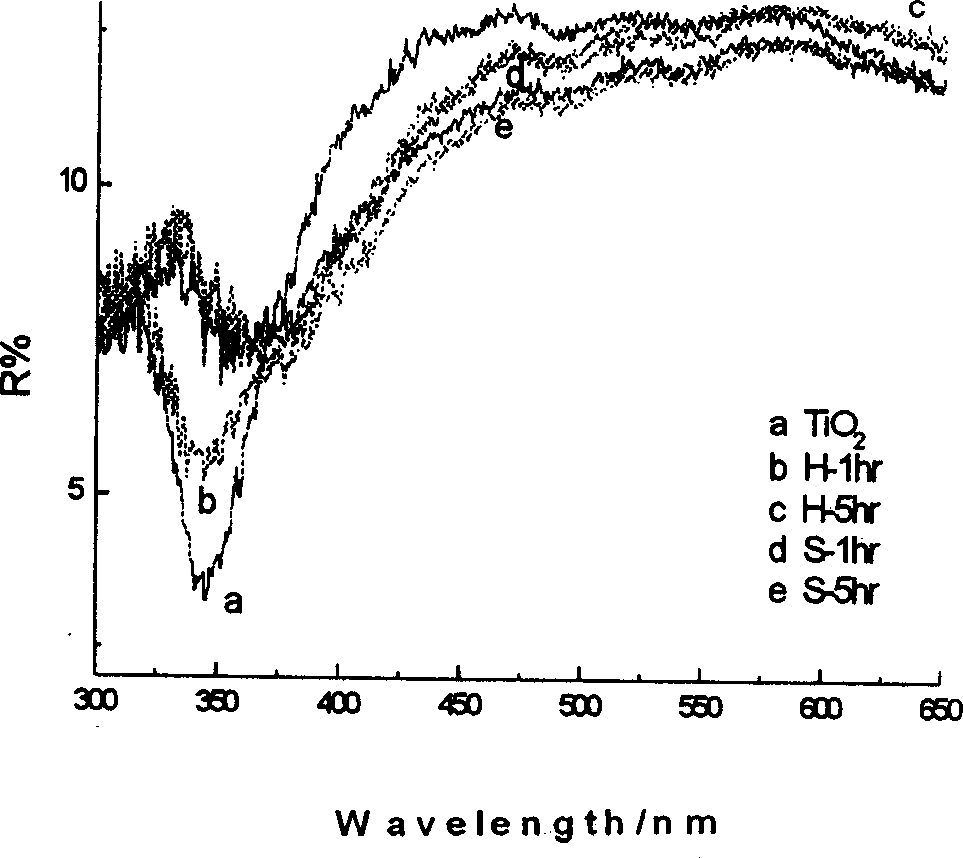

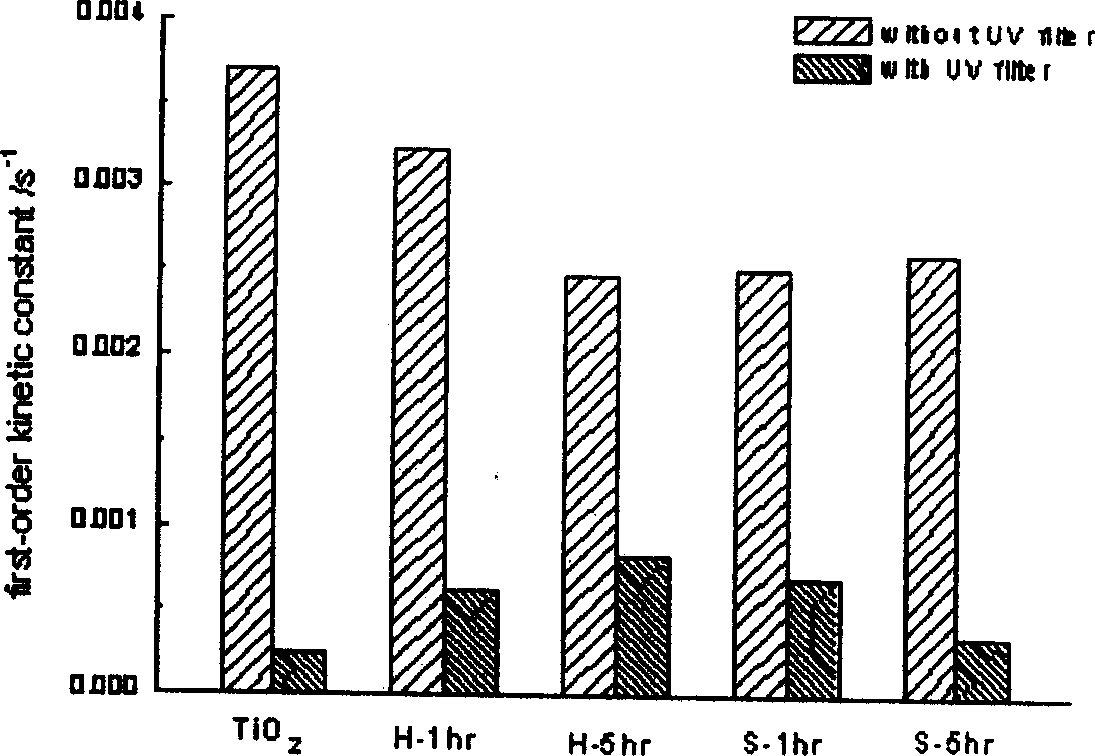

Photocatalyst film having light activity visible basal body and method for preparing the same

InactiveCN1467023ACatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalBasal body

A photocatalyst film with visual light activity has SiO2 layer and photocatalyst layer, and is prepared through preparing SiO2 film on a substrate by sol-gel method, preparing TiO2 film on SiO2 film by sol-gel method, sputtering metal or metal oxide by magnetically controlled sputter method, and heat treatment in inertial gas at 300-600 deg.C for 0.5-10 hr for diffusing the metal or metal oxide into TiO2 film. Its advantages are high visual light activity, and good self-cleaning and antifog effect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Carbon nano tube Poisson ratio material

InactiveCN101870463AHas negative Poisson's ratio propertiesMaterial nanotechnologyOther chemical processesCarbon nanotubeBasal body

The invention provides a carbon nano tube Poisson ratio material which comprises a carbon nano tube membrane structure, wherein the carbon nano tube membrane structure comprises a plurality of carbon nano tubes, the carbon nano tubes are respectively arranged in a first direction and a second direction, the first direction is perpendicular to the second direction, and the carbon nano tubes arranged in the first direction and the carbon nano tubes arranged in the second direction are arranged in an overlapping and crossing mode. The carbon nano tube Poisson ratio material further comprises a flexible macromolecule basal body, wherein the carbon nano tube membrane structure is uniformly arranged in the flexible macromolecule basal body. The carbon nano tube Poisson ratio material can be used for manufacturing leather belts, safety belts and the like.

Owner:TSINGHUA UNIV +1

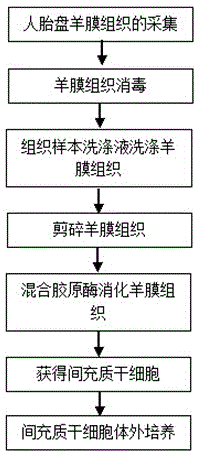

Isolated culture method of human amnia mesenchymal stem cells

InactiveCN105062959AGood repeatabilityShort training periodSkeletal/connective tissue cellsEmbryonic cellsDigestionCancer research

The invention discloses an isolated culture method of human amnia mesenchymal stem cells, which comprises the following steps: carrying out human placenta amnia tissue acquisition, amnia tissue disinfection, washing, shredding and mixed collagenase digestion to obtain mesenchymal stem cells, and carrying out mesenchymal stem cell in-vitro culture. The method can obtain abundant mesenchymal stem cells, which have the advantages of uniform and stable phenotype and high multiplication capacity and have the multidirectional differentiation potential, from the human amnia tissues; and the culture medium in-vitro amplification is performed to purify the cells, thereby satisfying the quantity for cryopreservation or clinical use. The method has the advantages of short cell culture period and high repetitiveness. The stem cells obtained by the method have the phenotypes of CD105<+>, CD90<+> and CD73<+>.

Owner:GENESIS STEMCELL REGENERATIVE MEDICINE ENG CO LTD

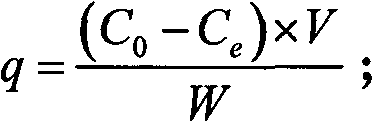

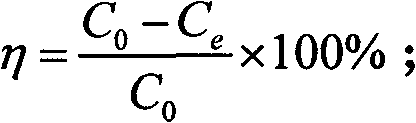

Heavy metal biological adsorbent using eggshell membrane as matrix and preparation method thereof

ActiveCN101829545ANew environmentally friendly and effective treatmentSmall and uniform particle sizeOther chemical processesWater/sewage treatment by sorptionEggshell membraneFreeze-drying

The invention discloses a heavy metal biological adsorbent using an eggshell membrane as a matrix and a preparation method thereof. The heavy metal biological adsorbent adopts chitosan as an immobilized carrier and eggshell membrane powder as a basis material, and comprises the following components in part by weight: 10 to 13 parts of the eggshell membrane powder, 20 to 30 parts of the chitosan of which the deacetylation degree is 86.9 percent, and a minute amount of gelatinous substance of a complex which contains sodium and potassium and is formed in the preparation process. The particle size of the biological adsorbent is 2 to 3 millimeters. The method comprises the steps of performing vacuum freeze drying and mechanical disintegration on a fresh eggshell membrane (a fibrous membrane between an eggshell and egg white), and then embedding the eggshell membrane with chitosan glue solution to obtain the biological adsorbent for adsorbing heavy metals. The biological adsorbent can be used for treating waste water containing the heavy metals of nickel, cobalt, cadmium, copper, lead and the like of which the concentration is lower than 100 mg / L, and the adsorption rate achieves 42 to 98 percent.

Owner:BEIHANG UNIV

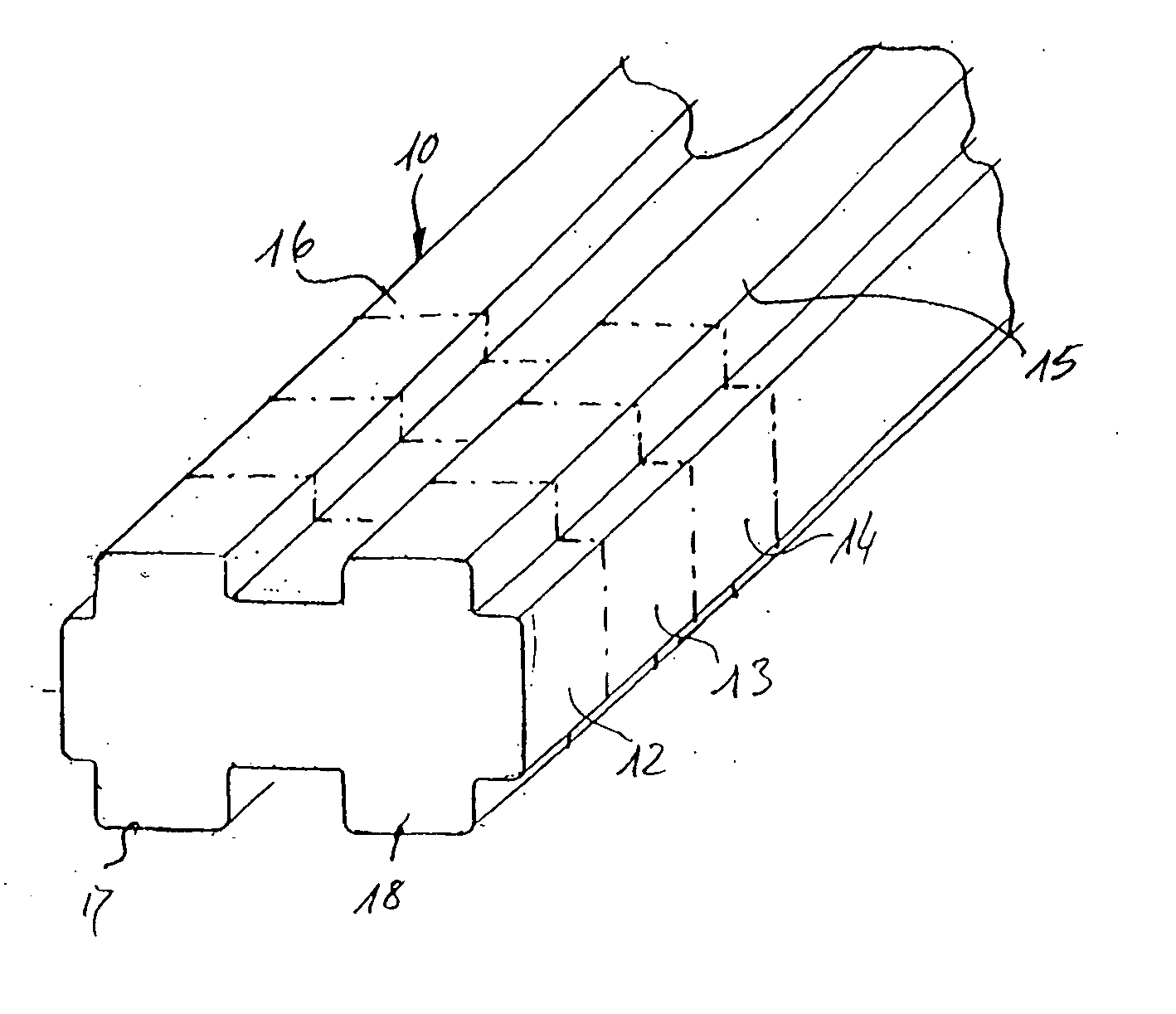

Honeycomb catalyst body

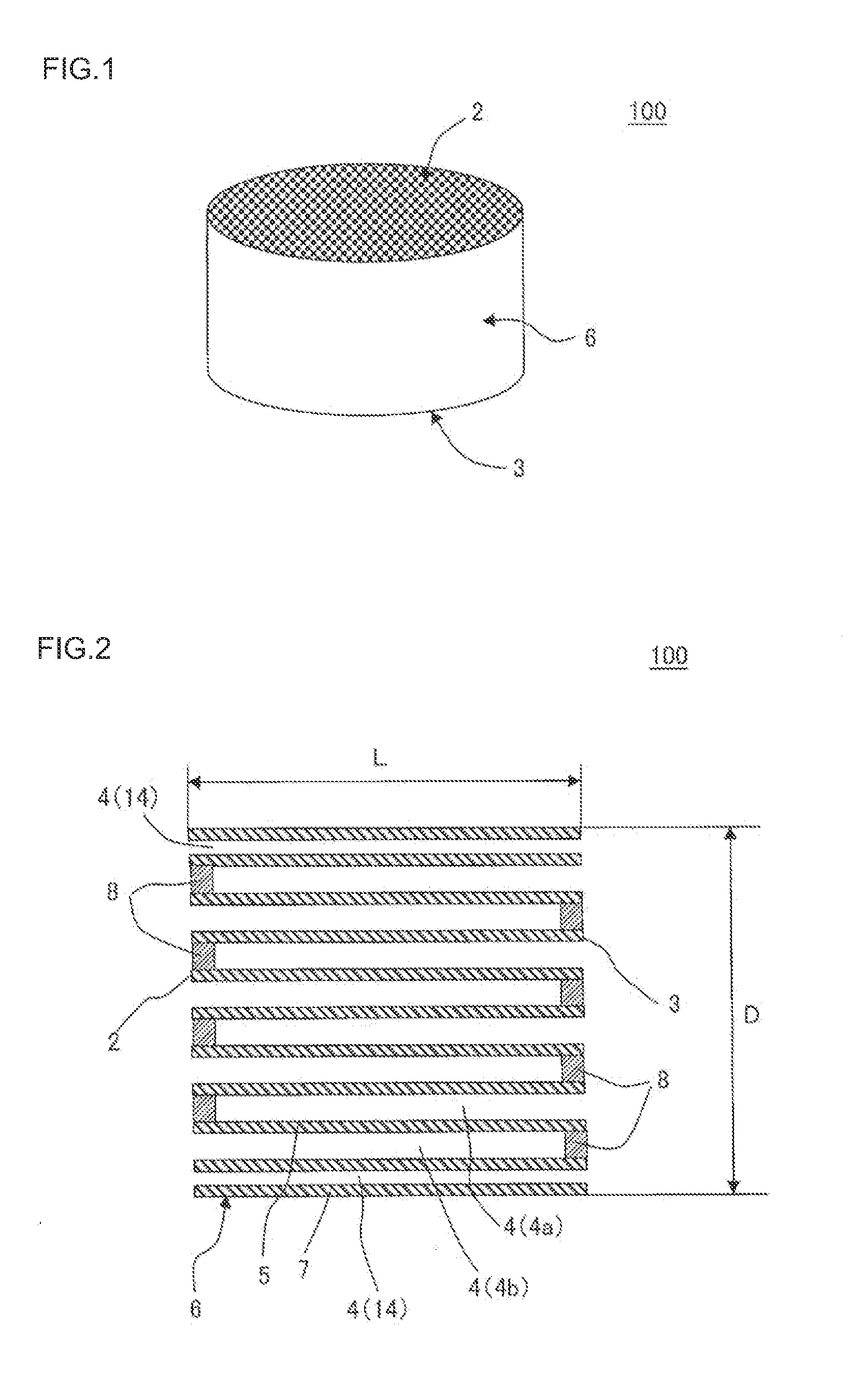

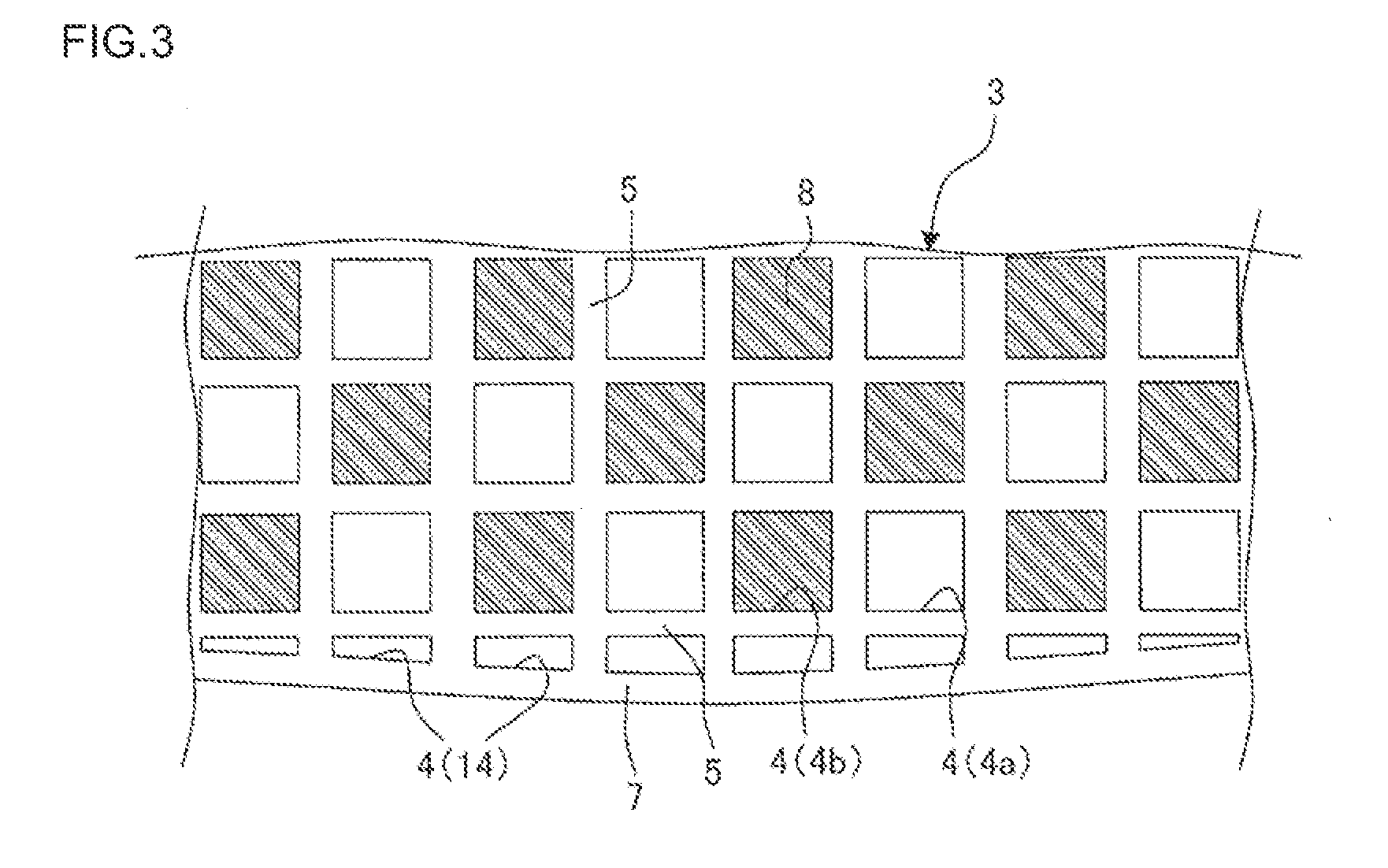

ActiveUS20110224069A1Efficient removalSmall pressure lossMolecular sieve catalystsDispersed particle filtrationHoneycombDiameter ratio

There is provided a honeycomb catalyst body comprising a honeycomb base body having porous partition walls forming a plurality of divided cells which extend from one end face of honeycomb base body to its other end face and which function as a fluid passage, and an outer wall present at the outermost peripheral portion of honeycomb base body, plugged portions provided so as to plug part of the plurality of divided cells, and a catalyst loaded on the partition walls of honeycomb base body. The plurality of divided cells include outermost peripheral cells formed by the partition walls and the outer wall, and of the outermost peripheral cells, those cells whose hydraulic diameter ratio to the hydraulic diameters of the cells other than the outermost peripheral cells is 5 to 75%, are through-cells having no plugged portion.

Owner:NGK INSULATORS LTD

Method for preparing molecular imprinting porous gel membrane for tissue engineering

The invention provides a method for preparing a molecular imprinting porous gel membrane for tissue engineering. Bioactive molecules such as growth factor, polypeptide, protein and the like are taken as template molecules, natural polymer sodium alginate which has good biocompatibility and can be absorbed in a degradable manner is used as a basal body, water-soluble polymer or inorganic salt serves as a pore-forming agent, and a green environment-friendly aqueous-phase imprinting method is adopted to prepare the molecular imprinting porous gel membrane with the thickness controlled between 20 and 1000mu m. The method is simple to operate and does not use any toxic and harmful solvents; the adopted materials have good biocompatibility; and cell culture porous gel membrane stents with identification and slow release performances to different template molecules can be obtained according to cell culture requirements and are used for regulating cell growth, and the method has a good application prospect in the tissue engineering field.

Owner:TIANJIN POLYTECHNIC UNIV

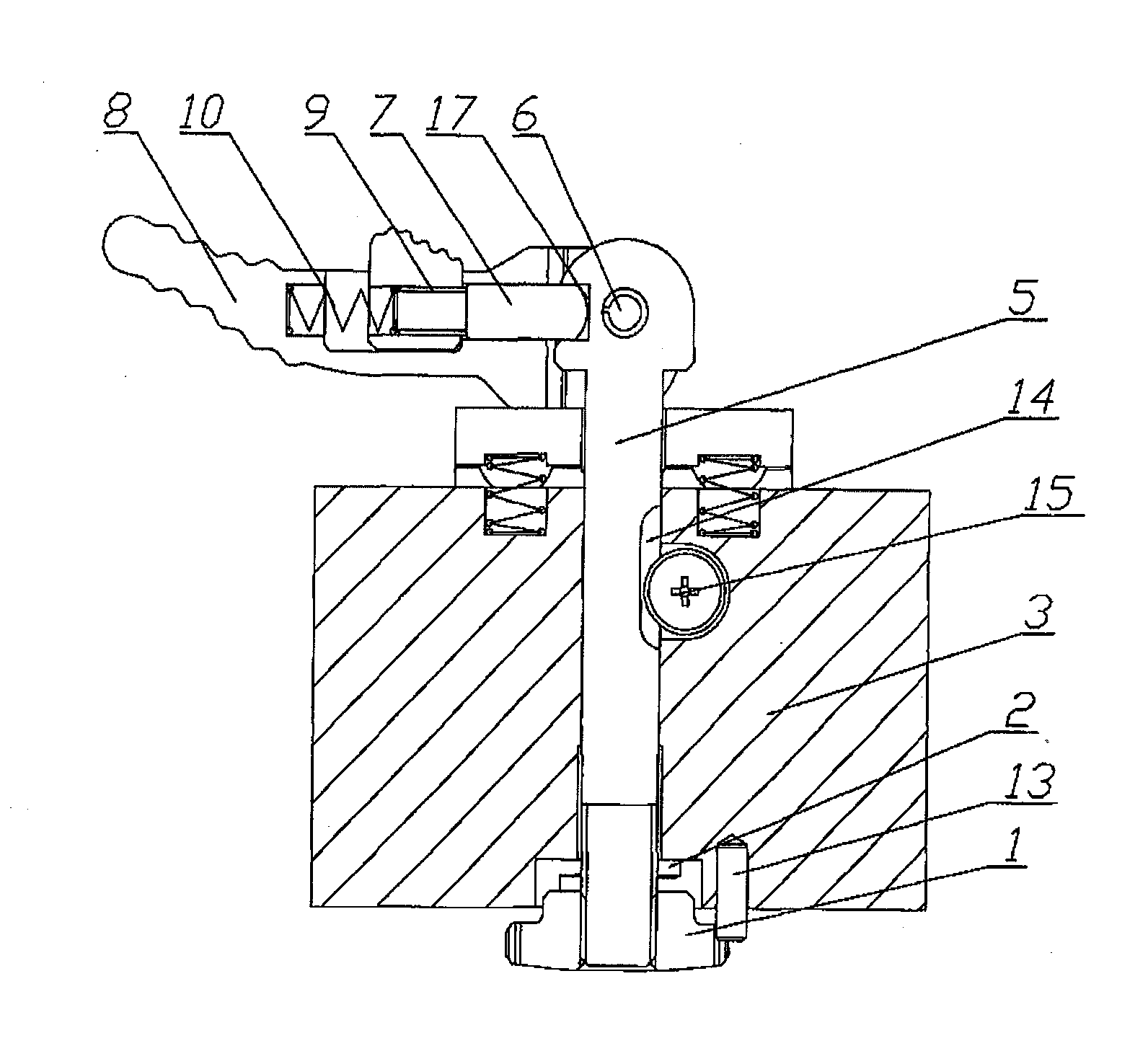

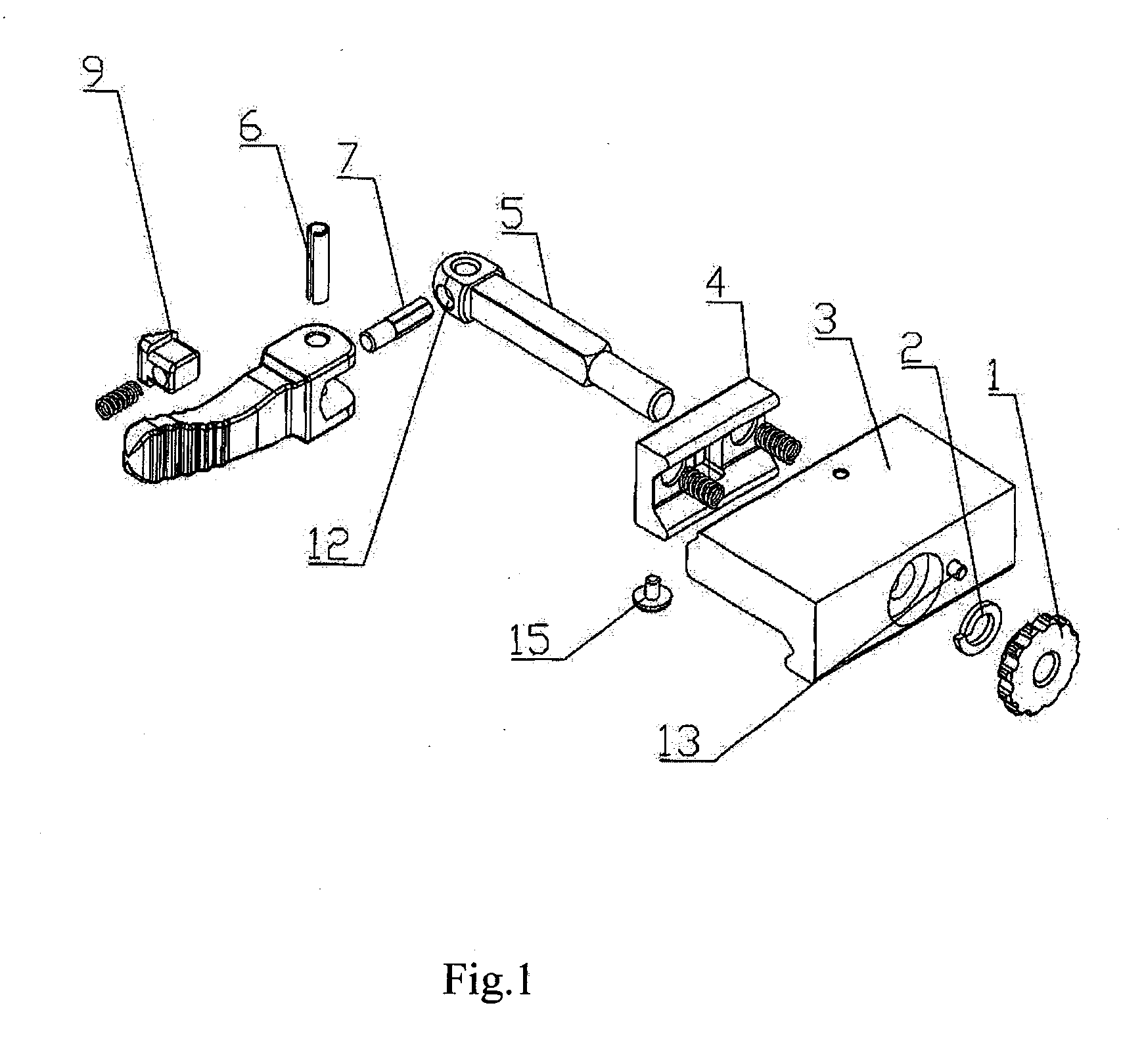

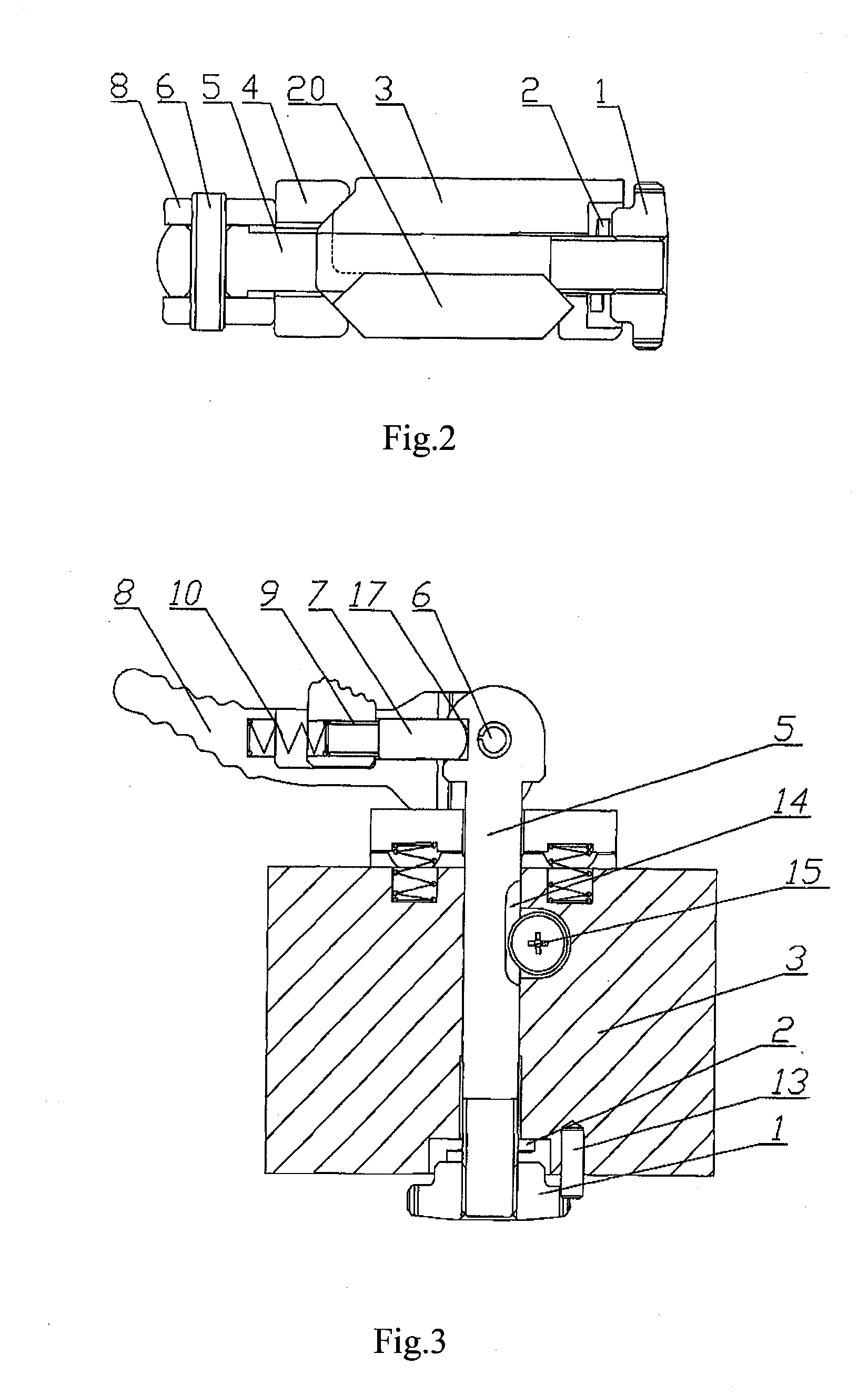

Eccentric handle device

An eccentric handle device which can be adapted for guiding rails of different sizes includes a base body (3), a pressure block (4), a pull rod (5), a pin (6), an eccentric handle (8) and a nut (1). The base body (3) is matched with the pressure block (4). The rod (5) passes through the base body (3) and the pressure block (4) respectively. One end of the rod (5) is movably connected with the eccentric handle (8) via the pin (6), the other end crosses the base body (3), and the rod is matched with the nut (1) by thread. The distance between the pressure block (4) and the base body (3) can be adjusted by rotating the nut (1), thus the device can be applicable to guiding rails of different sizes. The device can be widely used in the field of firearm aimer.

Owner:ZHUHAI CHUNQIU OPTICAL INSTR

One-step preparation method of multi-layer environmental barrier coatings through spark plasma sintering (SPS)

The invention relates to a one-step preparation method of multi-layer environmental barrier coatings through spark plasma sintering (SPS). The implementation method disclosed by the invention comprises the following steps of directly preparing an environmental barrier coating material on the surface by taking a silicon carbide fibre reinforced silicon carbide ceramic based composite material (SiC / SiC) as a basal body, carrying out SPS at 1050 DEG C according to different surface materials of the coatings, wherein the heat preservation time is set to 2 min; the pressure in a mould is set to 48 MPa; the temperature increasing rate is set to 50 DEG C / min; and putting the sheeted coating material together with the basal body into the mould so as to directly obtain the SiC / SiC composite material having the multi-layer environmental barrier coatings. The multi-layer environmental barrier coatings are prepared on the basal body material by using the method disclosed by the invention; compared with chemical vapour deposition (CVD), a plasma spraying method, a sol-gel method and the like, the method disclosed by the invention is more convenient; the cost is greatly reduced; the preparation period is shortened; furthermore, the quality of the coatings is controllable; and the prepared coatings are higher in density and excellent in property.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Coating blade for processing cast iron

ActiveCN101214743ADecreased strength and toughnessStrong enoughLayered productsAlloyCemented carbide

The invention discloses a coated tip used to processing cast iron, which comprises a hard alloy basal body and a coating. The invention is characterized in that the hard alloy basal body comprises 2 percent to 12 percent of cobalt by weight and 0.2 percent to 3.5 percent of cubic-structure compound of metallic elements from the families of IVb, Vb and / or VIb in the periodic table by weight. A binding phase surface enrichment area is formed on both sides of the cutting edge of the basal body. The middle pie-slice section of the binding phase surface enrichment area is a cubic structure enrichment area. The coating comprises an innermost layer of equiaxed grain TiCxNyOz, a middle layer of columnar crystal TiCxNy 2 microns to 13 microns thick, a transition layer of TiCxNyOz and an outer layer of fine crystal Alpha-Al2O3 4 microns to 12 microns thick. The tip disclosed by the invention not only has the characteristics of high wearing feature, high strength and high versatility, but also integrates the toughness and the plastic deformation resistance well. Accordingly, the invention is in particular applicable for processing cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

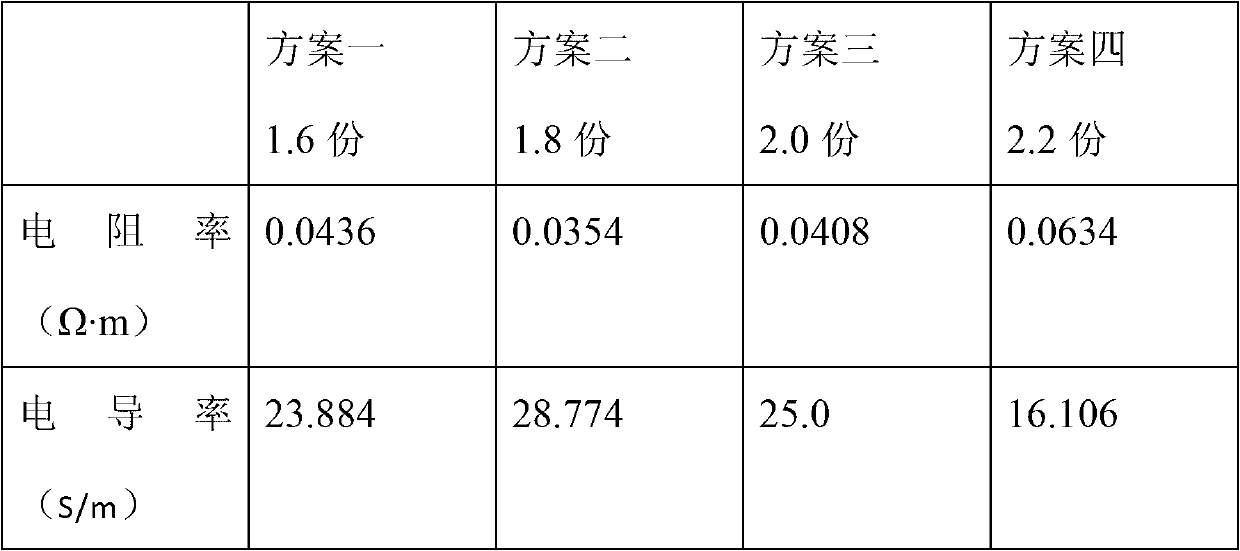

Nano silver wire added conductive composite material, and preparation method

InactiveCN1873838AImprove conductivityIndividual molecule manipulationNon-conductive material with dispersed conductive materialMetallurgyAcrylic resin

Blending ratio of each component in the composite material is as following according to mass: silver powder 20-41 portions, Nano silver wire 1-8 portions, and acrylic resin 100 portions. The preparation includes steps: mechanical stirring acetone added to acrylic resin being as basal body of macromolecule; adding acetone into mixed silver powder and silver wire; combining with ultra sonic dispersion, mechanical stirring the mixed silver powder and wire; combining with ultra sonic dispersion, mechanical stirring the prepared two liquids to disperse particles in resin; solidifying the admixture under aeration environment at 40-70 degrees. Comparing with prior art, the disclosed composite material possesses better conductivity when total silver fillings are same; lower quantity of silver is needed when conductivities are closes. The invention is applicable to connection of electronic package to meet military and civil requirements.

Owner:ZHEJIANG UNIV

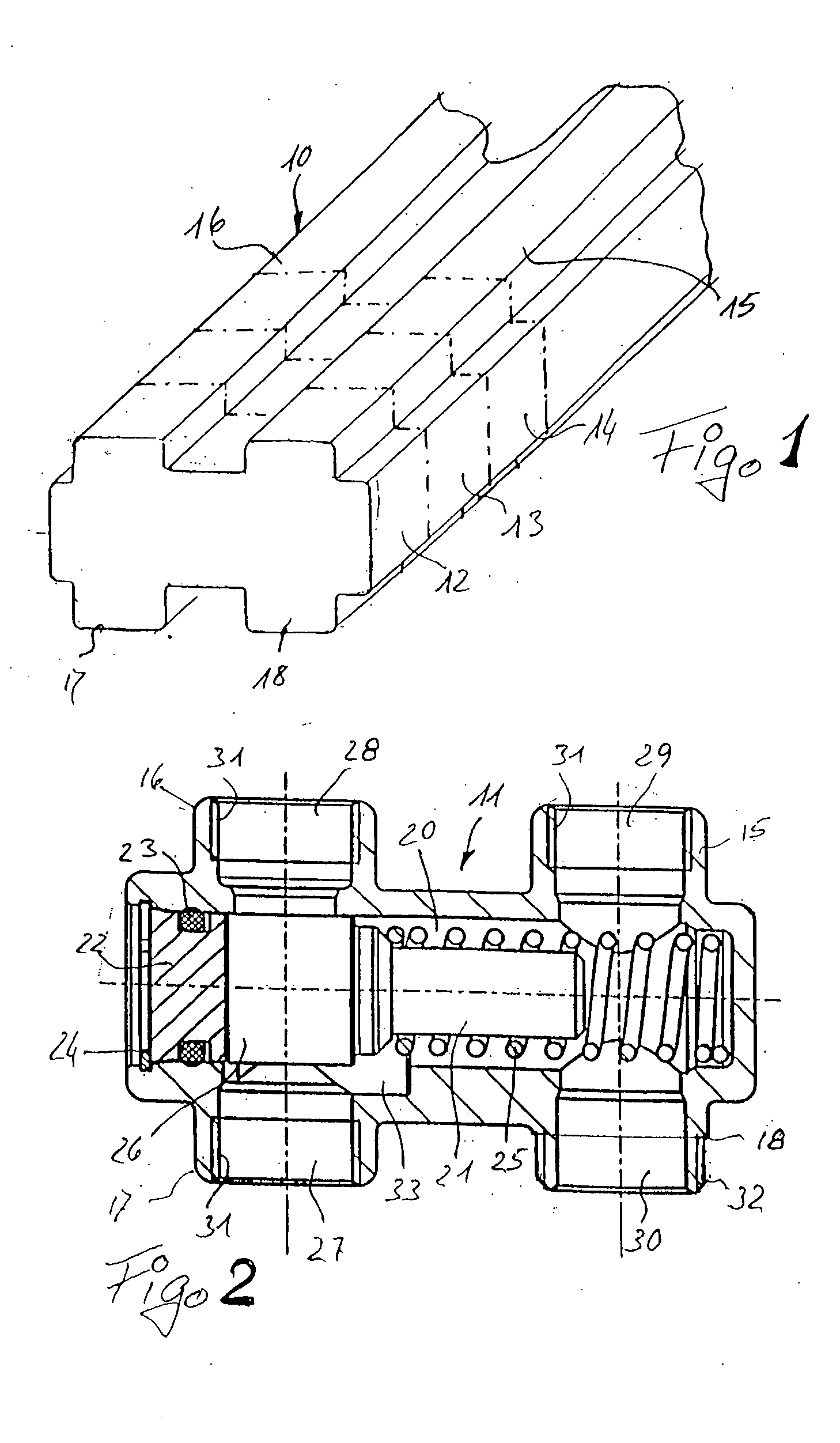

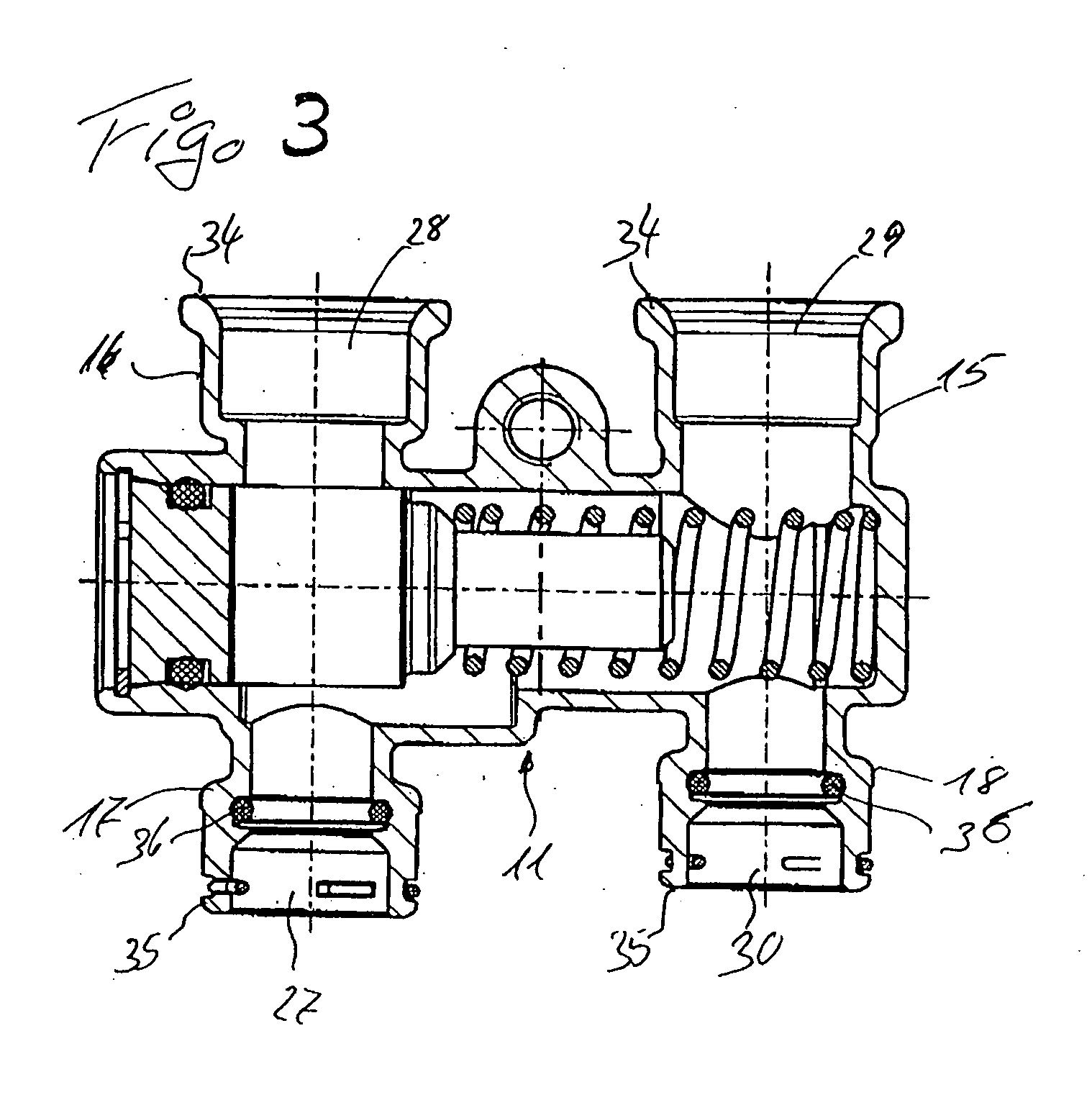

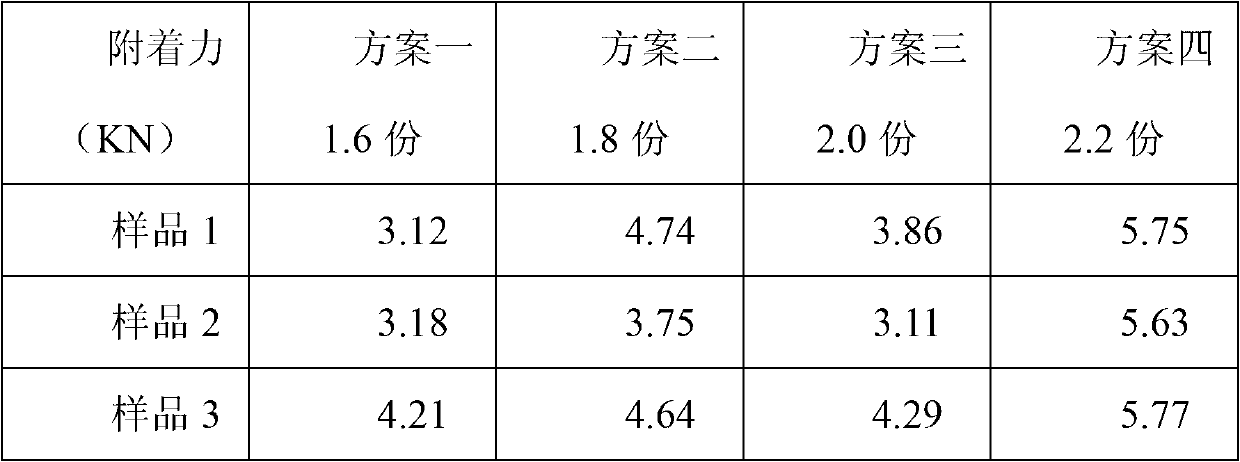

Method for producing valve housings, and a valve housing

ActiveUS20070164249A1Reduce in quantityShorten production timeOperating means/releasing devices for valvesSoldering apparatusEngineeringAbnormal shaped

Owner:BEHR THERMOT TRONIK

Carbon fiber grounding grid anti-corrosive paint and preparation and application methods thereof

InactiveCN102952438AImprove conductivityImprove adhesionPretreated surfacesAnti-corrosive paintsEpoxyFiber

The invention provides a carbon fiber grounding grid anti-corrosive paint and preparation and application methods thereof. The paint comprises the following components in parts by weight: 30 parts of acrylic resin, 50 parts of dissolving agent, 1.8 parts of epoxy resin, 25 parts of carbon fiber and 5 parts of carbon black serving as conductive filler, 2 parts of diluent, 0.5 part of silane coupling agent, 0.2 part of curing agent and 0.1 part of thickening agent. Strict pretreatment is performed on the surface of a basal body before construction; the surface of the basal body is required to be smooth, dustless and greaseless; the dissolving agent, the conductive filler, the curing agent and the like are required to be fully dissolved during construction; the coating contact is good; the thickness is uniform; the surface is flat; dry environment, ventilation and no pollution are required at a solidification stage; and a coating formed by coating the paint has the advantages of uniformity, compact structure and good conduction performance and has superior corrosion resistance performance.

Owner:XI AN JIAOTONG UNIV +1

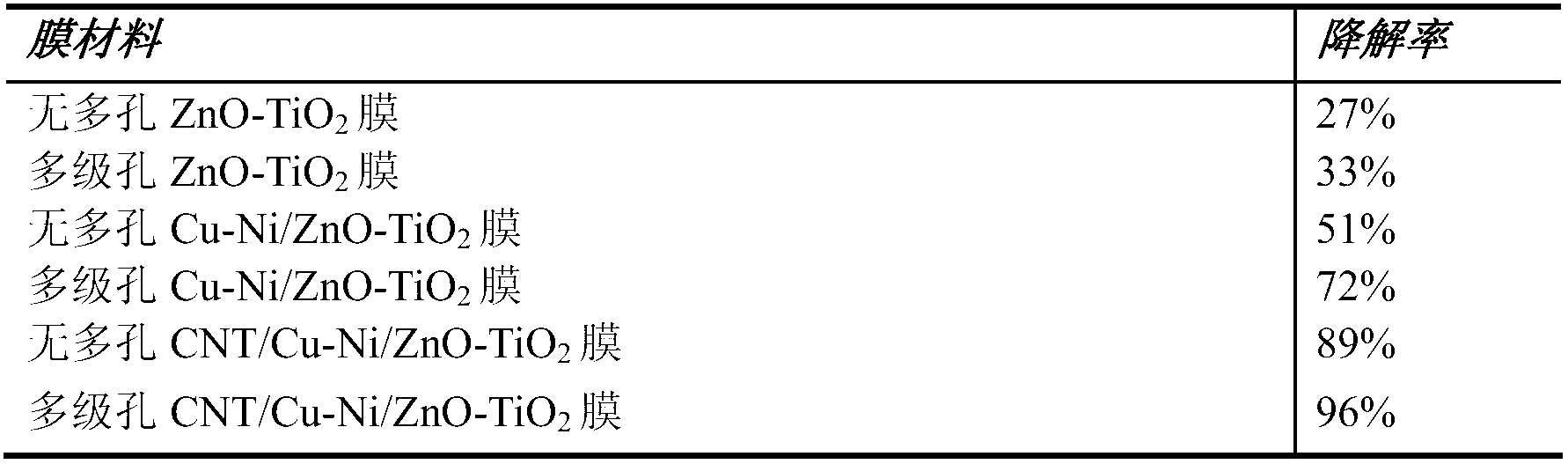

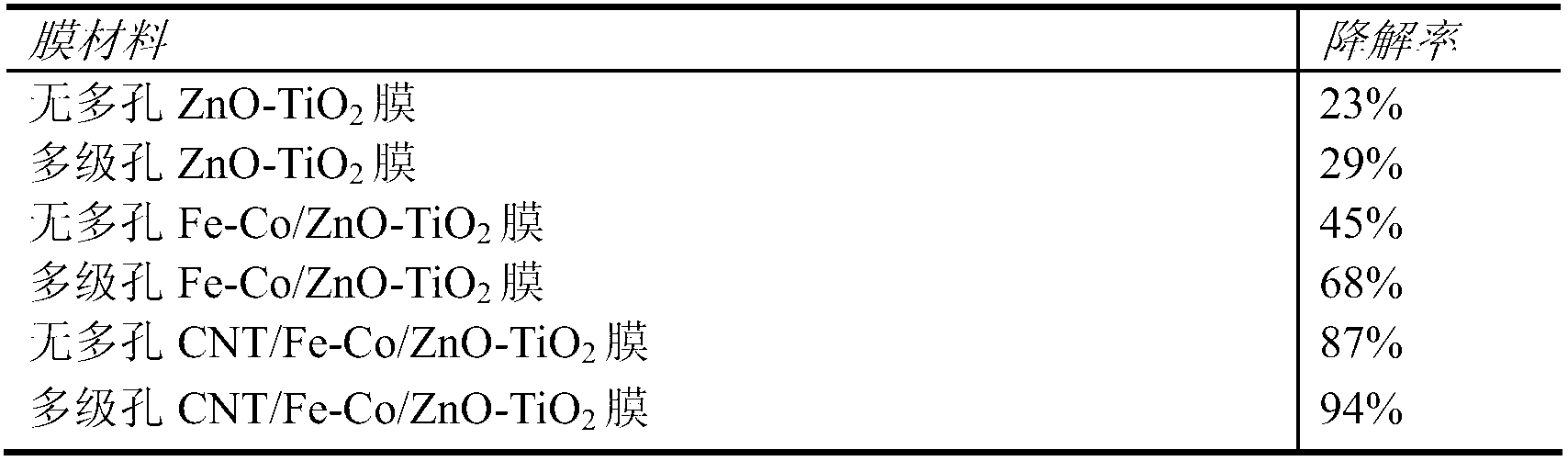

Composite photocatalyst membrane material with hierarchical pore structure and preparation method thereof

InactiveCN103055873ALarge specific surface areaImprove adsorption and enrichmentWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsPolyethylene glycolCarbon nanotube

The invention relates to a composite photocatalyst membrane material with a hierarchical pore structure and a preparation method thereof. A basal body of the composite photocatalyst membrane material is a transition a metal-doped hierarchical porous TiO2 and ZnO compound semiconductor membrane material membrane. The preparation method comprises the following steps: firstly preparing a TiO2 and ZnO compound photocatalyst precursor containing pore-forming agents P123, F127, PMMA (Polymethyl Methacrylate), PEG (Polyethylene Glycol), CTAB (Cetylt Trimethyl Ammonium Bromide) and transition metal Fe, Ni. Co, Mo, Cu, Pt, Au, Pd and Ag; then assembling the transition metal-modified ZnO / TiO2 hierarchical porous composite photocatalyst membrane material on FTO (Fluorinedoped Tin Oxide), ITO (Indium Tin Oxide) and Ni sheets and other carriers through a spray pyrolysis method, a dip-coating method, a spin-coating method, a silk-screen printing method, a doctor blade method and other coating methods; and finally, directly carrying out in-situ growth on a carbon nano tube on the composite photocatalyst membrane material through a chemical vapor deposition method. The hierarchical porous composite photocatalyst membrane material has the advantages of high photocatalytic activity, stable membrane binding, simple preparation process and easiness in industrialization realization.

Owner:EAST CHINA UNIV OF SCI & TECH +1

NURBS (Non-Uniform Rational B-Splines)-curved surface description-based five-axis linkage 3D printing method

InactiveCN107457995AAchieve preparationAdditive manufacturing apparatusManufacturing data aquisition/processingComputer graphics (images)3d printer

The invention discloses an NURBS (Non-Uniform Rational B-Splines)-curved surface description-based five-axis linkage 3D printing method which comprises the following calculating steps: 1, obtaining a basic surface curved surface equation of the bottom of a workpiece; 2, planning a printing route; 3, determining coordinates of all points on a curved surface; 4, determining coordinates of the top end of a printing head; and 5, determining rotational coordinates. According to the NURBS-curved surface description-based five-axis linkage 3D printing method provided by the invention, a curved surface function can be directly generated based on the curved surface of an object, and curved surface printing data are generated with a five-axis linkage 3D printer based on the curved surface function; one curved surface is printed for each layer; and the NURBS-curved surface description-based five-axis linkage 3D printing method is applicable to printing of complicated curved surfaces and objects of which printed parts having non-planar bottoms.

Owner:ANYANG INST OF TECH

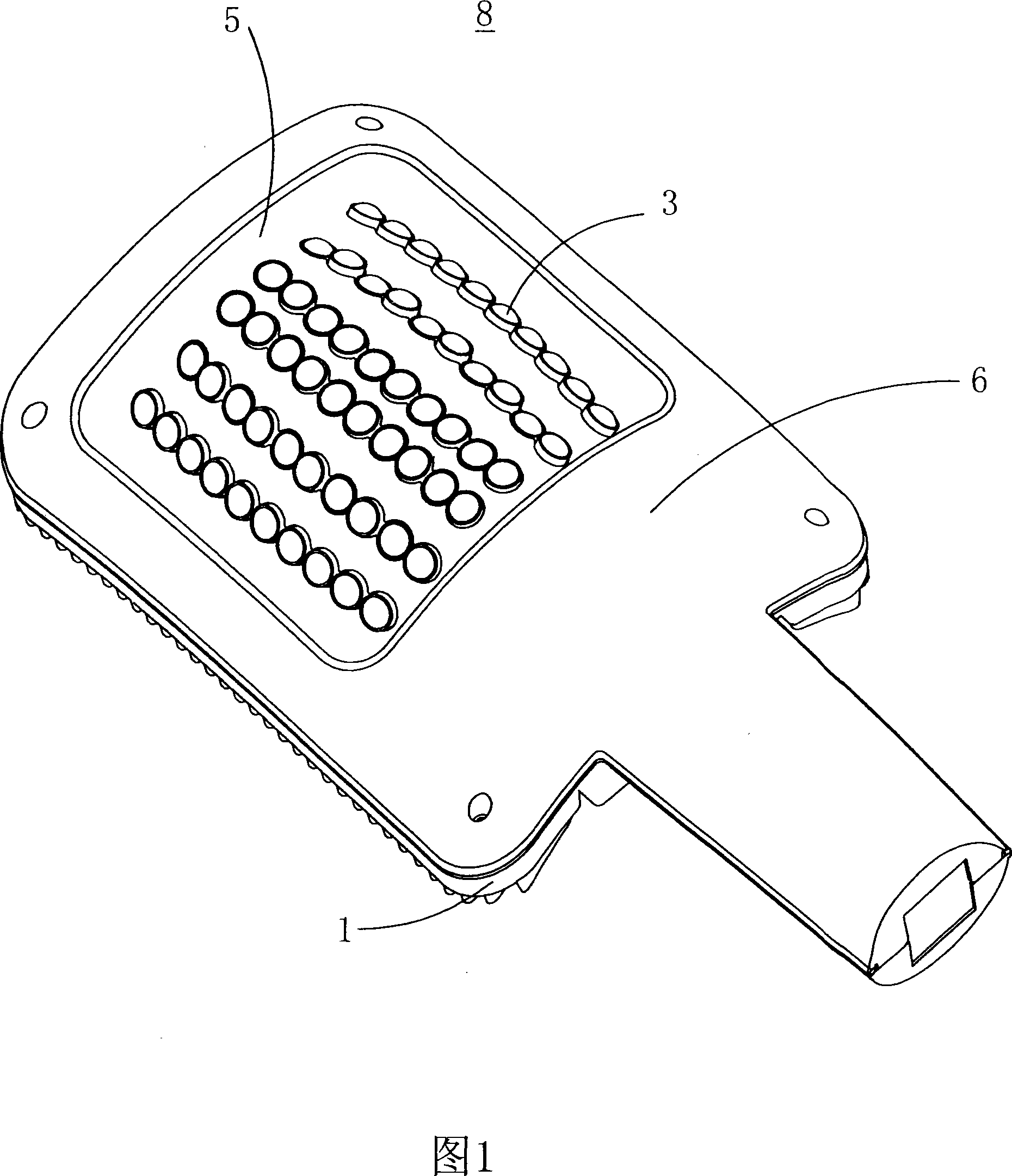

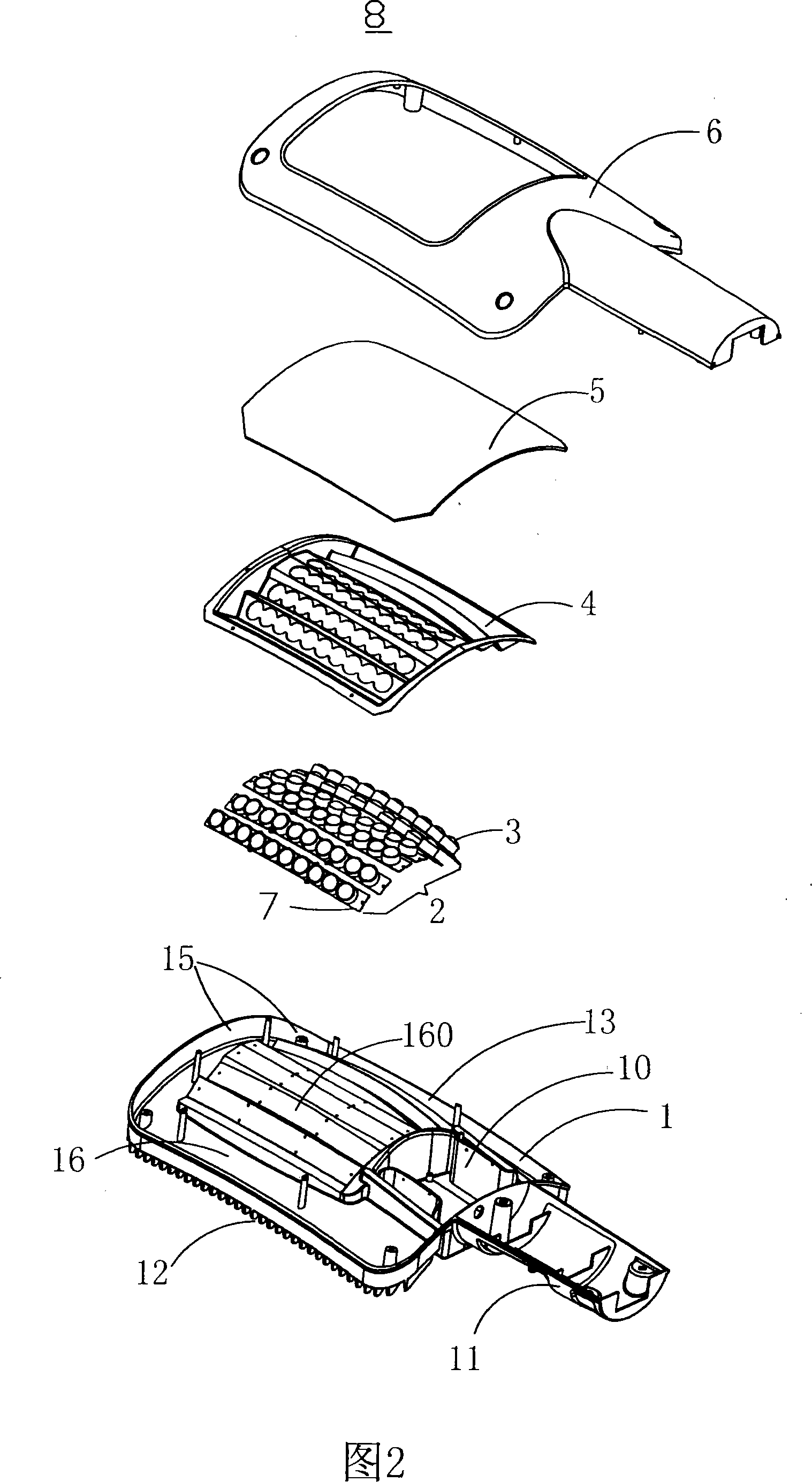

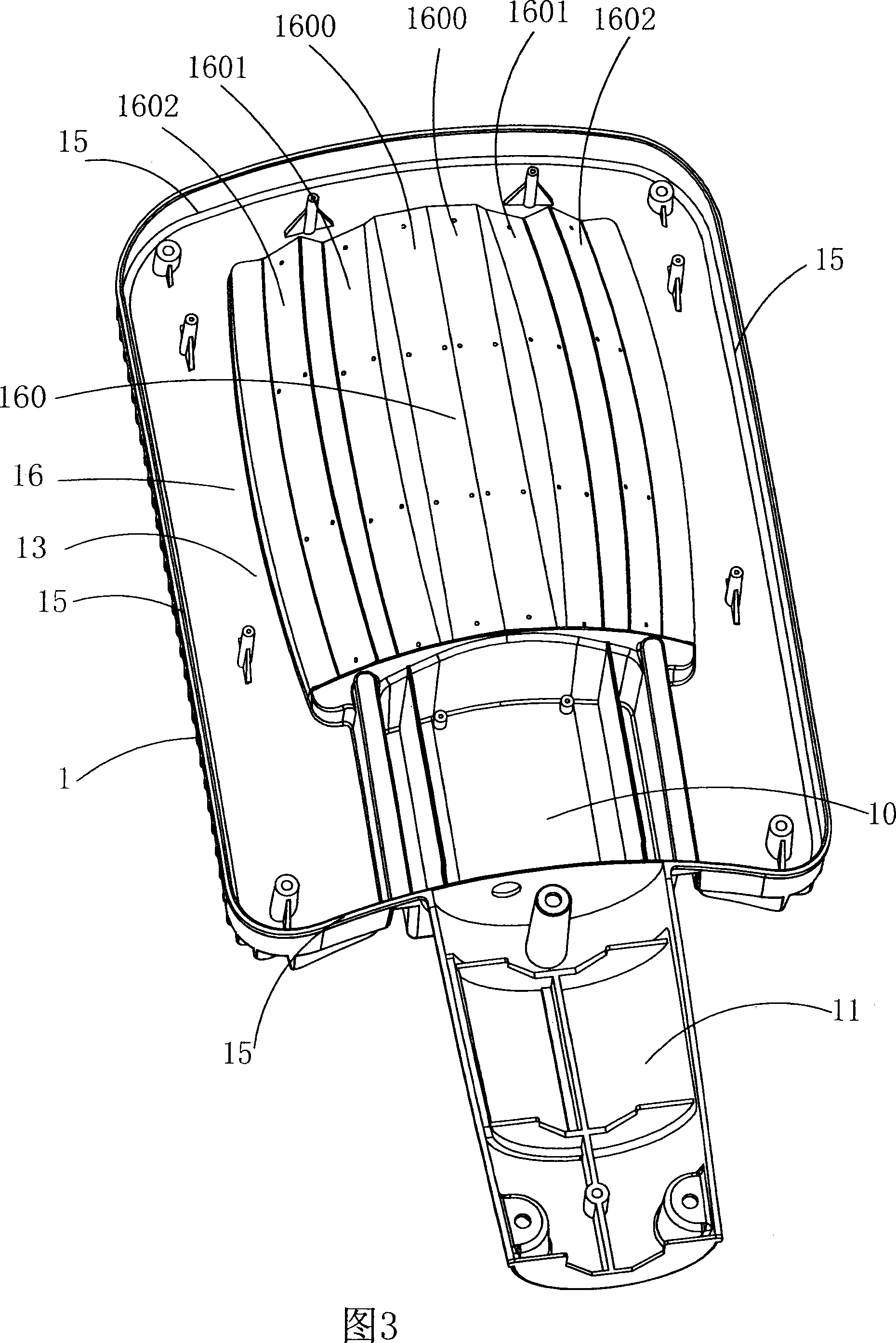

Large power LED road lamp

InactiveCN101101098AMeet lighting requirementsMechanical apparatusPoint-like light sourceEngineeringBasal body

The invention relates to high power LED street lamp. It includes shell, circuit board, LED, and lens unit. The LED and lens unit are set in circuit board to form many LED light source modules. The adjacent two are set in the basal body set many carrying surfaces formed by edge carrying surface. The included angle between LED emergence normal and the center plane of the basal body end surface is 45-60 degree.

Owner:NINGBO ANDY OPTOELECTRONIC CO LTD

Zr-position doped high conductivity proton conductor material for La2Zr2O7 basal body and preparing method thereof

InactiveCN101033078AImprove electrical performanceEasy to prepareNon-metal conductorsRare earth metal compoundsAdjuvantWater vapor

This invention discloses a proton conductor material of high electric conductance of La2Zr2O7matrix doped at Zr bit and its preparation method, in which, the molecular structure of the material is: La2Zr2-xMxO7-delta, and M is Yb3+, Er3+, Gd3+ or Sc3+, x is 0.01-1, delta is x / 2. The preparation process includes: taking La2O3, ZrO2 and Yb2O3 or Er2O3, Gd2O3 or Sc2O3 as the raw materials to match with them according to the mol ratio of each material in terms of the molecular formula and adds dispersant in light of the mass percentage of the adjuvant then to ball-mill and mix them with the adjuvant with water or alcohol as the medium to be dried to get powder to be milled, dried, screened, synthesized and heat-preserved to get the material, which is ball-milled and pressed to be sintered in 1400-1650deg.C and cooled to the room temperature to get the material.

Owner:TIANJIN UNIV

Magnetism-absorbing coating and preparation method thereof

InactiveCN101538437ALow costWaterproofAntifouling/underwater paintsUnspecified rubber coatingsEmulsionFerromagnetism

The invention relates to a magnetism-absorbing coating and a preparation method thereof. The magnetism-absorbing coating comprises 20-70 percent of emulsion, 10-80 percent of ferromagnetic powder of non-magnetite powder and non-iron scurf powder, 0.1-10 percent of preservative and rest percent of water which are all mixed uniformly according to a certain proportion. The coating has no original magnetism, does not influence peripheral electronic products, but utilizes the ferromagnetic powder or a ferromagnetic compound to be diffused to an aqueous or unctuous coating basal body coated on a wall body, and the coating basal body is coated on the surface of an object or the wall body to generate a large-area magnetism-absorbing surface so that blueprints, pictures or notices, and the like can be hung on the wall by stationery magnets. The coating has extremely wide applications, can be coated on the surfaces of glass, wood, wall bodies, cloth, ceramics, plastics, paper, and the like to generate the magnetism-absorbing surfaces and facilitate the suspension of notes, catalogues, and the like. The invention also has the waterproof function and can be applied outdoors.

Owner:张治君

Method for preparing antimicrobial material using nano calcium carbonate as substrate

InactiveCN101480194AImprove antibacterial propertiesHigh antibacterial materialBiocideFungicidesPhosphatePhosphoric acid

The invention relates to a method for preparing an antibacterial material by using nanometer calcium carbonate as a basal boy, which belongs to the field of biocide containing inorganic compounds. The method comprises the following steps: a dispersant is added to Ca(OH)2 slurry and is carbonized by pumping CO2 to prepare the slurry of the nanometer calcium carbonate basal body; titanium salt or / and zinc salt, silver salt and phosphate or phosphoric acid are mainly added to the slurry, or silicate is also added to the slurry; after 1 to 4 hours of reaction of the slurry, the slurry is sucked, filtered and dried so as to obtain the antibacterial material using the nanometer calcium carbonate as the basal boy. The method has lower cost, simple technology and low energy consumption, and the prepared antibacterial material product has higher antibacterial performance, higher whiteness and wide range of application.

Owner:HEBEI UNIV OF TECH

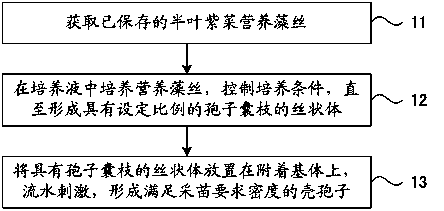

Semi-leaf laver seedling cultivating method

ActiveCN103798123ARapid seedlingEfficient seedling cultivationCultivating equipmentsSeaweed cultivationCulture fluidPorphyra

The invention discloses a semi-leaf laver seedling cultivating method. The method includes the following steps that semi-leaf laver nutritious trichome is obtained; the semi-leaf laver nutritious trichome is cultivated in nutritious liquid until a protonema of a sporangium branch with the set proportion is formed and the cultivating conditions include that the temperature ranges from 20 DEG C and 30 DEG C, the light intensity ranges from 1000 lx and 2600 lx, the lighting period is 10 hours to 16 hours and the nutritious liquid sea water ratio ranges from 1.026 to 1.031. The protonema of the sporangium branch with the set proportion is placed on an attachment basal body and stimulated by water currents until conchospores of which the density reaches the seedling collecting requirement are formed and seedling cultivating of the semi-leaf laver is finished. Thus, the problem that the seedlings of the semi-leaf laver can not be rapidly and efficiently cultivated with the prior art is solved.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Basal body for composite structure hard alloy

The invention discloses a carbide alloy base body taking TiC- WC or WC as hard phase and used for continuous interface composite construction. It comprises hard phase and adhesive phase, said hard phase is TiC- WC or WC, and said adhesive phase is Ni compound. The base body is added with part of WC-Co- containing prelacy powder made from regenerative hard alloy to reuse W and Co, and base body is added with a large part of hard phase (TiC) and Ni compound to reduce W and Co consumption, the adhesive phase Ni compound combines with adhesive phase Co through intermolecular linkage to make the composite interface transite continuously without foreign matter generation, no slit and carbon elimination, gash and stratification. So the carbide alloy base body is characterized by wide application and good comprehensive performance, which is the same to that of normal single layer hard alloy.

Owner:自贡市天恒合金应用技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com