Soluble carbon nanometer pipe absocped with polyelectrolyte on surface and its preparation method

A carbon nanotube and polyelectrolyte technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of inability to large-scale production, many steps, cumbersome preparation, etc., to improve processability, easy operation, wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

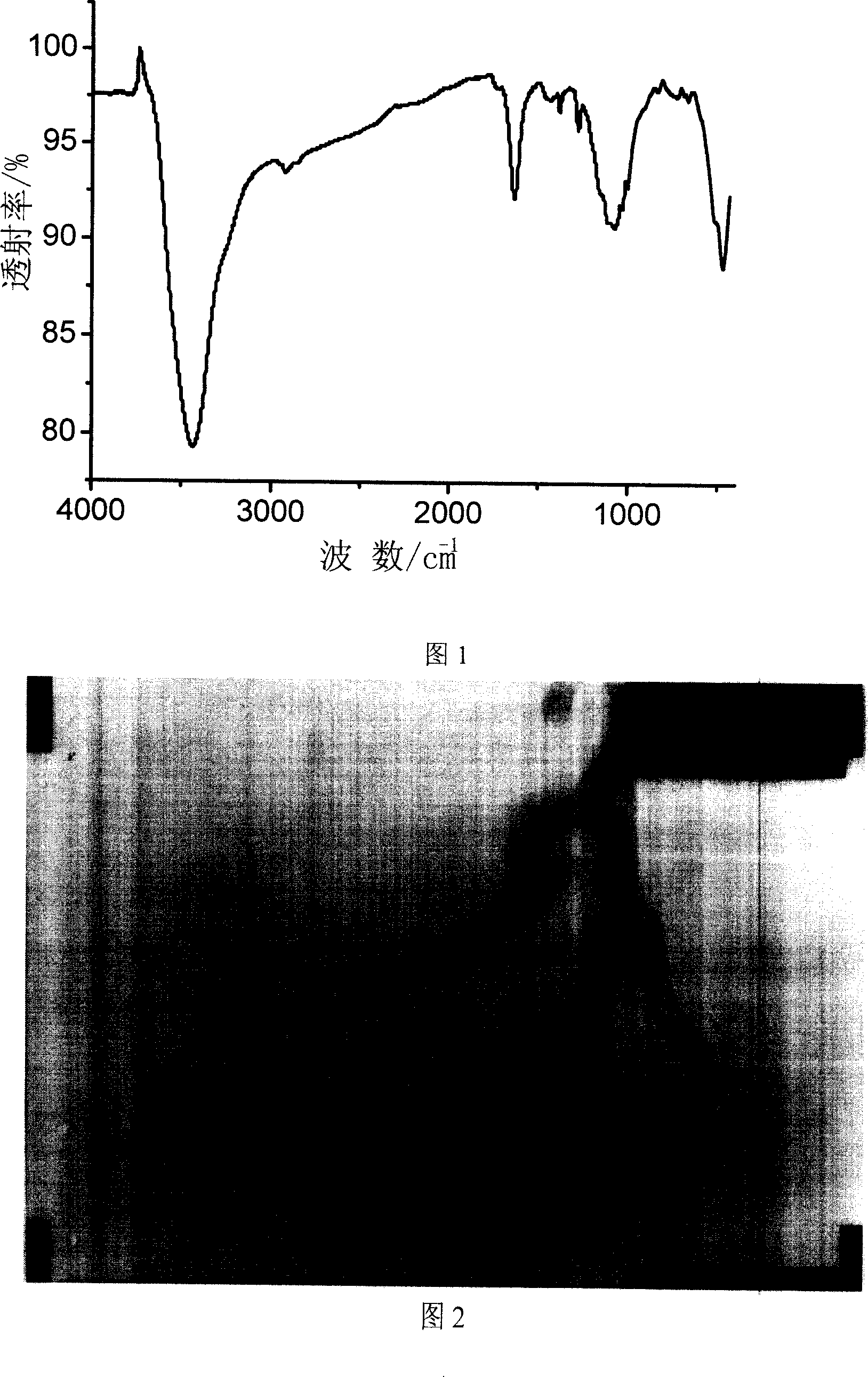

Image

Examples

Embodiment 1

[0028] In the following examples, the carbon nanotubes are prepared by the method disclosed in the literature (Appl. Phys. Lett., 1995, 67(17), 2477-2479.).

[0029] Step (1): Add 200ml of fuming sulfuric acid (20%, weight) and 2g of carbon nanotube raw materials in a 500ml Erlenmeyer flask, use 40kHz ultrasonic treatment for 18hr, filter with 0.22μm organic microporous membrane, use deionized Repeated washing with water several times to neutrality, and vacuum drying at 90°C for 24 hours to obtain acidified carbon nanotubes;

[0030] Step (2): Take 0.5g of the acidified carbon nanotubes obtained in step (1), put them into an 800ml beaker, add 250ml of deionized water, and after 40kHz ultrasonic treatment for 0.5hr, add 250ml of 2mg / ml polydiallyldimethyl Ammonium chloride (PDDA) sodium chloride aqueous solution, wherein the concentration of sodium chloride is 1mg / ml, after the mixed solution is treated in 40kHz ultrasonic wave for 15min, it is suction filtered with a 0.22μm ...

Embodiment 2

[0036] Adopt the same method of embodiment 1, wherein:

[0037]Acid is the sulfuric acid that weight concentration is 98%;

[0038] The cationic polyelectrolyte is protamine, the anionic polyelectrolyte is a mixture of dextran and sodium polystyrene sulfonate (1:1, mass ratio), and the salt is CaCl 2 ;

[0039] The concentrations of the various substances are:

[0040] Protamine (PRM) 1mg / ml; Dextran (DXS) 0.5mg / ml; Polystyrene Sodium Sulfonate (PSS) 0.5mg / ml; CaCl 2 0.5mg / ml.

[0041] The water dispersion test is also used for detection, and its water solubility is as follows: the carbon nanotubes adsorbed with multilayer polyelectrolytes are kept for more than 5 days without sedimentation.

[0042] The test results show that the water solubility of the carbon nanotubes is greatly improved, thereby improving the processability of the carbon nanotubes, and can be used as an added component of a water-soluble organic matrix.

Embodiment 3

[0044] Adopt the same method of embodiment 1, wherein:

[0045] Acid is the mixed acid (1:3, volume ratio) that the sulfuric acid of 98% and the concentrated nitric acid of 96% are the weight concentration;

[0046] The cationic polyelectrolyte is polyallyl ammonium chloride, the anionic polyelectrolyte is sodium polyacrylate, the salt is KCl,

[0047] The concentrations of the various substances are:

[0048] Polyallyl ammonium chloride (PAH) 1mg / ml; Sodium polyacrylate (PAA) 1mg / ml; KCl 1mg / ml.

[0049] The water dispersion test was also used to detect the water solubility, and its water solubility was as follows: the carbon nanotubes adsorbed with multi-layer polyelectrolytes remained without sedimentation for more than 7 days.

[0050] The test results show that the water solubility of the carbon nanotubes is greatly improved, thereby improving the processability of the carbon nanotubes, and can be used as an added component of a water-soluble organic matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com