Patents

Literature

225 results about "Electrolyte leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte leakage (EL) is a useful parameter to measure cell membrane damage [58, 64]; however, this parameter is influenced by plant and leaf age as well as leaf position on the plant [64] [65] [66] [67]. Hence, in both experiments the measurements were conducted at the same seedling age...

Plating apparatus and method

InactiveUS20020008036A1Strong Gap Filling CapabilityReduce stressCellsSemiconductor/solid-state device manufacturingElectrolyte leakageEngineering

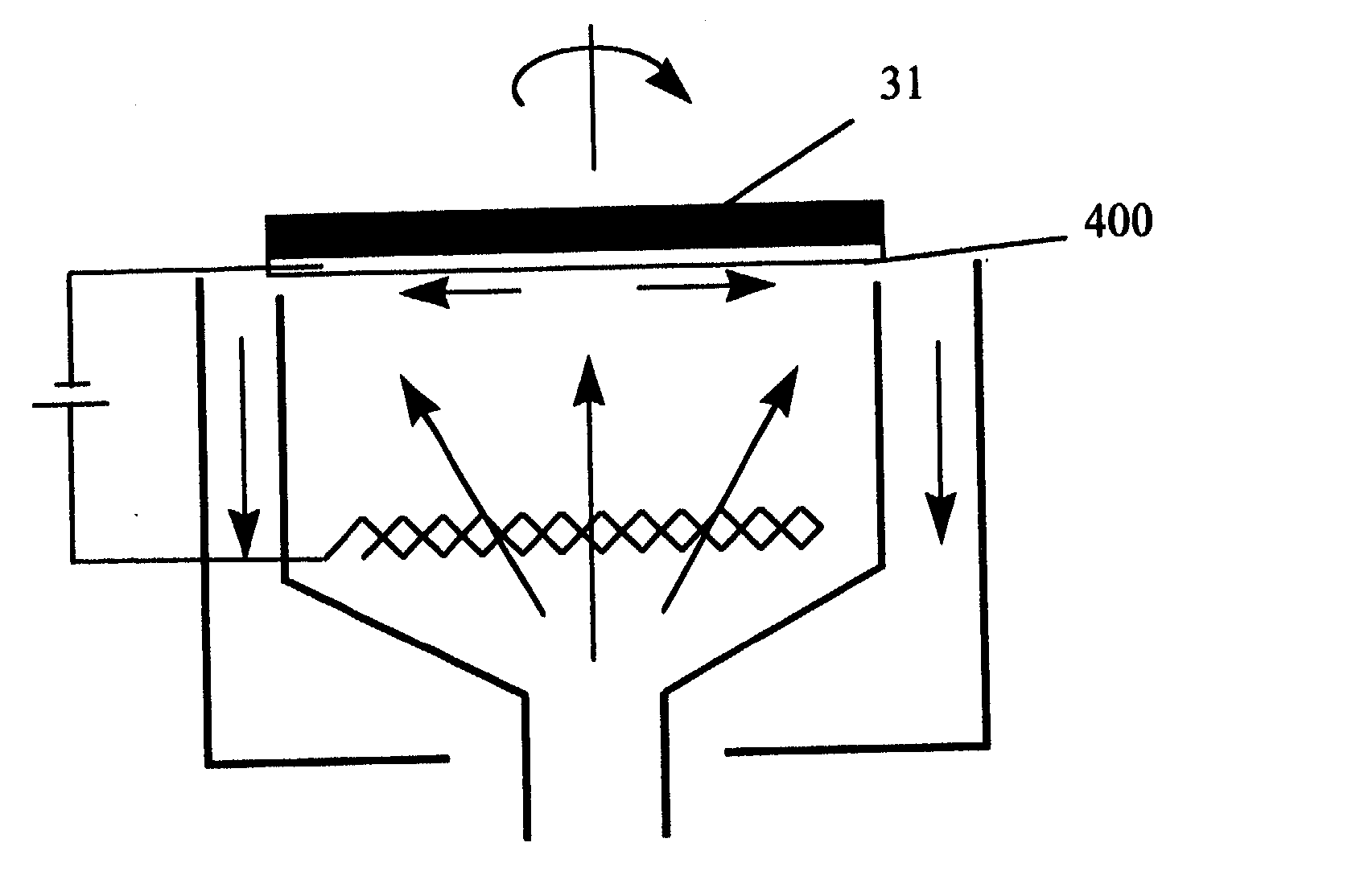

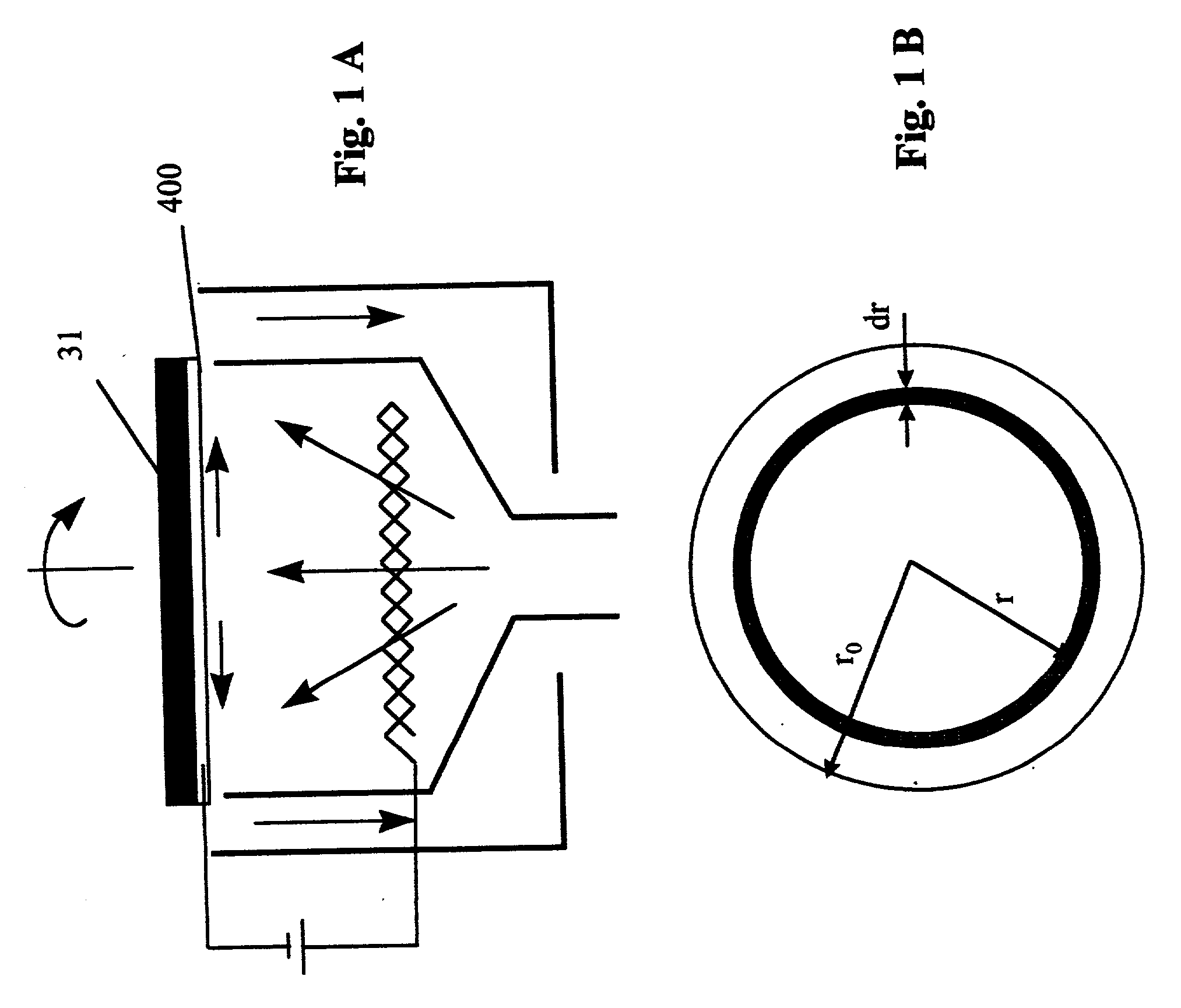

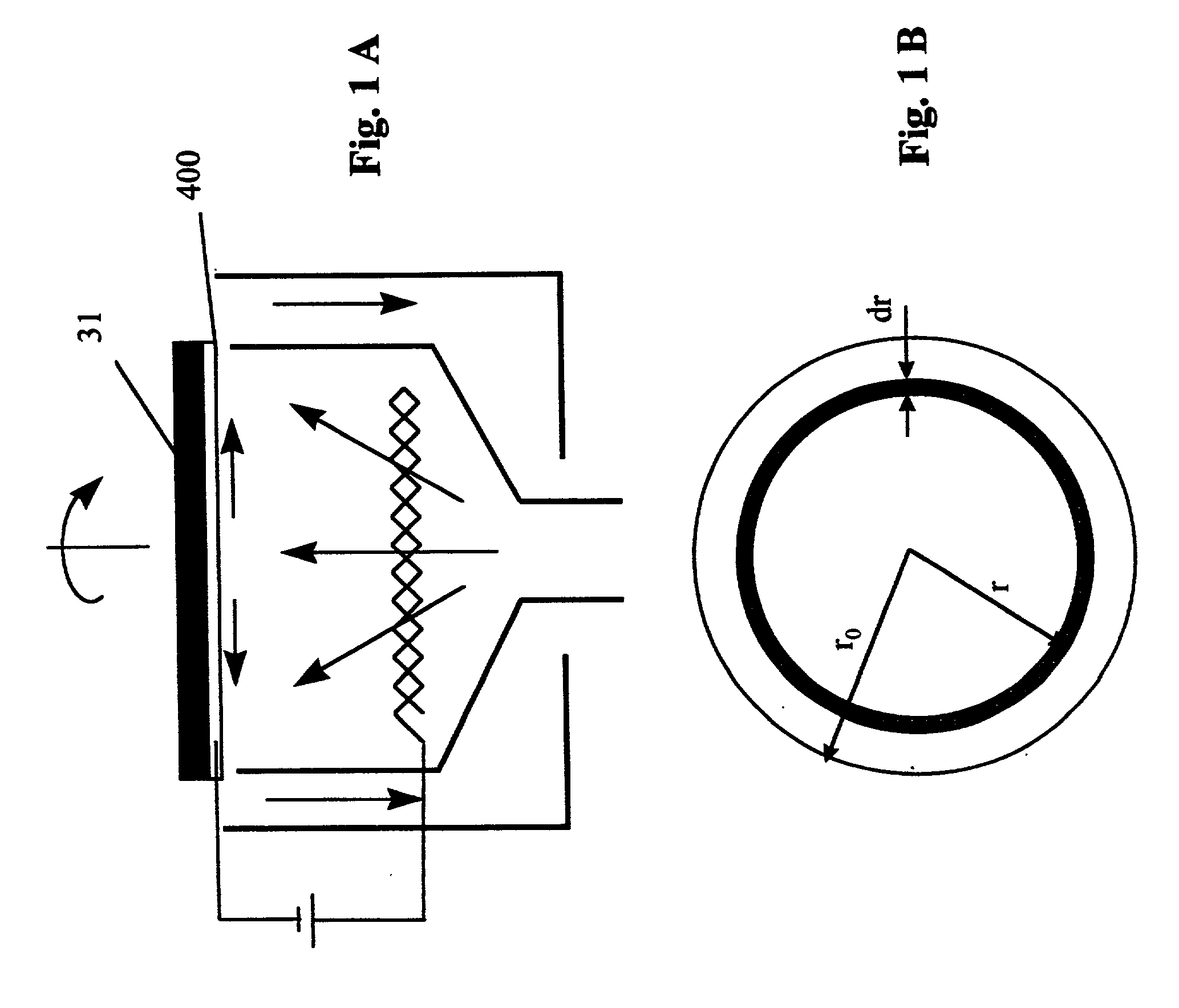

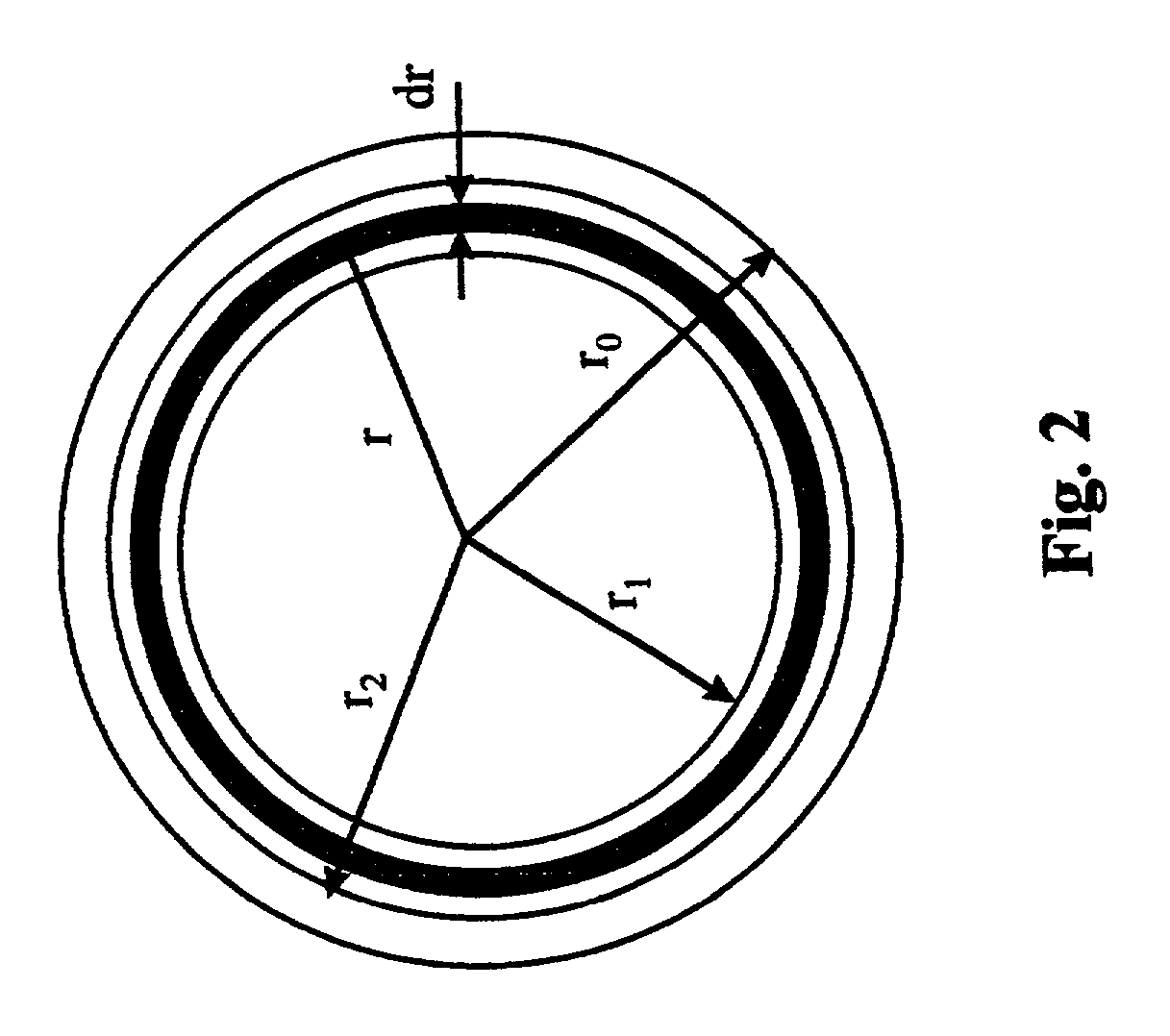

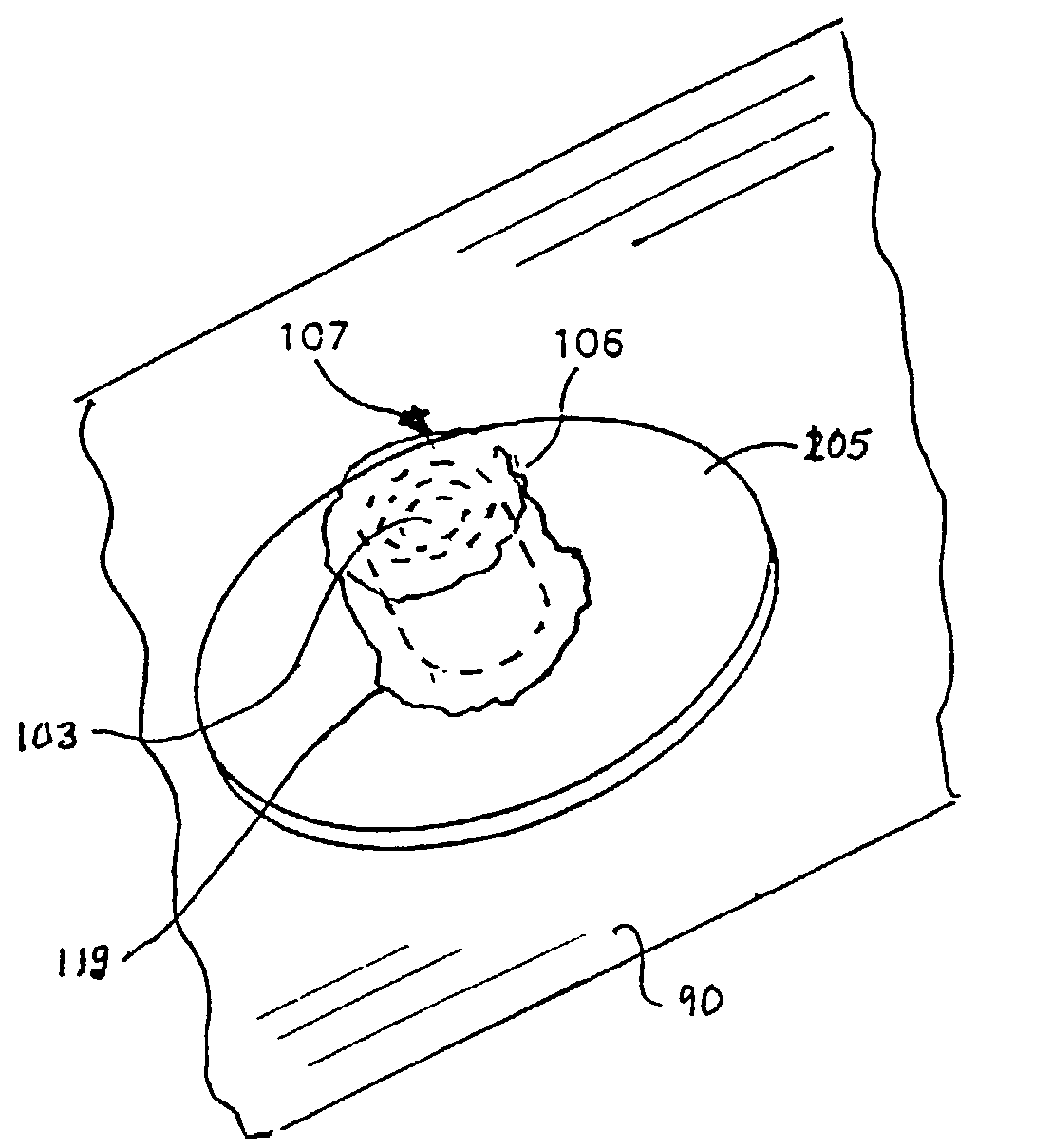

An apparatus for plating a conductive film directly on a substrate with a barrier layer on top includes anode rod (1) placed in tube (109), and anode rings (2), and (3) placed between cylindrical walls (107) and (105), (103) and (101), respectively. Anodes (1), (2), and (3) are powered by power supplies (13), (12), and (11), respectively. Electrolyte (34) is pumped by pump (33) to pass through filter (32) and reach inlets of liquid mass flow controllers (LMFCs) (21), (22), and (23). Then LMFCs (21), (22) and (23) deliver electrolyte at a set flow rate to sub-plating baths containing anodes (3), (2) and (1), respectively. After flowing through the gap between wafer (31) and the top of the cylindrical walls (101), (103), (105), (107) and (109), electrolyte flows back to tank (36) through spaces between cylindrical walls (100) and (101), (103) and (105), and (107) and (109), respectively. A pressure leak valve (38) is placed between the outlet of pump (33) and electrolyte tank (36) to leak electrolyte back to tank (36) when LMFCs (21), (22), (23) are closed. A wafer (31) held by wafer chuck (29) is connected to power supplies (11), (12) and (13). A drive mechanism (30) is used to rotate wafer (31) around the z axis, and oscillate the wafer in the x, y, and z directions shown. Filter (32) filters particles larger than 0.1 or 0.2 mum in order to obtain a low particle added plating process.

Owner:ACM RES

Plating apparatus and method

InactiveUS20010040100A1Uniform thicknessStrong Gap Filling CapabilityCellsSemiconductor/solid-state device manufacturingElectrolyte leakageEngineering

An apparatus for plating a conductive film directly on a substrate with a barrier layer on top includes anode rod (1) placed in tube (109), and anode rings (2), and (3) placed between cylindrical walls (107) and (105), (103) and (101), respectively. Anodes (1), (2), and (3) are powered by power supplies (13), (12), and (11), respectively. Electrolyte (34) is pumped by pump (33) to pass through filter (32) and reach inlets of liquid mass flow controllers (LMFCs) (21), (22), and (23). Then LMFCs (21), (22) and (23) deliver electrolyte at a set flow rate to sub-plating baths containing anodes (3), (2) and (1), respectively. After flowing through the gap between wafer (31) and the top of the cylindrical walls (101), (103), (105), (107) and (109), electrolyte flows back to tank (36) through spaces between cylindrical walls (100) and (101), (103) and (105), and (107) and (109), respectively. A pressure leak valve (38) is placed between the outlet of pump (33) and electrolyte tank (36) to leak electrolyte back to tank (36) when LMFCs (21), (22), (23) are closed. A wafer (31) held by wafer chuck (29) is connected to power supplies (11), (12) and (13). A drive mechanism (30) is used to rotate wafer (31) around the z axis, and oscillate the wafer in the x, y, and z directions shown. Filter (32) filters particles larger than 0.1 or 0.2 mum in order to obtain a low particle added plating process.

Owner:ACM RES

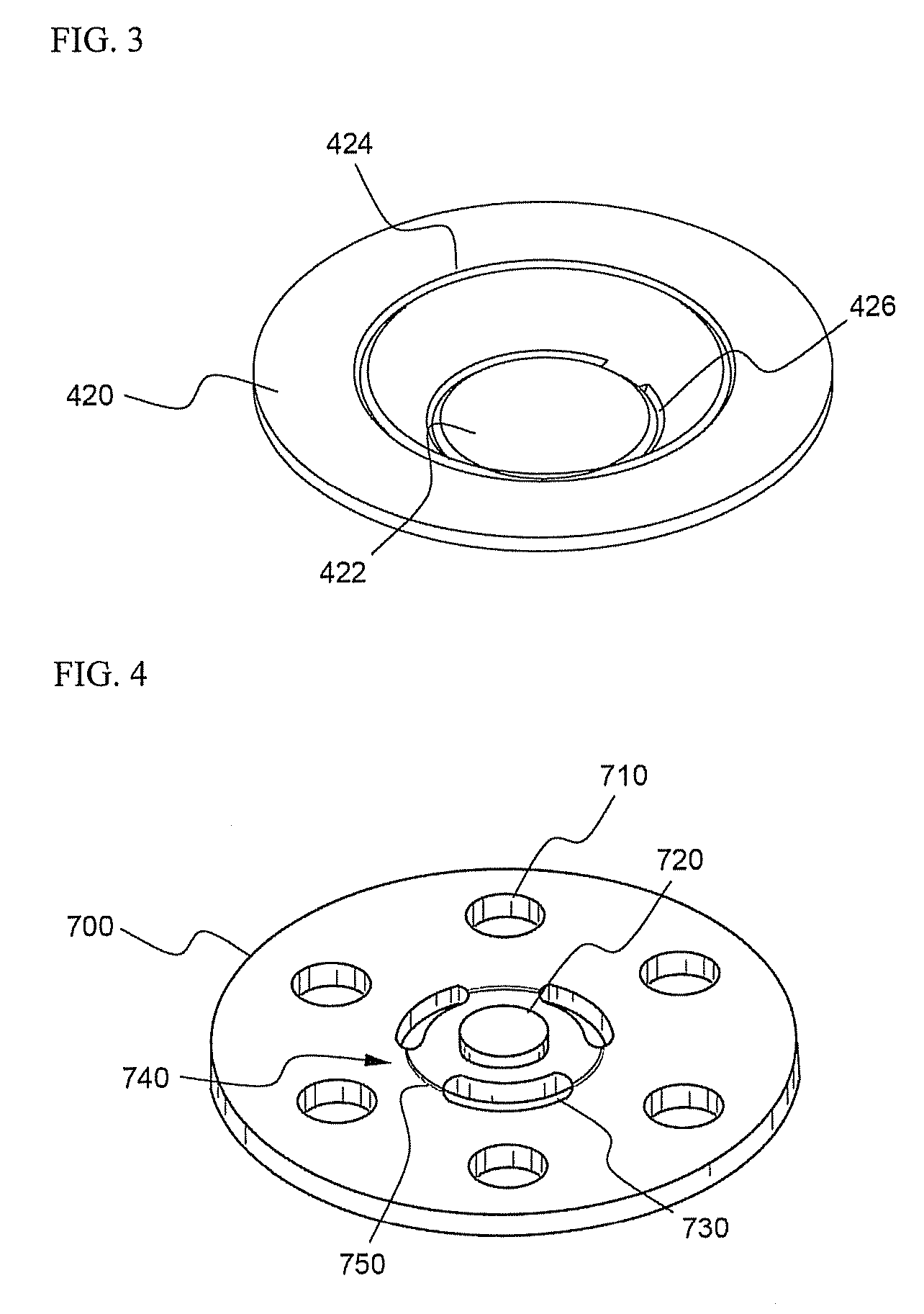

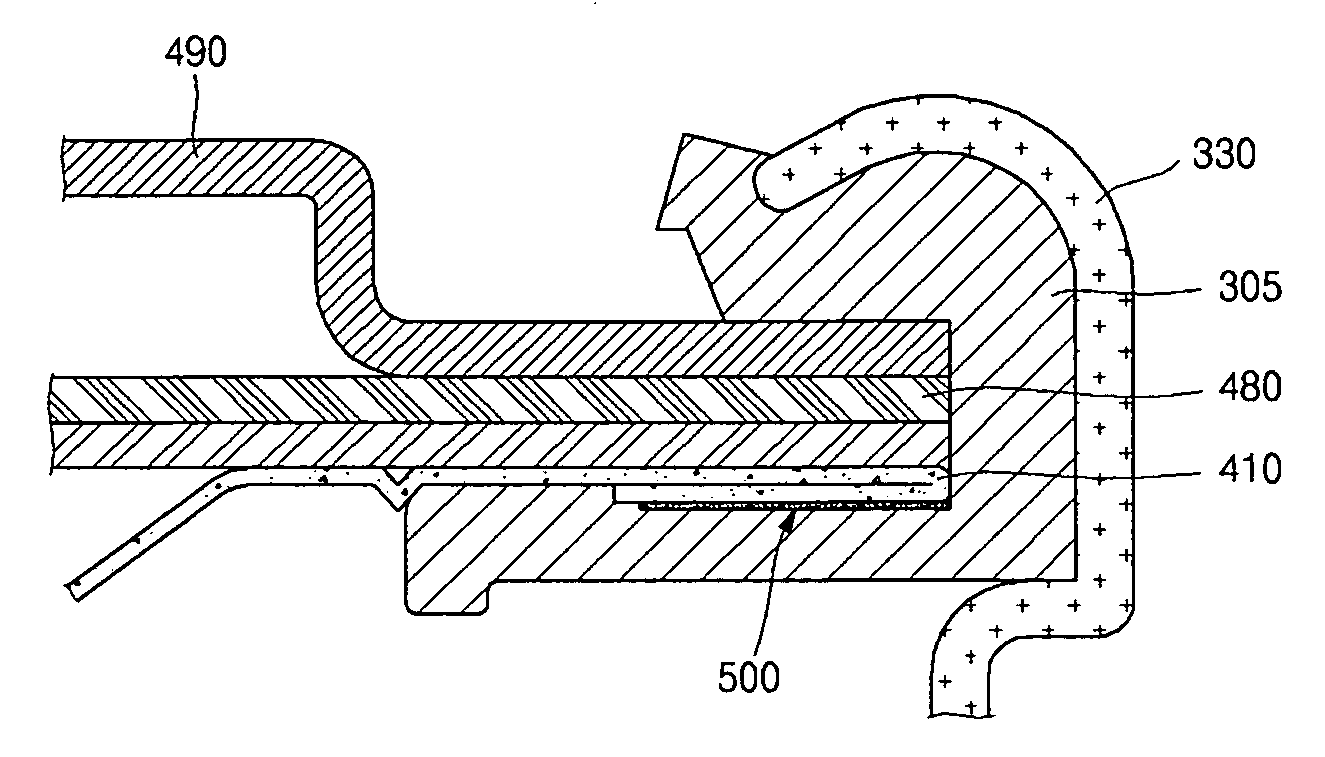

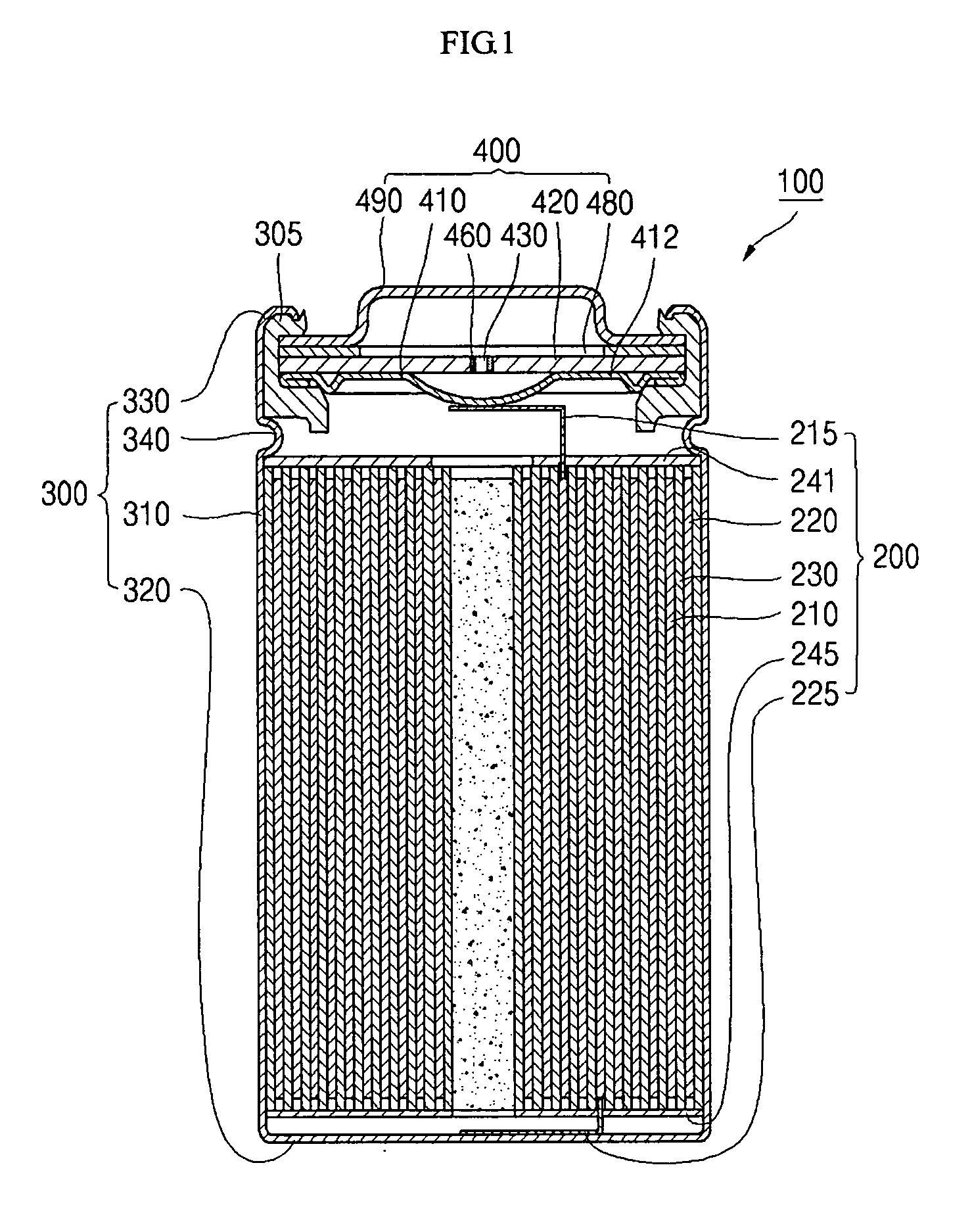

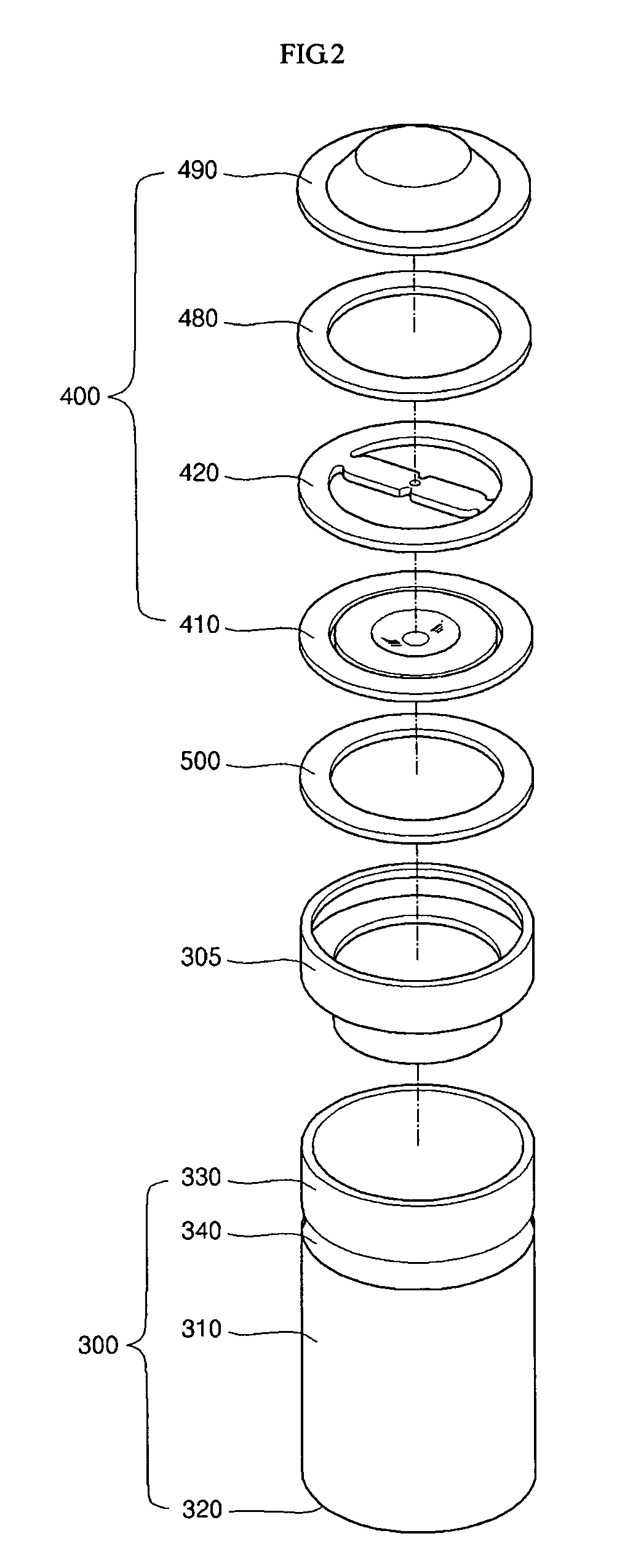

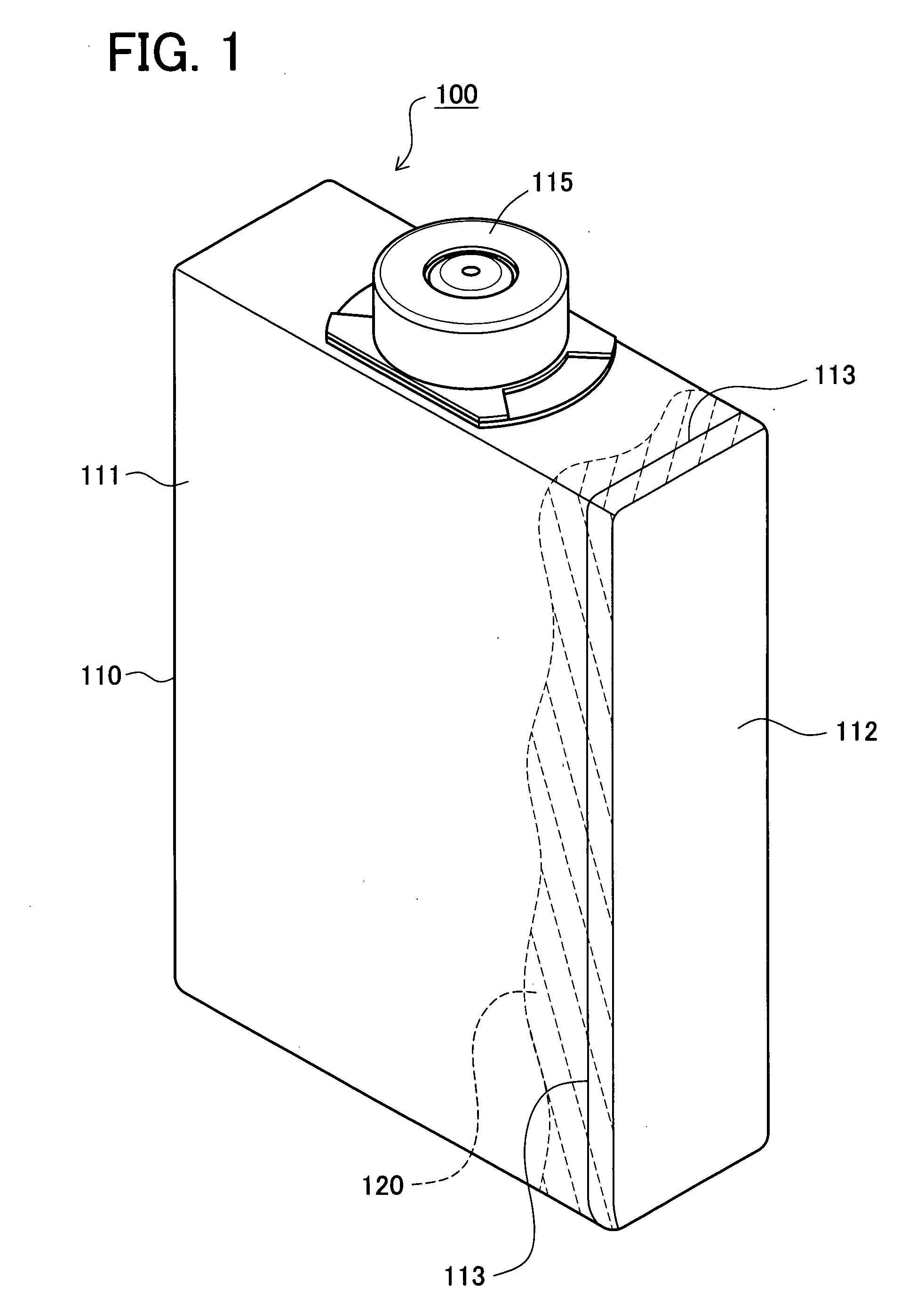

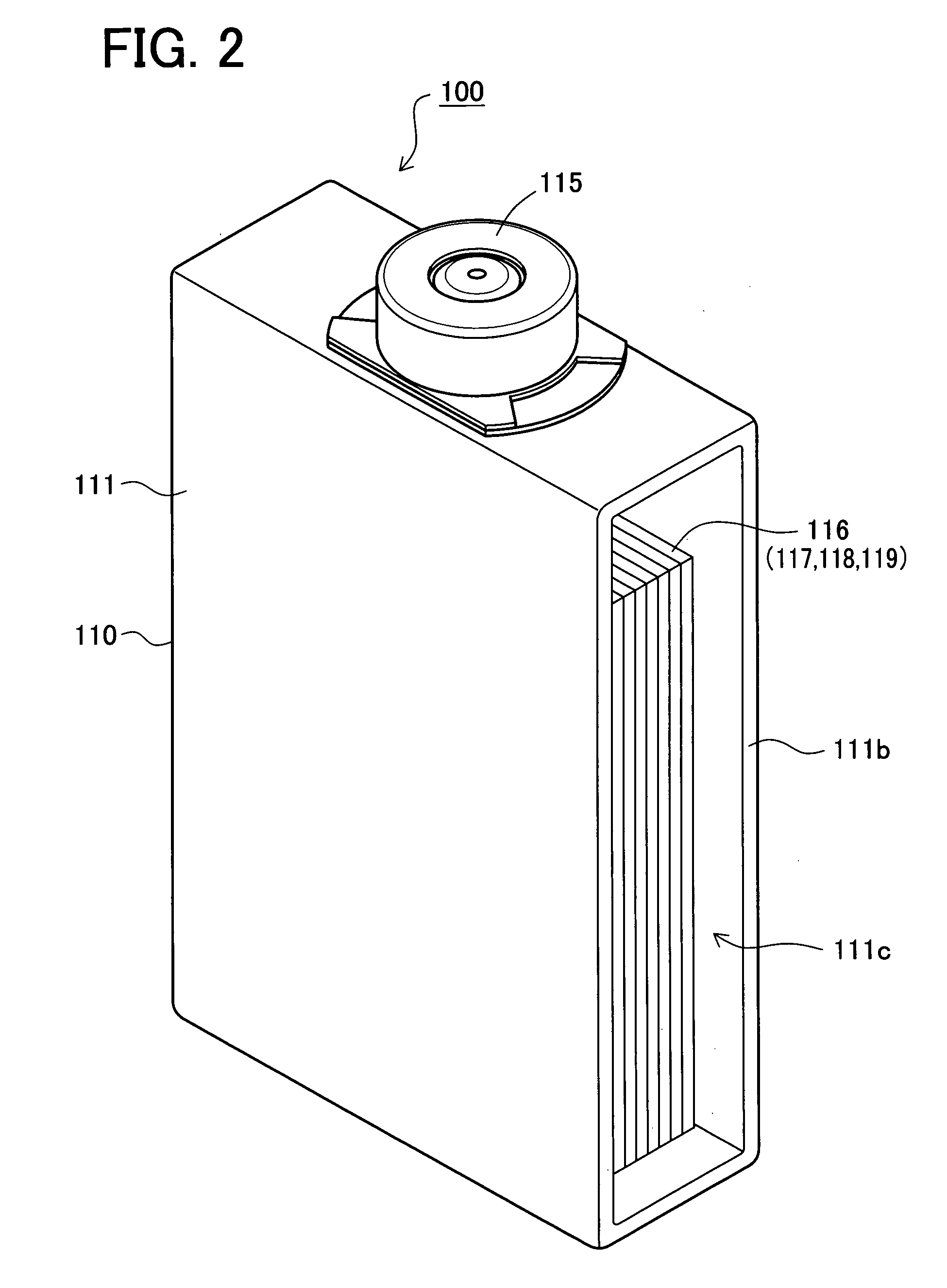

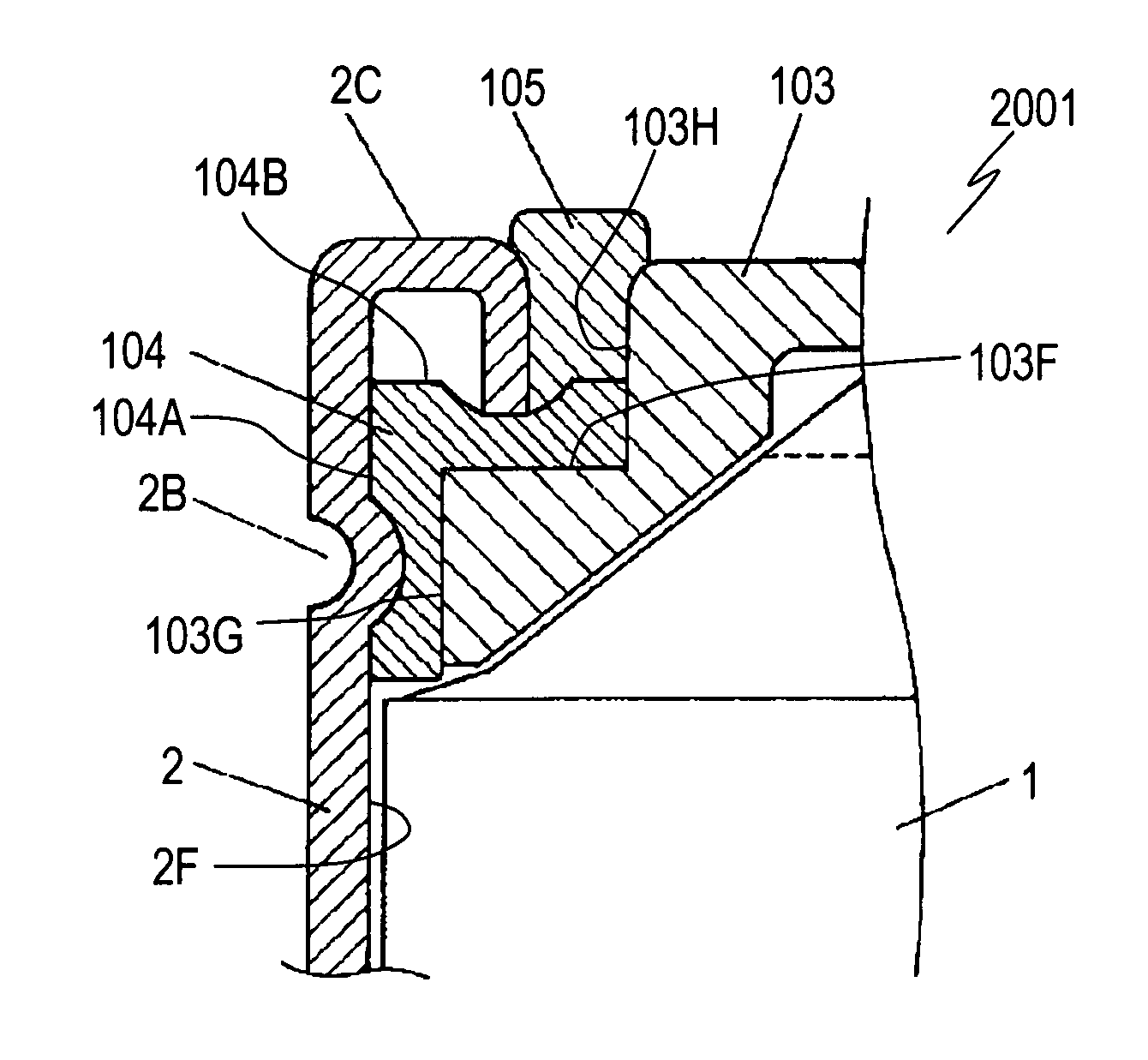

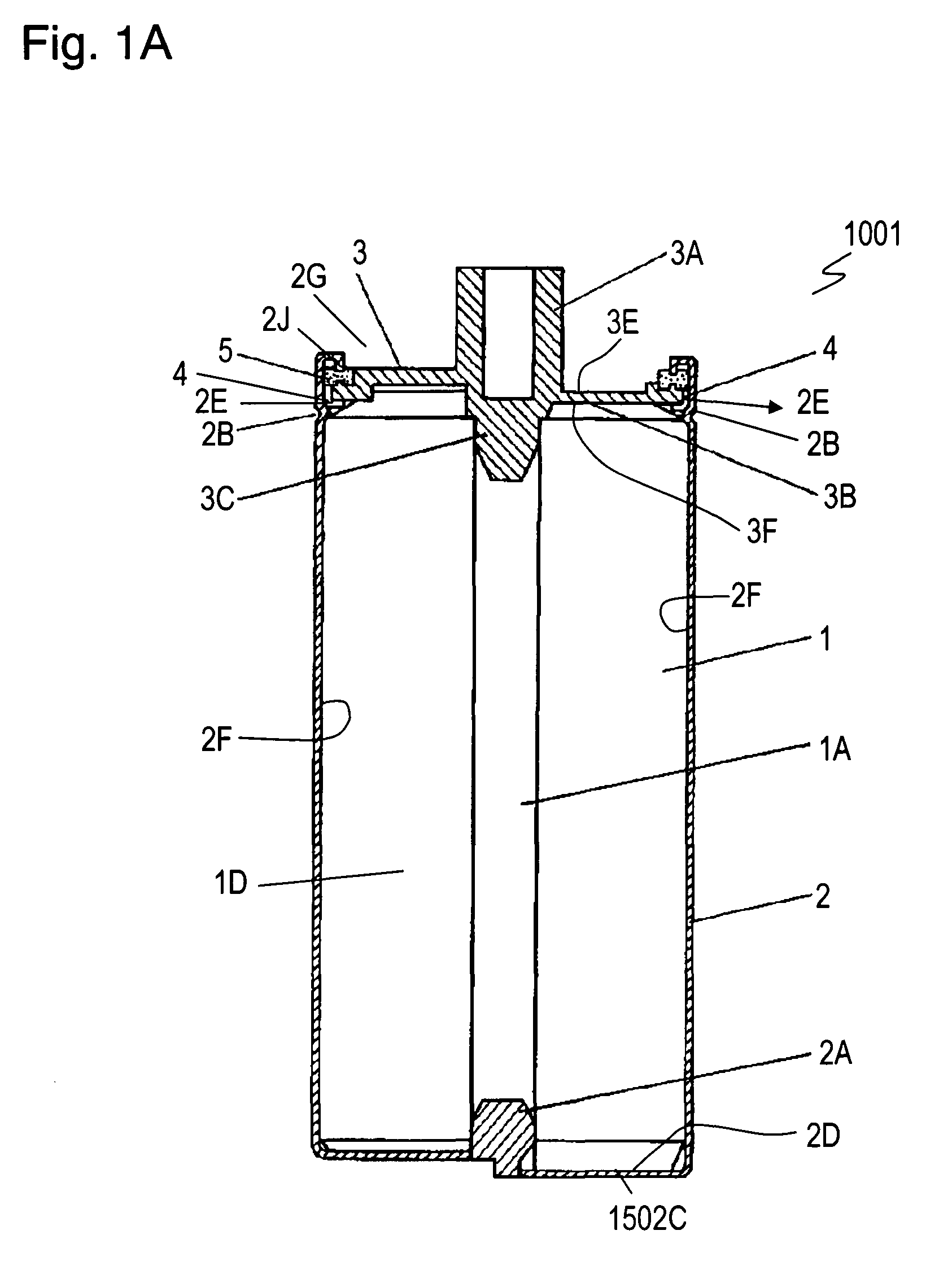

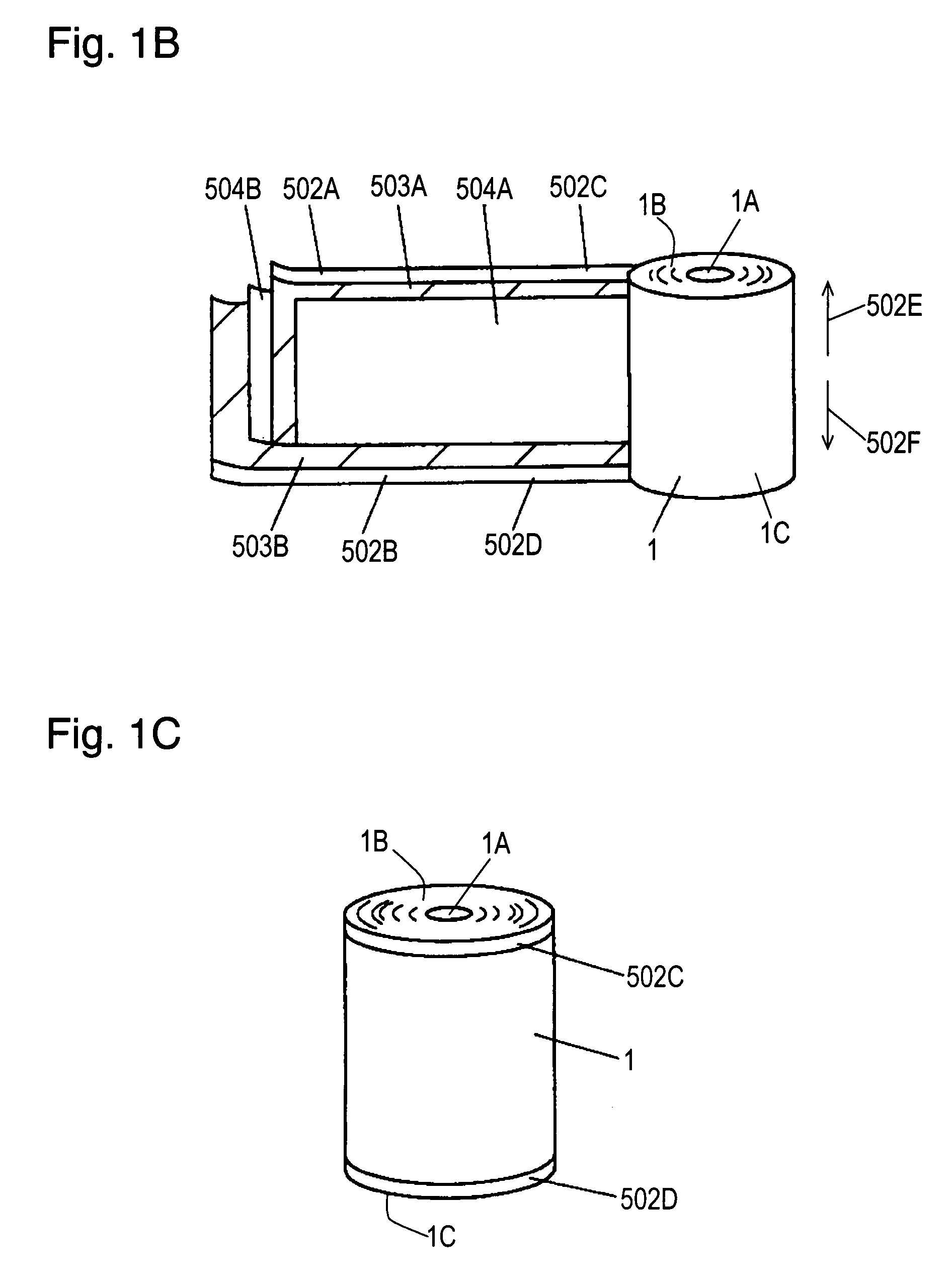

High rate charging and discharging cylindrical secondary battery

ActiveUS20070212595A1Significant stressBreakage of partFinal product manufactureVent arrangementsElectrolyte leakageInternal pressure

Disclosed herein is a cylindrical secondary battery including a cap assembly constructed in a structure in which a vent, which intercepts electric current and discharges pressurized gas when the interior pressure of the battery is increased due to abnormal operation of the battery, is in contact with a top cap having a protruding central part, wherein the end of the vent is bent to surround the outer circumferential surface of the top cap, and a groove for preventing the leakage of an electrolyte and preventing the occurrence of defectiveness of the battery during the assembly of the battery is formed at interfaces between the vent and the top cap such that the groove is arranged in parallel with the outer circumferential surface of the top cap. The secondary battery according to the present invention has the effect of accomplishing high charging and discharging rate, providing uniform output even when external physical impacts, such as vibration or dropping, are applied to the secondary battery, and preventing the occurrence of defectiveness during the assembly of the secondary battery. Furthermore, the leakage of the electrolyte out of the battery is restrained under these conditions. Consequently, the secondary battery according to the present invention can be preferably used as a high-output power source.

Owner:LG ENERGY SOLUTION LTD

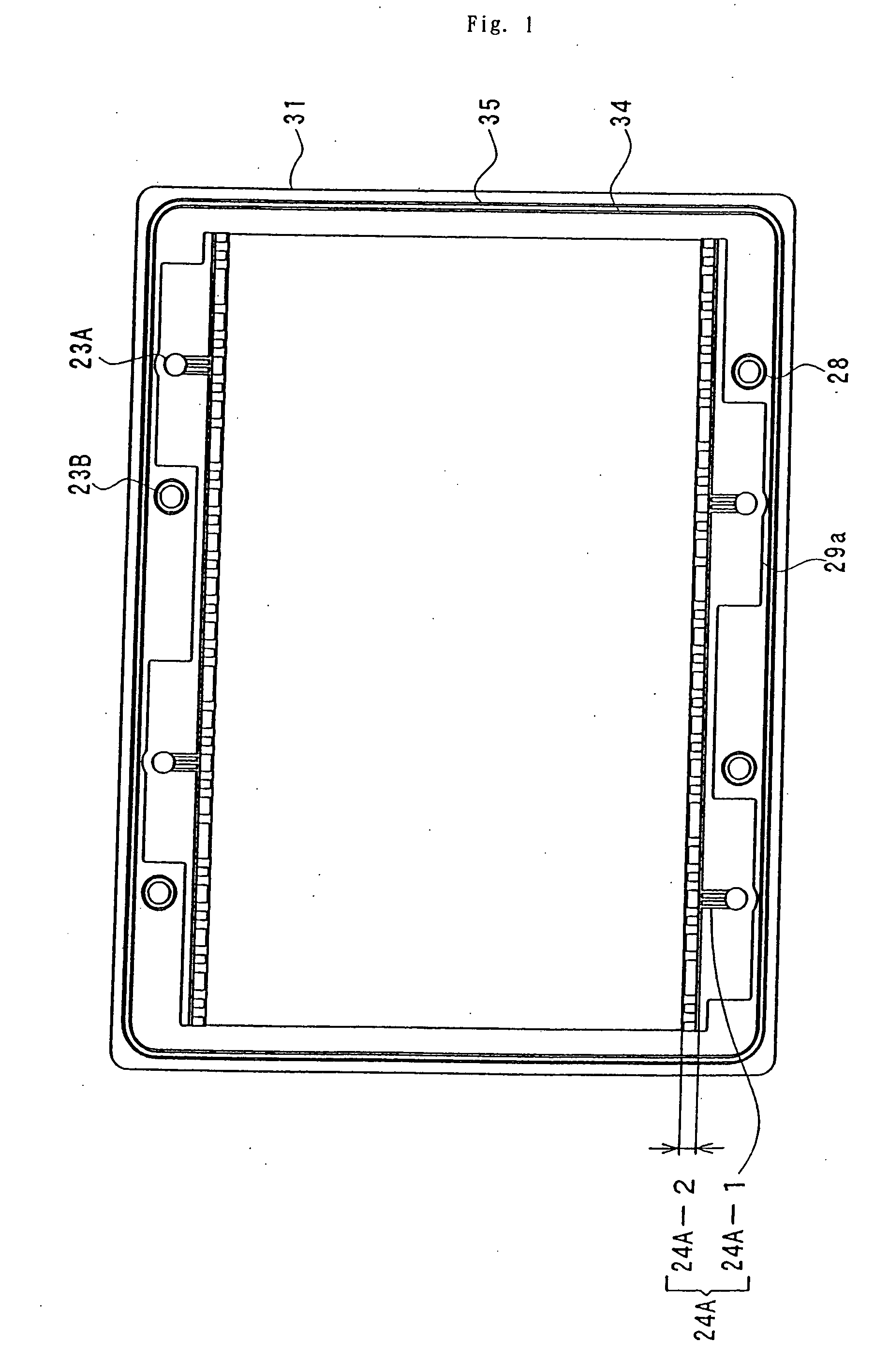

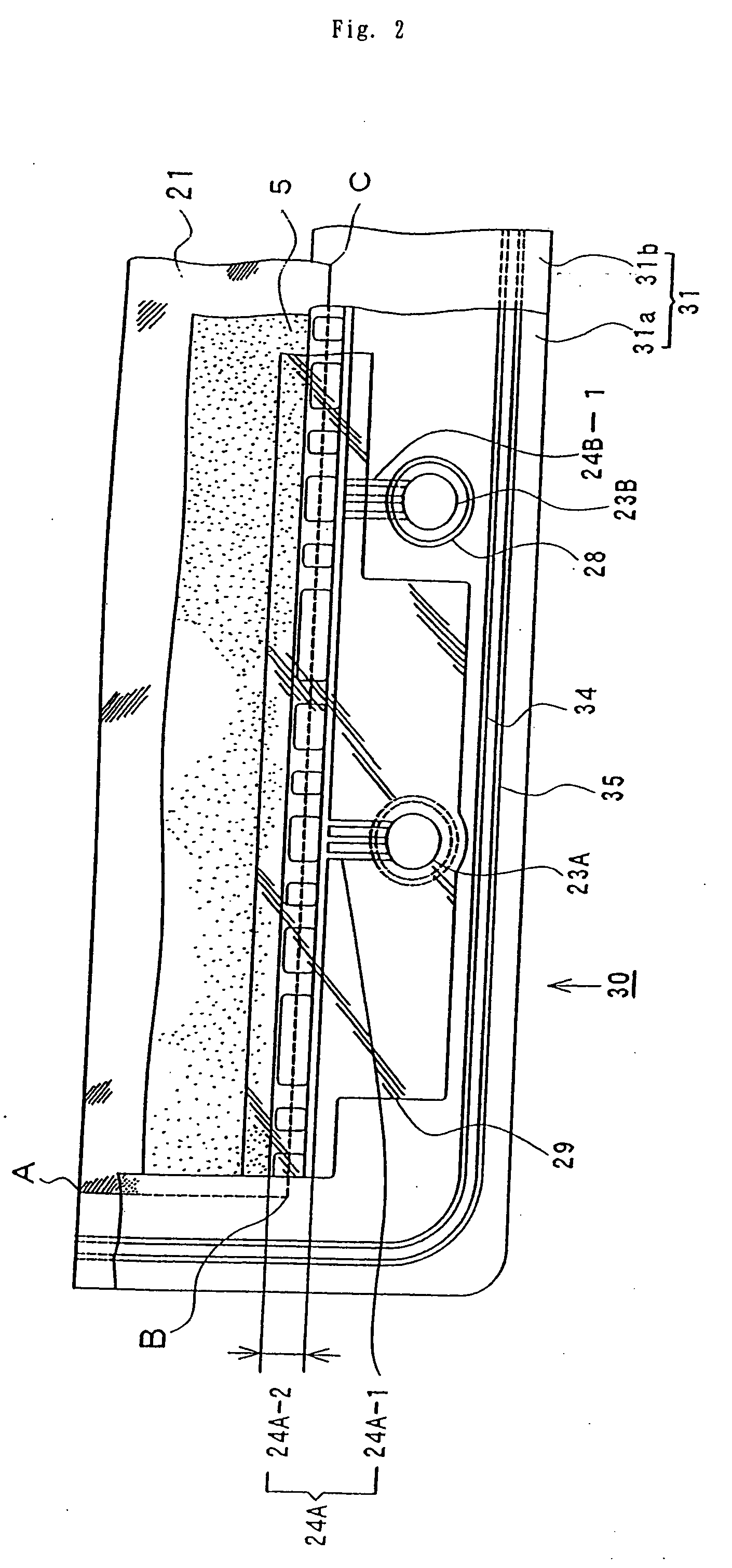

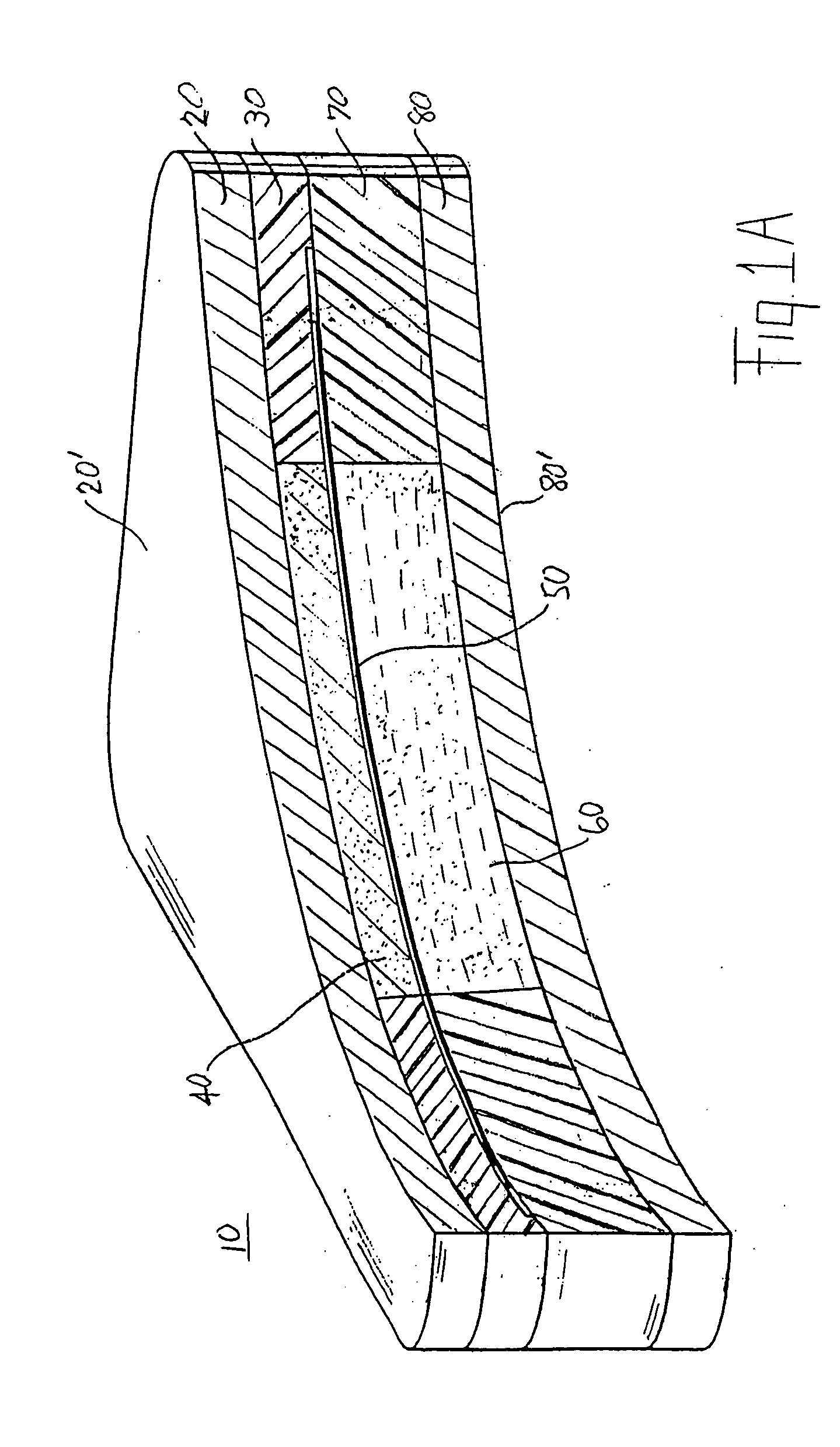

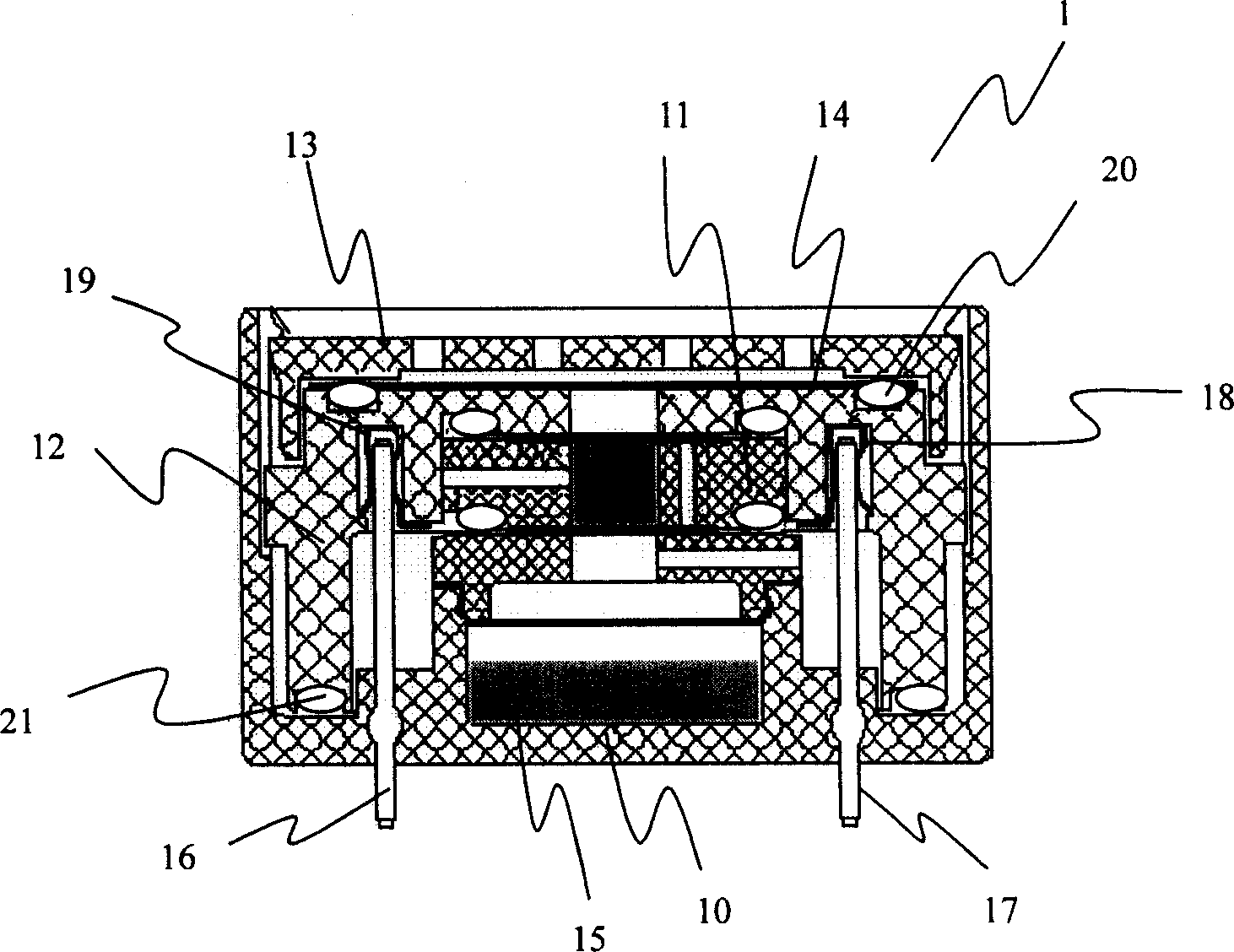

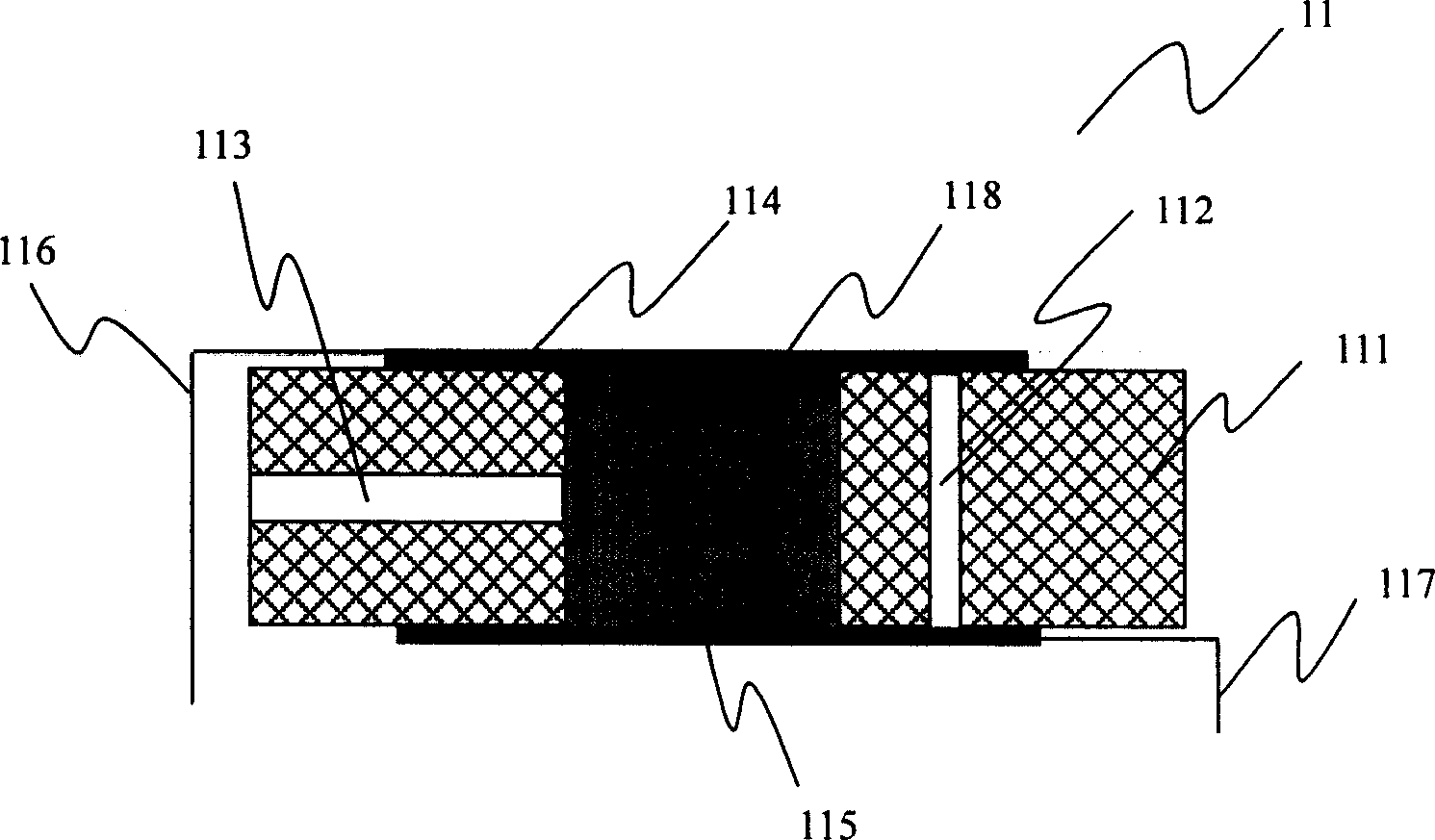

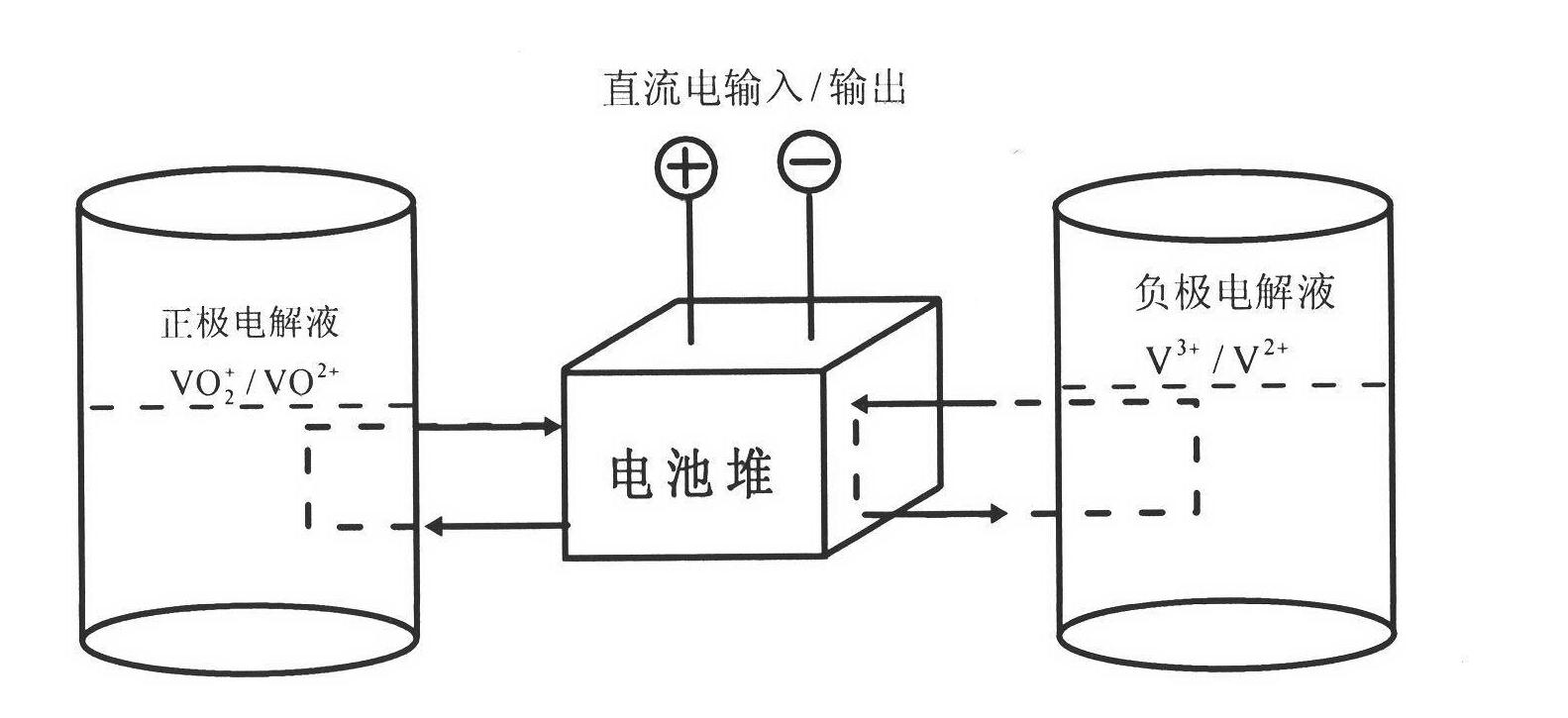

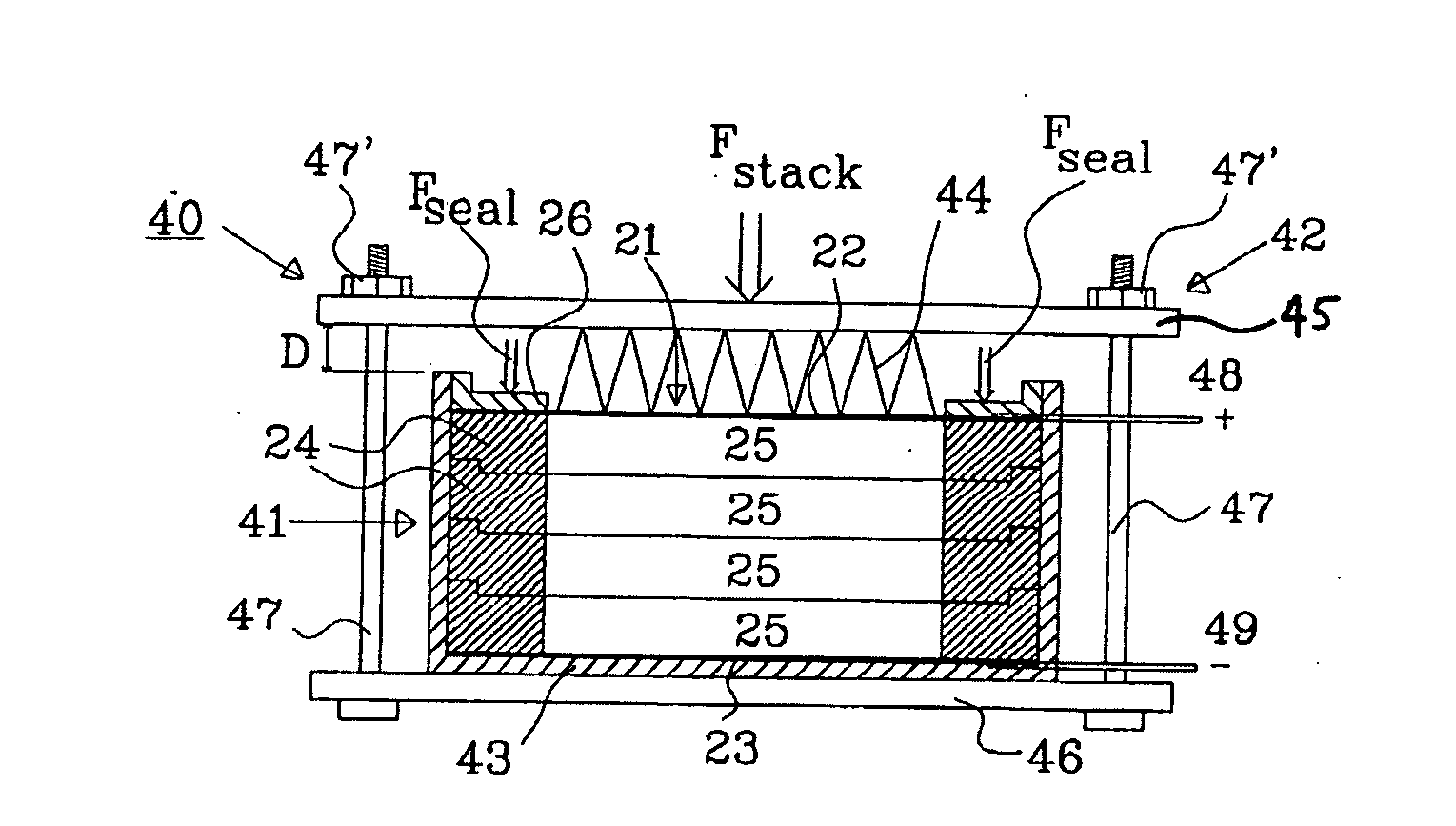

Cell frame for redox flow battery, and redox flow battery

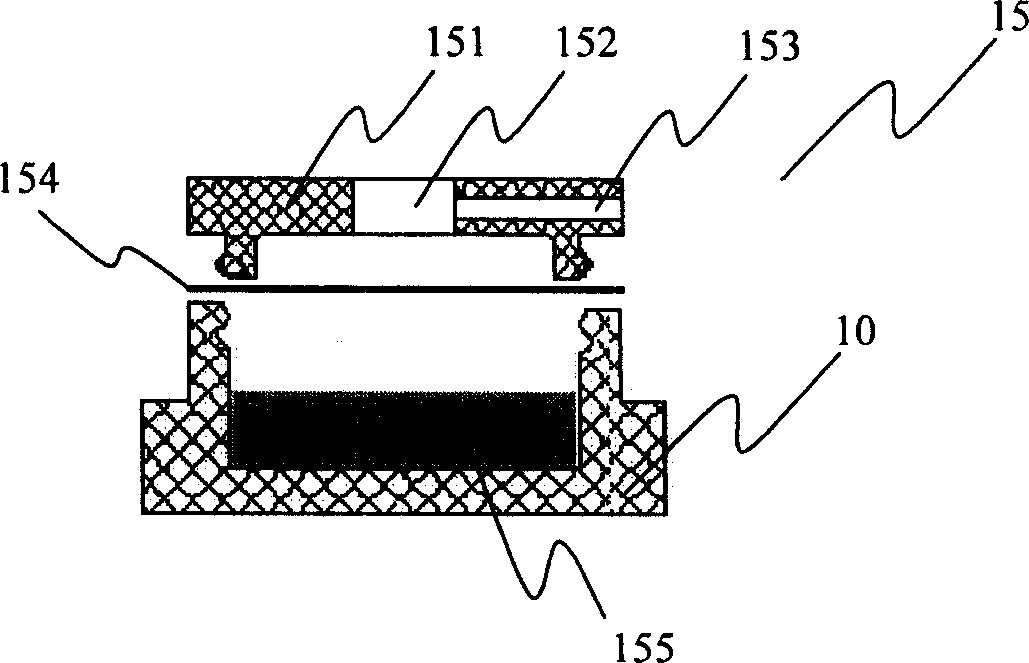

InactiveUS20080081247A1Avoid breakingPrevent a break in the membraneElectrolyte holding meansEngine sealsElectrolyte leakageOxidation-Reduction Agent

This invention provides a cell frame for a redox flow battery that prevents leakage of electrolyte out of the cell frame and also provides a good workability in assembling the redox flow battery. Also, this invention provides a redox flow battery using the cell frame. In the cell frame 30 for the redox flow battery 30 comprising a bipolar plate 21 and a frame 31 fitted around a periphery of the bipolar plate 21, the frame 31 has, on each side thereof, an inner seal and an outer seal to press-contact with a membrane and also seal electrolyte. The frame 31 has, on each side thereof, an inner seal groove 34 and an outer seal groove 35 for placing therein the inner seal and the outer seal, respectively, to prevent the electrolyte from leaking out, and O-rings are placed in the respective seal grooves.

Owner:SUMITOMO ELECTRIC IND LTD +1

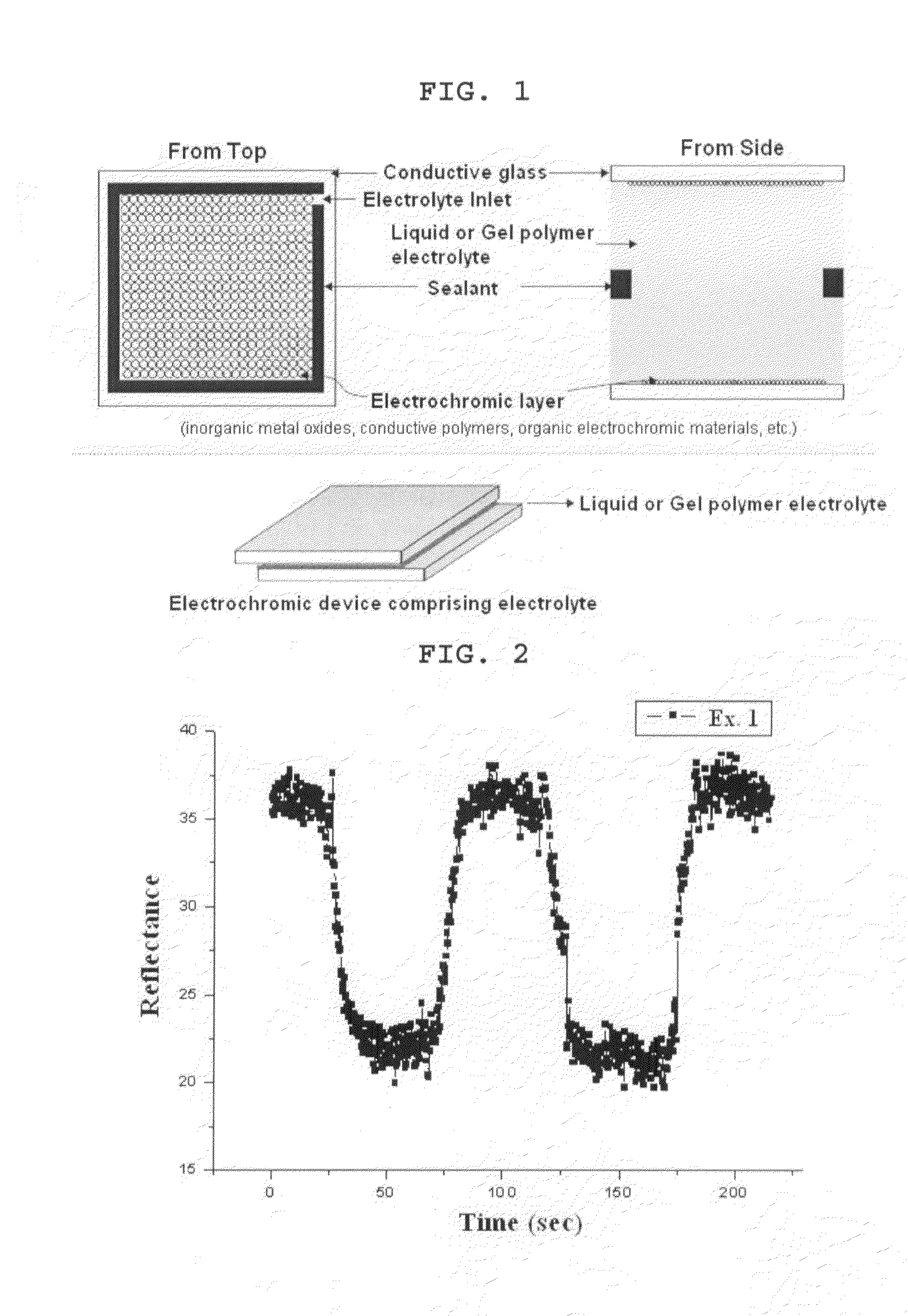

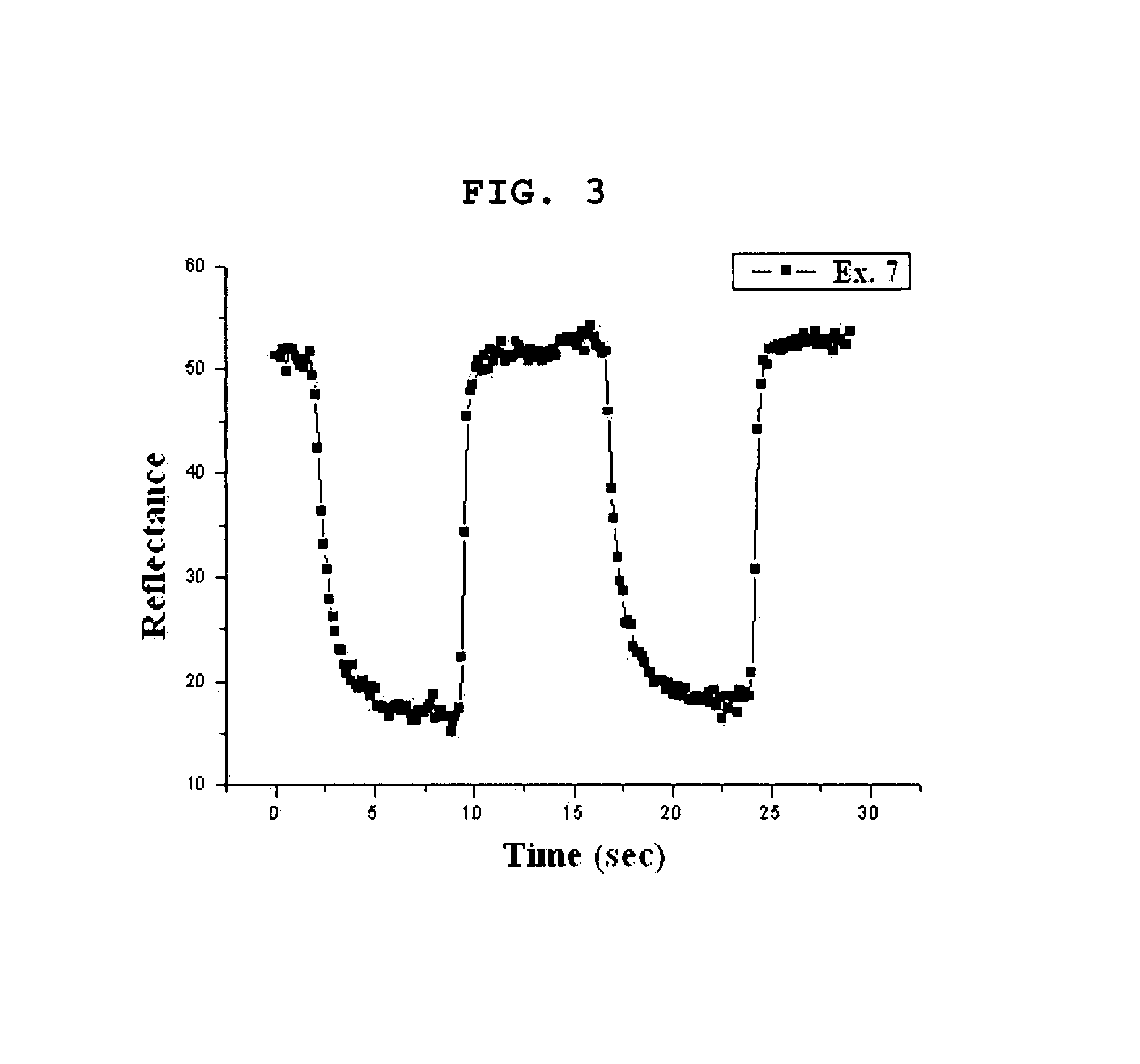

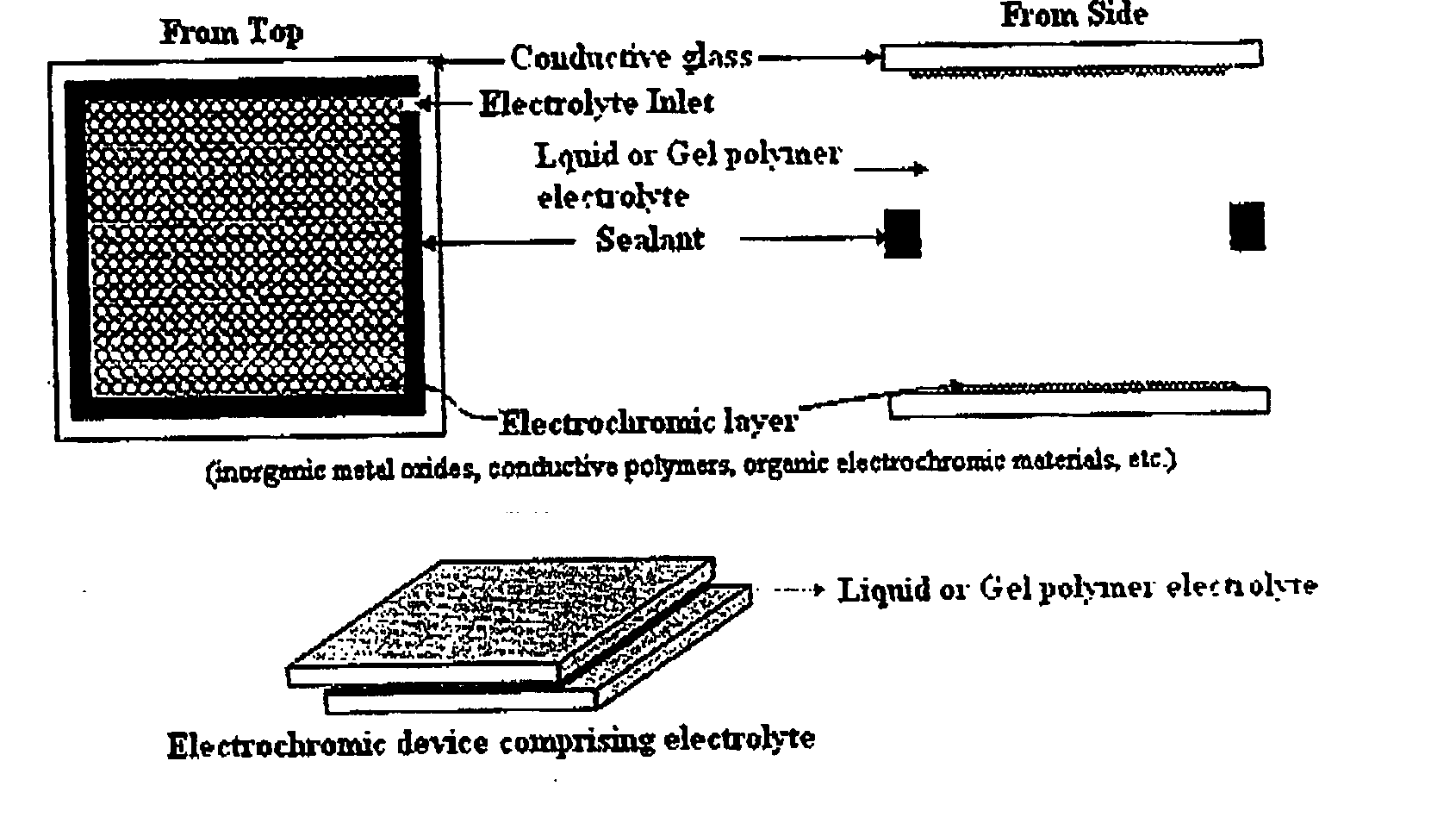

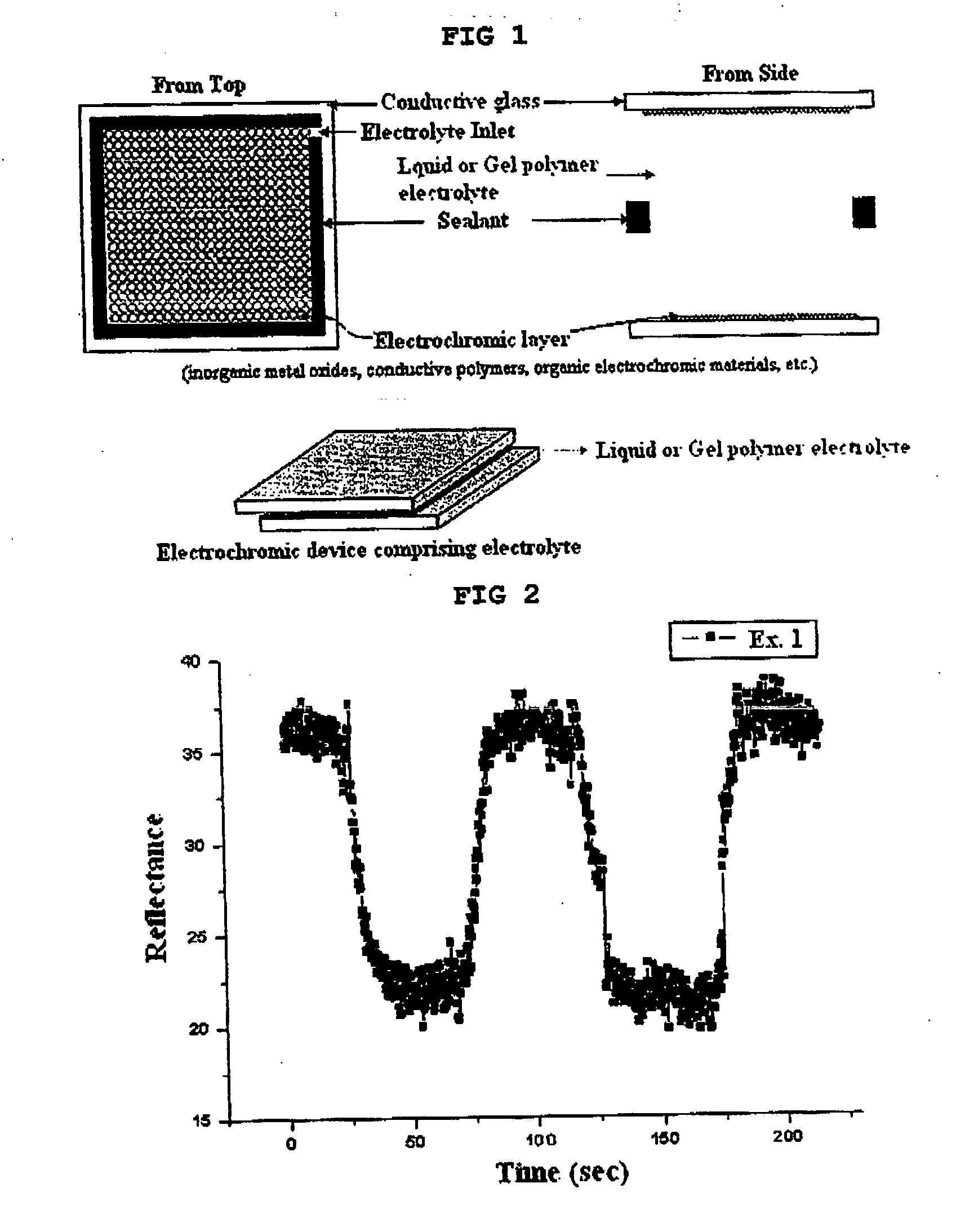

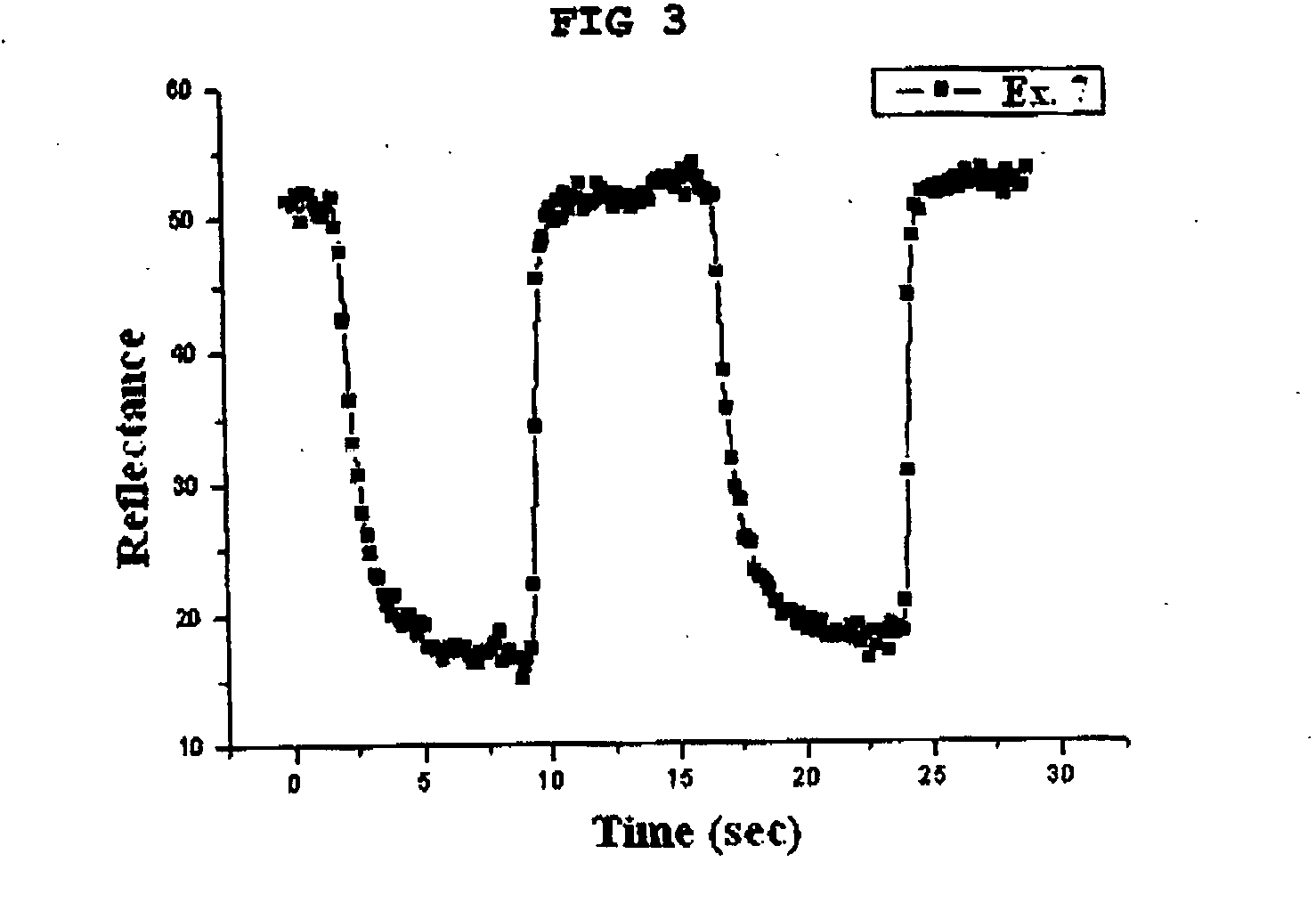

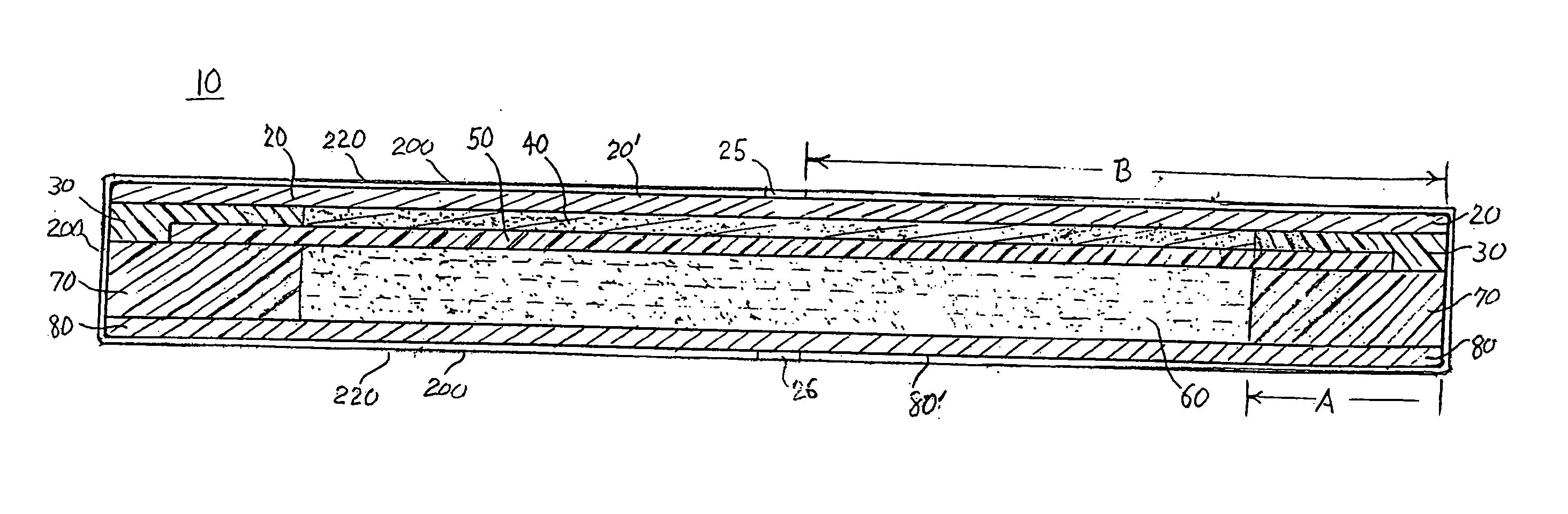

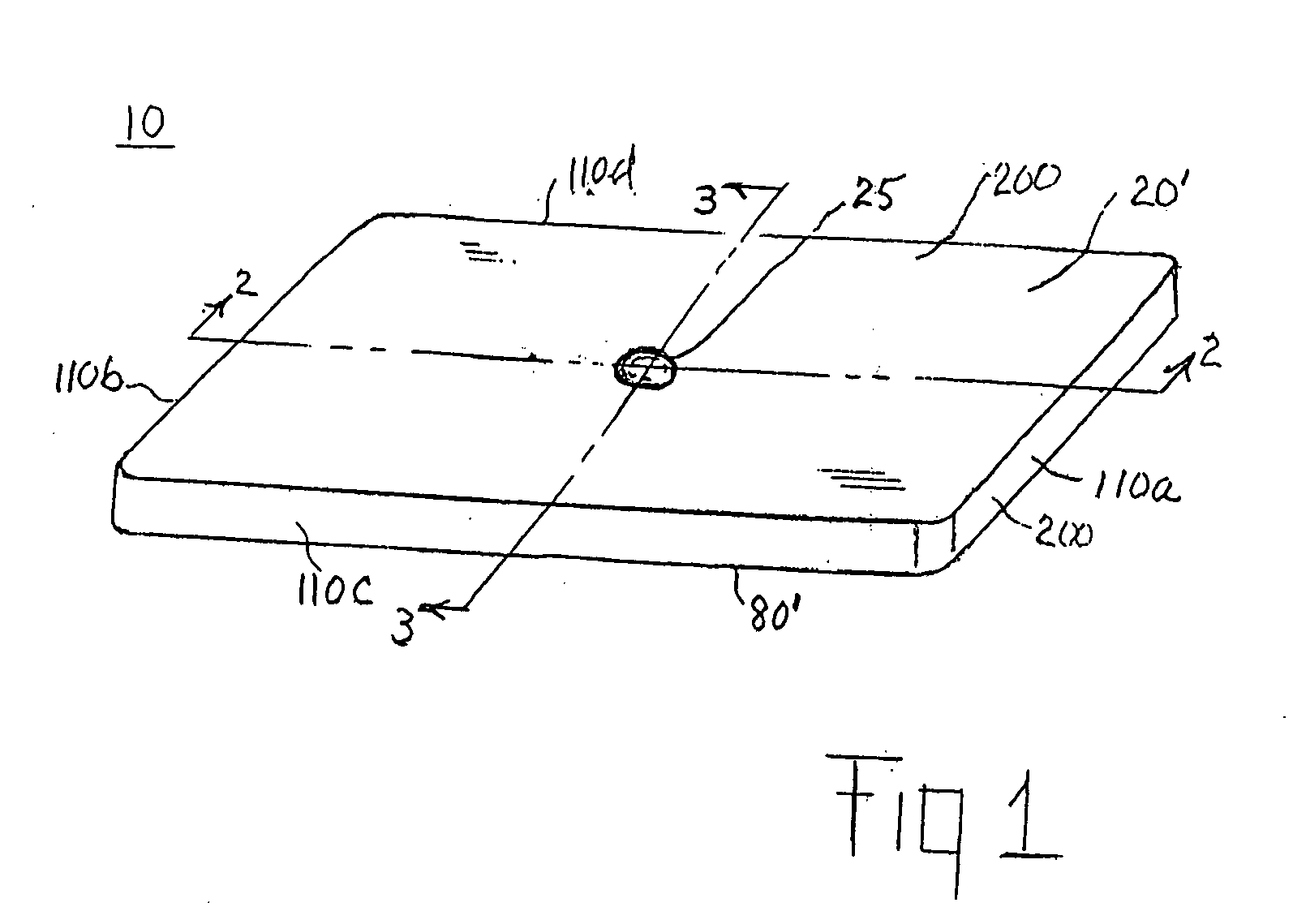

Gel polymer electrolyte containing ionic liquid and electrochromic device using the same

ActiveUS7411716B2Solve the real problemIncrease chanceLapping machinesTenebresent compositionsStructural deformationPolymer electrolytes

Owner:LG ENERGY SOLUTION LTD

Gel polymer electrolyte containing ionic liquid and electrochromic device using the same

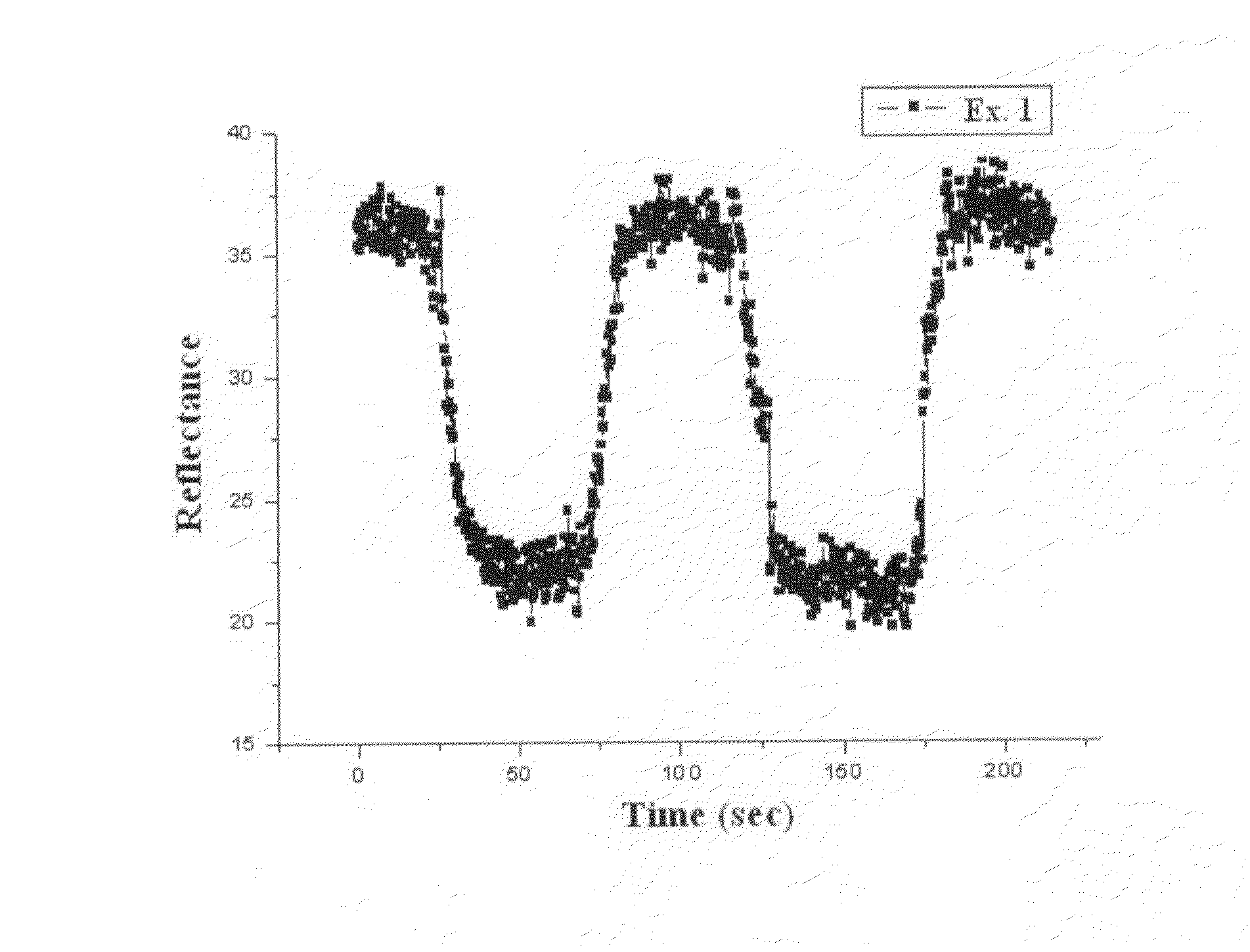

ActiveUS20050231785A1Good effectLow viscosityLapping machinesTenebresent compositionsStructural deformationElectrolytic agent

Disclosed is an electrochromic device comprising: (a) a first electrode; (b) a second electrode; (c) an electrochromic material; and (d) a gel polymer electrolyte containing an ionic liquid. A method for manufacturing the same is also disclosed. The electrochromic device uses a gel polymer electrolyte comprising an ionic liquid. Therefore, there is no problem related with electrolyte leakage. Additionally, it is possible to manufacture electrochromic devices by using plastic materials, because the ionic liquid gel polymer electrolyte permits structural deformation with ease. Further, because the electrochromic device uses an ionic liquid, it is possible to minimize side reactions between constitutional elements of an electrochromic device and electrolyte.

Owner:LG ENERGY SOLUTION LTD

Wafer alkaline cell

ActiveUS20050208381A1Conveniently insertedAvoid the needAlkaline accumulatorsSmall-sized cells cases/jacketsElectrolyte leakageMetal forming

Owner:DURACELL U S OPERATIONS

Gas sensor and its method of manufacture

InactiveUS7022213B1Reduce manufacturing costLess-prone to leakingContact materialsPretreated surfacesElectrolyte leakageElectricity

The invention relates to a gas sensor and its method of manufacture.Electrochemical gas sensors usually comprise an external housing, which acts as a reservoir for electrolyte; a wick to keep electrodes wetted with the electrolyte and external electrical terminals, for making electrical contact with the electrodes. Typically a gas permeable / microporous membrane has been used to seal a gas sensor in order to prevent leakage of electrolyte. A problem with existing sensors has been that there was a risk of electrolyte leaking through the membrane around the region where electrical connectors passed therethrough.The present invention overcomes this by providing a method of urging conductive polymer through the membrane under controlled conditions of heat and pressure, thereby ensuring the integrity of the membrane remains in tact while defining an electrically / conductive pathway therethrough.

Owner:INVENSYS CONTROLS UK

All solid state electrolyte and preparing method and application of the same

InactiveCN101183727AAct as an electrolytePlays double role as a diaphragmCell electrodesOrganic electrolyte cellsPolyethylene oxideUltra fine

The invention relates to an all-solid-state electrolyte, the preparation method and the application, which solves the problems that the liquid state electrolytet in the prior lithium ion secondary battery is easy to volatilize and has the leakage potential safety hazard, or the gel polymer electrolyte has a bad mechanical property and molding difficulty. The invention comprises lithium salt, polyethylene oxide, ultra fine powder packing. The invention prepares the all-solid-state electrolyte through the method that: firstly, the lithium salt and the solvent are mixed evenly and then the PEO powder is scattered in and mixed evenly; secondly, the ultra fine powder packing is added into the solvent and mixed evenly, and the mixture is stood; thirdly, the mixed liquids of the first step and the second step are mixed evenly, molded after being cast and dried, and then demoulded to form the product. The invention has the advantages that the all-solid-state electrolyte is used as the electrolyte of the all-solid-state secondary lithium battery and matches with the cathode of the metal lithium; thus the potential safety hazard of the liquid state electrolyte leakage is avoided, the mechanical property is good and the molding is easy.

Owner:HARBIN INST OF TECH

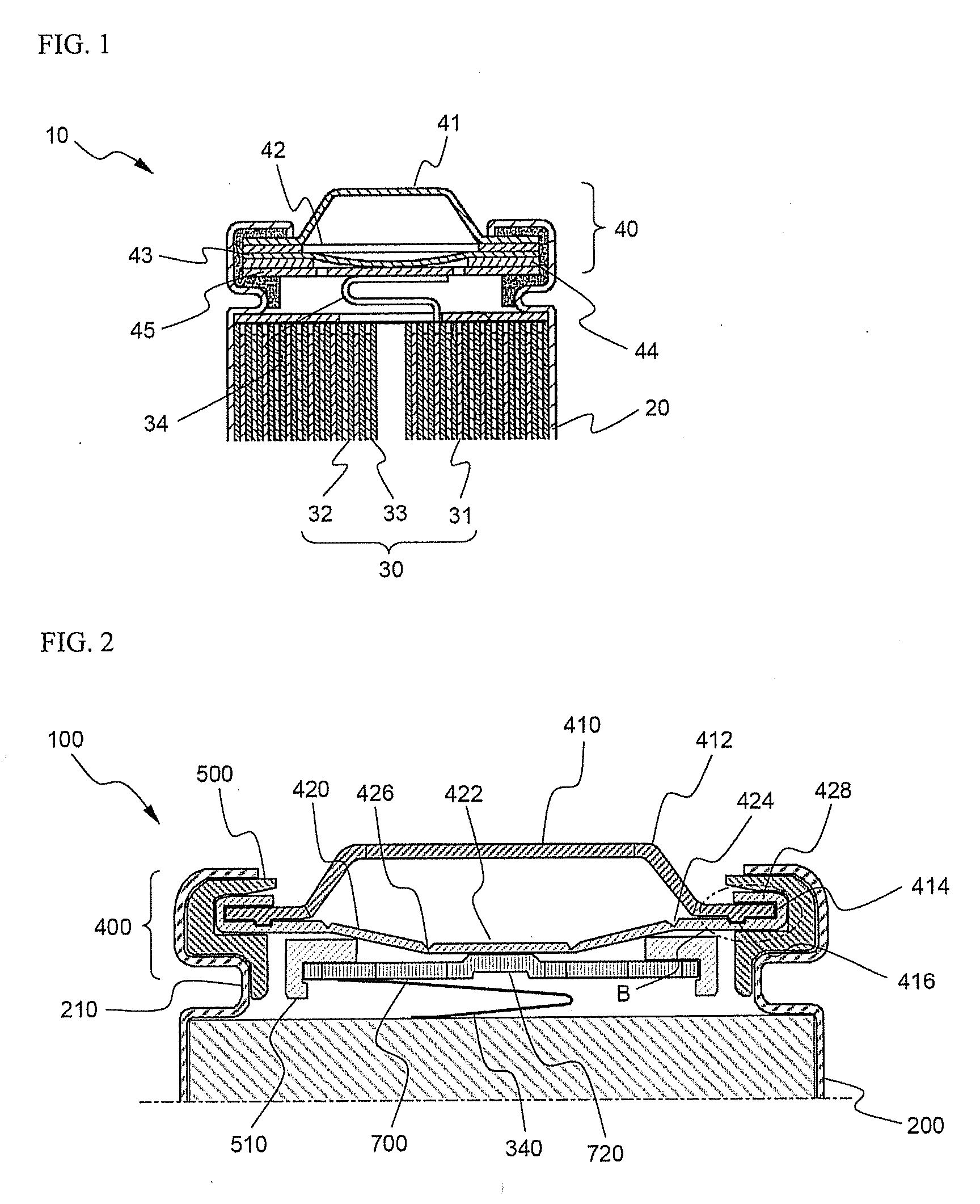

Lithium secondary battery

ActiveUS20070154781A1Improve sealingImprove tightnessFinal product manufactureVent arrangementsElectrolyte leakageLithium

A lithium secondary battery includes a supporting sealing member between a safety vent and a gasket to enhance a safety of the lithium secondary battery by preventing a gas or an electrolyte from leaking.

Owner:SAMSUNG SDI CO LTD

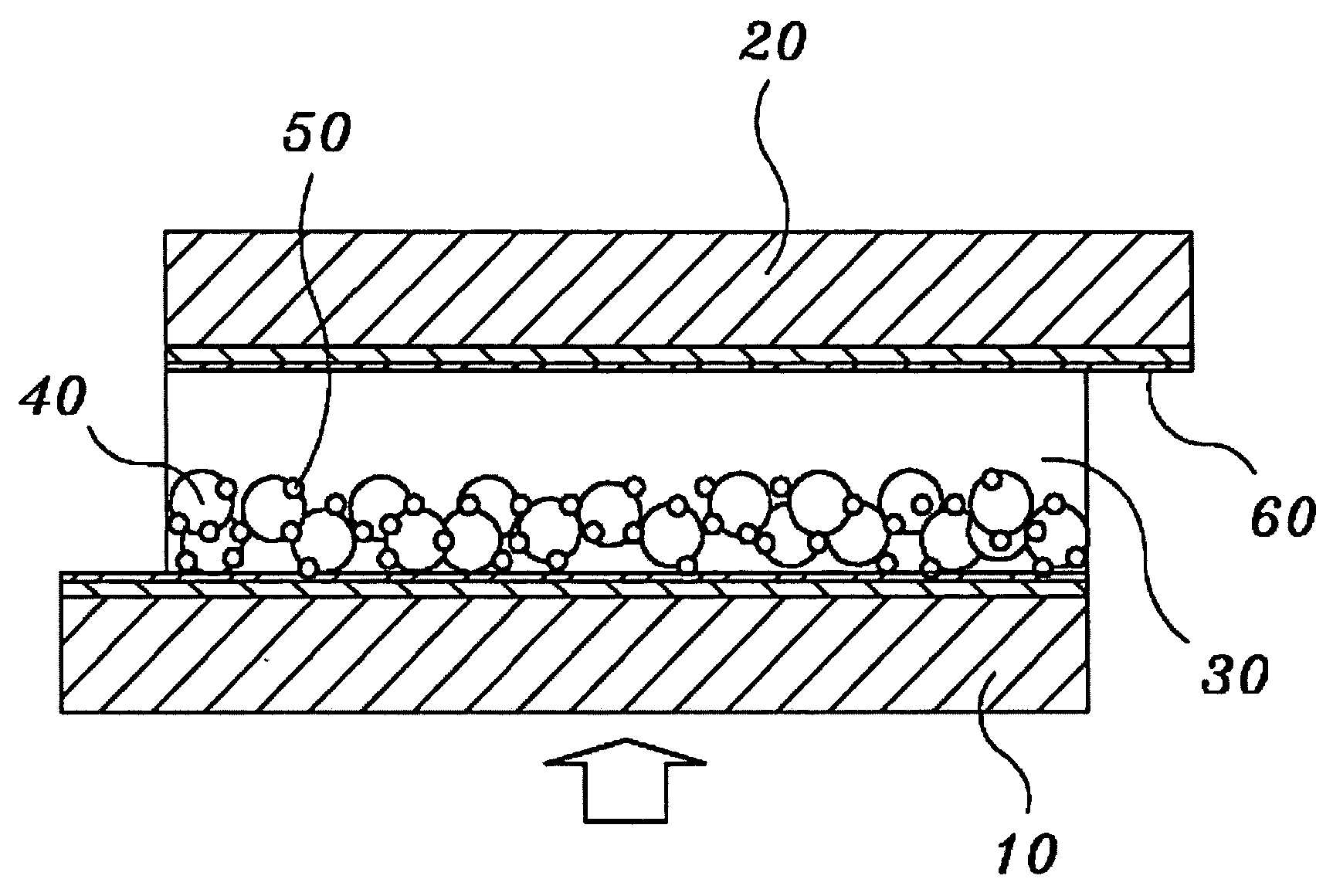

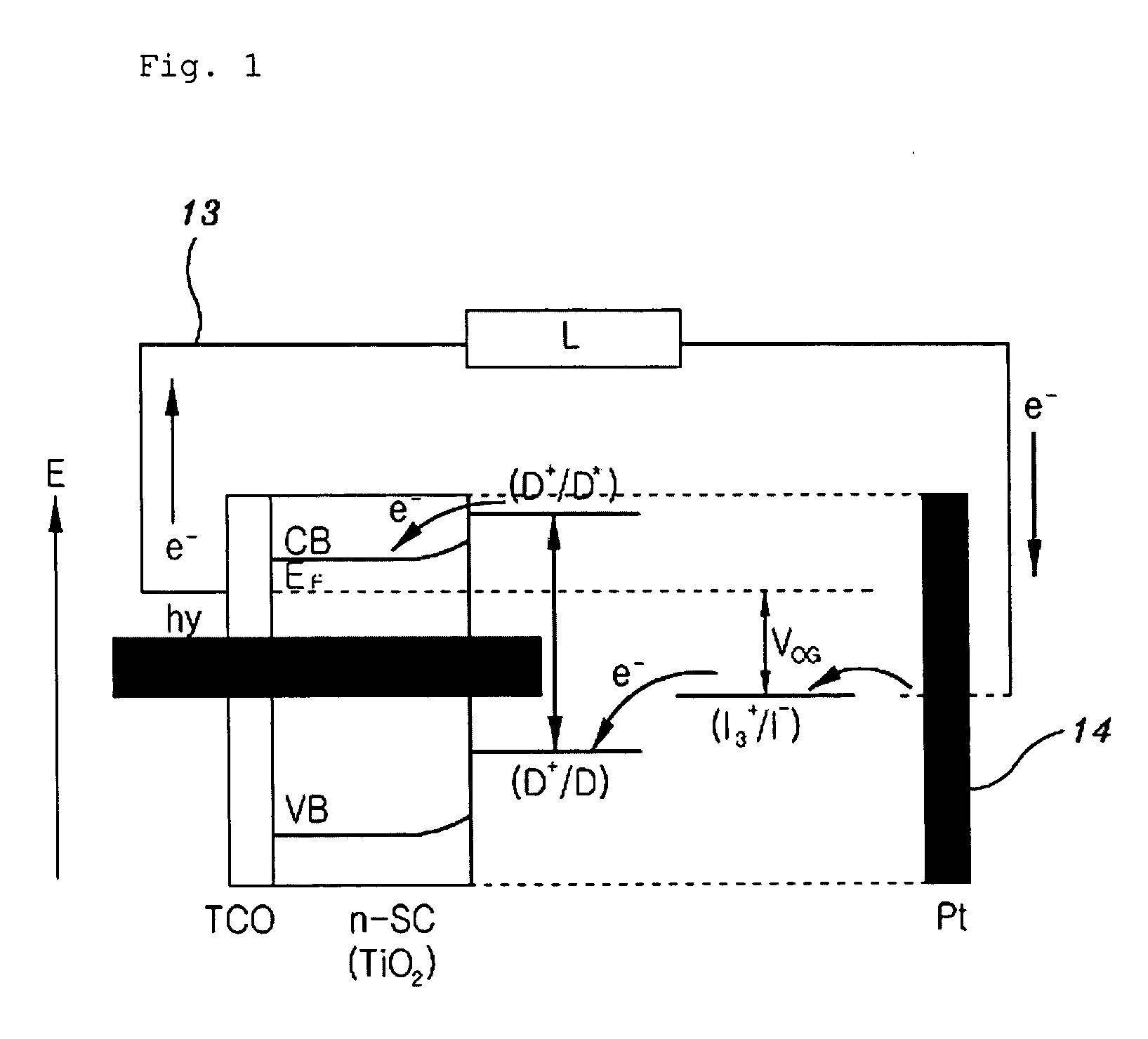

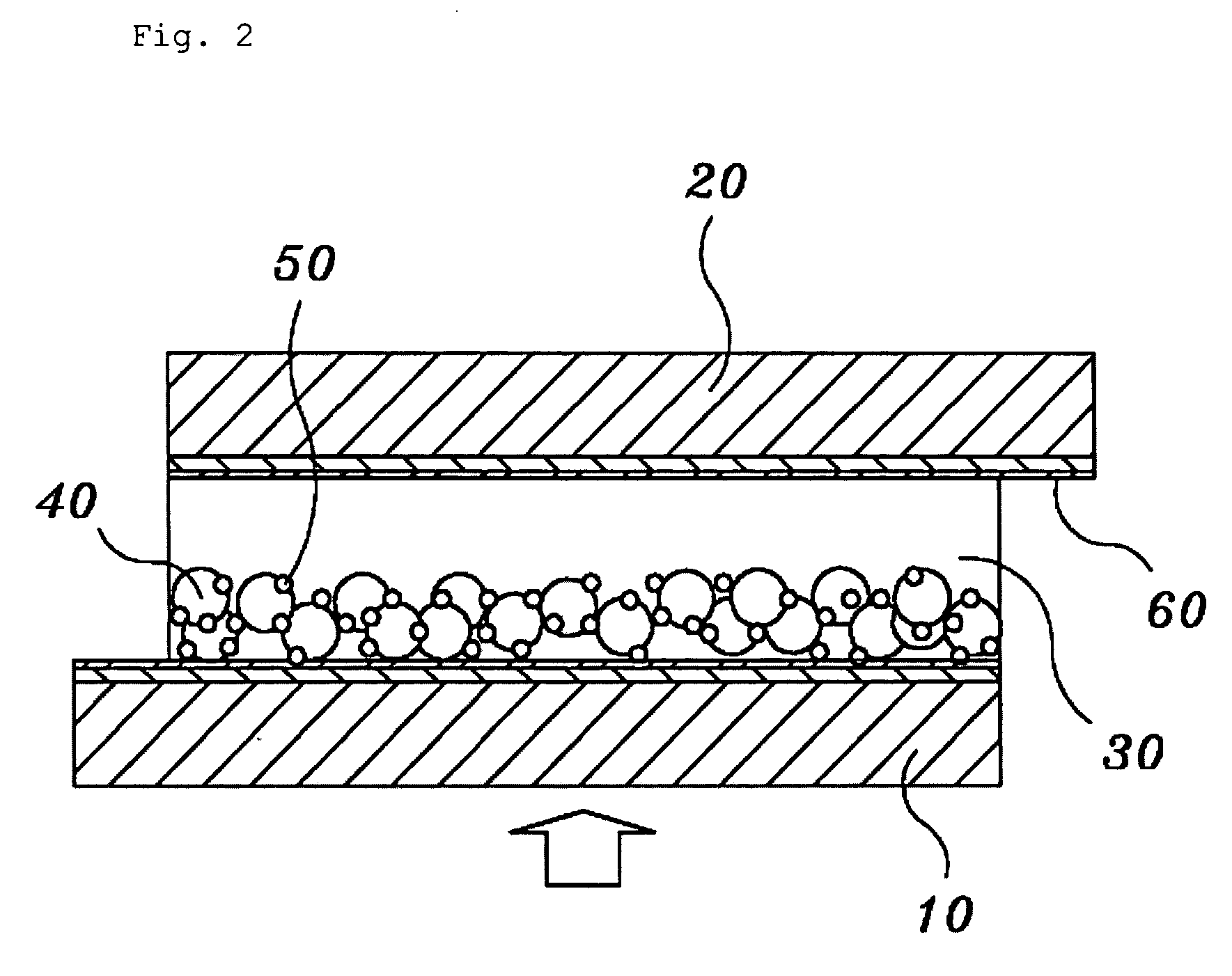

Solid state dye-sensitized solar cell employing composite polymer electrolyte

InactiveUS20050072462A1Improve energy conversion efficiencyLight-sensitive devicesPhotovoltaic energy generationHigh energySolar cell

Disclosed is a solid state dye-sensitized solar cell employing a composite polymer electrolyte, which includes a photoelectrode, a counter electrode, and an electrolyte interposed between the photoelectrode and counter electrode. The electrolyte includes at least one of a middle molecular substance, a polymer mixture, and inorganic nanoparticles, and a redox derivative. The dye-sensitized solar cell reduces crystallinity of the polymer electrolyte to significantly increase ionic conductivity, and enables the polymer electrolyte to smoothly permeate into a titanium oxide layer to improve mechanical properties, thereby significantly increasing energy conversion efficiency. Accordingly, the dye-sensitized solar cell assures high energy conversion efficiency without an electrolyte leak, and thus, it can be stably and practically used for a long time.

Owner:KOREA INST OF SCI & TECH

Gas sensor, gas detector, and self-testing and self-correcting method therefor

InactiveCN1865969ASolve the problem of electrolyte leakageExtended service lifeSpecial data processing applicationsMaterial electrochemical variablesGas detectorEngineering

The related gas sensor for fuel cell comprises: based on traditional device, designing a cell core expansion hole and an air hole, using gel electrolyte instead of common liquid, adding a constant moisture device for sensor. It also uses the sensor to prepare a gas detector with self test and adjust function and free to environment effect and calibration gas source. This invention overcomes defects in prior art.

Owner:ASENSOR TECH

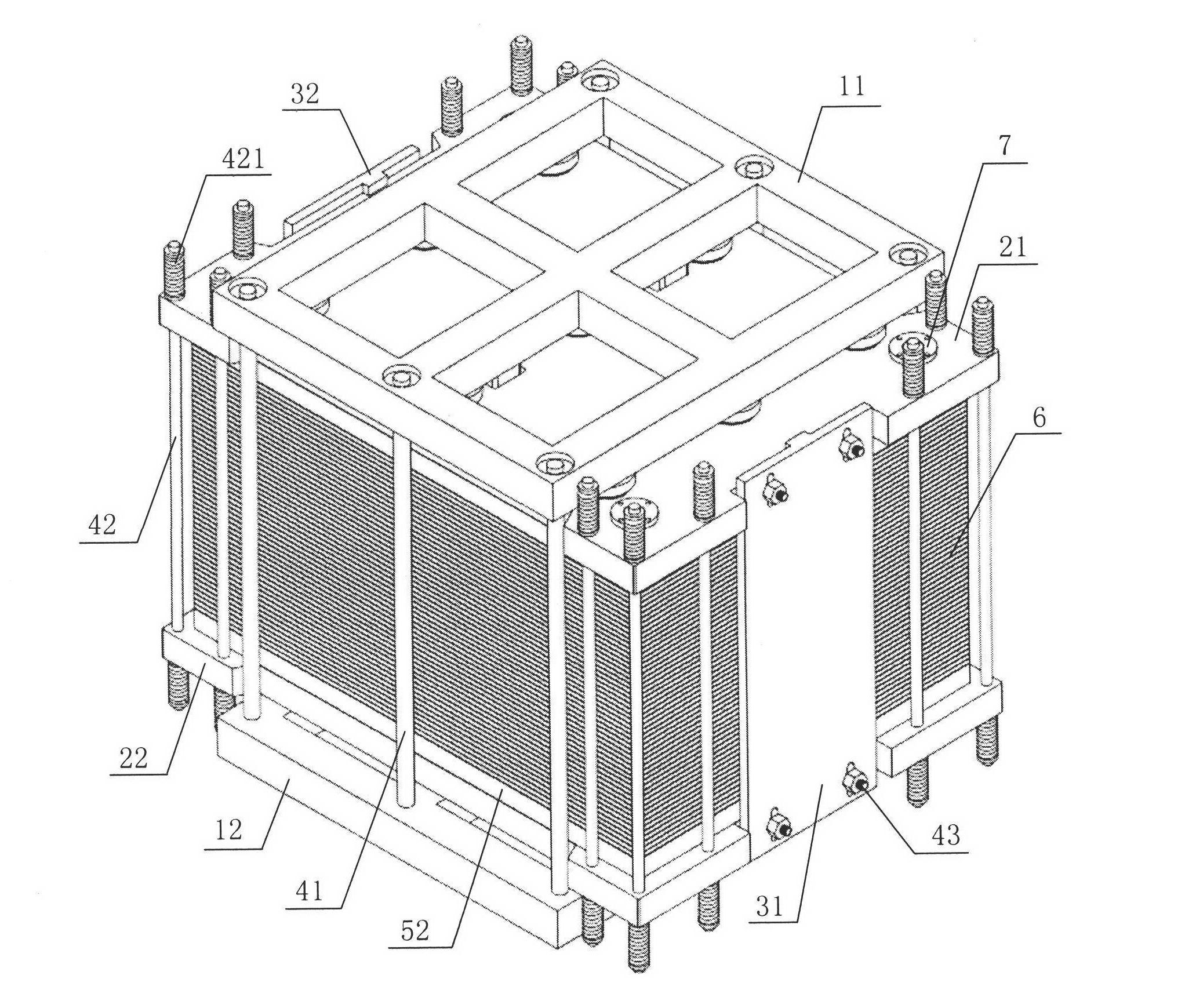

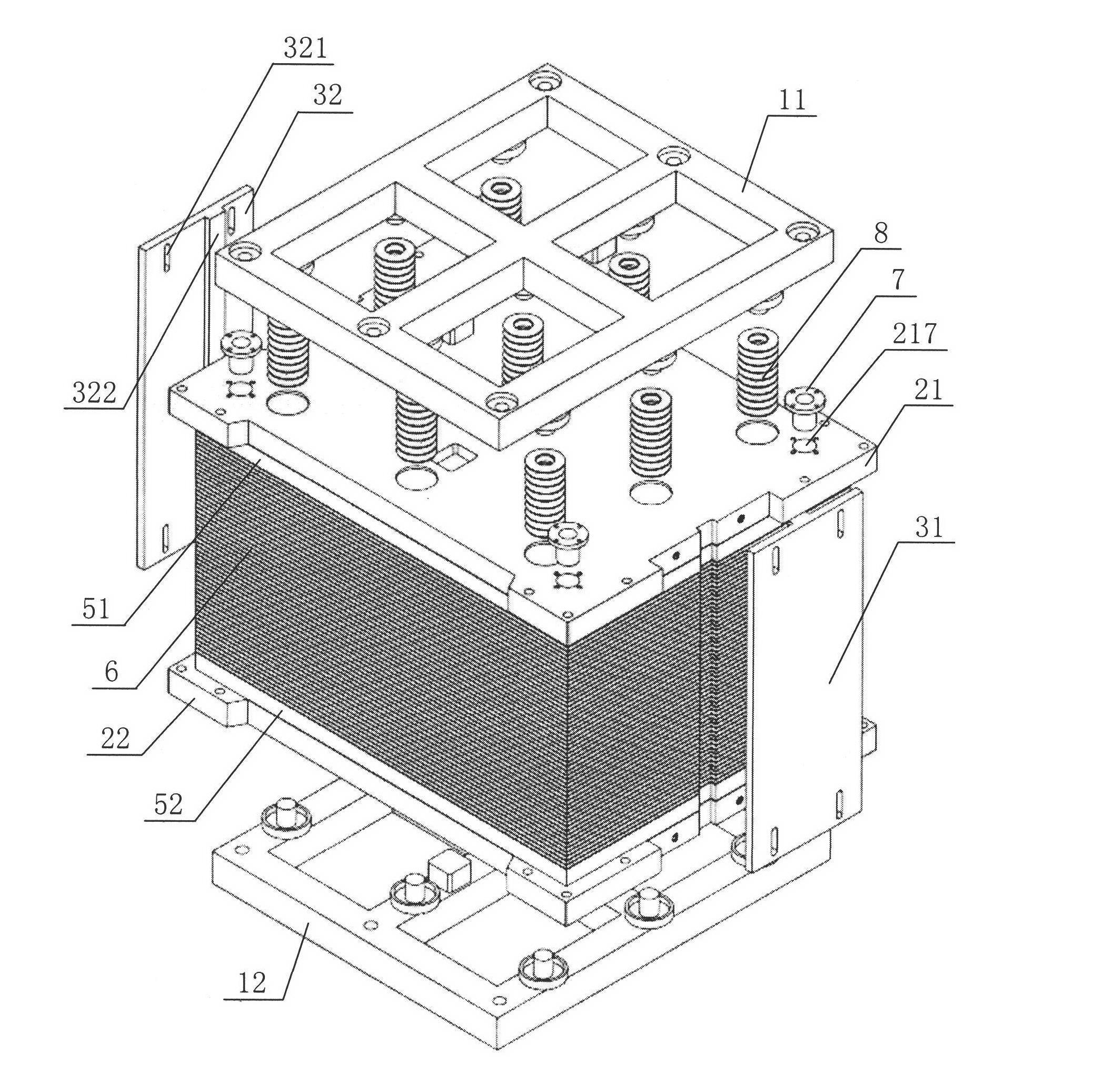

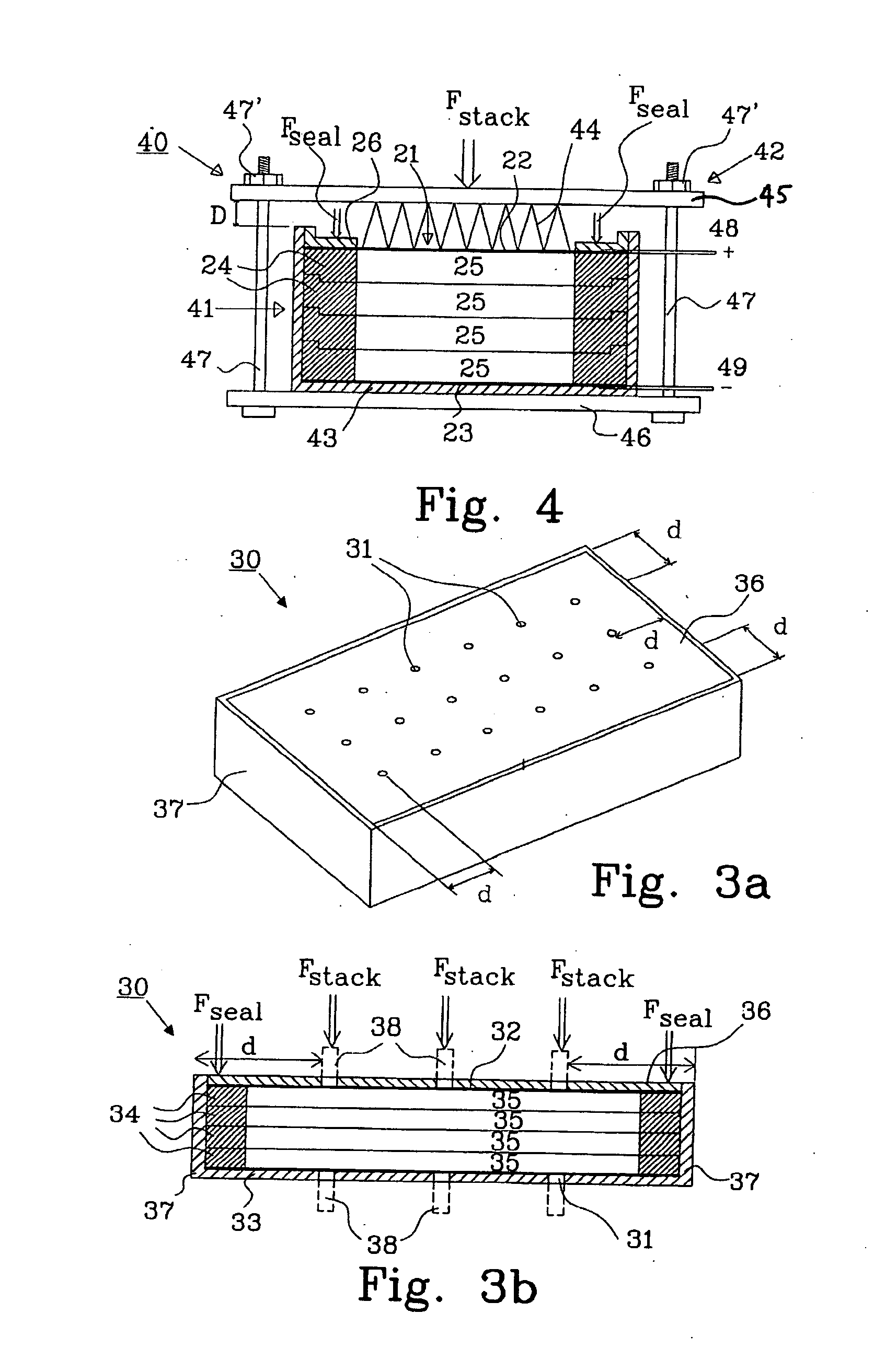

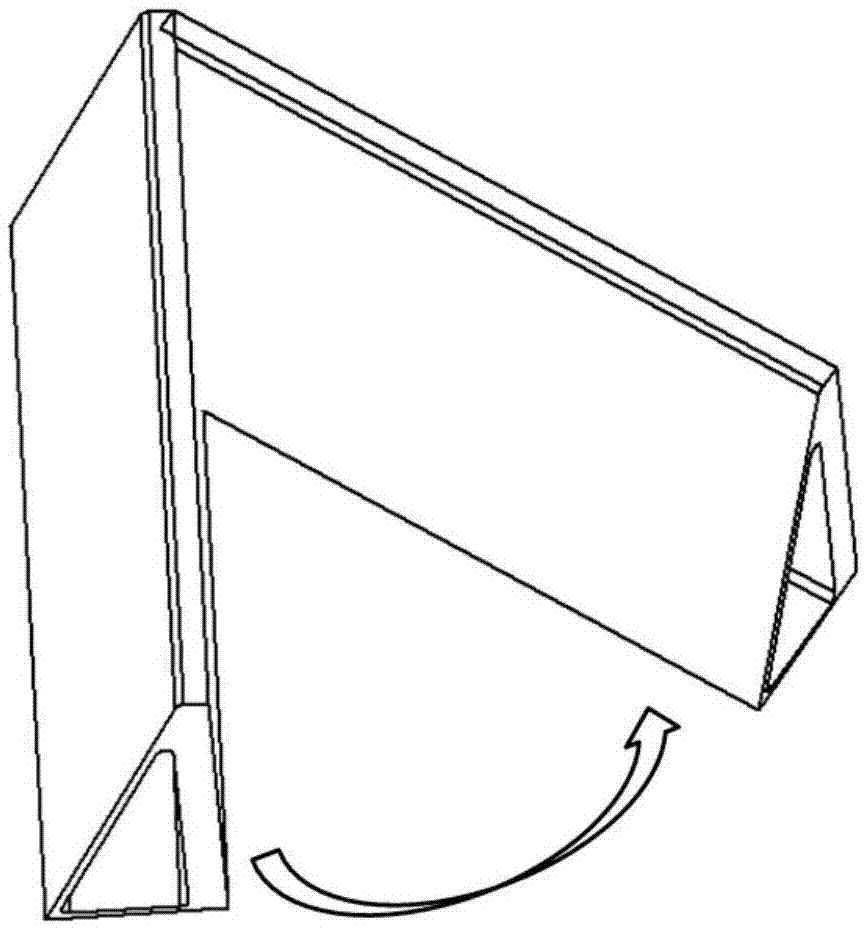

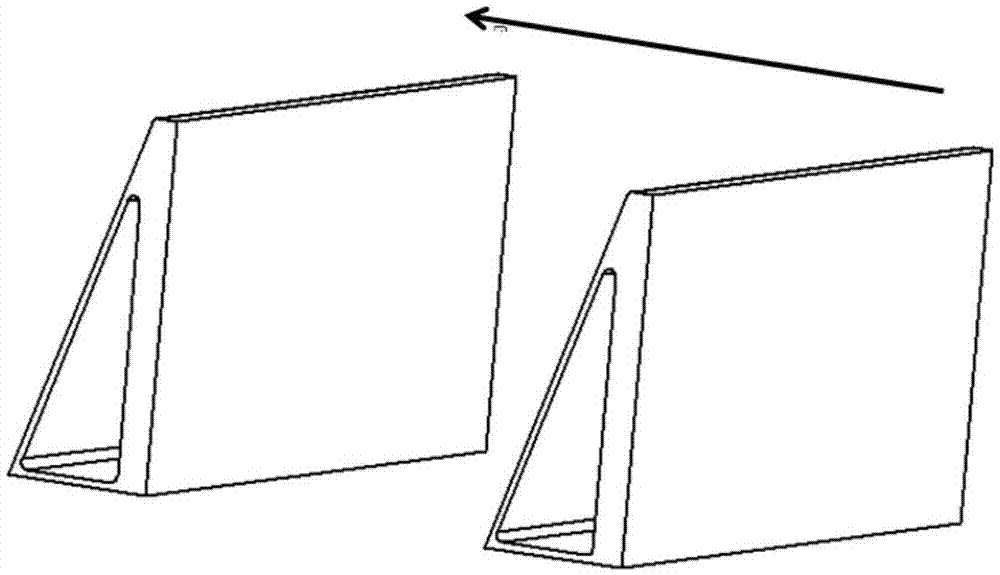

End plate pressing component of redox flow cell galvanic pile

ActiveCN102306821AEvenly distributed pressing forceGuaranteed pressing forceFuel cells groupingFinal product manufactureElectrolyte leakageManufacturing technology

The invention provides an end plate pressing component of a redox flow cell galvanic pile, belonging to the field of manufacturing technology of redox flow cell galvanic pile. The end plate compressing component is characterized by comprising end plates on two sides, pressing frames which are pressed on the end plates and pressing connecting pieces of the pressing frames, wherein the end plates are provided with blind holes for placing disc springs; and the pressing frames are provided with disc spring guide bars, guide posts for positioning the end plates and limit plates for positioning the end plates and each unit frame of the redox flow cell. The end plate pressing component provided by the invention can exactly position and press each part in the redox flow cell galvanic pile, ensures that pressing force on the plane of each plate frame of the redox flow cell is distributed evenly, and is convenient to assemble the galvanic pile. Through the matching between the strip bulges on the limit plates and the groove on each cell plate frame, the electrolyte leakage caused by local dislocation of each cell plate frame of the redox flow cell is avoided. Elastic parts are used for compensating the deformation caused by temperature change as well as the local deformation caused by vibration in the transport process, keeping the original pressing force on the galvanic pile and improving the sealing reliability of the galvanic pile.

Owner:TSINGHUA UNIV +1

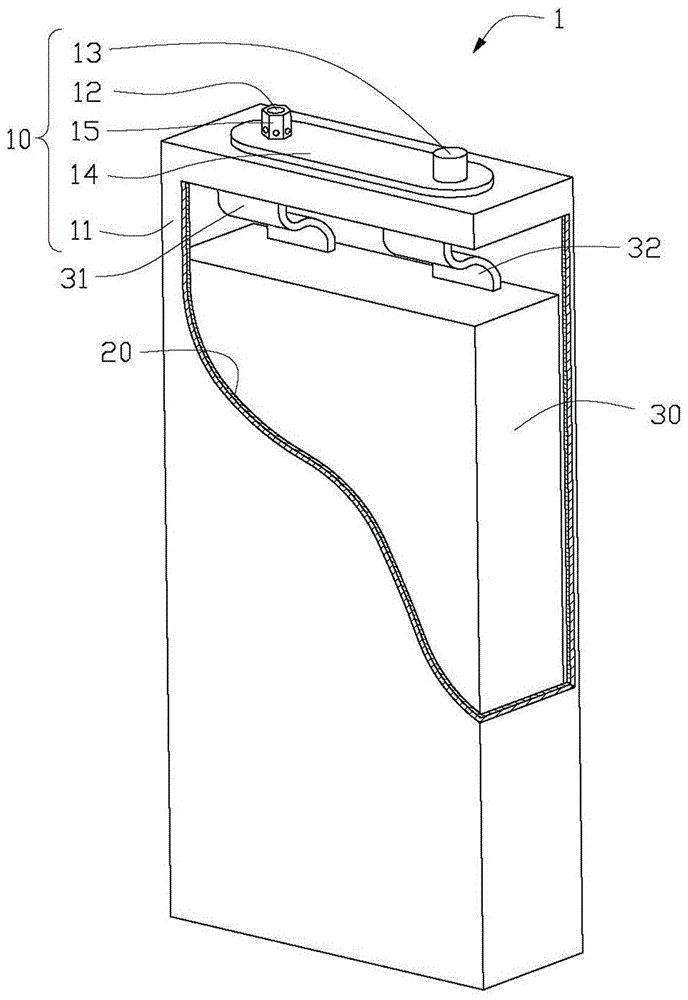

Safe soft-packing lithium ion battery and electronic cigarette

InactiveCN107432498AImprove securitySolve safety problems such as easy scratches, gas leakage and liquid leakageSmall-sized cells cases/jacketsTobacco devicesElectrolyte leakageElectrical battery

The invention relates to a safe soft-packing lithium ion battery and an electronic cigarette. The safe soft-packing lithium ion battery comprises a steel shell assembly as an outer-layer housing, an aluminum-plastic film housing and a cell. The aluminum-plastic film housing is located in the steel shell assembly and serves as an inner-layer housing. The cell is disposed in the aluminum-plastic film housing and comprises a positive pole lug and a negative pole lug. The steel shell assembly comprises a housing, a positive pole terminal, a negative pole terminal and an insulation sealing pad and further comprises a safety valve. The safety valve is arranged on the positive pole terminal. The positive pole lug is connected with the positive pole terminal by spot welding. The negative pole lug is connected with the negative pole terminal by spot welding. The positive pole terminal and the negative pole terminal penetrate through the insulation sealing pad. The invention further provides the electronic cigarette includingthe above battery. Therefore, safety performance of the soft-packing lithium ion battery is improved. Potential safety hazards such as air and liquid leakage becausea soft inner-layer aluminum-plastic film is easily cutare avoided. Additionally, outside air is effectively prevented from entering the housing and contacting organic electrolyte. Electrolyte leakage caused by an abnormal condition of the internal lithium ion battery is avoided. Hence, health of customers is protected by preventing them from electrolyte pollution.

Owner:SHENZHEN EPT BATTERY

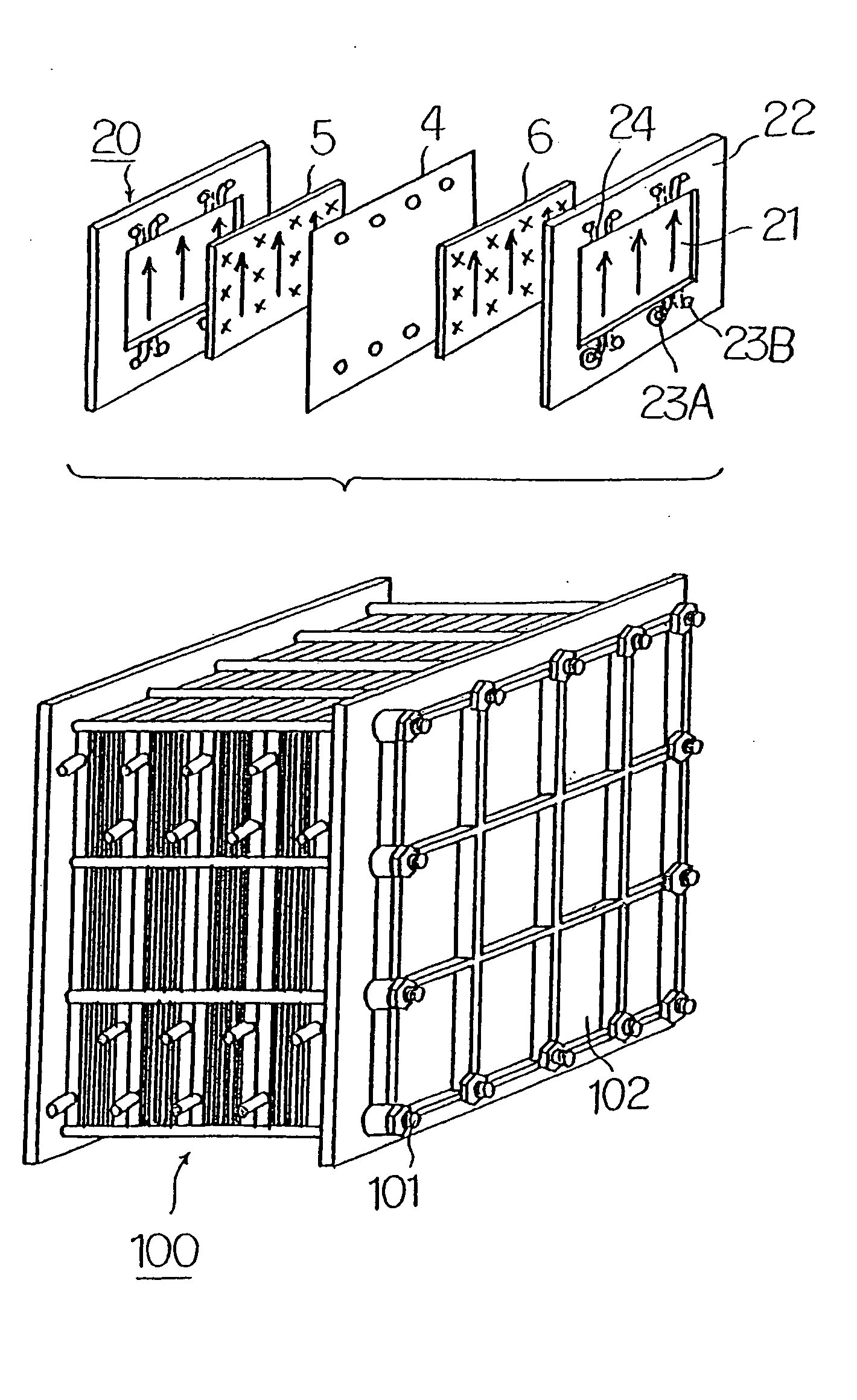

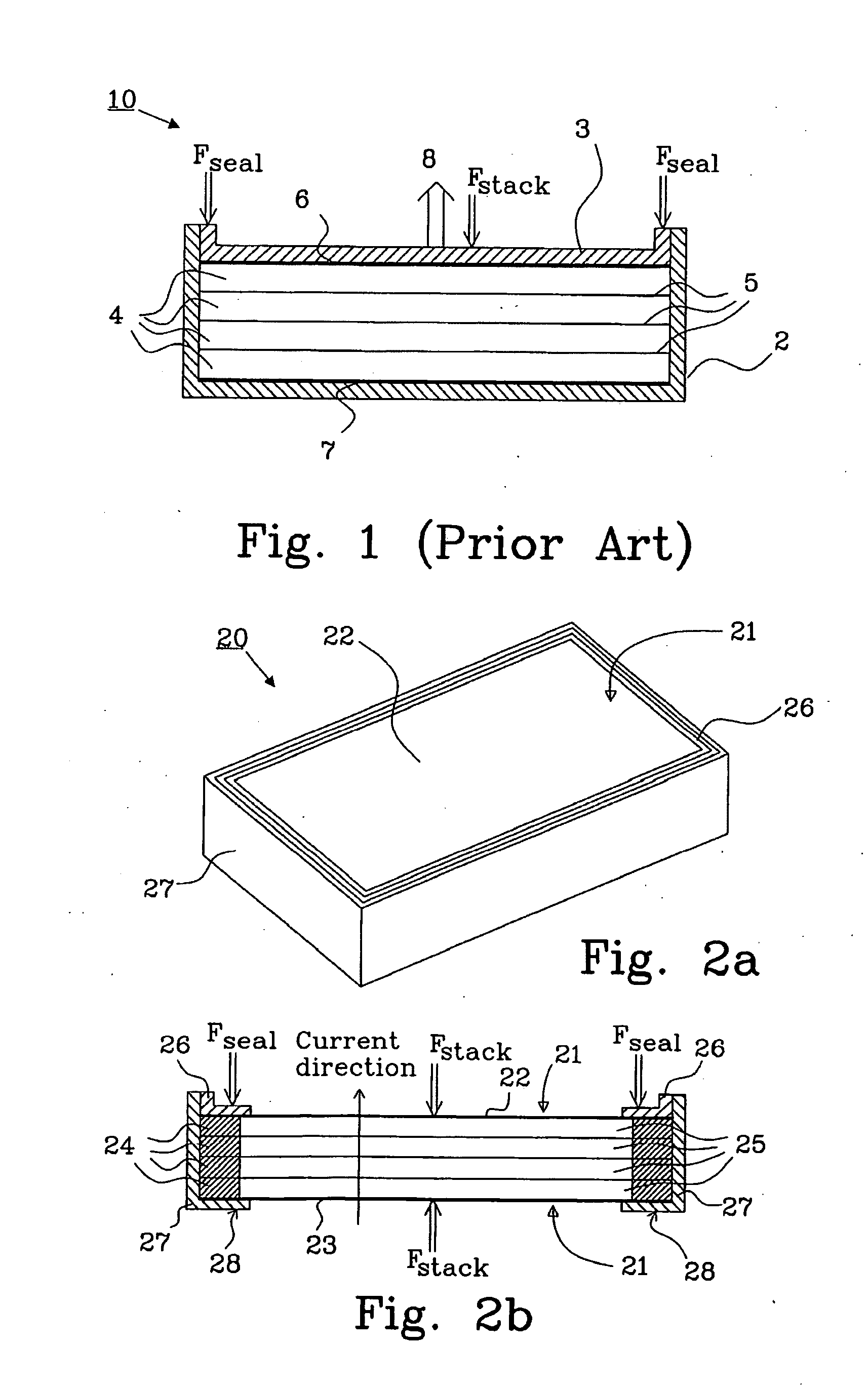

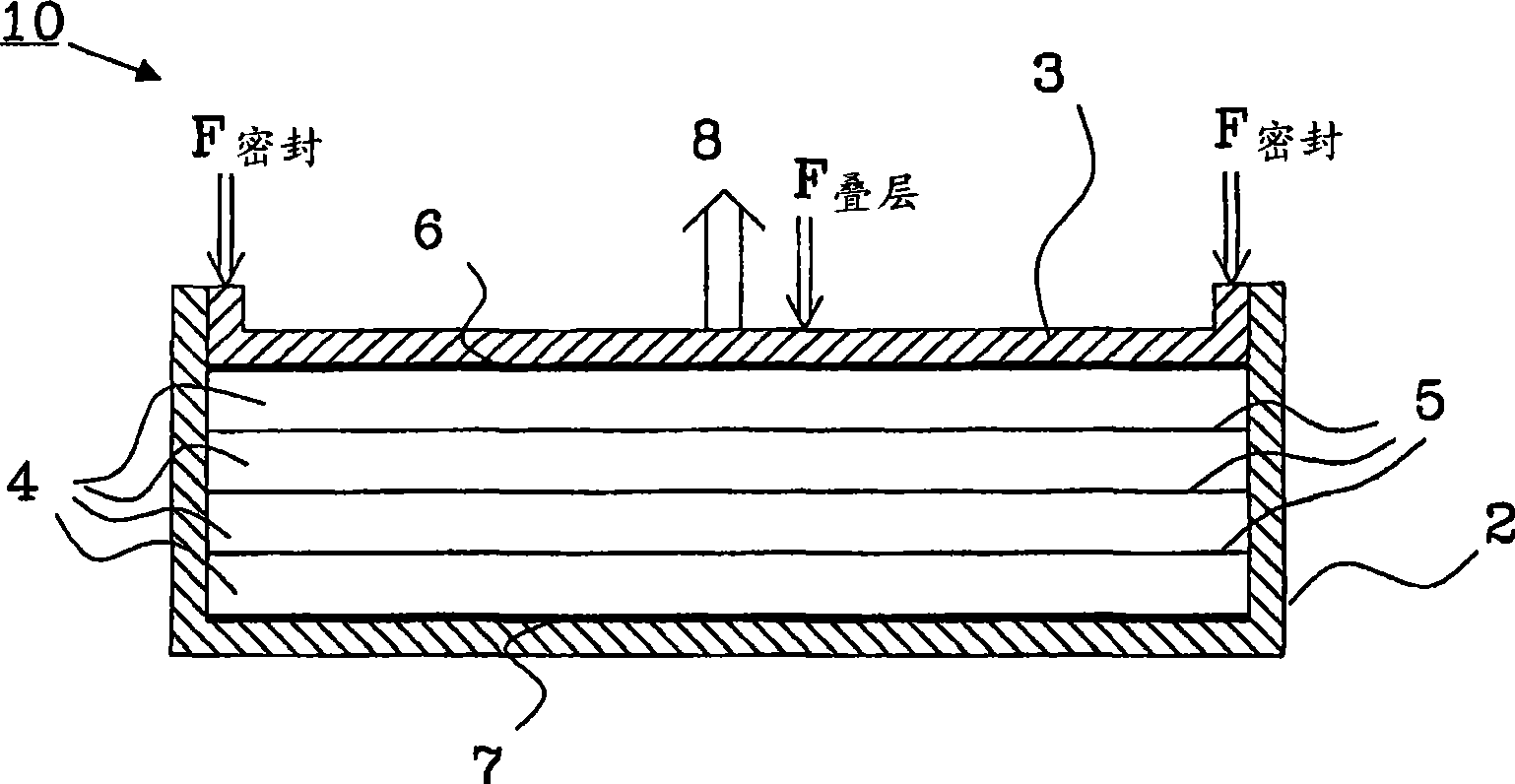

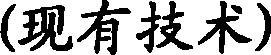

Battery stack arrangement

ActiveUS20100151306A1Increase pressureCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrolyte leakageBattery cell

The present invention relates to a battery stack arrangement (50) comprising at least one bipolar battery. Each bipolar battery comprises a plurality of battery cell arranged between endplates (22,23). Each battery cell is provided with a seal (24) arranged around the entire periphery of each cell, and a sealing pressure Fseal is applied over the seal to prevent electrolyte leakage between adjacent cells. The battery stack arrangement further comprises a mounting frame (57) including: at least two mounting units (58,59) and at least one tie unit (60, 60′, 60″) holding said mounting units together. The bipolar battery is arranged between the mounting units (58,59), and the battery stack arrangement further comprises at least one spacing element (61) arranged between the mounting units (58,59) and each spacing element (61) abuts against at least one endplate (22,23) and is held in place by said mounting frame (57) to create a stack pressure Fstack, independent of the sealing pressure Fseal. The stack pressure is controlled by the tie unit.

Owner:NILAR INT AB

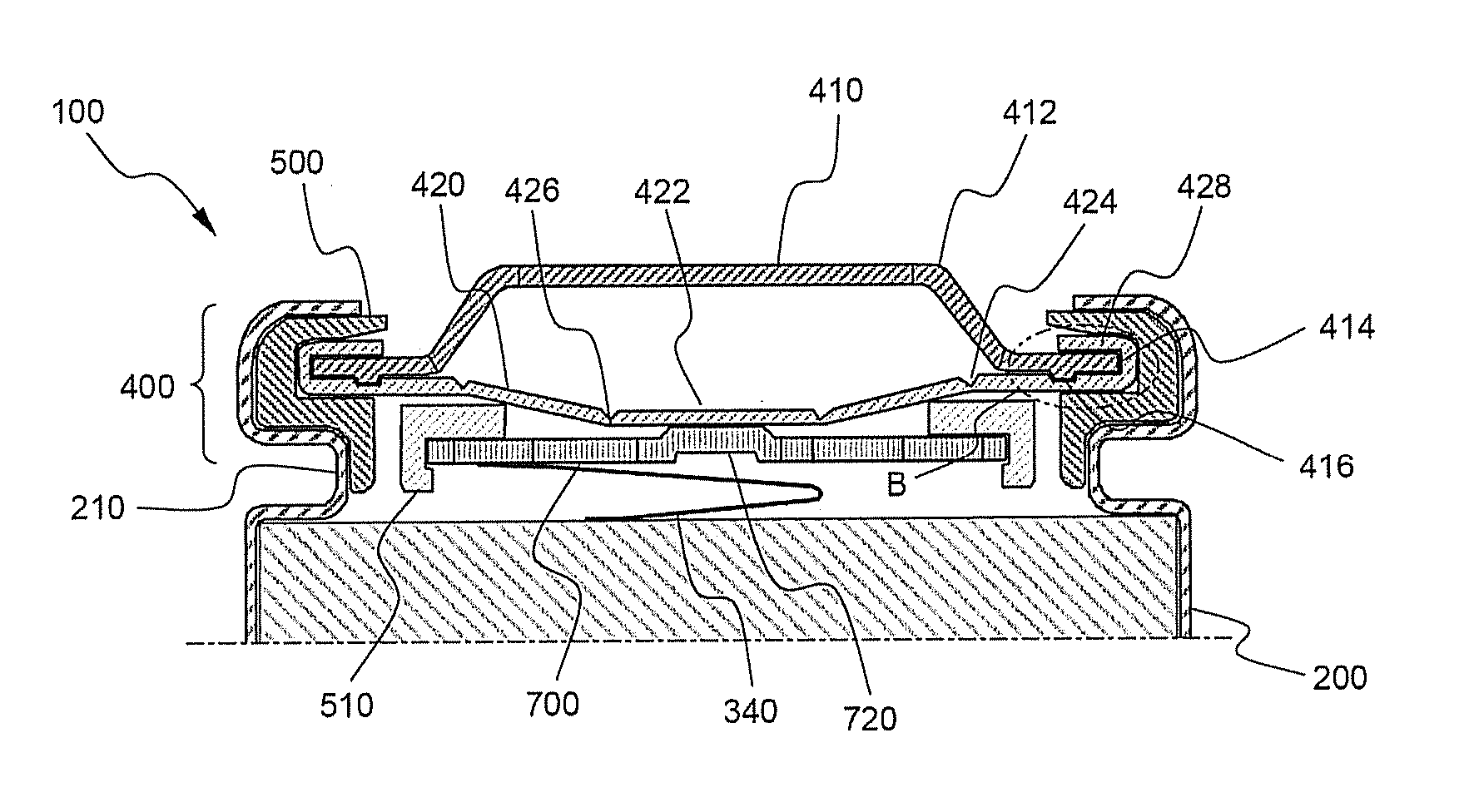

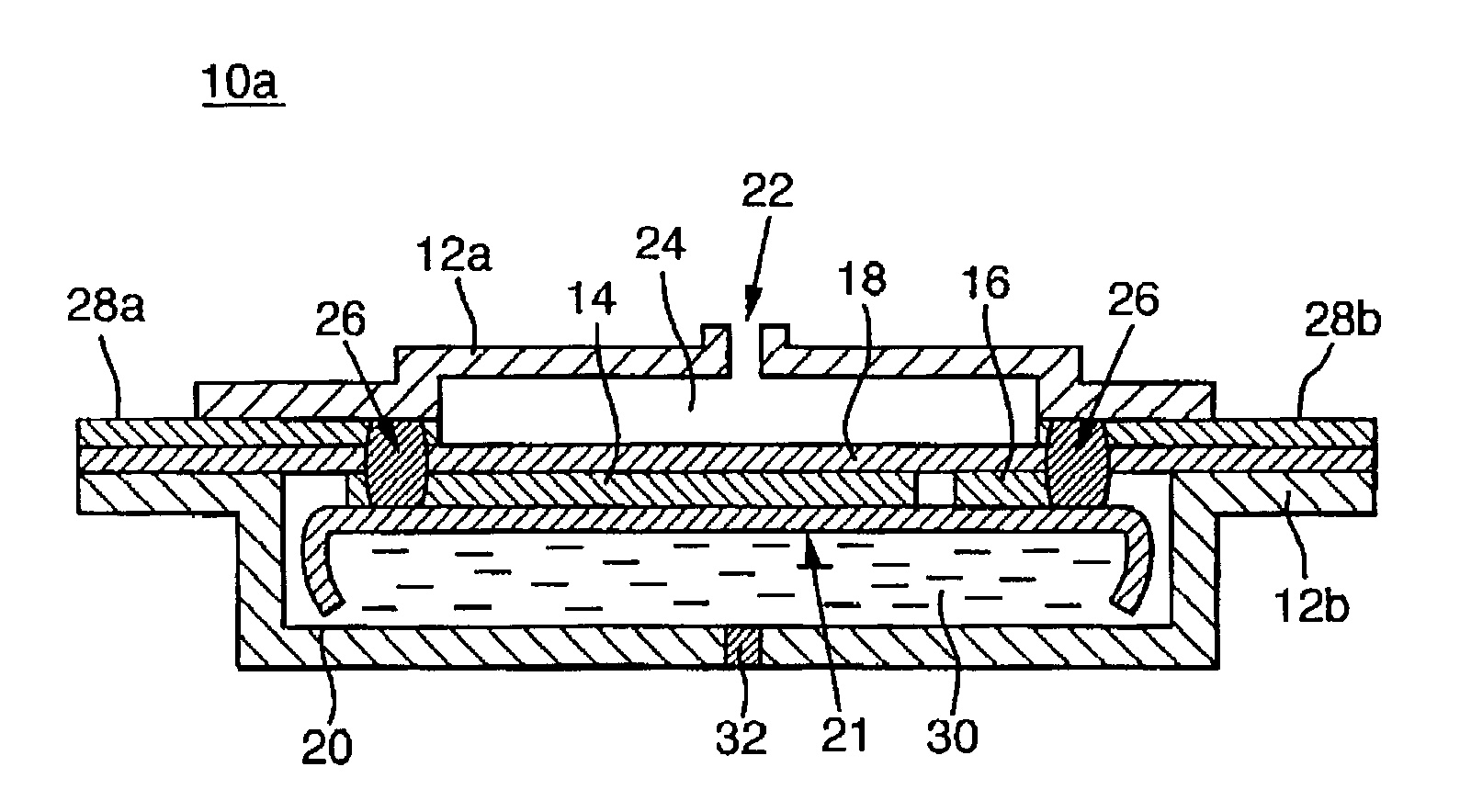

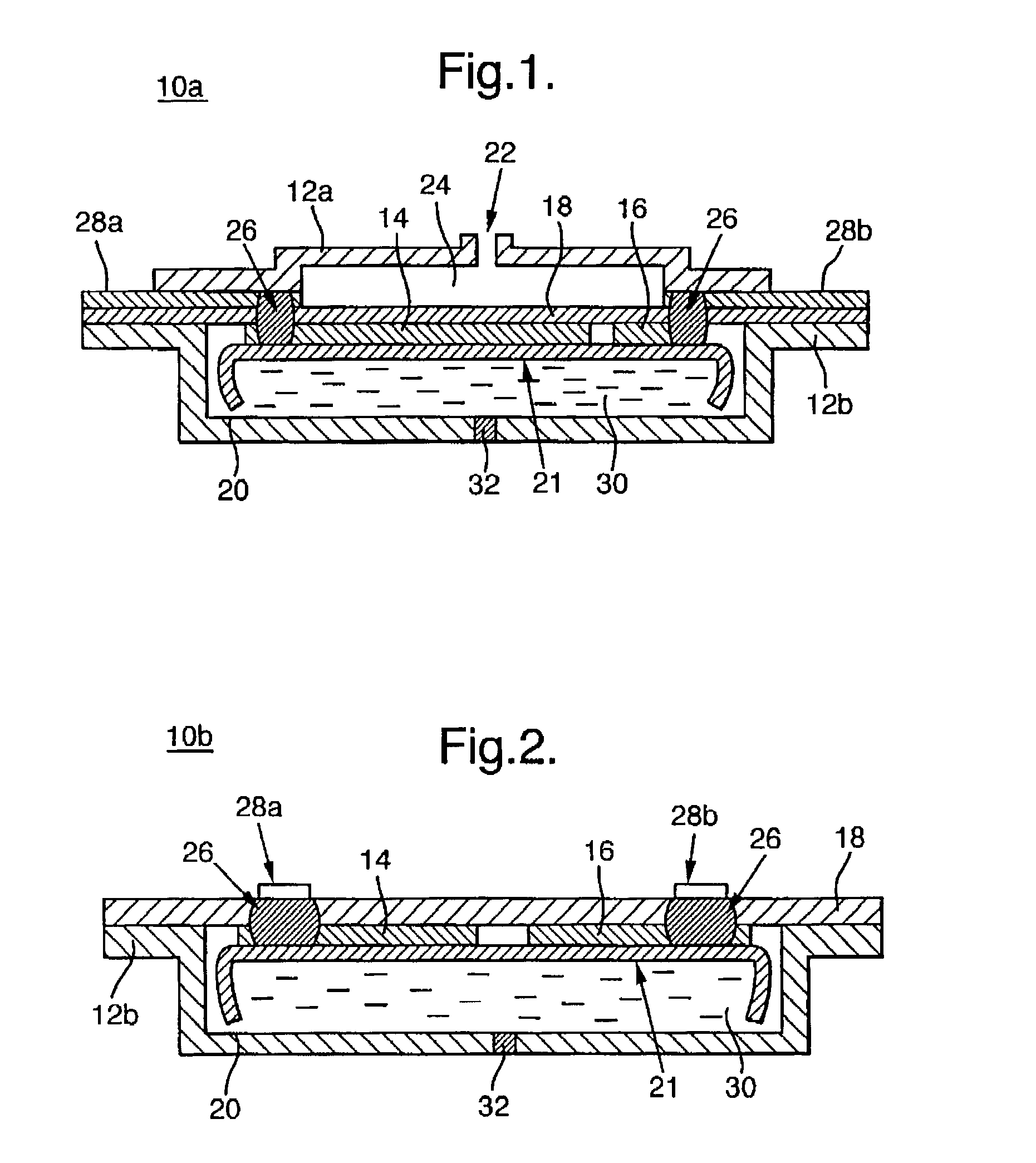

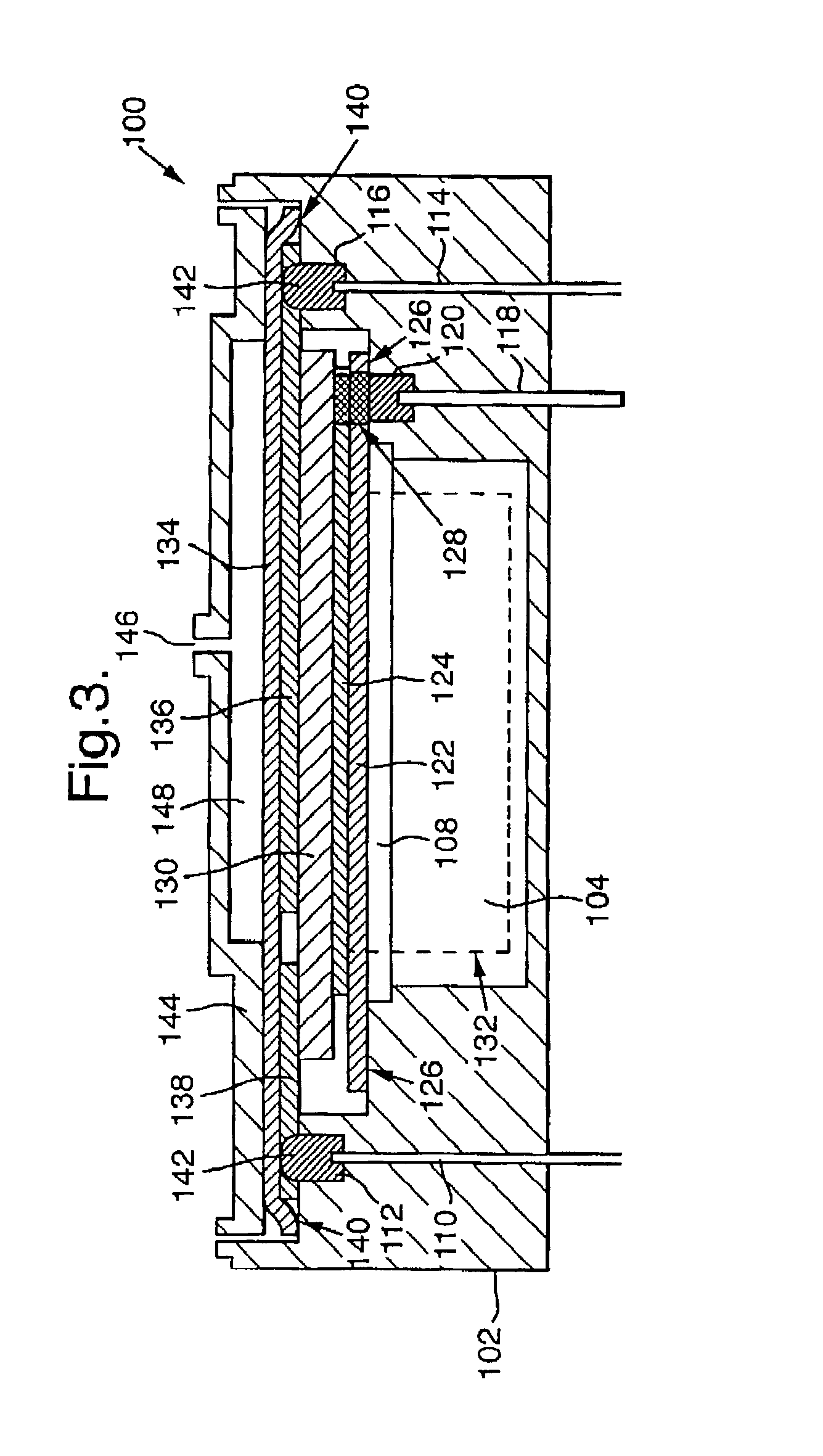

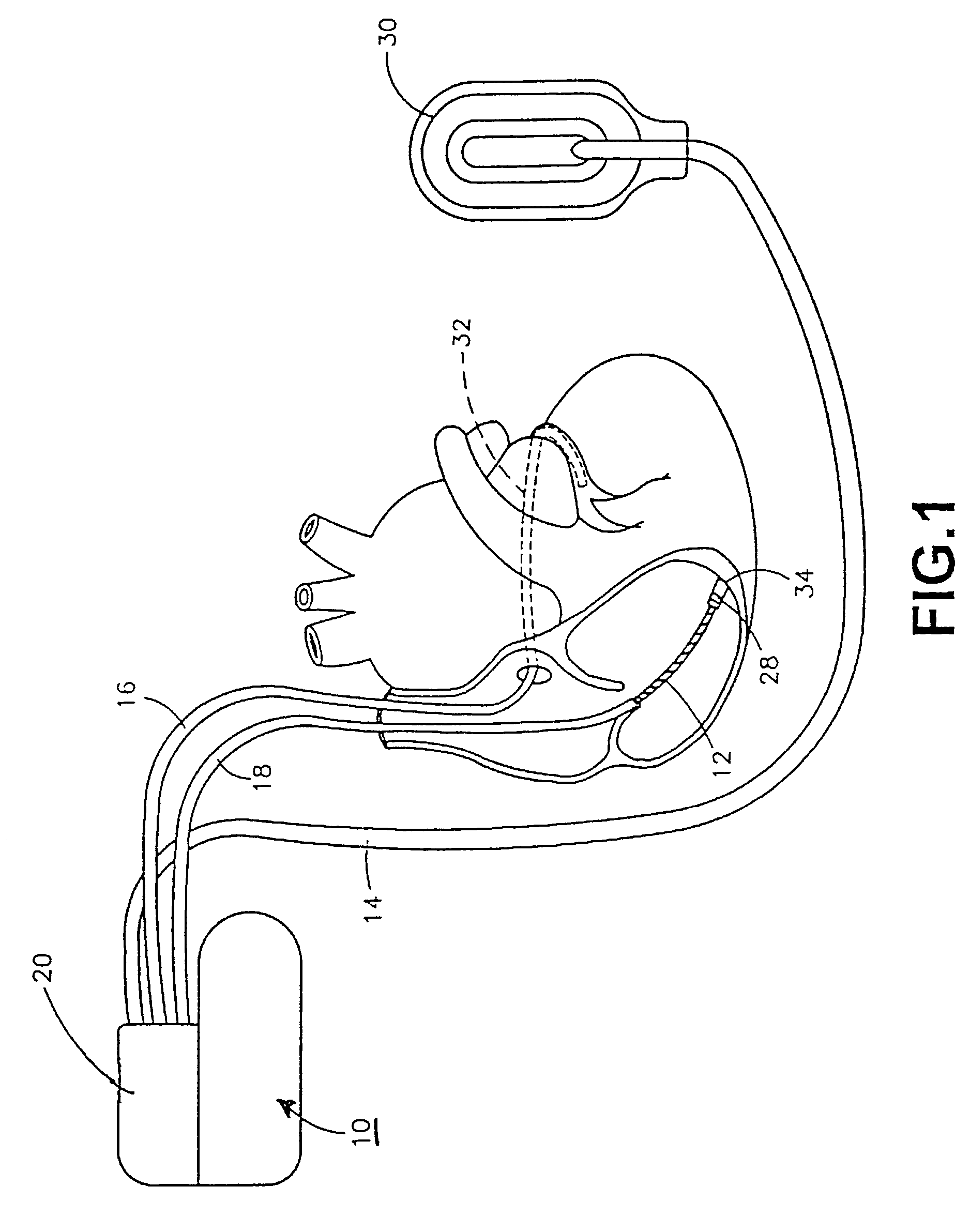

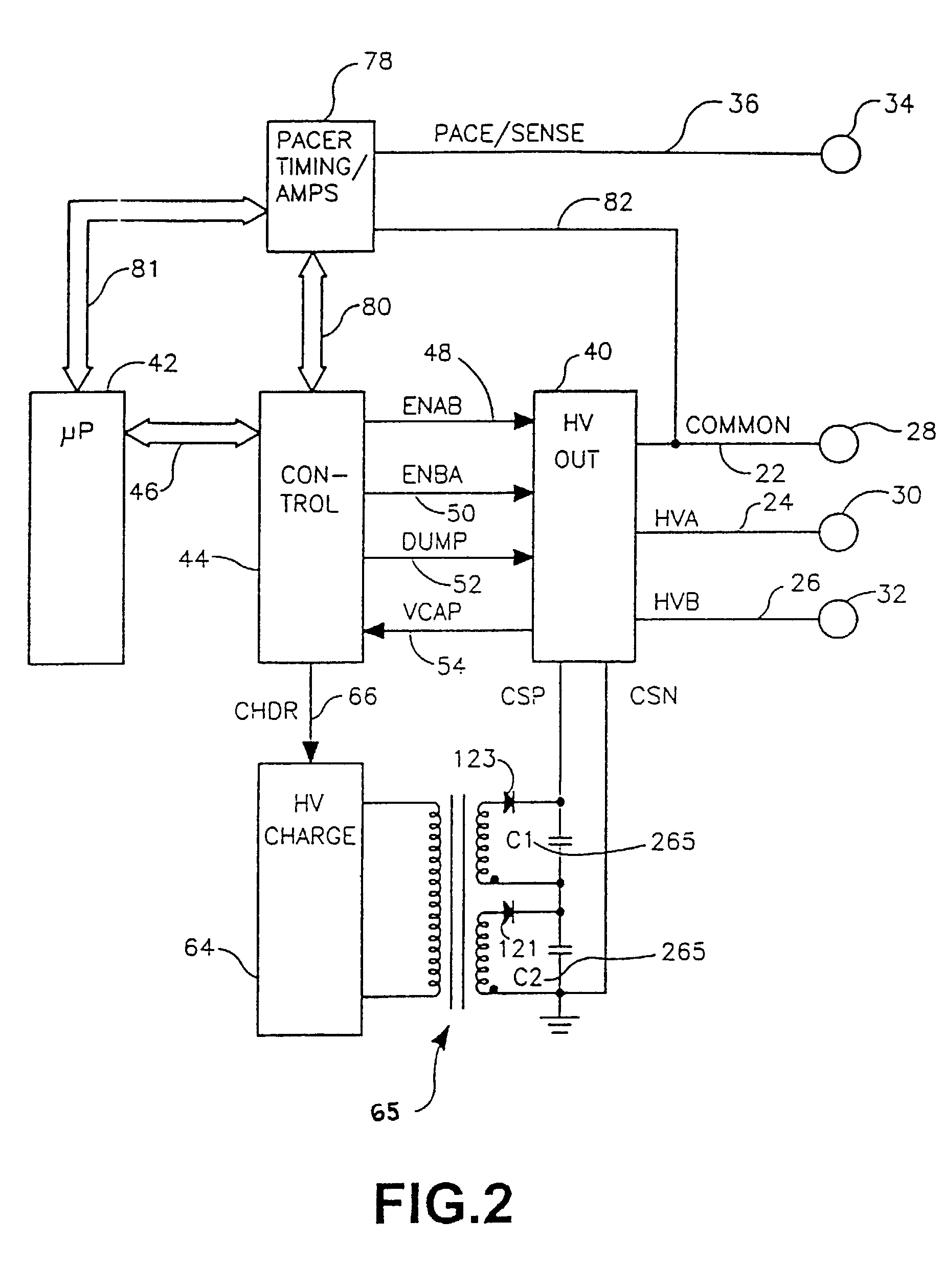

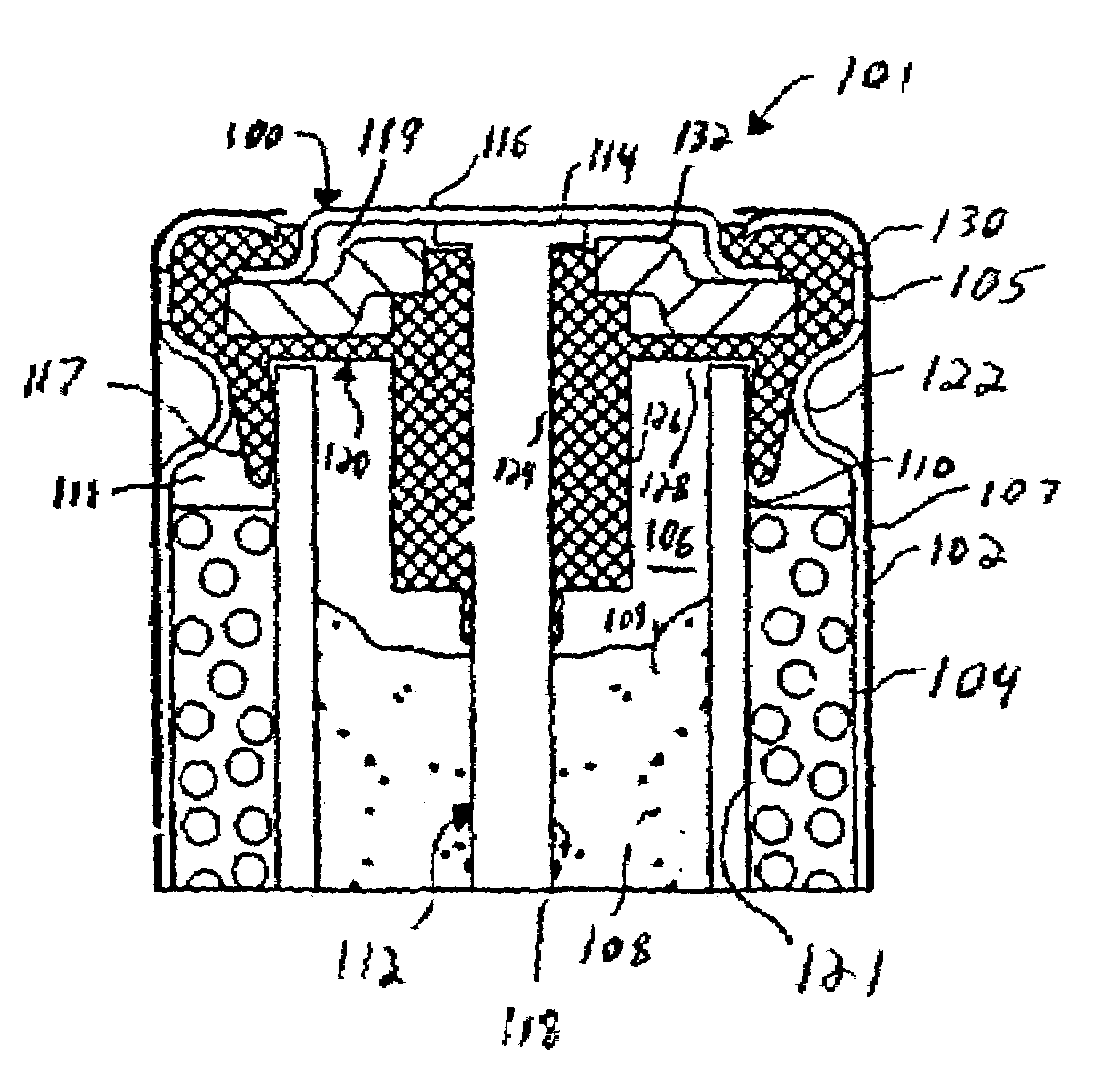

Implantable medical device having flat electrolytic capacitor with porous gas vent within electrolyte fill tube

InactiveUS7177140B2Prevent electrolyte leakageClosuresLiquid electrolytic capacitorsElectrolysisEngineering

Implantable medical devices (IMDs) and their various components, including flat electrolytic capacitors for same, and methods of making and using same and providing for outgassing of gases released during capacitor charge and discharge cycles are disclosed. A gas vent and liquid electrolyte barrier into the electrolyte fill tube lumen that is used to fill the interior case chamber with electrolyte and then needs to be closed to prevent leakage of electrolyte. The fill port is shaped to comprise a fill port tube having interior and exterior tube ends and a fill port ferrule intermediate the ends of the fill port tube and comprising a fill port ferrule flange extending transversely to and away from the fill port tube. The fill port ferrule is mounted in an opening disposed in one of the case wall and the cover wall with the ferrule flange in sealing engagement therewith to locate the exterior tube end extending outwardly away from the fill port ferrule flange and the interior tube end within the interior case chamber. A microporous plug is injected into and fills the fill port lumen, the plug formed of a microporous material allowing the escape of gas released from the liquid electrolyte during capacitor charging while preventing escape of liquid or vaporized electrolyte.

Owner:MEDTRONIC INC

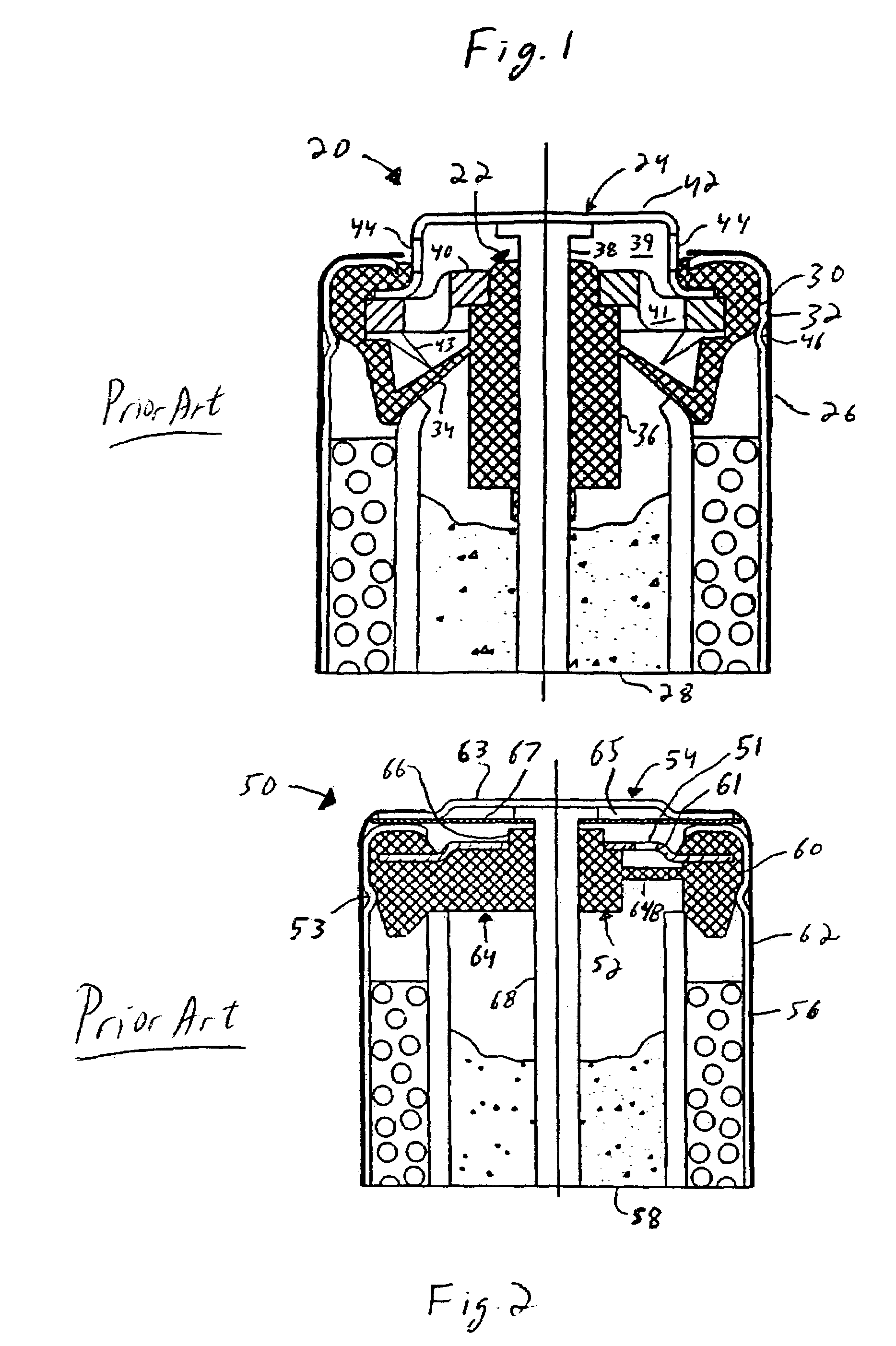

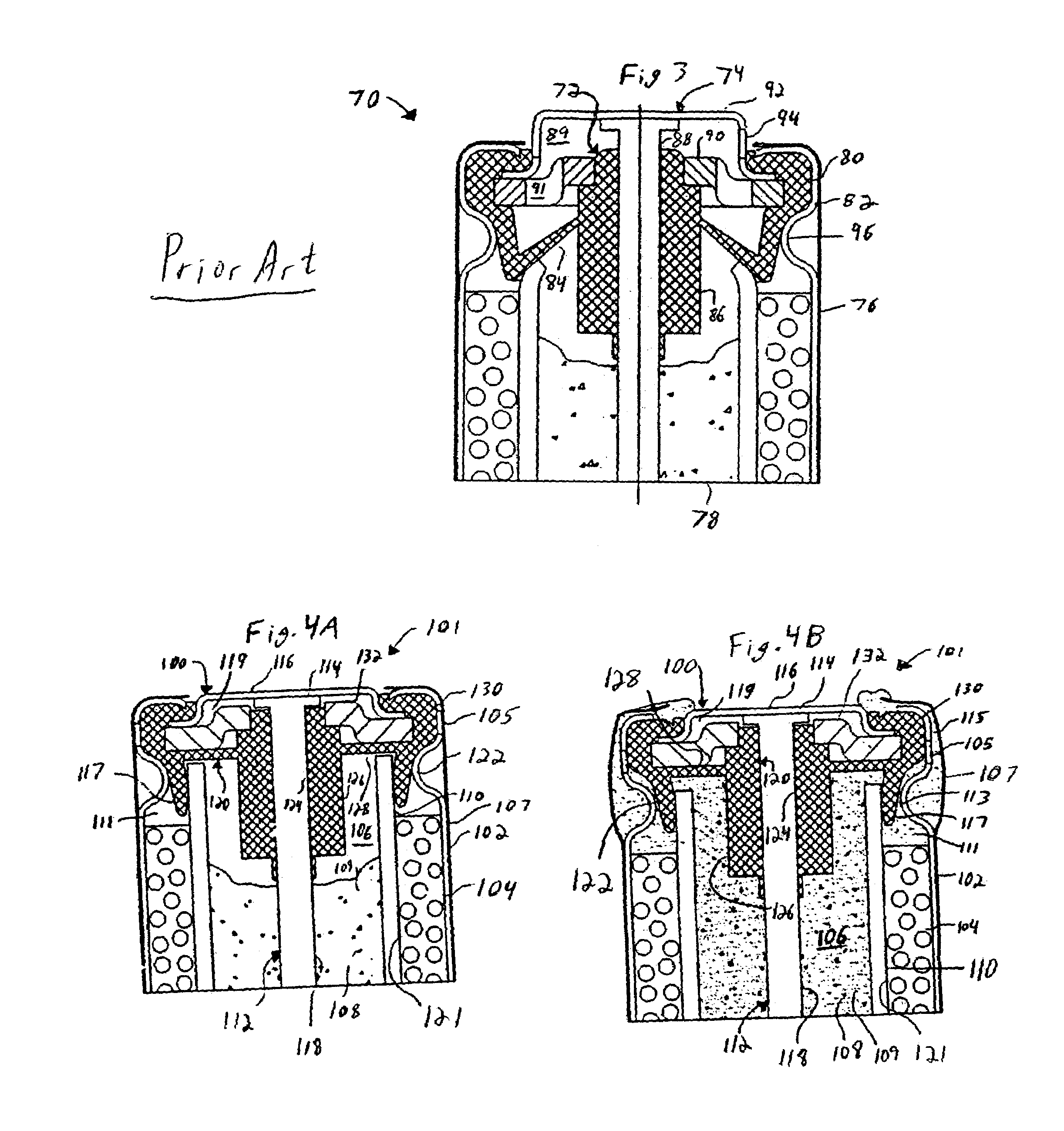

Vent for cylindrical electrochemical batteries

An electrochemical cell is presented having a gasket that is sealed against the container to prevent electrolyte leakage during normal operation. When the internal pressure of the cell reaches a predetermined threshold, the seal is removed, thereby permitting electrolyte to escape through a vent.

Owner:ENERGIZER BRANDS +1

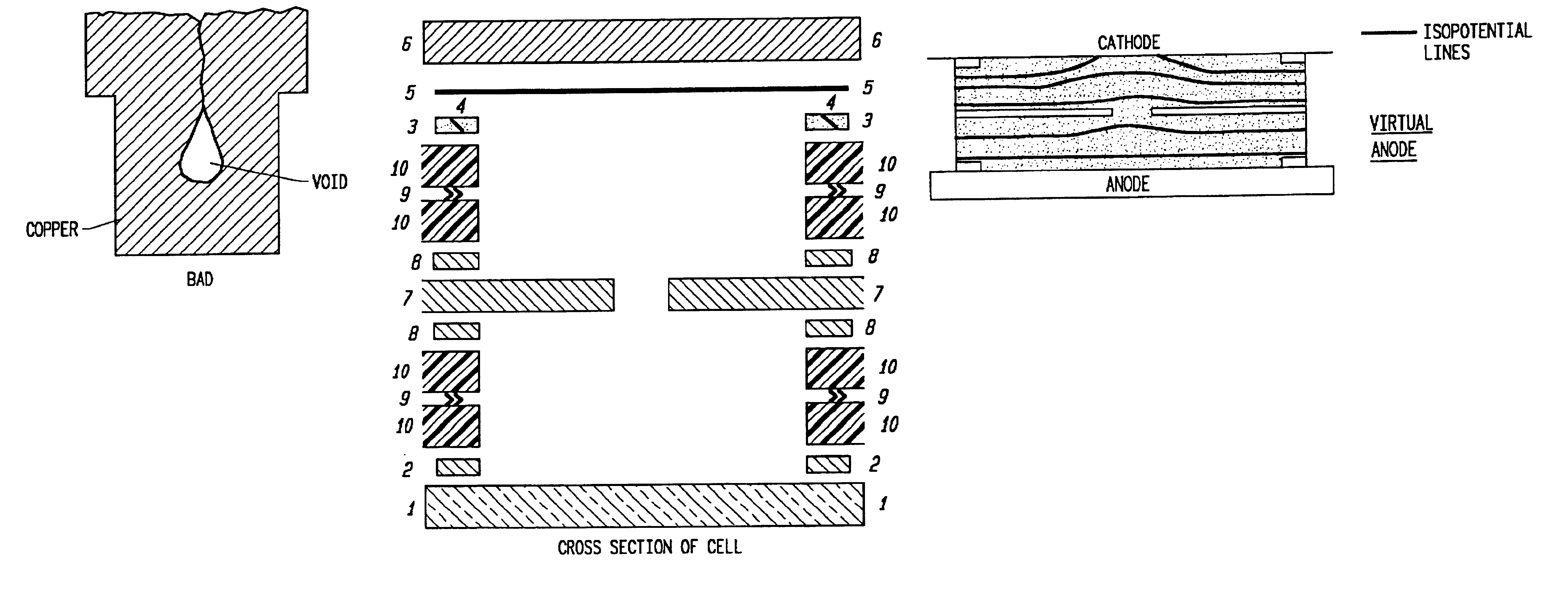

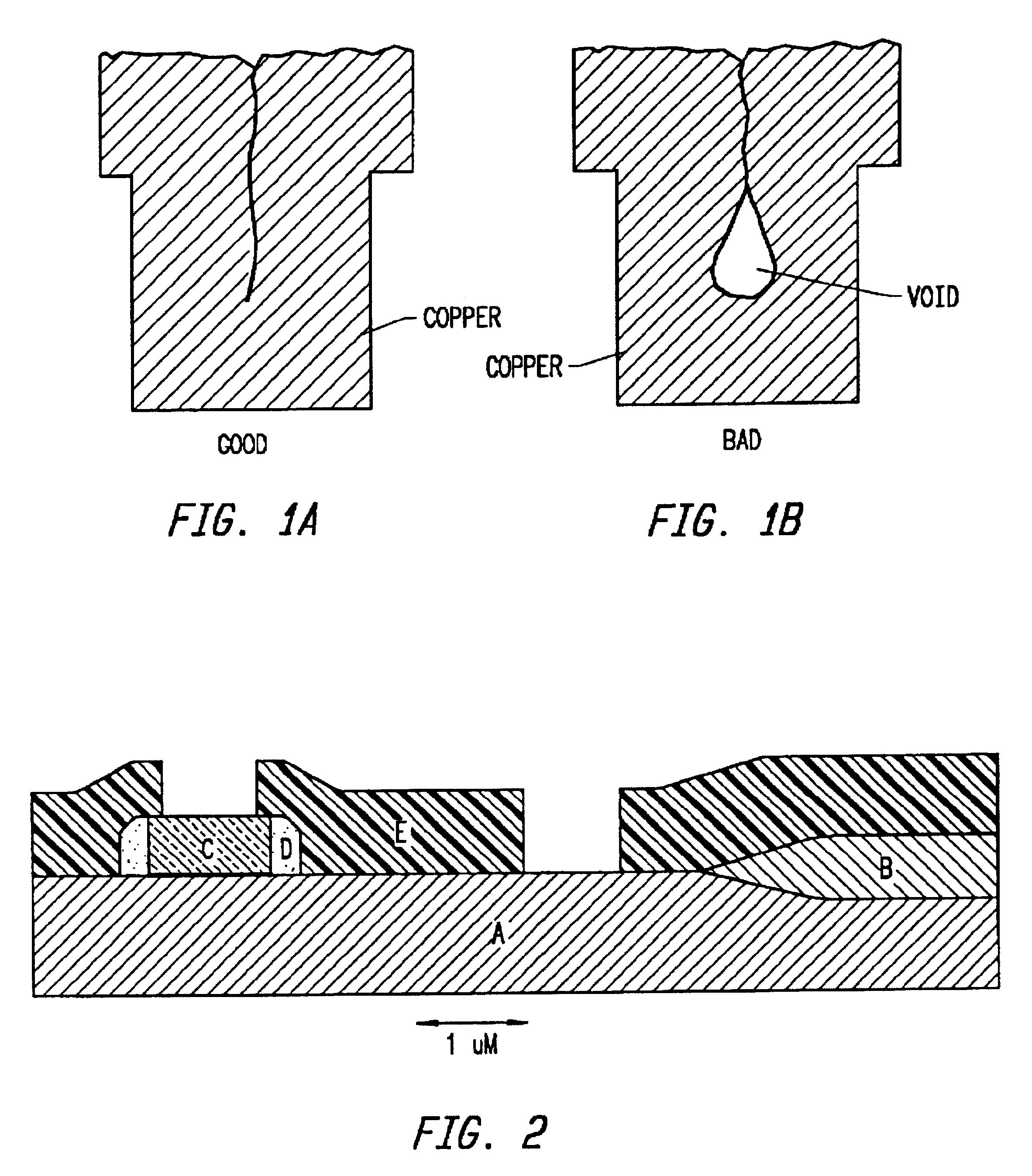

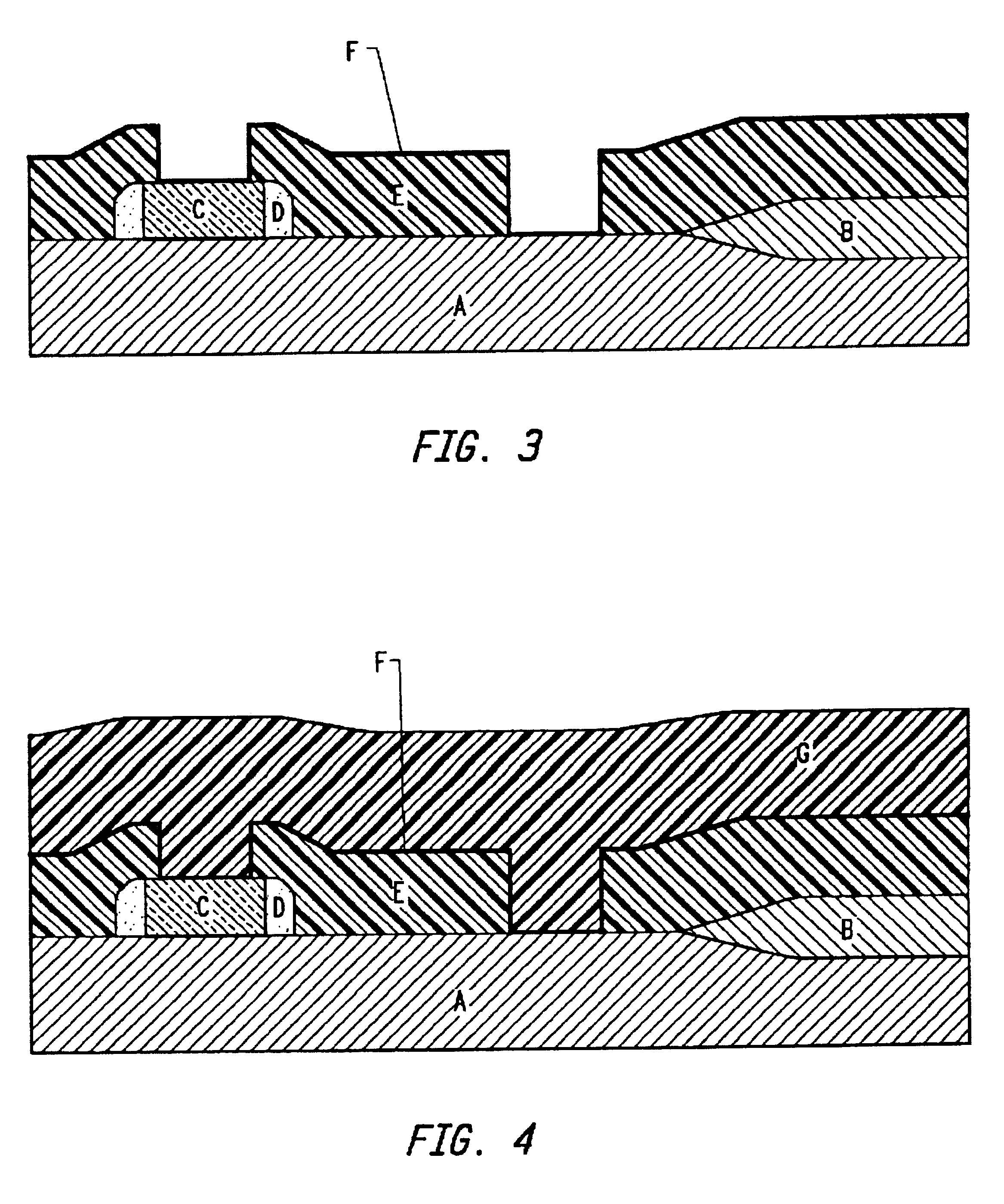

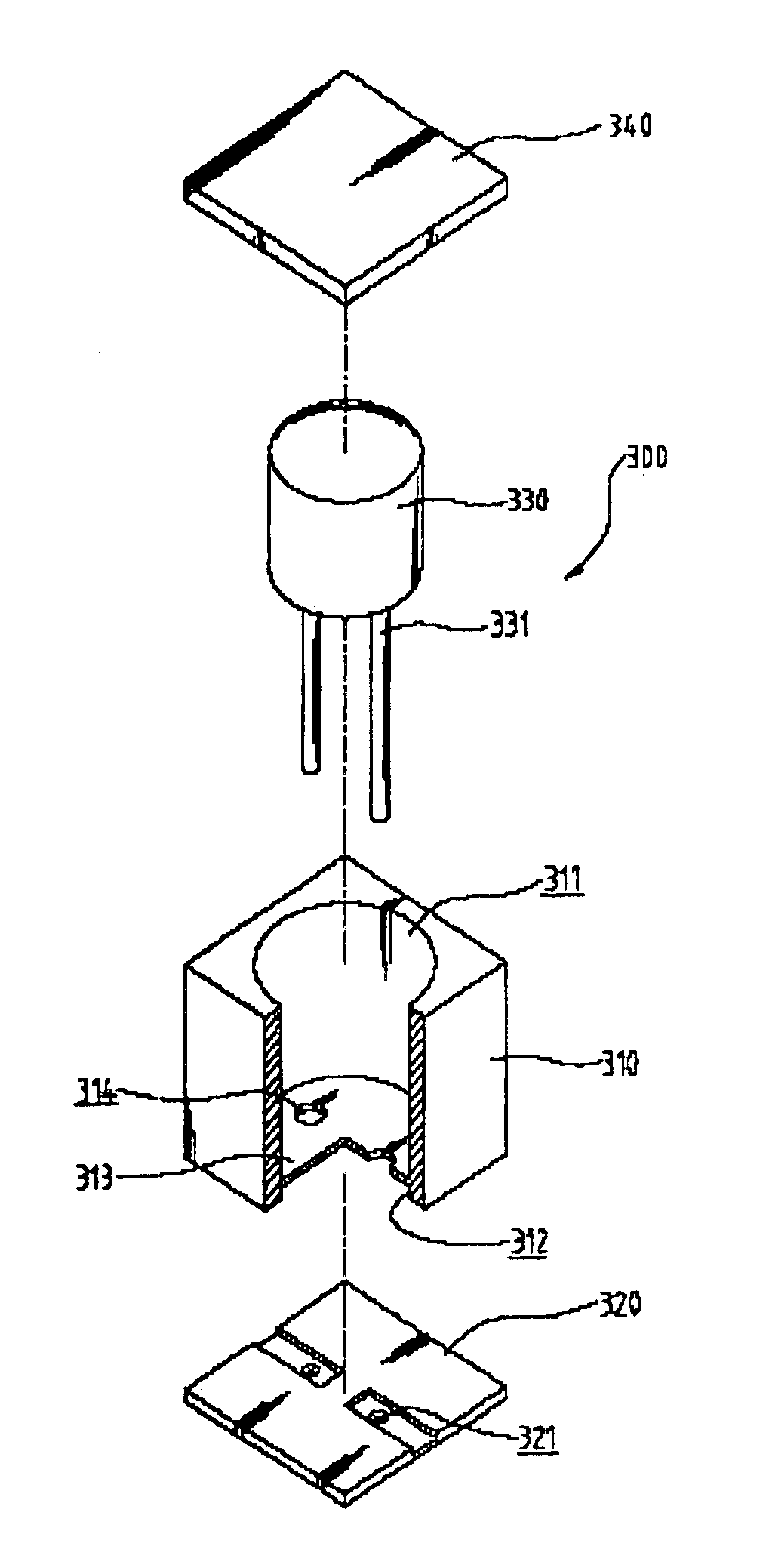

Electrodeposition apparatus with virtual anode

InactiveUSRE37749E1Inhibited DiffusionCellsSemiconductor/solid-state device manufacturingCapacitanceElectrochemistry

An electrochemical etching step in a semiconductor device fabrication process increases the radius of curvature of edges of metal lines deposited on the semiconductor device. The metal lines are fabricated by forming a mask, electrodepositing the metal, and removing the mask, and the electro-chemical etching step in performed subsequently. The increased radius of curvature of the metal lines simplifies subsequent planarization and decreases line-to-line capacitance, thereby enhancing device performance. In an apparatus for performing the fabrication process, wires sown into a gasket which secures the semiconductor wafer and prevents electrolyte leakage, allows the gasket to function also as a component of the cathode. A more uniform metal deposition is created by a virtual anode, i.e., a metal plate having an aperture and being located between the anode and the cathode.

Owner:PORIS JAIME

A battery stack arrangement

ActiveCN101390232ACell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrolyte leakageBattery cell

The present invention relates to a battery stack arrangement (50) comprising at least one bipolar battery. Each bipolar battery comprises a plurality of battery cell arranged between endplates (22,23). Each battery cell is provided with a seal (24) arranged around the entire periphery of each cell, and a sealing pressure Fseal is applied over the seal to prevent electrolyte leakage between adjacent cells. The battery stack arrangement further comprises a mounting frame (57) including: at least two mounting units (58,59) and at least one tie unit (60, 60', 60'') holding said mounting units together. The bipolar battery is arranged between the mounting units (58,59), and the battery stack arrangement further comprises at least one spacing element (61) arranged between the mounting units (58,59) and each spacing element (61) abuts against at least one endplate (22,23) and is held in place by said mounting frame (57) to create a stack pressure Fstack, independent of the sealing pressure Fseal. The stack pressure is controlled by the tie unit.

Owner:NILAR INT AB

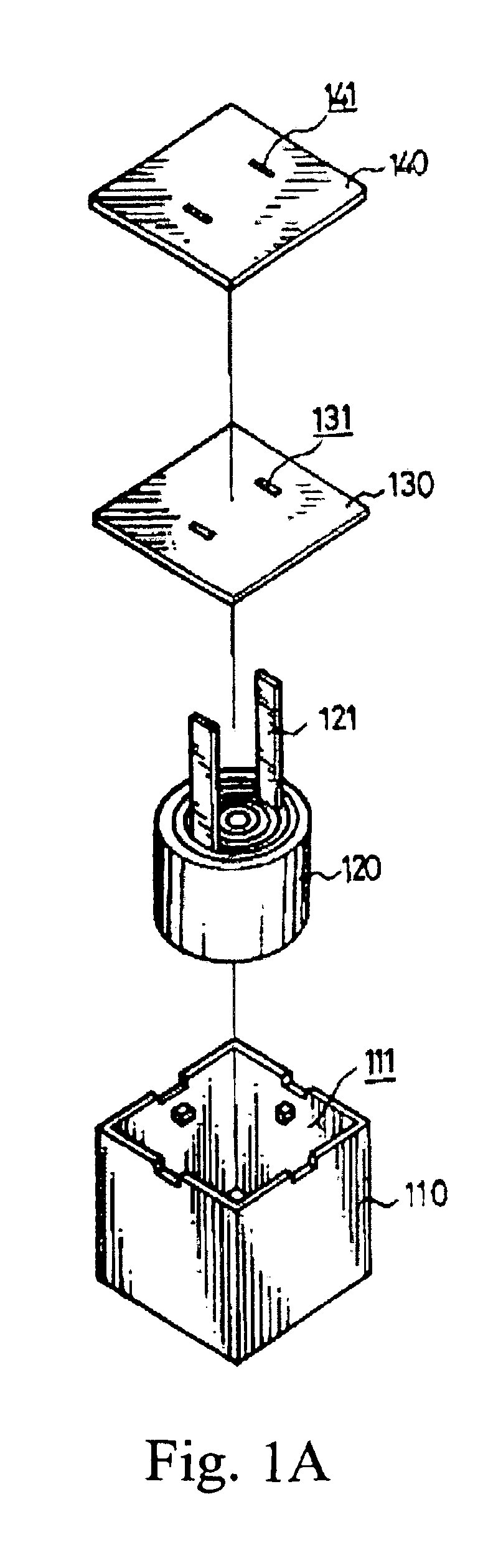

Structure of chip type electrolytic capacitor

InactiveUS6898066B1Improve air tightnessAvoid pollutionClosuresCasings/cabinets/drawers detailsEpoxyDielectric

The present invention relates to a structure of chip type electrolytic capacitor, which comprises a casing cover and a partition to separate space of casing cover into a dielectric chamber and a buffer chamber, a dielectric which includes lead pins, holes on the partition for the lead pins pass through. The dielectric is installed in the dielectric chamber, and lead pins pass through the holes on partition and extend to the buffer chamber. The buffer chamber is sealed with a bottom cover which also includes holes for lead pins. A stuff of epoxide is filled into the buffer chamber to fix the dielectric and its lead pins. A top cover is to seal the dielectric chamber for filling electrolyte. The casing cover is made with high strength engineering plastic by plastic injection machine. A supersonic welding and the epoxide adhesive solidification package technologies replace rubber packing. This skill of the art can enhance airtight and reduce volume of chip type electrolytic capacitor to anti shock and electrolyteleaking.

Owner:GEMMY ELECTRONICS

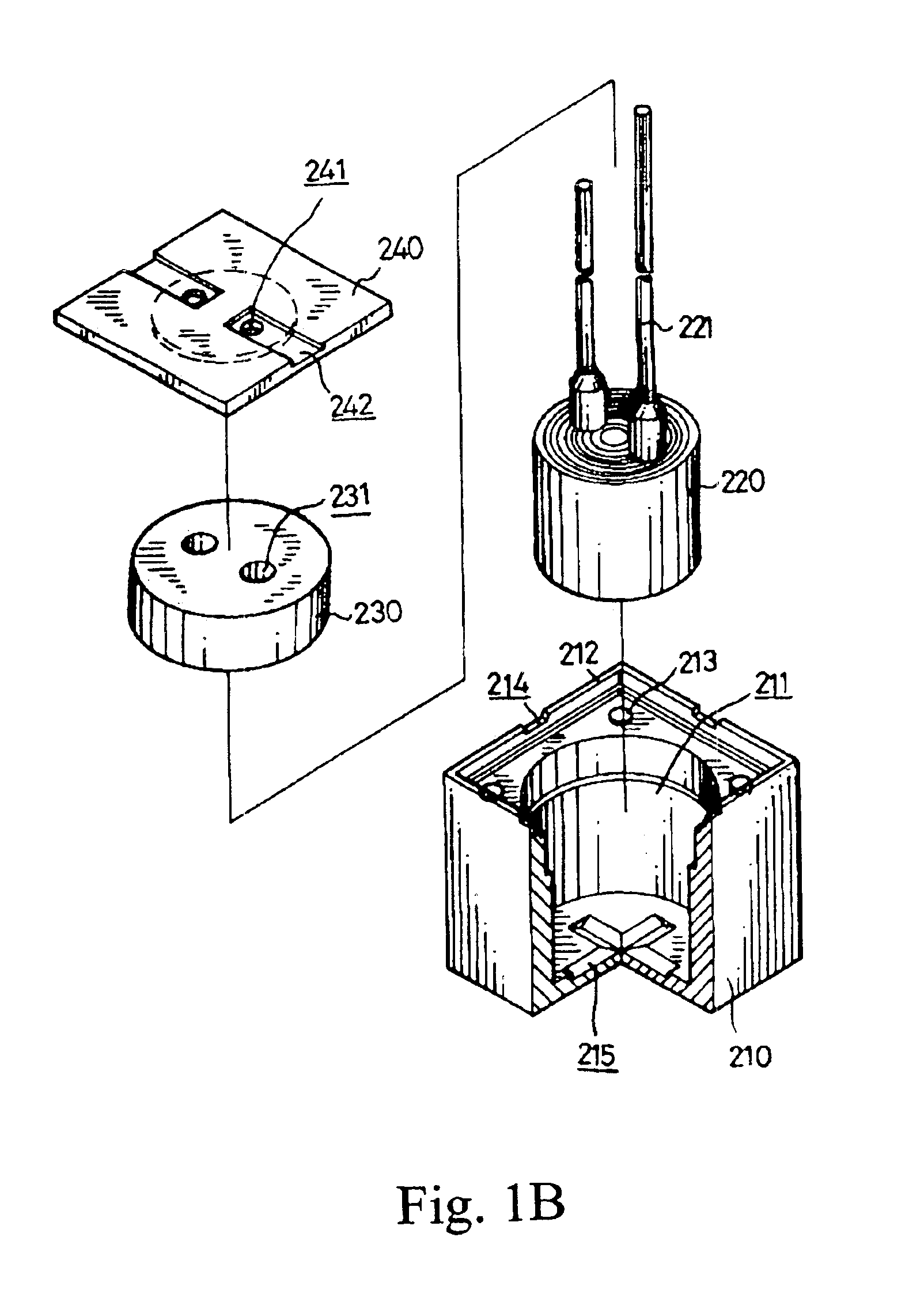

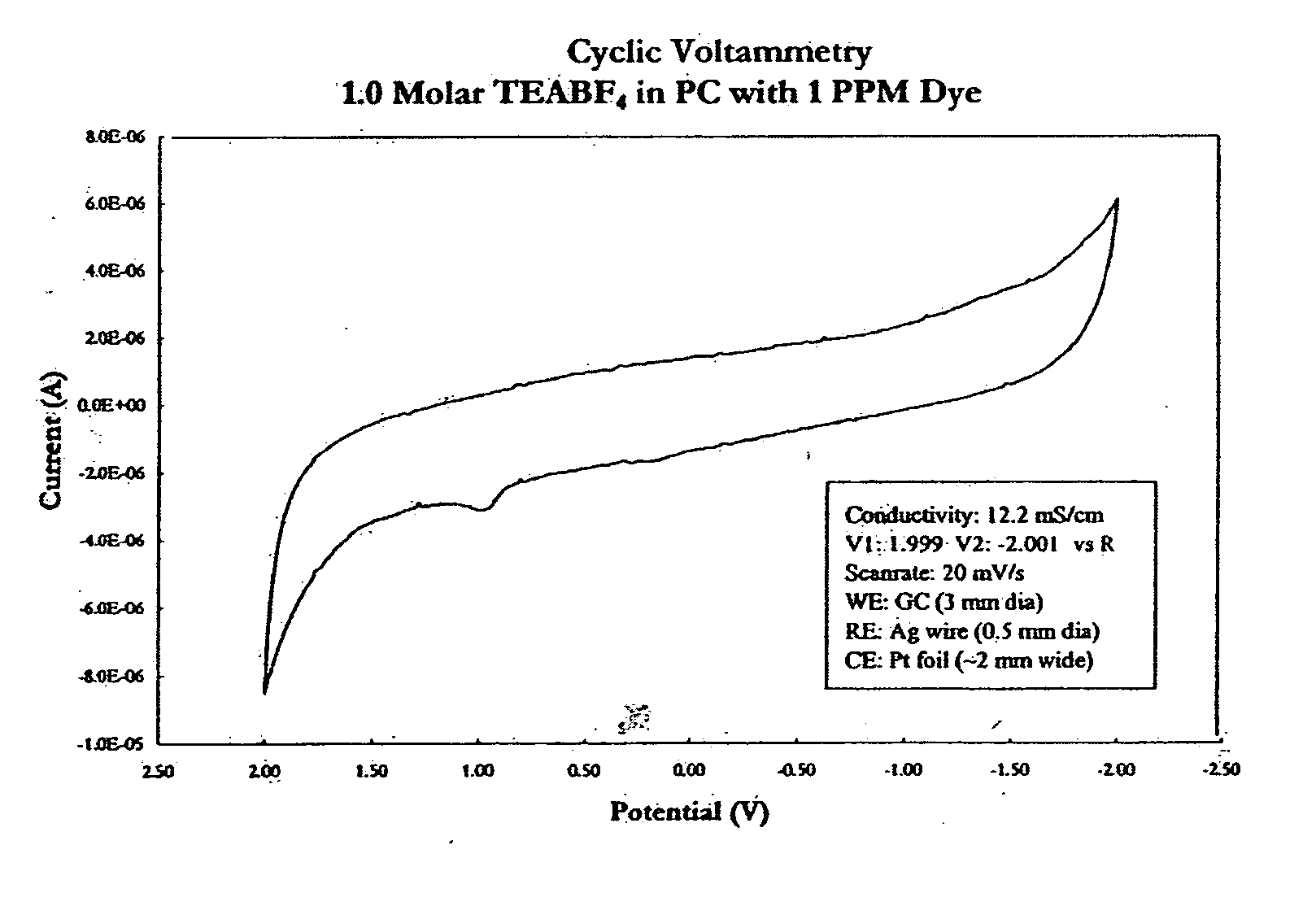

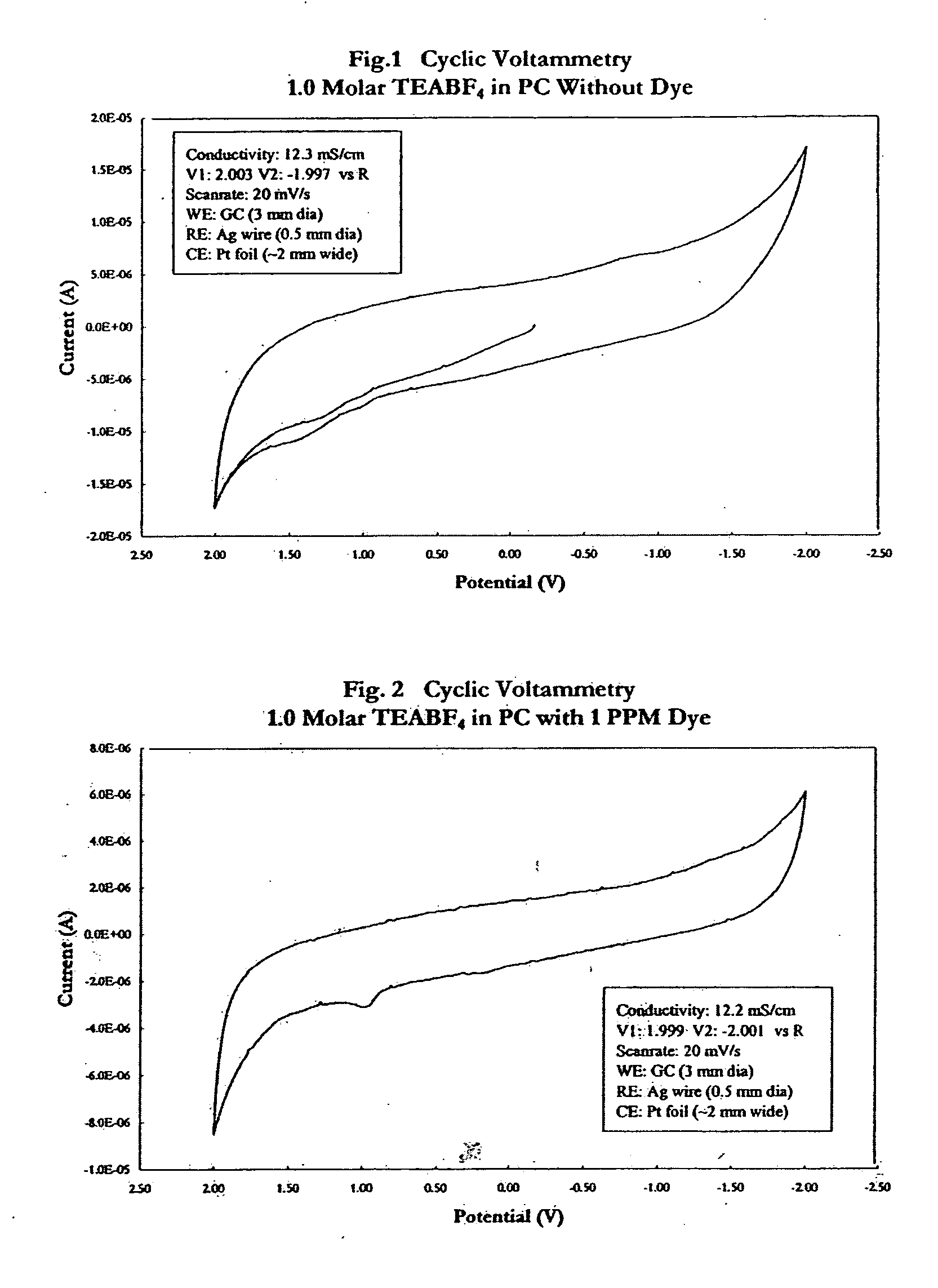

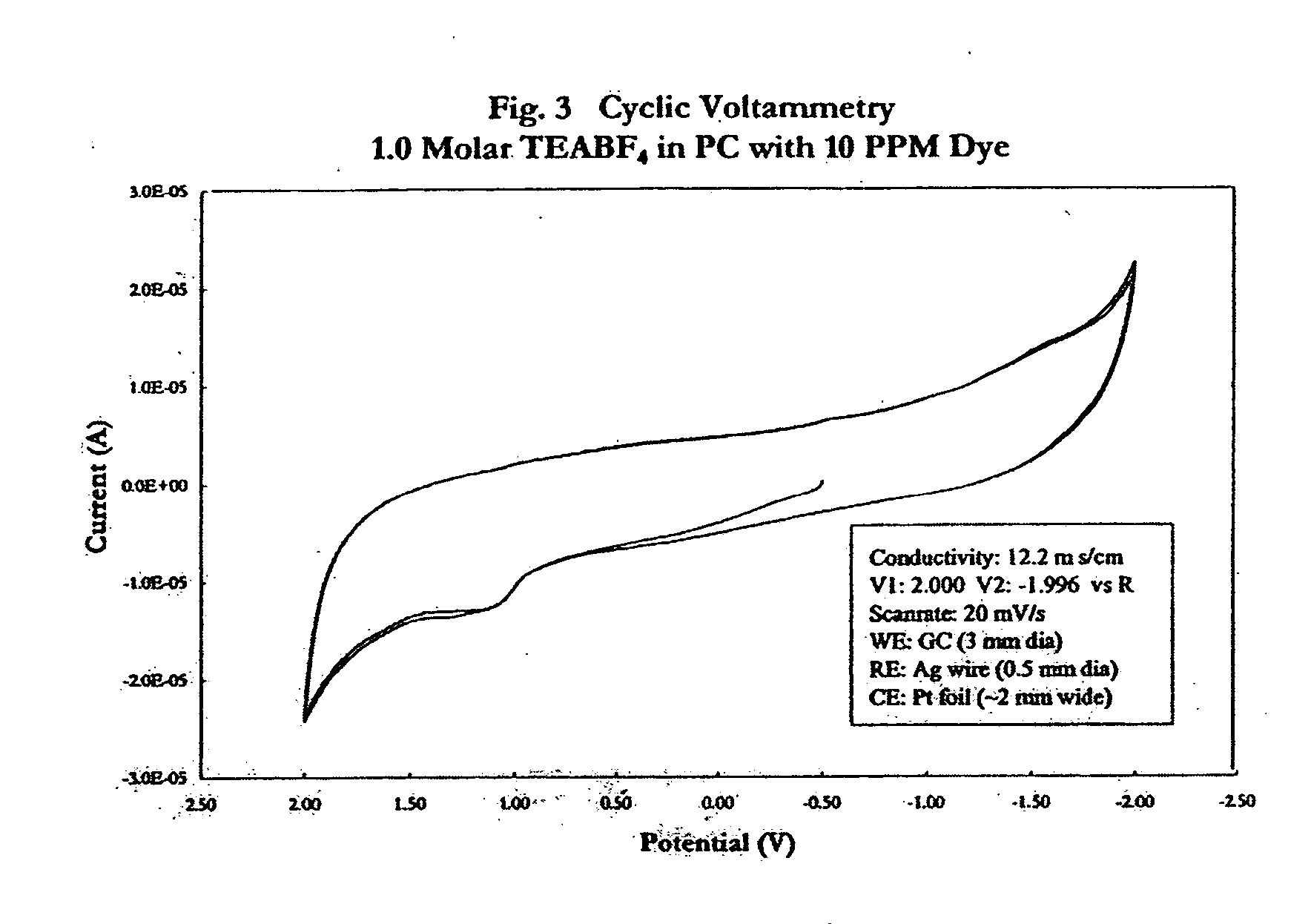

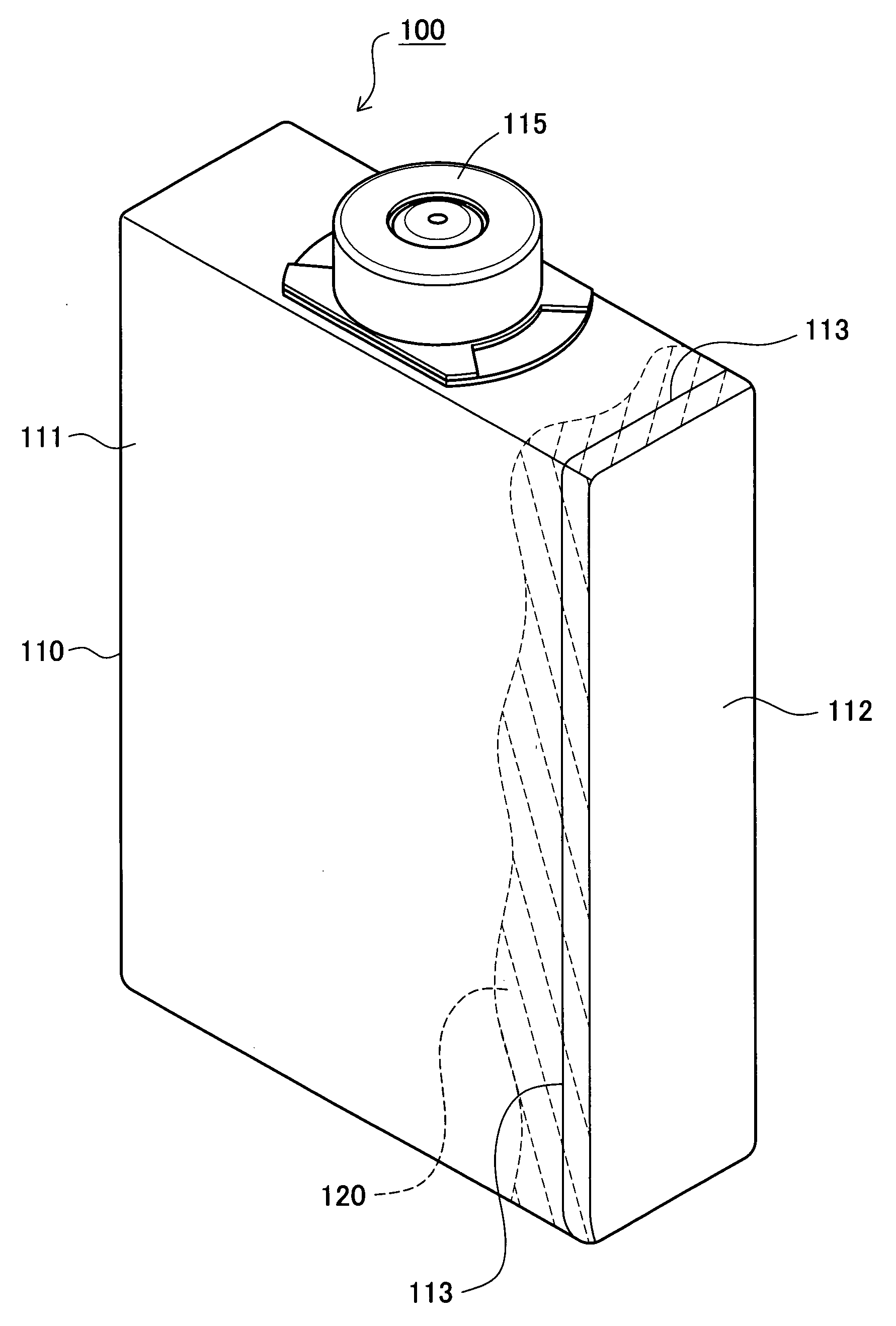

Electrolyte with indicator

InactiveUS20050069761A1Cell/batteries leak testingOrganic electrolyte cellsElectrolyte leakageEngineering

An electrolyte with an indicator, such as a dye, for detecting leakage from an electrochemical energy storage device is provided. Also provided is a method of making such an electrolyte with indicator; a device that incorporates such an electrolyte with indicator; a method of manufacturing an electronic or electrical system that incorporates such a device; and a method of detecting the leakage of electrolyte from a battery or capacitor.

Owner:HONEYWELL INT INC

Battery, manufacturing method of battery, and check method of electrolyte leakage

ActiveUS20060134511A1Appropriate detectionAlkaline accumulatorsMeasurement of fluid loss/gain rateElectrolyte leakageFluorescein

There is provided manufacturing method of battery comprising adhering process (S1) to adhere fluorescent material (leakage indicator including fluorescein) which emits fluorescence in response to predetermined light (ultraviolet radiation) irradiated under condition that electrolyte exists, to at least one portion of a surface on a battery case, and leakage detecting process (S2 through S9) to detect presence / absence of electrolyte leakage with fluorescence which an adhered portion emits in response to the predetermined light (ultraviolet radiation) irradiated on at least the adhered portion which has adhesion of the fluorescent material (leakage indicator including fluorescein), out of the surface on the battery case.

Owner:TOYOTA JIDOSHA KK

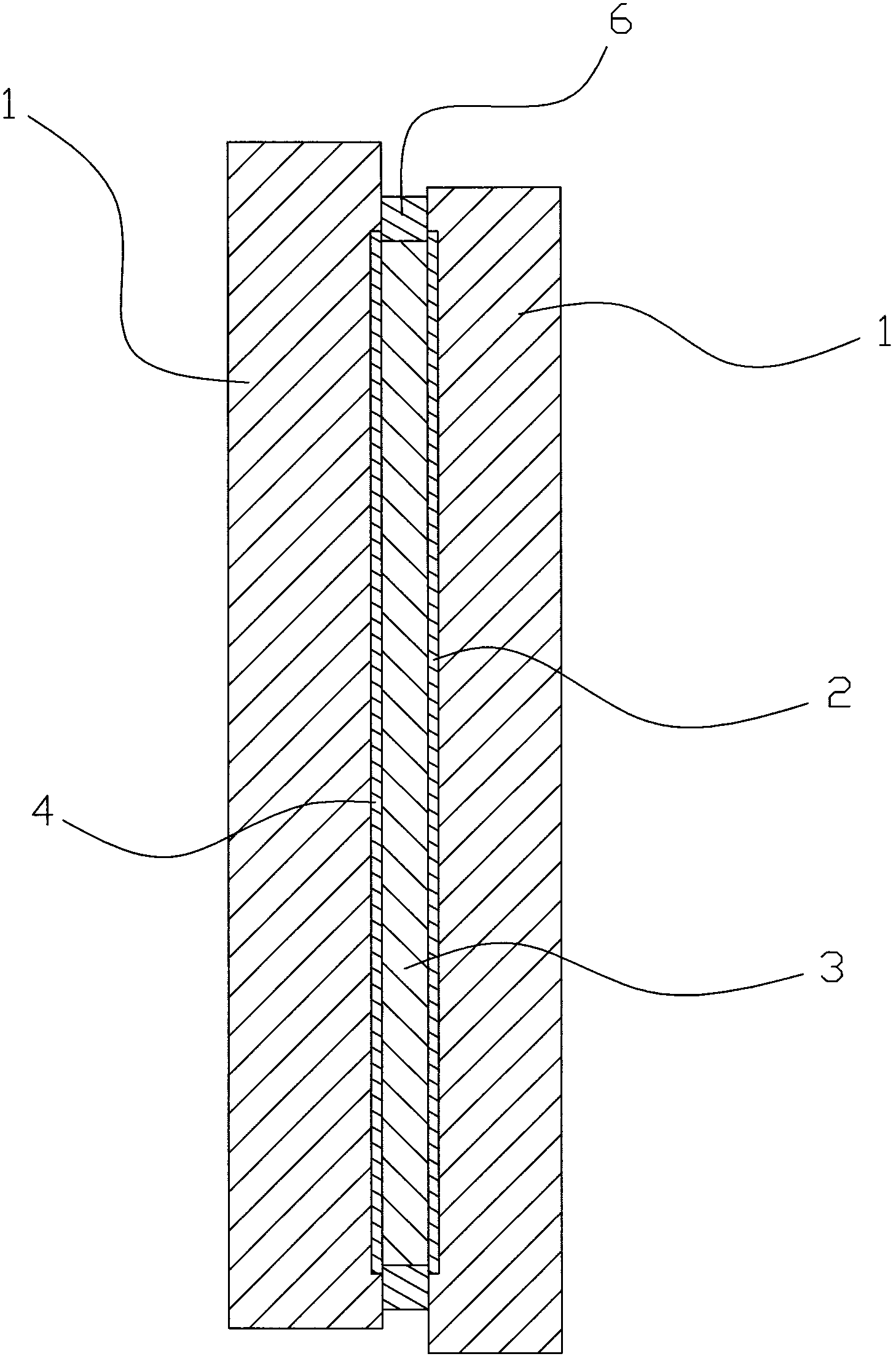

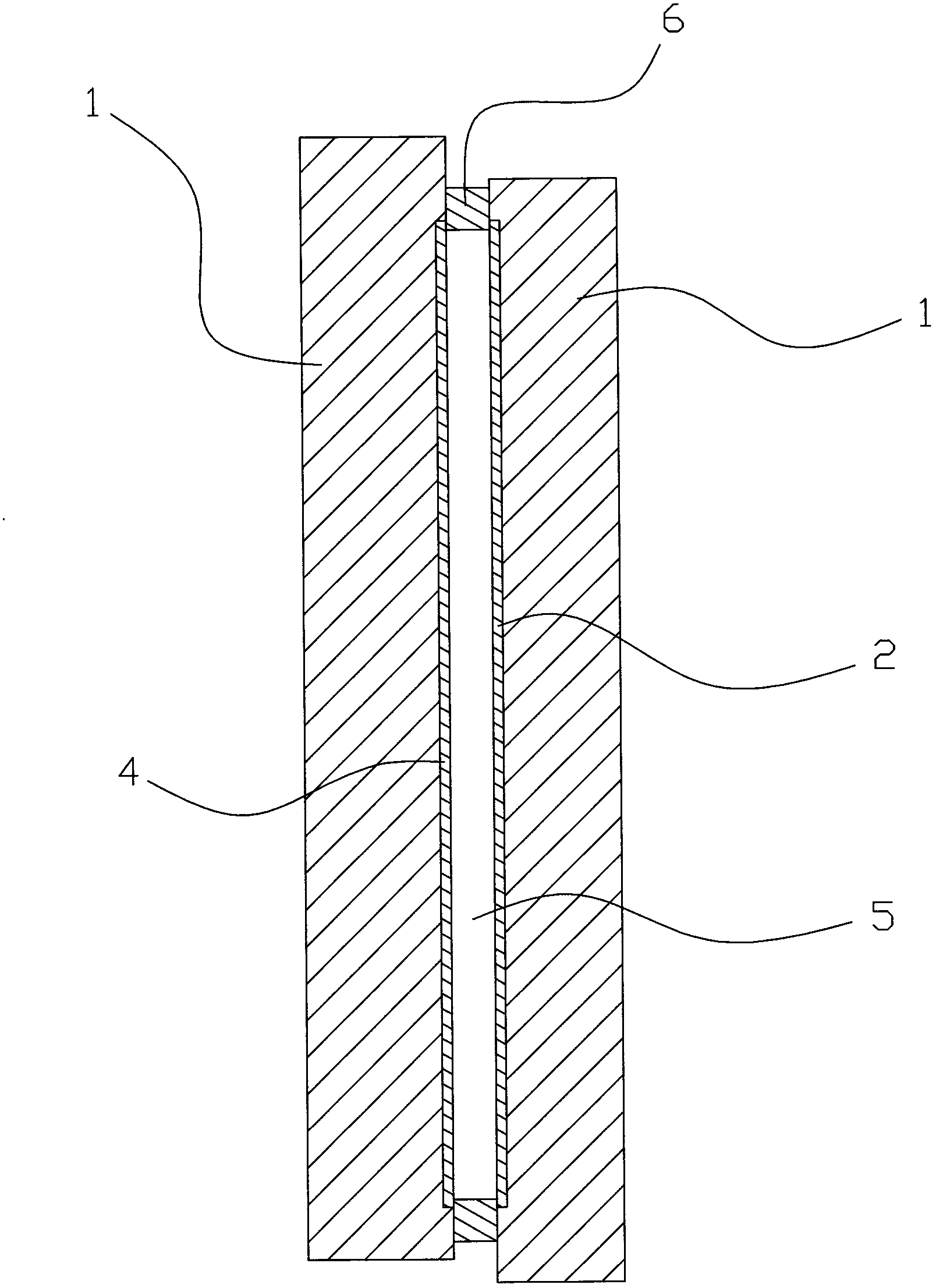

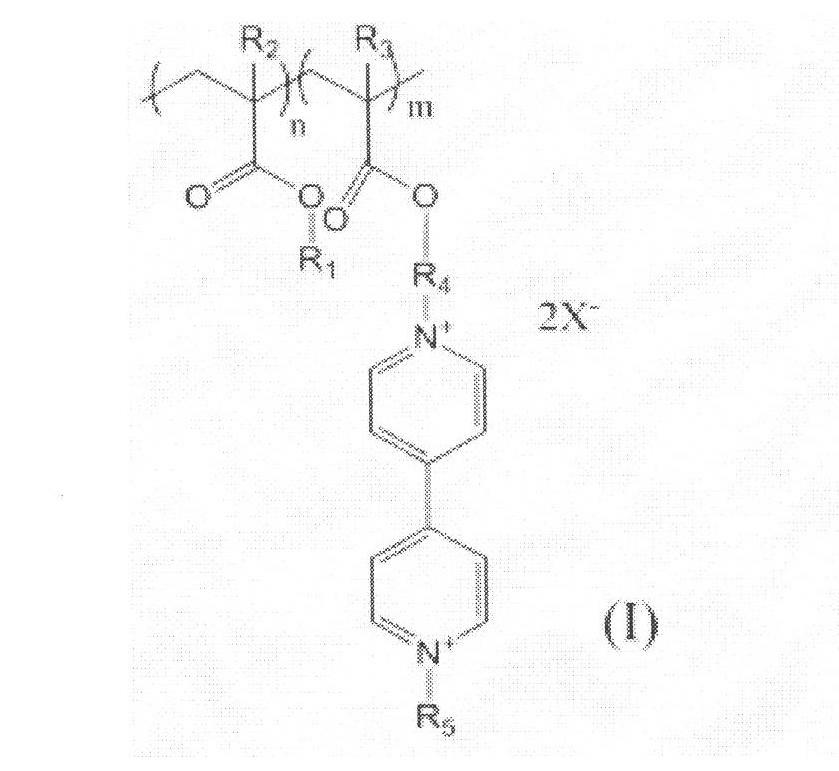

Electrochromism material and electrochromism device

ActiveCN102690646AImprove performanceAvoid harmOrganic chemistryTenebresent compositionsElectrolyte leakageOptoelectronics

The invention relates to an electrochromism material and an electrochromism device. The electrochromism material comprises a cathode electrochromism material (I) and an anode electrochromism material (II). The cathode electrochromism material (I) and the anode electrochromism material (II) are subjected to combination reaction and then are cured in an electrolyte, thereby forming gelatinous electrochromism material. The electrochromism device comprises a piece of glass (1) plated with a transparent conductive film (2) and a substrate (1) plated with a conductive reflecting layer (4). The gelatinous electrochromism material is arranged between the transparent conductive film (2) and the conductive reflecting layer (4). The invention has the advantages that the cathode and anode electrochromism materials are respectively grafted with a polymer and then are cured in the electrolyte, thereby forming the gelatinous electrochromism material; the stability of color change is increased; and the harm caused by electrolyte leakage when the electrochromism device is damaged by an external force is effectively avoided, so that the practical application property of the electrochromism material is further increased.

Owner:NINGBO MI RUO ELECTRONICS TECH CO LTD

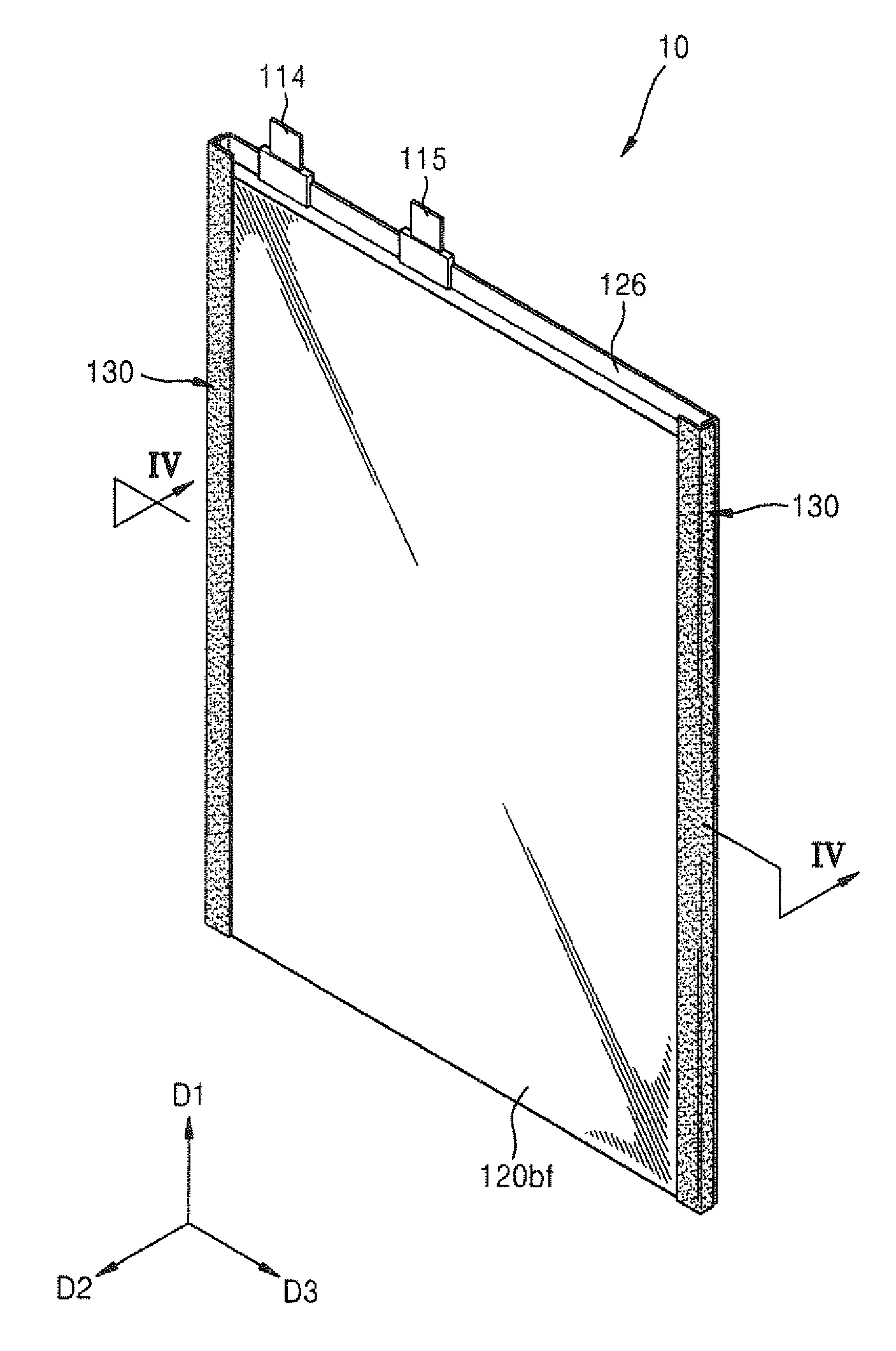

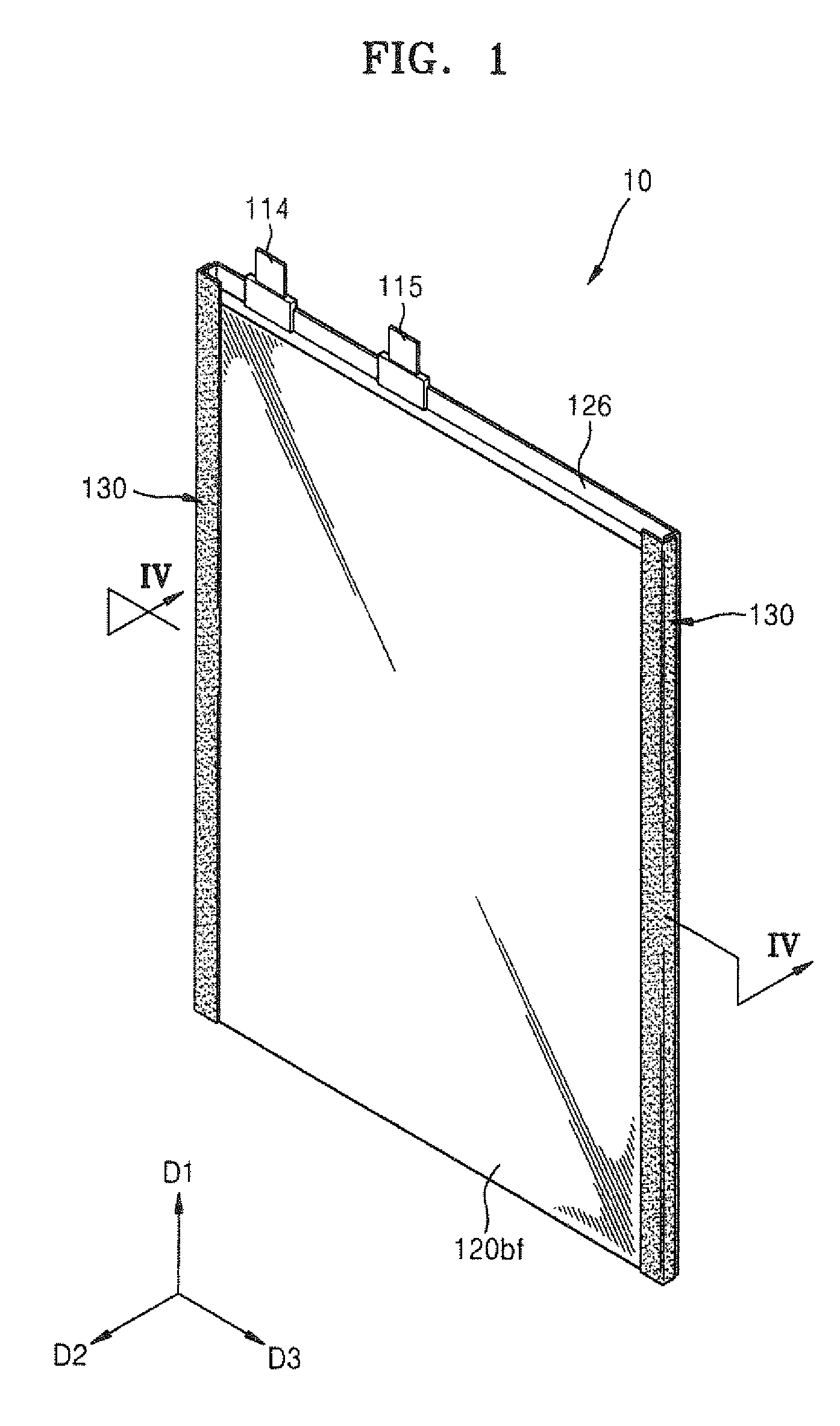

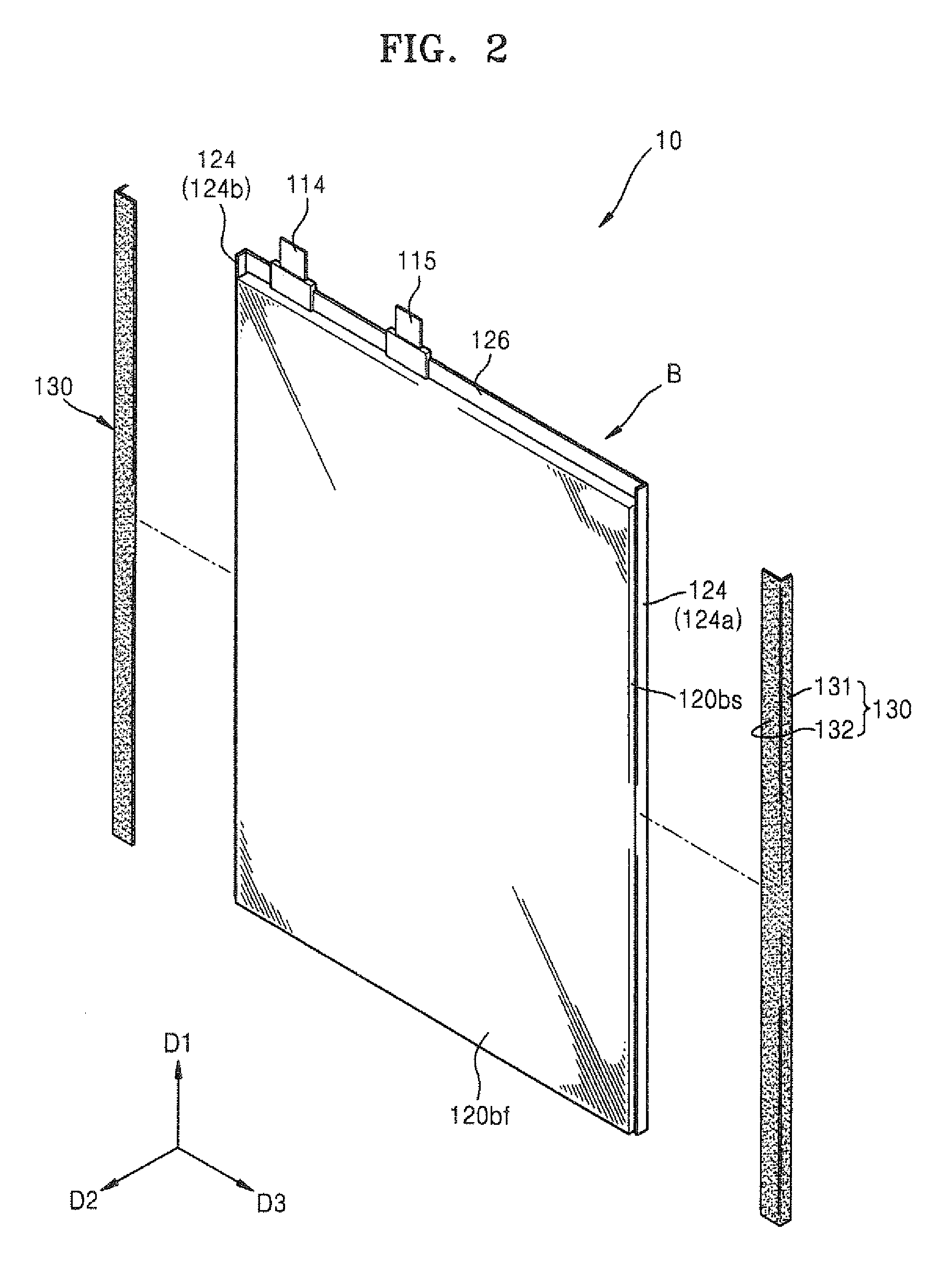

Insulating Film Attaching Jig and Battery Cell Manufactured by Using the Same

InactiveUS20130029212A1Avoid it happening againPrecise and repeatable alignmentFinal product manufactureSmall-sized cells cases/jacketsElectrolyte leakageEngineering

A secondary battery, a jig suitable for fabrication of the secondary battery, and a method for producing a secondary battery constructed with a case accommodating the electrode assembly. The case includes a front portion terminated along opposite edges by a first wing portion and a second wing portion, and a back portion positioned opposite to the front portion, with insulating film bent along a length of a junction between the front portion and each of the first wing portion and the second wing portion, a pair of holes in the insulating film are held in parallel alignment with respect to the length of the junction, with the insulating film adhering to and covering the front portion and a corresponding one of the first wing portion and the second wing portion, in order to prevent leakage of electrolyte, and resulting corrosion of the electrically conducting metal components of the secondary battery.

Owner:SAMSUNG SDI CO LTD

Capacitor and method for manufacturing same

InactiveUS7817404B2Improve reliabilityPrevent leakageMaterial analysis by electric/magnetic meansCapacitor housing/encapsulationElectrolyte leakageEngineering

A capacitor includes a metal case having an opening, a capacitor element accommodated in the metal case, an electrolyte accommodated in the metal case, and a sealing rubber sealing the opening of the metal case. The sealing rubber seals the opening of the metal case while the sealing rubber is compressed to have a stress applied thereto. The stress is not lower than 0.5 MPa and not higher than a predetermined maximum value. This capacitor prevents the electrolyte from leaking, thus having high reliability.

Owner:PANASONIC CORP

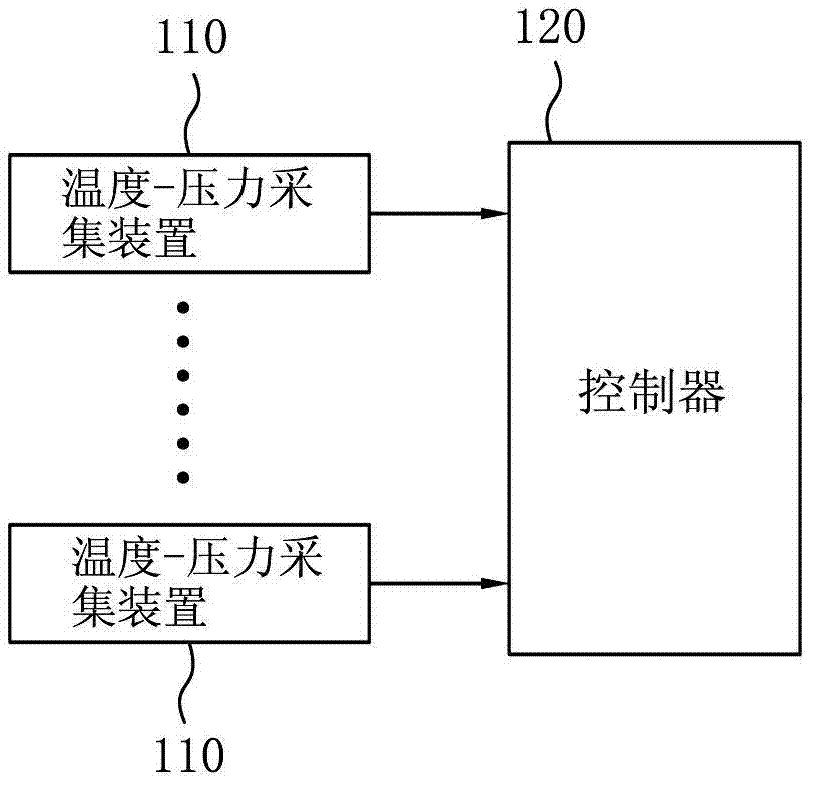

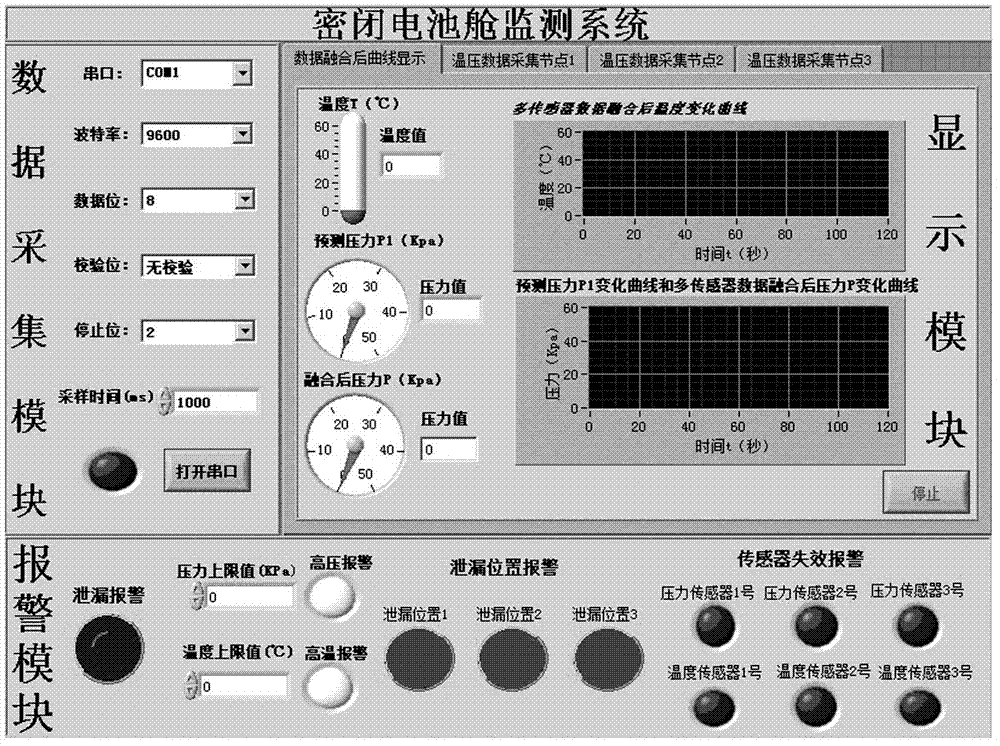

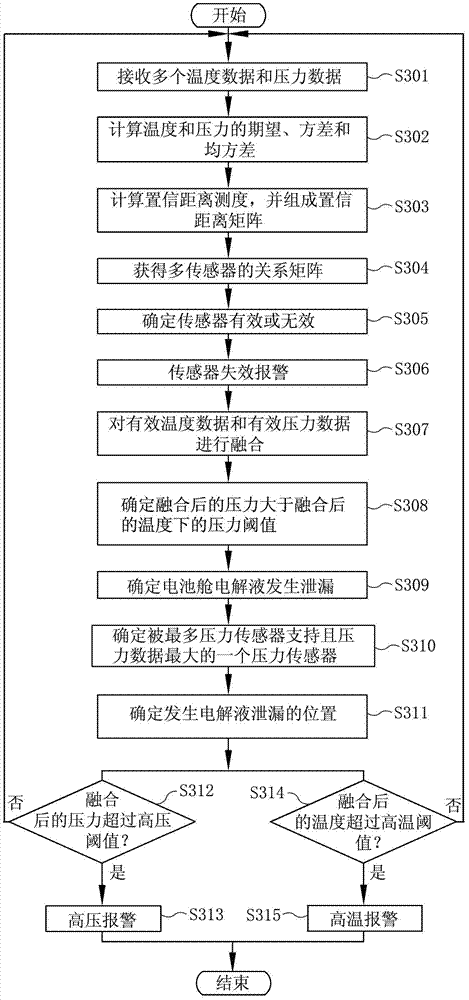

Method for detecting electrolyte leakage of battery tank and monitoring device using same

The invention discloses a method for detecting the electrolyte leakage of a battery tank and a monitoring device using the same. The method comprises the steps of: (a) respectively receiving a plurality of pairs of temperature data and pressure data from a plurality of temperature-pressure acquisition devices which are arranged at different positions in the battery tank, wherein each temperature-pressure acquisition device comprises a temperature sensor and a pressure sensor; (b) respectively fusing the received temperature data and the pressure data; (c) determining whether the fused pressure is greater than a pressure threshold under the fused temperature; and (d) determining that the battery tank has electrolyte leakage if the fused pressure is greater than the pressure threshold. According to the method for detecting the electrolyte leakage of the battery tank and a monitoring device using the same, the real-time changes of the temperature and the pressure in the battery tank can be effectively detected, so that alarm can be given in time when the battery tank has electrolyte leakage and the leakage position can be correctly obtained.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

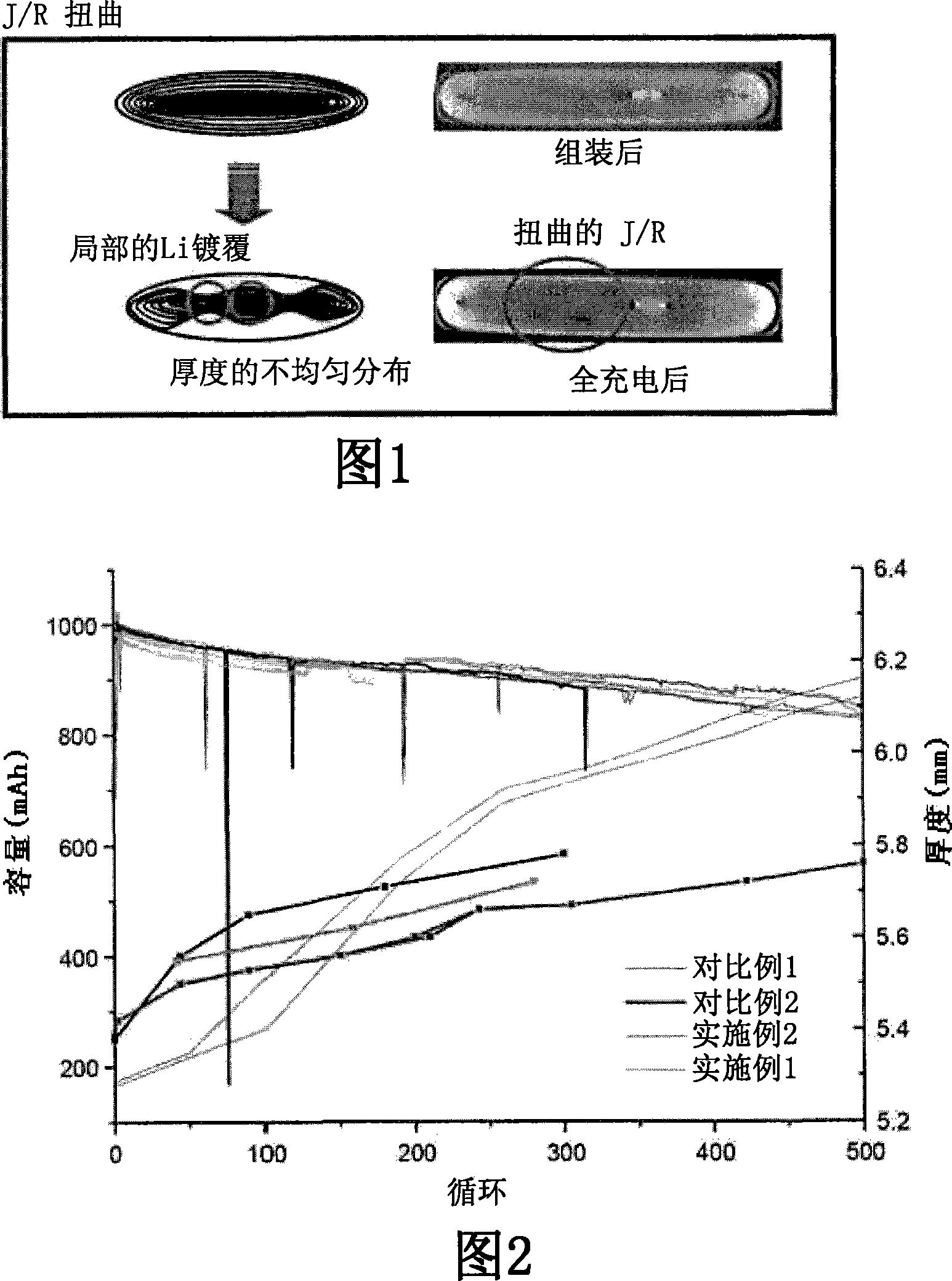

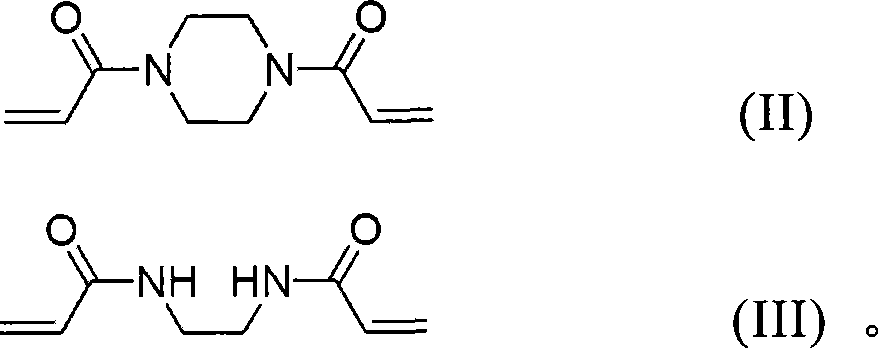

Gel-typed polymer electrolyte containing diacryl amide-based polymeric material and electrochemical device comprising the same

ActiveCN101195670APrevent leakageEnsure safetyHybrid capacitor electrolytesElectrolytic capacitorsElectrolyte leakagePolymer electrolytes

Provided is a gel polymer electrolyte comprising a diacrylamide compound as a precursor for formation of a crosslinked polymer. The gel polymer electrolyte in accordance with the present invention enables improvements of the battery safety by significant reduction of thickness swelling of the battery to thereby prevent the electrolyte leakage, while simultaneously preventing deterioration of charge-discharge rate characteristics and cycle characteristics which may occur upon use of a gel-type electrolyte.

Owner:LG ENERGY SOLUTION LTD

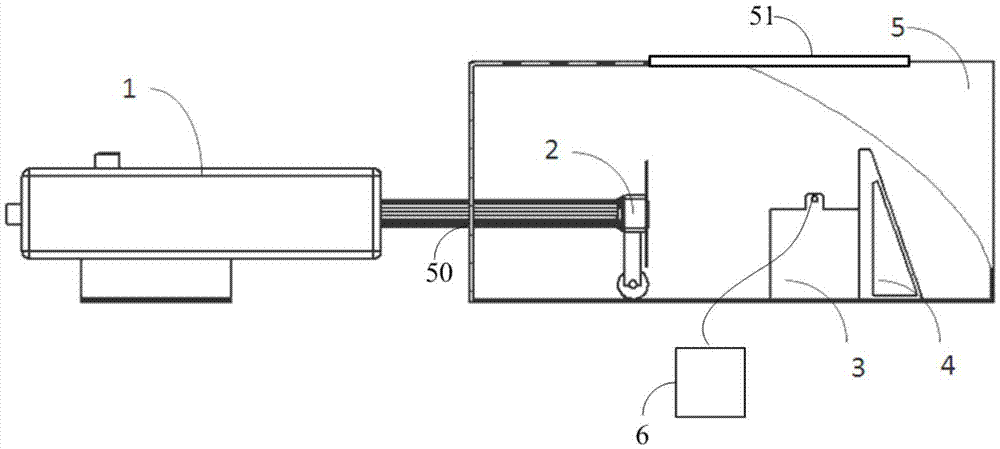

Automotive battery simulation collision test system and method

ActiveCN105444977AIncrease authenticityAvoid pollutionMaterial exposibilityShock testingElectrolyte leakageTest battery

The invention relates to an automotive battery simulation collision test system and method. The automotive battery simulation collision test system includes an explosion-proof box, a collision rod, an accelerator and an extrusion plate. The body of the explosion-proof box is made of a transparent and anti-collision material; the explosion-proof box is provided with an opening; the collision rod extends into the explosion-proof box through the opening; a collision plate is fixed to the tail end of the collision rod; the collision plate is located in the explosion-proof box; the accelerator drives the collision rod to move; the extrusion plate is located on the bottom plate of the explosion-proof box and is arranged at the advancing path of the collision plate; and a tested battery is arranged between the extrusion plate and the collision plate. With the automotive battery simulation collision test system and method of the environment adopted, the authenticity of automotive battery simulation collision parameters can be improved, and pollution to the environment caused by electrolyte leakage can be reduced.

Owner:CH AUTO TECH CORP CO LTD

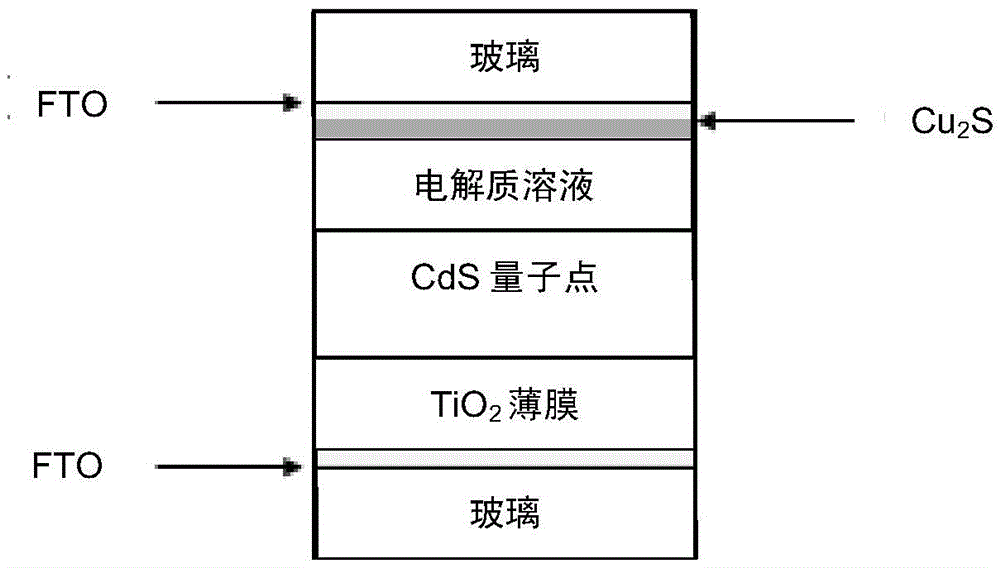

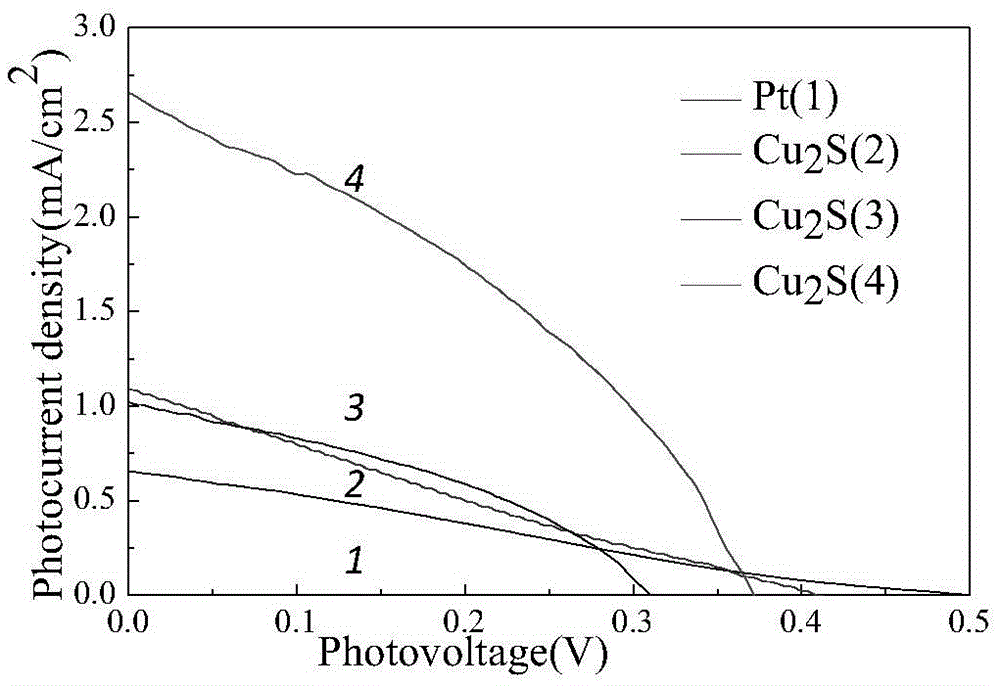

Solar cell Cu2S/FTO counter electrode and electrochemical deposition preparation method thereof

InactiveCN105655131ASimple preparation processLow costLight-sensitive devicesFinal product manufactureElectrolyte leakageThiourea

The invention provides a method for preparing a solar cell Cu2S / FTO counter electrode based on the electrochemical deposition process and belongs to the technical field of solar cells. According to the method, an electrolyte is prepared firstly and then a Cu2S / FTO counter electrode is obtained in a three-electrode system through electrochemically depositing the Cu material on an FTO according to the potentiostatic method and then sulfurizing the deposited Cu material in a polysulfide solution. The above electrolyte is composed of a buffer system comprising 0.03-0.05 mol / L of CuCl2, 6.6*10<-3>-1.3*10<-2> mol / L of thiourea and 0.3-0.5 mol / L of lactic acid, and the pH value of the buffer system is 5.0-7.0. The polysulfide solution is composed of a methanol solution comprising 0.5-1 M of Na2S*9H2O, 0.5-1 M of S and 0.05-0.1 M of KCl. The method is simple in preparation process and low in cost, which provides a reliable preparation scheme for the preparation of QDSCs counter electrodes. Meanwhile, the problems of the mechanical stability and the electrolyte leakage of Cu2S / FTO counter electrodes can be solved.

Owner:JILIN UNIV

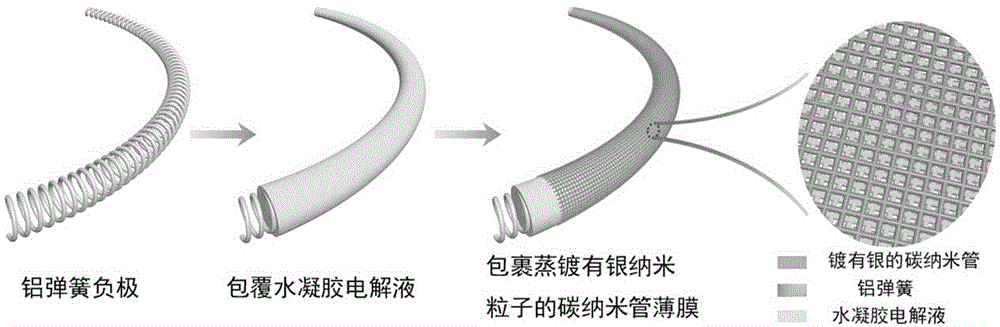

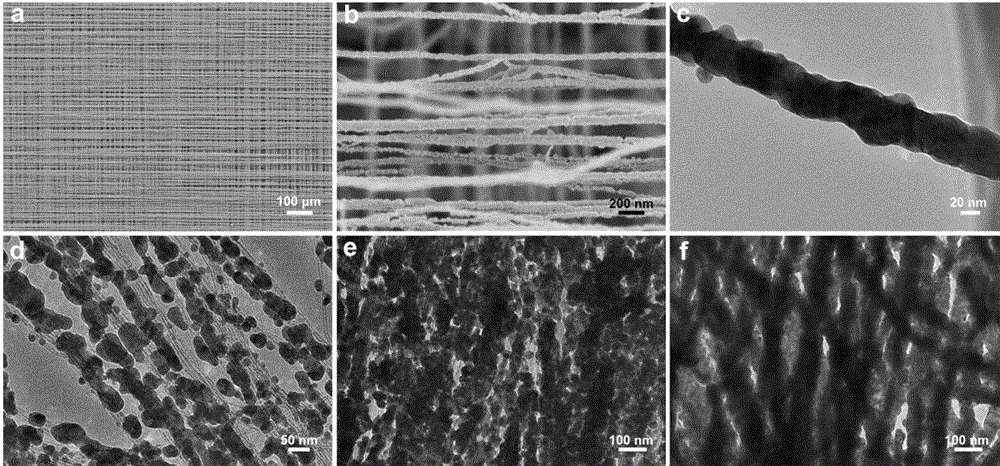

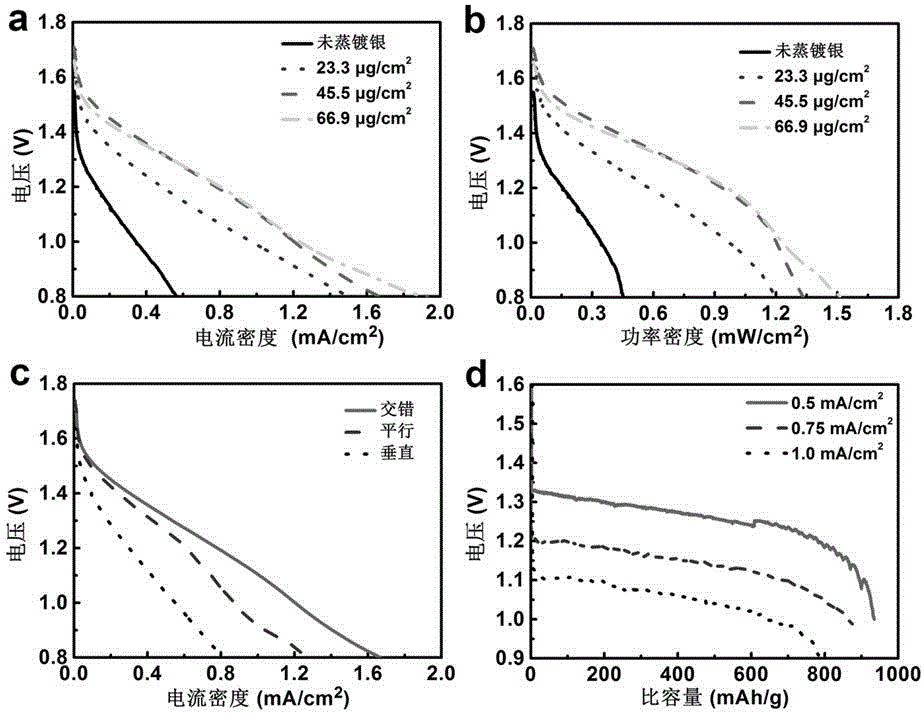

All-solid-state flexible and stretchable fibrous aluminum air battery and preparation method thereof

ActiveCN105811049AIncrease energy densityImprove power densityFuel and primary cellsCell electrodesElectrical batteryCarbon nanotube

The invention belongs to the technical field of aluminum air batteries, and particularly discloses an all-solid-state flexible and stretchable fibrous aluminum air battery and a preparation method thereof. According to the method, a hydrogel electrolyte is firstly prepared by a cyclic freezing method; the electrolyte coats an aluminum spring at a negative electrode and is crosslinked into a solid state; and staggered oriented carbon nanotube films evaporated with silver nanoparticles coat the outmost layer to obtain the fibrous aluminum air battery. The special air electrode structure does not need a metal current collector or a binder. Due to the structural design, the fibrous aluminum air battery has excellent electrochemical properties; the specific capacity can reach 935mAh / g; and the energy density can reach 1168Wh / kg. The battery also has flexibility and stretchability. The electrolyte is in the solid state, so that the risks of a short circuit and an electrolyte leakage in the bending and stretching process can be effectively prevented; the battery is easy to weave and integrate; and the battery can be woven into energy storage fabrics to provide energy for a wearable electronic device, and large-scale application is excepted to be achieved.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com