Patents

Literature

316 results about "Combination reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A combination reaction (also known as a synthesis reaction) is a reaction where two or more elements or compounds (reactants) combine to form a single compound (product). Such reactions may be represented by equations of the following form: X + Y → XY. The combination of two or more elements and form one compound is called combination reaction. Combination reactions can involve different types of reactants: There is no specific number of reactants in a combination reaction.

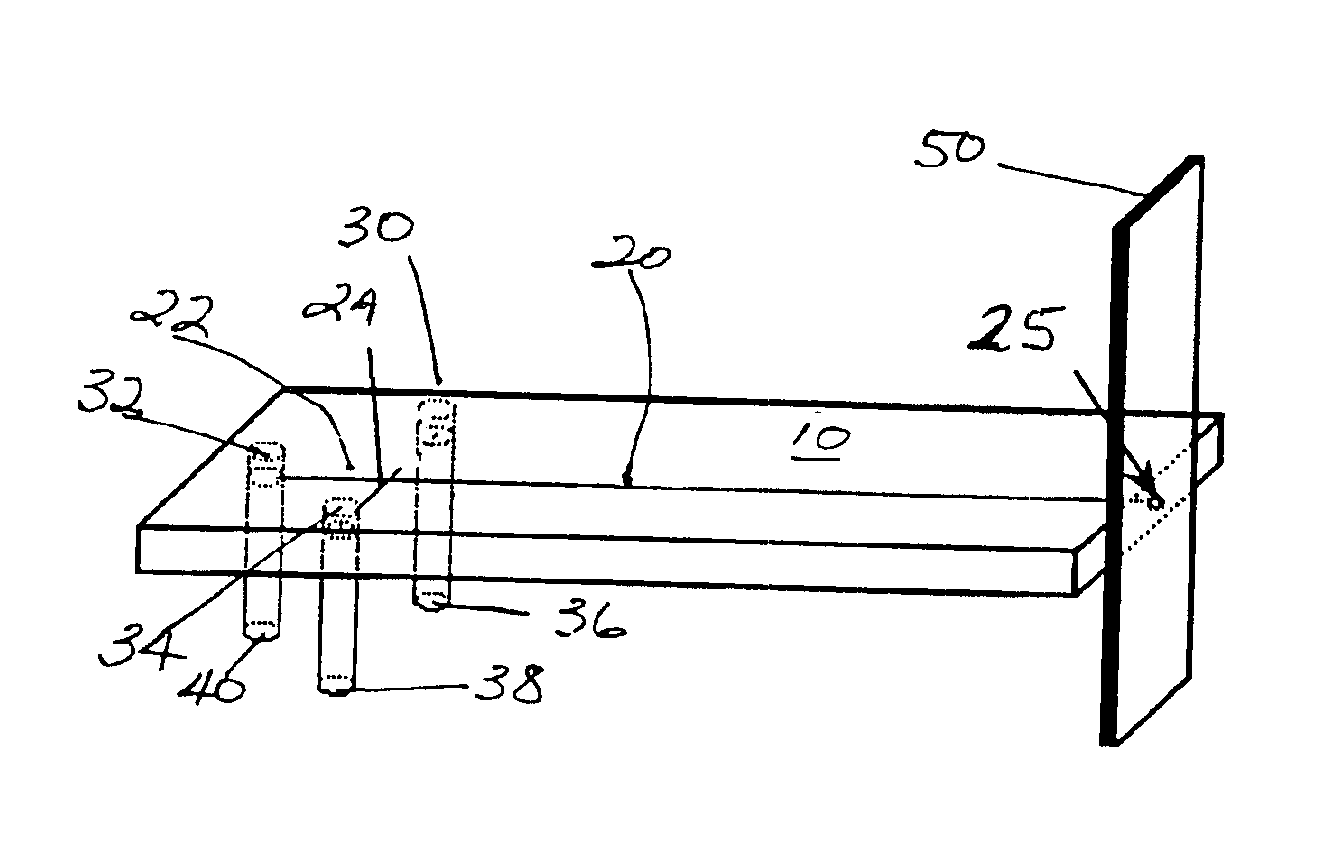

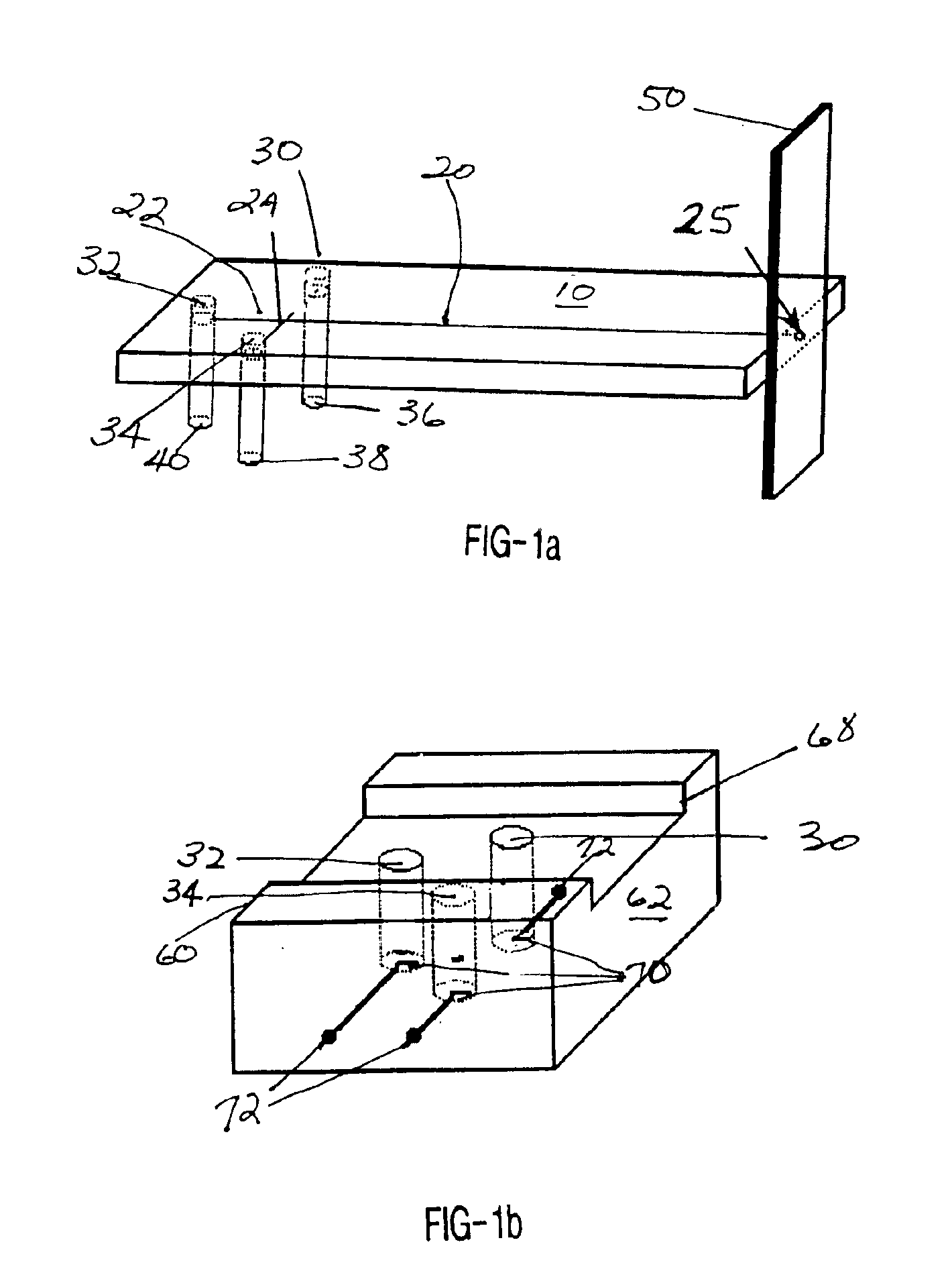

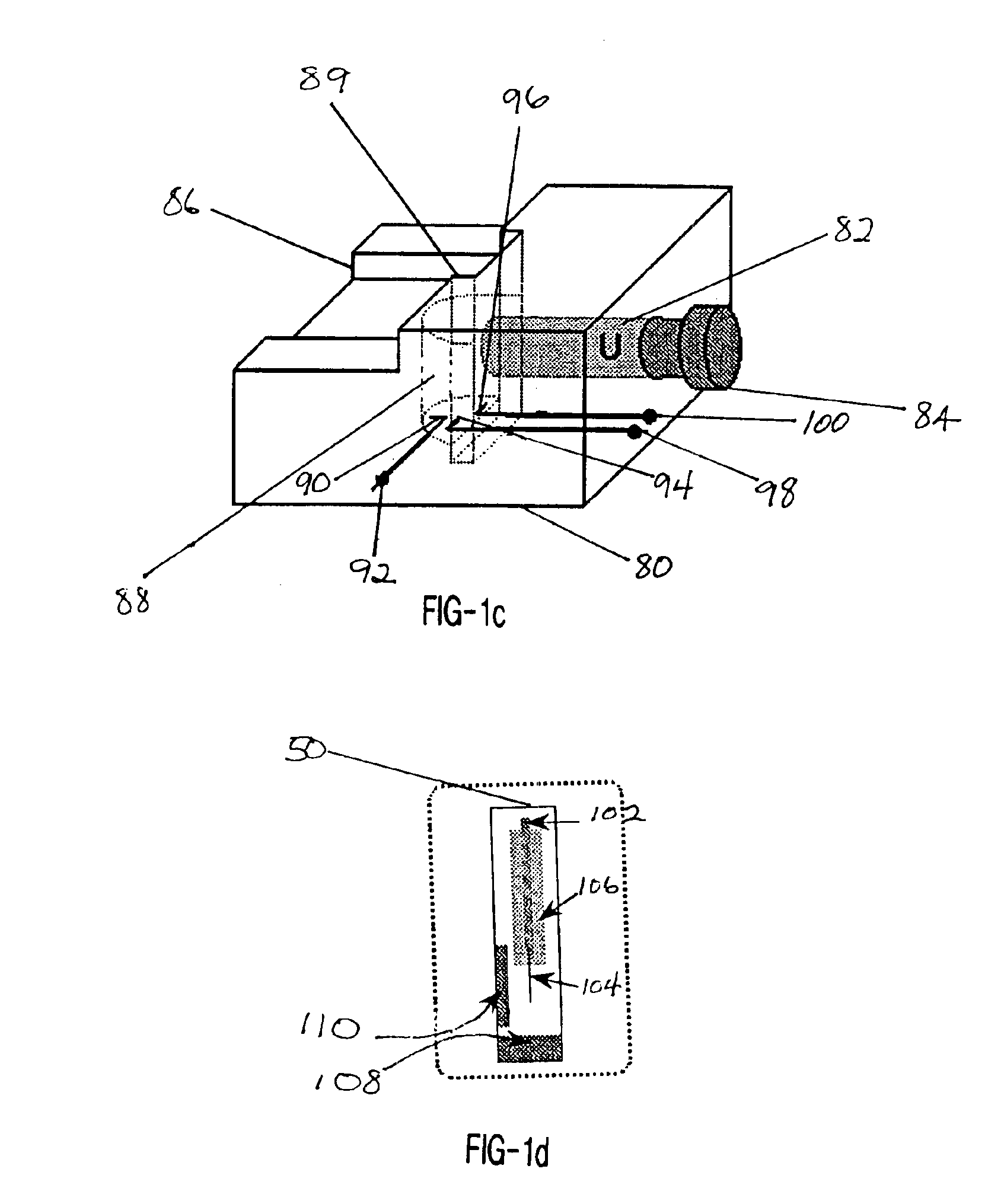

Microfluidic devices with thick-film electrochemical detection

InactiveUS6878255B1Reduce usageCost advantageSludge treatmentVolume/mass flow measurementAnalyteMicrofluidic channel

An apparatus for conducting a microfluidic process and analysis, including at least one elongated microfluidic channel, fluidic transport means for transport of fluids through the microfluidic channel, and at least one thick-film electrode in fluidic connection with the outlet end of the microfluidic channel. The present invention includes an integrated on-chip combination reaction, separation and thick-film electrochemical detection microsystem, for use in detection of a wide range of analytes, and methods for the use thereof.

Owner:ARROWHEAD CENT

Novel carbon-sulfur compound for lithium-sulfur battery

InactiveCN101587951AIncrease profitIncrease specific energyCell electrodesSulfur compoundsElectric capacityInternal resistance

The invention relates to a novel carbon-sulfur compound for an anode material of a lithium-sulfur battery and a preparation method thereof. Sulfur is filled into a nano and micron hole of a matrix in an elementary substance way by taking a macroporous carbon material with high pore volume, electrical conductivity and specific surface area as the matrix, and the sulfur and carbon can also carry out combination reaction so as to prepare the novel carbon-sulfur compound of which the sulfur exists in one or more chemical states in a carbon material. The novel carbon-sulfur compound used as the anode material of the lithium-sulfur battery has the advantages that the high pore volume has large contained sulfur contents and can ensure high electric capacity; the small granularity of the sulfur can reduce a conductive distance between ions and electrons and increase the utilization ratio of the sulfur; and the adsorption characteristics of the high specific surface of the carbon material can inhibit a discharging intermediate product from dissolving and moving towards a cathode, reduce the self discharge, prevent a nonconductive discharging product, namely lithium sulfide from largely accumulating outside carbon particles and reduce internal resistance, therefore, the material can improve the specific energy, the specific power and the cycle performance of the lithium-sulfur battery.

Owner:NO 63971 TROOPS PLA

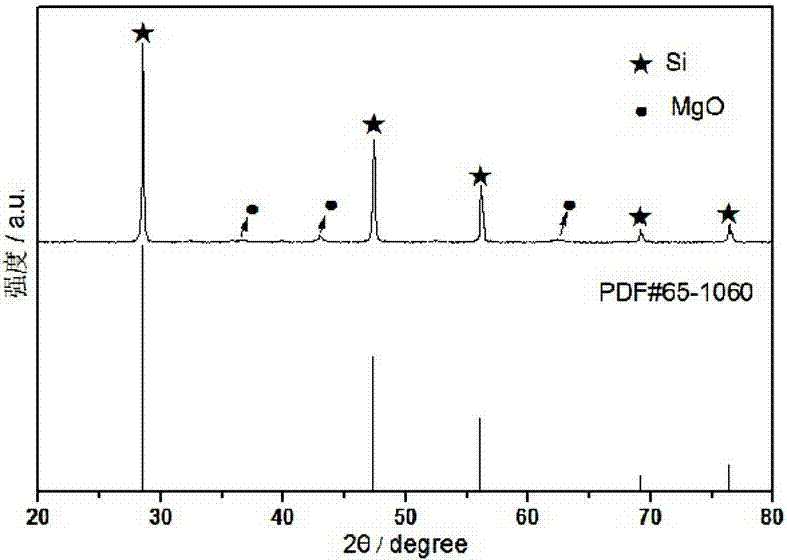

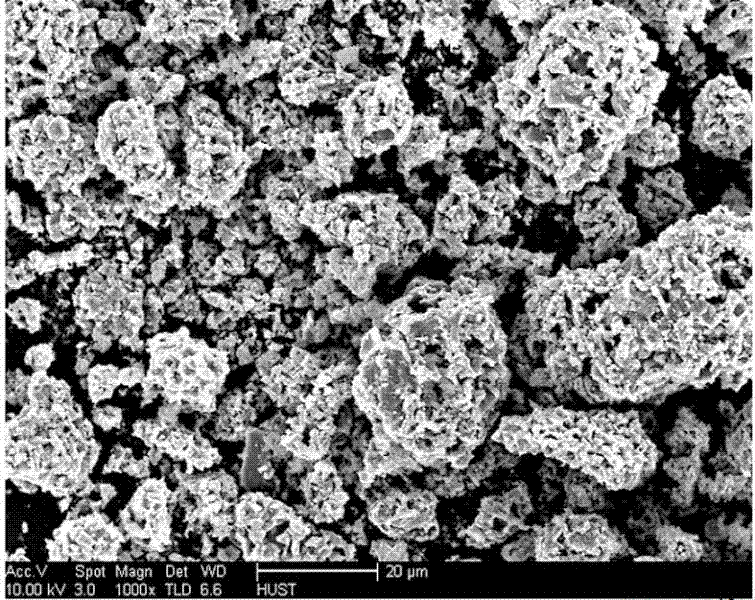

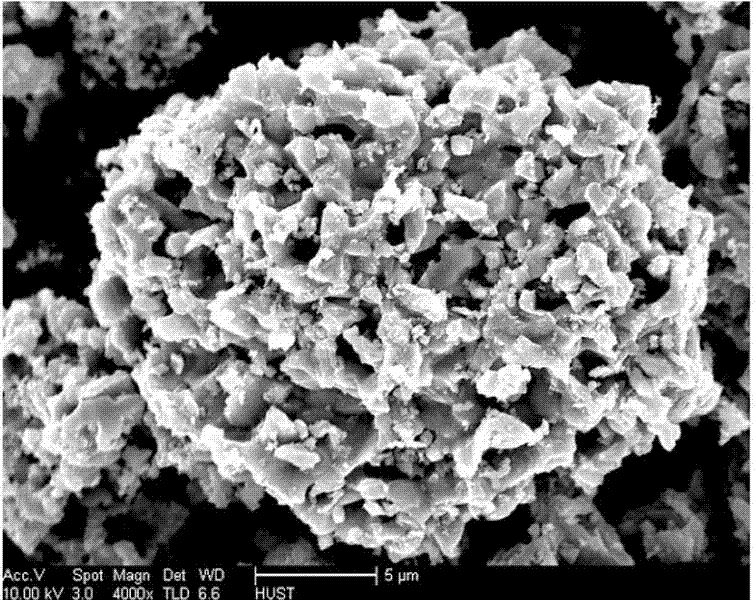

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

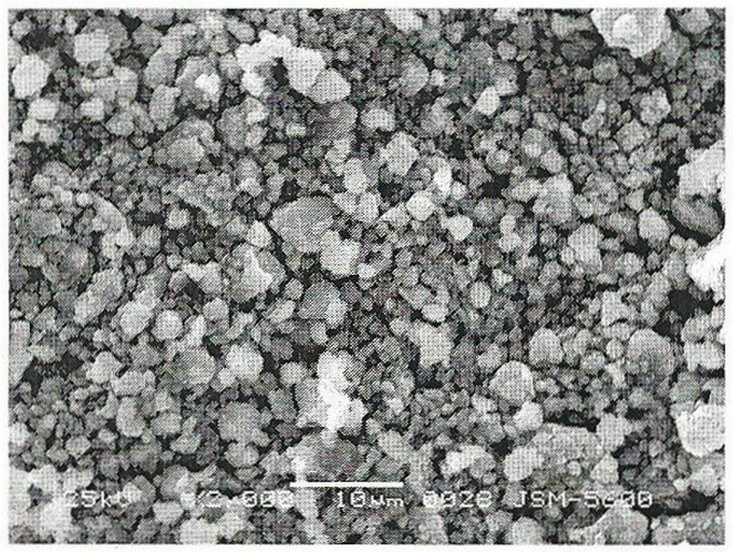

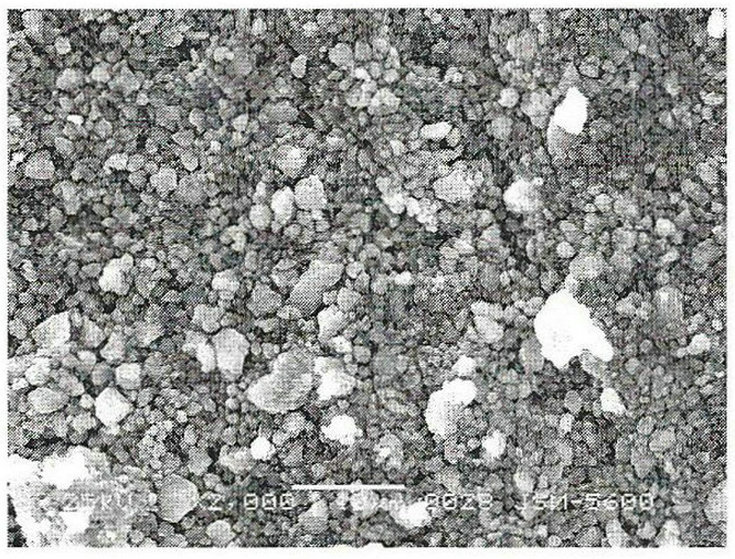

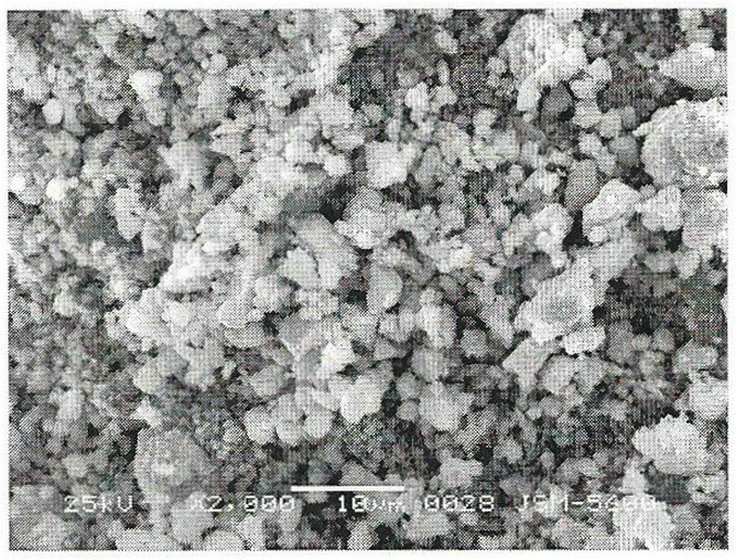

ActiveCN102237519AAvoid pollutionHigh specific capacityCell electrodesSodium-ion batterySilicon particle

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

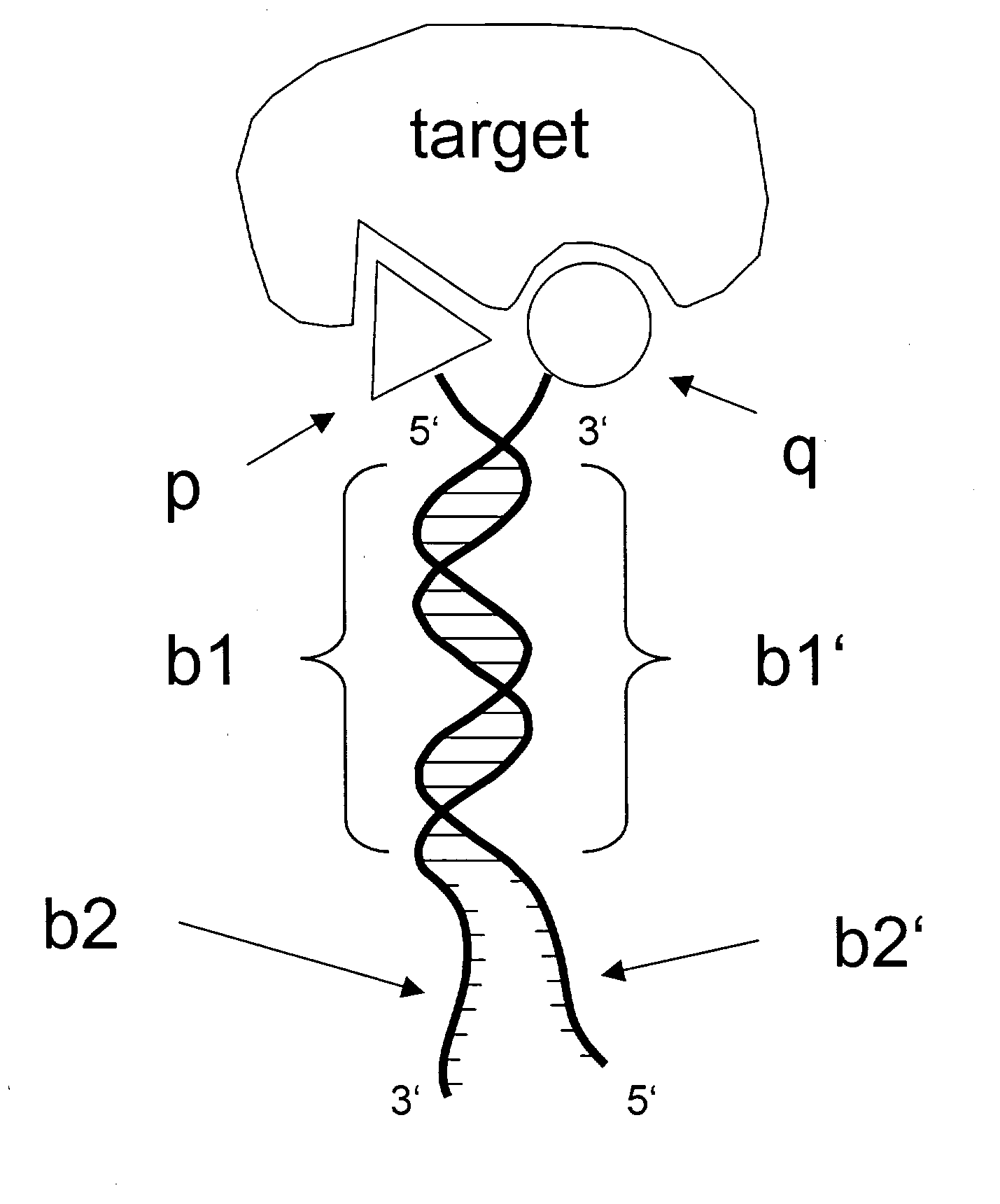

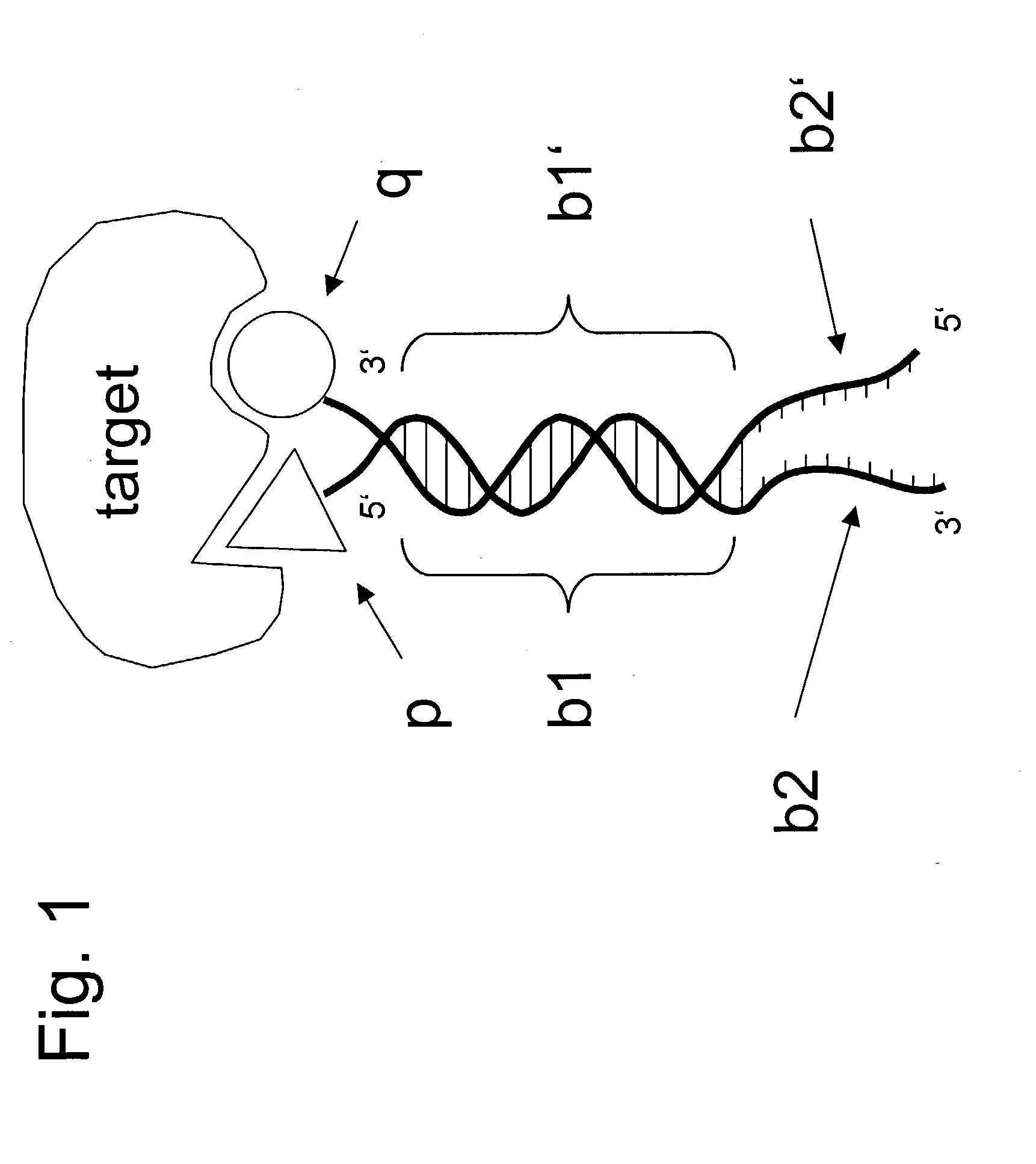

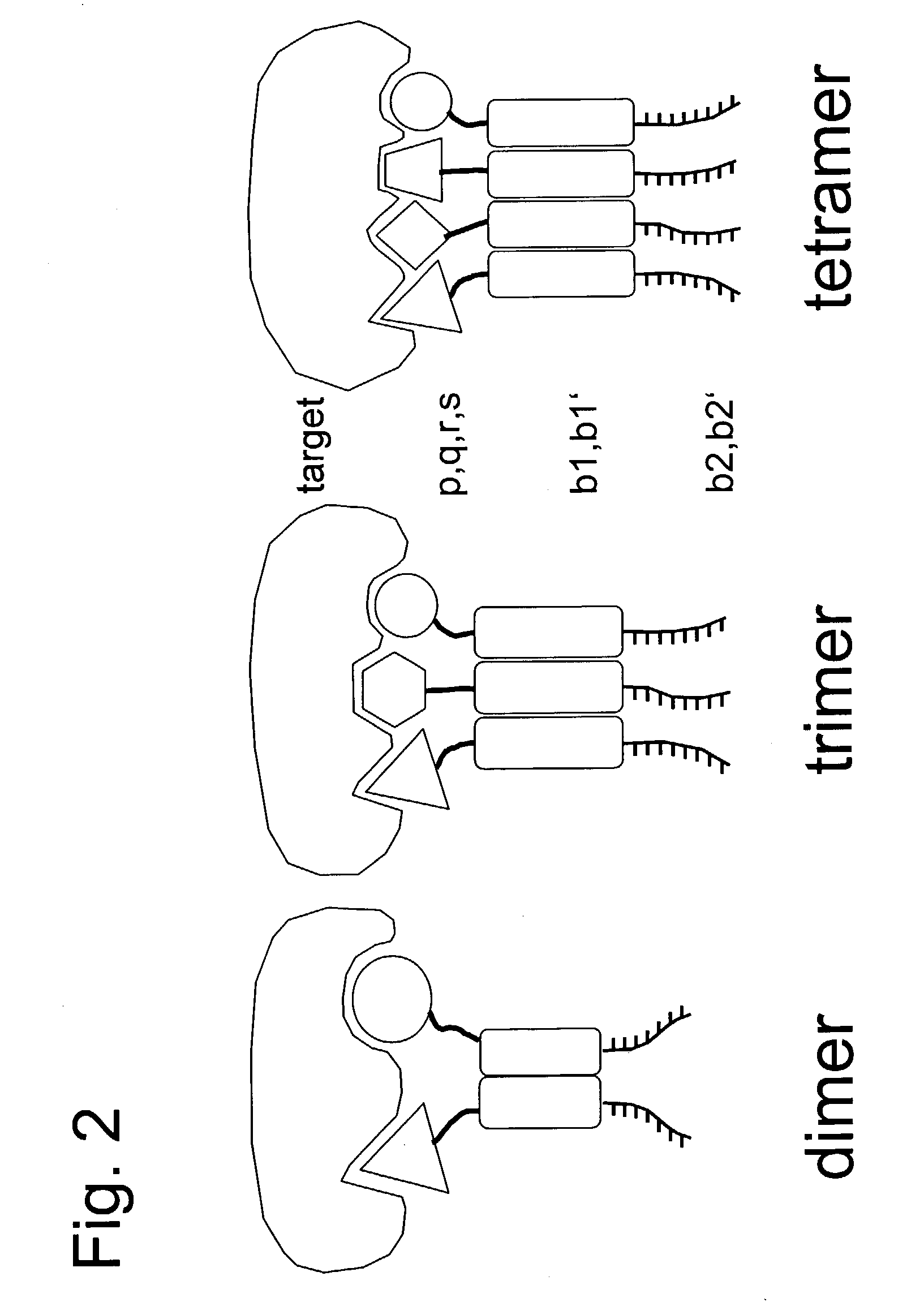

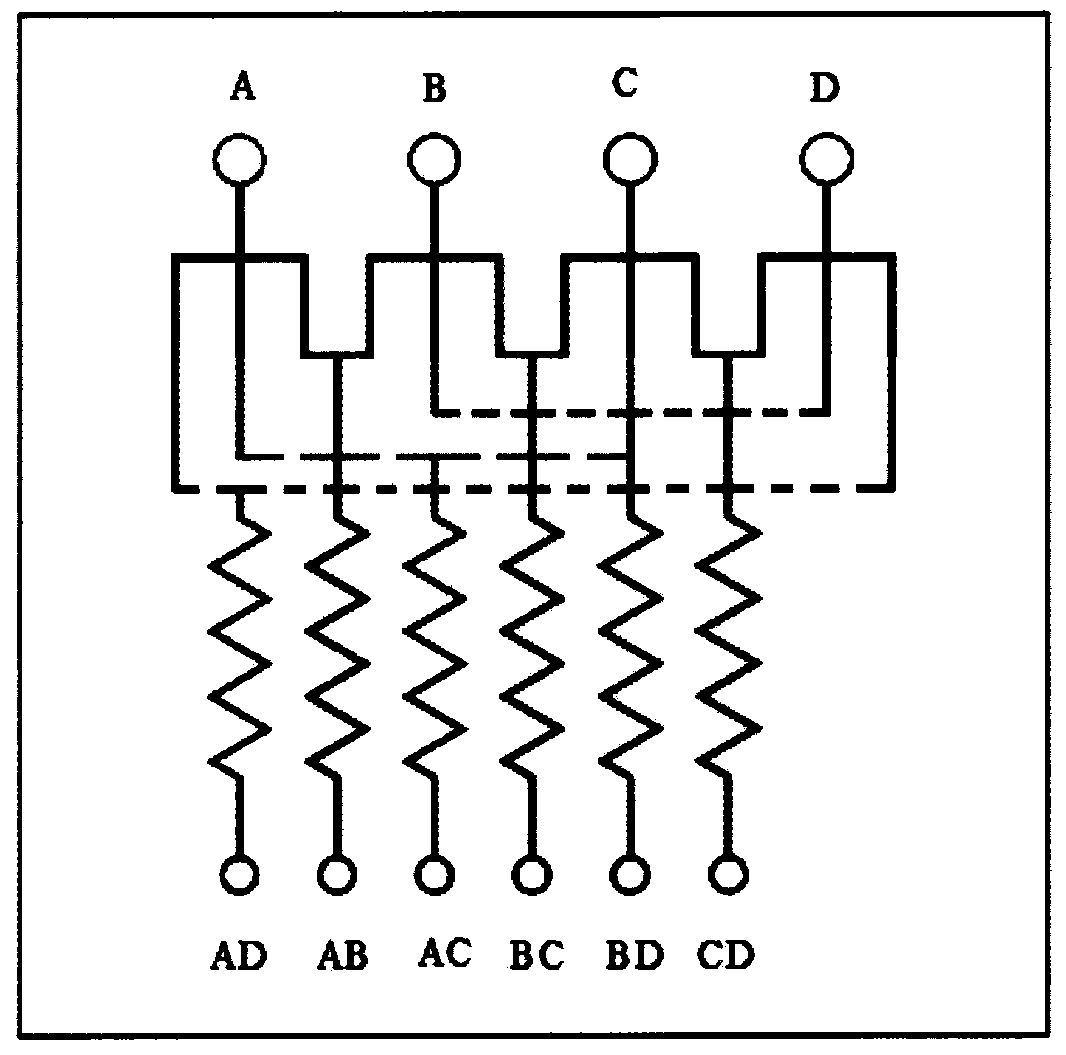

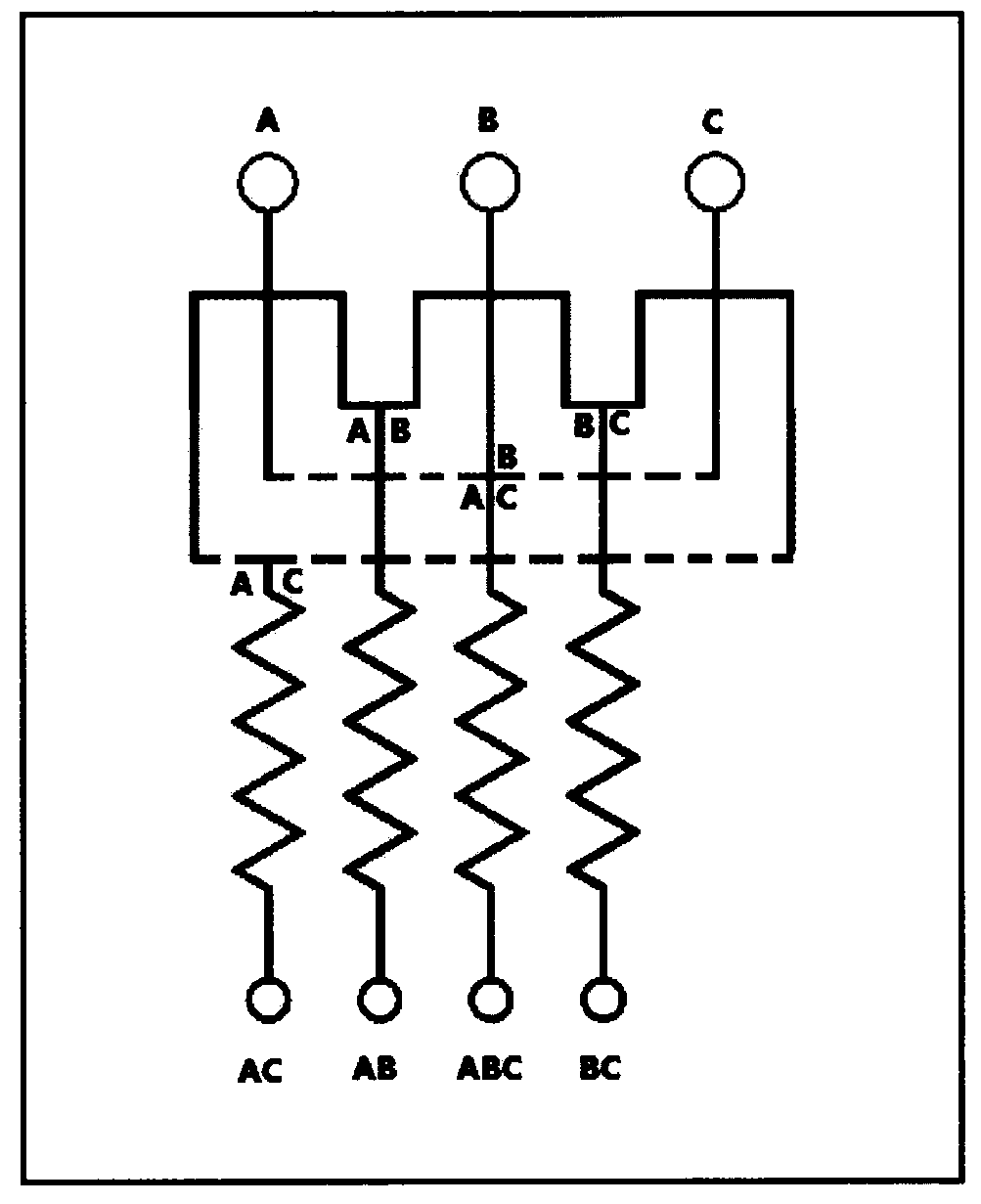

Encoded self-assembling chemical libraries (ESACHEL)

InactiveUS20040014090A1Promote formationSugar derivativesNucleotide librariesChemical MoietyNucleotide

The invention concerns a chemical compound comprising a chemical moiety (p) capable of performing a binding interaction with a target molecule (e.g. a biological target) and further comprising an oligonucleotide (b) or functional analogue thereof. In a first embodiment according to the invention, the chemical compound is characterized in that the oligonucleotide (b) or functional analogue comprises at least one self-assembly sequence (b1) capable of performing a combination reaction with at least one self-assembly sequence (b1') of a complentary oligonucleotide or functional analogue bound to another chemical compound comprising a chemical moiety (q). In a second embodiment according to the invention, the chemical compound which comprises a coding sequence (b1) coding for the identification of the chemical moiety (p) is characterized in that the chemical compound further comprises at least one self-assembly moiety (m) capable of performing a combination reaction with at least one self-assembly moiety (m') of a similar chemical compound comprising a chemical moiety (q). The invention comprises corresponding libraries of chemical compounds as well as methods of biopanning of target molecules and of identifying such targets.

Owner:ETH ZZURICH

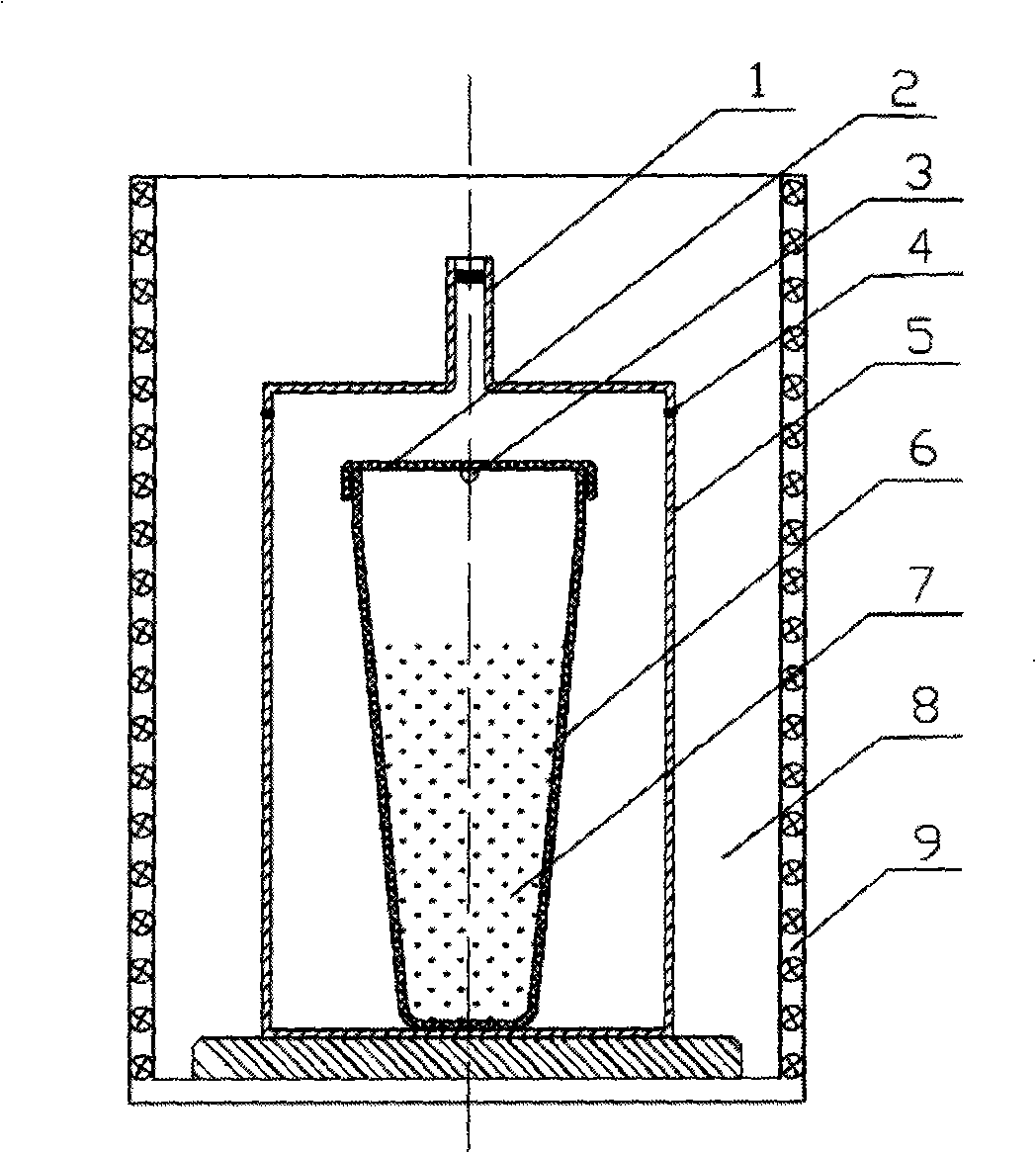

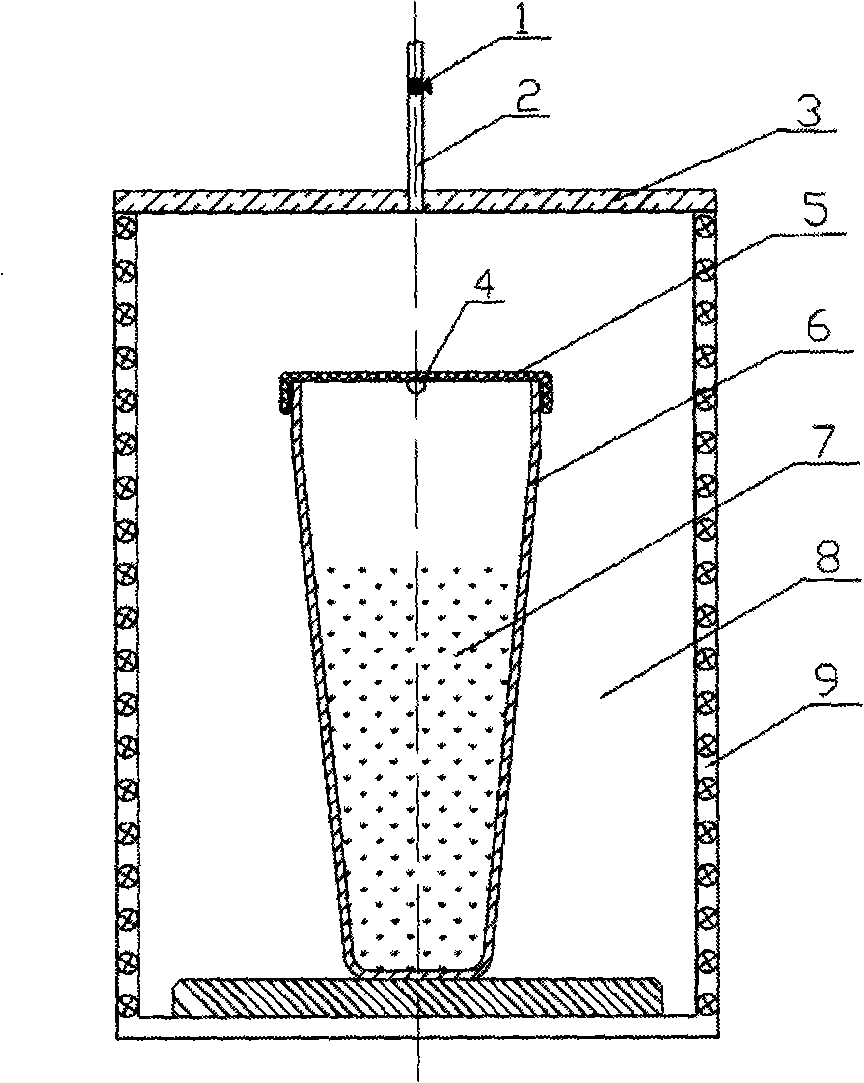

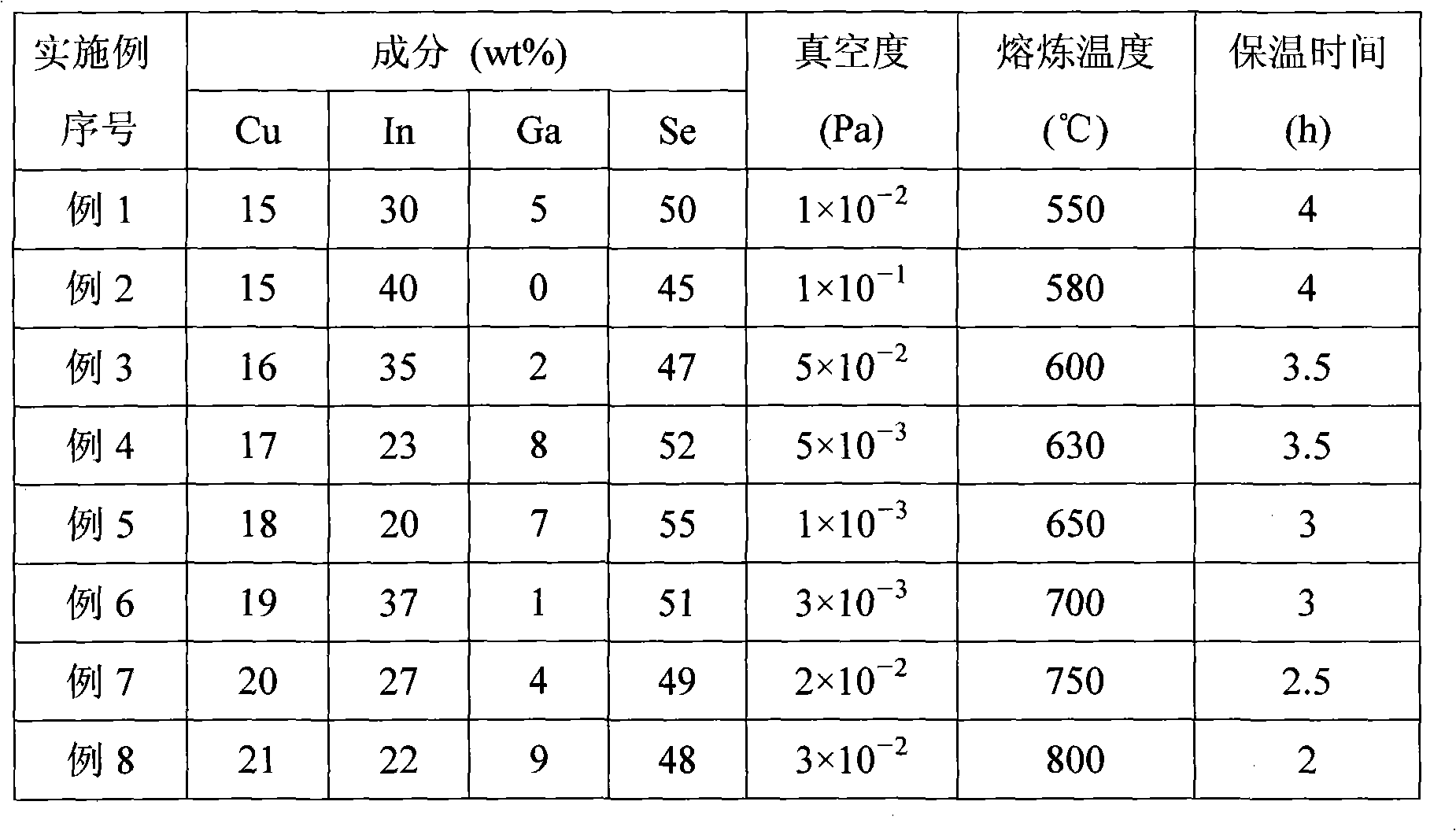

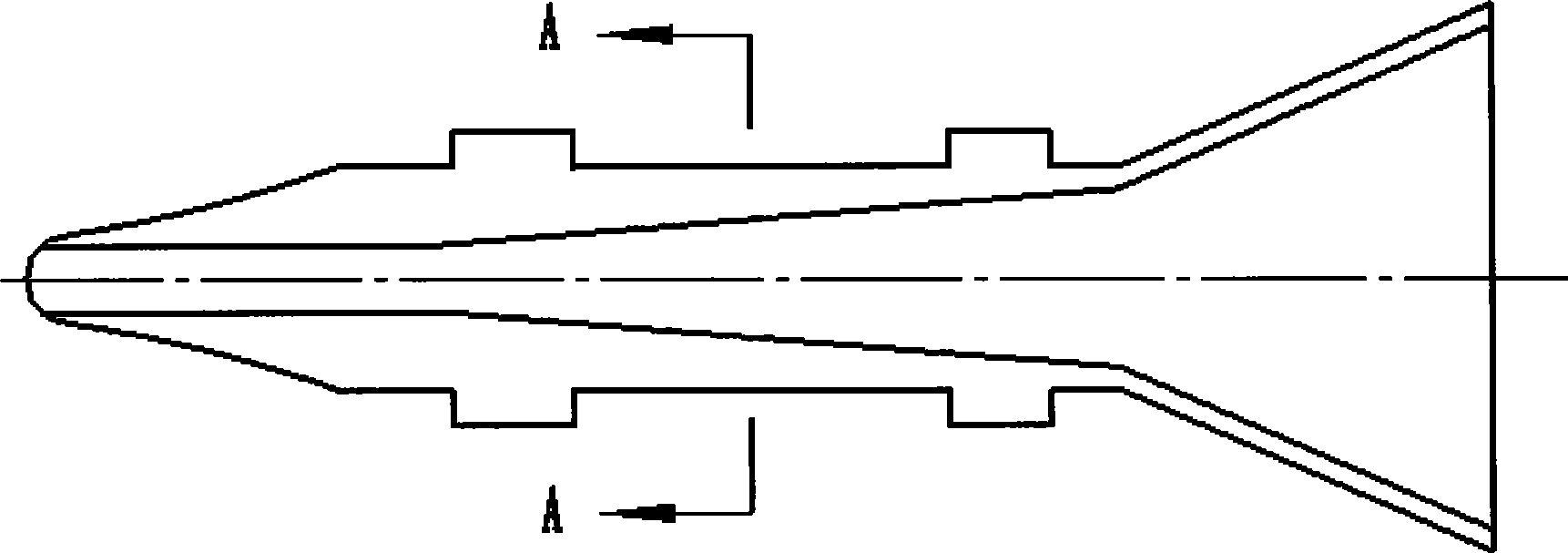

Vacuum smelting method and apparatus for copper-indium-gallium-selenium photovoltaic material

The invention provides a method and a device for melting a CIGS photovoltaic material in vacuum. The method comprises the steps as follows: four materials of copper Cu, indium In, gallium Ga and selenium Se are arranged in the same crucible, and are heated in vacuum, along with the rise of the temperature, the Ga and the In with the lowest melting point are melt into liquid first, and then the Se starts to melt; the liquid Se reacts with the liquid In and the liquid Ga violently to release massive heat, so that the temperature in the crucible rises rapidly; the Se, the In and the Ca continuously react with the Cu at a high temperature to release massive heat; finally, the Cu is completely melted and is involved in the combination reaction to form a stable CIGS CuInxGa1-xSe2 compound.

Owner:PIONEER MATERIALS INC CHENGDU +1

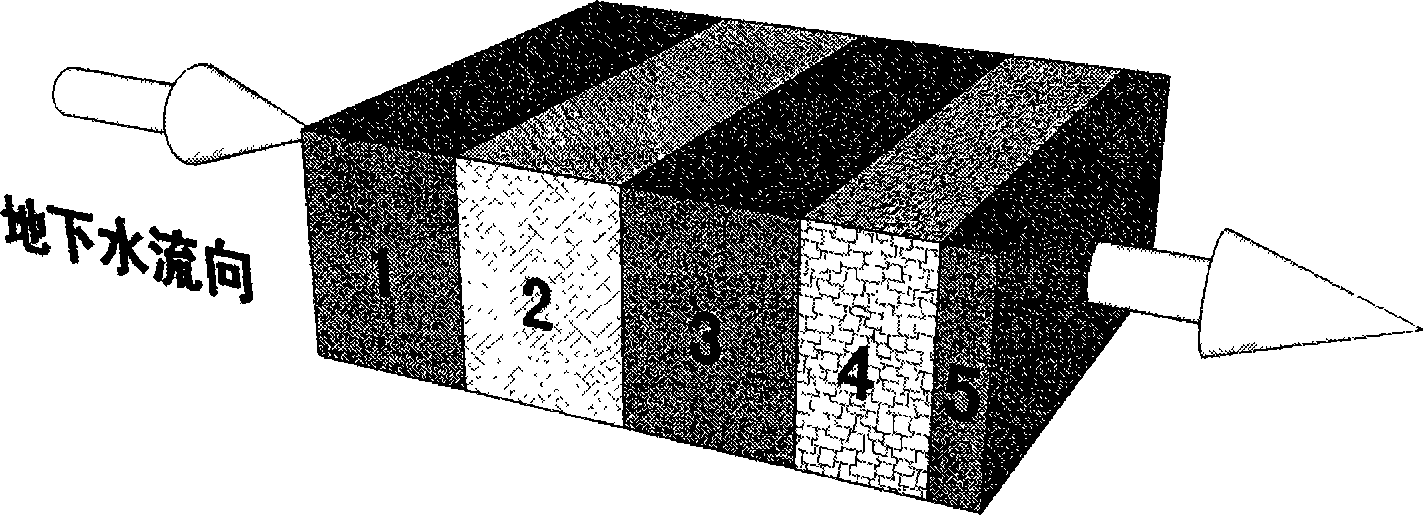

Method for renovating groundwater in situ with chemical and biological composite reaction wall

InactiveCN101172732AGood removal effectAdaptableMultistage water/sewage treatmentContaminated groundwater/leachate treatmentChemical reactionAniline

The invention discloses a method for treating underground sewage, in particular for the underground water which is polluted by nitrobenzene and aniline. The original restoration of the underground water with chemical and biological combination reaction wall is adopted in the method. The upper reach of the flowing underground water is provided with a chemical reaction wall, and a biological reaction wall is arranged below the chemical reaction wall with a certain distance away. The chemical reaction wall consists of nonvalent ferrum and active carbon at a certain proportion, and the biological reaction wall consists of the attached nitrobenzene degradation bacteria and the attached aniline degradation bacteria biological active carbon. The nitrobenzene is reduced to be the degradable nitrobenzene through the chemical reaction wall, and the nonvalent ferrum is good in the removal of the nitrobenzene organism which is difficult in degradation, so the chemical reaction wall has good applicability and can achieve 120-minute reaction time and the 97.4 percent of the reduction rate for the nitrobenzene. The production of the biological reaction wall with the biological active carbon is good in the removal of the target pollutant. The work of the biological reaction wall for 36 days can achieve more than 98.83 percent of the degradation rate for the nitrobenzene with the preliminary density of 300.89mg / L, and the work of the biological reaction wall for 71 days can achieve more than 99.6 percent of degradation rate.

Owner:JILIN UNIV

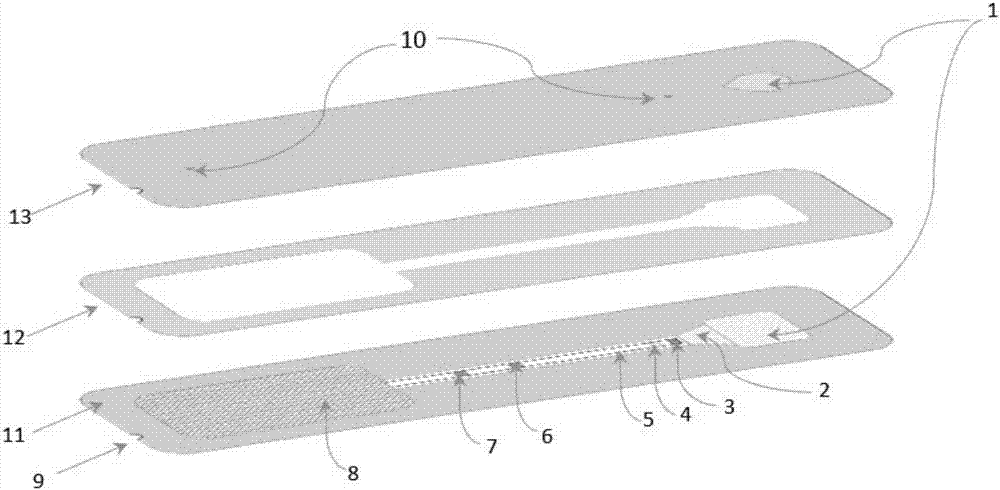

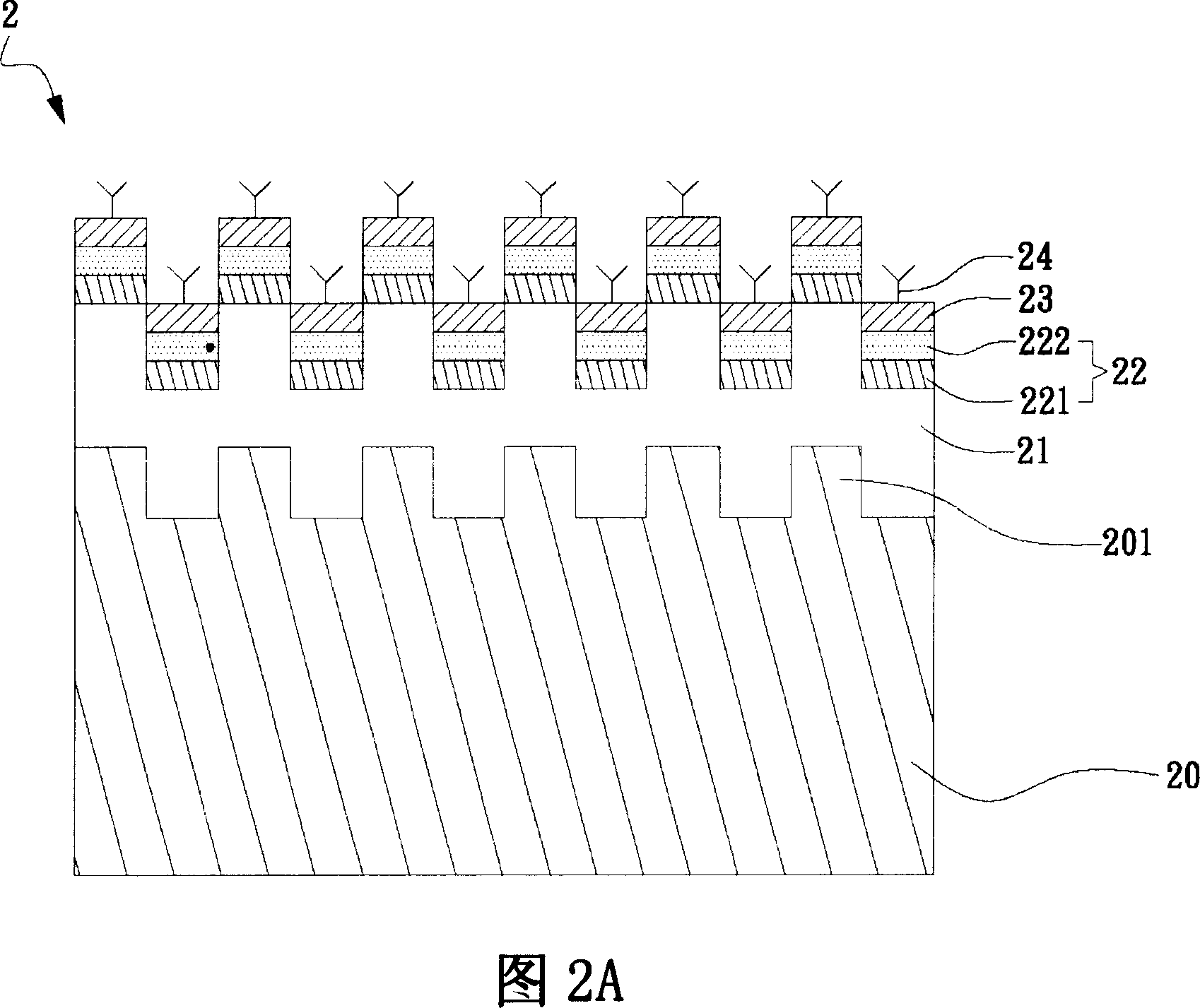

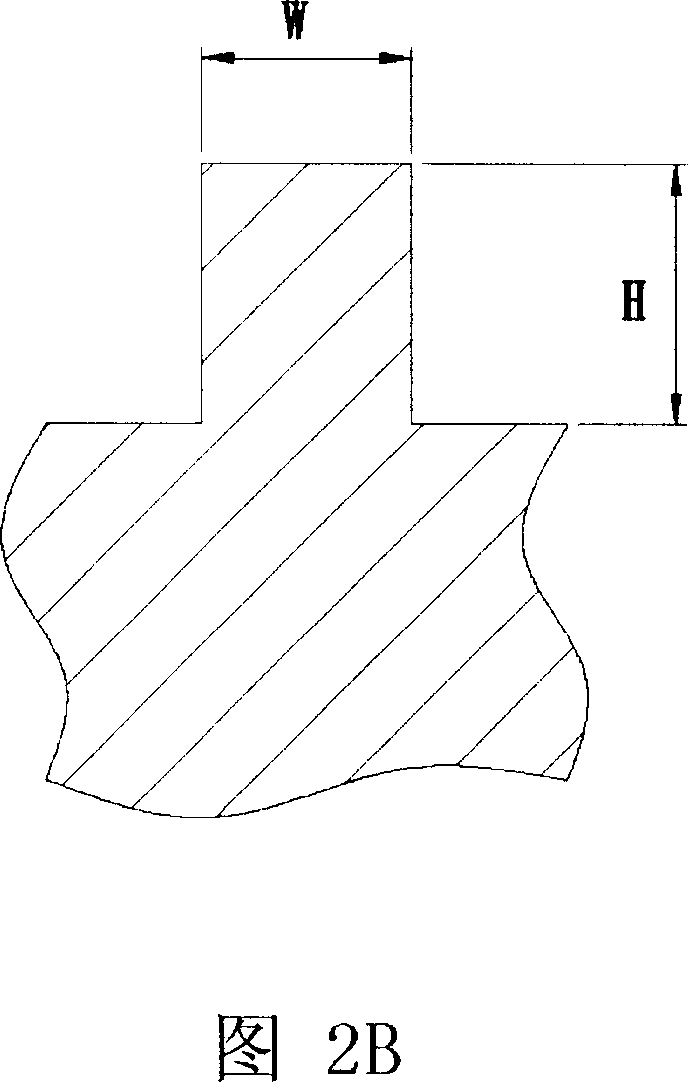

Micro fluidic chip and preparation method and application thereof

ActiveCN106914287AImprove reaction efficiencyResponse timeLaboratory glasswaresBiological testingReaction zoneRepeatability

The invention provides a micro fluidic chip, which belongs to the technical field of micro fluidic. The chip comprises a substrate, the surface of the substrate comprises at least one reaction zone; a target molecule combination object is arranged in the reaction zone, and is used for capturing and / or combining target molecules in a to-be-measured liquid sample and is subjected to a combination reaction in the reaction zone; according to a liquid flow direction, in the reaction zone, and / or, at least one speed control zone is arranged at downstream position close to the reaction zone, a hydrophobic agent is arranged in the speed control zone, and is used for intercepting the target molecule in the reaction zone for full reaction, continuous flowing of the liquid sample cannot be completely obstructed, so that the control on flow velocity of the liquid sample is realized. The invention also provides an application of the chip and its preparation method thereof. The chip has the advantages of good repeatability, high sensitivity, and low cost.

Owner:同昕生物技术(北京)有限公司

Production method of electrolytic manganese metal

The invention discloses a production method of electrolytic manganese metal, which sequentially comprises the following steps: (1) simultaneously adding mixed ore powder of manganese dioxide ores, sulfurous iron ores and manganese carbonate ores and sulfuric acid into a leaching combination tank, heating to 90-95 DEG C, performing leaching combination reaction for 4-6 hours, and performing solid-liquid separation to obtain a rough manganese sulfate solution; (2) performing two-stage purification on the rough manganese sulfate solution to remove impurities, wherein in the primary purification process, SDD or BaS is added for impurity removal, and then aluminum sulfate is added for purification; and in the secondary purification process, 10-30% of deep impurity removal agent is added, and then ammonium sulfide is added for zinc removal; reacting for 1-2 hours, checking and regulating the pH value to 6.0-8.0, performing pressure filtration, then transferring into a standing tank, and standing; and (3) injecting the purified manganese sulfate solution into an electrolytic tank, controlling the pH value of an electrolytic tank solution to be 7.0-8.0, and electrolyzing for at least 24 hours to obtain the electrolytic manganese metal product. According to the method disclosed by the invention, manganese ore resources are reasonably utilized, and the production cost is lowered.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

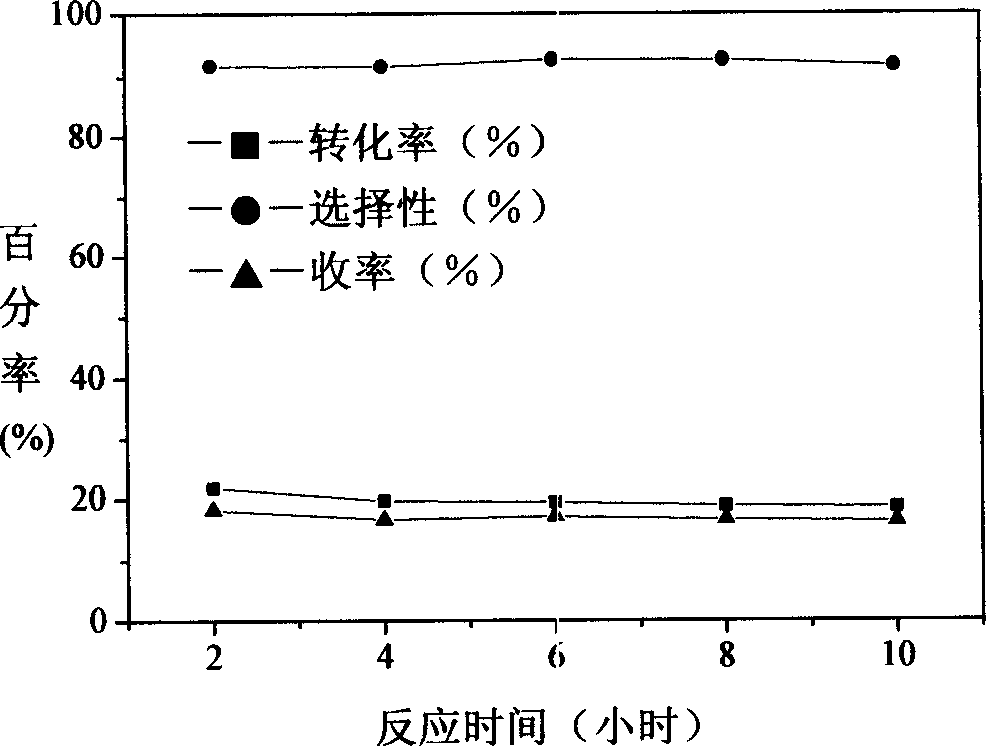

Catalyst for synthesizing para diethyl benzene by ethanol and ethyl benzene combination reaction and its preparation method

InactiveCN1605390AHigh yieldGood choiceOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The present invention relates to catalyst for alkylating ethanol and ethyl benzene into p-diethylbenzene and its preparation process. The industrial catalyst for efficient synthesis of p-diethylbenzene is prepared with the H-ZSM-5 molecular sieve with Si / Al ratio of 50 as basic matter and through surface acidity and tunnel regulation with B, Mg and Co, and has ideal pore size distribution and in-tunnel acidity distribution and strong coking resisting capacity. The precursor of B is boric acid, that of Mg is magnesium nitrate and that of Co is cobalt nitrate. The mass ratio between B and H-ZSM-5 molecular sieve is 1-3 %, that between Mg and H-ZSM-5 molecular sieve is 0.1-1 % and that between Co and H-ZSM-5 molecular sieve is 1-3 %. Compared with available similar catalyst, the present invention has the features one simple preparation process, low cost, high selectivity and yield of p-diethylbenzene, etc.

Owner:NANKAI UNIV

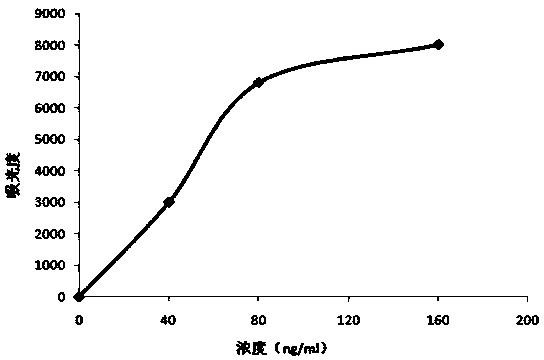

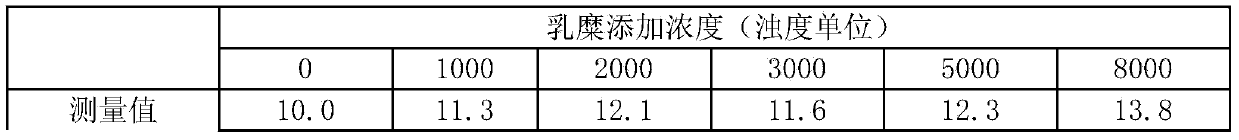

Latex immunoturbidimetry pepsinogen I detection kit for eliminating chyle interference

ActiveCN103698525AStrong interference abilityHigh sensitivityBiological material analysisBiological testingPepsinogen ITurbidity

The invention relates to the technical field of medical examination, and particularly relates to a latex immunoturbidimetry serum pepsinogen I detection kit for eliminating chyle interference. The kit provided by the invention comprises (1) a pepsinogen I calibrator; (2) a reagent 1 with a preset chyle remover; and (3) a reagent 2 containing the monoclonal antibody and polyclonal antibody coated latex particles against human pepsinogen I. According to the kit provided by the invention, the combination reaction between a substrate to be detected in a sample and a specific antibody in the reagent is amplified through the latex agglutination effect; with the given wavelength, the turbidity formed by the reaction is related to the content of the substrate to be detected, thus the content of the substrate to be detected is calculated. The kit provided by the invention is used for detecting the content of pepsinogen I in human serum, has high sensitivity and good specificity, and can eliminate chyle interference in the sample; moreover, the kit is simple and quick to operate and has high practicability and wide application range.

Owner:北京万泰德瑞诊断技术有限公司

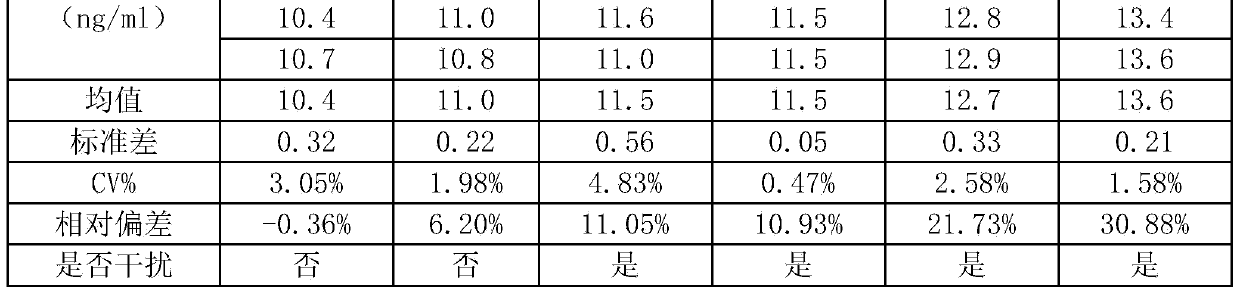

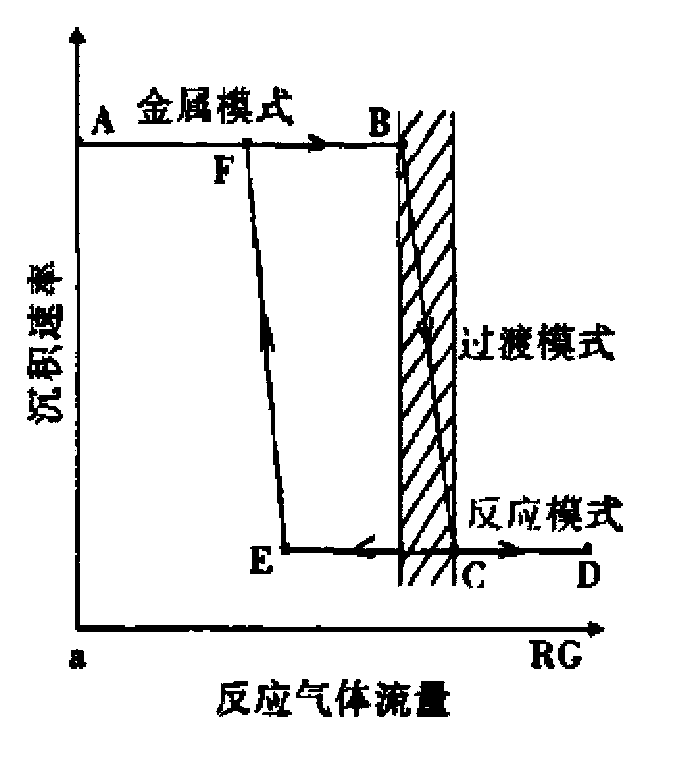

Plasma assisted magnetron sputtering depositing method

ActiveCN103668092ALow costStrong engineering magnificationVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

The invention relates to a plasma assisted magnetron sputtering depositing coating method. When a metal compound thin film is prepared by magnetron sputtering, in order to overcome target poisoning, anode disappearance and the like, an intermediate frequency or pulse direct current reaction magnetron sputtering method is common adopted. The invention provides a novel plasma assisted depositing method, wherein a plasma discharge area is additionally arranged in a vacuum chamber, a work rest rotates at a high speed along with a revolution plate which revolves at the same time, and when a workpiece rotates through the plasma discharge area, combination reaction is further carried out on the incompletely reacted ultrathin thin film and gas ions to obtain a compound thin film with a higher stoichiometric ratio, so that the depositing rate of the thin film is greatly improved. Compared with conventional plasma source assisted depositing technologies, the novel plasma generating technology provided by the invention is lower in cost and easy to amplify, can be used for the field of industrialized production on a large scale, and has an important application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

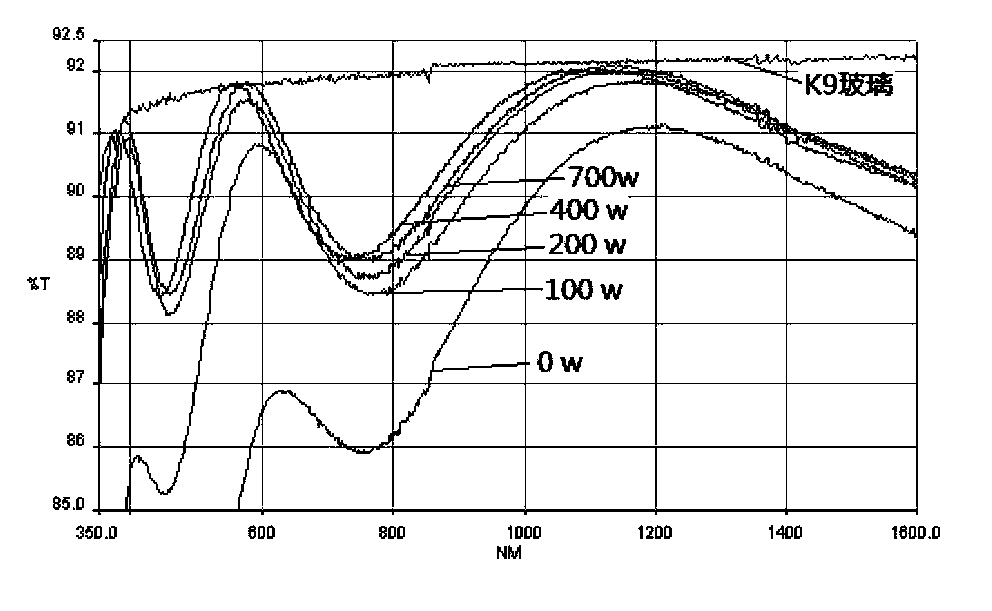

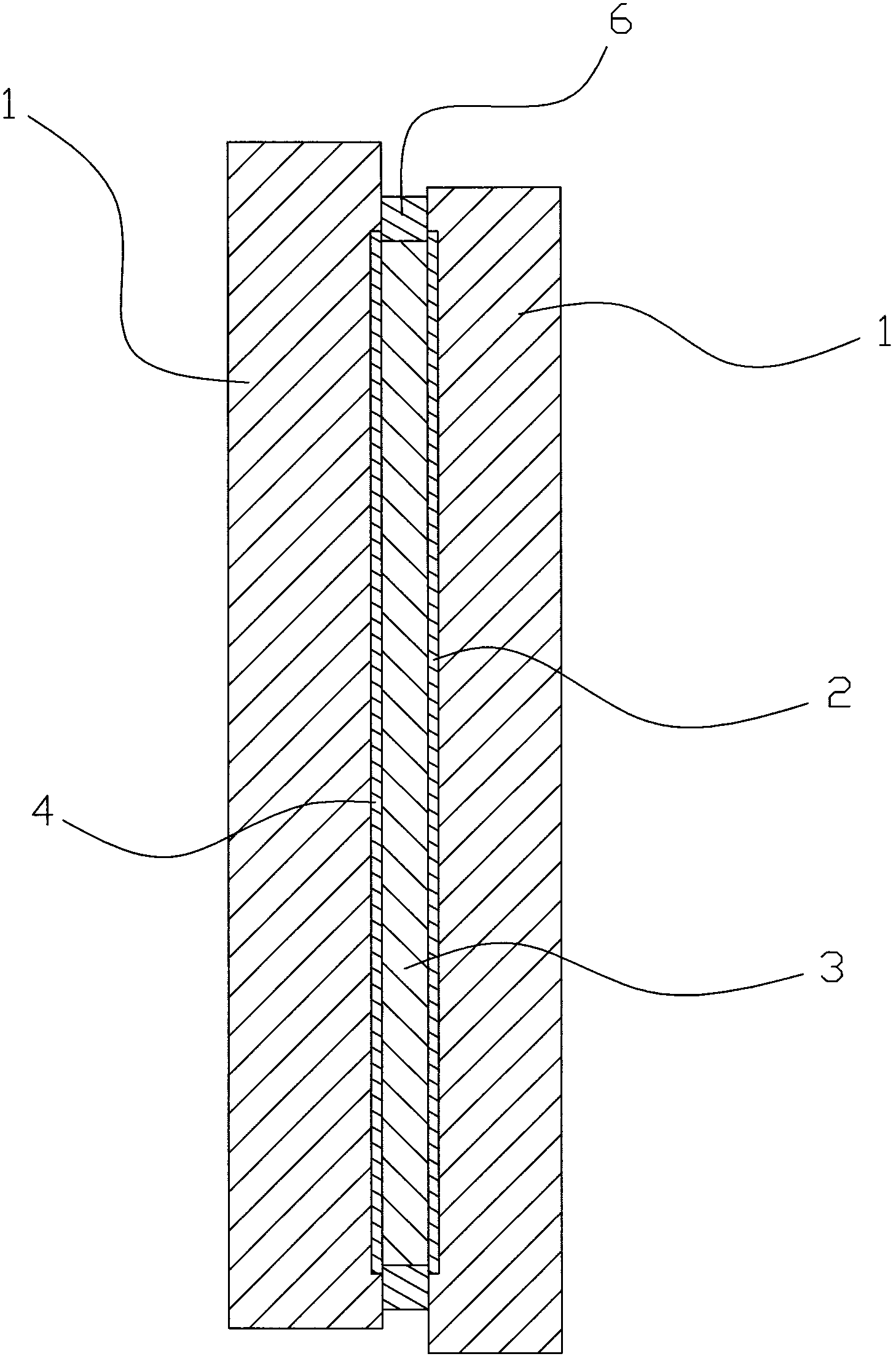

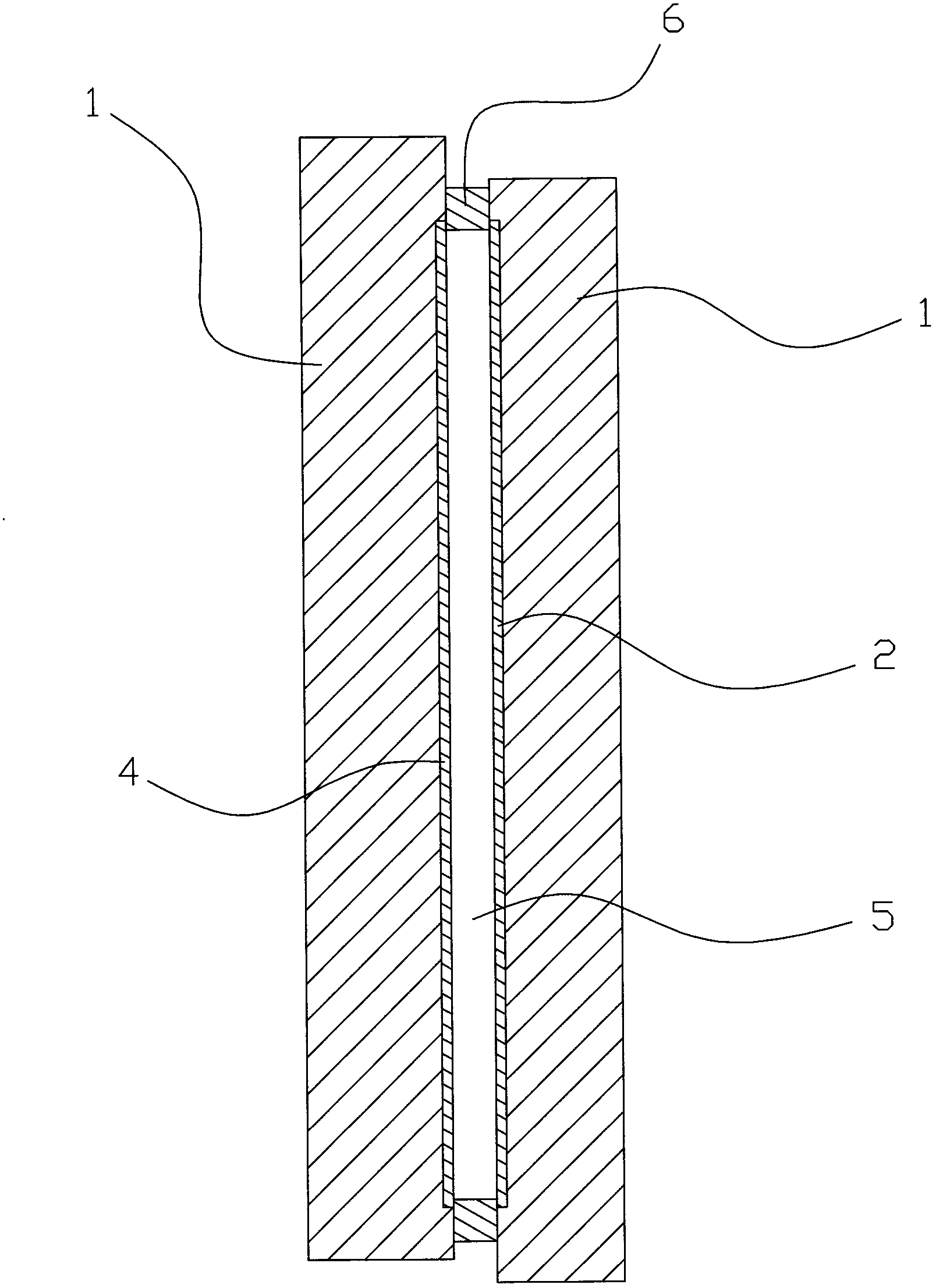

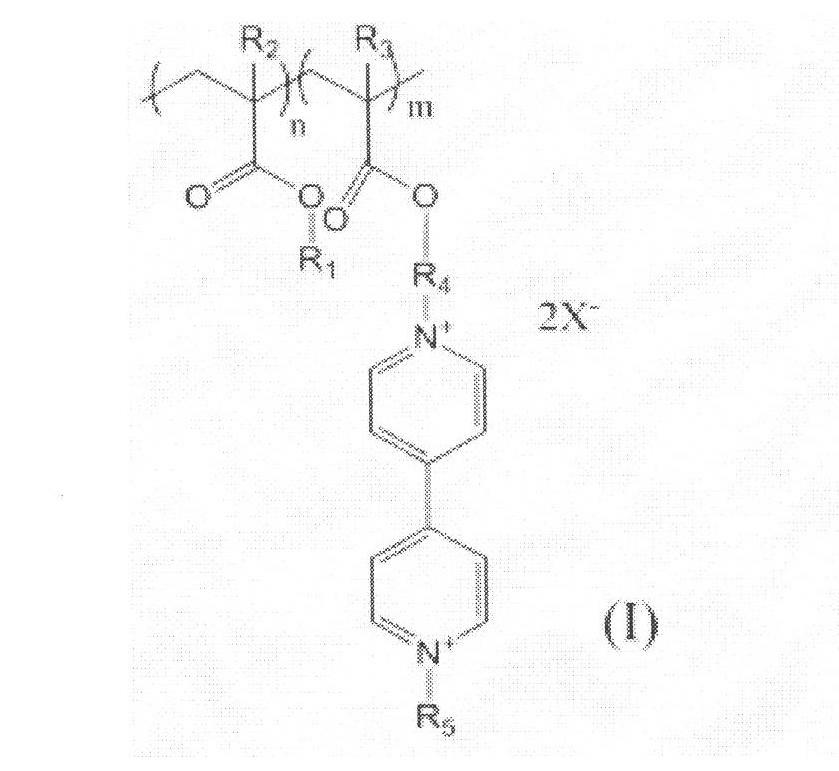

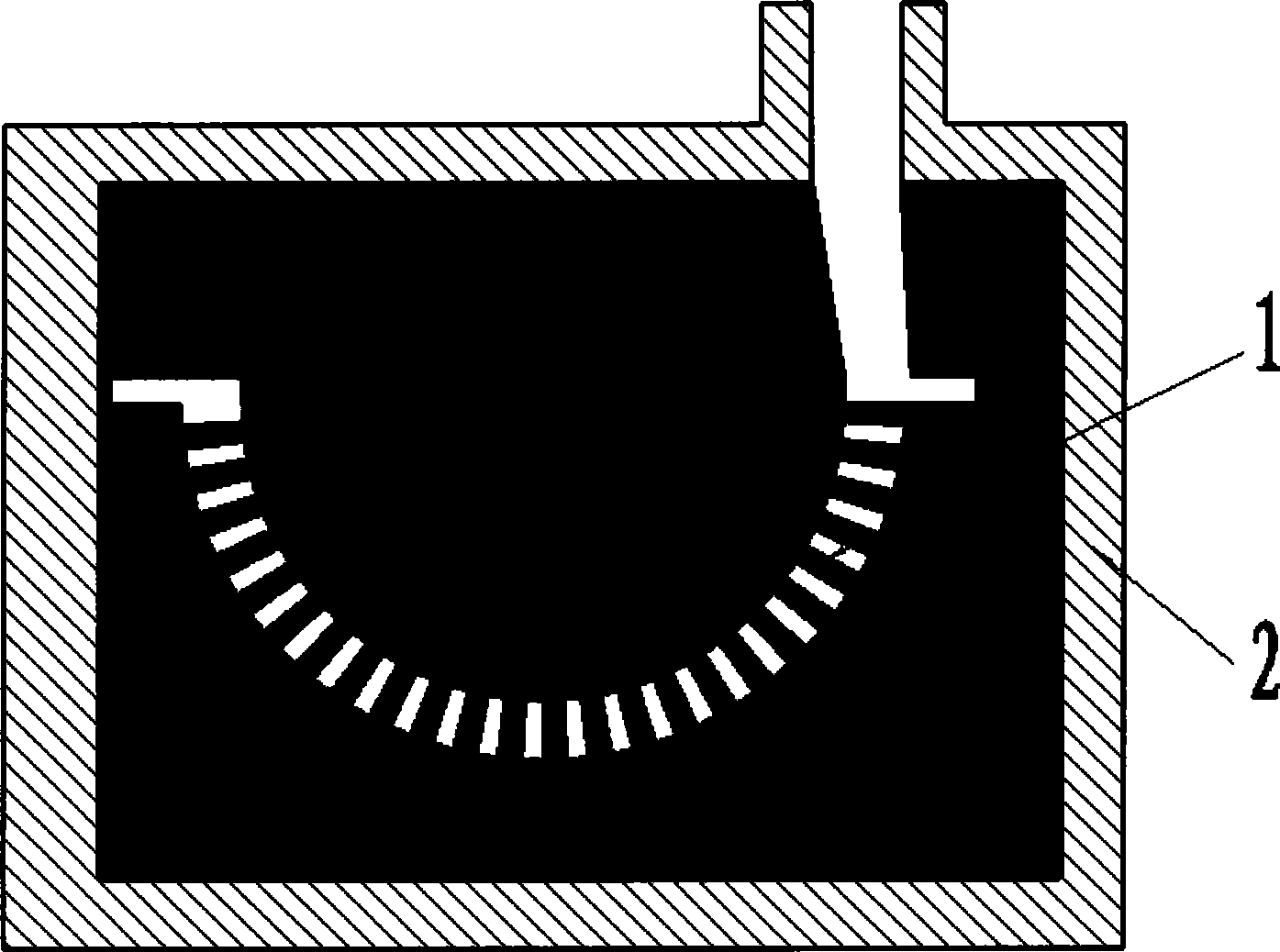

Electrochromism material and electrochromism device

ActiveCN102690646AImprove performanceAvoid harmOrganic chemistryTenebresent compositionsElectrolyte leakageOptoelectronics

The invention relates to an electrochromism material and an electrochromism device. The electrochromism material comprises a cathode electrochromism material (I) and an anode electrochromism material (II). The cathode electrochromism material (I) and the anode electrochromism material (II) are subjected to combination reaction and then are cured in an electrolyte, thereby forming gelatinous electrochromism material. The electrochromism device comprises a piece of glass (1) plated with a transparent conductive film (2) and a substrate (1) plated with a conductive reflecting layer (4). The gelatinous electrochromism material is arranged between the transparent conductive film (2) and the conductive reflecting layer (4). The invention has the advantages that the cathode and anode electrochromism materials are respectively grafted with a polymer and then are cured in the electrolyte, thereby forming the gelatinous electrochromism material; the stability of color change is increased; and the harm caused by electrolyte leakage when the electrochromism device is damaged by an external force is effectively avoided, so that the practical application property of the electrochromism material is further increased.

Owner:NINGBO MI RUO ELECTRONICS TECH CO LTD

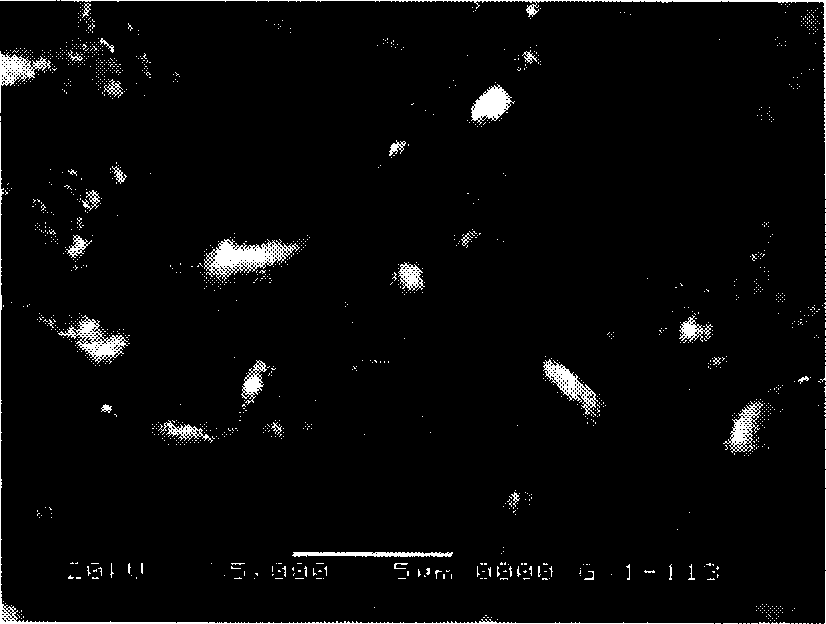

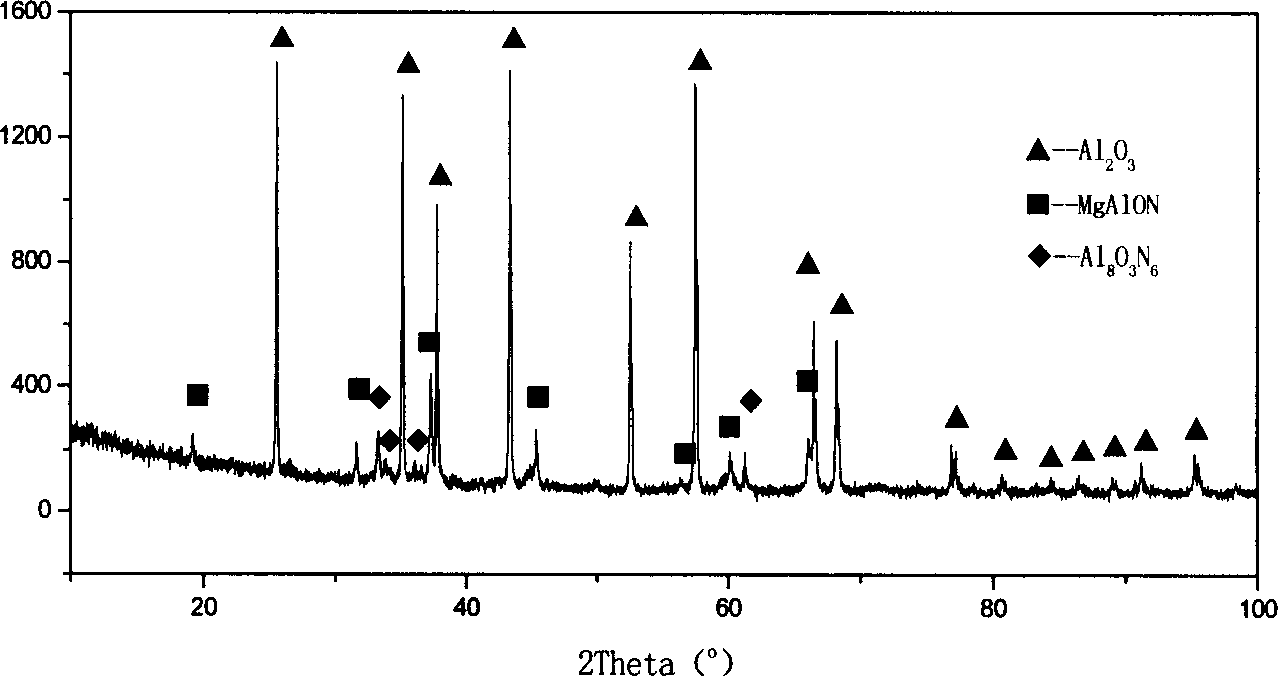

Microporous MgAlON composite corindon material preparation method

A preparing method of micro porous MgAlON composite alumina material belongs to the area of fire resistive material technology. The invention with the aggregate being multi-granular alumina and the base material being the mixture of active aluminum oxide powder, aluminum powder or alumina silica or aluminum-magnesium alloy powder containing the same quantity of aluminum, magnesium oxide powder or magnesite powder or magnesium aluminate spinel containing the same quantity of magnesium oxide produces the micro porous MgAlON composite alumina material by thermite azotizing reaction. The combination reaction of MgAlON is completed at he same time of sintering, that simplifies the preparing process of micro porous MgAlON composite alumina material; the micro porous MgAlON composite alumina material produced from the process with the fine crystal particle in base material and most of the diameters of gas pore being less than 1-2 mum can improve the strength of materials, stability of heat shock and slag resistance, and extend the use life. The invention can save the production cost largely, improve the ability of the material, favor the use in the industry of metallurgy, organic chemical industry, ceramics and aerospace technology, and etc.

Owner:ZHENGZHOU UNIV

Method for preparing composite wear-resistant foreplate

InactiveCN101412095AInhibited DiffusionReduce the temperatureGuiding/positioning/aligning arrangementsWear resistantHardness

The invention discloses a method for preparing a composite antiwear guide plate, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a guide plate casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the guide plate; molten matrix metal is cast into the guide plate casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite guide plate which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite anti-wear guide plate has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price, simple preparation and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

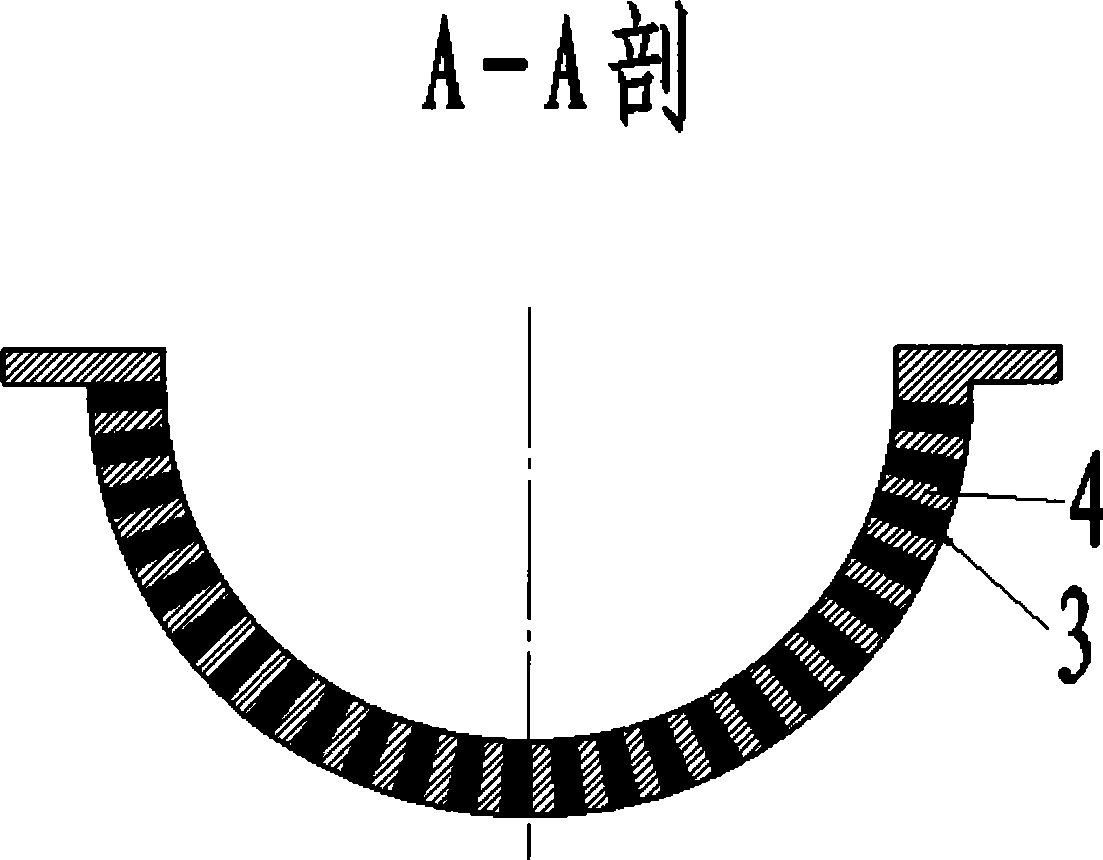

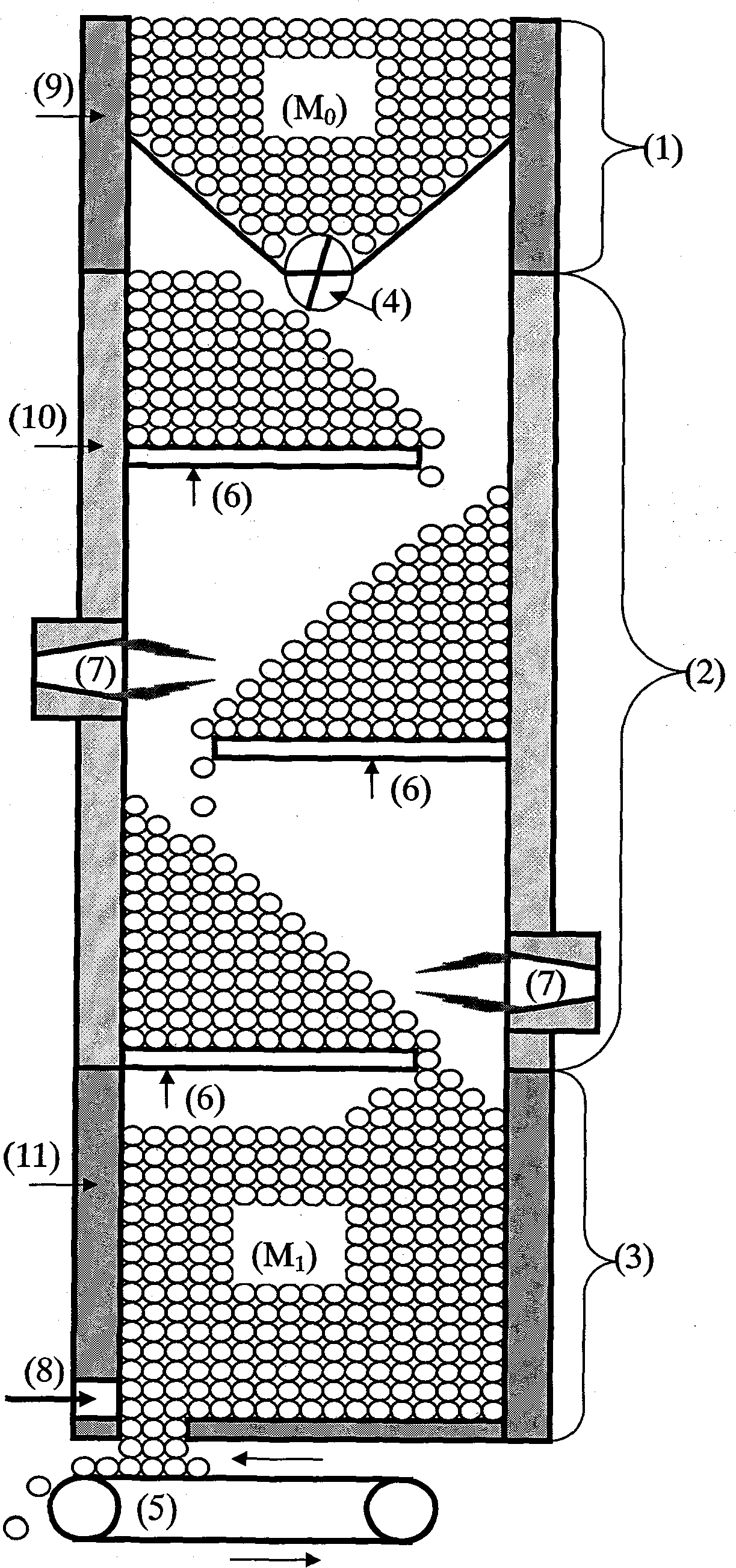

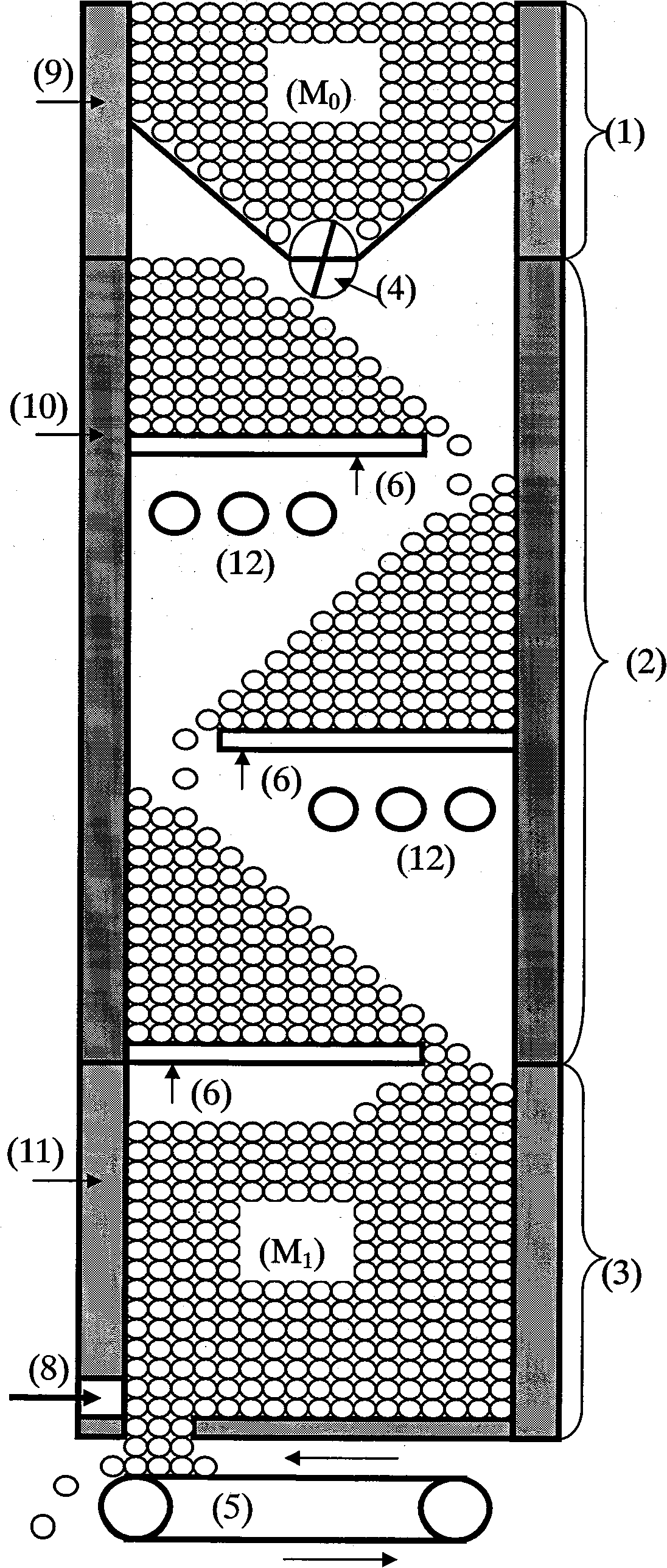

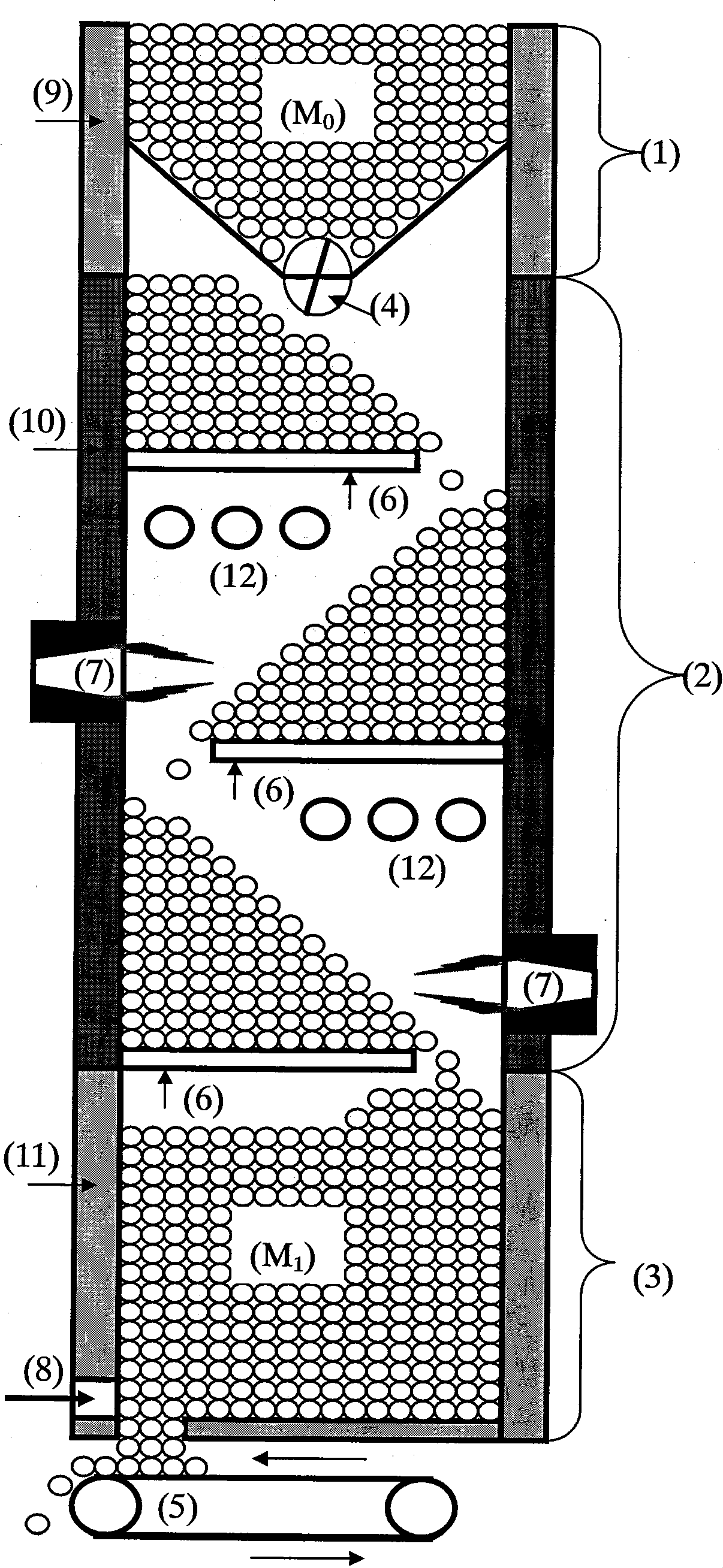

Stepped furnace

The invention provides a vertical kiln that is used for treatment on solid material, such as combination reaction, decomposition reaction, reaction between the solid material and gas, and sintering and compacting of the solid material or melting of the solid material into high-temperature liquid. The stepped furnace consists of an upper silo, a feeding mechanism, a step furnace, step plates, a bottom silo and a discharging mechanism; furthermore, a gas inlet and a gas outlet are arranged at the lower parts of the bottom silo and the top silo; the step plates in the stepped furnace can be staggered mutually in horizontal direction so that the step root is always connected with two furnace walls that are arranged in parallel and the step edge is always away from the two furnace walls by a certain distance; the step plates are away from one another by a certain distance in vertical direction; furthermore, the vertical distance from the step edge to the next step surface can meet the flowing of the material and can also have certain free space height. The vertical kiln can replace vertical reaction towers, vertical thermal decomposition furnaces, light-burning furnaces, clinker sintering furnaces, melting furnaces and special metallurgical smelting furnaces. Compared with the traditional vertical kiln, the vertical kiln in the invention has the characteristics of good material processing quality, high uniformity, and good energy-saving and consumption-reducing effect, and having no pollution to environment.

Owner:蒋明学

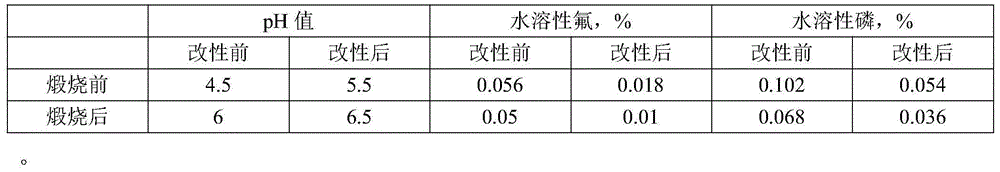

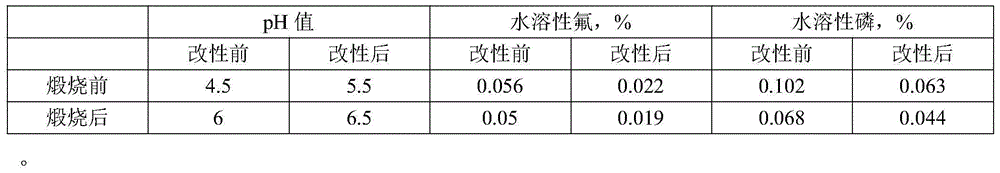

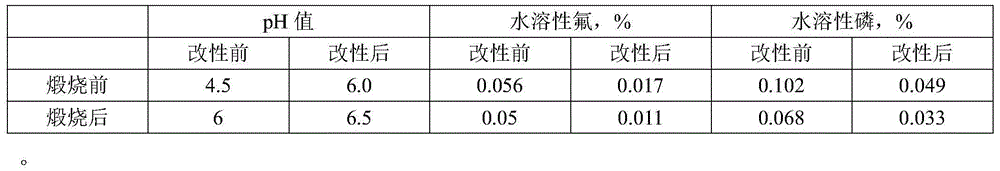

Phosphogypsum treatment method

The invention belongs to a phosphogypsum treatment method. The phosphogypsum treatment method comprises the following steps: (1) pre-treating: ageing phosphogypsum until the content of attached water is 8-10%; (2) combination reaction: adding a modifying agent into the aged phosphogypsum, stirring until the reaction is complete, wherein the weight ratio of the modifying agent to the phosphogypsum is (1-8): 100, the modifying agent is a mixture of lime and a cinerite mixed material, and the weight ratio of the lime to the cinerite mixed material is 1: (1.5-4); (3) drying: drying the phosphogypsum at 360-450 DEG C after the combination reaction until the content of attached water of the phosphogypsum is lower than 2%; and (4) calcining: calcining the dried phosphogypsum at 200-240 DEG C for 6-12 minutes. Granules of the phosphogypsum are more uniform by ageing, and due to the modification of the modifying agent, the acidity of the phosphogypsum is reduced, and the contents of water-soluble fluorine and water-soluble phosphorus are decreased; and then, the phosphogypsum is changed into building phosphogypsum with good performance by drying and calcining.

Owner:HENAN JUNENG NEW BUILDING MATERIAL

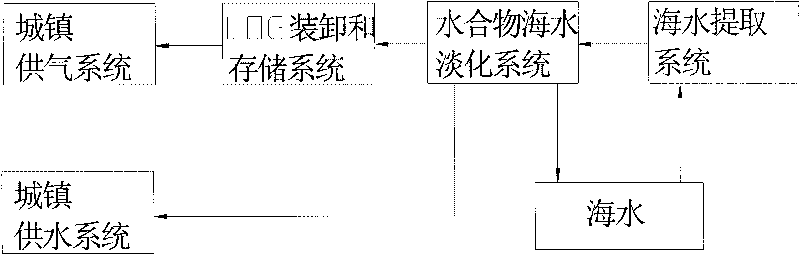

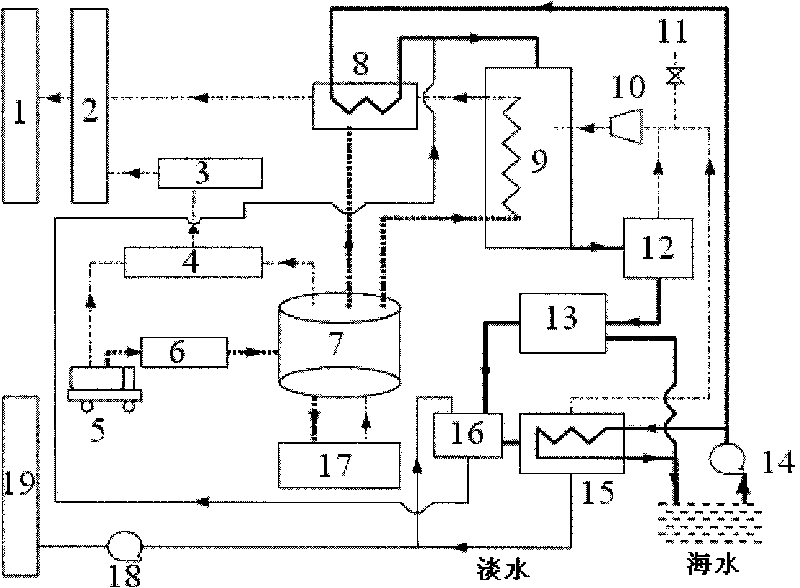

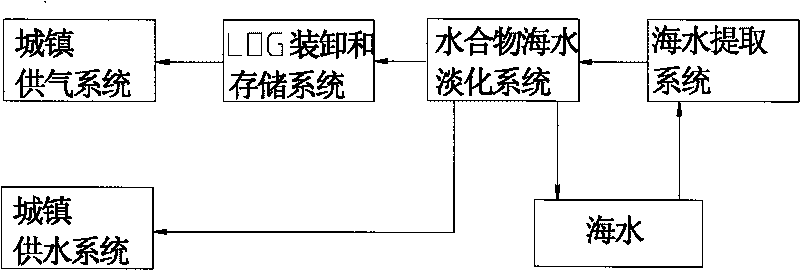

System for desalination of sea water by utilizing LNG cold energy

InactiveCN101746840AReduce energy consumptionReduce solubilityDomestic cooling apparatusGeneral water supply conservationSolubilityWater desalination

The invention discloses a system for desalination of sea water by utilizing LNG cold energy, comprising a town water system and town gas supply system, an LNG loading and unloading and storage system, a hydrate sea water desalination system and a sea water extraction system; one end of the LNG loading and unloading and storage system is connected with the town gas supply system, the other end is connected with the hydrate sea water desalination system, the LNG loading and unloading and storage system is used for receiving and storing liquefied natural gas (LNG) transmitted from an LNG receiving end and transmitting the LNG into the hydrate sea water desalination system, and the LNG is gasified and then is transmitted to the town gas supply system; the other end of the hydrate sea water desalination system is also connected with the sea water extraction system, and hydrate sea water desalination system is used for decomposing the sea water extracted by the sea water extraction system into fresh water by virtue of combination reaction of hydrate and the LNG; and the town water system is also connected with the hydrate sea water desalination system and used for transmitting the fresh water obtained by decomposition of the hydrate sea water desalination system. The invention has the characteristics that: energy consumption is low, equipment is simple; solubility in water or saline water is low; LNG cold energy utilization factor is high, economic benefit is high, investment cost is low, and environmental effect is less.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

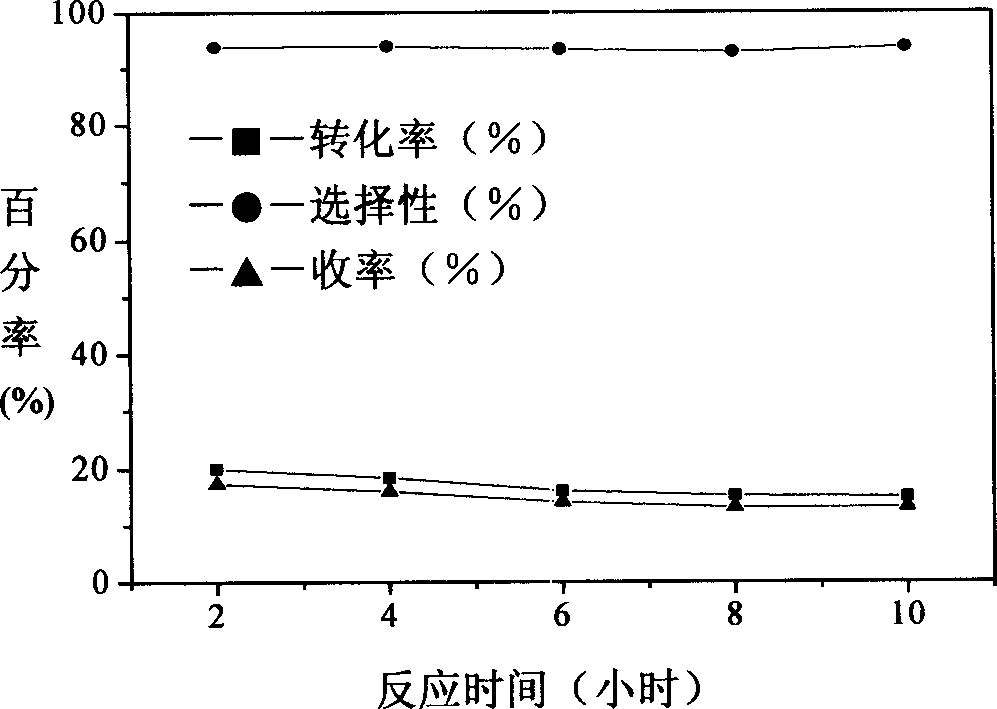

Liquid-phase fixed bed preparation method of cyclohexanone oxime

The invention discloses a liquid-phase fixed bed preparation method of cyclohexanone oxime. The liquid-phase fixed bed preparation method has the characteristic that high-selectivity cyclohexanone oxime combination reaction is carried out on cyclohexanone, hydrogen peroxide, ammonia gas and a tertiary butanol aqueous solution in a fixed-bed reactor under the catalytic action of titanium silicalite molecular sieve, wherein the mass concentration of the hydrogen peroxide is 5%-50%; the mass concentration of the tertiary butanol aqueous solution is 30%-90%; the weight ratio of the cyclohexanone to the hydrogen peroxide to the ammonia gas to the tertiary butanol aqueous solution is 1:(0.35-1.74):(0.19-0.70):3. Compared with the prior art, the liquid-phase fixed bed preparation method of the cyclohexanone oxime is good in selectivity, high in conversion rate, capable of separating reaction liquid without catalyst, simple in process, capable of continuously charging and discharging, environment-friendly and easy for industrial implementation.

Owner:EAST CHINA NORMAL UNIV

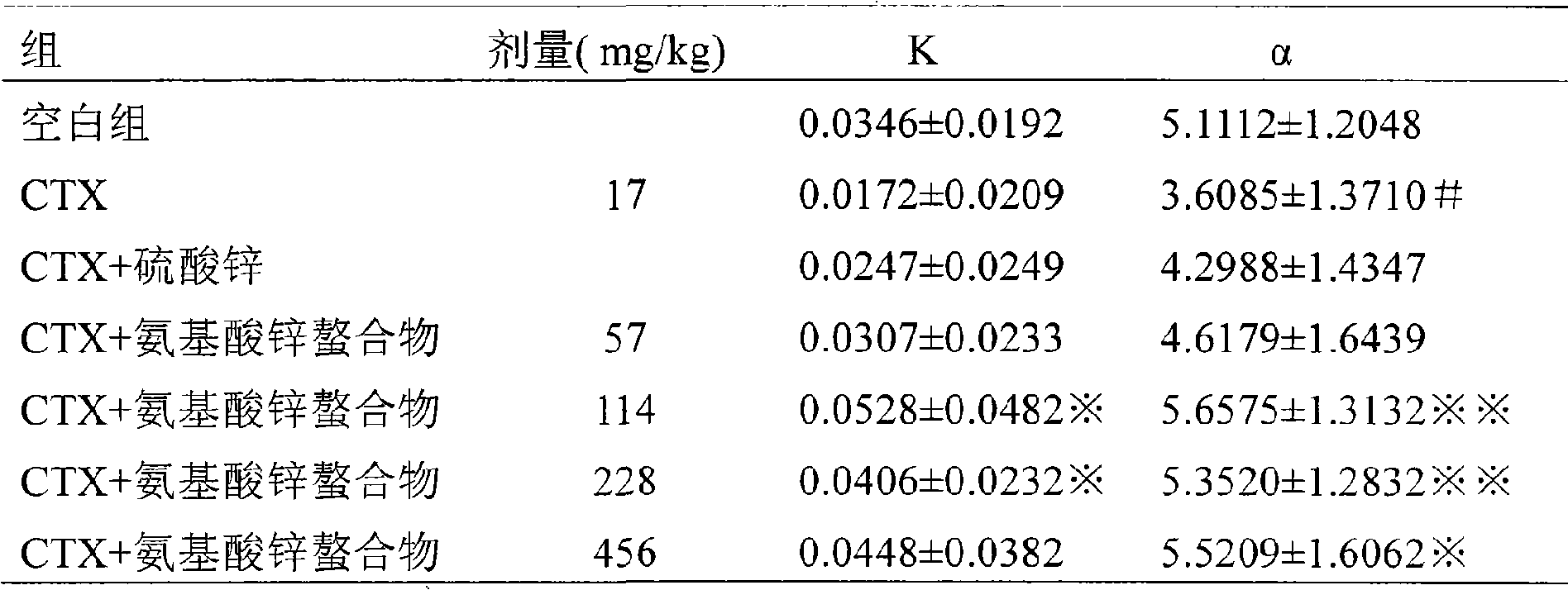

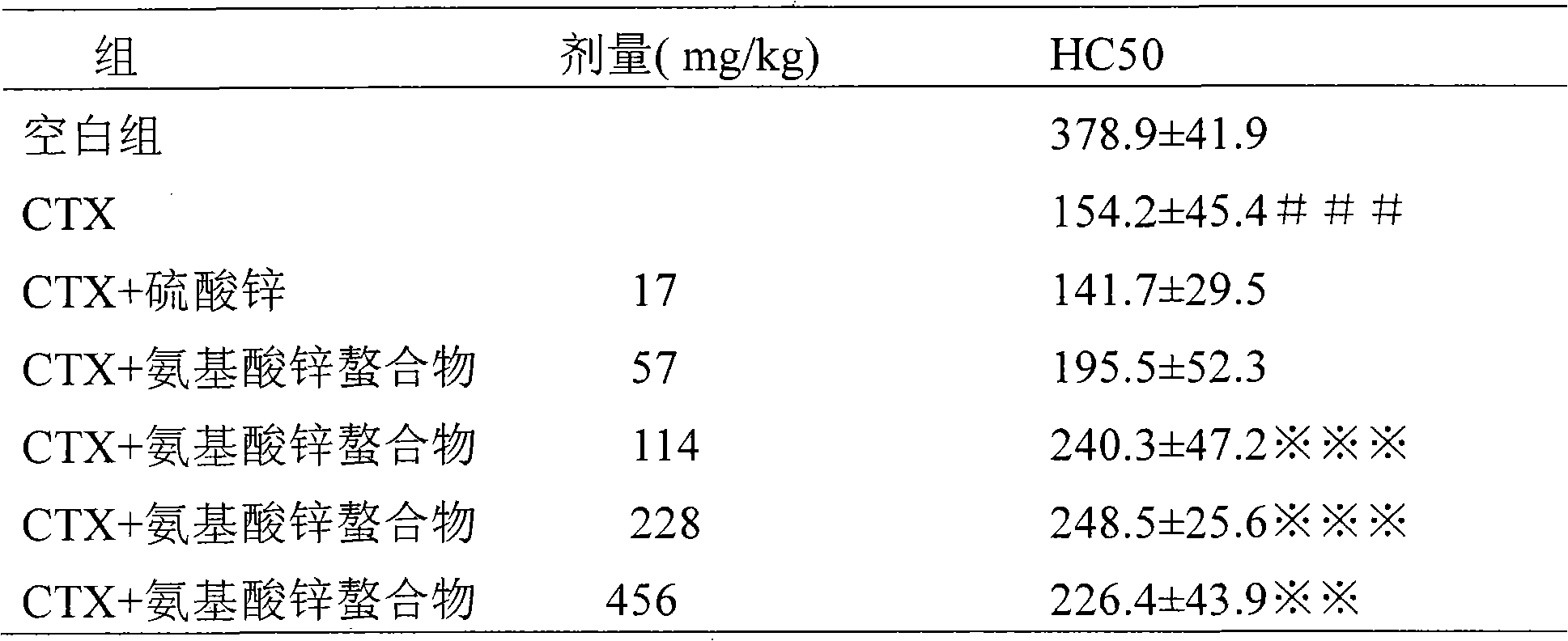

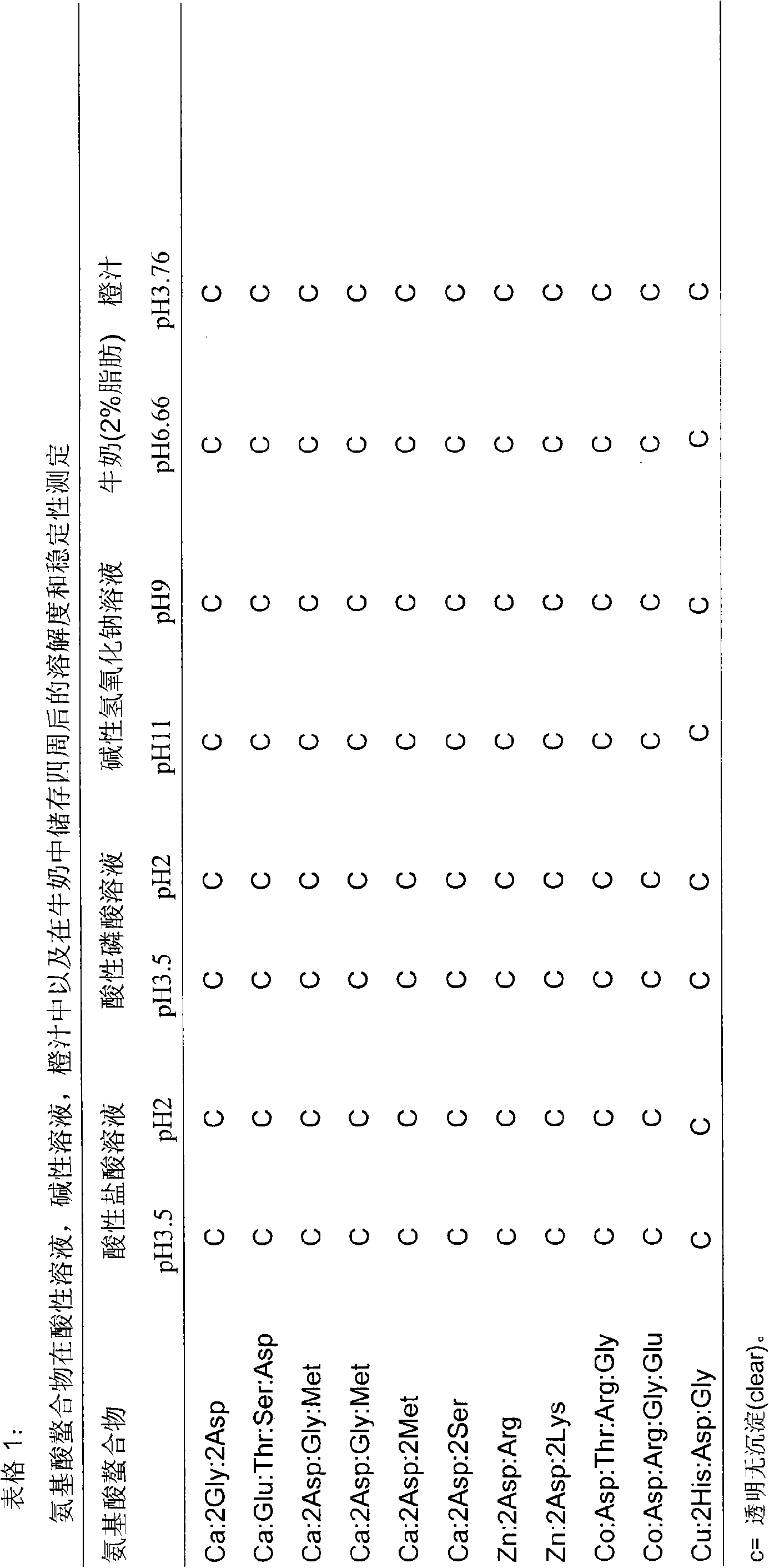

Production process of pure amino acid chelate and use thereof

InactiveCN101302171AImprove stabilityImprove solubilityOrganic active ingredientsOrganic chemistryWhite mouseZinc amino acid chelate

The invention provides a method for producing pure amino acid chelate and use thereof. The method is as followings: the first step is to reacting oxide or metal hydroxide and the amino acid to generate hydroxyl amino acetate; the second step is to conduct a combination reaction of the hydroxyl amino acetate which is generated in the first step and at least an amino-containing compound, and the compound with abundant amino is reacted with a metal ion, thus, the generated amino acid chelate structure is formed by combining one metal ion and a plurality of ligands of the amino acid, but the number of the ligands of the amino acid is equal to the number of the ligands of the metal ion, and the pure amino acid chelate is separated from reaction generation liquid. The second step also comprises several continuous sub-steps for reaction with a plurality of amino-containing compounds. The generated pure amino acid chelate can be applied to beverage, food, health products and medicine, in particular a zinc amino acid chelate that can obviously and effectively increase a white mouse immune function with lower immunity.

Owner:VIVA PHARMA

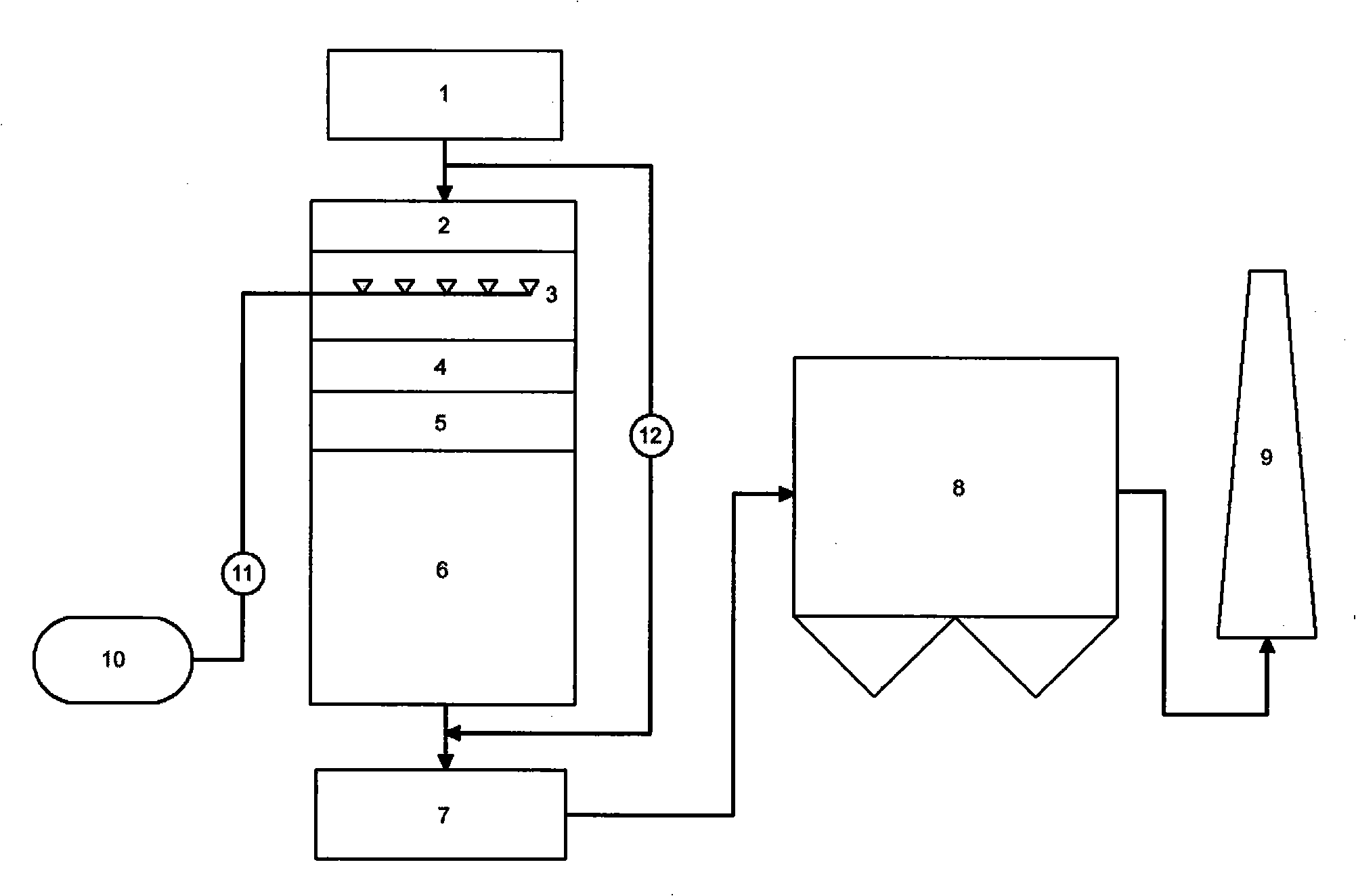

Flue gas dry-type method for simultaneously desulfurizing and denitrating

ActiveCN101279186ASimple structureSimple regeneration methodLighting and heating apparatusDispersed particle separationWorking temperatureFixed bed

The invention relates to a dry-type method of simultaneous desulfurization and denitration of flue gas, which takes iron-based metallic oxides and modules prepared by flay ash as catalyst of denitriation reaction of selective catalystic reduction and desulfurizer. The method of the invention utilizes one reactor to realize simultaneous desulfurization and denitration; the saturated modules after adsorption can be reused through the way of heat regeneration. The process of the invention is that: leading the boiler flue gas out of a coal economizer, distributing the flow of the flue gas through a first grade air deflector, fully mixing the distributed gas flow with the ammonia sprayed in, going through a second grade air deflector to cause the gas flow to be more even, leading the obtained material sequentially going through the catalystic modules of each layer in a fixed-bed reactor, carrying out oxidation-reduction reaction and combination reaction. The method of the invention has low bed pressure drop, can realize desulfurization and denitration simultaneously, has wide working temperature scope, and the desulfurization and denitration efficiency is over 80 percent by adopting the multi-layer catalyst with 4-17wt percent of sulfur capacity.

Owner:TSINGHUA UNIV

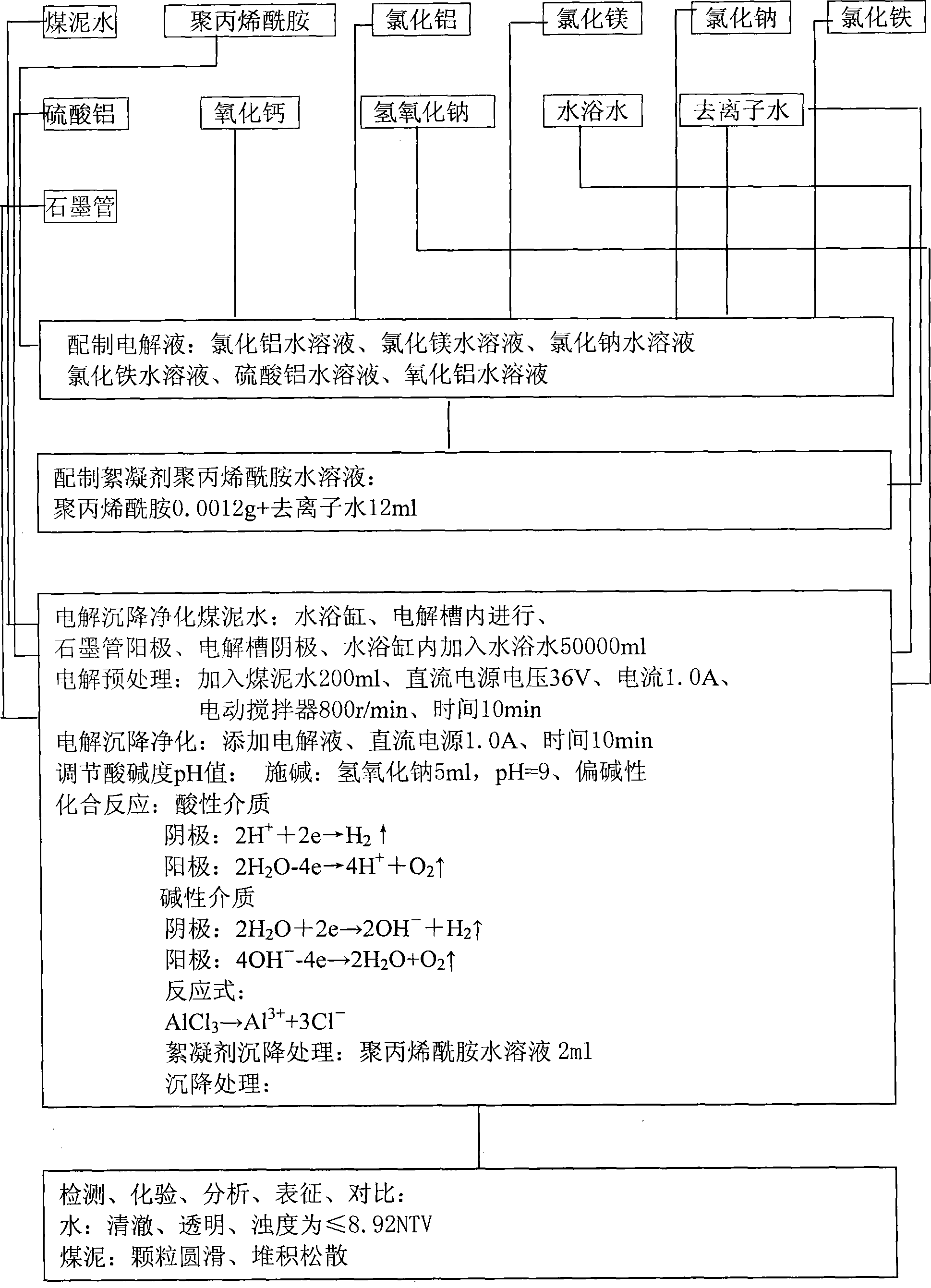

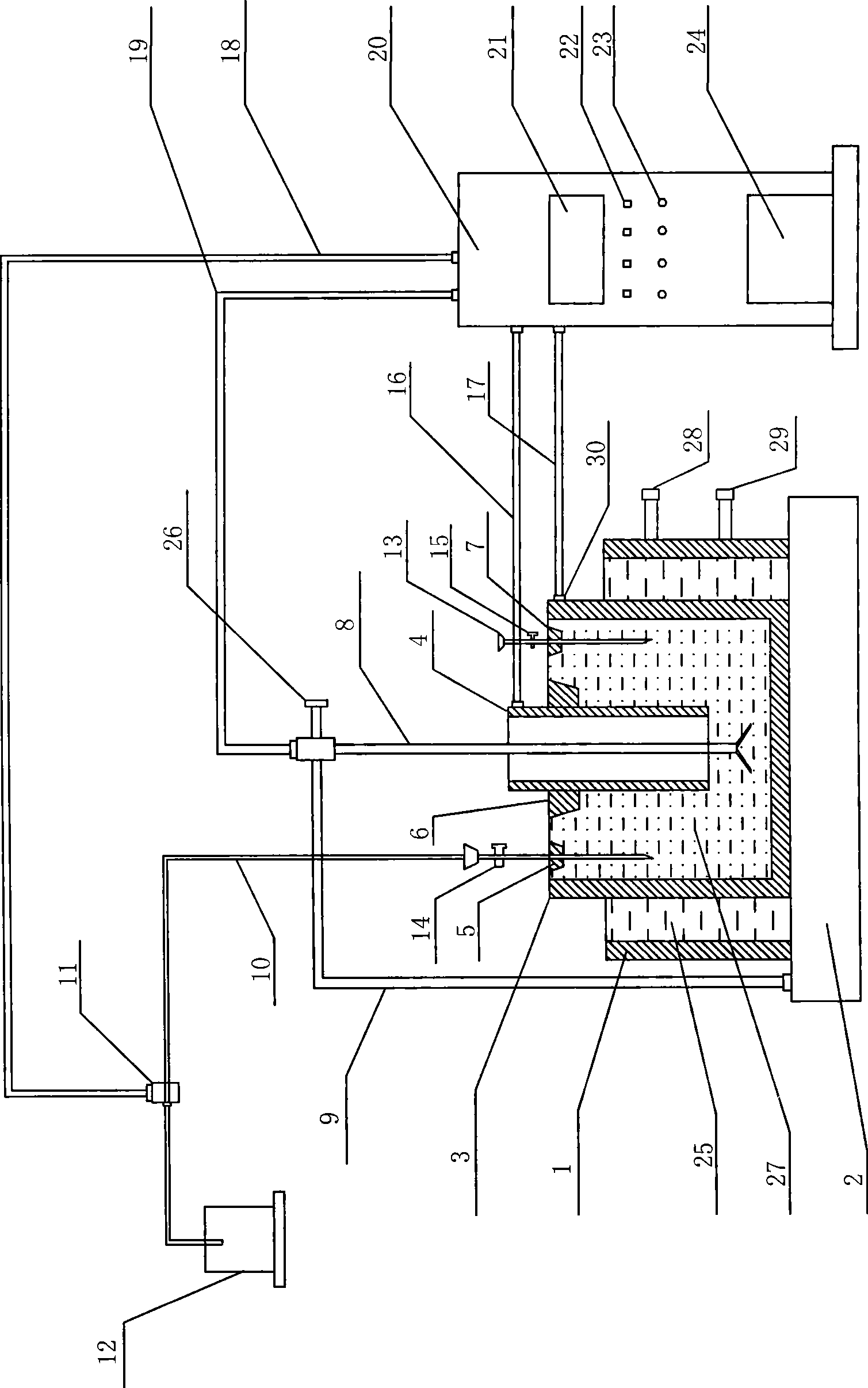

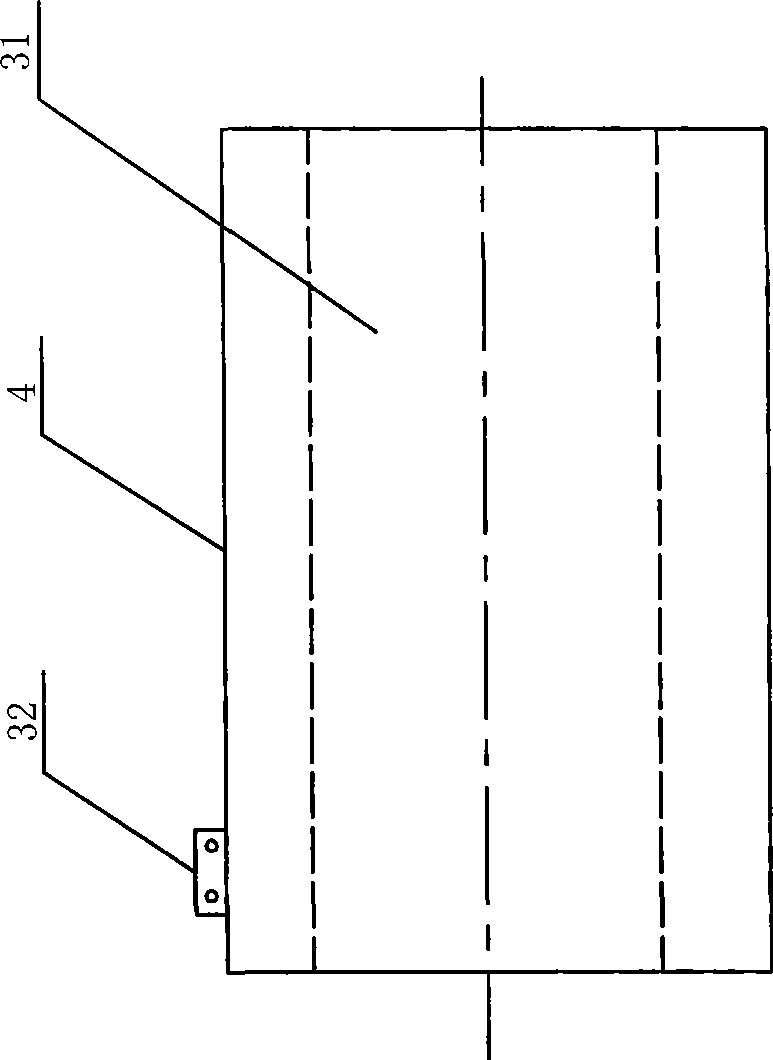

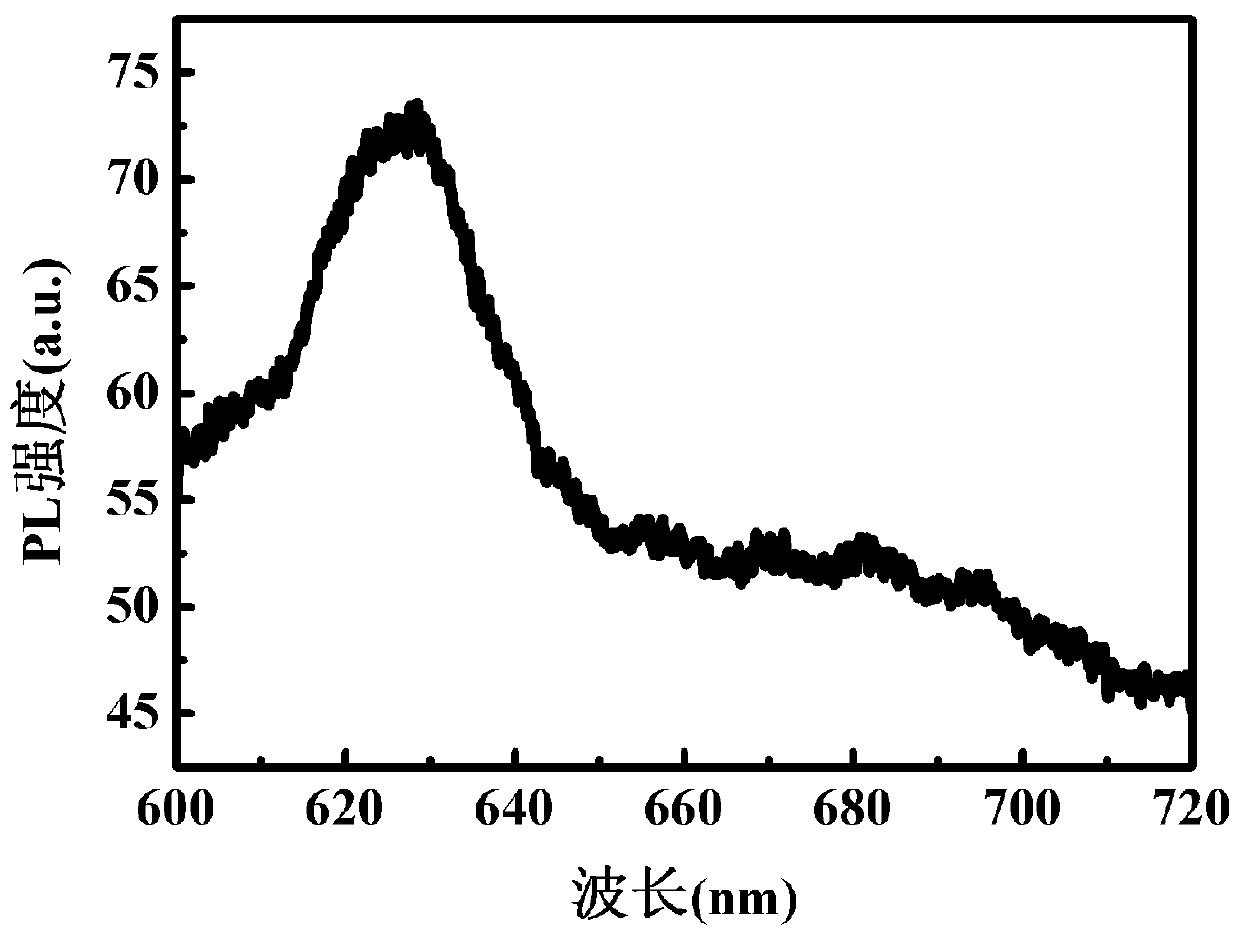

Method for subsiding and purifying slime water by electrolytic process

InactiveCN101496962AReduce turbidityReduce consumptionSedimentation separationAluminium chlorideTurbidity

The invention relates to a method for settling and purifying coal slurry water through electrolysis, which comprises the steps of selecting chemical substances, preparing an electrolyte and a flocculating agent and carrying out electrolysis for settlement and purification with power supplied by a 36V DC powder supply, wherein the flocculating agent is polyacrylamide, the electrolyte is aluminum chloride or magnesium chloride, and sodium chloride, ferric chloride, aluminum sulfate and calcium oxide, deionized water is used as a solvent, sodium hydroxide is used as an alkalinity adjusting agent, a graphite tube is used as an anode, a stainless steel electrolytic cell is used as a cathode, the coal slurry and water are separated through the DC powder supply electrolysis, stirring and combination reaction, the turbidity of water obtained after separation is 8.92NTU, the coal slurry grains are round and smooth and loosely piled, and compared with the prior art, the sedimentation speed is increased by 20 percent, the turbidity is reduced by 16 percent compared with the prior art, and the use of the polyacrylamide is reduced to 23 grams for per ton of raw coal. Therefore, the method is an ideal method for settling and purifying coal slurry water, represents the first like technology in China, and can be widely promoted and used in the technical field of coal dressing.

Owner:TAIYUAN UNIV OF TECH

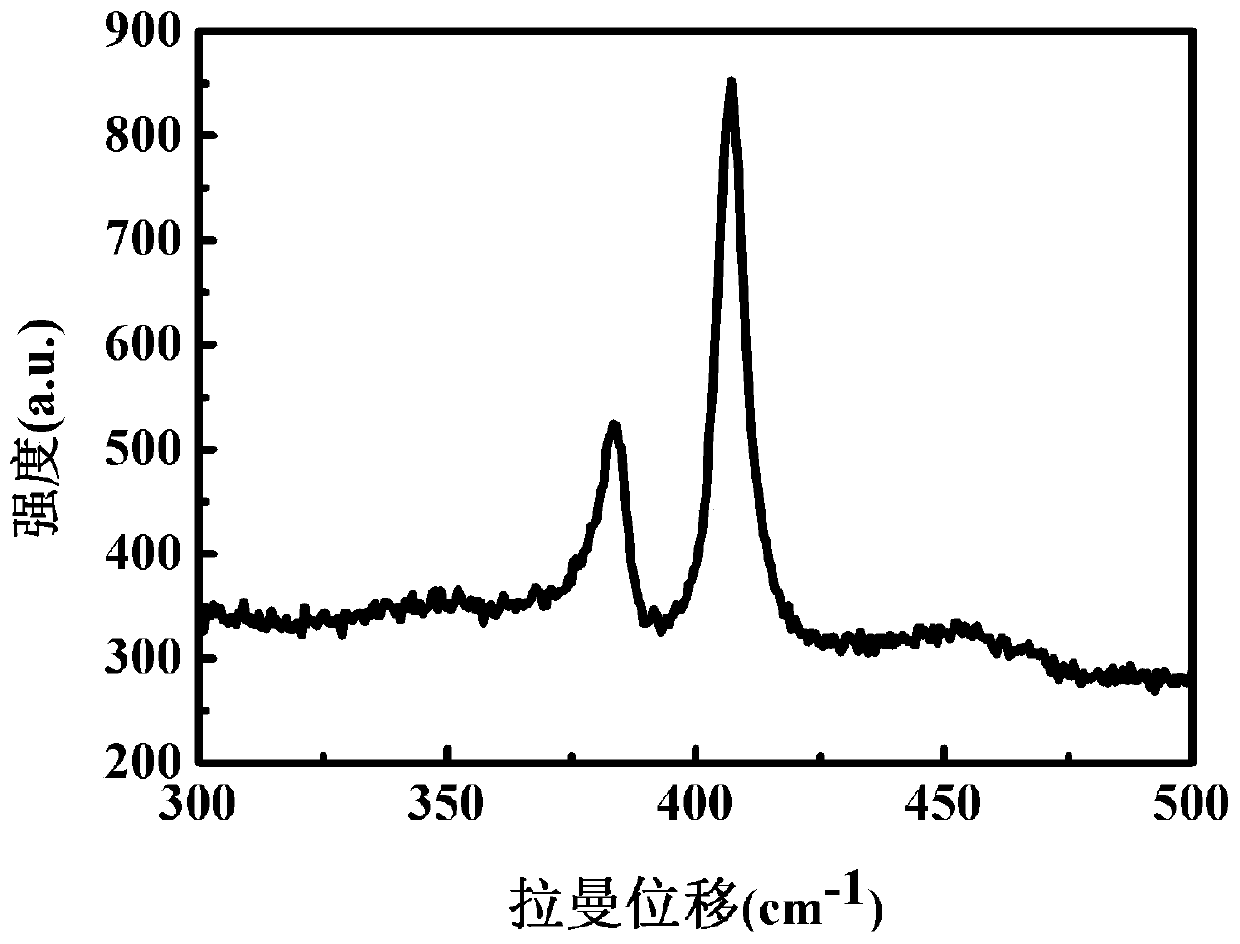

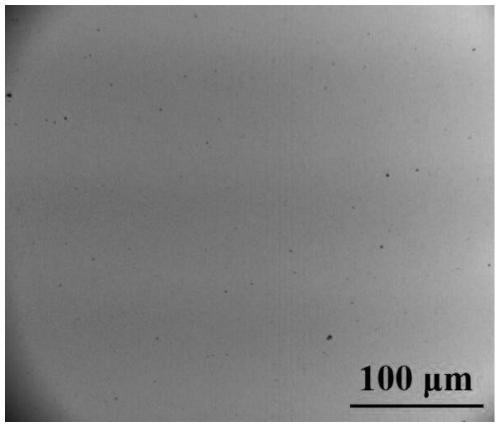

Molybdenum disulfide thin film gas sensitive material, preparation method and application

InactiveCN109825816ACreate pollutionSimple processVacuum evaporation coatingMaterial analysis by electric/magnetic meansAdhesiveEvaporation

The invention discloses a molybdenum disulfide thin film gas sensitive material, a preparation method and application. A MoS2 thin film material obtained through a CVD method is adopted as the gas sensitive material. Firstly, a SiO2 / Si substrate is pre-plated with a molybdenum atom layer of a certain thickness at the deposition rate of 0.1 A / s through electronic beam evaporation; and then at a certain temperature, the SiO2 / Si substrate and S steam generate a combination reaction to generate the MoS2 thin film gas sensitive material. The two ends of the obtained substrate with a MoS2 nanosheetgrowing on the surface are plated with gold electrodes correspondingly; and a wire and the gold electrodes are bonded through a conductive silver adhesive, finally an insulation AB adhesive is used for fixing so as to increase the strength of a gas sensitivity testing device, the testing device is aged and packaged, and therefore preparation of a NO2 gas sensitive element is achieved. The preparedgas sensitive element can achieve detection to NO2 gas under room temperature, energy consumption is low, selectivity to distribution gas is good, and great significance is achieved on real-time monitoring of the NO2 gas.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Fly ash calcium based flue gas desulfurizer and method for manufacturing same

InactiveCN101559317AStrong reactive absorption performanceLarge specific surface areaDispersed particle separationSucroseOperational costs

The invention discloses a fly ash calcium based flue gas desulfurizer and a method for manufacturing the same, the method comprising the following steps: grinding the components including 40-70 weight parts of fly ash, 15-30 weight parts of Ca(OH)2 or CaO with a purity of above 85 percent, 10-30 weight parts of excitant and 0-5 parts of sucrose, mixing the above components evenly, heating 1000-1500 weight parts of deionized water to a temperature of 60-90 DEG C, and adding the deionized water into the mixture; keeping the hydrothermal temperature constant, and stirring continuously the mixture for 8-15 hours at 200-400 rpm for hydrothermal combination reaction; performing suction filtration to serosity, placing the filtered and washed serosity in a constant-temperature drying box; drying the serosity to constant weight, taking out filter mass and cooling the filter mass to normal temperature; pressing the filer mass slightly into powder, and screening the power with a standard sieve of 40 mu and sealing the power. Compared with the prior art, the invention has stronger reaction and absorption performance to SO2, can reduce the operational cost of a desulfurization system and improves the use ratio of desulfurizer.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

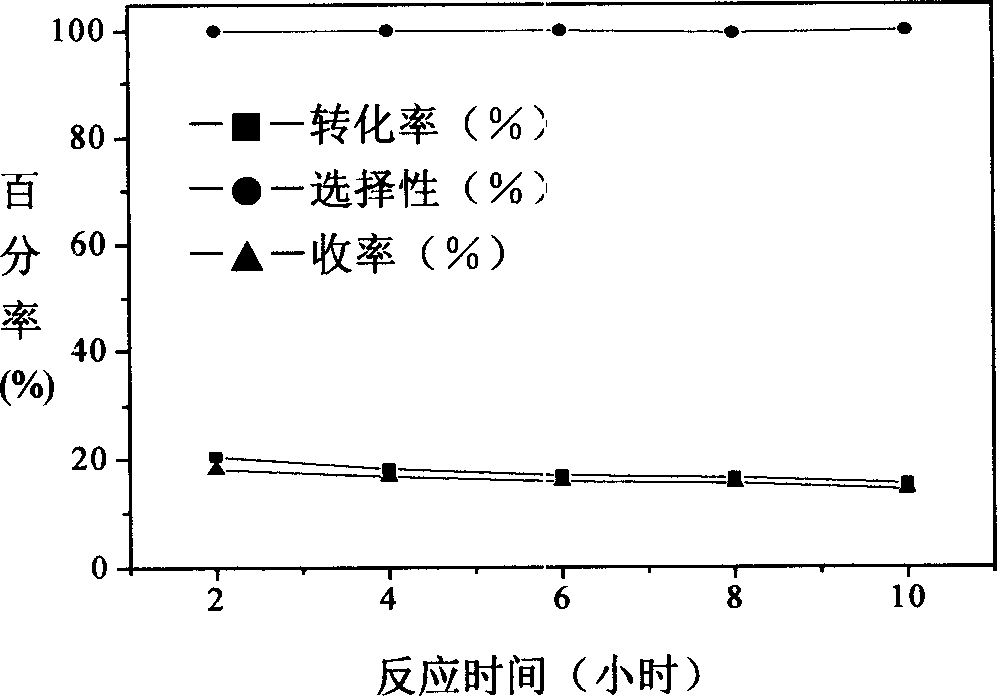

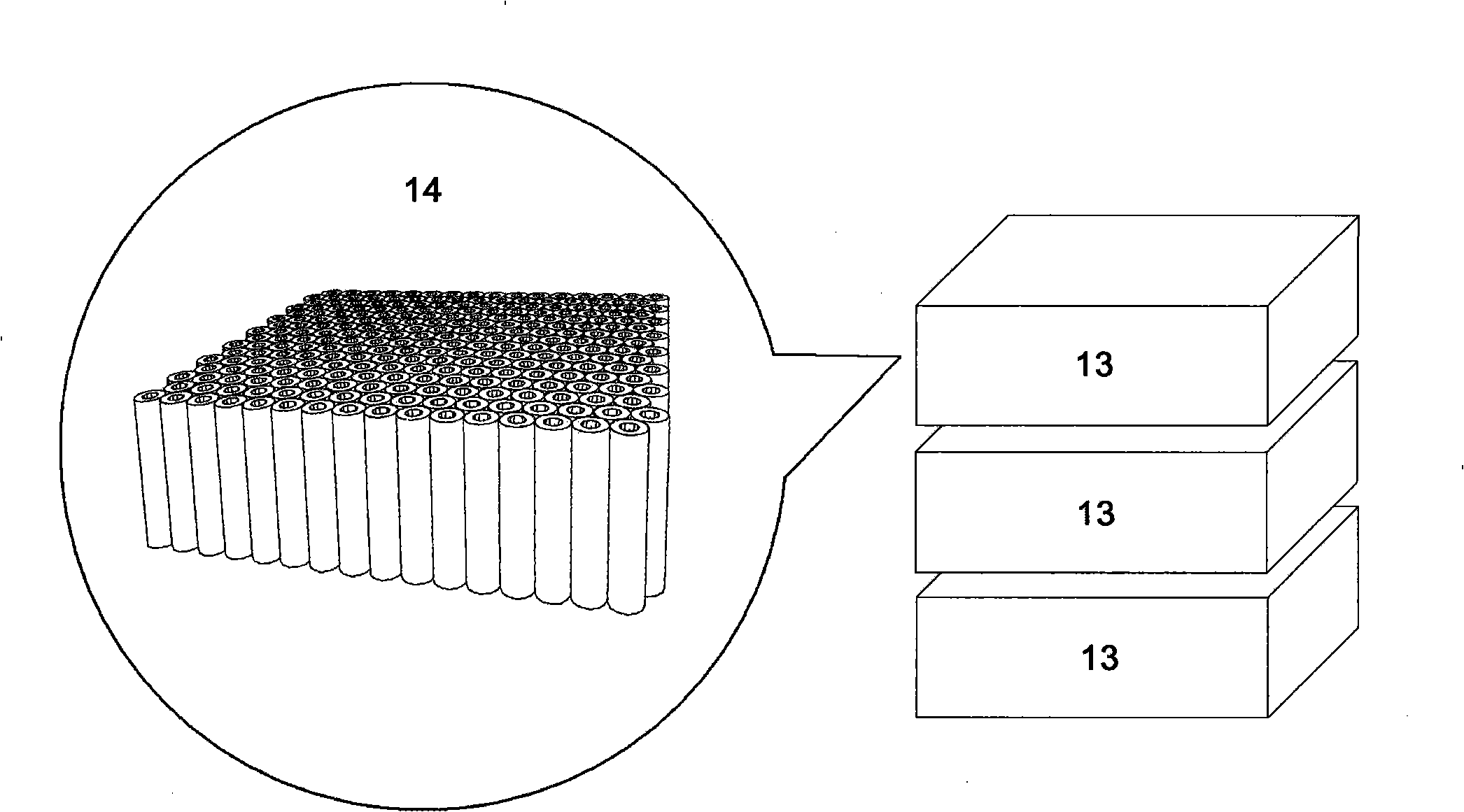

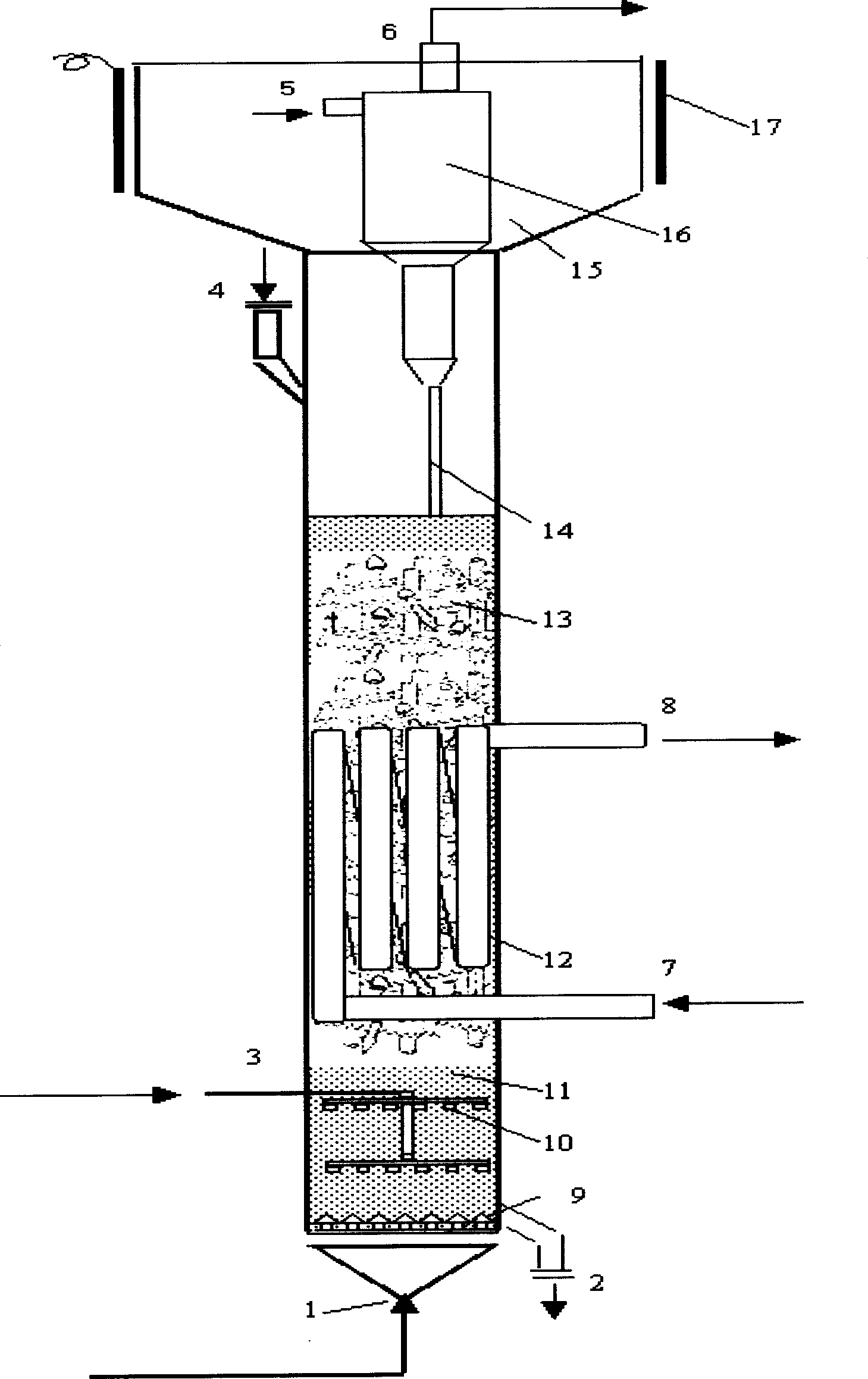

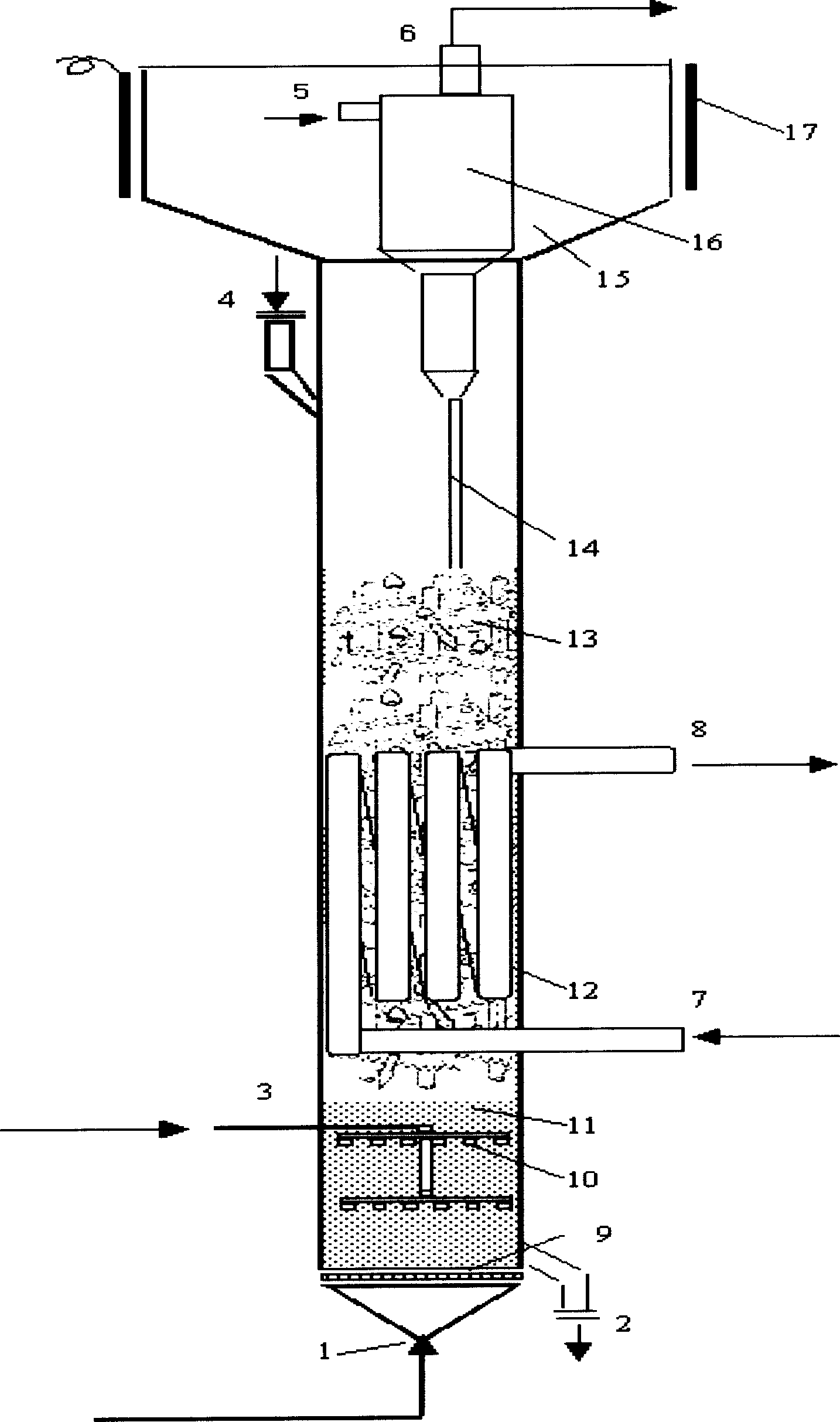

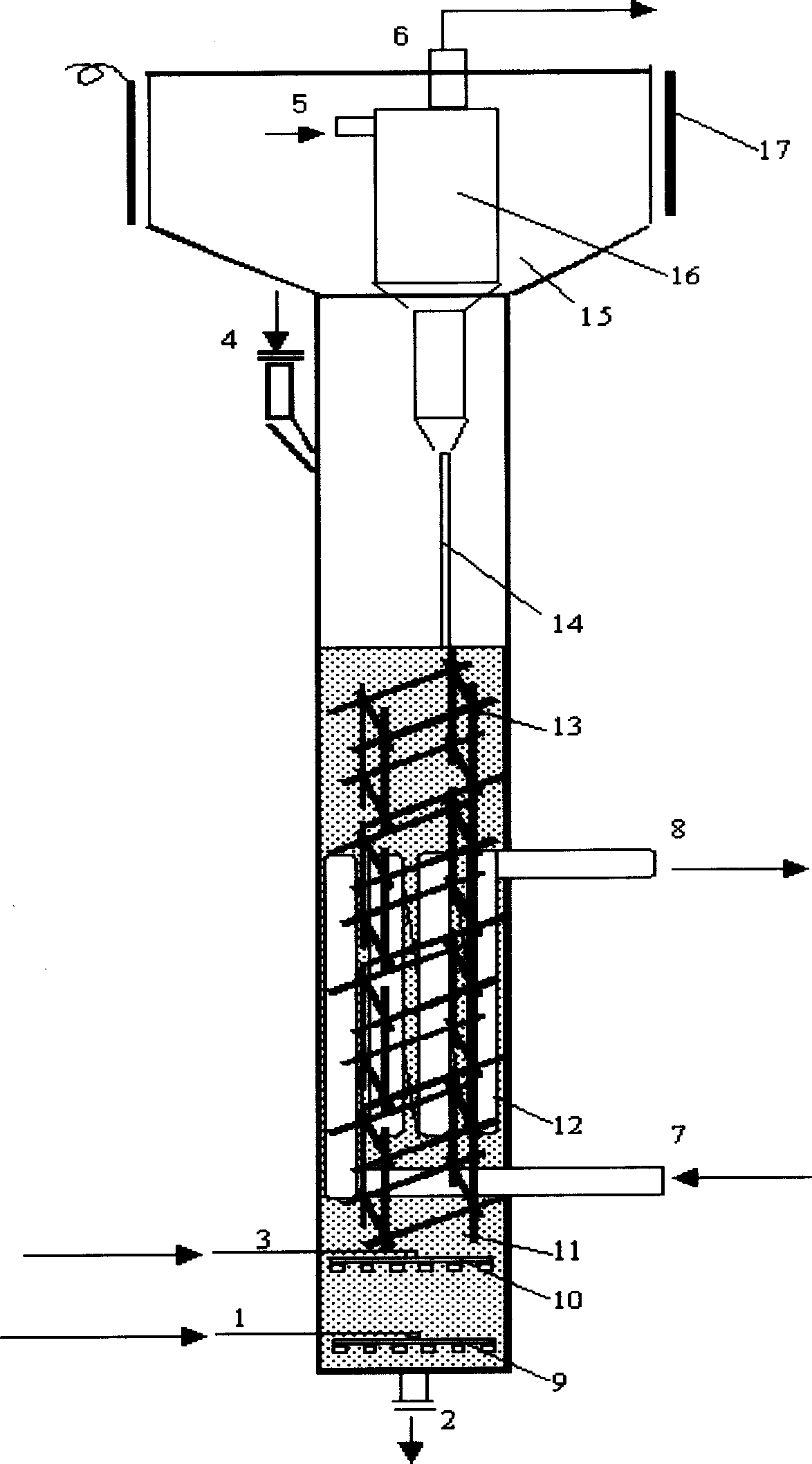

Apparatus and method for hydrogen oxygen composite reaction

ActiveCN1864844AFix security issuesPrevent removalNuclear energy generationGas-gas reaction processesGas solidHydrogen

The invention discloses a device and method for oxyhydrogen combination reaction. Said device comprises fluidized-bed reactor, the bottom of reactor is equipped with air containing oxygen inlet, said inlet is connected with hydrogen distributor, hydrogen distributor is fixed on tubular wall; a catalyst dense-flow area is equipped inside the reactor, heat exchanger is connected with said tubular wall; said dense-phase area is equipped with internal element connected with heat exchanger, the upper of said reactor is equipped with enlarged segment and gas-solid separation device connected with said enlarged segment; enlarged segment is equipped with heater; the tubular wall of reactor in axial direction is equipped with catalyst inlet, the bottom of reactor is equipped with devitalized catalyst outlet. The method essentially comprises controlling molecular ration between hydrogen and oxygen, controlling temperature, gas speed and air speed of catalyst in catalyst dense-phase area. The invention is characterized by strong elasticity of operation, convenient heat mobility, and high conversion rate for oxyhydrogen combination and need no inactive gas for dilution.

Owner:SICHUAN INST OF MATERIALS & TECH

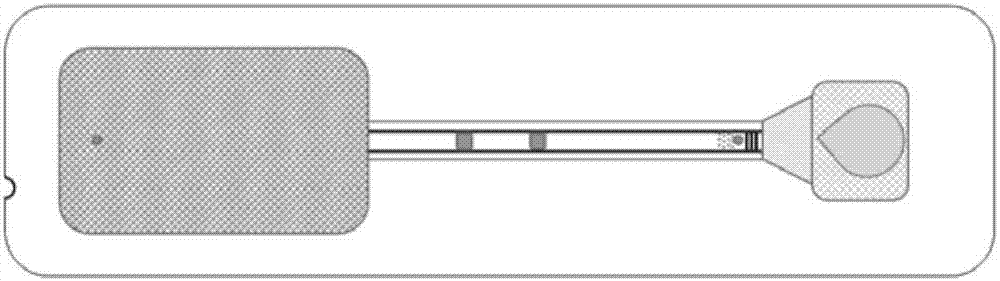

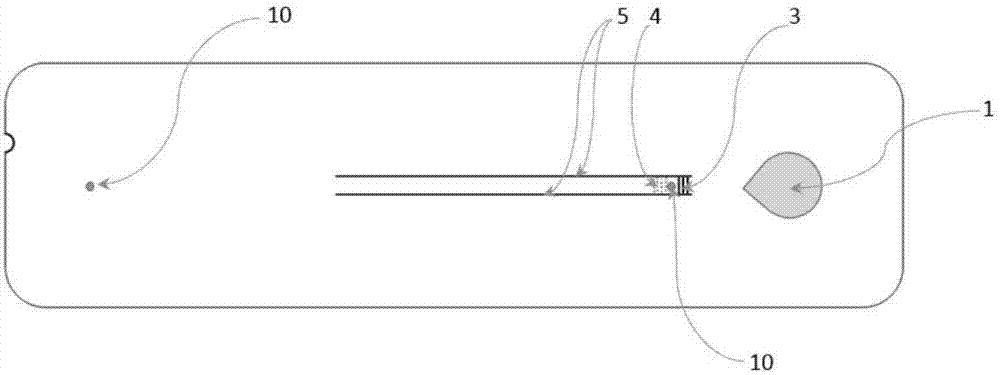

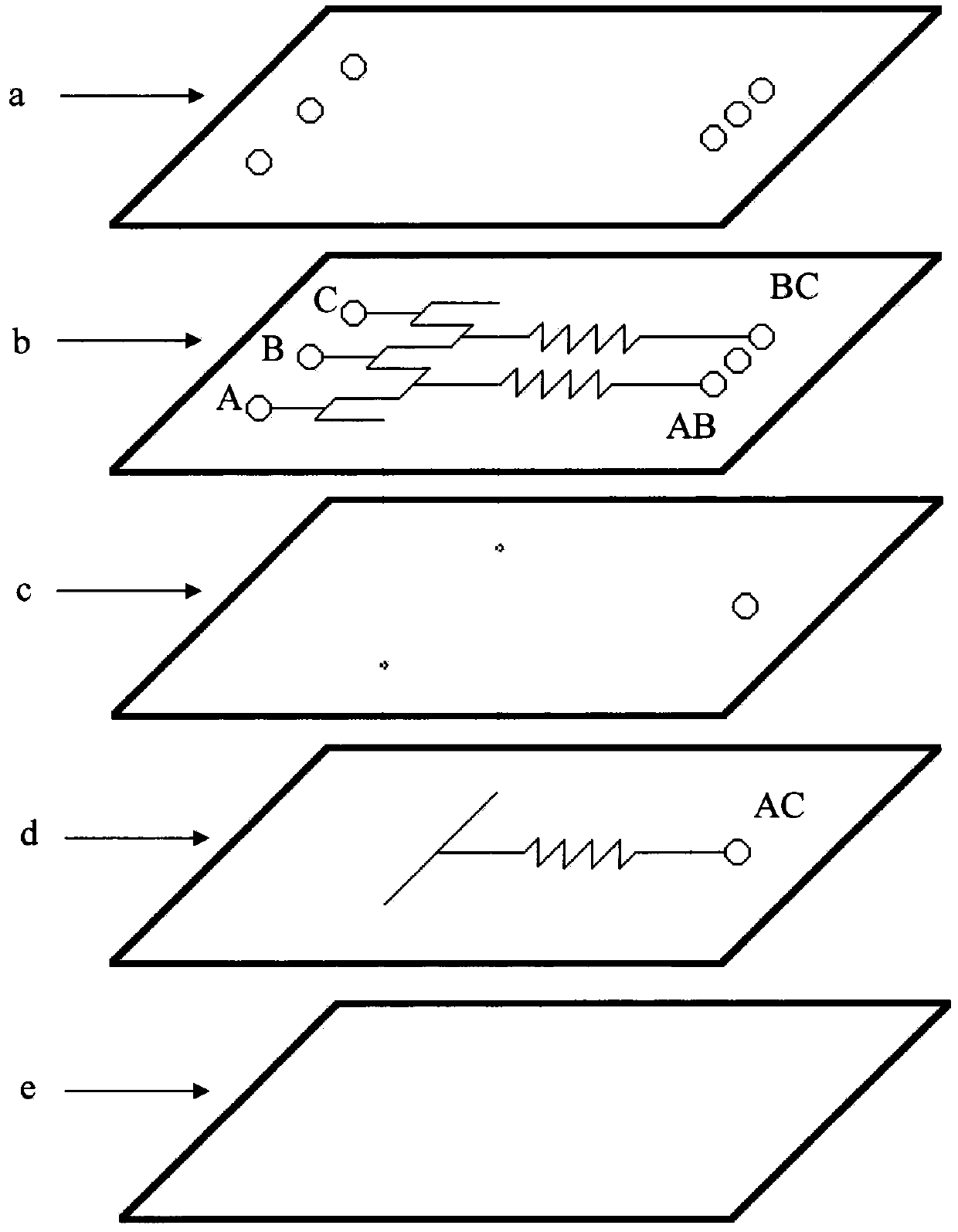

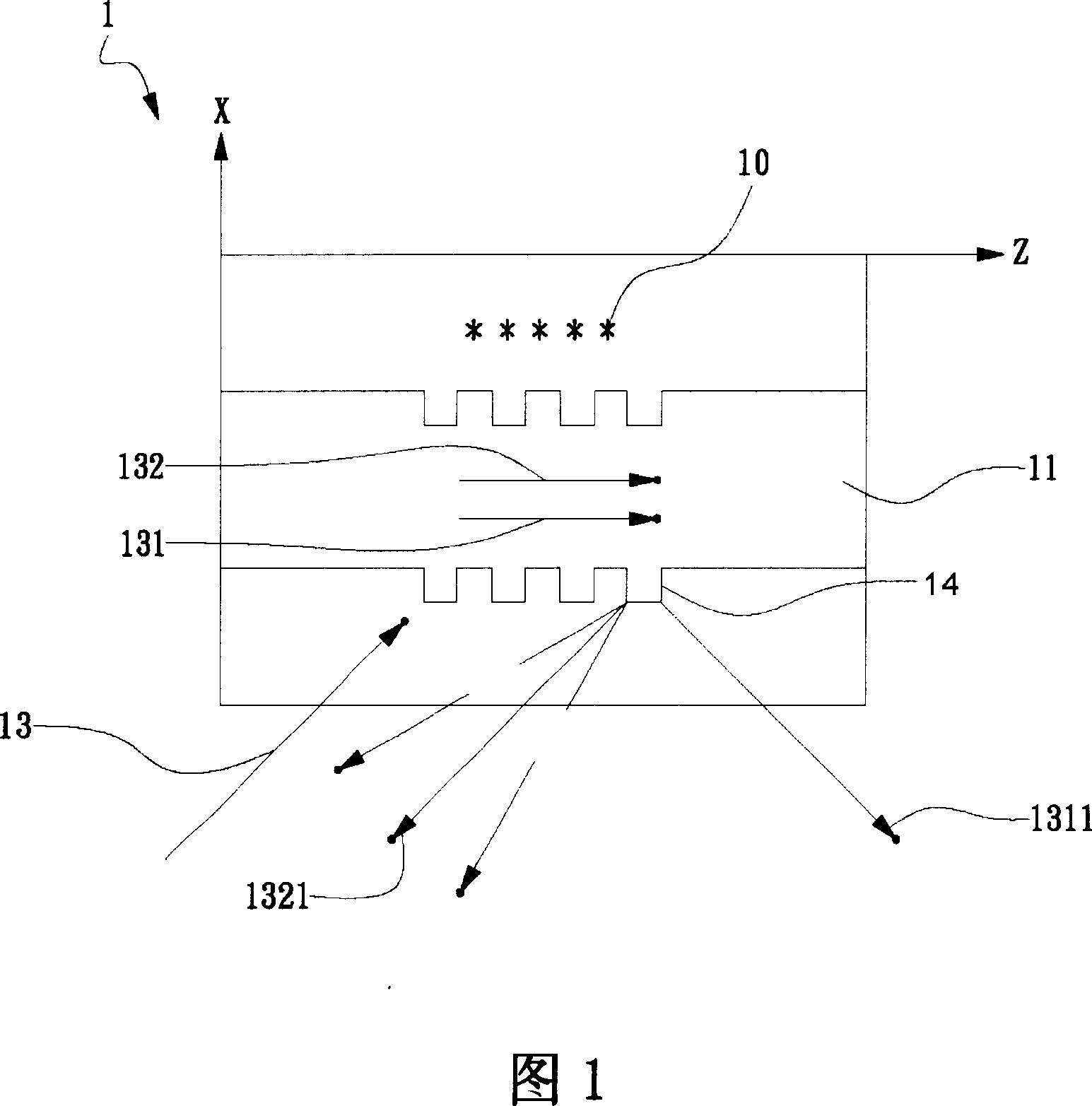

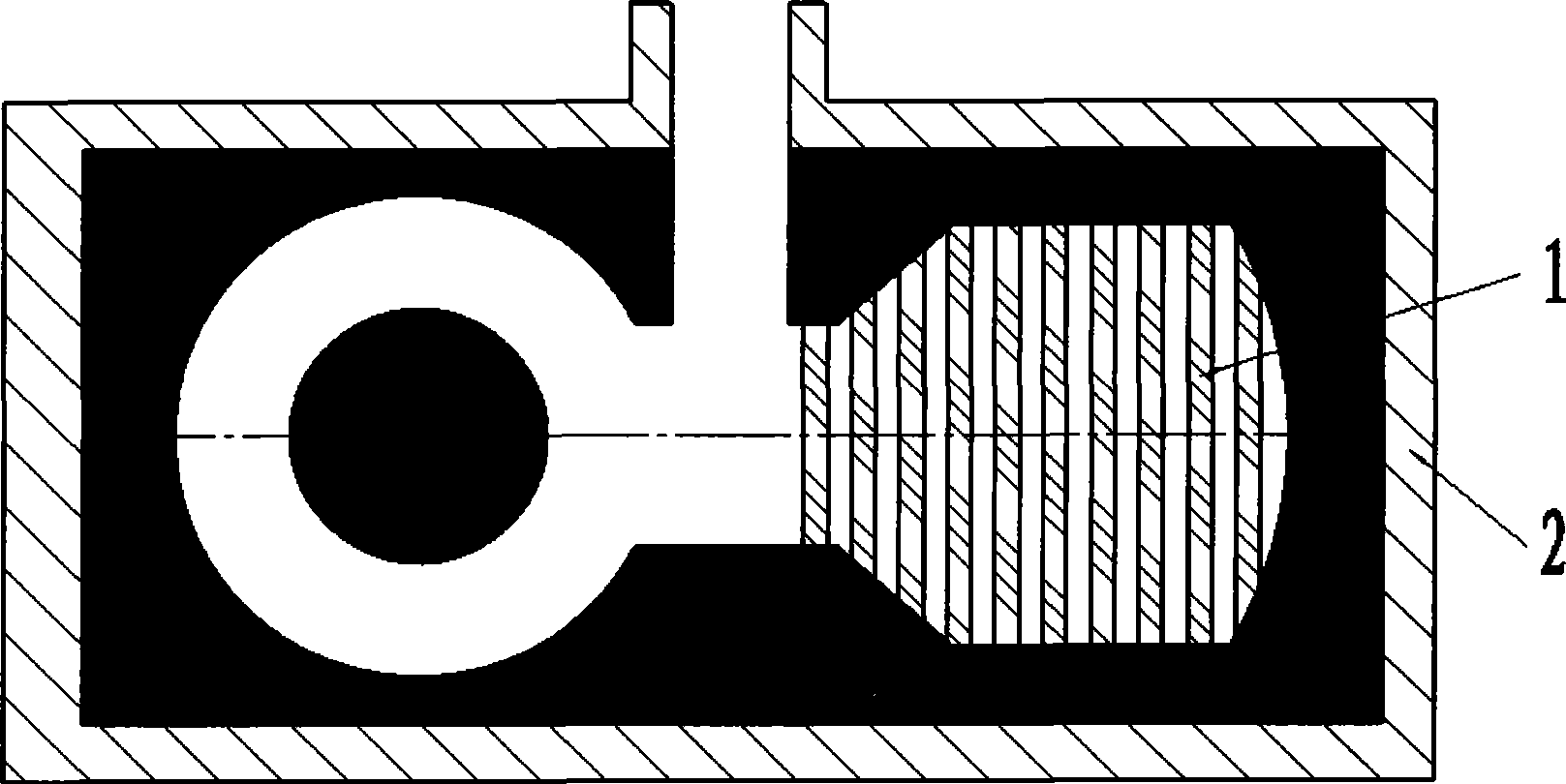

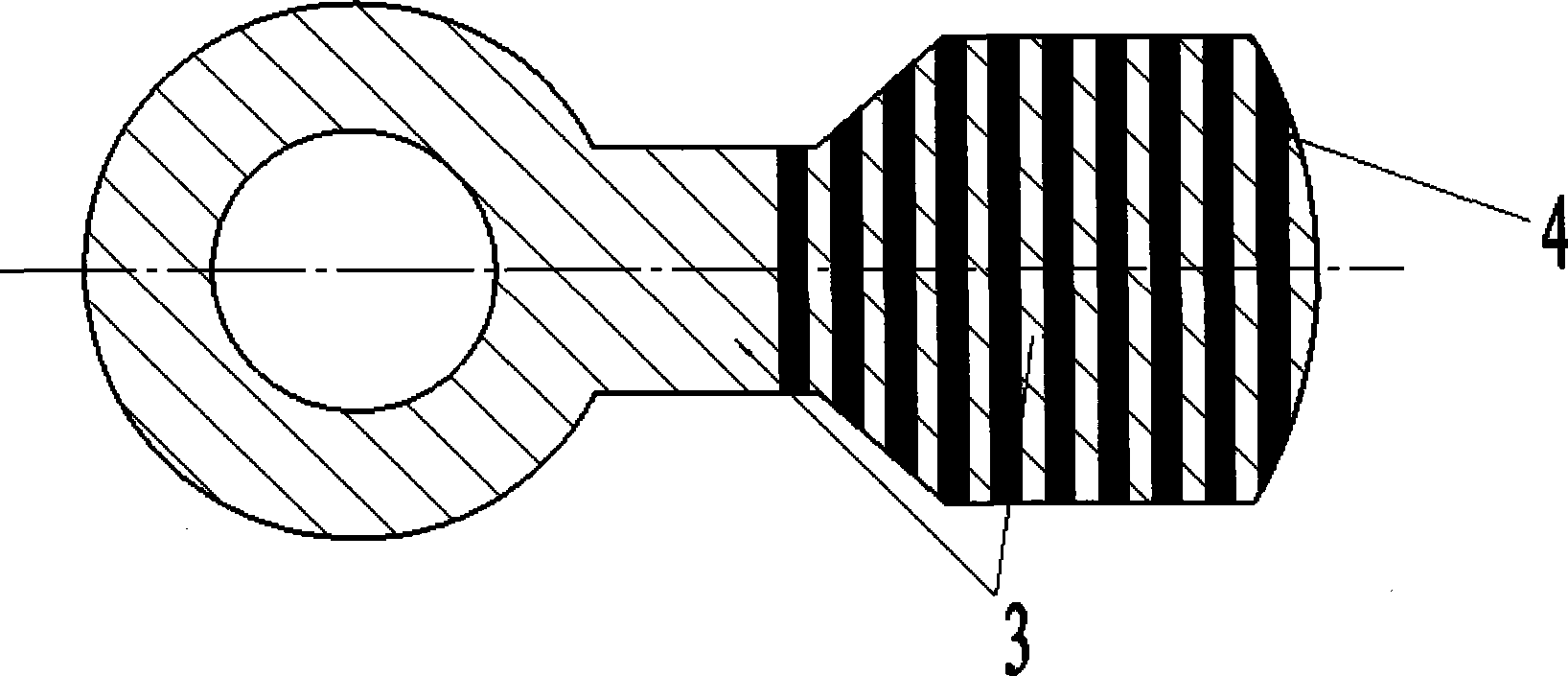

Micro-fluidic combined chemical reaction chip

InactiveCN103386338AReduce consumptionImprove throughputLaboratory glasswaresChemical synthesisMaterials preparation

The invention discloses a micro-fluidic combined chemical reaction chip. The micro-fluidic combined chemical reaction chip is characterized by consisting of a sample solution inlet, a sample intersection channel, a mixing unit and a product outlet. A combined chemical reaction is a chemical reaction happened between any two or among more than two types of various samples. Compared with the existing chemical reaction method, the combined chemical reaction chip provided by the invention has the significant advantages of low sample consumption, high flux, small volume, automatic operation and the like, can be used for realizing quick and online combined chemical reactions, and can be hopefully applied to the fields of dug screening, enzyme screening, chemical synthesis, material preparation, chemical production and the like.

Owner:苏州扬清芯片科技有限公司

Desulfurizing agent and preparation method thereof

InactiveCN102008873AImprove surface structureIncrease profitDispersed particle separationSewagePollution

The invention provides a calcium based desulfurizing agent loaded by coal ash and a preparation method thereof. Aiming at the problems of low absorbing agent utilization rate, large consumption and the like of the traditional dry method flue gas desulfurization process, the efficient calcium based desulfurizing agent loaded by the coal ash is prepared by using the coal ash, Ca(OH)2 and an activating agent as main raw materials through a solid phase reaction / hydrothermal combination reaction process. The coal ash waste of the traditional coal industries is fully utilized, and structurally modified to be used for treating SO2 waste gas, thus the invention has the advantages of simple preparation process and low cost; and the prepared desulfurizing agent has high desulfuration efficiency and no sewage during the desulfuration and does not produce the secondary pollution.

Owner:蒋历辉 +4

Titanium aluminum based powder metallurgy material for automobile engine exhaust doors and manufacturing method of titanium aluminum based powder metallurgy material

The invention discloses a titanium aluminum based powder metallurgy material for automobile engine exhaust doors and a manufacturing method of the titanium aluminum based powder metallurgy material. The ingredient and the content (in atomic percent) of the metallurgy powder material include that Ti takes 45.7% to 48.9%, Al takes 45.7% to 47.5%, and Nb takes 5.4% to 6.8%; purity of powder is 99.5%, , granularity of each of Ti and Al is smaller than 50 mu m, and granularity of Nb is smaller than 70 mu m; the powder which is prepared according to certain ingredients passes through a high-energy ball mill, rotation speed of the ball mill is 330 r / min, ball-to-powder weight ratio is 12:1, ball milling time is 30 hours, both a powder weighing and preparing process and a ball milling process are realized under protection of argon, pre-ball-milling powdery particles are nanocrystalline, and parts of the powder are in combination reaction; powder after ball milling pre-synthesizing is placed in a mold to be in hot-pressing vacuum sintering; and a prepared TiAl based alloy exhaust door has ultra-fine grains / nanocrystalline tissues, wherein the size of TiAl phase grains is smaller than 500nm, the size of Ti3Al phase grains is smaller than 100nm, ingredients are uniform, and performances are excellent.

Owner:CHANGCHUN UNIV OF TECH

Wave-guide coupling surface plasma resonance biosensor

ActiveCN1971267AReal-time measurement of interaction physical quantitiesHigh sensitivityMaterial analysis by optical meansGratingReaction rate

A waveguide coupling surface plasma resonance biosensor is disclosed that includes: a grating layer, a waveguide layer, a plasma resonance layer and a ligand layer. The grating layer which has a periodical first grating structure is made of translucent material, the waveguide layer is formed on the first grating structure, and the refractive index of the waveguide layer is bigger than the refractive index of the grating layer. The plasma resonance is formed on the waveguide layer which can generate plasma resonance by means of light wave excitation. The ligand layer is formed on the plasma resonance layer, and the ligand layer can generate combination reaction with the detecting substance. The analytical platform of molecular interaction can be built using the invention, and a detecting method without marking can detect the physical quantities of molecular interaction of chemical material, reaction rate and molecular dynamics.

Owner:IND TECH RES INST

Method for preparing composite wear-resistant hammerhead

The invention discloses a method for preparing a high-ductility and high-abrasion composite hammerhead, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a hammerhead casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the hammerhead; molten matrix metal is cast into the casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite hammerhead which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite hammerhead has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

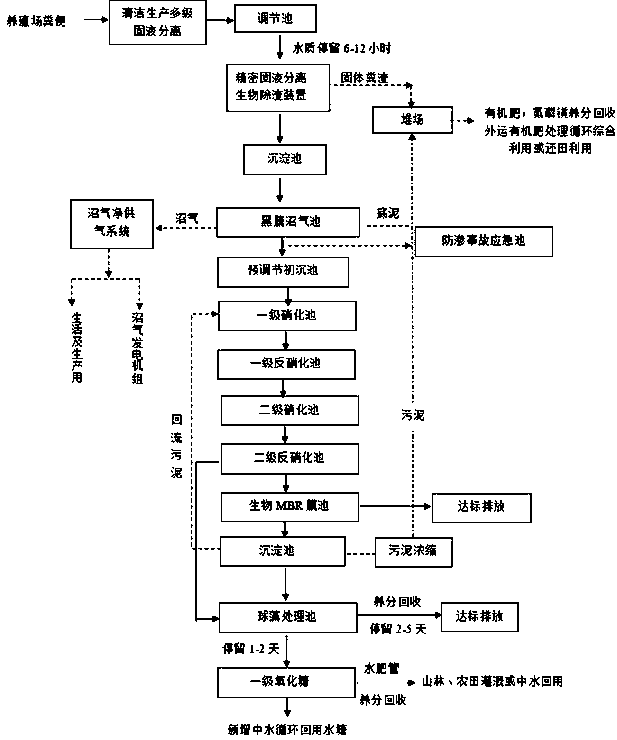

Livestock waste nutrient recovery and water quality standard-reaching technical method

InactiveCN108640453AUnderstand the purposeLearn about featuresExcrement fertilisersWaste water treatment from animal husbandryChemical reactionSlag

The invention discloses a livestock waste nutrient recovery and water quality standard-reaching technical method. According to the invention, primary solid-liquid separation is carried out on livestock waste, the separated solid manure slag is taken as an organic fertilizer raw material nutrient for outward transport for sale for benefit-increasing cycle utilization or returning utilization, scientific circulation uses combination of farming and animal husbandry, urine through emission reduction, solid-liquid separating and interception, sewage and domestic water flow into an equalizing tank,a solid-liquid separating biological slag removal apparatus, a black film methane tank, a combination reaction environmental-protection pool, a MBR membrane pool, and a ball algae treatment pool in order for multilevel processing, during a whole process, solid-liquid-gas omnibearing processing utilization is carried out on waste, the method is characterized in that biogas is used for generating orproduction and living, the processed water is subjected to nutrient recovery and returning utilization, the filtered manure slag stockyard is subjected to organic fertilizer recovery or returning utilization, and the energy cycle utilization is realized. The processed reclaimed water through a chemical reaction can reach standard time-limited zero pollution discharge, and the environmental protection performance is good.

Owner:HUIZHOU BAIOUJIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com