Microporous MgAlON composite corindon material preparation method

A composite corundum and microporous technology is applied in the field of refractory materials, which can solve the problems of expensive raw material AlN, difficult to store, and high sintering temperature of the material, and achieve the effects of reducing the preparation cost, prolonging the service life and improving the performance of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

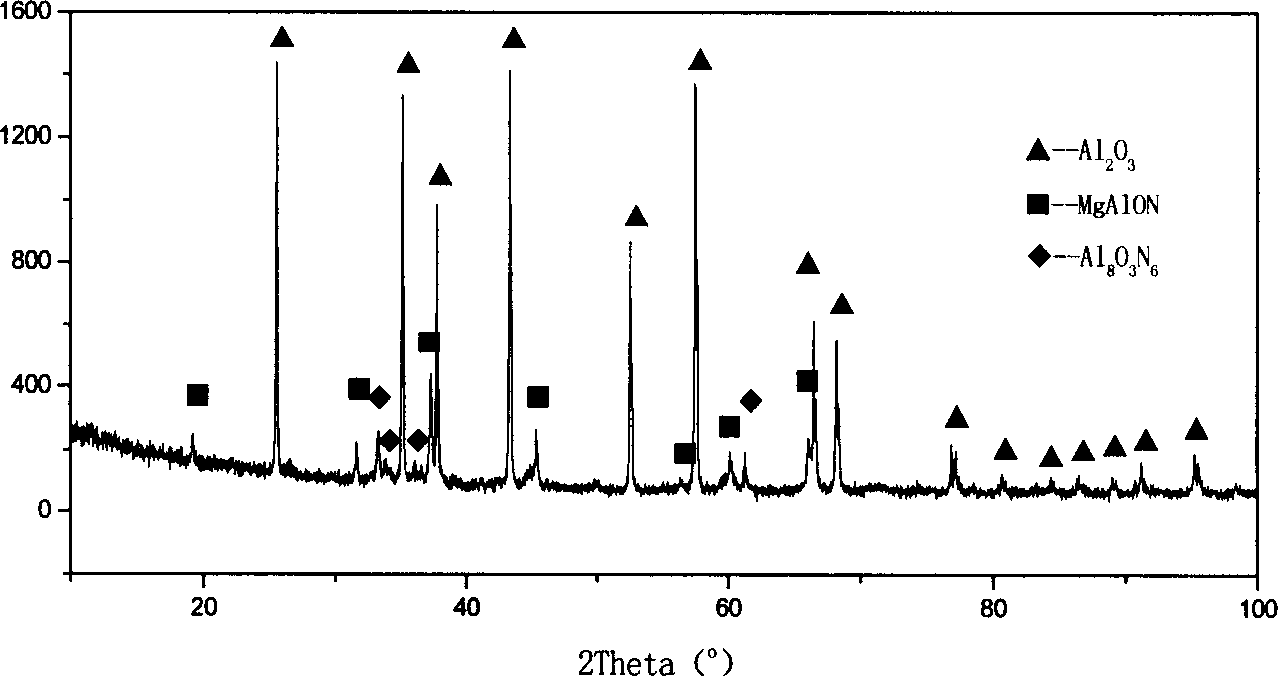

Embodiment 1

[0014] Embodiment 1, adopt electric fused white corundum (Al 2 o 3 98wt%) granular mixture (3-1mm 45wt%, 1-0.074mm 15wt%) as aggregate, using activated alumina powder 26wt% (particle size2 o 3 99wt%), metal aluminum powder 10wt%, the compound of chemically pure MgO 4wt% is made substrate; After various raw materials are weighed in proportion, earlier powder and granule are mixed in mixer respectively 5 minutes to evenly; Add the binding agent-sulfite pulp waste liquid (d=1.18g / cm3) of above-mentioned raw material amount 3wt% in the granular material 3 ) mix for 5 minutes until uniform, then add the pre-mixed powder, mix in the mixer for 10 minutes until uniform to make mud; put the mud into a press and mold it under 100MPa pressure to form 25×25×125mm Green body; After the green body is dried for 4 hours, put it into a nitrogen atmosphere furnace and burn it under the condition of 1500℃×1h; after the heat preservation is completed, the nitrogen gas flow can only be stopped...

Embodiment 2

[0015] Embodiment 2, adopt electric fused white corundum (Al 2 o 3 98wt%) granular mixture (3-1mm 45wt%, 1-0.074mm 15wt%) as aggregate, using activated alumina powder 29wt% (particle size2 o 3 99wt%), metal aluminum powder 6wt%, the compound of chemically pure MgO 5wt% is made substrate; After various raw materials are weighed in proportion, first powder and granulate are mixed in mixer respectively 5 minutes to evenly; Add the binding agent-sulfite pulp waste liquid (d=1.18g / cm3) of above-mentioned raw material amount 3wt% in the granular material 3 ) mix for 5 minutes until uniform, then add the pre-mixed powder, mix in the mixer for 10 minutes until uniform to make mud; put the mud into a press and mold it under 100MPa pressure to form 25×25×125mm Green body; After drying the green body for 4 hours, put it into a nitrogen atmosphere furnace and burn it under the condition of 1200°C×1h; after the heat preservation is completed, the nitrogen flow can only be stopped when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com