Patents

Literature

205results about How to "Improve slag resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forsterite-C-contained MgO-SiC-C fire-resistant material and preparation thereof

The invention relates to a forsterite-C-containing MgO-SiC-C material refractory and a method for preparing the same. The technical scheme comprises firstly mixing the 25-40wt% of magnesia particles with a grain size of 3-1mm, 20-35wt% of magnesia particles with a grain size of 1-0mm, 5-40wt% of forsterite-C mixed fine powders and 0-35wt% of magnesia fine powders, adding a 4-10wt% of bonding agent accounting for the weight of the mixed material, stirring or mulling for 10-30 minutes, drying after pressing formation, sintering at a reductive atmosphere with a sintering temperature of 1450-1700 DEG C and a heat preservation time of 4-8 hours, getting the MgO-SiC-C material composite refractory. The MgO-SiC-C material refractory prepared by adding the forsterite and carbon not only can solve the problem of magnesia resource shortage, reduces the production cost, but also the SiC prepared by the reaction of magnesia and carbon at a high temperature can reinforce the conjugation inside the material, and be useful for improving the refractory performance. The invention can also adopt low grade magnesia.

Owner:WUHAN UNIV OF SCI & TECH

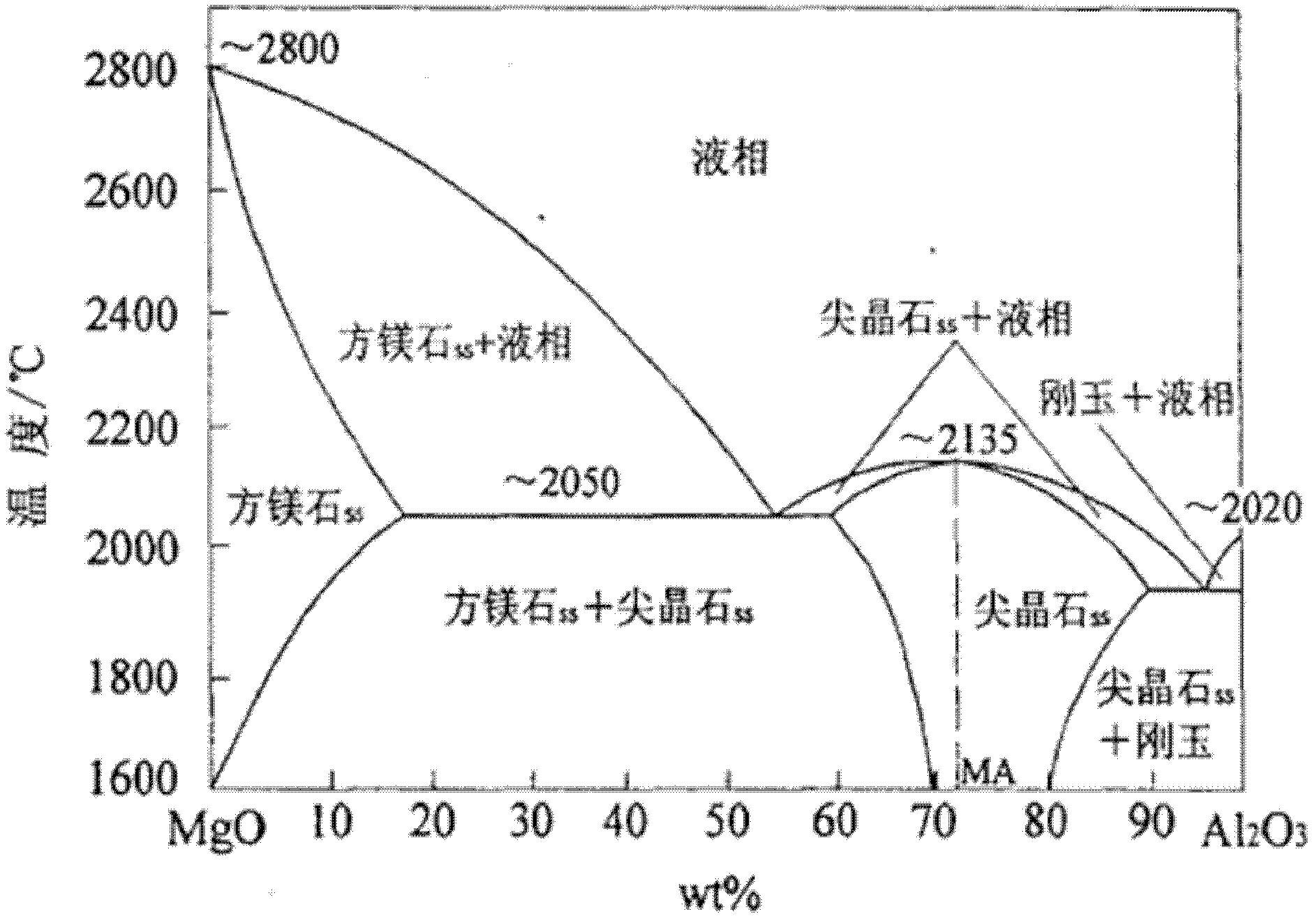

Light-weight corundum-magnesium aluminate spinel castable and preparation method thereof

The invention relates to a light-weight corundum-magnesium aluminate spinel castable and a preparation method thereof. The technical scheme of the invention is taking nano-aperture porous corundum-magnesium aluminate spinel ceramic particles with the partical sizes successively being 3-5mm, 1-2.5mm and 0.1-0.5mm as aggregates, taking nano-aperture porous corundum-magnesium aluminate spinel ceramic fine powder with the partical size being smaller than 0.074mm, magnesium aluminate spinel fine powder, corundum fine powder, magnesia fine powder and alpha-Al2O3 micro powder as matrixes and taking aluminate cement as a binding agent; the preparation method comprises the following steps: mixing the matrixes, the binding agent and sodium hexametaphosphate firstly, then adding the aggregates, uniformly mixing, then adding water, uniformly stirring, moulding by casting, carrying out maintenance, demoulding and drying, and keeping the temperature for 2-6h at the condition with the temperature being 1450-1600 DEG C to obtain the light-weight corundum-magnesium aluminate spinel castable. By adopting the light-weight corundum-magnesium aluminate spinel castable and the preparation method, the process is simple, and a prepared product has the average pore size in a nanoscale, is low in heat conductivity coefficient, good in medium erosion and penetrability resistance and high in thermal shock resistance, and is suitable for parts, including bottoms, walls and the like, of steel ladles.

Owner:WUHAN UNIV OF SCI & TECH

Silicon carbide-magnesium aluminum spinel composite refractory material

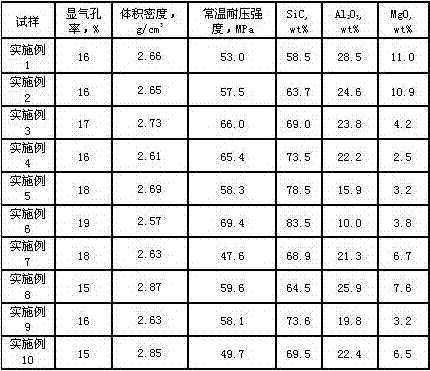

The invention belongs to the field of refractory materials and proposes a silicon carbide-magnesium aluminum spinel composite refractory material. Raw materials of the silicon carbide-magnesium aluminum spinel composite refractory material comprise aggregates and matrices; silicon carbide particles serve as the aggregates, fine powder or micro powder of magnesium aluminum spinel, aluminium oxide and magnesium oxide serves as the matrices, and antioxidants are also added in the matrices; the aggregates, the matrices and binders are mixed evenly and shaped, dried and burnt under the protection of a buried carbon or nitrogen atmosphere, and the composite refractory material with SiC as a main crystalline phase and magnesium aluminum spinel as a secondary crystalline phase is obtained, whereinthe mass fraction of SiC is 58.5-83.5%, the mass fraction of Al2O3 is 10-28.5%, the mass fraction of MgO is 2.5-11%, and the apparent porosity is 15-19%. The product does not contain chromium oxide and has the advantages of being low in cost, environmentally friendly, high in strength, good in thermal shock resistance, excellent in molten slag corrosion resistance and molten slag penetration resistance and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Magnesia brick containing antioxidant C-TiN composite powder and method for preparing the same

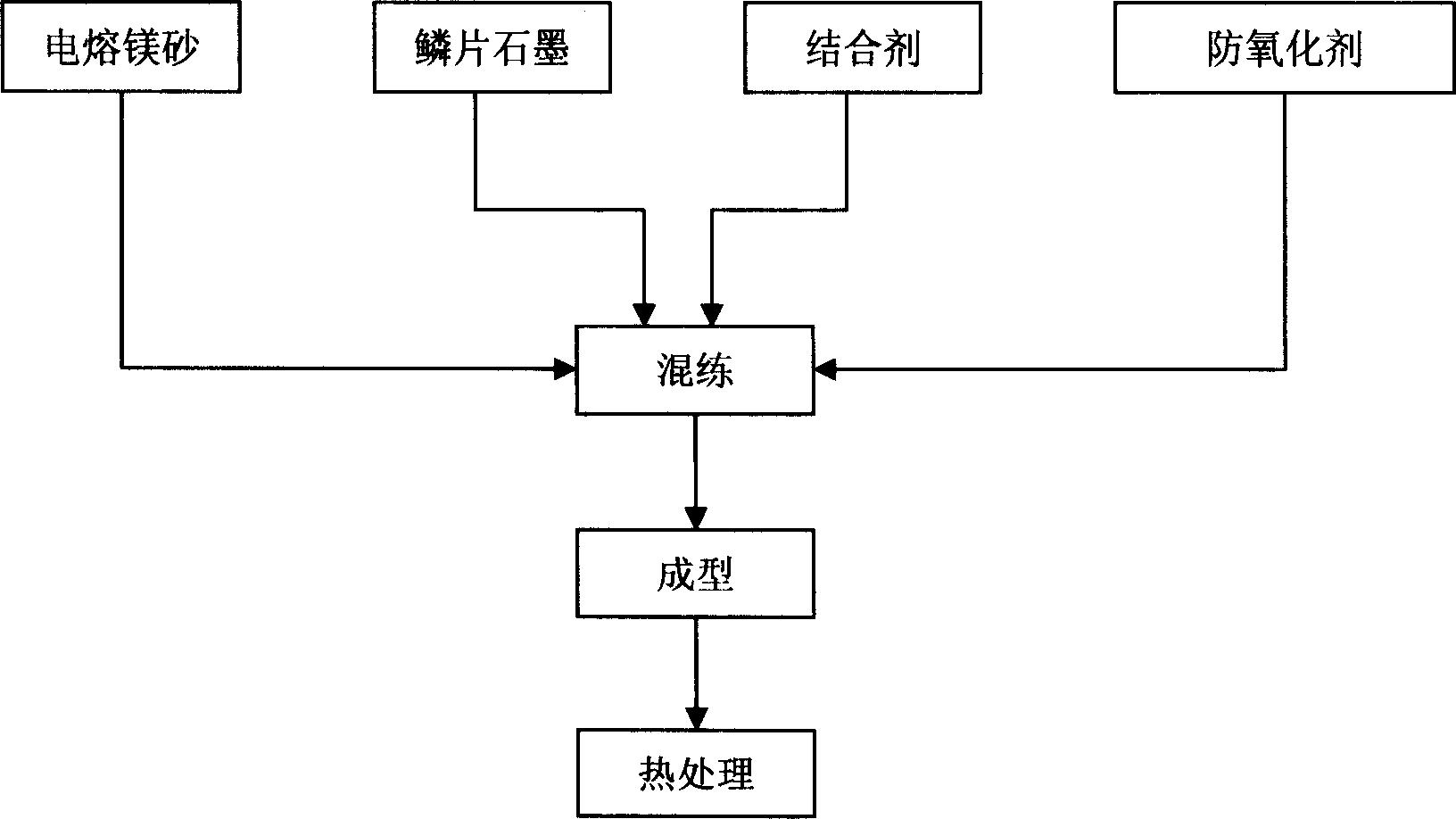

The invention provides a magnesite-carbon brick containing anti-oxidization agent of C-TiN composite powder, which comprises the following constituents: MgO 70-90%, C 6-22%, TiN 0.5-10%, Al 0-5%, Si 0-5%, and B4C 0-2%, the preparing process comprises raw material mixing, melting, forming and thermally processing.

Owner:UNIV OF SCI & TECH LIAONING

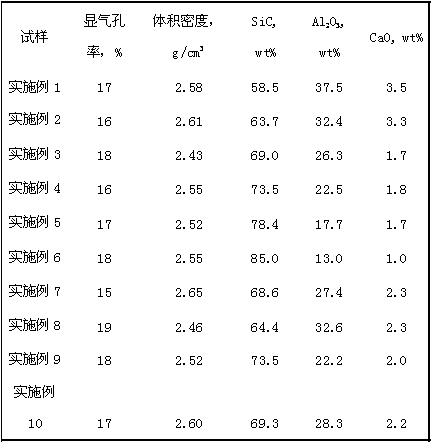

Silicon carbide-calcium hexaluminate composite refractory material

The invention belongs to the refractory material technical field, and discloses a silicon carbide-calcium hexaluminate composite refractory material. The silicon carbide-calcium hexaluminate compositerefractory material disclosed by the invention adopts the aggregate with the SiC mass fraction of more than or equal to 98.0%, the aggregate is silicon carbide particles with the particle size of 0.1-5 mm, and pre-synthesized calcium aluminate is contained in a matrix; calcium oxide and alumina which can undergo an in-situ reaction to generate calcium hexaluminate are also added in the matrix; anantioxidant is further added to the matrix; the aggregate, the matrix and a binder are mixed and formed, the mixture is dried and then is sintered at high temperature under carbon burying or nitrogenatmosphere protection to prepare the silicon carbide-calcium hexaluminate composite refractory material with SiC as a main crystal phase and calcium hexaluminate as a sub-crystal phase. The silicon carbide-calcium hexaluminate composite refractory material has the characteristics of high strength, good thermal shock resistance, excellent resistance to alkaline slag corrosion and excellent penetration resistance to slag, and is an environmentally friendly refractory material with excellent resistance to alkaline slag corrosion at high temperature and under reductive atmosphere.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Al2O3-MgO refractory castable and preparation method thereof

The invention discloses an Al2O3-MgO refractory castable and a preparation method thereof. Specifically, the refractory castable comprises: 55-75wt% of corundum grains, 10-25wt% of corundum fine powder, 5-25wt% of light burned spinel fine powder, 0.8-5wt% of magnesia fine powder, 3-6wt% of calcium aluminate cement, 1-4wt% of alpha-Al2O3 micropowder, 0.2-2wt% of silicon oxide micropowder, additional water accounting for 4.5-6wt% of the refractory castable and 0.1-1wt% of a water reducer. The preparation method includes: stirring the raw materials of the refractory castable evenly, conducting pouring vibration molding, letting the molded refractory castable green body dry naturally for 24h, and then conducting drying at 110DEG C for 12-36h, thus obtaining the Al2O3-MgO refractory castable. The refractory castable has the characteristics of controllable microstructure and controllable spinel crystal structure parameters, and the high temperature volume stability and slag resistance of refractory castable are effectively improved. The preparation method has the advantages of simple process, energy saving and environmental protection, and low cost.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

Waterless stemming and preparation method thereof

The invention relates to waterless stemming and a preparation method thereof. The waterless stemming is a fireproof, corrosion-resistant, washing-resistant and wear-resistant material for blocking an iron notch and filling iron notch gaps and cracks having various shapes. The waterless stemming has the advantages that 1, the waterless stemming does not yellow, does not produce black smoke, reduces benzpyrene content to a value less than 0.01% and has good filling performances, contractibility and sintering properties, 2, strength is high and stable blast furnace conditions are kept, 3, iron is produced stably, the iron notch can be opened easily, the pore is not broadened, melt iron flow and flow velocity can be effectively controlled, and strong slag resistance, erosion resistance and washing resistance are obtained, 4, the hearth is protected, crack is not produced in fast heating and high bonding strength of novel and old stemming is high, 5, opening performances are good and a boring process can be carried out easily by a tapping machine drill bit, 6, plasticity is good and clay gun operation and iron notch mud drum formation are convenient, and 7, a certain micro-expansion performance is obtained at a high temperature, gas permeability is good, strength is high and molten iron seepage caused by stemming contraction is avoided.

Owner:阜康市三工河乡樟兴新型耐火材料厂

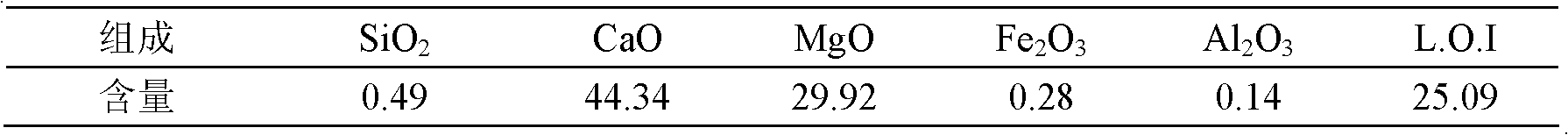

High-calcium low-iron magnesian dry method ramming mass and its production method

The present invention provides one kind of high calcium low iron magnesia material as refractory ramming material and its preparation process. The present invention has materials including light burnt magnesia powder, light burnt dolomite powder, fused magnesia, superfine fused magnesia powder, iron oxide scale as rolling waste, iron oxide powder as steel making side product, and diesel oil. The present invention has high heat resistance, high load softening performance, high breaking strength, high heat shock performance, high slag corrosion resistance and thin furnace bottom sintered layer. It is especially new steel making process, and can maintain excellent performance at high temperature.

Owner:海城华宇耐火材料有限公司

Aluminum-spinel-magnesia composite refractory as well as preparation method and application thereof

The invention belongs to the field of refractory, and discloses an aluminum-spinel-magnesia composite refractory as well as a preparation method and an application thereof. The aluminum-spinel-magnesia composite refractory comprises a raw material and an additional inorganic binding agent, wherein the raw material comprises the following components by weight: 60-94% of magnesia, 5-30% of magnesium-rich spinel or magnesium-aluminum spinel and 1-15% of metal aluminum powder, and the inorganic binding agent is 1-5% of the raw material. The aluminum-spinel-magnesia composite refractory is mainly used for substituting for magnesite-chrome bricks in an RH refining surface. The refractory can be thermally prepared at low temperature, so that energy consumption in the preparation process is lowered and the environmental pollution is reduced; and in the using process, part of the added aluminum powder is oxidized and forms a CA2 protective layer together with the calcium oxide in the slag so that the anti-slag permeability is improved.

Owner:江苏诺明高温材料股份有限公司

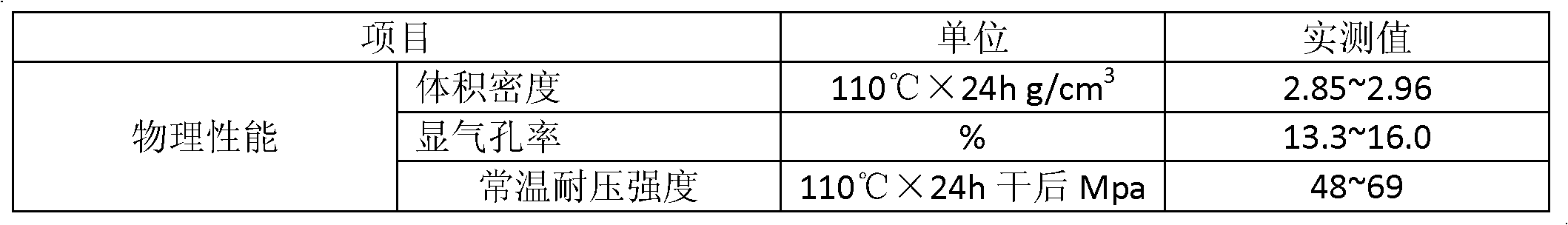

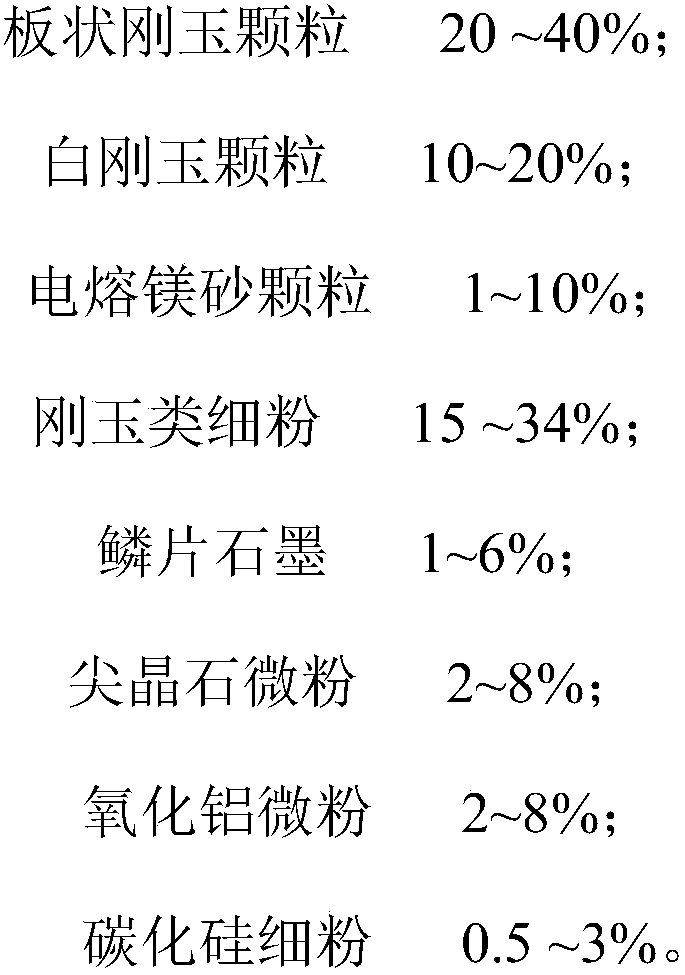

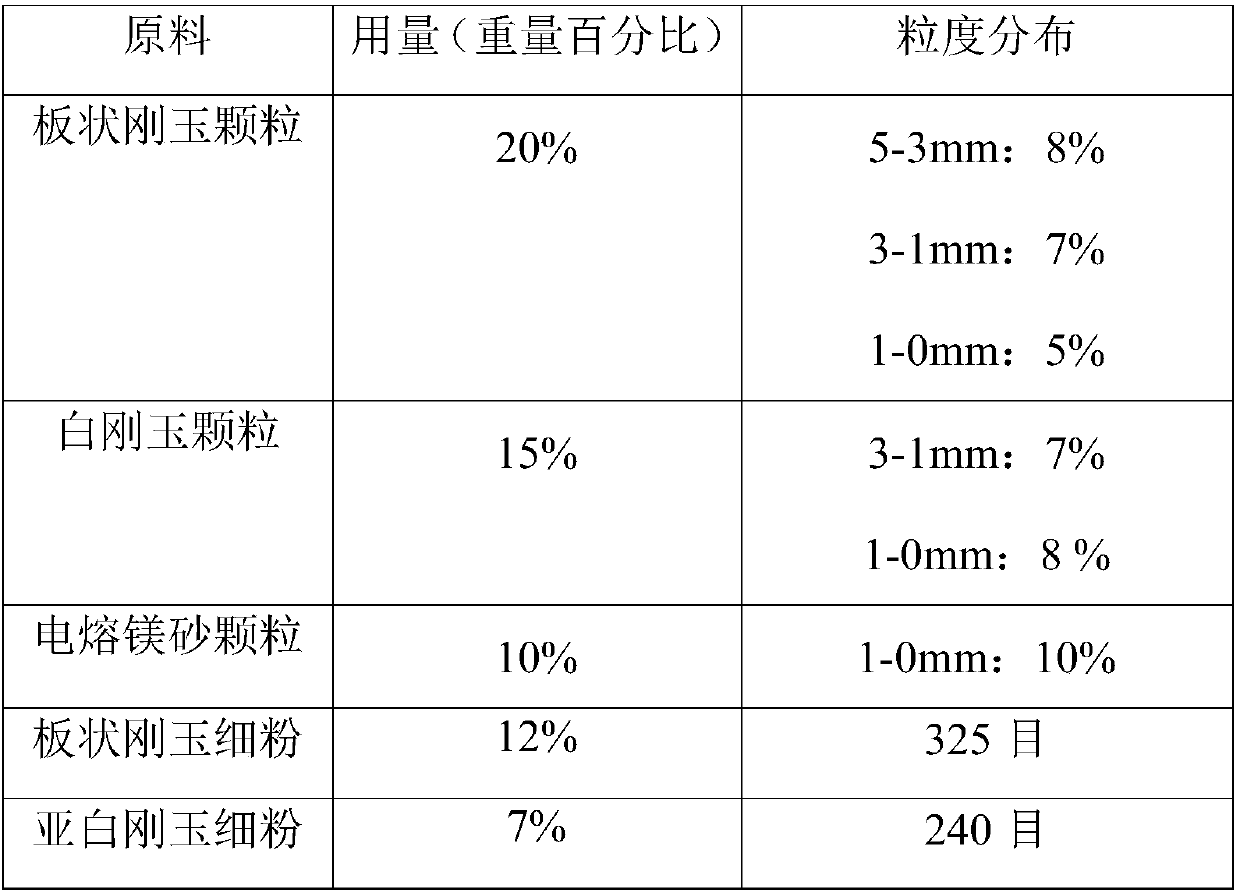

Corundum base brick for steel ladles and production method thereof

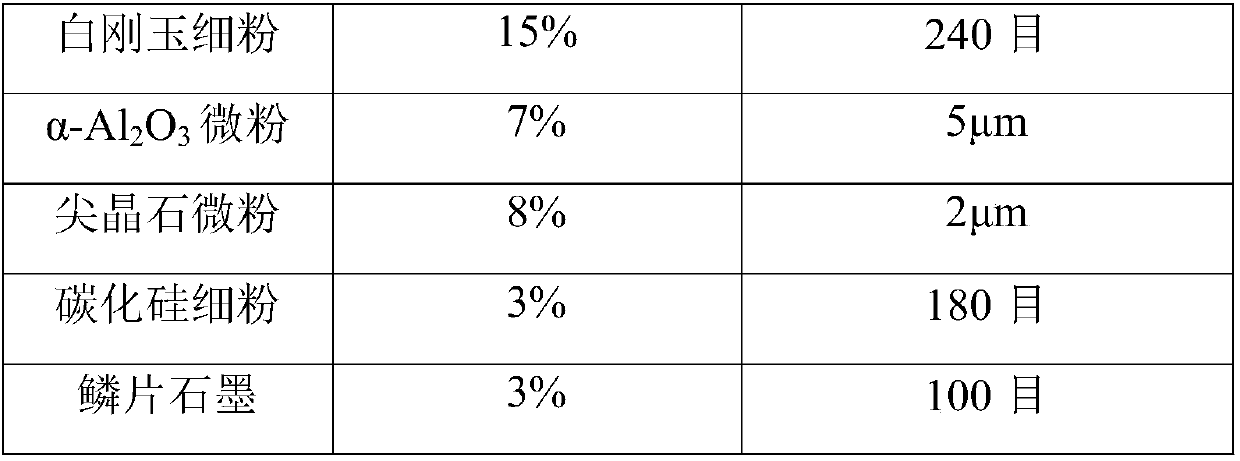

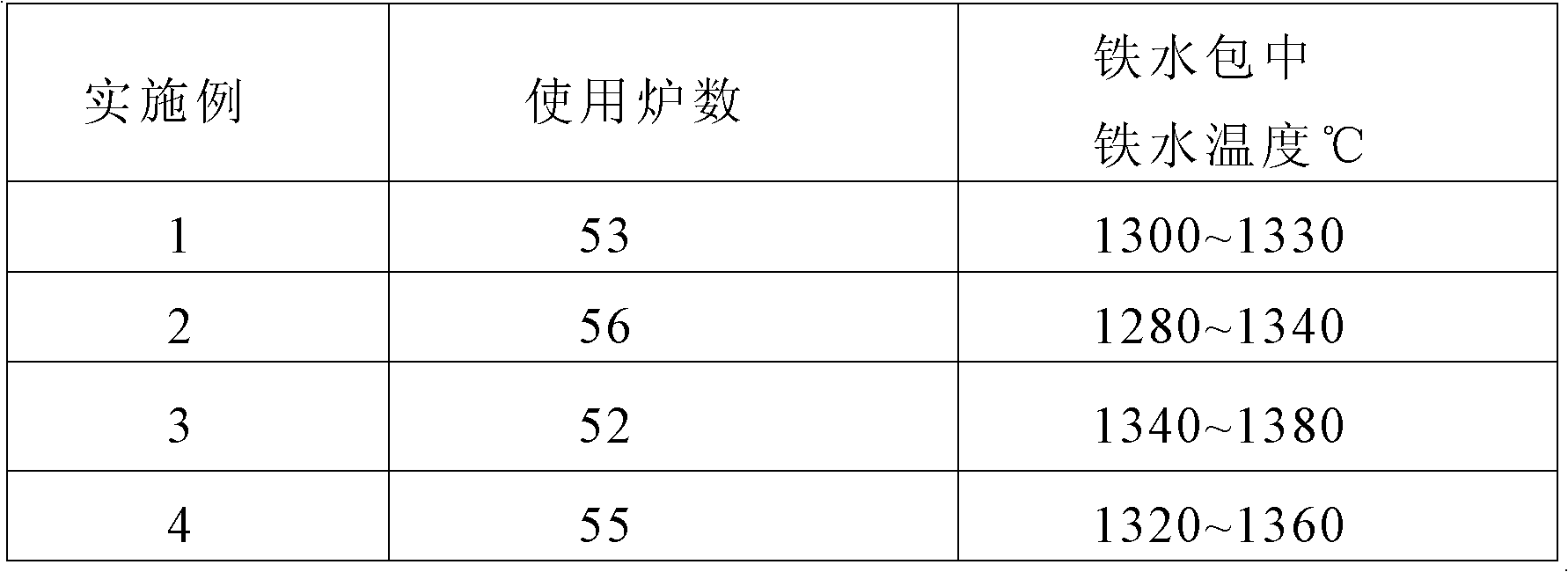

The invention provides a corundum base brick for steel ladles and a production method thereof. The corundum base brick for steel ladles is produced with a mixture and a binder; the mixture includes, by weight, 20-40% of platy corundum particles, 10-20% of white corundum particles, 1-10% of electro-melted magnesia particles, 15-34% of corundum fine powder, 1-6% of flake graphite, 2-8% of spinel micro powder, 2-8% of alumina micro powder and 0.5-3% of silicon carbide fine powder. Compared with alumina, the corundum base brick using the platy corundum particles, white corundum particles, electro-melted magnesia particles and the like as main materials has the advantages that after the platy corundum and white corundum are introduced in, the corundum base brick has greatly improved breaking and compression strength, thermal shock resistance, creep resistance and stripping resistance and the corundum base brick can fully meet the application needs of steel plants.

Owner:瑞泰马钢新材料科技有限公司 +1

Castable for ladle deslagging plate, and preparation method and applicable of castable

The invention discloses a castable for a ladle deslagging plate, and a preparation method and an applicable of the castable. The castable for the ladle deslagging plate comprises the following components in parts by weight: 50-70 parts of mullite, 10-20 parts of andalusite, 10-20 parts of bauxite powder, 3-5 parts of pure calcium aluminate cement, 4-6 parts of aluminum oxide micropowder, 3-5 parts of silicon carbide micropowder and 2-3 parts of compound additive, wherein the compound additive is a combination of two or more of organic fiber, steel fiber, and sodium tripolyphosphate or sodium hexametaphosphate. When the castable is cast on the outer surface of the ladle deslagging plate, the service life of the ladle deslagging plate can be prolonged and the preparation cost can be reduced; and the preparation method of the castable for the ladle deslagging plate is simple, and easy to operate.

Owner:WUGANG REFRACTORY CO LTD

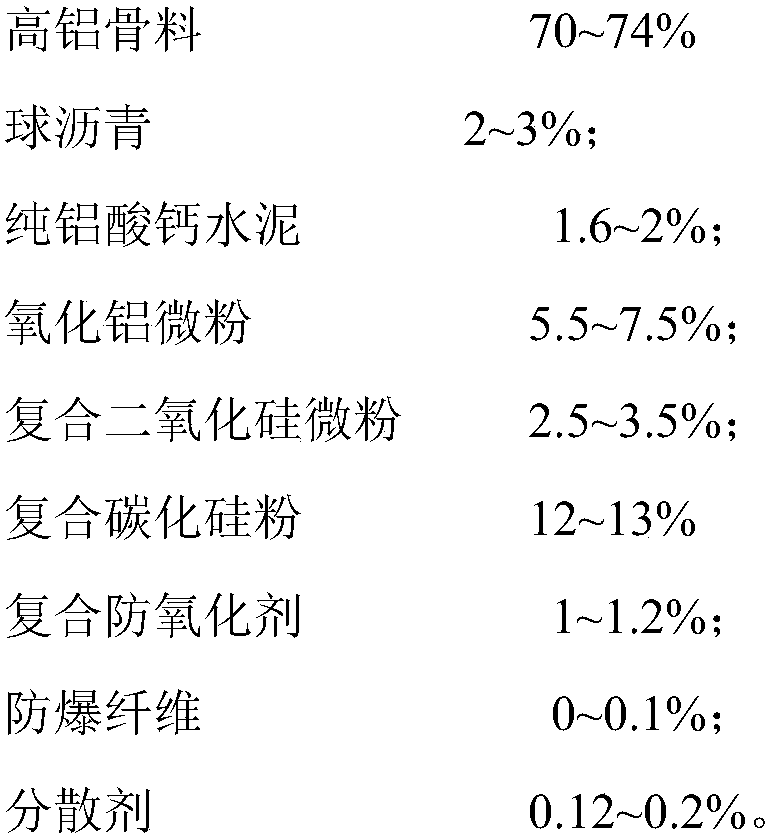

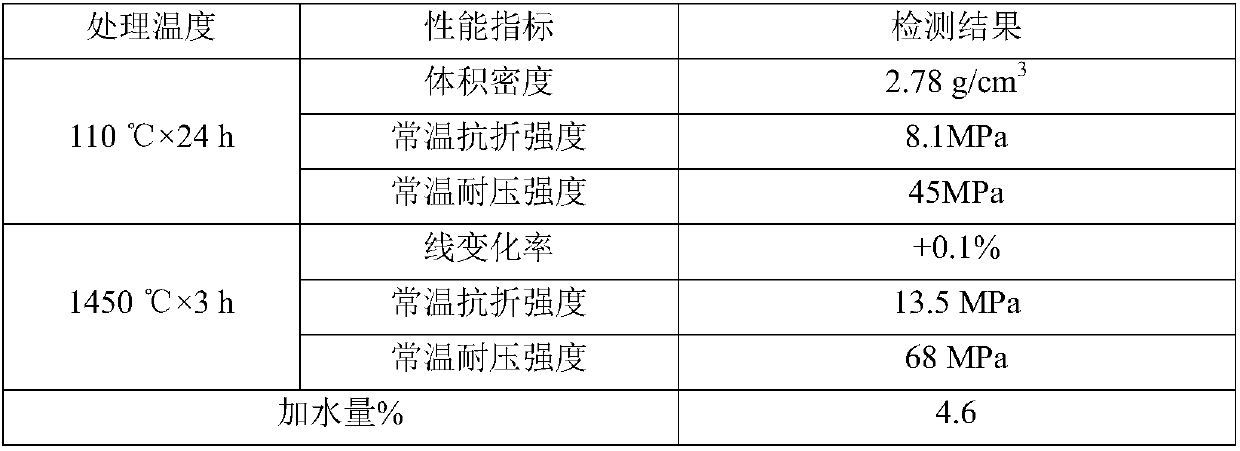

Iron trough castable containing 70% or above of high-aluminum aggregates

The invention belongs to the field of unshaped refractory materials and in particular relates to an iron trough castable containing 70% or above of high-aluminum aggregates. The iron trough castable comprises the components in percentage by mass: 70-74% of high-aluminum aggregates, 2-3% of spherical asphalt, 1.6-2% of calcium aluminate cement, 5.5-7.5% of alumina micropowder, 2.5-3.5% of compositesilicon dioxide micropowder, 12-13% of composite silicon carbide powder, 1-1.2% of composite antioxidant, 0-0.1% of anti-explosion fibers and 0.12-0.2% of dispersant. By combining with a plurality ofimprovement means, the addition amount of the high-aluminum aggregates can be effectively increased (the addition amount can reach 70% or above), and the water addition amount used when the castableis prepared is reduced; and proved by actual industrial applications, the use effect of the iron trough castable in a non-impact region of a main trough reaches the use effect of a common corundum iron trough castable, so that the production cost of the iron trough castable and the whole contracting cost of an iron trough can be greatly reduced.

Owner:中冶武汉冶金建筑研究院有限公司

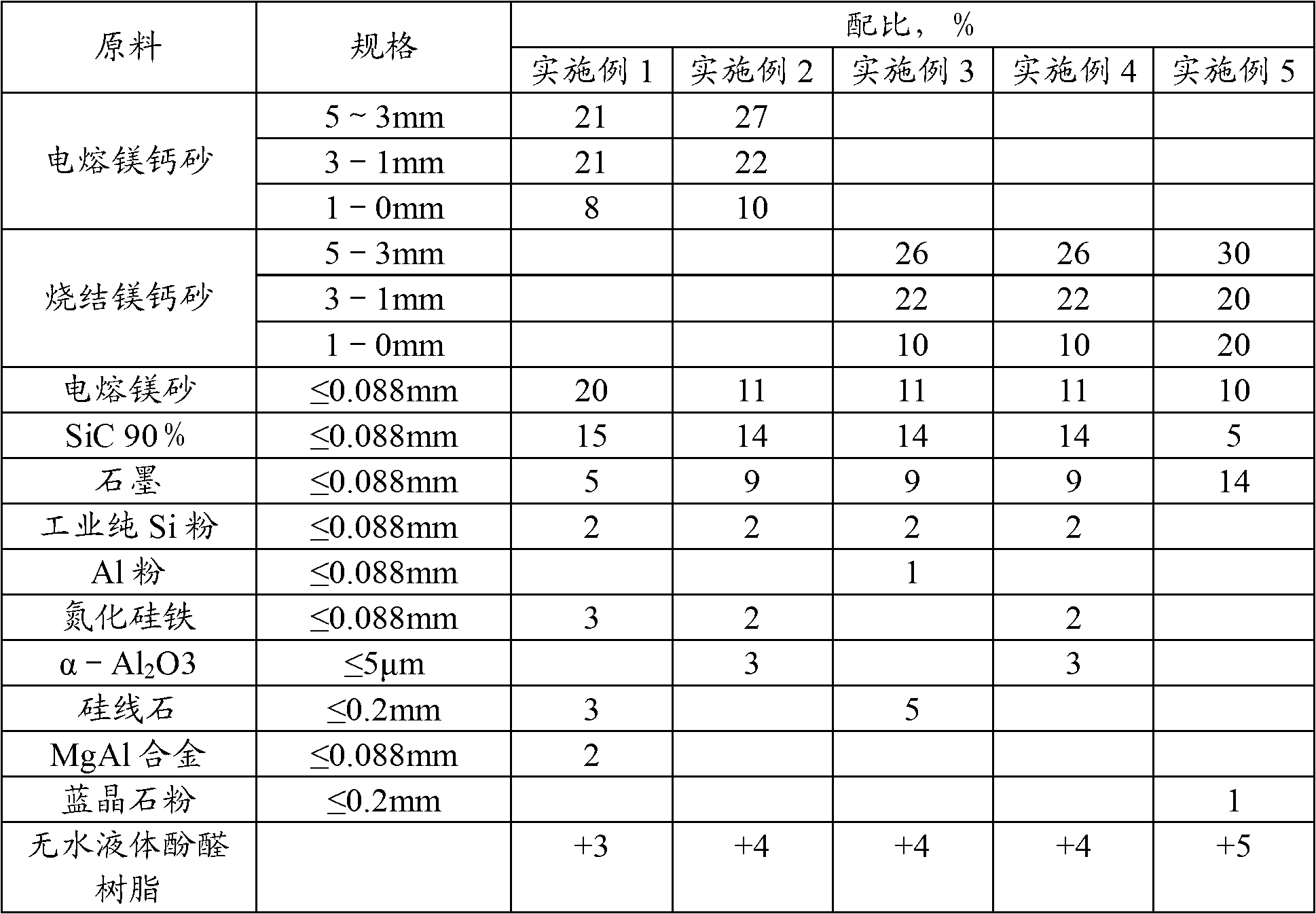

MgCa-SiC-C fireproof material and preparation method thereof

The invention discloses an MgCa-SiC-C fireproof material, belonging to the technical field of fireproof materials. The MgCa-SiC-C fireproof material comprises the following components by mass: 50-70% of electrically molten or sintered magnesium-calcium sand or magnesium-domolite sand granule, 10-20% of electrically molten or sintered magnesium sand fine powder, 5-17% of silicon carbonate, 5-15% of graphite, 1-10% of additive, and anhydrous resin bonder accounting for 3-5% of total mass percent of the electrically molten or sintered magnesium-calcium sand or magnesium-domolite sand granule, the electrically molten or sintered magnesium sand fine powder, the silicon carbonate, the graphite and the additive. The invention further discloses a preparation method of the MgCa-SiC-C fireproof material. The MgCa-SiC-C fireproof material can be applied to a high-temperature steel and iron metallurgy container, especially as an inner lining of a hot metal ladle for iron making, and can meet smelting requirements of the preprocessed hot metal ladle.

Owner:SHOUGANG CORPORATION

Tap hole reclaimed material recycled quick-dry anti-explosion castable

The invention discloses a tap hole reclaimed material recycled quick-dry anti-explosion castable which comprises the following components in parts by mass: 15-30 parts of electrically-fused dense corundum, 5-10 parts of brown fused alumina fresh material, 3-5 parts of brown fused alumina reclaimed material, 5-10 parts of mullite fresh material, 3-5 parts of mullite reclaimed material, 4-8 parts of silicon carbide, 4-6 parts of graphite, 2-5 parts of binding agent which is a mixture of pure calcium aluminate cement and nanometer silica-alumina gel powder, 3-8 parts of polycarboxylate superplasticizer, and 0.5-2 parts of compound anti-explosion agent. The tap hole reclaimed material recycled quick-dry anti-explosion castable has the beneficial effects that by adopting brown fused alumina reclaimed material and mullite reclaimed material, waste materials can be sufficiently utilized so as to reduce the cost of industrial products in the iron and steel industry, the condensation time can be effectively controlled by specially proportioning aggregate materials with different properties and particles and adding additional additives, the hardening time of the castable can be shortened, the quick-dry anti-explosion properties are good, the construction efficiency is improved, on-schedule tapping of a blast furnace can be guaranteed, and the service life of the castable can be prolonged.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

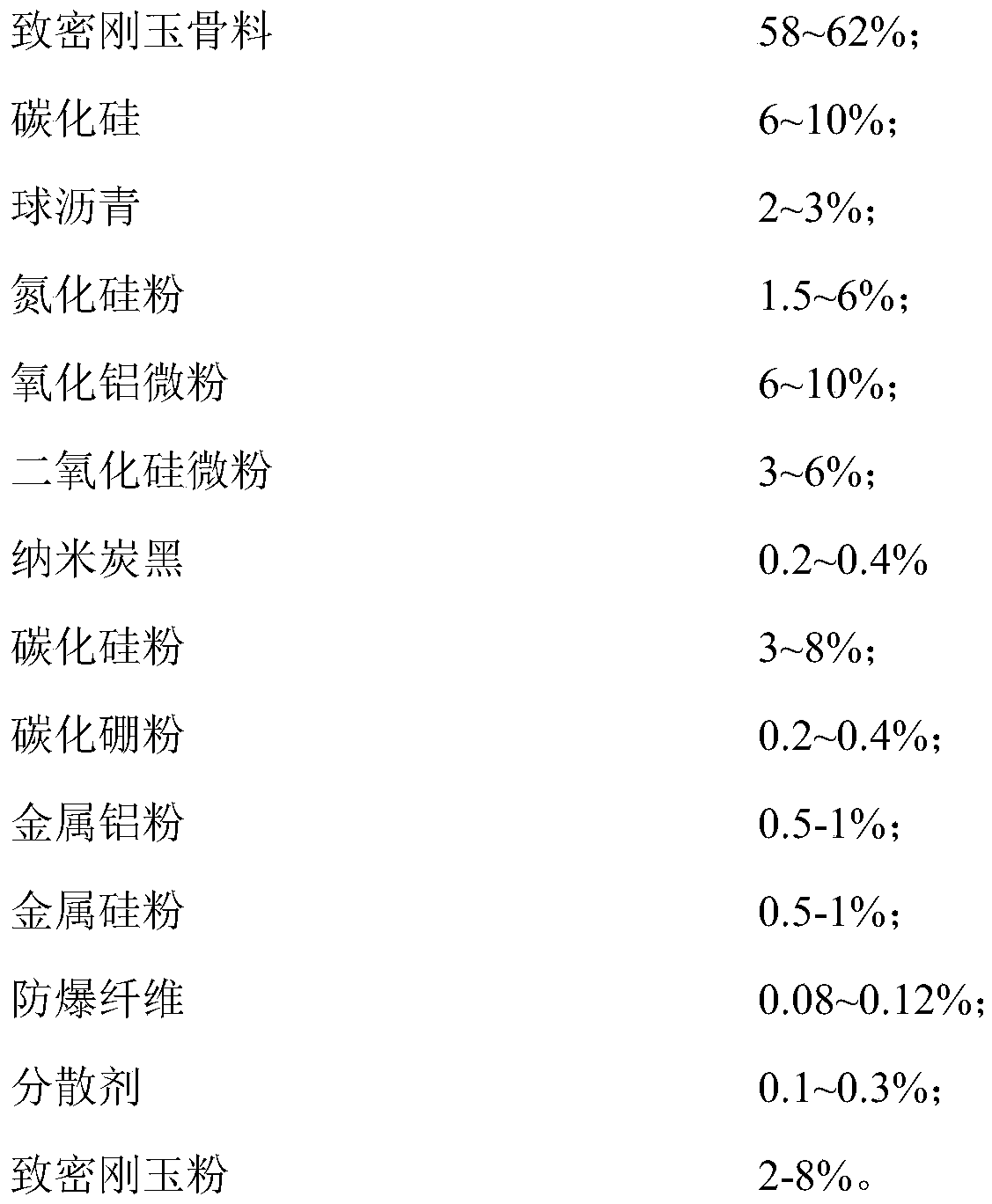

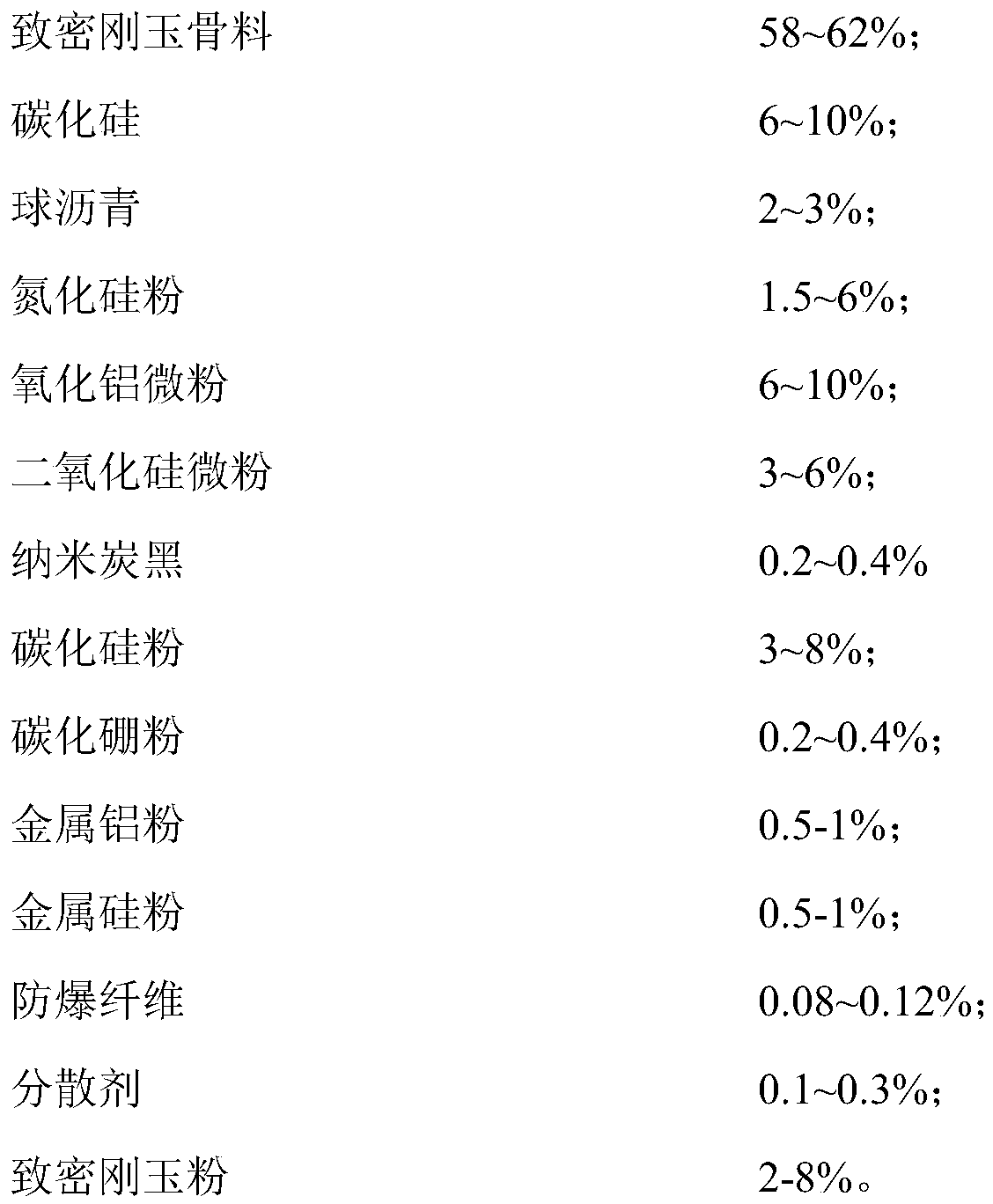

Cement-free iron runner castable for skimmer preformed unit

The invention discloses a cement-free iron runner castable. The cement-free iron runner castable is composed of 58-62% of a compact corundum aggregate, 6-10% of silicon carbide, 2-3% of spherical asphalt, 1.5-6% of silicon nitride powder, 6-10% of alumina micro powder, 3-6% of silicon dioxide micro powder, 0.2-0.4% of nano carbon black, 3-8% of silicon carbide powder, 0.2-0.4% of boron carbide powder, 0.5-1% of metal aluminum powder, 0.5-1% of metal silicon powder, 0.08-0.12% of explosion-proof fibers, 0.1-0.3% of a dispersing agent and 2-8% of compact corundum powder. According to the invention, an iron runner castable system is formed by combining high-purity silicon dioxide micro-powder and aluminum oxide micro-powder, so that the purity, refractoriness and compactness of the castable reach a new height. Through high-purity, high density and the like of the system disclosed by the invention, the heat-state rupture strength, which is the index with most high-temperature representativeness, after heat is preserved by 1 hour at 1400 DEG C reaches 10 MPa or above.

Owner:中冶武汉冶金建筑研究院有限公司

Al4SiC4-Al2O3 composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and Al2O3 and a method for preparing the same. The adopted technical proposal is as follows: firstly, 50 to 65 weight percent of bauxite and 35 to 50 weight percent of industrial carbon powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite refractory material of the Al4SiC4 and the Al2O3. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the Al2O3 prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a furnace lining material for nonferrous metal and iron and steel smelting equipment, and particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on.

Owner:WUHAN UNIV OF SCI & TECH

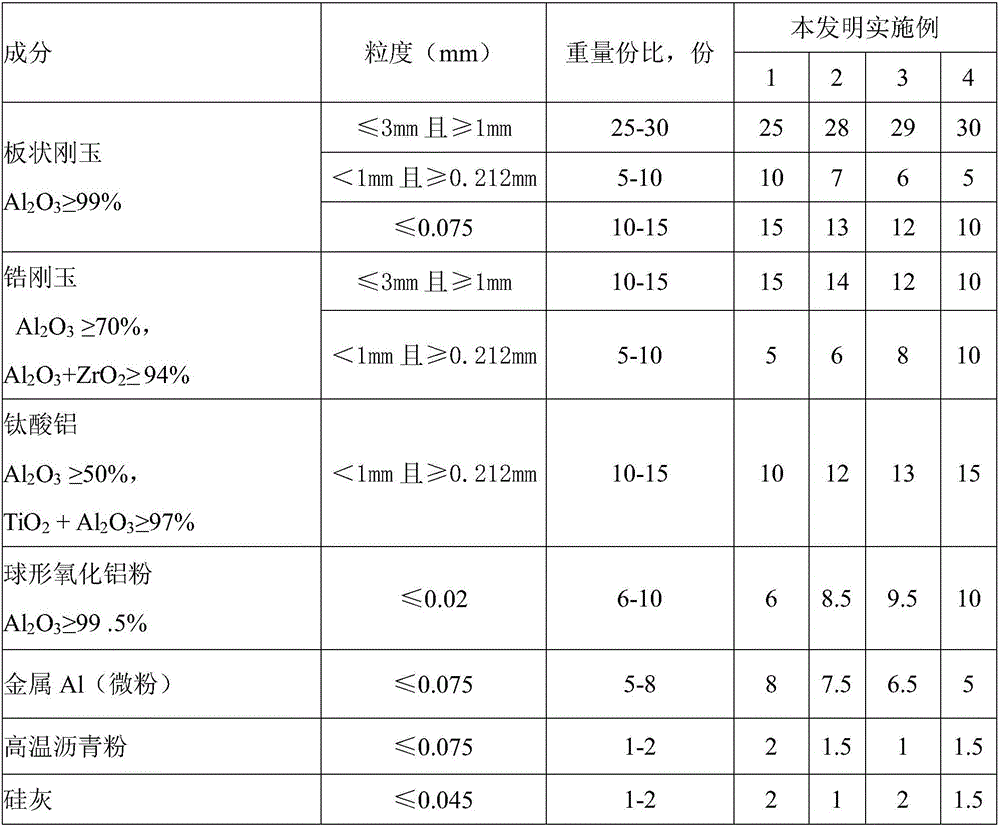

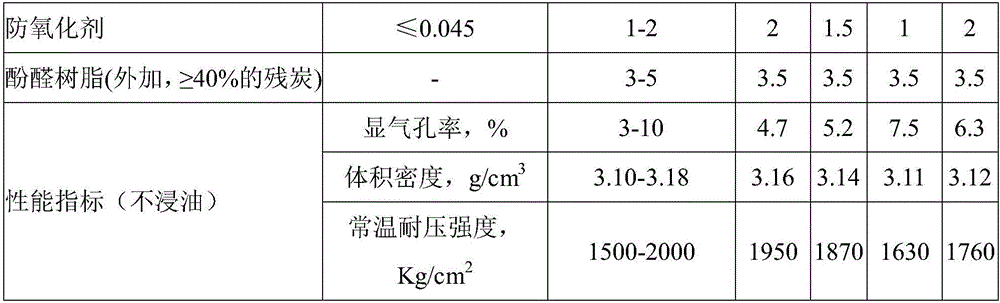

Corundum-zirconia corundum-titanic acid aluminum no-firing no-soaking sliding brick and preparation method thereof

ActiveCN106001532ASmall coefficient of thermal expansionImproved thermal shock stabilityMelt-holding vesselsPitchstoneOxidizing agent

The invention discloses a corundum-zirconia corundum-titanic acid aluminum no-firing no-soaking sliding brick and a preparation method thereof. The sliding brick is composed of, by weight, 40-55 parts of tabular corundum, 15-25 parts of zirconia corundum, 10-15 parts of titanic acid aluminum, 6-10 parts of spherical calcined alumina, 5-8 parts of metal aluminum powder, 1-2 parts of high-temperature asphalt powder, 1-2 parts of silicon ash, 1-2 parts of antioxidants and 3-5 parts of phenolic resin. According to the corundum-zirconia corundum-titanic acid aluminum no-firing no-soaking sliding brick and the preparation method thereof, the raw materials of the tabular corundum, the zirconia corundum and the titanic acid aluminum are added into the formula, the coefficient of thermal expansion of the material of the sliding brick can be obviously decreased, and the thermal shock stability, the erosion resistance and the slag resistance of the sliding brick are improved; selection and adding amount of the high-temperature asphalt powder, spherical calcined alumina powder and the silicon ash are controlled, and the reasonable strength of the sliding brick in the low-temperature, medium-temperature and high-temperature stages can be achieved; the thermal expansion difference caused by the thermal stress of the temperature difference between inside and outside of the hole diameter of cast steel when the product is used is improved, the crack number is decreased; and the high-temperature comprehensive performance of the sliding brick is remarkably improved, and the service life of the sliding brick is prolonged.

Owner:UNIV OF SCI & TECH LIAONING

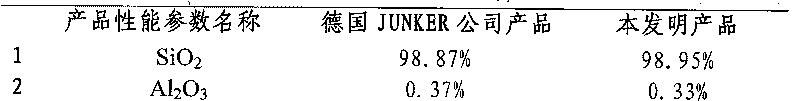

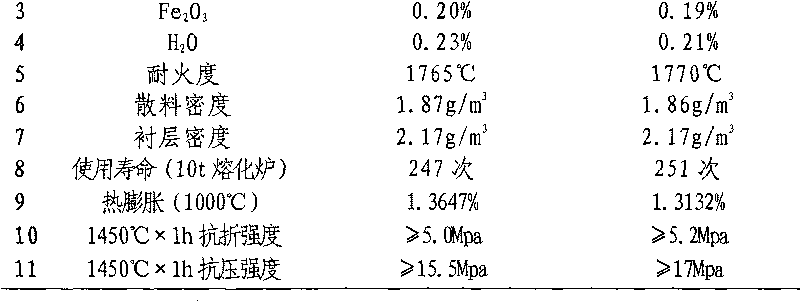

Novel acid furnace lining refractory material

The invention discloses a novel acid furnace lining refractory material. The novel acid furnace lining refractory material comprises the following raw materials in percentage by weight: 19 to 23 percent of 3 to 5mm high-purity microcrystal quartz sand, 28 to 32 percent of 1 to 2mm high-purity microcrystal quartz sand, 20 to 24 percent of 0 to 1mm semi-sintered microcrystal quartz sand, 24 to 28 percent of 325-mesh semi-sintered microcrystal quartz sand, 0.8 to 1.1 percent of B2O3 and 0.04 to 0.06 percent of special sintering flux. In the novel acid furnace lining refractory material, pre-sintered semi-sintered microcrystal quartz sand powder with stable volume and low thermal expansion is used as the raw material, and the special sintering flux is added so as to form a solid solution structure at a high temperature, so the volume expansion generated in the use process of a furnace lining is remarkably reduced, the furnace lining is prevented from forming cracks easily and the service life of the furnace lining is greatly prolonged.

Owner:长沙环宇耐火材料有限公司

Aluminum-magnesium casting material for ladle liner and preparation method thereof

The invention relates to an aluminum-magnesium casting material for a ladle liner and a preparation method thereof. ACcording to the technical scheme, the method comprises the following steps: preparing 50-65wt% of microporous alumina particles serving as aggregate; preparing 10-15wt% of fine corundum particles, 15-30wt% of fine corundum powder, 2-8wt% of magnesium oxide powder, 2-8wt% of alpha-A12O3 powder and 2-8wt% of aluminum powder silica gel which are used as base materials; adding water which accounts for 3-10wt% of the sum of the aggregate and the base materials; evenly agitating, and molding in a vibrating manner; carrying out heat preservation at 100-150 DEG C for 12-36 hours, so as to prepare the aluminum-magnesium casting material for the ladle liner. The aluminum-magnesium casting material for the ladle liner prepared by the method has excellent slag resistance and thermal shock stability, and the service life of the aluminum-magnesium casting material for the ladle liner can be effectively prolonged.

Owner:WUHAN UNIV OF SCI & TECH

Method for repairing inner lining of tundish

ActiveCN101214543AHigh turnoverReduce consumptionMelt-holding vesselsCeramic shaping apparatusRepair materialPhosphoric acid

The invention relates to a middle package liner repairing method. The method adopts a hot repairing mode for a the middle package for a lower line; under a temperature of 100 to 140 DEG C, firstly cleans the position of the middle package of a body needed repairing, then spray a phosphoric acid wedding agent uniformly on the position to be repaired; uniformly coats the hot repairing material after mixed on the position to be repaired with a coating thickness of 4 to 6mm higher than the surface of the body. The method directly uses the repairing material with no water to carry through hot repairing on the crack or defective part of the liner for the middle package turning over the lower line, improves the turning over times of the middle package, reduces the consumption of the middle package and has a good repairing effect.

Owner:ANGANG STEEL CO LTD

Aluminum-magnesium-zirconium brick for RH impregnating pipe and circulating pipe and preparation method thereof

The invention relates to an aluminum-magnesium-zirconium brick for an RH impregnating pipe and a circulating pipe and a preparation method thereof, and the aluminum-magnesium-zirconium brick is used for an inner pipe of the RH impregnating pipe and the circulating pipe. The aluminum-magnesium-zirconium brick is prepared from the following raw materials in percentage by weight: 25-45% of corundum particles, 15-35% of fused magnesia particles, 15% of corundum fine powder, 10% of alpha-alumina micropowder, 4.85% of zirconia fine powder, 5% of fused magnesia fine powder, 1% of silicon dioxide micropowder, 4% of activated alumina, 0.1% of water reducing agent and 0.05% of dispersant. The aluminum-magnesium-zirconium brick has the advantages of high green strength, no need of sintering, good thermal shock stability and strong resistance to acidic and basic fused slag corrosion.

Owner:郑州市裕丰耐火材料有限公司

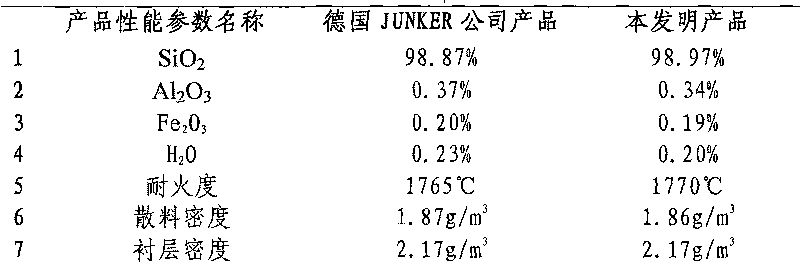

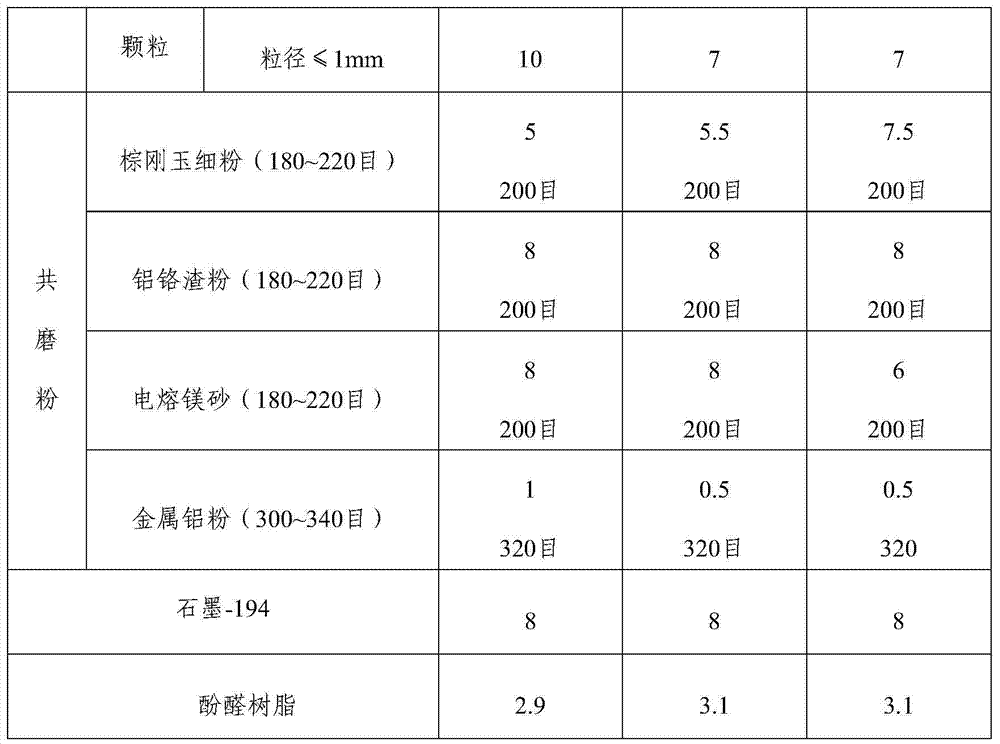

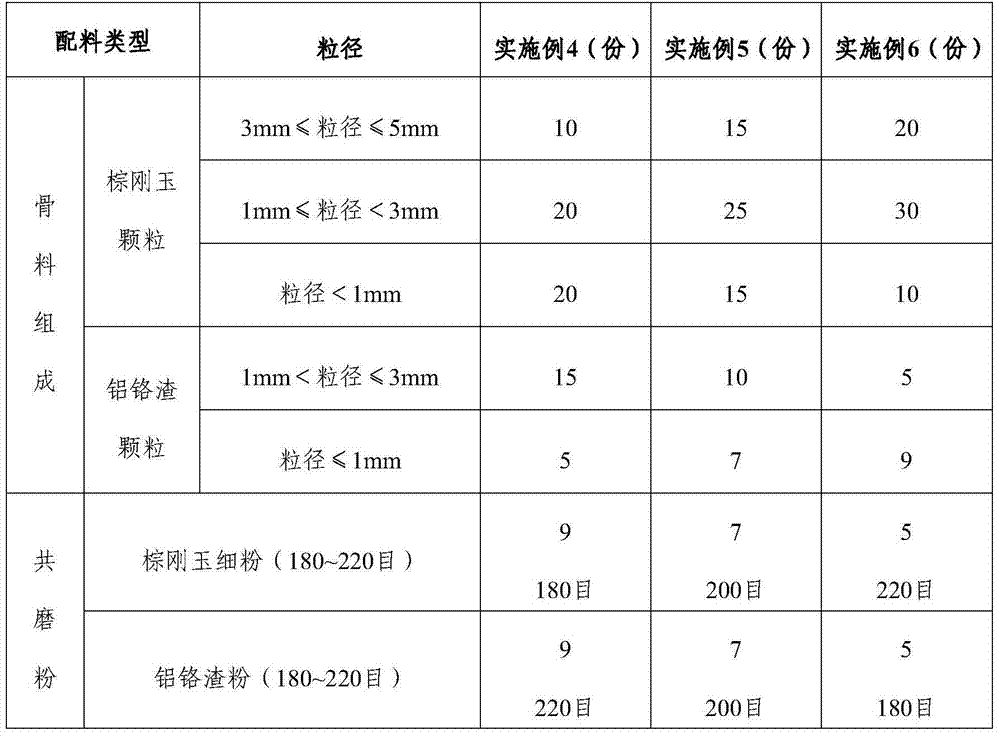

Alumina-spinel-carbon brick containing aluminachrome slag and preparation method of alumina-spinel-carbon brick

The invention relates to a refractory matter, and particularly relates to an alumina-spinel-carbon brick containing aluminachrome slag and a preparation method of thee alumina-spinel-carbon brick. The alumina-spinel-carbon brick is prepared from the following raw materials in parts by weight: 50-65 parts of brown fused alumina particles with the particle sizes of smaller than or equal to 5mm, 5-20 parts of aluminachrome slag particles with the particle sizes of smaller than or equal to 3mm, 5-15 parts of 180-220meshbrown aluminum oxide powder, 5-10 parts of 180-220mesh aluminachrome slag powder, 6-15 parts of 180-220mesh fused magnesite powder, 0.3-1.0 part of 300-340mesh metal aluminum powder, 6-12 parts of graphite and 2-4 parts of a binding agent. The alumina-spinel-carbon brick provided by the invention is high in strength, stable in chemical property, and excellent in slag corrosion resistance; and the aluminachrome slag component is added, and reacts with magnesia powder at a high temperature, so as to form a spinel structure, so that the anti-erosion properties and slag resistance of the alumina-spinel-carbon brick are enhanced.

Owner:北京利尔高温材料股份有限公司

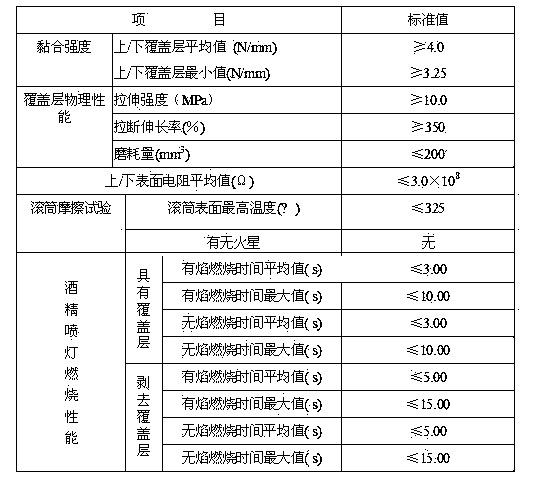

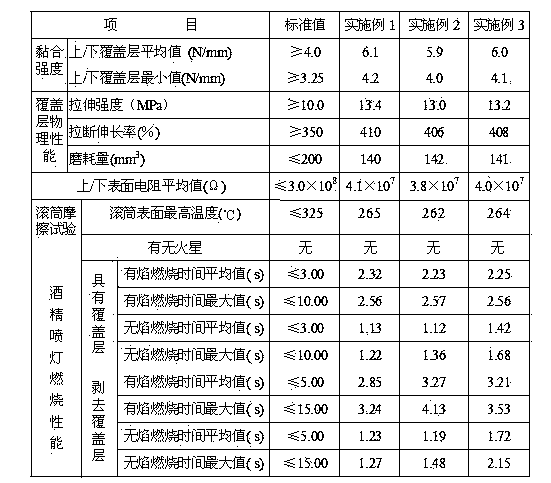

Flame-retardant conveying belt covering adhesive for mine and preparation method thereof

InactiveCN103524914ASpecial Flame RetardancyLower flame temperatureConveyorsChemistryThermal radiation

The invention discloses a flame-retardant conveying belt covering adhesive for a mine and a preparation method thereof. The flame-retardant conveying belt covering adhesive disclosed by the invention is added with nanometer magnesium hydroxide subjected to modification treatment in a preparation process, belongs to an environment-friendly green fire retardant and can play a high-efficiency smoke inhibition role; compared with a similar inorganic flame retardant, the flame-retardant conveying belt covering adhesive disclosed by the invention has a specific cooling technology, can promote the generation of a noncombustible compound and play a heat conduction and heat radiation obstructing role without corroding processing equipment, is low in price and low in production cost, and solves the problems of low extensibility and higher abrasion of the traditional covering adhesive and the problems of abrasion resistance and heat resistance especially through added superfine andalusite powder, thereby greatly prolonging the service life of a conveying belt.

Owner:JIUQUAN RONGTAI RUBBER PROD

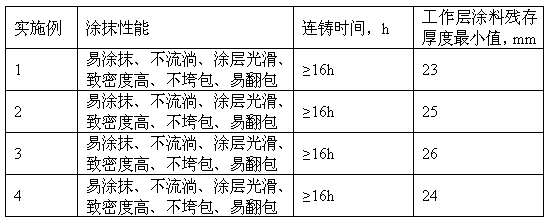

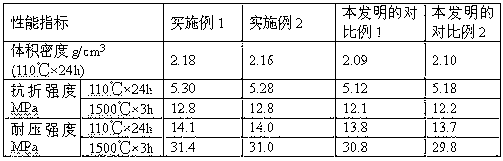

Continuous casting tundish working layer coating

The invention relates to the field of ferrous metallurgy technology and fireproof materials for ferrous metallurgy, in particular to a continuous casting tundish working layer coating. The invention has the following purposes: magnesite and boron mud are used as main base materials to invent a continuous casting tundish working layer magnesian coating without using silica powder, clay, active lime and other plasticizers, properties beneficial to a fireproof working layer, such as high MgO content, high fire resistance, high activity, high plasticity and the like, of the boron mud are fully utilized, and the boron mud is used for replacing the plasticizers used in the prior art, thus recycling the boron mud, improving the fire resistance, slag resistance and the like of the continuous casting tundish magnesian coating as well as prolonging the service life of the continuous casting tundish magnesian coating.

Owner:JIANGSU UNIV

Blast furnace waterless stemming

The invention discloses a blast furnace waterless stemming, composed of the following components by weight: 9.5-10% of dry quenching dedusting ash with a 0-1 mm size fraction, 9-10% of 180-mesh clay, 5% of 180-mesh sericite, 18-20% of 200-mesh silicon carbide, 16.5-17% of 0-1 mm brown corundum or dense corundum, 15-19% of 1-3 mm brown corundum or dense corundum, 3-4% of 200-mesh silicon nitride and 4-5% of 2 [mu]m aluminium micro-powder, with water content of each component lower than 0.5%. The blast furnace waterless stemming greatly enhances slag resistance of the waterless stemming, raises the volume density of the stemming and is capable of completely eliminating large splashing after opening.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

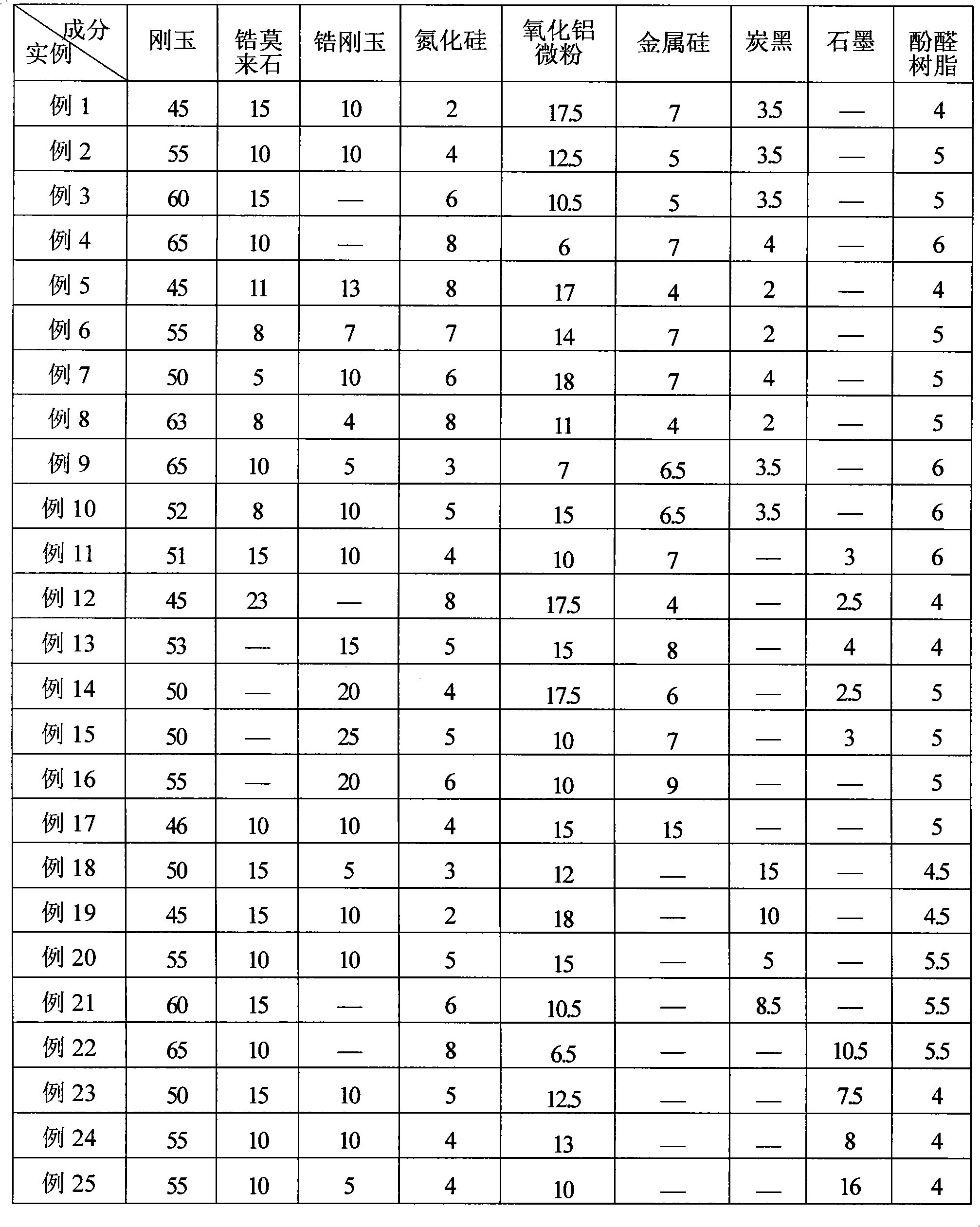

Slide plate refractory with silicon nitride added and production method thereof

The invention relates to a slide plate refractory with silicon nitride added and a production method thereof. The slide plate is prepared by the following raw materials in percentage by weight: 45-65% of corundum, 10-25% of zirconia-mullite and / or zirconia-corundum, 2-8% of silicon nitride, 6-18% of alumina fine powder and the balance one or more of silicon metal, carbon black and graphite powder and a phenolic resin binder accounting for 4-6% of the total above raw materials. The production method is characterized by proportionally weighing the raw materials, uniformly mixing the raw materials, obtaining the mixture through mixing, press-forming the mixture, drying the formed mixture at 190-210 DEG C for 6-10h and then carrying out nitridation firing on the dried mixture at1200-1400 DEG C. The invention has the following benefits: by adding silicon nitride and reasonably adding other components according to the amount and ratios, the slide plate composite material with structure of Al2O3-ZrO2-Si3N4-C is formed, and the oxidation resistance of the slide plate is improved; and the apparent porosity of the refractory is 1-4%, the cold compression strength is 150-220MPa, the high temperature rupture strength is 28-33MPa and such performance indexes as the oxidation resistance, the scouring resistance, the thermal shock resistance and the like are all excellent or good.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Corundum wearing-resistant plastic refractory and preparation method thereof

The invention provides a corundum wearing-resistant plastic refractory. The corundum wearing-resistant plastic refractory comprises corundum, chromium corundum, zirconite, alumina micro powder, zirconium powder, lanthanum and lanthanum group metal oxide micro powder, and 0.01-0.1% of yttrium powder. The invention further claims a preparation method of the corundum wearing-resistant plastic refractory at the same time. The preparation method comprises the steps of fine milling, pre-mixing, mixing, drying, sorting, checking, packaging and storing. Through adding zirconium powder, lanthanum and lanthanum group metal oxide micro powder, and yttrium powder, the high-temperature bonding property of the plastic is improved, and therefore the slag resistance, the thermal stability and the service life of the product are improved.

Owner:长兴正发热电耐火材料有限公司

Aluminum and magnesium low-weight castable used for steel ladle heat preservation

The invention discloses an aluminium and magnesium low-weight castable used for steel ladle heat preservation. The aluminium and magnesium low-weight castable used for steel ladle heat preservation isprepared from a castable main ingredient, wherein the castable main ingredient is prepared from the following components in percentage by weight: 10-55% of one or two of fused white corundum and tabular alundum, 10-55% of alumina hollow balls, 1-8% of fused magnesia powder, 1-5% of sintered spinel particles, 1-8% of ultra-fine spinel micro powder, 2-8% of activated aluminium oxide powder, 3-7% ofcalcium aluminate cement and 0-2% of silica micro powder. According to the aluminium and magnesium low-weight castable used for steel ladle heat preservation, by strictly controlling the weight percentages of the components of the castable main ingredient, continuous particles are formed and stacked closely, and compaction of the castable is achieved, so that the castable has high normal temperature strength, thermal state high temperature strength and low thermal conductivity, and can adapt to a severe environment of a steel mill.

Owner:武汉钢铁有限公司

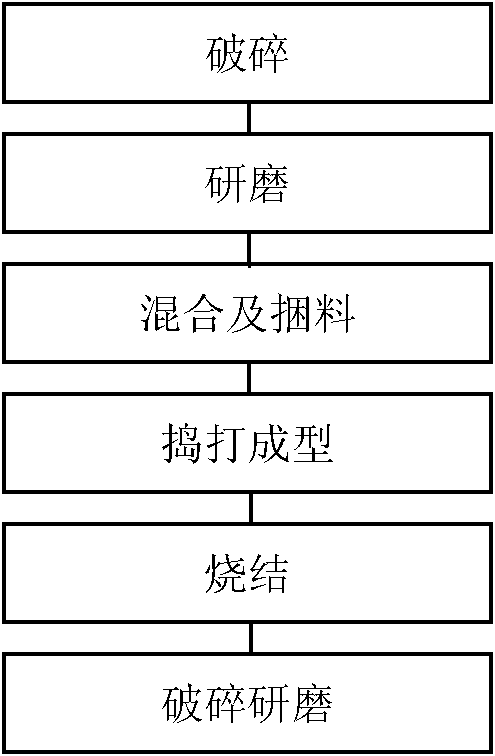

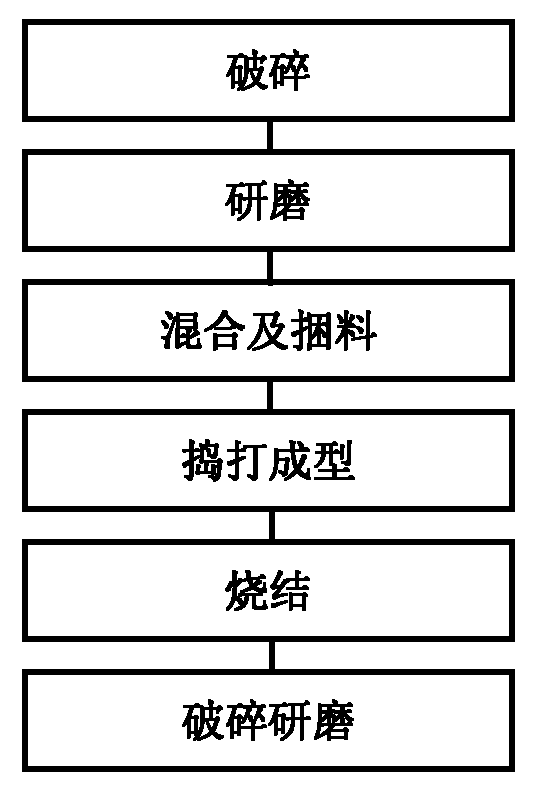

Method for preparing magnesia-alumina spinel-containing aluminate cement

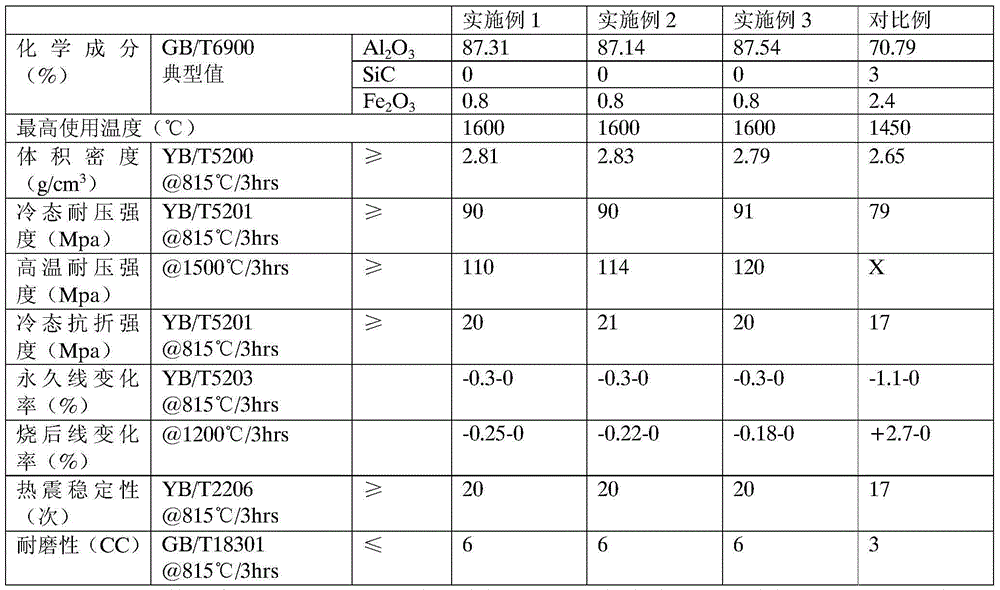

The invention discloses a method for preparing magnesia-alumina spinel-containing aluminate cement, which comprises the following steps of: firstly, crushing raw materials; secondly, grinding the crushed materials; thirdly, mixing the ground materials in proportion and bunching the mixture; fourthly, ramming and molding the material bunch after the bunching is finished; sixthly, placing the molded material into a furnace for heating and sintering; and finally crushing and grinding again the sintered material after the material is cooled to the room temperature to obtain the magnesia-alumina spinel-containing aluminate cement. The novel magnesia-alumina spinel-containing aluminate cement prepared by the method of the invention has relatively higher fire resistance, and as a bonding agent of a ladle castable, remarkably improves the slag resistance of the ladle castable. The method has the advantages of simple process and high applicability, and can be widely applied to a plurality of industries, such as metallurgy, building materials and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

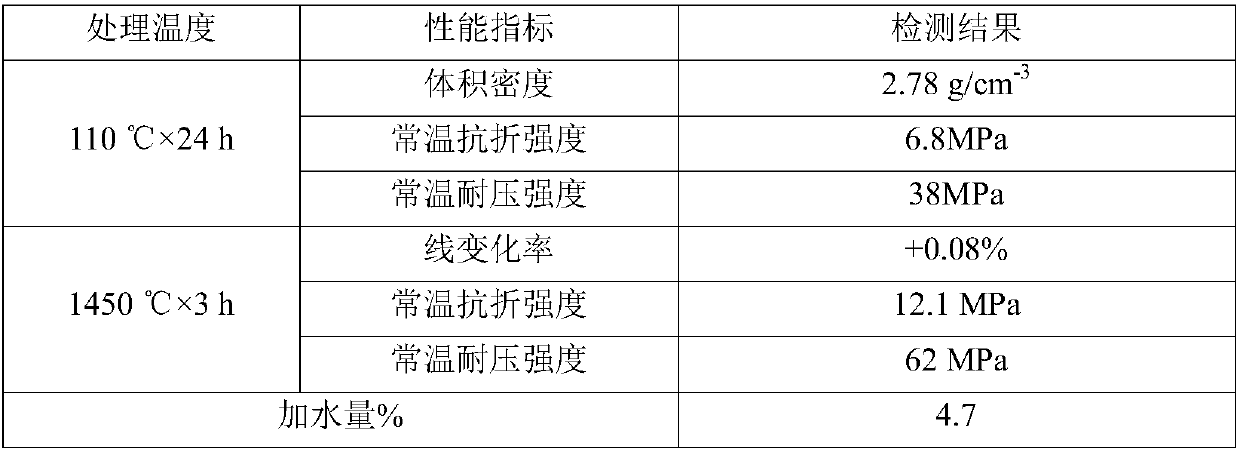

Refractory castable for producing air blowing assisted slagging-off spray gun

ActiveCN106565254AImprove mechanical properties and slag resistanceImprove liquidityFlexural strengthVolume density

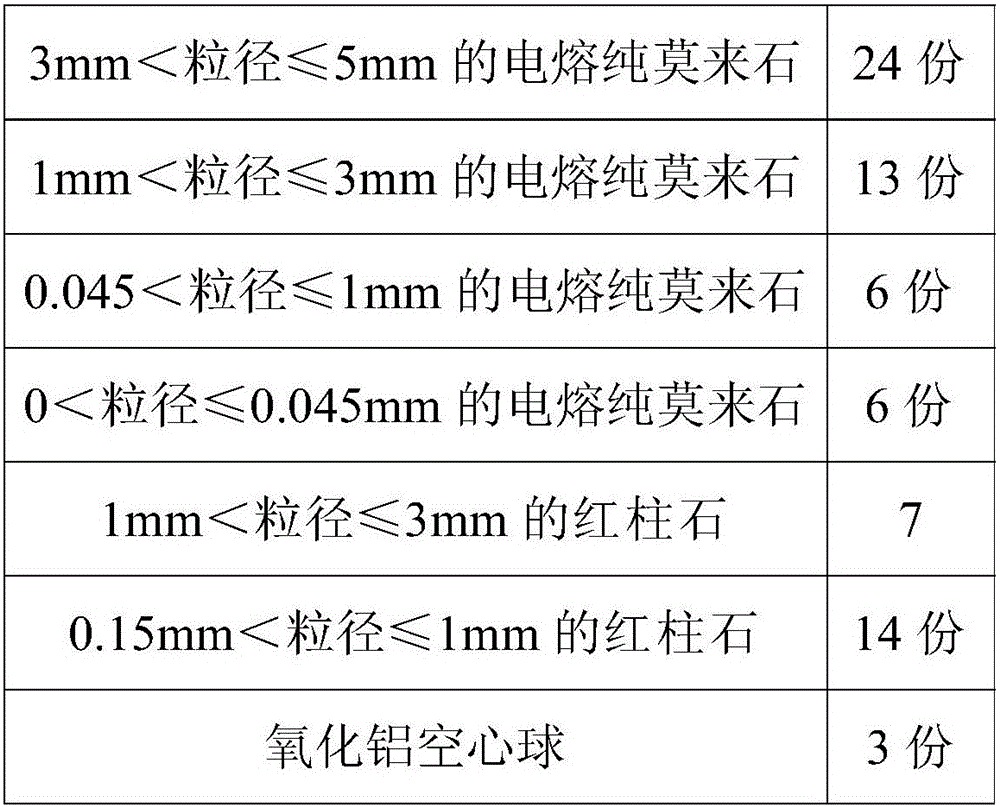

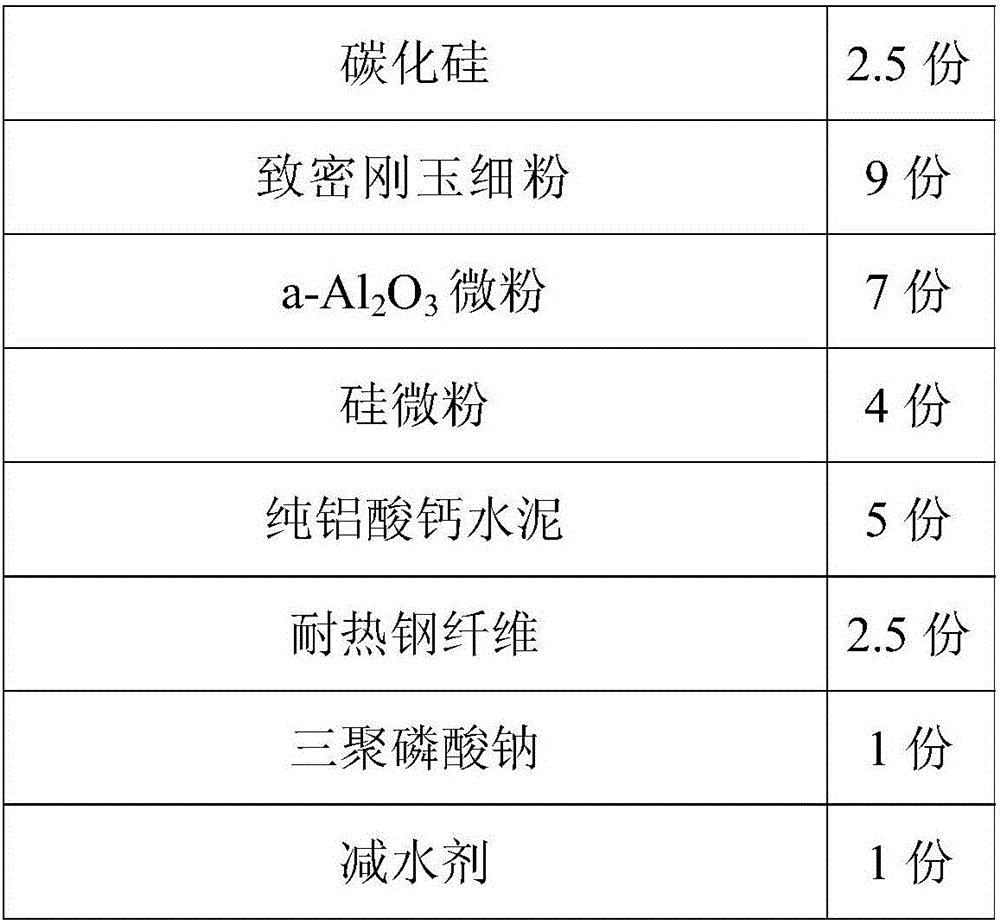

The invention discloses a refractory castable for producing an air blowing assisted slagging-off spray gun. The refractory castable includes, by weight, 40-60 parts of electric-smelting pure mullite, 15-30 parts of andalusite, 1-9 parts of aluminum oxide hollow spheres, 1-4 parts of silicon carbide, 5-10 parts of compact corundum fine powder, 5-10 parts of [alpha]-Al2O3 micro powder, 2-5 parts of silicon micro powder, 3-6 parts of pure calcium aluminate cement, and 1-5 parts of heat-resistant steel fibers. In the heavy castable, a proper amount of the aluminum oxide hollow spheres having proper diameters is introduced, so that the construction flowability of the castable is greatly improved, porosity ratio of the castable is reduced, volume density is increased and compactness of the castable is increased since the spherical shape of the hollow spheres has advantages on flowing of the castable slurry, thereby improving mechanical performance and anti-slagging performance of spray gun lining. The flexural strength of the castable is increased by 20% than that of a common castable while compression strength is increased by 45%.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com