Corundum base brick for steel ladles and production method thereof

A corundum-based, bottom-coated brick technology, which is applied in the field of refractory materials, can solve problems such as short service life and poor corrosion resistance, and achieve the effects of increasing service life, improving high-temperature performance, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

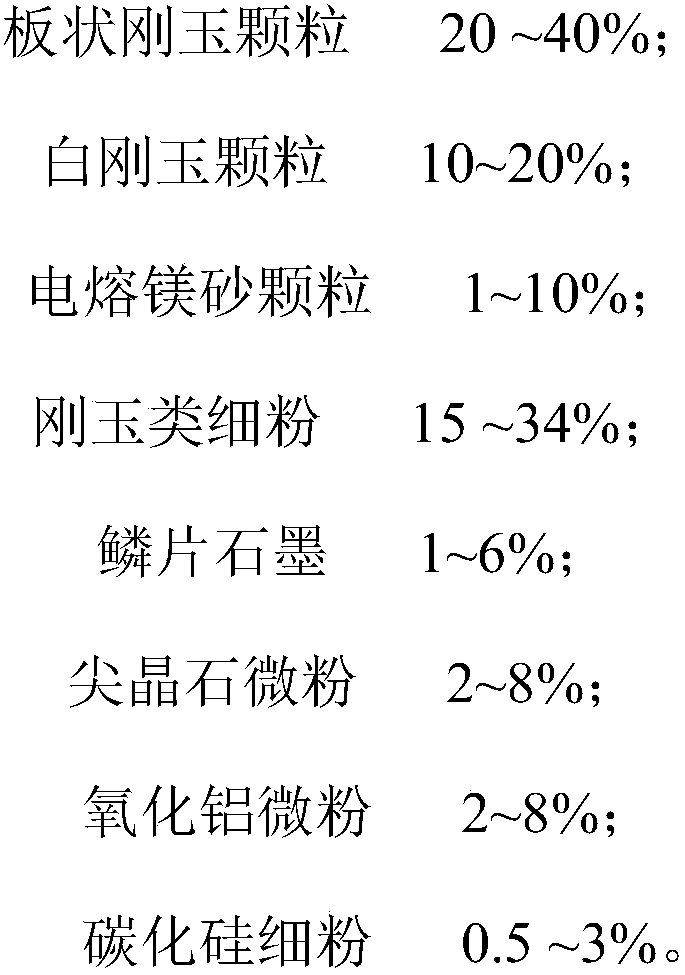

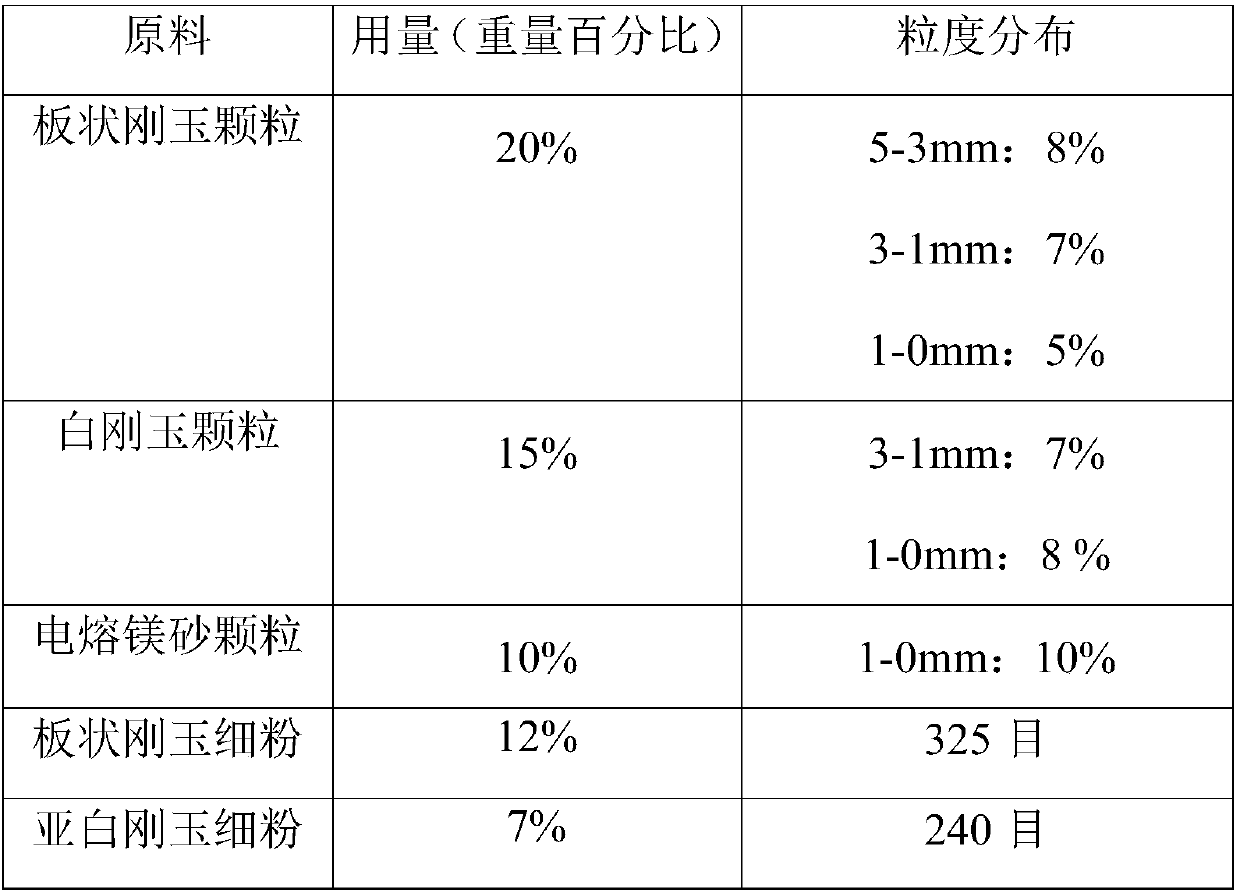

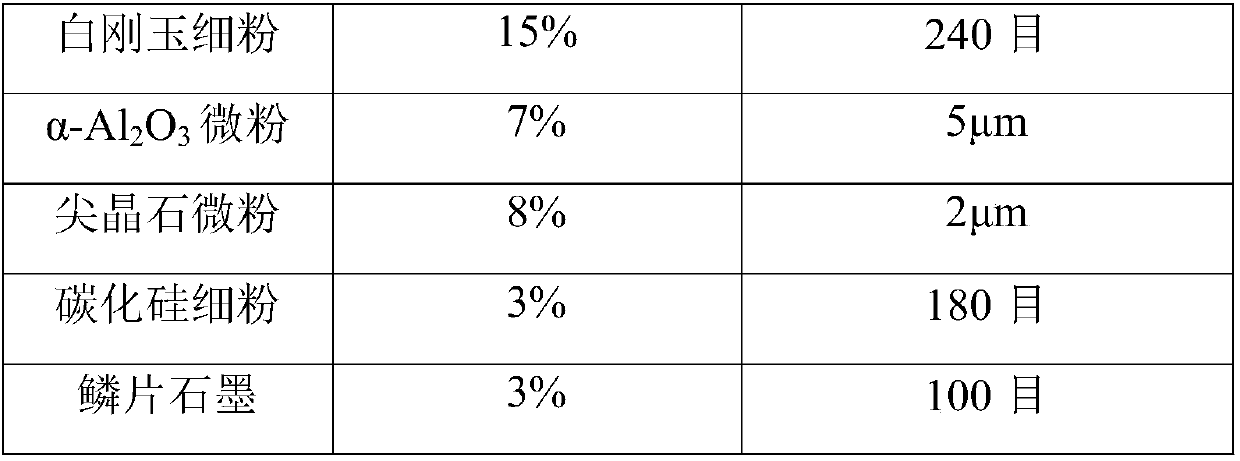

[0034] A corundum bottom brick for a ladle, prepared from a mixture and a phenolic resin, the amount of the phenolic resin is 4.5% of the amount of the mixture, and the mixture includes the following raw materials in weight percentages, as shown in Table 1 .

[0035] Its preparation method is:

[0036] (1) Premixing the corundum fine powder, spinel micropowder, alumina micropowder and silicon carbide fine powder of the formula amount for 40 minutes to obtain the premixed fine powder;

[0037] (2) Add plate-shaped corundum particles, white corundum particles, fused magnesia particles and flake graphite to the mixer, and mix and grind for 1 minute;

[0038] (3) in step (2), add part binding agent and carry out kneading 5min, the weight of part binding agent is 6% of binding agent gross weight, add premix fine powder and remaining binding agent then, continue mixing 25min, obtain mud material;

[0039] (4) the mixed mud material of step (3) is rolled and formed by a friction p...

Embodiment 2

[0045] A corundum bottom brick for a ladle, prepared from a mixture and a phenolic resin, the amount of the phenolic resin is 4.5% of the amount of the mixture, and the mixture includes the following raw materials in weight percentages, as shown in Table 2 .

[0046] Its preparation method is:

[0047] (1) Premixing the corundum fine powder, spinel micropowder, alumina micropowder and silicon carbide fine powder of the formula amount for 45min to obtain the premixed fine powder;

[0048] (2) Add tabular corundum particles, white corundum particles, fused magnesia particles and flake graphite into the mixer, and mix and grind for 2 minutes;

[0049] (3) add part binding agent in step (2) and carry out kneading 8min, the weight of part binding agent is 8% of binding agent gross weight, then add premixed fine powder and remaining binding agent, continue mixing 30min, obtain mud material;

[0050] (4) the mixed mud material of step (3) is rolled and formed by a friction press; ...

Embodiment 3

[0056] A corundum-based bottom brick for a ladle, prepared from a mixture and a phenolic resin, the amount of the phenolic resin is 4.5% of the amount of the mixture, and the mixture includes the following raw materials in weight percentages, as shown in Table 3 .

[0057] Its preparation method is:

[0058] (1) Premixing the corundum fine powder, spinel micropowder, alumina micropowder and silicon carbide fine powder of the formula amount for 50 minutes to obtain the premixed fine powder;

[0059] (2) Add plate-shaped corundum particles, white corundum particles, fused magnesia particles and flake graphite to the mixer, and mix and grind for 1 minute;

[0060] (3) Add part of binder to step (2) and knead for 10 minutes, the weight of part of binder is 10% of the total weight of binder, then add premixed fine powder and remaining binder, and continue mixing for 20 minutes to obtain mud material;

[0061] (4) the mixed mud material of step (3) is rolled and formed by a frict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com