Patents

Literature

252results about How to "Improve room temperature strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-component silicone sealant for solar module resisting damp, heat and ageing and preparation method thereof

InactiveCN102977840AWide range of adhesionImprove room temperature strengthNon-macromolecular adhesive additivesOther chemical processesChemistrySilicone sealant

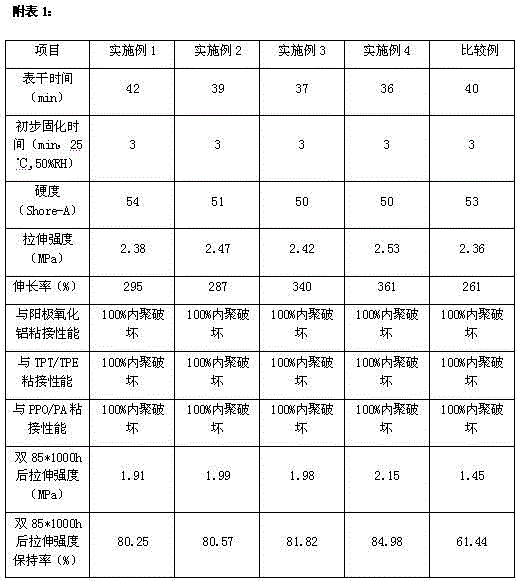

The invention discloses two-component silicone sealant for a solar module resisting damp, heat and ageing and a preparation method thereof. The sealant consists of a component A and a component B, wherein the component A adopts polydimethylsiloxane as the major material; and the component B comprises dispersion mediums, fillers, cross linking agent, coupling agent and catalyst; the component A comprises the following components in parts by weight: 100 parts of a, omega-dihydroxy polydimethylsiloxane with viscosity of 5000-50000cps, 3 to 20 parts of plasticizer and 50 to 150 parts of fillers; the component B comprises the following components in parts by weight: 100 parts of dispersion mediums, 10 to 45 parts of fillers, 20 to 50 parts of cross linking agent, 5 to 40 parts of silane coupling agent and 0.5 to 2 parts of catalyst; and the ratio of the component A to the component B in parts by weight is 100: (10-20). The sealant has the advantages of fast deep curing, wide adhesion, high strength of normal temperature and excellent resistance to damp, heat and ageing; after ageing for 1000 hours under the double-85 condition, the strength retention rate can be up above 80%; and the sealant is suitable for machine gluing, can largely improve module productivity, and adapts to the requirements of solar module mass production.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

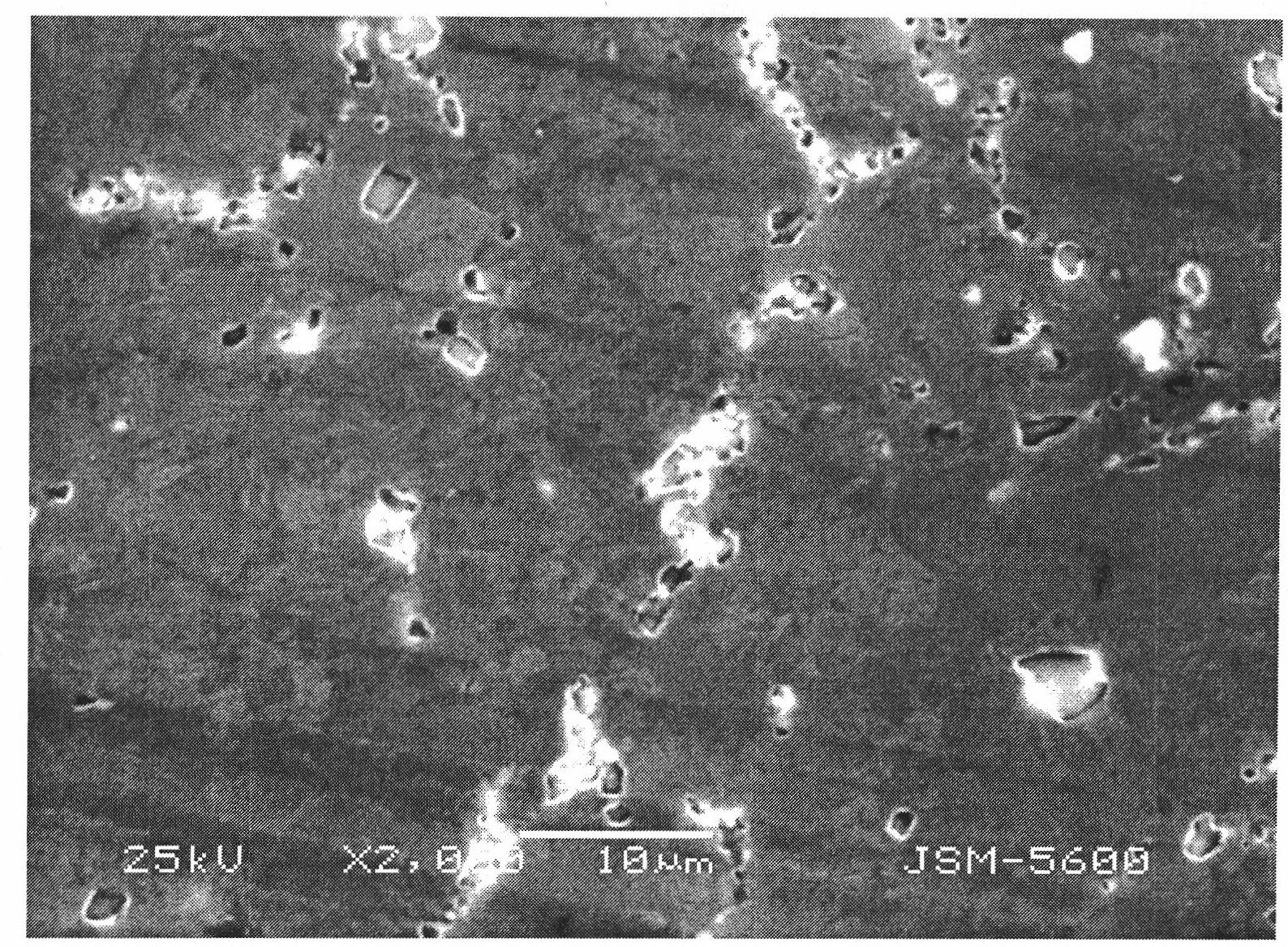

Graphene-reinforced titanium-based nanocomposite material and preparation method

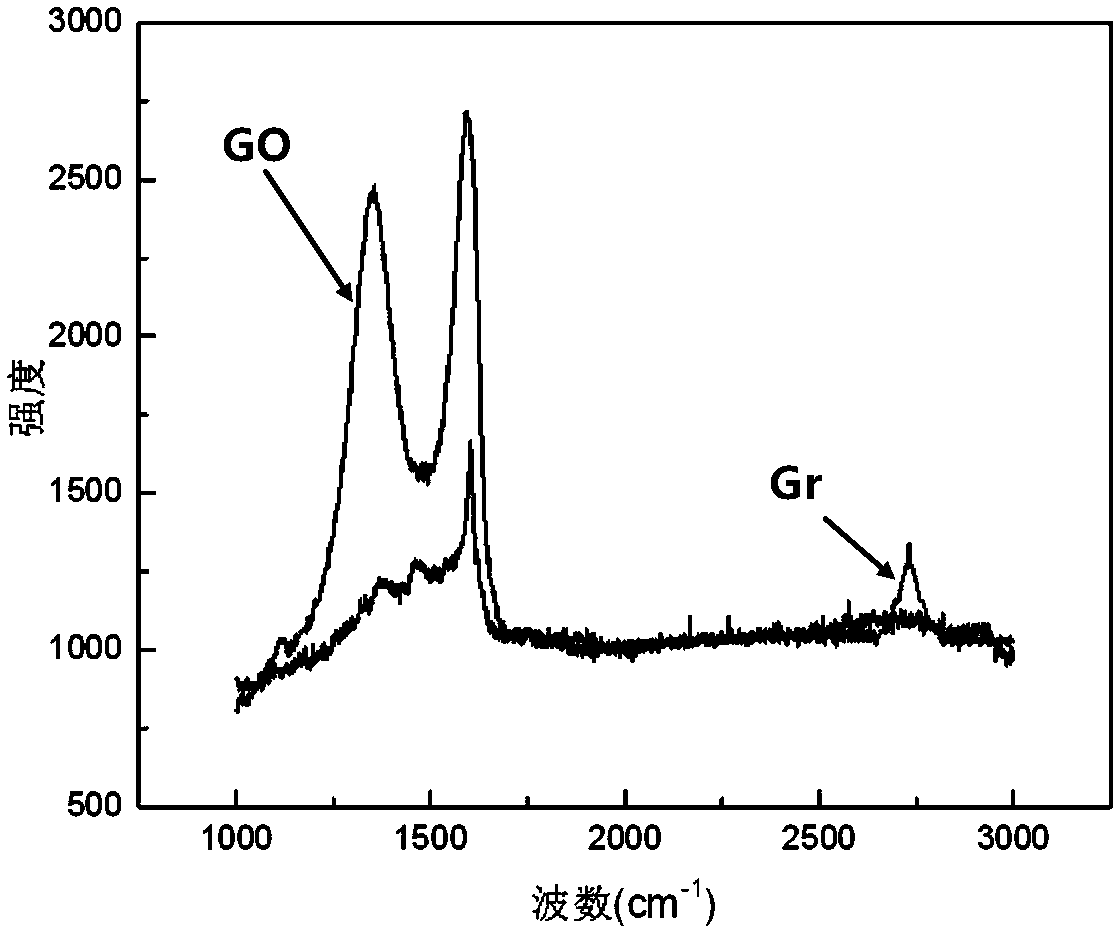

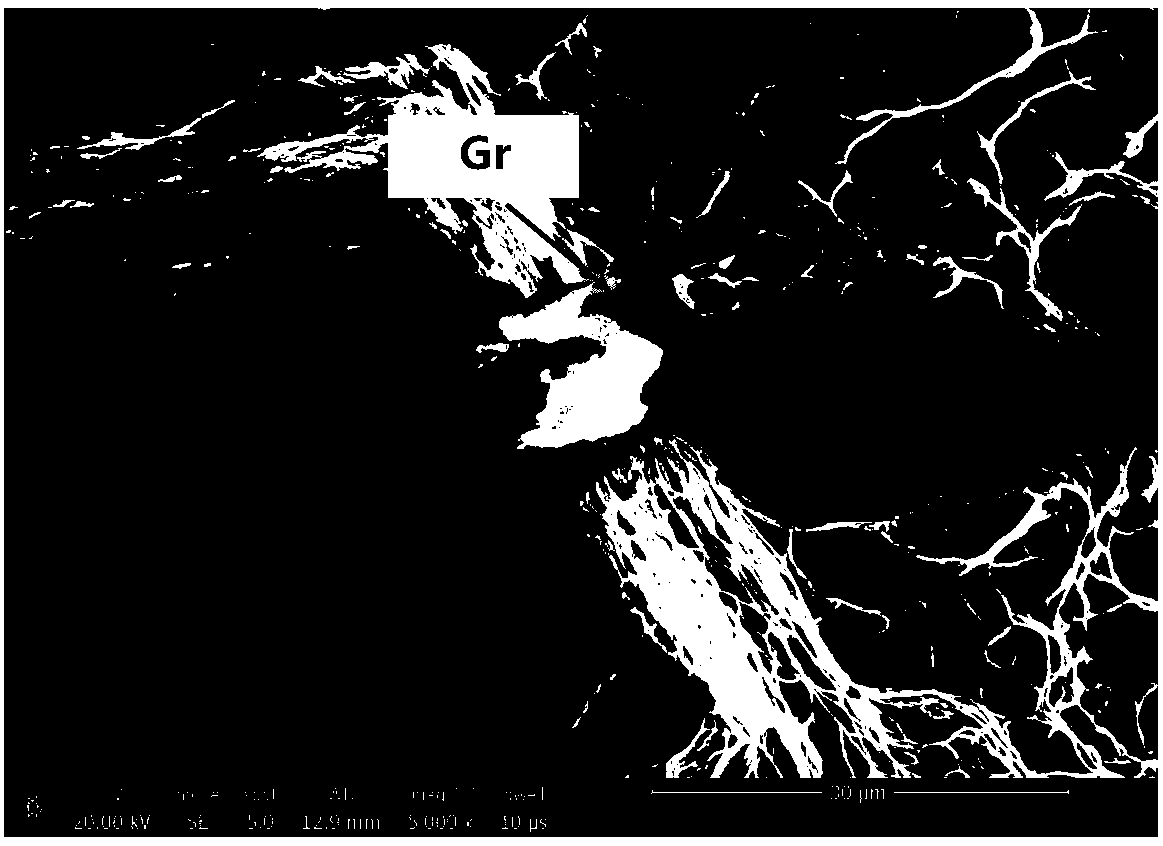

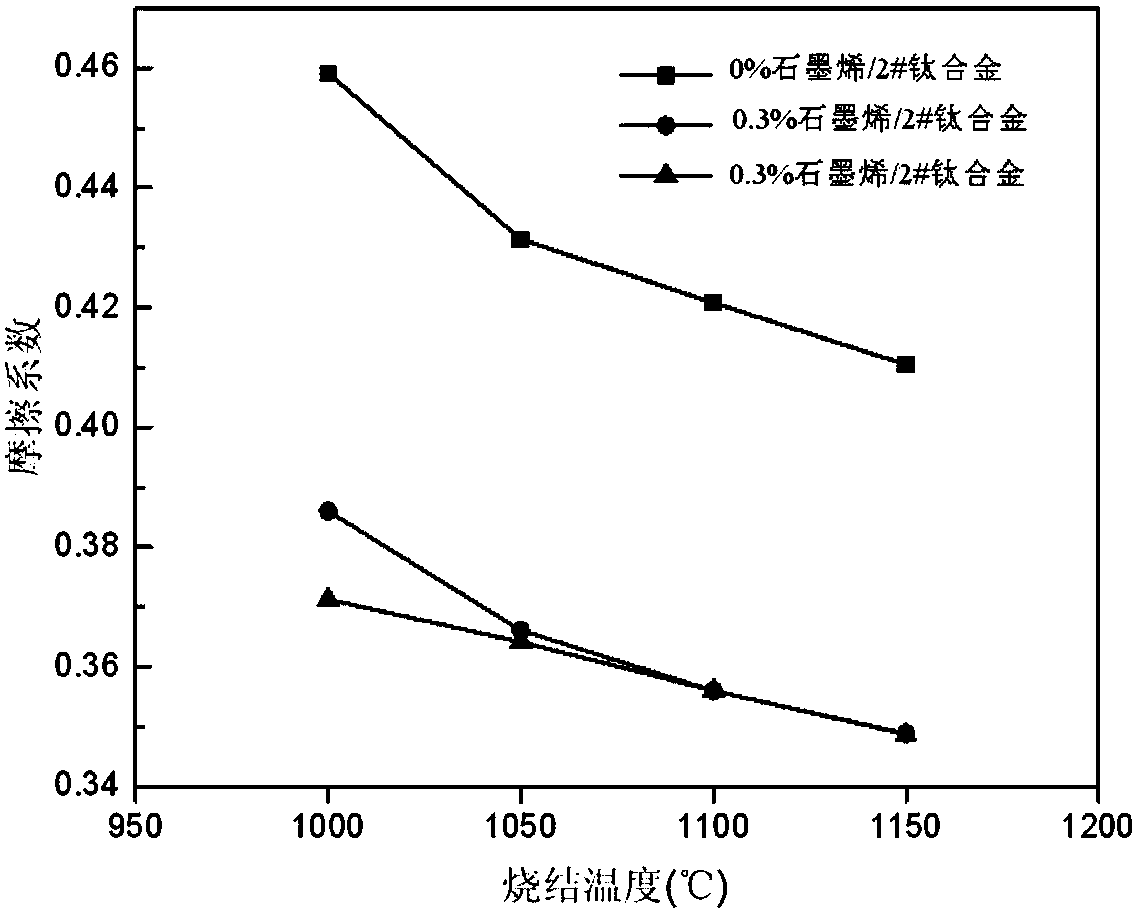

The invention belongs to the technical field of graphene composite materials and relates to a titanium-based nanocomposite material reinforced through graphene and a preparation method, in particularto a graphene-reinforced titanium-based nanocomposite material and a preparation method. Firstly, oxidized graphene nanosheets of 0.01 wt%-1.0 wt% of titanium alloy powder are weighed to be added intoabsolute ethyl alcohol to be stirred and mixed, then disperse treatment is conducted through an ultrasonic cell pulverizer, and an oxidized graphene solution is prepared; then the titanium alloy powder with the alloying element content being larger than 10 wt% and the oxidized graphene solution are stirred and mixed under inert protection, and oxidized graphene and titanium alloy powder compositepowder is obtained; and finally, the composite powder is loaded into a graphite mold to be sintered, through vacuum pumping and sintering forming, oxidized graphene is basically decomposed to form graphene, and therefore the graphene-reinforced titanium-based nanocomposite material with the excellent mechanical property is prepared. In the graphene-reinforced titanium-based nanocomposite material, the graphene is uniformly dispersed, and the preparation method is simple, efficient and suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

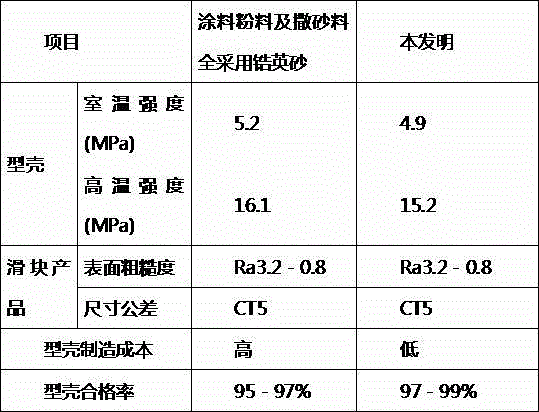

Preparation method of heat-resisting alloy sliding-block shell by investment casting

InactiveCN103600030AImprove room temperature strengthImprove pass rateFoundry mouldsFoundry coresAlloySurface coating

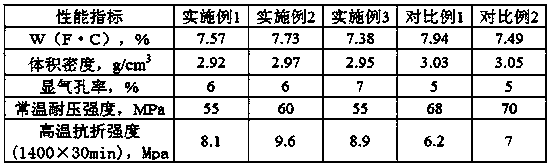

The invention discloses a preparation method of a heat-resisting alloy sliding-block shell by investment casting. The preparation method is characterized in that: the method comprises a first step of preparing coating, wherein surface coating comprises silica sol and a refractory powder material is fused alumina; and transition layer coating and back layer coating comprise the silica sol and a refractory powder material is one selected from the fused quartz, kaolin clinker and bauxite clinker; a second step of coating a wax mould with the surface coating, scattering the sand material of the fused alumina, drying and repeating for 2 times; coating the surface layer with the transistion layer coating, scattering one of the fused quartz, the kaolin clinker and the bauxite clinker, drying, and repeating for 5 times; and finally coating with a back layer coating, scattering one of the fused alumina, the kaolin clinker and the bauxite clinker and drying; and a third step of dewaxing and calcinating; and the shell produced by the method has advantages of high room-temperature strength and high-temperature strength, good internal surface quality, high percent of pass, low production cost and good economic benefit.

Owner:泰州枫叶冶金设备有限公司

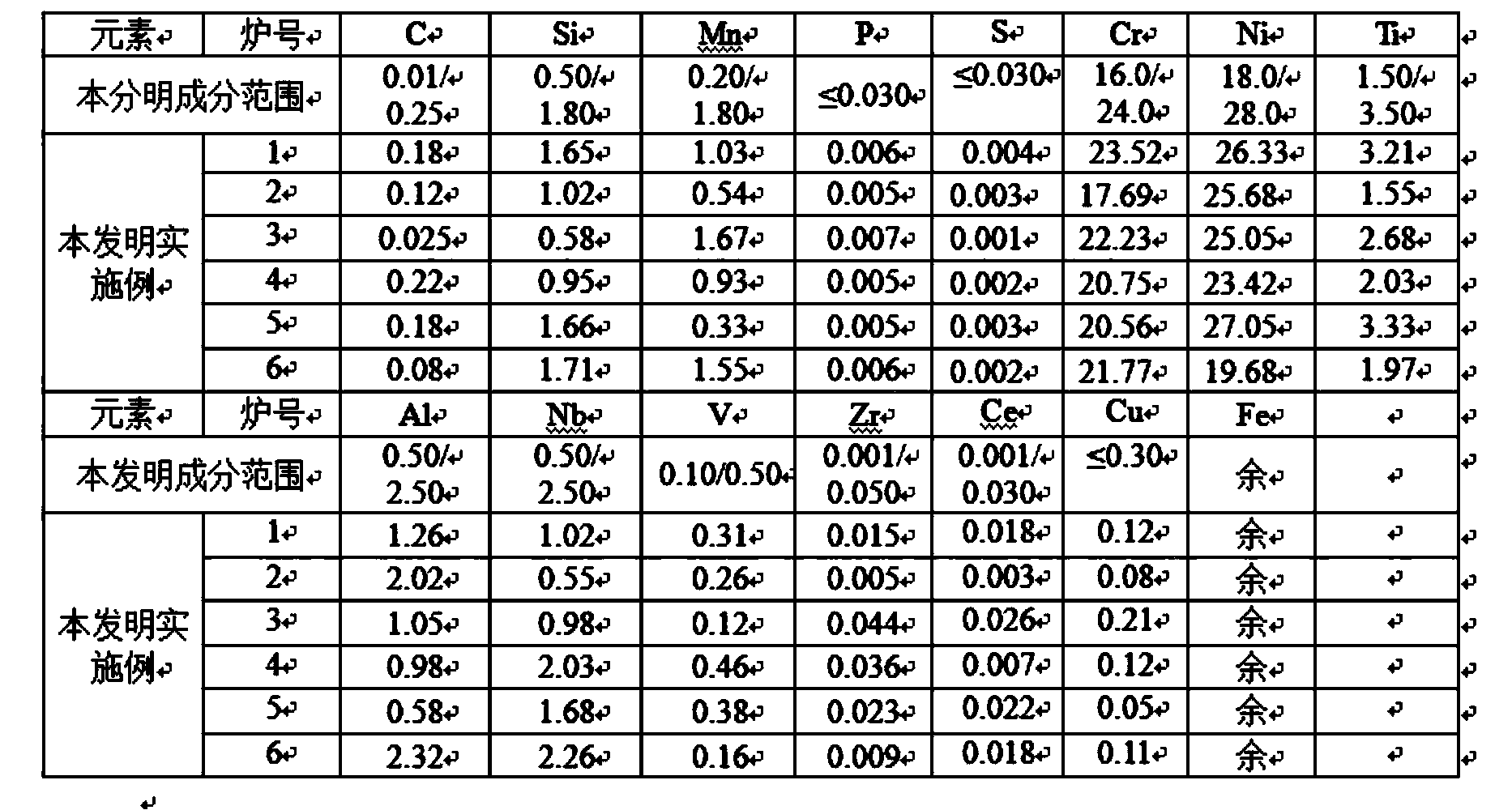

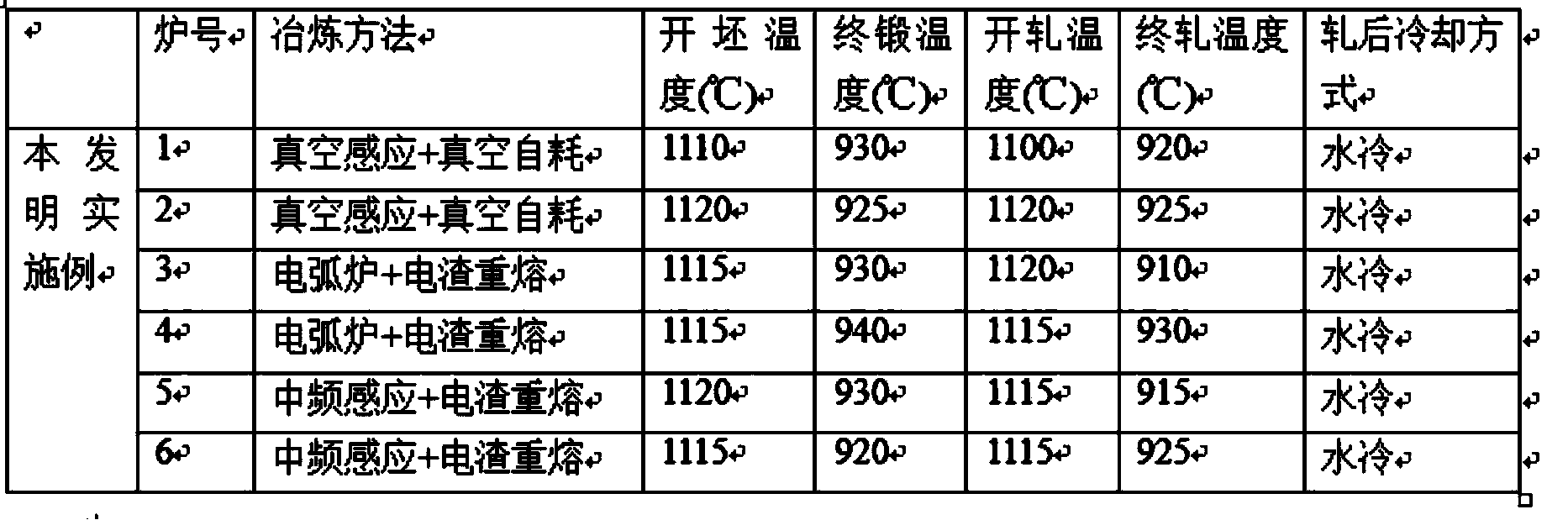

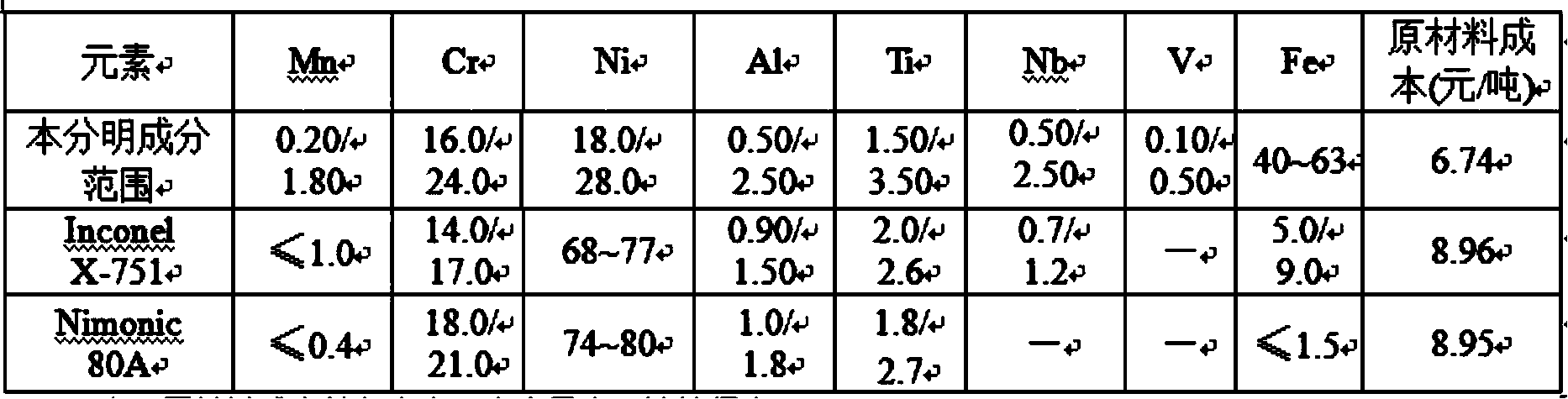

High-strength nickel-saving air valve steel and preparation method thereof

ActiveCN103397276AImprove room temperature strengthNi content decreasedElectric arc furnaceChemical composition

The invention relates to a high-strength nickel-saving air valve steel and a preparation method thereof. The high-strength nickel-saving air valve steel comprises the following chemical components in percentage by weight: 0.01-0.25% of C, 0.5-1.8% of Si, 0.20-1.80% of Mn, at most 0.030% of P, at most 0.030% of S, 16.0-24.0% of Cr, 18.0-28.0% of Ni, 0.5-2.5% of Al, 1.5-3.5% of Ti, 0.5-2.5% of Nb, 0.1-0.5% of V, 0.001-0.050% of Zr, 0.001-0.030% of Ce, at most 0.30% of Cu, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: after carrying out vacuum induction and vacuum self-consuming smelting, or arc furnace smelting+electroslag remelting or intermediate-frequency induction smelting and electroslag remelting smelting, forging to obtain a 140mm*140mm square billet, wherein the hammer cogging temperature of the steel ingot is 1100-1120 DEG C, and the final forging temperature is 920-940 DEG C; rolling, and cooling with water, wherein the hot rolling temperature is 1100-1120 DEG C, and the finishing temperature is 910-930 DEG C; and after rolling, carrying out solid solution treatment, unreeling, straightening, and polishing to form the silver air valve steel. Compared with the existing high-performance air valve alloy, the invention has the advantages of higher strength and low cost.

Owner:CENT IRON & STEEL RES INST

High melting metal liquid die forging paint, producing and using method thereof

InactiveCN101293270AHigh refractorinessImprove insulation performanceFoundry mouldsFoundry coresSodium BentoniteSoluble glass

The invention discloses a high-melting metal liquid die forging coating, a preparation method and a using method thereof, which can effectively solve the problem of short service life of a high-melting metal liquid die forging die. A bottom layer and a surface layer are consists of 100 portions of 200-500 mesh matrix, 100-300 portions of carrier, 2-25 portions of a cementing agent, 0.1-25 portions of suspending agent and 0.01-0.05 portion of foam suppressor. The matrix of the surface layer coating is forsterite or chromite, while the matrix of the bottom layer coating is processed diatomite. The suspending agent is the mixture of sodium bentonite and CMC sodium salt. The cementing agent of the surface layer coating is the mixture of aluminum phosphate and sodium hexametaphosphate, while the cementing agent of the bottom layer coating is the mixture of soluble glass and sodium hexametaphosphate. The components are evenly blended according to the proportion and stand for 3-8 hours to be ready for use. When in use, the bottom layer coating is coated on the surface of a metal die which is preheated to the temperature of 150-300 DEG C; after drying, the surface layer coating is coated on the bottom layer coating, and then liquid die forging is carried out after drying.

Owner:BEIJING JIAOTONG UNIV

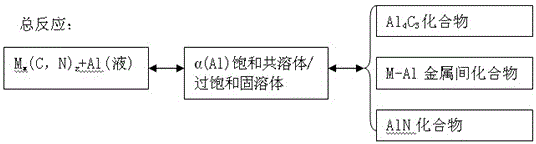

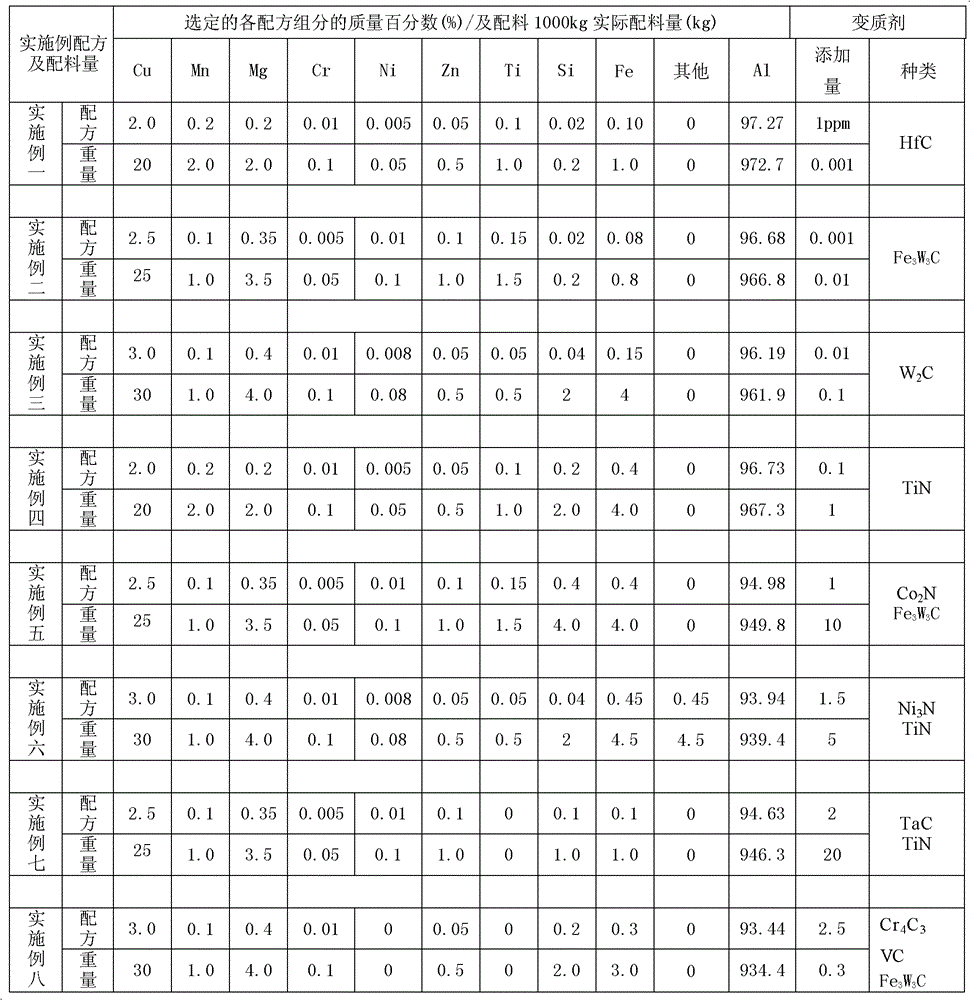

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

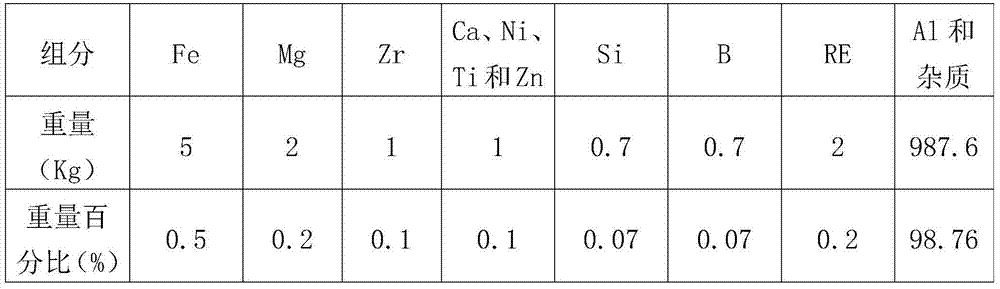

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

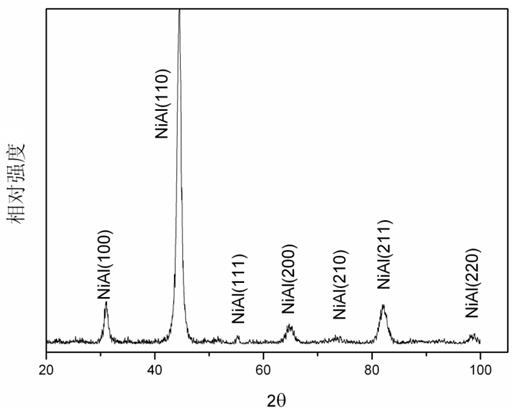

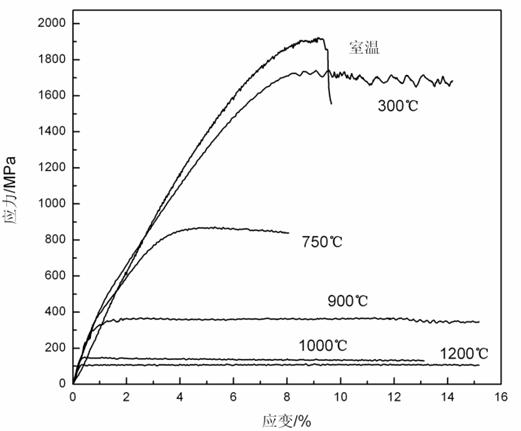

Preparation method of ultrafine grained Ni-Al alloy

InactiveCN101857925AImprove room temperature strengthIncrease room temperature strainRoom temperatureLow density

The invention relates to a preparation method of an alloy, in particular to an ultrafine grained Ni-Al alloy, which solves the problem that the Ni-Al alloy prepared by the prior art has low density and poor mechanical property. The method comprises the steps of: 1. mechanical alloying; and 2. sintering in a vacuum hotpressing way to obtain the ultrafine grained Ni-Al alloy. The prepared ultrafine grained Ni-Al alloy has average crystal grain size of about 400nm and Vickers hardness average value of 450; compared with as-cast state coarse-grained Ni-Al alloy, room temperature strength of the ultrafine grained Ni-Al alloy is improved greatly by about 800 MPa; and meanwhile, the room temperature dependent variable is improved to 9.5% from 5%.

Owner:HARBIN INST OF TECH

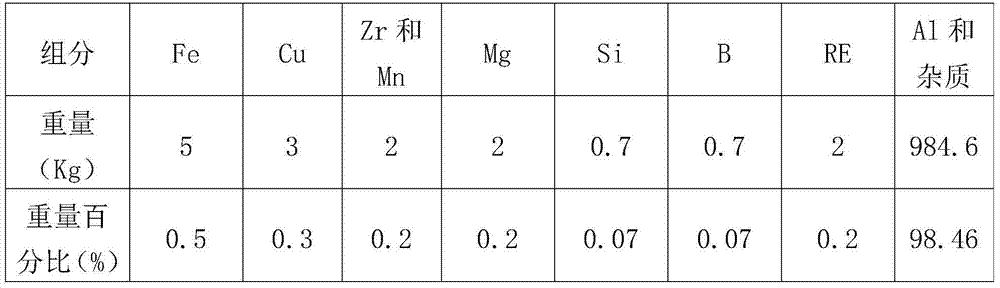

Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, aluminum alloy cable and preparation method of alloy cable

PendingCN104294093AImprove performanceImprove mechanical strength, tensile propertiesMetal/alloy conductorsCable/conductor manufactureCoalOmega

The invention discloses an Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, which comprises 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0-0.1% of Si, 0-0.2% of B, and the balance of Al and impurities, wherein the electrical resistivity of the aluminum alloy is not greater than 0.028264 Omega.mm<2> / m, the elongation at break is not less than 10%, and the number of times of 90-degree fatigue bending is greater than or equal to 30. An aluminum alloy cable is prepared by the steps of melting, casting and rolling the aluminum alloy material so as to obtain an aluminum alloy rod, carrying out drawing, bunch-stranding and softening on the aluminum alloy rod so as to obtain an aluminum alloy cable core, and carrying out extruded insulation, cabling, extruded sheathing or armoring on the cable core; and the prepared aluminum alloy cable has the characteristics of high strength, high electric conductivity, good bending performance and the like, and can satisfy the requirements on the properties of cables in the field of coal mines.

Owner:ANHUI JOY SENSE CABLE

High-performance and high-nitrogen austenitic stainless steel for non-magnetic drill collar and manufacturing method thereof

ActiveCN104264071AAvoid sensitive temperature rangesReduce manufacturing costDrilling rodsDrilling casingsRoom temperatureNon magnetic

The invention provides high-performance and high-nitrogen austenitic stainless steel for a non-magnetic drill collar and a manufacturing method thereof, and belongs to the technical field of stainless steel. The stainless steel comprises components in percentage by weight as follows: larger than or equal to 21.5% and smaller than or equal to 22.5% of Cr, larger than or equal to 0.5% and smaller than or equal to 1.5% of Mo, smaller than or equal to 0.040% of C, larger than or equal to 0.65% and smaller than or equal to 0.75% of N, larger than or equal to 0.40% and smaller than or equal to 0.50% of Nb, larger than or equal to 1.95% and smaller than or equal to 2.05% of Ni, larger than or equal to 16.0% and smaller than or equal to 17.0% of Mn, smaller than or equal to 0.20% of Si, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S and the balance of Fe, wherein the sum of weight percentage of Cr, a product obtained by multiplying the weight percentage of Mo by 3.3 and a product obtained by multiplying the weight percentage of N by 16.0 is larger than or equal to 33.0%. The manufacturing method of the high-performance and high-nitrogen austenitic stainless steel comprises the steps as follows: smelting by an electric furnace, argon oxygen decarburization for secondary refining, electroslag remelting, cogging by a fast forging machine, forming by a radial forging machine and water cooling treatment. The high-performance and high-nitrogen austenitic stainless steel for the non-magnetic drill collar has the advantages of good room-temperature strength as well as excellent spot corrosion resistance and intercrystalline corrosion resistance.

Owner:CENT IRON & STEEL RES INST

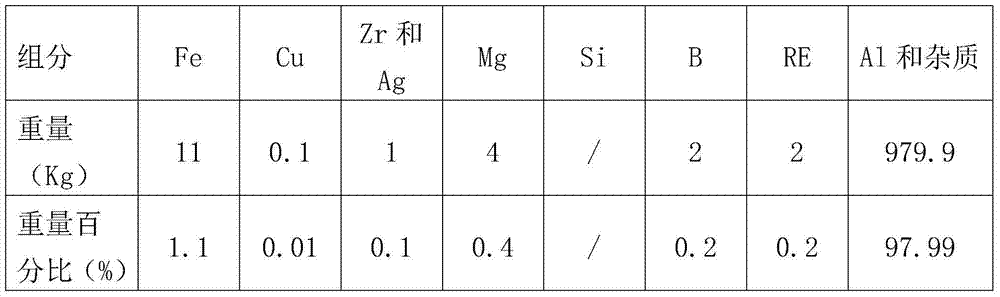

High strength and toughness rare earth magnesium alloy

The invention belongs to the magnesium alloy material field and particularly relates to a high strength and toughness rare earth magnesium alloy. The invention solves the defects of low strength and plasticity of the Mg-Al base alloy which is widely used now. The alloy comprises the following elemental compositions by weight percent: 3-9% of Al, 0.2-0.6% of Zn, 0.1-0.5% of Mn, 0.05-1.0% of Ce, 0.05-1.0% of La, 0.1-3.0% of Y, 0.1-2.0% of Er, 0.1-2.0% of Ho, 0.004% or less of impurity element Fe, 0.002% or less of impurity element Cu, 0.02% or less of impurity element Si, 0.001% or less of impurity element Ni and the balance Mg. Through combined action of the elements and proper homogenizing treatment, the comprehensive performance of the alloy is significantly improved.

Owner:TAIYUAN HUA YIN TAI ALLOY

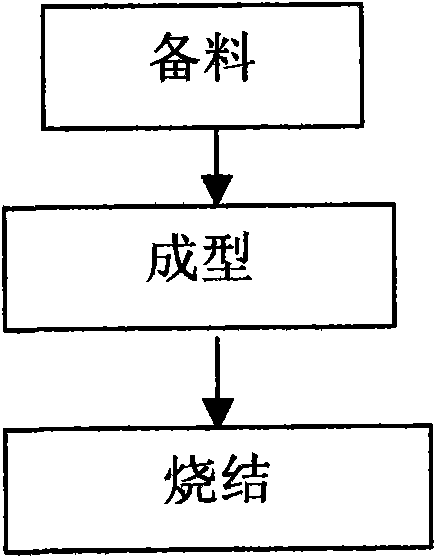

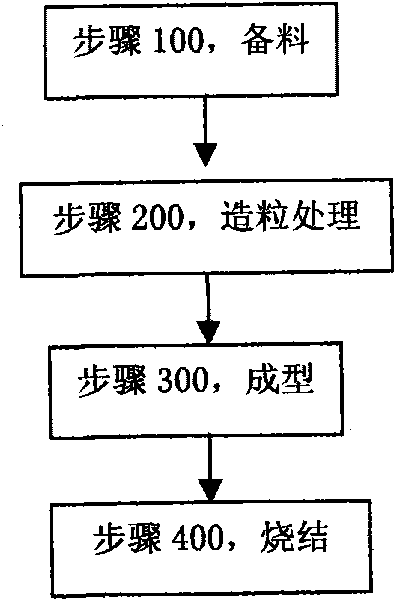

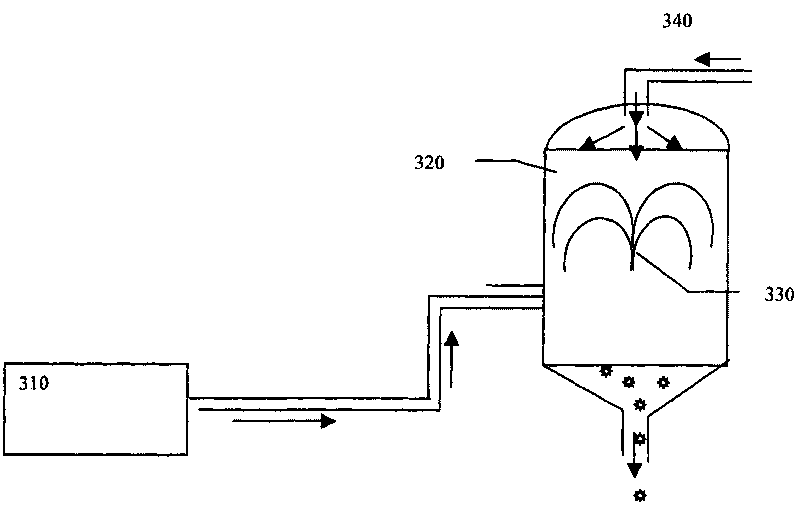

Manufacturing method of straight-bore ceramic filter and manufacturing system thereof

ActiveCN101745972AImprove yieldImprove room temperature strengthGranulation by liquid drop formationCeramic shaping apparatusPelletizingFilling Up Quickly

The invention relates to a manufacturing method of a straight-bore ceramic filter and a manufacturing system thereof. The method comprises the following steps: a) raw material preparing: evenly mixing raw materials and adding water to mix into raw material stuff; b) granulation process: granulating the raw material stuff to obtain powder lot; c) molding: mold pressing the powder lot into needed shapes to obtain a straight-bore ceramic filter green body; d) and sintering: sintering the straight-bore ceramic filter green body into a finished product at high temperature, wherein the raw material granulation process adopts a pressure spraying granulation method or a centrifugal granulation method. The method improves the fluidity of the raw material by the granulation process for the raw material, ensures the raw material to rapidly fill a die cavity of a die in dry press, and therefore improves the accuracy and yield of the straight-bore filter.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

High-strength electric-control solid propellant

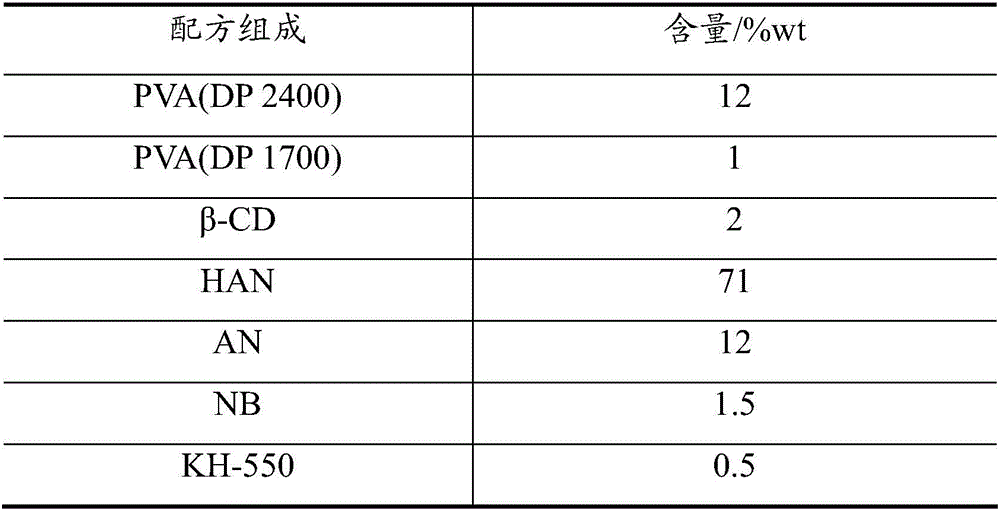

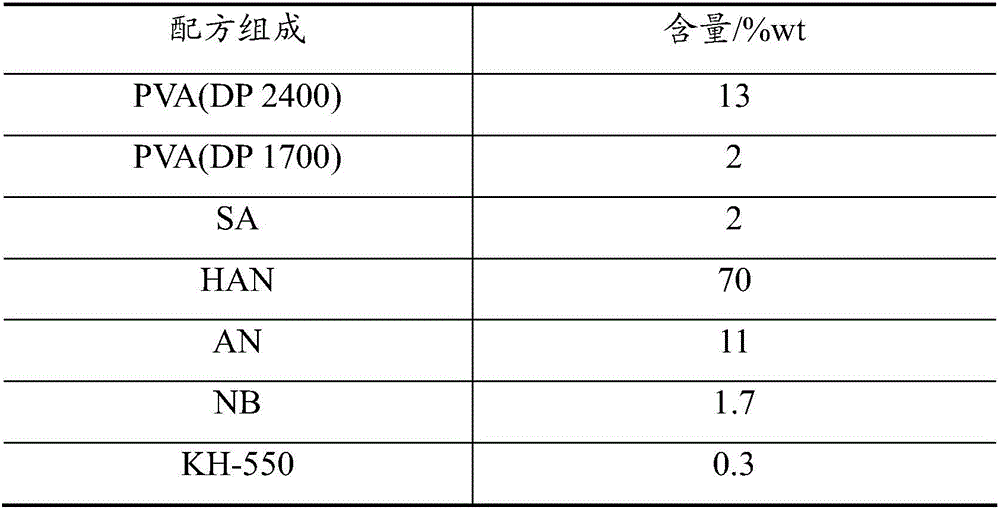

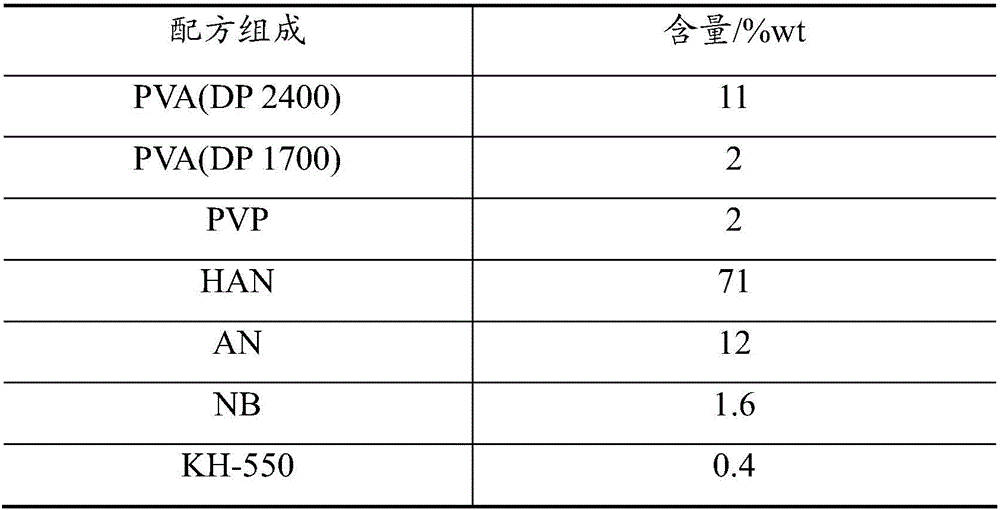

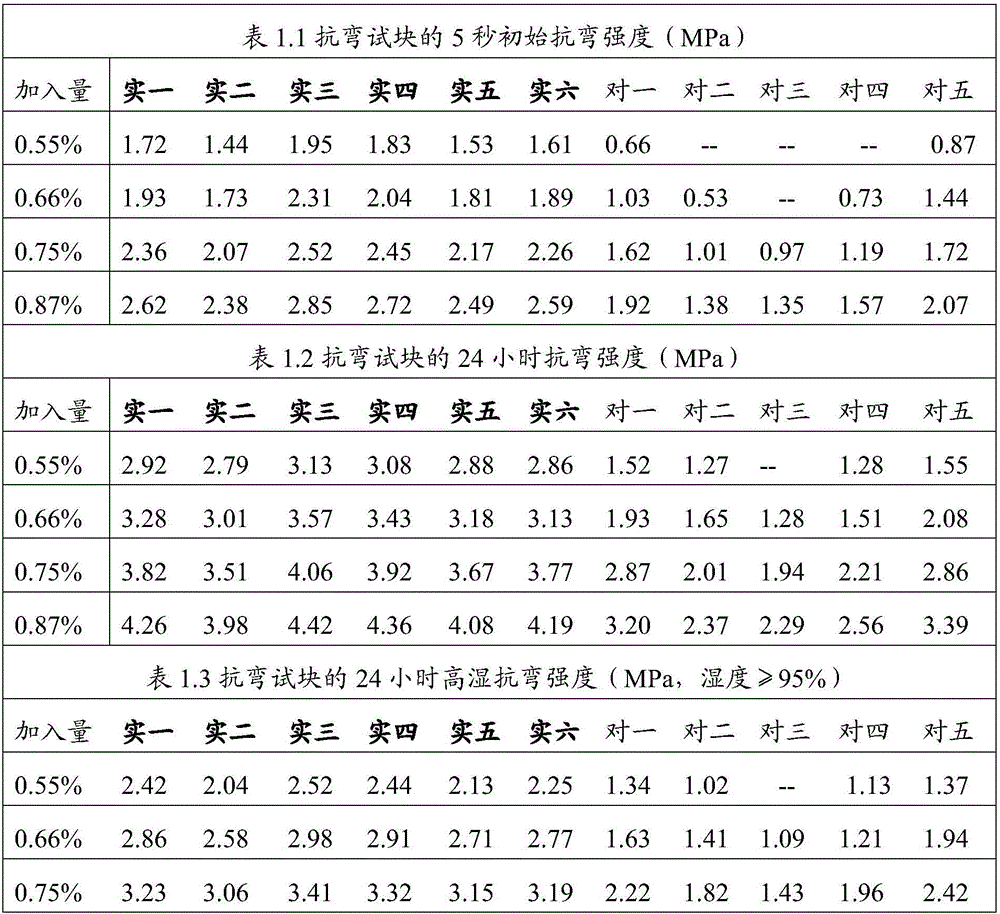

InactiveCN106365935AImproved viscosity and degree of crystallizationConducive to process performance and mechanical propertiesPressure gas generationChemistryWater soluble

The invention relates to a high-strength electric-control solid propellant which comprises the following components in percentage by mass: 10-20% of adhesive, 60-80% of main oxidizer, 5-20% of auxiliary oxidizer, 1-2% of crosslinking agent, 0.1-0.5% of coupling agent and 1-5% of fuel additive. The adhesive is water-soluble polyvinyl alcohol (PVA); the main oxidizer is hydroxylammonium nitrate (HAN); the auxiliary oxidizer is one or combination of ammonium nitrate (AN) and ammonium perchlorate (AP); the crosslinking agent is one or combination of boric acid and borax; the coupling agent is a silane coupling agent; and the fuel additive is one or combination of cyclodextrin, sodium alginate, polyvinylpyrrolidone (PVP) and gelatin. The normal-temperature tensile strength of the electric-control solid propellant can be obviously enhanced, and the maximum normal-temperature strength can reach 8 MPa or above. The electric-control solid propellant is suitable to be used as an attitude control or orbit control propellant with higher requirements for normal-temperature strength.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

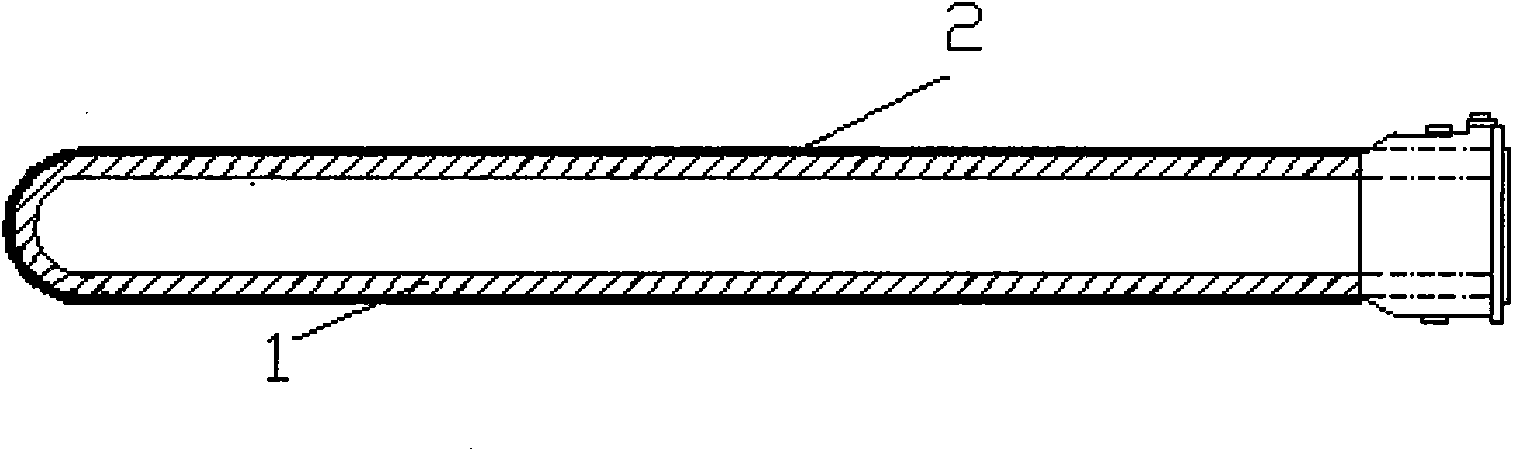

Aluminium-carbon water gap for continuous casting

InactiveCN1927507AReduce consumptionReduce pollutionMolten metal conveying equipmentsSpecific gravityWater gap

The invention relates to an aluminum carbon water open used in casting. Wherein, it uses baked bauxite chamotte powder to replace electro-melting corundum, to be mixed, shaped and sintered by other material. And the bauxite chamotte has abundant resource and low cost, therefore, the invention can reduce 36 million yuan / year. And the strength at normal temperature, the anti-bend strength at high temperature and the vibration resistance of water open are all improved. Since the specific weight of bauxite chamotte is lower than electro-melting corundum, it can reduce 1% weight.

Owner:山东耐材集团中齐耐火有限公司

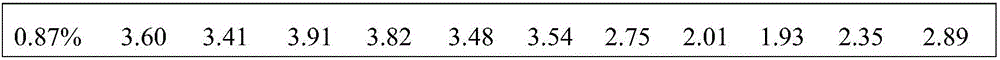

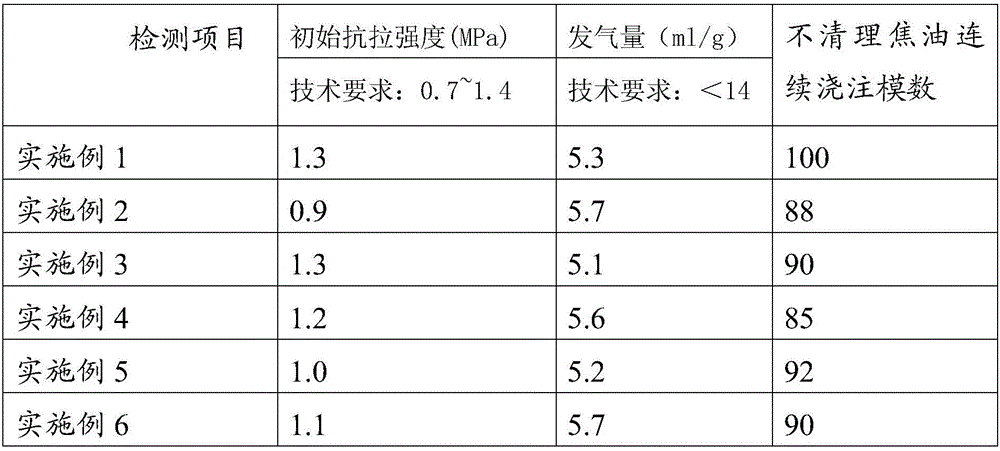

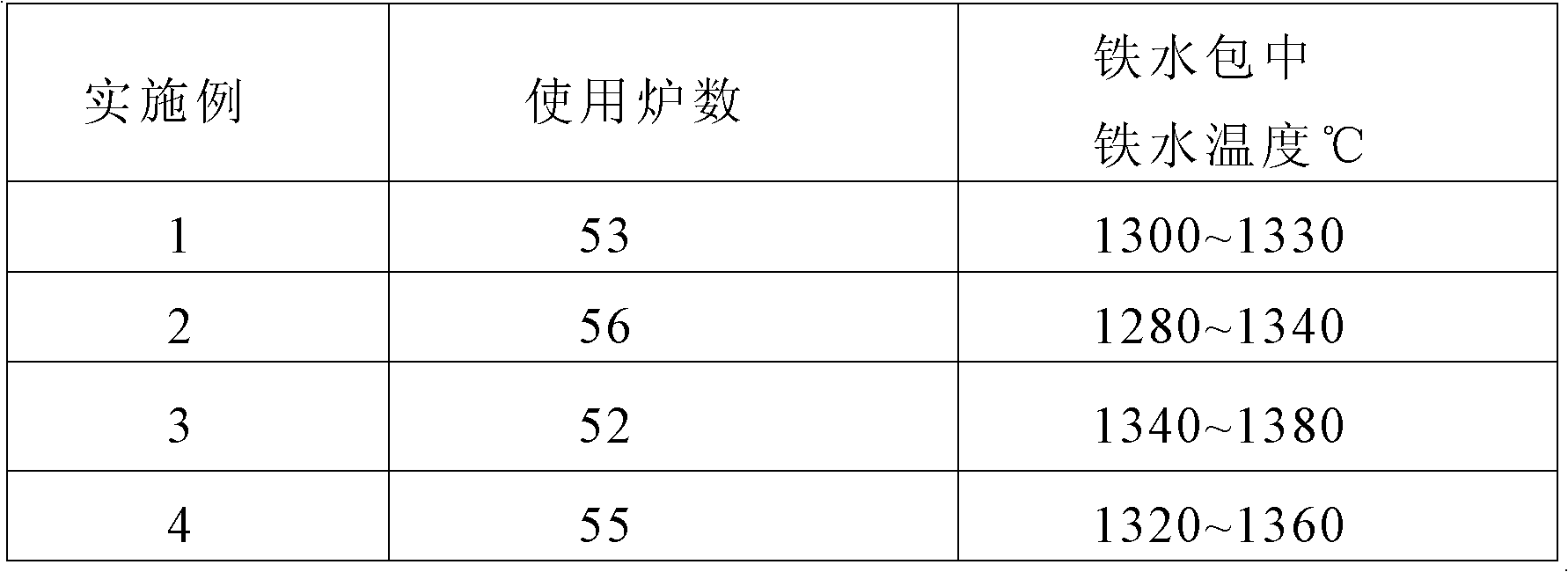

Cold core box binder and casting molding body

ActiveCN106040966AImprove room temperature performanceImprove room temperature strengthFoundry mouldsFoundry coresTarHydrocarbon solvents

The invention discloses a cold core box binder and a casting molding body and belongs to the technical field of binders. The cold core box binder comprises a first component. The first component is composed of, by weight, 40-80 parts of benzyl ether phenolic resin, 1-50 parts of high-boiling-point ester and / or hydrocarbon solvents and 0.1-10 parts of tackifying auxiliaries, wherein the content of hydroxymethyl of the benzyl ether phenolic resin is 32%-50%. According to the cold core box binder, the resin using amount is decreased to 0.55%-0.75% under the condition that the strength of a resin sand mold core is ensured; compared with the prior art, the resin using amount is greatly decreased, and the collapsibility of the resin sand mold core is greatly improved; and meanwhile, the residual quantity of tar on a metal mold is decreased, and the production efficiency is improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Corundum ladle seat brick casting material

The invention relates to corundum ladle brick cup casting material which can effectively deal with the problems of poor product consistency and environmental pollution. The invention has the technical proposal to take compact electro-melting corundum as the main skeletal material; corundum powder, Alpha-alumina powder, electrofusion spinel powder, oxidized chrome green powder and silicon fine powder as the substrate material; and alumina cement as the wedding agent. All materials are mixed evenly and then added with the additives. The ingredients have the proportions by weight: the compact electro-melting corundum of 60-70 percent, the corundum powder of 5-10 percent, the Alpha-alumina powder of 5-10 percent, the electrofusion spinel powder of 5-15 percent, the oxidized chrome green powder of 0.01-3percent, the silicon fine powder of 0.01-5 percent and the alumina cement of 0.01-5 percent. The above ingredients with a sum of 100 percent are mixed into the admixture and then added with 0.1-1.0 percent by weight of the metal powder and the organic fiber, and the added amount equals to 0.01-0.5 percent by weight of the admixture. The water capacity in the construction agitation is 4-7 percent of the total weight of the materials. The construction can be done on spot, thereby being flexile, swift and environment-friendly, and the service life is quite long.

Owner:郑州荣达工矿集团有限公司

Castable for ladle deslagging plate, and preparation method and applicable of castable

The invention discloses a castable for a ladle deslagging plate, and a preparation method and an applicable of the castable. The castable for the ladle deslagging plate comprises the following components in parts by weight: 50-70 parts of mullite, 10-20 parts of andalusite, 10-20 parts of bauxite powder, 3-5 parts of pure calcium aluminate cement, 4-6 parts of aluminum oxide micropowder, 3-5 parts of silicon carbide micropowder and 2-3 parts of compound additive, wherein the compound additive is a combination of two or more of organic fiber, steel fiber, and sodium tripolyphosphate or sodium hexametaphosphate. When the castable is cast on the outer surface of the ladle deslagging plate, the service life of the ladle deslagging plate can be prolonged and the preparation cost can be reduced; and the preparation method of the castable for the ladle deslagging plate is simple, and easy to operate.

Owner:WUGANG REFRACTORY CO LTD

Lost foam steel-casting paint formula and technology method thereof

InactiveCN103357813AImprove breathabilityImprove thixotropyFoundry mouldsFoundry coresLithiumEmulsion

The invention discloses a paint formula, particularly discloses a lost foam steel-casting paint formula and a technology method thereof. The lost foam steel-casting paint formula comprises the following components: 40-60% of bauxite, 30-50% of zirconium sand powder, 1-3% of phenolic resin, 1-5% of white emulsion, 1-5% of silica sol, 1-5% of lithium bentonite, 0.1-0.5% of isopropanol, 0.5-2% of CMC and 0.1-0.5% of JFC. The technology method of the lost foam steel-casting paint formula comprises the following steps: 1, in the ratio of paint powder to water of 1:0.7, putting the paint powder and the water into a stirrer for stirring for 1-1.5 hours, then measuring baume degree, and controlling the baume degree between 65 and 70 through dilution with water; 2, according to production requirements, dip-coating for two times or three times; and 3, the thickness of a coating layer being 1-2 mm. White molds of the paint formula have good wettability, good coating and hanging properties, high strength and good air permeability.

Owner:翼城县福旺铸造实业有限公司

Silicon-sol adhesive and preparing method

InactiveCN1438082AImprove room temperature strengthShorten drying timeFoundry mouldsFoundry coresInvestment castingAdhesive

The present invention discloses a silicon sol adhesive modified by using high polymer and its preparation method. Its composition comprises alkaline silicon sol containing 20-30%, SiO2 and PVA whose content is less than [(32-100XSiO2%) / 320]X100%. Its preparation method includes: a. preparing PVA aqueous solution; b. preparing alkaline silicon sol solution; and c. mixing said two solution uniformly, in which after the alkaline silicon sol solution is prepared or after the two solutions are mixed uniformly its pH value must be regulated. Said silicon sol adhesive can accelerate drying speed when it is used in investment casting industry, and can raise the normal temp. strength of pattern shell in the investment casting, and can reduce retained strength.

Owner:ZHEJIANG YUDA CHEM IND

Formula and technique of full-mould casting coating

InactiveCN103394631ANo brush marksImprove thixotropyFoundry mouldsFoundry coresCrack resistancePolyvinyl alcohol

The invention discloses a coating formula and particularly discloses a formula and technique of a full-mould casting coating. The formula of the full-mould casting coating contains 30-40% of bauxite, 40-50% of quartz powder, 10-20% of flake graphite, 1-3% of lithium-based bentonite, 0.5-1.5% of phenolic resin and 2-4.5% of polyvinyl butyral. The technique of the full-mould casting coating comprises the following steps of: according to different products to be painted, diluting the full-mould casting coating to the required viscosity, density or baume degree by adopting industrial alcohol, and fully and uniformly stirring before the full-mould casting coating is used, and painting a casting once or twice. The full-mould casting coating is better in suspension stability, low in gas evolution and high in crack resistance.

Owner:翼城县福旺铸造实业有限公司

Glaze-crawling-proof protection coating for immersion type water gap slag line and preparation method of glaze-crawling-proof protection coating

The invention discloses a glaze-crawling-proof protection coating for an immersion type water gap slag line and a preparation method of the glaze-crawling-proof protection coating. The coating is prepared from a main material, water and dextrin; the main material is prepared from the following components in percentage by weight: 62 percent to 66 percent of tabular corundum, 15 percent to 17 percent of Suzhou clay, 3 percent to 5 percent of bentonite, 12 percent to 16 percent of active aluminum oxide and 0.5 percent to 1 percent of sodium silicate; the weight ratio of the water to the dextrin to the main material is (31 to 33):(0.6 to 0.8):100. The glaze-crawling-proof protection coating disclosed by the invention can be used for effectively preventing an anti-oxidization coating of the immersion type water gap slag line part from generating glaze crawling, so that the strength and anti-corrosion performance of the immersion type water gap slag line are improved, and the service life of an immersion type water gap can be prolonged for 2.5 hours to 3.5 hours.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

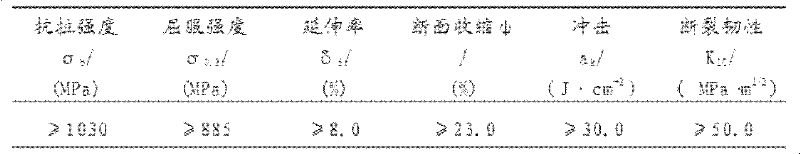

A kind of heat-strength damage-tolerant titanium alloy and preparation method thereof

ActiveCN102260806AImprove fracture toughnessImprove room temperature strengthDamage toleranceTitanium

The invention discloses a heat-strength damage-tolerant titanium alloy and a preparation method thereof. According to the mass percentage, the alloy contains the following components: 5.8-7.2% Al; 2.8-3.8% Mo; 1.6-2.5% Nb; 1.6% -2.5Sn; 1.6-2.5% Zr; 0.15-0.25% Si; the rest is Ti. The alloy preparation method includes: batching and electrode pressing, electrode preparation, preparation of primary ingot, preparation of secondary ingot, preparation of casting ingot, and finally the casting ingot is required to be cooled to below 200°C after smelting is completed. The high-temperature strength and fracture toughness of the parts produced by the titanium alloy obtained by the preparation method of the present invention are significantly higher than those of the currently used TC11 heat-strength titanium alloy at 350° C. to 550° C. TC11 heat-strength titanium alloy is in an order of magnitude, and has higher room temperature strength and better hot-working processability. These properties broaden the application range of the titanium alloy and its parts in aero-engines, improve the use efficiency, reduce the cost, and have good application prospects.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

Magnesium smelting reduction pot and preparation method thereof

InactiveCN101805833APrevent oxidationImprove high temperature resistanceFoundry mouldsFoundry coresPOWDERED CELLULOSEEmulsion

The invention relates to a magnesium smelting reduction pot and a preparation method thereof, which belong to the technical field of metal smelting. The magnesium smelting reduction pot comprises a pot body and an external application coating layer, and is characterized in that: the pot body comprises the following components in percentage by weight: 0.2 to 0.4 percent of C, 1.0 to 2.0 percent of Mn, 0.6 to 2.0 percent of Si, 24.0 to 26.0 percent of Cr, 6.0 to 8.0 percent of Ni, 0.015 to 0.05 percent of Ti, 0.03 to 0.10 percent of Re, and the balance of iron; and the external application coating layer comprises the following components in percentage by weight: 47.9 to 74.1 percent of zircon powder or graphite with the particle size of 200 to 270 meshes, 1.5 to 3.8 percent of bentonite, 1.5 to 2.9 percent of powdered cellulose (carboxymethylcellulose sodium), 0.7 to 2.4 percent of white latex (polyvinyl acetate emulsion), and 22.2 to 43.0 percent of ethanol. All types of the components of the pot body are put into an intermediate frequency furnace and are melted for pouring, and are brushed with a coating according to the component proportion after being cooled. Starting from each process step of preparing the magnesium smelting reduction pot, the components of materials of the reduction pot, a melting process and a centrifugal casting process are optimized and adjusted, and a high-temperature resistant coating is brushed on the surface of the reduction pot to effectively promote the oxidation resistance of the reduction pot at a high temperature, so the service life of the pot body is prolonged.

Owner:BAOTOU BINGKE SILICON MAGNESIUM MATERIAL ENG TECH RES CENT

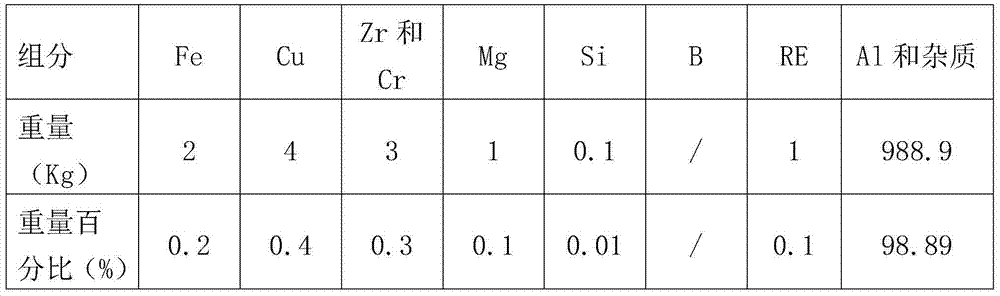

Al-Fe-Mg-Zr aluminum alloy used for coal mine cables, aluminum alloy cable and manufacturing method

PendingCN104299673AImprove performanceHigh mechanical strengthNon-insulated conductorsMetal/alloy conductorsCoalAluminium alloy

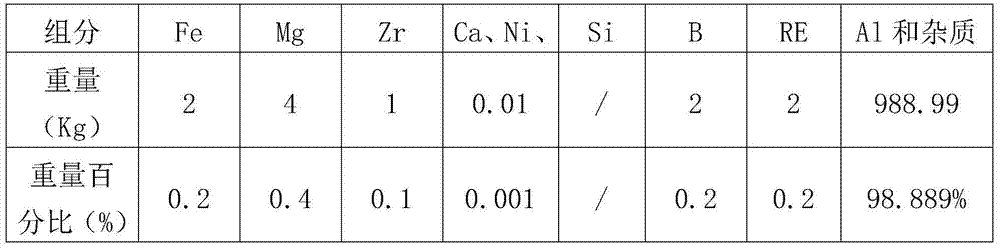

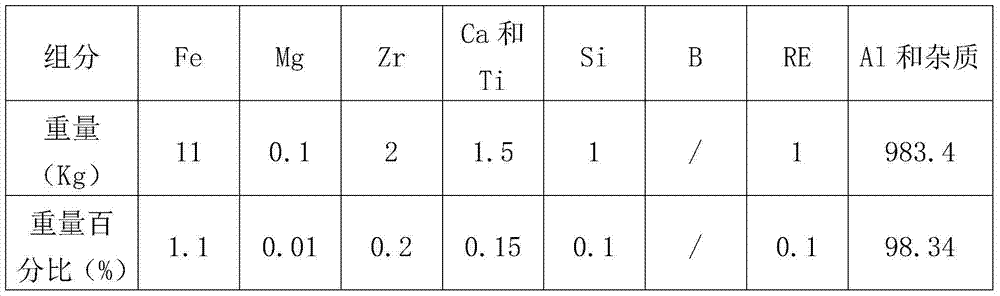

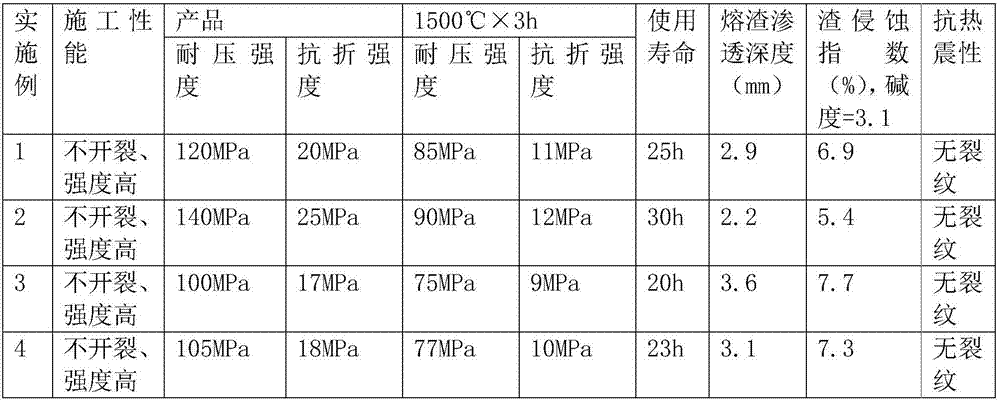

The invention discloses Al-Fe-Mg-Zr aluminum alloy used for coal mine cables. The Al-Fe-Mg-Zr aluminum alloy comprises 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.2 percent of Zr, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities, wherein the resistivity of the aluminum alloy is not larger than 0.028164 omega*mm<2> / m, the elongation at break is not lower than 10 percent, and ninety-degree fatigue bending frequency is larger than or equal to thirty. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that an aluminum alloy cable is manufactured. The manufactured aluminum alloy cable has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like, and therefore the requirements for cable performance in the field of coal mines can be satisfied.

Owner:ANHUI JOY SENSE CABLE

Universal siliceous castable

ActiveCN105000896AImprove room temperature strengthImprove sintering performanceBrickPortland cement

The invention discloses universal siliceous castable prepared from raw materials including waste silica bricks, quartz powder, silicon dioxide micro powder, Portland cement, high-alumina cement and efficient water reducing agents according to a certain ratio. Waste silica brick particles are used as skeletal materials of the siliceous castable. Main mineral phases of a construction body where pouring is conducted include the tridymite phase and the cristobalite phase. Cracking or stripping caused by large crystal transfer can not be generated. The silicon dioxide micro powder which is used as reinforcing agents and agglomerant as well is used, and therefore the normal temperature strength is improved, and the high temperature sintering performance is improved as well. The Portland cement is adopted as a binding agent, and conversion of residual quartz into tridymite and cristobalite can be promoted under the high temperature. The castable can be directly used under the high temperature after being constructed, the use performance is close to the performance of silica bricks, the overall performance of the castable is superior to that of a construction body spliced and built by small bricks, large-size siliceous cast-in-place construction bodies or prefabricated pieces good in overall performance can be manufactured, and great breakthrough is achieved on the aspect of siliceous castable.

Owner:郑州市科源耐火材料有限公司

Magnesia castable and production process of slag baffling component for tundish

The invention discloses a magnesia castable and a production process of a slag baffling component for a tundish. The magnesia castable comprises the following raw materials in parts by weight: 70-95 parts of magnesia consisting of magnesia aggregate and magnesia fine powder, 4-15 parts of silica, 5-30 parts of waste magnesia-chrome brick consisting of waste magnesia-chrome brick aggregate and waste magnesia-chrome brick fine powder, 2-10 parts of silicon dioxide micropowder, 0.1-0.5 part of a composite additive, 0.01-0.1 part of organic fiber and 0.1-1 part of steel fiber. The slag baffling component for the tundish, which is produced from the magnesia castable provided by the invention, is long in service life, resistant to molten steel erosion, resistant to slag erosion and good in anti-peeling performance.

Owner:PUYANG REFRACTORIES GRP CO LTD

Al2O3-SiC-C refractory brick for torpedo ladle produced by utilizing waste Al2O3-C and preparation method of Al2O3-SiC-C refractory brick

InactiveCN107555970AExtended service lifeHigh degree of densificationMelt-holding vesselsBrickMaterials science

The invention belongs to the field of refractory matters for ferrous metallurgy and in particular relates to an Al2O3-SiC-C refractory brick for a torpedo ladle produced by utilizing a waste Al2O3-C material and a preparation method of the Al2O3-SiC-C refractory brick. The Al2O3-SiC-C refractory brick comprises the following raw materials in percentage by weight: 10-40% of special grade bauxite clinker particles with the particle size of 3-5mm, 10-30% of special grade bauxite clinker particles with the particle size of 1-3mm, 5-20% of alundum particles with the particle size of 0.088-1mm, 5-20% of corundum fine powder with the particle size of less than 0.088mm, 2-8% of silicon carbon particulates with the particle size of 0.088-1mm, 2-8% of silicon carbon fine powder with the particle size of less than 0.088mm, 10-25% of waste Al2O3-C material fine powder with the particle size of less than 0.088mm, 5-15% of alumina micro powder with the particle size of less than 0.088mm, 3-10% of binding clay fine powder with the particle size of less than 0.088mm, 1-10% of crystalline flake graphite powder with the particle size of less than 0.088mm, 0.5-5% of asphalt powder with the particle size of less than 0.088mm, and 4-8% of additional phenolic resin.

Owner:UNIV OF SCI & TECH LIAONING

Novel powder high-temperature alloy and preparing method thereof

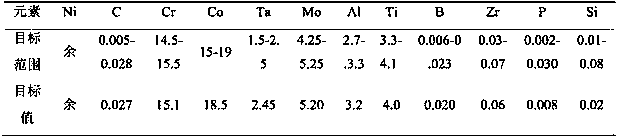

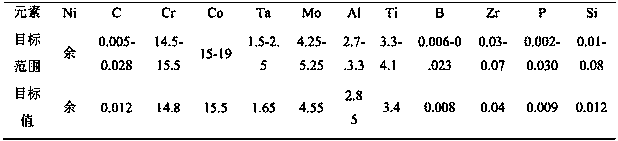

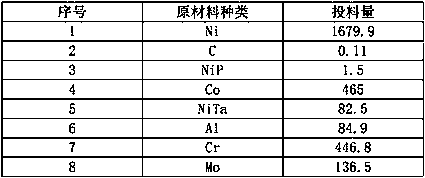

The invention relates to novel powder high-temperature alloy and preparing method thereof. The novel powder high-temperature alloy comprises, by weight percent, 14.00 to 15.00% of Cr, 14.50 to 19.50%of Co, 4.5 to 5.5% of Mo, 3.25 to 4.10% of Ti, 2.50 to 3.10% of Al, 1.45 to 2.50% of Ta, 0.55 to 1.55% of Hf, 0.045 to 0.068% of Zr, 0.005 to 0.030% of C, 0.006 to 0.023% of B, 0.002 to 0.030% of P, 0.01 to 2.0% of Re, 0.1 to 2.0% of W, 0.1 to 1.0% of Nb, smaller than 0.5% of Y, smaller than 0.3% of V, smaller than 0.5% of Fe, smaller than 0.15% of Si, smaller than 0.12% of Mn, and the balance Ni.The gamma' phase content in the l powder high-temperature alloy is about 40 to 50%. The novel powder high-temperature alloy prepared through the preparing method has the good room temperature strength, high temperature strength and high temperature creep properties, and the use temperature is up to 750 DEG C.

Owner:西部超导材料科技股份有限公司

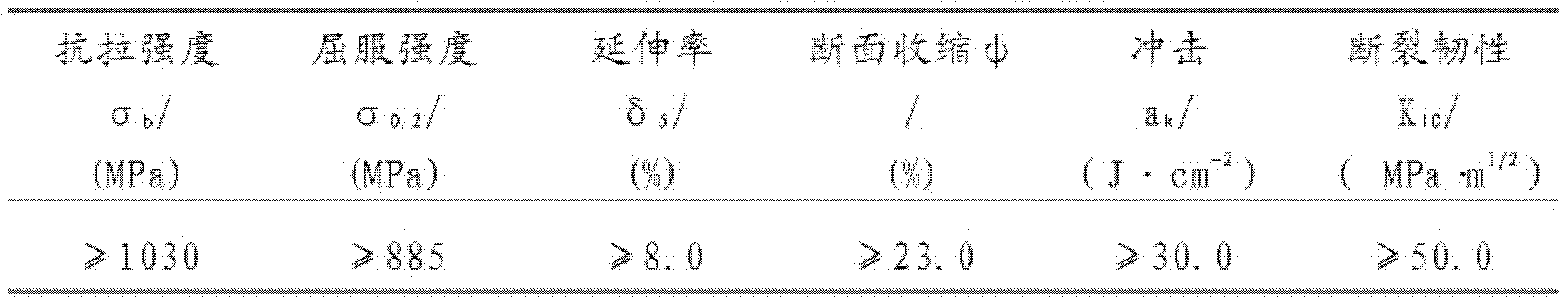

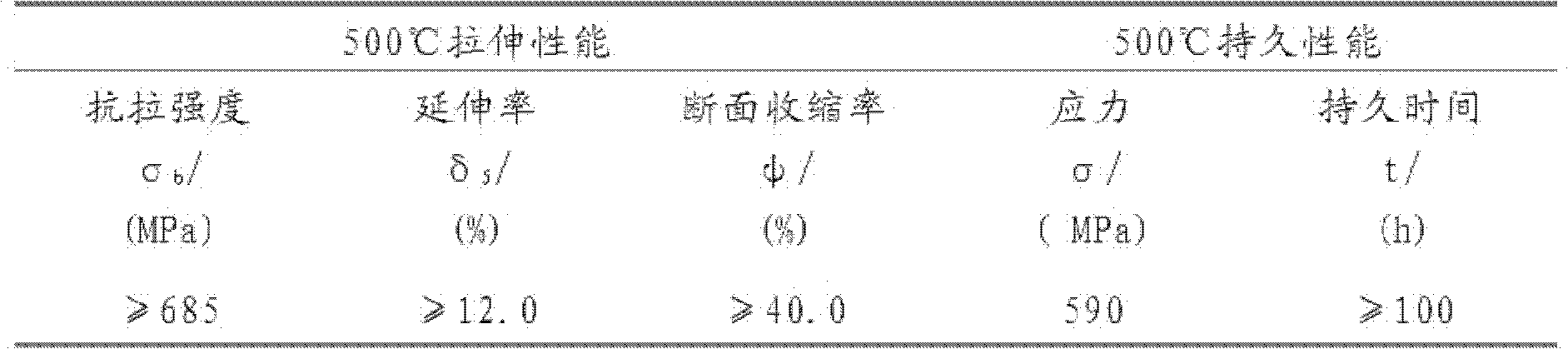

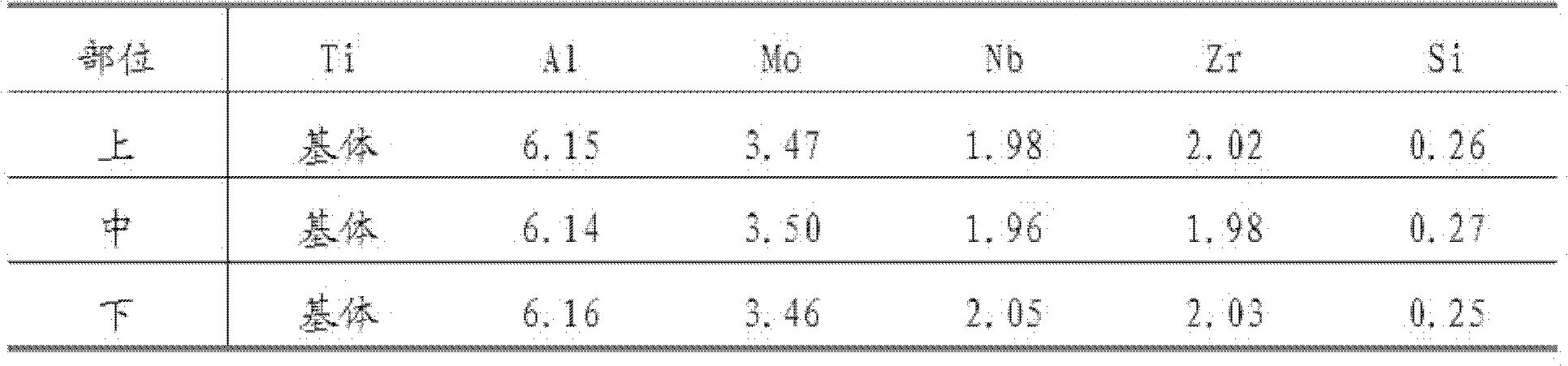

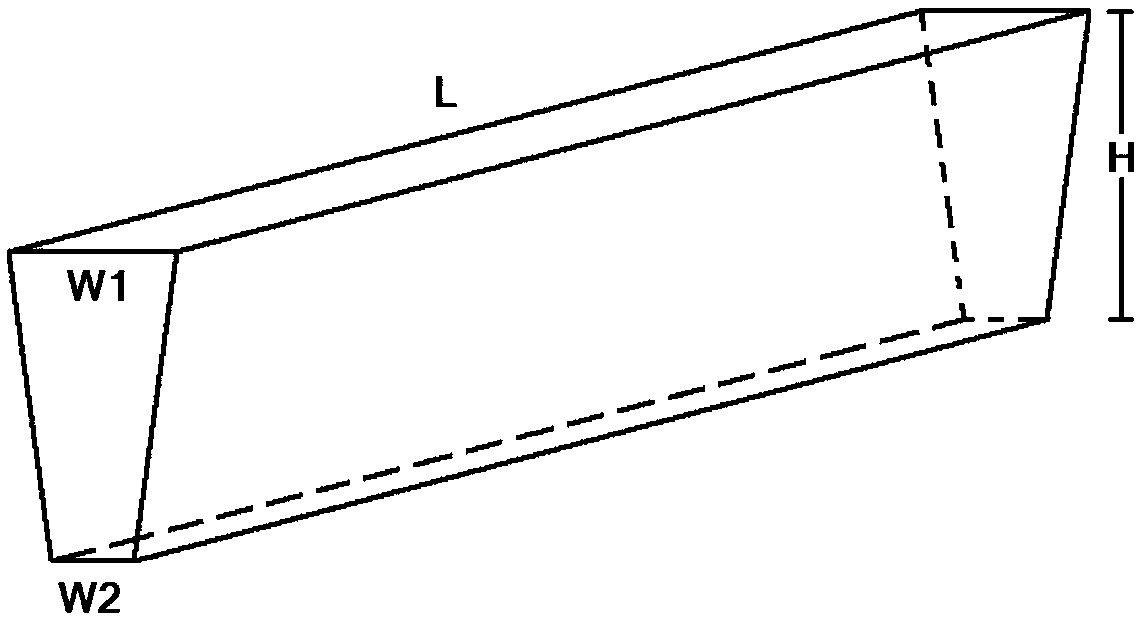

1100 MPa level thermal strength titanium alloy and preparation method thereof

The invention discloses a 1100 MPa level thermal strength titanium alloy and a preparation method thereof. The alloy comprises the following components by weight percent: 5.8-7.2% of Al, 2.8-3.8% of Mo, 1.6-2.5% of Nb, 1.6-2.5% of Zr, 0.20-0.30% of Si and the balance of Ti. The preparation method comprises the following steps: dosing, performing electrode pressing and electrode preparation, preparing primary ingots, preparing secondary ingots, preparing cast ingots, cooling, discharging, and the like. The performances such as room temperature strength and high temperature strength of the titanium alloy parts prepared from the titanium alloy disclosed by the invention are obviously higher than those of titanium alloy parts prepared from the existing TC11 thermal strength titanium alloy; and the performances such as plasticity and impact of the titanium alloy parts and the same performances of the TC11 thermal strength titanium alloy are in the same order of magnitude. In addition, the preparation method of the titanium alloy with excellent performances is simple and is easy to operate while the excellent performances are ensured.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

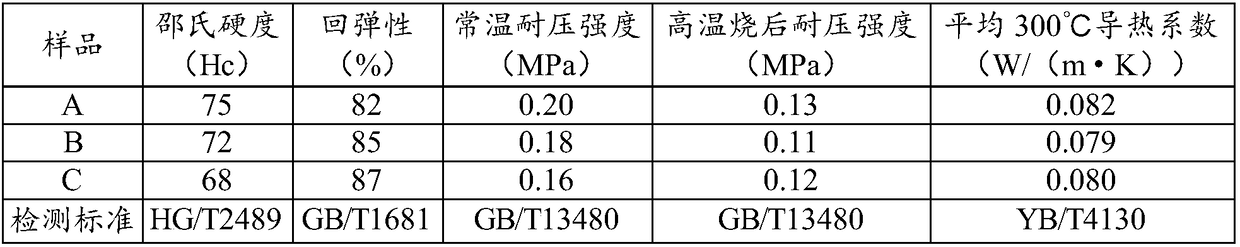

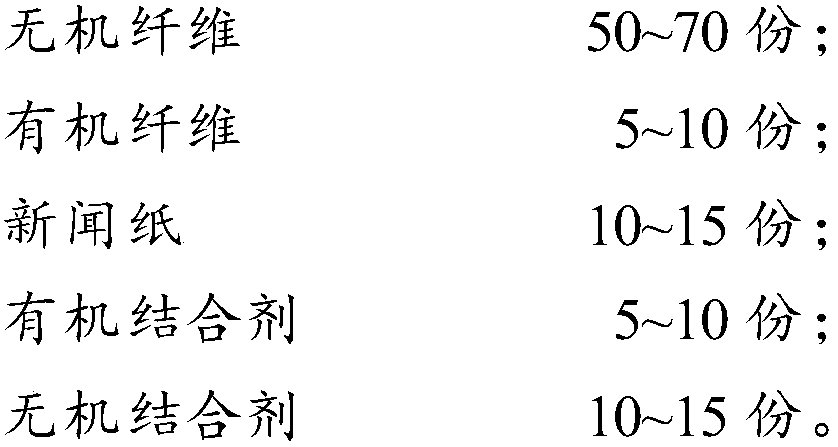

Heat insulation material

ActiveCN108439869AImprove room temperature strengthImprove sealingBasalt fiberUltimate tensile strength

The invention belongs to the field of materials and particularly relates to a heat insulation material. The heat insulation material is prepared by: a), mixing raw materials and water, and beating toobtain pulp, wherein the raw materials include inorganic fibers, organic fibers, newspaper, an organic binder and an inorganic binder, the inorganic fibers include one or more of ceramic fiber, basaltfiber and quartz fiber, and the organic fibers include polyethylene fiber and / or polypropylene fiber; b), mixing the pulp with a flocculating agent to obtain flocculated pulp; c), dewatering the flocculated pulp, and calcining to obtain the heat insulation material. The components in the heat insulation material are tightly combined together, showing excellent sealing performance and mechanical strength, with no picking occurred during use.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

High-thermal-conductivity die-casting magnesium alloy and preparation technology thereof

The invention discloses high-thermal-conductivity die-casting magnesium alloy and a preparation technology thereof. Chemical components of the high-thermal-conductivity die-casting magnesium alloy comprise, by mass, 8-13% of Zn, 0.1-1% of Ca, 0-1% of Mn, 0-1% of La, 0-1% of Ce and the balance Mg, wherein the content of Mn, the content of La and the content of Ce are not zero at the same time. The magnesium alloy is suitable for die casting and has excellent mechanical properties and high thermal conductivity, the thermal conductivity of the magnesium alloy at room temperature can reach about two times that of commonly used die-casting AZ91, and the tensile strength of the magnesium alloy is similar to that of AZ91 magnesium alloy.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com