Patents

Literature

44results about How to "Adapt to the requirements of mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-component silicone sealant for solar module resisting damp, heat and ageing and preparation method thereof

InactiveCN102977840AWide range of adhesionImprove room temperature strengthNon-macromolecular adhesive additivesOther chemical processesChemistrySilicone sealant

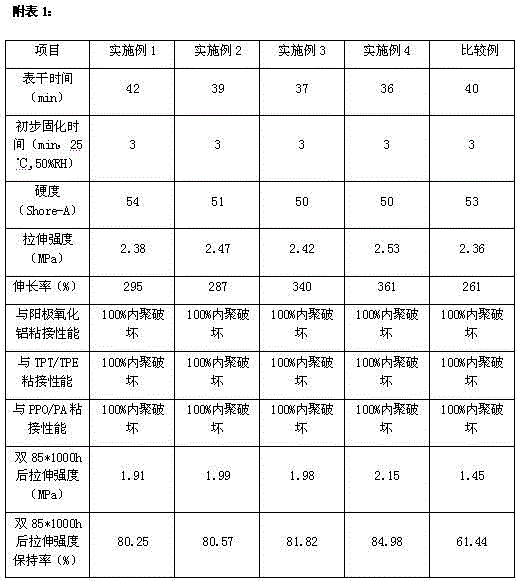

The invention discloses two-component silicone sealant for a solar module resisting damp, heat and ageing and a preparation method thereof. The sealant consists of a component A and a component B, wherein the component A adopts polydimethylsiloxane as the major material; and the component B comprises dispersion mediums, fillers, cross linking agent, coupling agent and catalyst; the component A comprises the following components in parts by weight: 100 parts of a, omega-dihydroxy polydimethylsiloxane with viscosity of 5000-50000cps, 3 to 20 parts of plasticizer and 50 to 150 parts of fillers; the component B comprises the following components in parts by weight: 100 parts of dispersion mediums, 10 to 45 parts of fillers, 20 to 50 parts of cross linking agent, 5 to 40 parts of silane coupling agent and 0.5 to 2 parts of catalyst; and the ratio of the component A to the component B in parts by weight is 100: (10-20). The sealant has the advantages of fast deep curing, wide adhesion, high strength of normal temperature and excellent resistance to damp, heat and ageing; after ageing for 1000 hours under the double-85 condition, the strength retention rate can be up above 80%; and the sealant is suitable for machine gluing, can largely improve module productivity, and adapts to the requirements of solar module mass production.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

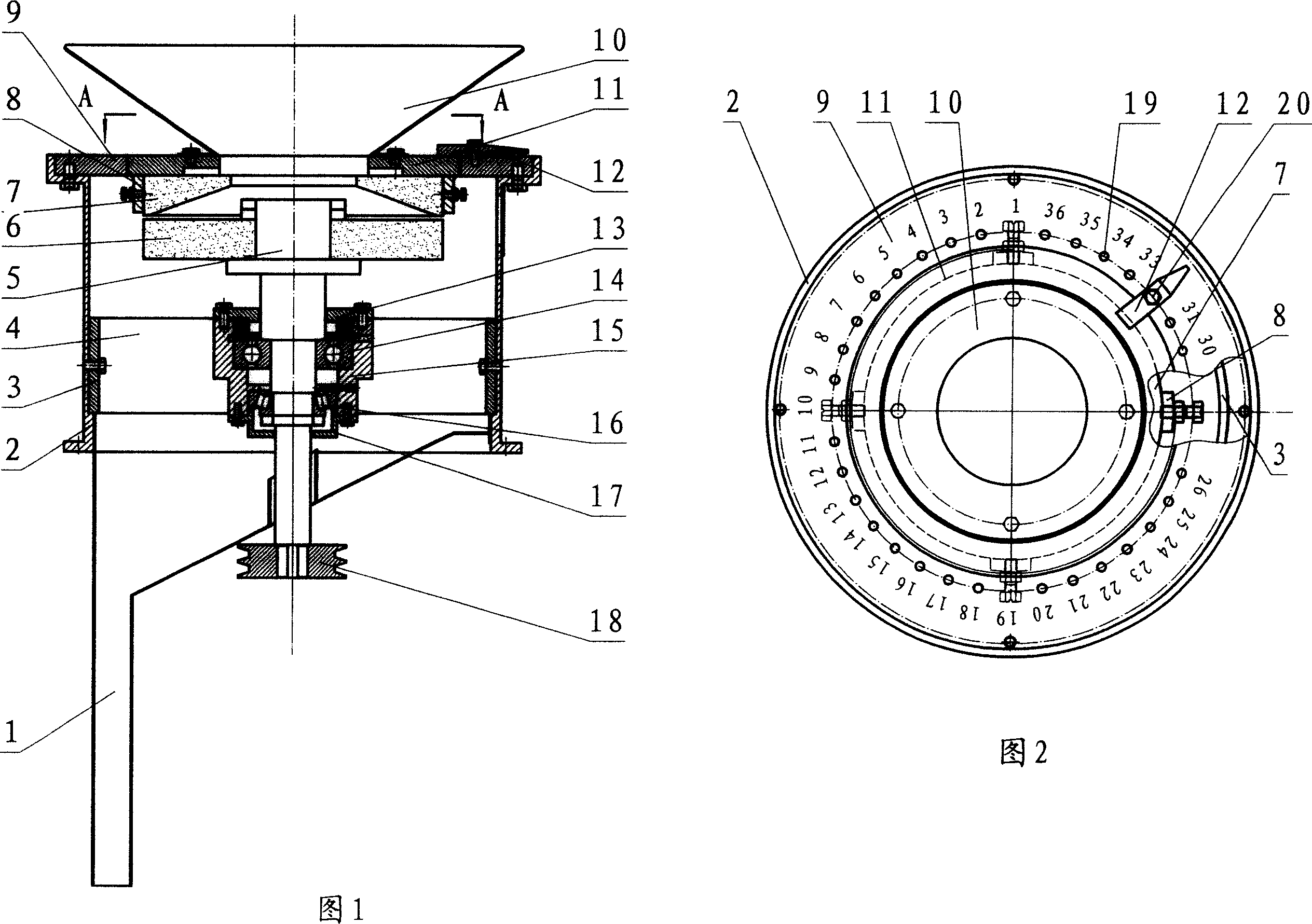

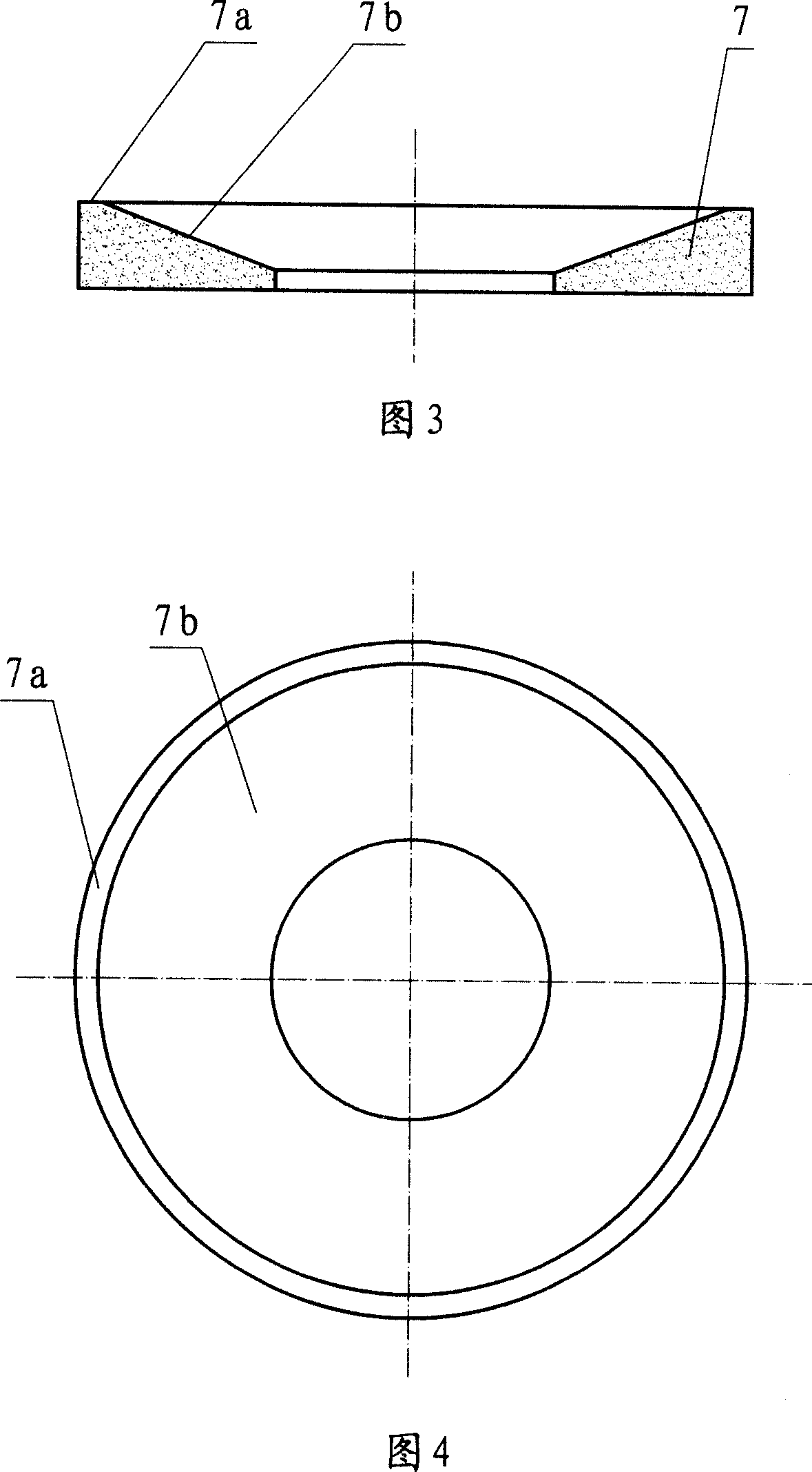

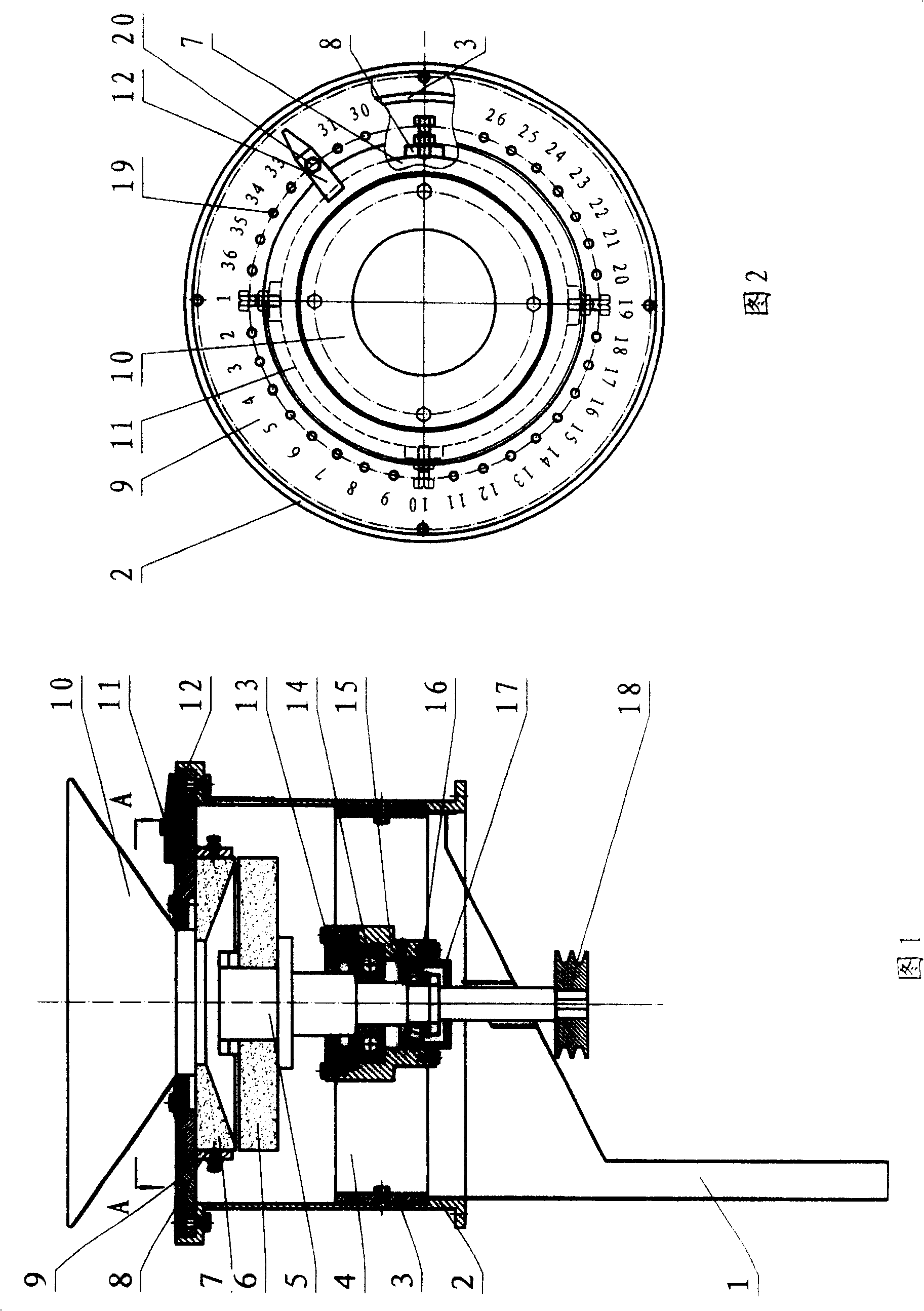

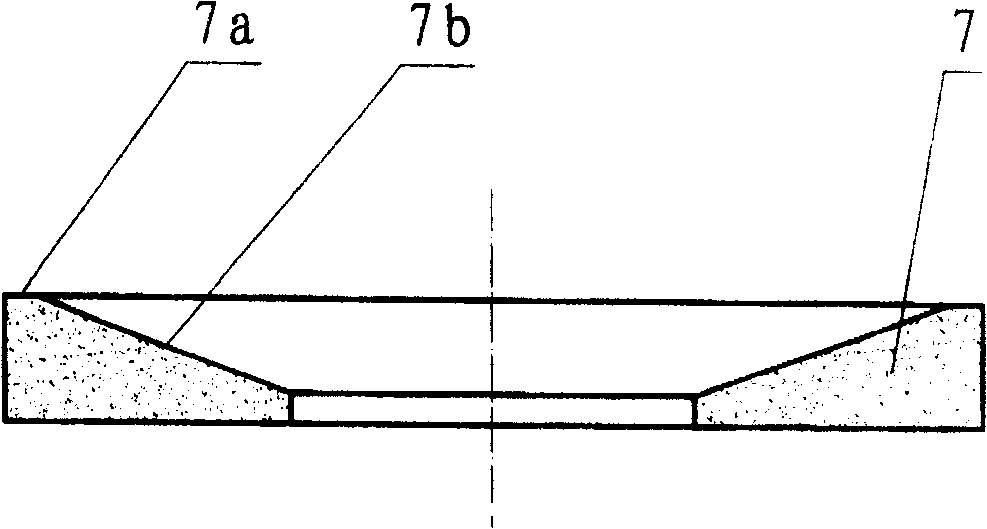

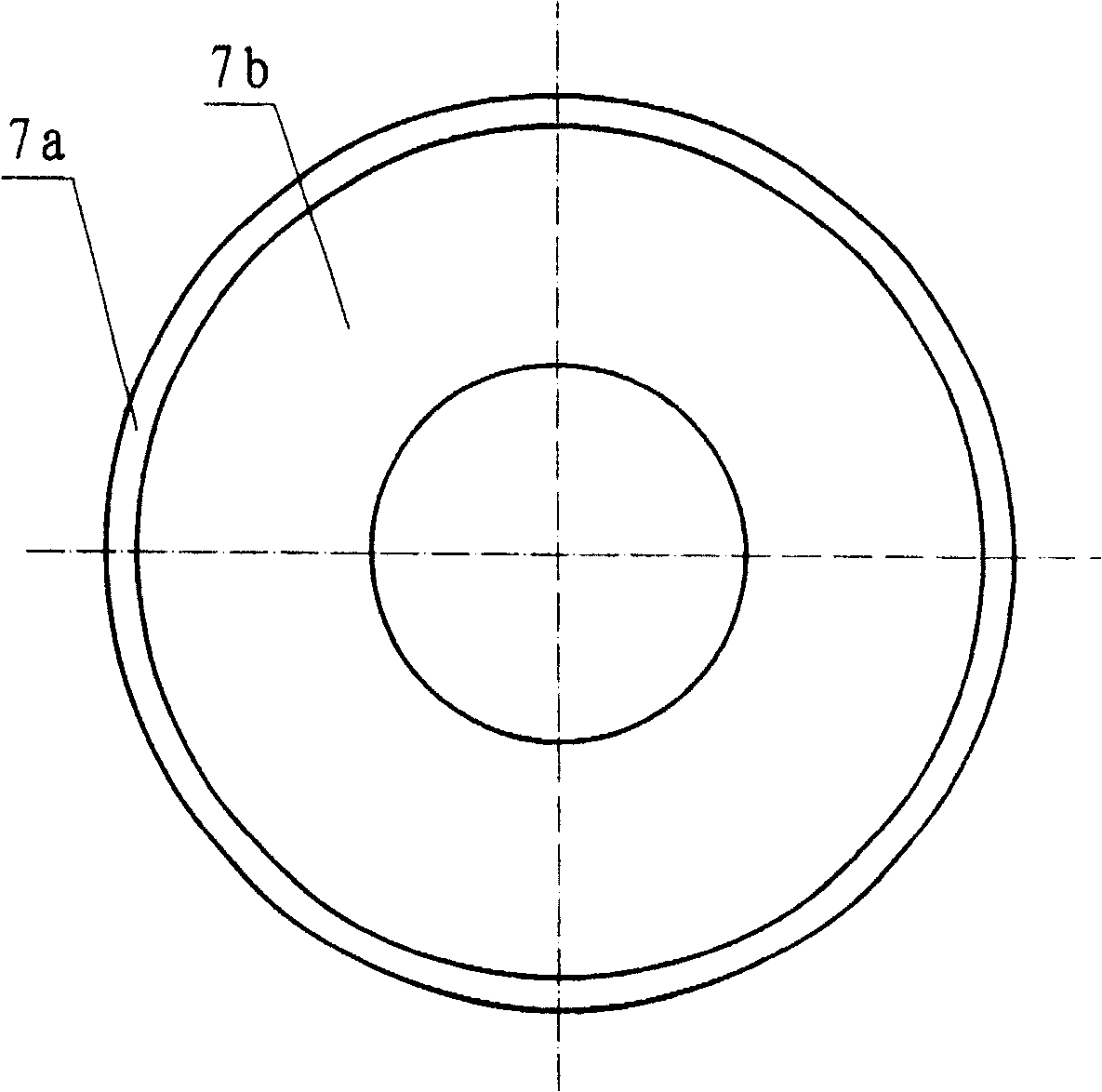

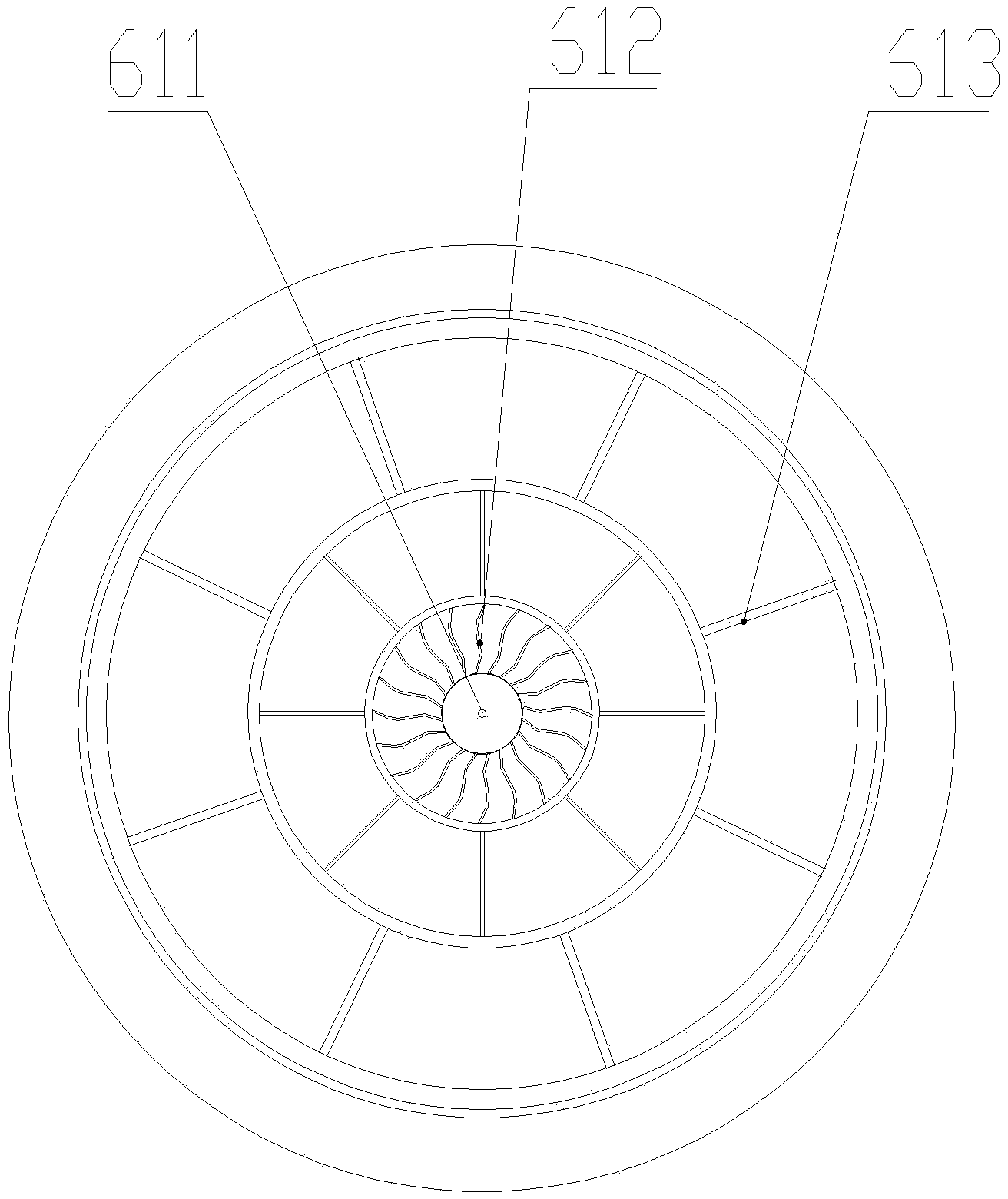

Micro regulating buckwheat sheller

ActiveCN1986062AAchieve fine-tuningHigh precisionGrain huskingGrain polishingPolygonum fagopyrumEngineering

The trimmed buckwheat sheller includes one outer barrel serving as the casing, one inner bushing, one bearing seat with one rotating shaft, one movable wheel on the shaft, one upper cover, one fixed wheel fitting the movable wheel. It features the upper cover comprising one inner ring and one outer ring connected through threads for easy interval regulating and trimming. The present invention has the advantages of high regulating precision, simple and fast regulation, high production efficiency and capacity of processing buckwheat in different plumpness.

Owner:JINZHOU QIAOPAI MACHINERIES

Alkaline polishing method during production of passivated emitter rear contact (PERC) crystalline silicon solar cell

ActiveCN105428450AAdapt to the requirements of mass productionFinal product manufacturePhotovoltaic energy generationScreen printingEtching

The invention belongs to a manufacturing technique of a solar cell, and relates to an alkaline polishing method during production of a passivated emitter rear contact (PERC) crystalline silicon solar cell. The method comprises the following steps of carrying out conventional processes of etching, diffusion and groove etching on a single-silicon wafer to remove positive-negative (PN) junctions at an edge and a back surface and plating of a silicon nitride film on a front surface by plasma enhanced chemical vapor deposition (PECVD), etching to remove silicon nitride plated on the back surface and at the edge in a rolling way by a belt driving way, and then carrying out polishing processing on the back surface through an alkaline groove; and depositing an aluminum oxide plated thin film on the back surface by an atomic layer, and carrying out conventional processes of laser grooving, metal paste silk-screen printing on the front surface and the back surface and sintering to prepare a PERC battery piece. The alkaline polishing process is integrated into the traditional PERC battery production process, the problems of complicated production process during the current introduction process of alkaline polishing, poor controllability, poor back surface passivation effect caused by plating a film layer on the front surface in a rolling way and the like are solved, so that the production the PERC battery based on alkaline polishing can meet the requirement of yield better.

Owner:JINENG CLEAN ENERGY TECH LTD

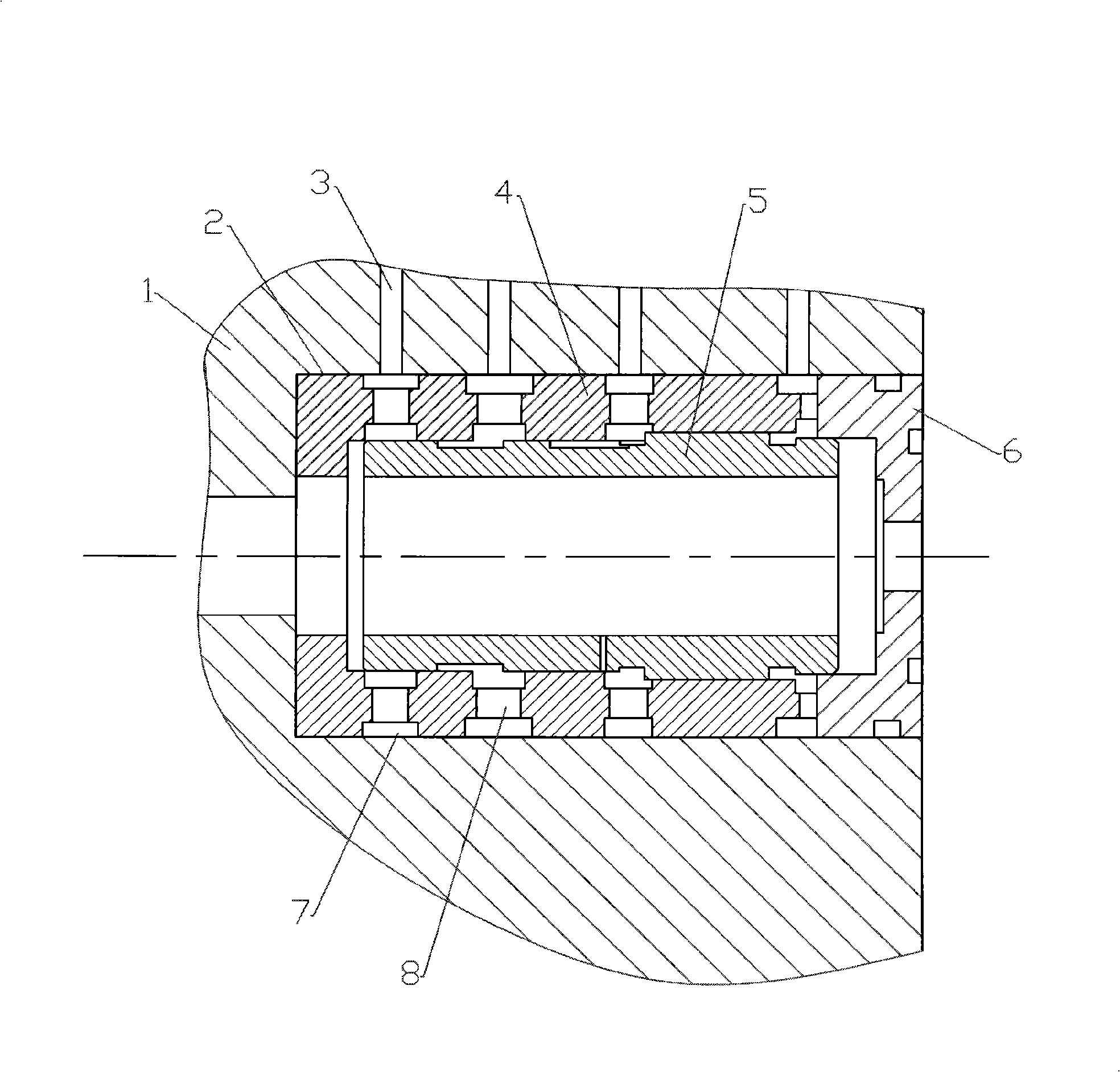

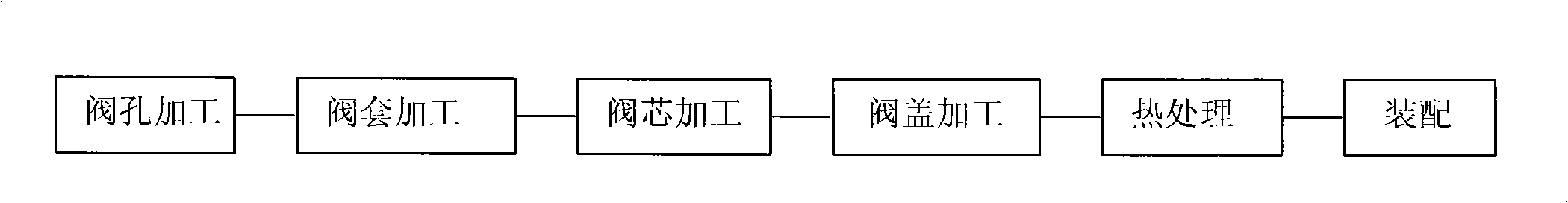

Hydraulic breaking hammer change-over valve and manufacturing method thereof

InactiveCN101324278AReasonable structureLow costServomotor componentsMultiple way valvesCylinder blockProcessing cost

The invention discloses a hydraulic pressure breaking hammer selector valve and a manufacturing method thereof in the technical field of hydraulic components. The hydraulic breaking hammer selector valve takes a middle cylinder body as a valve body; a valve opening is formed on the valve body; an oil duct is communicated with the inner wall of the valve hole and led to a cylinder of the middle cylinder body; a valve jacket is arranged in the valve hole and matched with the valve hole; a valve plug is arranged in the valve jacket; and a valve cover is arranged on the end part of the valve hole. The selector valve is characterized in that the valve hole is an unthreaded hole; an annular groove is formed on the outer wall of the valve jacket corresponding to the position of an opening of the oil duct; and an oil hole communicates the annular groove with a centre hole of the valve jacket. The manufacturing method comprises the steps of processing the valve hole, the valve jacket, the valve plug and the valve cover; conducting heat treatment; and assembling finished products. The method of the hydraulic pressure breaking hammer selector valve has the advantages of processing conveniently, reducing processing difficulty and effectively ensuring precision. The selector valve has the advantages of high functional reliability, lower processing cost and suitability for batch production.

Owner:NANYANG KAITIAN ENG MACHINERY +1

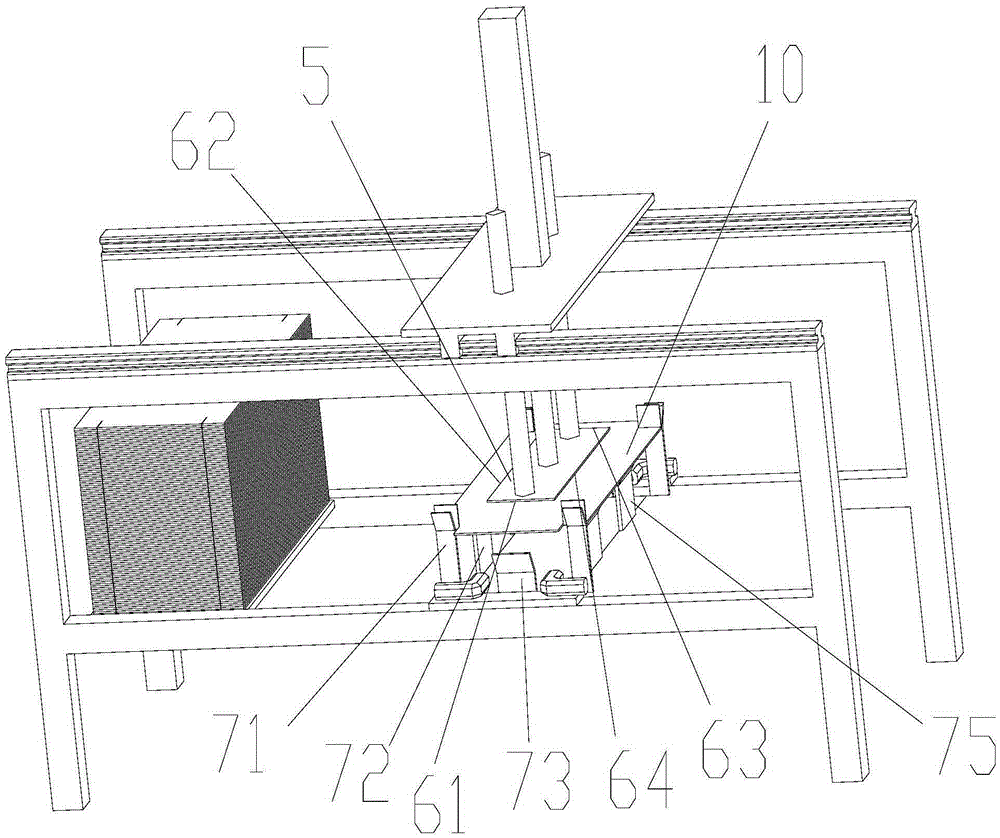

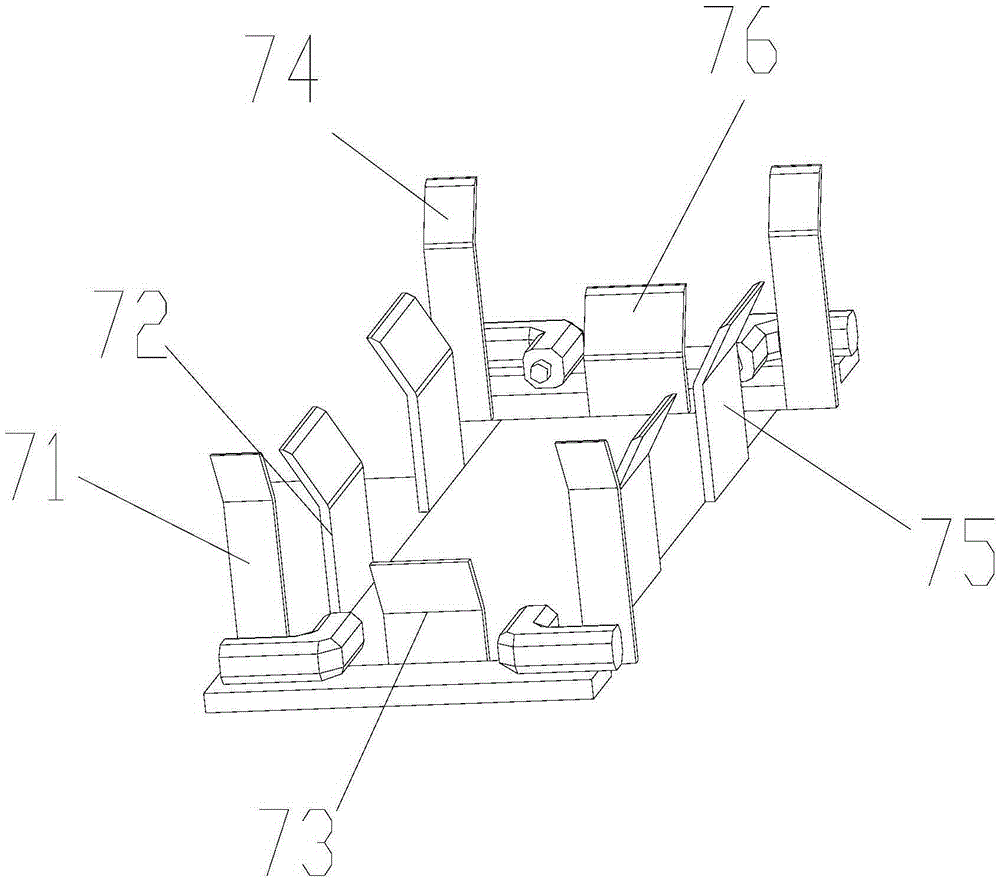

Packing box folding device

The invention provides a packing box folding device which is used for folding paper. The packing box folding device comprises a machine frame, a shifting pressing device and a folding device. The shifting pressing device is installed on the machine frame and comprises a driving device and a pressing plate, and the pressing plate comprises a folded edge, is in transmission connection with the driving device and performs linear reciprocating motion under the driving of the driving device. The folding device is fixedly connected with the machine frame and comprises a locating block, the locating block comprises a folding plane, the folded edge corresponds to the folding plane, the pressing plate pushes the paper to move towards the folding device under the driving of the driving device, and the paper is folded to form an angle of 90 degrees through the matching of the folded edge and the folding plane. The packing box folding device has the advantages of being reasonable in design, simple in structure, not only high in automation degree, but also capable of meeting the large-scale production requirements and guaranteeing product consistency and improving product quality.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

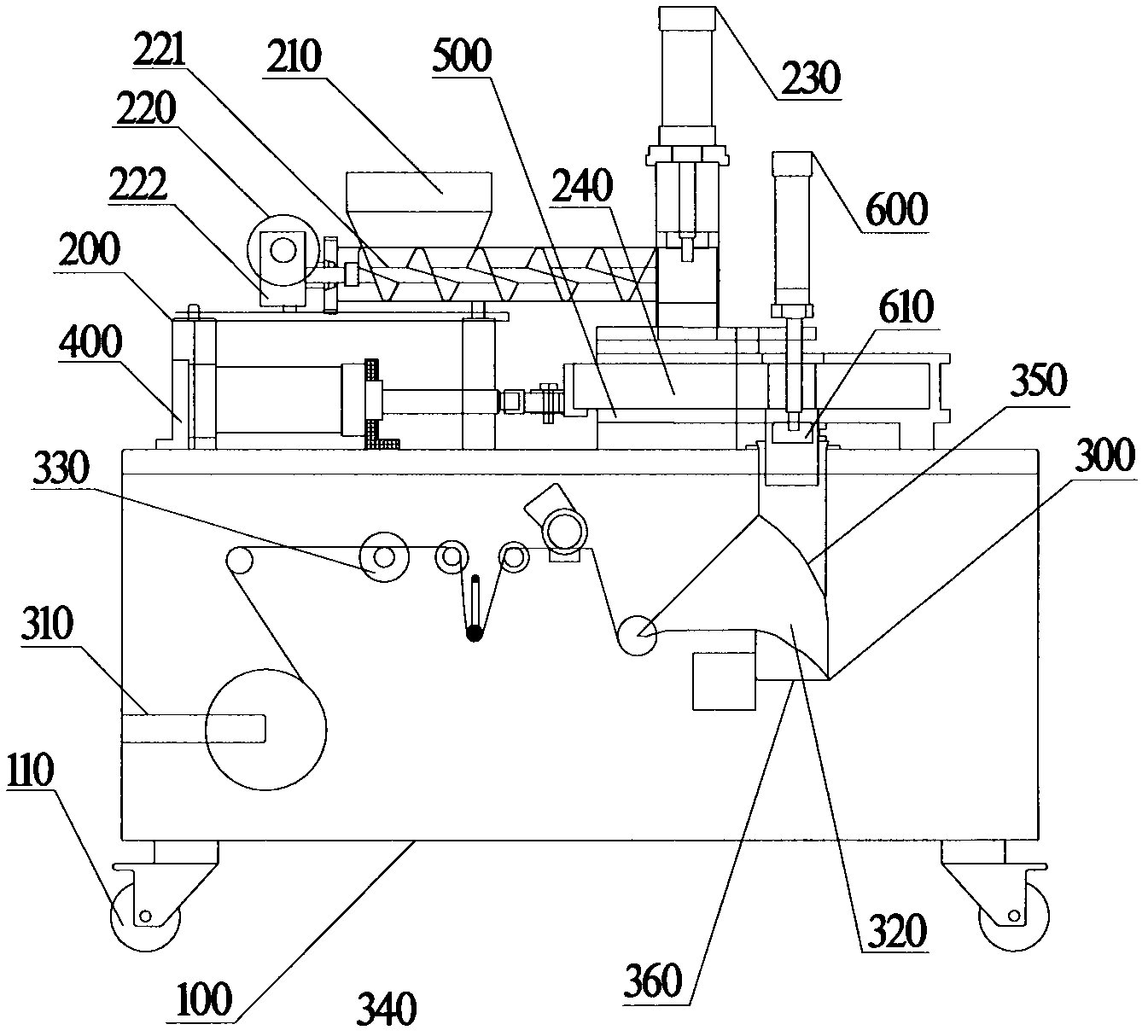

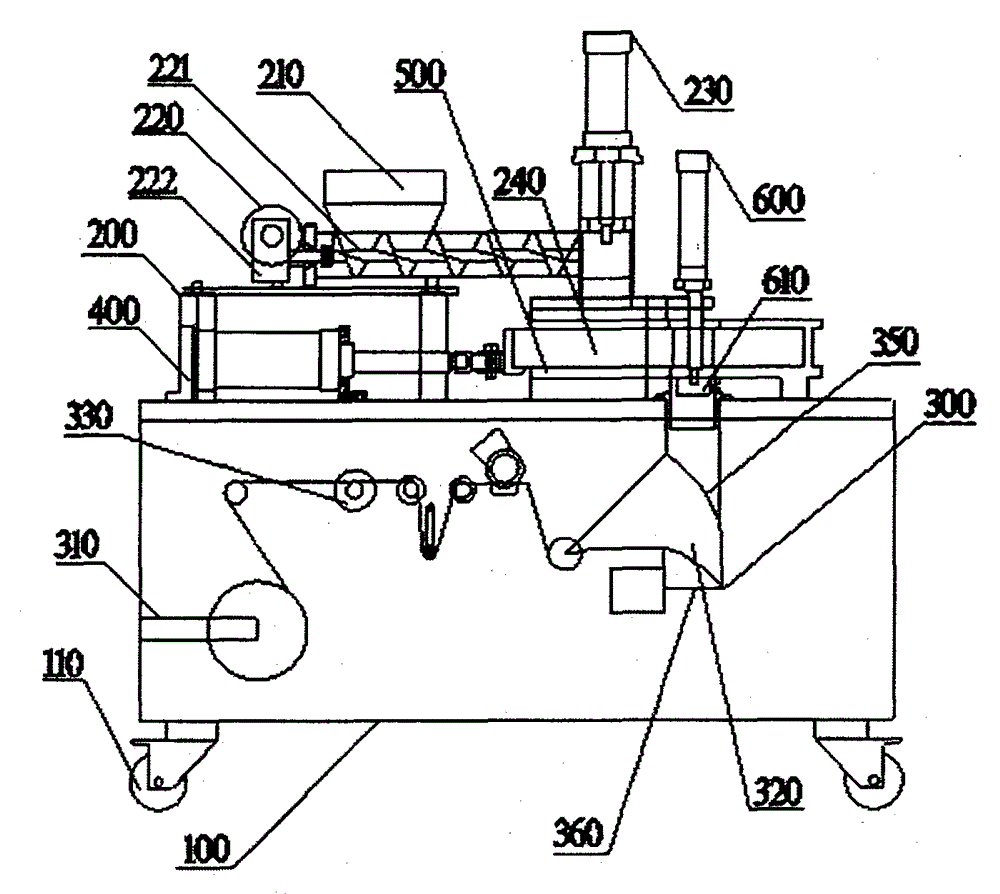

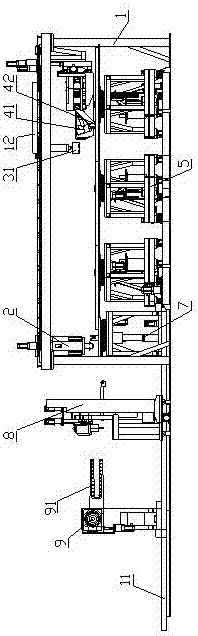

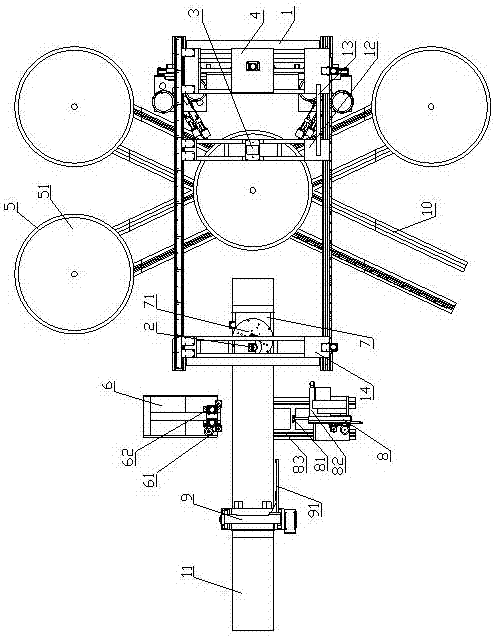

Beef packing machine

A beef packing machine comprises a support, a feeding mechanism and a bag making mechanism. The feeding mechanism and the bag making mechanism are disposed on the support, the feeding mechanism is connected with the bag making mechanism and consists of a hopper, a screw pushing device, a pressing cylinder and a metering cup, the screw pushing device is arranged below the hopper, the pressing cylinder is disposed at one end of the screw pushing device and positioned at the finish end of the pushing direction, and the metering cup is disposed below the pressing cylinder and connected with the bag making mechanism. Beef is quantitatively packed mechanically, manual packing is replaced, squeezing, smashing and stirring of the beef are avoided, moisture and freshness of the beef are guaranteed, the requirements of batch production are met, and the beef packing machine is high in quantitative precision, fast in packing speed and simple in structure and is quite practical.

Owner:SUZHOU HAODELAI FOOD

Combined extraction method of purslane polysaccharide and total flavone on basis of micellar medium treatment

ActiveCN110101728AHigh extraction rateAvoid wastingAntibacterial agentsAntimycoticsBatch extractionPolysaccharide

The invention provides a high-efficiency combined extraction method of high-purity purslane polysaccharide and total flavone, and relates to a method for deproteinizing and decoloring an extracting solution. The high-efficiency combined extraction method can achieve efficient and rapid extraction of purslane polysaccharide and total flavone from portulaca oleracea L. in a large scale, and single-step operation of specific micellar medium extraction is adopted for jointly removing protein and pigment components in a polysaccharide extraction step, and correspondingly the defect is avoided thatprotein removal and pigment removal need to be independently carried out during purslane polysaccharide purification in the prior art; the extraction flow is shortened, and the method is suitable forlarge-scale extraction.

Owner:NANJING XIAOZHUANG UNIV

Automatic sleeving device of magnetic ring insulating sleeves

The invention discloses an automatic sleeving device of magnetic ring insulating sleeves. The automatic sleeving device comprises a punching machine provided with a base, and magnetic rings arranged between the two insulating sleeves in a sleeved mode. One end face of each insulating sleeve is provided with an opening. The punching machine is provided with a punching head, a mechanical arm, a control panel and a displacement sensor. The bottom of the punching head is provided with a pressure sensor, and the periphery of the base is respectively provided with an automatic feeding device and a discharging and pushing device. The first automatic feeding device is provided with a first conveying rail, a second conveying rail and a third conveying rail. By means of the structure, the magnetic rings and the insulating sleeves can be matched through the automatic feeding device and the mechanical arm, and the magnetic rings and the insulating sleeves can be completely matched through the punching head. The pressure sensor can detect the pressure between the punching head and the insulating sleeves, the pressure is prevented from being excessively large, and the magnetic rings are prevented from being broken. The sleeving process of the magnetic rings and the insulating sleeves is wholly finished automatically, manual work participation is not needed, labor intensity is low, the automation degree is high, production efficiency is high, and the requirement for batched production can be met.

Owner:WUJIANG ZHENYU SEWING EQUIP

Promoting digestion effervescent tablets for child health and its preparing method

InactiveCN1562150AImprove easy stickingGood effectDigestive systemUnknown materialsEffervescent tabletChild health

A Chinese medicine in the form of effervescent tablet for treating infantile indigestion is prepared from 7 Chinese-medicinal materials including asragalus root, tangerine peel, haw, radish seed, etc through extracting, mixing with additives, vacuum drying pulverizing and coating.

Owner:浙江天一堂医药管理有限公司

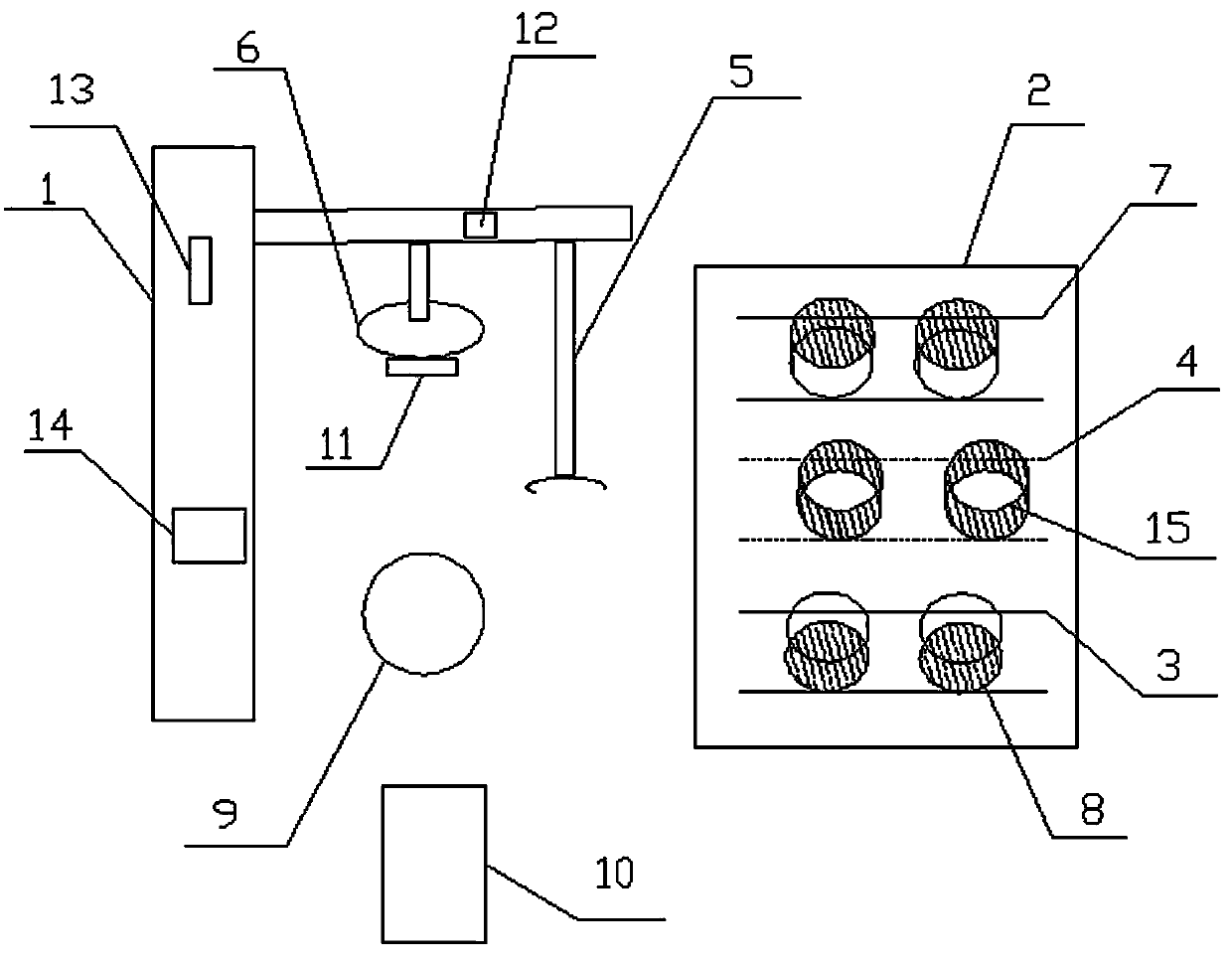

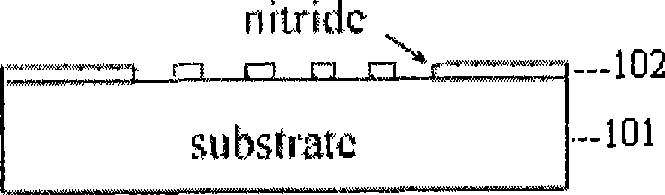

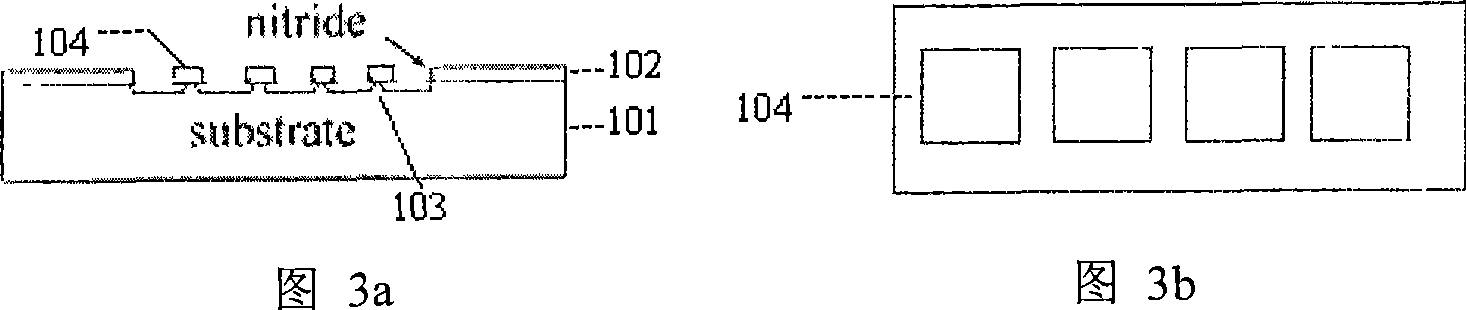

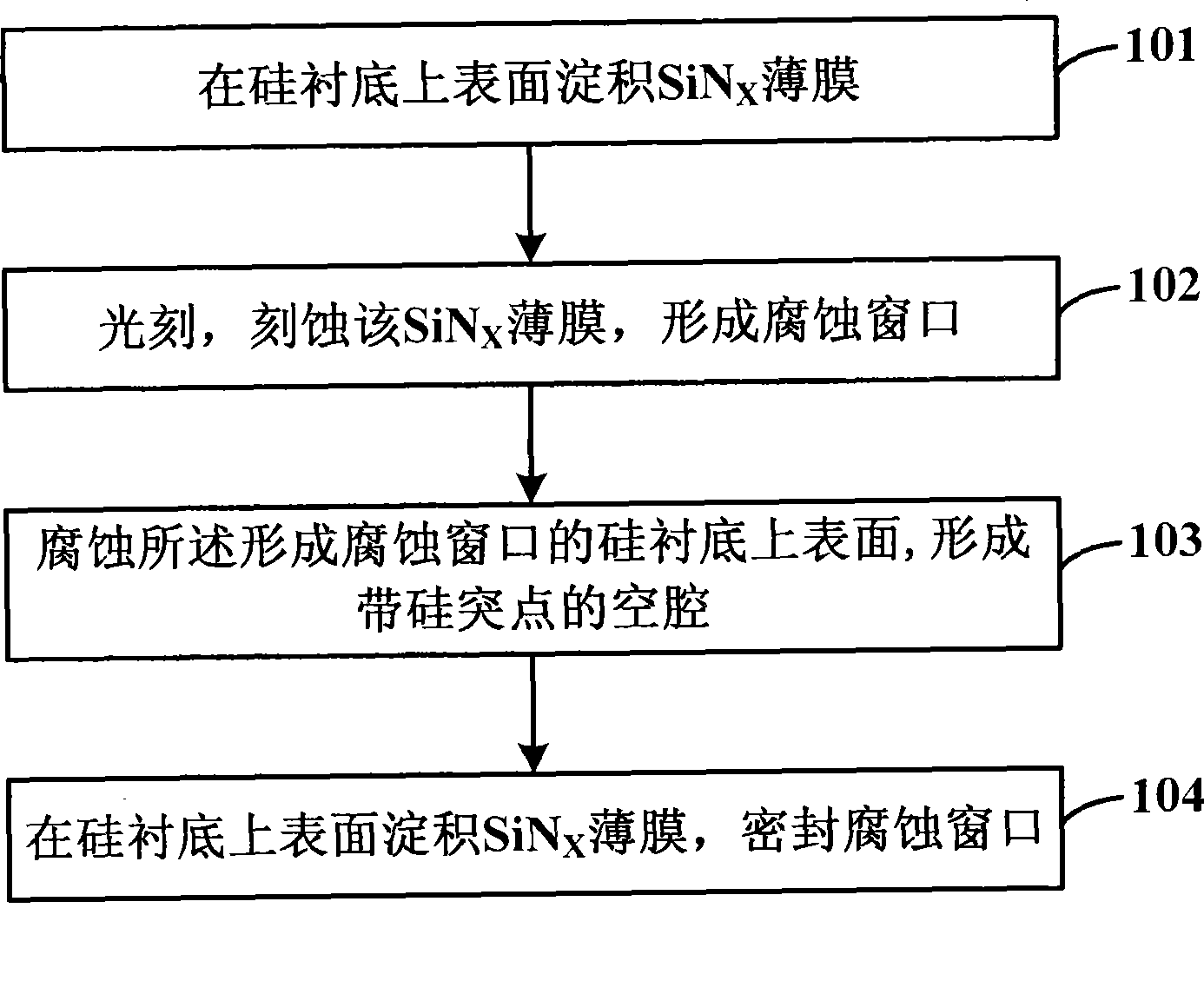

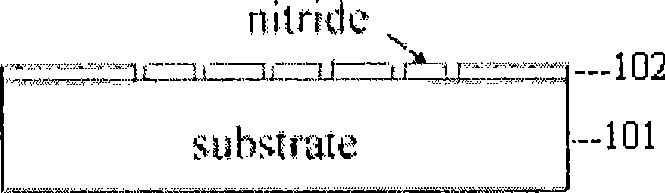

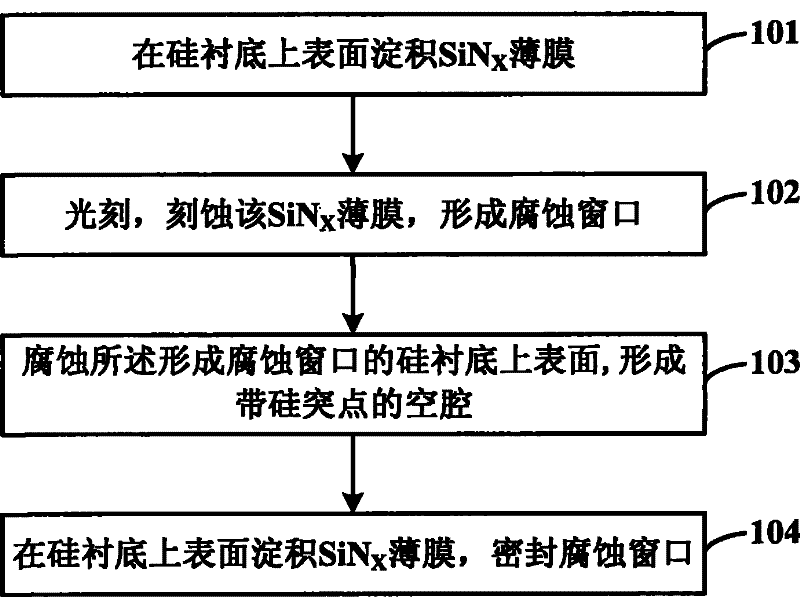

Method for manufacturing micro-mechanical cantilever beam array with substrate silicon as fixing column

InactiveCN101439842AProcess steps to avoid fillingAvoid process stepsDecorative surface effectsChemical vapor deposition coatingCantileverPhotoresist

The invention discloses a method for producing a micromechanical cantilever array taking substrate silicon as a clamping support, which comprises the following steps: a <100> silicon substrate is double-sidedly deposited with SiNx thin films; the surface lithography is performed, wherein the SiNx thin films are etched to form corrosion windows, and a photoresist is removed; the silicon substrate is corroded to form a square cantilever array with a substrate silicon clamping column at the center; and the frontal lithography is performed, wherein the SiNx thin films are etched, and the photoresist is removed to form a rectangular cantilever array with single-point clamped supporting, symmetry and high length-width ratio, or form a rectangular cantilever array clamped at one end. The utilization of the method simplifies a production process and can adapt to the requirement of mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

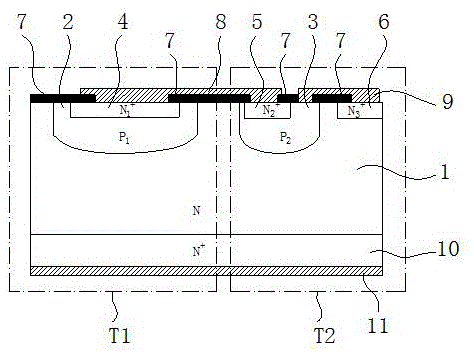

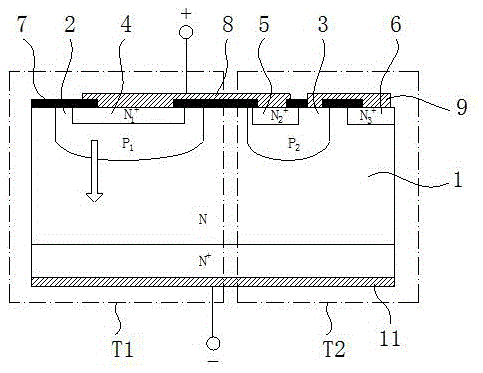

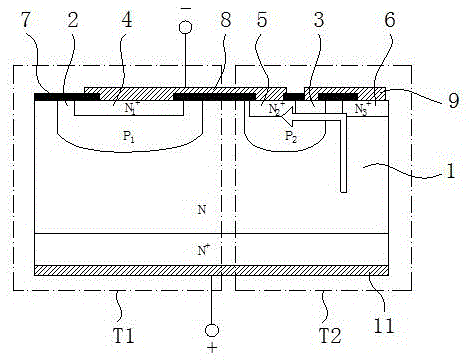

One-way low-voltage TVS device and manufacturing method thereof

ActiveCN105489657ALower breakdown voltageReduce leakageSemiconductor/solid-state device manufacturingSemiconductor devicesLow voltageOptoelectronics

The invention discloses a one-way low-voltage TVS device which comprises an N-type silicon wafer. A P1 doped region and a P2 doped region are arranged in the N-type silicon wafer. An N1+ doped region is arranged in the P1doped region. An N2+ doped region is arranged in the P2 doped region. An N3+ doped region is arranged on the side, away from the P1 doped region, of the P2 doped region in the N-type silicon wafer. An oxidation layer is arranged on the front face of the N-type silicon wafer. An upper metallization electrode and an interconnection metal layer are arranged on the upper surface of the oxidation layer. An N+ doped region and a lower metallization electrode are sequentially arranged on the back face of the N-type silicon wafer. Two inverted triodes are arranged inside the one-way low-voltage TVS device, the one-way TVS device with the low breakdown voltage and low electric leakage can be manufactured by setting the reasonable magnification times by means of the triode collector-emitter breakdown principle, the problem that high electric leakage is caused by Zener breakdown during low breakdown voltage is avoided, a manufacturing method is simple and easy to implement, and the one-way low-voltage TVS device meets the requirement for batch production.

Owner:捷捷半导体有限公司

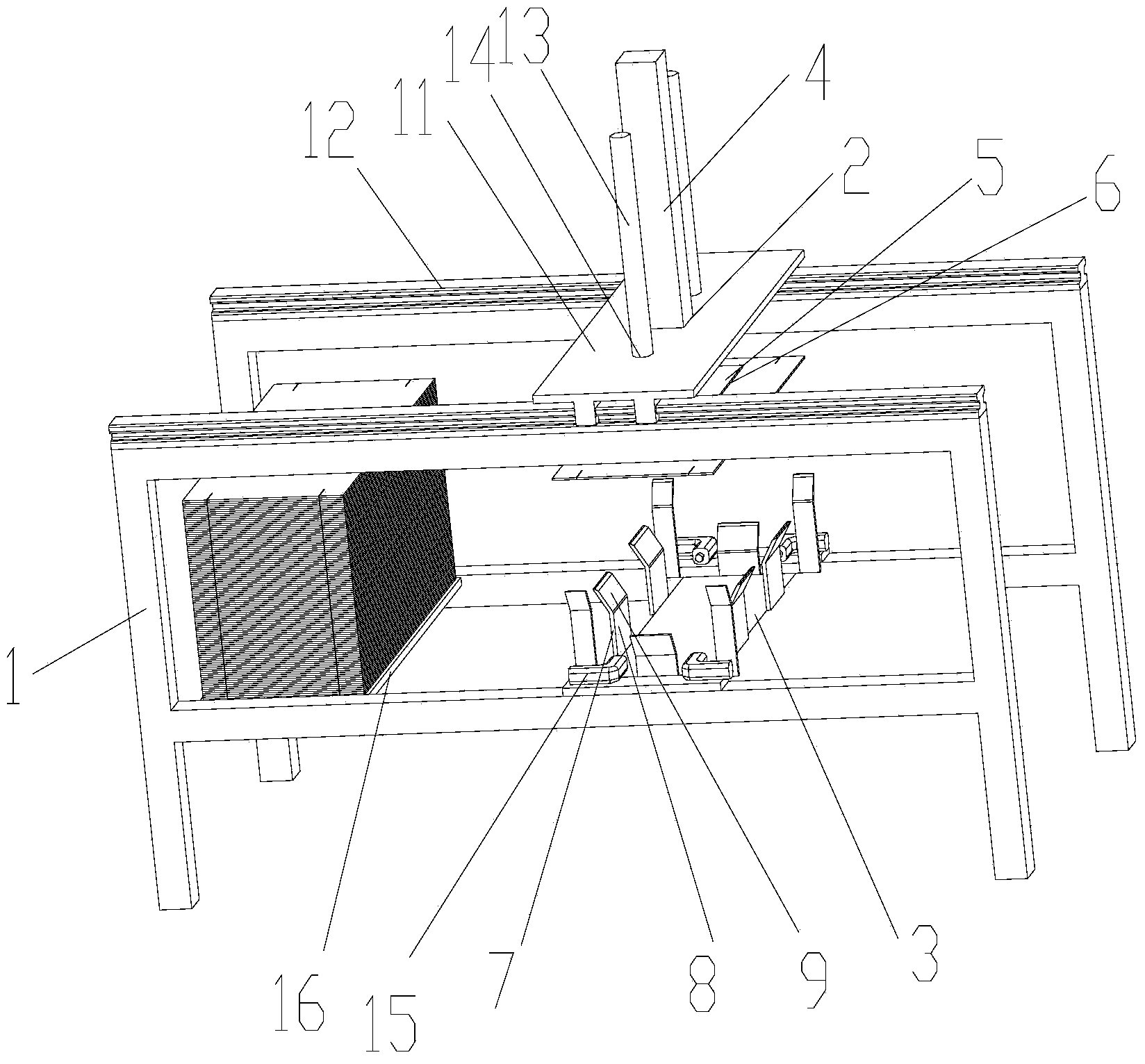

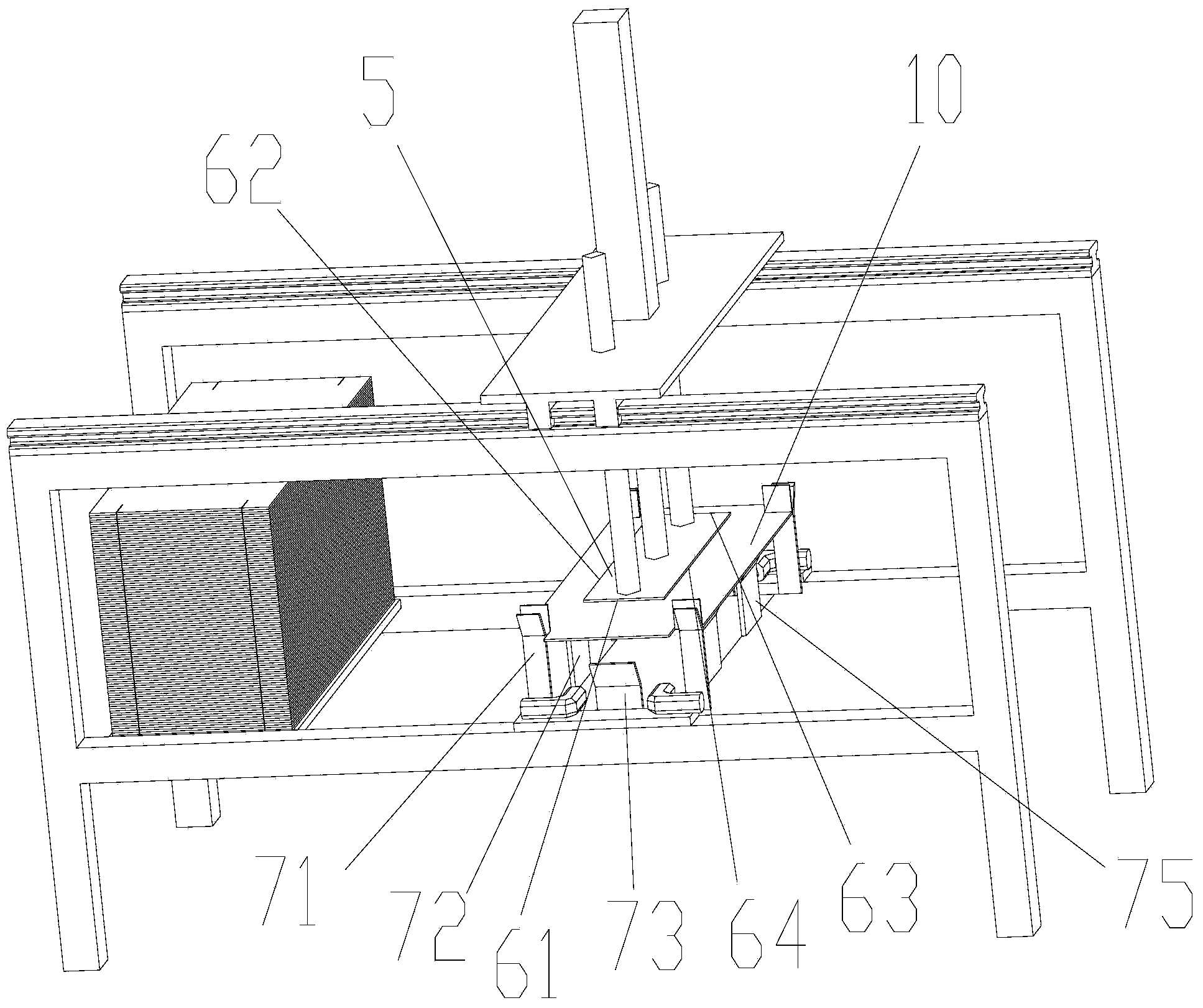

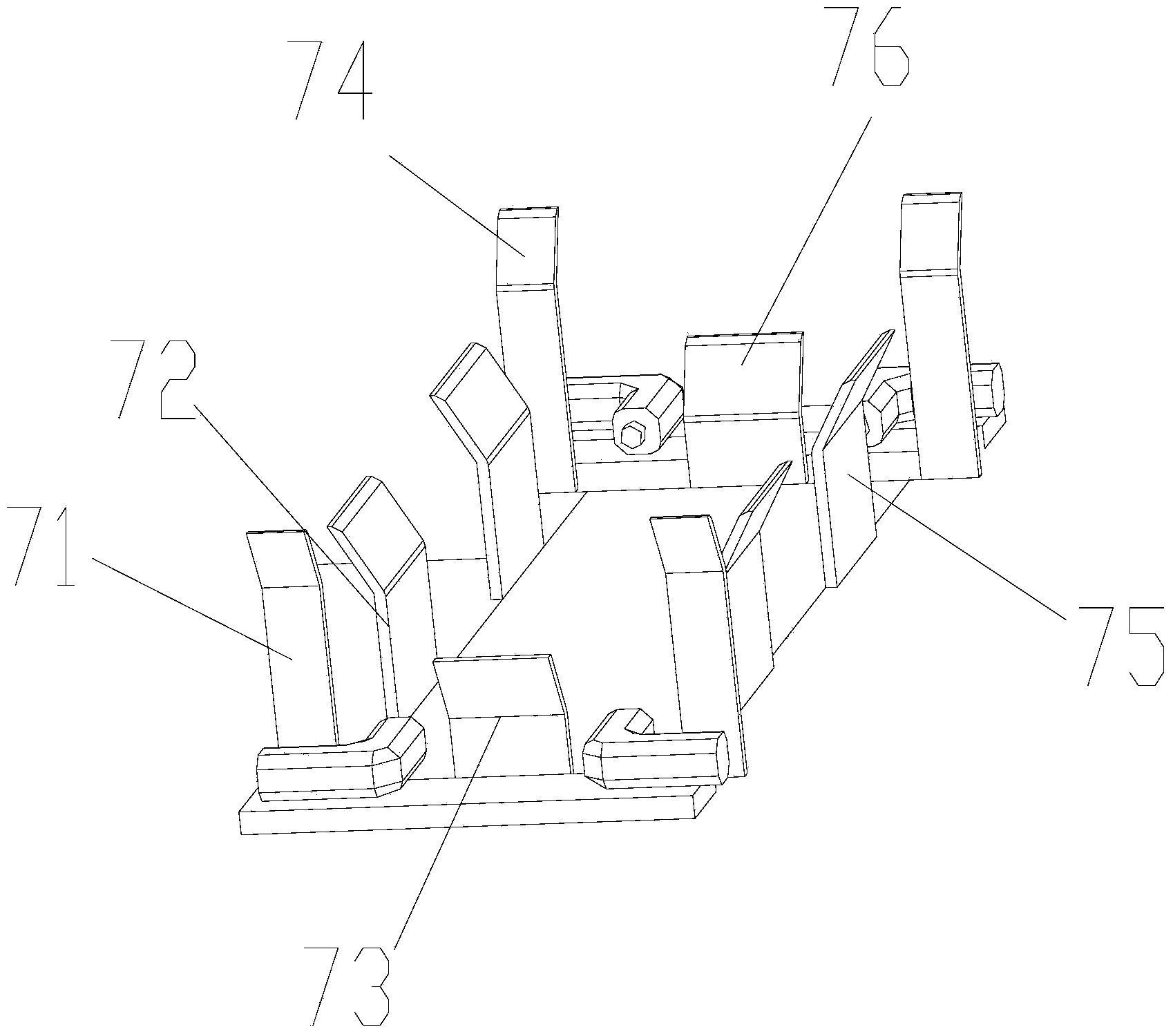

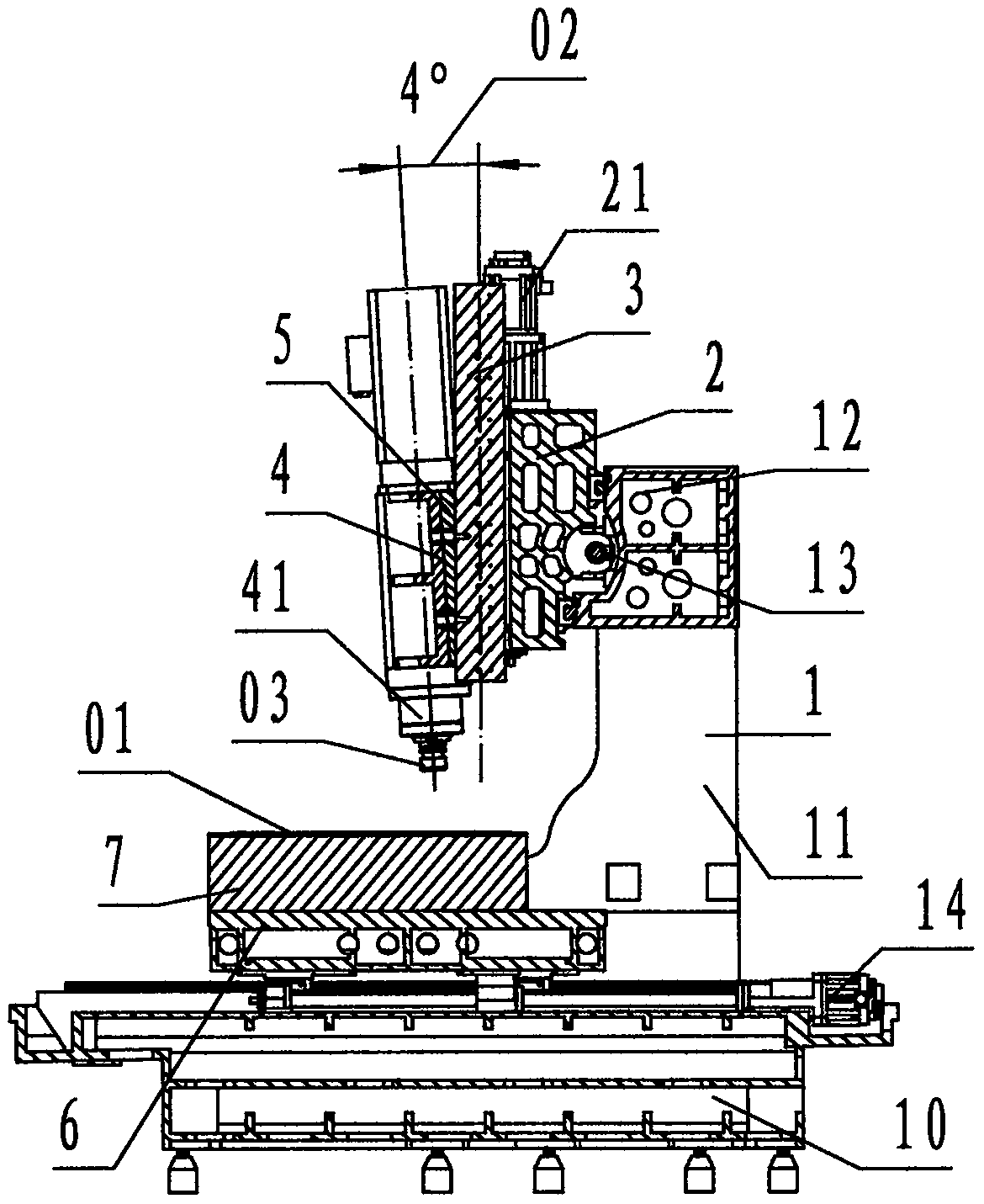

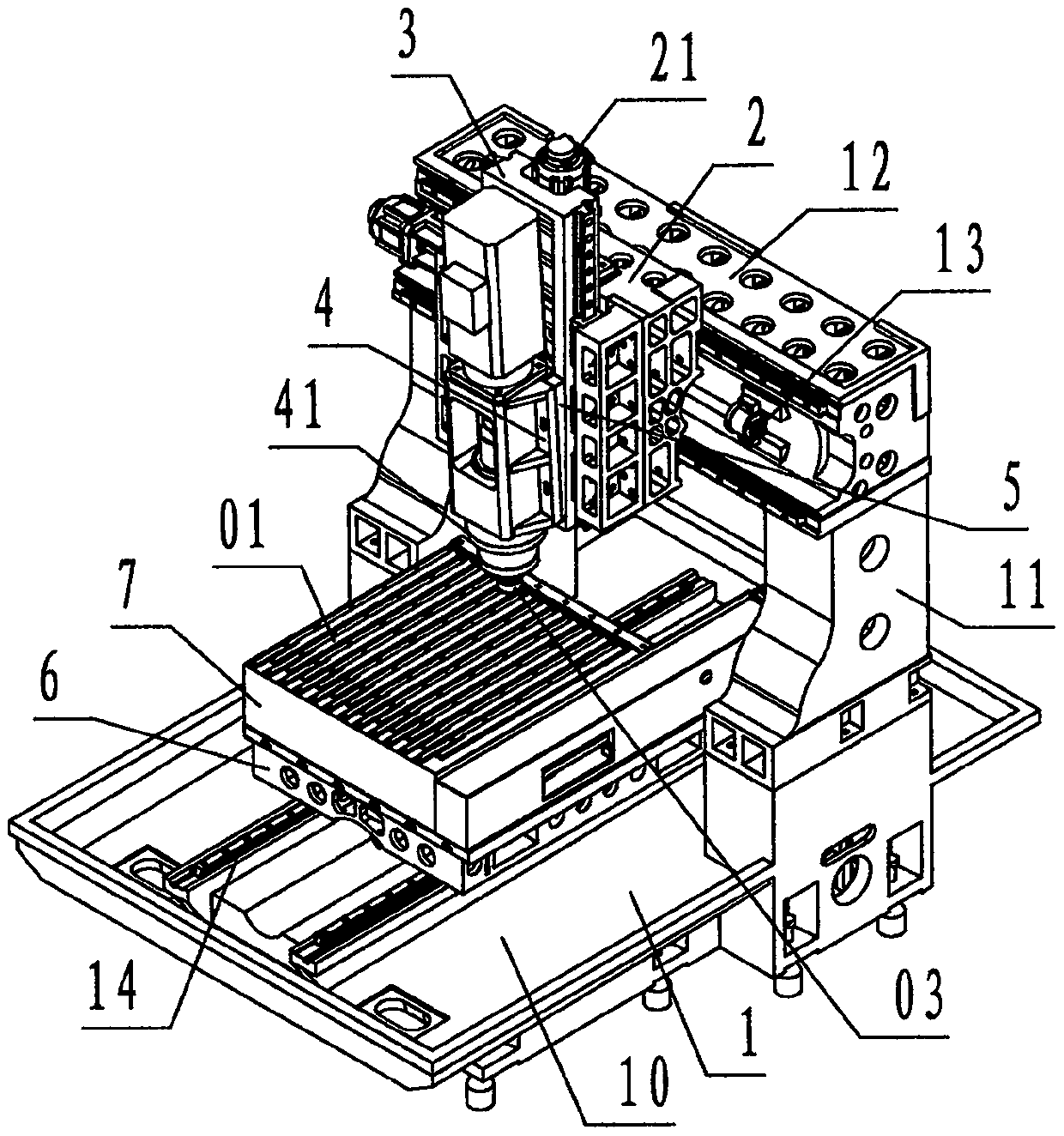

Special portal type numerical-control milling machine for efficiently milling arc-shaped surface of tool

InactiveCN107717031AReduce layout spacingLow costMilling machinesFeeding apparatusNumerical controlMilling cutter

The invention discloses a special portal type numerical-control milling machine for efficiently milling an arc-shaped surface of a tool. The special portal type numerical-control milling machine comprises a portal lathe body (1), an orthogonal dragging plate (2), a Z-direction dragging plate (3), a main shaft base plate (4), tapered iron (5), a movable workbench (6) and an electromagnetic workbench (7). According to the special portal type numerical-control milling machine disclosed by the invention, the inclined iron is lined between the Z-direction dragging plate and the main shaft base plate, so that the rotation axis of an electric main shaft and the up-down motion axis of the Z-direction dragging plate form an inclination angle of 45 degrees; during working, a disc-shaped milling cutter performs intercross milling on a main rear surface of a hand hay cutter workpiece in a mode that the cutting rotation axis and a cutting feeding direction tilt at an angle of 86 degrees so as to form the arc-shaped surface; the tilting mode enables the small-diameter disc-shaped milling cutter to meet milling forming for the arc-shaped surface of the main rear surface of the hand hay cutter workpiece, so that the tool cost is reduced, and milling vibrations are reduced, and therefore, the technical scheme of deep-feeding, quick-advancing and heavy-load efficient milling can be achieved; andmilling processing for the arc-shaped main rear surface hand hay cutter by a paper cutter is achieved, and therefore, the purposes of improving efficiency, reducing cost and suitable for large-scalebatch production are achieved.

Owner:宁波德凯数控机床有限公司

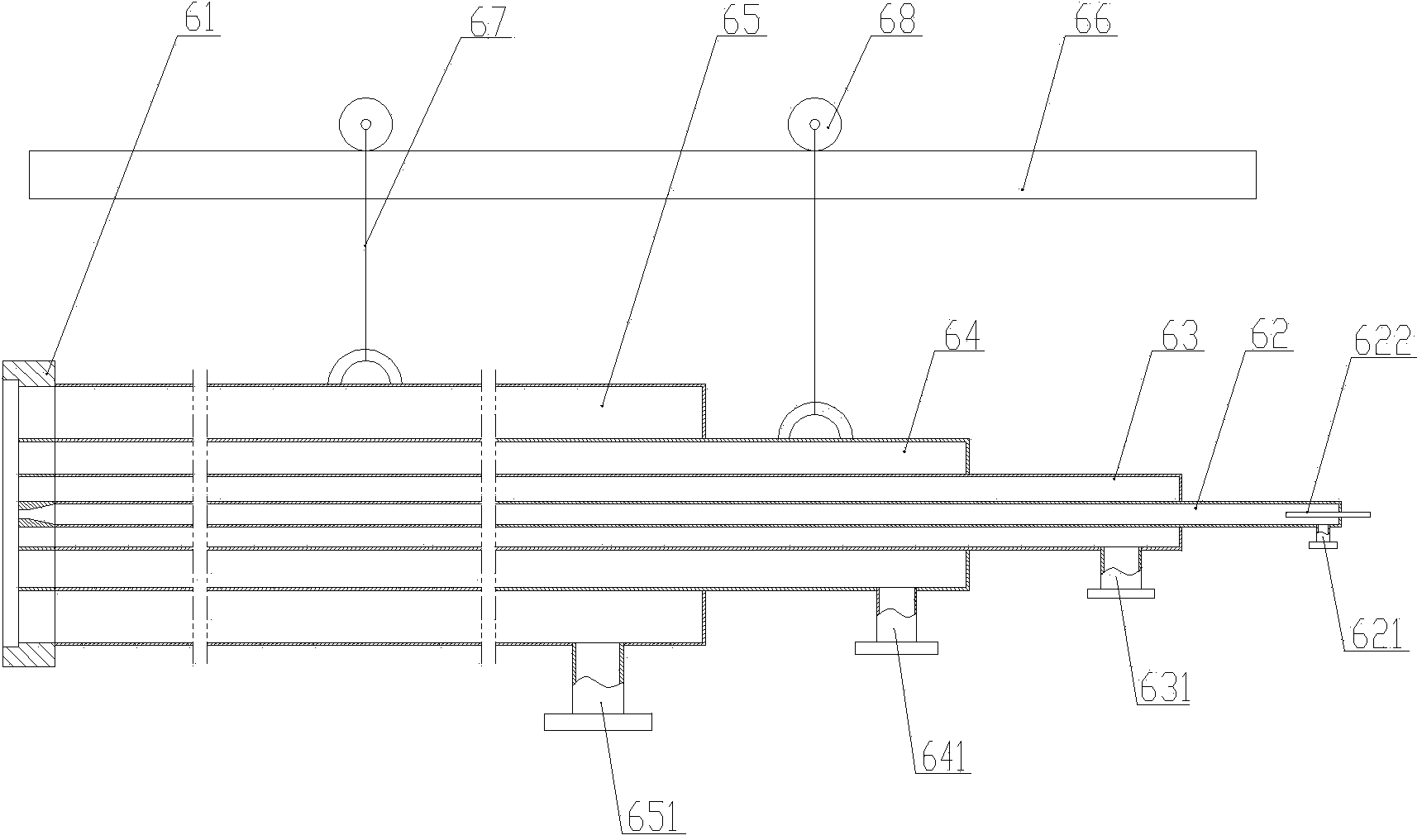

Beef Packing Machine

A beef packing machine comprises a support, a feeding mechanism and a bag making mechanism. The feeding mechanism and the bag making mechanism are disposed on the support, the feeding mechanism is connected with the bag making mechanism and consists of a hopper, a screw pushing device, a pressing cylinder and a metering cup, the screw pushing device is arranged below the hopper, the pressing cylinder is disposed at one end of the screw pushing device and positioned at the finish end of the pushing direction, and the metering cup is disposed below the pressing cylinder and connected with the bag making mechanism. Beef is quantitatively packed mechanically, manual packing is replaced, squeezing, smashing and stirring of the beef are avoided, moisture and freshness of the beef are guaranteed, the requirements of batch production are met, and the beef packing machine is high in quantitative precision, fast in packing speed and simple in structure and is quite practical.

Owner:SUZHOU HAODELAI FOOD

Micro regulating buckwheat sheller

ActiveCN100423842CAchieve fine-tuningHigh precisionGrain huskingGrain polishingPolygonum fagopyrumEngineering

The trimmed buckwheat sheller includes one outer barrel serving as the casing, one inner bushing, one bearing seat with one rotating shaft, one movable wheel on the shaft, one upper cover, one fixed wheel fitting the movable wheel. It features the upper cover comprising one inner ring and one outer ring connected through threads for easy interval regulating and trimming. The present invention has the advantages of high regulating precision, simple and fast regulation, high production efficiency and capacity of processing buckwheat in different plumpness.

Owner:JINZHOU QIAOPAI MACHINERIES

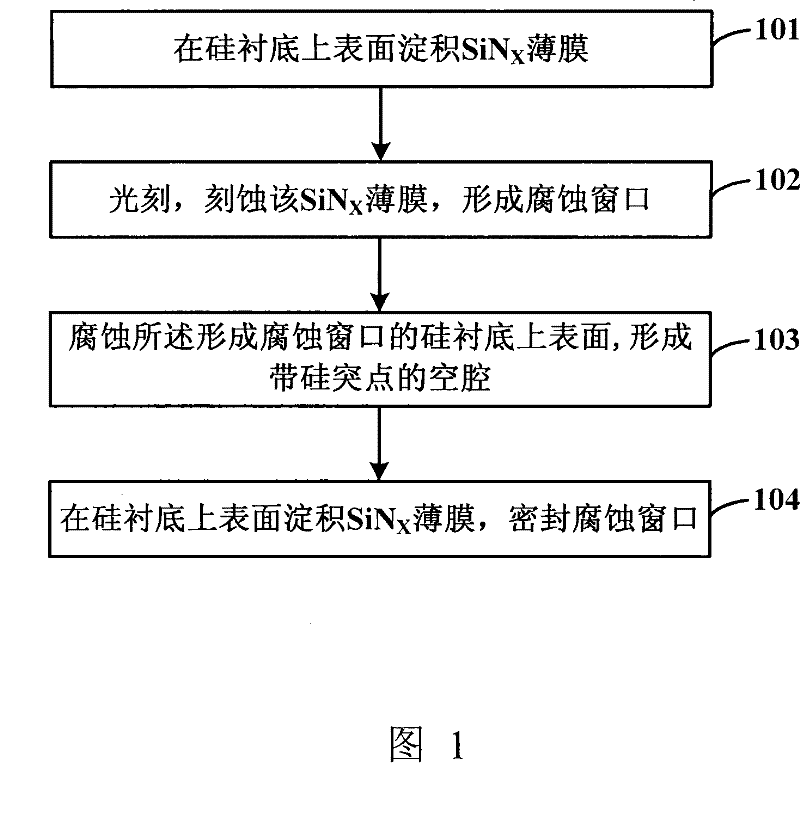

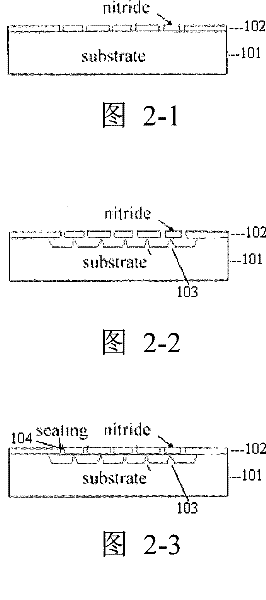

Method for producing heat insulation antiblocking cavity based on silicon substrate

InactiveCN101450787AThe process steps are simpleLow costDecorative surface effectsChemical vapor deposition coatingThermal insulationSilicon

The invention discloses an adiabatic anti-adhesion cavity manufacturing method based on silicon substrates. The method comprises the steps of depositing a SiNX film on the upper surface of a silicon substrate, photoetching and etching the SiNX film so as to form a corrosion window, corroding the upper surface of the silicon substrate where the corrosion window is formed, forming a cavity with silicon protruding points, depositing the SiNX film on the upper surface of the silicon substrate and sealing the corrosion window. The method provided by the invention has the advantages of simple process steps, low cost, high production efficiency, stable process, high practical value and capability of adapting to the requirements of mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

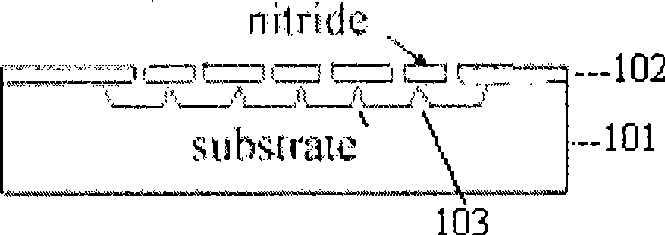

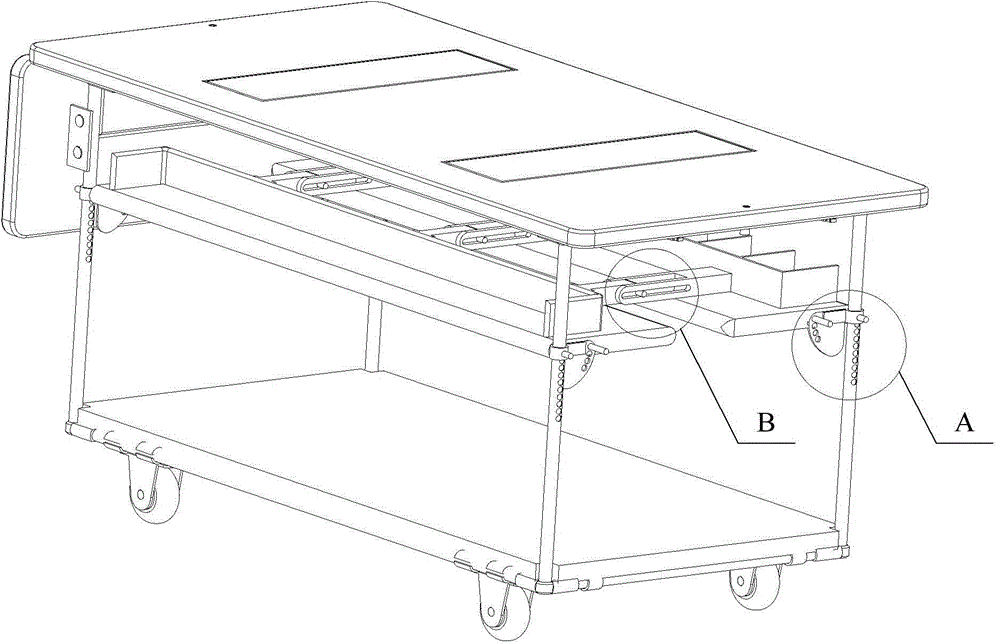

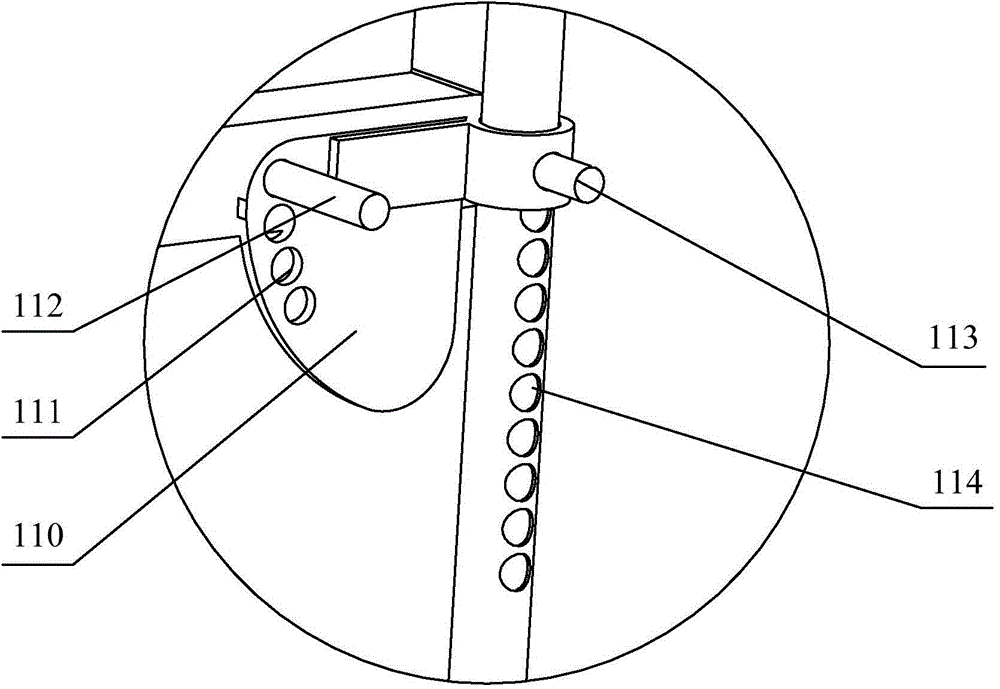

Tool trolley

ActiveCN104627219AAvoid wastingShorten the timeOther workshop equipmentHand carts with multiple axesProduction lineHigh volume manufacturing

The invention discloses a tool trolley. The tool trolley comprises a supporting frame, a workbench arranged on the top of the supporting frame, a first material placement table arranged on the lower portion of the supporting frame, and a second material placement table arranged on the supporting frame and located between the workbench and the first material placement table, wherein the material placement area of the first material placement table is larger than that of the second material placement table. Due to the tool trolley, when small-scale production is performed, the placement requirements of all materials can be met through the two types of material placement tables of the tool trolley, the problem that the various kinds of materials need to be delivered to a production line through a plurality of material trolleys is solved, it is not needed that the materials at the station are assembled only after assembly of a previous procedure is completed, all the materials can be assembled on the same tool trolley, time is greatly shortened, waste of staff and resources is avoided, and the resource utilization rate is increased. The tool trolley can also be combined with an assembly line body so that the large-scale production requirement can be met.

Owner:GREE ELECTRIC APPLIANCES INC

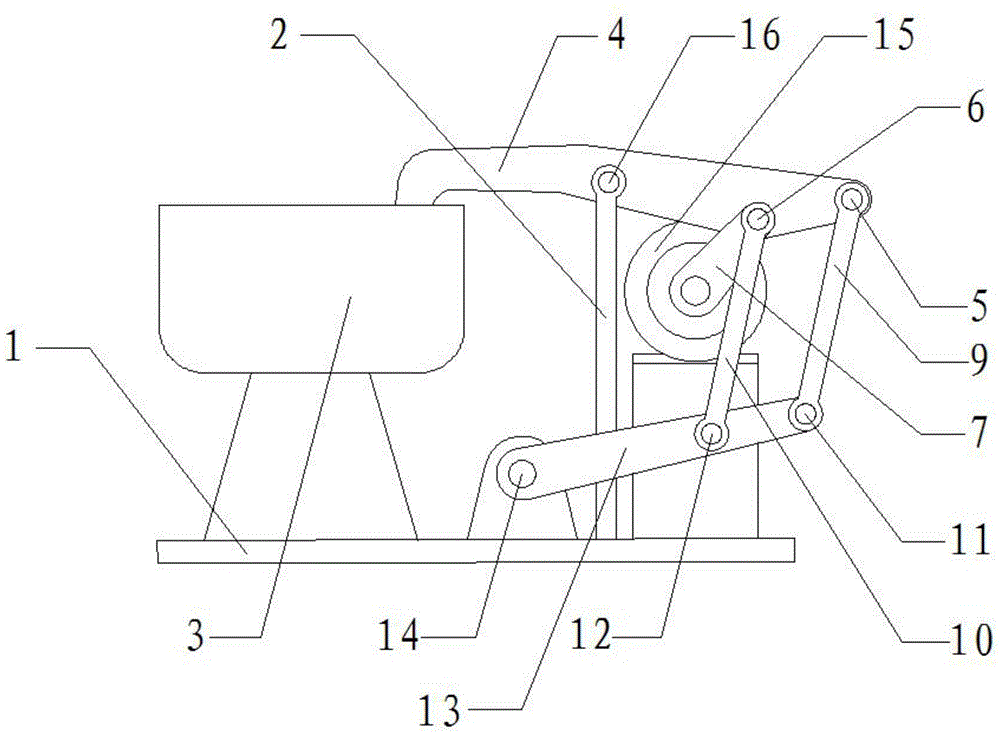

Dough mixing device

InactiveCN106472620AAdapt to the requirements of mass productionIncrease productivityMixing/kneading with vertically-mounted toolsEngineering

The invention relates to a dough mixing device. The lower end of a supporting rod of the device is fixed on a machine frame, the middle part of a dough mixing rod is connected to the upper end of the supporting rod through a seventh rotating pair, a dough mixing hammer is fixed to one end of the dough mixing rod, the dough mixing hammer is located in a dough mixing box, the other end of the dough mixing rod is connected with one end of a second connecting rod through a first rotating pair, the other end of the second connecting rod is connected with one end of a fourth connecting rod through a fourth rotating pair, and the other end of the fourth connecting rod is connected to the machine frame through a sixth rotating pair; a motor is fixed on the machine frame; and one end of a first connecting rod is fixed on the output shaft of the motor, the other end of the first connecting rod is connected with one end of a third connecting rod through a second rotating pair, and the other end of the third connecting rod is connected to the middle part of the fourth connecting rod through a fifth rotating pair. The device disclosed by the invention simulates the movement process of manually making glutinous rice cakes, and the produced glutinous rice cakes are the same in flavor as manually made glutinous rice cakes.

Owner:GUANGXI UNIV

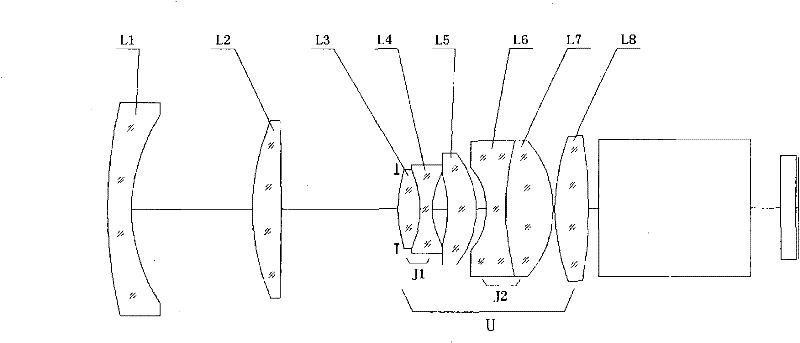

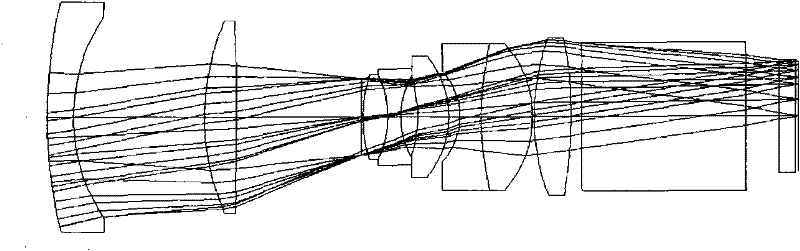

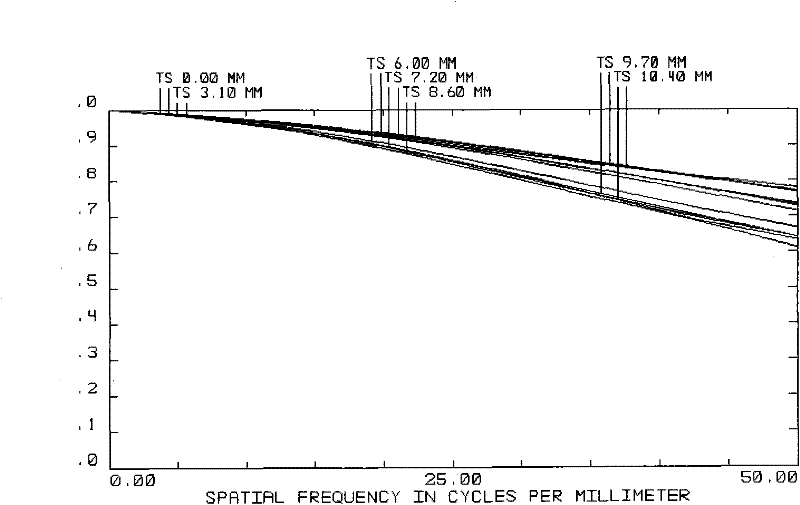

Image space telecentric projection camera lens

Owner:NANYANG LIDA PHOTOELECTRIC

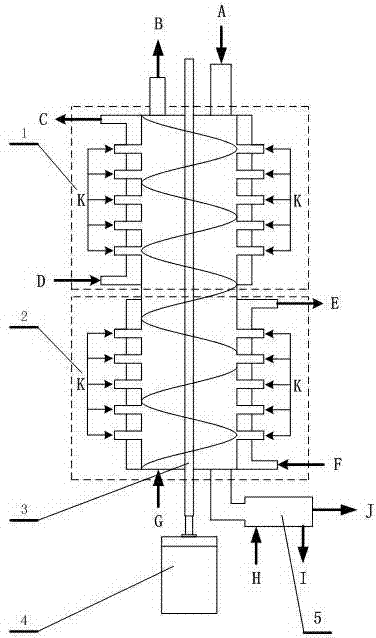

Reaction device for anode or cathode material of lithium battery

ActiveCN102416311BPromotes relative motionEvenly heatedCell electrodesChemical/physical/physico-chemical stationary reactorsElectric machineFlue gas

The invention discloses a reaction device for an anode or cathode material of a lithium battery. In the device, the lower end of a preheating section is connected with the upper end of a reaction section; a spiral feeding device passes through the insides of the preheating section and the reaction section; the lower end of the spiral feeding device is connected with a rotating motor; the bottom of the reaction section is connected with a cooling device; the outer wall of the preheating section is provide with a jacket for introducing hot flue gas; the lower part of the preheating section is provided with a hot flue gas inlet communicated with the jacket; the upper part of the preheating section is provided with a hot flue gas outlet communicated with the jacket; the outer wall of the reaction section is provided with a jacket for introducing hot flue gas; the lower part of the reaction section is provided with a hot flue gas inlet communicated with the jacket; the upper part of the reactions section is provided with a hot flue gas outlet communicated with the jacket; the preheating section and the outer wall of the reaction section are provided with loose air holes; the top of the preheating section is provided with a material inlet; a material outlet is formed outside the cooling device; and the top of the preheating section is provided with a gas outlet. The reaction device is easy to operate, runs stably, can be used for continuously and accurately producing anode and cathode materials for lithium batteries, and meets the requirement of large-scale industrial production.

Owner:济宁市无界科技有限公司

Corrosion-resistant treatment method for aluminum alloy parts with pipes

ActiveCN103822053BExtended service lifeImprove anti-corrosion performancePretreated surfacesCorrosion preventionMetallic aluminumChloride

The invention belongs to the technical field of a corrosion resistance treatment for aluminum alloy workpieces, and particularly relates to a corrosion resistance handling method for aluminum alloy workpieces with pipes. The corrosion resistance handling method includes: coating an anti-corrosion material on the inner wall of the pipe of the aluminum alloy workpiece, sintering the aluminum alloy workpiece when the anti-corrosion material is dry, and then cooling. By means of forming a uniform coating material on the inner wall of the pipe via the anti-corrosion material, a corroding mechanism formed by active metallic aluminum and chloride ions as well as water is stopped, so that the corrosion resistance handling method can reach a good corrosion resistance effect and can fundamentally prevent the metallic aluminum from contacting with the chloride ions and the water; furthermore, the anti-corrosion material is resistant to corrosion of the chloride ions and the water, so that the corrosion resistance handling method is high in reliability, and service life of the aluminum alloy workpieces is prolonged. Long-term high-temperature high-pressure sintering to the aluminum alloy workpieces is not required, so that energy consumption and cost are reduced, working efficiency and productivity are improved, and requirements on large-scale production can be well met.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Box folding device

Owner:GREE ELECTRIC APPLIANCES INC

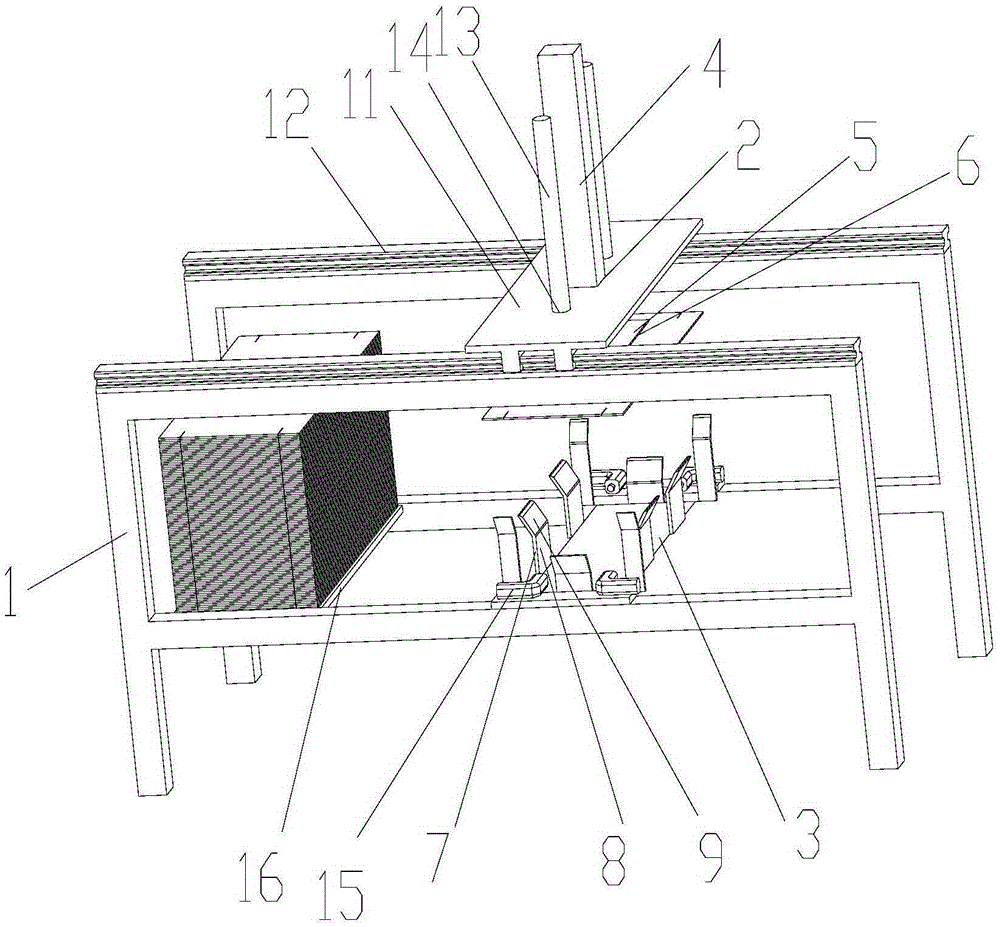

An automatic production device for all-wood discs

ActiveCN105108864BImprove unityImprove controllabilityWood working apparatusLayout planningWell drilling

The invention discloses an automatic production device for all-wood discs. Slot milling table, chamfering table, center hole drilling machine, etc. The invention efficiently combines the processes of assembling, nailing, drilling the center hole, drilling the cable hole, milling the cylinder groove, cutting the circle, drilling the designated hole, drilling the threaded hole and chamfering and milling, so as to achieve the automatic production of the whole wooden plate. The purpose of the film, the layout planning is reasonable, the labor cost is greatly saved, and the production preparation time is also effectively shortened.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

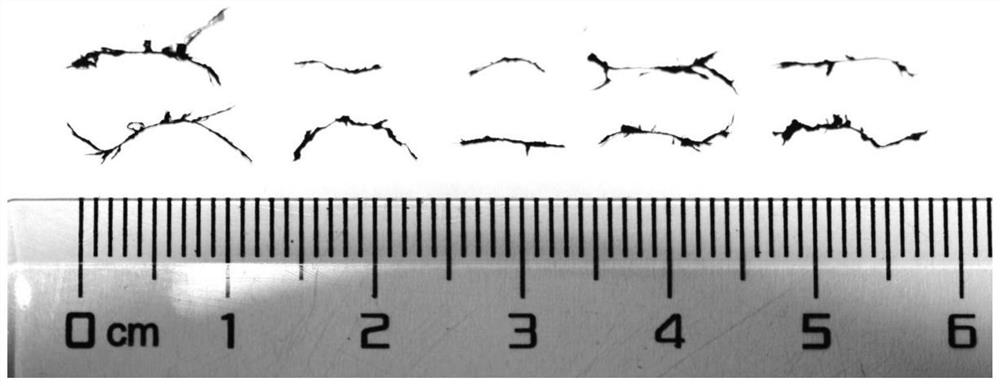

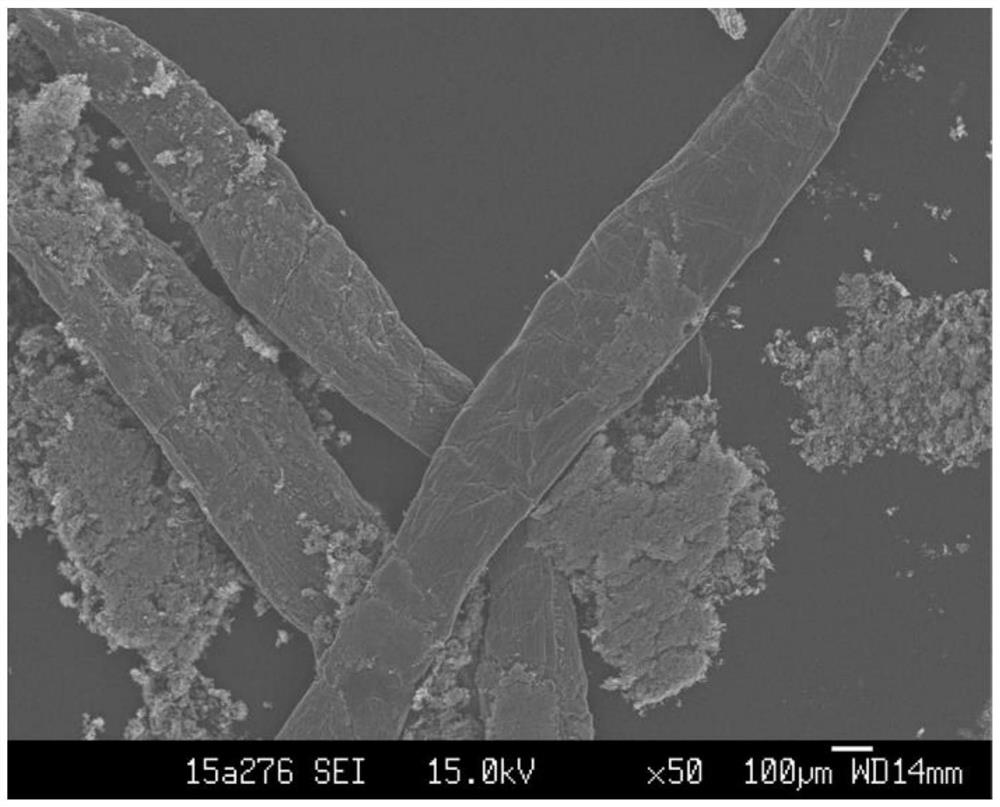

A kind of preparation method of ultralong polypyrrole nanofiber

The invention discloses a preparation method of ultra-long polypyrrole nanofibers. The ultra-long polypyrrole nanofiber comprises the following steps: mixing pyrrole monomer with a solvent, reacting the obtained pyrrole monomer solution with vanadium pentoxide sol, and then reacting with an oxidant to obtain centimeter-level polypyrrole nanofiber. The invention provides a method for preparing polypyrrole nanofibers with a centimeter-level length, and the method has the characteristics of simple operation, easy realization and the like. Compared with conventional powdered polypyrrole nanofibrous particles, this ultralong conductive nanofiber can be directly used in chemical, stress, electrical resistance and other sensing devices.

Owner:SUN YAT SEN UNIV

Combined extraction method of polysaccharides and total flavonoids from purslane based on micellar media treatment

ActiveCN110101728BHigh extraction rateAvoid wastingAntibacterial agentsAntimycoticsPolysaccharideMicelle

The invention provides a high-efficiency joint extraction method of high-purity polysaccharides and total flavonoids of purslane, which relates to a deproteinization and depigmentation method of the extract, which can efficiently and rapidly jointly extract purslane polysaccharides and total flavonoids from purslane in large quantities. total flavonoids, and use a specific micellar medium to extract single-step operations combined with removal of protein and pigment components in the polysaccharide extraction step, avoiding the disadvantages of deproteinization and pigment removal in the prior art when purslane polysaccharides are purified, The extraction process is shortened and is suitable for mass extraction.

Owner:NANJING XIAOZHUANG UNIV

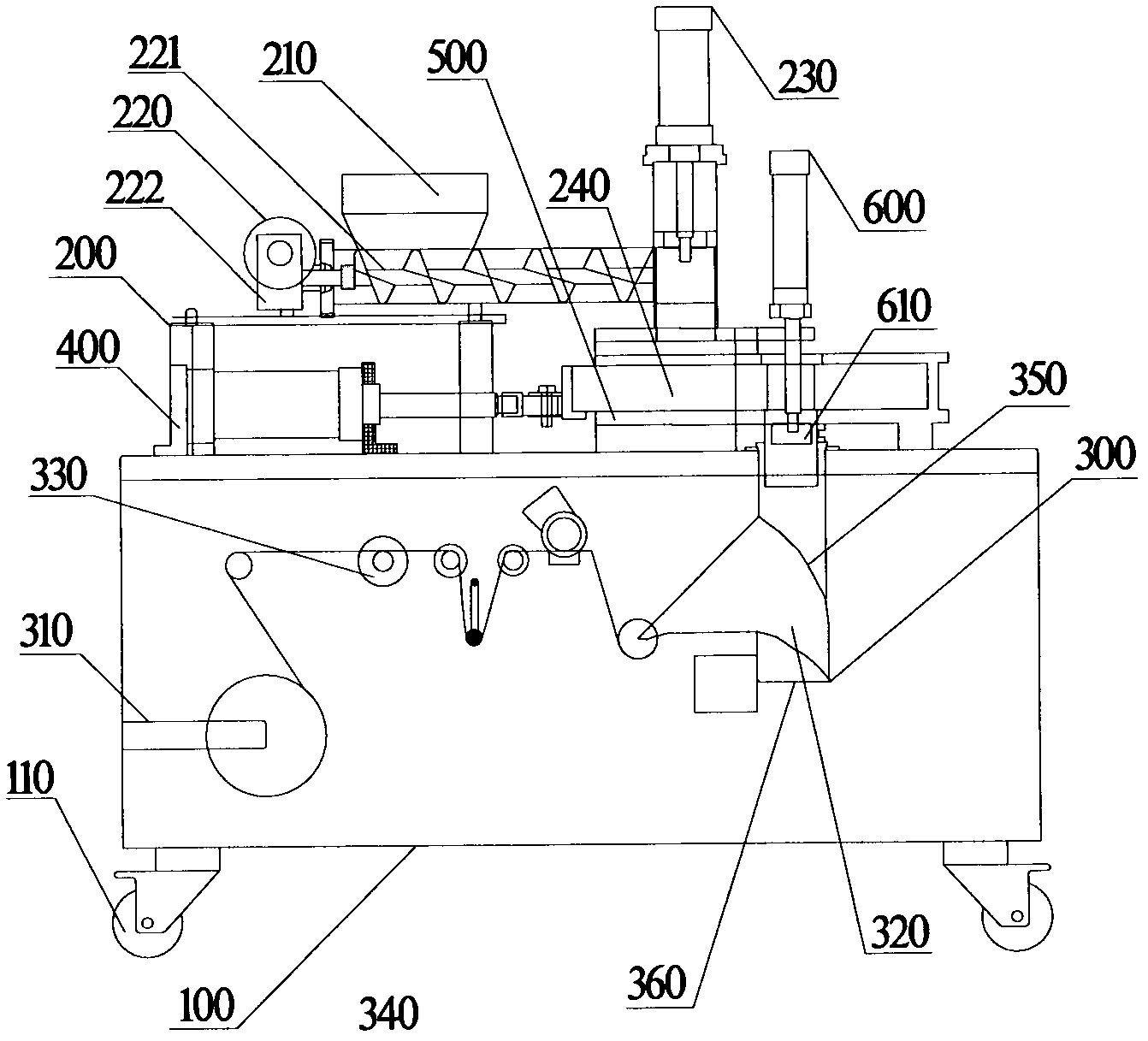

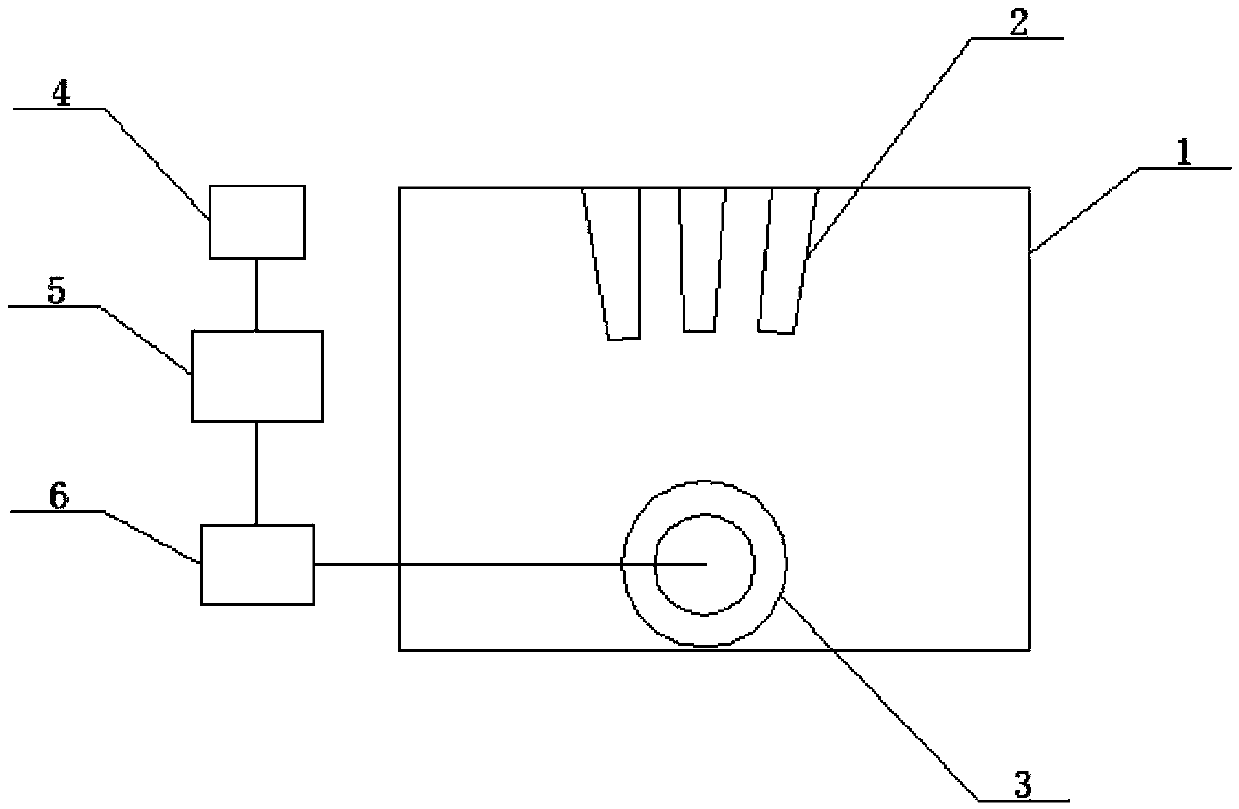

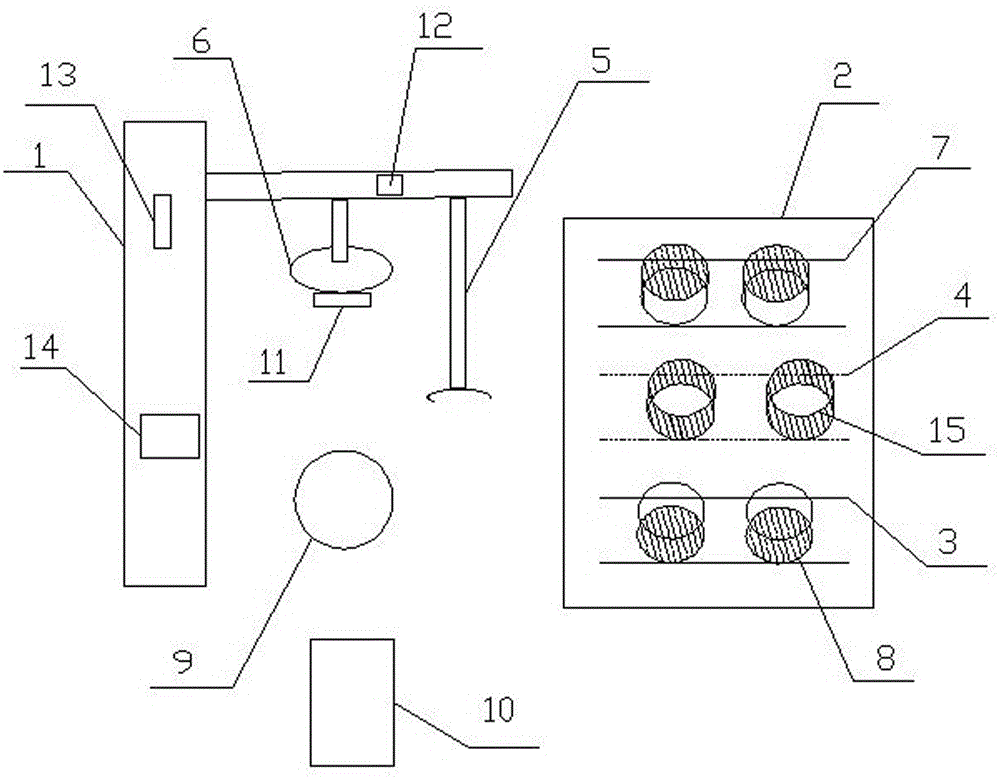

Semiconductor porcelain plate sand blasting machine capable of performing timing rotating sand blasting

InactiveCN103962969APracticalSimple structureAbrasive blasting machinesGrinding/polishing apparatusSand blastingBlast effects

The invention provides a semiconductor porcelain plate sand blasting machine capable of performing timing rotating sand blasting, and relates to the field of semiconductor processing equipment. According to the semiconductor porcelain plate sand blasting machine, a plurality of spraying guns (2) are arranged on the top end in a sand blasting machine body (1), the orientations of the plurality of the spraying guns (2) are the same, a rotation disk (3) is arranged inside the sand blasting machine body (1) and on the orientation position of the plurality of the spraying guns (2), the semiconductor porcelain plate sand blasting machine further comprises a timer (4), a controller (5) and a driver (6), the rotation disk (3) is connected with the driver (6) arranged on the outer portion of the sand blasting machine body (1), the driver (6) is connected with the controller (5), and the timer (4) is connected with the controller (5). According to the present invention, with the semiconductor porcelain plate sand blasting machine, timing rotating sand blasting can be performed on the semiconductor porcelain plate, the problems of high labor intensity, low work efficiency and not good sand blasting effect of manual sand blasting can be solved, characteristics of no requirements of worker care at any time, time saving, labor saving, simple structure, easy achieving and strong practicality are provided, and the requirements of mass production can be met.

Owner:KUNSHAN SHANGDAZHI MACHINERY

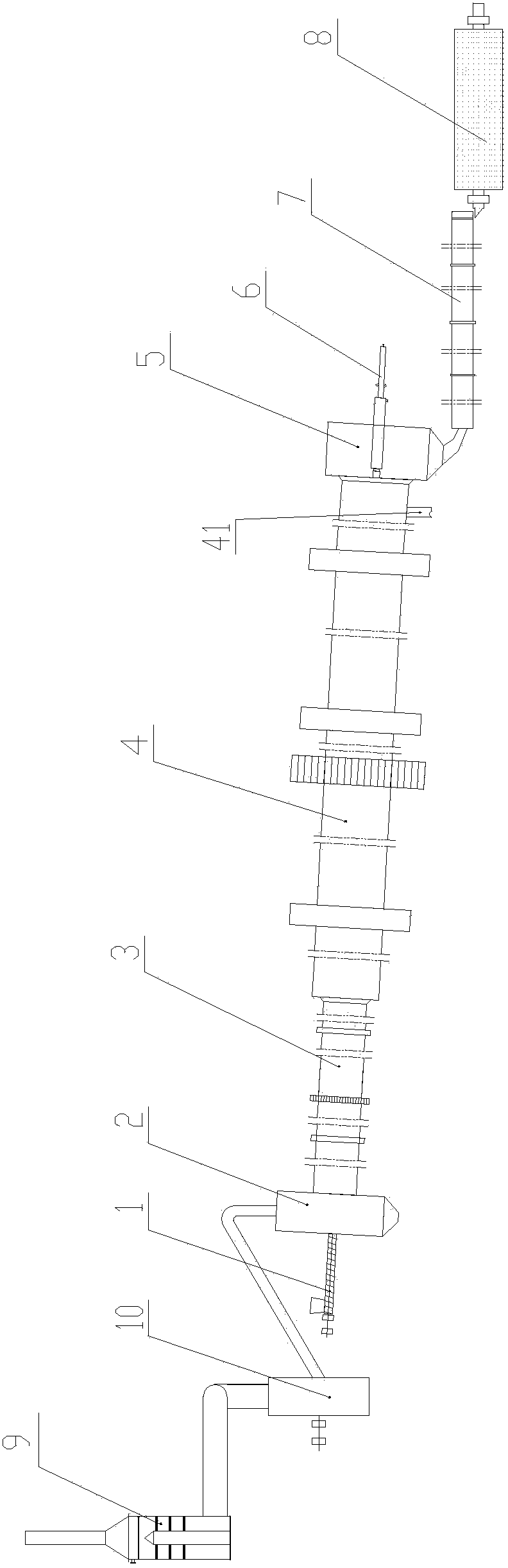

Manganese oxide reduction system of internal heating type rotary kiln

The invention discloses a manganese oxide reduction system of an internal heating type rotary kiln, which comprises a preheating drying kiln, the internal heating type rotary kiln, a powder spraying type combustor, a water cooling conveyer and a desulphurization dust removing tower, wherein the preheating drying kiln, the internal heating type rotary kiln, the powder spraying type combustor and the water cooling conveyer are connected sequentially in an inclined manner; the preheating drying kiln is a feed end of the system, and the water cooling conveyer is a discharge end of the system; and the desulphurization dust removing tower is connected to a feed end of the preheating drying kiln through a fan and a pipeline. The desulphurization dust removing tower is a countercurrent rotation type water film desulphurization dust removing tower and includes a tower body made of plastic. A lower part of the tower body is provided with an inlet chamber, an upper end is provided with an emptying chimney, and an upper part in the tower body is provided with a spraying device, a multi-layer water diversion sieve plate and a tilting swirling flow plate. The water diversion sieve plate is arranged below the spraying device. The tilting swirling flow plate is arranged between the water diversion sieve plate and the inlet gas. The manganese oxide reduction system of the internal heating type rotary kiln used for producing electrolysis manganese metal largely reduces the production of waste residue, and has advantages of high mechanization degree, high productivity, and strong technique continuity.

Owner:湘西自治州德邦锰业有限责任公司

An automatic fitting device for a magnetic ring insulating sleeve

Owner:WUJIANG ZHENYU SEWING EQUIP

Method for producing heat insulation antiblocking cavity based on silicon substrate

InactiveCN101450787BThe process steps are simpleLow costDecorative surface effectsChemical vapor deposition coatingThermal insulationSilicon

The invention discloses an adiabatic anti-adhesion cavity manufacturing method based on silicon substrates. The method comprises the steps of depositing a SiNX film on the upper surface of a silicon substrate, photoetching and etching the SiNX film so as to form a corrosion window, corroding the upper surface of the silicon substrate where the corrosion window is formed, forming a cavity with silicon protruding points, depositing the SiNX film on the upper surface of the silicon substrate and sealing the corrosion window. The method provided by the invention has the advantages of simple process steps, low cost, high production efficiency, stable process, high practical value and capability of adapting to the requirements of mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

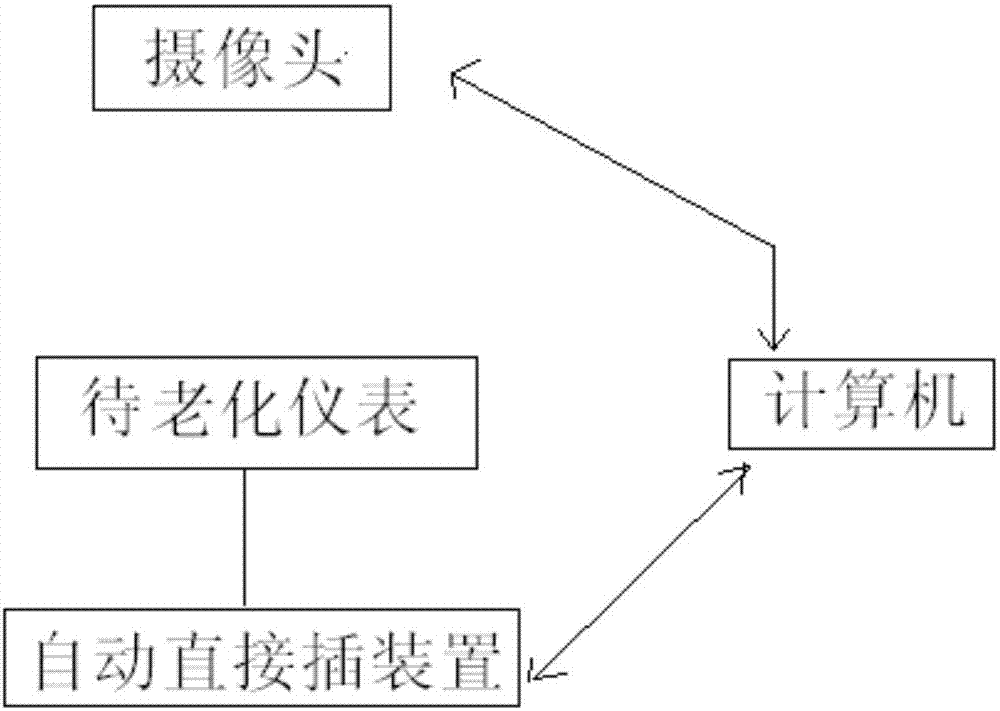

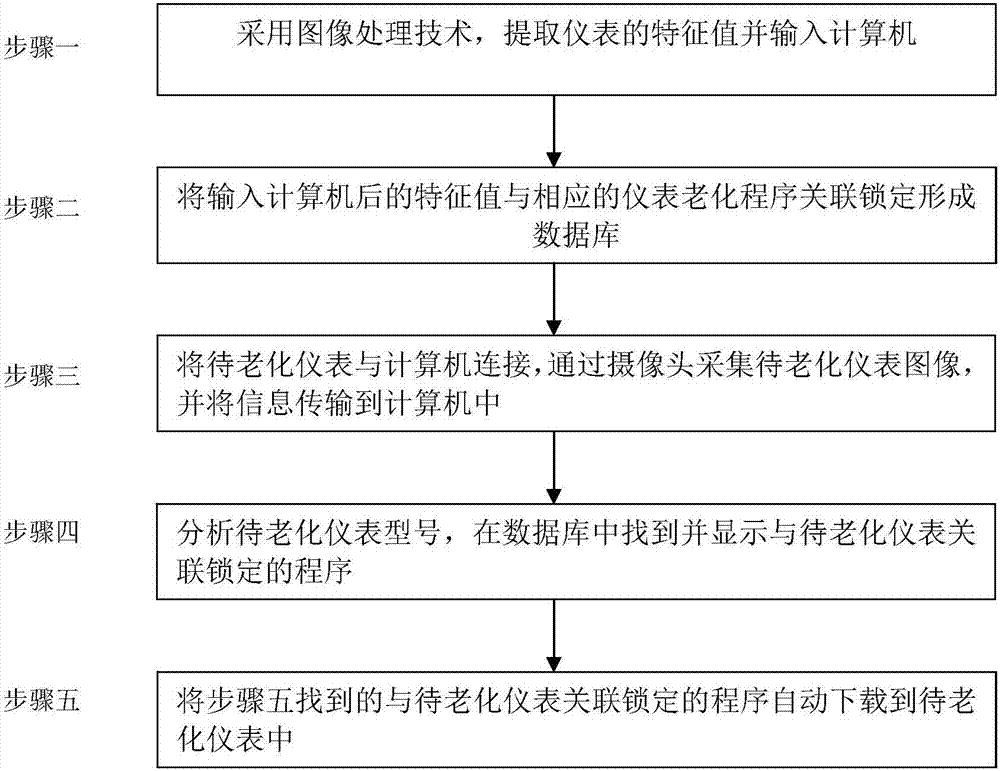

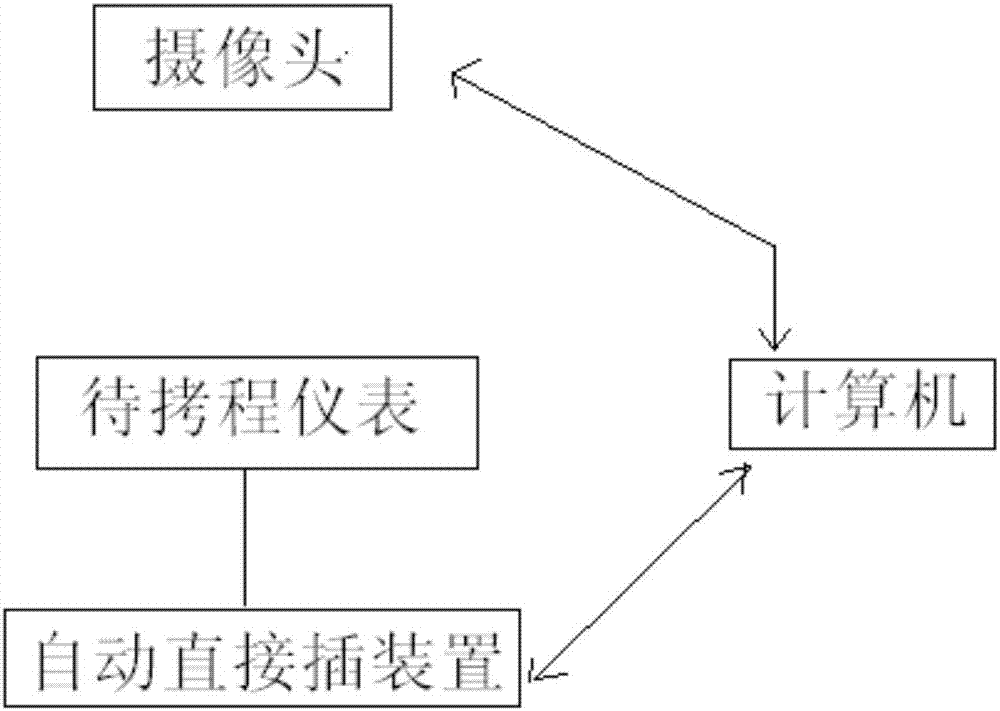

System and method for self-adaptively downloading automobile instrument aging processes on basis of graphic comparison mode

PendingCN107038049AImprove accuracyImprove efficiencyProgram loading/initiatingSoftware deploymentGraphicsImaging processing

The invention discloses a system and method for self-adaptively downloading automobile instrument aging processes on the basis of a graphic comparison mode, relates to a system and method for self-adaptively downloading instrument aging processes, and aims at solving the problem that the existing downloading of instrument aging processes is relatively low in correctness due to excessive manmade operations. The system comprises an instrument information input module, a database forming module, a to-be-aged instrument information acquisition module, a to-be-aged instrument model analysis module and a process downloading module, wherein the instrument information input module is used for adopting an image processing technology to extract feature values of instruments and inputting the feature values into a computer; the database forming module is used for associating and locking the feature values input in the computer with corresponding instrument aging processes to form a database; the to-be-aged instrument information acquisition module is used for connected to-be-aged instruments with the computer and transmitting information into the computer; the to-be-aged instrument model analysis model is used for finding and displaying processes associated and locked with the to-be-aged instruments in the database; and the process downloading module is used for automatically downloading the found processes associated and locked with the to-be-aged instruments into the to-be-aged instruments. The system and method disclosed by the invention are used for the field of instrument aging process downloading.

Owner:AEROSPACE HI TECH HLDG GROUP

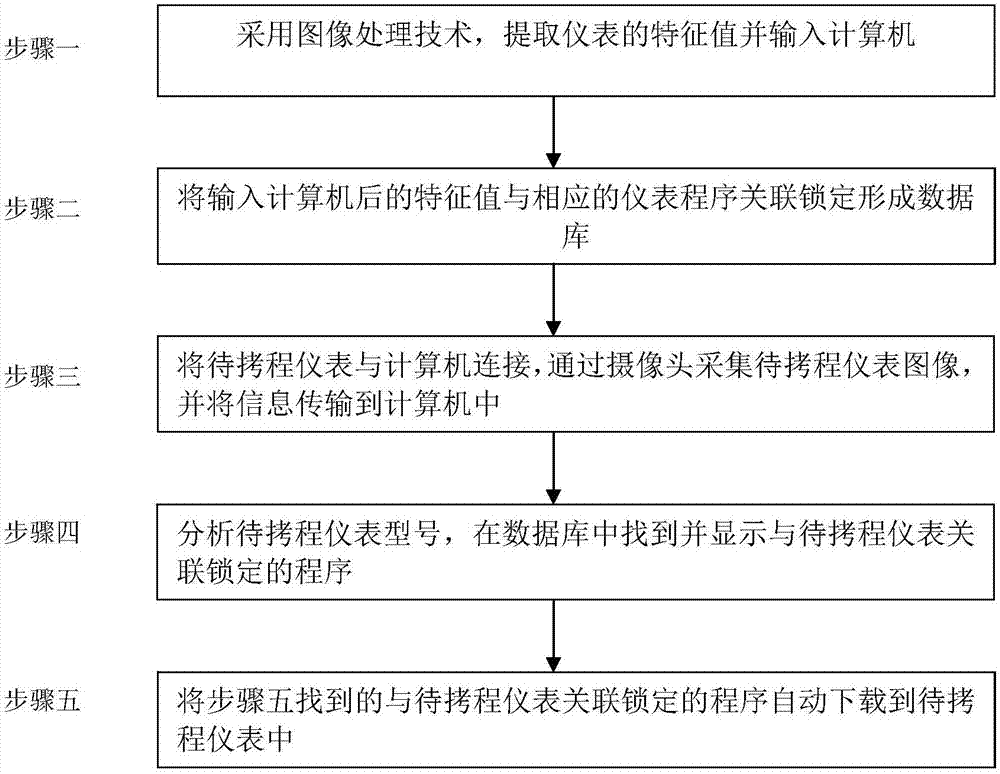

Automobile instrument program adaptive downloading system and method based on graphic comparison mode

InactiveCN107122210AImprove accuracyImprove efficiencyCharacter and pattern recognitionProgram loading/initiatingGraphicsImaging processing

The invention discloses an automobile instrument program adaptive downloading system and method based on a graphic comparison mode, relates to automobile instrument program adaptive downloading systems and methods and aims to solve the problem that existing instrument program downloading is low in accuracy due to excessive manual operation. The method comprises the steps that an image processing technology is adopted, and a feature value of an instrument is extracted and input into an instrument information input module of a computer; the feature value input into the computer is associated and locked with a corresponding instrument program to form a database formation module of a database; a program-to-be-copied instrument is connected with the computer, and information is transmitted to a program-to-be-copied instrument information collection module in the computer; a program-to-be-copied instrument model analysis module of a program associated and locked with the program-to-be-copied instrument is found in the database and displayed; and the found program which is associated and locked with the program-to-be-copied instrument is automatically downloaded to a program downloading module in the program-to-be-copied instrument. The automobile instrument program adaptive downloading system and method are applied to the field of instrument program downloading.

Owner:AEROSPACE HI TECH HLDG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com