A kind of preparation method of ultralong polypyrrole nanofiber

A polypyrrole nanofiber technology, which is applied in the field of preparation of ultra-long polypyrrole nanofibers, can solve the problems of limiting the application of polypyrrole nanofibers forming ability and the like, and achieves the effects of adapting to large-scale production, being easy to implement and simple to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

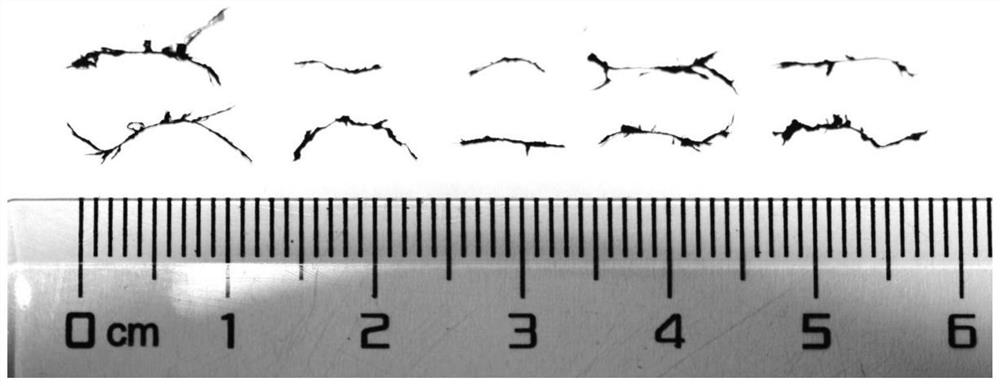

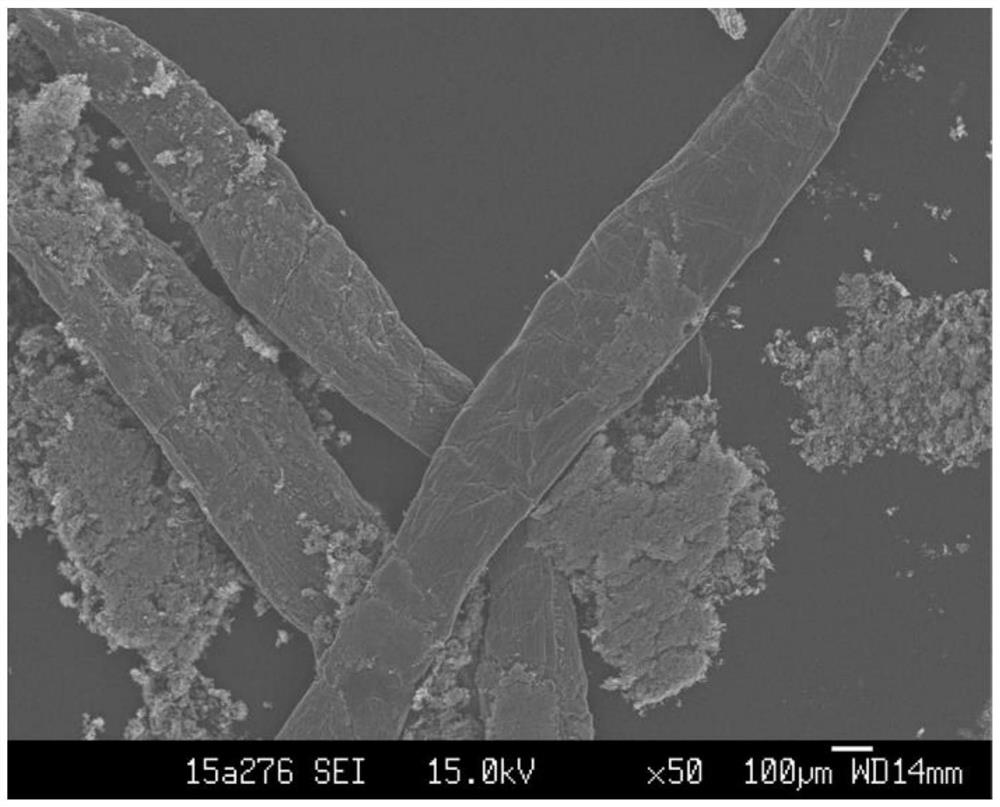

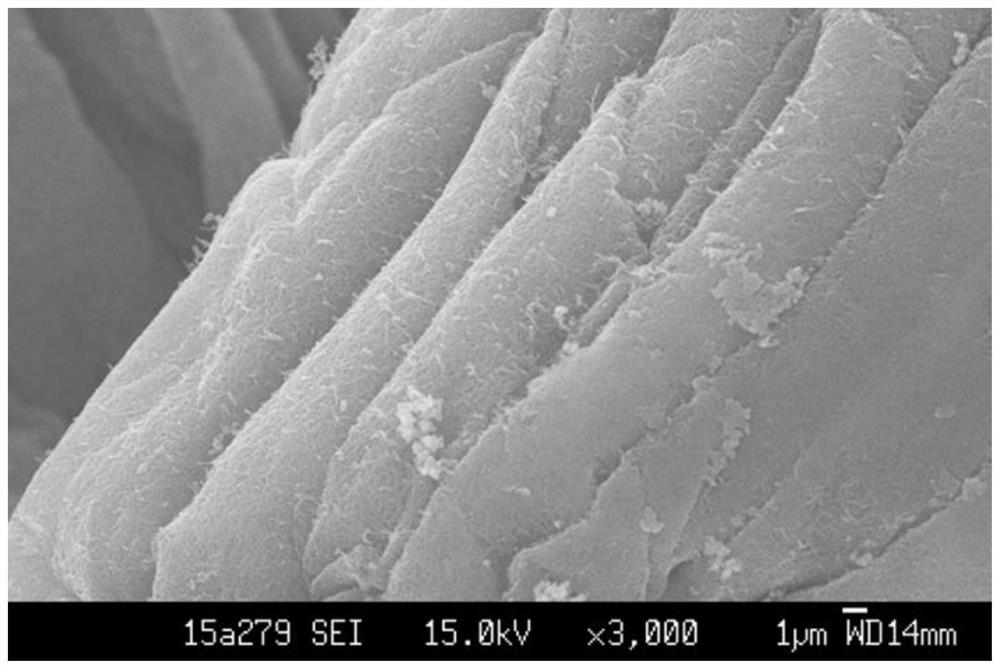

[0041] Add 1 mL of pyrrole monomer into 60 mL of hydrochloric acid solution with a concentration of 1 mol / L, and stir the solution for 5 minutes at a speed of 800 r / min to achieve the effect of uniformly dispersing the pyrrole monomer. Then inject 1 mL of vanadium pentoxide gel into the pyrrole monomer solution at a rate of 1 mL / second under stirring, and keep the reaction for 1-2 minutes. Then 1.09 g of ammonium persulfate was added to the reaction solution, and the reaction was continued for 1 hour while stirring. After the reaction was completed, the reaction solution was placed in a Buchner funnel and vacuum filtered to separate the product. Then, the product is washed with hydrochloric acid, deionized water, and ethanol in the order, and the amount of solvent used for each washing is at least 30 mL, and the washing process is repeated at least three times. After washing, the product is dried in an oven at 45°C for 12 hours to obtain polypyrrole nanofibers with a length o...

Embodiment 2

[0043] Add 1 mL of pyrrole monomer to 60 mL of 0.5 mol / L hydrochloric acid solution, and stir the solution for 5 minutes at a speed of 1000 r / min to achieve the effect of uniformly dispersing the pyrrole monomer. Then inject 2 mL of vanadium pentoxide gel into the pyrrole monomer solution at a rate of 1 mL / sec under stirring, and keep the reaction for 1-2 minutes. Then 1.0 g of ferric chloride was added into the reaction solution, and the reaction was continued for 1 hour while stirring. After the reaction was completed, the reaction solution was placed in a Buchner funnel and vacuum filtered to separate the product. Then, the product is washed with hydrochloric acid, deionized water, and ethanol in the order, and the amount of solvent used for each washing is at least 30 mL, and the washing process is repeated at least three times. After washing, the product is dried in an oven at 45°C for 12 hours to obtain polypyrrole nanofibers with a length of 0.5-2 cm.

Embodiment 3

[0045]Add 1 mL of pyrrole monomer into 60 mL of a mixed solution of hydrochloric acid and ethanol water with a concentration of 1 mol / L (the volume ratio of ethanol and water is 1:5, the volume of hydrochloric acid is 50 mL, and the volume of ethanol aqueous solution is 10 mL), at 800 r / min The solution was stirred for 3 minutes to achieve the effect of uniformly dispersing the pyrrole monomer. Then inject 1 mL of vanadium pentoxide gel into the pyrrole monomer solution at a rate of 1 mL / second under stirring, and keep the reaction for 1-2 minutes. Then add 4mLH 2 o 2 Hydrogen peroxide with a mass concentration of 30% was added to the reaction solution, and the reaction was continued for 1 hour while stirring. After the reaction was completed, the reaction solution was placed in a Buchner funnel and vacuum filtered to separate the product. Then, the product is washed with hydrochloric acid, deionized water, and ethanol in the order, and the amount of solvent used for each w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com