Patents

Literature

7012results about How to "Increase reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

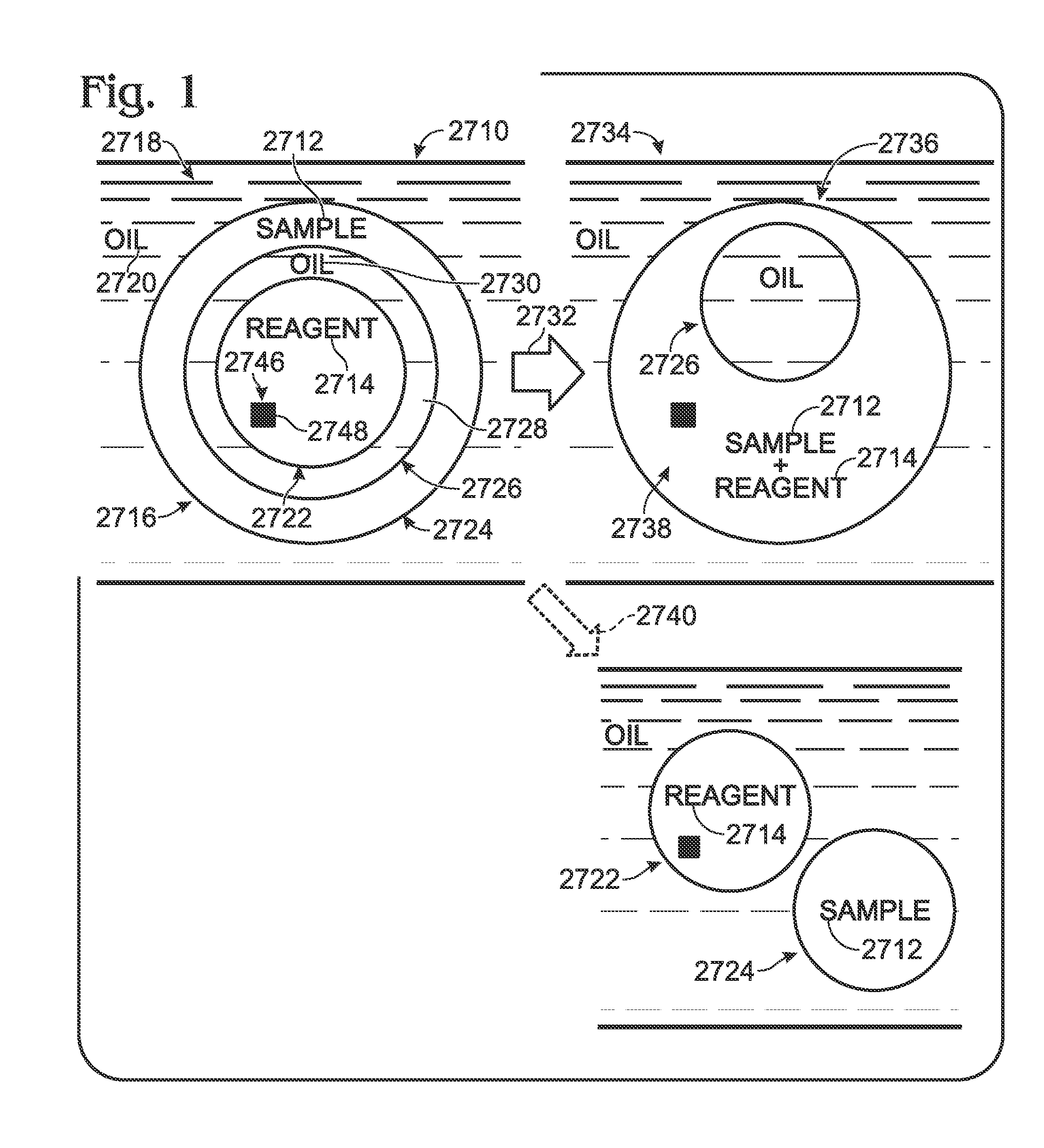

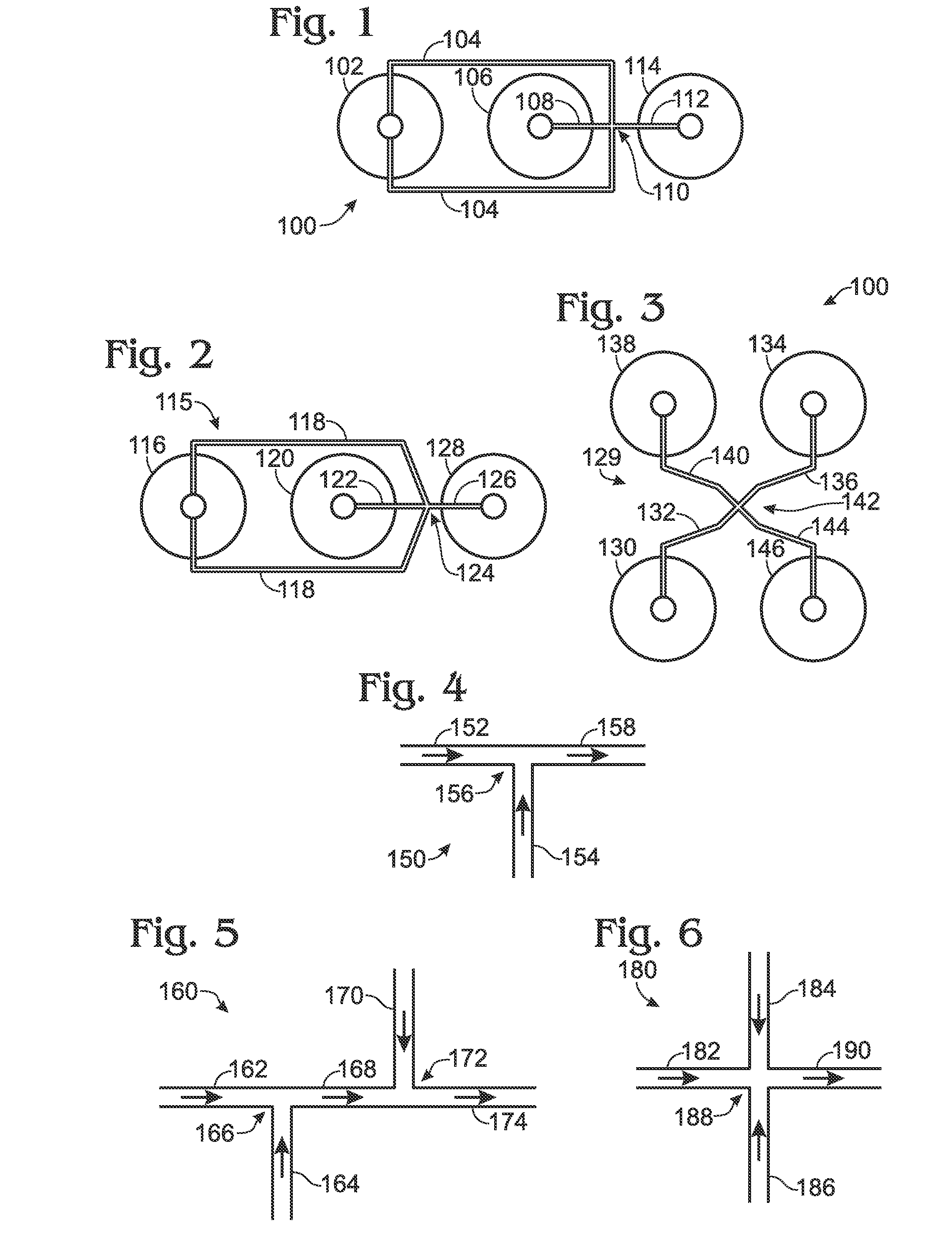

System for mixing fluids by coalescence of multiple emulsions

ActiveUS20110053798A1High-confidence resultLower the volumeSequential/parallel process reactionsHeating or cooling apparatusEmulsionChemistry

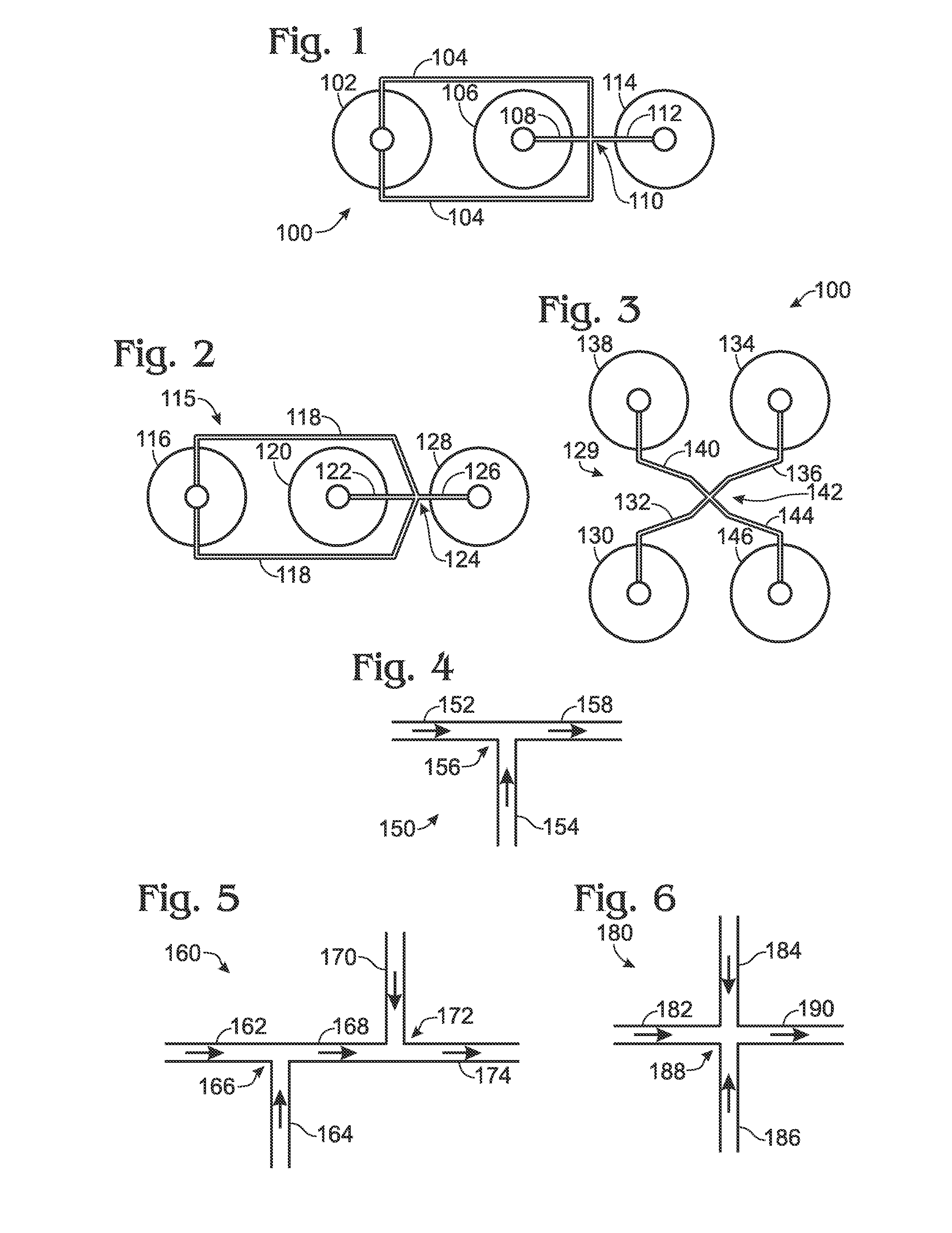

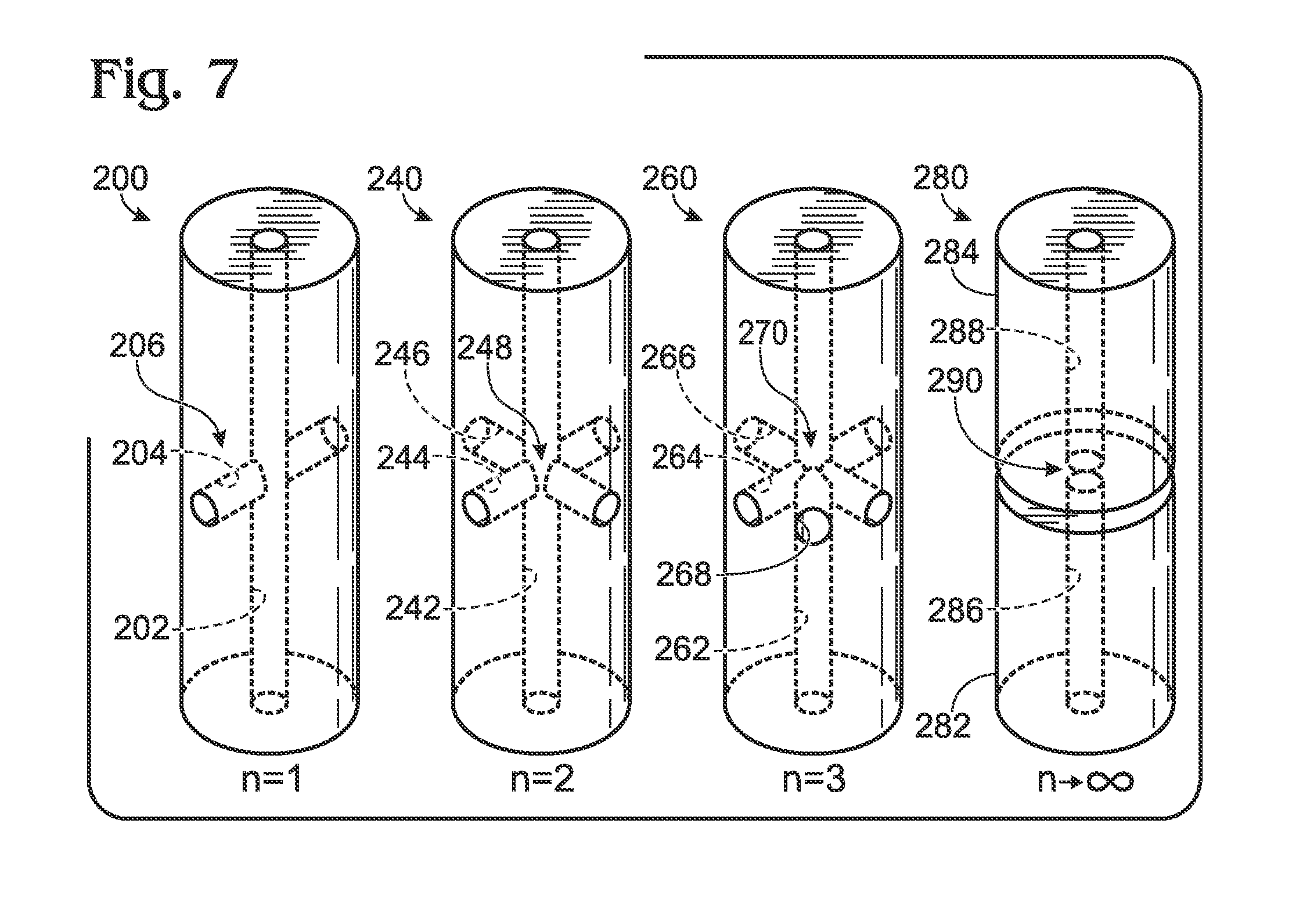

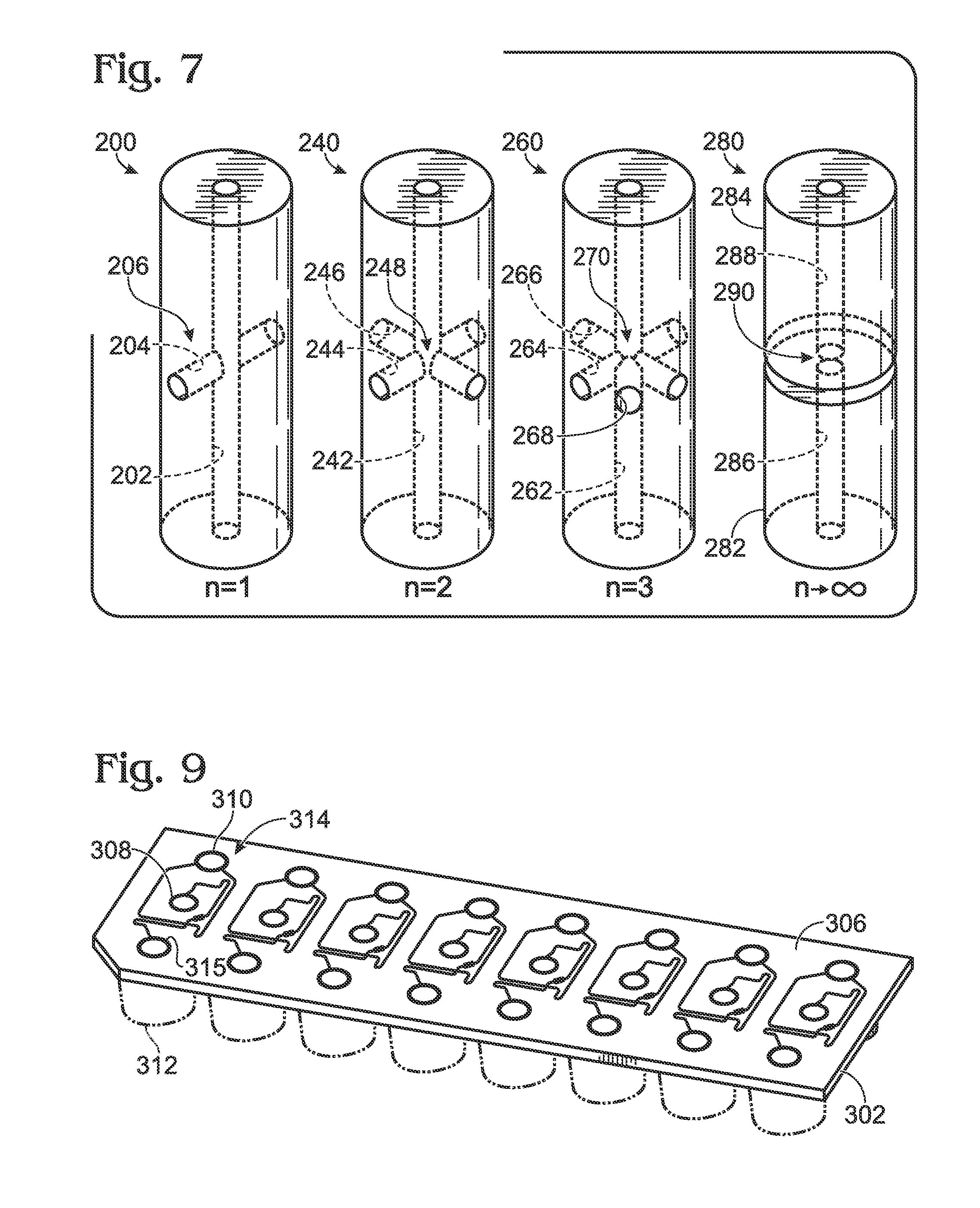

System, including methods, apparatus, compositions, and kits, for the mixing of small volumes of fluid by coalescence of multiple emulsions.

Owner:BIO RAD LAB INC

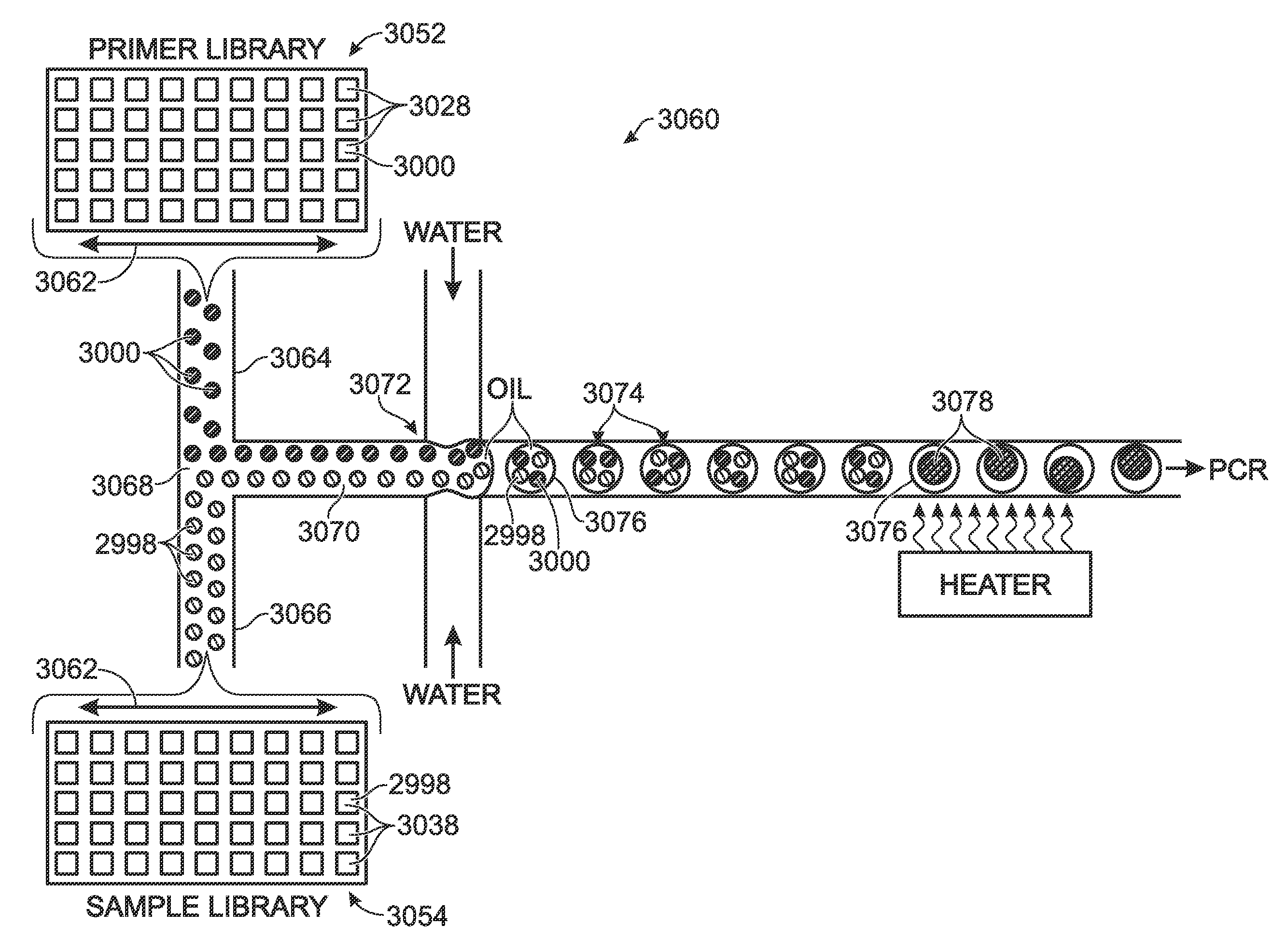

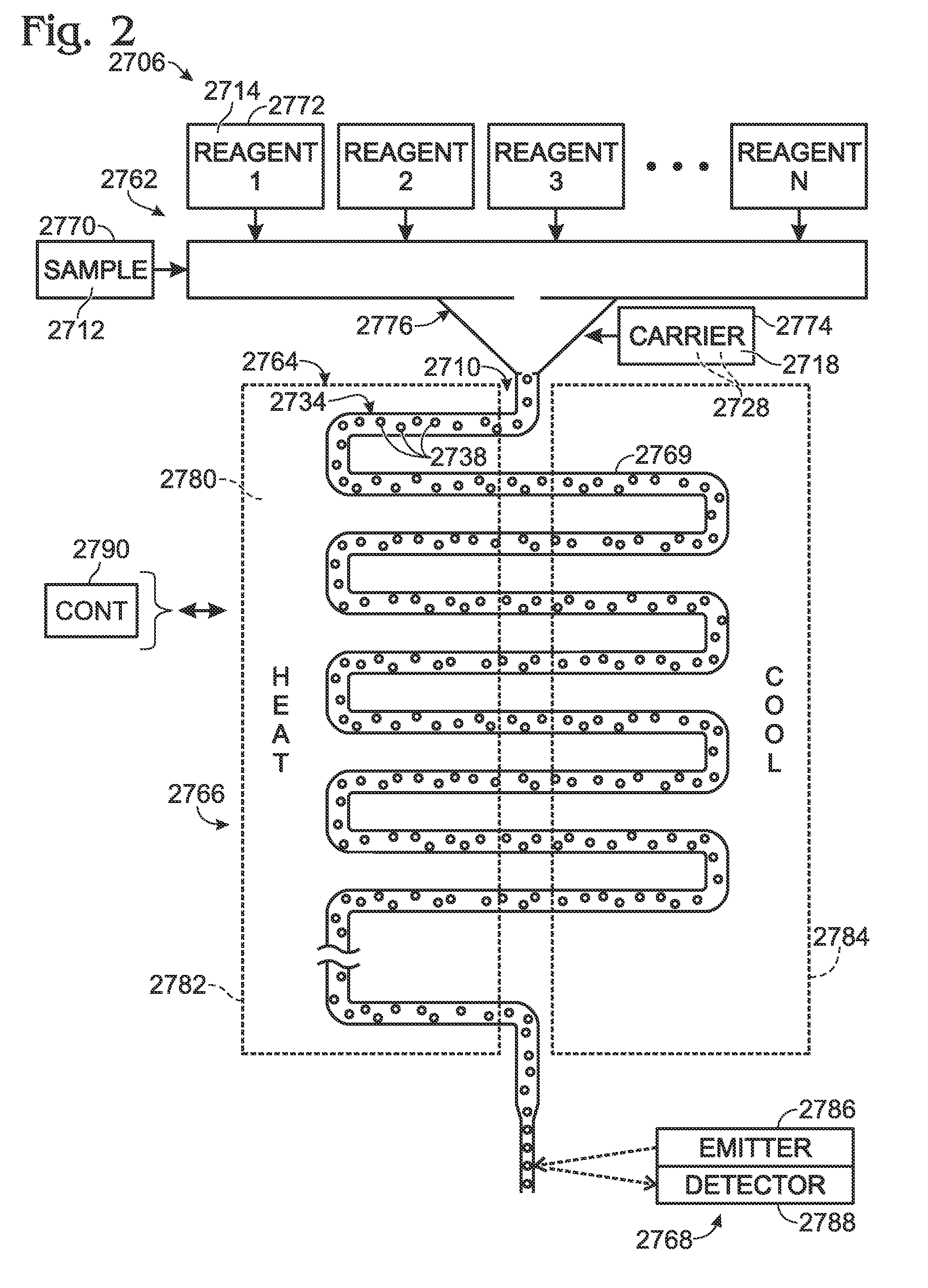

Droplet generation for droplet-based assays

ActiveUS20120190032A1High-confidence resultLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsAssayEmulsion

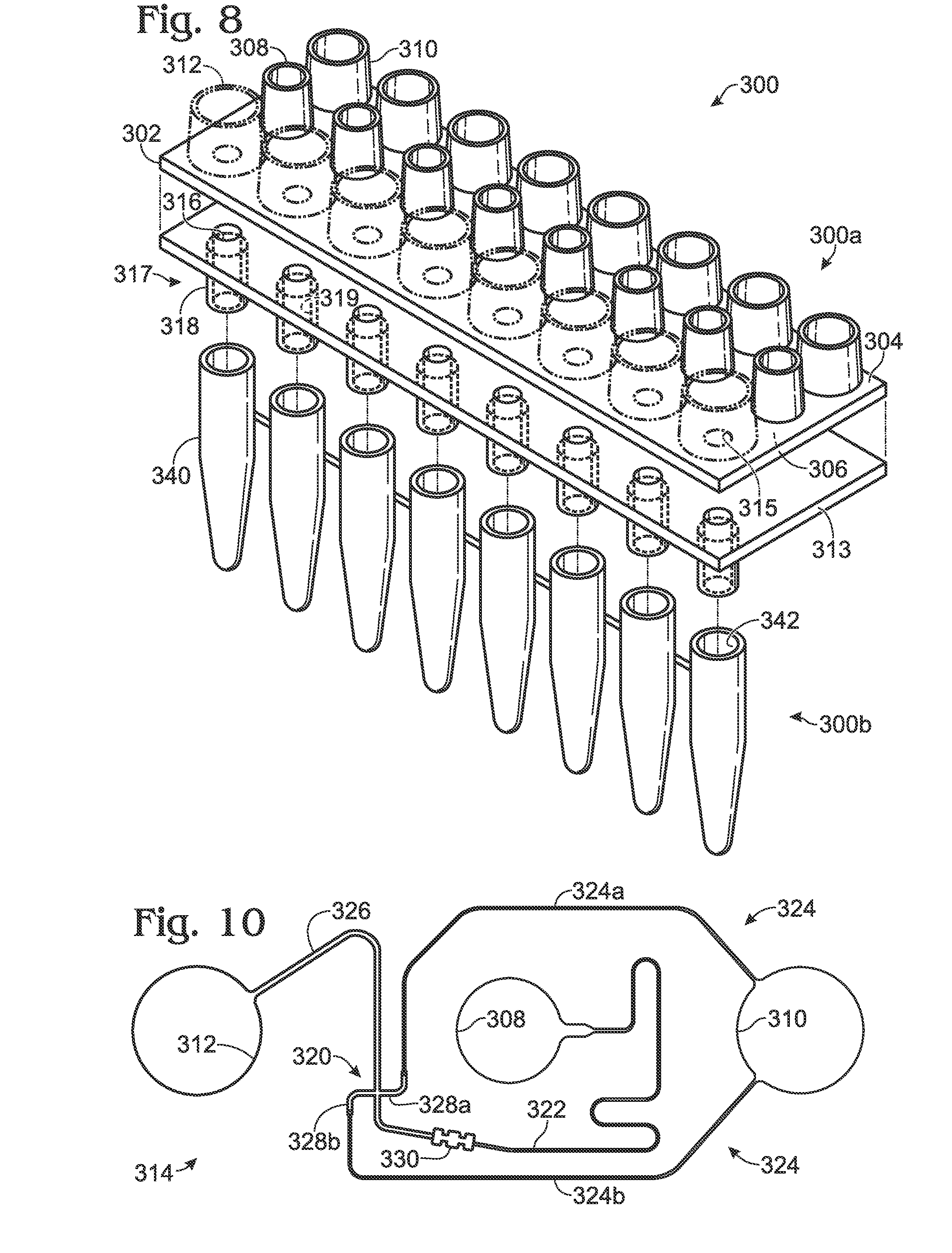

A system, including method and apparatus, for generating droplets suitable for droplet-based assays. The disclosed systems may include either one-piece or multi-piece droplet generation components configured to form sample-containing droplets by merging aqueous, sample-containing fluid with a background emulsion fluid such as oil, to form an emulsion of sample-containing droplets suspended in the background fluid. In some cases, the disclosed systems may include channels or other suitable mechanisms configured to transport the sample-containing droplets to an outlet region, so that subsequent assay steps may be performed.

Owner:BIO RAD LAB INC

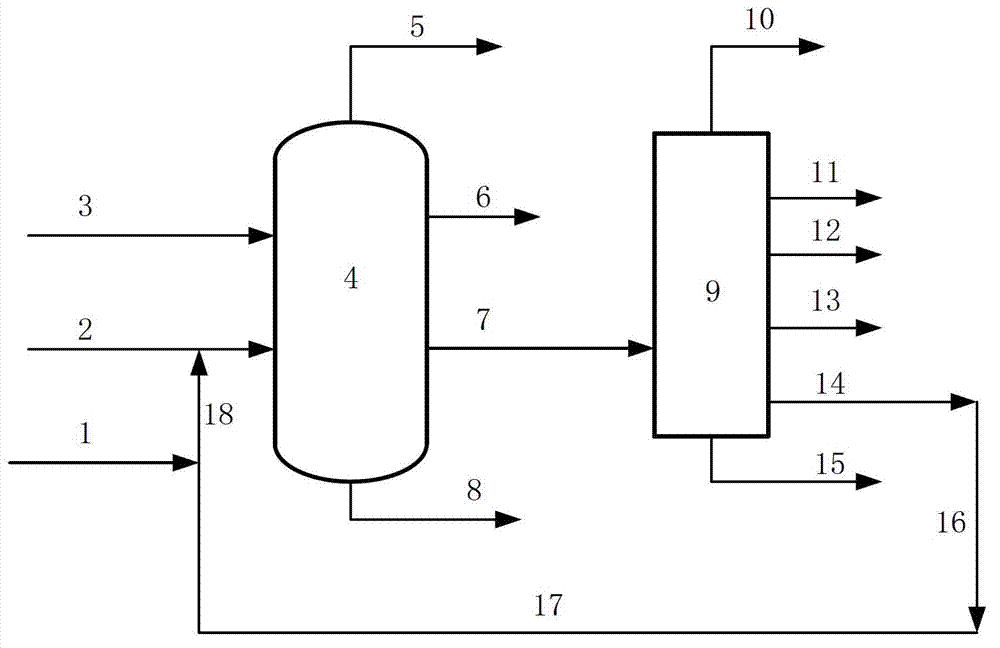

Device and technique for producing cyclohexane by benzene hydrogenation

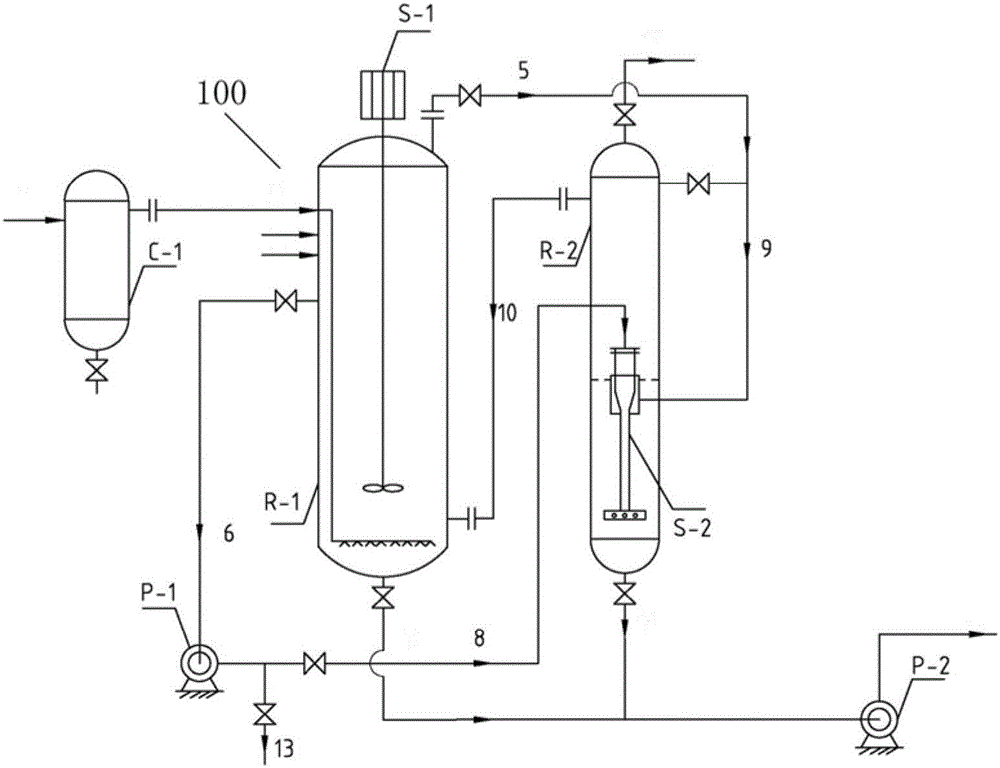

ActiveCN106187660AImprove mass transfer efficiencyIncrease reaction rateHydrocarbon by hydrogenationBenzeneGas phase

The invention discloses a device and technique for producing cyclohexane by benzene hydrogenation. The device for producing cyclohexane by benzene hydrogenation comprises a reactor, a superfine bubble generator and a bubble breaker, wherein the reactor is provided with a first containing cavity; the wall of the first containing cavity is provided with a feed port, a circulation discharge port, a circulation return port and a gas phase outlet; the superfine bubble generator is provided with a second containing cavity; the wall of the second containing cavity is provided with a return port and a gas phase outlet; the return port of the superfine bubble generator communicates with the circulation return port of the reactor; the bubble breaker is arranged in the second containing cavity; the bubble breaker is provided with a gas phase inlet and a liquid phase inlet which communicates with the circulation discharge port of the reactor; and the gas phase inlet of the bubble breaker communicates with the gas phase outlet of the reactor. The device disclosed by the embodiment of the invention has the advantages of high mass transfer efficiency, high reaction rate, short reaction time, low material consumption and energy consumption, simple structure, low manufacturing cost and low maintenance cost.

Owner:NANJING UNIV

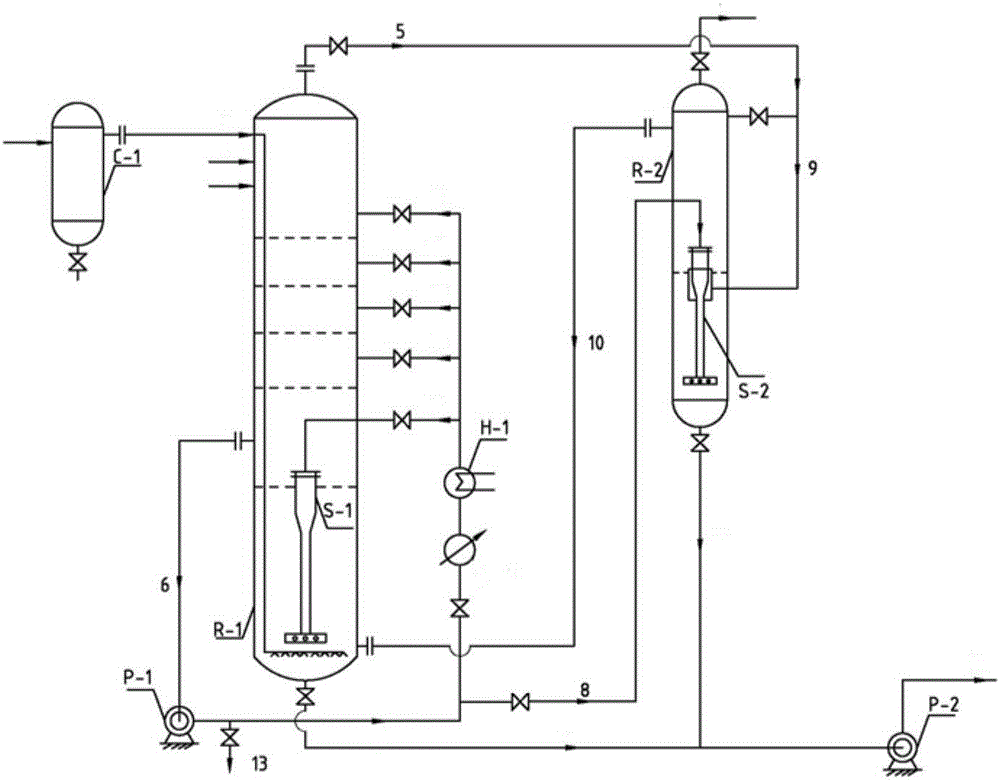

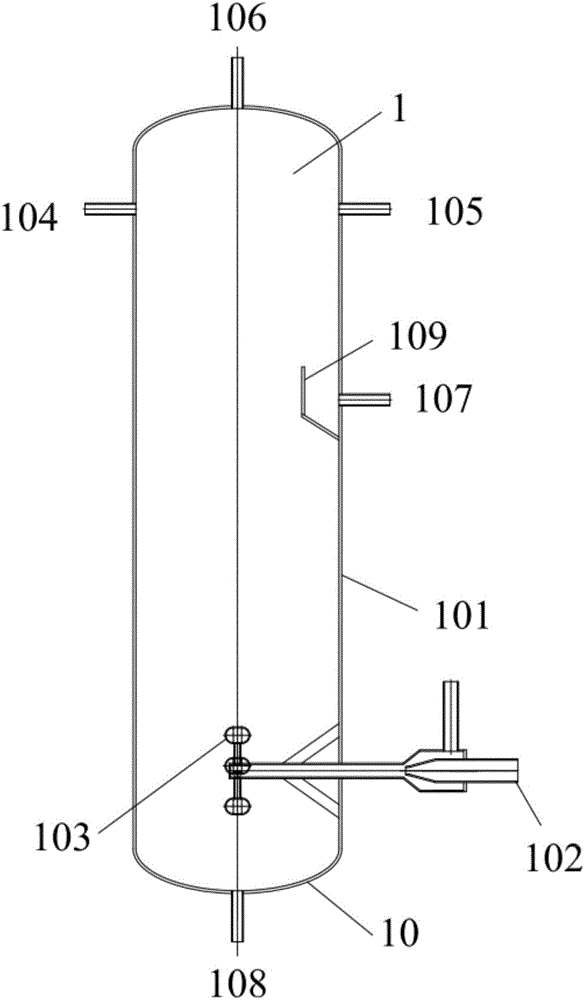

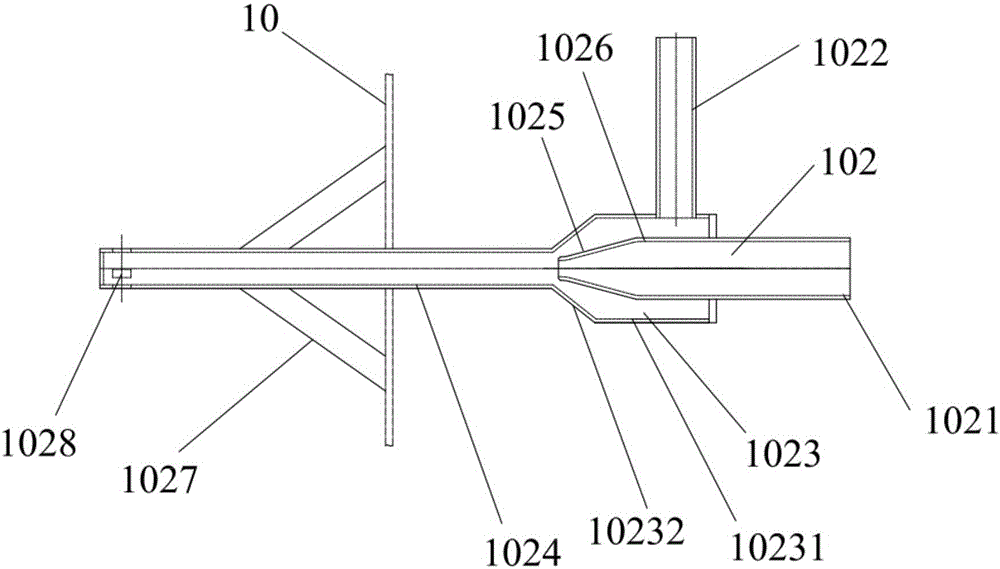

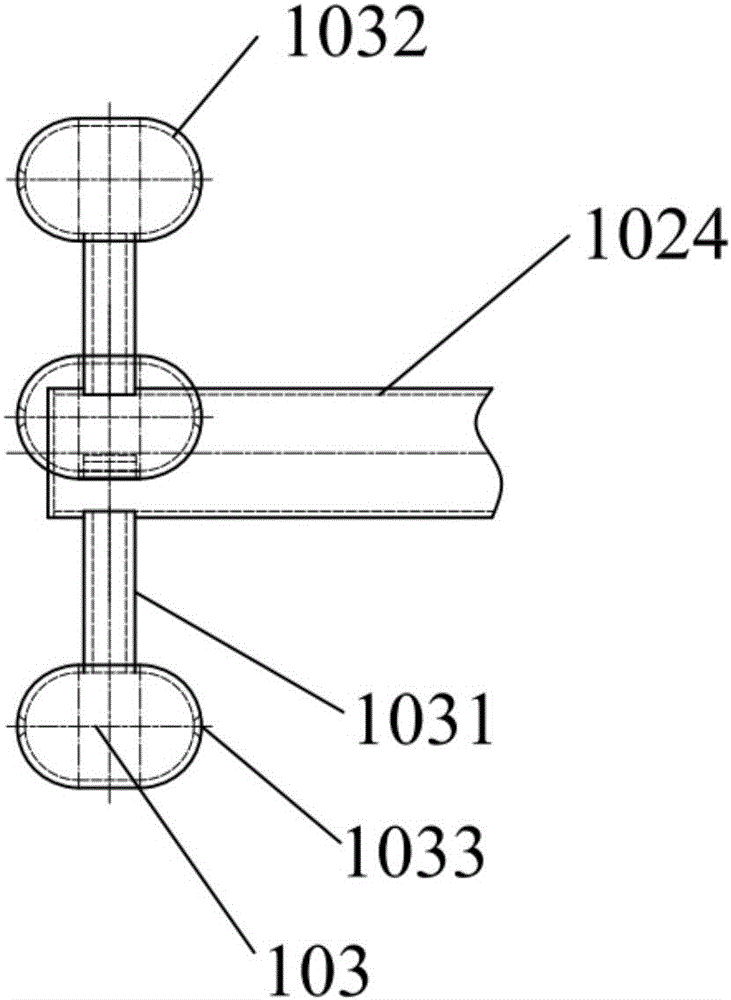

Tower-type super fine bubble reactor

ActiveCN106268544AImprove mass transfer efficiencyIncrease reaction rateLiquid-gas reaction processesReaction rateEngineering

The invention discloses a tower-type super fine bubble reactor. The tower-type super fine bubble reactor comprises a body, a primary bubble breaker and a secondary bubble breaker, wherein a reaction cavity is formed in the body, a through hole, a liquid inlet, a circulating liquid outlet, an air inlet and a circulating air outlet are formed in the wall of the reaction cavity, one part of the primary bubble breaker penetrates through the through hole and extends into the reaction cavity, the primary bubble breaker is provided with a circulating liquid inlet, a circulating air inlet and an air-liquid mixture outlet, the circulating liquid inlet is communicated with the circulating liquid outlet, and the circulating air inlet is communicated with the circulating air outlet. The secondary bubble breaker is provided with a feeding port and a discharging port, and the feeding port is communicated with the air-liquid mixture outlet. The tower-type super fine bubble reactor has the advantages of being high in mass transfer efficiency, high in reaction rate, low in energy consumption and the like, the reaction time can be remarkably shortened, and reactor size can be decreased.

Owner:NANJING UNIV

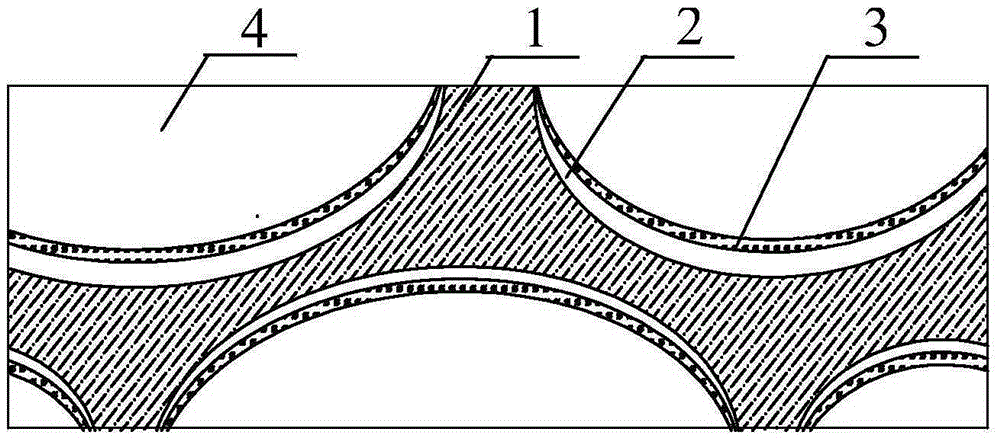

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

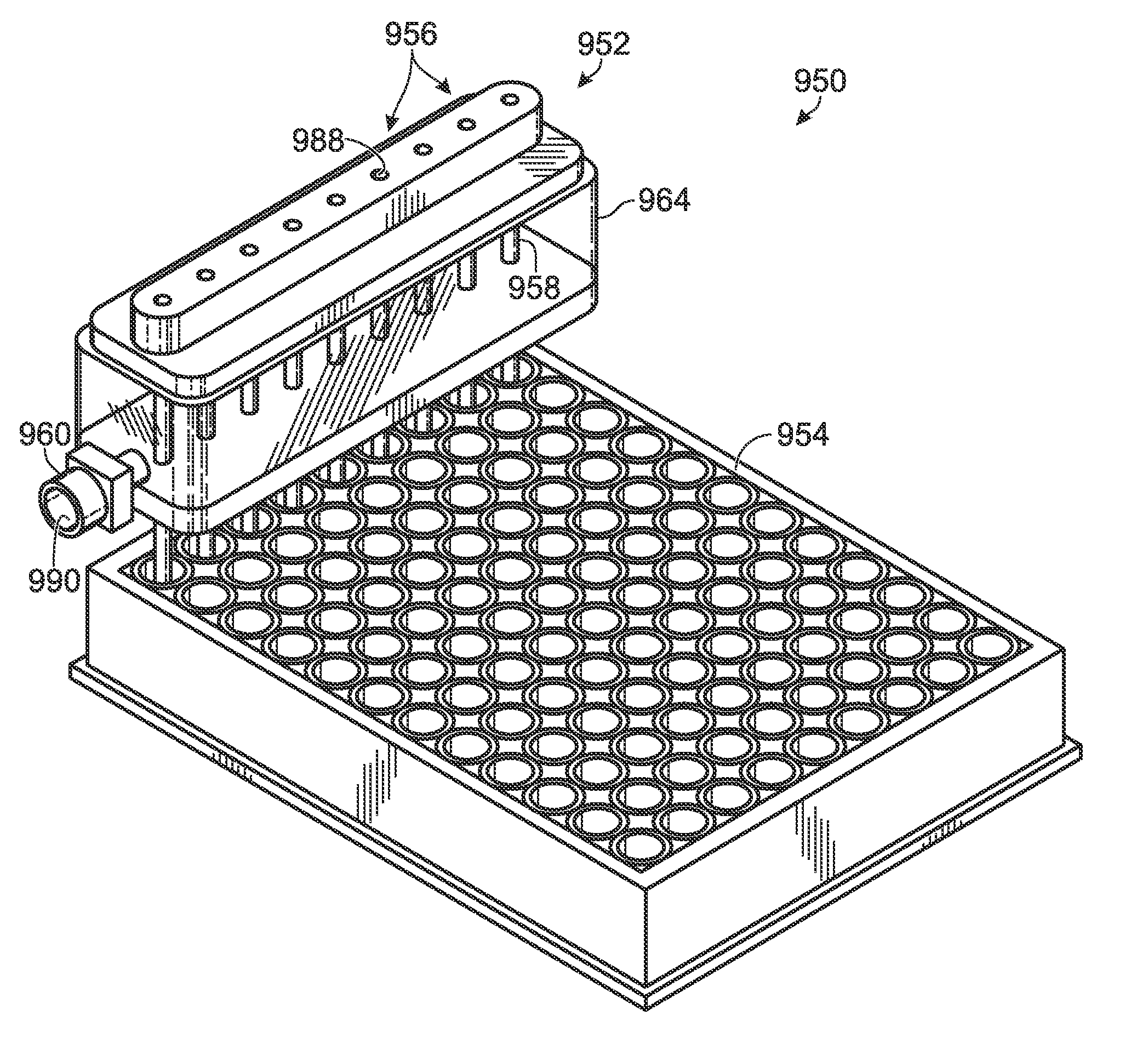

Droplet generator with collection tube

InactiveUS20140272996A1Convenient steppingHigh-confidence resultBioreactor/fermenter combinationsBiological substance pretreatmentsEmulsionIndustry standard

A system, including methods and apparatus, for generating droplets suitable for droplet-based assays. The disclosed systems may include (1) a droplet generation component configured to form sample-containing droplets by merging aqueous, sample-containing fluid with a background emulsion fluid such as oil, to form an emulsion of sample-containing droplets suspended in the background fluid, and (2) a droplet reservoir component configured to receive the droplet emulsion from the droplet generation component and then to be separated from the droplet generation component, so that subsequent assay steps may be conveniently performed using the droplet reservoir component. In some examples, the droplet reservoir component may be an industry standard PCR tube or a strip of interconnected PCR tubes.

Owner:BIO RAD LAB INC

Low-temperature SCR catalyst using nitrogen-dopped activated carbon as carrier and preparation technique thereof

InactiveCN101352681AIncrease the degree of oxidationEasy to handleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen

The invention discloses a low-temperature SCR catalyst which takes nitrogen mingled with active carbon as a carrier. The catalyst takes the nitrogen mingled with active carbon prepared by ammonia gas ignition as the carrier and one of the oxides loaded with metallic element of Mn, V, Fe, Co or Cu as an active ingredient. The invention also discloses a specific method for preparing the catalyst. The carrier of nitrogen mingled with active carbon increases the number of base sites on the surface of the active carbon, so as to improve the adsorptive capacity of NO and O2 and lead more NO to be oxidized into NO2. The load of the metal metallic oxides of Mn, V, Fe, Co and Cu forms a large amount of acid sites on the surface of the catalyst, which promotes the absorption capability of the catalyst to NH3. The measures effectively enhances the denitration activity of the low-temperature SCR catalyst which takes the nitrogen mingled with active carbon as the carrier and extends the activity temperature window of the reaction thereof.

Owner:ZHEJIANG UNIV

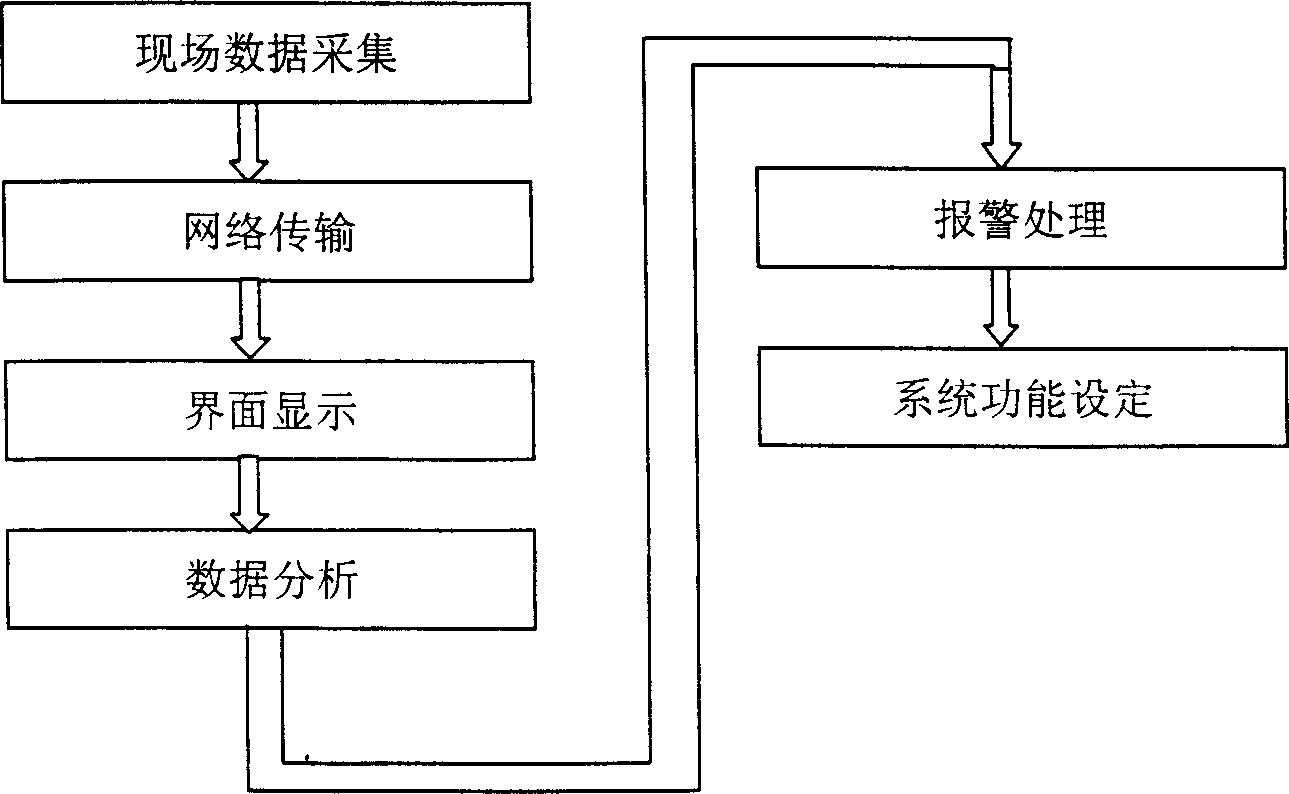

Method and device for intelligent diagnosis and location of leakage fault of fluid delivery pipeline

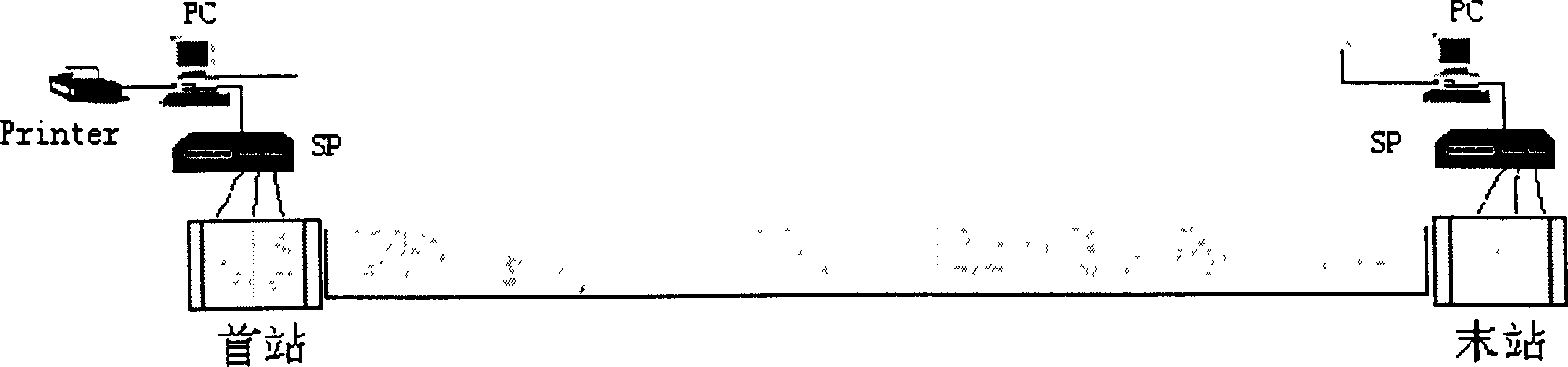

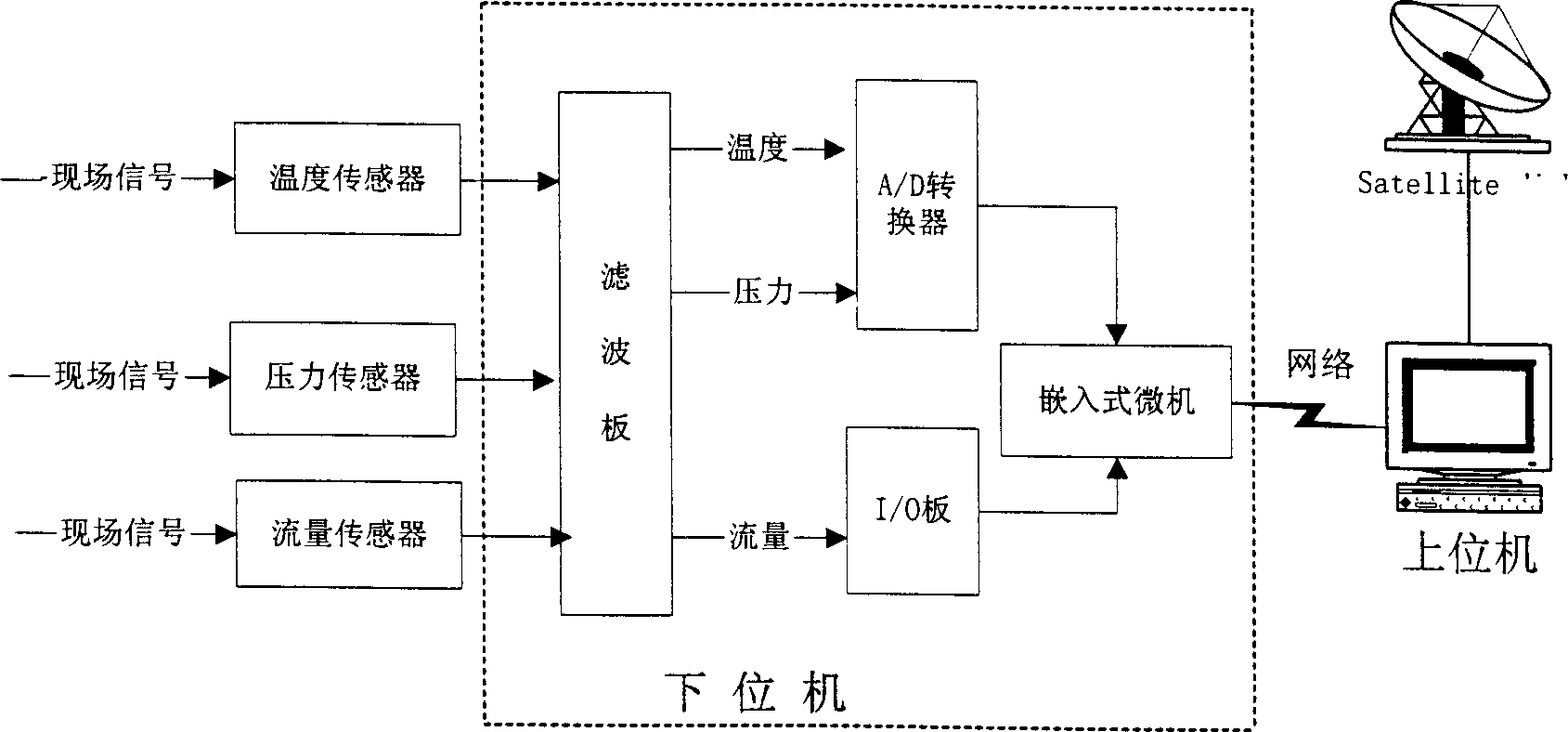

InactiveCN1435678APrevent overpressureAvoid wastingFluid-tightness measurementReal time analysisReal-time data

An intelligent device and method for diagnosing and positioning the leakage of fluid delivery pipeline are disclosed. Said method includes detecting leakage by delivery difference-pressure wave coupling method, and positioning by transient pressure wave locating method to calculate the leakage position. Its device is composed of the start and end stations to which the pressure flow and temp meters, upper-layer set and lower-layer set are mounted, communication network for real-time data exchange, and GPS correction system.

Owner:NORTHEASTERN UNIV

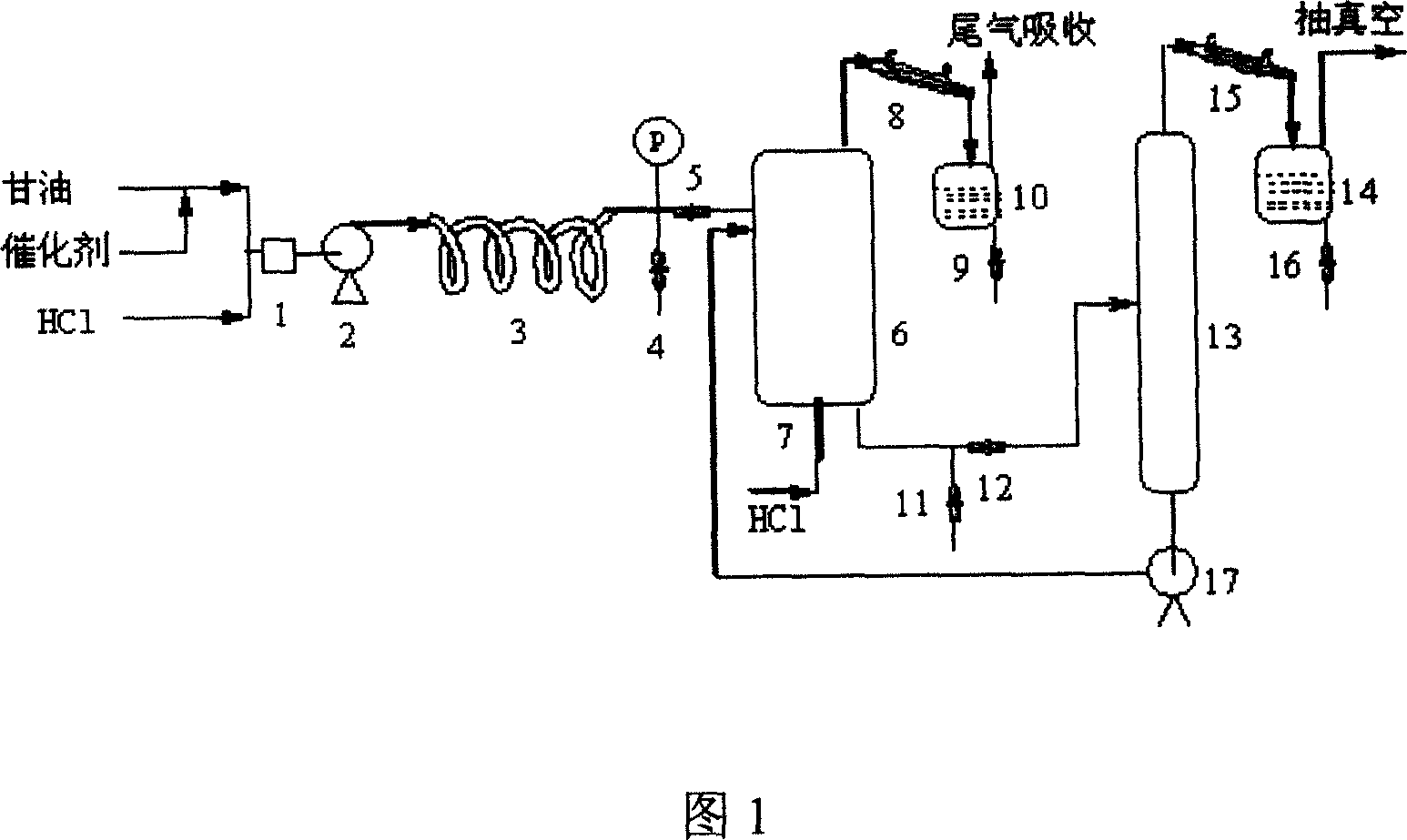

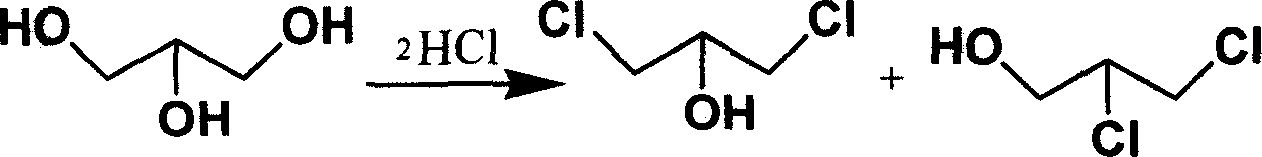

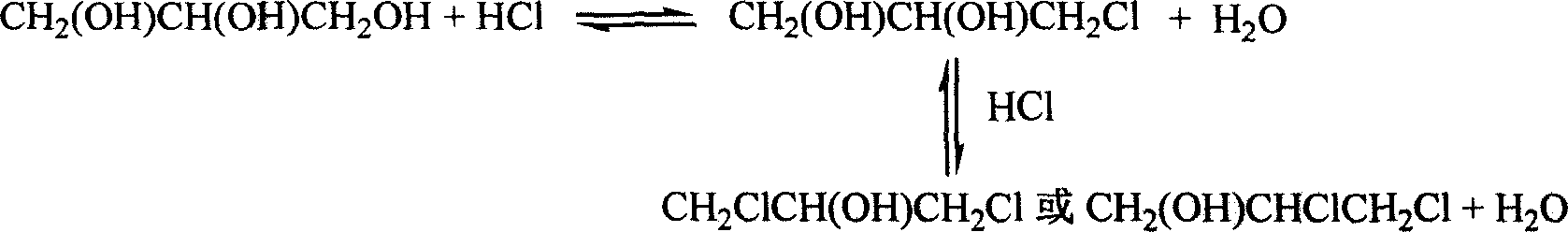

Preparation method of dichloro propanol from glycerin

ActiveCN101007751AIncrease reaction rateImprove equipment utilizationOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by halogen introductionPropanolGlycerol

The invention discloses a preparing method of dichlorohydrin from glycerol, which comprises the following steps: adding glycerol and HCl and carboxyl acid activator into mixer; charging into tubular reactor continually to proceed chlorination reaction; reacting through chlorination reaction; transforming glycerol swiftly; entering into HCl bubbling still to react continually; evaporating azeotropic material comprised by water through reaction, dichlorohydrin, HCl and part of activator from the top of bubbling still; recycling product through condensation; separating liquid of bubbling still in the fractionating tower; getting dichlorohydrin from the top of fractionating tower; delivering liquid of fractionating tower to proceed circular response.

Owner:溧阳常大技术转移中心有限公司

Multi-component oxidation micro-electrolytic filler and preparation method thereof

ActiveCN102276021AIncrease contact areaAvoid separationWater/sewage treatment by sorptionActivated carbonIron powder

The invention belongs to the technical field of environmental engineering wastewater treatment, and particularly relates to multi-component oxidized micro-electrolysis filler and a preparation method thereof. The multi-component oxidized micro-electrolysis filler is mainly prepared from the following components in percentage by mass: 50-60% of iron, 20-30% of activated carbon, 12-15% of adhesive and 3-5% of catalyst through mixing, wherein iron is iron scrap or iron powder with particle size not more than 80 mesh; and activated carbon is in a powder and has particle size not more than 100 mesh. The preparation method of the multi-component oxidized micro-electrolysis filler comprises uniformly mixing iron, activated carbon, the adhesive and the catalyst according to the ratio, adding water, stirring and aging, then carrying out extrusion molding to obtain molded filler, demolding to obtain a filler blank, after naturally drying, drying, sintering in the absence of air, and cooling thefiller blank to obtain the multi-component oxidized electrolysis filler. According to the invention, the hardening, dead pool, stoppage and other practical problems existing in the use of the traditional micro-electrolysis fillers are solved.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

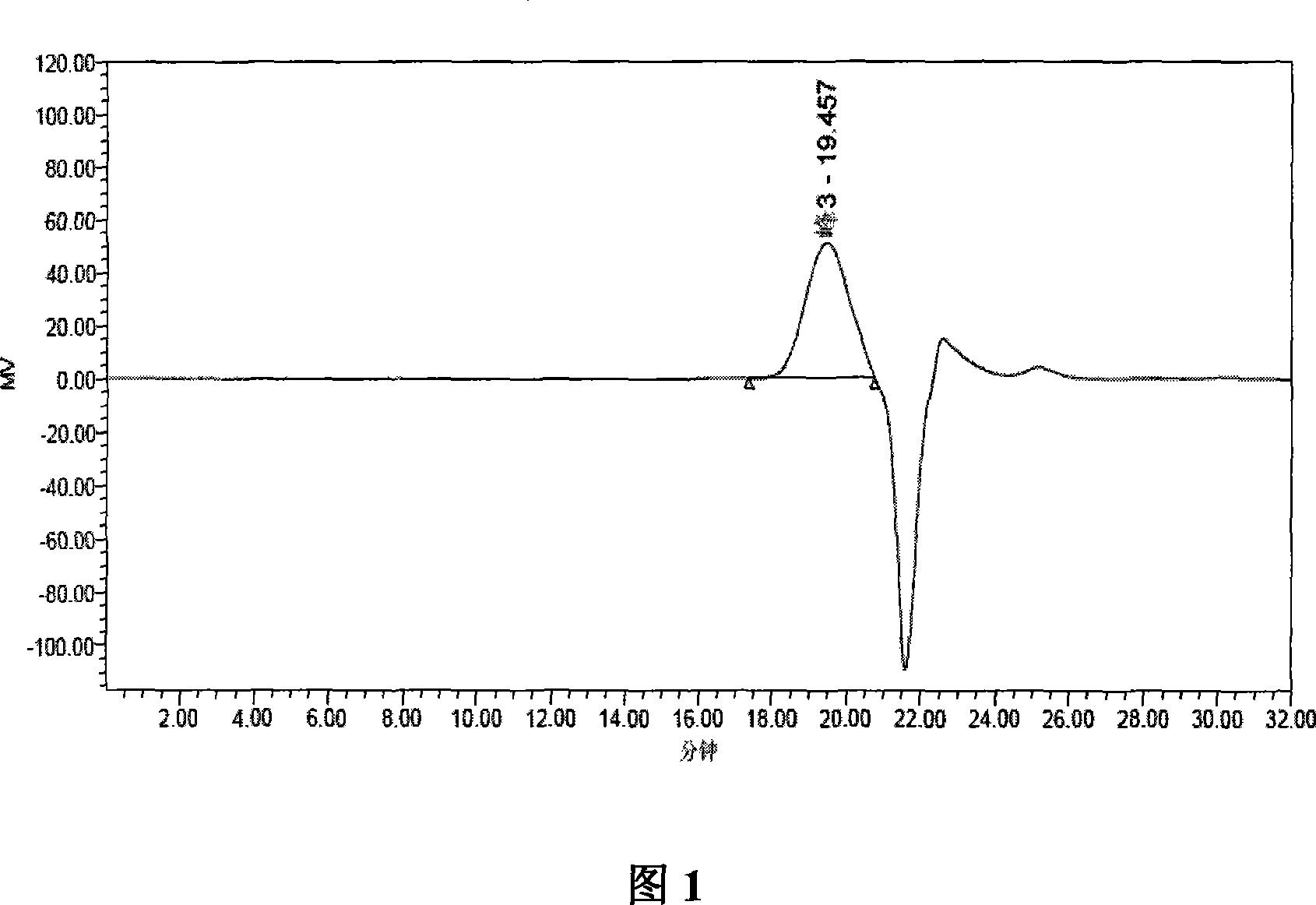

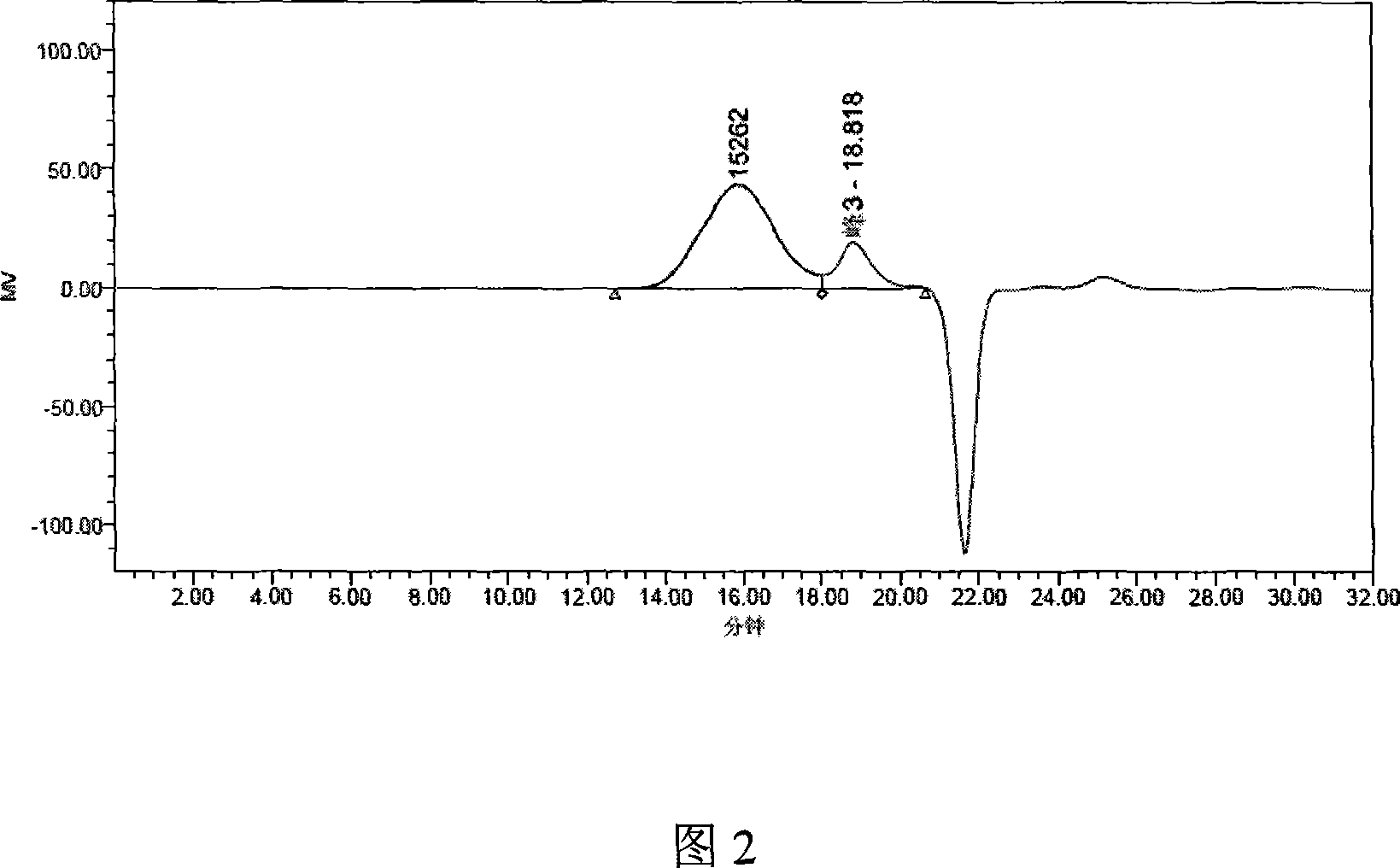

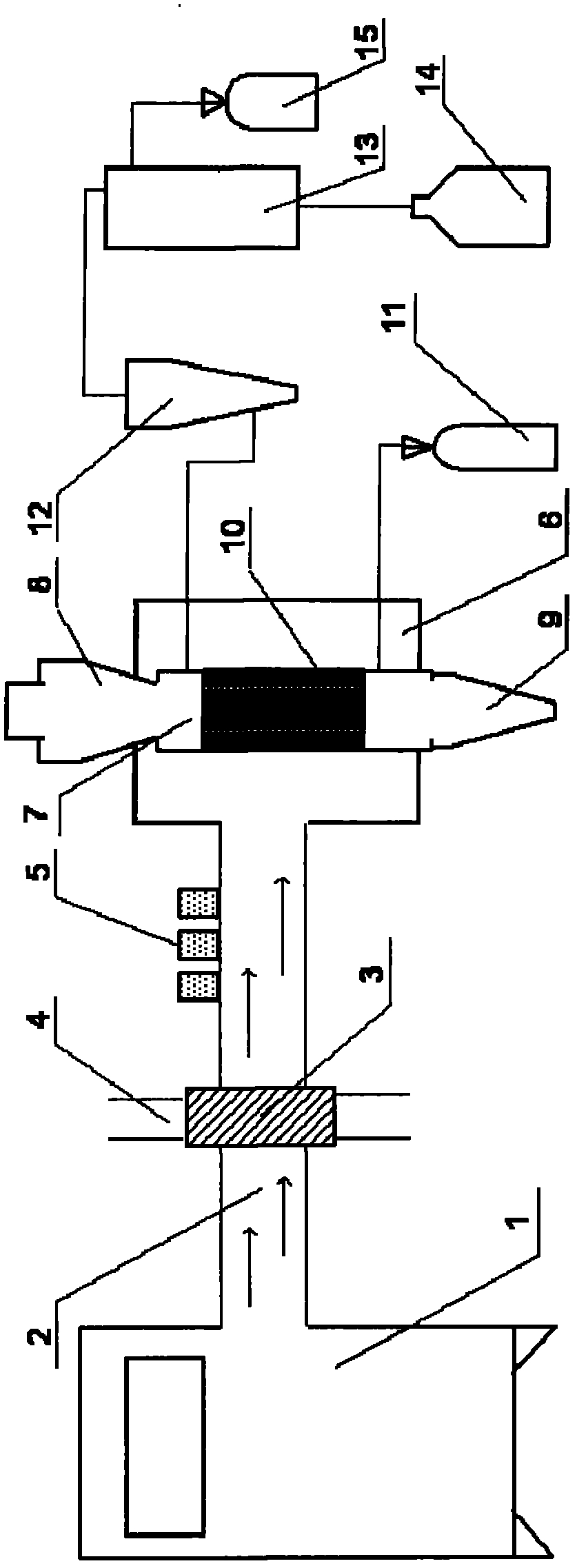

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

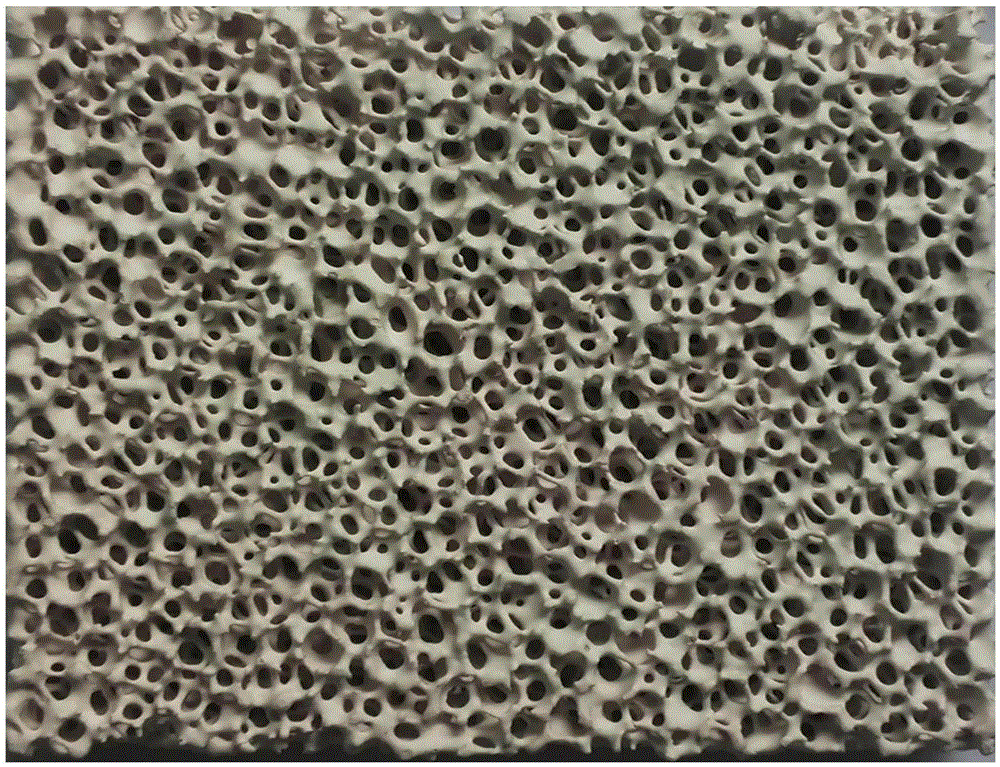

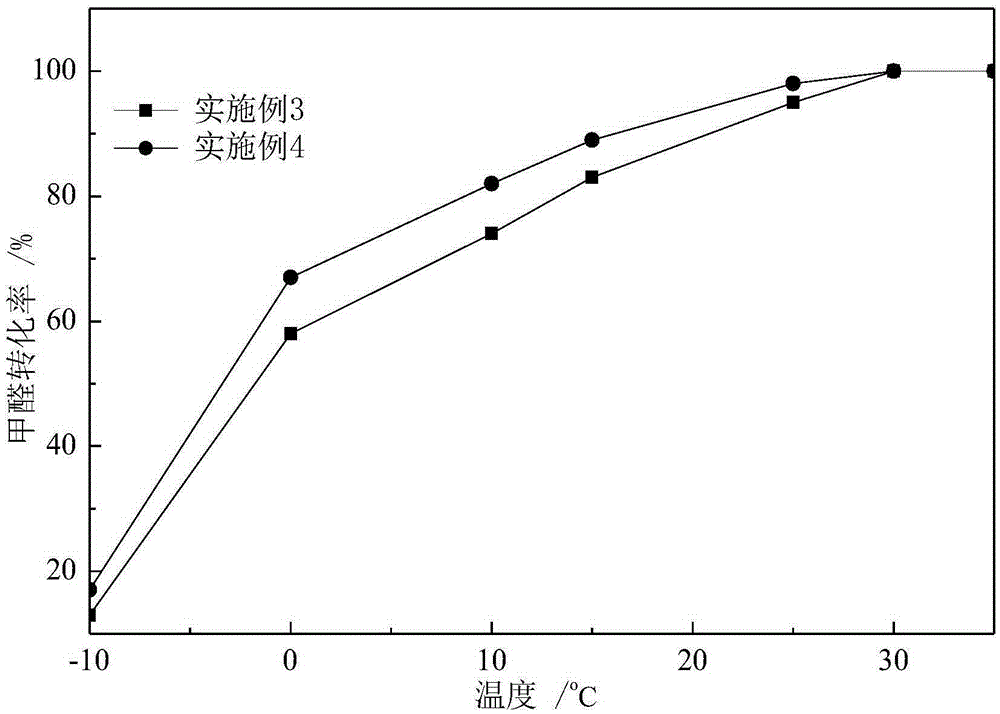

Catalytic module capable of removing formaldehyde at room temperature and preparation method thereof

ActiveCN105289298AImprove catalytic activity and purification efficiencyExcellent low temperature activity and removal efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryLight source

The invention discloses a catalytic module capable of removing formaldehyde at room temperature and a preparation method thereof. The catalytic module comprises a skeleton carrier, coatings and catalyst layers, the skeleton carrier is a foam ceramic structure with three-dimensional pore channels, and the foam ceramic structure is internally provided with multiple pore channels which are interwoven into a net-shaped structure and arranged in any one of the X direction, the Y direction and the Z direction; the coatings are evenly coated on the surfaces of the pore channels in the foam ceramic structure and the other surface of the foam ceramic structure, and the catalyst layers are highly dispersed on the coatings. By means of the catalytic module capable of removing the formaldehyde at the room temperature and the preparation method thereof, at the room temperature and environment humidity, low-concentration formaldehyde can be oxidized into H2O and CO2, excellent low-temperature activity and removing efficiency are achieved, and the formaldehyde removing efficiency can be kept above 98 percent at the airspeed SV equal to 50,000 h<-1>. The preparation process is simple, the precious metal load is low, and accessory equipment such as light sources and heating are not needed. The catalytic module is suitable for air purification of closed and semi-closed spaces such as living rooms, office buildings, schools, dormitories, shopping malls, furniture markets and automobiles.

Owner:展宗城

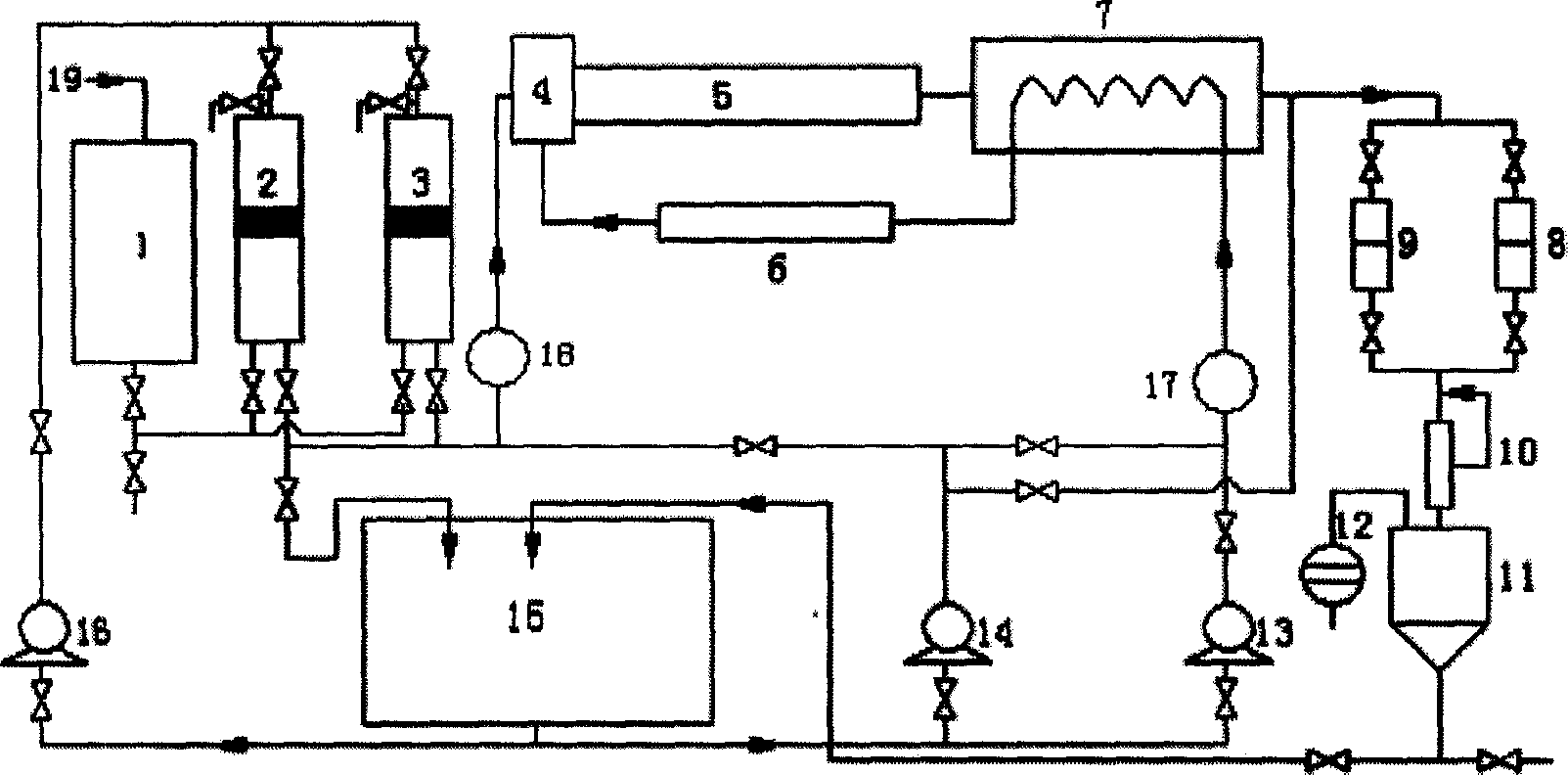

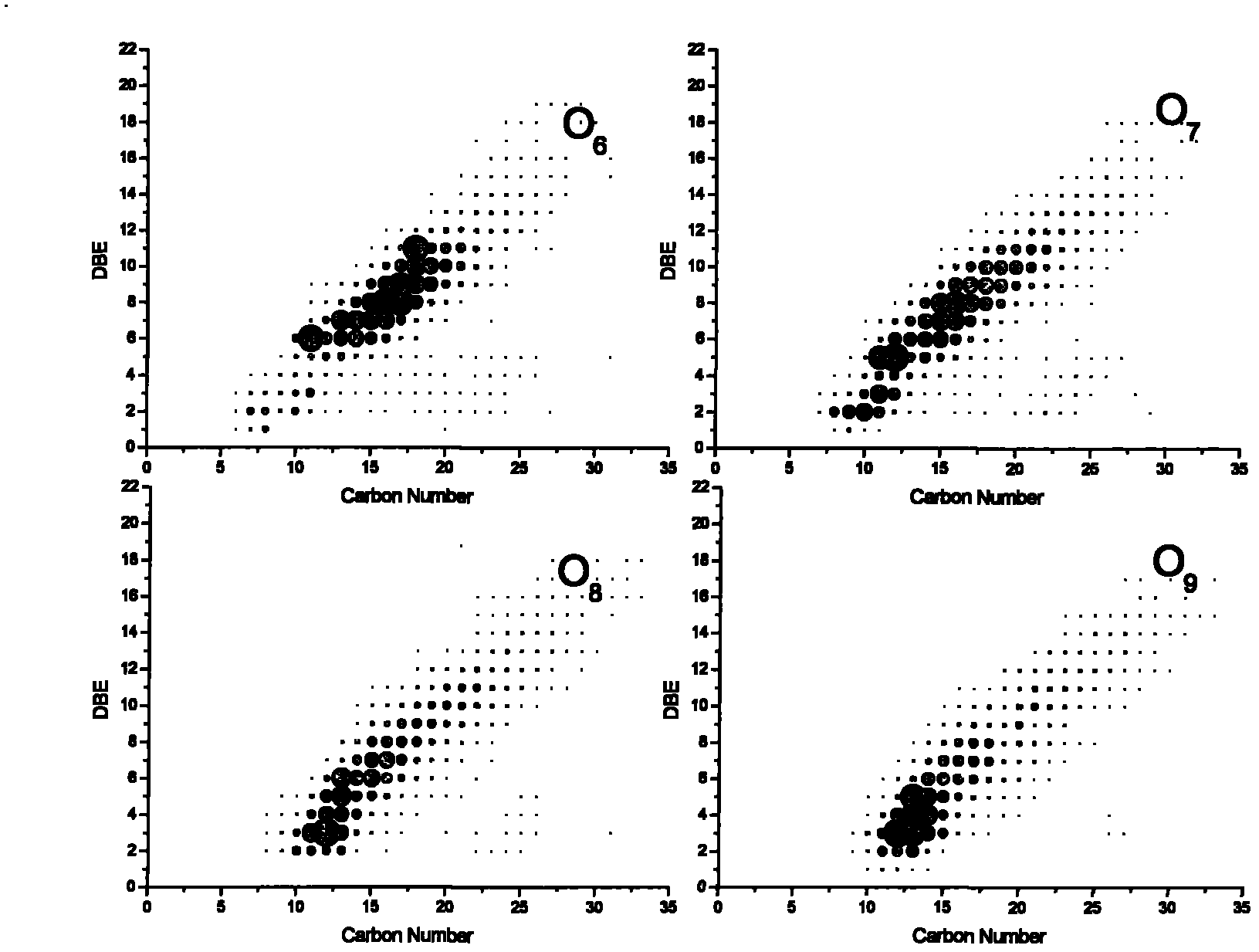

Coal-biomass co-overcritical water catalysis-gasification hydrogen production plant and method

ActiveCN1654313AMild reaction conditionsEasy to controlHydrogen productionBulk chemical productionCO2 contentHydrogen content

The present invention discloses one kind of supercritical water catalytic coal and biomass gasifying process and apparatus for producing hydrogen. The apparatus has material feeder with one inlet connected to the outlet of the material pump and the other inlet connected to the outlet of feeding tank, pre-heater with outlet connected to the preheated water inlet and inlet connected to the outlet of inner pipe outlet of the cooler, cooler with inlet connected to the inlet of water pump, water pump with outlet connected to the water tank, cooler jacket with outlet connected to the inlet of the first filter and the inlet of the second filter, and back pressure valve with inlet connected to the outlets of the first filter and the second filter. The present invention has special heating mode for fast heating of the reaction material, raised hydrogen content in the gas product, raised CO2 content in the gas product, and easy separation of CO2 and feeding of CO2 to the processing terminal. The present invention is simple, effective and feasible.

Owner:陕西中核交大超洁能源技术有限公司

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

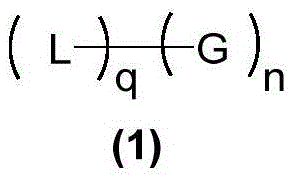

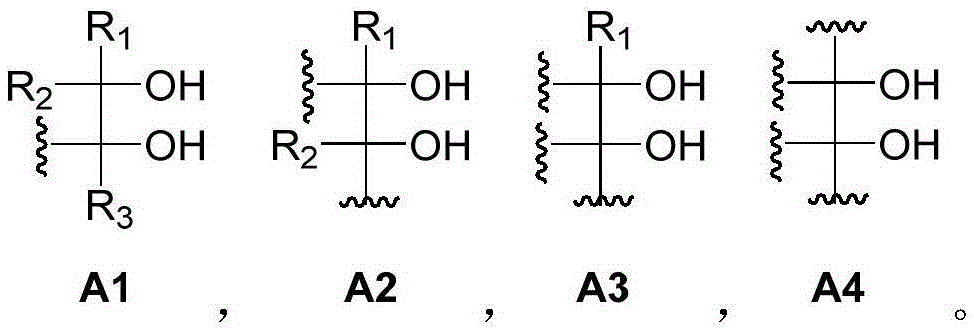

Dynamic polymer material

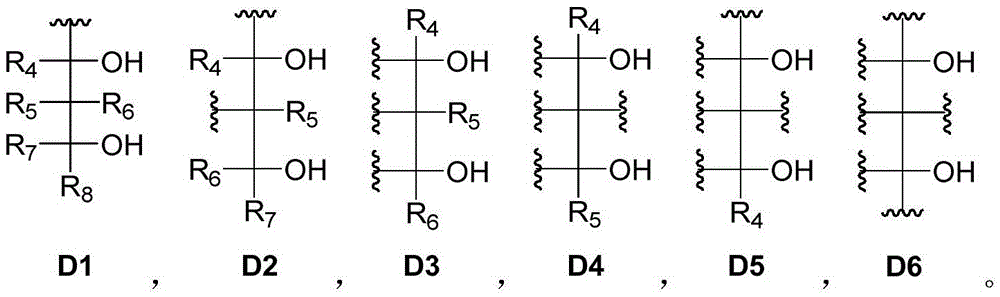

InactiveCN105646872ADynamic responsivenessMild reaction conditionsCoatingsPhenylboronic acidCross-link

The invention discloses a dynamic polymer material. The dynamic polymer material comprises a product obtained through reaction of the following components: at least one polyol compound containing two or more 1,2-diol motifs or 1,3-diol motifs as well as at least one phenylboronic acid compound containing two or more phenylboronic acid motifs provided with aminomethyl groups in ortho-positions. Dynamic reversible phenylborate bonds are formed through the reaction of the components and then constitute a dynamic cross-linked polymer. The polymer material has reusability and recoverability because of the dynamic reversibility of the special phenylborate bonds; besides, when the polymer material adopting a specific formula receives external force, dynamic bonds break preferentially to have energy dissipation and stress elimination functions, so that the material has good toughness. The material has broad application prospect in the fields of military space equipment, functional paint and coatings, biomimetic materials, biomedical materials and the like.

Owner:翁秋梅

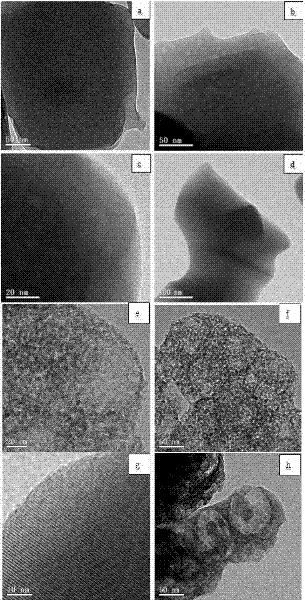

Catalyst for normal paraffin hydroisomerization reaction and preparation method as well as application thereof

InactiveCN102658197AExtend your lifeIncreased diffusion rateHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveHydrogen

The invention relates to a catalyst for a normal paraffin hydroisomerization reaction and a preparation method as well as an application thereof. The catalyst has the characteristics that the activity is high in an n-hexane hydroisomerization reaction, and the selectivity and stability are good for a double-branched-chain product. The catalyst comprises modified zeolite molecular sieve ZSM-12 treated by alkaline solution and noble metal of family VIII, wherein the zeolite molecular sieve ZSM-12 adopts zeolite molecular sieve ZSM-12 containing organic amine template. The preparation method of the catalyst comprises the following steps of: desilication of zeolite molecular sieve ZSM-12 containing template after being treated with alkaline solution to obtain zeolite molecular sieve ZSM-12 with high content of mesoporous, and preparing isomerized catalyst by loading Pt. The catalyst is applied in the normal paraffin hydroisomerization reaction, when the catalyst is applied, the n-hexane hydroisomerization reaction is carried out on a fixed bed miniature reactor, the reacting raw material n-hexane is fed into the reactor by a force pump, and is contacted with the catalyst to react in the reactor after being mixed with hydrogen in a mixer.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for preparing biodiesel by using supported solid acid combining cosolvent

InactiveCN101418225AReduced post-processingReaction is easy to controlMolecular sieve catalystsBiofuelsBiodieselAlcohol

The invention discloses a method for producing biodiesel in the presence of a supported solid acid catalyst and a solubilizing agent. The method is characterized in that: (1) a hydrophobic solid acid catalyst which is high in catalytic efficiency, recyclable, easily separable and simple in post treatment process is adopted; (2) a cosolvent is introduced during a reaction process to improve reaction conditions and reduce reaction temperature and pressure; (3) the cosolvent and lower alcohols used in the reaction can be recycled; and (4) equipment corrosion and environmental pollution are avoided and advantages of low requirements on equipment corrosion, short technical process, environmental-friendly production, low investment in equipment and low operation cost are achieved.

Owner:BEIJING UNIV OF CHEM TECH

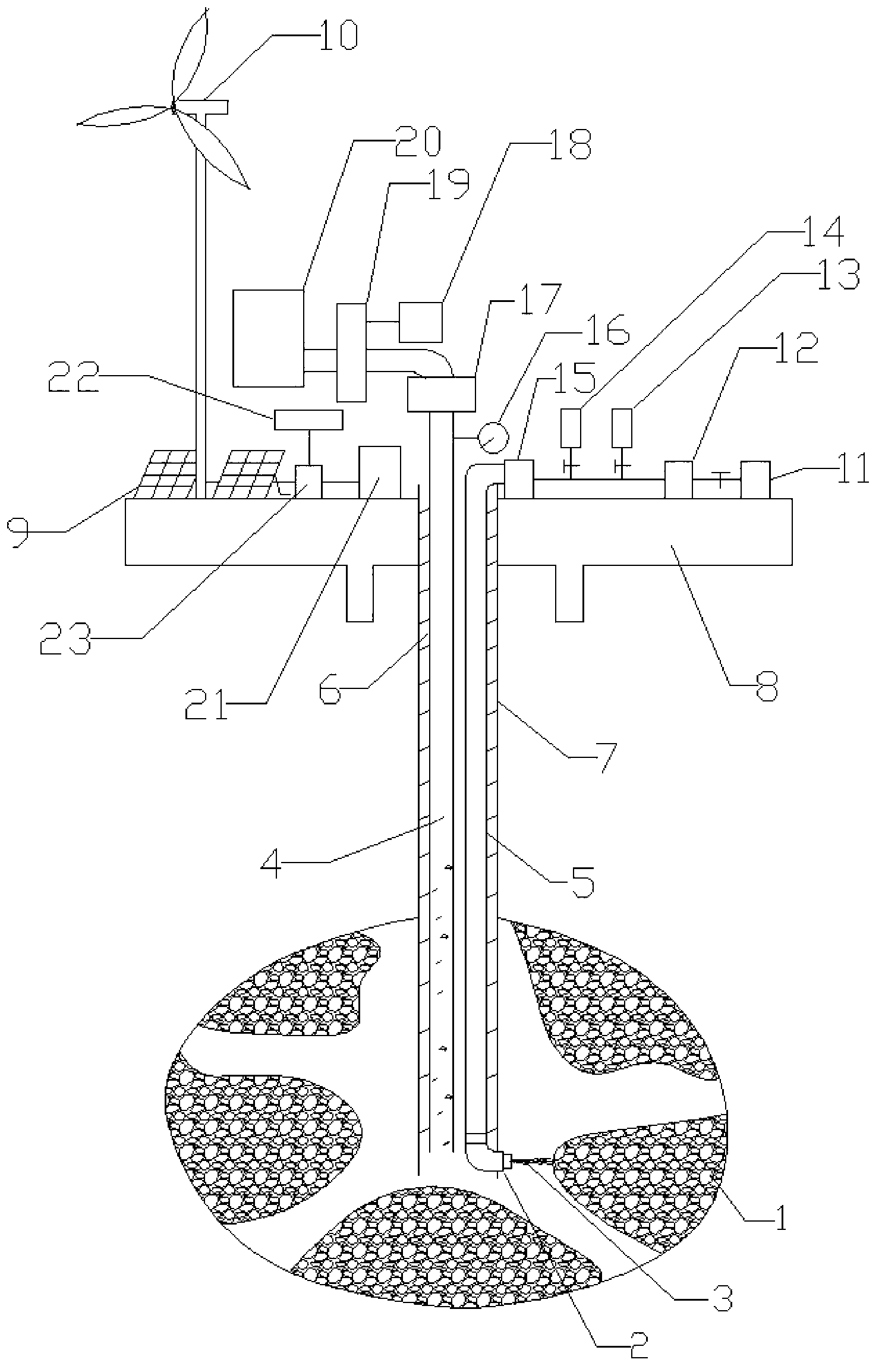

In-situ submarine natural gas hydrate exploiting device and method thereof

InactiveCN102704894AIncrease reaction rateSpeed up miningBatteries circuit arrangementsConstructionsGreenhouse gasSubmarine

The invention relates to an in-situ submarine natural gas hydrate exploiting device and a method thereof, and belongs to the technical field of exploitation of natural gas hydrates. The exploiting device comprises a solar and wind power generating system, a rotary telescopic water gun, an insulating pipeline, a conveying pipeline, a sleeve pipe, an ocean platform, a sea water pump, an electric heater, a CO2 liquid storing tank, a decomposition accelerator storing tank, a high-pressure pump, a pressure gauge, a filtering device, a water storing tank, a gas-liquid separator and a gas recovering device. A thermal activation method and a chemical reagent catalyzing method are utilized to trigger a decomposition reaction of the natural gas hydrate, and then the high-pressure CO2 jetting technology is utilized to enable the natural gas hydrate to be cut while a substitution reaction occurs. According to the invention, the natural gas hydrate is exploited by fully utilizing rich solar power and wind power in ocean areas, so that the effects of cleaning and environmental protection are realized; the thermal activation method and the chemical reagent catalyzing method are matched with the CO2 substitution method, and therefore the exploitation rate is improved, the dosage of a chemical reagent is reduced, the stability of submarine geology is protected effectively, and meanwhile the greenhouse gas is treated to a certain extent.

Owner:SHANGHAI JIAO TONG UNIV

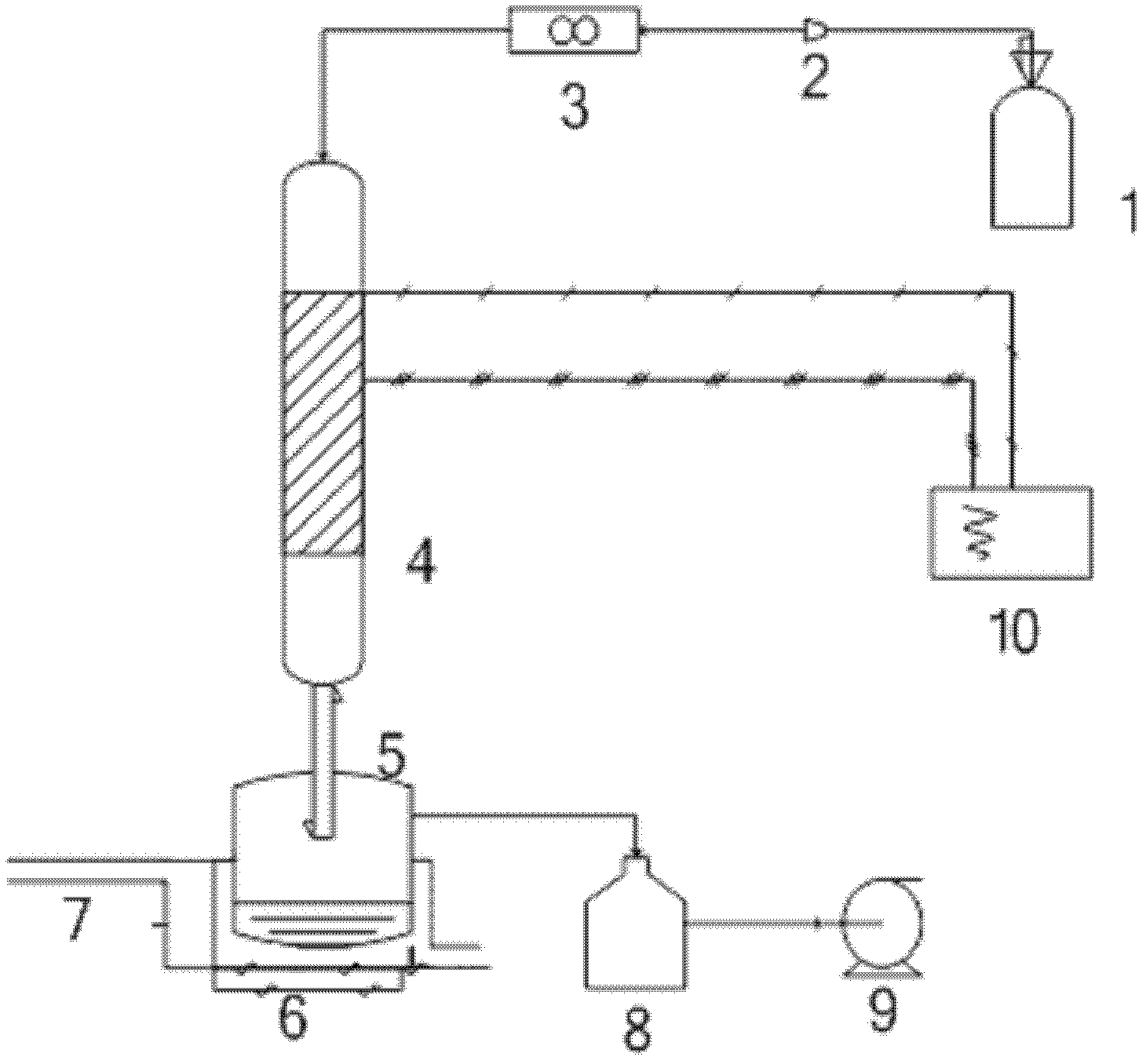

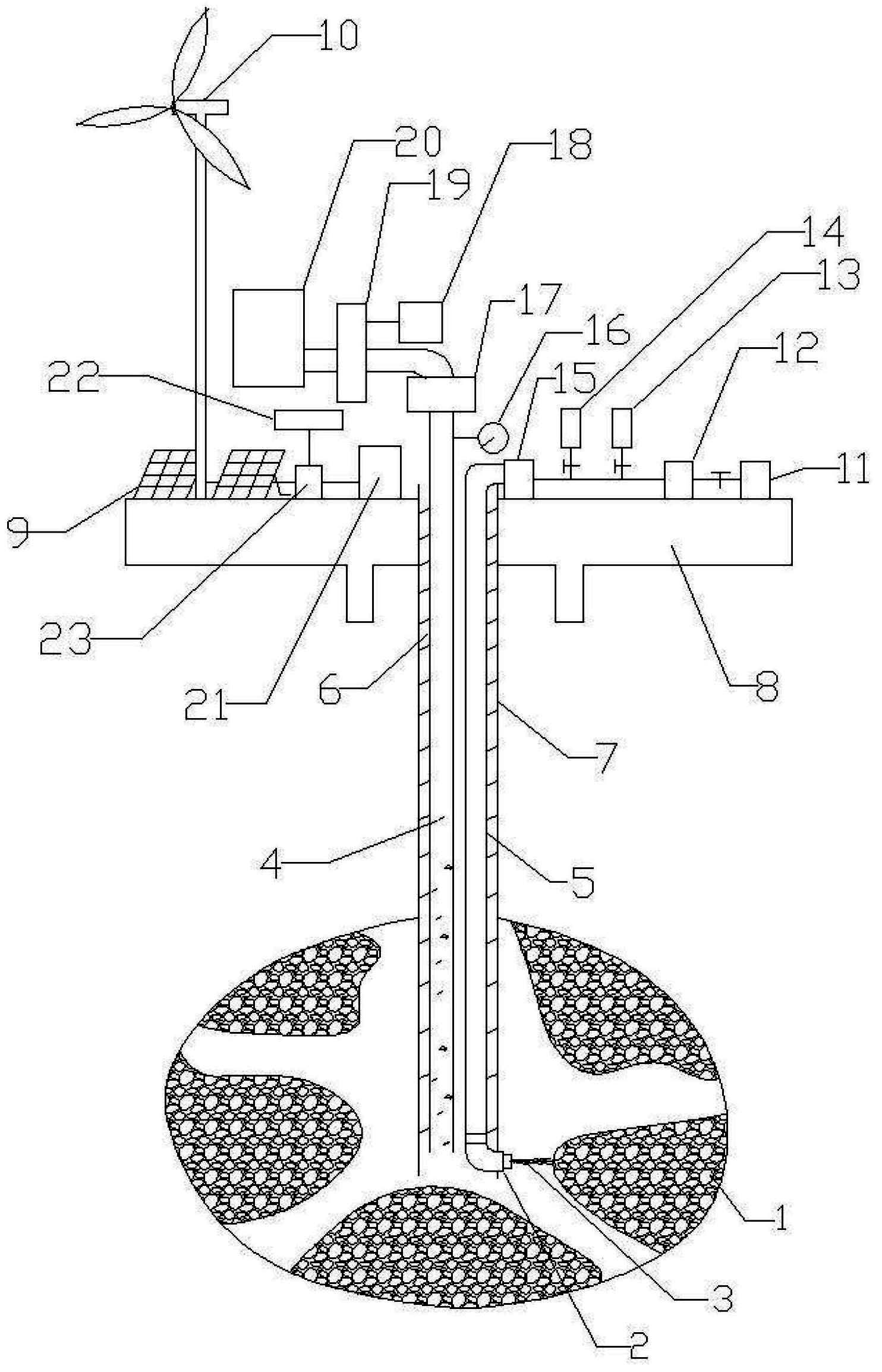

Continuous reaction device and method for microwave biomass pyrolysis

InactiveCN102580650APyrolysis continuous reaction realizedIncrease reaction rateBiofuelsLiquid hydrocarbon mixture productionMicrowaveFuel gas

The invention relates to a continuous reaction device and a method for microwave biomass pyrolysis. The continuous reaction device for the microwave biomass pyrolysis mainly comprises a microwave generator, a reactor and a resultant separating device. The continuous reaction device is a continuous operating system and can process 10-50kg of the biomass every hour. According to the continuous reaction device for the microwave biomass pyrolysis, characteristics of microwave volume heating, transient heating and selective heating are fully utilized, undried biomass is directly pyrolyzed so as toobtain three products of liquid bio-oil, bio-gas and solid coke, the pylolysis efficiency of the biomass is greatly improved, the yield and the quality of the liquid bio-oil are improved, the structure is simple, the design is reasonable, and the achievement of industrial application of the microwave biomass pyrolysis is facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for producing cellulose ester acetate by using plant cellulose

This invention relates to a method for preparing cellulose ester acetate from plant cellulose in ionic liquid. The method comprises: (1) utilizing plant cellulose as the raw material; (2) dissolving plant cellulose in ionic liquid; (3) adding acylation agent into the ionic liquid, performing homogeneous acetylation on plant cellulose, washing the intermediate with water and drying; (4) separating and purifying dried intermediate to obtain cellulose ester acetate. This invention provides a method for homogeneously preparing cellulose ester acetate in clean solvent (ionic liquid) by using low quality plant cellulose as the raw material. The method solves the problem of high cost faced by the present methods.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

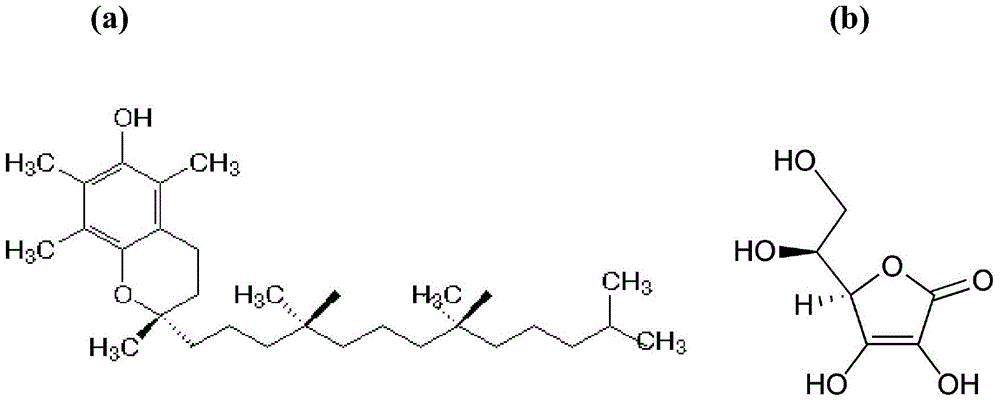

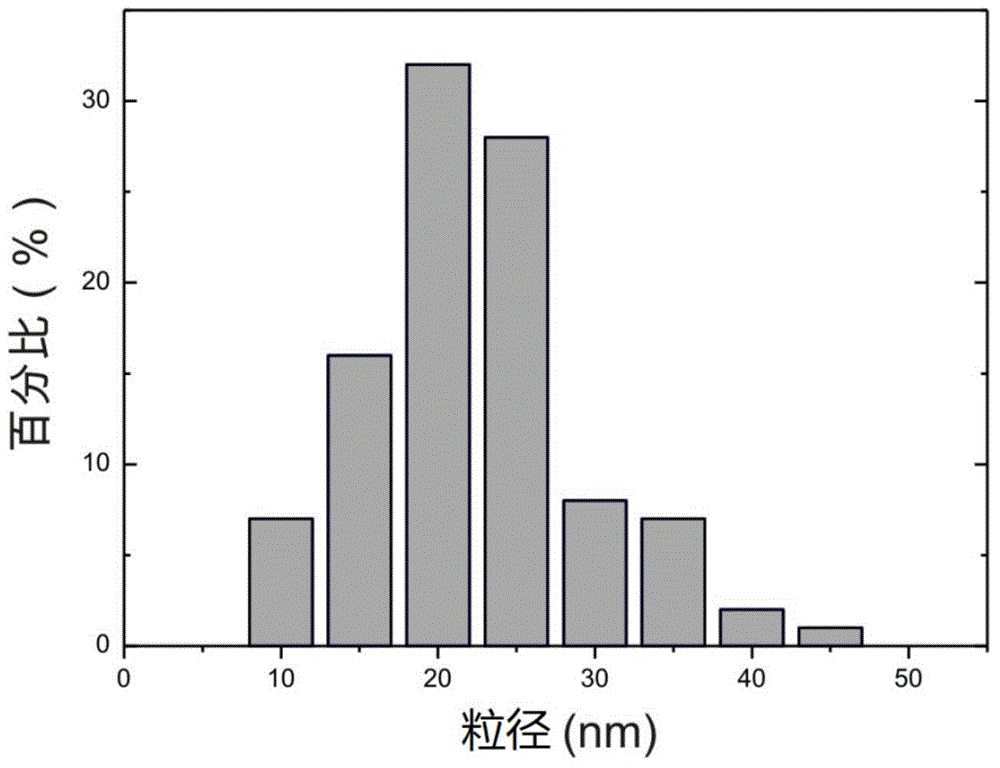

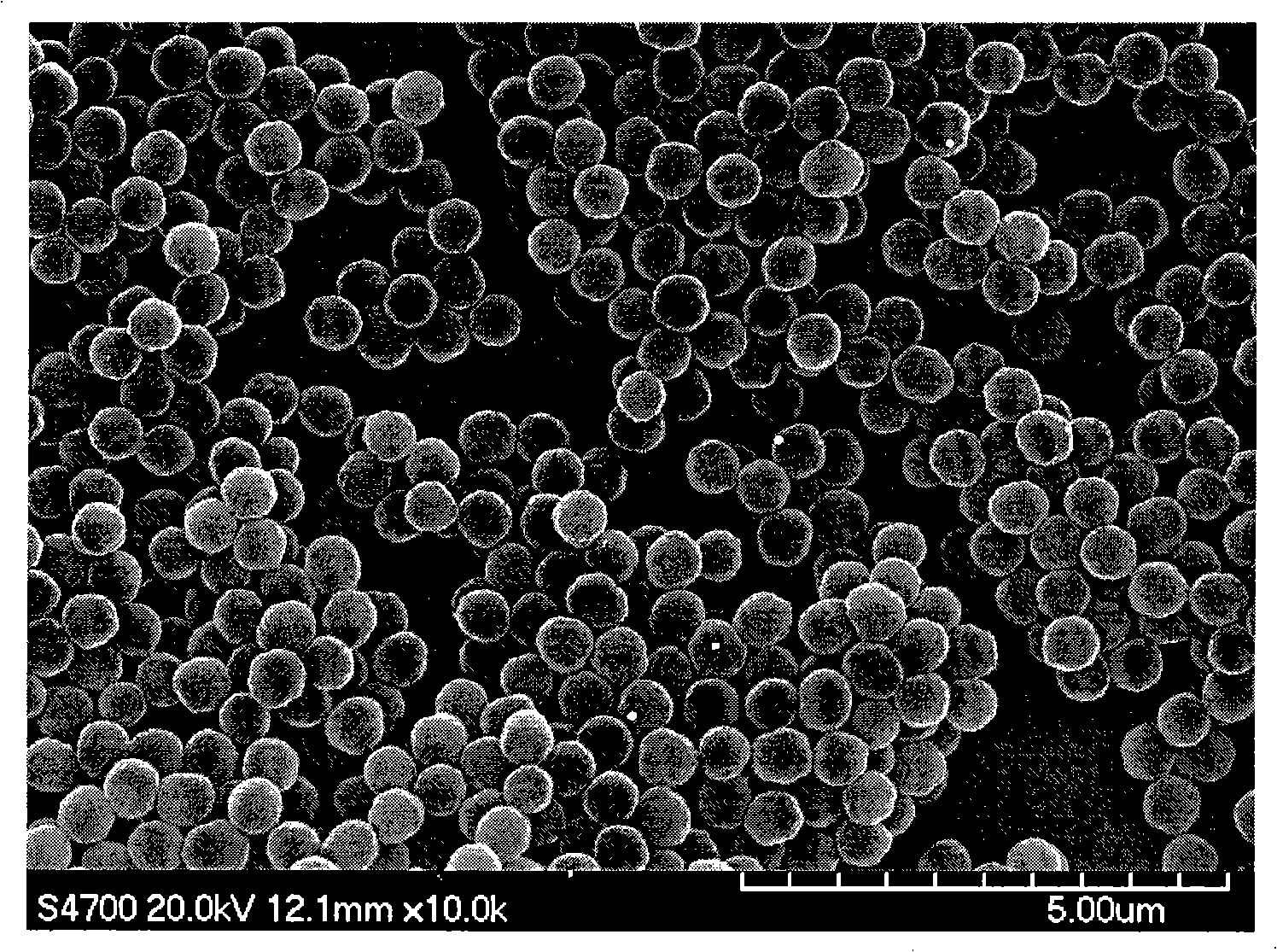

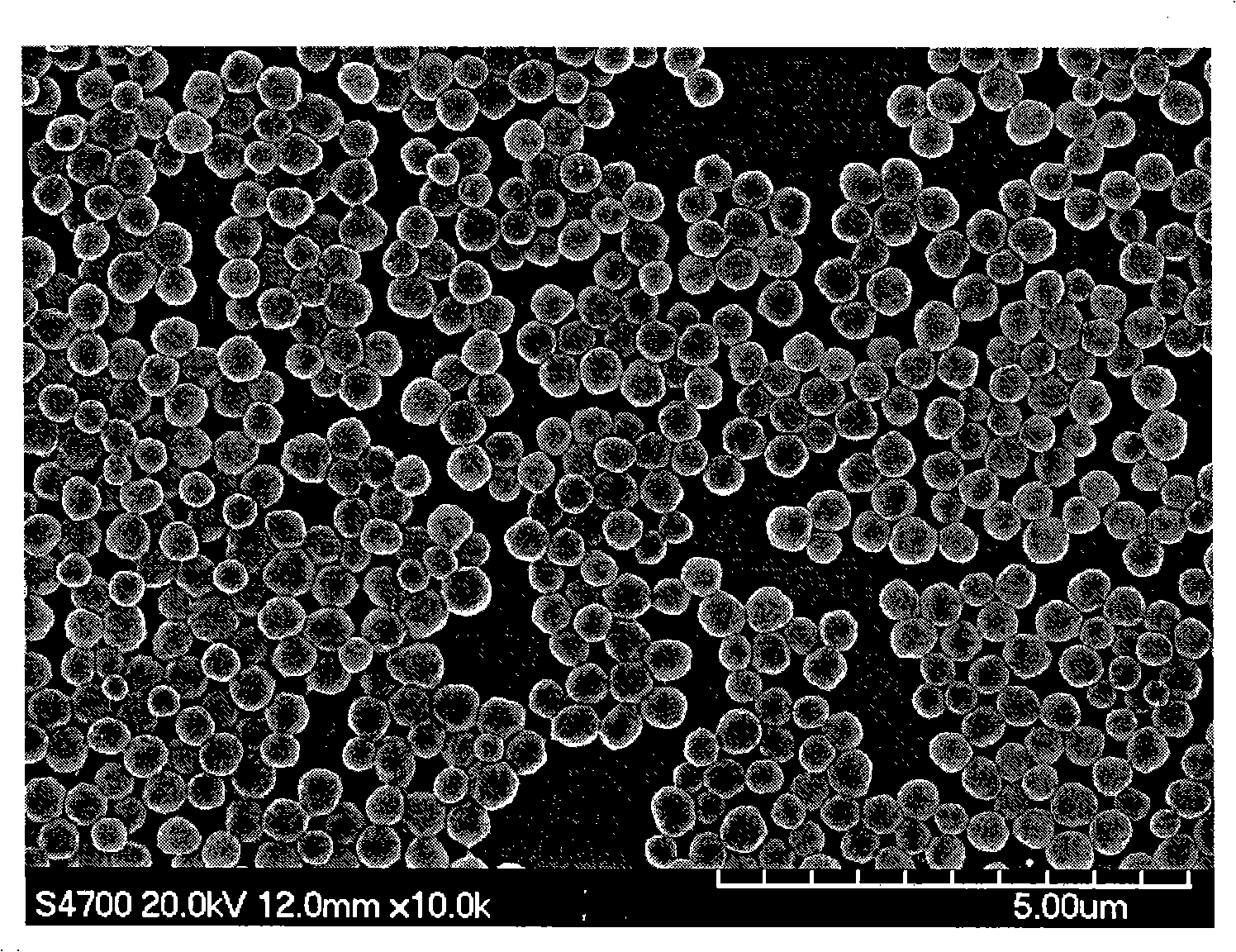

Cosmetic active ingredient-containing lipidosome as well as preparation method and application thereof

ActiveCN104606063ASmall particle sizeNarrow distributionCosmetic preparationsToilet preparationsMedicineCuticle

The invention relates to cosmetic active ingredient-containing lipidosome as well as a preparation method and application thereof. The cosmetic active ingredient-containing lipidosome is small and uniform in particle size, so that the wrapped active ingredients can permeate the cuticles to the deep layer of skin so as to effectively realize deep skin care. Moreover, due to the small particle size, the collision and sedimentation probability of the finished lipidosome product is decreased and the stability of the lipidosome cosmetic is improved. The cosmetic active ingredient-containing lipidosome is prepared by a host-guest chemical method, so that the lipoid molecules and the active ingredient molecules are uniformly mixed on the molecular level, so that the gathering inactivation phenomenon of the active ingredients is avoided; the preparation condition is mild, so that the active ingredients are prevented from damage.

Owner:王海龙

Process for preparing cross-linking maleic anhydride-styrene copolymer

A cross linking maleic anhydride-vinyl acetate copolymer preparation method belongs to the field of copolymers. At present, the research on maleic anhydride-vinyl acetate copolymers mostly focuses on the polymerization research of linear polymers. The invention introduces a monomer, cross linking agents and initiators into medium to dissolve under the condition of nitrogen protection, and reacts for 2 to 24 hours under the temperature of 60 DEG C to 90 DEG C; the monomer is maleic anhydride Man and styrene St, the mol ratio is 1:1, and the mass concentration in the polymerization system is 5 percent to 45 percent; the initiators are organic peroxides or azo compounds, and are 0.05 percent to 1 percent of the total mass of the monomers; the cross linking agents are polyfunctionality alkene organic compounds, and are 0.08 percent to 8.8 percent of the total mass of the reactions system, and the rest is the alkyl ester of medium organic acid. The invention does not use surface active agents or stabilizers, can realize the adjustment and control of crosslinking polymer particle size, appearance and chemical physical properties through the adjustment of the addition amount of the cross linking agents.

Owner:BEIJING UNIV OF CHEM TECH

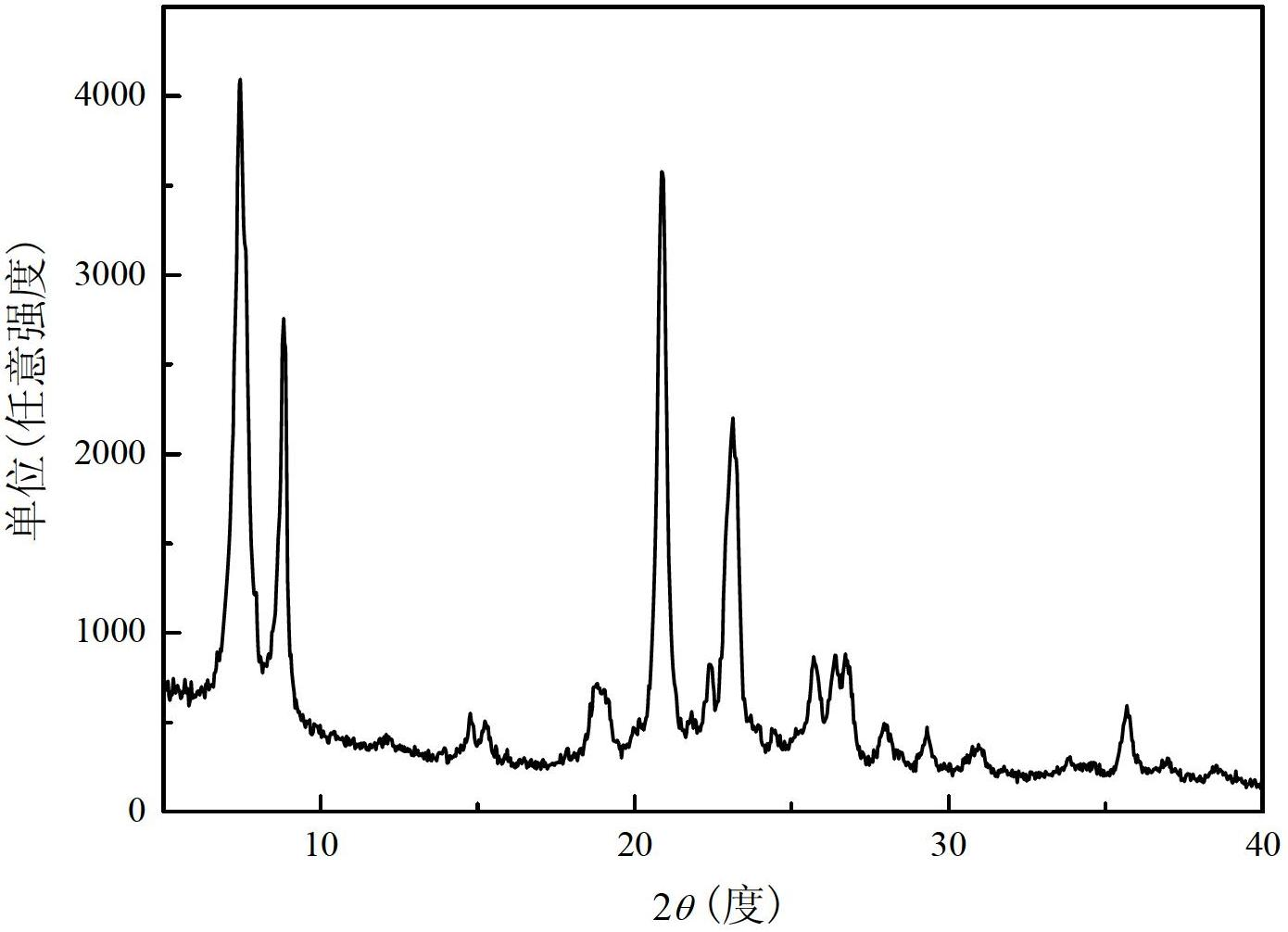

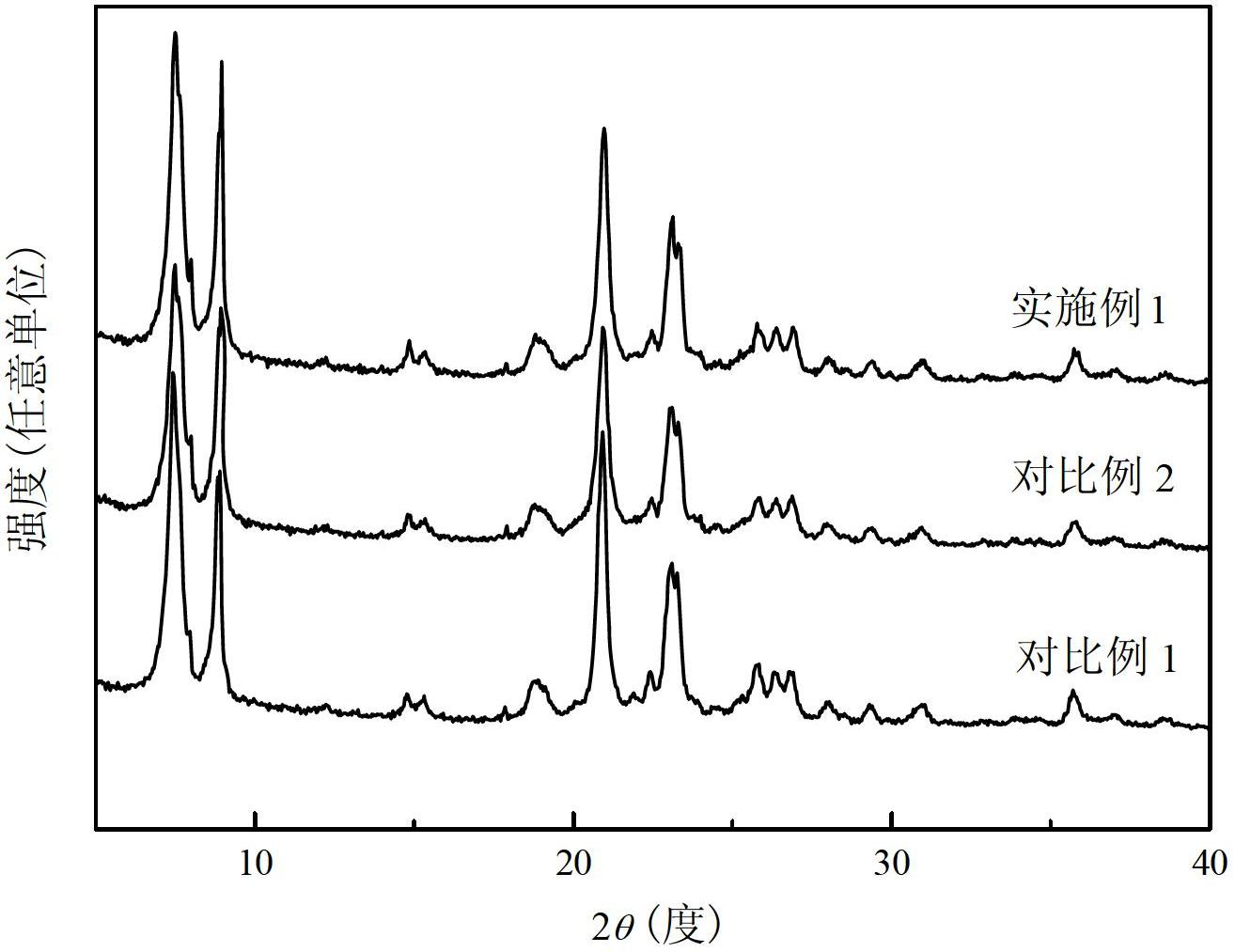

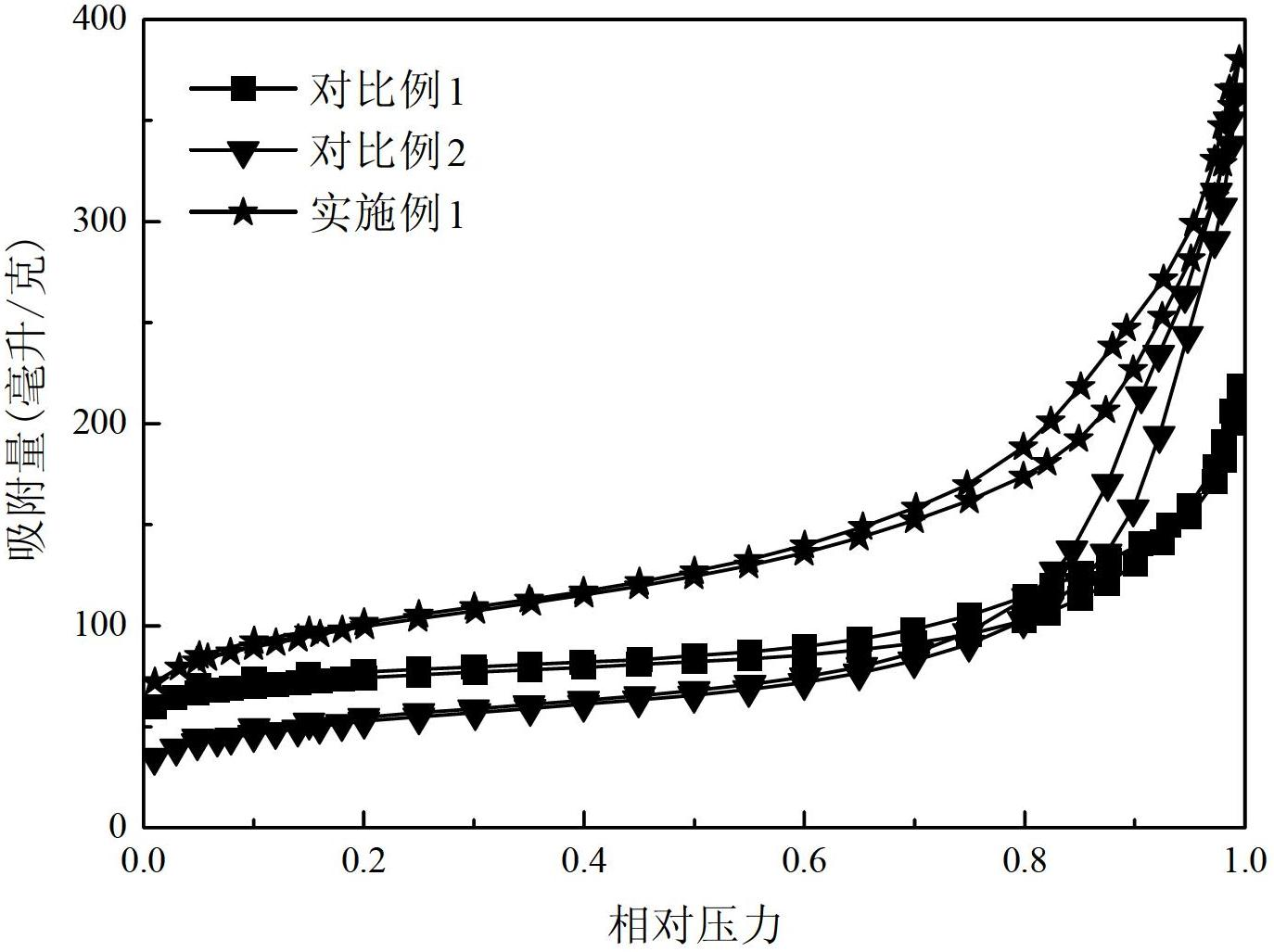

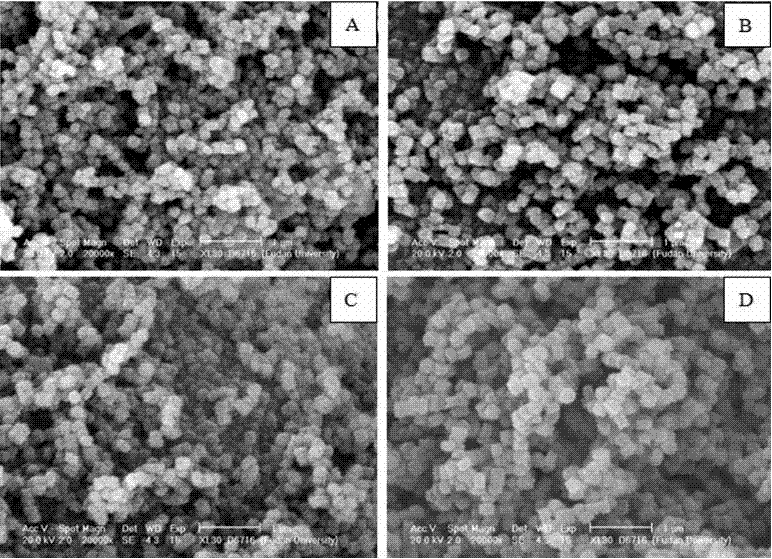

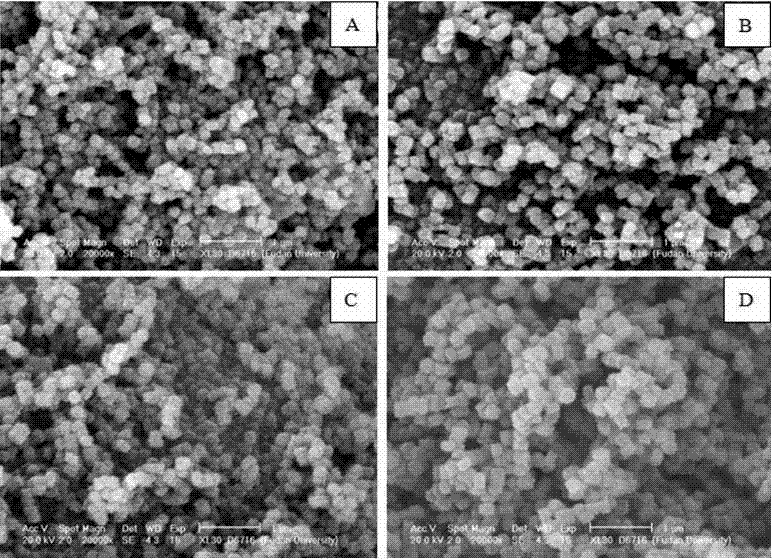

Three-dimensional interconnected hierarchical-structured zeolite molecular sieve material and preparation method thereof

InactiveCN102390843AIncrease mass transfer rateIncrease reaction rateCrystalline aluminosilicate zeolitesActive agentPetrochemical

The invention belongs to the technical field of mesoporous composite materials, and particularly relates to a three-dimensional interconnected hierarchical-structured zeolite molecular sieve material and a preparation method thereof. The method comprises the following steps of: self-assembling anionic and cationic surfactants, serving as primary constitutional units, in solution phase to form a secondary constitutional unit; self-assembling in solution to be compounded into amphipathic block copolymer; then, self-assembling in the solution by taking the amphipathic block copolymer as a template agent and by using a structural guide agent and inorganic silicon to obtain a silicon dioxide / surfactant / template agent composite material; and finally, calcining to remove the surfactant and the template agent to obtain the hierarchical-structured mesoporous zeolite molecular sieve material consisting of interconnected mesopores, micropores and macropores. The material has higher specific surface area and stronger hydrothermal stability, and has a broad application prospect in the aspects of petrochemical industry, heavy oil catalysis cracking, biological separation, adsorption and the like. The material obtained in the invention has the advantages of superior performance, simple synthesis method and readily available raw material and is suitable for industrial production.

Owner:FUDAN UNIV

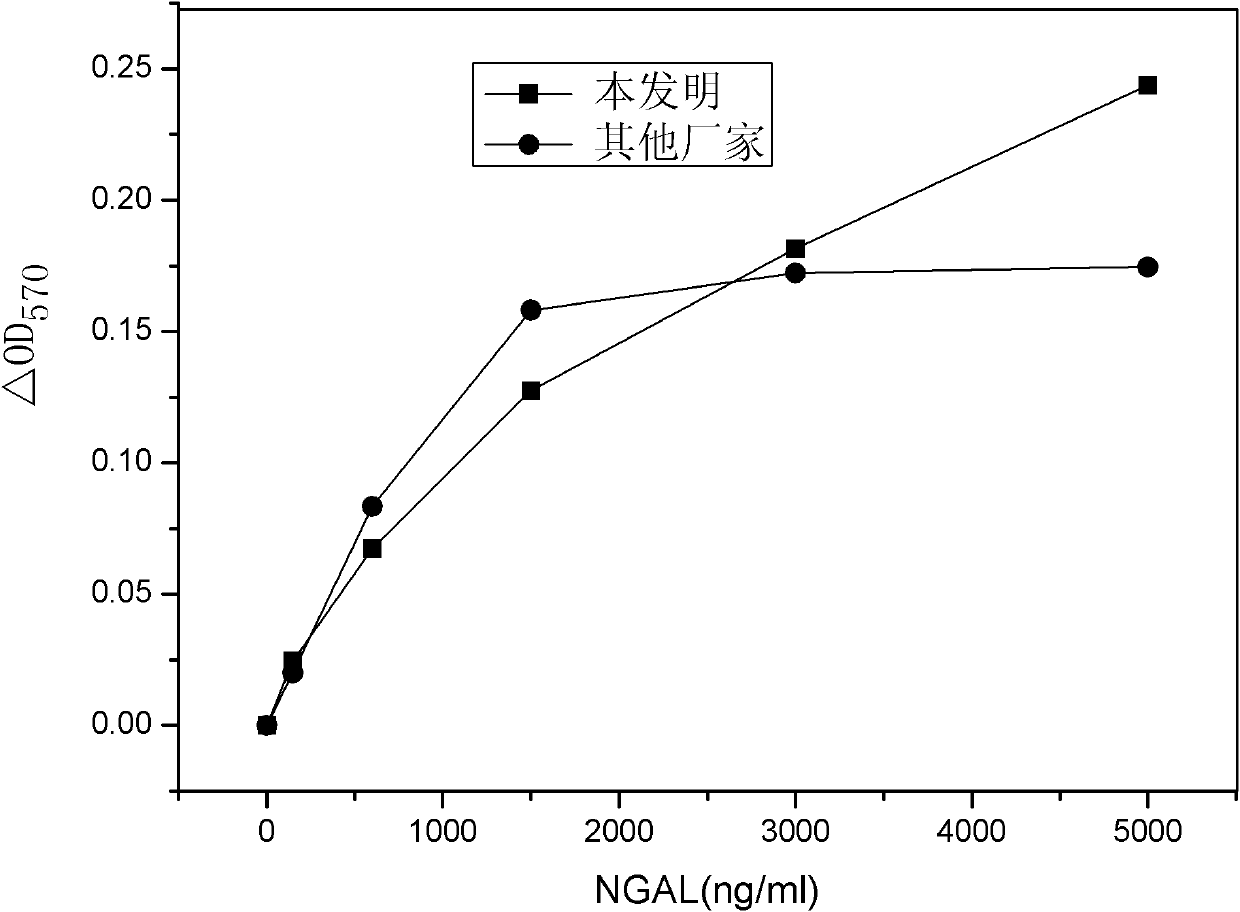

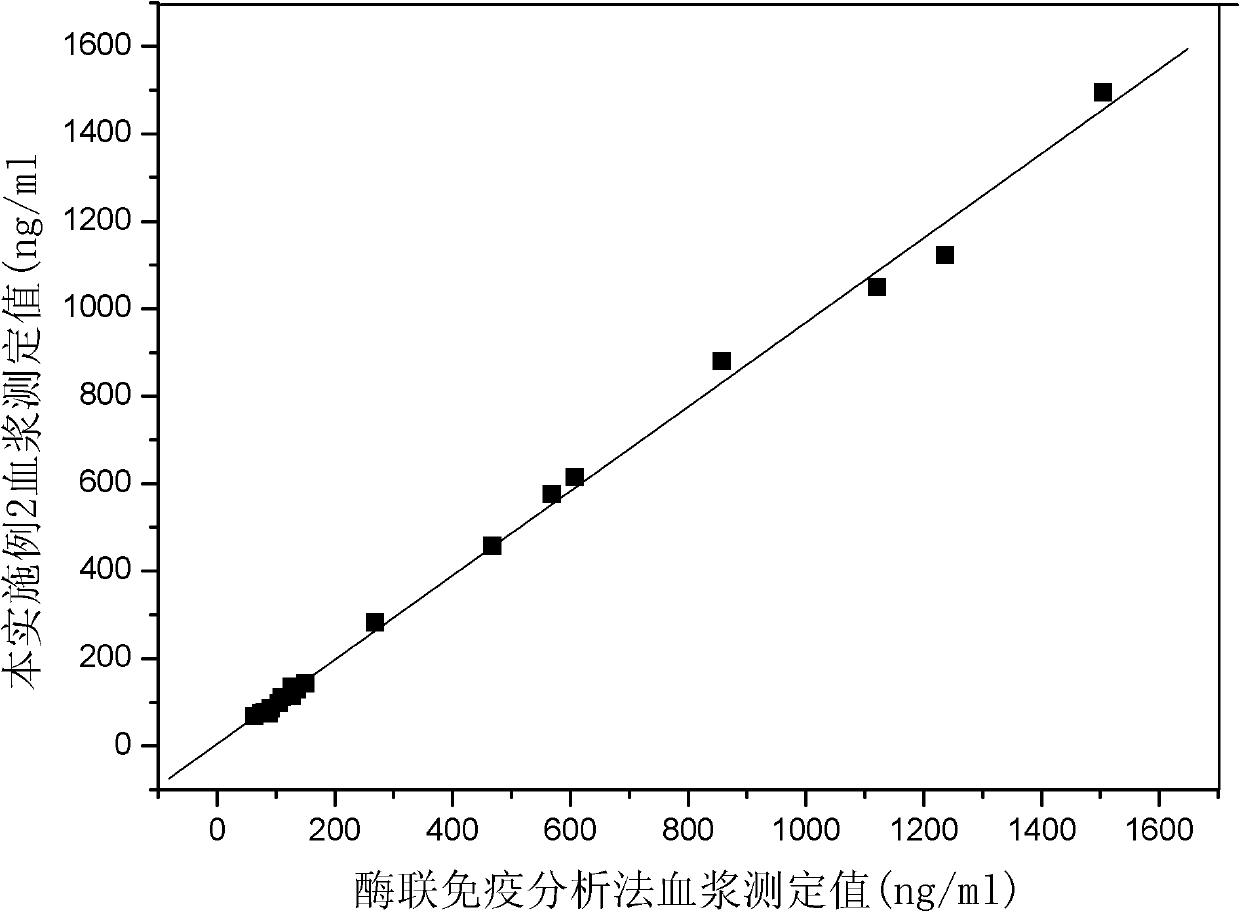

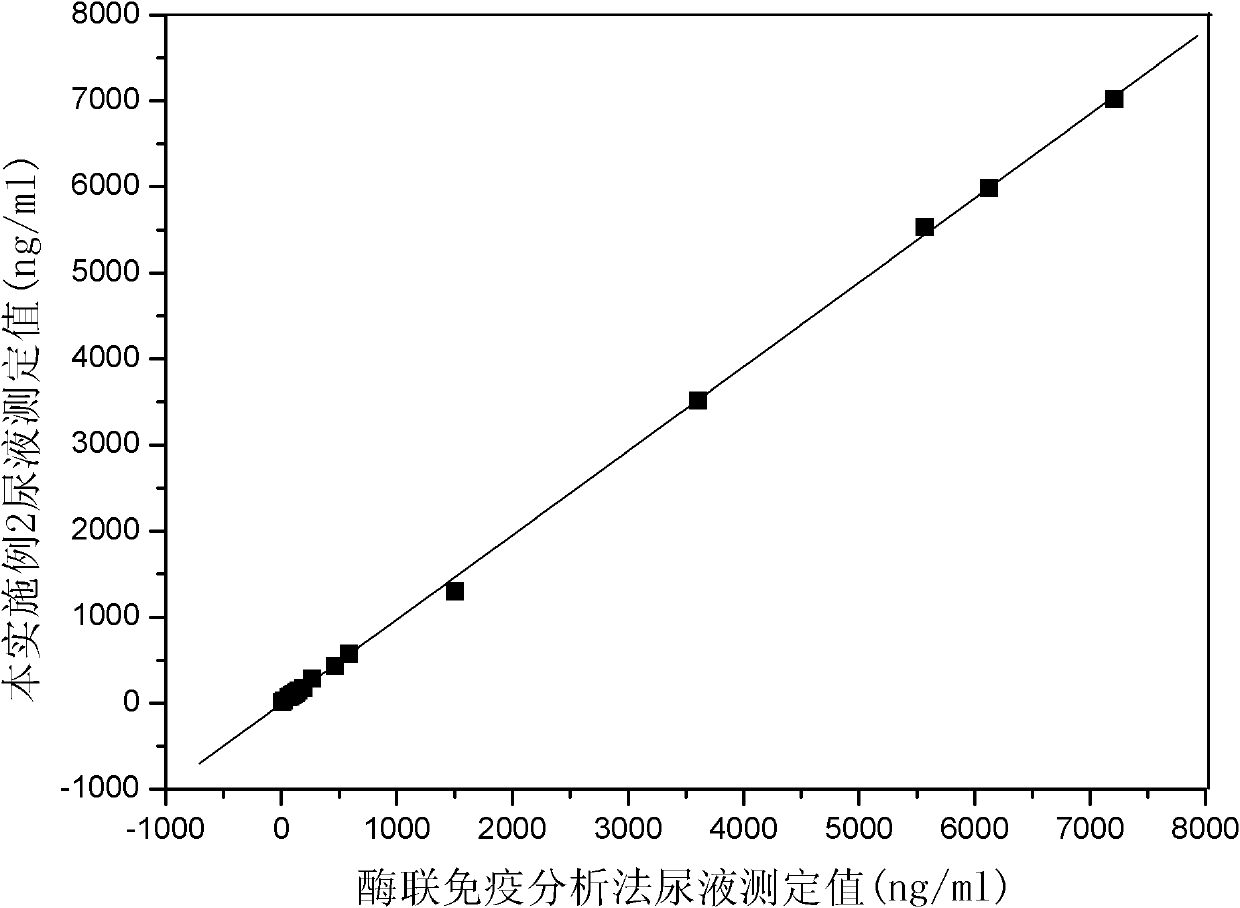

Assay kit for neutrophil gelatinase-associated lipocalin

ActiveCN102590524AIncrease reaction rateHigh sensitivityBiological testingCalibration curveChemistry

The invention relates to an assay kit for neutrophil gelatinase-associated lipocalin (NGAL), in particular to an assay kit for detecting the concentration of the NGAL in human body fluids and a preparation method for the assay kit. The kit comprises a reagent R1, a reagent R2 and a working calibrator, wherein the reagent R1 is a buffer solution which is suitable for antigen-antibody reaction; and the reagent R2 is a solution simultaneously containing nanospheres which have two particle sizes and are combined with an anti-human NGAL antibody, and ensures that the nanospheres are coagulated to cause the change of the turbidity through antigen-antibody specific reaction, and the NGAL can be quantificationally determined by contrasting calibration curves. The kit has relatively high sensitivity when determining low NGAL concentration and has a relatively wide linear range when determining high NGAL concentration, so a prozone phenomenon is avoided. The kit has stable physical and chemical properties, is convenient to use, and has a broad application prospect in clinical laboratory science.

Owner:BEIJING STRONG BIOTECH

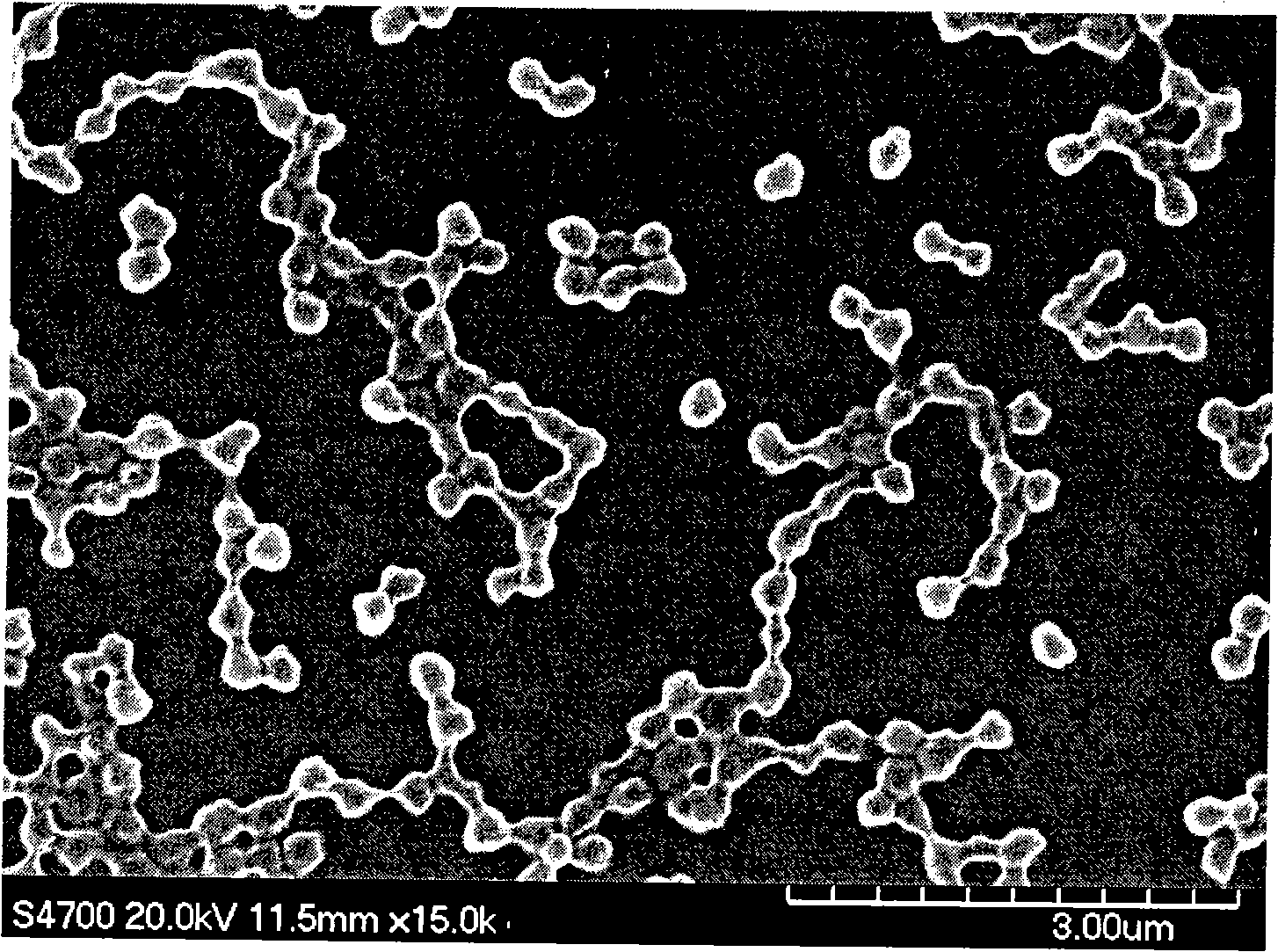

Method of preparing clubbed nano-cellulose

The invention discloses a method for preparing nano-rod cellulose, which comprises the following steps: dispersing fiber raw material into sulphuric acid water solution of which mass concentration is 50 to 65 percent, hydrolyzing the fiber raw material by single-mode microwave radiation for 5 to 60 minutes at a temperature of between 20 and 50 DEG C and at the microwave radiation power of 10 to 100 watts, then adding distilled water into hydrolysis solution and diluting the hydrolysis solution to have 10 times of volume, and obtaining stable nano-rod cellulose suspension through post treatment processes such as centrifugal separation, dialysis, filter, ultrasonic dispersion and the like of the diluent, so as to obtain the nano-rod cellulose of which width is about 10 nanometers and length is about 200 to 300 nanometers.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

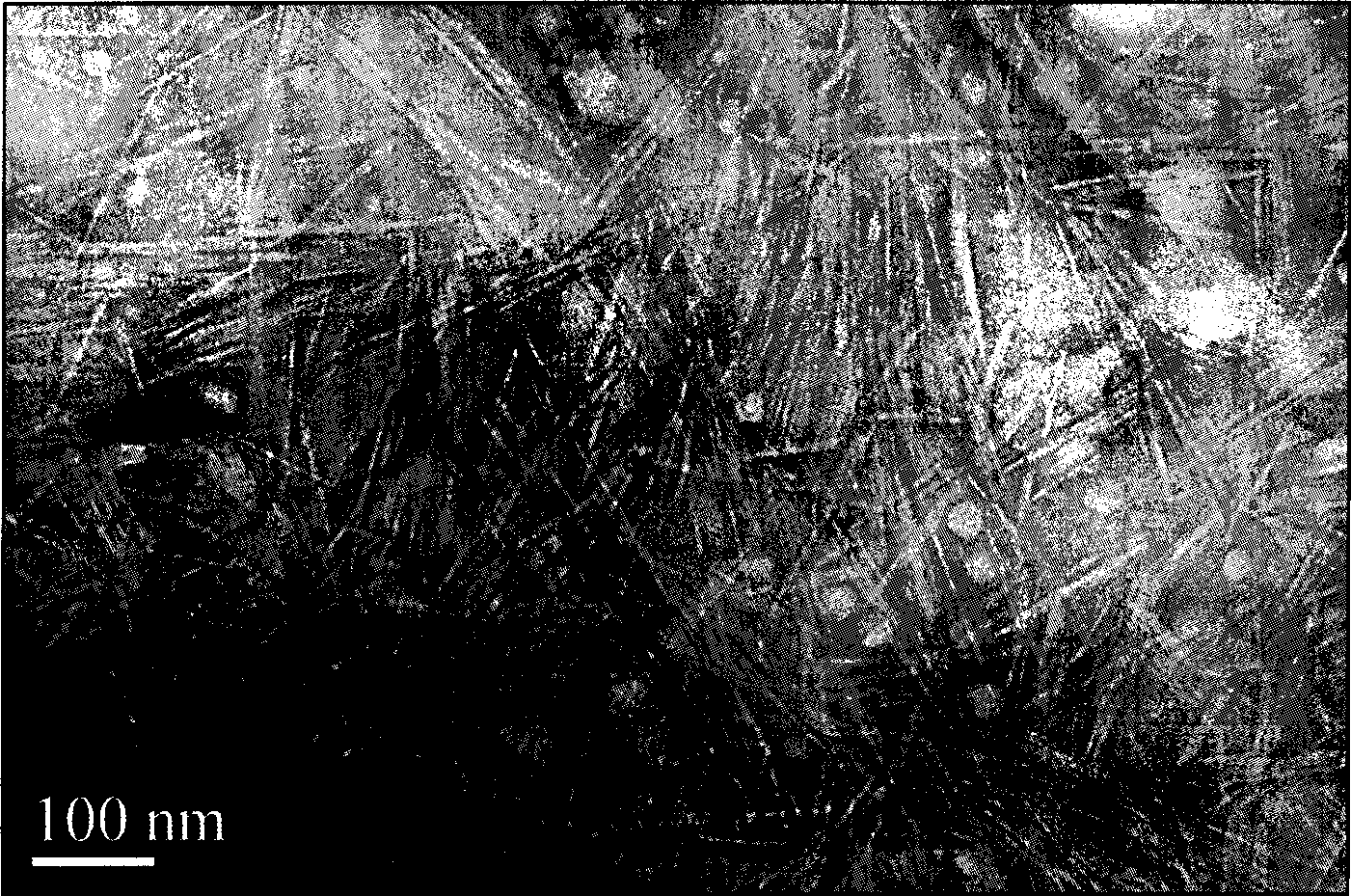

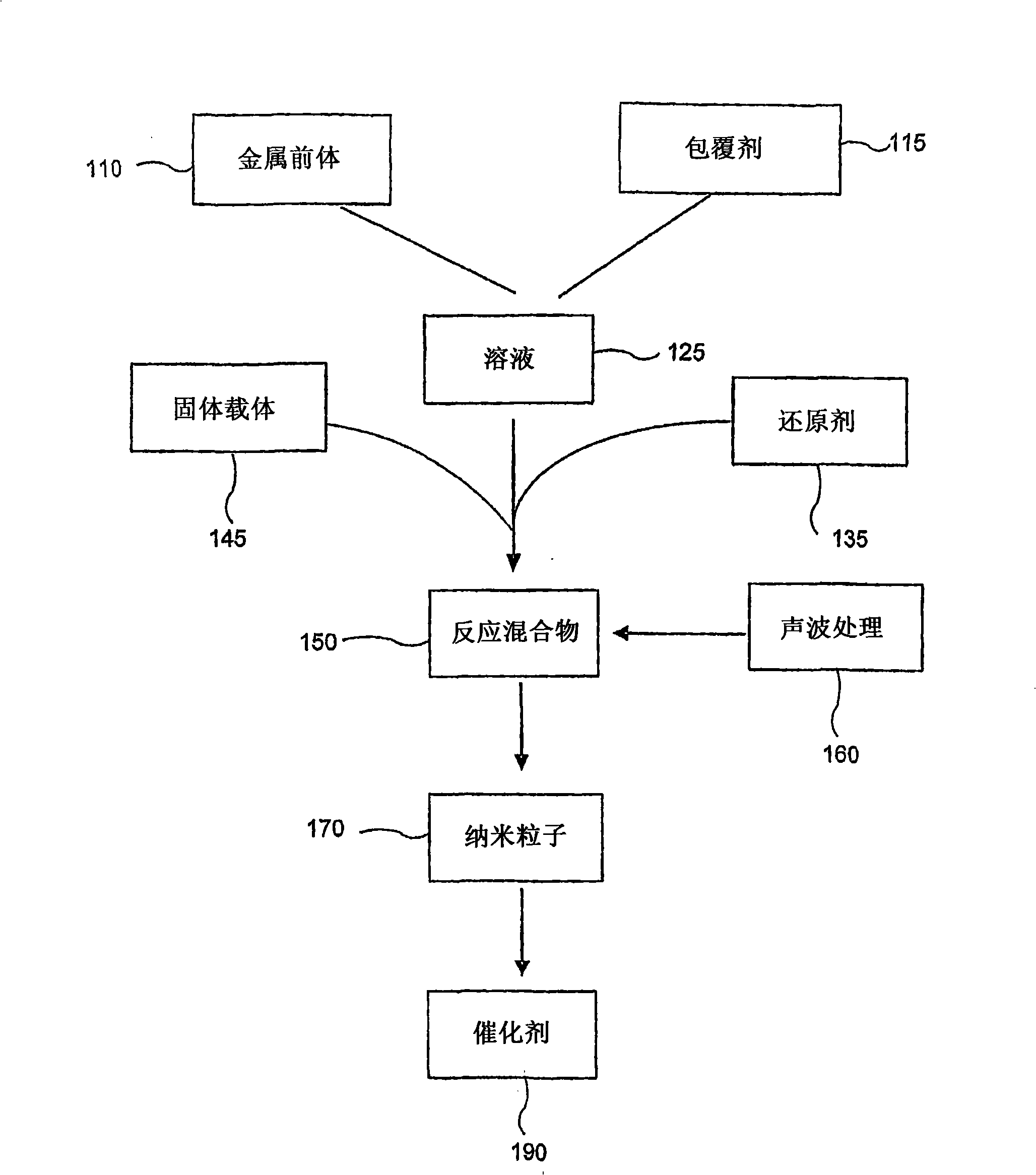

Highly dispersed metal catalysts

InactiveCN101356004AHigh activityIncrease reaction rateOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPurification methodsAir filter

The present invention relates to a novel method for preparing a new type of catalyst for the oxidation of CO in a reactant gas or air. The method provides the preparation of a catalyst having nano-sized metal particles and a capping agent deposited on a solid support. The size and distribution of the metal particles can be easily controlled by adjusting reaction condition and the capping agent used. The catalyst prepared has high activity at low temperature toward selective oxidation of CO and is stable over an extended period of time. The catalyst can be used in air filter devices, hydrogen purification processes, automotive emission control devices (decomposition of NOx, x is the integer 1 or 2), F-T synthesis, preparation of fuel-cell electrode, photocatalysis and sensors.

Owner:AGENCY FOR SCI TECH & RES

Calcium carbide production method

The invention relates to a carbide preparation method belonging to the field of carbide preparation. The conventional carbide preparation technology adopts block materials and electric arc as a heat-supply, while the preparation method according to the invention adopts powdery carbon-containing materials and powdery calcium-containing materials, and the combustion of partial carbon-containing materials and oxygen-containing gas as a heat-supply at 1700-2300 DEG C to prepare carbide, wherein the carbon-containing materials is coal or coke, calcium-containing materials is calcium carbonate, calcium oxide, calcium hydroxide or carbide slag, the granularity of the carbon-containing materials and calcium-containing materials is less than 1mm, and the quality ratio is 0.5-3:1. The oxygen-containing gas for combustion is oxygen, oxygen-enriched air or air. The method solves the problems of high energy consumption and high pollution of the carbide preparation and has advantages of wide choice scope of materials, high energy utilization rate, continuous operation and large production capacity. The technology also couples with the process of carbon-containing materials coking and calcium-containing materials calcining, preheats the materials to 500-1500 DEG C utilizing the combustion of by-products CO of the carbide preparation and the assistant fuel, thereby further reducing the oxygen and energy consumption of the carbide preparation.

Owner:BEIJING UNIV OF CHEM TECH

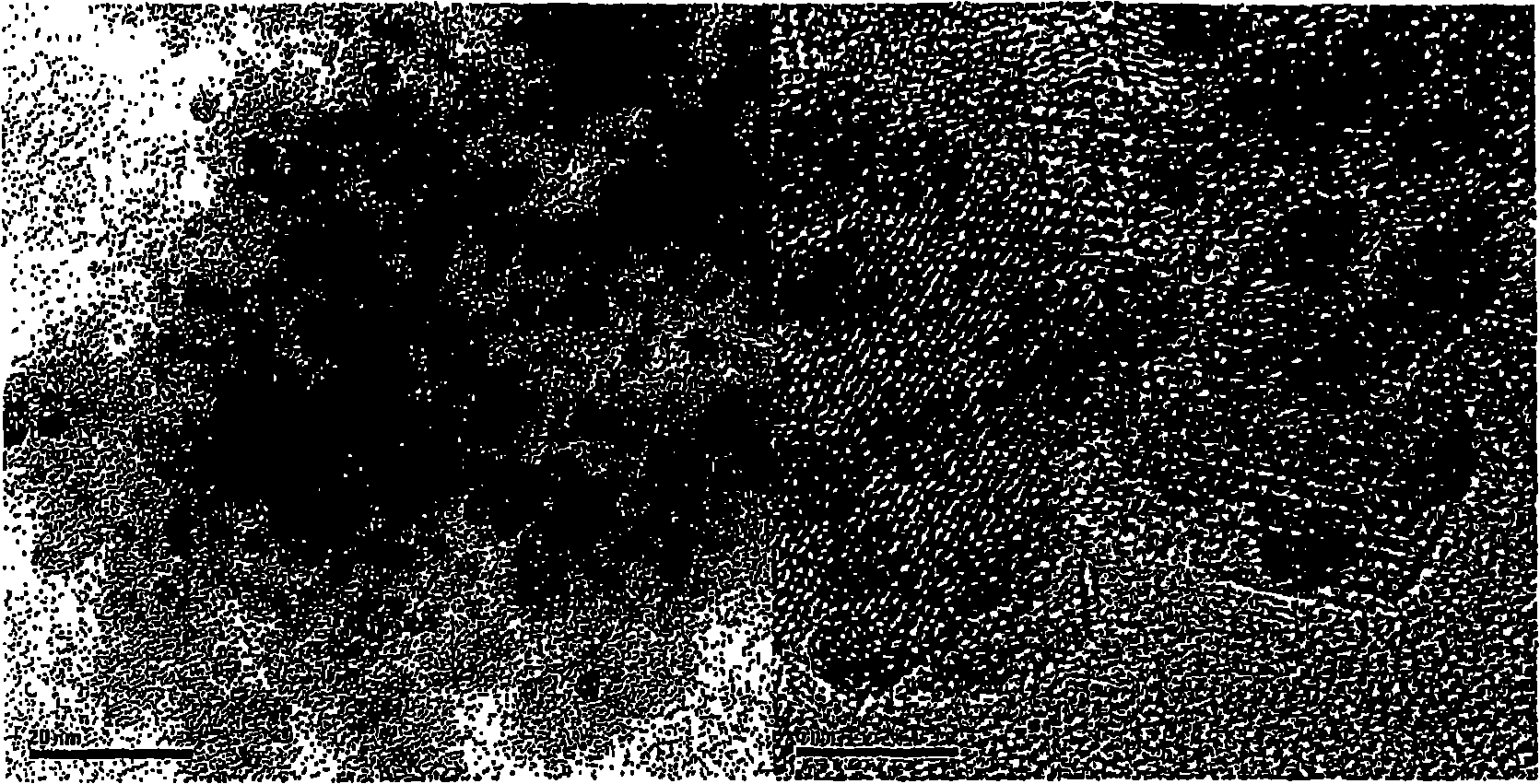

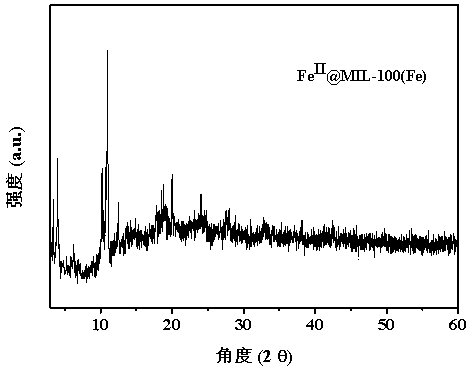

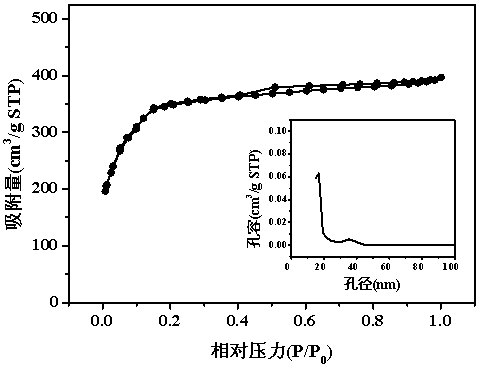

Preparation method of loading iron based metal organic skeleton out phase Fenton catalyst and application thereof

InactiveCN103934034APromote enrichmentIncrease reaction rateOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatment by oxidationFenton reactionPorosity

The invention relates to a preparation method of a loading iron based metal organic skeleton out-phase Fenton catalyst and an application thereof. The preparation method comprises the following steps of by taking MIL-100 (Fe) as a basal body, loading a ferrous component through a hydrothermal method so as to obtain the loading iron based metal organic skeleton out-phase Fenton catalyst, namely Fell@ MIL-100 (Fe). The catalyst is used for degrading an organic pollutant in waste water by using an out-phase Fenton catalyst system. Compared with the prior art, the loading catalyst prepared by the invention fully utilizes the advantages of MIL-100 (Fe) and a ferrous component in an out-phase Fenton reaction, so that the loading catalyst has high porosity, large specific surface area, and is stable in a water phase, catalytic activity sites are uniformly dispersed, the capacity is controllable and the like, meanwhile, the mutual circulation action of the Fe<2+> component in a carrier and a Fe<3+> in the basal body are utilized to further strengthen the Fenton reaction activity, the catalyst is suitable for removing refractory organics in waste water by catalytic oxidation of out-phase Fenton, the operation of the technology is simple, the cost is low, the preparation method is an efficient and energy-saving new technology, and the catalyst has the far-reaching application prospect and wide social and economic benefits.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com