Patents

Literature

63results about How to "Speed up mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

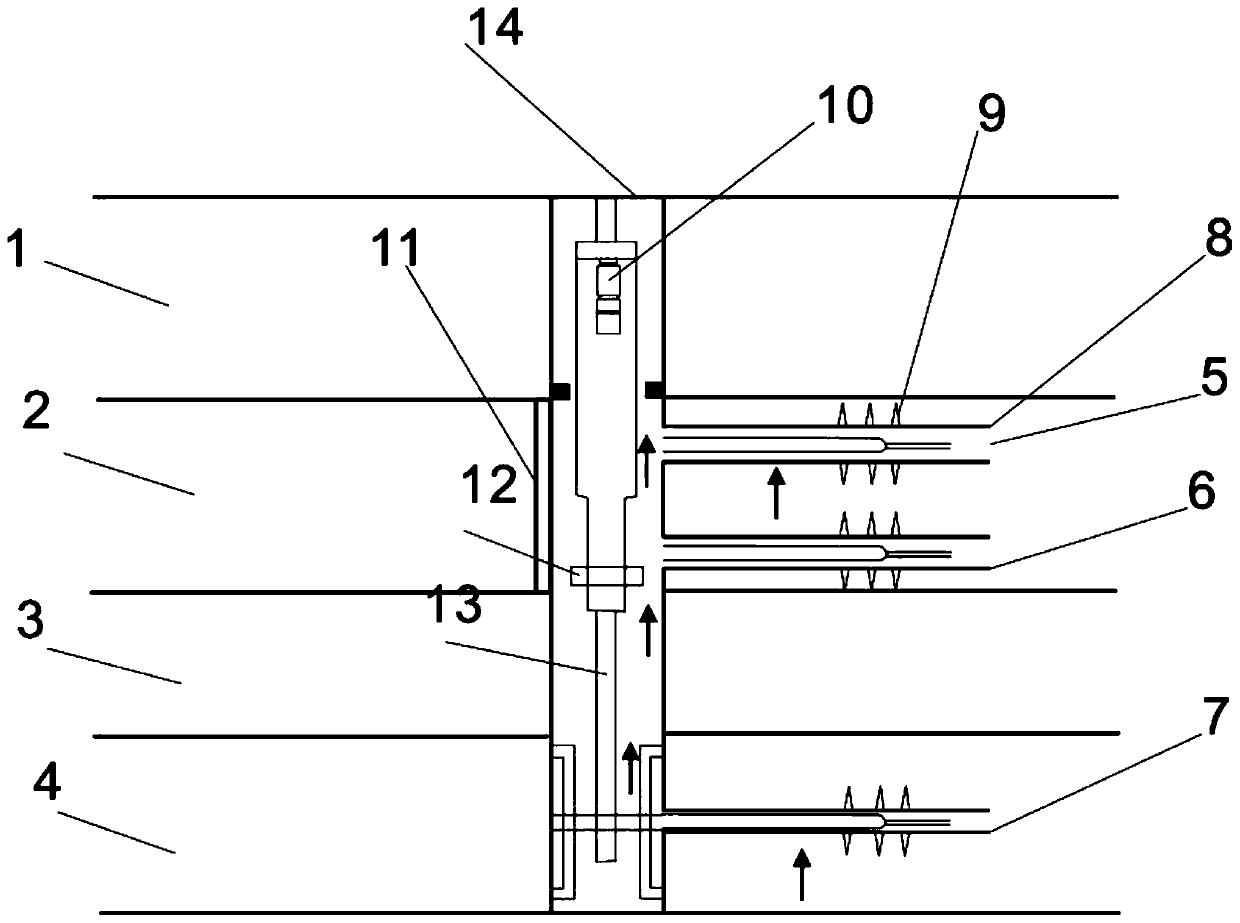

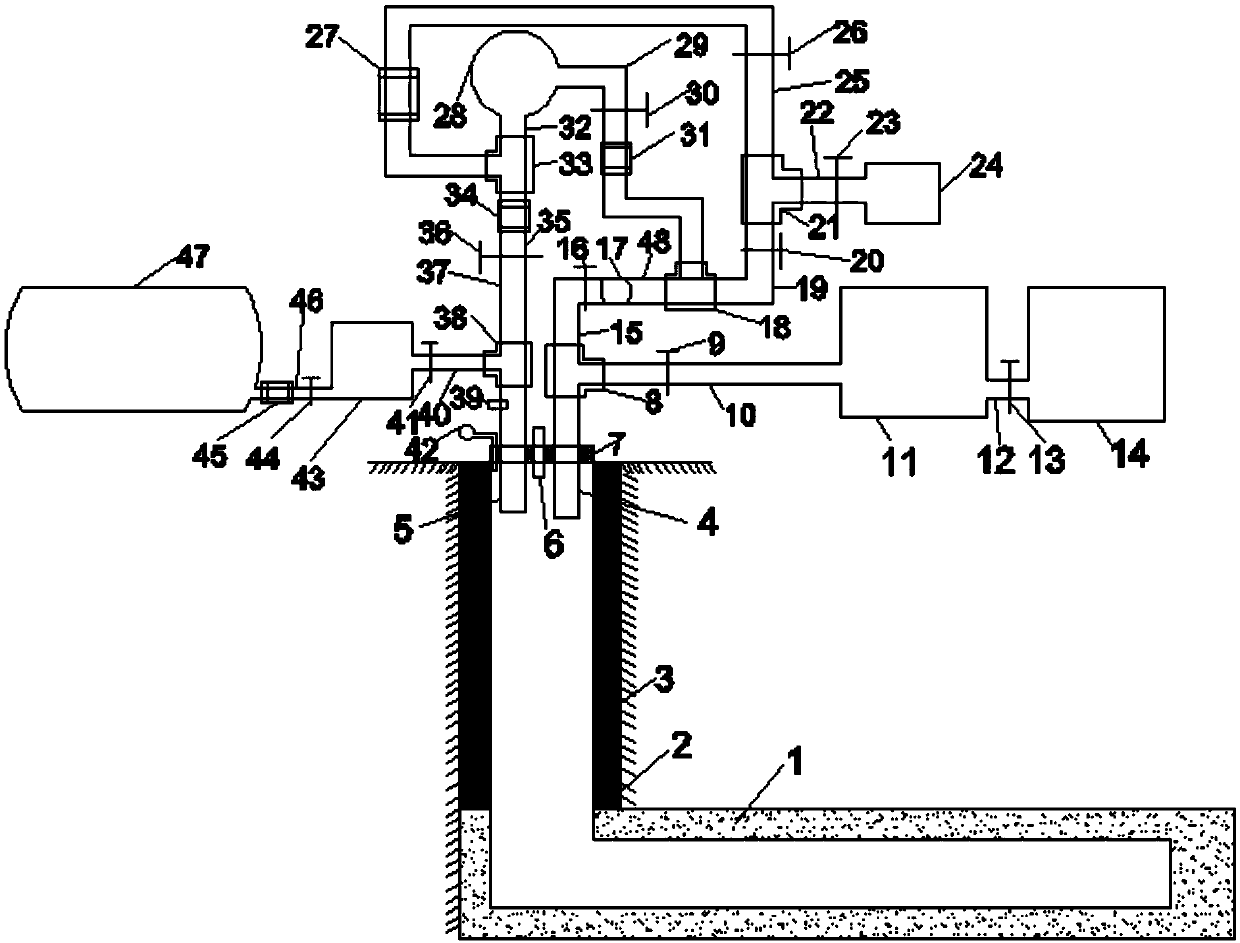

In-situ submarine natural gas hydrate exploiting device and method thereof

InactiveCN102704894AIncrease reaction rateSpeed up miningBatteries circuit arrangementsConstructionsGreenhouse gasSubmarine

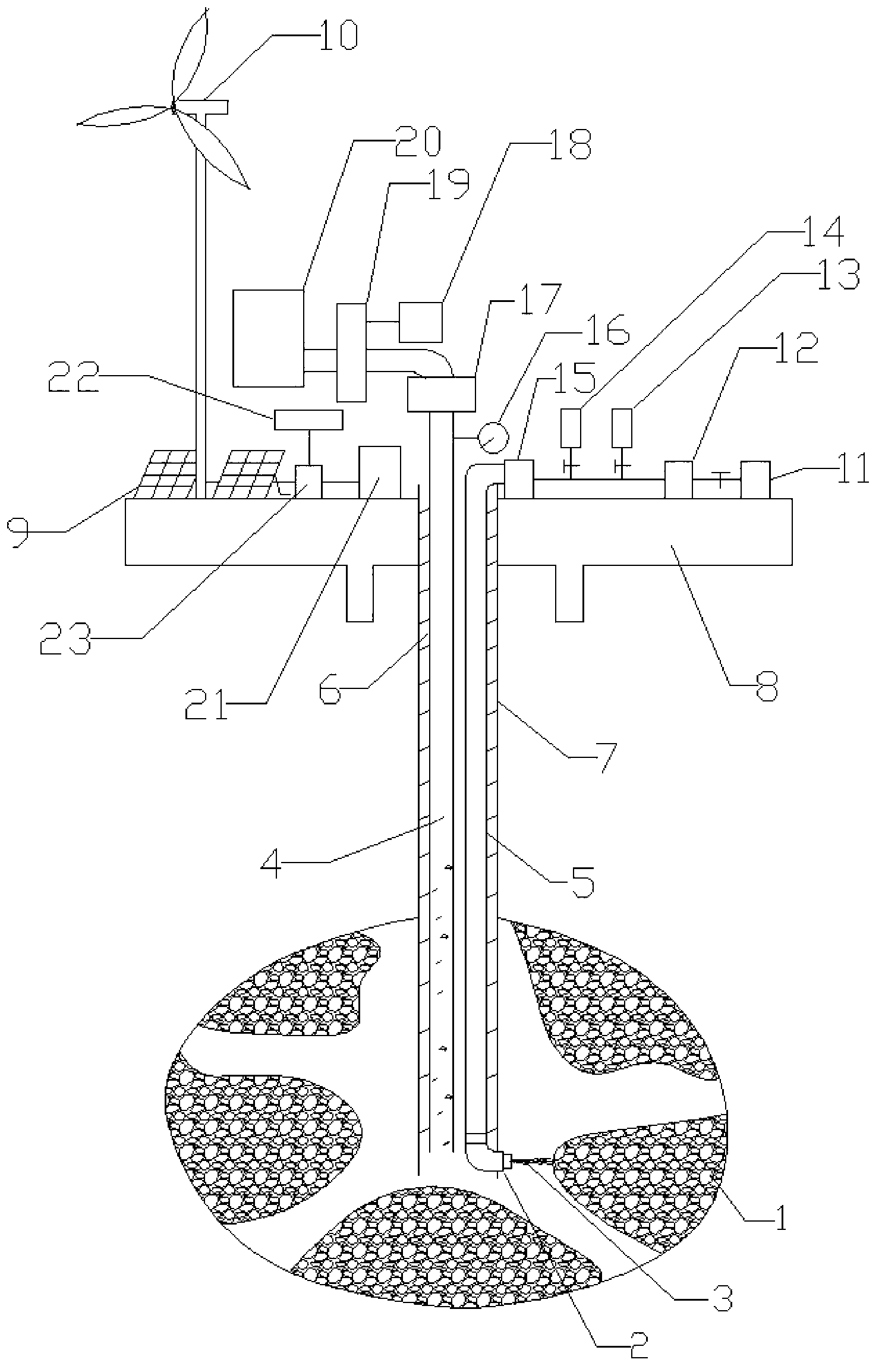

The invention relates to an in-situ submarine natural gas hydrate exploiting device and a method thereof, and belongs to the technical field of exploitation of natural gas hydrates. The exploiting device comprises a solar and wind power generating system, a rotary telescopic water gun, an insulating pipeline, a conveying pipeline, a sleeve pipe, an ocean platform, a sea water pump, an electric heater, a CO2 liquid storing tank, a decomposition accelerator storing tank, a high-pressure pump, a pressure gauge, a filtering device, a water storing tank, a gas-liquid separator and a gas recovering device. A thermal activation method and a chemical reagent catalyzing method are utilized to trigger a decomposition reaction of the natural gas hydrate, and then the high-pressure CO2 jetting technology is utilized to enable the natural gas hydrate to be cut while a substitution reaction occurs. According to the invention, the natural gas hydrate is exploited by fully utilizing rich solar power and wind power in ocean areas, so that the effects of cleaning and environmental protection are realized; the thermal activation method and the chemical reagent catalyzing method are matched with the CO2 substitution method, and therefore the exploitation rate is improved, the dosage of a chemical reagent is reduced, the stability of submarine geology is protected effectively, and meanwhile the greenhouse gas is treated to a certain extent.

Owner:SHANGHAI JIAO TONG UNIV

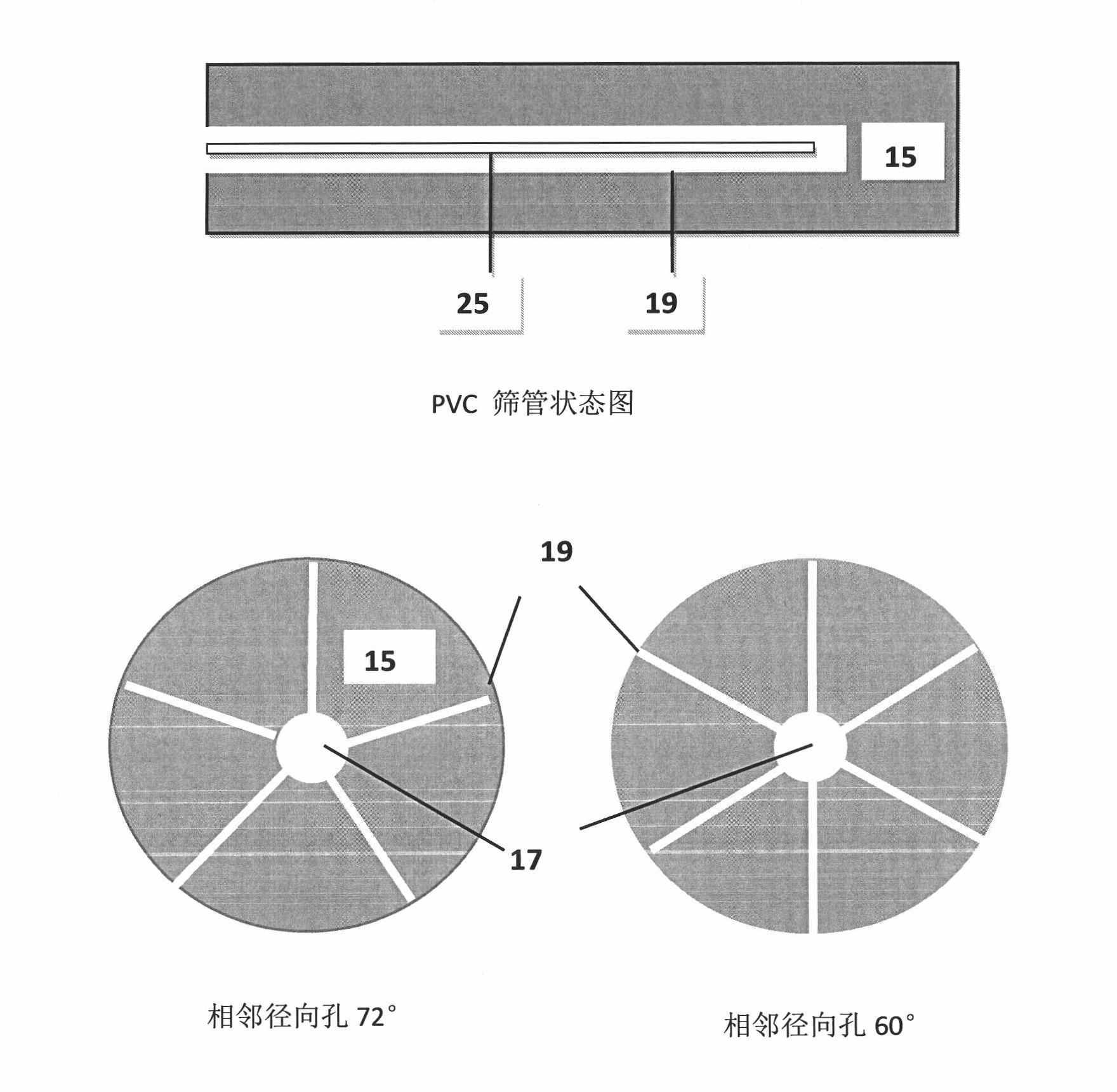

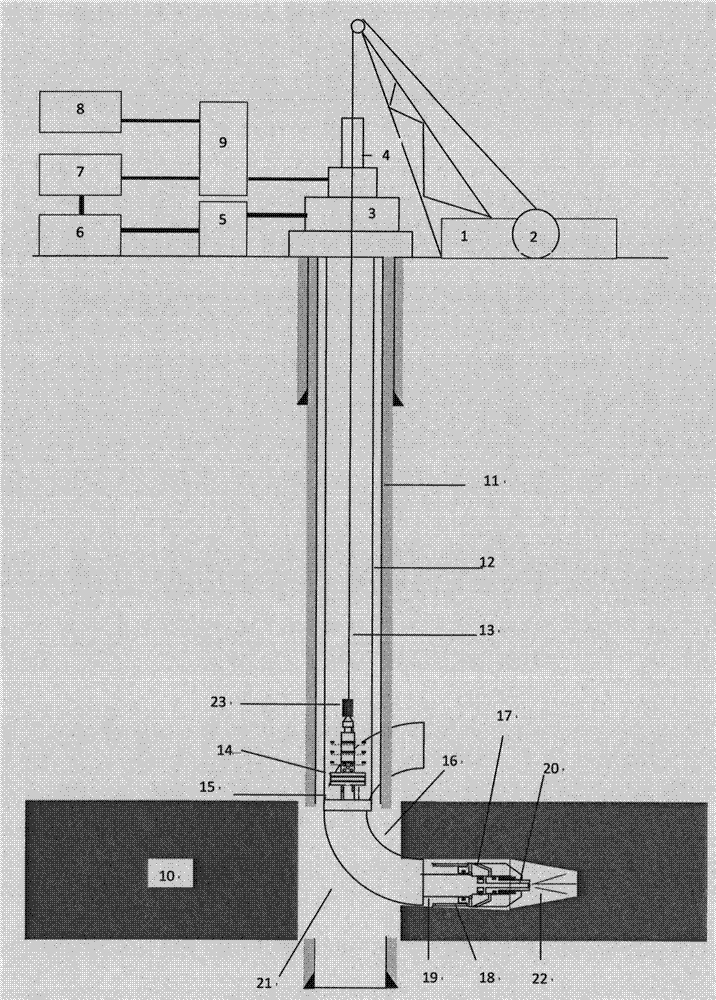

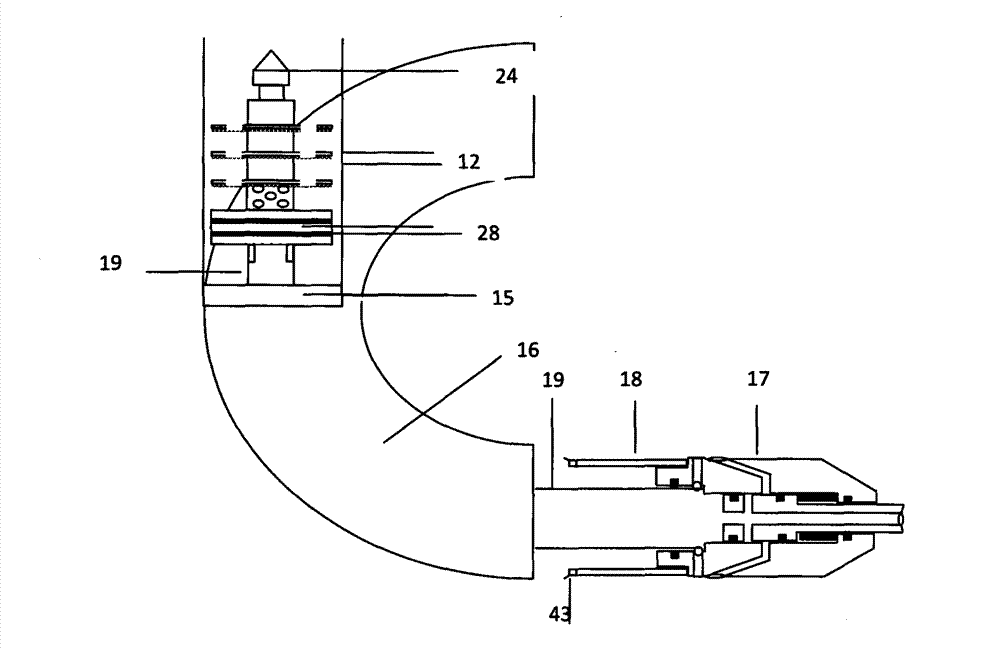

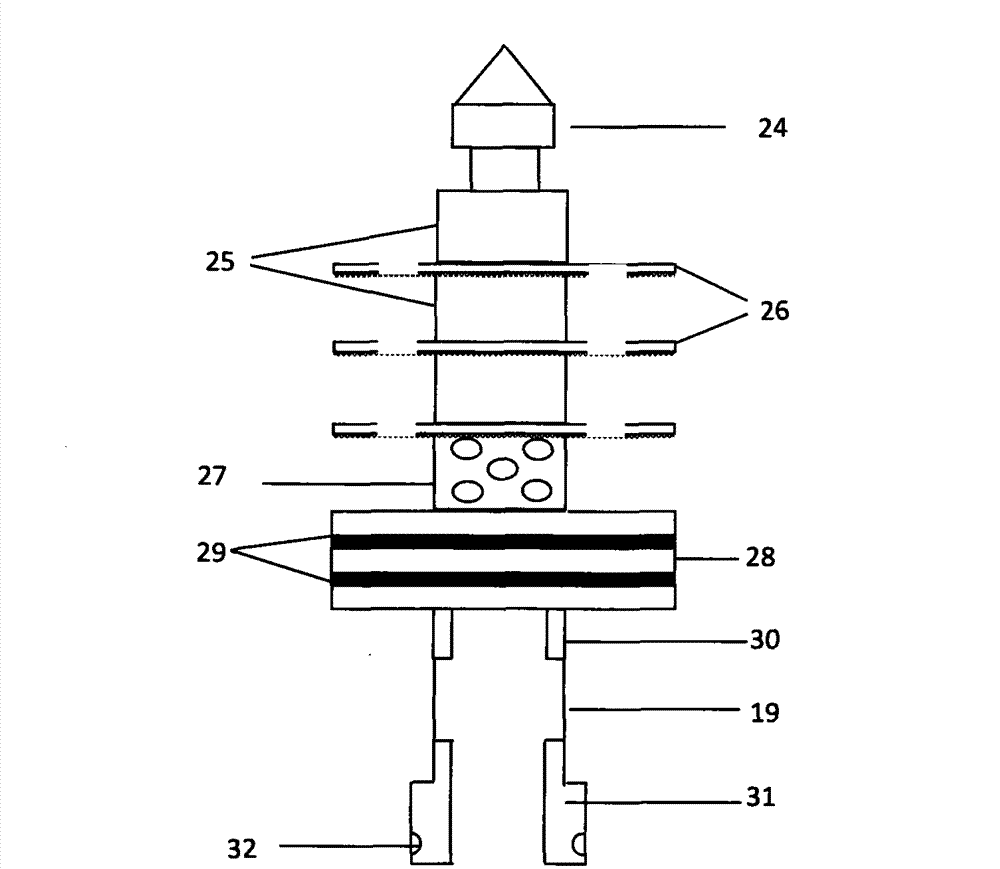

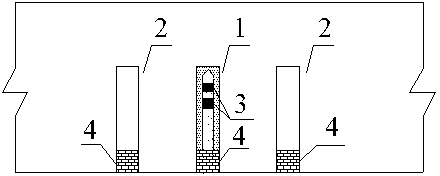

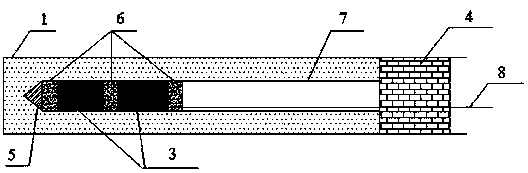

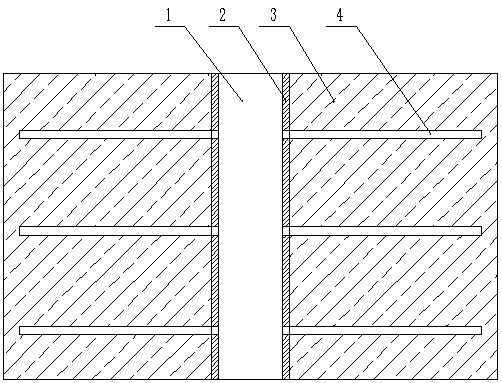

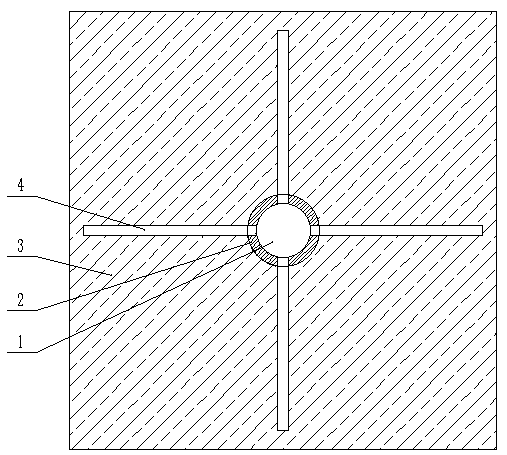

Coal bed methane exploring method of spraying gas-water mixed liquid to drill well and forming quincunx radial horizontal well

InactiveCN102493794ARapid combined drainage and depressurizationSpeed up miningLiquid/gas jet drillingFluid removalWell drillingHorizontal wells

The invention discloses a coal bed methane exploring method belonging to the field of coal bed methane exploring, and in particular relates to a coal bed methane exploring method. In the coal bed methane exploring method, a continuous oil pipe with a high pressure fluid jet gun is used after hole enlargement of a vertical well in a coal bed well section. By means of a radial guide tool, high pressure gas-water mixed liquid is adopted to spray and drill out one group of radial horizontal holes with certain diameter and length or a plurality of groups of vertically distributed radial horizontal holes with the certain diameter and length in a coal bed at different azimuthal angles and along the radial direction. High-strength polyvinyl chloride (PVC) sieve tubes provided with diversion holes are arranged into the radial horizontal holes to form a quincunx radial horizontal well with support and diversion functions, a group or a plurality of groups of (multiple coal beds) quincunx radial horizontal wells and well patterns formed by the radial horizontal wells.

Owner:王建生

Mining method for support pipe following air liquid spraying and drilling into coal bed gas of radial well

InactiveCN102926730ARapid combined drainage and depressurizationSpeed up miningLiquid/gas jet drillingFluid removalPolyvinyl chlorideHigh pressure

The invention relates to a mining method for coal bed gas in the field of mining of the coal bed gas, in particular to a mining method for a coal bed gas of a radial well. A directional radial guide tool is placed from an oil pipe on a coal bed well after chambering of a vertical well, then a steel wire rope is used to combine and place a support pipe following spraying and drilling tool into the oil pipe and the directional radial guide tool, a group or a plurality of groups (multiple coal bed) of radial horizontal holes are sprayed and drilled along the radial direction in a coal bed by high pressure air water mixed liquid. Meanwhile, when the radial holes are drilled, high-strength polyvinyl chloride (PVC) kerf sieve pipe is automatically followed to form the radial horizontal holes with a support function and a river diversion function, and underbalance drilling and negative pressure reinforced coal bed are achieved.

Owner:王建生

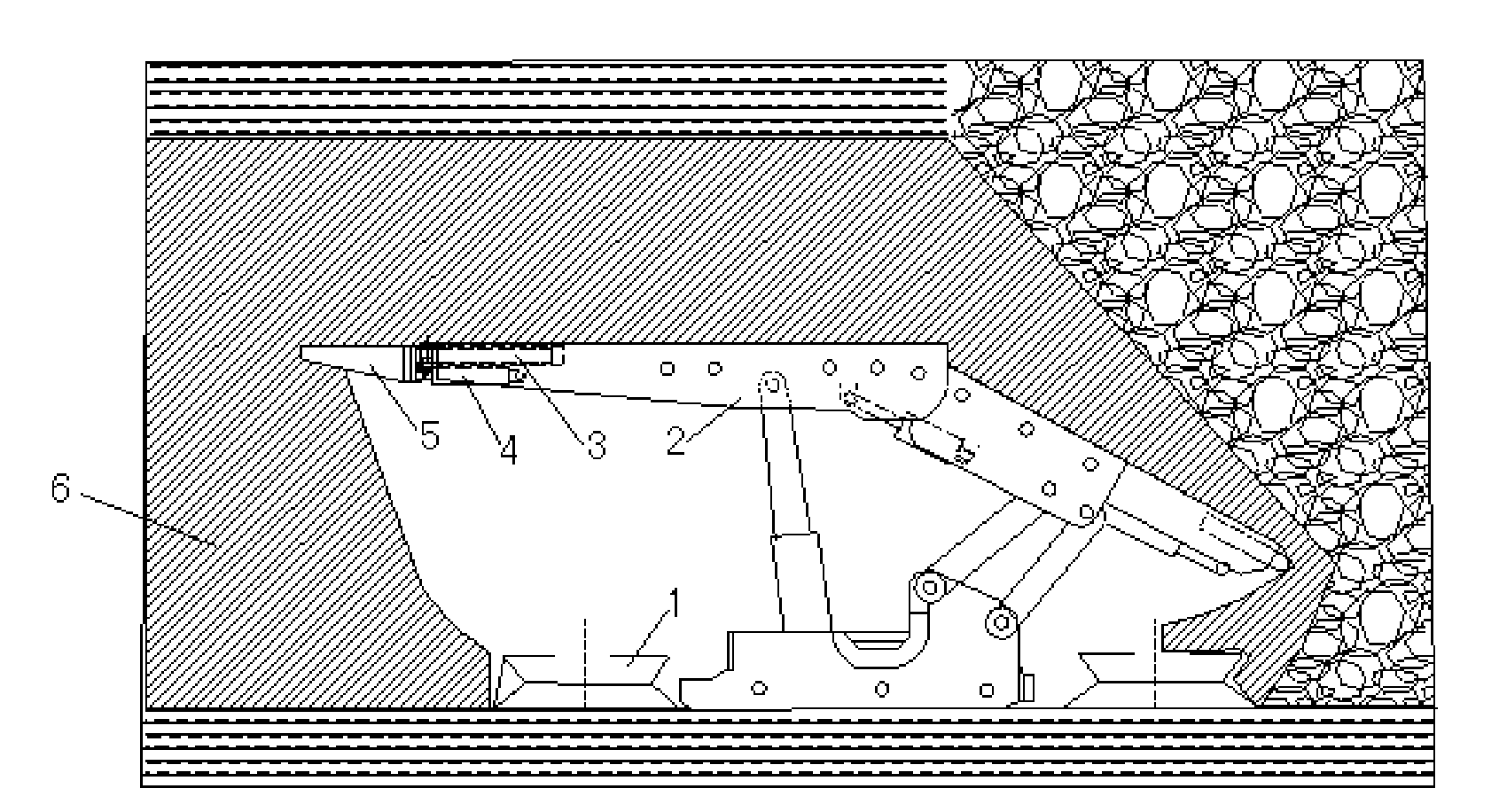

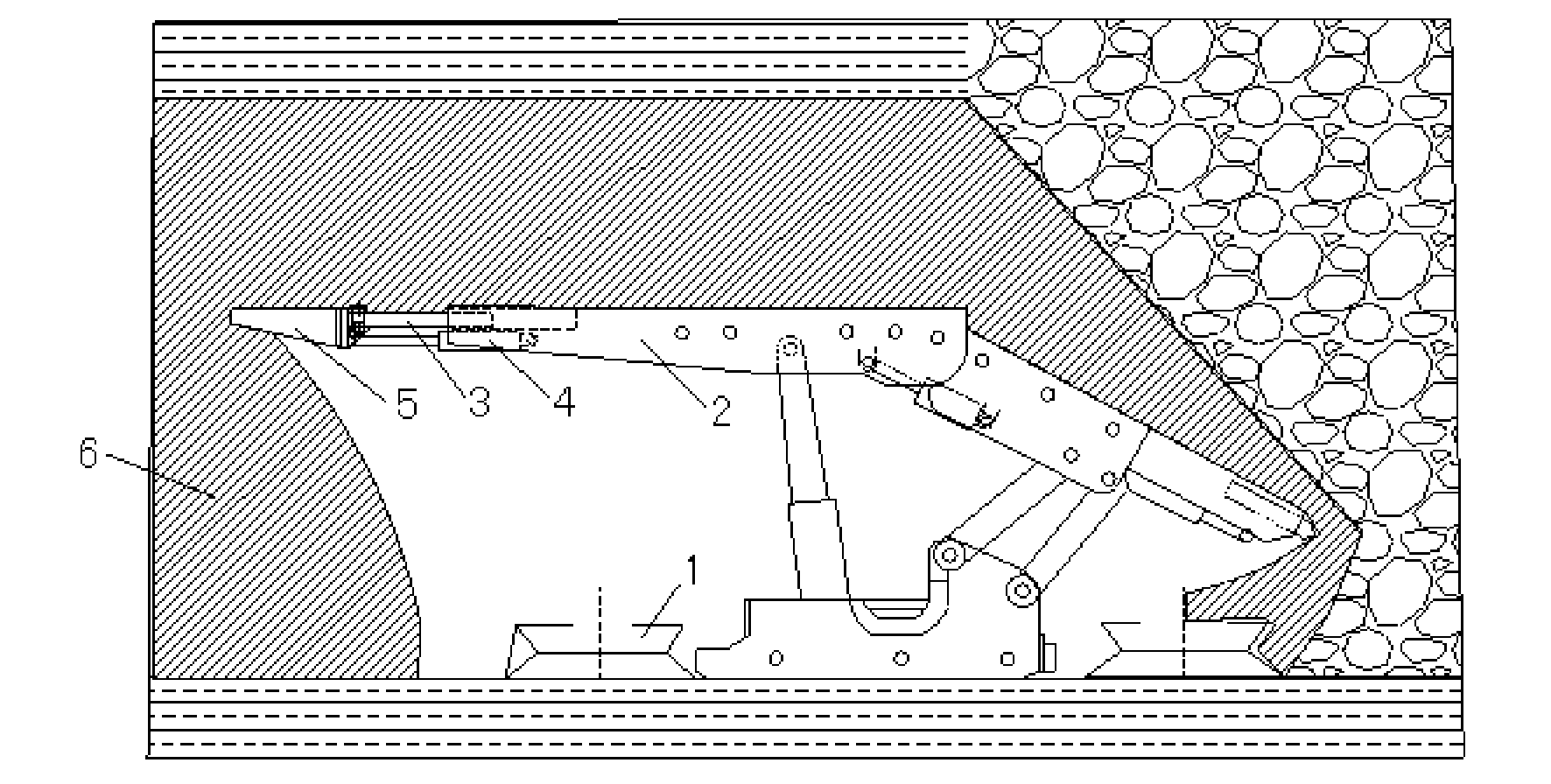

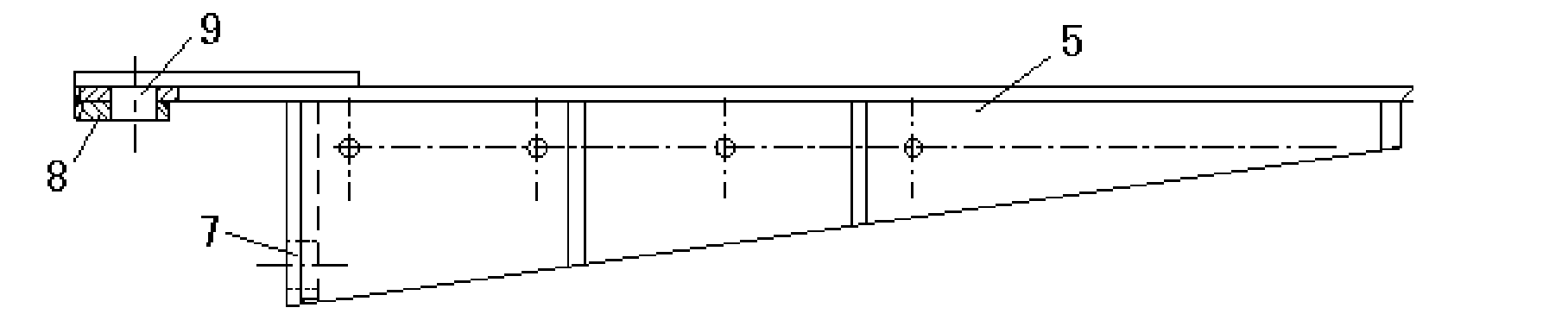

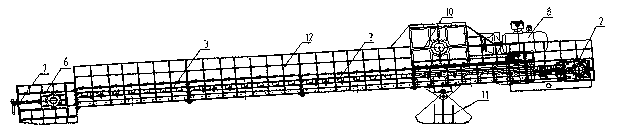

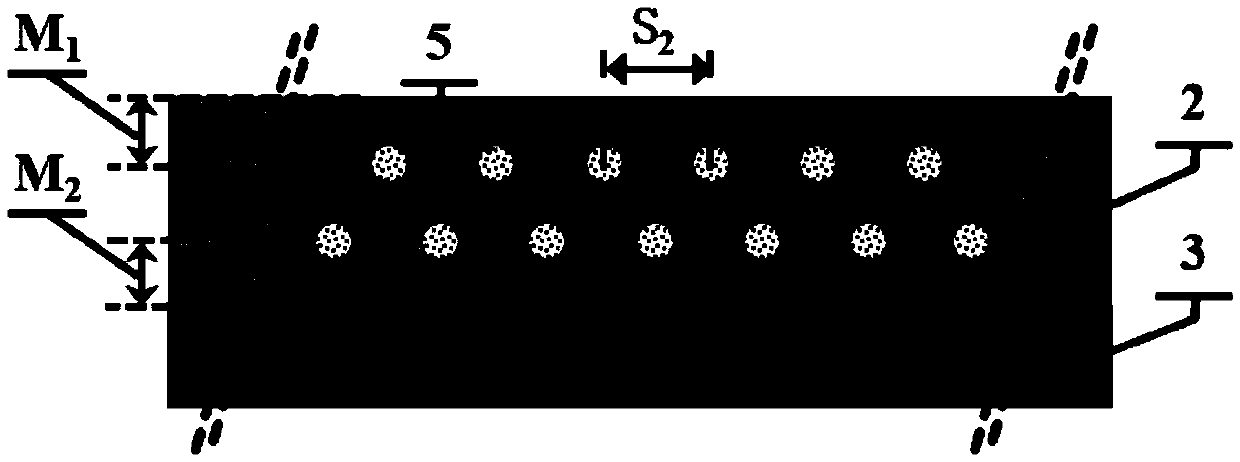

Coal mining method of lengthened front-beam fully-mechanized mining and fully-mechanized top coal carving of three-soft coal seam and equipment

ActiveCN101666230AChange stressImprove stress conditionUnderground miningSlitting machinesHydraulic cylinderEngineering

The invention discloses a coal mining method of a lengthened front-beam fully-mechanized mining and fully-mechanized top coal carving of a three-soft coal seam and an equipment. The invention is characterized in that the front end of the expansion front end of a fully-mechanized mining hydraulic bracket is provided with the lengthened front beam, a hydraulic cylinder of the expansion front beam isextended after a coal mining machine cuts coal; one part of the front end of the lengthened front beam extends into a coal wall so as to lead the lengthened front beam to support a top plate or top coal; then a scraping plate conveyor is gradually moved to be close to the coal wall behind the coal mining machine; then the hydraulic bracket is moved forward; at the time, the hydraulic cylinder ofthe expansion front beam is in retracted state again; and and top coal carving at the rear part is carried out at the place where the hydraulic bracket is moved. The invention can control the top coalor the top plate at the coal slide of the coal wall of fully-mechanized caving working face and the fully-mechanized mining working face of the three-soft unstable coal seam to lead the top coal or the top plate not to have the occurrence of leakage and roof fall and is characterized by moving the bracket fast, saving cost, having simple technique, being safer, saving working hour and having highproduction efficiency and the like.

Owner:耿学文

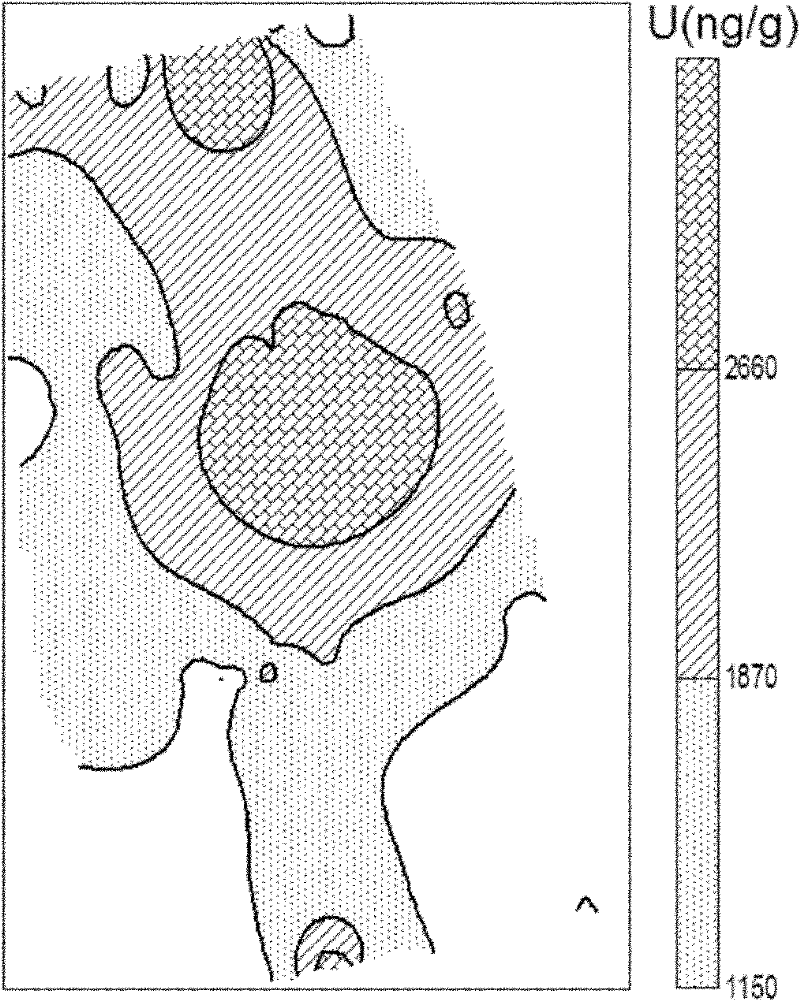

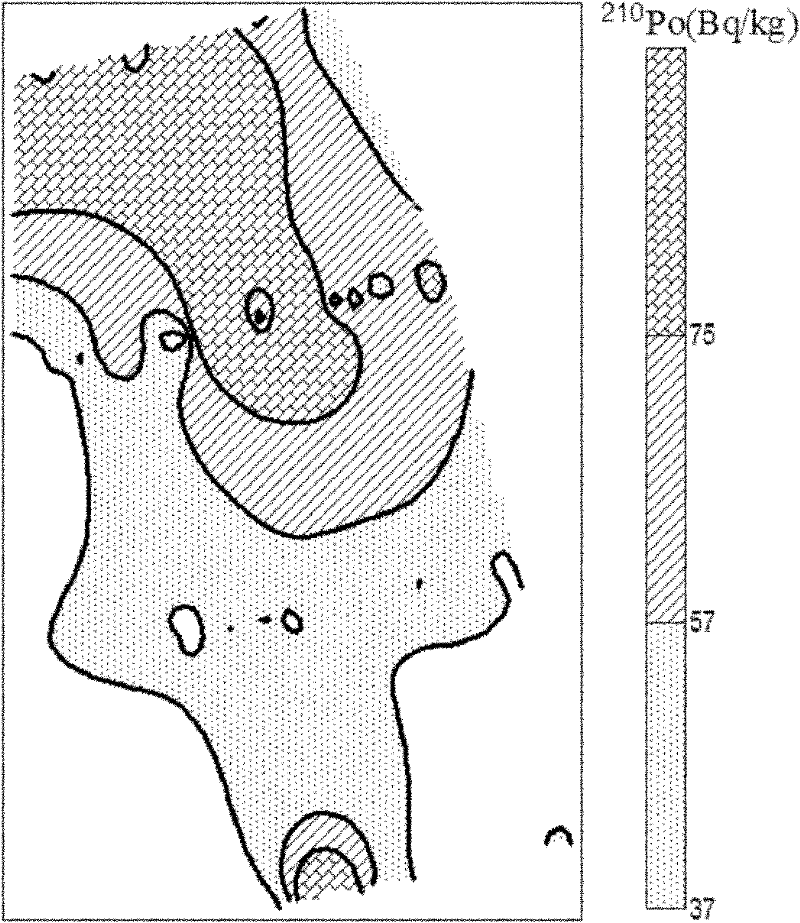

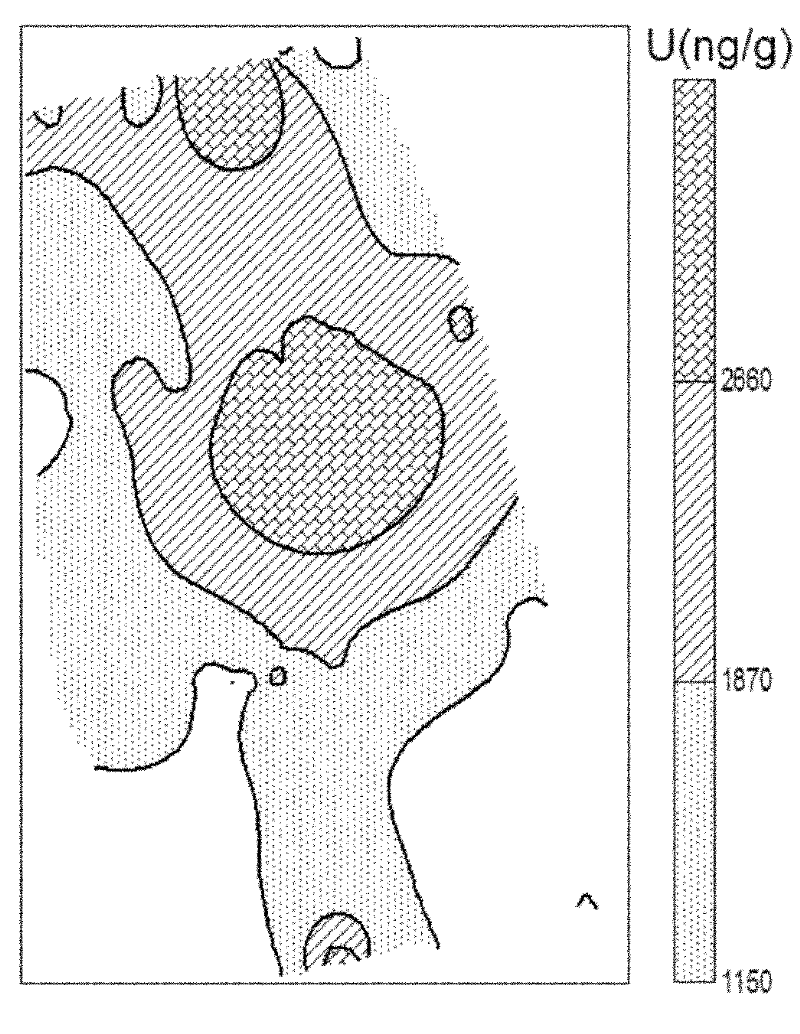

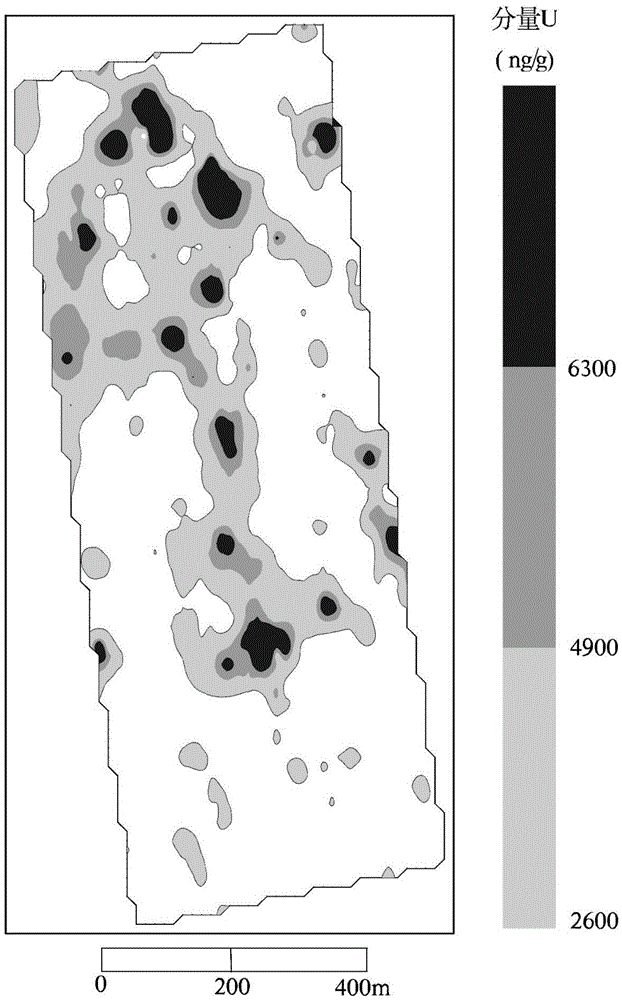

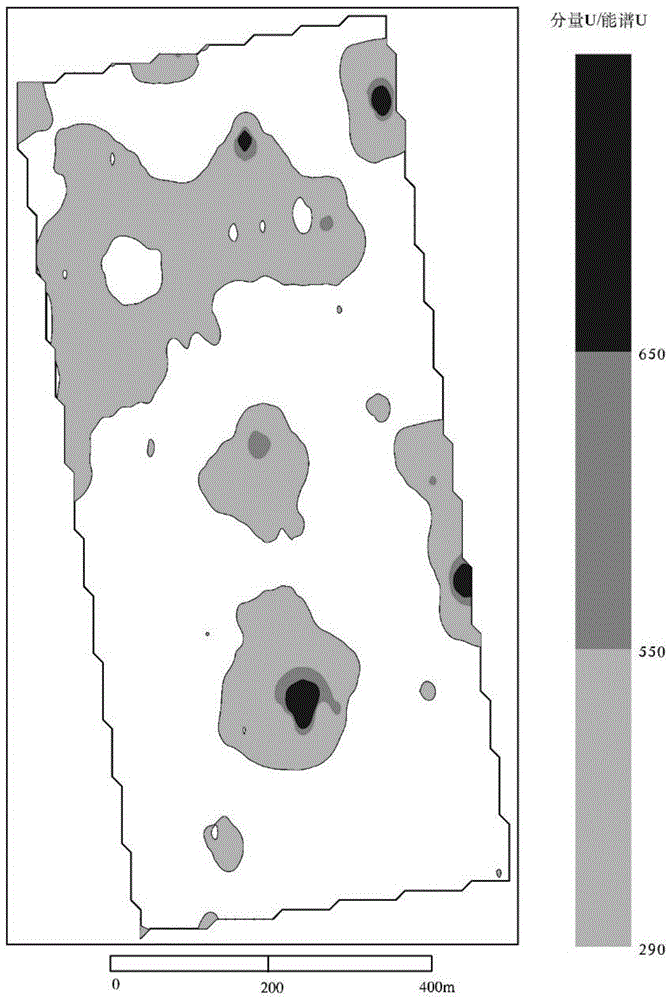

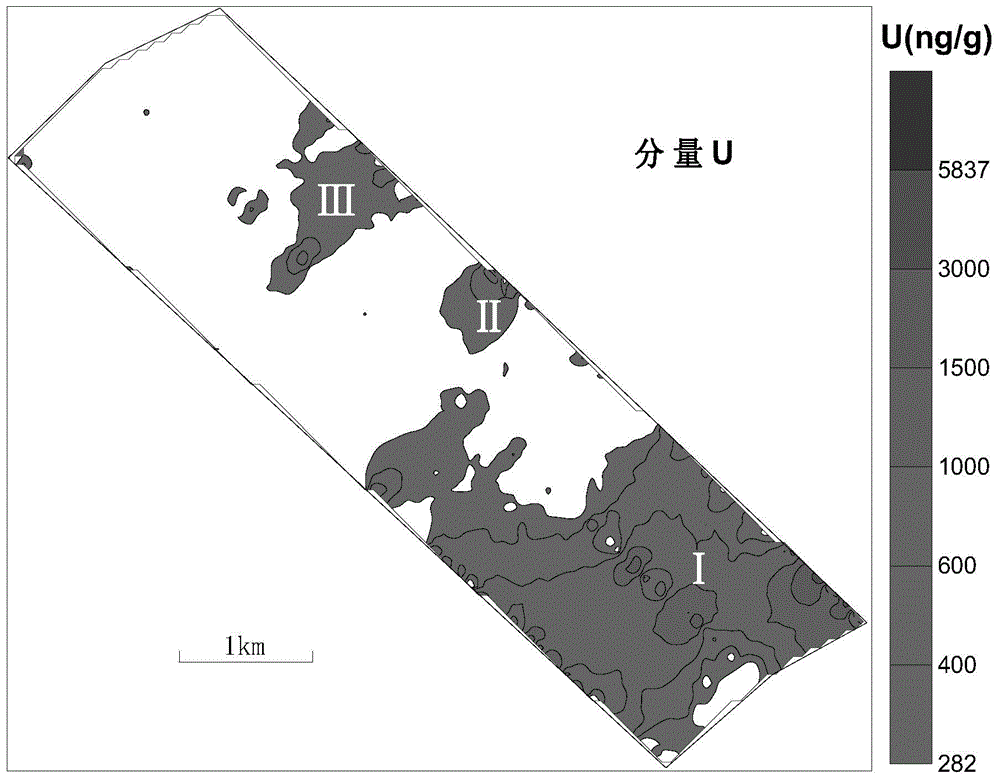

Method for combined tracing exploration on hydrothermal uranium ore through geochemical elements

ActiveCN102478674ASimple methodLow costMaterial analysis using wave/particle radiationPreparing sample for investigationUranium oreComputer science

The invention belongs to a uranium ore exploration method and particularly discloses a method for combined tracing exploration on a hydrothermal uranium ore through geochemical elements. The method comprises the following steps of: measuring a uranium component in soil in an exploration area; measuring 210Po; drawing a plane isoline graph of the uranium component and the 210Po element; judging whether an ore-induced uranium component is abnormal or not according to the ratio between the uranium component and uranium total amount; if the ore-induced uranium component is abnormal, further judging (1) whether the uranium component has an abnormal concentration center or not according to a uranium component isoline graph, judging (2) whether the uranium component and the 210Po are abnormally combined or not according to a 210Po isoline graph, and judging (3) whether a uranium component abnormal area and a beneficial ore-forming fracture structure alteration zone correspondingly compound asection; and if at least two results of the steps (1) to (3) are positive, judging that the hydrothermal uranium ore exists. The hydrothermal uranium ore of which the covering layer is 10 meters to several hundred meters can be detected by extracting and measuring the uranium component and the 210Po in a surface soil sample.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

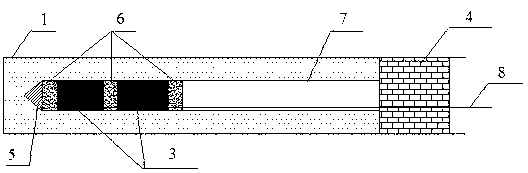

Gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method

ActiveCN103161493AChange the physical and mechanical propertiesImprove breathabilityFluid removalGas removalStress concentrationBlast effects

Provided is a gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method. By coal seam water injection and changing of a powder charge structure of traditional blasting, common gas-solid two-phase blasting is converted into gas-liquid-solid three-phase blasting. Blast wave in water, jet flow, secondary pressure wave and other effects are generated by water pressure blasting to enhance blasting effect, after drilled holes are formed, coal bodies are wetted through water injection firstly, physical and mechanical properties around the drilled holes are changed, the gas-solid two-phase coal bodies are converted into gas-liquid-solid three-phase media, a stress concentrating zone is pushed to the deep parts of the coal bodies, stress concentration is lowered; coal seam fractures around blasting holes and in an influence zone are stretched and developed, the fractures are communicated with each other, a facture network is formed, stress concentration is removed, channels are provided for coal seam pressure relief gas flow, and accordingly the purpose that rock burst and gas outburst are prevented is achieved.

Owner:CHINA UNIV OF MINING & TECH

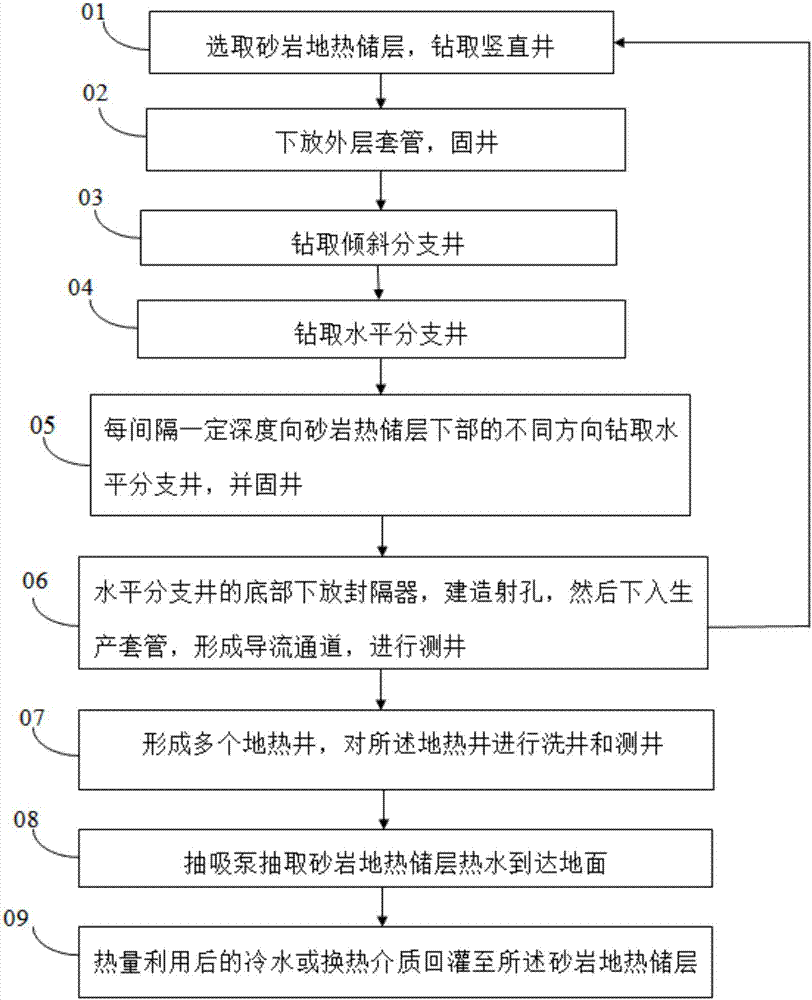

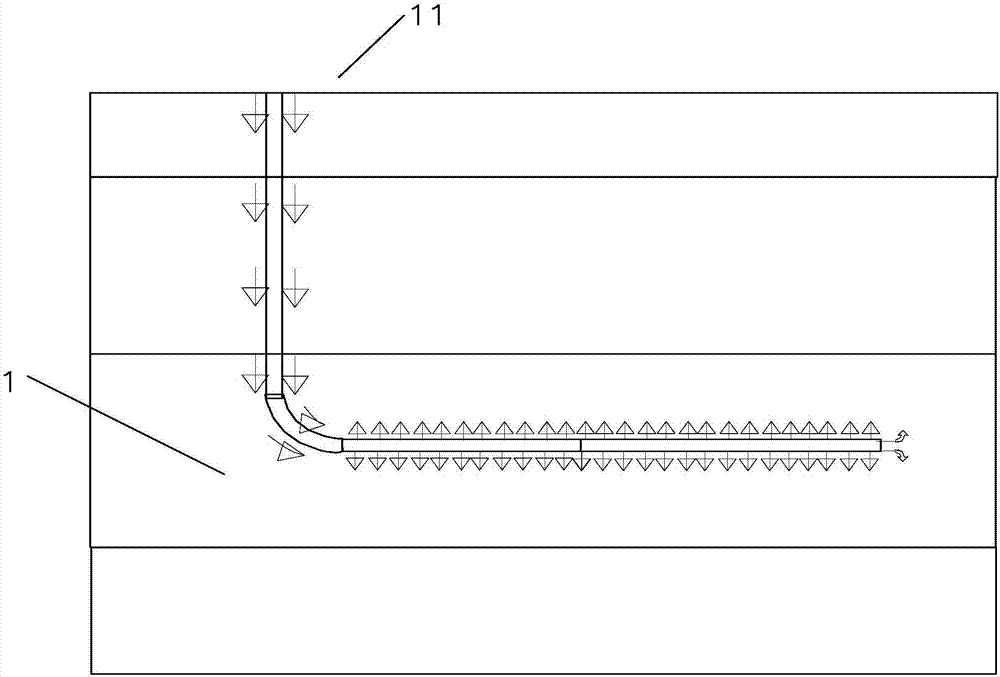

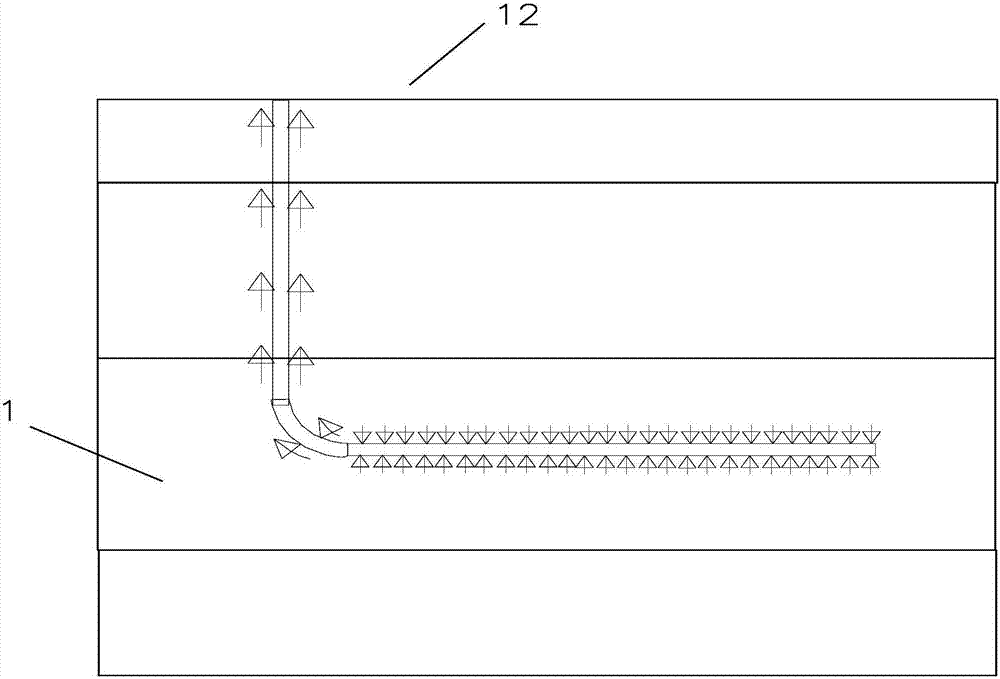

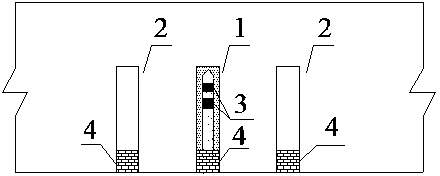

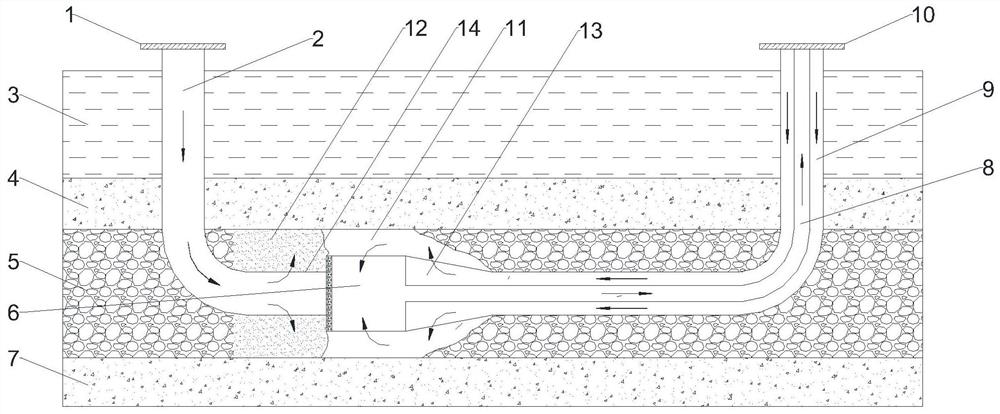

Medium-deep sandstone geothermal horizontal level exploitation method and structure

PendingCN106978993AIncrease geothermal mining productionSpeed up miningOther heat production devicesGeothermal energy generationWell drillingHorizontal wells

The embodiment of the invention discloses a medium-deep sandstone geothermal horizontal level exploitation method and structure. A horizontal well is built on a sandstone geothermal reservoir, a production well composed of a vertical well and the horizontal well is formed, and finally, the novel technology and method for exploiting and recharging the geothermal generation well are formed; the horizontal well is a single horizontal well or a plurality of parallel horizontal wells; the effective contact superficial area of the drilled well and the reservoir is increased, the exploitation and recharging efficiency is improved, the geothermal well yield is greatly increased, and economic benefits are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

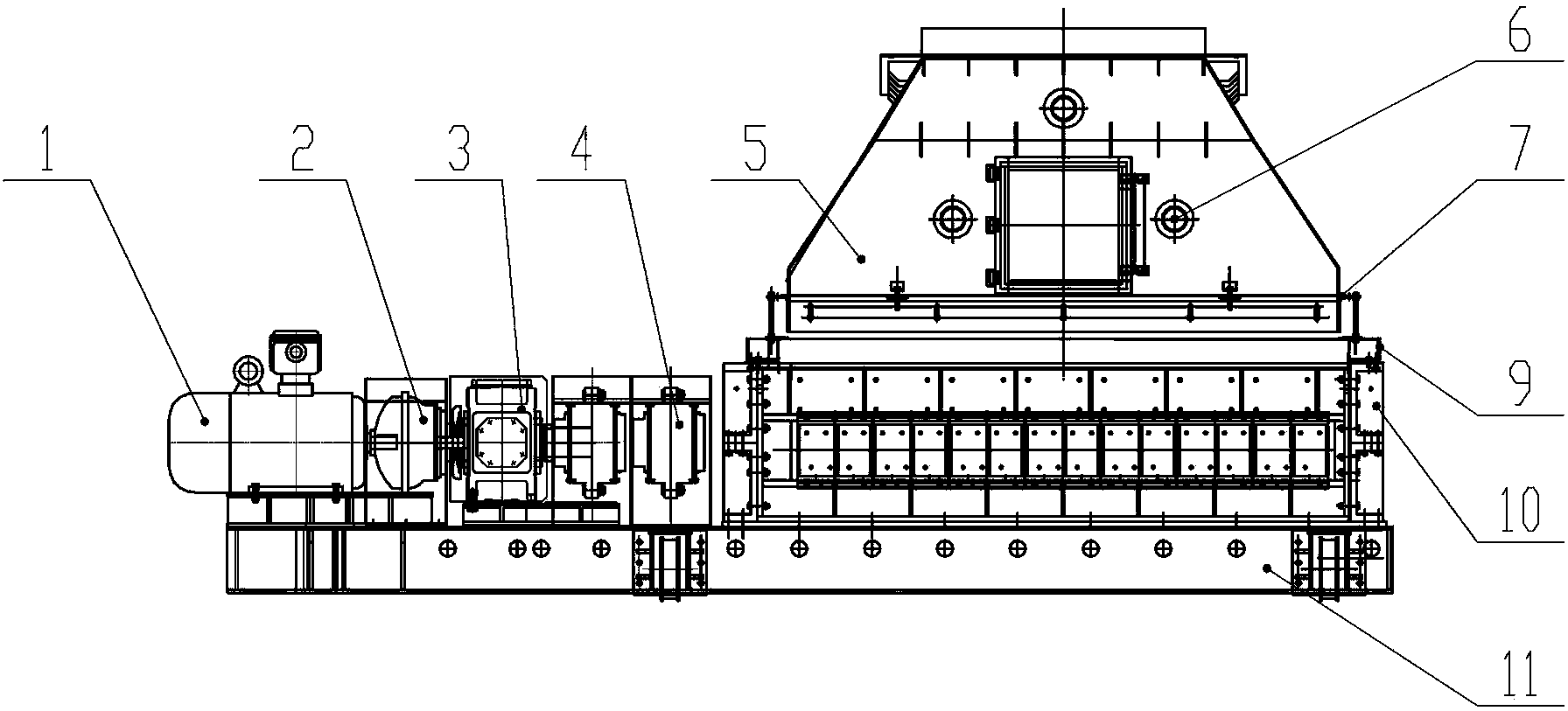

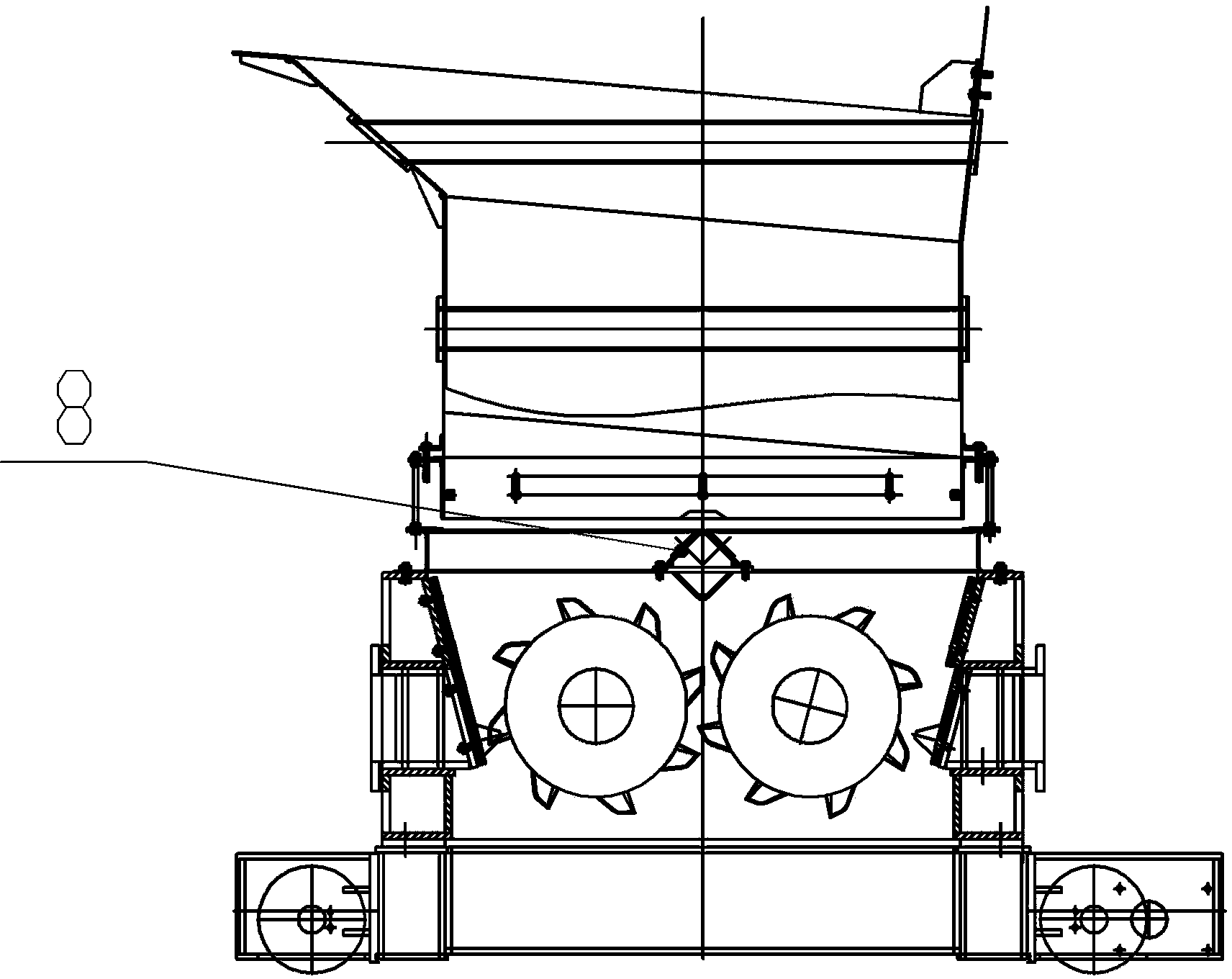

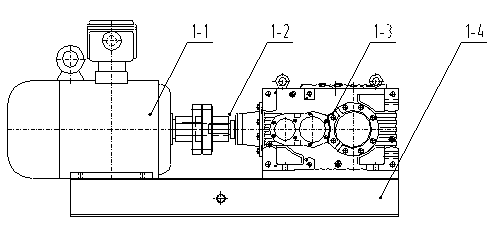

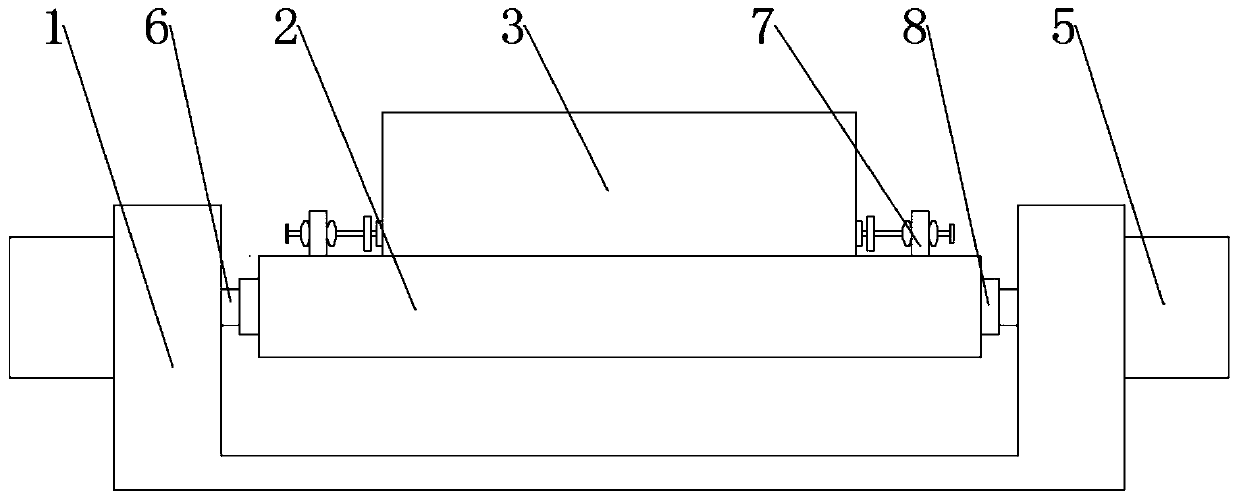

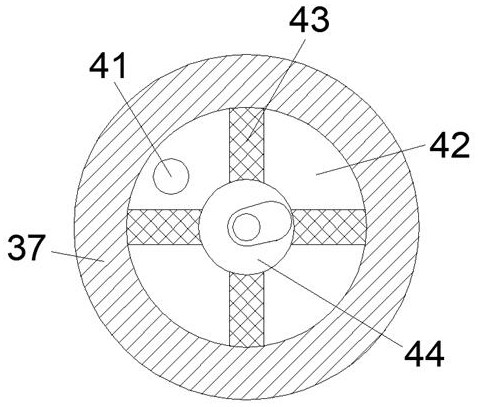

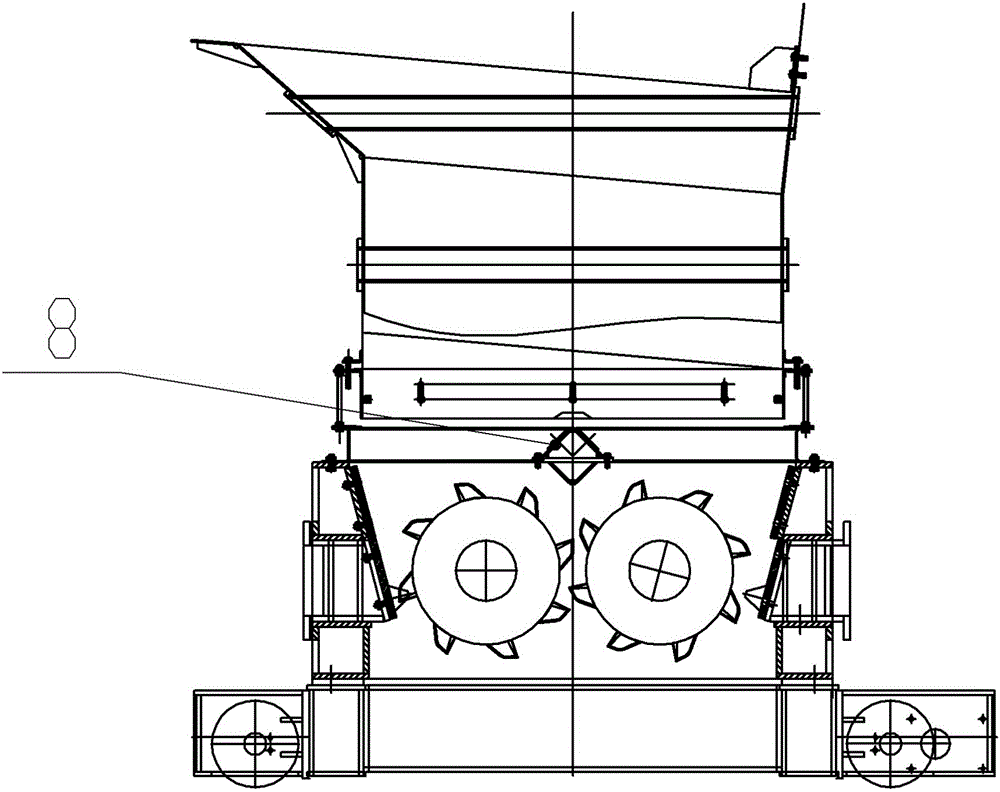

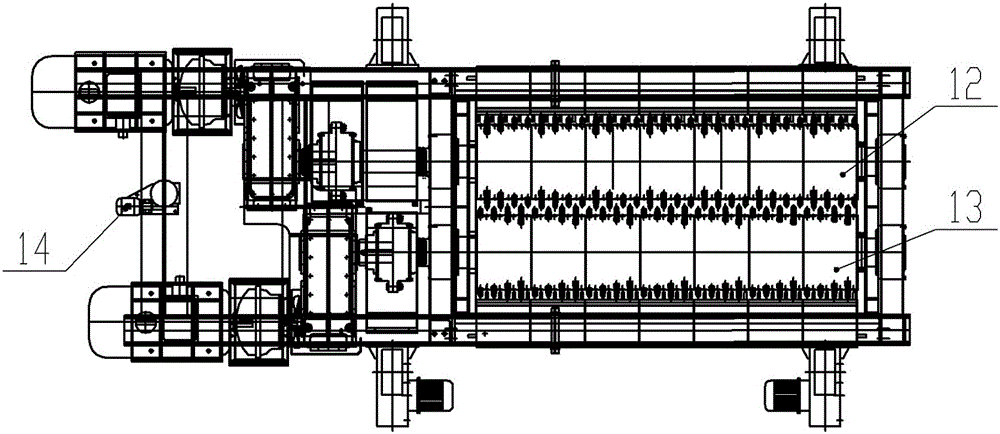

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

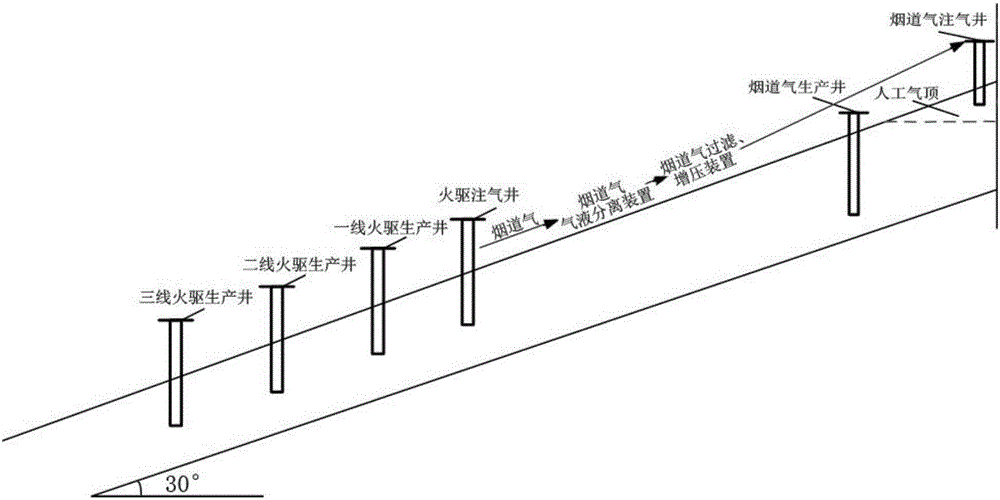

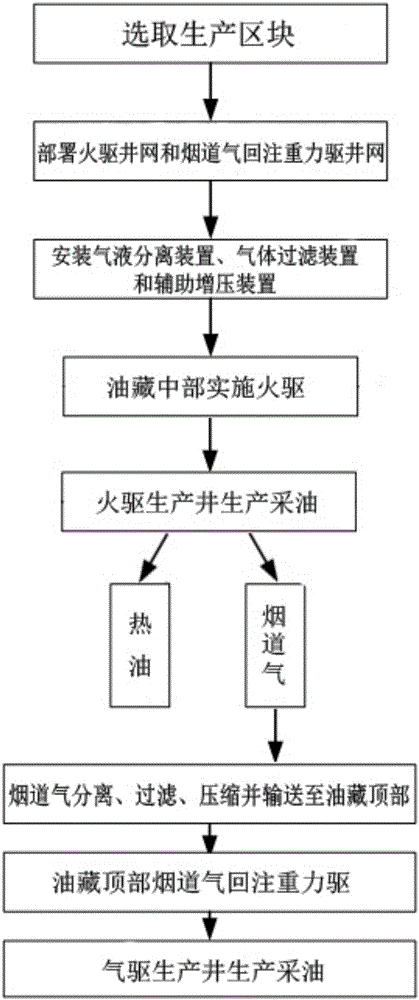

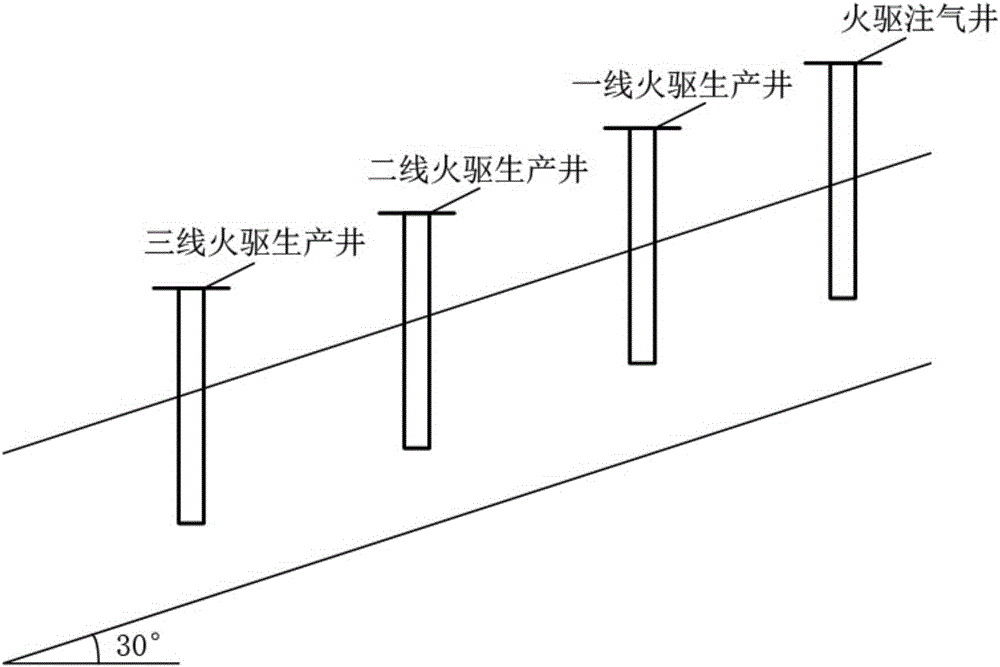

Fireflooding and flue gas reinjection gravity driving collaborative exploitation method for high-inclination-angle thick oil reservoir

The invention provides a fireflooding and flue gas reinjection gravity driving collaborative exploitation method for a high-inclination-angle thick oil reservoir. The exploitation method comprises the following steps: selecting a production block, and respectively arranging a fireflooding linear flooding well pattern and a flue gas reinjection gravity driving well pattern at the middle part and the top of the production block; installing a ground facility, and paving a conveying pipeline; injecting air from a fireflooding gas injection well to an oil layer and igniting, extracting hot oil and flue gas which are generated by combustion from a fireflooding production well, separating and filtering the flue gas, then reinjecting the filtered flue gas into a flue gas injection well, and producing and extracting oil through a gas driving production well. The exploitation method can avoid the shortcomings of non-uniform fire line boosting and small use area due to single fireflooding, and the use area of the oil reservoir is enlarged; under the collaborative action of the fireflooding and flue gas reinjection gravity driving, the oil recovery ratio can be increased; furthermore, through the flue gas generated by the fireflooding, a stable gas source can be supplied to top gas injection; by reinjection of the flue gas, discharge of tail gas can be reduced, the operation cost is reduced, the air pollution is relieved, and the environment is protected.

Owner:PETROCHINA CO LTD

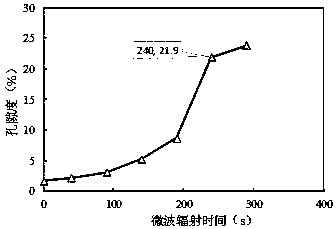

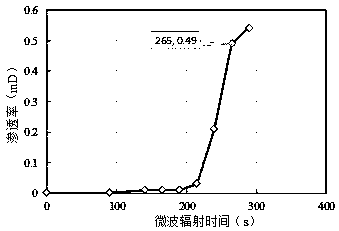

Production increasing method for shale oil/gas reservoir

The invention relates to a production increasing method for a shale oil / gas reservoir. The production increasing method for the shale oil / gas reservoir comprises the steps that firstly, exploitation horizontal wells and a microwave radiation horizontal well extending in the same direction with the exploitation horizontal wells are arranged; secondly, staged fracturing is conducted on the exploitation horizontal wells, volume reformation is conducted on the shale oil / gas reservoir, and a fracturing propping agent with the microwave absorbing capacity is adopted in fracturing fluid; thirdly, microwave emitters are installed in the microwave radiation horizontal well at intervals and used for radiating microwave to the fracturing reformation area of the reservoir; fourthly, exploitation is conducted, and a microwave generator is started at the same time. According to the production increasing method for the shale oil / gas reservoir, microwave radiation is utilized to conduct in-situ heating on the shale oil / gas reservoir, organic matter in the shale reservoir generates pyrolysis to generate hydrocarbon matter to a certain extent, desorption of natural gas and crude oil disengagement from the solid surface in the shale are promoted, the viscosity of the gas and the crude oil is lowered, the flow speed of the gas and the crude oil is increased, the penetration rate of the reservoir is further improved, development of the shale oil / gas is accelerated, the recovery ratio is improved, and the exploitation cost is lowered.

Owner:SOUTHWEST PETROLEUM UNIV

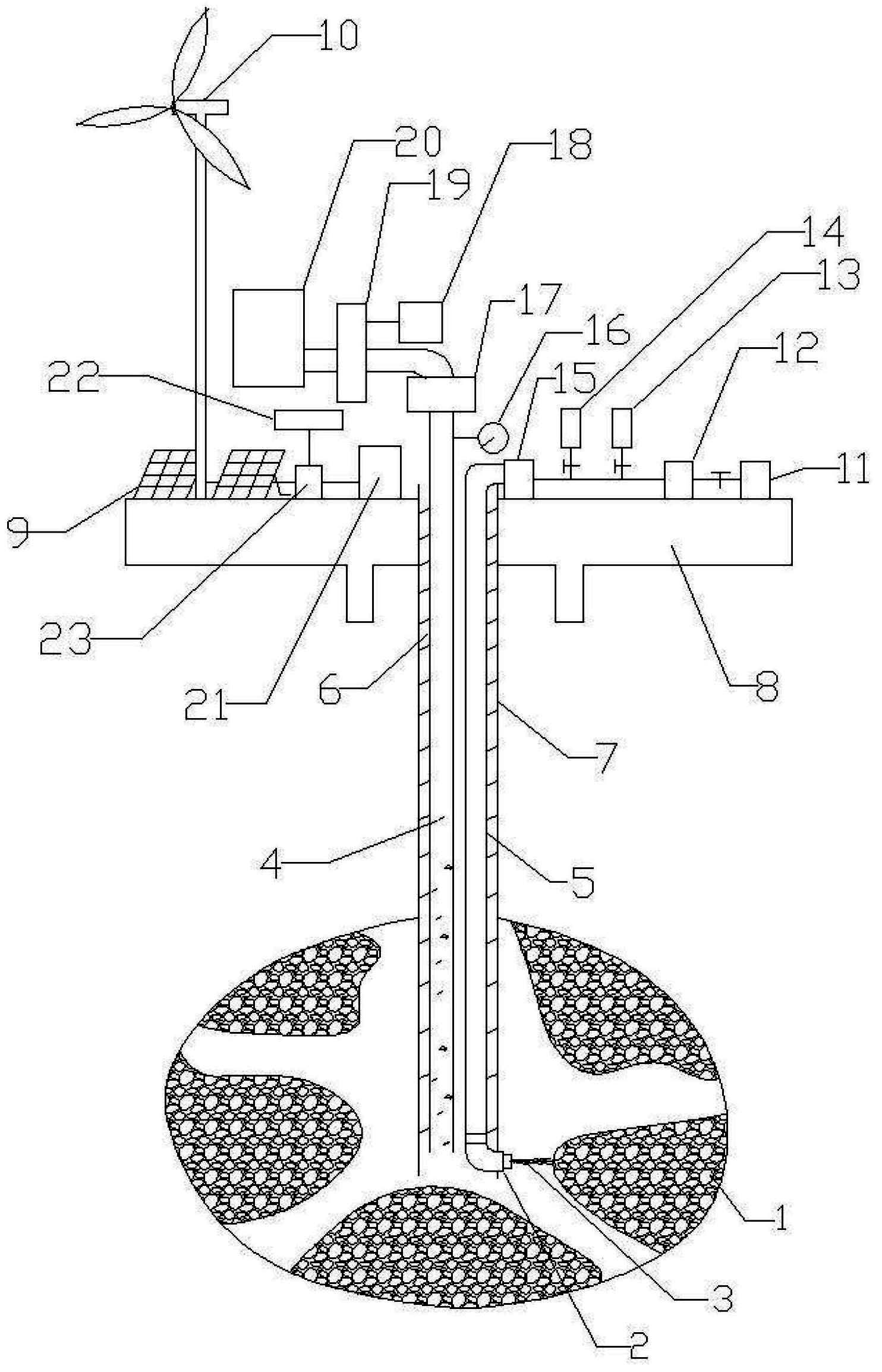

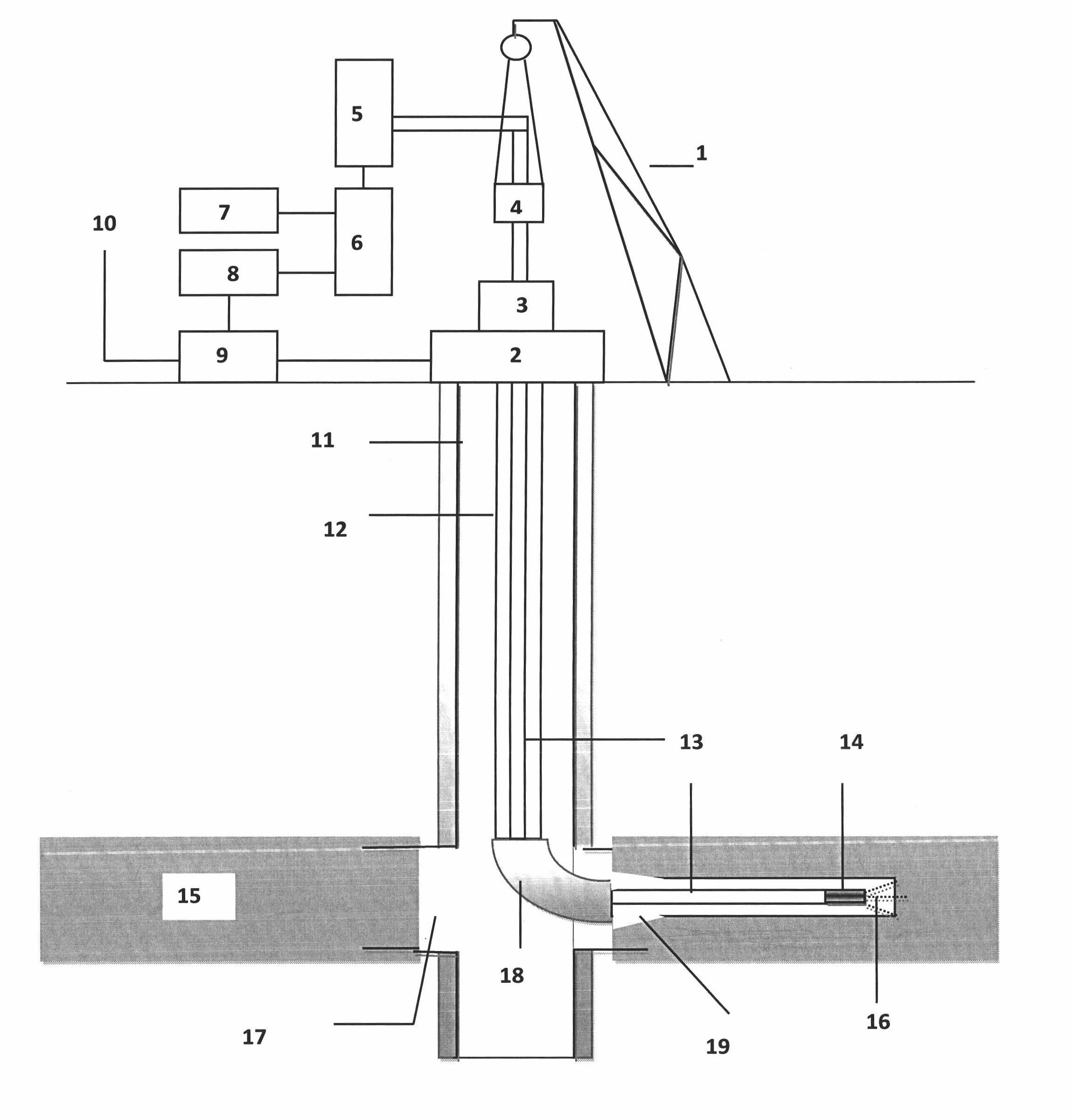

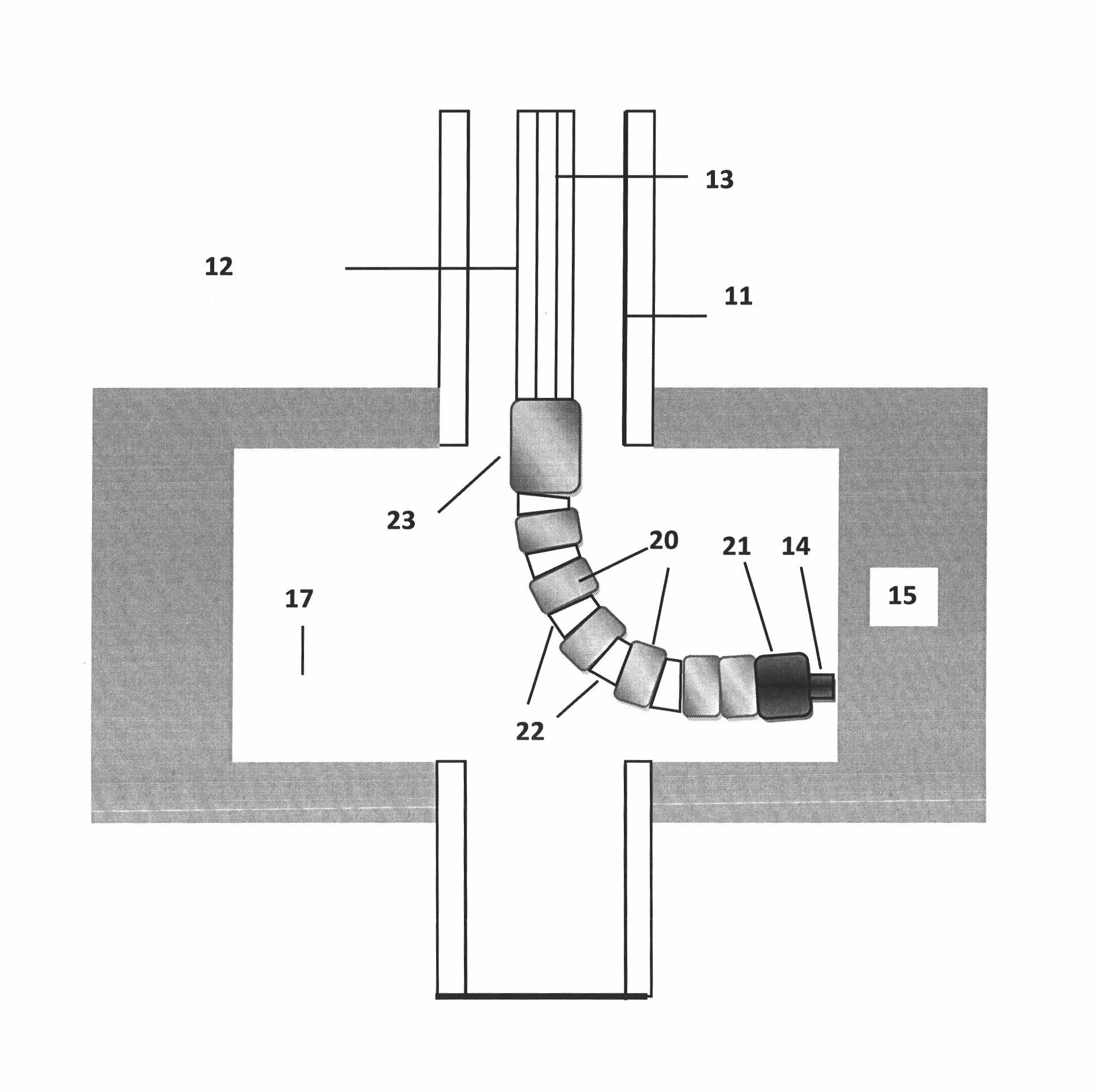

Method for mining hydrate based on multilateral wells

A method for mining hydrate based on multilateral wells is provided. The method includes the following steps: deploying a vertical well in a target measure area and two horizontal multilateral wells in a natural gas hydrate reservoir, wherein one of the horizontal multilateral wells is deployed at the upper third of the natural gas hydrate reservoir, and the other horizontal multilateral well is deployed at the lower third of the gas hydrate reservoir; installing a gas-water separation device and a pump at the junction of the vertical well and the lower third horizontal well; deploying the vertical well to the top of a high-temperature and high-pressure water-bearing gas reservoir; performing perforation to open the high-temperature and high-pressure water-bearing gas reservoir and the hydrate reservoir; separating the mined mixture into natural gas and high-temperature water by the gas-water separation device, wherein separated natural gas enters an oil pipe and the high-temperature water is pumped into a hydrate reservoir by the gas-water separation device; at the same time, mining the hydrate reservoir in horizontal wells located at the upper third of the natural gas hydrate reservoir, and mining horizontal well groups of the hydrate reservoir by injecting high-temperature water under the formation of the natural gas hydrate reservoir. According to the present invention, thenatural gas hydrate reservoir is mined by heating and depressurizing, thereby achieving the cyclic utilization of formation energy.

Owner:NORTHEAST GASOLINEEUM UNIV

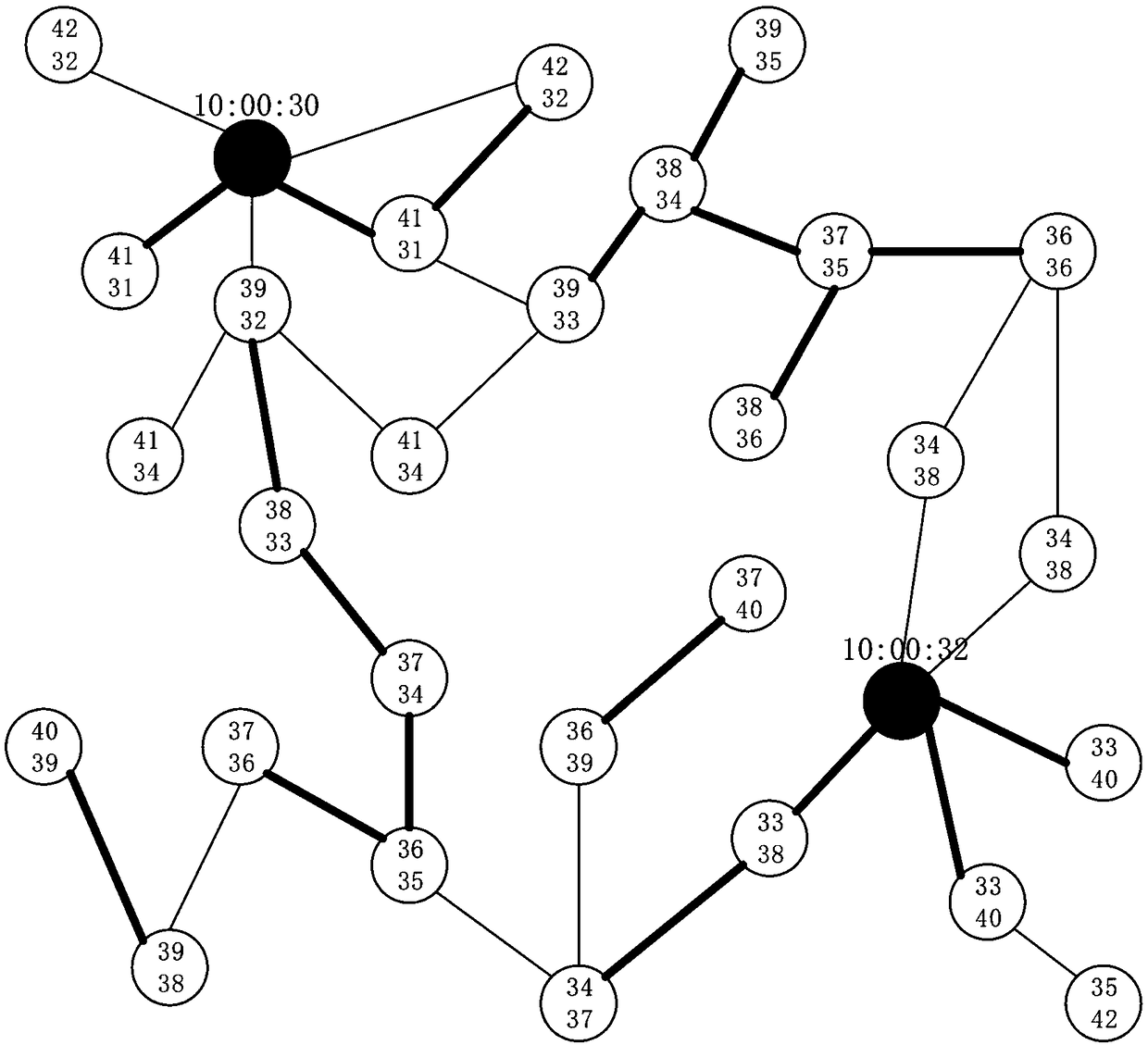

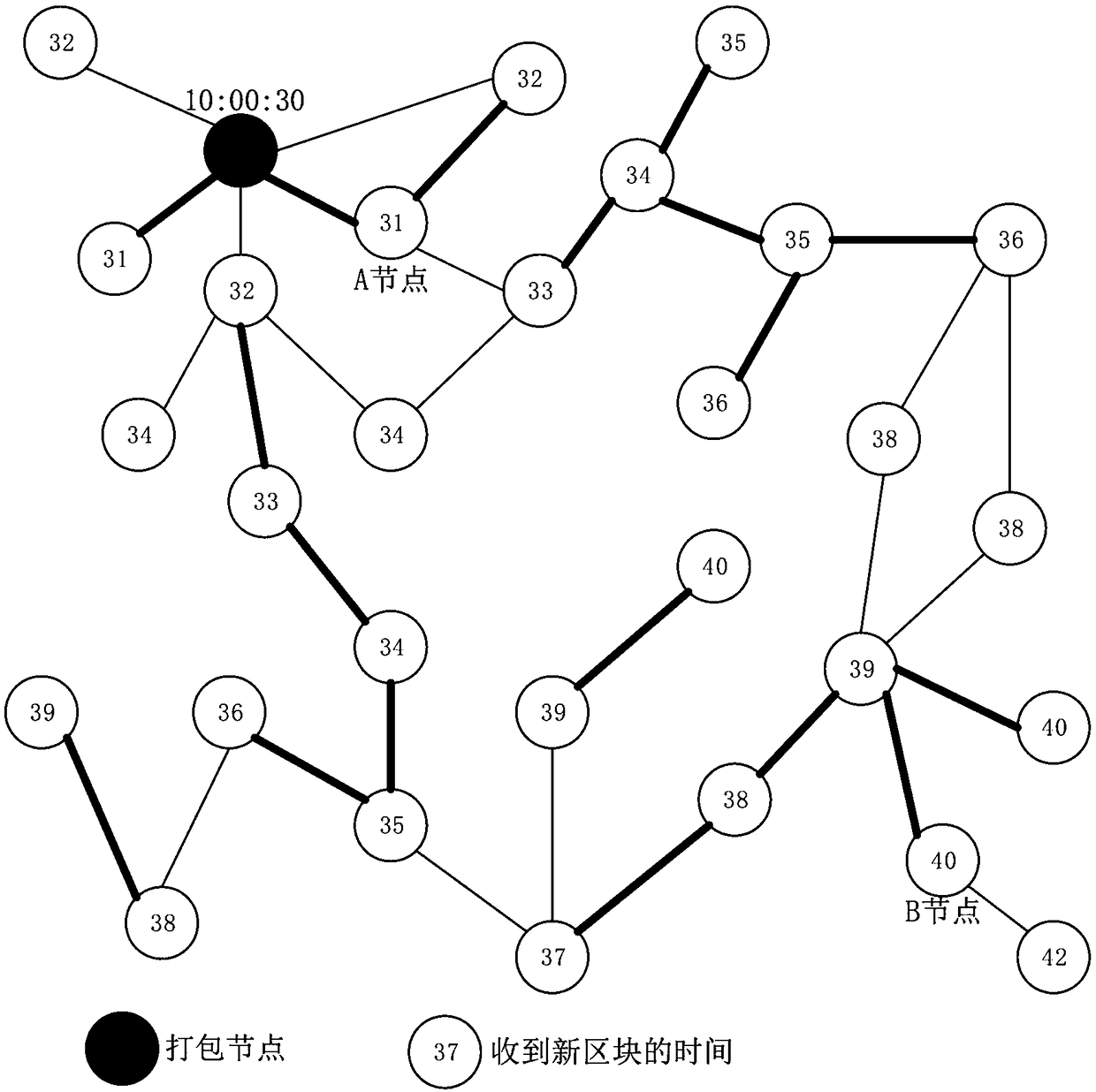

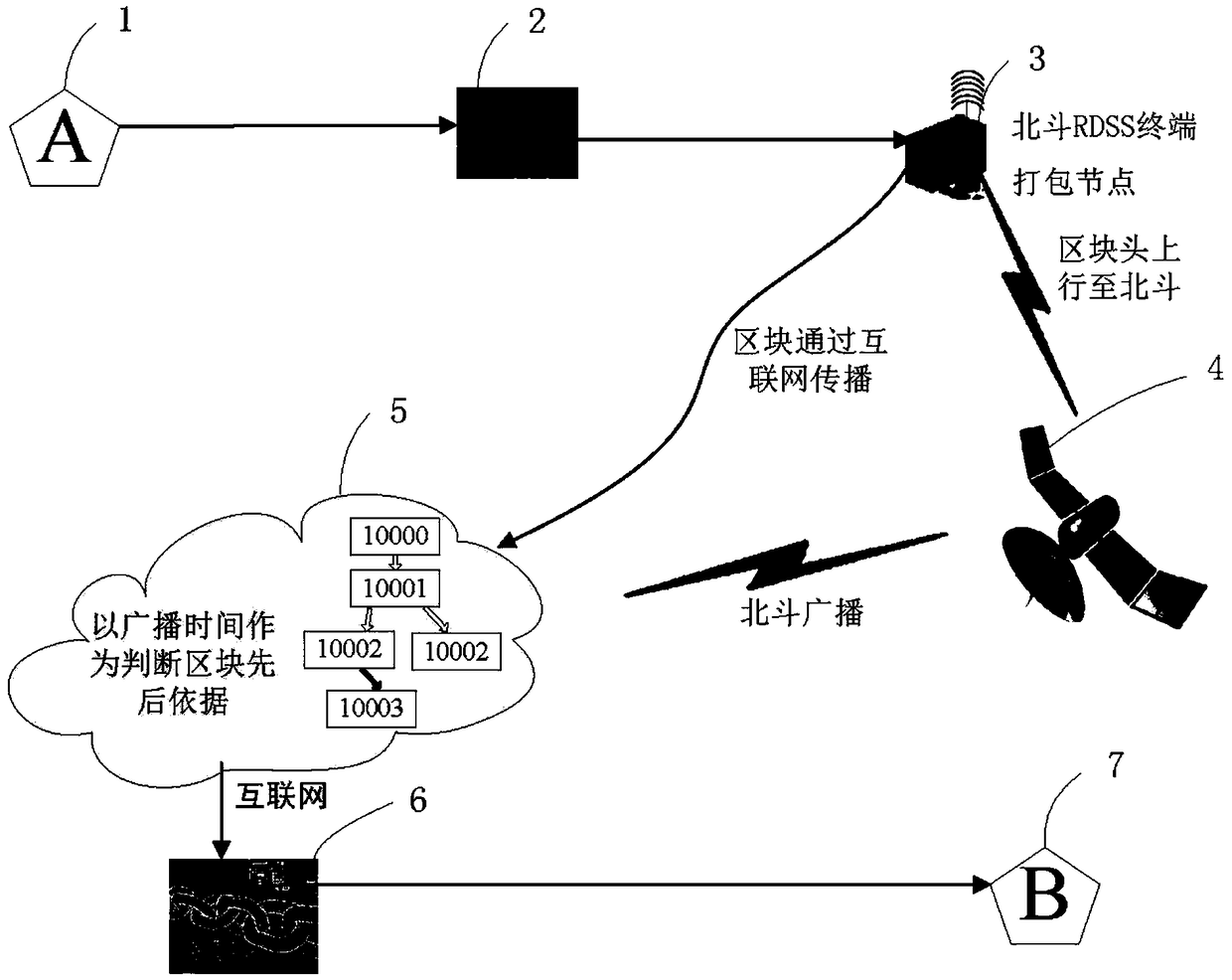

Blockchain system based on Beidou RDSS and implementation method thereof

InactiveCN109246192AAvoid unfairnessSpeed up miningUser identity/authority verificationBroadcast service distributionTimestampThe Internet

The invention discloses a blockchain system based on Beidou RDSS (Radio Determination Satellite Service) and an implementation method thereof. The system comprises a plurality of Beidou RDSS terminalsconnected with a blockchain node, and a Beidou satellite. When a packaging node generates a block, the complete block is broadcasted through the Internet, and is transmitted to the Beidou satellite via the packaging node through the Beidou RDSS terminals. After the Beidou satellite receives the data, the Beidou satellite broadcast the block head to other nodes at the superframe format; the BeidouRDSS terminals of other nodes resolve the block head and the precise time of broadcasting, and record the Beidou broadcast time in the TimeStamp field of a new block structure, thereby obtaining theBeidou block head. According to the invention, the system can broadcast the abstract information of the block through the Beidou RDSS, and solves the above problems in a conventional blockchain systemthrough the characteristic that the Beidou satellite can provide a clock with the high time service precision.

Owner:北斗链信息科技(广州)有限公司

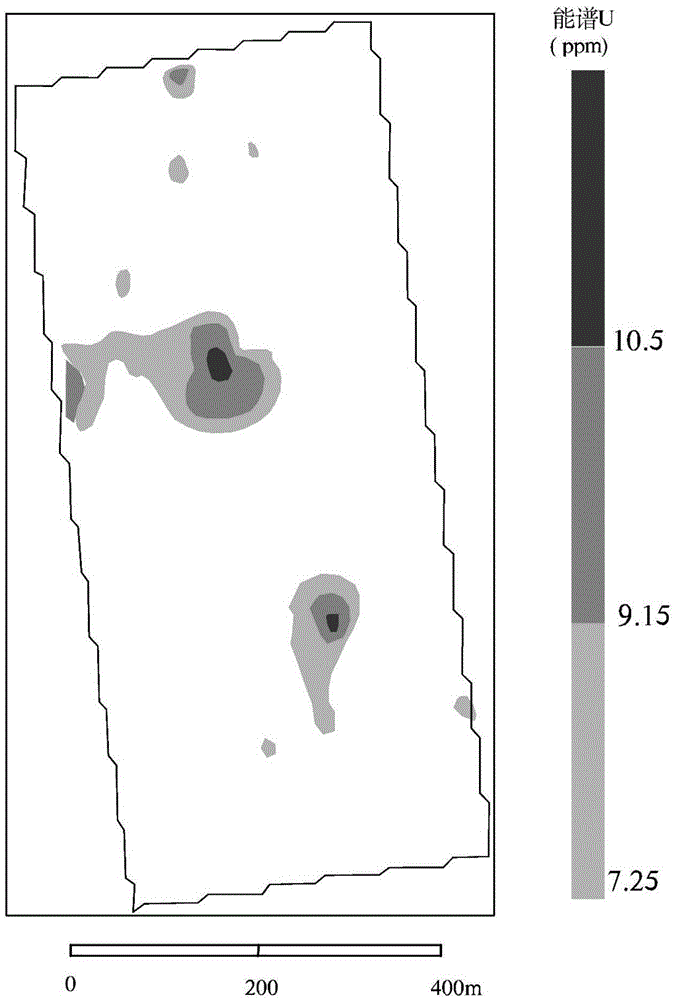

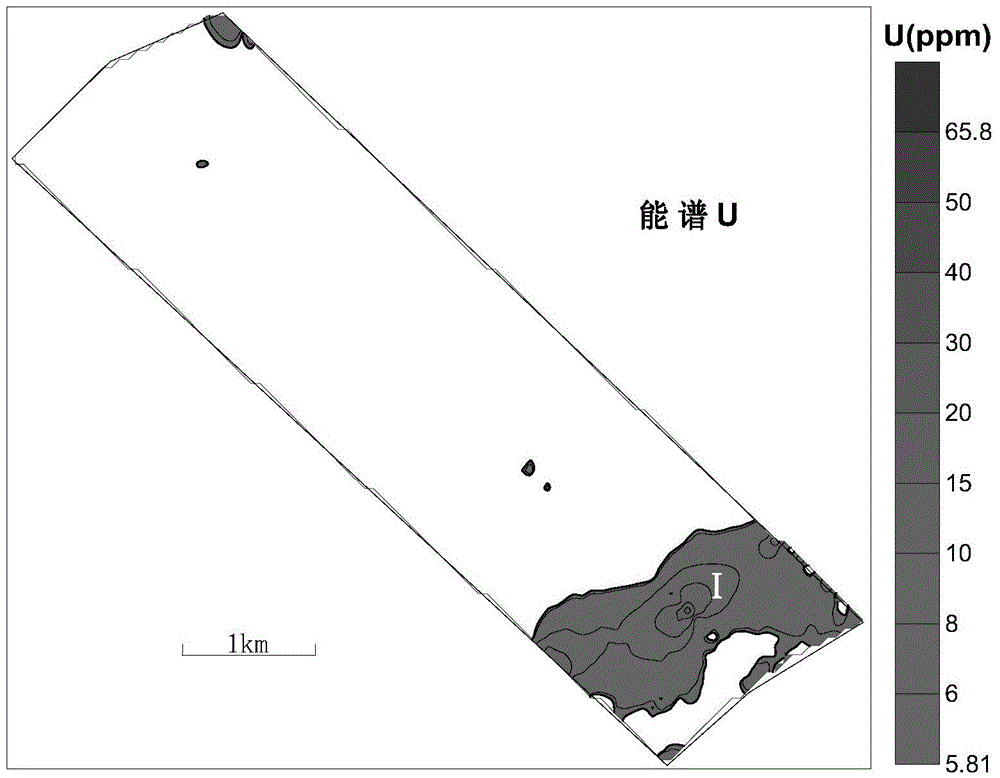

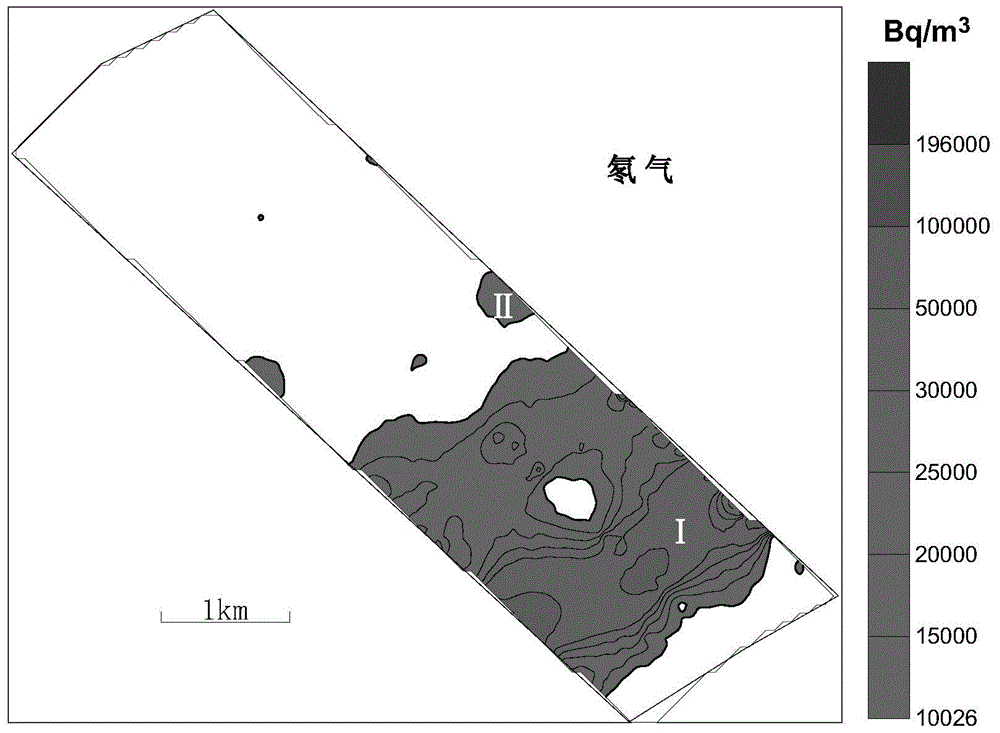

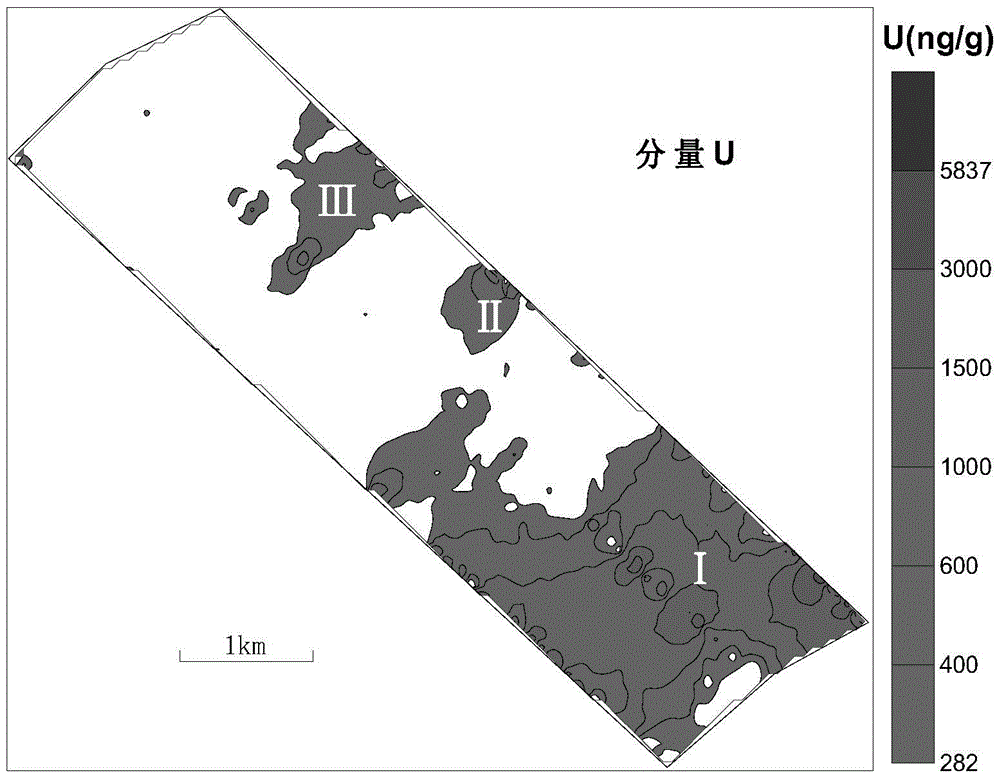

Method for identifying deep uranium mineralization information

InactiveCN106842345AEfficient identificationReliable identificationNuclear radiation detectionUranium mineralizationEnergy spectrum

The invention belongs to the technical field of uranium exploration and discloses a method for identifying deep uranium mineralization information in particular. The method for identifying deep uranium mineralization information comprises the following steps: (1) determining the measuring position in the measuring area; (2) taking the soil sample from the measuring position determined in the above step (1); (3) measuring the gamma spectrum of uranium content in the pit after taking the soil sample in the above step (2); (4) drying, grinding, and sieving the retrieved soil sample; (5) drying the sieved soil samples in the above steps (4); (6) extracting component uranium from the soil sample after drying by step (5) by using a medicament; (7) determining the component uranium extracted in the above steps (6); (8) making a plane contour map; (9) delineating abnormal areas; (10) according to energy spectrum uranium, component uranium, component uranium / energy spectrum abnormal uranium ratio, identifying deep uranium mineralization information. The method for identifying deep uranium mineralization information can greatly improve work efficiency and shorten the prospecting period.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

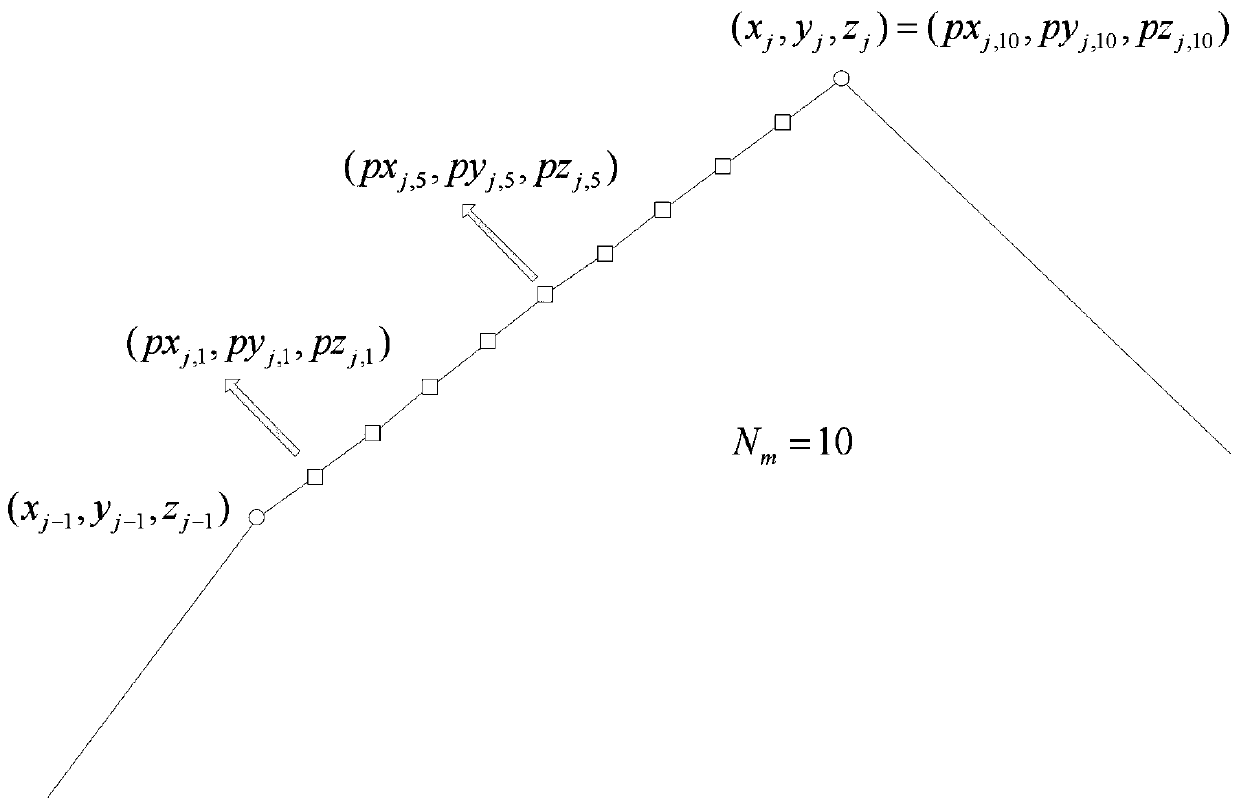

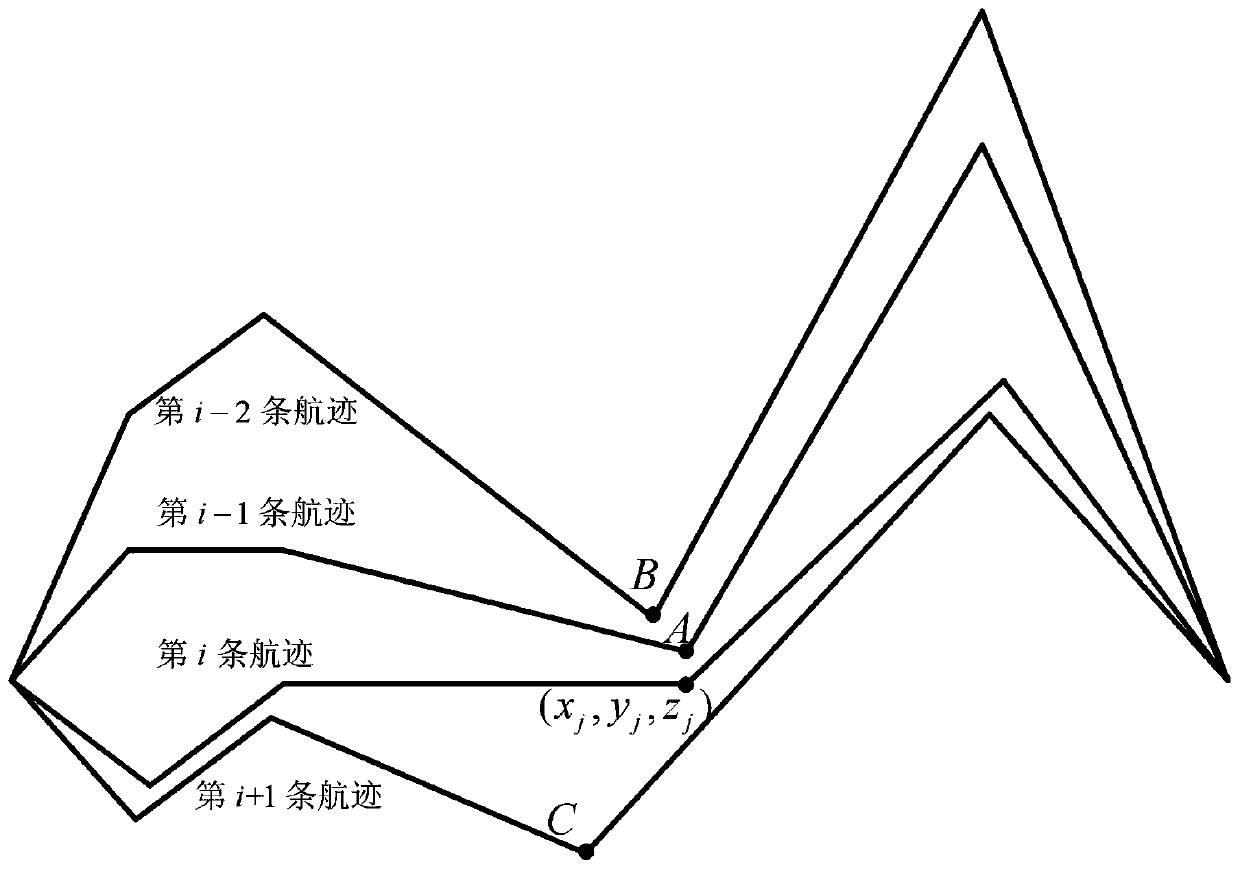

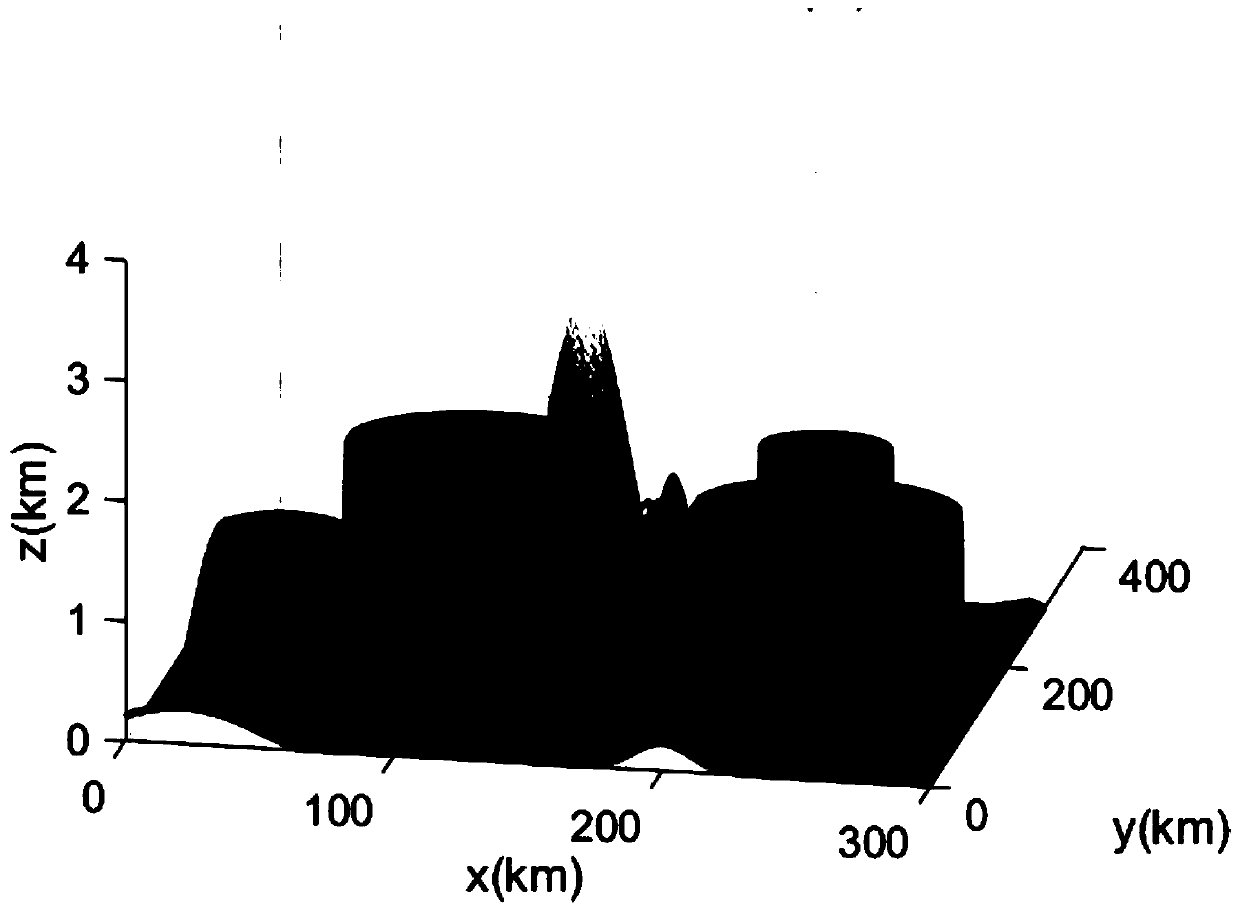

Unmanned aerial vehicle flight path planning method based on improved clustering algorithm

ActiveCN110986960ASolve practicalImprove explorationNavigational calculation instrumentsCharacter and pattern recognitionCluster algorithmSimulation

The invention discloses an unmanned aerial vehicle flight path planning method based on an improved clustering algorithm, and aims to solve the problems of low accuracy and large calculation amount caused by clustering of each flight path in an existing multi-target route planning method. The method comprises the steps of 1, setting a differential evolution operator control parameter, a maximum clustering number and a mating limit probability, generating an initial population and calculating a target value, and establishing an external document; 2, setting the number of iterations to be T, andenabling t to be equal to 1; 3, finding a neighbor path point of each path point; 4, setting the number of flight paths, and enabling i to be equal to 1; 5, generating a new flight path; 6, calculating a target value of the new flight path; 7, storing the better flight path in the external document; 8, enabling i to be equal to i+1, and repeating the steps 4-8 until i is equal to N; and 9, updating the population, setting t to be equal to t+1, and repeatedly executing the steps 2-9 until t is equal to T. The method is applied to the field of unmanned aerial vehicle flight path planning.

Owner:HARBIN INST OF TECH

Method for prospection of calcrete type uranium ore

InactiveCN103913780ASolve the problem of not being able to detect deep calcareous uranium depositsImprove resolutionComponent separationGeological measurementsUranium oreWorkload

The invention belongs to a uranium ore exploration method, and particularly relates to a method for prospection of calcrete type uranium ore through component uranium. The method includes the following steps of (1) determining sampling positions in a measuring area, (2) collecting soil samples of measuring points in the measuring area, (3) extracting component uranium in the soil samples of the measuring points, (4) measuring the component uranium, (5) making a component uranium plane contour map, (6) judging whether the measuring area is a calcrete type uranium metallogenic prospect or not, and (7) judging whether the measuring area is a calcrete type uranium metallogenic province or not and judging that the uranium metallogenic prospect is the calcrete type uranium metallogenic province when the calcrete type uranium metallogenic prospect determined in the step (6) is also a favourable geological and geophysical prospecting metallogenic prospect. According to the method, misering workloads can be greatly relieved, the prospecting hit rate can be increased, the prospecting speed can be quickened, the prospecting cycle can be shortened and cost can be lowered.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

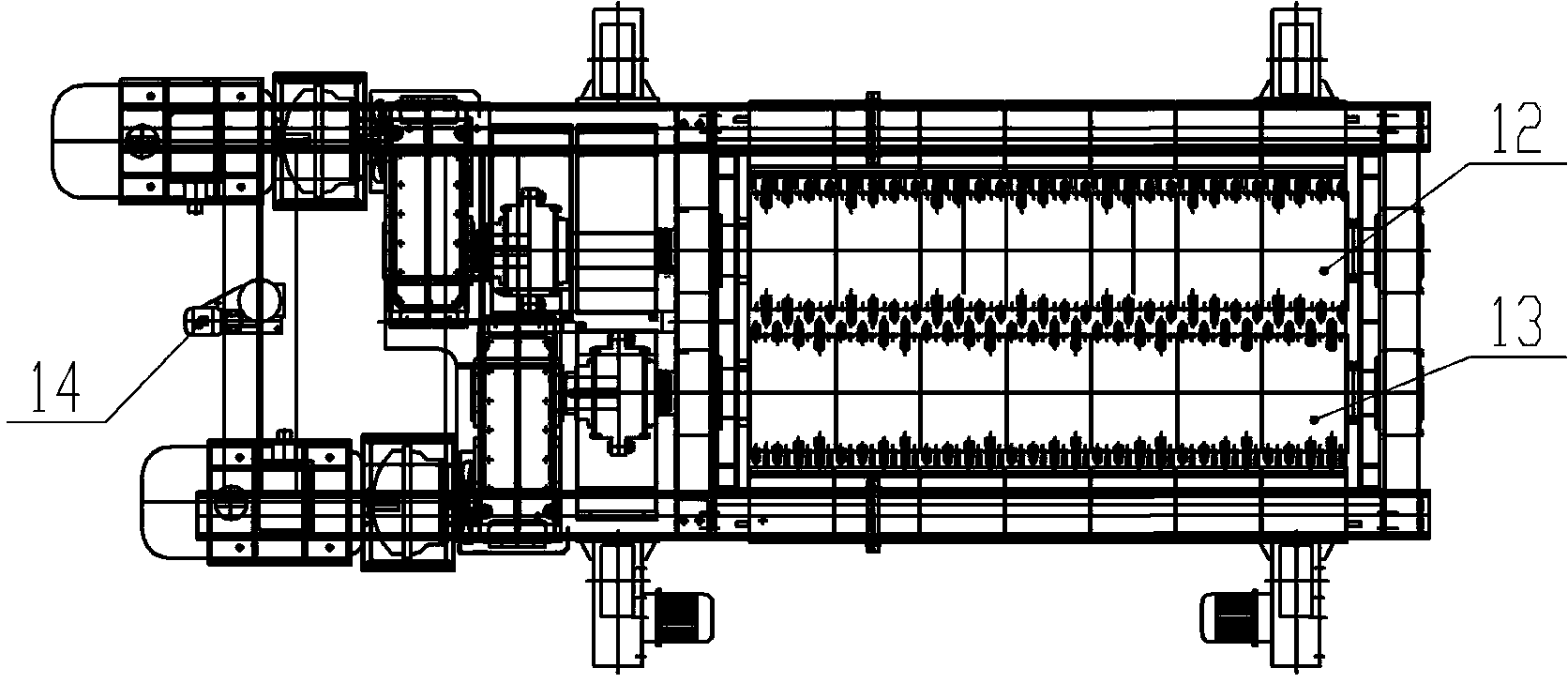

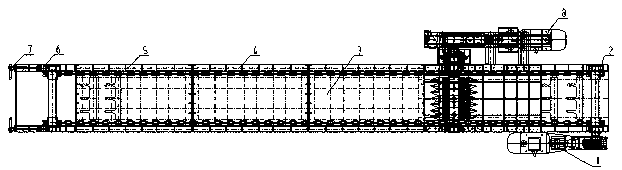

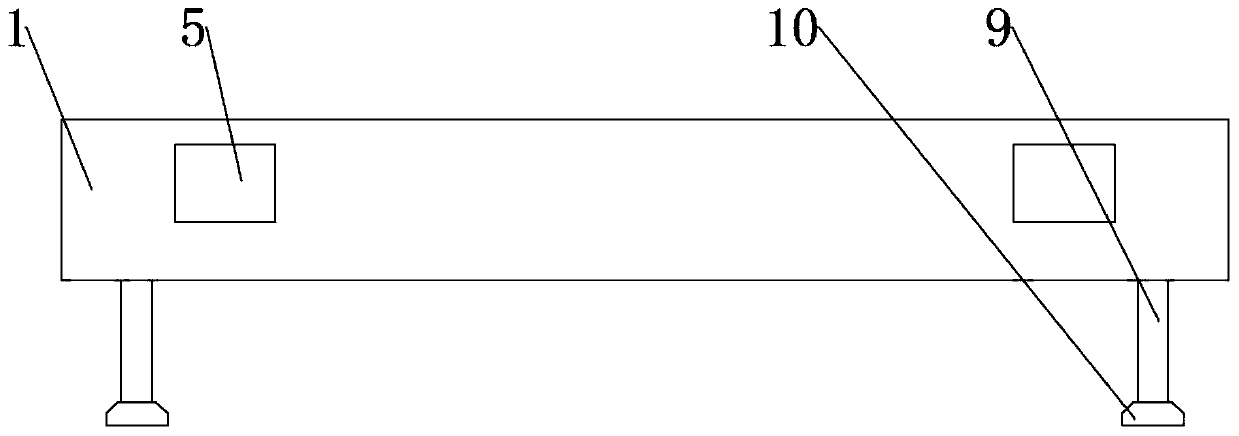

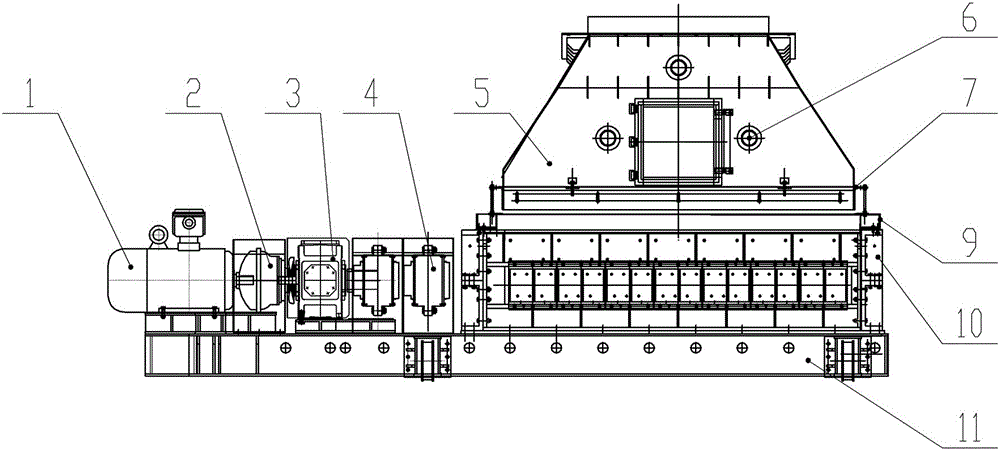

Continuous pass-through crushing station

The invention discloses a continuous pass-through crushing station, which comprises a conveying device and a crushing device, wherein the conveying device comprises a conveying driving device, a conveying transmission device, a scratch board, a conveying box body, a machine frame and a material baffle, wherein the conveying driving device drives the conveying transmission device to rotate, and the conveying transmission device drags the scratch board connected with the conveying transmission device and materials above the scratch board to do horizontal motion in the conveying box body; the crushing device comprises a crushing driving device, a crushing box and a rotating base; and the crushing driving device drives a crushing tooth roller in the crushing box to rotate and crush conveyed massive materials. According to the crushing station, the materials flow in the single direction, so that a production system which is compact and high in yield is formed; and the crushing station has the characteristics of low cost, compact structure and no need of foundation facilities during installation and running, so that the crushing station has high adaptability to on-site environment, the cost of capital construction is reduced, the problems of capital investments, equipment movement and the like caused by a semiportable crushing station which is combined by a plurality of equipment are solved fundamentally, the labor intensity of daily maintenance equipment is reduced, and the exploitation of open-air mine materials is accelerated.

Owner:新乡市振源机械设备有限责任公司

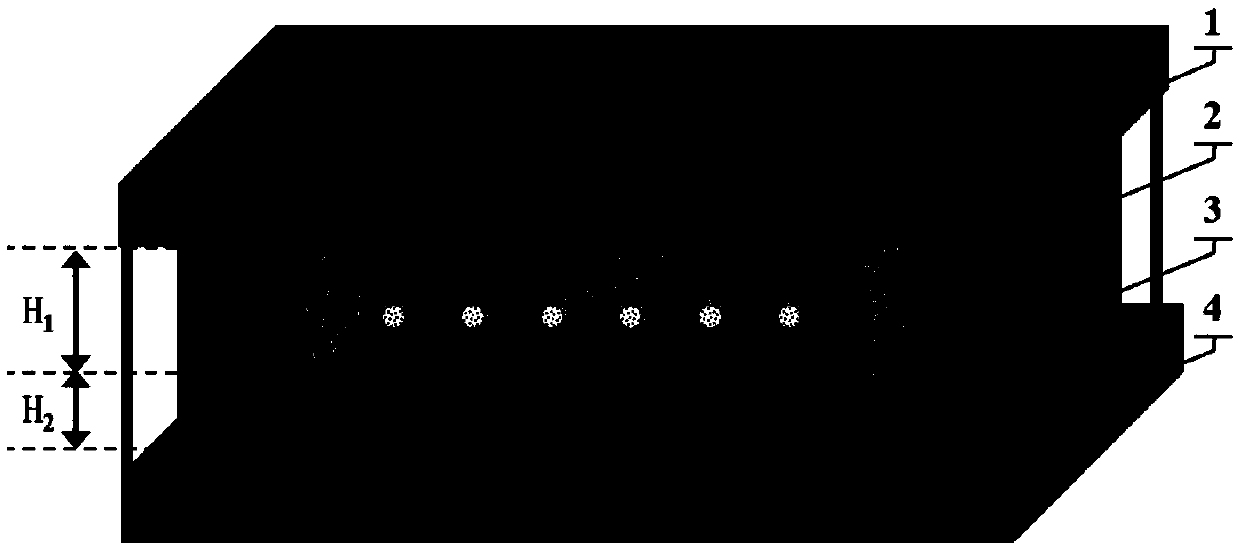

Graded mining method of coal-rock co-mining working face

ActiveCN105507902AImprove mining efficiencySpeed up miningUnderground miningSurface miningUltimate tensile strengthMineralogy

The invention relates to a graded mining method of a coal-rock co-mining working face. The rock stratum strength f of different areas is judged in a graded manner, and mining is performed by targeted measures. If f<1.5, the rock stratum strength is grade I; if 1.5< / =f<3.0, the rock stratum strength is grade II; if f> / =3.0, the rock stratum strength is grade III. When the rock stratum strength is grade I, a coal mining machine is directly used to mine the working face, and the coal mining machine uses external-rotation cutting during mining; when the rock stratum strength is grade II, the coal mining machine is directly used to mine the working face, and the coal mining machine uses internal-rotation cutting during mining; when the rock stratum strength is grade III, explosion holes are designed according the rock stratum thickness H1 of the working face before mining, explosion is performed after all the explosion holes are filled with dynamite, and then the coal mining machine is used to mine the working face through internal-rotation cutting. The graded mining method has the advantages that efficient mining of the coal-rock co-mining working face under complex conditions can be achieved, equipment wear is reduced by above 30%, the mining speed of the working face is increased by above 50%, and the method is worthy of popularization.

Owner:PINGDINGSHAN TIANAN COAL MINING +2

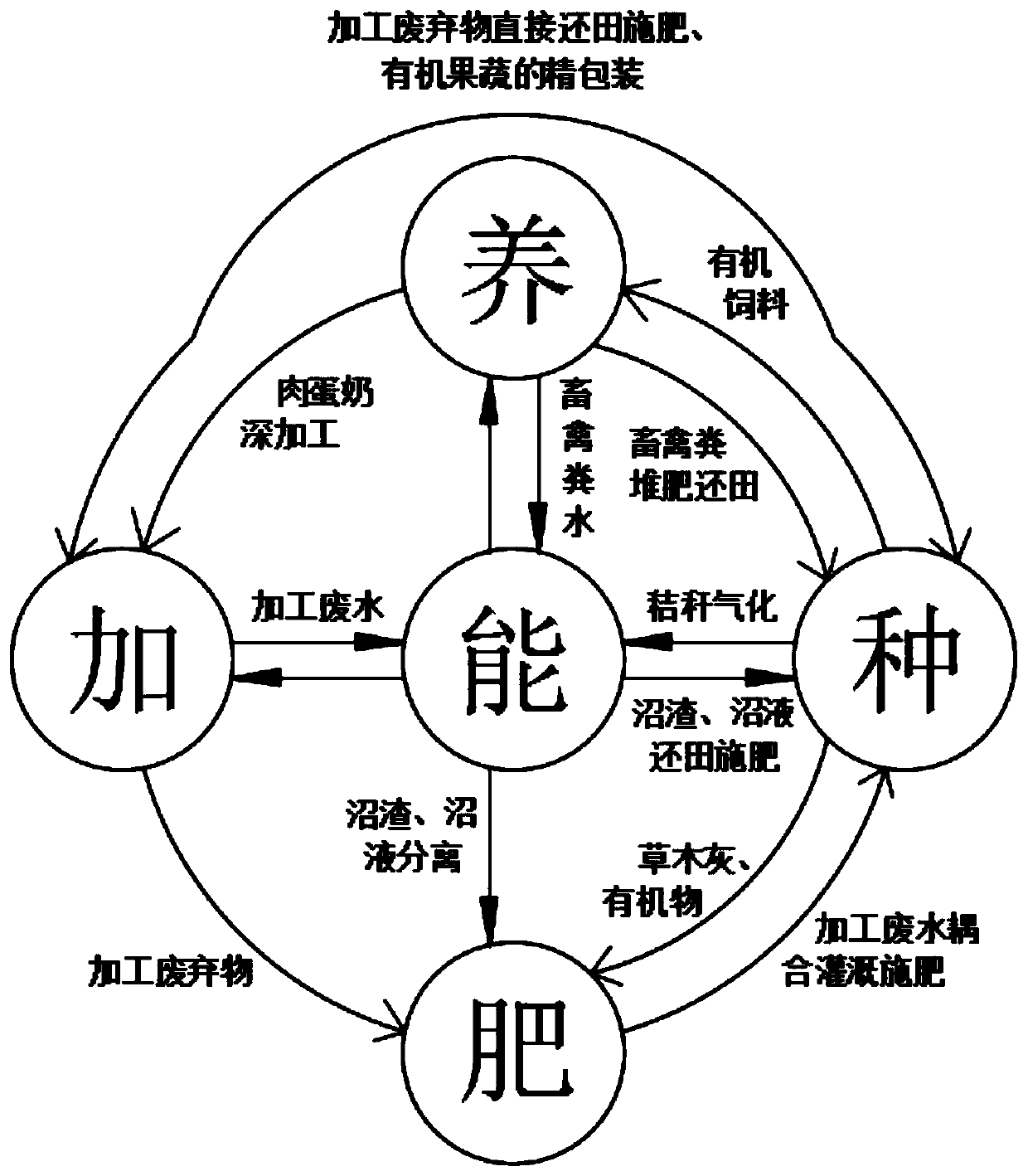

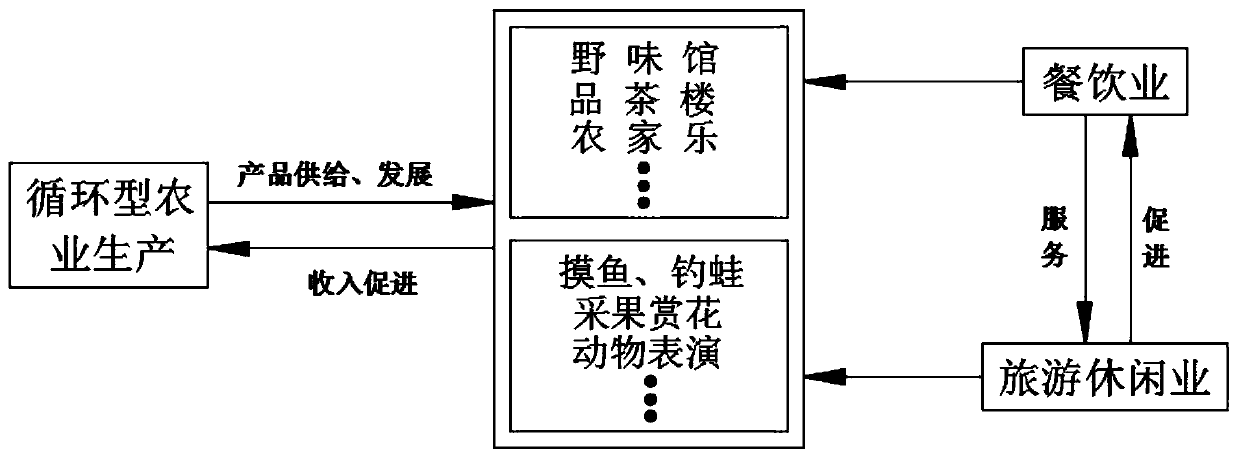

Production method for circulating type modern efficient agriculture

InactiveCN110269041AQuality improvementImprove efficiencyClimate change adaptationExcrement fertilisersResource utilizationAlternative technology

The invention discloses a production method for circulating type modern efficient agriculture, and particularly relates to the technical field of agricultural production. A circulating agricultural production framework adopting planting industry, breeding industry, processing industry, renewable energy and fertilizer industry as cores is formed, the circulating agricultural production framework specifically comprises the substitute technology for replacing conventional resources, materials and products by developing and using novel agricultural resources and improving the agricultural resource utilization efficiency. By constructing the circulating agricultural production framework adopting planting industry, breeding industry, processing industry, renewable energy and fertilizer industry as cores, the good circulation is formed that circulating type agricultural production product supply and catering industry development, the catering industry helps tour industry, and the tour industry promotes development of the catering industry, and meanwhile rapid development of the catering industry and the tour industry can further promote development of the circulating type agriculture.

Owner:漳州市芗林信息咨询服务有限公司

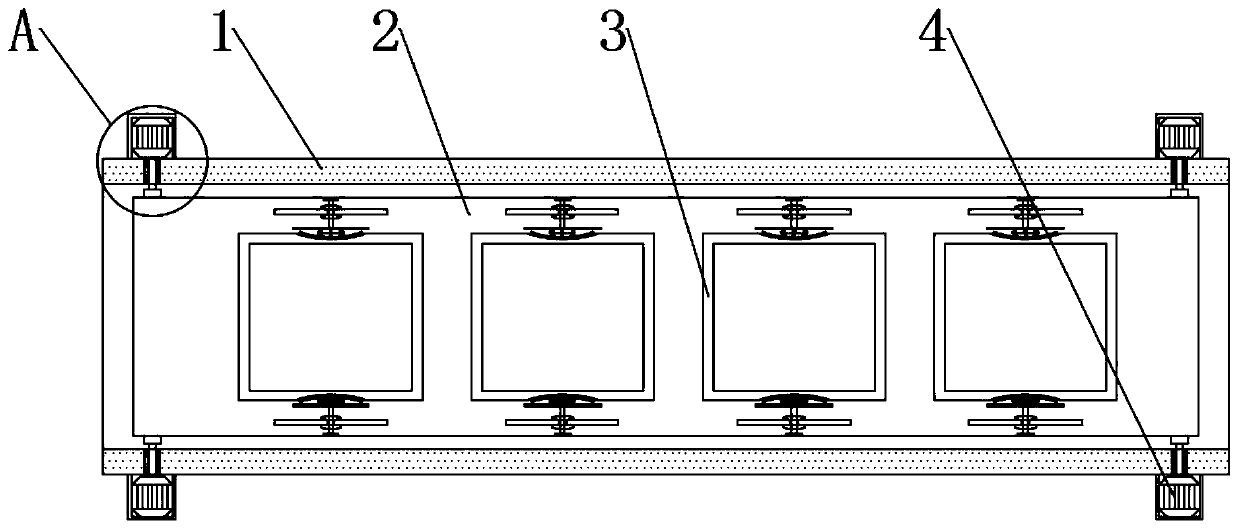

Multi-station integrated chain transmission type coal mine mining device

ActiveCN110821489ASimple structureEasy to operateSlitting machinesCutting machinesMining engineeringElectric machinery

The invention discloses a multi-station integrated chain transmission type coal mine mining device. The multi-station integrated chain transmission type coal mine mining device comprises a concave shell of the coal mine mining device, a chain transmission type conveying belt, coal mine device boxes, servo motors, center plates and anti-skid pads, wherein the chain transmission type conveying beltis arranged in the center of the concave shell of the coal mine mining device, the two sides of the chain transmission type conveying belt are sleeved with chain transmission type rotating shafts, a plurality of motor shells are welded to the two sides of the concave shell of the coal mine mining device, and the servo motors are welded in the motor shells. The multi-station integrated chain transmission type coal mine mining device is simple in structure, multi-station mining can be carried out manually in a plurality of coal mine device boxes at the top of the chain drive conveyor belt, and the plurality of coal mine device boxes can avoid uneven accumulation of raw materials during coal mining, so that multi-station coal mining is convenient for users; and meanwhile, coal mine transportation after mining is facilitated, the mining speed of the coal mine is increased, the time and manpower are saved, and the usage of the users is facilitated.

Owner:TAIYUAN UNIV OF TECH

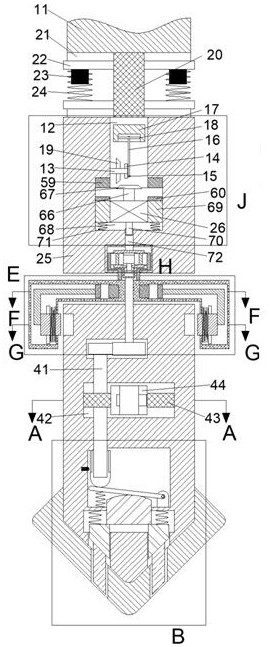

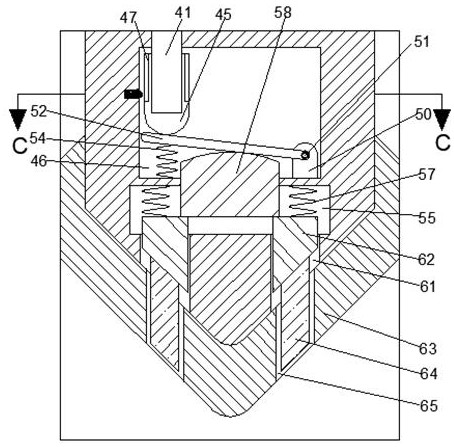

Safe and efficient ore extraction drill bit

InactiveCN111691820ASpeed up miningReduce miningDrilling rodsConstructionsMining engineeringReciprocating motion

The invention discloses a safe and efficient ore extraction drill bit. The safe and efficient ore extraction drill bit comprises a machine body, a rotating machine body is arranged on the lower side of the machine body, a reciprocating motion cavity with an upward opening is formed in the upper side of the rotating machine body, a reciprocating hammer capable of moving up and down is arranged on the upper side of the reciprocating motion cavity, and rubber non-slip mats are fixedly arranged on upper end surface of rotating machine body and lower end surface of machine body. According to the safe and efficient ore extraction drill bit, clamping a drill bit main body is carried out through a locking sliding block, meanwhile, ore extraction is accelerated through high-frequency vibration of avibration motor, a rotating motor is driven to drive the drill bit main body to rotate, and a cutter extends out at the same time, so that the service life of the cutter can be well prolonged; and ore extraction can be accelerated through reciprocating motion of the drill bit, and meanwhile, reducing vibration generated when the drill bit is impacted is carried out through a damping spring and abuffer block, so that the drill bit connecting position is advantageously protected against damage caused by reciprocating impact.

Owner:广州力寄采矿设备有限公司

High-efficiency screening type large-scale double-toothed roller crusher with self-contained material distribution device

Owner:HENAN ZHENYUAN TECH

Gas-liquid-solid three-phase coupled blasting method for weakening rock burst and increasing permeability

ActiveCN103161493BChange the physical and mechanical propertiesImprove breathabilityFluid removalGas removalStress concentrationBlast effects

Provided is a gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method. By coal seam water injection and changing of a powder charge structure of traditional blasting, common gas-solid two-phase blasting is converted into gas-liquid-solid three-phase blasting. Blast wave in water, jet flow, secondary pressure wave and other effects are generated by water pressure blasting to enhance blasting effect, after drilled holes are formed, coal bodies are wetted through water injection firstly, physical and mechanical properties around the drilled holes are changed, the gas-solid two-phase coal bodies are converted into gas-liquid-solid three-phase media, a stress concentrating zone is pushed to the deep parts of the coal bodies, stress concentration is lowered; coal seam fractures around blasting holes and in an influence zone are stretched and developed, the fractures are communicated with each other, a facture network is formed, stress concentration is removed, channels are provided for coal seam pressure relief gas flow, and accordingly the purpose that rock burst and gas outburst are prevented is achieved.

Owner:CHINA UNIV OF MINING & TECH

Method for enhancing shale gas exploitation through large-temperature-difference freeze-thaw cycle

ActiveCN109577939AImprove water absorptionGood cracking effectFluid removalHigh concentrationFreezing thawing

The invention discloses a method for enhancing shale gas exploitation through a large-temperature-difference freeze-thaw cycle. The method comprises the following steps of firstly, injecting magnetized water into a shale gas exploitation pipe of a shale gas well through pulsation; secondly, driving the magnetized water to move into shale as much as possible through high-pressure nitrogen, and thenconducting liquid-nitrogen freezing and high-temperature nitrogen melting on the magnetized water several times to fully utilize the permeability of the magnetized water, the driving property of thehigh-pressure nitrogen, the expansion force of the frozen magnetized water and an ultra-large-temperature-difference freeze-thaw cycle formed by the liquid nitrogen and the high-temperature nitrogen in order to cause complete cracking of the shale. Moreover, the high-temperature nitrogen can also provide energy for the shale gas to be separated from the shale, correspondingly the cracking effect of the shale can be effectively improved, the crack expansion range of the shale can be effectively expanded, and the shale permeability is increased, so that large-flow, high-concentration and long-time exploitation of the shale gas is improved.

Owner:XUZHOU UNIV OF TECH

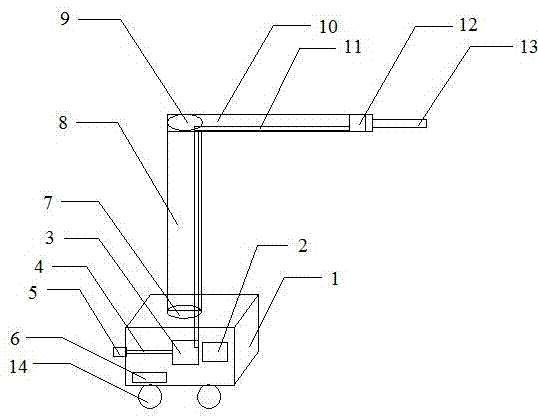

Coal-mining robot

The invention discloses a coal digging robot, which relates to the field of robots and includes an operation box (1), a control module (2), a water tank (3), a water inlet pipe (4), a water inlet (5), a motor (6), a A connection valve (7), a support rod (8), a second connection valve (9), a connection arm (10), a water pipe (11), a shower nozzle (12), a drill bit (13) and a pulley (14). The invention provides a coal digging robot. The drill bit is used for digging coal, and the spray nozzle installed sprays water on the coal base to make the coal soft, accelerate the speed of coal digging, and reduce the damage caused by gas explosion and mine subsidence. Accidents endanger the life of underground workers.

Owner:王孟美

Seabed combustible ice filling mining device and mining method thereof

ActiveCN111894530AIncrease downhole pressurePromote natural gas extractionOther gas emission reduction technologiesFluid removalMining engineeringHeat flow

The invention provides a seabed combustible ice filling mining device and a mining method thereof. The seabed combustible ice filling mining device comprises a mining platform and a grouting platform,wherein the mining platform is arranged on the sea surface of a combustible ice reservoir; a mining pipeline is arranged in a mining well; a mining device is arranged at the front end of the mining pipeline; one end of the mining device is provided with a high-pressure hot flow sprayer; and the other end of the mining device is provided with a grouting sieve pipe. The mining method of the seabedcombustible ice filling mining device comprises the following steps of Step 1, performing drilling operation by marine oil and natural gas drilling equipment; Step 2, performing well cementation and well completion on the mining well; Step 3, transforming a pre-mining face; Step 4, filling a goaf area; and Step 5, recovering the mining equipment. The combustible ice mining and the grouting platform grouting filling are performed at the same time; through filling, the underground pressure can be increased, and the natural gas extraction is promoted; and in addition, a filling material can achieve the support effect, so that the mining and the use of the combustible ice are convenient.

Owner:JILIN JIANZHU UNIVERSITY

Underground drilling track measuring method and coal seam fracturing permeability increasing method

InactiveCN112696190AImprove construction efficiencySpeed up miningConstructionsFluid removalMining engineeringCoal

The invention discloses an underground drilling track measuring method and a coal seam fracturing permeability increasing method. The underground drilling track measuring method comprises the steps that drilling track monitoring data are processed; and track monitoring is carried out through a micro-seismic tester in the drilling process, and data processing is carried out through three-dimensional software to construct a drill hole trend three-dimensional model. The coal seam fracturing permeability increasing comprises the steps of drilling construction and fracturing permeability increasing construction, and fracturing permeability increasing is implemented on the basis of fracturing drilling holes obtained through drilling. The drilling construction is carried out according to the method, before drilling, a drilling design trend three-dimensional model is constructed, after drilling, the actual trend is compared with the design trend, and the scheme is adjusted according to the difference. The underground drilling track measuring method has the beneficial effects that the drilling direction and the distribution condition of a plurality of drilled holes can be accurately judged. According to the coal seam fracturing permeability increasing method, the actual trend of a fracturing drill hole is compared with the design trend, so that a design scheme is adjusted in real time according to the difference, the construction efficiency is improved, the mining progress is accelerated, and the mining efficiency is improved.

Owner:重庆市能源投资集团科技有限责任公司 +2

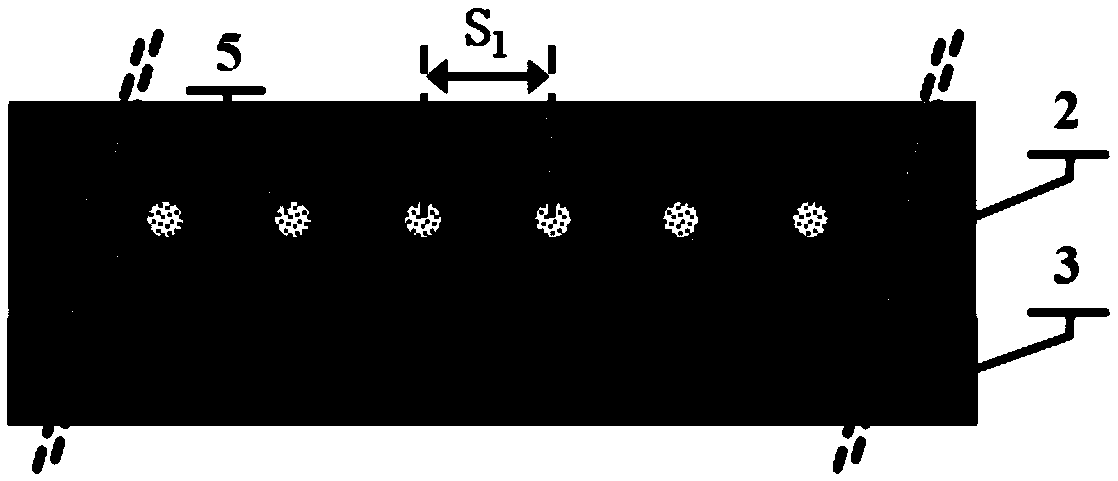

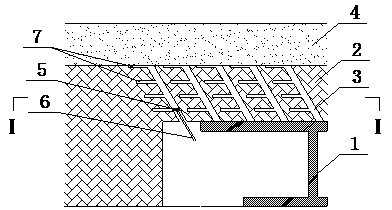

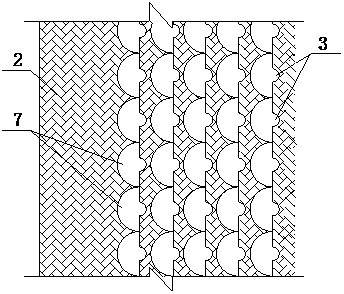

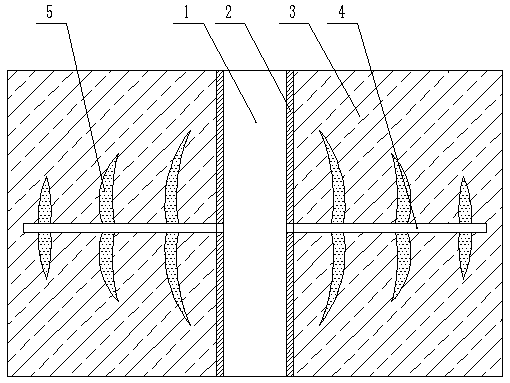

Method for cutting and pre-breaking top coal to improve mining efficiency by utilizing water power

The invention relates to a method for cutting and pre-breaking top coal to improve mining efficiency by utilizing water power, which solves the problem that a relatively hard and complete roof coal seam, particularly a coal seam tightly attached to an upper rock body, is difficult for top coal caving, large in coal falling lumpiness and not high in mining efficiency. The method comprises the following steps of: drilling advanced boreholes in a roof coal body to a coal rock boundary surface on a mining working surface by utilizing a drilling machine; extending a high-pressure water pipe in the boreholes; and cutting a plurality of subhorizontal semicircular transverse slots by utilizing the impact force of high-pressure water from top to bottom in the top coal. A plurality of yielding regions are formed by the boreholes in linear distribution in the roof coal body, the mechanical conditions in the coal body are changed, the hard and complete coal body is promoted to be deformed and broken under the effect of advanced concentrated stress, and a plurality of cracks are generated; the coal-rock and coal-coal contact areas are reduced through the transverse slots, and the coal body on the boundary surface is further extruded under the effect of roof high stress, so that the coal body is broken, the adhesive power is lost, manual layering is achieved, and coal is convenient to fall. The method is simple and quick, high in operability and good in timeliness, the coal mining speed can be efficiently increased, and the mining efficiency of the top coal is improved.

Owner:CHINA UNIV OF MINING & TECH

Shale gas directional fracturing yield-increasing method

The invention discloses a shale gas directional fracturing yield-increasing method. The method comprises the following steps of a, drilling a vertical shaftway, and utilizing a casing pipe for well cementation; b, drilling several fine branch radial shaftways in different radial directions at different flat layers; c, implementing a fracturing technology in all the fine branch radial shaftways insequence, and adopting a coiled tube for drainage. According to the method, by drilling the directional fine branch radial shaftways, the direction randomness of fracturing gaps generated by traditional fracturing modes can be avoided, exploitation on directional parcels is promoted, the construction efficiency is improved, and the exploitation amount is also increased. Carbon dioxide in a super-critical state is adopted in fractured prepad liquid so that carbon dioxide can quickly permeate into tiny pores, and shale gas in the pores is replaced; meanwhile, carbon dioxide serves as acid gas tocorrode a shale bed, communication among the adjacent pores is promoted, and the development of the pores can also be promoted; besides, added powder ceramsite can block the tiny pores, the loss of the fracturing liquid is reduced, and the development of large pores is promoted.

Owner:SOUTHWEST PETROLEUM UNIV +1

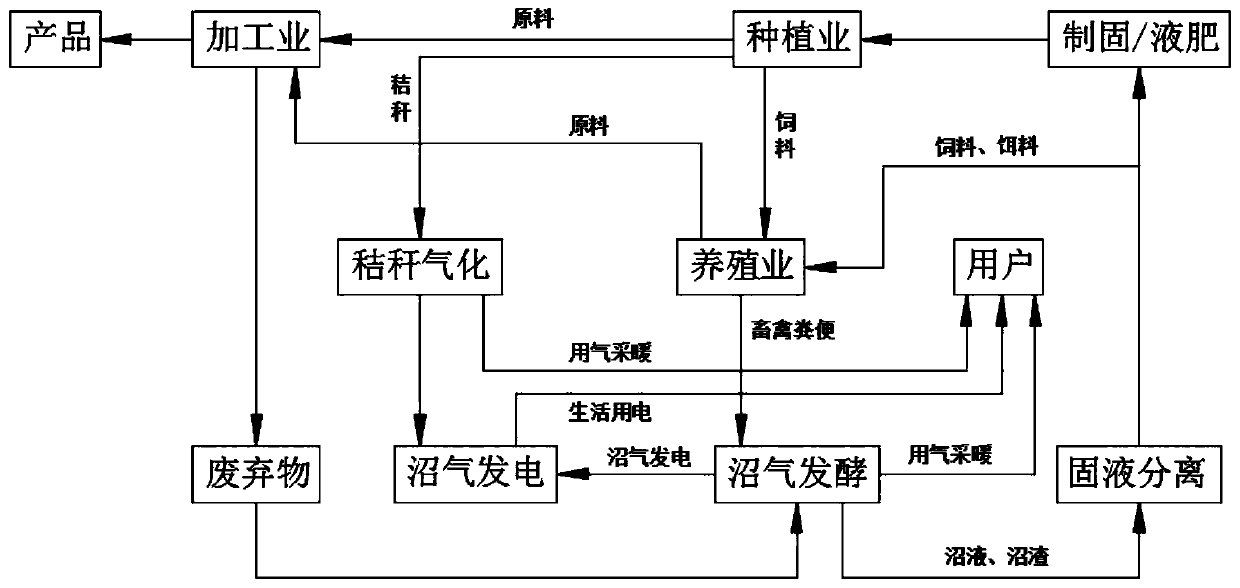

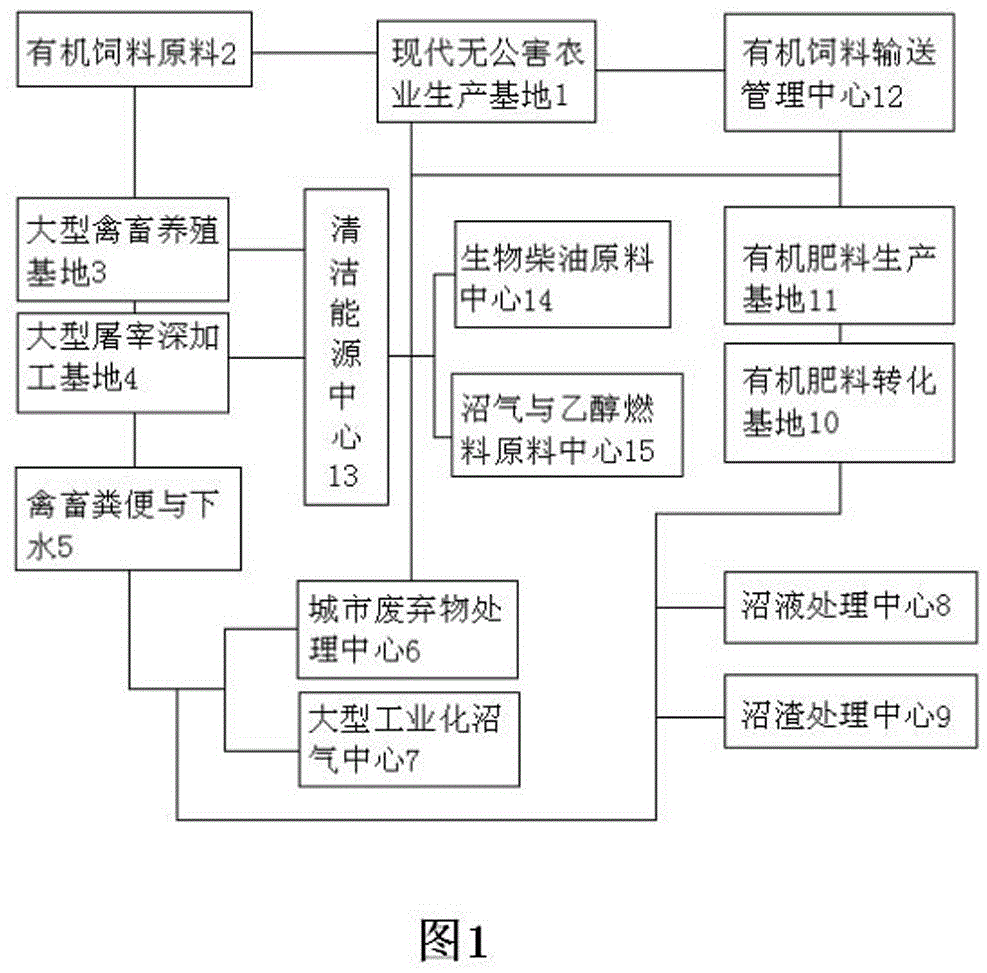

Grain production and water environment protection circulation system for modern agriculture

InactiveCN106245946AEasy to changePromote sustainable developmentBio-organic fraction processingAgricultural buildingsBiodiesel feedstockLivestock manure

The invention discloses a grain production and water environment protection circulation system for modern agriculture and belongs to the technical field of agriculture and environment. A large livestock breeding base and a large slaughter deep processing base convey livestock manure and offal into a large industrial biogas center; the large industrial biogas center is combined with an urban waste processing center to send biogas slurry and biogas residue to a biogas slurry processing center and a biogas residue processing center, and then converts the biogas slurry and the biogas residue and sends the biogas slurry and the biogas residue to an organic fertilizer production base; produced organic fertilizers are sent into a modern pollution-free agricultural production base; and fuel and raw materials which are processed through the large industrial biogas center are sent to a biodiesel raw material center and a biogas and ethanol fuel raw material center. The agricultural circulation can be developed towards targets of two zero growths which are agricultural resource and agricultural energy consumption zero growth and agroecological environment degradation rate zero growth zero growth, and thus an agricultural development model of efficient sustainable use of the agricultural resources and virtuous circle of the ecological environment is adopted positively.

Owner:ANHUI LONGCOM INTERNET OF THINGS

A Combined Detection Method for Predicting Burial Depth of Uranium Ore Body

ActiveCN103913781BBurial depth is effectiveBurial depth is reliableGeological measurementsSoil scienceGamma energy

The invention belongs to a uranium ore exploration method, and particularly relates to a combined prospection method for predicting the uranium ore body burial depth. Specifically, the method includes the following steps of determining measuring positions in a measuring area, measuring the content of ground gamma energy spectrum uranium at the measuring positions, measuring the content of instantaneous soil radon gas at each measuring position, taking soil samples at the measuring positions, airing, pulverizing and screening the soil samples, drying the soil samples, using agentia to extract component uranium in the dried soil samples, measuring and determining the extracted adsorbed state component uranium, making a plane contour map, circling an abnormal area, and predicting the uranium ore body burial depth according to abnormal combination conditions of the energy spectrum uranium, the instantaneous soil radon gas, the component uranium, the instantaneous soil radon gas / energy spectrum uranium ratio, the component uranium / energy spectrum uranium ratio and the component uranium / instantaneous soil radon gas ratio. According to the method, the misering workload can be greatly reduced, the prospecting hit rate is improved, and cost is reduced.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com