Graded mining method of coal-rock co-mining working face

A coal and rock simultaneous mining and graded mining technology, which is applied in surface mining, earth drilling, underground mining, etc., can solve problems such as low mining efficiency, and achieve the effects of improving mining speed, efficient mining, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described below through specific embodiments and accompanying drawings.

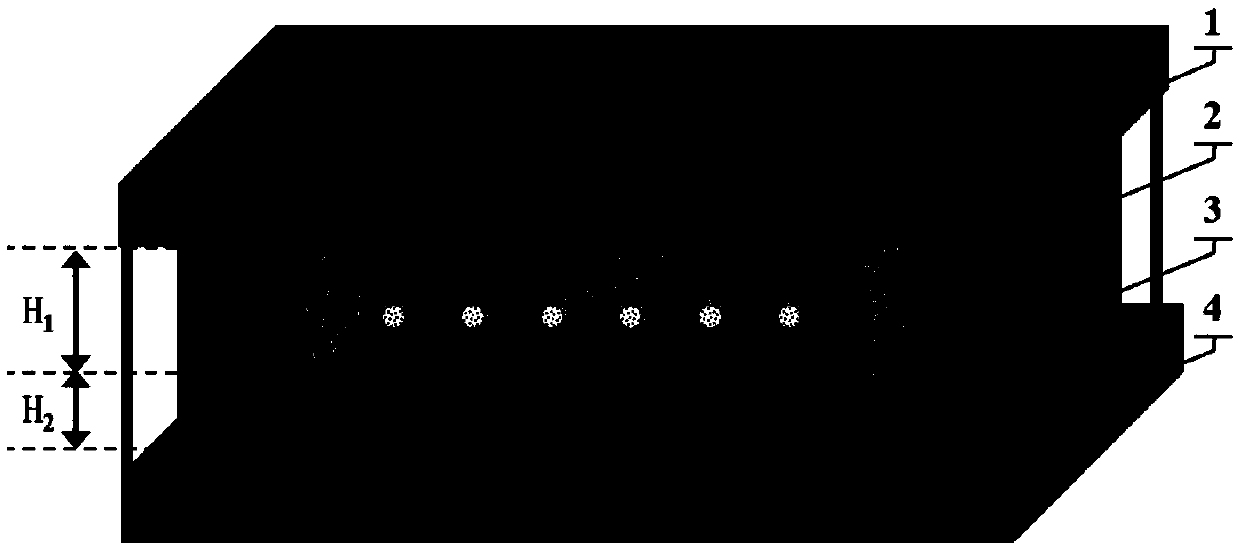

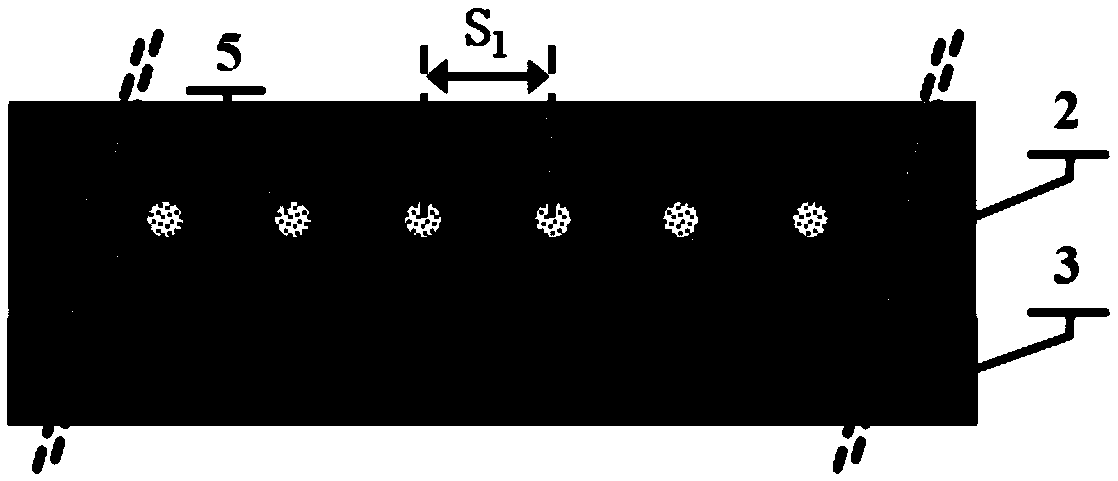

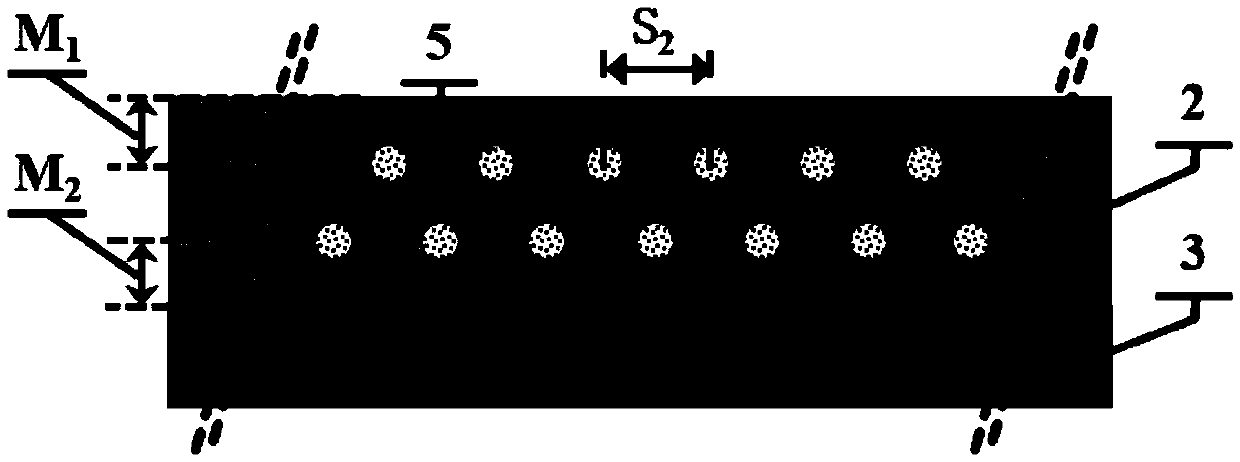

[0019] figure 1 It is a schematic diagram of the present invention carrying out the coal-rock co-mining working face graded mining, including a roof 1, a rock formation 2, a coal seam 3, a bottom plate 4, and blasting holes 5, etc., wherein H 1 is the rock thickness, H 2 is the coal seam thickness.

[0020] Coal and rock co-mining working face classification mining method of the present invention, its steps are as follows:

[0021] First of all, the rock formation strength f of the coal and rock simultaneous mining face is tested before mining, and the mining strength of the working face is classified according to the size of the rock formation strength f:

[0022] If f<1.5, the rock formation strength is grade I (f is a dimensionless parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com