Patents

Literature

173results about How to "Reduce excavation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

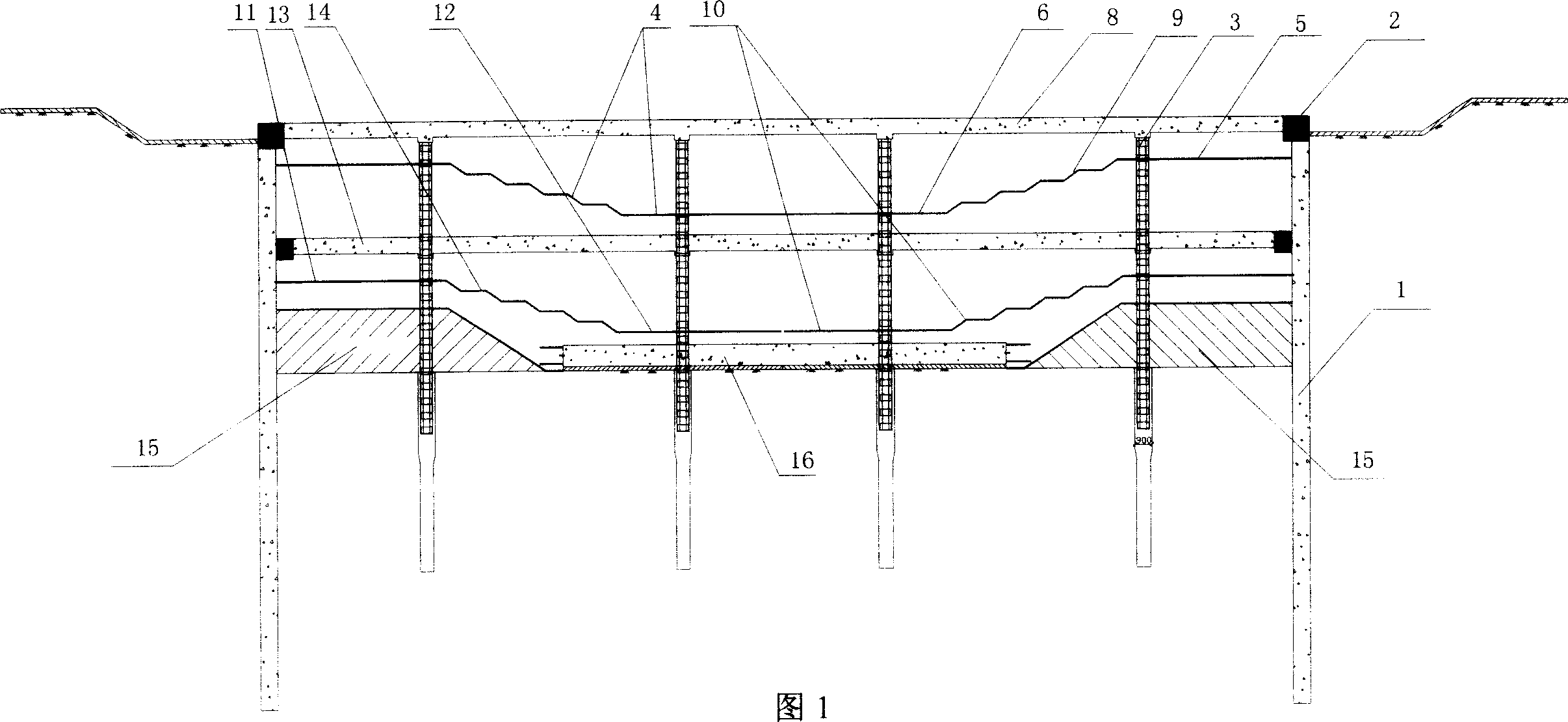

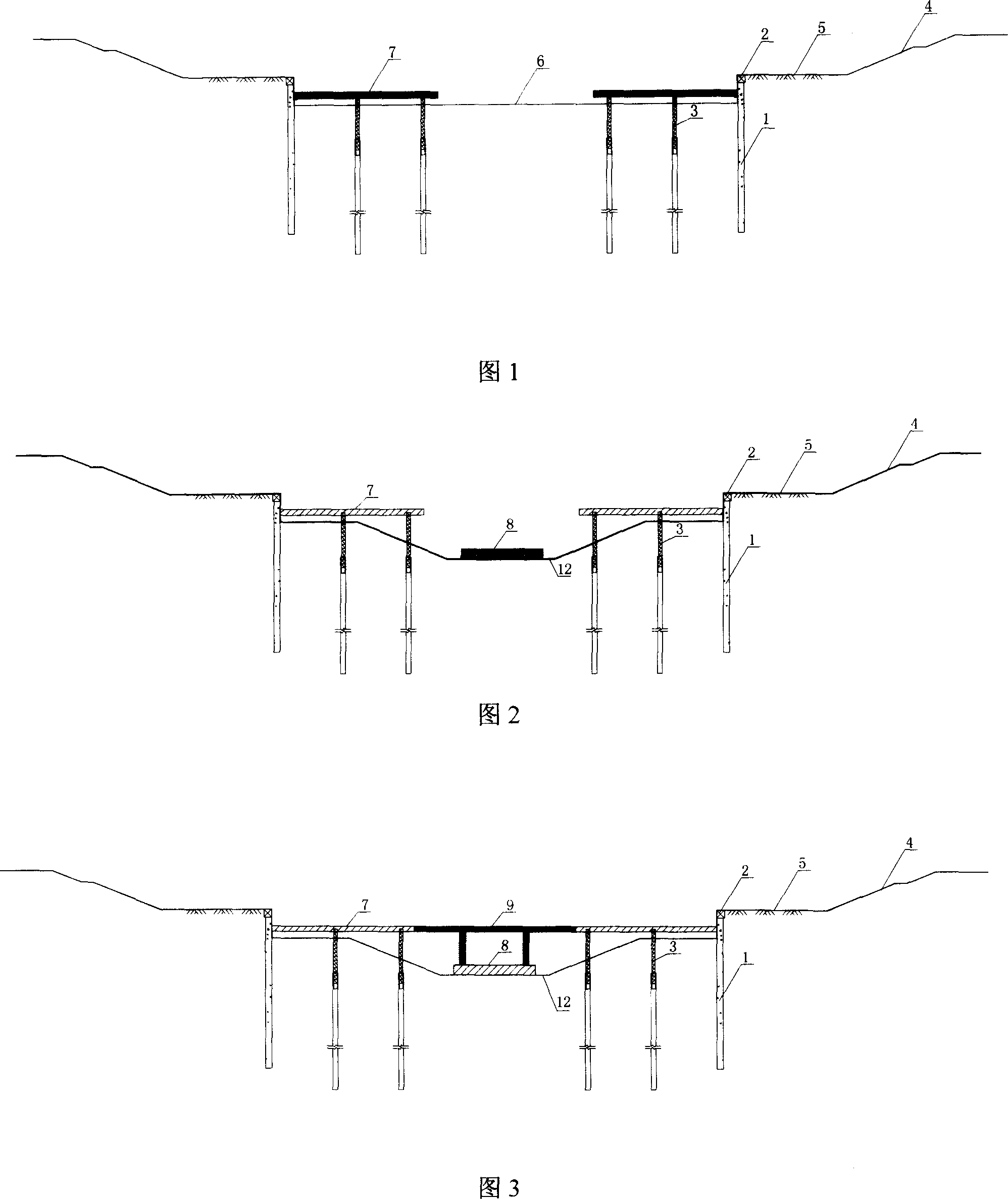

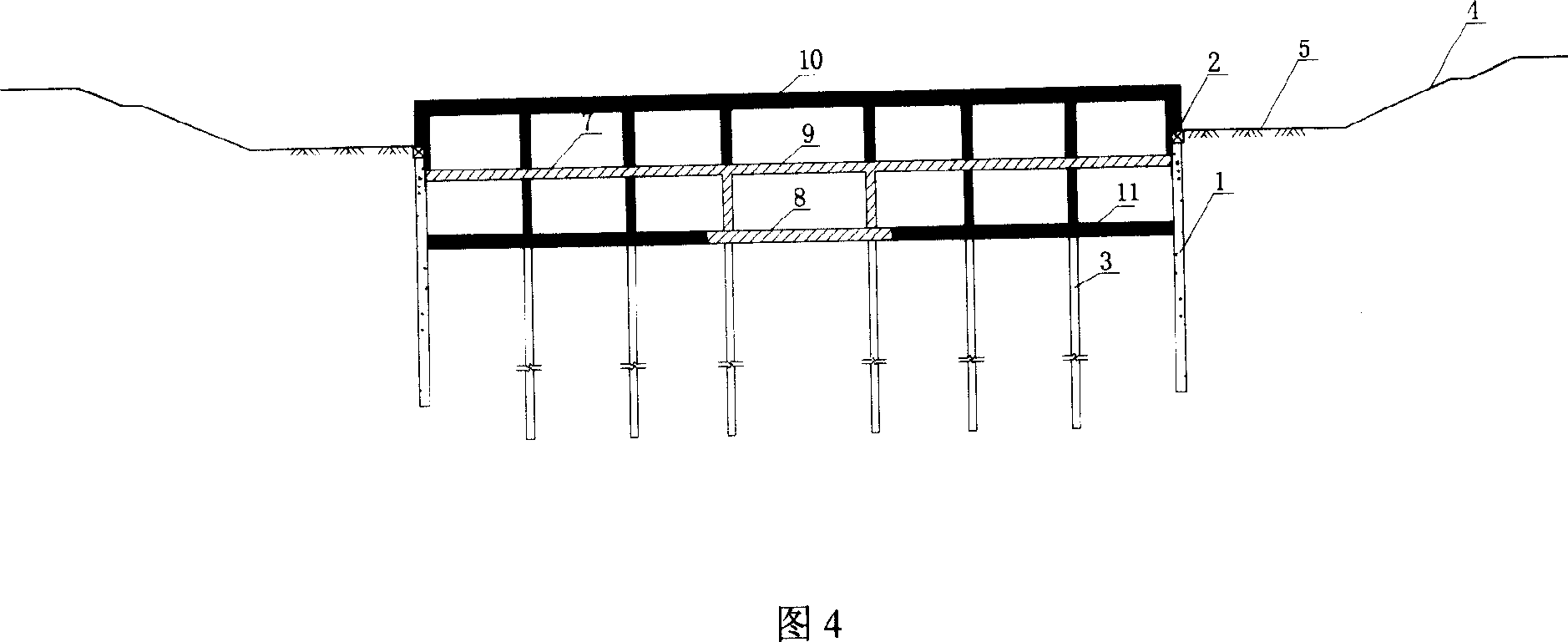

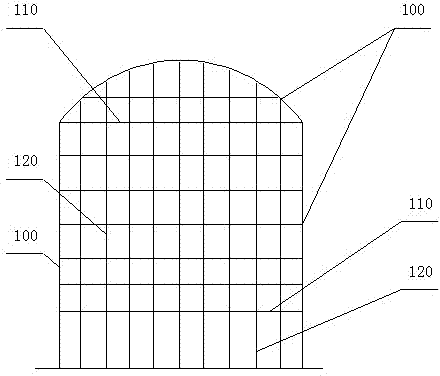

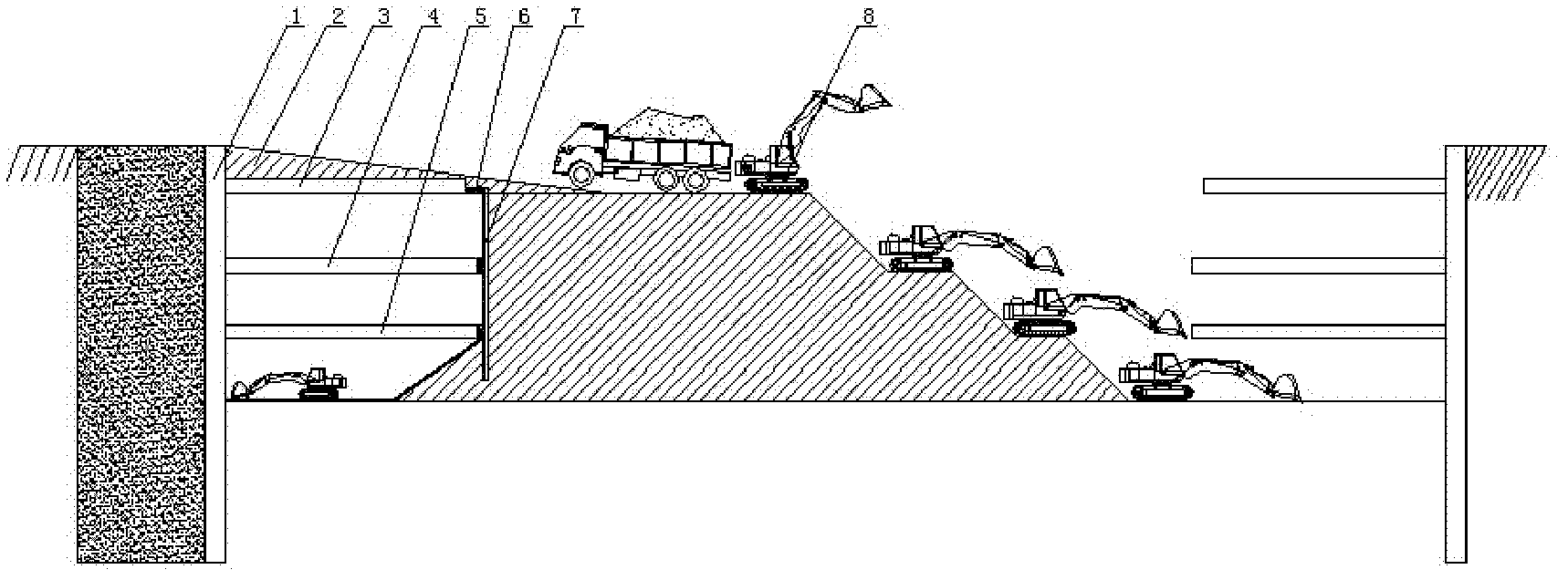

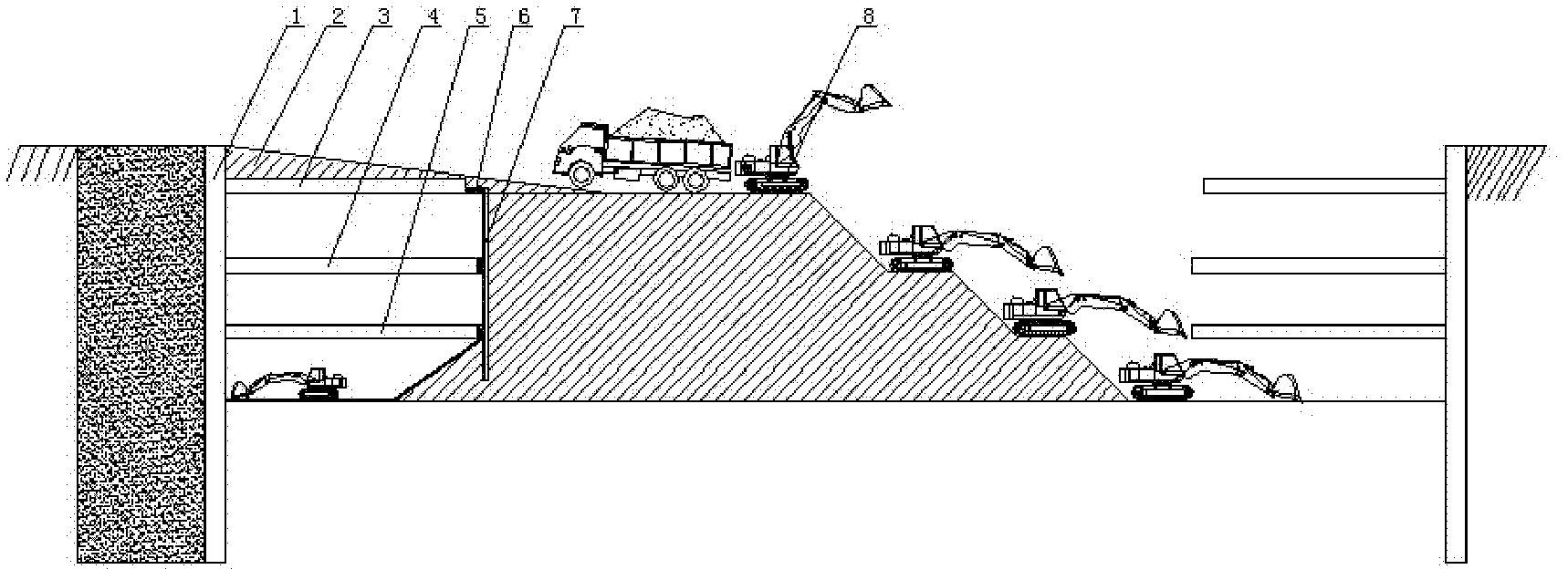

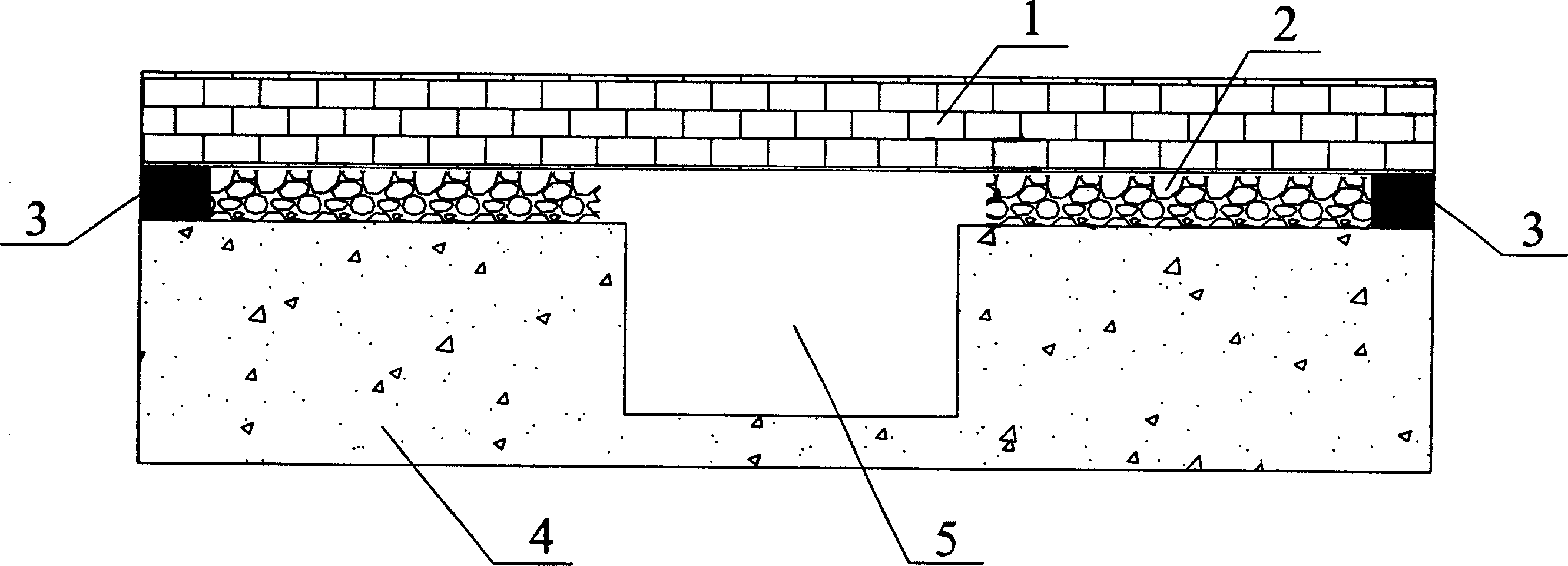

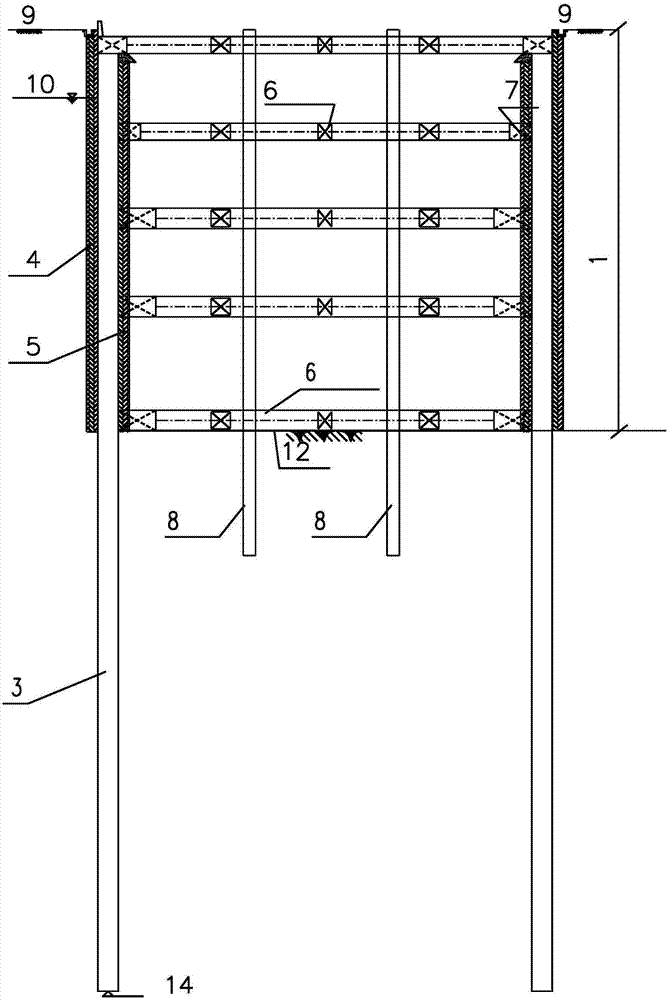

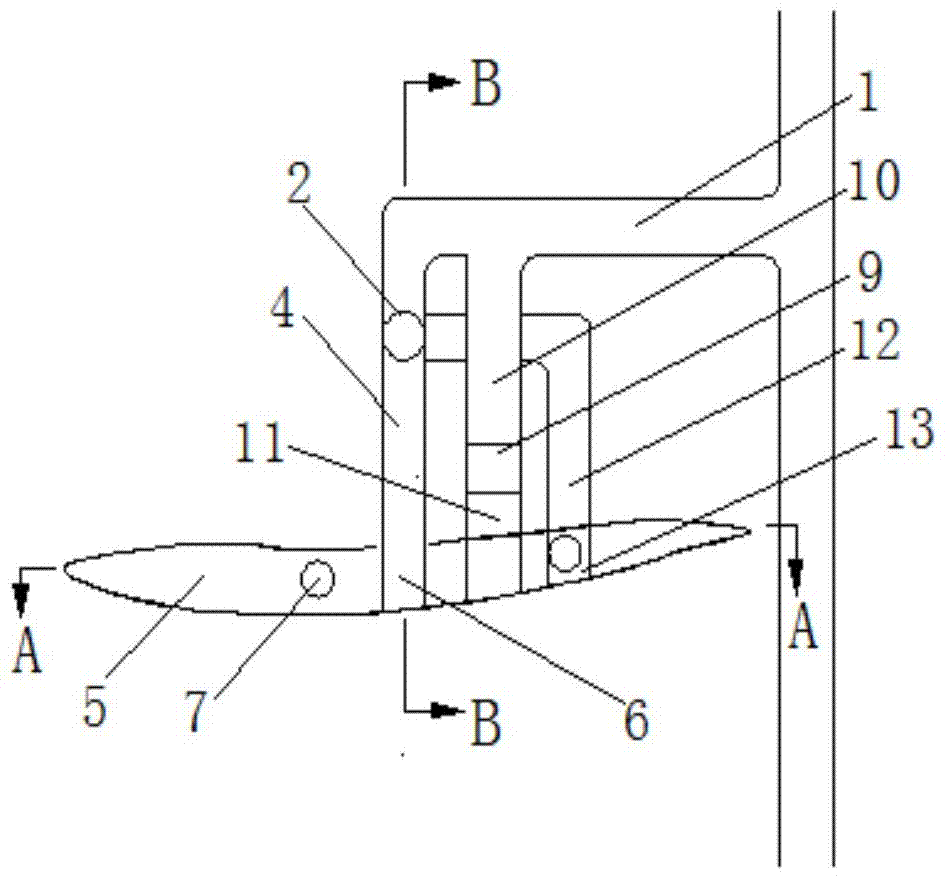

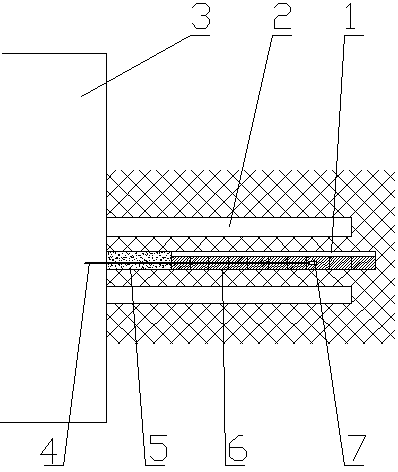

Tray type excarvating contrary construction method

InactiveCN1948633AReduce excavation costsReduce distortionBuilding constructionsExcavationsInverse methodBuilding construction

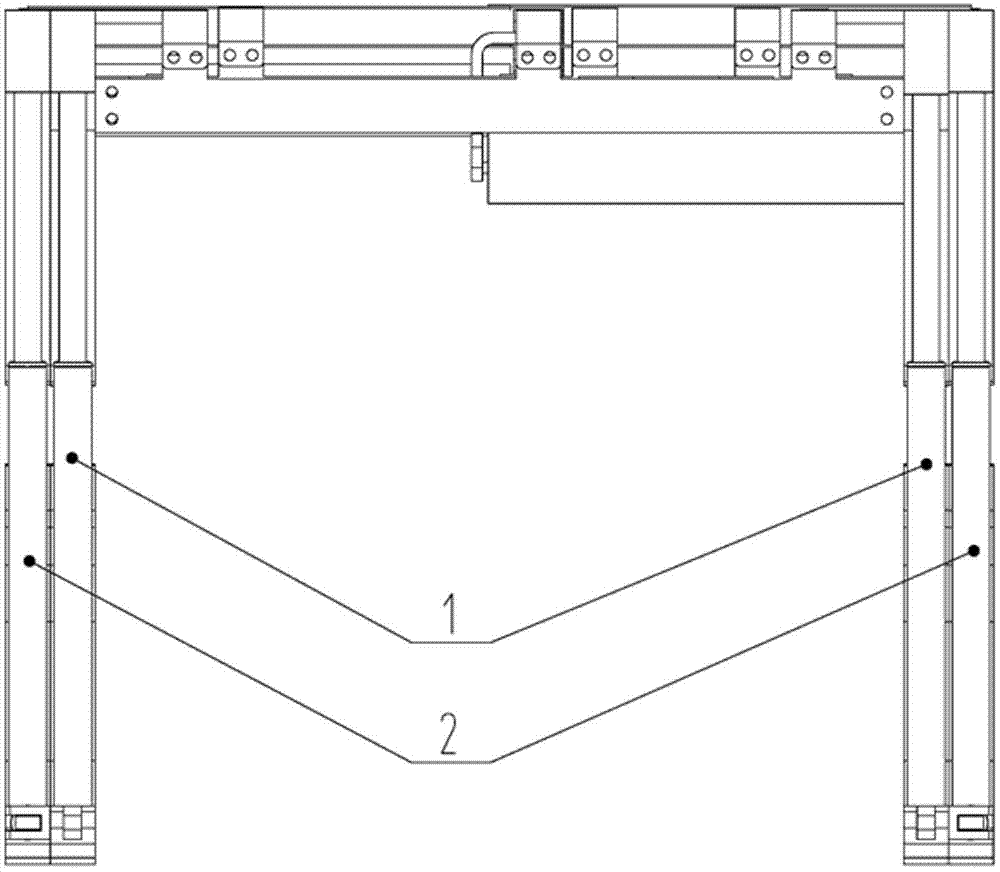

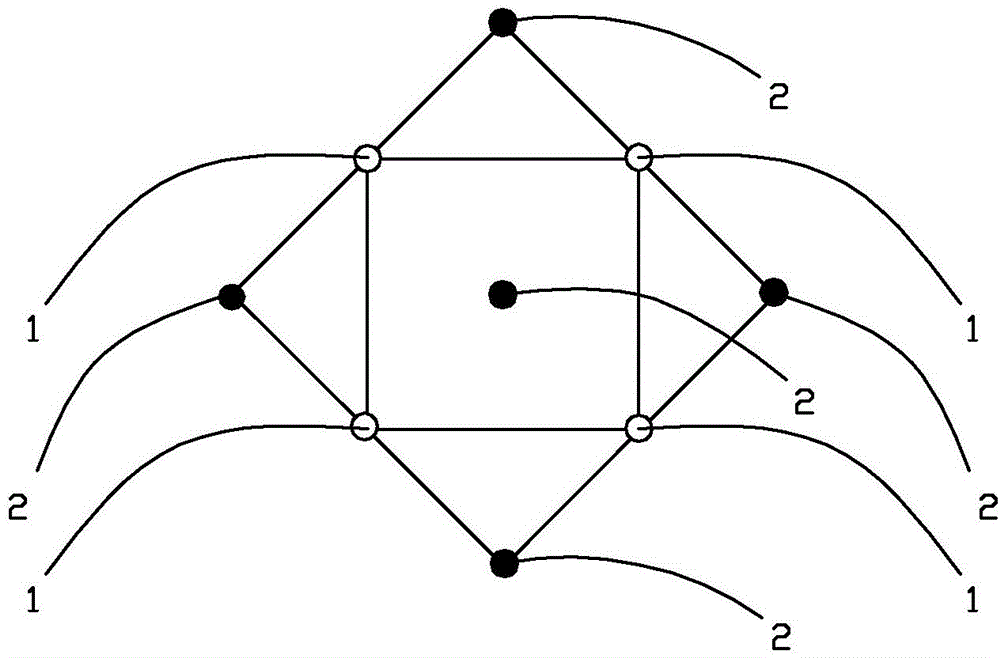

This invention provides a basin excavation inverse method. Its major construction step is the open excavation in retaining structure edge at the first step , and digs a kind of pot-style structure, and pour the top layer concrete of underground structure, and provides dug holes; then excavates in another way, it is a pot of architecture, and pours the top structure concrete of the underground two-story, and allows dug holes; following mining, and pouring the top three underground structure plate and the top four floors underground structure ; the bottom of base plate structure is divided into two parts ;it excavates scope of the bottom floor firstly, the pit digs to the bottom, pouring concrete, then the envelope around 6 ~ 10 meters pumps the excavation. This construction method is suitable for the large pit area, depth deeper large-scale construction projects, as it constructs conveniently, saves manpower and resources to improve the progress of the project, and shortens the construction periods.

Owner:SHANGHAI NO 7 CONSTR

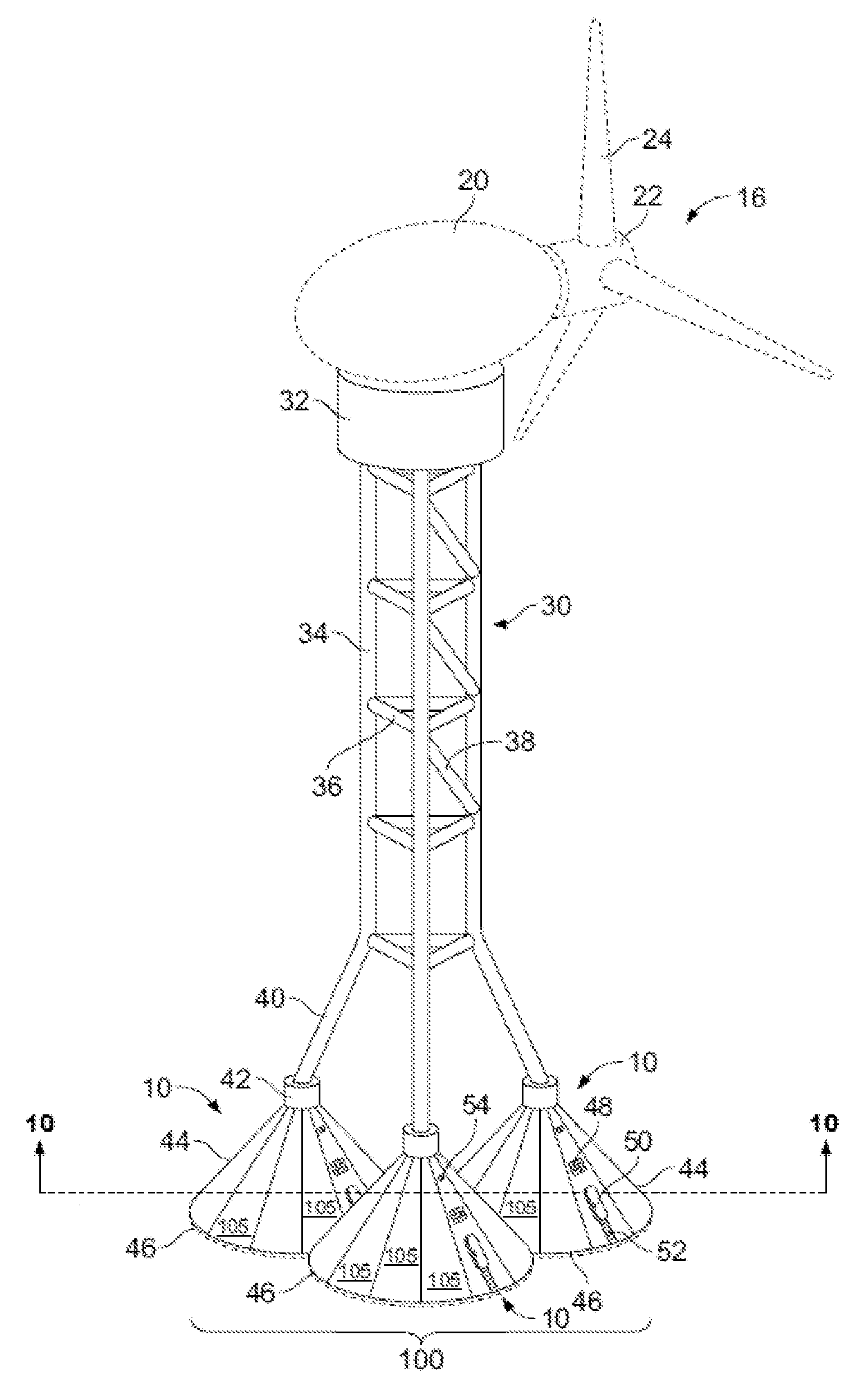

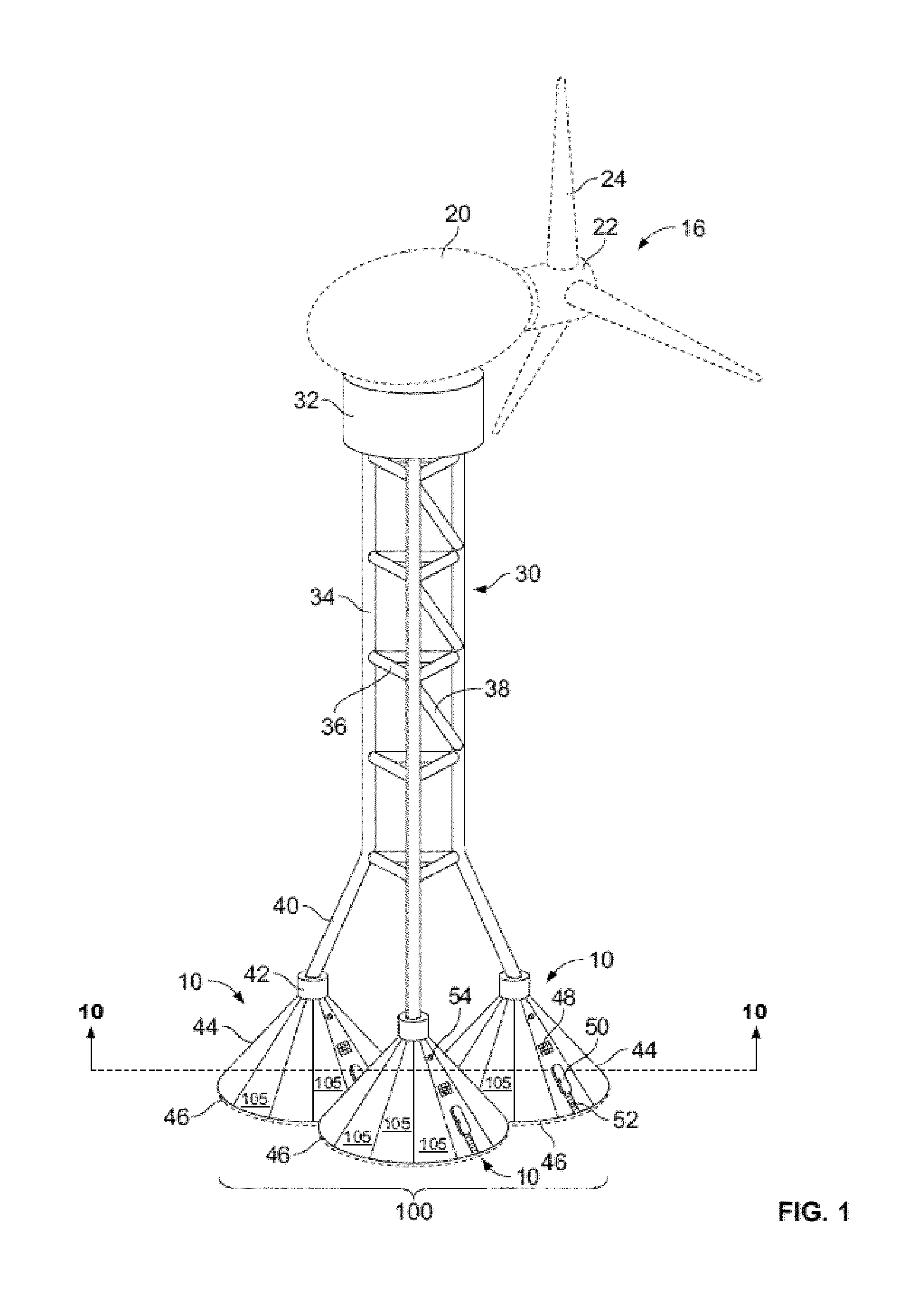

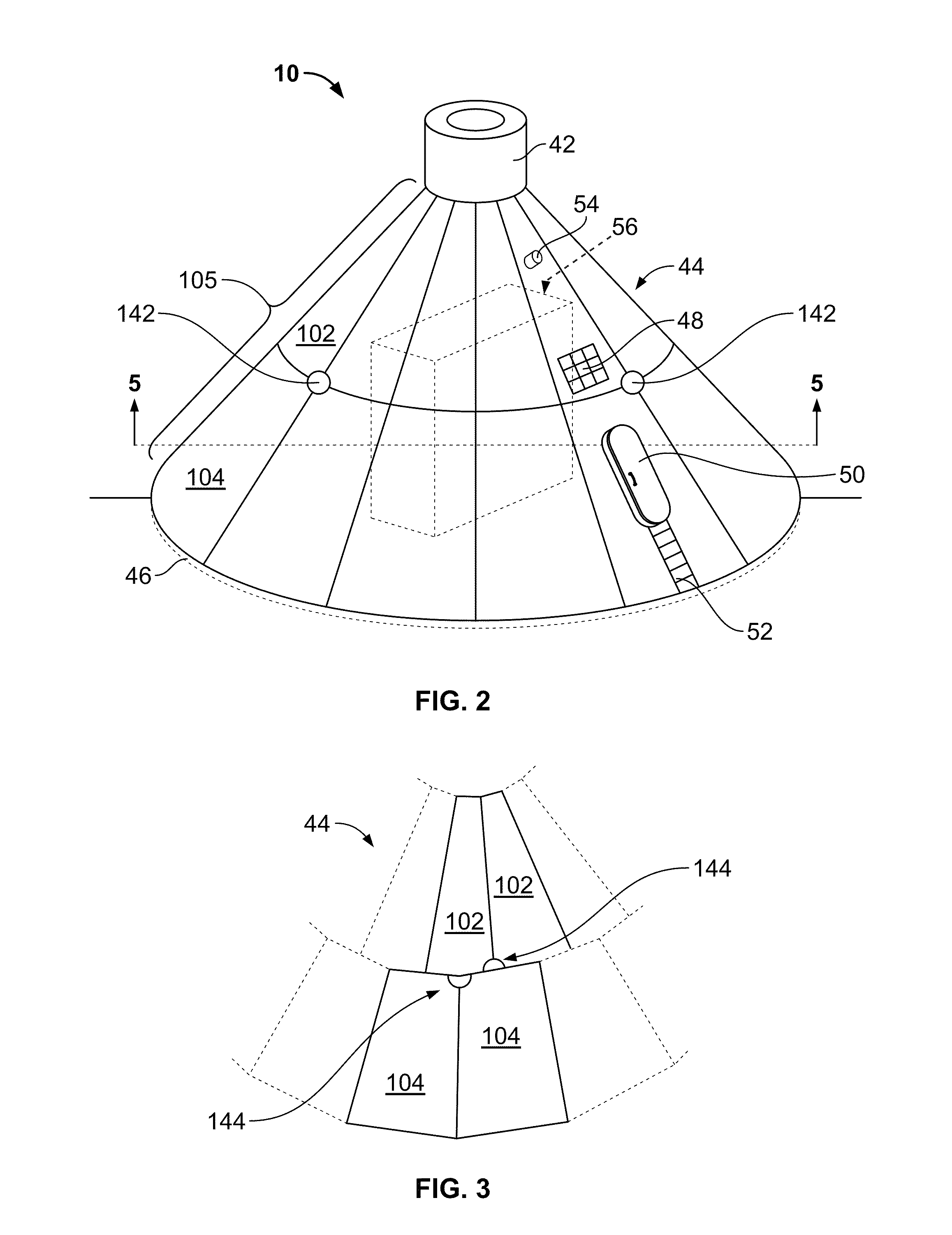

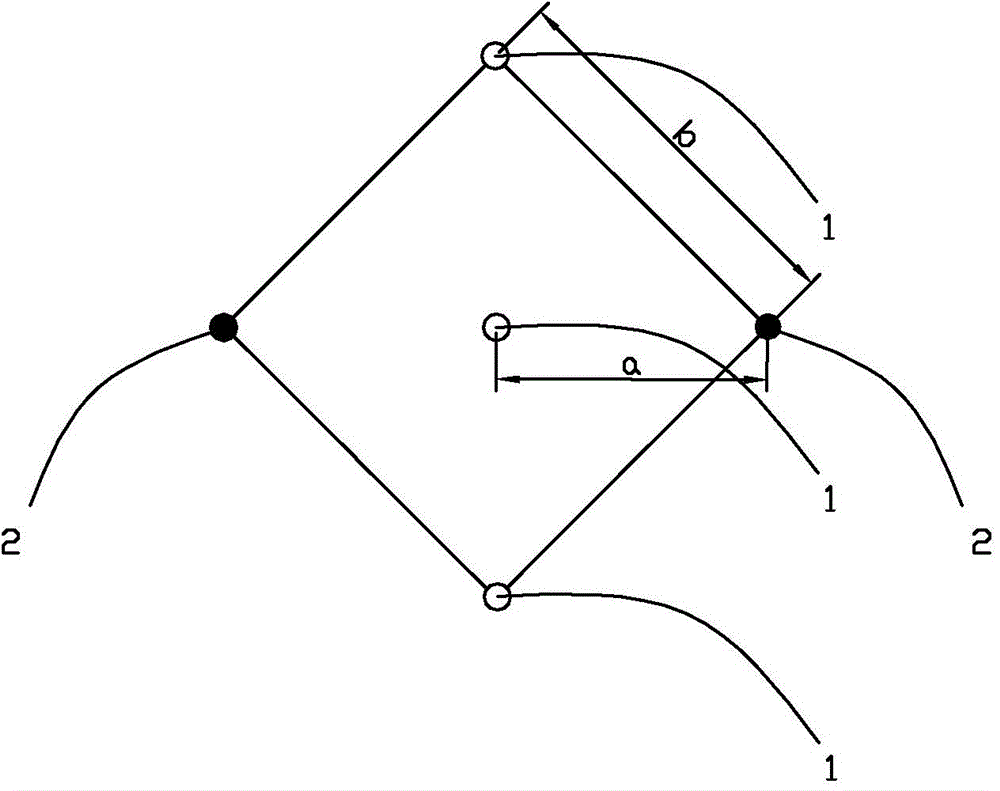

Modular surface foundation for wind turbine space frame towers

InactiveUS20100132270A1Reduce excavation costsLess material to installTransformer housesWind motor assemblyInterior spaceTower

A modular surface foundation for wind turbine space frame towers, an apparatus to form panels of housing members of modular surface foundation, and method of forming the modular surface foundation for wind turbine space frame towers is provided. The modular surface foundation comprises a plurality of footing members, and a housing member disposed on each of the footing members, the housing members extending from the footing members and attaching to one or more structural members forming a portion of a wind turbine tower, wherein the housing member provides support and increased height for the space frame tower and includes an interior space.

Owner:GENERAL ELECTRIC CO

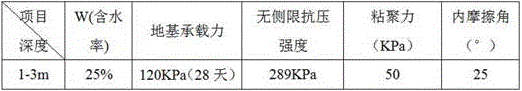

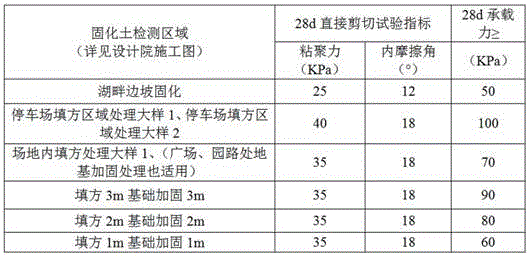

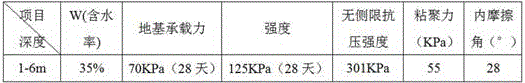

Silt solidification soil construction technology

The invention discloses a silt solidification soil construction technology which comprises the steps of surface cleaning drainage, silt sampling, detection analysis, excavation stacking, stirring and mixing, filling and grinding and stabilized soil maintenance. Through solidification soil in-situ solidification, silt and a curing agent are stirred and mixed to form silt solidification soil, and the curing agent is prepared through expanded graphite, activated carbon, cement, quick lime, gypsum, lignocelluloses, coal ash, granulated blast-furnace slag powder, coal gangue, caustic dross, hydroxypropyl methyl celluloses, furfural residues, medical stone and smectite clay. By means of the silt solidification soil construction technology, original flowing high-water-content low-strength high-compressibility silt is converted into high-compressive-strength excellent-entire-board-performance, good-durability and environment-friendly solidification soil, and the requirement of shallow ground earthwork materials for roads, storage yards, ports, reclamation projects, afforesting and the like can be met.

Owner:福建港湾岩土工程集团有限公司

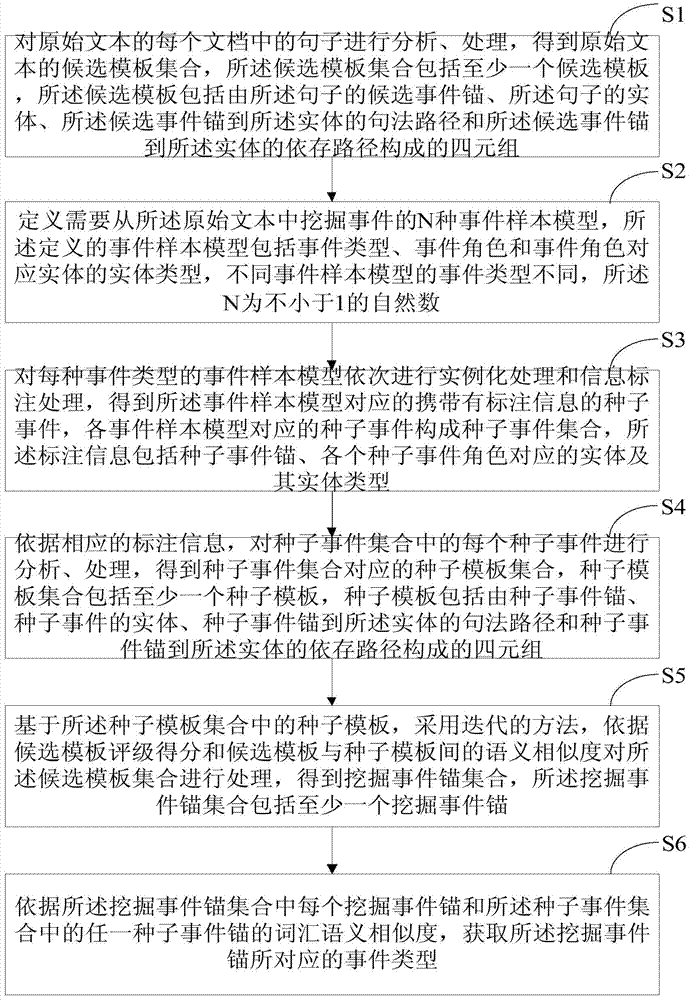

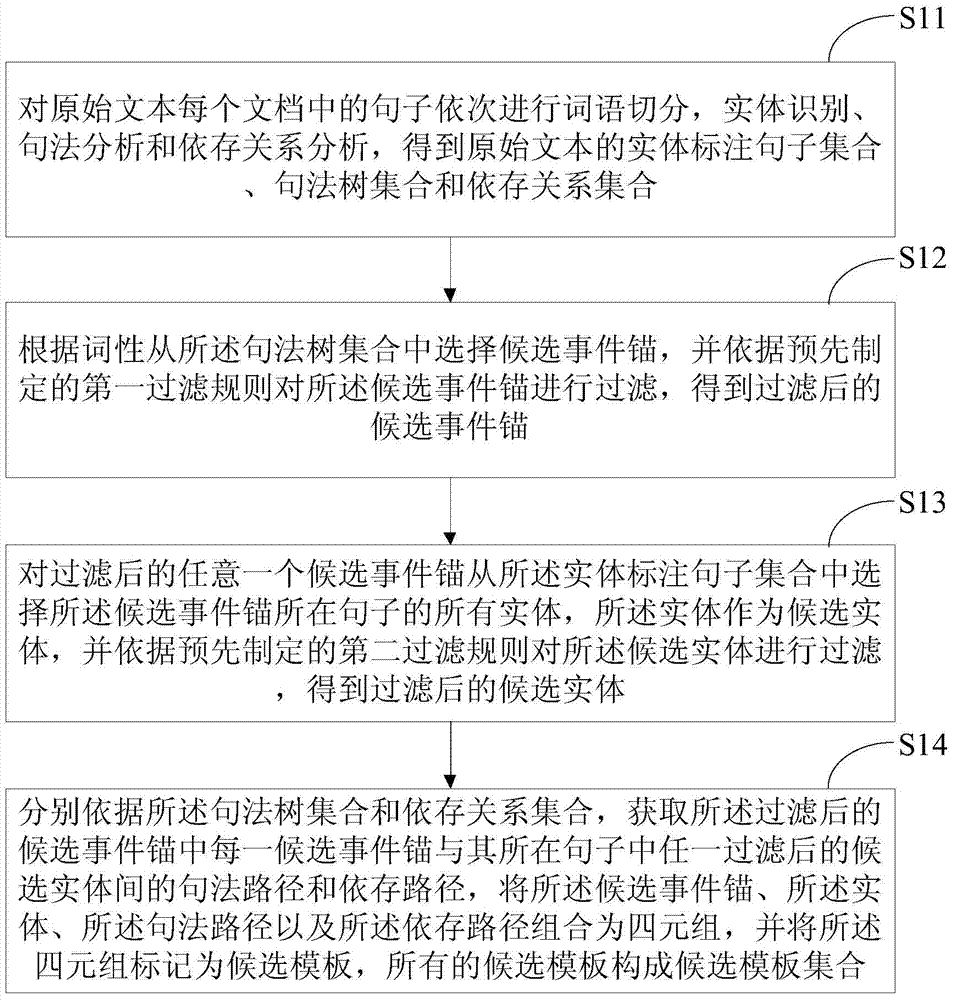

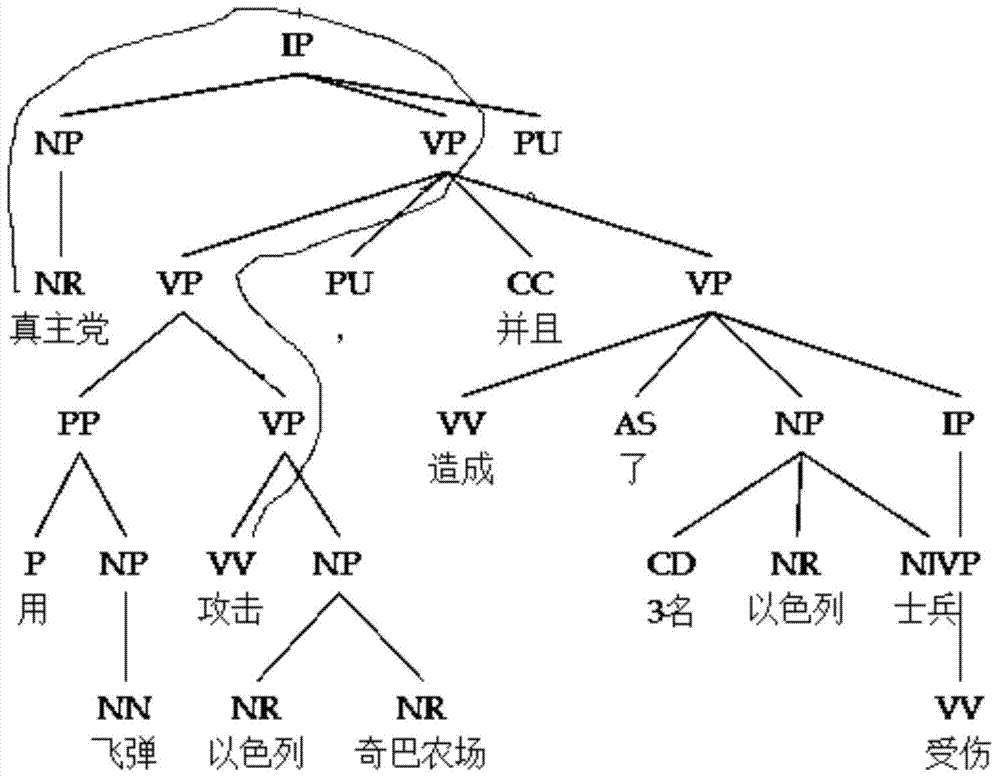

Method and system for mining Chinese event information

ActiveCN103617280AReduce excavation costsImprove digging efficiencySpecial data processing applicationsEvent typeIterative method

The invention discloses a method and system for mining Chinese event information. The method includes the steps of defining an event sample model based on the mining requirement, instantiating the event sample model to obtain a seed event, taking the seed event as the foundation of an event mined from an original text, conducting preprocessing on the original text to obtain a candidate template set, conducting information labeling on the seed event, processing the seed event on the basis of labeling information to obtain a seed template set, then, processing the candidate template set through an iterative method according to the grade scores of candidate templates and the semantic similarity between the candidate templates and seed templates so that an event mining anchor set can be obtained, and obtaining the event types corresponding to mining event anchors according to the lexical semantic similarity between each event mining anchor in the event mining anchor set and any seed event anchor in the seed event set. The aim of mining the Chinese event information from the original text can be achieved only by labeling a small amount of samples, namely, the seed events, and the mining cost is reduced.

Owner:苏州大数据有限公司 +2

Direct local skirt border reversing construction for central island

InactiveCN1982546AReduce distortionEnsure safetyArtificial islandsBuilding constructionsSupporting systemPurlin

A job practice of which center island is done in sequence and partial skirts done inversely, comprising the following steps : set up exterior-protected construction, purlin and steel upright columns around the foundation ditch; dig on basin pattern for the first time to the depths to structural plane of purlin, earthwork are unified dig beneath the designed to the surrounding medium plate in the foundation ditch, pour the surrounding medium plate; dig for the second time with basin pattern downwards from the position of foundation ditch medium plate to the bottom of the designed foundation ditch, pour the center island plate; after the center island plate meets the maintenance time request of plate, construct in sequence to close the medium plate, setting fetching holes; then use medium plate for support system, construct criss-cross structural upper plate and plates in inverse zones. This construction method is convenient, save labor force and resources, improves the progress of the project, shorten the construction period.

Owner:SHANGHAI NO 7 CONSTR

Excavation construction method for mine hard rock roadway

The invention discloses an excavation construction method for a mine hard rock roadway. A cutting device is used for cutting out the outline of the roadway, cutting in the horizontal direction and in vertical direction is carried out in the outline of the roadway to obtain parallel horizontal cut grooves and parallel vertical cut grooves, and the horizontal cut grooves and the vertical cut grooves intersect and cut the section of the roadway inside the cut grooves of the outline to a longitudinally and transversely intersected grid-shaped structure. A crushing device is used for crushing or breaking a first rock inside the grid-shaped structure of the section of the roadway in a prizing mode and then crushing or breaking other rocks in the prizing mode, the crushed or broke rocks are taken out until all the rocks within the cutting depth are taken out, and a manual or mechanical conveying device is used for conveying cut rocks. The excavation construction method for the mine hard rock roadway resolves the problem of excavation of hard rocks or superhard rocks through a mechanical method, eliminates an explosion work procedure, is safe and efficient, and is not restrained by use and management regulations of explosive products. The roadway is good in forming performance, damage to surrounding rocks is small, supporting can be simplified or eliminated, operation time and engineering cost are saved, the construction speed is improved, and excavation cost is lowered.

Owner:重庆能投渝新能源有限公司

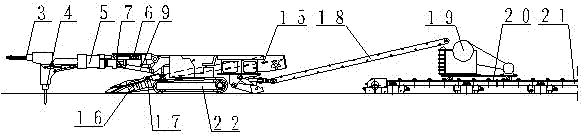

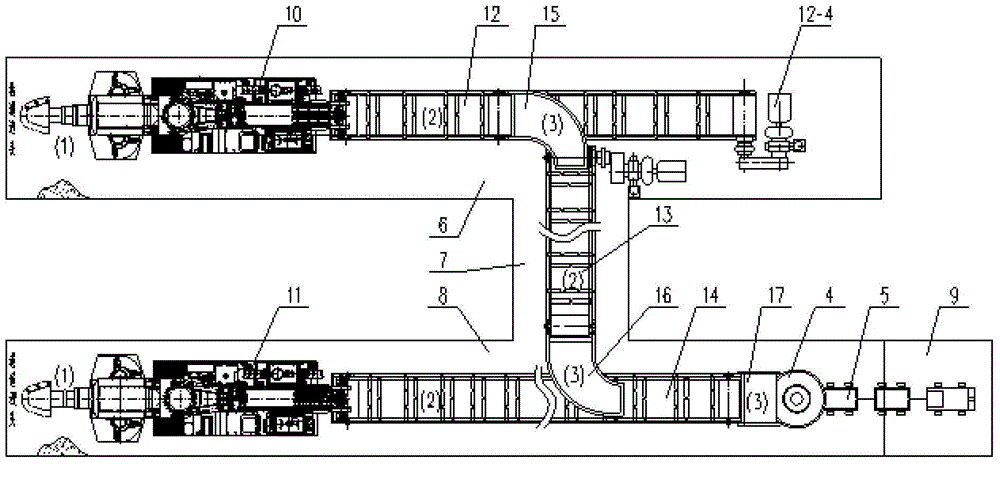

Double-roadway combining speedy drivage waste rock exhaust system and method

InactiveCN104533429AReduce excavation costsAvoid unsafe factors in operationTunnelsUnderground transportAssembly lineLeather belt

The invention discloses a double-roadway combining speedy drivage waste rock exhaust system and method, the system comprises a speedy drivage waste rock exhaust assembly line consisting of a boom-type roadheader, a belt conveyer, a waste rock transfer device, a waste rock bin and a mine car. The roadheader is arranged in a roadway I and a roadway II respectively, the roadway I is communicated with the roadway II via a middle drivage connection roadway, the roadheader is connected with the belt conveyer via a tail bracket, the waste rock that is cut down is conveyed onto the belt conveyer via a roahheader scraper chain, the waste rock transfer device is connected at a position where the belt conveyer is close to the tail in the roadway I, so as to convey the waste rock into the roadway II, the waste rock on the roadway II directly enters into the waste rock bin at the upper part of the roadway II via belt conveying, the waste rock falls into the mine car in a traveling roadway via pipeline conveying, and by means of continuous waste lock loading by the mine car, the waste rock is conveyed to the ground for unloading. The system and method adopts double-roadway simultaneous drivage, exhaust the waste rock automatically in a combined manner, have a fast waste rock exhaust speed, reduce the auxiliary operation personnel, and can effectively improve the roadway mechanization level and efficiency.

Owner:CHINA UNIV OF MINING & TECH +1

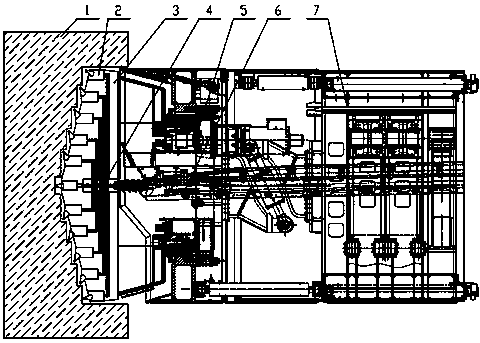

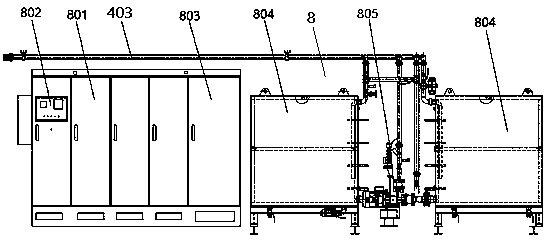

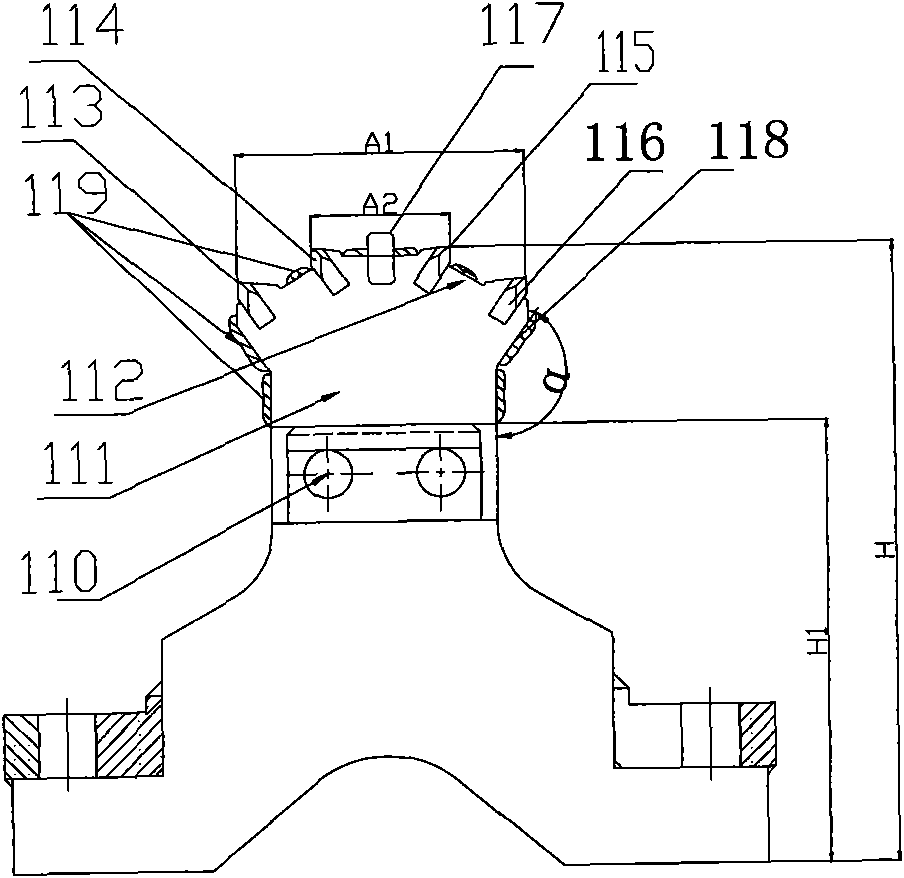

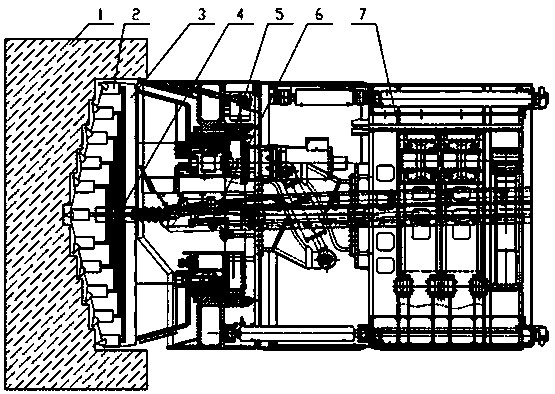

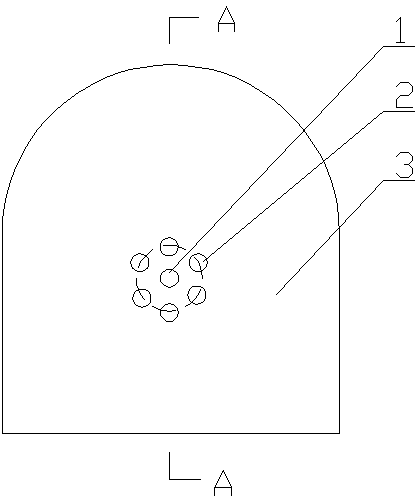

Tunneling machine using laser for rock breaking

InactiveCN108561148ASolve the problem of abnormal damage proneImprove rock breaking efficiencyTunnelsElectricitySlag

The invention discloses a tunneling machine using laser for rock breaking. The tunneling machine structurally comprises a tunneling machine host and a water and electricity output system matched withthe tunneling machine host, wherein a cutter head system is arranged at the front part of the tunneling machine host; a plurality of laser generators are uniformly arranged on a cutterhead of the cutterhead system along the movement track; the emitting ends of the laser generators form an inclined angle with the tunnel face rock in the digging position; the laser generators are connected with thewater and electricity output system through a conveying and distribution pipe of a water and electricity conveying and distribution system; the conveying and distribution pipe is a porous pipeline integrating a water pipe and an electric wire pipe; the middle part of the tunneling machine host is provided with a driving system for driving the cutterhead system; a slag discharging system matched with the cutterhead system is arranged inside the tunneling machine host; a step system is arranged on the tunneling machine host. A laser ray system is used for solving the problem that the abnormal damage can easily occur during the rock cutting by a metal cutter; the suspension cutting rock breaking is used, so that the digging efficiency is improved; the digging cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

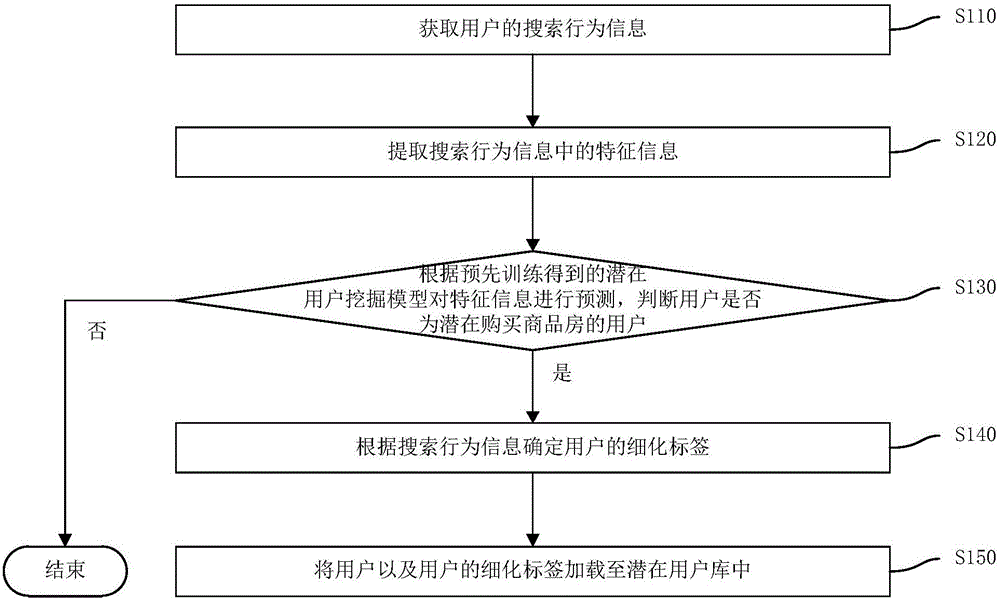

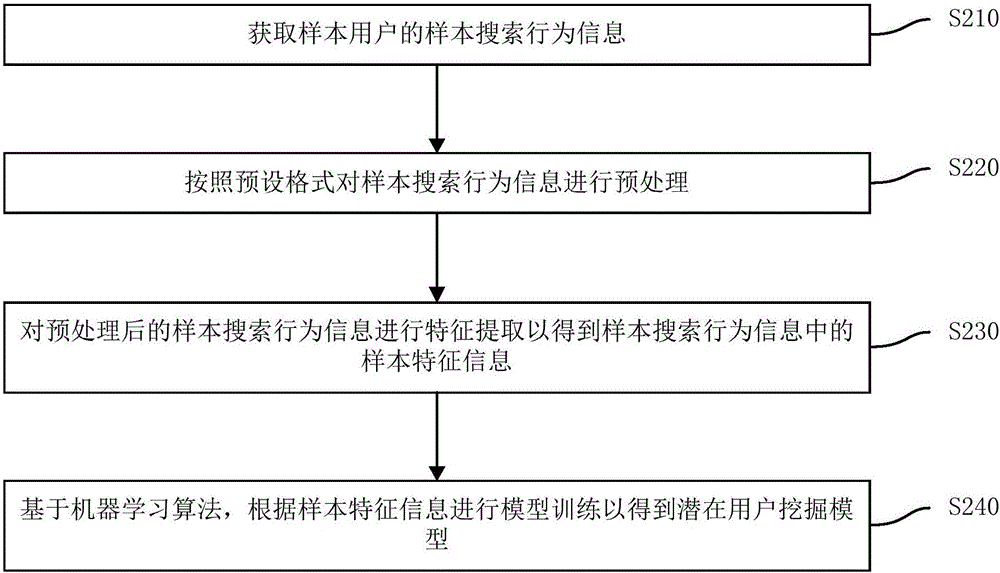

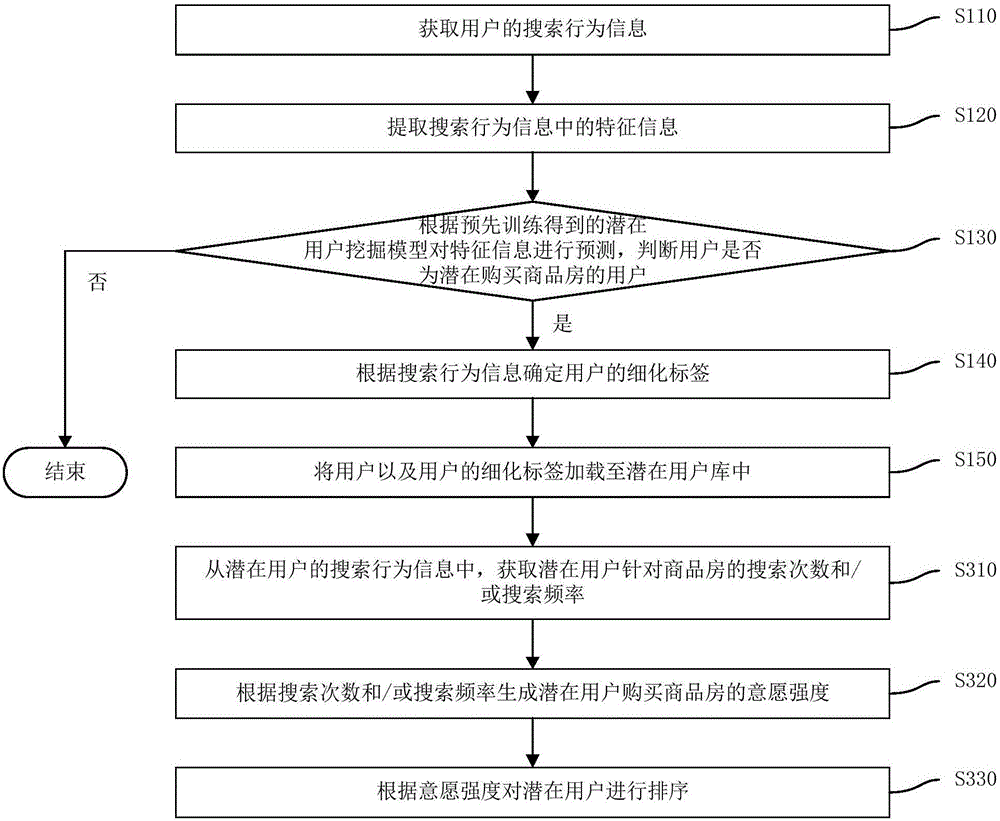

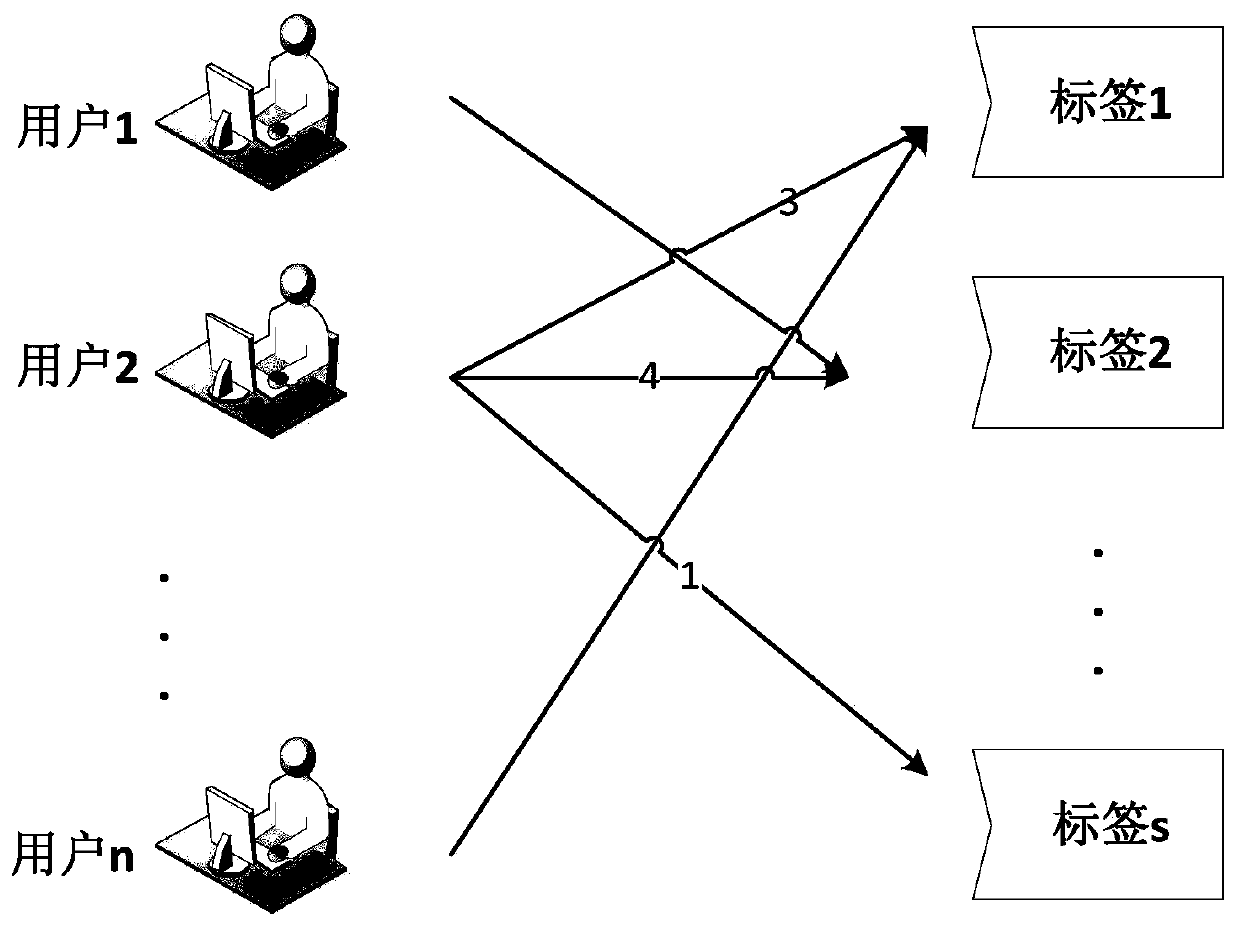

Potential client mining method and device

InactiveCN106846061AReduce excavation costsImprove interactivityWeb data indexingSpecial data processing applicationsAcquisition ratePurchasing

The invention discloses a potential client mining method and device. The method comprises the steps that searching behavior information of a user is obtained; feature information in the searching behavior information is extracted; according to a potential user mining model obtained by pre-training, the feature information is predicted, and whether or not the user is a potential user for a commodity house purchasing is judged; if yes, an elaborated tag of the user is determined according to the researching behavior information; the user and the elaborated tag of the user are loaded into a potential user library. According to the potential client mining method, the mining cost of the potential user can be significantly reduced, the interaction of the user is improved, and the acquisition rate and accuracy of the potential user are also improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

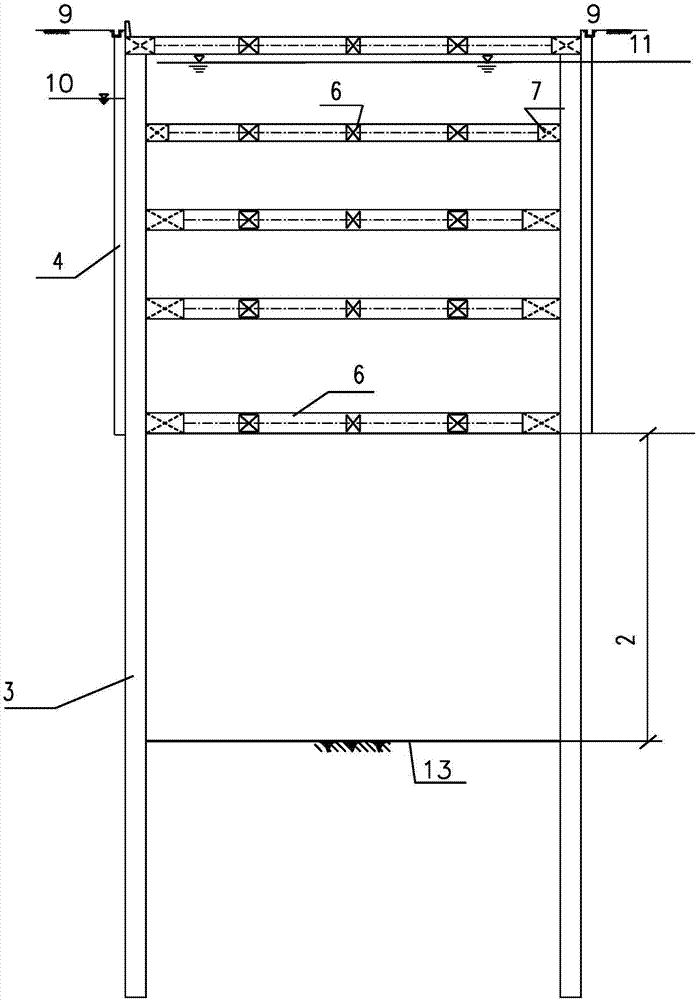

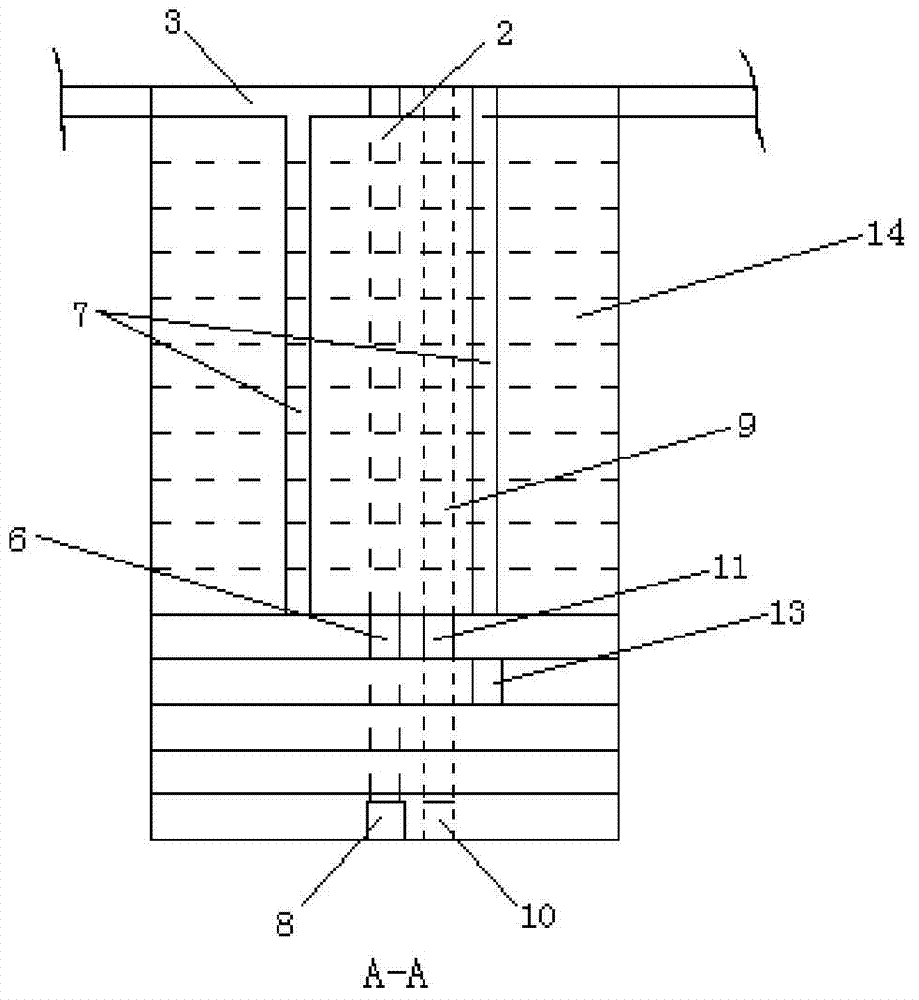

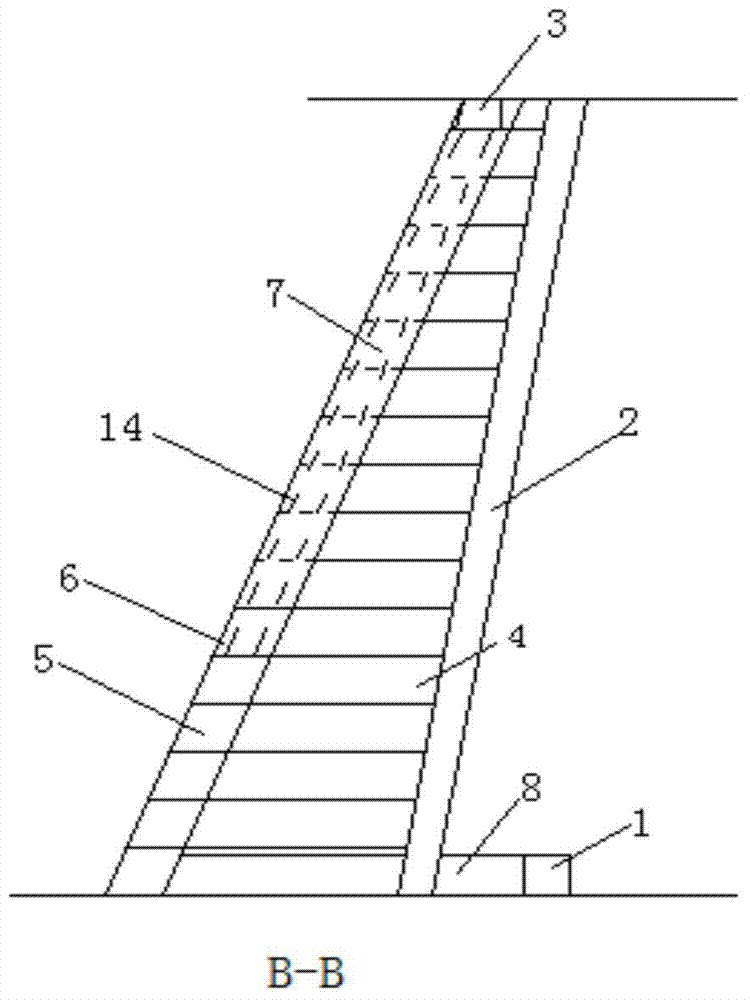

Deep foundation pit earthwork digging method

ActiveCN102425173AEnsure safetyAvoid repeated digging and fillingExcavationsBulkheads/pilesBuilding constructionSteel plates

The invention relates to a deep foundation pit earthwork digging method. The method comprises the following steps of: (1) after paying-off measurement of a deep foundation pit is finished, designing N layers of horizontal supporting steel plates according to the deep foundation pit engineering conditions in the deep foundation pit from top to bottom, and digging the foundation pit earthwork layerby layer by adopting an island type digging method, wherein N is more than or equal to 1 and less than or equal to 20; (2) downwards driving an outside steel plate pile along the wall of the deep foundation pit; and (3) digging the earthwork above the first layer of horizontal supporting steel plate, welding one end of the first layer of horizontal supporting steel plate to the outside steel plate pile, downwards driving an inside steel plate pile at the other end of first layer of the horizontal supporting steel plate and the like, constructing the Nth layer of horizontal supporting steel plate, building a ramp, digging the earthwork below the Nth layer of horizontal supporting steel plate, regressing, digging the ramp, removing the inside steel plate pile, digging the rest earthwork, and thus finishing digging the earthwork of the deep foundation pit. The construction method is simple and feasible; a trestle is not required, the construction period is effectively quickened, and the digging cost of the earthwork of the deep foundation pit is reduced; and the deep foundation pit earthwork digging method is safe and reliable.

Owner:MCC TIANGONG GROUP

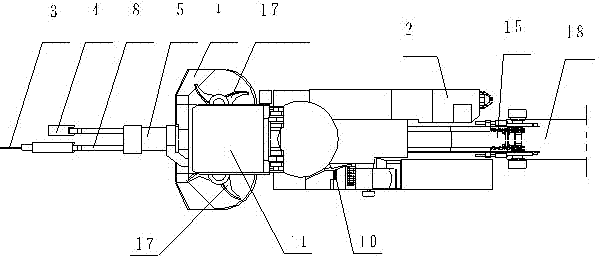

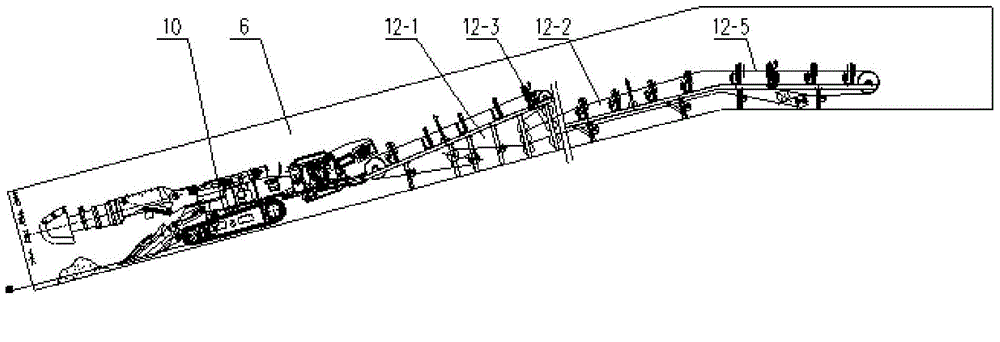

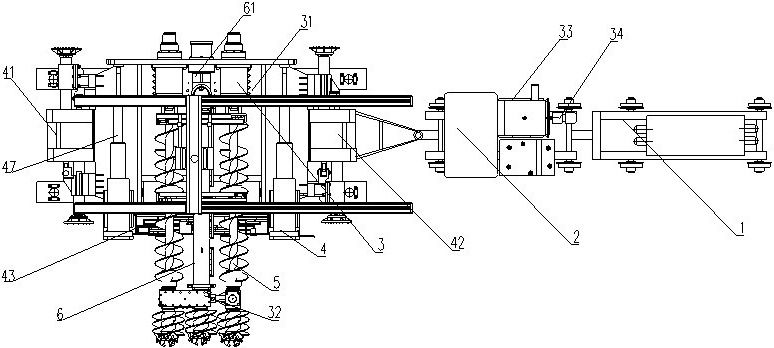

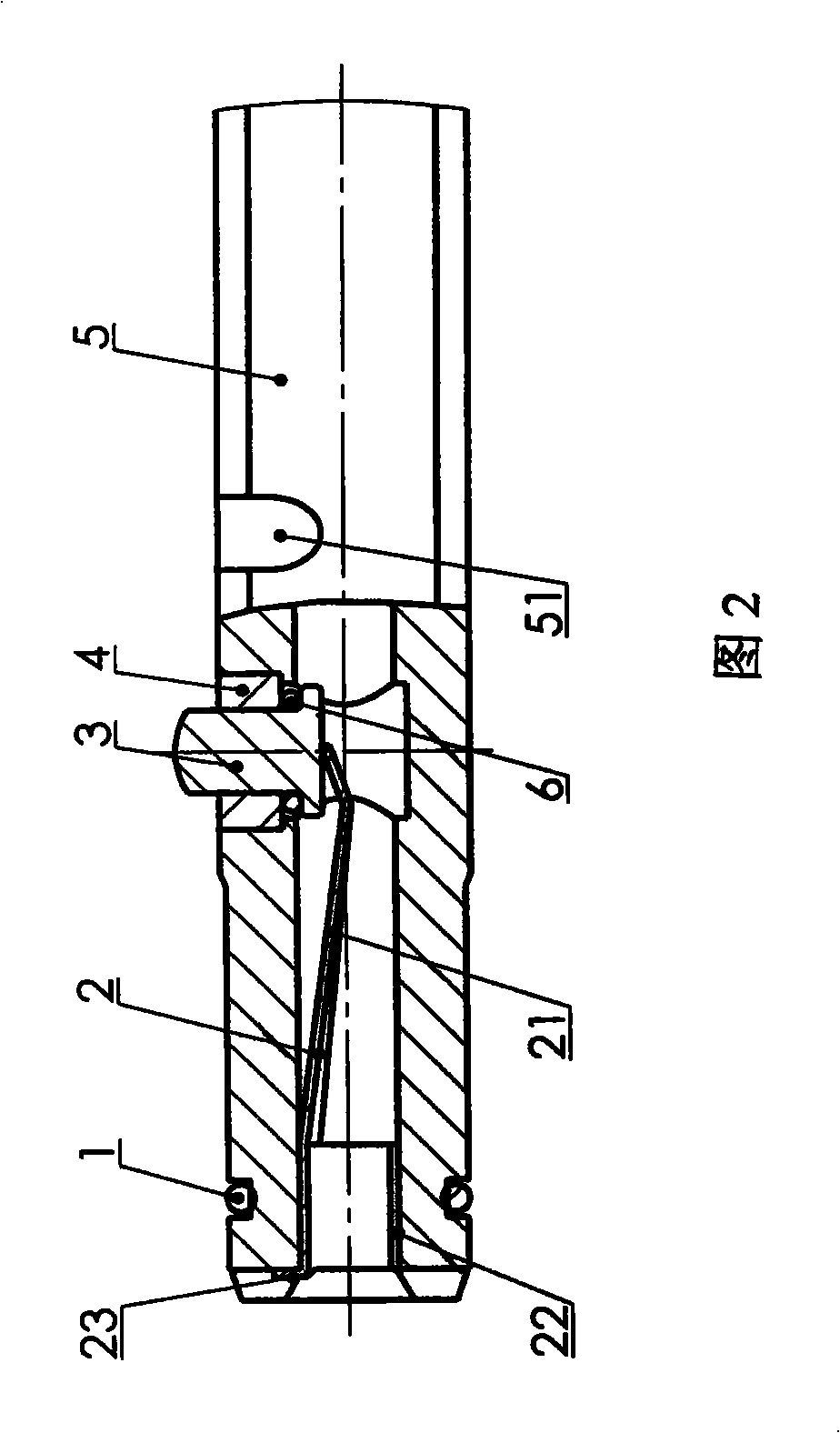

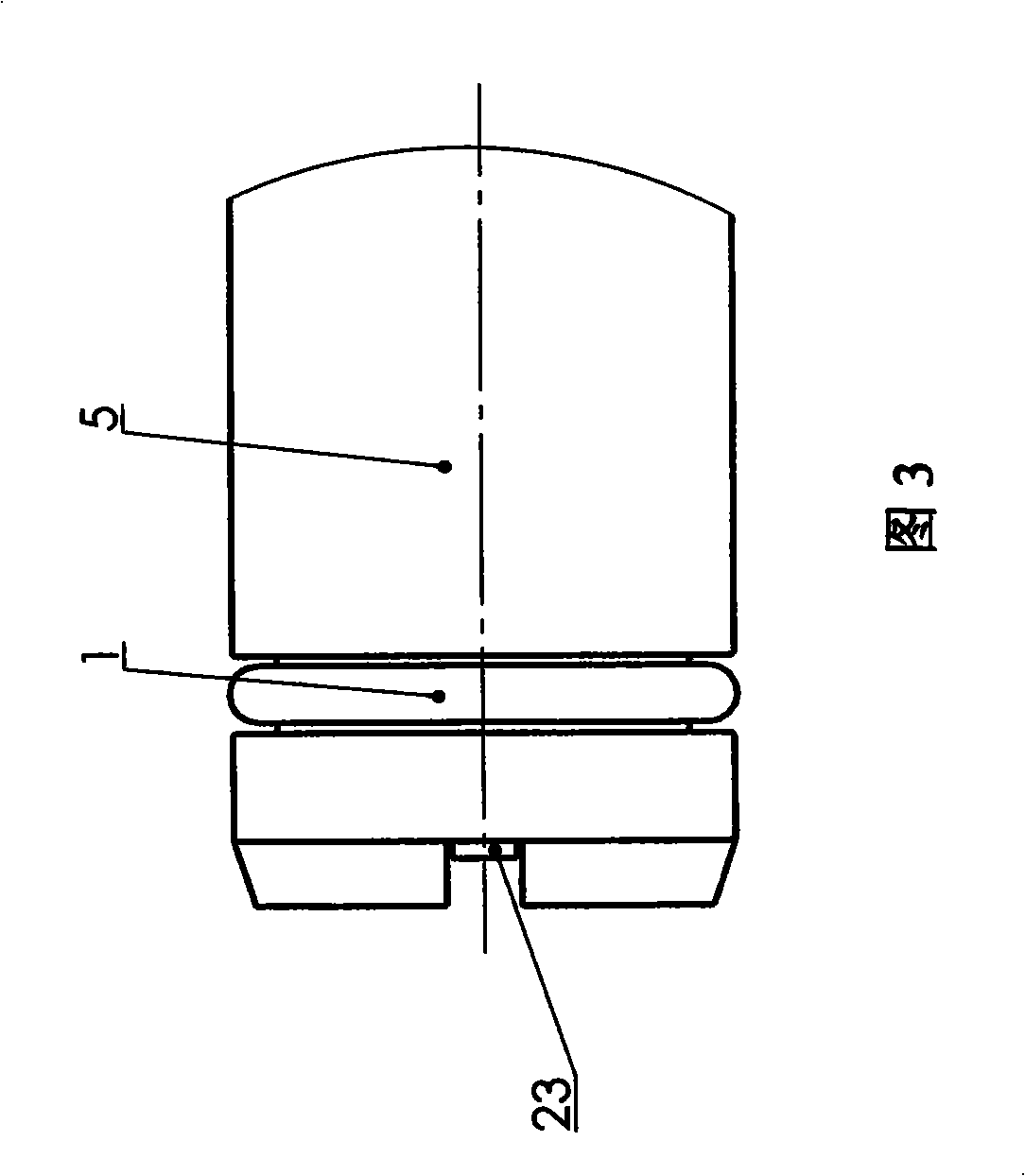

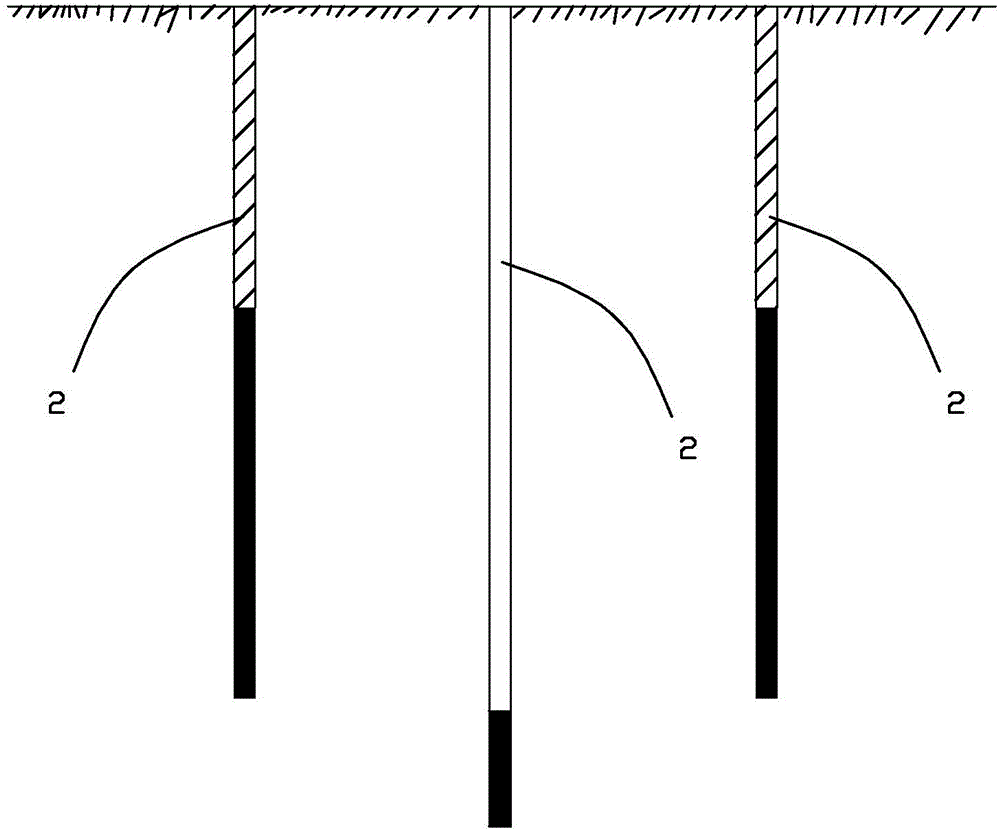

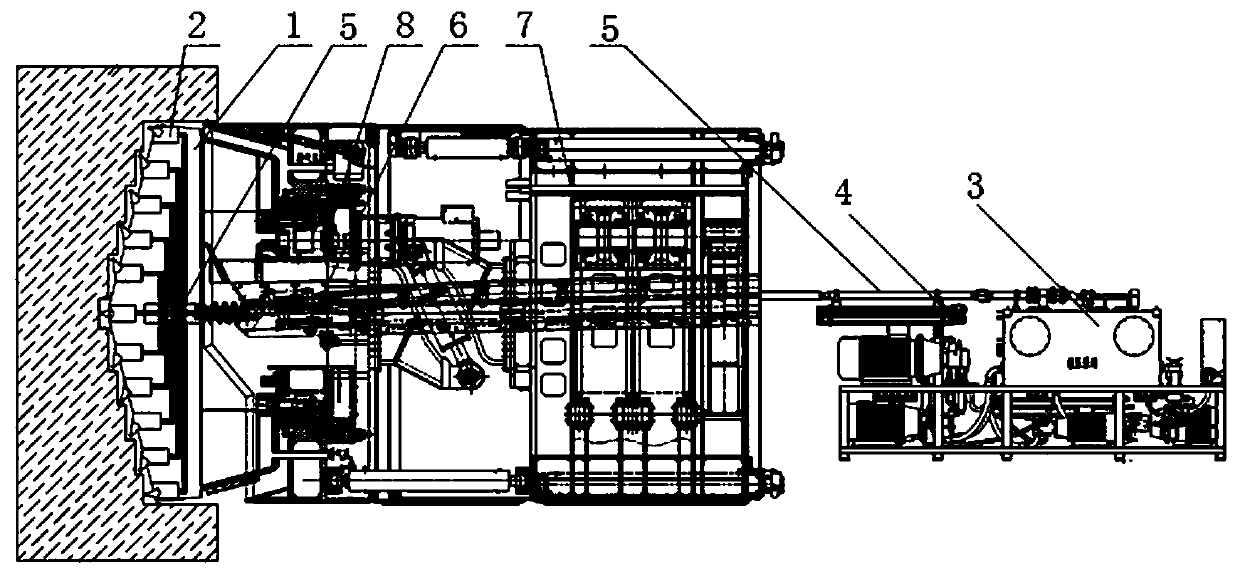

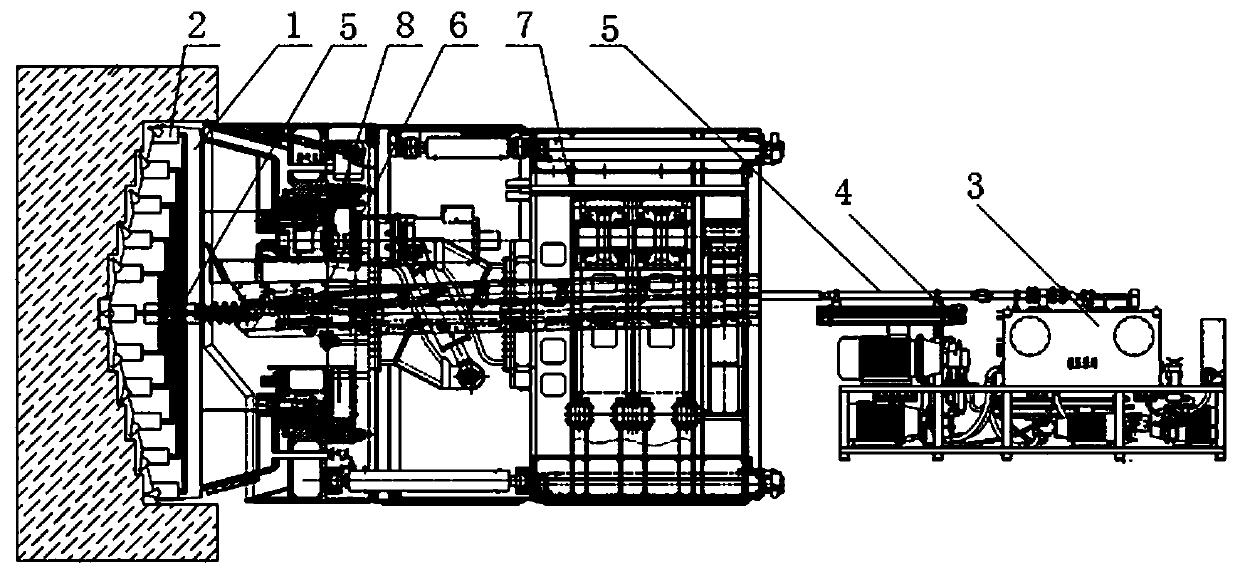

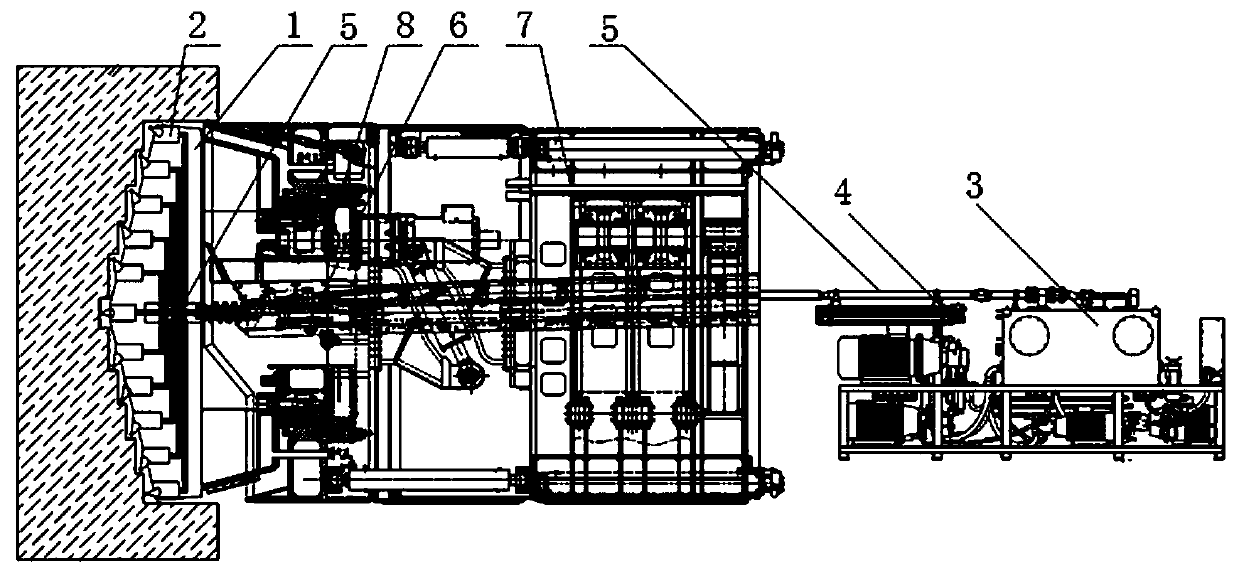

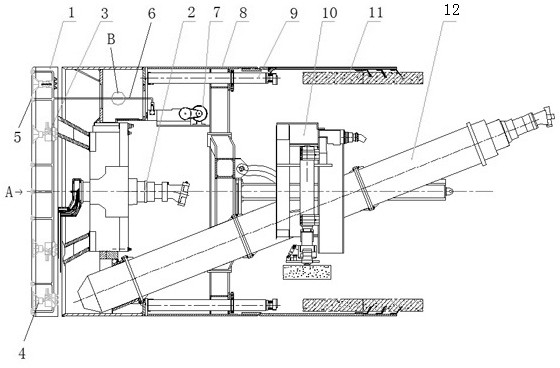

Ultralow surface full-hydraulic drill type coal mining machine

ActiveCN102168555AReduce mining costsReduce excavation costsConstructionsDerricks/mastsAgricultural engineeringDrive motor

The invention discloses an ultralow surface full-hydraulic drill type coal mining machine, belonging to the technical field of coal mining machinery. The ultralow surface full-hydraulic drill type coal mining machine comprises an electric control assembly, a hydraulic assembly, a drill assembly, a ventilating device, a transmission device and a frame, wherein the transmission device comprises a driving frame, a front moving box, a motor, a twin plunger pump and a driving motor; the motor is connected with the driving motor by the twin plunger pump; the driving motor is connected with the front moving box by an output shaft; the front moving box is connected with a drill bit; the frame comprises a left side frame, a right side frame, a front frame and a connecting beam; the left side frame and the right side frame are connected with the connecting beam by using high-strength bolts; and the front frame is connected with the left side frame and the right side frame by using pin shafts. The ultralow surface full-hydraulic drill type coal mining machine disclosed by the invention has the advantages of reducing the height of the whole machine, reducing roadway excavation cost, extracting coal rocks without damaging a bottom plate, increasing the utilization rate of coal resources and reducing the cost per ton of mined coal.

Owner:国科中迈(徐州)能源科技有限公司

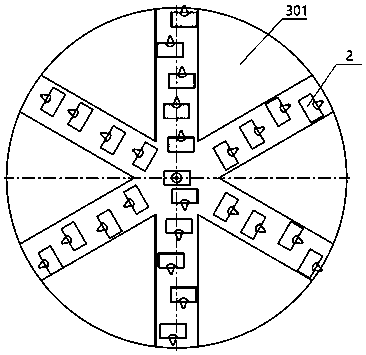

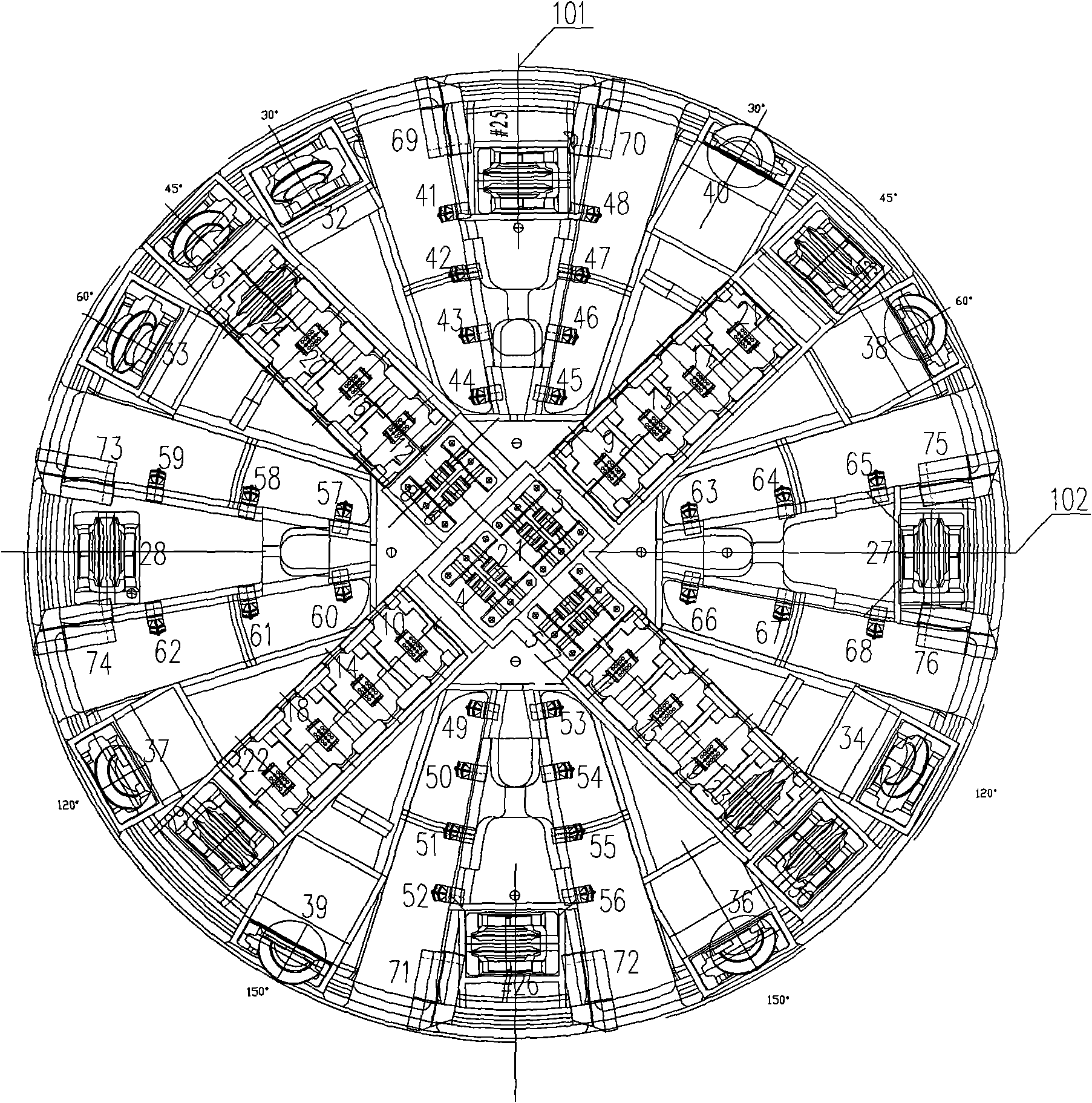

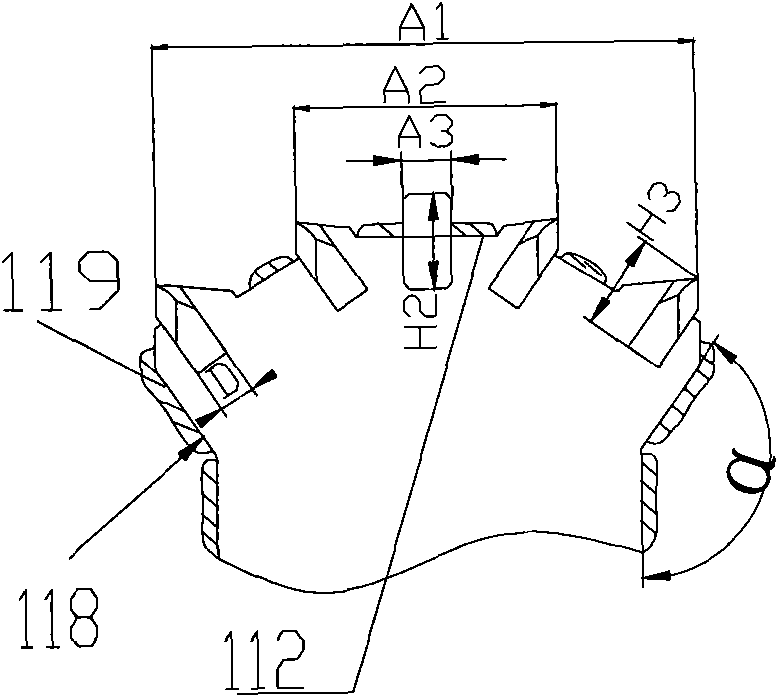

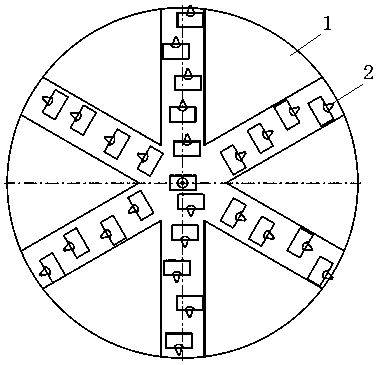

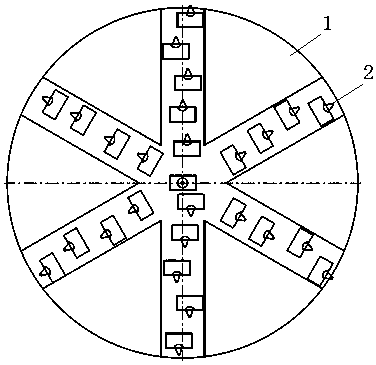

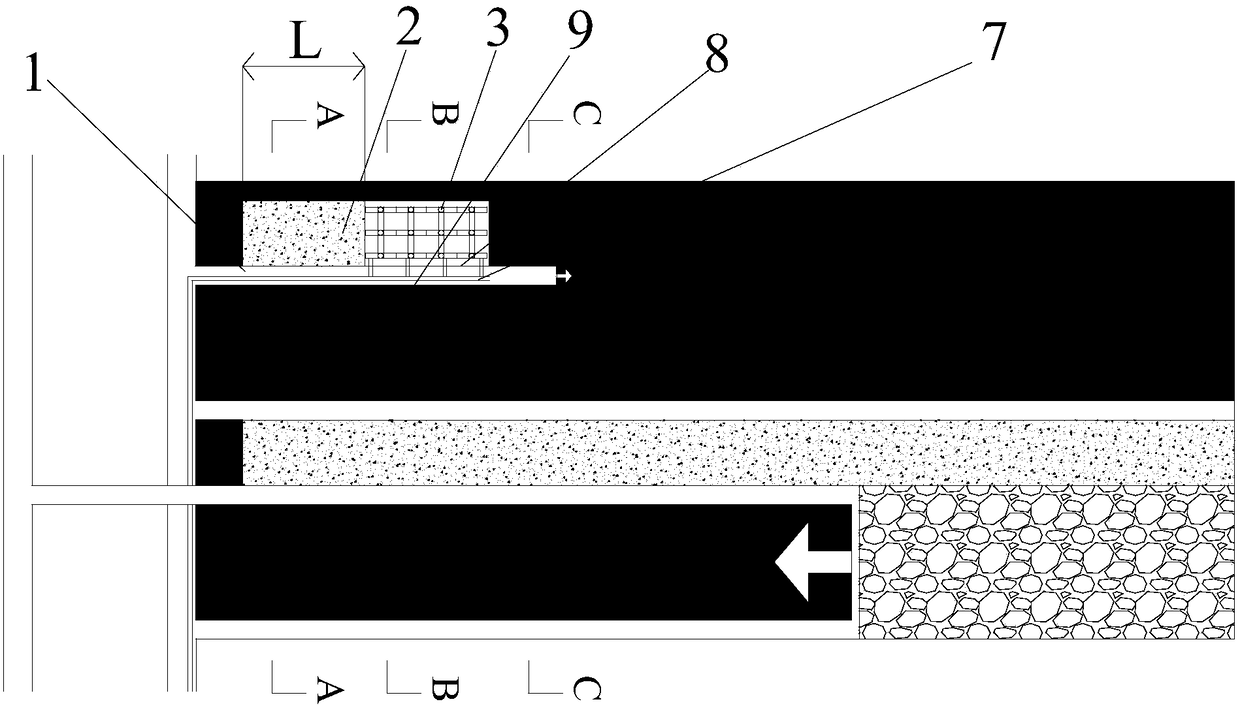

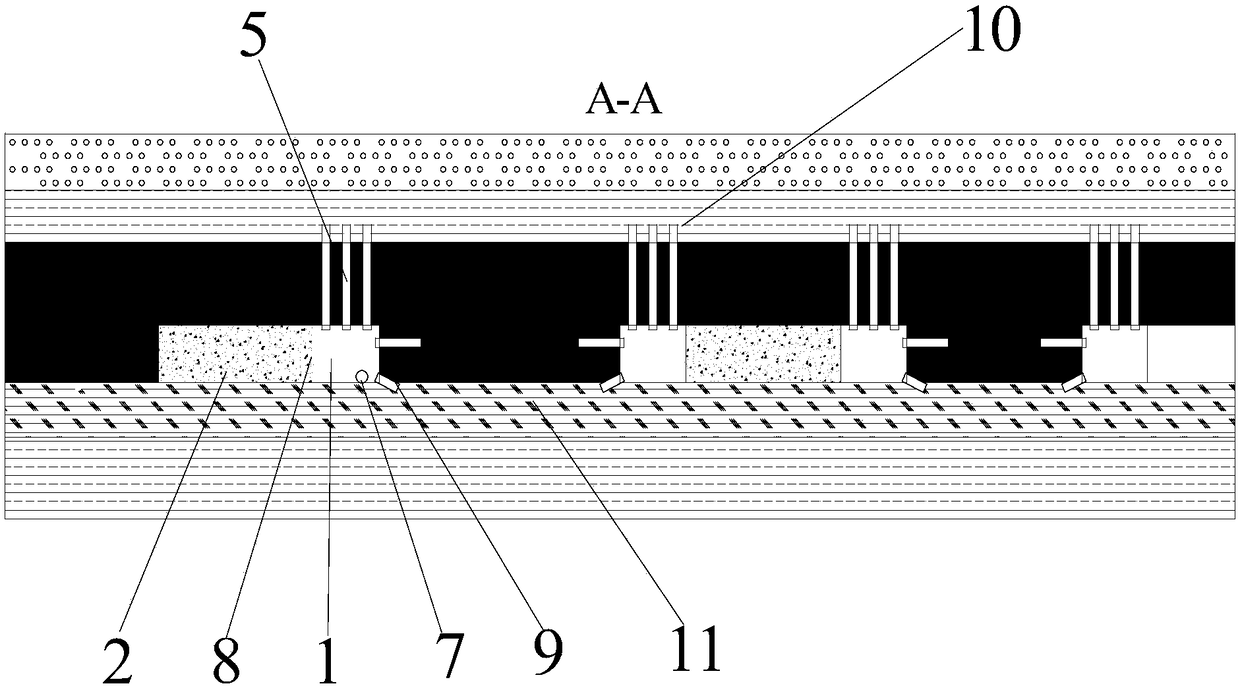

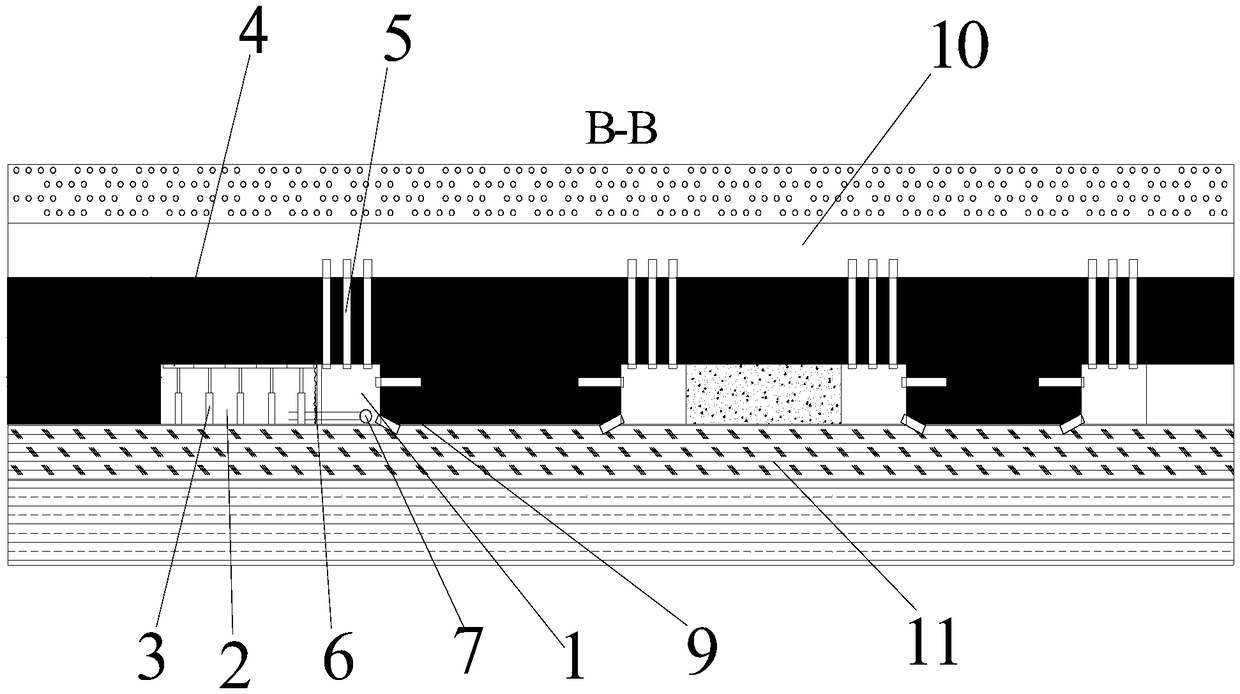

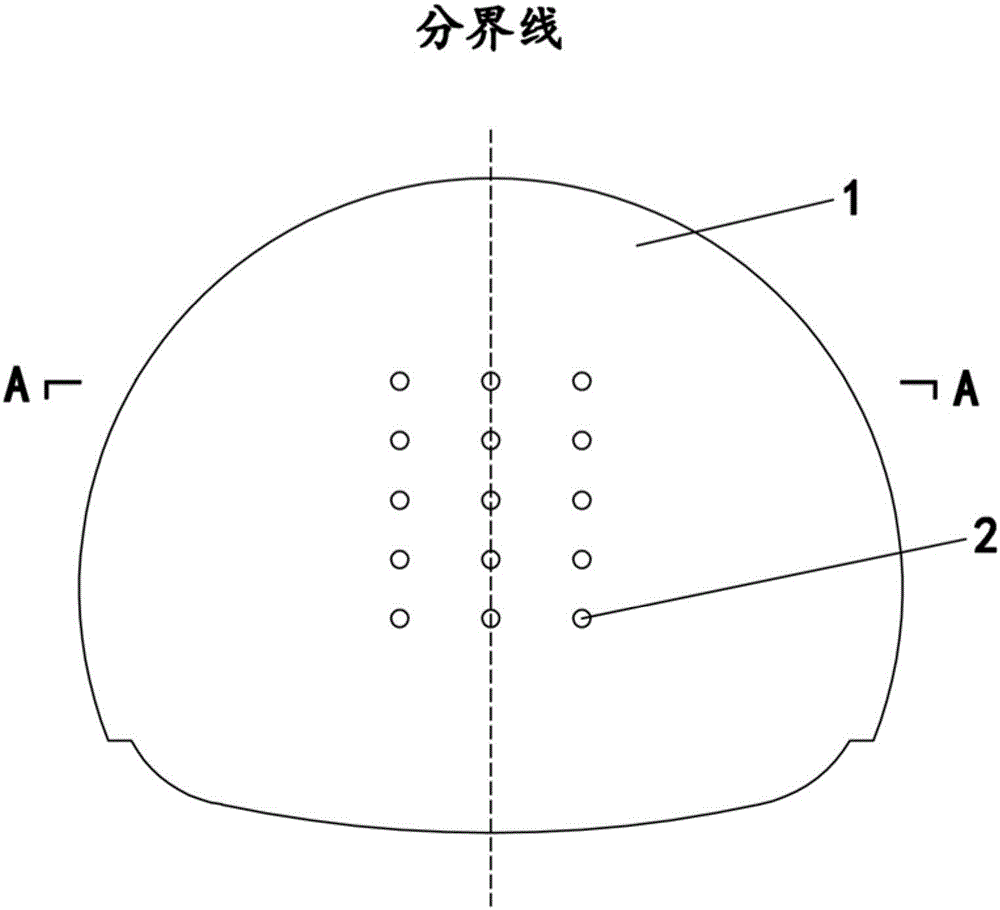

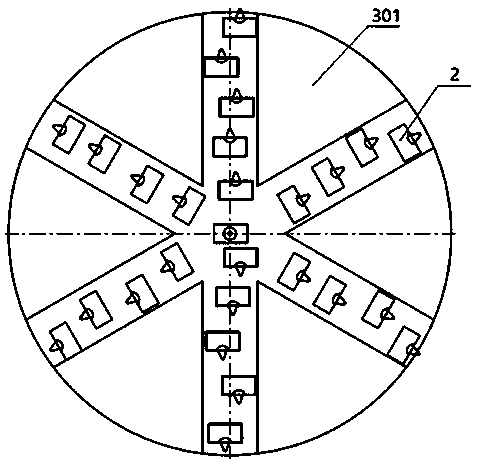

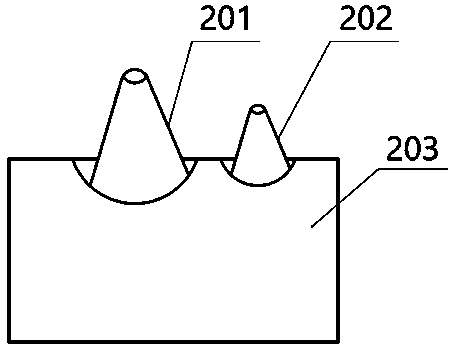

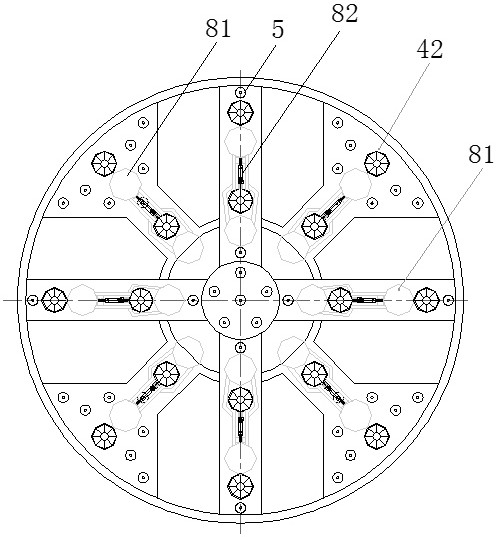

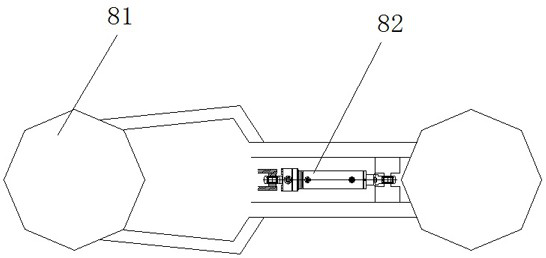

Earth pressure balance shield machine cutterhead

The invention discloses an earth pressure balance shield machine cutterhead. The surface of the cutterhead comprises a central area, a facial area and a marginal area, wherein each two-edged serrated cutter arranged on No. 1 to No. 8 cutter seats comprises two cutter bodies and two cutter heads fixedly connected on the cutter bodies, wherein the top face of each cutter head adopts the higher-middle and lower-side structure by gradually raising areas from both sides to the middle parts; the upper part of each side face of the cutter head is an externally expanded inclined face; the middle part of the top face is fixedly connected with a strip-shaped hard alloy, and the top faces of both sides of the strip-shaped hard alloy are fixedly connected with four rows of symmetrically distributed hard alloy column teeth; height differences are respectively formed between the tops of the hard alloy column teeth and the top of the strip-shaped hard alloy; and abrasion proof overlaying welding layers are fixedly connected with the peripheral top faces and the side faces of the strip-shaped hard alloy and the hard alloy column teeth. The cutterhead provided with the structure of the invention can increase advance rate, reduce abrasion and prolong service lives of the cutters, and reduce advancing cost under the circumstance of water-rich sandy cobble strata.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

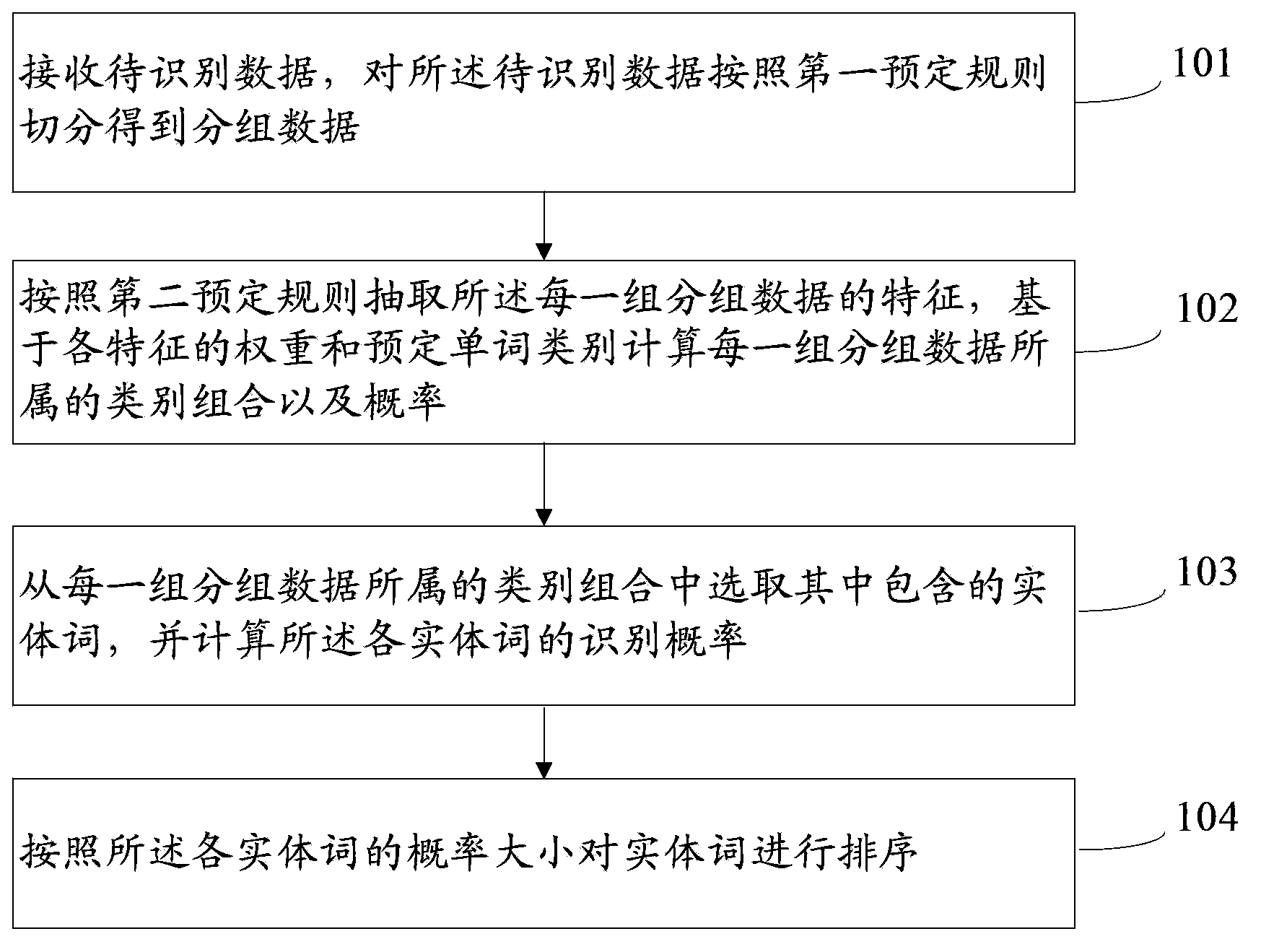

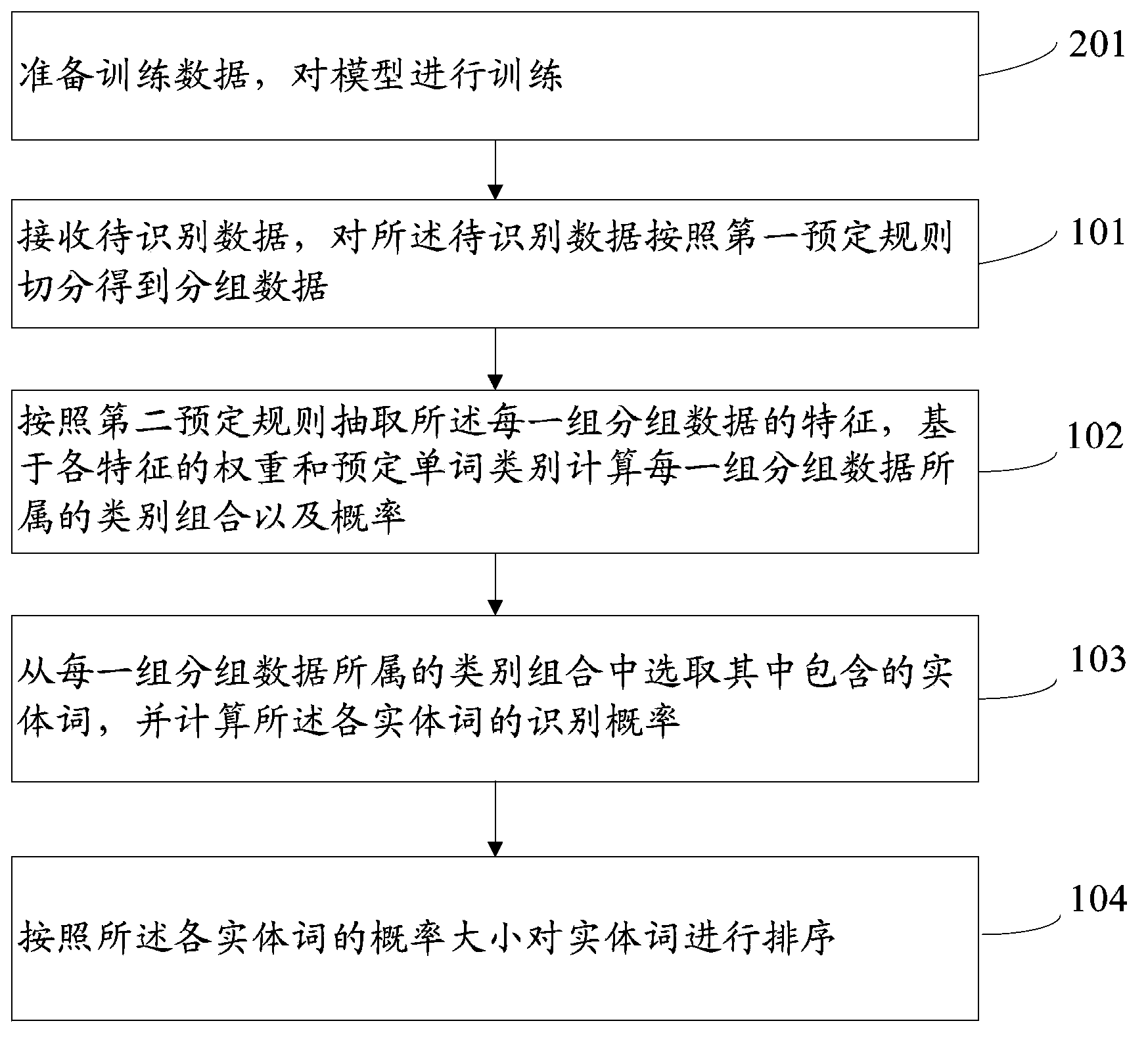

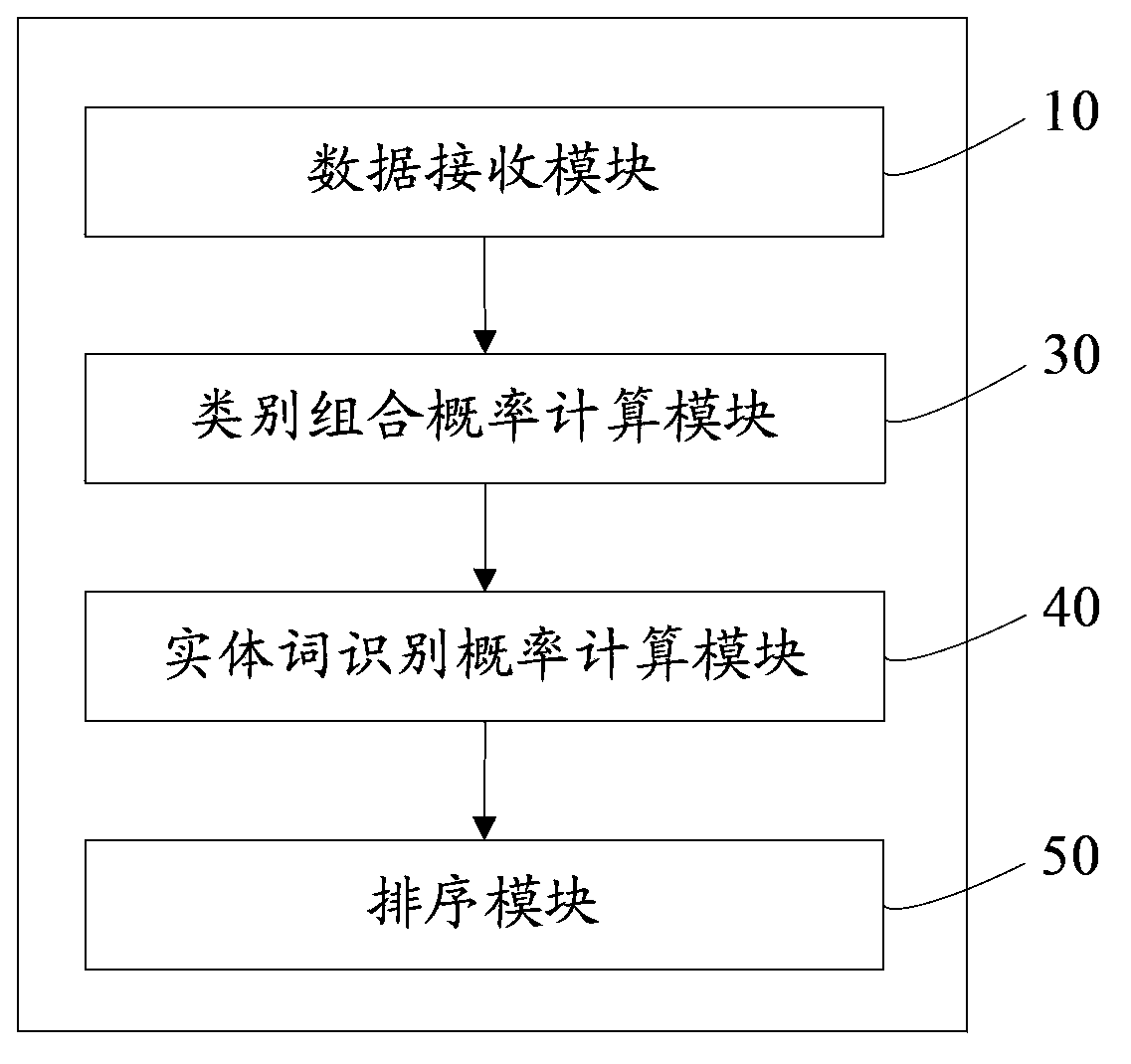

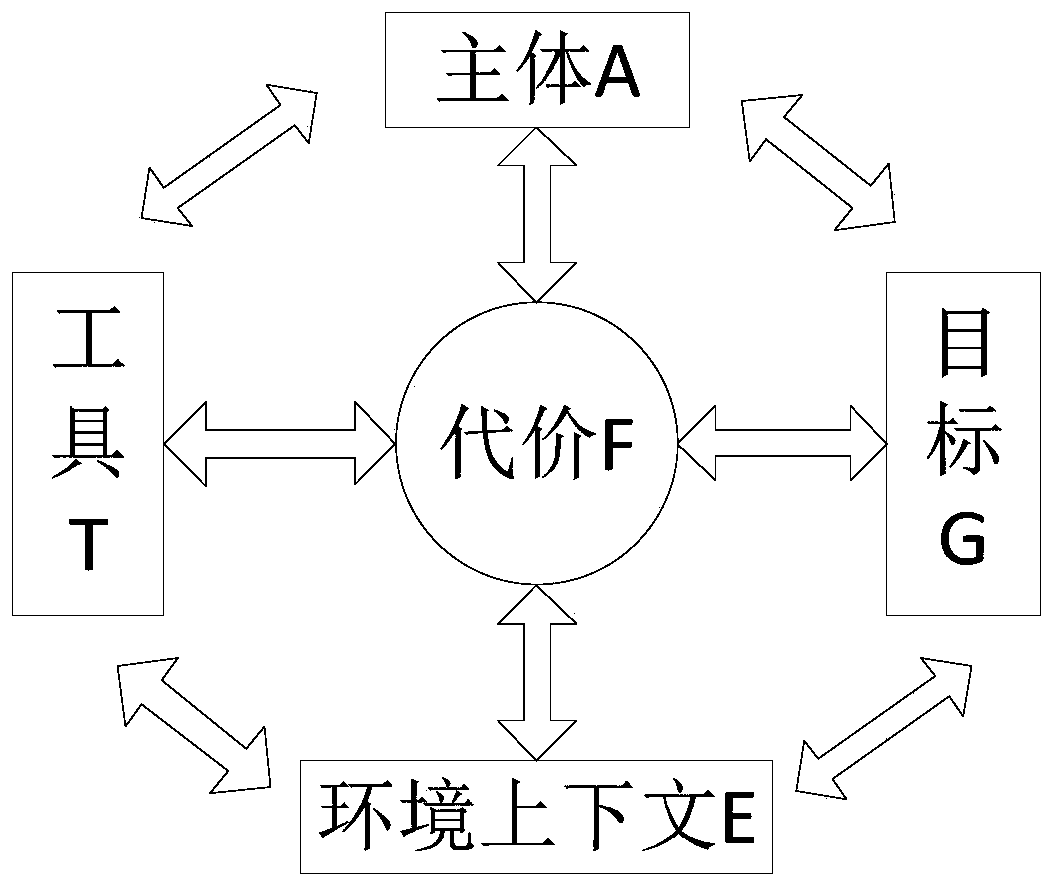

Method and device for identifying entity words

ActiveCN103678336AQuick identificationTimely updateNatural language data processingSpecial data processing applicationsIdentification deviceData mining

Owner:ALIBABA GRP HLDG LTD

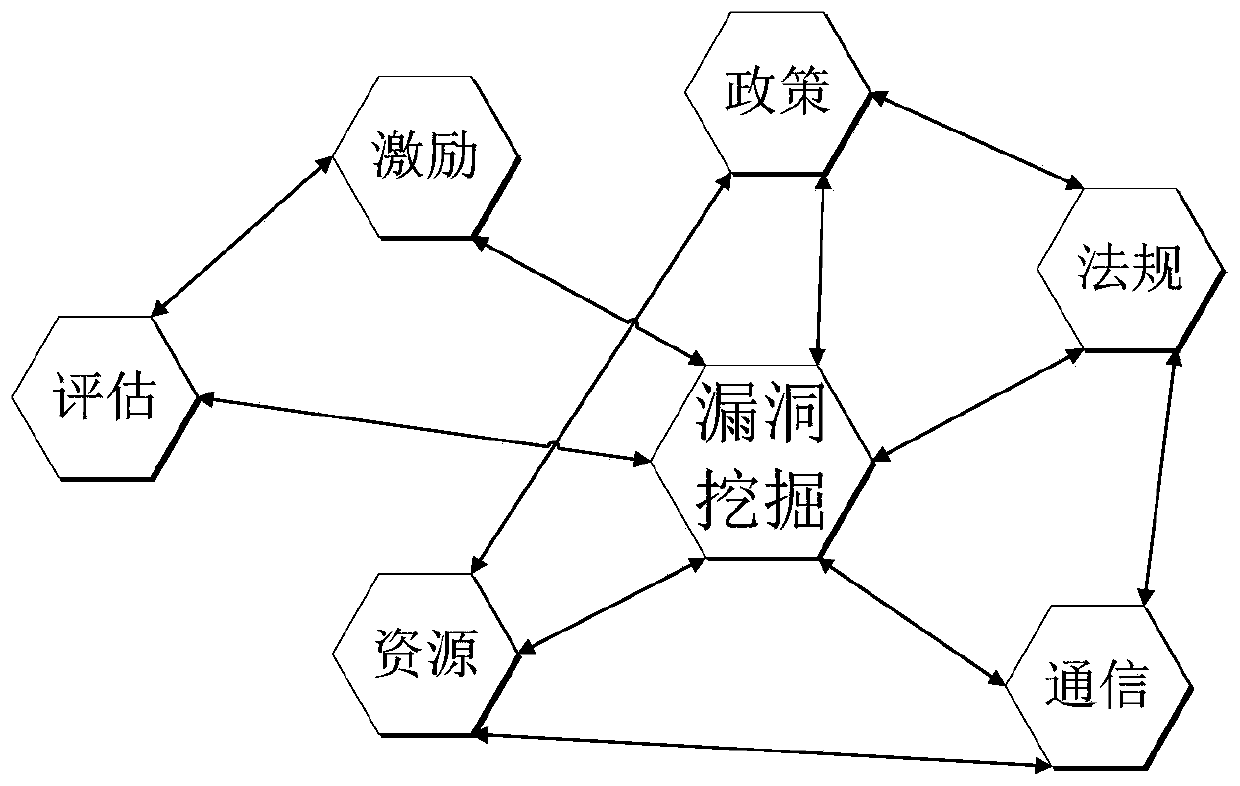

Vulnerability mining model construction method based on swarm intelligence

ActiveCN110708279AImprove digging efficiencyReduce excavation costsPlatform integrity maintainanceTransmissionCrowd sourcingEngineering

The invention discloses a vulnerability mining model construction method based on swarm intelligence. The vulnerability mining model construction method comprises the following steps: step 1, modelinga user individual; step 2, performing intelligent decomposition on a vulnerability mining task based on a vulnerability mining scene; 3, solving an optimal vulnerability mining path; and step 4, gathering and fusing crowd sourcing vulnerability mining results and establishing a feedback learning model. Compared with the prior art, the invention has the advantages that: the invention has positiveeffects; the model reflects crowd-sourcing concepts such as crowd collaboration, machine collaboration, computing resource collaboration and tool sharing; the method has the advantages of natural high-concurrency capability, rapid and efficient search and solution capability, extremely strong environmental adaptability, high robustness and self-recovery capability, strong expandability and high flexibility, the vulnerability mining efficiency is effectively improved, and the vulnerability mining cost is reduced.

Owner:CHINA ELECTRONICS TECH CYBER SECURITY CO LTD

Waste filling thin coal seam tunnelling method

InactiveCN101021153AReduce roadway excavation costsReduce waste rock outputUnderground miningSurface miningCoal gangueMining engineering

The present invention relates to a tunneling method by filling thin coal layer with coal gangue. Said method is characterized by that after the tunnel meeting production requirements is excavated in the thin coal layer zone, the width of said tunnel section is 1.5-2 m, at two sides of said tunnel a coal layer whose length is less than 12 m is respectively excavated along the thin coal layer, then the obtained coal body space can be filled up with coal gangue obtained by tunneling, if necessary, the filled coal gangue can be grouted.

Owner:CHINA UNIV OF MINING & TECH

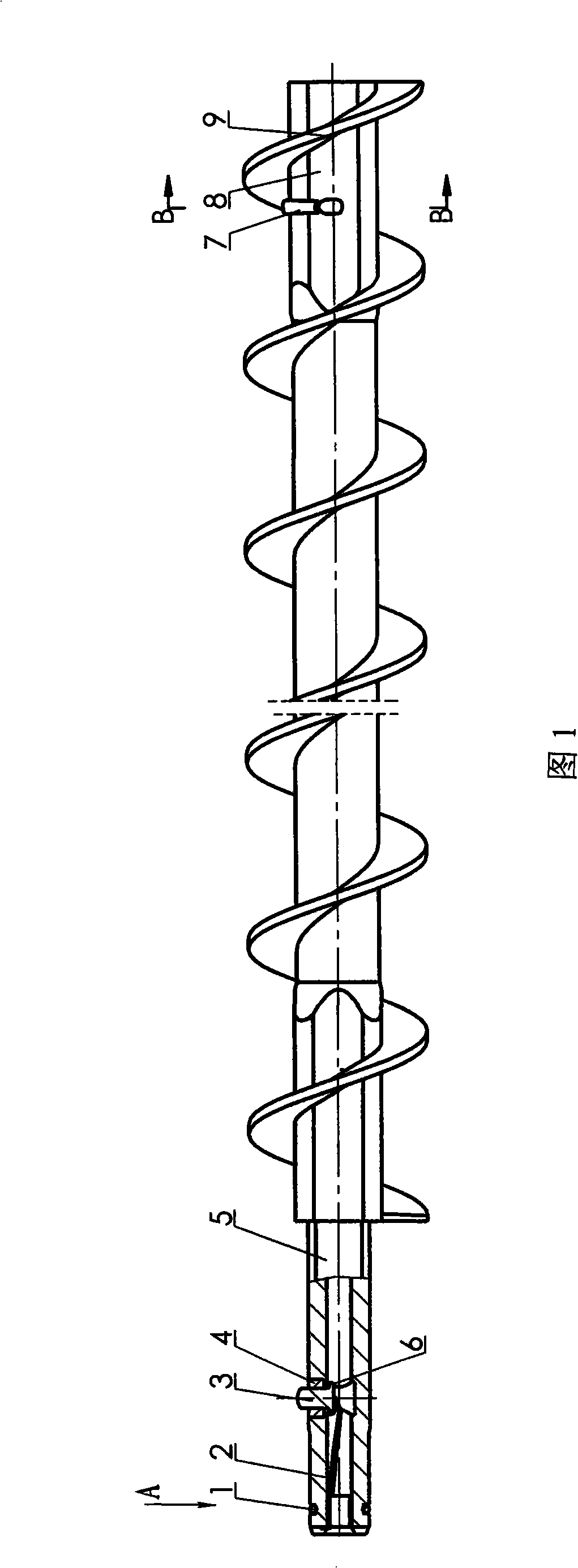

High-efficiency helical water-through jackrod

InactiveCN101294481AImprove water flow capacityImprove ventilationDrilling rodsDrilling casingsWorking environmentGas passing

The invention discloses an efficient water spiral drill pipe which comprises a plurality of drill pipe units. Each drill pipe unit comprises a drill pipe core, a spiral body, a tetragonal rod, a retaining ring, a lateral pin and a spring body which supports the lateral pin for splicing-positioning and connecting two adjacent drill pipe units into one body. The spring body of each drill pipe unit is provide with a cylindrical connector which is nested and clamped in a water and gas vent at the end of the tetragonal rod of the drill pipe unit, a bending knob which is connected with the connector into one body and is clamped in the end groove of the tetragonal rod, and a flat spring which is connected with the connector into one body and is inclined in the water and gas vent of the tetragonal rod; and the tail of the flat spring bends upwards for supporting the bottom end of the lateral pin on the tetragonal rod. The drill pipe has little possibility of blockage, solves the problem that drill pipe is difficult for water and gas passing through, and effectively reduces the occurrence of hole collapse, drill pipe sticking and drill pipe losing, and improves the working environment by reducing coal dust. The drill pipe has the advantages of wide application, high drilling efficiency and reduced drilling cost.

Owner:HEBEI JIKAI IND GRP +1

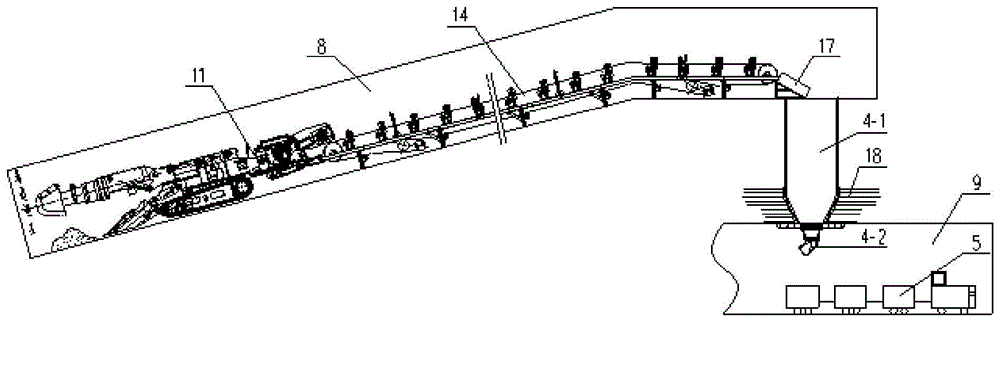

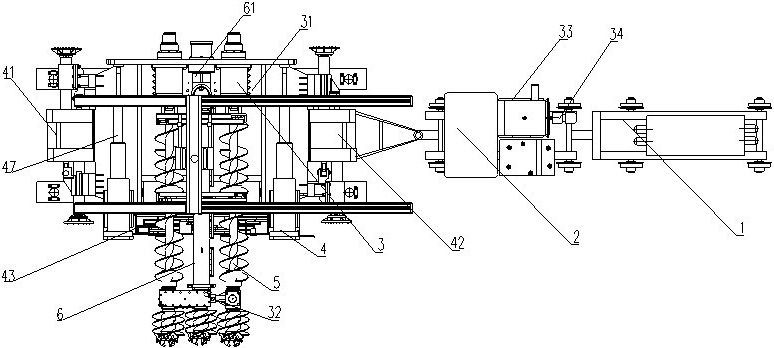

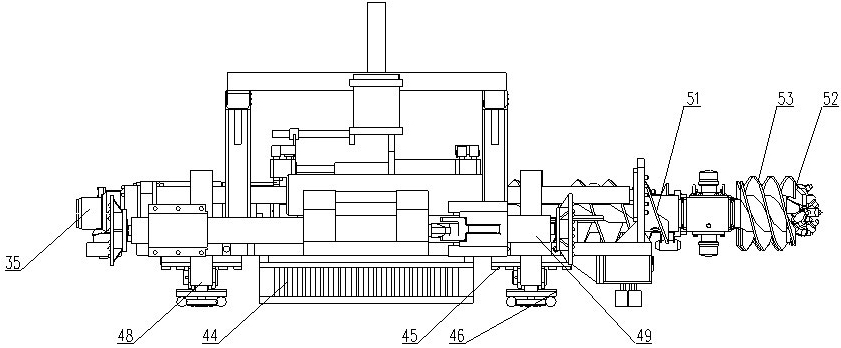

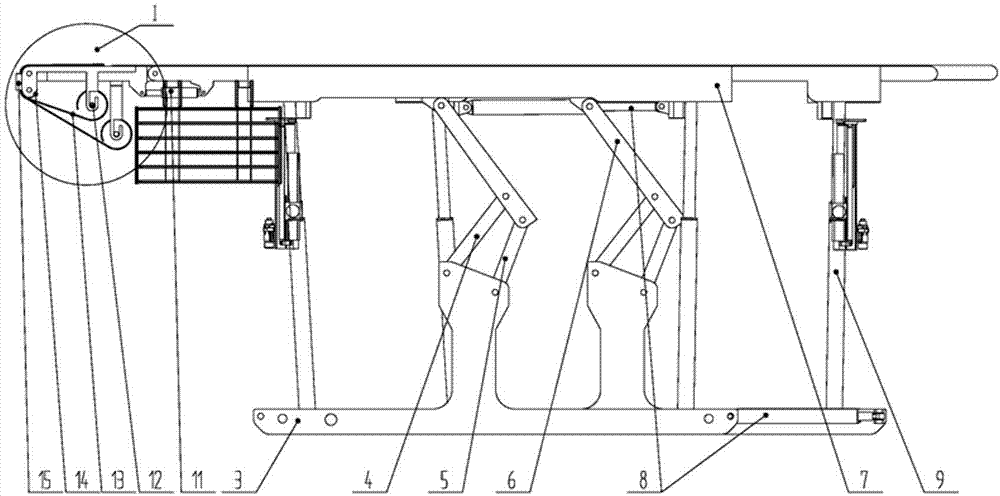

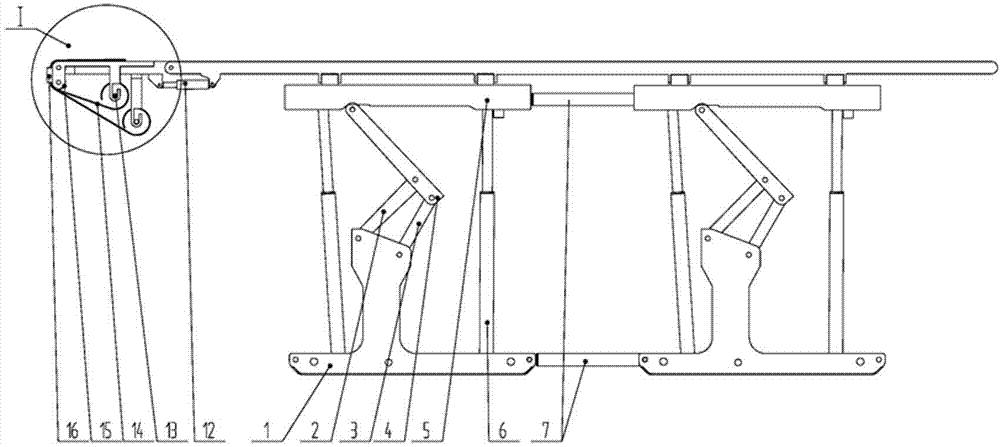

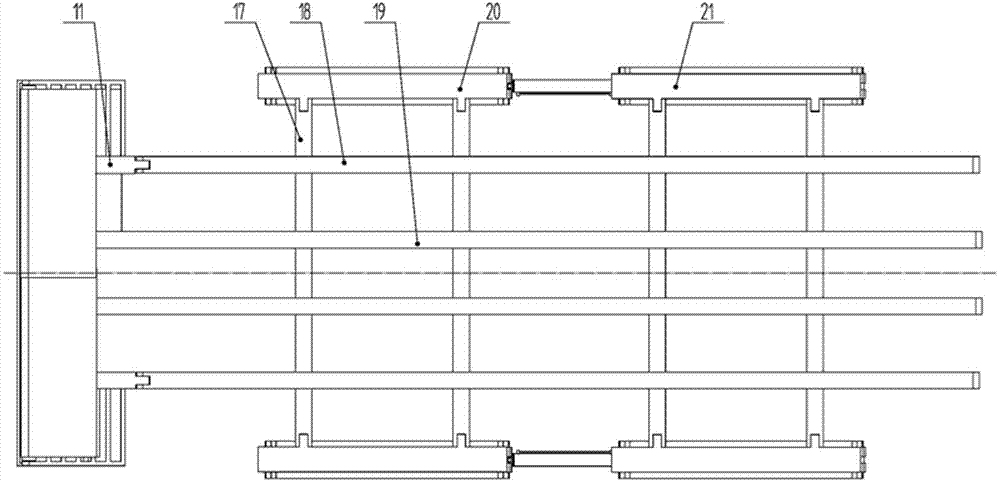

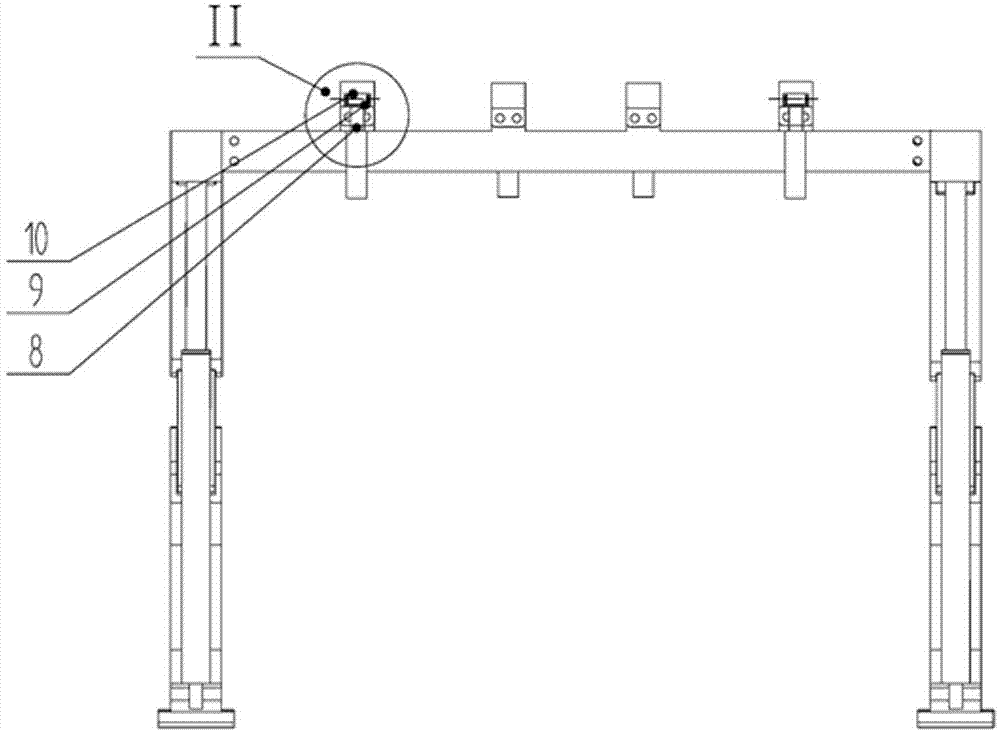

Automatic bolt mesh laying step type temporary support for fully mechanized excavation faces

ActiveCN104278999AReduce labor intensityEnsure safetyUnderground chambersMine roof supportsEngineeringHeight difference

The invention belongs to the technical field of temporary supports for underground fully mechanized excavation faces of coal mines, and particularly relates to an automatic bolt mesh laying step type temporary support for fully mechanized excavation faces, which solves the current problem that the efficiency of high-performance excavators cannot be sufficiently exerted because excavation, temporary supporting and bolting cannot be carried out synchronously. The automatic bolt mesh laying step type temporary support for fully mechanized excavation faces comprises an inner support assembly and an outer support assembly, the inner support assembly and the outer support assembly respectively comprise a left support and a right support, the left support and right support of the inner support assembly are arranged at the inner sides of the left support and right support of the outer support assembly, a height difference exists between the tops of crossbeams and the bottoms of longitudinal beams of one set of support assembly, and carrier rollers are arranged at positions where the tops of the crossbeams correspond to the bottoms of longitudinal beams of the other set of support assembly. Excavation, temporary supporting, bolt mesh laying, bolt mesh connection and bolting can be carried out synchronously, the labor intensity of workers is decreased greatly, the efficiency of excavation is increased, a working face can be supported in time, and a powerful guarantee is provided for the safety of operating personnel.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

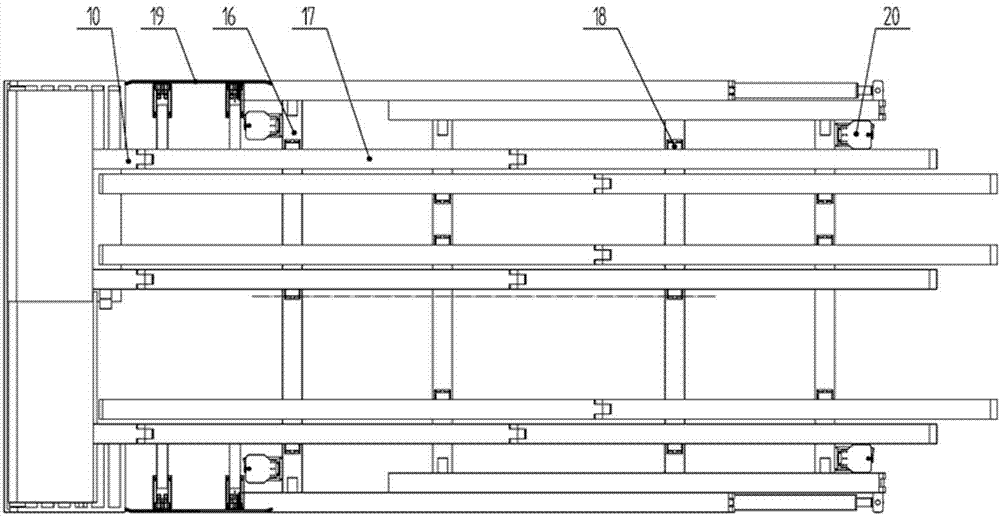

Automatic bolt mesh laying and connection excavation temporary support device

ActiveCN104279000AImprove driving speed and productivityReduce labor intensityUnderground chambersMine roof supportsCoalPush pull

The invention belongs to the technical field of temporary supports for underground fully mechanized excavation faces of coal mines, and particularly relates to an automatic bolt mesh laying and connection excavation temporary support device, which solves the current problem that the efficiency of high-performance excavators cannot be sufficiently exerted due to the frequent occurrence of injuries caused by waste rocks dropping from roofs. The automatic bolt mesh laying and connection excavation temporary support device comprises a front support assembly and a rear support assembly, the front support assembly and the rear support assembly respectively comprise a left support and a right support, an automatic bolt mesh laying mechanism and an automatic bolt mesh connection device are arranged on the front ends of longitudinal beams of the front support assembly, the left and right bases and left and right top beams of the front support assembly and the rear support assembly are respectively connected through push-pull cylinders, a height difference exists between the tops of crossbeams and the bottoms of the longitudinal beams of one set of support assembly fixedly connected with the crossbeams, and liftable carrier rollers are arranged at positions where the tops of the crossbeams correspond to the bottoms of the longitudinal beams of the other set of support assembly. Supporting and bolt mesh laying can be carried out synchronously, the labor intensity of workers is decreased greatly, the efficiency of excavation is increased, a working face can be supported in time, and a powerful guarantee is provided for the safety of operating personnel.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

High-pressure-bearing square deep foundation pit applicable to water-rich sand gravel stratum and excavation method of high-pressure-bearing square deep foundation pit

ActiveCN107119691ASolve the problem that the excavation cannot be dewatered and drainedSolve the problem that excavation is feasible but has many defectsProtective foundationExcavationsReinforced concreteRebar

The invention discloses a high-pressure-bearing square deep foundation pit applicable to a water-rich sand gravel stratum and an excavation method of the high-pressure-bearing square deep foundation pit. The foundation pit comprises a dewatering excavation area on the upper portion of the foundation pit and a water entrainment excavation area on the lower portion of the foundation pit. A dewatering well is arranged in the dewatering excavation area. A pit external groove sidewall reinforcing device and a pit internal groove sidewall reinforcing device are arranged inside and outside a diaphragm wall of the whole dewatering excavation area correspondingly. The whole dewatering excavation area is further provided with at least two reinforced concrete waist supporting beams and reinforced concrete supports. The water entrainment excavation area is provided with muddy water sucking equipment and filtered water recharge equipment, and multiple stages of settling ponds are arranged outside the foundation pit correspondingly. The stepped excavation method that the reinforced concrete supports are arranged and unwatering excavation is adopted on the upper portion and water entrainment excavation is adopted on the lower portion is adopted. The construction quality of the diaphragm wall is effectively ensured, the probability that water seepage, water burst and sand burst appear in the diaphragm wall is lowered, the excavation safety of the foundation pit is ensured, the excavation schedule of the foundation pit is accelerated, and the excavation cost of the foundation pit is reduced.

Owner:中交(南京)建设有限公司

Medium-length hole blasting and cutting method in underground construction

The invention relates to a medium-length hole blasting and cutting method in underground construction. In the underground construction, deep-hole blasting adopts parallel cutting, and continuous cylindrical explosive loading of cutting blast holes includes breaking rock by cylindrical explosive loading on the upper portion, and forming a weak throwing to generate a blasting crater; generating an extruding and crashing function by cylindrical explosive loading on the lower portion; drilling a hollow hole 200-300mm deeper than the cutting blast holes but equal in the diameter and the depth at the center of a cutting position, properly loading blasting-delayed explosives into the hollow hole, and enhancing slag throwing action. Both the medium-length hole blasting and cutting method and parameters thereof have theoretical basis and practicality, tunneling efficiency is greatly improved, tunneling cost is reduced, and considerable economic benefits are gained. The medium-length hole blasting and cutting method has excellent explosion effects in application in the underground construction such as mines and tunnels, and utilization rate of the cutting blast holes is higher than 90%.

Owner:HUAQIAO UNIVERSITY

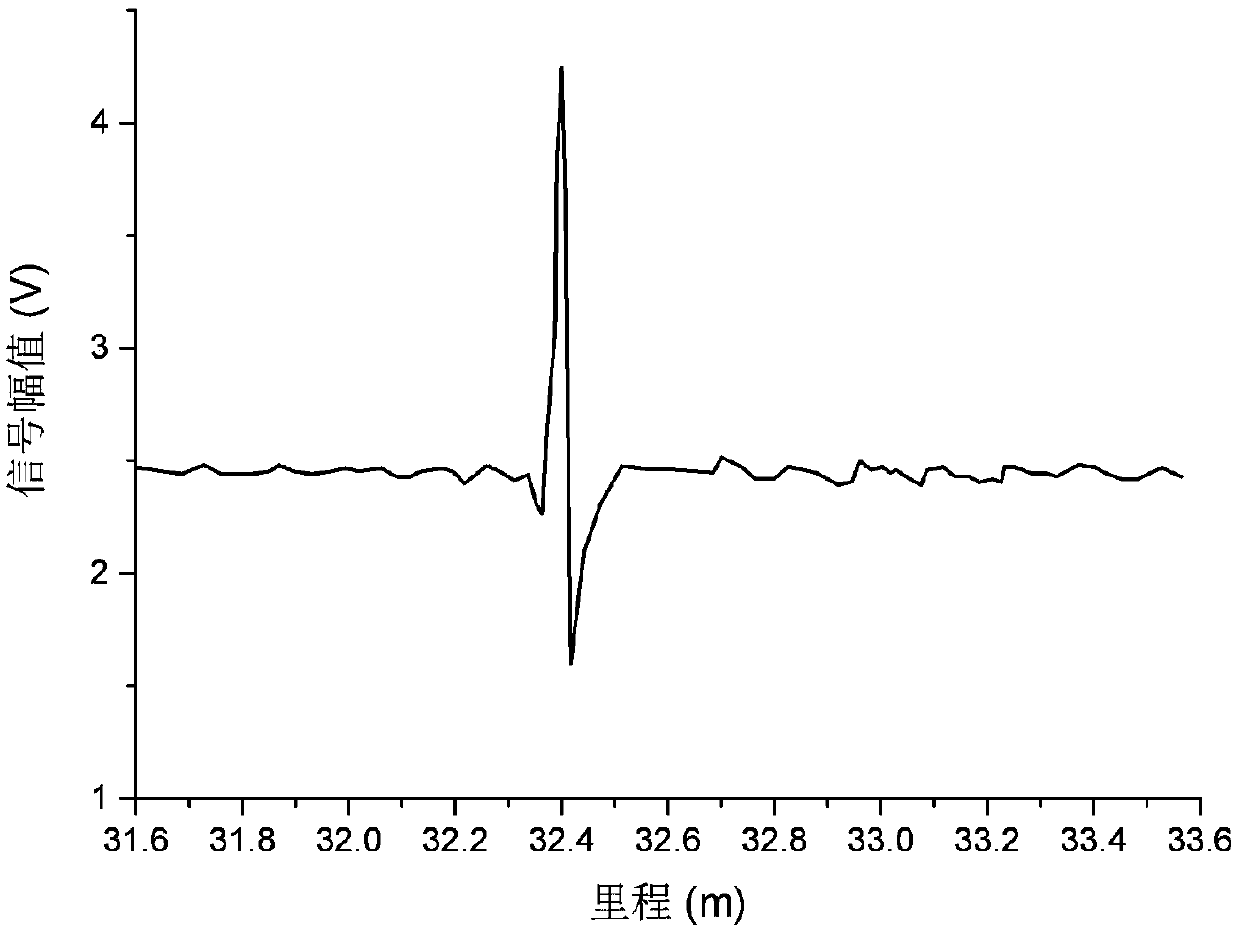

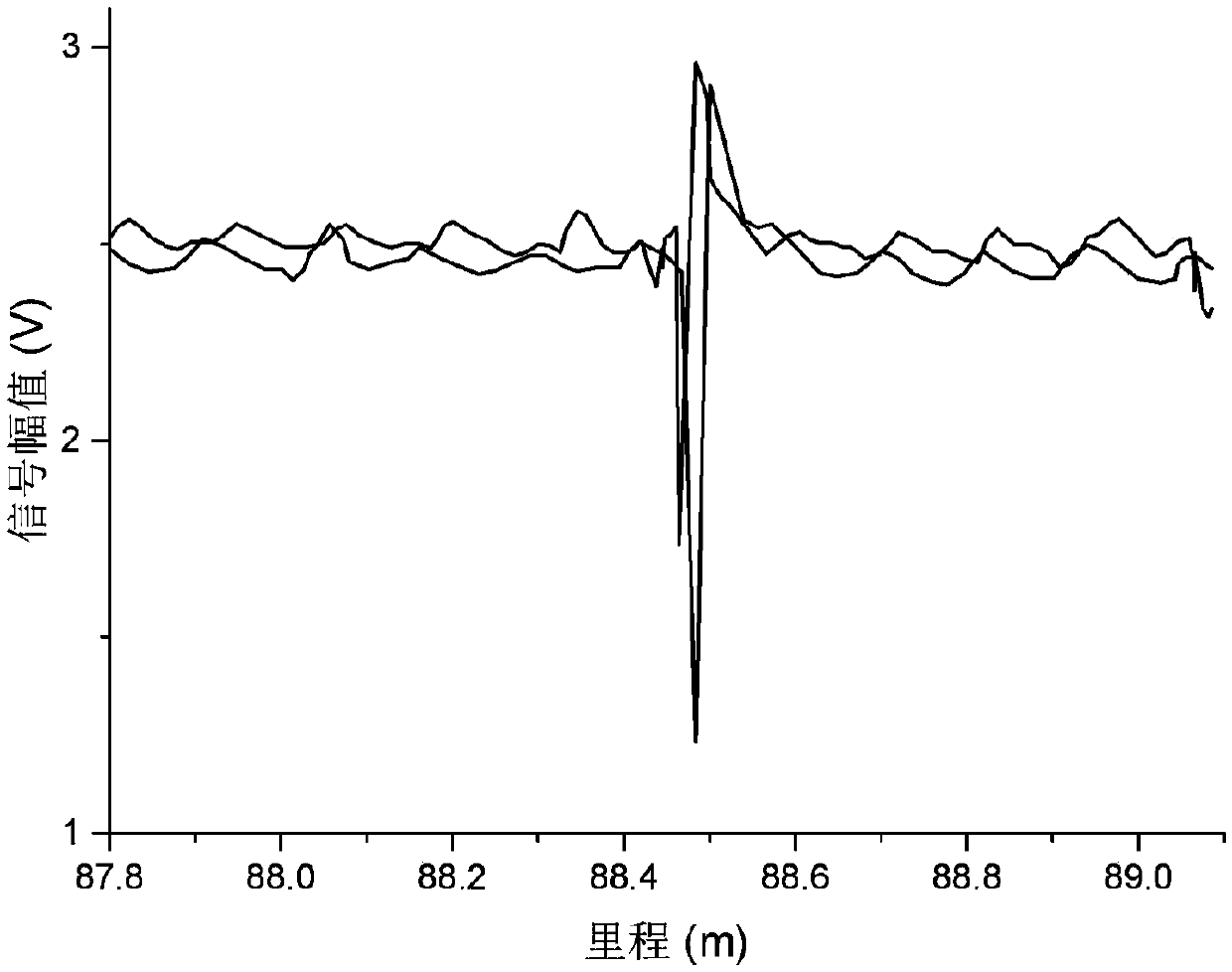

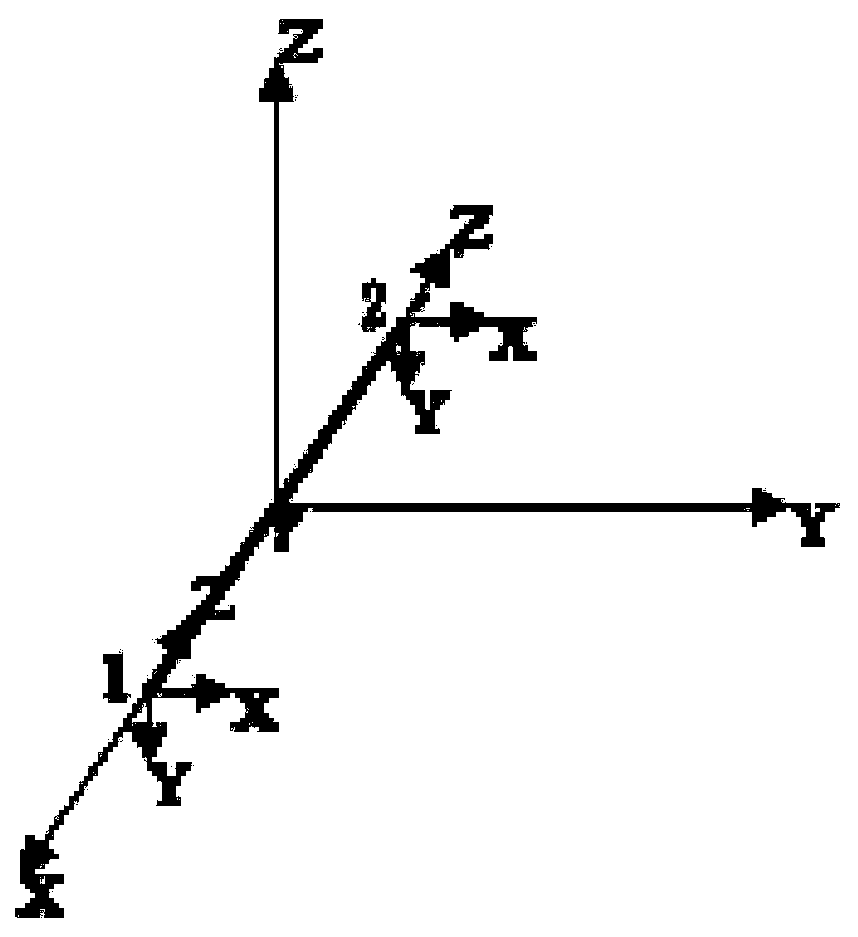

Mountain pipeline ring welding seam non-contact recognizing and positioning method

ActiveCN109632940ATest applicableAchieving large-scale detectionMaterial magnetic variablesTerrainEngineering

The invention discloses a mountain pipeline ring welding seam non-contact recognizing and positioning method. The method comprises the following steps of firstly, labeling a pipeline axis on the ground; secondly, adopting the non-contact type scanning magnetometer to move along the axis of the pipeline on the ground, wherein two magnetic sensors of the magnetometer are used for measuring three components Bx1, By 1, Bz1 and Bx2, By 2, Bz2 of the magnetic field; and calculating a gradient component and a gradient modulus dQ through data acquisition software; and arranging a DGPS positioning device in the magnetometer, synchronizing the mileage of the detecting points and the detecting data of the magnetometer; and dividing the axes of the pipelines into a plurality of detection intervals atequal interval, wherein each interval is numbered C1, C2 ,......Cn in sequence; collecting and storing the gradient component and the gradient modulus data which are detected after each interval is detected and labeling the numbers C1, C2,......Cn in sequence; carrying out ring welding seam identification through collected data. The method is not limited by the structure and the size of the pipeline, can be applied to complex and diverse terrain environments and is suitable for detecting mountain pipelines.

Owner:SOUTHWEST PETROLEUM UNIV

Rock breaking tunneling machine using liquid nitrogen and jet of ice particles

The invention discloses a rock breaking tunneling machine using liquid nitrogen and jet of ice particles.The technical problems of abnormal wear and high replacement frequency ofa disc cutter of an existing tunneling machine are solved. The rock breaking tunneling machine using liquid nitrogen and jet of ice particles comprises a cutterhead system, the cutter head system is provided with a liquidnitrogen emission nozzle, the liquid nitrogen emission nozzle is connected with a liquid nitrogen generating device through a high pressure pipeline, the liquid nitrogen emission nozzle and the liquidnitrogen generating device are connected through a high pressure pumping station,an ice particle production device is arranged adjacent to the liquid nitrogen emission nozzle, and the ice particle production device is coupled to the liquid nitrogen emission nozzle through a negative pressure device. According to the rock breaking tunneling machine using liquid nitrogen and jet of ice particles,the rock breaking efficiency is high,the cost is low, and the rock breaking medium is environment-friendly.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Heading machine using supercritical carbon dioxide jet flow to break rock

InactiveCN109899081AGuaranteed reliabilityImprove diffusivityMining devicesTunnelsSpray nozzleEngineering

The invention discloses a heading machine using a supercritical carbon dioxide jet flow to break a rock. The technical problems that a disc cutter of the existing heading machine is easy to damage anomaly, low in heading efficiency, and high in cost are solved. The heading machine includes a cutter head system, a supercritical carbon dioxide jet nozzle is arranged on the cutter head system, the supercritical carbon dioxide jet nozzle is connected with a supercritical carbon dioxide generating device through a high-pressure pipeline, and the supercritical carbon dioxide jet nozzle is connectedwith the supercritical carbon dioxide generating device through a high-pressure pump station. The supercritical carbon dioxide generating device can generate supercritical carbon dioxide, the supercritical carbon dioxide can be transported to the supercritical carbon dioxide jet nozzle by the high-pressure pump station, the supercritical carbon dioxide can be jetted at a higher speed by the supercritical carbon dioxide jet nozzle to form a jet flow beam with high concentrated energy, and the jet flow beam is provided with the high destructive effect and can broke the rock to realize heading. According to the heading machine using the supercritical carbon dioxide jet flow to break the rock, the rock breaking efficiency is high, the cost is low, and a rock breaking medium is green and environmental protection.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method

ActiveCN108412542ARealize green miningTo achieve the effect of digging an alleyUnderground miningSurface miningMining engineeringCoal pillar

The invention discloses a thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method and belongs to the technical field of mining industry. The method comprises the steps that firstly, according to the coal seam geological condition, the widths of a filled belt and a newly-tunneled roadway are designed; secondly, according to the mine existing tunneling technological condition, the filling length, namely the circular filling step pitch, of each time is determined; when the newly-tunneled roadway is tunneled, through high strength anchor rods abd anchor net cables, top plates, bottom plates and roadway inner coal walls are supported; then, after the newly-tunneled roadway is tunneled by the circular filling step pitch, roadway-expanding tunneling begins to be conducted along the roadway outer coal wall; during roadway-expanding tunneling, hydraulic supporting columns are adopted to be matched with metal hinging top beams for temporary support of the filled belt and the junction of the filled belt and the newly-tunneled roadway; finally, after roadway-expanding tunneling is completed, the temporary support is removed, the filled belt is filled; and then the steps are sequentially and alternately implemented. According to the thick coal seam wide-roadway tunneling and gangue paste body filling roadway forming method, the coal loss caused by unexploited coal pillars can be effectively reduced, the influence of mine pressure in roadway tunneling is reduced, and the gangue treatment and roadway tunneling costs are reduced.

Owner:SHANDONG UNIV OF SCI & TECH

Mining method of layering and non-segmented roadway filling in downward approach of broken surrounding rock ore body

InactiveCN103628878BReduce construction difficultyOperational aspectsUnderground miningSurface miningLoss rateMineralogy

Owner:SHANDONG UNIV OF SCI & TECH

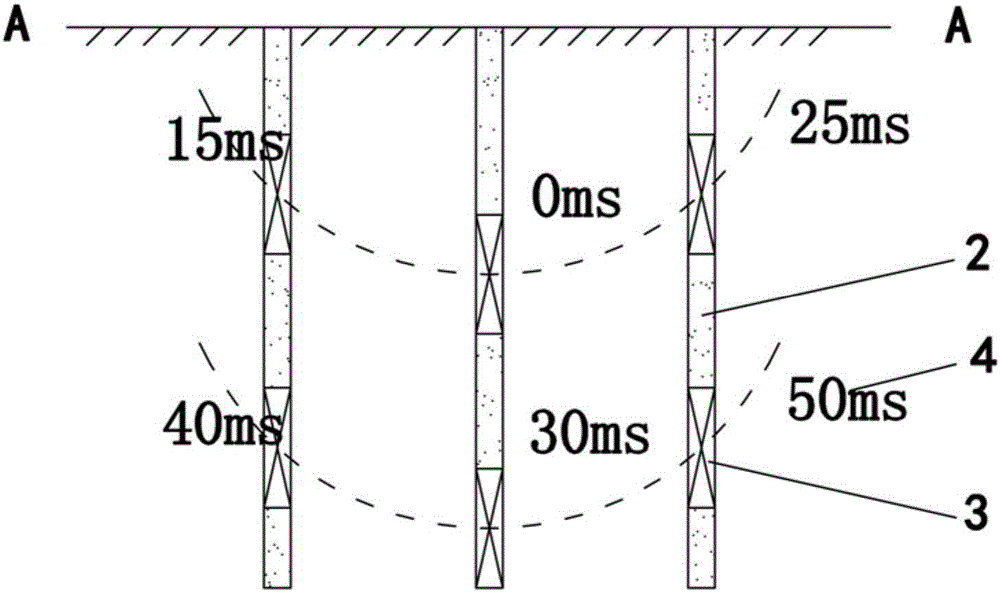

Efficient segmented blasting method in tunneling process

The invention relates to the technical field of tunnel gun hole blasting vibration, in particular to an efficient segmented blasting method in a tunneling process. Gun holes are distributed according to a tunneling section, geological conditions, circulating footage and the like; the in-hole segmented millisecond blasting is performed by a digital electronic detonator; the millisecond time precision is improved; the first blasting of explosives at the upper parts of the gun holes is realized; and a free surface is provided for blasting of explosives at the lower parts, so that the blasting effect is guaranteed. The method adopts the in-hole segmented millisecond blasting, reduces the blasting vibration speed, and increases the circulating footage.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

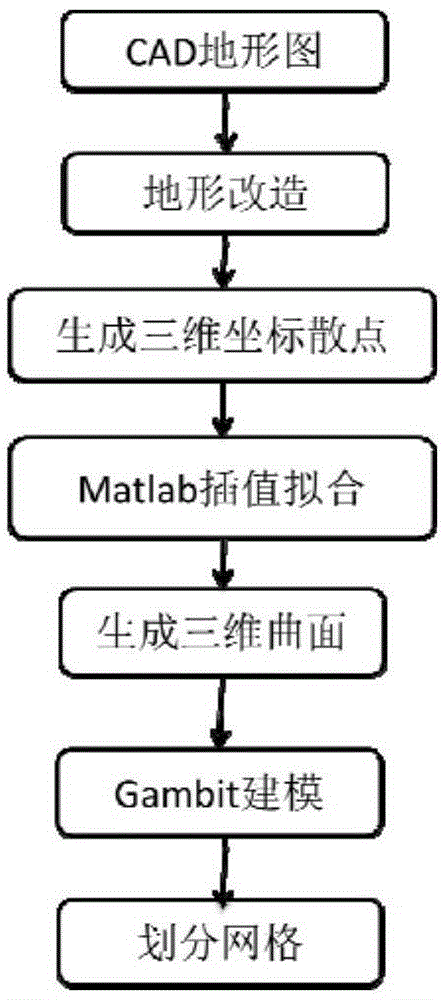

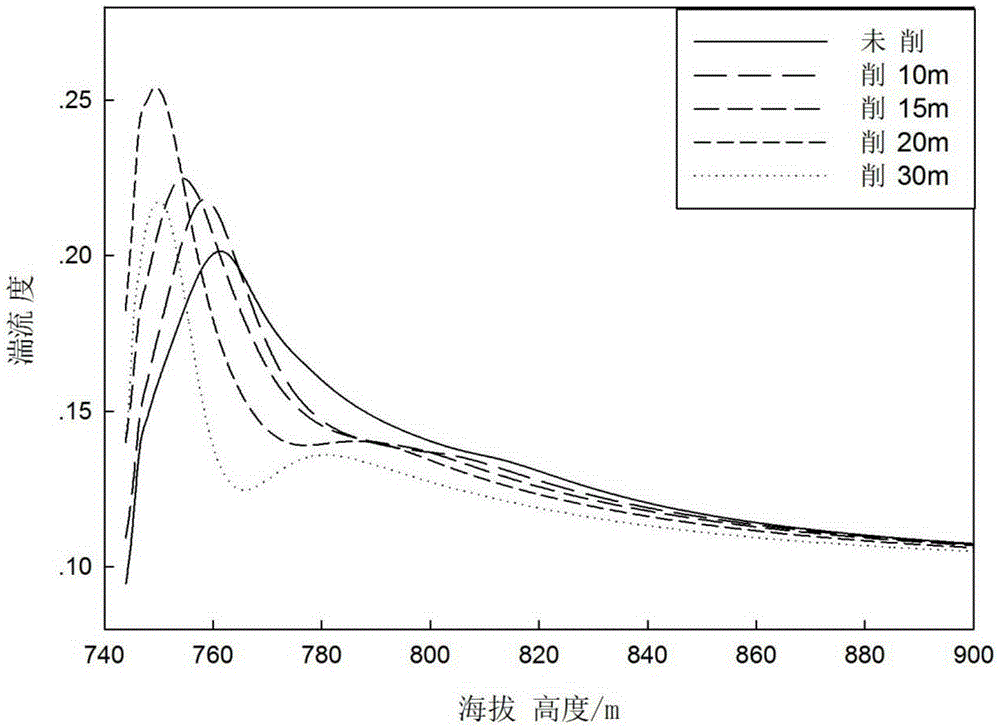

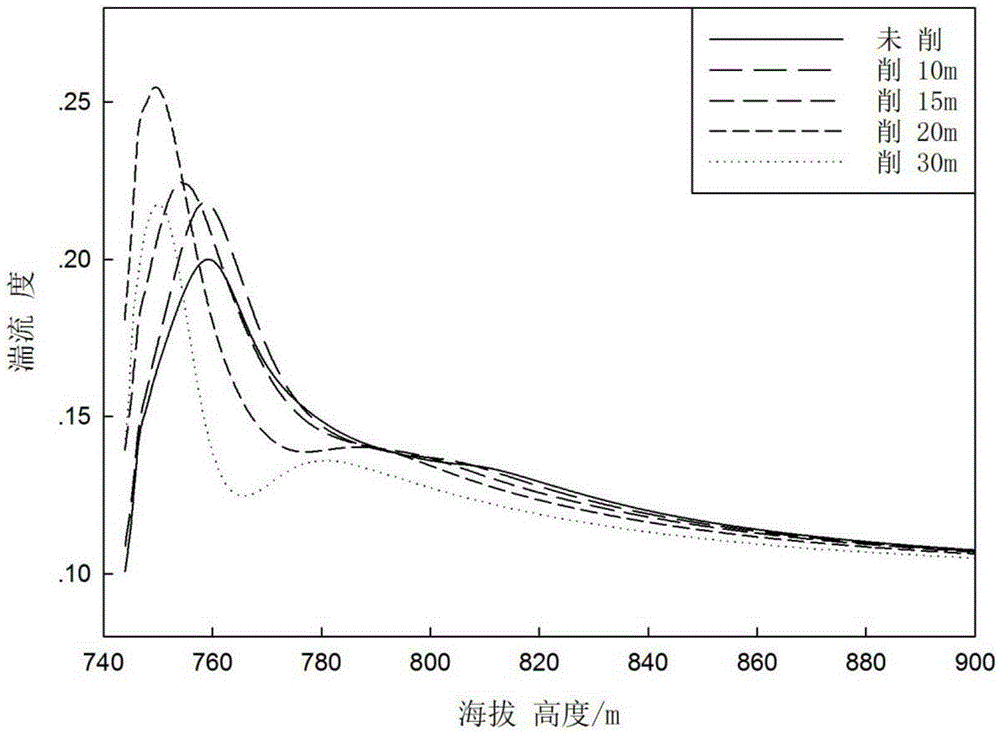

Terrain reformation method of complex-terrain wind farm

InactiveCN105405164AReduce excavation costsReduce project costData processing applicationsICT adaptationElectric fieldMicro level

The invention discloses a terrain reformation method of a complex-terrain wind farm. The method includes: realizing terrain modeling, and performing meshing of a calculation basin model; setting boundary conditions of a calculation basin; and solving the calculation basin model in a solver according to the boundary conditions set in the solver. According to the method, reasonable terrain reformation height can be determined, the turbulence level of a preselected position is reduced within the usage requirement of a fan, the earthwork excavation cost is greatly reduced, the lowest engineering cost is guaranteed, a certain guiding significance is provided for microscopic location selection of local terrains of the complex-terrain wind farms, the method is applicable to the flow field analysis and scheme economy analysis in microscopic location selection of the wind farms, and the application prospect in engineering is good.

Owner:HOHAI UNIV +1

Tunneling machine adopting laser to break rocks and tunneling method of tunneling machine

PendingCN109555531ASolve the problem of abnormal damage proneLow costTunnelsEngineeringShield tunneling

The invention discloses a tunneling machine adopting a laser to break rocks and a tunneling method of the tunneling machine. The problems that as the strength of the rocks increases, abnormal wear andthe replacement frequency of a hob increase, subsequently, the shield tunneling efficiency is lowered, and the tunneling cost is increased are solved. The tunneling machine comprises a tunneling machine main engine, a cutterhead is arranged on the tunneling machine main engine, and laser generating devices are arranged on the cutterhead. According to the tunneling machine adopting the laser to break the rocks and the tunneling method of the tunneling machine, traditional metal cutting tools are replaced with a laser and water cooling principle, the efficiency of rock breaking is greatly improved, meanwhile, when tunnelingthe serious uneven geology such as softness-up and hardness-down, the difficult problem that the traditional metal cutting tools are extremely prone to being abnormally damaged is solved, thus the cutting tool cost is saved, and the risk of tool replacing is lowered; and a mode of suspension cutting rock breaking or extruding rock breaking is adopted, the efficiency of excavation is greatly improved, and the excavation cost is lowered.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Mine gallery driving cut blasting method

The invention relates to a mine gallery driving cut blasting method which includes the steps that a center blasting hole perpendicular to a working plane is drilled in the center of the gallery driving working plane, five to eight evenly-distributed peripheral holes are drilled in the circumference with the center blasting hole of the working plane as the circle center and the radius ranging from 9 cm to 12 cm, the depth of the center blasting hole is 20 cm-40 cm larger than the depths of the surrounding peripheral holes, the depths of the surrounding peripheral holes are equal, the center blasting hole and the surrounding peripheral holes are parallel to each other, the center blasting hole serves as a powder filling hole, the surrounding peripheral holes are hollow holes, hole openings are packed with stemming after the center blasting hole is filled with an explosive reel and a blasting cap connected with an explosion conducting pipe, when explosives in the center blasting hole are detonated, the hollow peripheral holes serve as free surfaces and compensation space, and the aim of breaking and throwing rock in a cutting frame is achieved; due to the fact that the depth of the center blasting hole is 20 cm-40 cm larger than the depths of the surrounding peripheral holes, the rock throwing force is strengthened, the rock is completely thrown out, and the cutting effect is improved and guaranteed.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

Hob-free hard rock tunneling machine for breaking rocks by utilizing microwaves and supercritical carbon dioxide

The invention discloses a hob-free hard rock tunneling machine for breaking rocks by utilizing microwaves and supercritical carbon dioxide. The technical problems of high cost and long construction period caused by maintenance such as cutter replacement of a cutterhead in the tunneling process of an existing heading machine are solved. The hob-free hard rock tunneling machine comprises a central main driving unit connected with a hob-free cutterhead, a microwave emitter and a large slag outlet are arranged on the hob-free cutterhead, the microwave emitter is connected with a microwave radiation arm, a supercritical carbon dioxide nozzle is arranged on the hob-free cutterhead, and the supercritical carbon dioxide nozzle is connected with a supercritical carbon dioxide high-pressure pump station through a supercritical carbon dioxide high-pressure conveying pipe. A microwave and supercritical carbon dioxide jet flow coupled rock breaking system is adopted, a conventional cutter rock breaking technology is thoroughly abandoned, the problem that abnormal damage is extremely prone to occurring when a metal cutter of the tunneling machine cuts rocks is solved, the excavation efficiency is improved, and the excavation cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com