Hob-free hard rock tunneling machine for breaking rocks by utilizing microwaves and supercritical carbon dioxide

A hard rock boring machine, carbon dioxide technology, applied in mining equipment, earth-moving mining, tunnels, etc., can solve the problems of high cost and long construction period, achieve the effect of light weight, reduce excavation cost, and improve excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

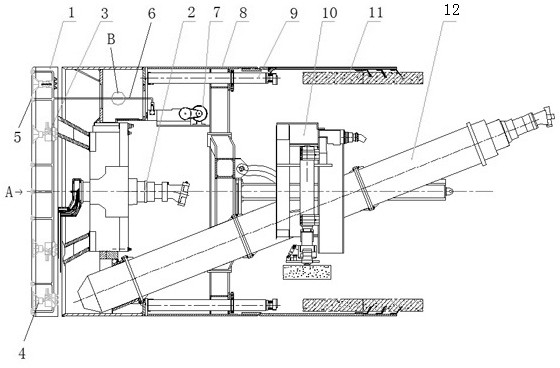

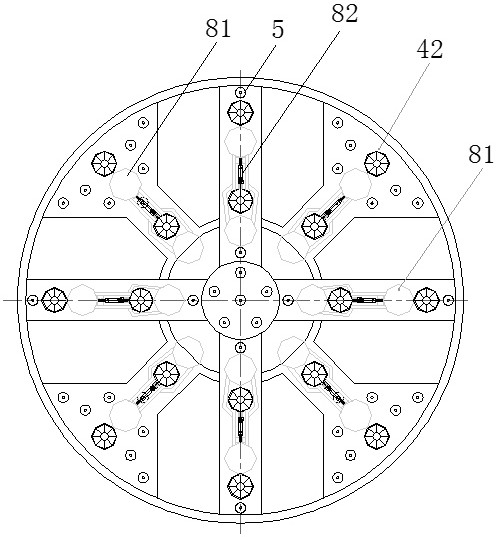

[0029] Embodiment 1, a kind of hard rock tunneling machine without hob that utilizes microwave and supercritical carbon dioxide to break rock, such as figure 1 As shown, the shield body 8 is included, and the shield body 8 is provided with a central main driving unit 2 connected to the hob-free cutterhead 1, and the central main driving unit 2 drives the non-hob cutterhead 1 to rotate in a circumferential direction. A segment assembly machine 10 and a screw conveyor 12 are arranged inside the shield body 8 , and the feeding end of the screw conveyor 12 is located at the rear side adjacent to the hobless cutter head 1 .

[0030] Since the hobless cutterhead 1 is driven by the central main drive unit 2, the back of the hobless cutterhead can have enough assembly space, and a microwave transmitter 3 is arranged on the back of the hobless cutterhead 1. The microwave launcher 3 is connected with a microwave radiation arm 4 leading to the front side of the hobless cutter head 1 . M...

Embodiment 2

[0034] Embodiment 2, a kind of hard rock tunneling machine without hob that utilizes microwave and supercritical carbon dioxide to break rock, such as figure 1 and Figure 6 As shown, the outside of the supercritical carbon dioxide high-pressure delivery pipe 6 is wrapped with a glass fiber layer 61, and the glass fiber layer 61 can effectively maintain the temperature of supercritical carbon dioxide in the supercritical carbon dioxide high-pressure delivery pipe 6, and can effectively increase the temperature of supercritical carbon dioxide. delivery efficiency.

[0035] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

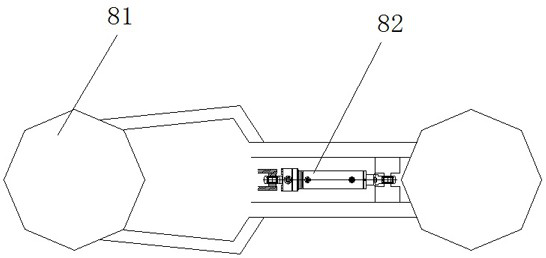

[0036] Embodiment 3, a kind of hard rock roadheader without hob that utilizes microwave and supercritical carbon dioxide to break rock, such as Figure 5 As shown, the microwave radiation arm 4 is retractable, and the retractable microwave radiation arm 4 can be adjusted according to the distance between the hobless cutter head 1 and the rock, so that the microwave radiation arm 4 can always closely fit the rock section , to avoid excessive scattering or reflection of microwaves to reduce heat dissipation efficiency.

[0037] The microwave radiating arm 4 includes a microwave emission terminal 42 that is plugged and matched with the hobless cutterhead 1. The microwave emission terminal 42 is connected to a first telescopic cylinder 41, and one end of the first telescopic cylinder 41 is connected to the microwave emission terminal 42. , The other end is connected to the hobless cutterhead 1. The expansion and contraction of the first telescopic cylinder 41 can drive the microw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com