Underwater sinking well heading machine and construction method thereof

A technology of roadheader and caisson, which is applied to mechanically driven excavators/dredgers, caisson, infrastructure engineering, etc., can solve the problem of caisson attitude deflection, difficult control of excavation contours, and excavation efficiency of caisson roadheaders. Low problems, to achieve the effect of accurate posture, improved excavation efficiency, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

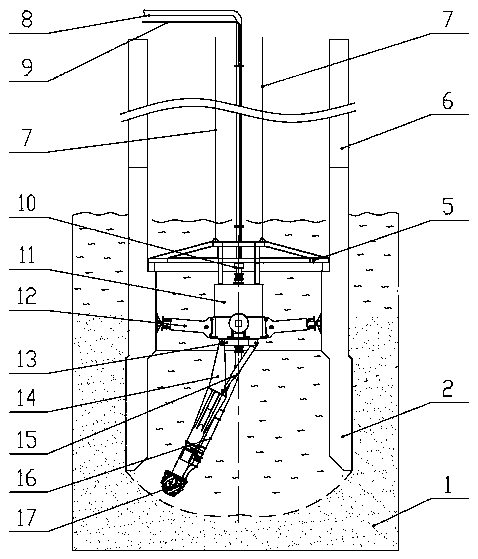

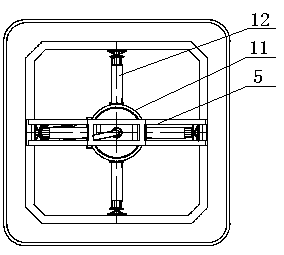

[0027] Example 1, such as Figure 1-2 As shown, an underwater caisson boring machine includes a support seat 5 arranged in the lower part of the shaft 2, the support seat is arranged on a preset cap of the lower part of the caisson, the support seat 5 is connected with a lifting device, and the lifting device is lifted. The device can be a gantry crane or a large floating crane, and 7 pairs of steel wire ropes are used to hoist the supporting seats with double ropes to control the adjustment posture, so that the supporting seats are placed on the preset bearing platform of the lower part of the caisson, and the pump station and the control room are placed on the caisson. department. The upper part of the support base is connected with a steel wire rope, and after the support shoes and the working arm are retracted, the whole set of equipment can be quickly hoisted out through the steel wire rope. The lower part of the support seat 5 is provided with a sealed cabin 11, the sea...

Embodiment 2

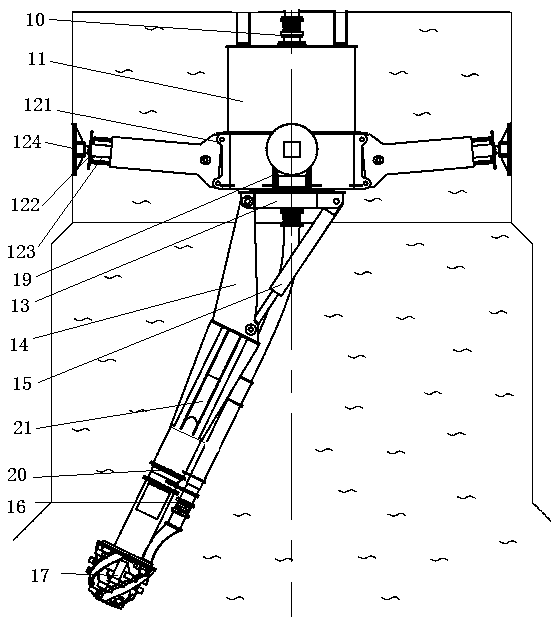

[0029] Example 2, such as image 3 As shown, an underwater caisson boring machine, the driving mechanism includes at least one working arm 14, one or two working arms 14 can be provided, and the number is set according to the excavation diameter. When a working arm 14 is used, the working arm is arranged at the center position of the revolving seat; Telescopic arm 20, telescopic arm 20 is connected with working arm 14 through telescopic oil cylinder 21, and the front end of telescopic arm 20 is provided with twisting suction head 17. The expansion and contraction of the working arm is realized by the telescopic oil cylinder, and the excavation diameter is changed. The compound movement of the above-mentioned mechanism can control the excavation of the rock and soil 1 at the lower part of the caisson with circular and rectangular cross-sections by the twisting suction head.

[0030] Further, one side of the working arm 14 is provided with a telescopic mud pipe 16, and the tel...

Embodiment 3

[0033] Embodiment 3, a construction method of an underwater caisson boring machine, comprising the following steps: S1: Use a tugboat or a large floating crane to place the lower part 2 of the caisson at the design coordinate position, and perform precise positioning of the anchor cable as required. Concrete is injected into the cavity of the lower part of the caisson 2, and under the action of gravity, the lower part of the caisson 2 initially sinks;

[0034] S2: On the working platform above water, the submerged caisson boring machine is hoisted into the lower part 2 of the caisson under the action of the lifting device. The seat 5 is placed on the preset inner wall platform of the lower part of the caisson 2; the power station and the control room are placed on the water working platform, connected to the power pipeline and control pipeline, and connected to the slurry discharge and compressed air pipeline.

[0035] S3: Control the stretcher device 12 to stretch out and tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com