Mixing machine for engineering plastic modification

A technology of engineering plastics and mixers, which is used in drying solid materials, cleaning methods and utensils, drying solid materials without heating, etc. High tide efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

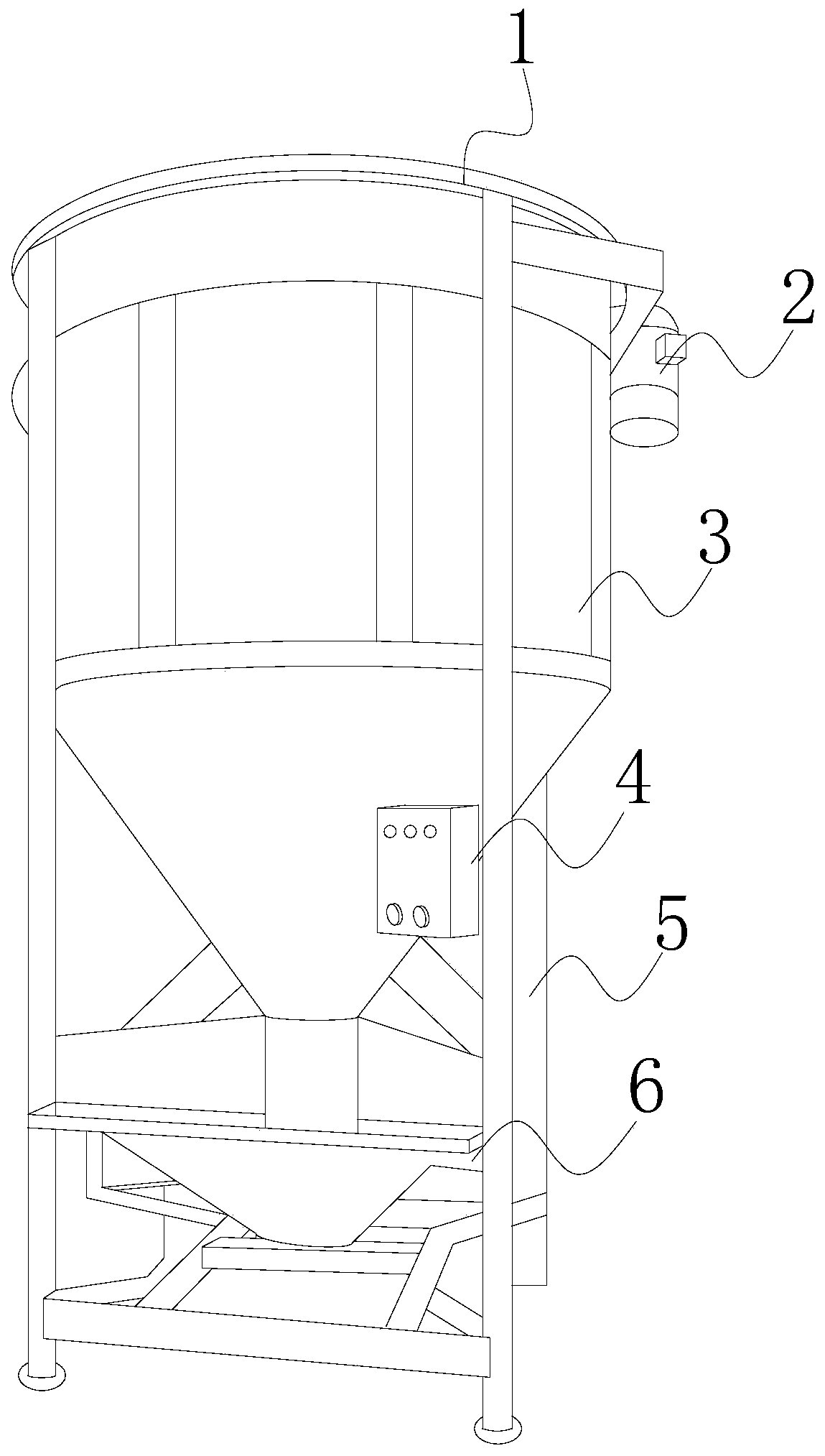

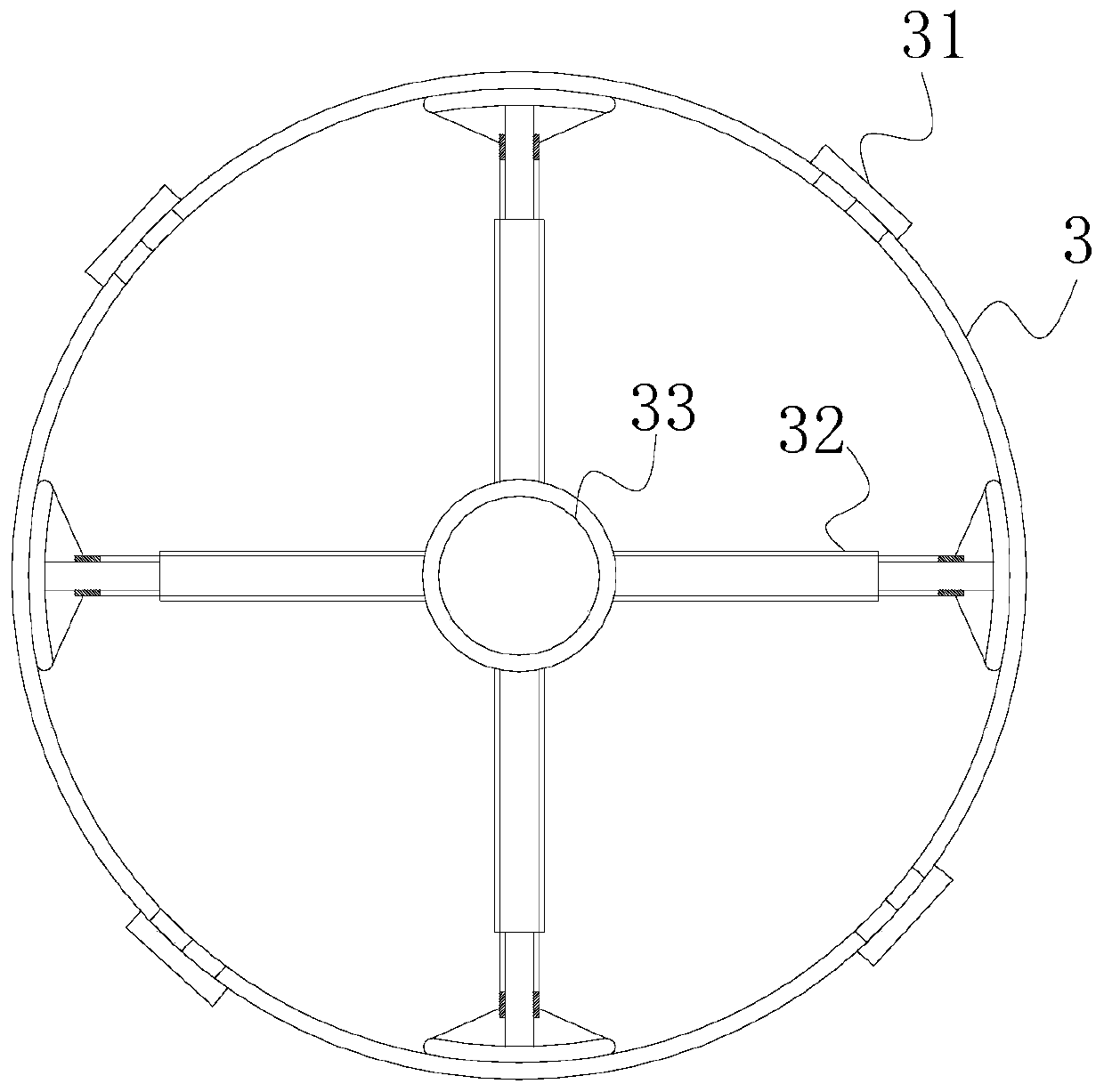

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a mixer for modification of engineering plastics, and its structure includes a top cover 1, a motor 2, a mixing cylinder 3, an operating cabinet 4, a support frame 5, and a discharge chassis 6. The top cover 1 Installed on the upper end of the mixing cylinder 3, the rotating shaft 33 inside the mixing cylinder 3 is driven by the motor 2, the operating cabinet 4 controls the motor 2, the bottom of the mixing cylinder 3 and the discharge chassis 6 are internally connected and welded together, The support frame 5 is mechanically connected to the outer surface of the mixing cylinder 3 and the discharge chassis 6, and the inside of the mixing cylinder 3 is provided with a chuck 31, a telescopic stirring shaft 32, and a rotating shaft 33, and the chuck 31 is provided with four, It is evenly distributed on the outside of the mixing cylinder 3 in a circle, and the telescopic stirring shaft 32 is provided with f...

Embodiment 2

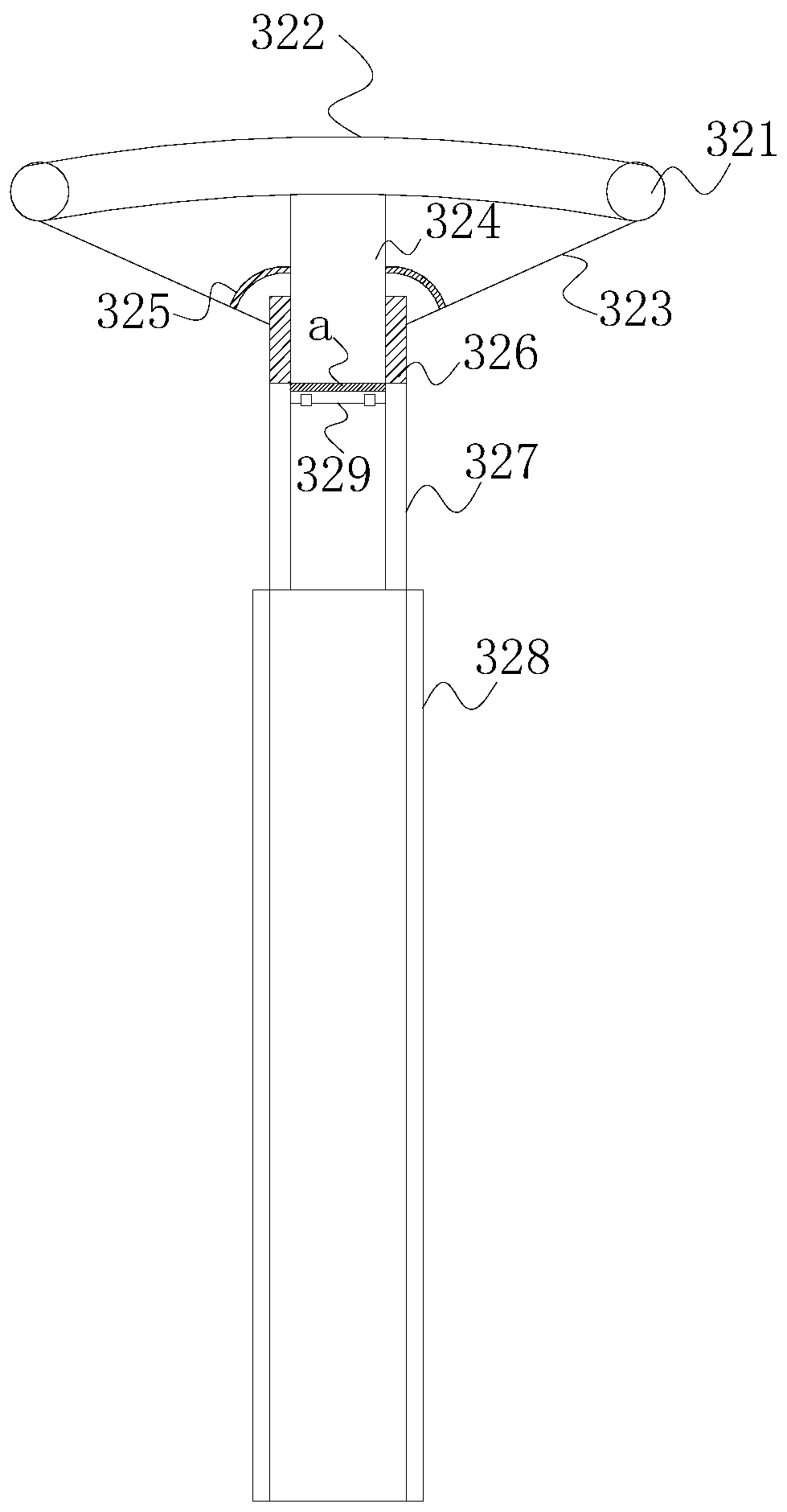

[0029] Such as Figure 5 As shown, based on Example 1, the telescopic plastic tube is used to scrape off the water on the cylinder wall before mixing, so as to avoid the humidity inside the mixing cylinder, and solve the problem of difficult moisture removal on the cylinder wall. The sealing piston changes the pressure inside the telescopic plastic tube On the basis of making the telescopic plastic tube fuller when opened and having higher moisture removal efficiency, the chuck 31 includes a fixed frame 311, a propeller 312, a mounting groove 313, and a movable sealing plate 314 through the mutual cooperation of the following structural components , a liquid outlet hole 315, a liquid contact layer 316, a propeller 312 is installed inside the fixed frame 311, and the propeller 312 is respectively arranged on both sides of the installation groove 313 and connected with the movable sealing plate 314, and the movable sealing plate A liquid contact layer 316 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com