Plate cutting device capable of achieving automatic stabilization and self-cleaning

A cutting device and self-cleaning technology, applied in wood processing equipment, special forming/shaping machines, bark areas/debris/dust/waste removal, etc., can solve the pollution of the surrounding environment, easy to fly around, and a large number of Debris and other problems can be avoided to achieve the effect of avoiding consumption, ensuring stability and facilitating positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

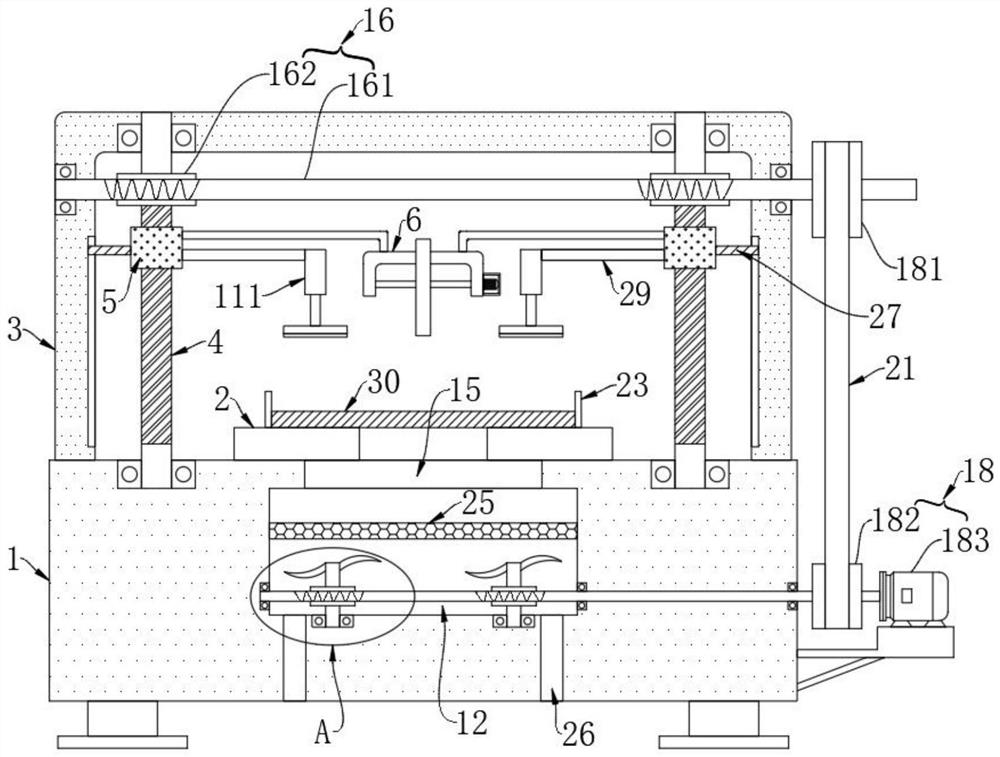

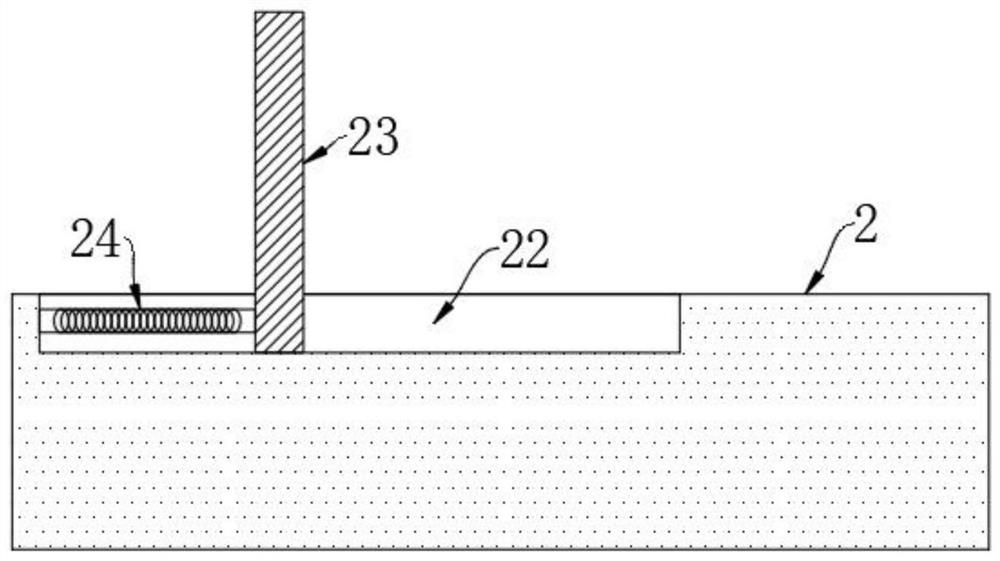

[0031] like Figure 1-3 As shown, a plate cutting device that can be automatically stabilized and self-cleaning includes a workbench 1, and two symmetrically arranged placement blocks 2 are fixedly connected to the workbench 1, and a chute 22 is provided on the placement block 2, and the chute 22 is slidably connected with a butt plate 23, and a plurality of back springs 24 are fixedly connected between the sliding end of the back plate 23 and the inner wall of the chute 22. Under the action, the butt plate 23 can be pressed against the wooden board 30 to realize the pre-fixation of the wooden board 30 , and the two placement blocks 2 are symmetrically arranged to facilitate the positioning of the wooden board 30 .

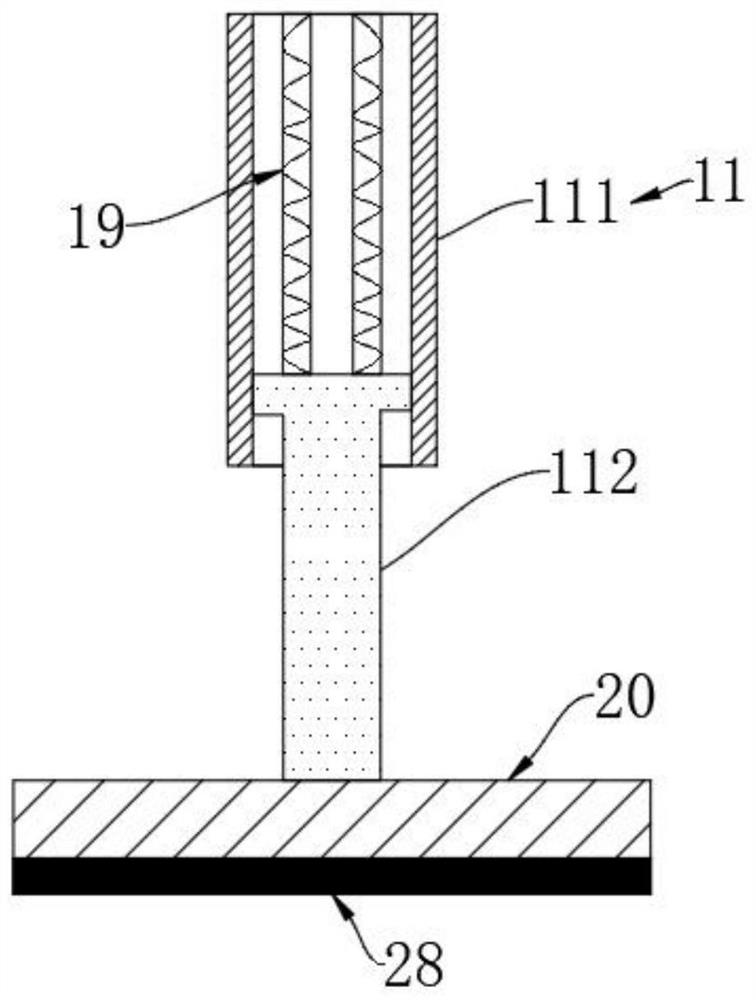

[0032] A bracket 3 is fixedly connected to the workbench 1, and two symmetrically arranged reciprocating lead screws 4 are rotatably connected between the support 3 and the workbench 1, and the reciprocating lead screw 4 is threadedly connected with a sleeve 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com