Patents

Literature

50results about How to "Achieve pre-fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

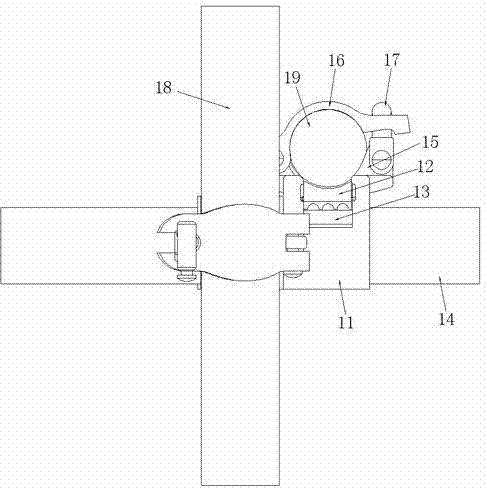

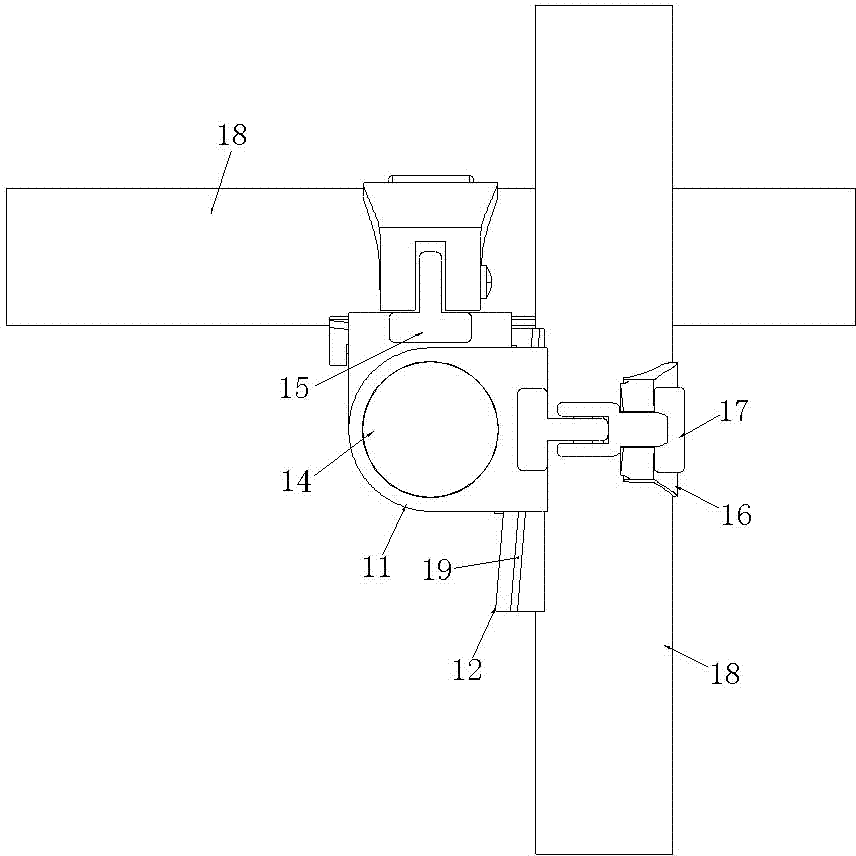

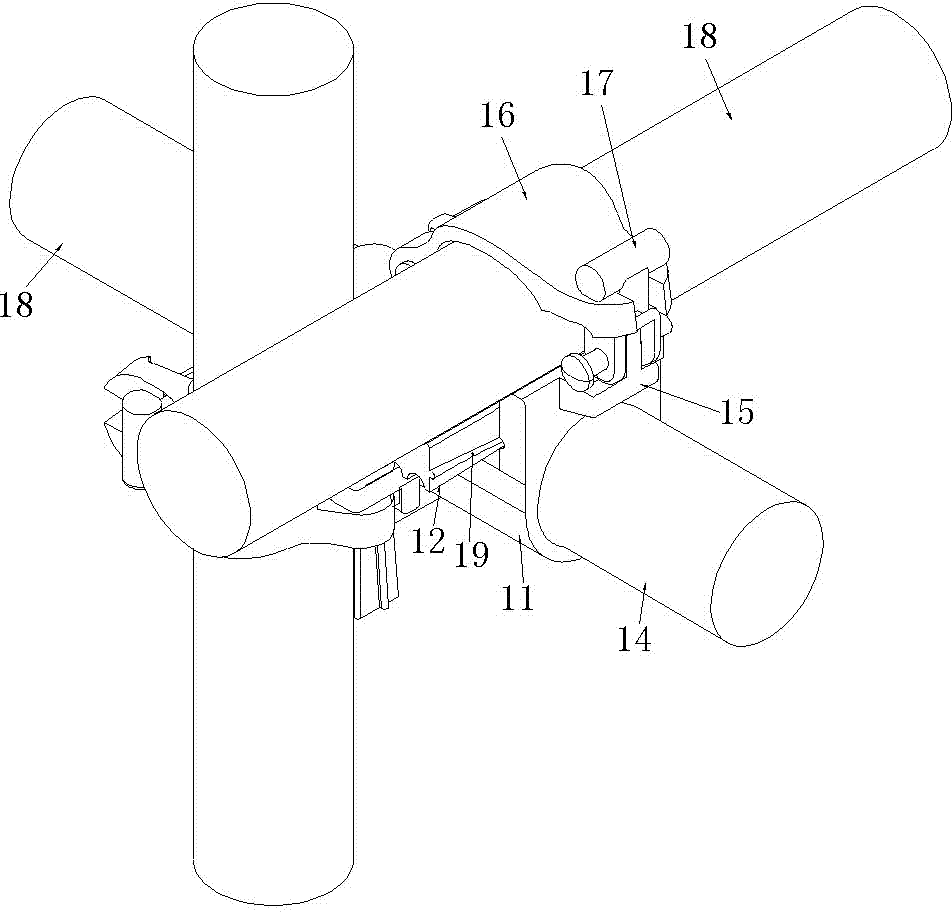

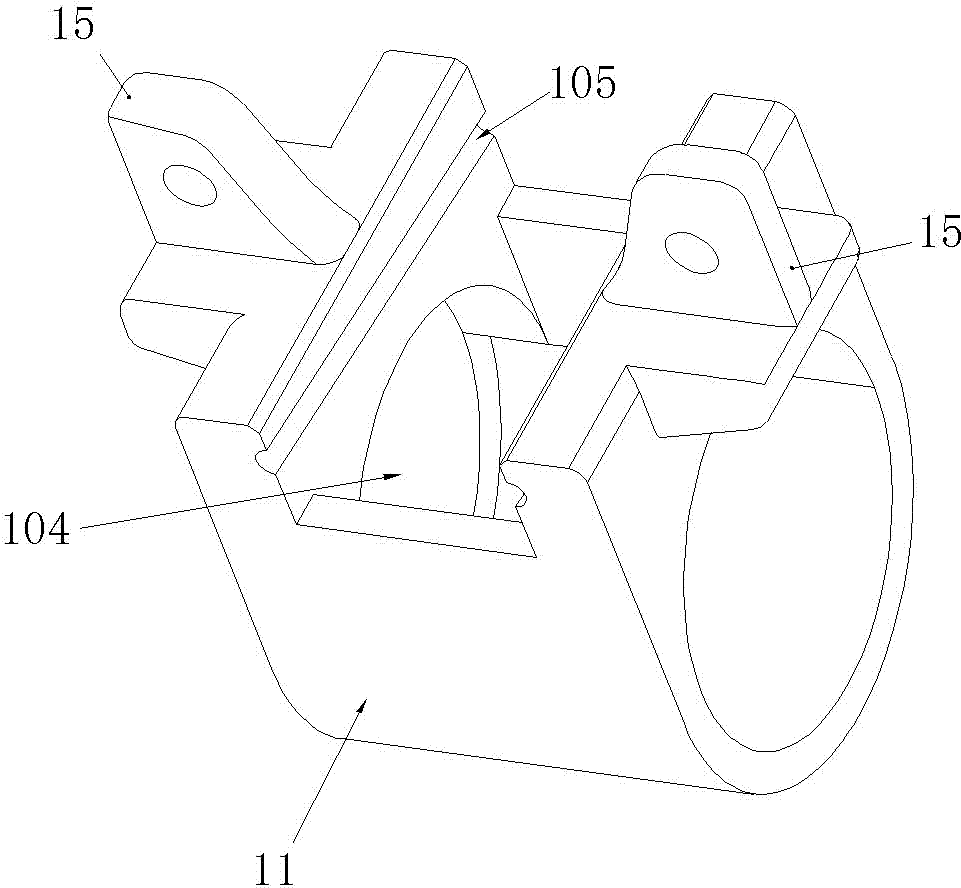

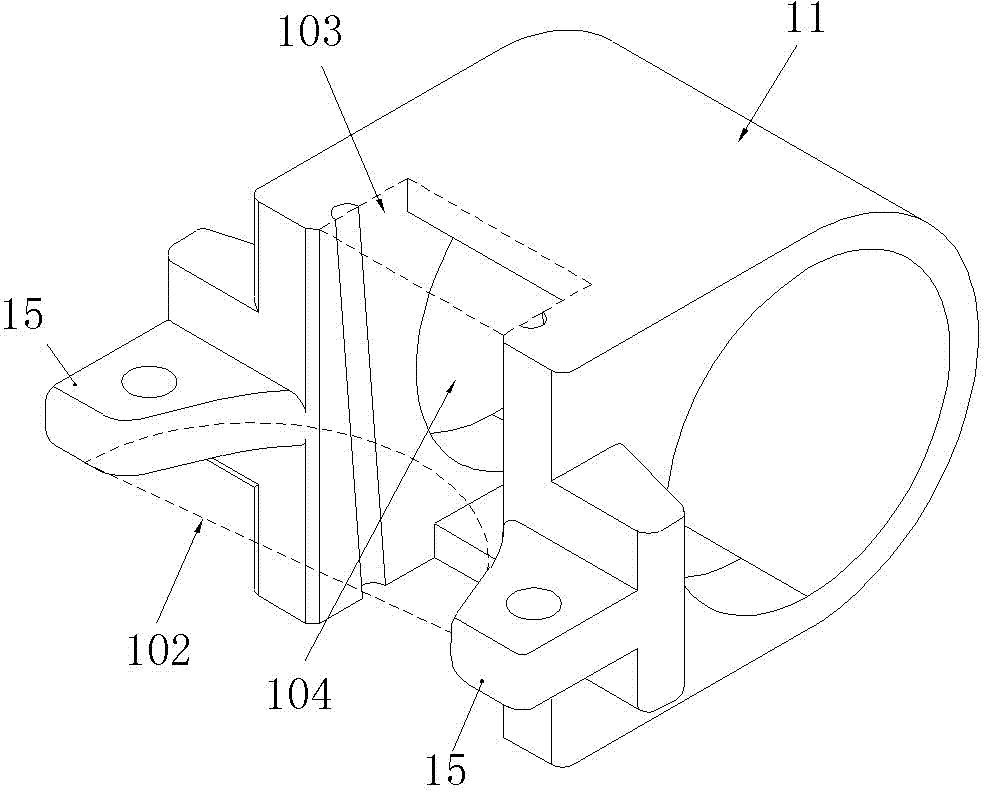

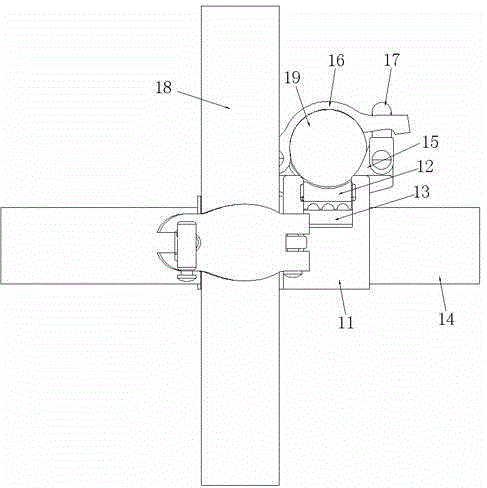

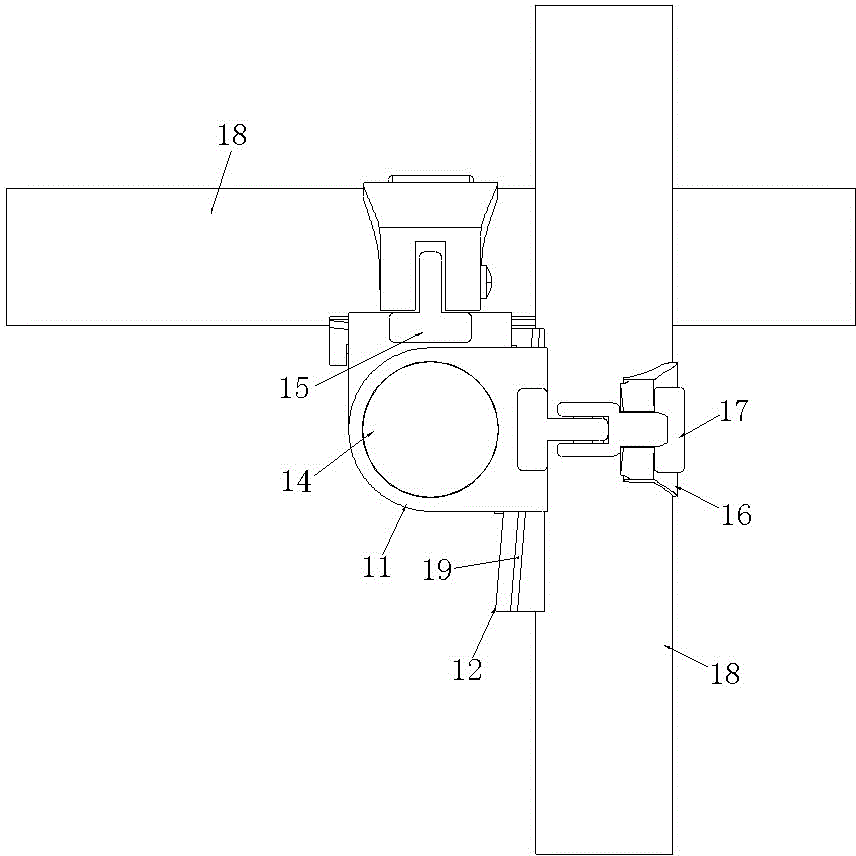

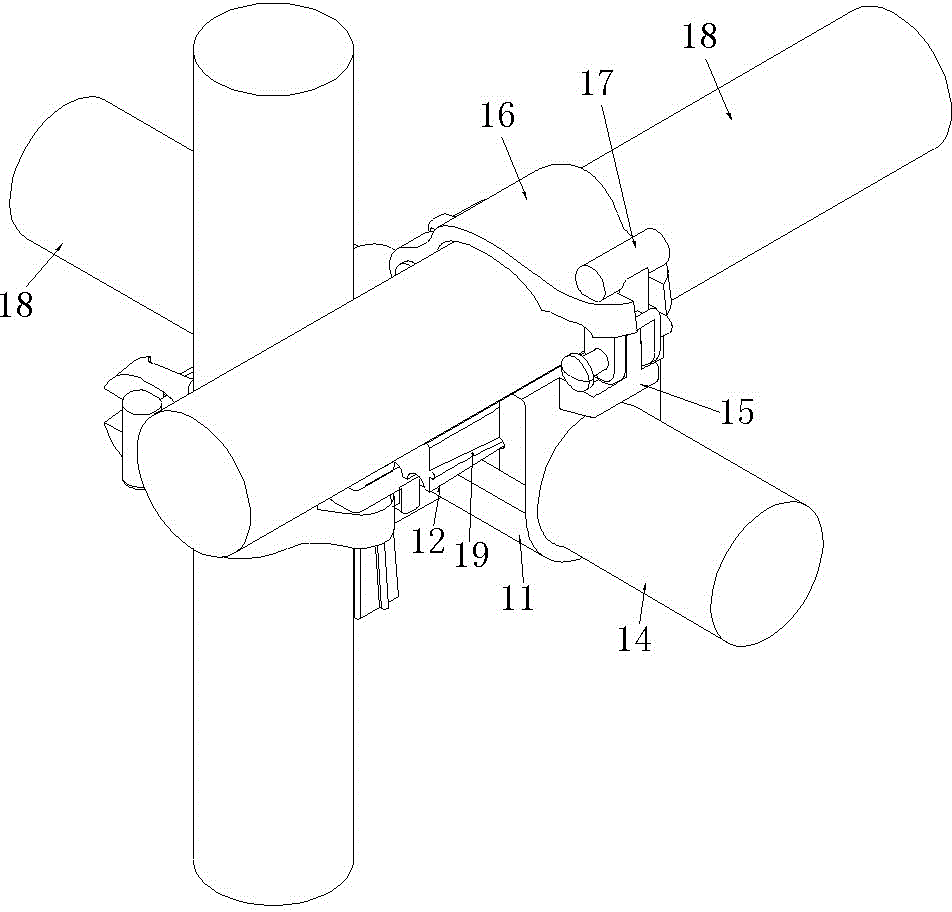

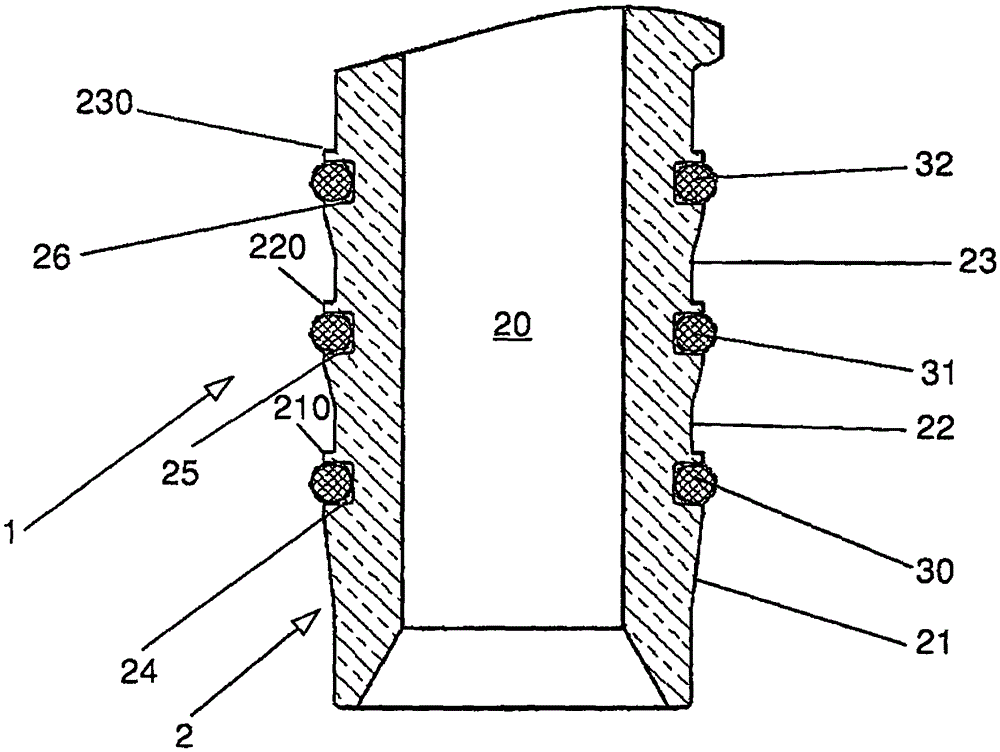

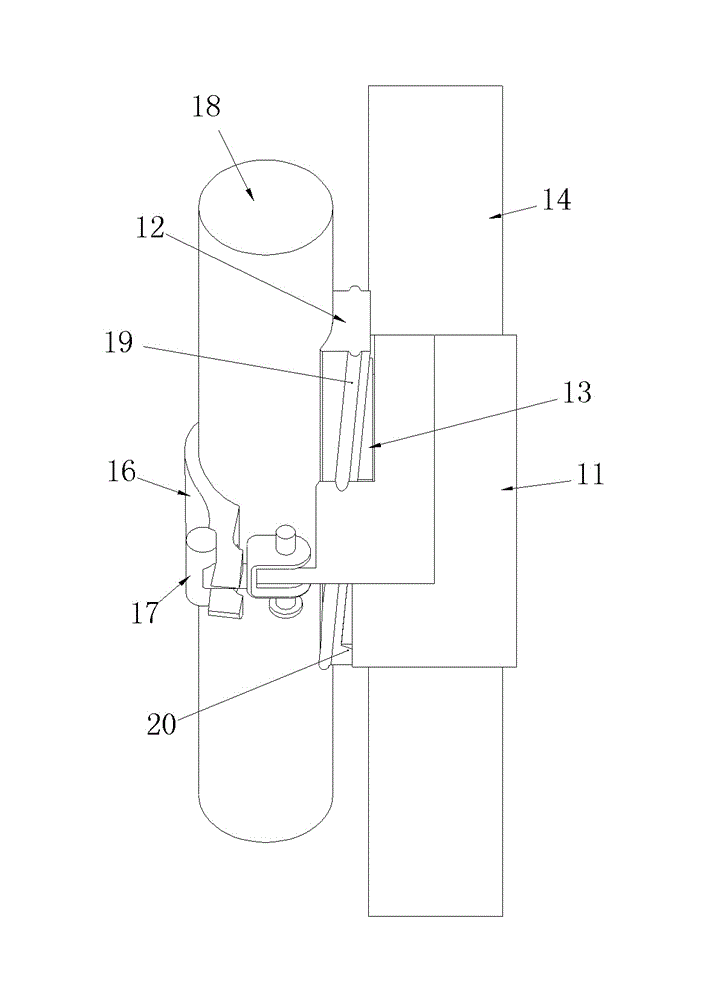

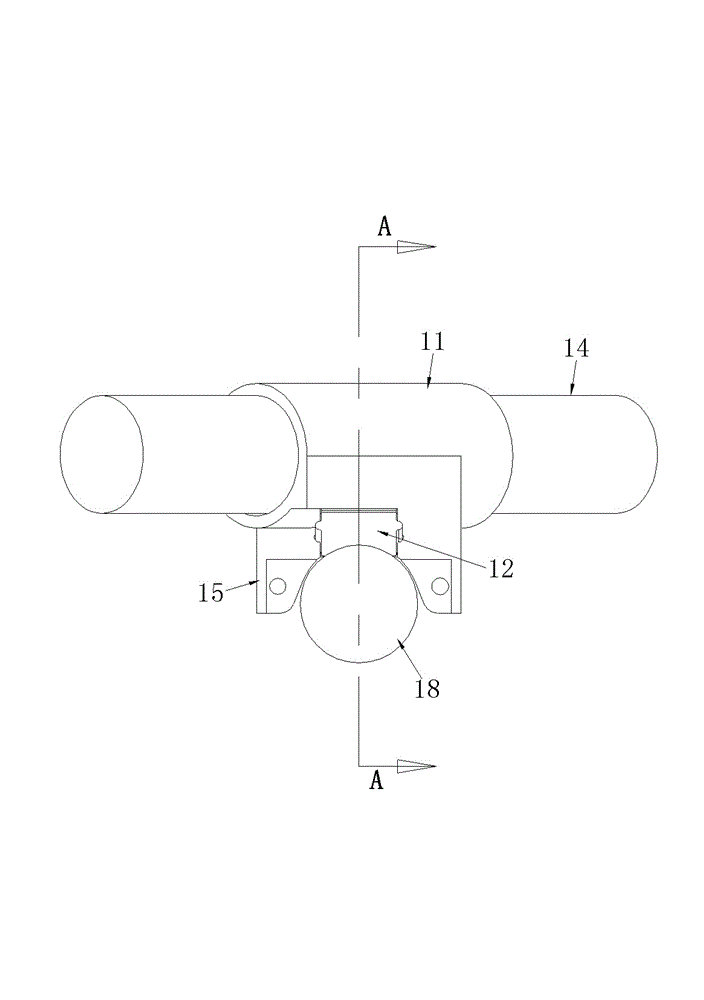

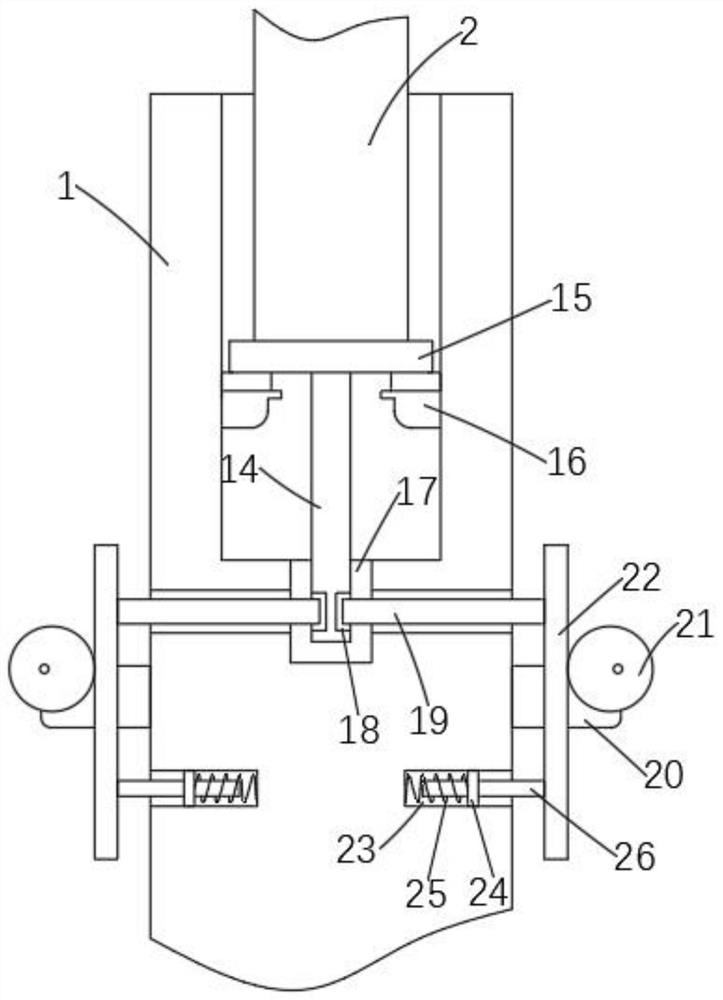

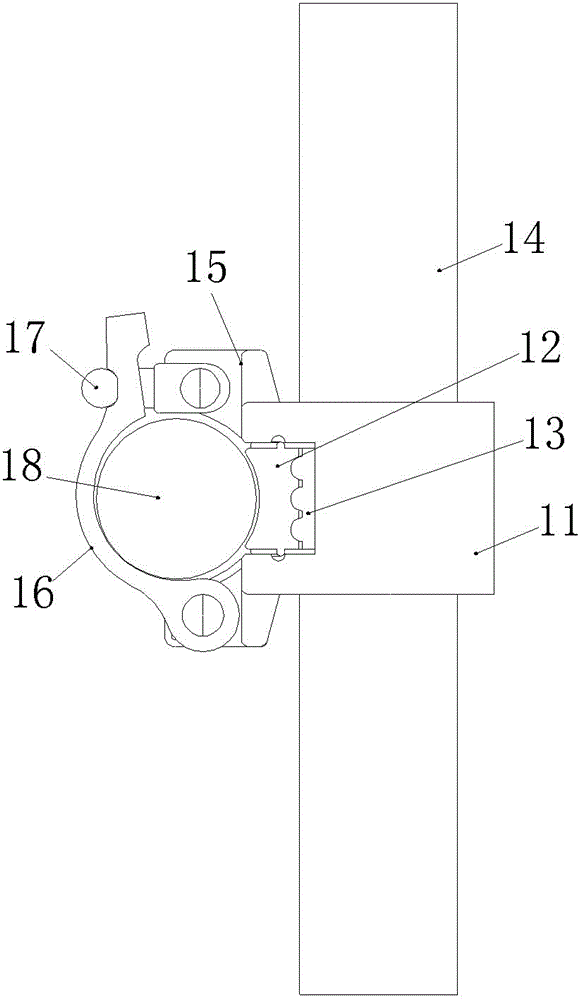

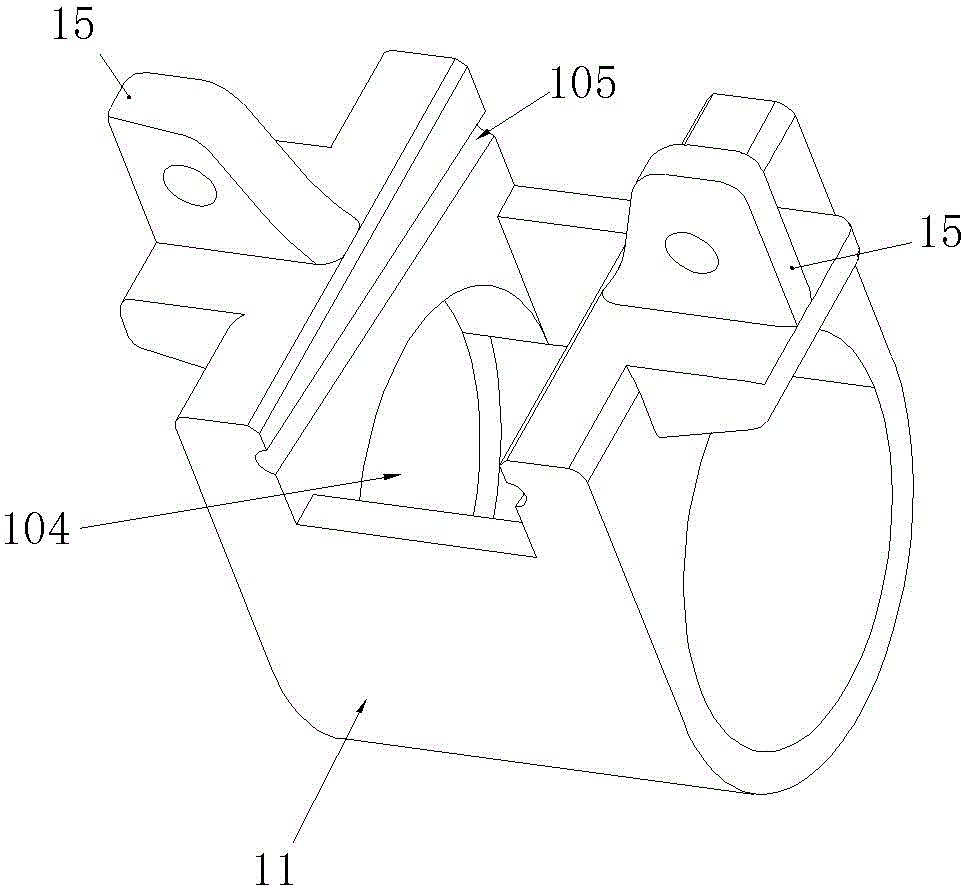

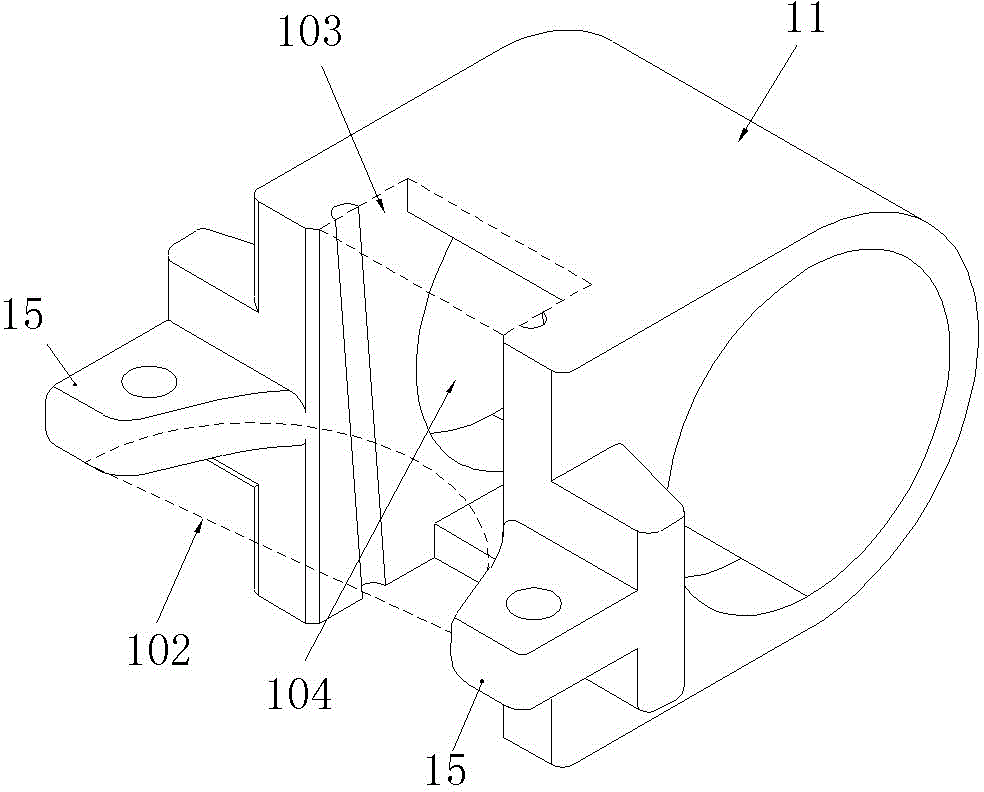

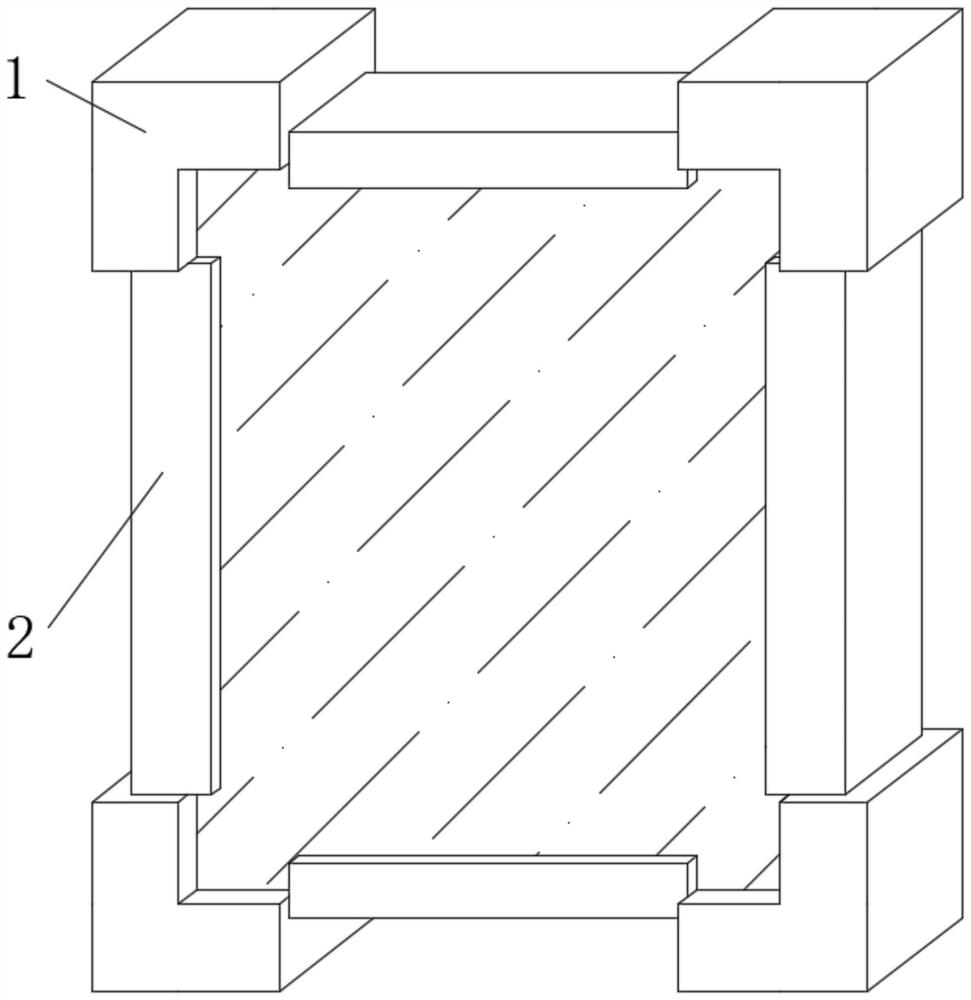

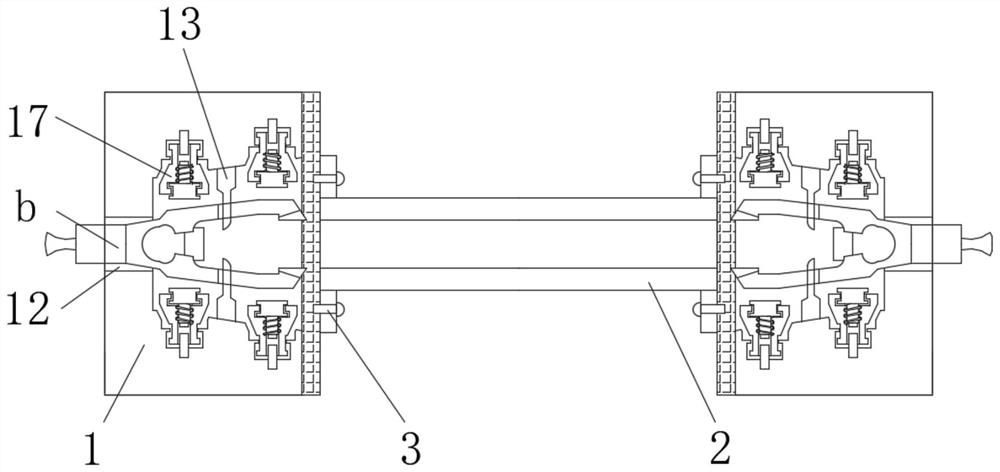

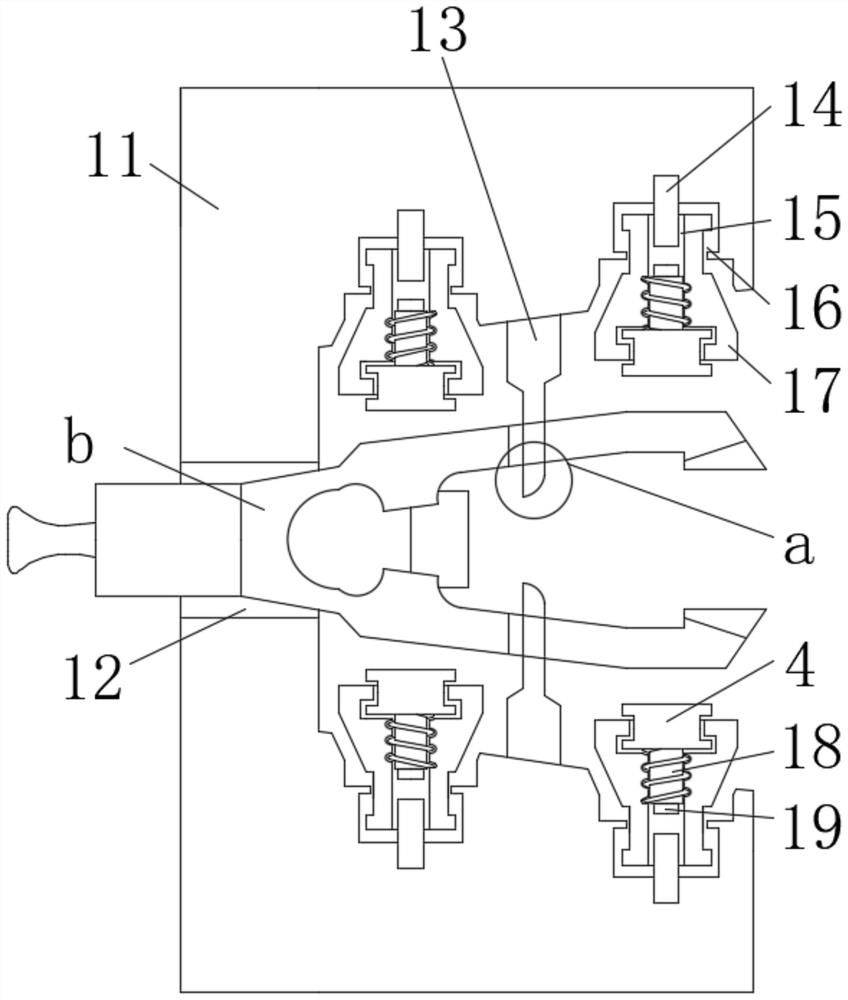

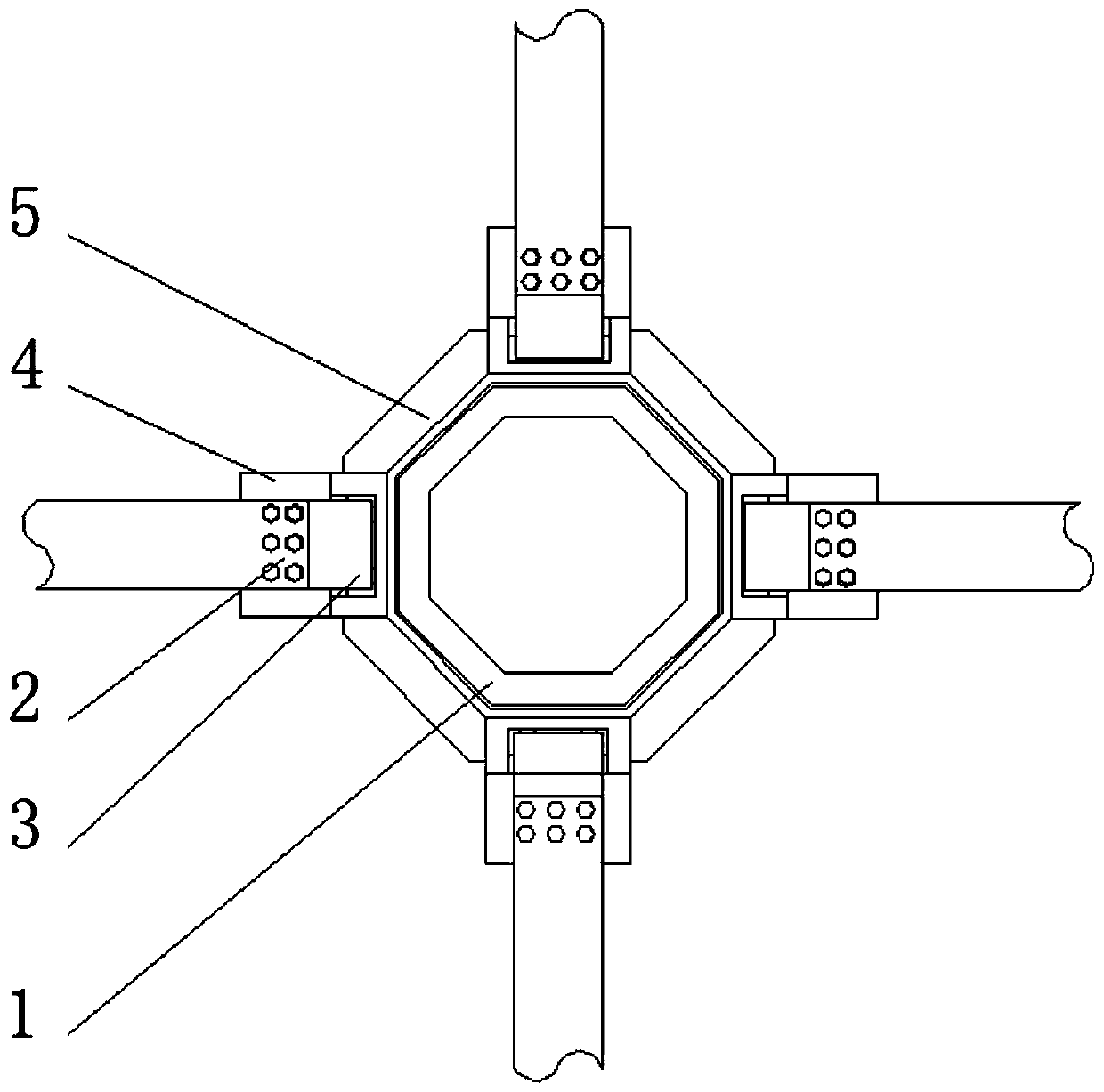

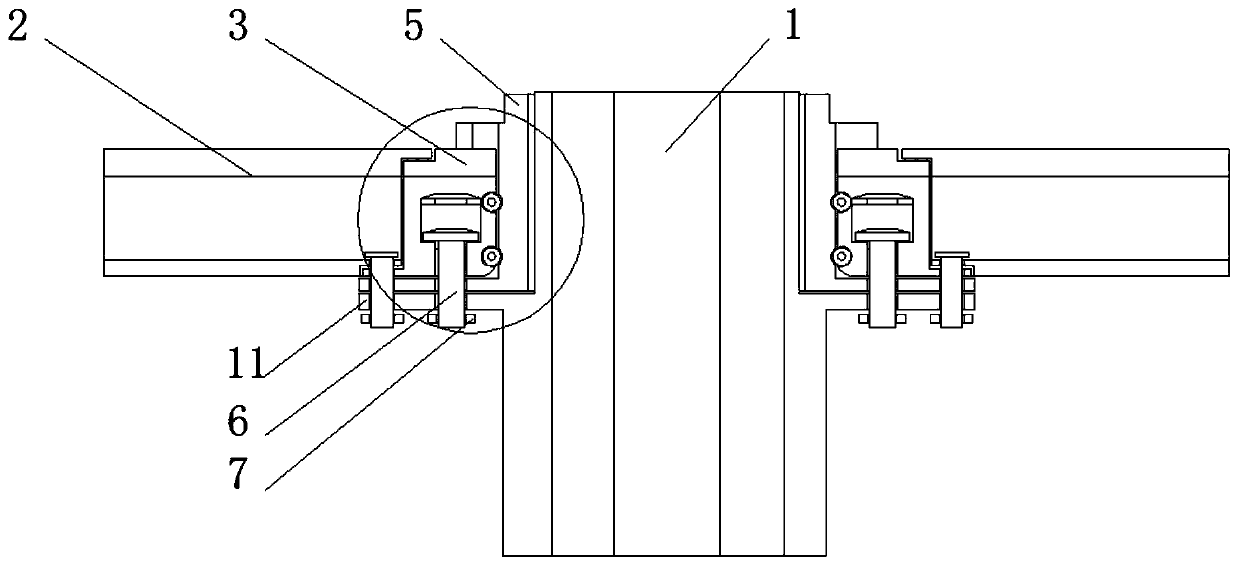

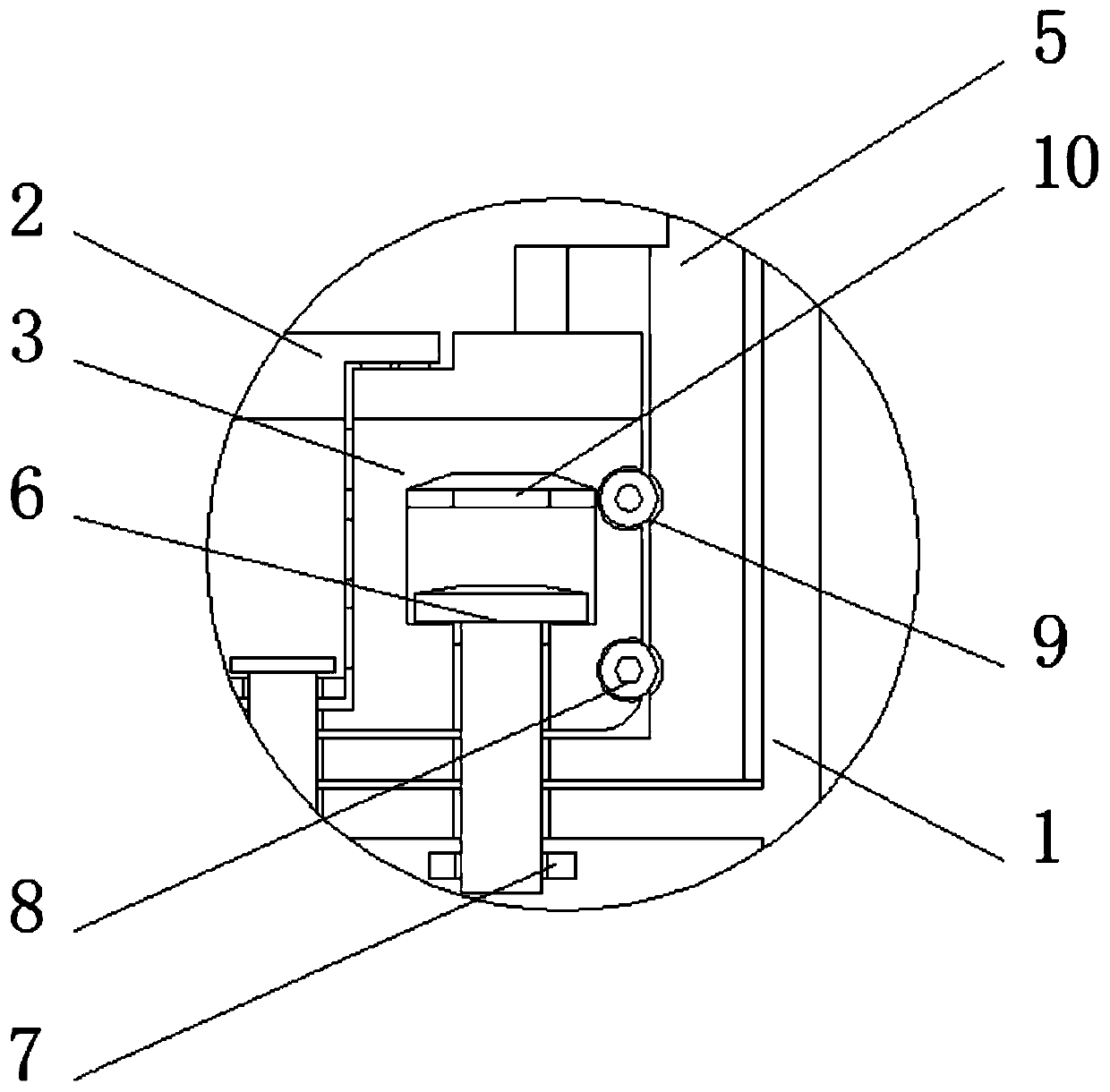

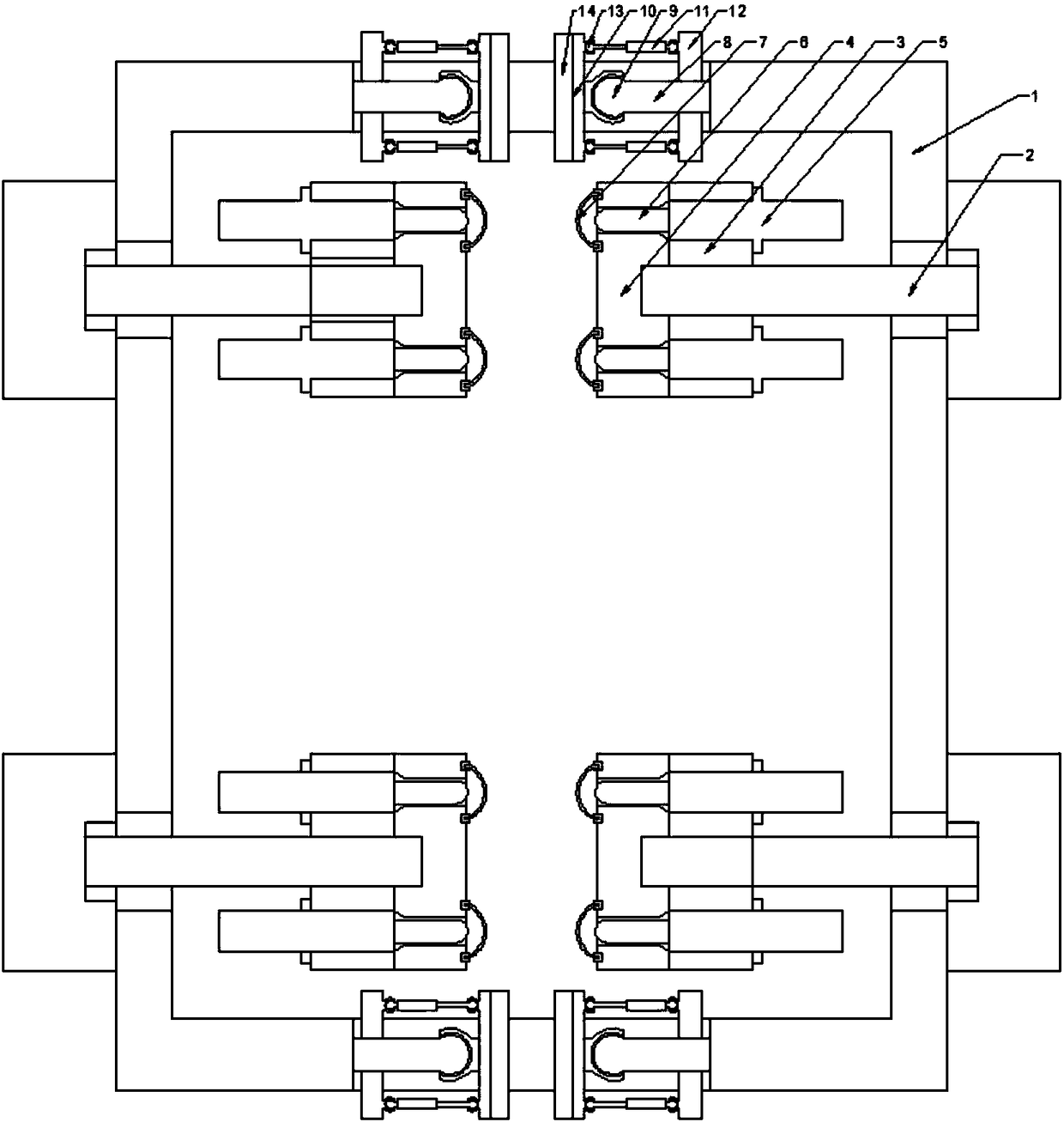

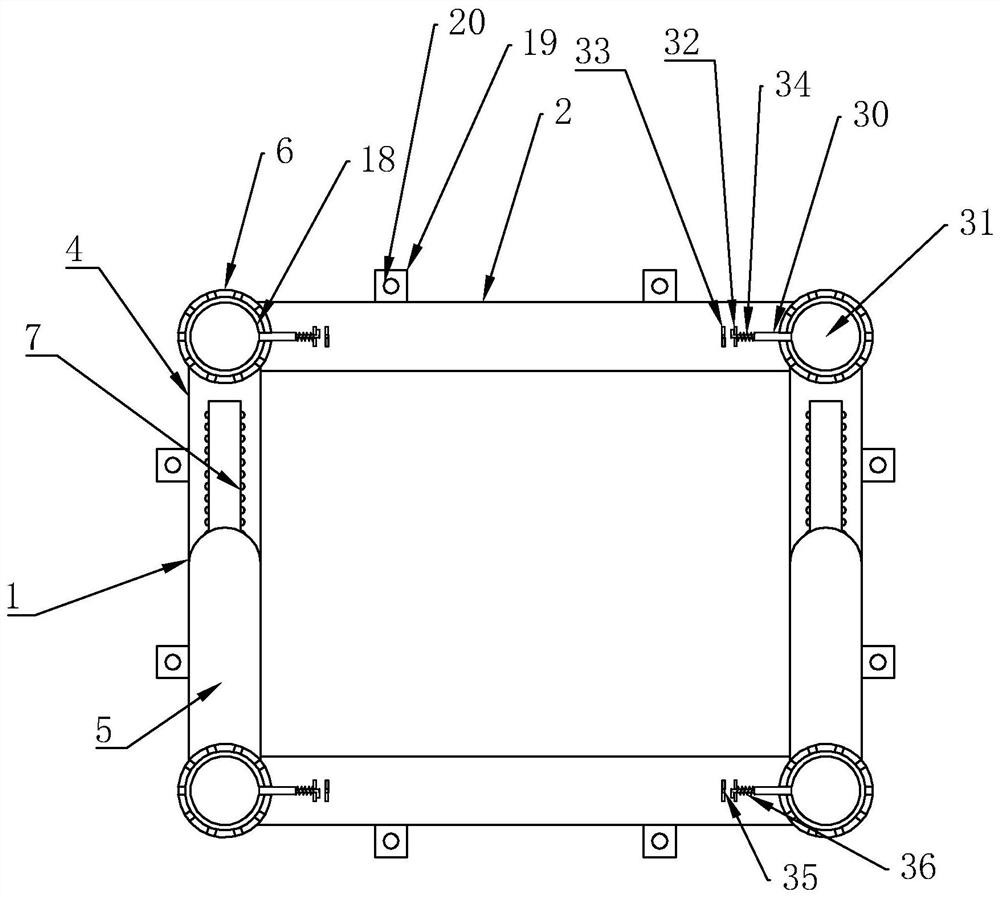

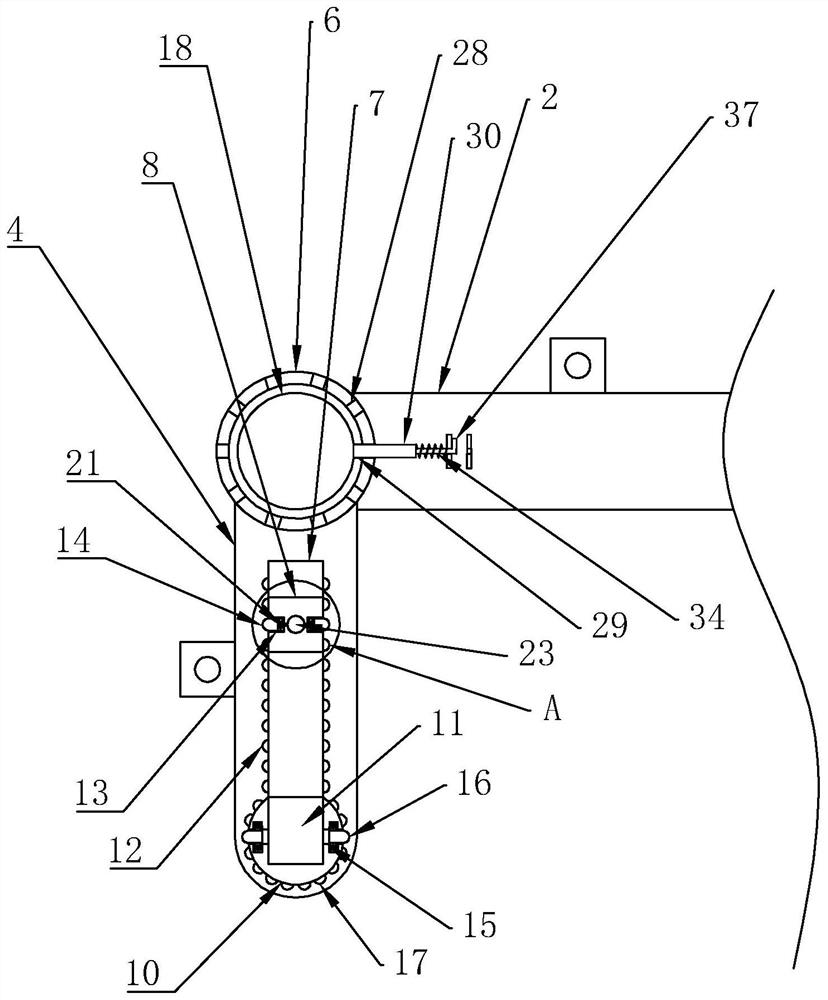

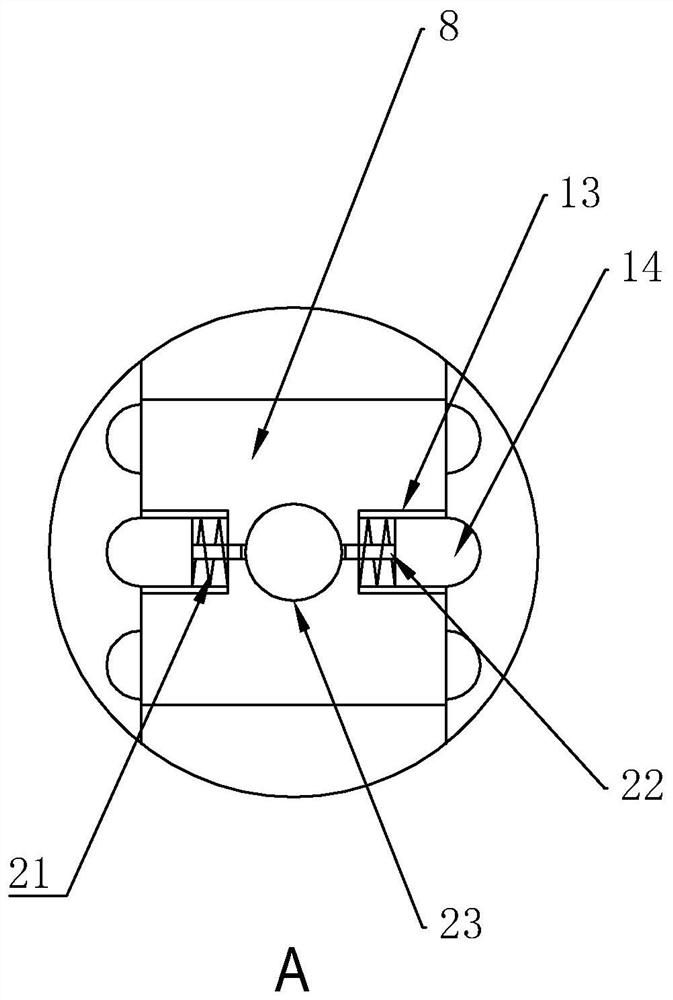

Scaffold steel tube spatial assembling fastener and sliding sleeve thereof

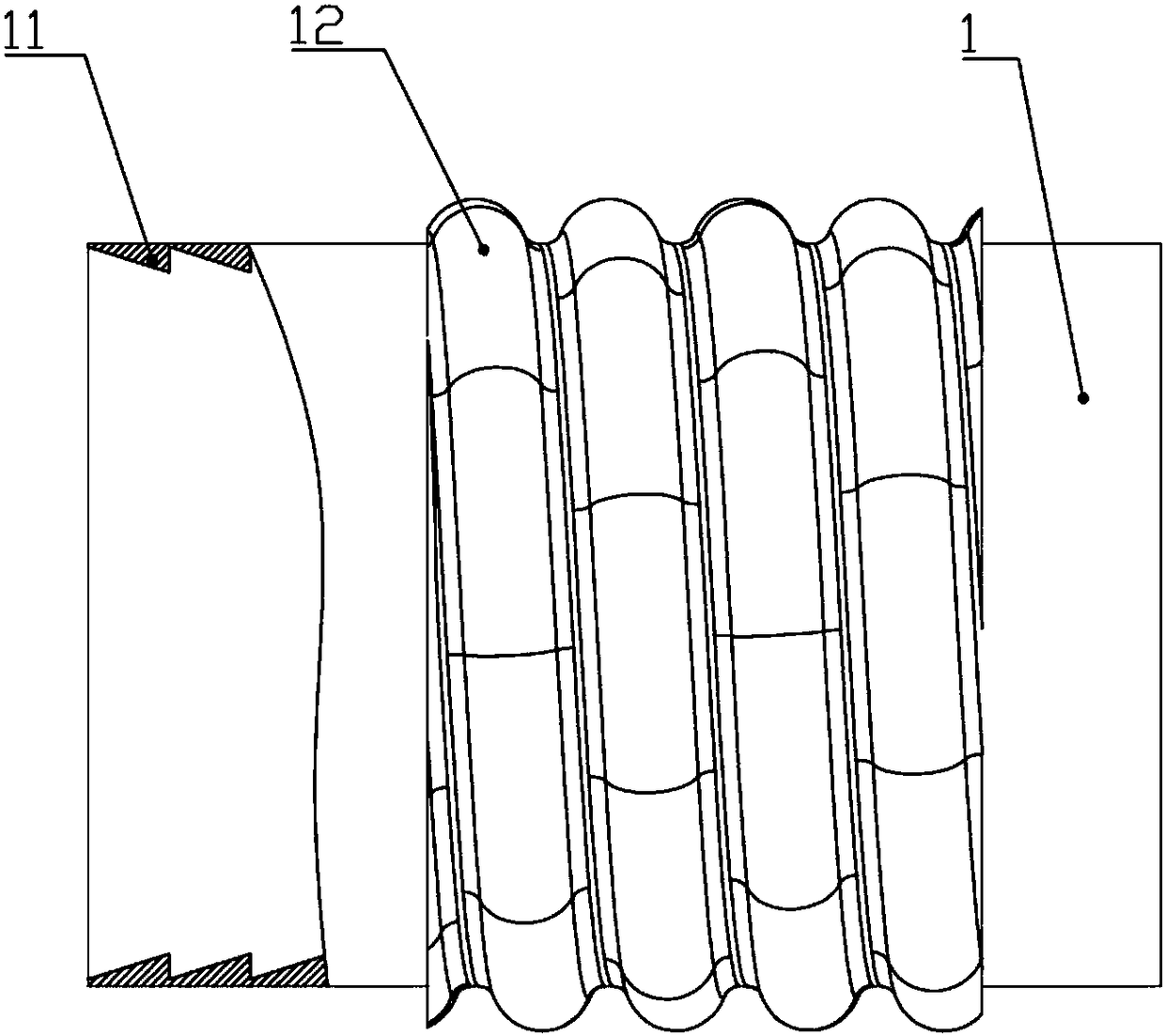

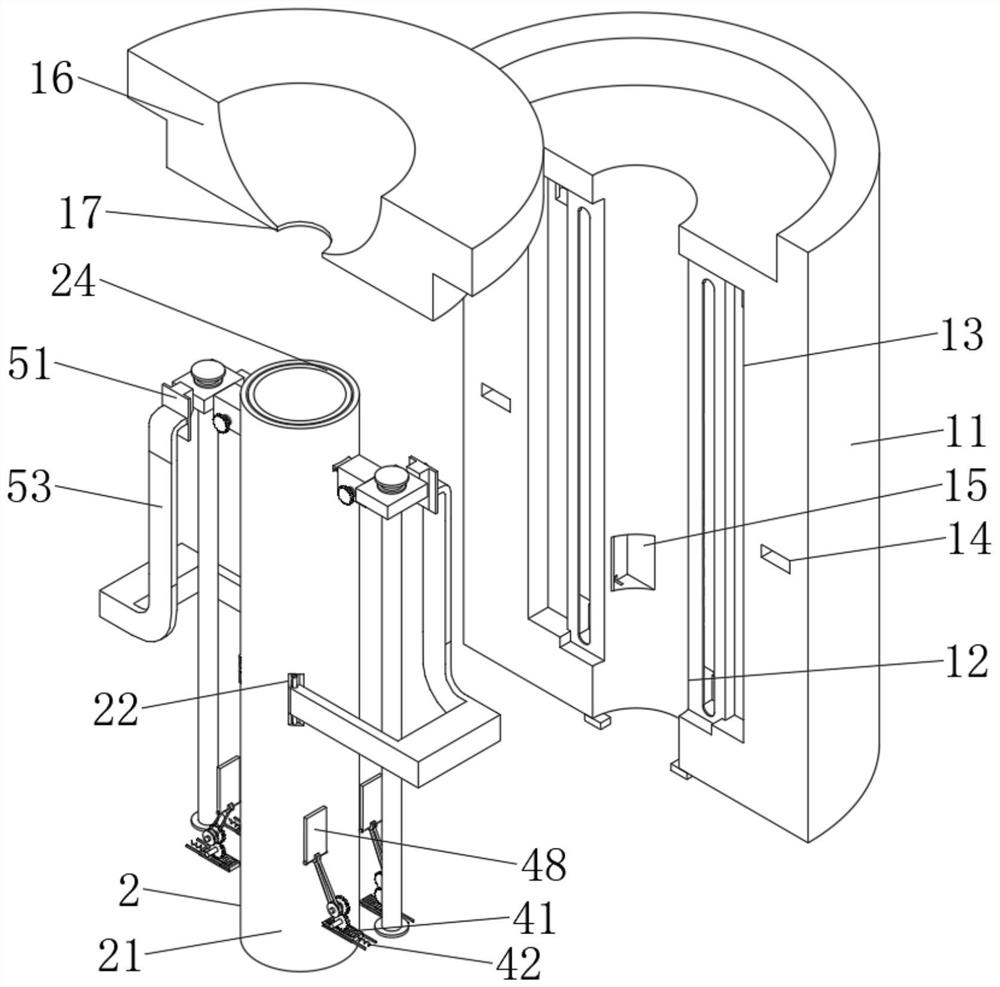

The invention relates to the field of scaffold fasteners and particularly relates to a scaffold steel tube spatial assembling fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve, two sets of pressing assemblies are arranged on the outer sides of the sliding sleeve, each pressing assembly comprises hinge bases oppositely distributed on the sliding sleeve along the axial direction of the sliding sleeve, the hinge axes of the two hinge bases are parallel and spatially and perpendicularly crossed with a central line of the sliding sleeve, a containing opening for containing scaffold steel tubes is enclosed between the upper portions of the two hinge bases, an expansion block installation groove is enclosed between the lower portions of the two hinge bases, an opening is arranged between the two hinge bases on the wall of the sliding sleeve, a pressing slider is assembled in the opening, an expansion slider for being firmly wedged between the scaffold steel tubes and the pressing slider in the containing opening is assembled in the expansion block installation groove, and the hinge bases of the two sets of pressing assemblies are spatially and perpendicularly crossed. The scaffold steel tube spatial assembling fastener has the advantages of being convenient to operate, reliable to fix and not apt to lose and can simultaneously fix three spatially crossed scaffold steel tubes.

Owner:朱晓龙

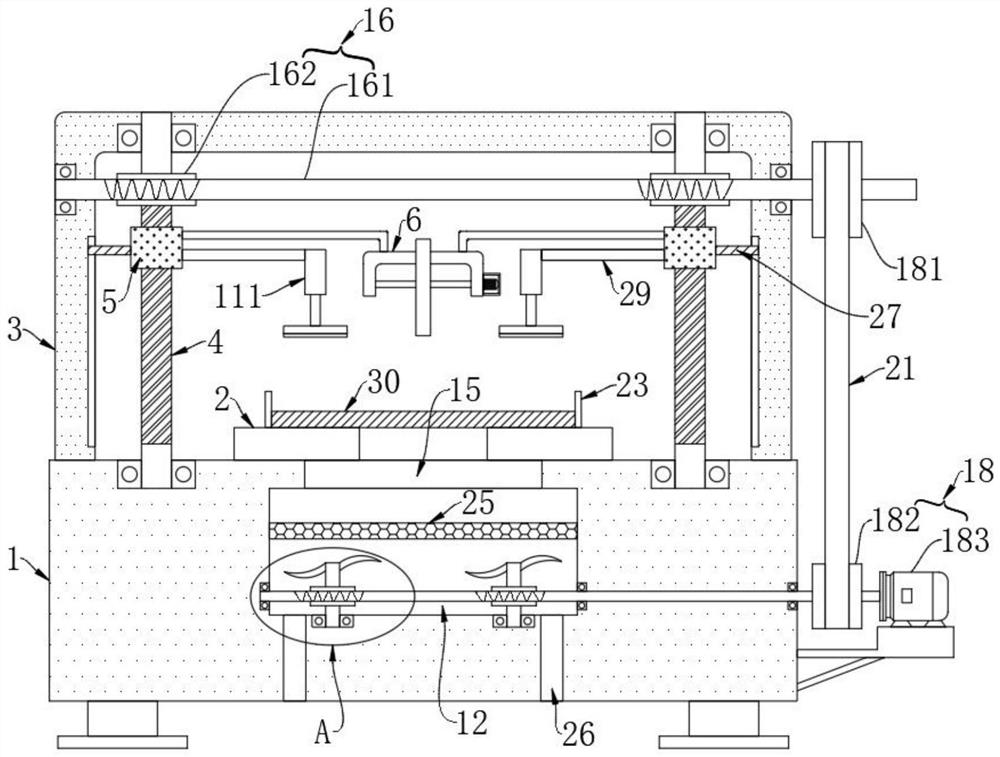

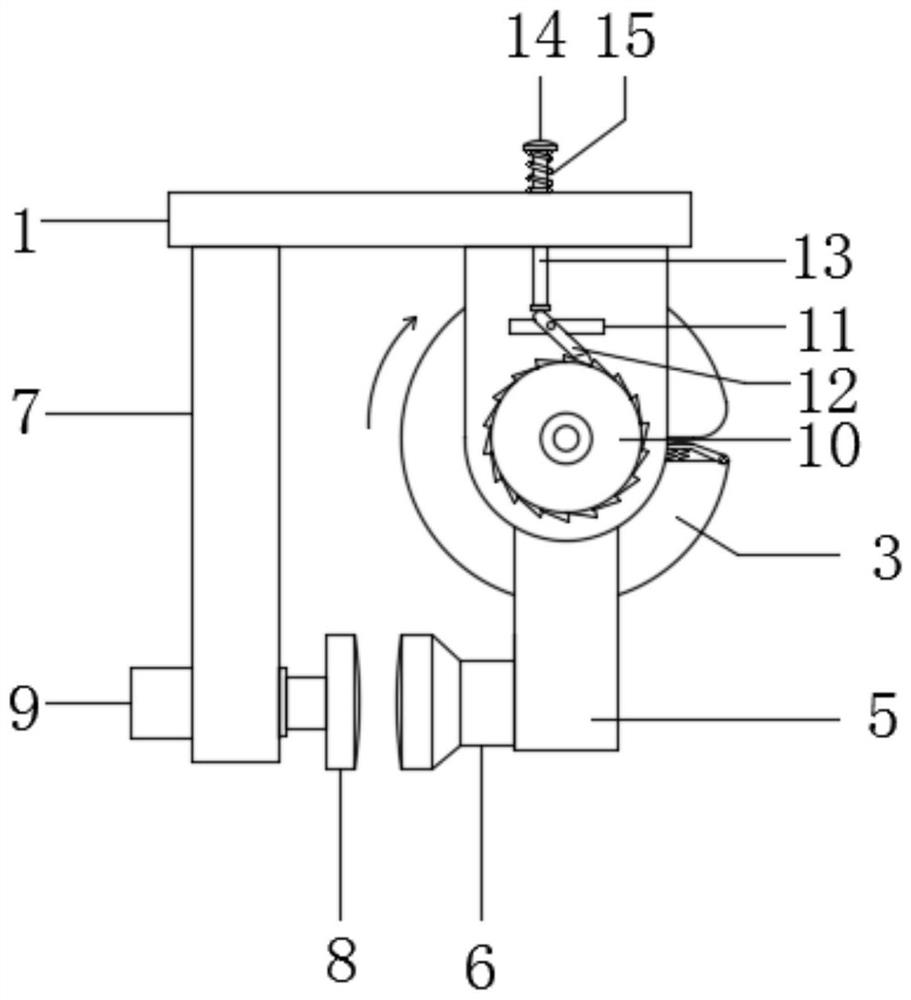

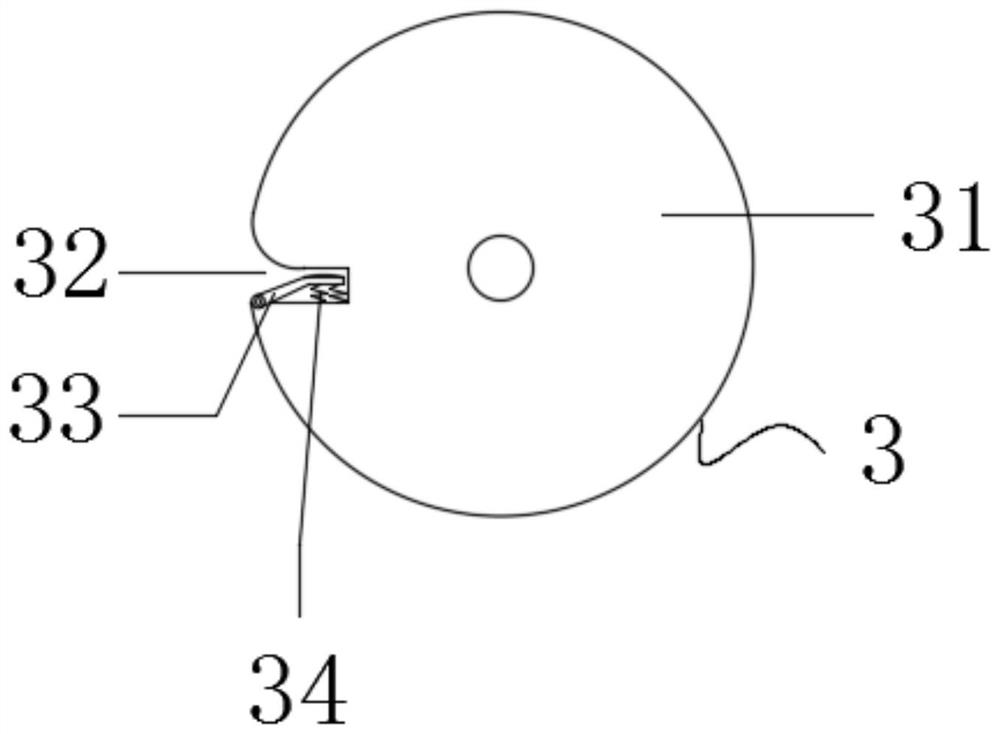

Plate cutting device capable of achieving automatic stabilization and self-cleaning

PendingCN112792925ALow costAvoid pollutionProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringFan blade

The invention belongs to the field of plate processing, and particularly relates to a plate cutting device capable of achieving automatic stabilization and self-cleaning. The plate cutting device comprises a workbench, two symmetrically-arranged placement blocks are fixedly connected to the workbench, a support is fixedly connected to the workbench, two symmetrically-arranged reciprocating lead screws are rotatably connected to a portion between the support and the workbench, sleeves are connected to the reciprocating lead screws in a threaded manner, and a frame is fixedly connected to a position between the two sleeves. According to the plate cutting device capable of achieving automatic stabilization and self-cleaning, through cooperation of a first linkage mechanism, a second linkage mechanism and a driving mechanism, a cutting knife and a pressing plate can be matched with air suction fan blades to synchronously work, and therefore it is guaranteed that the pressing plate presses a wood board in the cutting process, the wood board is kept stable, and manpower consumption is avoided; and meanwhile, in the cutting process, chippings generated by air suction of the air suction fan blades can be utilized, and therefore the situation that the chippings fly randomly and pollute the surrounding environment is avoided.

Owner:李炀炀

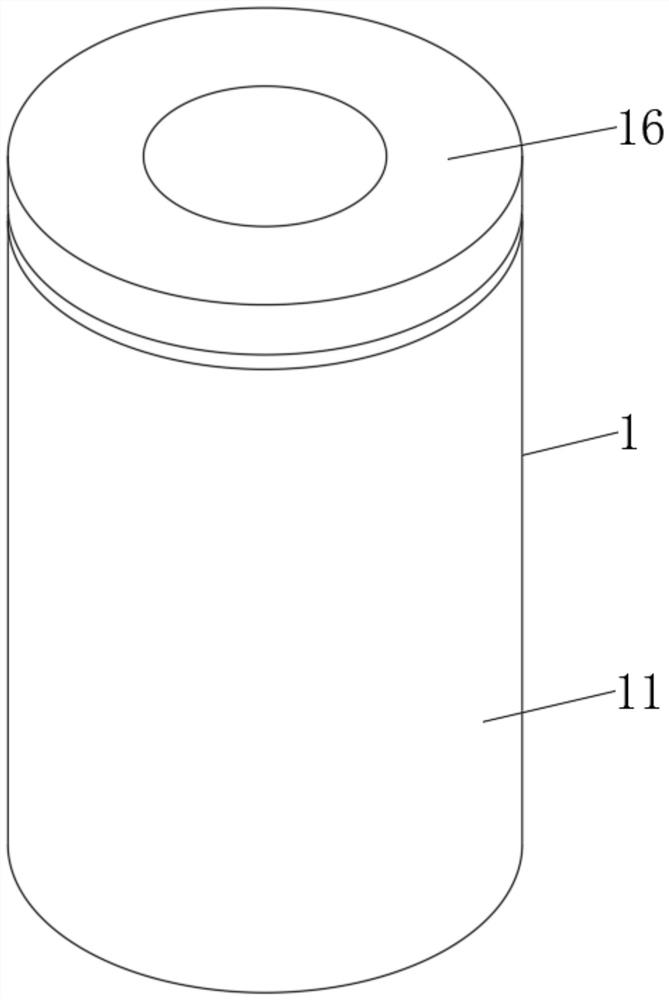

Battery pack manufacturing method

InactiveCN112421088AEasy to inject glueIncrease productivityAssembling battery machinesFinal product manufactureProcess engineeringElectrical and Electronics engineering

The invention provides a battery pack manufacturing method, and the method comprises the following steps: 1, putting an assembled battery module into a lower shell, and keeping a certain gap between the battery module and the peripheral side wall of the lower shell; 2, injecting a pouring sealant into a gap between the battery module and the lower shell, performing standing for a period of time, solidifying the pouring sealant, and achieving the pre-fixing of the battery module; 3, connecting the upper shell to the lower shell in a sealing manner to form a complete battery shell; 4, injectingthe pouring sealant into the battery shell from the sealant pouring hole in the upper shell until the pouring sealant fills the remaining space in the battery shell, and then performing standing for aperiod of time, so that the pouring sealant is cured. The battery module has the beneficial effects that after the battery module is placed in the lower shell, glue is injected firstly to realize pre-fixation, and the upper opening of the whole lower shell can be used as a glue injection hole, so that the glue injection is very convenient, and the production efficiency can be greatly improved; inaddition, the whole process is visible, quality control is facilitated, and the uniformity of the thickness of the peripheral adhesive layer is guaranteed.

Owner:HENAN BENMA +1

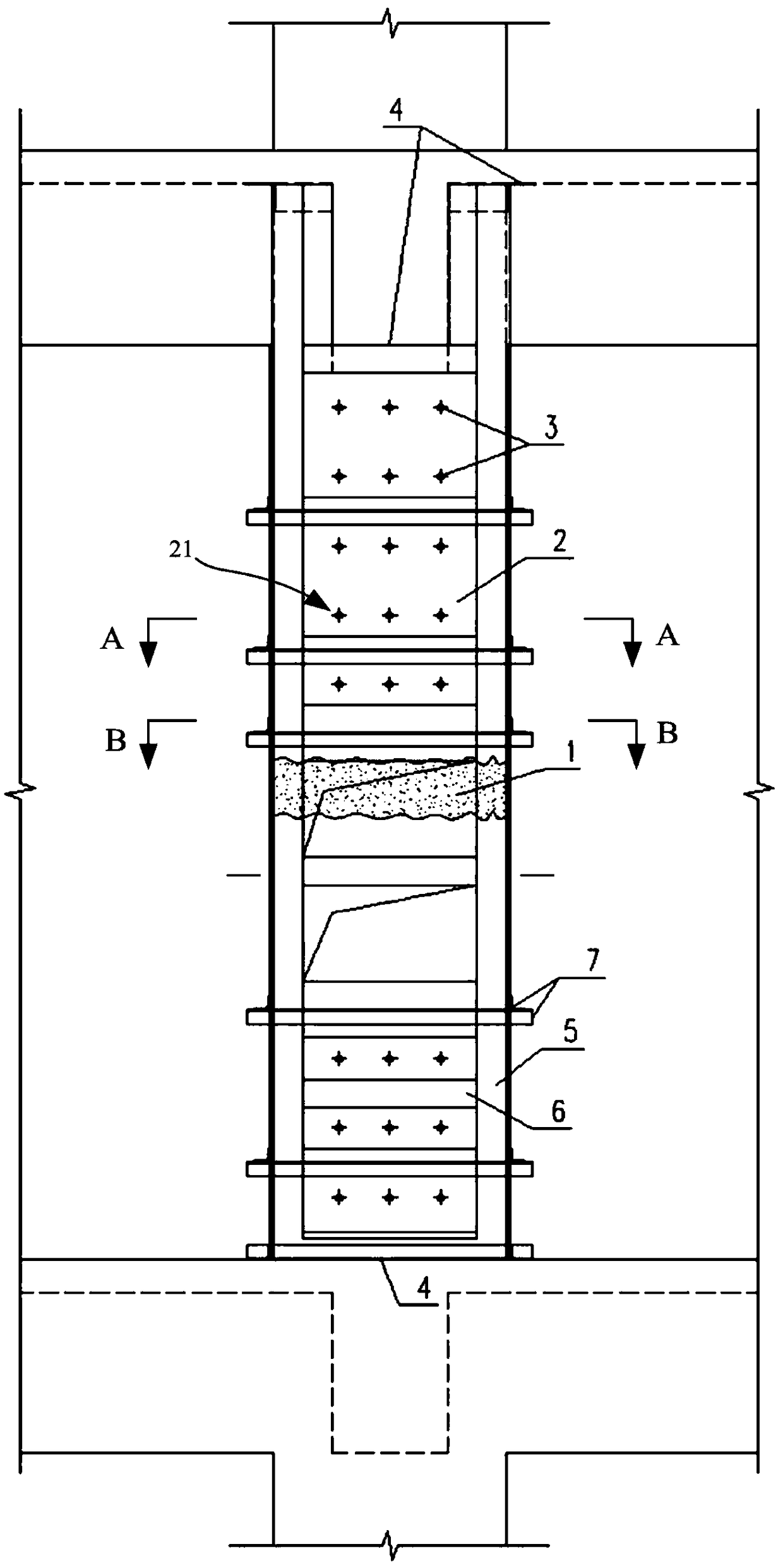

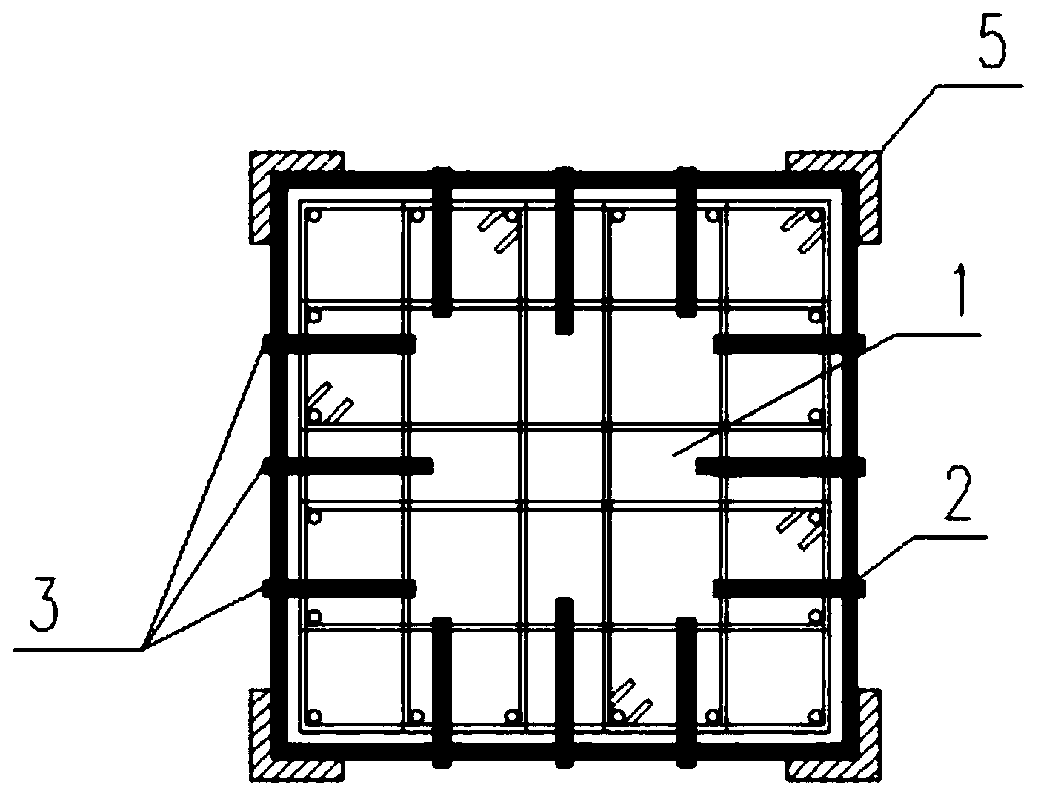

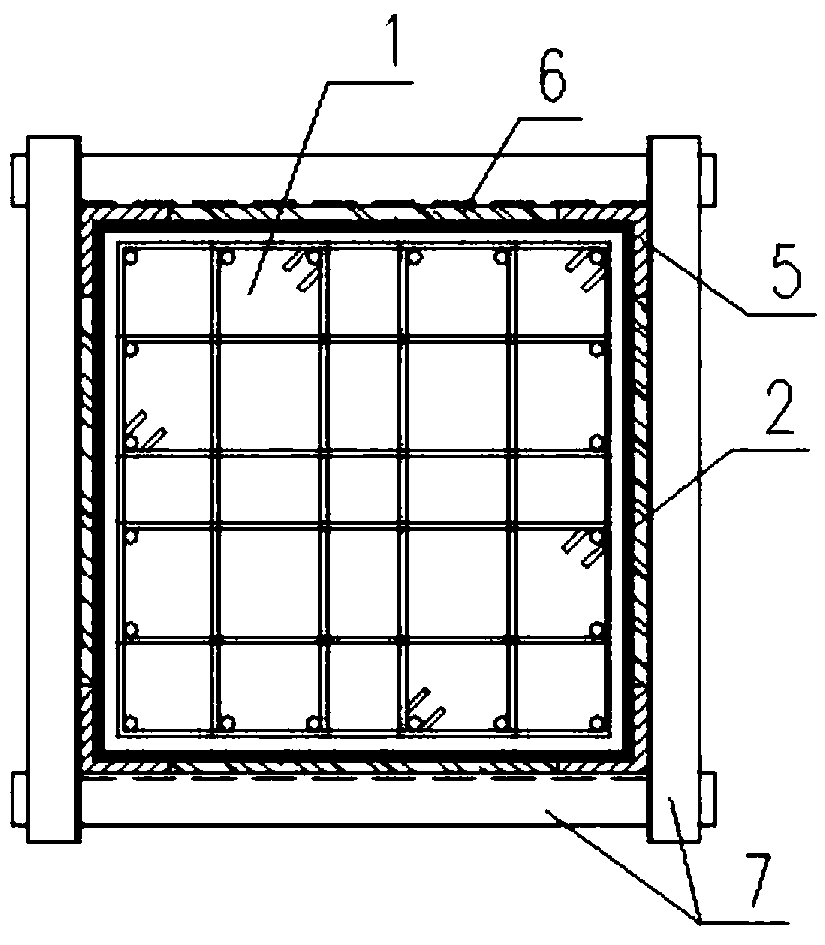

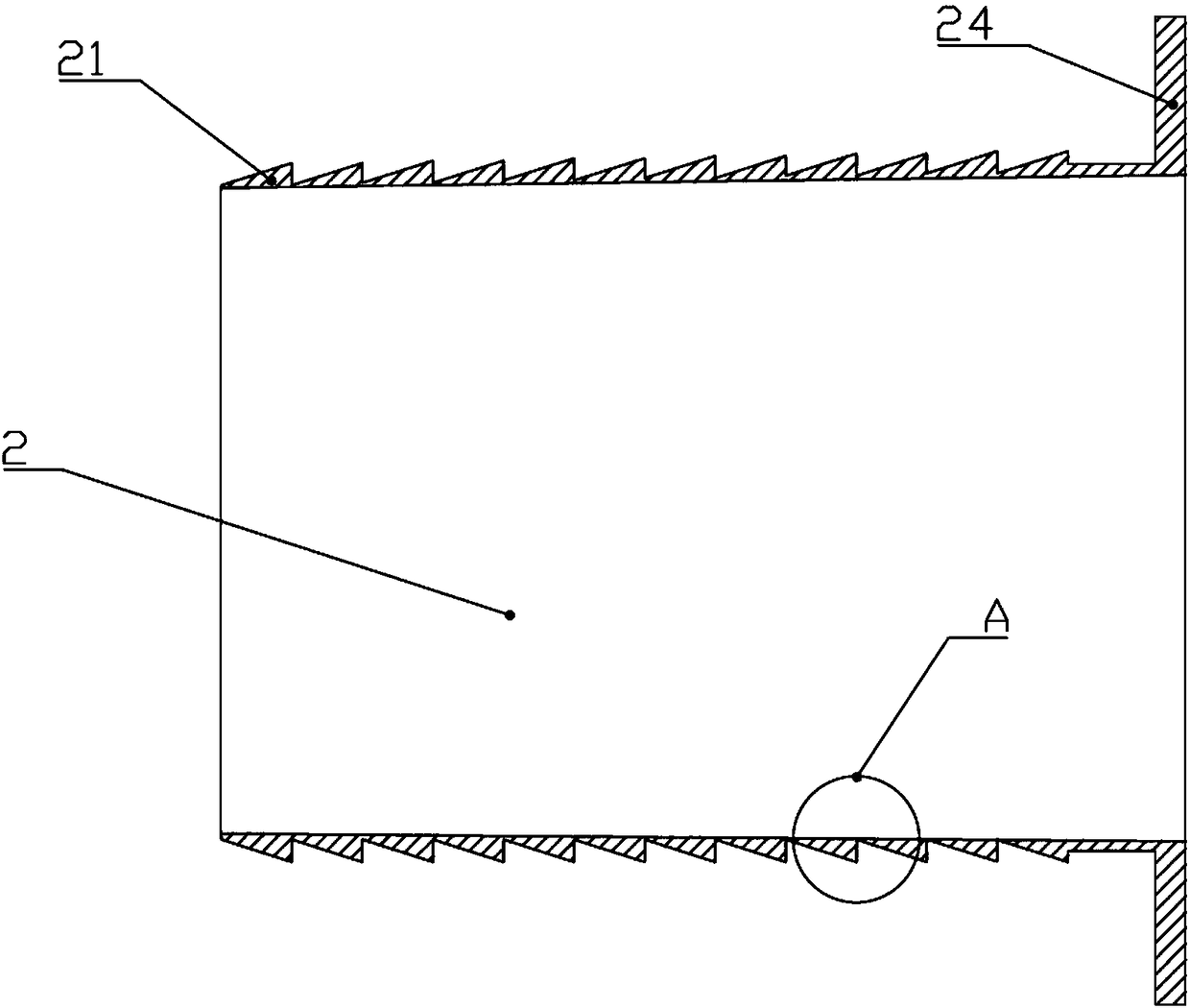

Reinforced structure and reinforced method for large-tonnage concrete column replacement

PendingCN108756291AAvoid influenceImprove bearing capacity safety factorBuilding repairsAdhesiveUltimate tensile strength

The invention discloses a reinforced structure for large-tonnage concrete column replacement. The reinforced structure comprises a plurality of inner bundle steel plates which surround the outer circumference surface of a concrete column. The adjacent edges of the inner bundle steel plates are fixedly connected to form an integrated structure, the edges of the inner bundle steel plates are fixedlyconnected with reinforced angle steel, and the end portions of the inner bundle steel plates are fixedly connected with joint angle steel. A plurality of preformed holes are formed in the surfaces ofthe inner bundle steel plates and connected with the concrete column in a pre-fastening mode through a fastening structure. The outer circumference surfaces of the inner bundle steel plates are tightened by structural steel hoops, and adhesives are poured between the inner surfaces of the inner bundle steel plates and the outer circumference surface of the concrete column to bond the inner surfaces of the inner bundle steel plates and the outer surface of the concrete column. The invention also discloses a reinforced method using the reinforced structure for the large-tonnage concrete columnreplacement. Compared with the prior art, the technical scheme has the advantages of convenient construction and reliable structure and the like, and can simplify the steps of defect replacement of the concrete column, ensure the structural strength of the concrete columns after the defect replacement and avoid the impact on subsequent use.

Owner:广东华科大建筑技术开发有限公司 +1

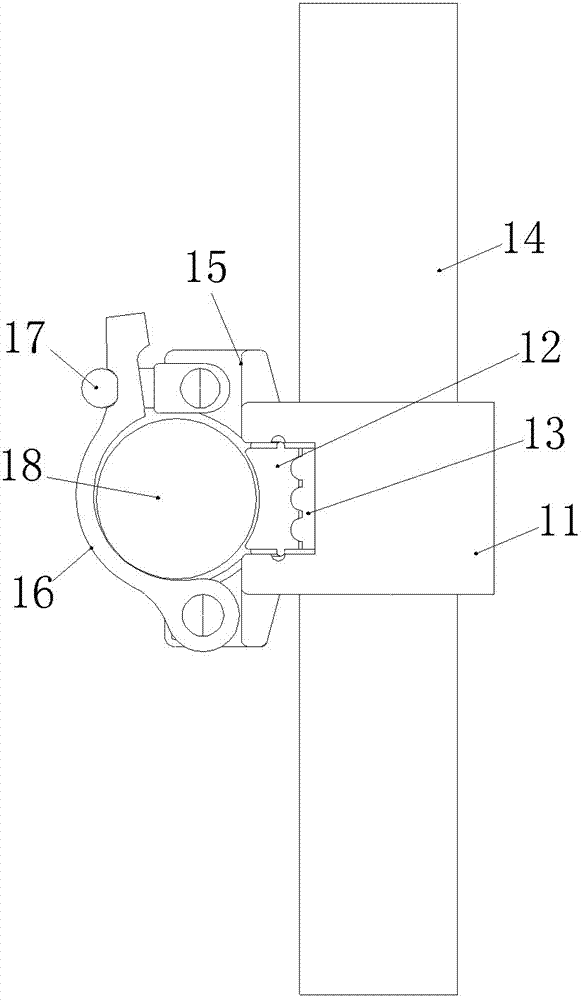

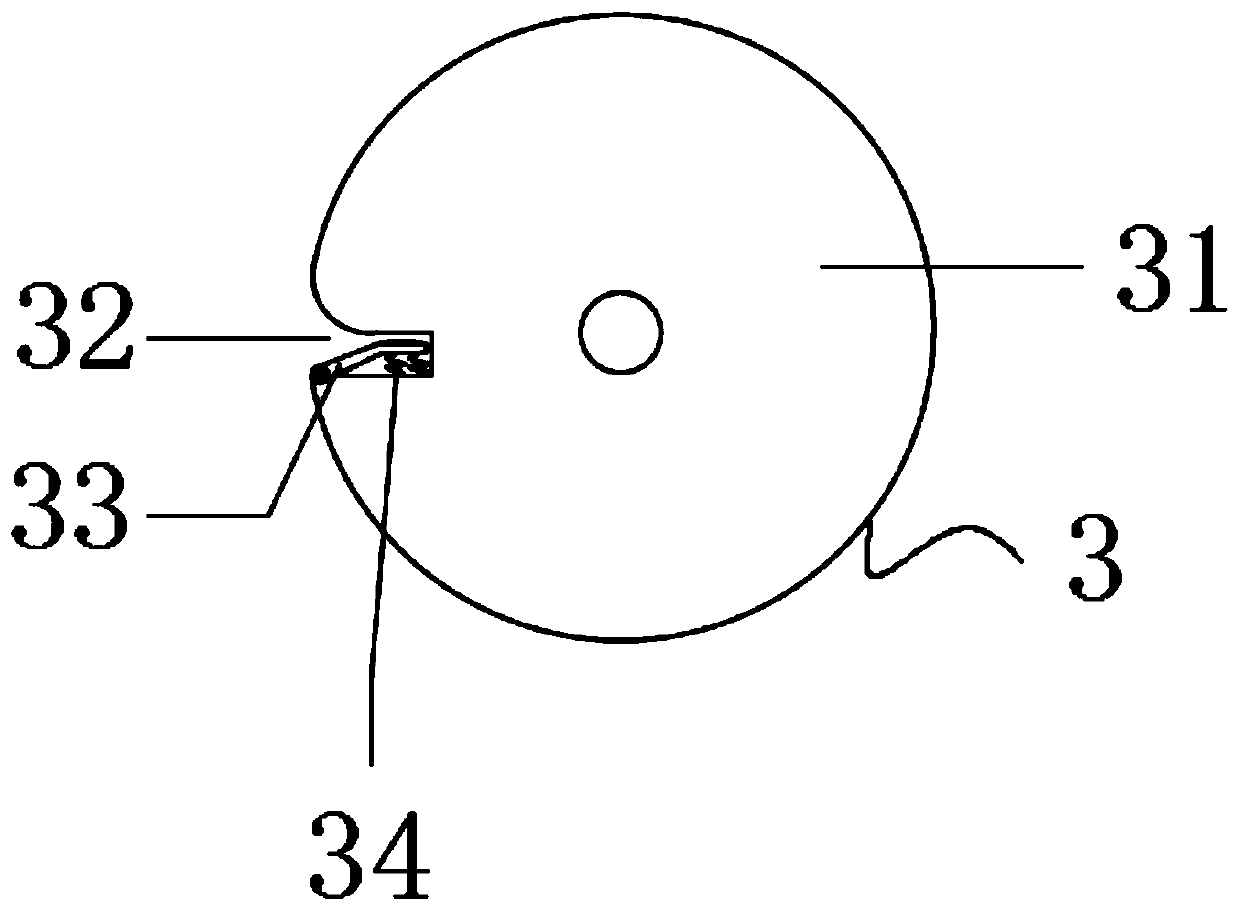

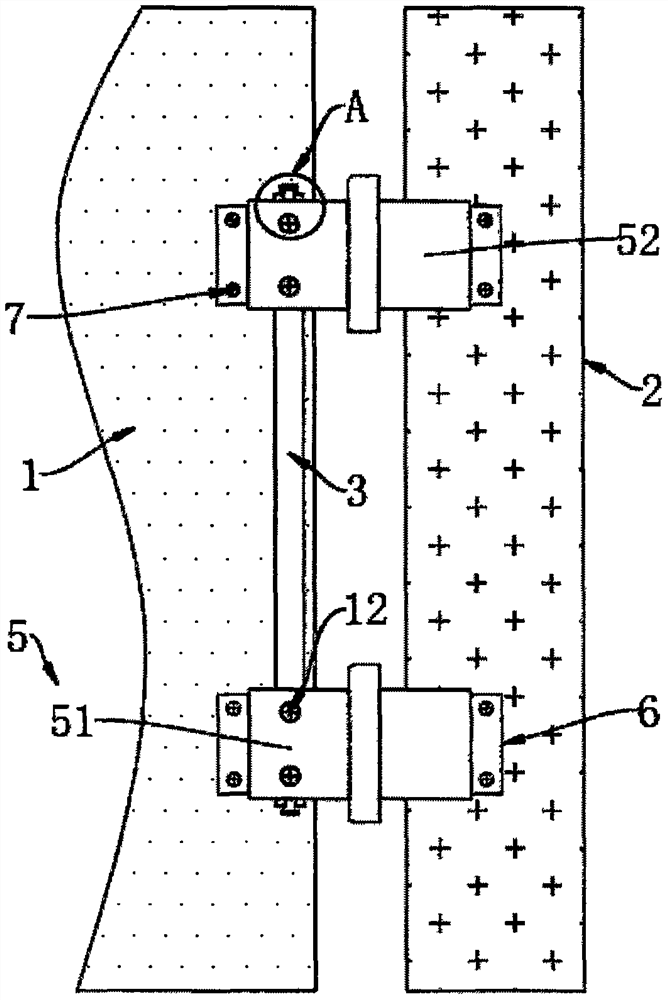

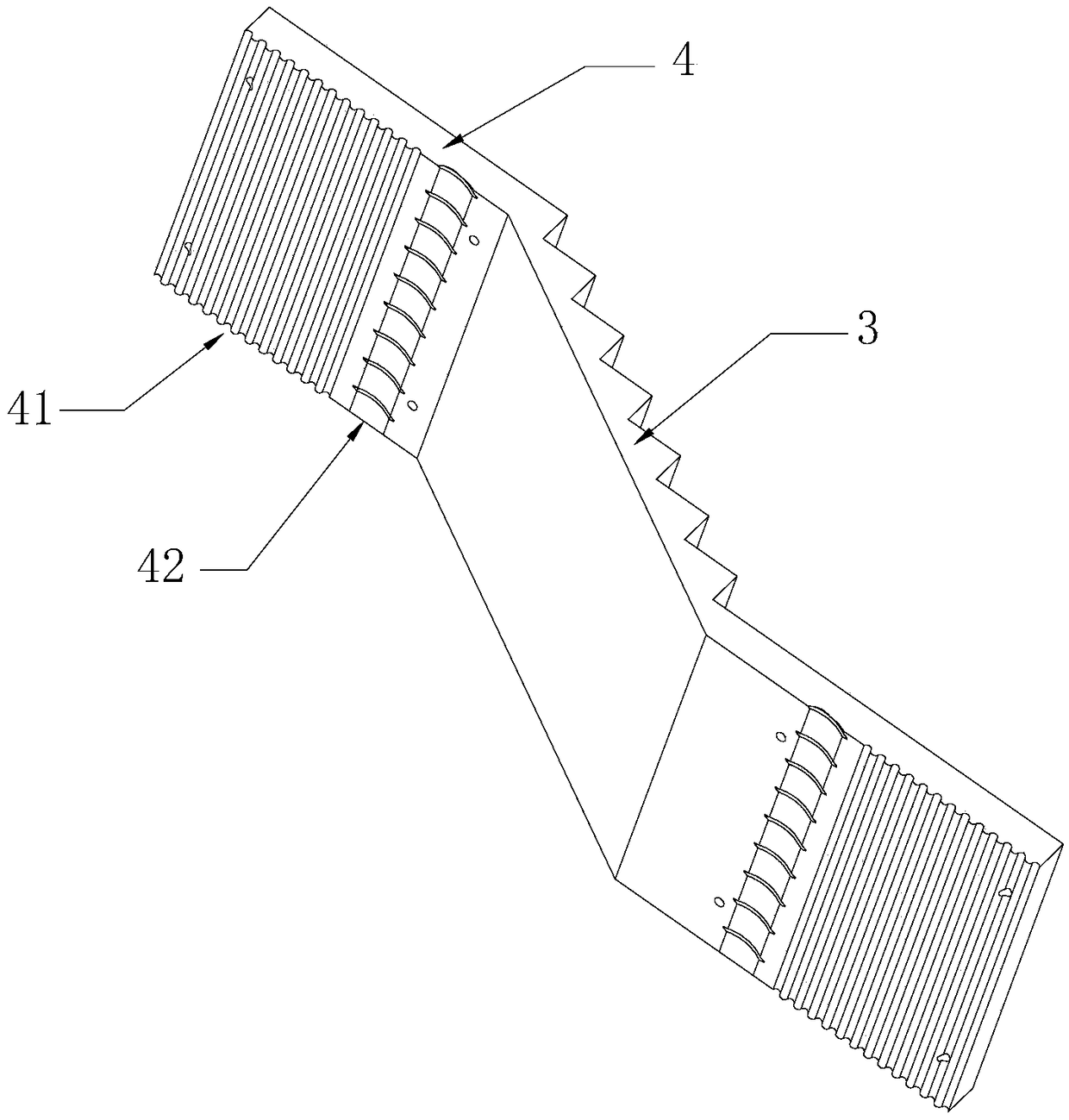

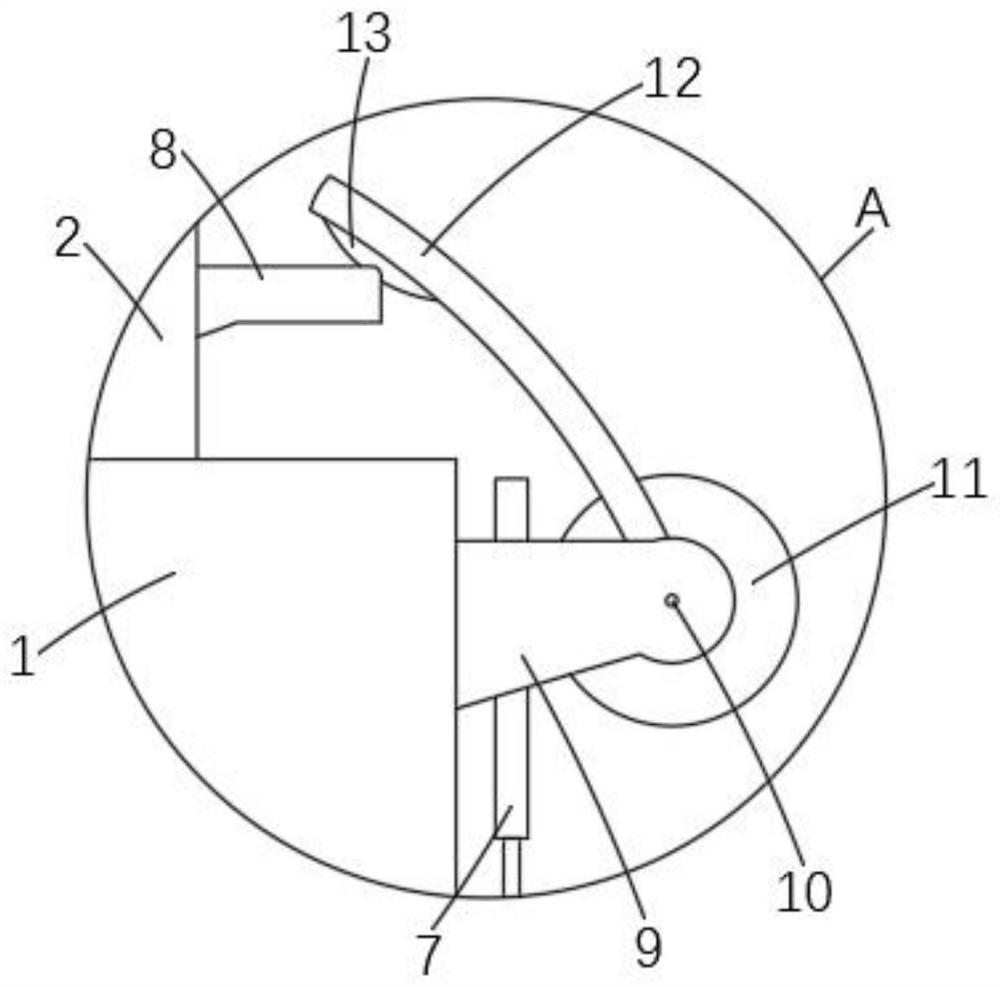

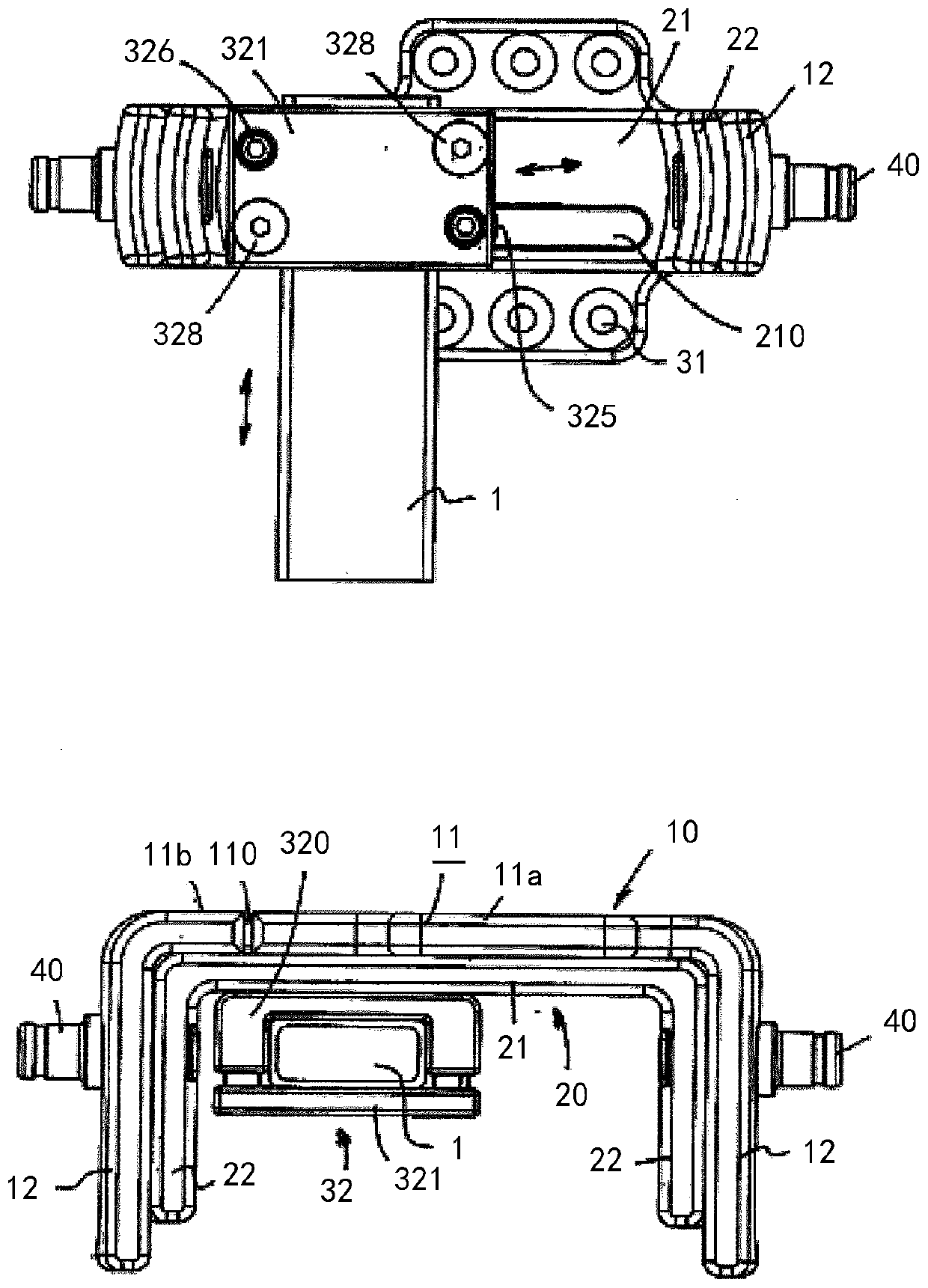

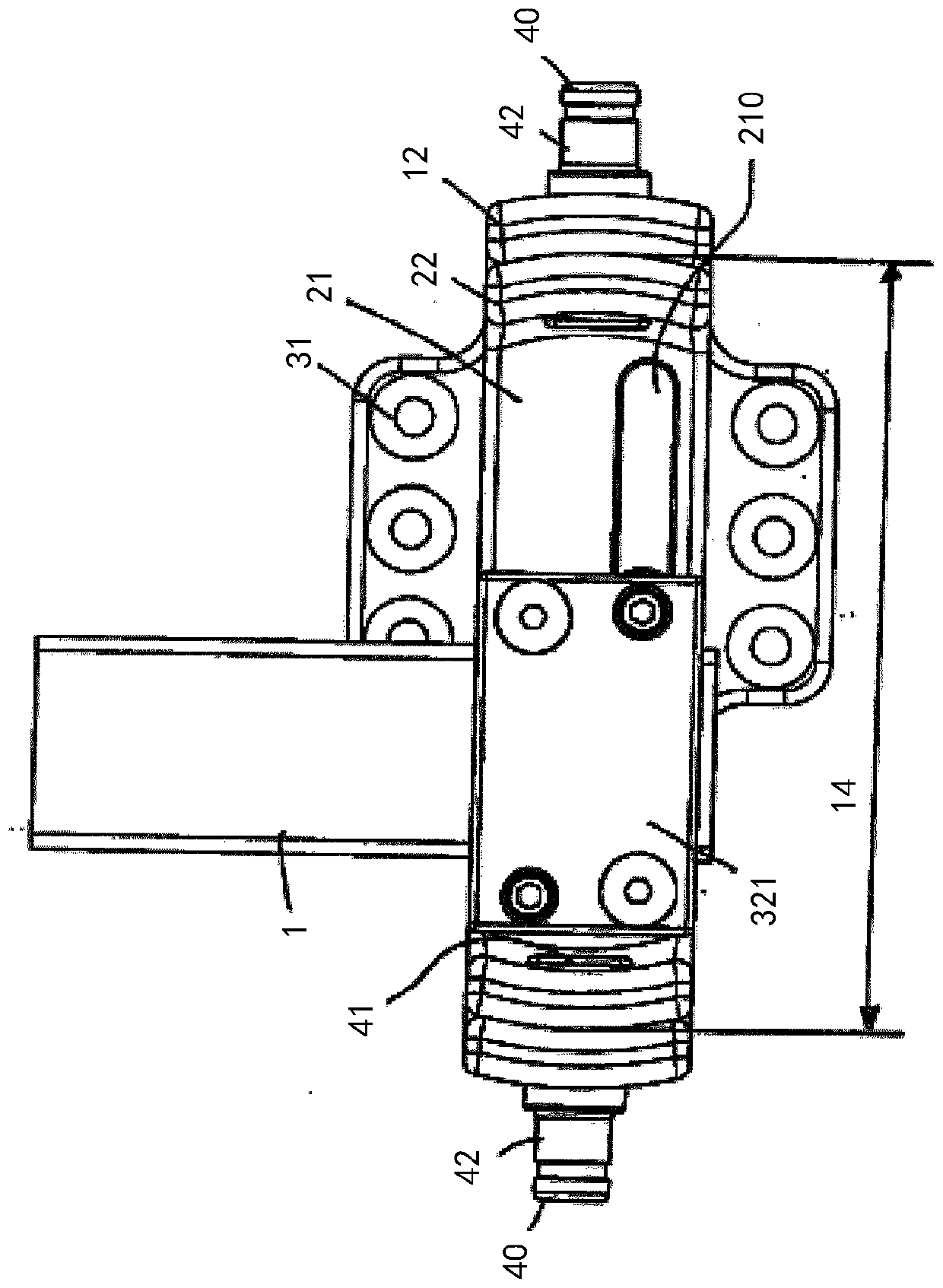

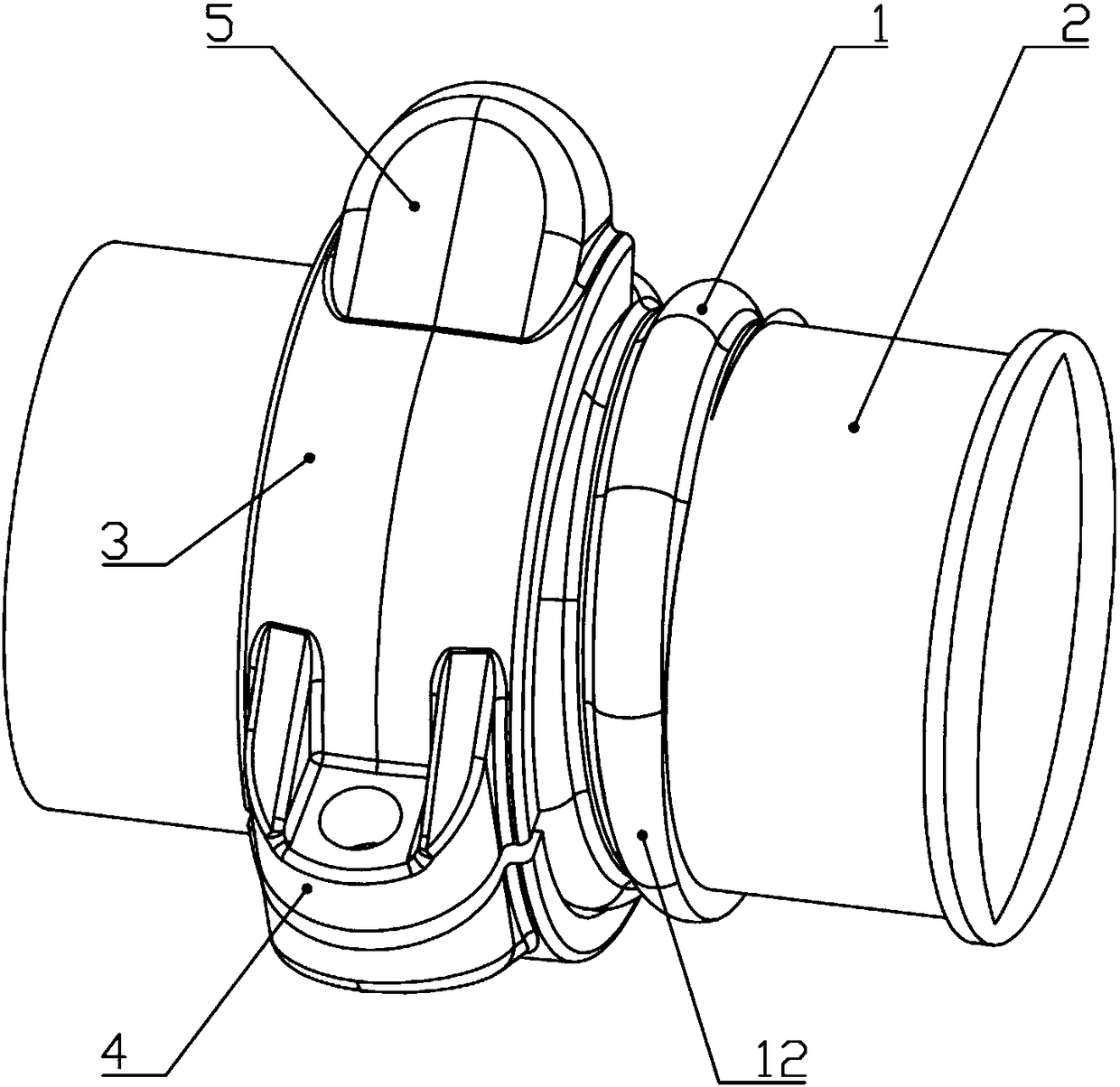

Wedge-caulking type cross fastener and sliding sleeve thereof

The invention relates to scaffold fasteners, in particular to a wedge-caulking type cross fastener and a sliding sleeve thereof. The wedge-caulking type cross fastener comprises the sliding sleeve capable of being sleeved on a scaffold base pipe in sliding mode. Two hinged supports for assembling a pressing cover and a hasp in hinged mode respectively are arranged on one side of the sliding sleeve. The two hinged supports are arranged oppositely along the axial direction of the sliding sleeve, the upper portions of the two hinged supports define an accommodating port for containing a scaffold cross pipe, and the lower portions of the two hinged supports define an expansion block installing groove. An opening penetrating through the inside and the outside is arranged at a position between the two hinged supports on a sleeve wall of the sliding sleeve. A pressing sliding block for pressing the scaffold base pipe is arranged in the opening, and an expansion sliding block for being wedged between the scaffold cross pipe and the pressing sliding block is assembled in the expansion block installing groove. During use of the fastener, only one pressing cover is required to be operated, then the expansion sliding block is knocked, operation is convenient and fast, and convenience of operation of the fastener is improved. The safety and operation convenience of the cross fastener are further improved.

Owner:朱新伟

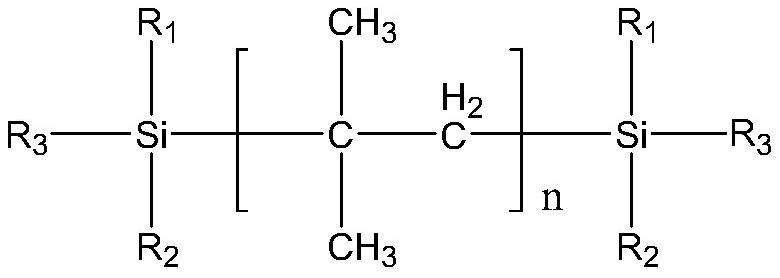

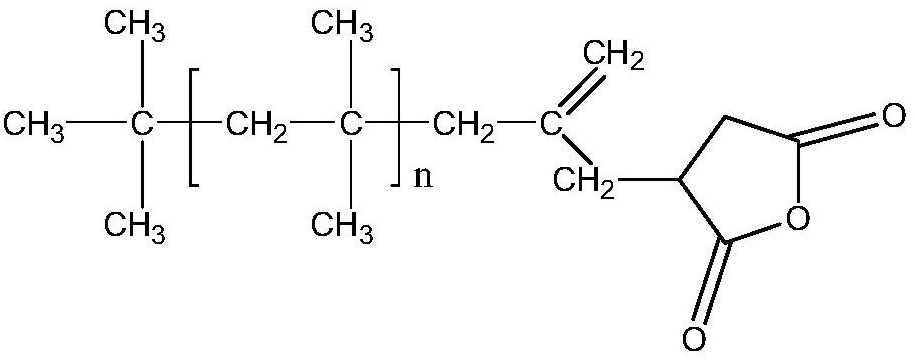

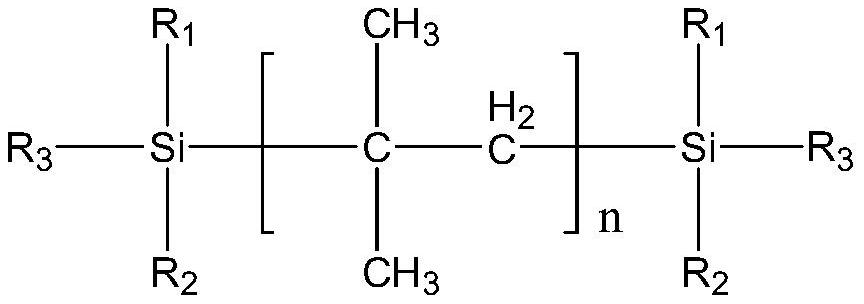

UV light and heat dual-curing high-airtightness polyisobutene glue and preparation method thereof

ActiveCN112980355AReduced Si-O bond contentAchieve pre-fixationNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer sciencePolyolefin

The invention relates to a UV light and heat dual-curing high-airtightness polyisobutene adhesive and a preparation method thereof. The method comprises the following steps: under the condition of eliminating ultraviolet light or in a yellow light chamber, sequentially adding 40-100 parts by weight of vinyl terminated polyisobutylene polymer, 30-100 parts by weight of maleic anhydride terminated polyisobutylene polymer, 10-50 parts by weight of epoxy resin, 5-15 parts by weight of inorganic filler, 5-15 parts by weight of poly-alpha-olefin plasticizer, 0.05-5 parts by weight of silane coupling agent, 0.01-1 part by weight of anti-aging agent, 0.05-2 parts by weight of hydrogen-containing silicone oil and 1.0-10 * 10 <-6 > parts by weight of ultraviolet light initiator, 1.0-10 * 10 <-5 > parts by weight of a catalyst and 5-100 * 10 <-6 > parts by weight of a maleate inhibitor into a planetary stirrer, carrying out vacuum stirring for 1 hour, and carrying out vacuum stirring again for 0.5 hour to obtain the viscous adhesive composition. Compared with the prior art, the adhesive has the advantages of high bonding strength, good air tightness, good curing effect and the like.

Owner:SHANGHAI RELAND PHOTOVOLTAIC MATERIAL

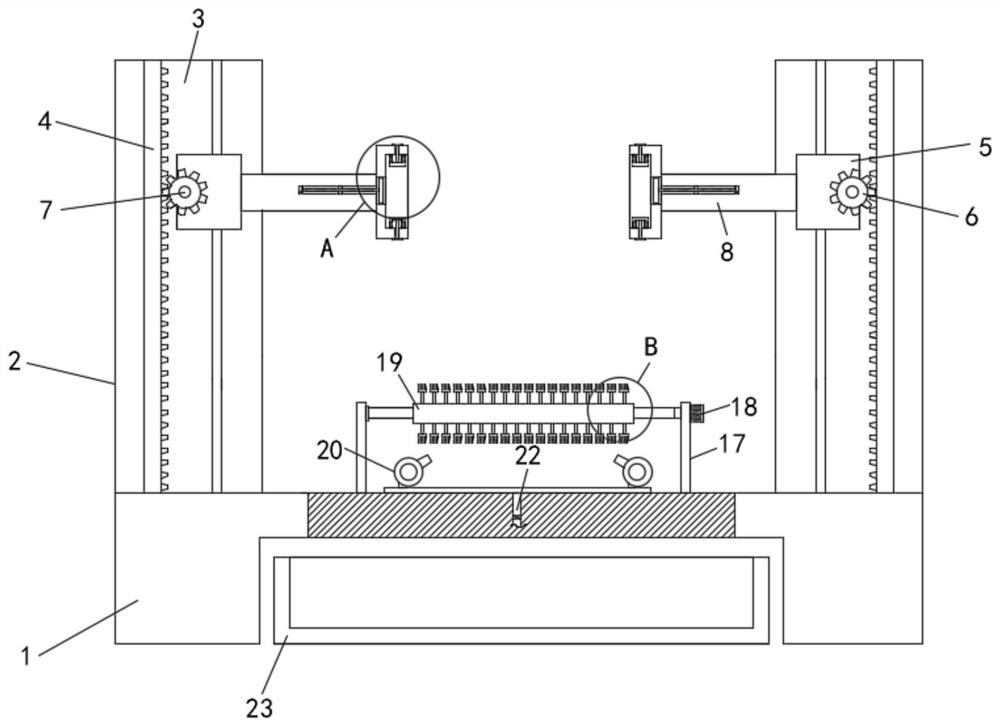

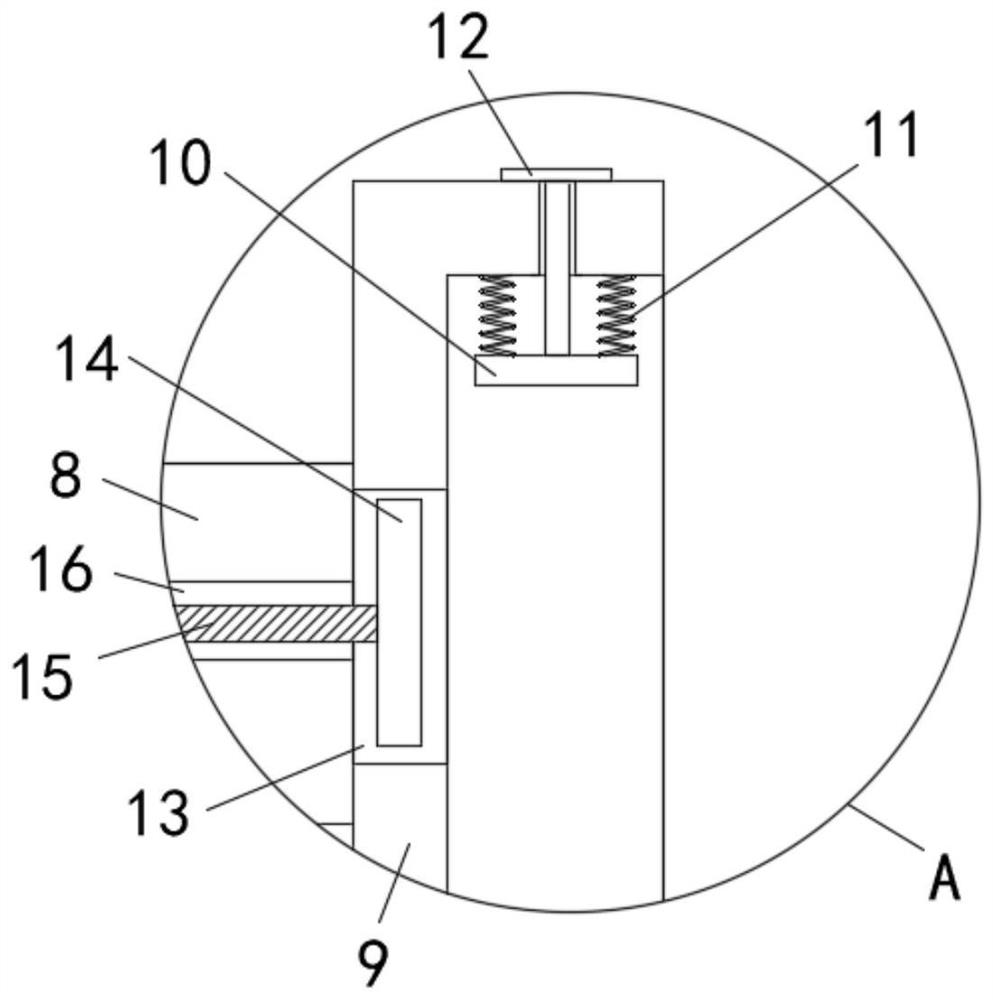

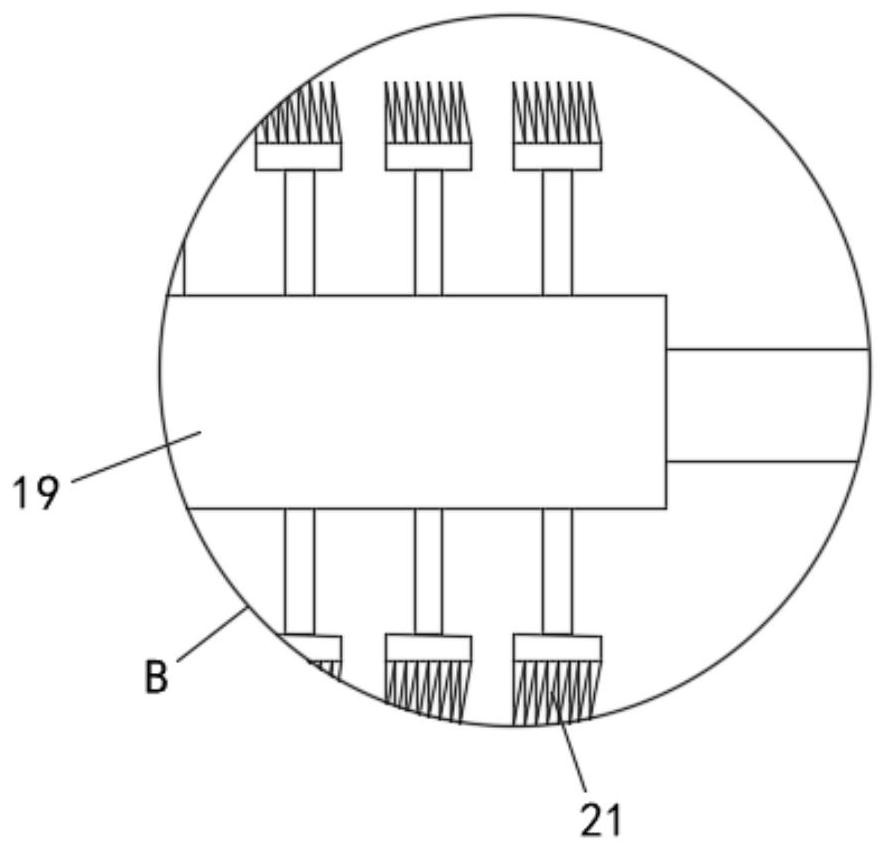

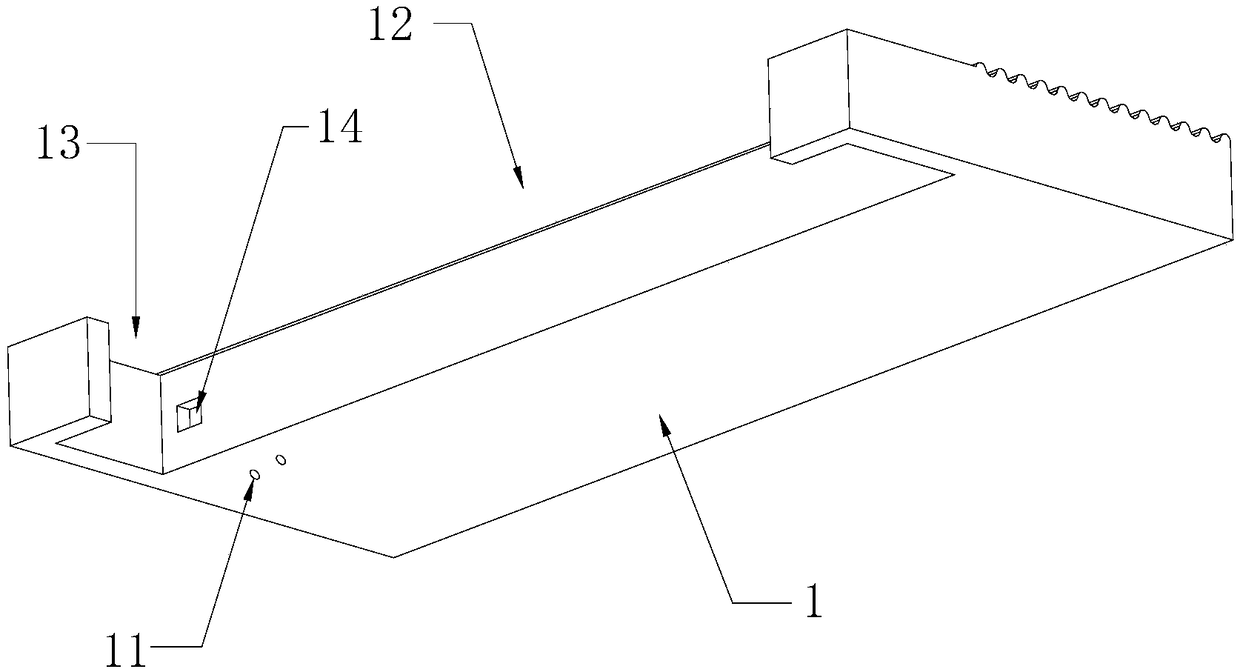

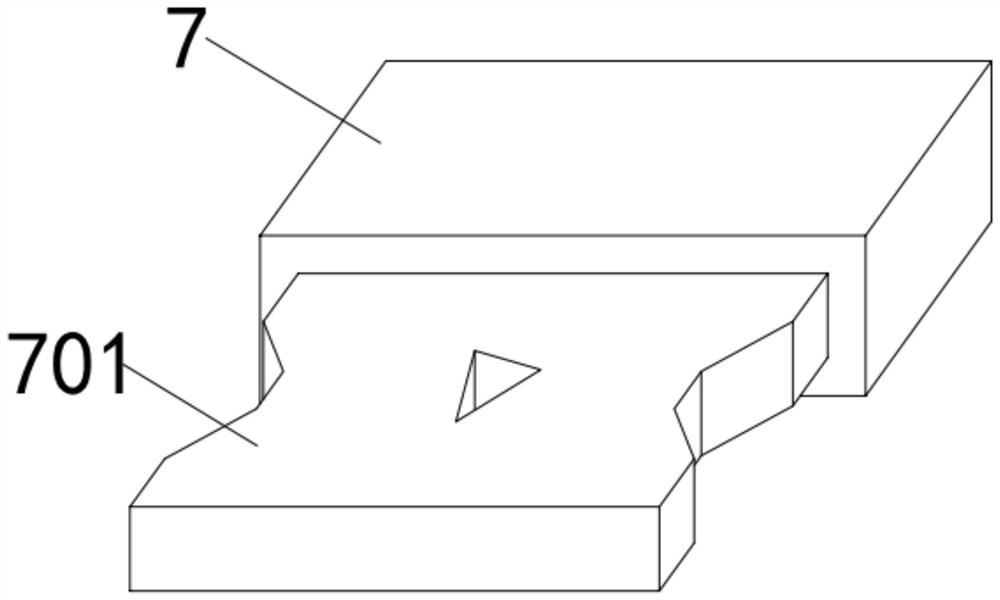

Convenient-to-use positioning device for aluminum machining

InactiveCN112775690AAchieve clampingAchieve pre-fixationCleaning using toolsCleaning using liquidsElectric machineryDrive motor

The invention discloses a convenient-to-use positioning device for aluminum machining. The positioning device comprises a supporting plate, wherein mounting plates are fixed on both sides of the top of the supporting plate; mounting grooves are arranged in the sides, close to each other, of the two mounting plates; racks are assembled on the inner walls of the mounting grooves; gears are meshed with the side surfaces of the racks; the gears are arranged in gear seats; driving motors are assembled on the inner walls of the gear seats; output shafts of the driving motors are fixed to the inner rings of the gears; side plates are fixed to the sides, close to each other, of the two gear seats; U-shaped plates are connected to the sides, close to each other, of the two side plates; first clamping plates are elastically connected to the two sides of the inner wall of each U-shaped plate; a containing groove is arranged in one side of the inner wall of each U-shaped plate; and a second clamping plate is arranged in each containing groove. According to the positioning device, the positioning range is widened, aluminum materials can be conveniently machined at different heights, meanwhile, the problem that an existing positioning device cannot conveniently clean the surfaces of the aluminum materials is solved, and the positioning device is reasonable in design and suitable for popularization.

Owner:上饶市广利装饰材料有限公司

Scaffold steel tube spatial assembling fastener and sliding sleeve thereof

The invention relates to the field of scaffold fasteners and particularly relates to a scaffold steel tube spatial assembling fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve, two sets of pressing assemblies are arranged on the outer sides of the sliding sleeve, each pressing assembly comprises hinge bases oppositely distributed on the sliding sleeve along the axial direction of the sliding sleeve, the hinge axes of the two hinge bases are parallel and spatially and perpendicularly crossed with a central line of the sliding sleeve, a containing opening for containing scaffold steel tubes is enclosed between the upper portions of the two hinge bases, an expansion block installation groove is enclosed between the lower portions of the two hinge bases, an opening is arranged between the two hinge bases on the wall of the sliding sleeve, a pressing slider is assembled in the opening, an expansion slider for being firmly wedged between the scaffold steel tubes and the pressing slider in the containing opening is assembled in the expansion block installation groove, and the hinge bases of the two sets of pressing assemblies are spatially and perpendicularly crossed. The scaffold steel tube spatial assembling fastener has the advantages of being convenient to operate, reliable to fix and not apt to lose and can simultaneously fix three spatially crossed scaffold steel tubes.

Owner:朱晓龙

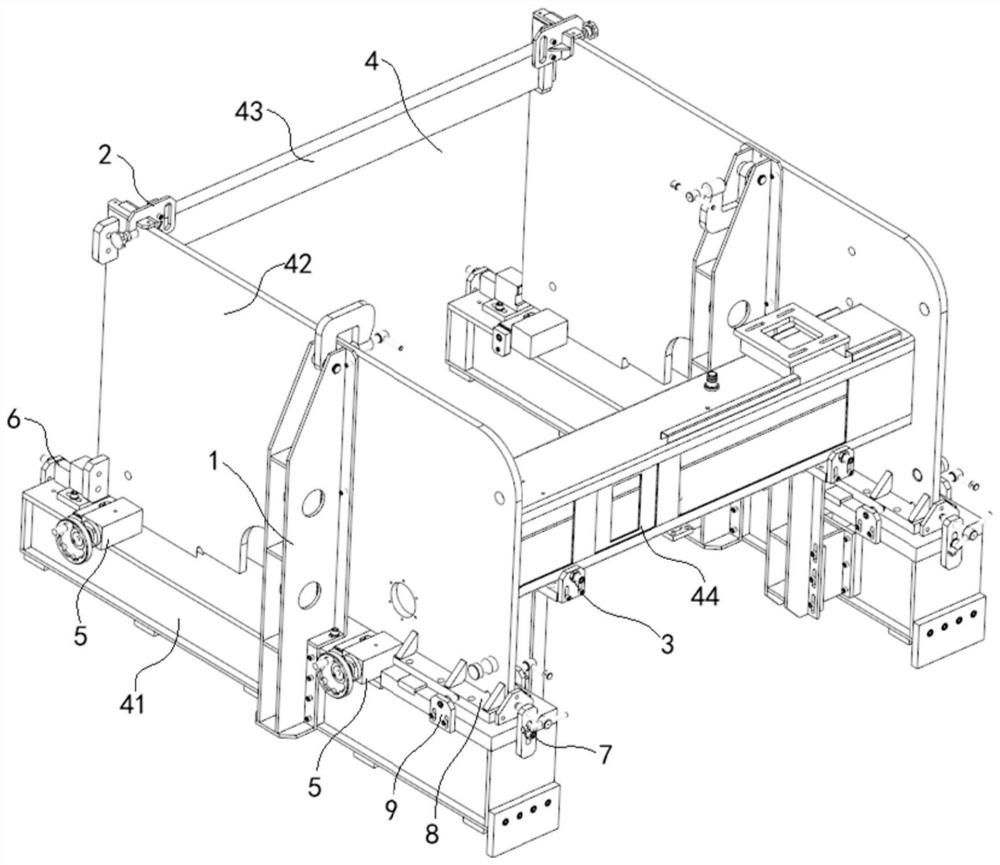

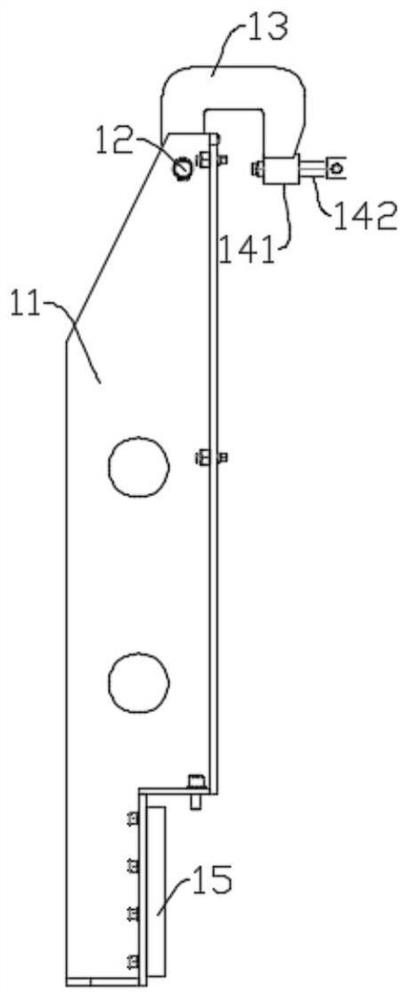

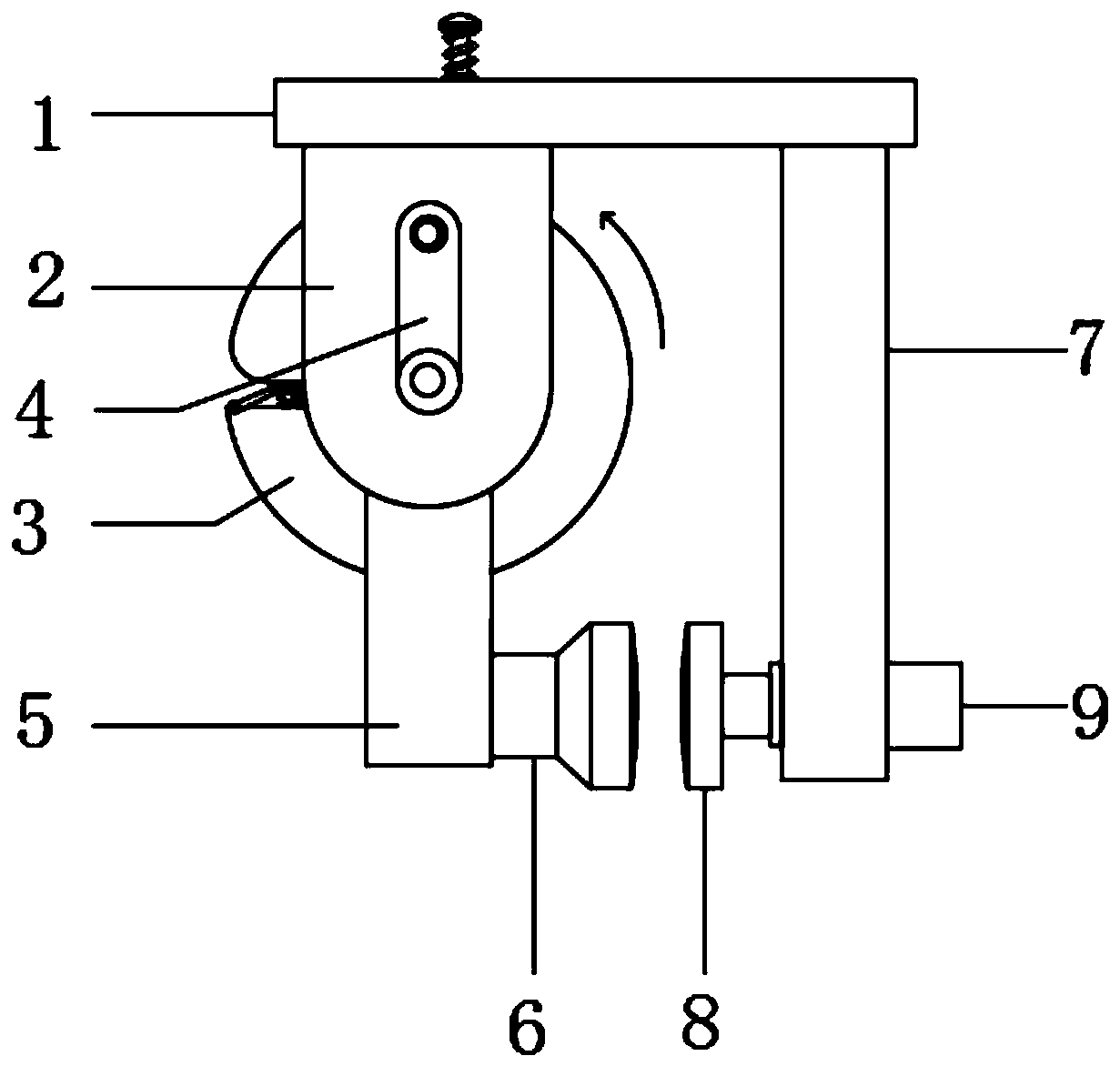

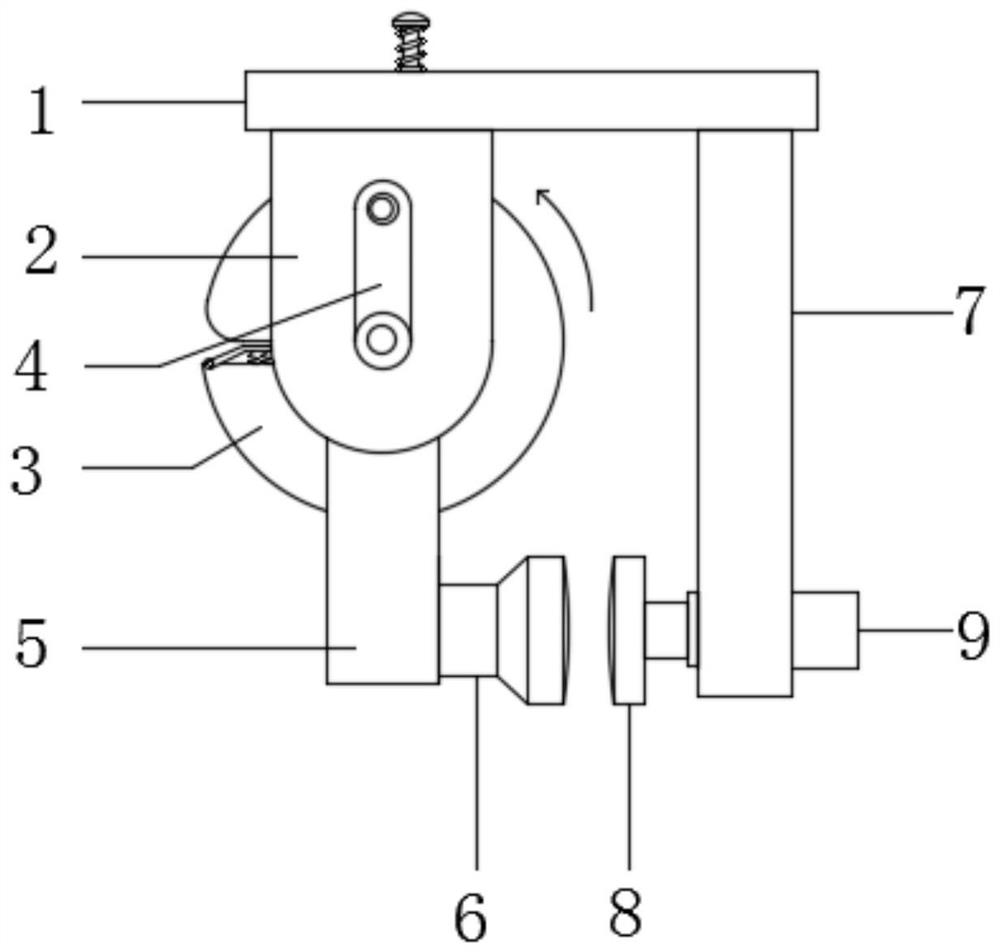

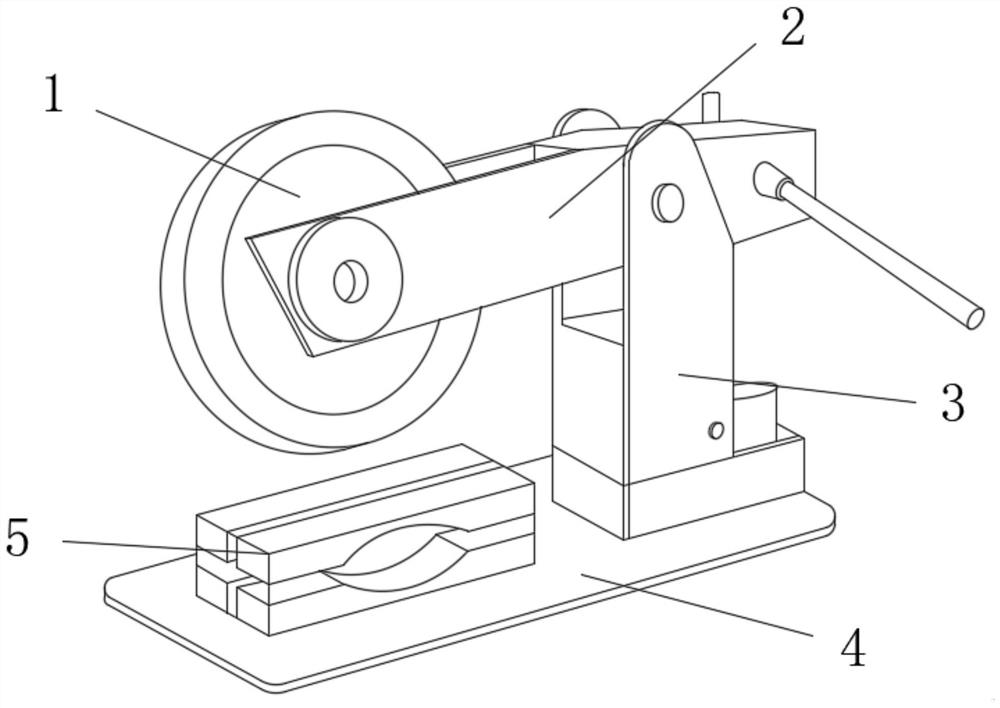

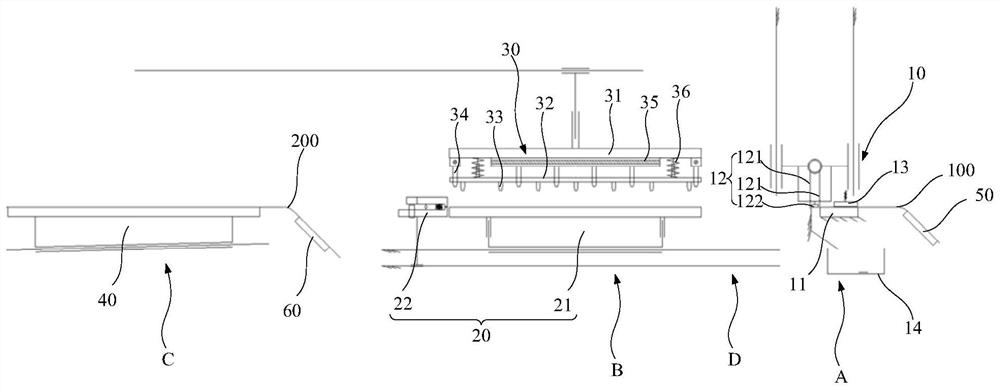

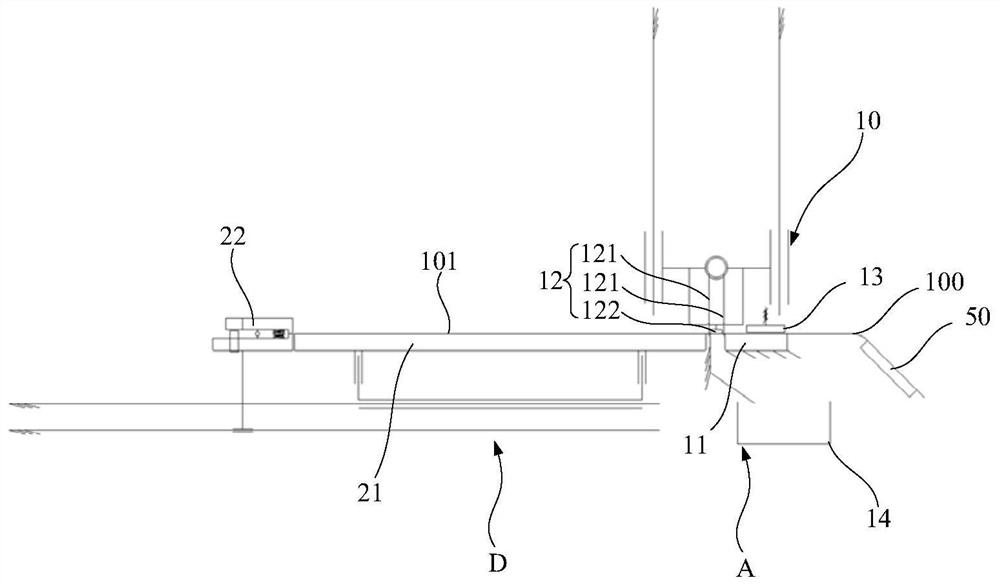

Welding method of bending machine rack

ActiveCN111822896AImprove welding precisionEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringPress brake

The invention discloses a welding method of a bending machine rack, and belongs to the field of rack welding. By the adoption of a welding tool of the bending machine rack, after the relative positionrelation of all parts of the rack is adjusted through multiple fixing devices, all the parts can be accurately pre-positioned and fixed, the welding precision of the rack is improved, and welding ismore convenient.

Owner:安徽省华夏机床制造有限公司

Fixing device for laser film tension test

ActiveCN110732985AAchieve fixationAchieve pre-fixationWork holdersWebs handlingMechanical engineeringMaterials science

The invention discloses a fixing device for a laser film tension test in the technical field of laser films. The fixing device includes a supporting plate, the left side of the bottom of the supporting plate is fixedly connected with fixing blocks in front-rear symmetry, a film rolling roller is rotatably connected between the two groups of fixing blocks, the front end of the film rolling roller is fixedly connected with a hand rotating rocker in a sleeved mode, the bottoms of the two groups of fixing blocks are fixedly connected with extension blocks correspondingly, the right sides of the two groups of extension blocks are fixedly connected with abutting blocks, the right side of the bottom of the supporting plate is fixedly connected with a vertical plate, the right parts of the abutting blocks are provided with compression blocks, and electric push rods are evenly and fixedly installed between the compression blocks and the vertical plate. The fixing device is suitable for the laser film tension test, a laser film is fixed and clamped, by inserting one end of the laser film into a clamping groove, elastic force produced by an elastic part enables a support pressing plate to clamp the laser film tightly, thus pre-fixation of the laser film is realized, and by manually rotating the hand rotating rocker, the film rolling roller can be driven to rotate, so as to be able to tighten the laser film.

Owner:福融新材料股份有限公司

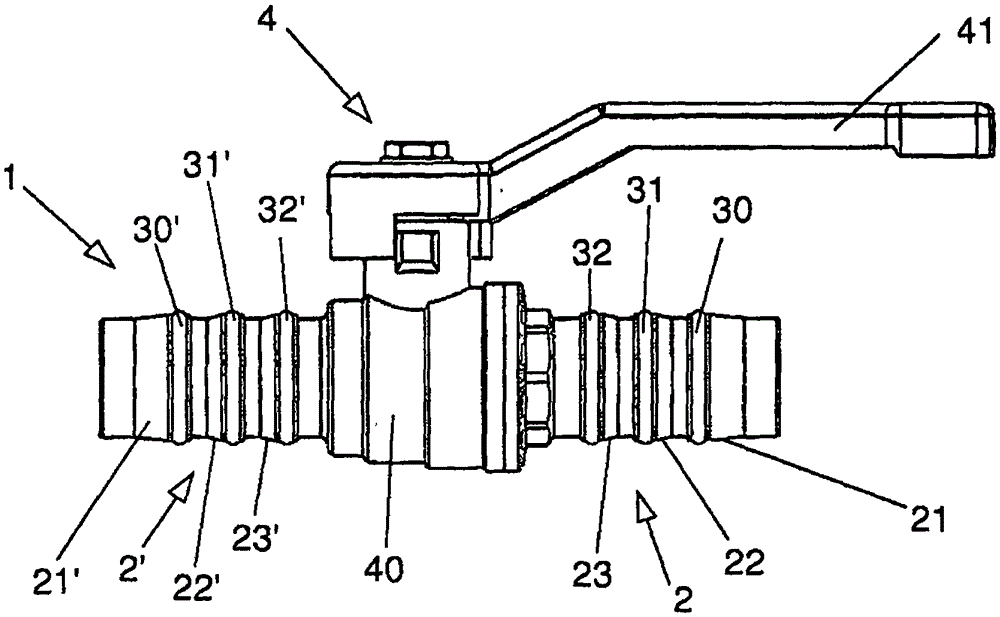

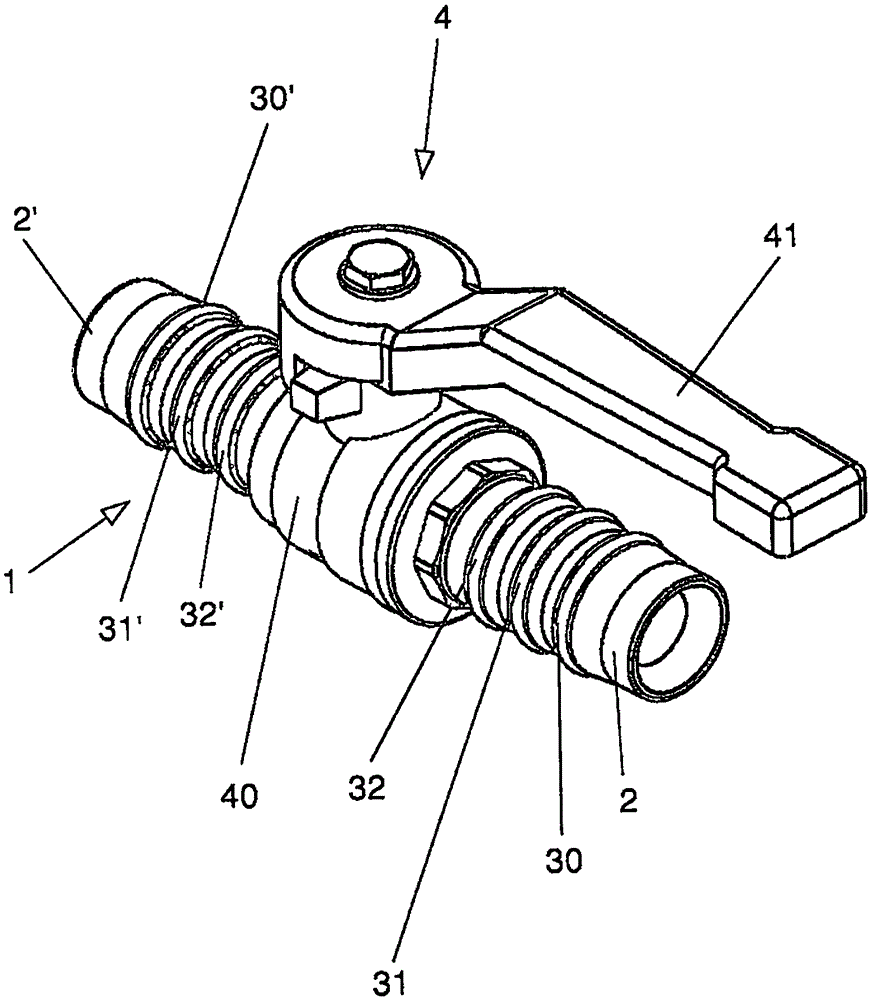

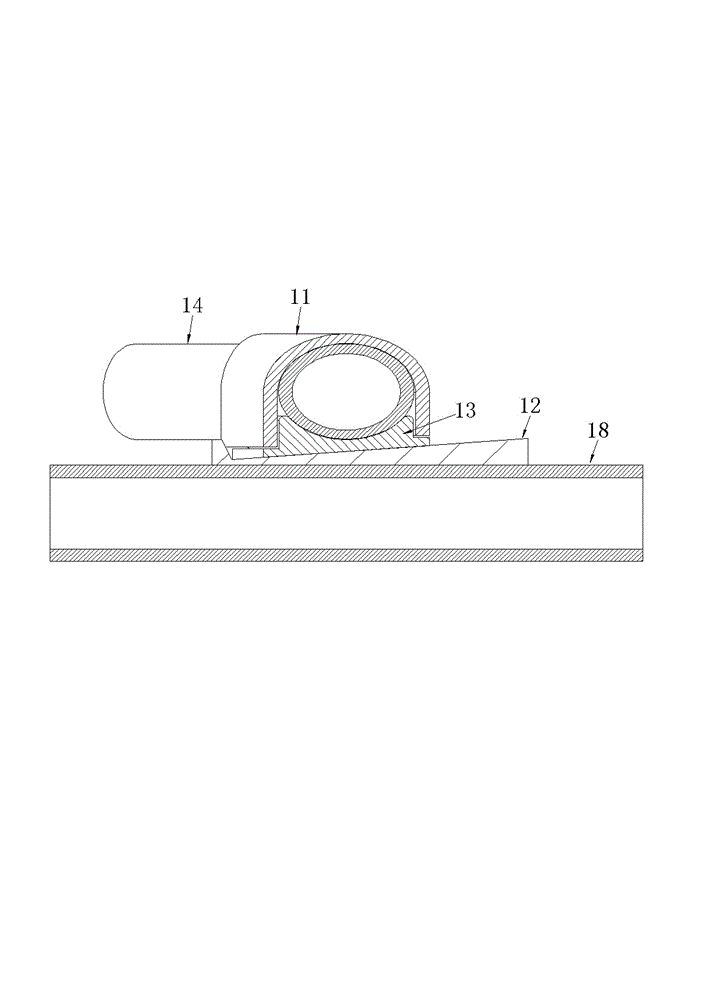

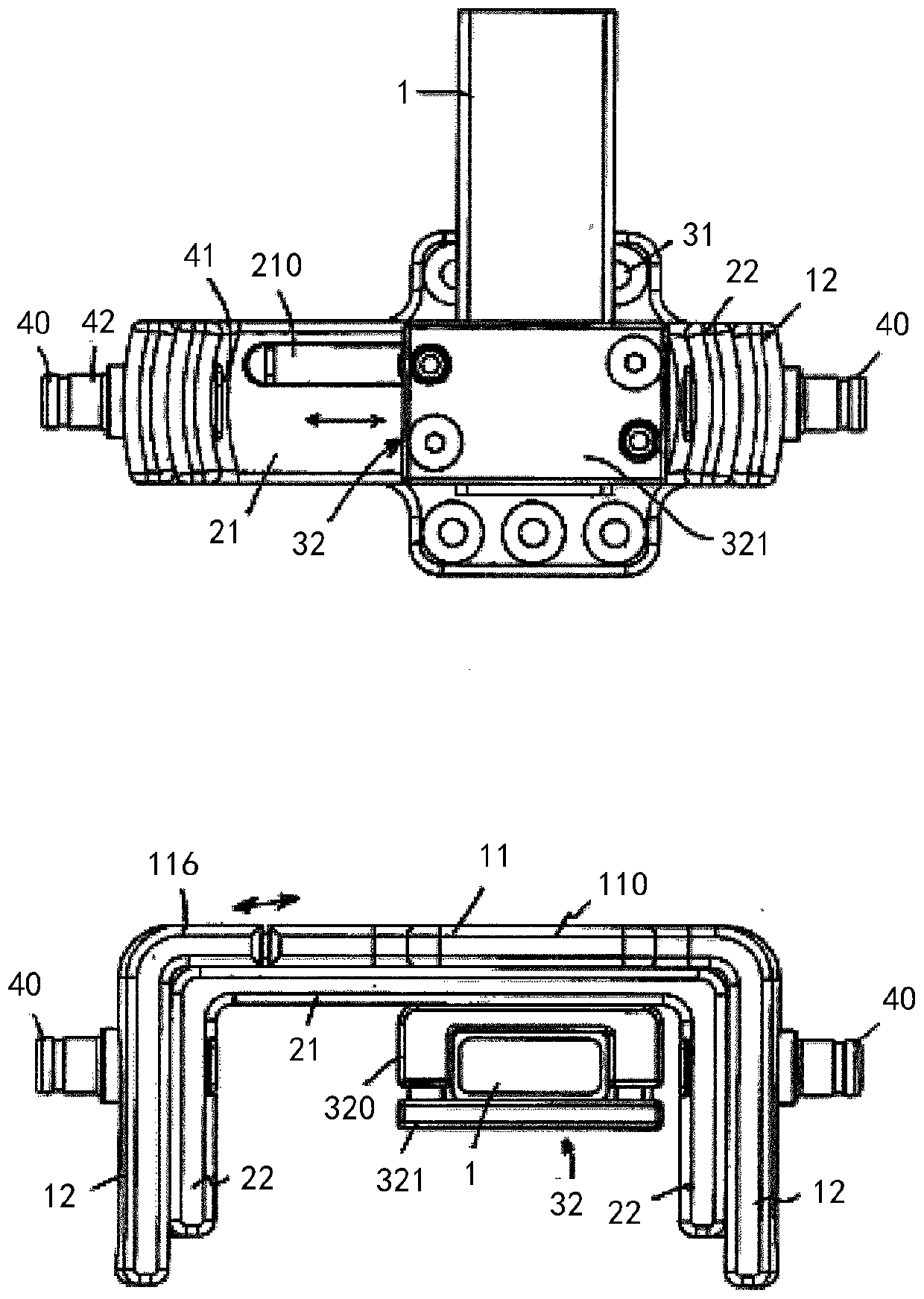

Hose Connection Device

InactiveCN105402526APrevent slippingEasy to plug inJoints with fluid cut-off meansCouplingsEngineeringMechanical engineering

Owner:PUTEUS

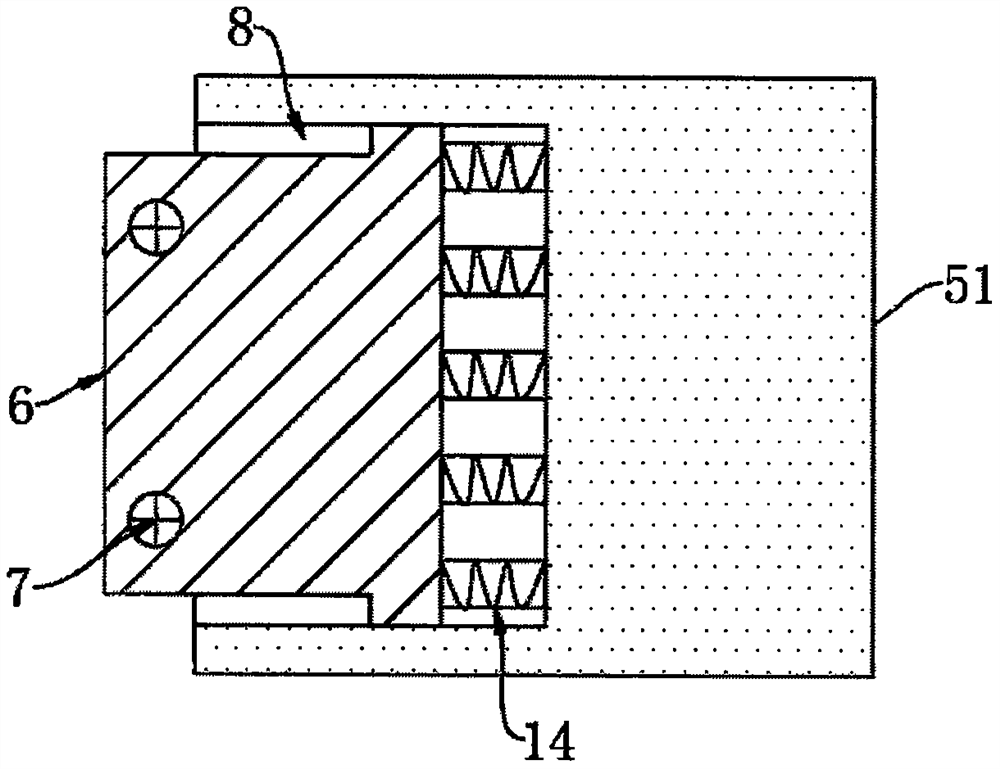

All-directional adjusting device for security door hinges

InactiveCN112196386AAchieve pre-fixationAdjust front and rear anglesWing accessoriesPin hingesButt jointEngineering

The invention discloses an all-directional adjusting device for security door hinges. The all-directional adjusting device comprises a door leaf and a door frame, wherein a sliding groove is formed inthe side wall of the side, close to the door frame, of the door leaf; and two symmetrically-arranged sliding blocks are slidably connected into the sliding groove, and the two symmetrically-arrangedhinges are mounted on the front faces of the two sliding blocks and comprise the first half hinge and the second half hinge. The invention relates to the technical field of security doors. Through cooperation of the arranged sliding groove and the sliding blocks, the hinges can be moved up and down to be guided, and thus the two hinges are kept in a parallel state; in addition, through cooperationof arranged inserting blocks and inserting grooves, the hinges can be positioned, and thus the hinges can be in butt joint with the door leaf and the door frame conveniently; and through butt joint of the inserting blocks and the inserting grooves, the hinges can be pre-fixed, the front-back angles of the hinges are adjusted and controlled conveniently, and thus the hinges and the door frame reach the optimal butt joint angle.

Owner:BUYANG GRP

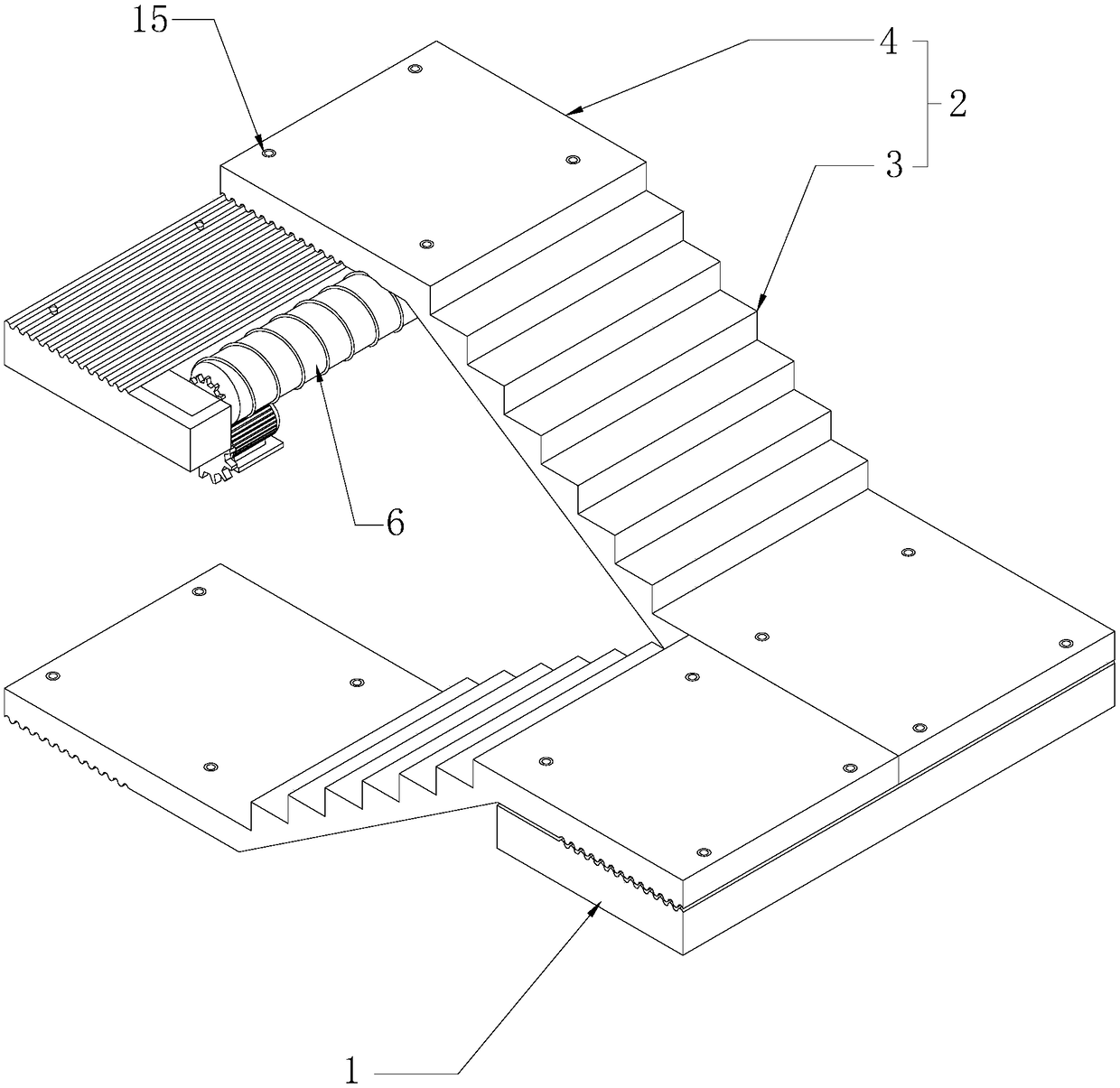

Prefabricated stair structure

Owner:浙江大经住工科技有限公司

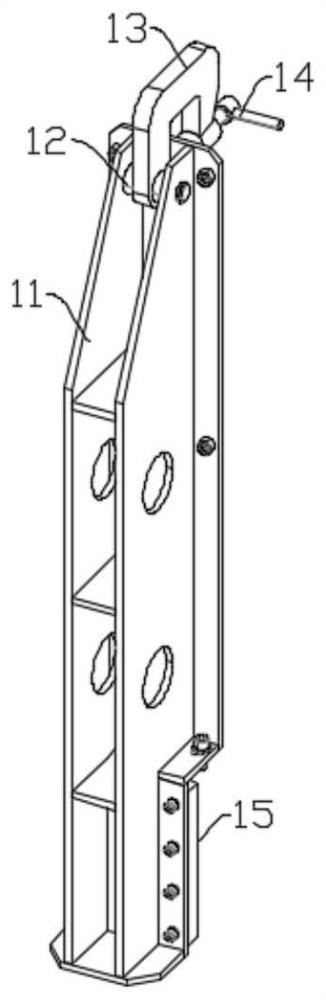

Scaffold diagonal-bracing fastener and sliding sleeve thereof

The invention relates to the field of scaffold fasteners, in particular to a scaffold diagonal-bracing fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve which can be sleeved on a scaffold steel tube in a sliding manner, wherein two hinged supports, which are assembled with pressure covers and hasps in a hinged way respectively, are oppositely arranged at the outer side of the sliding sleeve; the hinged axes of the hinged supports are parallel to each other and spatially crossed with the central line of the sliding sleeve; a set included angle of 30 degrees to 60 degrees is formed between the central line of the sliding sleeve and each of the hinged axes of the two hinged supports; a containing port for containing the scaffold steel tube is enclosed by the upper parts of the two hinged supports; an expansion block installation slot is enclosed by the lower parts of the two hinged supports; an opening is formed in the sleeve wall of the sliding sleeve at a position between the two hinged supports; a pressing slide block for pressing the scaffold steel tube in the sliding sleeve is assembled in the opening; and an expanding slide block which is wedged between the scaffold steel tube in the containing port and the pressing slide block is assembled in the expansion block installation slot. The scaffold diagonal-bracing fastener simultaneously has the characteristics of being convenient to operate, reliable in fixation and unlikely to lose.

Owner:朱新伟

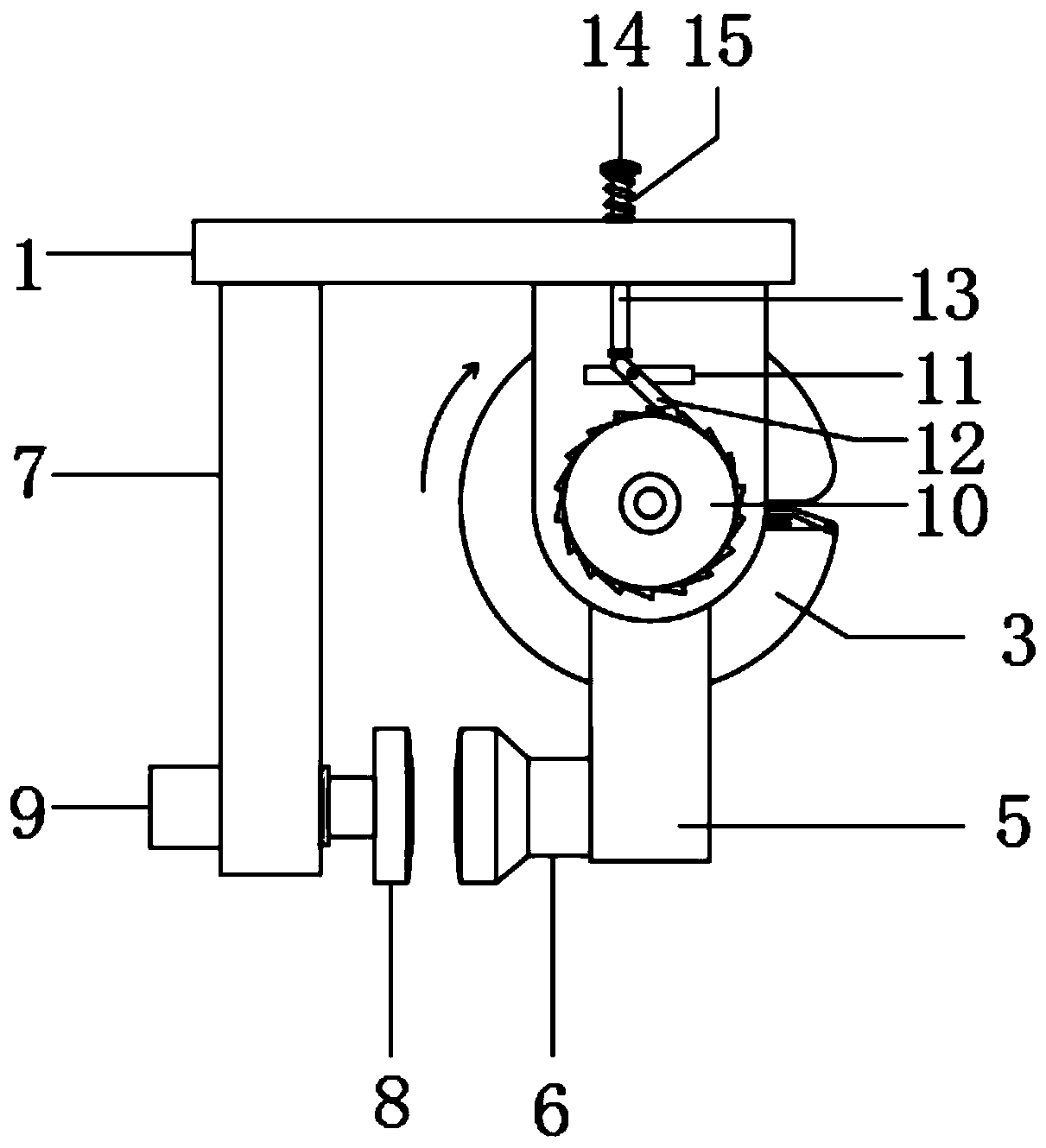

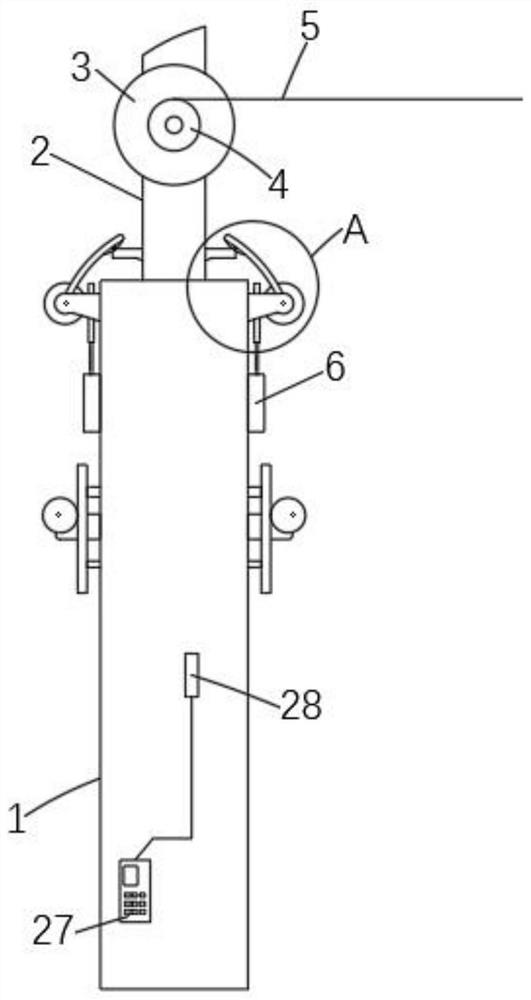

Bridge erecting crane auxiliary arm quick installation mechanism

ActiveCN111702709AAchieve pre-fixationAchieve secondary fixationWork holdersMetal-working hand toolsMarine engineeringElectric machinery

The invention discloses a bridge erecting crane auxiliary arm quick installation mechanism. The bridge erecting crane auxiliary arm quick installation mechanism comprises a main arm and an auxiliary arm. The end of the main arm is provided with a groove for mounting of the auxiliary arm. A traction motor is fixed to the auxiliary arm. A winding wheel is fixed to the outer side of an output shaft of the traction motor. A traction steel rope is wound around the outside of the winding wheel. Two convex blocks are symmetrically mounted outside the auxiliary arm. Abutting assemblies matched with the two convex blocks are symmetrically mounted outside the main arm. A fixed insertion rod is fixed to the end, inserted into the groove, of the auxiliary arm. The inner bottom of the groove is provided with an insertion groove matched with the fixed insertion rod. The outside of the end, far away from the auxiliary arm, of the fixed insertion rod is symmetrically provided with two limiting grooves. Opposite insertion assemblies matched with the two limiting grooves are symmetrically mounted outside the main arm. The bridge erecting crane auxiliary arm quick installation mechanism implements three-time fixation on the auxiliary arm inserted at the end of the main arm in a mechanical driving mode, saves time and labor, improves the opposite insertion installation efficiency, can also preventaccidental injuries to workers and is practical and reliable.

Owner:滕州潍达智能科技有限公司

Heating station for seamless bonding of underwear

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

A fixing device for laser film tensile test

ActiveCN110732985BAchieve fixationAchieve pre-fixationWork holdersWebs handlingLaserElectrical and Electronics engineering

The invention discloses a fixing device for the tensile test of the laser film in the technical field of the laser film, which includes a support plate, and fixed blocks are fixed symmetrically front and back on the left side of the bottom of the support plate, and two groups of the fixed blocks are rotationally connected with each other. The film rolling roller, the front end of the film rolling roller is sleeved and fixed with a hand-rotating rocker, the bottom of the two sets of fixed blocks is fixed with an extension block, and the right side of the two sets of extension blocks is fixed with an abutment block , the right side of the bottom of the support plate is fixedly connected with a vertical plate, and the right side of the abutment block is provided with a pressing block, and an electric push rod is evenly fixed and installed between the pressing block and the vertical plate. In the laser film tensile test, it is fixed and clamped. By inserting one end of the laser film into the clamping groove, the elastic force generated by the elastic member will clamp the supporting platen to the laser film, so as to realize the pre-fixation of the laser film. Turning the rocker by hand can drive the film rolling roller to rotate, so that the laser film can be tightened.

Owner:福融新材料股份有限公司

Wedge-caulking type cross fastener and sliding sleeve thereof

The invention relates to scaffold fasteners, in particular to a wedge-caulking type cross fastener and a sliding sleeve thereof. The wedge-caulking type cross fastener comprises the sliding sleeve capable of being sleeved on a scaffold base pipe in sliding mode. Two hinged supports for assembling a pressing cover and a hasp in hinged mode respectively are arranged on one side of the sliding sleeve. The two hinged supports are arranged oppositely along the axial direction of the sliding sleeve, the upper portions of the two hinged supports define an accommodating port for containing a scaffold cross pipe, and the lower portions of the two hinged supports define an expansion block installing groove. An opening penetrating through the inside and the outside is arranged at a position between the two hinged supports on a sleeve wall of the sliding sleeve. A pressing sliding block for pressing the scaffold base pipe is arranged in the opening, and an expansion sliding block for being wedged between the scaffold cross pipe and the pressing sliding block is assembled in the expansion block installing groove. During use of the fastener, only one pressing cover is required to be operated, then the expansion sliding block is knocked, operation is convenient and fast, and convenience of operation of the fastener is improved. The safety and operation convenience of the cross fastener are further improved.

Owner:朱新伟

Glass clamping device for building decoration

InactiveCN112922259AImprove stability and securityAvoid damageCovering/liningsCarpet cleanersArchitectural engineeringEngineering

The invention discloses a glass clamping device for building decoration, which comprises four fixing devices, the fixing devices are in threaded connection through side edge clamping plastic cement, the contact surfaces of the fixing devices and the side edge clamping plastic cement are fixedly connected through connecting rivets, each fixing device comprises a fixing block, and the fixing blocks are fixedly connected with the side edge clamping plastic cement through connecting rivets. A first through hole is formed in the middle of the surface of the left side of the fixing block, a clamping device is arranged in the first through hole in a sleeved mode, four first grooves are formed in the concave position of the right side of the fixing block, and the building decoration device relates to the technical field of building decoration. According to the glass clamping device for building decoration, glass is clamped in the clamping device, and the dust filtering device at the bottom of the pre-clamping rod is clamped on the glass, so that pre-fixation of glass installation is realized, damage to the glass caused by accidental falling when a constructor installs the glass is prevented, and the dust filtering device can achieve the effect of safe pre-clamping.

Owner:刘飞艳

Steel structure beam-column joint

PendingCN109972734AAchieve pre-fixationSolve the problem of inconvenient splitting and recyclingBuilding constructionsMaterials scienceBeam column

The invention discloses a steel structure beam-column joint, which comprises a bearing column, a steel beam, a buffer steel block, a protective steel sleeve, a reinforcing bolt, a reinforcing nut, anda bearing supporting plate. The protective steel sleeve sleeves outside the bearing column; the bearing supporting plate is arranged vertically and horizontally on the outer side of the bearing column and is arranged on the lower edge of the protective steel sleeve; the buffer steel block is arranged between the steel beam and the protective steel sleeve, and is placed above the bearing supporting plate; the buffer steel block is internally provided with a groove; and the upper end of the reinforcing bolt is movably arranged in the groove, the lower end of the reinforcing bolt penetrates through the buffer steel block and the bearing supporting plate successively, and the buffer steel block and the bearing supporting plate are fixedly connected by using the reinforcing nut. According to the steel structure beam-column joint, extension treatment of the connection point between the bearing supporting column and the steel beam is realized, at the same time, it is greatly convenient to disassemble and recycle the bearing column and the steel beam, the reinforcing bolt is mounted movably on the inner side of the buffer steel block, thus prefixing of the steel beam and the bearing supporting plate is realized, hole finding time is shortened, and the assembly efficiency is greatly improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

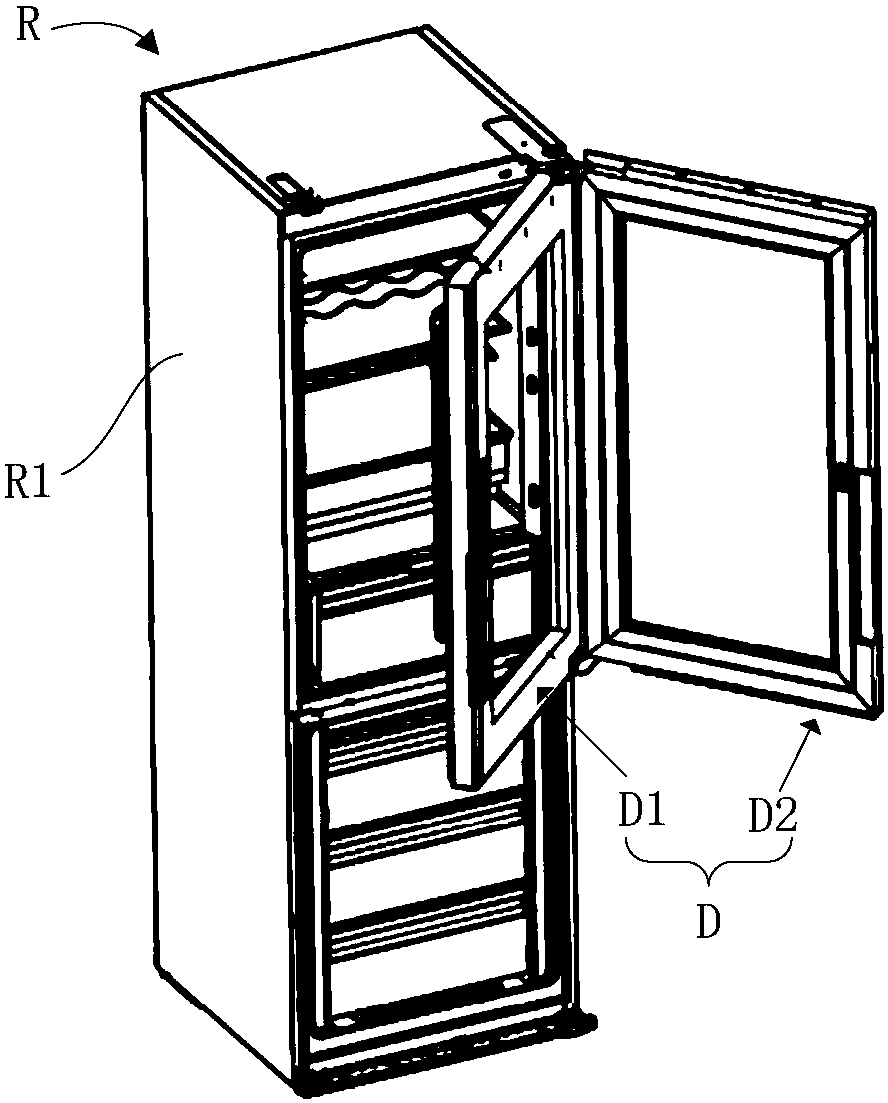

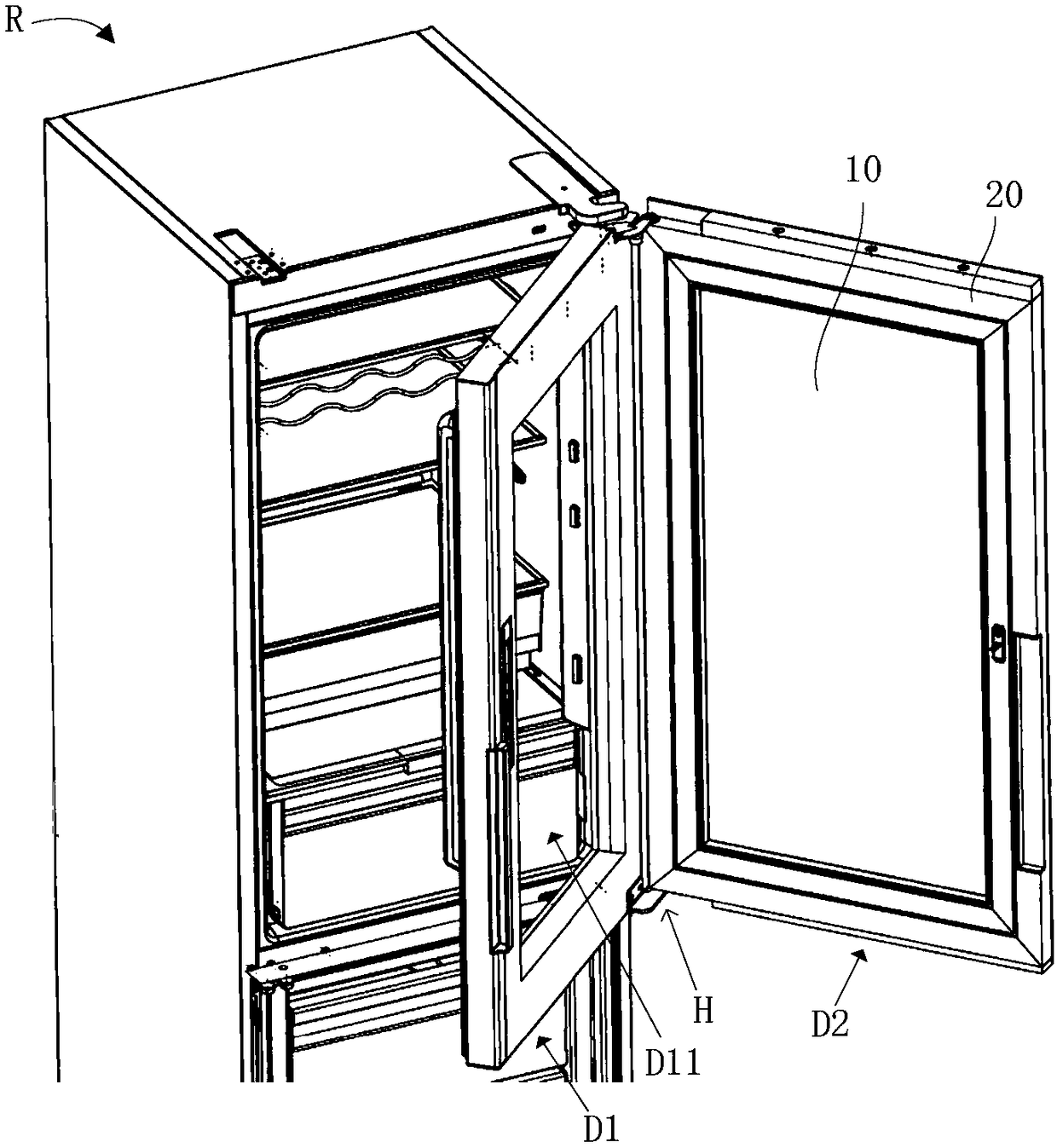

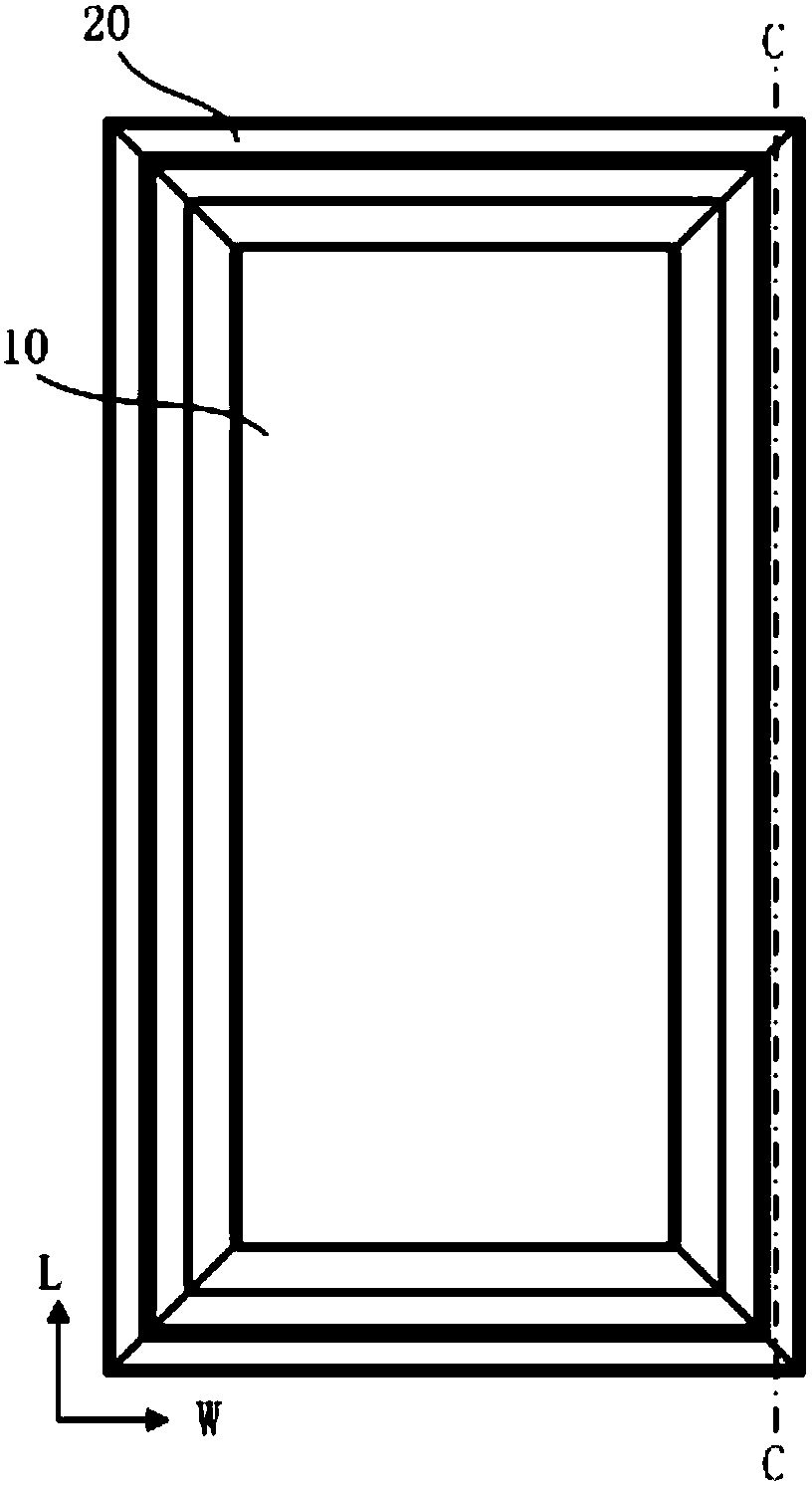

Household electrical appliance

InactiveCN108612423AFulfill the installation requirementsCompact structureDomestic cooling apparatusLighting and heating apparatusHome applianceElectrical and Electronics engineering

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

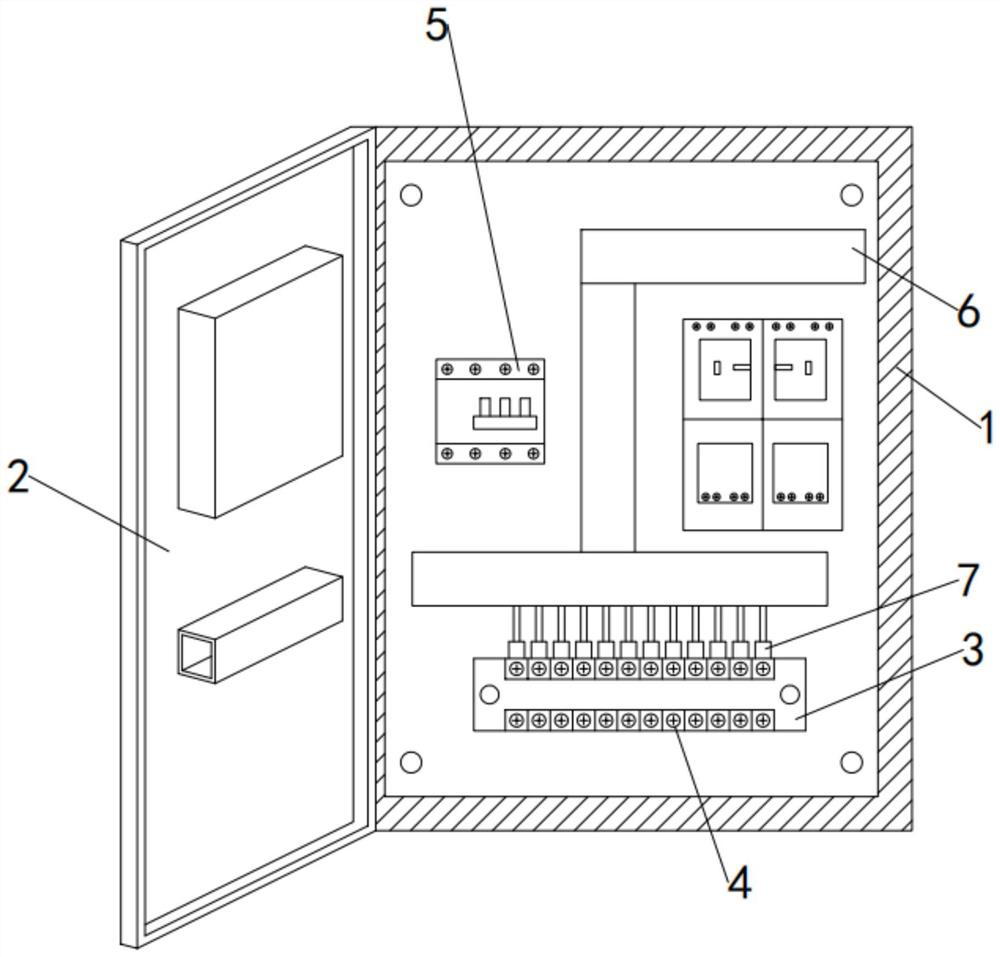

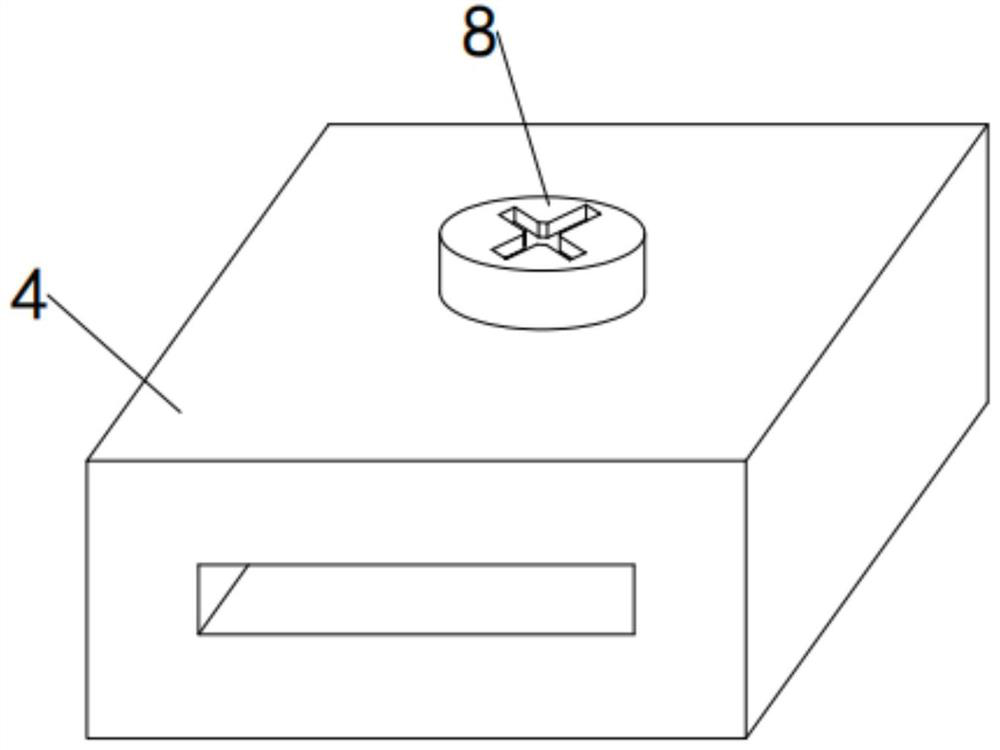

Electrical automation control box

PendingCN114237118AAchieve fixationAchieve pre-fixationProgramme controlComputer controlStructural engineeringElectric equipment

The invention provides an electrical automation control box, and belongs to the technical field of electrical equipment, the front surface of a box body is rotatably connected with a box body cover, a wiring board, an air switch and a wire management pipe are sequentially arranged in the box body, wiring terminals are embedded and fixed in the upper and lower sides of the wiring board, and the front surface of each wiring terminal is provided with a rectangular opening; a wire end is embedded in the wiring terminal, elastic clamping pieces are embedded in the left side and the right side of the interior of the wiring terminal, and the tail end of the wire end is fixedly connected with an embedded block. The electrical automation control box is provided with the inner rod and the limiting end, after the embedded block is pre-fixed and clamped by rebounding of the elastic clamping piece, the inner rod descends through a screwdriver until the bottom end of the limiting end is close to a groove in the center of the embedded block and is inserted into the groove, and embedding of the limiting end is pressed and matched through descending of the locking screw. The connection stability between the wiring terminal and the wire end can be effectively improved, and the embedded block is prevented from loosening in the use process.

Owner:深圳市龙创华宇科技有限公司

Adjusting device, and orthosis having adjusting device

InactiveCN111417368AChange spacingSpacing matchNon-surgical orthopedic devicesEngineeringMechanical engineering

Owner:OTTOBOCK SE & CO KGAA

Automatic profile straightening device

InactiveCN108555068ARealize partial extrusion correctionNot easy to cause excessive deformationMetal working apparatusEngineeringBall joint

The invention relates to an automatic profile straightening device comprising a supporting machine frame. A plurality of groups of profile extrusion machines which are in mirror symmetry are arrangedin the supporting machine frame. Leading-in mechanisms are arranged at the two ends in the axial direction of the supporting machine frame. The profile extrusion machines are connected into the supporting machine frame through linear extending and retracting machines. Each travel squeezing machine comprises a supporting block fixed to the corresponding linear extending and retracting machines. Each supporting block is provided with two groups of sliding holds. Each squeezing oil cylinder comprises an oil cylinder shell and an oil cylinder rod. The end of each oil cylinder shell is fixed to theedge of the corresponding sliding hole of the corresponding supporting block. Each oil cylinder rod penetrates through the corresponding sliding hole to extend out from the surface of the supportingblock. Each leading-in mechanism comprises two groups of linear sensors A which are arranged at the axial end of the supporting machine frame in a mirror symmetry manner. The ends of the linear sensors A are connected with leading-in plates through universal ball joints A. The linear extending and retracting portions are fixedly provided with supporting plates. Linear sensors B are connected between the supporting plates and the leading-in plates.

Owner:张超

Electric cutting tool

ActiveCN112676636AAchieve a fixed effectReduce shakingShearing machinesShearing machine accessoriesEngineeringPhysics

The invention discloses an electric cutting tool and relates to the technical field of electric tools. The electric cutting tool comprises a bottom plate, a supporting column is fixedly connected to the right side of the upper surface of the bottom plate, a pressing arm is rotationally connected to the top of the supporting column, a cutting disc is rotationally connected to the left end of the pressing arm, a fixing device is fixedly connected to the upper surface of the bottom plate, and the fixing device is arranged under the cutting disc. The fixing device comprises two fixing blocks, the two fixing blocks are stacked up and down, an extrusion bag is fixedly connected between the concave positions of the opposite faces of the fixing blocks, and the left end and the right end of the extrusion bag are movably connected with pressure devices. According to a cutting machine fixing device, the effect that the extrusion bag fixes an internal cutting target is achieved by pressing the fixing block on the upper side, meanwhile, during cutting operation, the extrusion bag can relieve shaking of the cutting disc, so that the cutting target is cut more stably, and the cutting efficiency is improved.

Owner:南京庚鼠科技有限公司

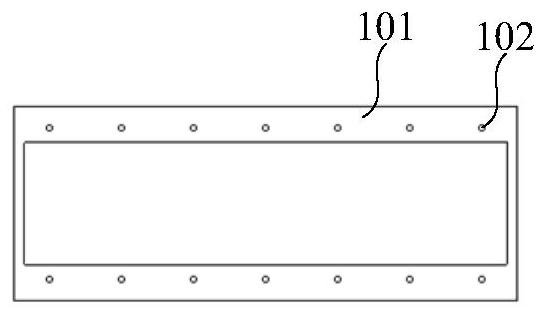

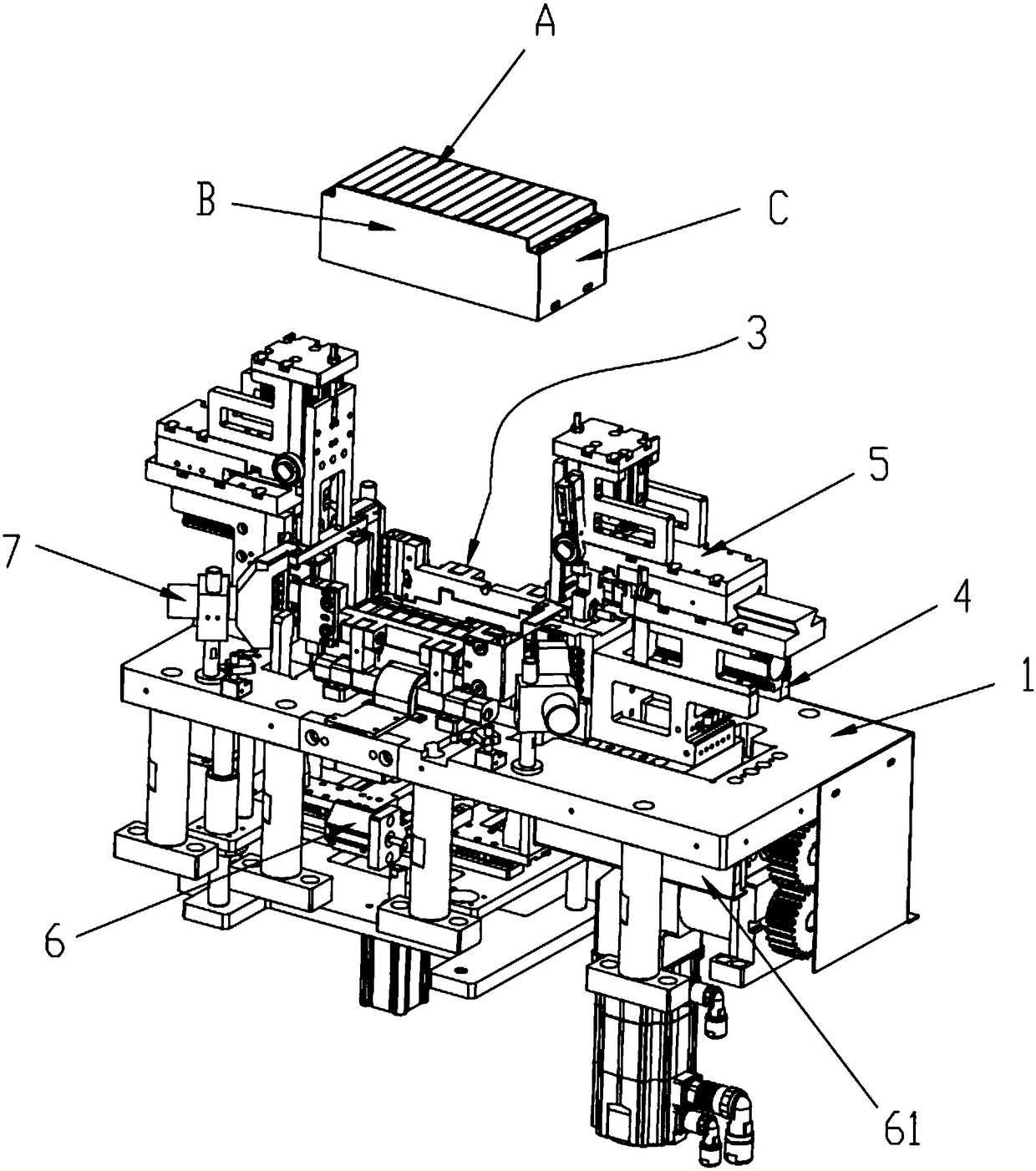

Frame laminating equipment

ActiveCN113964339AAchieve pre-fixationPrecise alignmentFinal product manufactureFuel cell auxillariesEngineeringMechanical engineering

The invention relates to frame laminating equipment. The frame laminating equipment comprises a cutting assembly used for cutting off a passing first frame material belt; a transfer assembly used for transferring the first frame sheet to the positioning station; a positioning assembly which comprises an adsorption mechanism, and a positioning pin and a heating pin which are mounted on the adsorption mechanism; and a laminating assembly used for bearing the passing second frame material belt. When the adsorption mechanism moves to the positioning station, in the process that the adsorption mechanism moves close to the transfer assembly, the positioning pin can penetrate through a positioning hole in the first frame piece, and the adsorption mechanism can adsorb and fix the first frame piece. When the adsorption mechanism moves to the attaching station, in the process that the adsorption mechanism moves close to the attaching assembly, the positioning pin penetrates through the positioning hole in the second frame material belt, and the heating pin tightly presses the first frame piece and the second frame material belt to the attaching assembly.

Owner:JIANGSU HYDROGEN GUIDE INTELLIGENT EQUIP CO LTD

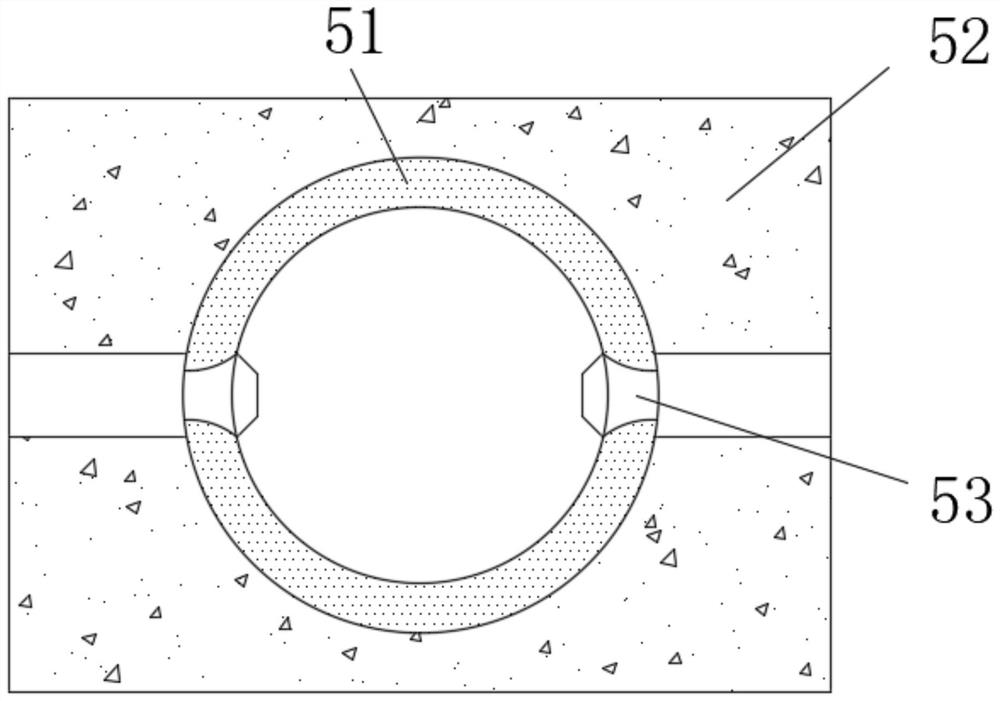

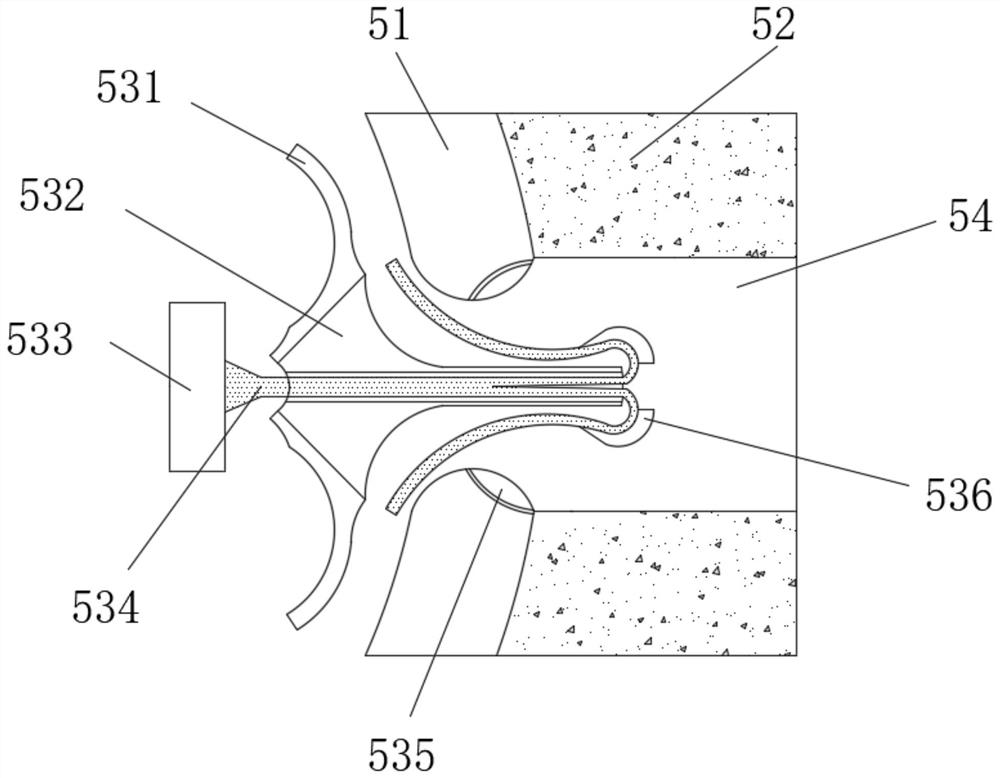

Fire hose connector

The invention belongs to the technical field of firefighting equipment, particularly relates to a fire hose connector, and aims to solve problems in the prior art. In order to solve the above problems, the fire hose connector which has the beneficial effects that the connecting position can be prevented from leaking at high pressure, the structure is simple, the cost is low, the assembly is convenient, and the service life is long is provided. According to the implementation scheme, the fire hose connector comprises a pipe body, wherein one end part of a sleeve is arranged in the tube body ina sleeving manner; a plurality of clamping slots used for fixing in advance are arranged on the cavity wall of an inner cavity of the pipe body; clamping rings matched with the clamping slots are arranged on the sleeve; and a clamping component consisting of a plurality of clamping sleeves which are locked in pairs is arranged on the outer wall of the pipe body, and used for clamping the positionwhere the outer wall of the pipe body and the sleeve are overlapped.

Owner:台州沃拉消防设备有限公司

Vacuum suction casting mold capable of adjusting casting size

The invention relates to the technical field of molds, and particularly relates to a vacuum suction casting mold capable of adjusting the casting size. The vacuum suction casting mold comprises a mold body. The mold body comprises an outer mold shell. A mold cavity is formed in the inner side of the outer mold shell. A first movable groove is formed in the outer mold shell. A second movable groove is formed in one side of the first movable groove. A third movable groove is formed in one side of the second movable groove. According to the suction casting mold, the size of the mold cavity can be changed by dismounting and mounting the outer mold shell and an inner mold shell, so that suction castings of different sizes are obtained, the suction castings of different sizes do not need to be provided with the outer mold shell, the utilization rate of the outer mold shell is increased, and the production cost is reduced; and when the outer mold shell and the inner mold shell are mounted, pre-positioning of the outer mold shell and the inner mold shell can be assisted through a turning plate, the outer mold shell and the inner mold shell can be lifted into the mold cavity through a clamping plate, labor force is saved, meanwhile, the outer mold shell and the inner mold shell are pre-fixed, and use is more convenient.

Owner:JIANGSU OCEAN UNIV

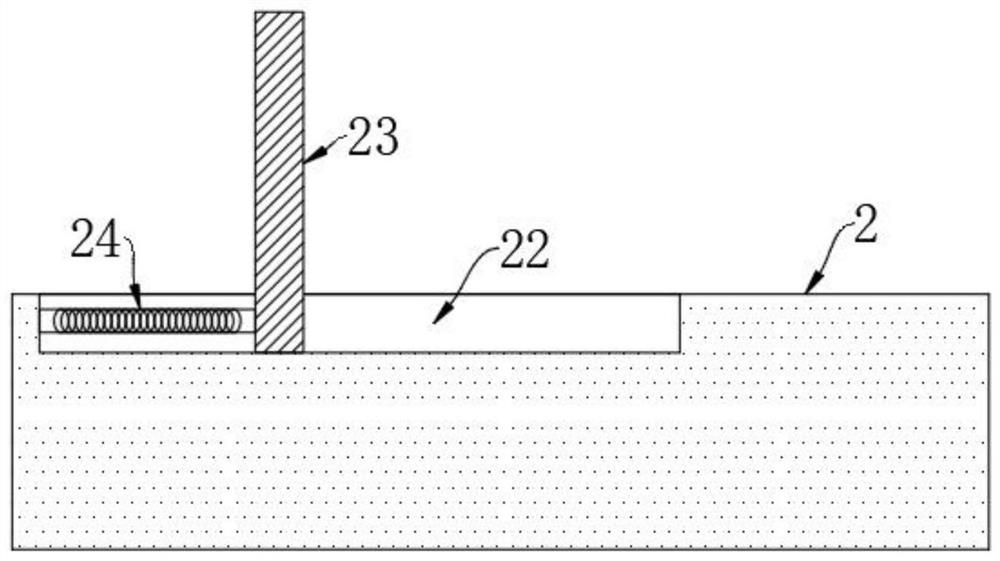

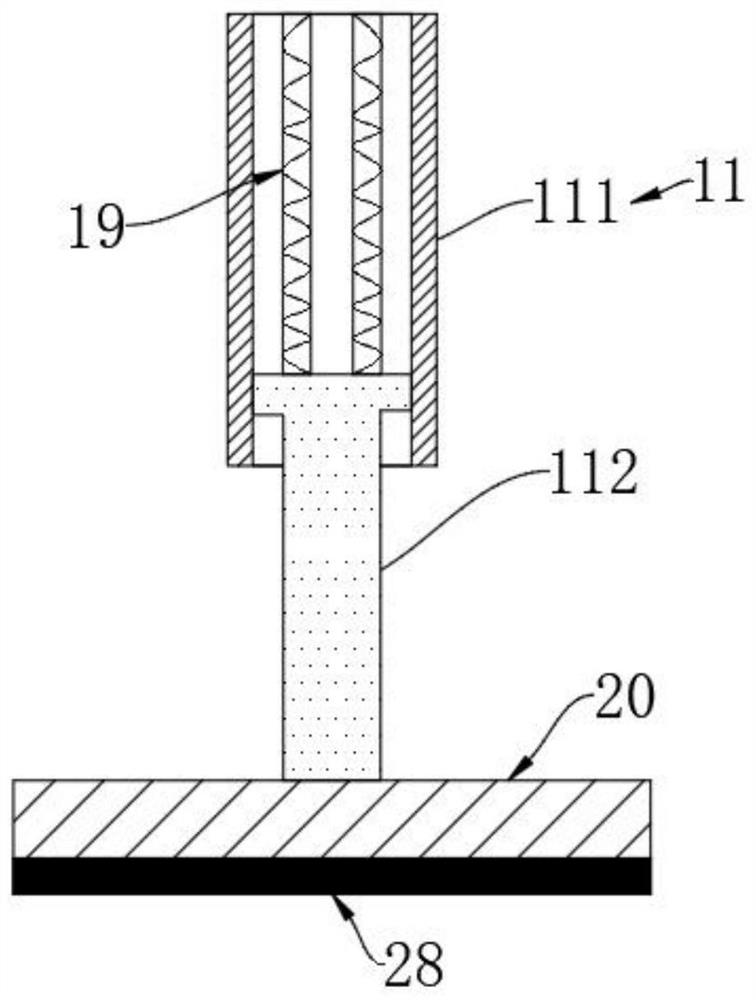

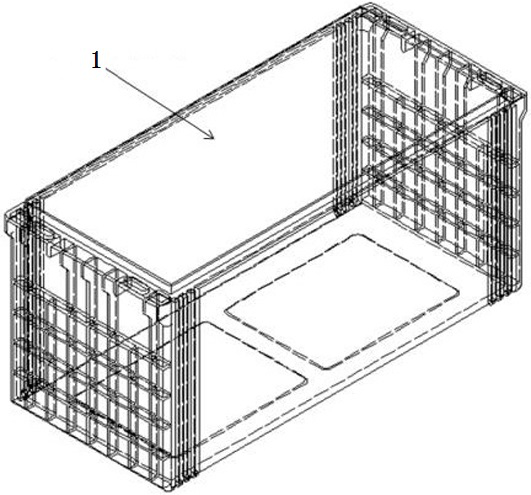

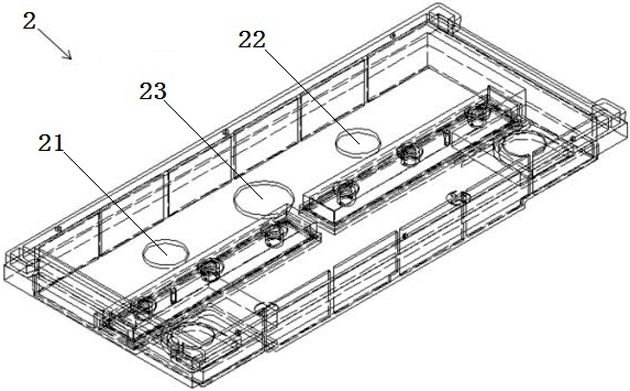

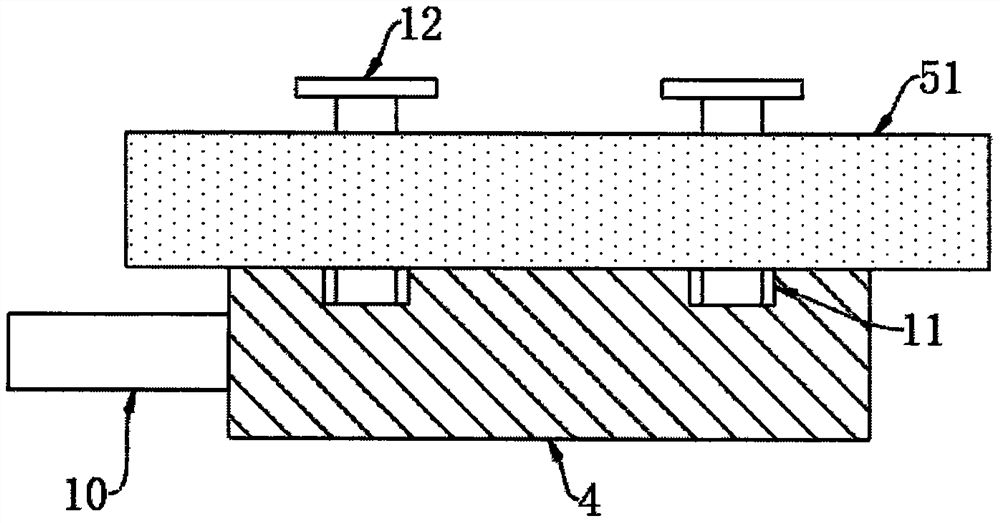

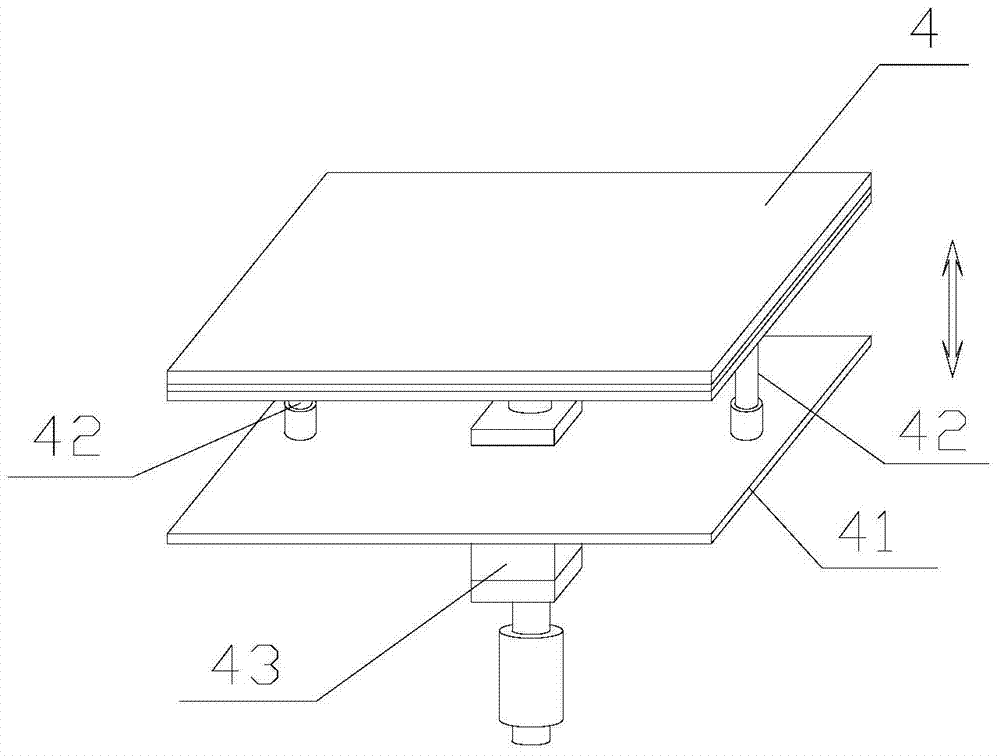

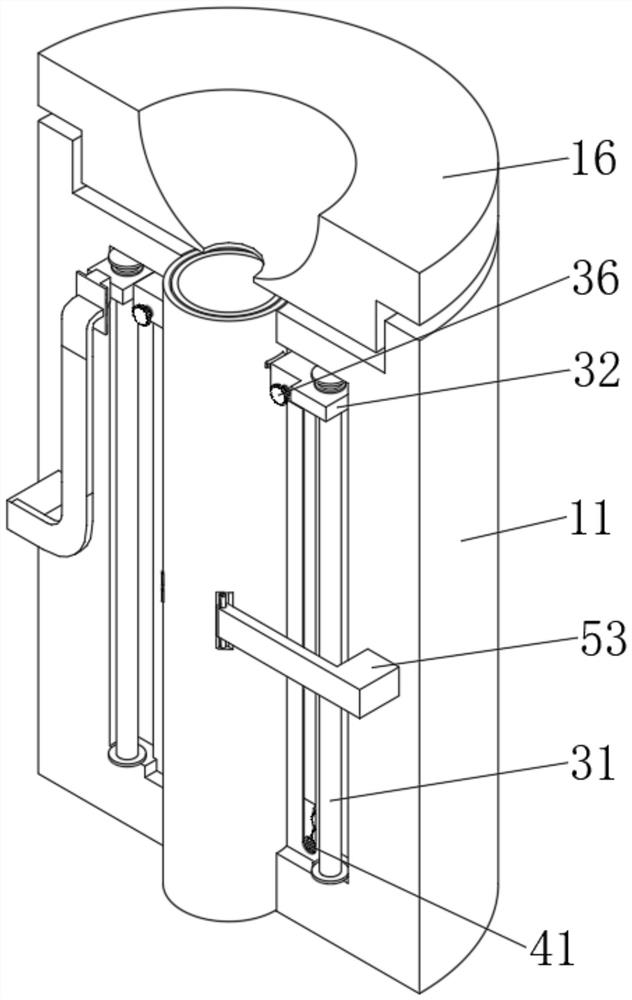

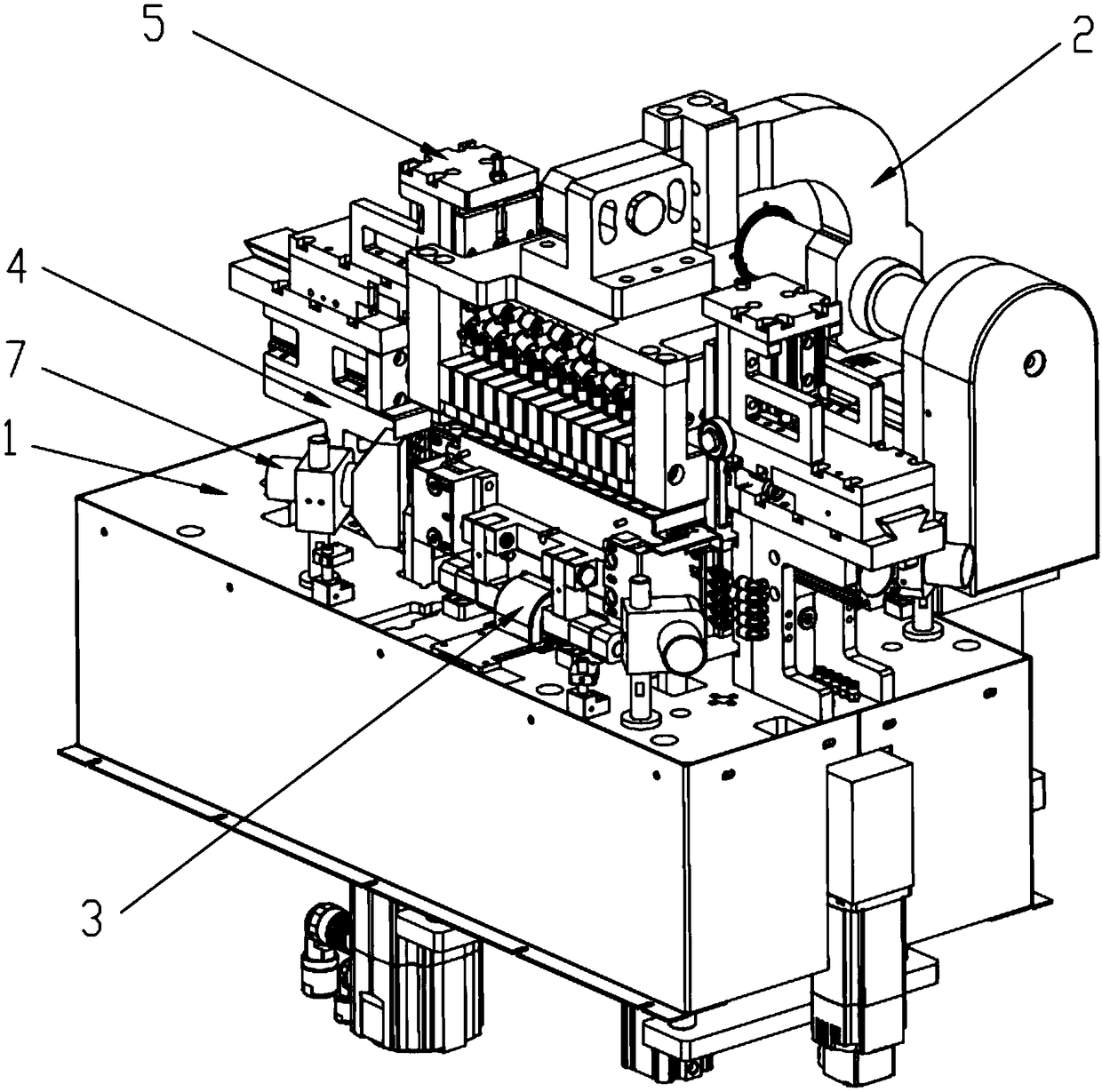

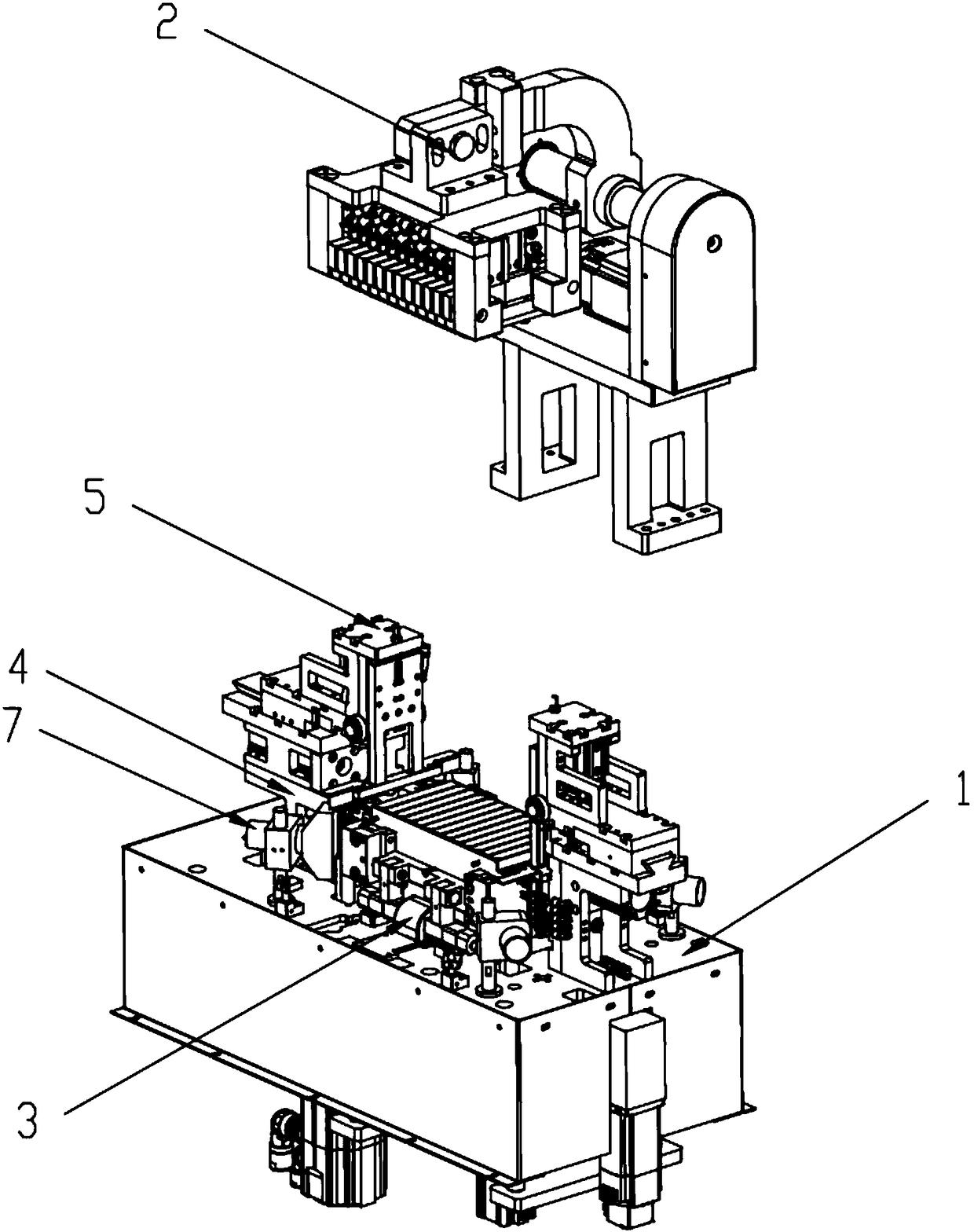

High-precision self-adaption battery module welding fixture

PendingCN108907464AAchieve pre-fixationImprove production and processing pass rateWelding/soldering/cutting articlesMetal working apparatusEngineeringMachining

The invention relates to the technical field of battery module production equipment, in particular to a high-precision self-adaption battery module welding fixture. The high-precision self-adaption battery module welding fixture comprises a platen for bearing an outer battery module, a first hold-down mechanism, a second hold-down mechanism pressing an outer long side plate to the long side face of the battery module in an attaching manner, a third hold-down mechanism pressing an outer short side plate to the short side face of the battery module in an attaching manner and a fourth hold-down mechanism used for carrying out fine adjustment on the long side plate. The first hold-down mechanism is used for abutting against the top of the battery module, the top of the outer long side plate and the top of the outer short side plate and is hinged to the platen. The second hold-down mechanism and the third hold-down mechanism are both connected to the platen in a sliding manner. The platen is provided with the second hold-down mechanism and the third hold-down mechanism, so that position pre-fixation of the battery module, the long side plate and the short side plate is achieved; and dueto the fact that the first hold-down mechanism presses the top of the battery module, the top of the long side plate and the top of the short side plate, the position fixation of the battery module,the long side plate and the short side plate is finally completed, and the production machining yield is increased.

Owner:东莞仕能机械设备有限公司

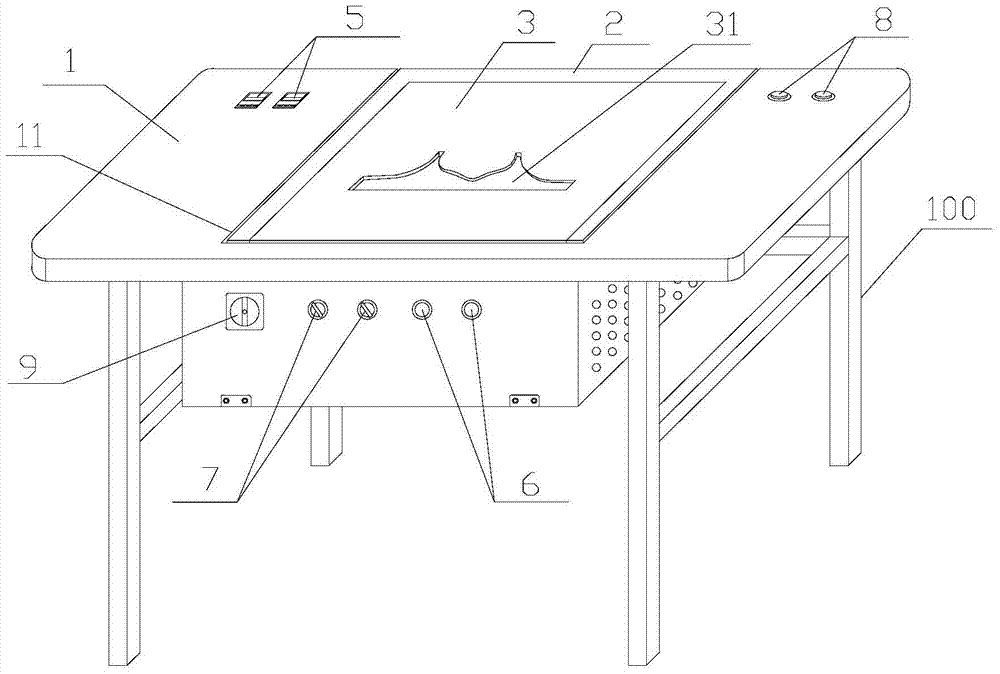

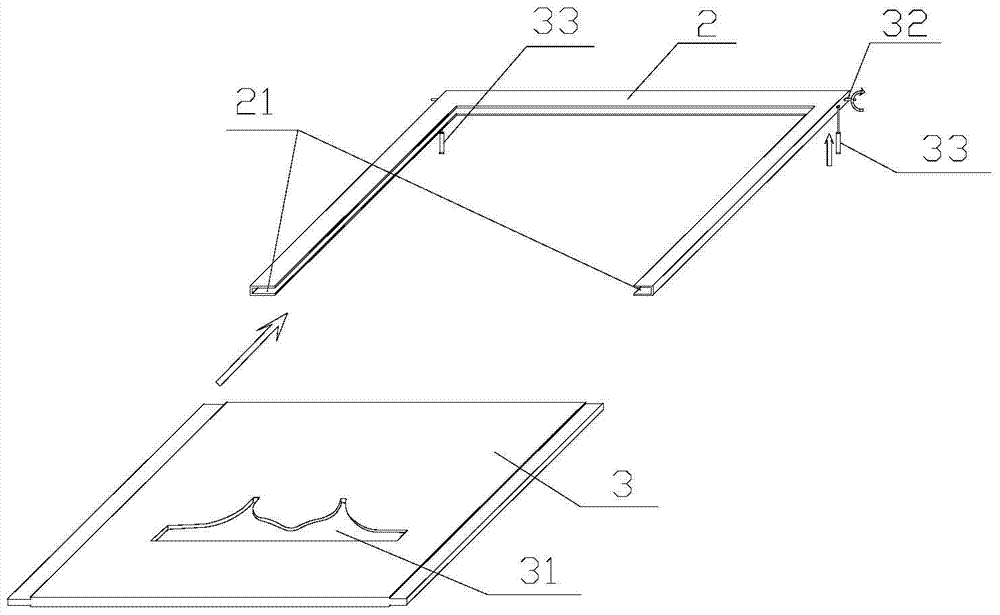

frame for table

ActiveCN108741631BAchieve movementAchieve fixationTablesFeetStructural engineeringMechanical engineering

Owner:浙江博艺游乐设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com