Patents

Literature

803results about How to "Change spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

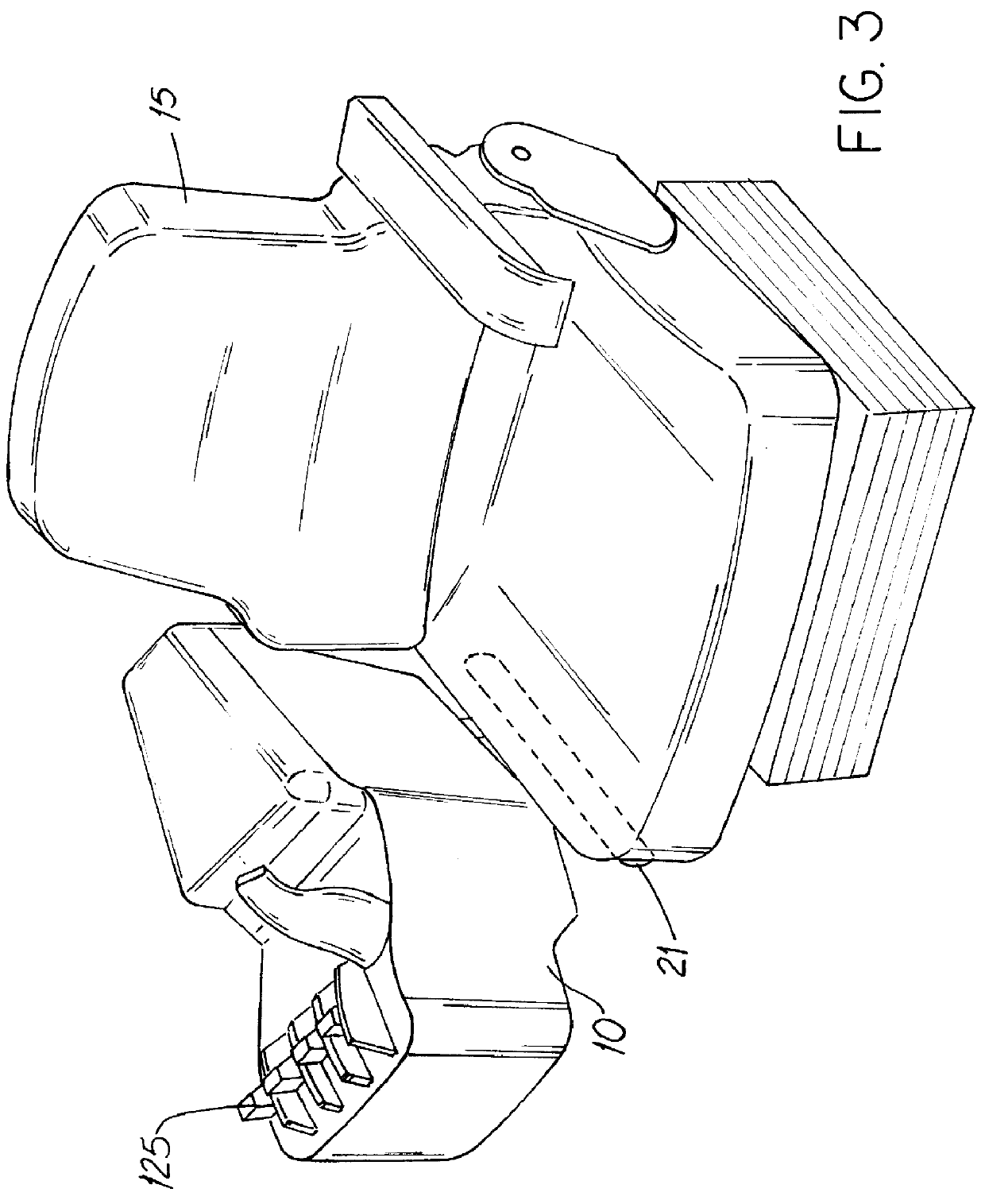

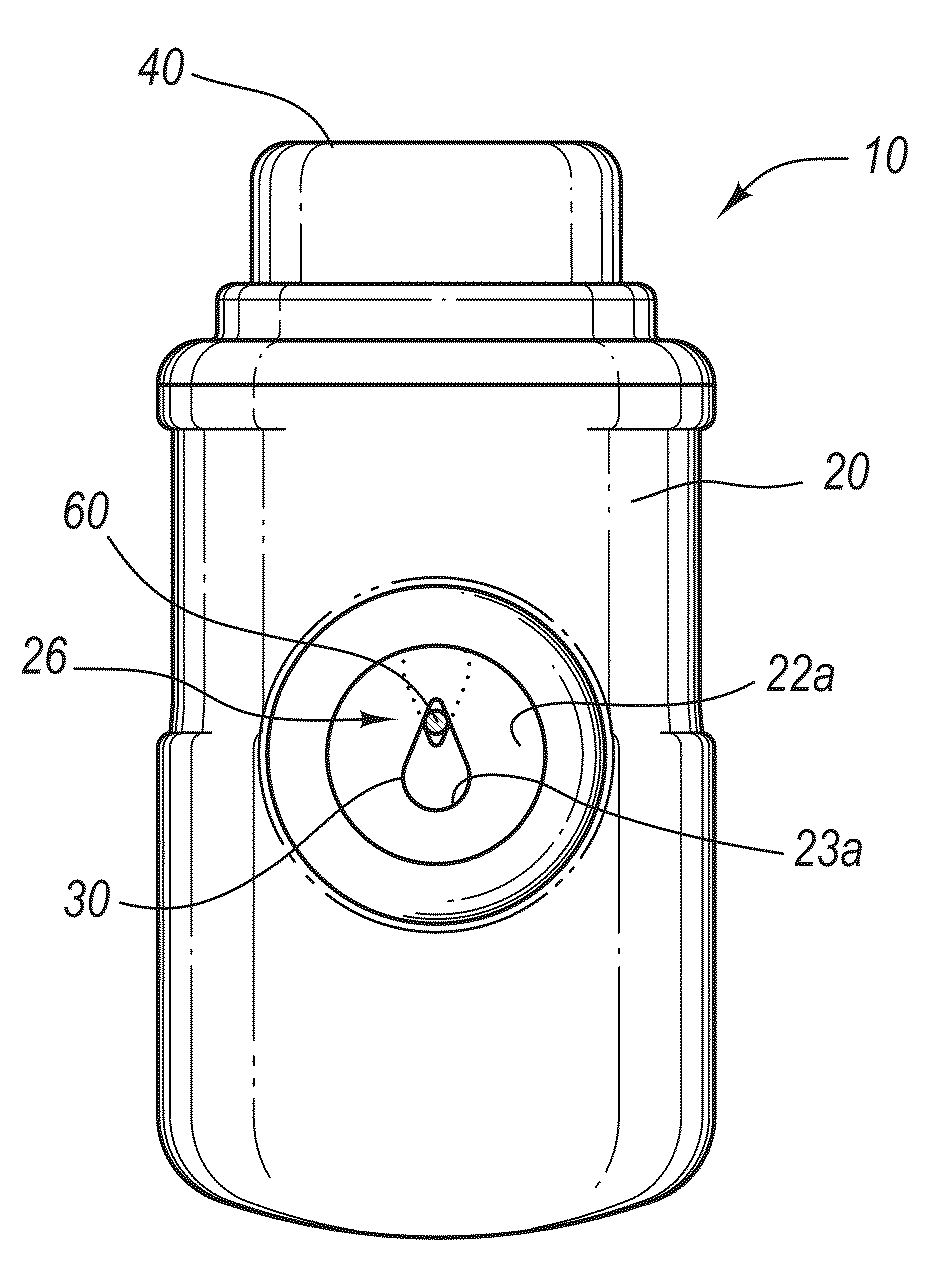

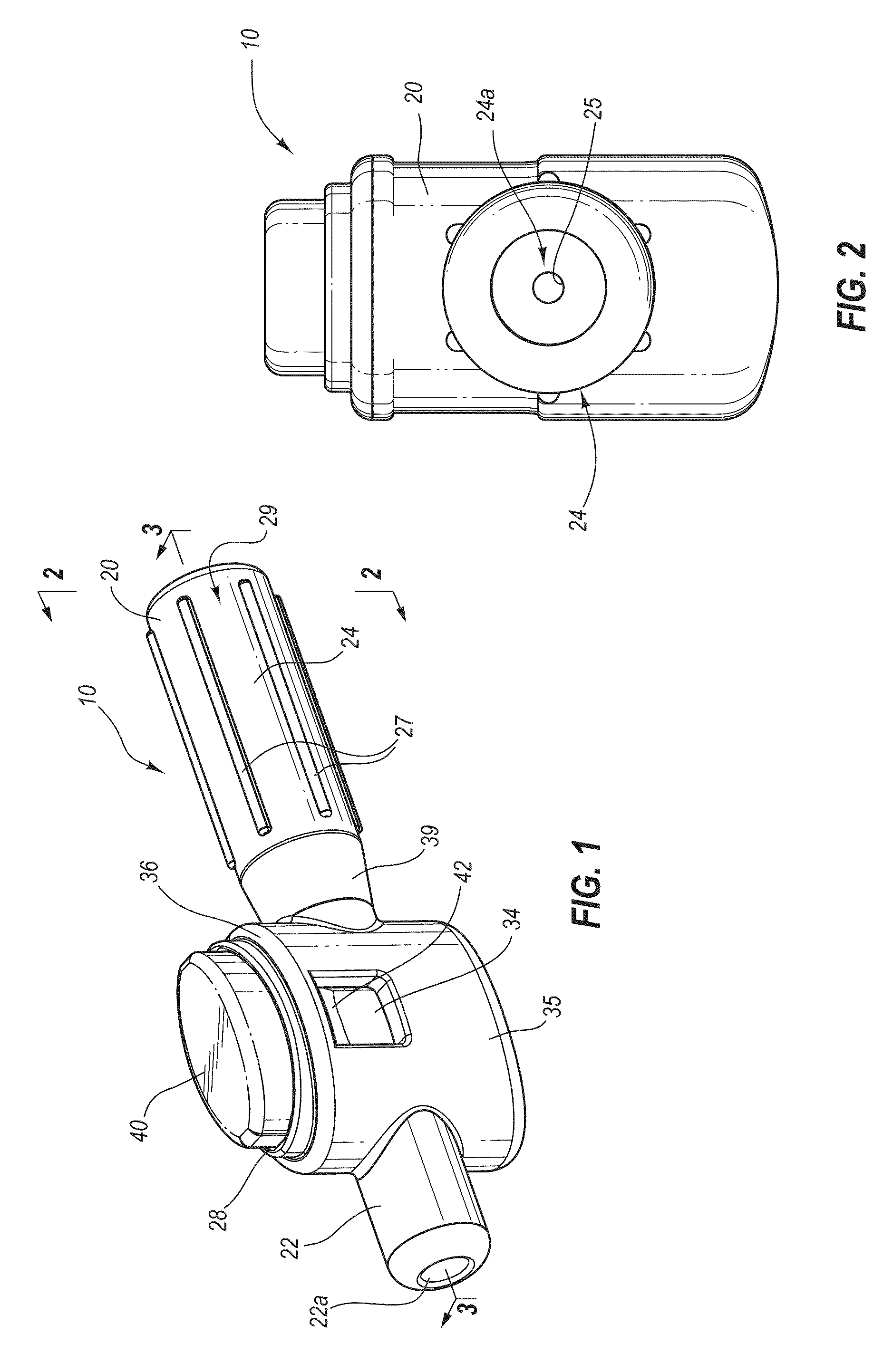

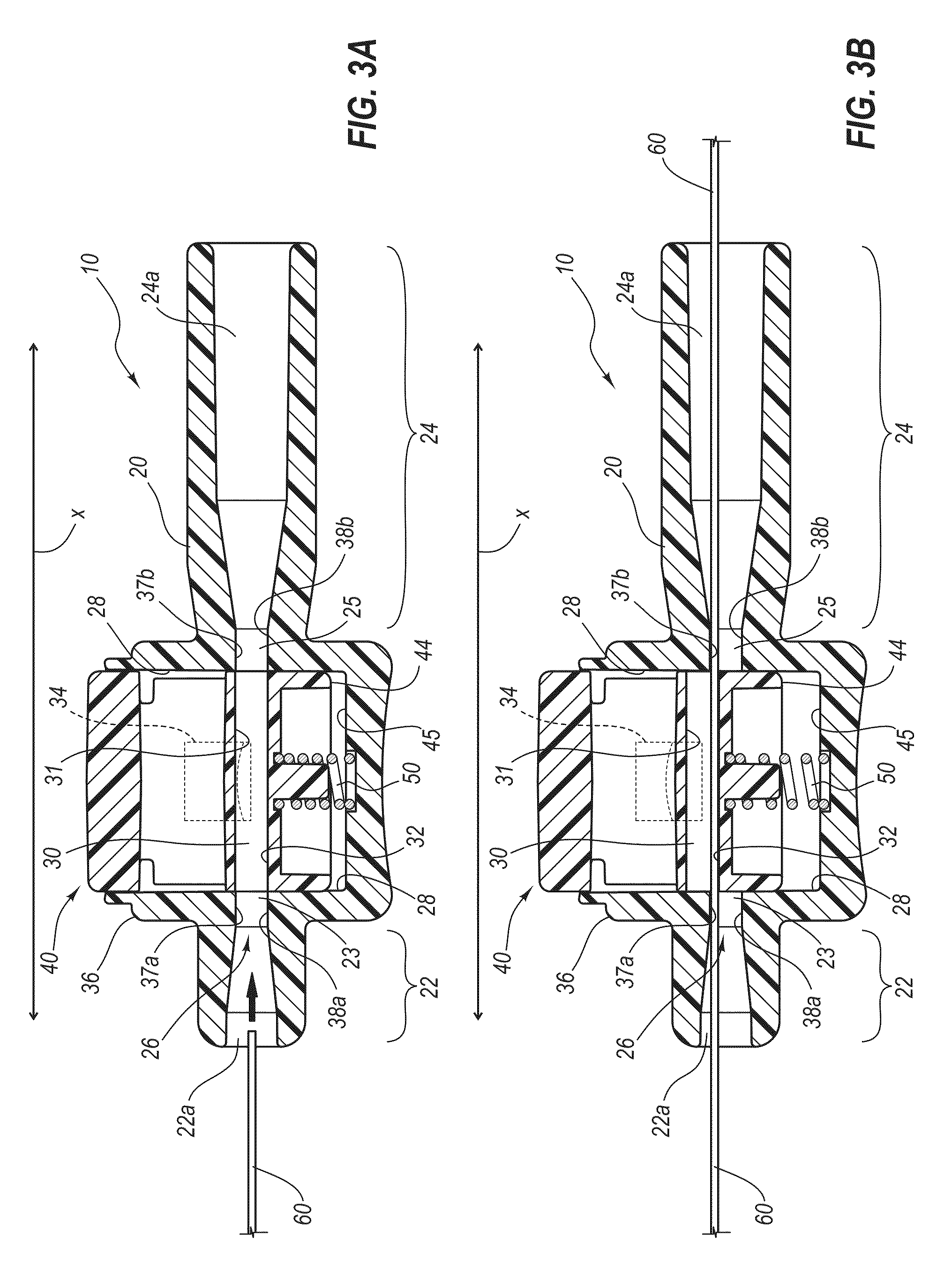

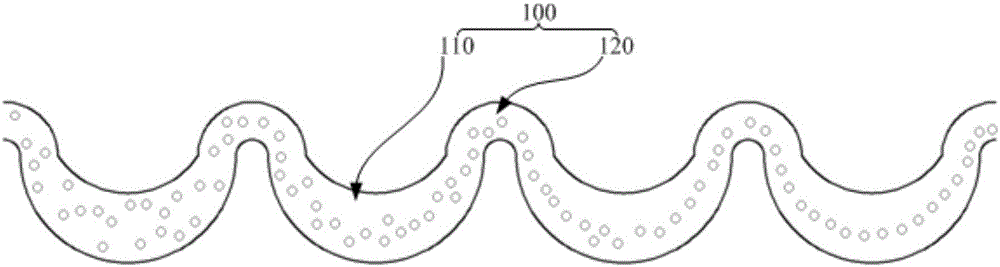

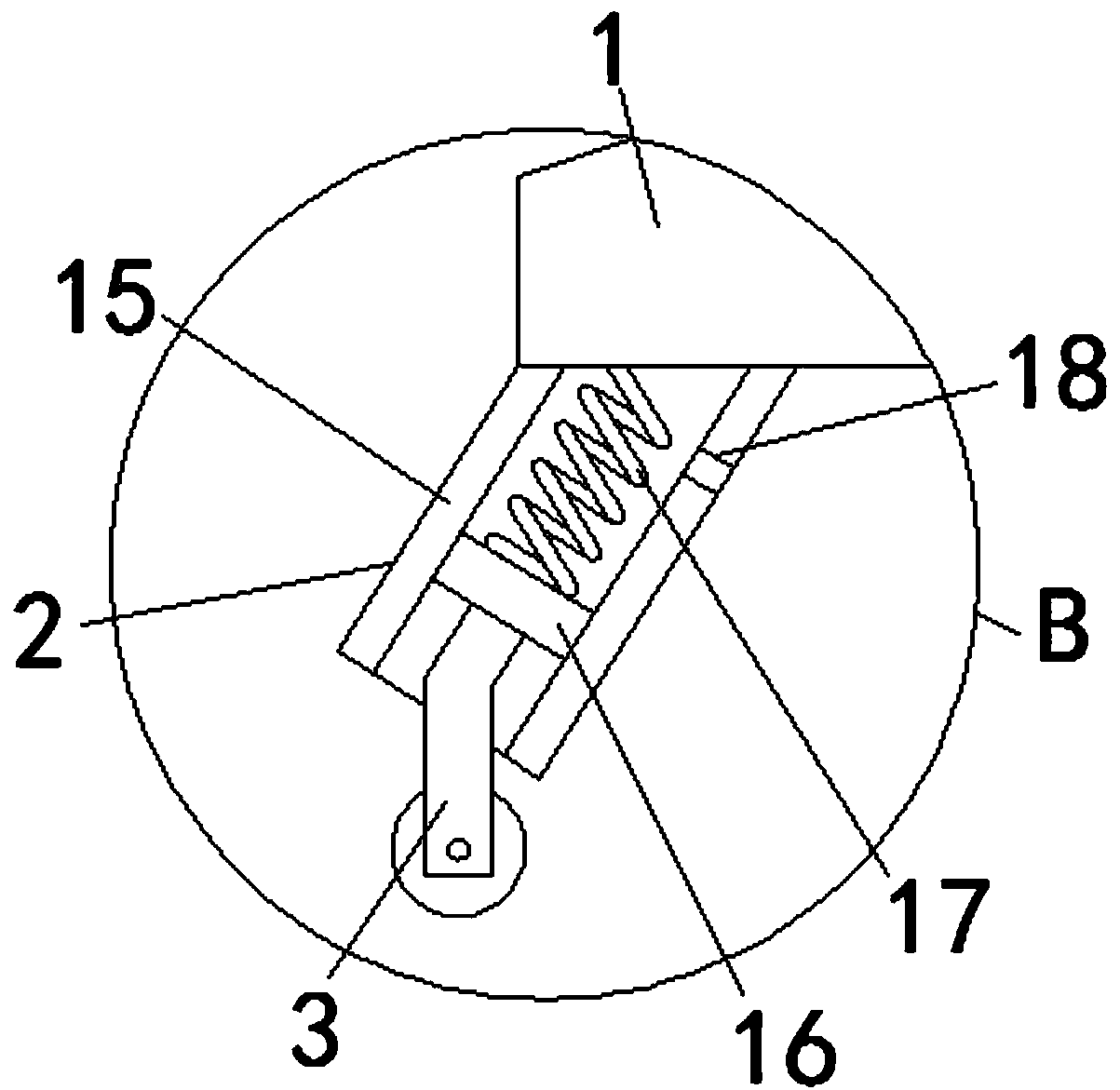

Torque device for a medical guidewire

ActiveUS20070219467A1Improve gripAvoid misuseGuide wiresDiagnostic recording/measuringConical cavityEngineering

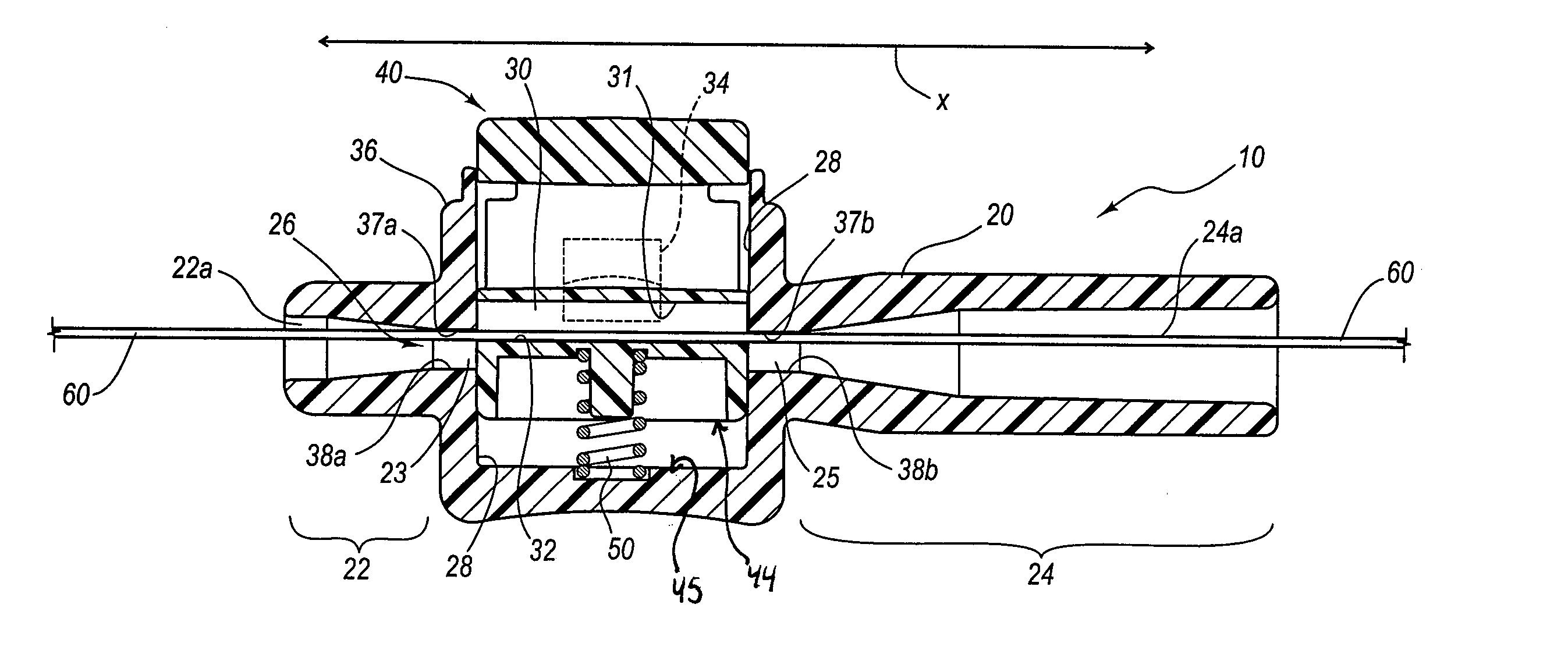

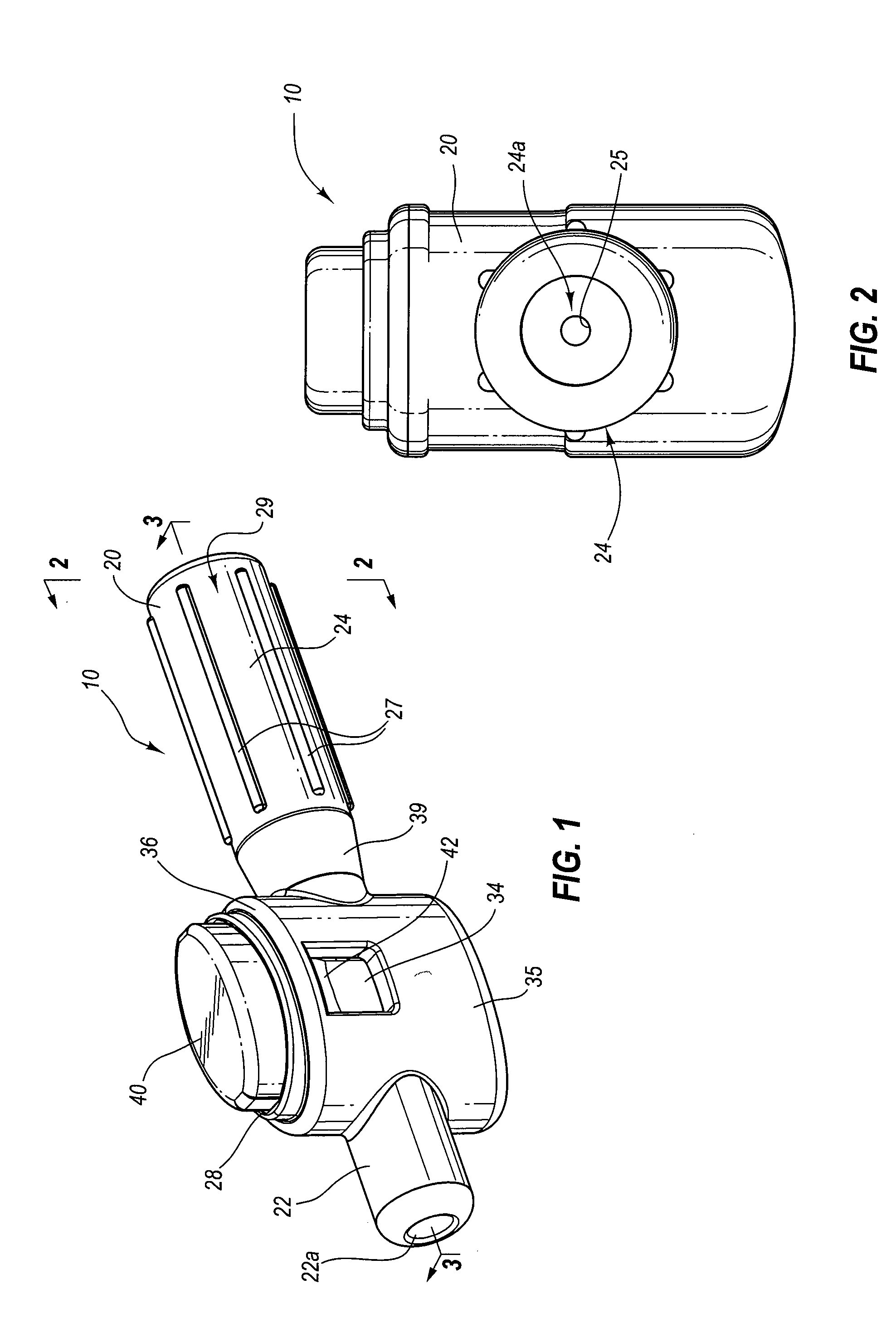

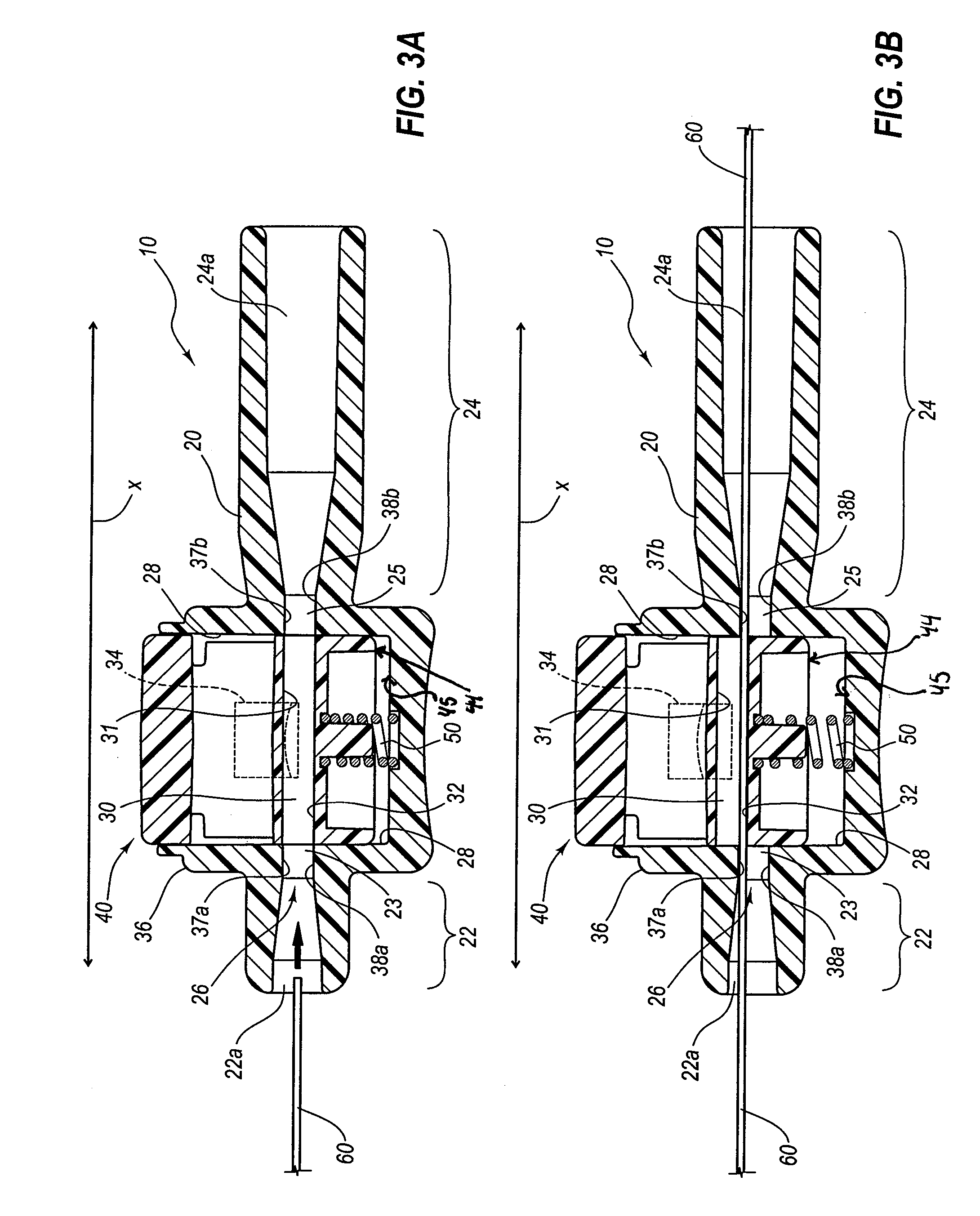

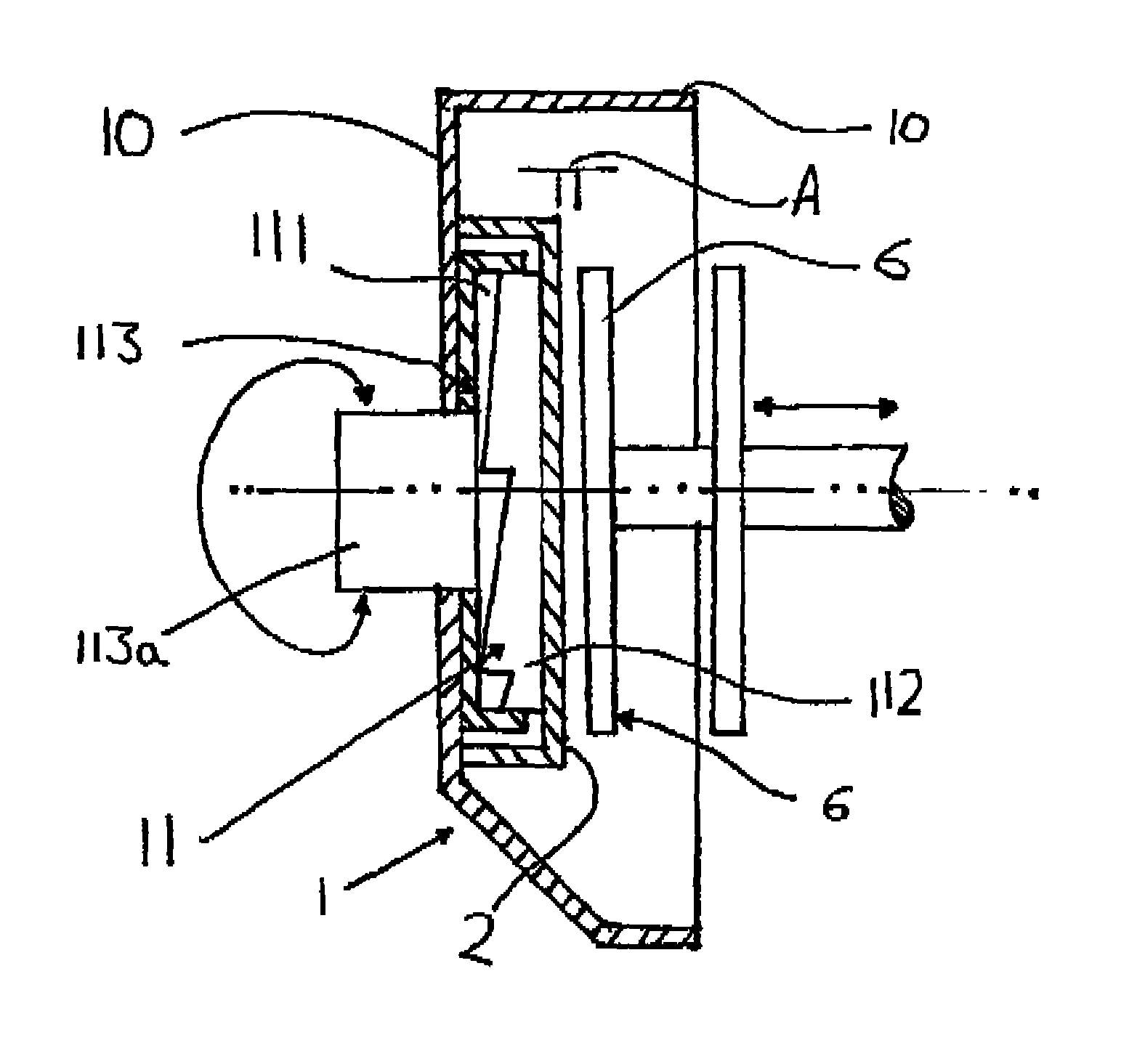

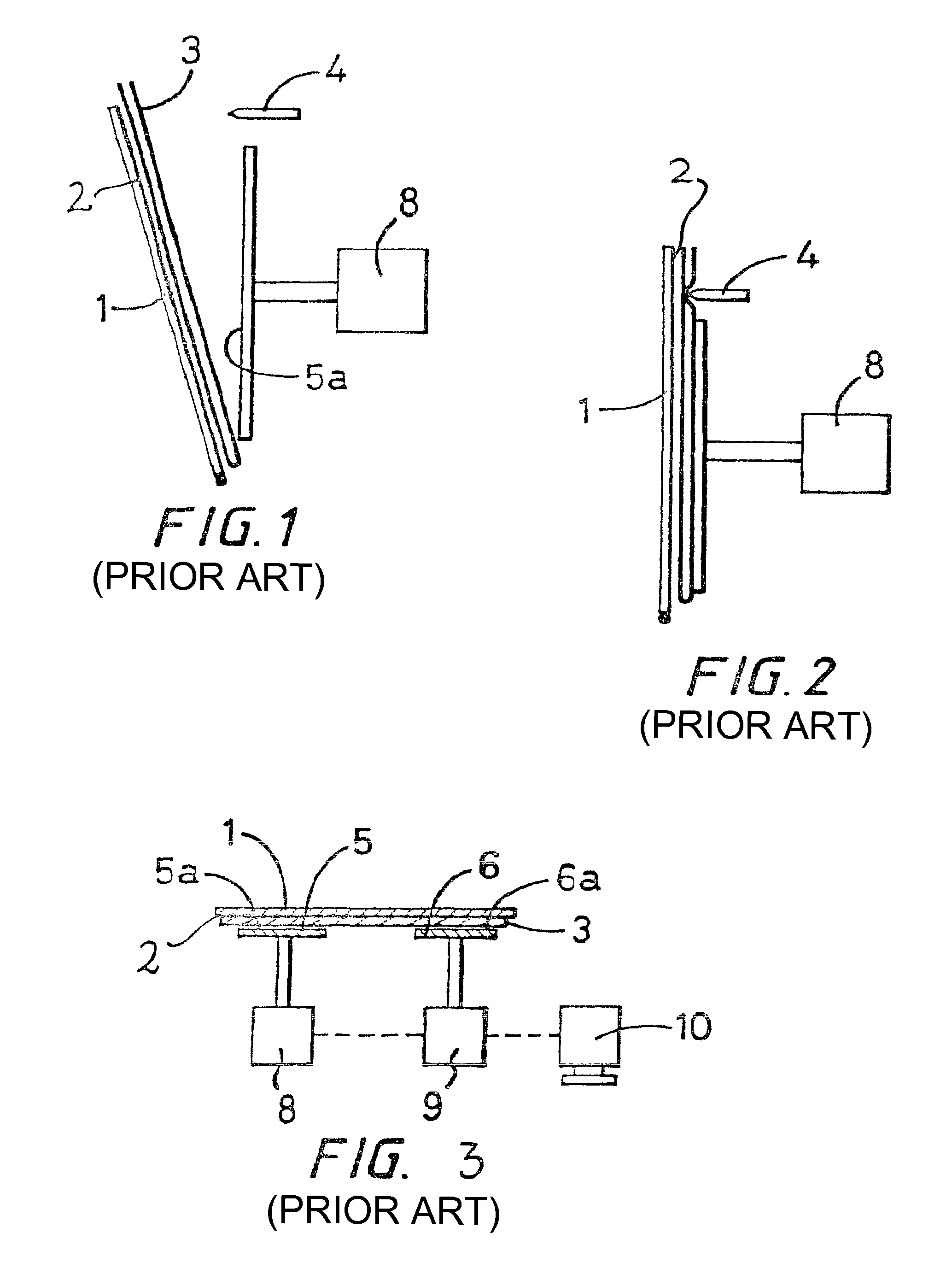

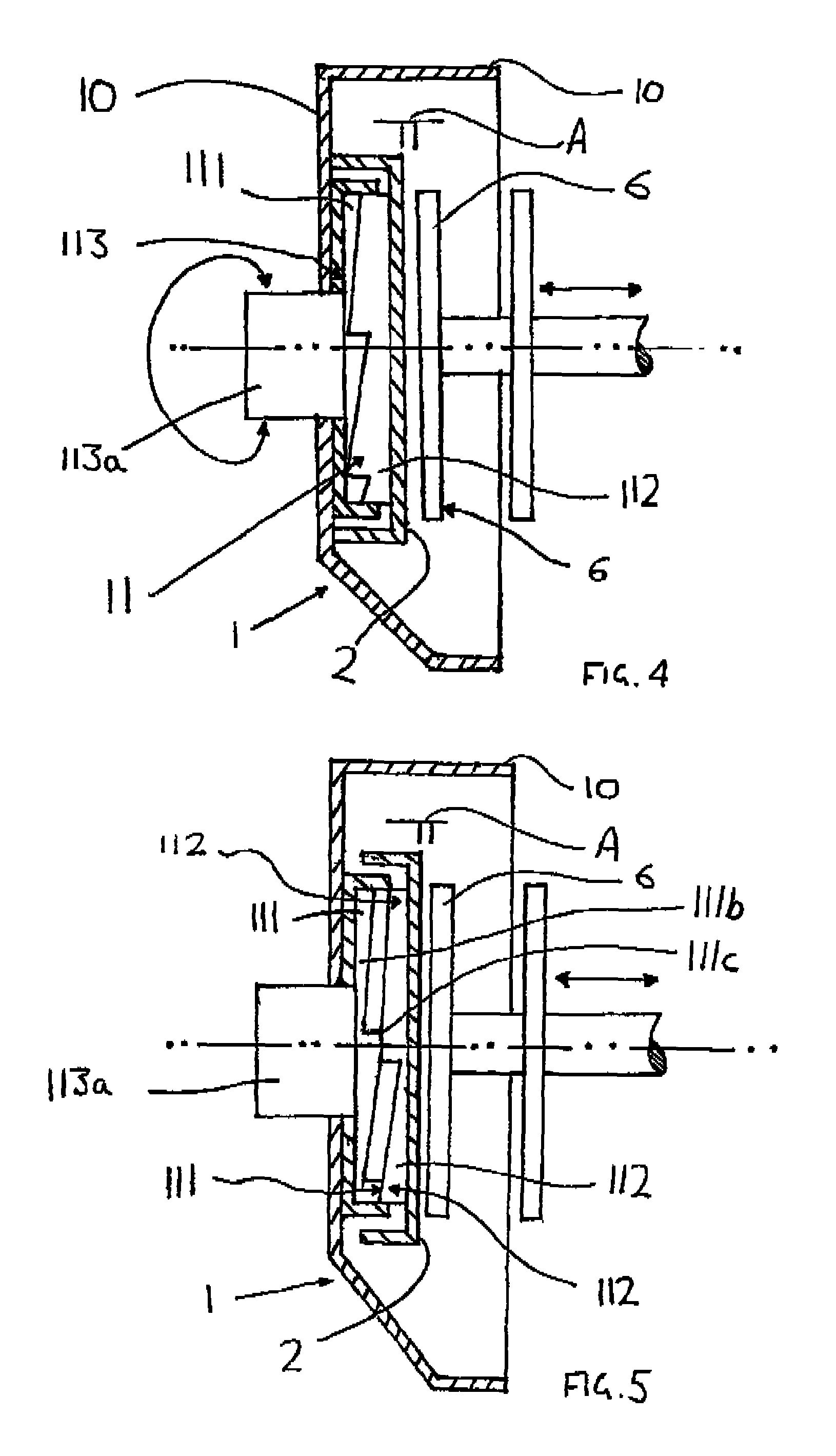

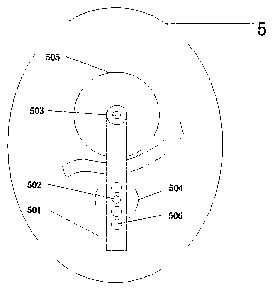

A torque device for selectively gripping a medical guidewire. The device includes a housing, an actuator slidably mounted on the housing, and a resilient member biasing the actuator. A lumen dimensioned to receive the guidewire extends through the housing and actuator. The resilient member biases the actuator from a first position in which the lumen portions are aligned, toward a second position in which the lumen portions are misaligned. The actuator may include a catch that interferes with a stop of the housing to retain the actuator within the housing. The actuator may be oblong or otherwise shaped to maintain the lumen portions in substantial alignment in a longitudinal direction. Preferably, at least a portion of the lumen is teardrop-shaped in cross-section. The housing may include circumferentially or longitudinally extending ribs defining an outer grasping surface. Frusto-conical cavities may be defined at entry and exit ends of the lumen.

Owner:MERIT MEDICAL SYST INC

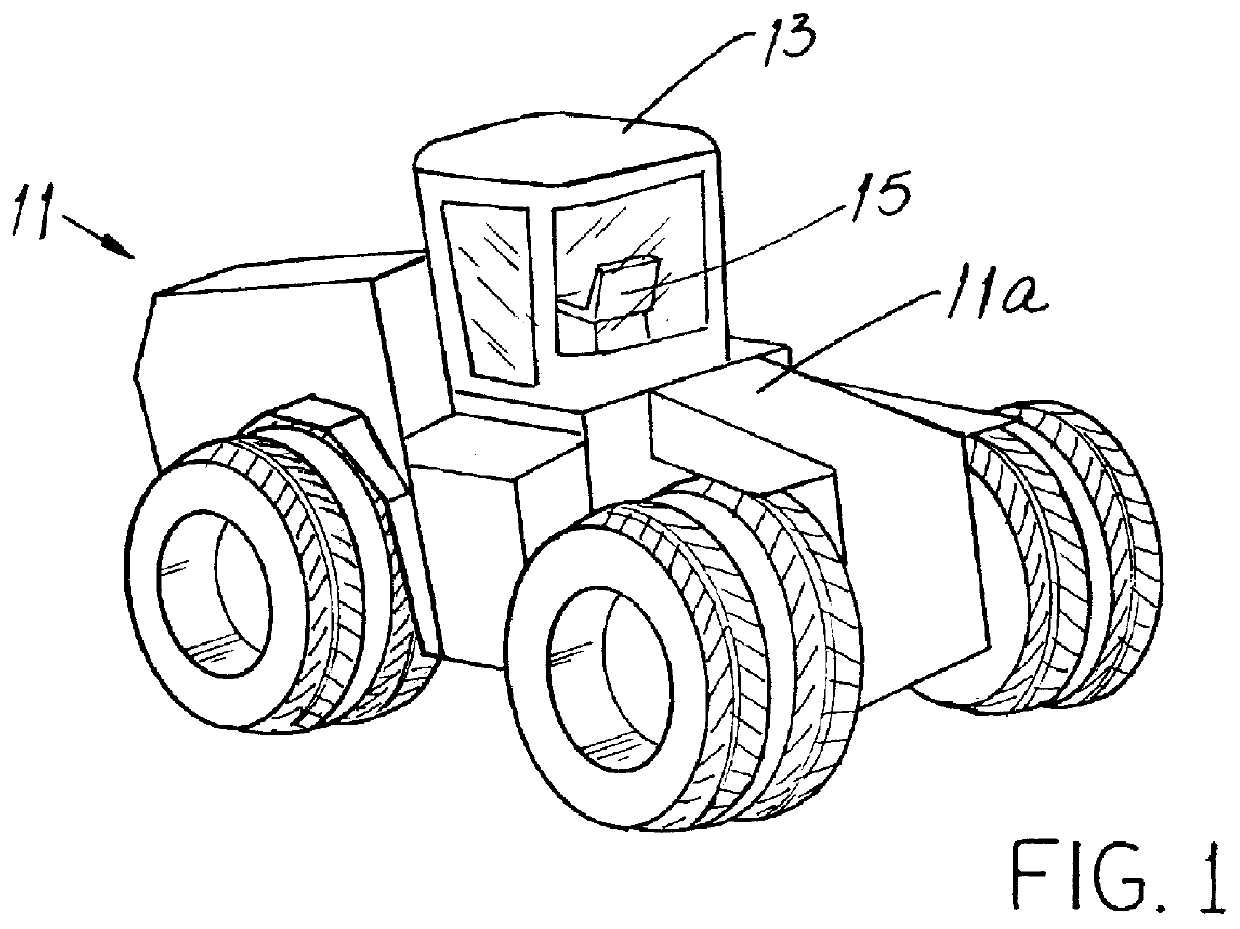

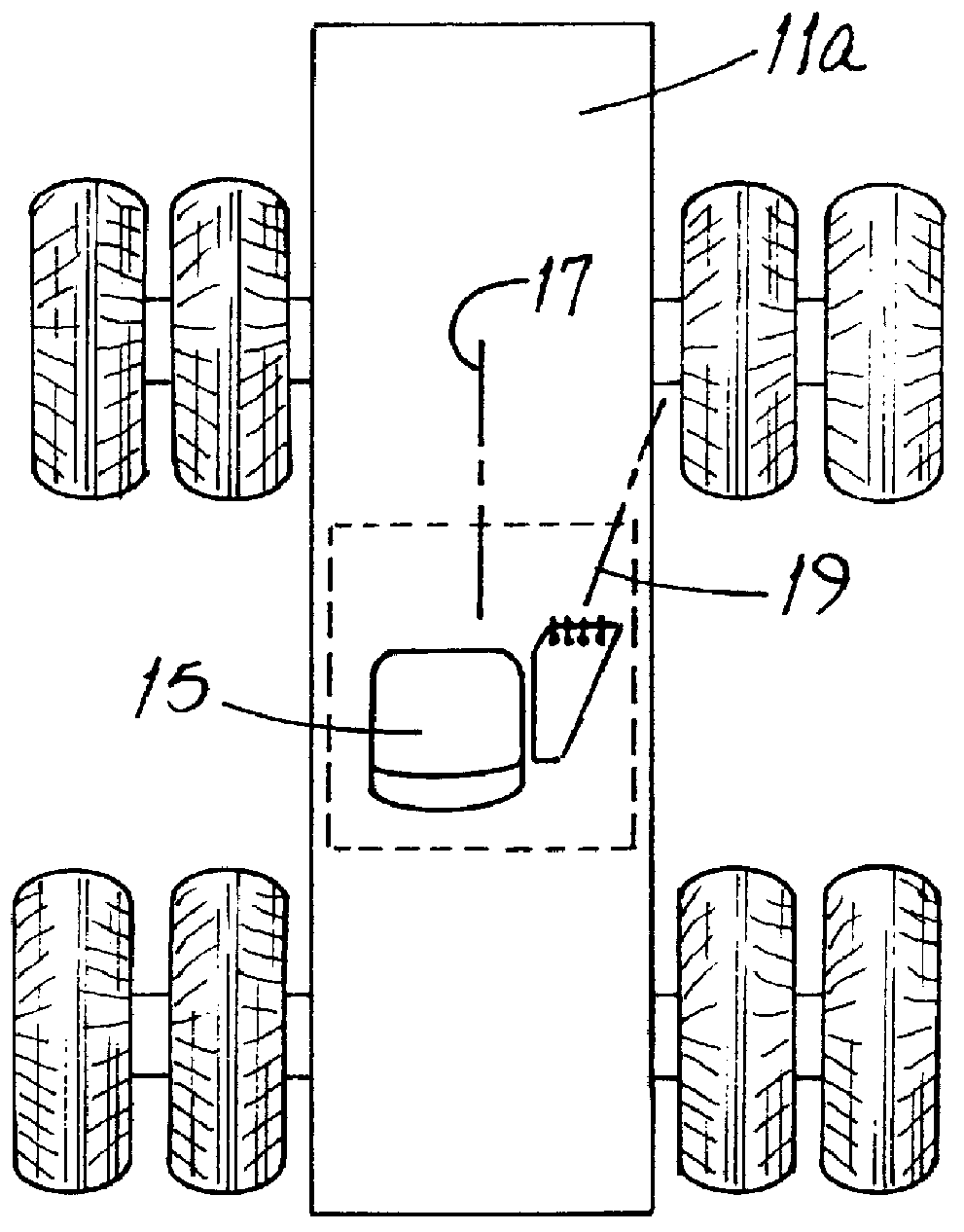

Position-adjustable control console

InactiveUS6164285AAdd dimensionPrevent rotationAlternative steering controlMetal-working hand toolsJoystickEngineering

A control console for a mobile machine includes a lower support device, a first platform and a pair of links pivotally coupled between the support device and the first platform. A second platform is mounted atop the first platform for sliding movement parallel thereto and a compression mechanism coacts with the platforms and secures them in respective positions. More specifically, each platform includes a horizontal support member and a web extending downwardly from such members. The platform webs are closely proximate one another and when the compression mechanism is tightened, the webs and one of the links are compressed together. Web / link compression prevents up-down movement of the platforms in unison and also prevents movement of the second platform with respect to the first platform. A new method for moving the position of a control lever mounted on the console is also disclosed.

Owner:BLUE LEAF I P +1

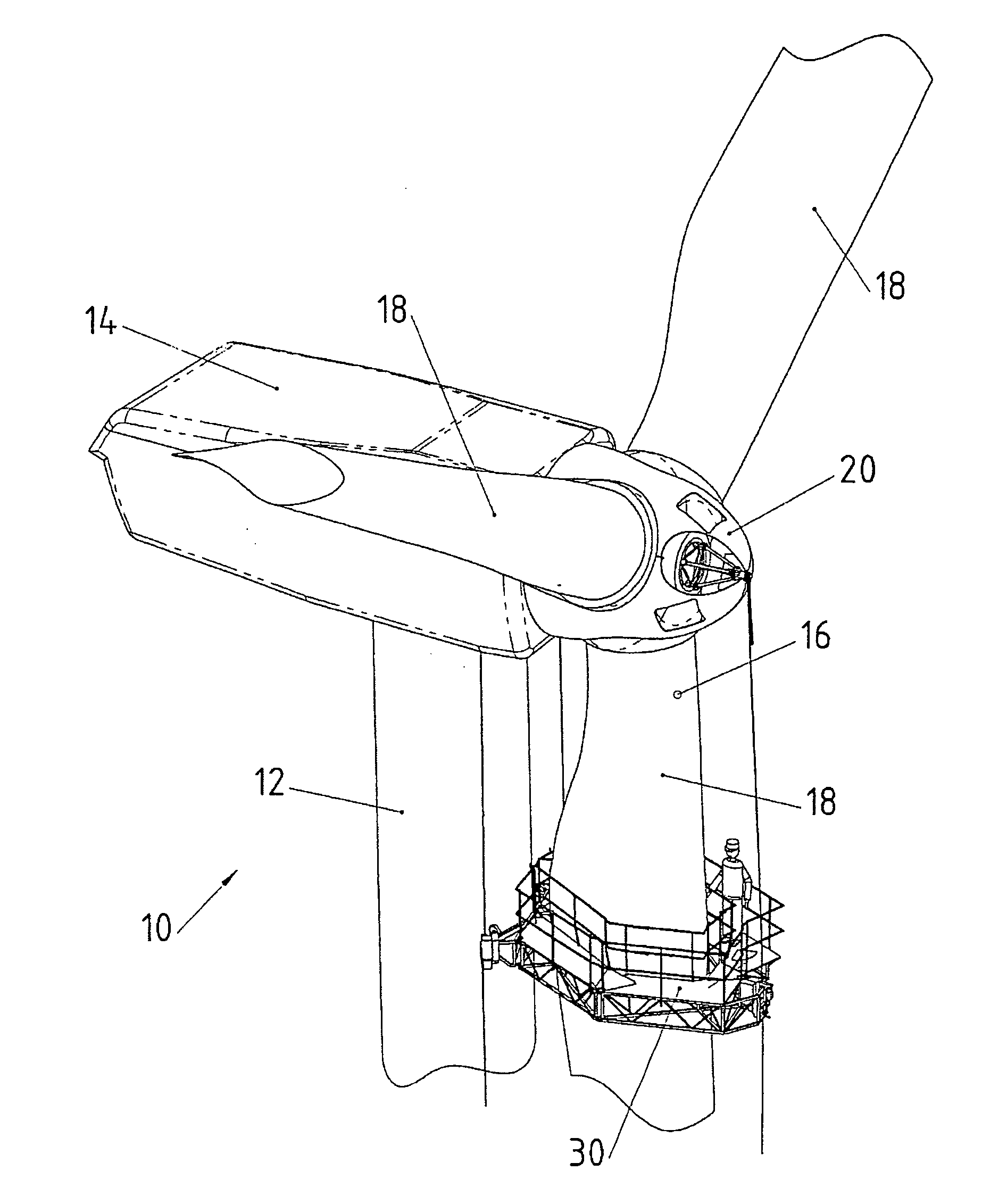

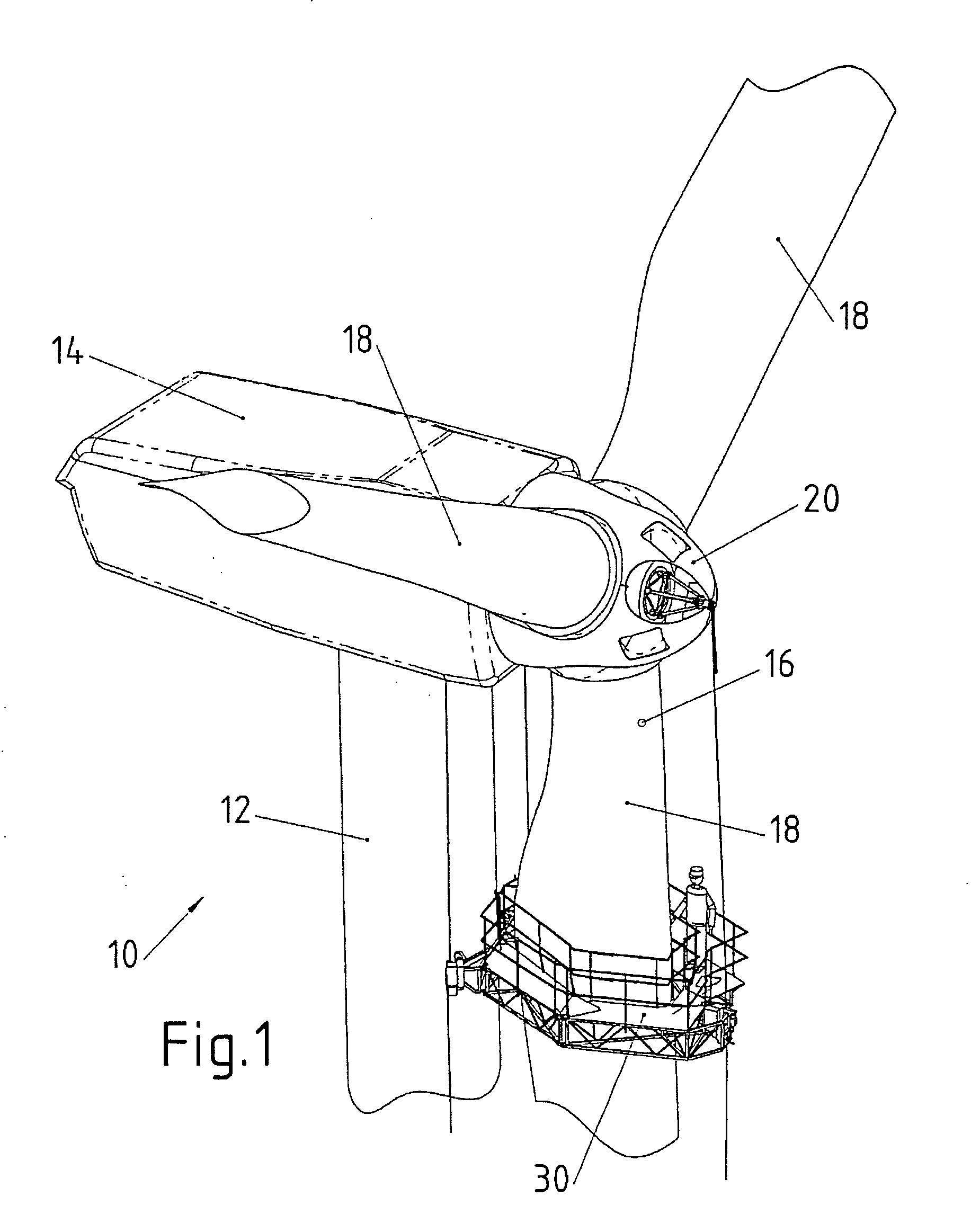

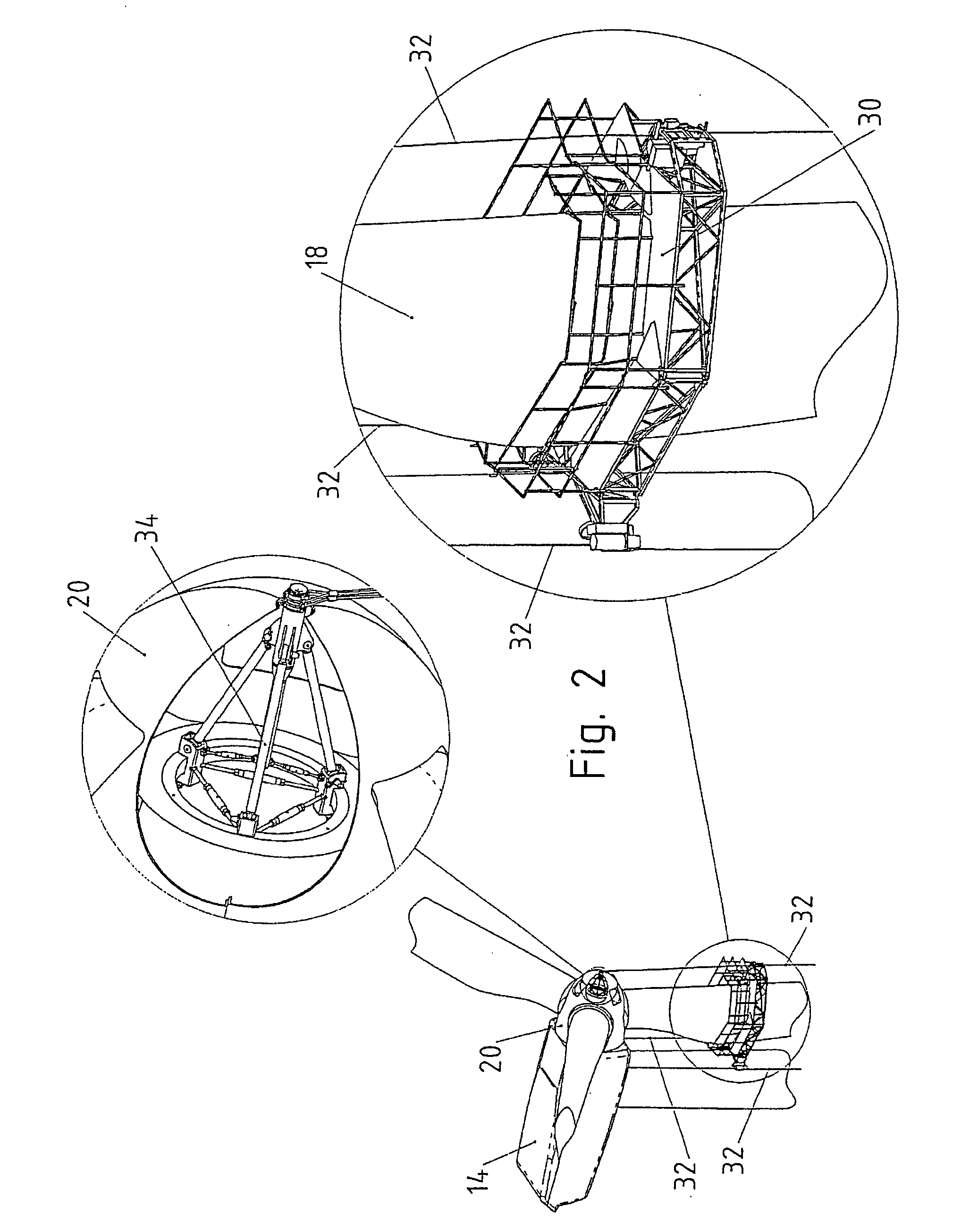

Maintenance platform

InactiveUS20070007074A1Suitable for useImprove stabilityMachines/enginesWind energy generationTurbineWind force

Owner:AEROCONCEPT ING FUR LUFTFAHRTECHN & FASERVERBUNDTECH MBH

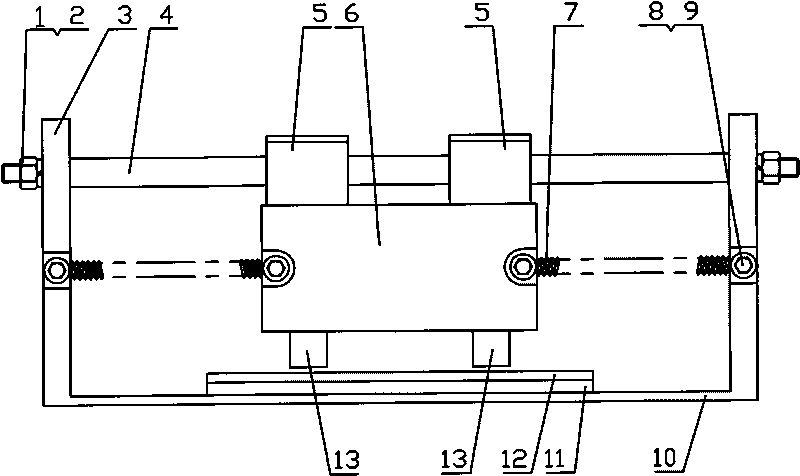

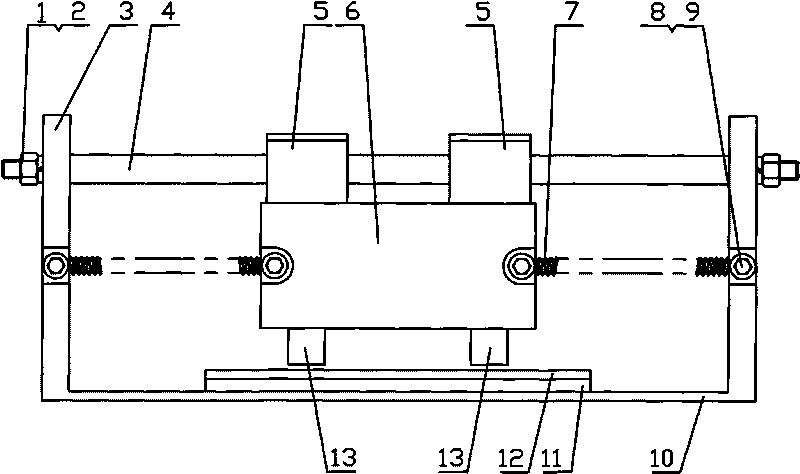

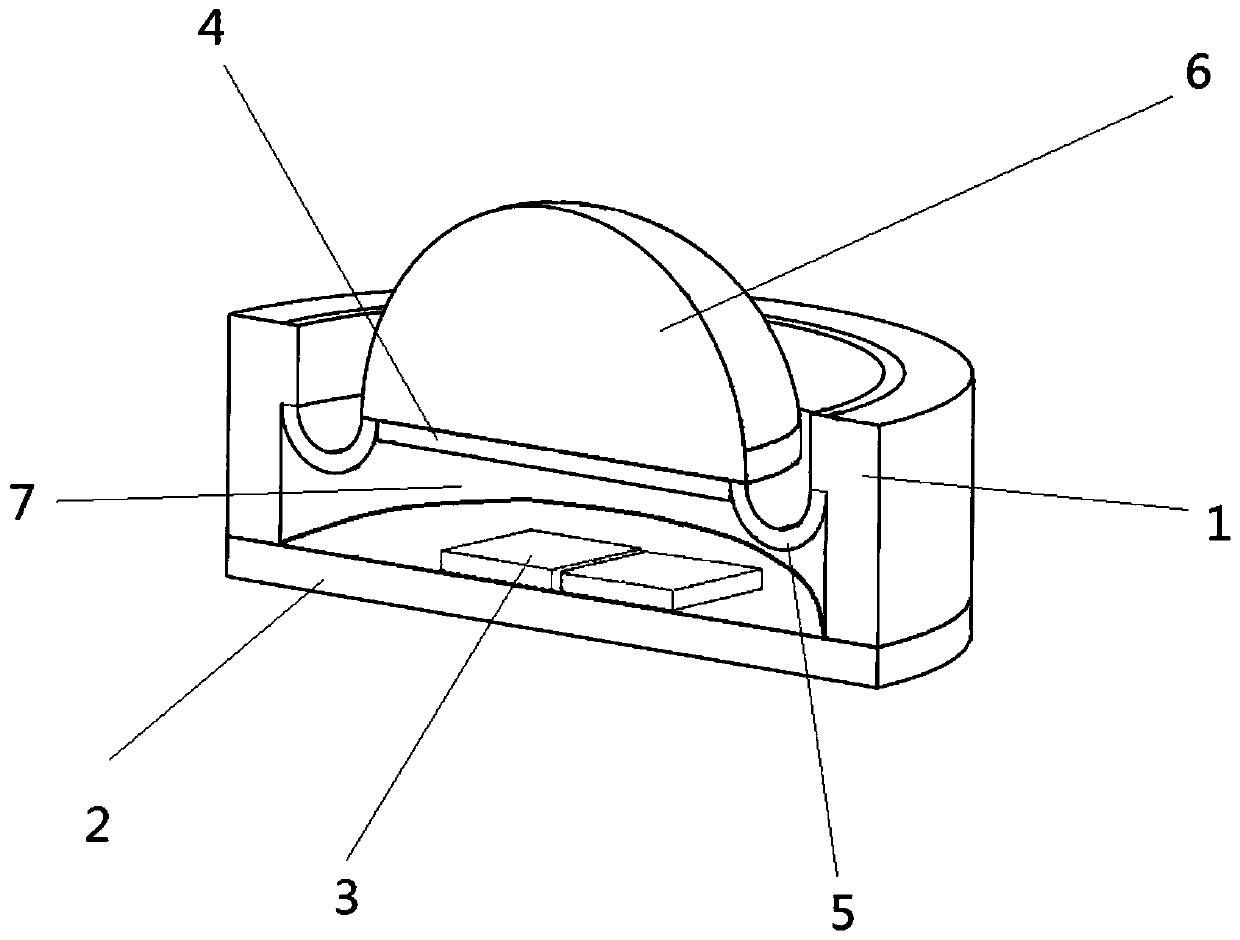

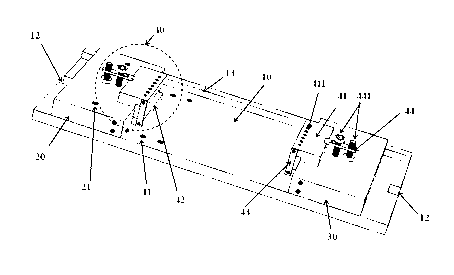

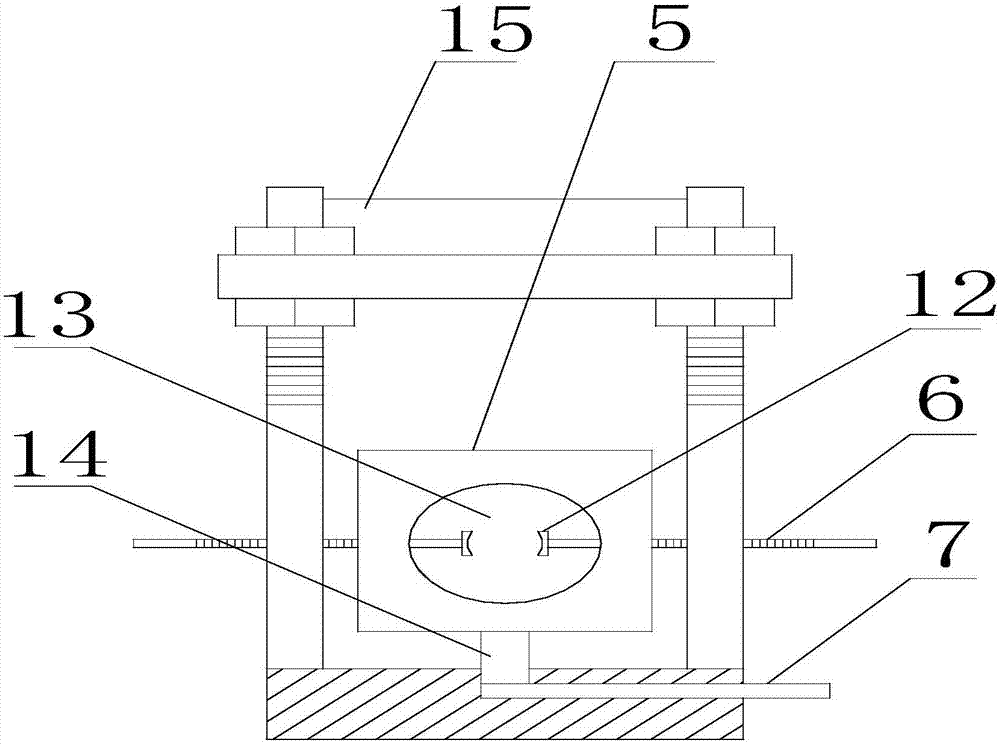

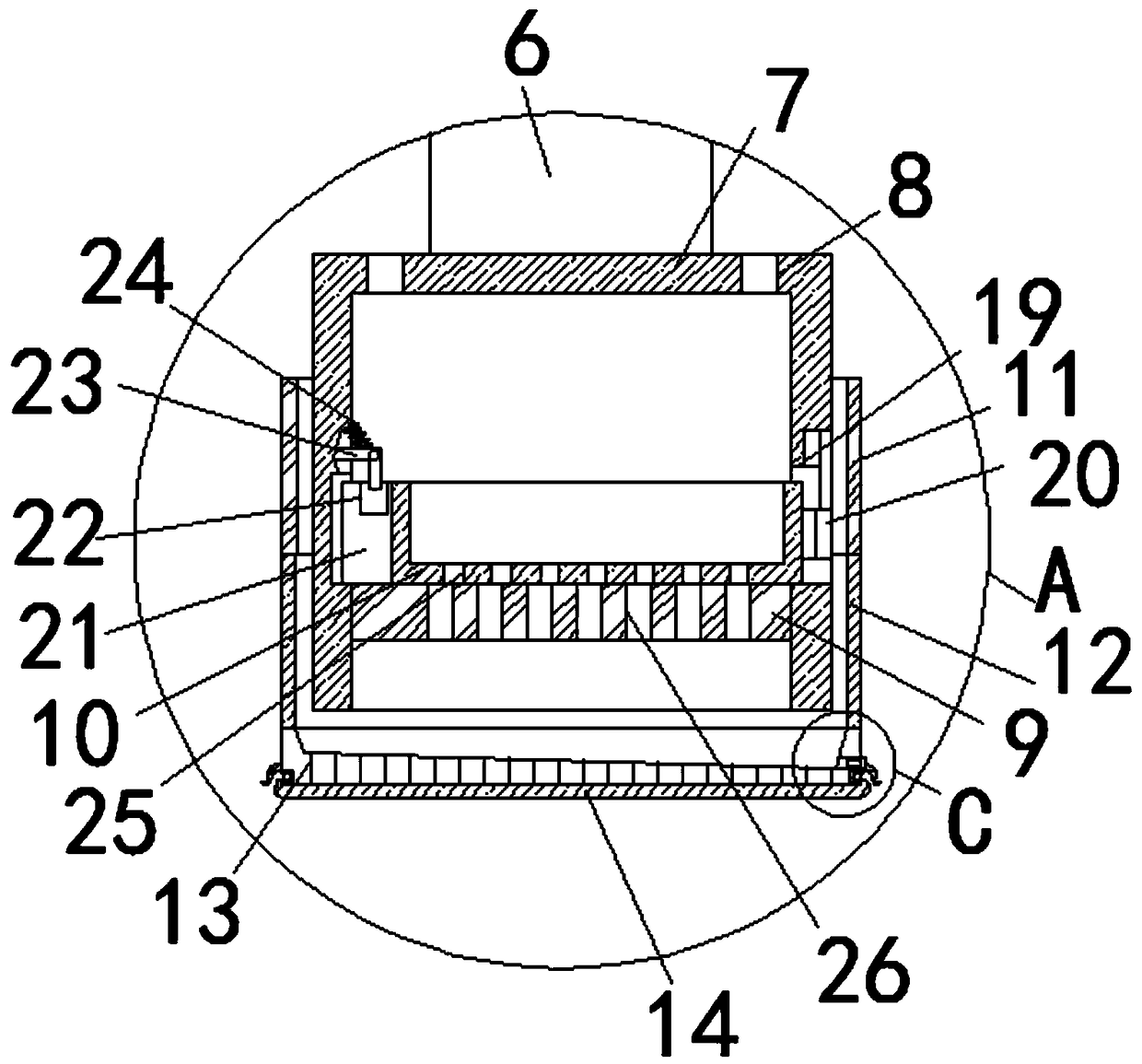

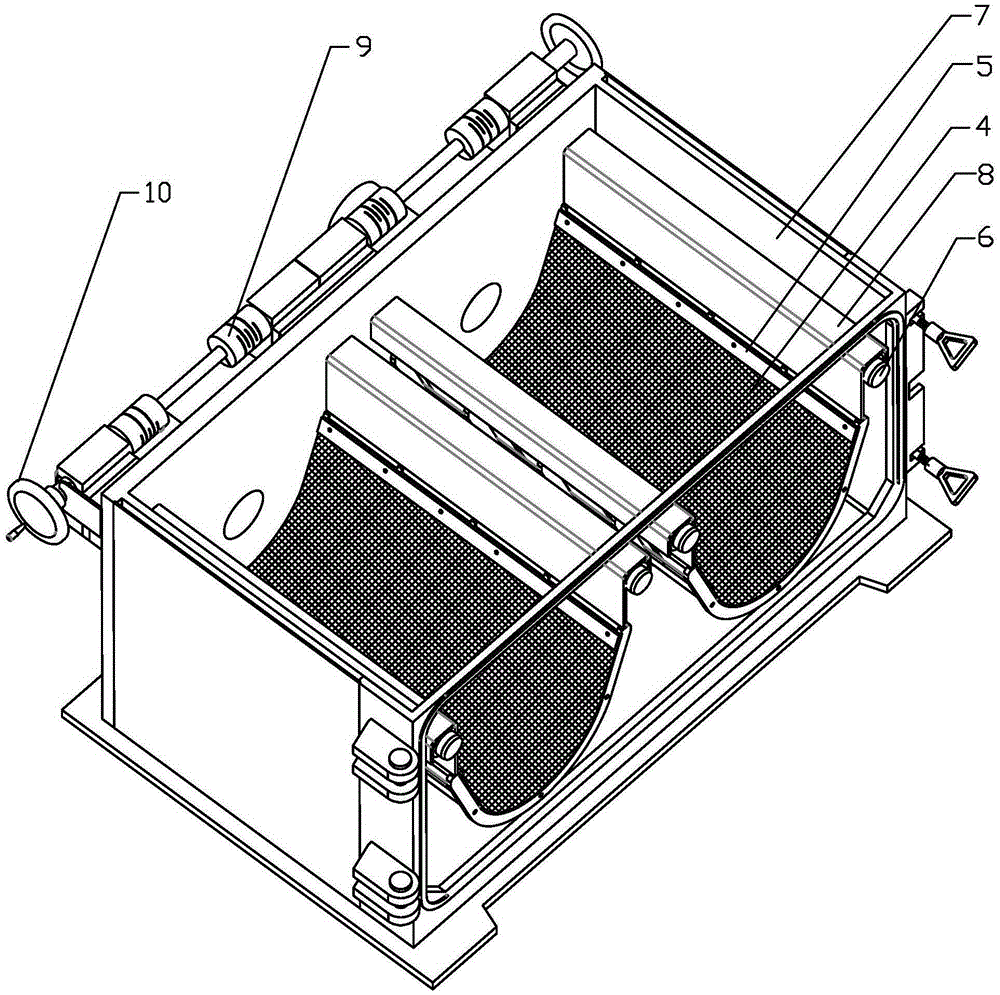

Permanent-magnet type eddy current tuned mass damper

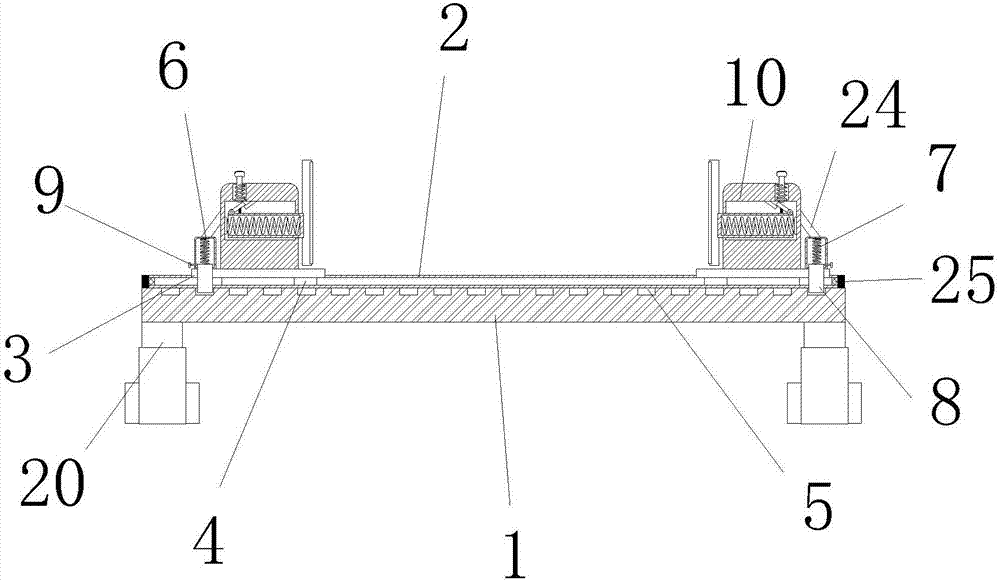

ActiveCN101761146APrecise linear motionStructural damping dropBridge structural detailsTowersStress concentrationElectricity

The invention relates to a permanent-magnet type eddy current tuned mass damper which comprises a steel magnetic-conducting baseplate (10), wherein end plates (3) are respectively arranged at two ends of the baseplate (10). The permanent-magnet type eddy current tuned mass damper is characterized by also comprising a circular shaft (4) and a linear bearing seat (5), wherein two ends of the circular shaft (4) are respectively arranged on the corresponding end plates (3), and the linear bearing seat (5) is sleeved on the circular shaft (4) and can slide on the circular shaft (4); the lower part of the bearing seat (5) is connected with a mass block (6), and two ends of the mass block (6) are respectively connected with the corresponding end plates (3) through spiral springs (7); the lower part of the mass block (6) is connected with a permanent magnet (13), and a copper plate (12) is arranged below the permanent magnet (13) and connected with the baseplate (12) through a cushion block (11). By adopting an eddy current damping model with special design, the permanent-magnet type eddy current tuned mass damper realizes the damping adjustability of the damper in a larger range, realizes the complete separation between the system rigidity and the damper, and cancels the mechanical friction energy consumption and stress concentration elements, thereby avoiding the common TMD damage failure.

Owner:湖南省潇振工程科技有限公司 +1

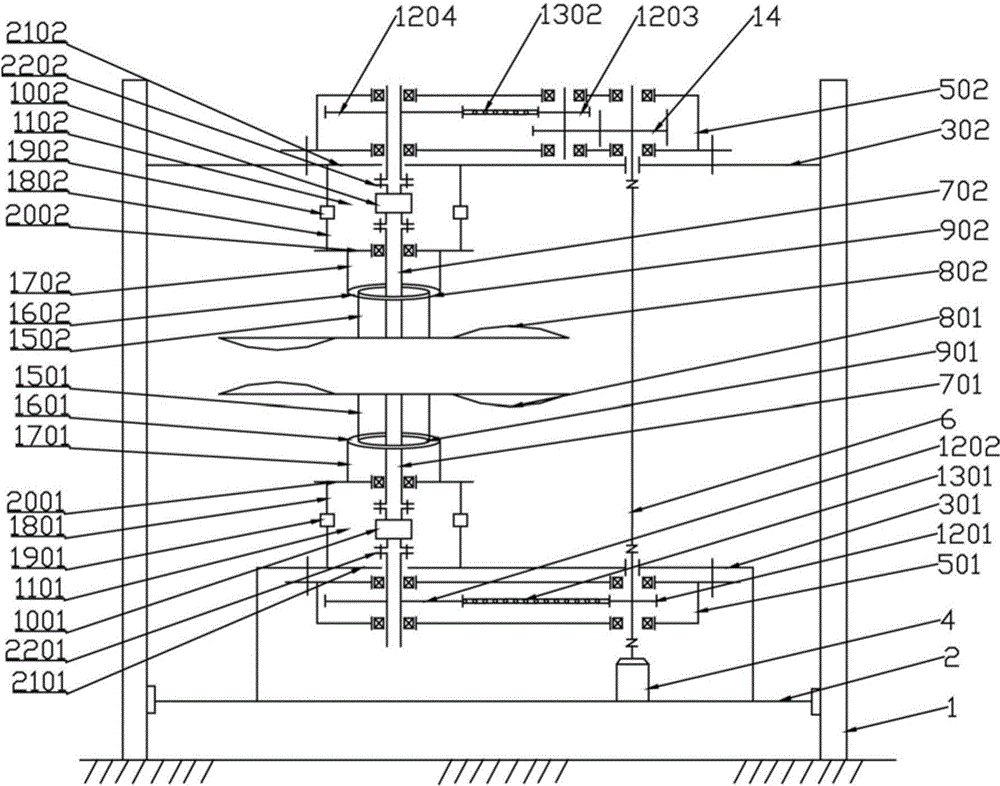

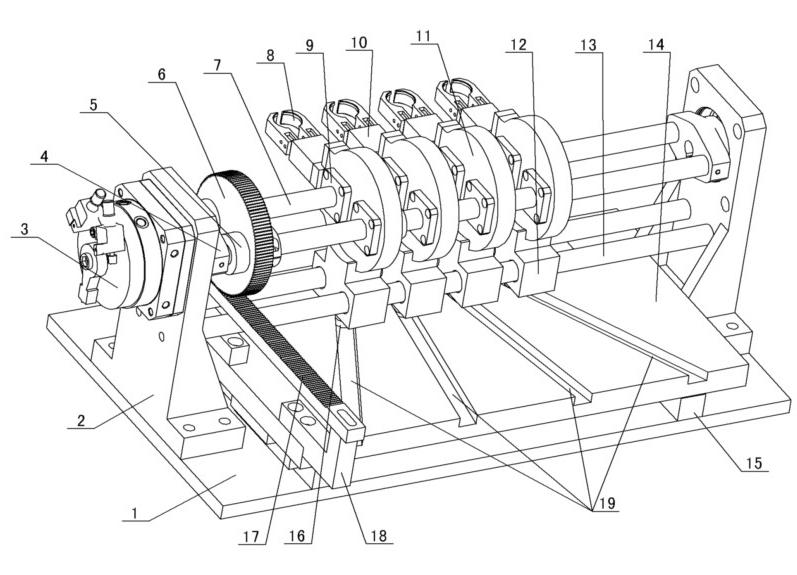

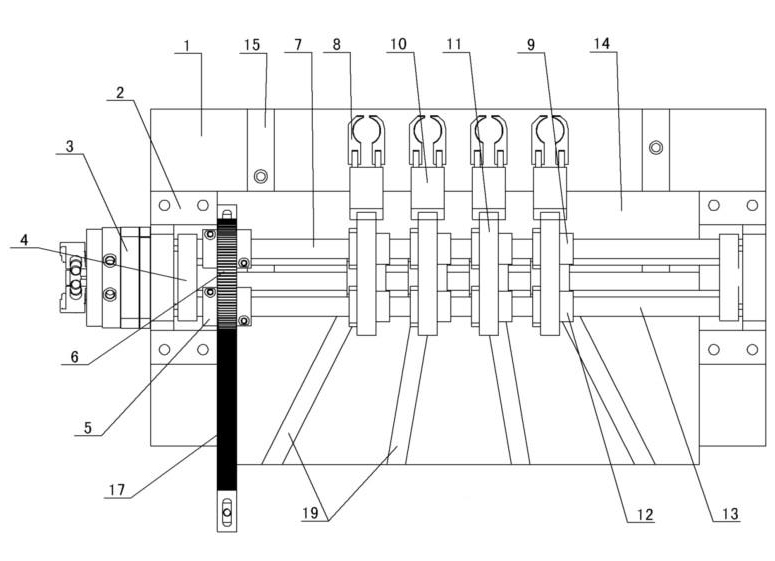

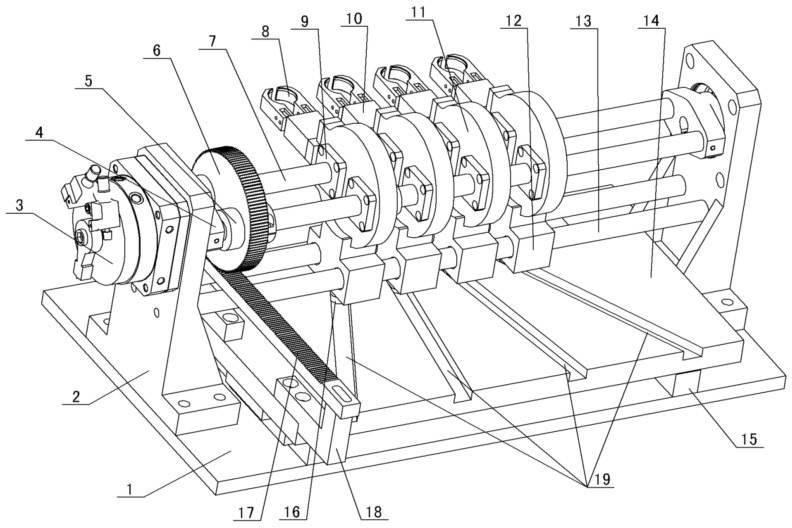

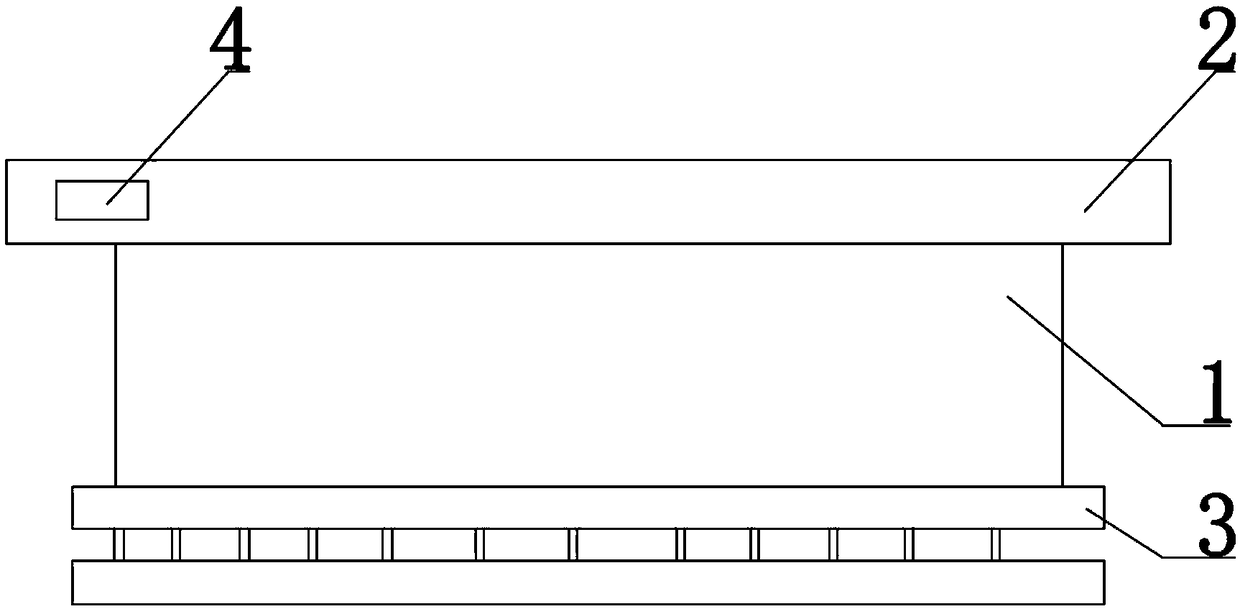

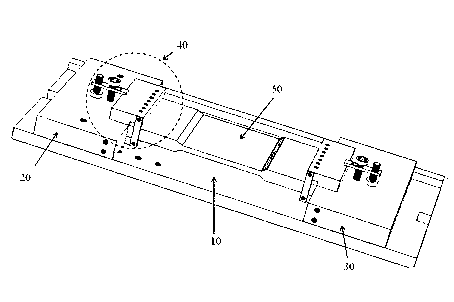

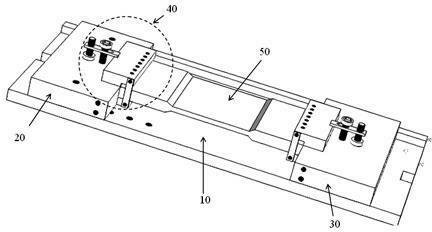

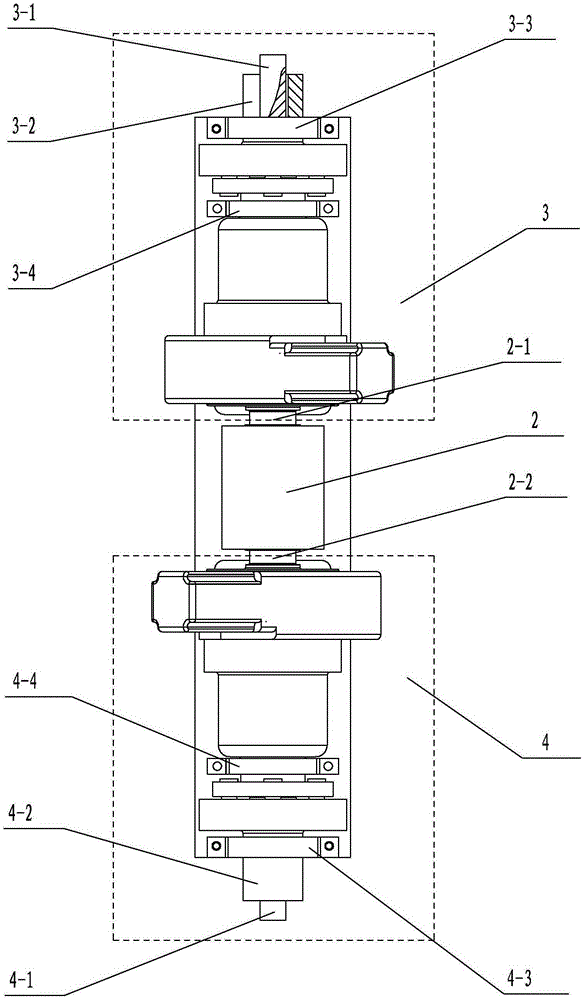

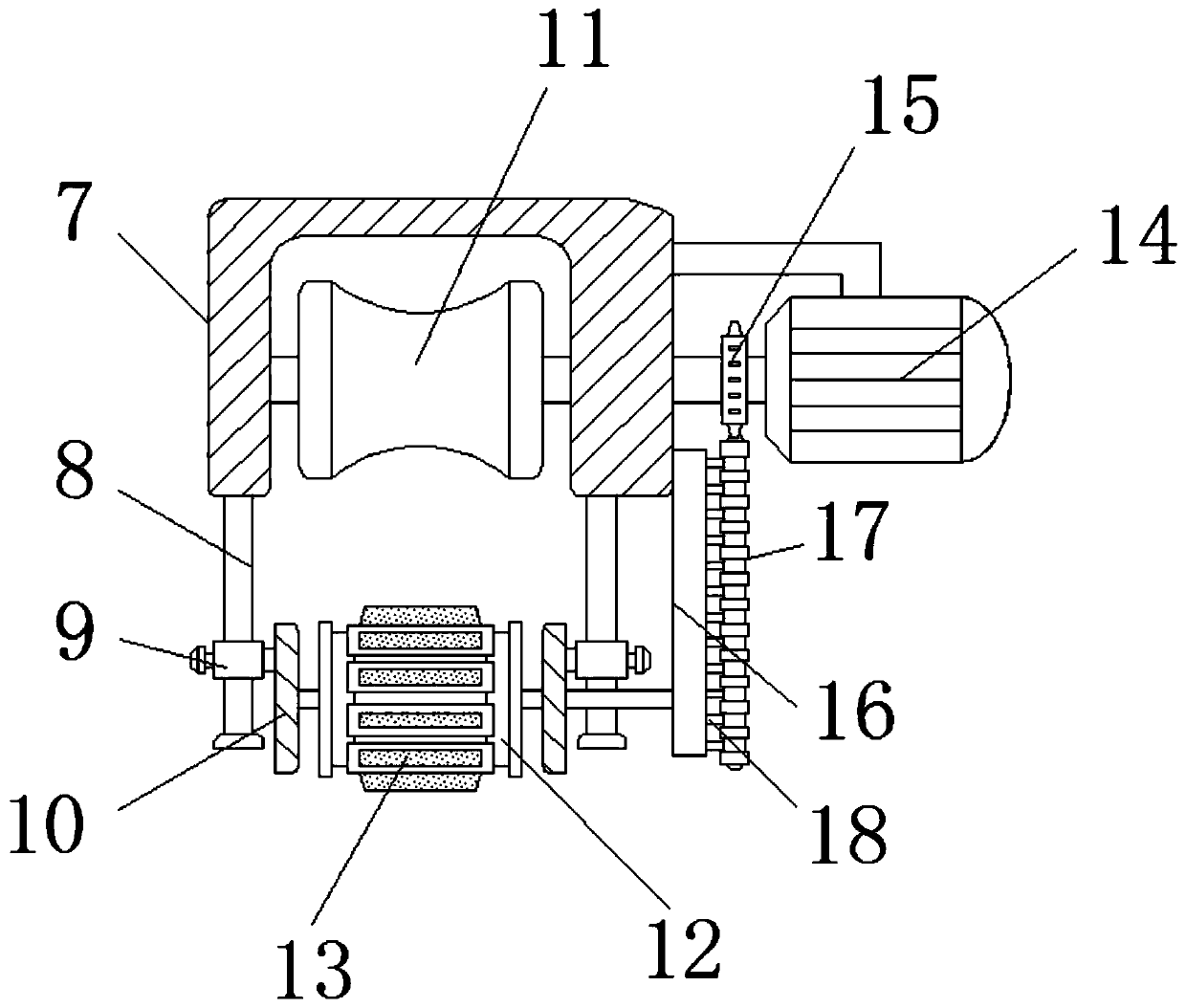

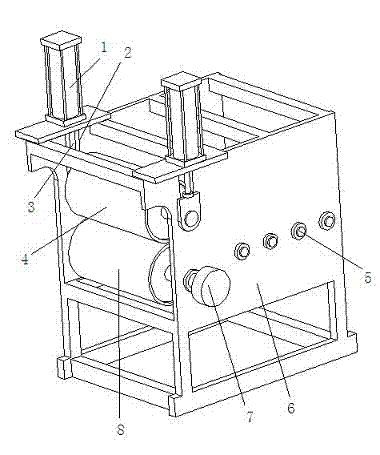

Hanging type coaxial contrarotating rotor wing testing device

InactiveCN104913912AStudy aerodynamic propertiesEvaluate Rotor PerformanceMachine part testingWork measurementElectric machineRotary wing

The invention relates to the technical field of helicopter comprehensive tests, and discloses a hanging type coaxial contrarotating rotor wing testing device. The hanging type coaxial contrarotating rotor wing testing device comprises a lifting platform, a lower base, an upper base, a motor, an upper rotor wing speed changer, a lower rotor wing speed changer, an upper rotor wing unit, a lower rotor wing unit, an upper rotor wing measuring unit and a lower rotor wing measuring unit, wherein the lifting platform is arranged on a bracket in a mode of being capable of sliding up and down, the lower base is arranged on the lifting platform, the upper base is connected with the bracket and located above the lower base, the motor is arranged on the lower base, the upper rotor ring speed changer and the upper rotor wing speed changer are connected with the motor, the upper rotor wing unit and the lower rotor wing unit are coaxially arranged. Both the upper rotor wing unit and the lower rotor wing unit comprise a rotor wing shaft, a rotor wing arranged in the rotor wing shaft and a rotor wing manipulating assembly connected with the rotor wing. Both the upper rotor wing measuring unit and the lower rotor wing measuring unit comprise a torque balance which is connected with the speed changer and the rotor wing shaft and a rotor wing balance which is connected with the rotor wing manipulating assembly. According to the invention, the upper rotor wing and the lower rotor wing are separated and respectively equipped with the measuring unit, a force, the bending moment and the torque of each rotor wing can be measured independently, and the space between the upper rotor wing and the lower rotor wing can be adjusted, thereby being capable of effectively evaluating the performance of each rotor wing and studying aerodynamic characteristics of each rotor wing.

Owner:BEIHANG UNIV +1

Torque device for a medical guidewire

ActiveUS7972282B2Improve gripAvoid misuseGuide wiresDiagnostic recording/measuringEngineeringConical cavity

A torque device for selectively gripping a medical guidewire. The device includes a housing, an actuator slidably mounted on the housing, and a resilient member biasing the actuator. A lumen dimensioned to receive the guidewire extends through the housing and actuator. The resilient member biases the actuator from a first position in which the lumen portions are aligned, toward a second position in which the lumen portions are misaligned. The actuator may include a catch that interferes with a stop of the housing to retain the actuator within the housing. The actuator may be oblong or otherwise shaped to maintain the lumen portions in substantial alignment in a longitudinal direction. Preferably, at least a portion of the lumen is teardrop-shaped in cross-section. The housing may include circumferentially or longitudinally extending ribs defining an outer grasping surface. Frusto-conical cavities may be defined at entry and exit ends of the lumen.

Owner:MERIT MEDICAL SYST INC

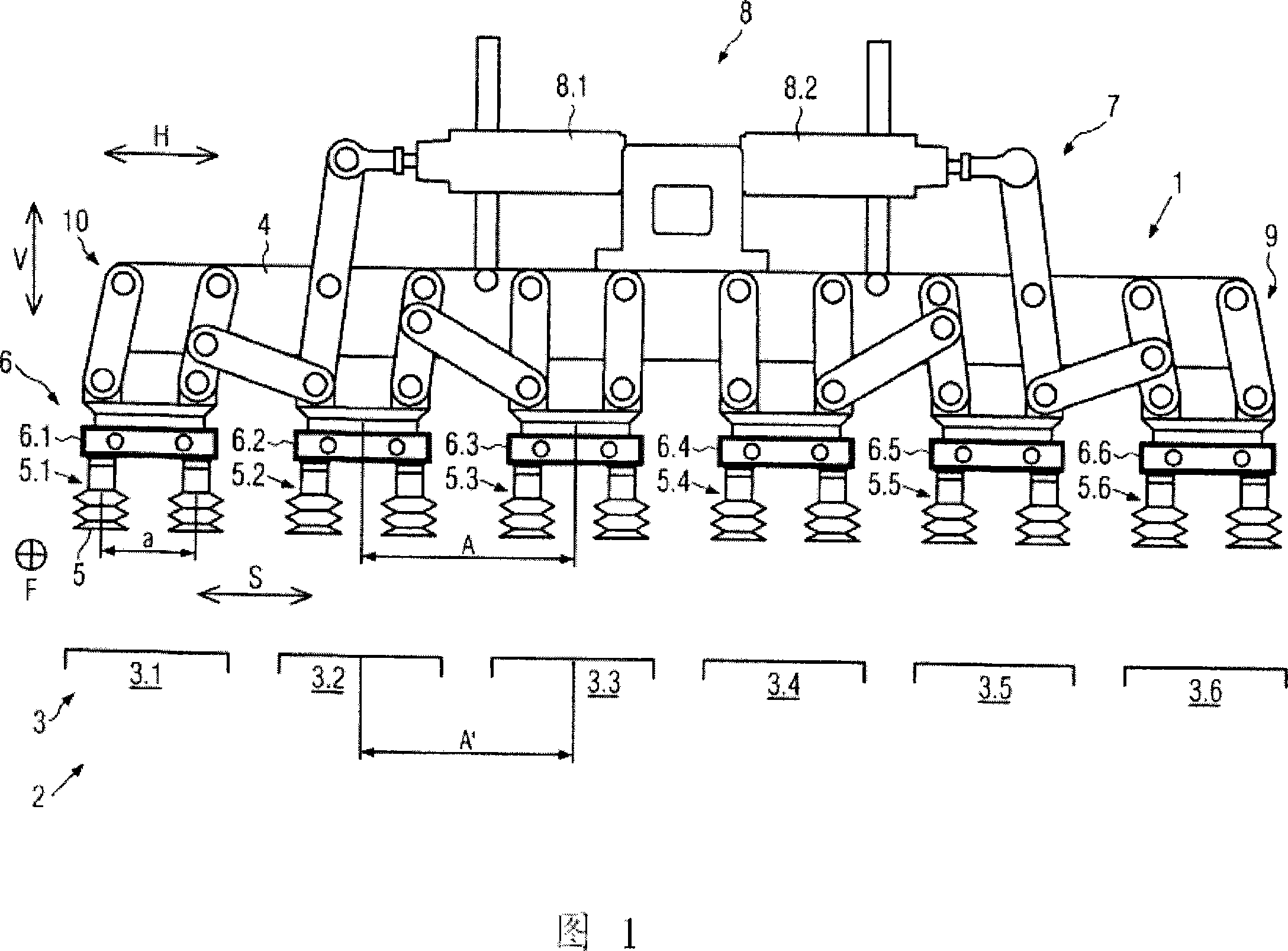

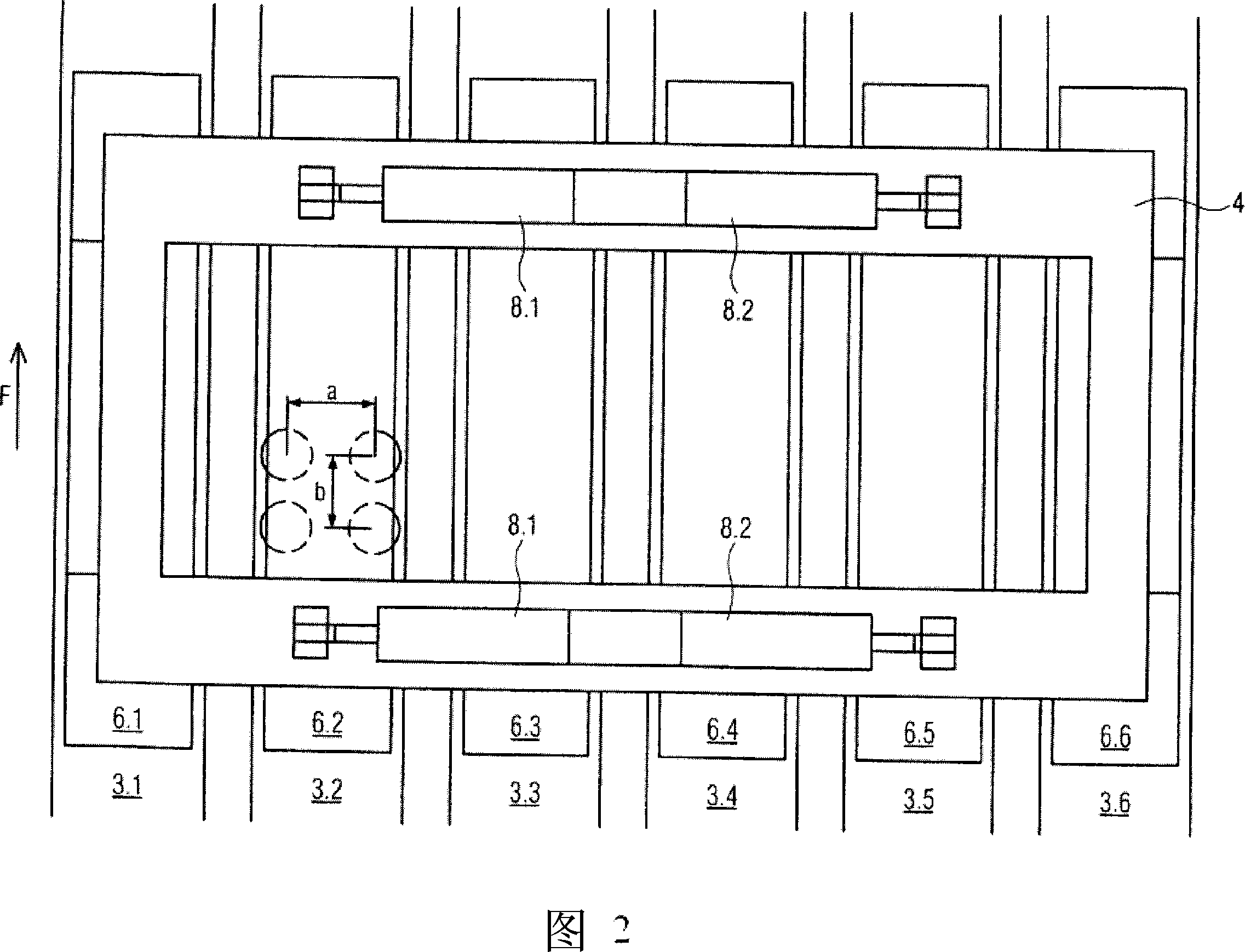

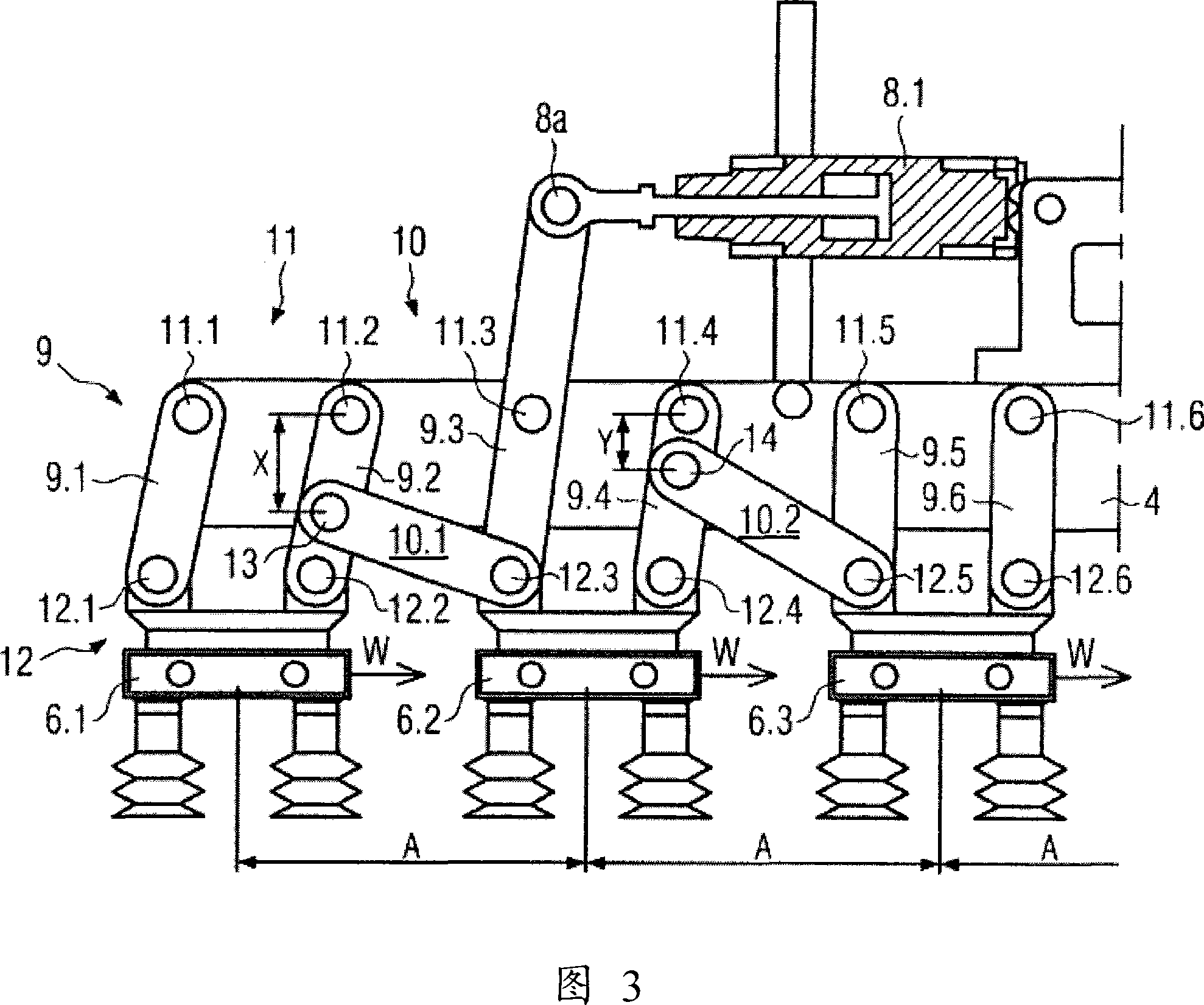

Gripping device

InactiveCN101112759AAchieve crawlingRealize transmissionConveyorsGripping headsEngineeringMechanical engineering

An apparatus for transporting objects may include a plurality of grippers having a first spacing at a first position and second spacing at a second position. A drive mechanism may be provided is for selectively displacing the grippers from the first position to the second position to adjust the spacing between the grippers.

Owner:INDAG GES FUER INDBEDARF & BETRIEBS

Deburring device for plastic processing

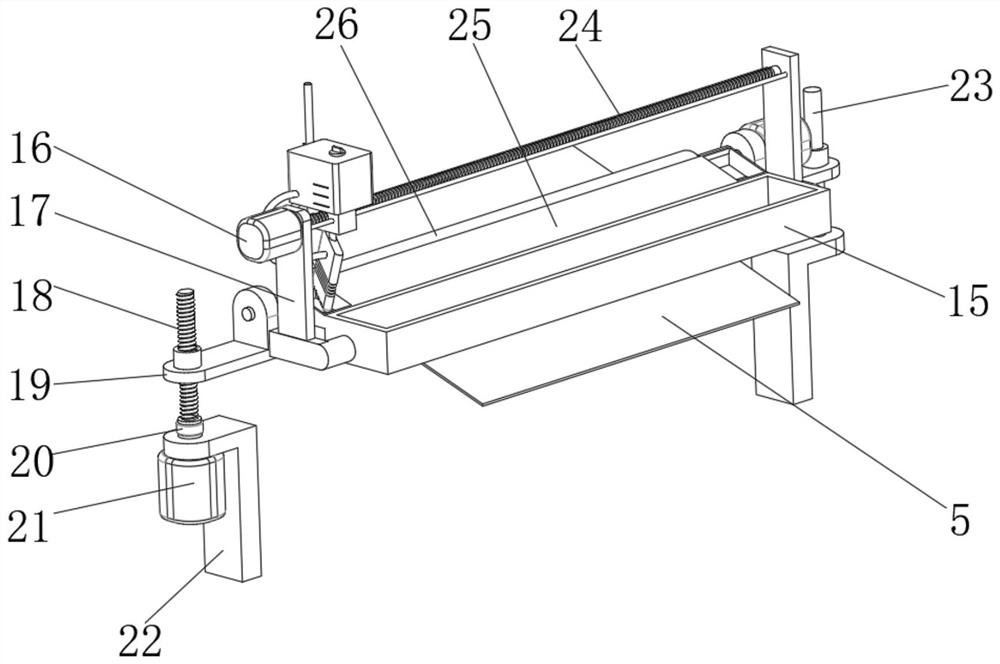

InactiveCN106239310AImprove adaptabilityChange heightEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention discloses a deburring device for plastic processing. The deburring device comprises support legs. A workbench is fixedly mounted at the tops of the support legs. An operating platform is fixedly mounted on the upper surface of the workbench. A moving screw rod is movably mounted at the end, located on the side face of the operating platform, of the upper surface of the workbench through a support. An output shaft of a first servo motor is fixedly connected to one end of the moving screw rod, wherein the output shaft of the first servo motor is fixedly mounted at the top of the support. An electric extending-and-contracting rod is fixedly connected with the moving screw rod through a connection block. A clamping seat is fixedly mounted at the end, far away from the moving screw rod, of the electric extending-and-contracting rod. A first driving motor is fixedly mounted inside the clamping seat. According to the deburring device, edge clearing mechanisms are arranged, and therefore support shafts can be driven by a second servo motor to rotate; furthermore, the first edge clearing mechanism and the second edge clearing mechanism are made to rotate synchronously, so that the purpose of clearing burs at the side edges of a plastic product is achieved; and the production requirements and the requirements for product quality can be effectively met.

Owner:新昌县厚道机械有限公司

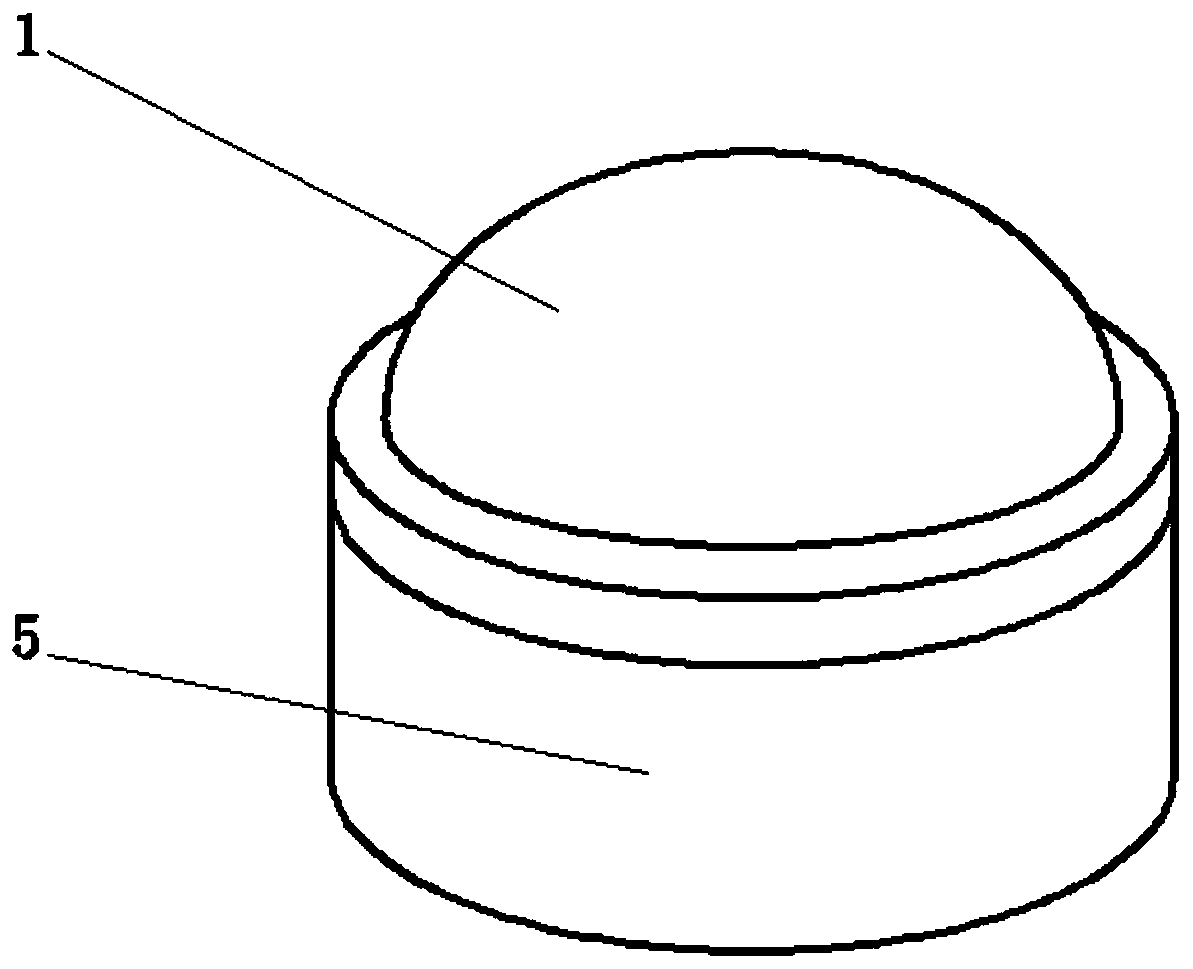

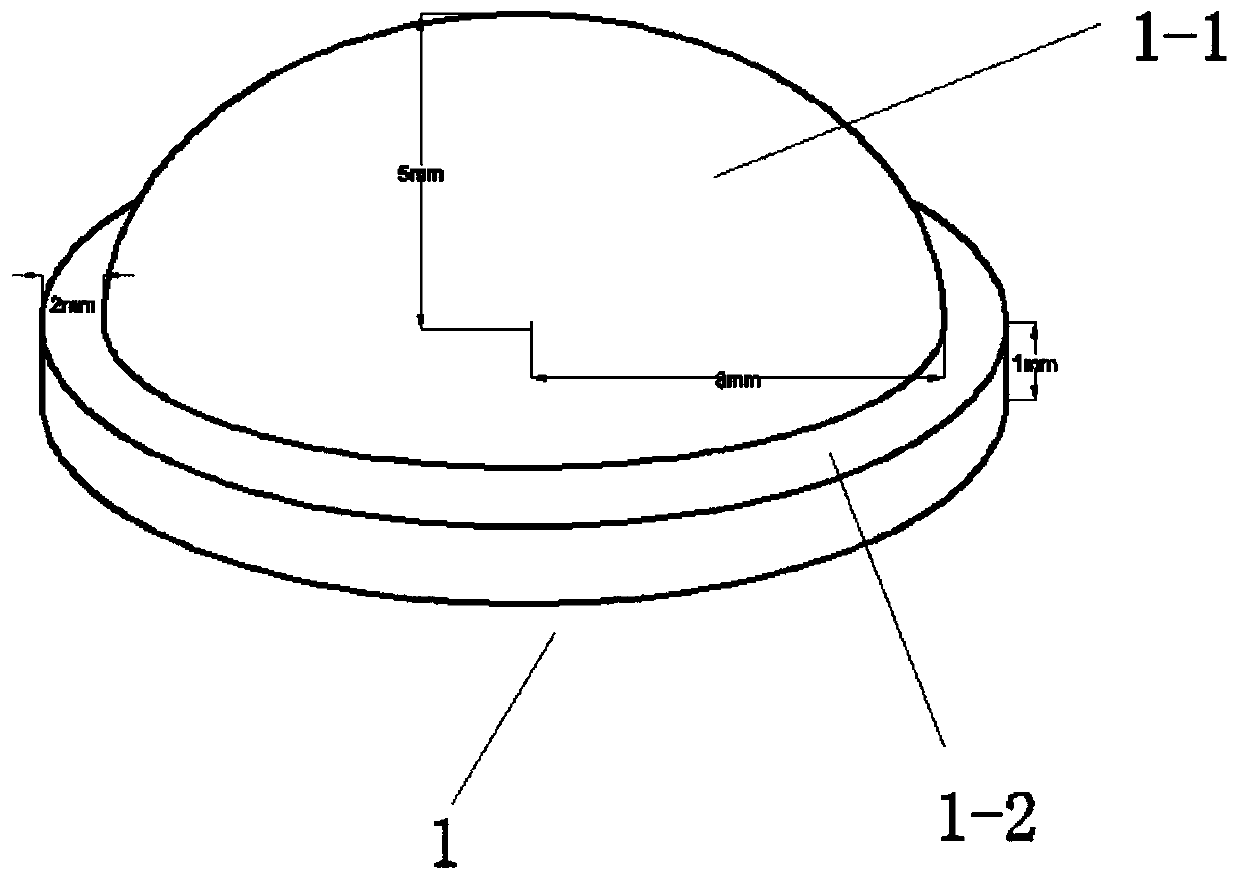

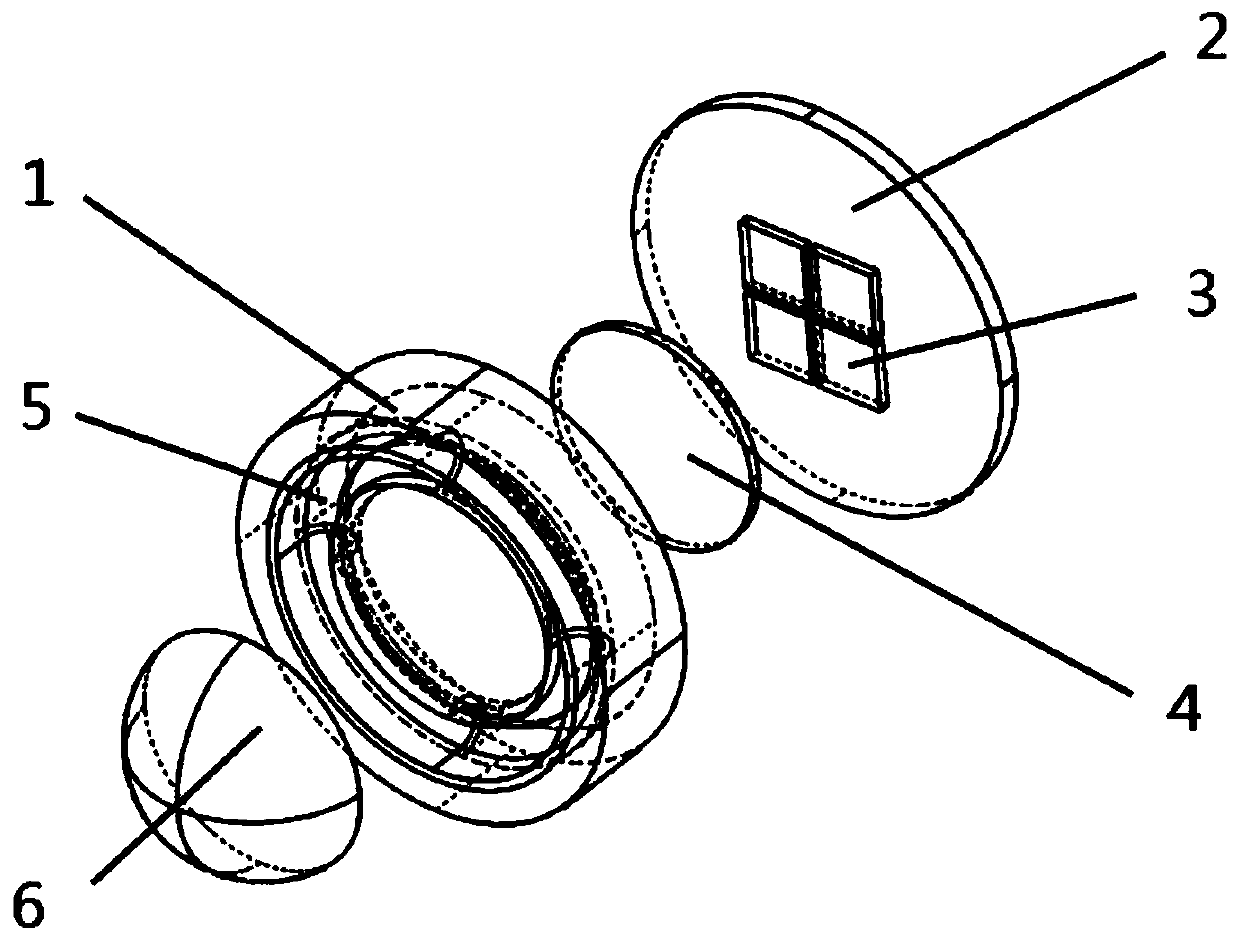

High-sensitivity capacitive flexible three-dimensional force tactile sensor and preparation method thereof

ActiveCN110793701AHigh detection sensitivityQuick responseDomestic articlesApparatus for force/torque/work measurementRobotic rehabilitationCapacitance

The invention discloses a high-sensitivity capacitive flexible three-dimensional force tactile sensor mainly comprising a hemispherical contact, flexible spherical-curved-surface excitation electrodes, a flexible common electrode and a flexible substrate. The flexible substrate serves as a bottom support; the top of the hemispherical contact is covered and an air cavity is formed in the hemispherical contact; the flexible common electrode and four flexible spherical-curved-surface excitation electrodes are bonded in the air cavity; the flexible common electrode is connected between the hemispherical contact and the flexible substrate and is arranged at the center of the four flexible spherical-curved-surface excitation electrodes; and the four flexible spherical-curved-surface excitation electrodes are distributed on the flexible substrate uniformly at intervals; and insulating layers are arranged on the surfaces of the flexible spherical-curved-surface excitation electrodes. The flexible common electrode and the flexible spherical-curved-surface excitation electrodes form four capacitors which are distributed in a spatial three-dimensional mode to form an overall inverted mushroom-shaped structure. The high-sensitivity capacitive flexible three-dimensional force tactile sensor has advantages of higher detection sensitivity and higher response speed and can be used as a flexible electronic skin applied to the fields of human-computer interaction, intelligent robots, rehabilitation therapy and the like.

Owner:ANHUI UNIVERSITY

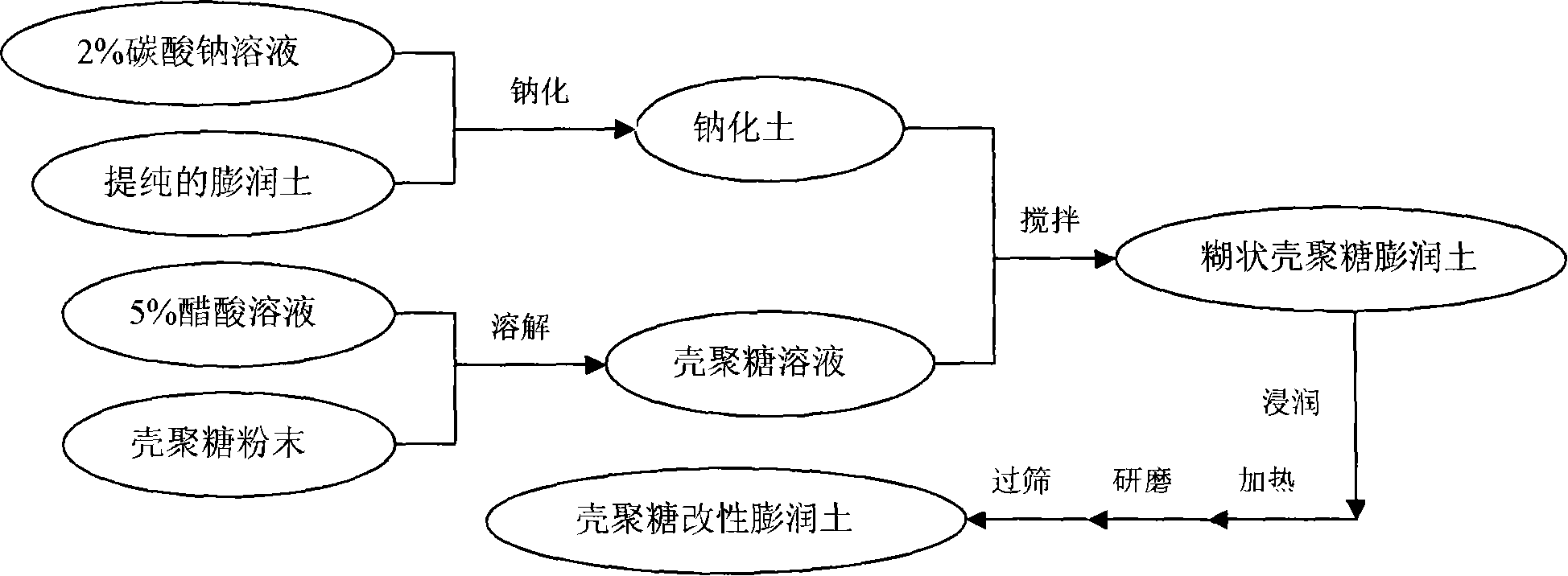

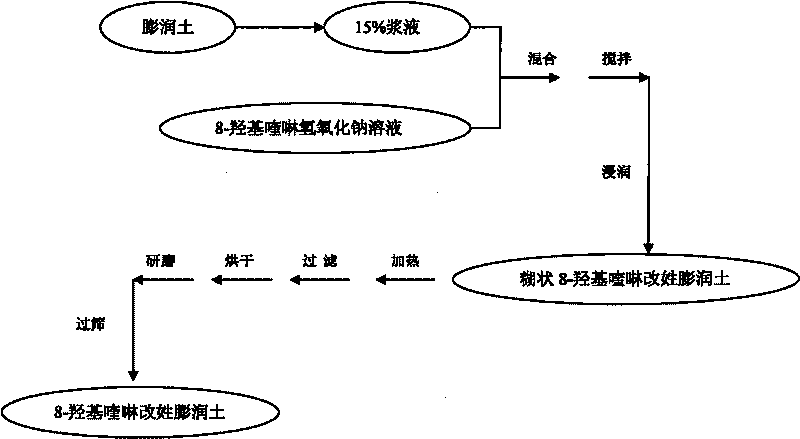

Environment-friendly modified bentonite and preparation method thereof

The invention discloses an environment-friendly modified alta-mud and making method, which comprises the following steps: adopting natural polysaccharide without toxicity and harm such as chitosan as modifier to modify sodium-based alta-mud; disposing original mud; allocating chitosan acetic solution; weighing 50-60ml chitosan solution with density at 0. 5-1. 0% and diacetyl degree at 90%; allocating 50g alta-mud into paste-shaped material; stewing; infiltrate the alta-mud completely; placing the paste-shaped material into microwave oven; heating to dry; grinding finely; sieving in the screen at 0. 16mm; obtaining the product with low price, good property and environment friendly without any polluting; fitting for disposing industrial waste water, manufacturing drug and food industry.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

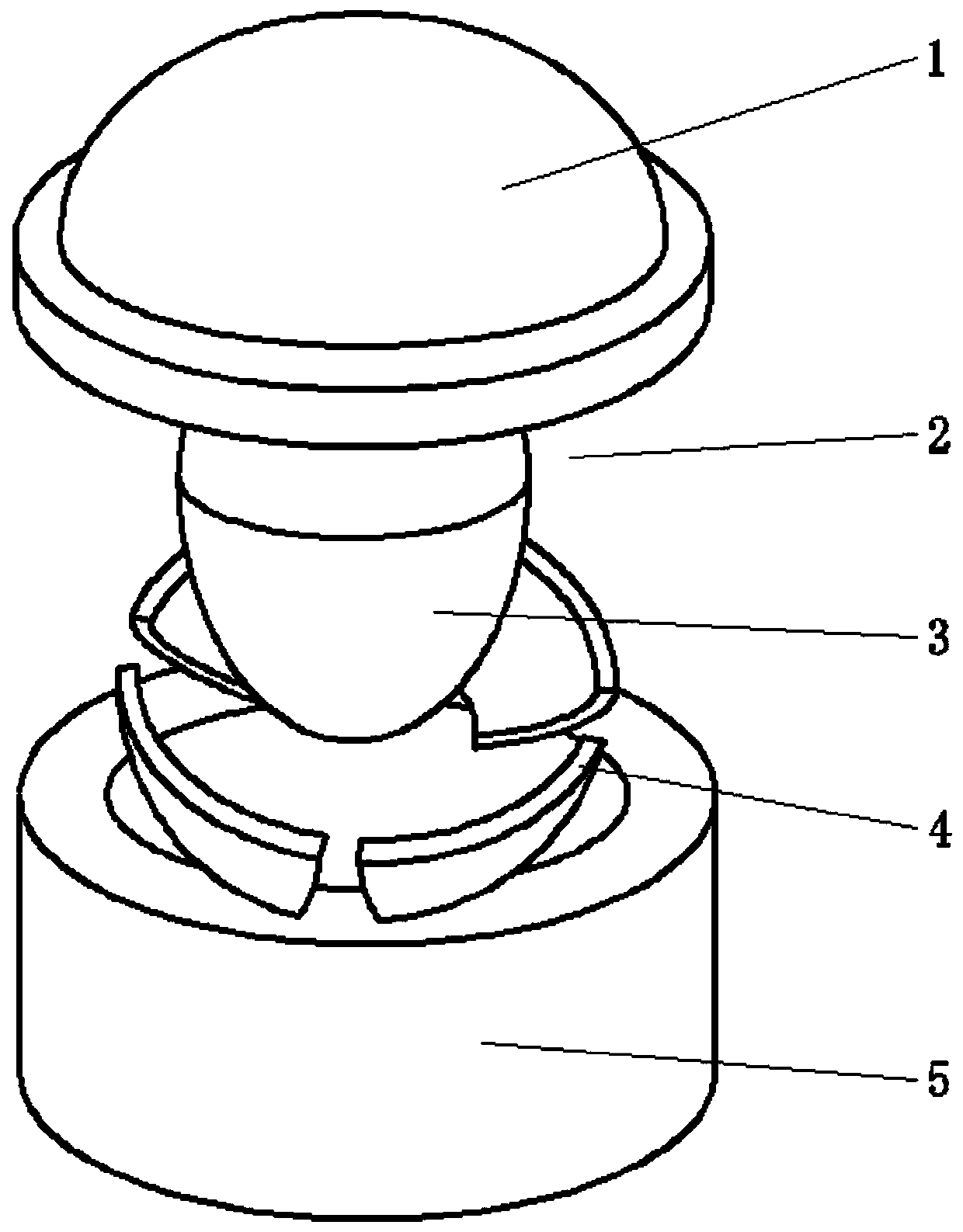

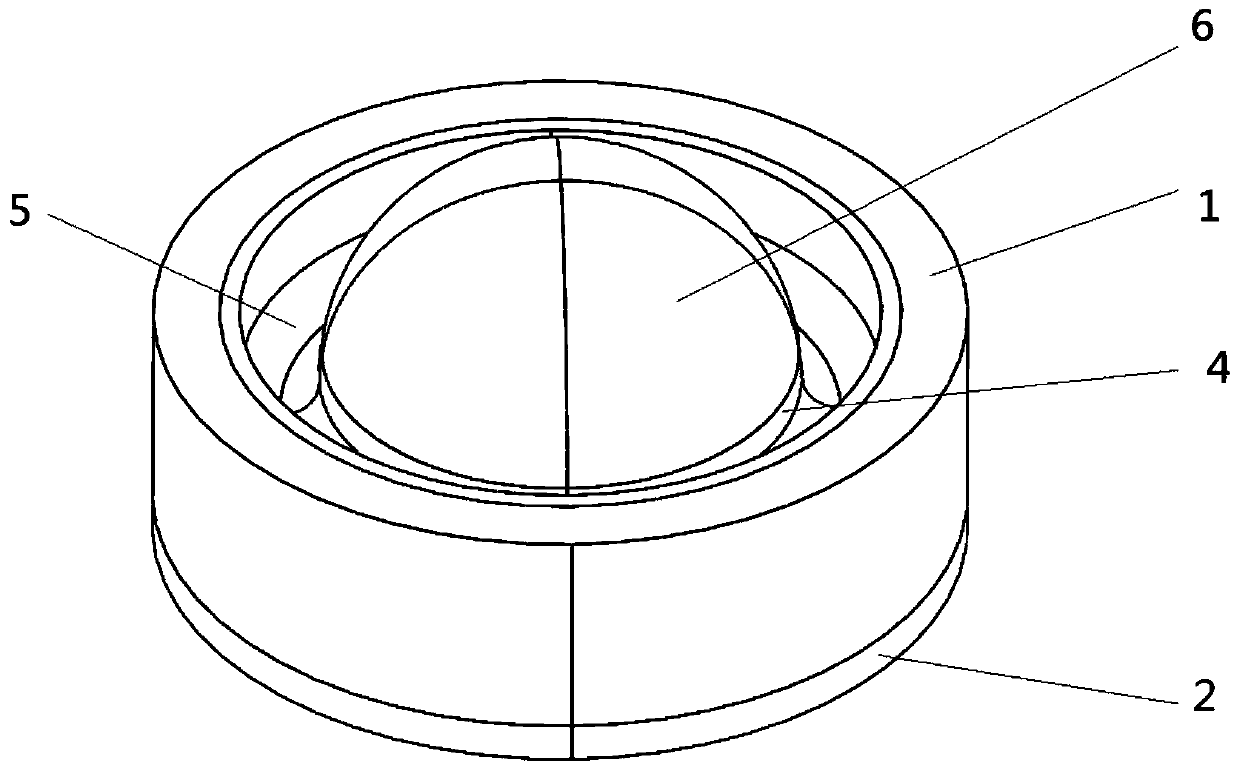

Full-flexible capacitive three-dimensional force touch sensor

ActiveCN111366274AHigh dielectric constantHigh detection sensitivityForce measurementApparatus for force/torque/work measurementPhysicsTactile sensor

A full-flexible capacitive three-dimensional force touch sensor comprises a flexible cavity, a flexible substrate, a flexible electrode, a semi-circular groove and a semi-spherical contact, and the flexible electrode is led out through a wire and grounded to form a common end. The flexible cavity is a cylinder body, the flexible substrate is a circular plate, and the flexible cavity is adhered tothe flexible substrate. The square flexible induction electrodes form a 2 * 2 array structure and are adhered to the upper surface of the flexible substrate. The circular flexible common pole plate isadhered to the bottom surface of the hemispherical contact. The semi-circular groove is adhered around the bottom of the hemispherical contact and is connected to the inner surface of the flexible cavity. The semi-circular groove is adhered to the circular flexible common pole plate. An air layer is arranged between the circular flexible common polar plate and the square flexible induction electrodes as a dielectric layer, and the vertical projection area of the circular flexible common polar plate on the flexible substrate always comprises the areas of the four square flexible induction electrodes. The touch sensor has the advantages of novel structure, higher detection sensitivity and faster response speed.

Owner:ANHUI UNIVERSITY

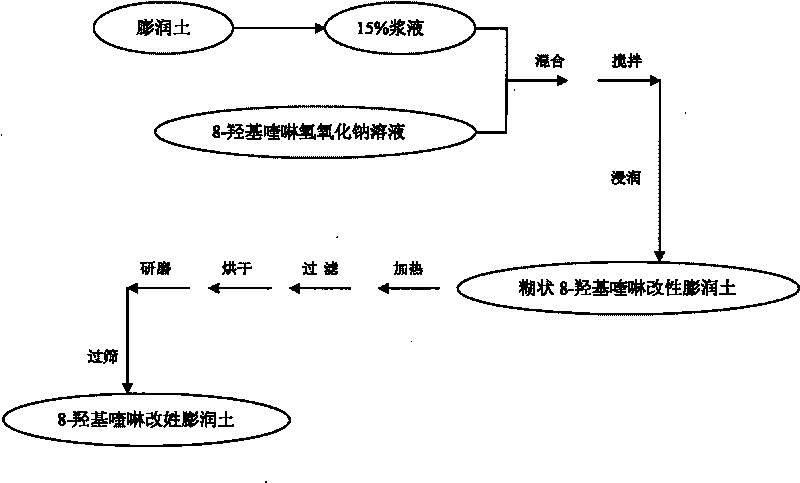

Organic modified bentonite and preparation method thereof

InactiveCN101734678AGood performanceSimple and efficient operationSilicon compoundsWater/sewage treatment by sorptionChemistryHydroxyquinolines

The invention discloses an organic modified bentonite and a preparation method thereof, and relates to an organic mineral and a preparation method thereof. 8-hydroxyquinoline is used as a modifying agent to modify calcium-based bentonite so as to prepare the modified bentonite-8-hydroxyquinoline modified bentonite. The preparation method for the 8- hydroxyquinoline modified bentonite comprises the following steps: firstly, processing raw soil; then, preparing solution of 8-hydroxyquinoline sodium hydroxide; and finally preparing the 8-hydroxyquinoline modified bentonite. The preparation method for the 8-hydroxyquinoline modified soil particularly comprises the following steps: adding distilled water into a certain amount of the bentonite, and stirring the mixture to prepare 15 percent soil suspension; adding 0.2 to 0.3 g / L solution of 8-hydroxyquinoline sodium hydroxide into the suspension for uniform mixing,; and stirring and heating for 60 minutes in a water bath, filtering, drying, grinding, and sifting through a 0.096 mm sieve to prepare the 8-hydroxyquinoline modified soil. The organic modified bentonite serving as an adhesive, a thickener, a purification decolorant, a catalyst and the like has quite wide application prospect in the fields of metallurgy, mechanical foundry, drilling, petrochemical engineering, agriculture, forestry, animal husbandry and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

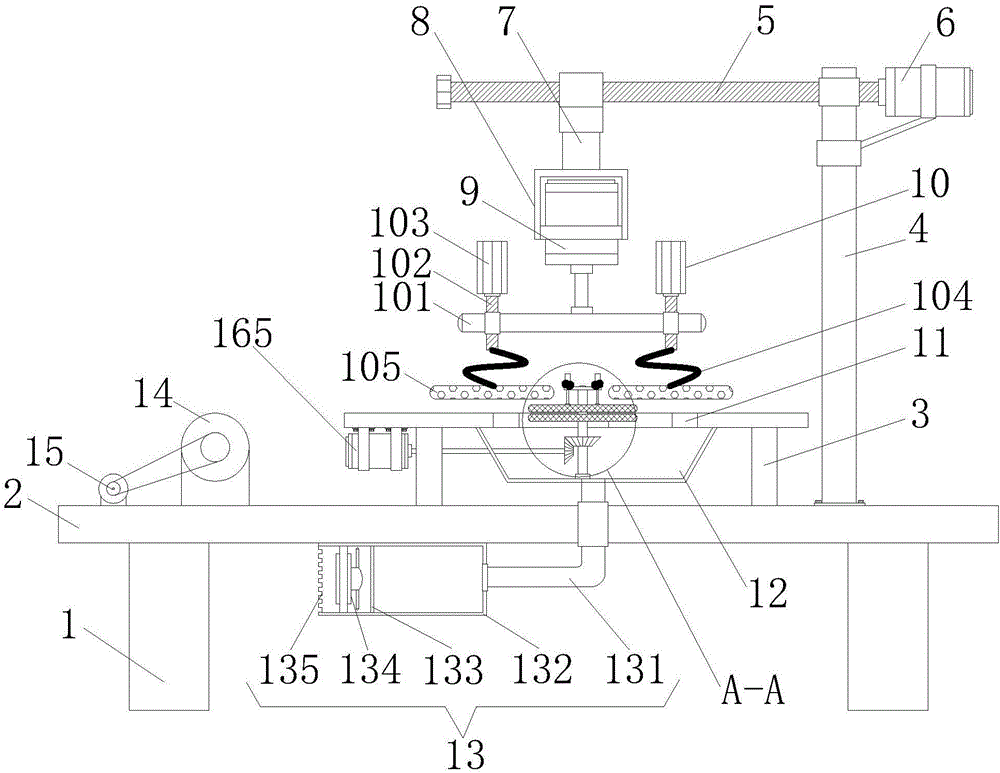

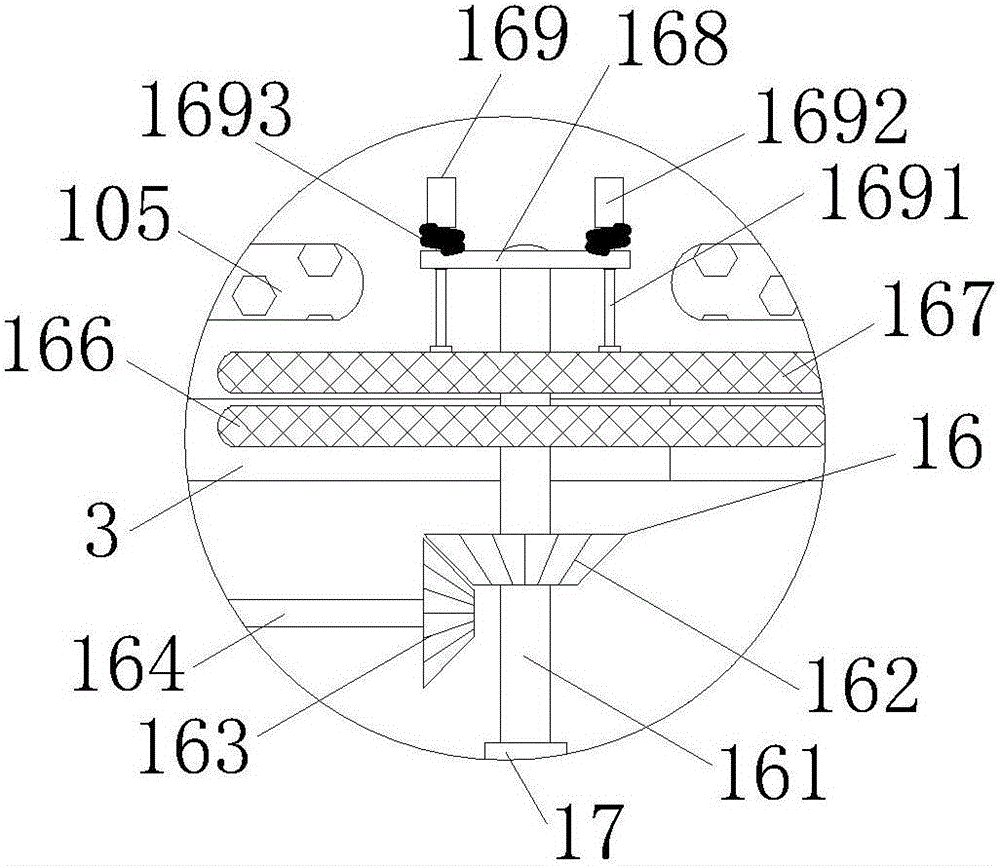

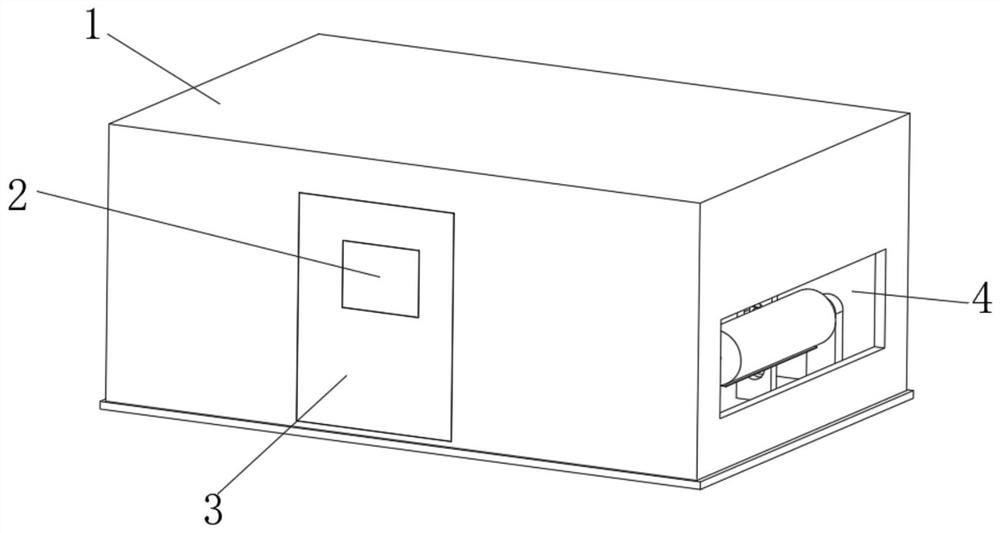

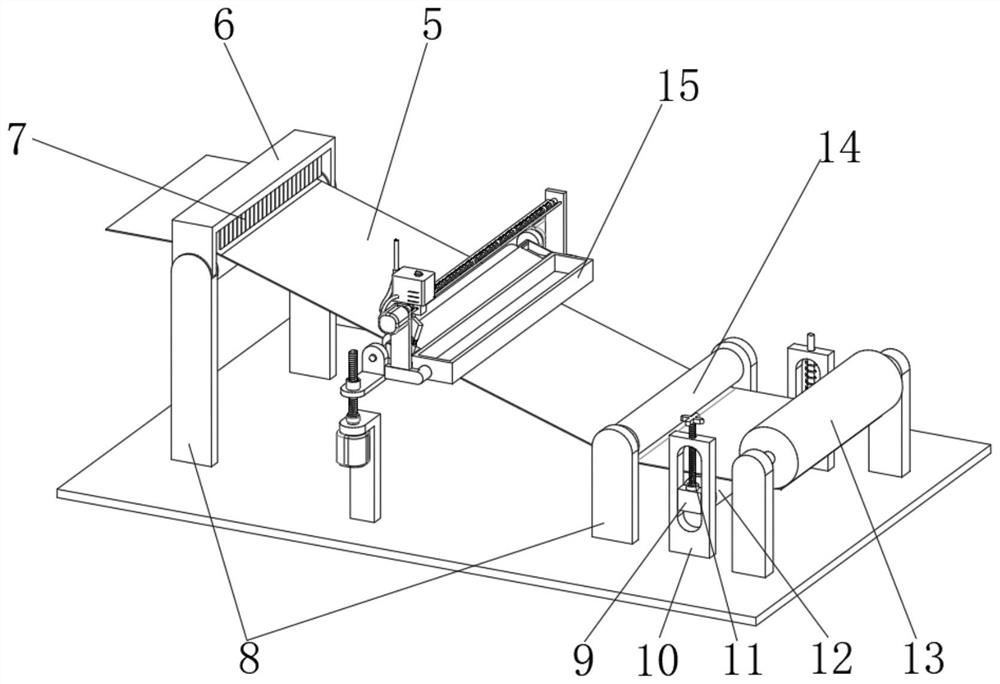

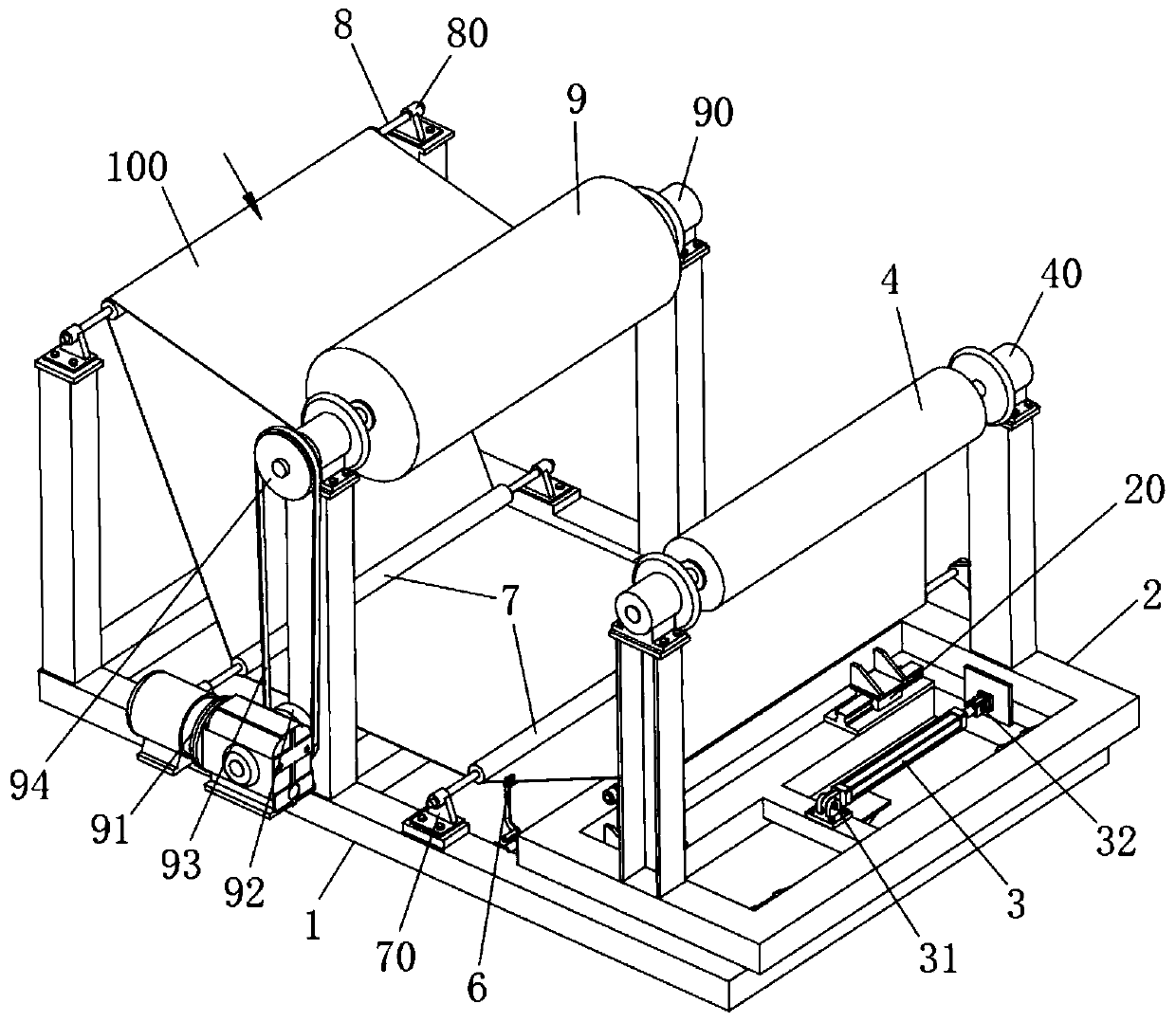

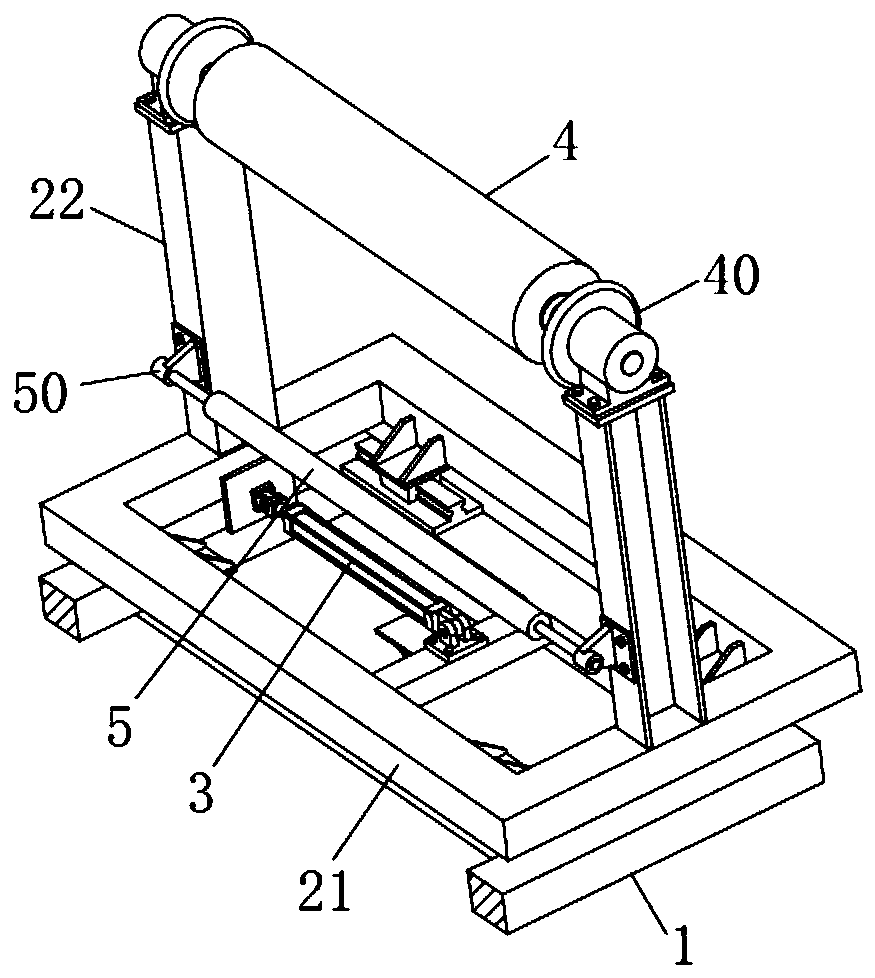

Ultrathin adhesive tape preparation method and thickness adjusting device

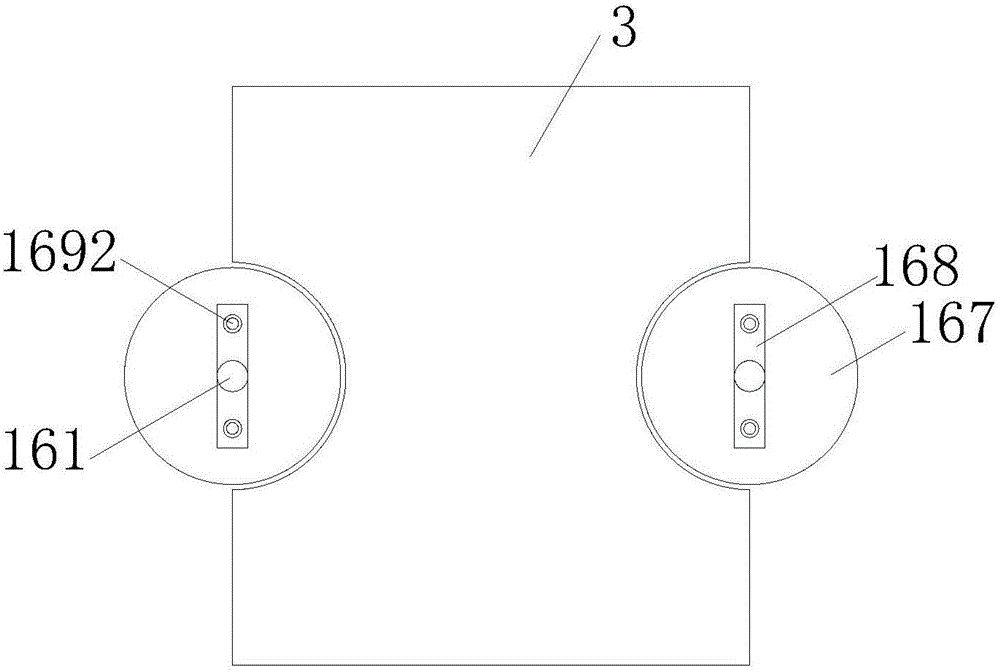

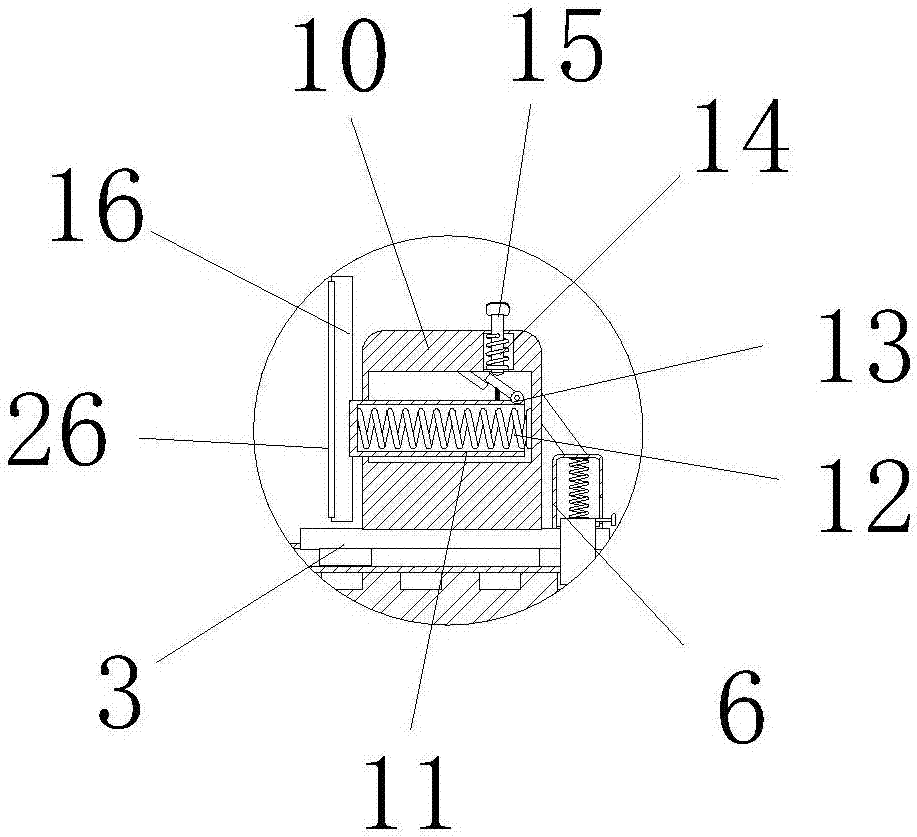

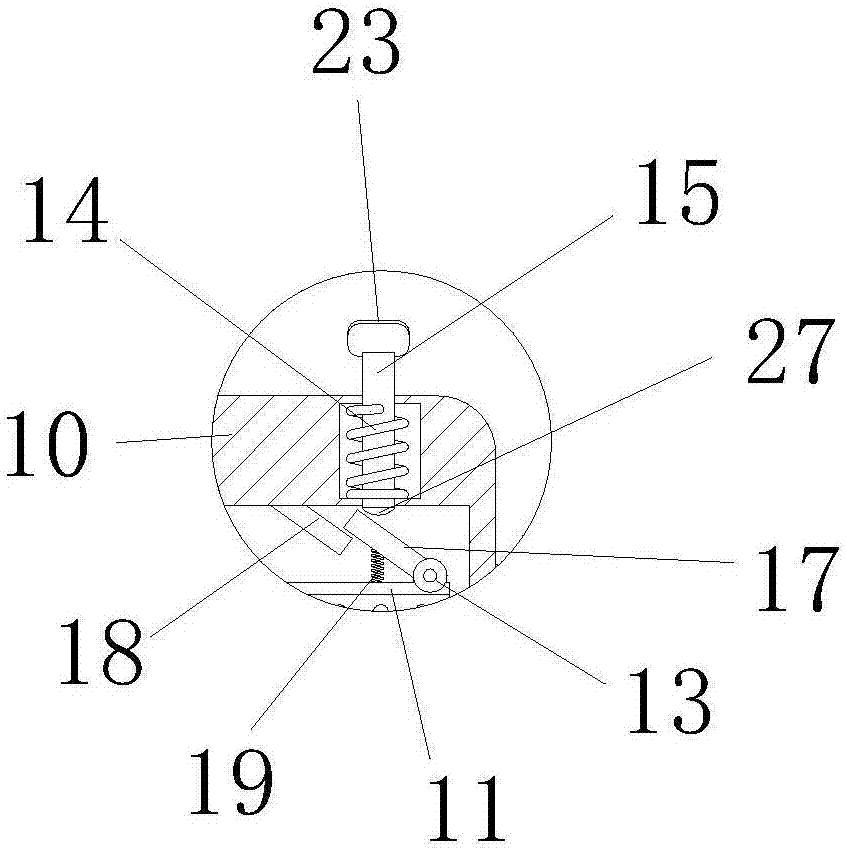

InactiveCN112871584AChange spacingAdjustable thicknessLiquid surface applicatorsSpraying apparatusAdhesiveElectric machinery

The invention discloses an ultrathin adhesive tape preparation method and a thickness adjusting device thereof, and relates to the technical field of ultrathin adhesive tape preparation. The spraying thickness of an adhesive is convenient to control. The ultrathin adhesive tape thickness adjusting device comprises a glue scraping mechanism and two first supporting frames, the glue scraping mechanism and the two first supporting frames are installed in a dust-free chamber, an adjusting stud is rotatably installed on the outer wall of the top of one first supporting frame, an adjusting guide rod is fixed to the outer wall of the top of the other first supporting frame through a screw, and a servo adjusting motor is fixed to one outer wall of the first supporting frame through a screw. The ultrathin adhesive tape preparation method comprises the following steps that one end of an adhesive tape base film is pulled to a winding roller to be fixed; and parameters are adjusted through a control screen, so that the servo adjusting motor controls the adjusting stud to rotate. By arranging a glue scraping roller, an adjusting frame and other structures, the servo adjusting motor can be controlled to work to drive the adjusting stud to rotate, and then the adjusting frame is made to ascend and descend, so that the distance between the glue scraping roller and the adhesive tape base film is changed, and the purpose of adjusting the thickness is achieved.

Owner:苏州睿泰鑫材料科技有限公司

Automobile part clamping device

Owner:肇庆连信自动化设备有限公司

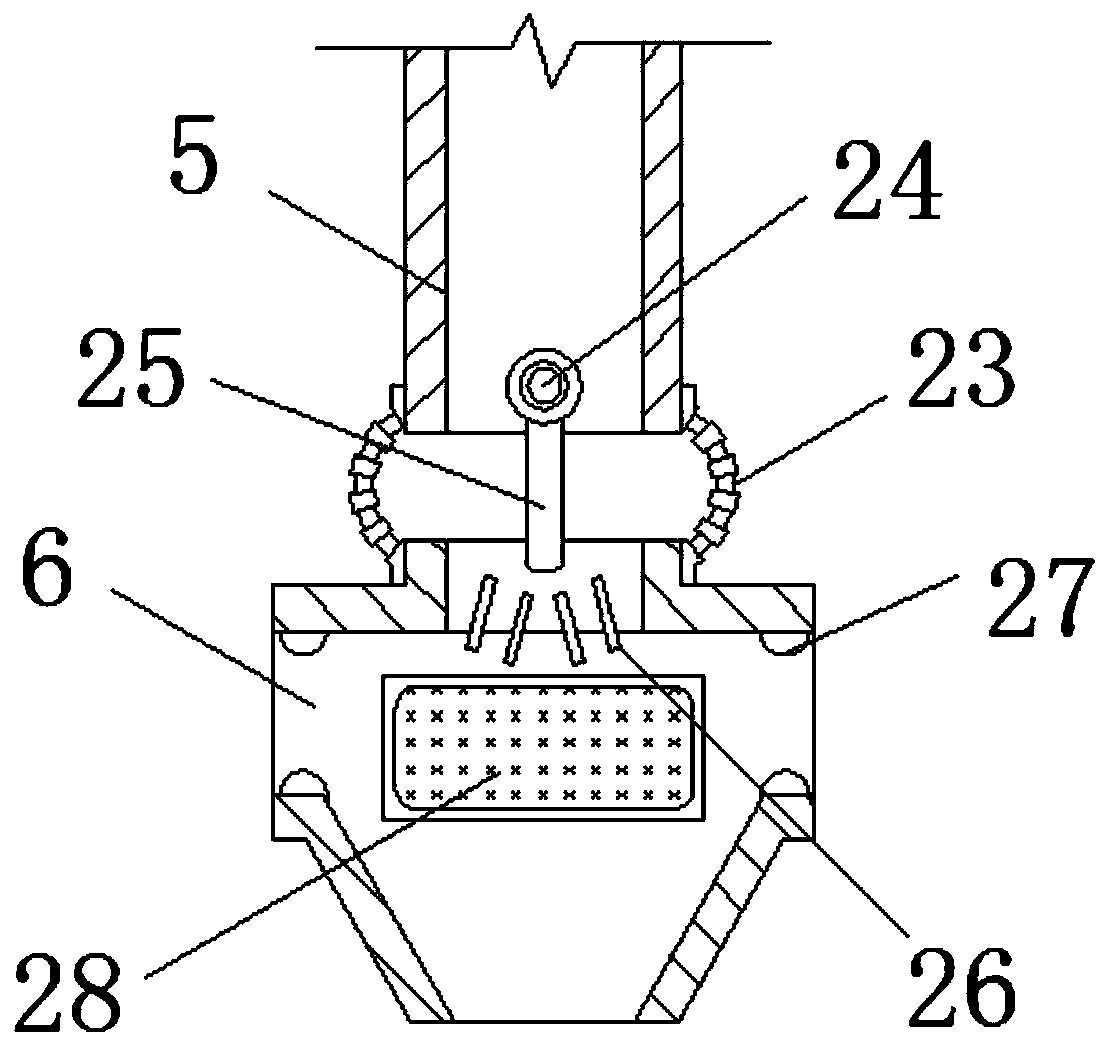

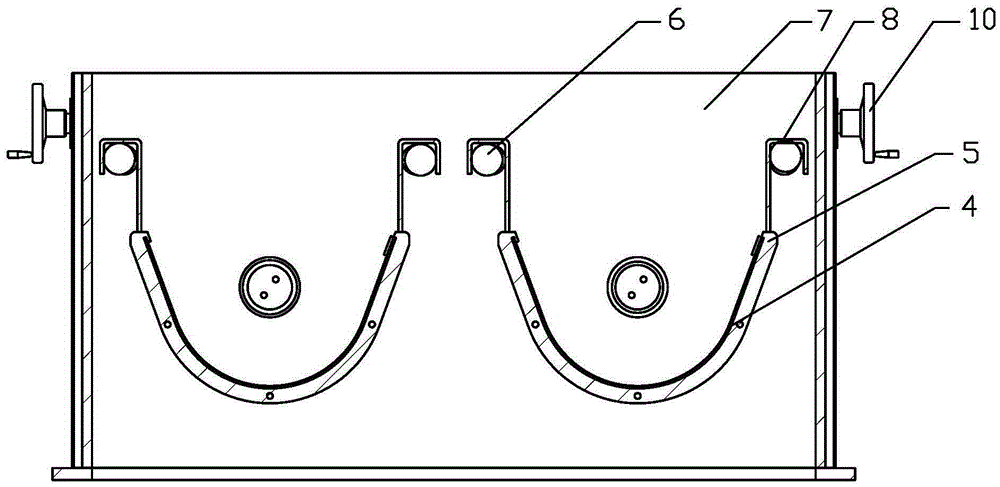

Devices for blending materials and bags and for use in such devices

InactiveUS7789551B2Well mixedChange spacingShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringElectrical and Electronics engineering

A device for blending materials and a bag for use in such devices. The device has at least one paddle for acting on a sample and a carrier against which a sample may be crushed by the paddle. The device is arranged to allow adjustment of the spacing between the paddle and carrier during operation. The bag is suitable for use in such a device but can be used in other devices.

Owner:SEWARD

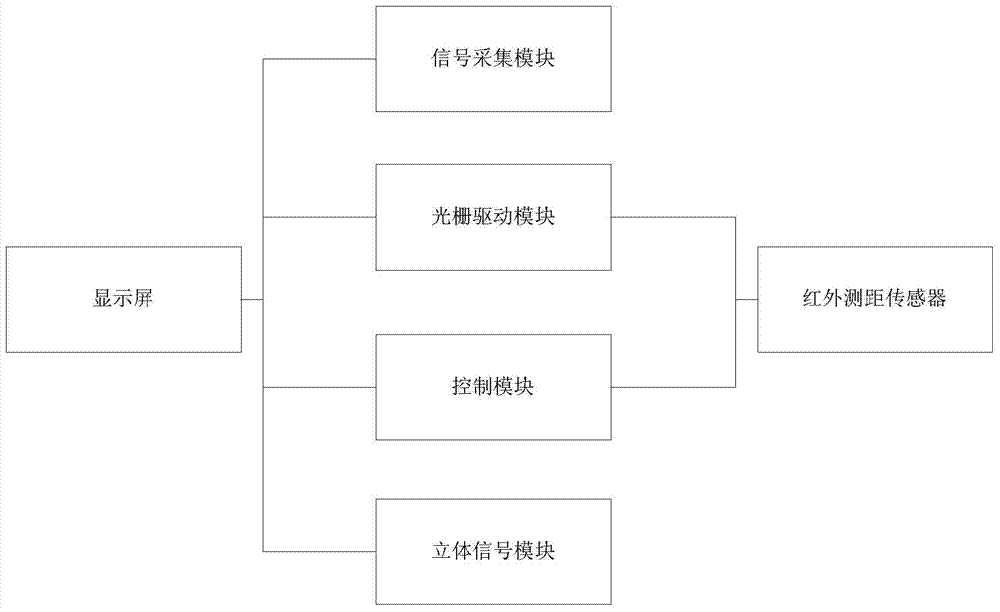

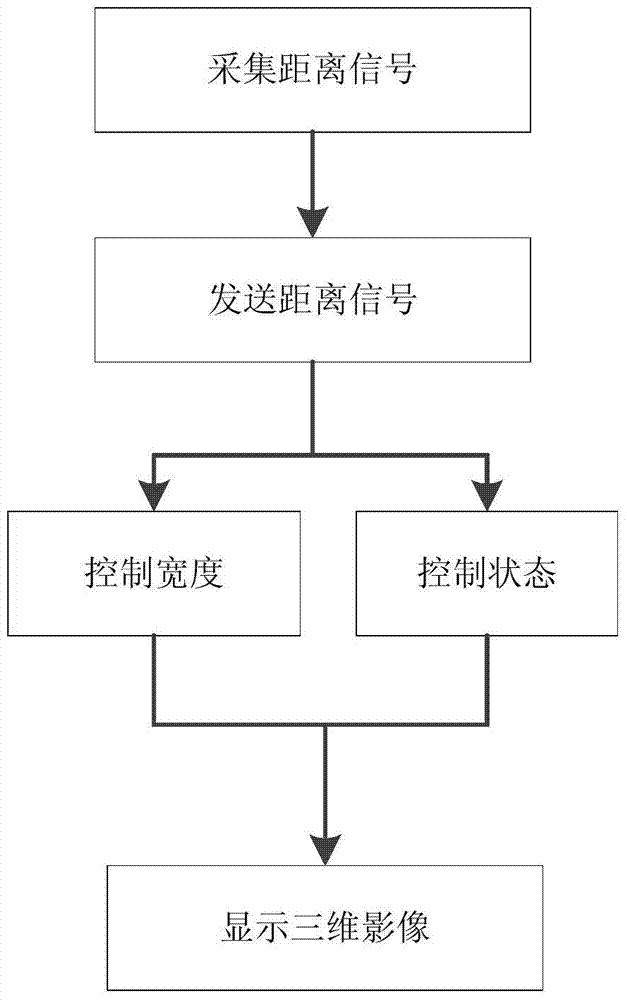

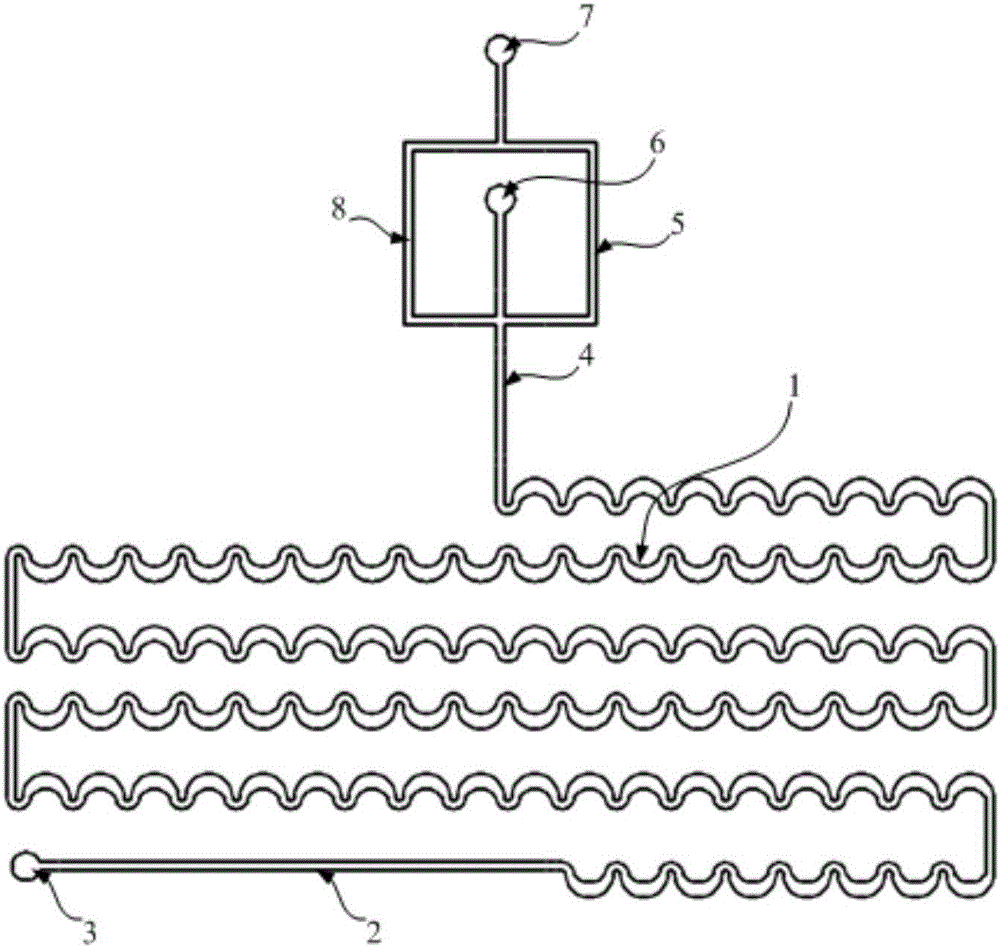

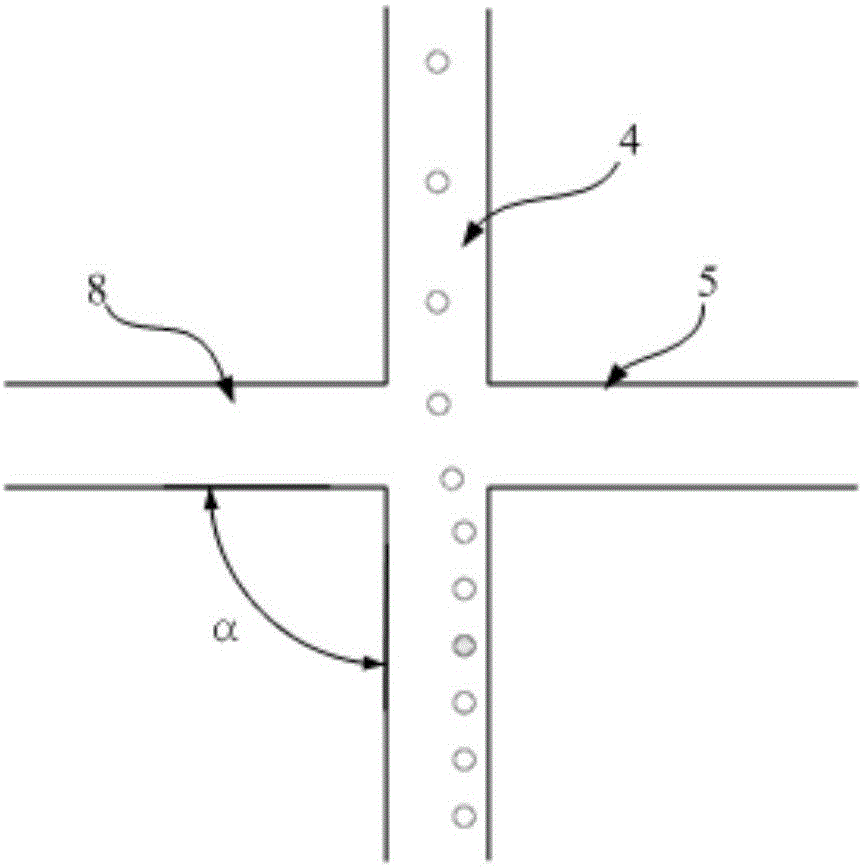

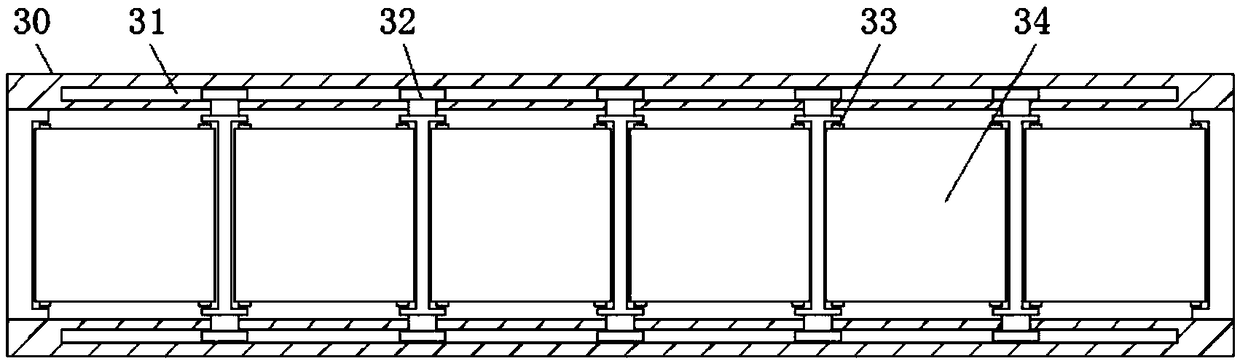

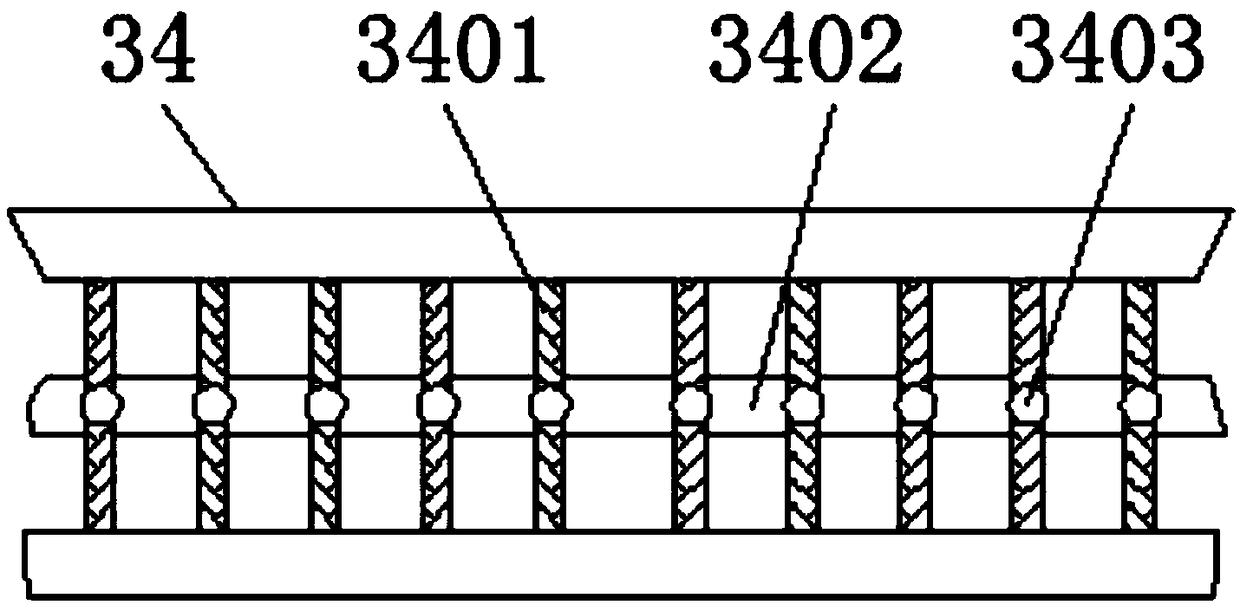

Naked eye three-dimensional image display device and method

InactiveCN103581649AChange spacingEasy to watchSteroscopic systemsOptical elementsGratingDisplay device

The invention discloses a naked eye three-dimensional image display device and method. The device comprises a signal acquisition module, a stereoscopic signal module, a display screen, an infrared distance measurement sensor, a control module and a grating drive module. The display screen is connected with the signal acquisition module, the stereoscopic signal module, the control module and the grating drive module through a data bus. The infrared distance measurement sensor is connected with the control module and the grating drive module. According to the method, the infrared distance measurement sensor is utilized to acquire distance signals between a user and a liquid crystal slit grating, the control module controls the interval between the liquid crystal slit grating and a two-dimensional liquid crystal displayer according to the distance signals, the grating drive module controls the state of the liquid crystal slit grating according to the distance signals, then, the displayer displays three-dimensional images, and the user can see the three-dimensional images at different distances from the liquid crystal slit grating.

Owner:XIDIAN UNIV

Microfluidic chip device and micro-fluid channel structure thereof

InactiveCN105854967AChange spacingFocusLaboratory glasswaresFluid controllersMicrofluidic chipEngineering

The invention discloses a microfluidic chip device and its microchannel structure, wherein the microchannel structure includes an asymmetric focusing curve, a straight focusing channel and a sheath fluid channel, wherein the first of the asymmetric focusing curve One end communicates with the sample liquid inlet; the first end of the direct focusing channel communicates with the second end of the asymmetric focusing bend, and the second end communicates with the mixed solution outlet; the sheath fluid channel includes a left symmetrical channel about the direct focusing channel The flow channel and the right flow channel, the first ends of the left and right flow channels are connected with the sheath liquid inlet, and the second ends of the left flow channel and the right flow channel are respectively connected with the direct focusing flow channel from both sides; When in use, the sheath fluid focus and the Dean flow focus can be used to cooperate with each other. The particles of different particle sizes are first focused in the asymmetric focus bend to form a straight line, and then in the direct focus flow channel by two symmetrical sheath fluids. The second focusing function of the flow is all focused on the center line of the direct focusing flow channel, so as to achieve the purpose of improving the focusing effect.

Owner:GUANGDONG UNIV OF TECH +1

Full-automatic slide pitch-changing manipulator of bottle blowing machine

The invention provides a full-automatic slide pitch-changing manipulator of a bottle blowing machine, comprising a base plate, wherein the base plate is provided with a fixing base; a fixing plate is provided with a rotating air cylinder; the rotating air cylinder is connected with a sliding shaft; the sliding shaft is provided with a movable block; the movable block is provided with pipe billet fingers; and the pipe billet fingers are driven by a finger air cylinder. The full-automatic slide pitch -changing manipulator is characterized in that: the base plate is slidably provided with the movable plate; the movable plate is provided with racks; the sliding shaft is provided with gears; the gears are engaged with the racks; the movable plate is manufactured with a pitch-changing slide; rolling wheels are arranged below the movable block; and the rolling wheels are fitted with the pitch-changing slide. By the technical scheme in the invention, the gears and the racks are engaged and turned, and the slide has a changed pitch, so that the bottle billets tightly arranged in a heater are accurately arranged on bottle billet supporting bases which are arranged widely in a pull-blow machine through the pitch-changing manipulator; and the slide pitch-changing manipulator is simple in structure, stable and reliable in action.

Owner:ZHEJIANG DEMARK MACHINERY

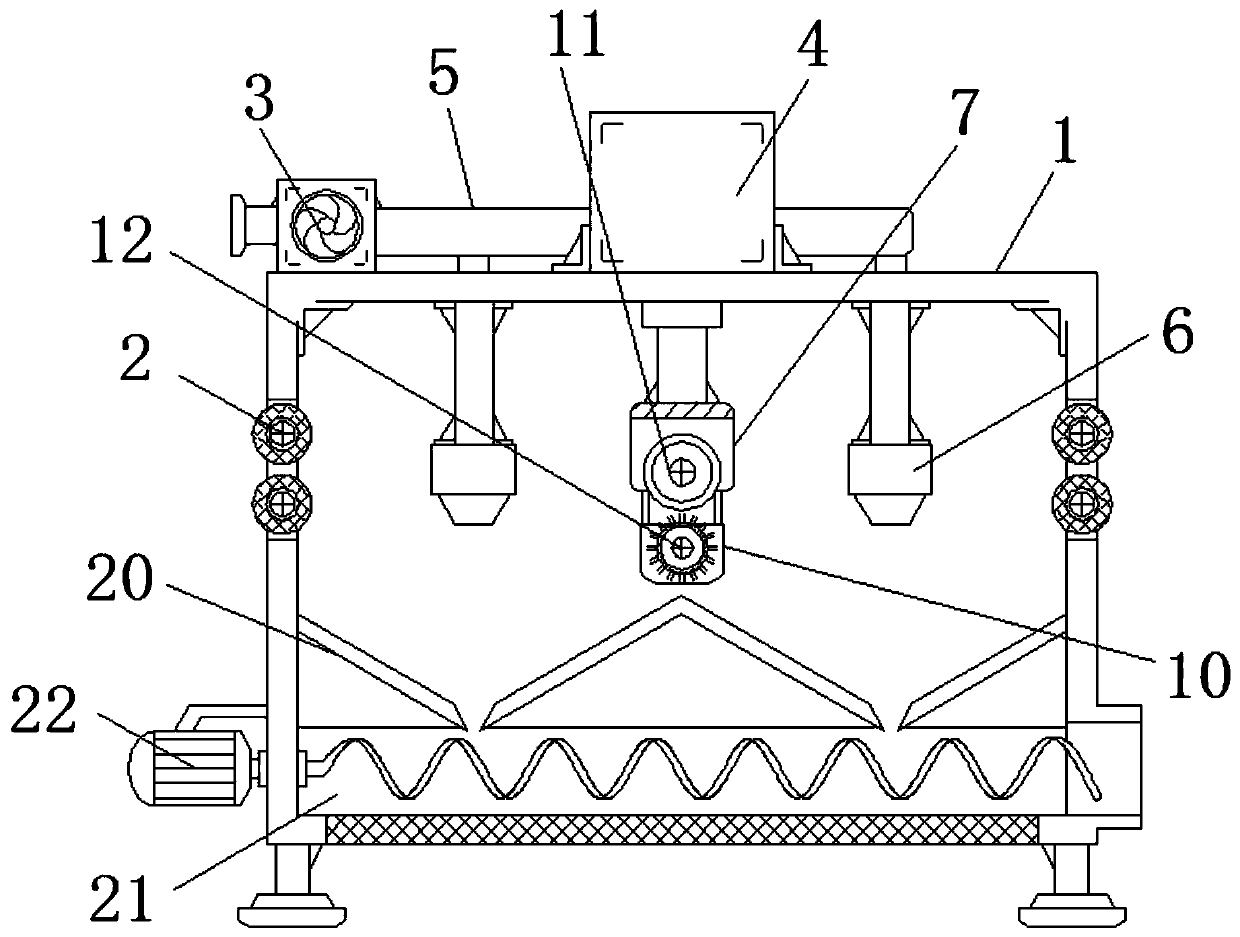

Ceiling humidifier

InactiveCN108870611AImprove the air environmentEvenly dispersedMechanical apparatusLighting and heating apparatusEngineeringIndoor air

The invention discloses a ceiling humidifier. Through a cooperation relation between sliding rods and movement grooves, the positions of the sliding rods on a horizontal supporting board can be adjusted, and therefore the spacing between every two sliding rods is changed; after the spacing between every two sliding rods is changed, the unit covering area of an aromatic board can be correspondinglychanged, aromatic materials are stored in the aromatic board in order to improve the indoor air environment, the spreading area of the aromatic materials can be adjusted by moving the sliding rods, and therefore the effect of adjusting the concentration of aroma is achieved. On the one hand, cotton partitions in the aromatic board achieve the effect of reinforcing an internal hollow structure ofthe aromatic board; on the other hand, perfume can be uniformly dispersed in the aromatic board, and the installation angle of the cotton partitions on reinforcing rods can be adjusted in order to compact the aromatic materials. Moreover, the ceiling humidifier can atomize water mist inside into gas according to an actual indoor humidity condition to achieve adjustment of the indoor humidity condition, correspondingly the comfort degree during use of an air conditioner can be increased for people, and the practical value of the ceiling humidifier is higher.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

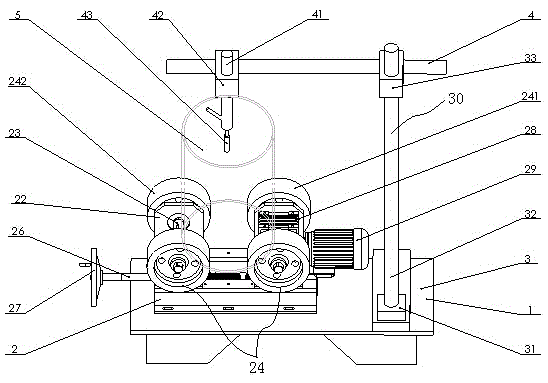

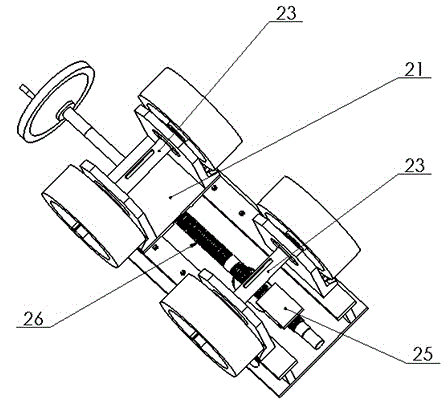

Automatic rotating welding device for pipeline

InactiveCN104801916APrecise positioningStable welding working distanceWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelSlide plate

The invention relates to an automatic rotating welding device for a pipeline. The device is that a driving wheel is assembled on a driving wheel bracket, wherein the driving wheel is divided into a driving wheel and a driven wheel which are arranged in parallel and mounted on the driving wheel bracket through driving wheel shafts; the driving wheel bracket is mounted on a driving base through a driving sliding plate; the driving sliding plate can horizontally move along the driving base; a welding gun bracket comprises a lifting vertical column which is vertically arranged, and a transverse cantilever which horizontally extends to be above the driving wheel loading an object; the rear end of the transverse cantilever is detachably connected to the lifting vertical column through a lifting guide sleeve; the transverse cantilever can move up and down; the front end of the transverse cantilever is detachably connected with a welding gun fixing frame of the welding gun through a cantilever arm guide sleeve; the welding gun fixing frame can horizontally move along the cantilever; the welding gun can move in a three-dimensional direction, wherein the three-dimensional direction is namely the guide sliding plate direction, the lifting vertical column direction and the cantilever direction; the welding gun in a certain three-dimensional space can be positioned to any point, so that a weld joint of a welded part can be conveniently positioned, and a stable welding working distance from the welding gun to the weld joint can be kept all the time.

Owner:SHANGHAI INST OF TECH

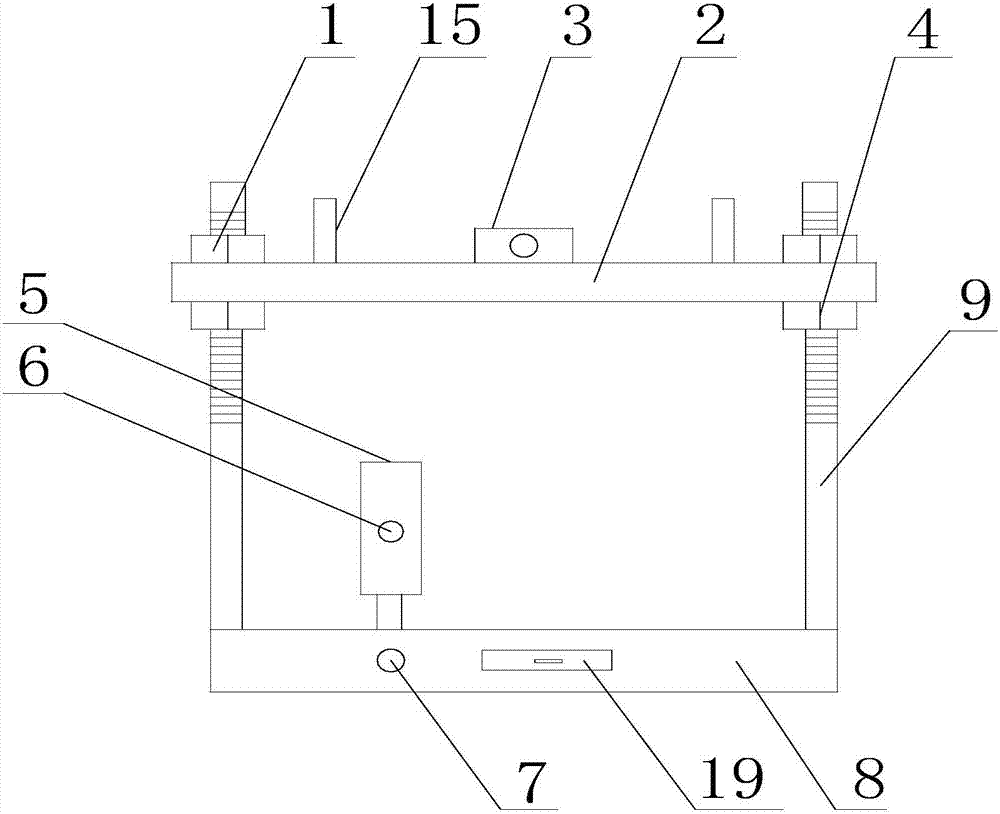

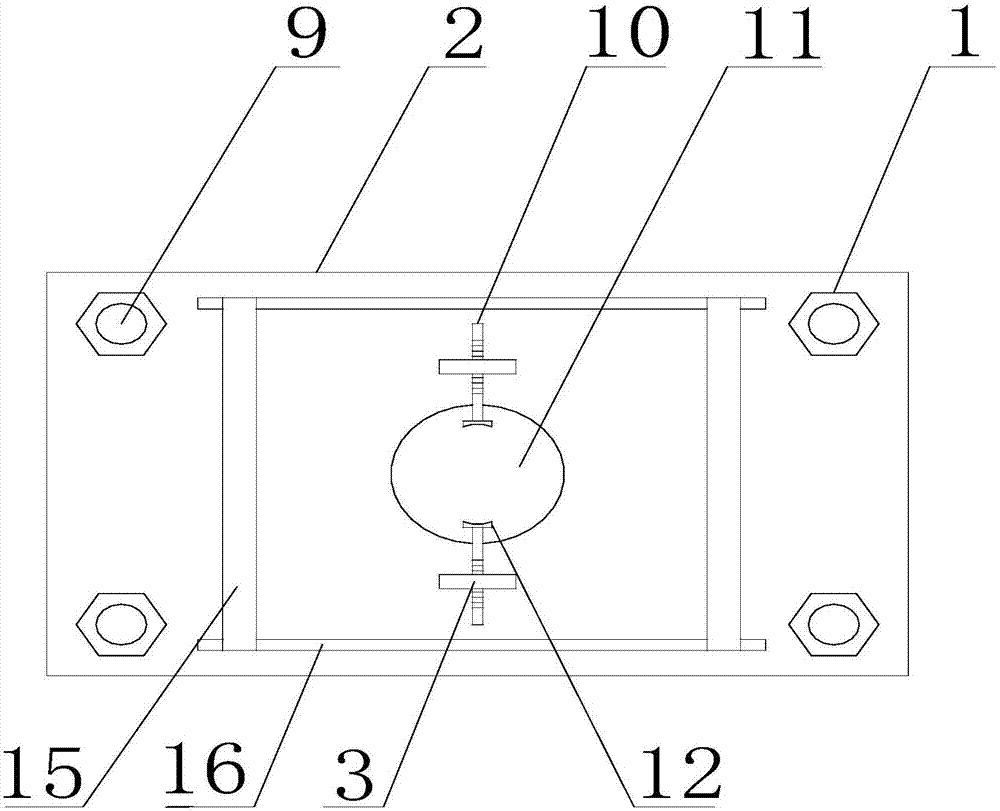

Machining tooling fixture for welding joint tensile sample and clamping and positioning method for machining tooling fixture

ActiveCN102699724AChange spacingAdjustable positionPositioning apparatusMetal-working holdersMachiningIndustrial engineering

The invention relates to a machining tooling clamp for a welding joint tensile sample and a clamping and positioning method for the welding joint tensile sample. A base is mounted on a milling machine. A sample to be machined is fixedly arranged between a fixed support block and a movable support block which are arranged in opposite positions on the base through two clamping parts of a sample clamping device; the space between the movable support block and the fixed support block can be changed by adjusting the position of the movable support block on the base so as to adapt to the length of the sample; after one surface of the sample is machined, the sample clamping device and the sample are taken out and turned and refixed between the movable support block and the fixed support block; and then the other surface of the sample is machined. Therefore, according to the machining tooling fixture and the clamping and positioning method disclosed by the invention, the machining work efficiency can be increased, the machining precision is ensured and the machining cost is greatly reduced simultaneously.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

Operating platform capable of realizing quick cleaning of petroleum pipeline machining waste chips

The invention discloses an operating platform capable of realizing quick cleaning of petroleum pipeline machining waste chips. The operating platform comprises a base and a machining table, wherein supporting columns are arranged between the base and the machining table, each supporting column is provided with a first nut and a second nut, and the machining table is located between the first nuts and the second nuts; the machining table is provided with a first through hole, a fixed block, sliding grooves and push plates, the push plates are located in the sliding grooves, and the fixed block is provided with first clamping rods; the base is provided with a groove and a leakage hole, a connecting rod is arranged in the groove, and a supporting platform is arranged at the top of the connecting rod and provided with a second clamping rod and a second through hole; the side wall of the base is further provided with a rotating shaft and a drawer, the drawer communicates with the leakage hole, the rotating shaft is connected with the connecting rod and located in the groove, and when the rotating shaft is rotated, the supporting platform will rotate together with the rotating shaft. The operating platform can meet the requirement for clamping petroleum pipeline bends with different angles, lengths and diameters, and is simple in structure and convenient to operate, and the iron chips on a workbench can be cleaned up and stored in a concentrated mode.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

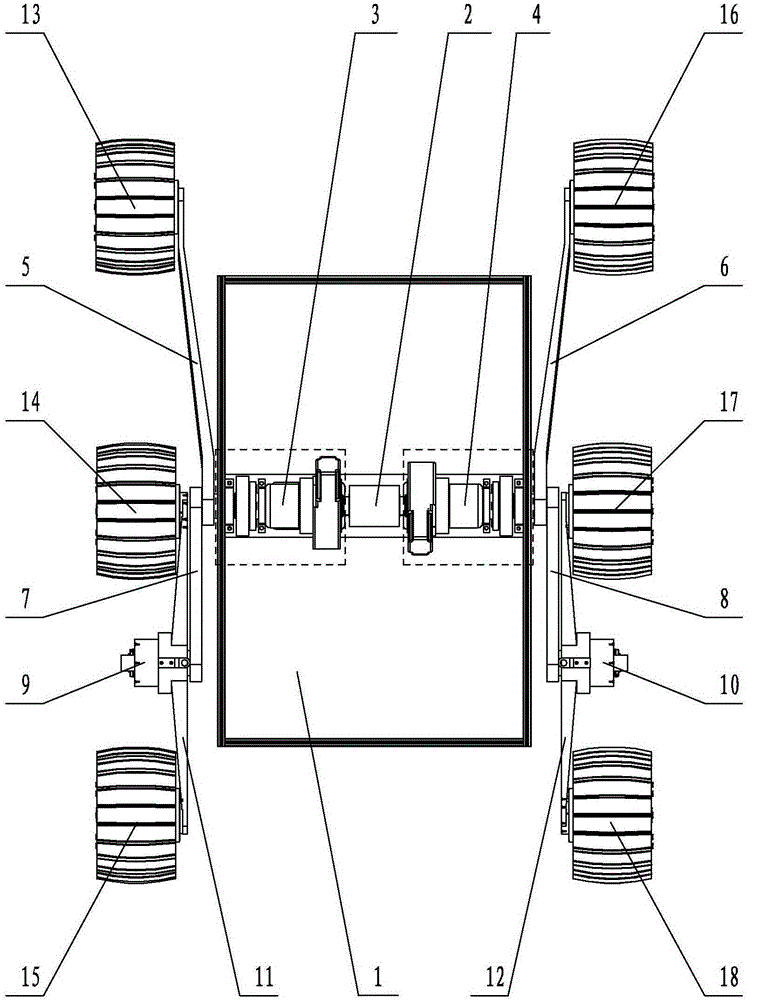

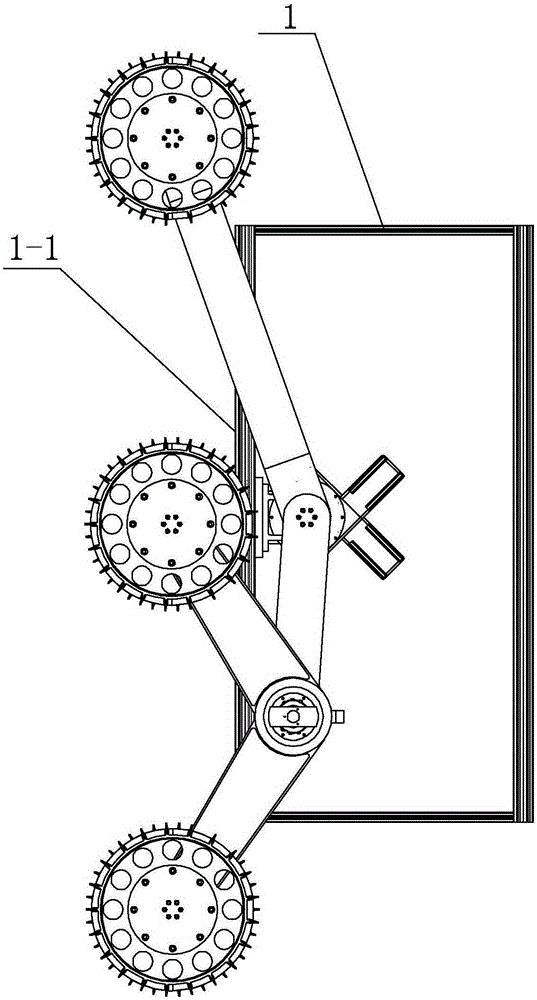

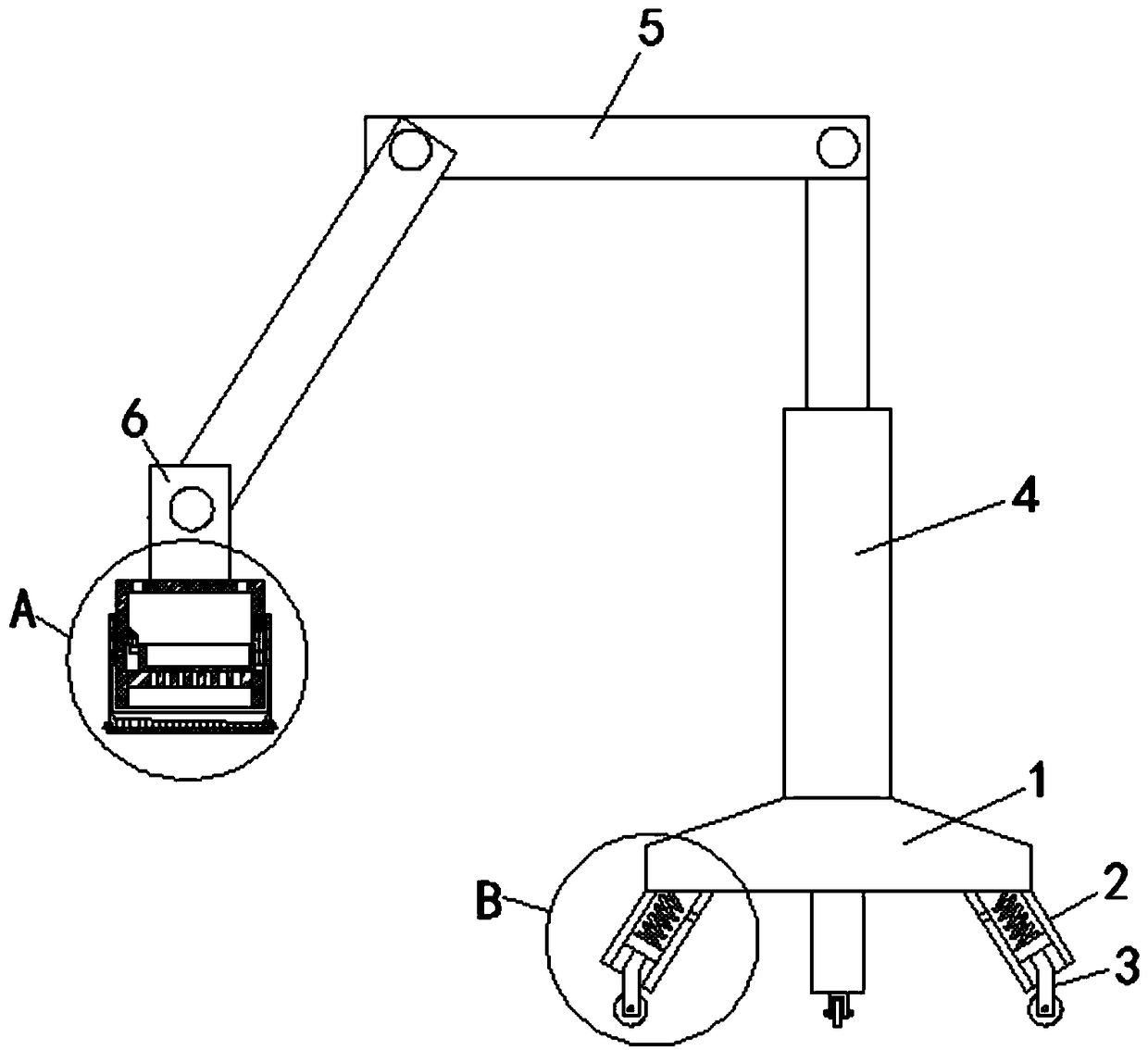

Active suspension type Mars rover moving mechanism

ActiveCN105235468ASimple structureEasy to operateExtraterrestrial carsResilient suspensionsDifferentiatorMars rover

The invention relates to a Mars rover moving mechanism, in particular to an active suspension type Mars rover moving mechanism. The active suspension type Mars rover moving mechanism solves the problems that in existing Mars rover moving mechanisms, the suspension structure is complex, unfolding mechanisms are additionally arranged, the mechanism movement is complex, repeated unfolding cannot be achieved and the size of driving mechanisms is excessively large. An output shaft at one end of a differentiator is connected to a first field angle regulator, an output shaft at the other end of the differentiator is connected to a second field angle regulator, the two output shafts of the differentiator are coaxial with the first field angle regulator and the second field angle regulator respectively, and the first field angle regulator and the second field angle regulator are installed on the upper end surface of a rover compartment floor in a bilateral symmetry mode. One end of a first main long rocker arm is fixedly arranged on an external output shaft of the first field angle regulator in a sleeving mode, one end of a first main short rocker arm is fixedly arranged on an internal output shaft of the first field angle regulator in a sleeving mode, and the other end of the first main long rocker arm is connected to the upper part of a first auxiliary rocker arm through a first main and auxiliary rocker arm clutch. The active suspension type Mars rover moving mechanism is used for Mars exploration.

Owner:HARBIN INST OF TECH

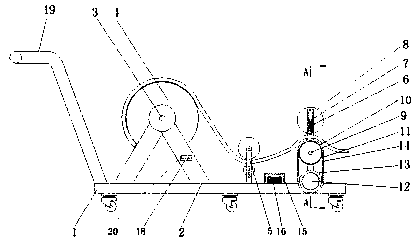

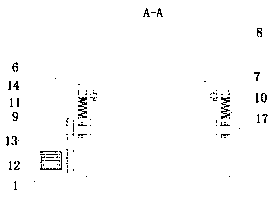

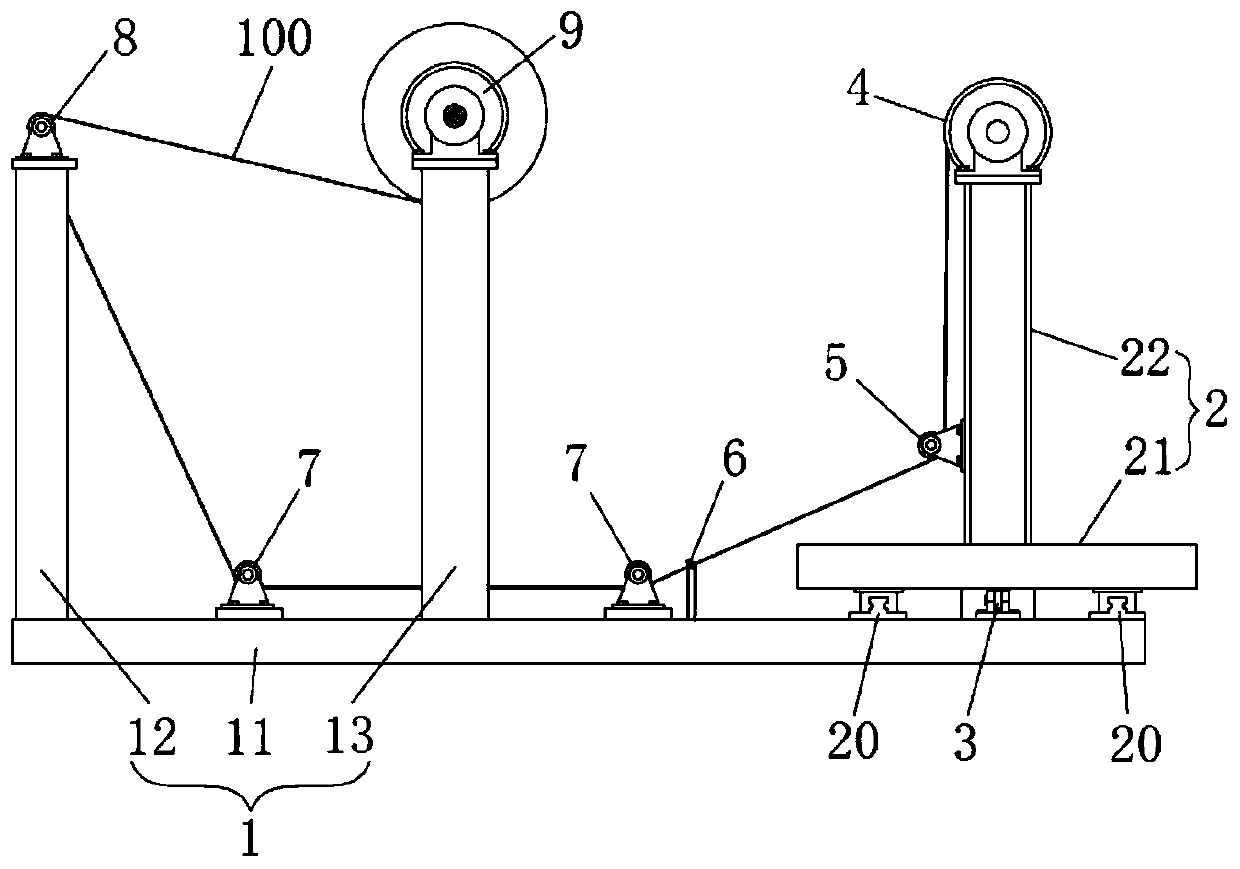

Unwinding device for measuring lengths of electric wires and optical cables

InactiveCN109110560ARealize automatic pay-offSave human effortFilament handlingOptical axisConductor Coil

Owner:CHANGGUANG COMM SCI & TECH JIANGSU CO LTD

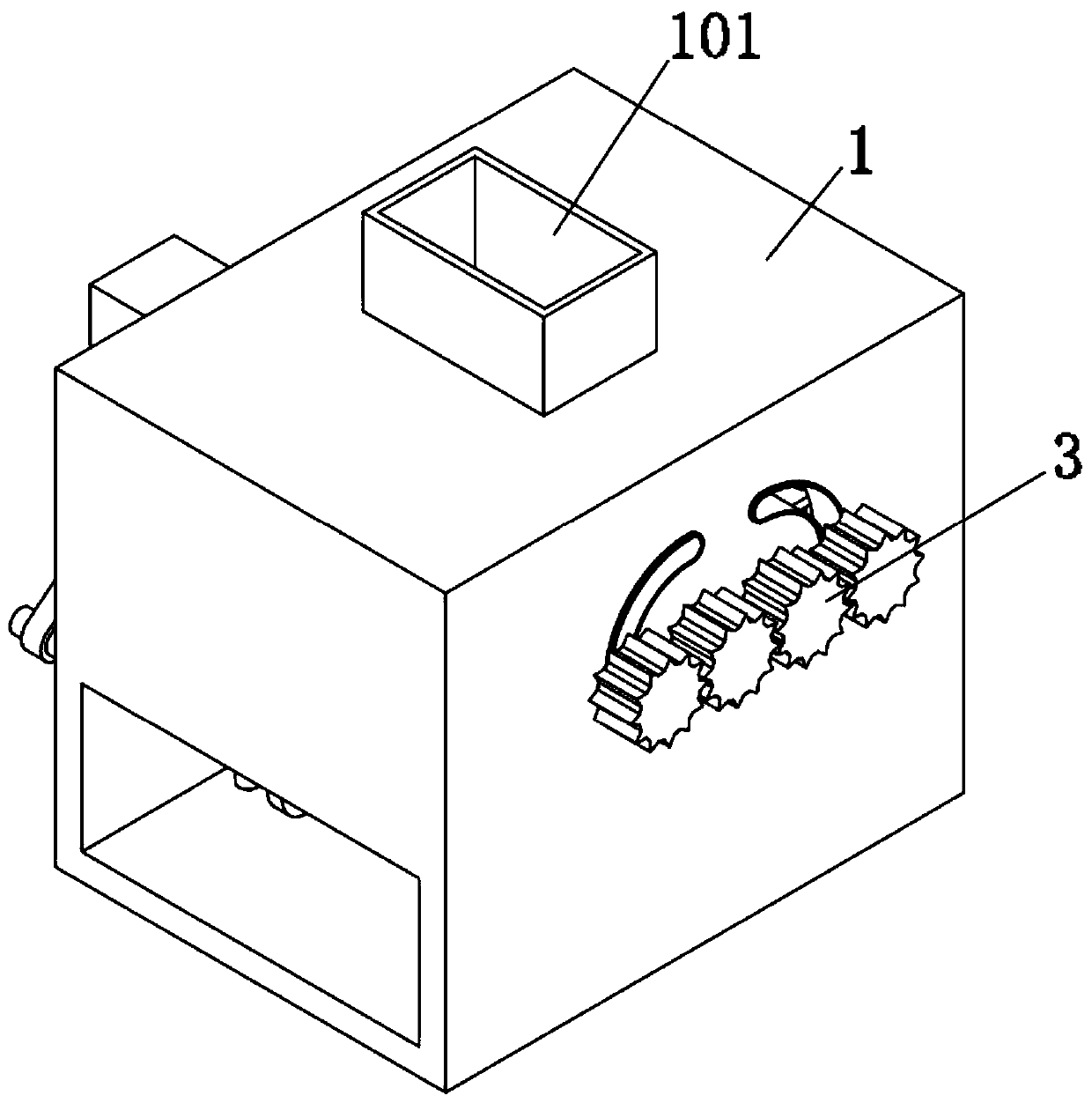

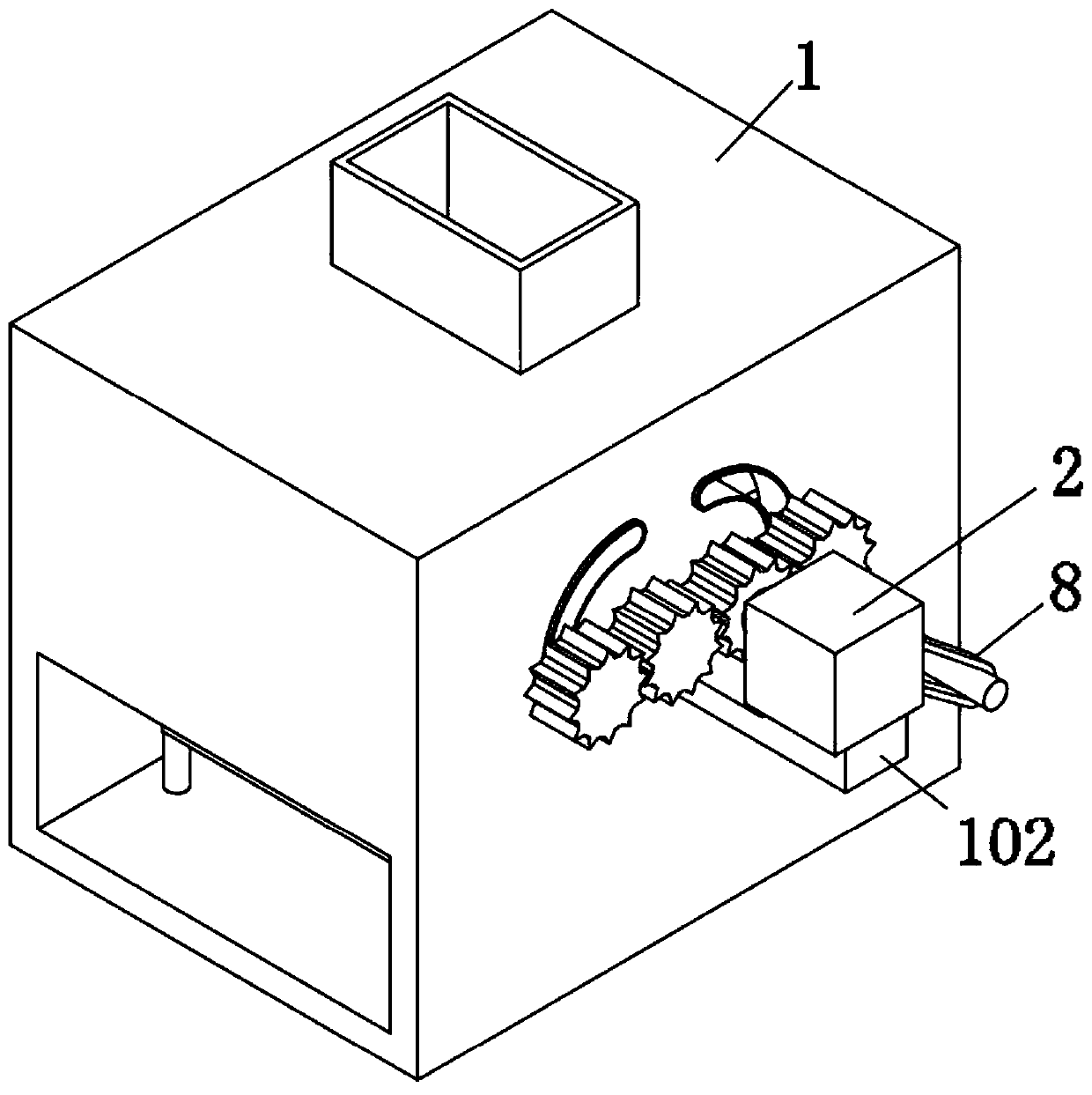

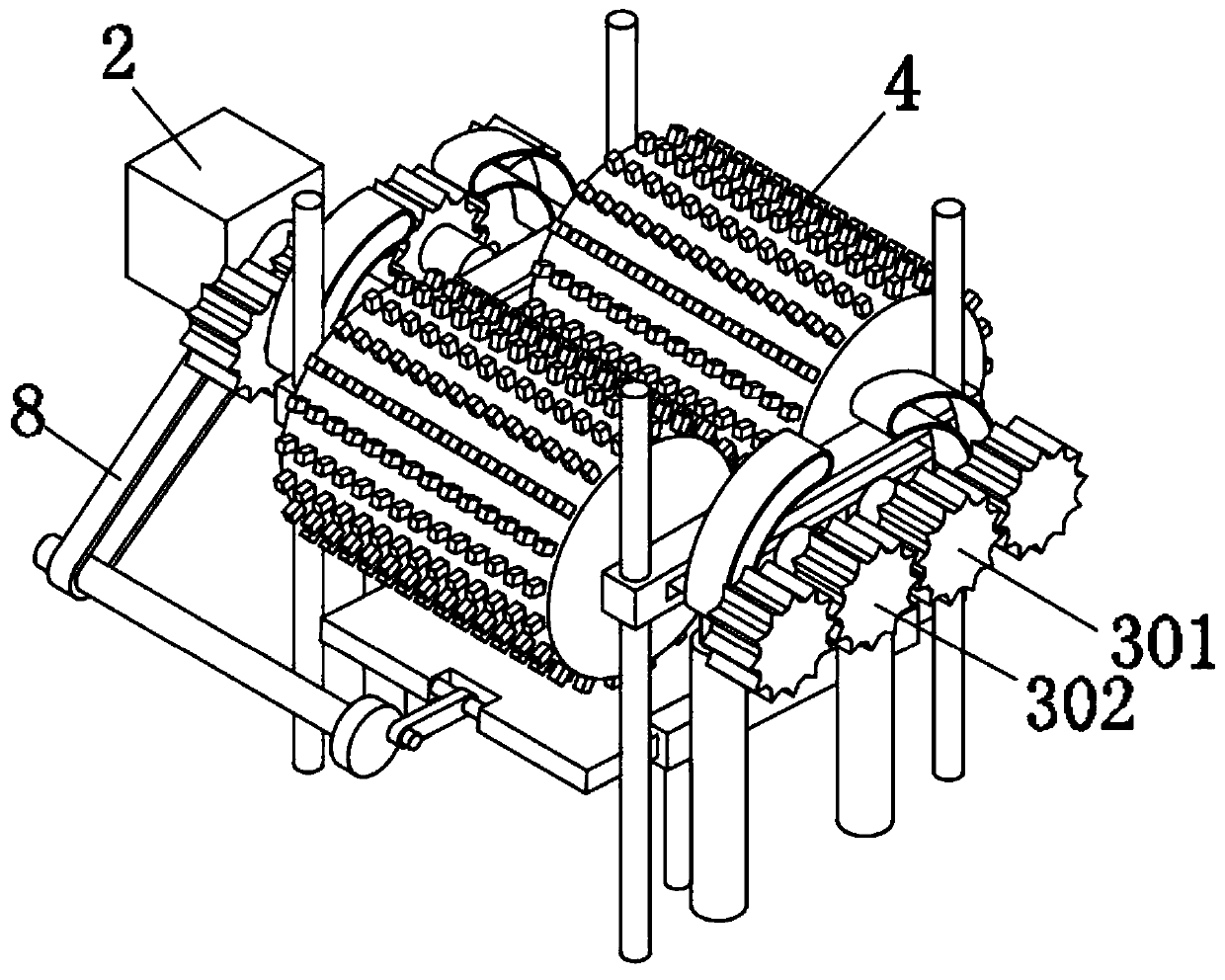

Concrete crushing device for constructional engineering

The invention discloses a concrete crushing device for constructional engineering. The device comprises a box body; supporting mechanisms are arranged on the two sides of the bottom of the interior ofthe box body in a supporting mode, and the supporting mechanisms comprise connecting frames, sliding rods and electric telescopic rods; crushing mechanisms are arranged at the interior of the box body, and the crushing mechanism comprise crushing wheels, fixing rods, connecting rods and third gears; guiding mechanisms are arranged on the inner walls of the two sides of the box body, and the guiding mechanisms comprise guiding frames; and gear sets are arranged on the two sides of the exterior of the box body, and the gear sets comprise first gears and second gears, and a motor is arranged onone sides of the gear sets. According to the device, when the electric telescopic rods jack up the connecting frames, the connecting frames can slide on the sliding rods, and the connecting frame scandrive the fixing rods to ascend along the guiding frames, so that the crushing wheels in the crushing mechanisms can carry the third gears to change the distance between the two crushing mechanisms,and the third gears are engaged with the gear sets all the time; and the distance between the crushing mechanisms can be changed through ascending and descending of the supporting mechanisms.

Owner:王翔宇

Yarn combing and impurity removing mechanism for textile machine that facilitates collection of impurities

ActiveCN111270383AEasy to collectFast collection processingFibre cleaning/openingYarnHydraulic cylinder

The invention discloses a yarn combing and impurity removing mechanism for a textile machine that facilitates collection of impurities. The yarn combing and impurity removing mechanism comprises an impurity removing cavity, an air pump, a hydraulic cylinder and a motor; guide pulleys are rotatably installed at the left and right sides of the impurity removing cavity, and the air pump and the hydraulic cylinder are respectively fixedly installed at the top edge and the middle part of the impurity removing cavity; the output end of the hydraulic cylinder penetrates through the top of the impurity removing chamber and is fixedly connected with a guide frame; an inner rotating shaft of the guide frame is provided with a take-up pulley; the motor is fixedly installed on the outer wall of the guide frame; a fixing frame is fixed on the outer wall of the guide frame leaning towards one side of the motor, and a chain belt is slidably installed on the fixing frame; and a guide plate is fixed ata lower position of the inner wall of the impurity removing chamber. According to the yarn combing and impurity removing mechanism for the textile machine that facilitates the collection of the impurities provided by the invention, yarns of different thicknesses and materials can be conveniently subjected to impurity removal, the working efficiency of carding fluff impurities on the yarns is improved, and the overall rapid collection and processing of the fluff impurities can be facilitated.

Owner:浙江永红纺织有限公司

Moxibustion treatment device for Chinese internal medicine

InactiveCN109394526AEasy to move and fixEasy to adjust and fixDevices for heating/cooling reflex pointsDevices for locating reflex pointsCombustion chamberSelf locking

The invention relates to the technical field of traditional Chinese medicine, and discloses a moxibustion treatment device for Chinese internal medicine. The moxibustion treatment device for Chinese internal medicine comprises a base, wherein the bottom of the base is fixedly connected with a vibration reduction rod; self-locking universal wheels are arranged at the bottom of the vibration reduction rod; the top of the base is fixedly connected with a telescopic rod; the top of the telescopic rod is provided with a foldable installing frame; one end, far away from the telescopic rod, of the installing frame is rotationally connected with an installing plate; and a combustion chamber is welded at the bottom of the installing plate. The moxibustion treatment device for Chinese internal medicine has the advantages that the height of a sleeve outside the combustion chamber can be changed by rotating the sleeve; the space between a contact element and a combustion box can be further changed; through the space change, the temperature on the contact element is changed; the structure of the whole temperature regulation device is simple; the operation is convenient; through annular elasticbands, the dismounting and mounting of isolation gauze are more convenient; the sanitary effect is better; through the isolation gauze, the direct contact of the contact element with the skin of a patient can be prevented, so that the scald injury on the patient due to the high-temperature contact element can be avoided; and the safety is higher.

Owner:朱萌

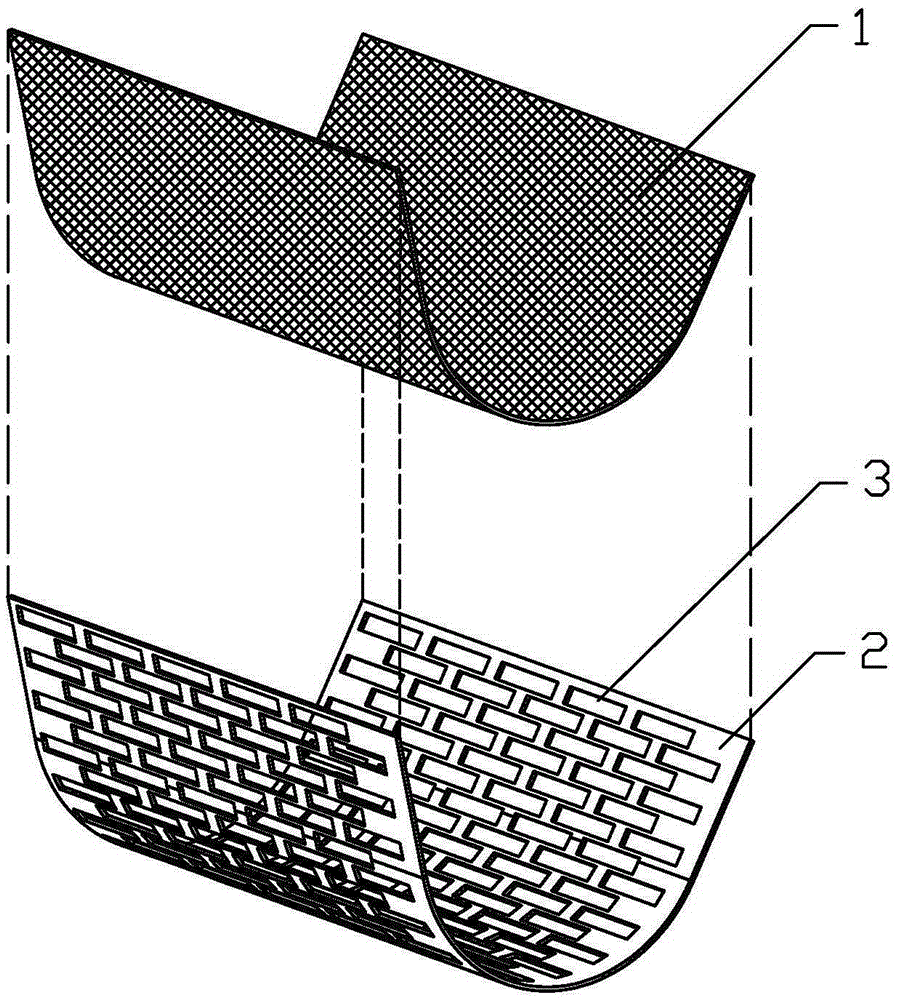

Granulate machine screen and screen mechanism of swing type granulate machine with screen

The invention relates to a screen and a screen mechanism, in particular to a granulate machine screen and a screen mechanism of a swing type granulate machine with the screen. After the screen of the conventional swing type granulate machine is broken or crushed, the crushed screen falls into medicine materials so as to pollute the medicine materials, and the replacement process of the crushed screen is tedious and time-consuming, and the working efficiency is affect and reduced virtually. The invention aims to solve the problems. A plurality of vertically-penetrated through holes are densely formed in a stainless steel plate, and a stainless steel wire net and the stainless steel plate are thermally sealed from top to bottom to form the screen. Two transmission shafts of the screen mechanism are rotationally mounted in a granulate barrel of the swing type granulate machine in parallel from the front and back, and a screen frame is U-shaped. The left end and the right end of the screen frame are detachably hooked on the two transmission shafts respectively, and the screen is detachably mounted on the inner side of the arc-shaped part of the screen frame. The granulate machine screen is used for the swing type granulate machine.

Owner:NANO PHARM TECH MACHINERY EQUIP

Sheet material graining machine with gap adjusting mechanism

InactiveCN102756597ASimple structural designImprove processing efficiencyEmbossing decorationsEngineeringMachining

The invention relates to sheet material machining equipment and particularly relates to a sheet material graining machine with a gap adjusting mechanism. The sheet material graining machine is provided with a bracket provided with a driven roller and a driving roller which are arranged in a vertical direction; the two ends of the driven roller are placed into square through holes on the two sides of the top of the bracket; two air cylinders are arranged at the top of the bracket; retracting rods of the two air cylinders are connected with the two ends of the driven roller; and the driving roller is connected with a motor, and the driving roller and the driven roller are provided with texture protruding structures. The sheet material graining machine with the gap adjusting mechanism disclosed by the invention is simple in structure design and high in processing efficiency. By virtue of the operation of the air cylinders, the driven roller is driven to ascend or descend, so that the distance between the driven roller and the driving roller is changed.

Owner:芜湖美亚特新型建材有限公司

Cloth rolling device and method for producing glue canvas

PendingCN110697478ALow costIncrease productivityArticle deliveryWebs handlingGlue lineMechanical engineering

The invention discloses a cloth rolling device and method for producing glue canvas and belongs to the technical field of glue canvas production. The cloth rolling device comprises a cloth roller anda winding roller horizontally arranged, a primary bracket for mounting the winding roller, a secondary bracket for mounting the cloth roller, a driving device for driving the secondary bracket to moveleft and right relative to the primary bracket, and a detecting device for detecting cloth deviation, wherein the secondary bracket is movably connected onto the primary bracket; and the detecting device is arranged on one side of cloth between the cloth roller and the winding roller. During the production process, the detecting device detects that cloth deviates, then, the secondary bracket is controlled to move to change the position of the cloth roller, so that the purpose of correcting cloth deviation is further realized; the glue line at the edge of the produced glue canvas is in order,the edge does not to be cut during the using process, so that the material cost is lowered, and the production efficiency is improved; and moreover, during the production process, the glue line does not exceed the cloth edge to be glued to the cloth rolling device, so that the periodic cleaning cost is reduced.

Owner:马鞍山锐生工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com