Organic modified bentonite and preparation method thereof

A bentonite and modified technology, applied in the field of organic modified bentonite and its preparation, can solve the problems of poor dehydration effect of flocs, affecting practical application, slow solid-liquid separation speed of bentonite, etc. Effects of layer spacing and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

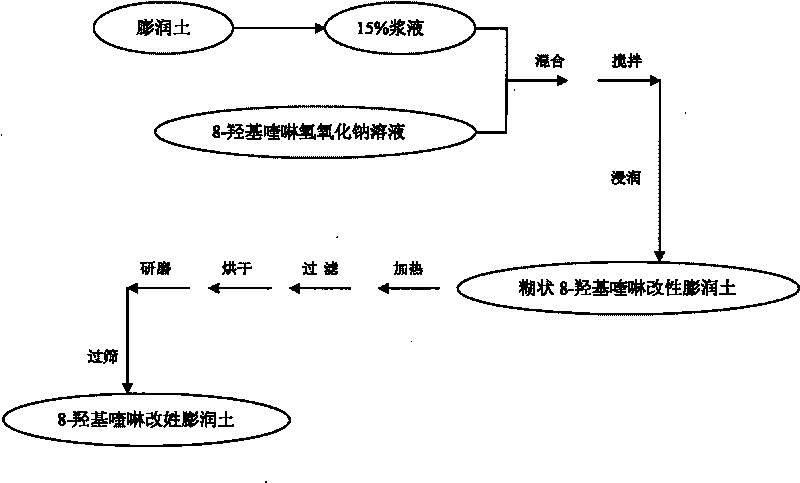

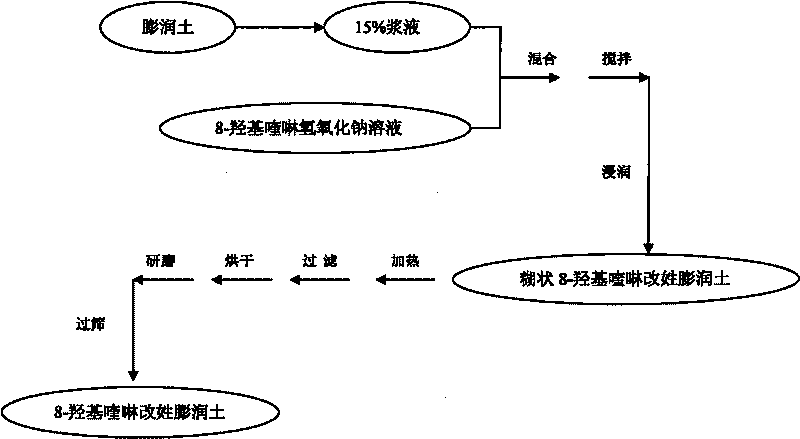

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

[0019] The organic modified bentonite of the present invention uses 8-hydroxyquinoline as a modifier to modify the bentonite to prepare a novel organic modified bentonite. The organic modified bentonite of the present invention can be seen in the IR diagram of the water-washed soil after modification, 3438cm -1 The relative intensity of the absorption peak at the site becomes smaller than that of the original soil, indicating that the addition of the activator plays a hydrophobic role, causing the association between hydroxyl groups to become smaller and the hydrophobic effect enhanced. In addition, at 2854cm -1 The C-H stretching characteristic absorption peak is added nearby, at 1449cm -1 The characteristic absorption peak of C-N increases nearby, indicating that the modifier has entered the interlayer of bentonite. The X-ray spectrum of modified bentonite shows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com