Full-automatic slide pitch-changing manipulator of bottle blowing machine

A blow molding machine, fully automatic technology, applied in the field of fully automatic blow molding machine slideway variable distance manipulator, can solve the problems of increased machine energy consumption, low heater heat utilization rate, large spacing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

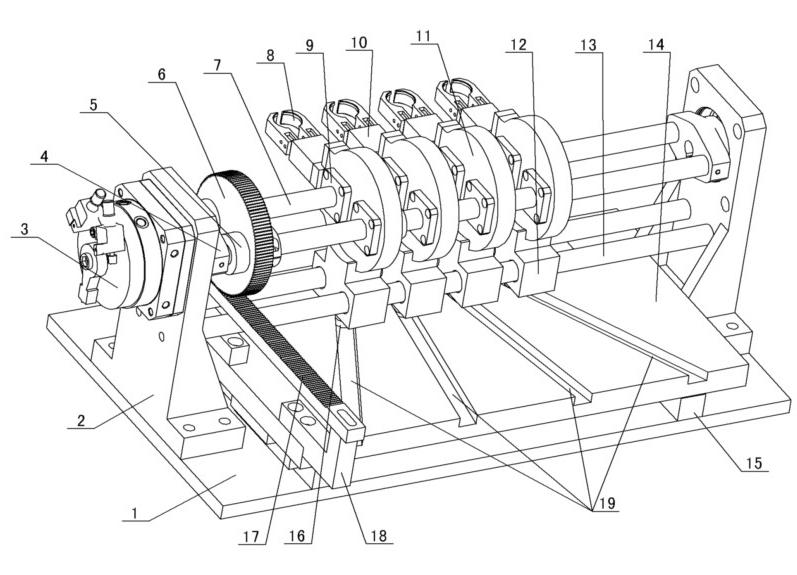

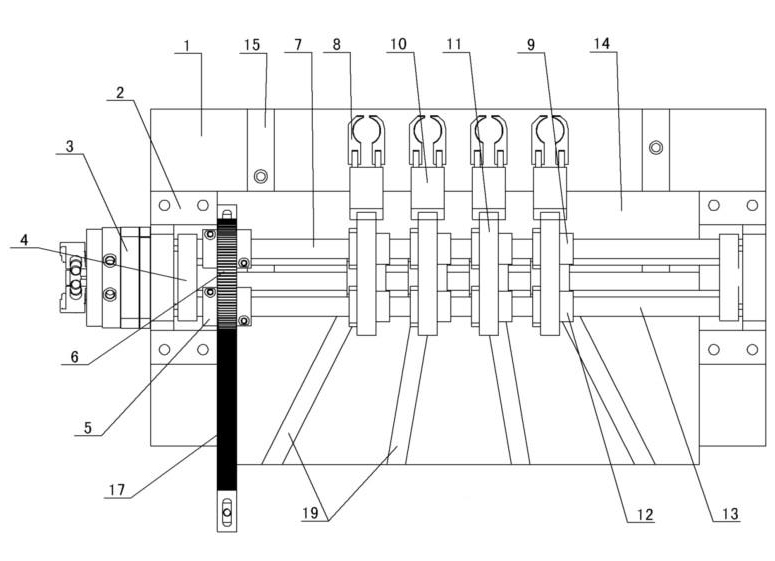

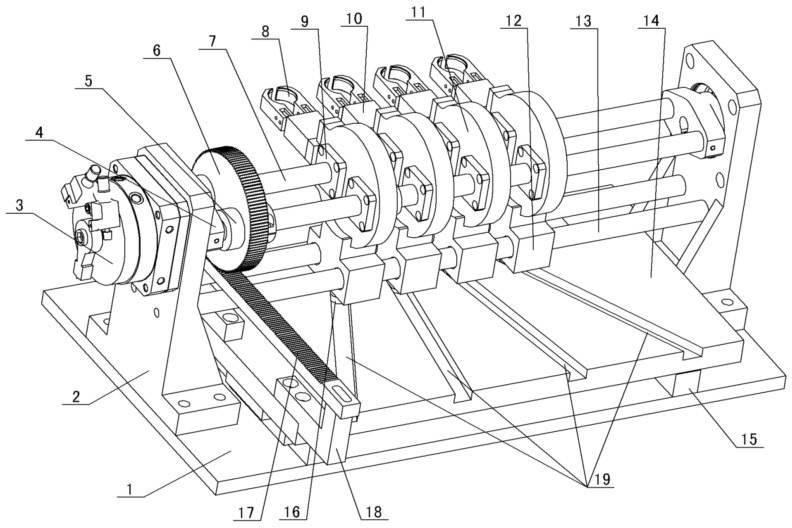

[0009] The invention relates to a fully automatic bottle blowing machine slideway variable distance manipulator, such as figure 1 , figure 2 As shown, it includes a bottom plate 1, a fixed seat 2 is installed on the bottom plate 1, a rotating cylinder 3 is installed on the fixed plate 2, the rotating cylinder 3 is connected to the sliding shaft 7, a moving block 11 is set on the sliding shaft 7, and a tube embryo finger 8 is installed on the moving block. The tube embryo finger 8 is driven by the finger cylinder 10. It is characterized in that a moving plate 14 is slidably arranged on the bottom plate 1, a rack 17 is installed on the moving plate 14, and a gear 6 is installed on the sliding shaft 7. The gear 6 is in phase with the rack 17. Engagement, described moving plate 14 is shaped on variable distance slideway 19, is equipped with roller 16 under moving block 14, and roller 16 cooperates with variable distance slideway 14. When working, firstly, the tube embryo finger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com