Patents

Literature

2714results about How to "Reliable action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

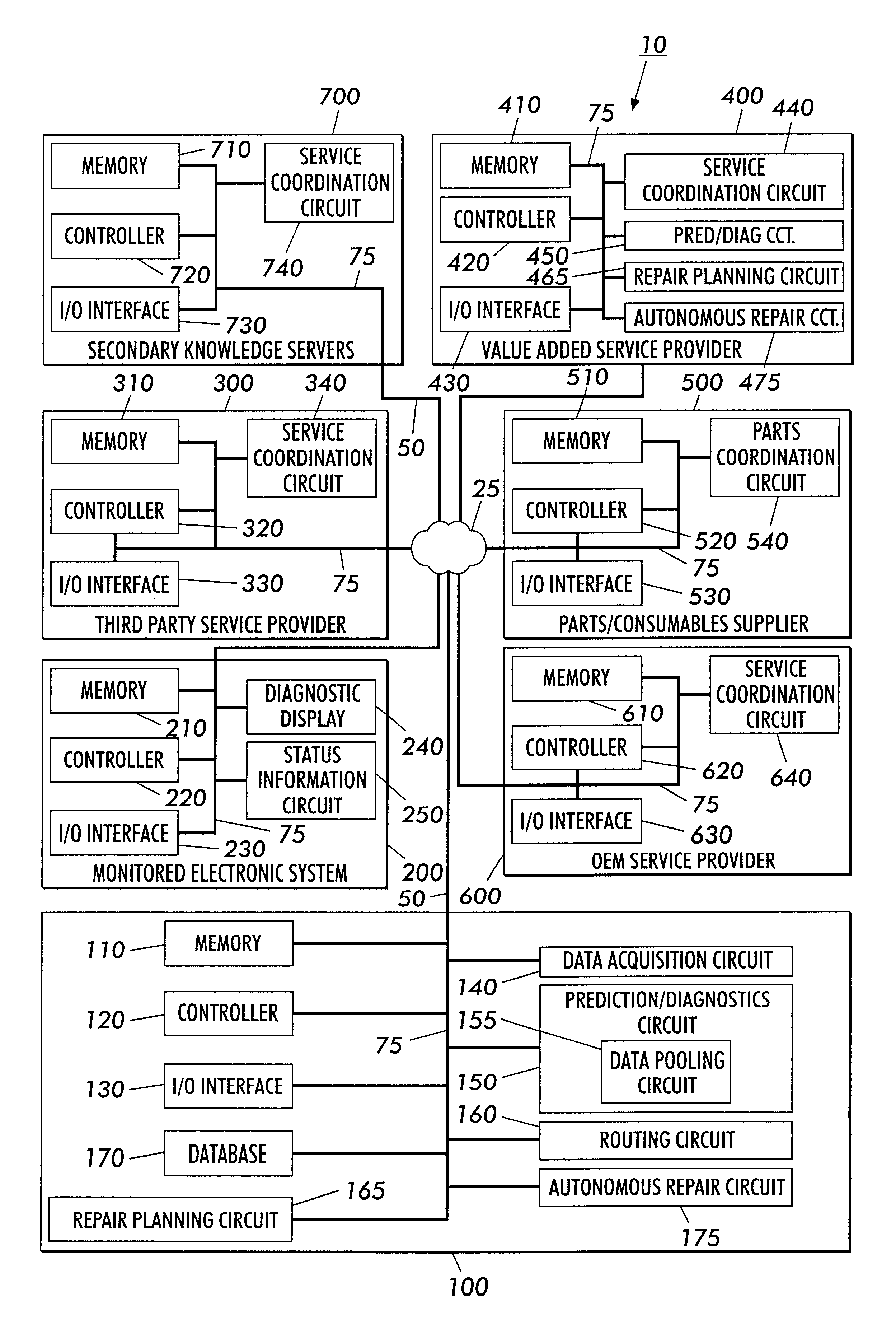

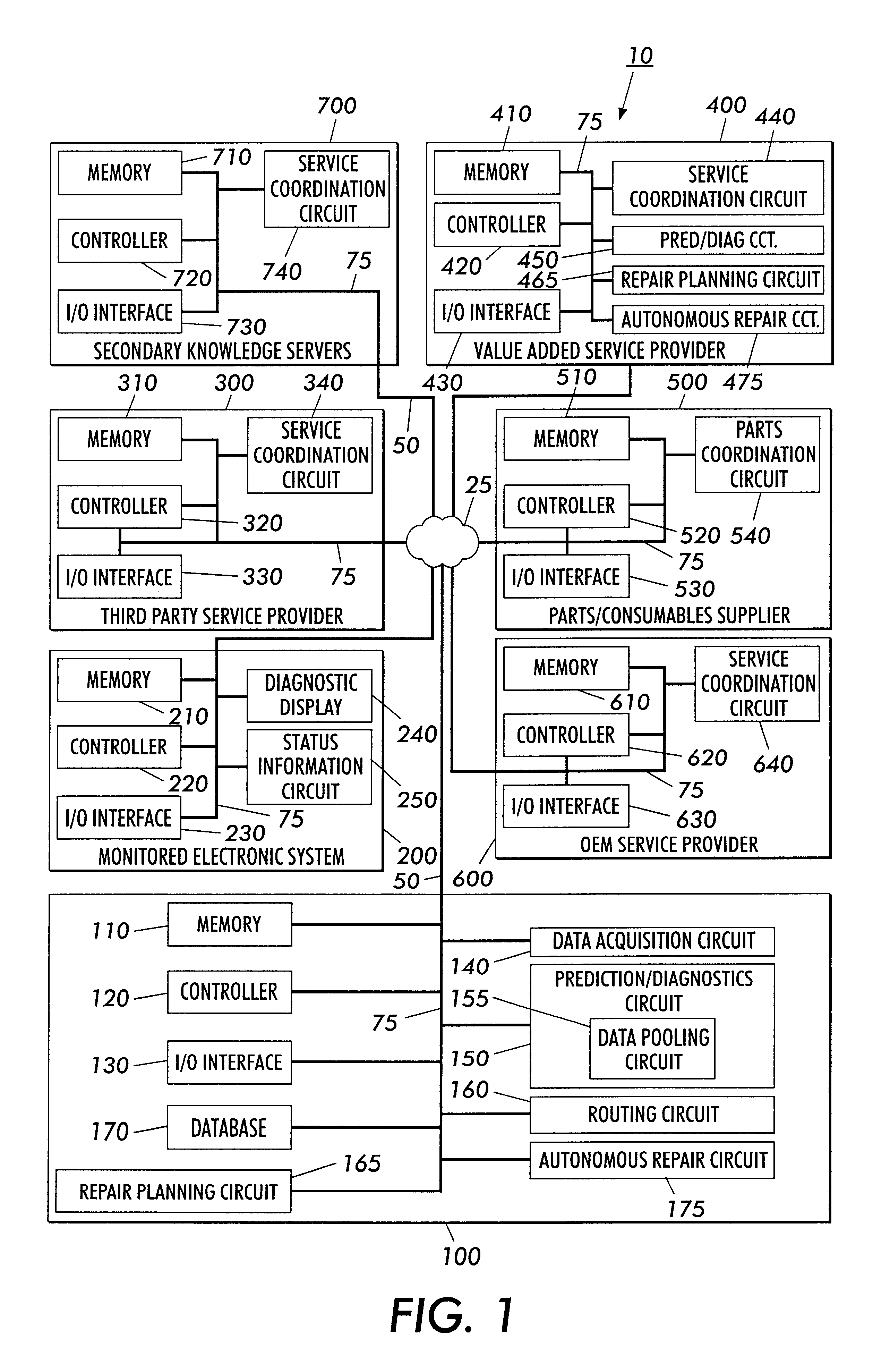

Systems and methods for failure prediction, diagnosis and remediation using data acquisition and feedback for a distributed electronic system

InactiveUS6892317B1Highly reliable actionHighly reliable responseData processing applicationsLogical operation testingPredictive systemsElectronic systems

By using monitoring data, feedback data, and pooling of failure data from a plurality of electronic devices, real-time failure prediction and diagnoses of electronic systems operating in a network environment can be achieved. First, the diagnostic system requests data on the state of a machine and / or its components and collections thereof as part of the machine's normal operation. Secondly, real-time processing of the data either at the machine site or elsewhere in the distributed network allows for predicting or diagnosing system failures. Having determined and / or predicted a system failure, a communication to one or more remote observers in the network allows the remote observers to view the diagnostic information and / or required action to repair the failure. Furthermore, interrogation of either the particular electronic system, or a database containing data on similar electronic systems by the diagnostic server allows the diagnostic server to refine original diagnoses based on this population data to achieve a comprehensive failure predication / diagnosing system.

Owner:LONGHORN HD LLC

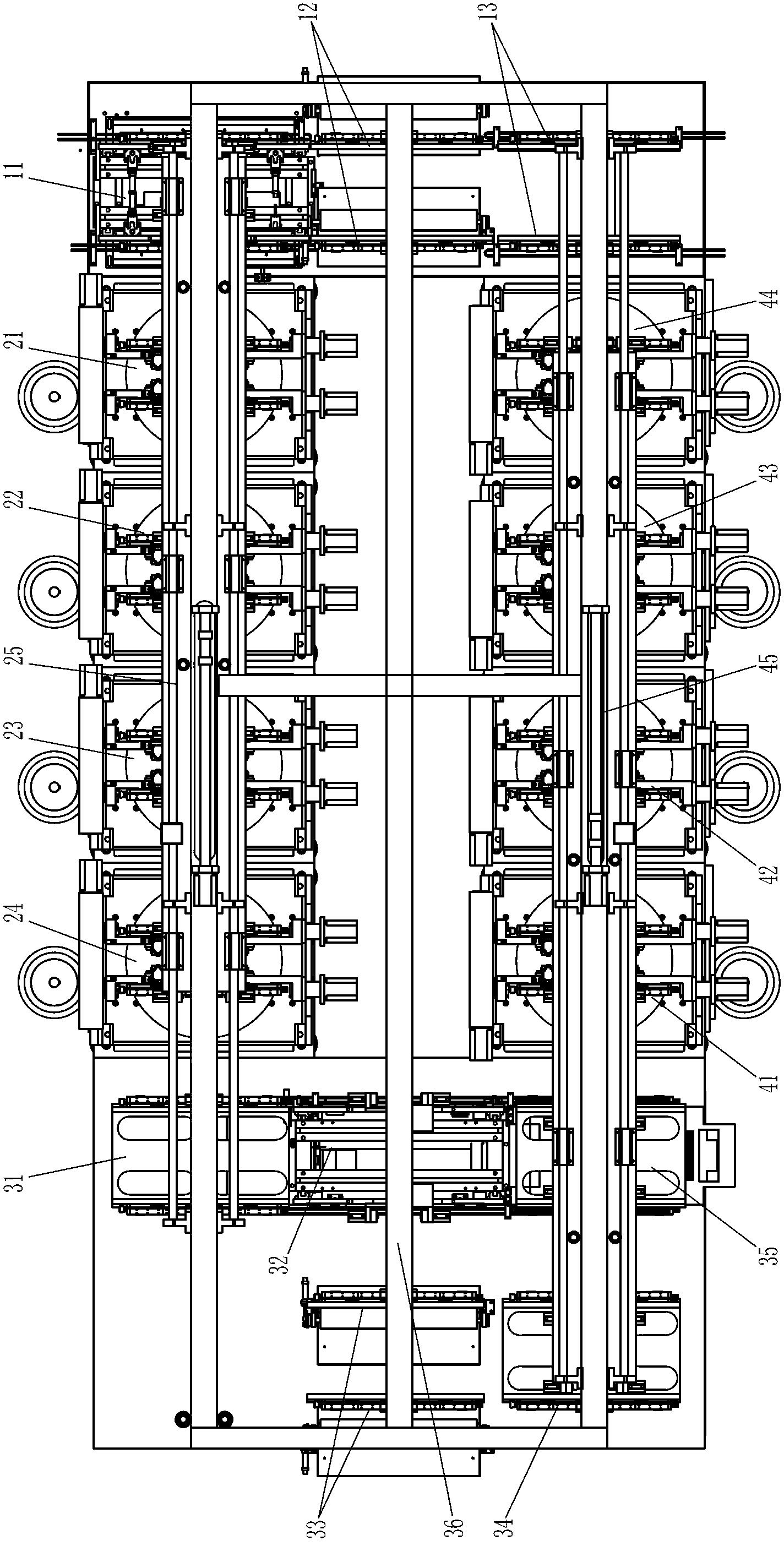

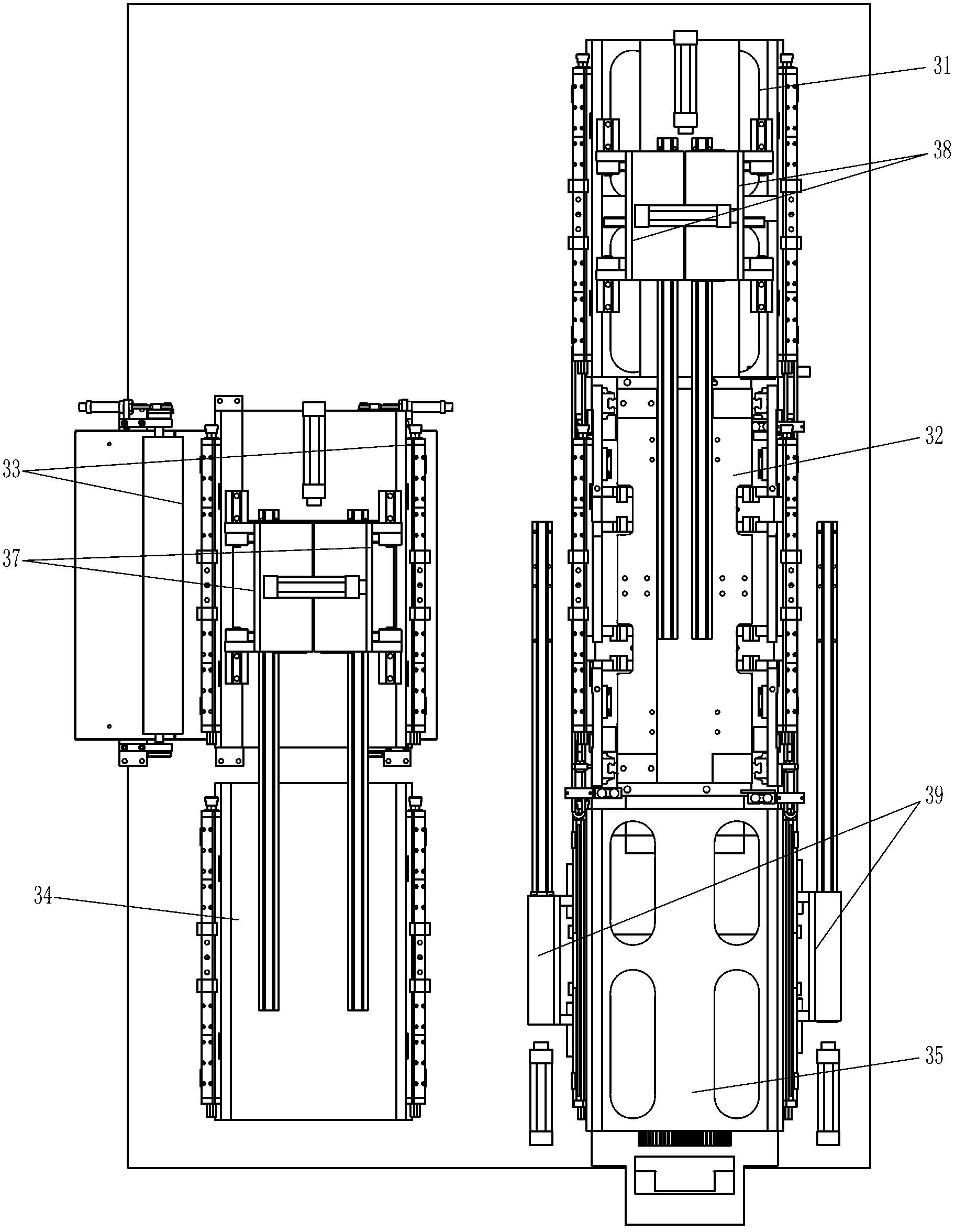

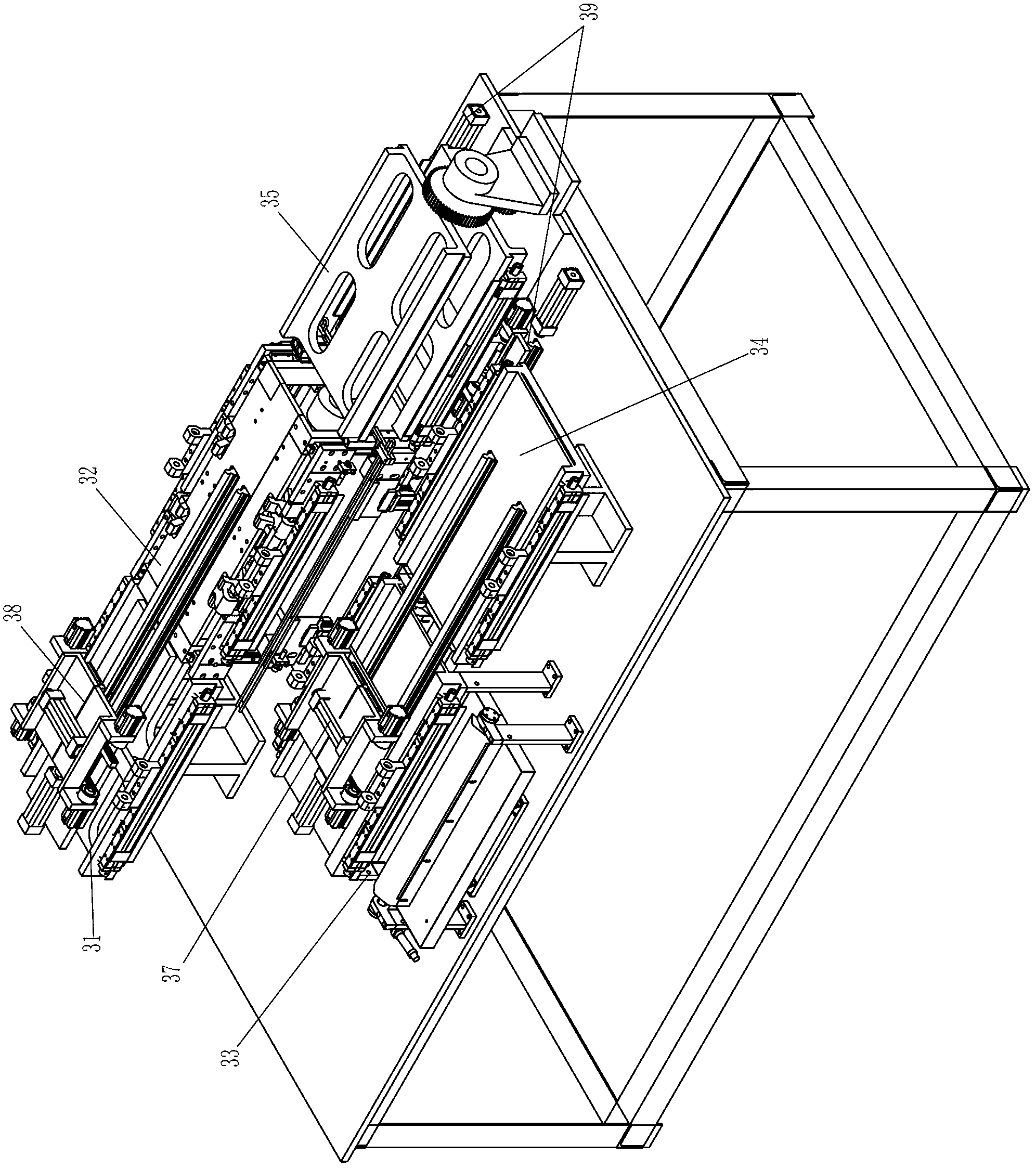

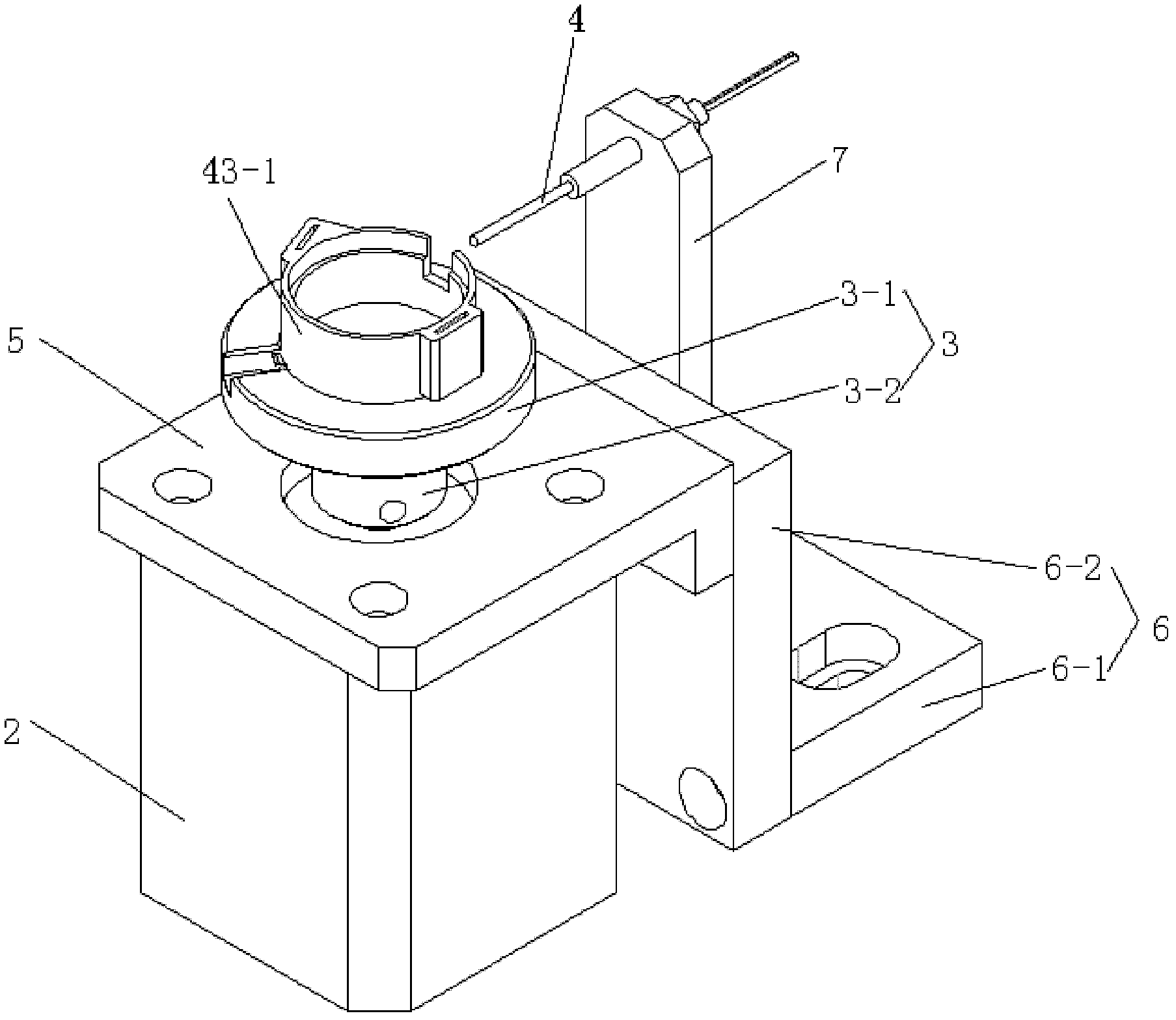

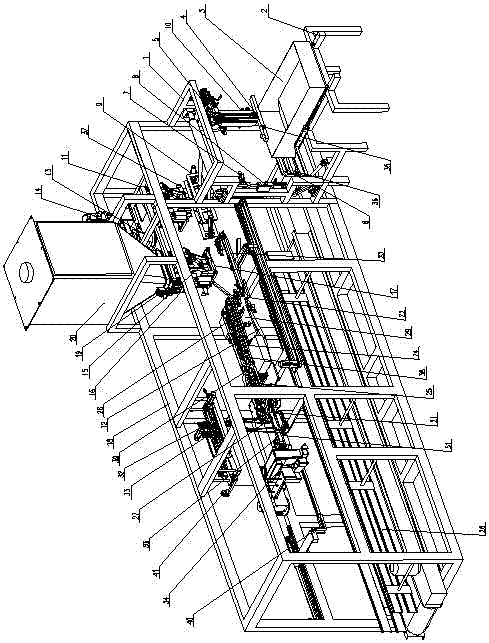

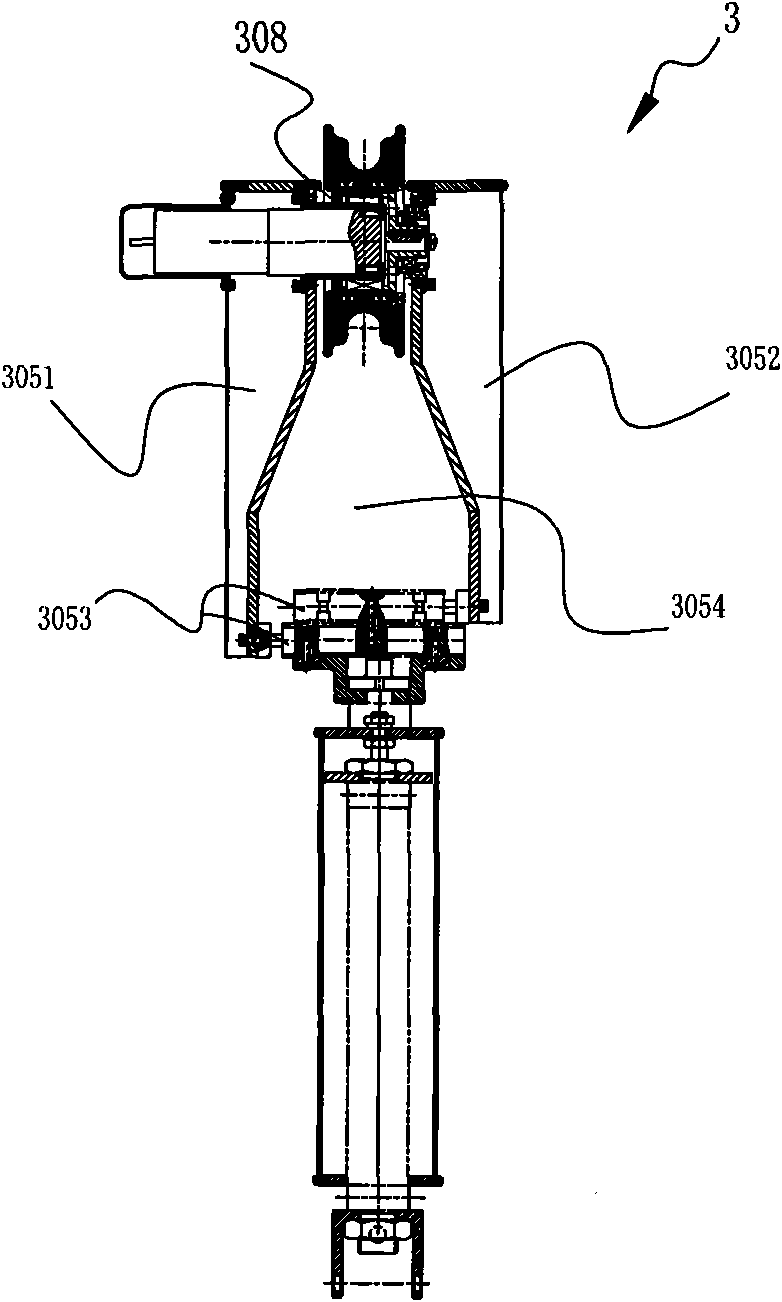

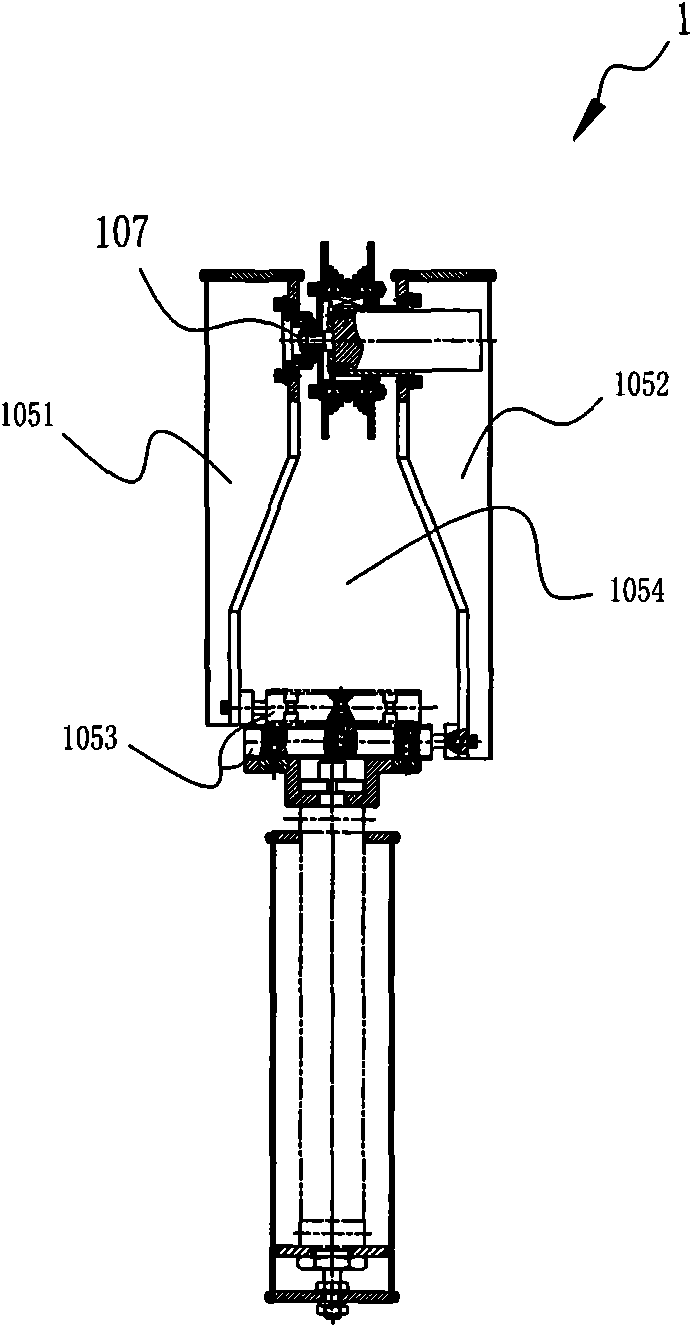

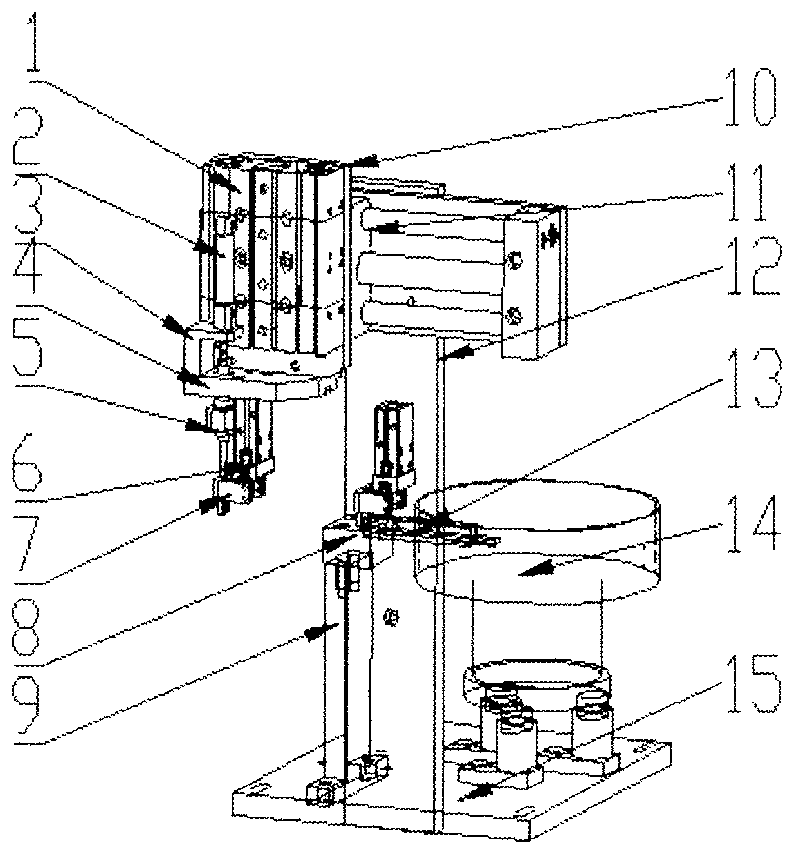

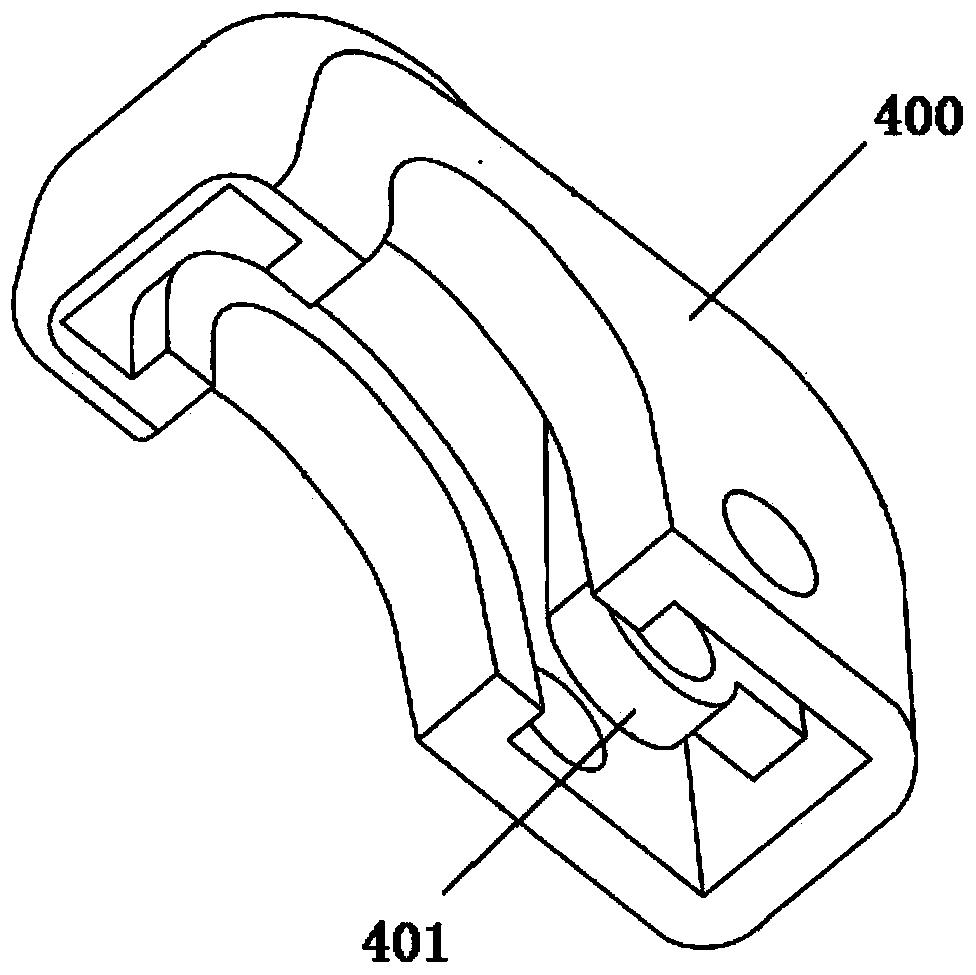

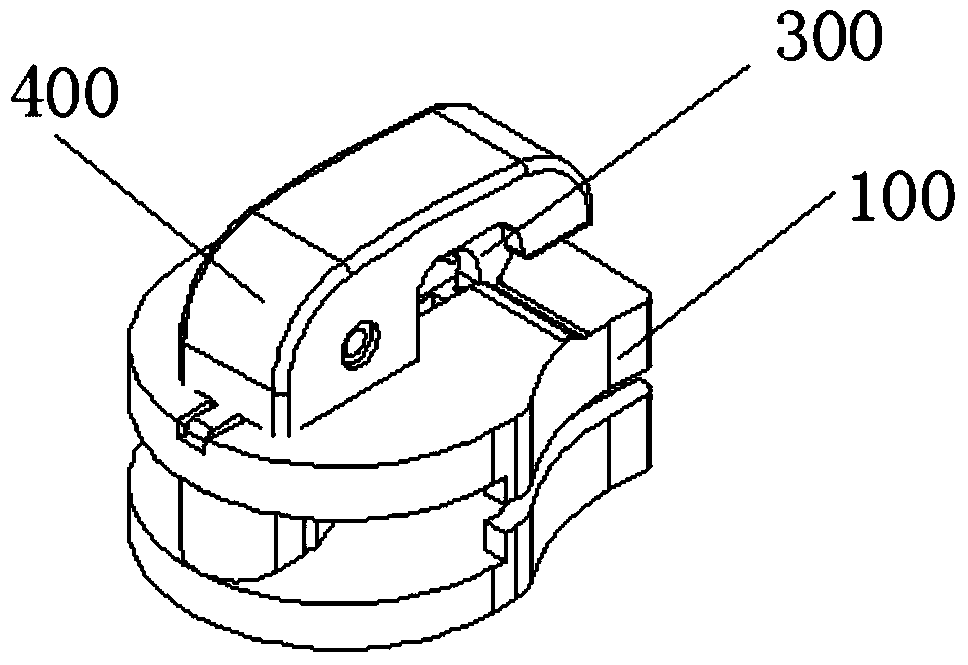

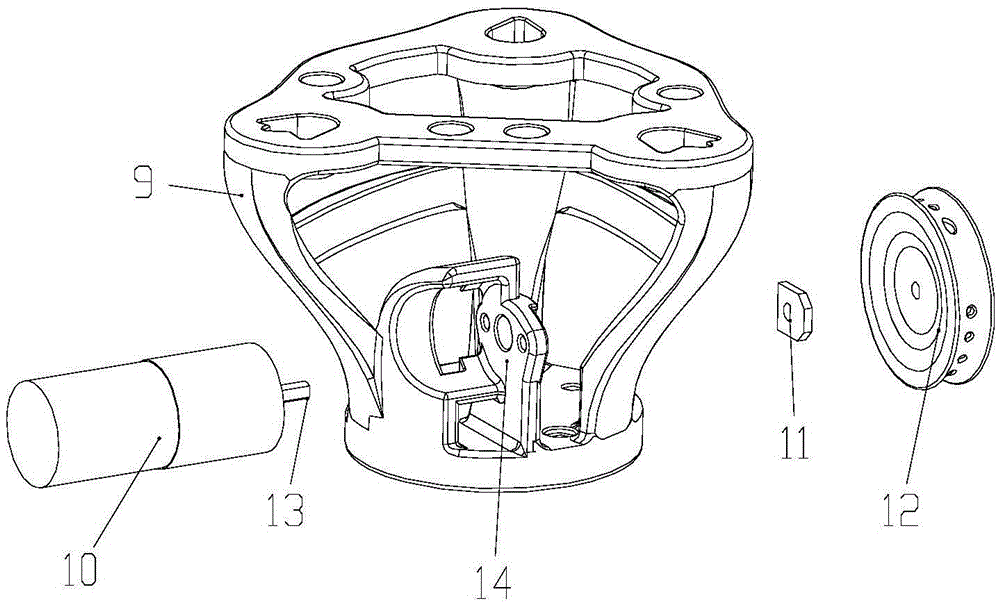

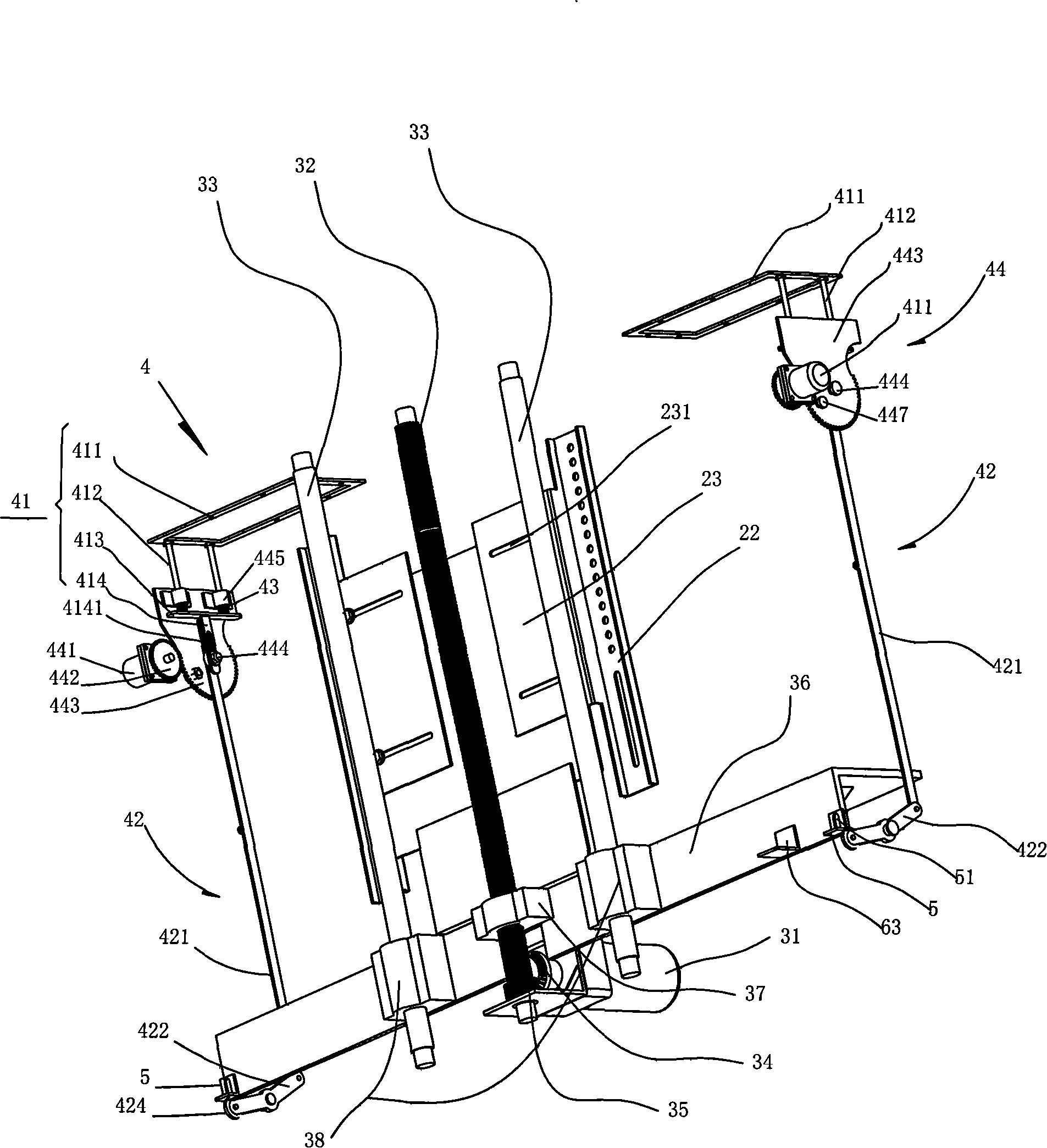

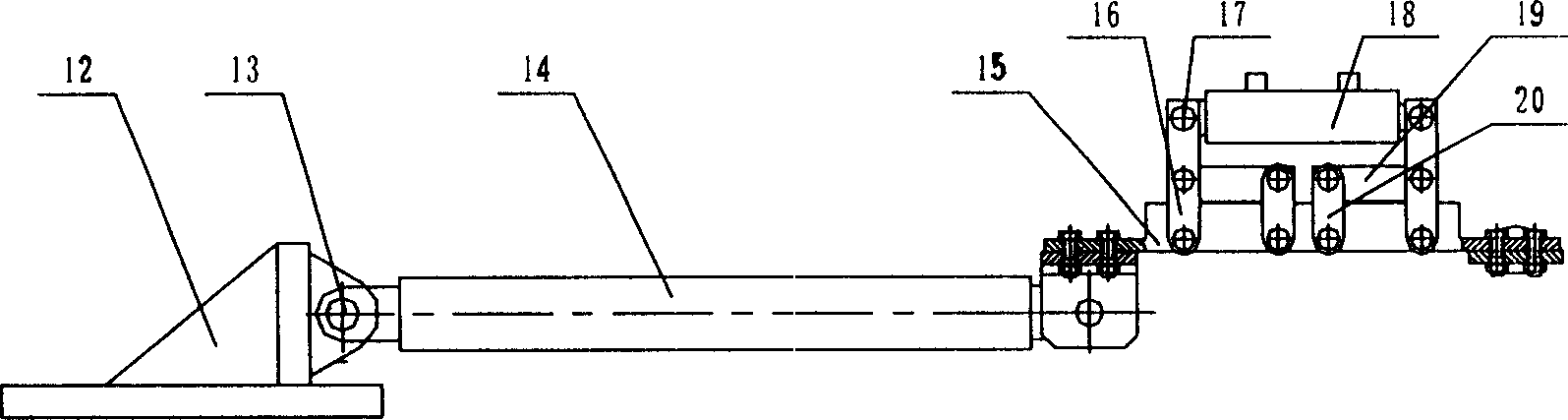

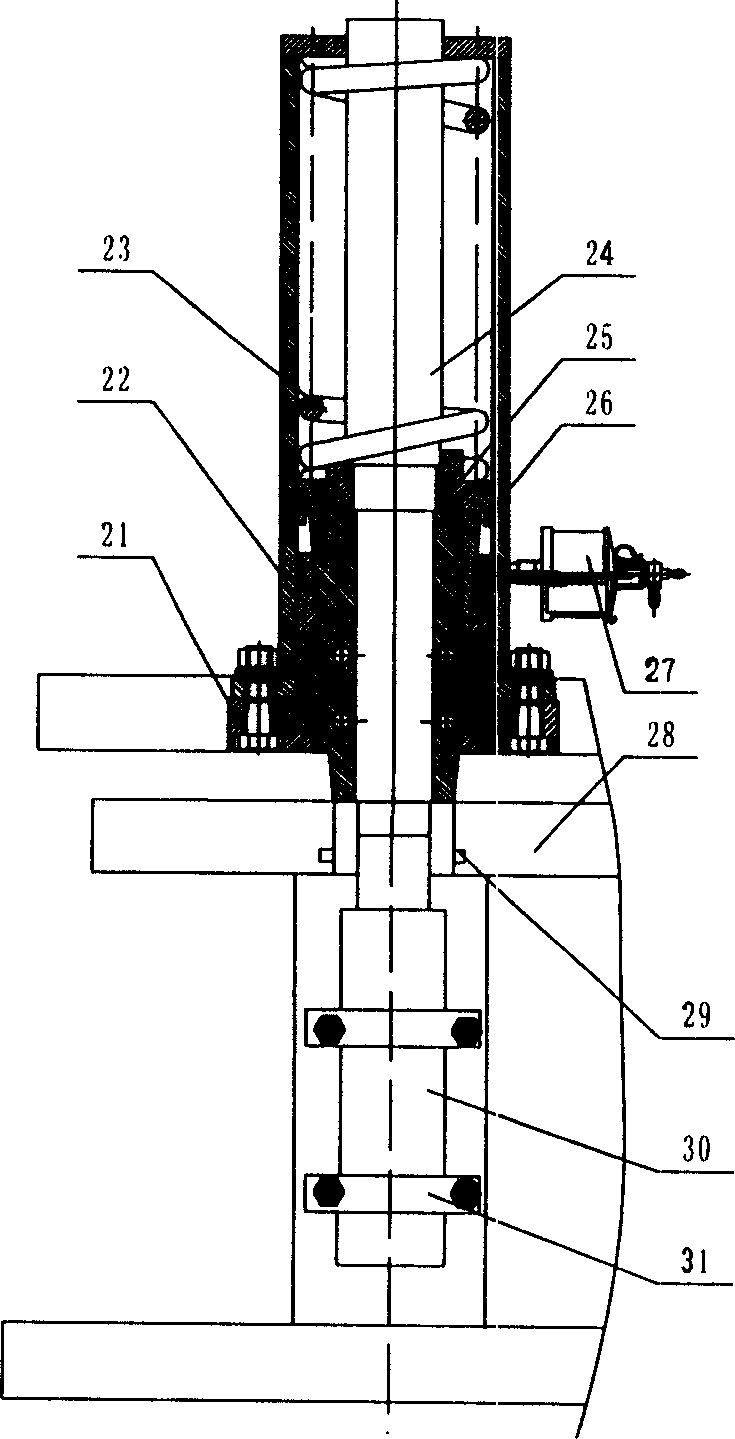

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

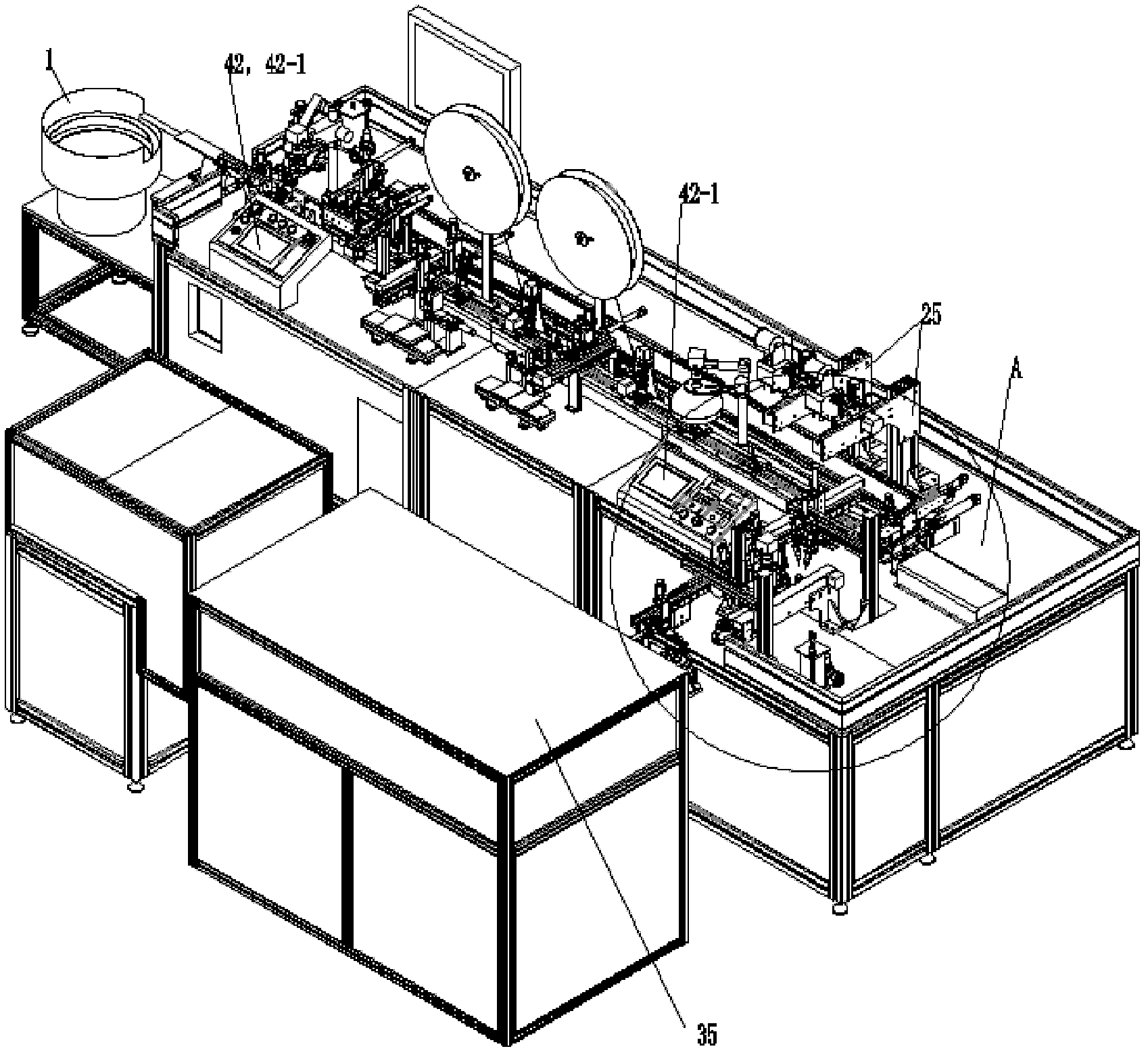

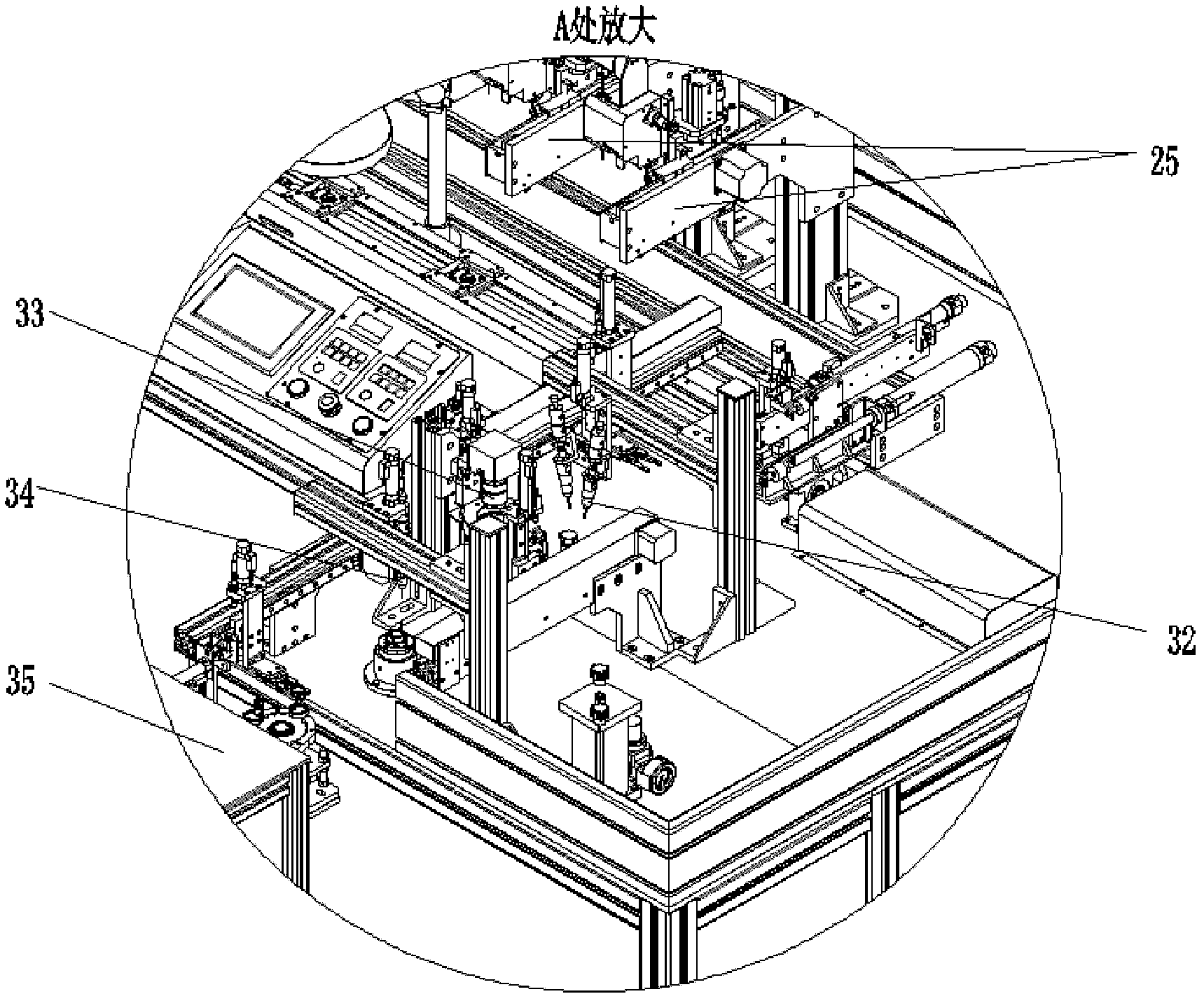

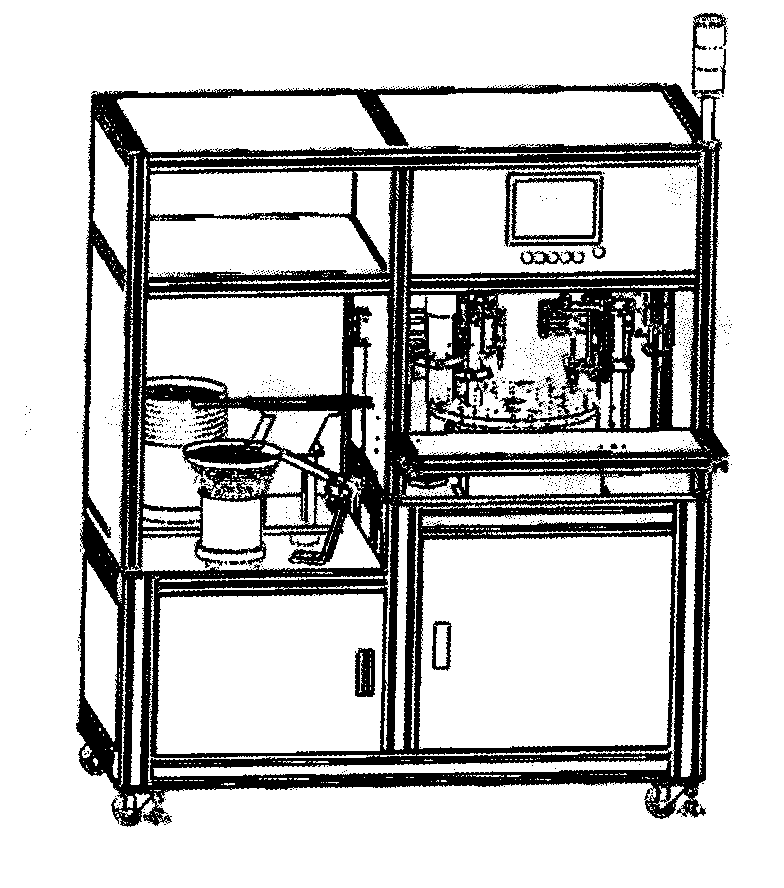

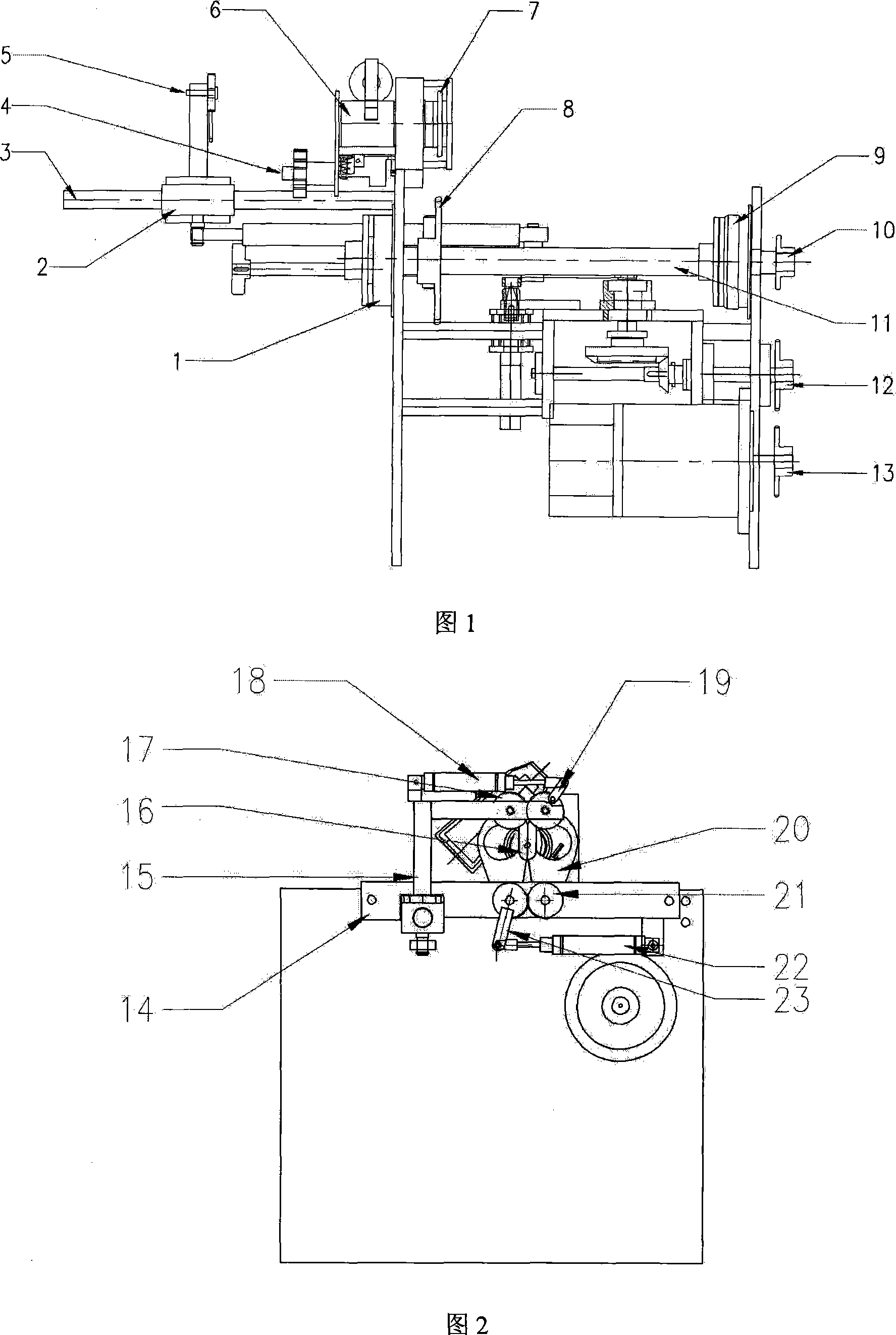

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

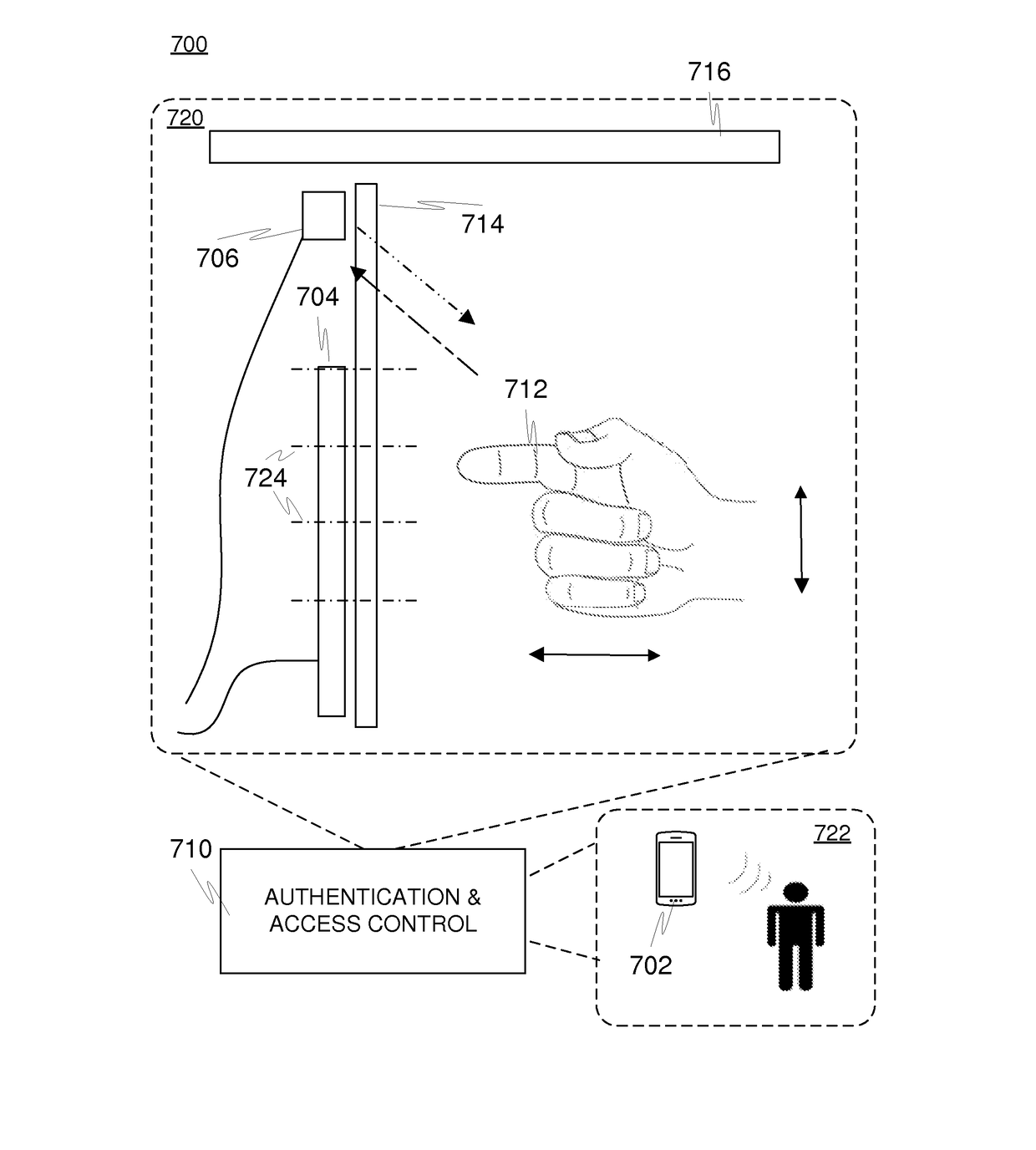

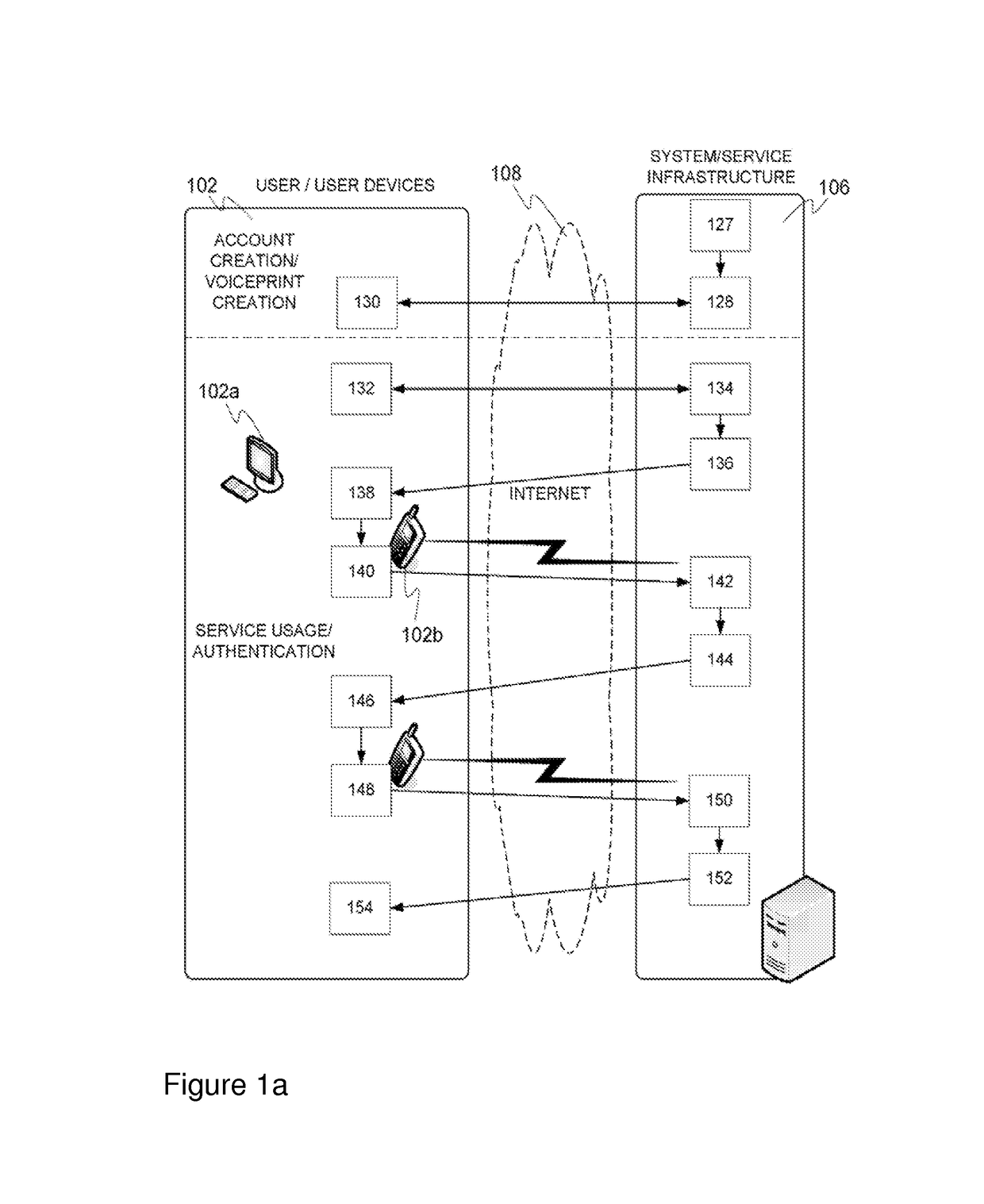

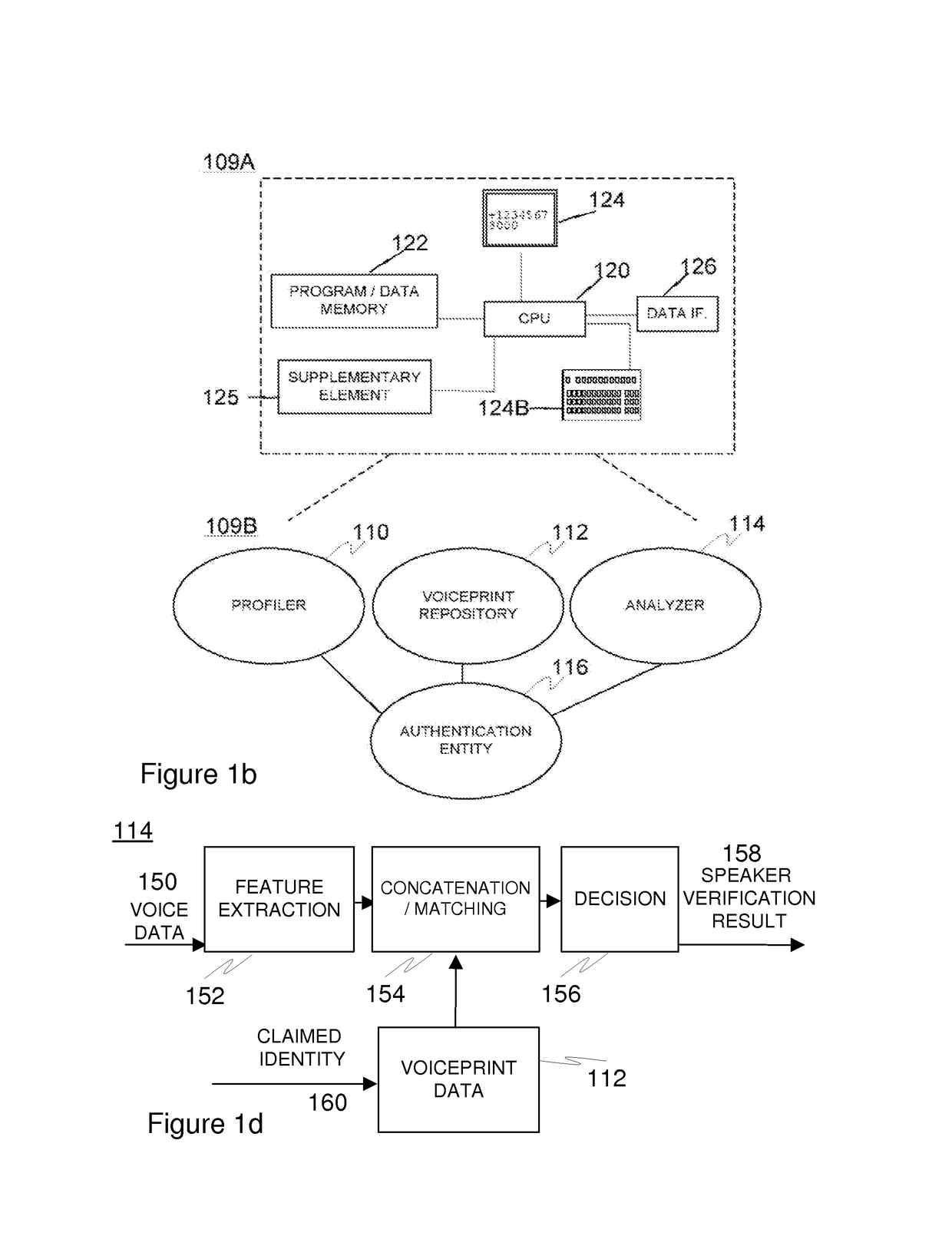

Audiovisual associative authentication method, related system and device

ActiveUS20180068103A1Reliable actionImprove reliabilitySpeech analysisPayment architectureElectronic systemsInternet privacy

Electronic system (106, 109A) for authenticating a user of an electronic service, said system preferably comprising at least one server apparatus, the system being configured to store (122, 112, 200), for a number of users, a plurality of personal voice-prints (204) each of which being linked with a dedicated visual, audiovisual or audio cue (202), for challenge-response authentication of the users, wherein the cues are user-selected, user-provided or user-created, pick (116, 200C, 142, 144), upon receipt of an authentication request associated with a claim of an identity (160) of an existing user of said number of users, a subset of cues (212) for which there are voiceprints of the existing user stored (112), and provide the cues for representation to the user as a challenge, receive (126, 148, 150) sound data indicative of the voice responses uttered by the user to the represented cues, said voice responses being captured utilizing both air and throat microphones, determine (114, 152, 154, 156, 158) on the basis of the sound data, the represented cues and voiceprints linked therewith and the existing user, whether the response has been uttered by the existing user of said number of users, wherein the sound data indicative of the voice responses uttered to the represented cues are preferably matched as concatenated against a concatenated voiceprint established based on the voiceprints linked with the represented cues and the existing user, and provided that this seems to be the case, elevate (116, 152, 200D, 218, 216) the authentication status of the user as the existing user, preferably regarding at least the current communication session. Related method and device (102c) are presented.

Owner:APLCOMP

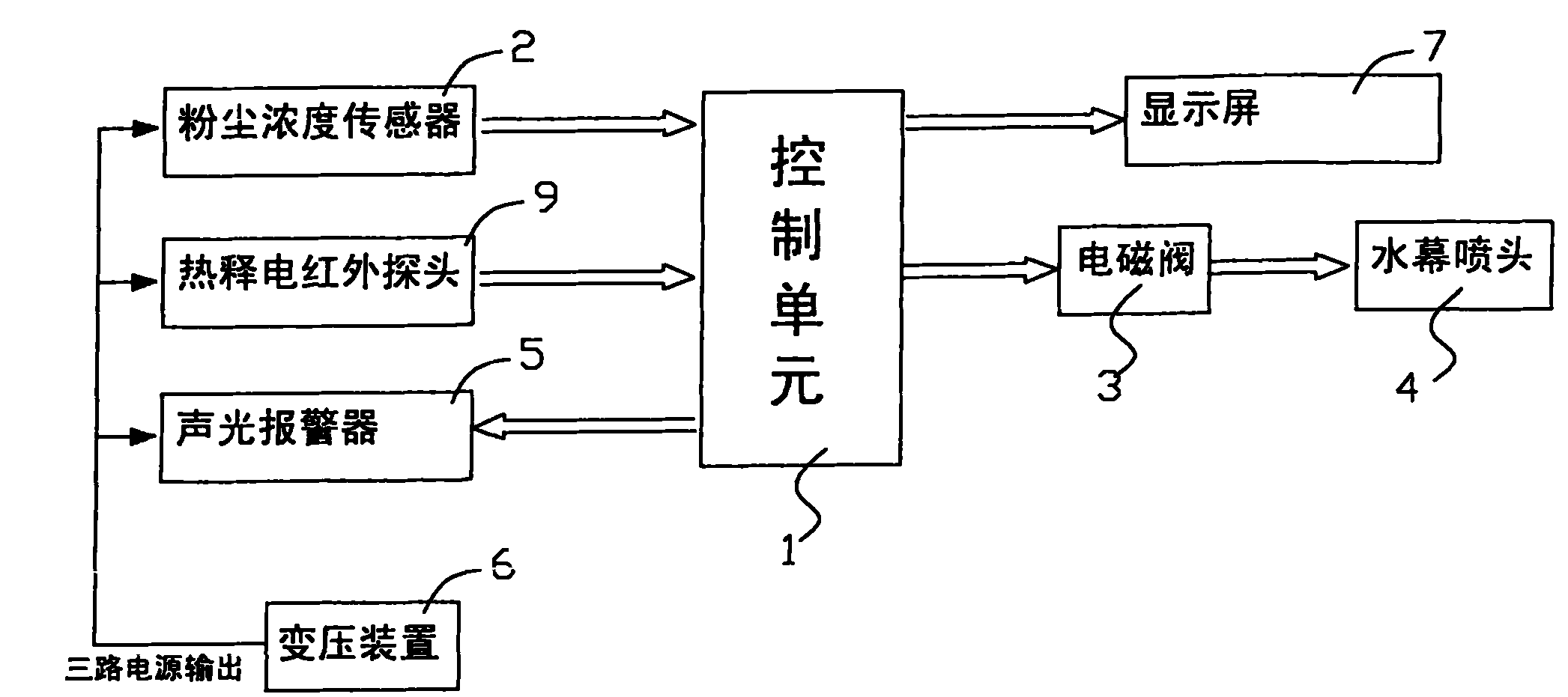

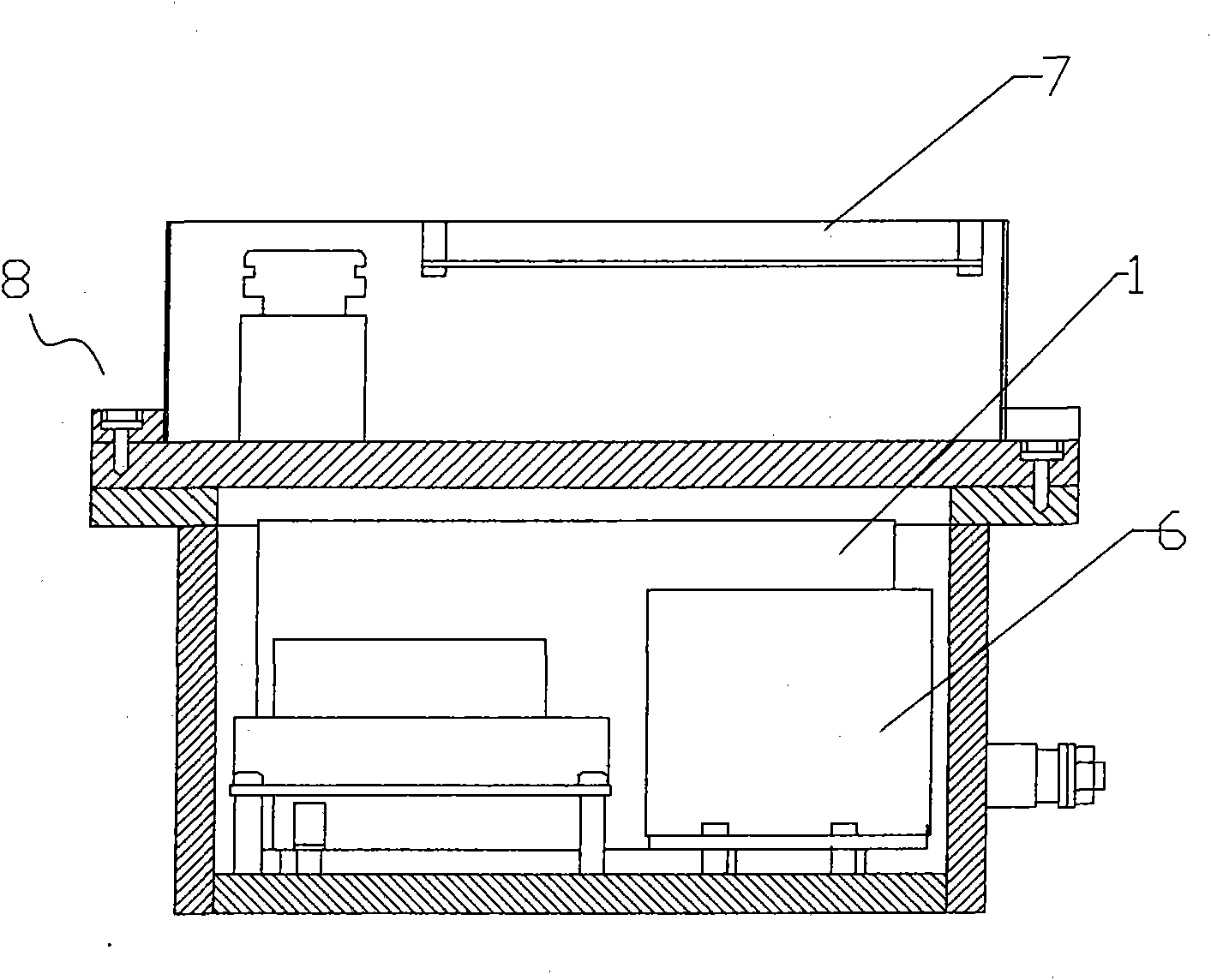

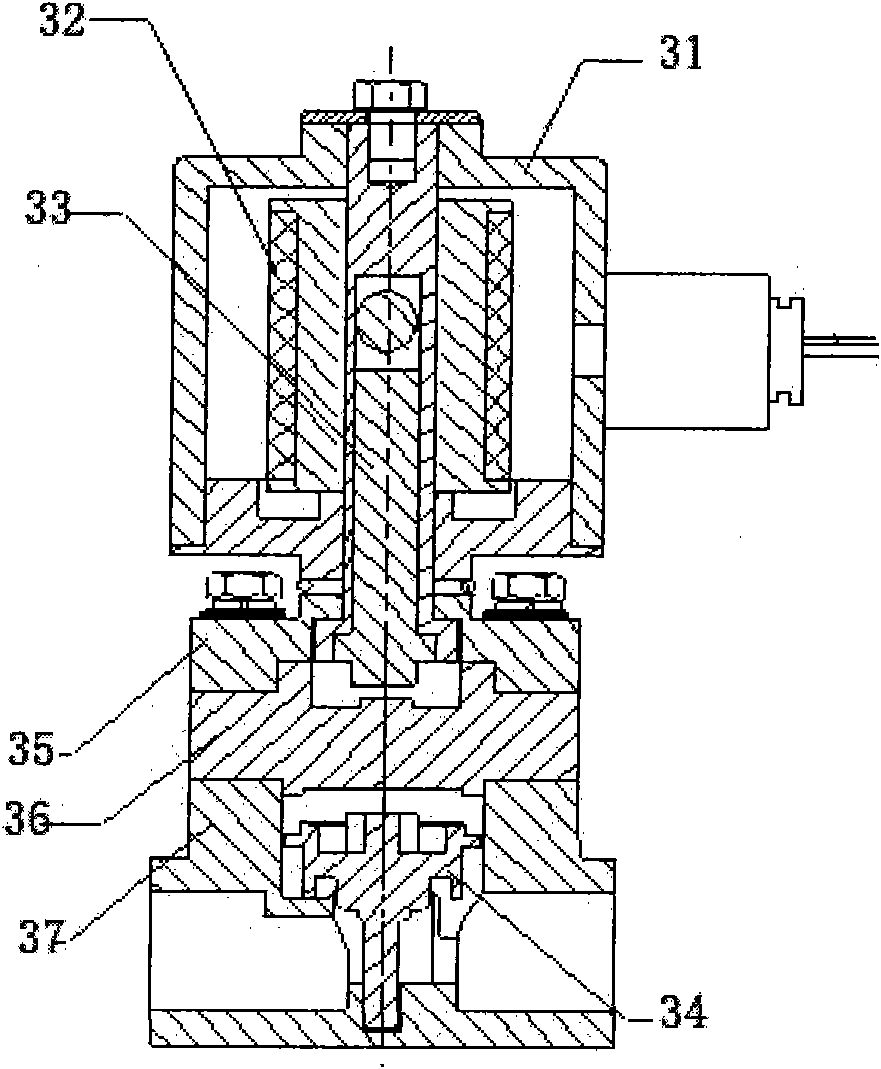

Intelligent dust concentration limit setting spray dust settling device, system and method

InactiveCN101915116AAvoid unnecessary wasteReduce Waterlogging ProblemsMining devicesDust removalLower limitControl signal

The invention discloses an intelligent dust concentration limit setting spray dust settling device. The device comprises a control unit, a dust concentration sensor, an electromagnetic valve and a sprinkler head, wherein the signal output end of the dust concentration sensor is connected with a signal input end of the control unit; a control signal output end of the control unit is connected with a control signal input end of the electromagnetic valve; and the control unit realizes spray control over the sprinkler head through the switching of the electromagnetic valve. In the device of the invention, the dust concentration limit is manually set; the spraying starts when the dust concentration limit exceeds an upper limit value and stops when the dust concentration limit is less than a lower limit value; and thus the meaningless waste of water resource is prevented, the water logging in roadways is reduced, the working conditions are improved and the health and the safety of mine workers are ensured. In addition, the invention also discloses an intelligent dust concentration limit setting spray dust settling system, so the remote on-line monitoring of the dust concentration can be realized; meanwhile, the invention also discloses an intelligent dust concentration limit setting spray dust settling method.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Full-automatic material packaging production line based on sleeved type inner-outer bags and packaging method of full-automatic material packaging production line

InactiveCN107380547ACompact structureReliable actionWrapper twisting/gatheringPackaging automatic controlProduction lineEngineering

The invention discloses a full-automatic material packaging production line based on sleeved type inner-outer bags and a packaging method of the full-automatic material packaging production line. The full-automatic material packaging production line comprises a bag fetching and bagging rack, a bag storage table, a bag storage box, a bag clamping and expanding rack, a machine frame, a material platform, an automatic packaging scale, a belt conveyor, a heat-seal bottom plate and a bag sewing device, and further comprises a bag fetching mechanism, a bag arranging mechanism, a bag folding mechanism, a bag clamping mechanism, a bag opening adjusting mechanism, a bag opening mechanism, a bagging mechanism, a rotating mechanism, an outer bag protecting and conveying mechanism, another bag clamping mechanism, a bag expanding mechanism, a bag sealing mechanism, a discharge hopper powdered-sugar sealing device, an air squeezing mechanism, an inner bag transferring mechanism, an opening heat-seal mechanism, an opening cooling sealing mechanism, an outer bag suction cup mechanism, a mechanism for placing the inner bag into the outer bag, and a sewing guide device. By means of the production line, the inner film bag of the sleeved bags can be loaded with small granular materials and then subjected to opening heat-sealing, and opening of the inner film bag of the sleeved bags can also automatically be disposed into the outer woven bag opening. Therefore, the invention further provides an automatic packaging method using the full-automatic material packaging production line.

Owner:GUANGXI RES INST OF MECHANICAL IND

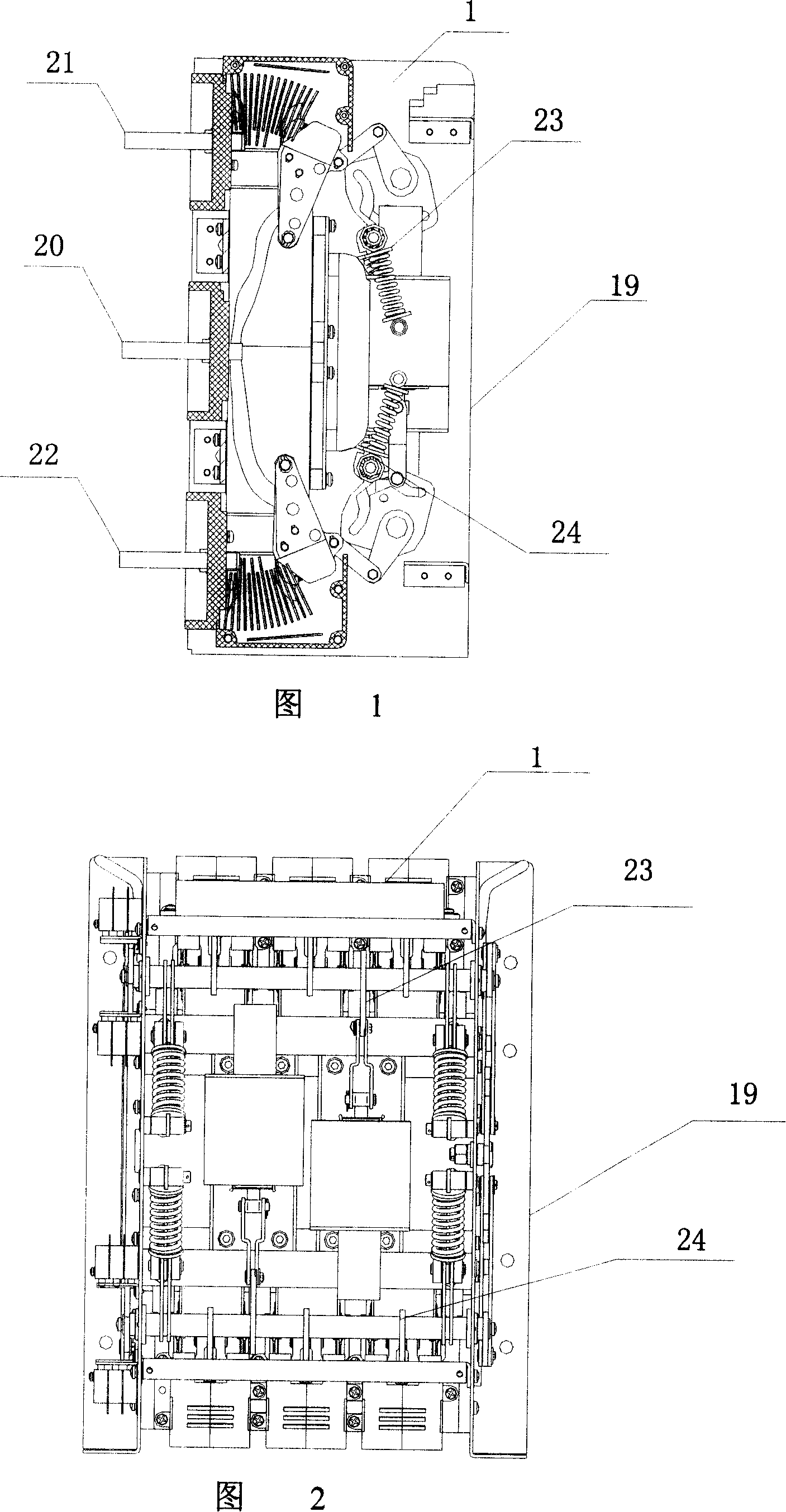

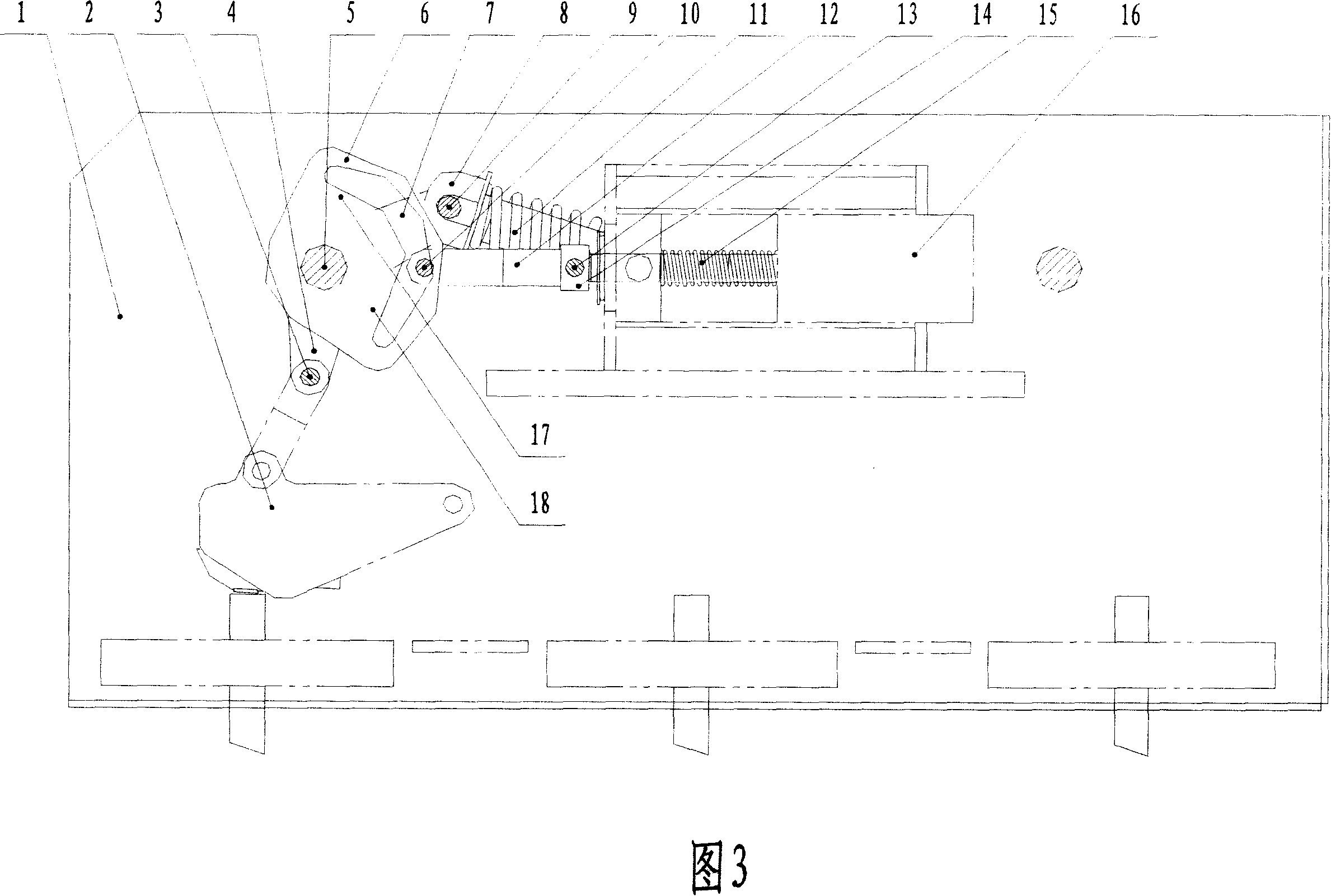

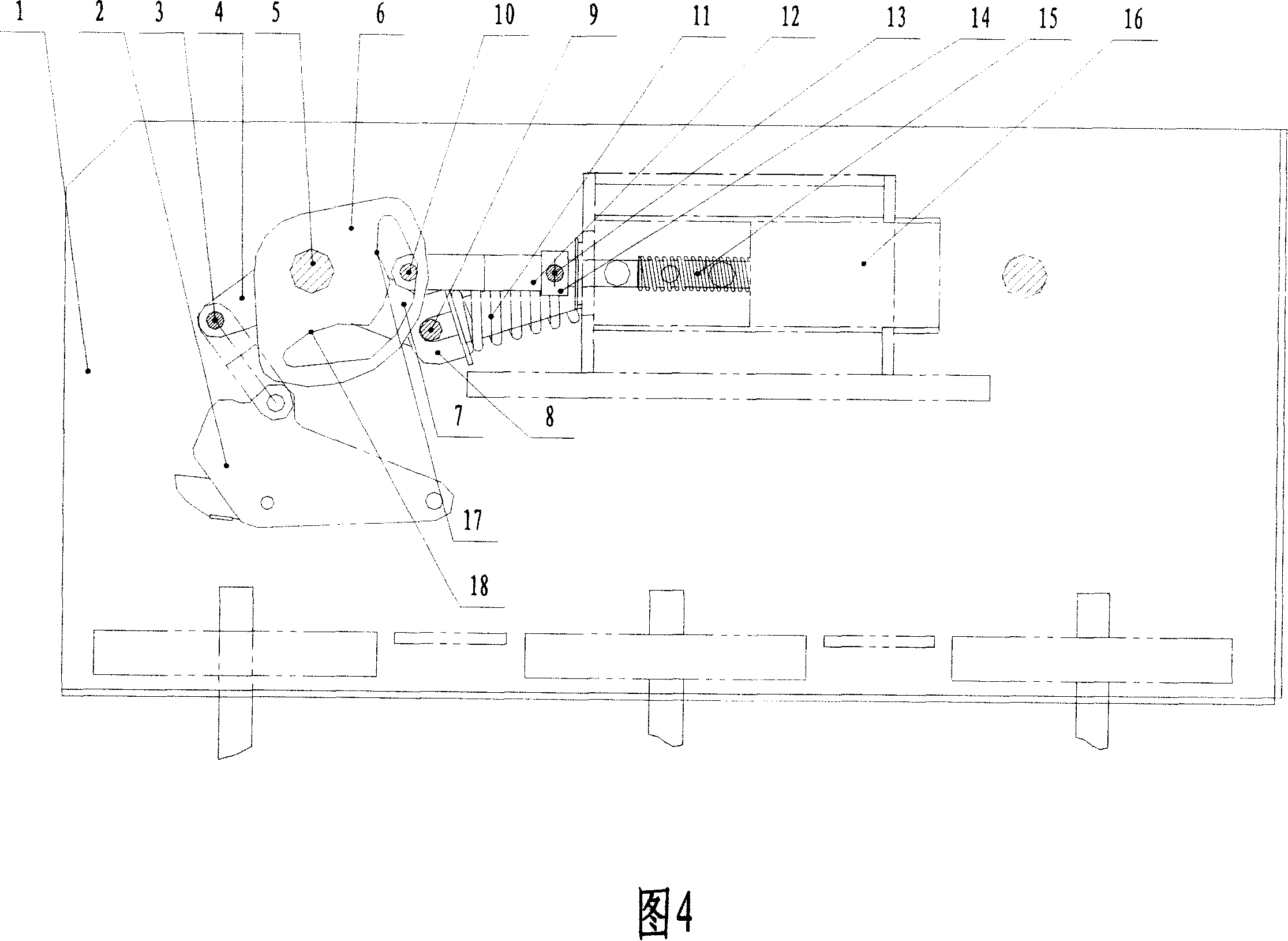

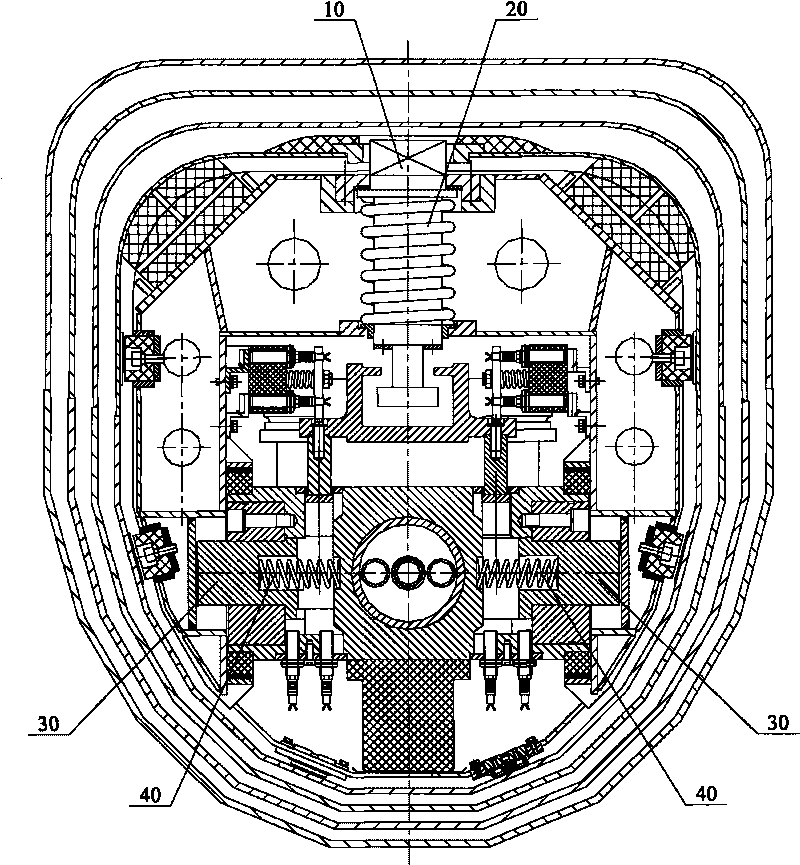

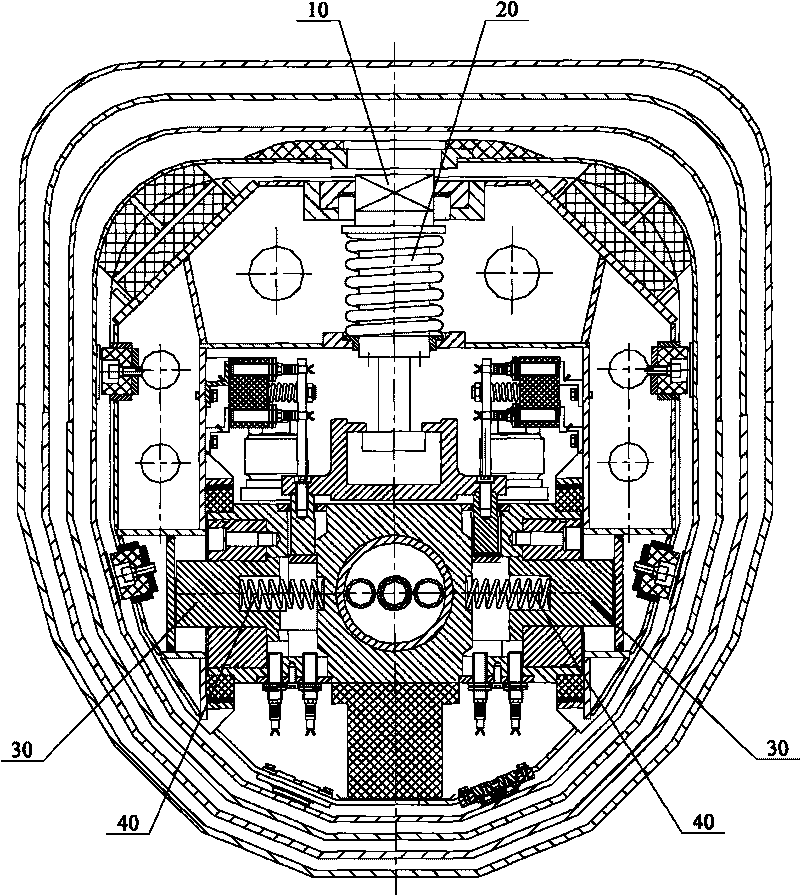

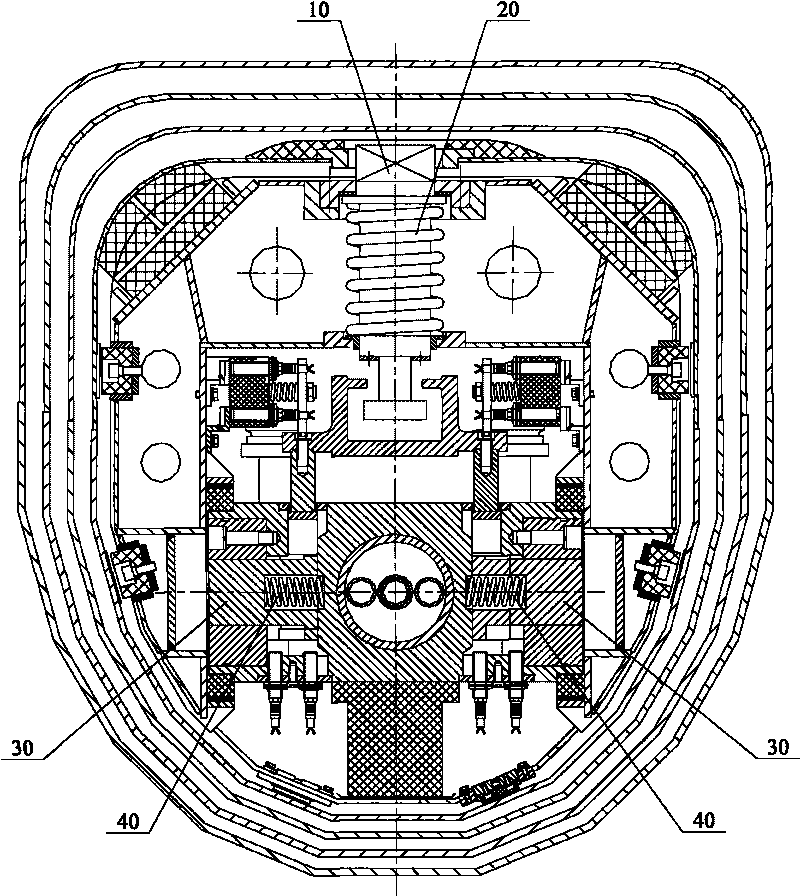

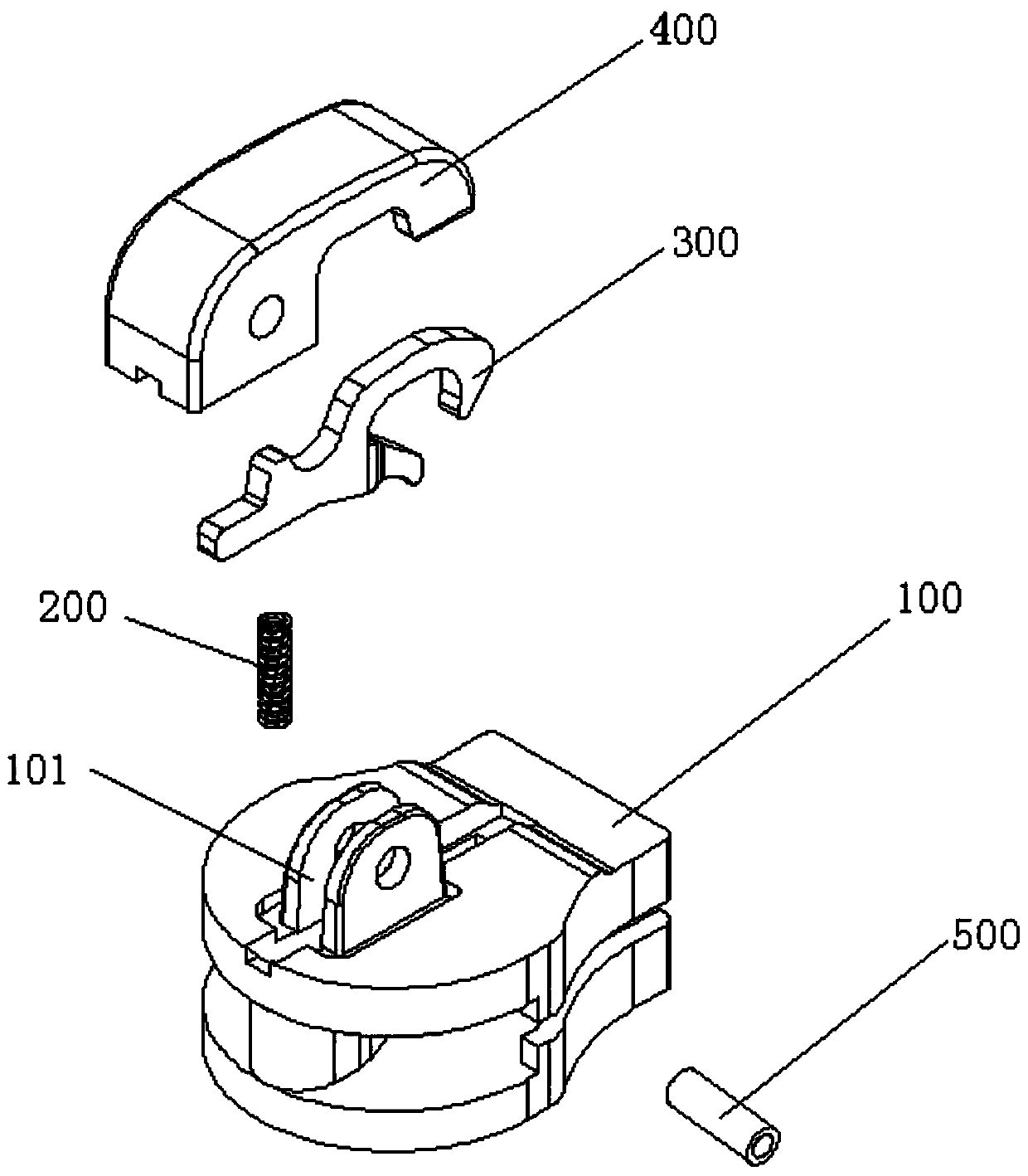

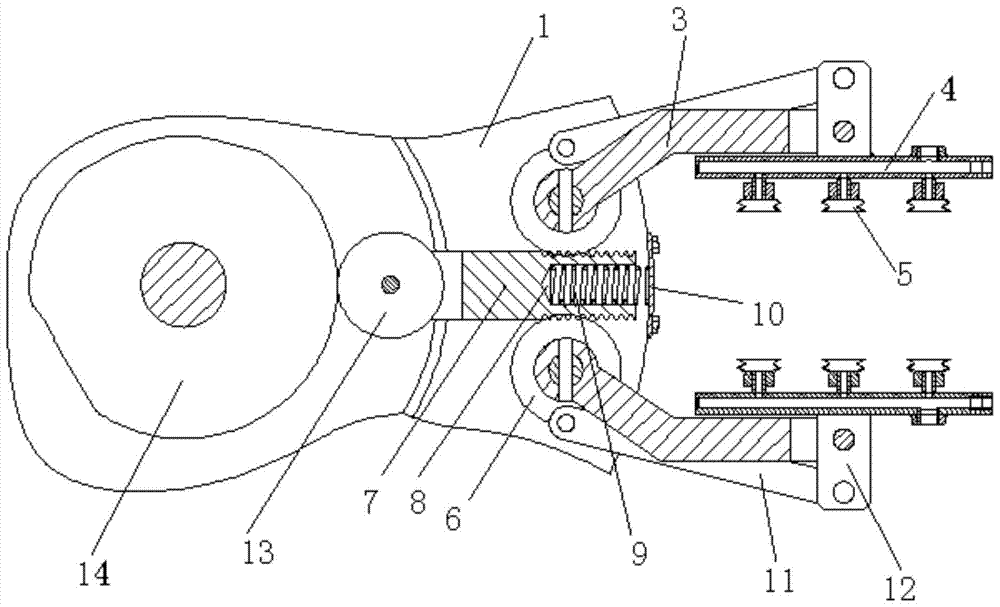

Automatic conversion switch electrical appliance

InactiveCN101127278APrevent Simultaneous ClosingRealize the chainContact driving mechanismsSwitch power arrangementsEngineeringContact Transmission

The utility model relates to an automatic change-over switch electric appliance, comprising a housing; wherein, a load wiring terminal, a first power end and a second power end are arranged on the housing; an automatic change-over apparatus, which comprises a first movable contactor operated with the first terminal, a second movable contactor operated with the second terminal, is arranged inside the housing; the first movable contactor and the second movable contactor are electrically connected with the load wiring terminal; the automatic change-over apparatus also comprises a mounting plate and the first movable contact transmission, mechanism and the second movable contactor transmission mechanism positioned on the mounting plate. The utility model provides an automatic change-over electric appliance, which has the advantages of simple structure, precise inverting, stable and reliable the apparatus motion, and excellent security.

Owner:NINGBO QILE ELECTRIC APPLIANCE TECH

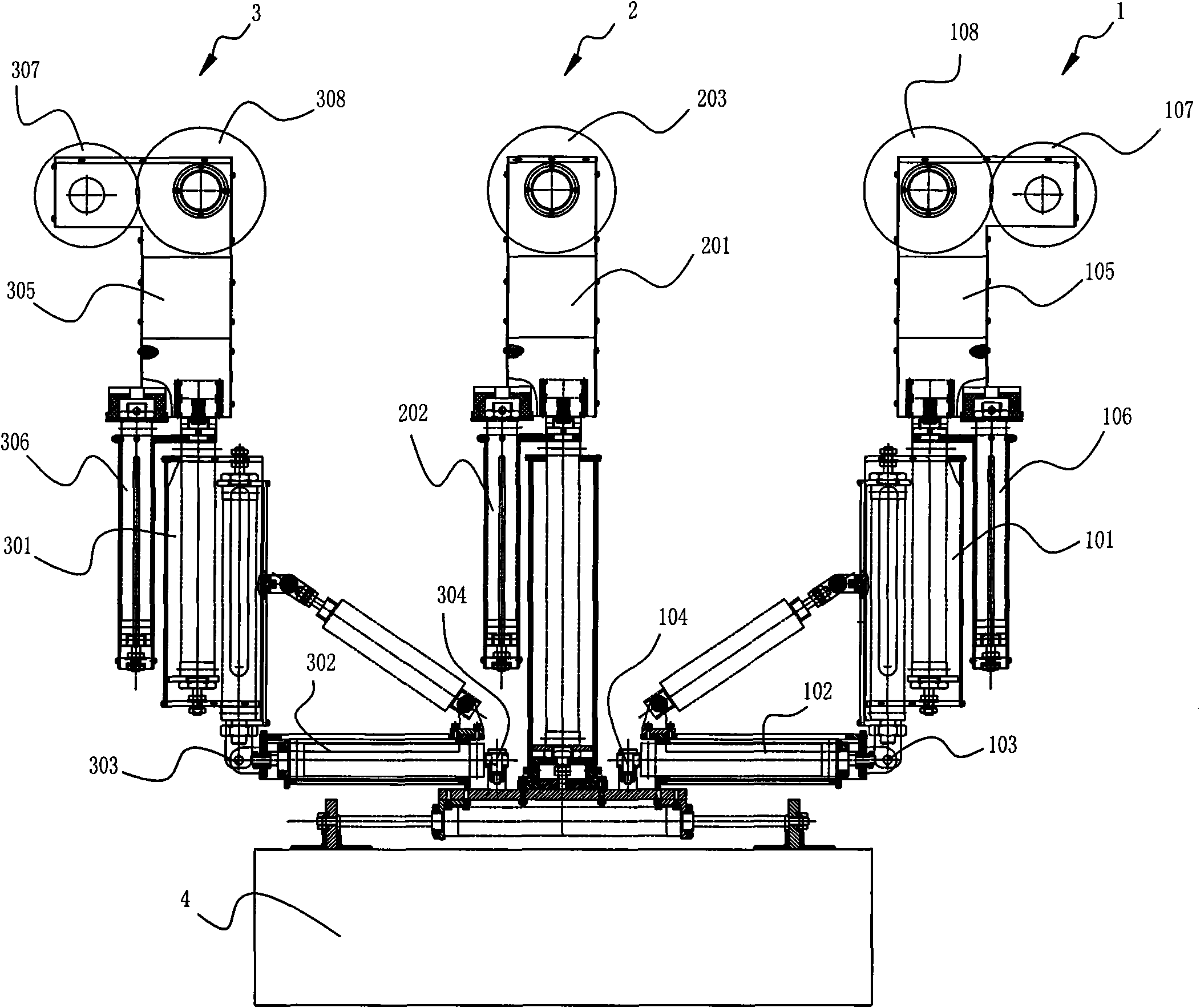

Novel structure of deicing robot based on pneumatic type electric transmission line

InactiveCN101938095AReduce weightIncrease working spaceOverhead installationApparatus for overhead lines/cablesControl engineeringGravity center

The invention discloses a novel structure of a deicing robot based on a pneumatic type electric transmission line, comprising a forearm unit, a middle arm unit, a rear arm unit and a gravity center adjustment balance mechanism, wherein the forearm unit, the middle arm unit and the rear arm unit are sequentially connected with the gravity center adjustment balance mechanism positioned below the forearm unit, the middle arm unit and the rear arm unit; the forearm unit and the rear arm unit are symmetrically arranged; the forearm unit comprises a stacked type mechanical arm mechanism, a travelling driving mechanism, a deicing mechanism, a palm opening and closing mechanism and a brake braking mechanism; the middle arm unit comprises a vertical type telescopic arm mechanism, the travelling driving mechanism, the palm opening and closing mechanism and the brake braking mechanism; and the rear arm unit is the same as the forearm unit in structure and comprises a pneumatic control loop which enables the forearm unit, the middle arm unit and the rear arm unit to take telescopic actions, travelling actions, obstacle detouring actions and deicing actions and takes compressed air as a power source. The invention can complete the deicing operation, the on-line stable travelling and high-efficiency autonomous obstacle detouring under the conditions of intelligent control and has the advantages of compact structure, light weight, easy control, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

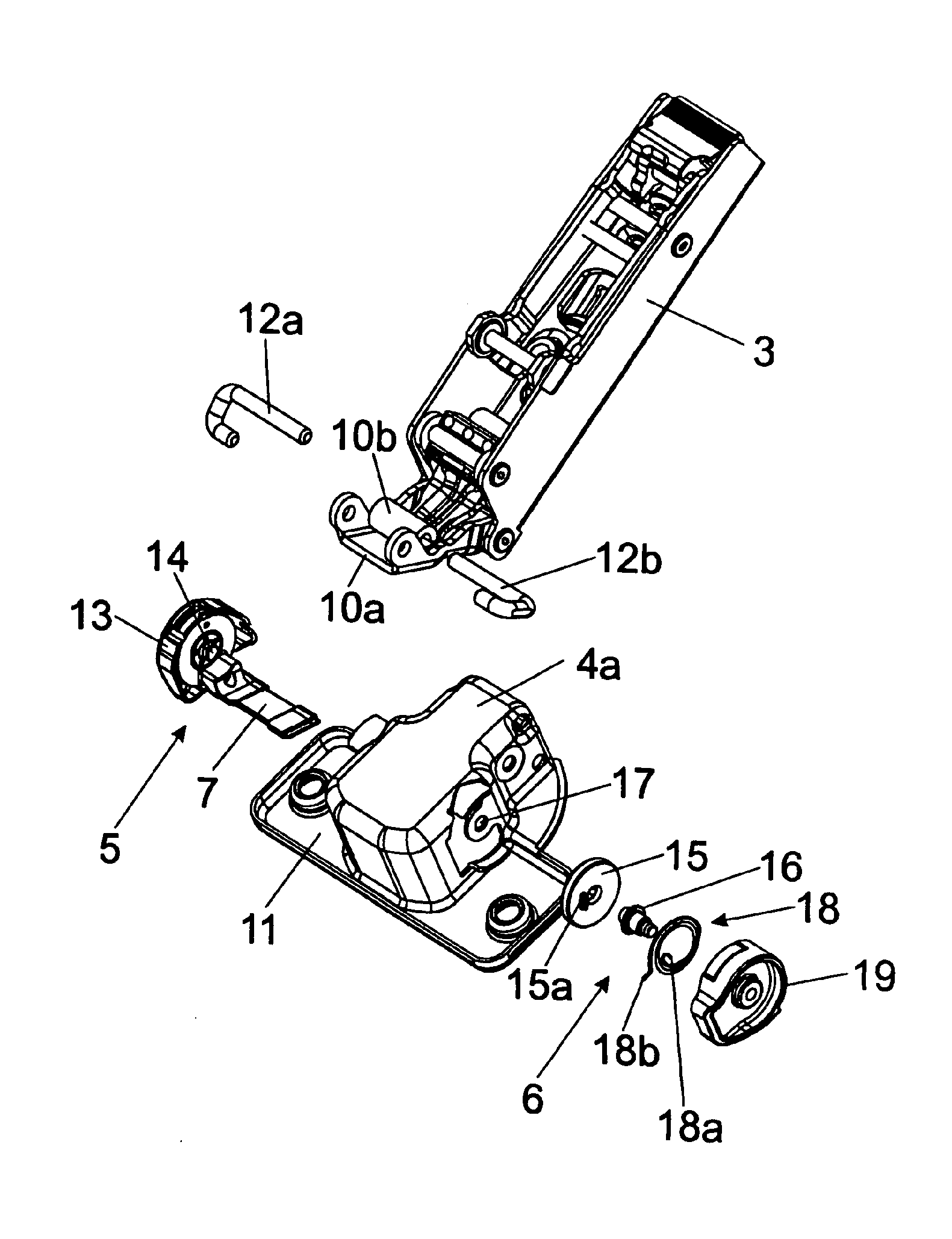

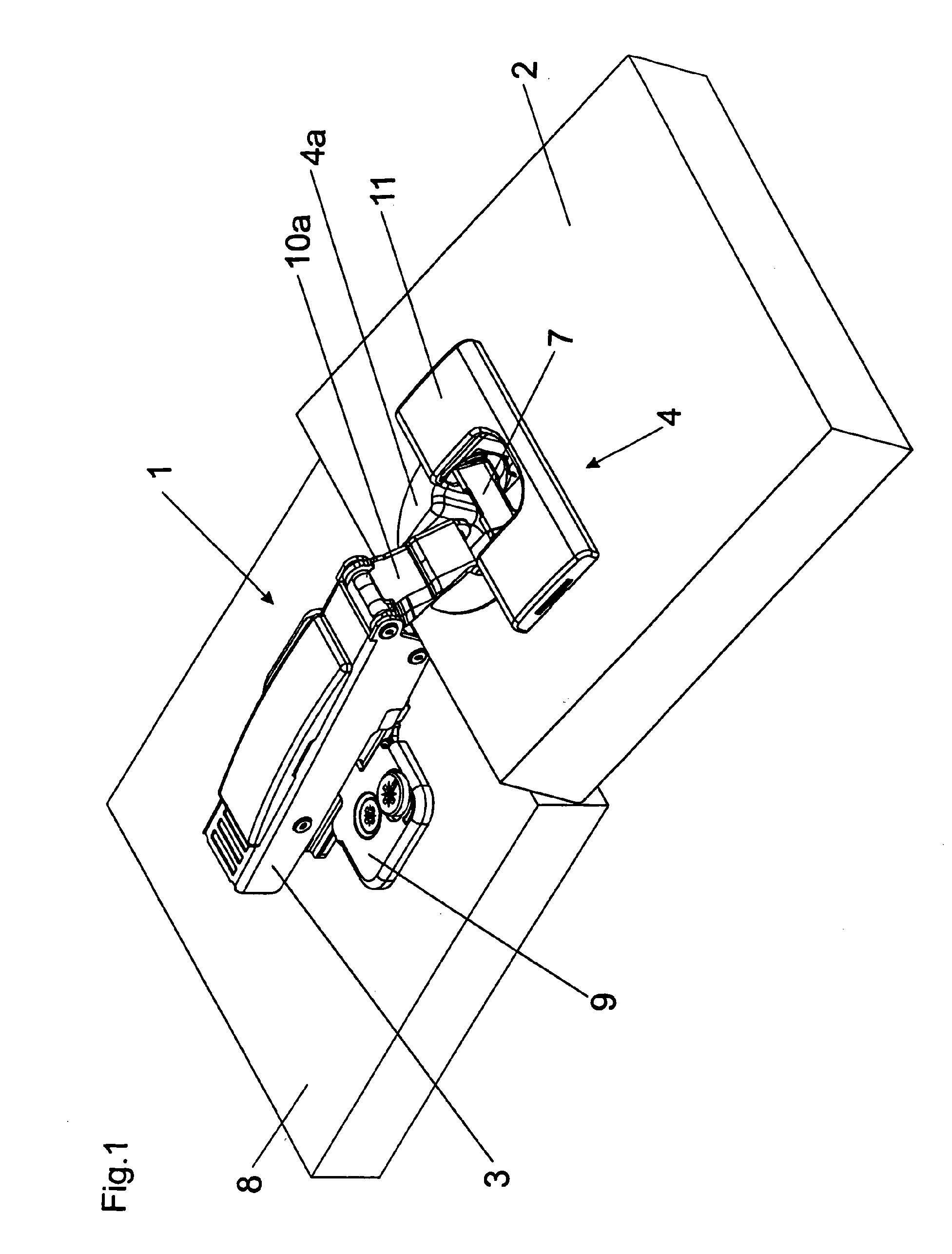

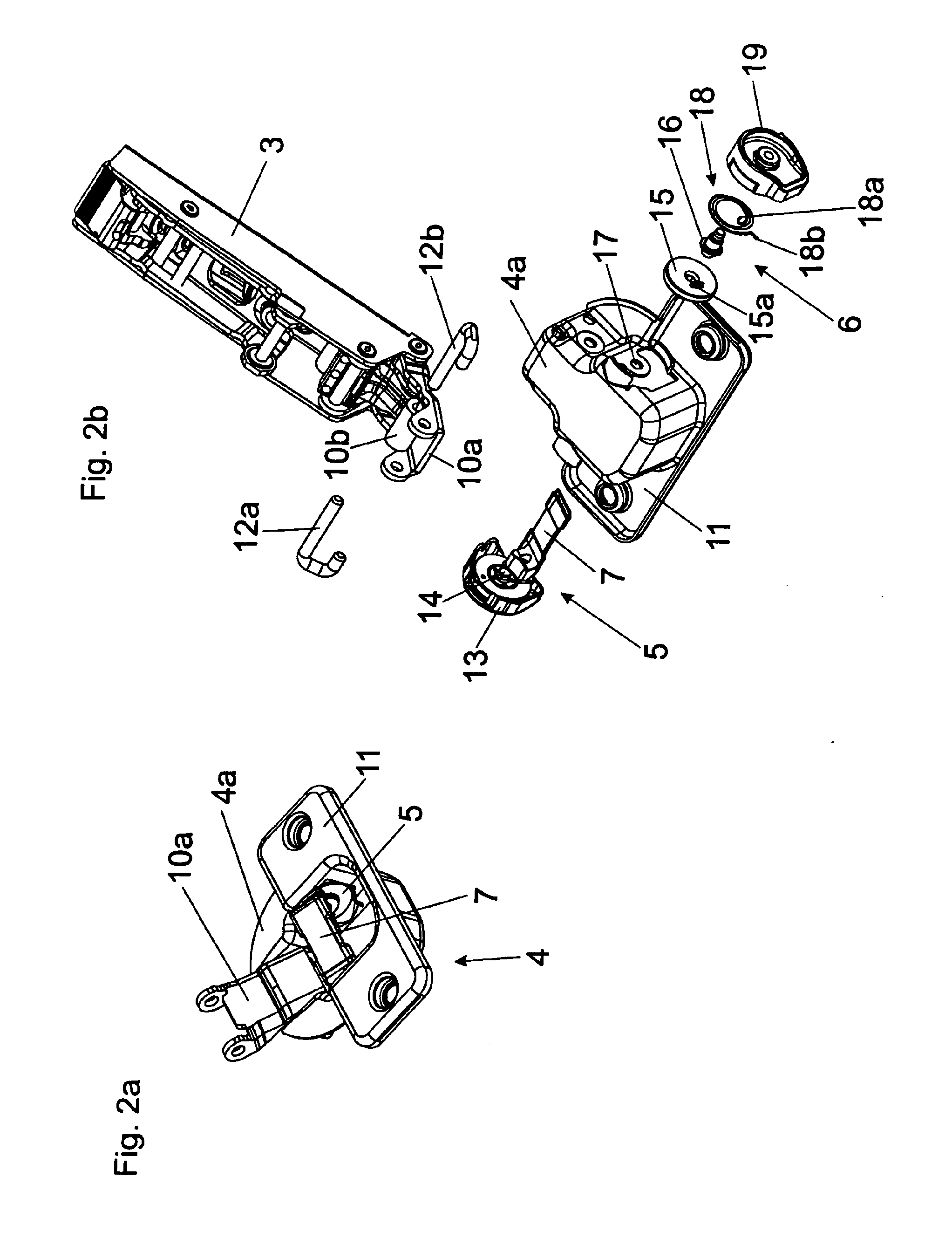

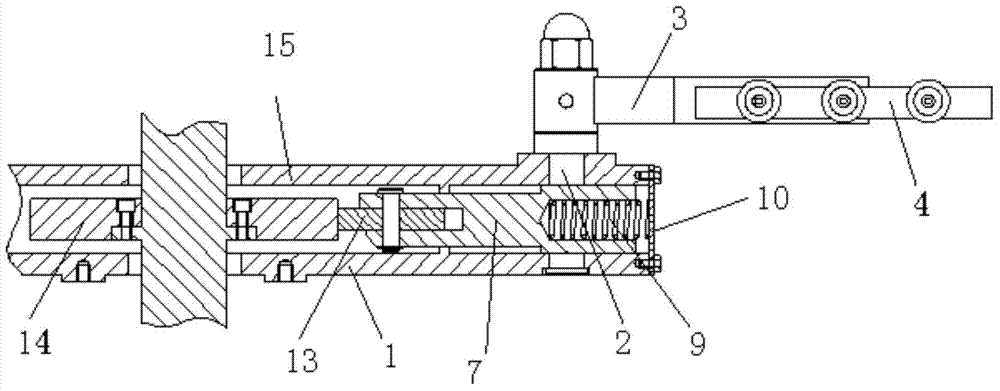

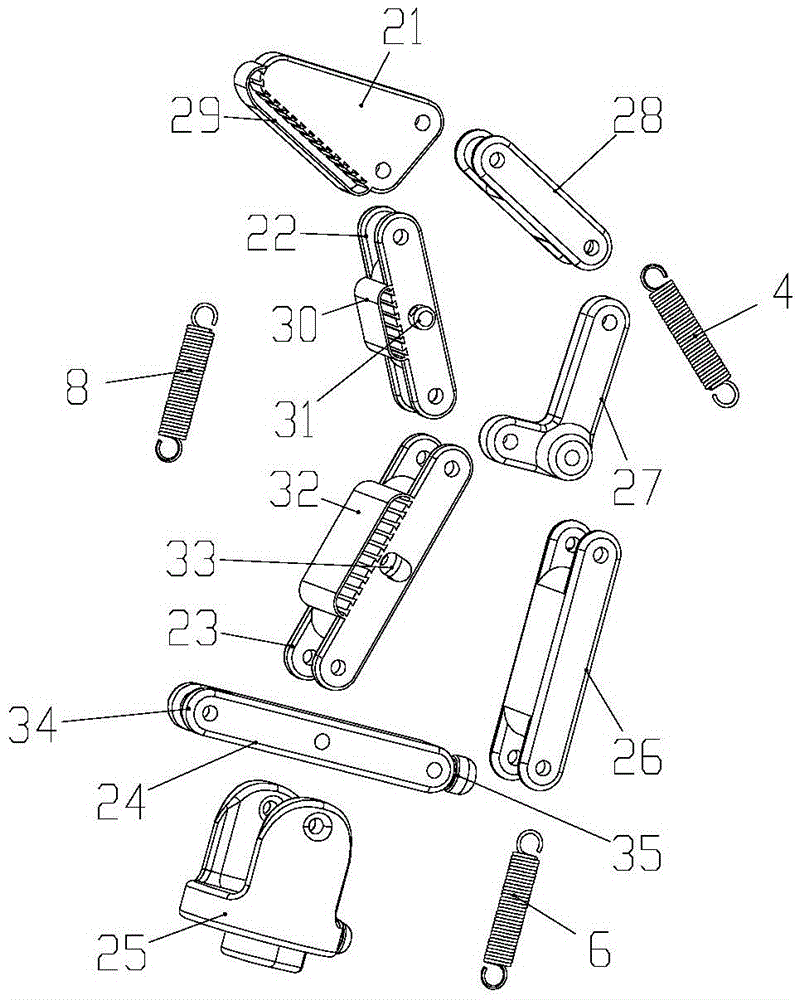

Hinge having a damping device

ActiveUS7966696B2Reliable damping actionReliable actionBuilding braking devicesHingesEngineeringMechanical engineering

A hinge, particularly for movable pieces of furniture, has at least two stop parts connected in an articulated manner (which is to say a hinge arm and a hinge cup) for fastening to pieces of furniture. The hinge has a damping device for damping the hinge movement, and has a restoring mechanism, by which an actuating element of the damping device can be moved into a starting position for the next damping stroke after damping has taken place. The damping device and the restoring mechanism are disposed as separate components on the hinge cup. The damping device, which has no restoring mechanism, is disposed on a lateral wall of the hinge cup, and the restoring mechanism is disposed on an opposing lateral wall of the hinge cup.

Owner:JULIUS BLUM GMBH

Control system of telescopic boom bolt mechanism

The invention discloses a control system of a telescopic boom bolt mechanism, which comprises an oil tank, a hydraulic pump, a motor and a second directional control valve which are arranged on a telescopic boom, wherein the oil tank is used for storing hydraulic oil; the hydraulic pump is used for outputting the hydraulic oil in the oil tank into a hydraulic circuit; the motor is used for driving the hydraulic pump; and the second directional control valve is used for controlling the route between the hydraulic circuit and the hydraulic pump or the oil tank to be turned on. Preferably, the control system also comprises a third one-way valve, an energy accumulator and a pressure relay; when a pressure value detected by the pressure relay is more than a preset maximum pressure value, the pressure relay outputs control signals to the motor, and the motor is switched off; and when a pressure value detected by the pressure relay is less than the maximum pressure value, the pressure relay outputs control signals to the motor, and motor is switched on. The system has simple and reasonable design, and can effectively avoid the problem that hydraulic volume in a large chamber influences the control response speed, so as to ensure the sensitive and reliable motions of an arm pin hydro cylinder and a cylinder pin hydro cylinder.

Owner:XUZHOU HEAVY MASCH CO LTD

Automatic assembly machine for cooling fins and transistors

InactiveCN103317321AImprove work efficiencyReduce manufacturing costMetal working apparatusLocking mechanismEngineering

The invention discloses an automatic assembly machine for cooling fins and transistors. The automatic assembly machine comprises a workbench, a multi-station rotary table mechanism adopting a cam indexer, an automatic screw locking mechanism, an automatic nut feeding mechanism, an automatic crystal feeding mechanism, an automatic glue printing mechanism and an automatic blanking mechanism. The automatic assembly machine is characterized in that circulation of tooling is achieved through a multi-station index plate, and different products are produced only through replacing the tooling. Manual arrangement of the cooling fins, automatic feeding of nuts and crystals, automatic glue printing, automatic locking of screws and automatic blanking can be achieved. The automatic assembly machine has the advantages that the structure is stable, the production efficiency is high, the labor intensity is greatly reduced, and the production efficiency is improved.

Owner:SUZHOU ASILAN AUTOMATION SCI & TECH

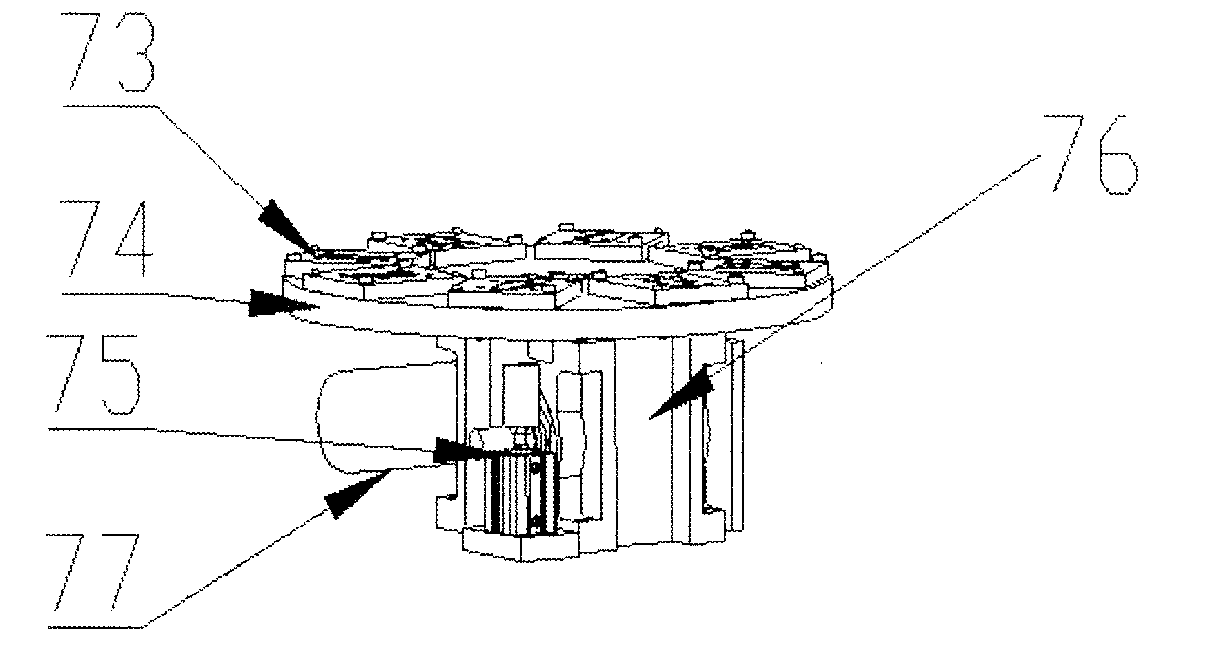

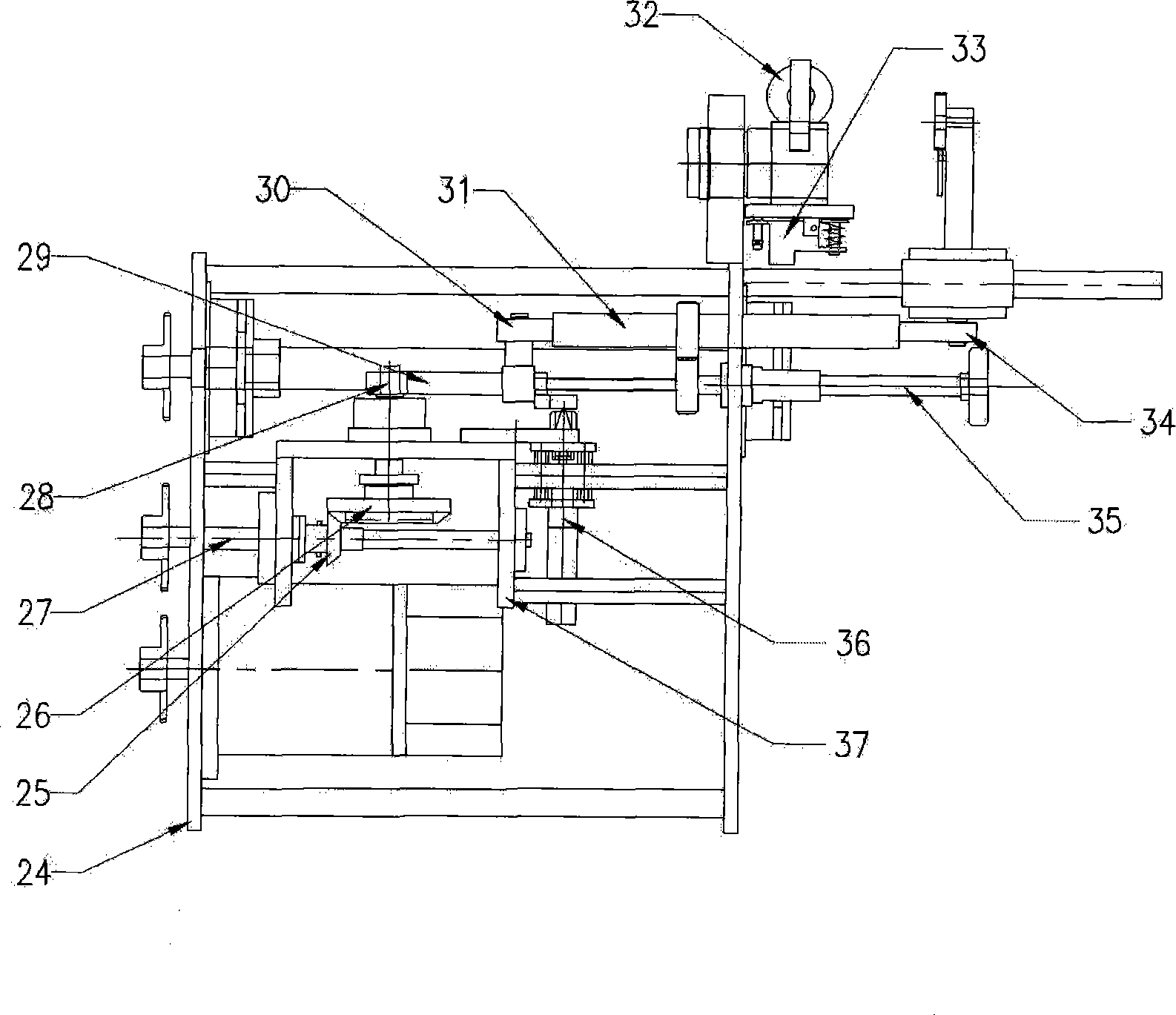

Automatic all-purpose zipper head assembly machine

ActiveCN103445407AGuaranteed smooth assemblyGuaranteed smooth productionSlide fastenersPunchingEngineering

The invention provides an automatic all-purpose zipper head assembly machine. The automatic all-purpose zipper head assembly machine comprises a machine base, wherein a power transmission device is arranged in the machine base; a rotary disc and a pressure disc are mounted above the machine base; the power transmission device not only enables the rotary disc to perform graduation intermittent rotation, but also enables the pressure disc to perform lifting movement; molds for placing a pull head are uniformly distributed on the periphery of the rotary disc; work station devices corresponding to the stop positions of the molds are fixed on the pressure disc or the table surface of the machine base; the work station devices include a feeding device, a detection device, a riveting device and a material returning device. The automatic all-purpose zipper head assembly machine is characterized by further comprising a burr removing device in front of the copper tube feeding device, and the burr removing device is formed by a cap cover pressing and fixing device mounted on the pressure disc and a punching device mounted on the table surface of the machine base. The automatic all-purpose zipper head assembly machine can automatically complete multi-wall pin penetrating all-purpose zipper head assembly, and is reliable in movement and high in production efficiency; in addition, the automatic all-purpose zipper head assembly machine is simple in structure and easy to debug and maintain, and lowers equipment cost.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

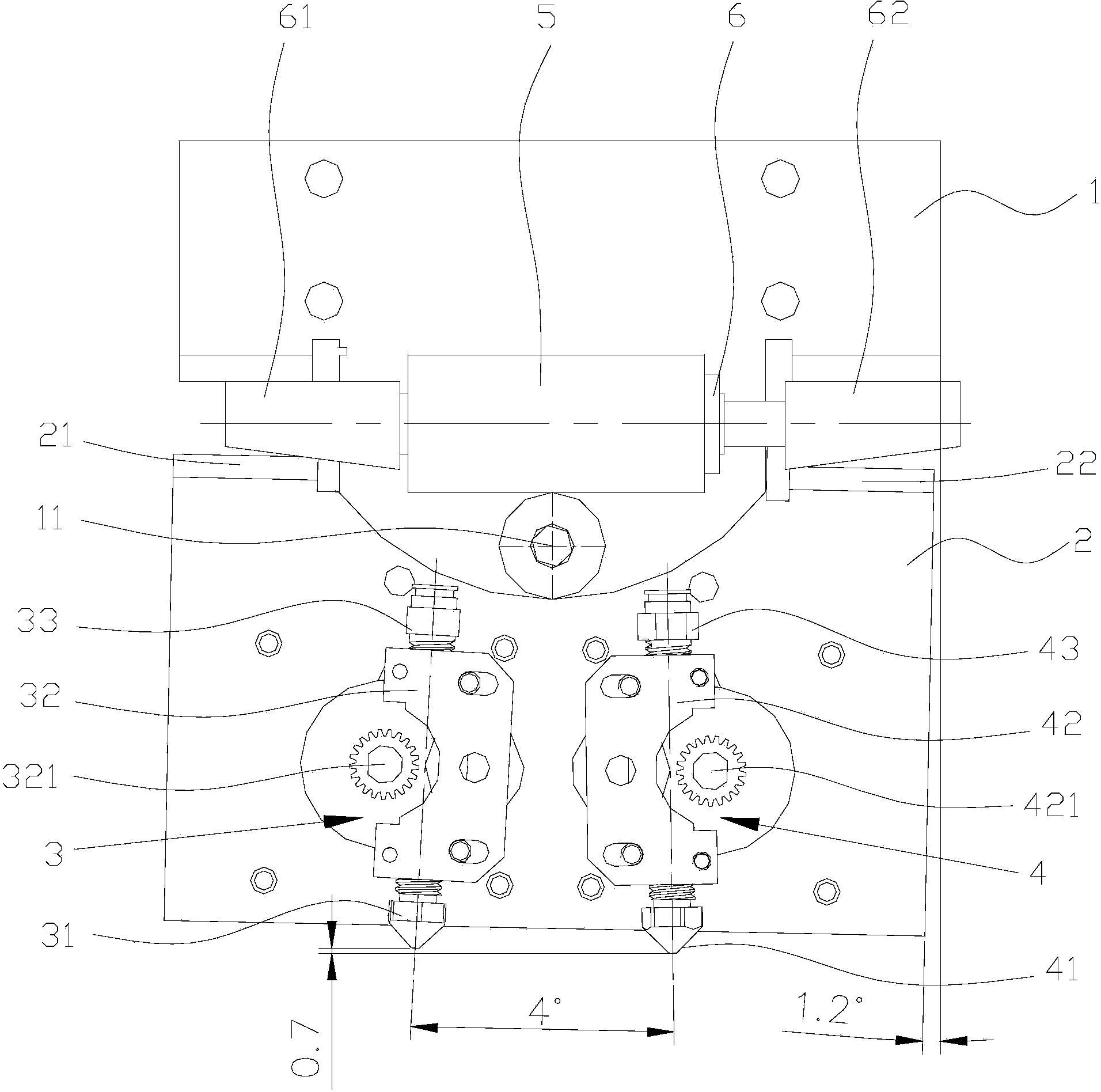

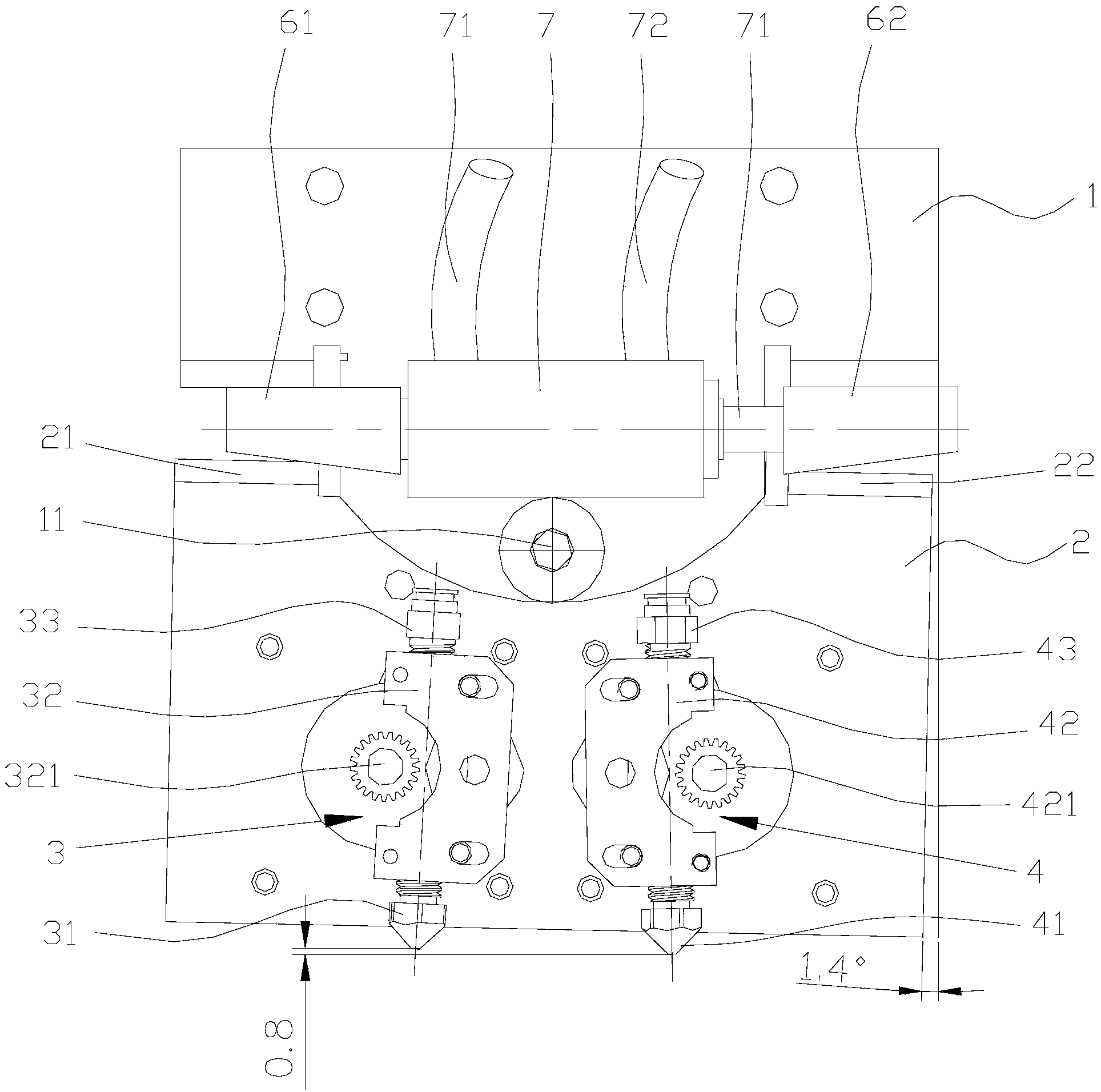

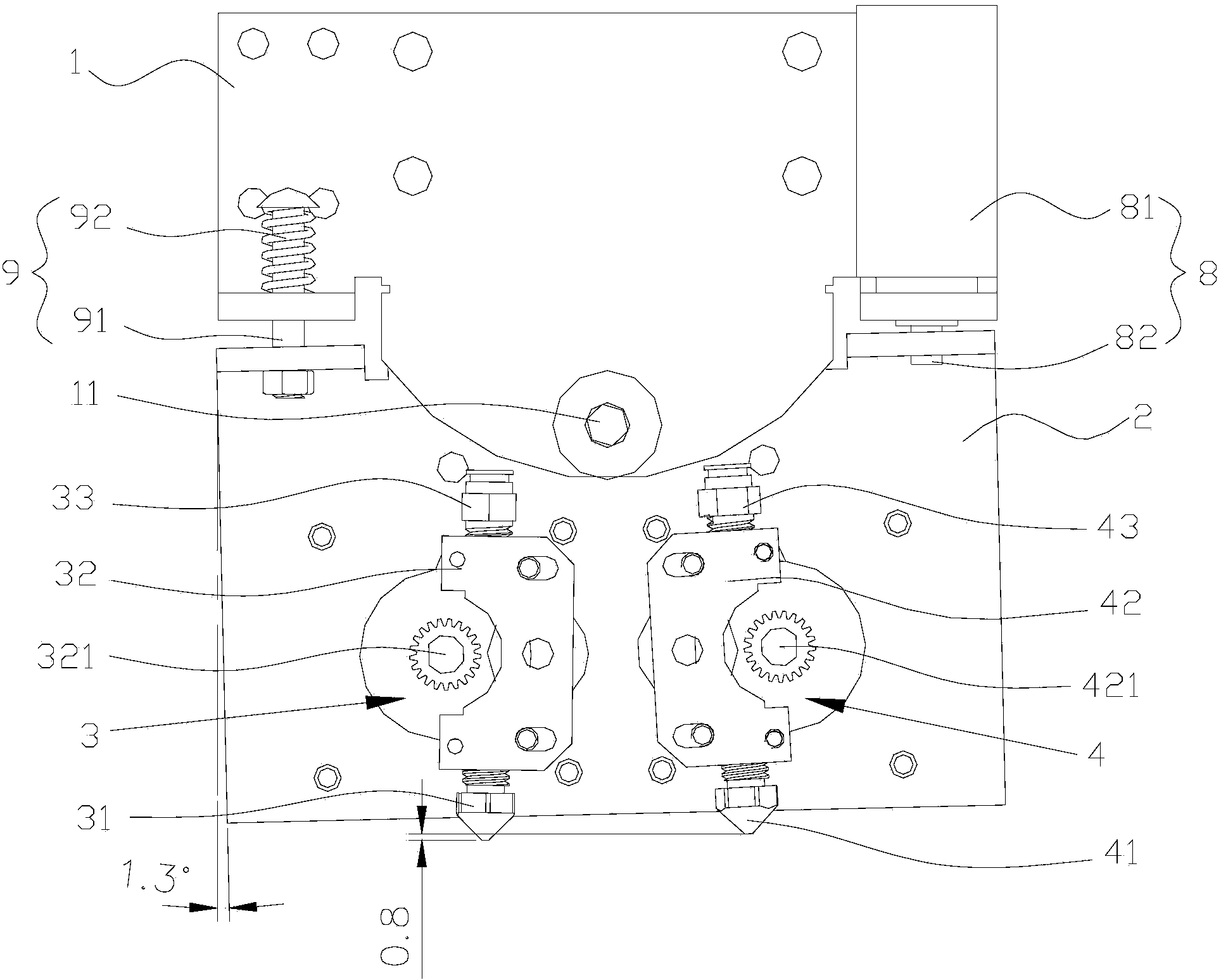

Dual-head 3D printer capable of rotatably switching printing heads

ActiveCN104228069AGuaranteed heightOvercoming problems with being at the same heightEngineering3d printer

Owner:苏州江南嘉捷光机电技术有限公司

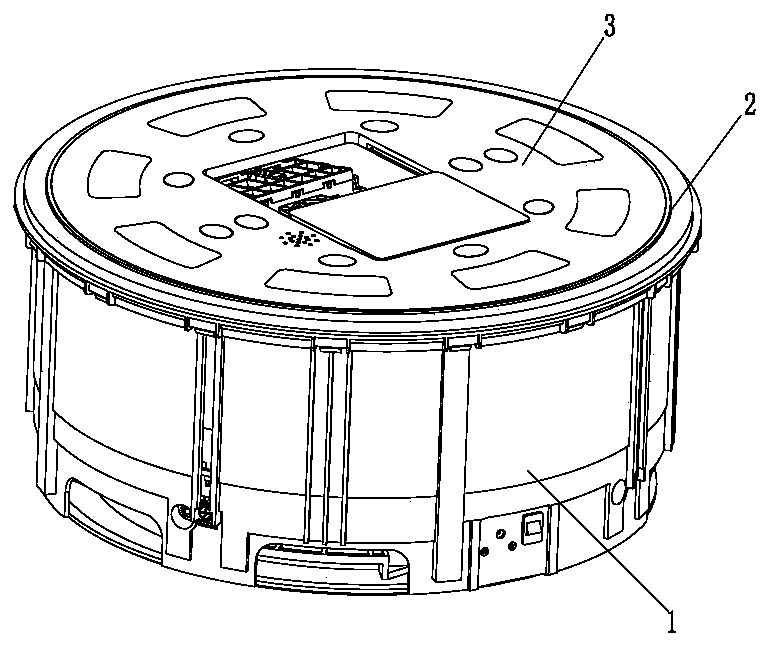

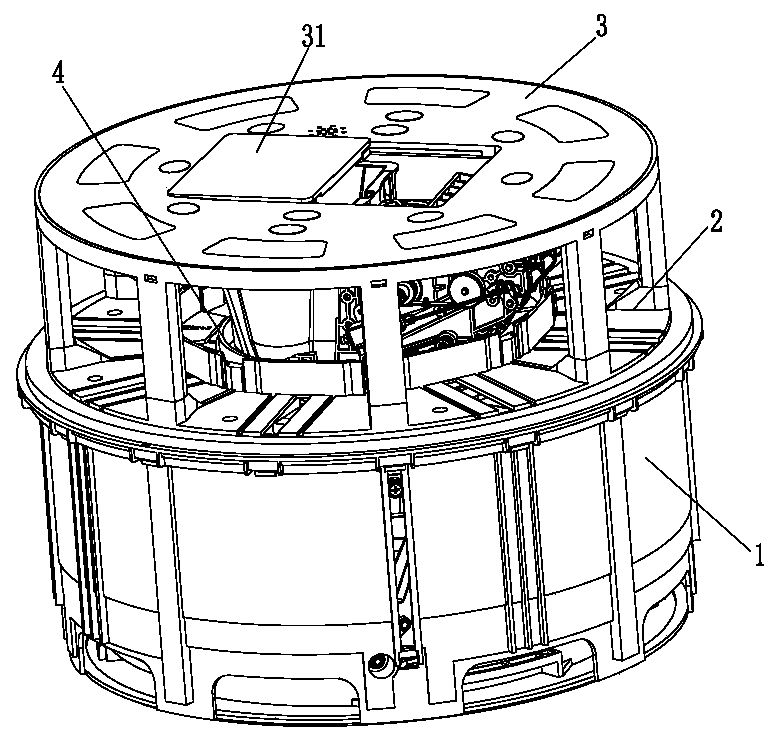

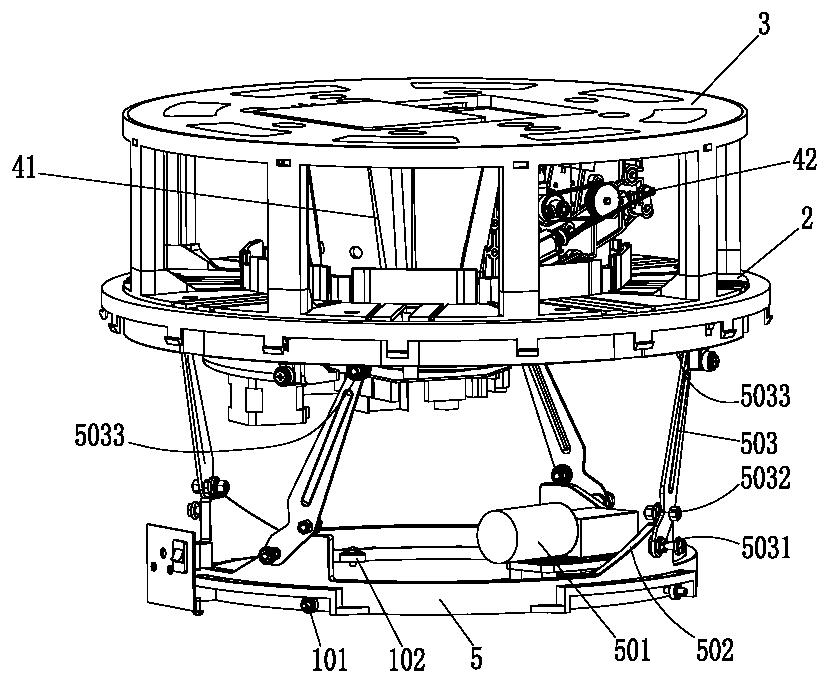

Poker machine and poker card arrangement method thereof

ActiveCN110193184ASimple structureReliable actionCoin-freed apparatus detailsCard gamesDrive wheelInlet channel

The invention discloses a poker machine. The poker machine comprises a base and a machine core. The machine core is mounted on the base or in the base. The machine core comprises a card receiving seatand a card distributing device. The machine core is driven by a machine core lifting driving mechanism to ascend and descend on the base. The card distributing device is mounted in the center of thecard receiving seat and is driven by a rotary driving mechanism to rotate relative to the card receiving seat. The card distributing device comprises a card storage box, a card distributing mechanismand a conveying mechanism. The card receiving seat is provided with a plurality of card receiving positions around the card distributing device. Channels used for the passing of playing cards inside the card distributing device comprise a card inlet channel, a conveying channel and a first card outlet channel which are sequentially connected. The card distributing mechanism is mounted at the cardinlet channel of the card distributing device. The conveying mechanism is installed at the conveying channel of the card distributing device. The card outlet of the first card outlet channel is provided with a card outlet wheel and a first card outlet pressing wheel of the card outlet wheel. The card outlet wheel is a driving wheel and is in transmission connection with the card distributing device. The first card outlet pressing wheel matched with the card outlet wheel for card distributing device is a driven wheel.

Owner:浙江承驰科技有限公司

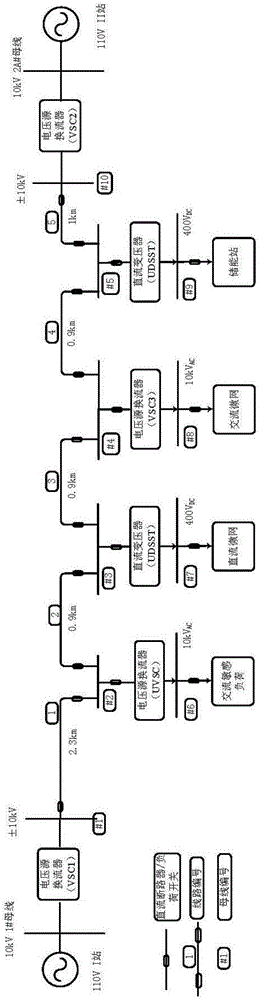

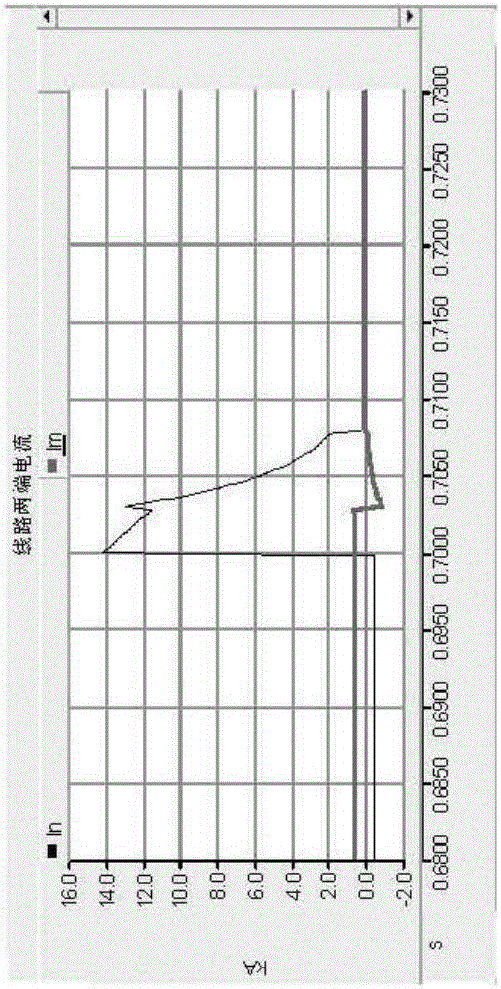

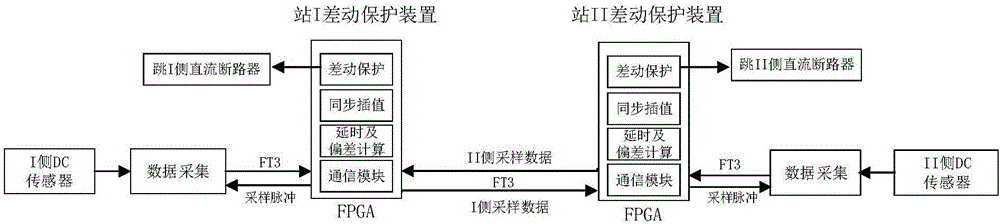

Differential protection system and differential protection method for flexible DC distribution network line

ActiveCN106099879AHigh data time synchronizationAccurately capture transient componentsEmergency protective circuit arrangementsTransmission time delayData acquisition

A differential protection system and a differential protection method for a flexible DC distribution network line are provided. An FPGA-based protection device sends a sample pulse to a data collector. To achieve synchronized sampling and data window synchronization, line dual-end protection devices are arranged as a reference end and a following end respectively. The following end firstly sends a synchronization request command including a number of a sample and a corresponding time of the sample. The reference end returns information including a sample number and a corresponding sample time of the reference end after receiving the command sent by the following end. After receiving a corresponding data message of the reference end, the following end calculates a communication transmission time delay and a deviation between the sample times of the two sides. Through compensation of the communication transmission time delay and a secondary interpolation sampling synchronization method, synchronized sampling of the following end and the reference end is achieved. Through calculating the differential current of two ends of a direct current line, the method determines whether differential current protection criteria are satisfied and achieves differential protection of the direct current line. The system and the method can ensure correct actions on internal faults and correct non-actions on external faults.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

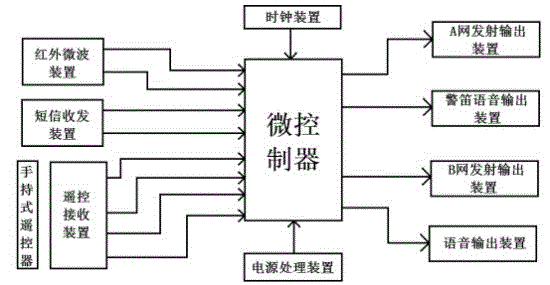

Anti-intercepting net shooting device

InactiveCN104422340AReliable actionEasy to useWeapons typesBurglar alarm short radiation actuationVIT signalsMicrowave

The invention discloses an anti-intercepting net shooting device, which comprises a microcontroller. The anti-intercepting net shooting device is characterized in that the input end of the microcontroller is respectively connected with the output ends of a remote receiving device, a message receiving device, an infrared microwave device, a power source processing device and a clock device, the other end of the microcontroller is respectively connected with a transmitting output device of a net A, a whistle voice output device, a transmitting output device of a net B and a voice output device, the microcontroller is an eight-bit single chip microprocessor, the output ends of the remote receiving device are four signal output ends, the remote receiving device is in wireless connection with a handheld remote controller, the message receiving device is provided with two signal output ends, and the infrared microwave device is provided with two signal output ends. The anti-jacking transmitting net device has the advantage that one complete set of integral control, monitoring and communication system is adopted, so the action is reliable, and the repeated use is easy.

Owner:XIAN SIKUN ELECTRONICS SCI & TECH

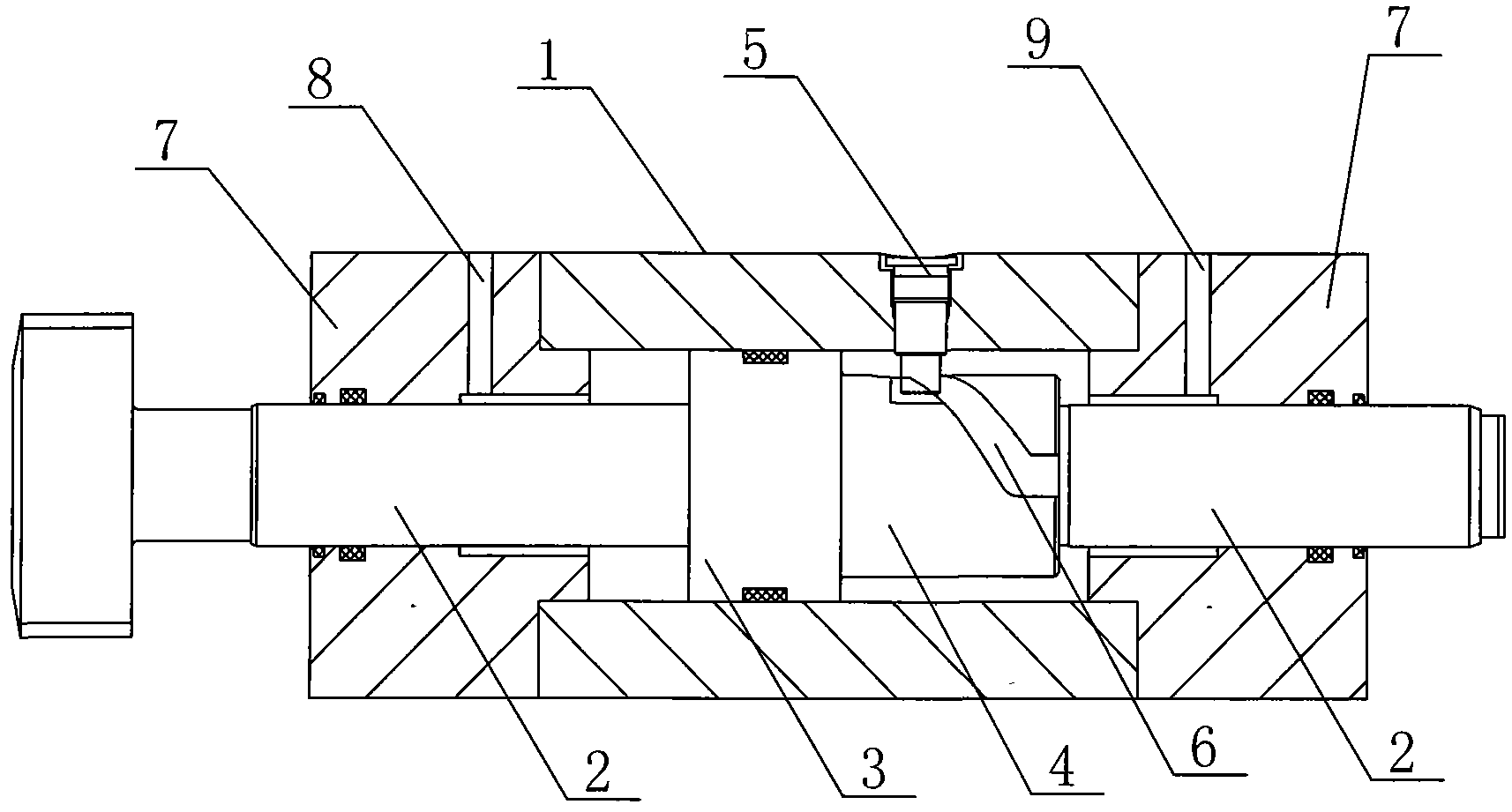

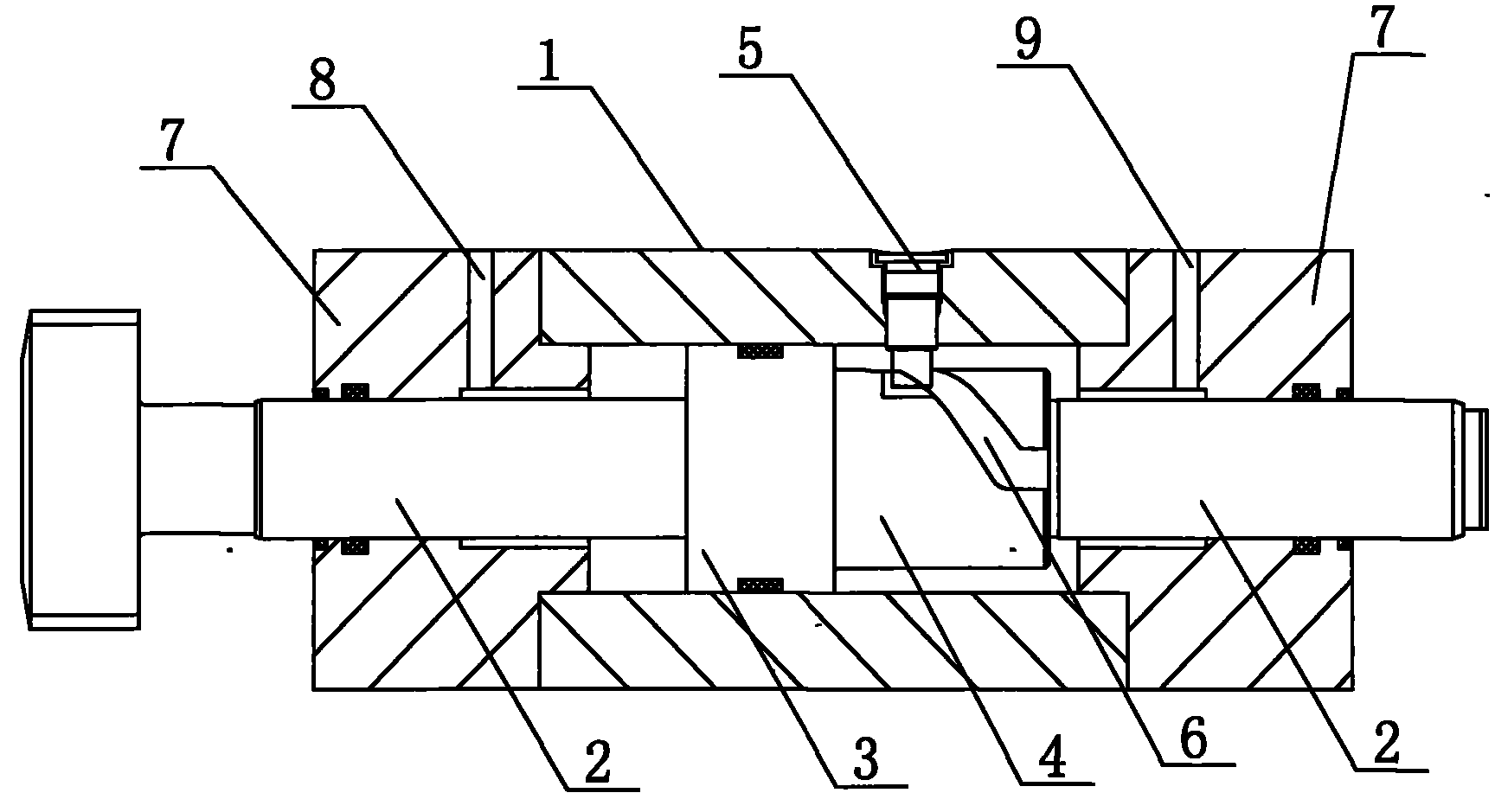

Telescopic-swivel hydraulic cylinder

ActiveCN102322457ASimple structureReliable actionFluid-pressure actuatorsEngineeringEconomic benefits

The invention discloses a telescopic-swivel hydraulic cylinder comprising a cylinder body, a piston and piston rods, wherein the piston rods are arranged at two sides of the piston, a swivel guiding device is arranged between the piston rod on at least one side of the piston and the cylinder and comprises a spiral guiding groove arranged on the piston rod, a limiting plug screw is fixed on the inner wall of the cylinder, matched with the spiral guiding groove and clamped in the spiral guiding groove and can slide along the spiral guiding groove. In the telescopic-swivel hydraulic cylinder, the spiral guiding groove and a limiting pin which are matched with each other are additionally arranged between the piston rod and the cylinder; when the piston rod of the hydraulic cylinder performs rectilinear motion, the limiting pin clamped in the spiral guiding groove is used for driving the piston rod to swivel synchronously so that the piston rod swivels while performing the rectilinear motion. The telescopic-swivel hydraulic cylinder has the advantages of simple structure, reliable action, omittance of an additional mechanism required by completing compound actions, reduction of expenses and improvement of economic benefits.

Owner:无锡市长江液压缸有限公司

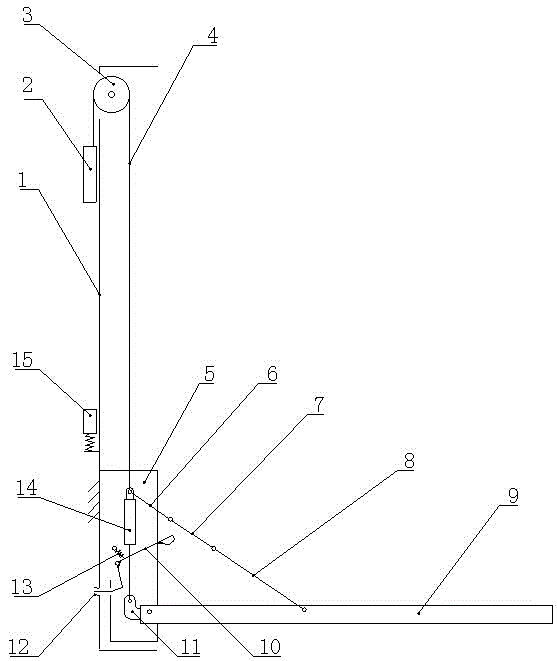

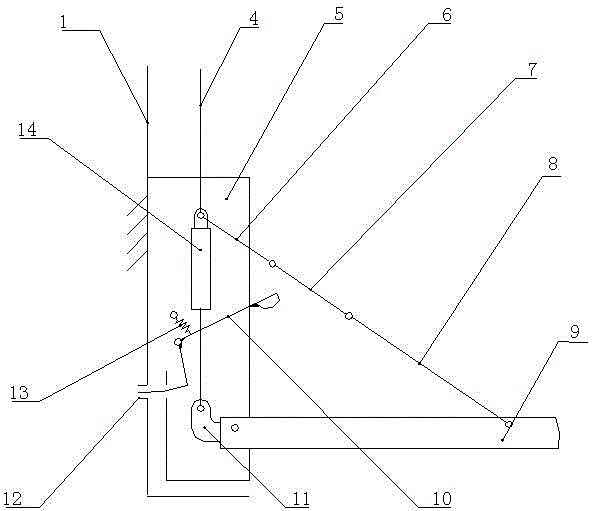

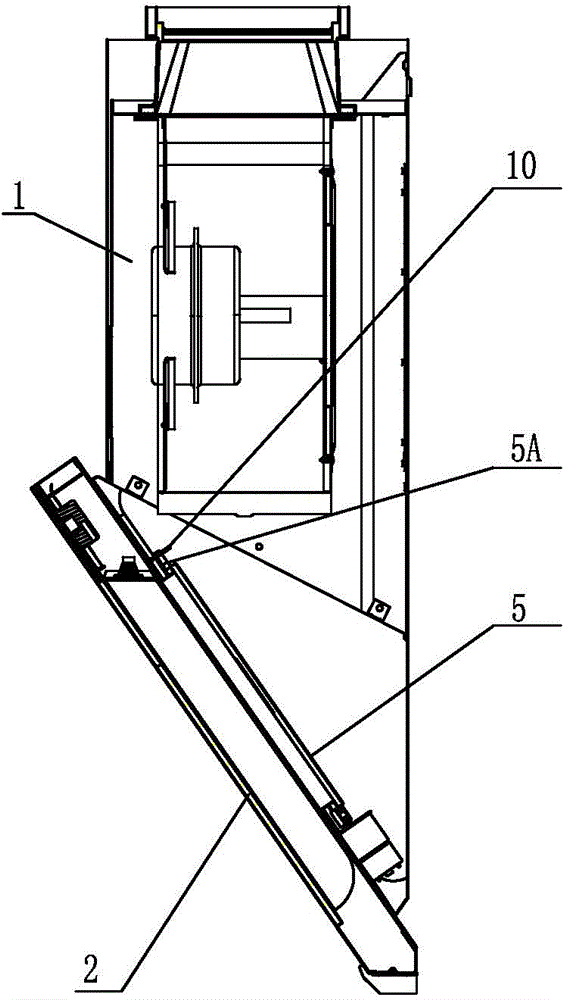

Double-deck parking device

The invention relates to a double-deck parking device which comprises a plurality of lifting devices arranged side by side and lower-deck parking frames (30) arranged among the adjacent lifting devices. Each lifting device comprises a vertical stand column (1). The tops of the stand columns (1) are provided with fixed pulleys (3). One end of each steel wire rope (4) wound on the corresponding fixed pulley (3) is provided with a balance weight (2) in a hanging mode. The other end of each steel wire rope (4) is connected with a lifting body (5). The lifting bodies (5) are horizontally connected with upper-deck parking frames (9) in the transverse direction. The double-deck parking device is simple in structure and convenient to operate.

Owner:JIANGYIN POLYTECHNIC COLLEGE

M-shaped packaging bag opening mechanism

The invention discloses an M-shaped packaging bag opening mechanism, which comprises a rotary master disc, wherein the front end of the rotary master disc is rotatably provided with two corresponding swing arm spindles; the upper ends of the swing arm spindles are respectively provided with a swing arm; the front ends of the swing arms are respectively provided with a sucking disc seat; the lower ends of the swing arms are respectively provided with a gear; a rack respectively meshed with the two gears is arranged between the gears; a guide hole is arranged in the front end of the gear; a spring is installed in the guide hole; a connecting plate is arranged between the gear and the sucking disc seat; one end of the connecting plate is rotatably installed on the outer edge of the gear; the other end of the connecting plate is rotatably installed on a fixed support plate on the sucking disc seat; an idler wheel is rotatably installed in the rear end of the rack; and the idler wheel is in rolling cooperation with a swinging cam behind the idler wheel. The M-shaped packaging bag opening mechanism disclosed by the invention has the advantages of reasonable layout, small part amount, reliability in acting, stability in operation, high bag opening efficiency, pure mechanical mechanism, small travel, high operation speed, small inertial impact, convenience in regulation, high interchangeability, good adaptation on the packaging bag material and long service life.

Owner:合肥远新包装机械有限公司

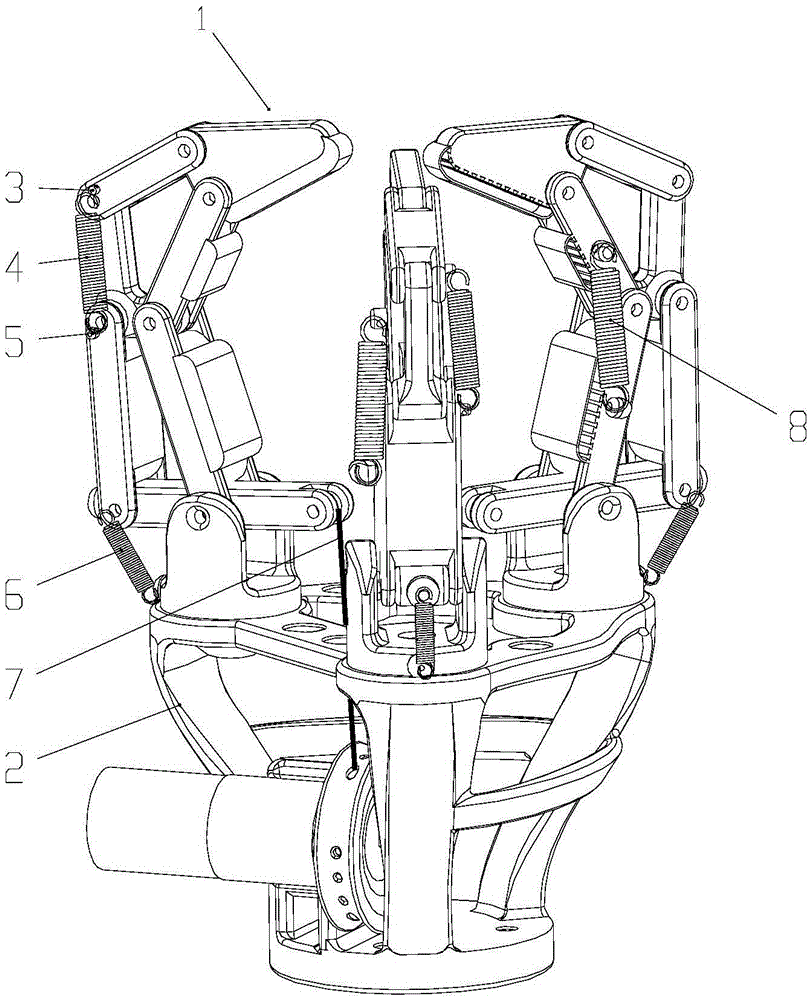

Flexible self-adaption under-actuated robot hand

ActiveCN105563513AGuaranteed crawlGuaranteed crawling workProgramme-controlled manipulatorGripping headsRobot handWinch

The invention relates to a hand, in particular to a flexible self-adaption under-actuated robot hand. The flexible self-adaption under-actuated robot hand comprises fingers and a wrist; the wrist includes a skeleton, a direct-current motor, a potentiometer and a winch; the direct-current motor is fixedly connected to a motor mounting surface of the skeleton; the potentiometer is fixedly connected to a potentiometer mounting surface of the skeleton by penetrating through an output shaft of the motor; the winch is fixedly connected to the tail end of the output shaft of the motor; multiple fingers are provided; and the fingers are embedded in clamping grooves of the skeleton or multiple clamping grooves through convex blocks of rotating bodies. The flexible self-adaption under-actuated robot hand is assembled at the tail end of an industrial robot for assisting mechanical assembly or mechanical manufacturing process and finishing automatic workpiece loading / unloading; and the fingers can flexibly adapt to geometric shapes of products, and realize automatic adjustment according to the geometric shapes of workpieces to realize stable grabbing.

Owner:华粹智能装备有限公司

High-speed binding machine

InactiveCN101164416AReasonable structureCompact structureSausage skin tying apparatusGear wheelEngineering

The present invention relates to a high-speed wire-binding machine. It mainly is composed of machine frame, holding mechanism, reducing mechanism and one-way synchronous regulation mechanism. The described one-way synchronous regulation mechanism is formed from curved bar, transmission-retaining screw rod, regulation transmission screw rod, double-pitch two-head screw rod and hand wheel regulation component. The described holding mechanism includes the following several portions: holding jaw supporting frame, holding jaw rotating shaft core, holding jaw intermittent gear, holding jaw driving lug and holding jaw cylinder.

Owner:嘉兴市瑞胜食品有限公司

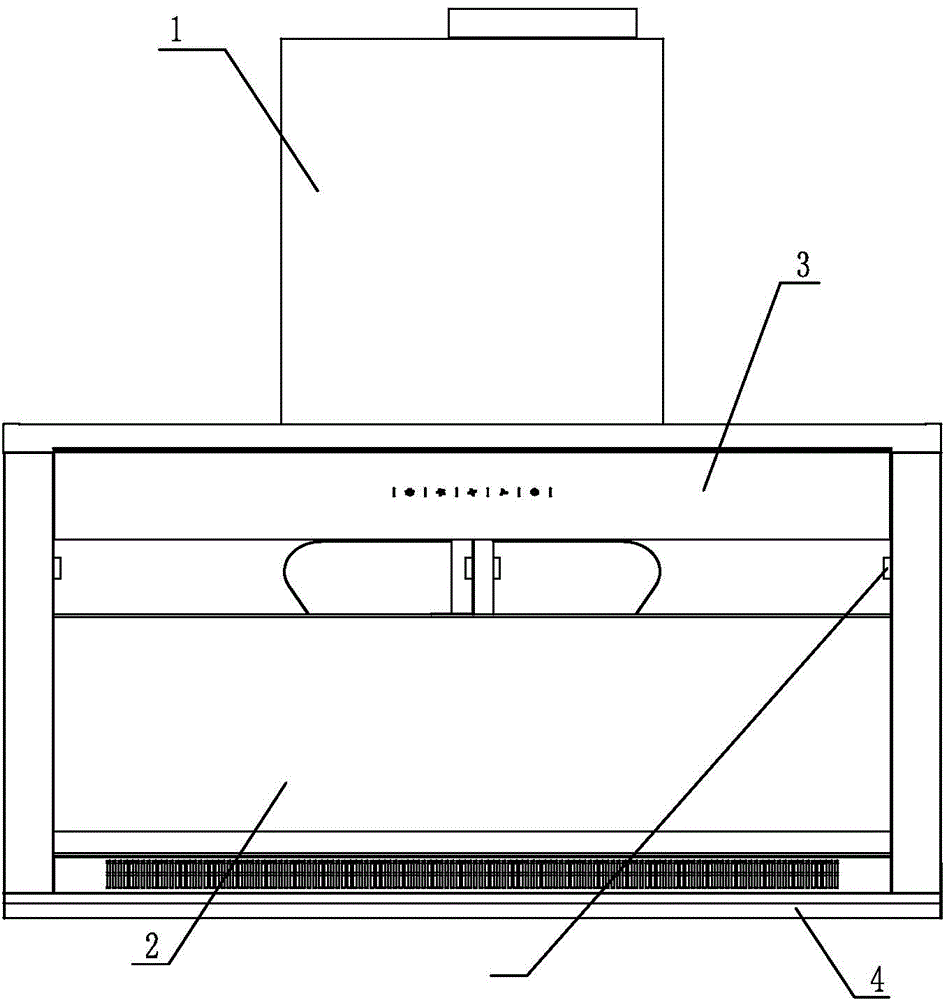

Double-air-inlet range hood and control method thereof

ActiveCN104456675ATake advantage ofReasonable shape and structureDomestic stoves or rangesLighting and heating apparatusAuto regulationEngineering

The invention provides a double-air-inlet range hood. The double-air-inlet range hood comprises a box body, an air deflector and a switch panel, wherein a smoke collection chamber is arranged on the inner side of the air deflector; an opening for communicating the smoke collection chamber with the outside is formed between the switch panel and the air deflector; a left air inlet and a right air inlet are formed in the base plate of the smoke collection chamber; a division board is arranged between the two air inlets; an air inlet seal plate is arranged on the back of the smoke collection chamber in a hinged mode; the air inlet seal plate is provided with a driving device for driving the air inlet seal plate to overturn; a group of smoke detection devices is arranged in each of the two areas, separated by the division board, of the smoke collection chamber, and the smoke collection chamber is further provided with a controller for controlling the driving device to adjust the overturning angle of the air inlet seal plate. The double-air-inlet range hood has the benefits that the left air inlet and the right air inlet are formed, inlet air of the left air inlet and inlet air of the right air inlet do not disturb with each other through the division board arranged in the middle, and the air inlet seal plate capable of overturning is arranged, so that the double-air-inlet range hood is simple in structure and reliable in action; the opening of the air inlets of the air inlet seal plate is automatically adjusted by detecting smoke concentration, so that the efficiency of the range hood is fully utilized, and the adaptability is good.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

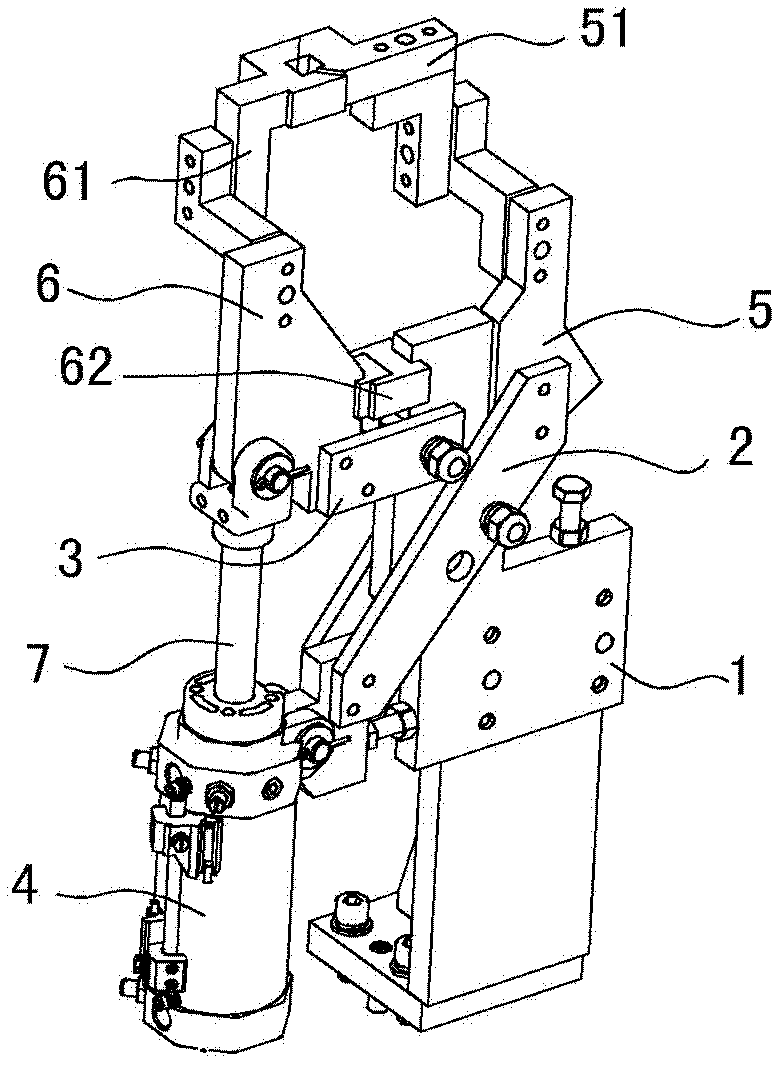

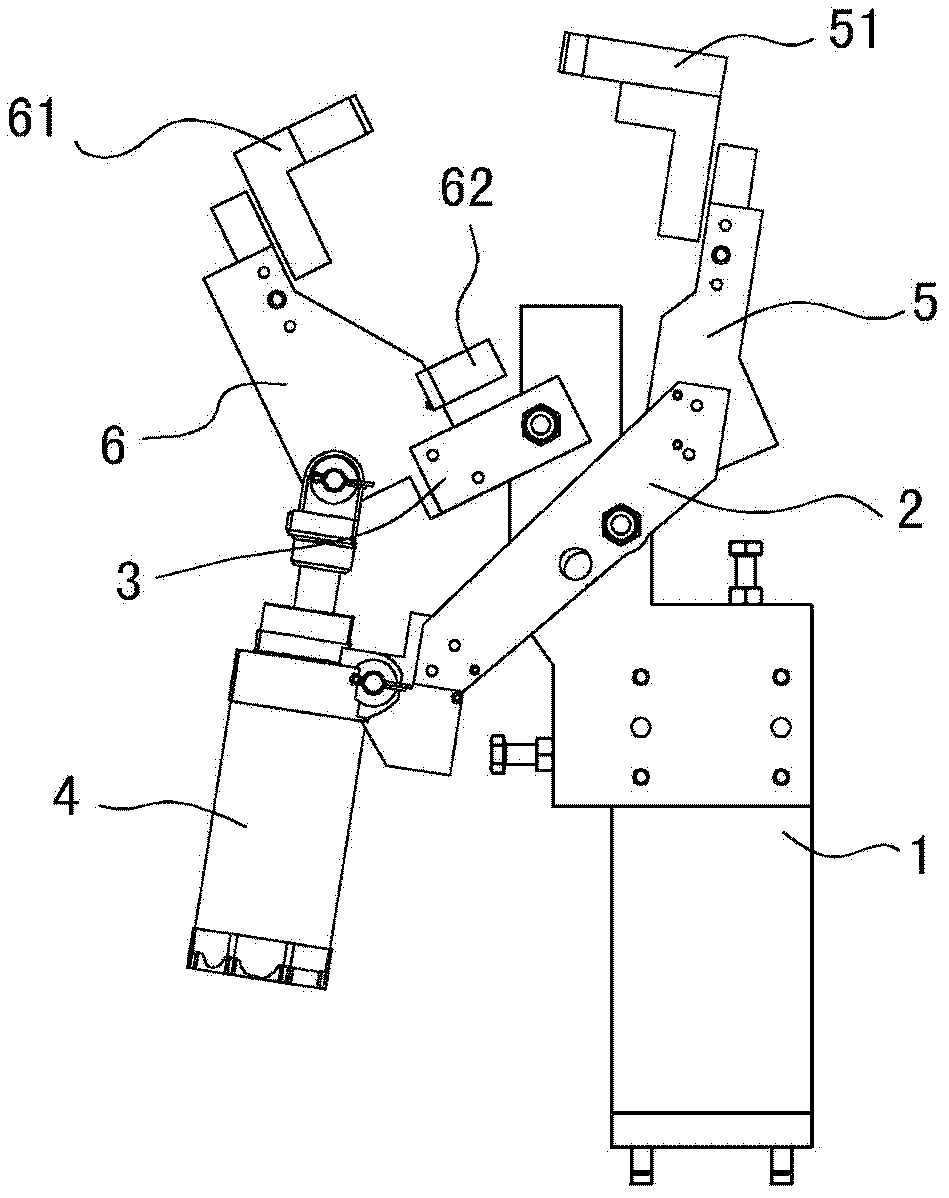

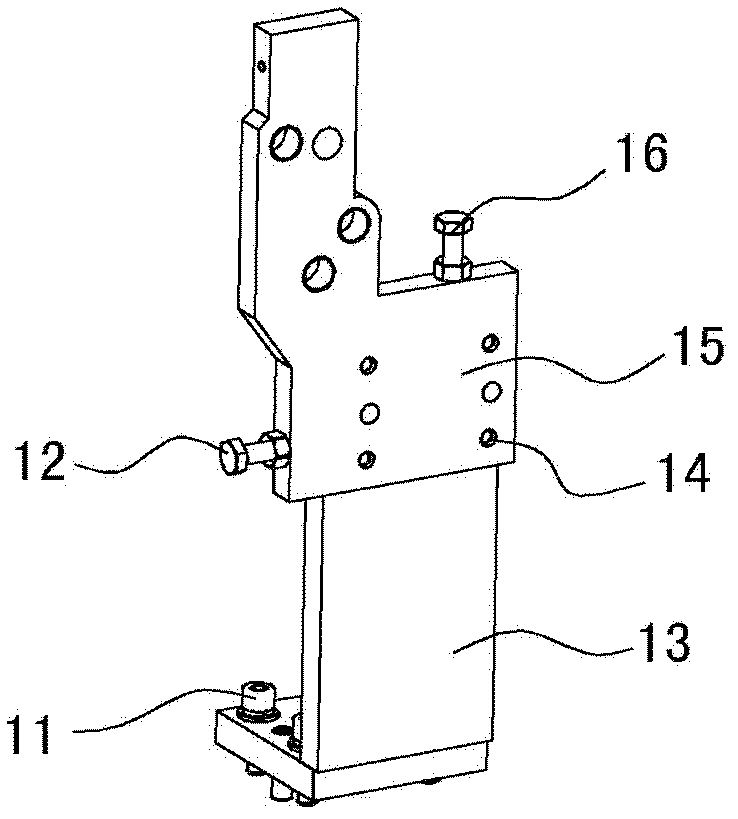

Bidirectional lateral linkage and clamping mechanism

InactiveCN102328177ASimple structureEasy maintenanceWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringTelescopic cylinder

The invention discloses a bidirectional lateral linkage and clamping mechanism, which is characterized in that: a rotatable hinging rod and a rotatable connecting rod are respectively hinged on a fixing bracket, and the connecting rod is positioned above the hinging rod; a driving cylinder as a driving member is positioned at one side of the fixing bracket, a cylinder seat of the driving cylinder is hinged at one rod end of the hinging rod, the other rod end of the hinging rod is fixedly connected with a first rotating arm, a second rotating arm which is opposite to the first rotating arm is fixedly connected to the rod end of the connecting rod, and the rod end of a telescopic cylinder rod in the driving cylinder is hinged with the second rotating arm. According to the invention, bidirectional lateral linkage drive to the first rotating arm and the second rotating arm by the driving cylinder is formed; and the bidirectional lateral linkage and clamping mechanism has the advantages of simple structure, easiness in maintenance and high working efficiency.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

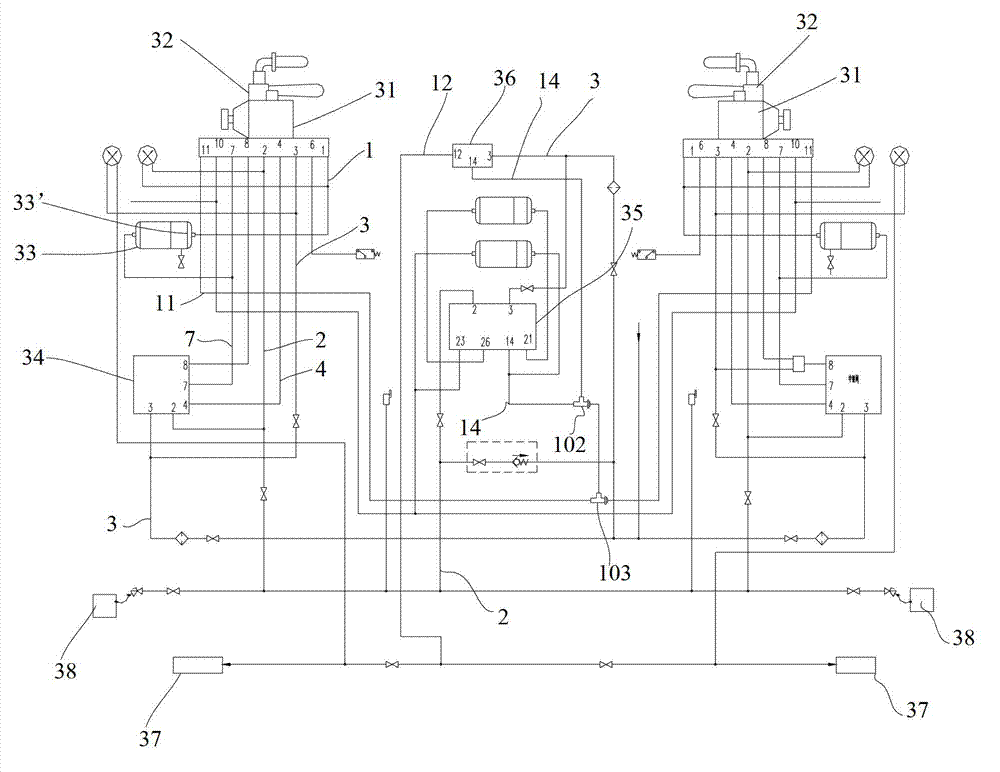

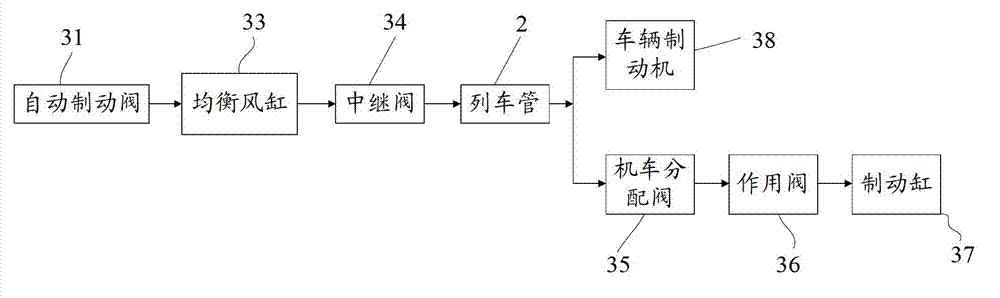

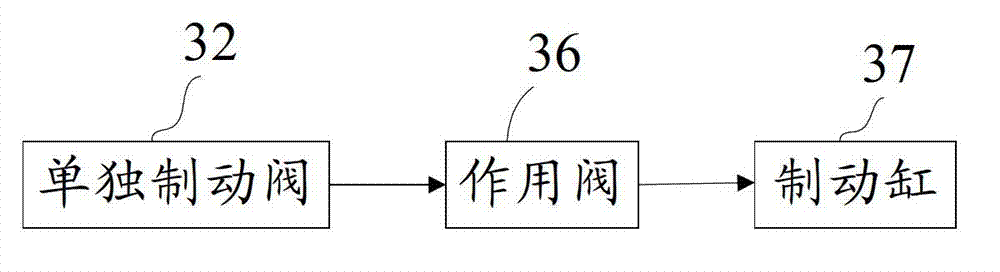

Control device of air braking system of rail vehicles

InactiveCN102963344AReliable actionEasy to manufactureRailway hydrostatic brakesRailway hydrodynamic brakesRelay valveElectromagnetic valve

The invention provides a control device of an air braking system of rail vehicles. The control device comprises an air brake, a locomotive distribution valve, an operating valve, at least one automatic brake unit, a first two-way valve, a brake electromagnetic valve and a release electromagnetic valve, wherein the unit comprises an equalizing air cylinder, an overcharge air cylinder, a relay valve and an automatic brake valve; an air inlet of the brake electromagnetic valve is connected with a main air pipe; an air outlet of the brake electromagnetic valve and an air inlet of the release electromagnetic valve are connected with a first air inlet of the first two-way valve; an air outlet of the release electromagnetic valve is communicated with the atmosphere; a second air inlet of the first two-way valve is connected with the operating valve through a twelfth pipe; an air outlet of the first two-way valve is connected with a brake cylinder; and the control ends of the brake electromagnetic valve and the release electromagnetic valve are connected with a switch through leads. The switch is mounted at the required position, controls the two electromagnetic valves to inflate and exhaust the brake cylinder and controls the locomotive to brake and release. The control device is reliable in action, simple in connection, easy to manufacture and maintain and low in cost.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

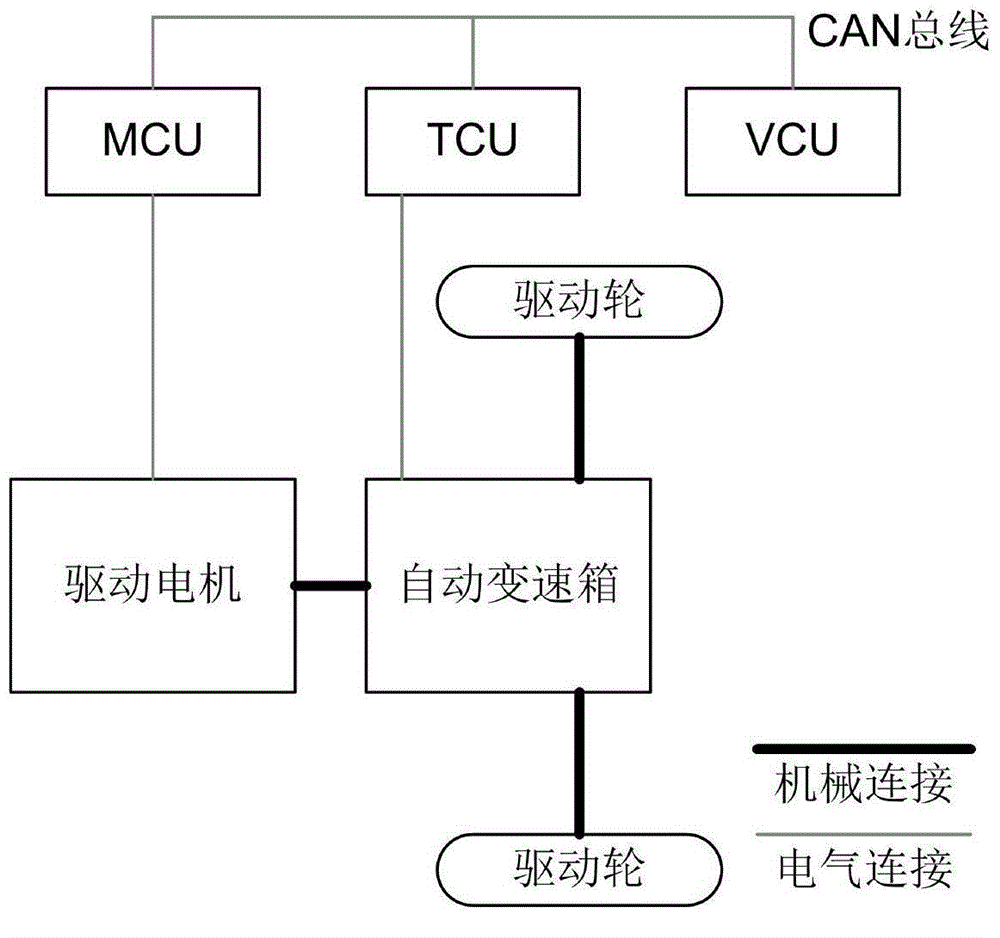

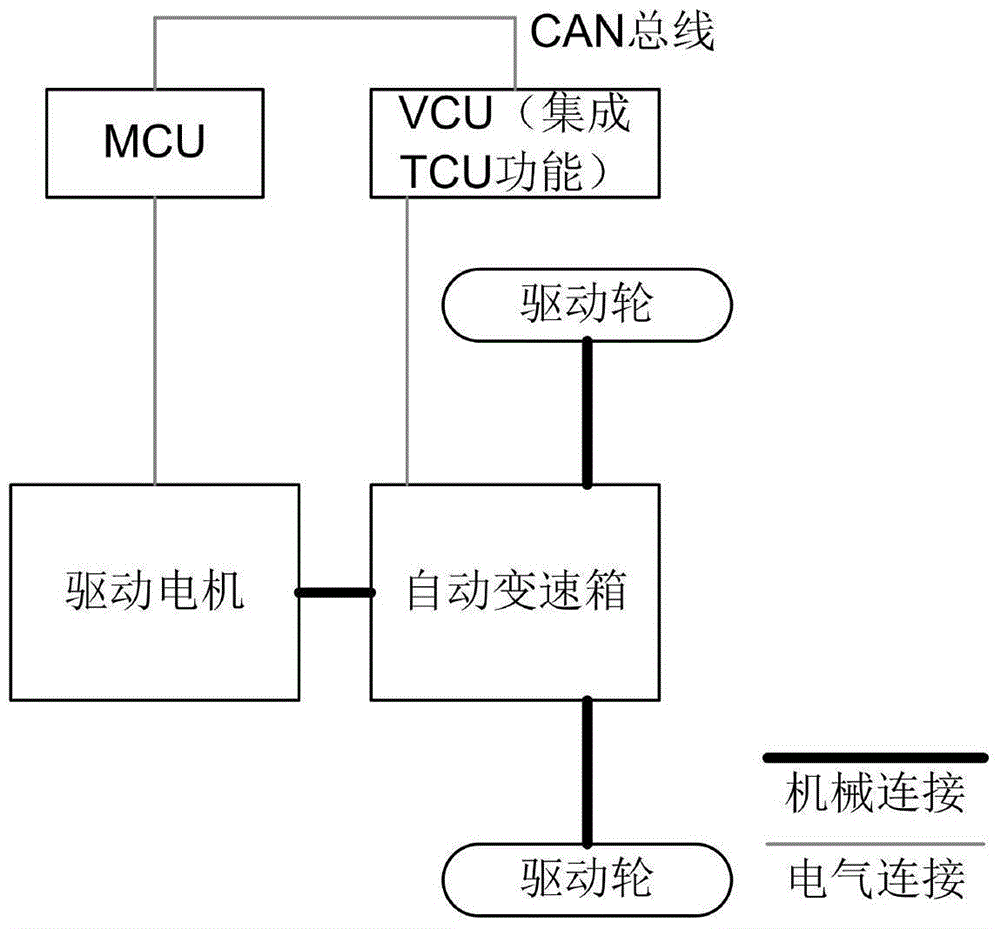

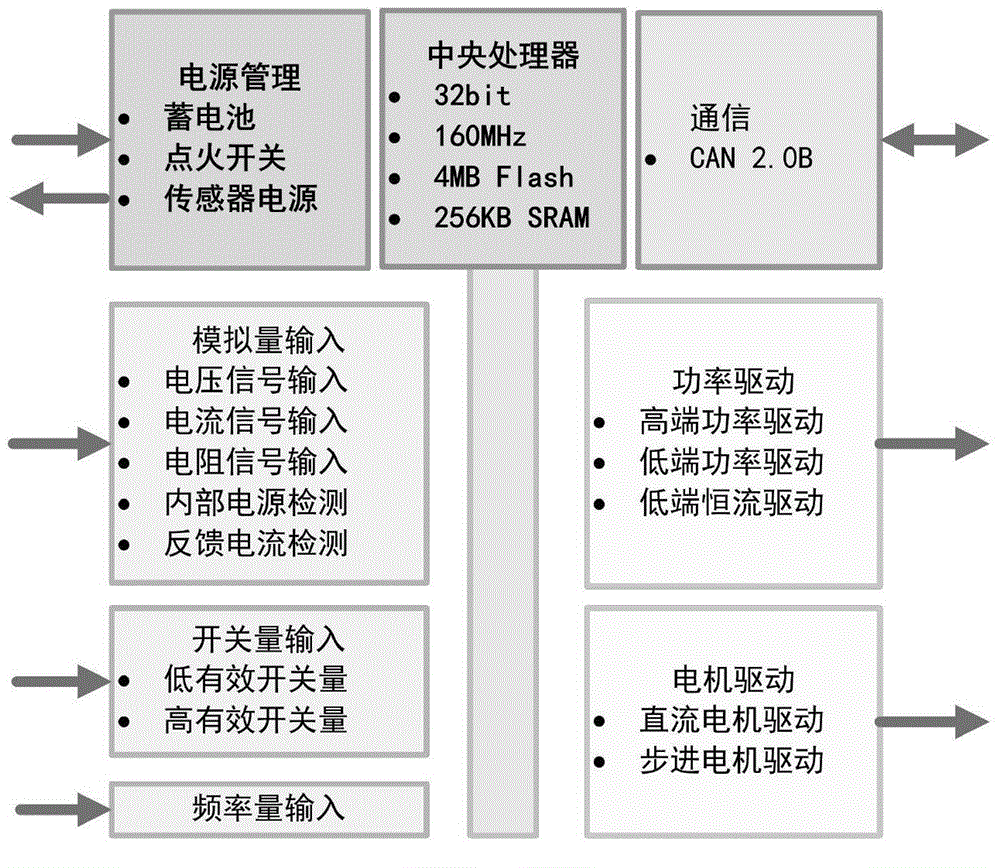

New-energy entire car controller integrated with transmission case control function

InactiveCN104802790ASmooth startReduce in quantitySpeed controllerElectric energy managementMotor driveNew energy

The invention provides a new-energy entire car controller integrated with a transmission case control function. The controller is integrated with the transmission case control function, i.e., an original entire car control function and a transmission case control function are integrated in the entire car controller, so that a special TCU (transmission control unit) is not needed any more; analog input, on-off input and frequency input are connected with respective sensors; a power-driven part and a motor-driven part are connected with respective actuators; the components are connected together with an internal bus on a controller circuit board by virtue of internal connecting wires so as to form a complete controller hardware circuit. New-energy entire car controller software integrated with the transmission case control function is realized by virtue of an entire car control algorithm and a transmission case control algorithm. The new-energy entire car controller can be used for shortening the development cycle, lowering the development cost, reducing automobile parts such as a controller, an auxiliary connector and wire harnesses and lowering the purchase costs of the parts.

Owner:BEIJING JIUZHOU HUAHAI TECH

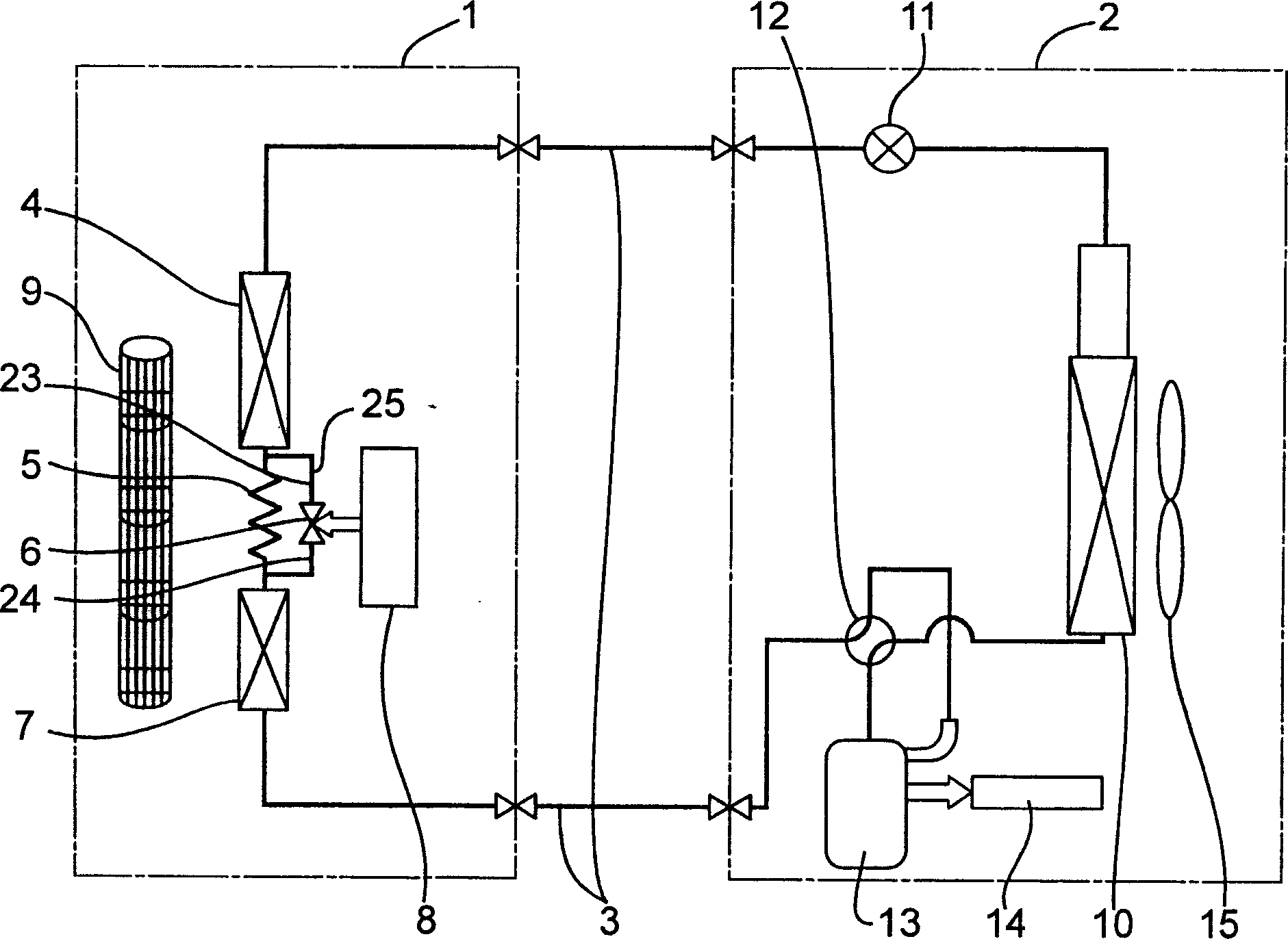

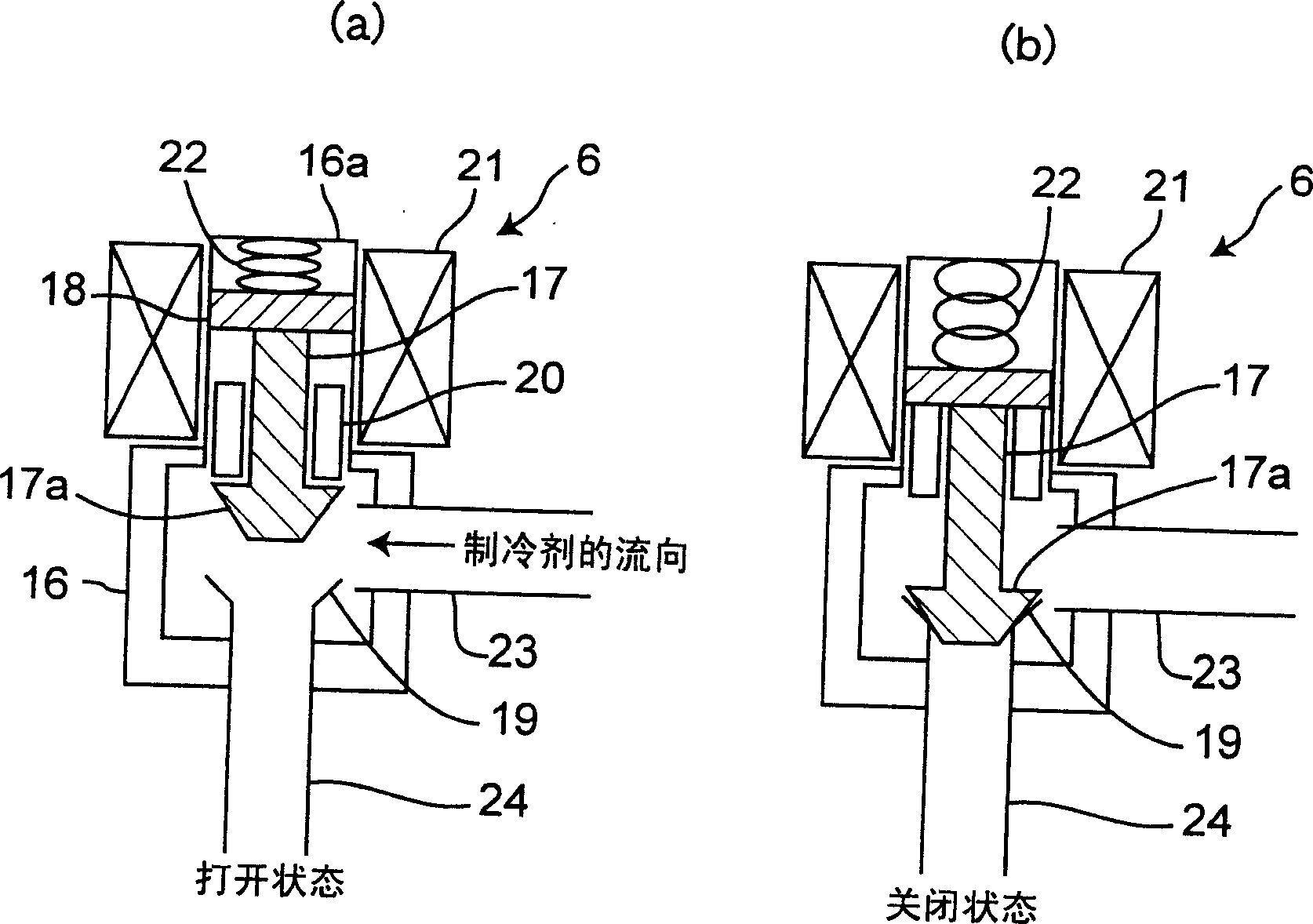

Air conditioner

InactiveCN1590890AShorten the timeSave electricitySpace heating and ventilation safety systemsSpace heating and ventilation control systemsElectric power systemEngineering

An indoor heat exchanger is structured with a first indoor heat exchanger and a second indoor heat exchanger serially connected to the first indoor heat exchanger via a diaphragm means. A bypass route, parallely connected to the diaphragm means, having the open / close means of an always-open type. When starting a re-heat-dehumidifying operation which operates the first indoor heat exchanger as a condenser and operates the second heat exchanger as an evaporator, electric power is supplied to the open / close means to close and, after electric power supply is stopped, high refrigerant pressure is applied to a valve element and a status in which a valve seat is closed by the valve element is maintained. Thus, it can provide an air conditioner of which power consumption to activate an open / close means is small.

Owner:PANASONIC CORP

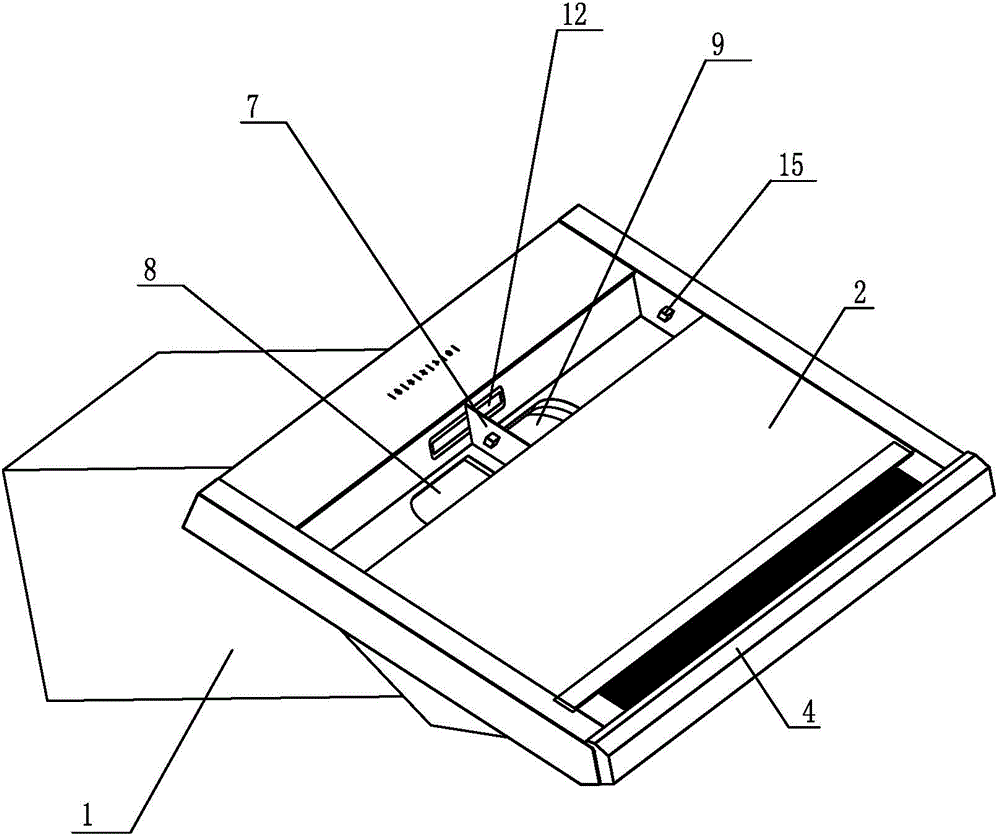

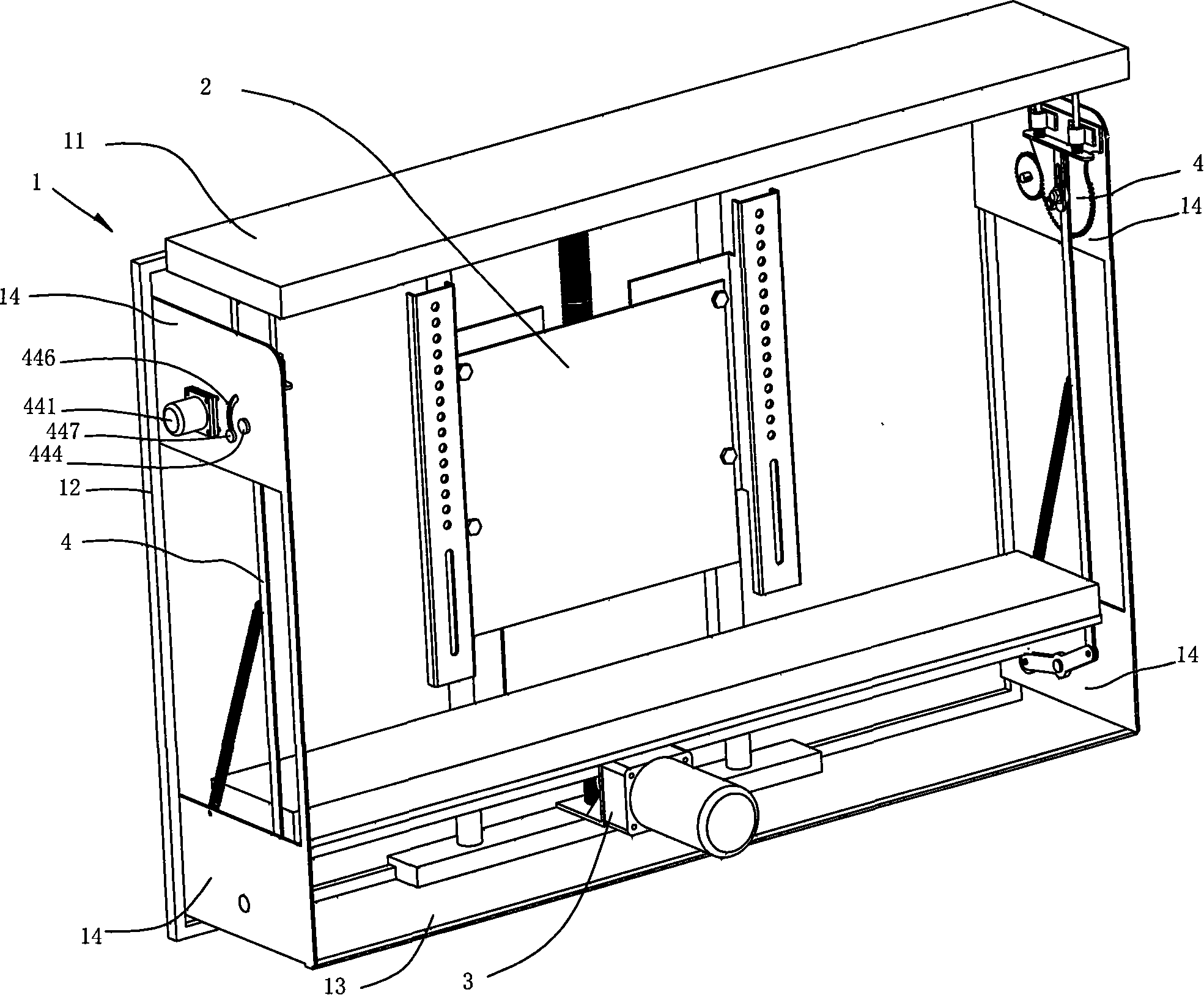

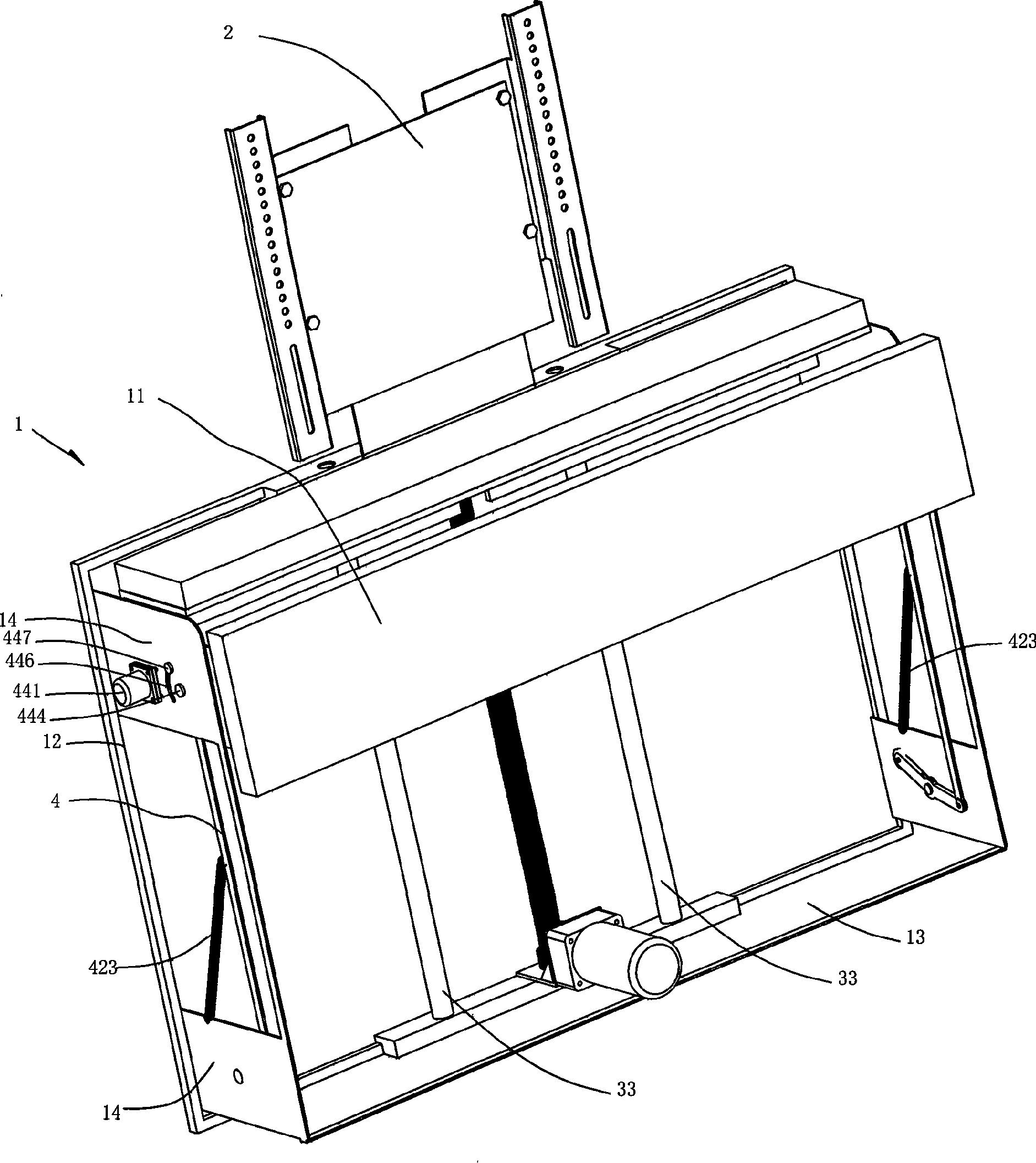

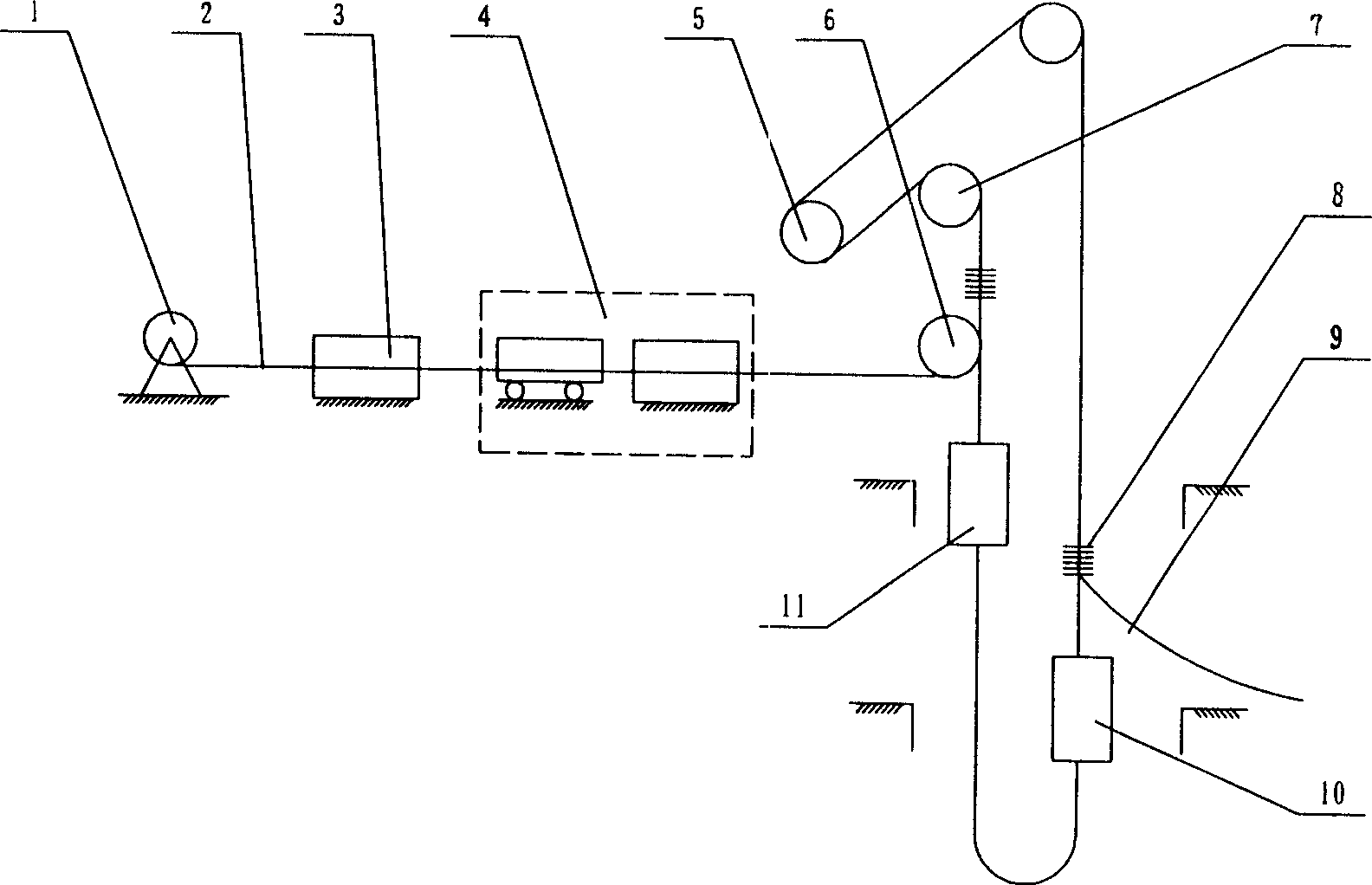

Panel television or liquid crystal display screen lifting machine

InactiveCN101190776AAchieve the purpose of openingIngenious designLifting devicesHoisting equipmentsLiquid-crystal displayTelevision screen

The invention discloses an elevator of a flat television or a liquid crystal display, comprising an elevator outer shell, an elevating system of flat screen mounts which is fixedly arranged in the elevator outer shell and a flat screen mounts; wherein, the upper end of the elevator outer shell is provided with a head cover plate which can be opened and closed. The invention is characterized in that two opening mechanisms of the head cover plate are connected between the two ends of the head cover plate and the two lateral plates of the elevator outer shell respectively; the opening mechanism of the head cover plate comprises a jacking bracket which is connected with the head cover plate, a linkage mechanism which is used for pushing the pushing the jacking bracket up and down, a return spring which leads the jacking bracket to be retracted and a rotating mechanism which leads the jacking bracket to forward reverse 90 degrees. The invention overcomes the defect that the present elevator has a complex structure and does not have a beautiful exterior because after the television screen rises out, the opened cover plate is turned over or tilted on a table. The invention has the advantages of novel and simple structure, etc.

Owner:王招永 +2

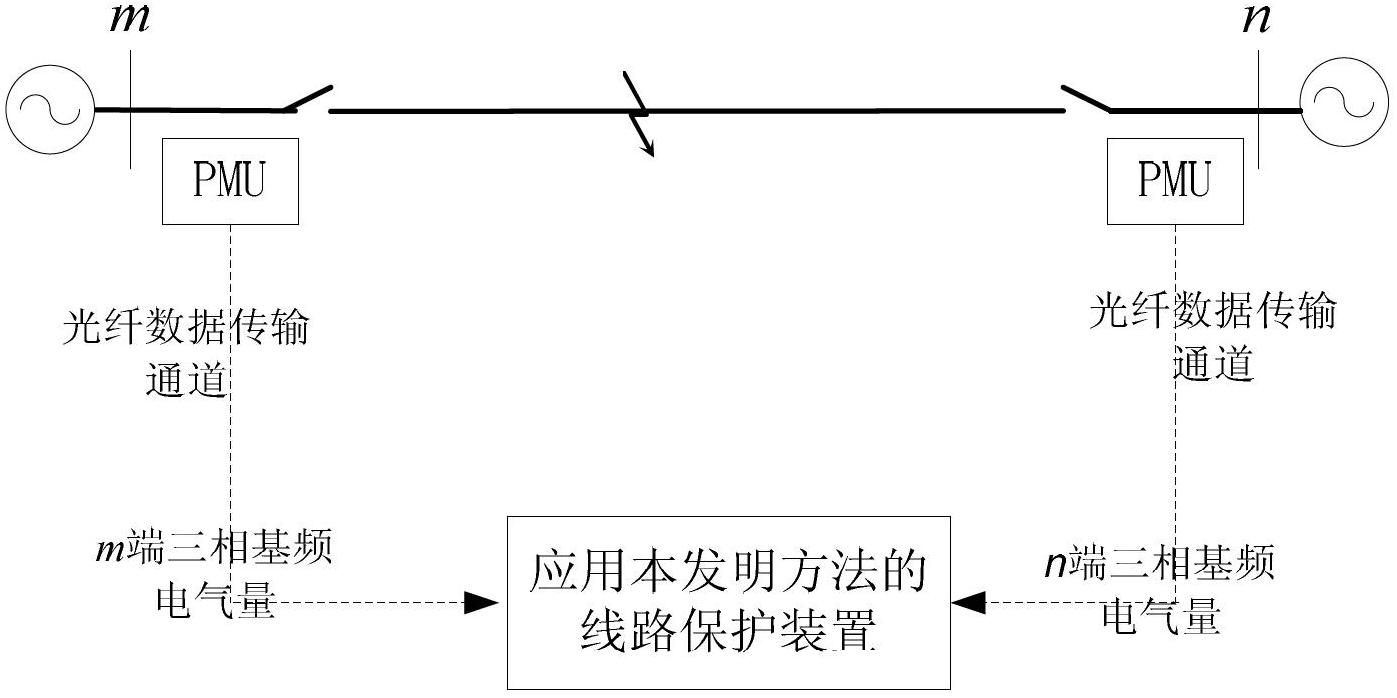

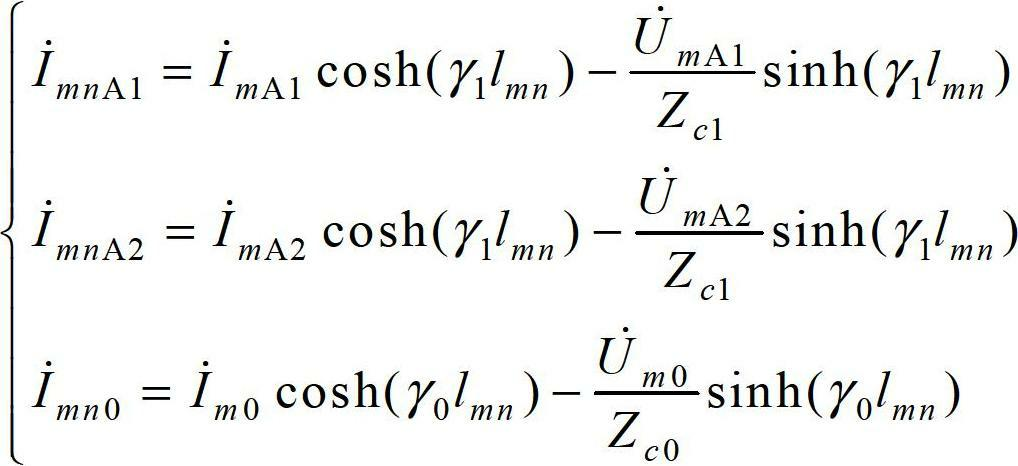

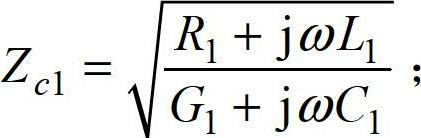

Ultra high-voltage alternating current transmission line protection method based on all-component differential coefficient matrix

ActiveCN102694375AAccurate identificationReliable actionEmergency protective arrangements for automatic disconnectionDifferential coefficientHigh resistance

The invention discloses an ultra high-voltage alternating current transmission line protection method based on an all-component differential coefficient matrix, comprising the following steps that the fundamental frequency electric amount on both ends of an ultra high-voltage alternating current transmission line is measured; the positive, negative and zero sequence current amount on the other end is calculated from that on one end of the line with a long line equation; the fundamental frequency current amount on the other end is calculated through a symmetrical component method; and then a differential coefficient matrix is calculated. A fault type is judged according to the values of all elements of the differential coefficient matrix, and a fault phase is enabled to be correctly tripped. The method is applicable to protecting the whole fault process of the ultra high-voltage alternating current transmission line; and particularly when the ultra high-voltage alternating current transmission line has a single-phase high-resistance grounding short-circuit fault, the method can accurately identify and correctly trip the fault phase, and circuit breakers on both ends of other two normal phase lines are reliable without working.

Owner:STATE GRID CORP OF CHINA +1

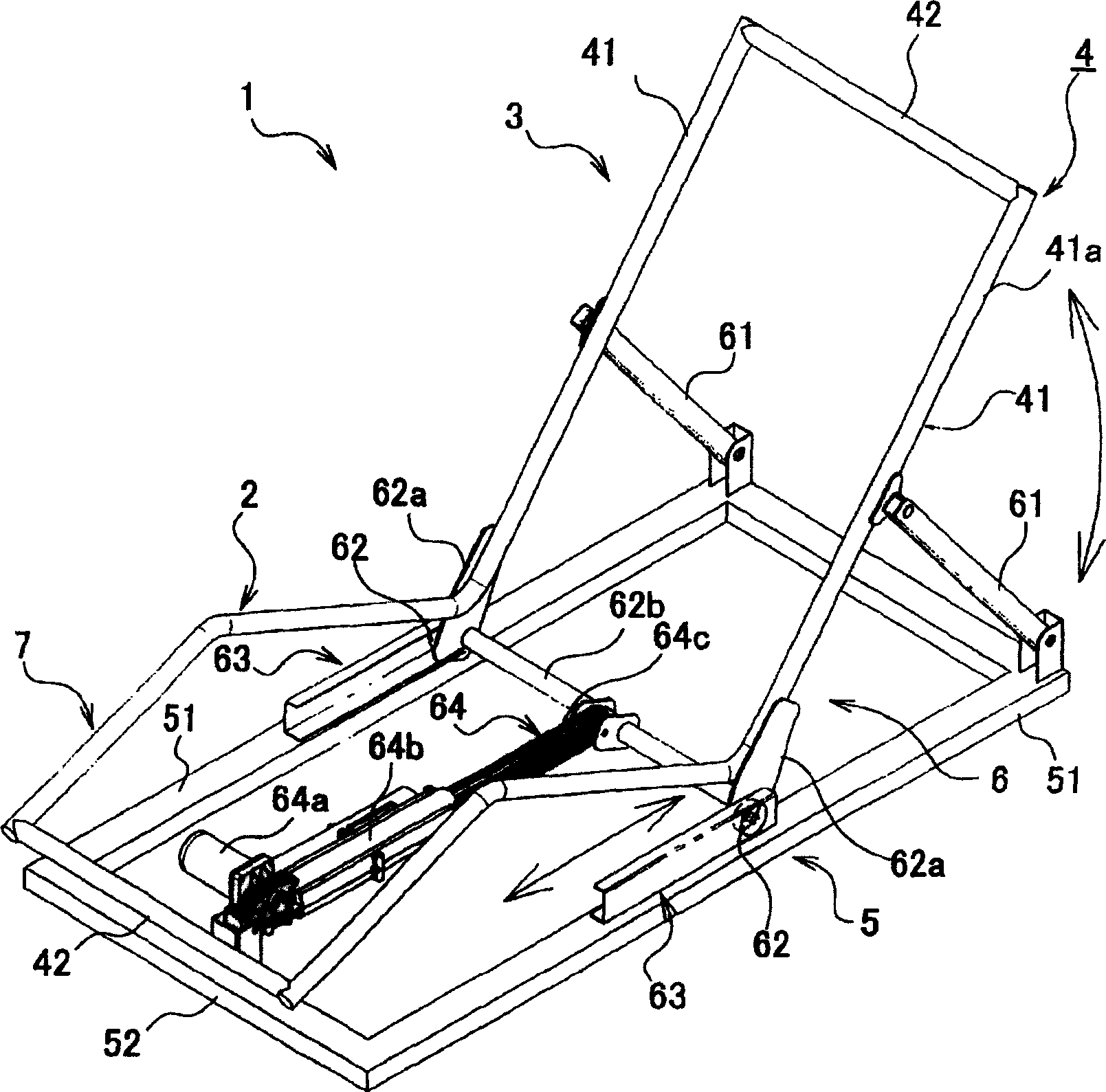

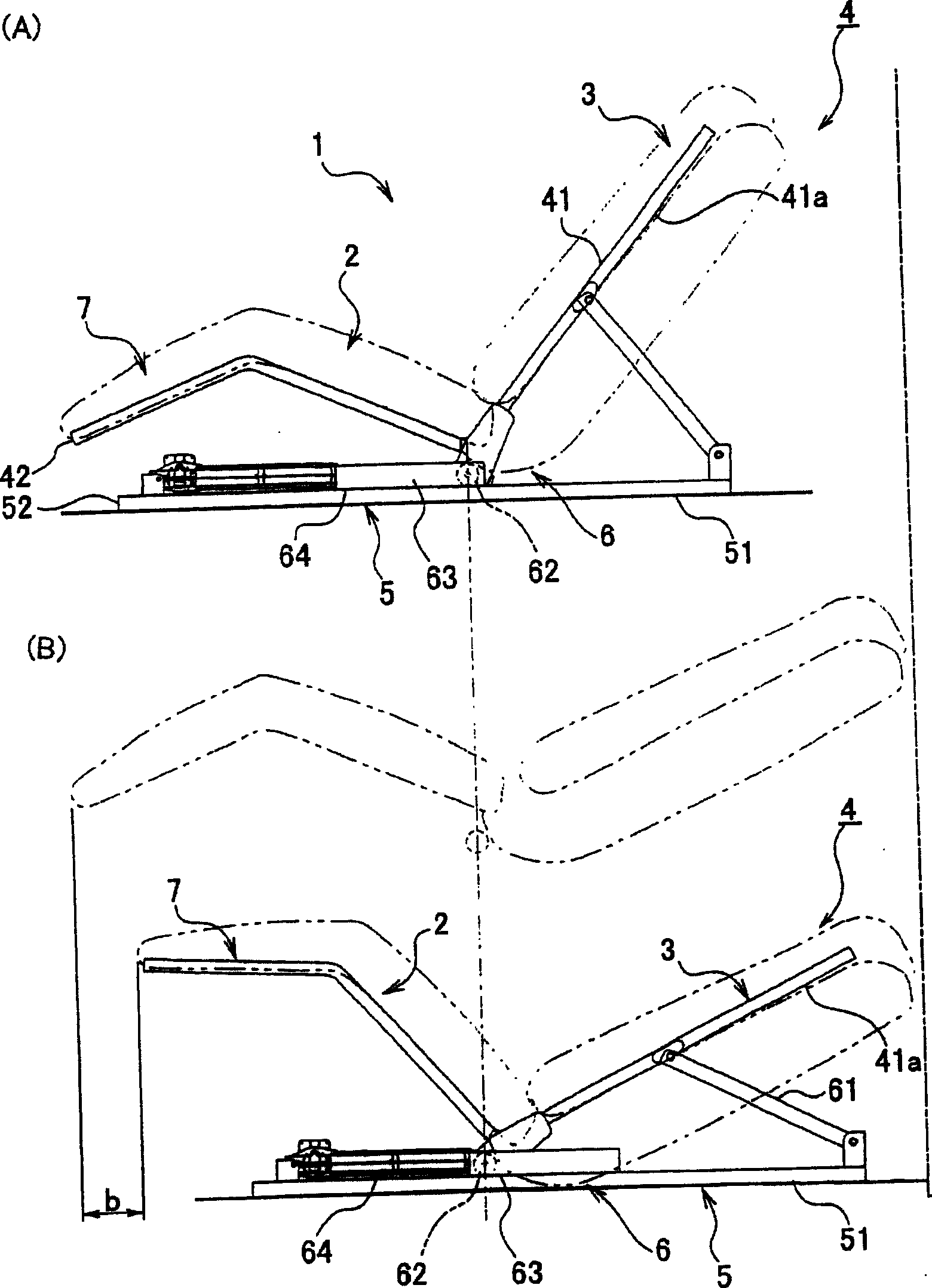

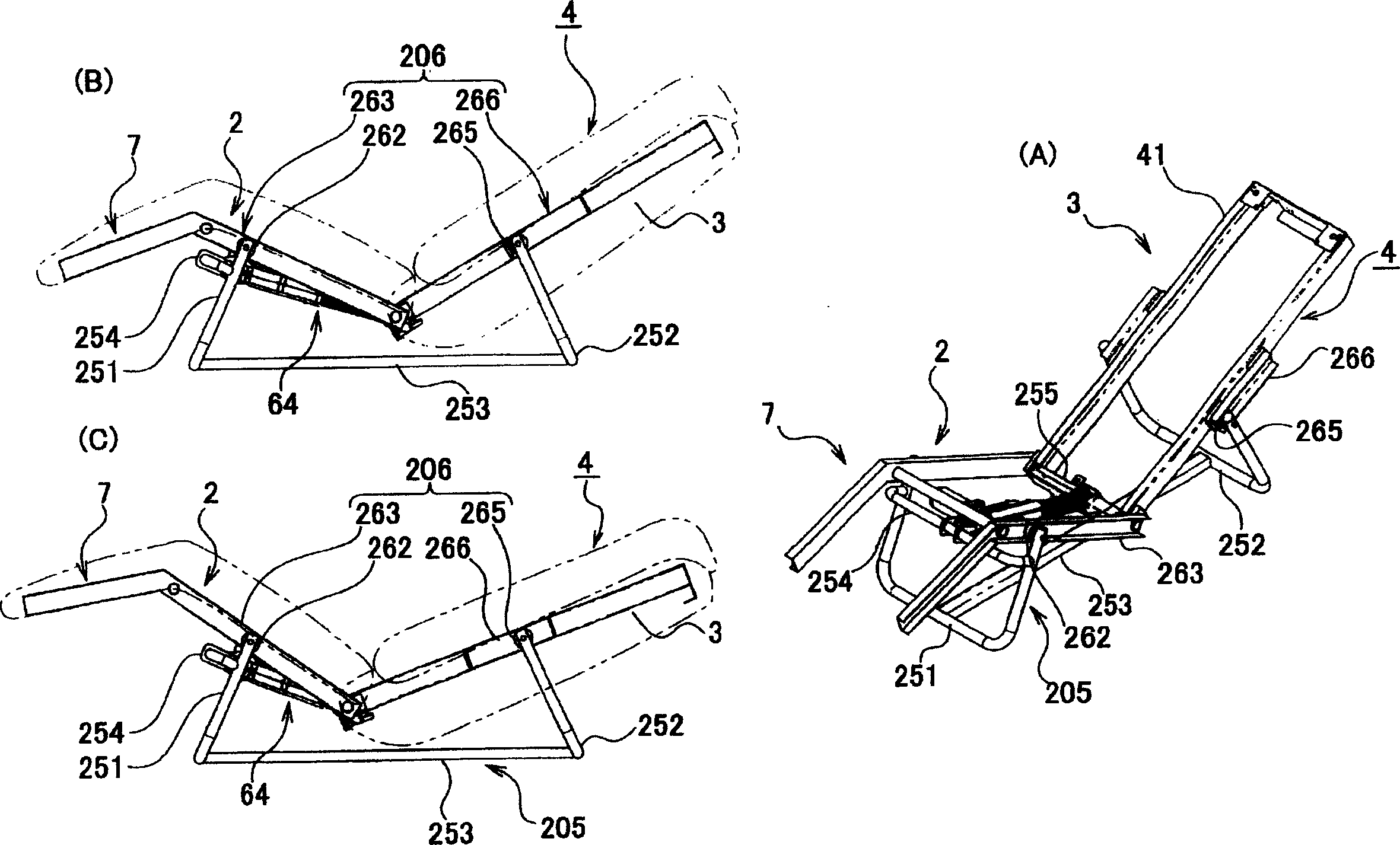

Chair

InactiveCN1647724ASmall footprintImprove securityChiropractic devicesRocking chairsEngineeringContact position

The chair comprises: a chair body having a seat surface part and the backrest part and a support part for supporting the chair body, and the reclining mechanism which moves the backrest part forward simultaneously with the backward falling in a state where an angle between the seat surface part and the backrest part is fixed constant is arranged between the support part and the chair body. To provide a chair having a reclining mechanism, by which an occupancy area is reduced as much as possible, while preventing the backward protrusion of a backrest part in the case of reclining and the contact position with a body such as shoulders is not changed.

Owner:OMRON HEALTHCARE CO LTD

Fast rope changing device of floor type multirope friction elerator

A quick replacement of multi-cable friction elevator achieves reducing of replacement time and labor intensity, and fsafety. Its apparatus consists of a stepped replacing mechansm, a cable-off preventing unit, and an automatic monitor. The stepped replacing mechansm comprises a stepping cylinder, a clamp, and a basement. The cable-off preventing unit comprises a sleeve, a cable going-through unit, a press cap, a wedge, a spring and a spring base, a hydraulic cylinder, an installing rack, pins, U-shaped clips, needle oil cups, and H-shape steel. The automatic monitor comprises a pressure monitoring alarm which includes an A / D converter, a pressure sensor, PLC, relays, and pressure modules, and a cable-off monitoring alarm which includes a tachogenerator, solenoid valves, an A / D converter, PLC and relays.

Owner:山西潞安矿业(集团)有限责任公司常村煤矿 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com