Automatic assembly machine for cooling fins and transistors

A technology of transistors and assembly machines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as poor stability, high failure rate, and difficult manual maintenance, and achieve reduced production costs, low cost, and assembly accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

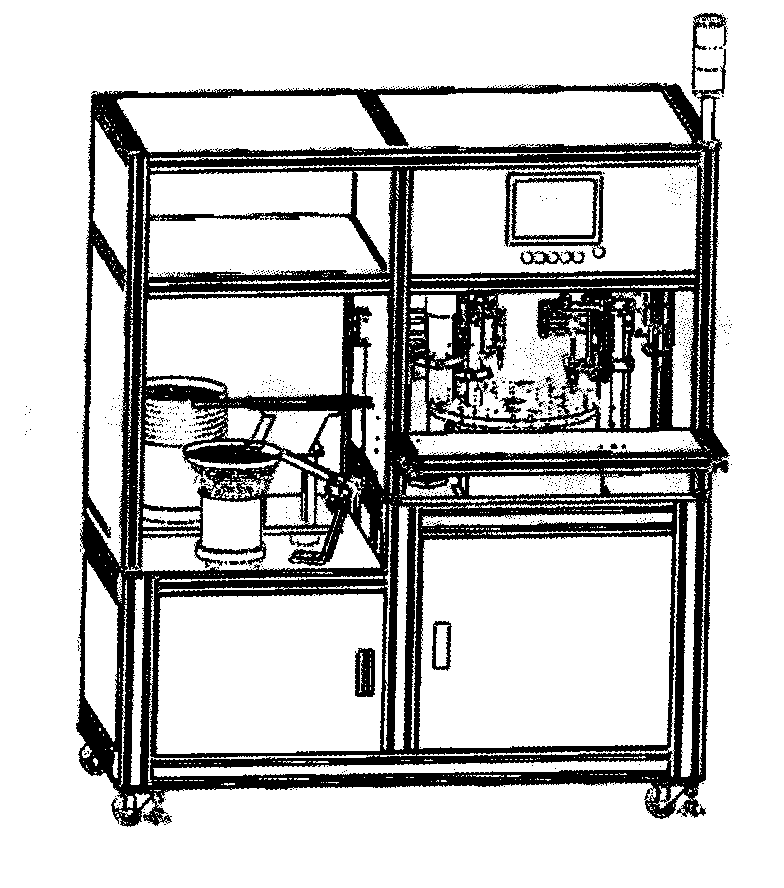

[0026] An automatic assembly machine for heat sinks and transistors, including a workbench, an automatic nut placement mechanism, an automatic crystal placement mechanism, an automatic glue printing mechanism, an automatic screw locking mechanism, an automatic feeding mechanism, and a multi-station using a cam divider Turntable mechanism.

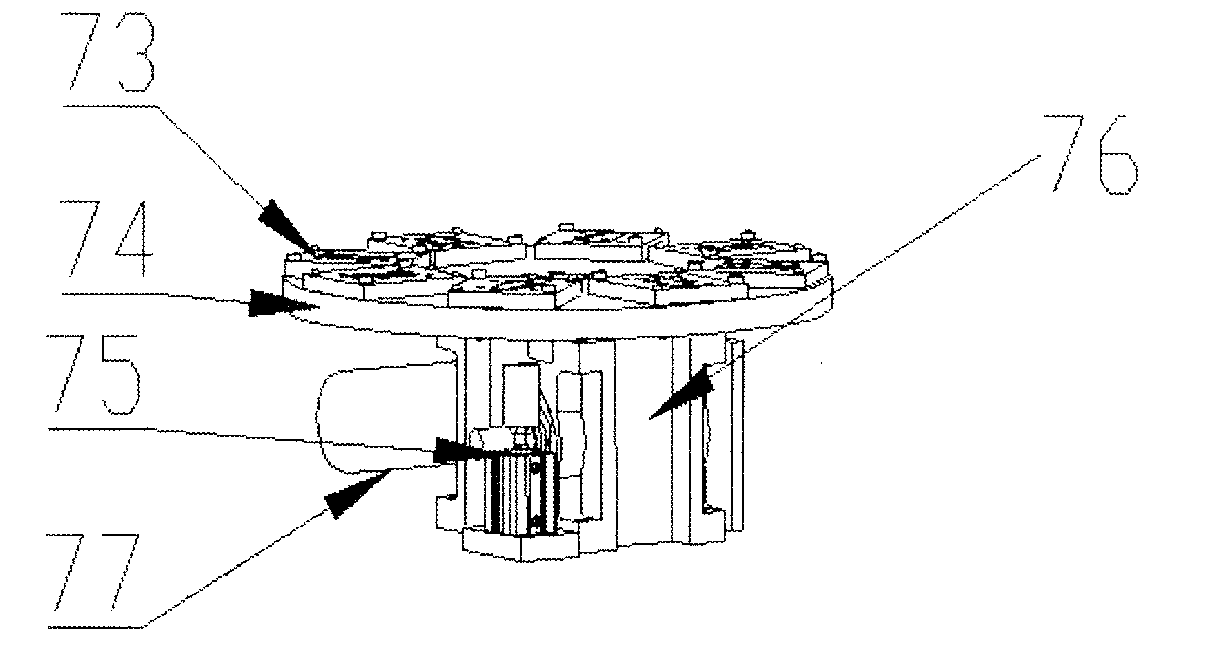

[0027] Referring to the accompanying drawings, the cam divider 76 is connected to the index plate 73, and the index plate 73 indexes each positioning fixture through the positioning sensor;

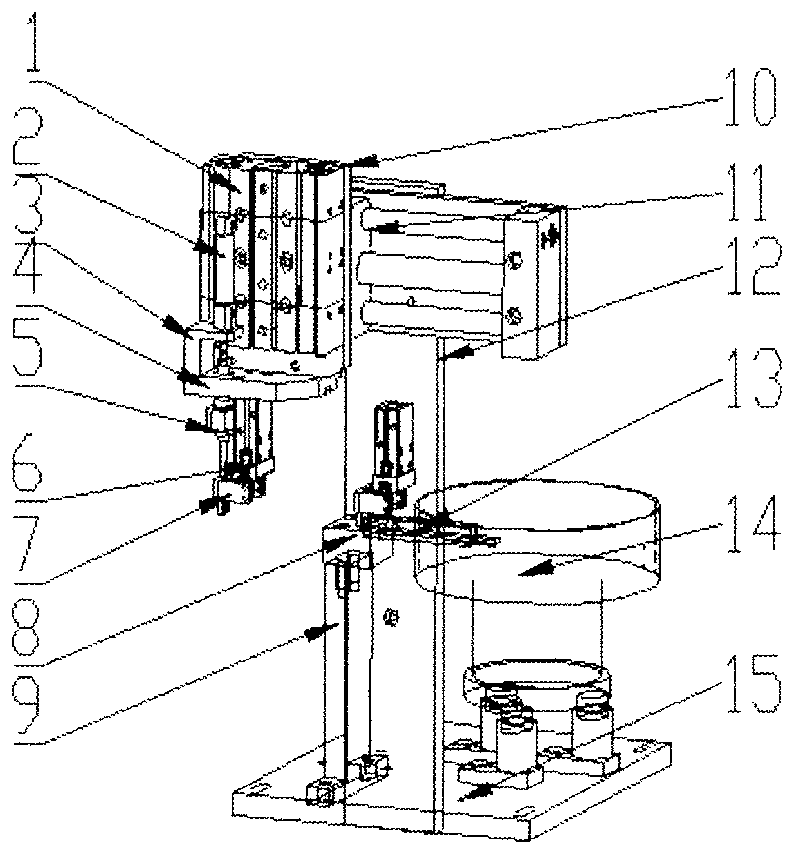

[0028] The automatic nut-putting mechanism includes: nut feeding vibrating plate 14, nut positioning mechanism 9, nut in-position sensor 8, nut retrieving jaw 7, nut lifting cylinder 1, nut translation cylinder 11, nut Eject the cylinder 2, and place the ejector rod 5 on the nut. The vibrating plate 14 sends the nut to the positioning mechanism 9, the sensor 8 detects the position of the nut, the nut lifting cylinder 1 moves down, the nut fetching jaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com