Patents

Literature

2670results about How to "Realize automatic feeding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

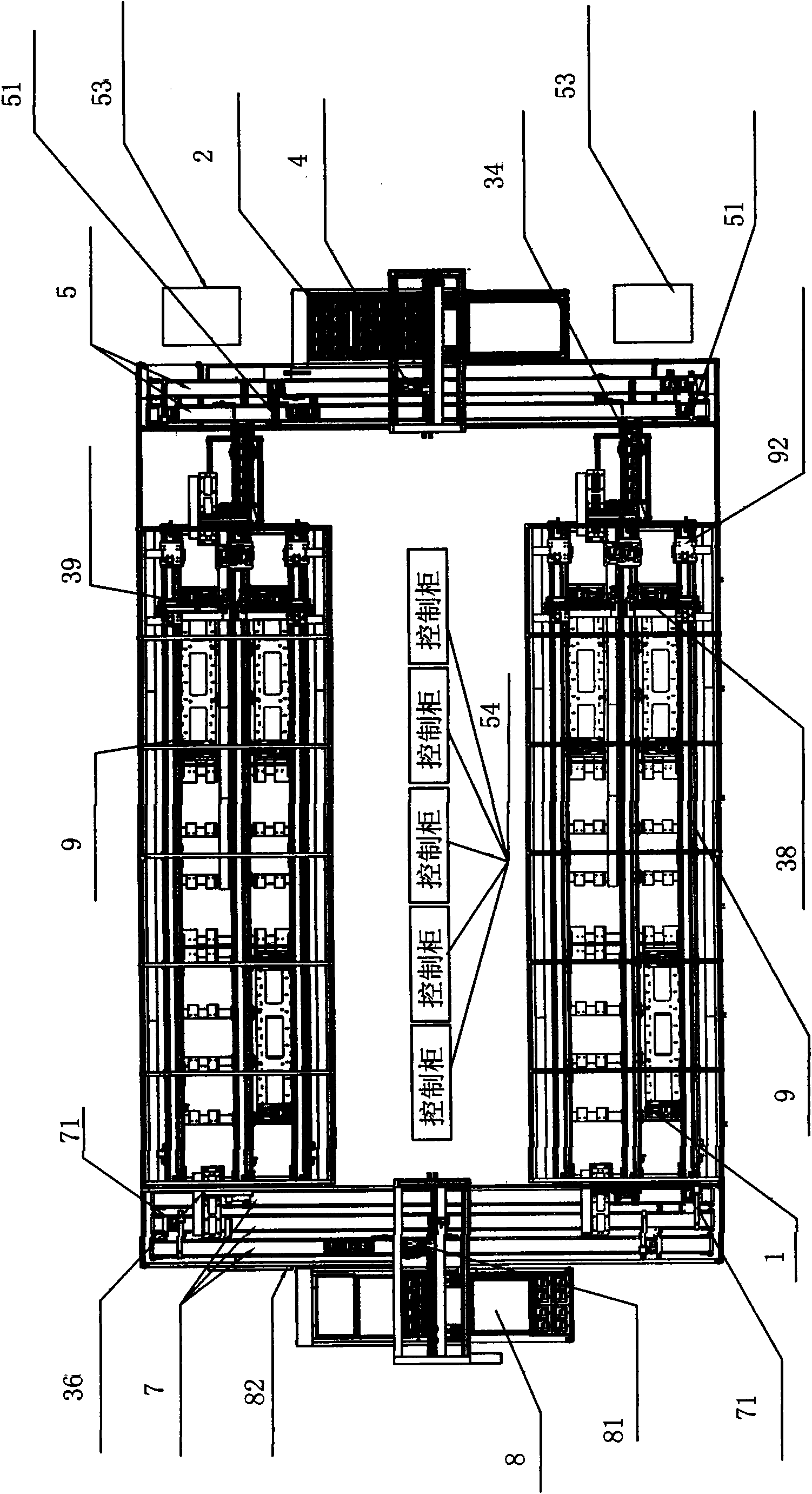

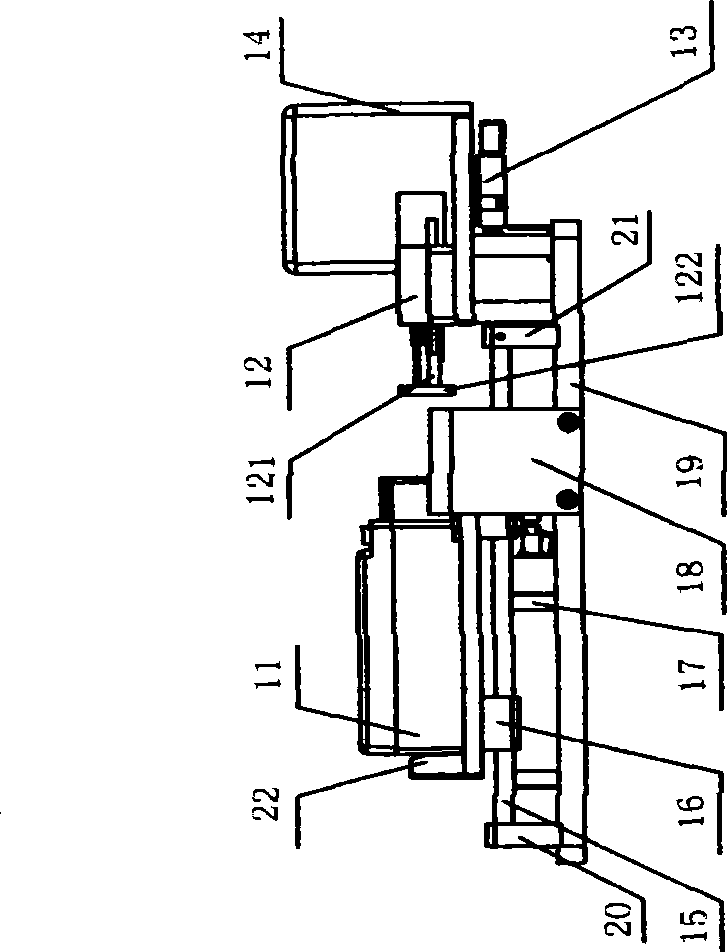

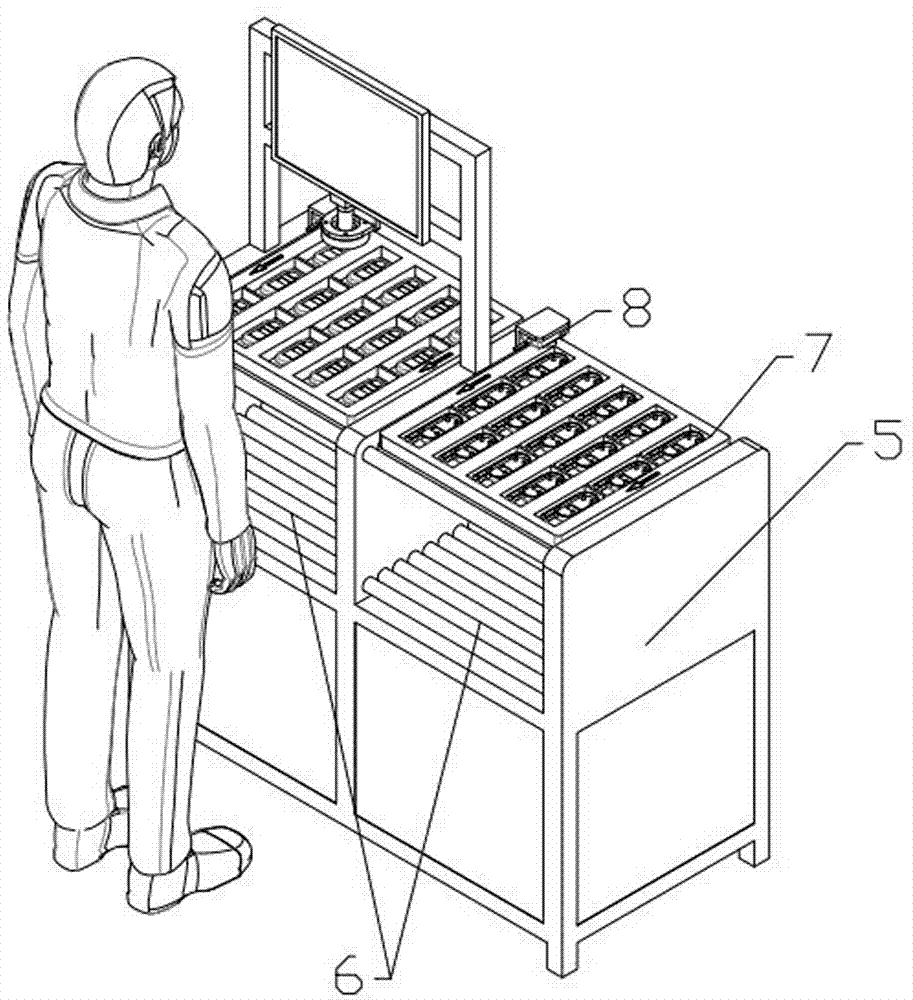

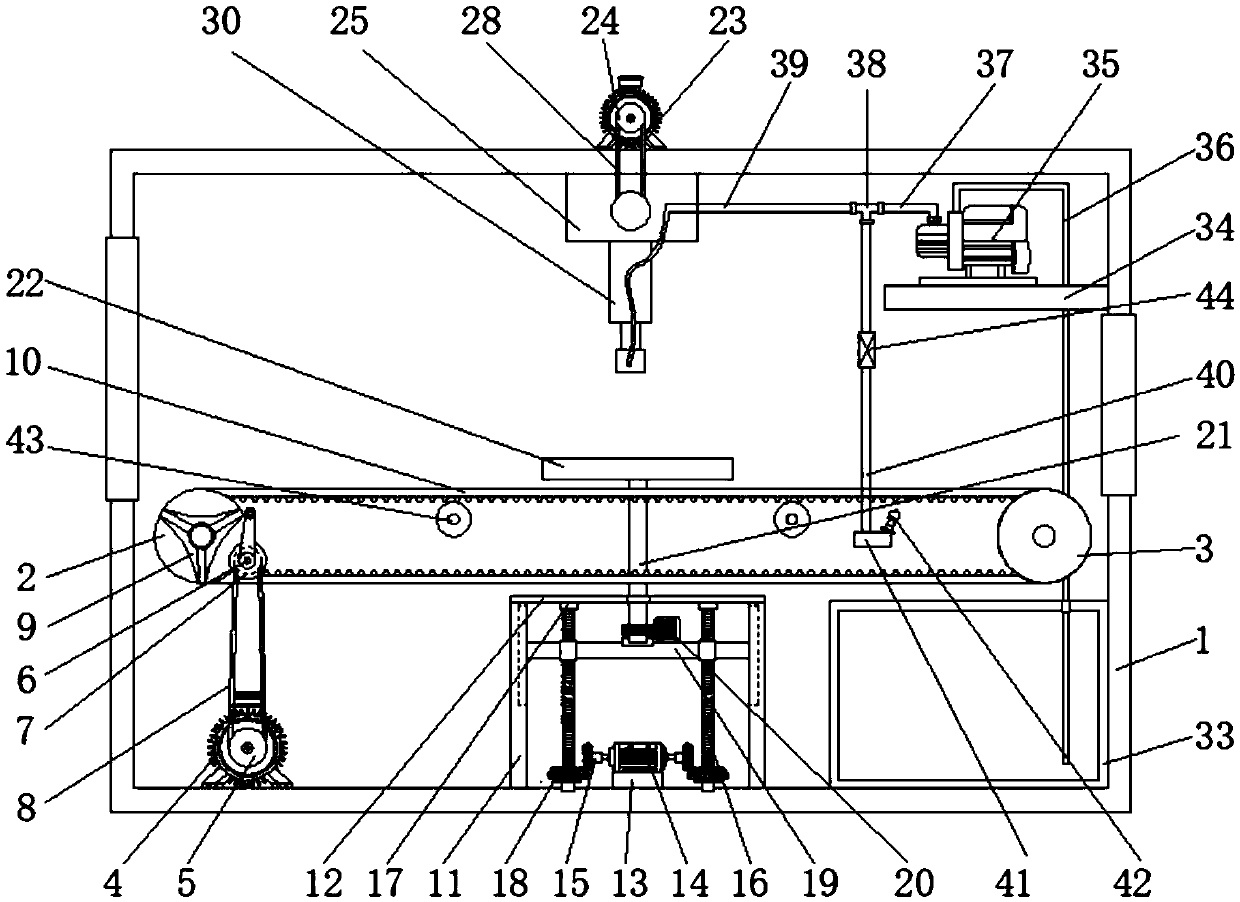

Automatic holographic management system integrating detection of electric energy meter and warehousing management

ActiveCN101539617ARealize automatic feeding processAchieve contactRadiation pyrometryElectrical measurementsTemperature monitoringEngineering

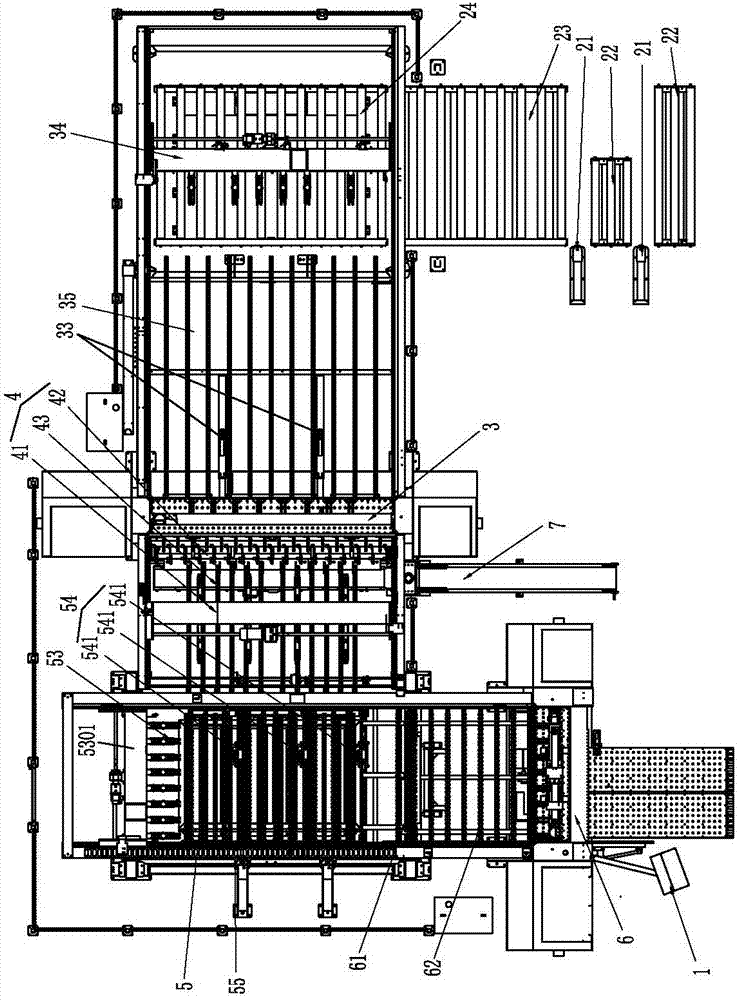

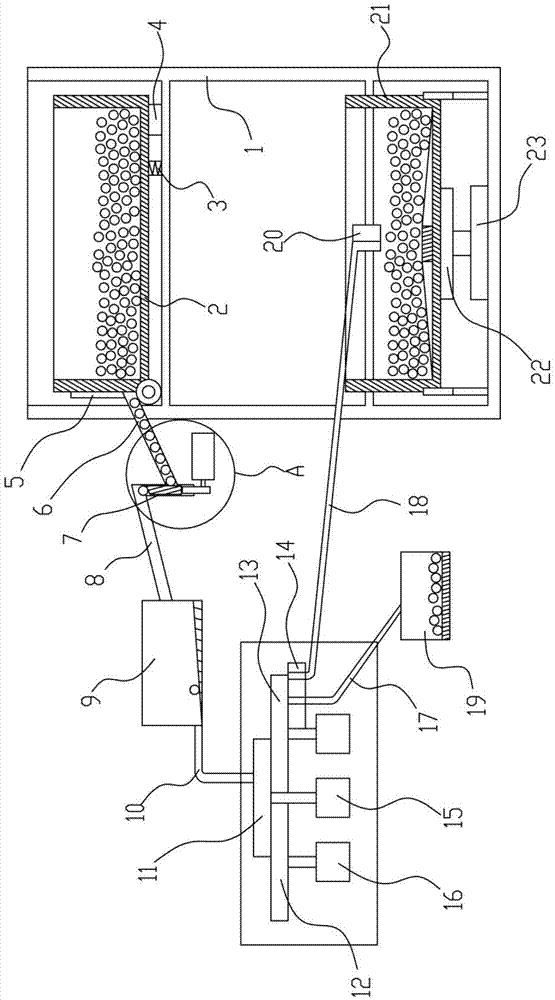

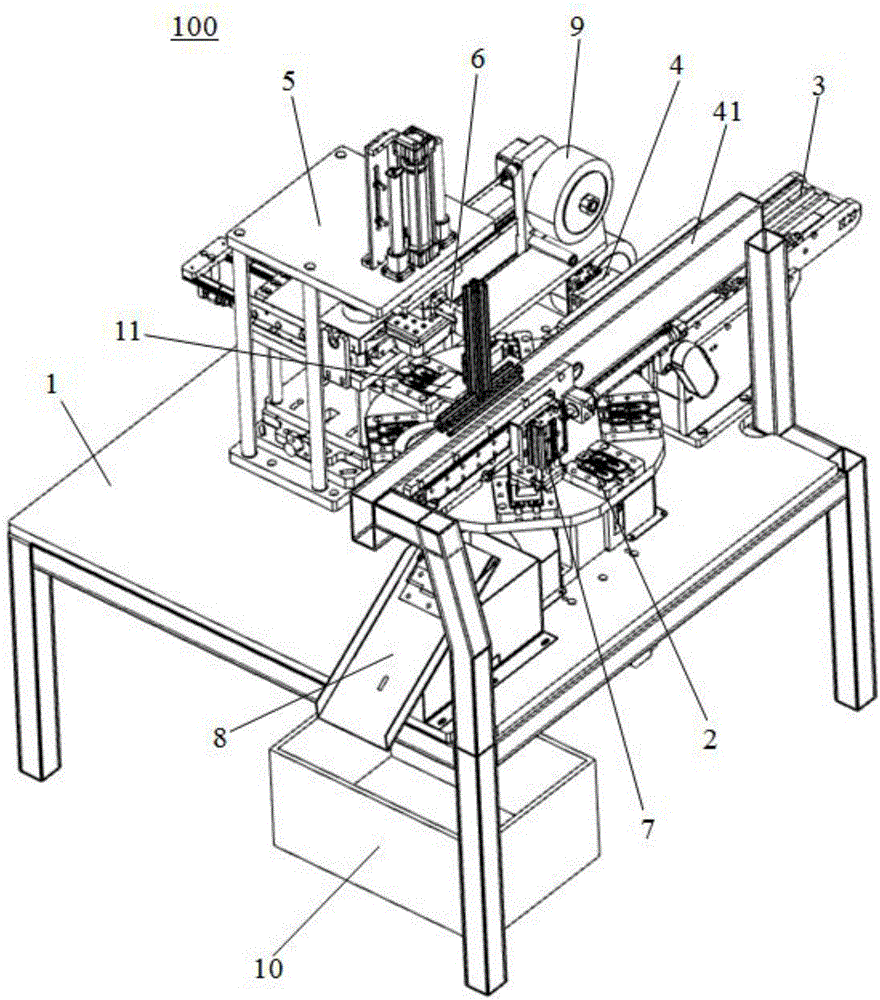

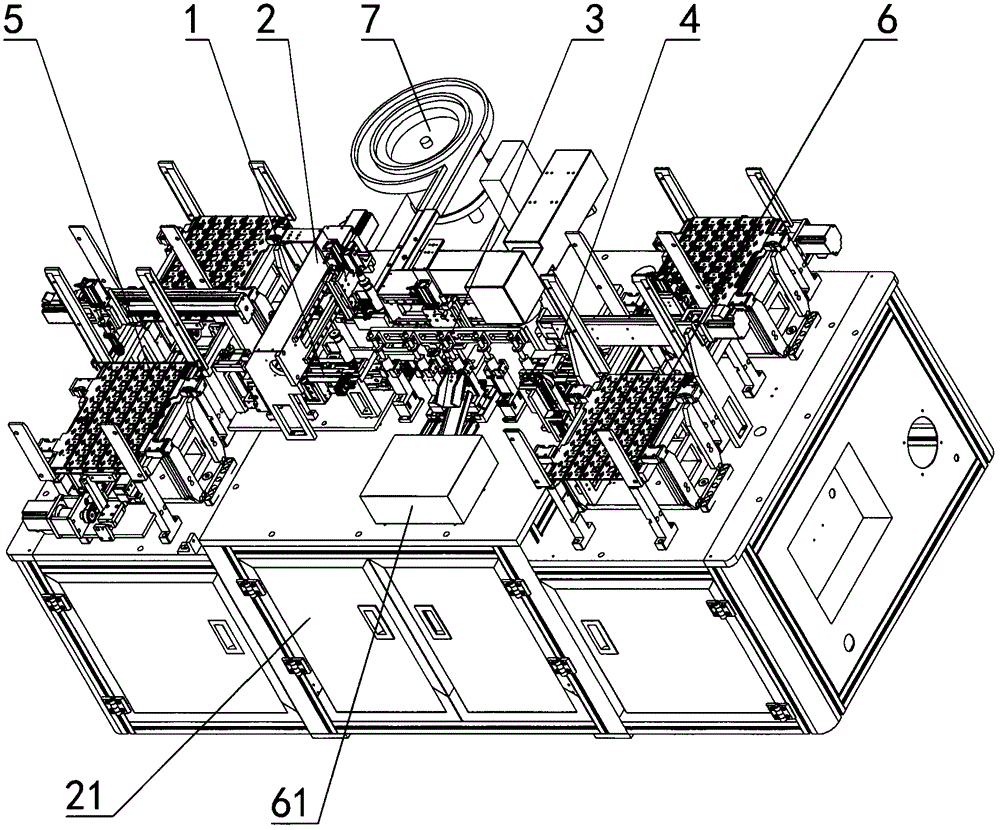

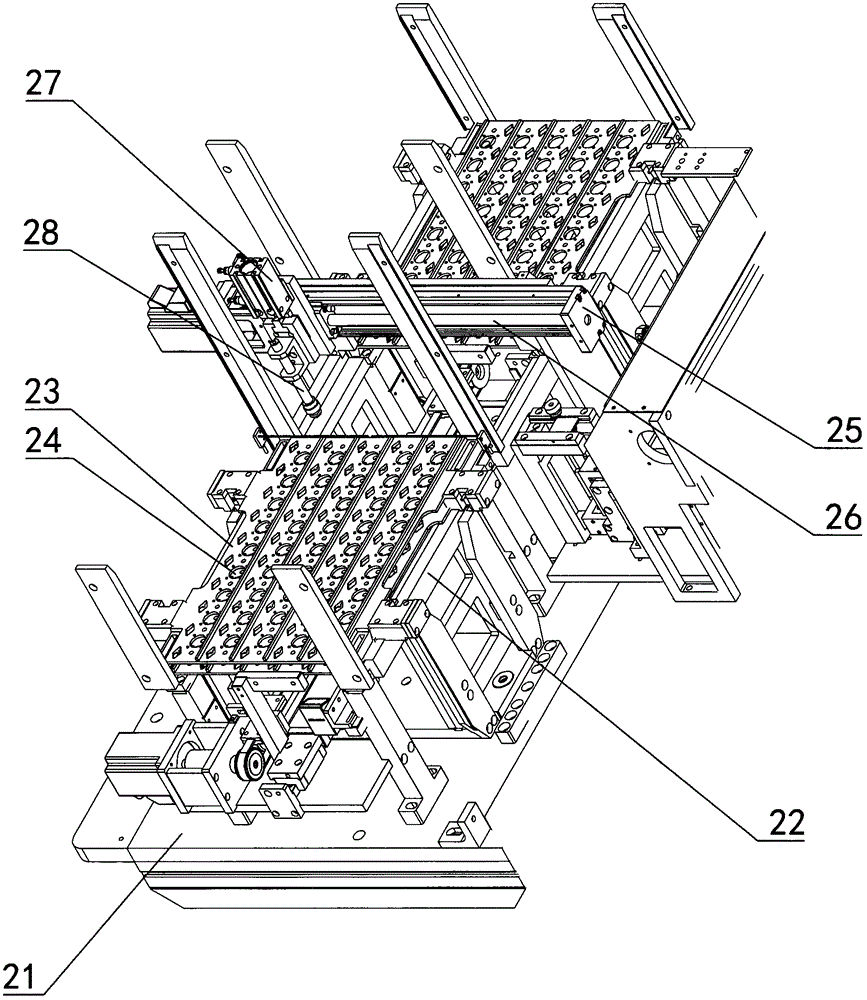

The invention discloses an automatic holographic management system integrating detection of an electric energy meter and warehousing management, comprising an automatic pipelining standard device for detection of the electric energy meter, an unboxing machine, a boxing machine and a three-dimensional table library; wherein the three-dimensional table library is respectively connected with the boxing machine and the unboxing machine; and the boxing machine and the unboxing machine are respectively connected with the automatic pipelining standard device for detection of the electric energy meter by a conveying belt. The system changes large amount of repeated and mechanical manual modes in the whole process of the operation of the electric energy meter, and has the automatic functions of automatic delivery from the warehouse, automatic distribution, automatic feeding, automatic positioning, automatic wire connection, automatic image recognition, automatic temperature monitoring, automatic wire disconnection, automatic discharging, automatic boxing, automatic disc packing and automatic warehouse entry.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

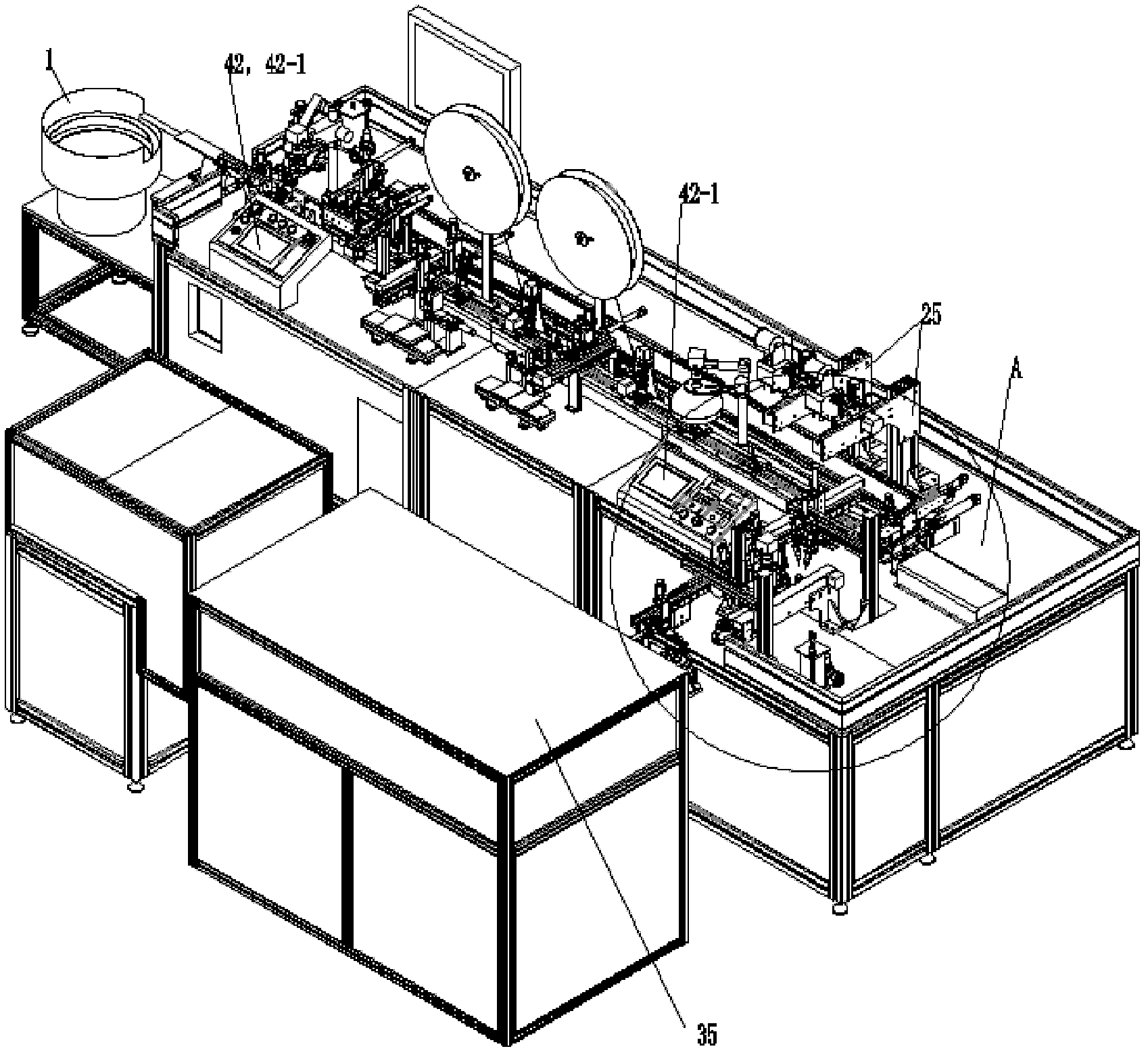

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

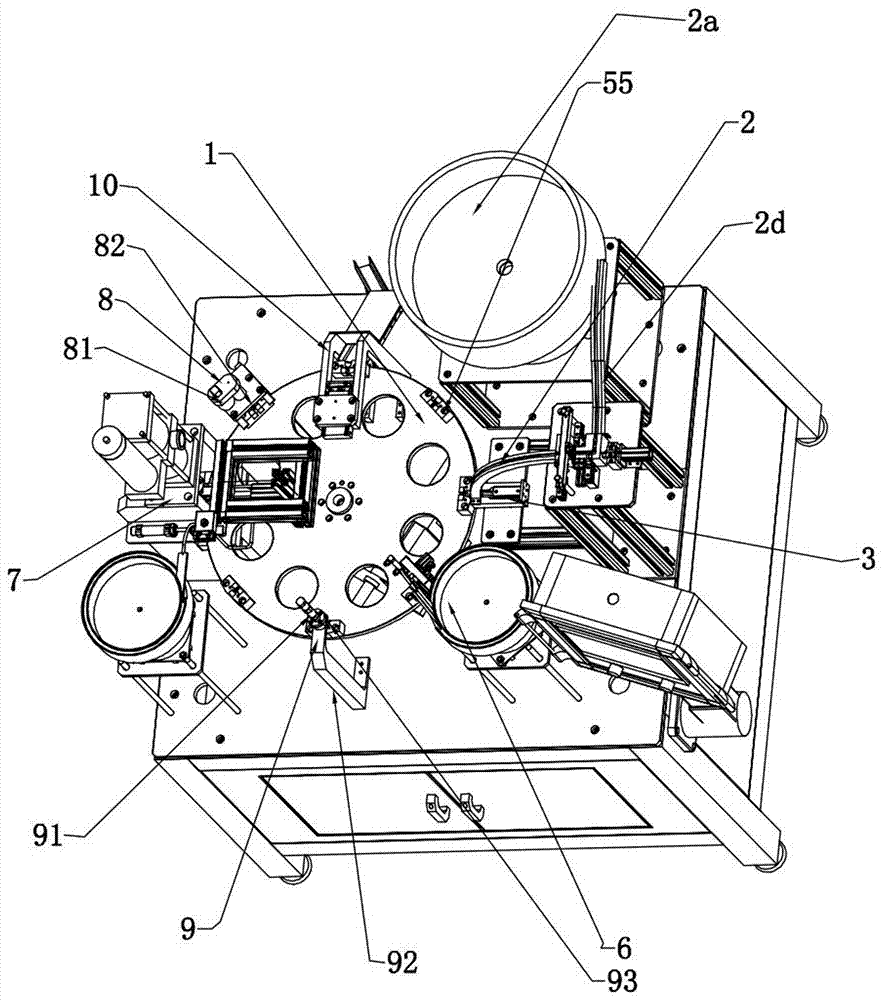

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

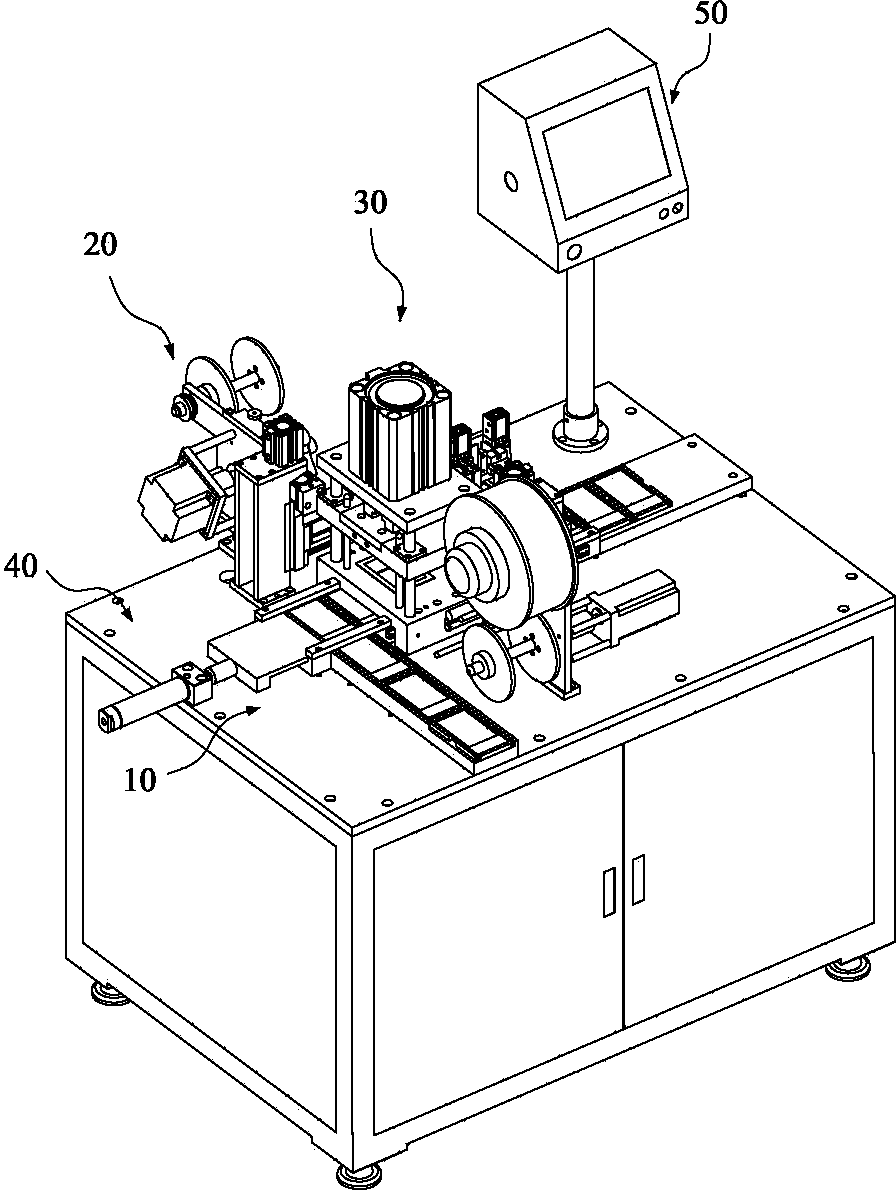

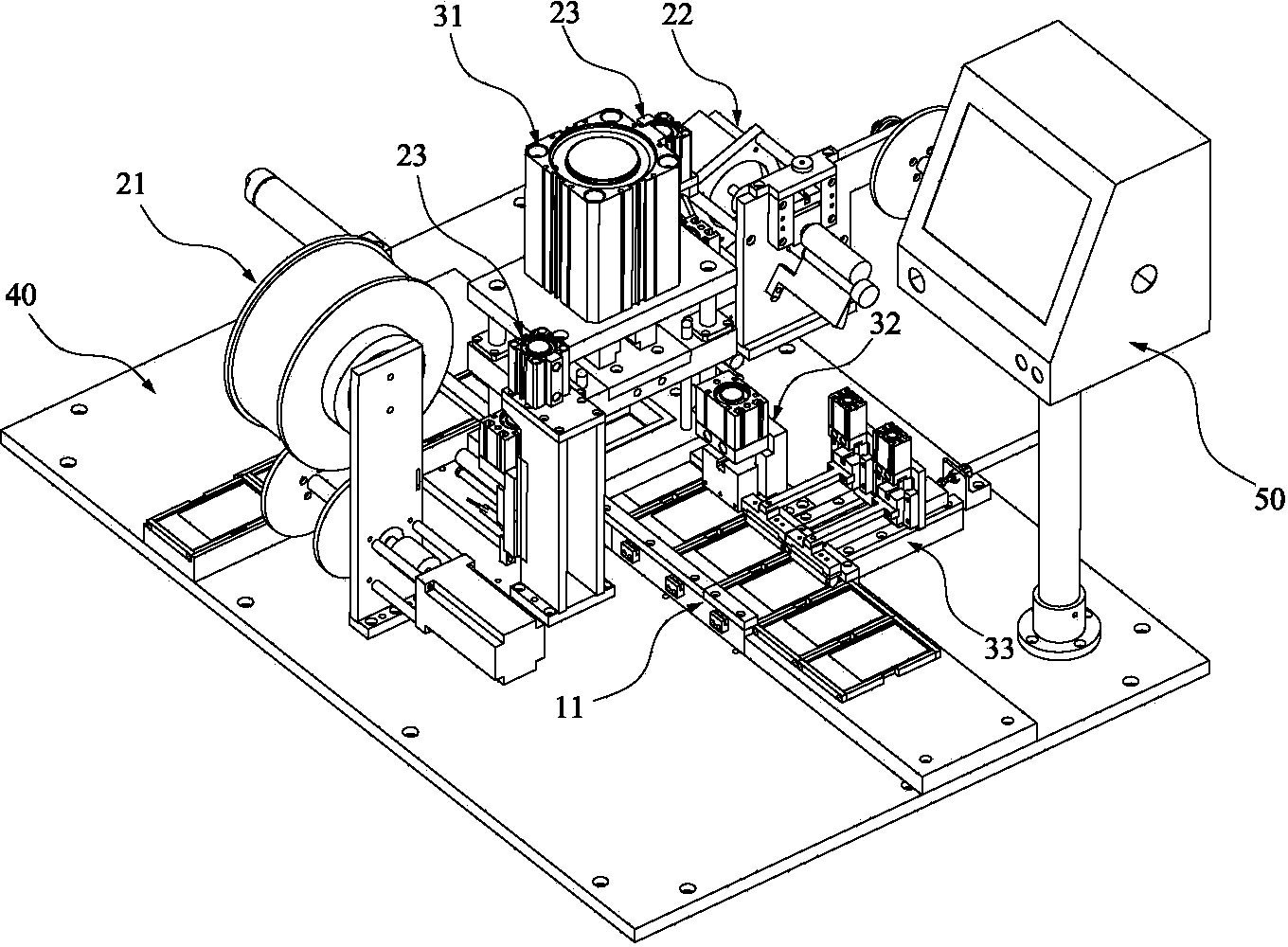

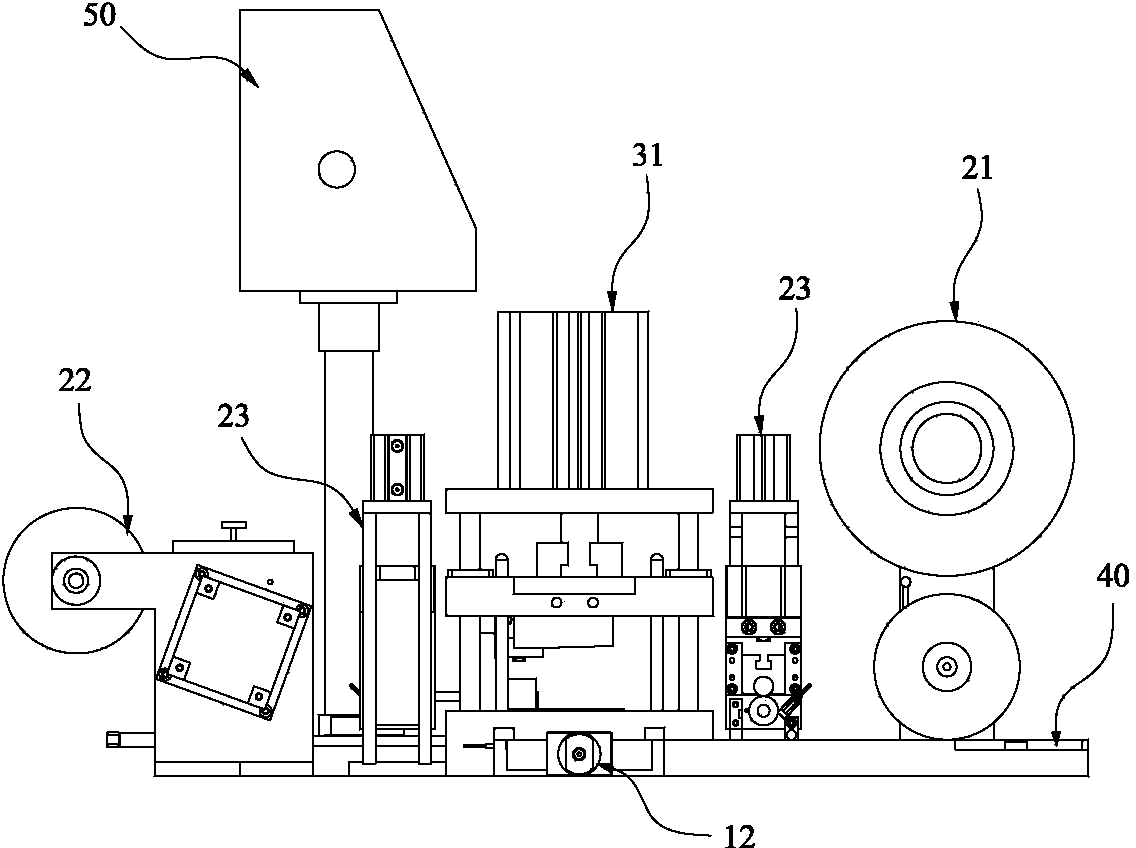

Automatic coating machine

InactiveCN103359313ARealize automatic feeding processImprove positionPackagingCoating systemEngineering

The invention discloses an automatic coating machine which comprises a work platform as well as a product conveying system, a coating system and a protection film conveying and recycling system which are arranged on the work platform, wherein the protection film conveying and recycling system comprises an adhesive tape conveying part and a protection film residue recovering part. When the machine runs, the product conveying system is used for automatically conveying a product and a protection film to a coating station, the coating system is used for cutting the protection film and applying the cut protection film to the surface of the product, production film residues generated during cutting of the production film are automatically recycled after the coating action is finished, and the product is automatically conveyed out, wherein the two-time rolling operation is performed to completely squeeze out air in the protection film to enable the protection film to completely cling to the product before the product is conveyed out. According to the automatic coating machine, the automatic coating operation is finished instead of a manual coating operation, the coating efficiency can be effectively improved, the manpower cost is reduced, the coating operation is simpler and easy, air bubbles in the protection film are squeezed out to enable the protection film to completely cling to the product, and the coating effect is ideal.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

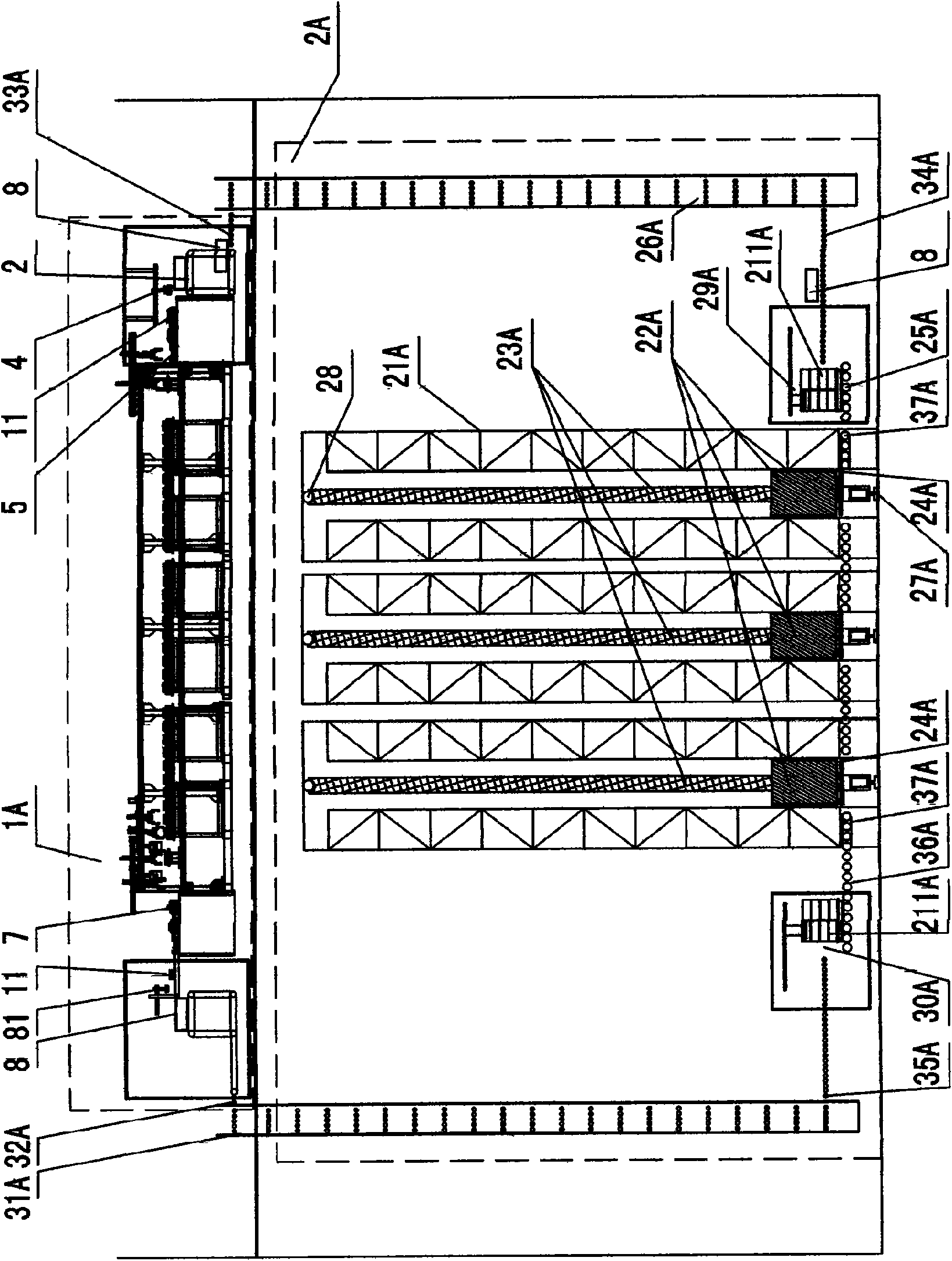

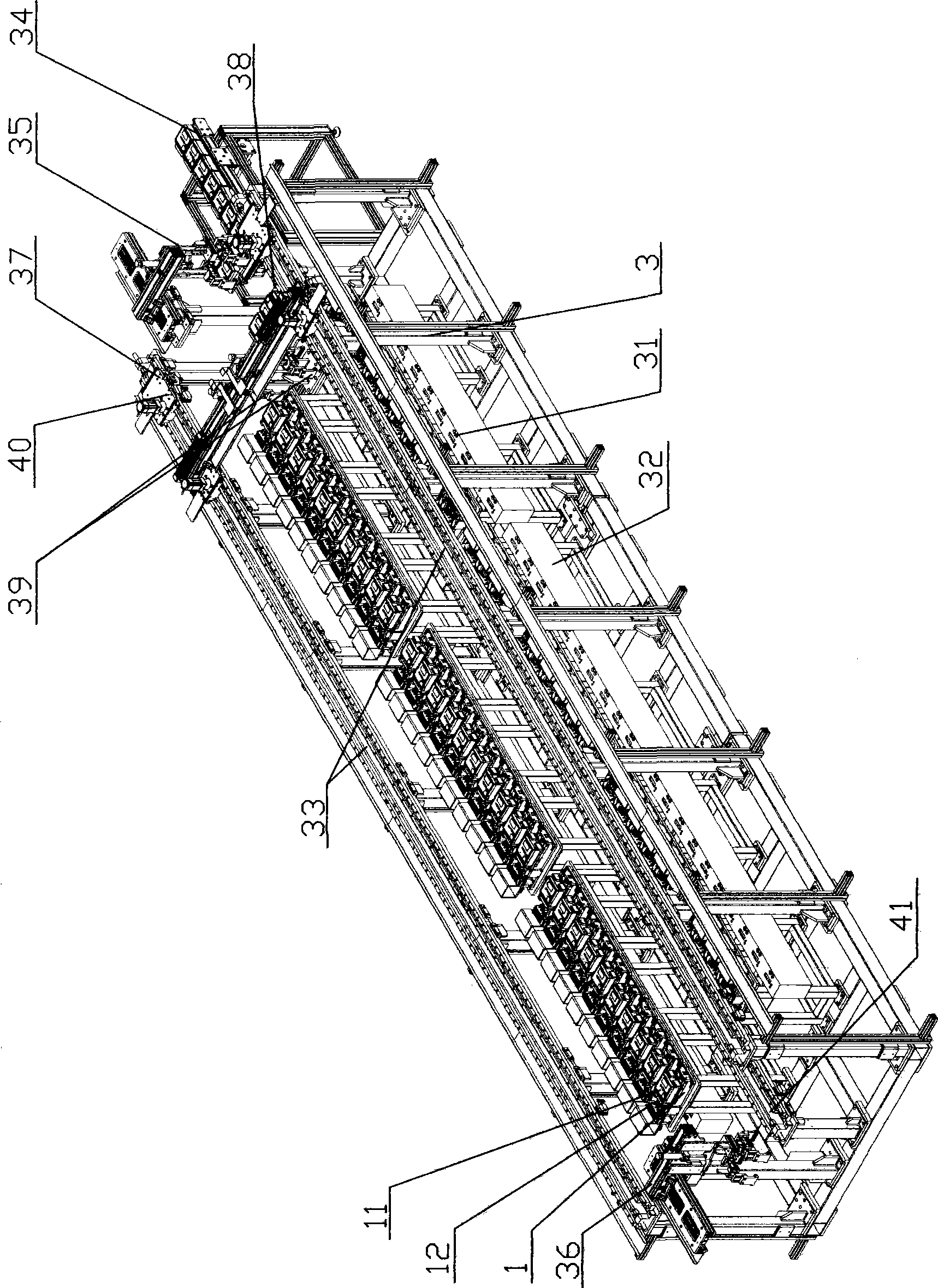

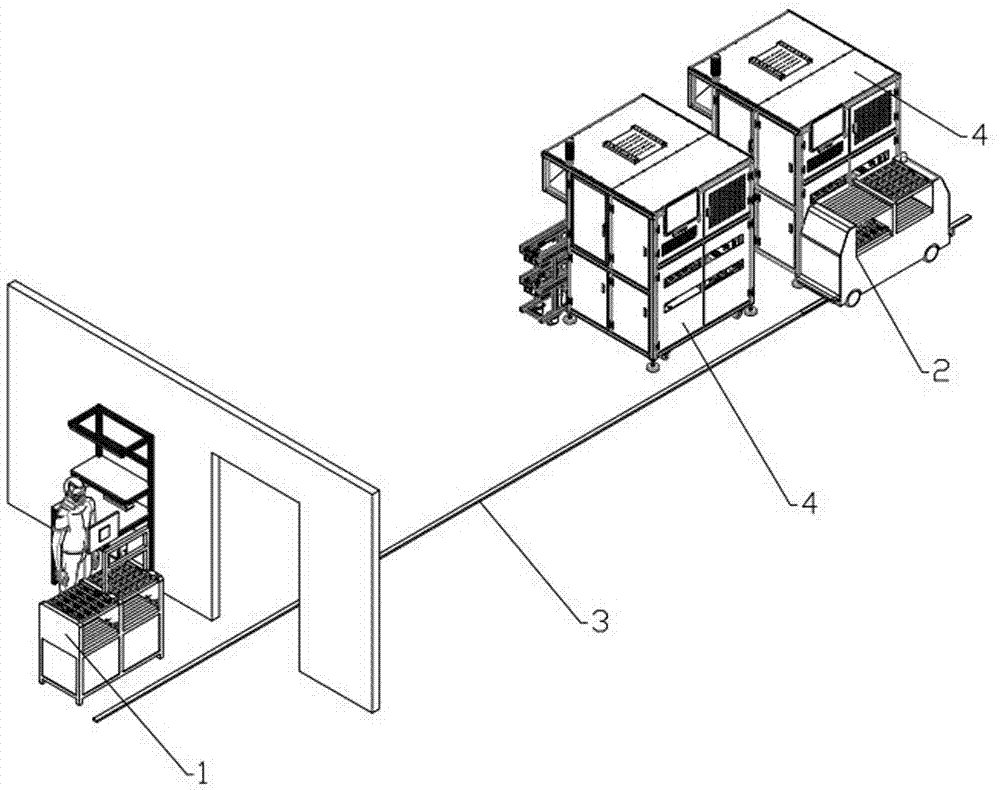

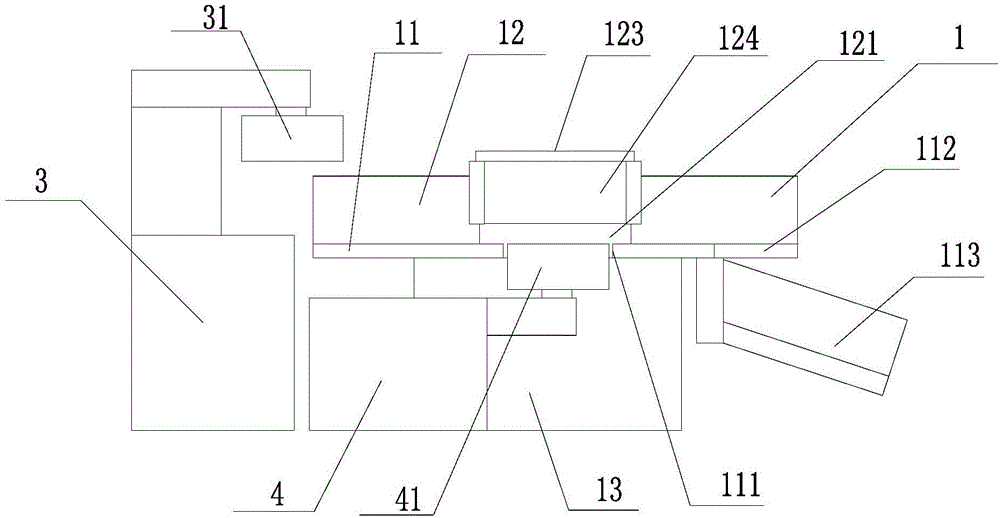

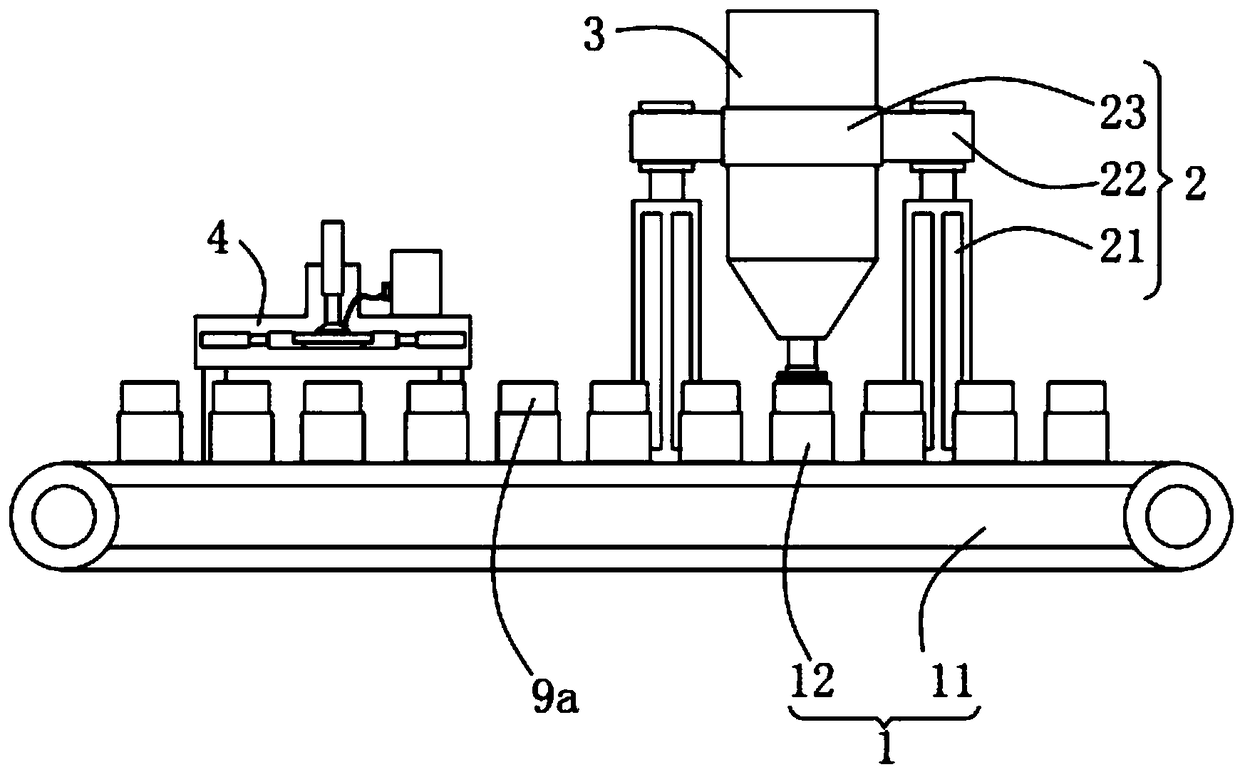

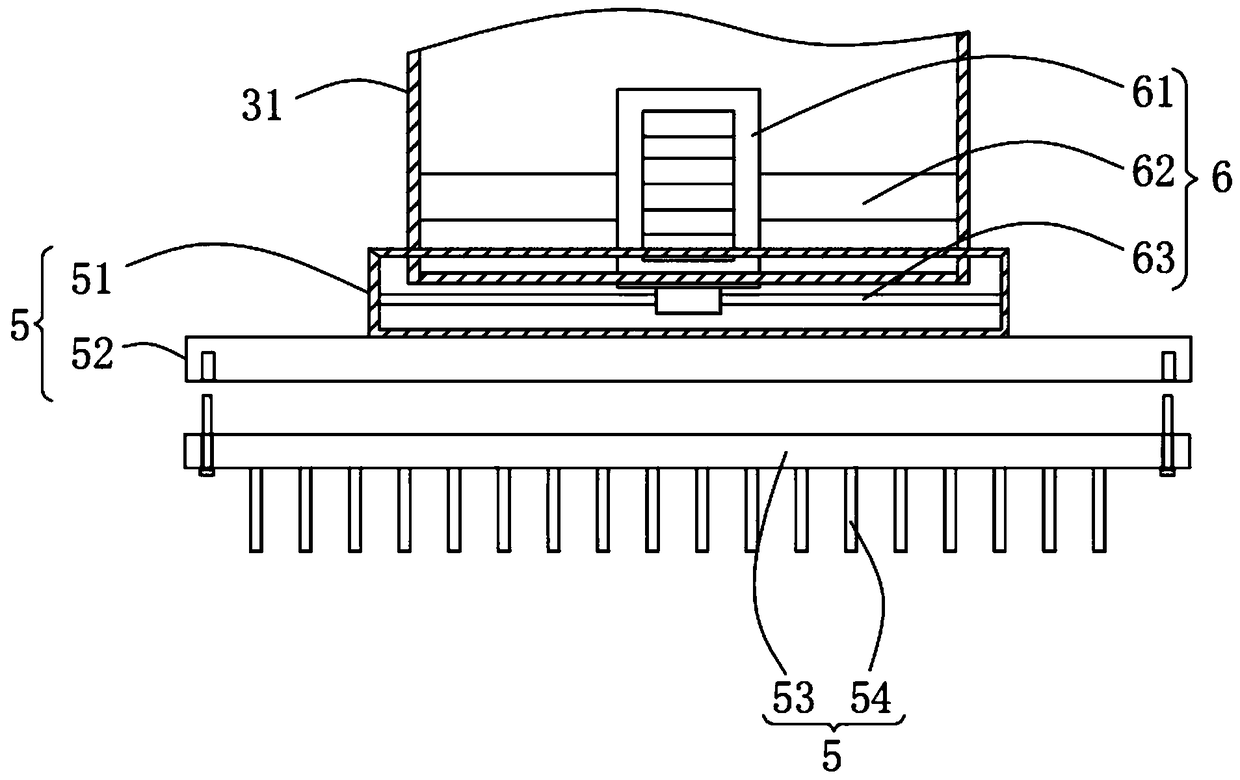

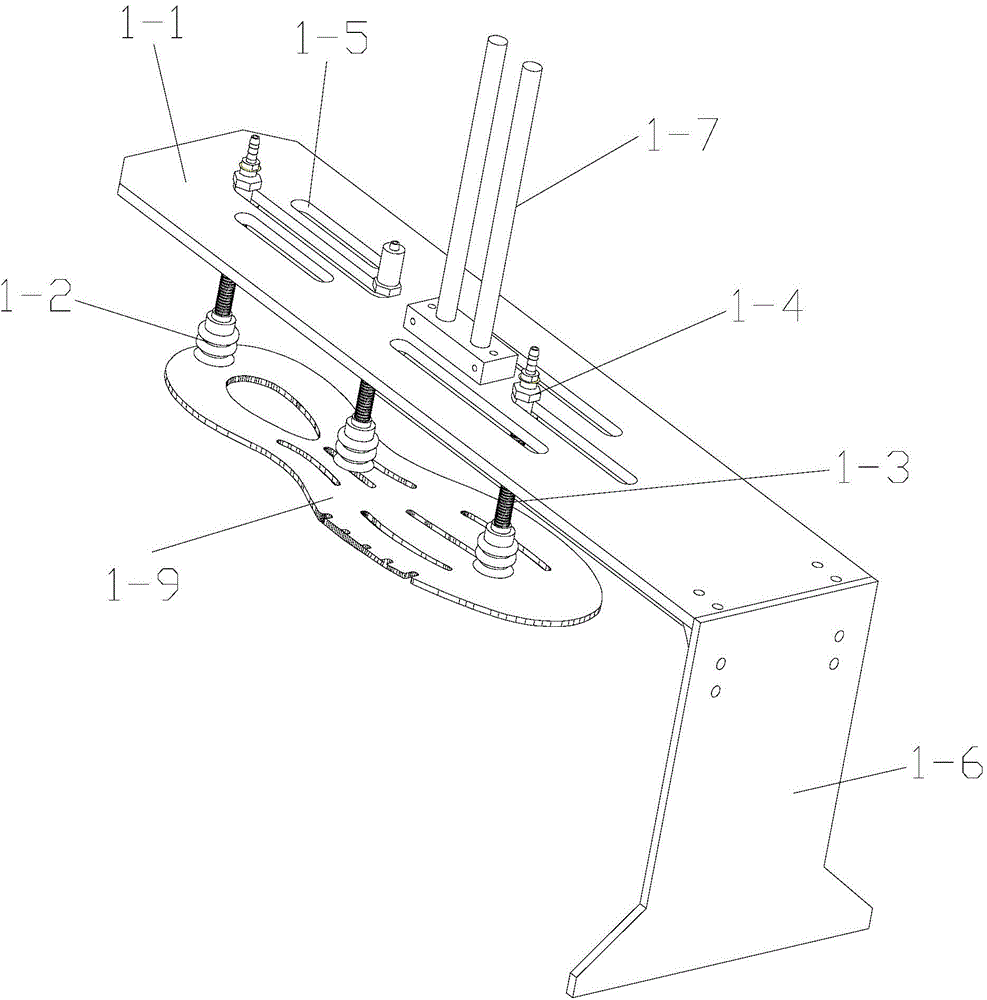

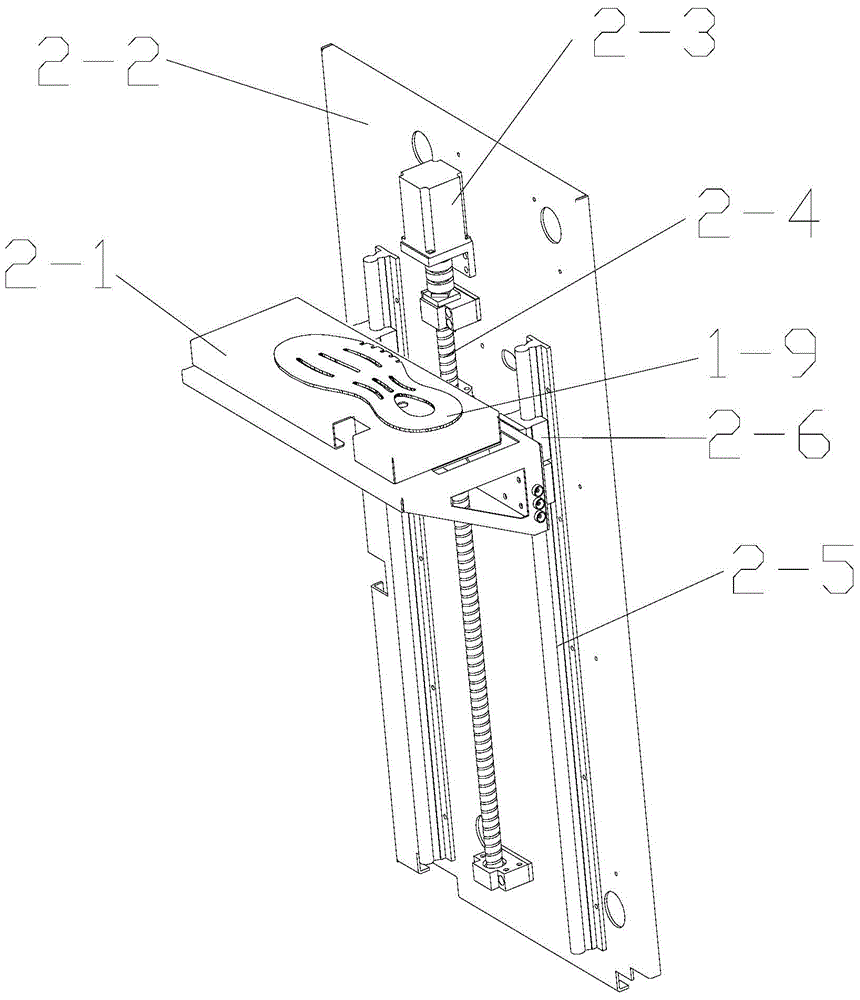

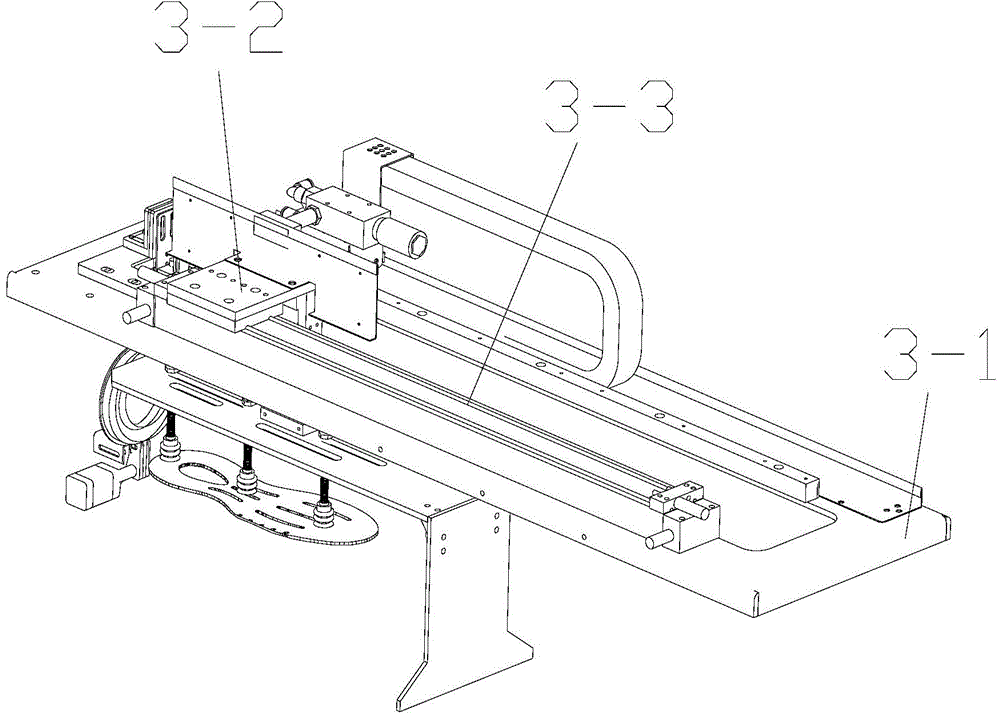

Automatic assembly line standard apparatus for electric energy meter calibration

ActiveCN101464504ARealize automatic feeding processAchieve contactElectrical measurementsProduction lineElectrical connection

The invention discloses an automatic production line standard device detected by an electric energy meter, which comprises a loading platform, a feeding loop line belt and an electric energy meter automatic standard device. The loading platform is connected with the feeding loop line belt; a material taking manipulator and a bar code reader are mounted on the feeding loop line belt; the feeding loop line belt is connected with the electric energy meter automatic standard device; the electric energy meter automatic standard device is simultaneously connected with a blanking conveying loop line belt; a loading manipulator and another bar code reader are mounted on the blanking conveying loop line belt; the loading manipulator is connected with an electric energy meter feeding box; an unqualified product outlet is formed on the blanking conveying loop line belt; the working process of the whole production line in the whole device is controlled by a computer program through a production line control cabinet; and the calibration / detection of the electric energy meter is controlled by a computer calibrating procedure through a calibrating control cabinet. The invention has the advantages of completely improving the calibrating / detecting work efficiency, reducing the labor intensity, improving the work quality, achieving the reliability and the safety of electrical connection, etc.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

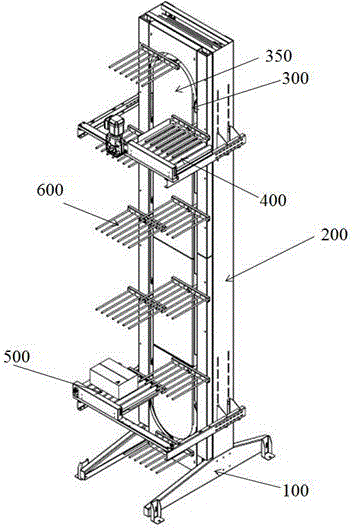

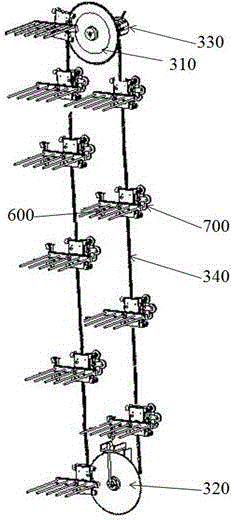

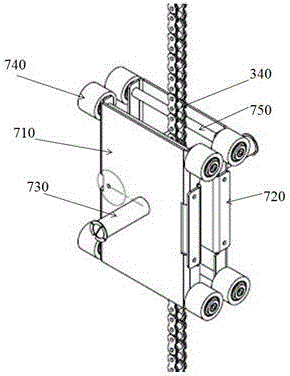

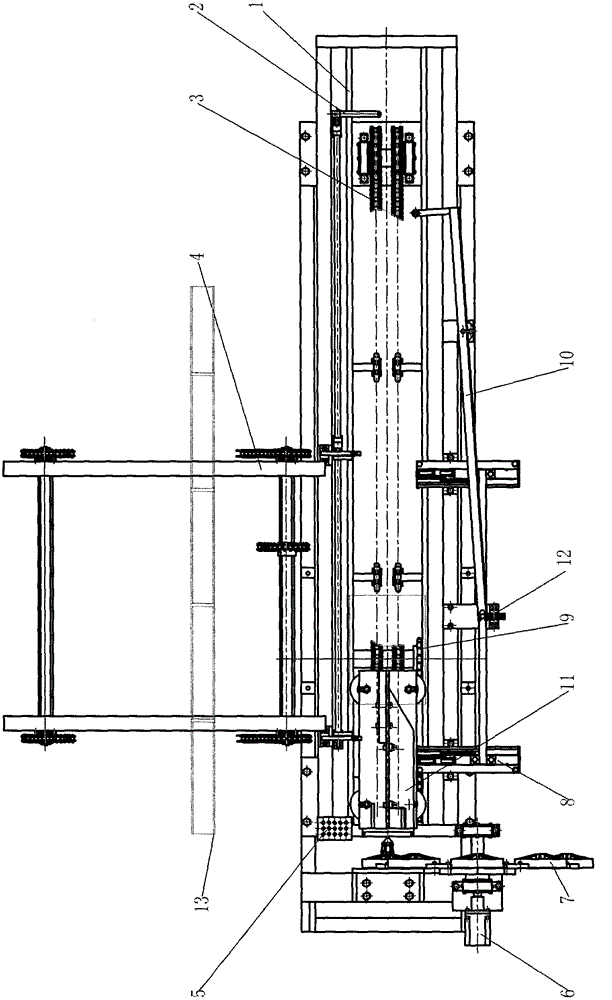

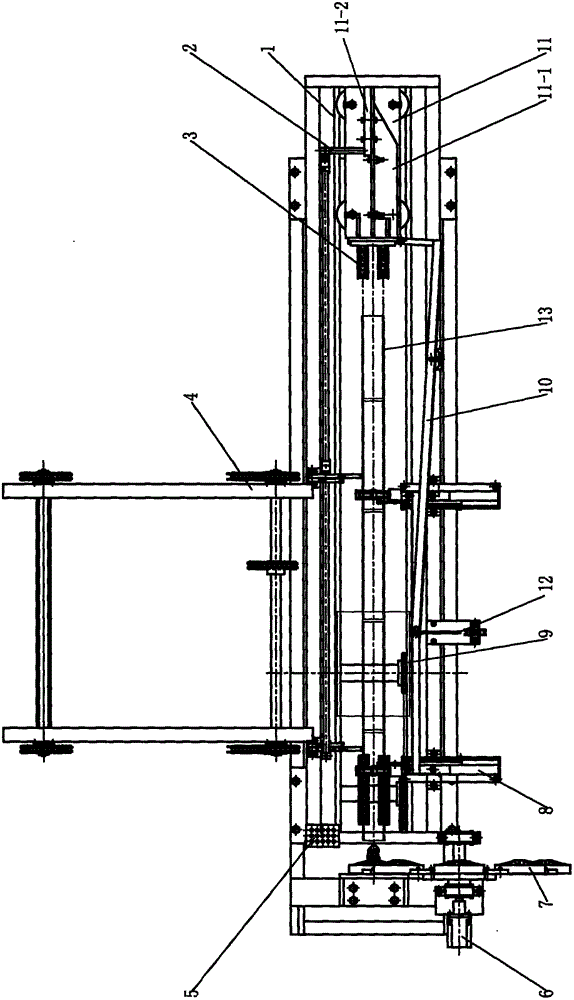

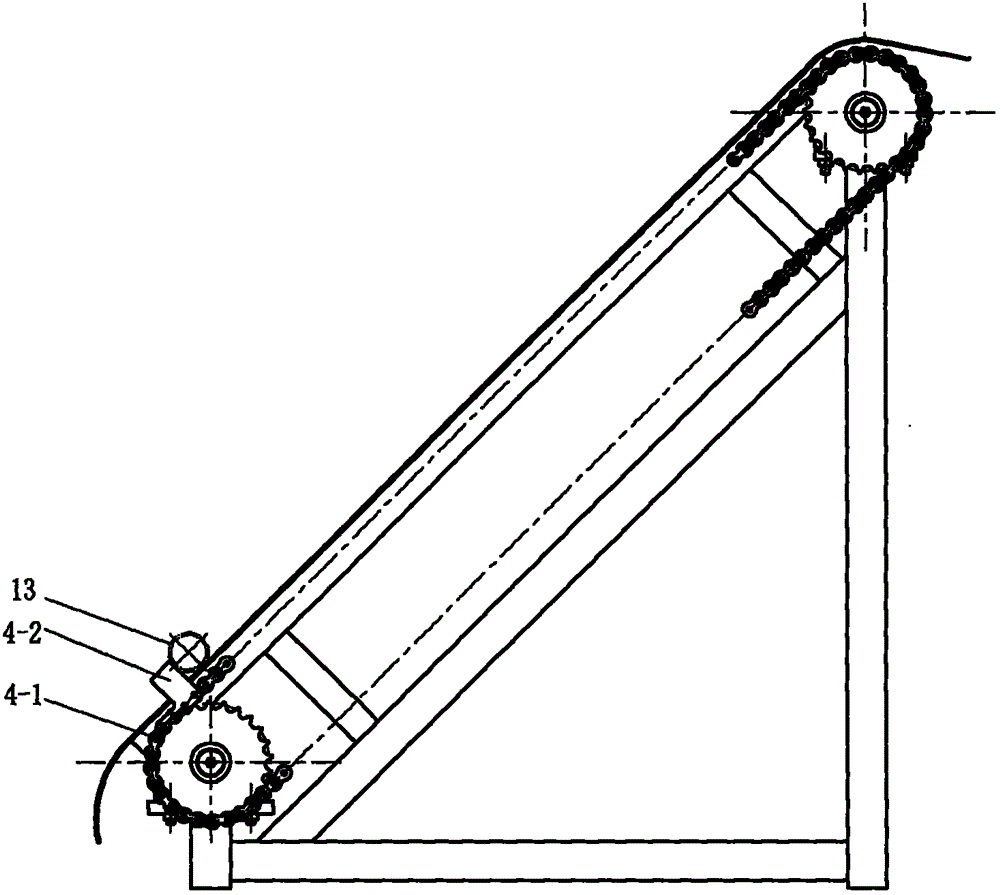

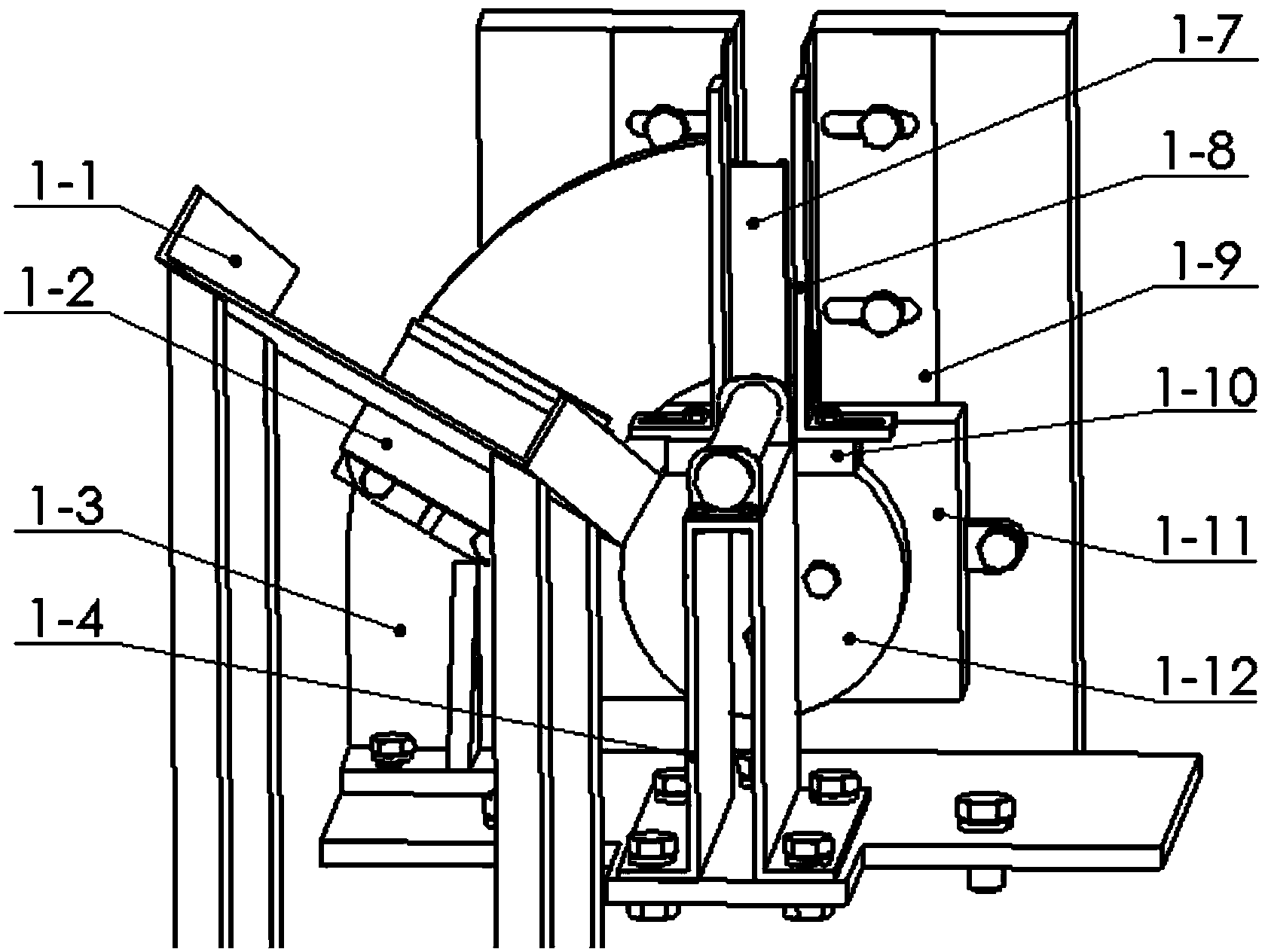

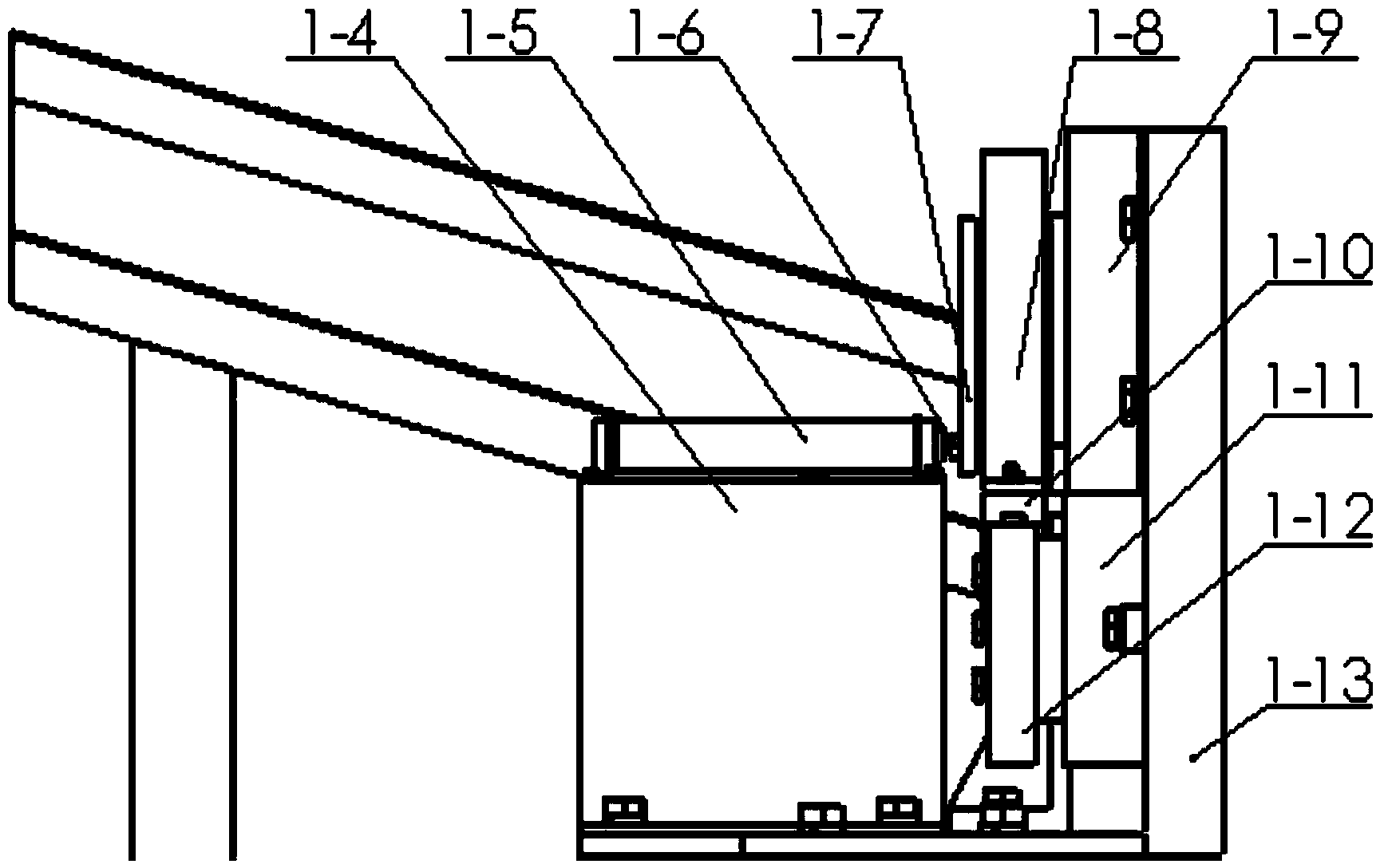

Circulating vertical conveyer

InactiveCN106697750ACompact structureSmall footprintConveyorsConveyor partsDrive motorSmall footprint

The invention provides a circulating vertical conveyer comprising bases, a rack, a driving gear, a driven gear, a feeding and conveying device, a discharging and conveying device, a plurality of moving retainers and fork rods; the rack is fixedly arranged on the bases and is provided with a guide rail; the driving gear is mounted on the guide rail, and the rear of the driving gear is provided with a driving motor; the driven gear is mounted on the guide rail and is connected with the driving gear by a driving chain; the feeding and conveying device is mounted at the upper end of the guide rail; the discharging and conveying device is fixedly arranged at the lower end of the guide rail; the plurality of moving retainers are uniformly and fixedly arranged on the driving chain at intervals; and the fork rods are fixedly arranged on shaft sleeves of the moving retainers. The circulating vertical conveyer is compact in structure, small in floor area, high in circulating speed, capable of realizing automatic feeding and discharging, keeping the stability of goods in a moving process and preventing the goods from shaking or dropping in the moving process and particularly suitable for the situations that the plant layout is urgent, the production speed is high, and a product is required to be vertically conveyed from a high position to a low position or is vertically lifted from the low position to the high position.

Owner:广州市烨兴融集团有限公司

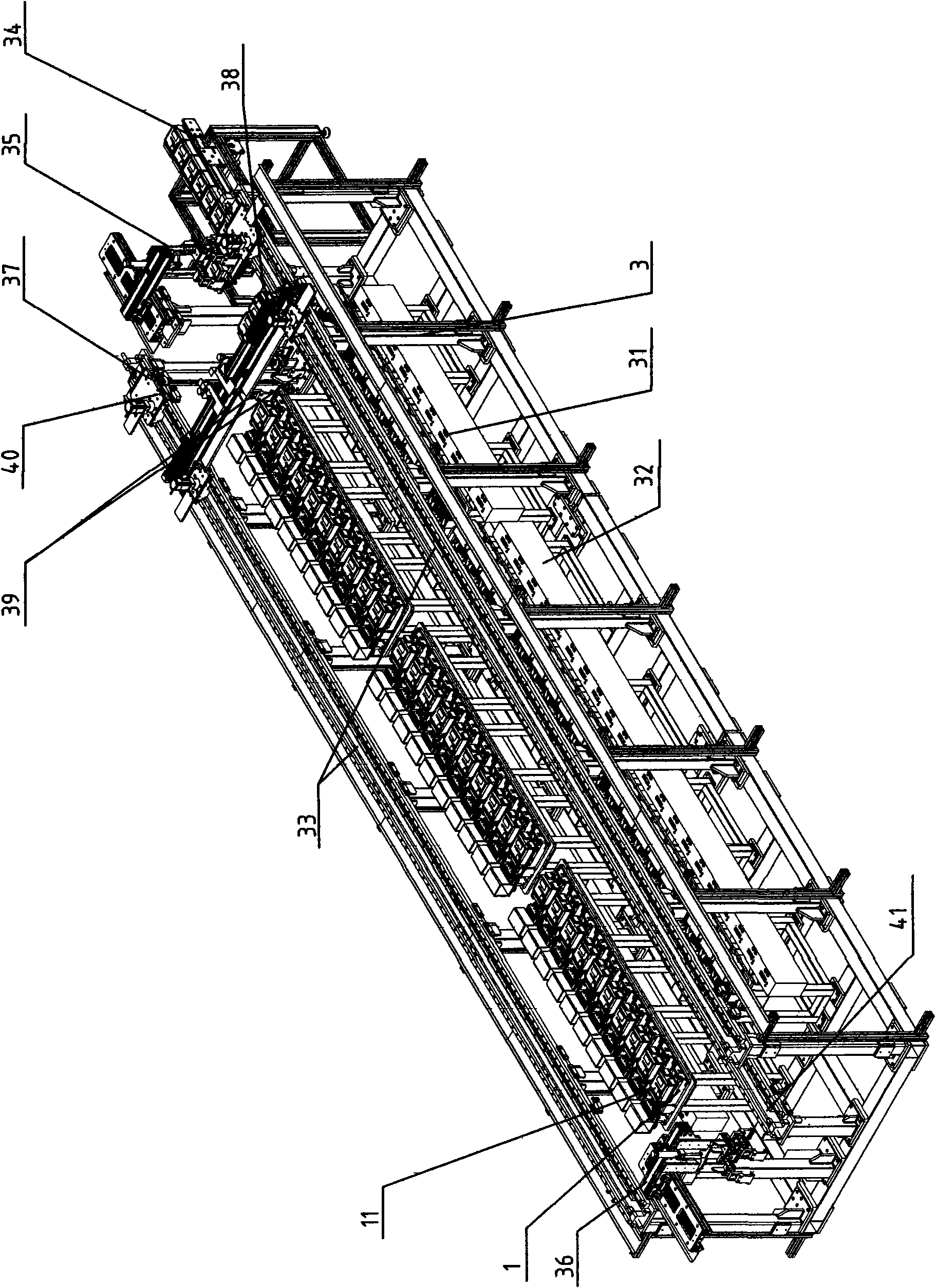

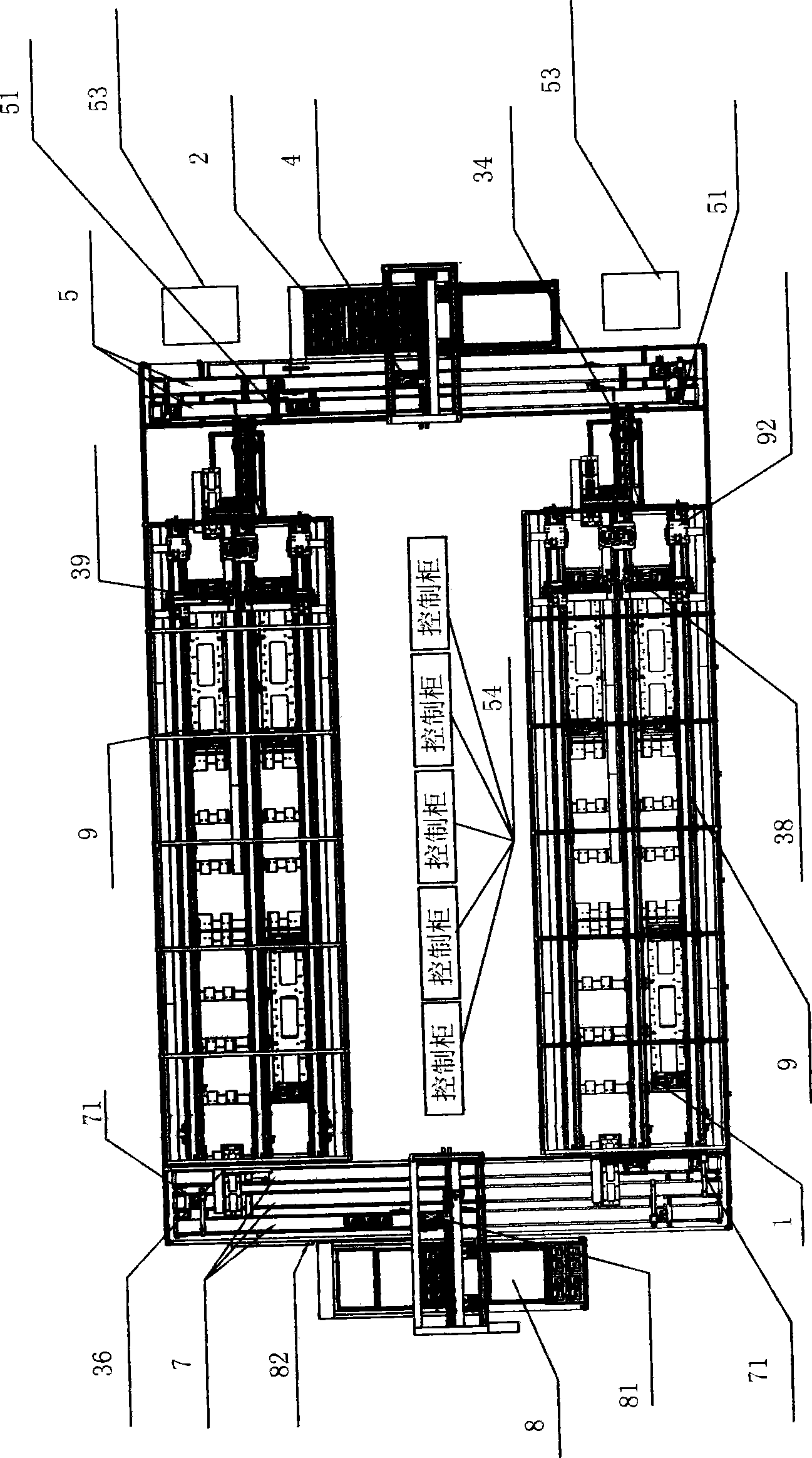

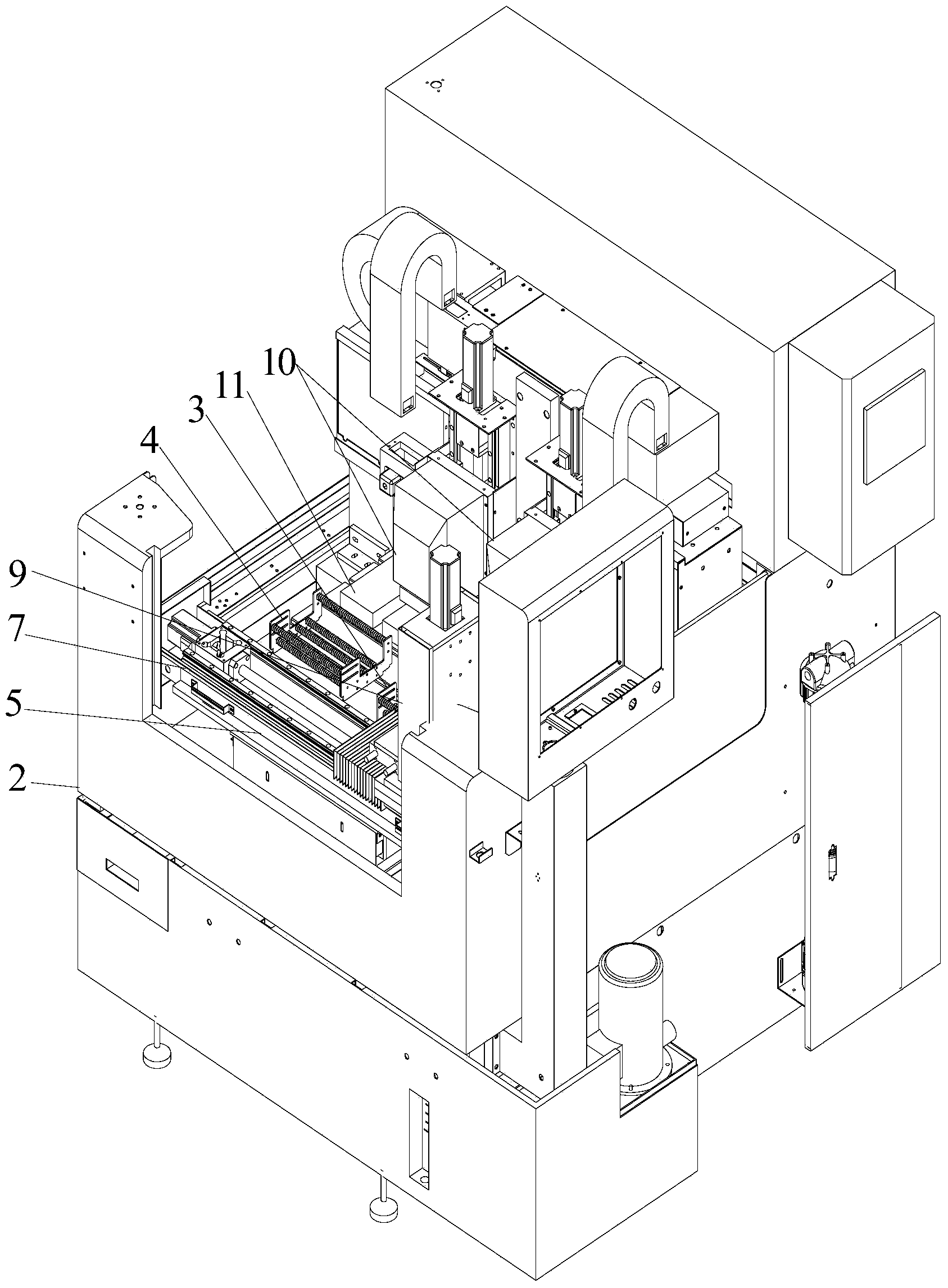

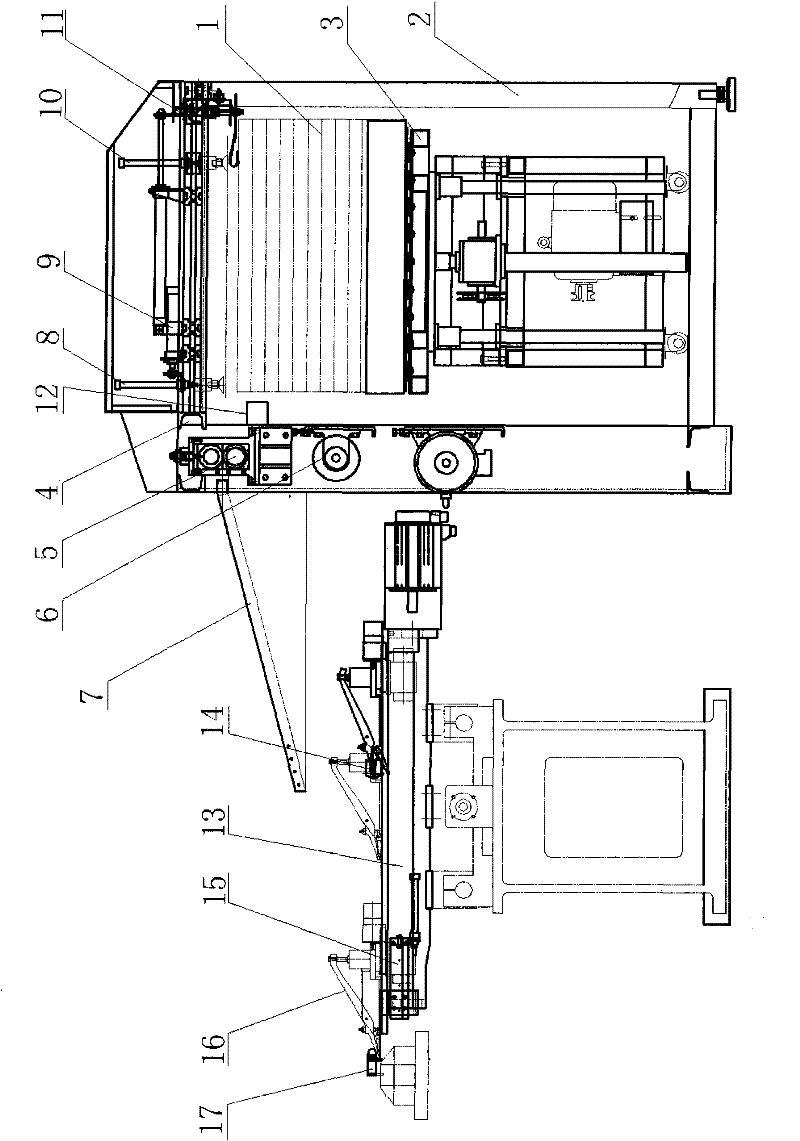

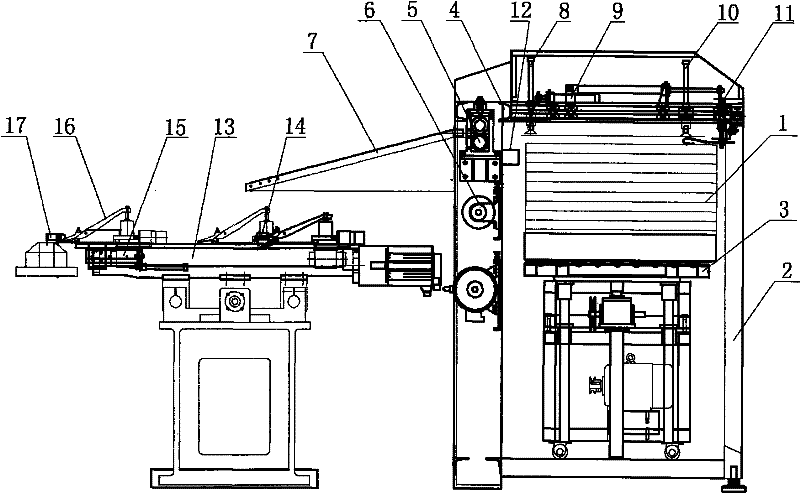

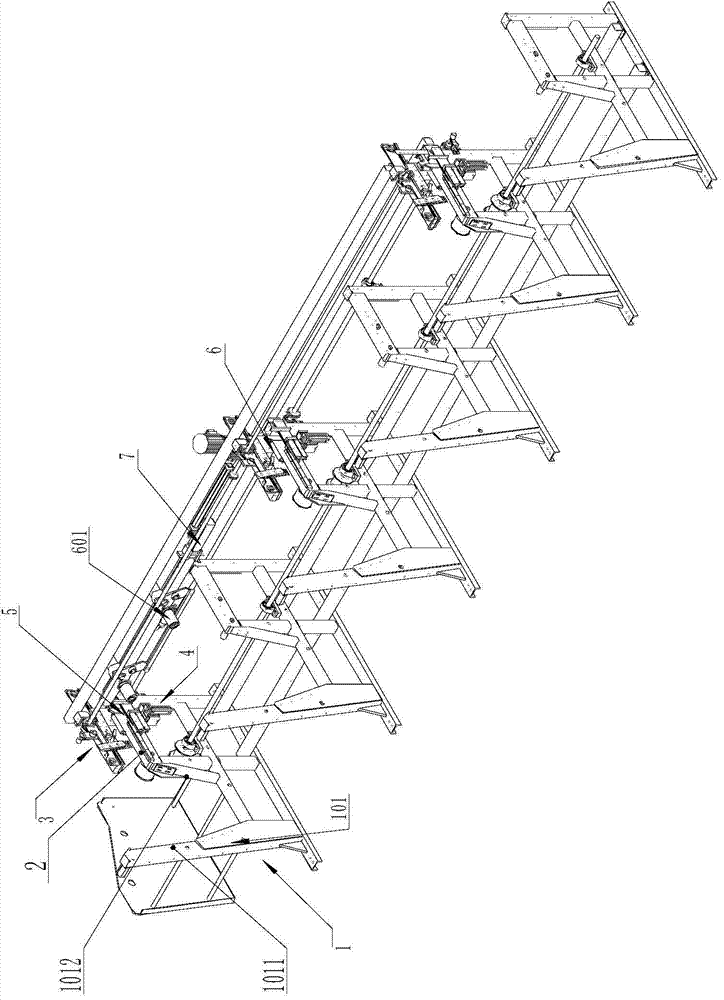

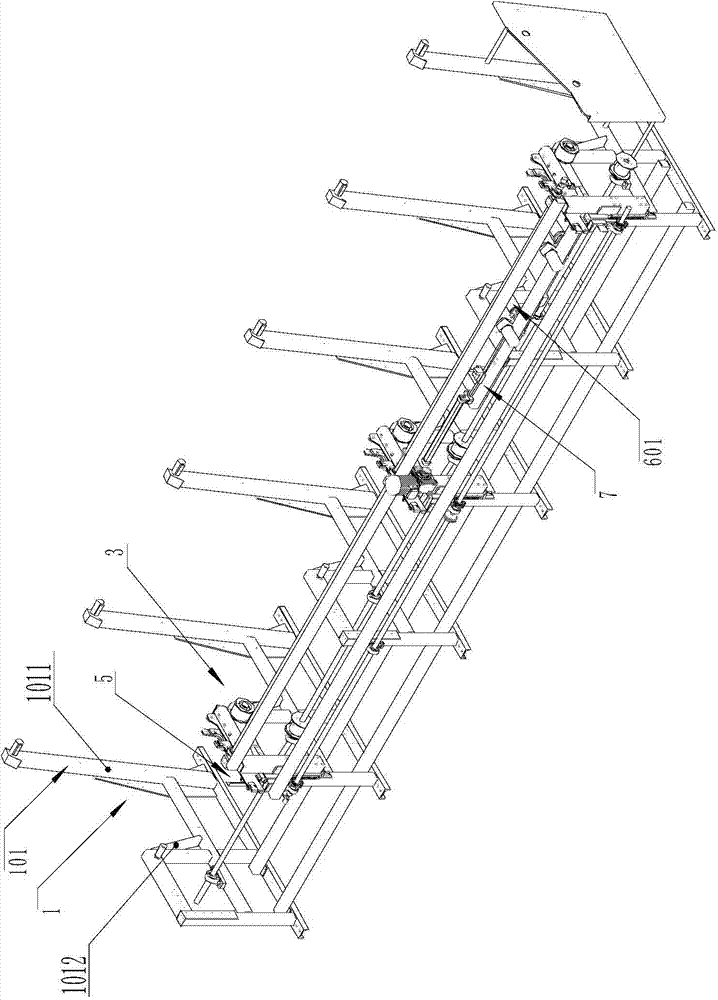

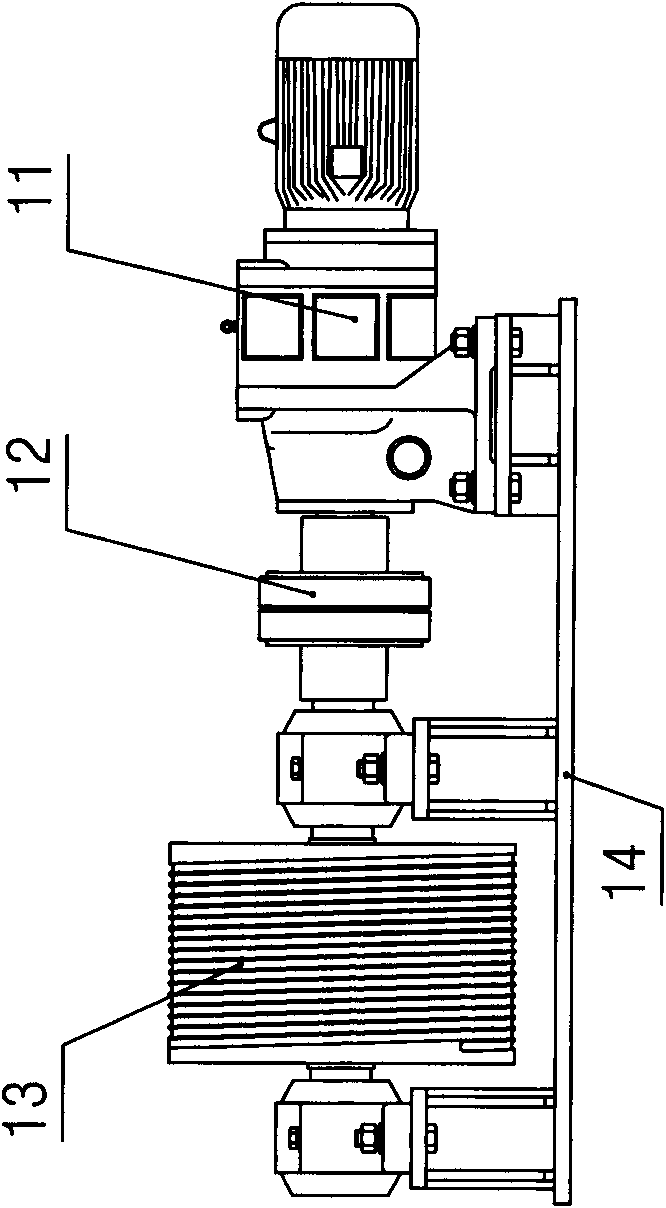

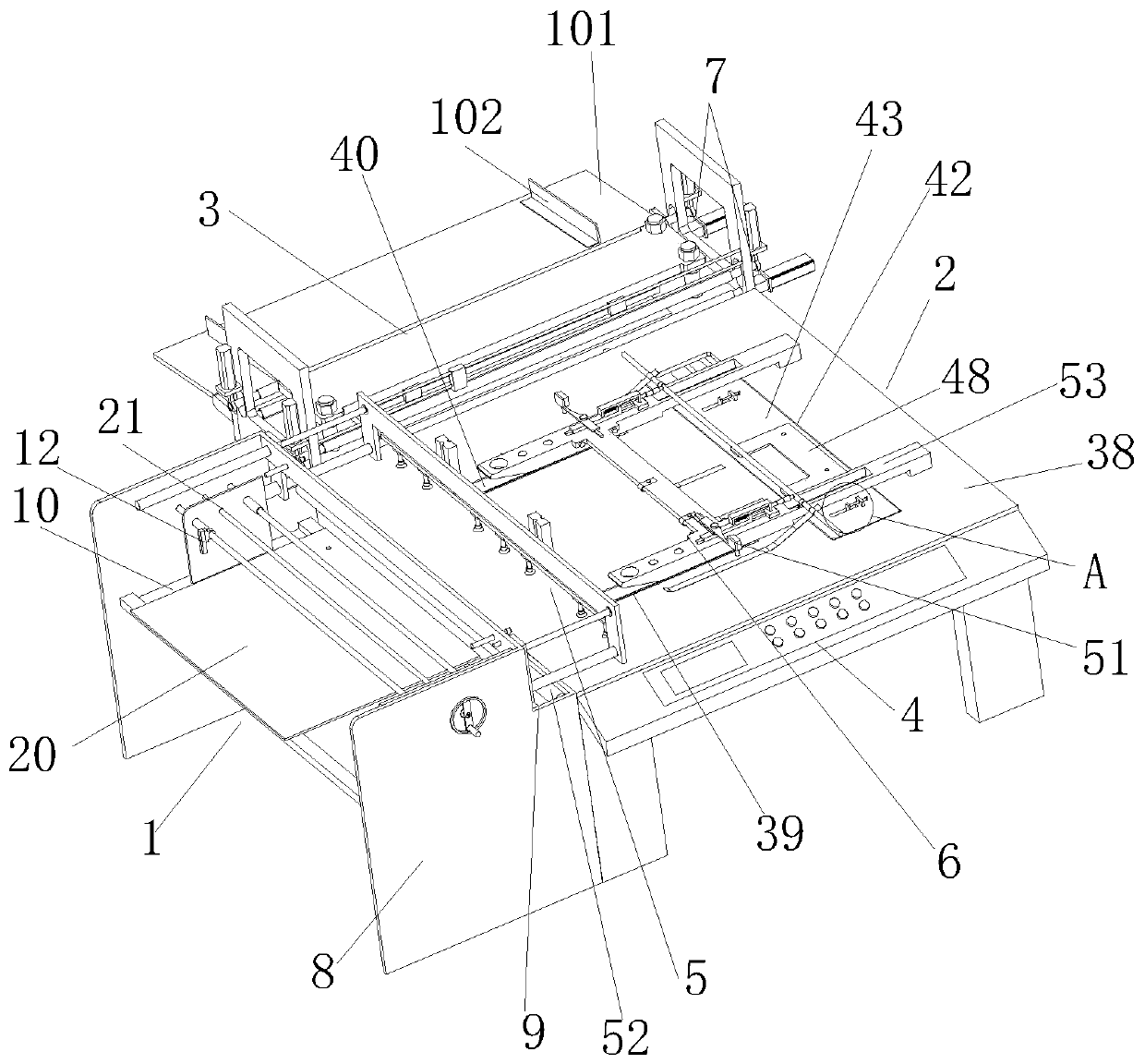

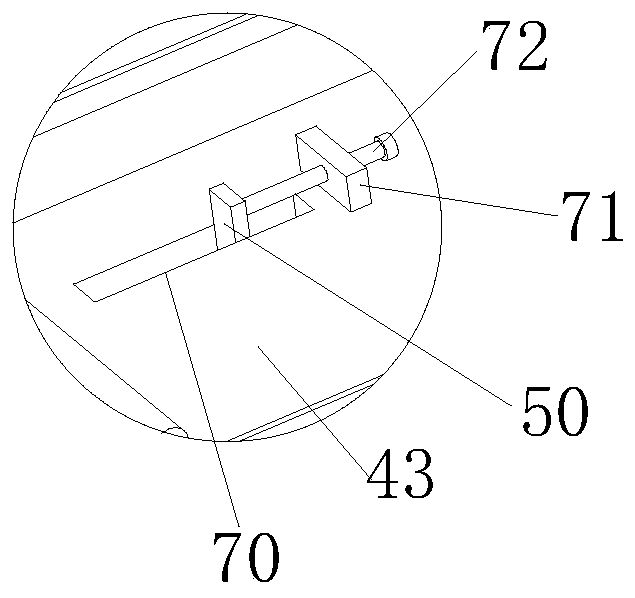

Longitudinal and transverse cutting computer cut-to-size saw equipment

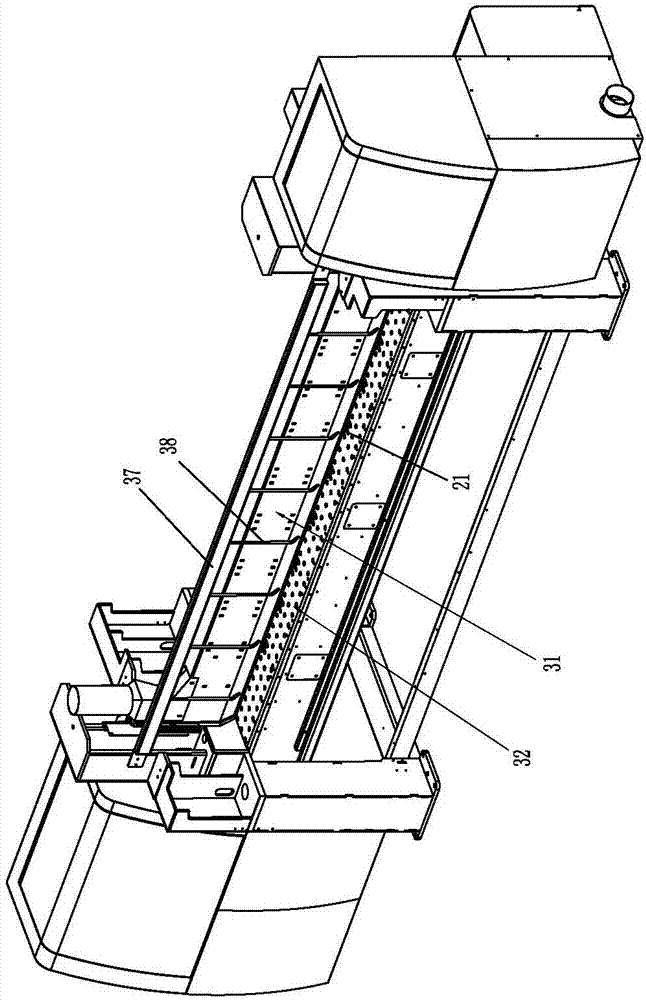

ActiveCN106965261ARealize automatic feeding processImprove processing efficiencyFeeding devicesBark-zones/chip/dust/waste removalEngineeringWaste treatment

The invention discloses longitudinal and transverse cutting computer cut-to-size saw equipment which comprises a control unit, a feed unit, a longitudinal sawing unit, a transition feed unit, a lift type longitudinal and transverse bidirectional conveying platform, a transverse sawing unit and an excess material and waste treatment unit. The longitudinal sawing unit comprises a longitudinal sawing main machine rack, a longitudinal sawing saw carriage, a longitudinal sawing pressure cross beam, a longitudinal sawing plate front alignment device, a longitudinal sawing feed pushing rod cross beam assembly and a first conveying platform. The transition feed unit comprises a feed hooking hand mechanism, an excess material discharge mechanism and a second conveying platform. The lift type longitudinal and transverse bidirectional conveying platform comprises a transverse conveying unit and a longitudinal conveying unit which are arranged in a staggered mode. The transverse sawing unit comprises a transverse sawing main machine rack, a transverse sawing saw carriage, a transverse sawing pressure cross beam, a transverse sawing plate front alignment device and a third conveying platform. By adoption of the longitudinal and transverse cutting computer cut-to-size saw equipment, plate automatic feeding, automatic longitudinal cutting and automatic transverse cutting are achieved, trimming excess materials can be automatically treated, processing efficiency is greatly improved, and labor force is saved.

Owner:NANXING MACHINERY CO LTD

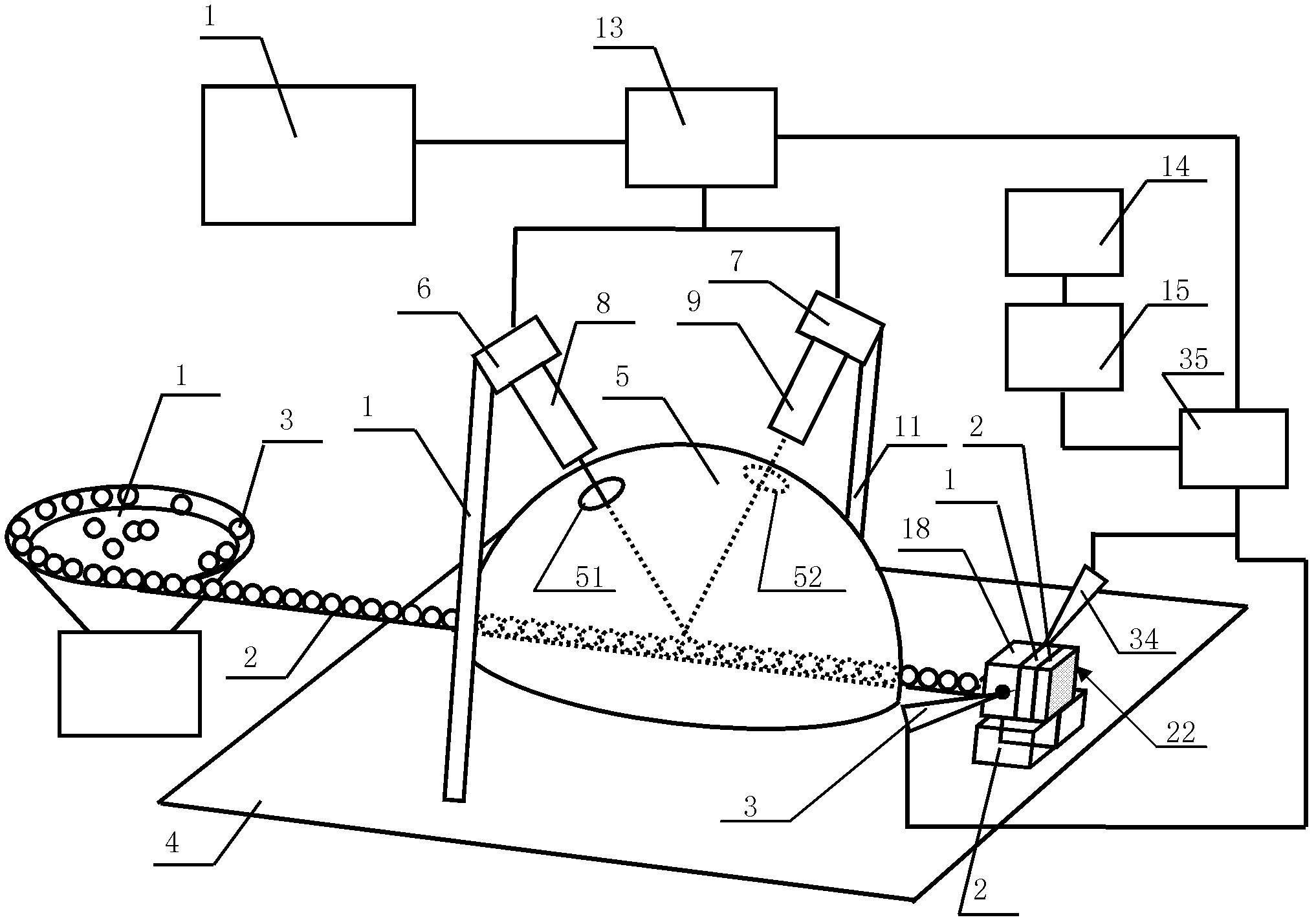

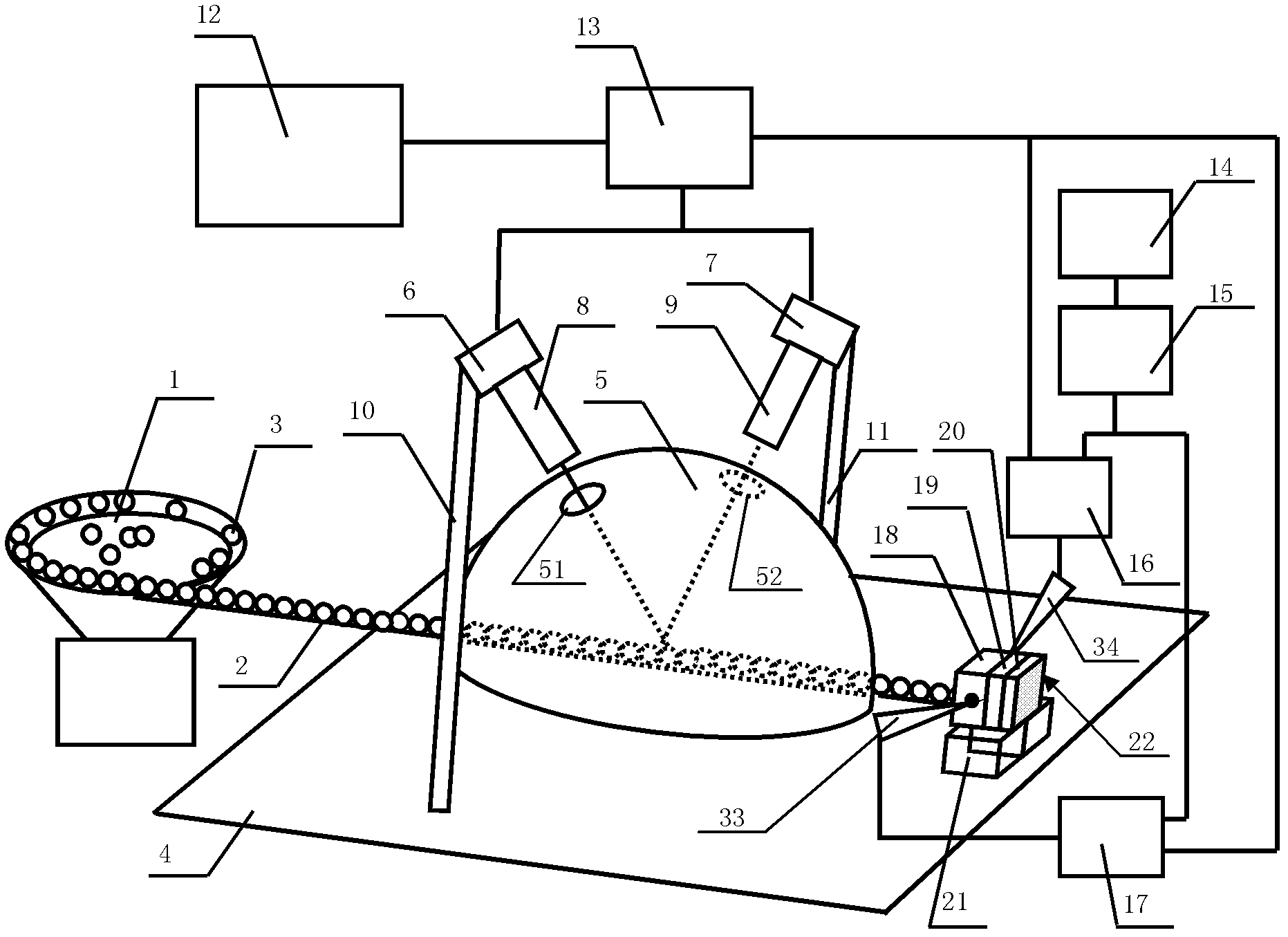

Detection sorting device for steel balls

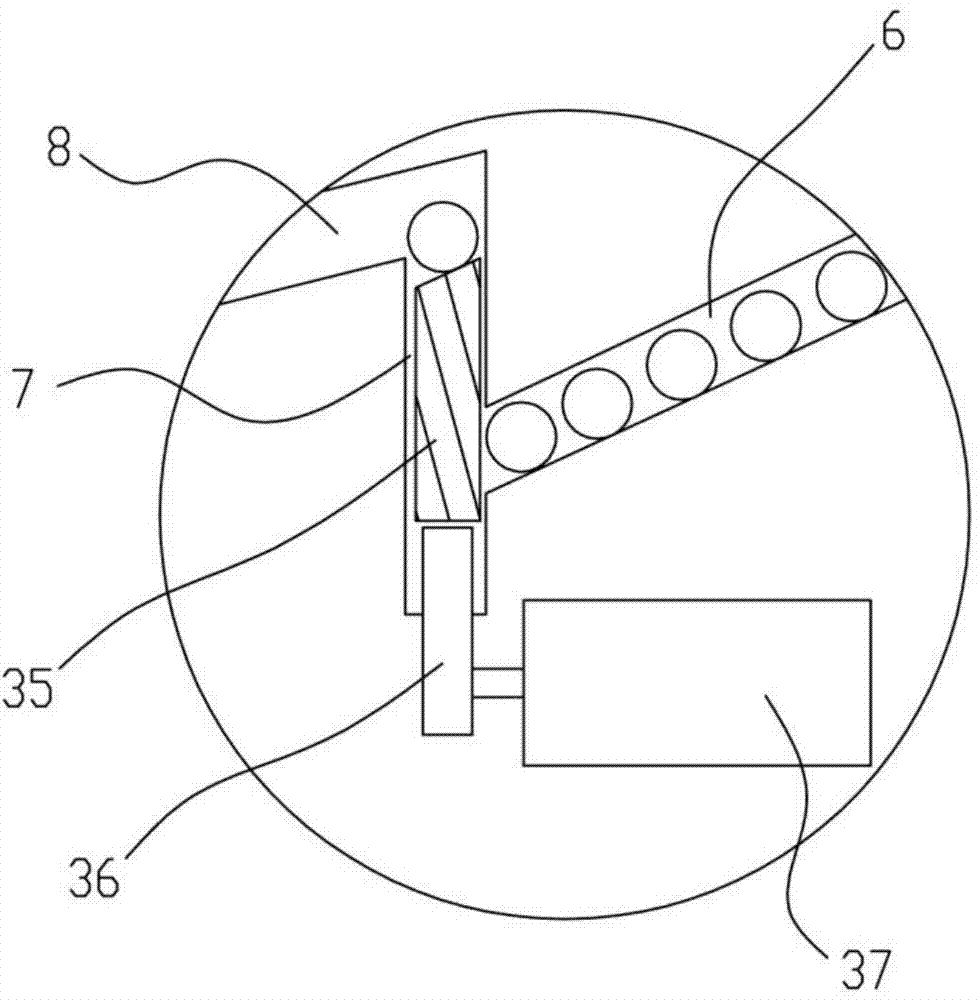

ActiveCN104043596ARealize automatic feeding processEasy to detectOptically investigating flaws/contaminationSortingEngineeringStructural engineering

The invention relates to a detection sorting device for steel balls The detection sorting device comprises a rack, a feed mechanism, an unfolding mechanism, a stock stop, a detecting mechanism, a sorting mechanism and a material collecting mechanism, wherein the feed mechanism comprises a material storing box, a material discharging hopper and a material discharging pipe; the unfolding mechanism comprises a material transporting guide rail, the material transporting guide rail is a V-shaped linear guide rail, the material discharging hopper is connected with an initiating end of the material transporting guide rail through the material discharging pipe, and the detecting mechanism comprises a light source assembly and a camera assembly; the light source assembly is arranged on the material transporting guide rail in a sleeved mode, the sorting mechanism and the material collecting mechanism are arranged on the tail end of the material transporting guide rail, and the separate collection of defect steel balls and qualified steel balls are realized through the sorting mechanism and the material collecting mechanism. The detection sorting device provided by the invention has the advantages that the automatic feed, detection and sorting of the steel balls are realized, a detection process is that two-dimensional motion of a traditional unfolding disc is changed into single one-dimensional rolling of one-sided steel balls, the detection efficiency is high, a false drop ratio and an omission ratio are low, and the steel balls are not magnetized or the surfaces of the steel balls are not damaged in a detection process.

Owner:LUOYANG FANGZHI MEASUREMENT & CONTROL

Novel numerical control bamboo splitting machine

ActiveCN102717414AAchieve broken bambooRealize empty back movementWood splittingVeneer manufactureNumerical controlMeasurement device

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

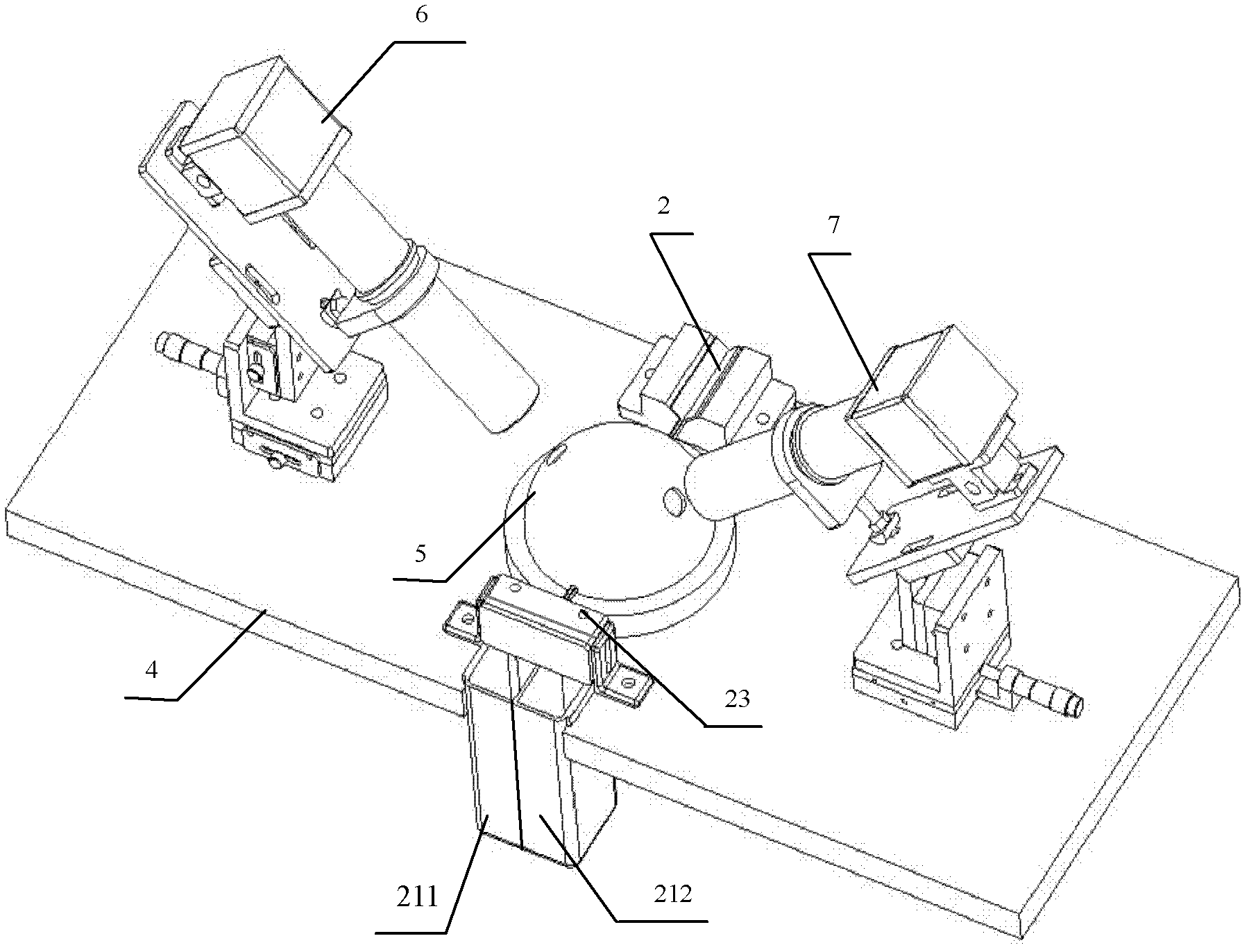

Steel ball surface defect detection automatic sorting device

InactiveCN102680490ARealize automatic feeding processEasy to detectOptically investigating flaws/contaminationSortingSteel ballInterconnection

Disclosed is a steel ball surface defect detection automatic sorting device. A light source is arranged on a work bench, a left camera mounted on a left support and a right camera mounted on a right support are symmetrically arranged on the left side and the right side of a light source bowl cover, camera lenses of the left camera and the right camera are arranged symmetrically and corresponding to a left observation hole and a right observation hole formed on the light source bowl cover, a vibration feed table and a material transferring channel connected to a discharge hole of the vibration feeding table are arranged behind the light source, the material transferring channel penetrates through the power source bowel cover and the front of the light source, a sorting mechanism and a collecting box placed below the sorting mechanism are arranged in front of the light source, a discharge terminal of the material transferring channel is inserted into a feeding hole end of the sorting mechanism, the left camera and the right camera are respectively connected with a peripheral component interconnection (PCI) card, PCI cards are respectively connected with a computer and a pneumatic unit, and an output end of the pneumatic unit is connected with the sorting mechanism. According to the steel ball surface defect detection automatic sorting device, the detecting process can achieve automation completely, no easily-worn part exists, the service life is long, and defect detection is accurate and efficient.

Owner:TIANJIN UNIV

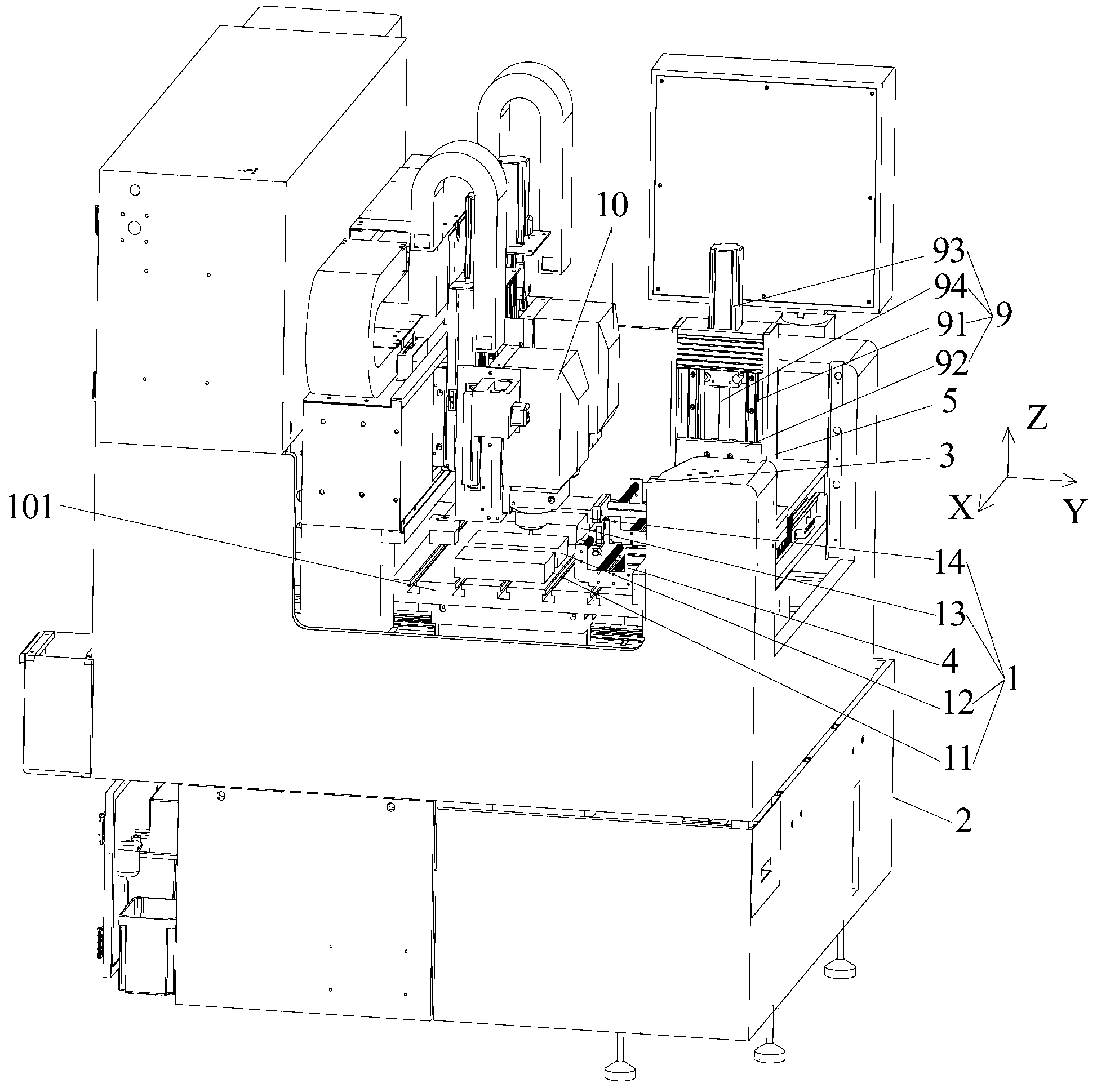

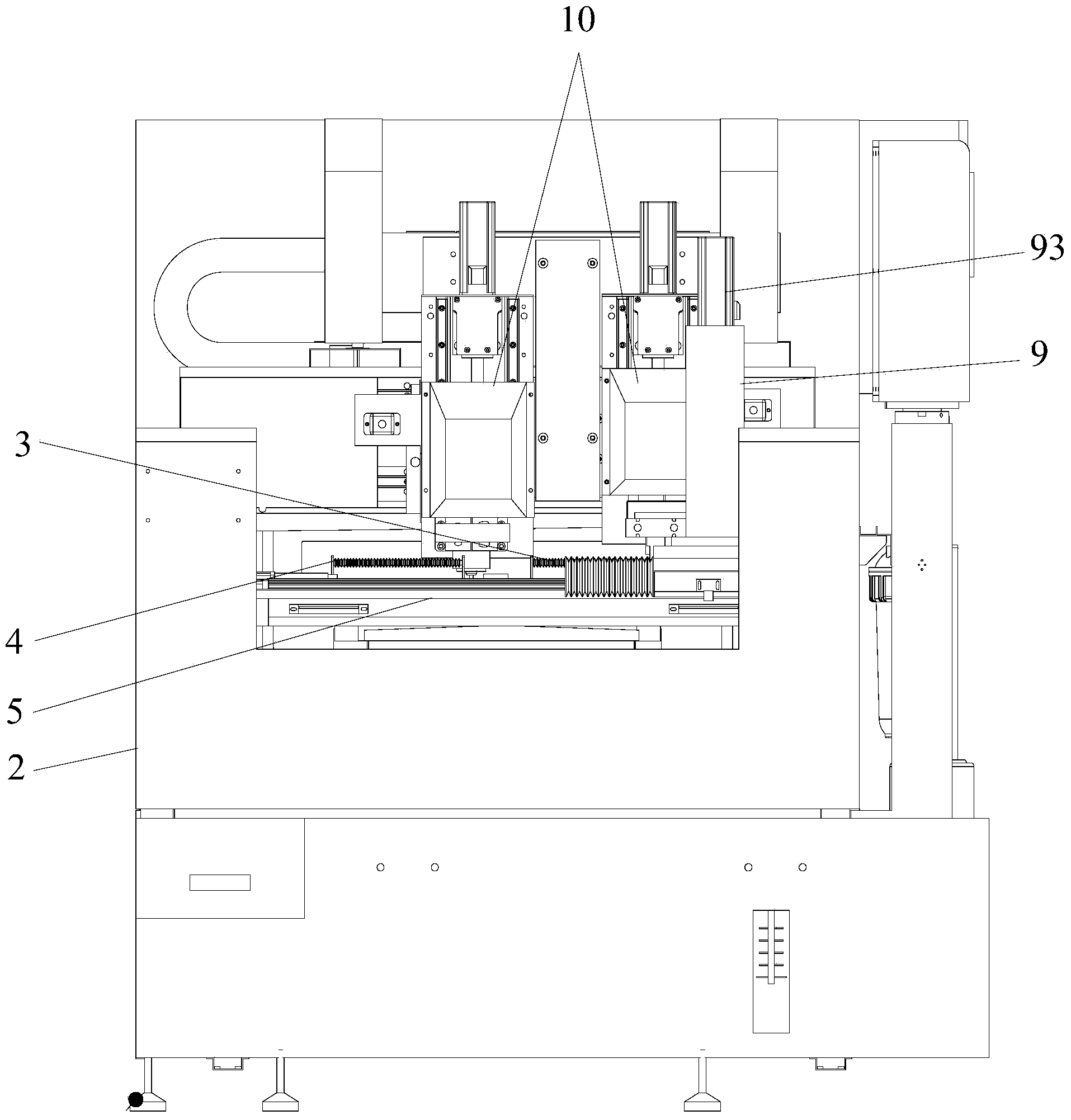

Automatic loading and unloading device for numerically-controlled machine tool

ActiveCN104354097ARealize automatic loading and unloadingRealize automatic feeding processWorking accessoriesGrinding feedersNumerical controlEngineering

The invention discloses an automatic loading and unloading device for a numerically-controlled machine tool. The automatic loading and unloading device is driven by using an axis-X driving structure and an axis-Z driving device, and a glass workpiece is grabbed by virtue of a flexible air cylinder, a rotating air cylinder and a vacuum sucking disc, so that automatic loading of glass pieces to be machined and automatic unloading of the machined glass workpiece are realized; because the numerically-controlled machine tool is in a double-head design, four positioning jigs are provided, and a second positioning jig and a fourth positioning jig load during the machining of a first poisoning jig and a third positioning jig, so that automatic loading and unloading can be realized, circulating machining without stopping is also realized, and the machining efficiency is greatly improved.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

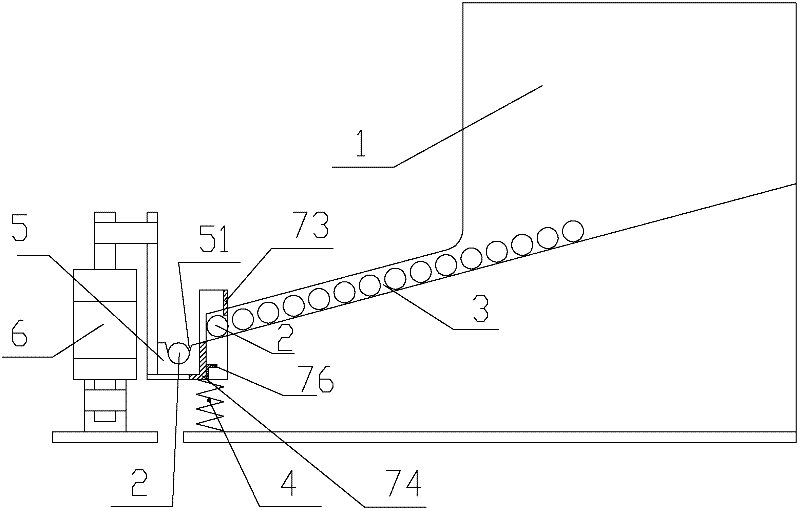

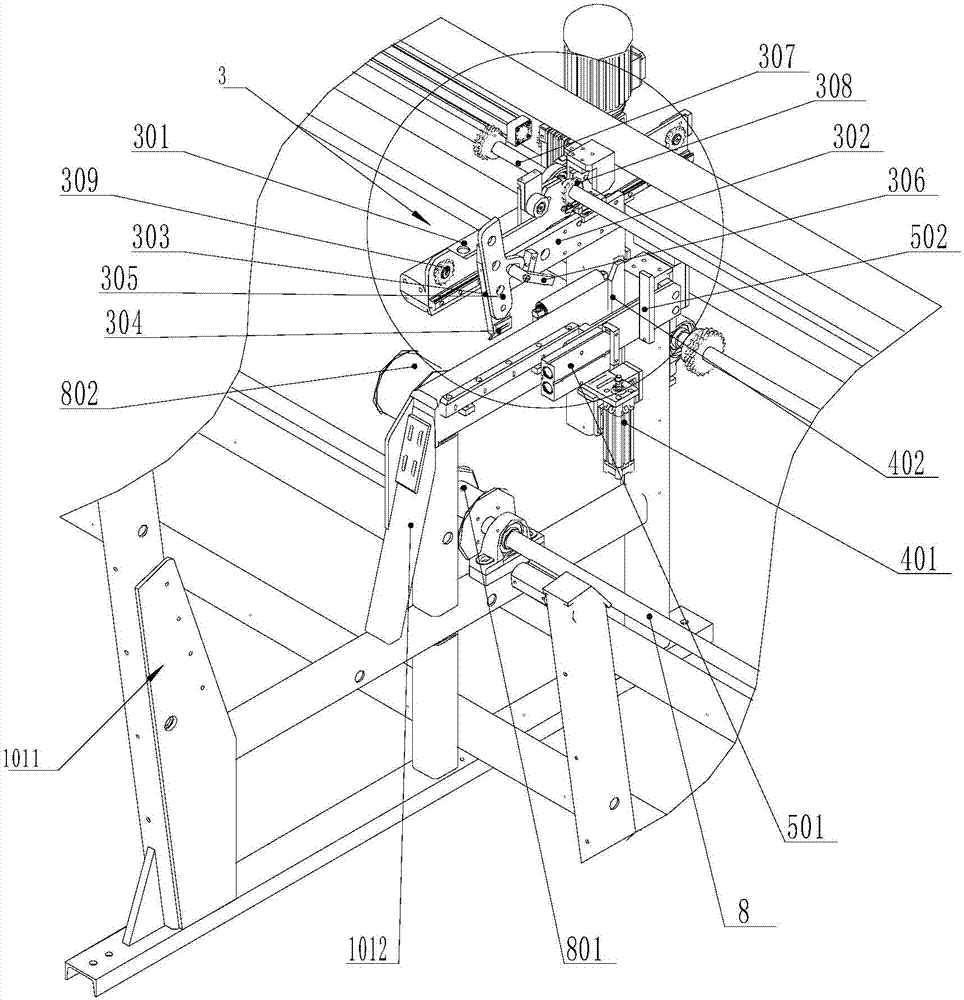

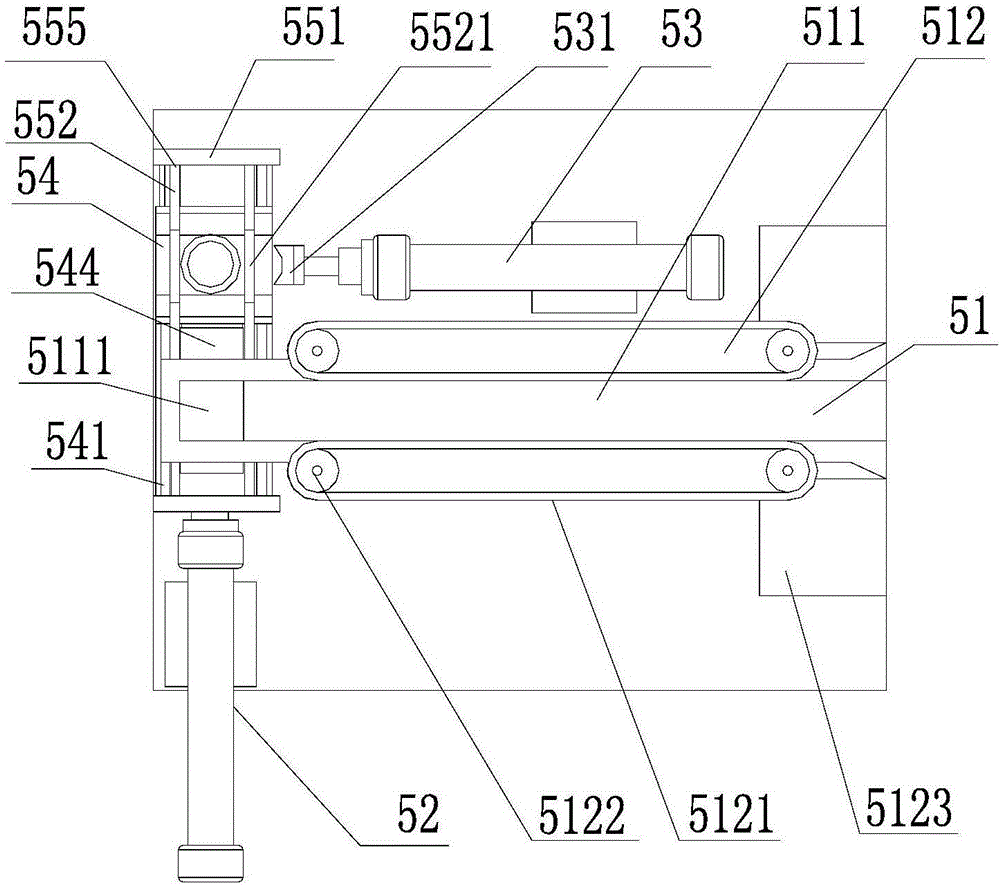

Automatic feeding device suitable for production line of pipes

InactiveCN102381563ASuitable for automatic feedingRealize automatic feeding processConveyor partsProduction lineEngineering

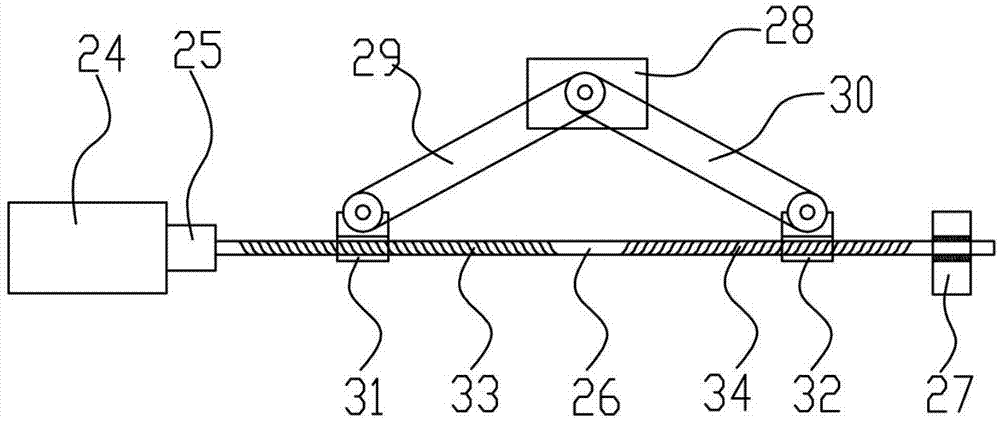

The invention relates to an automatic feeding device suitable for a production line of pipes. The automatic feeding device comprises a bracket. A storage bin, a bias slide rail and a baffle mechanism are arranged on the bracket, wherein horizontally placed pipes are stored in the storage bin; the pipes in the storage bin are discharged from the bias slide rail; the baffle mechanism is located at a discharging port of the bias slide rail and allows only a single pipe to pass through; a spring is arranged between the baffle mechanism and the bracket; the spring is connected to a feeding supporting component for the single pipe which passes through the baffle mechanism; one end of the feeding supporting component is hinged with the bracket; an accommodating slot matched with the pipe is formed on the feeding supporting component; a clamping element for clamping the pipe is arranged on the feeding supporting component; when the feeding supporting component is in a horizontal state, the spring is compressed; and a cylinder is connected to the feeding supporting component and is used for turning the pipe therein from a horizontal state to a vertical state. The automatic feeding device has the advantages of suitability for the feeding of the production line of the pipes and high production efficiency.

Owner:ZHEJIANG UNIV

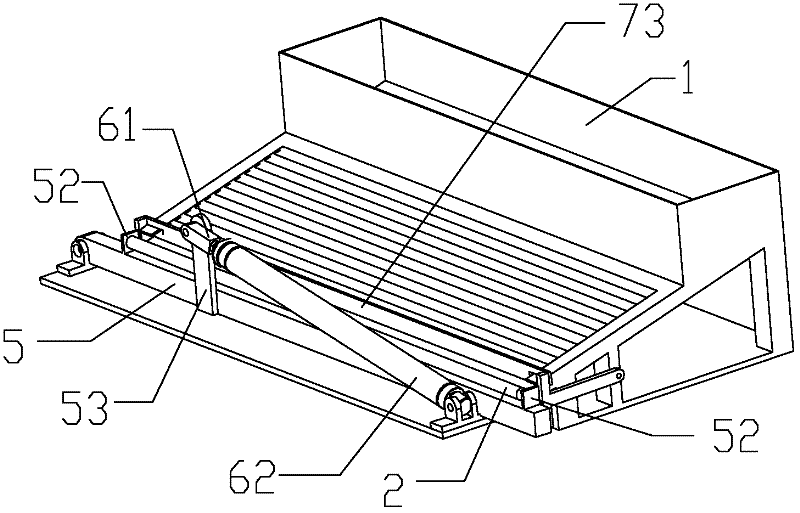

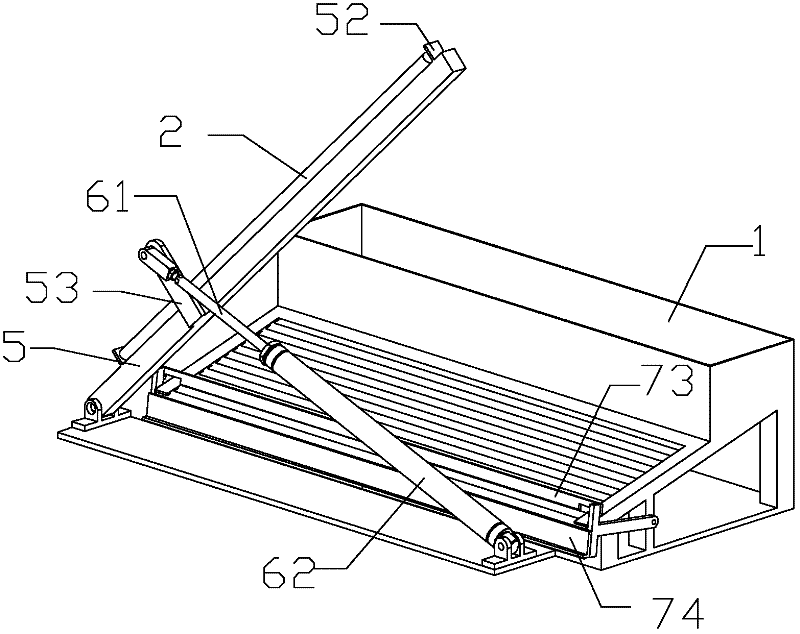

Automatic conveying device for sheets

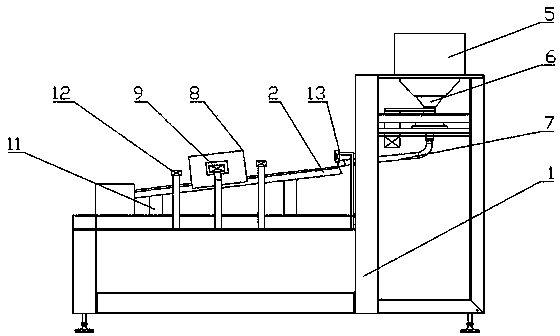

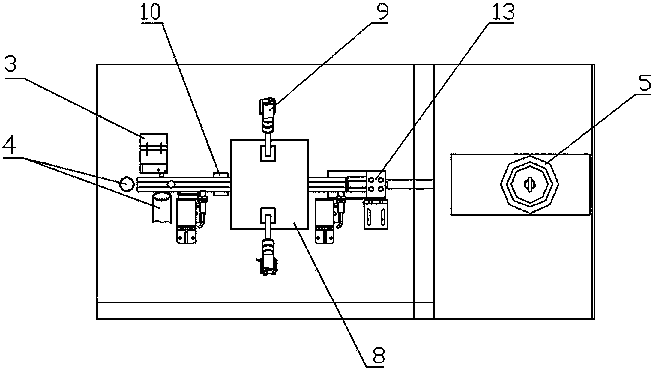

InactiveCN102225723ARealize automatic feeding processAchieve initial positioningArticle feedersArticle separationEngineeringDrive motor

The invention discloses an automatic conveying device for sheets. The device comprises a fixed frame, a conveying mechanism, a positioning processing platform and an automatic lift positioning workbench, wherein the conveying mechanism is arranged above the automatic lift positioning workbench through the fixed frame; the positioning processing platform is positioned in the front of the conveying mechanism; the conveying device comprises a guiding sliding rail which can move longitudinally and transversely, a front cylinder sucker, a middle cylinder support plate, a rear cylinder sucker, a front push cylinder push plate, a feed roller driven by a drive motor and a sheet sliding rail support; the front cylinder sucker, the middle cylinder support plate, the rear cylinder sucker and the front push cylinder push plate are arranged on the guiding sliding rail; the front push cylinder push plate is positioned at the rear side of the middle cylinder support plate; the feed roller is positioned in the front of the guiding sliding rail; the sheet sliding rail support is positioned in the front of the feed roller; and the positioning processing platform is positioned below the sheet sliding rail support. The device has the advantages of high working efficiency, low labor intensity and safety in operation.

Owner:YANTAI SHANKE AUTOMATIZATION PACKAGING EQUIP

Self-discharging type stamping and forming all-in-one machine

InactiveCN111001720ARealize automatic feeding processSustainable workMetal-working feeding devicesPositioning devicesPunchingElectric machinery

The invention relates to a stamping and forming all-in-one machine, in particular to a self-discharging type stamping and forming all-in-one machine. The self-discharging type stamping and forming all-in-one machine can achieve automatic feeding, can continuously work, can save time, is easy and convenient to operate and can also avoid stamping accidents. The self-discharging type stamping and forming all-in-one machine comprises a chassis, a rack, an arc-shaped plate, a supporting column, an L-shaped block, a motor and the like. The rack, the supporting column and the motor are fixedly arranged on the chassis, the rack is located on the right side of the supporting column, and the motor is located below the rack. According to the invention, a stamped workpiece can be pushed out through apushing mechanism, and the other workpiece in a discharging frame can be pushed into a punching frame, so that people can take down the punched workpiece, the workpiece does not need to be placed manually, automatic feeding and continuous work can be achieved, a large amount of time is saved, operation is easy and convenient, and punching accidents can be avoided.

Owner:申继州

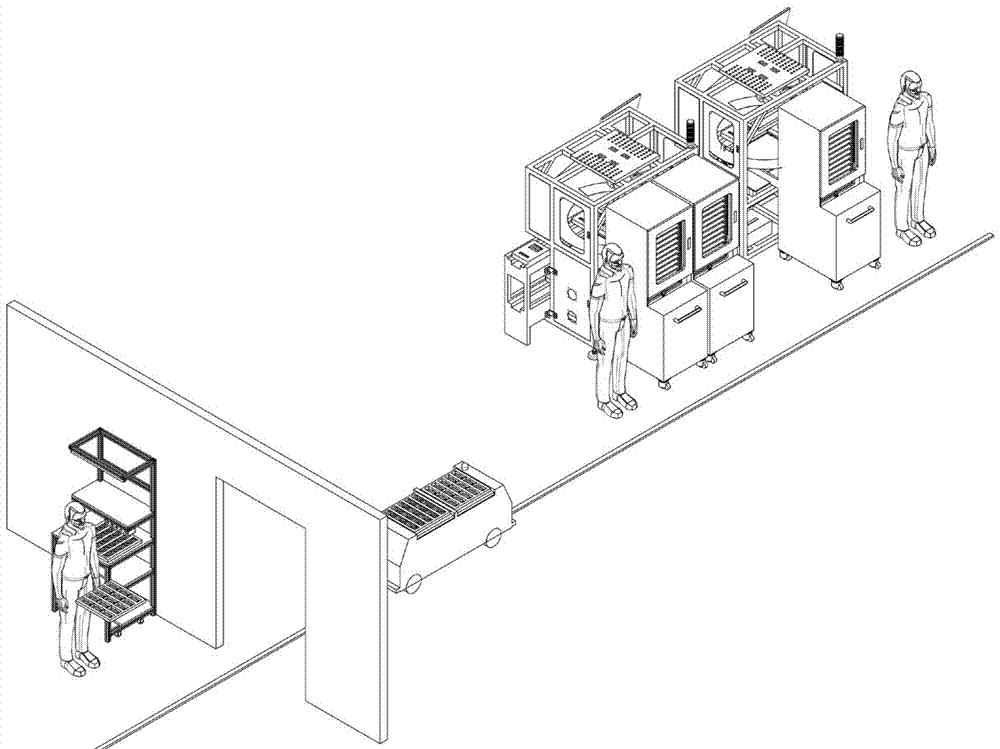

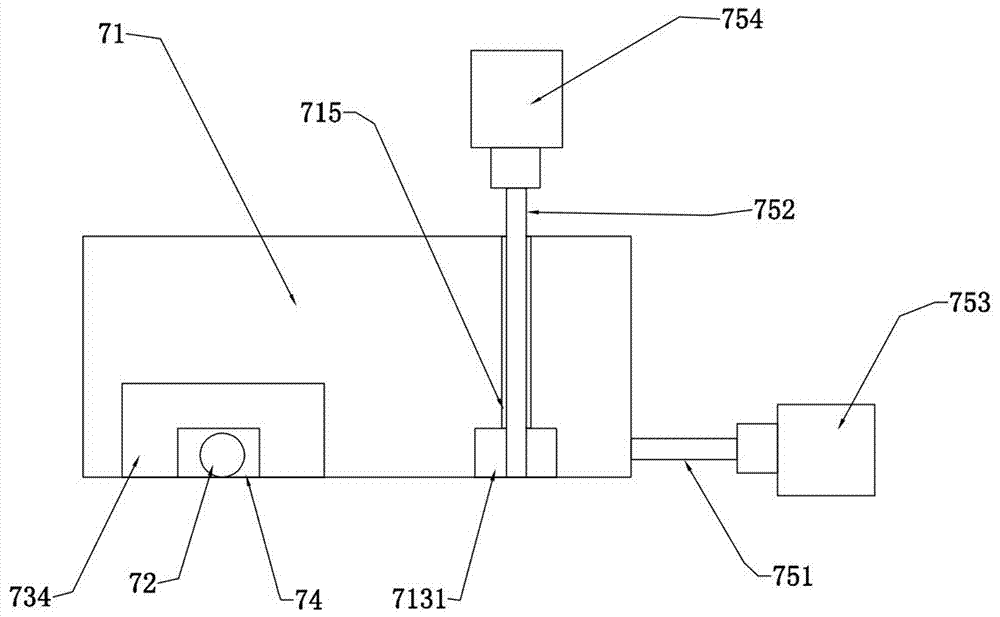

Automated material distributing system

PendingCN107336962ARealize automatic feeding processRealize blankingControl devices for conveyorsStorage devicesEngineeringMechanical engineering

The invention provides an automated material distributing system. The automated material distributing system comprises an AGV inspection conveyor, an AGV trolley, an AGV trolley track, three-dimensional feeding mechanisms and a central controller, wherein the AGV inspection conveyor comprises multiple first horizontal conveying mechanisms, trays used for containing materials are arranged on the first horizontal conveying mechanisms, and the AGV trolley is provided with second horizontal conveying mechanisms which are connected with the first horizontal conveying mechanisms in a butted manner; and each three-dimensional feeding mechanism comprises a stock bin, a butting platform, a vertical lifting mechanism and a horizontal conveying mechanism, wherein the stock bin is used for enabling the trays to be stored in a stacked manner, the butting platform is fixed to the vertical lifting mechanism, the horizontal conveying mechanism is arranged at the bottom end of the butting platform, and the butting platform is driven by the vertical lifting mechanism and the horizontal conveying mechanism to enable the trays to move between the stock bin and the AGV trolley. According to the automated material distributing system, automatic feeding and discharging of materials can be achieved, and artificial burdening and material changing are reduced; and meanwhile, automatic conveying is achieved, artificial distribution is reduced, the tool efficiency can be effectively improved, and the labor cost is reduced.

Owner:SHENZHEN HYTERA COMM

Automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

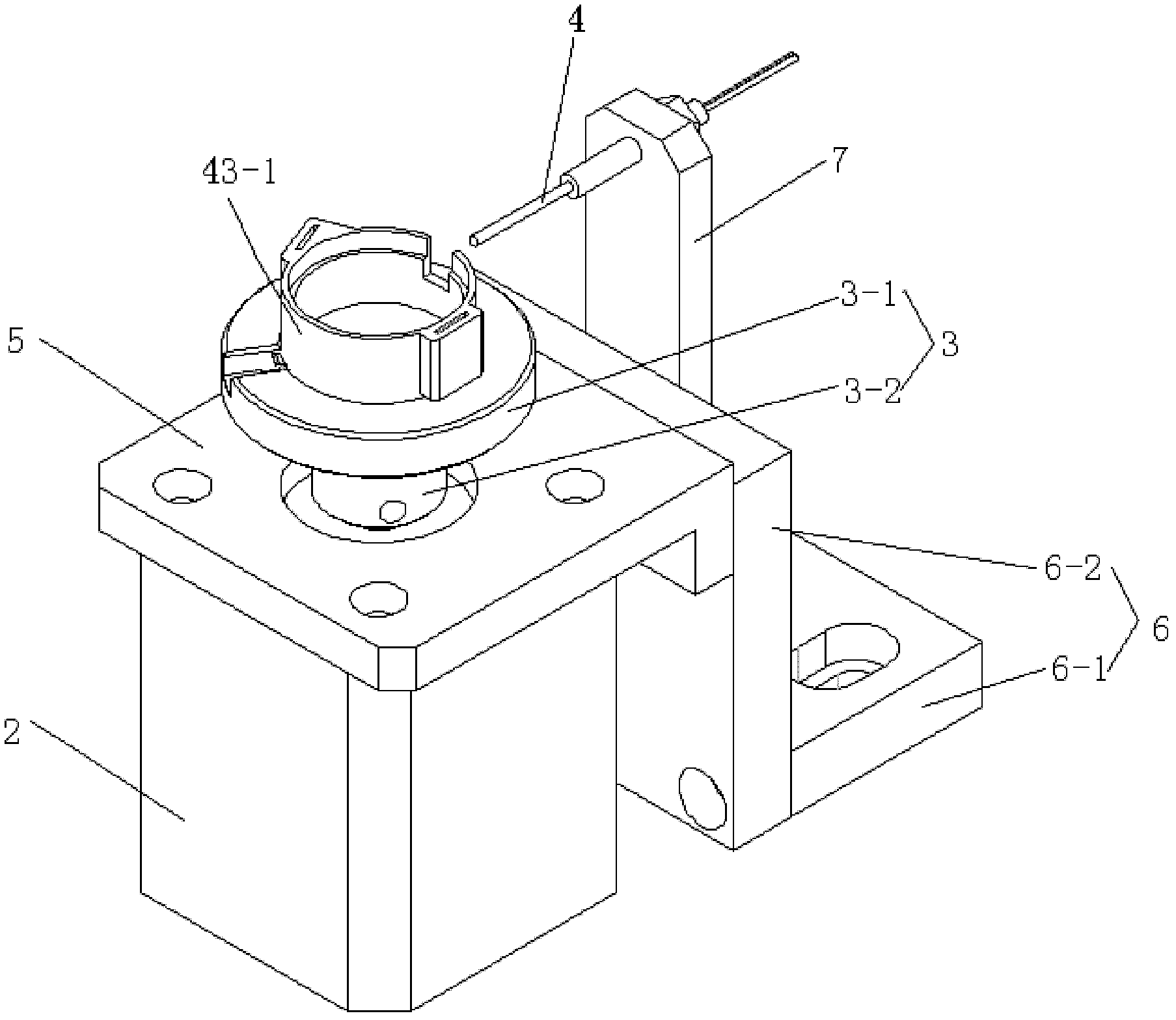

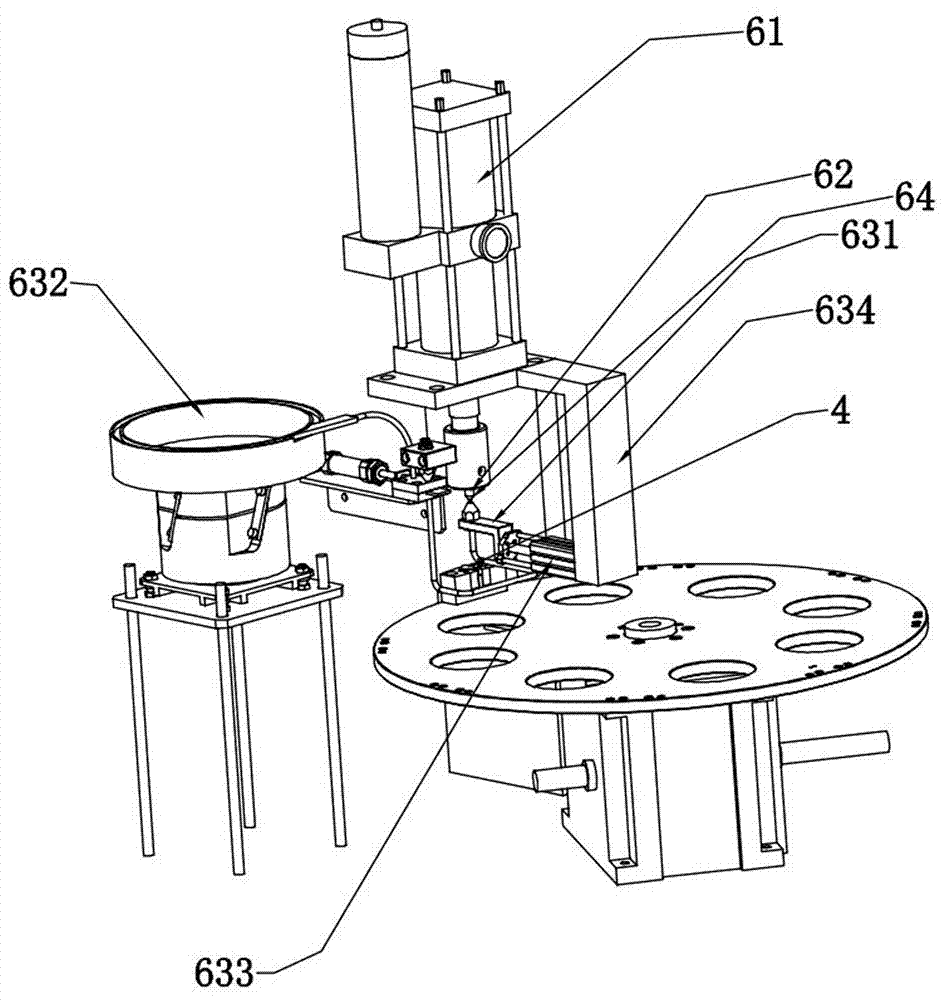

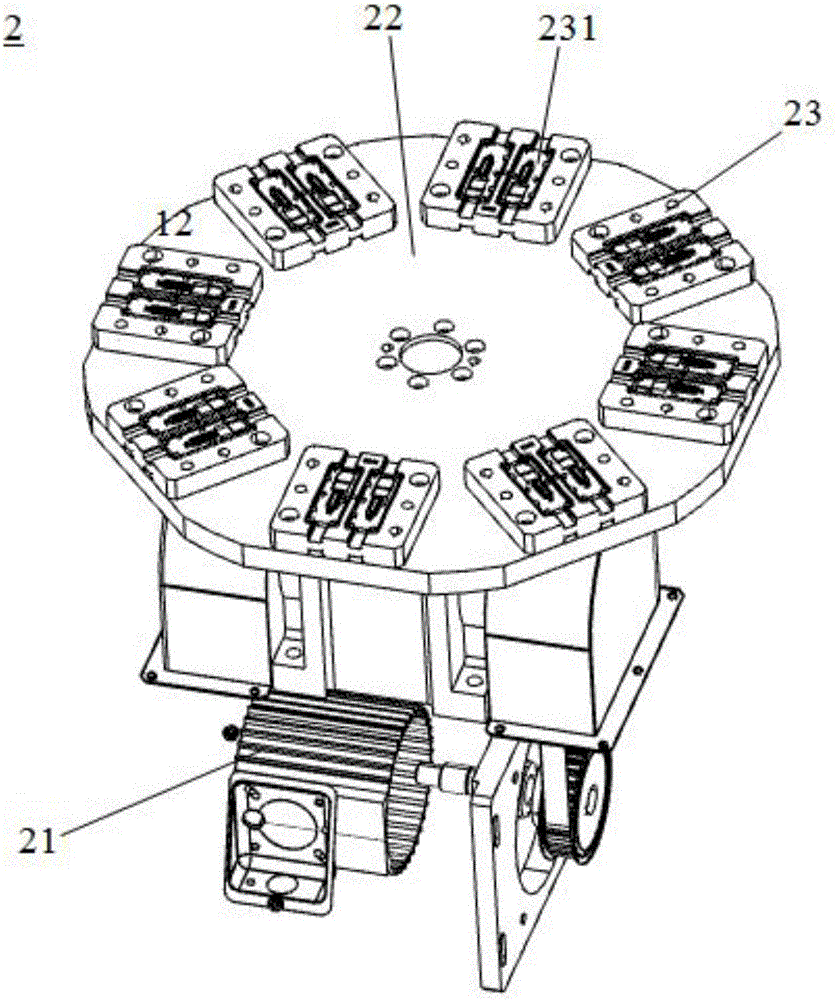

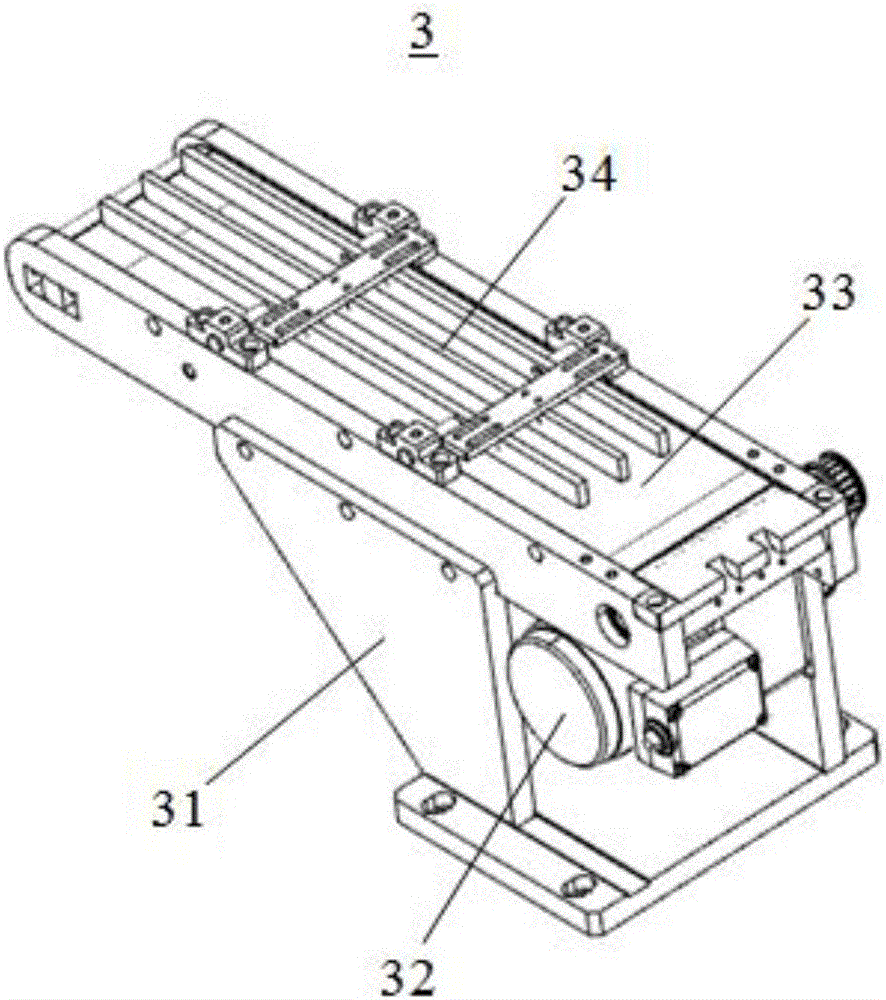

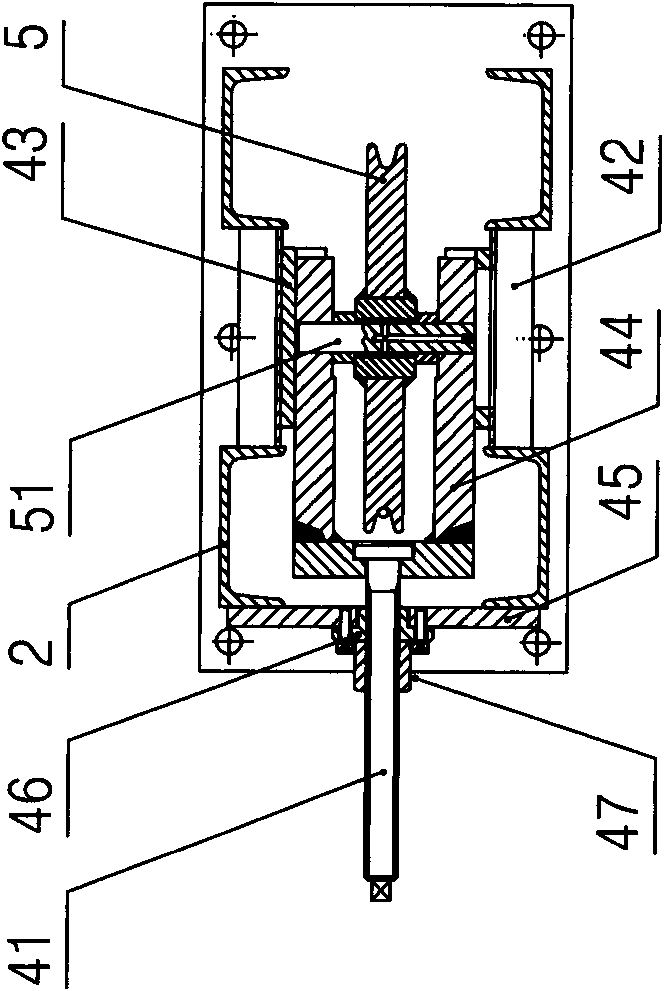

Automatic assembling equipment for elastic steel balls of sleeve adapter

ActiveCN107398724ARealize automatic feeding processReasonable positionAssembly machinesStructural engineeringSteel ball

The invention discloses automatic assembling equipment for elastic steel balls of a sleeve adapter. The automatic assembling equipment comprises a turntable and a plurality of station assemblies which are arranged close to the side of the edge of the turntable, wherein clamping fixing seats for fixing workpieces are arranged on the edge of the turntable; and the station assemblies comprise a feeding station assembly, a spring mounting station assembly, a steel ball mounting station assembly and a discharging pushing assembly. The workpieces are arranged on the clamping fixing seats through the feeding station assembly, rotated to the lower end of the spring mounting station assembly for spring assembly through the turntable, and then rotated to the lower end of the steel ball mounting station assembly for steel ball assembly through the turntable; after the assembly is completed , the clamping fixing seats are rotated to be aligned with the discharging pushing assembly, and the discharging pushing assembly is used for pushing the workpieces in the clamping fixing seats to fall down, and therefore the workpieces and the accessories can be automatically conveyed to the tooling positions and the stations respectively, springs and steel balls can be sequentially and automatically installed in steel ball mounting holes of the workpieces, the cost of manpower and material resources is saved, and the assembly efficiency of the workpieces is improved.

Owner:ZHEJIANG SEOKHO ROBOT TECH CO LTD

Automatic rectangular tube feeding device

ActiveCN104722831AGuaranteed accuracyImprove overall efficiencyShearing machine accessoriesEngineeringMechanical engineering

The invention discloses an automatic rectangular tube feeding device which comprises a rack, a feeding box, horizontal sorting platforms, at least two sets of material poking devices arranged on the rack, at least two sets of overturning mechanisms arranged on the rack and a horizontal conveying roller set arranged on the rack and used for longitudinally conveying rectangular tubes. Each material poking device set comprises a material poking lifting frame arranged on the rack in a vertically lifting mode. The material poking lifting frames are driven by a material poking lifting power device and arranged on horizontal material poking frames in a horizontally sliding mode. The horizontal material poking frames are driven by a horizontal material poking power device and provided with material poking rods. The overturning mechanisms comprise jacking rods, and the jacking rods are driven by an overturning lifting power device. The horizontal conveying roller set is arranged on the rack. By means of the automatic feeding device, automatic feeding of the rectangular tunes can be achieved, and the rectangular tubes are turned over and conveyed out according to the actual requirements, so that the rectangular tubes can be cut by a downstream process conveniently, rectangular tube cutting is more automated, and overall efficiency is higher.

Owner:SUZHOU KINKALTECK MACHINERY TECH

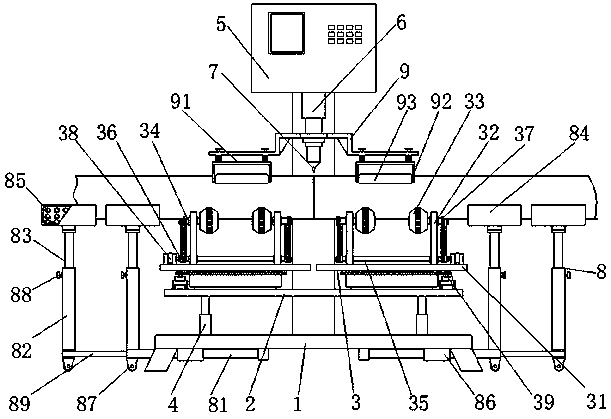

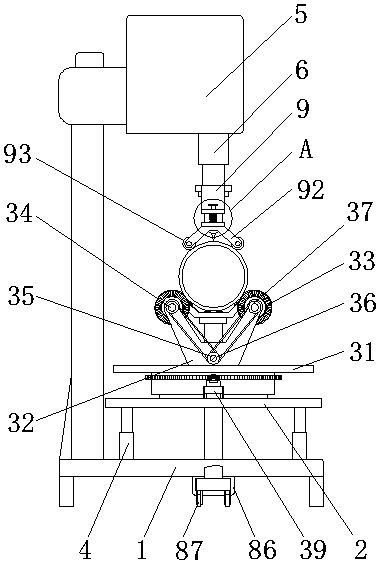

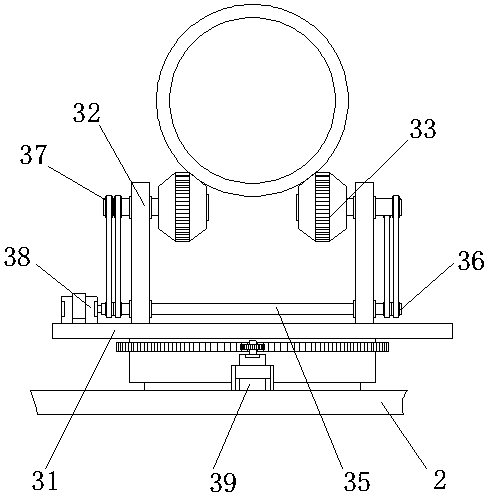

Automatic welding device for nanometer thin-wall pipe fitting

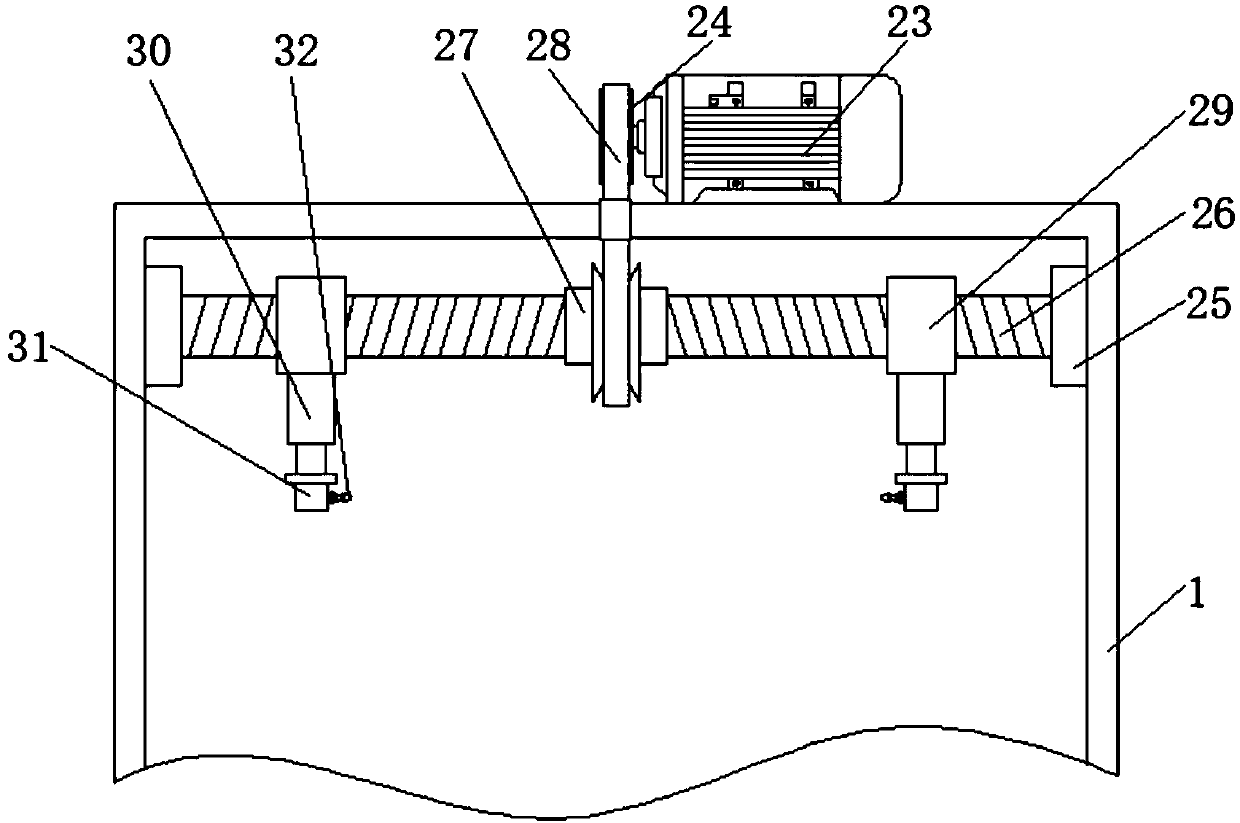

ActiveCN111375941AEnable mobilityAchieve rotation controlWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderPipe fitting

The invention discloses an automatic welding device for a nanometer thin-wall pipe fitting. The automatic welding device comprises a base, wherein a lifting plate is arranged at the top of the base, supporting conveying mechanisms are arranged at the two ends of the top of the lifting plate correspondingly, a first hydraulic cylinder is fixedly installed between the lifting plate and the base, a welding machine is arranged at the top of the base, a second hydraulic cylinder is fixedly installed at the bottom of the welding machine, a welding gun is fixedly connected to the bottom end of the second hydraulic cylinder, each supporting conveying mechanism comprises a supporting base, the supporting bases are rotationally connected to the top of the lifting plate, and gear teeth are arranged on the circumferential side of the bottom end of each supporting base. By means of rotation of the supporting bases, two sets of supporting idler wheels can change states continuously, moving and rotating control over a to-be-welded pipe is achieved, and then the processes of automatic feeding, aligning, seam aligning, automatic welding and automatic discharging of the to-be-welded pipe are achieved, so that the practicability and convenience of using the device are improved.

Owner:聊城市瀚格智能科技有限公司

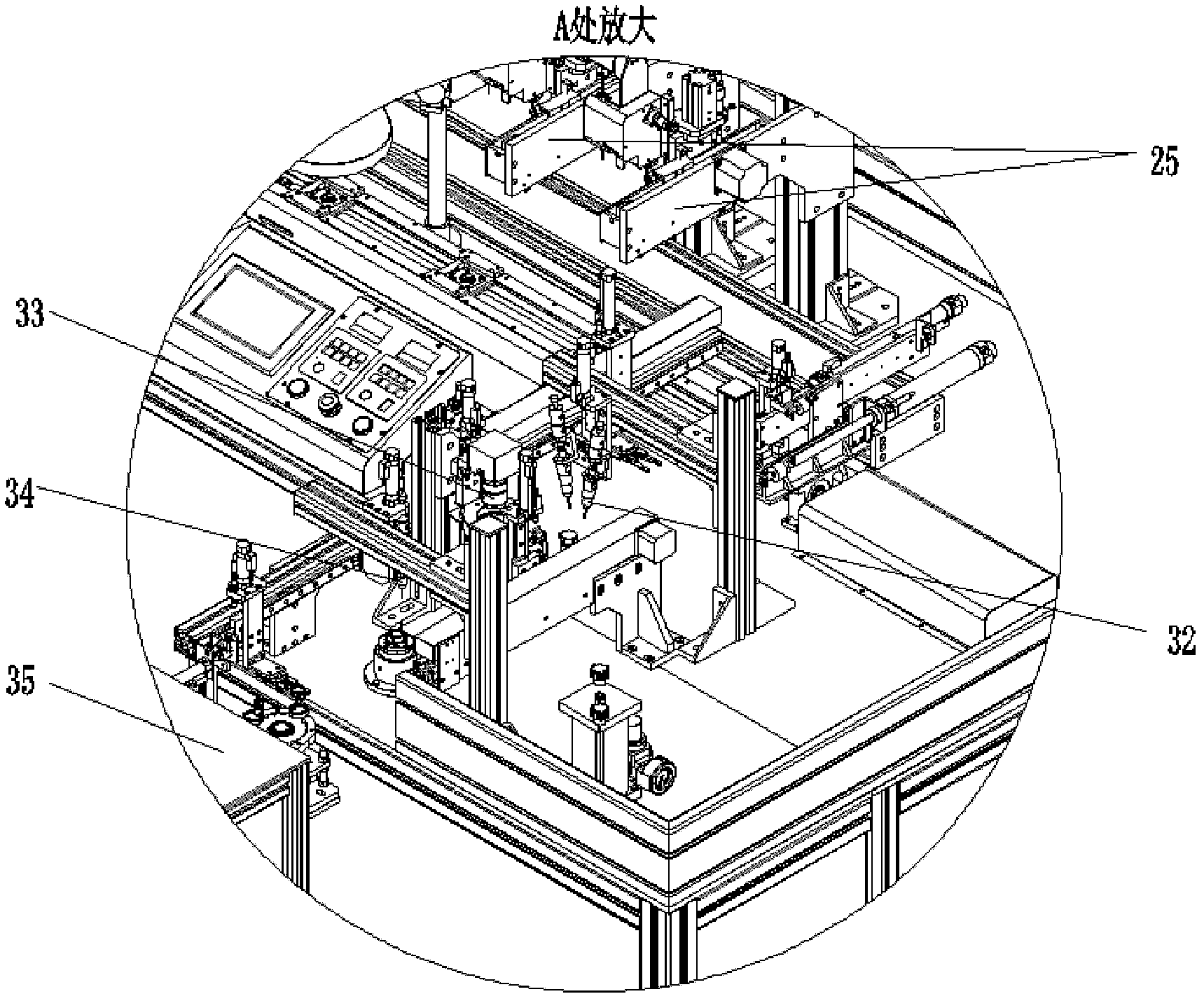

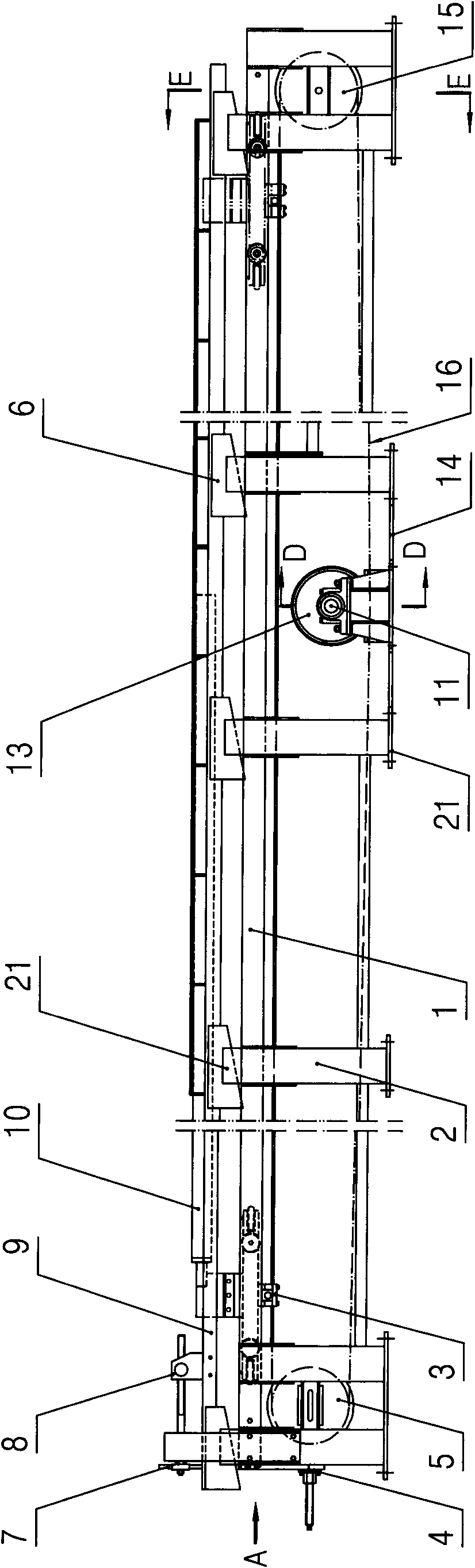

Rotating type multi-station pad printing machine

InactiveCN106113923ARealize automatic feeding processIncrease productivityRotary pressesPad printingButt joint

Owner:KUNSHAN YITIAN AUTOMATION

Feeding device

InactiveCN101628302AWill not affect feedingRealize automatic feeding processConveyorsMetal rolling arrangementsEngineeringRolling mill

The invention discloses a feeding device applicable to material blanks of various specifications, comprising: a feeding frame that is provided with a pair of supporting plates and supporting plate lifting devices parallel to each other, wherein the pair of supporting plates is provided with a pair of V-shaped shelves provided with a pushing slot at the bottom; two ends of the feeding frame are respectively provided with a belt pulley; the two belt pulleys are linked with a rolling barrel arranged in a traction device on the feeding frame through a wire rope; the feeding frame is further provided with a pushing trolley capable of moving linearly; the top of the pushing trolley is provided with a pushing arm, and the bottom of the pushing trolley is provided with a traction seat, wherein the pushing arm extends from the pushing slot to connect a pushing pipe, and the traction seat is fixed on the wire rope. The invention is mainly used in cold-rolling mills.

Owner:张家港恒立机械有限公司

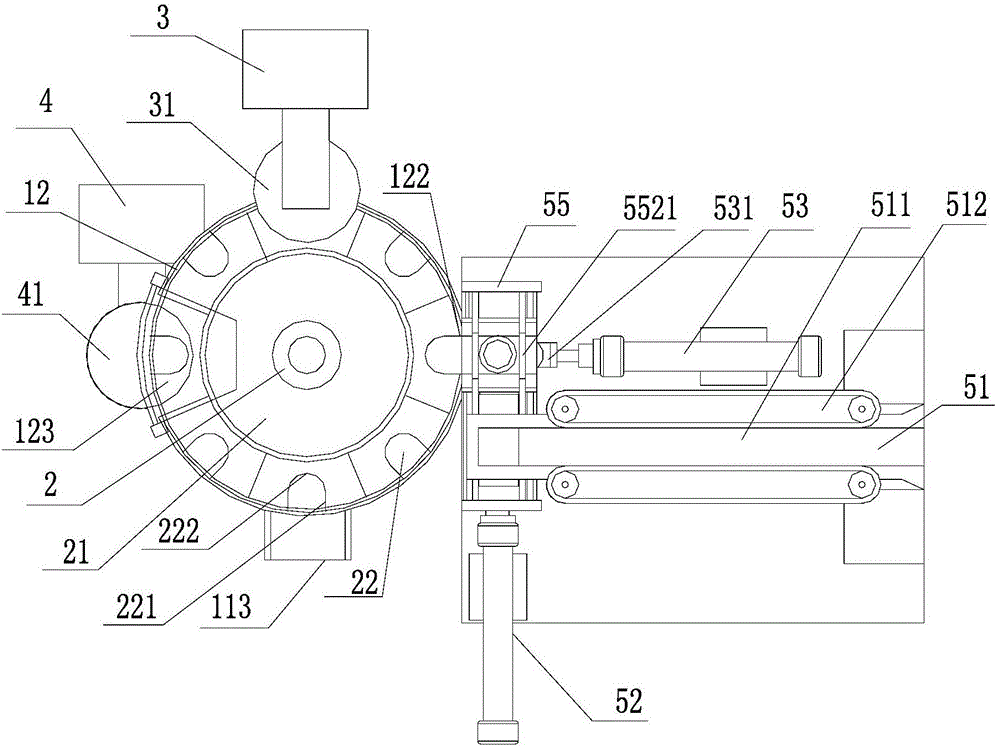

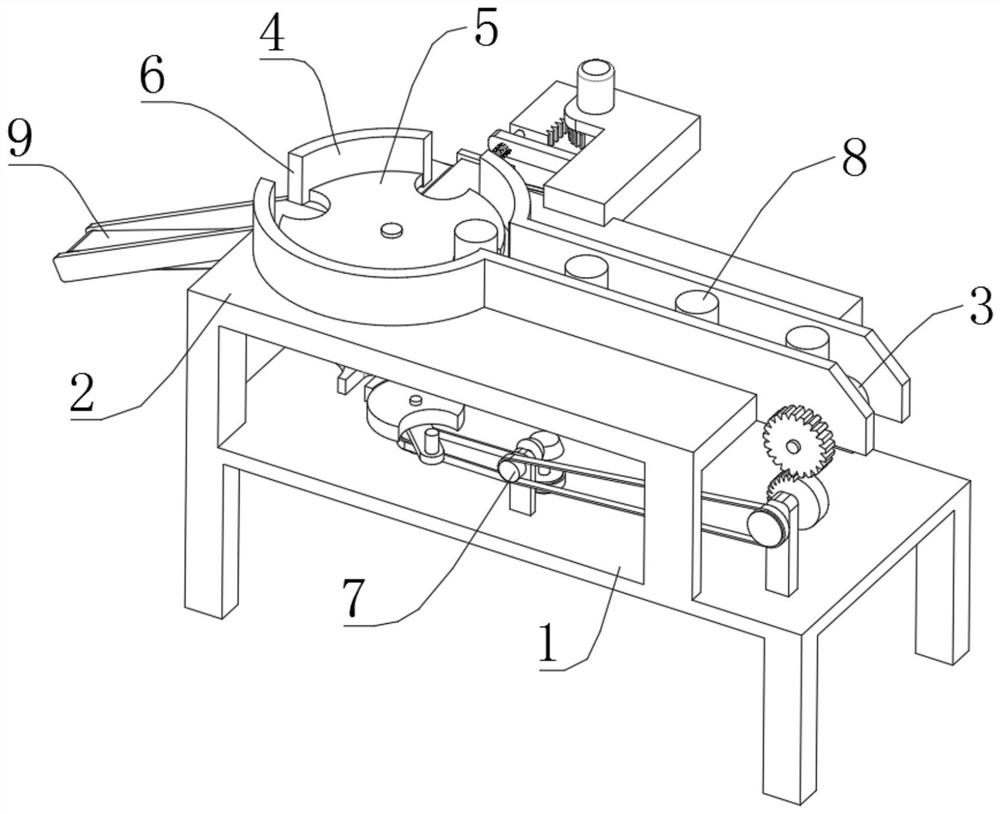

Spring double-face polishing device capable of carrying out feeding automatically

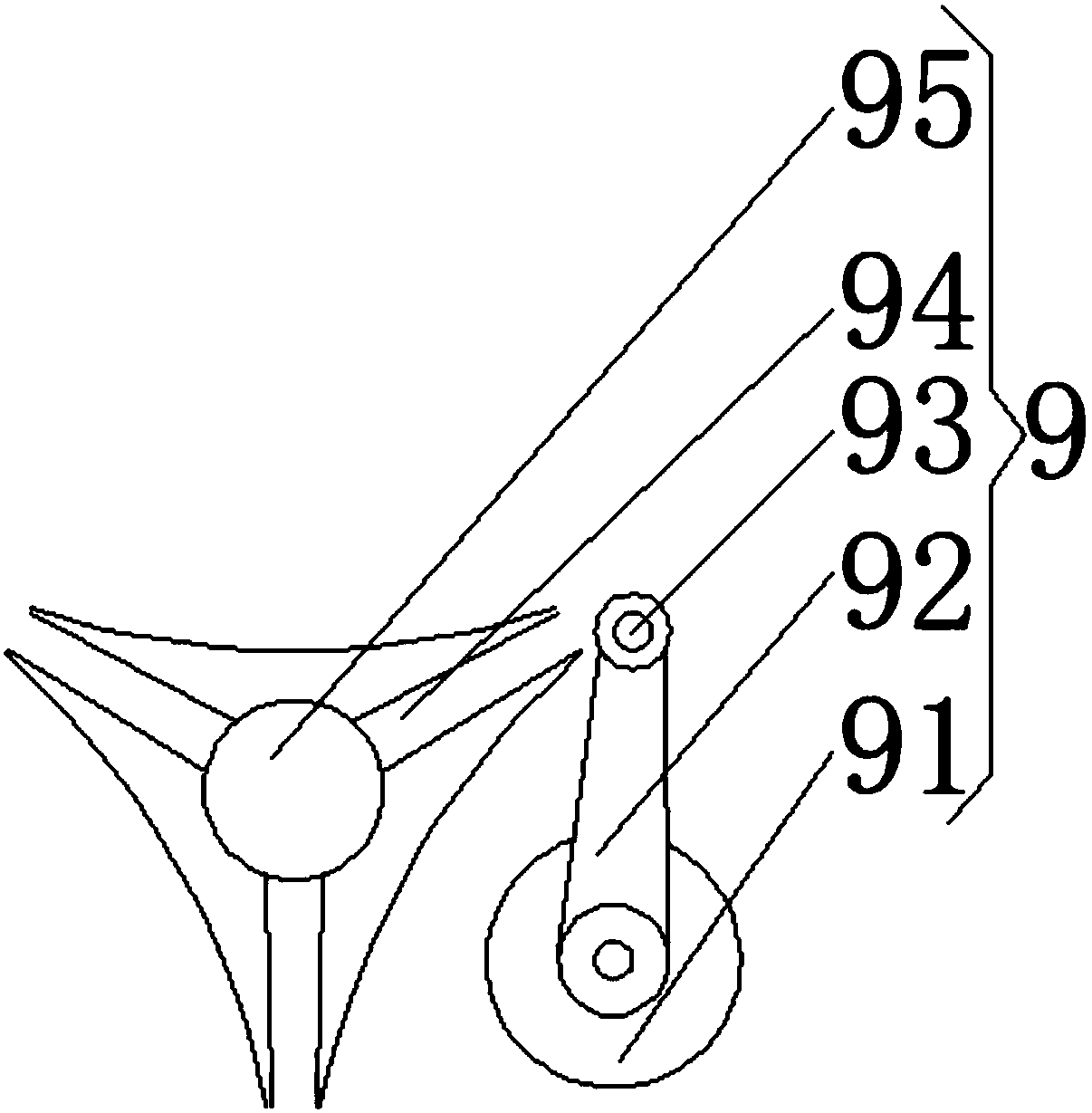

ActiveCN106670911AReduce workloadIncrease productivityGrinding feedersGrinding work supportsEngineeringGrinding wheel

The invention discloses a spring double-face polishing device capable of carrying out feeding automatically. The spring double-face polishing device comprises a rack, a rotary feeding base, an upper end face polishing mechanism, a lower end face polishing mechanism and an automatic feeding device. The rack is provided with a fixing chassis. A blocking frame is arranged on the periphery of the fixing chassis. A rotary disc is arranged on the rotary feeding base. A plurality of embedding grooves are formed in the rotary disc. The automatic feeding device, the upper end face polishing mechanism, the lower end face polishing mechanism and a discharging frame are sequentially arranged on the outer side of the rotary feeding base in the periphery direction. The automatic feeding device is provided with a feeding sliding base. A spring chute is formed in the feeding sliding base. The upper end face polishing mechanism is provided with a first abrasion wheel. The lower end face polishing mechanism is provided with a second abrasion wheel. An air cylinder is utilized for driving the sliding base to be conveyed to the feeding position, a spring is pushed into the rotary feeding base through the air cylinder, the vertical spring is fed automatically, the two abrasion wheels polish the upper end face and the lower end face of the spring sequentially, and the production efficiency can be improved.

Owner:ZHEJIANG HUAWEI SPRING

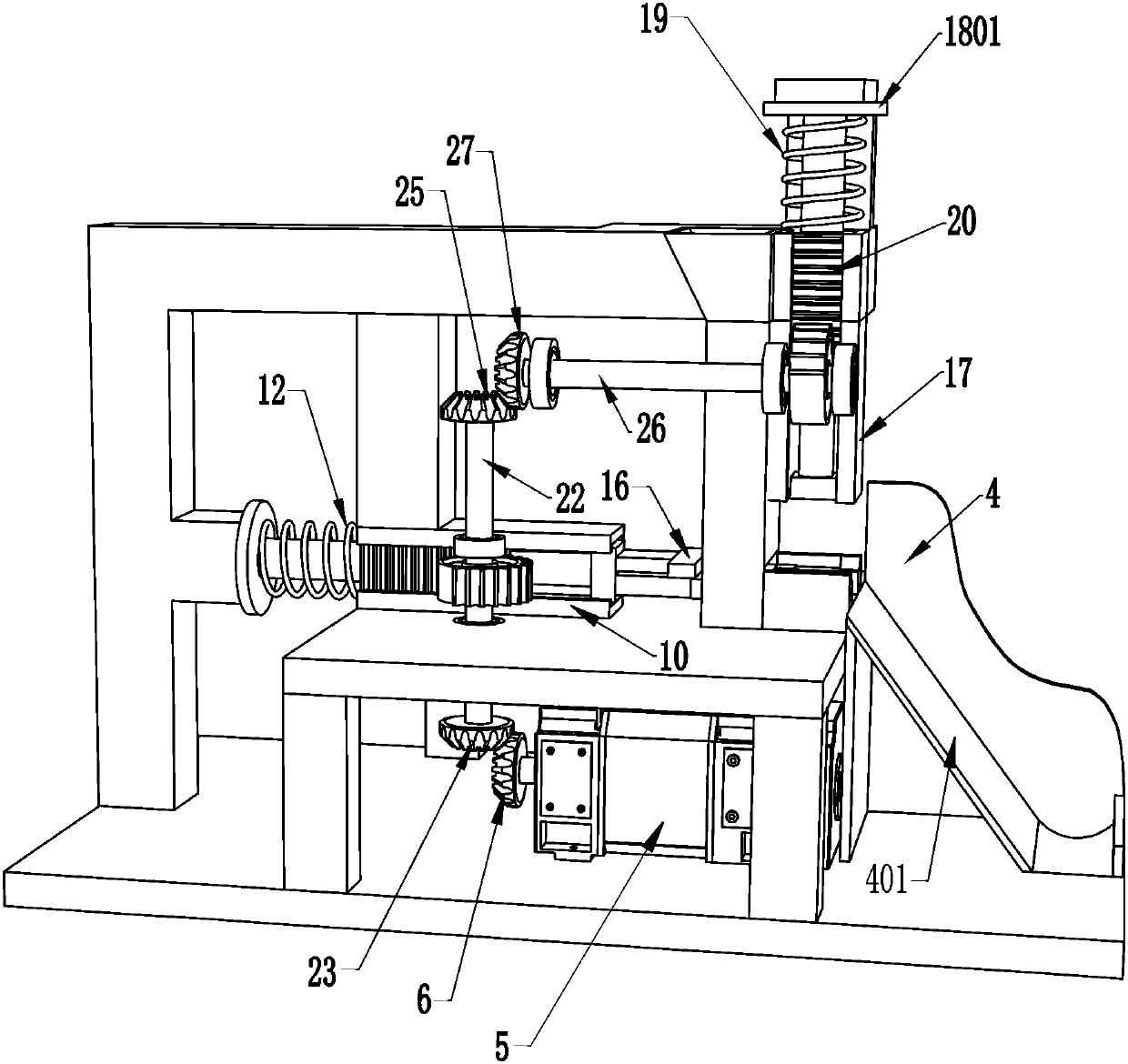

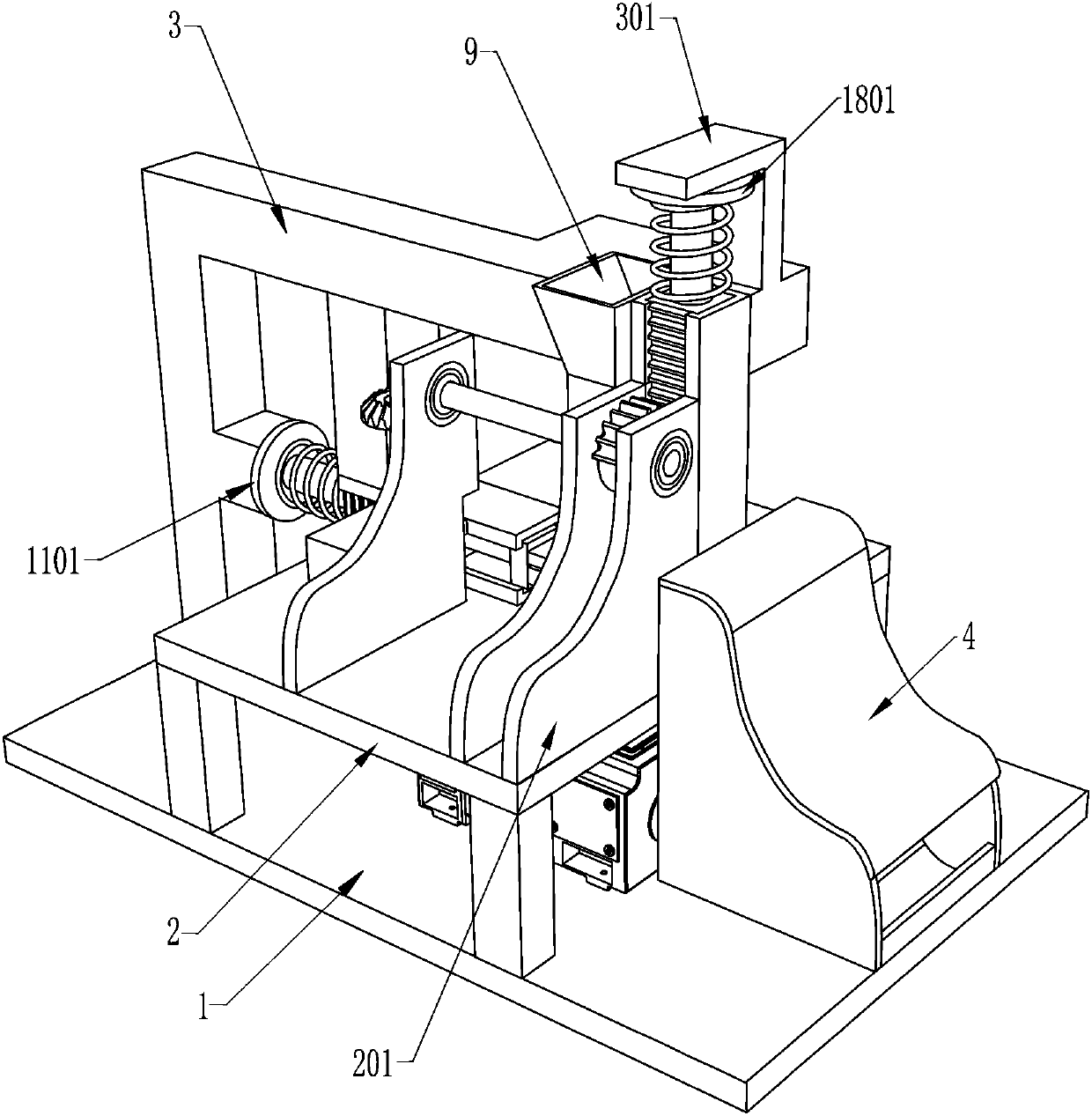

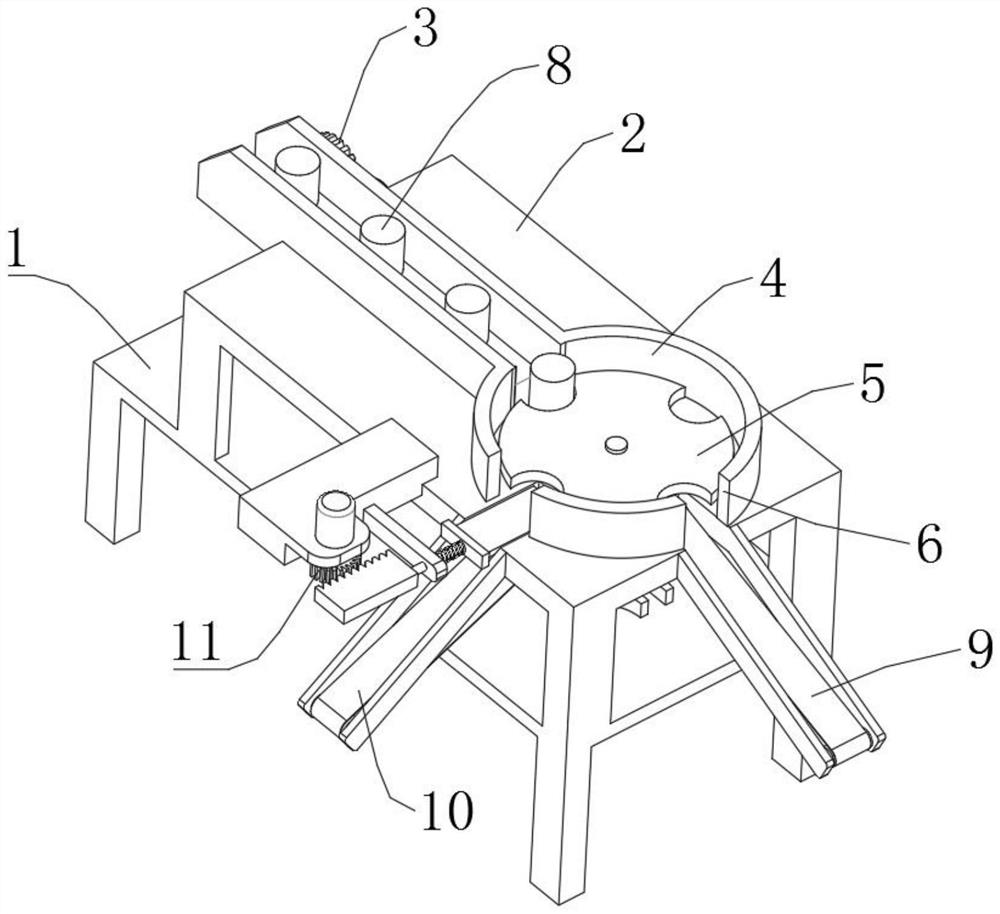

Casting carrying and separating equipment

PendingCN111776686ARealize automatic feeding processOrderly arrange the dischargeConveyor partsGear wheelWorkbench

The invention relates to the technical field of casting separation, in particular to casting carrying and separating equipment. The casting carrying and separating equipment comprises a supporting frame. A workbench is installed at the top of the supporting frame. A feeding mechanism is installed at one end of the workbench and comprises a fixed frame plate, two conveying rollers, a conveying beltand a transmission gear. An installation seat is installed at the output end of the conveying belt and is fixedly connected with the top of the workbench. A material separating mechanism is installedon the inner side of the installation seat and comprises a material separating disc. A rotary shaft is fixedly installed at the bottom of the material separating disc. A rotary seat is fixedly installed at the bottom end of the rotary shaft. A plurality of butt joint grooves are formed in the outer extending part of the rotary seat. A rotary disc is arranged on the outer extending part of the rotary seat. The bottom of the rotary disc is fixedly provided with a fixed plate. One end of the top of the fixed plate is fixedly provided with a lug. By means of the equipment, perfect cooperation ofautomatic feeding, automatic separating and automatic discharging of castings is achieved, the manual labor amount is greatly saved, the castings can be arranged and discharged in order, and accumulation is avoided.

Owner:林素芹

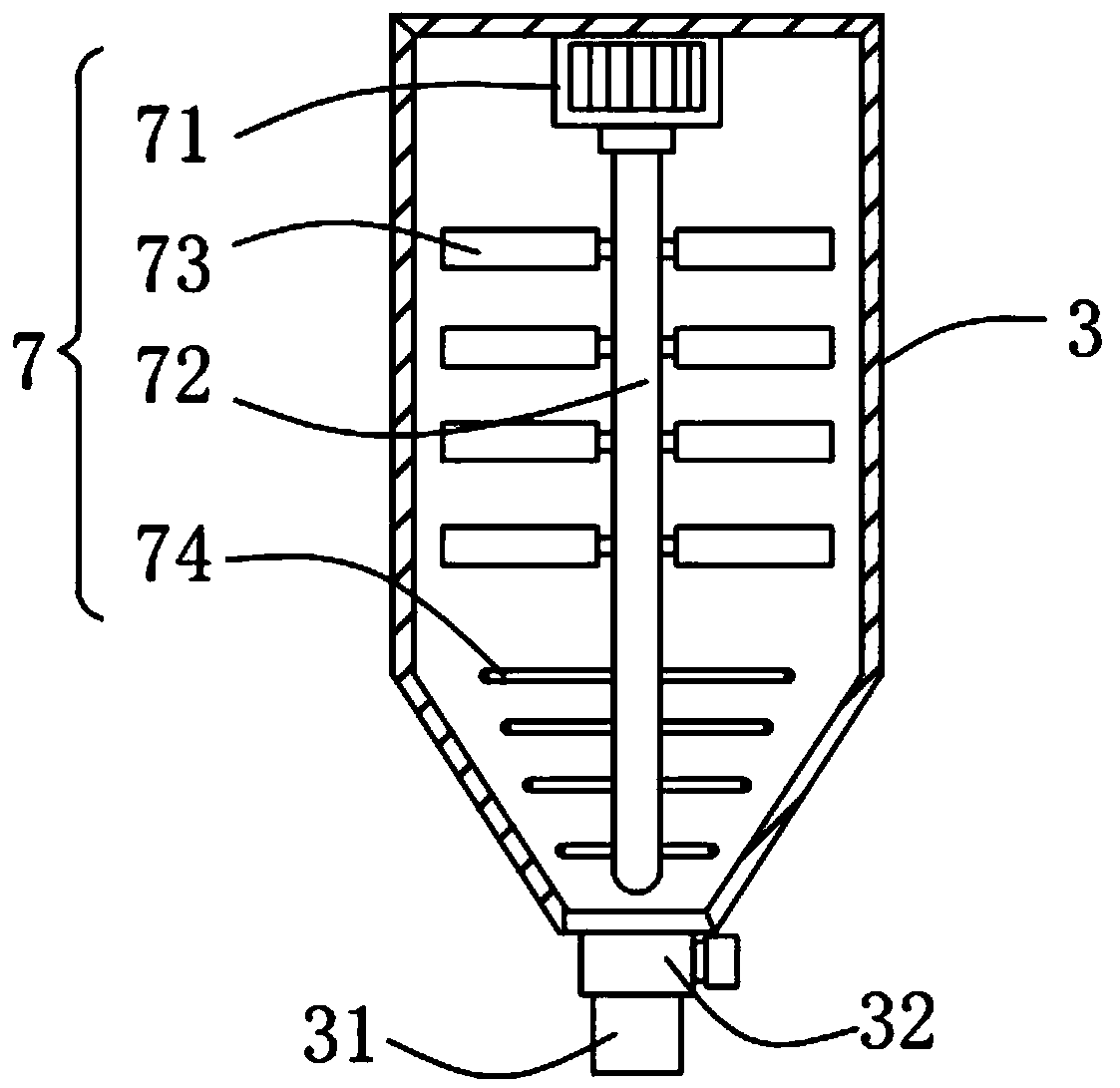

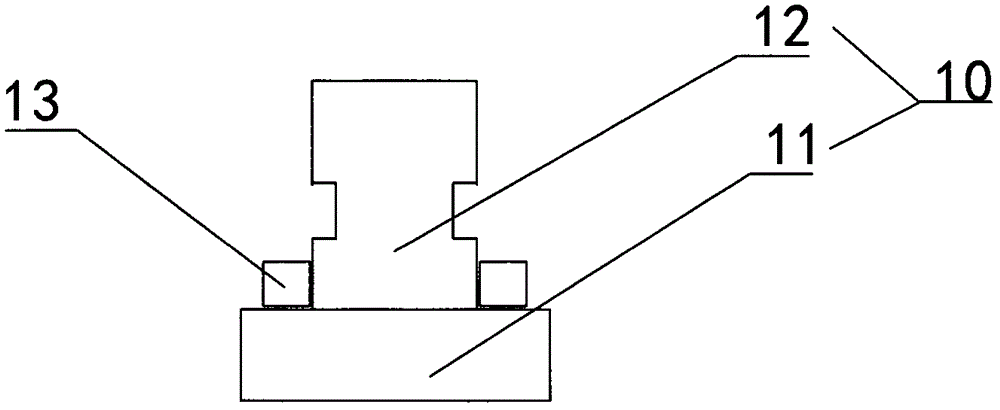

Powder material packaging machine

ActiveCN109335113AEvenly stackedQuick unloadingRotary stirring mixersSolid materialPackaging TankEngineering

The invention relates to the technical field of food processing equipment, in particular to a powder materials packaging machine. The powder material packaging machine comprises a conveying mechanism,a lifting mechanism, a material storage cylinder, a sealing mechanism, a flattening mechanism, a rotating mechanism, a stirring mechanism and a feeding mechanism. According to the machine, a discharging pipe can be driven to move upwards gradually from the bottom layer in a packaging tank through the lifting mechanism, so that the materials are gradually accumulated from bottom to top, and the accumulation is more uniform; meanwhile, the rotating mechanism can drive the flattening mechanism to rotate, a shifting rod can shift and scatter the materials, a flattening plate can flatten the materials, so that the powder materials can fully fill the whole packaging tank; in the discharging process, stirring blades can stir the top area of the packaging tank, stirring rods which are distributedin a funnel shape can stir the outlet area of the packaging tank, so that the discharging is more rapid and the blockage is prevented; and automatic feeding and packaging can be realized.

Owner:台州佑辅机械实业有限公司

Automatic sealing ring sleeving device

ActiveCN105710626AFlipRealize automatic feeding processVehicle componentsMetal working apparatusEngineeringCopper

The invention discloses an automatic sealing ring sleeving device. The automatic sealing ring sleeving device comprises a power device for providing motion power, a turnover mechanism, a sealing ring assembly mechanism, a detection mechanism, a laser marking mechanism, a feeding mechanism and a discharging mechanism, wherein the feeding mechanism and the discharging mechanism are of the same structure. The feeding mechanism is connected with the head end of the turnover mechanism. A vibration disc for containing a large number of sealing rings is connected to the sealing ring assembly mechanism. The sealing ring assembly mechanism is connected with the tail end of the turnover mechanism. The turnover mechanism is connected with the laser marking mechanism through the detection mechanism. The laser marking mechanism is connected with the discharging mechanism. The automatic sealing ring sleeving device is composed of the power device, the turnover mechanism, the sealing ring assembly mechanism, the detection mechanism, the laser marking mechanism, the feeding mechanism and the discharging mechanism, wherein the feeding mechanism and the discharging mechanism are of the same structure. Mechanization and automation are adopted for replacing manpower to mount the sealing rings on aluminum-copper pole pillars, and the work efficiency is greatly improved.

Owner:NINGBO BLUE WHALE AUTOMATION TECH CO LTD

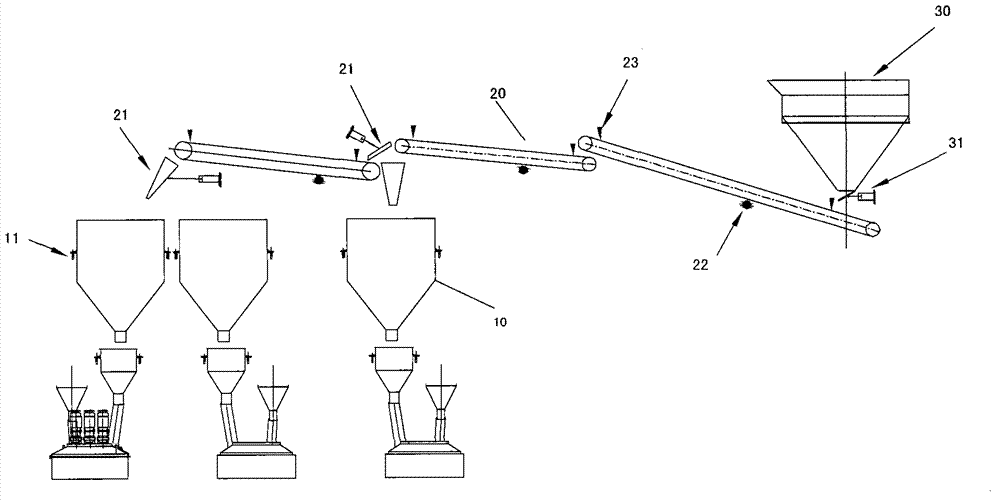

Automatic feeding system for storage hopper

ActiveCN102785951ARealize automatic feeding processControl the output statusLoading/unloadingElectricityControl system

The invention provides an automatic feeding system for a storage hopper. The automatic feeding system comprises a feed bin, the storage hopper and a control system. The feed bin is provided with a discharge outlet. The storage hopper is provided with a feed inlet and a weight sensor, the feed inlet receives materials discharged from the feed bin, and the weight sensor senses and transmits weight information of materials in the storage hopper. The control system is electrically connected with the weight sensor for receiving the weight information transmitted by the weight sensor and is electrically connected with the feed bin to control discharge states of the feed bin according to the received weight information transmitted by the weight sensor. The automatic feeding system for the storage hopper realizes automatic feeding for the storage hopper by adding the weight sensor on the storage hopper, connecting the control system with the weight sensor electrically and controlling the discharge states of the feed bin according to the weight information transmitted by the weight sensor.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

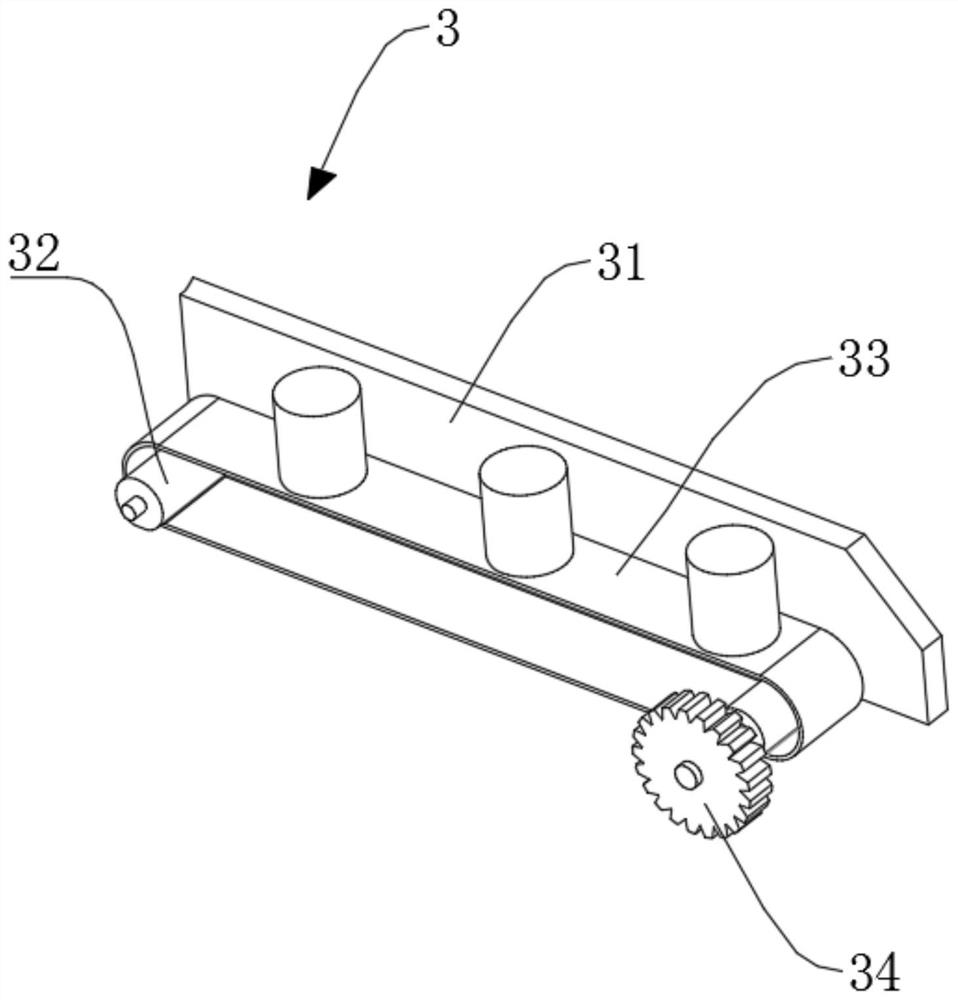

Automatic detection and screening device for hardness of bolt fastening piece

The invention discloses an automatic detection and screening device for the hardness of a bolt fastening piece. The automatic detection and screening device comprises a charging part, a rotary table, a workpiece pressing part, a discharging part, a hardness meter and a table, wherein the charging part is fixedly arranged on a swinging platform mounting base; the swinging platform mounting base and the rotary table are mounted on a base of the hardness meter. The continuous and reciprocating motion of the charging part, the workpiece pressing part, the rotary table, the discharging part and the hardness meter realizes continuous multi-point hardness detection and screening of a bolt. According to the automatic detection and screening device, a movable part is driven by an air cylinder and an electromagnet; the control manner is simple and the work is reliable and easy to realize; an adjusting bolt on a driving piece, a gasket on a spring material stopping part, a workpiece positioning sleeve and a rotary baffle are adjusted simply so as to realize hardness detection of the bolts with different specifications and the flexibility is good; meanwhile, the multi-point hardness detection can be carried out on the bolt by controlling the rotary angle of the rotary table so as to meet the requirements of the use of the hardness meter and the hardness detection; the charging part and the discharging part are mounted on a hardness meter worktable and the structure space of the whole machine is compact.

Owner:SHANGHAI JIAO TONG UNIV

Full-automatic paper cutting machine

PendingCN111360917ARealize automatic feeding processFully automatedMetal working apparatusIndustrial engineeringPaper sheet

The invention provides a full-automatic paper cutting machine by aiming at the defects of manual paper cutting in the prior art, and belongs to the technical field of paper cutting. The full-automaticpaper cutting machine comprises an automatic feeding mechanism, a deviation correction locating mechanism with the deviation correction locating function and the conveying function, a cutting mechanism with the cutting function and a controller with the feedback control function. A paper grabbing device is arranged between the automatic feeding mechanism and the deviation correction locating mechanism. A pressing device used for preventing paper from hiking up is arranged on the deviation correction locating mechanism. A conveying device used for conveying paper to be cut by the cutting mechanism is further arranged on the cutting mechanism. The controller is connected with the automatic feeding mechanism, the deviation correction locating mechanism, the paper grabbing device, the cuttingmechanism and the conveying device. By means of the full-automatic paper cutting machine, automatic feeding, deviation correction locating and cutting can be achieved on paper, automation of paper cutting can be achieved, the labor intensity of workers can be reduced, and the work efficiency of paper cutting can be improved remarkably.

Owner:浙江佰格迪科技有限公司

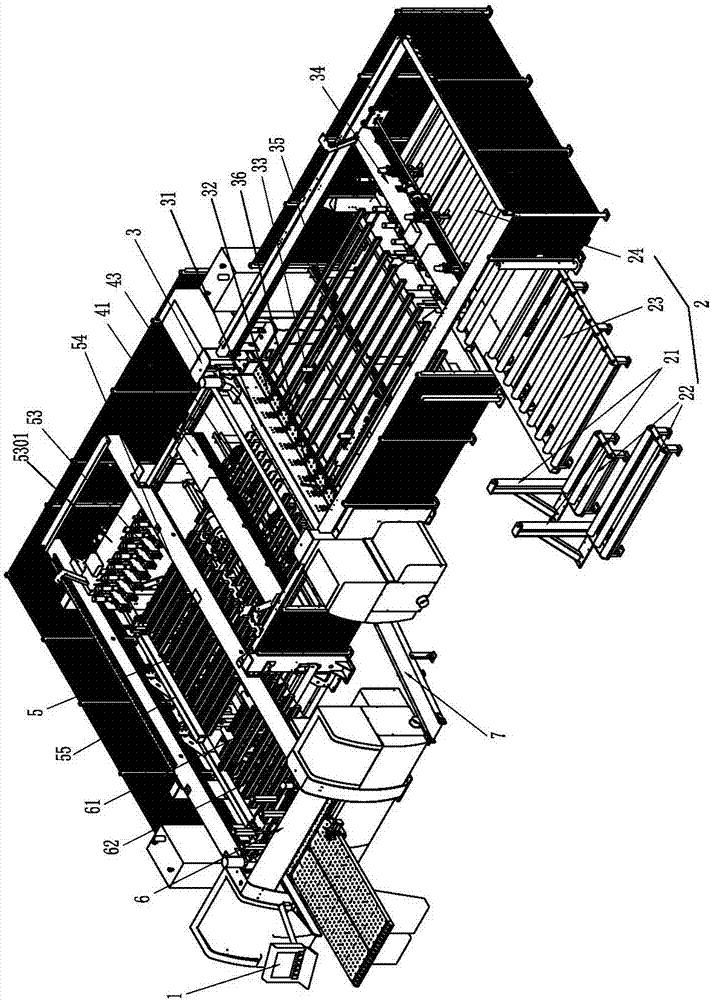

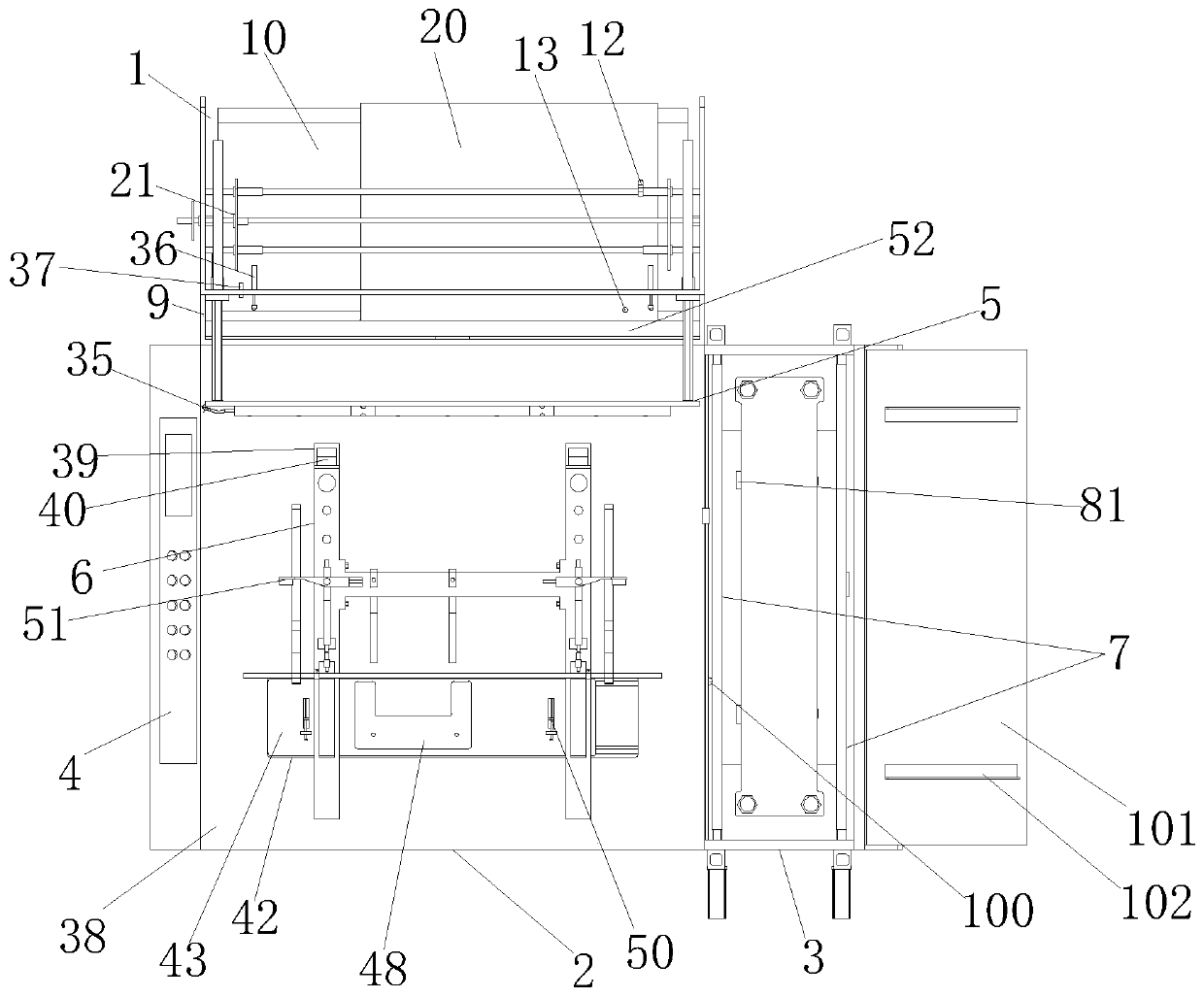

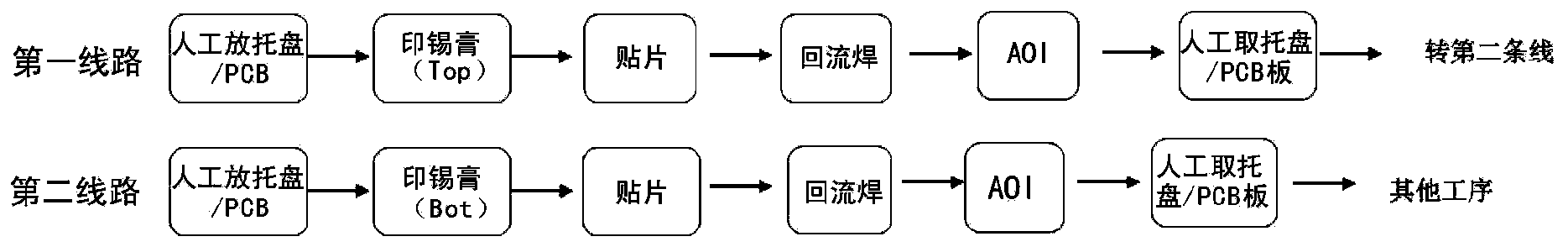

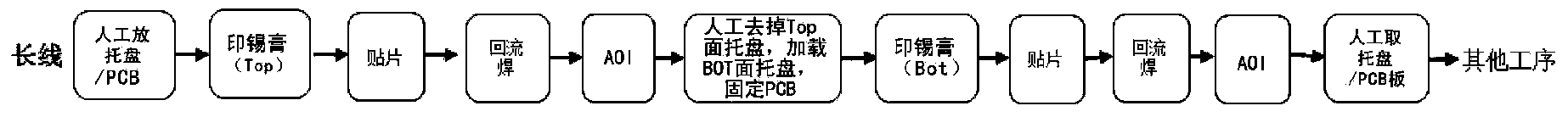

Automatic PCB detaching, overturning and pasting integrated machine

ActiveCN103763866AAchieve disassemblyImprove processing efficiencyPrinted circuit assemblingEngineeringMechanical engineering

The invention discloses an automatic PCB detaching, overturning and pasting integrated machine which comprises an equipment body, a machine hood arranged on the equipment body in a sleeved mode and a rack for supporting the equipment body. The equipment body comprises a conveying mechanism, a large gantry mechanism, small gantry mechanisms and automatic feeding and discharging mechanisms. At least two working stations are arranged on the large gantry mechanism and the small gantry mechanisms are arranged on one side of the large gantry mechanism in parallel. The small gantry mechanisms and the large gantry mechanism are matched for automatically detaching, overturning and pasting a PCB again. The automatic feeding and discharging mechanisms are arranged on one side below the conveying mechanism in parallel and used for conveying cover plates or carriers to all the working stations. According to the automatic PCB detaching, overturning and pasting integrated machine, unloading of an old carrier and cover plates, overturning of the PCB and repeated pasting of the PCB and a new carrier are performed automatically and the machining efficiency of the PCB is improved. Meanwhile, labor force and labor cost are saved, cost is reduced and in addition, automatic feeding and discharging are achieved, especially materials can be automatically replaced in a non-stopping state.

Owner:SUZHOU INTELLIGENT AUTOMATION EQUIP CO LTD

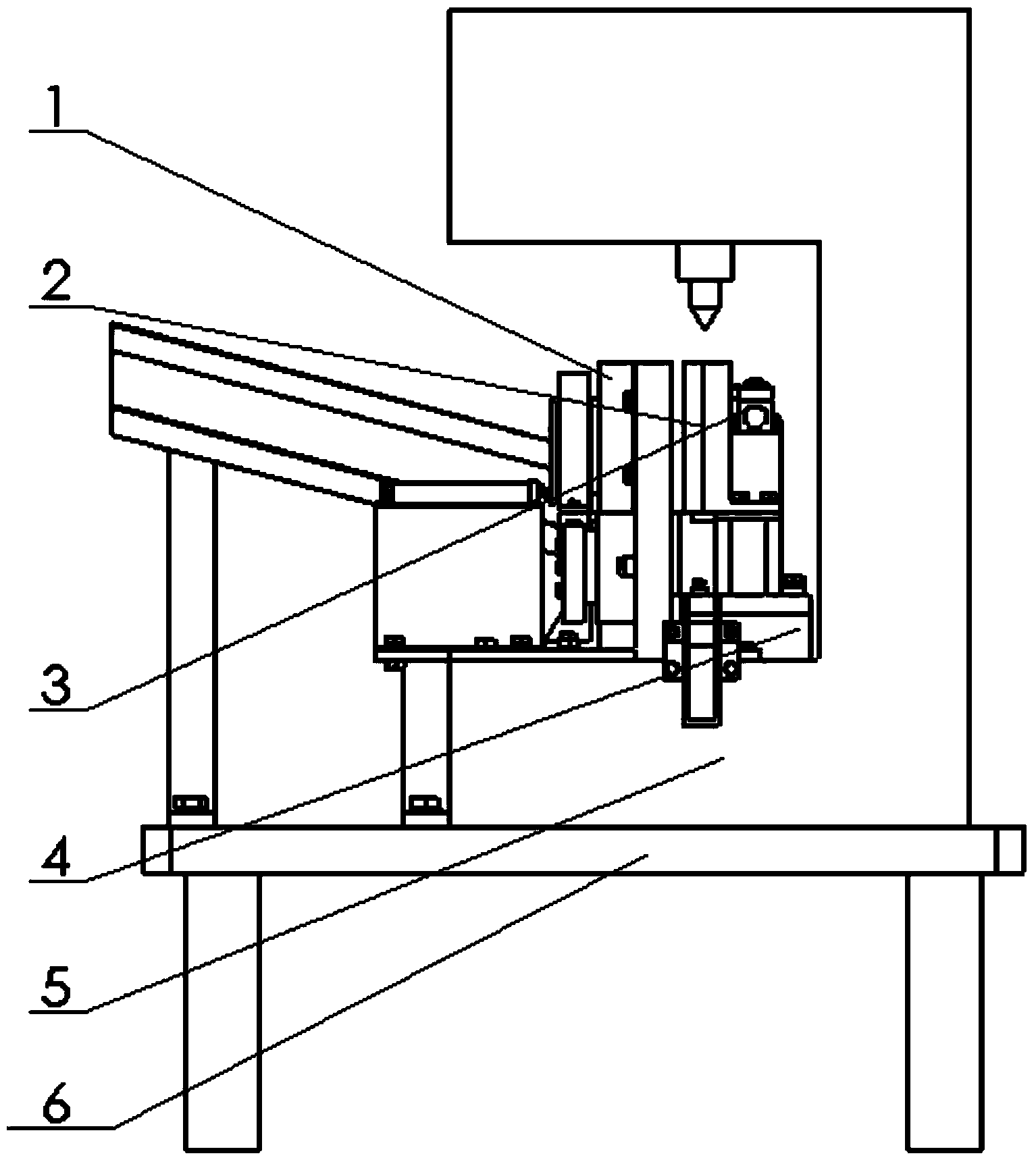

Double-station shoe sole laser cutting machine and method

ActiveCN104942450ASimple structureEasy to operateLaser beam welding apparatusLaser cuttingEngineering

The invention relates to a double-station shoe sole laser cutting machine, and belongs to the technical field of shoe sole machining machines. The double-station shoe sole laser cutting machine comprises a rack, a machining table, two groups of feeding mechanisms for feeding shoe soles to the machining table and a group of laser machining mechanisms for cutting the shoe soles on the machining table through a laser. The machining table comprises two cutting tables arranged side by side from left to right. The two cutting tables for holding the shoe soles move horizontally on the rack through a double-station horizontal movement mechanism from left to right. One group of feeding mechanisms is fixed to the left end of the rack, and the other group of feeding mechanisms is fixed to the right end of the rack. The laser machining mechanism is located between the groups of feeding mechanisms. The cutting table on the right side right faces the laser machining mechanisms when the cutting table on the left side right faces the feeding mechanisms on the left side. The cutting table on the left side right faces the laser machining mechanisms when the cutting table on the right side right faces the feeding mechanisms on the right side. The invention further relates to a double-station shoe sole laser cutting method. The double-station shoe sole laser cutting machine and method have the advantages of being simple in structure, automated in machining process and high in machining efficiency.

Owner:GUANGZHOU RUISU INTELLIGENT TECH CO LTD

Spray paint device of loudspeaker box

InactiveCN107812647AAvoid close contactRealize automatic feeding processLiquid spraying apparatusSpray boothsElectric machineryEngineering

The invention discloses a spray paint device of a loudspeaker box. The spray paint device comprises a box, and a driving roller and a driven roller are rotatably connected between two opposite sides of the inner wall of the box in sequence; one side of the bottom of the inner wall of the box is fixedly connected to a first motor, and the output shaft end of the first motor is connected to a rotating device through a belt; one side of the rotating device is fixedly connected to one end of the driving roller, and the driving roller is rotatably connected to the surface of the driven roller through a conveyor chain; the bottom of the inner wall of the box is fixedly connected to a lifting rotation device, and the top of the box is fixedly connected to a third motor; and two opposite sides ofthe inner wall of the box are rotatably connected to second screw rods through bases, and the surfaces of the second screw rods are fixedly connected to first nozzle bases through electric telescopicrods of movable blocks. The invention relates to the technical field of loudspeaker machining. According to the spray paint device of the loudspeaker box, the problem of uneven thickness of existing spray paint is solved; and the purpose of automatic uniform spray paint is achieved, and the paint harm to human bodies is reduced.

Owner:湖州宏跃电子器件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com