Feeding device

A technology of loading rack and lifting device, which is applied in the direction of transportation and packaging, conveyors, metal rolling, etc. It can solve the problems of restricting the application range of pinch rollers, high labor intensity, and inability to load materials, so as to shorten the feeding time , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

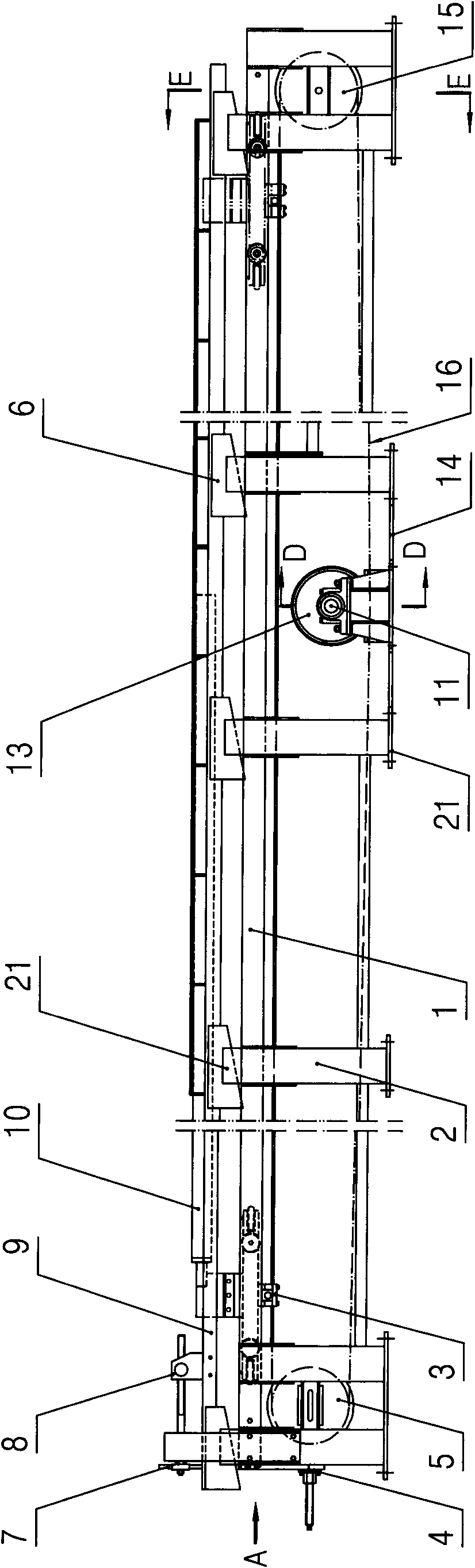

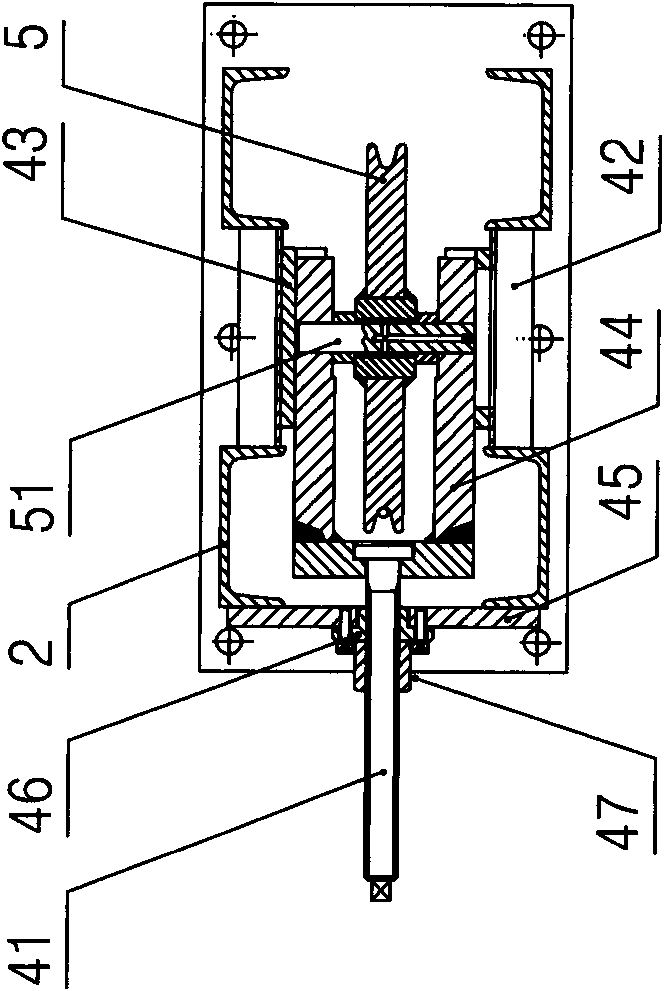

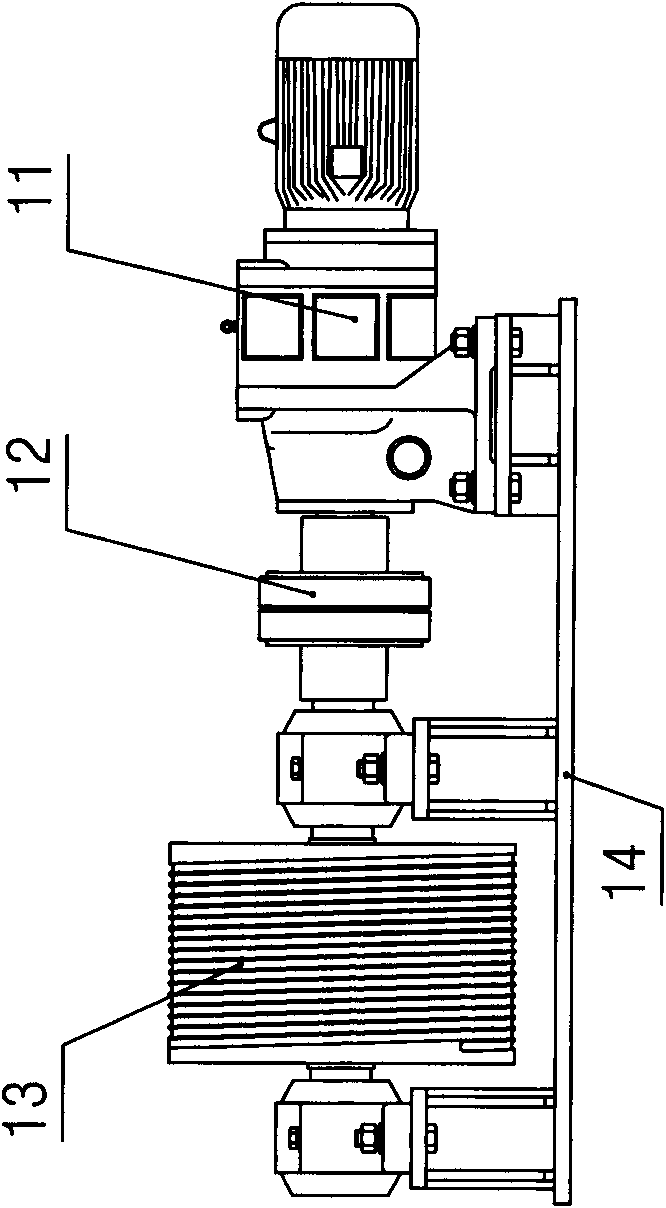

[0018] Such as figure 1 As shown, the feeding device of the present invention includes: a feeding rack 1 mainly composed of a base 21 and a plurality of pairs of columns 2 arranged on the base 21, the inner sides of many pairs of columns 2 in the middle are provided with a connecting block 22 For rails 17 parallel to each other—see figure 2 , Figure 6 As shown, the pair of guide rails 17 is provided with a pushing trolley 3, and the pushing trolley 3 can slide in the guide rail 17 through its pair of front and rear rollers 31 and two pairs of upper and lower rollers 32—see image 3 As shown, the bottom of the pusher trolley 3 is provided with a traction seat 30, and the top of the pusher trolley 3 is provided with a pusher arm 33, and the upper end of the pusher arm 33 is provided with a pusher tube 10 by threads—the pusher tube 10 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com