Patents

Literature

275results about How to "Save loading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

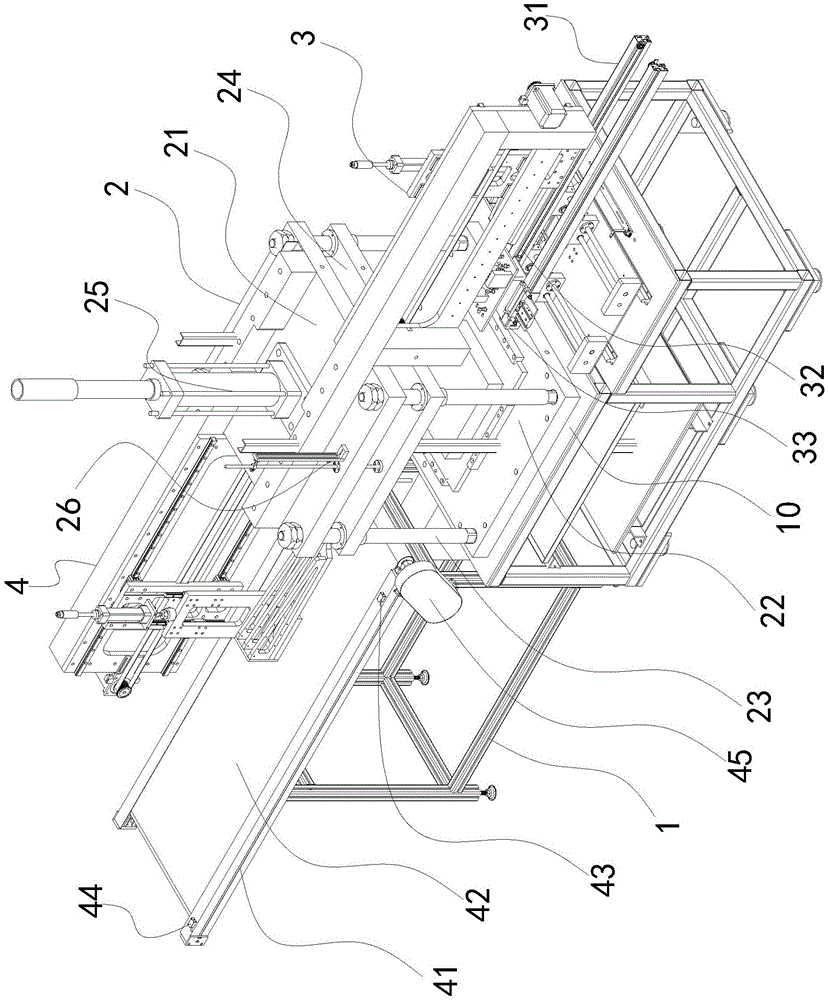

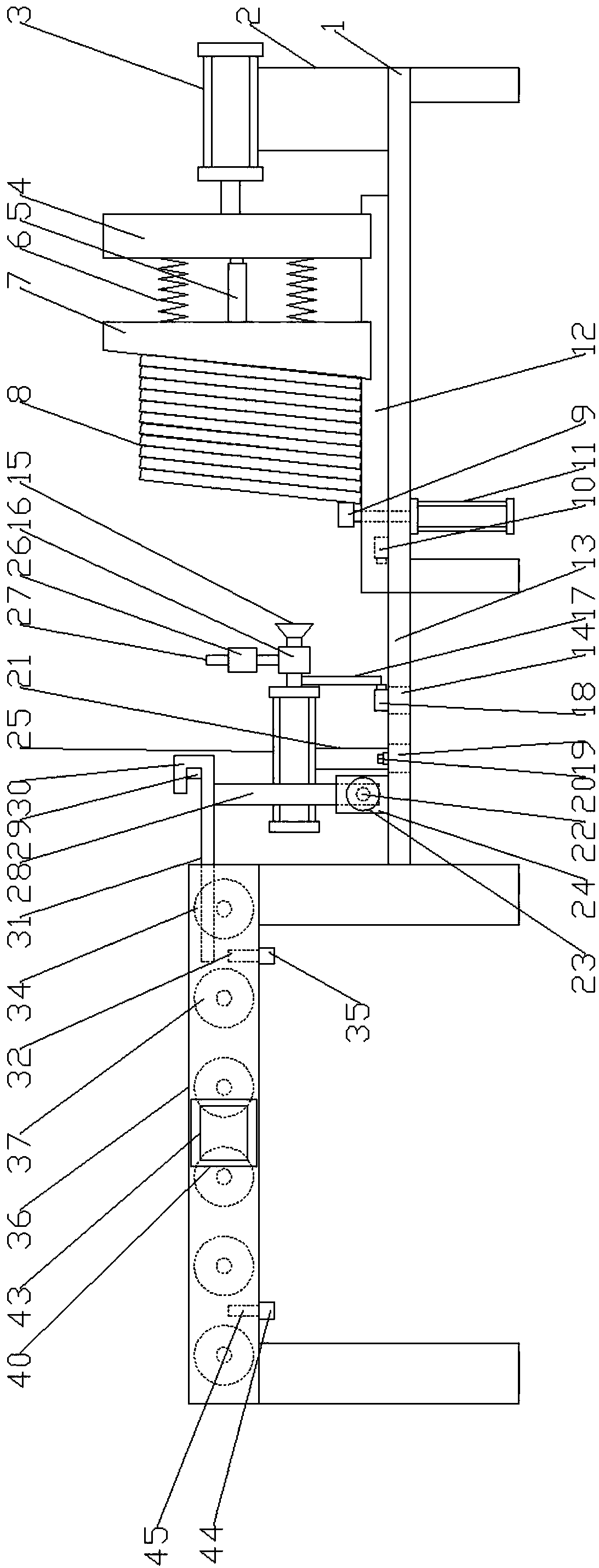

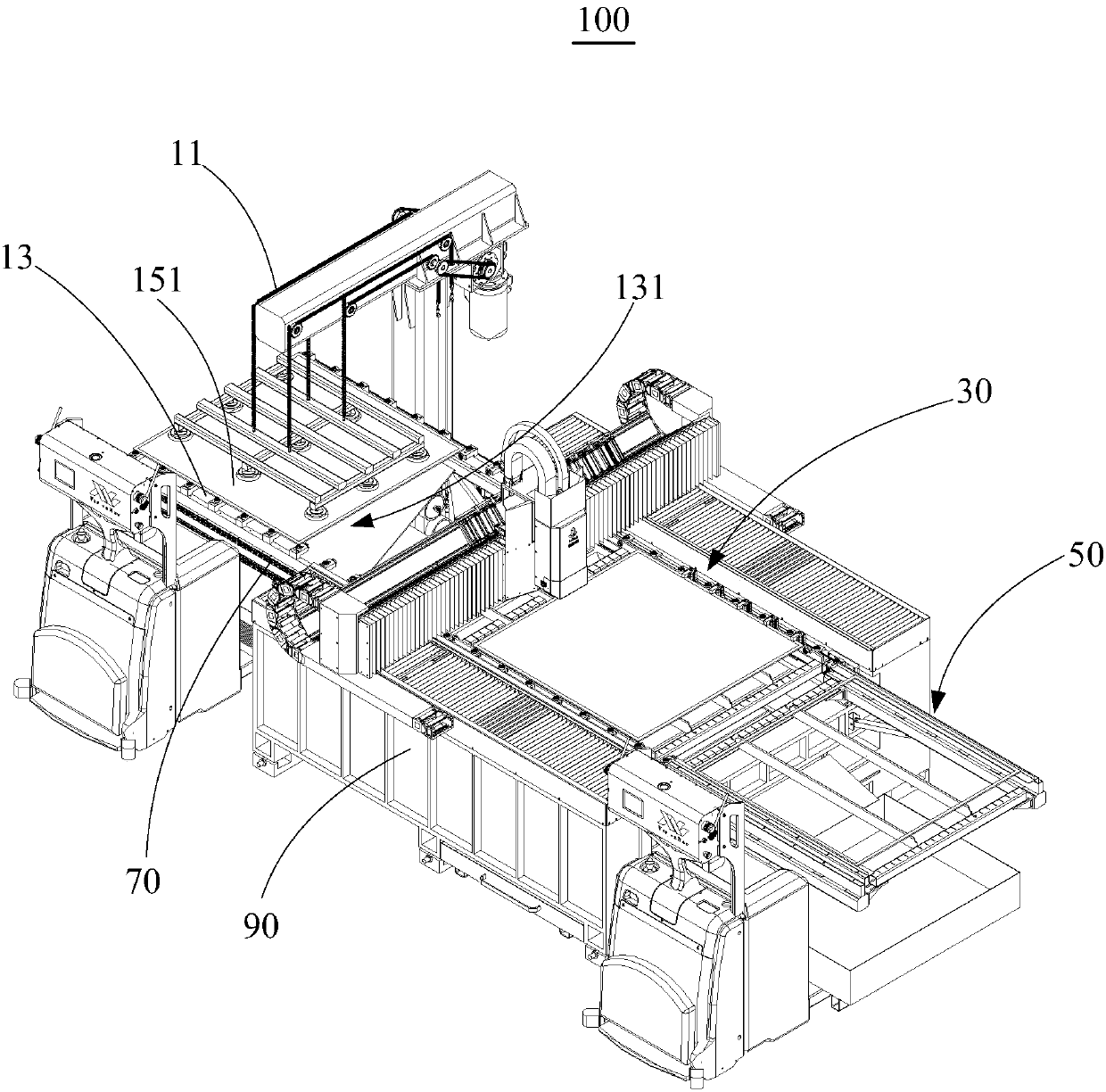

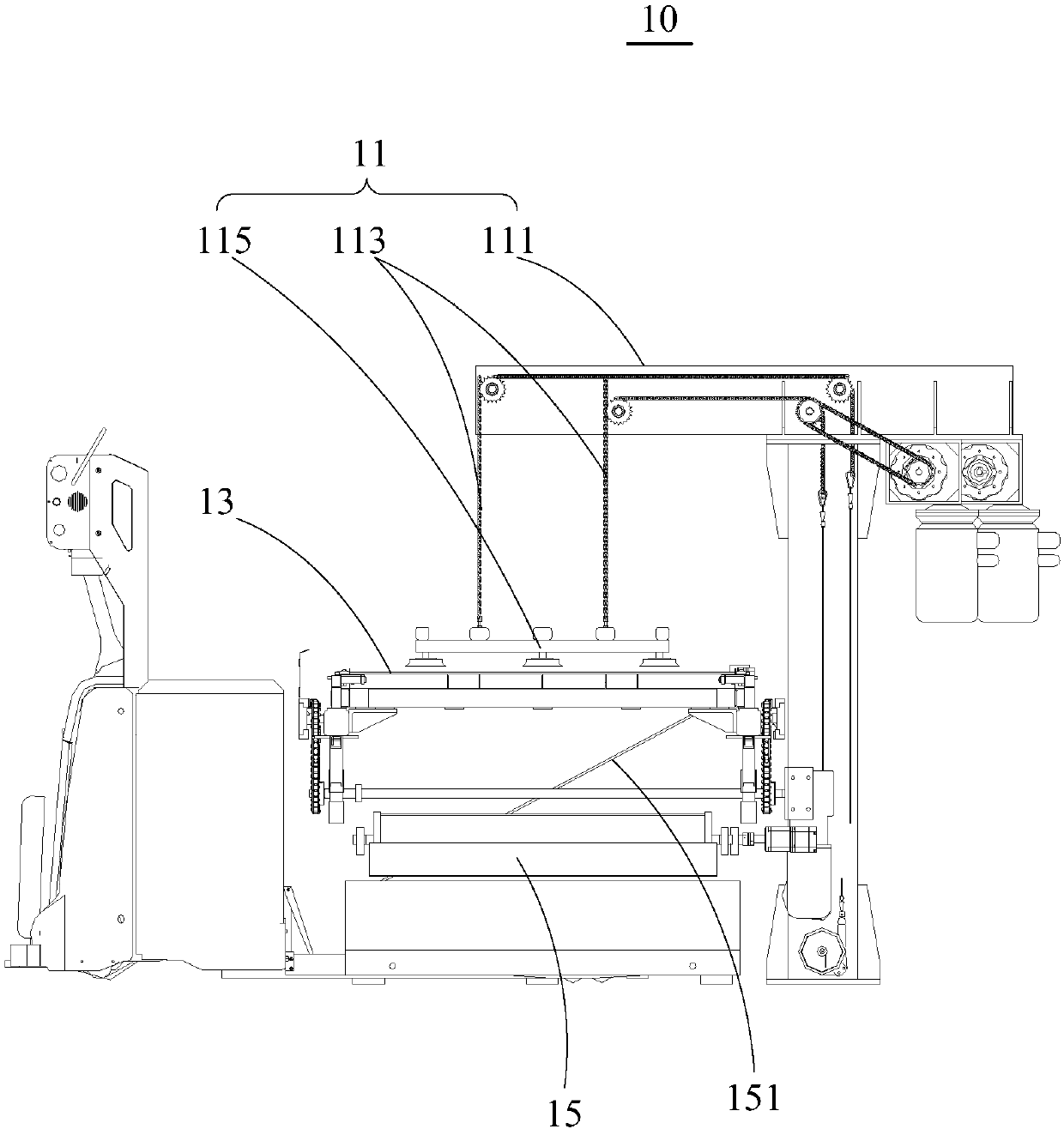

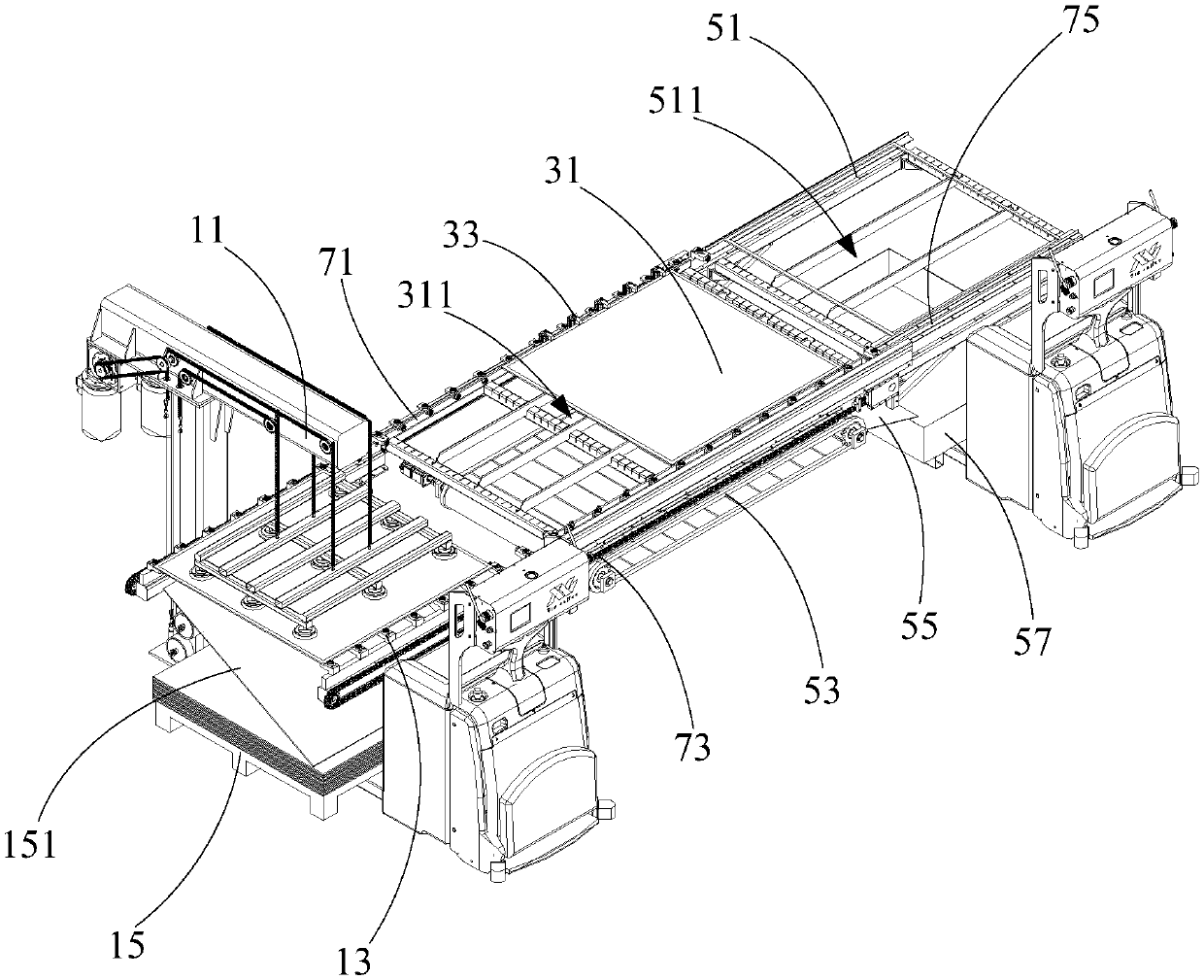

Online automatic board cutting device

ActiveCN105621094ASave loading timeSave time for blankingConveyorsMetal working apparatusEngineeringManipulator

The invention discloses an online automatic board cutting device which comprises a rack. A workbench is arranged on the rack. A stamping mechanism is arranged on the workbench and comprises an upper fixing plate, a lower fixing plate, guiding columns arranged between the upper fixing plate and the lower fixing plate, a lifting plate in sliding fit with the guiding columns and a lifting cylinder arranged on the upper fixing plate to drive the lifting plate to go up and down. A lower die is arranged on the lower fixing plate, and an upper die is arranged at the bottom of the lifting plate. A feeding conveying mechanism and a feeding manipulator are arranged on one side of the workbench, and the feeding manipulator is used for carrying a product on the feeding conveying mechanism to the lower fixing plate. A discharging conveying mechanism and a discharging manipulator are arranged on the other side of the workbench, and the discharging manipulator is used for carrying the product on the lower fixing plate to the discharging conveying mechanism. After the discharging manipulator carries the product to a discharging mechanism, the feeding manipulator feeds a next product to be stamped, and the feeding manipulator and the discharging manipulator work in turn, so that feeding and discharging time is shortened, and production efficiency is improved.

Owner:广东华技达精密机械有限公司

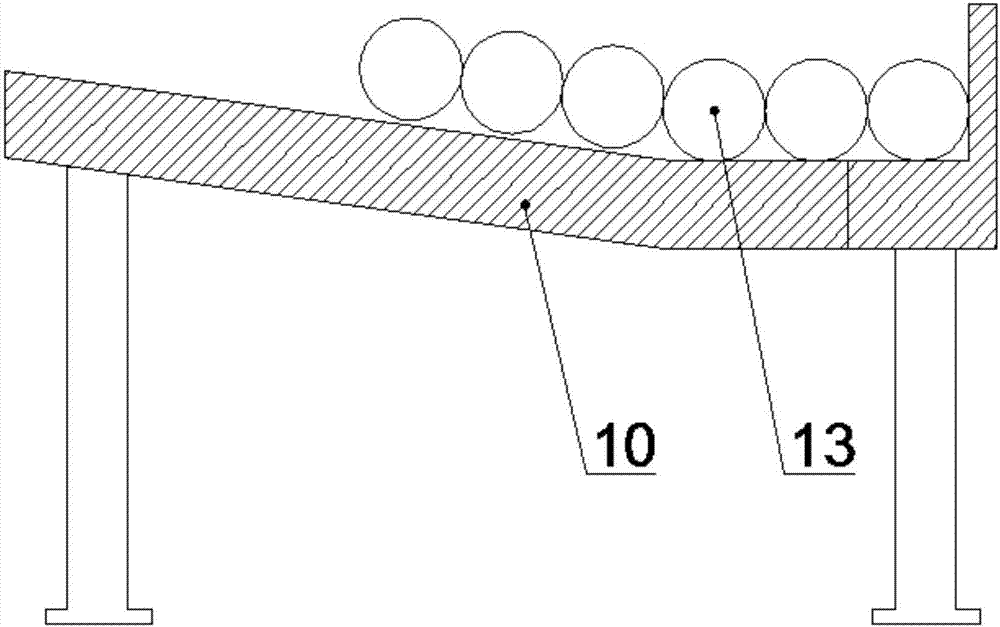

Feeding device

InactiveCN101628302AWill not affect feedingRealize automatic feeding processConveyorsMetal rolling arrangementsEngineeringRolling mill

The invention discloses a feeding device applicable to material blanks of various specifications, comprising: a feeding frame that is provided with a pair of supporting plates and supporting plate lifting devices parallel to each other, wherein the pair of supporting plates is provided with a pair of V-shaped shelves provided with a pushing slot at the bottom; two ends of the feeding frame are respectively provided with a belt pulley; the two belt pulleys are linked with a rolling barrel arranged in a traction device on the feeding frame through a wire rope; the feeding frame is further provided with a pushing trolley capable of moving linearly; the top of the pushing trolley is provided with a pushing arm, and the bottom of the pushing trolley is provided with a traction seat, wherein the pushing arm extends from the pushing slot to connect a pushing pipe, and the traction seat is fixed on the wire rope. The invention is mainly used in cold-rolling mills.

Owner:张家港恒立机械有限公司

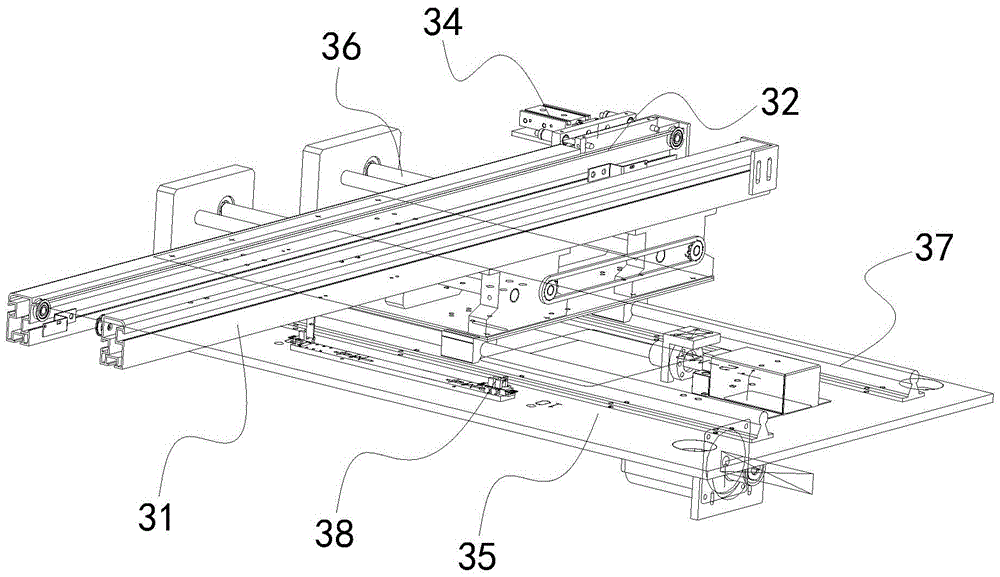

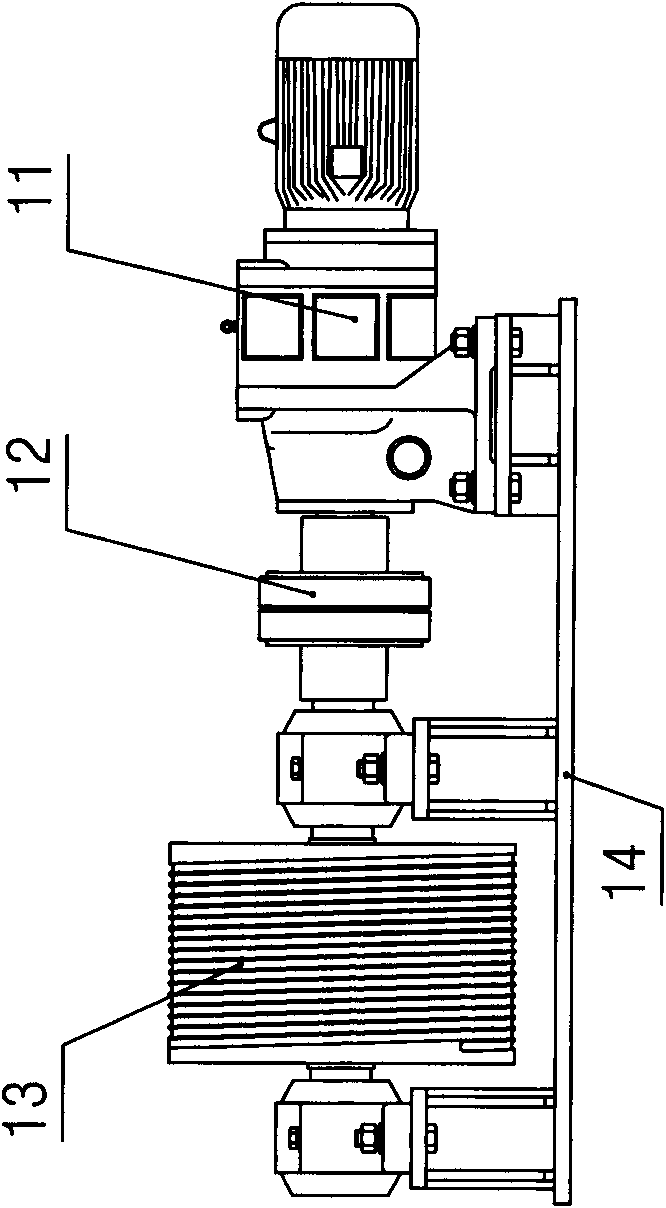

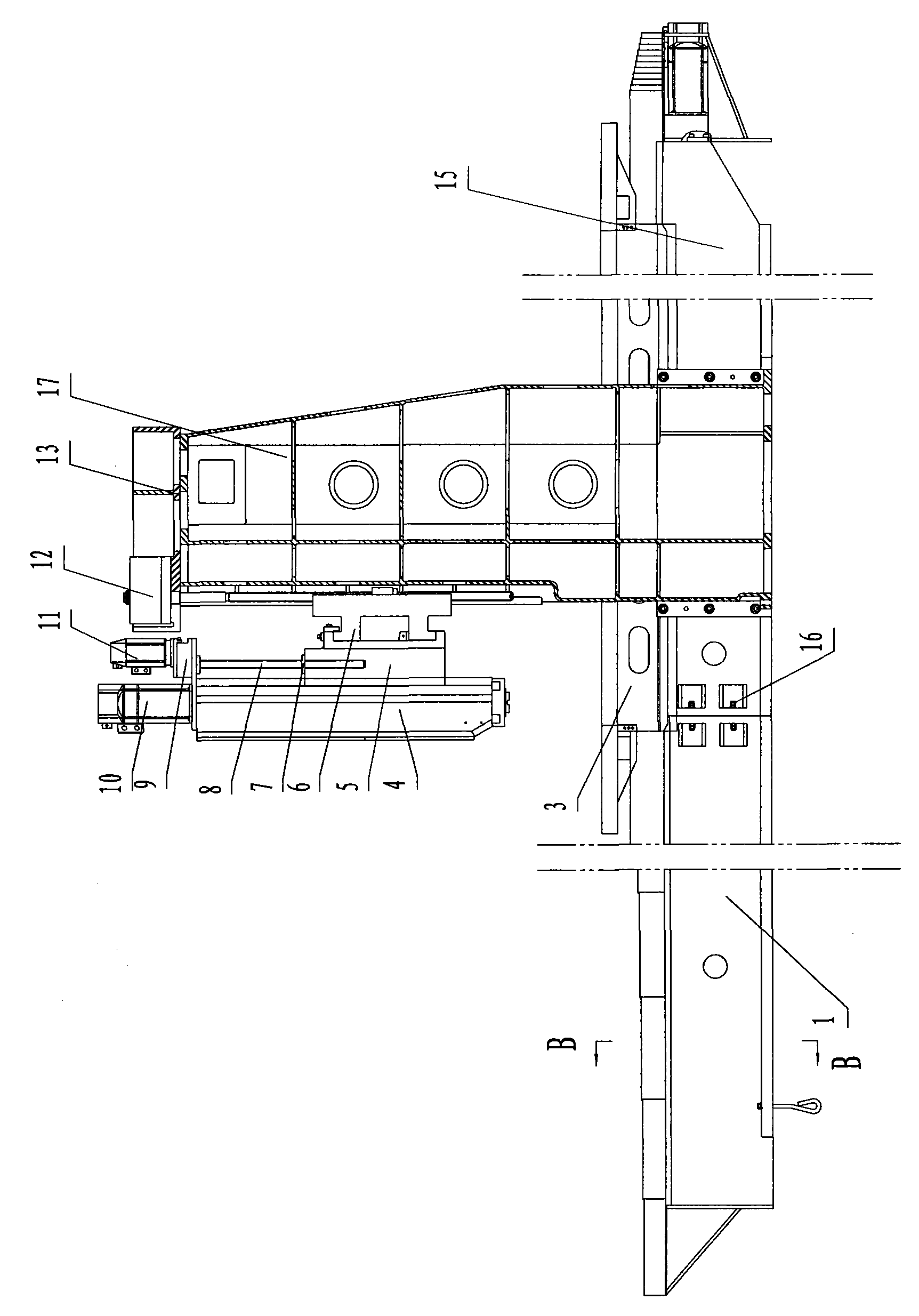

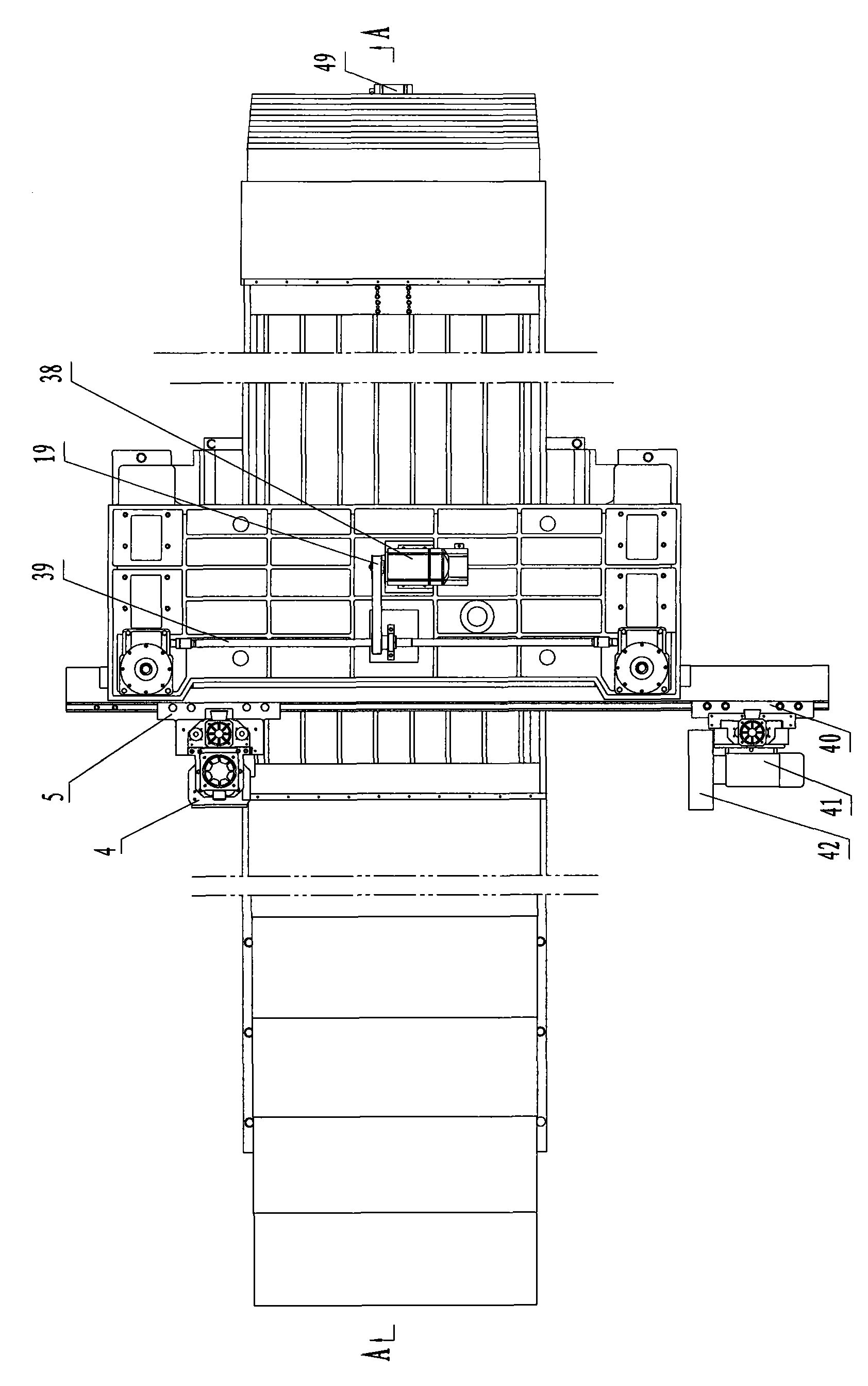

Gantry numerical-control milling and grinding integrated lathe of fixed column and movable beam type

ActiveCN101856789AVersatileGuaranteed accuracyOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a gantry numerical-control milling and grinding integrated lathe of a fixed column and movable beam type, comprising a lathe bed (2), a worktable (3), a left column (17), a right column (14), a beam (6), a spacing beam (22), a top beam (13), an electrical cabinet (33), a system control panel (32) and a tool clamp. The beam (6) is arranged on the left column (17) and the right column (14) through a beam-driving device, a boring and milling head (4) and a universal grinding head (41) are respectively arranged on the beam (6), the boring and milling head (4) is driven by a boring and milling head left-and-right driving device and a boring and milling head up-and-down driving device, the universal grinding head (41) is driven by a grinding head left-and-right driving device and a grinding head up-and-down driving device, and the worktable (3) is arranged on the lathe bed (2) through a ball screw pair (34). On the lathe, after once clamping, a workpiece can be processed by milling, boring, drilling, grinding, rigidly tapping and other continuous working procedures with high accuracy.

Owner:山东大侨发展股份有限公司

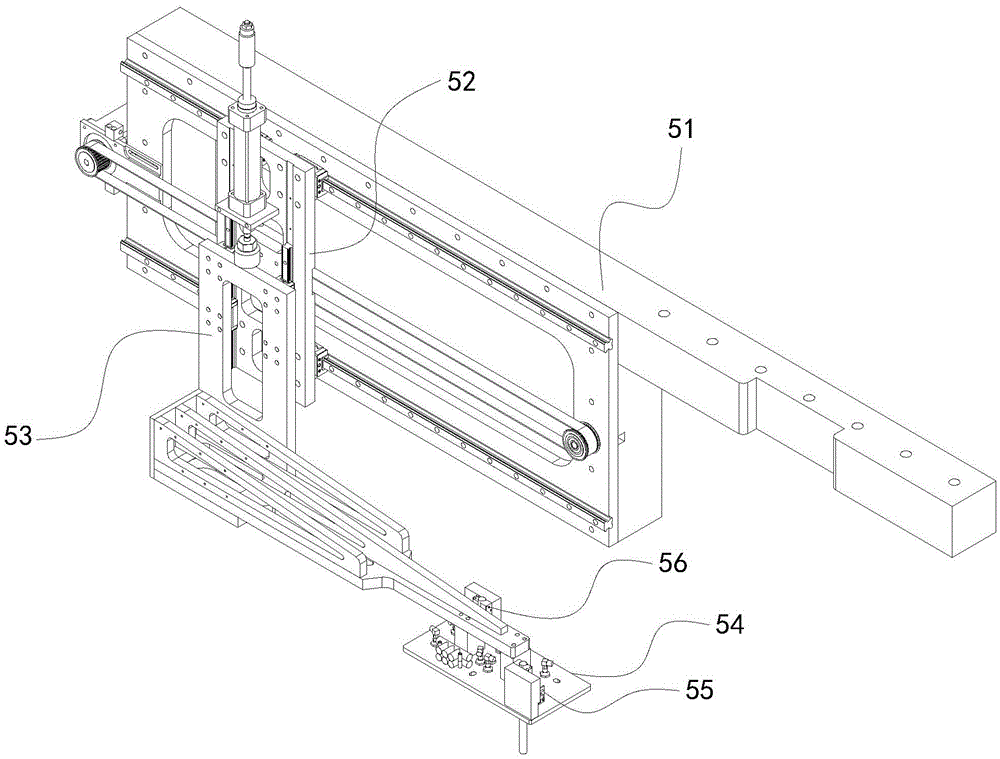

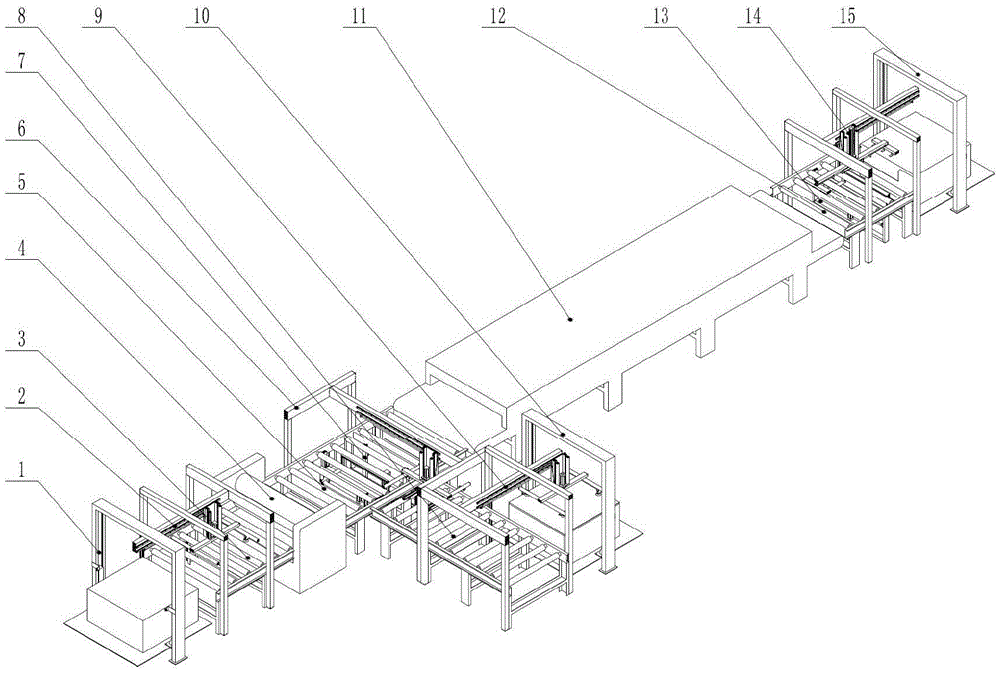

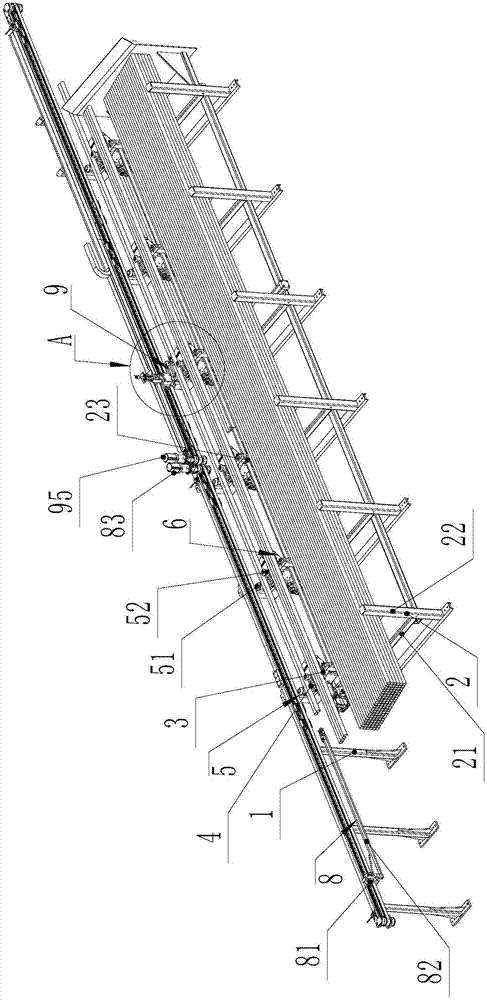

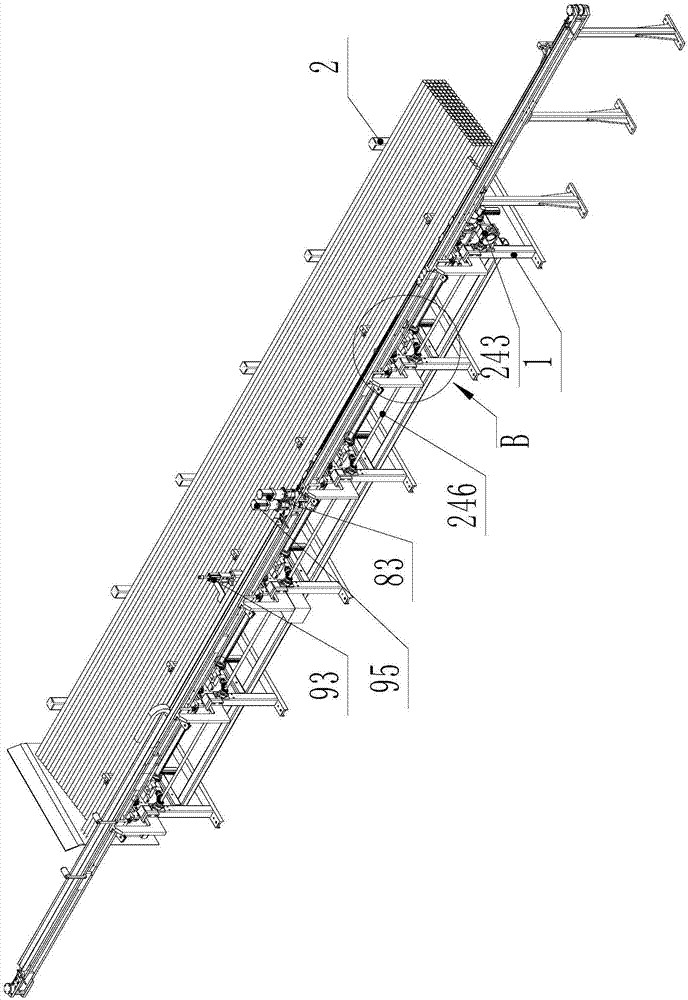

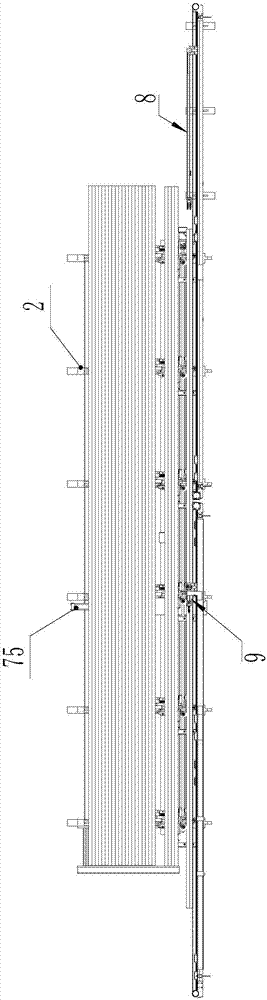

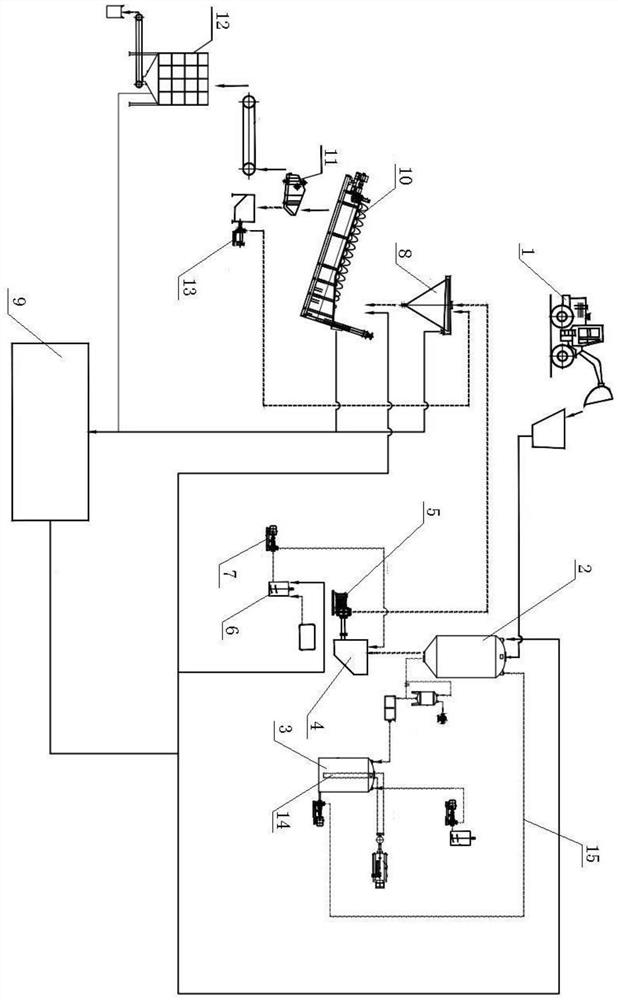

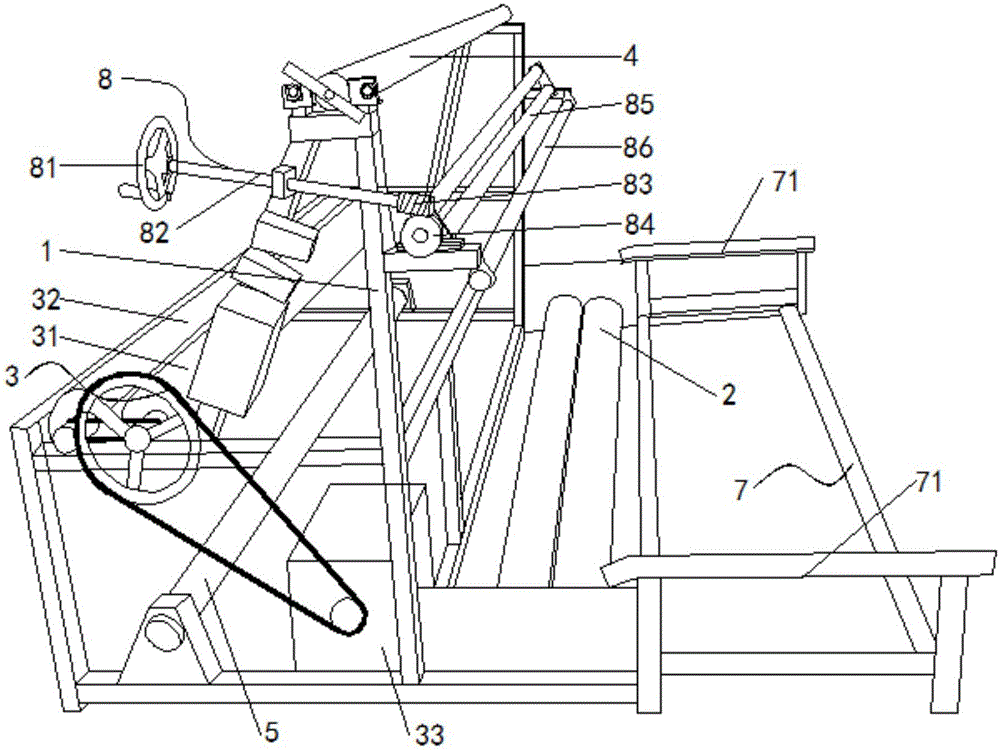

Automatic glue spreading and veneering device and method for production of wood-plastic floorboards

The invention discloses an automatic glue spreading and veneering device and method for production of wood-plastic floorboards. The automatic glue spreading and veneering device comprises a bottom board feeding device, a glue spreading machine, a face board feeding device, a veneering device, a drying machine and a stacking device. The bottom board feeding device conveys bottom boards to the glue spreading machine for glue spreading; the bottom boards subjected to glue spreading are conveyed to the veneering device to wait for veneering; the face board feeding device is used for feeding face boards; the veneering device is used for enabling the face boards and the bottom boards to be subjected to accurate veneering; the face boards and the bottom boards are conveyed to the drying machine after the completion of veneering; and finally, the stacking device is used for accurately stacking the floorboards. The automatic glue spreading and veneering device is convenient to operate, capable of conducting full-automatic working without any manual carrying, glue spreading or veneering, capable of conducting accurate veneering and stacking, high in production efficiency and capable of saving time and labor.

Owner:江苏坤美新材料科技有限公司

Heuristic car-distribution method under multiple constraint conditions

InactiveCN1936937AReduce the human factorAvoid fragmentationLogisticsThree-dimensional spaceDistribution method

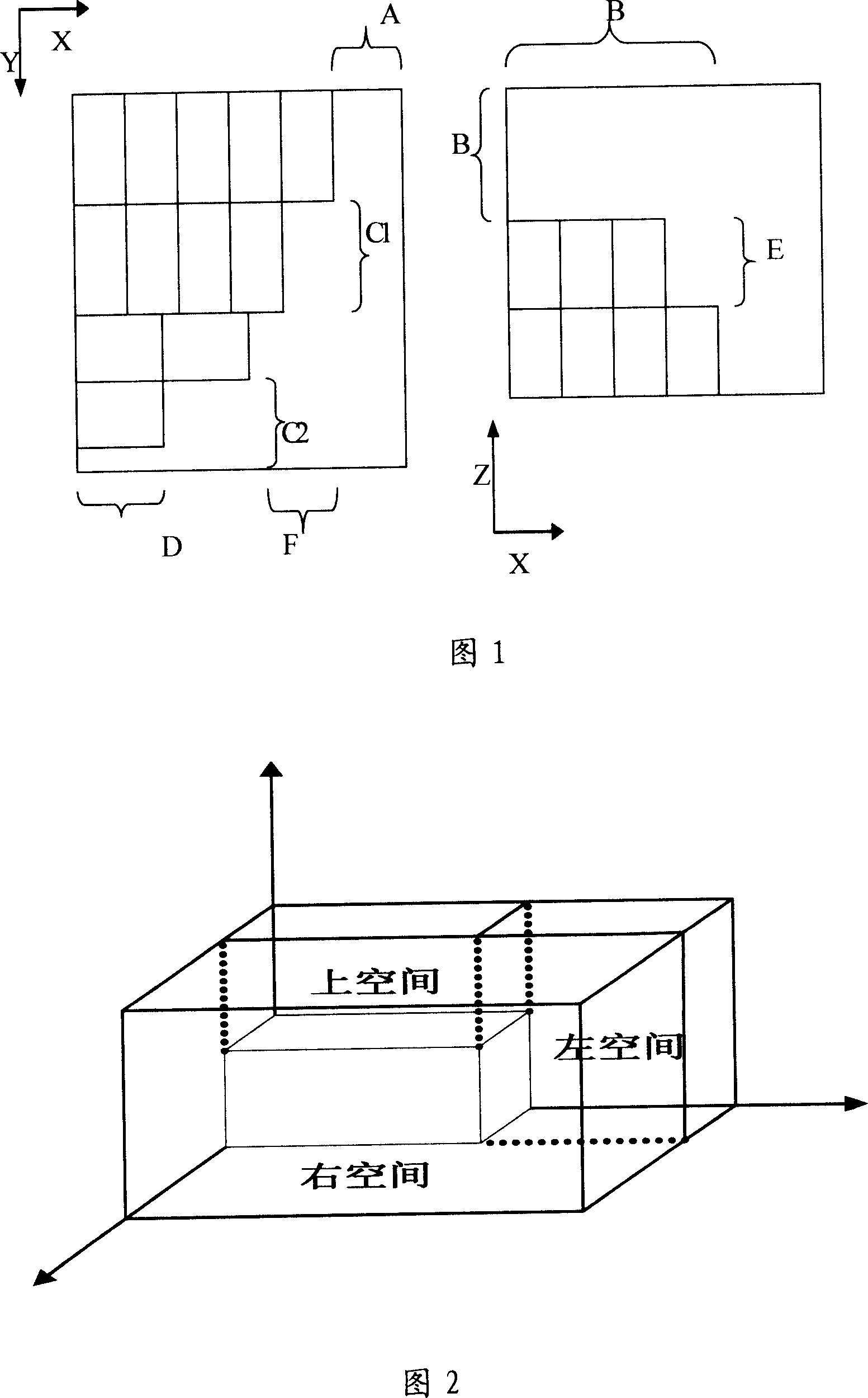

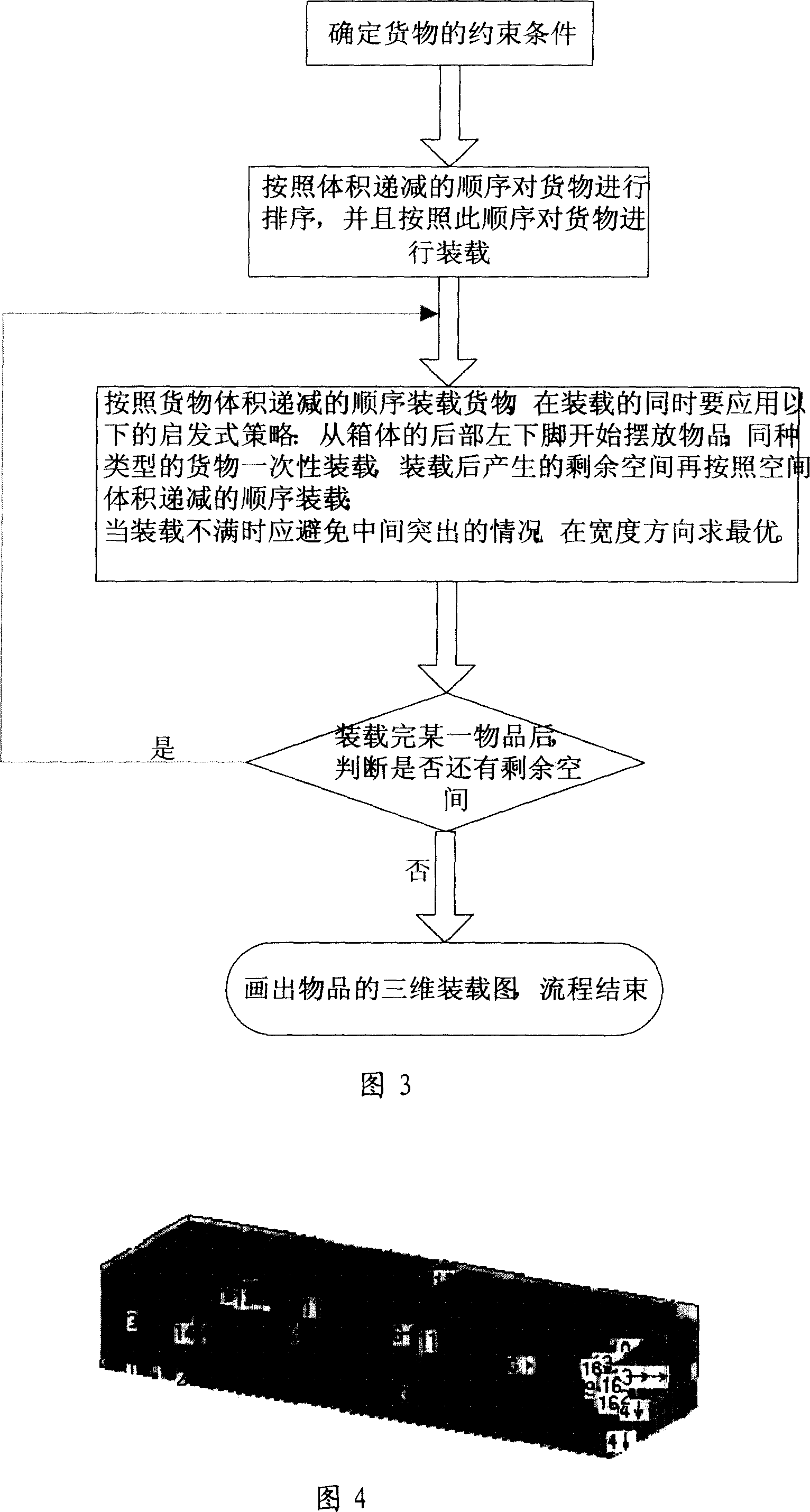

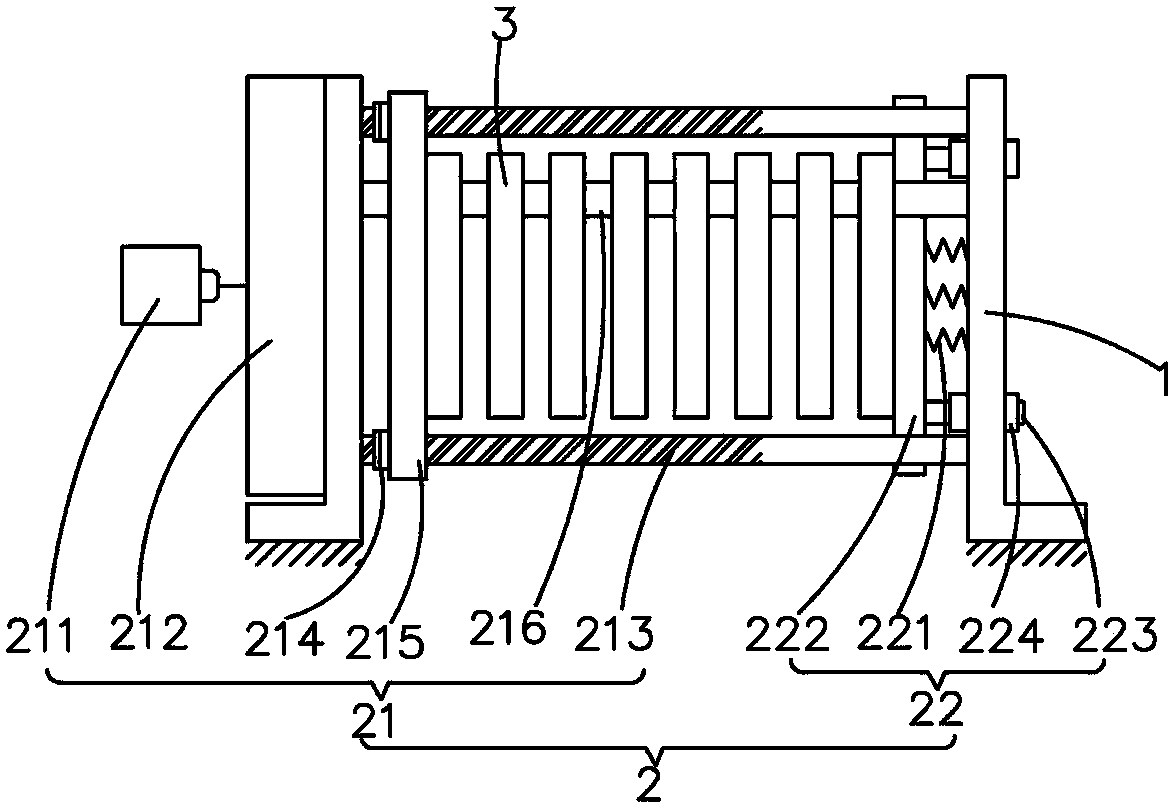

Introducing heuristic strategy into specific loading procedure for vehicle, the system uses 3D loading space of cabinet in maximization and high efficiency. The method includes following characters and steps: first, determining all constraint condition and processing mode in procedure of distributing cargoes; next, applying heuristic strategy for deploy vehicle; then, partitioning cabinet space of vehicle, loading sequence carried out according to descending order according to cubage of space; determining ordering and positioning rules, ordering according to descending sequence of cubage of cargo to be loaded; positioning strategy is to take corner first, that is to say that cargo to be loaded is placed on a corner in 3D space in three dimension; finally, dividing space up, loading order in sequence: left space, right space and up space.

Owner:OCEAN UNIV OF CHINA

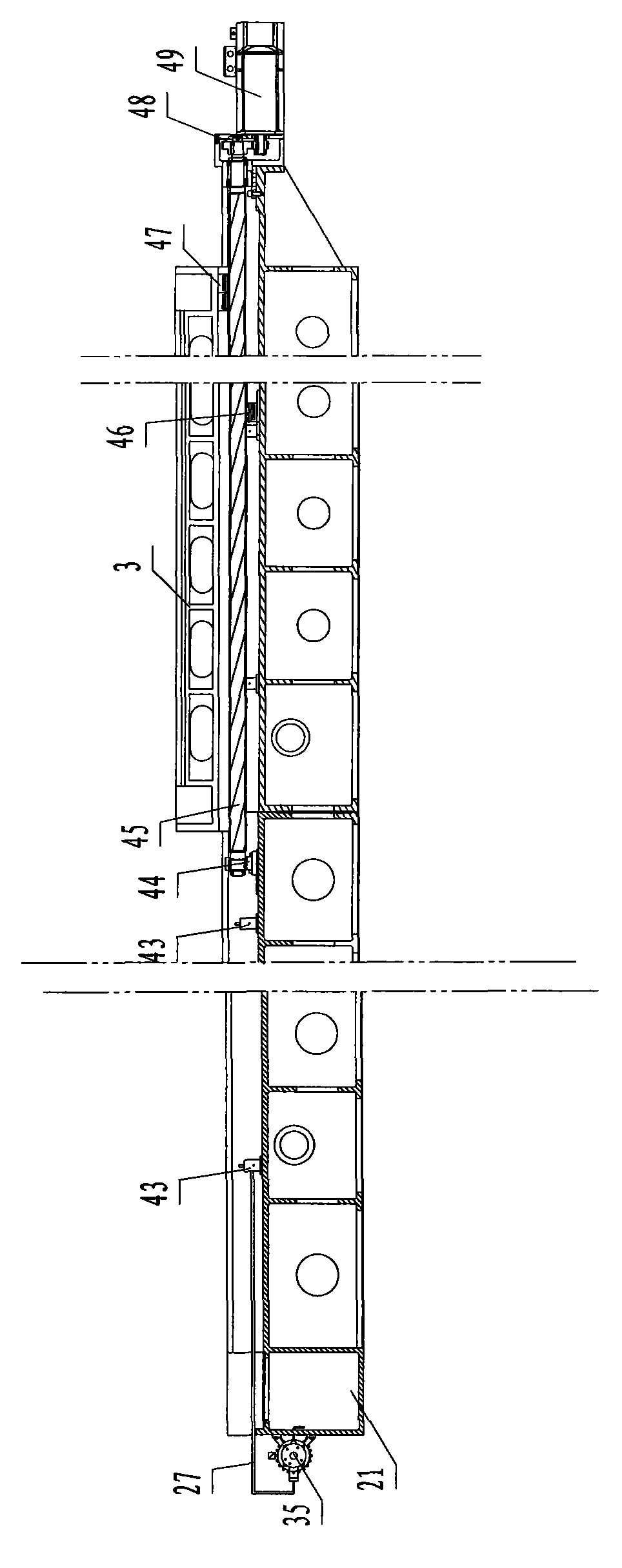

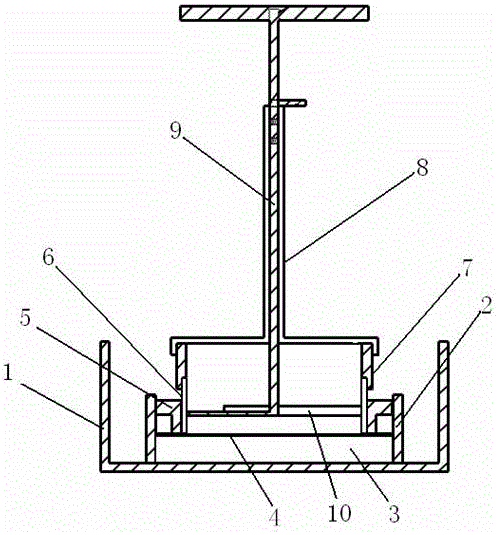

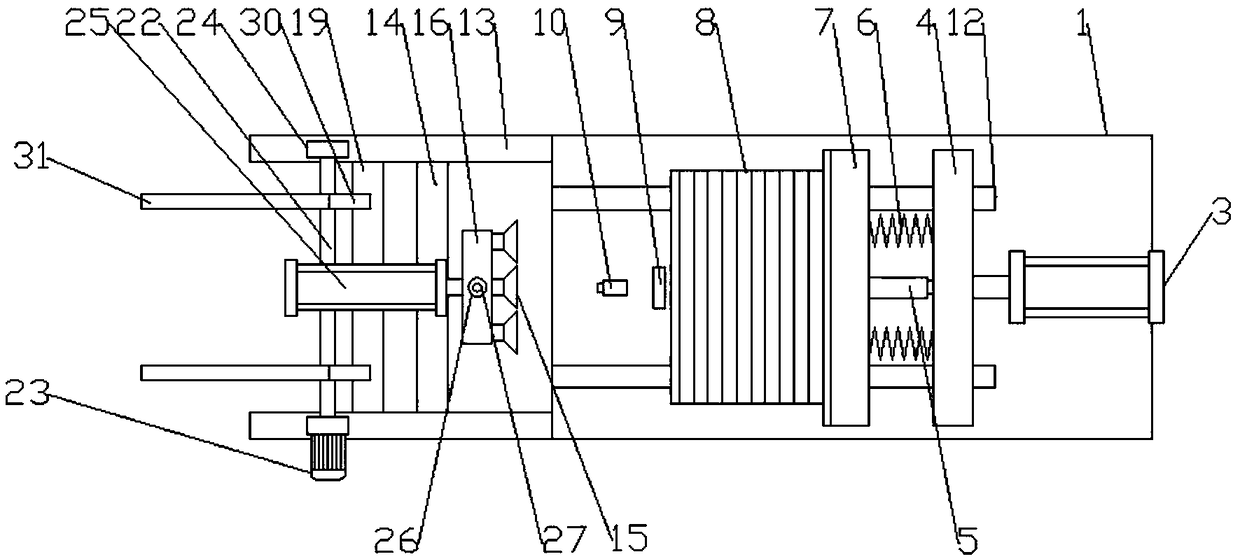

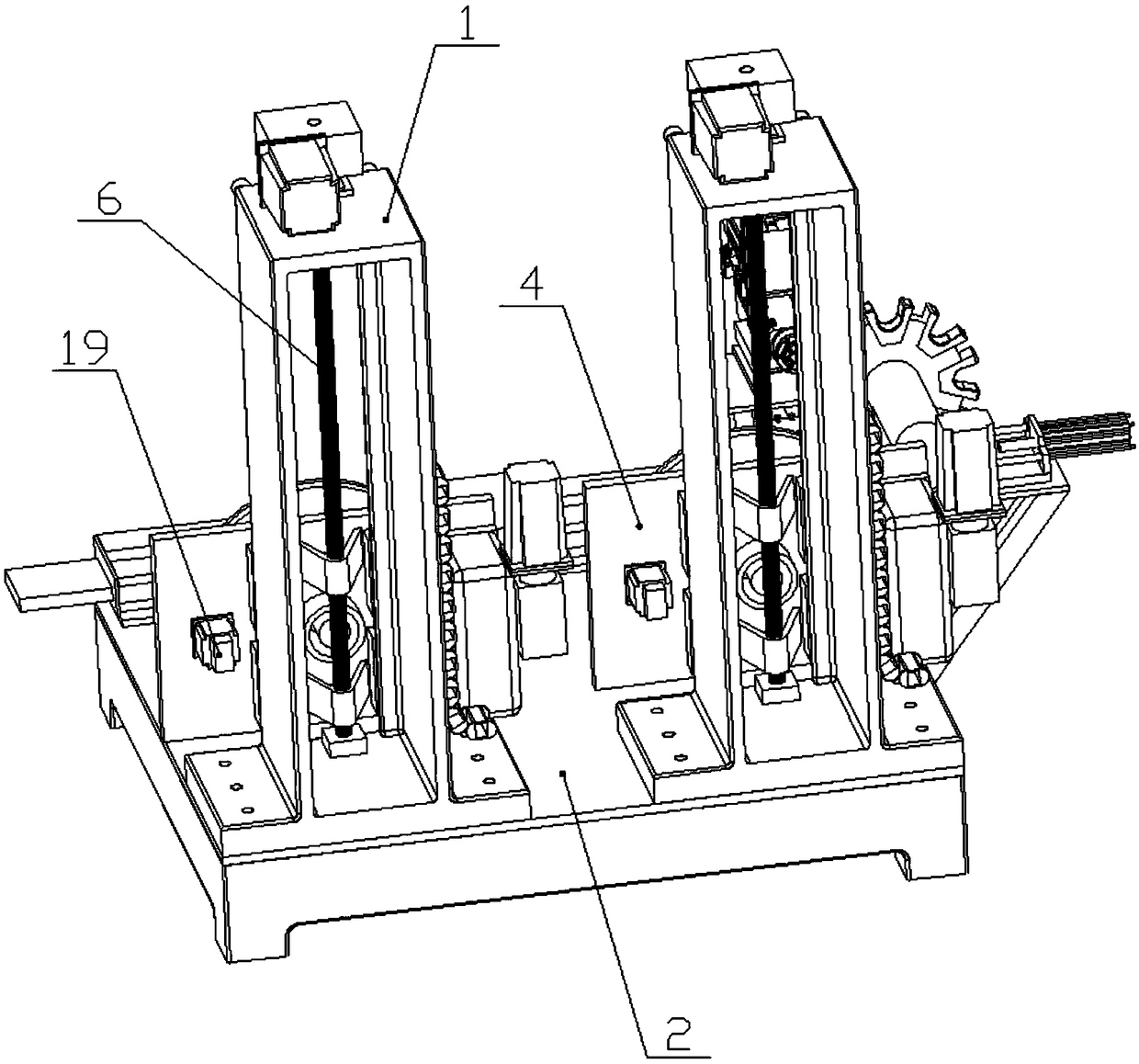

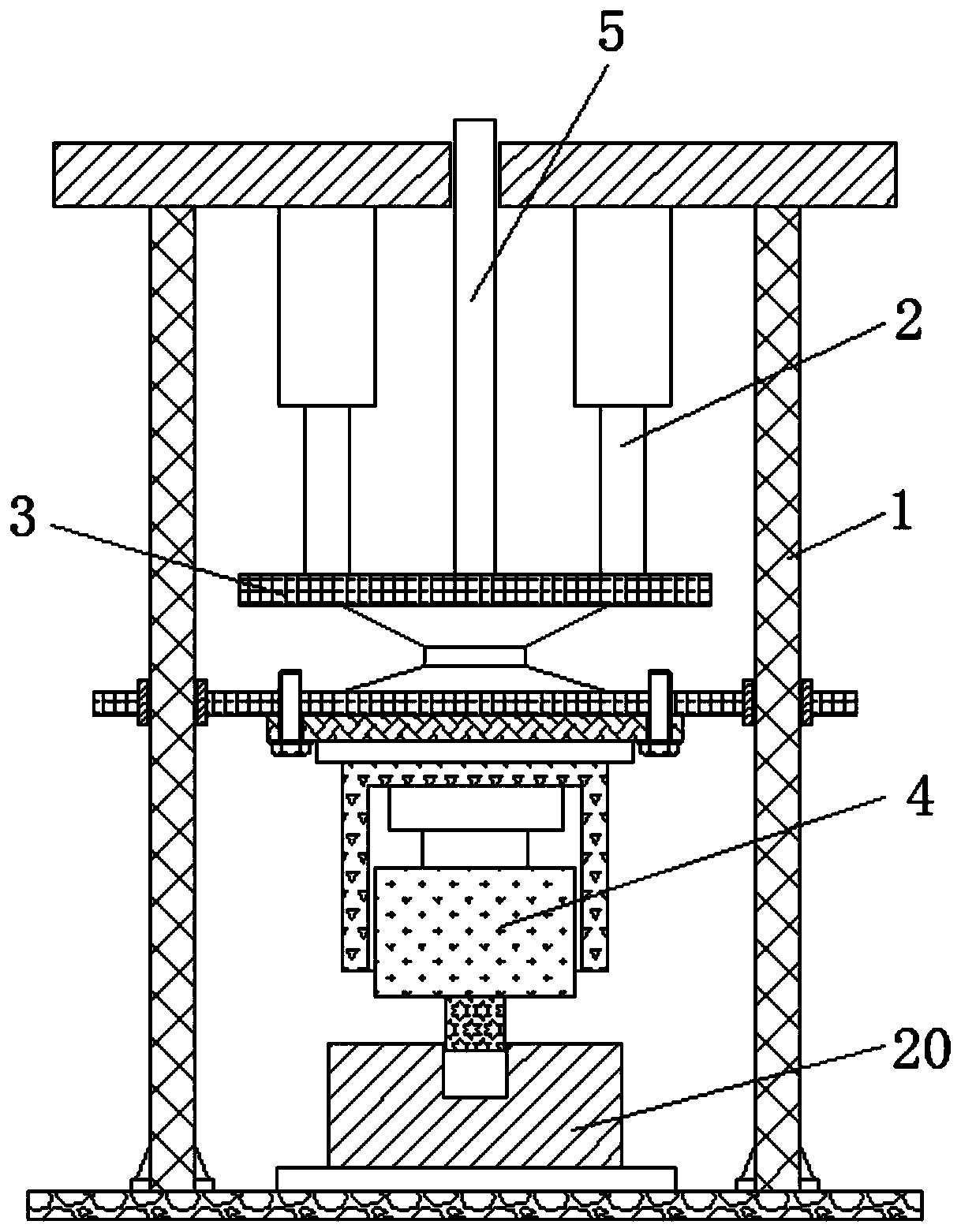

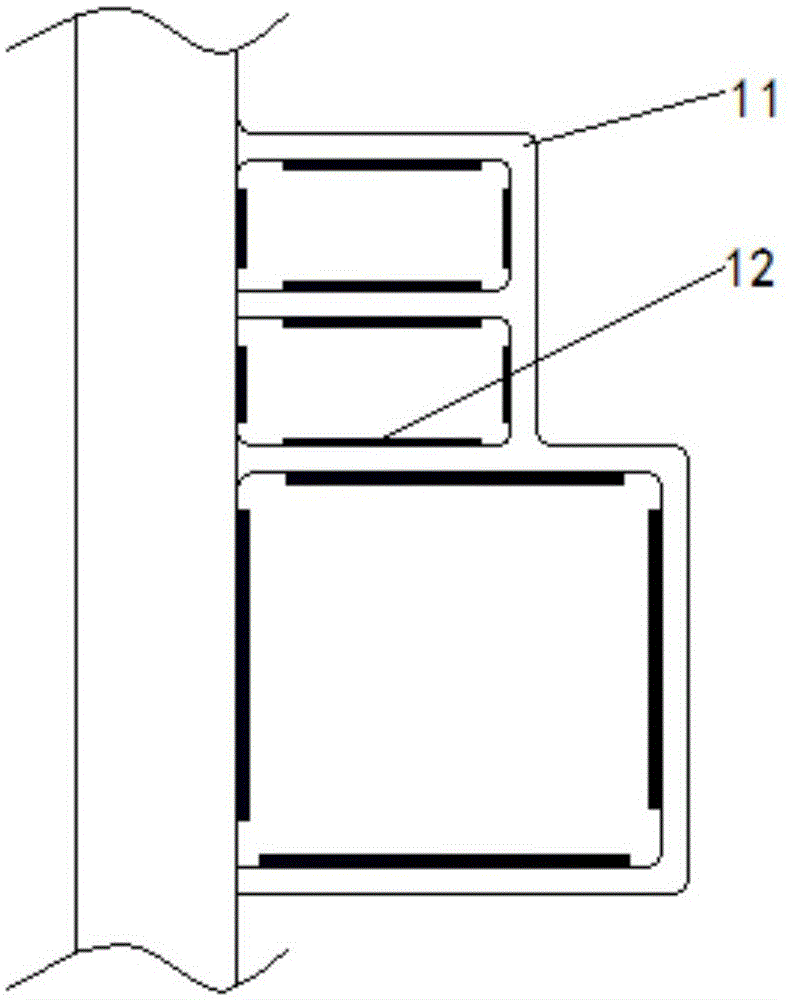

Lithium ion battery hot-press formation clamp

InactiveCN103811817ASimplify the manufacturing processSave loading timeFinal product manufactureElectrolyte accumulators manufactureHot pressEngineering

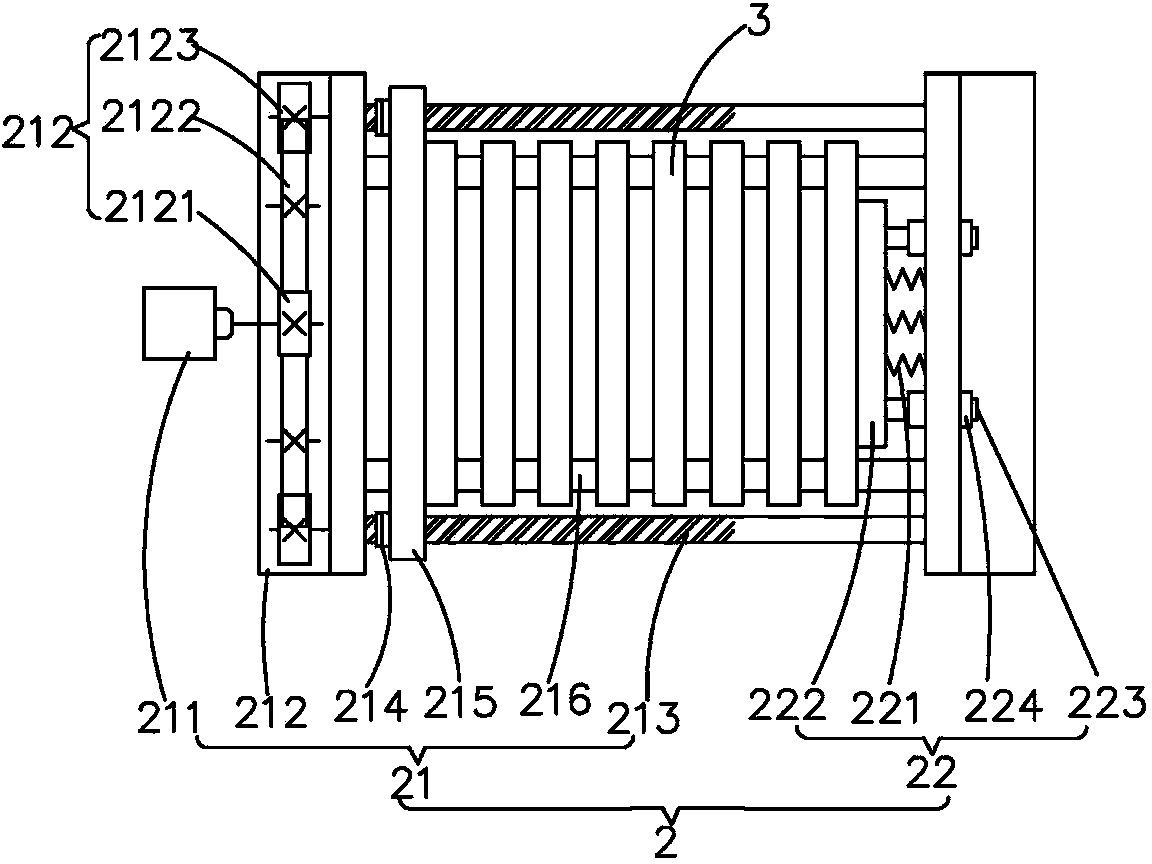

The invention belongs to the technical field of lithium ion battery manufacturing and in particular relates to a lithium ion battery clamp. A lithium ion battery hot-press formation clamp comprises a fixed seat, a power device, a plurality of laminated plates, a heating device, a formation device and a lithium battery, wherein the power device is arranged on the fixed seat; the heating device and the formation device are arranged on the laminated plates; a lithium ion battery is arranged between every two of the laminated plates for formation; the power device pressurizes the laminated plates and keeps the pressure; an included angle formed between the contact surface of each laminated plate and the lithium ion battery and the horizontal plane is 90+ / -0.5 degrees, and preferably 90 degrees. Compared with the prior art, the lithium ion battery hot-press formation clamp has the advantages that the laminated plates are arranged vertically, so that disposable material feeding of the lithium ion batteries can be realized, the material feeding time is shortened, and the production period of the batteries is shortened; furthermore, the automation degree of a battery production process can be increased; meanwhile, the formation clamp with the structure cannot be limited by the height of a formation cabinet, so that the number of the laminated plates can be increased to the maximum extent, and the number of the lithium ion batteries subjected to one-step hot-press formation is increased.

Owner:NINGDE AMPEREX TECH

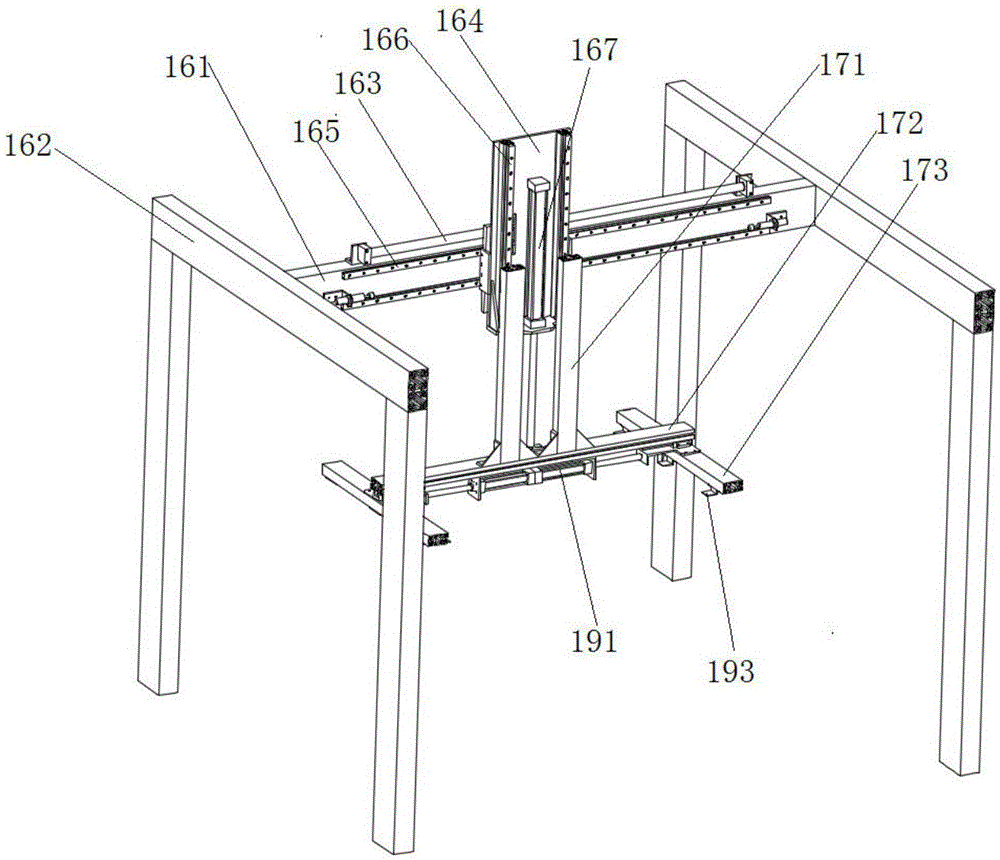

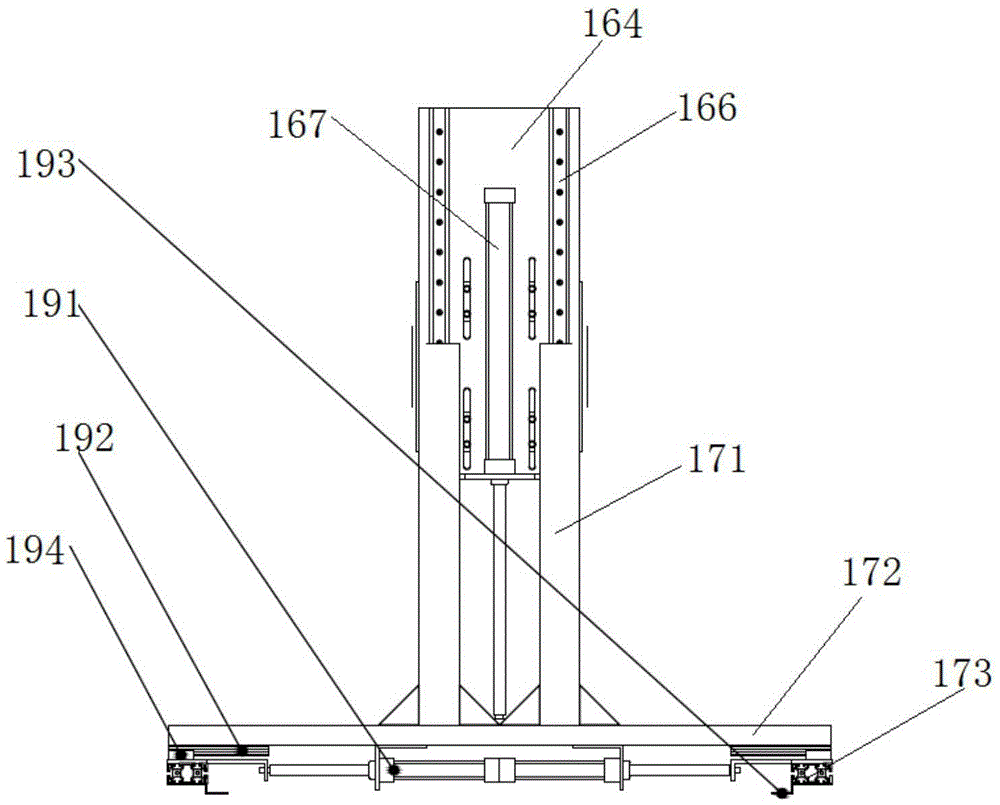

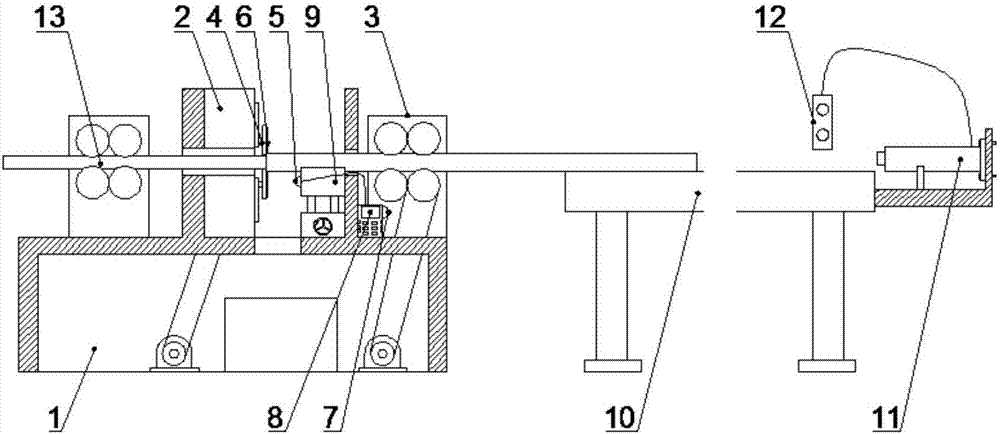

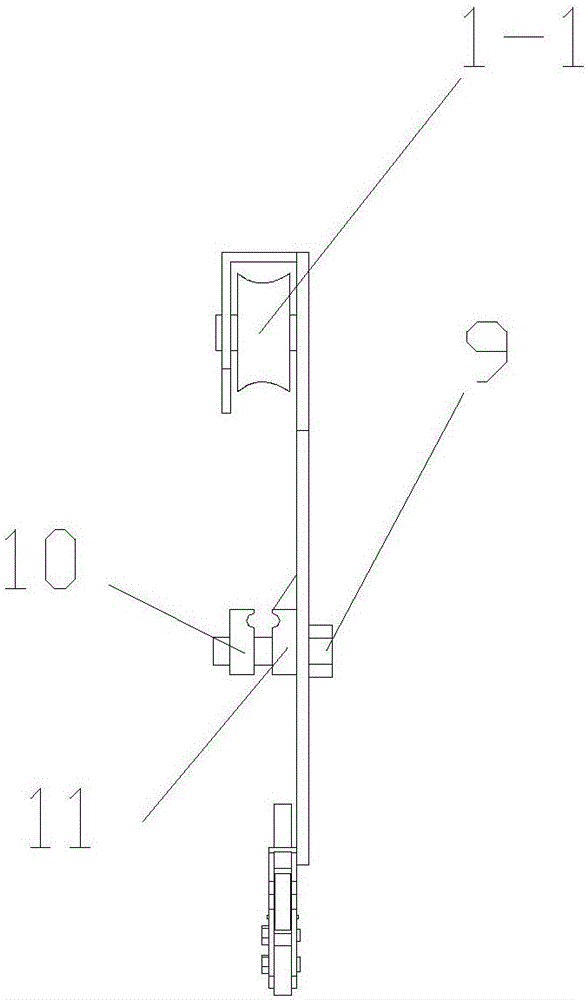

Feeding device and feeding method of saw cutting machine

The invention discloses a feeding device and feeding method of a saw cutting machine. The feeding device includes a rack, a material frame, a material storage platform, a material squeezing mechanism, a conveying platform, a limiting assembly and a material turning mechanism; the rack is provided with a first material pushing device and a second material pushing device in a sliding mode in the longitudinal direction, a first material pushing rod is used for pushing pipe materials to a first limiting position in the longitudinal direction, a second first material pushing rod is used for pushing pipe materials at the first limiting position to a second limiting position, the upstream end portions of the pipe materials located on the first limiting position are conveniently cooperated with the second material pushing rod, and upstream end portions of the pipe materials located on the second limiting position are located on the downstream position of the downstream end portion of the pipe materials on the material storage platform. The feeding device can achieve rapid feeding of the pipe materials and greatly improve the efficiency of feeding. The feeding method can greatly improve the feeding efficiency by using the feeding device.

Owner:SUZHOU KINKALTECK MACHINERY TECH

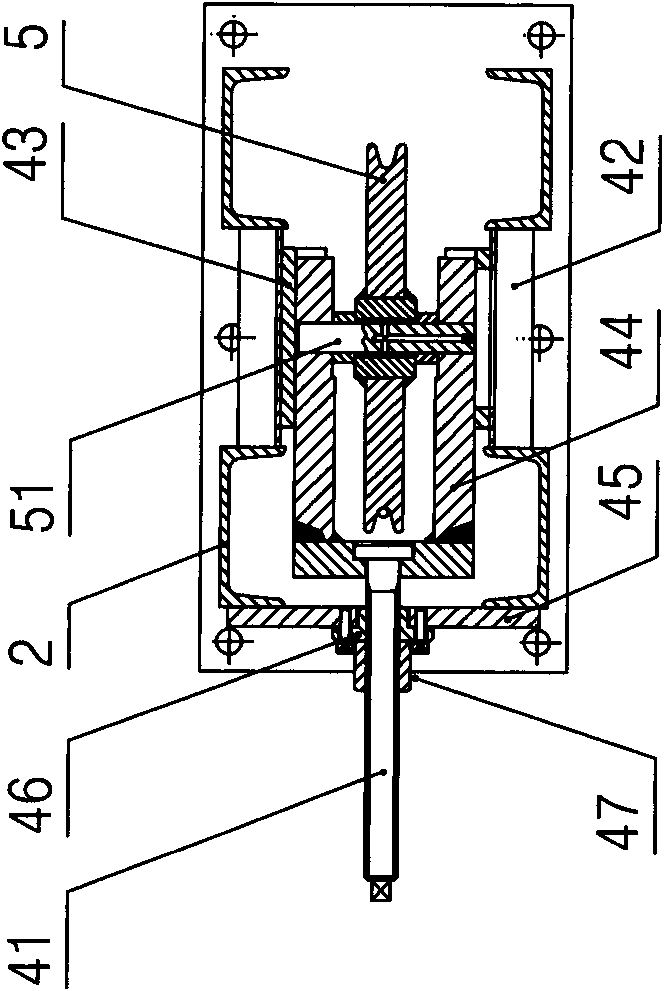

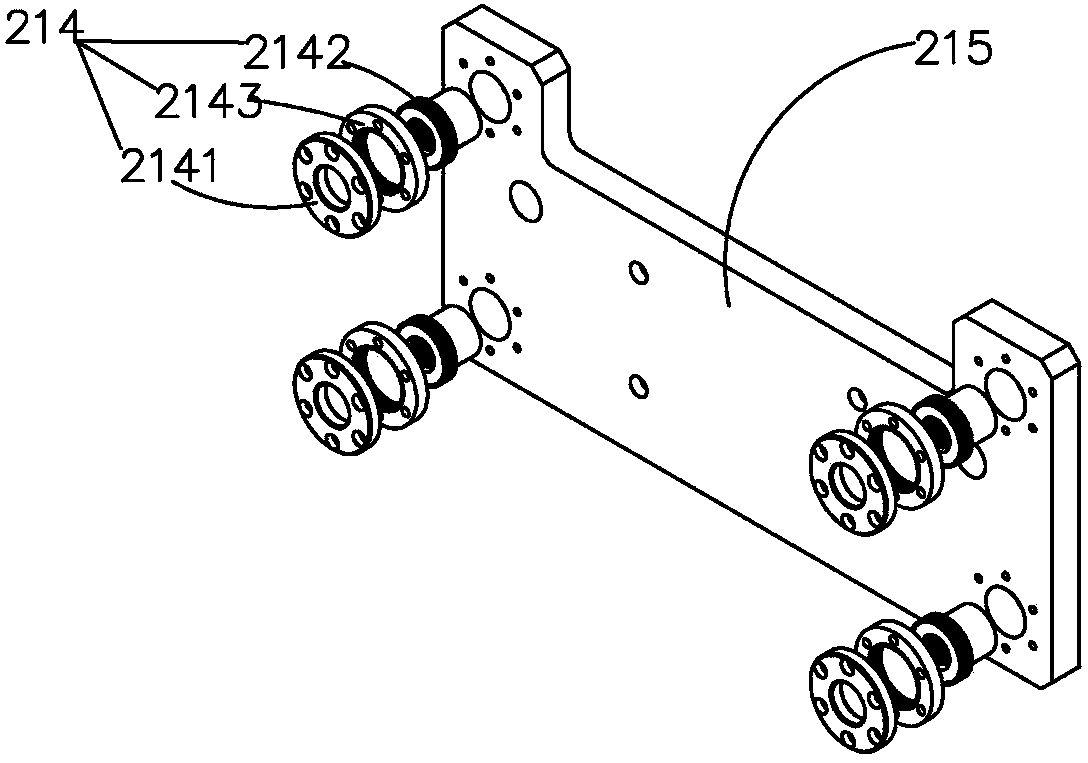

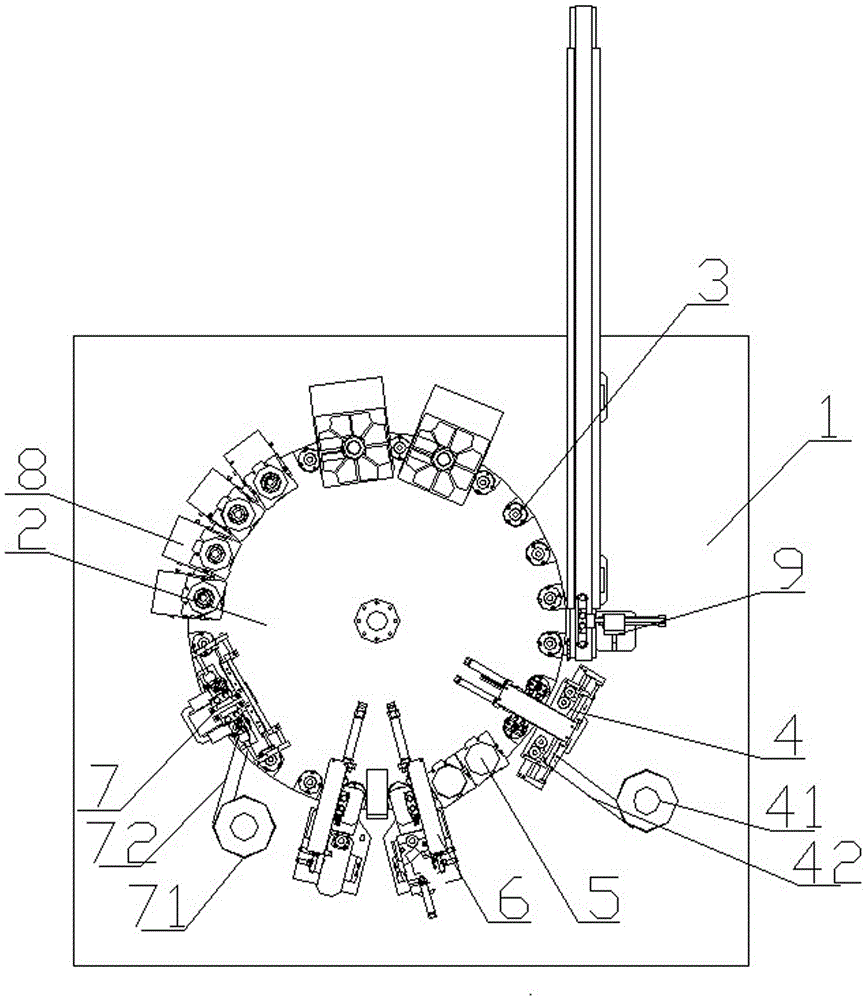

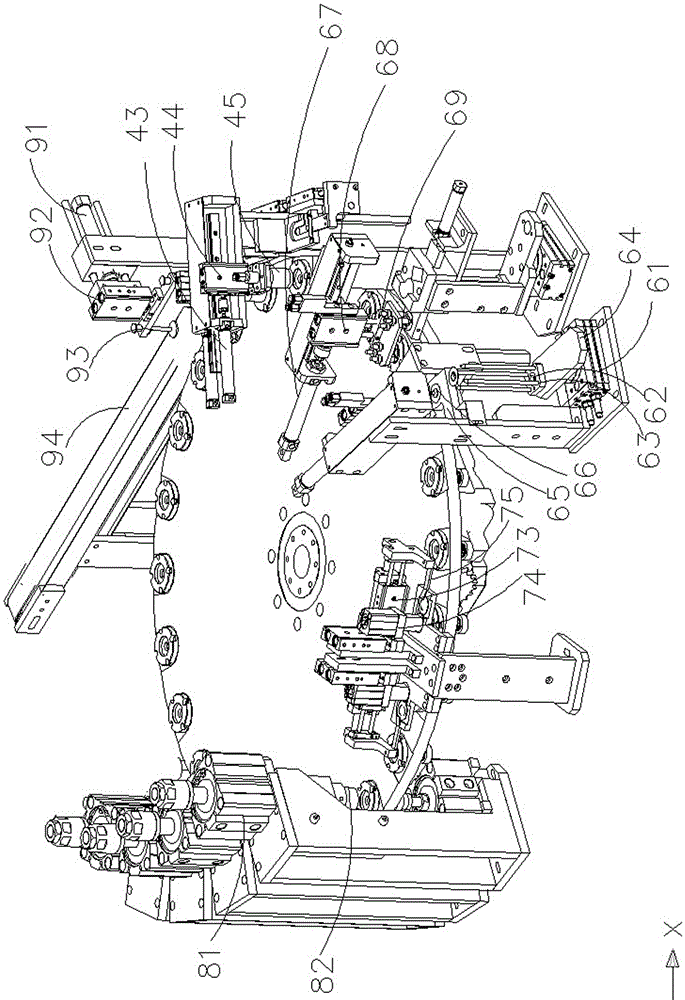

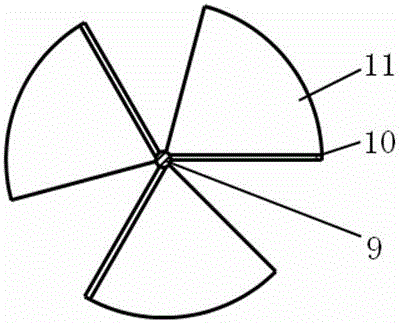

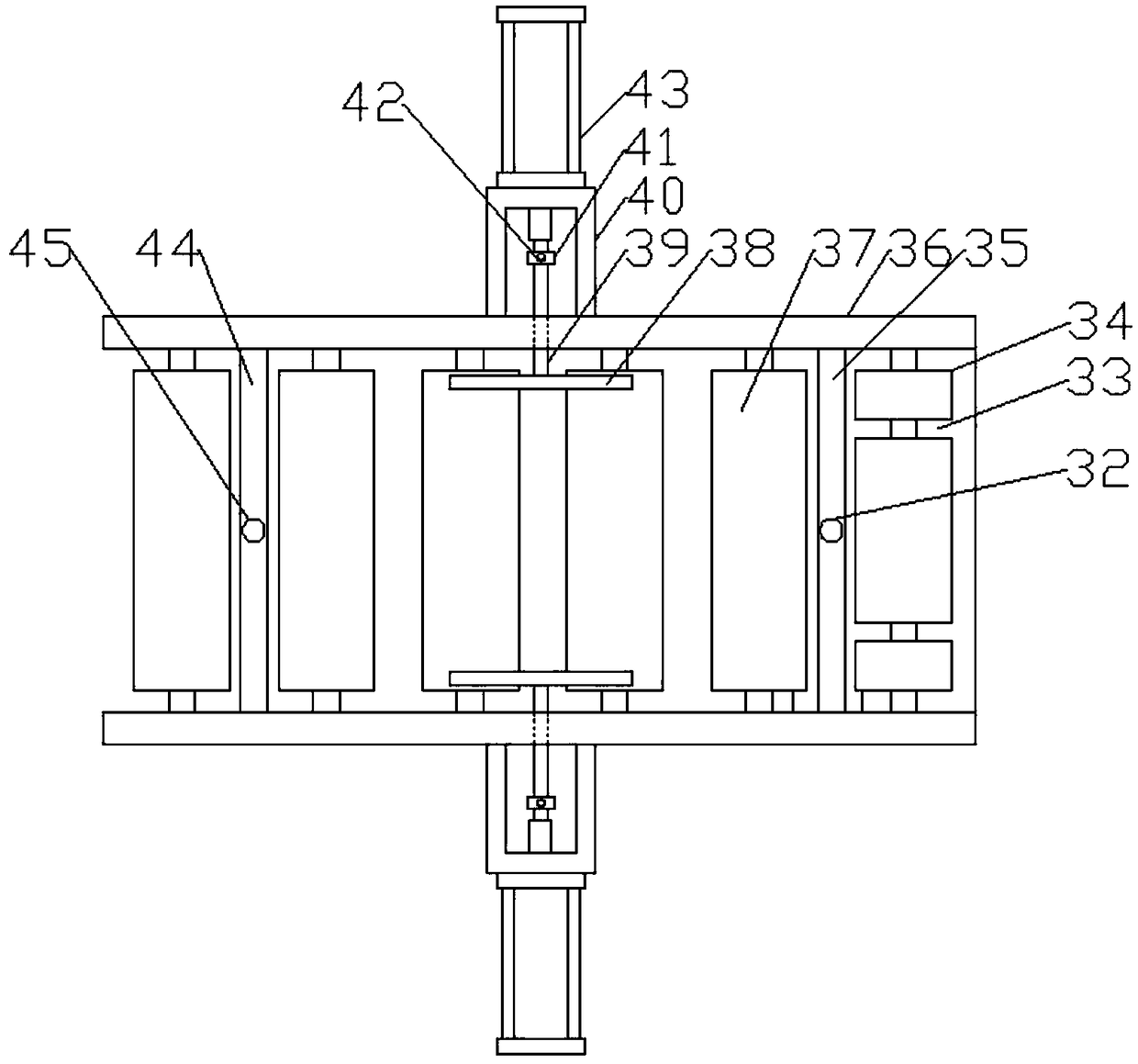

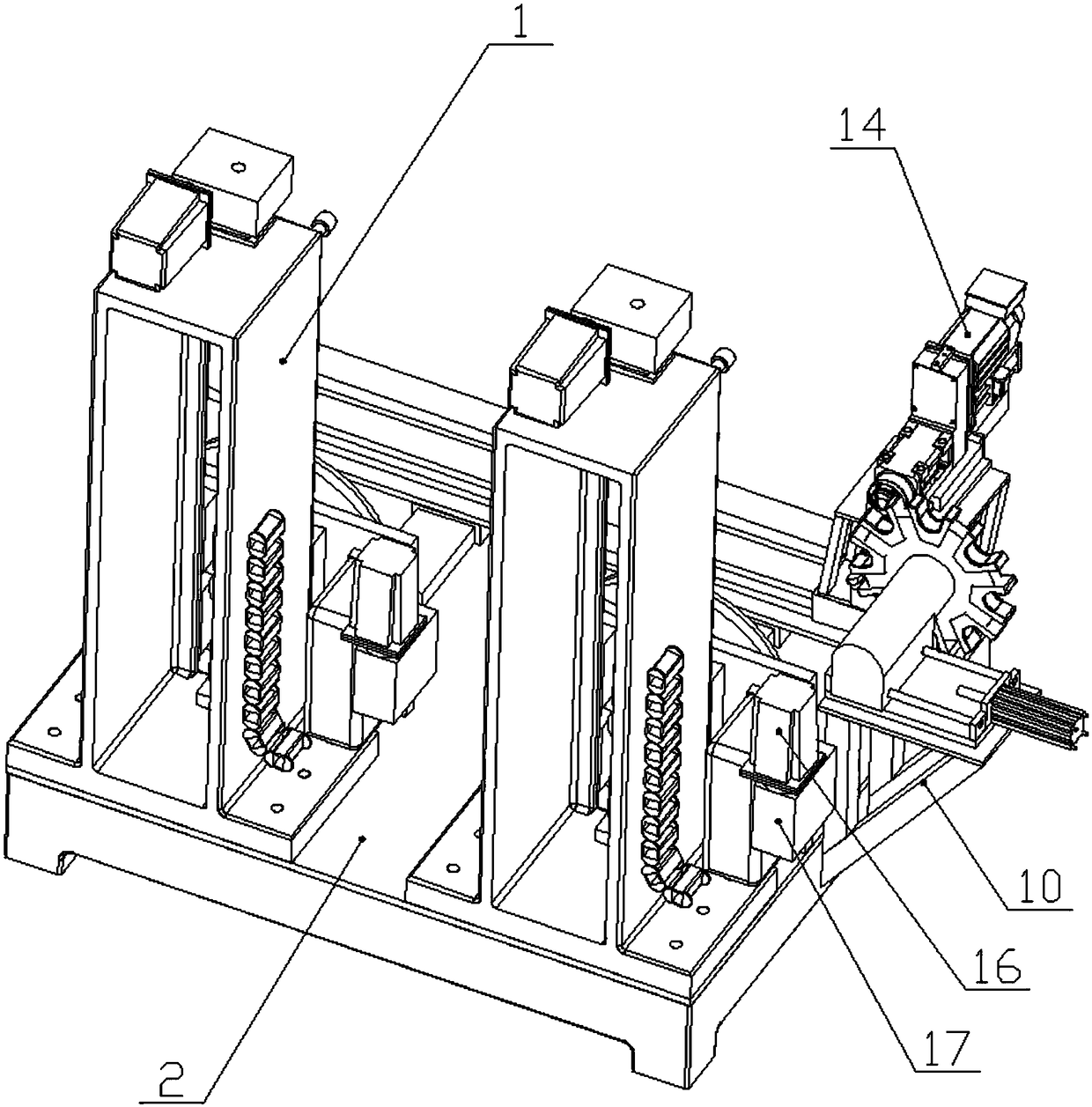

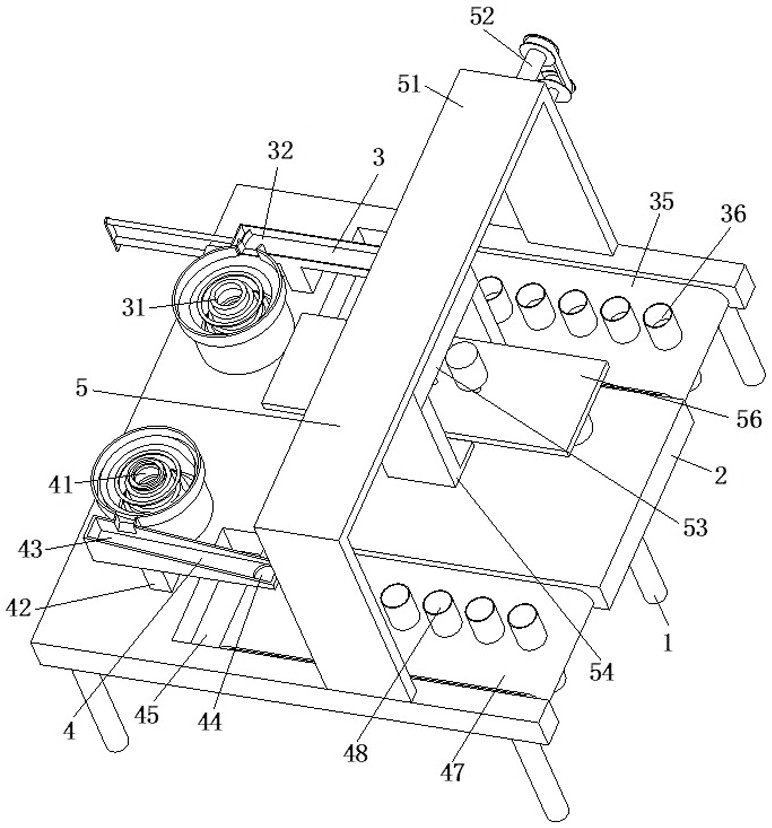

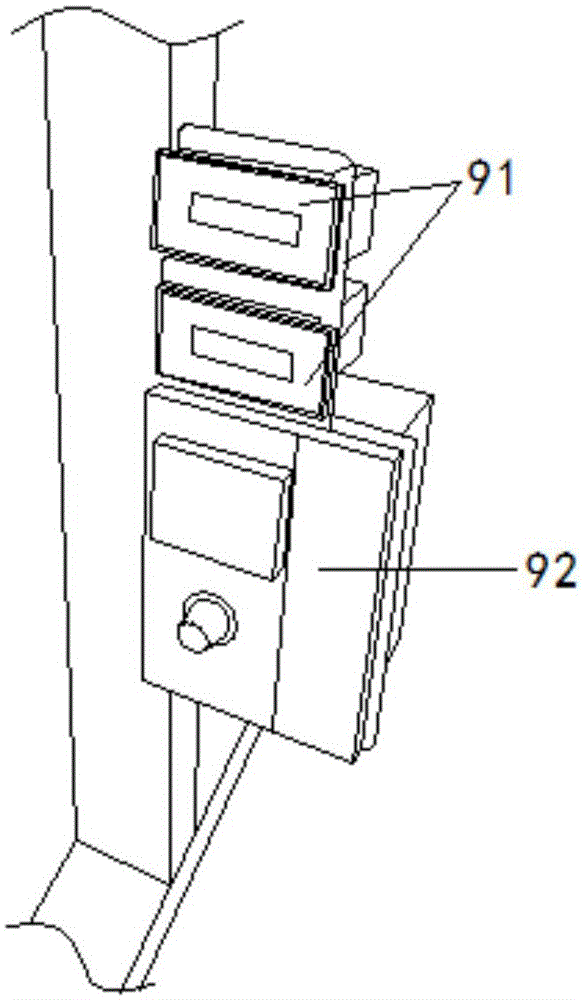

Three-in-one lithium battery cap assembly device

InactiveCN105489922ASave loading timeGuaranteed continuityAssembling battery machinesFinal product manufactureElectrical and Electronics engineeringLithium battery

The invention relates to a three-in-one lithium battery cap assembly device. The three-in-one lithium battery cap assembly device comprises a base, wherein a rotary disc is arranged on the base and driven by a stepping motor, a circle of internally-sunken round stations which are uniformly arranged are arranged on the rotary disc, and an anti-explosion sheet feeding station, a gasket feeding station, an upper cover feeding station, a press sealing station and a discharge station are sequentially arranged along the external circumference of the rotary disc; the gasket feeding station adopts multiple clips to sequentially feed; when a gasket in a clip is finished, a support rod retracts, a rotary air cylinder rotates, another clip fully loaded with gaskets is transferred to the part above the support rod for continuously feeding, the feeding time is saved, and the production continuity is maintained; and anti-explosion sheet is in press fit with an upper cover, and one-time forming is prevented to cause deformation of the anti-explosion sheet. According to the technical scheme, lamination is gradually carried out by three times, and the lamination effect is good; a hole expansion station is additionally arranged behind the anti-explosion sheet station, the mouth of the anti-explosion sheet is expanded, the gasket and the upper cover are conveniently loaded into the anti-explosion sheet in subsequent stations, the efficiency and the yield are effectively improved, and the loss is reduced.

Owner:TAIXING ZHENGXING ELECTRON

Sand soil consolidation compression test sample loading device and sample loading method thereof

ActiveCN106813961ALow densityGuaranteed uniformityPreparing sample for investigationEngineeringSand sample

The invention discloses a sand soil consolidation compression test sample loading device and a sample loading method thereof. A limiter is arranged on an upper outer frame and comprises a cover portion and a pipe portion, a dowel bar is arranged in the pipe portion, and one end, in a cutting ring, of the dowel bar is provided with a sand scraping device to divide a sand sample into multiple parts. The sand sample is spread into the cutting ring and consolidated under actions of continuous pressing and rotational spreading of the sand scraping device, then another part of the sand sample is poured, the above process repeats, and sampling loading is completed after pressing of a permeable stone is finished finally. Compared with the prior art, the sand soil consolidation compression test sample loading device and the sample loading method thereof have advantages that dry density and relative compaction of sand soil samples in a one-dimensional consolidation test can be controlled accurately to guarantee uniformity in sand soil sample loading, and accordingly influences caused by dry density and relative compact differences of the sand soil samples or nonuniformity in sample loading to test results can be reduced, and test errors are reduced.

Owner:HOHAI UNIV

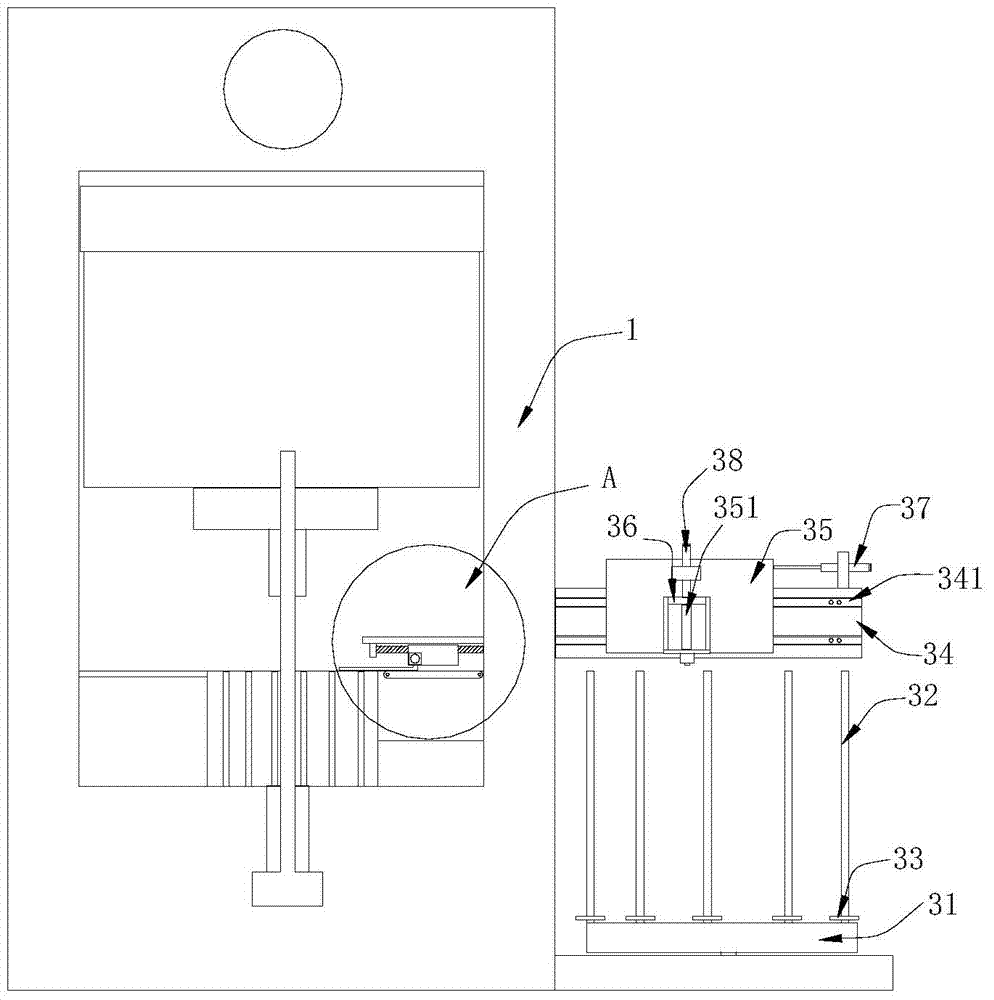

Feeding device for PCBs

InactiveCN109368214AEasy to processEasy to correctConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a feeding device for PCBs. The feeding device comprises a conveying frame and a placing frame located on one side of the conveying frame, two parallel sliding rails are arranged at the upper end of the placing frame, a backup plate is arranged at the upper ends of the sliding rails, a propelling device is arranged on the right side of the backup plate, a PCB stack is placedon the left side of the backup plate, a second air cylinder is fixed at the lower end of the placing frame, a pressing strip is arranged at the upper end of a piston rod of the second air cylinder, two parallel longitudinal supports are arranged on the right side of the placing frame in an extending mode, mounting side plates are arranged at the upper ends of the left sides of the longitudinal supports, a rotating shaft is arranged between the mounting side plates, a motor is further arranged on one mounting side plate, an output shaft of the motor is connected with the rotating shaft, a turnover device is arranged on the rotating shaft, second transverse supports are fixed on the portion, on the right side of the motor, of the longitudinal supports, and the middles of the upper ends of the second transverse supports are provided with a transferring device. According to the feeding device, the PCBs are taken out one by one, are conveyed to the turnover device through the transferringdevice, are conveyed to the conveying frame through the turnover device, and are corrected through a correcting device, manual work is replaced for transferring, so that the labor amount of workers isreduced, the feeding time is shortened, and the feeding efficiency is improved.

Owner:ANHUI SHENZE ELECTRONICS TECH

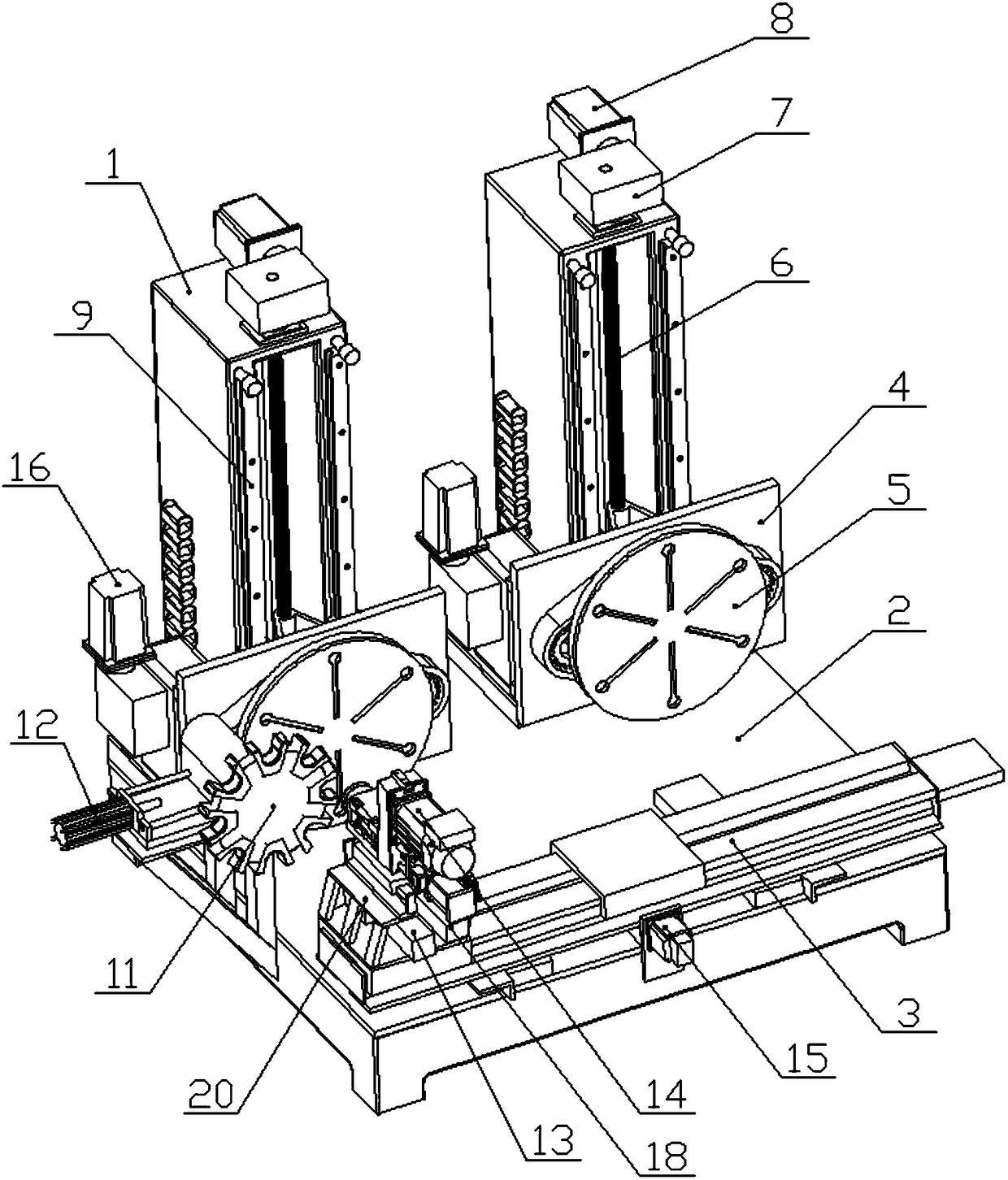

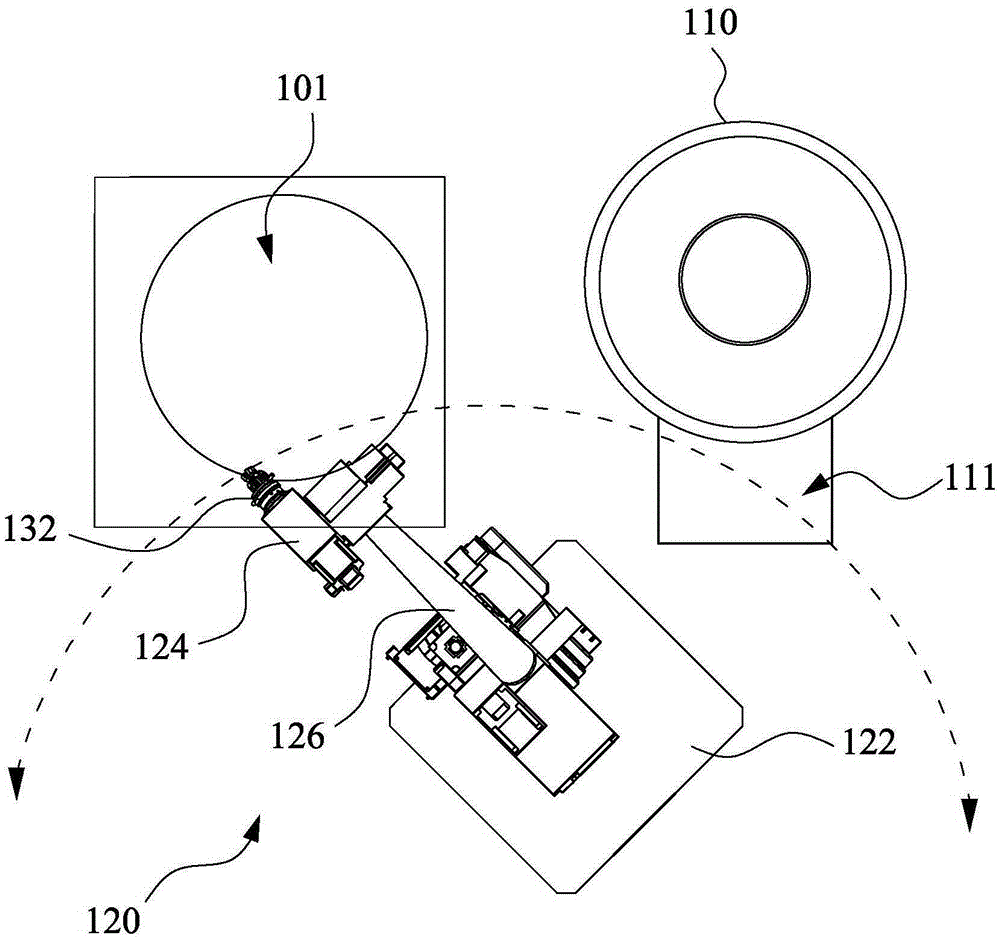

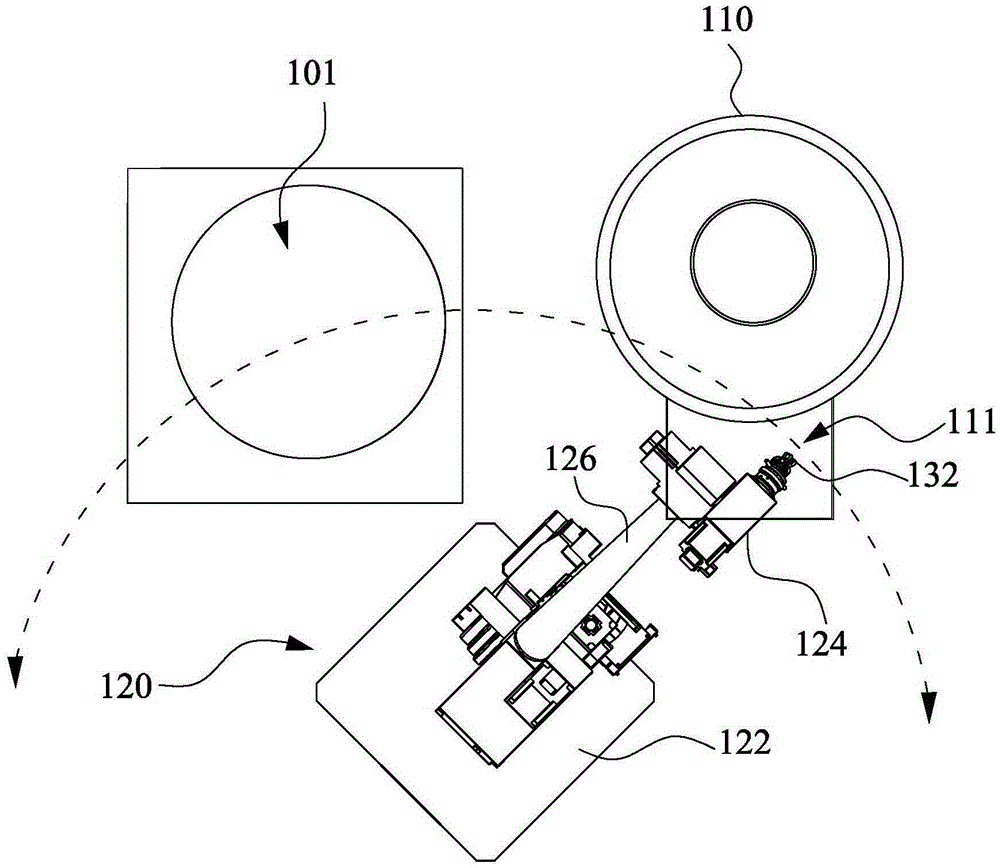

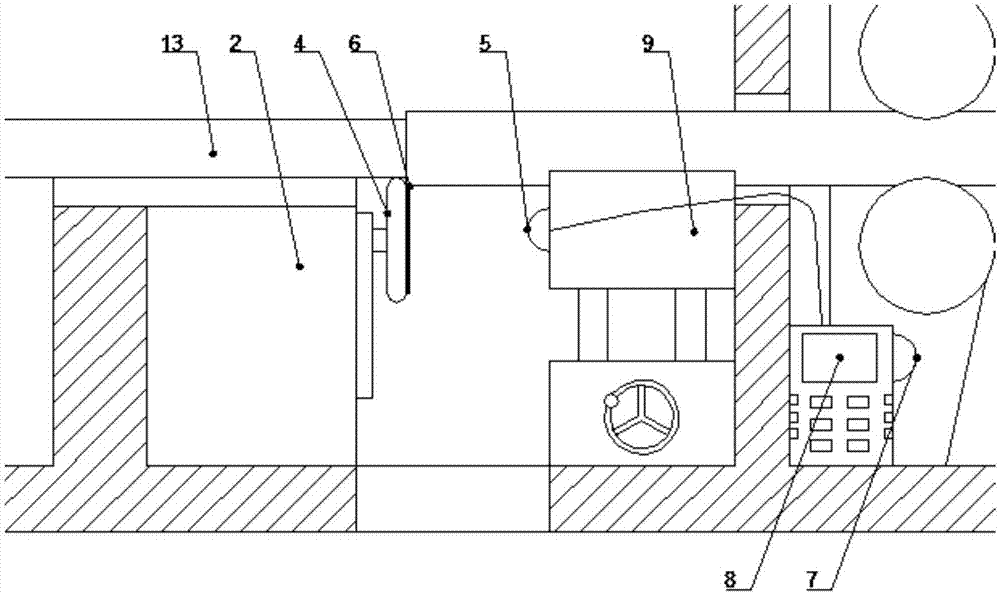

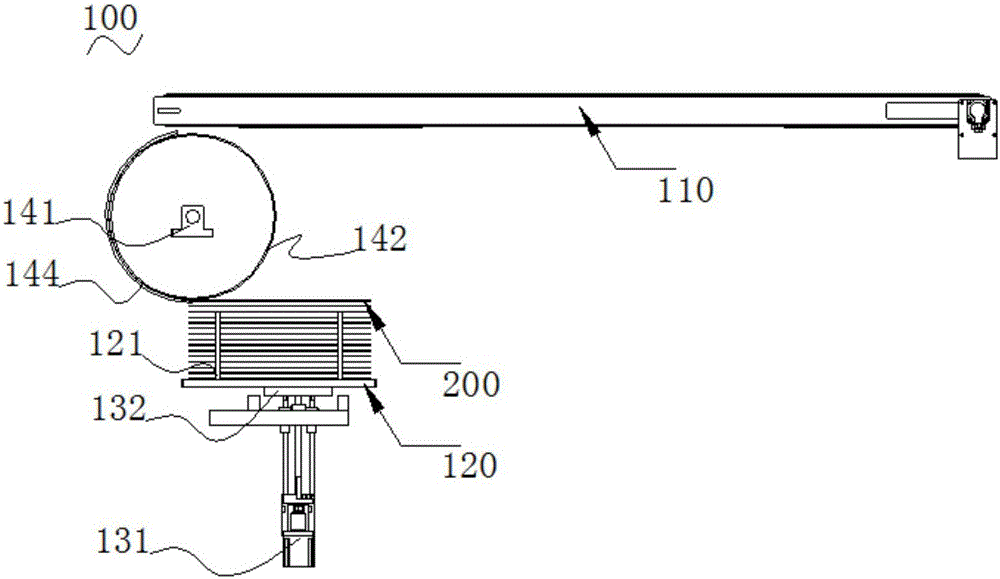

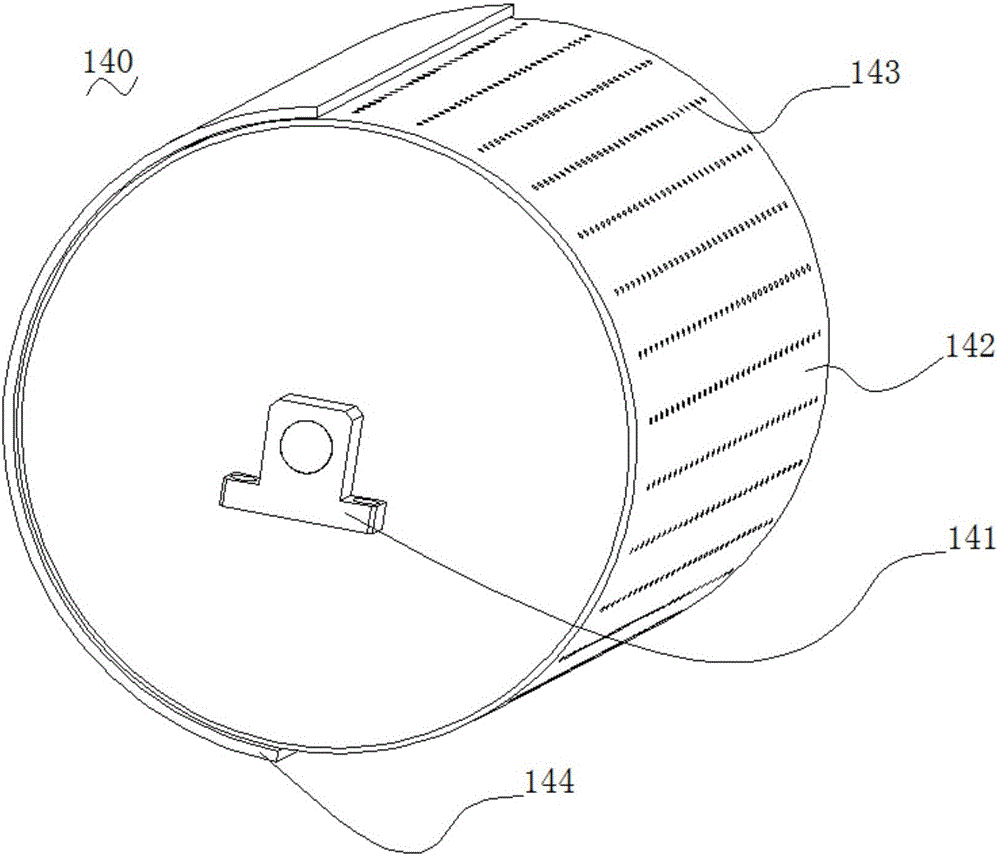

Automatic charging machine on punch

ActiveCN104493001ASave loading timeImprove processing efficiencyMetal-working feeding devicesPositioning devicesSteel platesManipulator

The invention relates to the field of feeding equipment, in particular to an automatic charging machine on a punch. The charging machine comprises a feeding mechanism and a charging mechanism, wherein the charging mechanism comprises a conveying belt for intermittent conveying and a tooling fixture for conveying raw material steel plates on the conveying belt to a punching station; the tooling fixture is movably arranged above the conveying belt; a moving direction of the tooling fixture is parallel to a feeding direction of the conveying belt; the feeding mechanism comprises a feeding frame and a feeding device arranged above the feeding frame; the feeding frame comprises a feeding turntable capable of rotating circumferentially, a plurality of feeding shafts arranged along the periphery of the upper end face of the feeding turntable and feeding check rings capable of moving axially on the feeding shafts; the feeding device comprises a fixing frame located above the feeding frame, a sliding frame arranged on the fixing frame in a transverse sliding manner, and a manipulator for conveying the raw material steel plates on the feeding shaft to the conveying belt; and the manipulator is arranged on the sliding frame in a longitudinal sliding manner. The automatic charging machine can save charging time and improve processing efficiency.

Owner:浙江瑞虹机电股份有限公司

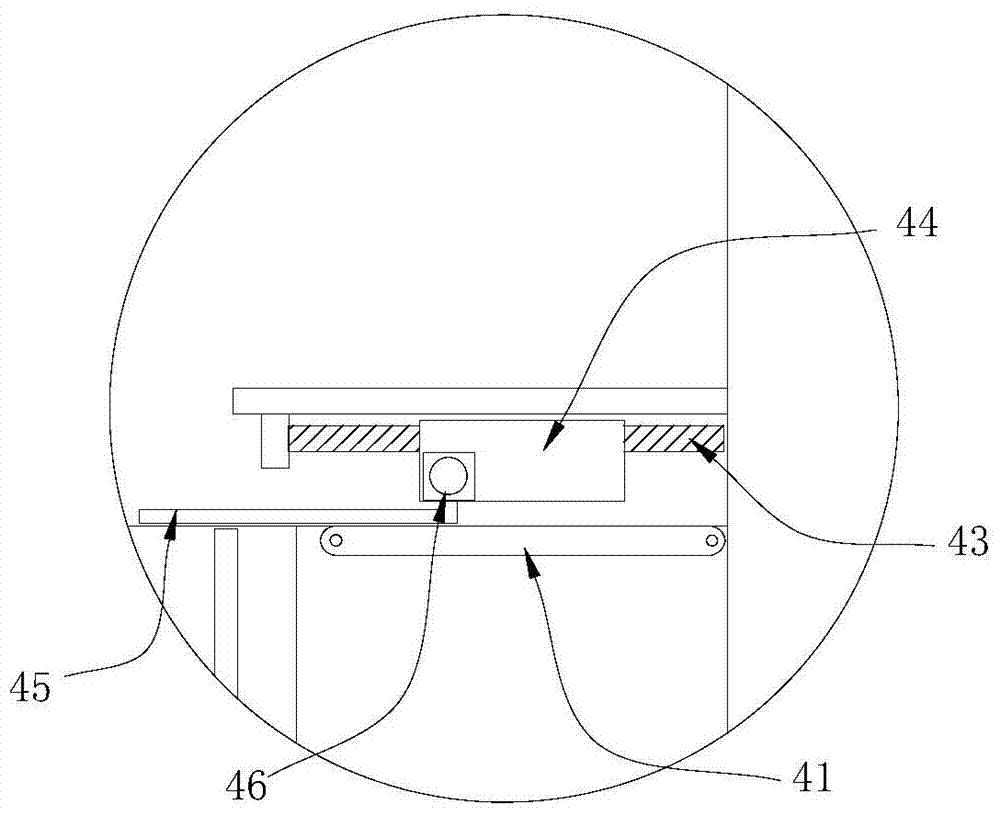

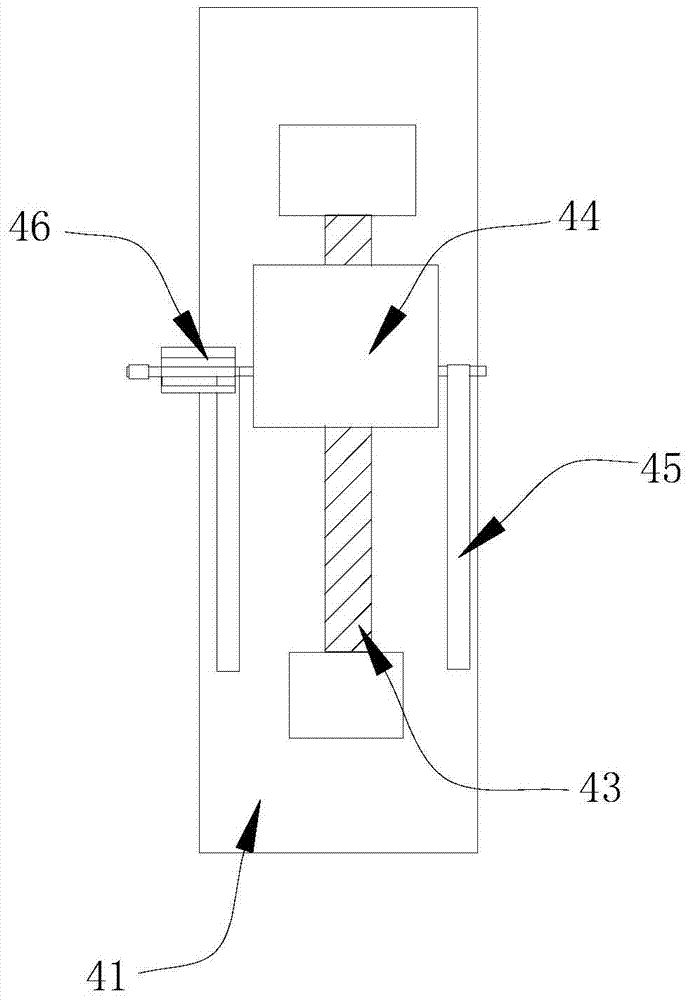

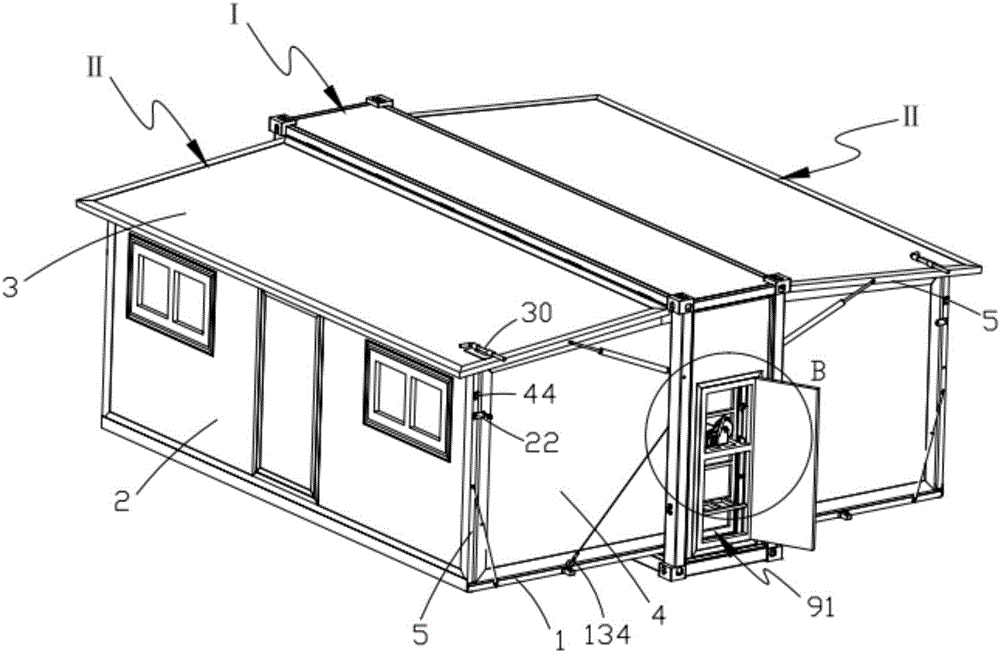

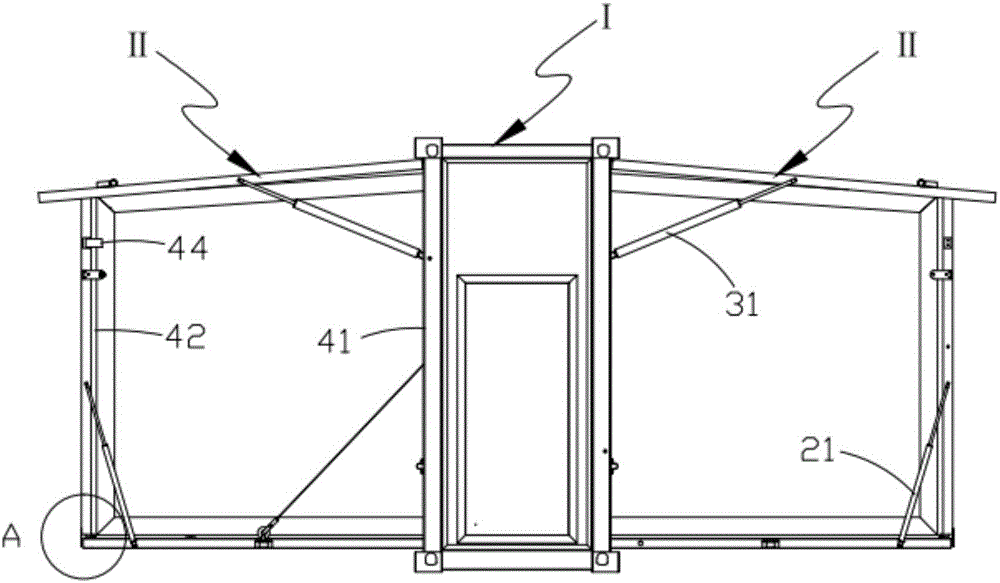

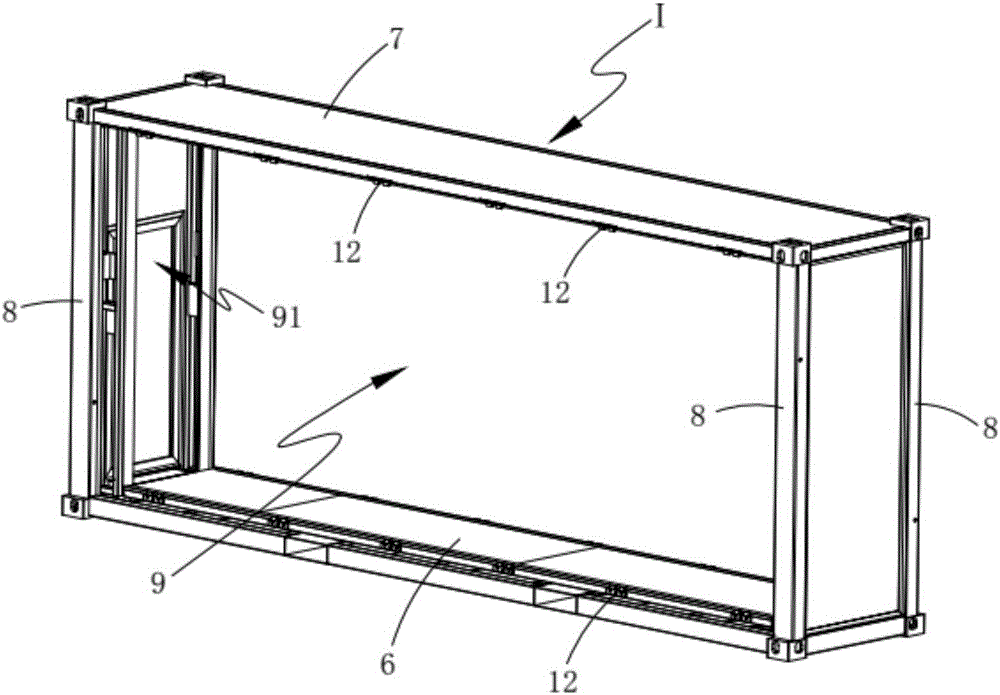

Unfolding and folding method for container type folding combination house

ActiveCN106836500AImprove operational safetyWork efficiency doubledBuilding constructionsEngineeringWall plate

The invention relates to an unfolding and folding method for a container type folding combination house. The unfolding steps of the combination house are as follows: (1), the folded combination house is put in place; (2), firstly, any folding unit of a first folding unit and a second folding unit which are symmetrically arranged on a main frame of the combination house is unfolded, specifically, a fixing pin on a roof slab in the folding unit is opened, and the roof slab is turned over upward; (3), a base plate and a side wall plate of the corresponding folding unit are driven to be turned over outward synchronously to a horizontal condition; (4), the corresponding side wall plate is pushed to be turned over upward to a vertical condition; (5), a gable wall plate is pushed outward to rotate to a position perpendicular to the corresponding side wall plate, so that the folding unit is unfolded; and (6), the unfolding process of the other folding unit is the same as the step (2) to the step (5). The folding steps of the combination house are opposite to the unfolding steps. The operation of the unfolding process and the folding process is simplified, and accordingly time and labor are saved.

Owner:上海明燎机电成套设备工程有限公司

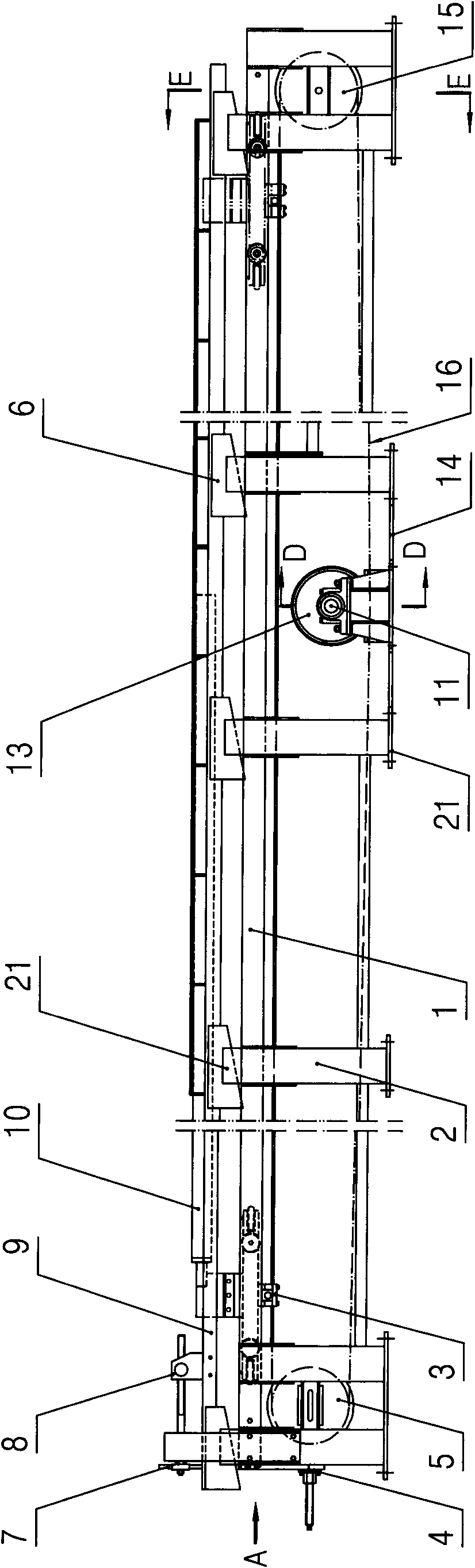

Turning integrated turning plate numerical control machining center

InactiveCN108857582ASolve the machining accuracySolve processing efficiencyFeeding apparatusDriving apparatusNumerical controlEngineering

The invention provides a turning integrated turning plate numerical control machining center composed of four-axis transmission mechanisms, a double-layer tool rest, a main shaft tool magazine and a lathe tool magazine. The four-axis transmission mechanisms include a Z axis responsible for lifting, an X axis, a Y axis, a rotation mechanism for rotating chucks and a rotating shaft of an automatic switching mechanism correspondingly, wherein the X axis and the Y axis are responsible for feeding and moving of the tool rest, and the rotating shaft is used when the turning integrated turning platenumerical control machining center is used for turning. The double-layer tool rest mechanism comprises a main shaft feeding mechanism on the upper layer and the tool automatic switching mechanism on the lower layer. The main shaft tool magazine mainly conducts automatic tool changing for the main shaft feeding mechanism on the upper layer. The lathe tool magazine mainly conducts automatic tool switching for the tool automatic switching mechanism on the lower layer during rotating turning. The chucks are fixedly connected with the rotation mechanism. The rotation mechanism is fixedly connectedwith a lifting mechanism. By means of rotating and lifting, the workpiece position of the turning integrated turning plate numerical control machining center is adjusted through numerical control, andthe cutting requirement of full-function numerical control machining is met through cooperation with an X-axis and Y-axis feeding mechanism, the tool automatic switching mechanism and the tool magazine mechanism; and the turning integrated turning plate numerical control machining center can be widely used for various types of machining occasions.

Owner:湖南鈊耐自动工装系统发展有限公司

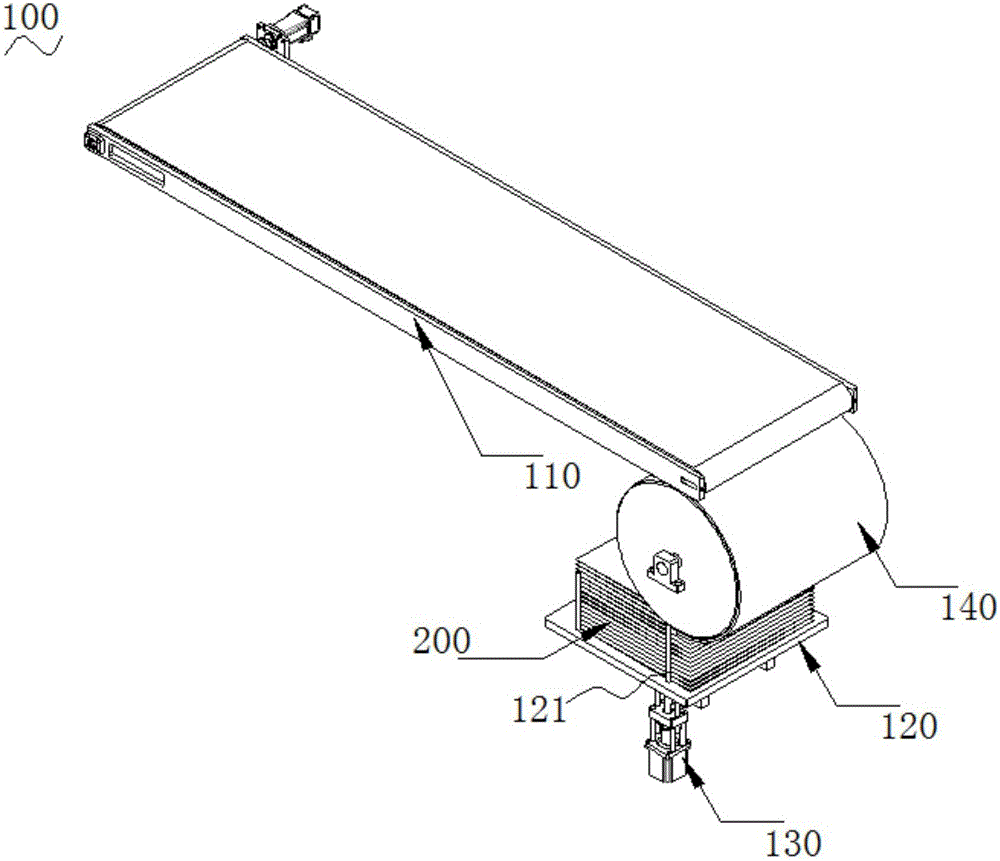

Feeding device and metal plate cutting machine

The invention discloses a feeding device and a metal plate cutting machine applying the same. The feeding device comprises a feeding mechanism and a feeding platform, wherein the feeding mechanism isarranged above the feeding platform, a material plate is arranged below the feeding platform, an abdication opening is formed in the feeding platform, the feeding mechanism penetrates through the abdication opening to do lifting motion in material taking, so that the material plate is put on the feeding platform. According to the technical scheme, the occupied area of the feeding device can be saved, and the feeding time can be saved, so that the production efficiency can be improved.

Owner:SHENZHEN H TECH CO LTD

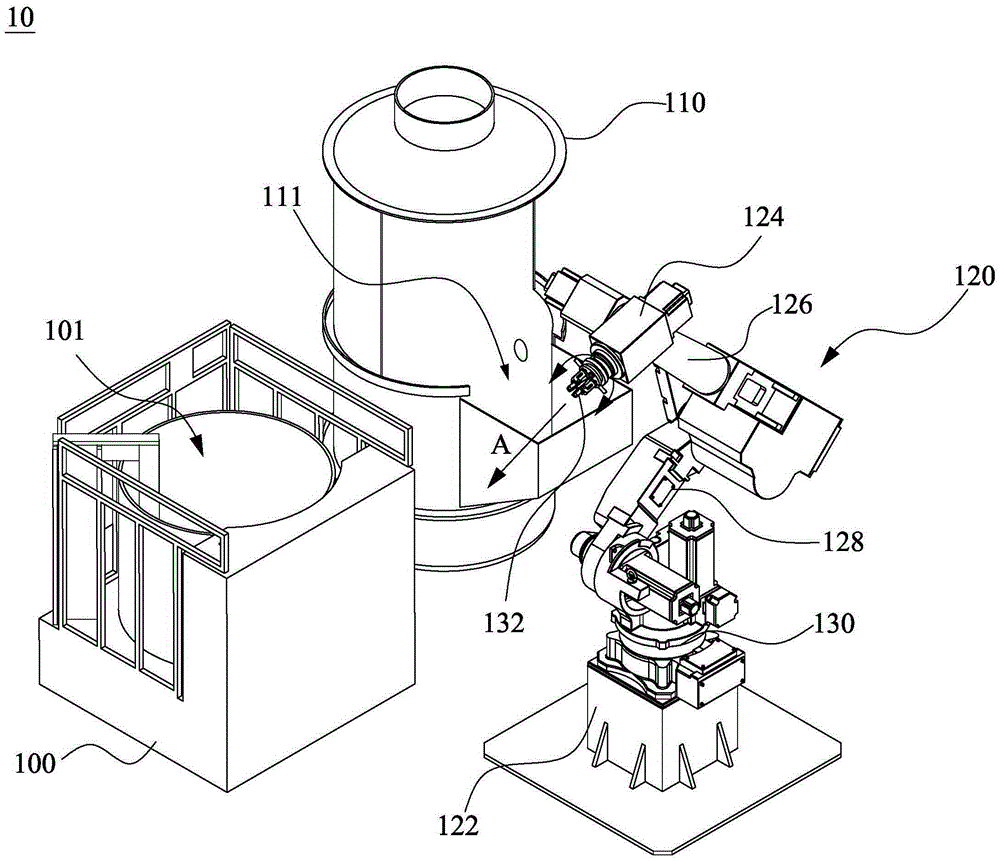

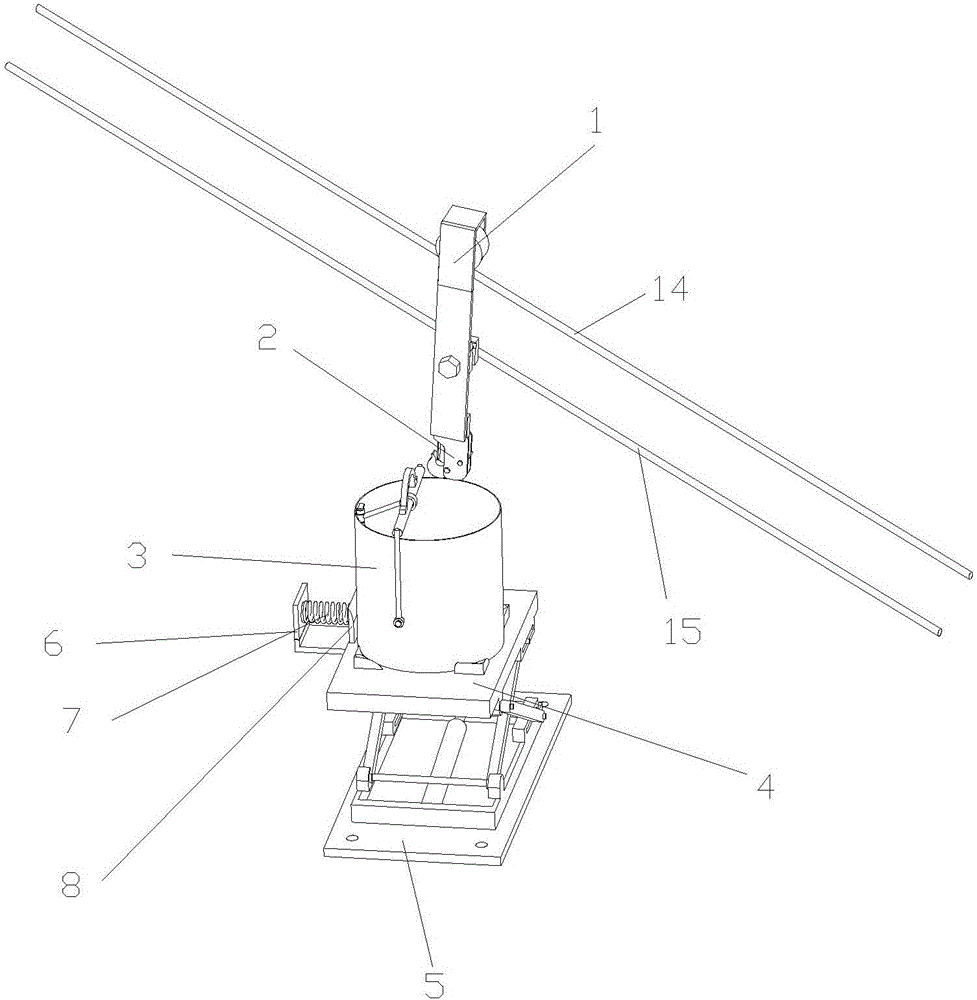

Slurry moistening equipment

PendingCN105251941AUniform adhesionReduce labor costsMoulding toolsFoundry mouldsPulp and paper industrySlurry

The invention relates to slurry moistening equipment which comprises a main slurry barrel, a float sand barrel and a mechanical clamping device, wherein a slurry containing groove is formed in the main slurry barrel; the float sand barrel has a sand floating area; the slurry containing groove is used for containing slurry; the mechanical clamping device comprises a base, a first joint spiral arm pivoted on the base and a clamping mechanism pivoted with the first joint spiral arm, the first joint spiral arm rotates relative to the base, so as to drive the clamping mechanism to reciprocate between the slurry containing groove of the main slurry barrel and the sand floating area of the float sand barrel, and the clamping mechanism rotates relative to the first joint spiral arm when the clamping mechanism is positioned in the slurry containing groove. Thus, according to the slurry moistening equipment, the slurry moistening and sand wrapping operations are performed in a manner that a shell mold is automatically clamped by the mechanical clamping device, so that the human cost can be saved, and the working efficiency can be improved.

Owner:GUANGXING MACHINERY SCI & TECH HUIZHOU CO LTD

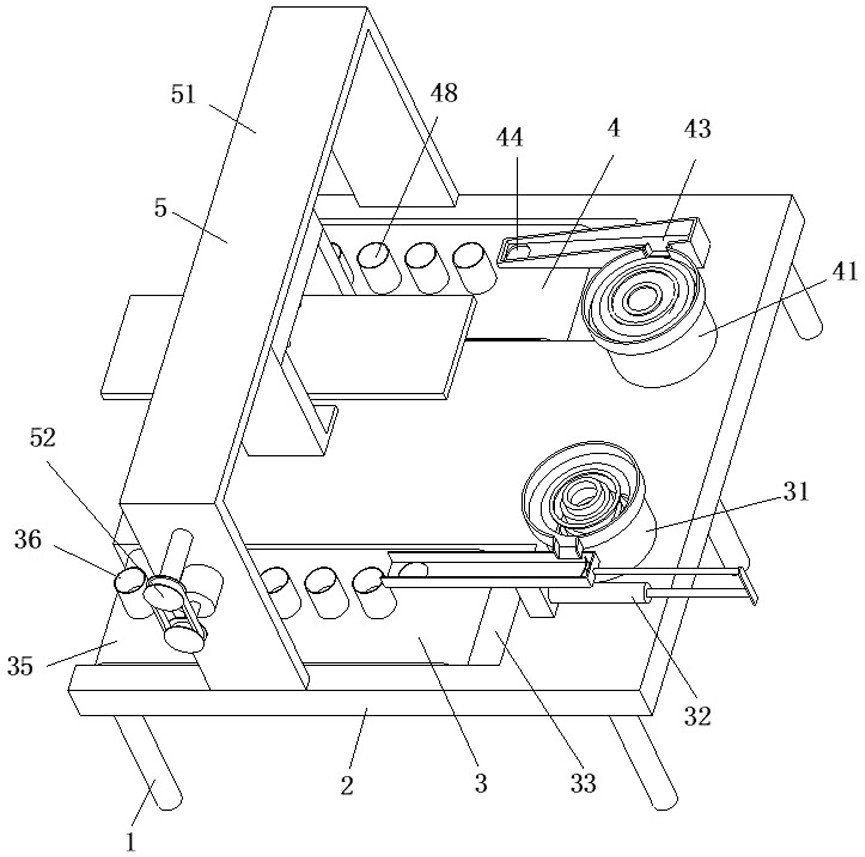

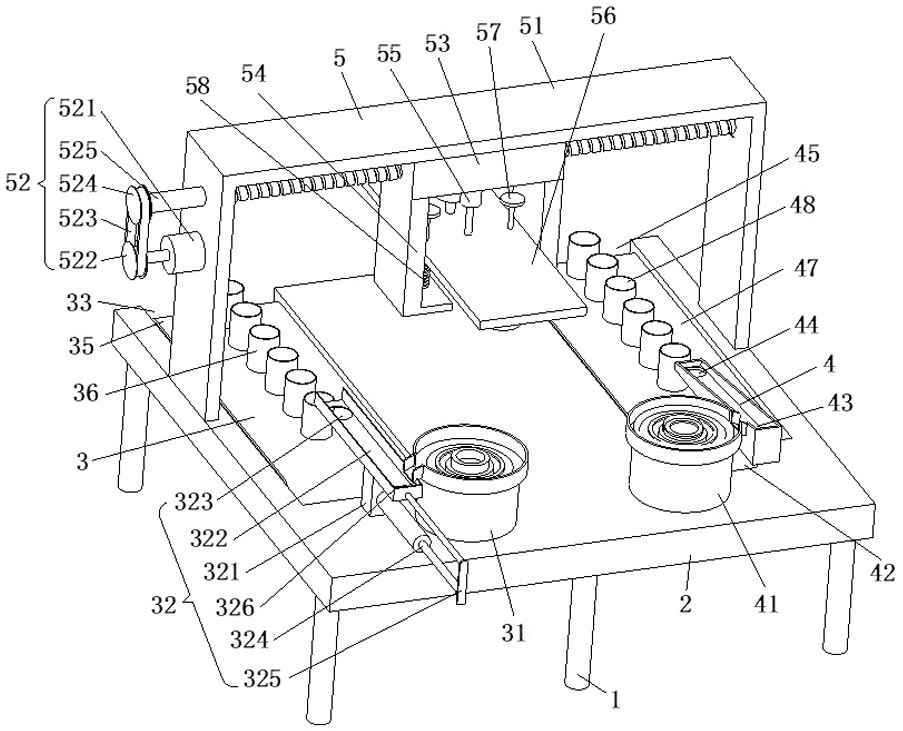

Motor rotor assembling workbench

ActiveCN113381572AReduce labor intensitySave loading timeManufacturing stator/rotor bodiesElectric machineEngineering

The invention relates to the field of motor rotor assembling, in particular to a motor rotor assembling workbench which comprises supporting legs, a supporting plate, a shell feeding device, a rotor feeding device and a press fitting device. The motor rotor assembling workbench can solve the following problems that in the assembling process of an existing motor rotor, a, the motor rotor and a shell are assembled manually, the alignment process of the motor rotor and the shell can be completed only through manual visual inspection during assembling, and due to the fact that the requirement for the mounting precision of the motor rotor and the shell is high, by adopting a manual mounting mode, the difficulty degree of the mounting process is increased, the requirement of mounting precision cannot be met, and thus the production quality is reduced; and b, after the assembling is finished, manual blanking is needed, so that the labor intensity of workers is increased, a large amount of time is consumed, and meanwhile, the next assembling efficiency of the motor rotor and the shell is also reduced.

Owner:SHENZHEN GOLF & FEIHUANG TECH

Vanadium titanium magnetite smelting method

ActiveCN106755670APrevent distribution imbalanceImprove smelting efficiencyBlast furnace detailsDistribution systemBlast furnace smelting

The invention discloses a vanadium titanium magnetite smelting method. The smelting method is characterized in that a burden distribution system is J333313293272202 and K312293272262, wherein J represents coke, K represents mineral, the inclined angle of a burden distribution chute is divided into a sixth gear, a fifth gear, a fourth gear, a third gear, a second gear and a first gear, number superscripts represent corresponding angles, and number subscripts correspond to number of rings of corresponding gears. The smelting method is even in burden distribution, gas flow distribution is reasonable, the gas using rate is improved, the blast furnace smelting intensity is improved, and furnace wall scaffolding is prevented.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

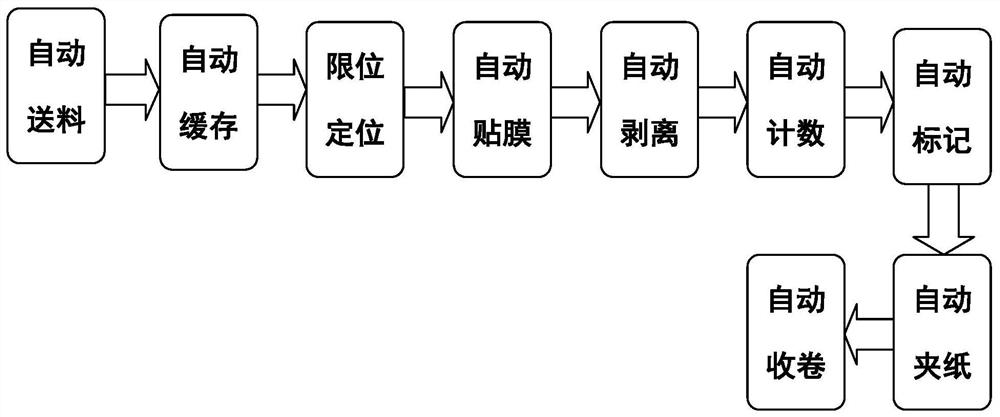

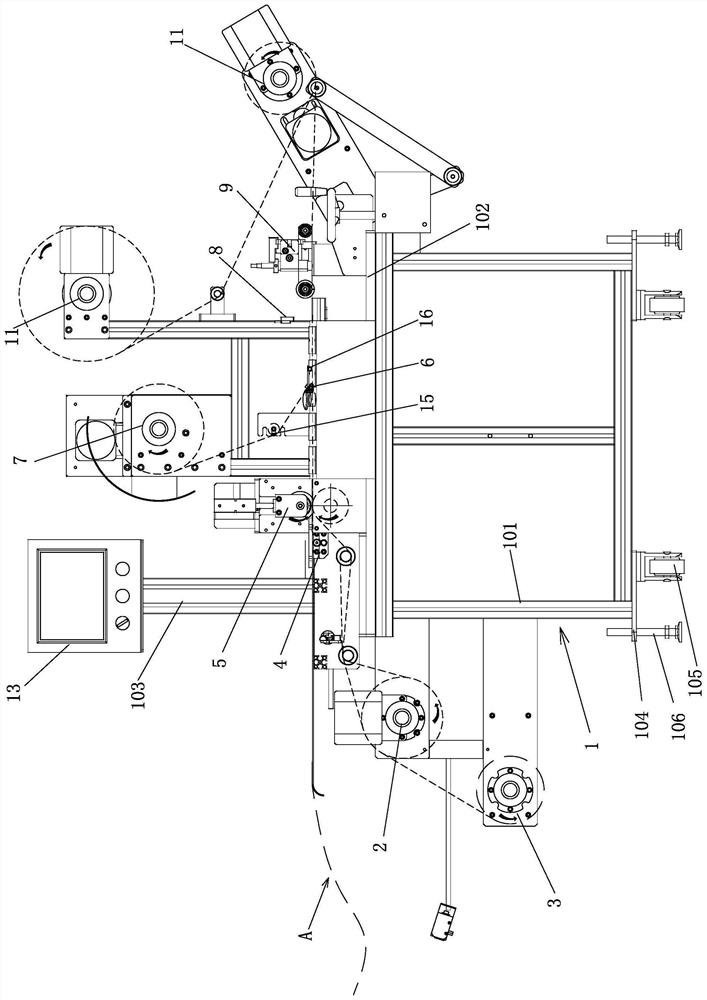

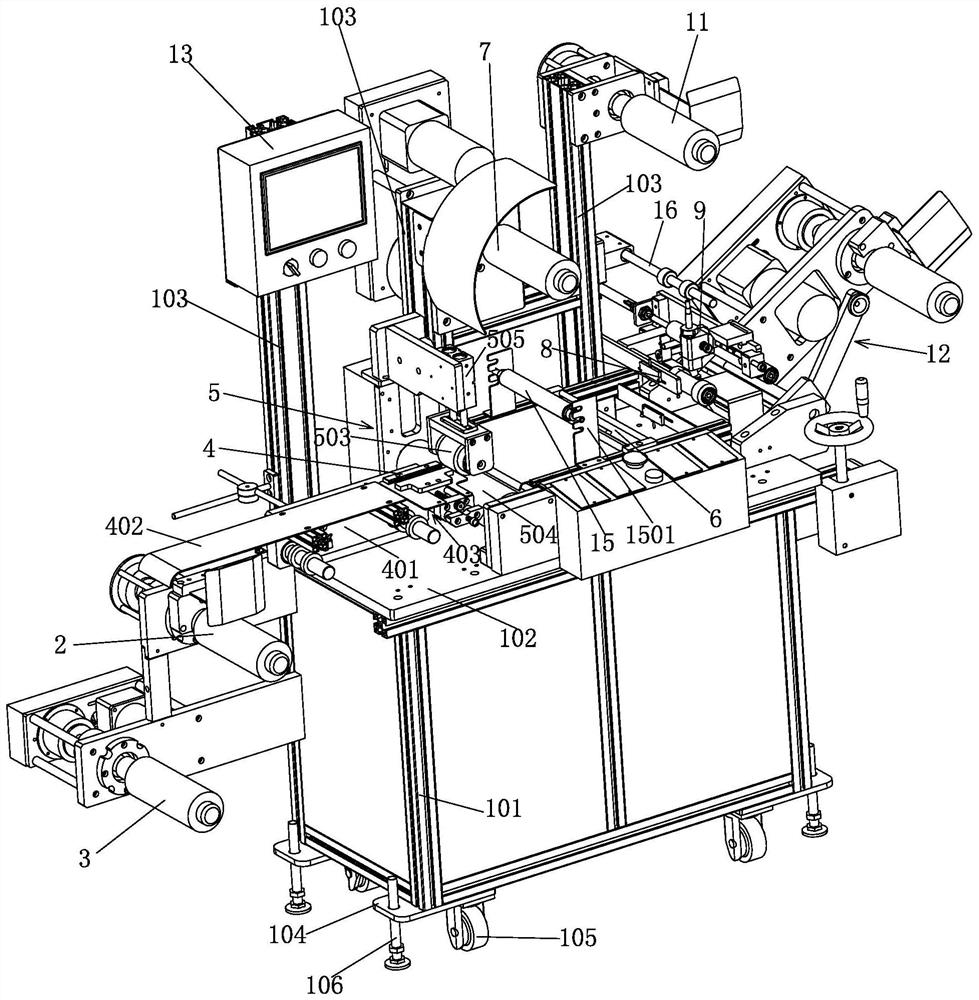

Automatic stainless steel sheet rolling and packing machine

PendingCN112141389AContinuous and smooth operationAvoid scratchesWrappingStructural engineeringWaste material

The invention provides an automatic stainless steel sheet rolling and packing machine. The automatic stainless steel sheet rolling and packing machine comprises a rack, and a film releasing mechanism,a waste film collecting mechanism, a positioning and adjusting mechanism, a film laminating mechanism, a stripping assembly, a waste material collecting mechanism, a counting photoelectric mechanism,an automatic marking mechanism, a paper releasing mechanism, a material collecting mechanism and a control box which are disposed on the rack. The automatic stainless steel sheet rolling and packingmachine has the advantages of improving the collection efficiency, being simple and practical to operate and complete in function, reducing the cost and improving the productivity.

Owner:深圳市龙锋泰自动化有限公司

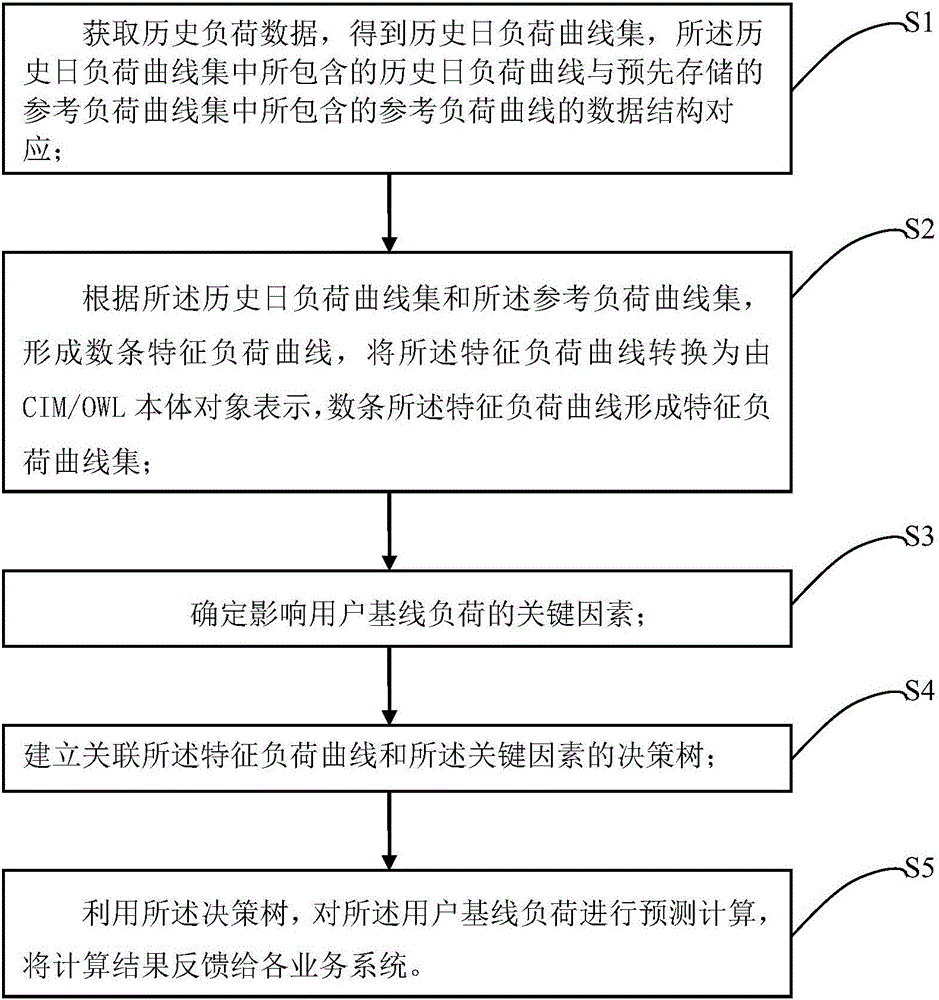

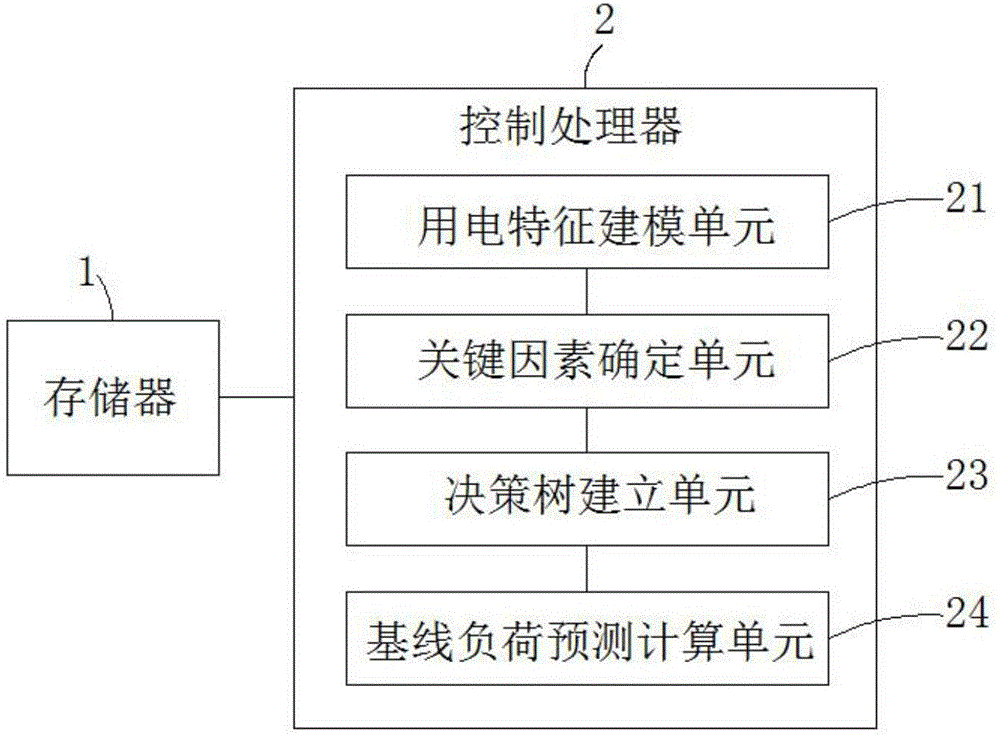

Electric power user baseline load calculating method and apparatus thereof

InactiveCN106682999AImprove predictive computing efficiencySave loading timeForecastingKey factorsDemand response

The invention discloses an electric power user baseline load calculating method and an apparatus thereof. The method is characterized by according to a history day load curve set and a reference load curve set, forming several characteristic load curves; determining a key factor influencing a user baseline load and establishing a decision tree associated with the characteristic load curves and the key factor; and using the decision tree to carry out prediction calculating on the user baseline load, and feeding back a calculation result to each service system. A lot of data loading time is saved, accuracy of a baseline load calculating result is effectively increased, and an accurate data basis is provided for reasonably making and implementing electric power demand side management and demand response measures. Simultaneously, the apparatus is used for executing the method; an automation degree of electric power user baseline load prediction calculating is increased; baseline load prediction calculating efficiency is improved; and a problem that each service system is easy to frequently generate faults during a data interaction process is avoided.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Grinding type stripping machine capable of monitoring grinding disc and working method for grinding type stripping machine

InactiveCN107443229AMonitor wearAvoid the phenomenon of large depth of cutGrinding drivesGrinding machinesPulp and paper industryVision sensor

The invention discloses a grinding type stripping machine capable of monitoring a grinding disc. The grinding type stripping machine comprises a machine frame, a stripping mechanism, a positioning mechanism, feeding and supporting mechanisms, a conveying mechanism and a monitoring mechanism, wherein the stripping mechanism is arranged on the machine frame, the positioning mechanism is arranged on one side of the stripping mechanism, and the monitoring mechanism is arranged on the positioning mechanism; the grinding disc is arranged on the stripping mechanism; and the monitoring mechanism comprises a visual sensor, a marking patch, a buzzer and a PLC, wherein the visual sensor is opposite to the grinding disc, the marking patch is arranged on the grinding disc and covers the side surface of the grinding disc, and the buzzer is arranged on the PLC. The invention further discloses a working method and a monitoring method for the grinding type stripping machine. According to the grinding type stripping machine and the working method and the monitoring method for the grinding type stripping machine, the phenomenon of the large cutting depth can be effectively avoided, and a tool can be protected; the grinding degree of the grinding disc can be automatically monitored, and an alarm can be given; and by means of mechanical feeding, time and manpower resources can be saved.

Owner:TAICANG BEST MECHANICAL EQUIP

Quartz sand pickling purification processing technology

ActiveCN111661850ASimple structureSave loading timeSilicaWater contaminantsOXALIC ACID DIHYDRATEEngineering

The invention discloses a quartz sand pickling purification processing technology, which comprises the following steps: heating oxalic acid and hydrofluoric acid solutions with prepared concentrationsto 75 DEG C, conveying the oxalic acid and hydrofluoric acid solutions to 1 / 3 volume in a reaction tank, adding quartz sand to be processed into the reaction tank, and supplementing acid liquor untilthe quartz sand is completely covered; recovering the acid liquor when the materials react to the target taste in the reaction tank; and after the acid liquor is recycled, performing steps of sand discharging, cleaning, dewatering and warehousing. According to the quartz sand acid pickling purification processing technology, acid does not need to be added from the bottom of the reaction tank, meanwhile, acid does not need to overflow, the feeding time is saved, energy consumption during acid adding is reduced, the structure of the reaction tank is also simplified (an overflow device is not needed), and the cost is reduced.

Owner:合肥诺玛非金属矿科技有限公司

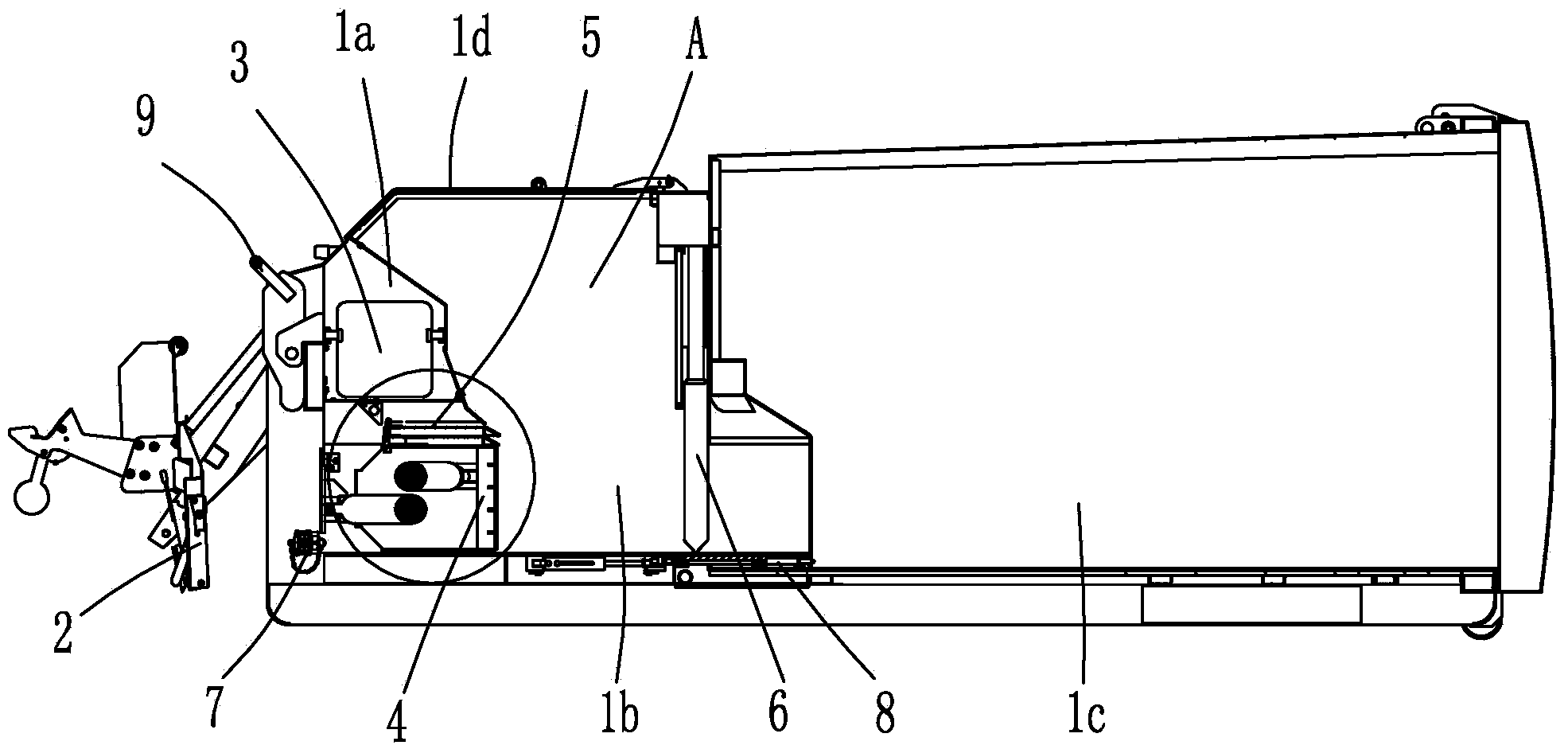

Prepressing type movable trash compactor

ActiveCN103754538ANo reduction in volumeGuaranteed normal loadingRefuse transferringStorage devicesMutually DefinedEngineering

The invention discloses a prepressing type movable trash compactor which comprises an overturn feeding mechanism, a hydraulic and electric control system, a push head assembly and a box body structure which is formed by a hydraulic and electric cabin, a push chamber and a trash can from front to back in sequence. The overturn feeding mechanism is located dead ahead of the box body structure and is hinged to the box body structure. The hydraulic and electric control system is mounted in the hydraulic and electric cabin, the push head assembly is located under the hydraulic and electric cabin and the dead ahead of the push chamber, a gate mechanism capable of moving up and down is arranged at the connecting position of the push chamber and the trash can, after the gate mechanism falls down completely, the rear wall of the hydraulic and electric cabin, a push plate of the push head assembly, a left side plate and a right side plate of the push chamber and the gate mechanism mutually define a closed prepressing chamber, and a main drain system and an auxiliary drain system are arranged on the bottom of the box body structure. Prepressing is carries out on trash through the prepressing chamber, sewage generated through the prepressing is discharged, water content of the trash is lowered, the loading amount of the compactor is improved, and the phenomena of overflowing, leakage and dripping in a transport process are avoided.

Owner:CHONGQING DIMA IND

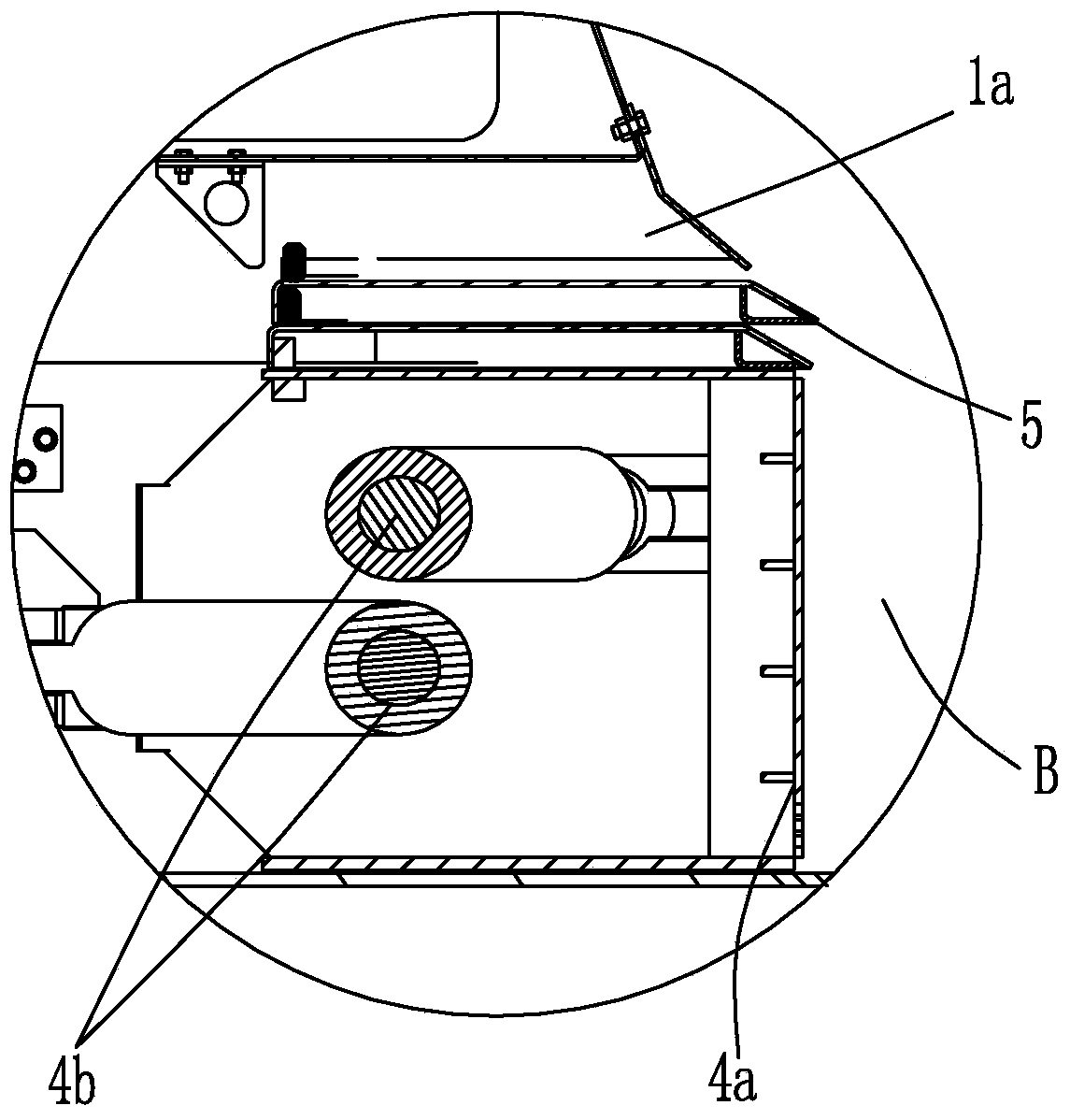

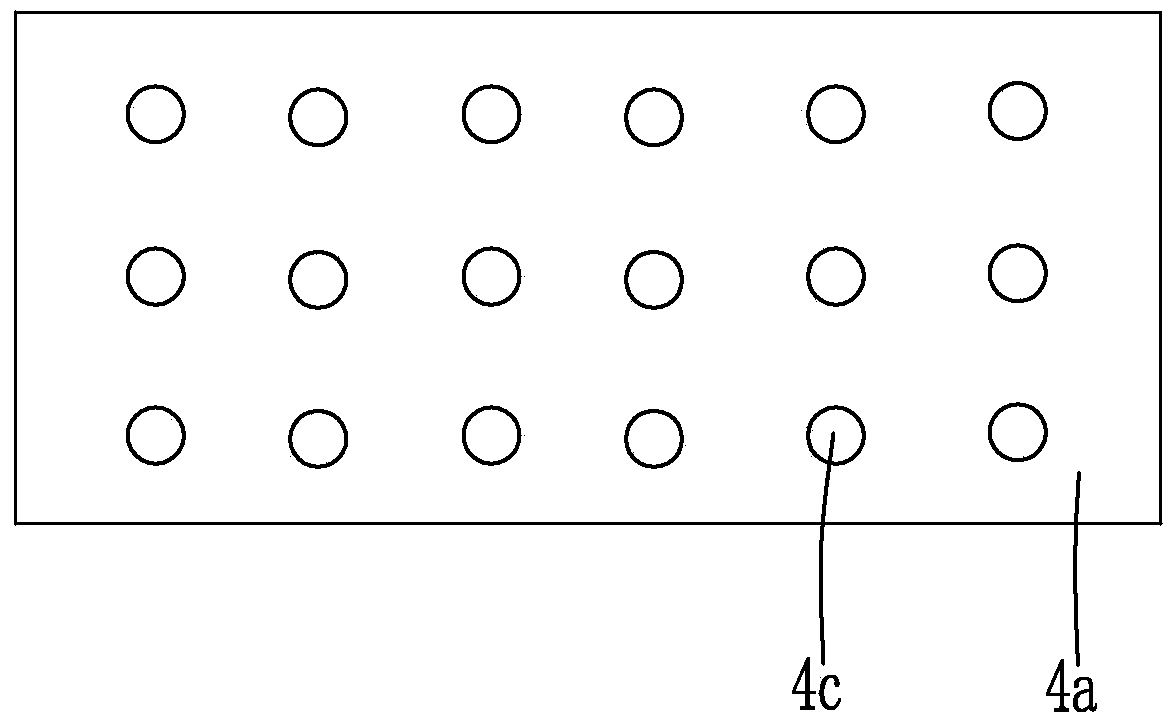

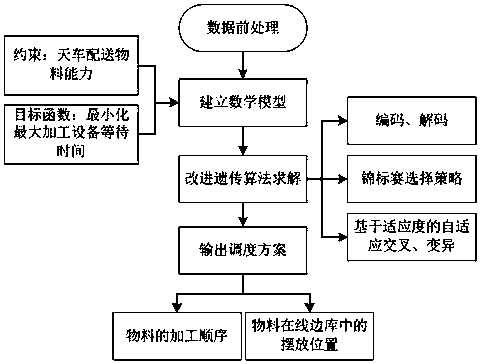

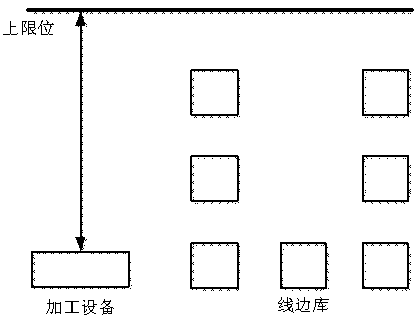

Material delivery-based automobile chassis blanking workshop scheduling method

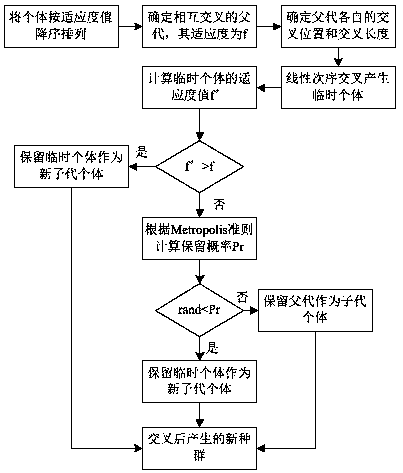

InactiveCN108596455ALess waitingSave loading timeResourcesGenetic algorithmsOptimal schedulingGenetic algorithm

The invention discloses a material delivery-based automobile chassis blanking workshop scheduling method. According to the method, modeling is carried out in allusion to scheduling problems of automobile chassis blanking workshops which are limited in material delivery ability and arrange storage areas besides machining equipment, and solution is carried out through an improved genetic algorithm so as to obtain optimal scheduling schemes of the automobile chassis blanking workshops; and meanwhile, placing positions of materials in the storage areas are optimized according to the scheduling schemes, so that the waiting time of the machining equipment is shortened, the production efficiency is improved and continuous and stable production is realized.

Owner:HARBIN UNIV OF SCI & TECH

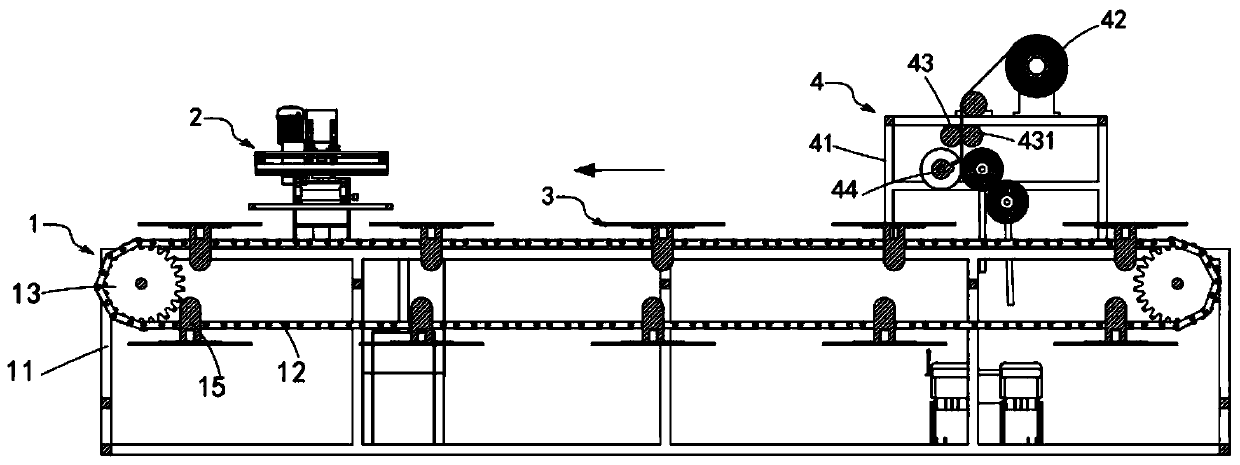

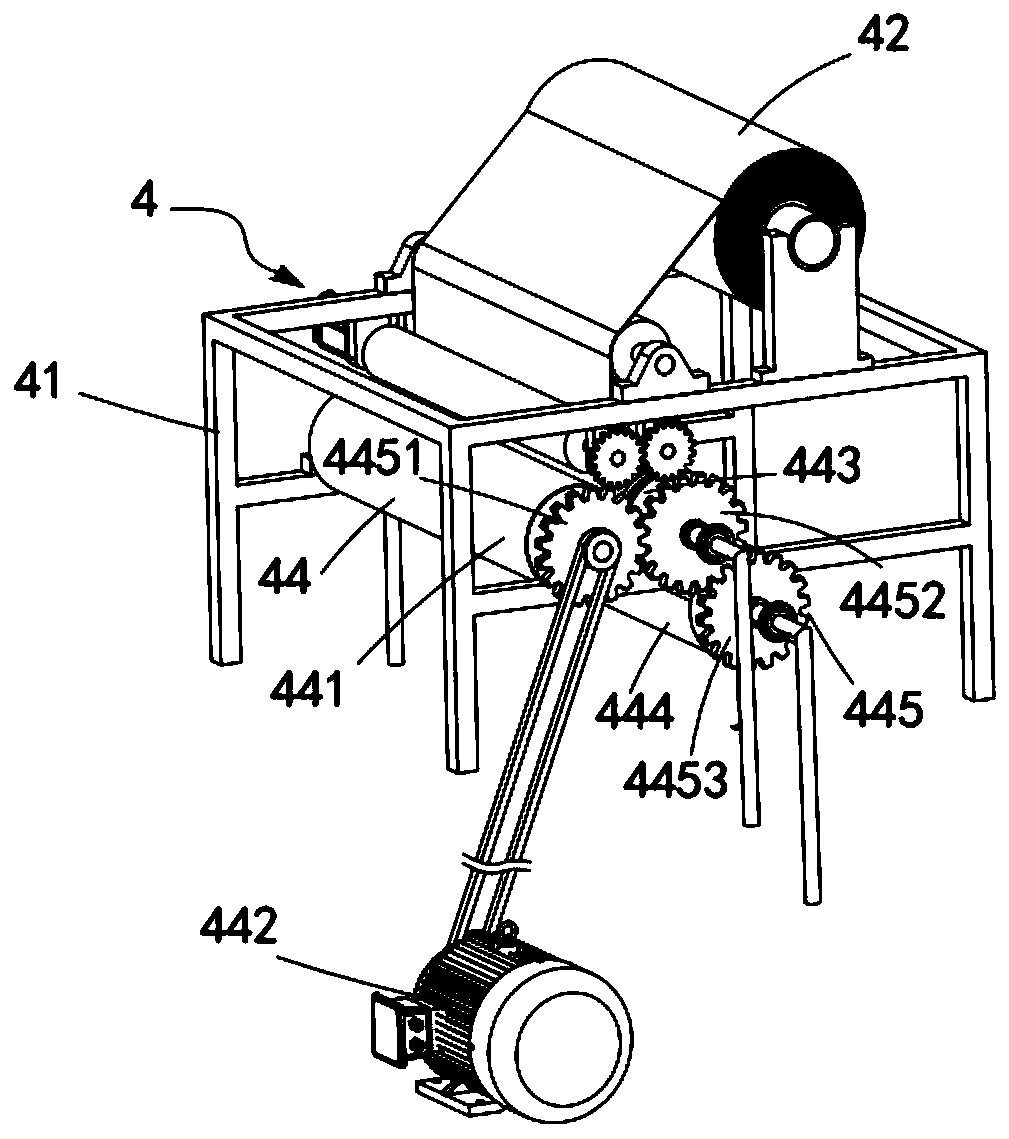

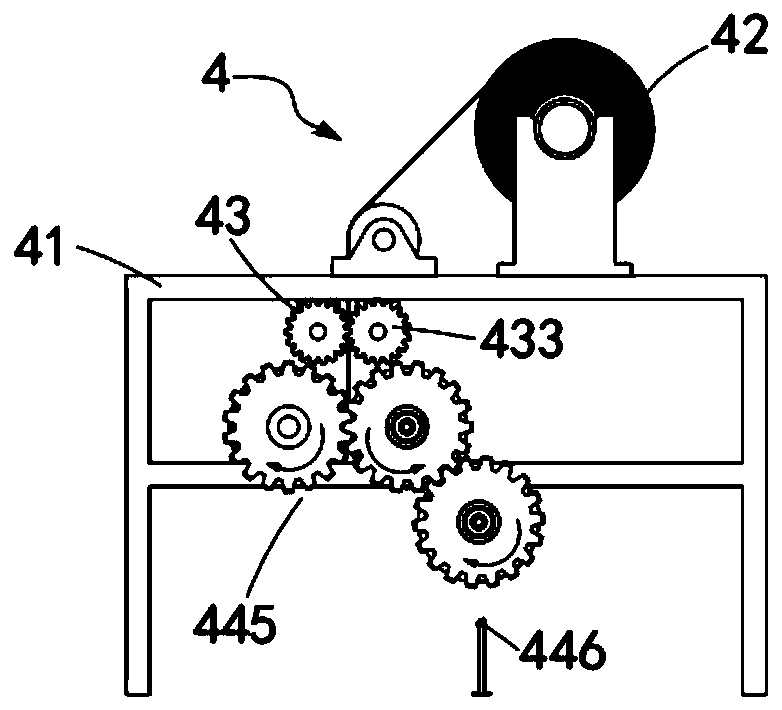

Fabric continuous color printing system

InactiveCN111362030ARolling achievedRealize tiling loadingScreen printersArticle feedersTextile printerColor printing

The invention relates to the technical field of garment fabric automatic printing machines, and discloses a fabric continuous color printing system. The fabric continuous color printing system comprises a feeding line, printing equipment, a platen and continuous supply equipment. By means of the fabric continuous color printing system, the feeding line is used for driving a machining table for loading garment fabric for printing to be transferred below the continuous supply equipment, the continuous supply equipment is used for slitting and transferring the garment fabric, meanwhile, in cooperation with a positioning mechanism arranged on the machining table, the positioning mechanism pulls one end of the garment fabric, the garment fabric passes through the lower end of a second vacuum suction roller set, through the cooperation and the speed difference between the second vacuum suction roller set and the machining table, the garment fabric is rolled, and while the system assists thefabric in continuous tiling and feeding, it is not needed to additionally arrange a rolling device for rolling the garment fabric.

Owner:长兴创智科技有限公司

High-precision production injection molding process and injection molding machine

The invention belongs to the technical field of data joint injection production, and aims to provide a high-precision production injection molding process and an injection molding machine. According to the technical scheme, the injection molding machine comprises a rack, wherein a workbench is arranged on the rack; a first oil cylinder is arranged at the lower end of the rack; a driving plate is slidably connected to the output end of the first oil cylinder; a driving rod is fixedly connected to the upper end of the driving plate; the upper end of the driving rod is fixedly connected with a fixing plate; the upper end of the workbench is provided with a lower die; the lower end of the fixing plate is provided with an upper die; the upper end of the fixing plate is fixedly connected with aguiding column; one side of the rack is provided with an extension platform; a feeding mechanism is arranged on the extension platform; and a cooling circulation system is arranged in the lower die and the upper die. According to the high-precision production injection molding process and the injection molding machine, the cooling circulation system is additionally arranged to the injection molding machine, so that a molten plastic in a die cavity is cooled by the cooling circulation system after the molten plastic is injected into the die cavity, the cooling effect is good, the molding speedis high, and the working efficiency is improved.

Owner:深圳市宏科电子有限公司

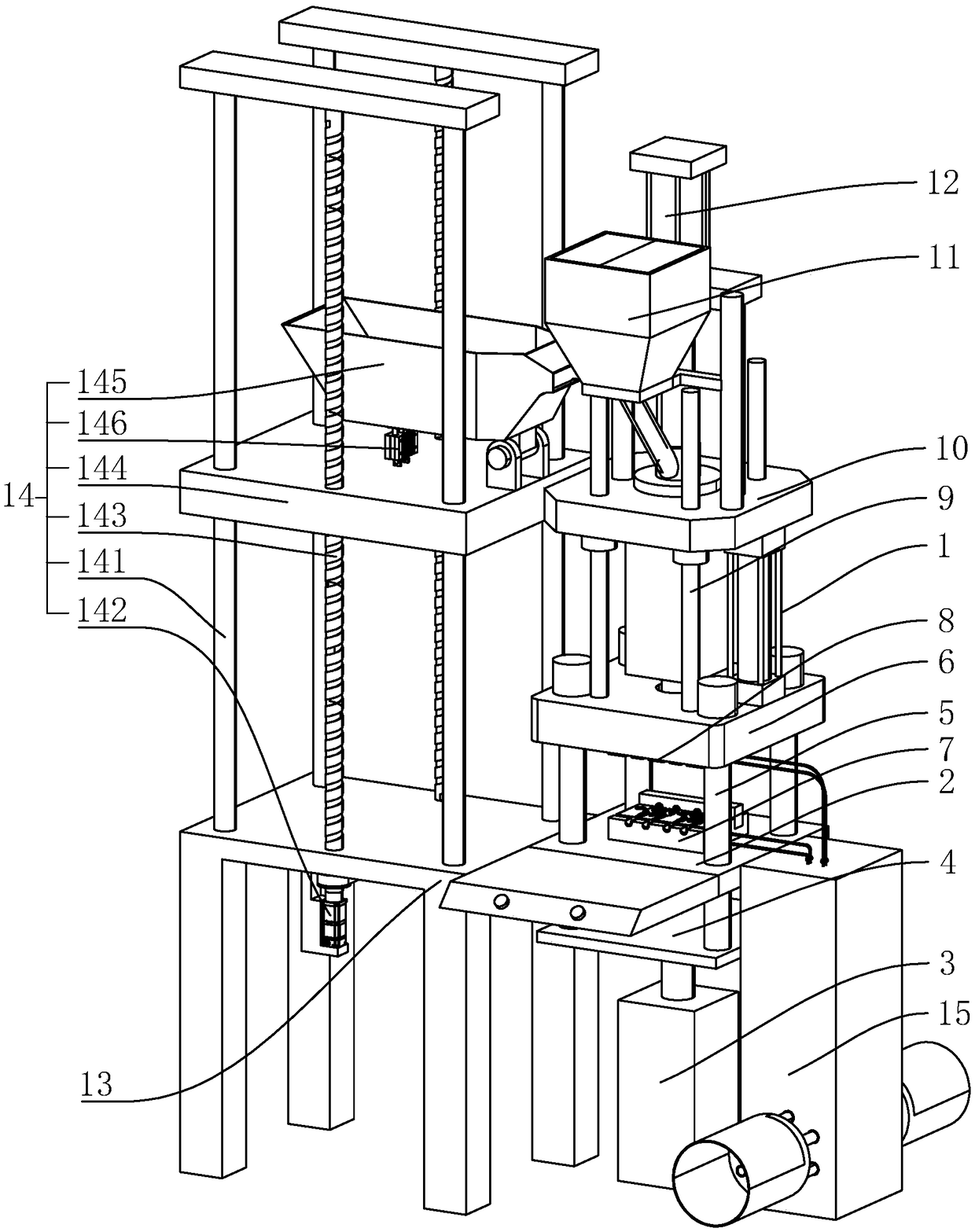

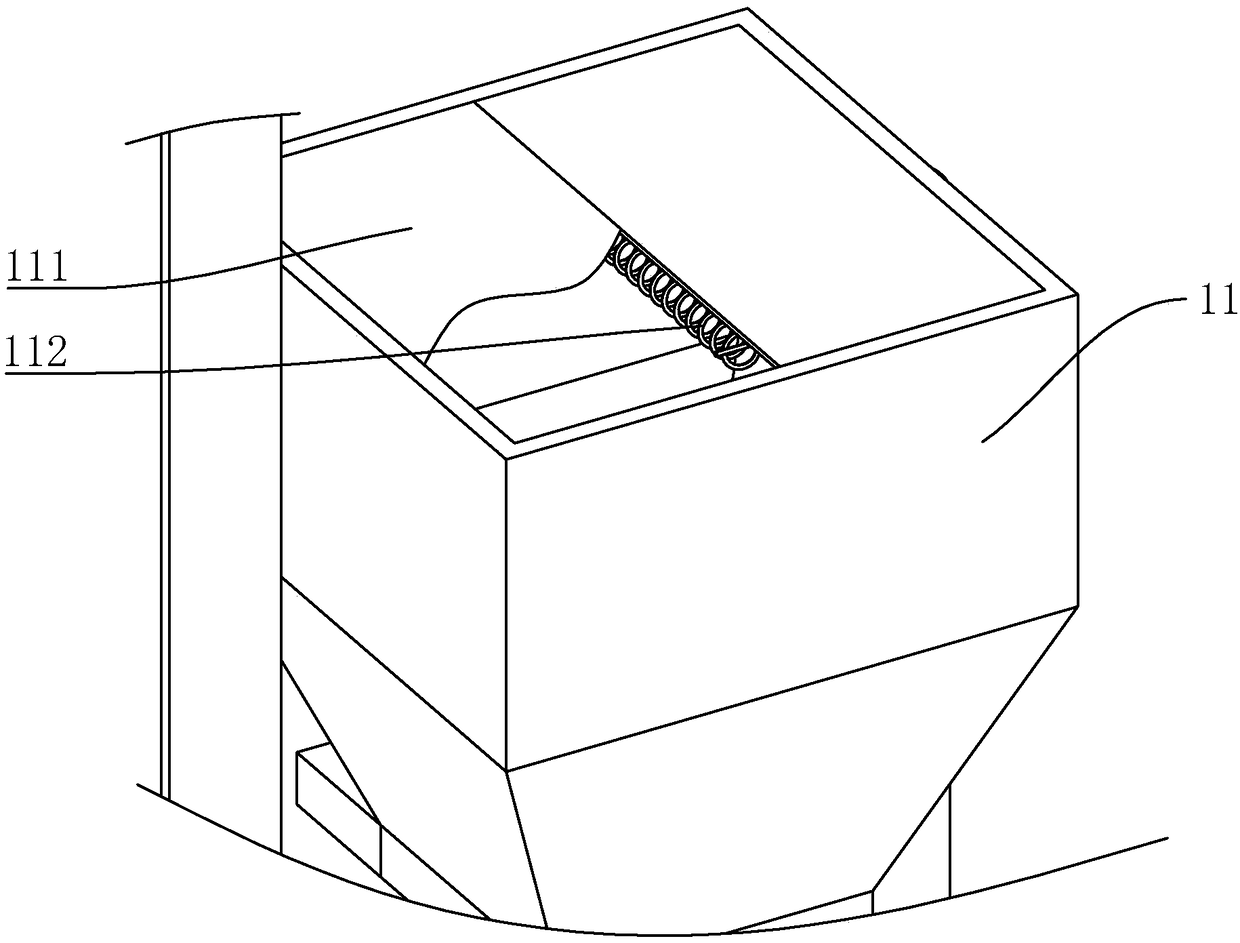

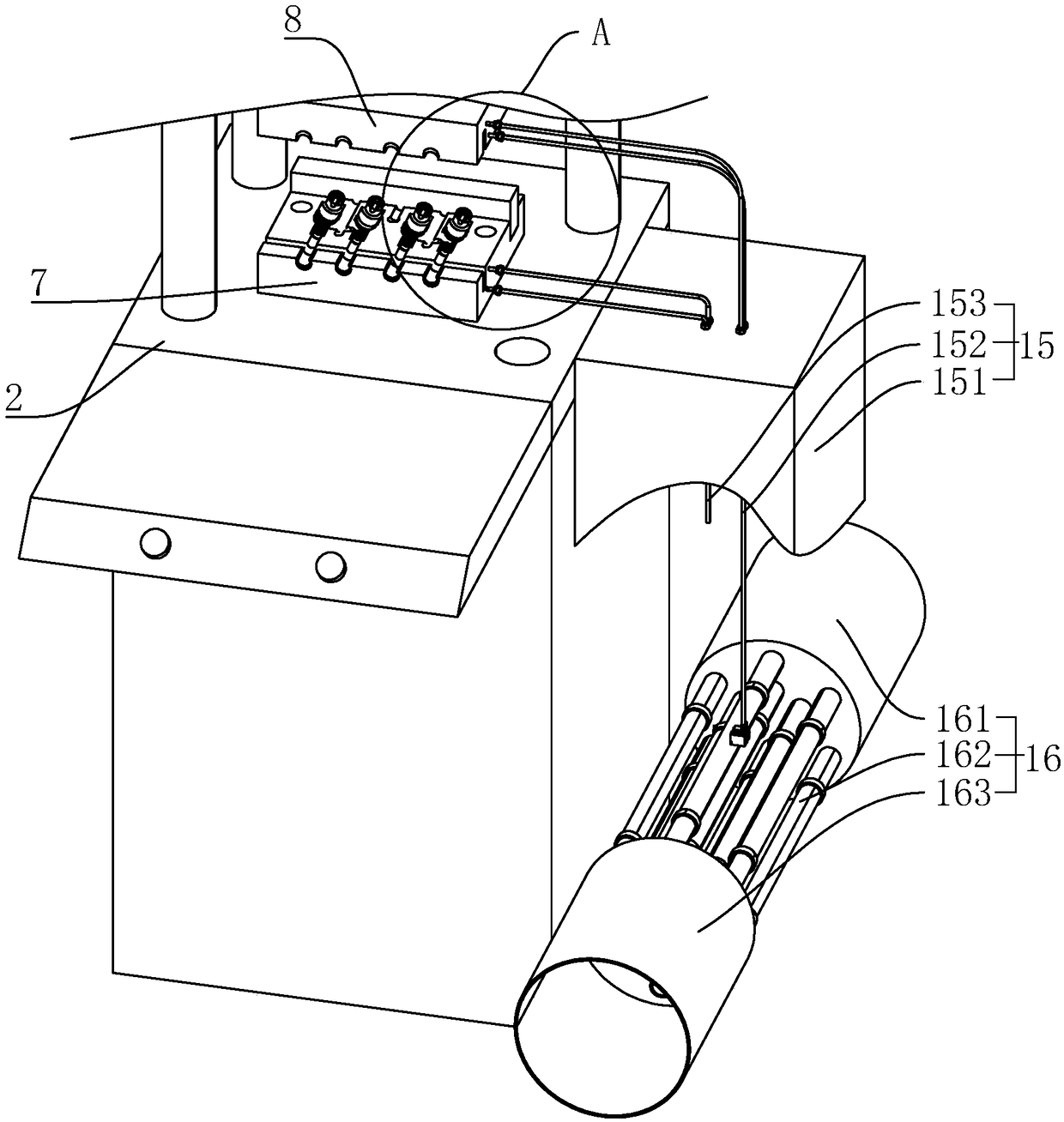

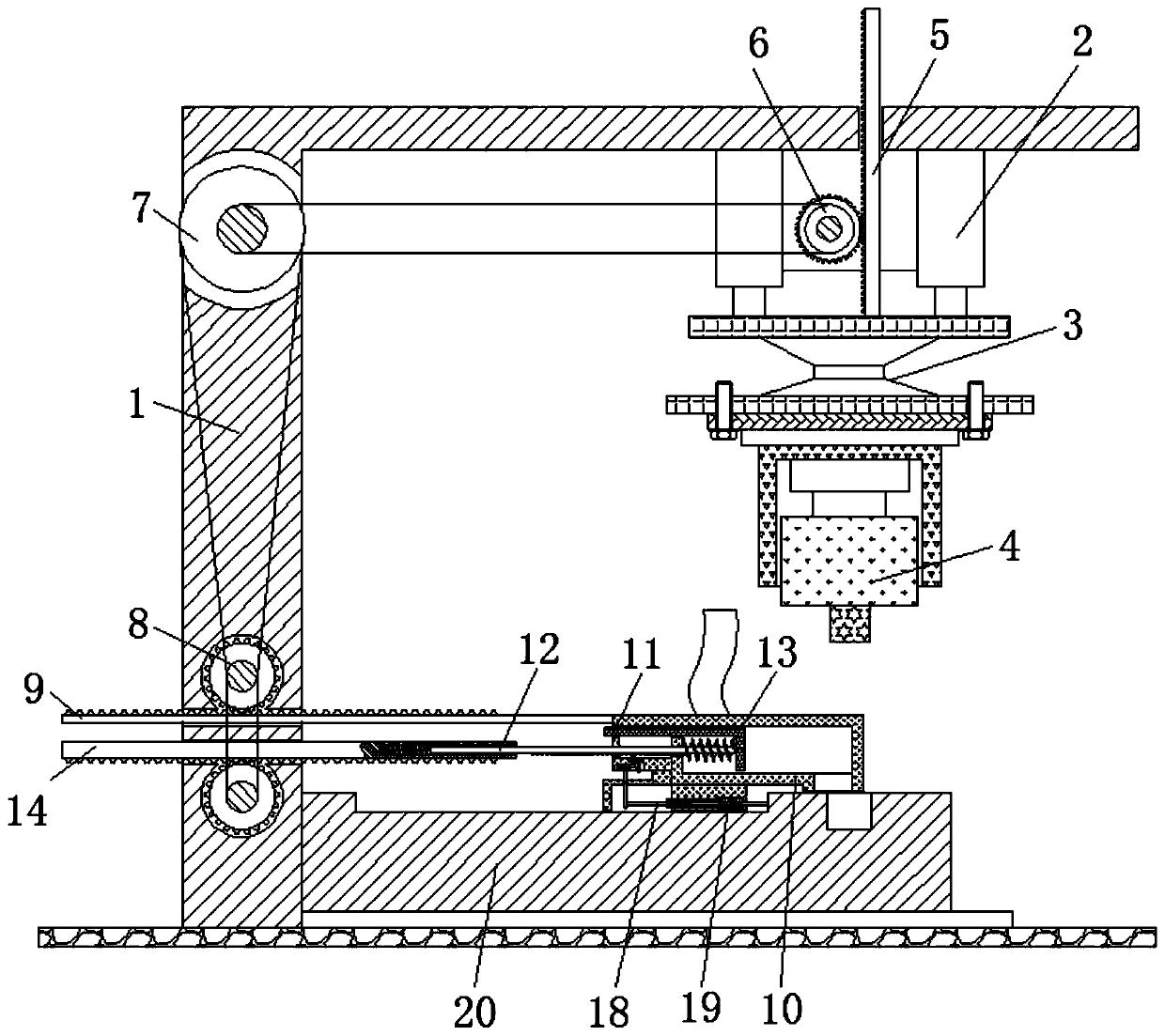

Powder metallurgy automatic feeding device based on gear rod transmission principle

The invention relates to the technical field of powder metallurgy, and discloses a powder metallurgy automatic feeding device based on a gear rod transmission principle. The device comprises a supportframe, a hydraulic pump is fixedly connected to the outer part of the support frame, and a lifting block is fixedly connected to the bottom of the hydraulic pump. An upper pressing block is movably connected to the inner part of the lifting block, a vertical toothed bar is fixedly connected to the top of the lifting block, and a rotating gear is connected to the outer part of the vertical toothedbar in an engaging mode. A connecting wheel is movably connected to the inner part of the support frame, an adjusting gear is movably connected to the inner part of the support frame, and a feeding block is fixedly connected to the outer part of an upper toothed bar. Through the cooperation of the lifting block, the vertical toothed bar, the rotating gear, the connecting wheel, the adjusting gear, the upper toothed bar and the feeding block, the effect of automatic metallurgy and feeding in the metal powder metallurgy process is achieved, the operation is simple, the operation intensity is low, and the feeding time is effectively reduced, so that the working efficiency of powder metallurgy is effectively improved.

Owner:南知周

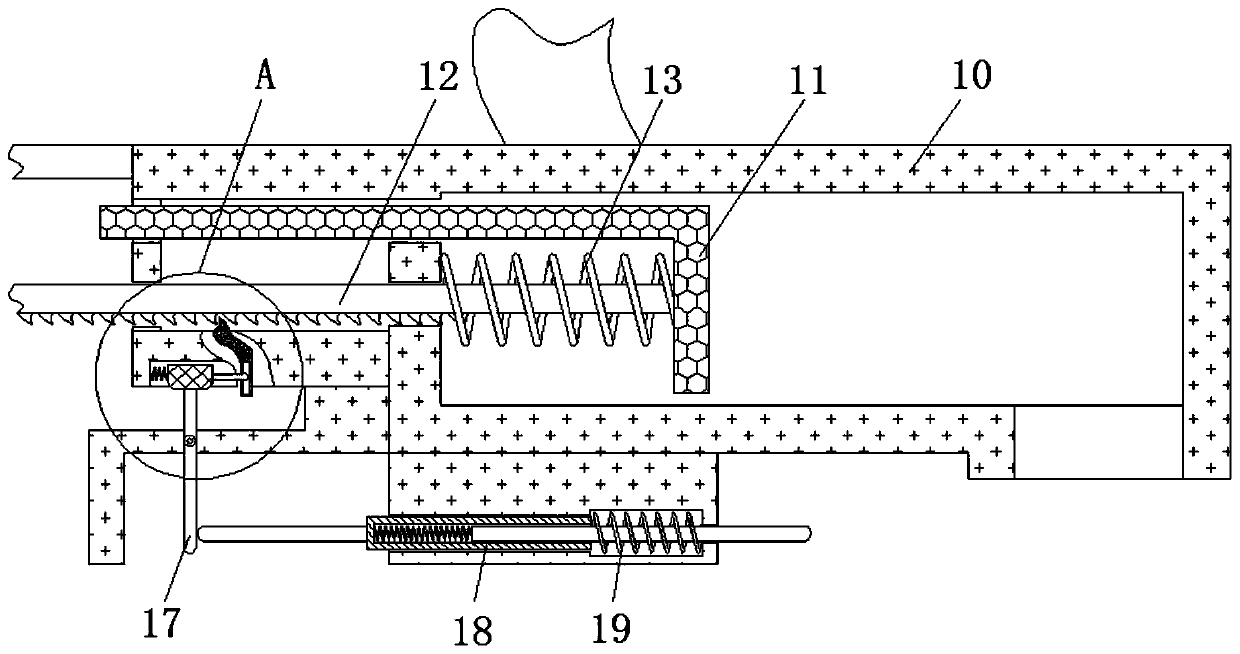

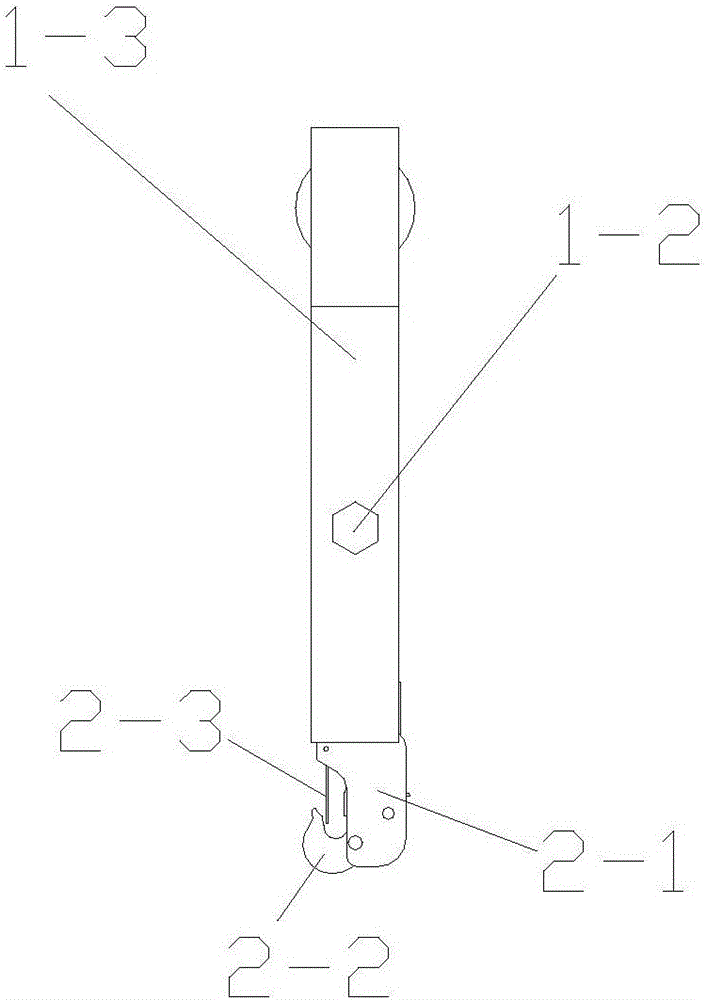

Automatic hooking device of freight ropeway

ActiveCN106696970ASimple structureReasonable designRope railwaysConveyor partsElectric power transmissionSelf locking

The invention discloses an automatic hooking device of a freight ropeway. The automatic hooking device comprises a walking mechanism, a hook self-locking mechanism, a material barrel mechanism, an installation platform and a limiting mechanism; the material barrel mechanism comprises a material barrel and a hanging ring part, the hook self-locking mechanism comprises a connecting plate, a hook and a self-locking part, the installation platform comprises a horizontal platform and a positioning part, the positioning part comprises multiple positioning stop blocks and a baffle part arranged on one side of the horizontal platform, the hanging ring part comprises two rotating arms, a cross beam and a hanging ring, and the cross beam is provided with an eccentric self-locking device for positioning the hanging ring. The automatic hooking device is simple in structure, reasonable in design, high in adaptability and good in positioning effect, the material barrel mechanism is precisely positioned, automatic feeding and discharging are achieved, the feeding hooking action and the discharging action are accurate, the labor intensity of workers is reduced, and the construction efficiency and safety of electric power transmission are improved.

Owner:XIAN UNIV OF SCI & TECH

Cloth reeling machine

InactiveCN105110050AGuaranteed roll effectImprove versatilityWebs handlingElectric machineryAgricultural engineering

The invention discloses a cloth reeling machine, and relates to the technical field of textile equipment. The cloth reeling machine comprises a frame, a support frame disposed at the outer bottom of one side of the frame, a roller device disposed at the other side of the frame, a top shaft disposed at the top of the frame, and a bottom shaft rotatingly disposed, under the roller device, on the frame. The roller device comprises a motor disposed at the bottom of the frame, a length counter disposed on the frame and a speed regulator electrically connected with the motor. The cloth reeling machine is simple in whole structure, the length of reeled cloth can be clearly mastered through the length counter, laying-off is convenient. The rotational speed of the motor can be adjusted according to features of the reeled cloth through the speed regulator, the reeling effect can be ensured, the whole versatility can be raised.

Owner:长兴联丰纺织有限公司

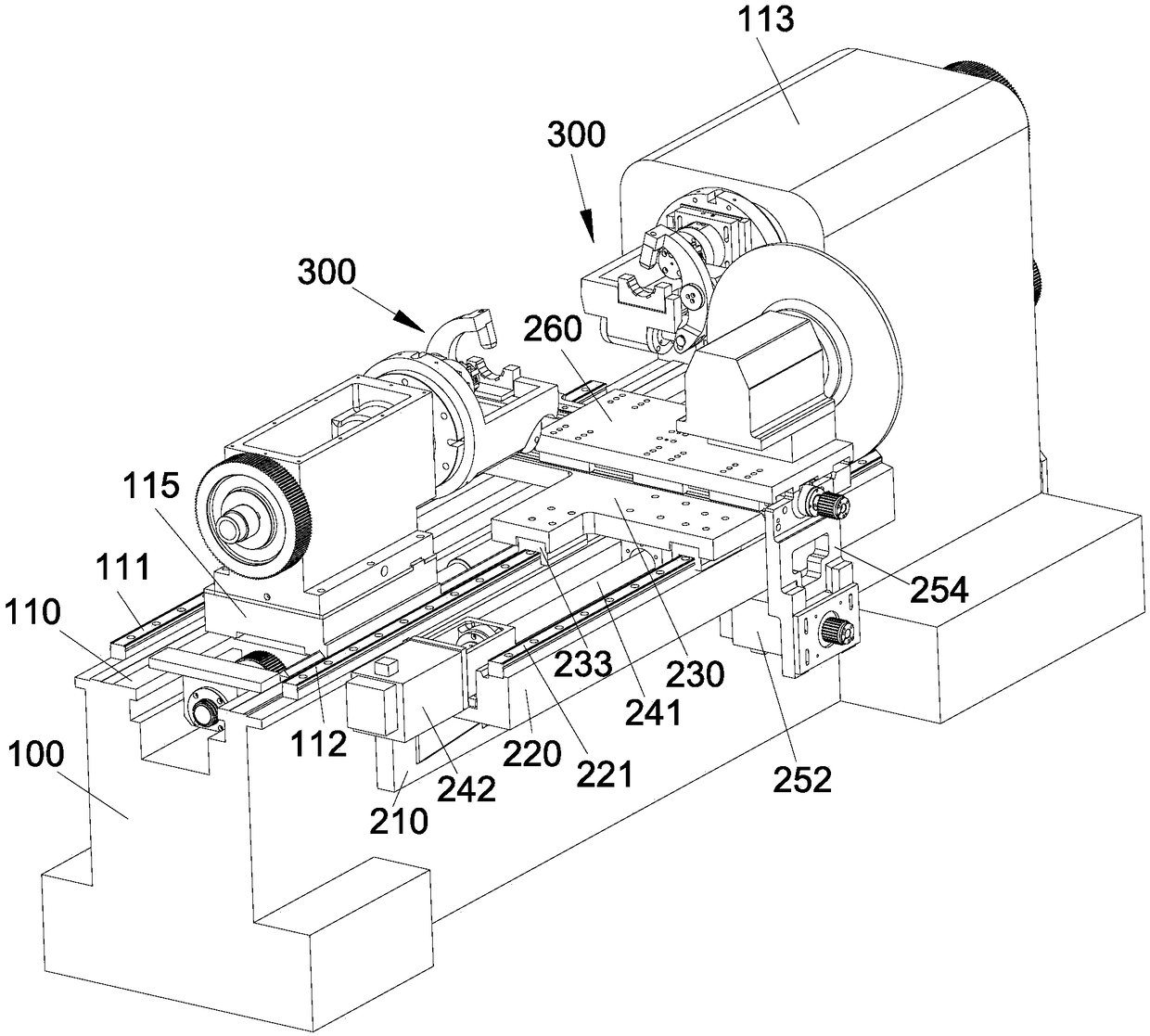

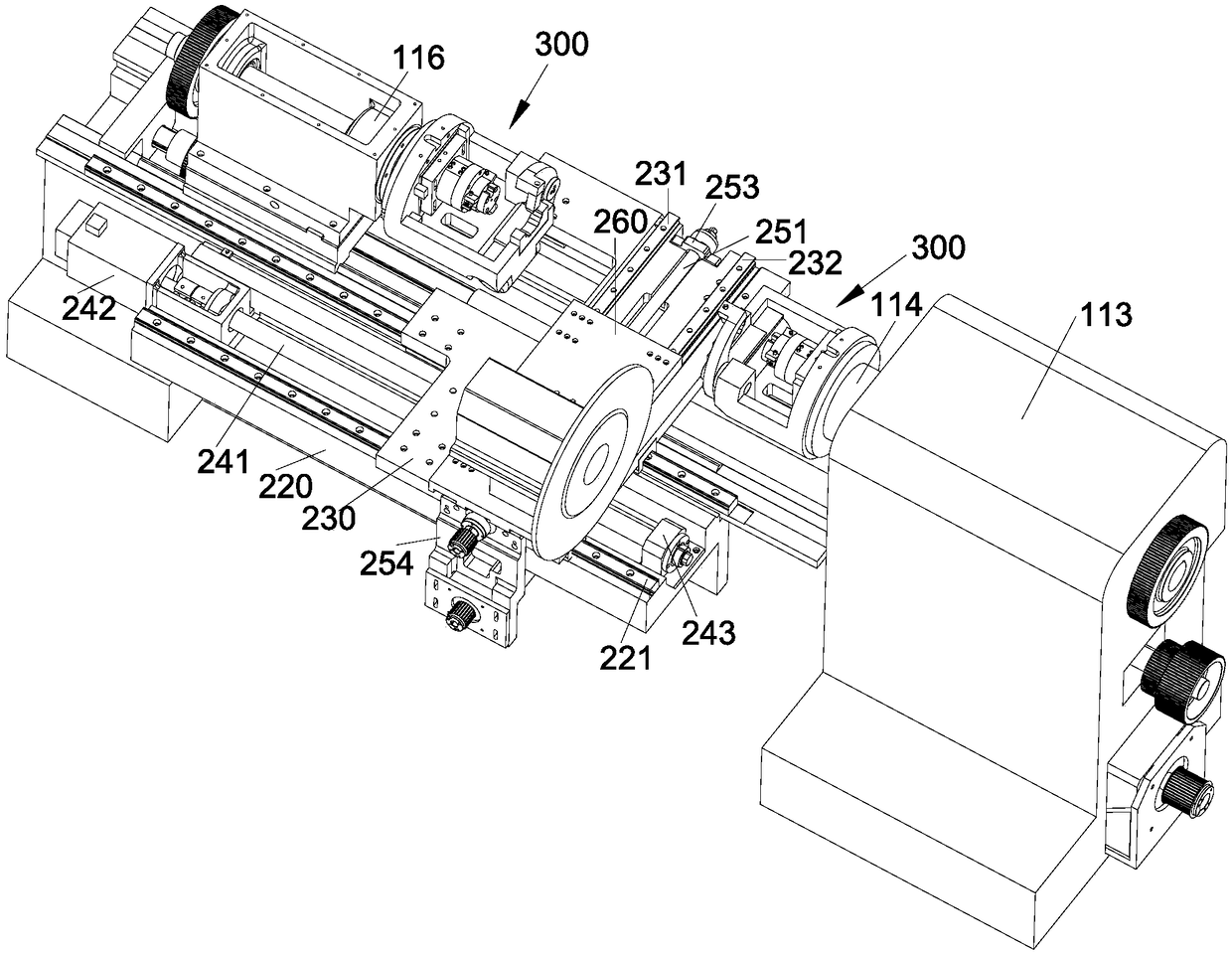

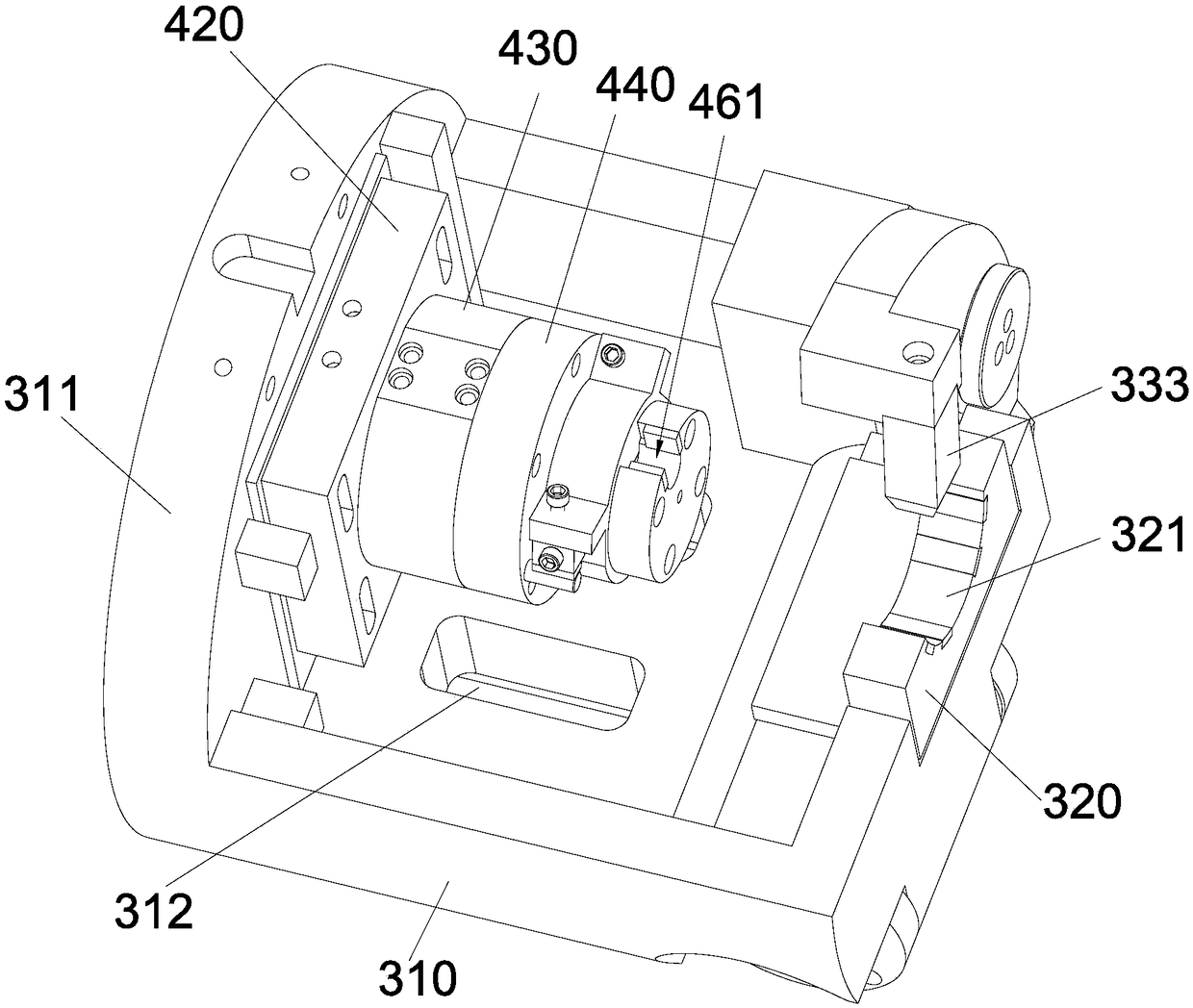

Machine tool special for machining crankshaft connecting rod neck

PendingCN109365913AEven by forceSave loading timePrecision positioning equipmentWork clamping meansEngineeringTailstock

The invention discloses a machine tool special for machining a crankshaft connecting rod neck. The machine tool comprises a machine body, a main shaft box, a tailstock, a clamp set, a tool apron, andan inclined supporting device; the machine body comprises a working table board; the clamp set comprises a pair of clamp assemblies used for carrying out end part positioning on a crankshaft; each clamp assembly is cooperatively provided with an indexing assembly, the indexing assembly comprises an indexing plate and a positioning plate fixedly connected with the indexing plate, the indexing plateis fixedly connected with the end part of the crankshaft, and the positioning plate is rotationally connected with the clamp assembly; the tool apron is used for being connected with a tool assembly;and the inclined supporting device comprises a tool apron driving device and a supporting panel, wherein the tool apron driving device is used for driving the tool apron to move along the supportingpanel and the working table board, and the supporting panel is used for bearing the tool apron. According to the machine tool special for machining the crankshaft connecting rod neck, feeding and discharging can be facilitated, the indexing operation can be carried out rapidly and accurately, the production efficiency can be improved, the stability of the tool apron can be improved, the accuracy of positioning and the stability of fixing of clamps can be improved, and the machining precision can be improved.

Owner:SICHUAN FEIYA AUTO PARTS CO LTD

Pole piece feeding device

InactiveCN105752681ASave loading timeImprove feeding efficiencyElectrode manufacturing processesSecondary cellsPole pieceConveyor belt

The invention relates to the technical field of battery pole piece processing equipment, in particular to a pole piece feeding device.The pole piece feeding device comprises a vacuum conveyor belt, a tray for containing pole pieces, an ascending and descending assembly for driving the tray to ascend and descend and a feeding roller for sucking and transferring the pole pieces in the tray to the vacuum conveyor belt; the pole piece feeding device further comprises a rotating assembly for driving the feeding roller to rotate and a vacuumizing assembly for conducting vacuumizing on the feeding roller; the feeding roller is located between the vacuum conveyor belt and the tray, the upper surface of the feeding roller is close to the lower surface of the vacuum conveyor belt, the lower surface of the feeding roller is close to the pole pieces on the tray, and the ascending and descending assembly is located below the tray.The pole piece feeding device is simple in structure, convenient to use and high in feeding efficiency.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com