Grinding type stripping machine capable of monitoring grinding disc and working method for grinding type stripping machine

A grinding disc and peeling machine technology, which is applied in the directions of grinding workpiece supports, grinding machine parts, grinding feed motion, etc., can solve the problems of reducing the working efficiency of the peeling machine, delaying the production progress, and large peeling depth, etc. Achieve the effect of low cost, optimized positioning capability, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

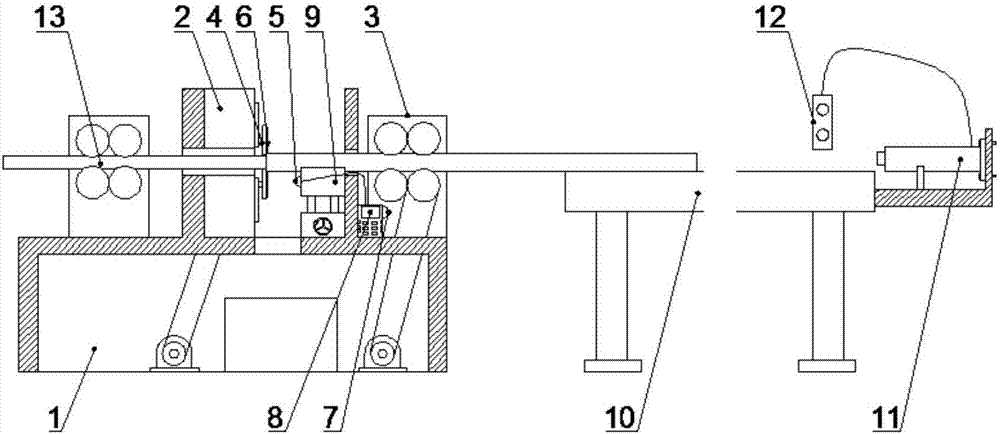

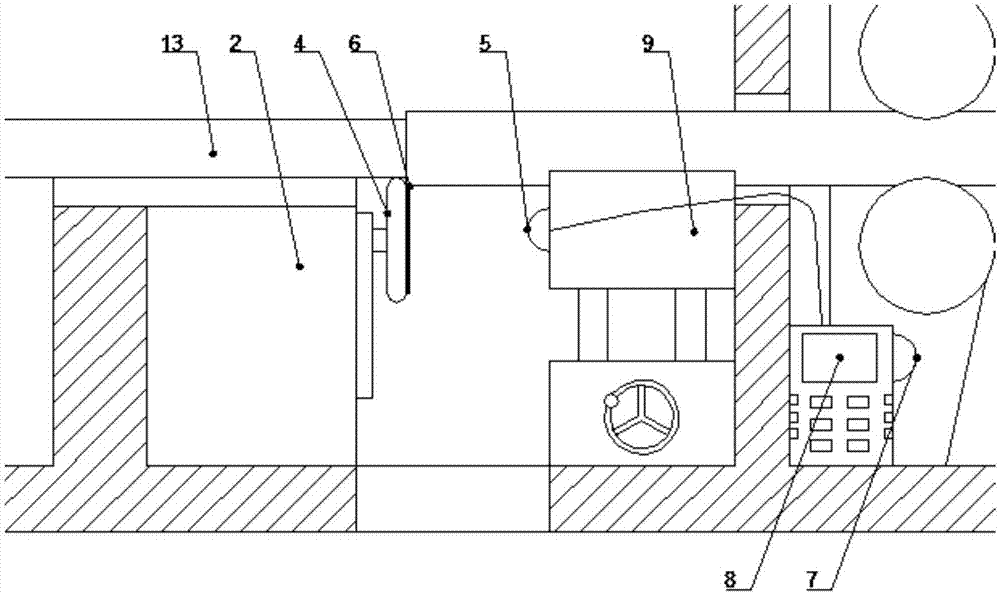

[0037] Such as figure 1 A grinding peeling machine for monitoring grinding discs is shown, comprising: a frame 1, a peeling mechanism 2, a positioning mechanism, a feeding support mechanism 3, a feeding mechanism, and a monitoring mechanism. The frame 1 is provided with a peeling mechanism. Mechanism 2. A positioning mechanism is provided on one side of the peeling mechanism 2, a feeding support mechanism 3 is provided at both ends of the frame 1, a feeding mechanism is provided on one side of the frame 1, and a monitoring mechanism is provided on the positioning mechanism. Mechanism; The peeling mechanism 2 is provided with a grinding disc 4.

[0038] The monitoring mechanism described in this embodiment includes a visual sensor 5, a marking patch 6, a buzzer 7, and a PLC controller 8. The visual sensor 5 is provided on the positioning mechanism, and the marking patch 6 is provided for grinding. On the disc 4, the marking patch 6 covers the side surface of the grinding disc 4, t...

Embodiment 2

[0045] Such as figure 1 A grinding peeling machine for monitoring grinding disks is shown, comprising: a frame 1, a peeling mechanism 2, a positioning mechanism, a feeding support mechanism 3, a feeding mechanism, and a monitoring mechanism. The frame 1 is provided with a peeling mechanism. Mechanism 2, a positioning mechanism is provided on one side of the peeling mechanism 2, a feeding support mechanism 3 is provided at both ends of the frame 1, a feeding mechanism is provided on one side of the frame 1, and a monitoring mechanism is provided on the positioning mechanism Mechanism; The peeling mechanism 2 is provided with a grinding disc 4.

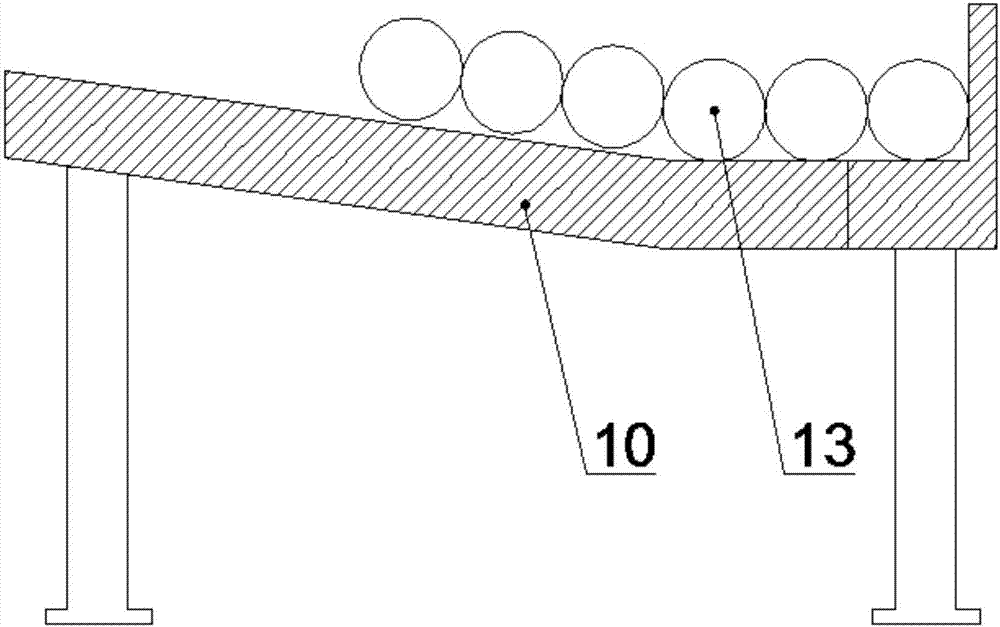

[0046] The working method of a grinding type peeling machine described in this embodiment includes: the feeding mechanism pushes the bar 13 to the peeling machine, and after positioning, the peeling machine uses the peeling mechanism 2 to peel the bar 13; Step 1: Position the bar material 13, that is, the operator places the bar material 1...

Embodiment 3

[0048] Such as figure 2 A grinding peeling machine for monitoring grinding disks is shown, comprising: a frame 1, a peeling mechanism 2, a positioning mechanism, a feeding support mechanism 3, a feeding mechanism, and a monitoring mechanism. The frame 1 is provided with a peeling mechanism. Mechanism 2, a positioning mechanism is provided on one side of the peeling mechanism 2, a feeding support mechanism 3 is provided at both ends of the frame 1, a feeding mechanism is provided on one side of the frame 1, and a monitoring mechanism is provided on the positioning mechanism Mechanism; The peeling mechanism 2 is provided with a grinding disc 4.

[0049] The monitoring mechanism described in this embodiment includes a visual sensor 5, a marking patch 6, a buzzer 7, and a PLC controller 8. The visual sensor 5 is provided on the positioning mechanism, and the marking patch 6 is provided for grinding. On the disc 4, the marking patch 6 covers the side surface of the grinding disc 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com