Ejector for a mobile ground preparation machine

一种排出器、整地机的技术,应用在道路、道路修复、道路等方向,能够解决没有强度特性、排出器难拆卸更换等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The same components are provided with the same reference numerals in the various exemplary embodiments.

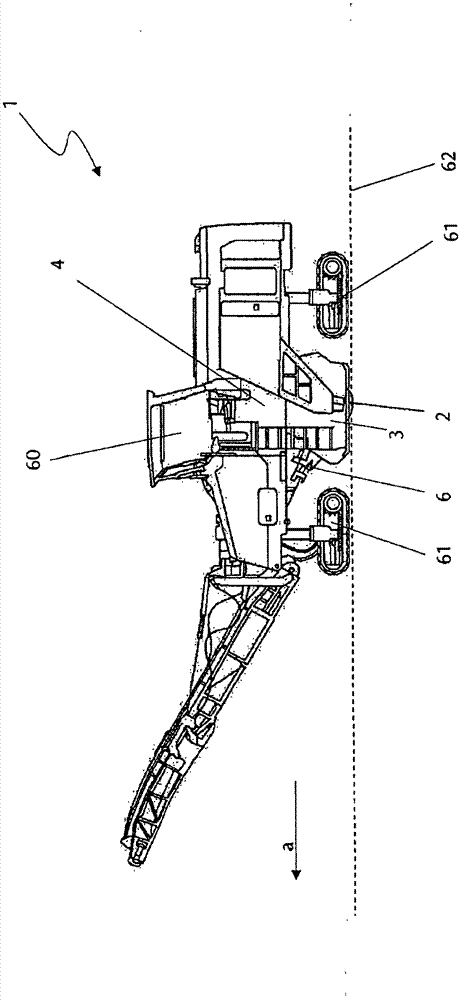

[0033] figure 1 A front-loading ground milling machine 1 is shown comprising a centrally placed milling drum 2 within a drum housing 3 . The working direction (forward direction) is indicated by arrow "a". Ground milling machine 1 also comprises machine frame 4, and this frame 4 comprises console 60 and crawler type travel device 61, and crawler type travel device 61 is installed on the machine frame 4 by lifting column, so that vertical adjustment (here can also wheeled chassis as an alternative).

[0034] In operating mode, the ground milling machine 1 travels on the ground 62 in the working direction "a" of the machine, during which ground material is milled off the ground 62 by the milling drum 2 set in rotation. Due to the rotation of the milling drum 2, the milled material is thrown from the drum shell 3 to a conveyor belt 6 communicating with the drum shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com