Patents

Literature

359 results about "Bearing wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

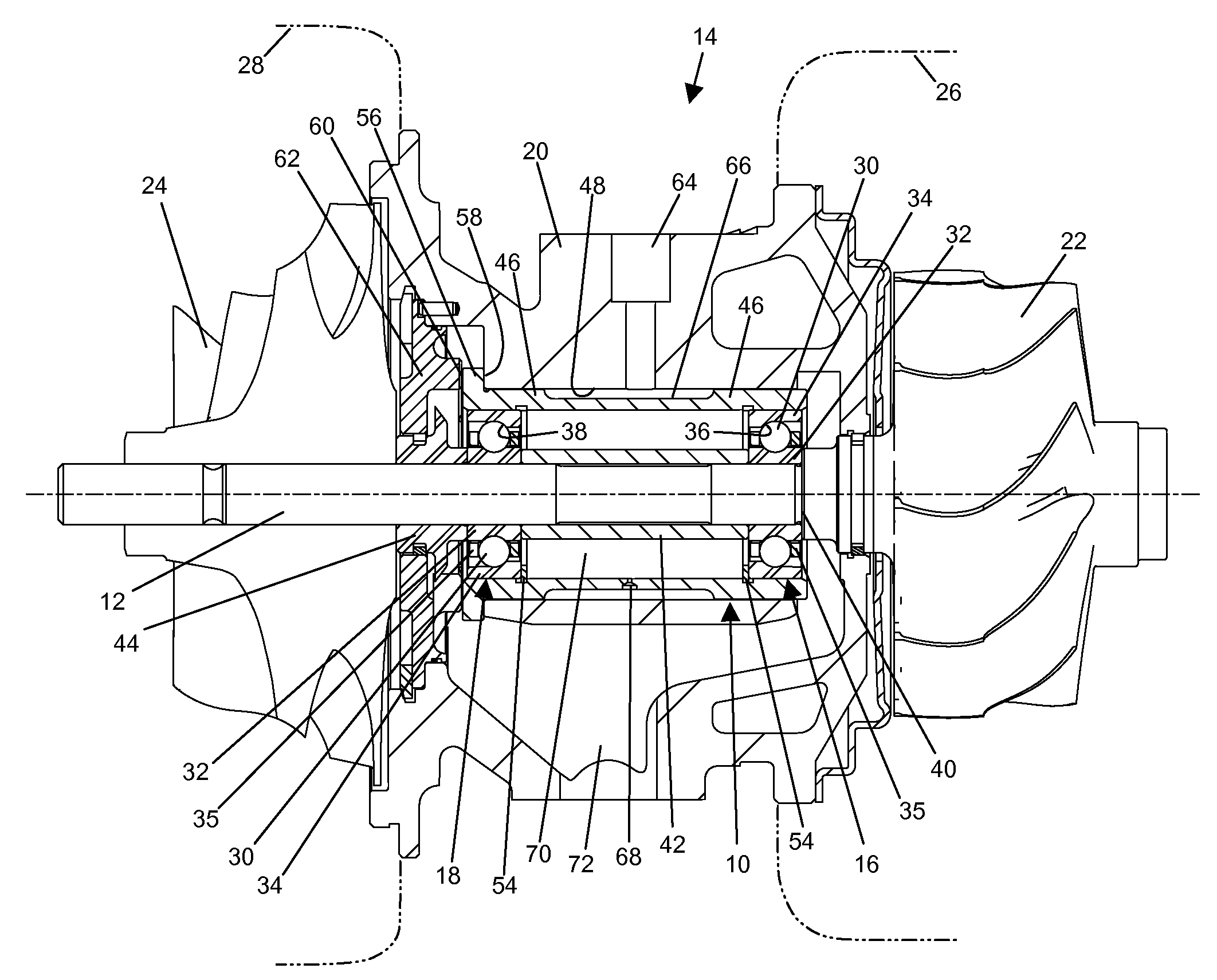

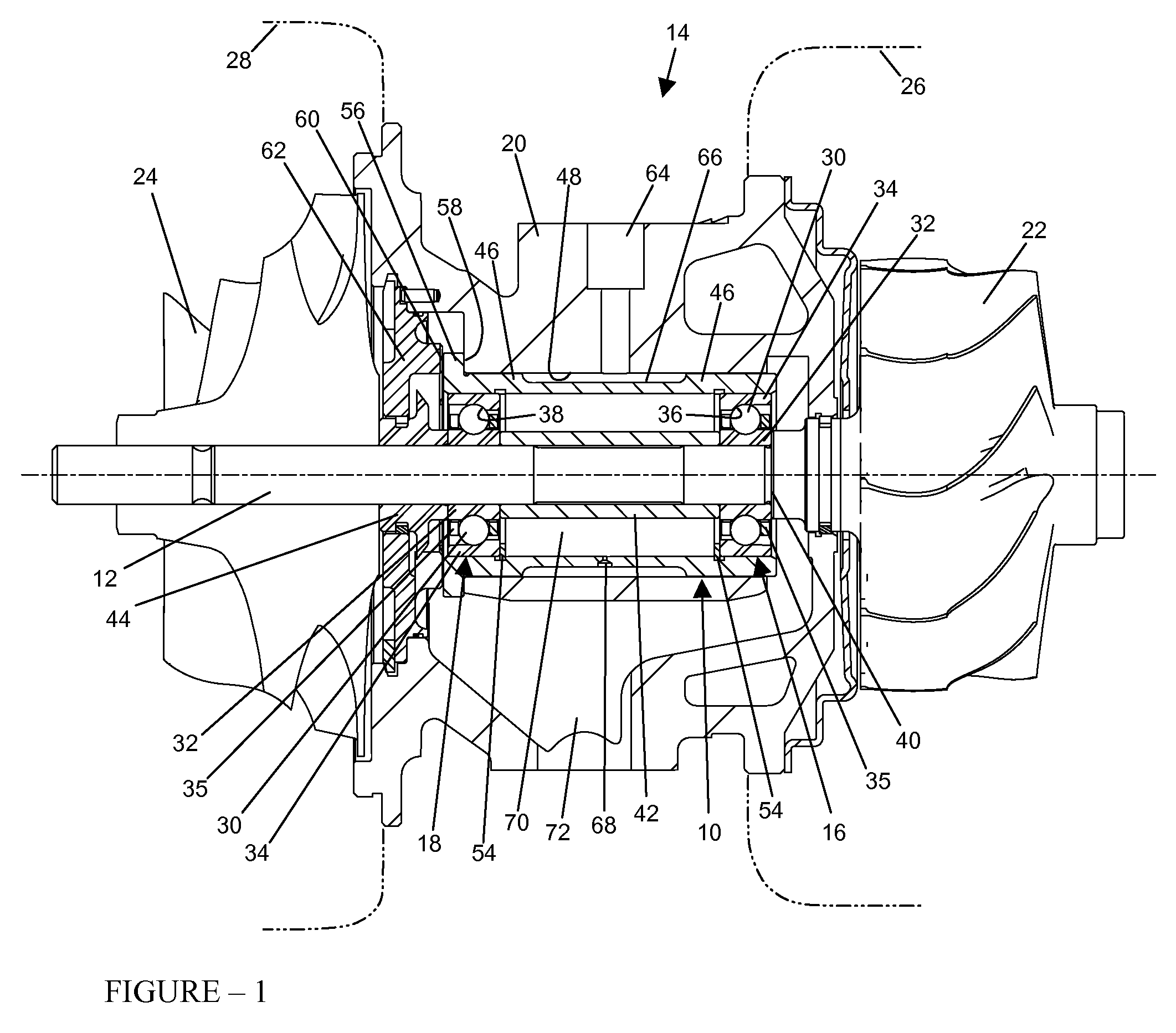

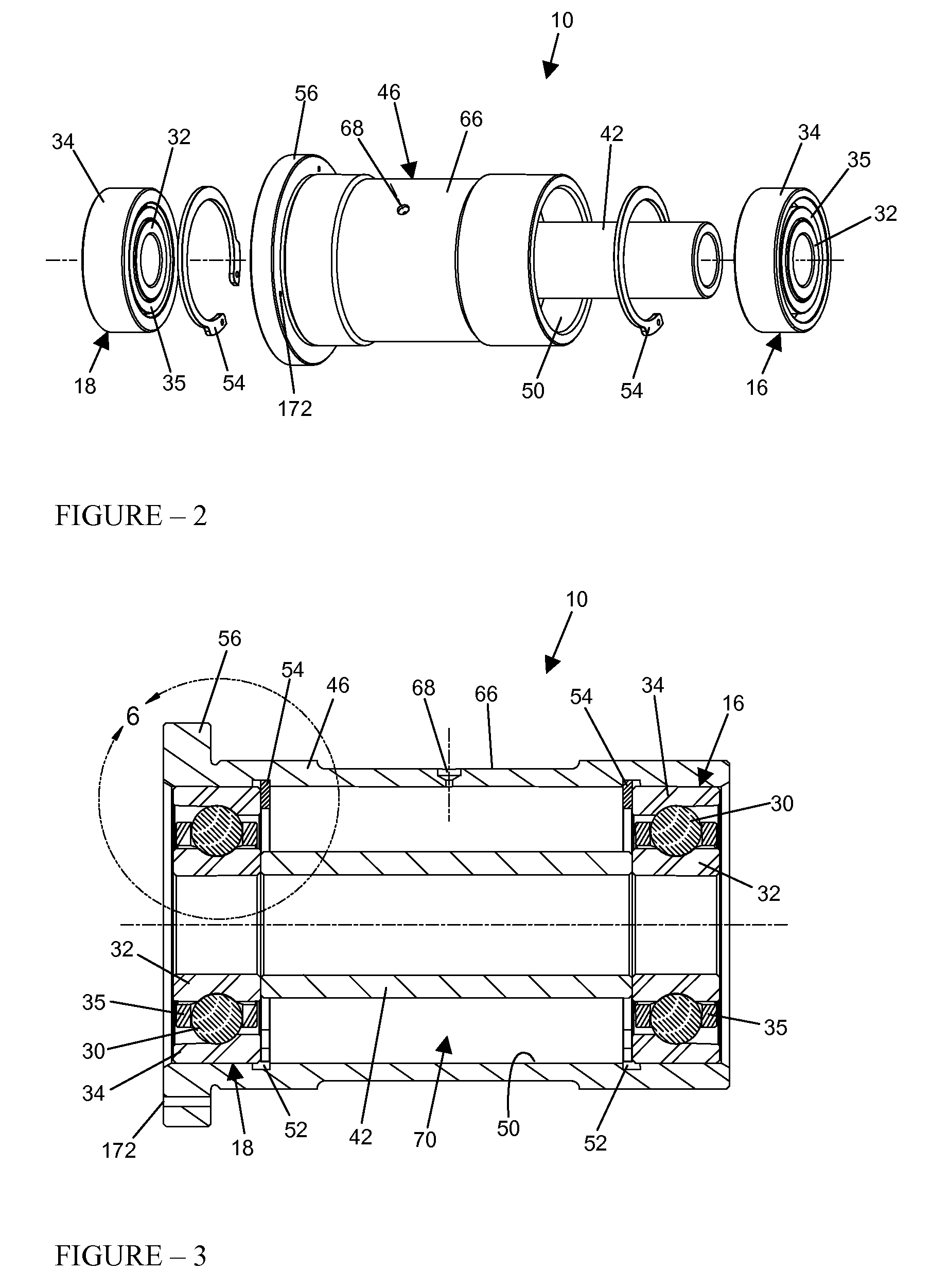

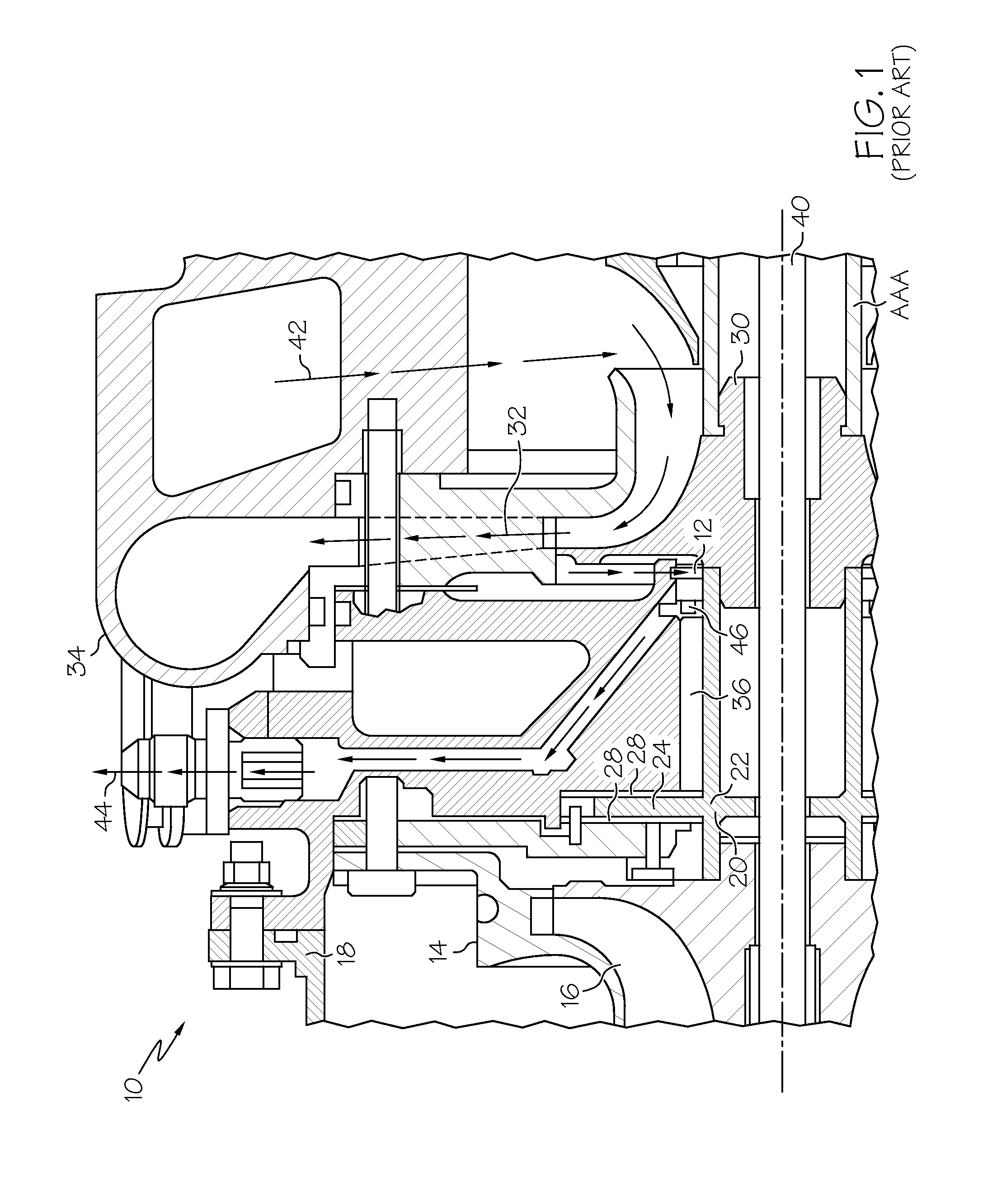

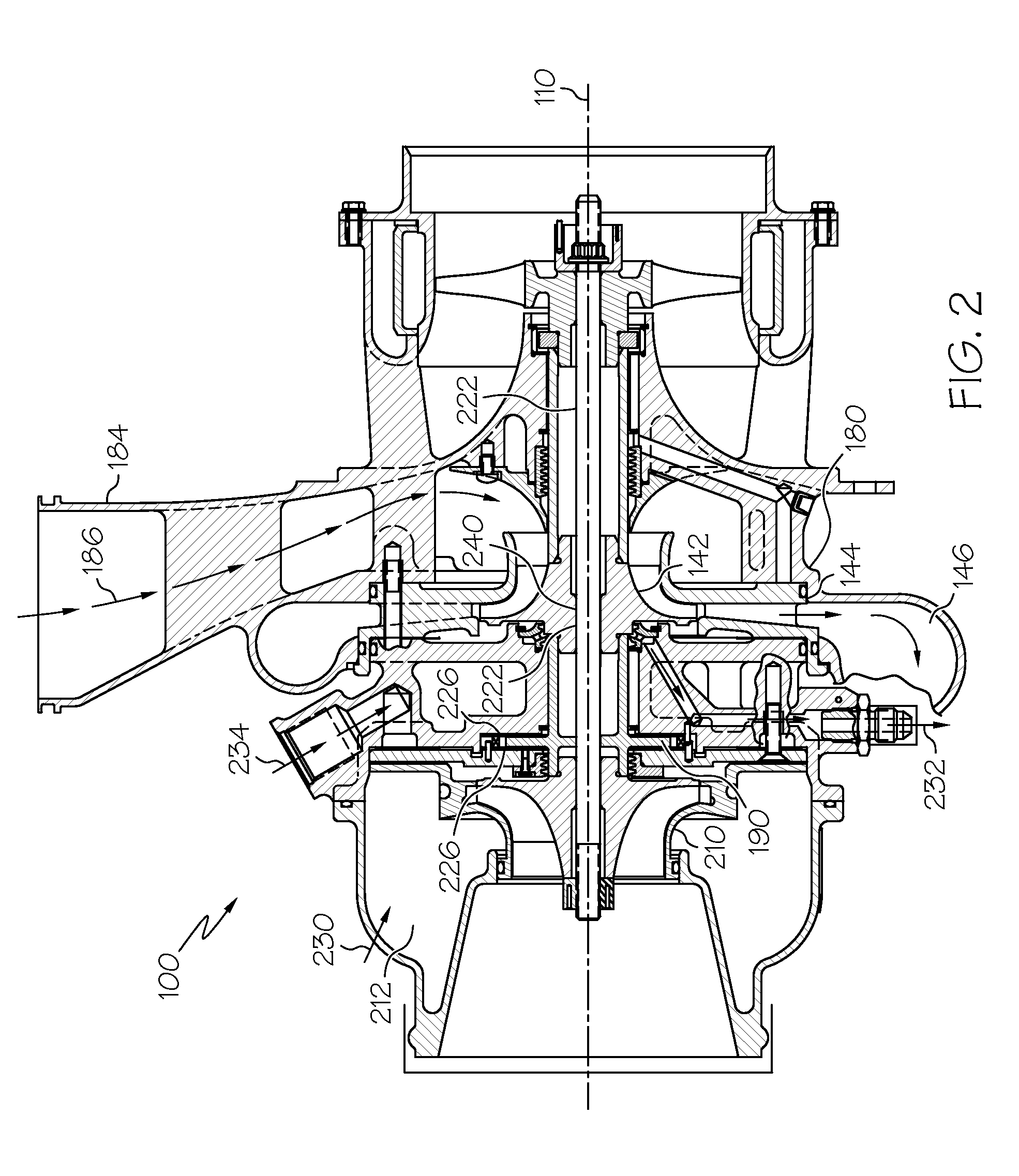

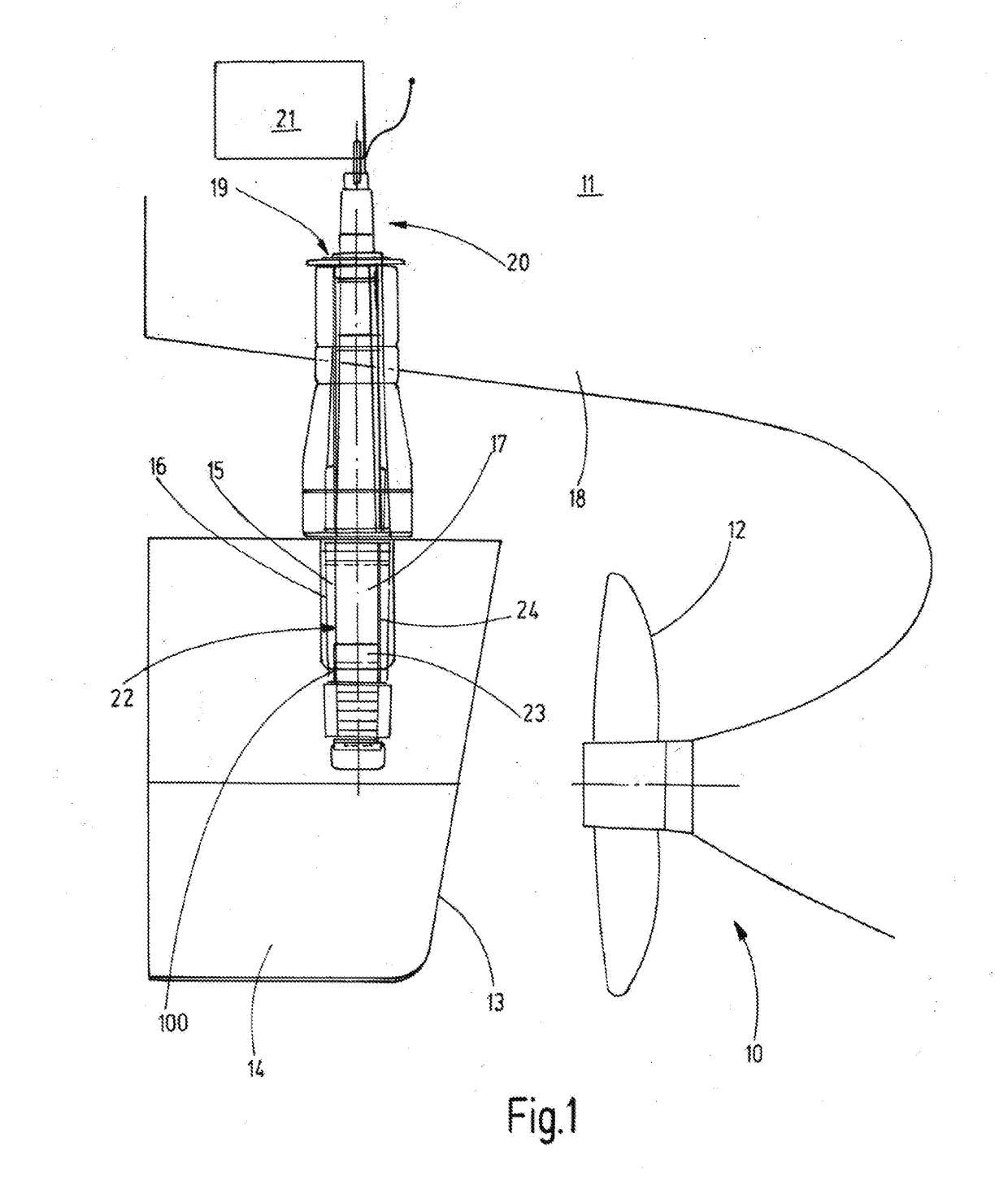

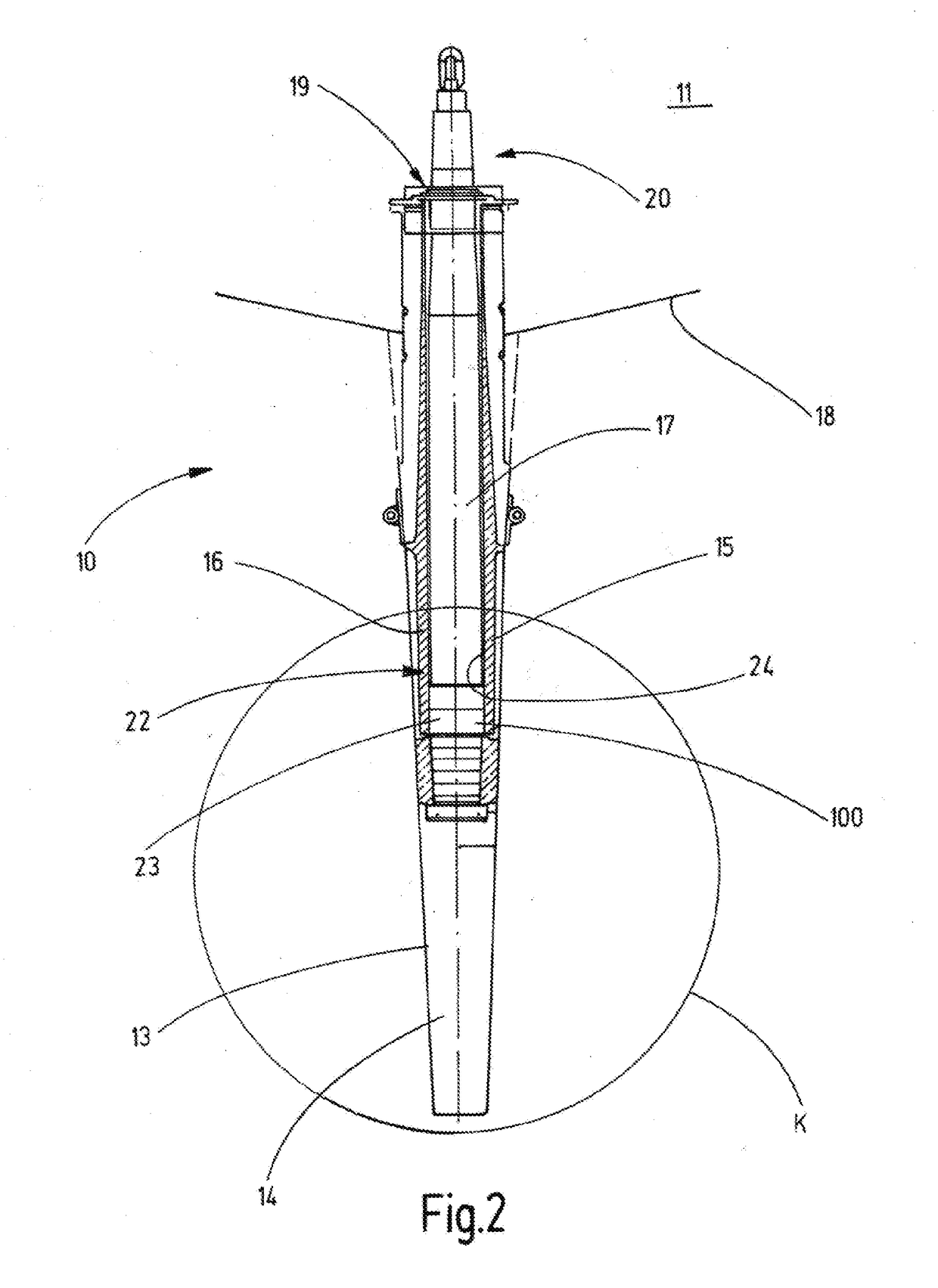

Floating bearing cartridge for a turbocharger shaft

InactiveUS20080019629A1Conducive to stable operationReduced and minimal wearRolling contact bearingsShaftsTurbochargerBearing wear

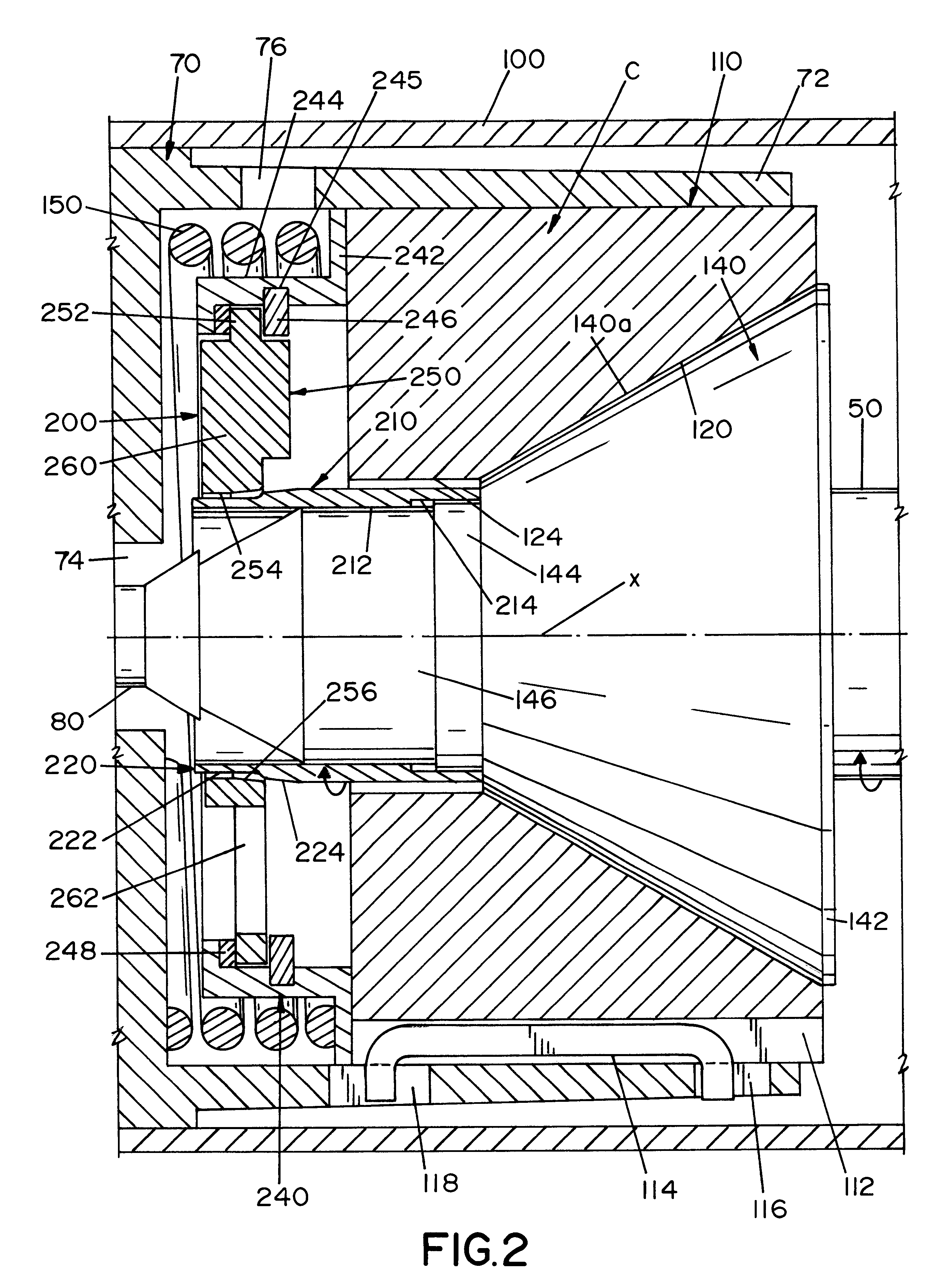

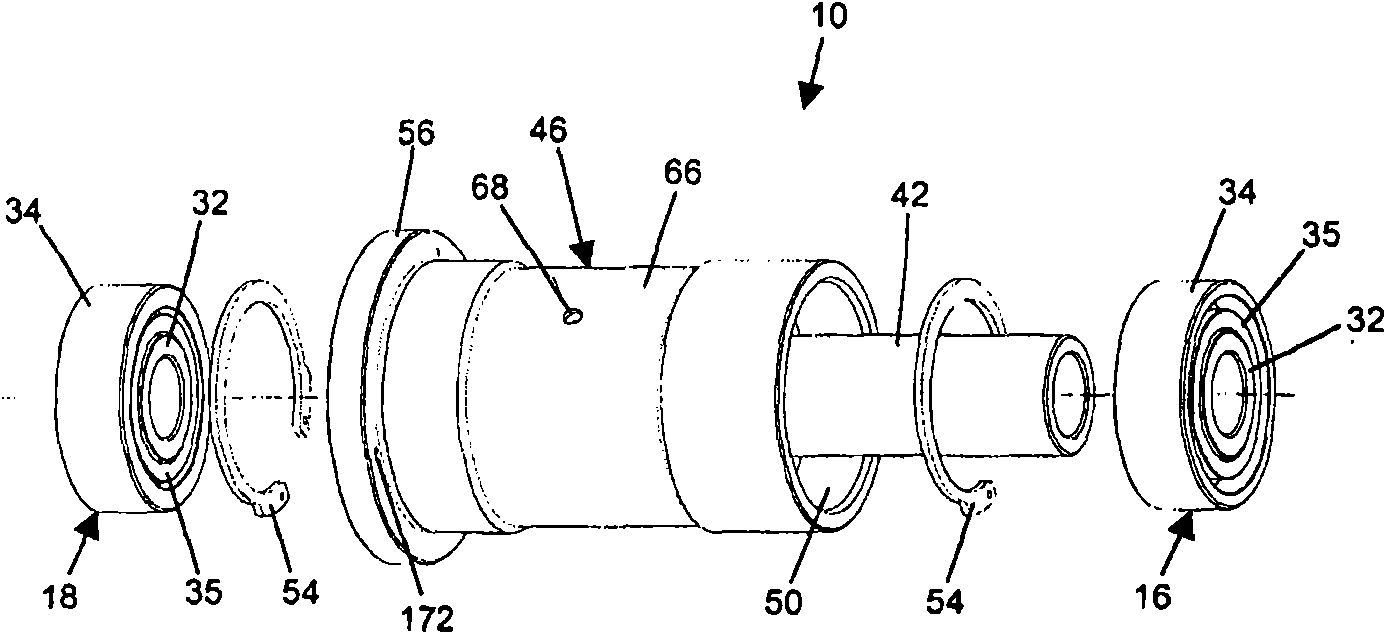

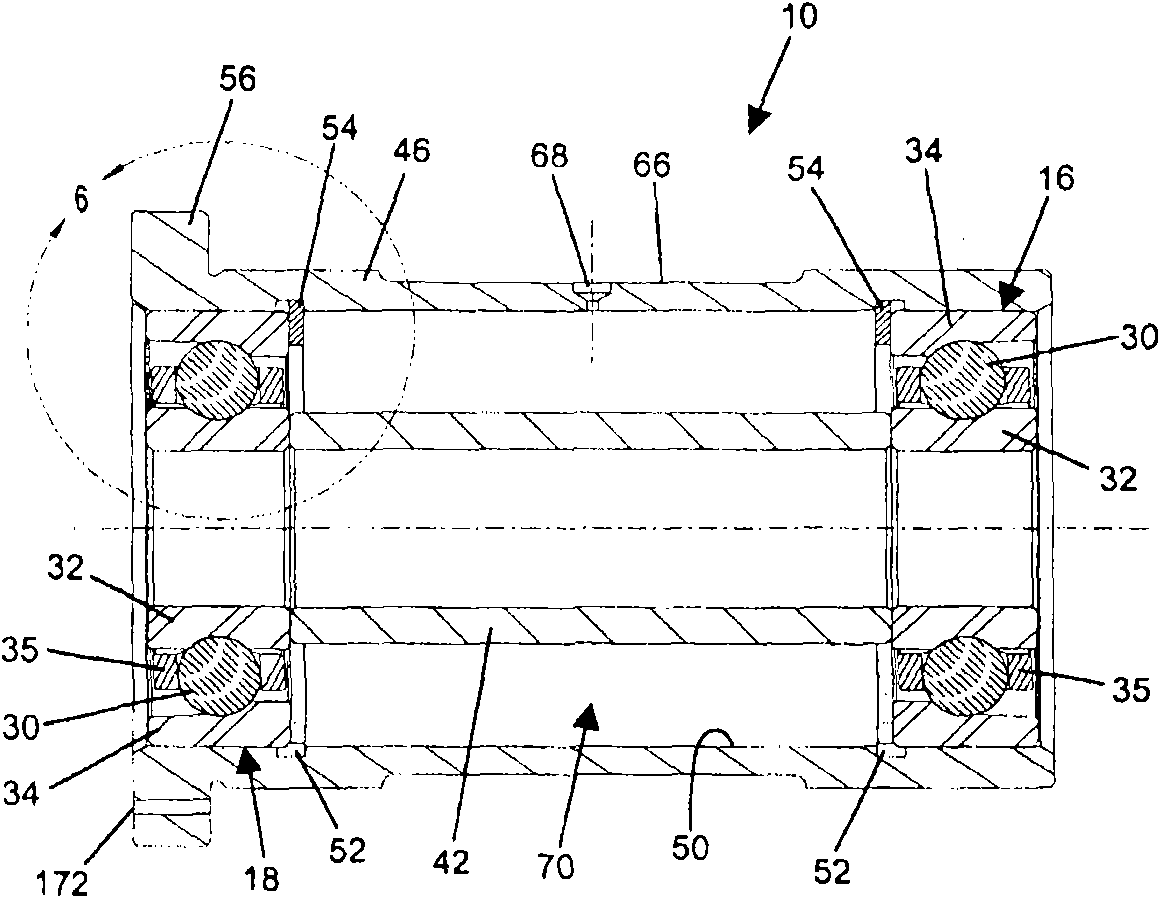

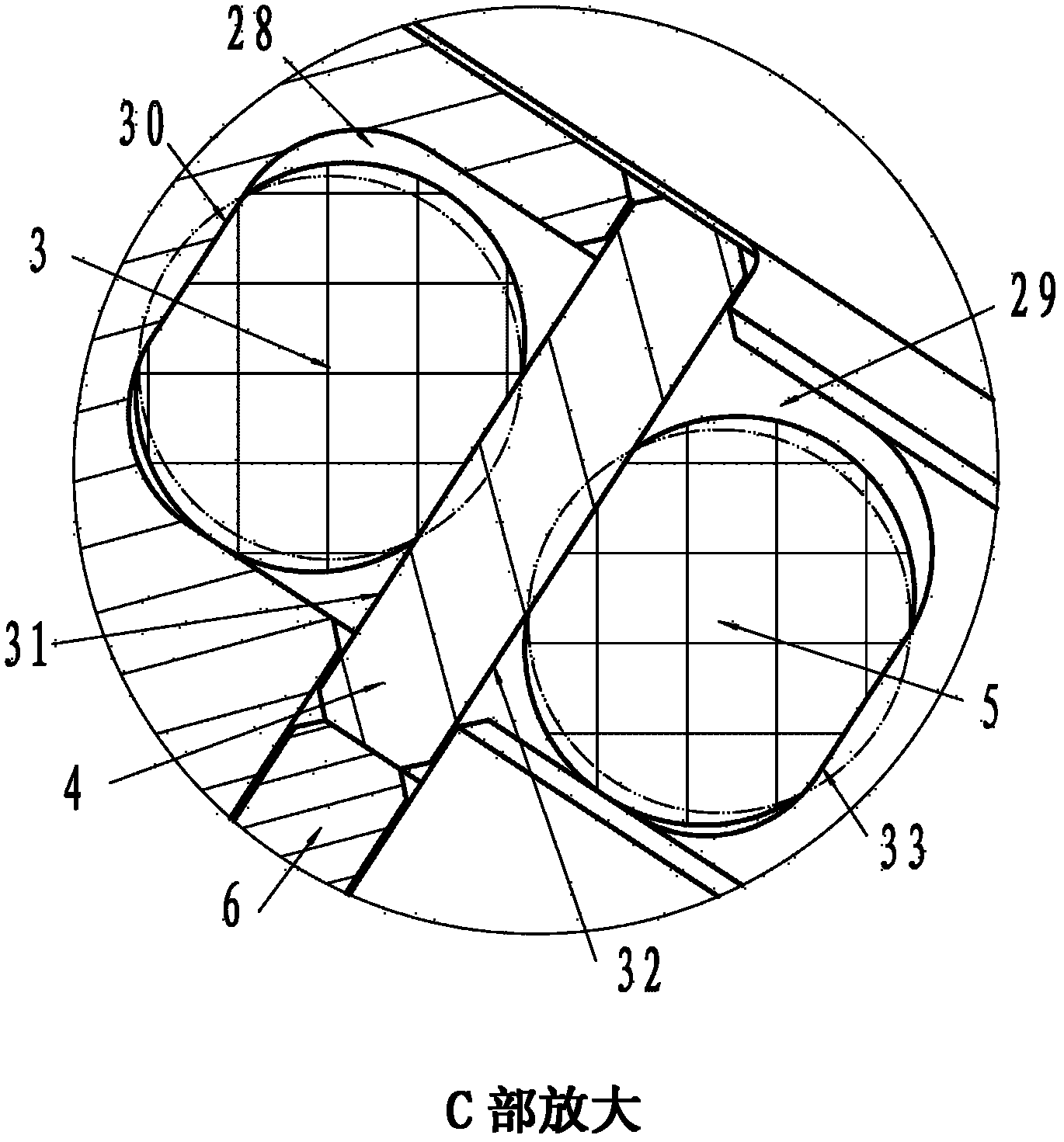

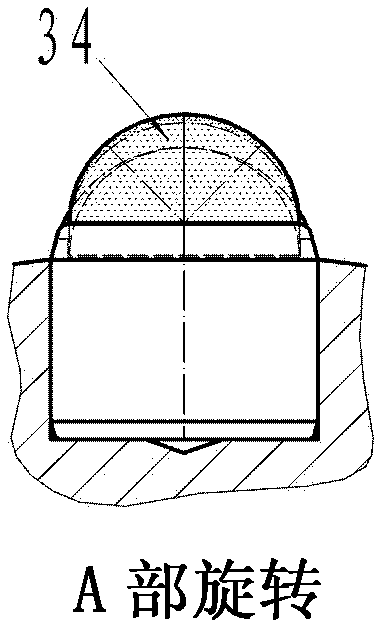

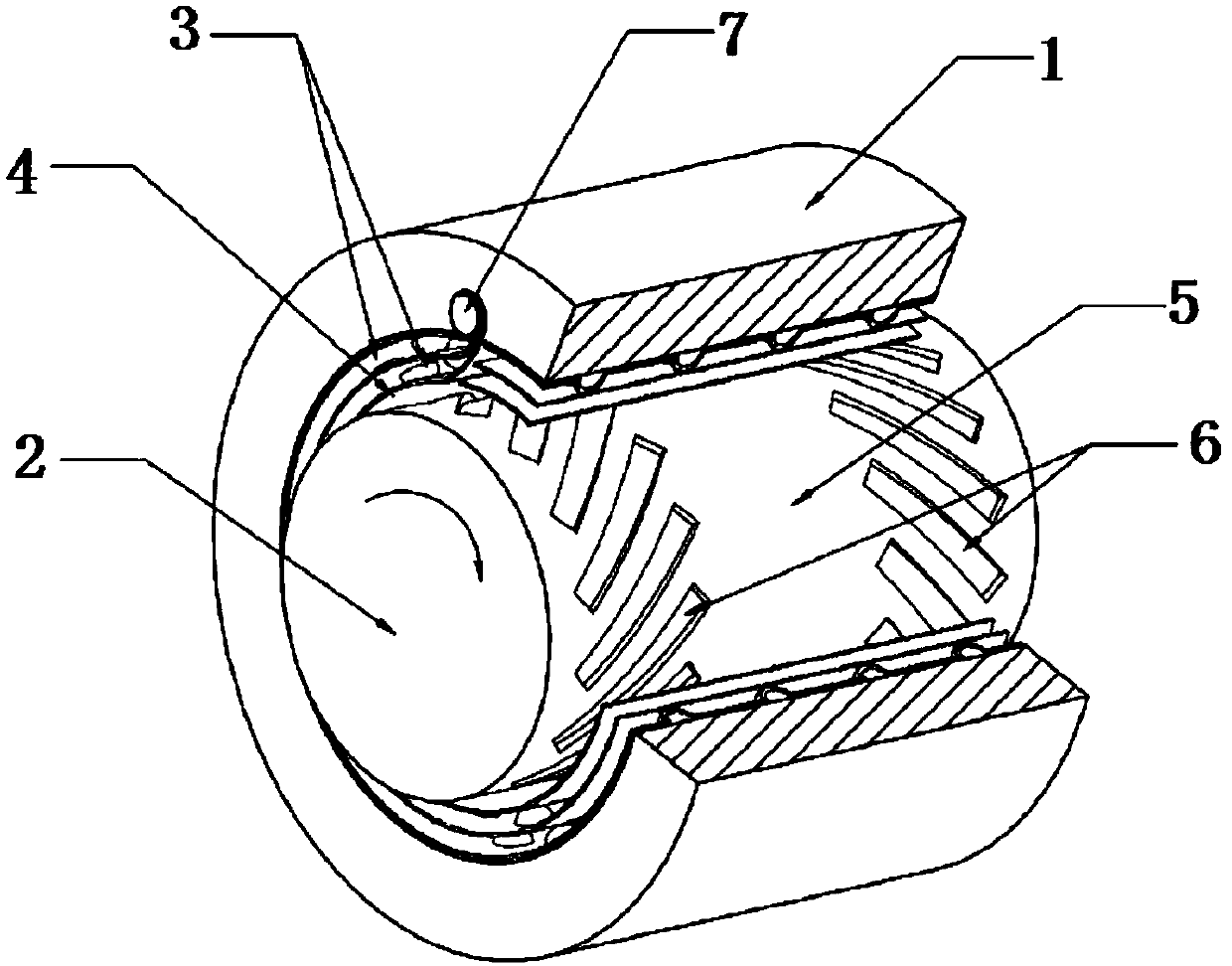

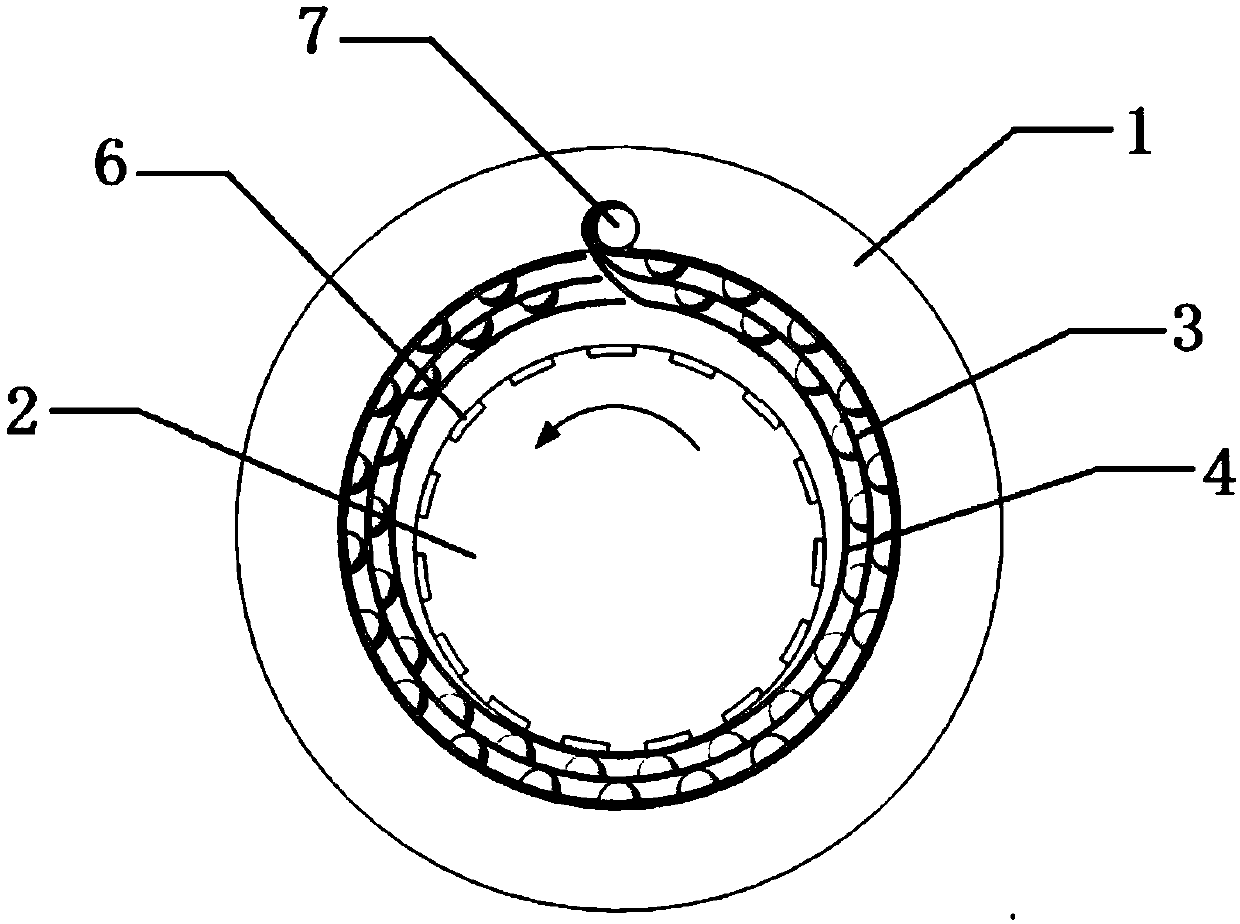

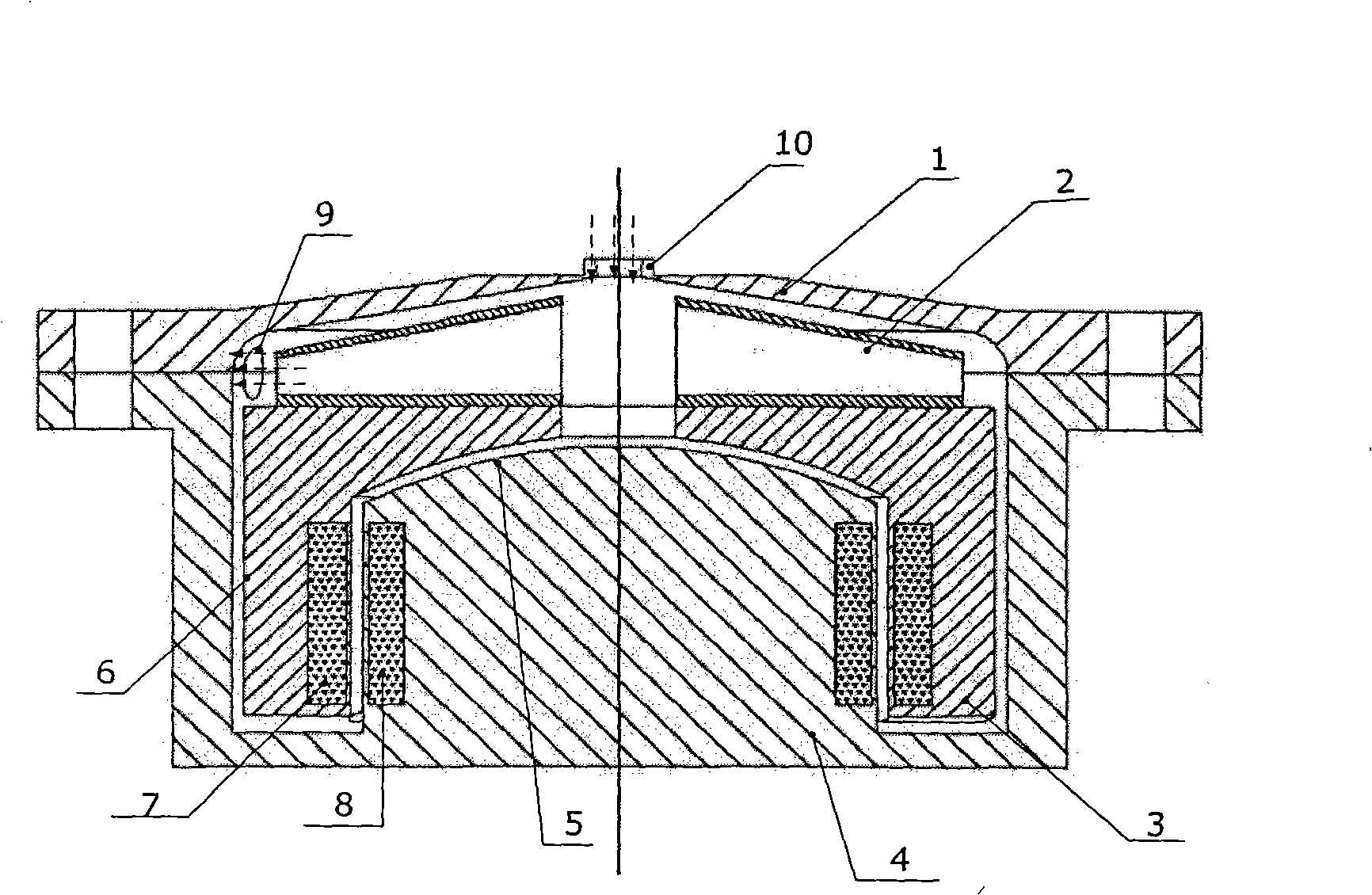

An improved bearing system for use in high speed rotating machinery, such as a turbocharger, wherein a shaft is rotatably supported by a floating bearing cartridge having axially spaced angular contact bearings each with a set of bearing balls supported between inner and outer races. The bearing cartridge includes an inner spacer sleeve for axially spacing the inner bearing races, and a rotationally floating outer sleeve having a pair of radially inwardly open grooves for removably receiving snap-type retaining rings which engage and axially space the outer bearing races. The axial dimension of the inner spacer sleeve is elongated slightly relative to an axial dimension defined between outboard faces of the installed retaining rings, thereby slightly unloading the sets of bearing balls from their respective outer bearing races. Such slight axial unloading enhances smooth-running operation with minimal bearing wear, while accommodating transient loads during operation.

Owner:CPI HLDG

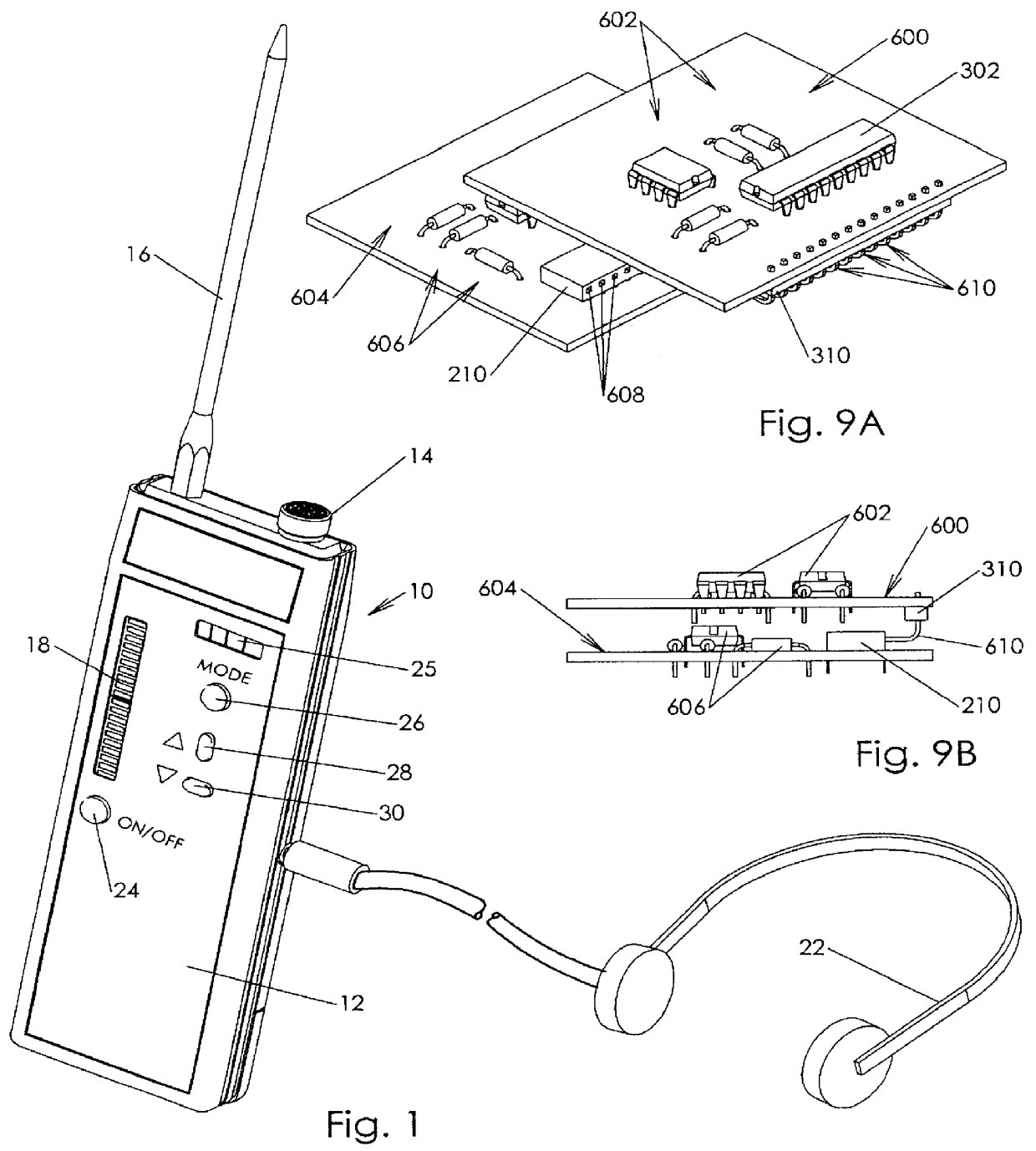

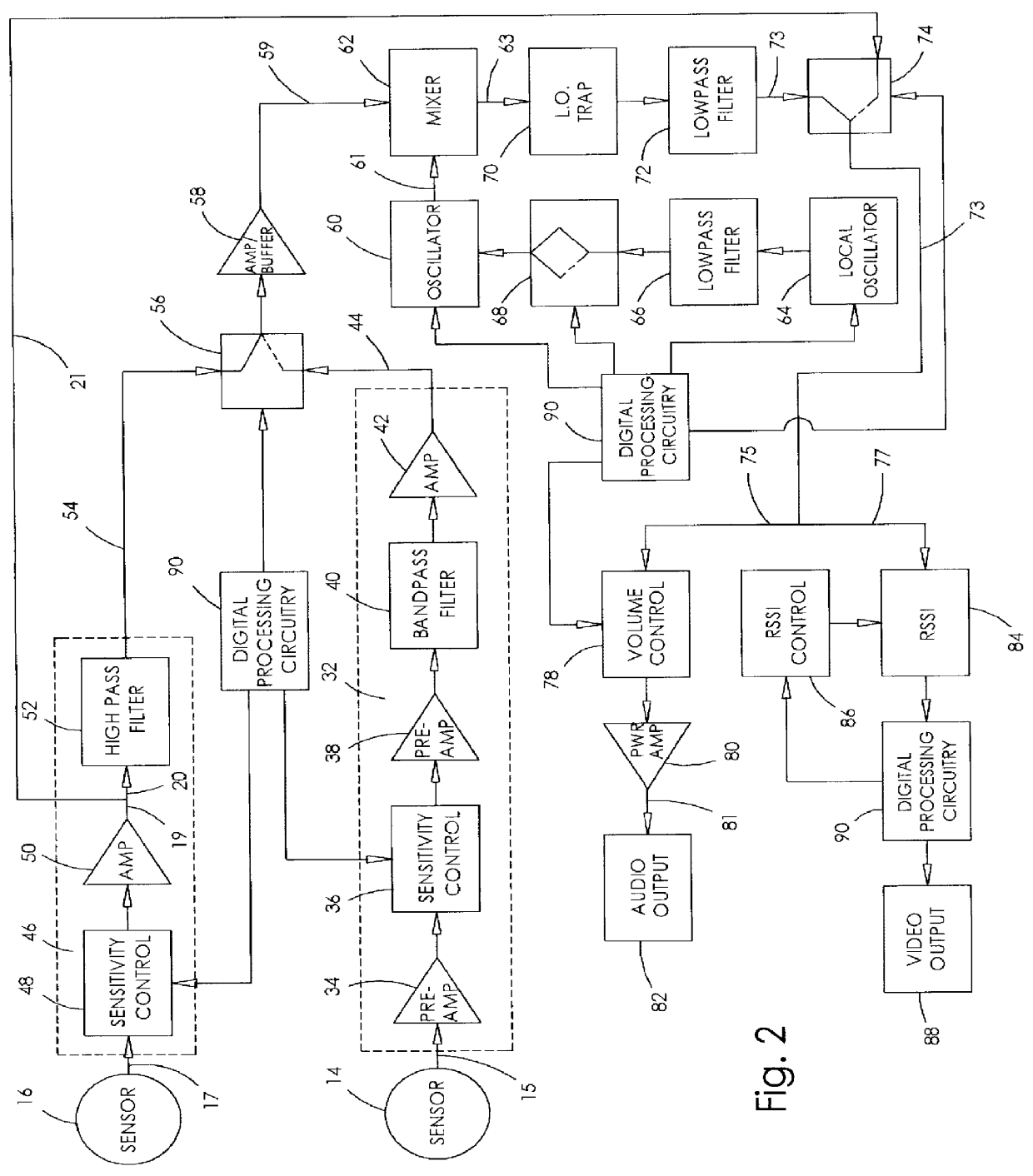

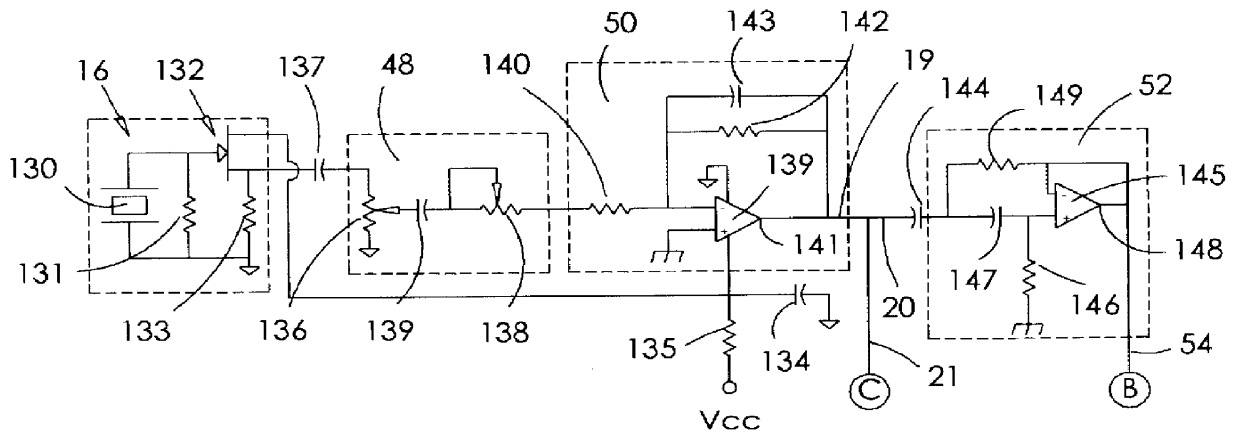

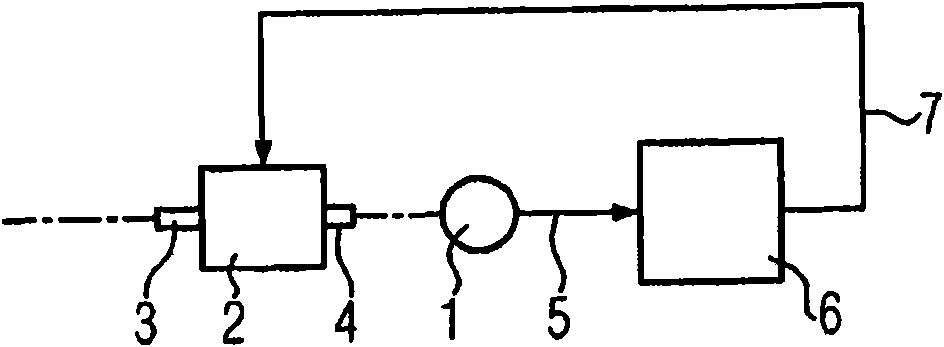

Signal detector and method for detecting signals having selected frequency characteristics

InactiveUS6058076ALow production costSmall and portableVibration measurement in solidsVibration measurement in fluidSonificationTarget signal

The present invention generally relates to procedures and apparatus for monitoring incoming signals to detect the presence of selected target signals contained within the universe of signals received. More particularly, the present invention is directed to monitoring audio signals to detect selected ultrasonic and sonic signals in an ambient environment. Thus, the present invention is even more specifically directed to leak detectors and bearing wear indicators and methods for detecting sound signals which either travel in the air or are present in solids.

Owner:RADIAULICS

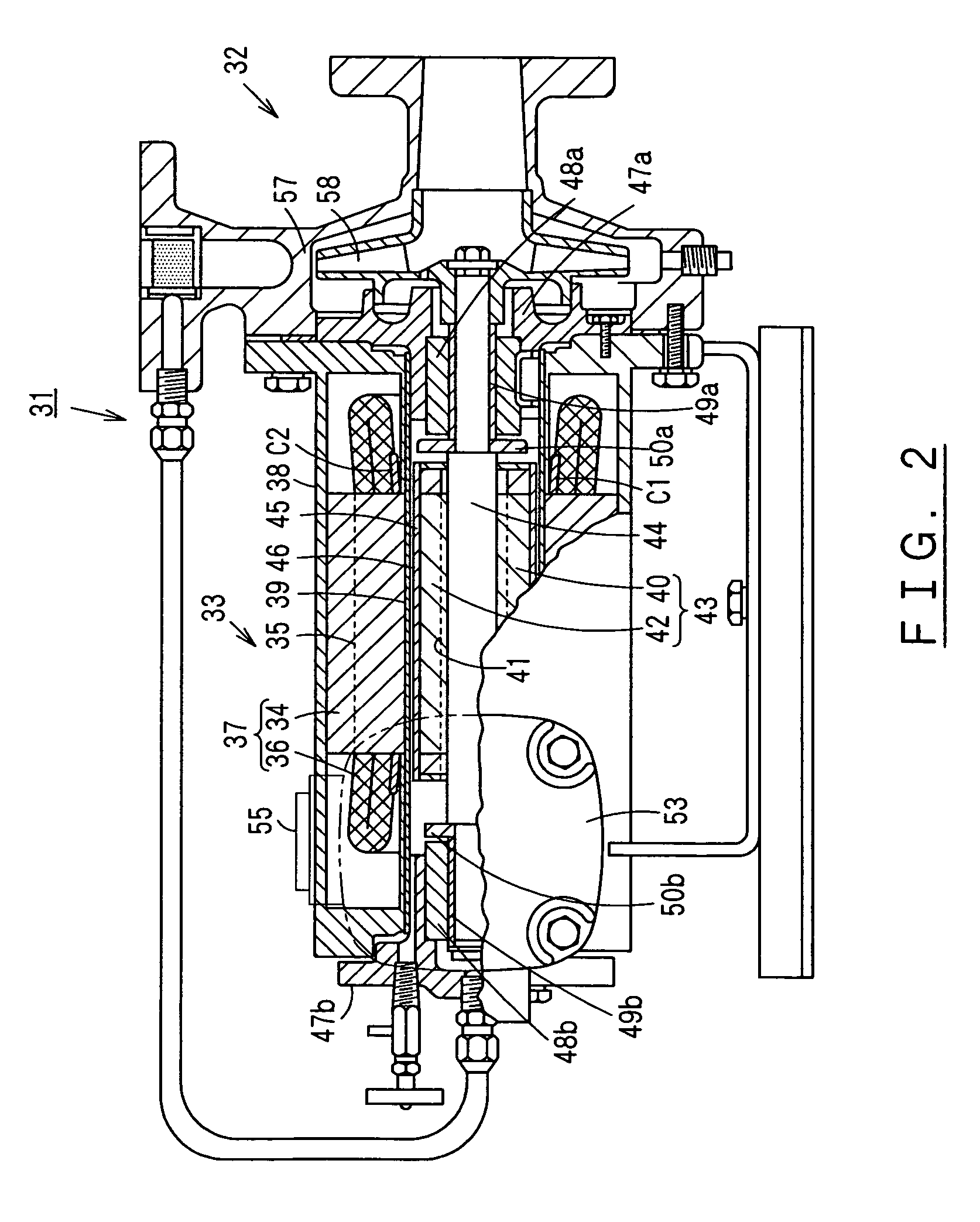

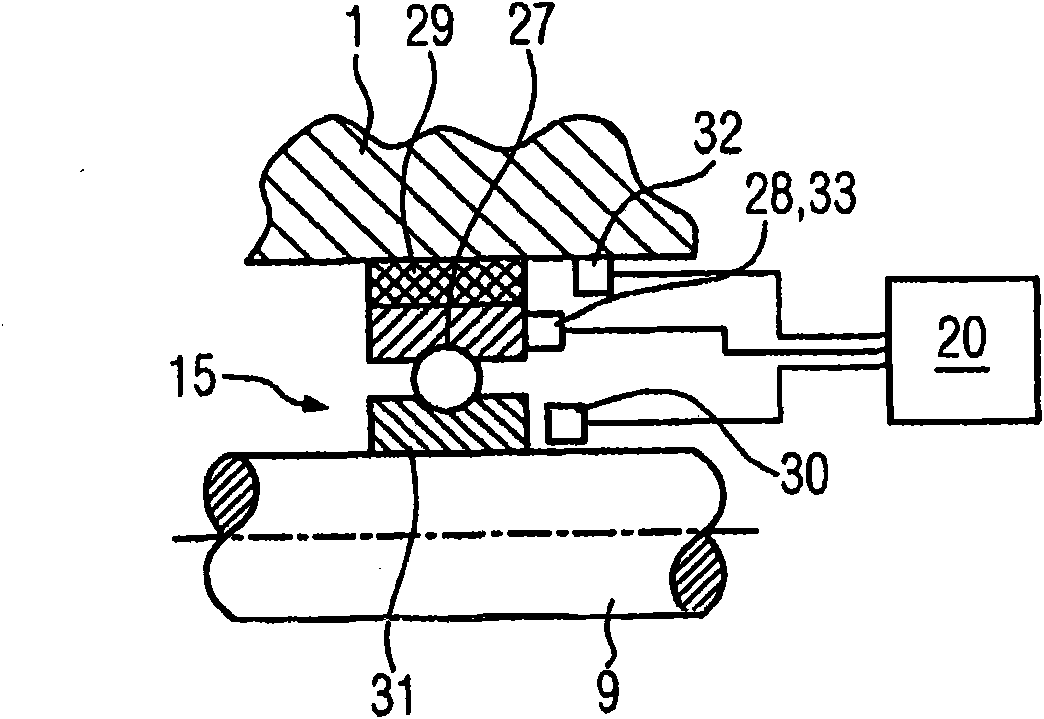

Rotary pump with bearing wear indicator

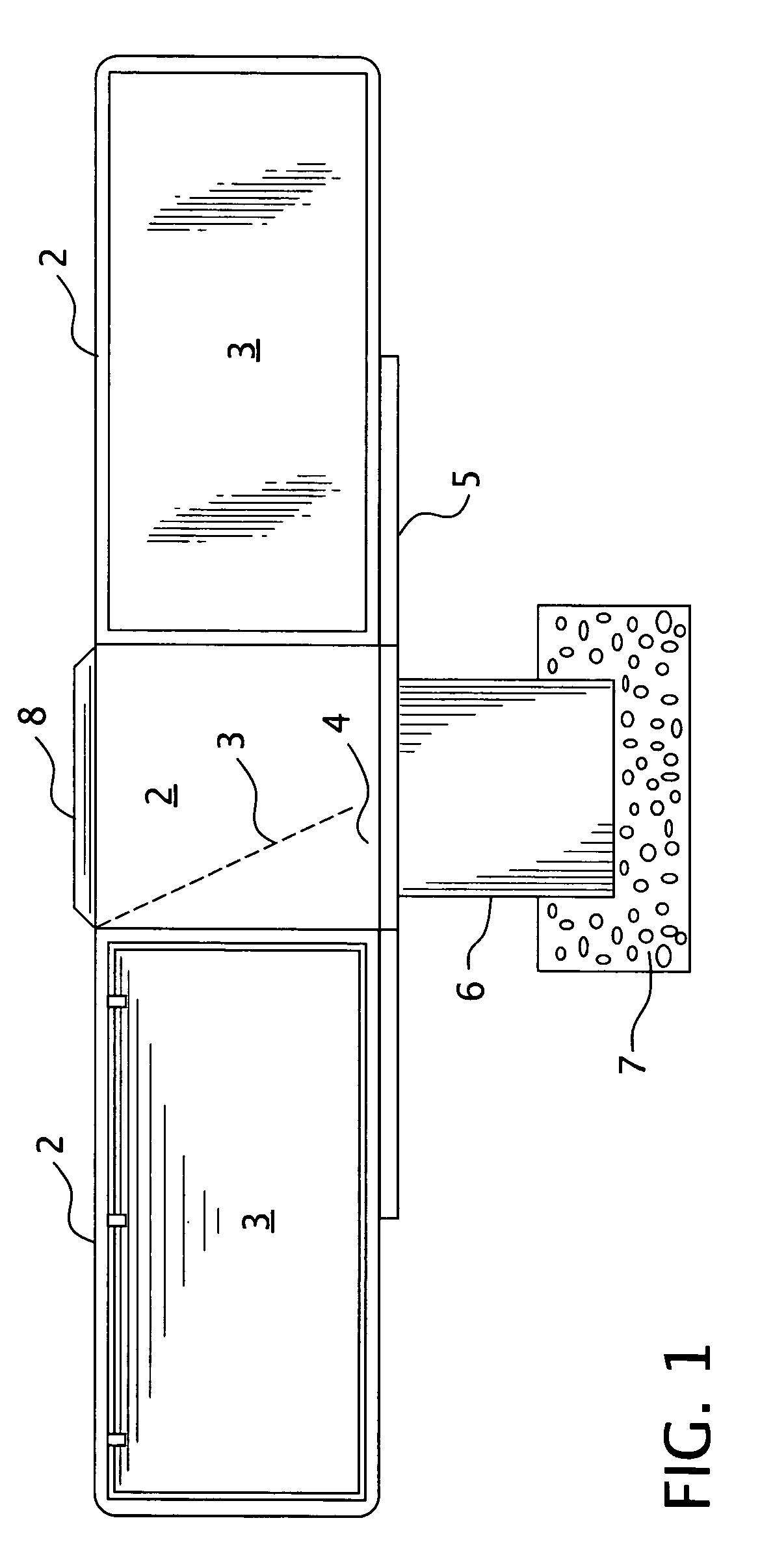

InactiveUS6617731B1Avoid catastrophic failureImprove vibrationBearing assemblyPumpsRotary pumpSpring force

A rotary pump for liquid having a housing, a shaft carrying a motor rotor, a motor stator fixed in the housing and surrounding the rotor to rotate the rotor and shaft about an axis. The shaft is mounted in the pump housing by axially spaced conical bearings, each bearing including a first element fixed on the shaft with a first conical bearing surface concentric with the axis, a coacting second element carried by the housing with a second conical bearing surface concentric with the axis and slidably engaging the first bearing surface and a spring forcing the elements together. This pump includes a wear indicator comprising: a first drive member on the shaft, an imbalance member carried with the second element of a bearing with a second drive member aligned with the first member and movable axially toward the first drive member as the bearing surfaces wear so the first and second drive members engage when the imbalance member moves axially a given distance. A sensor detects vibrations caused by rotation of the imbalance member by the shaft.

Owner:AIR & LIQUID SYST LLC

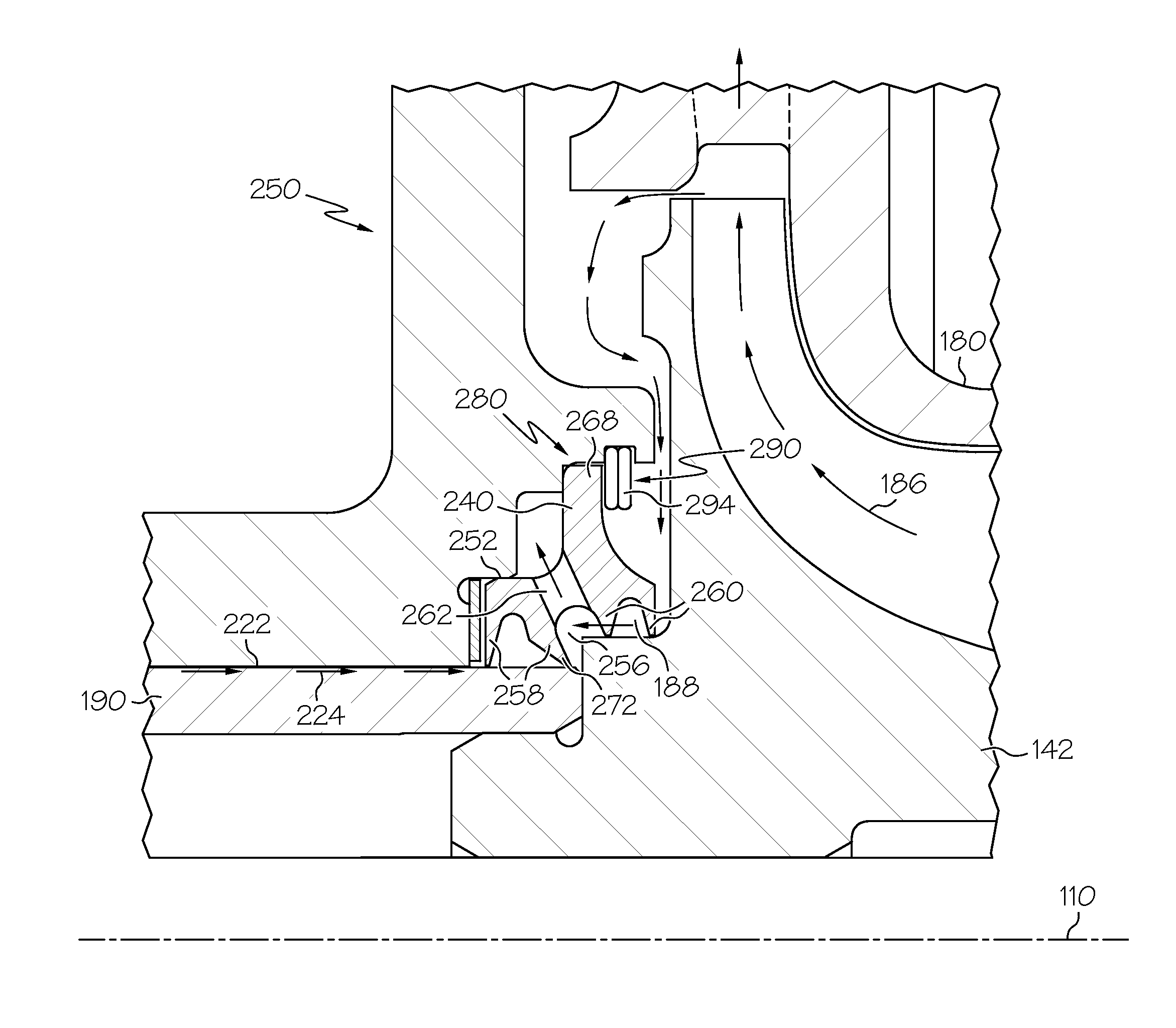

Contaminant-deflector labyrinth seal and method of operation

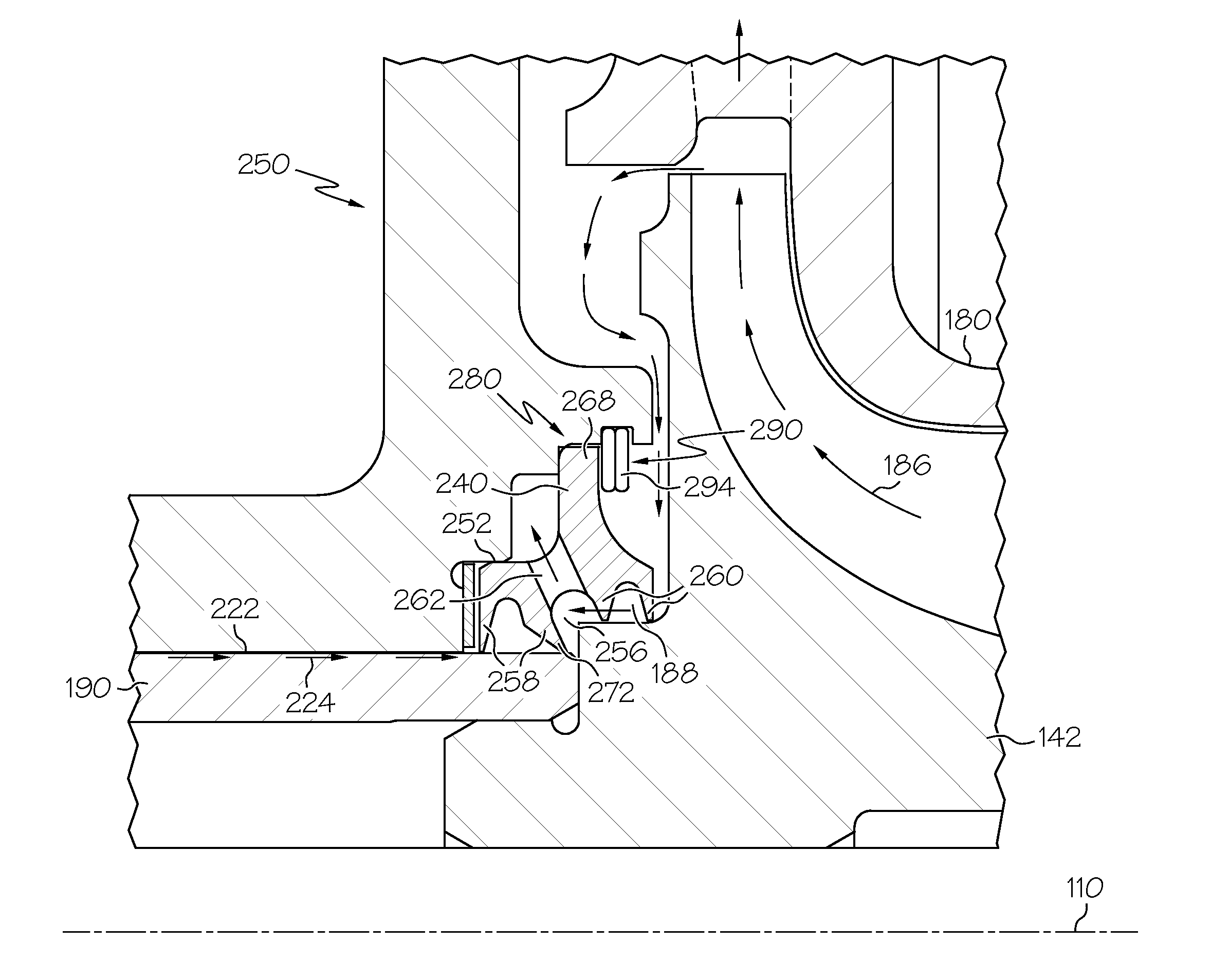

ActiveUS20090274548A1Avoid problemsAvoid componentsEngine sealsPump componentsAir bearingBearing wear

A seal assembly for deflecting contaminated fluid flowing through the seal assembly from an upstream space to a downstream space includes an annular housing, at least one vent hole peripherally disposed on the annular housing, a first set of seals disposed within the annular housing adjacent to the downstream space, the first set of seals having an inclined surface to deflect the flow of contaminated fluid through the at least one vent hole, and a second set of seals mounted on the shaft, disposed within the annular housing, adjacent to the first set of seals and adjacent to the upstream space. The second set of seals may have larger inside diameter than the first set of seals. The seal assembly may prevent contaminated fluid from entering an air bearing cooling circuit, thereby preventing bearing wear, erosion and failure.

Owner:HONEYWELL INT INC

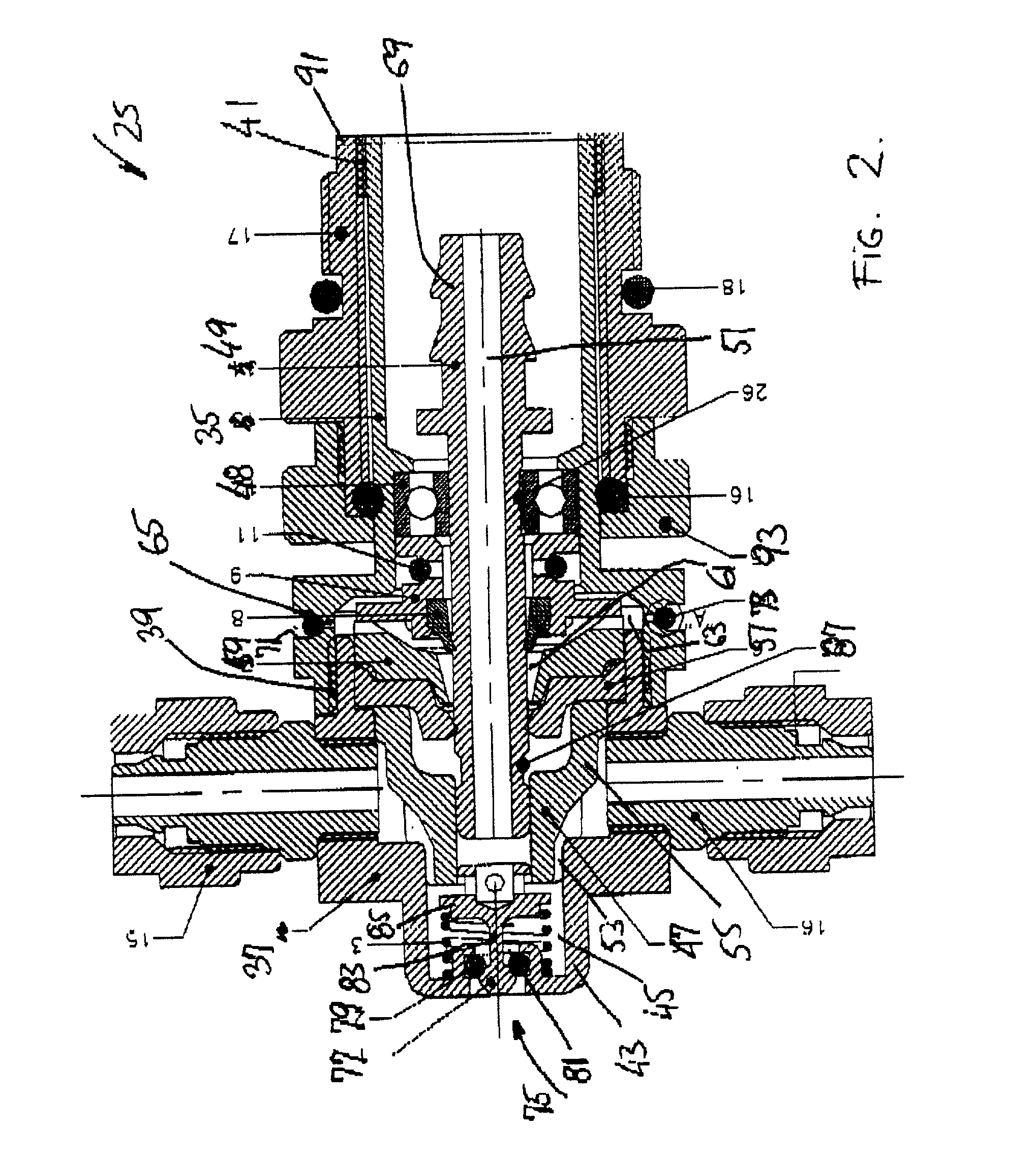

Pneumatic rotary wheel coupling with early wheel bearing wear warning

InactiveUS20020124926A1Increased sensitivityImprove protectionTyre measurementsTyre-inflating valvesBearing wearEngineering

A pneumatic rotary coupling (25) for an air pressure installation for one or more wheels of a vehicle. The coupling's tube (49) has one end formed in the shape of a nozzle which extends in the plane of the wheel, disposed as an axial extension of the wheel's axle end. The tube is located rotary and slidable inside block (35) that is fixed to the wheel's hub cover. A cover (37) fixed to the block presents a chamber (45) with an edge that defines a seat for a plastic bushing (47) that supports the coupling's tube. The external surface of this bushing is conformed by grooves (53) that communicate the chamber towards the orifices linking with the tires. The coupling includes a valve (75) that is pushed open by the tube in the event of outward wheel offset, thereby depressurizing the chamber. The tube further includes grooves (87) for bypassing a seal (57) in the event of inward wheel offset, thereby depressurizing the chamber through a vent opening (65). In either case, the chamber depressurization signals the fault to the driver. The vent opening is in a circumferential recess (71) for housing an o-ring (73) that prevents dust, dirt and other undesirable particles from entering the coupling and the wheel bearings.

Owner:COL VEN

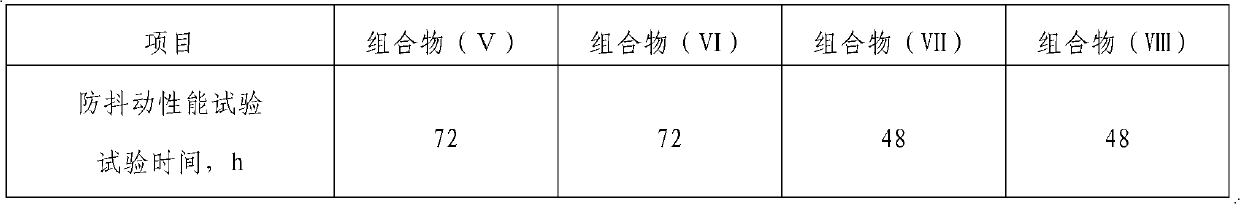

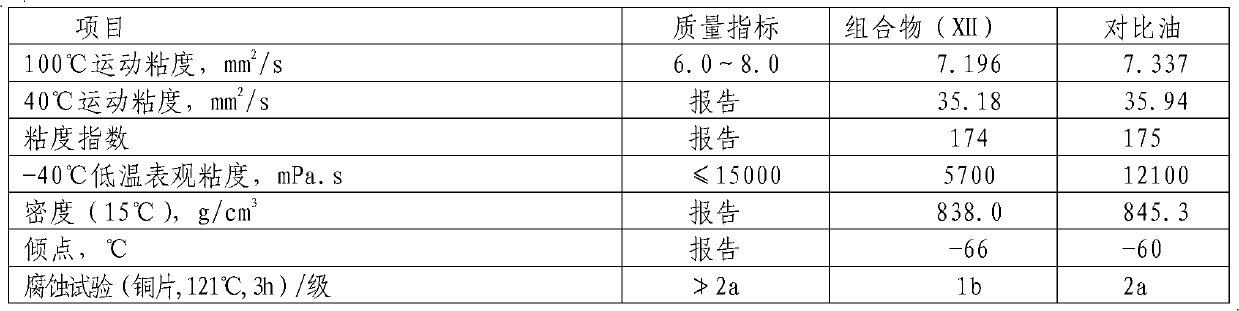

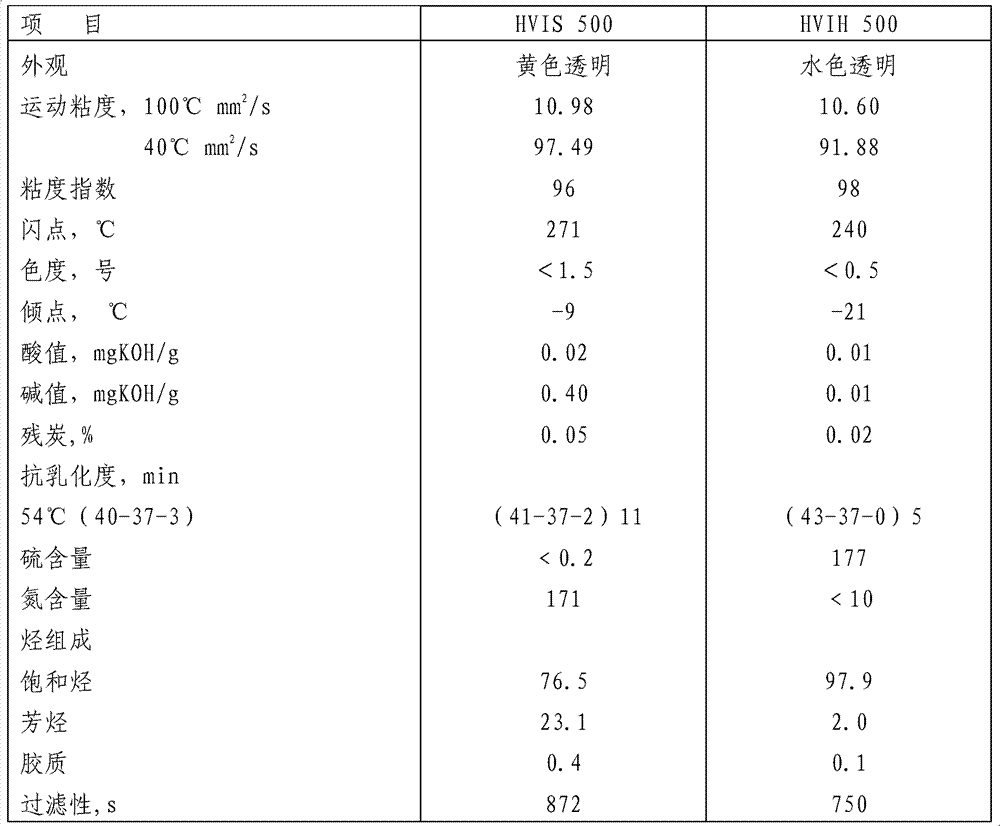

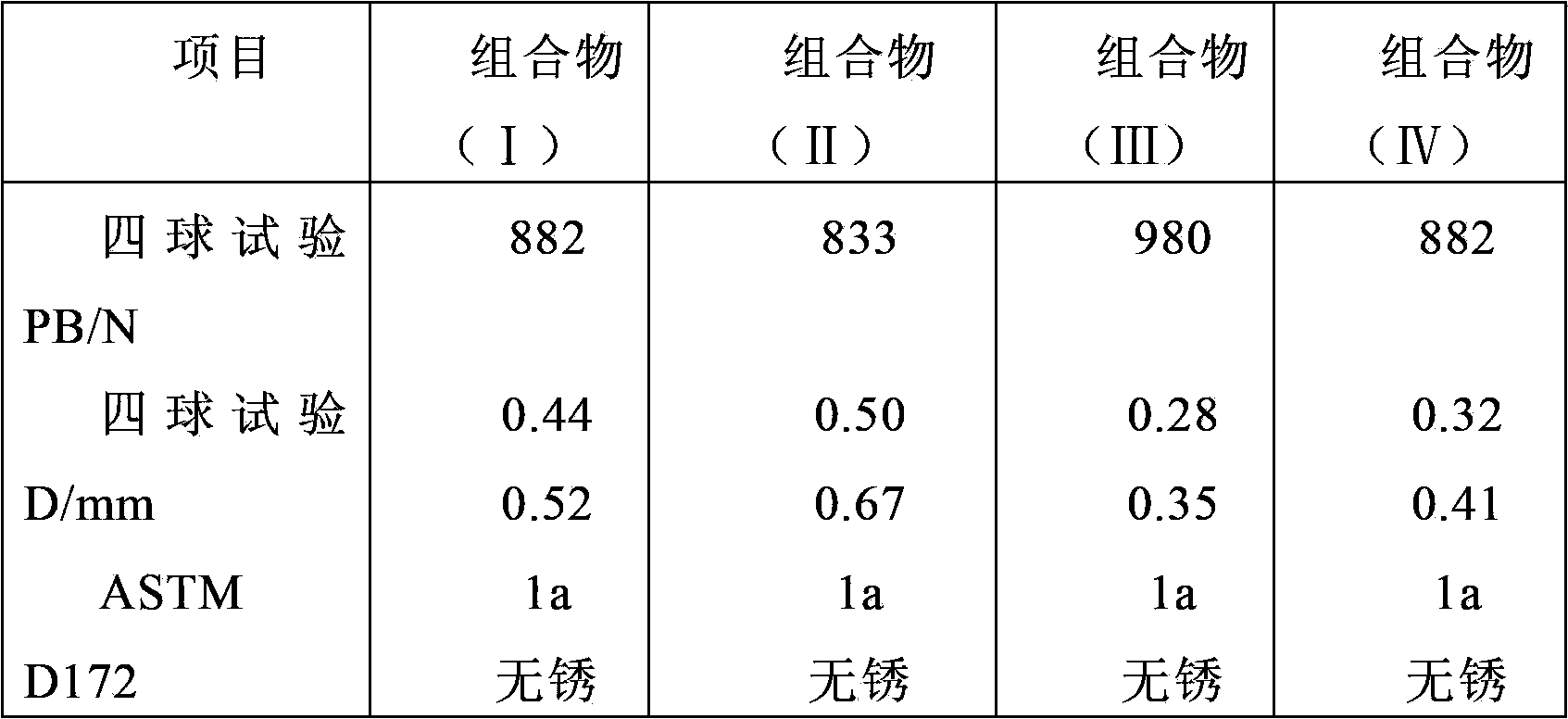

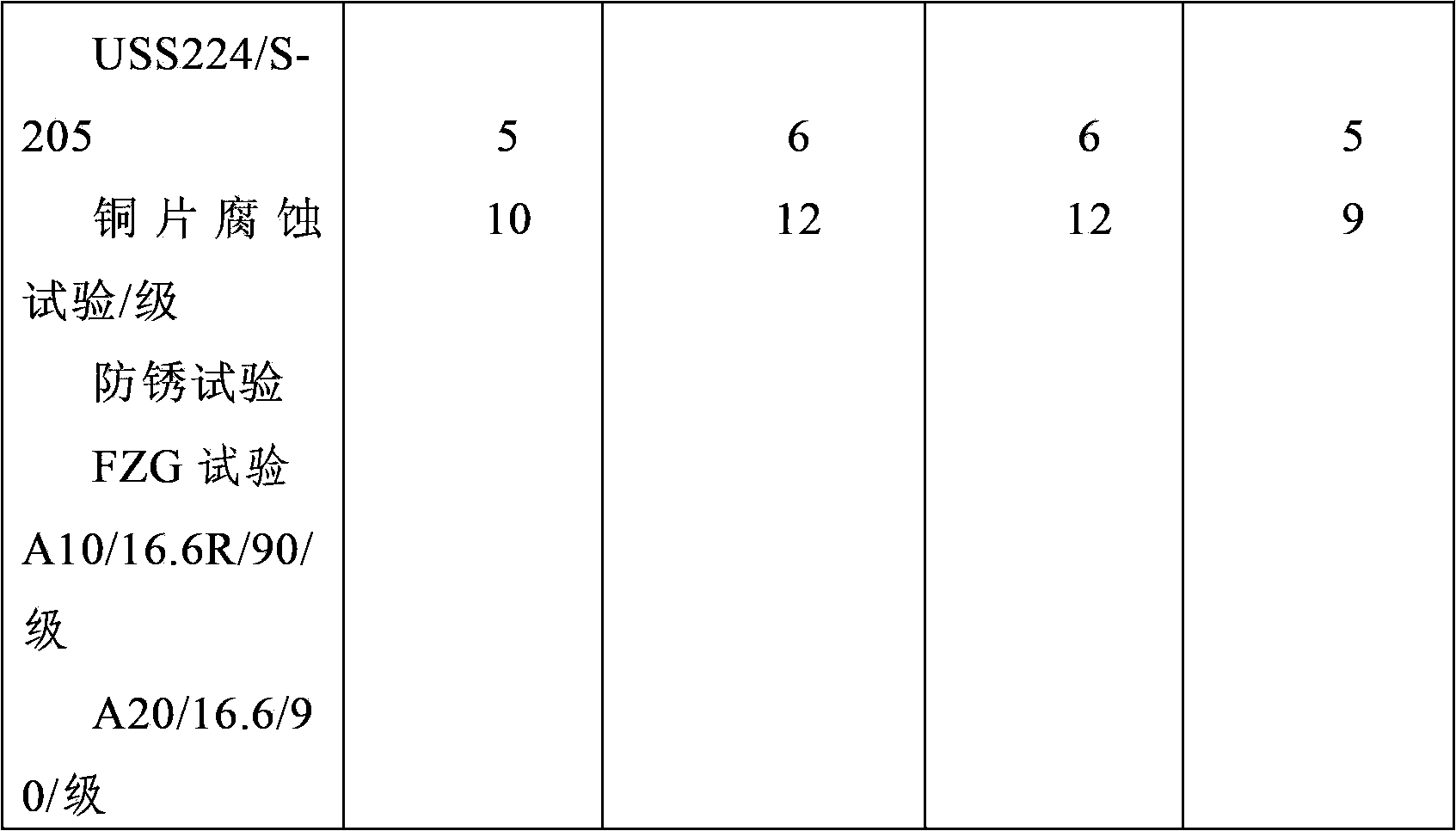

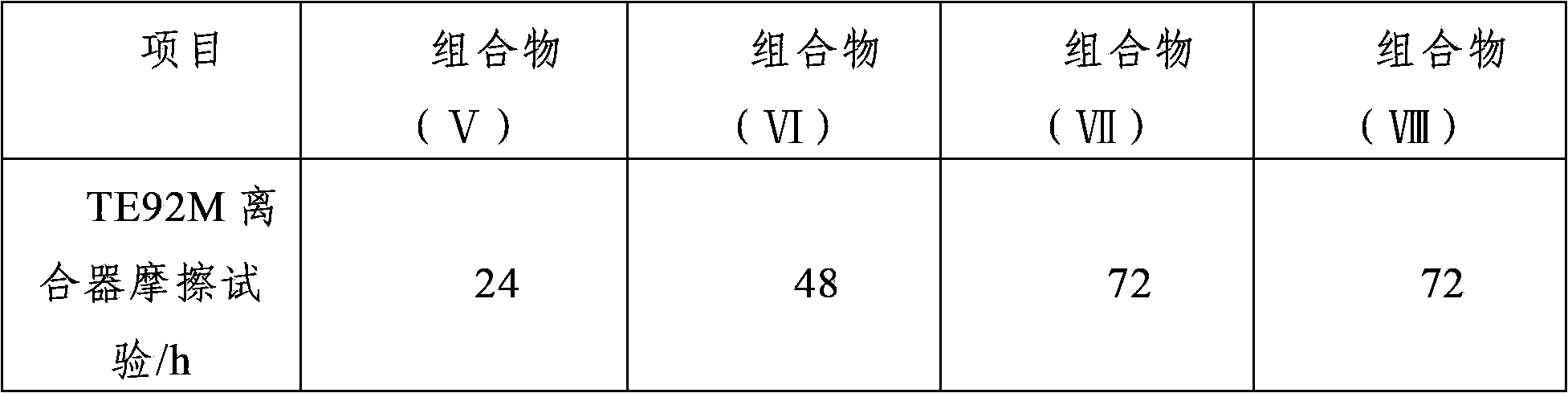

Lubricant composition for double-clutch gearbox

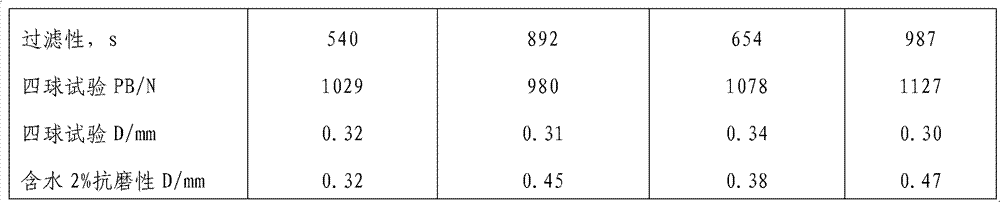

ActiveCN102766507AImprove wear resistanceImprove friction characteristicsLubricant compositionDispersityPolyolefin

The invention provides a lubricant composition for a double-clutch gearbox. The lubricant composition comprises: (A) at least a hydrofinishing III mineral oil with high viscosity index, or polyolefin cogasin, or ester cogasin, or any combination of the above components; (B) at least a viscosity index improver; (C) at least a pour-point depressant; (D) at least a phosphorus-containing antiwear additive; (E) at least a friction modifier; (F) at least a high-temperature anti-oxidant; (G) at least an ashless dispersant; (H) at least a metal detersive; and (I) at least a metal passivator. The above lubricant composition has excellent abrasion resistance, frictional characteristic, synchronization performance, antiwear endurance, high-temperature lubrication stability, antirust and anti-corrosive property, high and low temperature performance, shearing stability, cleaning dispersity, high-temperature anti-foaming property and micropoint corrosion resistance, passes through Vickers pump experiments, FAGFE-8 bearing wear experiments, SAE No.2 frictional characteristic experiments, TE92M anti-shake experiments, SSP-180 synchronous bench durability experiments, CEC L-45 taper roller shearing experiments, CEC L-84 thermooxidizing soundness experiments and FAV-54 mircopoint corrosion experiments, and simultaneously meets lubrication requirements of clutches, a synchronizer, gears and bearings in the double-clutch gearbox.

Owner:PETROCHINA CO LTD

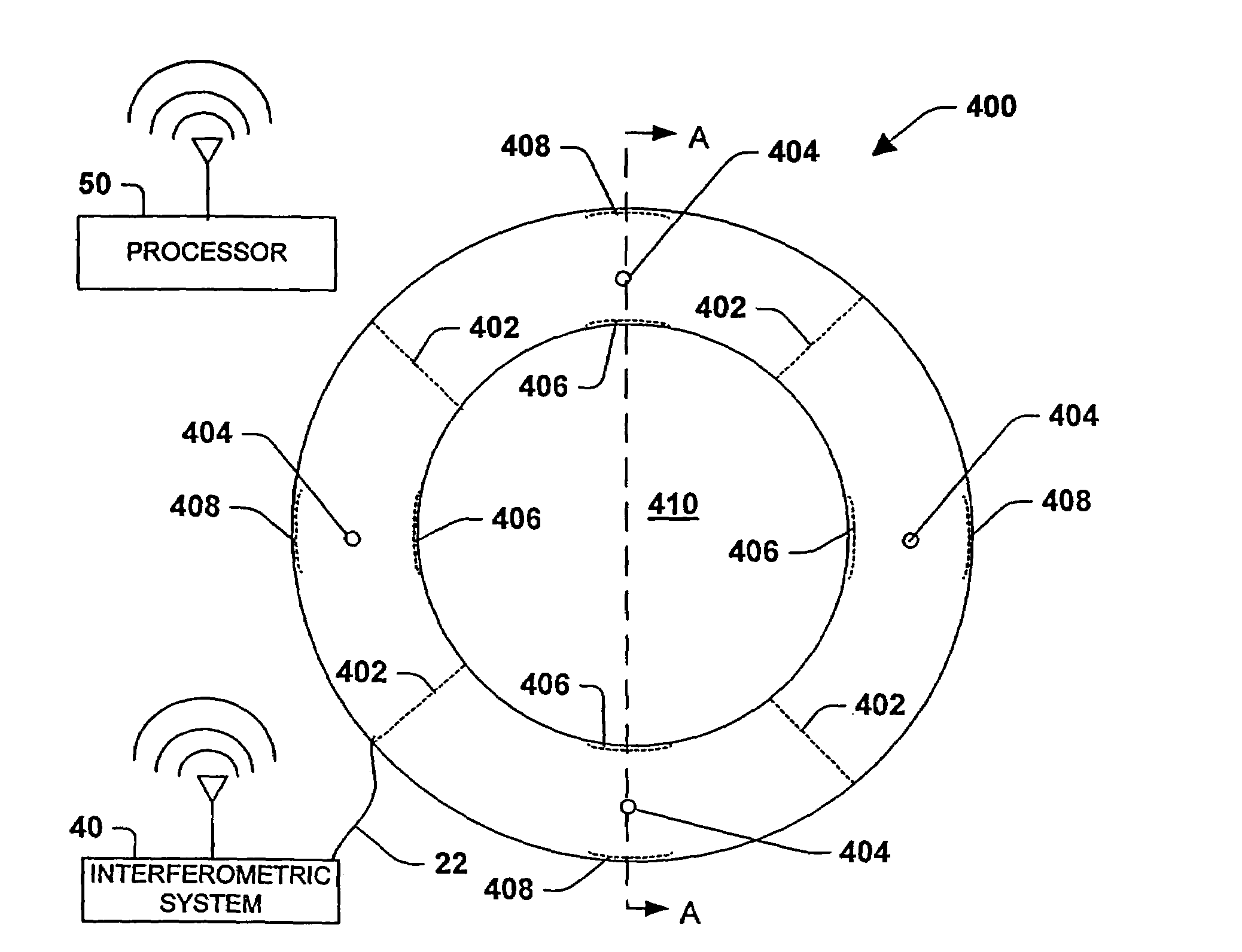

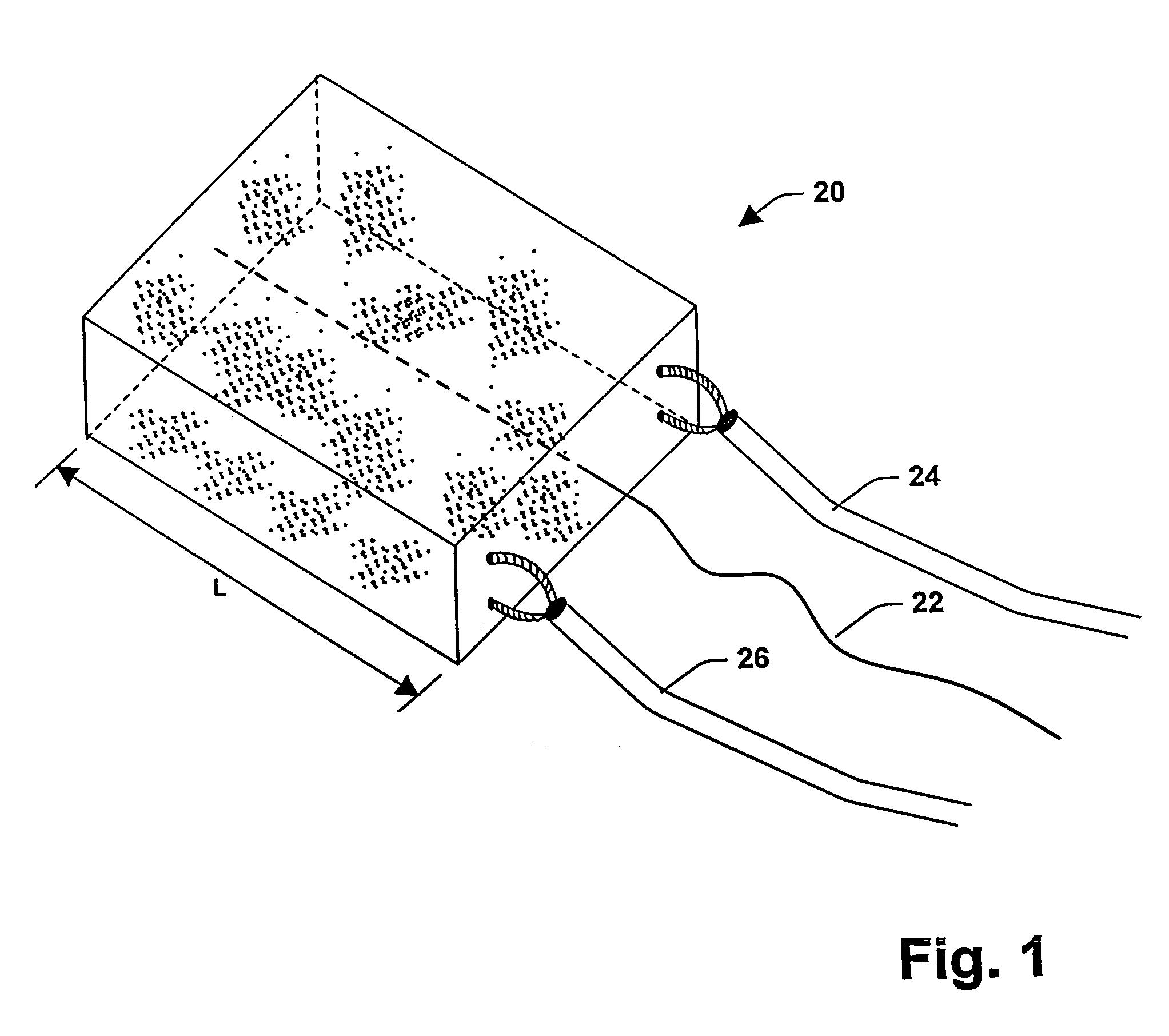

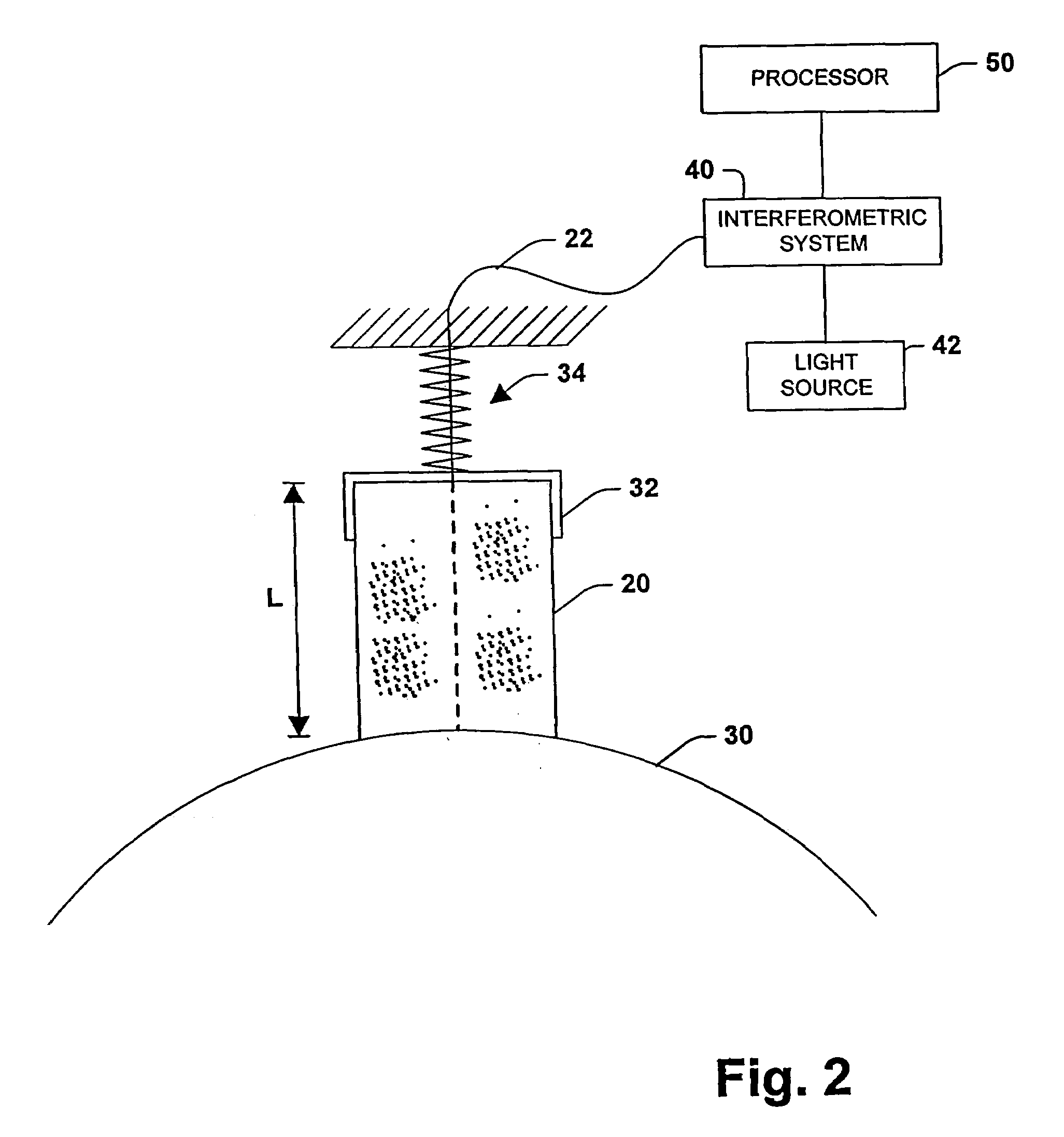

System for monitoring bearing wear

InactiveUS7551288B1Accurately determineAssociation with control/drive circuitsEngine sealsEngineeringBearing wear

A system for determining at least one condition of a bearing including an optical fiber for transmitting light from a light source. The optical fiber is embedded in the bearing and operatively coupled to an interferometric system. The interferometric system is operatively coupled to a processor. The interferometric system provides the processor with information relating to wear of the optical fiber, and the processor determines wear of the bearing, rate of wear and remaining useful life of the bearing based on the information relating to wear of the optical fiber.

Owner:ROCKWELL AUTOMATION TECH

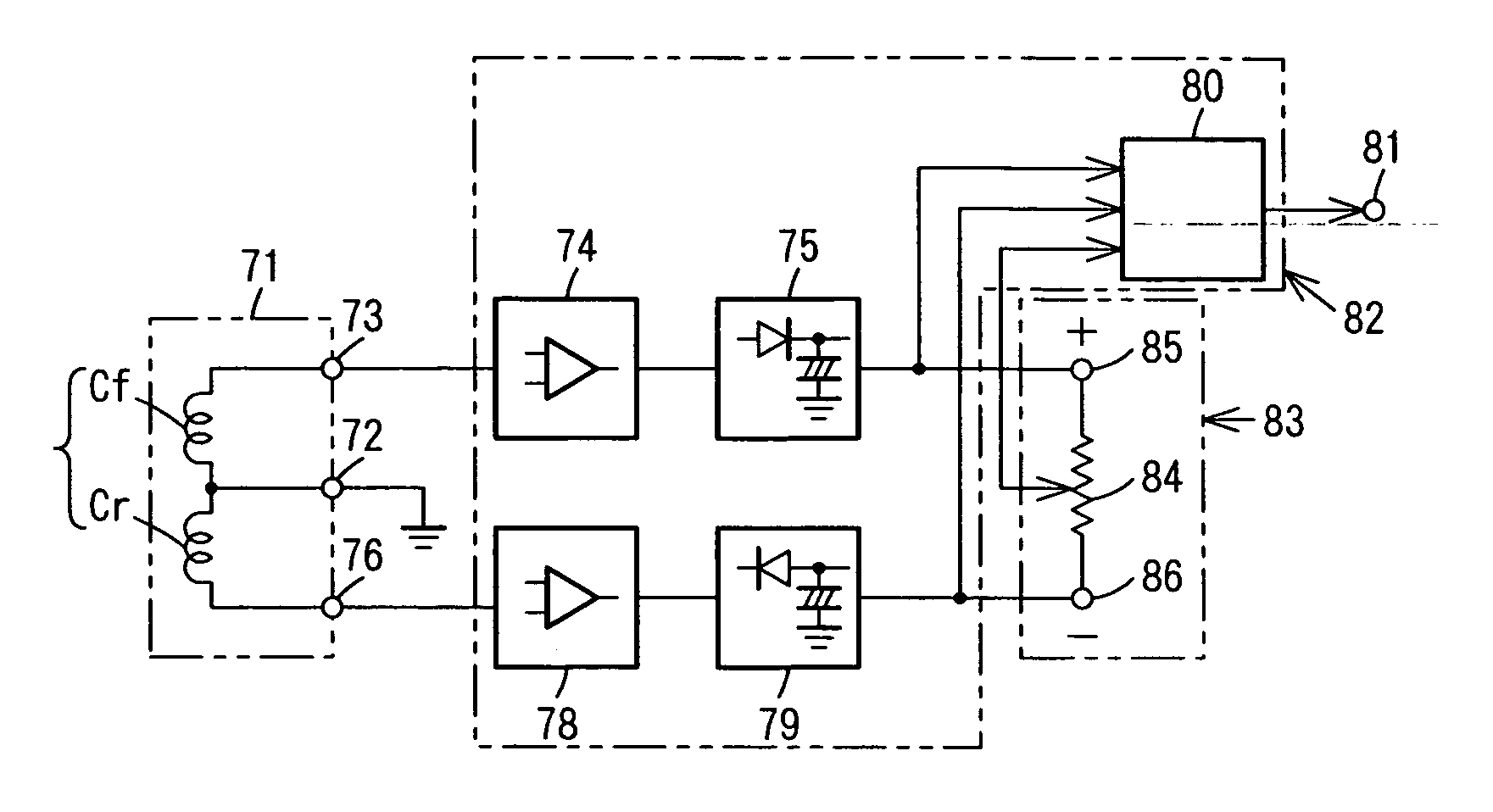

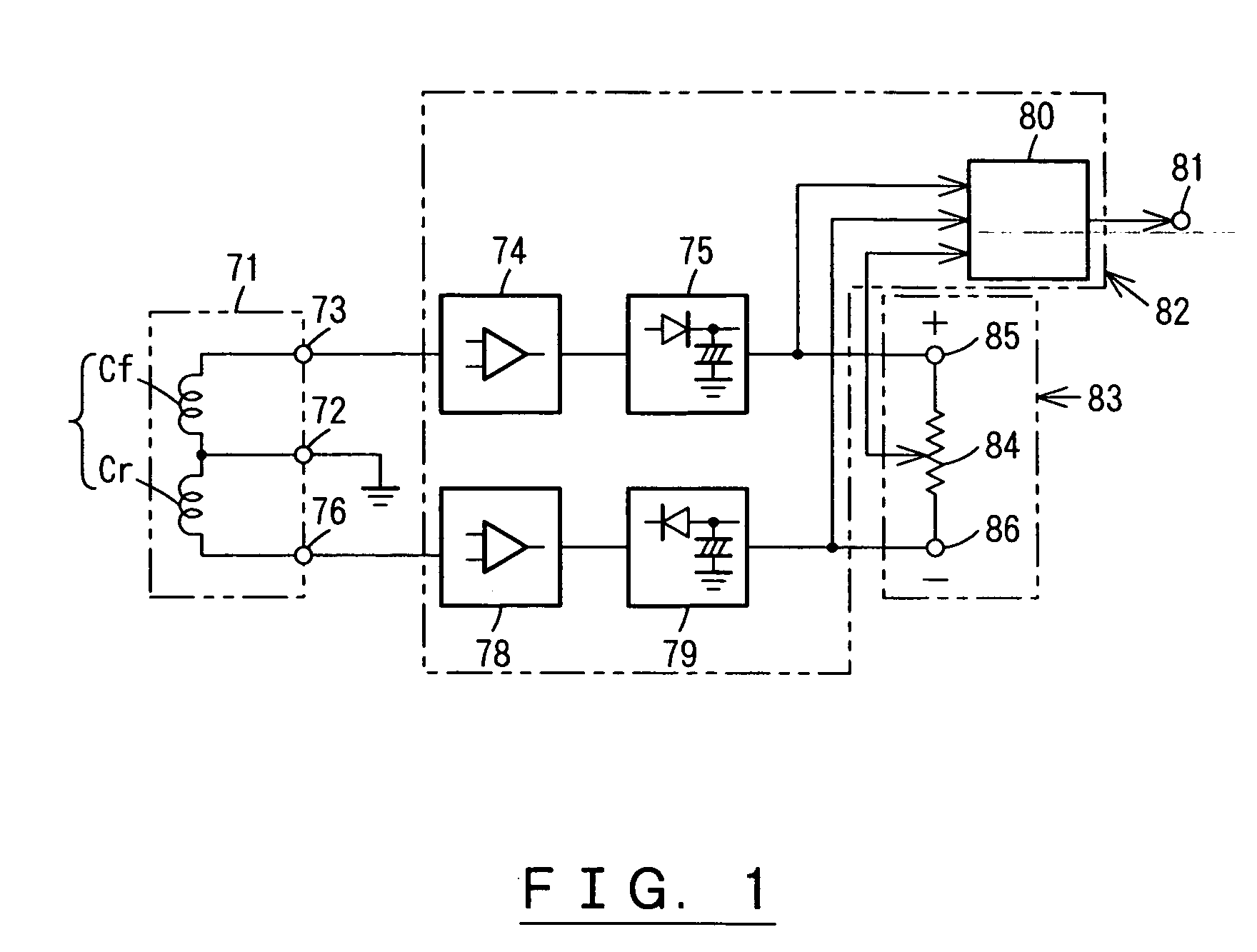

Axial bearing wear detection device for canned motor

InactiveUS7019661B2Improve accuracyAssociation with control/drive circuitsStatic/dynamic balance measurementLocation detectionBearing wear

An axial position detection circuit detects the axial position of a rotor from the difference in voltages generated at axial position detection coils disposed at both ends in the axial direction of a stator of a canned motor. An axial zero point adjustment circuit uses a voltage supply, which varies proportionately with the power supply voltage of the canned motor, as a bias power supply to adjust the voltage difference of the axial position detection coils to zero when the rotor is at a reference position in the axial direction. Even if the power supply voltage of the canned motor varies, since the bias power supply of the axial zero point adjustment circuit varies in likewise manner, the zero point adjustment by the axial zero point adjustment circuit is not affected and axial bearing wear detection of high precision is enabled.

Owner:TEIKOKU ELECTRIC MFG

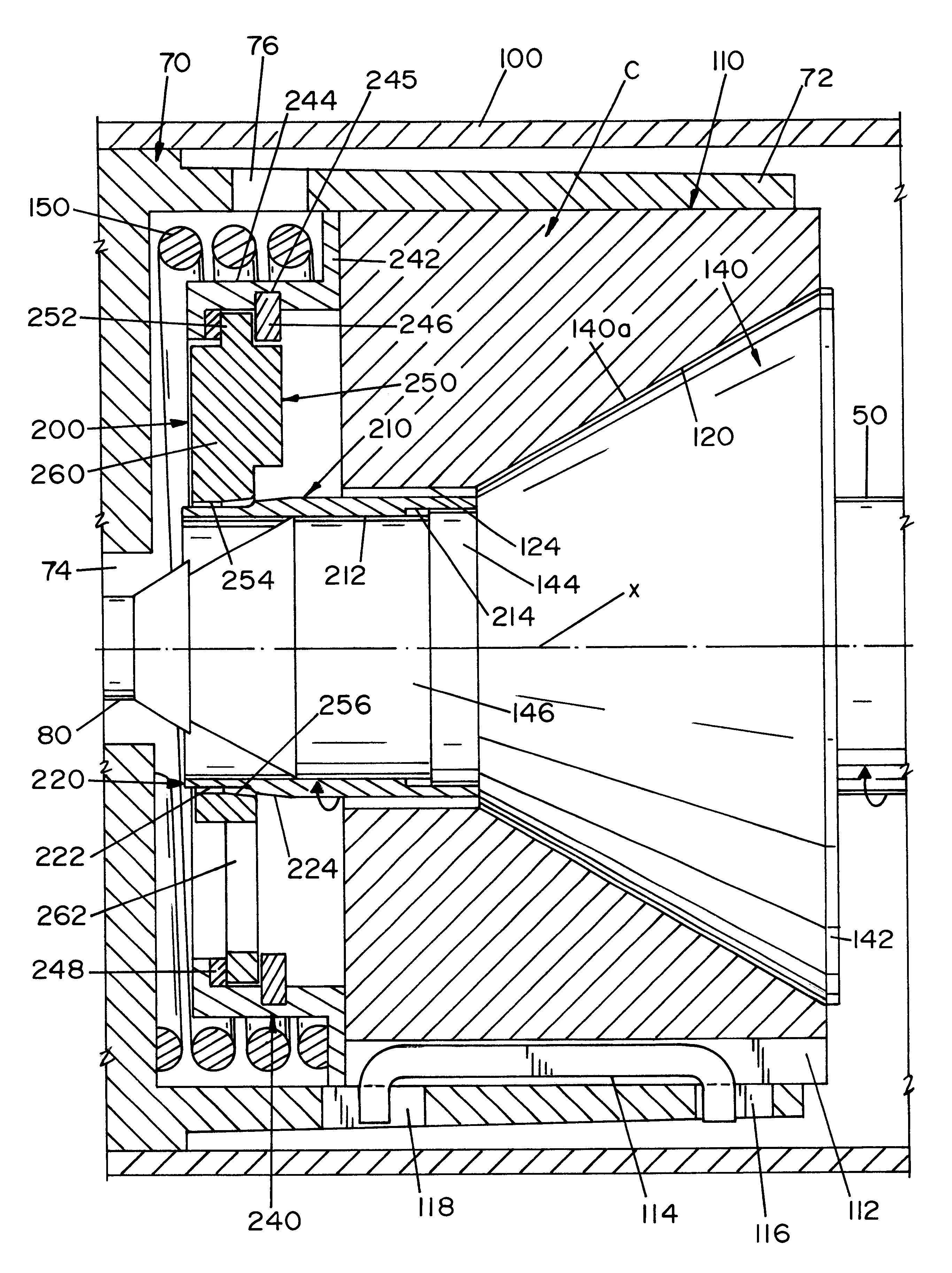

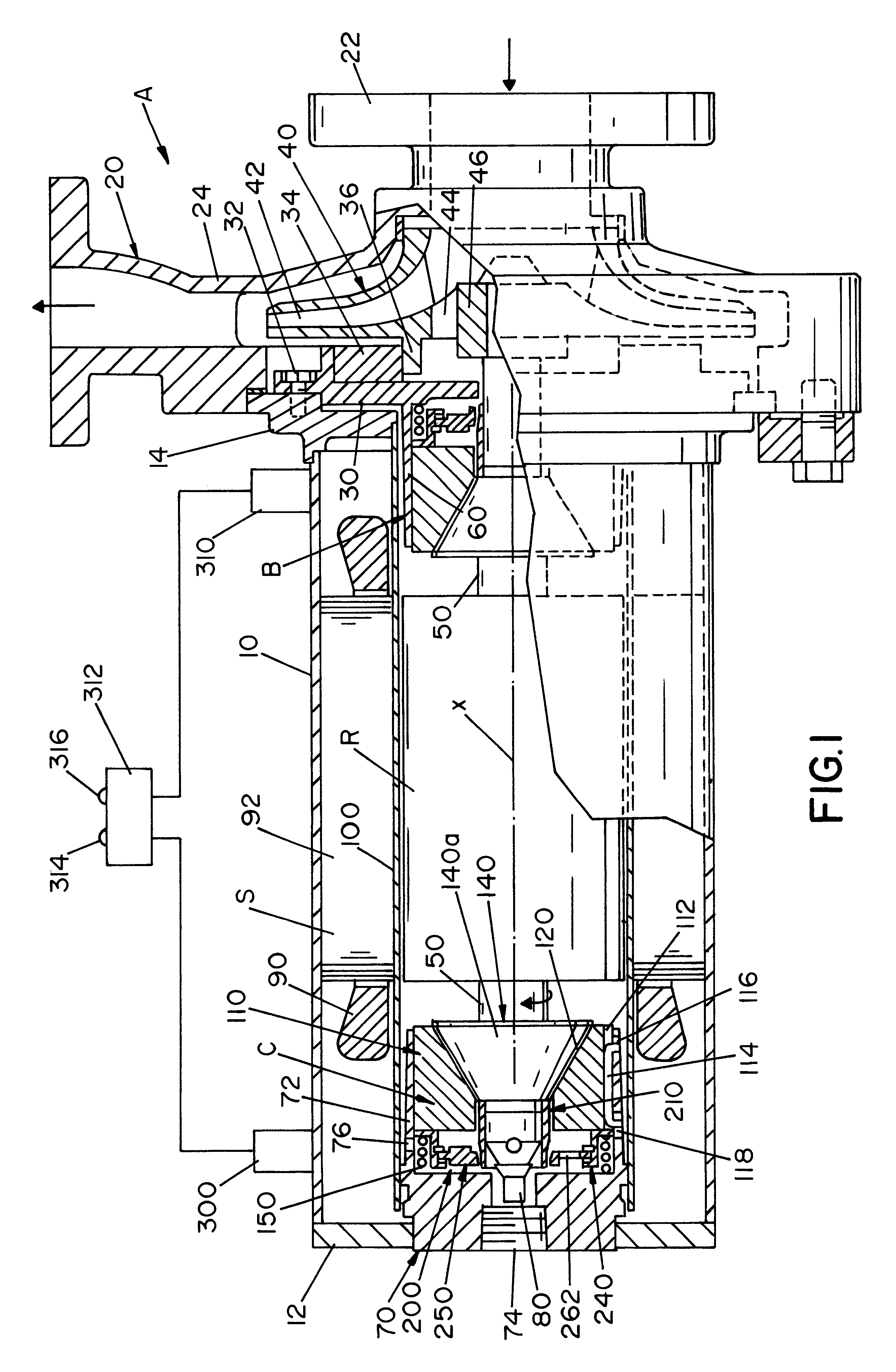

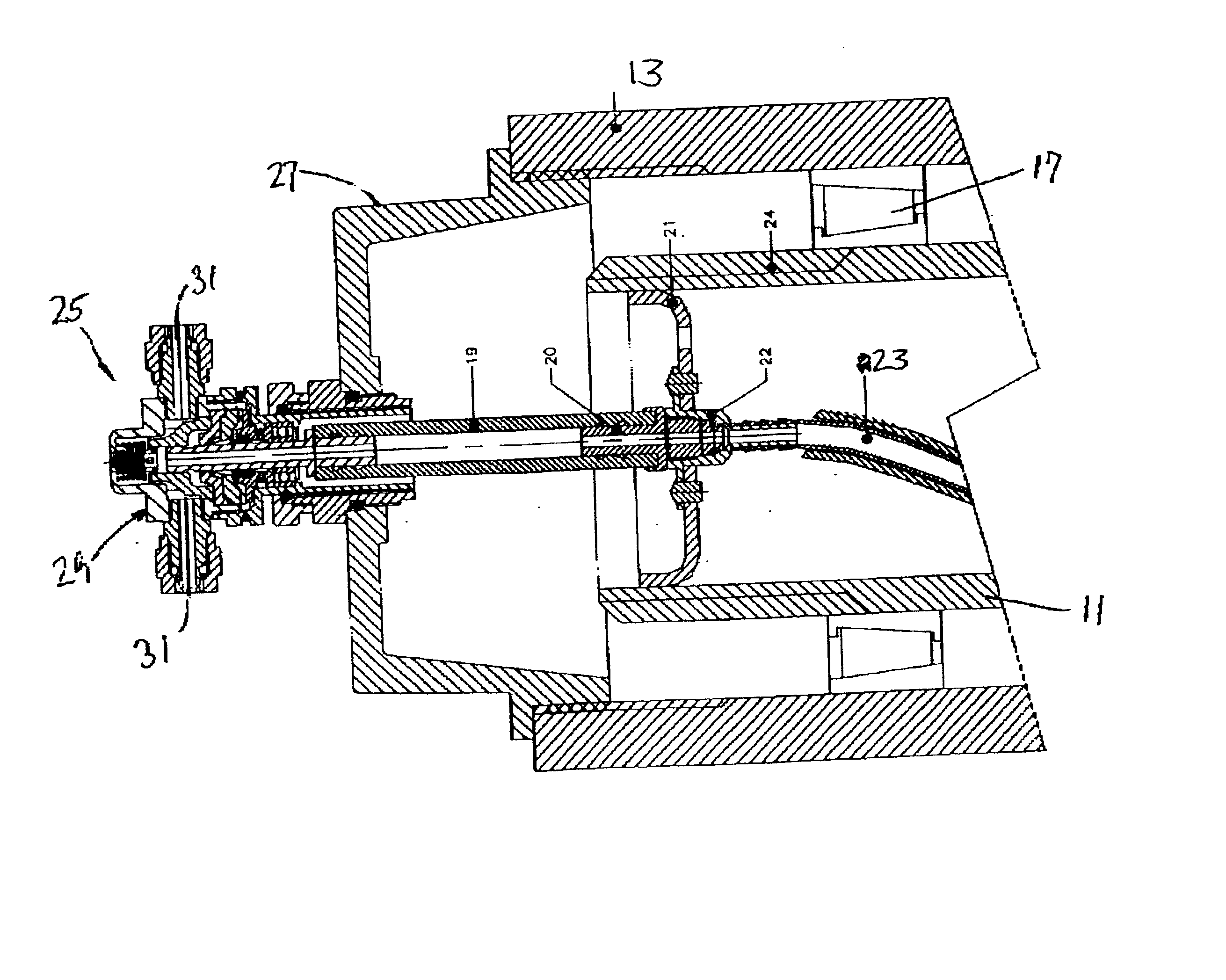

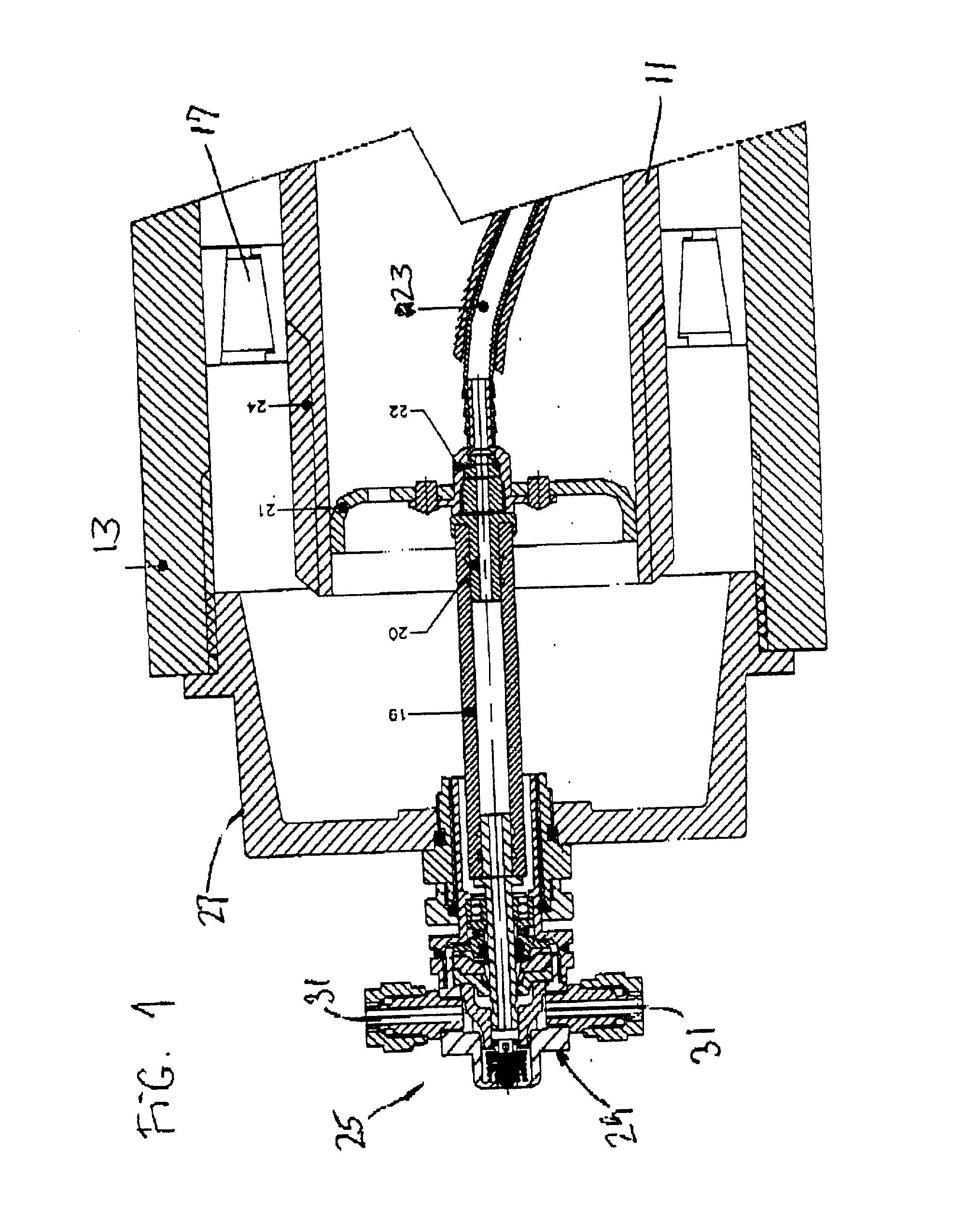

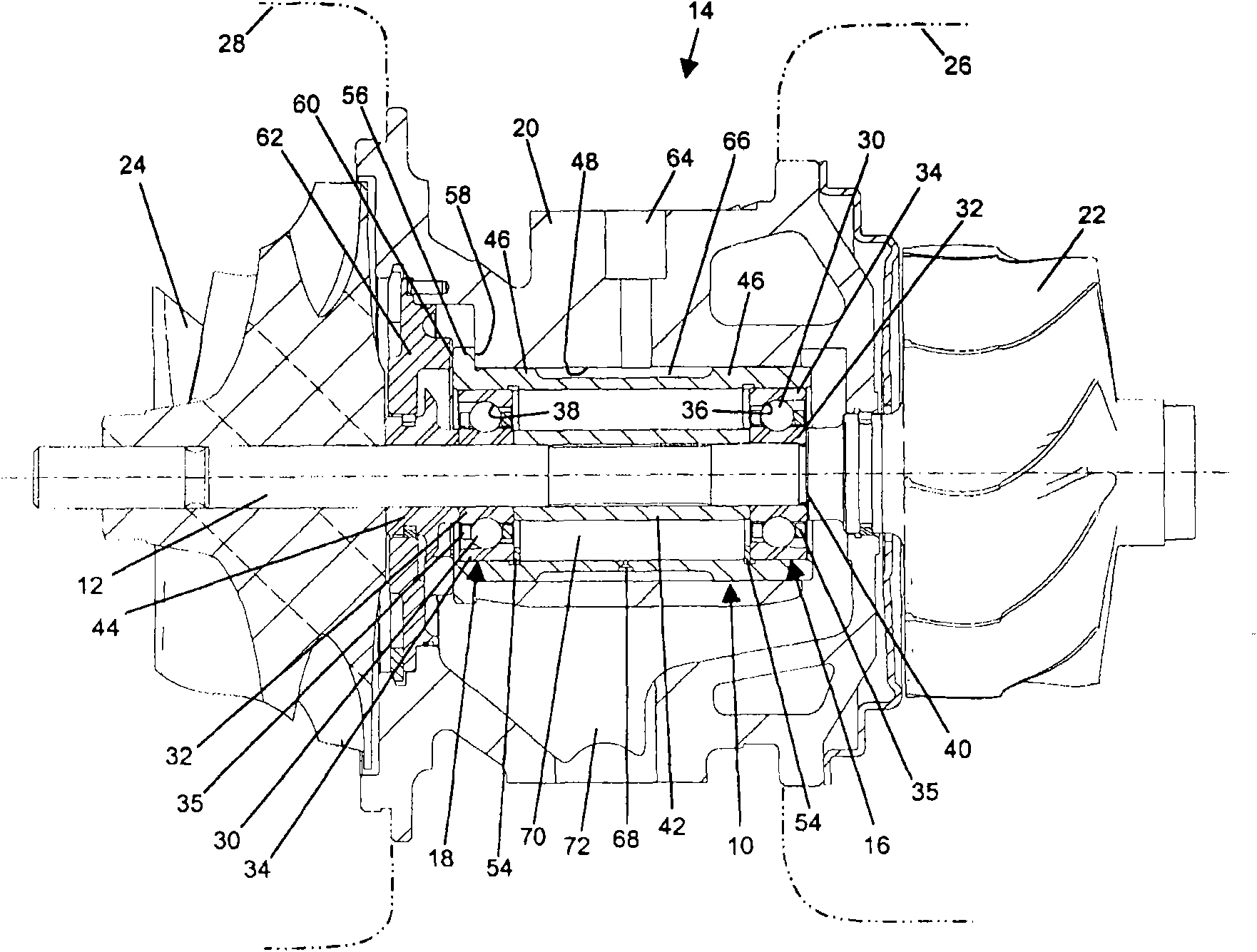

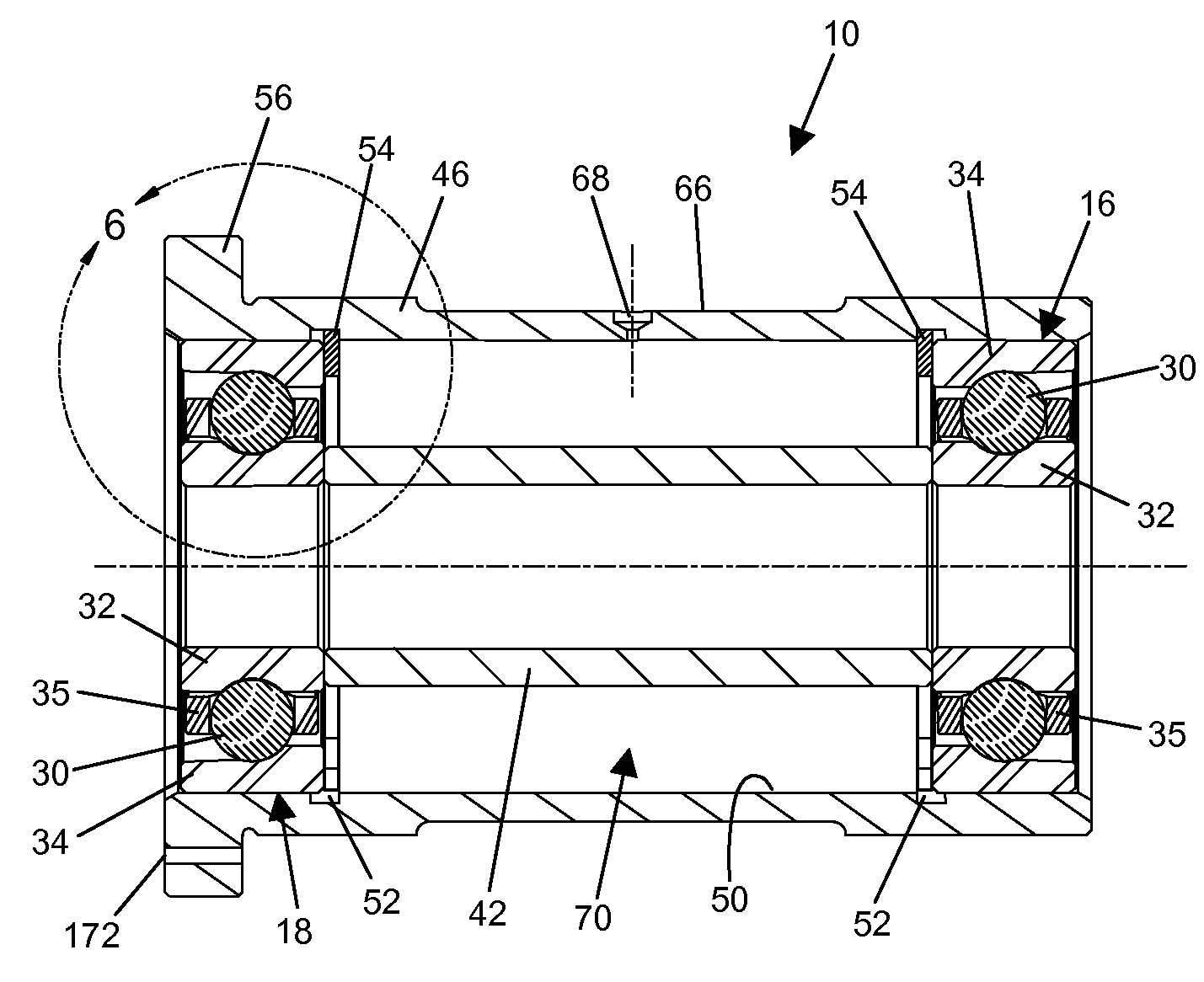

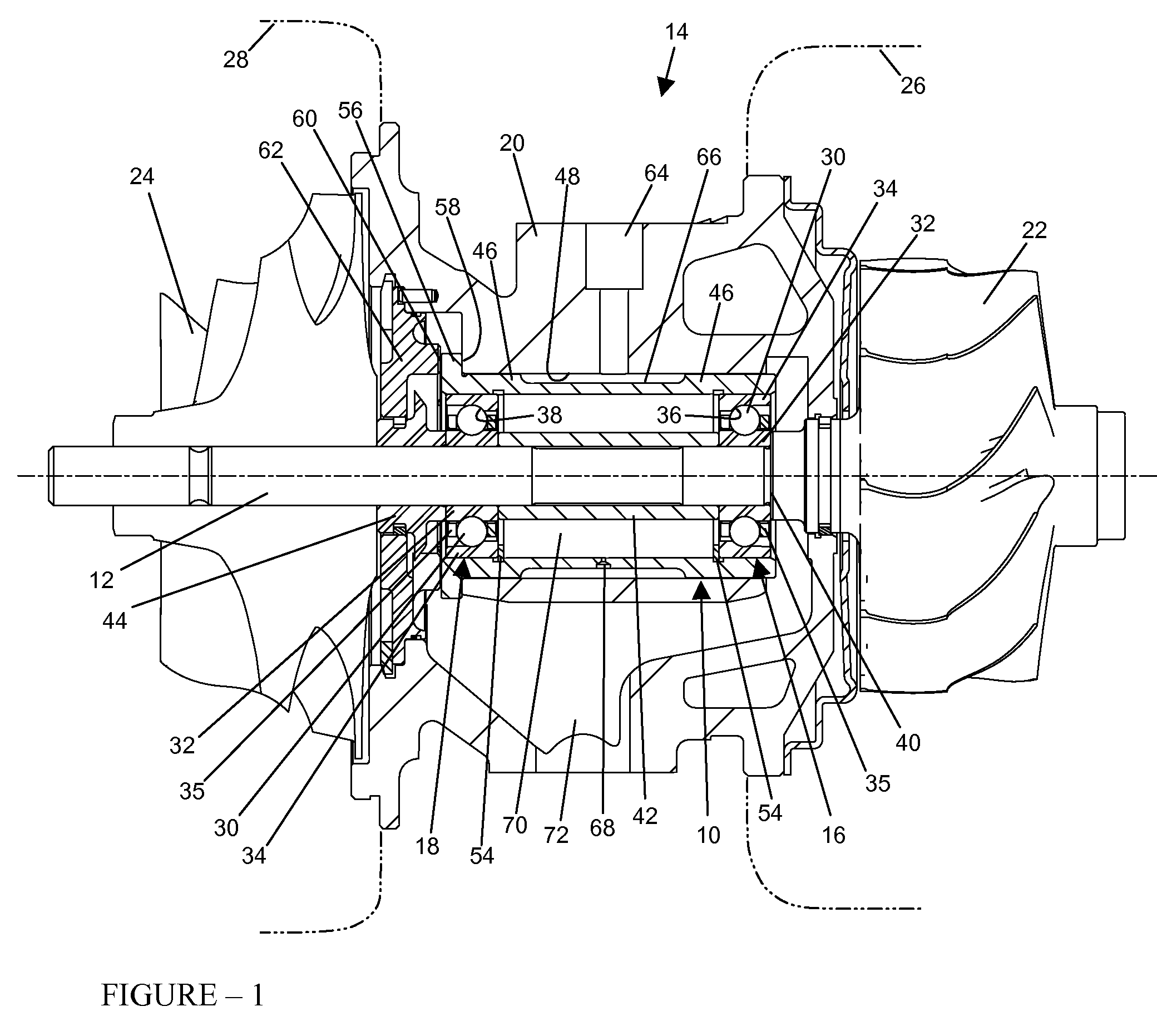

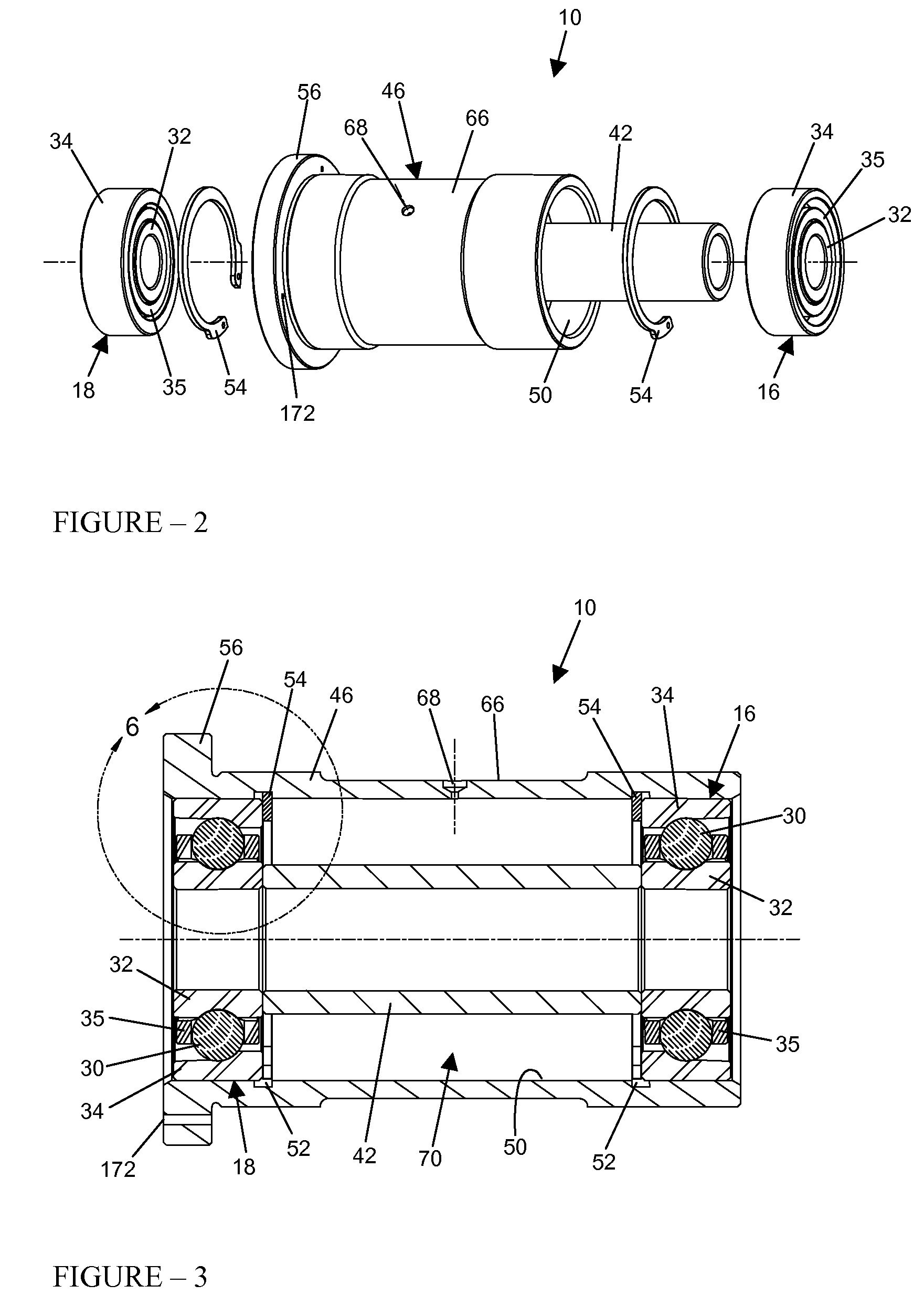

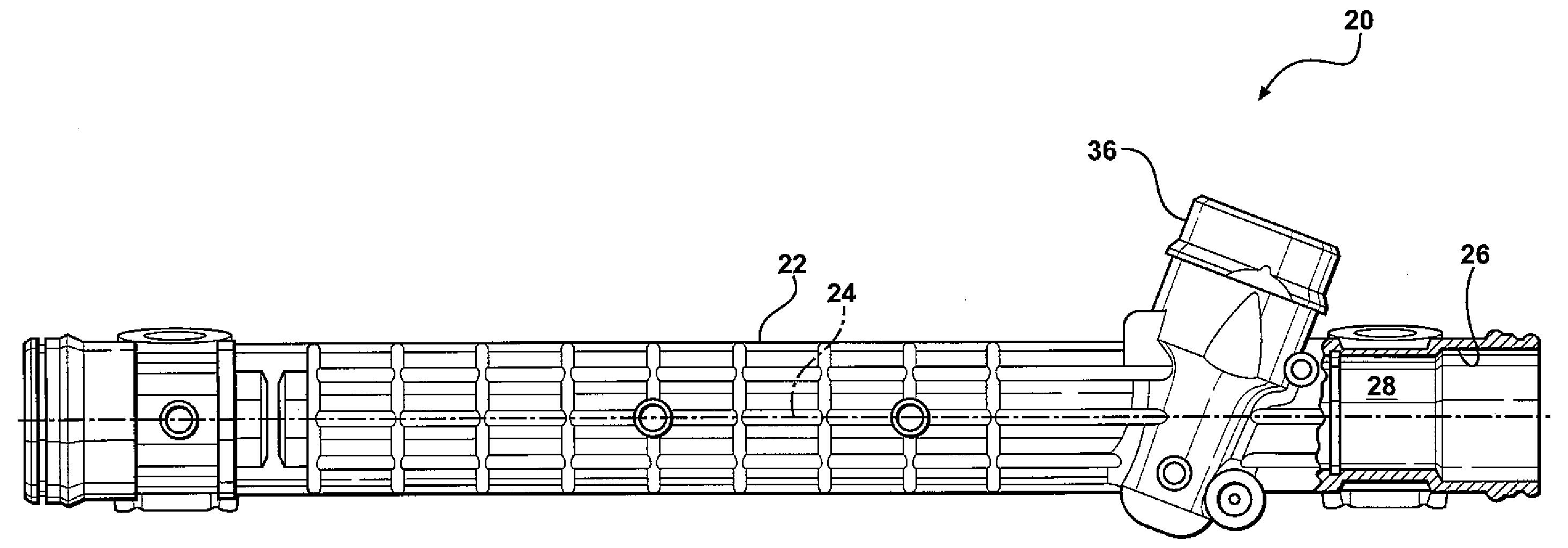

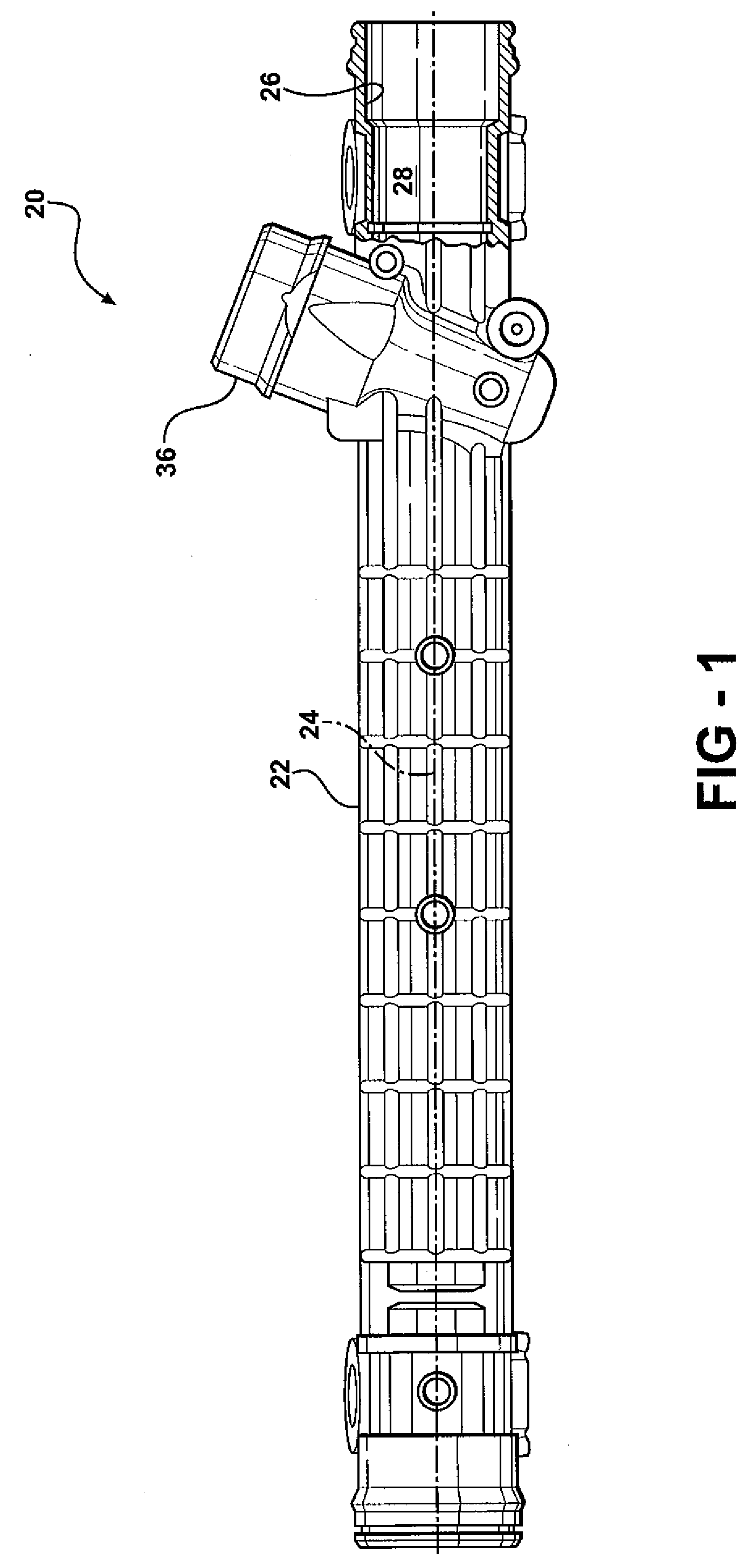

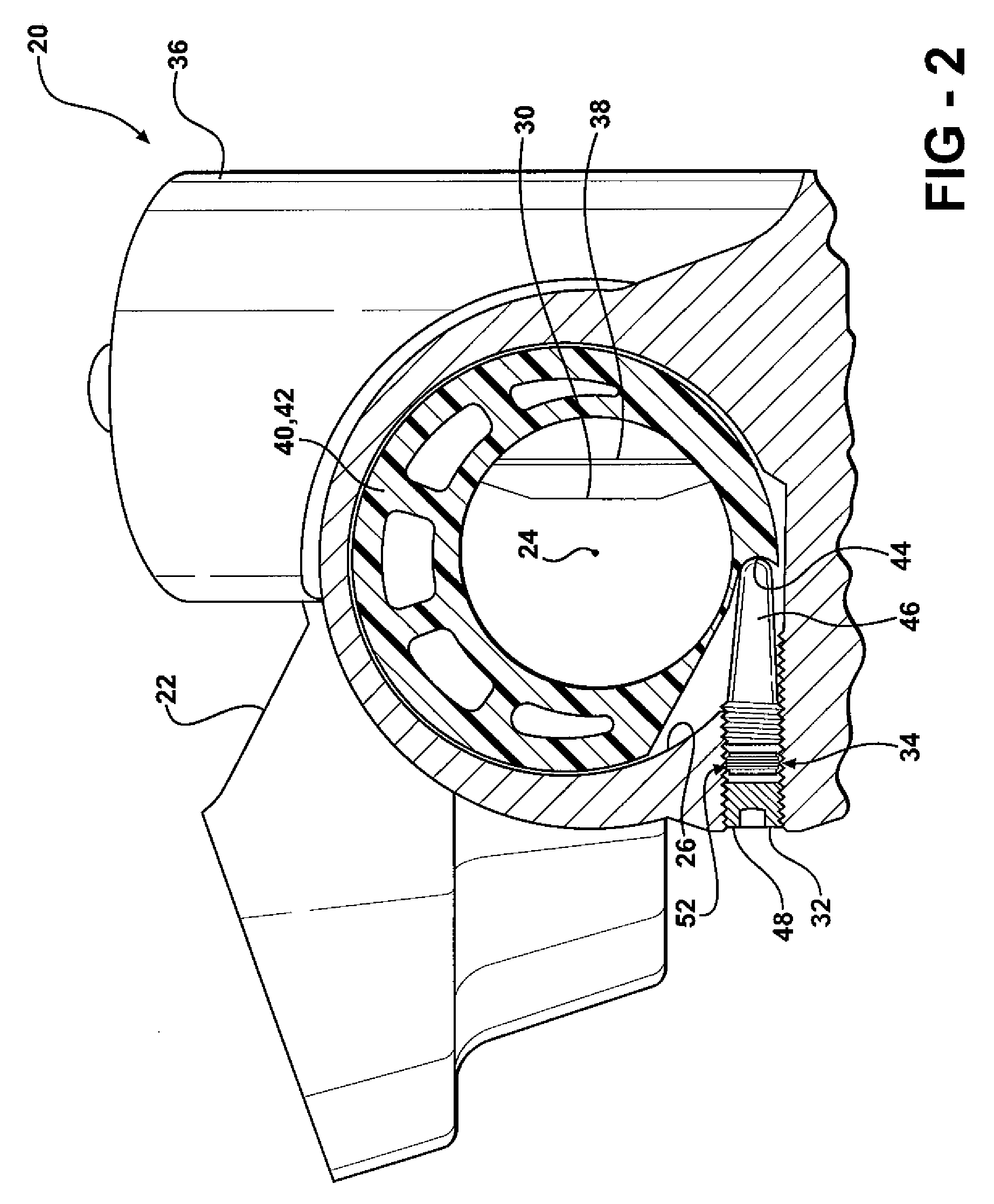

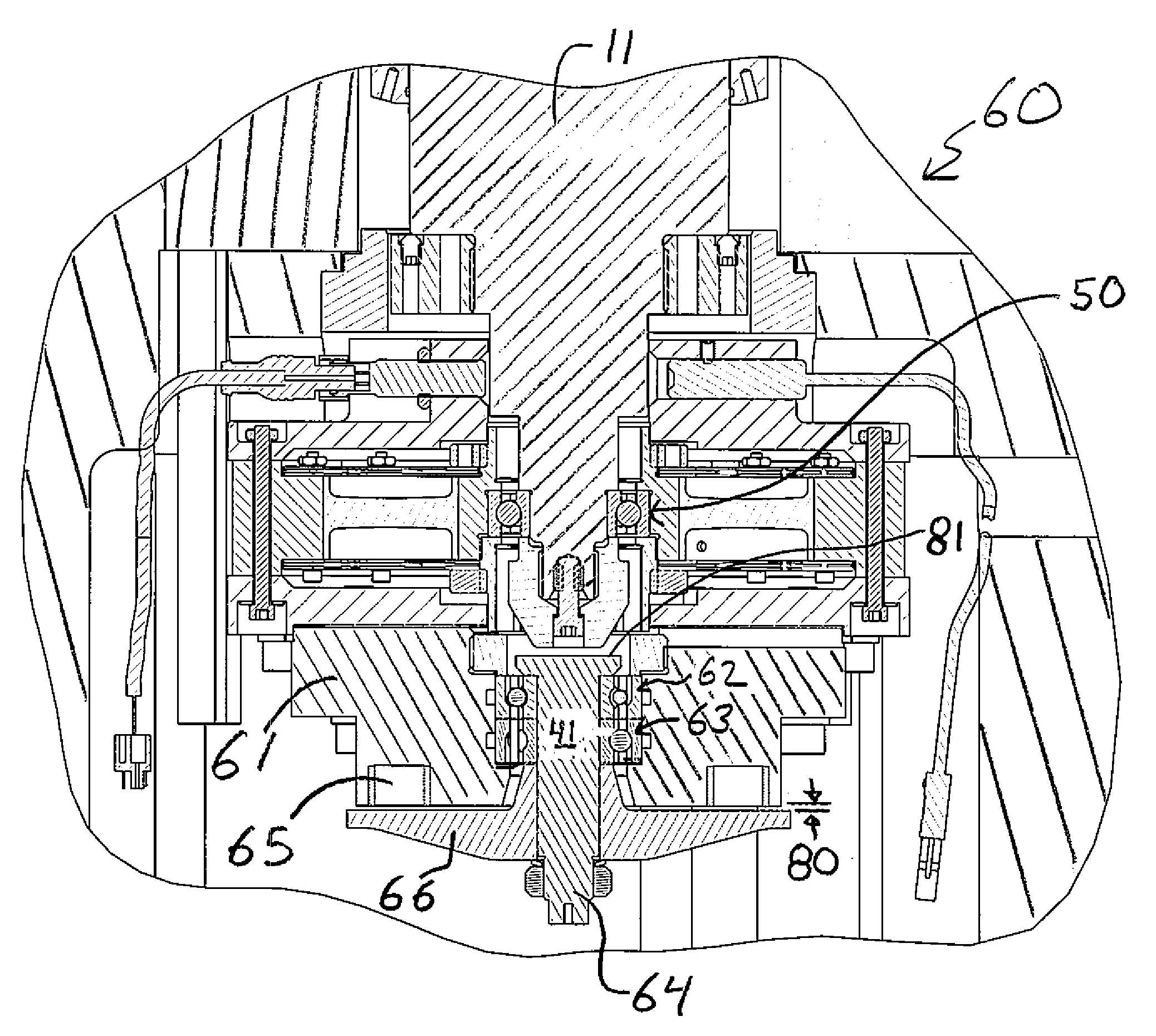

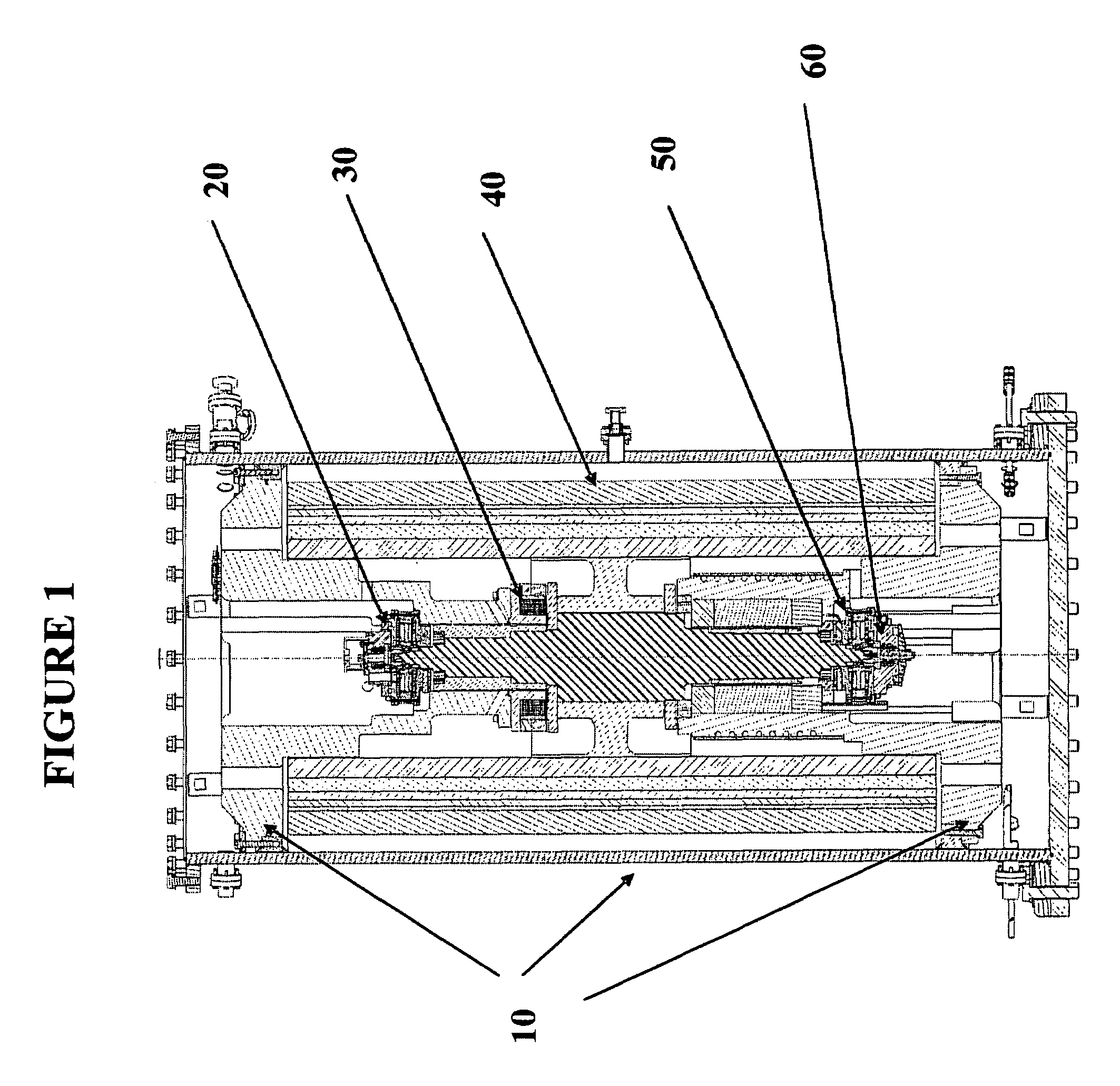

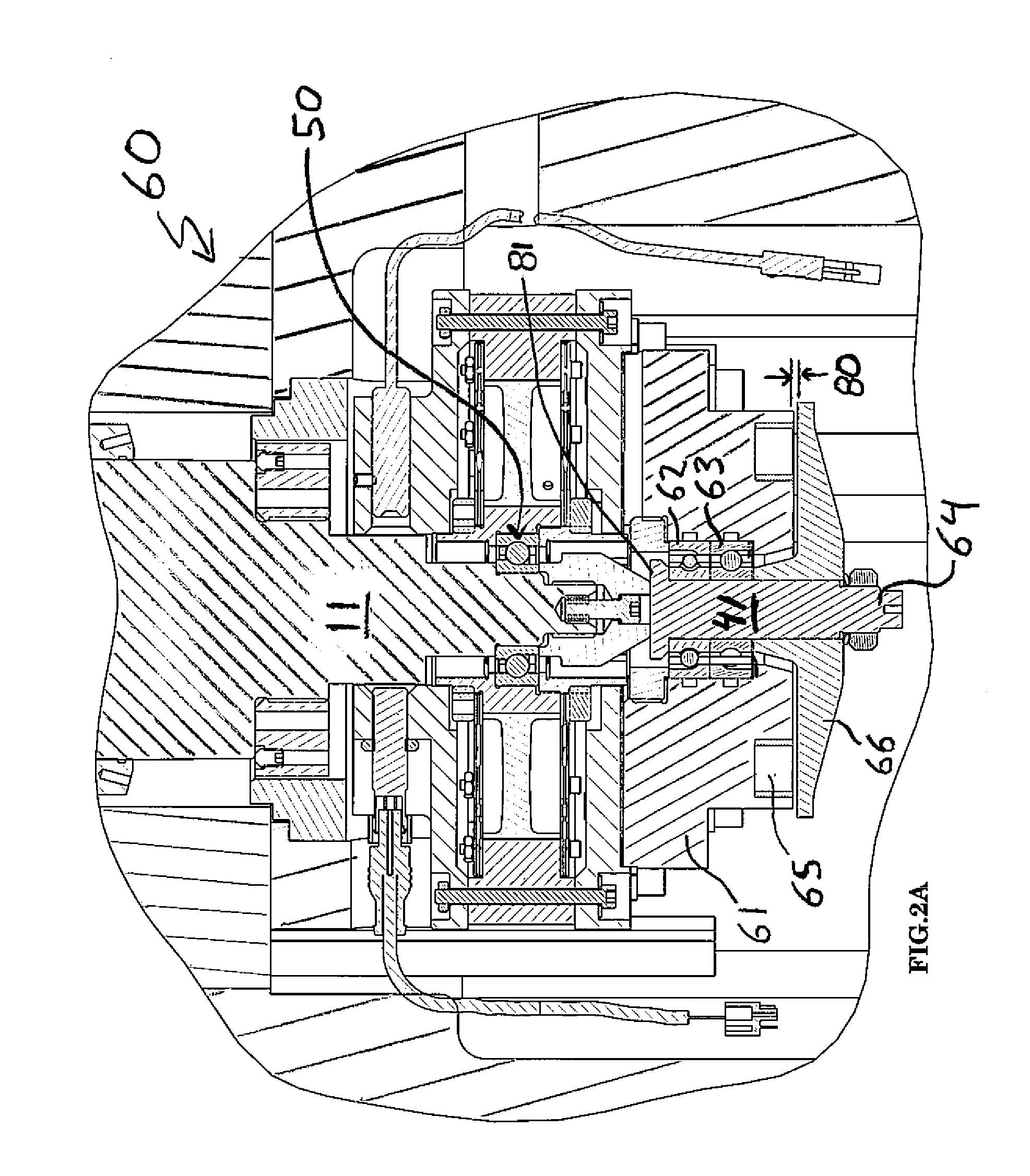

Floating bearing cartridge for a turbocharger shaft

InactiveCN101568736AReduce wearReduced or minimal wearRolling contact bearingsTurbochargerEngineering

A bearing system for use in high speed rotating machinery, such as a turb ocharger (14), wherein a shaft (12) is rotatably supported by a floating bea ring cartridge ( 10) having axially spaced angular contact bearings (16, 18) each with a set of bearing balls (30) supported between inner and outer rac es (32, 34). The bearing cartridge includes an inner spacer sleeve (42) for axially spacing the inner bearing races, and a rotationally floating outer s leeve (46) having a pair of radially inwardly open grooves (52) for removabl y receiving snap-type retaining rings (54) which engage and axially space th e outer bearing races. The axial dimension of the inner spacer sleeve is elo ngated slightly relative to an axial dimension defined between outboard face s of the installed retaining rings, thereby slightly unloading the sets of b earing balls from their respective outer bearing races. Such slight axial un loading enhances smooth- running operation with minimal bearing wear, while accommodating transient loads during operation.

Owner:CPI控股有限责任公司

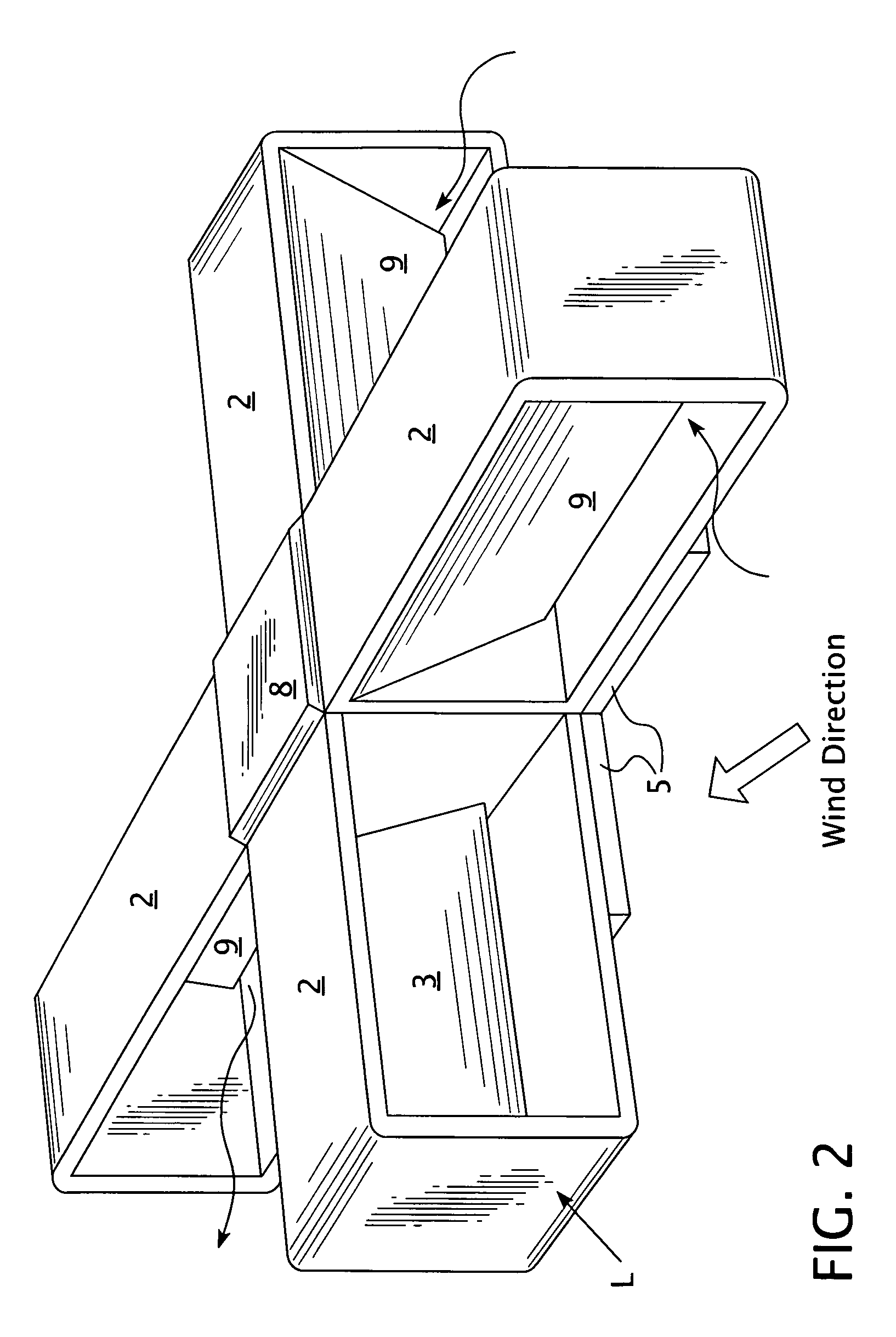

Vertical axis wind turbine with angled braces

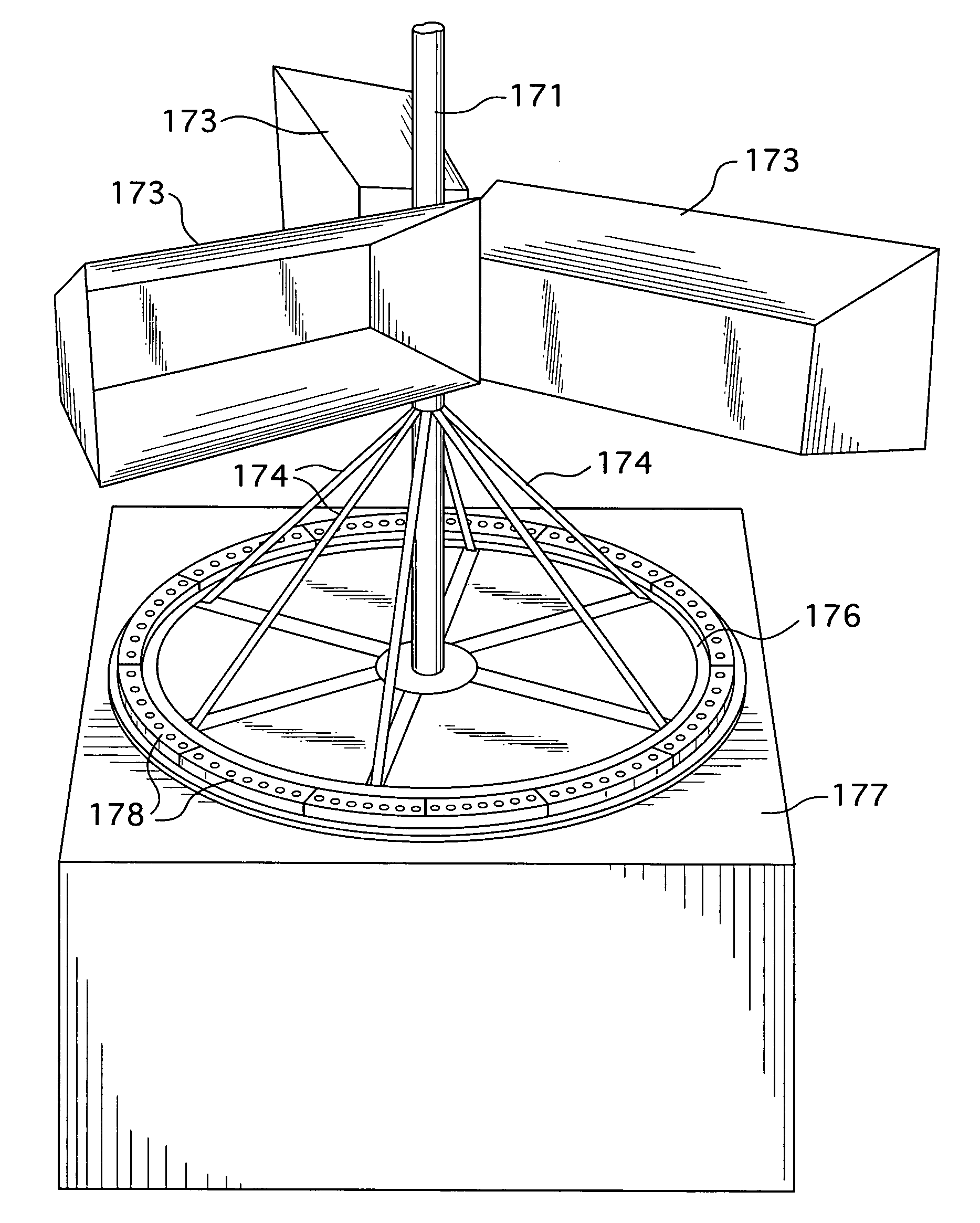

ActiveUS8164210B2Energy efficiencyImprove the immunityEngine manufactureWind motor supports/mountsVertical axis wind turbineBearing wear

An improved wind turbine comprises: (i) a turbine rotor with a support platform; (ii) a rotatable vertical shaft extending from or through that platform; (iii) at least one bearing for the shaft; (iv) a plurality of horizontally disposed, box-shaped wind catchment vanes connected about the shaft; and (v) a plurality of angled braces affixed to the platform for reducing wind force leverage effects and bearing wear.

Owner:BOONE DANIEL N +2

Floating bearing cartridge for a turbocharger shaft

InactiveUS7832938B2Conducive to stable operationReduced and minimal wearRolling contact bearingsShaftsTurbochargerBearing wear

Owner:CPI HLDG

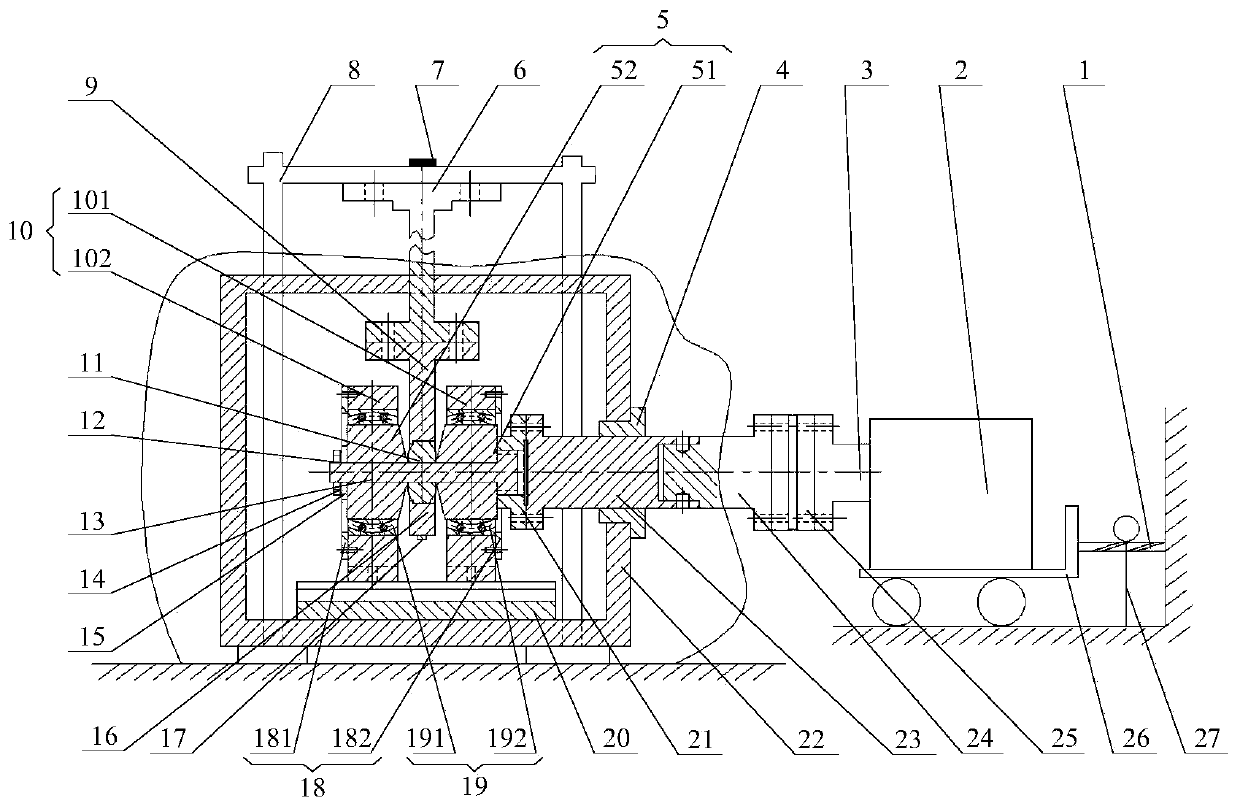

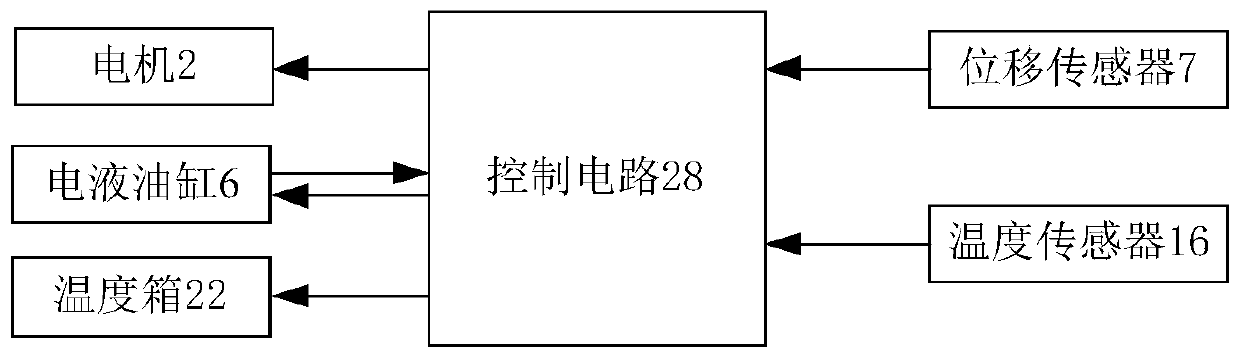

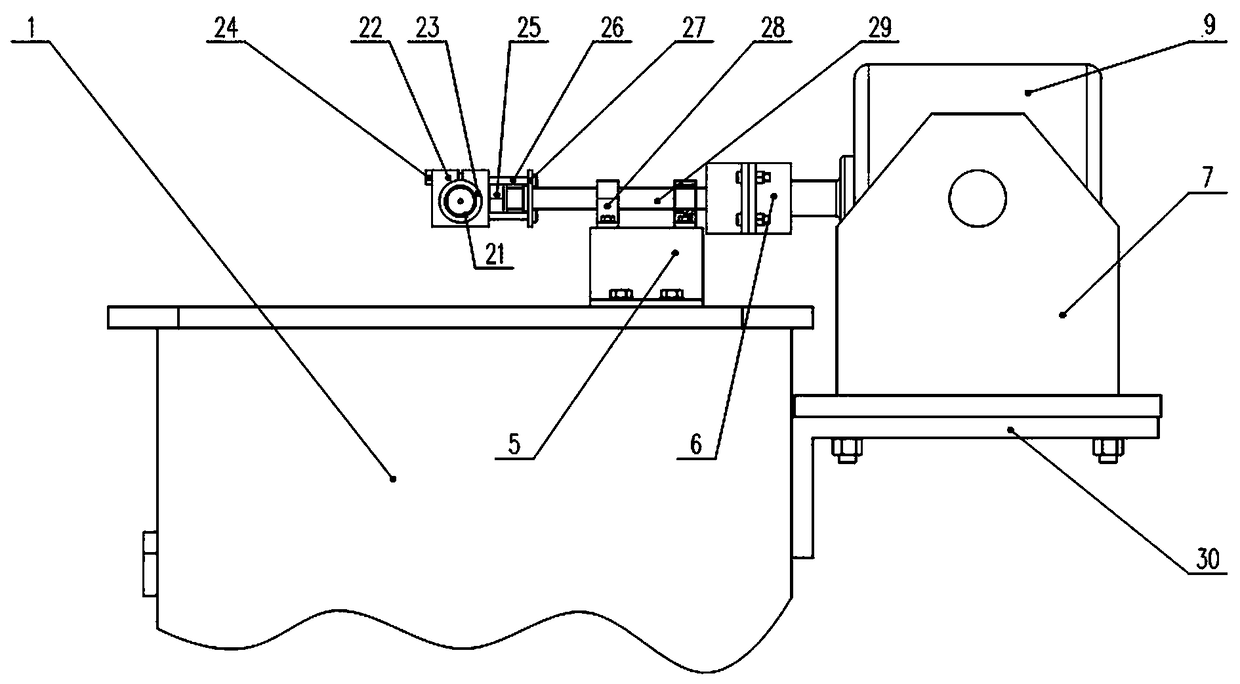

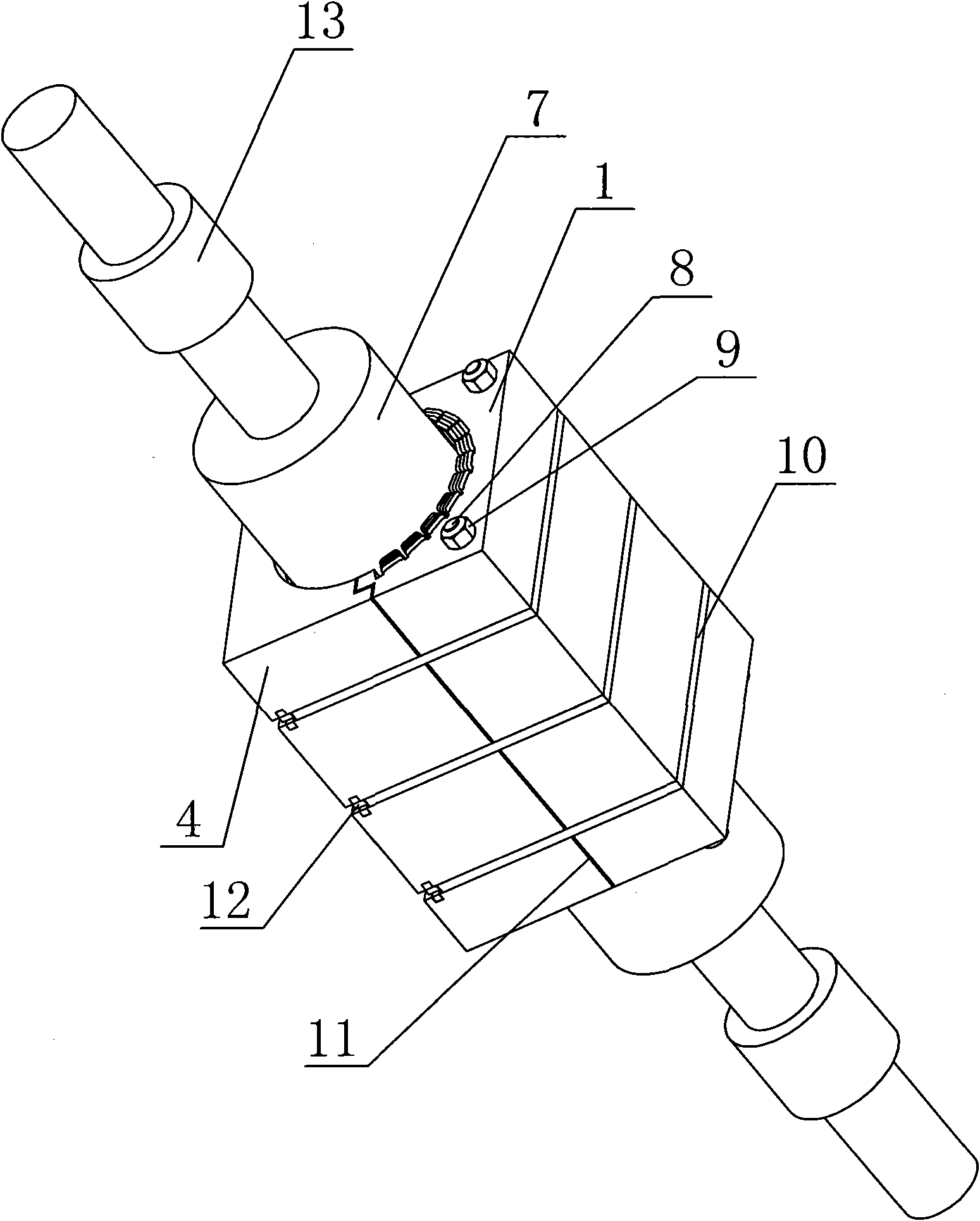

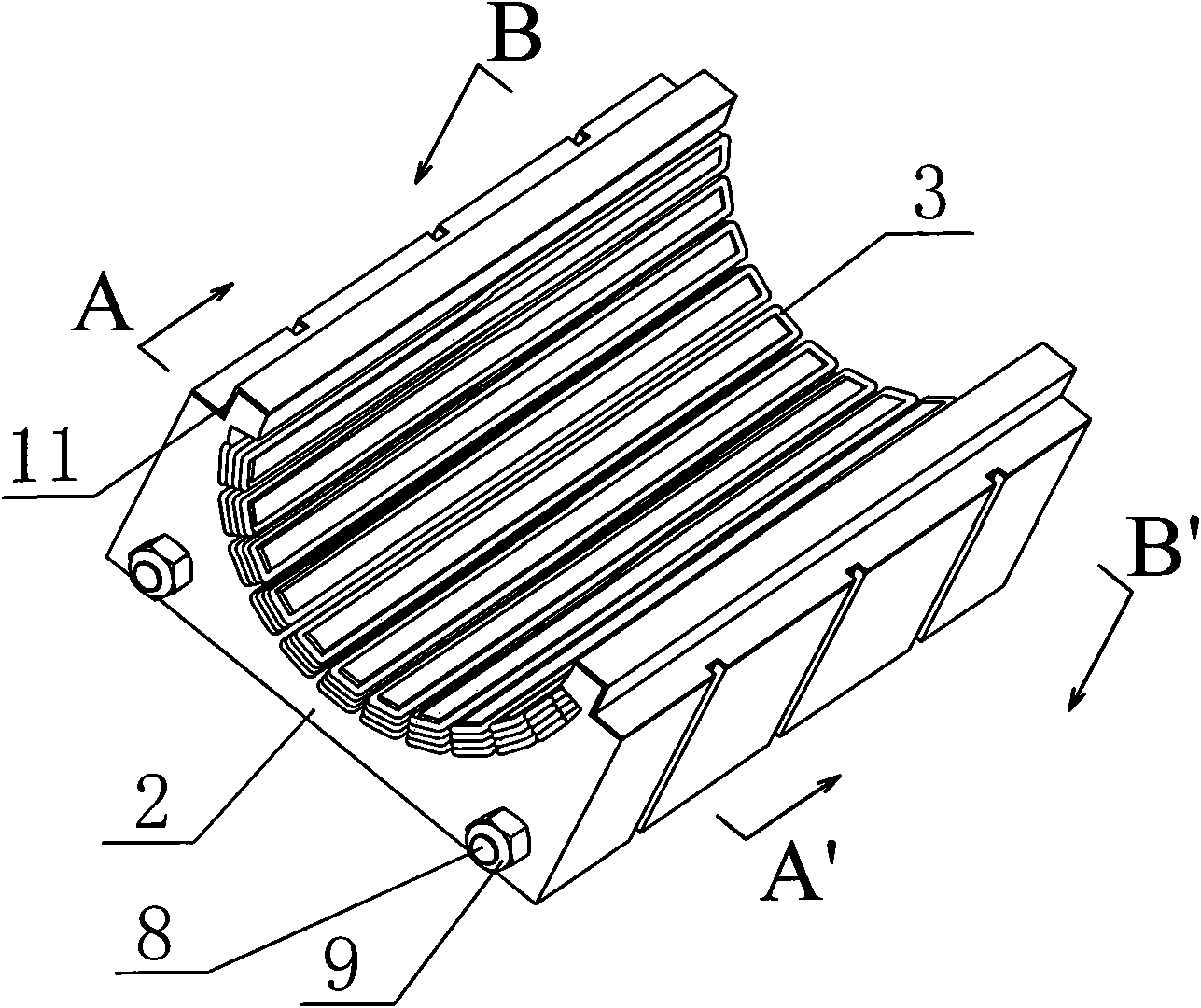

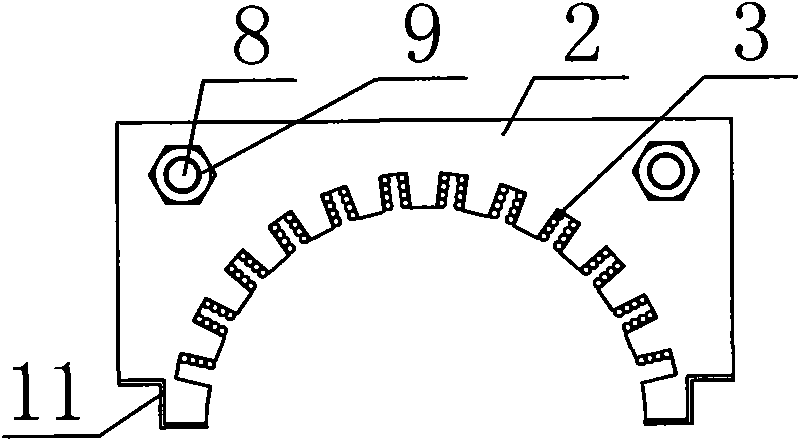

Joint bearing low-temperature wear test system and assembly method thereof

ActiveCN110243602AEasy to disassembleImprove general performanceMachine bearings testingInvestigating abrasion/wear resistanceTemperature controlRadial stress

The invention provides a joint bearing low-temperature wear test system. The system comprises a base, a temperature box, a radial stress subsystem, a power subsystem, a temperature control subsystem, a wear measurement subsystem and a clamp subsystem. The clamp subsystem comprises a pushing block, a loading plate, an accompanying test bearing seat, a mandrel, an accompanying test bearing, an end cover and a locking part, which are independent detachable parts; the mandrel, the pushing block or the loading plate can be replaced to realize clamping in a life test of joint bearings with different diameters, so that the utilization rate and the universality of a test clamp are improved; and in addition, the clamp subsystem adopts the structural design improvement that a single-side flange is added to an inner hole of the loading plate, the thickness of the pushing block is reduced, the flange and the end cover cooperatively fix the accompanying test bearing, and the like, so that the mandrel deformation or breakage easily caused in the joint bearing wear test process is effectively avoided.

Owner:CHINA AERO POLYTECH ESTAB

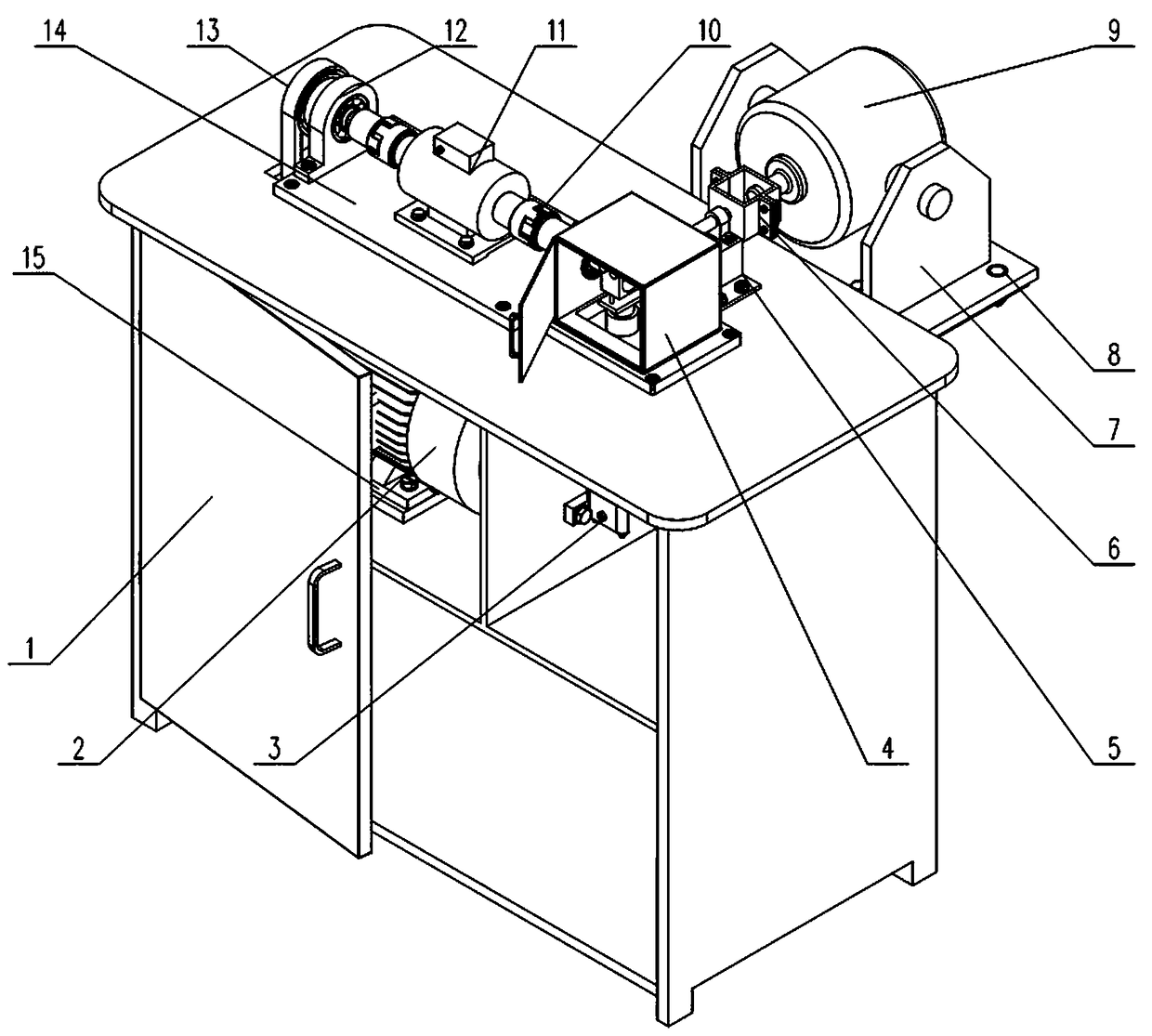

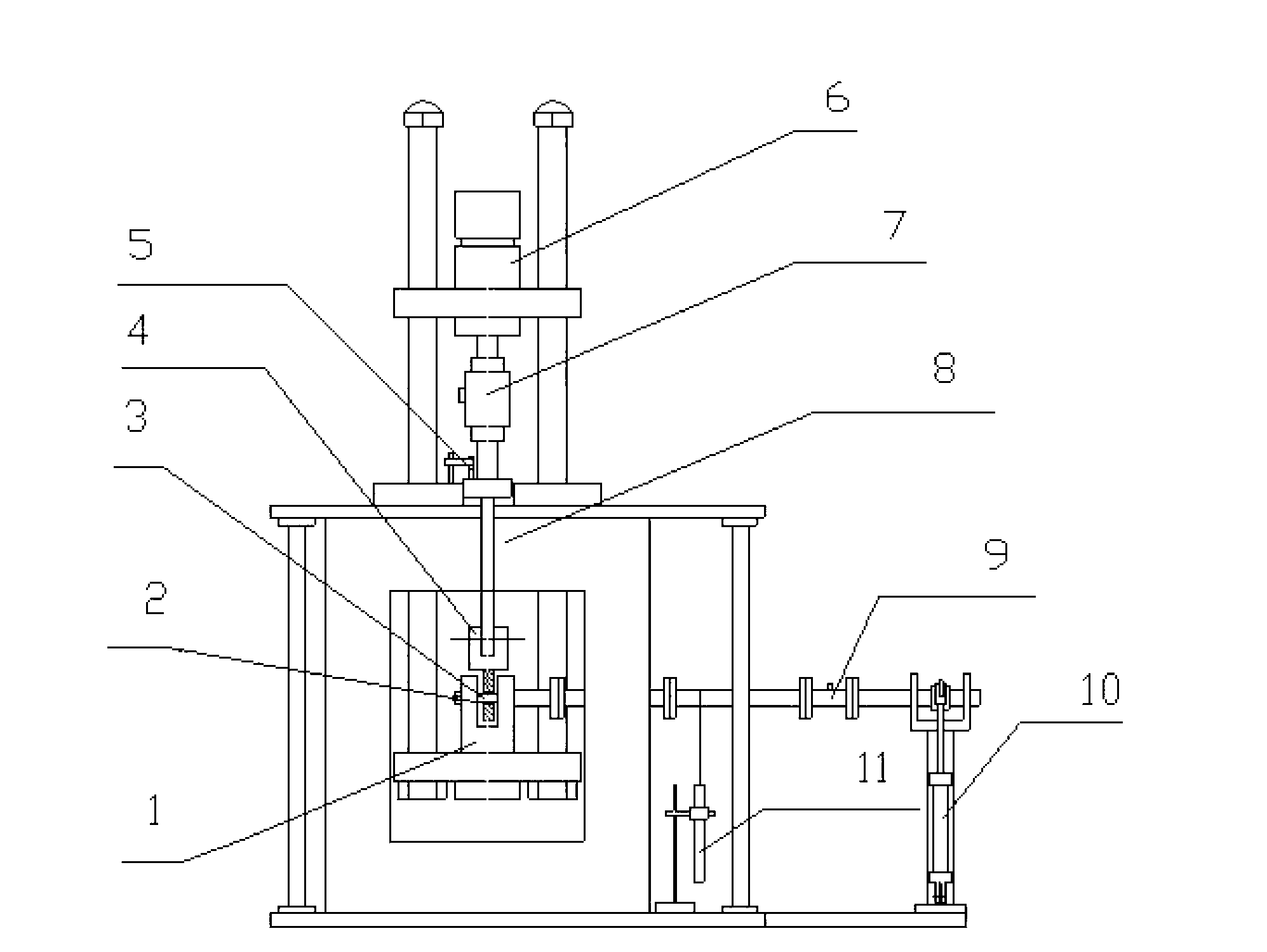

Bearing impact friction-wear testing machine

ActiveCN109084981AMachine bearings testingInvestigating abrasion/wear resistanceWear testingImpact system

The invention discloses a bearing impact friction-wear testing machine. The bearing impact friction-wear testing machine comprises a test stand, a main drive system, a friction pair system, a radial impact system, a hydraulic loading system, a temperature and humidity control system, a signal acquisition and detection system and a computer. The working condition in the friction pair system duringa bearing friction-wear test is changed through the main drive system, the hydraulic loading system and the temperature and humidity control system, and the vibration condition in the vibration bearing operation is simulated by the radial impact system; and the bearing friction-wear output parameters in the friction pair system are collected and monitored in real time by the signal acquisition anddetection system, and are transmitted to the computer through a data acquisition card for data processing and analysis so as to carry out a friction-wear test of a bearing under the coupling effect of impact and friction. The bearing impact friction-wear testing machine provides an effective testing platform for studying the wear behavior of the bearing under the coupling effect of the impact andfriction, and the collected test parameters can be used as judging criterions for bearing wear state identification.

Owner:CHINA UNIV OF MINING & TECH

Rack and pinion steering apparatus having rack bearing wear compensation with damping

ActiveUS20080190229A1Reaction is slowAvoid over-tighteningSpringsNon-rotating vibration suppressionGear wheelBearing wear

A power steering apparatus includes a housing defining a chamber. A rack is disposed within the chamber and is moveable along a longitudinal axis. A pinion extends into the chamber for meshing engagement with the rack. A bearing supports the rack relative to the housing and is moveable relative to the housing to re-position the rack relative to the pinion. An adjustment mechanism continuously biases the bearing in response to loosening of the meshing engagement to re-position the rack. A dampener resists the movement of the bearing to slow the re-positioning of the bearing. Preferably, the dampener includes a plastic fluid having a very high viscosity. The plastic fluid is disposed between adjacent moving parts to resist the relative movement between the bearing and the housing.

Owner:STEERING SOLUTIONS IP HLDG +1

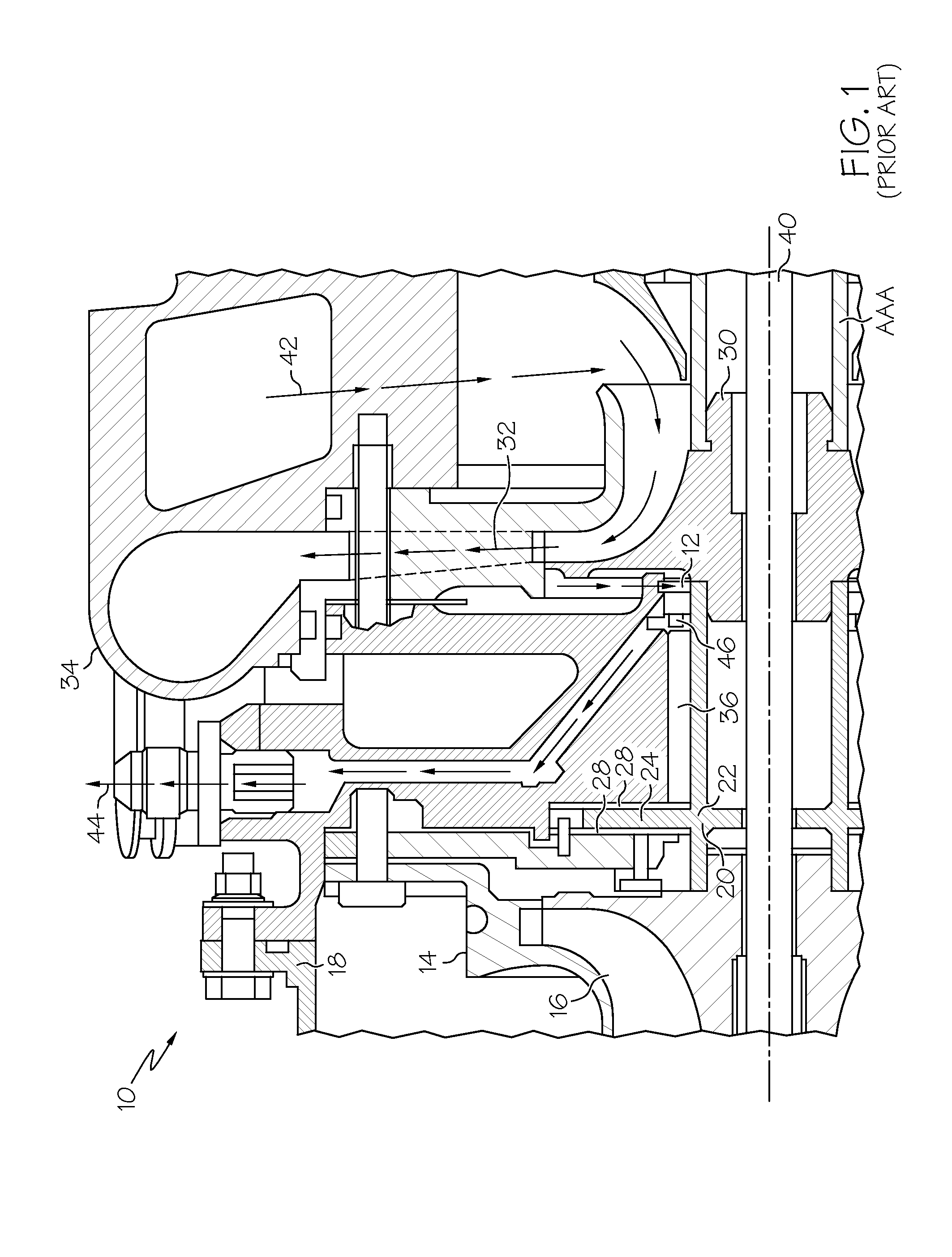

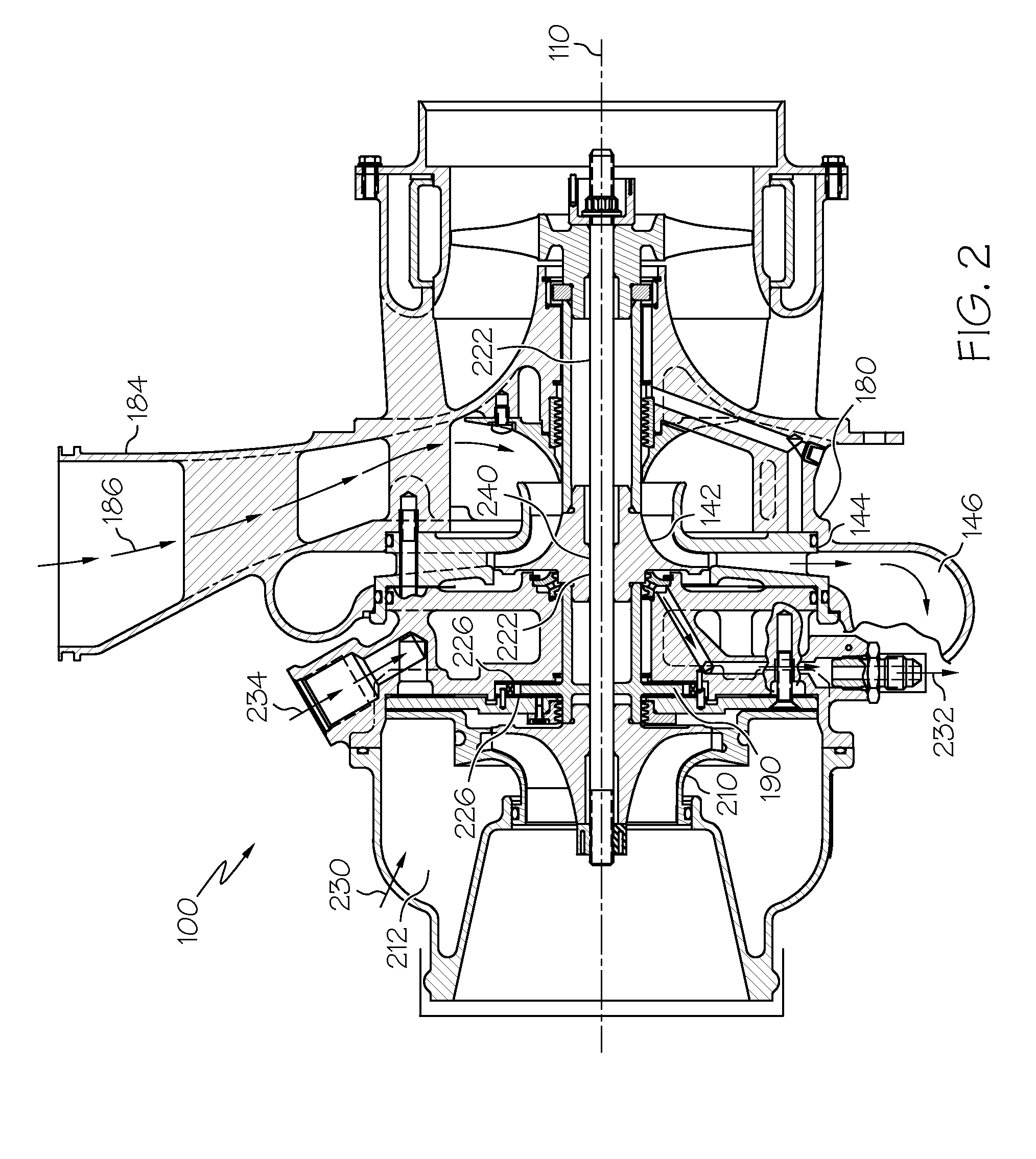

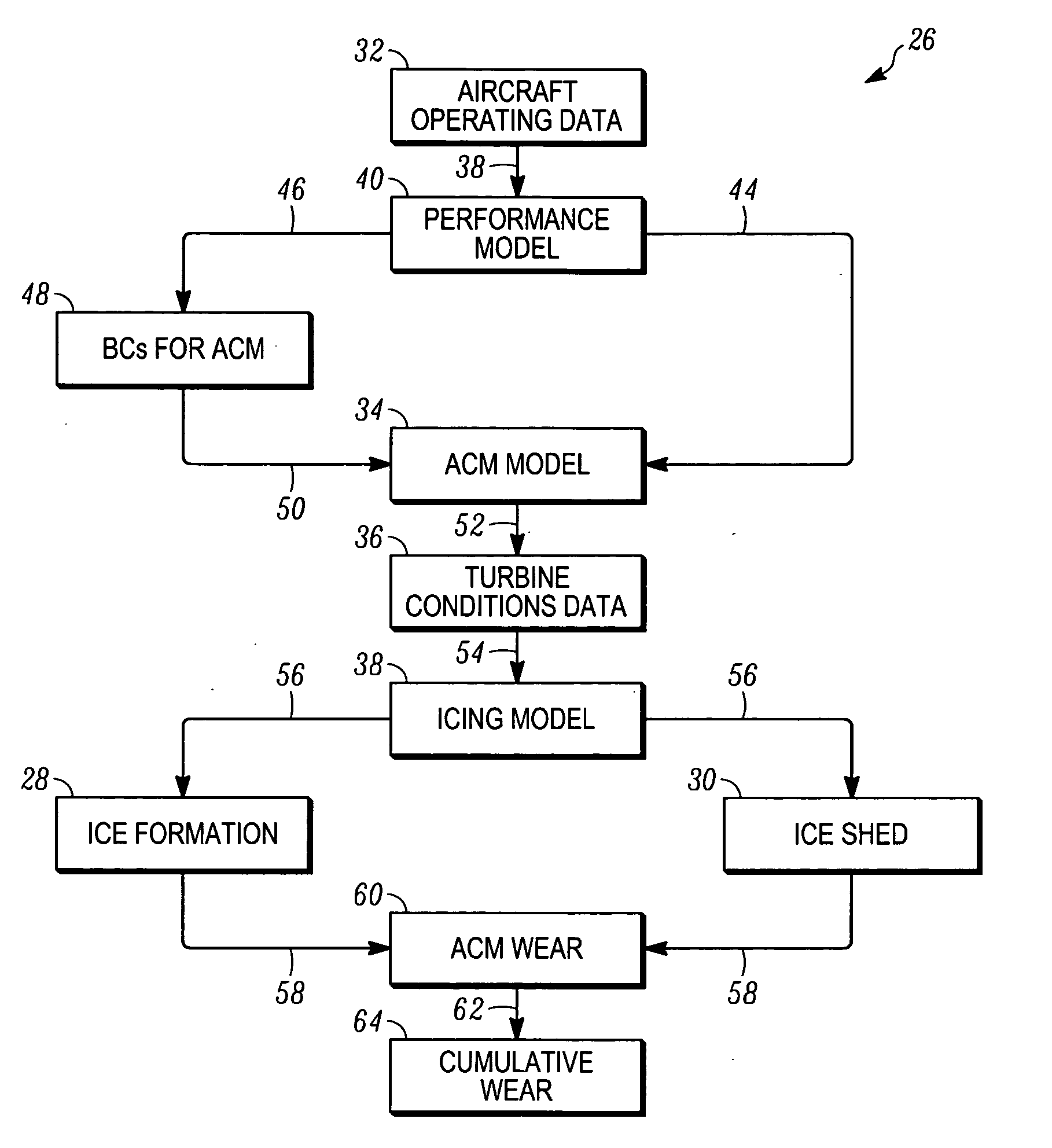

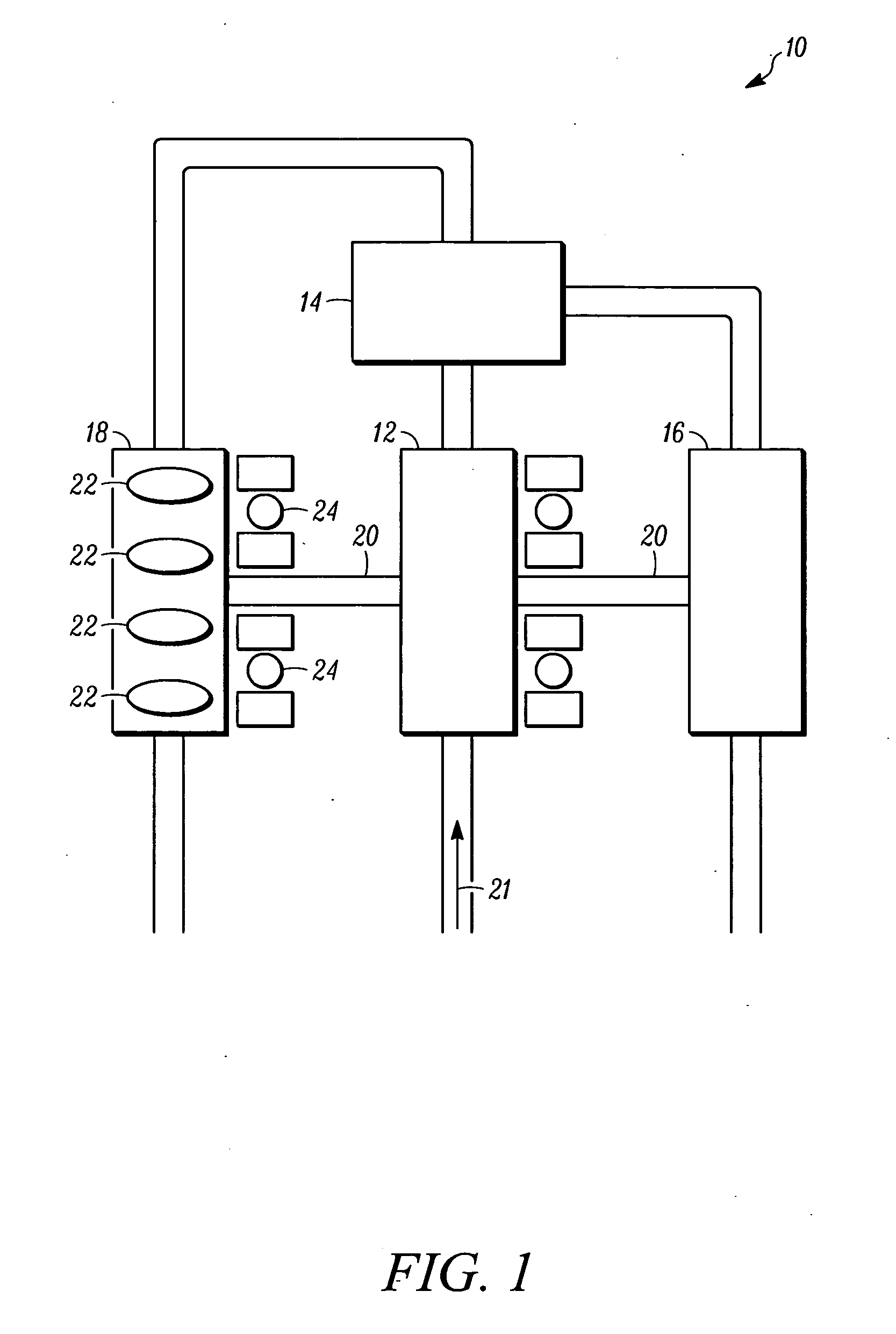

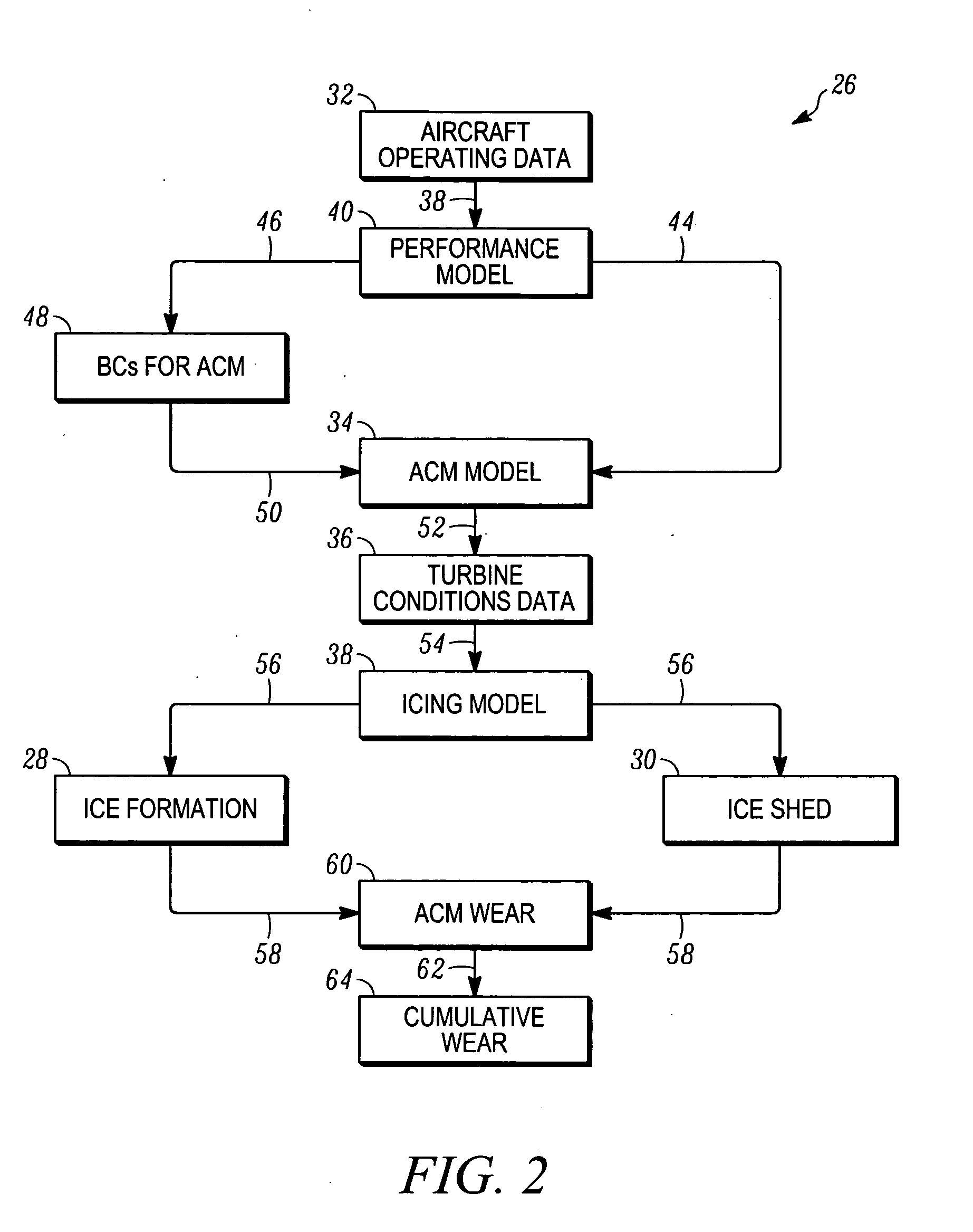

Method for predicting air cycle machine turbine ice formation and shedding and journal bearing wear

Methods and apparatus are provided for predicting ice formation on and shedding from blades of an air cycle machine (“ACM”) turbine. The method comprises generating operational condition data representative of ACM turbine operating conditions using a software model of the ACM, determining an amount of ice formation on the blades of the ACM turbine, and determining an amount of ice shed from the blades of the ACM turbine. The apparatus comprises means for generating operational condition data representative of ACM turbine operating conditions using a software model of the ACM, means for determining an amount of ice formation on the blades of the ACM turbine, and means for determining an amount of ice shed from the blades of the ACM turbine. In some embodiments, the means and apparatus may also involve predicting ACM wear, based at least in part on the predicted ice formation and shedding.

Owner:HONEYWELL INT INC

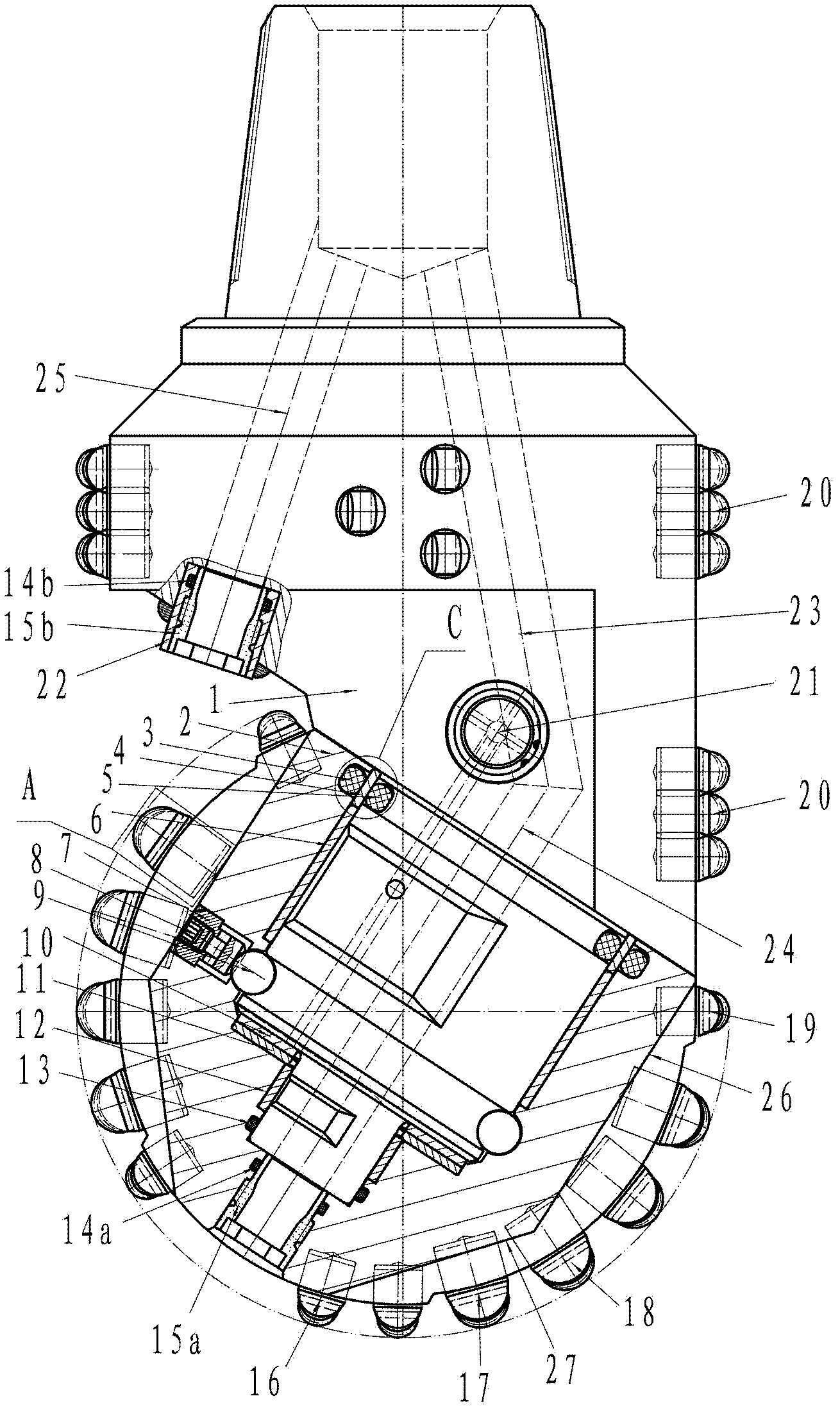

Single-roller bit with PDC (polycrystalline diamond compact) composite plates

ActiveCN102536124AReduce frictional heatExtend your lifeDrill bitsConstructionsWork performanceWell drilling

The invention discloses a single-roller bit with PDC (polycrystalline diamond compact) composite plates, which is characterized in that diamond PDC plates are brazed on a toothed column and then are embedded on a roller, a bearing is sealed with a metal ring in a combined manner by two O-shaped rings, high-speed rotating radial combined sealing of a roller groove diameter and a ring outer diameter and high-speed rotating radial combined sealing of a ring inner diameter and a shaft groove diameter are respectively realized alternatively by the aid of the two O-shaped rings, the sealing life of each single O-shaped ring is prolonged, and bearing abrasion speed is reduced by the aid of double thrust cushions; gauge protection ability and work stability of the bit are increased by two-stage gauge protection; and high-speed slurry sprayed out via a hydraulic jetting system cleans rocks of a shaft bottom, a surface of the roller and PDC teeth and carries rock scraps at the shaft bottom to return upwards, the multiple groups of gauge protection PDC composite plates are arranged reasonably, work indexes of the bit are greatly increased under the condition of ultra-high rotation speed, well drilling cost is reduced, the rotation speed of the bit and torque of the PDC plates are reduced as compared with a PDC bit, damage to the PDC plates due to rotation is reduced, and work performances of the single-roller bit can be greatly improved.

Owner:陕西金刚石油机械有限公司

Additive system for lubricants

ActiveUS20060229214A1Improved lubricant compositionSimple compositionAdditivesTriazole antifungalsBearing wear

The invention relates to compositions suitable as additive packages for lubricants and other functional fluids, the composition comprising sulfur-containing extreme pressure components, phosphorus-containing anti-wear additives, a triazole-containing species. A preferred use is in industrial gear oils. In embodiments, enhance protection in the areas of bearing wear and micropitting are obtained.

Owner:THE LUBRIZOL CORP

Elastic support foil hydrodynamic gas bearing with inherent structure pre-wedge space

PendingCN107725593AReduce shakingWhirl suppressionGas cushion bearingsSliding contact bearingsContact timeEngineering

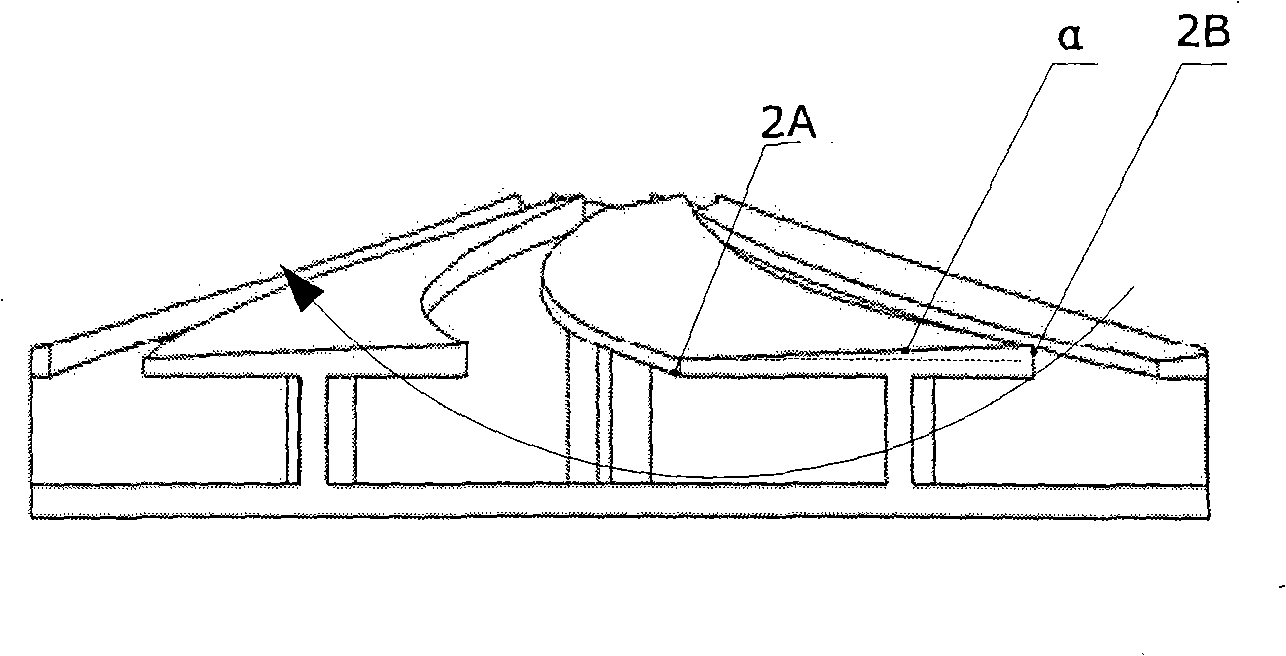

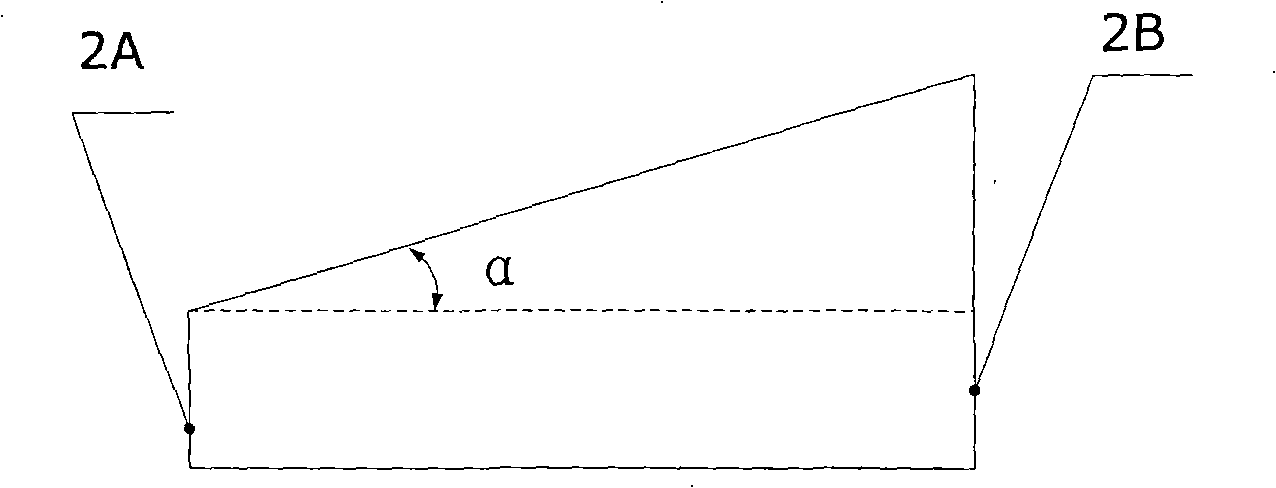

The invention discloses an elastic support foil hydrodynamic gas bearing with inherent structure pre-wedge space. The elastic support foil hydrodynamic gas bearing comprises a bearing body and a rotary shaft located in the bearing body. An elastic support element is arranged on the inner side of the bearing body. Top-layer flat foil is arranged between the elastic support element and the rotary shaft. A smooth shaft segment is arranged on the axial middle area of the surface of the rotary shaft. The positions, located on the two sides of the smooth shaft segment, of the surface of the rotary shaft are each provided with a line of inclined grooves. The inner side of the top-layer flat foil surrounds and wraps the rotary shaft, a pre-clearance is formed between the top-layer flat foil and the rotary shaft, meanwhile, the elastic support element and one end of the top-layer flat foil are fixed to the same position of the bearing body, and the other end of the top-layer flat foil is free.The elastic support foil hydrodynamic gas bearing has the beneficial effects that a hydrodynamic gas film can be formed at the relatively-low rotating speed with small foil deformation, the rotary shaft and the bearing body are in contact uniformly in the start stage and the stop stage, the contact friction time between the rotary shaft and the bearing body is shortened, wear between the rotary shaft and the bearing body is reduced, and the operation stability and reliability of a system are improved.

Owner:XI AN JIAOTONG UNIV +1

Hybrid touchdown bearing system

InactiveUS7830055B2Extend your lifeIncrease speedRolling contact bearingsEngine componentsLevitationMomentum

Owner:BEACON POWER LLC

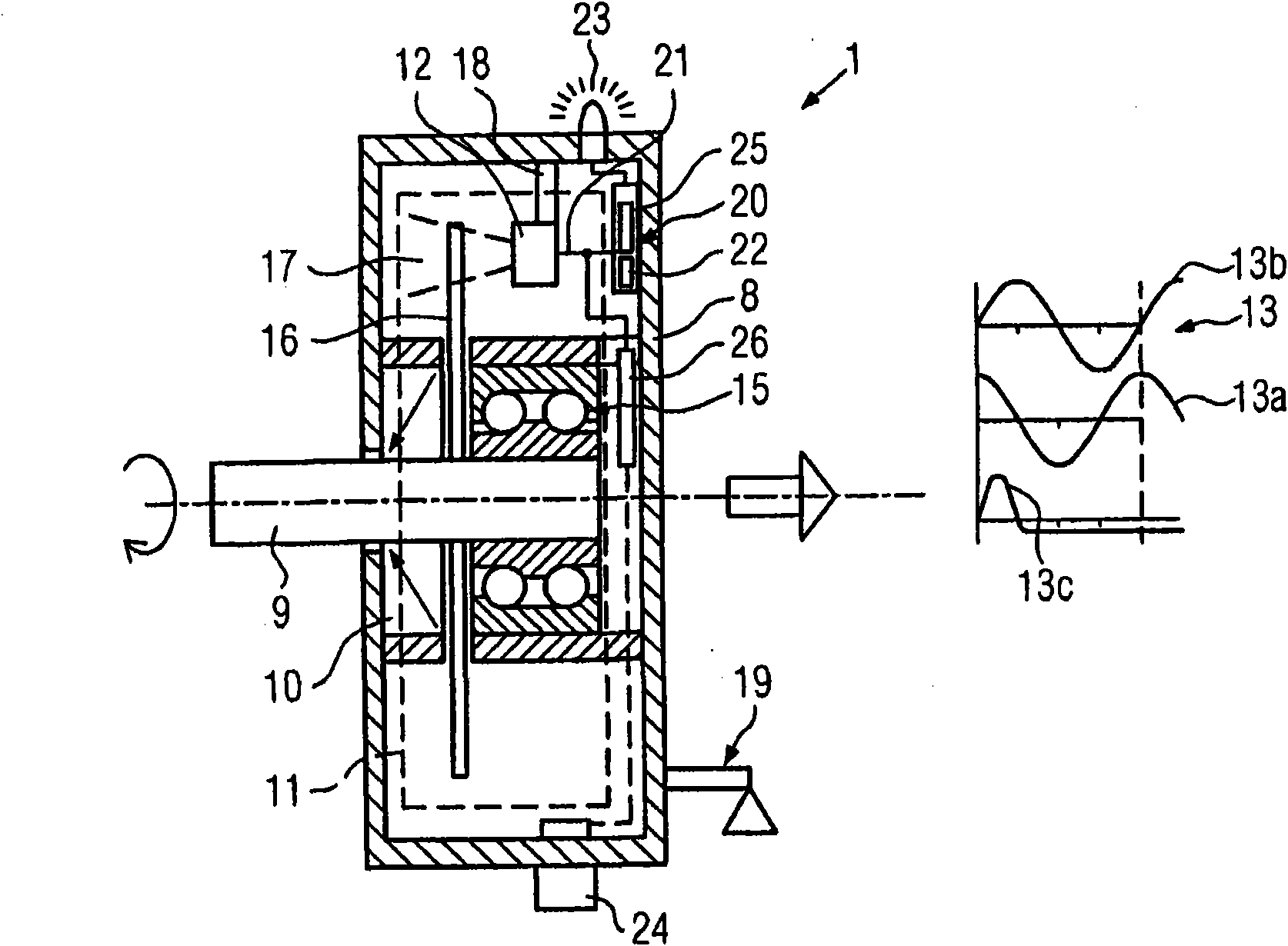

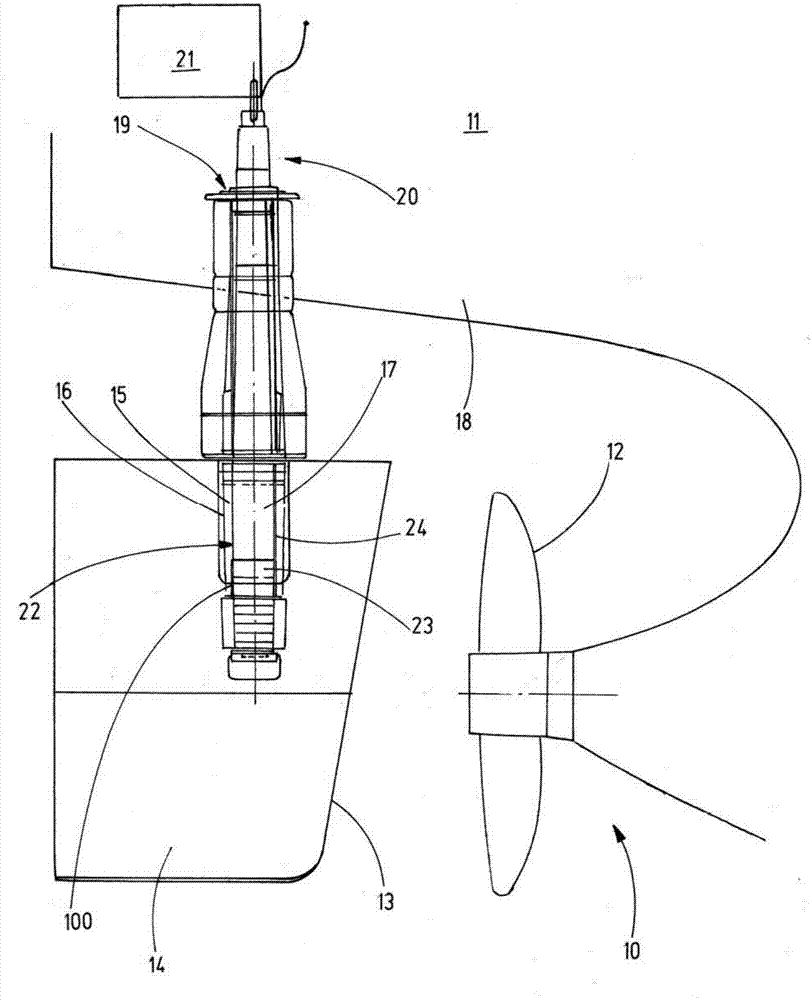

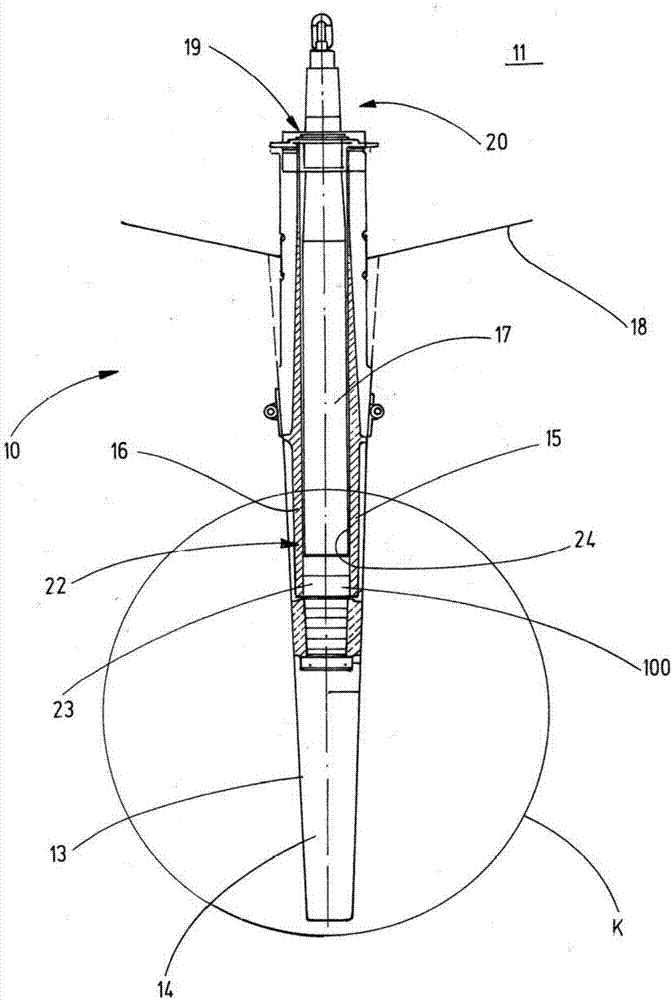

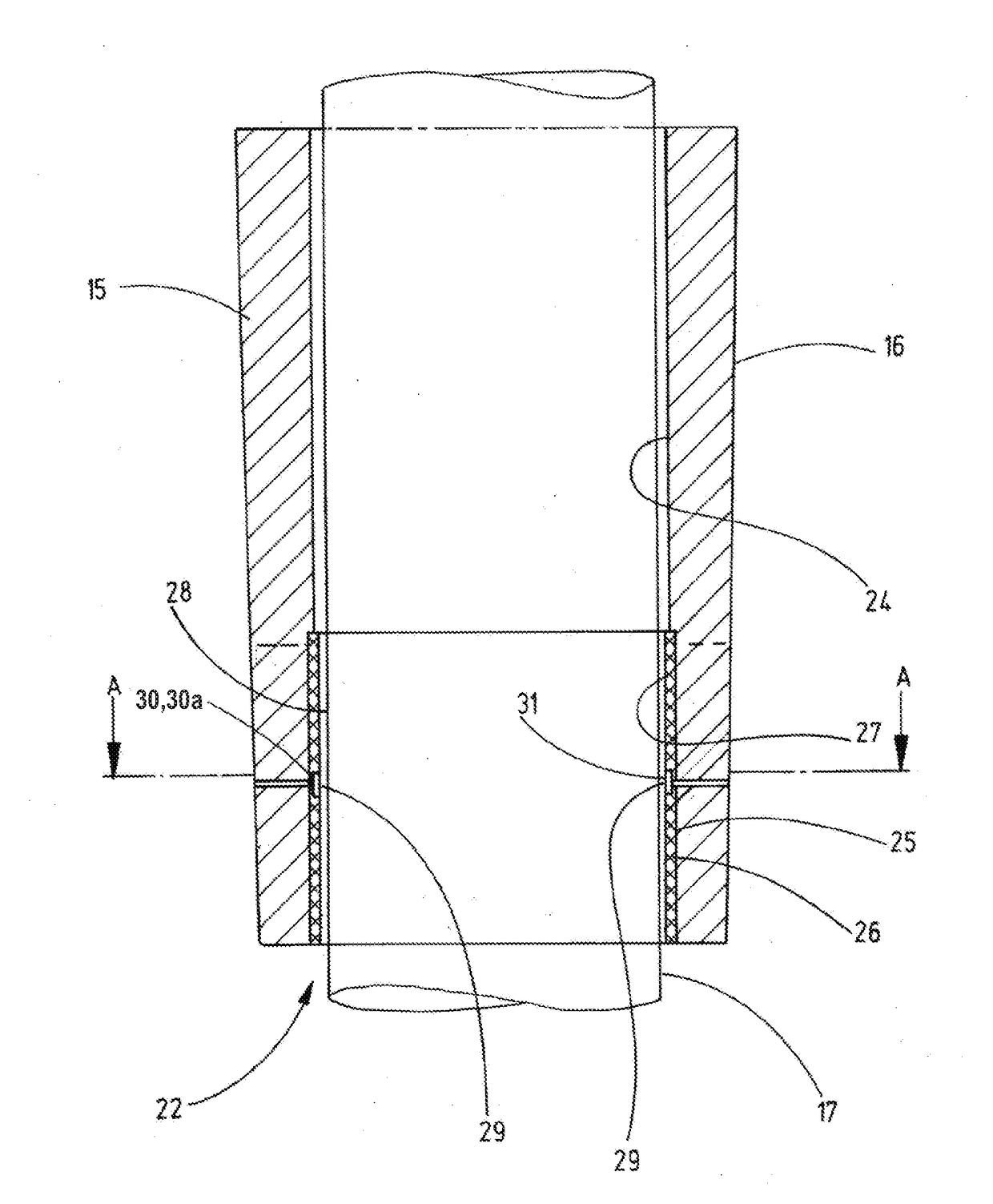

Rotary transducer with monitoring of the bearing wear and method therefor

The invention relates to a rotary transducer (1) and to a method for monitoring wear on the latter. The rotary transducer has a detector device (11) having at least one measurement sensor (12). During operation, the measurement sensor can be used to generate a measurement signal (13) which is representative of the angular position and / or velocity of an object which can be connected to the rotary transducer. The detector device (11) has at least one rotary bearing (15) and at least one material measure (16) which can be rotated, by means of the rotary bearing, relative to the measurement sensor and is arranged in the measurement field (17) of the latter. A monitoring device (20) which is connected to the measurement sensor such that data are transmitted and can be used, during operation, to output a state signal (23), which is representative of the state of wear of the rotary transducer, on the basis of the measurement signal is also integrated in the rotary transducer (1). In order tobe able to warn of mechanical failure of the rotary transducer in good time, the monitoring device (20) is provided, according to the invention, with a register (25) which can permanently store a value which is representative of the state of wear of the rotary bearing and is formed from the information relating to the angular position and / or velocity which is contained in the measurement signal.

Owner:堡盟德国有限两合公司

Contaminant-deflector labyrinth seal and method of operation

A seal assembly for deflecting contaminated fluid flowing through the seal assembly from an upstream space to a downstream space includes an annular housing, at least one vent hole peripherally disposed on the annular housing, a first set of seals disposed within the annular housing adjacent to the downstream space, the first set of seals having an inclined surface to deflect the flow of contaminated fluid through the at least one vent hole, and a second set of seals mounted on the shaft, disposed within the annular housing, adjacent to the first set of seals and adjacent to the upstream space. The second set of seals may have larger inside diameter than the first set of seals. The seal assembly may prevent contaminated fluid from entering an air bearing cooling circuit, thereby preventing bearing wear, erosion and failure.

Owner:HONEYWELL INT INC

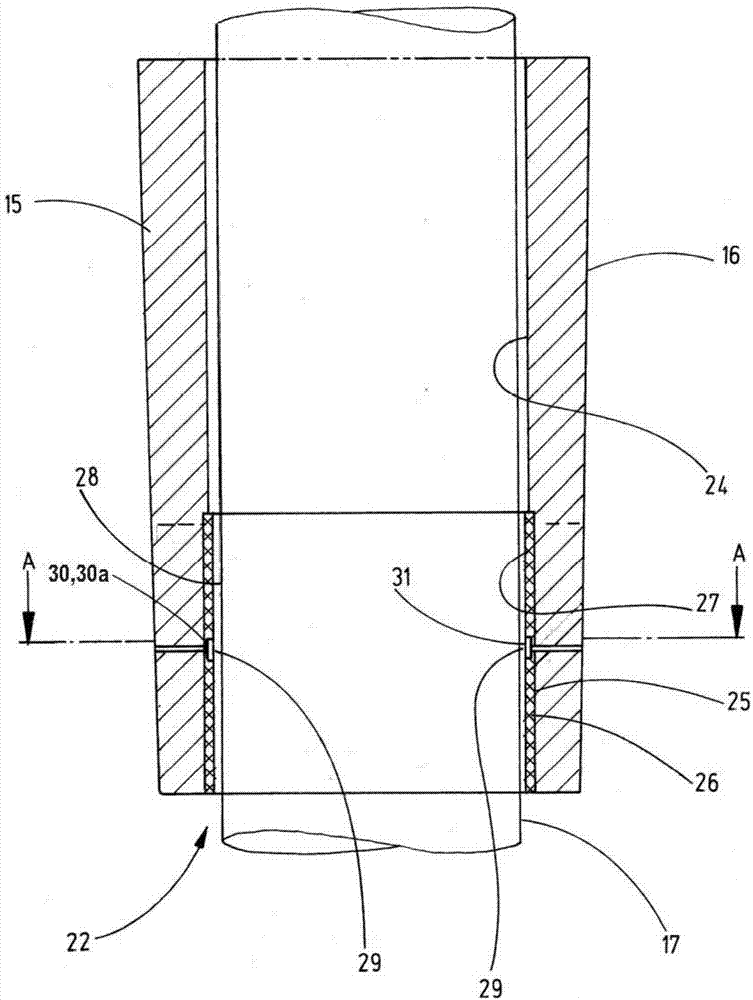

Bearing for supporting a shaft, in particular a rudder shaft, or a rudder blade, electronic bearing clearance measuring device, rudder comprising a bearing for supporting a shaft or a rudder blade, and method for measuring wear of a bearing for supporting a shaft or a rudder blade

The invention relates to a bearing for supporting a shaft, in particular a rudder shaft, or a rudder blade, by means of which bearing the bearing play or the bearing wear can be continuously monitored, determined, and optionally documented. According to the invention, for a bearing for supporting a shaft, in particular a rudder shaft, comprising a first bearing element and a second bearing element, wherein the first bearing element has a sliding surface for contacting the second bearing element in a sliding manner, and a measurement-value sensor having a wear surface for contacting the second bearing element in a sliding manner, the at least one measurement-value sensor is not pin-shaped.

Owner:BECKER MARINE SYST

Hydrodynamic suspension bearing for artificial heart

The invention discloses a hydrodynamic suspension bearing for artificial heart. A rotor with arc inner top surface is embedded in a circular groove of stator with arc top, a circular permanent-magnet magnetic steel is arranged on the inner ring of the rotor, a electromagnetic coil is fixed on the outer ring of the stator, the top of the stator is provided with a pitch-variable helical groove, a constant-pitch helical groove is arranged on the outer ring of the stator, an impeller is arranged at the upper top of the stator and in the pump shell, the pump shell is integrated with the stator, the blood flow in from the inlet of the pump shell, most of blood flow out from the outlet of the pump shell by the rotating of the impellor, a small amount of blood form a closed loop in the clearance between the helical grooves of the rotor and the stator, the clearance between the lower surface of stator and the bottom of the rotor and clearance between the inner wall of the rotor and the stator, and is merged with the blood at the inlet. The invention has simple structure, less bearing wearing, small heating amount and power consumption, reduces the energy input of the artificial heart, thus being beneficial for the light and portable artificial heart.

Owner:ZHEJIANG UNIV

Bearing for supporting a shaft, in particular a rudder shaft, or a rudder blade, electronic bearing clearance measuring device, rudder comprising a bearing for supporting a shaft or a rudder blade, and method for measuring wear of a bearing for supporting a shaft or a rudder blade

InactiveUS20170122366A1Reduce riskAvoid damageSteering ruddersMachine bearings testingBearing wearEngineering

The invention relates to a bearing for supporting a shaft, in particular a rudder shaft, or a rudder blade, by means of which bearing the bearing clearance or the bearing wear can be continuously monitored, determined, and optionally documented. According to the invention, for a bearing for supporting a shaft, in particular a rudder shaft, comprising a first bearing element and a second bearing element, wherein the first bearing element has a sliding surface for contacting the second bearing element in a sliding manner, and a measurement-value sensor having a wear surface for contacting the second bearing element in a sliding manner, the at least one measurement-value sensor is not pin-shaped.

Owner:BECKER MARINE SYST

Multivariant linear arc-shaped motor

InactiveCN101789646AReduce wearEliminate radial forceMechanical energy handlingPerformance indexBearing wear

The invention discloses a multivariant linear arc-shaped motor, comprising a rotary motion linear arc-shaped motor, a rectilinear motion linear arc-shaped motor, a motion shaft and the like. Bridge arc-shaped stators of the rotary motion linear arc-shaped motor and the rectilinear motion linear arc-shaped motor are integrated into a whole by fasteners and step-shaped structures, stator core laminations are distributed in space in an orthogonal manner, stator windings are arranged in an orthogonal and zoning manner, a cylindrical rotor is shared by the two motors, and stator core zone areas and structural parameters thereof can be respectively selected for the two linear arc-shaped motors according to performance indexes. By adopting the scheme in the invention, a load can be directly driven to do linear, rotary or spiral motion, and the multivariant linear arc-shaped motor has the advantages of simple and compact structure, concise transmission mechanism, small bearing wear, easy control and the like.

Owner:HENAN POLYTECHNIC UNIV

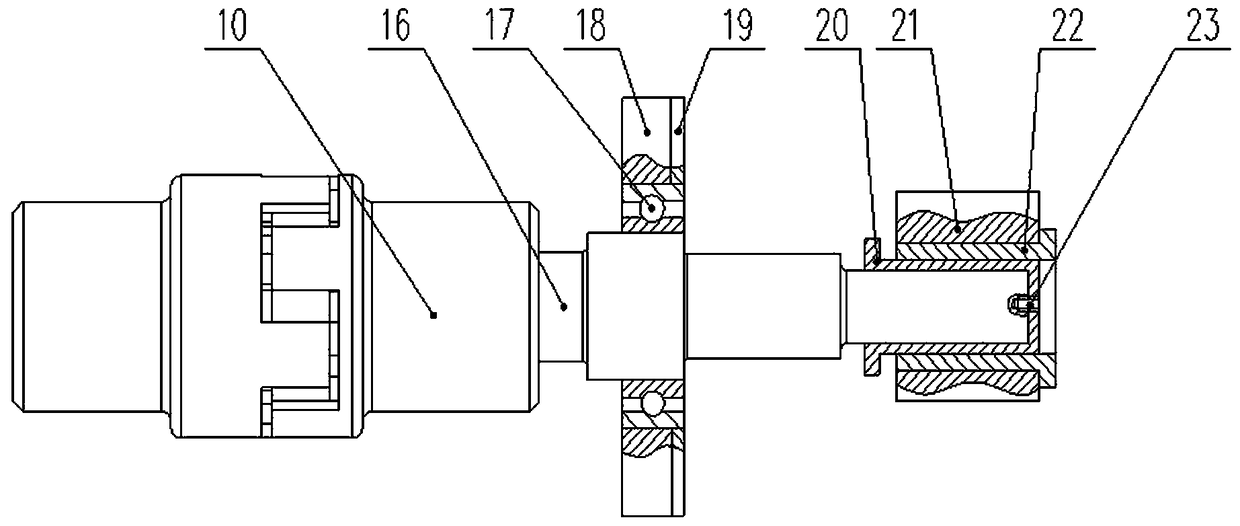

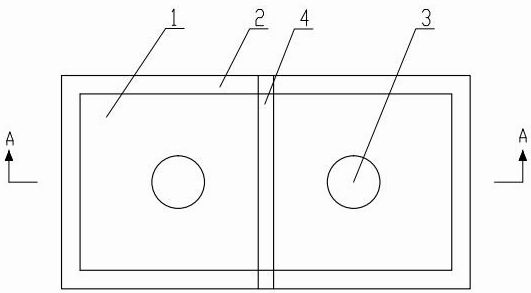

Apparatus used for bearing wearing test

InactiveCN103267697ASolve the problem of wear and tearAvoid destructionInvestigating abrasion/wear resistanceEngineeringBearing wear

The invention relates to an apparatus used for a bearing wearing test. The apparatus includes a double-fork pedestal (1), a bearing test piece (2) is installed on the double-fork pedestal (1) through a mandrel (3), the upper portion of the bearing test piece (2) is attached to a loading single ear (4), the loading single ear (4) is connected with a loading actuating cylinder (6), the loading actuating cylinder (6) downward applies radial vertical compression to the bearing test piece (2), and the above assemblies are disposed in a temperature test box (8); and the mandrel (3) is connected with a swing actuating cylinder (10), the swing actuating cylinder (10) drives the mandrel (3) to rotationally move back and forth at + / -25DEG, and the mandrel (3) is provided with a torque sensor (9) and a spacing sensor (11). Compared with apparatuses in the prior art, the apparatus provided by the invention has the advantages of realization of the various requirements of performance tests of a bearing and a liner which are used by an undercarriage, satisfying of the various requirements of the performances of joint bearing test pieces in Technological Standard of Aerospace Series of Corrosion Resistant Steel Made Self-lubricating Loading Joint Bearing, test cost reduction, and energy consumption saving.

Owner:HARBIN

Ashless antiwear oil film bearing lubricant composition

ActiveCN102766505AImprove filtering effectGood demulsibilityLubricant compositionWire rodFoaming agent

The invention provides an ashless antiwear oil film bearing lubricant composition, which comprises: (A) at least a highly refined mineral oil with high viscosity index; (B) at least an emulsifier; (C) at least an anti-foaming agent; (D) at least an ashless phosphorus-containing antiwear additive; (E) at least an anti-oxidant; and (F) at least a metal passivator. The above lubricant component has excellent demulsibility, filterability, anti-foaming property, air release property, abrasion resistance and oxidation resistance, passes through FAG FE-8 bearing wear experiments, SKFEMCOR bearing corrosion experiments and FLENDER anti-foaming experiments, and is suitable for lubricating various bearings and industrial gears, especially lubricating highspeed wire rod oil film bearings.

Owner:PETROCHINA CO LTD

Polymer composite side bearing wear plate

ActiveCN102050128AStable coefficient of frictionImprove stabilitySynthetic resin layered productsBogie-underframe connectionsWear resistantPlastic materials

The invention discloses a polymer composite side bearing wear plate which is suitable for the field of rail freight. The main body of the plate is a double-layer structure, wherein the upper layer is a wear resistant layer made of a wear resistant material, and the lower layer is an enhancement layer made of a glass fiber reinforced plastic material; and the wear resistant material is prepared from the following raw materials in parts by weight: 12-22 parts of sepiolite fiber, 4-6 parts of glass fiber, 6-10 parts of kaolin, 1.5-2.5 parts of aramid fiber, 5-9 parts of graphite particle, 1.5-2.5 parts of copper fiber, 0.5-1.5 parts of titanium stone powder, 3-5 parts of crystalline flake graphite, 4-8 parts of bauxite and 0.5-1.5 parts of inorganic composite fiber. In the invention, the friction coefficient of the polymer composite side bearing wear plate has small change under the influences of temperature and humidity, thus the friction coefficient is stable, which is beneficial to the improvement of the stability of an elastic side bearing gyroscopic resistance moment so as to further improve the stability and the reliability of the running properties of a heavy-load speed increased freight car.

Owner:HEBEI XINJI TENGYUE INDAL +1

Automobile automatic transmission liquid composition with excellent anti-wear property

Owner:PETROCHINA CO LTD

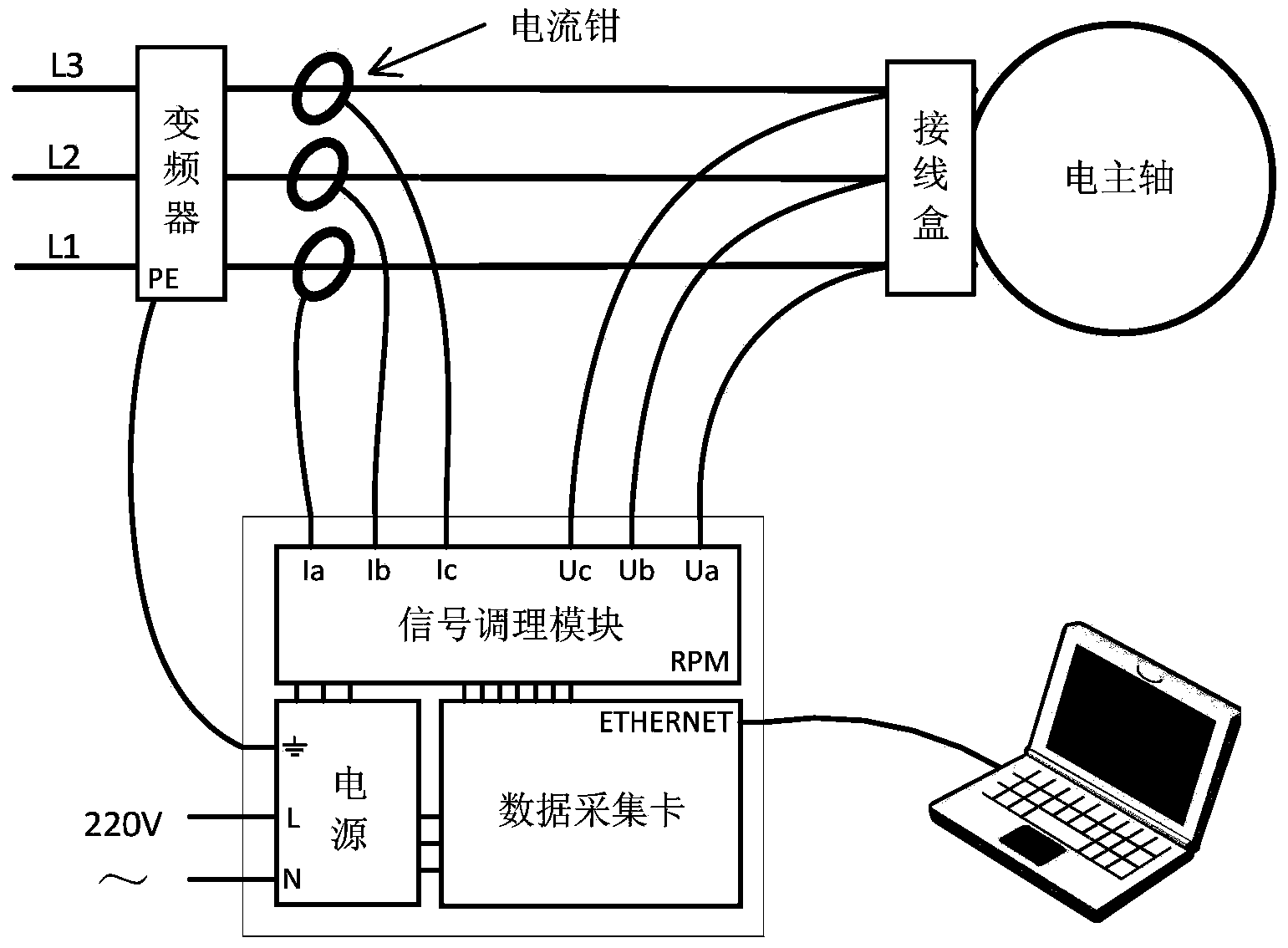

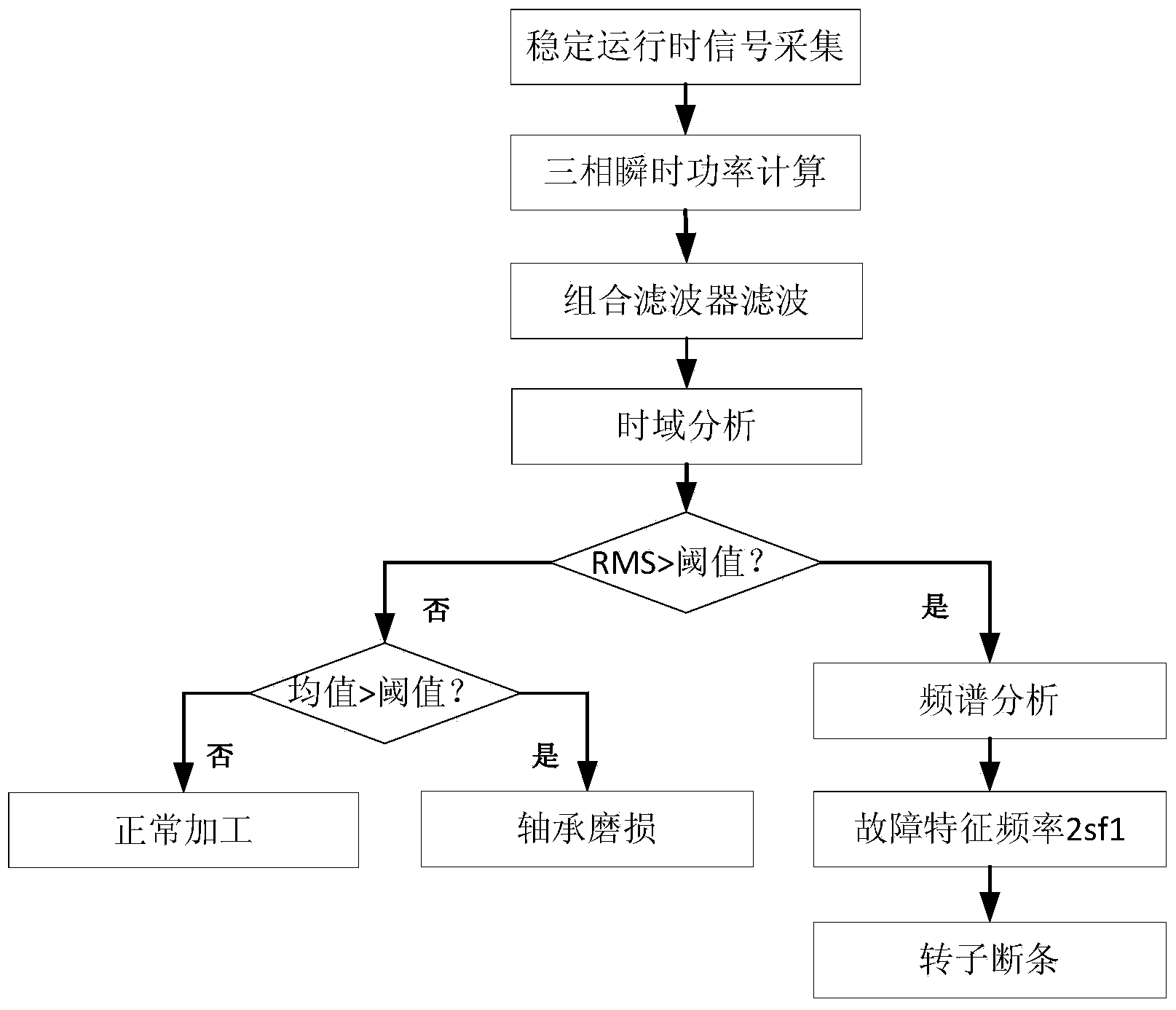

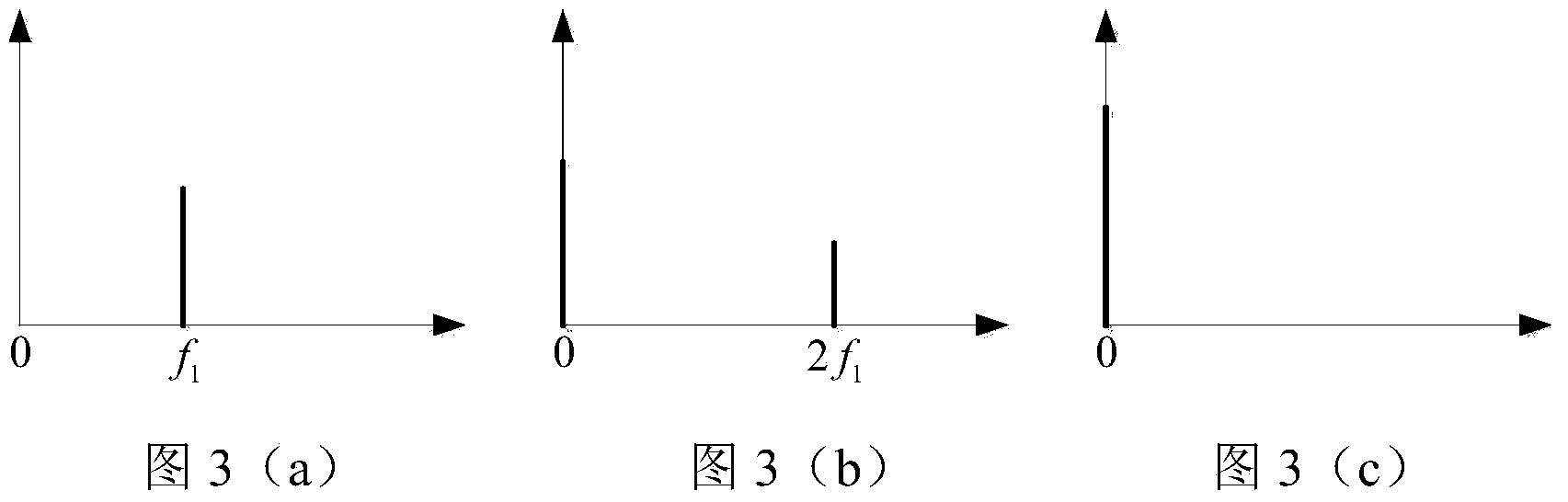

Three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method

The invention discloses a three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method and belongs to the technical field of motorized spindle fault monitoring. According to the three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method, by means of signal demodulation properties and three-phase symmetry characteristics of three-phase instantaneous power, three-phase input voltage and three-phase stator current signals are collected when a motorized spindle is stably operated, three-phase instantaneous power signals are calculated, the influence of supply frequency modulation, frequency rotating and frequency doubling on monitoring and diagnosing results is eliminated through a design of a junction filter, whether the motorized spindle breaks down is determined according to comparison between a mean value and a root-mean-square (RMS) value of the three-phase instantaneous power signals and standard reference values during the operation process, and a fault type is determined according to generation of fault character frequency during spectral analysis, so that monitoring and diagnosing of faults of the motorized spindle are achieved. According to the three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method, the signal collection and processing process is simple, bearing wearing and rotor broken bar faults of the motorized spindle can be effectively monitored, and the method is applicable to state monitoring and fault diagnosing of the motorized spindle on an industrial scene.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com