Elastic support foil hydrodynamic gas bearing with inherent structure pre-wedge space

A dynamic pressure gas bearing and elastic support technology, which is applied in the direction of air cushion bearings, sliding contact bearings, bearings, etc., can solve the problem of reduced bearing stability and reliability, unfavorable dynamic pressure gas film establishment and stability, and reduced service life of shafts and bearings, etc. problems, to achieve the effect of promoting stable operation, improving operation stability and reliability, and suppressing whirl of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

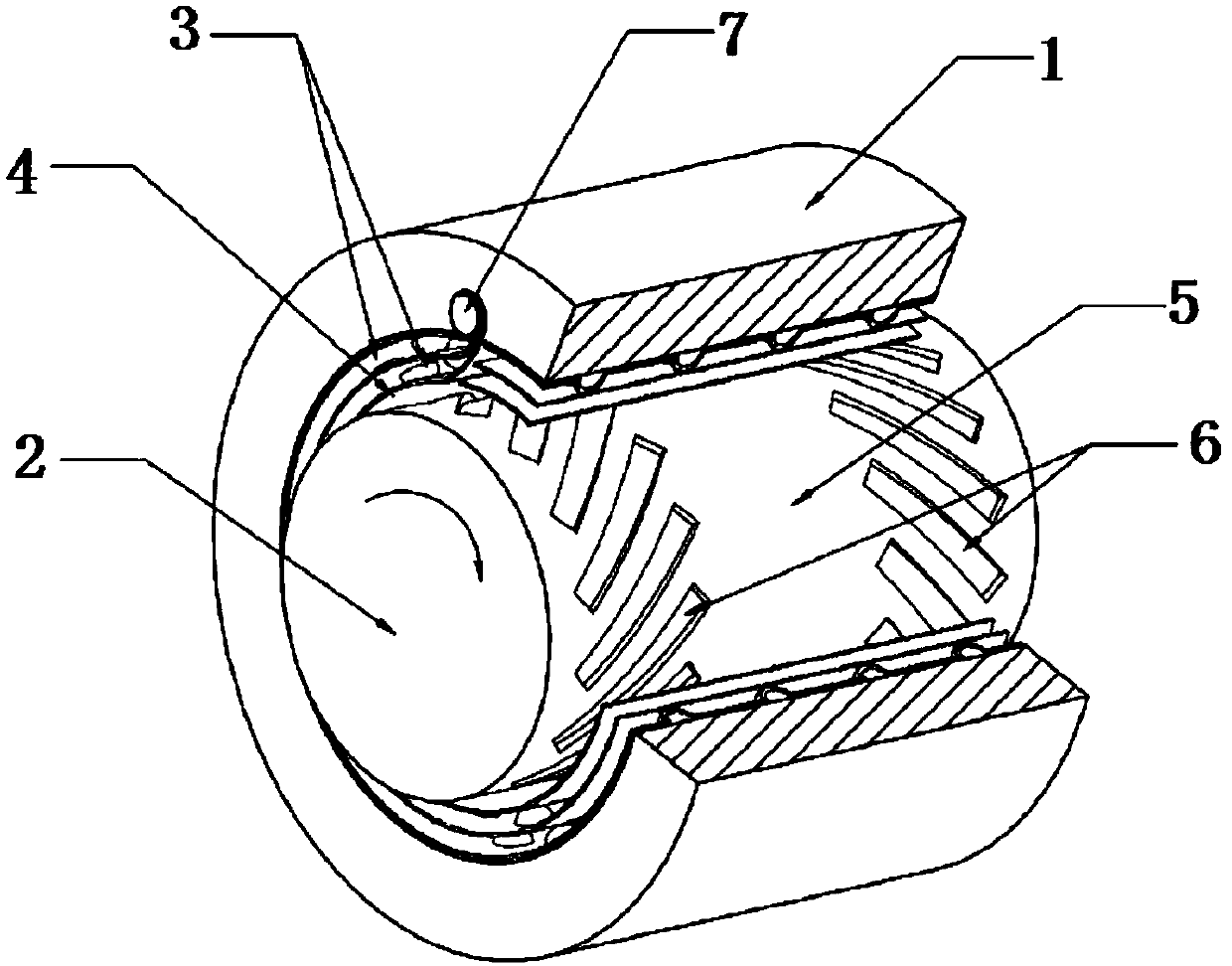

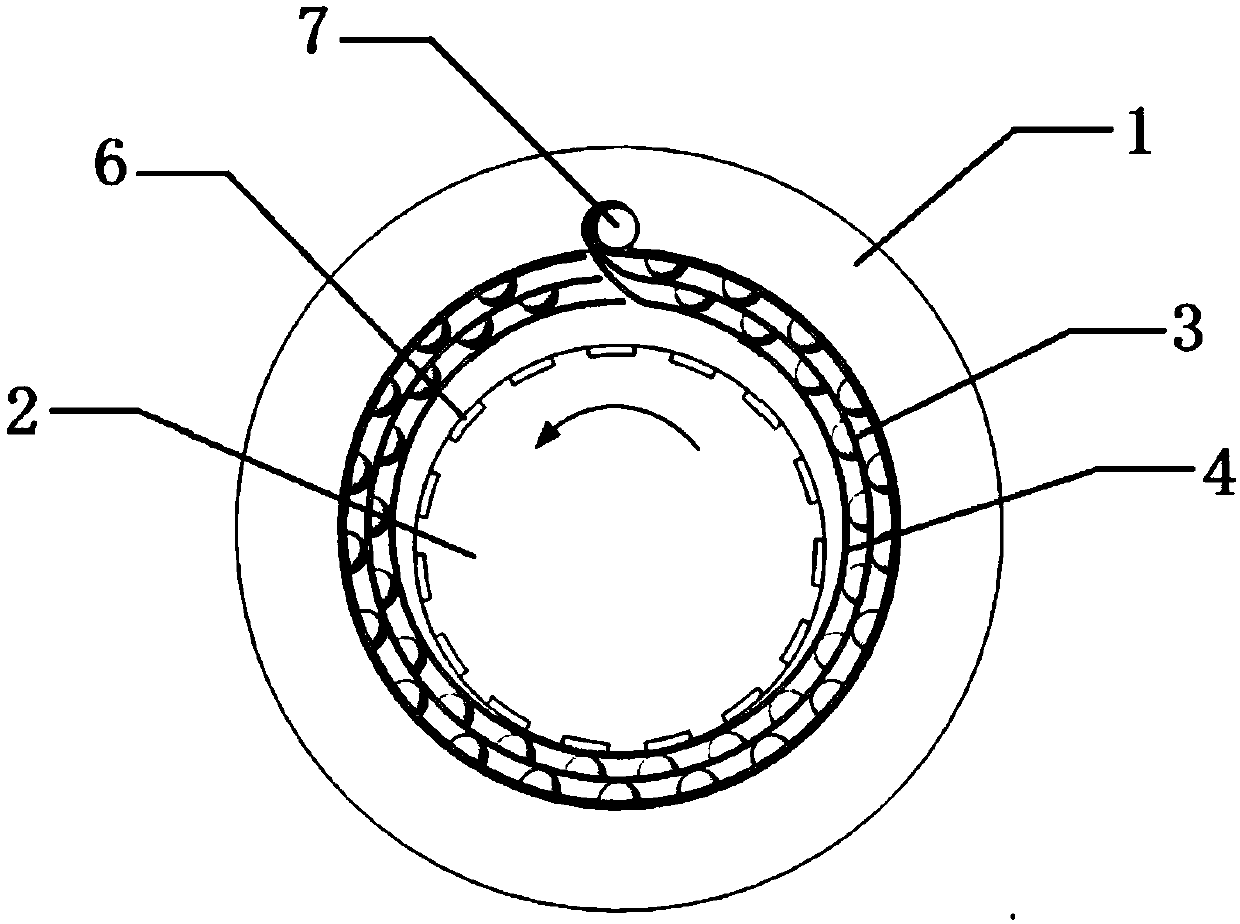

[0024] Example: refer to figure 1 with 2 As shown, an elastically supported foil dynamic pressure gas bearing with an inherent structural pre-wedge space includes a bearing 1 and a rotating shaft 2 inside the bearing 1; an elastic supporting element 3 is arranged inside the bearing 1, and an elastic supporting element 3 The top layer of flat foil 4 is arranged between the shaft 2, the smooth shaft section 5 is arranged in the axial middle area of the surface of the shaft 2, and a row of inclined grooves 6 is respectively arranged on the surface of the shaft 2 and on both sides of the smooth shaft section 5, and the top layer is flat. The inner side of the foil 4 wraps around the rotating shaft 2 and forms a pre-gap between the top flat foil 4 and the rotating shaft 2, while the elastic support element 3 and one end of the top flat foil 4 are fixed on the same position of the bearing 1 and the other end is free.

[0025] The outer end of the inclined groove 6 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com