Novel PDC drill bit utilizing impact effect for improving heart rock breaking efficiency

A technology of rock breaking efficiency and impact action, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of the central rock column affecting the drilling effect, deviating from the center of the wellbore, and shaking from side to side, so as to improve the ROP. , reduce turbulence and recirculation phenomenon, reduce the effect of left and right shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

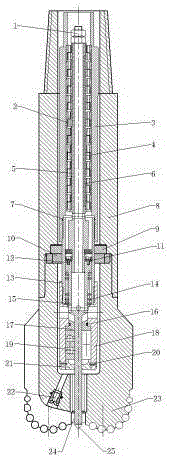

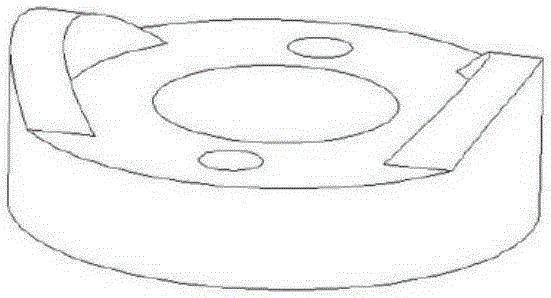

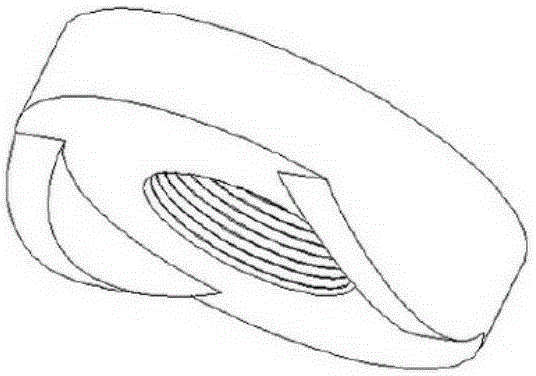

[0012] According to attached figure 1 As mentioned above, the new PDC drill bit, which utilizes the impact action to improve the rock-breaking efficiency of the core, is composed of a drill bit base 8 and an internal device, and the internal device includes a transmission part, a driving part and an impact part. The transmission part includes nut 1, turbine stator 2, upper casing 3, turbine rotor 4, turbine shaft 5, key 6, O-ring 7; the driving part includes upper cam 9, flange 10, lower cam 11, countersunk head Screw 12, cam housing 13, spring 14, hammer body 15, O-ring 16, retaining ring 17; the impact part has lower housing 18, two-way thrust ball bearing 19, countersunk head screw 20, end cover 21, water Eye 22, crown structure 23, central hole 24, pointed composite sheet 25. It is characterized in that the upper casing 3, the cam casing 13 and the lower casing 18 are respectively threaded; the turbine stator 2 is connected with the turbine rotor 4, and is assembled on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com