Patents

Literature

213results about How to "Eliminate slippage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

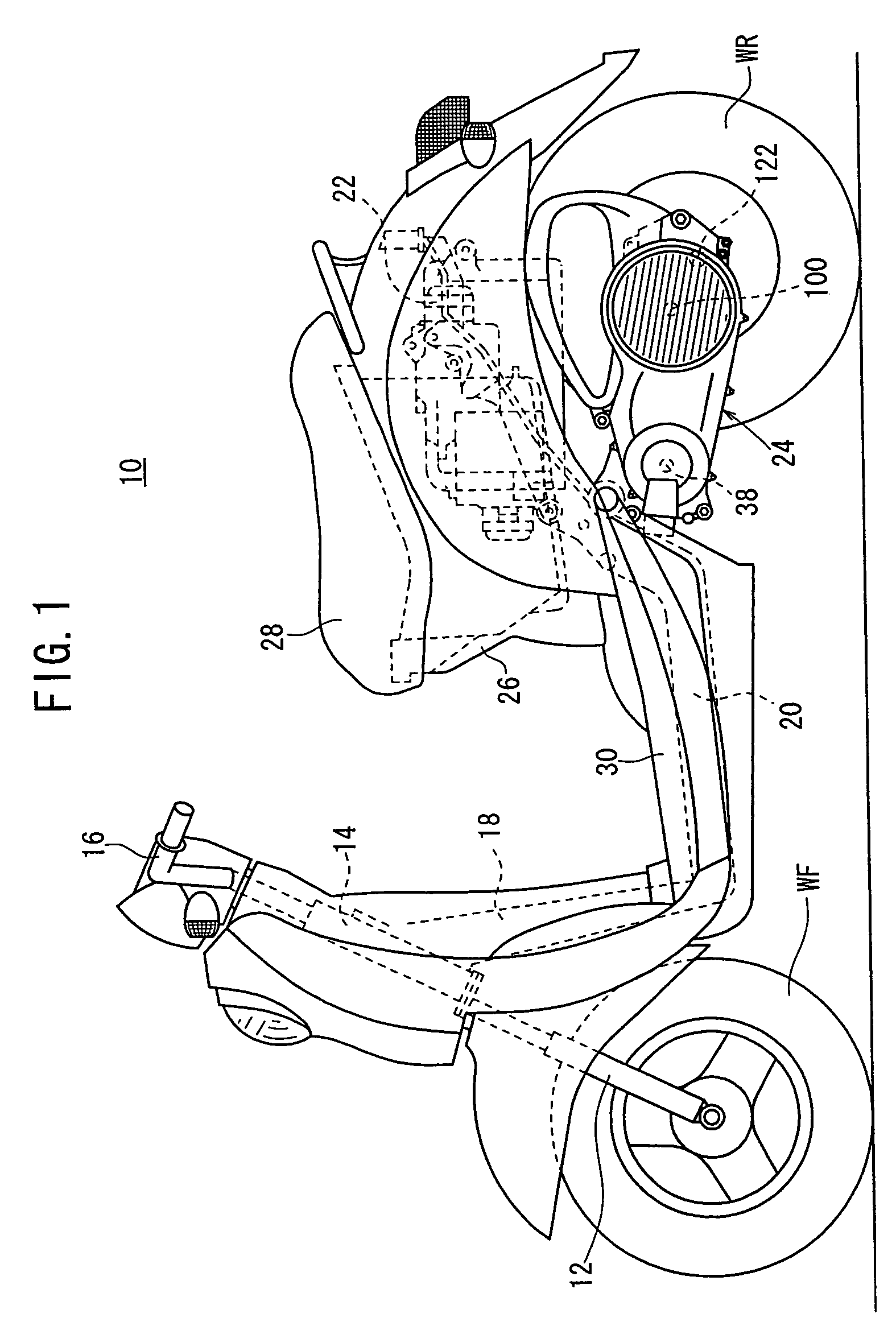

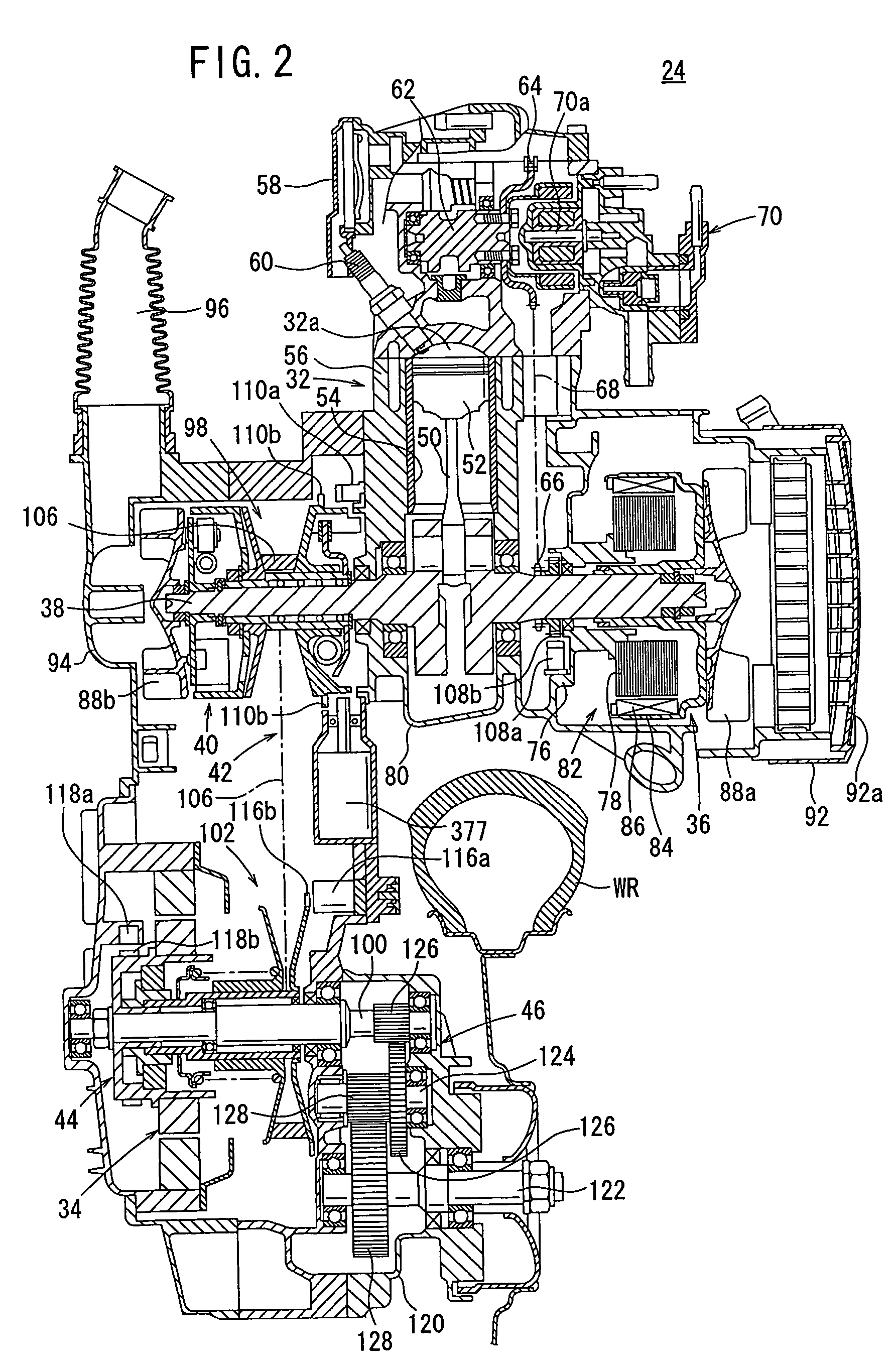

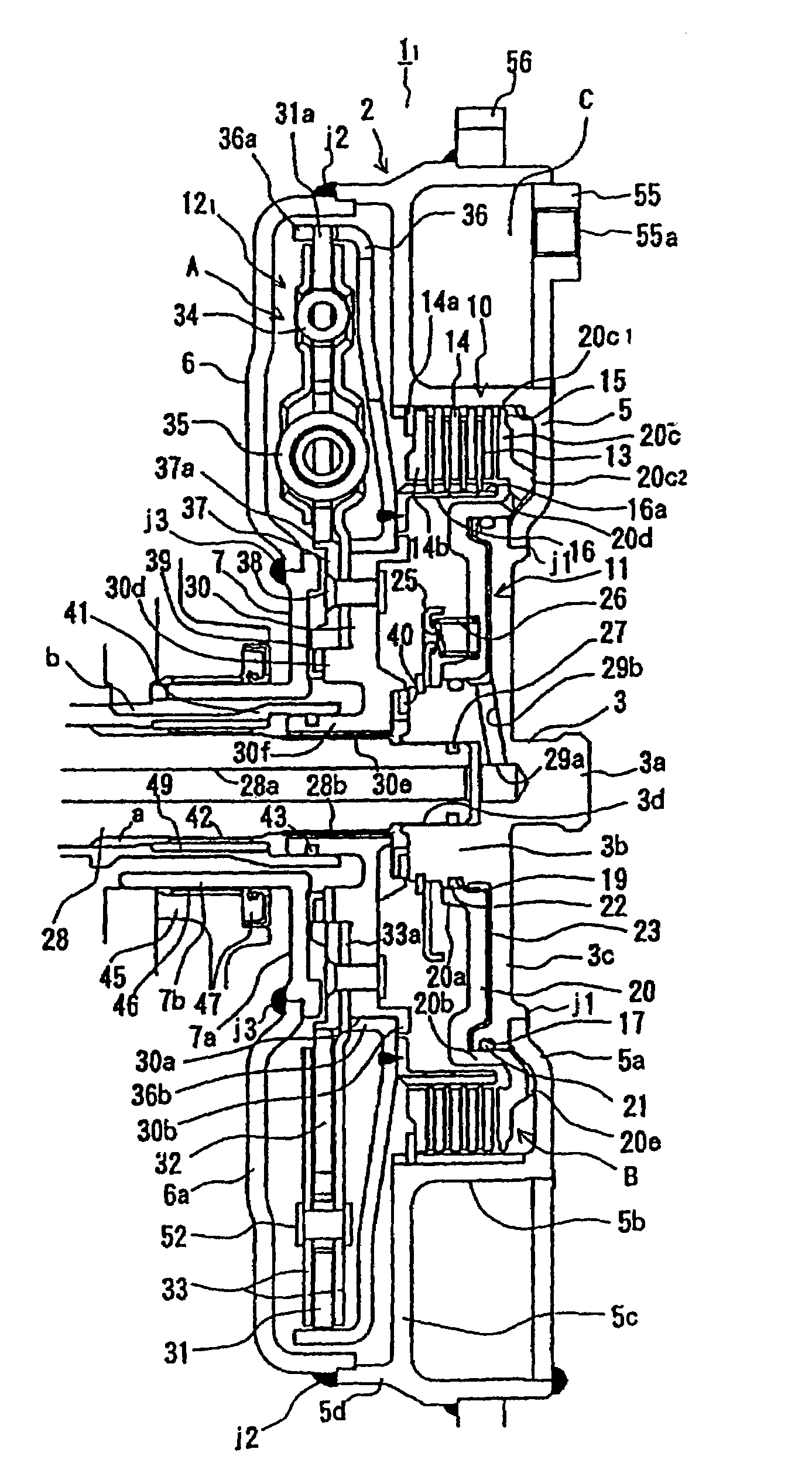

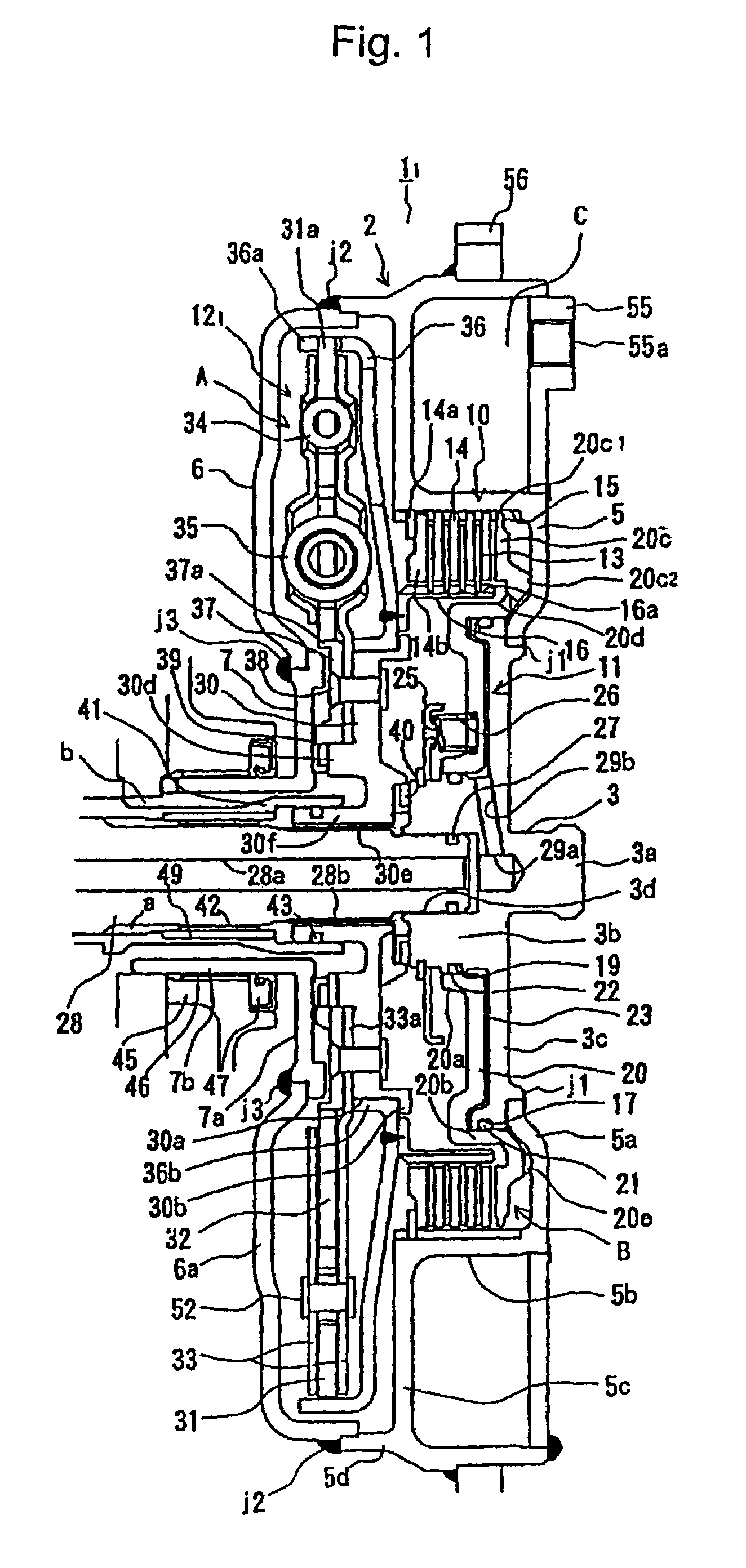

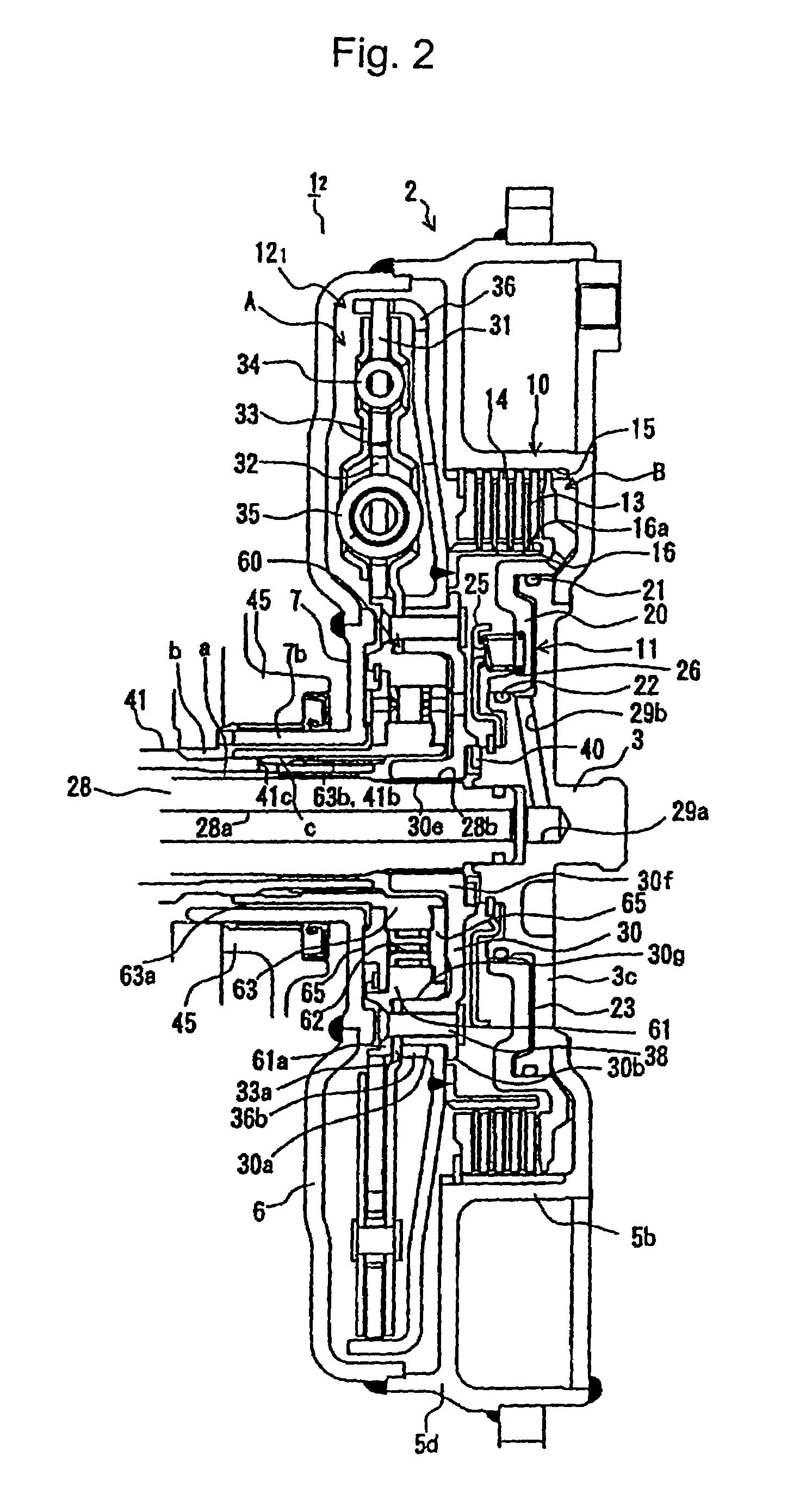

Power control unit

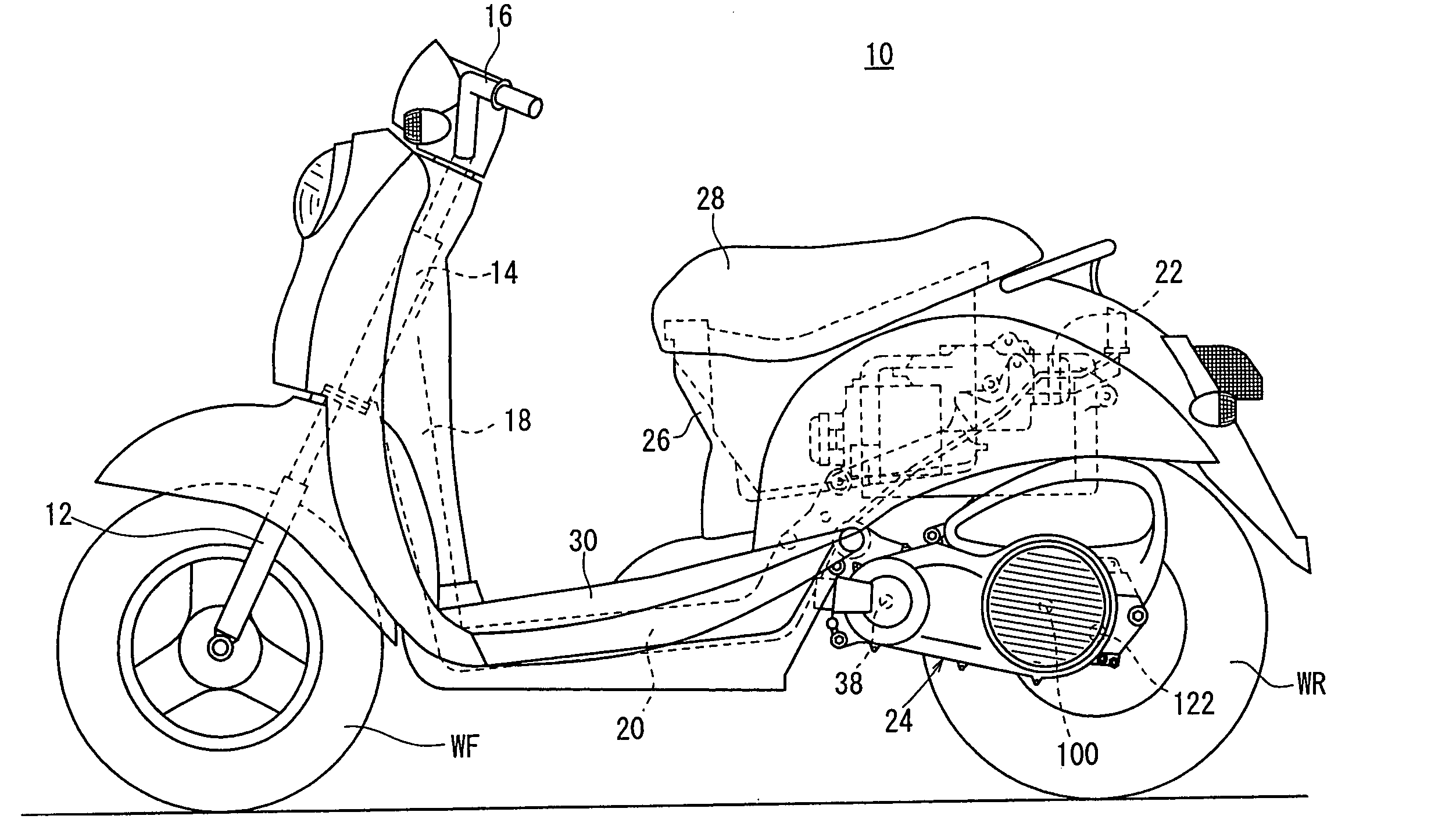

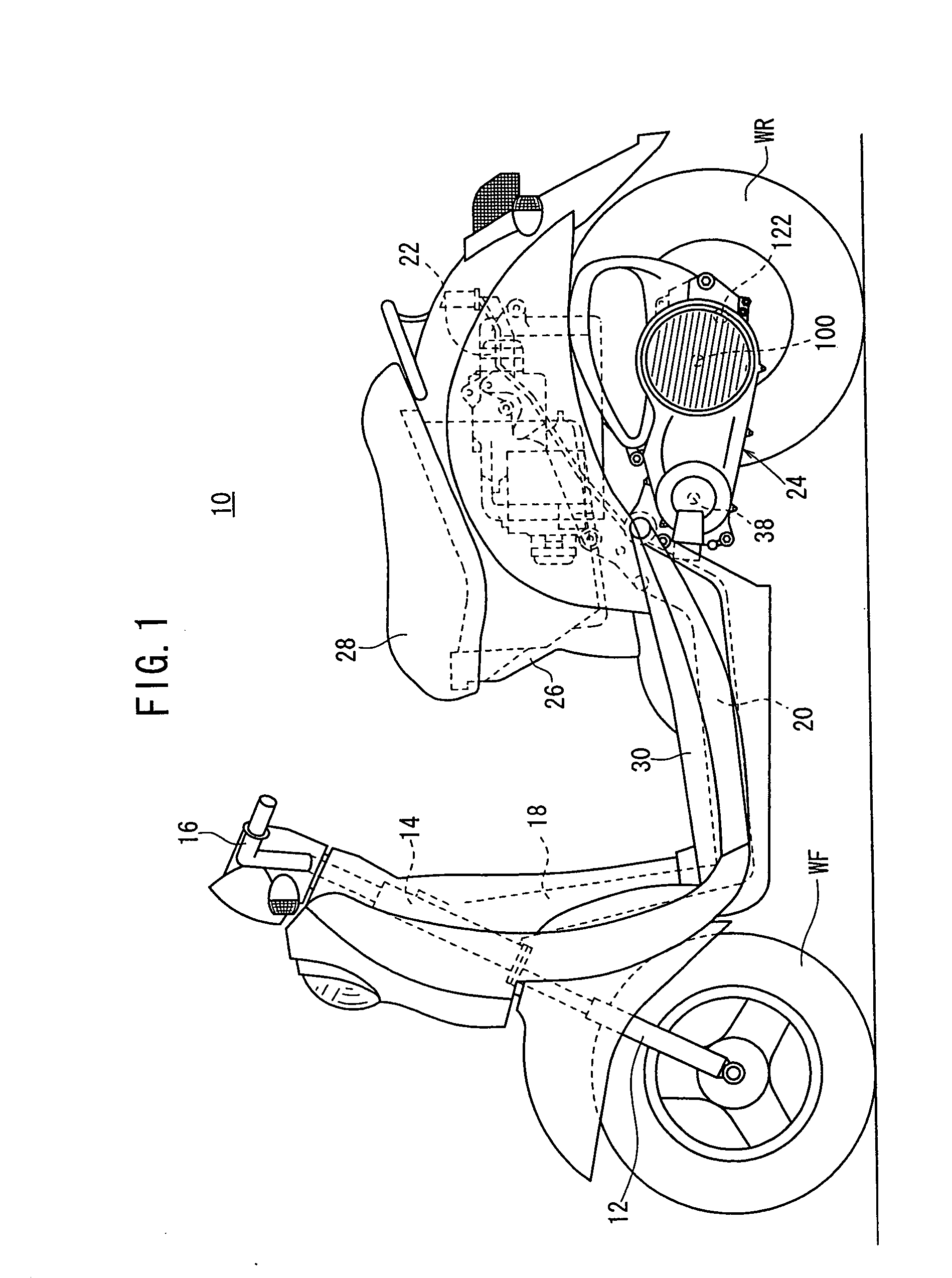

InactiveUS20060180363A1Eliminate needSimple structureAuxillary drivesDigital data processing detailsEngineeringDrive motor

A hybrid vehicle includes an engine and a drive motor which adds power to power generated by the engine in a superimposed manner to assist the engine. A power control unit includes: a fourth rotor sensor as a vehicle speed sensor which detects vehicle speed of the hybrid vehicle; an accelerator sensor which detects an amount of accelerator operation; and an ECU having an assist map which determines an output command reference value for the drive motor based on the vehicle speed and the amount of accelerator operation. The ECU outputs, to the drive motor, a corrected output command value which is calculated by adding an additional value corresponding to a rate of change in the amount of accelerator operation, to the output command reference value obtained from the assist map.

Owner:HONDA MOTOR CO LTD

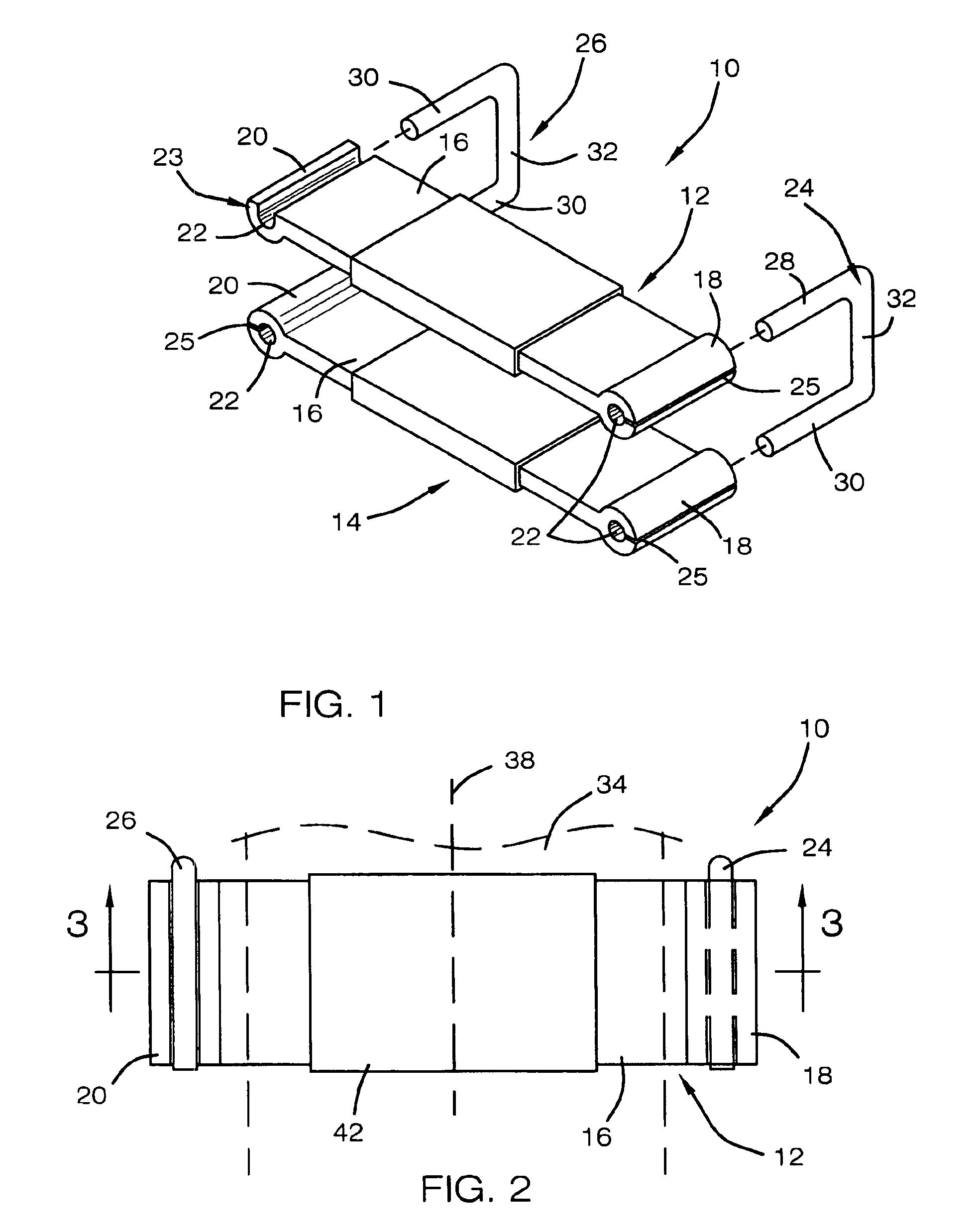

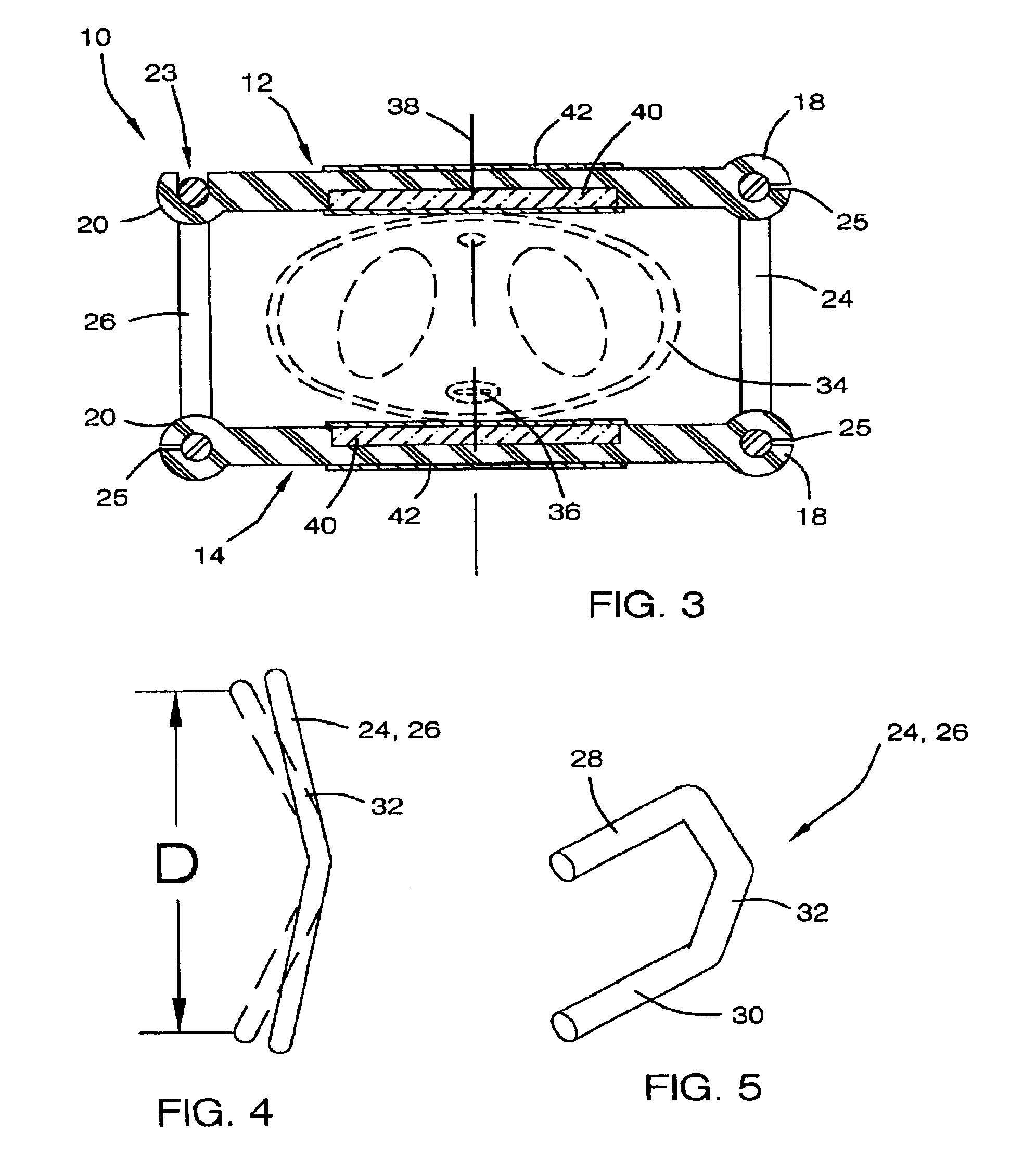

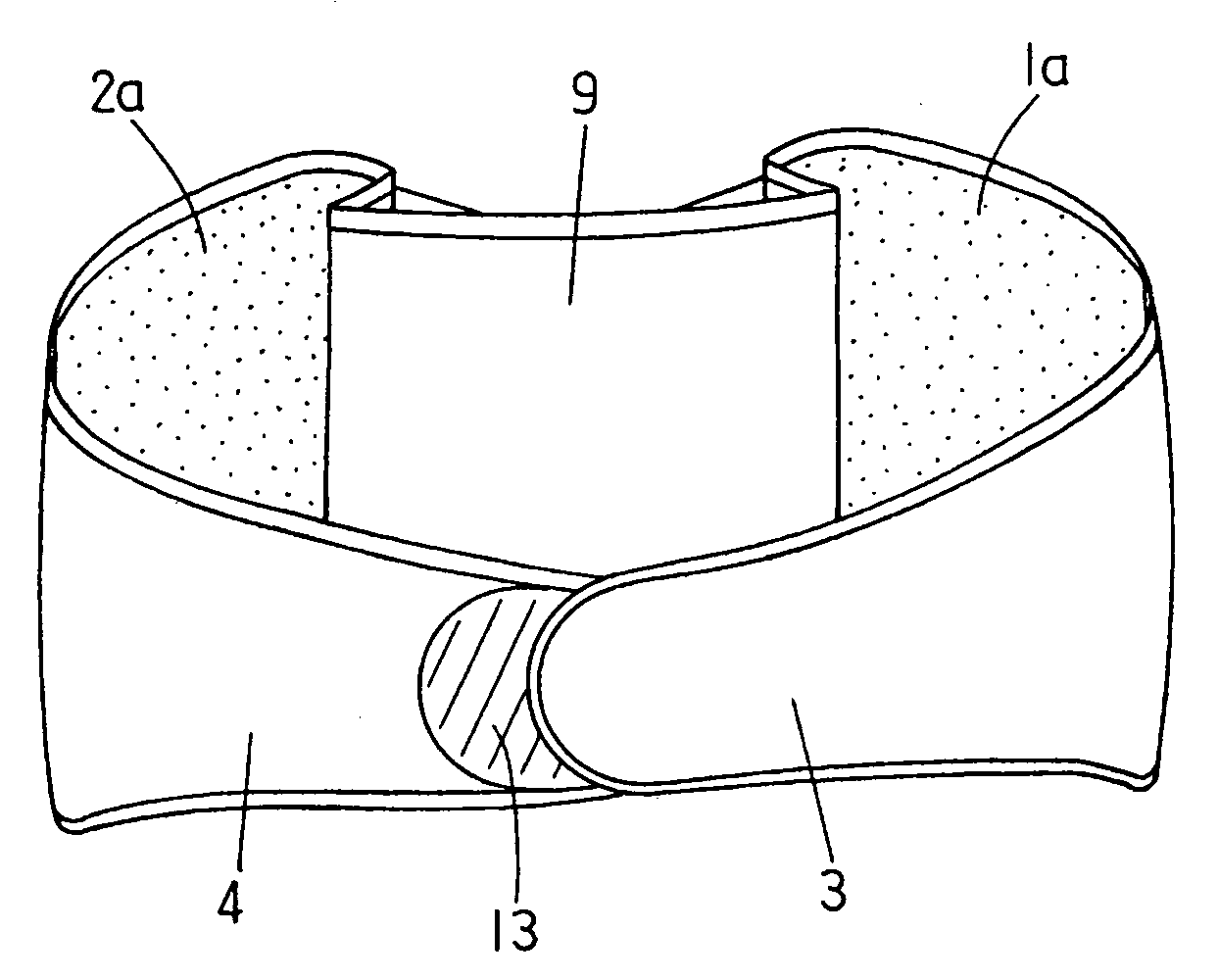

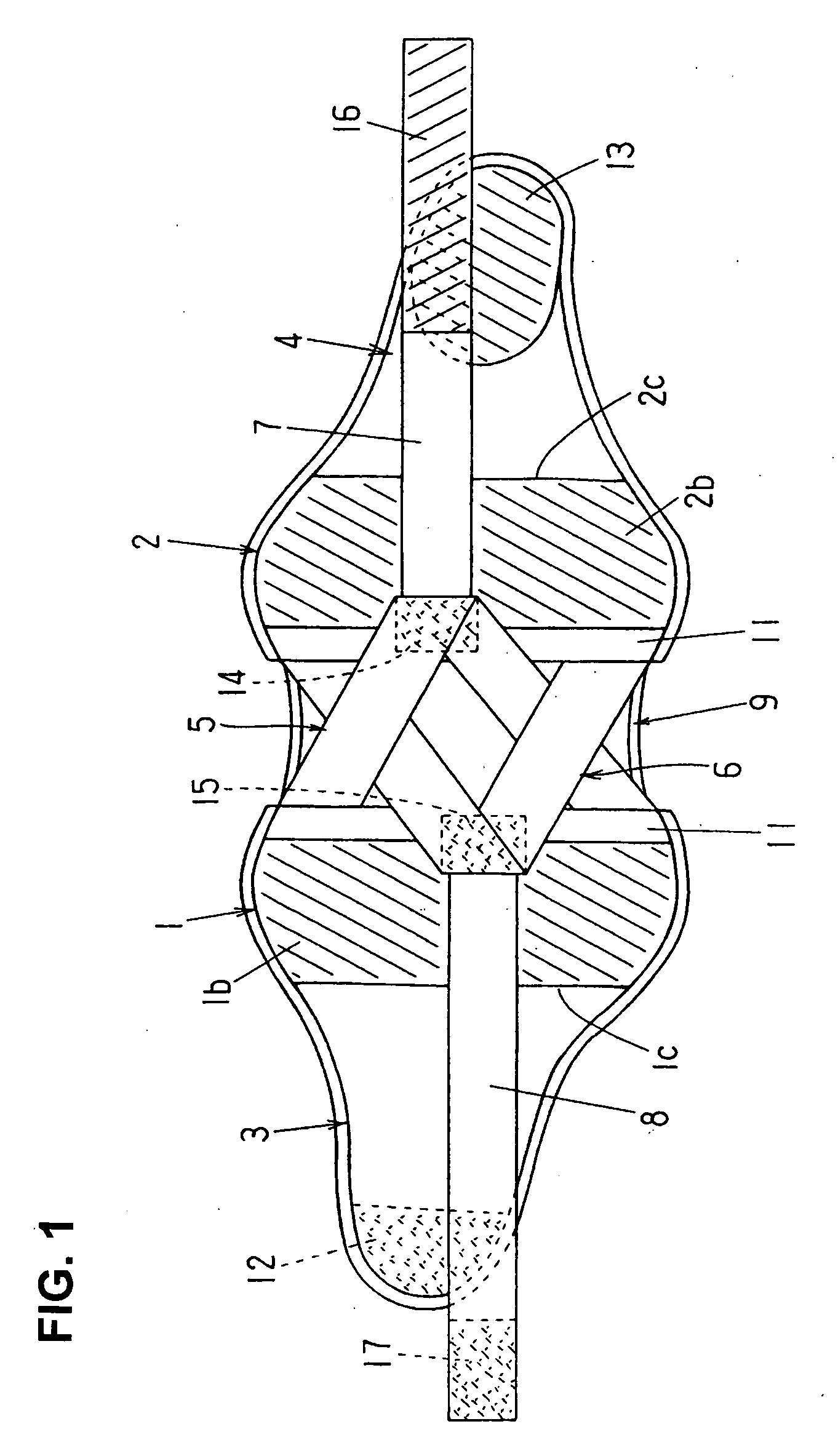

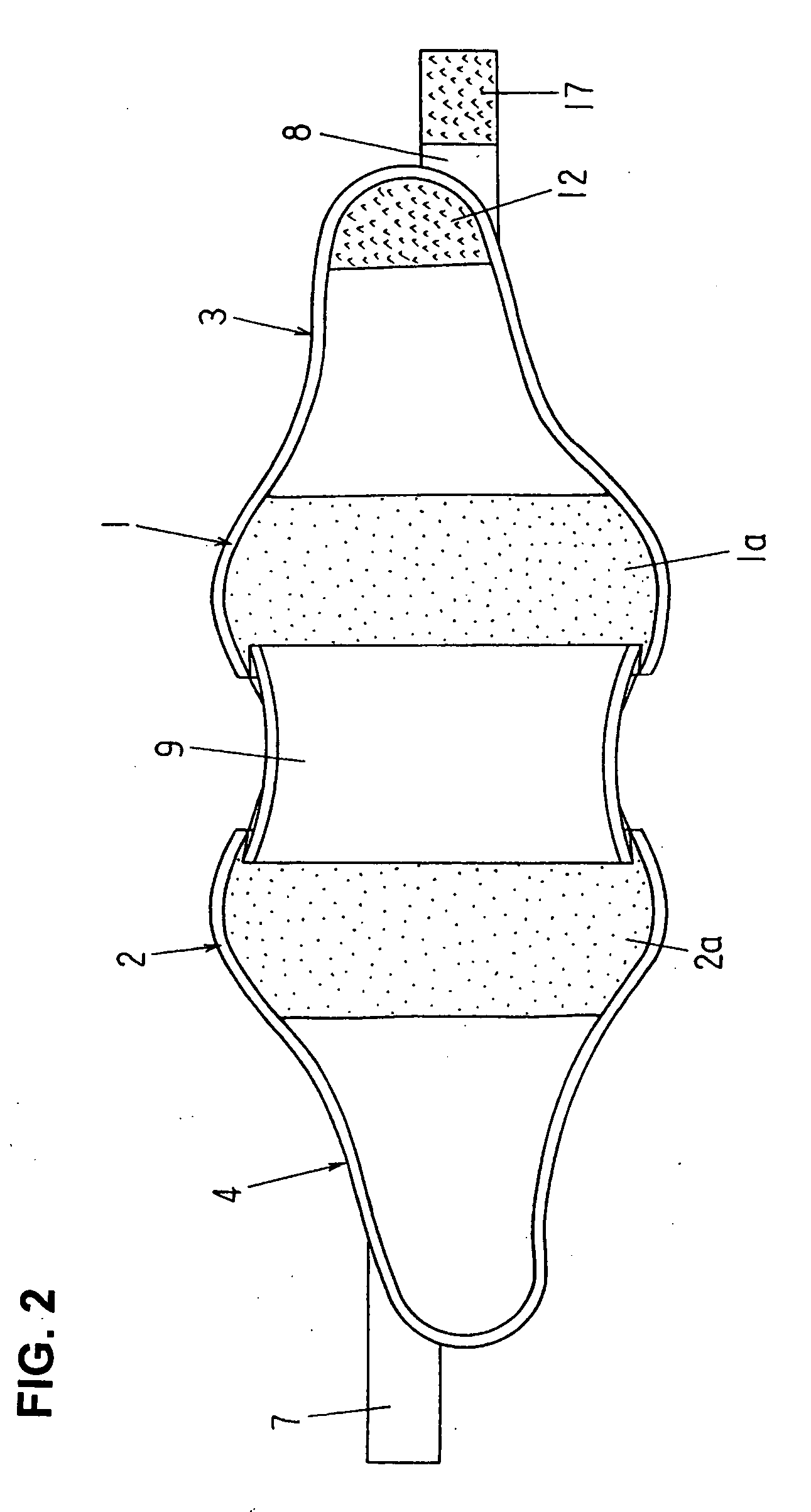

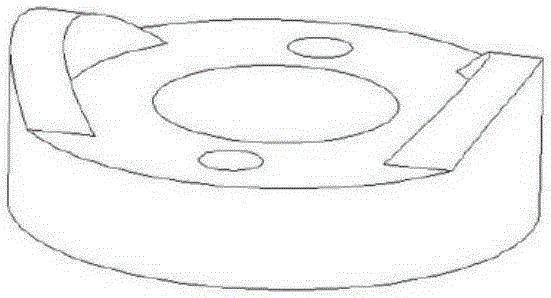

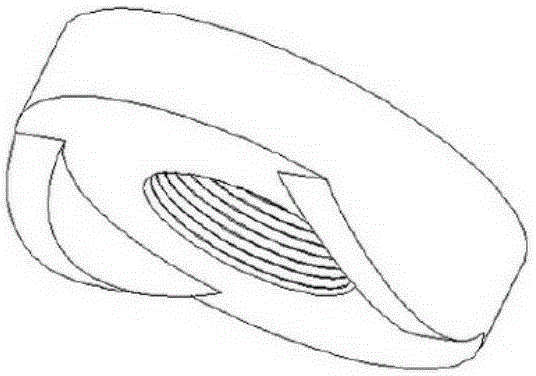

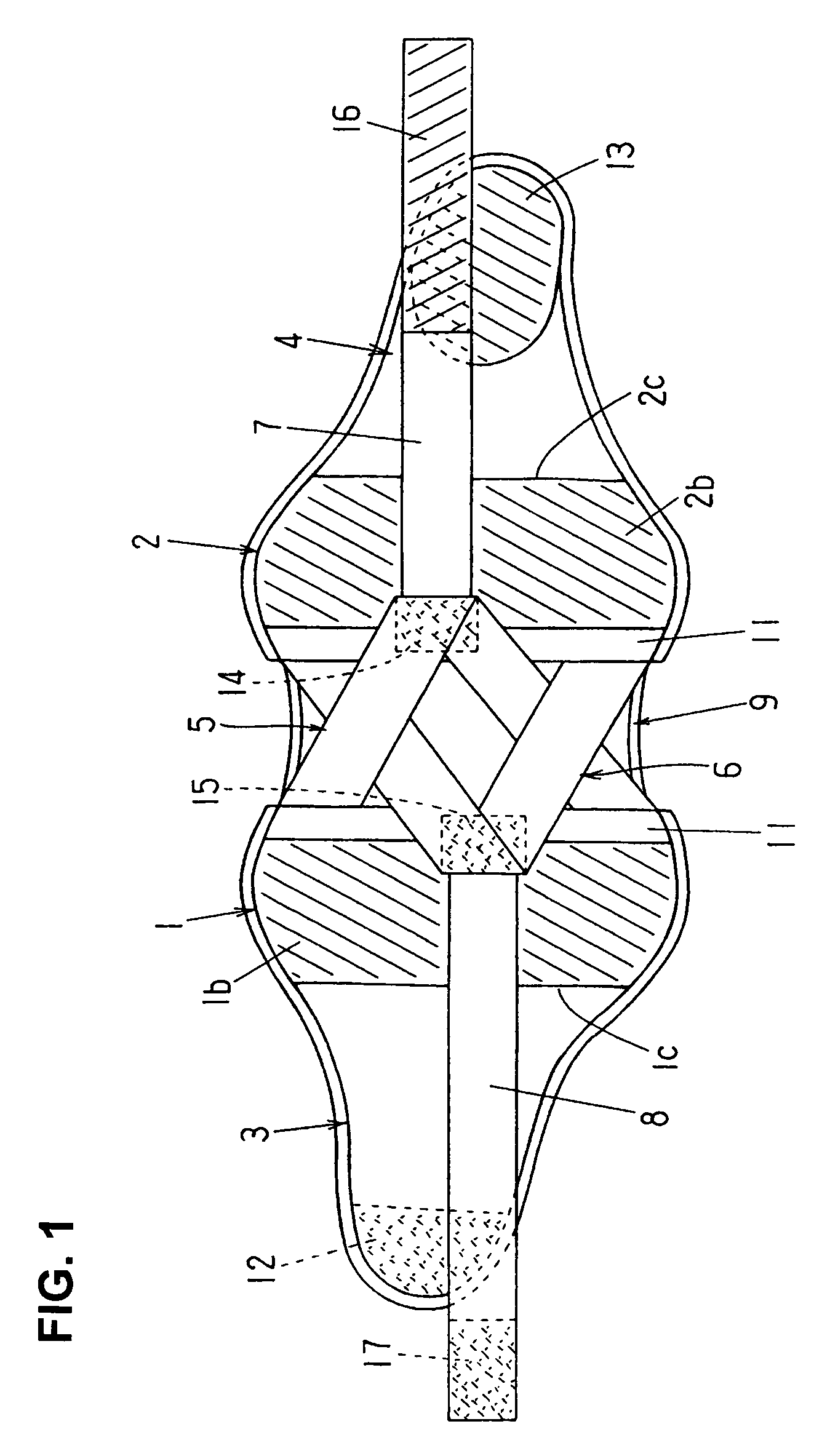

External incontinence clamp

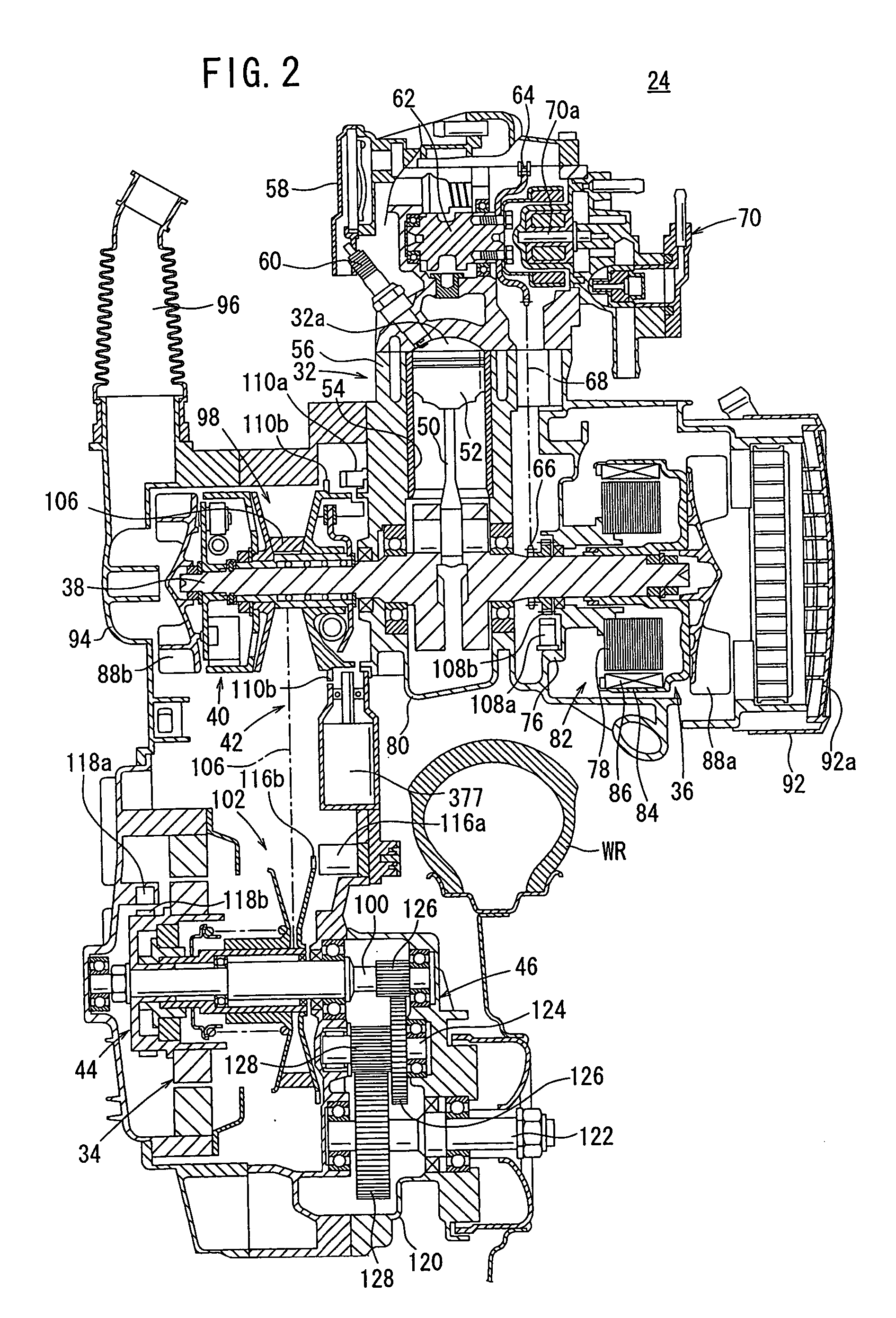

InactiveUS6960218B2Improve wearing comfortEliminate slippageSuture equipmentsMale contraceptivesPenisEngineering

An external incontinence clamp for stopping involuntary voiding of urine is provided. The clamp includes a first rigid member having opposed ends, each end defining a passage extending therethrough, a second rigid member having opposed ends, each end defining a passage extending therethrough, and two pins of generally u-shape. The pins are adapted to be received by the passages defined by the ends of the first rigid member and of the second rigid member so as to secure the first rigid member in a spaced and generally parallel relationship to the second rigid member. The penis is positioned between the first and second members so that the underside of the penis is in contact with the second member and the top surface of the penis is in contact with the first member, thereby stopping involuntary voiding of urine. A clamp kit includes a plurality of pins of different width to vary the force applied to the penis.

Owner:RENNICH HENRY

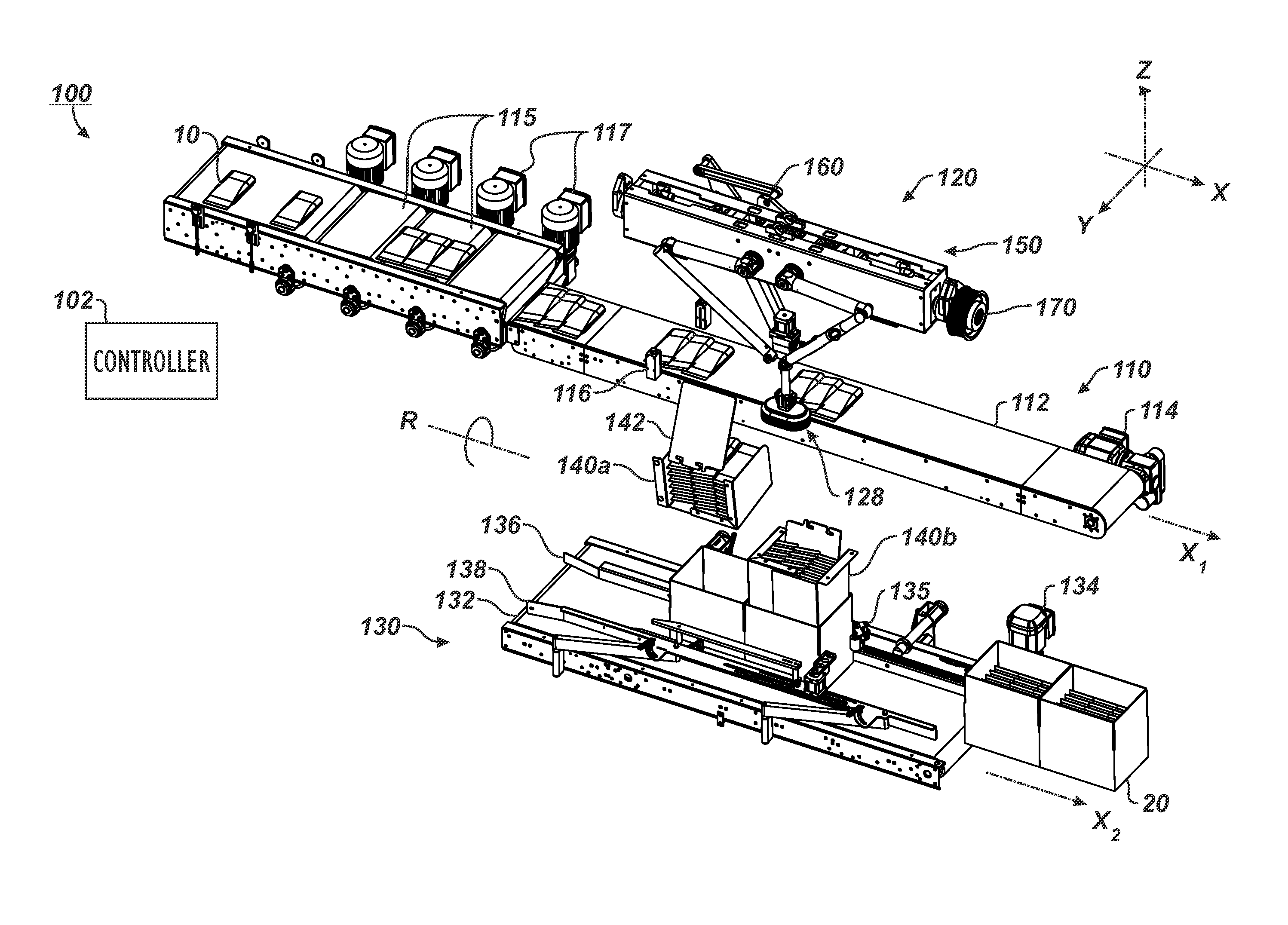

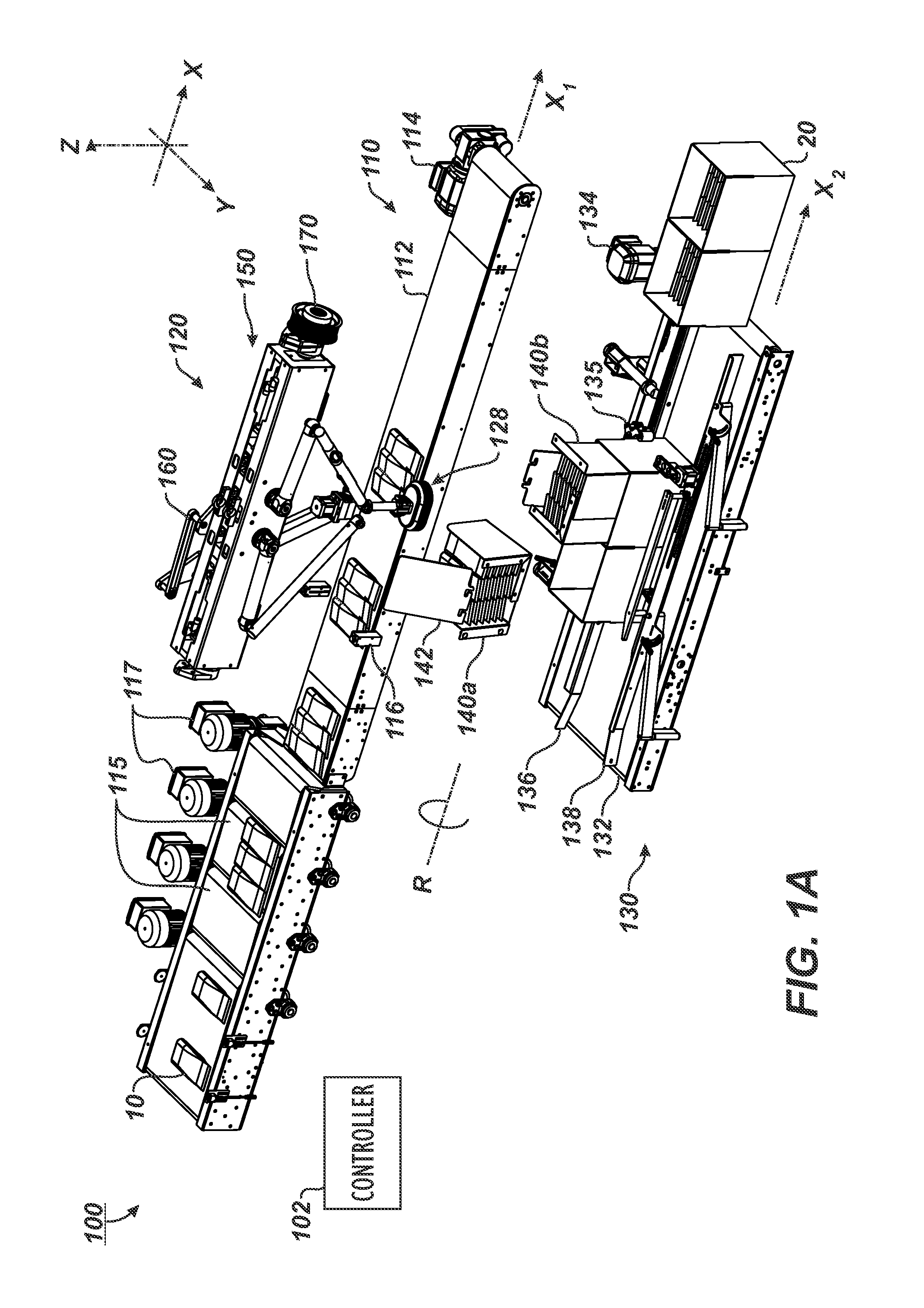

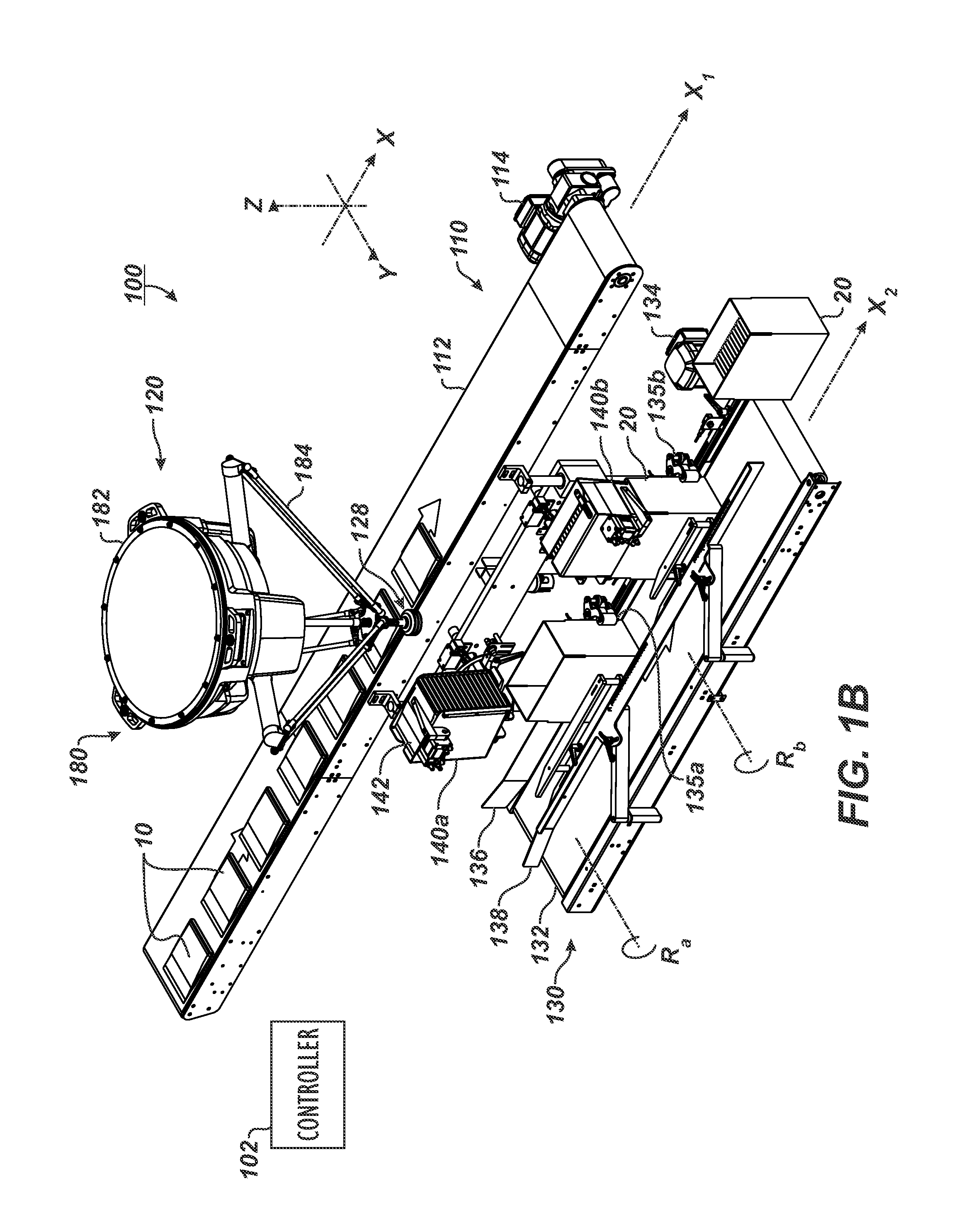

Case packing system having robotic pick and place mechanism and dual dump bins

ActiveUS8997438B1Easy to handleEliminate slippageProgramme-controlled manipulatorSolid materialEngineeringMechanical engineering

A robotic case packing system loads articles from one conveyor into containers on another conveyor using a robotic pick and place mechanism and a set of pivoting bins. A controller moves the robotic mechanism in first picking movements to pick and place articles from the conveyor into the first bin. Once the first bin is full, the controller pivots the first bin to allow the articles stacked in the first bin to be loaded into a container held below. While the first bin is pivoting, the controller moves the robotic mechanism to pick and place articles from the conveyor into the second bin. The process repeats with the controller pivoting the second bin during the picking movements used to fill the first bin and vice versa.

Owner:FALLAS DAVID M

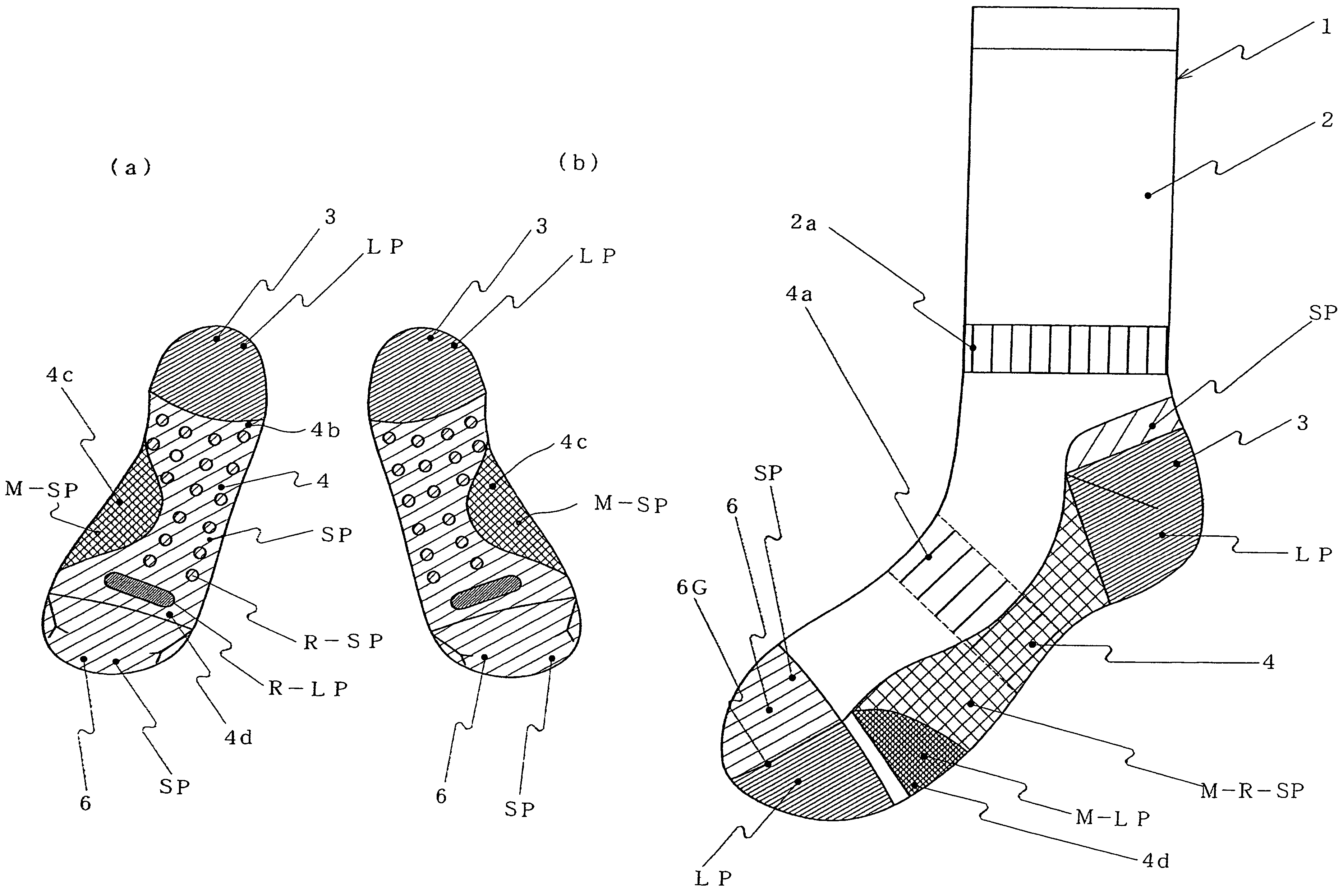

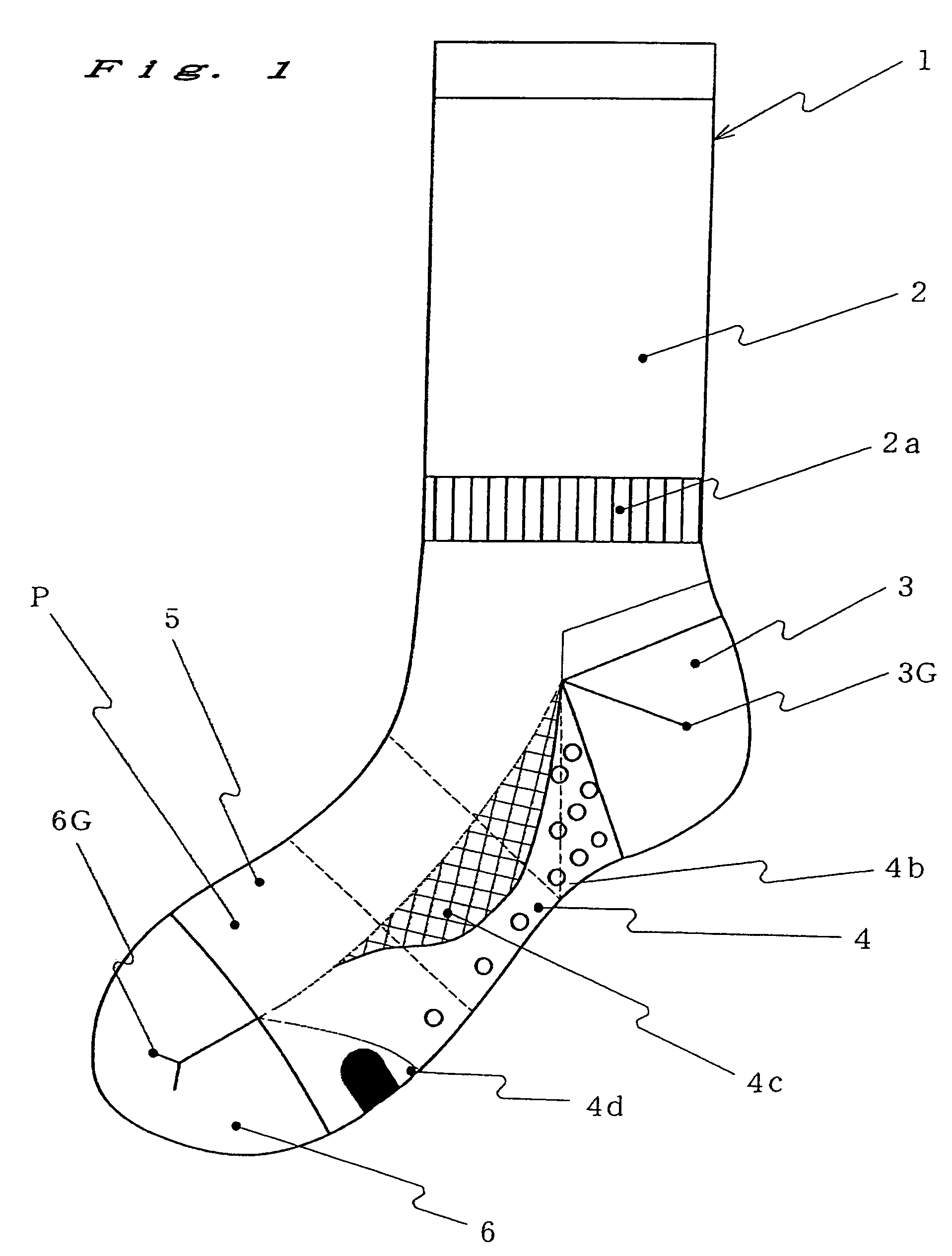

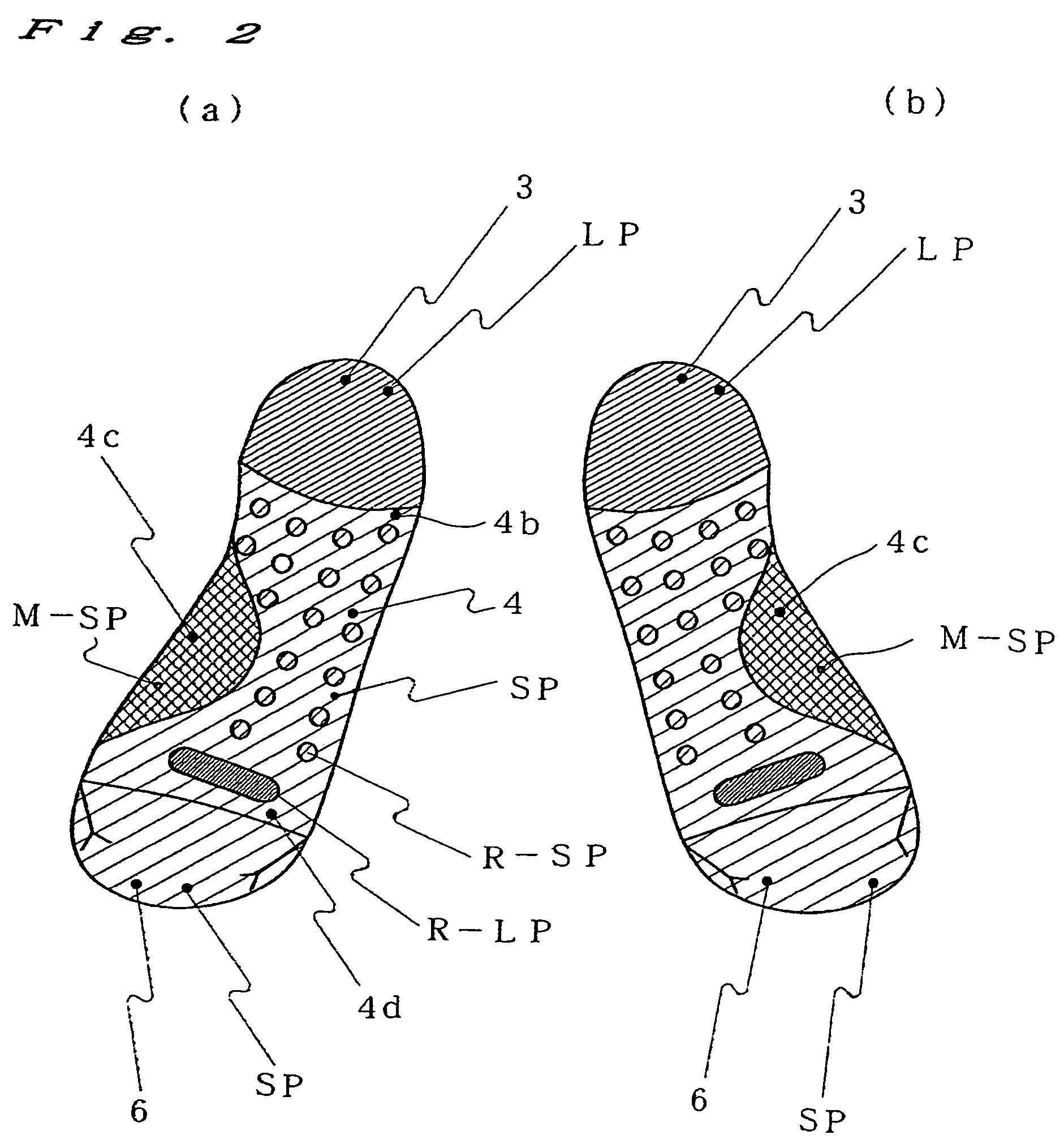

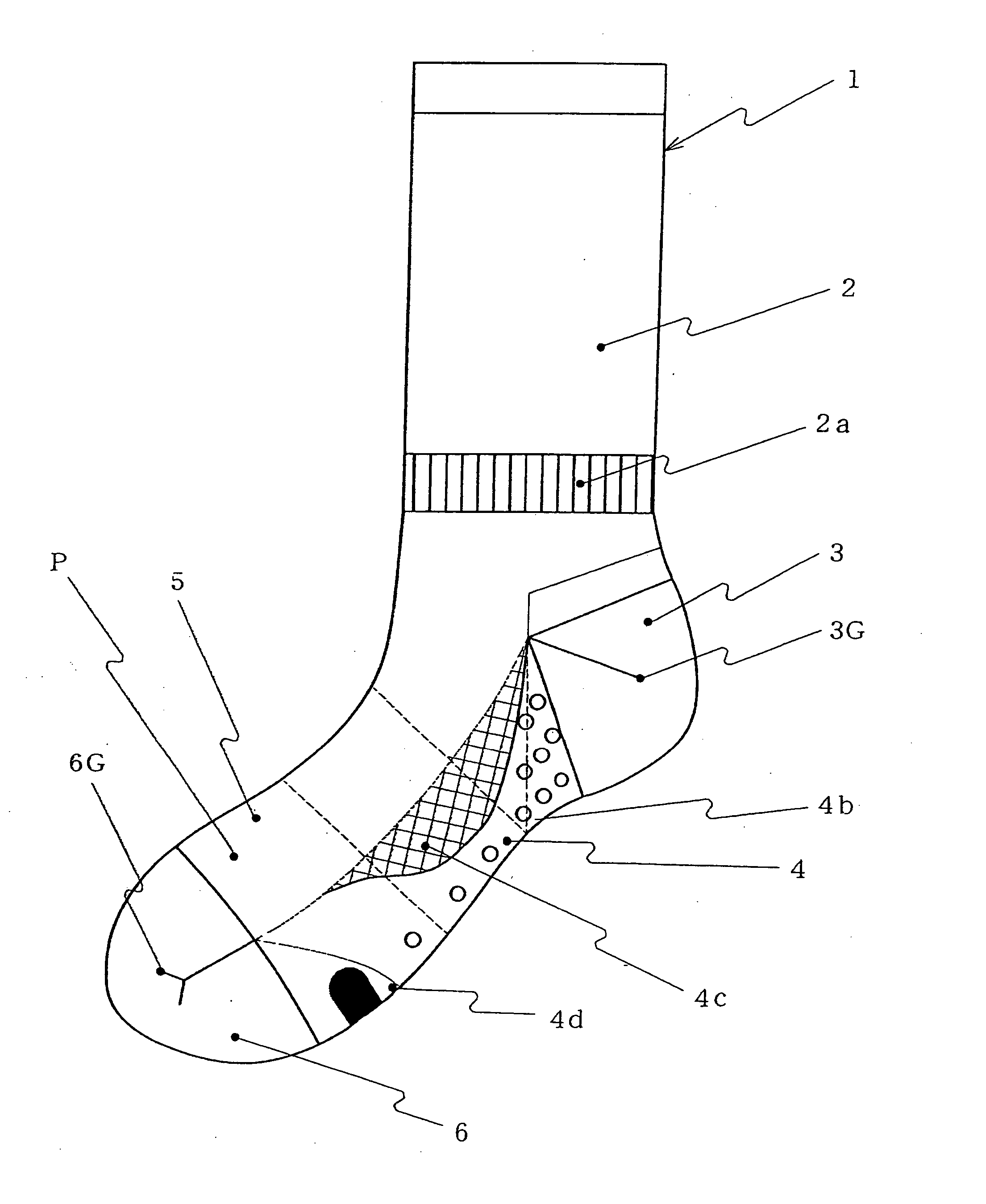

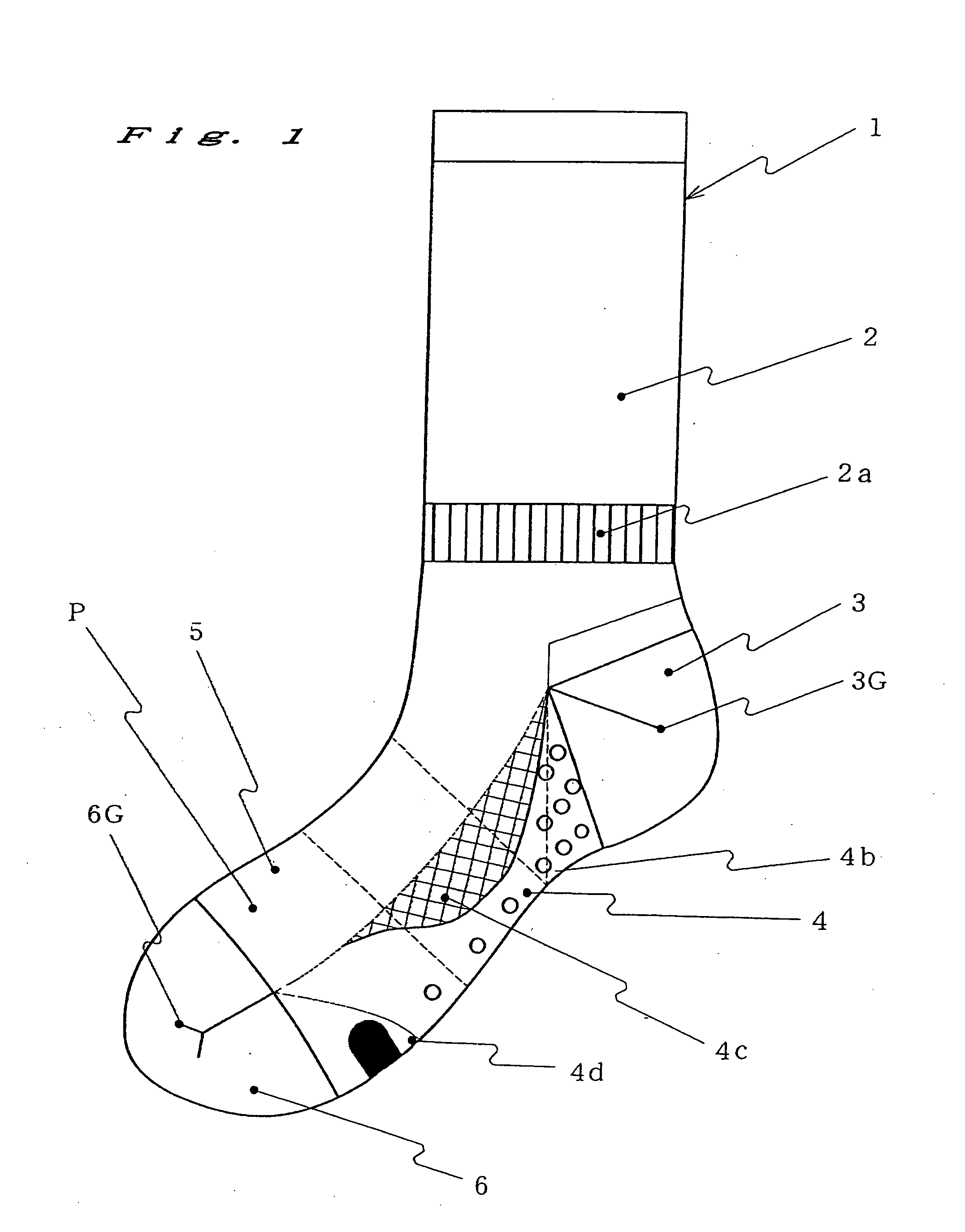

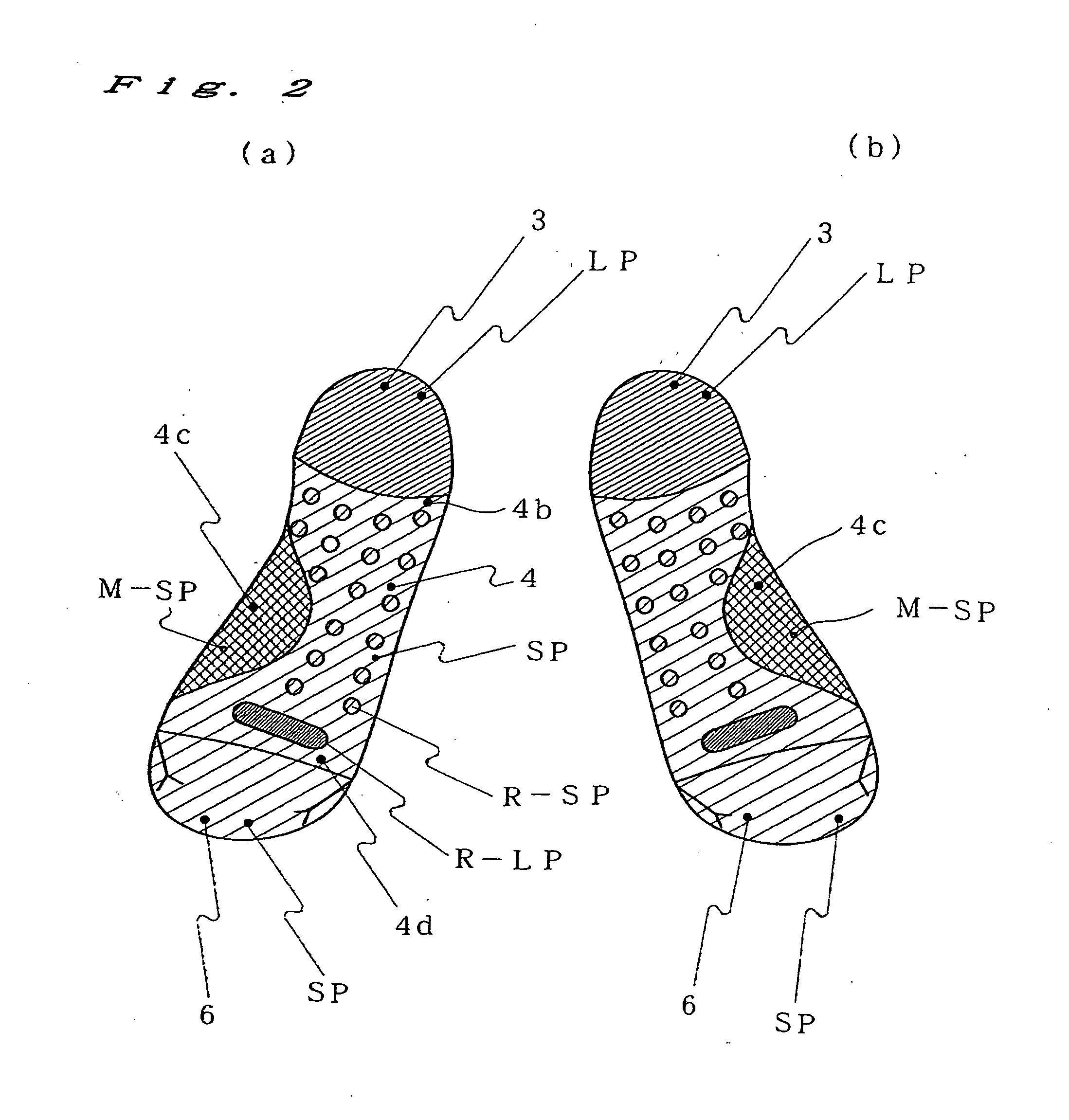

Socks of multi-stage pile structure

InactiveUS7677061B2Effective absorptionPrevent sock-slippageTextile/flexible product manufactureHandkerchiefsYarnEngineering

To provide a sock with a performance that matches its purpose of use and seasonal requirements. To change the thickness and strength of different parts of the sock according to the load distribution on the sole and the impact that the different parts of the sock are subjected to when walking and running.Knitting structures of different thicknesses and airspace ratios, e.g., flat stitches P, short-terry stitches SP, long-terry stitches LP, mesh stitches M, short-terry stitches based on mesh stitches M-SP, long-terry stitches based on mesh stitches M-LP, short-terry stitches based on reinforced mesh stitches M-R-SP, long-terry stitches based on reinforced mesh stitches M-R-LP, short-terry stitches with reinforcement yarn R-SP and long-terry stitches with reinforcement yarn R-LP are distributed in different parts of the sock.

Owner:OKAMOTO INDS

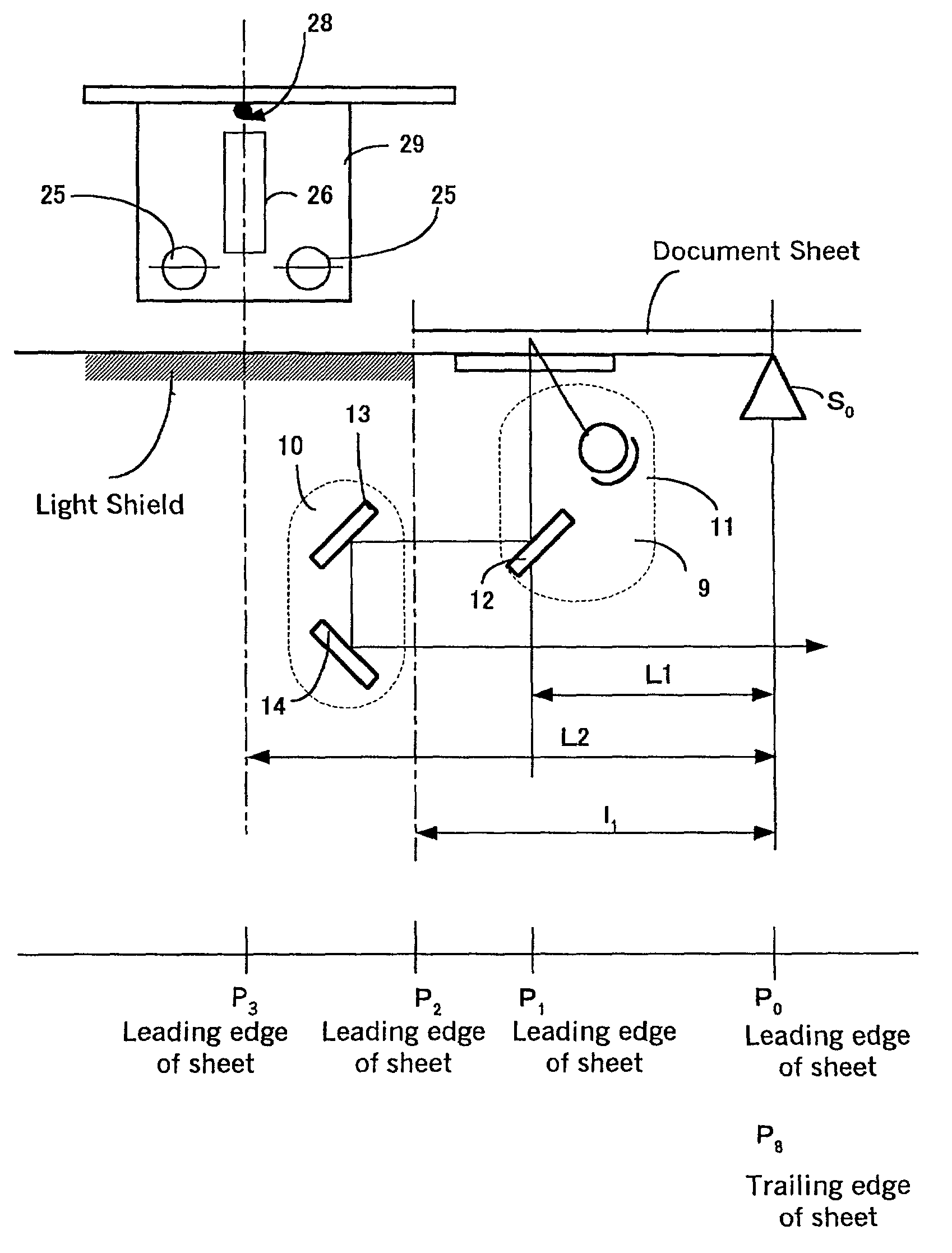

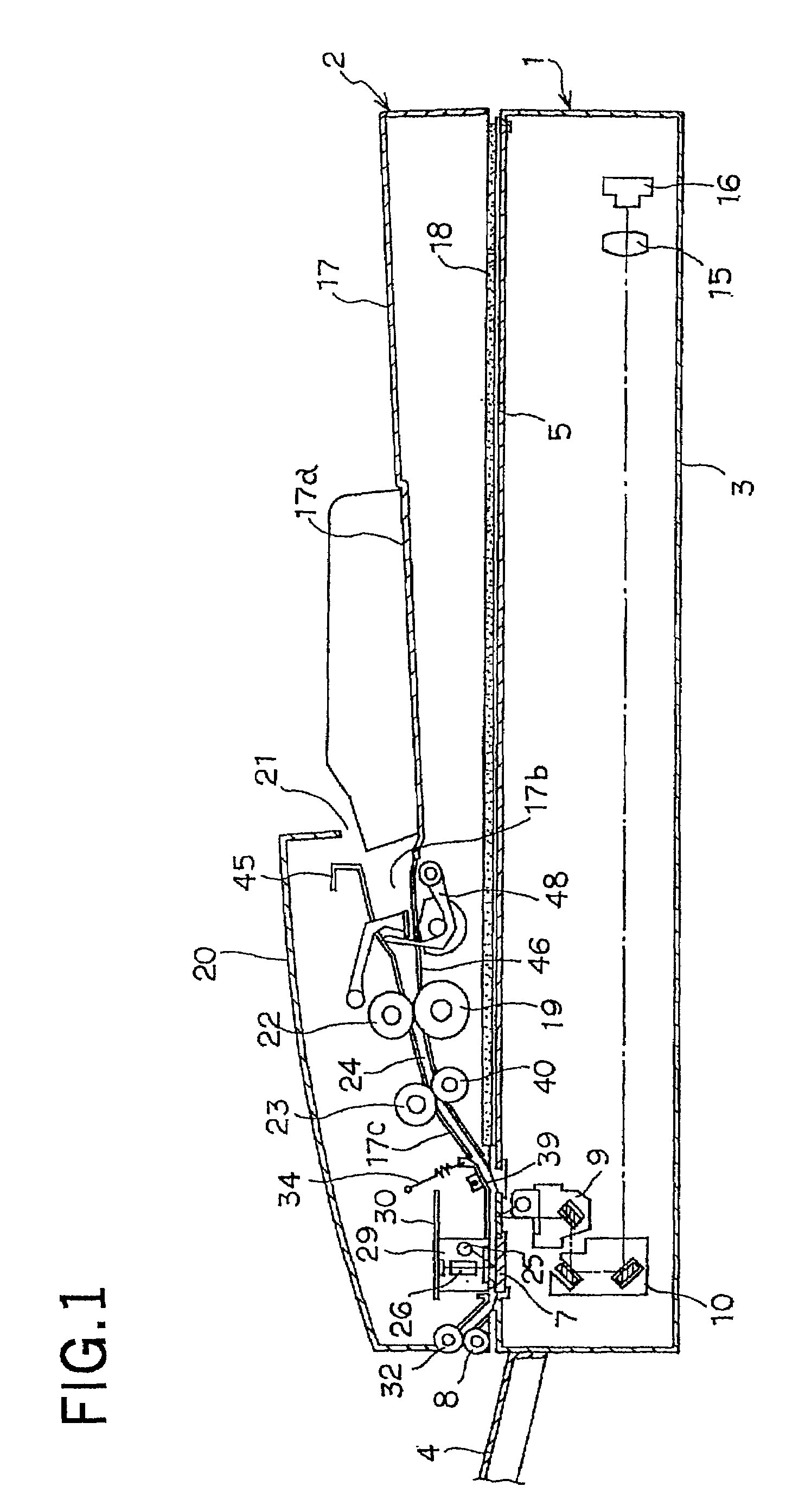

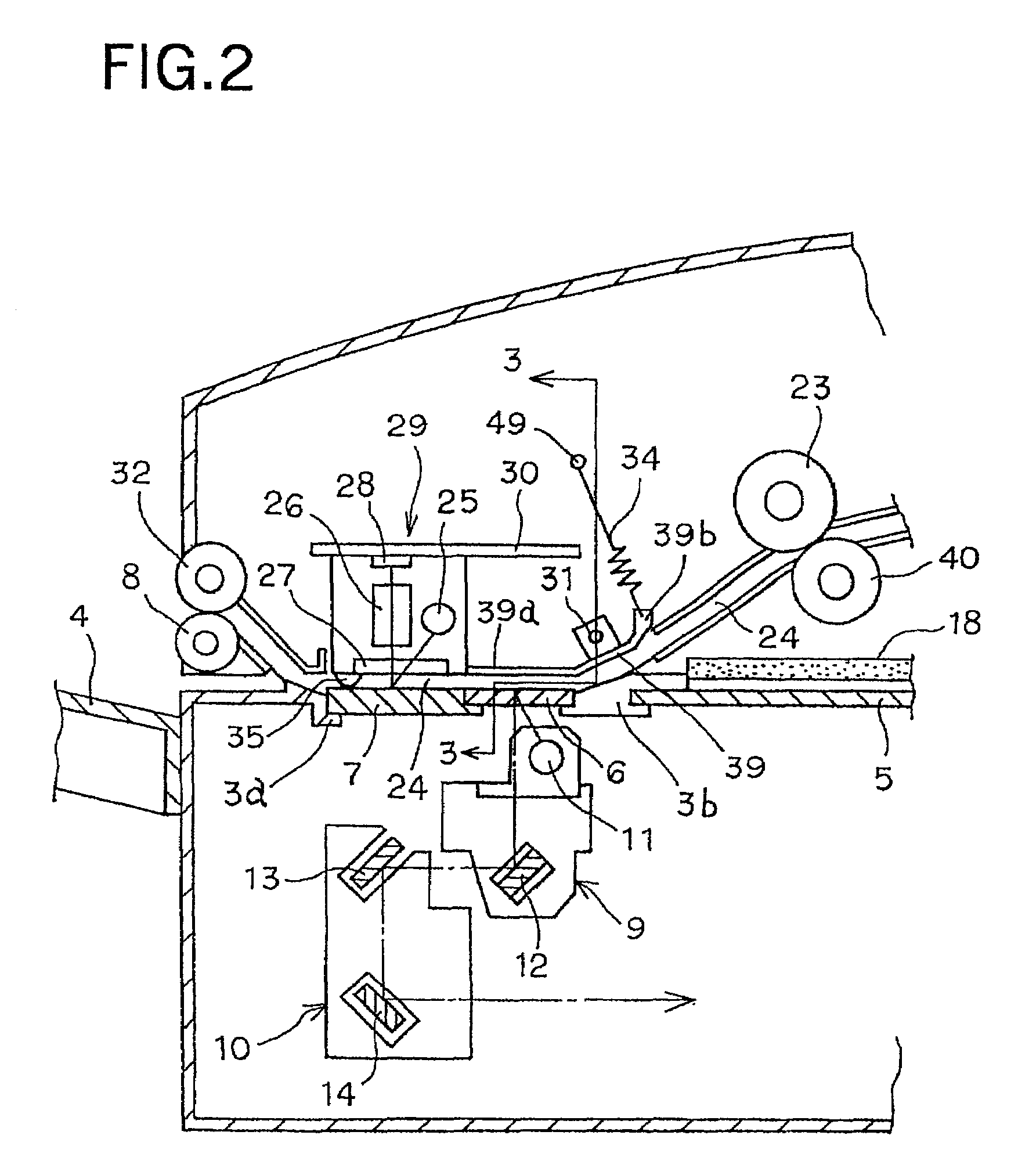

Image reading apparatus and image reading method

ActiveUS7027194B2Simple timing controlReduce noiseElectrographic process apparatusImage data processing detailsLeading edgeComputer science

An image reading apparatus for reading indicia on the front and back surfaces of a document using two image sensors includes a document detection sensor to detect the document, a first image sensor for reading an image on one surface of the document, a second image sensor for reading an image on the other surface of the document, and a controller. The controller starts to read the image data from the first and second image sensors when prescribed amounts of time have passed after the document detection sensor detects the leading edge of the document, and stops the reading of the image data from the image sensors. The structure provides a lightweight and compact apparatus while reducing image noise caused by the mutual interferences of the light sources in reading the image data.

Owner:NISCA KK

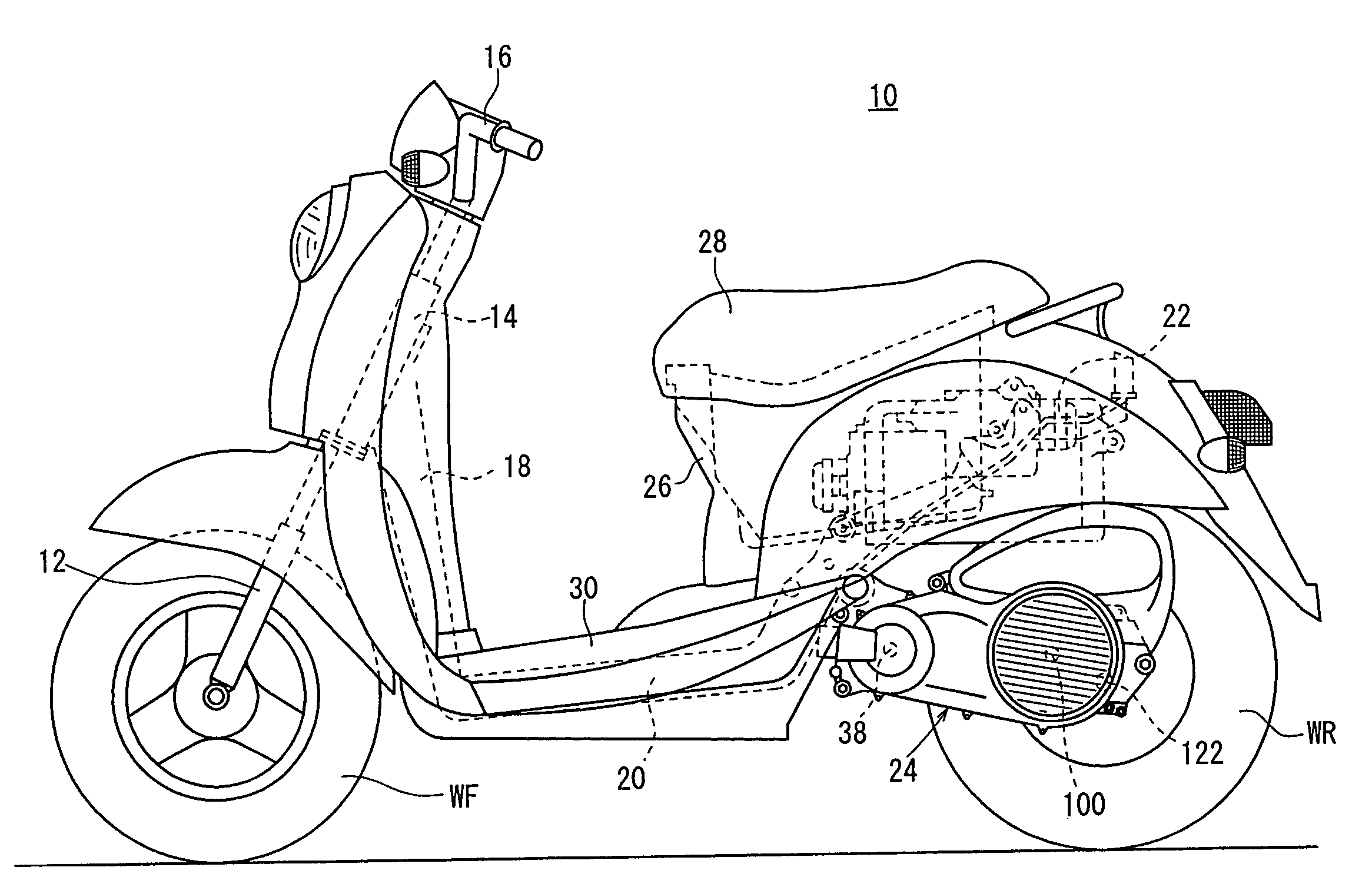

Power control unit

InactiveUS7520351B2Eliminate needSimple structureAuxillary drivesDigital data processing detailsDrive motorAdditional values

A hybrid vehicle includes an engine and a drive motor which adds power to power generated by the engine in a superimposed manner to assist the engine. A power control unit includes: a fourth rotor sensor as a vehicle speed sensor which detects vehicle speed of the hybrid vehicle; an accelerator sensor which detects an amount of accelerator operation; and an ECU having an assist map which determines an output command reference value for the drive motor based on the vehicle speed and the amount of accelerator operation. The ECU outputs, to the drive motor, a corrected output command value which is calculated by adding an additional value corresponding to a rate of change in the amount of accelerator operation, to the output command reference value obtained from the assist map.

Owner:HONDA MOTOR CO LTD

Socks of Multi-Stage Pile Structure

InactiveUS20080041113A1Reduce shockImprove ventilationTextile/flexible product manufactureHandkerchiefsYarnEngineering

Objective To provide a sock with a performance that matches its purpose of use and seasonal requirements. To change the thickness and strength of different parts of the sock according to the load distribution on the sole and the impact that the different parts of the sock are subjected to when walking and running. Means Knitting structures of different thicknesses and airspace ratios, e.g., flat stitches P, short-terry stitches SP, long-terry stitches LP, mesh stitches M, short-terry stitches based on mesh stitches M-SP, long-terry stitches based on mesh stitches M-LP, short-terry stitches based on reinforced mesh stitches M-R-SP, long-terry stitches based on reinforced mesh stitches M-R-LP, short-terry stitches with reinforcement yarn R-SP and long-terry stitches with reinforcement yarn R-LP are distributed in different parts of the sock.

Owner:OKAMOTO INDS

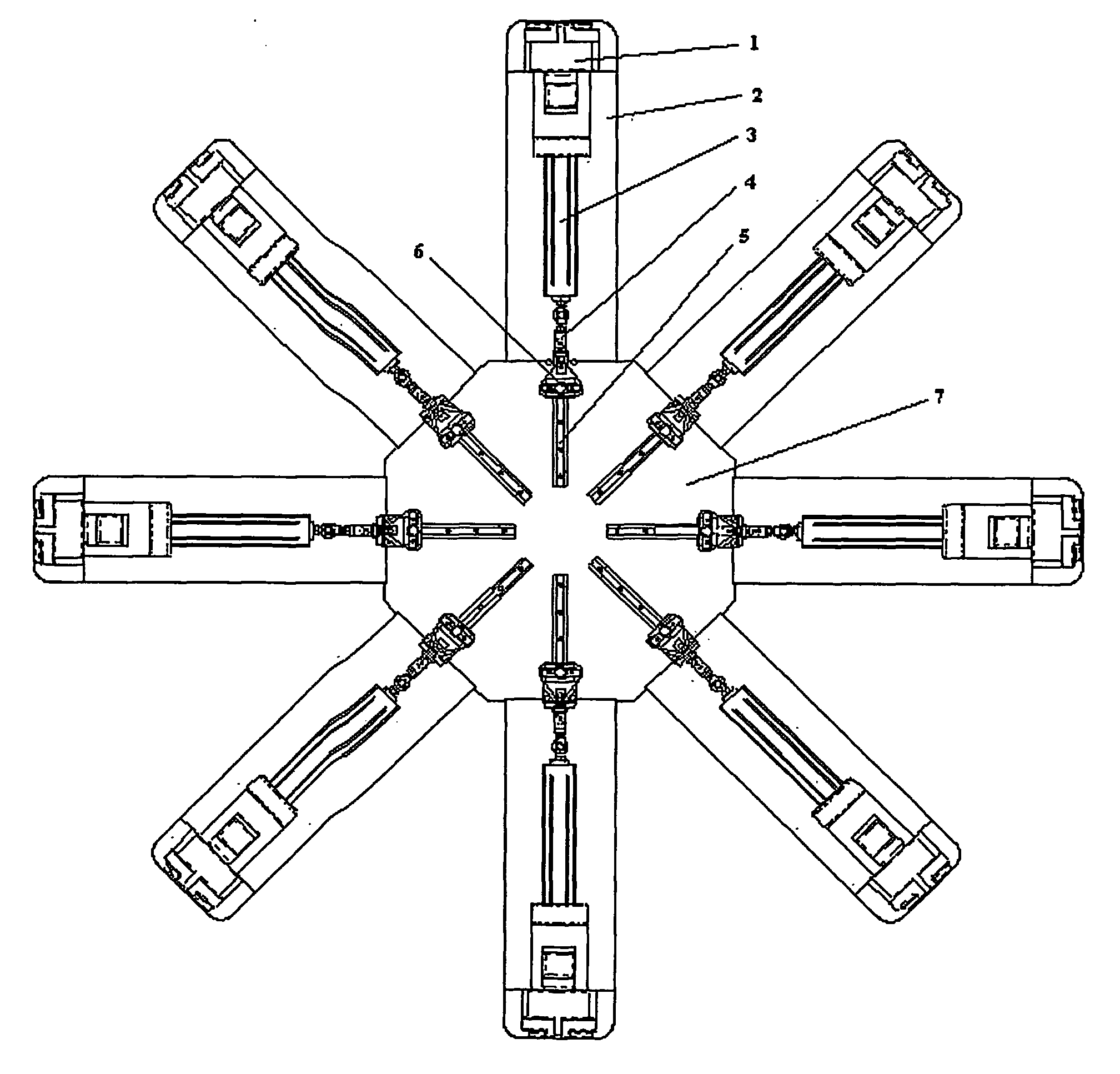

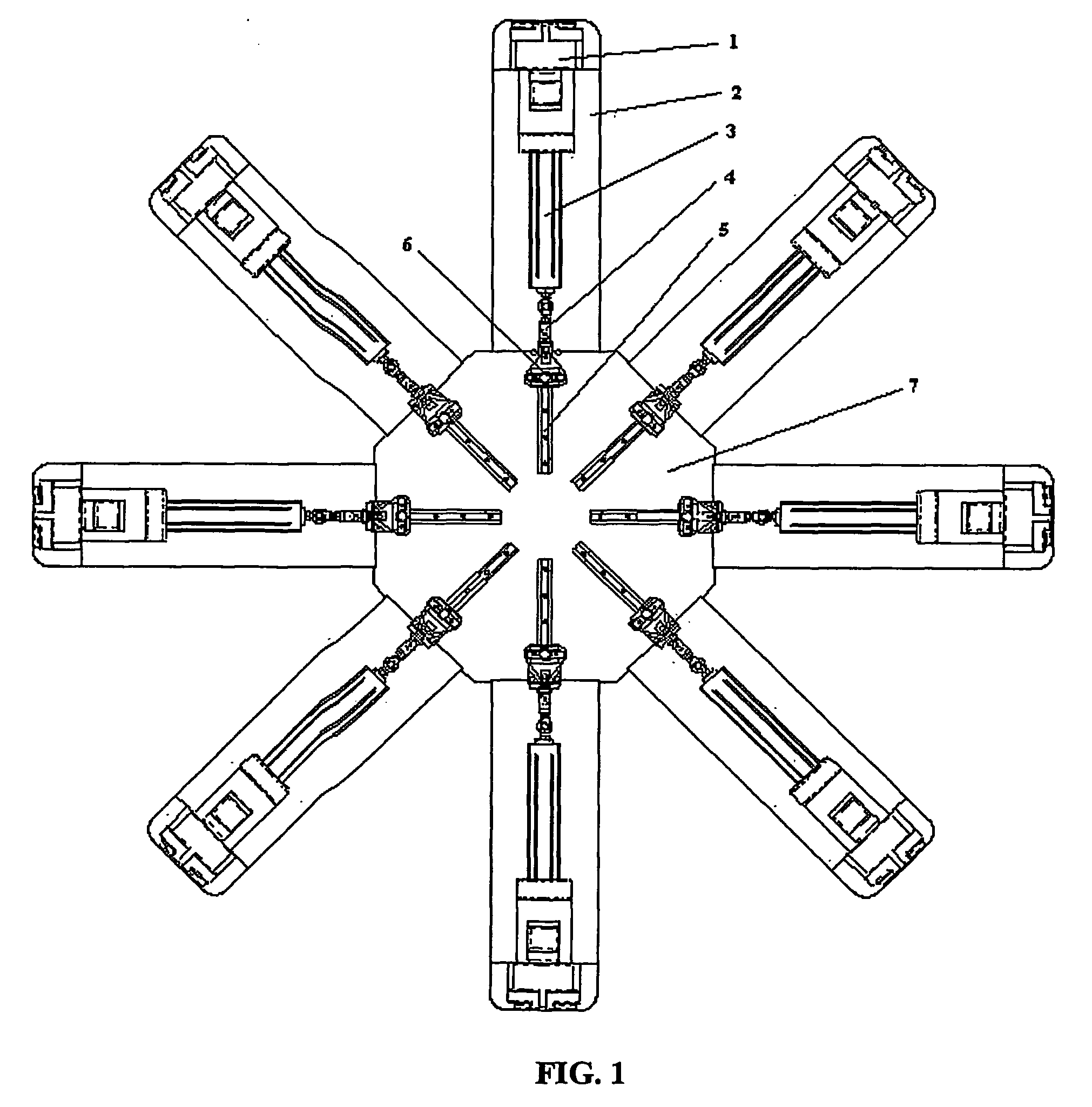

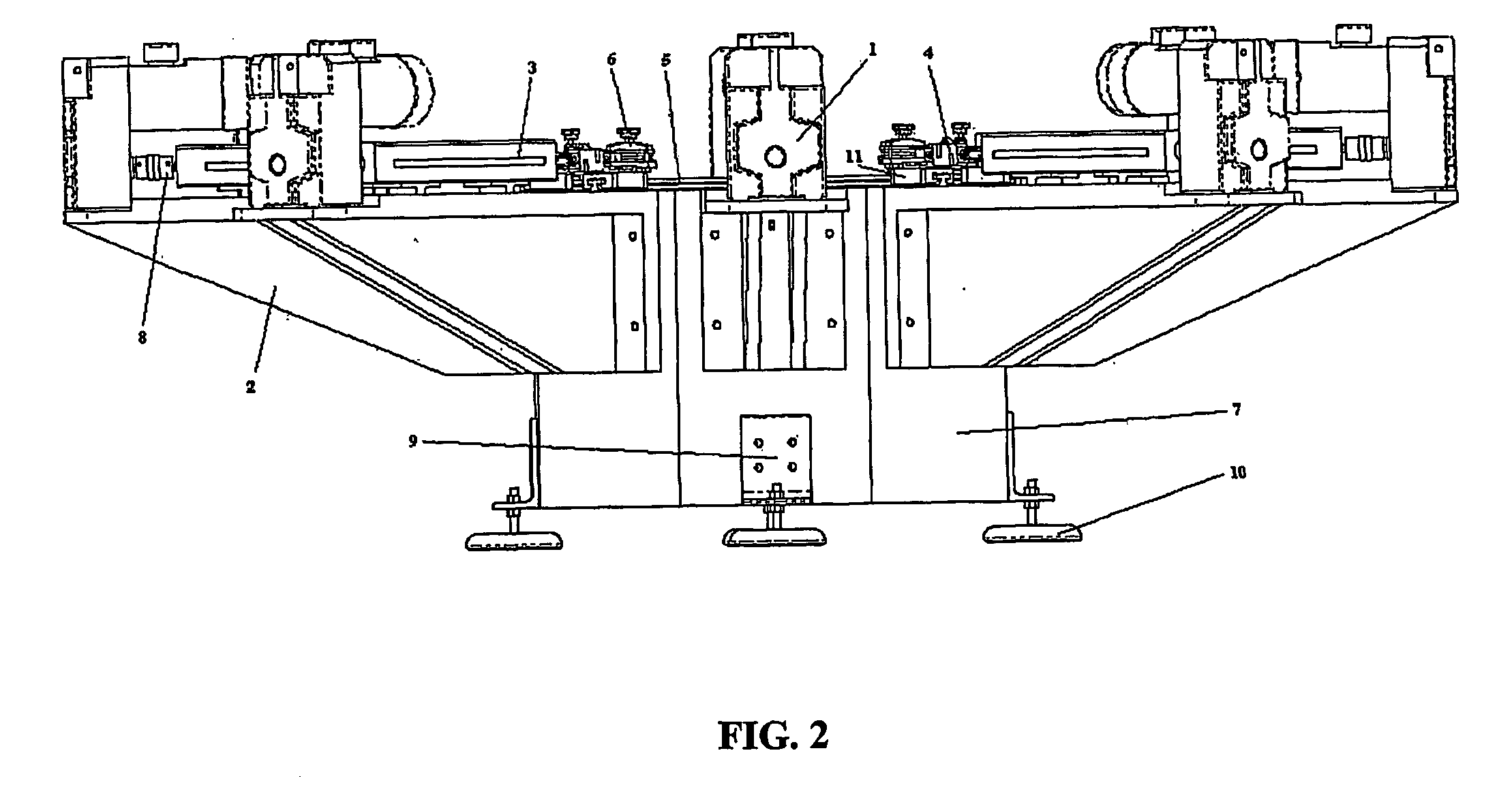

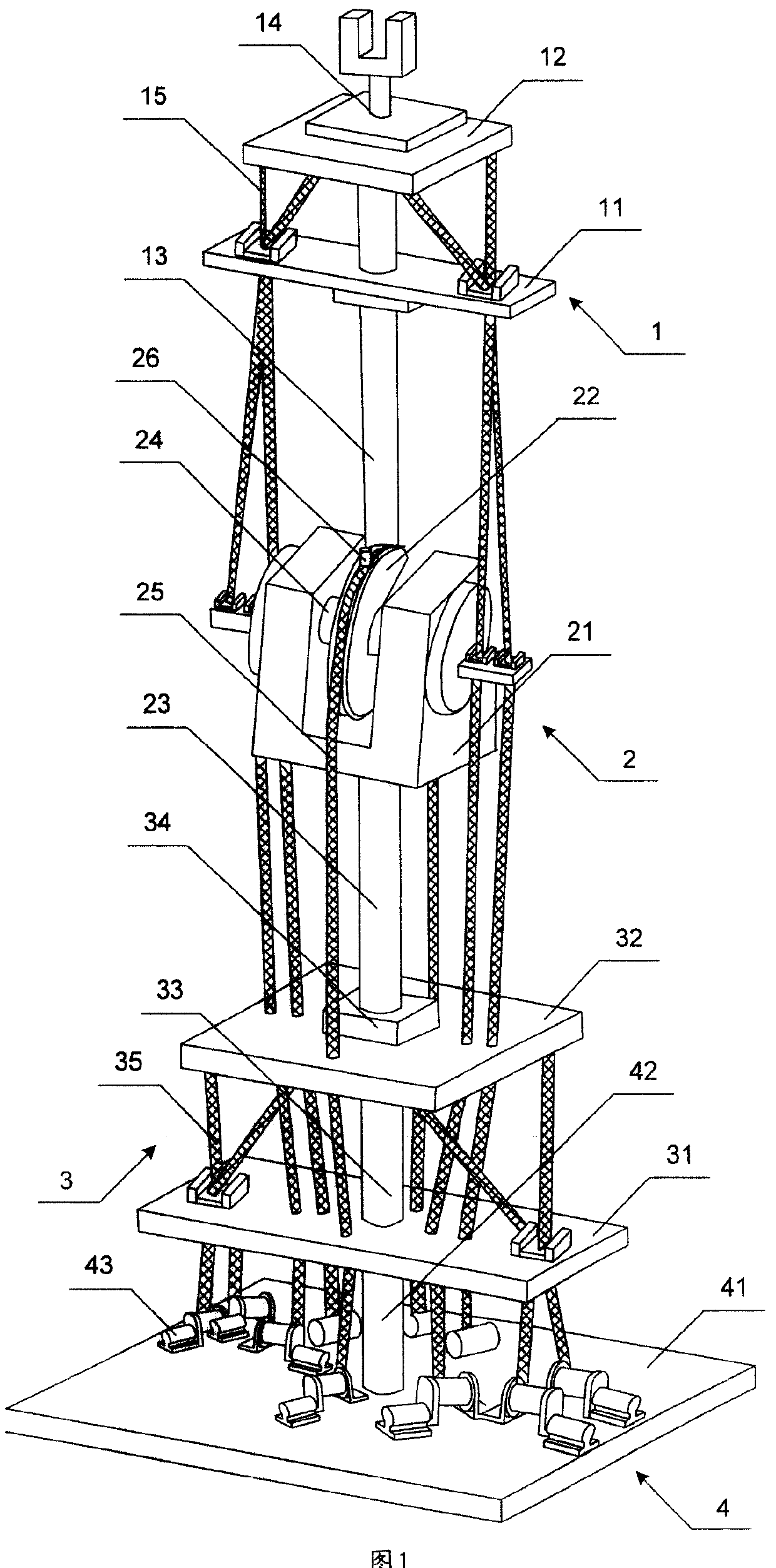

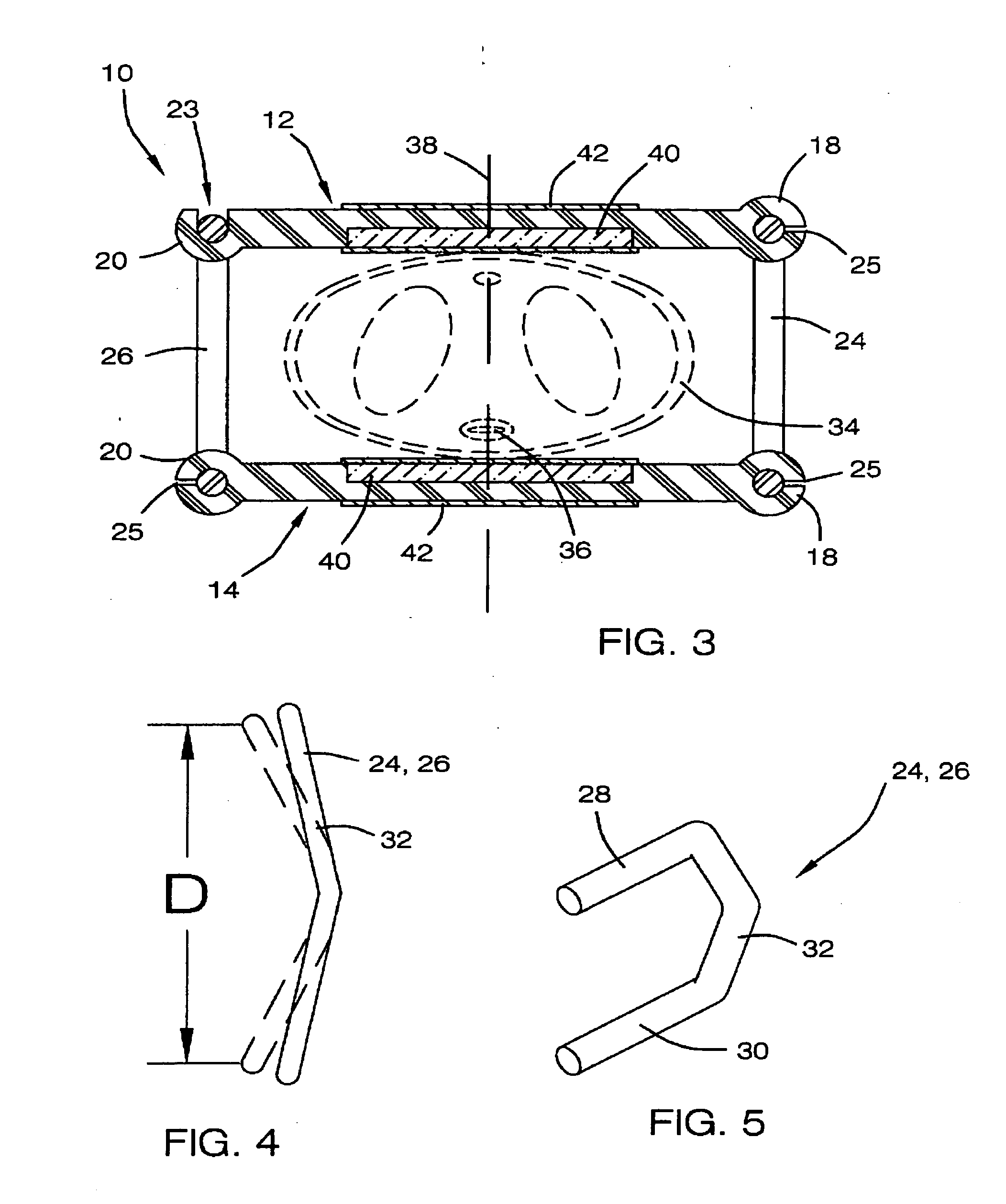

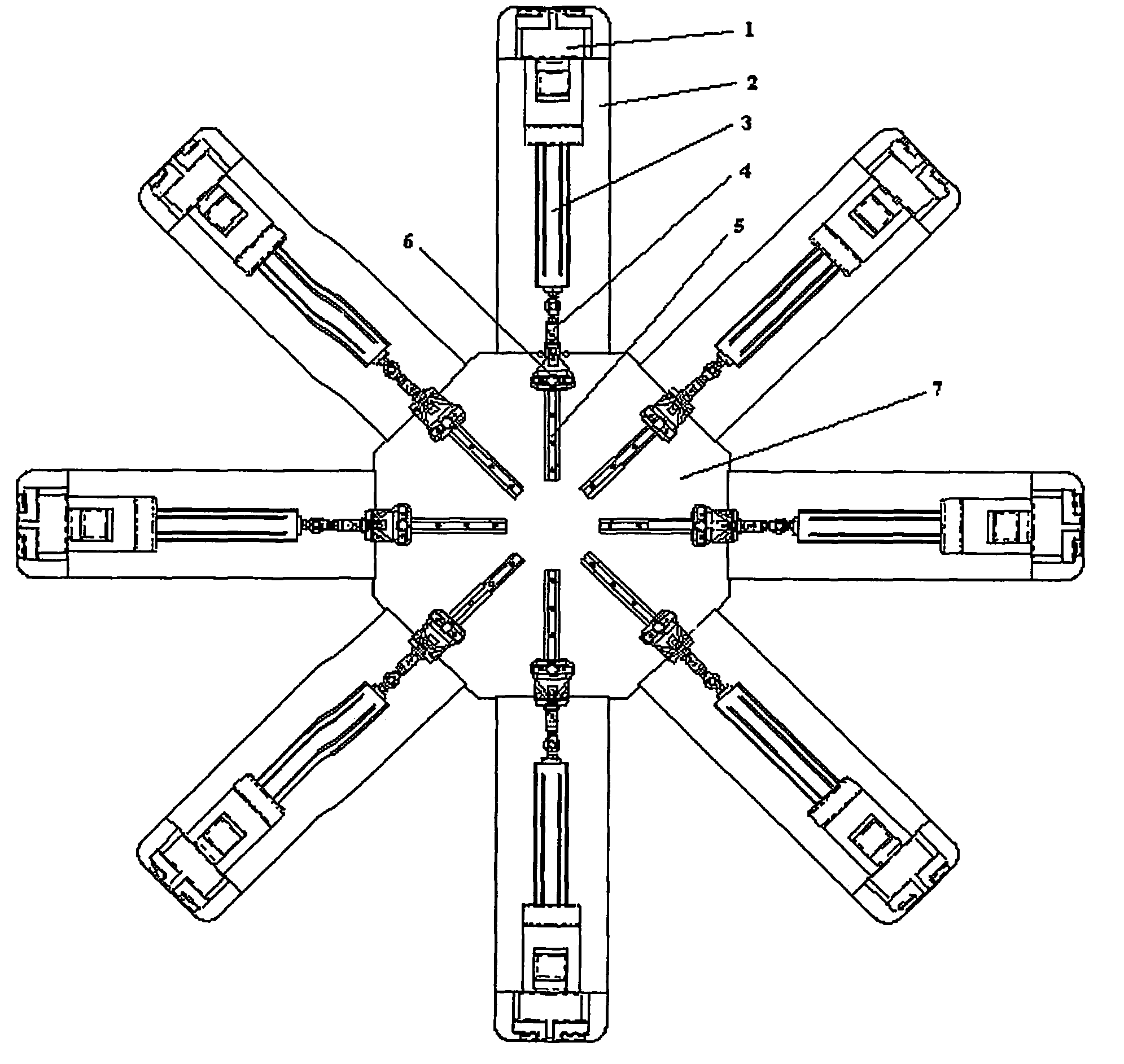

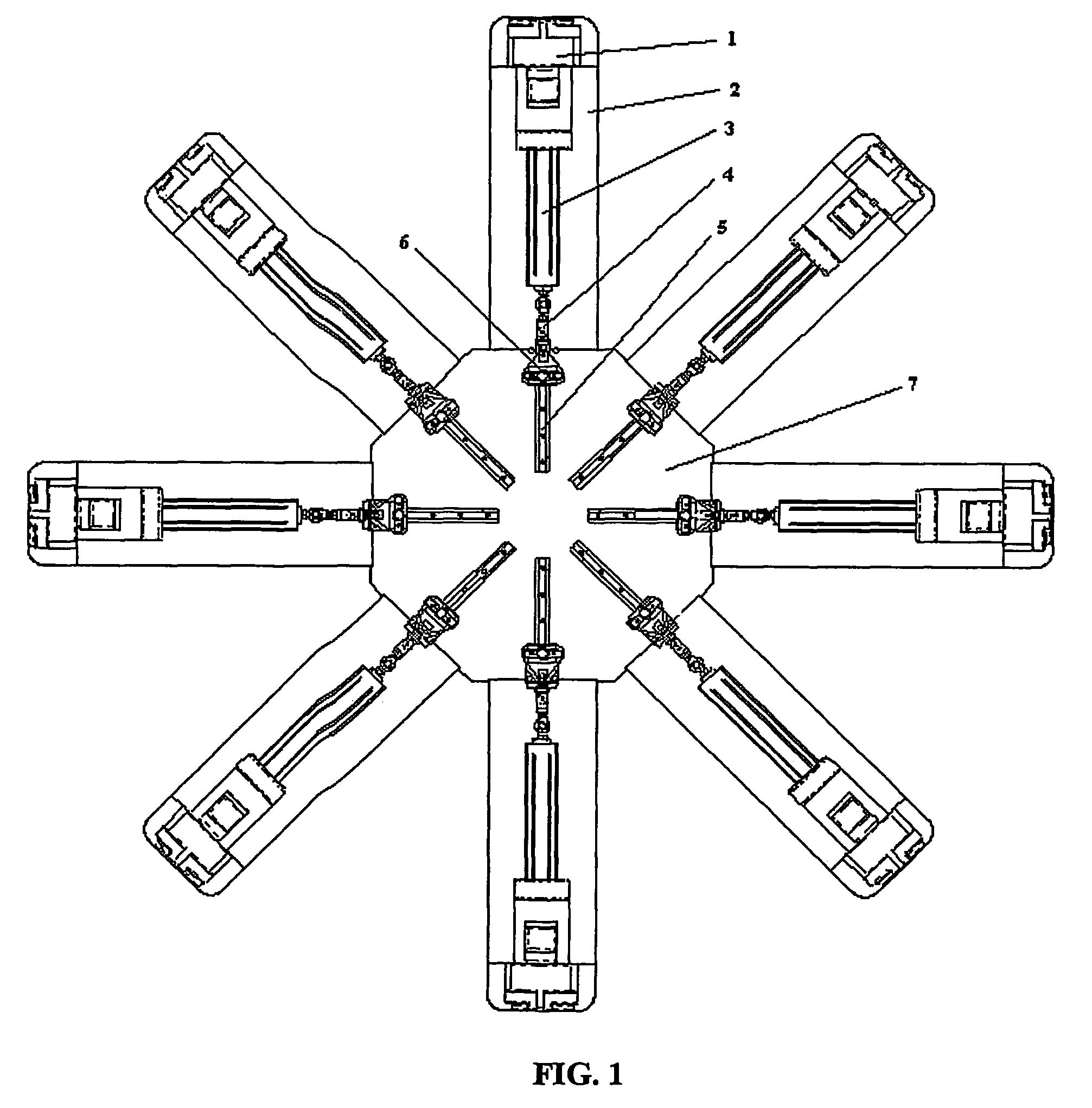

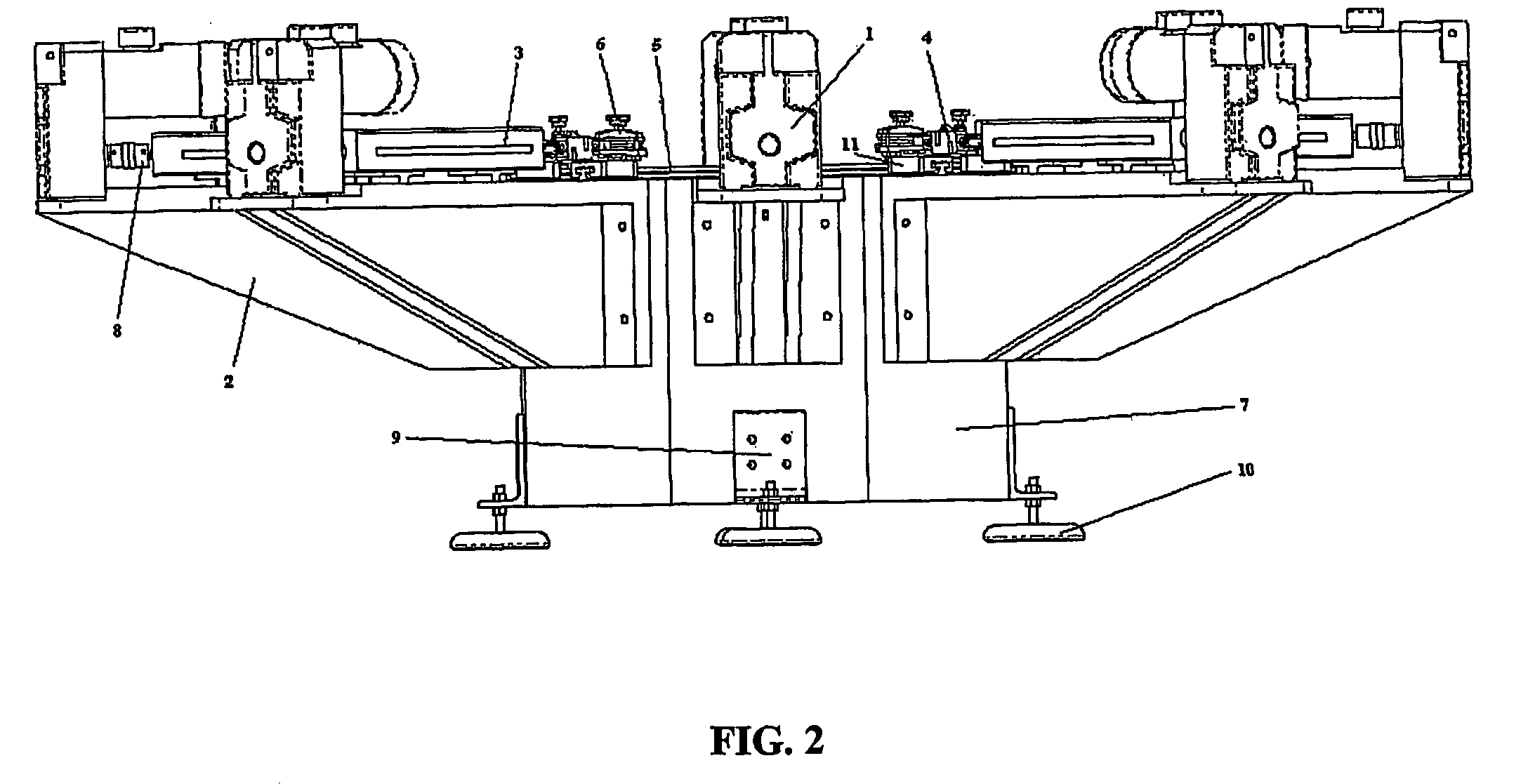

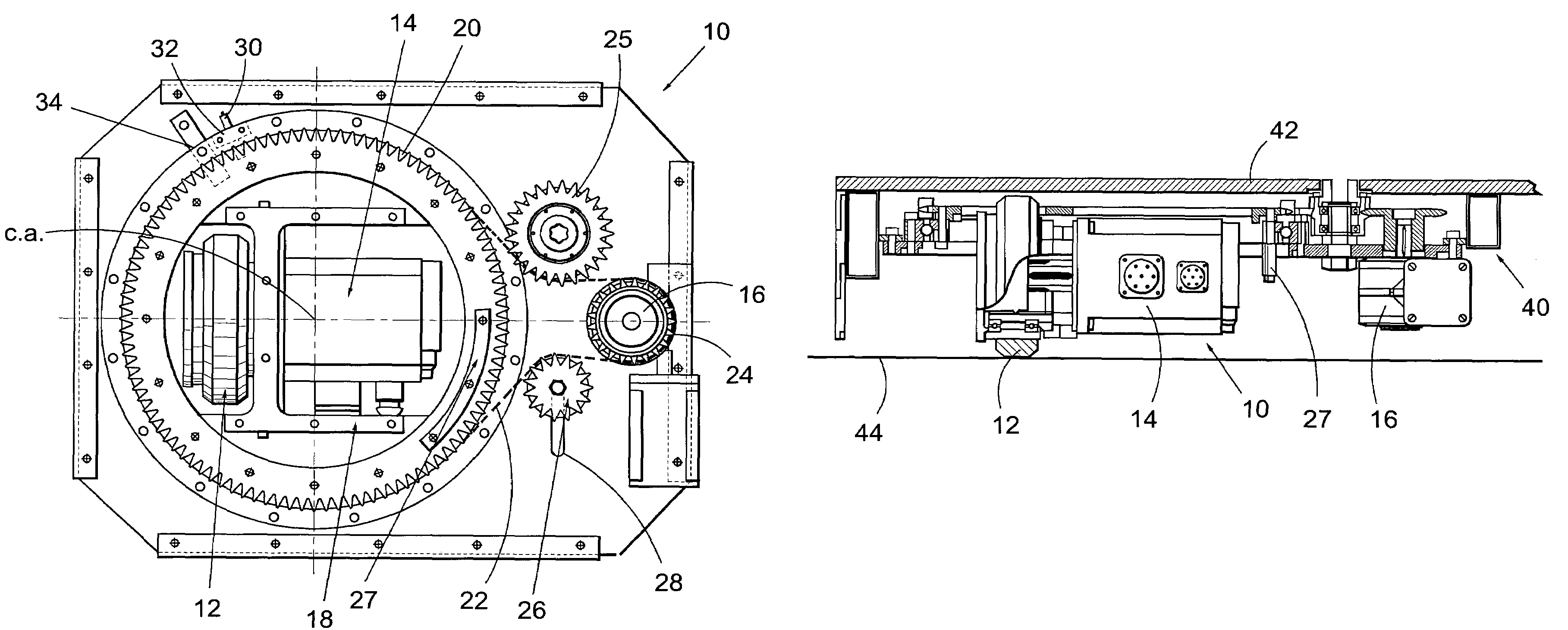

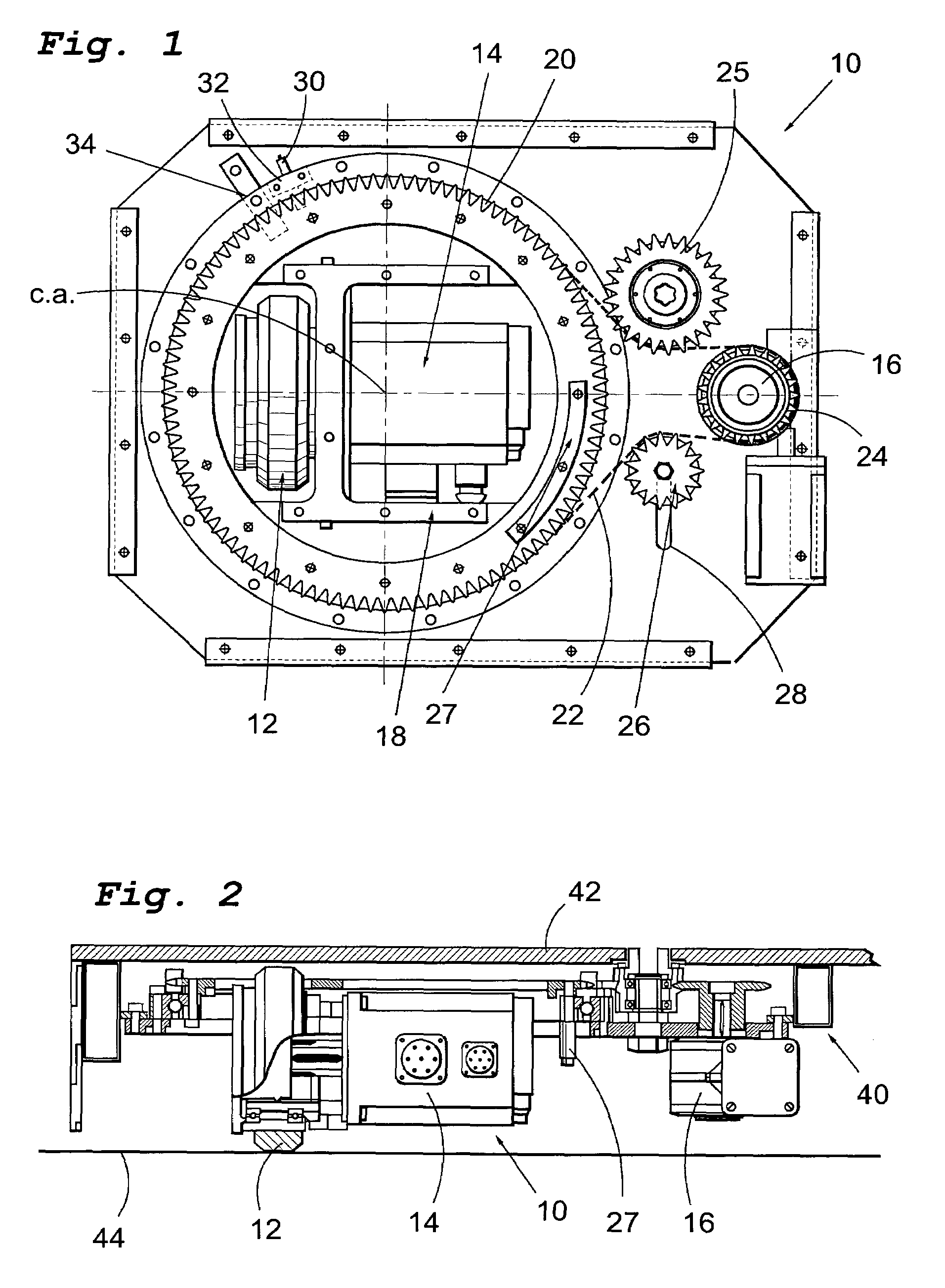

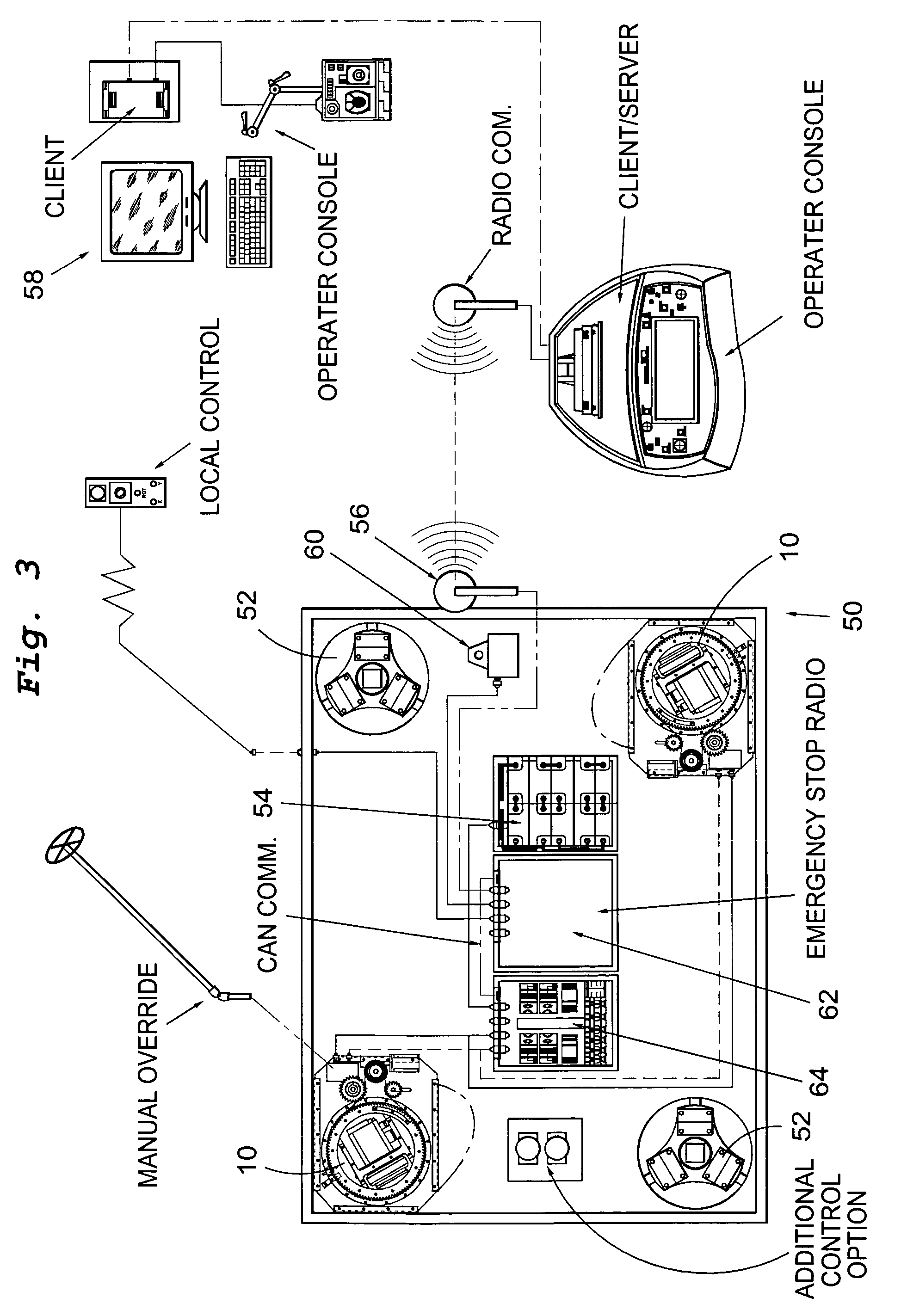

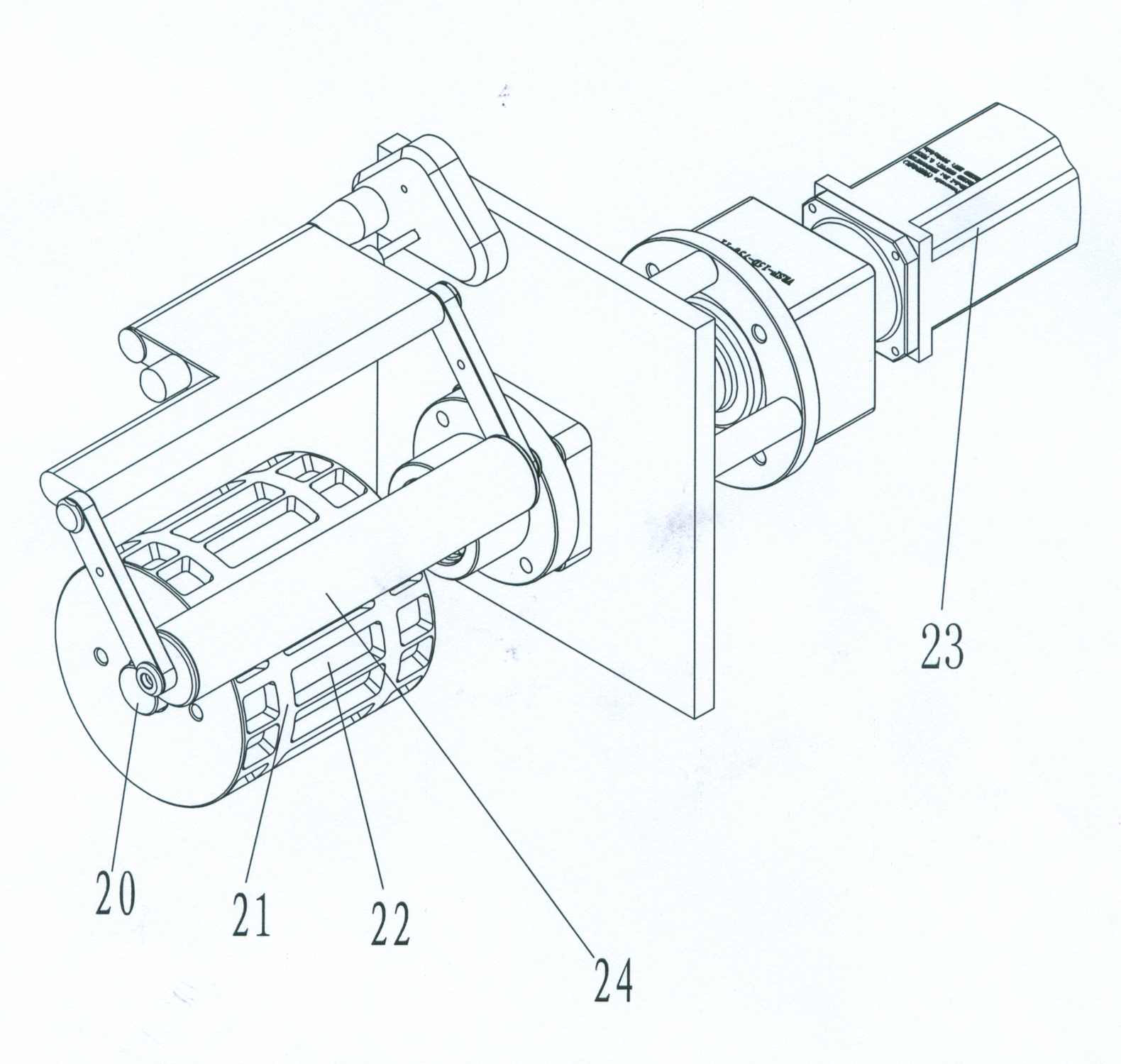

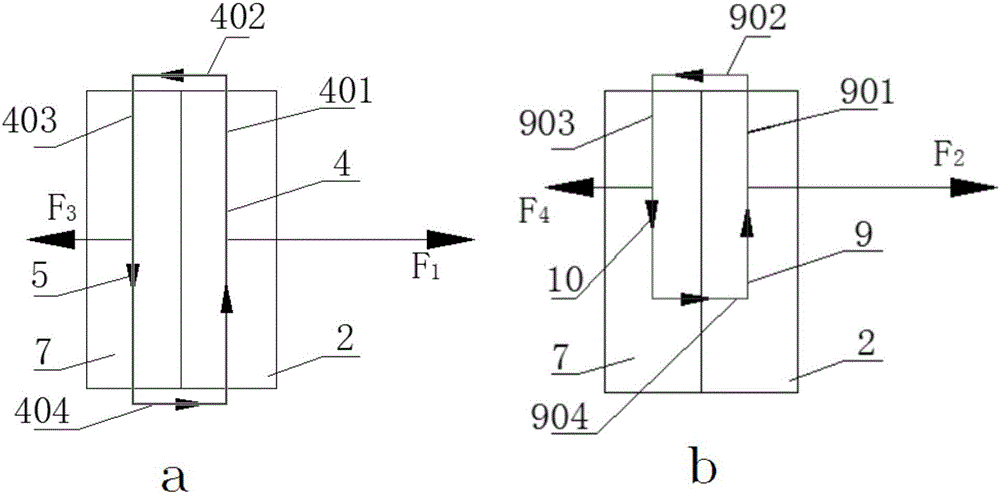

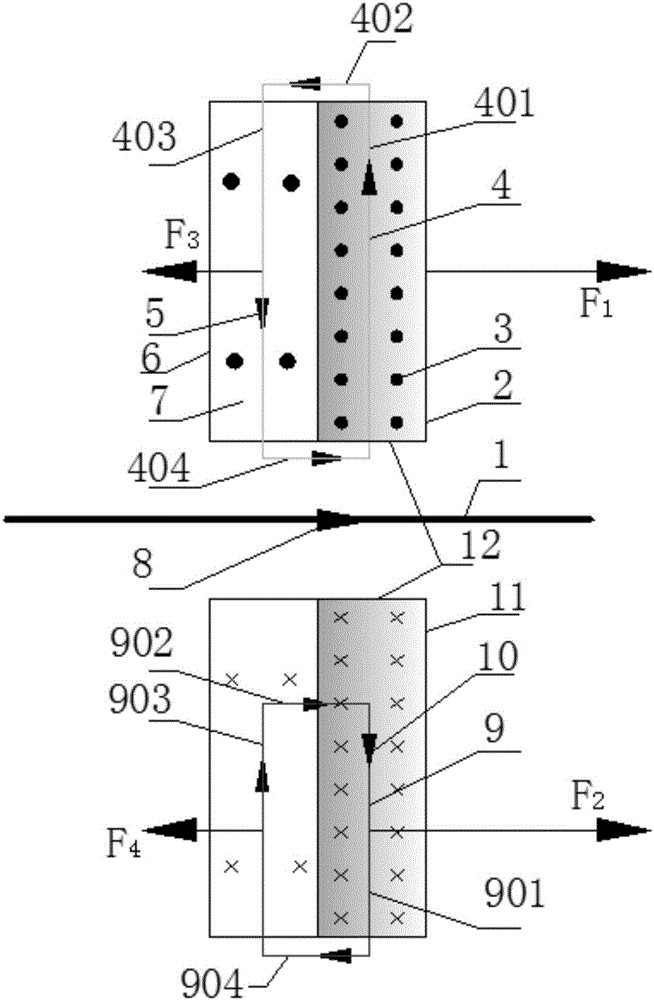

Multiaxial Universal Testing Machine

InactiveUS20080034885A1Reduce speedIncrease torqueMaterial strength using tensile/compressive forcesHorizontal axisElectric machinery

The invention concerns a multiaxial universal testing machine, which allows evaluating the mechanical behaviour and performance of materials with planar structures, such as fabrics, composites and laminates. The machine comprises 4 horizontal axes at 45°, with 8 gripping jaws displaceable along slide rails and moved by the action of 8 independent motors. The connection between a gripping jaw and its respective motor is assured by a linear actuator. The test specimen is fixed by the gripping jaws and can be subject to tensile, compression and fatigue testing, making possible the analysis of the materials behaviour under simultaneous multi-directional loads.

Owner:UNIVERSITY OF MINHO

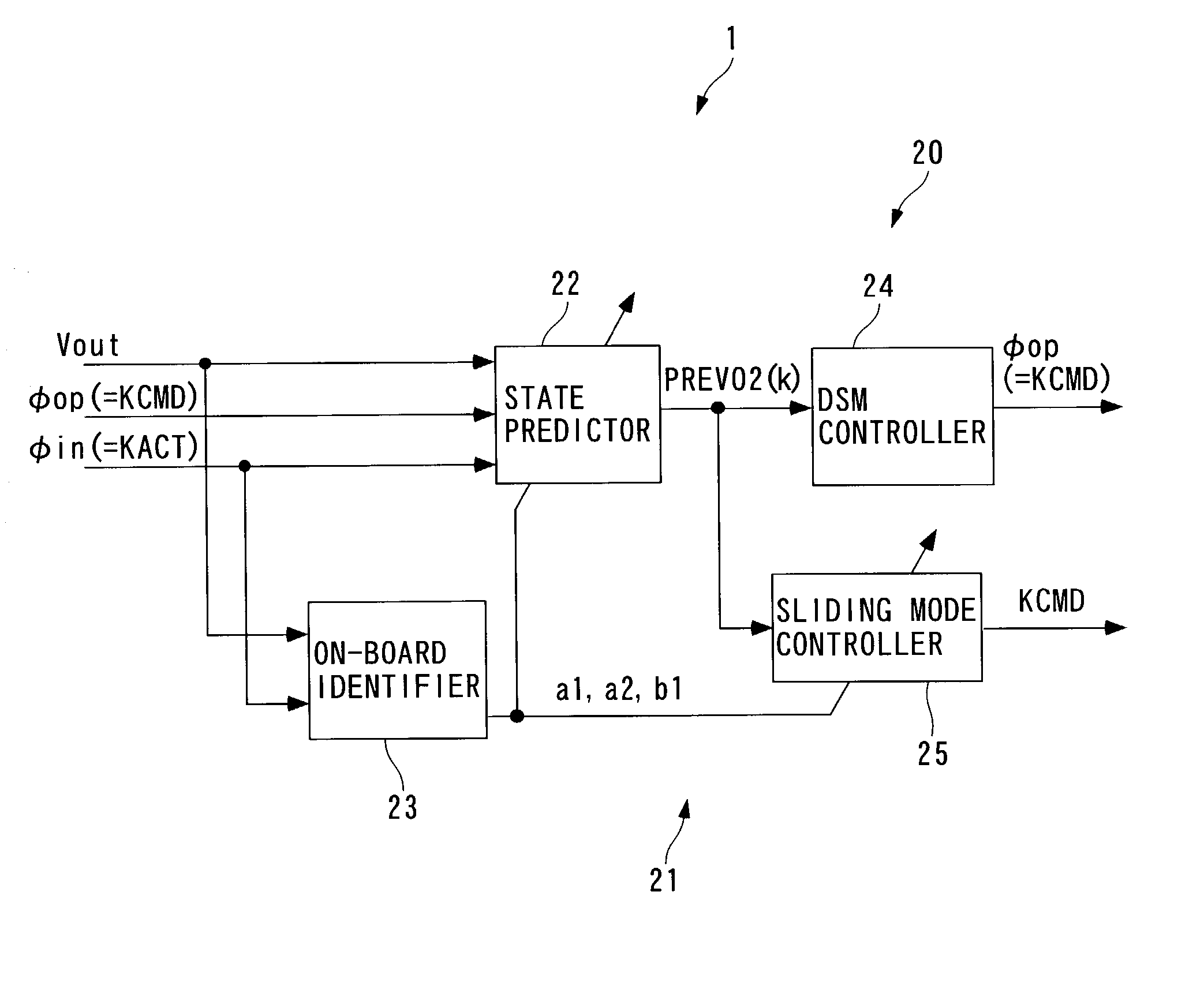

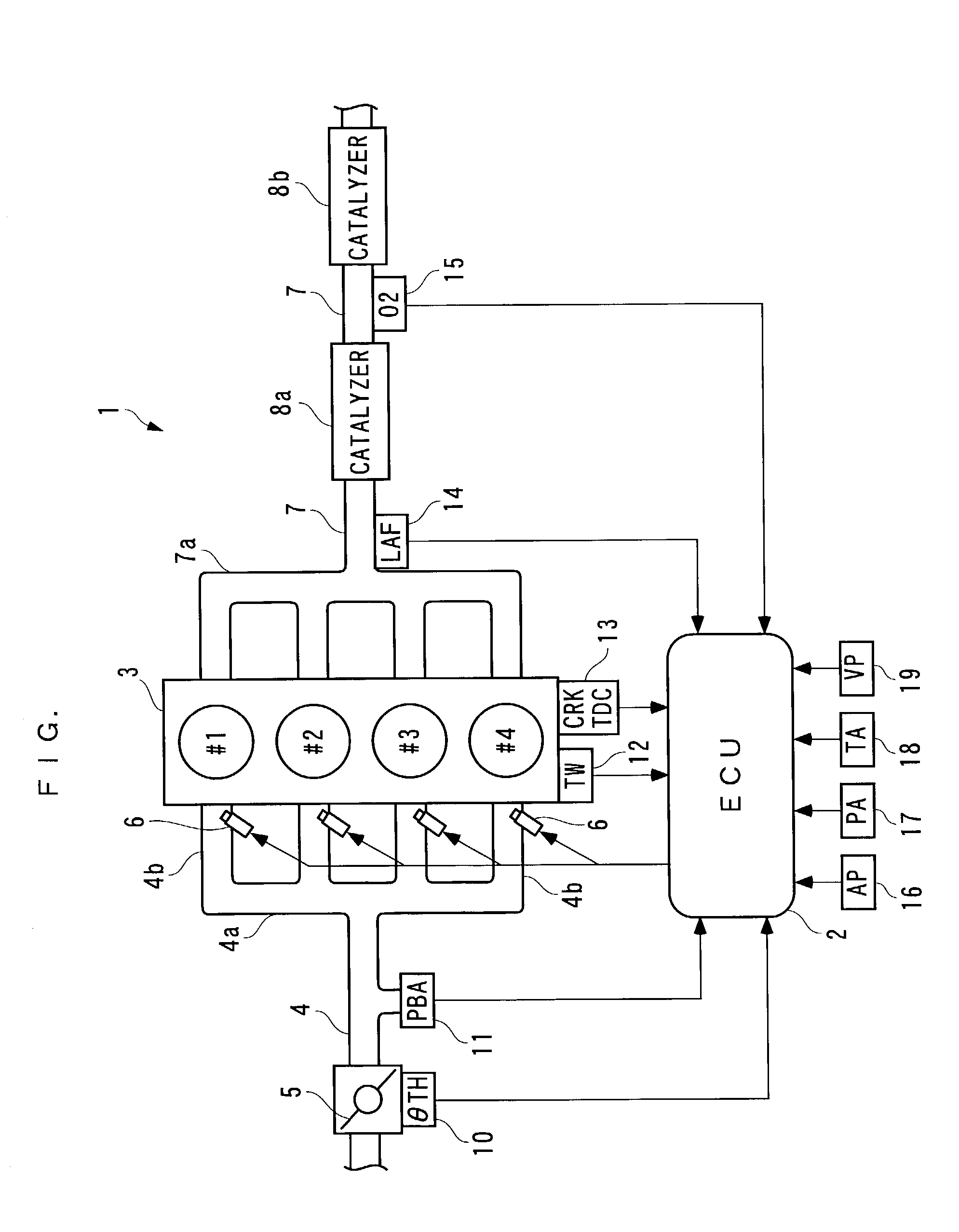

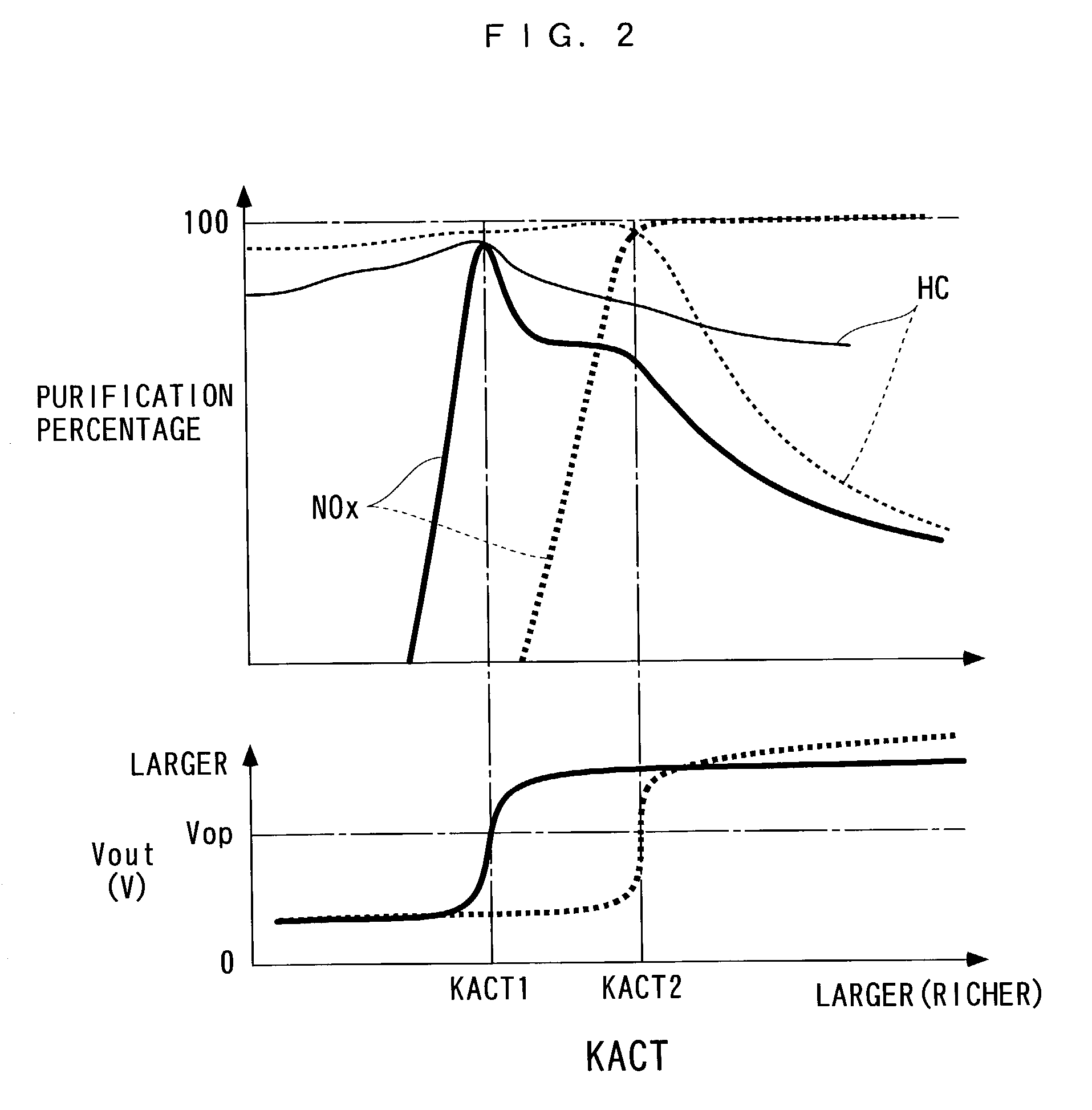

Control apparatus, control method , and engine control unit

InactiveUS20030125865A1Eliminate slippageImproving stability and controllabilityElectrical controlExhaust apparatusPrediction algorithmsObject based

A control apparatus is provided for eliminating a slippage in control timing between the input / output of a controlled object, even when the control object exhibits a relatively large dynamic characteristic such as a phase delay, a dead time, or the like, to improve the stability and the controllability of the control. The control apparatus comprises a state predictor for calculating a predicted value of a value indicative of an output of a controlled object based on a prediction algorithm, and a DSM controller for calculating a control input to the controlled object based on one modulation algorithm selected from a DELTA modulation algorithm, a DELTASIGMA modulation algorithm, and a SIGMADELTA modulation algorithm for controlling the output of the controlled object in accordance with the calculated predicted value.

Owner:HONDA MOTOR CO LTD

Lower back supporter

A lower back supporter including a pair of flat anchor parts that come into contact with the lower back of a wearer with a specified space in between, a pair of anchor belts that wrap around the abdomen with the end portions connected to each other, a first and second support belt that cross over each other on the back, and a connecting belt that connects the anchor parts. The inner side surface of the anchor part comprising a non-slip material that closely contacts the skin of the wearer, and the outer side surface comprising a material that fastens to surface fasteners. After the anchor belts are put on, operation belts connected to the first and second support belts are pulled, the surface fasteners are fastened to the outer side surfaces of the anchor parts, applying tensile force between the anchor parts in closely contact to the lower back.

Owner:DAIYA IND +1

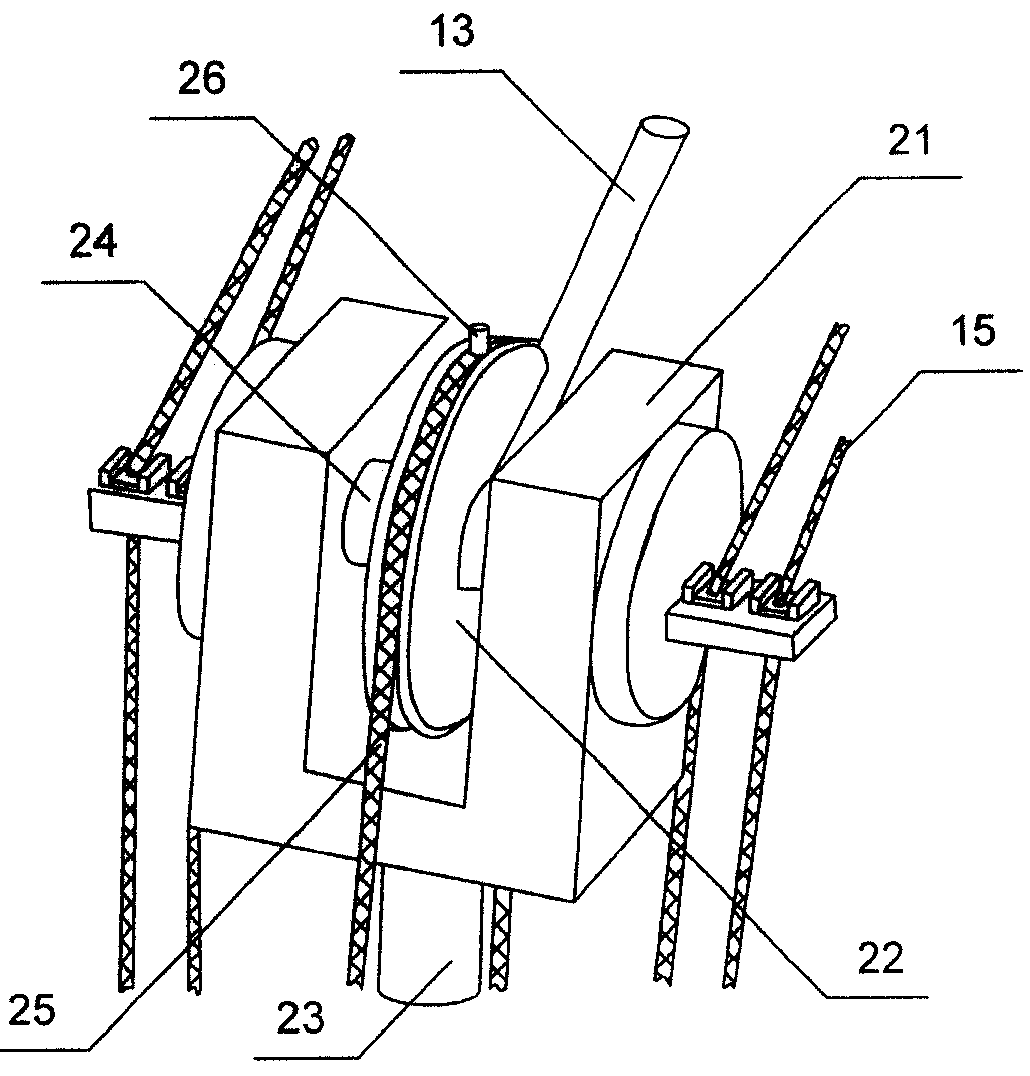

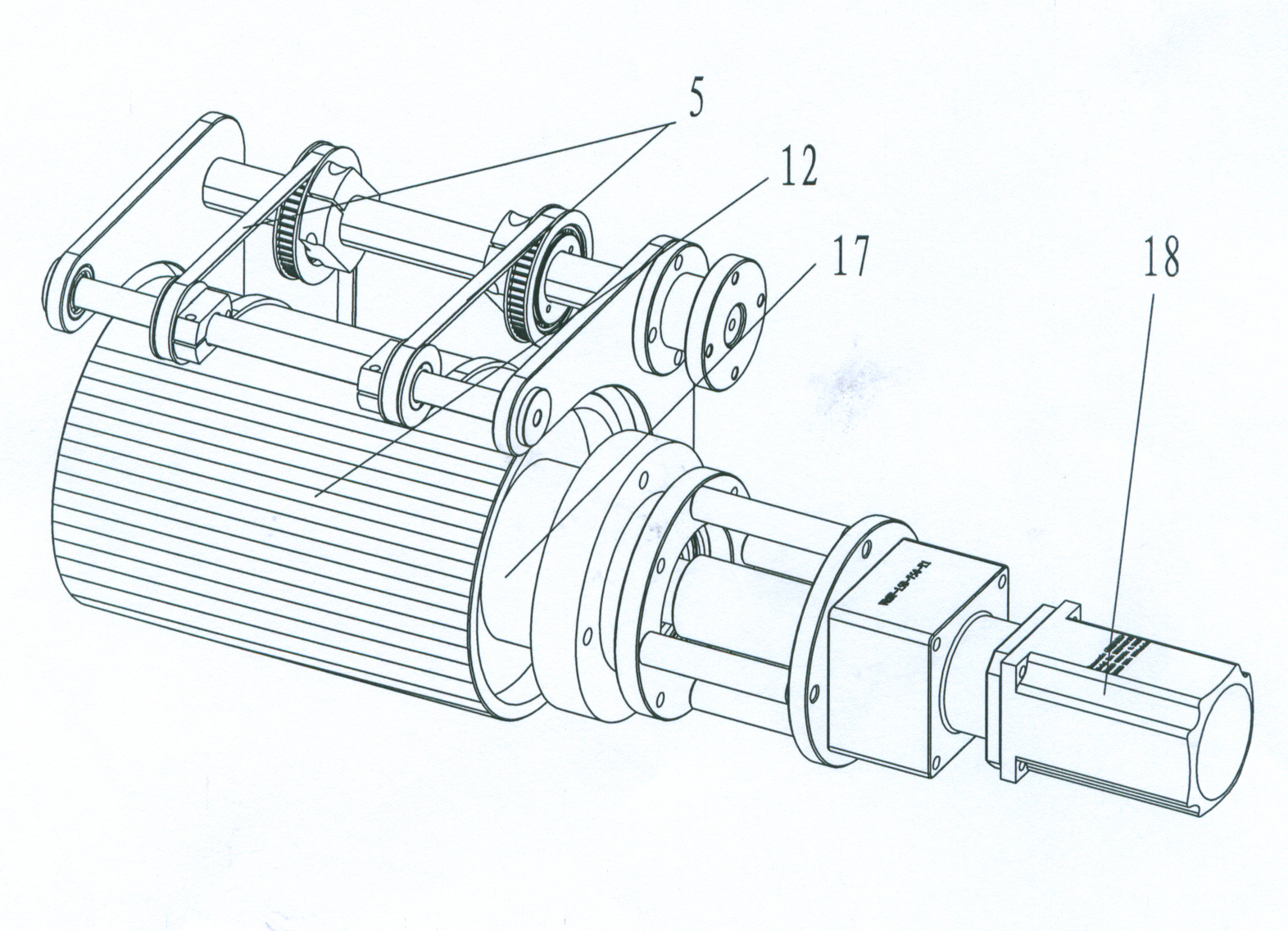

Rope-driven redundancy mechanical arm

InactiveCN101028712AEliminates prone to slippage problemsEliminate slippageJointsArmsSpherical bearingDrive wheel

A redundant manipulator driven by strings is composed of a base, a one-freedom elbow joint consisting of fixing platform, drive wheel, joint rod, drive axle and manipulating strings, and the three-freedom wrist and shoulder joints consisting of fixed platform, movable platform, joint rod, spherical bearing, and manipulating strings. Said manipulating string and / or drive wheel have stop mechanism, preventing skid.

Owner:BEIHANG UNIV

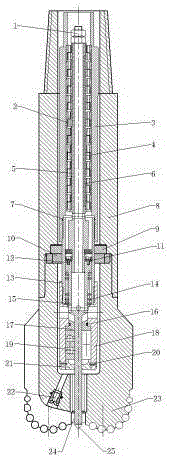

Novel PDC drill bit utilizing impact effect for improving heart rock breaking efficiency

The invention belongs to the field of technical equipment used in oil and natural gas drilling engineering, mine exploiting, geological drilling, constructional engineering, tunnel engineering, shielding and non-excavation, and relates to a novel PDC drill bit utilizing the impact effect for improving heart rock breaking efficiency. The PDC drill bit solves the problems that in the drilling process, a center rock column left in the center part influences drilling efficiency, and the position deviating from the center of a well hole shakes left and right. According to the technical scheme, the upper end of a turbine is fixed through a nut, the lower end of the turbine is fixed through a boss on a turbine shaft, an upper cam is connected to the turbine shaft through threads, a lower cam is fixed to a punch hammer through a sunk screw, the upper section of the punch hammer is hollow, a pore passage enabling drilling fluid to flow out is formed in the upper end of a shell on the lower portion, a pressing head with the top end provided with a tip-shaped PDC tooth is added to the tail end of a connecting cavity, as a main impact part, the lower end of the punch hammer becomes thin, and a bi-directional thrust ball bearing is placed at the lower end. The equipment enables the heart to generate longitudinal impact, improves the rock breaking efficiency and reduces drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

Lower back supporter

A lower back supporter including a pair of flat anchor parts that come into contact with the lower back of a wearer with a specified space in between, a pair of anchor belts that wrap around the abdomen with the end portions connected to each other, a first and second support belt that cross over each other on the back, and a connecting belt that connects the anchor parts. The inner side surface of the anchor part comprising a non-slip material that closely contacts the skin of the wearer, and the outer side surface comprising a material that fastens to surface fasteners. After the anchor belts are put on, operation belts connected to the first and second support belts are pulled, the surface fasteners are fastened to the outer side surfaces of the anchor parts, applying tensile force between the anchor parts in closely contact to the lower back.

Owner:DAIYA IND +1

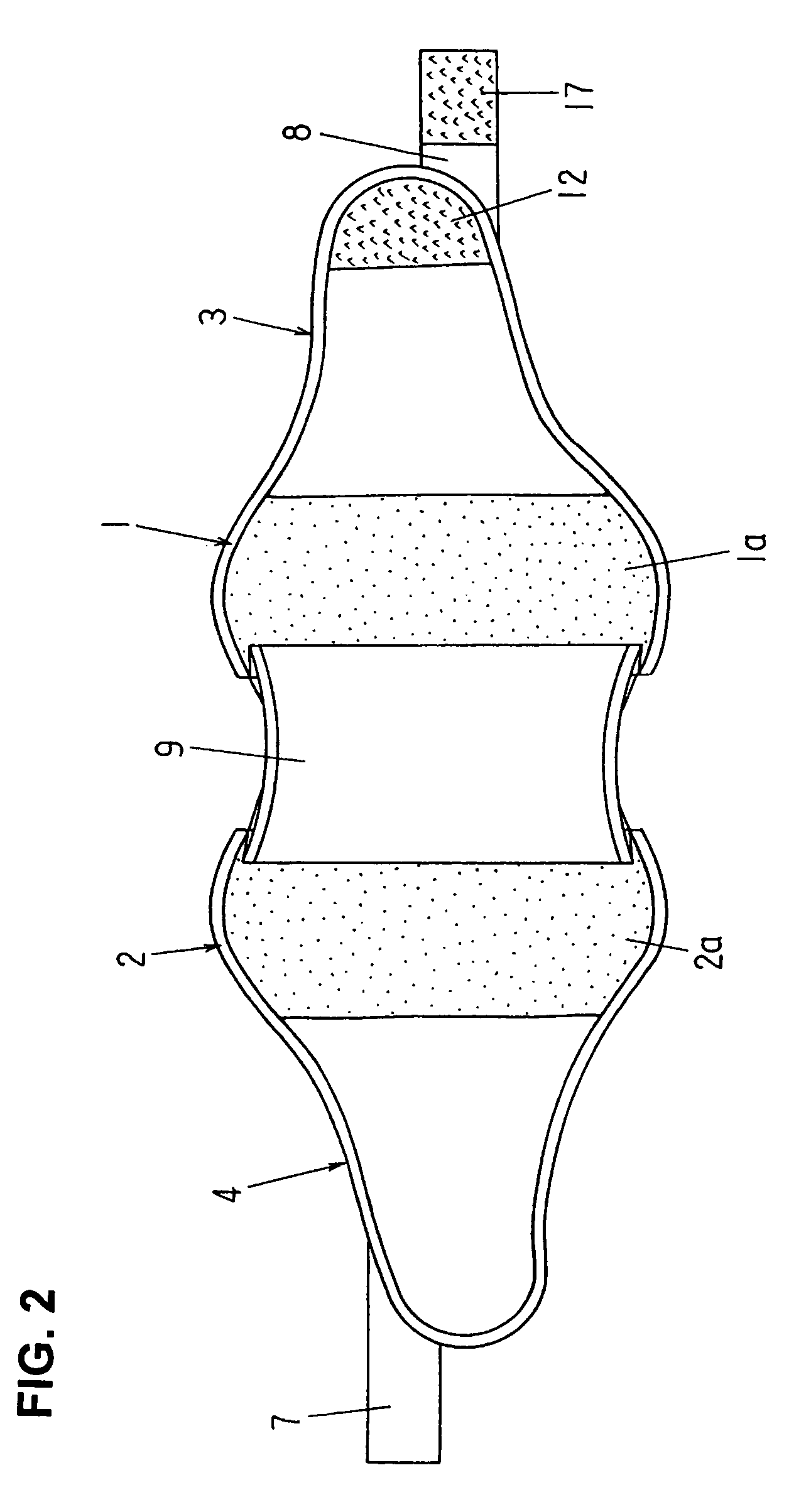

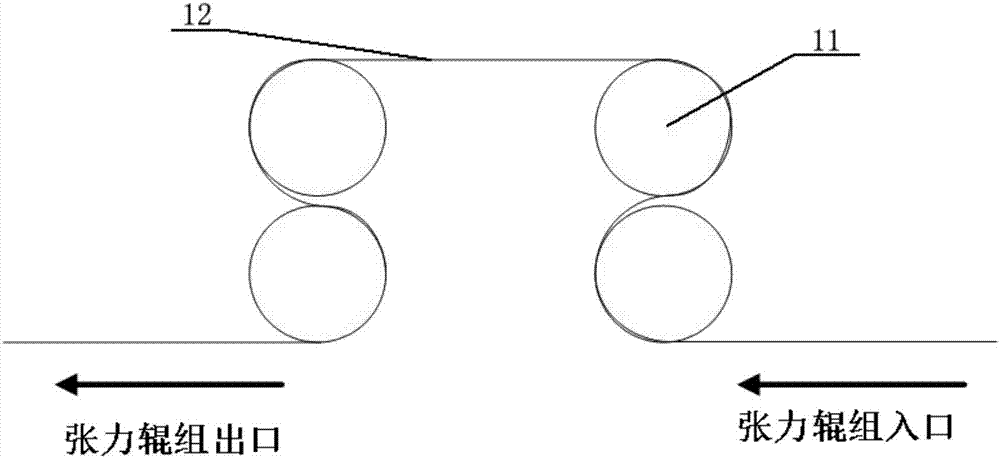

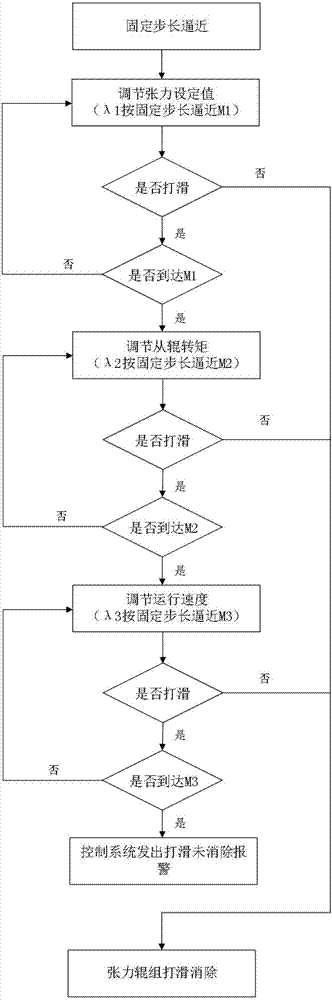

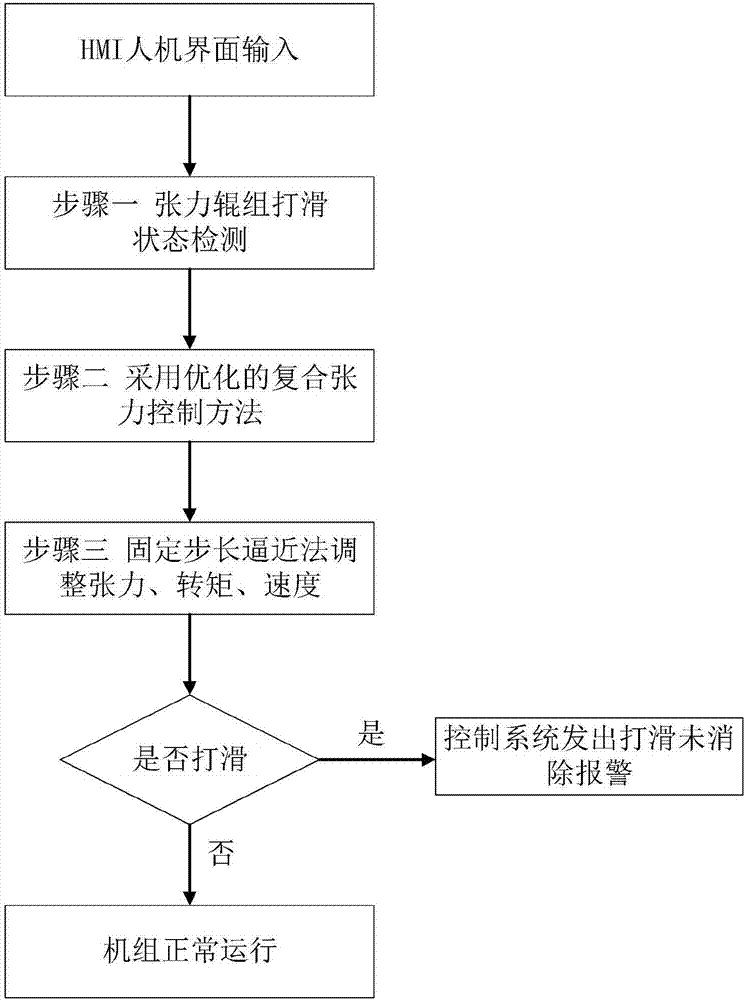

Control method for reducing influence of slipping of tension roll set

ActiveCN107952799AReal-time monitoring of slippageEliminate slippageTension/compression control deviceProduction lineControl system

The invention provides a control method for reducing the influence of slipping of a tension roll set. The control method is characterized by comprising the following steps of 1, monitoring of the tension roll set slipping state, 2, formulating of a tension roll set tension control method, and 3, reducing and even eliminating of the tension roll set slipping state through a fixed-step approach method. According to the control method for reducing the influence of slipping of the tension roll set, in a control system, through three slipping judgment strategies, whether the tension roll set in a cold rolling strip material production line slips or not and which tension roll slips are monitored in real time, and according to the production state, the tension roll set in the production line is controlled through the formulated composite control method. When the slipping state occurs, through the fixed-step approach method, the tension, torque and speed are adjusted so as to reduce and finally eliminate the occurring slipping phenomenon of the tension roll set.

Owner:WUHAN UNIV OF SCI & TECH

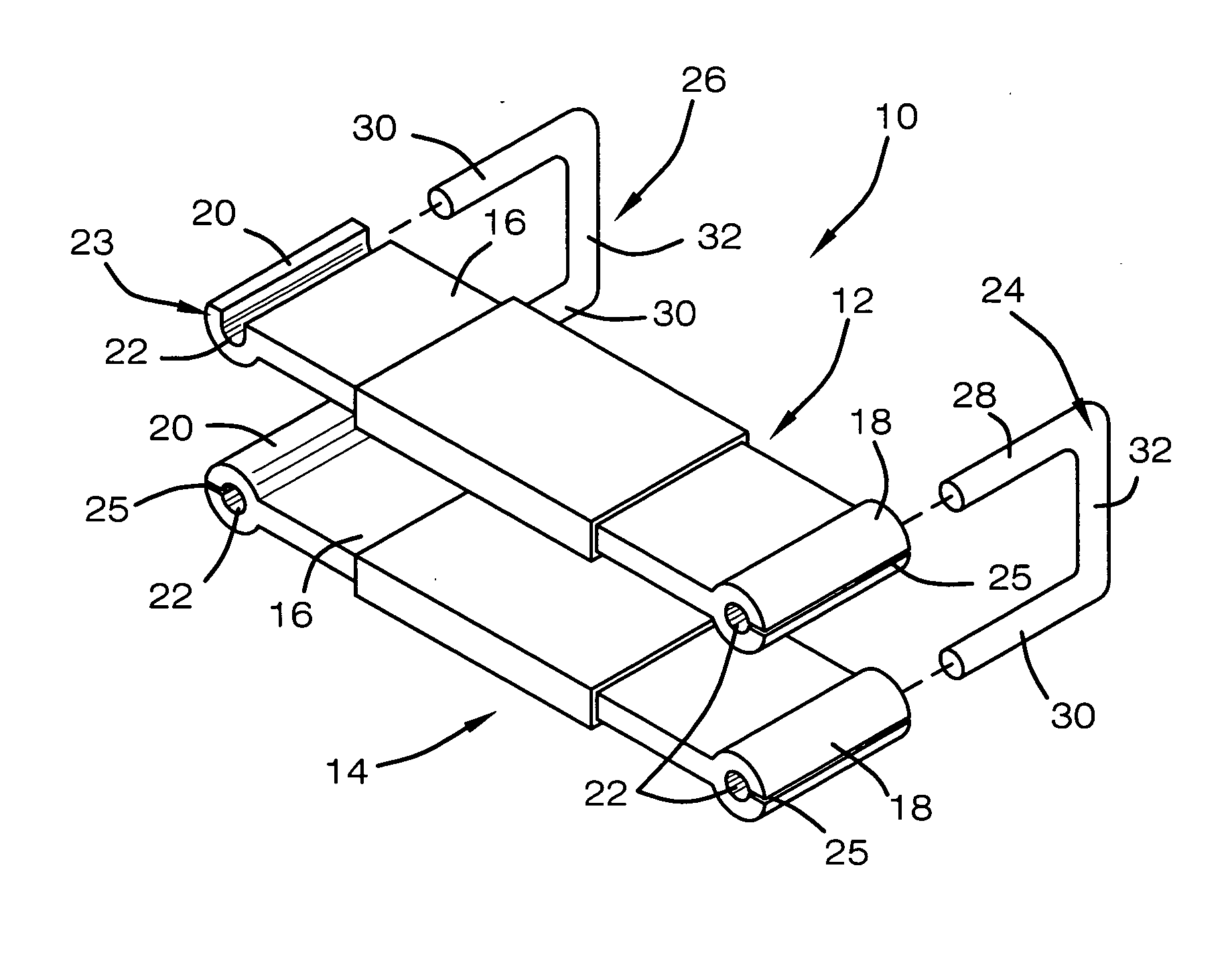

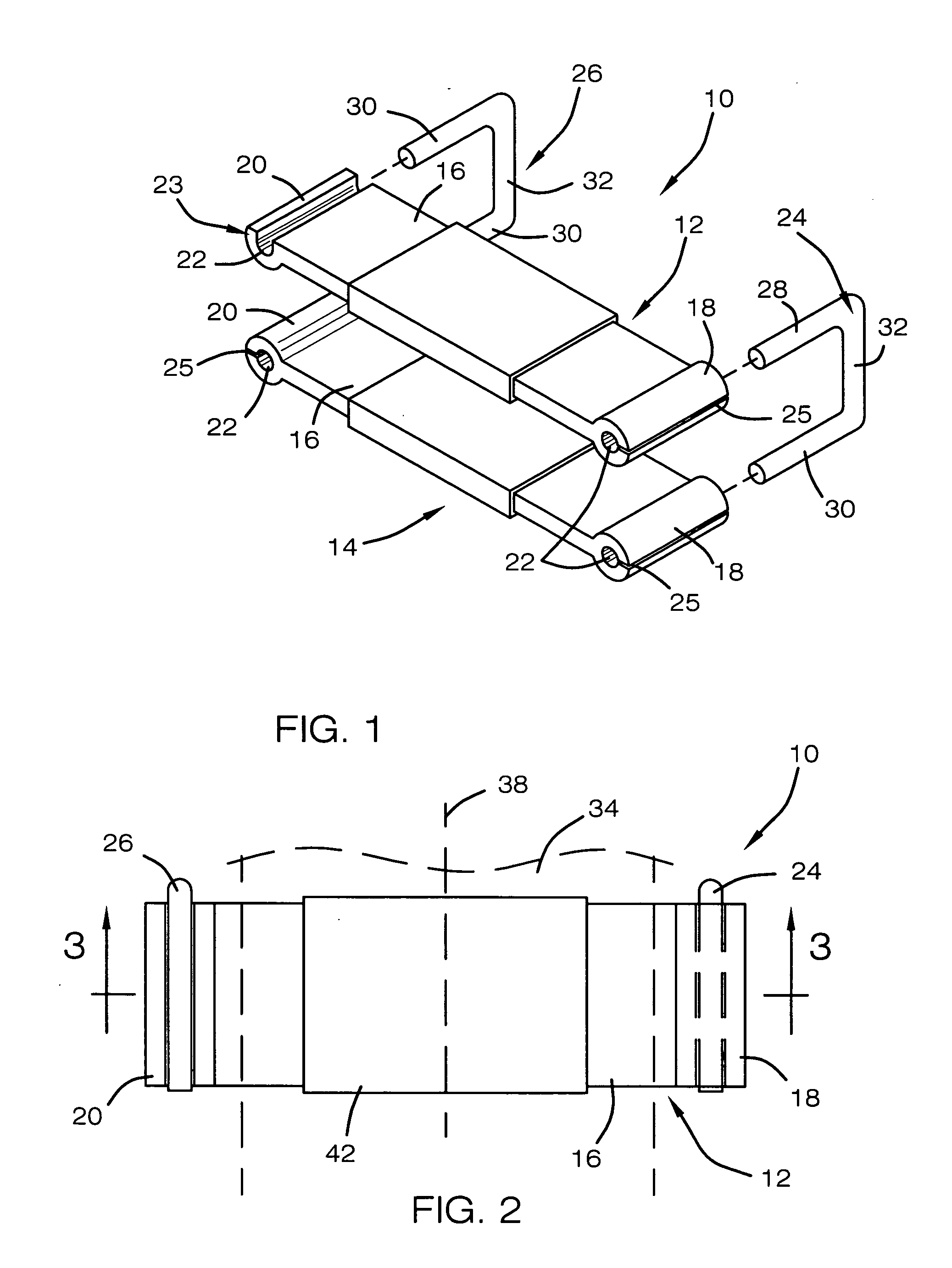

External incontinence clamp

InactiveUS20050085835A1Improve wearing comfortEliminate slippageMale contraceptivesAnti-incontinence devicesUrineEngineering

An external incontinence clamp for stopping involuntary voiding of urine is provided. The clamp includes a first rigid member having opposed ends, each end defining a passage extending therethrough, a second rigid member having opposed ends, each end defining a passage extending therethrough, and two pins of generally u-shape. The pins are adapted to be received by the passages defined by the ends of the first rigid member and of the second rigid member so as to secure the first rigid member in a spaced and generally parallel relationship to the second rigid member. The penis is positioned between the first and second members so that the underside of the penis is in contact with the second member and the top surface of the penis is in contact with the first member, thereby stopping involuntary voiding of urine. A clamp kit includes a plurality of pins of different width to vary the force applied to the penis.

Owner:RENNICH HENRY

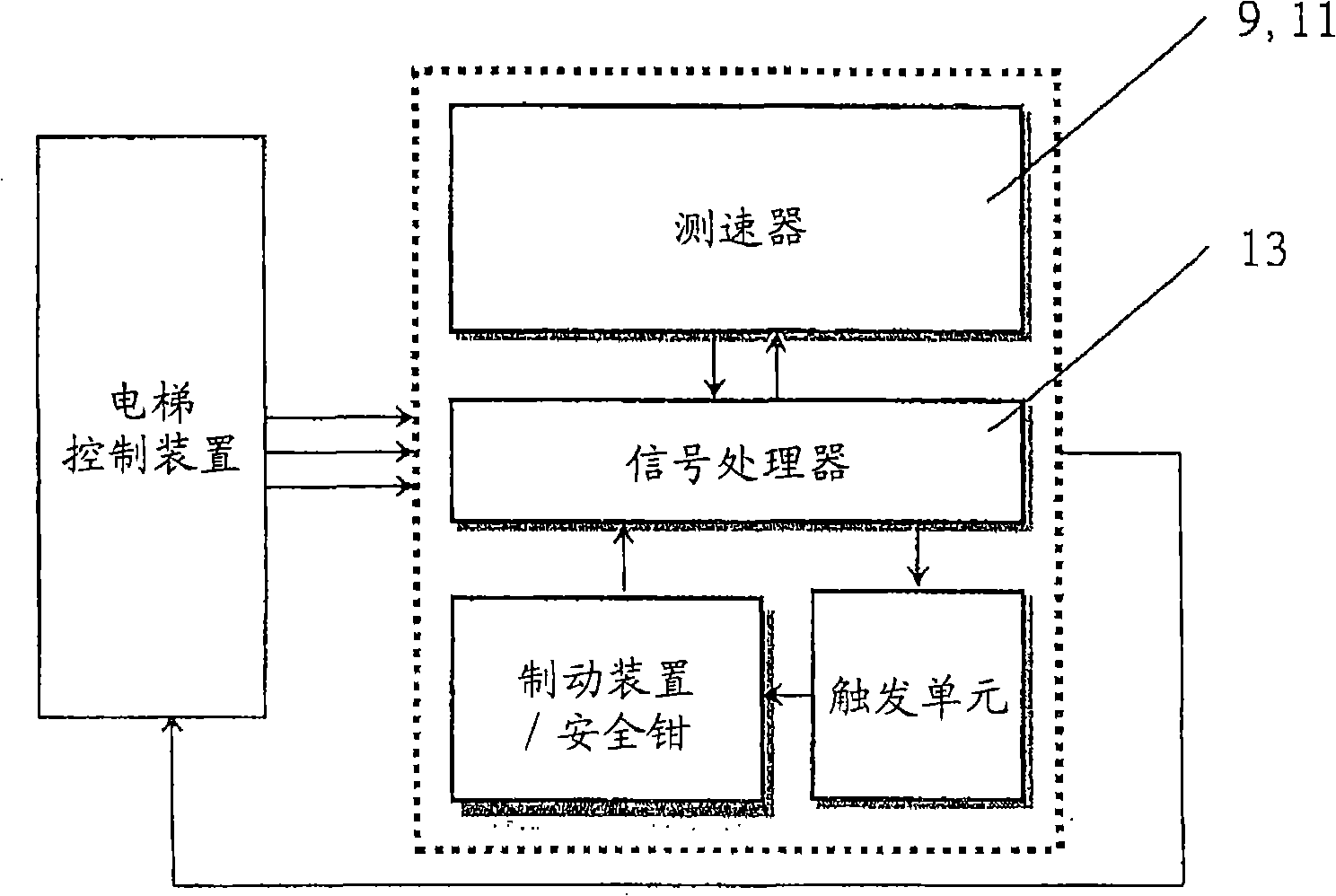

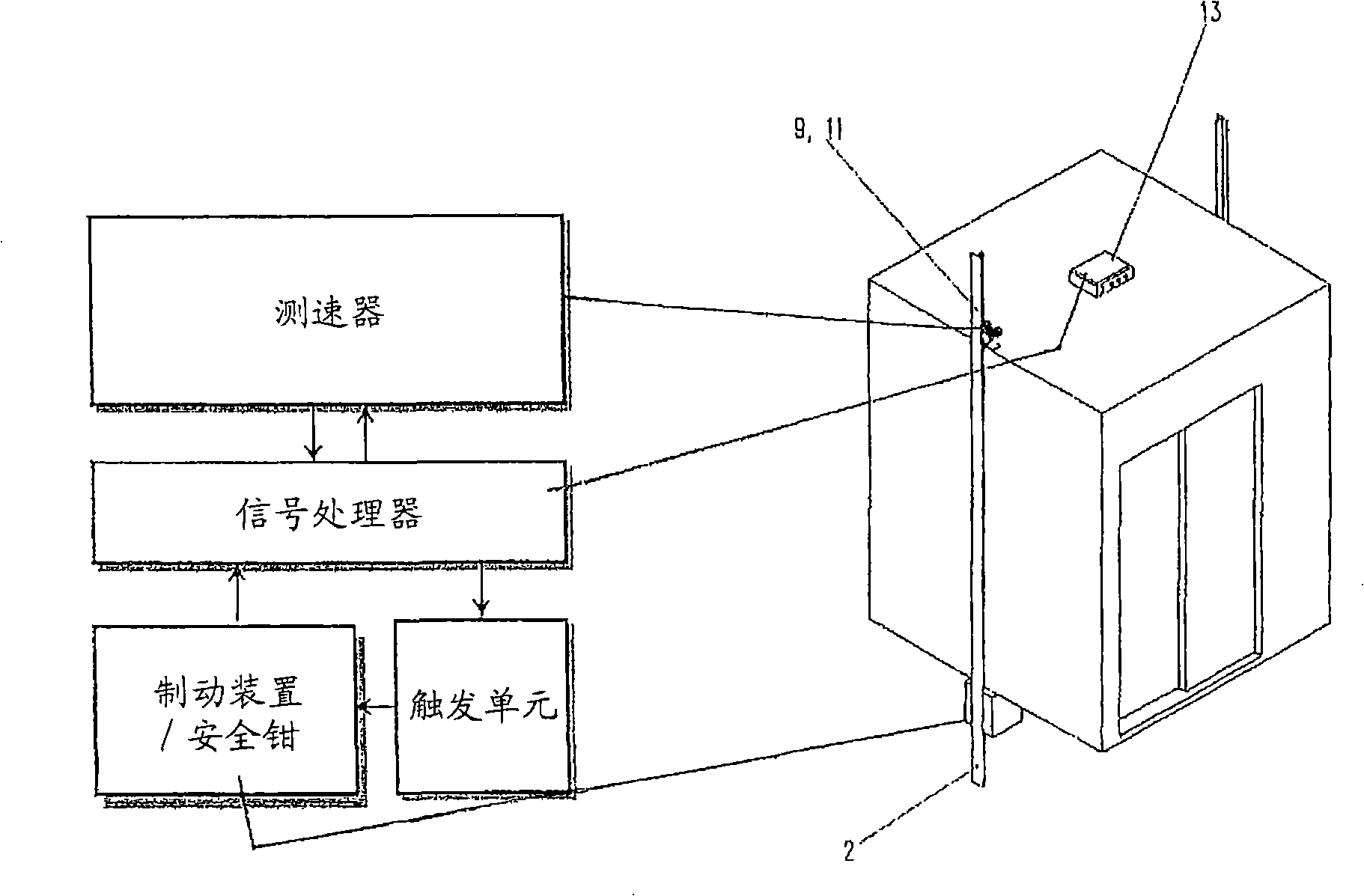

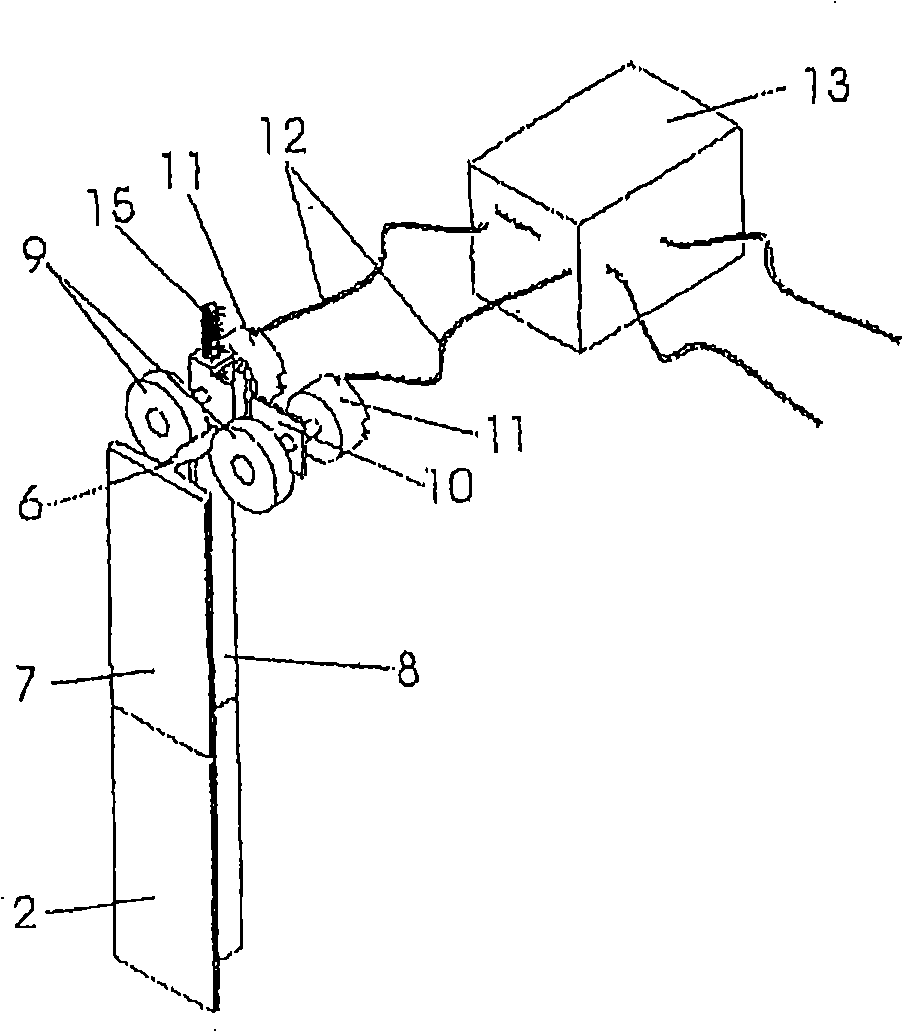

ISG type multifunctional electronic urgent safety clamp

The invention relates to an elevator comprising an elevator car that is guided inside an elevator shaft on guide rails. Said elevator also comprises electronics for inter alia travel control or regulation and an emergency braking device for preventing excess speed of the elevator car. Said emergency braking device has a braking device and a detector unit (11) the signal of which actuates the braking device when the elevator car reaches an excess speed. The detector unit (9, 11) comprises at least two wheels (8) that rest against a guide rail (2), each driving a respective detector (11) the signal of which is a measure for the rotational angle or rotational speed of the corresponding wheel. The electronics are adapted to functionally utilize the detector signal.; For this purpose, at least one detector signal is used during operation of the elevator within the admissible speed range for determining at least travel, speed and / or acceleration variable of the elevator car influencing the operation of the elevator system. The electronics actuate the braking device as soon as at least one of the detectors (11), by way of its detector signal, indicates an excess speed of the elevator car outside the admissible speed range.

Owner:WITTUR

Multiaxial universal testing machine

InactiveUS7509882B2Reduce speedIncrease torqueWork measurementMaterial strength using tensile/compressive forcesElectric machineryHorizontal axis

The invention concerns a multiaxial universal testing machine, which allows evaluating the mechanical behavior and performance of materials with planar structures, such as fabrics, composites and laminates. The machine comprises 4 horizontal axes, each one with 2 arms, resulting in a final arrangement of 8 gripping jaws at 45°, displaceable along slide rails and moved by the action of 8 independent motors. The connection between a gripping jaw and its respective motor is assured by a linear actuator. The test specimen is fixed by the gripping jaws and can be subject to tensile, compression and fatigue testing, making possible the analysis of the materials behavior under simultaneous multi-directional loads.

Owner:UNIVERSITY OF MINHO

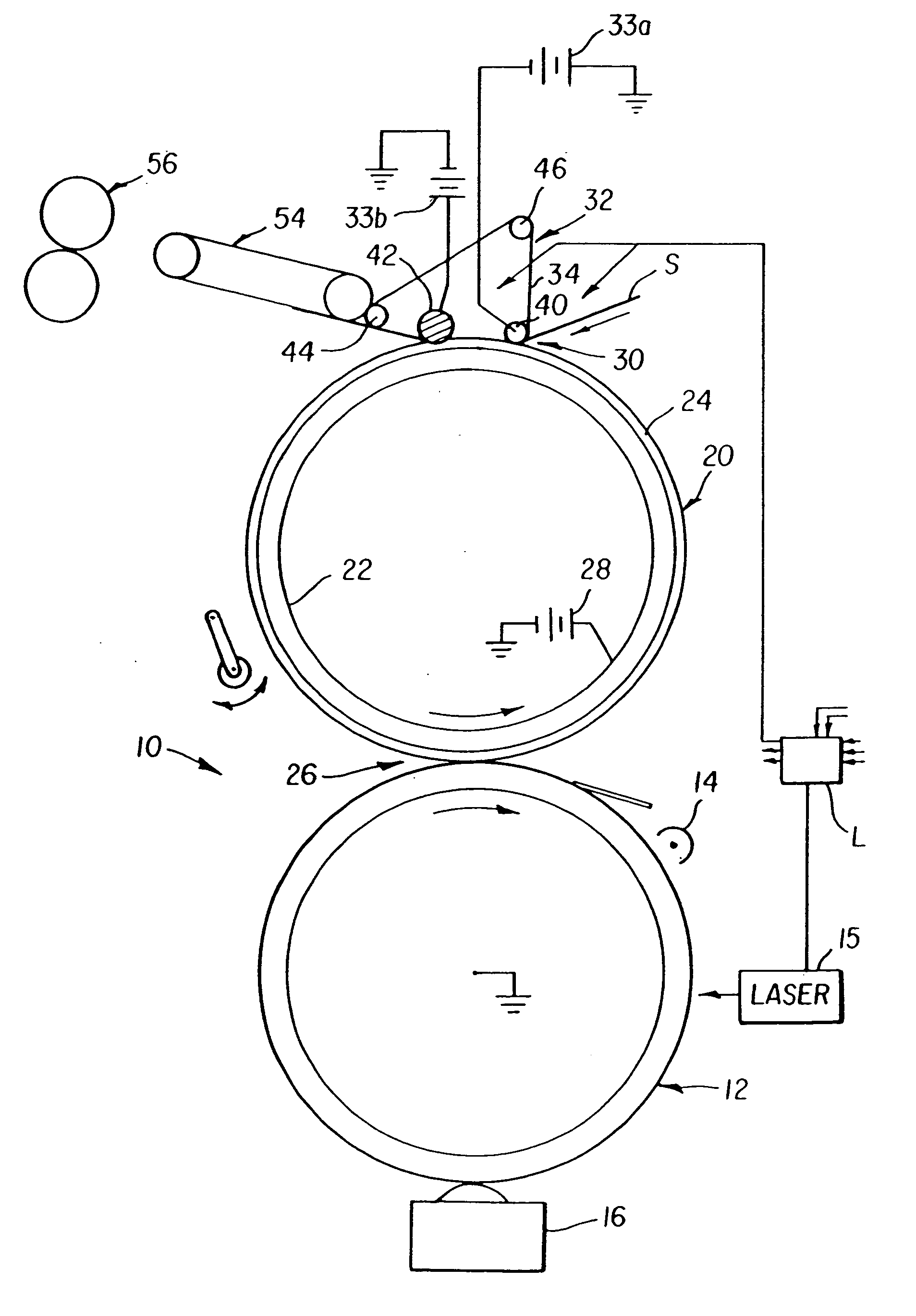

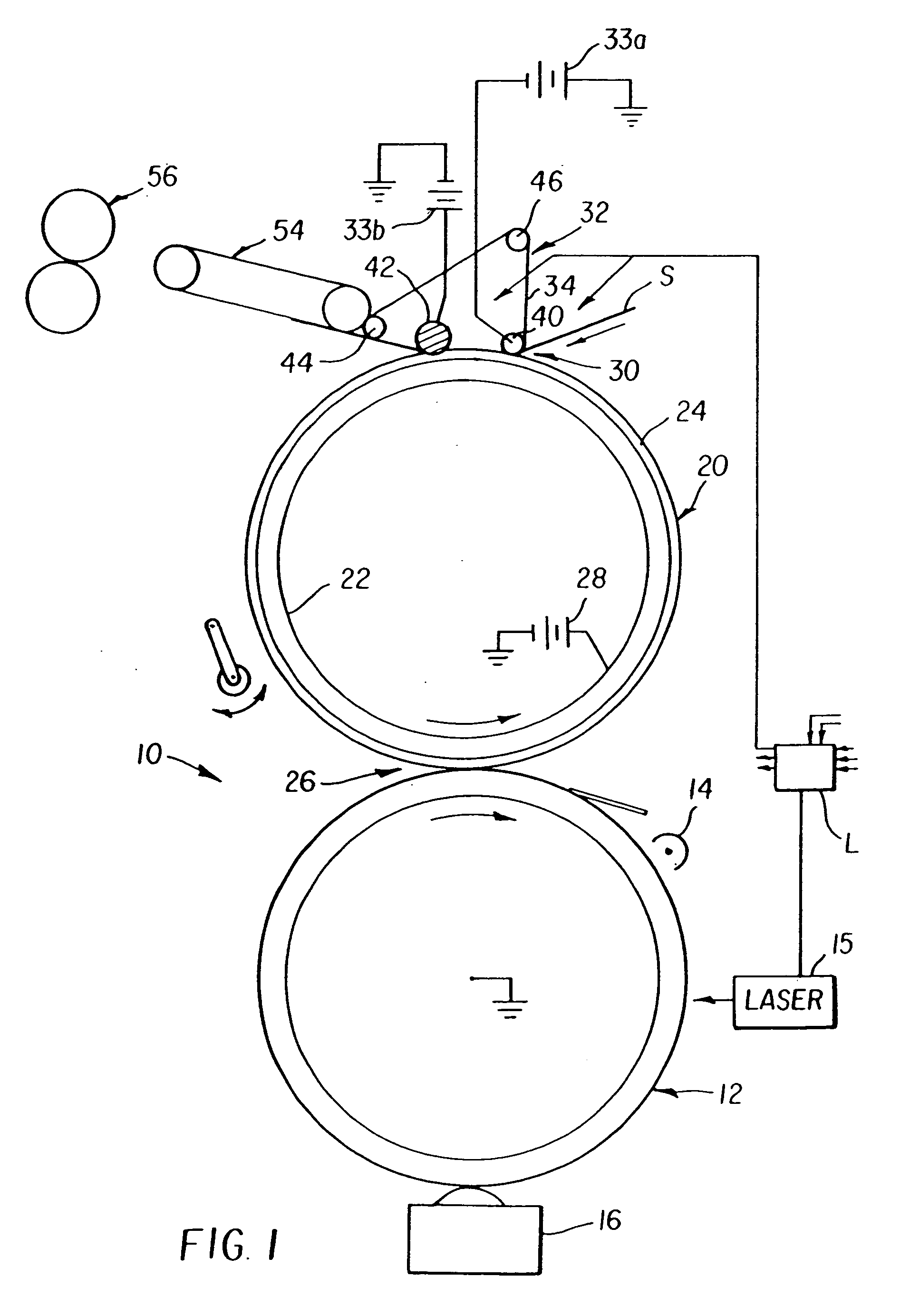

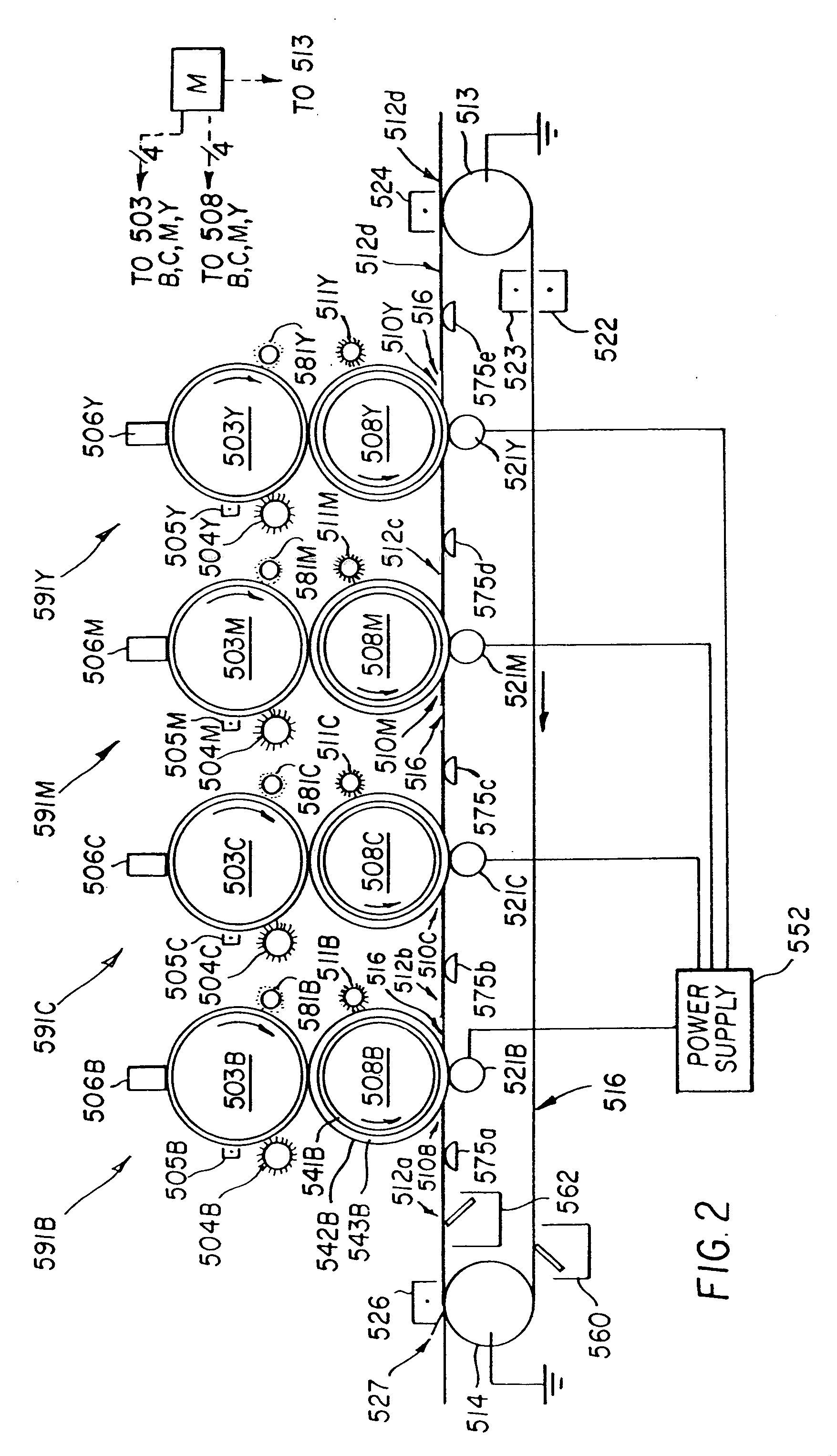

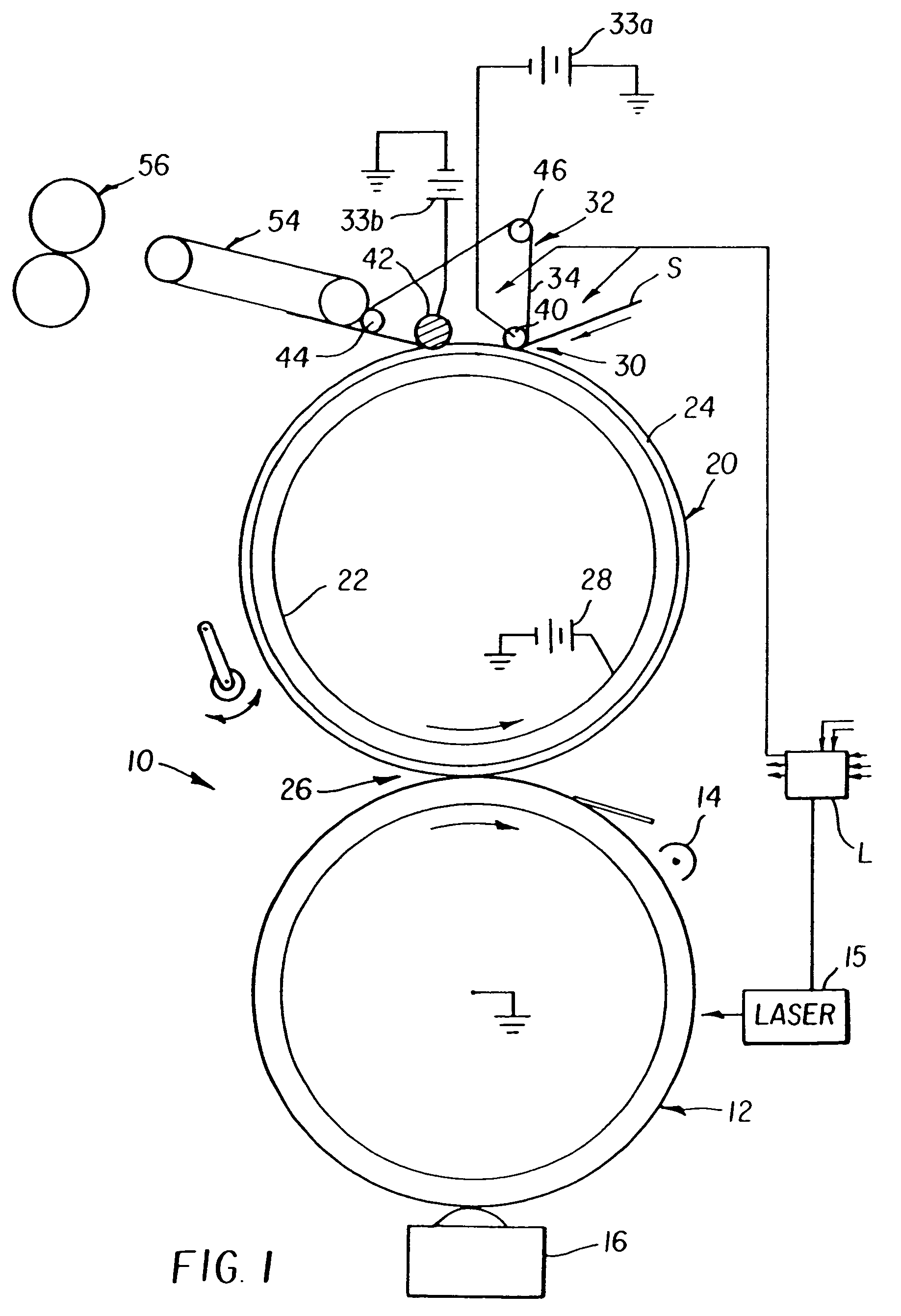

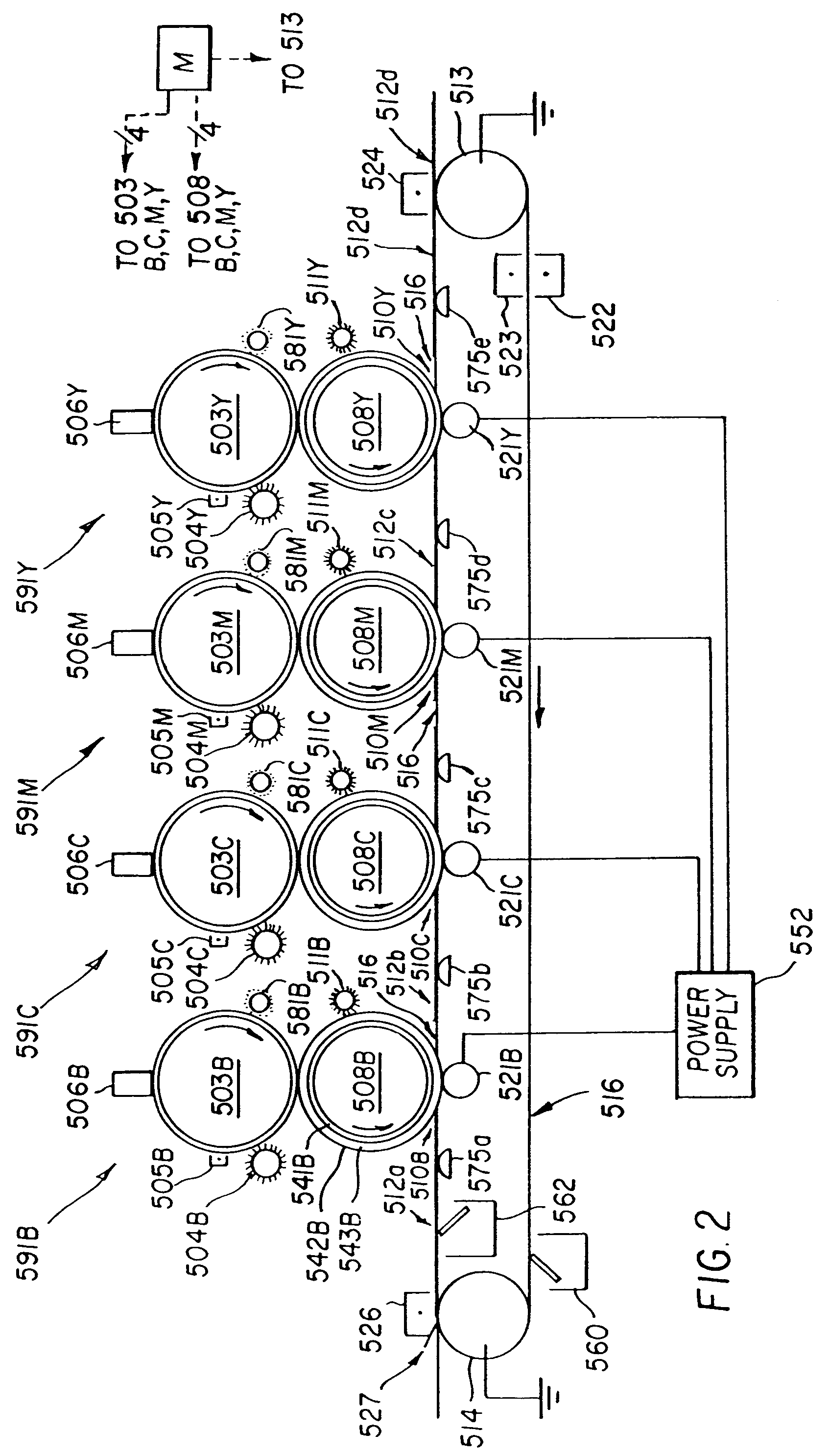

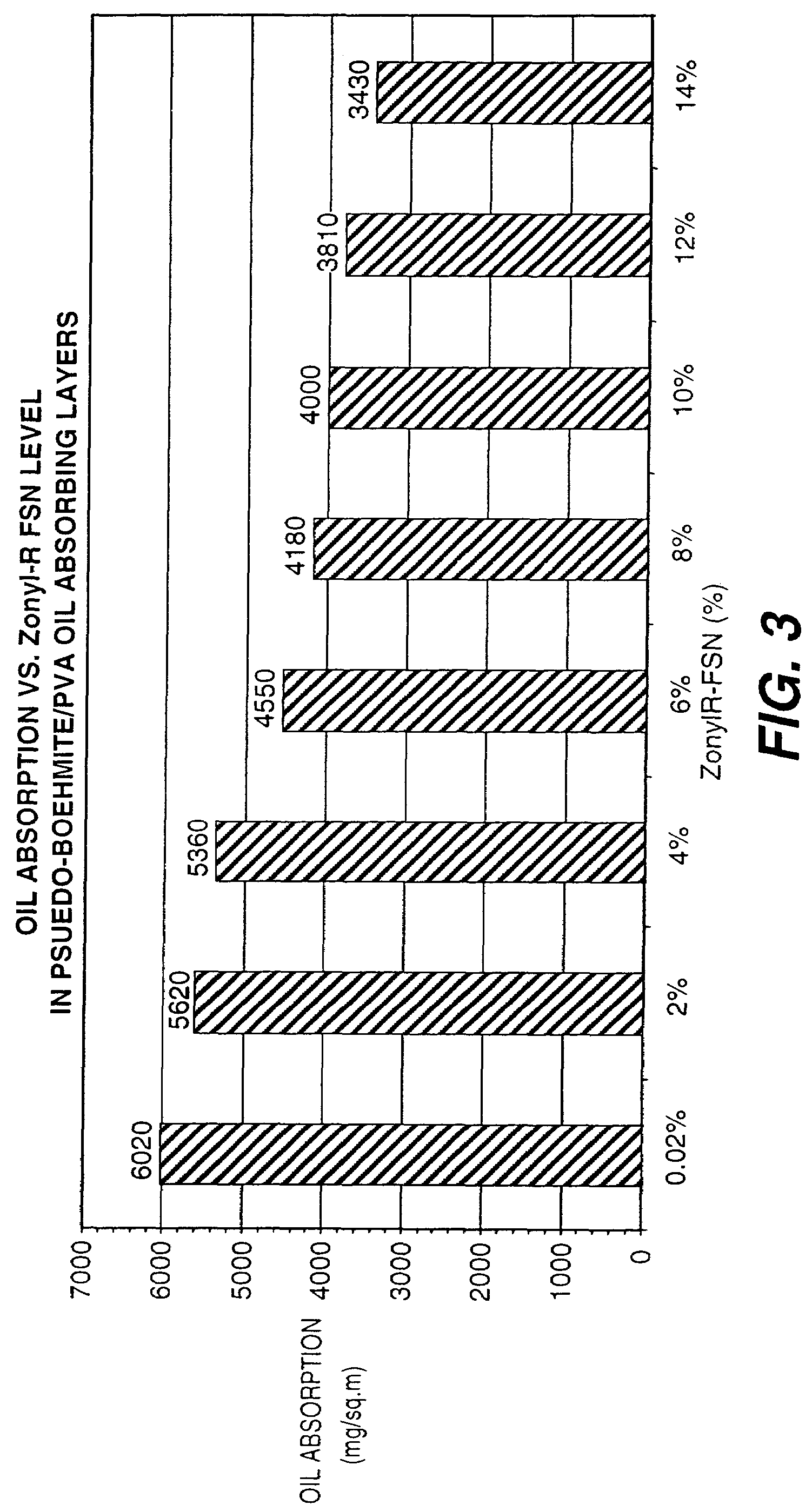

Electrostatographic apparatus having transport member with high friction layer

ActiveUS20060165974A1Eliminate slippageConvenient registrationSynthetic resin layered productsRecord information storageInorganic particleAlumina hydrate

A method for forming a receiver transport member for an electrostatographic reproduction apparatus. The transport member transports receiver members with respect to a fuser assembly and is frictional coupled to a transfer member for driving the transfer member. The method for forming the transport member provides a substrate bearing a high friction layer that includes inorganic particles, with a compound of aluminum selected from the group consisting of aluminum hydroxide, alumina hydrate, aluminum oxide, pseudo-boehmite, boehmite alumina, aluminum salts, and mixtures thereof, dispersed in an organic binder so that the high friction layer is capable of preventing a loss of frictional coupling due to release oil applied to a receiver member bearing a fused toner image.

Owner:EASTMAN KODAK CO

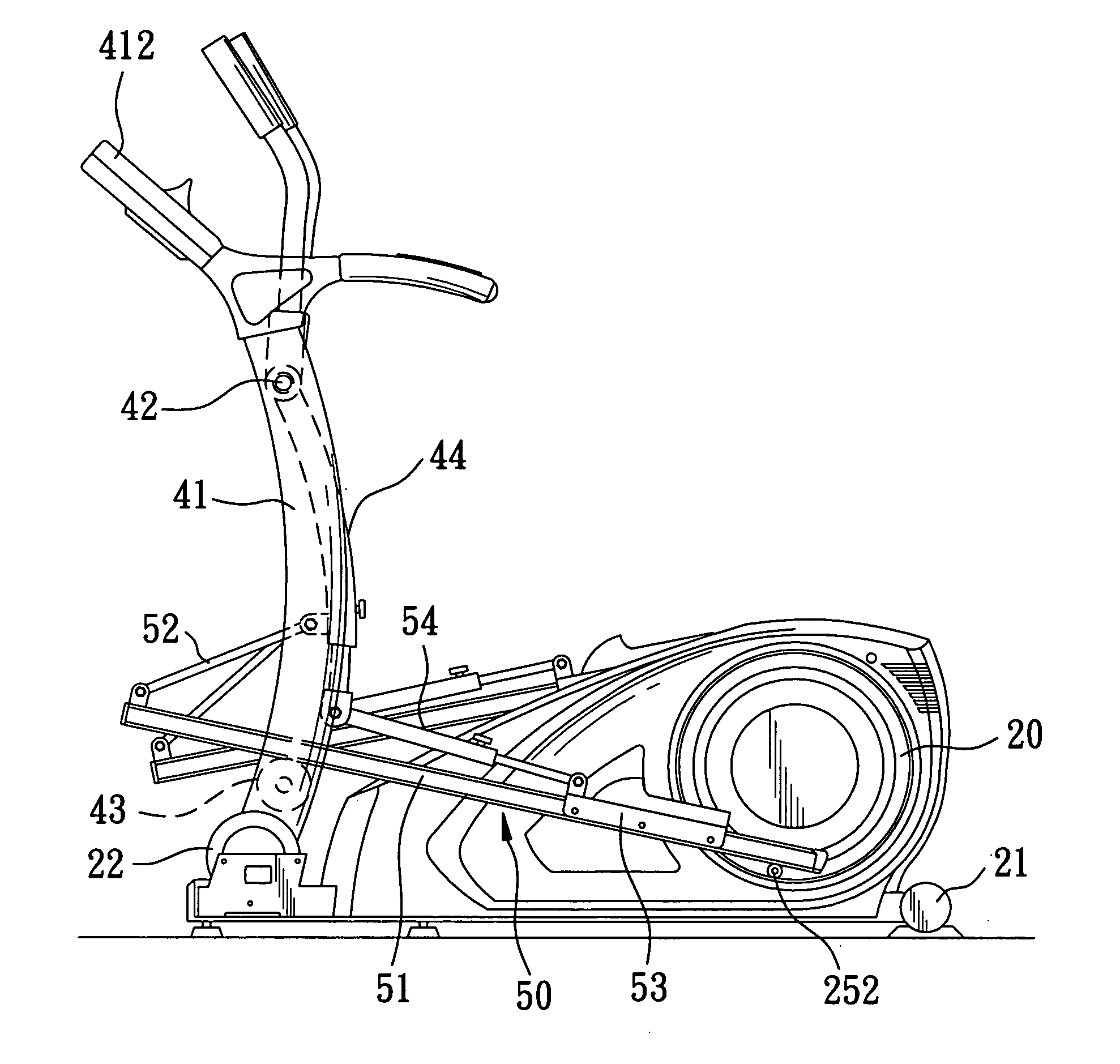

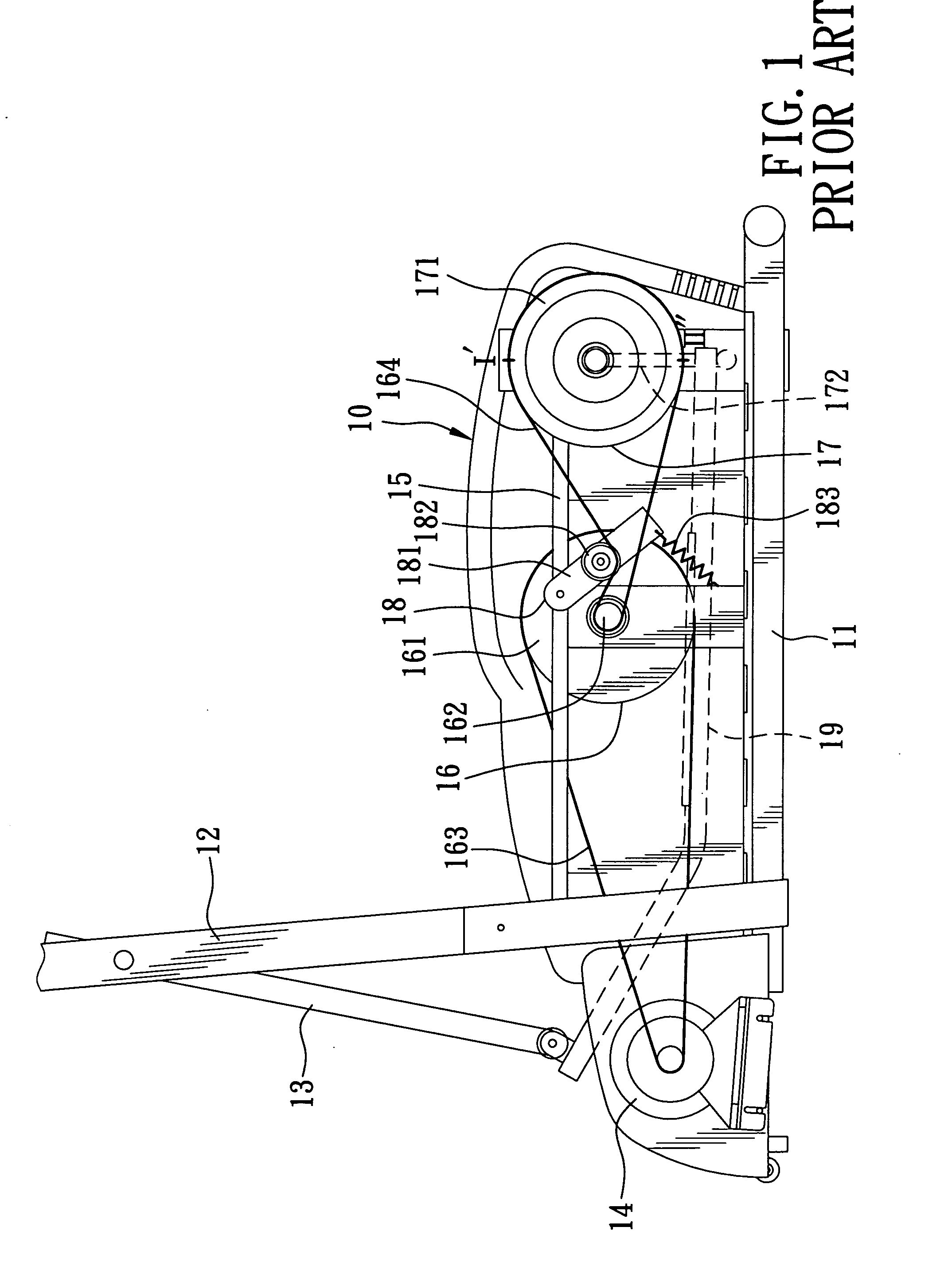

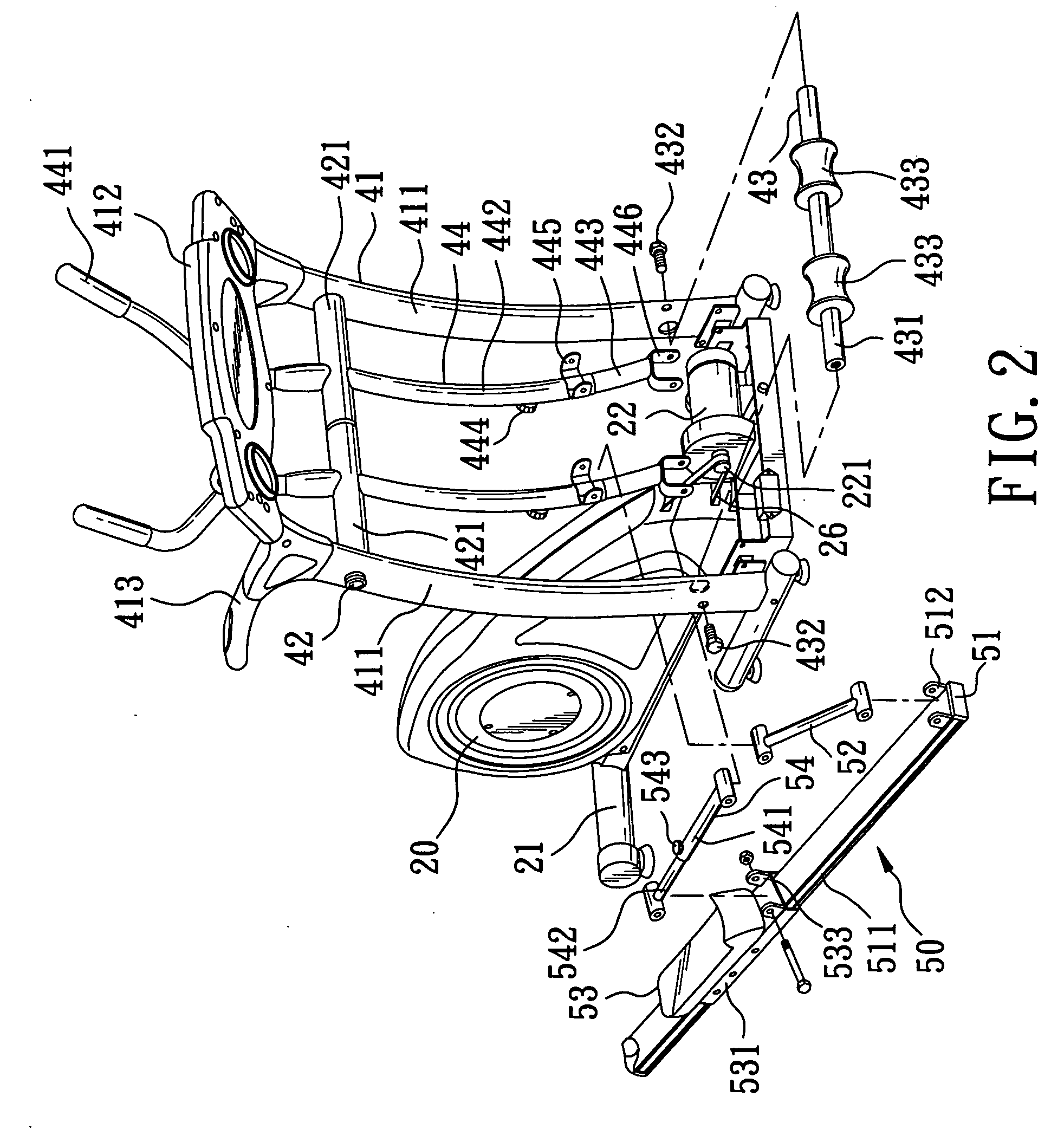

Exercise machine

InactiveUS20080064571A1Eliminate slippageMovement coordination devicesMuscle exercising devicesBraced frameTransmission belt

An exercise machine includes: a flywheel mounted rotatably to a support frame; a crank wheel mounted rotatably to the support frame; a transmission belt trained on the flywheel and the crank wheel; and a pressurizing wheel mechanism including a mounting seat mounted to the support frame, upper and lower pressure wheel units provided pivotally on the mounting seat, and upper and lower limiting members mounted to the mounting seat. The upper and lower pressure wheel units respectively have upper and lower pressure wheels biased to move in first and second directions so as to press and tense upper and lower segments of the transmission belt that extend between the flywheel and the crank wheel. The upper and lower limiting members limit movement of the upper and lower pressure wheel units in directions opposite to the first and second directions, respectively.

Owner:SUPERWEIGH ENTERPRISE

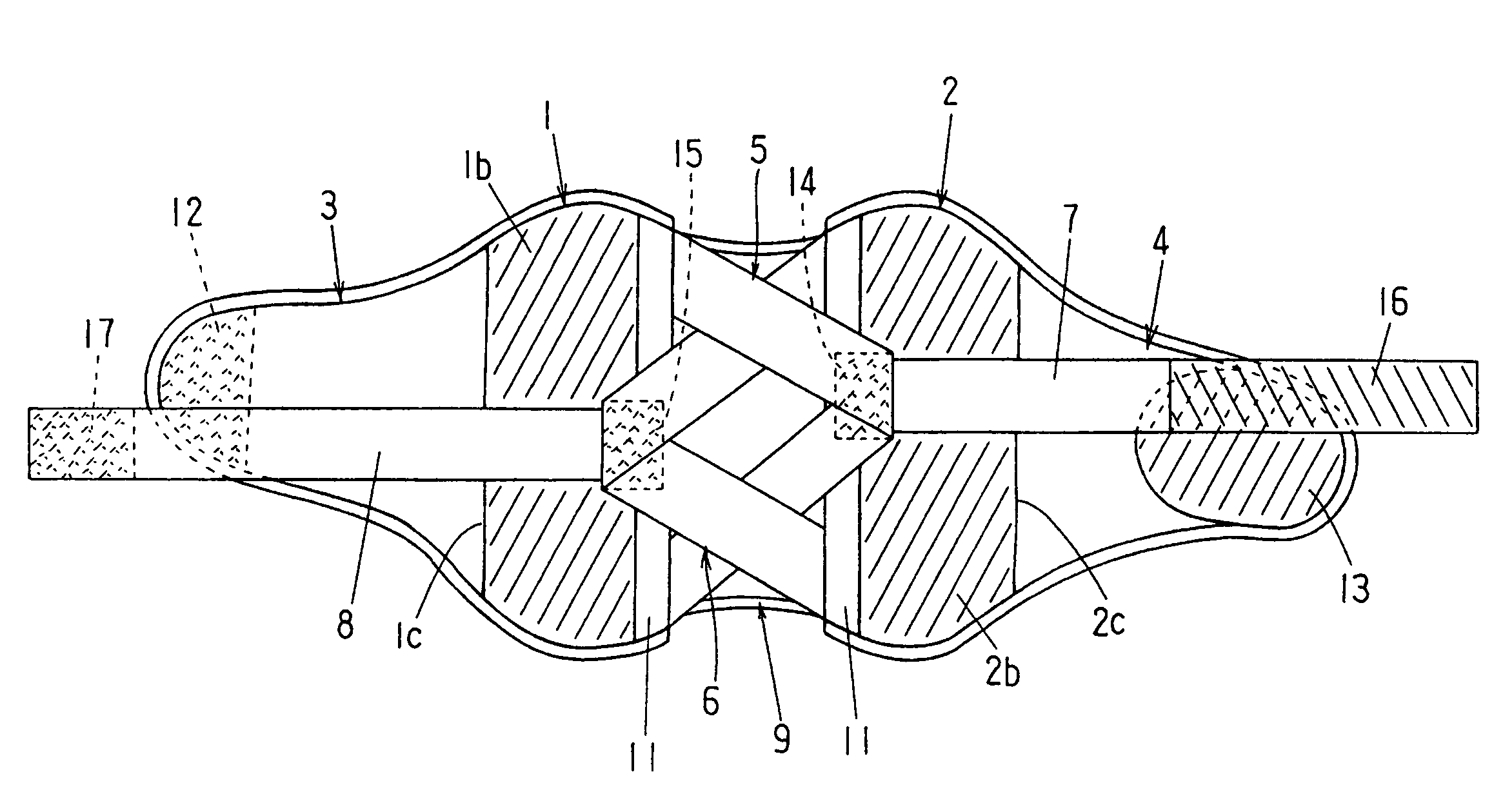

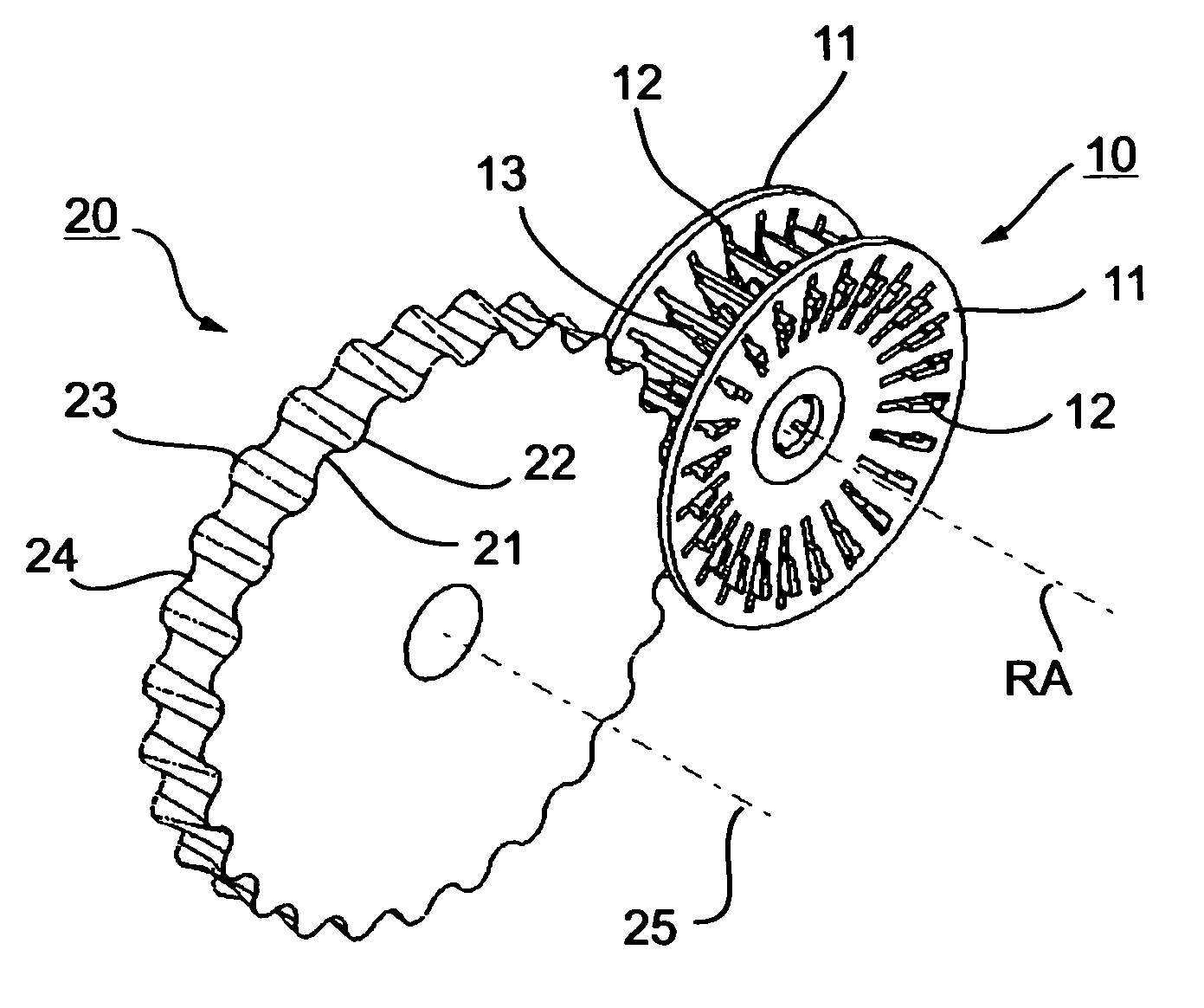

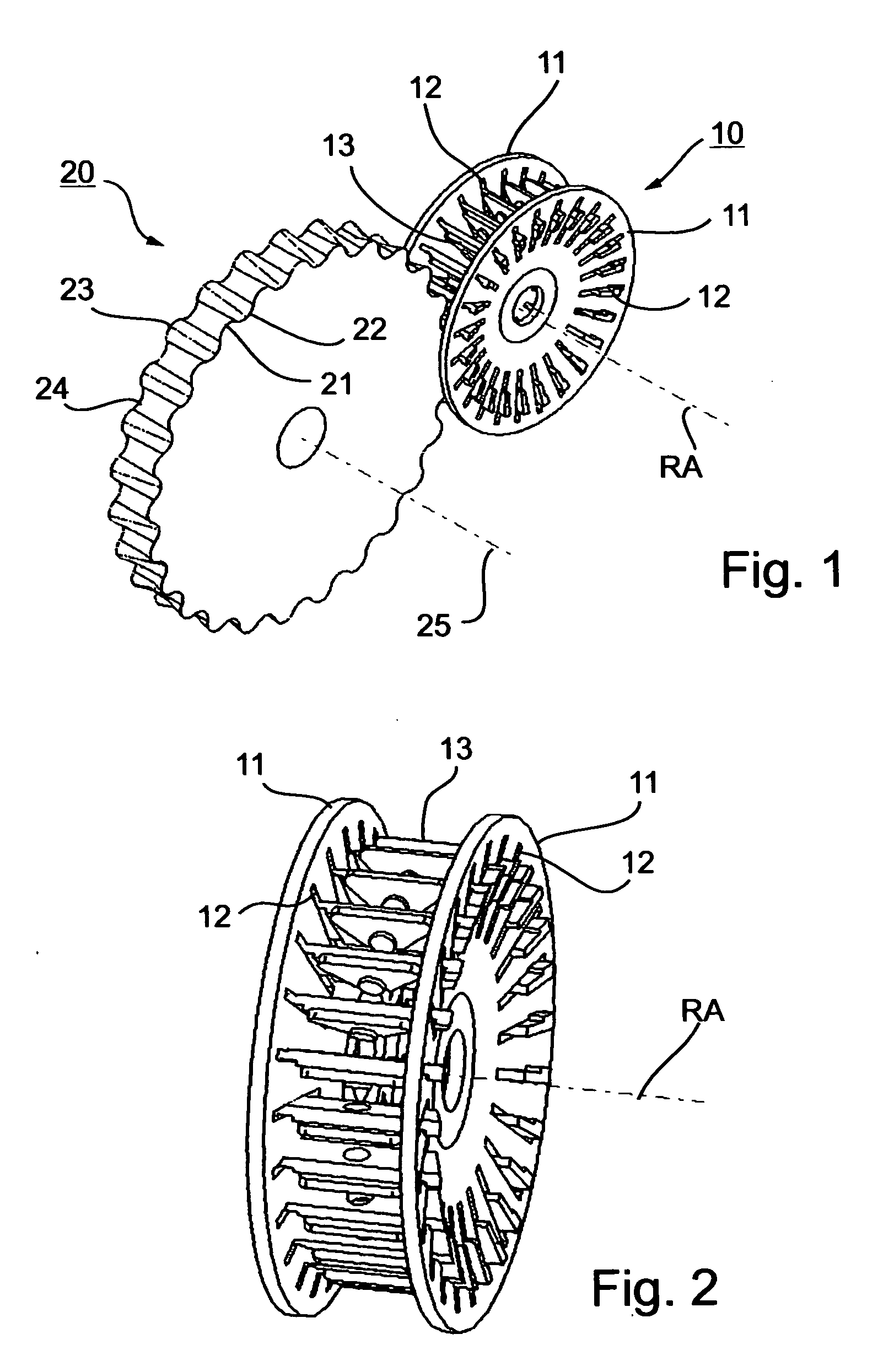

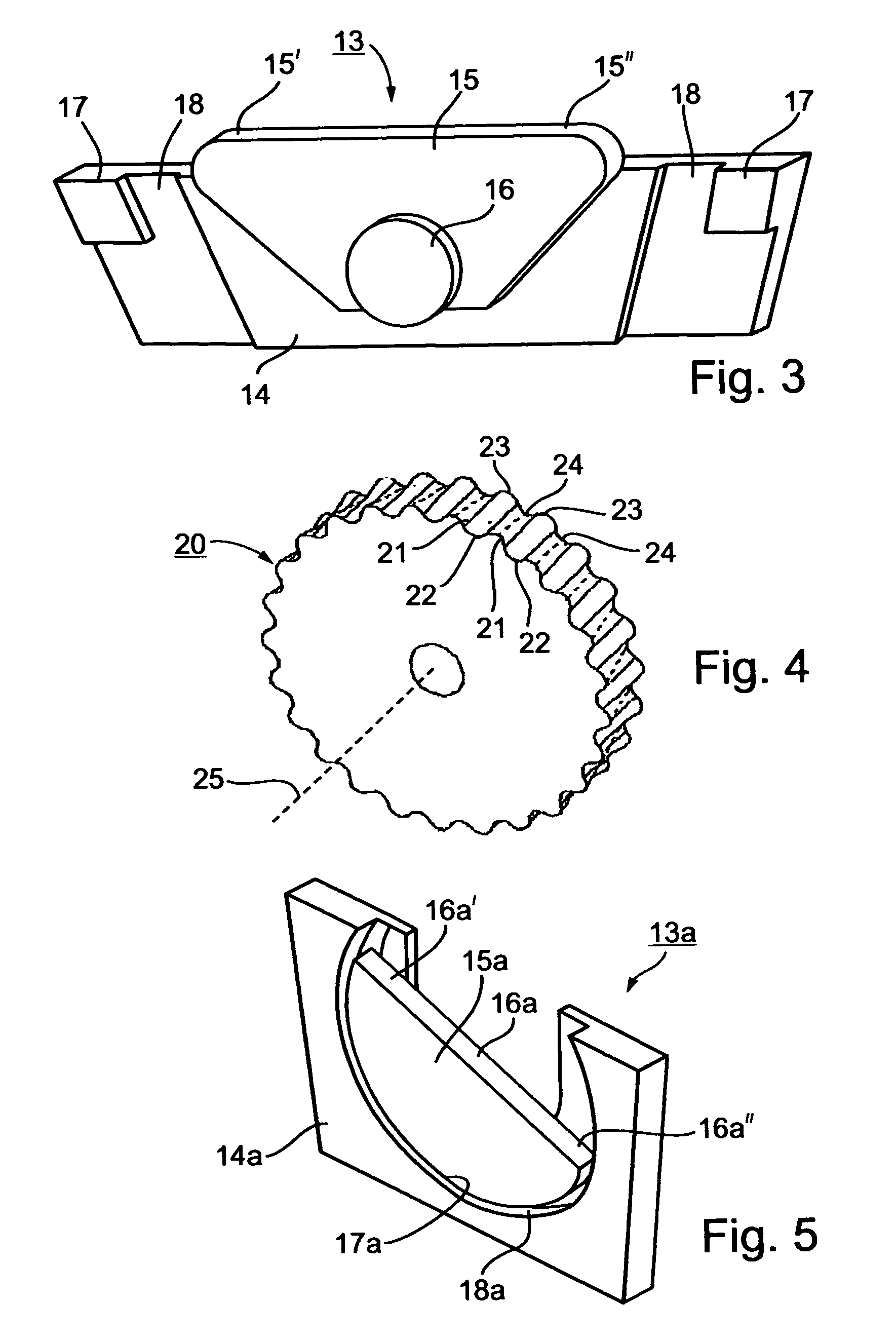

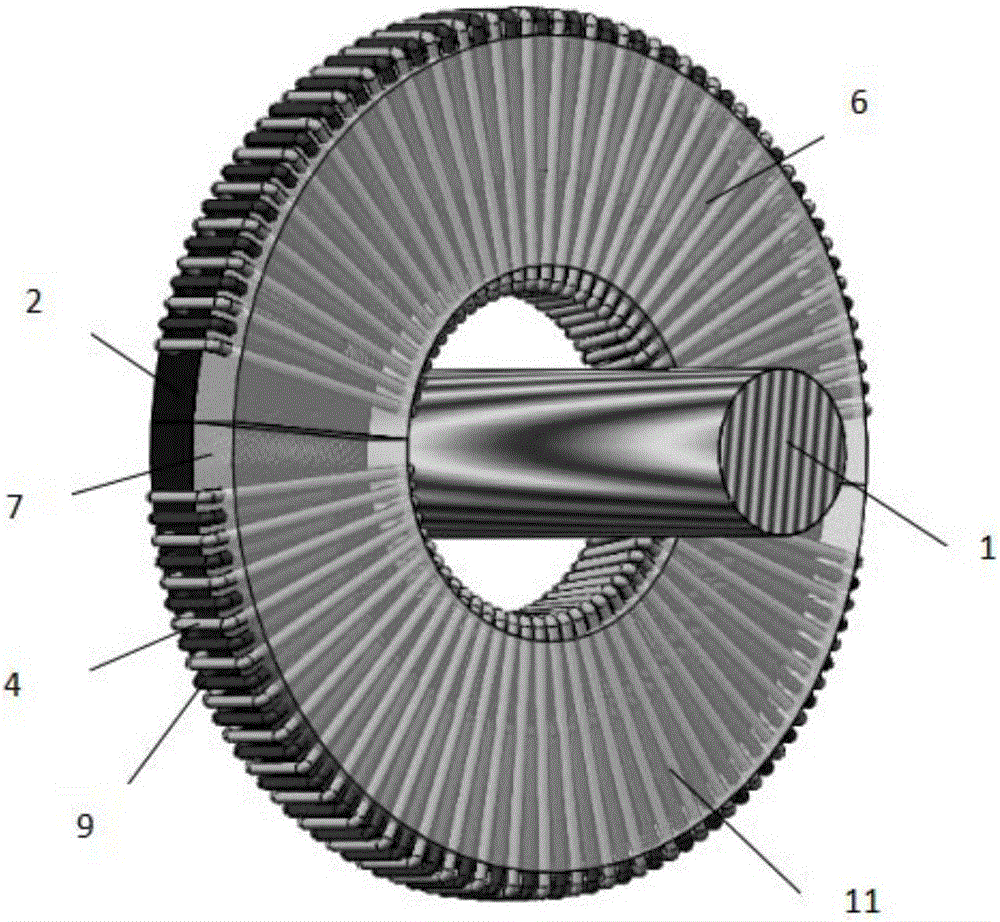

Non-slip transmissions particularly useful as continuously-variable transmissions and transmission members thereof

InactiveUS20040220012A1Eliminate slippageReduce friction lossPortable liftingToothed gearingsRotational axisCoupling

A continuously-variable transmission includes two transmission members each having coupling elements engageable to couple the transmission members for movement together. At least one of the transmission members is a rotary member rotatable about a rotary axis; and at least one of the groups of coupling elements is radially displaceable towards and away from the rotary axis to change the conversion ratio of the transmission. The coupling elements of one group on one transmission member are of a fixed configuration defining projections alternating with depressions each of a fixed configuration formed on a surface of the transmission member between opposite side faces and having the same pitch for every cross section of the surface perpendicular to the mentioned rotary axis. The coupling elements of the other group are of a self-adaptive configuration, each movable in opposite directions to adapt itself to the configuration of the fixed-configuration coupling elements in all displacement positions of the radially-displaceable coupling elements and to effect a non-slip coupling therewith.

Owner:CVTRON LTD

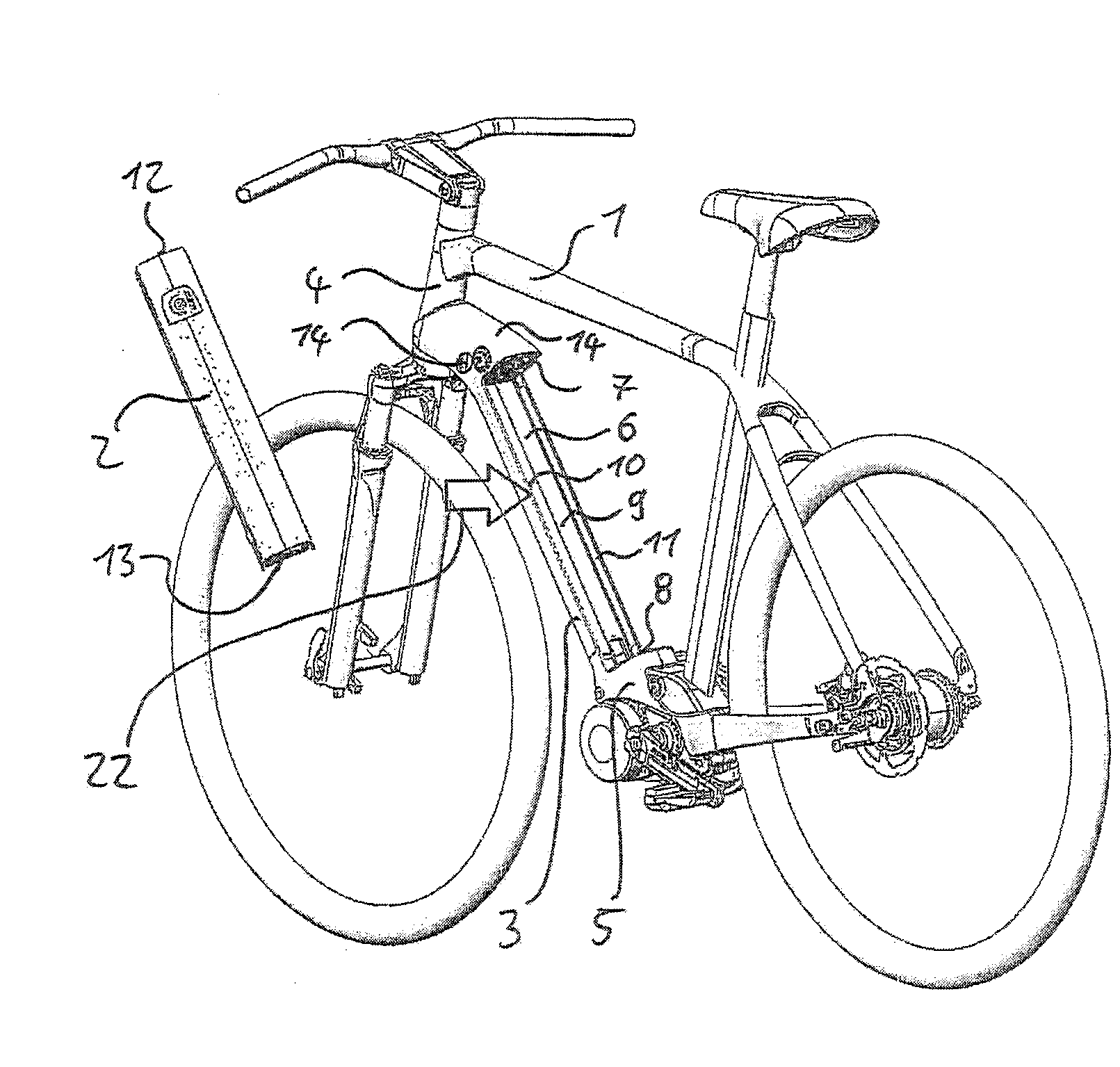

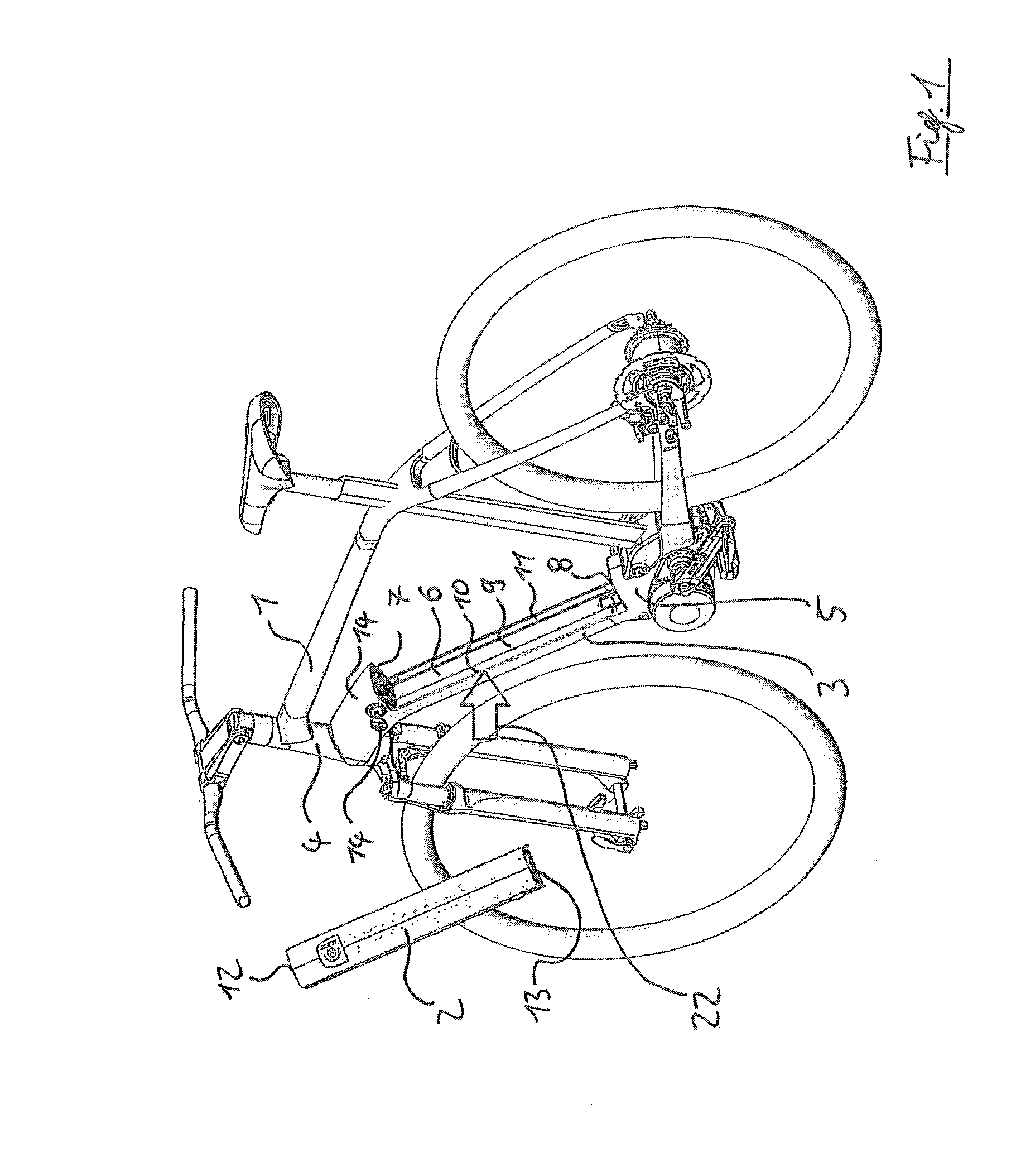

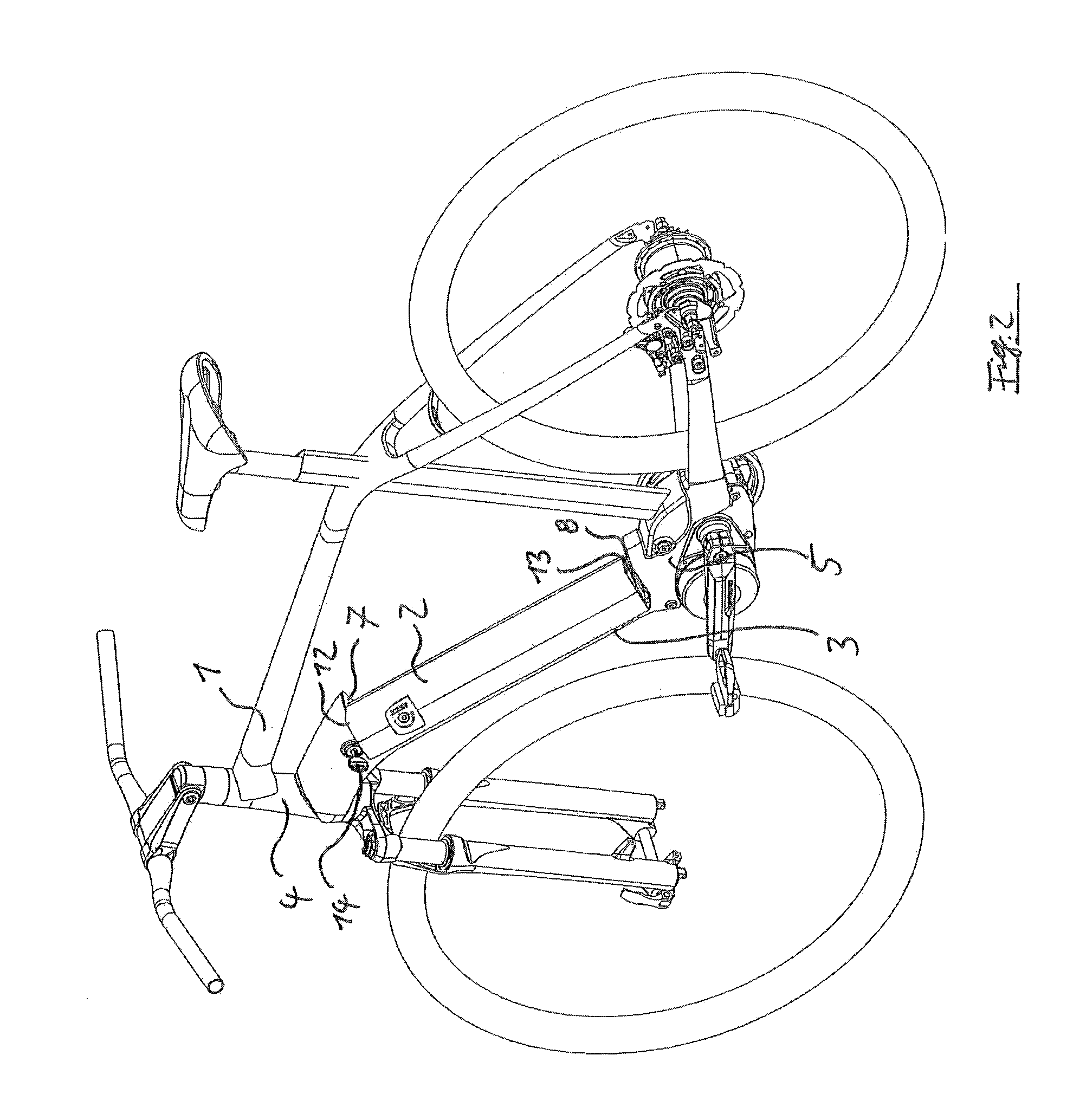

Drive unit, and a powered vehicle

InactiveUS7296643B2Eliminate slippageElectric devicesSteering linkagesEngineeringMechanical engineering

Owner:WICREATIONS BVBA

Unknown

InactiveUS20160311494A1Simple and cost-effective productionEasy to operateRider propulsionBicyclesVehicle frameEngineering

A vehicle frame, in particular a bicycle frame with frame tubes, in particular with a seat tube and a down tube. At least one frame tube has at least one mounting for at least one energy storage device. Provision is made for at least one mounting to be designed as a recess in at least one frame tube, for the frame tube to have at least one bounding surface bounding the recess in at least one or more sections, for the frame tube to have a locating edge bounding the recess in at least one or more sections, and for at least one bounding surface to have at least one clamping projection.

Owner:DERBY CYCLE WERKE

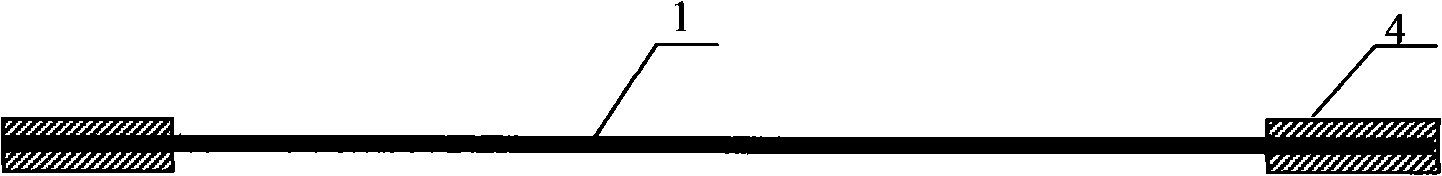

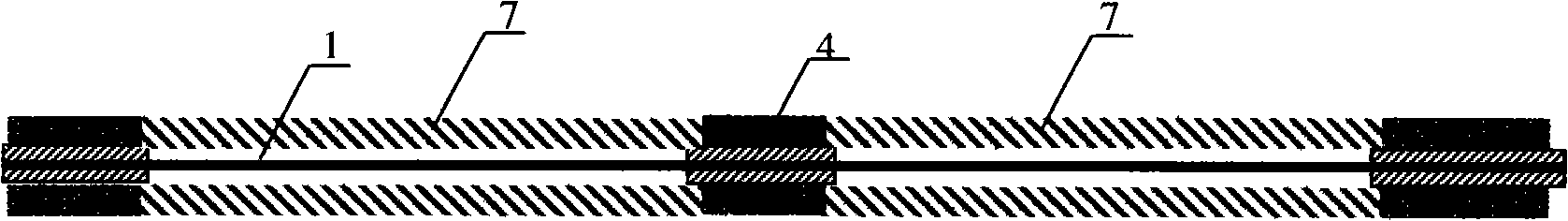

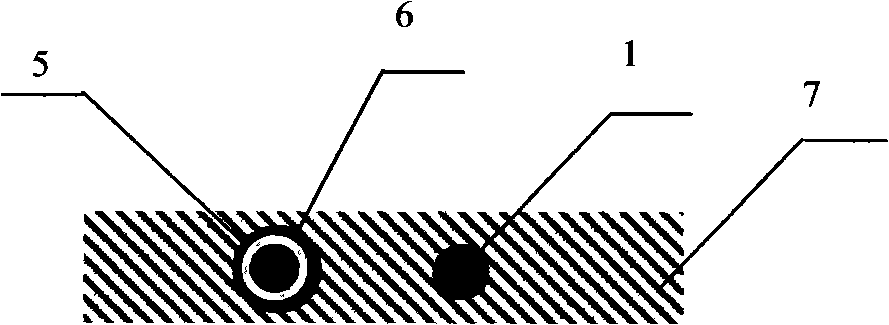

Distributed type non-slippage optical fiber strain sensor and manufacturing method thereof

ActiveCN101275916AImproved compression setGood for measuring compression setOptically investigating flaws/contaminationUsing optical meansEpoxyBare fiber

A distributed no-slippage optical fiber stain sensor and a manufacturing method thereof are a distributed no-slippage Brillouin scattering optical fiber which is used for the health detection and monitoring of the structural facility and the manufacturing method thereof. The invention is characterized in that the sensor uses an UV resin signle mode fiber as a substrate, and a single mode bare fiber part which is eliminated with an UV resin coating layer is provided thereon. The exterior part of the bare fiber is provided with a basalt fiber packaging layer to form an optical fiber strain sensor. To the total adhibition packaging mode, the exterior part is immersed with epoxy resin and is packaged. To the fixed-point adhibition packaging optical fiber, a sleeve pipe is provided outside the bare optical fiber. A certain space is preserved between the sleeve pipes. The bare fiber between the sleeve pipes and the sleeve pipes are fixed on the immersed basalt fiber through the epoxy resin. The distributed no-slippage optical fiber sensor of the invention has high precision and high sensitivity. The long-distance and large-area structural stain information can be accurately obtained, and the manufacturing method is simple and easy.

Owner:SOUTHEAST UNIV +1

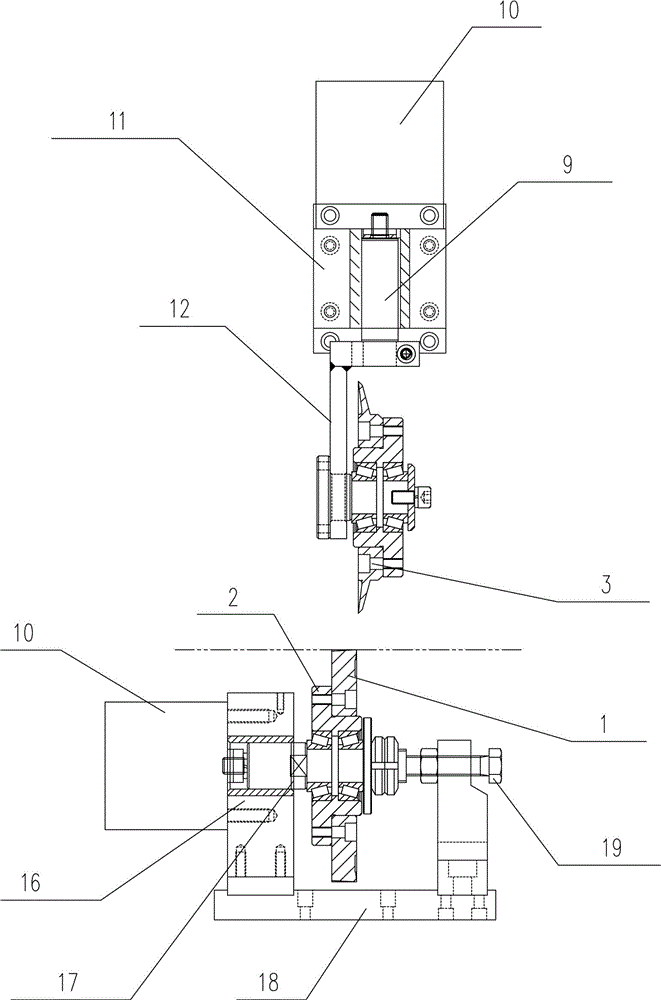

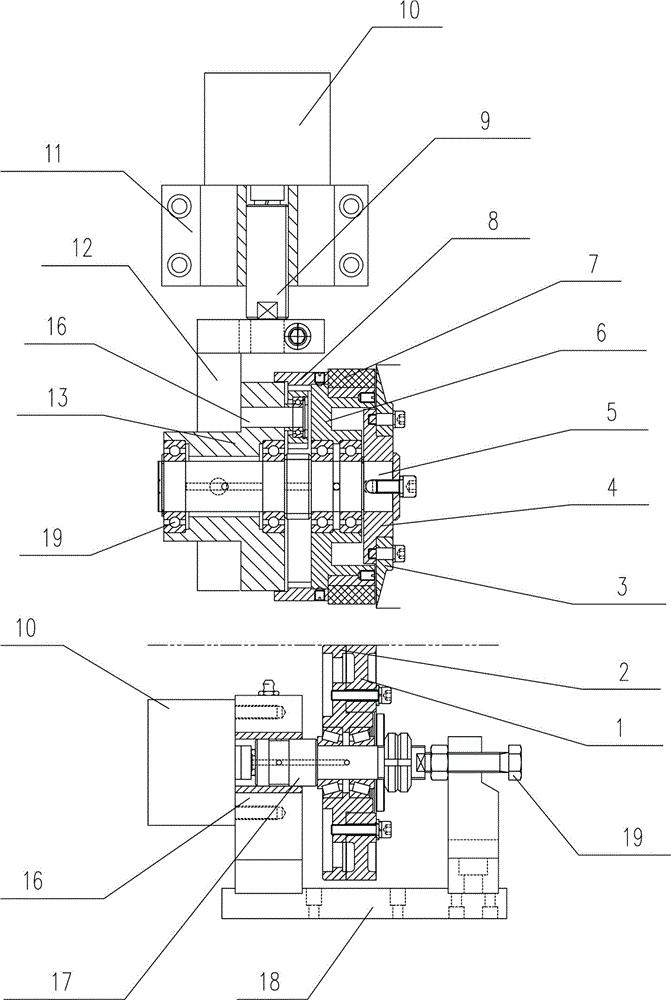

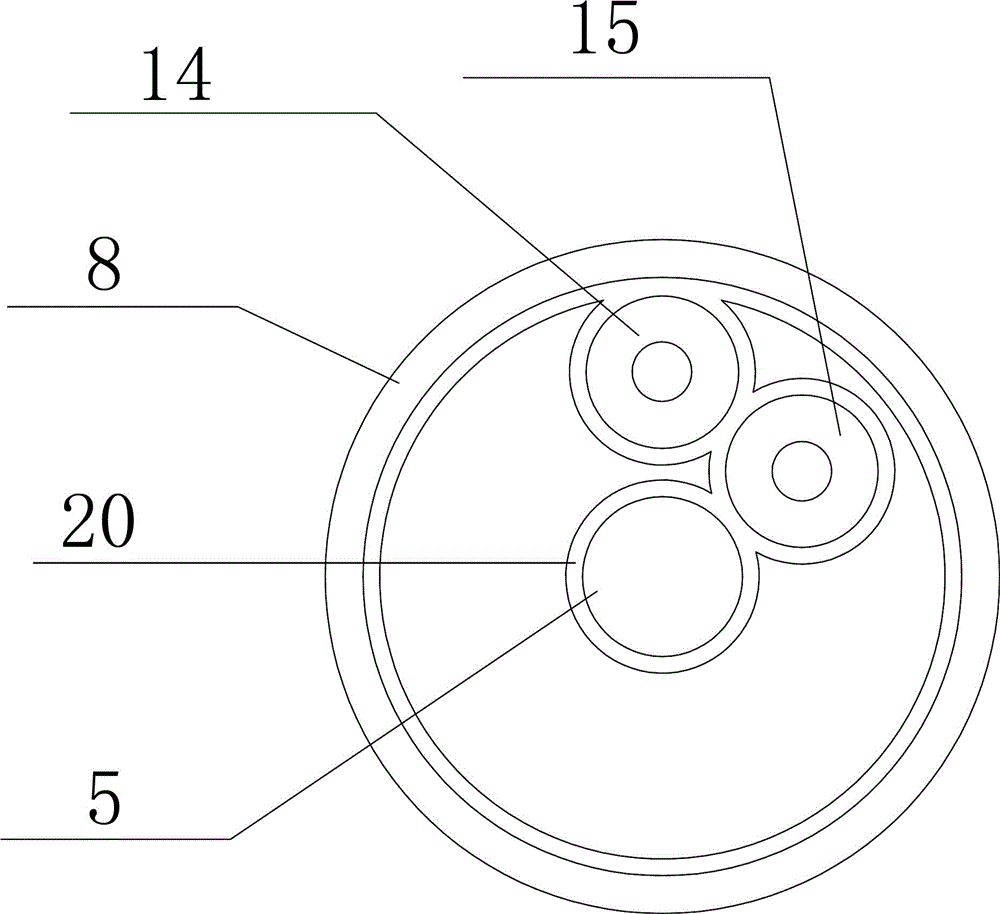

Disc cutter trimming mechanism of sheet extrusion machine

ActiveCN104890208APrevent non-rotationAvoid the situationMetal working apparatusDisc cutterExtrusion

The invention discloses a disc cutter trimming mechanism of a sheet extrusion machine. The mechanism comprises a lower disc cutter, a first rotating shaft, an upper cutter base, an upper cutter base positioning mechanism, an upper disc cutter, a second rotating shaft, a lower cutter base and a lower cutter base positioning mechanism, and is characterized in that an upper cutter acceleration mechanism is mounted on the upper cutter base, wherein a sheet following ring drives the upper disc cutter to rotate through a gear acceleration mechanism; and the gear acceleration mechanism enables the rotating linear velocity of the upper disc cutter to be quicker than the rotating linear velocity of the lower disc cutter. Compared with the prior art, the mechanism has the following beneficial effects: as the upper cutter acceleration mechanism is arranged, sheets are pulled to effectively drive the lower cutter and the upper cutter to rotate, the rotating linear velocity of the upper cutter is quicker than the passing linear velocity of the sheets, and the cutting of the cutter is facilitated; and the mechanism is simple in structure and excellent in use effect, effectively eliminates the slip phenomenon, and prevents the condition of incapability of cutting off the sheets due to no rotation of the upper cutter.

Owner:GUANGDONG DESIGNER MASCH CO LTD

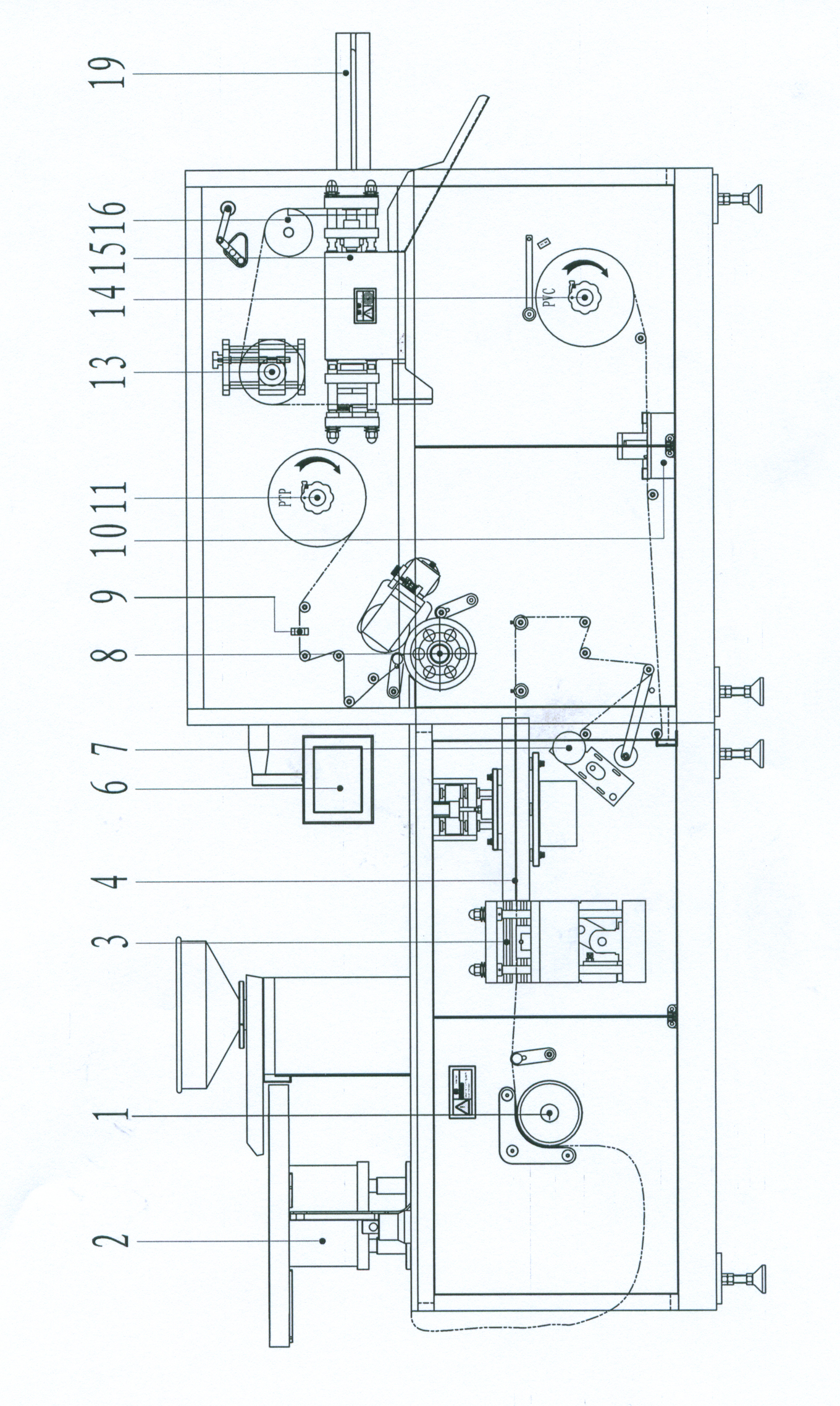

Intelligent high-speed rolled sheet type blister packing machine

ActiveCN101850857AIncrease frictionEliminate slippageWrapping material feeding apparatusWrappingPolyvinyl chlorideElectric machinery

The invention discloses an intelligent high-speed rolled sheet type blister packing machine, which is mainly characterized in that: lines are distributed on the roll surface of a traction roll of a polyvinyl chloride (PVC) forming traction mechanism; a hollowed blister hole is formed on the roll surface of a roll of a blister traction mechanism; the blister hole corresponds to a sealed board blister eye; the blister traction roll is in transmission connection with a driving motor; the roll surface of the blister traction roll is matched with that of a pressing roll; a heat-seal roll of a PVC and aluminium foil heat-seal mechanism is provided with a heat-seal anilox roll with a buffer spring; the heat-seal anilox roll is linearly contacted with the two roll surfaces of the heat-seal roll during heat seal; and the heat-seal anilox roll is provided with a driving device which can make the heat-seal anilox roll compress the heat-seal roll tightly. When drawing a PVC plastic sheet, the intelligent high-speed rolled sheet type blister packing machine can increase a friction force, without slipping and pass-line deflection; and after a spring device is installed, the pressure between the heat-seal anilox roll and the heat-seal roll is adjusted properly, so that the sealed board is clear and beautiful.

Owner:ZHEJIANG HOPING MACHINERY

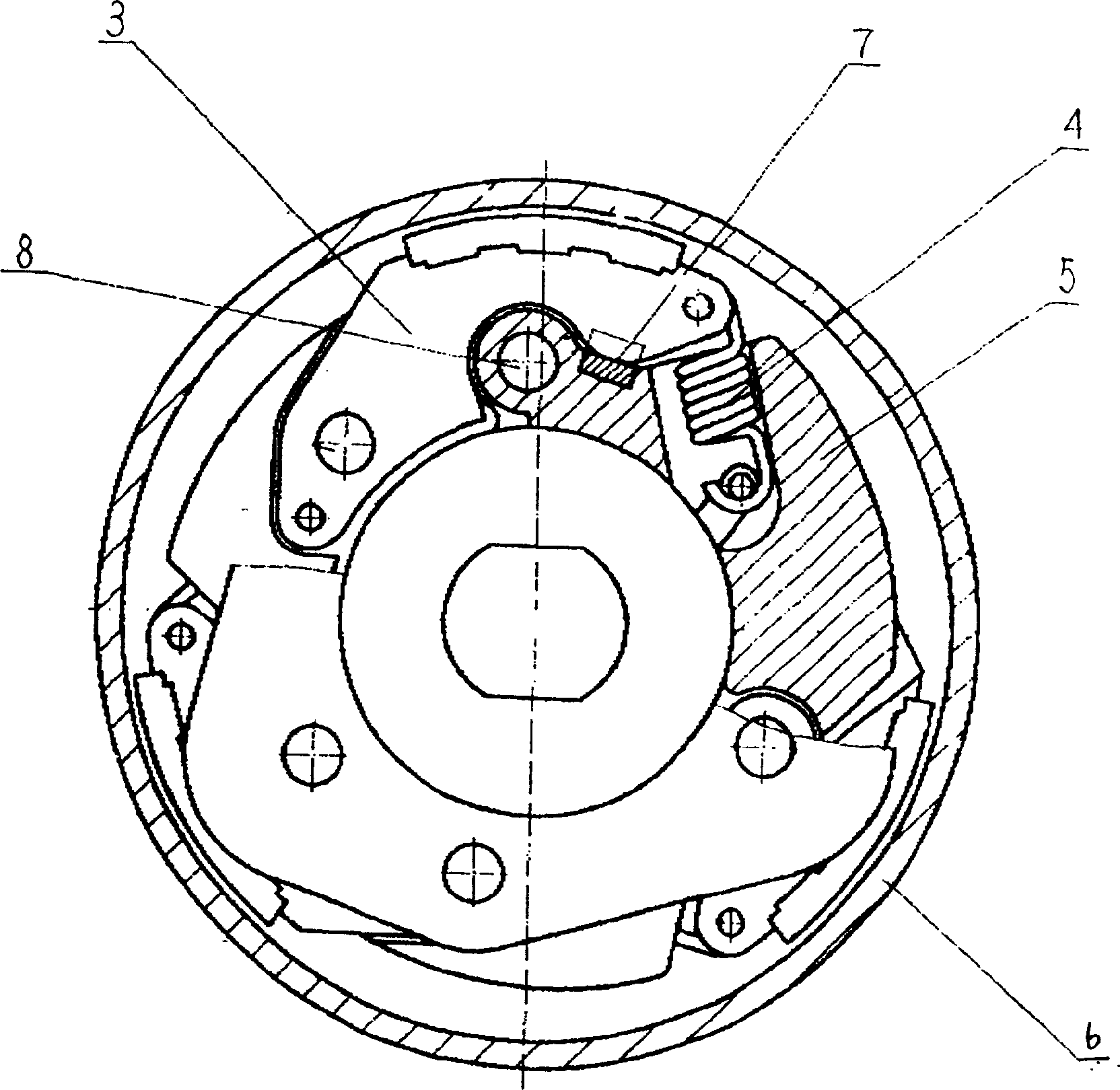

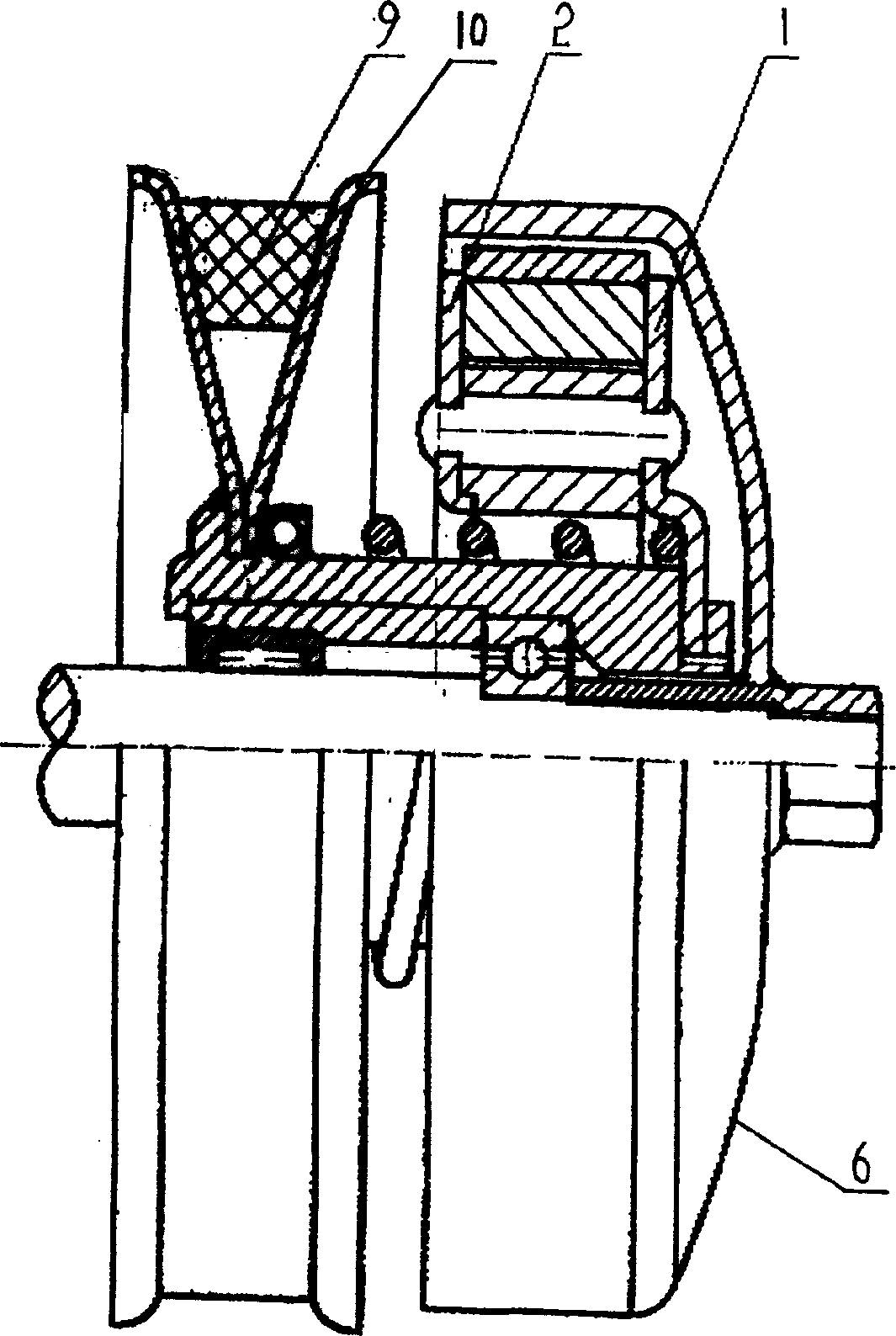

Clutch assembly

InactiveUS7017724B2Improve installabilitySimple structureYielding couplingFluid actuated clutchesAutomatic transmissionControl theory

A clutch assembly for starting a vehicle without using a torque converter has a simple structure yet providing high reliability. In the clutch assembly, a clutch and a damper device are housed in a housing connected to a crank shaft of an engine. A boss serving as an output member is connected to an input shaft of an automatic transmission. An output of the engine is connected / disconnected to / from the input shaft upon engagement / disengagement of the clutch. The clutch includes a friction member and a piston fit oil tightly with the housing so as to apply pressure to the friction member. One end of the damper device is connected to a clutch hub, and the other end is connected to the output member. The clutch and the damper device are aligned on the axis of the housing.

Owner:AISIN AW CO LTD +1

Dual-coil magnetic force driving device for high-voltage line inspection robot

InactiveCN106026781AEliminate slippageMove fastMagnetic holding devicesMagnetic tension forceDual coil

The invention discloses a dual-coil magnetic force driving device for a high-voltage line inspection robot. The dual-coil magnetic force driving device comprises a driving body. The driving body is composed of an upper openable driving engine body and a lower openable driving engine body which are centrally symmetric about the high-voltage lead, the driving device is characterized in that the upper driving engine body and the lower driving engine body both comprise a magnetic core, a layer, a large rectangular coil and a small rectangular coil, wherein the magnetic core and the layer are arranged in an attached mode in the axial direction of the high-voltage lead, and the large rectangular coil and the small rectangular coil are alternately wound around the magnetic core and the layer. Under the same size, compared with the prior art, the driving force of the dual-coil magnetic force driving device reaches 50% or above, a magnetic field generated by high-voltage current on the high-voltage lead is used for ampere force of an electrified coil so that a robot can move, and a traditional wheel rail type driving mode is replaced, so that the problem that the robot skids is solved; the driving mechanism is simplified, the cost is lowered, the weight, energy consumption and size of the body are lowered, and the movement speed of the robot can be improved.

Owner:HUBEI UNIV OF TECH

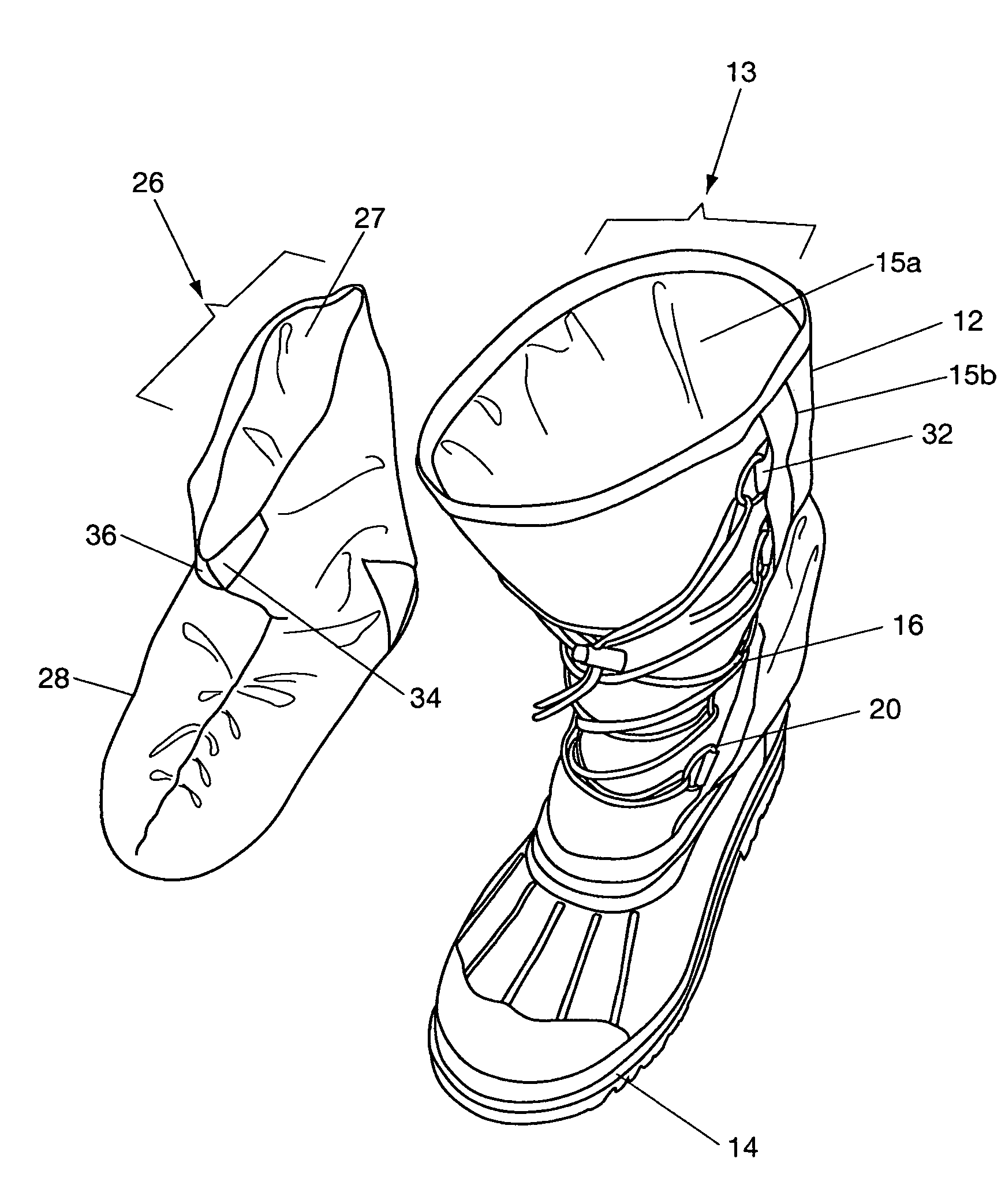

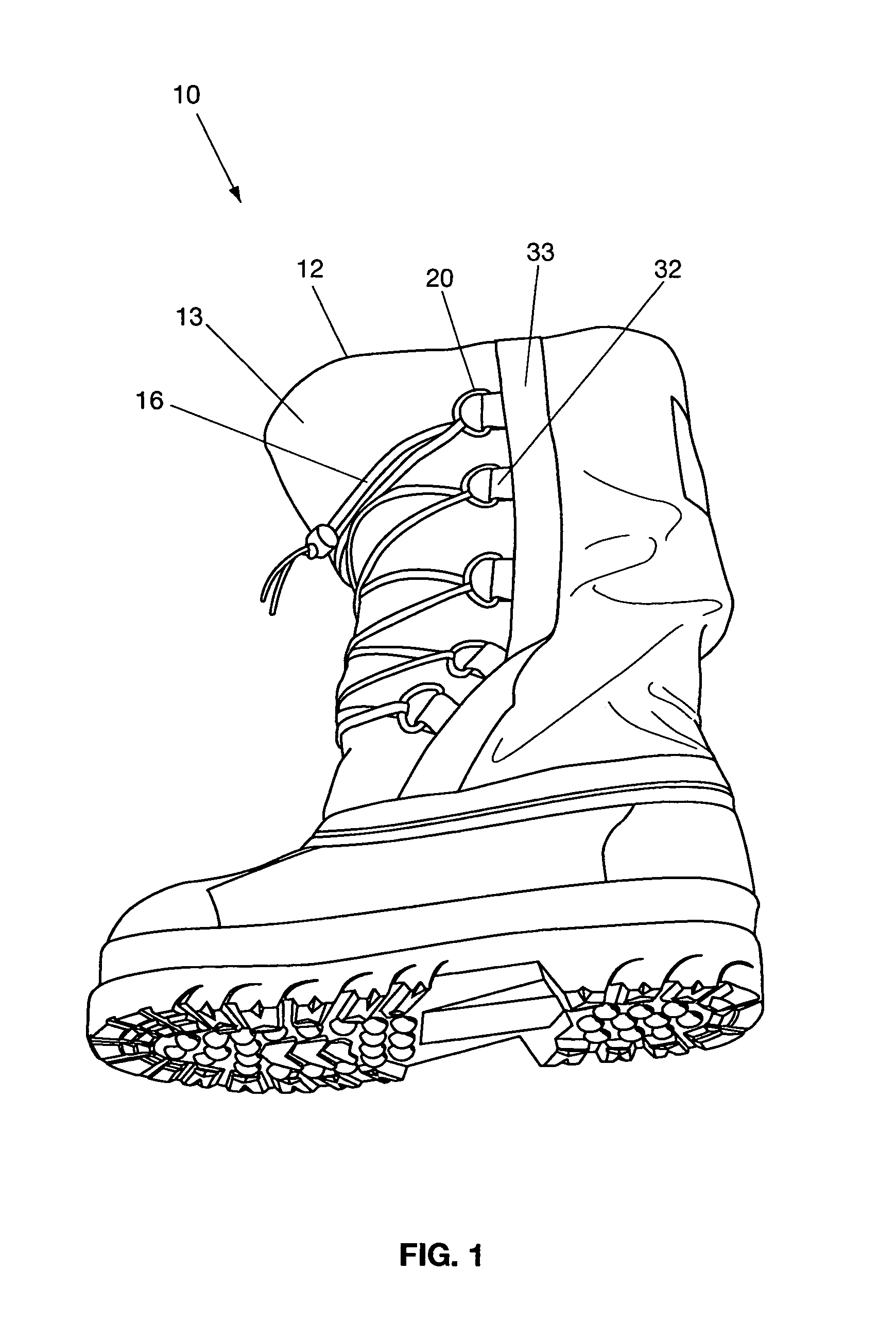

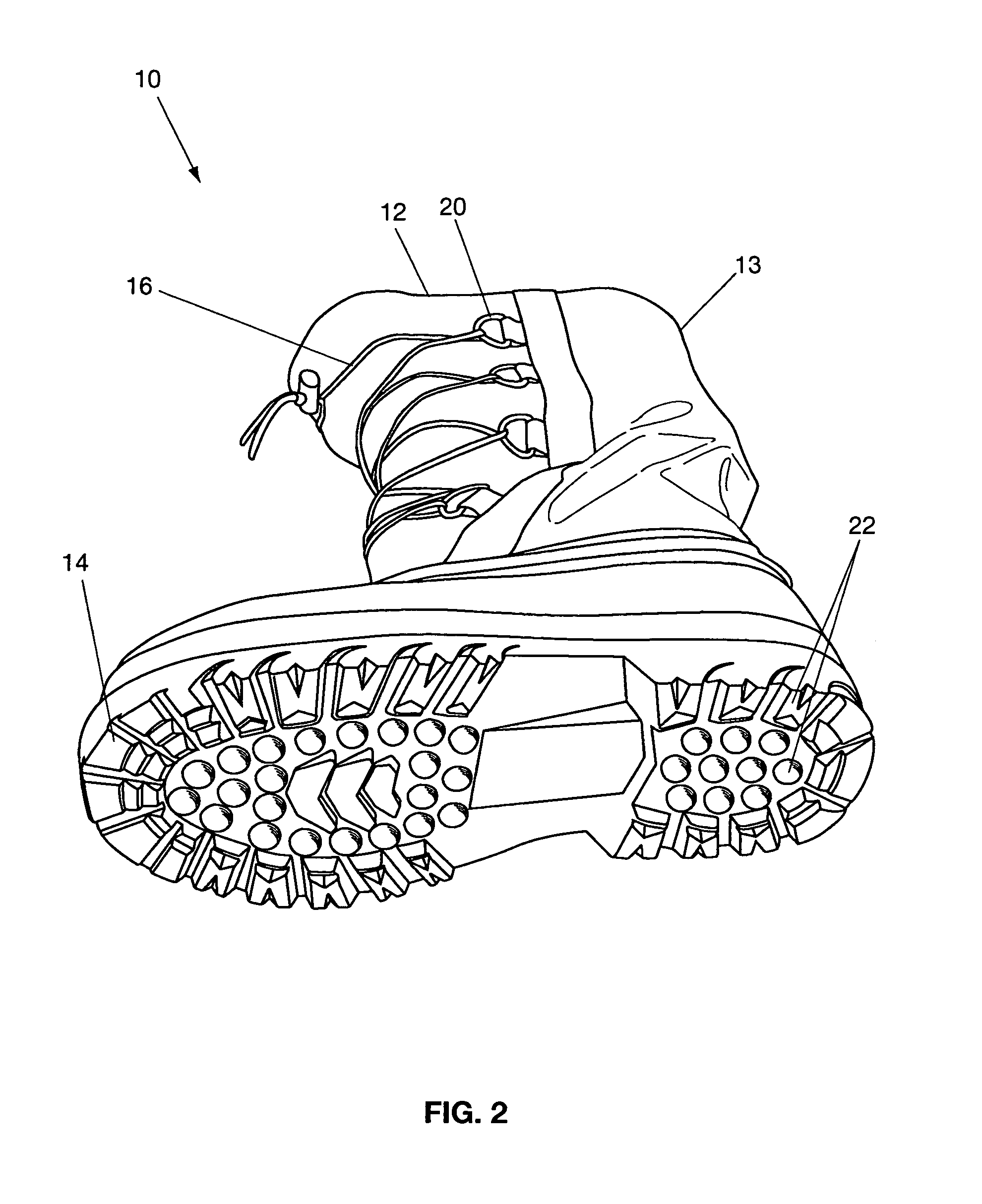

Insulated lightweight pack boot

A lightweight cold and wet weather pack boot comprising an outer boot including an upper boot with an exterior material layer constructed of waterproofing coated polyester, an interior layer of oxford nylon with insulation batting between the exterior and interior layers, further including a molded rubber bottom with cleats, and an inner bootie with outer and inner layers of oxford nylon with insulations between said outer and inner layers.

Owner:HAAS STEPHAN

Electrostatographic apparatus having transport member with high friction layer

ActiveUS7252873B2Eliminate slippageConvenient registrationSynthetic resin layered productsRecord information storageAlumina hydrateInorganic particle

A method for forming a receiver transport member for an electrostatographic reproduction apparatus. The transport member transports receiver members with respect to a fuser assembly and is frictional coupled to a transfer member for driving the transfer member. The method for forming the transport member provides a substrate bearing a high friction layer that includes inorganic particles, with a compound of aluminum selected from the group consisting of aluminum hydroxide, alumina hydrate, aluminum oxide, pseudo-boehmite, boehmite alumina, aluminum salts, and mixtures thereof, dispersed in an organic binder so that the high friction layer is capable of preventing a loss of frictional coupling due to release oil applied to a receiver member bearing a fused toner image.

Owner:EASTMAN KODAK CO

Lever-type clutch for motorcycle

This invention provides a lever-typed clutch of motorcycle. It includes: the chief plywood, the assistant plywood, a centrifugal clump with frictional flakes, and its one side is connected to the thief and the assistant plywood, the other side of the clump has a spring, there is a strength-adding block between the chief and the assistant plywood, the block contacts the wall of the centrifugal clump, the centrifugal power produced by the block strengthens the sticky capability of the centrifugal block and the hubcap through this contacting point. This invention has strong sticky capability, good driving and controlling capacity, and is suitable for gears shifting of the motorcycle.

Owner:李义良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com