Lever-type clutch for motorcycle

A lever-type, clutch technology, applied in the field of clutches, can solve the problems of power loss friction plate wear, insufficient centrifugal force, deterioration of motorcycle power performance and control performance, etc., to eliminate slipping, reduce fuel consumption, improve control performance and power performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

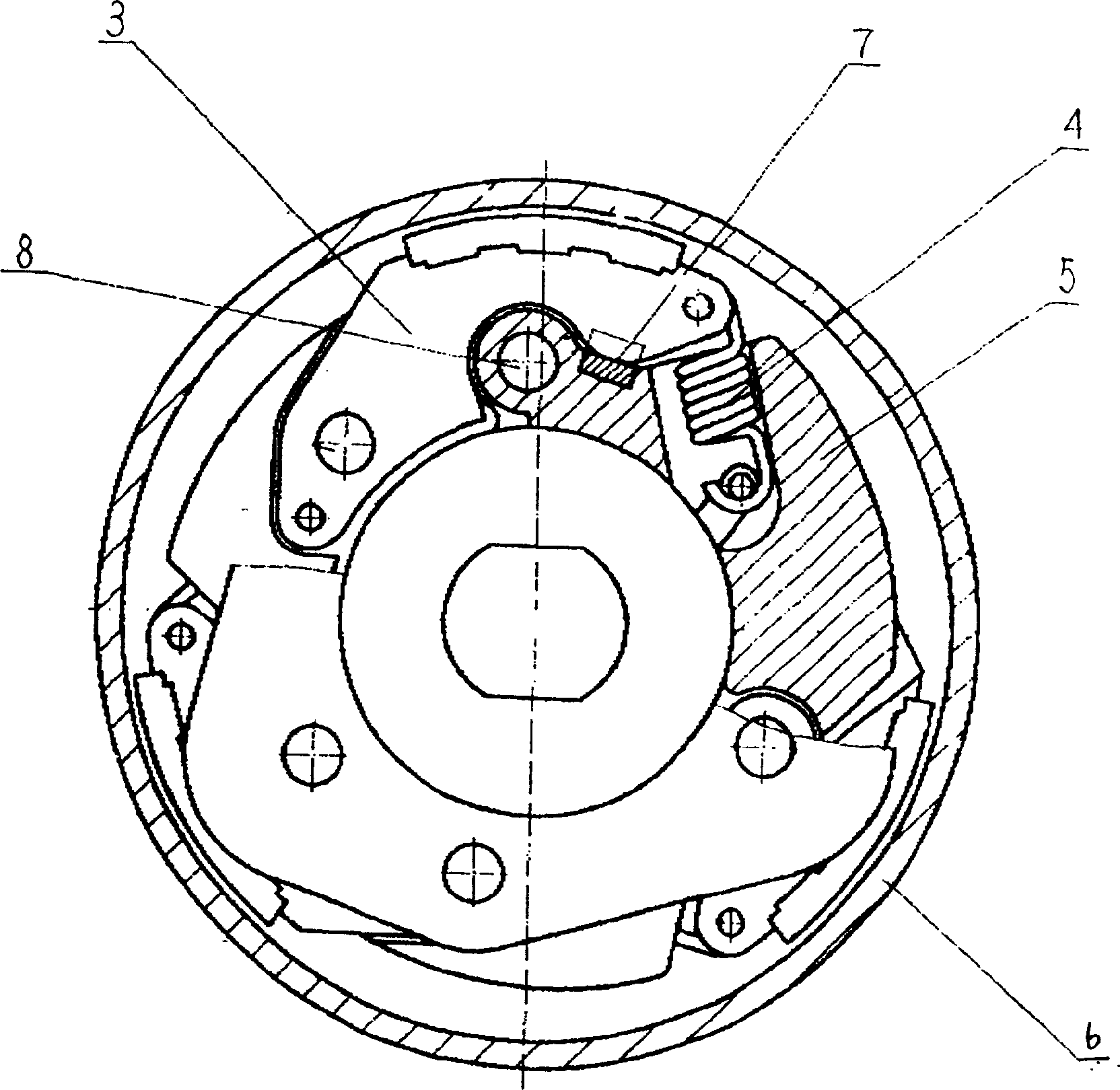

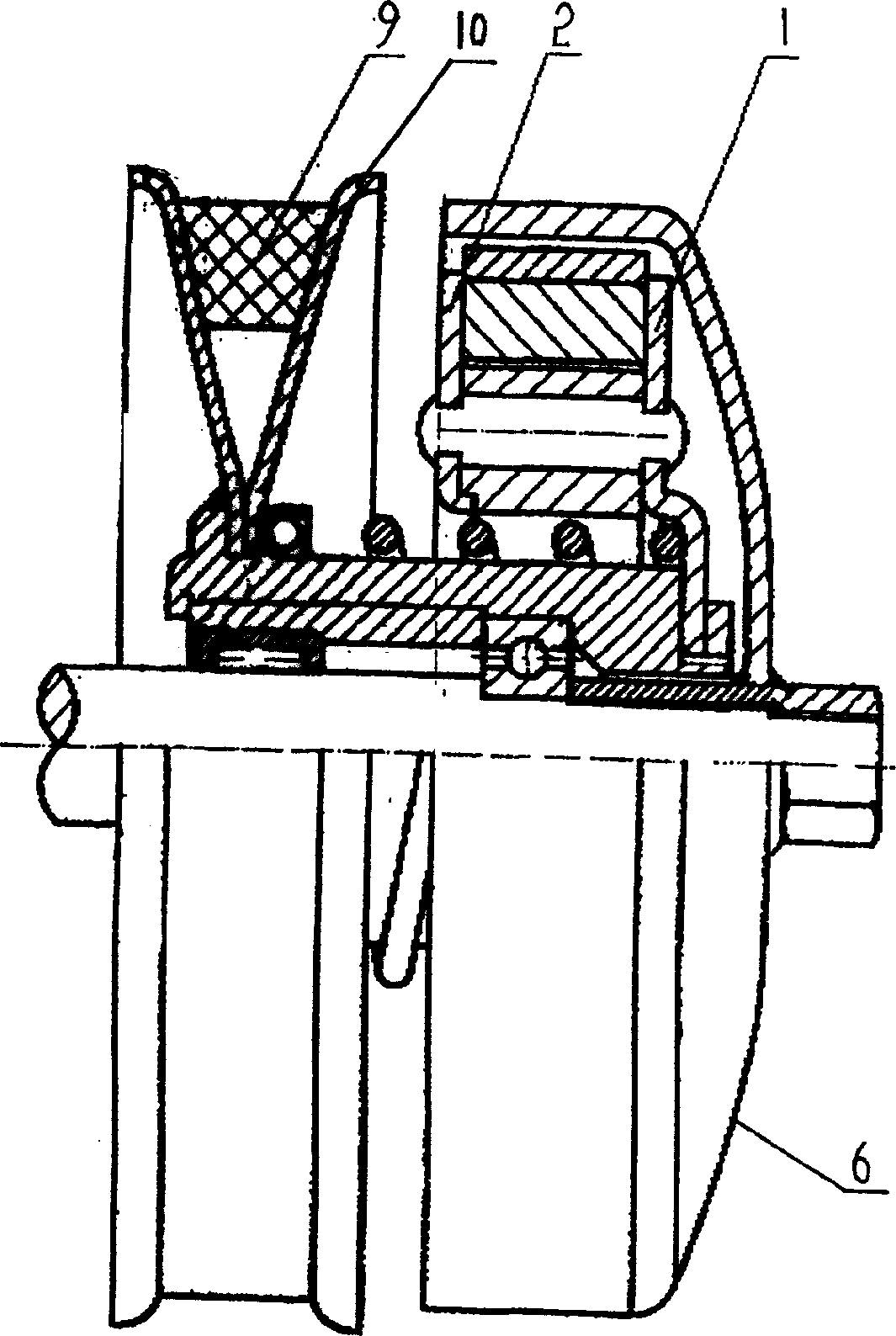

[0011] Such as figure 1 , figure 2 As shown, it is a preferred embodiment of the motorcycle lever clutch of the present invention. The main splint 1 and the secondary splint 2 are arranged in the wheel drum 6, and three friction plates are evenly distributed between the main splint 1 and the secondary splint 2. The centrifugal block 3 is hingedly connected between one end of the centrifugal block 3 and the auxiliary splint 2, and the other end of the centrifugal block 3 is provided with a return tension spring 4, and three booster weights are hinged between the main splint 1 and the auxiliary splint 2. Block 5, the hinge pins 8 at the end of each booster weight 5 are respectively located inside the middle of the centrifugal block 3; the booster weight 5 is in contact with the inner side of the centrifugal block 3; In between, the centrifugal force generated by the booster weight 5 can increase the bonding force between the centrifugal block 3 and the wheel drum 6 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com