Patents

Literature

496results about How to "Eliminate wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

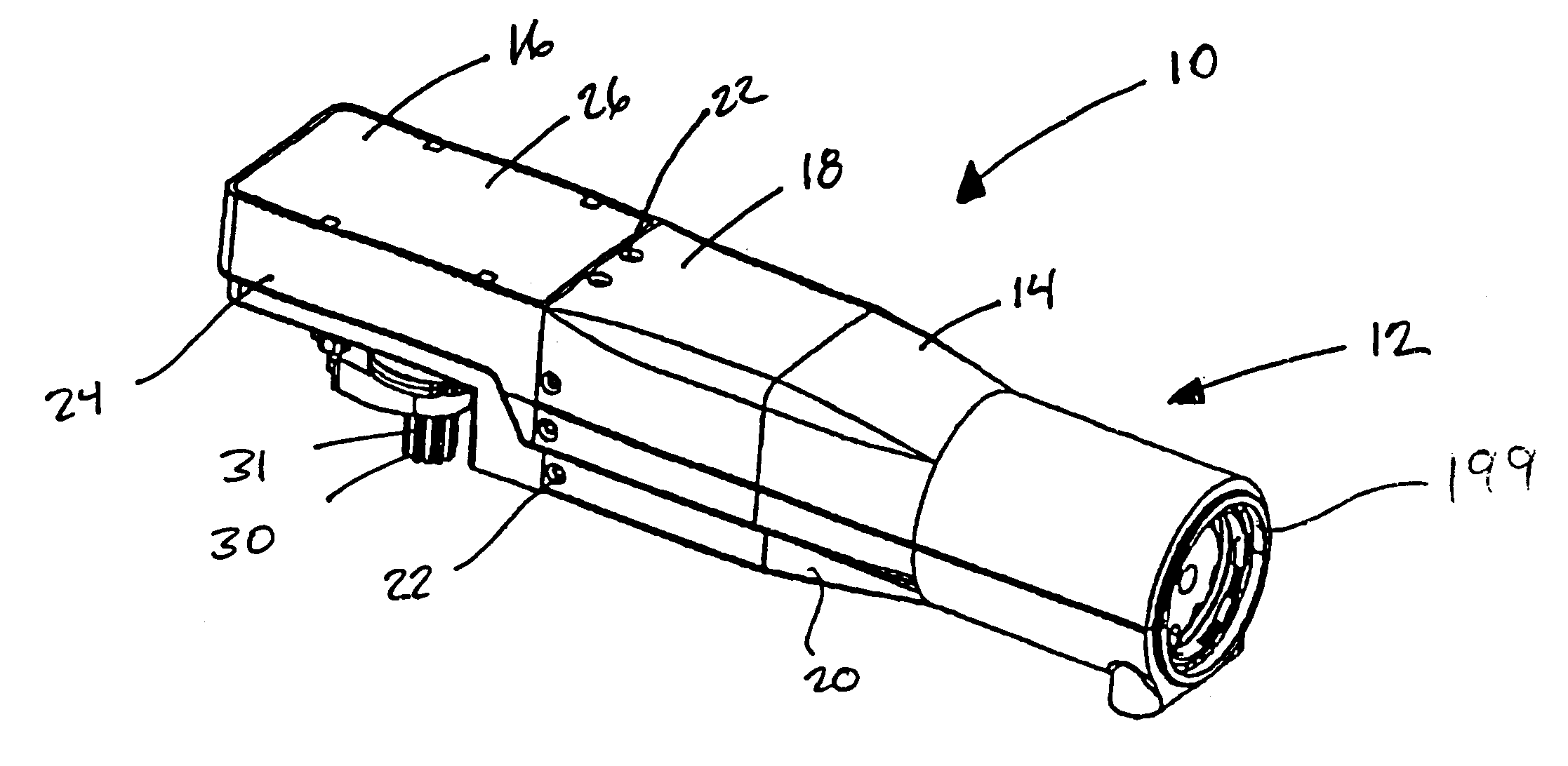

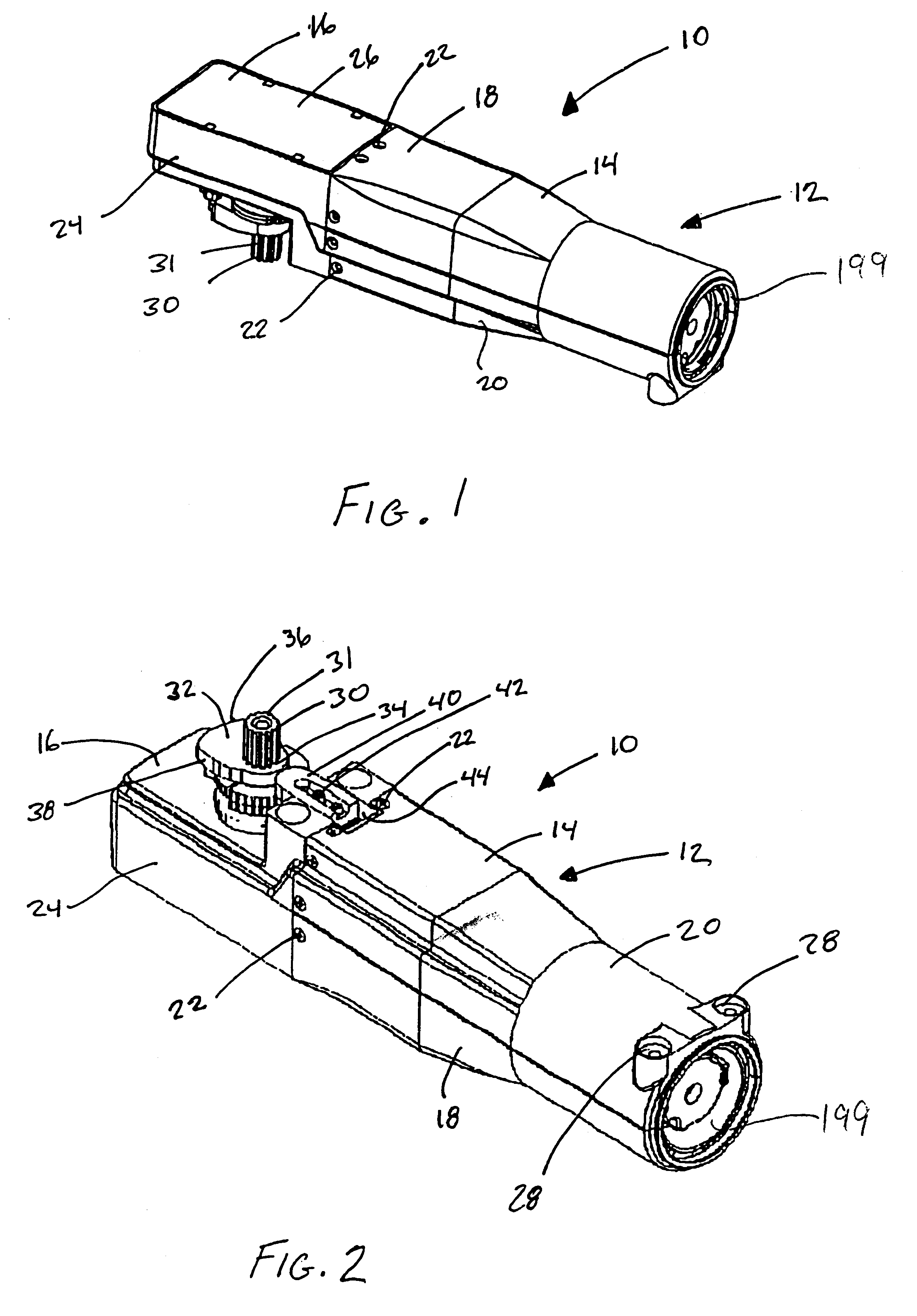

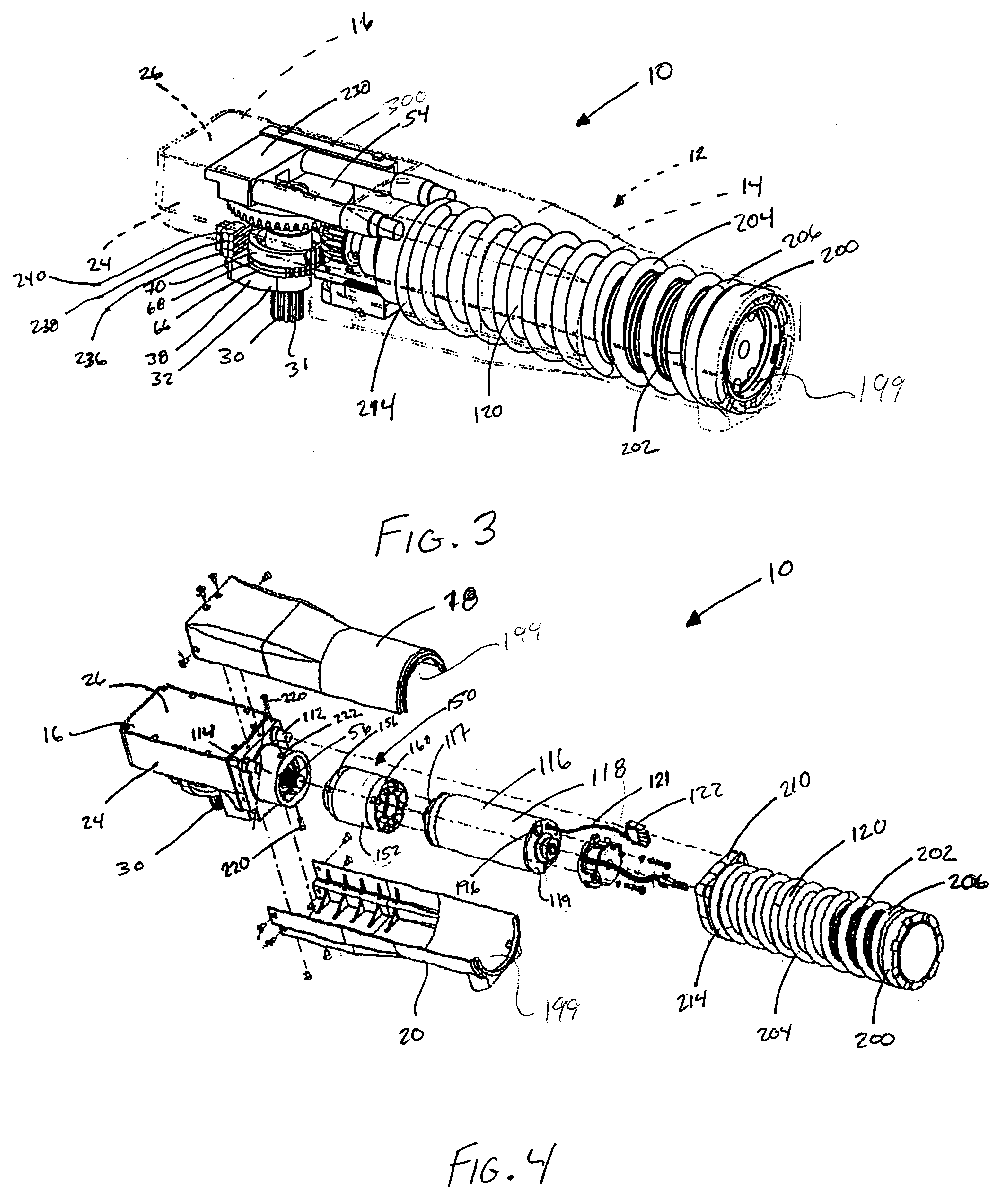

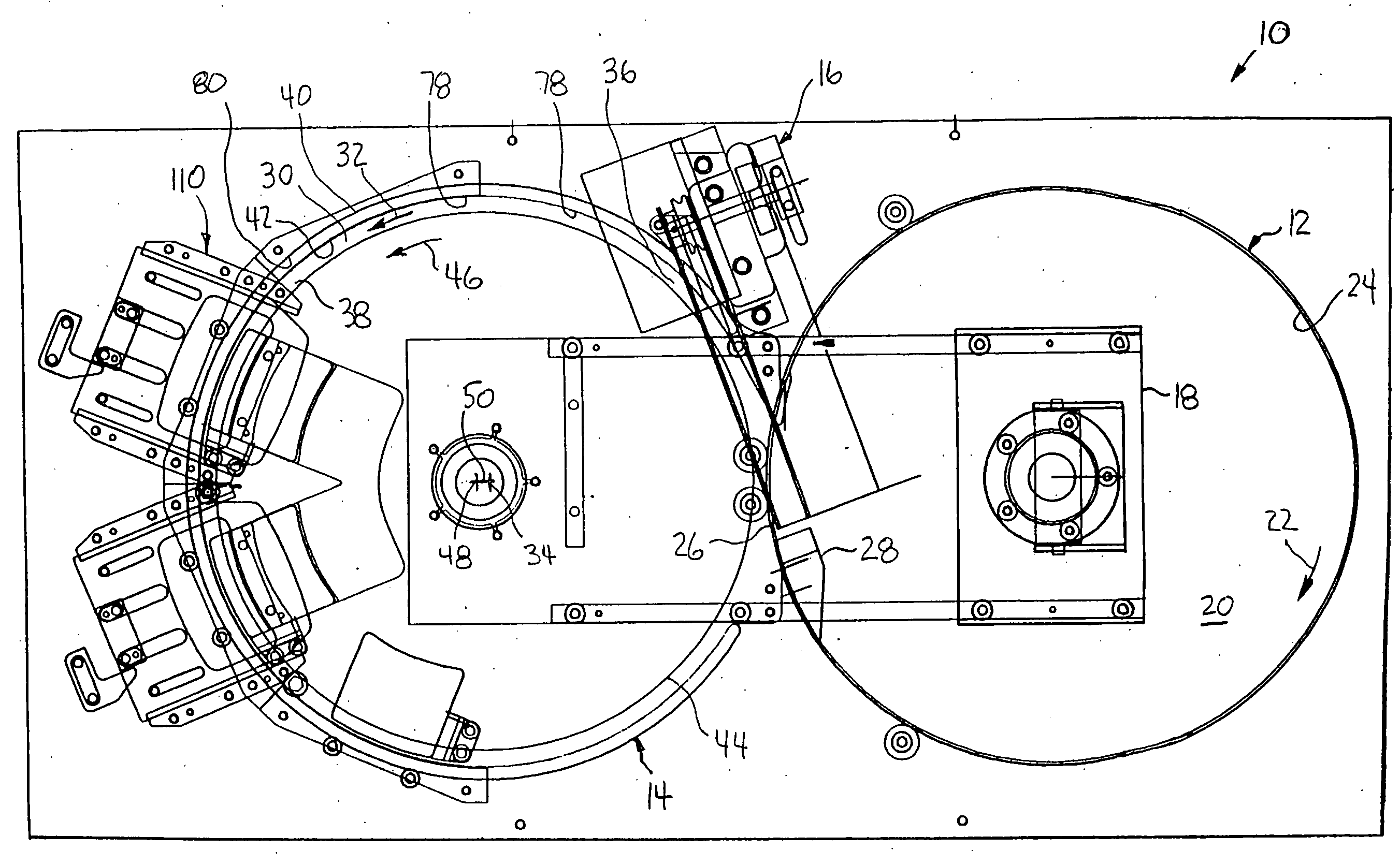

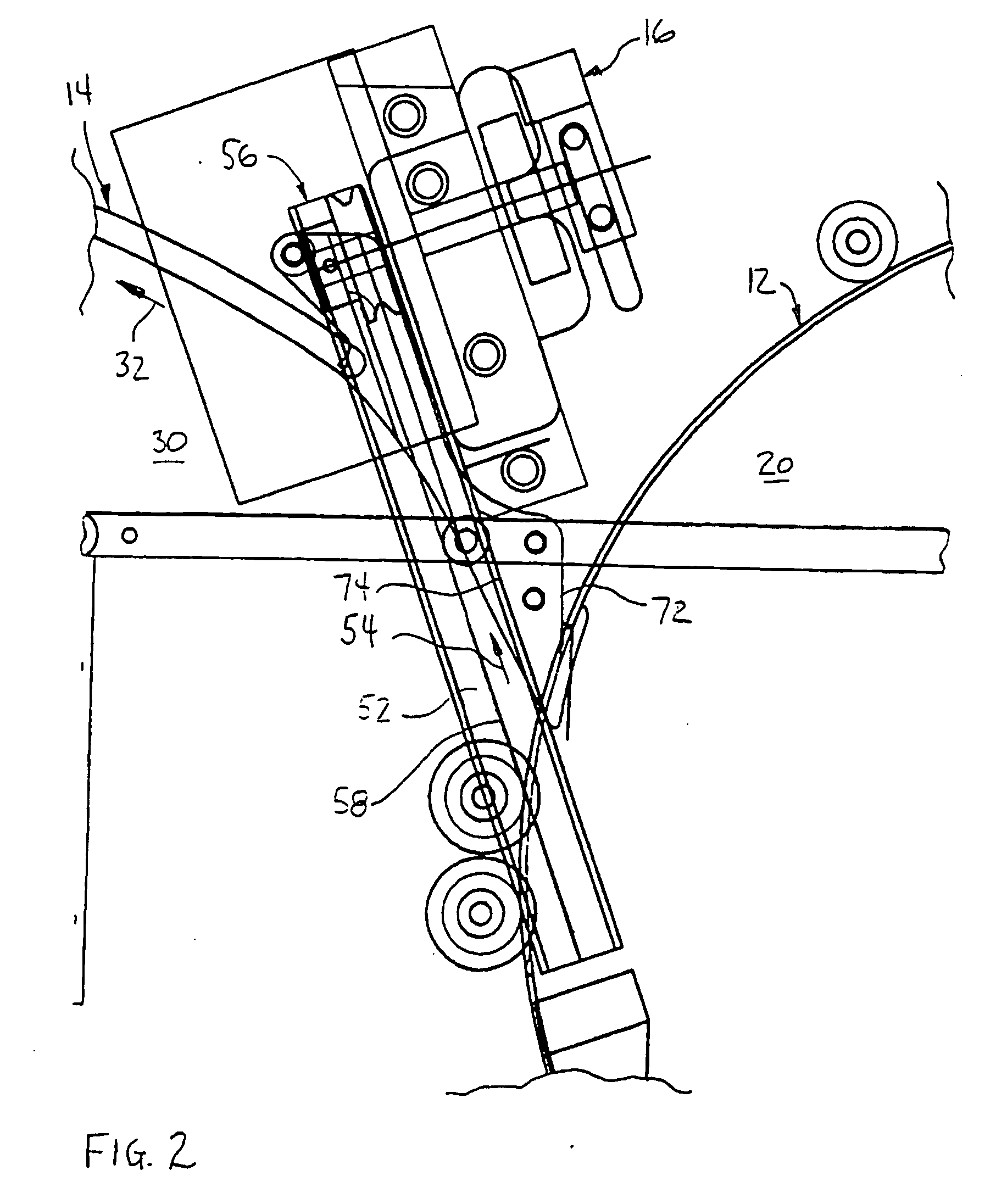

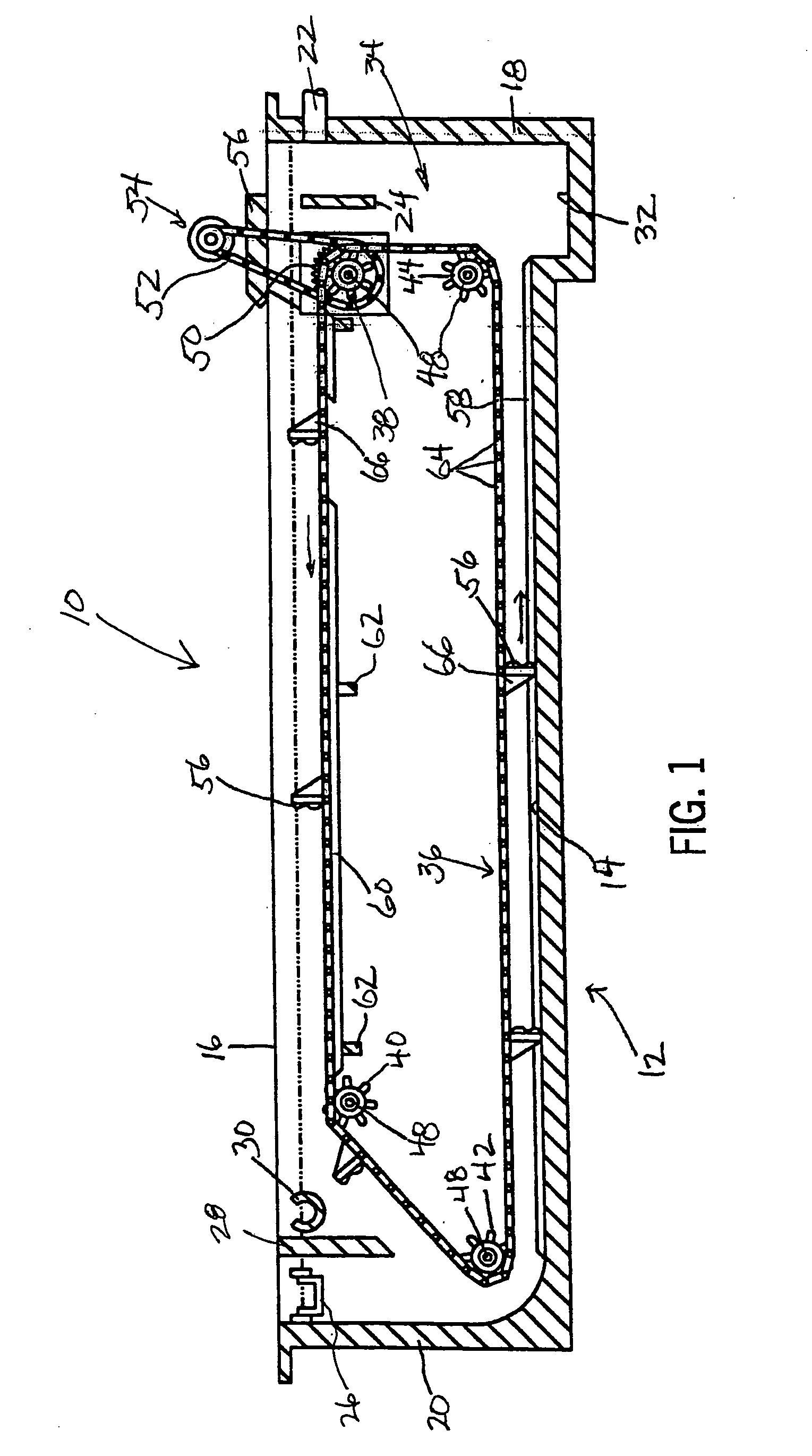

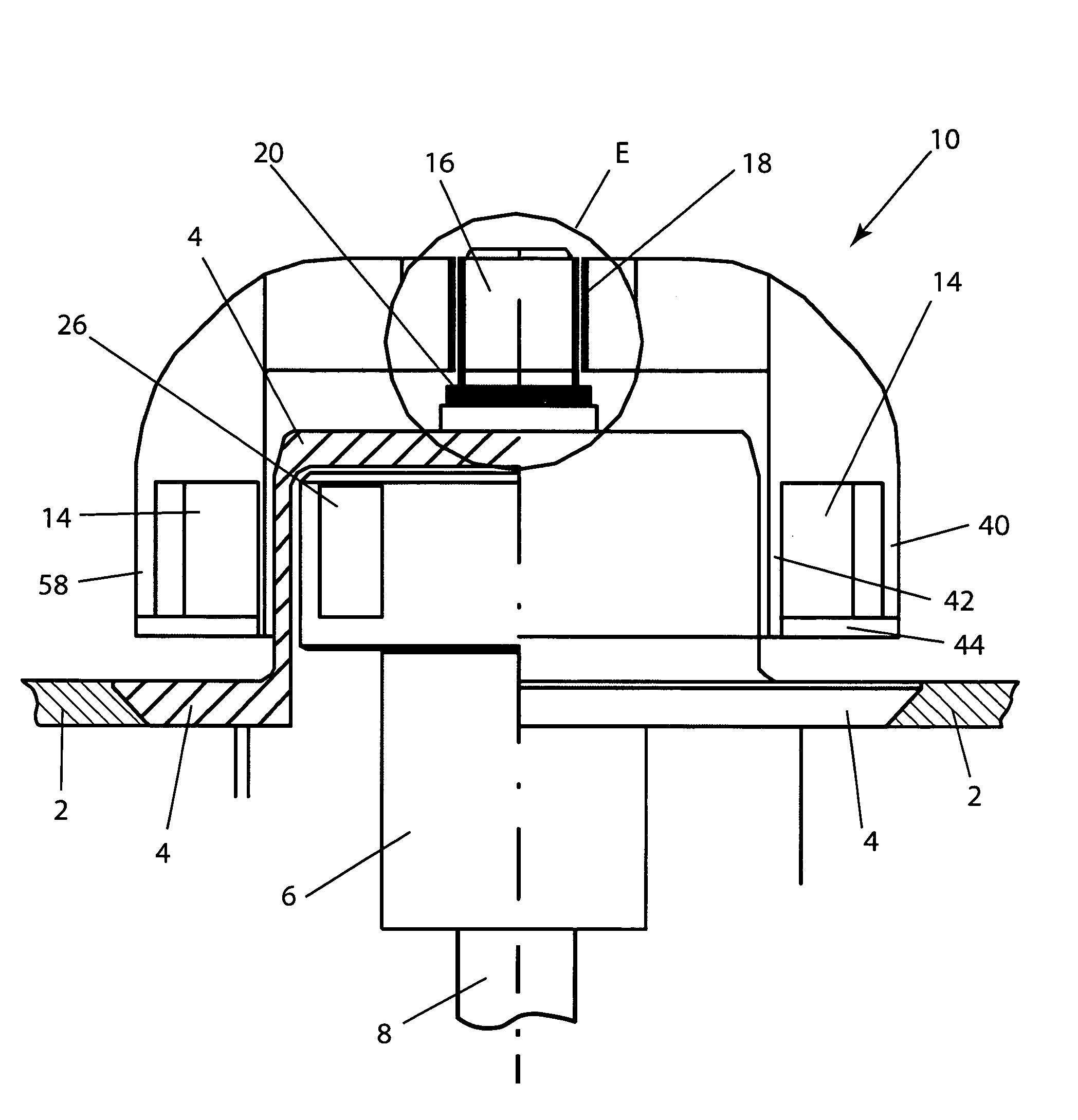

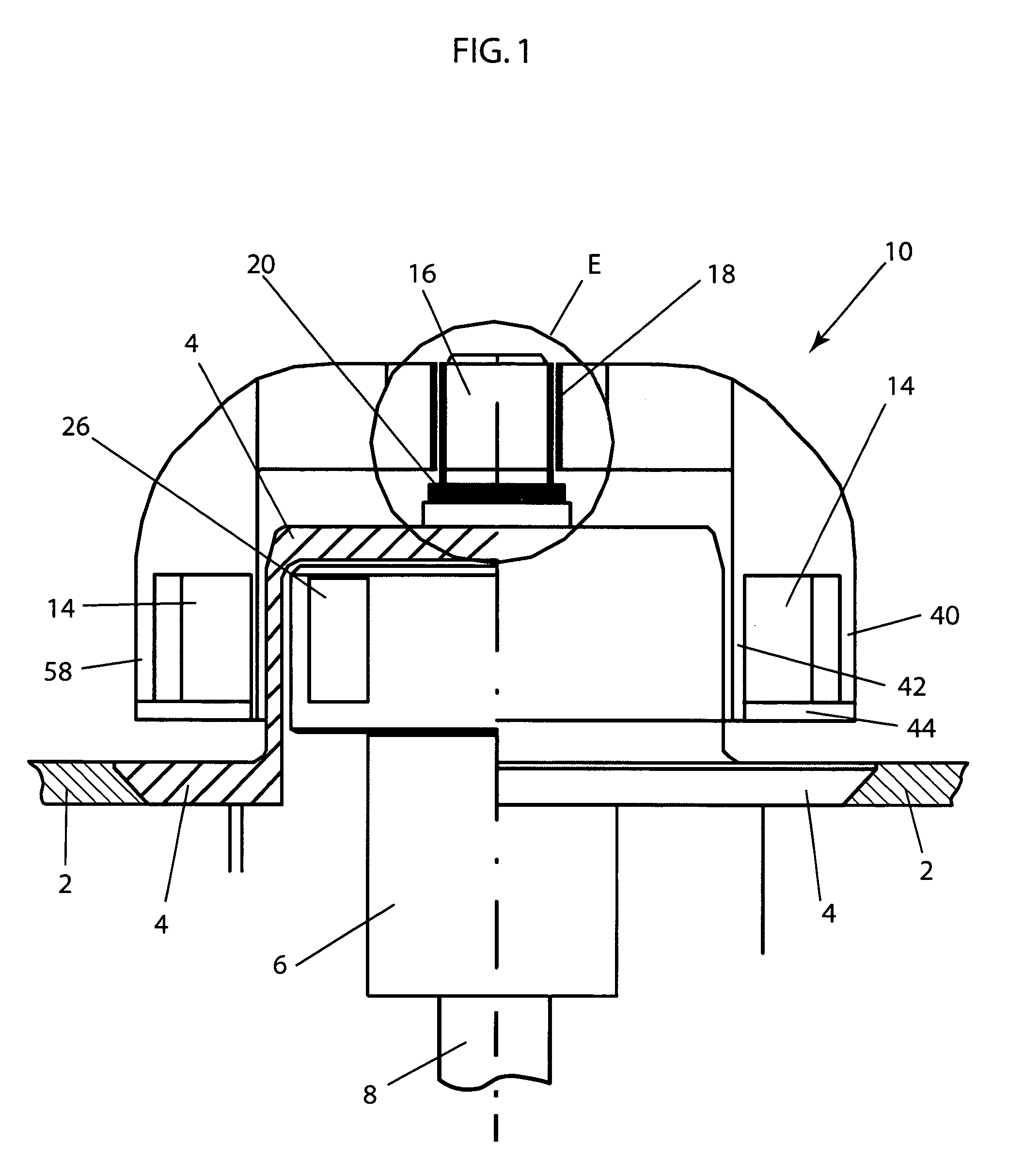

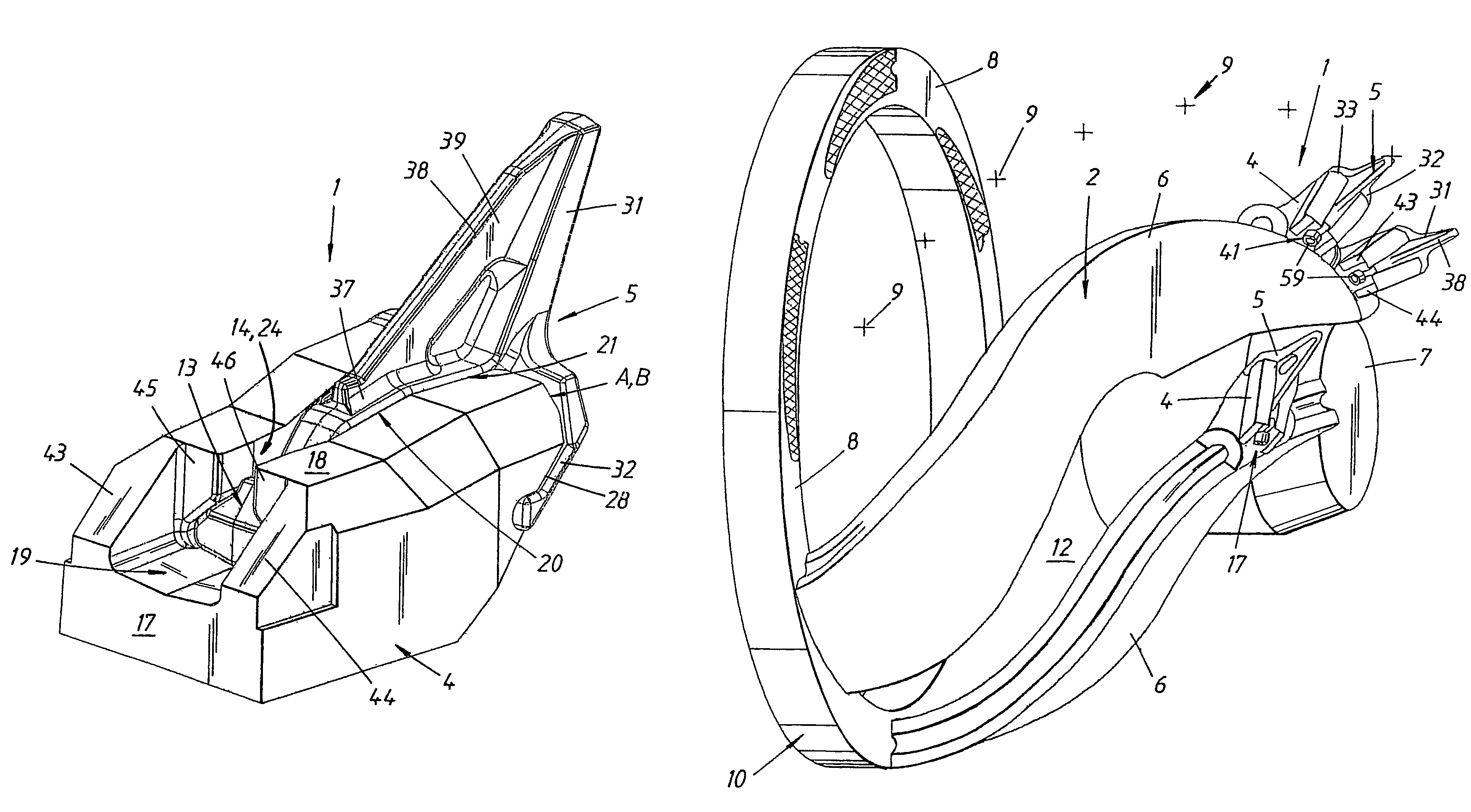

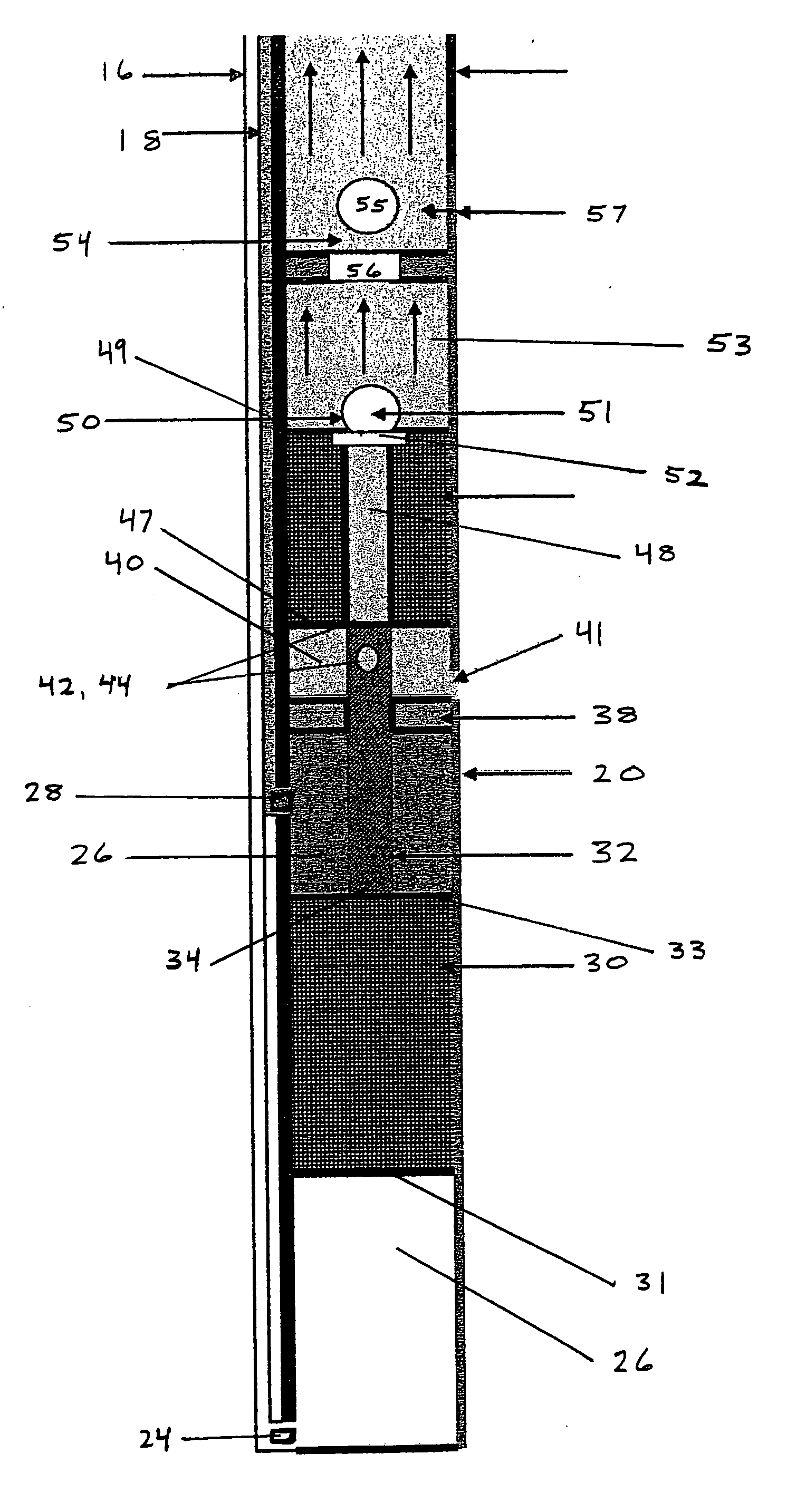

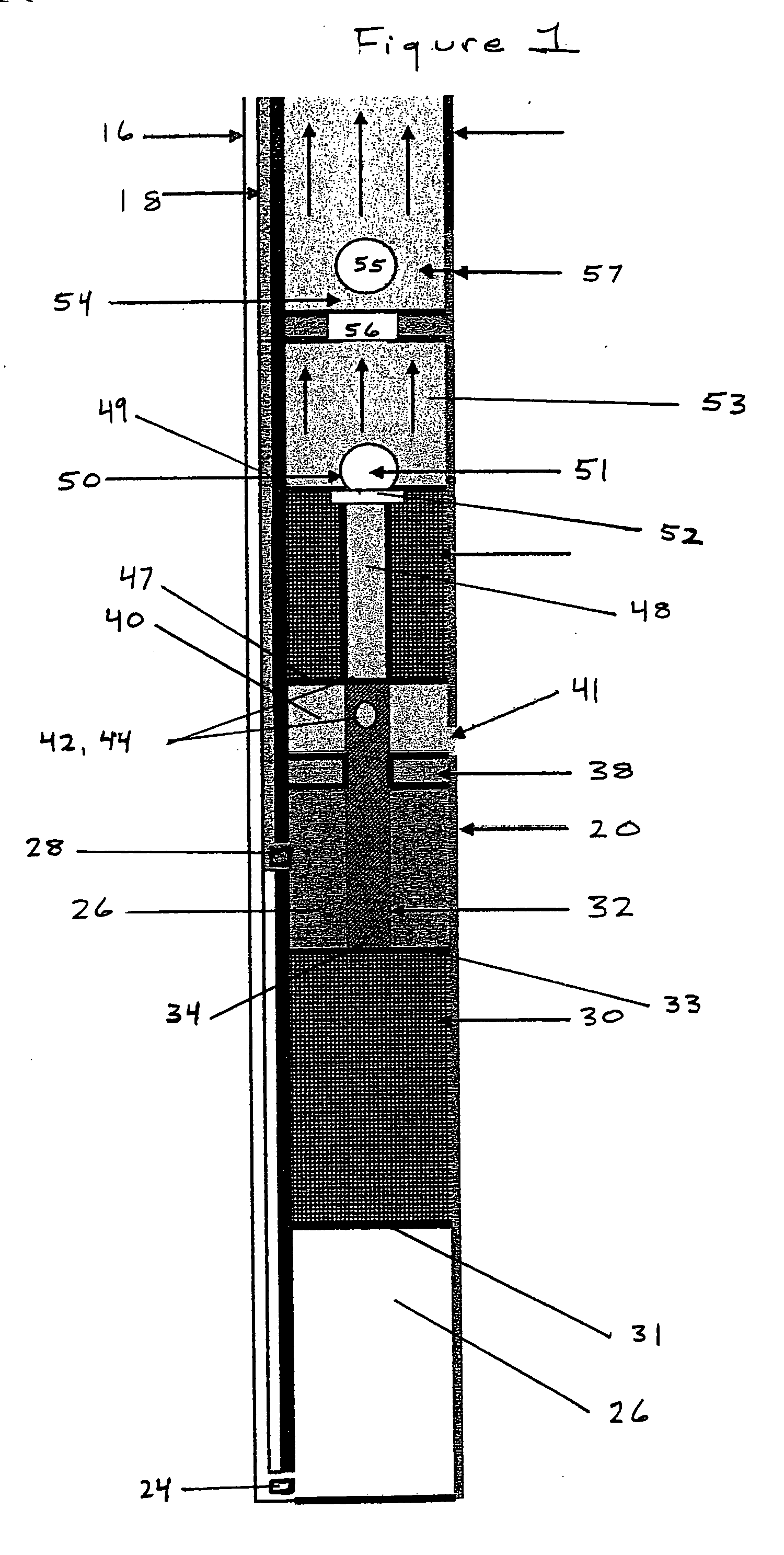

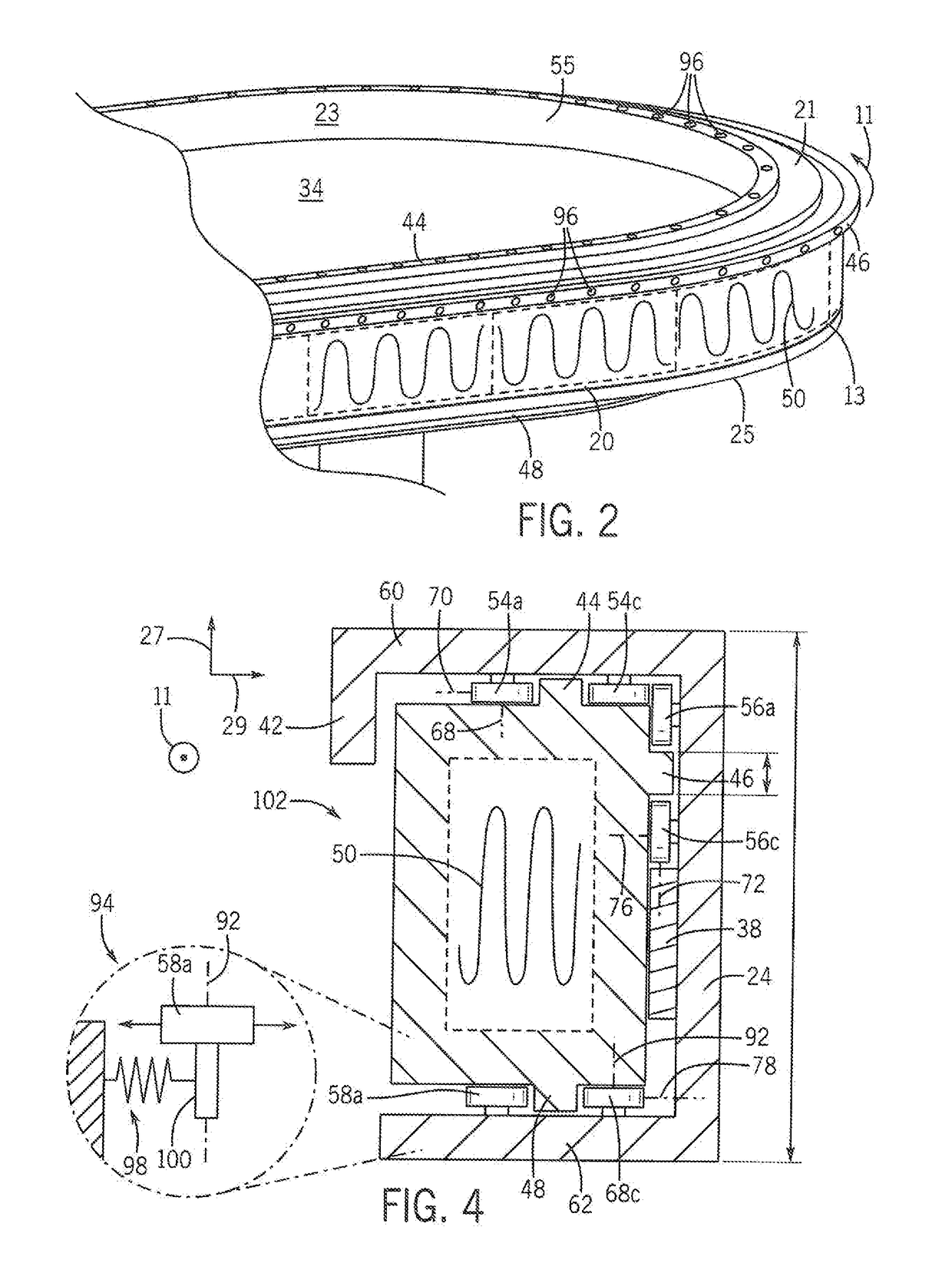

Automatic door assembly and door operator therefor

InactiveUS6336294B1Eliminate wear and tearProvide capabilityBuilding braking devicesMan-operated mechanismMotor driveSpring force

The present application discloses automatic door assemblies and swing operators therefor. One aspect of the disclosure provides a swing door operator that has spring return breakout and from motor driven opening. Another aspect of the disclosure provides a swing door operator that is non-handed with spring return from either direction. Another aspect of the disclosure provides a swing door operator in which spring force is transmitted to the operator output member via a cam structure.

Owner:STANLEY WORKS THE

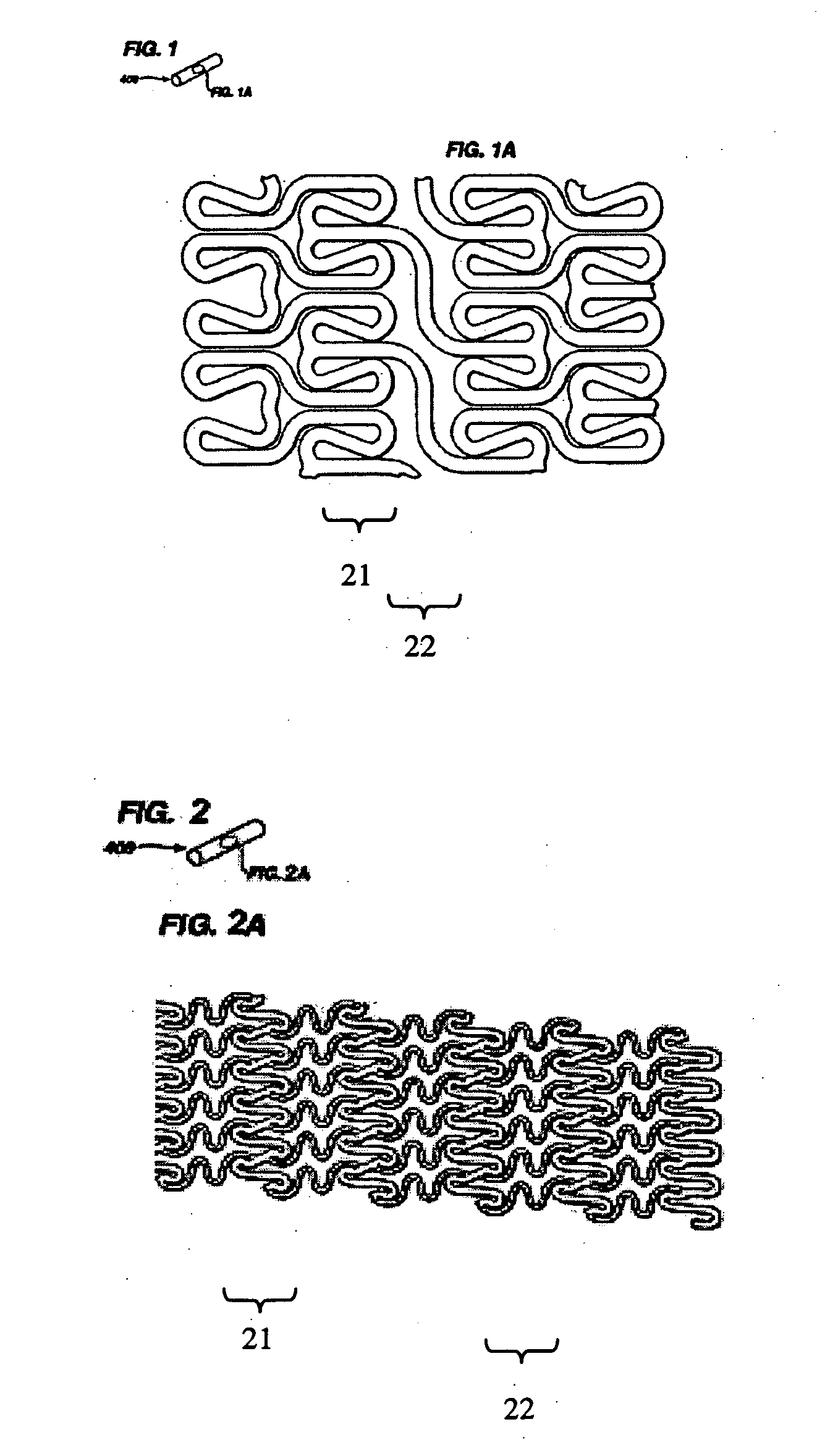

Biodegradable medical devices with enhanced mechanical strength and pharmacological functions

ActiveUS20060264531A1Eliminate riskEliminate wearCosmetic preparationsHalogenated hydrocarbon active ingredientsBiomedical engineeringMedical device

The present invention is directed to a medical device, specifically a prosthesis which utilizes a novel class of blends between biodegradable polymers and bioceramics for medical device applications allowing one to capitalize on the biodegradable nature of these two distinct materials while enhancing the strength of these devices through the addition of various amounts of bioactive ceramic and glasses to biodegradable polymers. The blend may be fabricated into a medical device such as a stent or a distal protection device, and may incorporate various agents to enhance radioapacity and / or pharmacological function. In addition, the blend may be used as a coating to a medical device.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

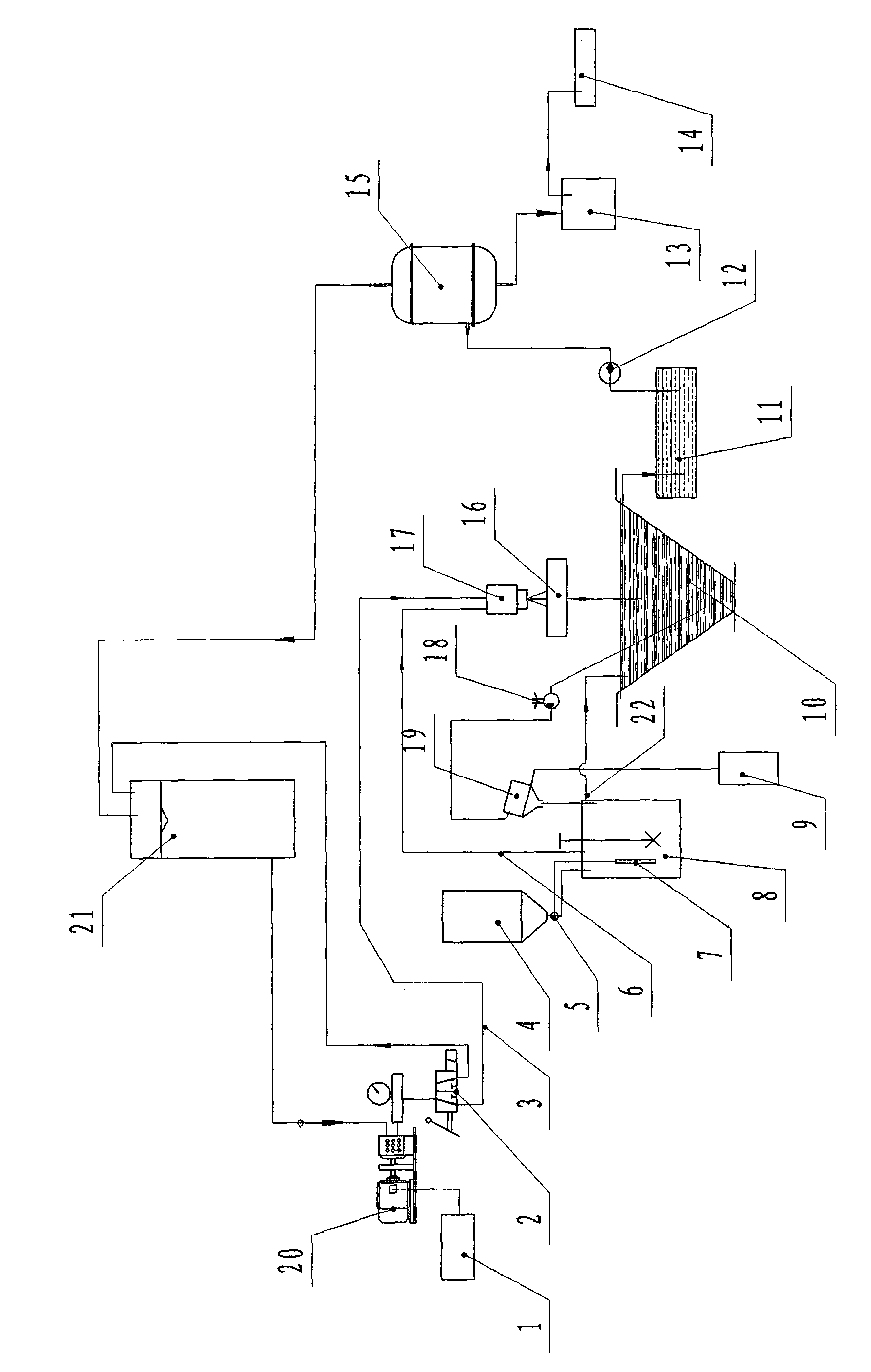

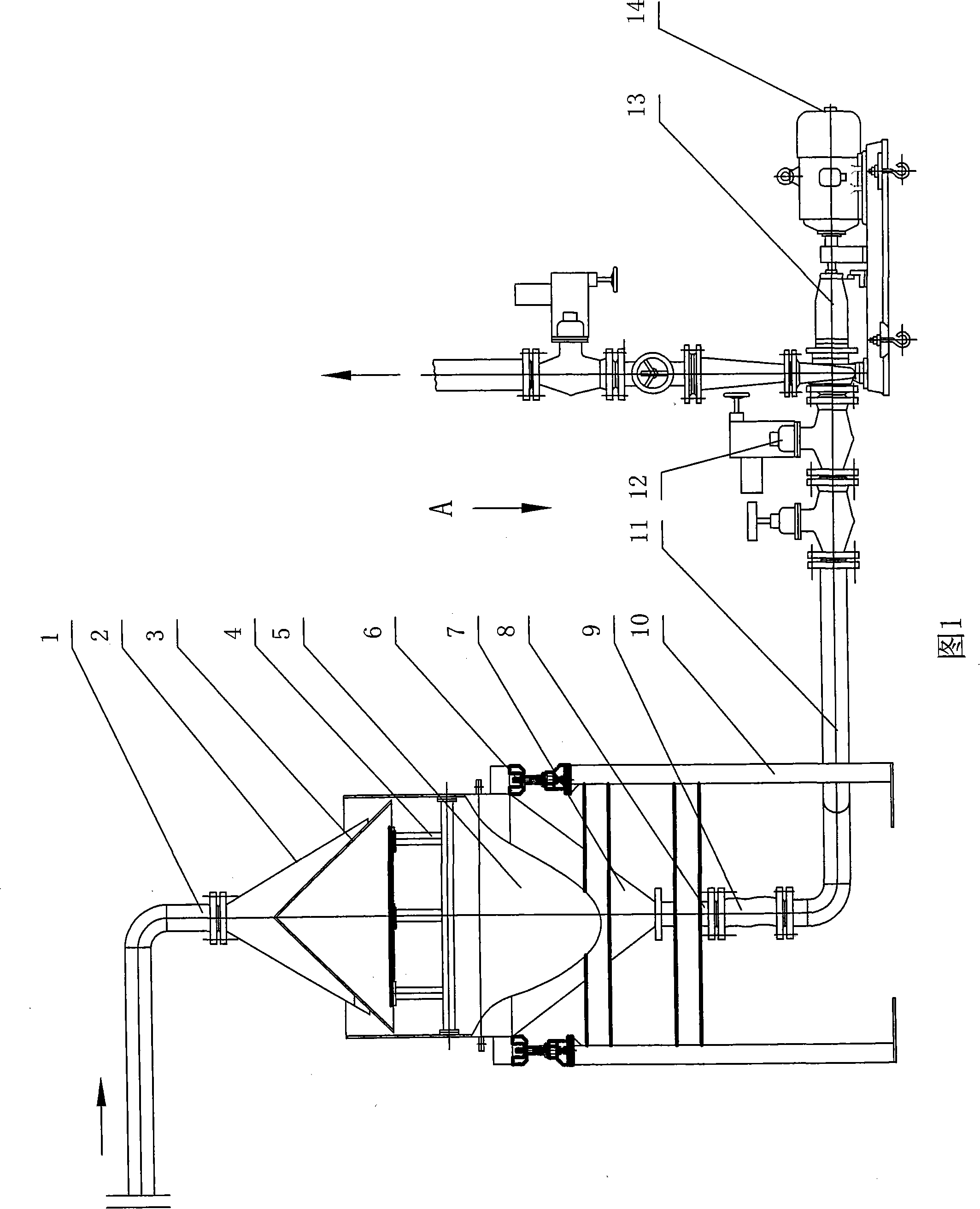

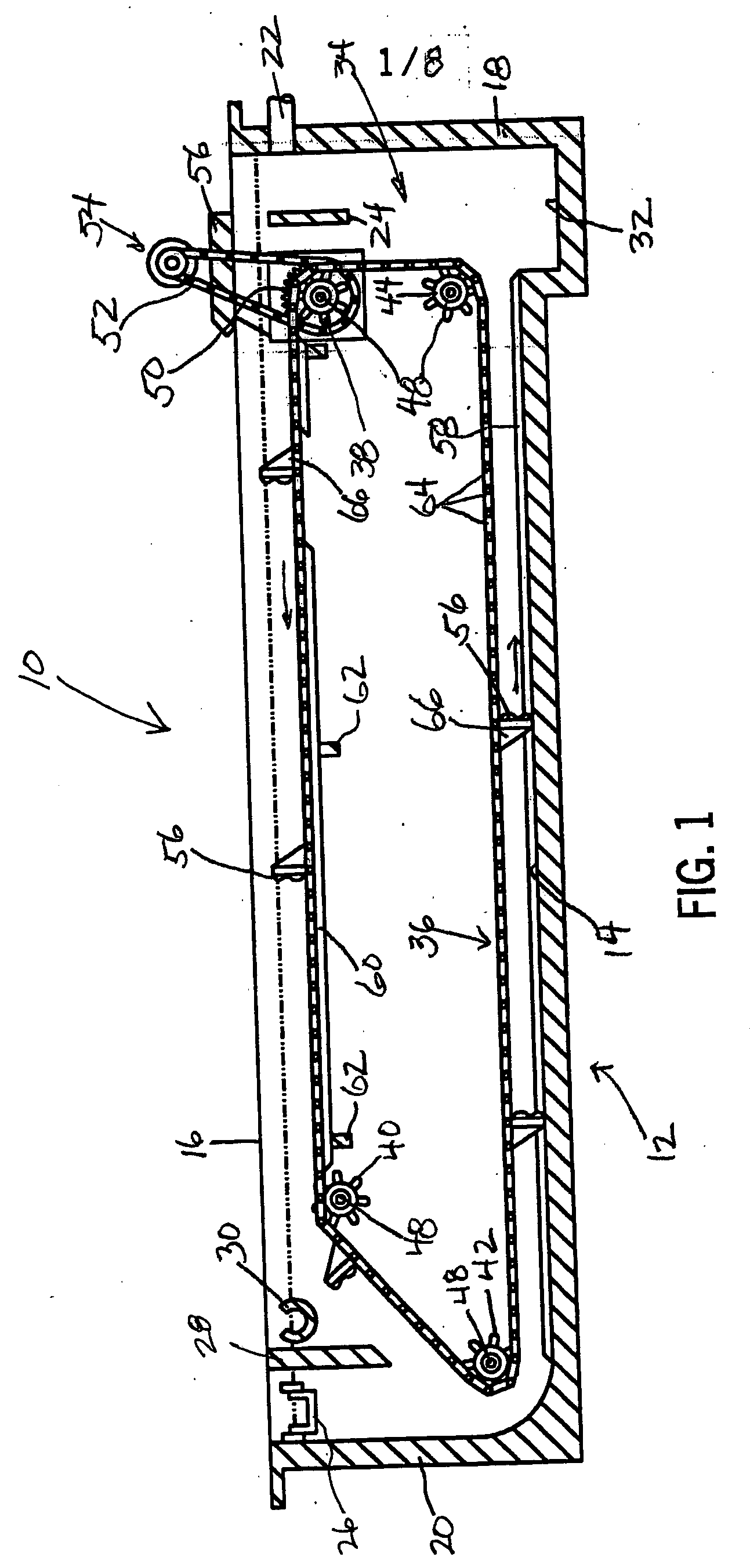

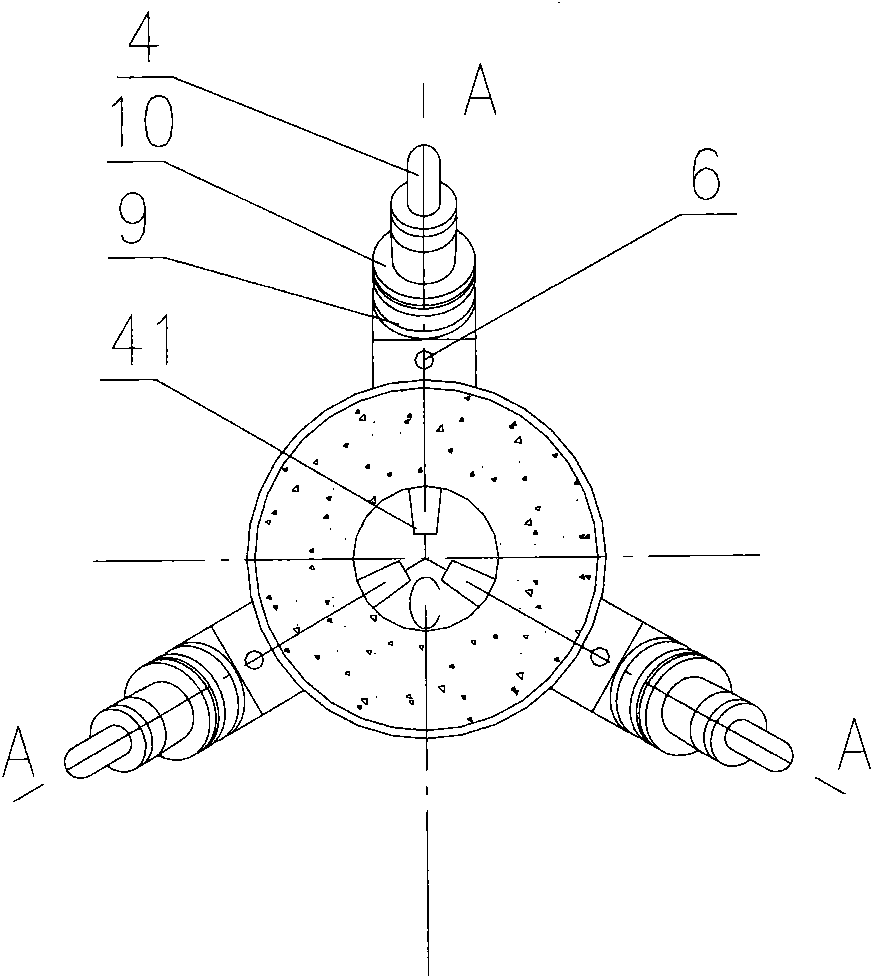

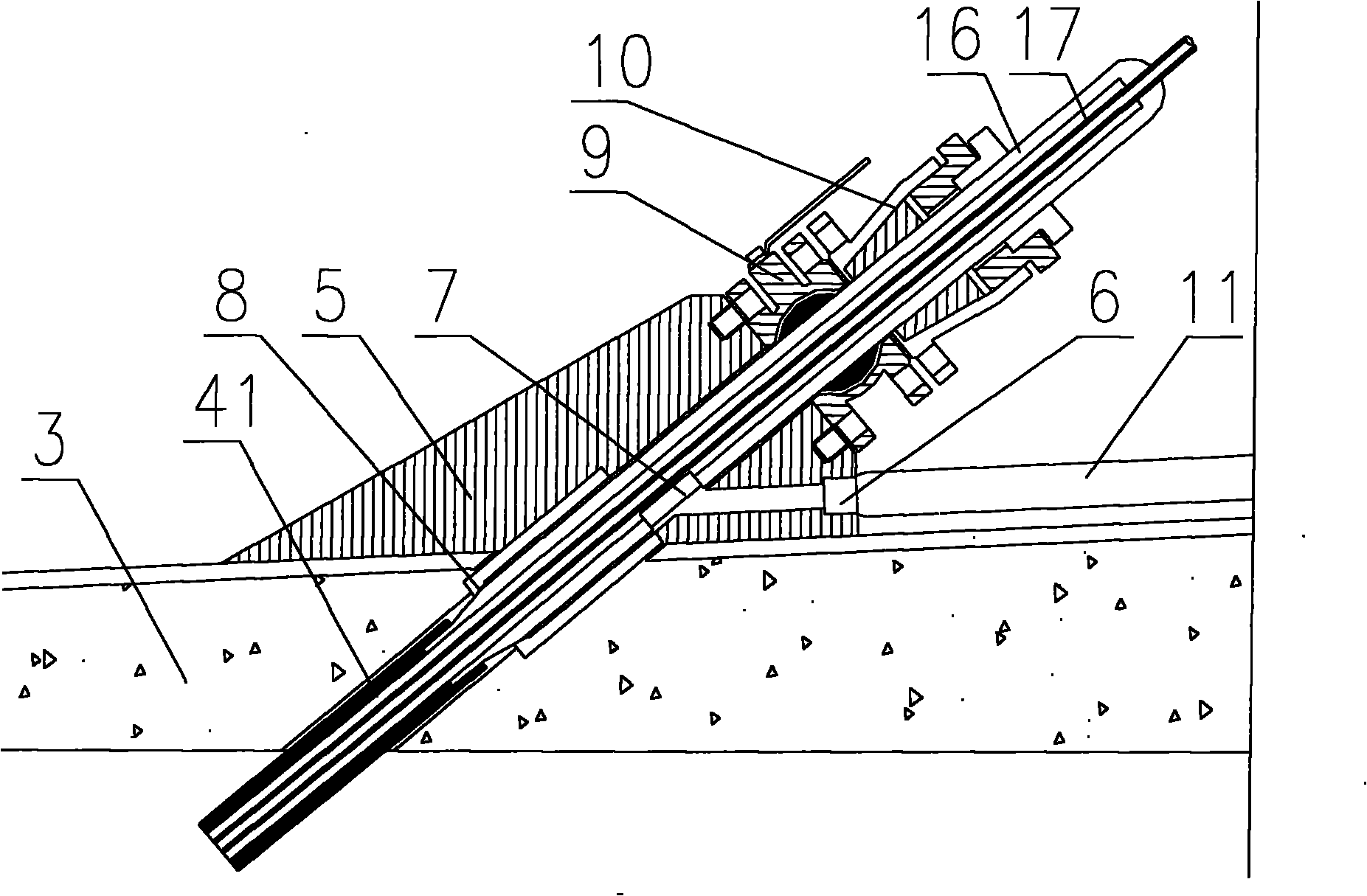

Online high-pressure water-jet blasting surface cleaning system

ActiveCN101633154AUniform supplyGuaranteed uptimeAbrasive feedersAbrasive machine appurtenancesSlagSurface cleaning

An online high-pressure water-jet blasting surface cleaning system comprises a high pressure water feed mechanism, an abrasive material feed mechanism and a spray nozzle. The high pressure water feed mechanism and the abrasive material feed mechanism are communicated with an input end of the spray nozzle, an abrasive material collecting pit is arranged below the spray nozzle, an output end of the abrasive material collecting pit is divided into two paths, one path is connected with an input end of an abrasive material sorting device by an abrasive material cyclical feeding device and a pipeline, and the other path is connected with an input end of a waste water treatment circulating mechanism by a pipeline, an output end of the waste water treatment circulating mechanism is connected with the high pressure water feed mechanism by a pipeline, an output end of the abrasive material sorting device is divided into two paths, one path is connected with the abrasive material feed mechanism, and the other path is connected with a slag collection barrel by a pipeline. The online high-pressure water-jet blasting surface cleaning system has the advantages of simple and compact structure, low energy consumption, good environmental protection, good operational reliability and stability, and recycled water and abrasive materials.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

High speed coin processing machine

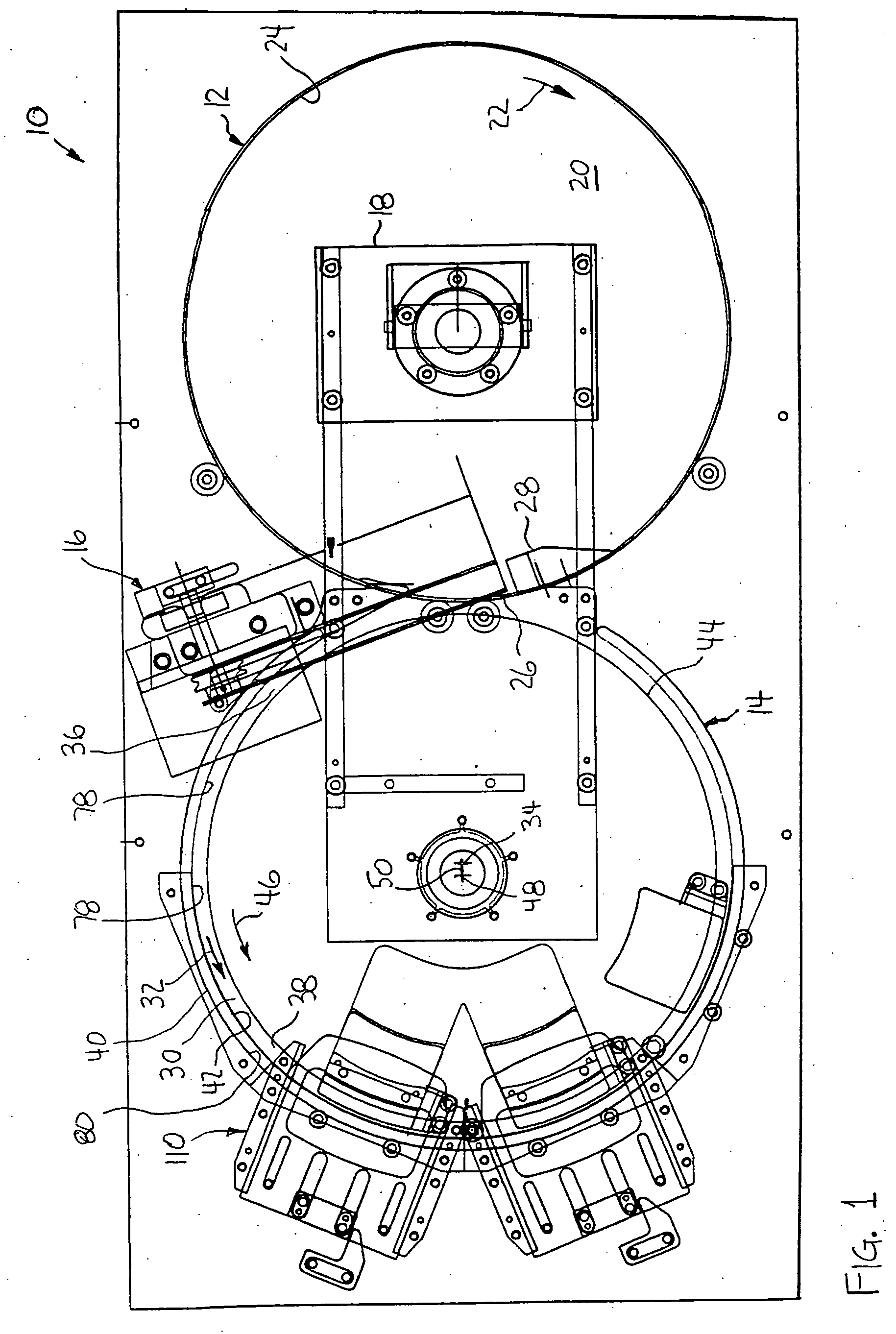

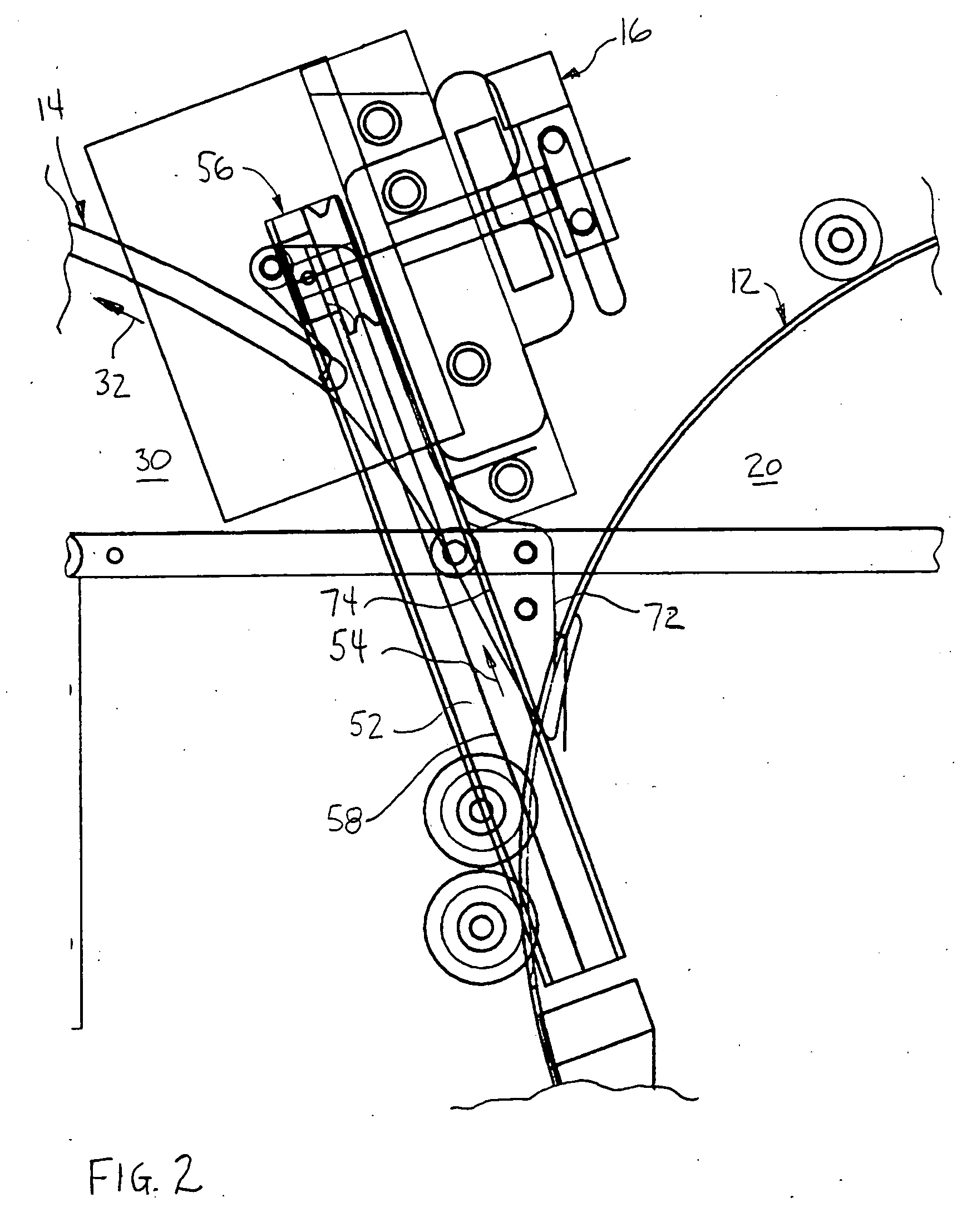

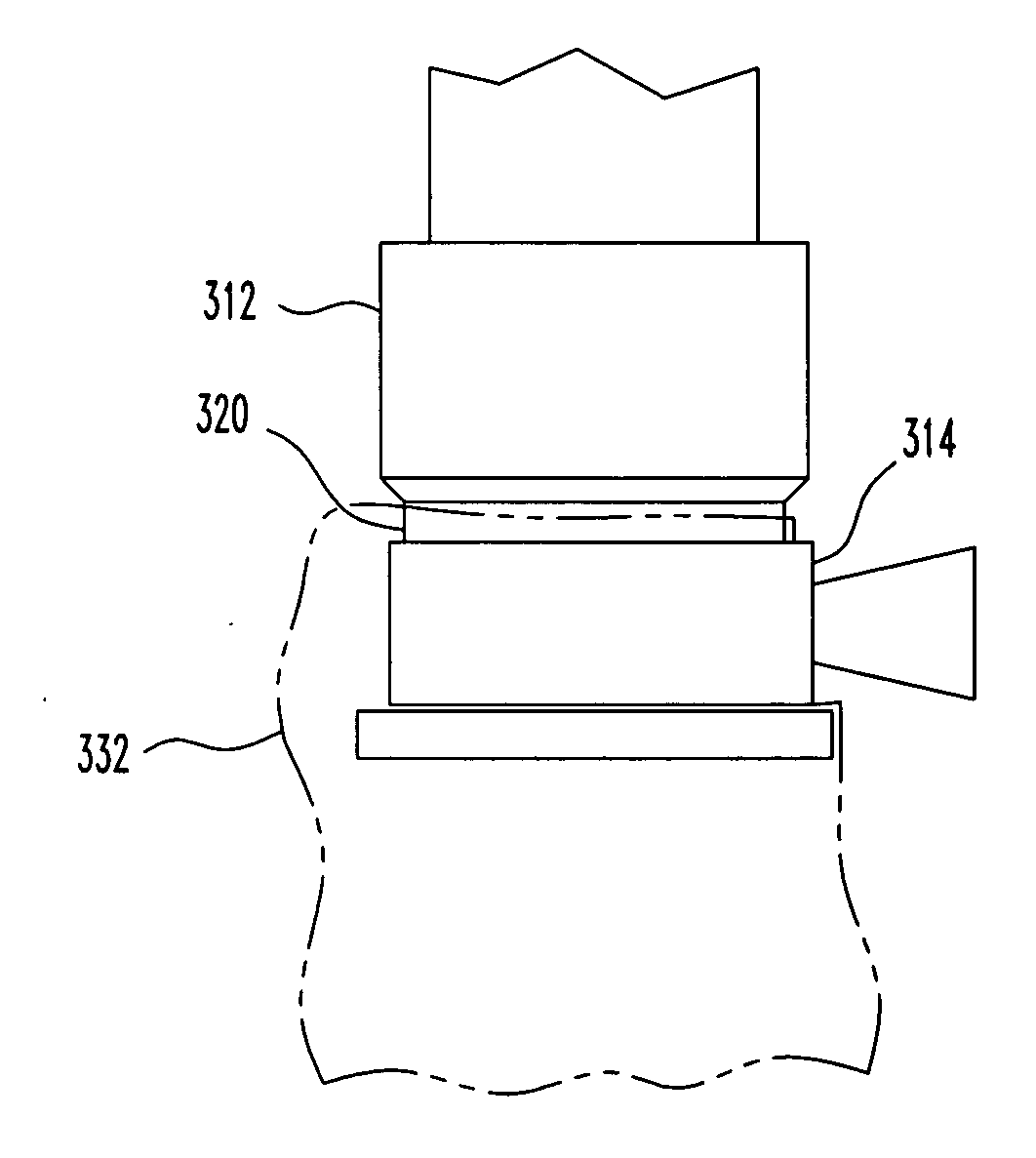

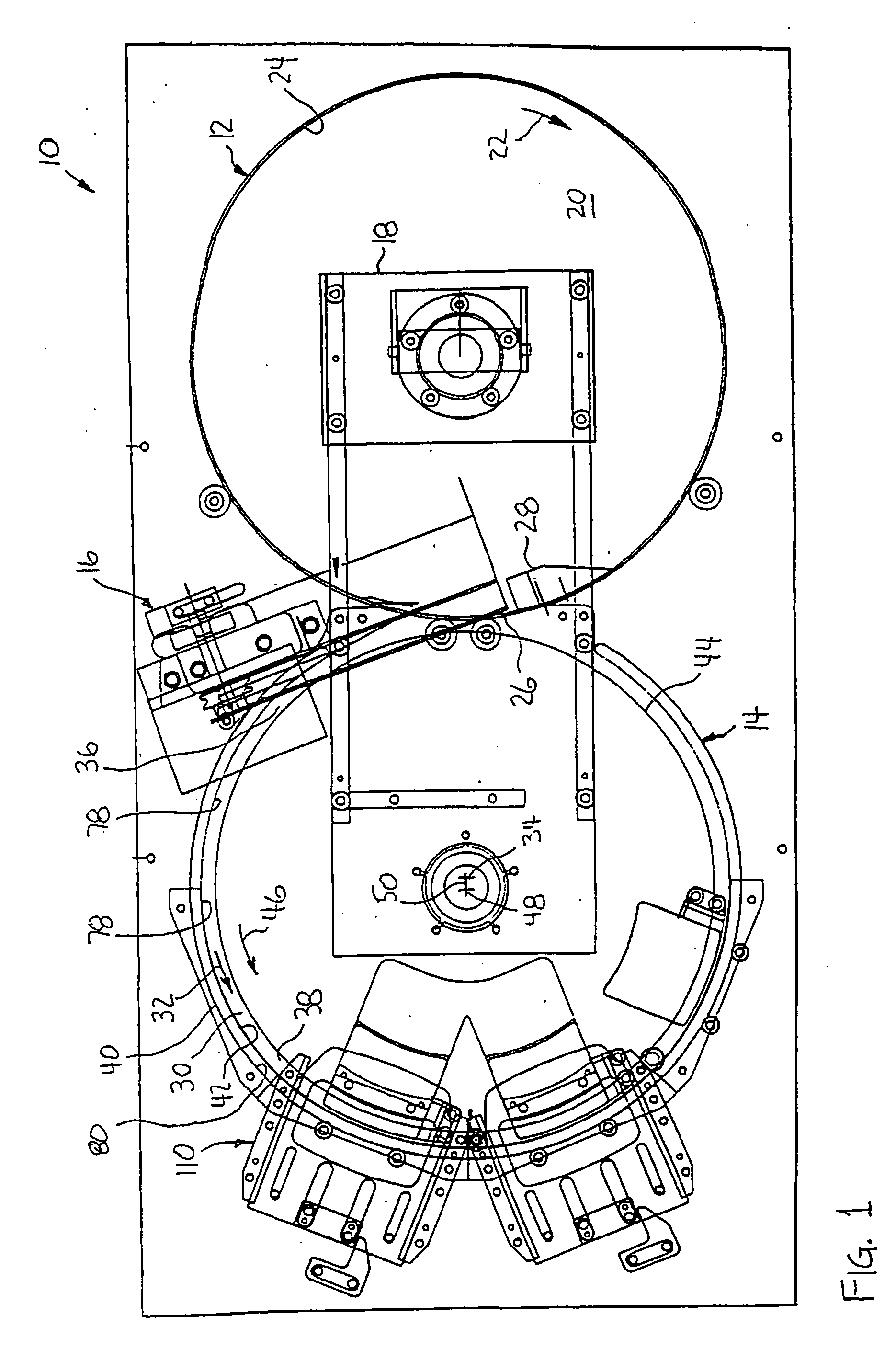

InactiveUS20060154589A1Reduce wearFast processingCoin testingCoin countersMechanical engineeringEngineering

A coin processing machine for sorting or verifying coins includes a hopper for receiving and discharging coins, a processing device to one side of the hopper, and a feed device extending between the hopper and the processing device to drive coins discharged from the hopper to the processing device. The feed device has a belt drive that drives coins along the transfer plate. The processing device has a processing plate that defines a circular coin path, a wall extending along the coin path, and a rotating drive disk that drives coins along the coin path. The disk rotates concentrically with respect to the wall to reliably locate coins against the wall for sensing or processing.

Owner:STRING GREGORY F

High speed coin processing machine

A coin processing machine for sorting or verifying coins discharges coins through one or more coin tubes and includes a disk mounted on a drive shaft by a nut threaded on the shaft. Each coin tube includes a coin bag support with a non-flexible bracket that presses the bag against the support. A high-friction washer is located between the nut and disk to resist loosening of the nut during machine operation.

Owner:STRING GREGORY F

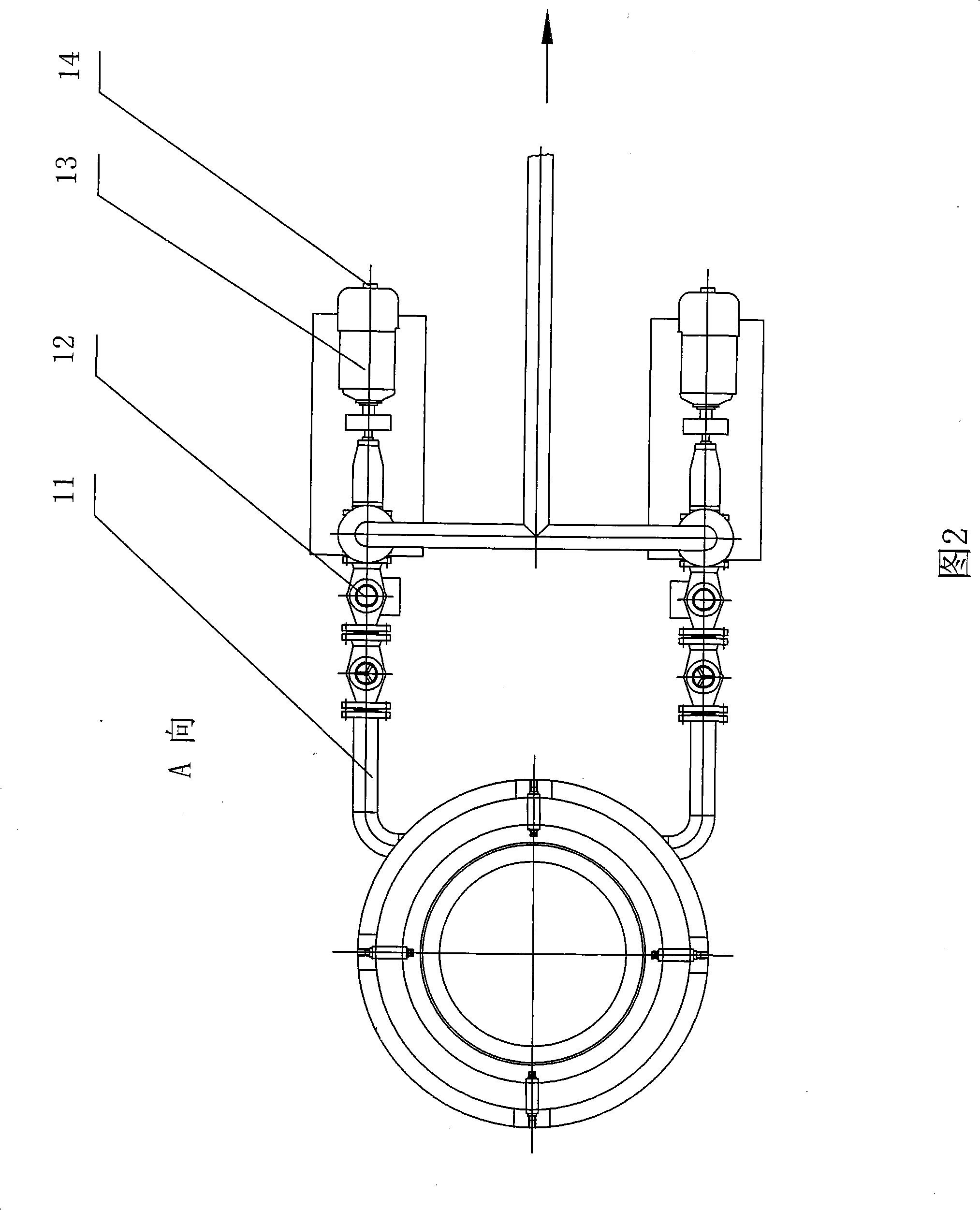

Mineral slurry flux on-line detecting device and multi-parameter on-line detecting integrated system

InactiveCN101251395AAccurate measurementEliminate wear and tearVolume/mass flow measurementMaterial analysis by electric/magnetic meansLiquid productMeasurement device

The invention provides an online detection device for the pulp flow rate and a multi-parameter online detection integration system, which comprise a pulp container which has a feed port and a discharge port and is arranged on a support through a, weighing cell, a pulp flow rate detection device which is provided with a soft connector at the discharge port, and / or a pulp density measuring device, a pulp grain size measuring device and a pulp grade measuring device. The online detection device for the pulp flow rate and a multi-parameter online detection integration system can not only measure any single index of the flow rate, density, grain size and grade of the pulp according to requirements, but also simultaneously measure two or above two or even all of the indexes with high measuring accuracy, good stability and reliability. The online detection device for the pulp flow rate and a multi-parameter online detection integration system also have the advantages of simple structure, high working efficiency, low labor intensity, wide application range, etc., thereby being capable of providing the highly reliable flow rate, density, grain size and grade control parameters for liquid products to ensure product quality, reduce cost and improve working efficiency, and providing a highly guaranteed measuring device and system for full automatic control.

Owner:罗放明

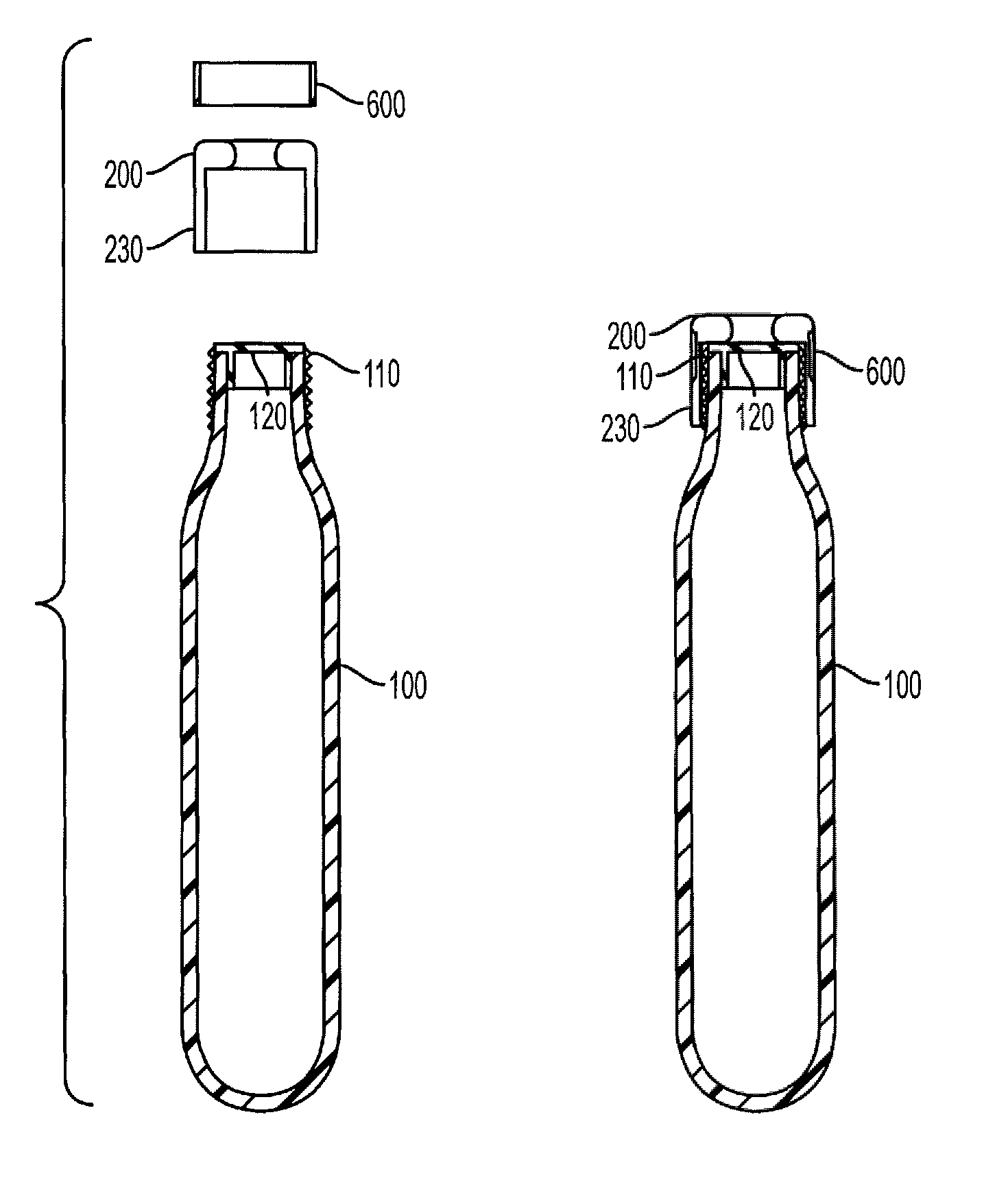

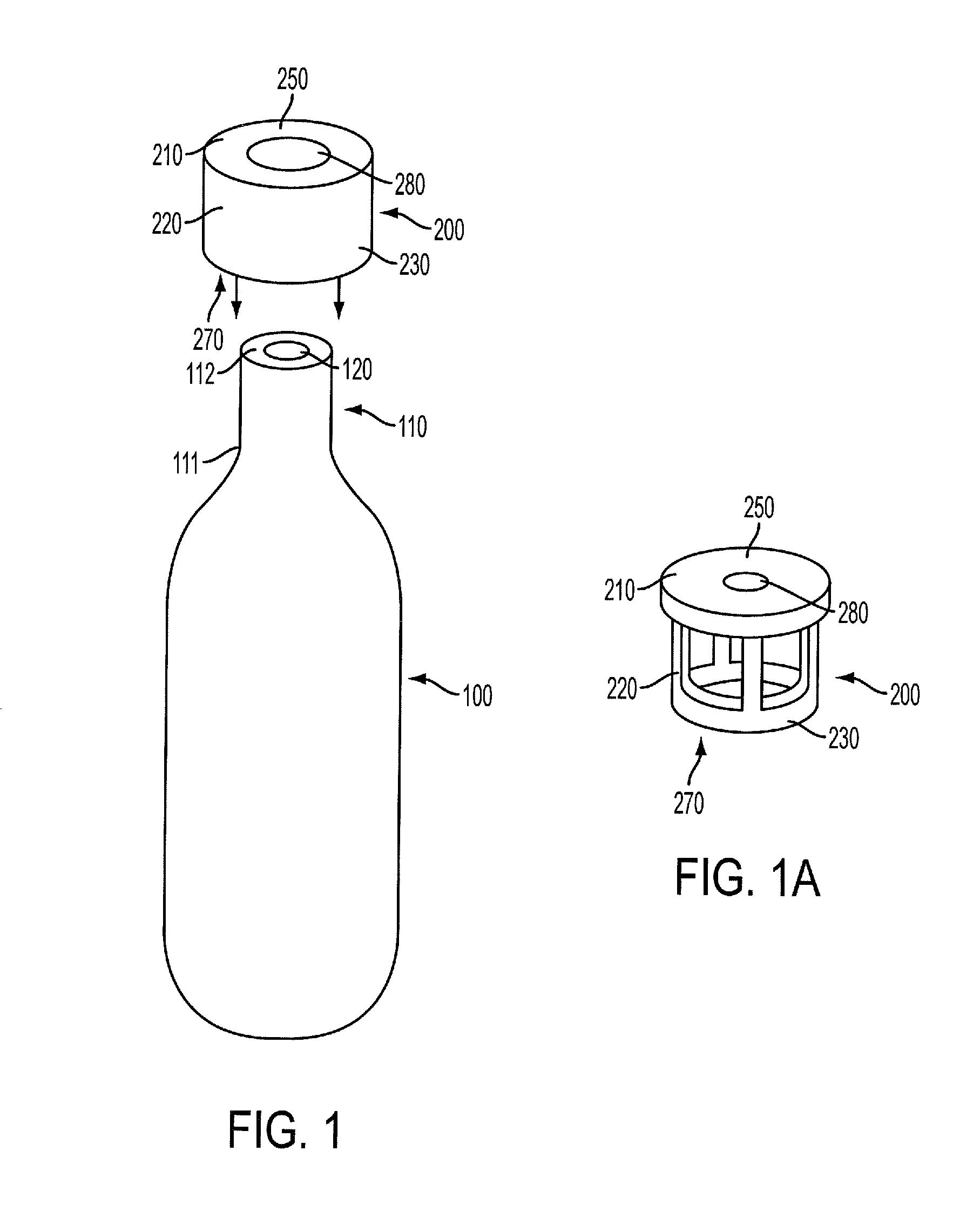

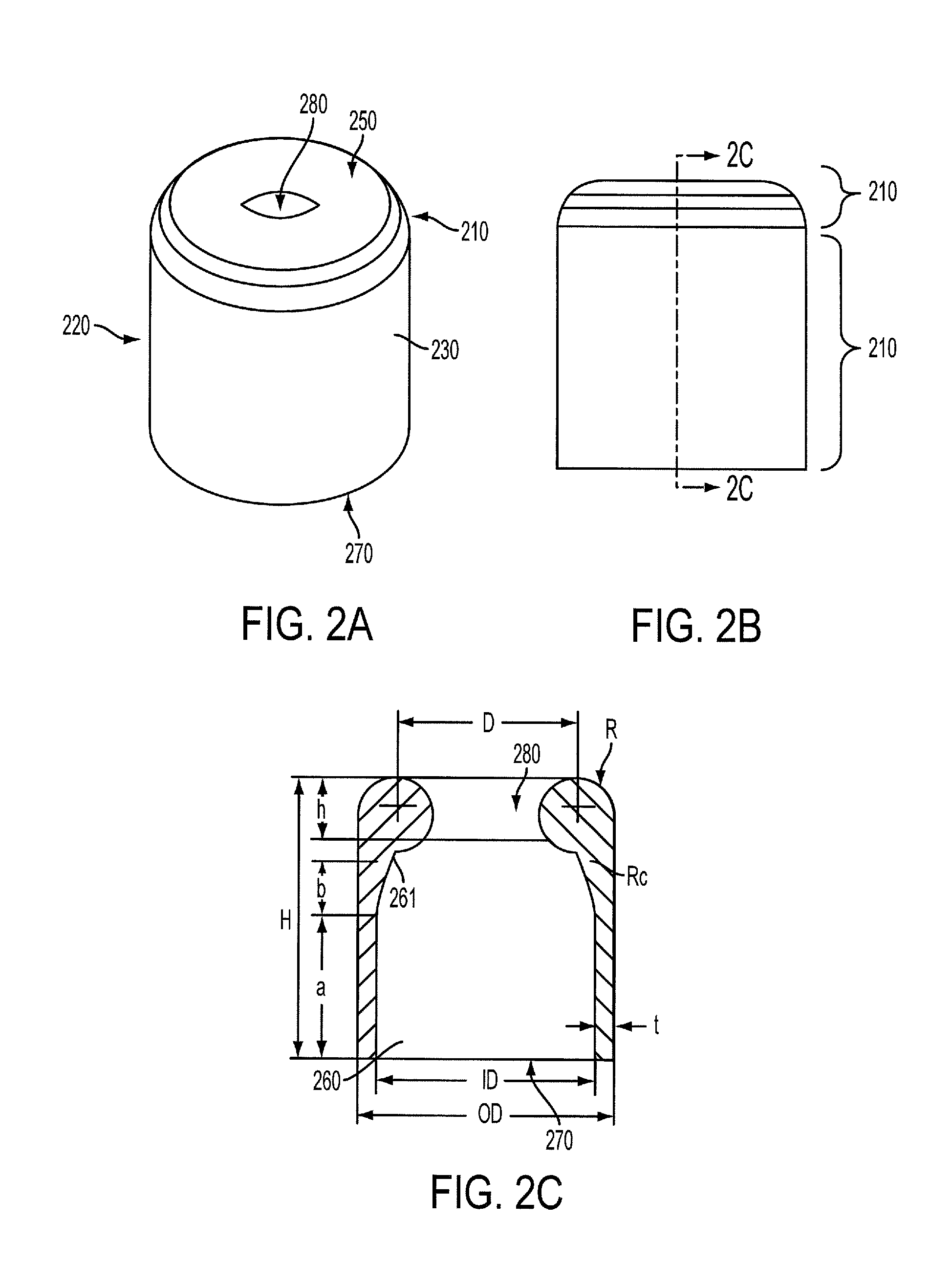

Method and apparatus for gas cylinder sealing

ActiveUS8925756B2Improve sealingLower the volumeCapsContainer filling methodsGas cylinderEngineering

A gasket for a compressed gas cylinder arranged to operate with a gas cylinder having a neck with a top surface around a gas outlet and a side surface extending downwardly from the top surface. The gasket may include an upper portion arranged for positioning on the top surface of the cylinder and for making a seal with the top surface, and a lower portion extending downwardly from the upper portion and around the side surface of the neck of the cylinder, such that the lower portion is arranged to make a seal with the side surface of the gas cylinder. Face and gland seals may be established by the gasket with an opening that receives the gasket and an associated cylinder neck.

Owner:CORAVIN

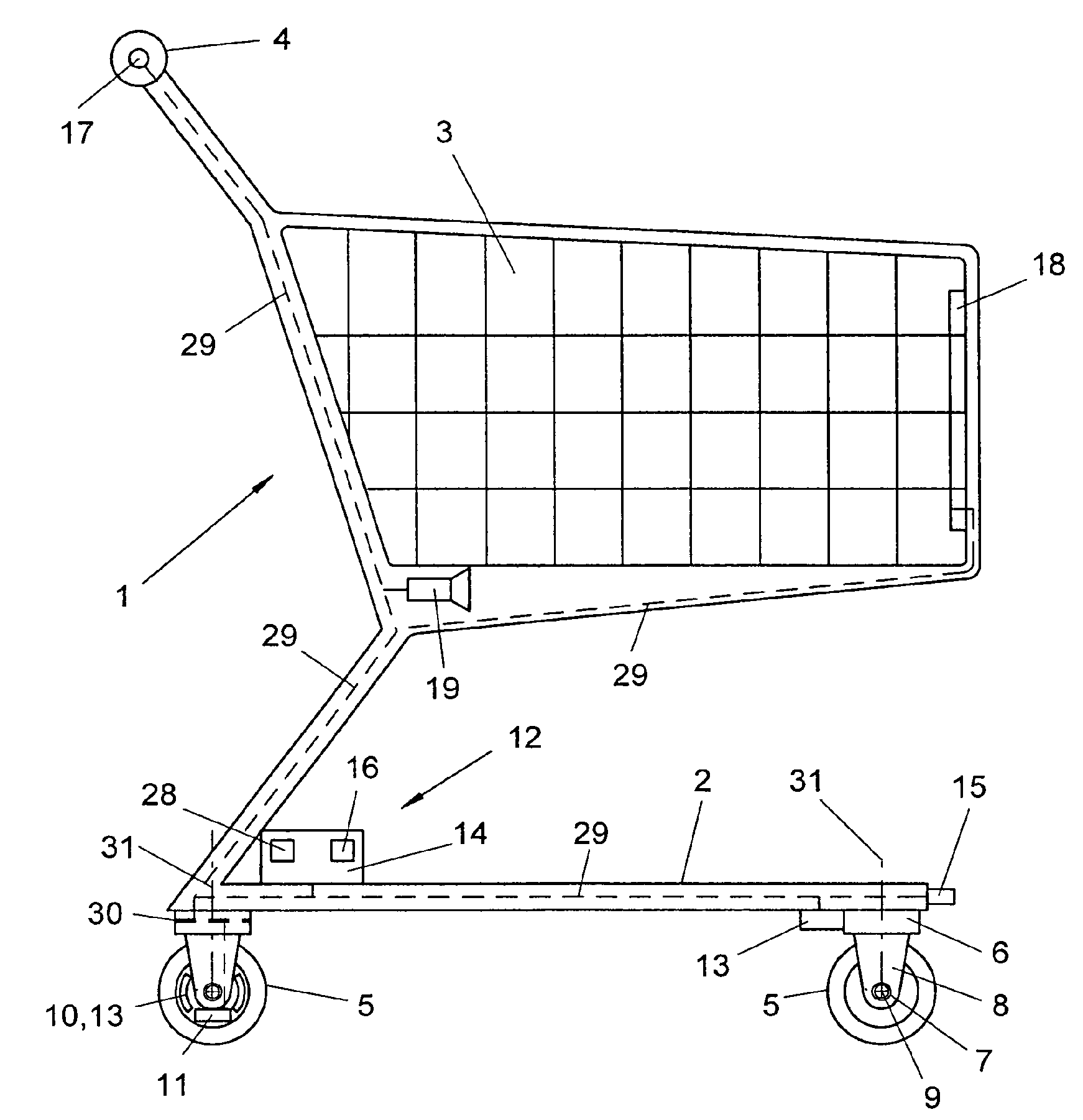

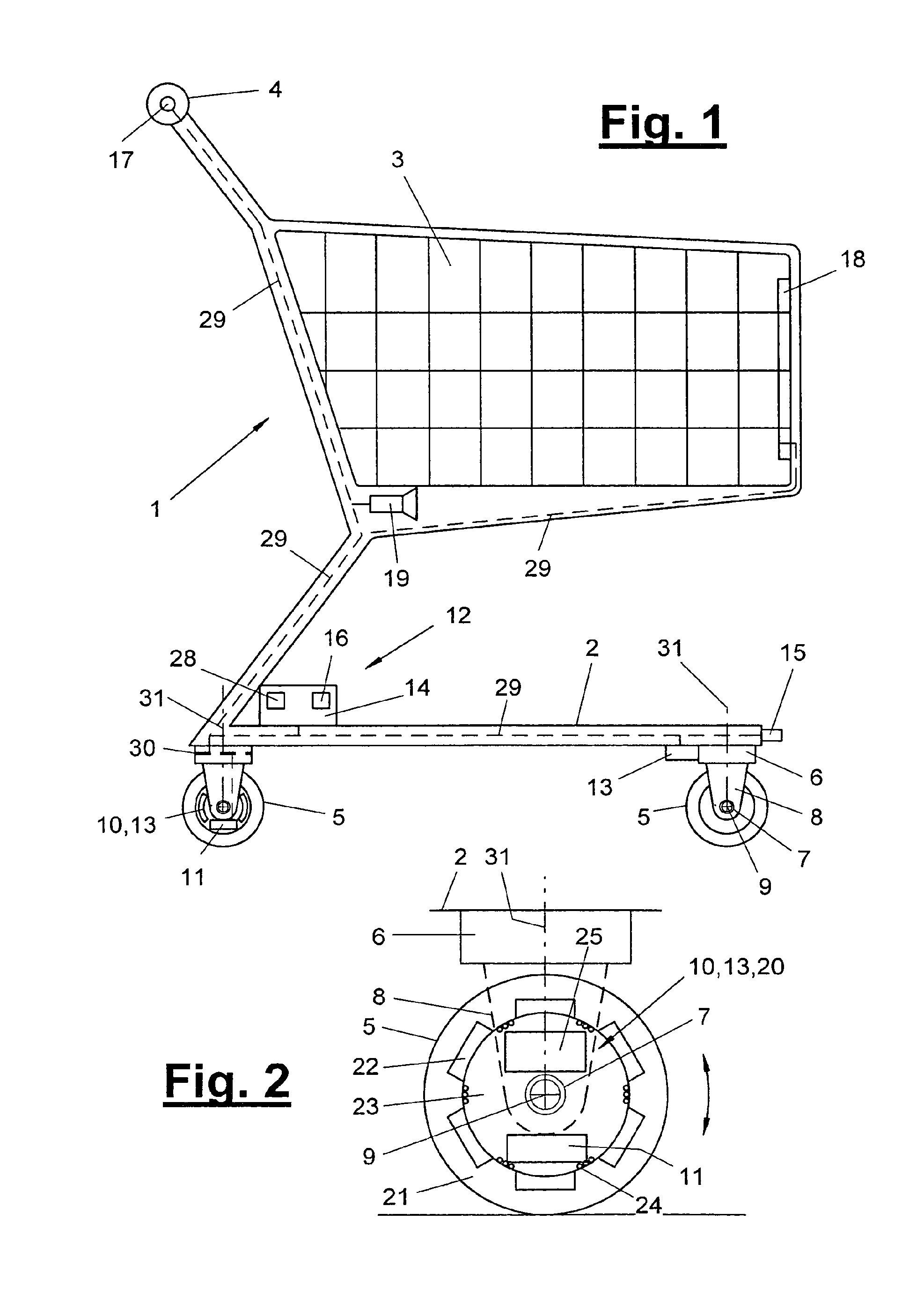

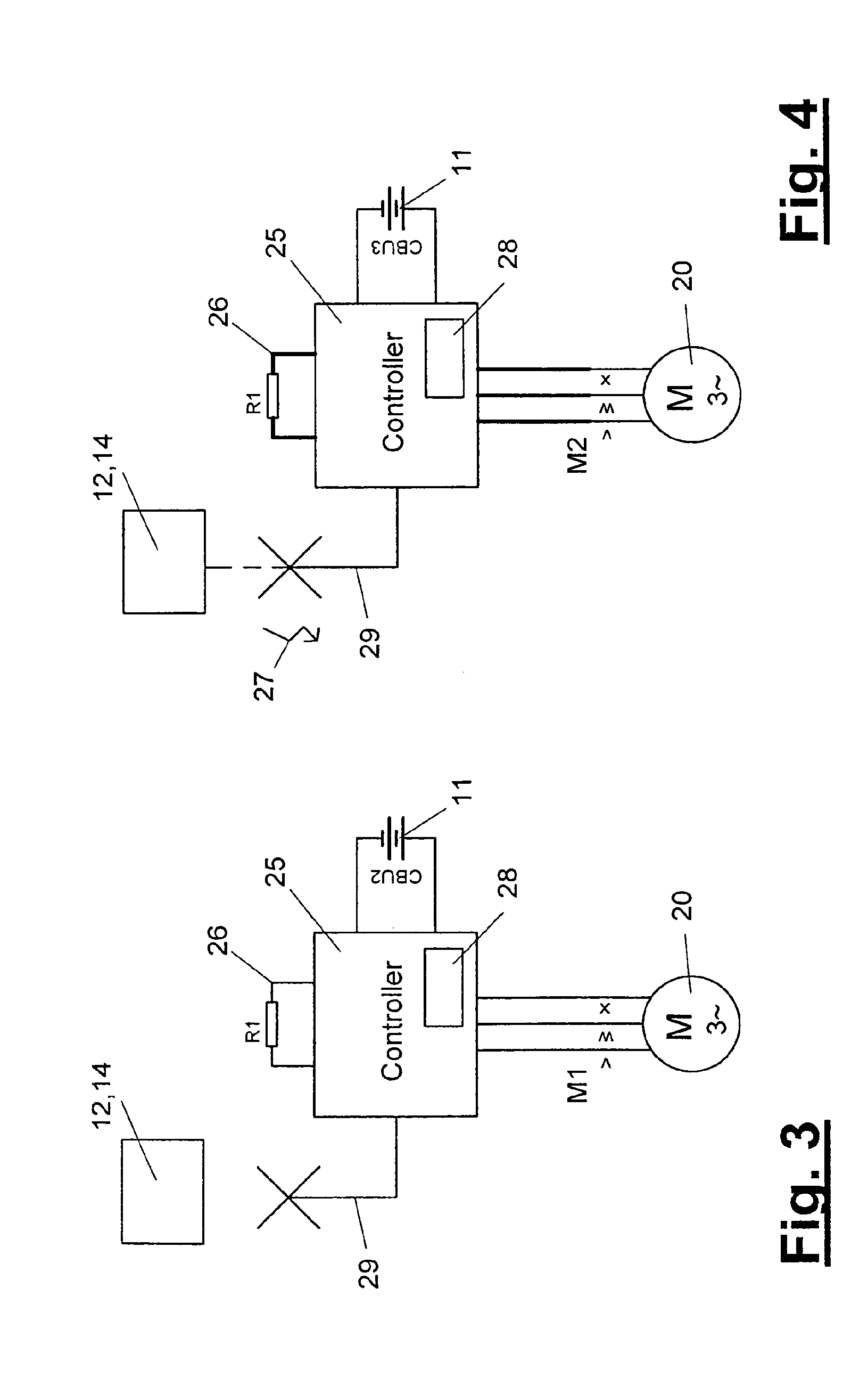

Shopping cart

InactiveUS7562729B2Easy to useOperating reliability can be highAnti-theft devicesElectric propulsion mountingRechargeable cellEngineering

Owner:WANZL METALLWARENFAB

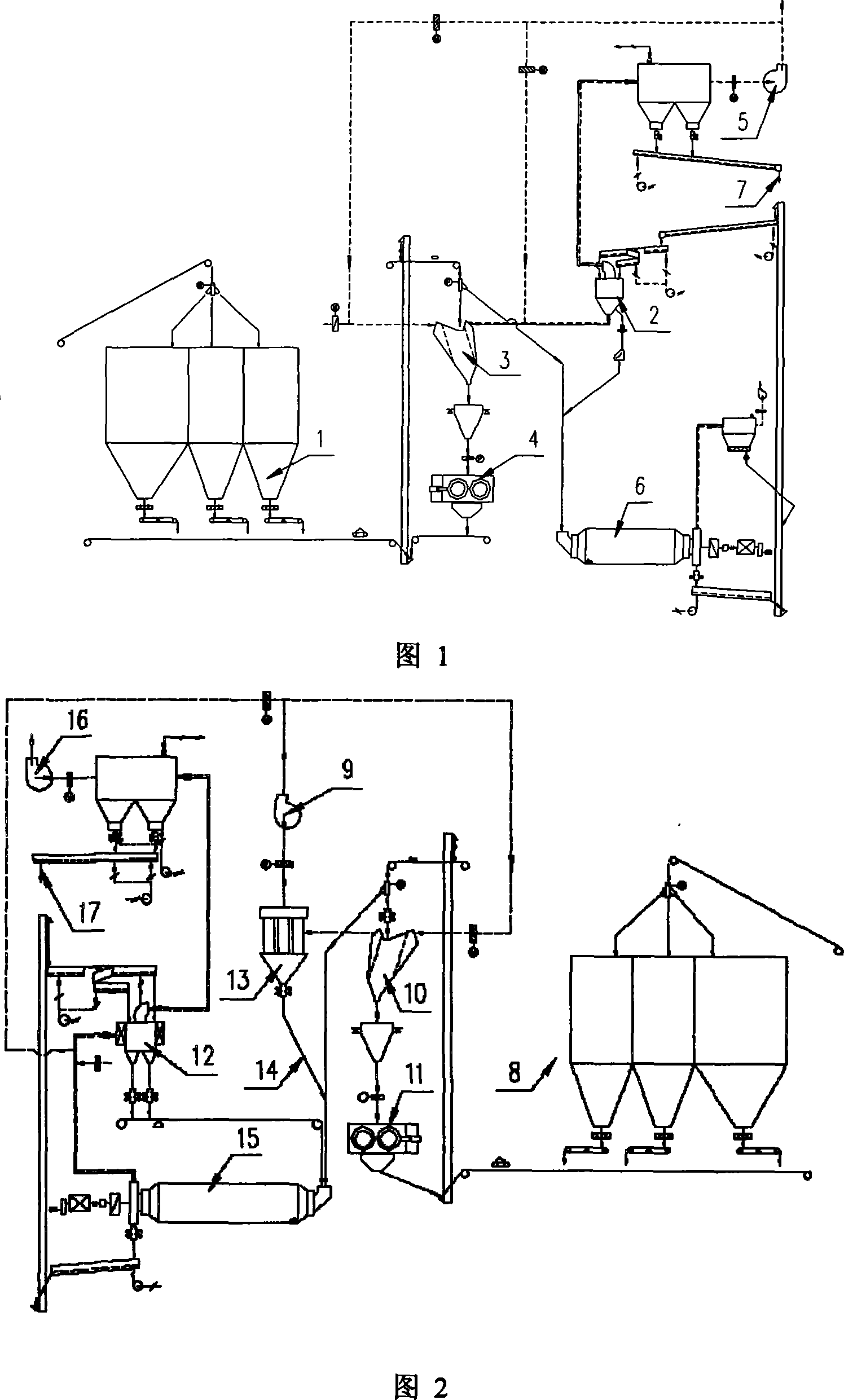

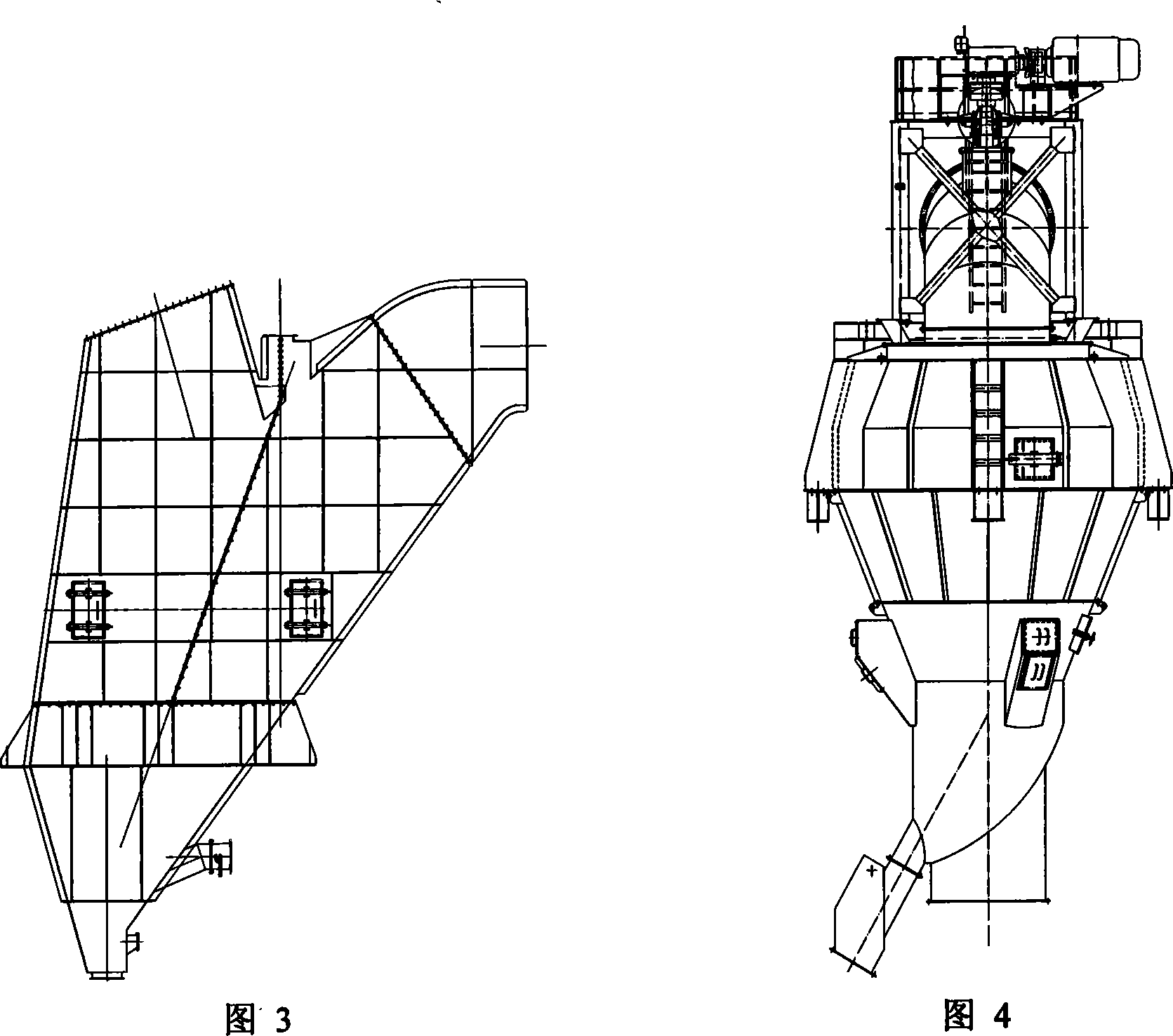

Roller press combination grinding device

ActiveCN101134175AEliminate wear and tearAdapt to the requirements of different statesGrain treatmentsMetallic materialsOperation mode

The present invention relates to one kind of combined rolling press grinding apparatus, and belongs to the field of inorganic non-metal material grinding technology. The combined rolling press grinding apparatus includes one dispensing mechanism, one lifting and conveying mechanism, one rolling press, one ball mill, one powder concentrator, one dust collector and one fan. The present invention has the advantages of low milling loss, simple structure, several operation mode, high grinding efficiency, low power consumption, etc.

Owner:天津椿本输送机械有限公司 +1

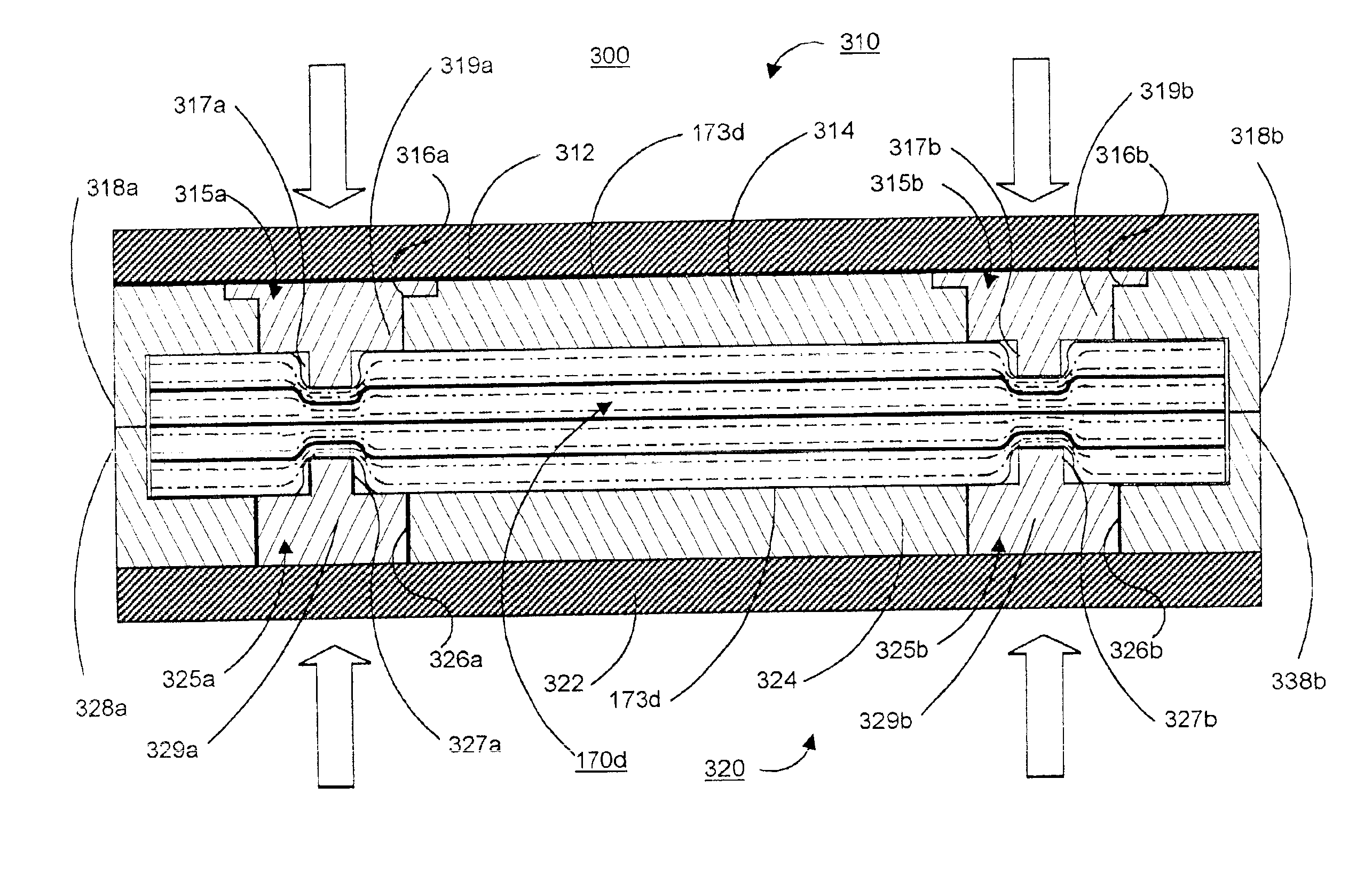

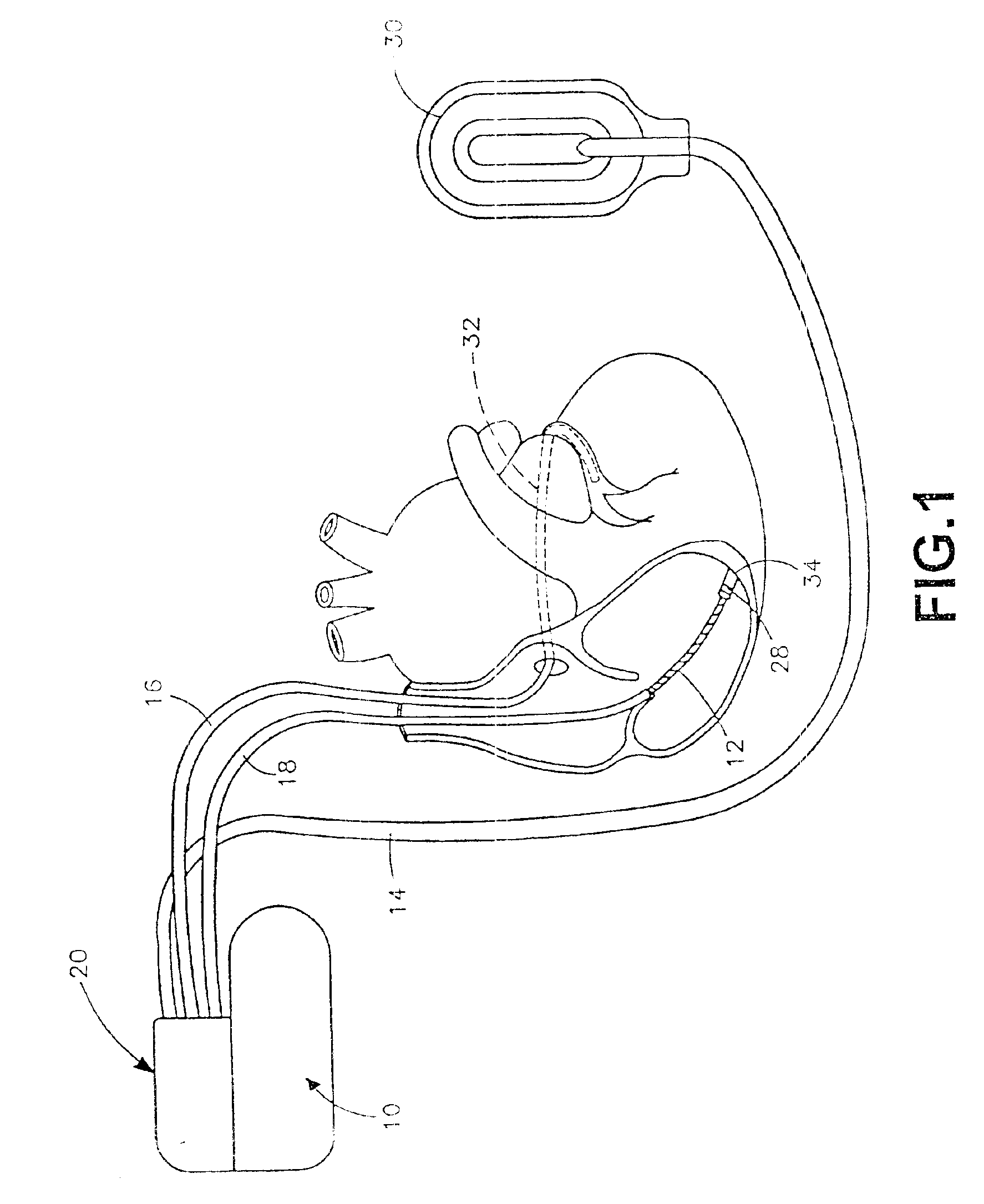

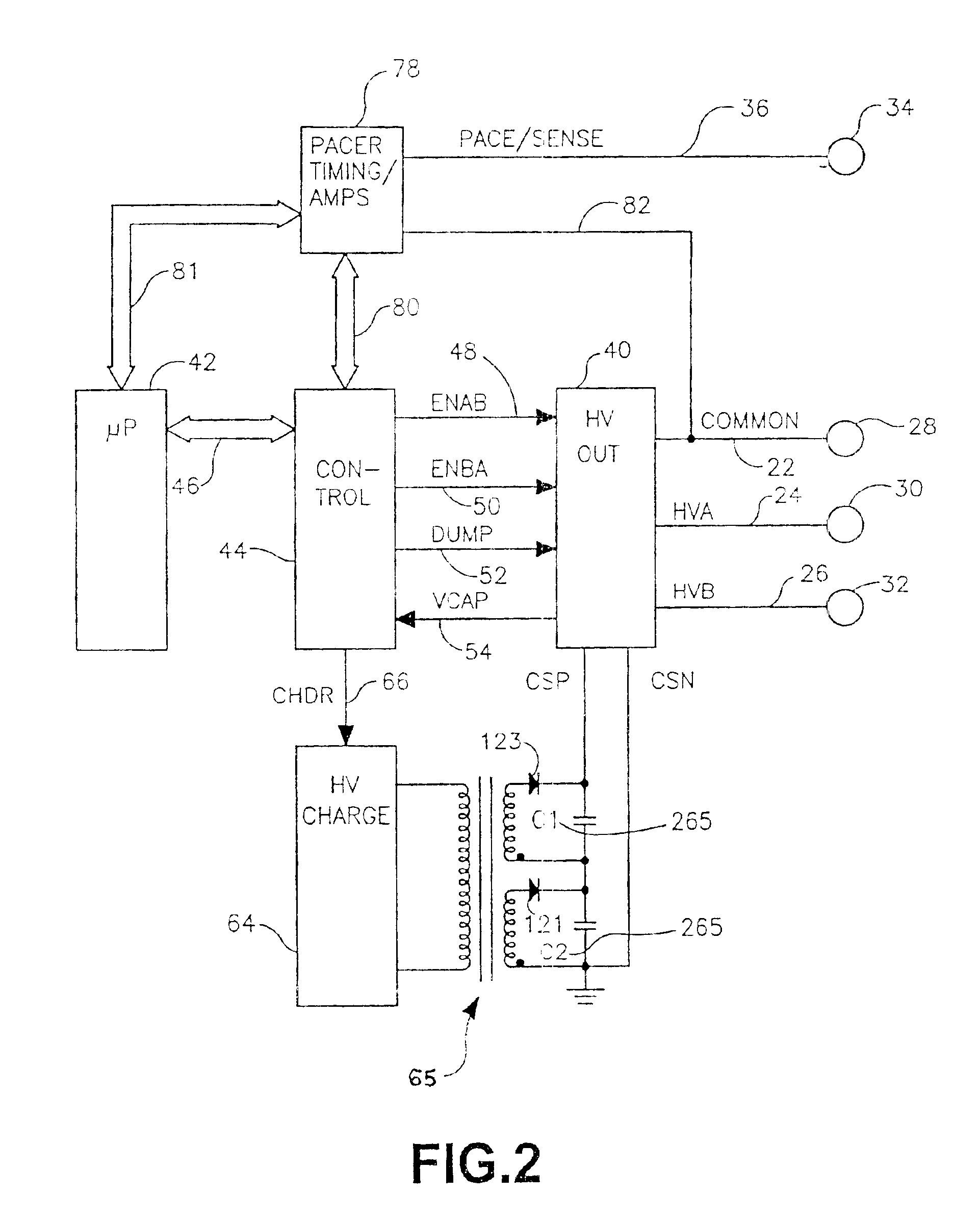

Methods of fabricating anode layers of flat electrolytic capacitors

InactiveUS6885548B2Minimizing damageArea maximizationLiquid electrolytic capacitorsHeart defibrillatorsElectricityOxide

Implantable medical devices (IMDS) and their various components, including flat electrolytic capacitors for same, and methods of making and using same, particularly an improved electrolytic capacitor. Methods and apparatus for securely mechanically and electrically attaching anode sheets of multi-sheet anode layers of electrolytic capacitors together in a simple manner that does not without unduly damage adjacent or exposed oxide layers are disclosed. The side-by-side stacked multiple anode sheets of a multi-sheet anode layer are joined together by precision cold welding the anode sheets together wherein deformation of the anode sheets is effected by simultaneously driving one or more set of first and second axially aligned cold weld pins into respective first and second stack sides of the stacked anode sheets to substantially equal cold weld depths.

Owner:MEDTRONIC INC

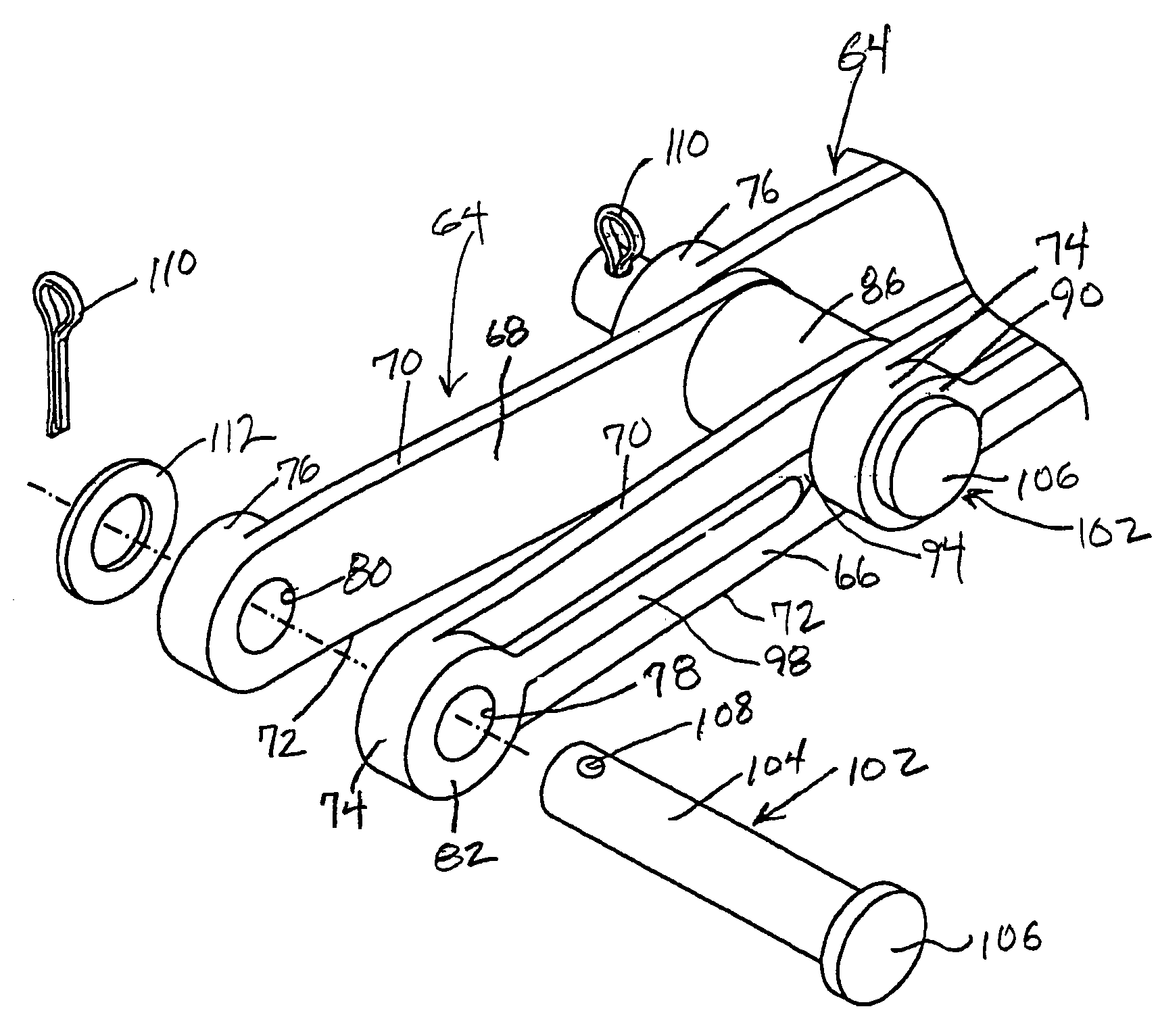

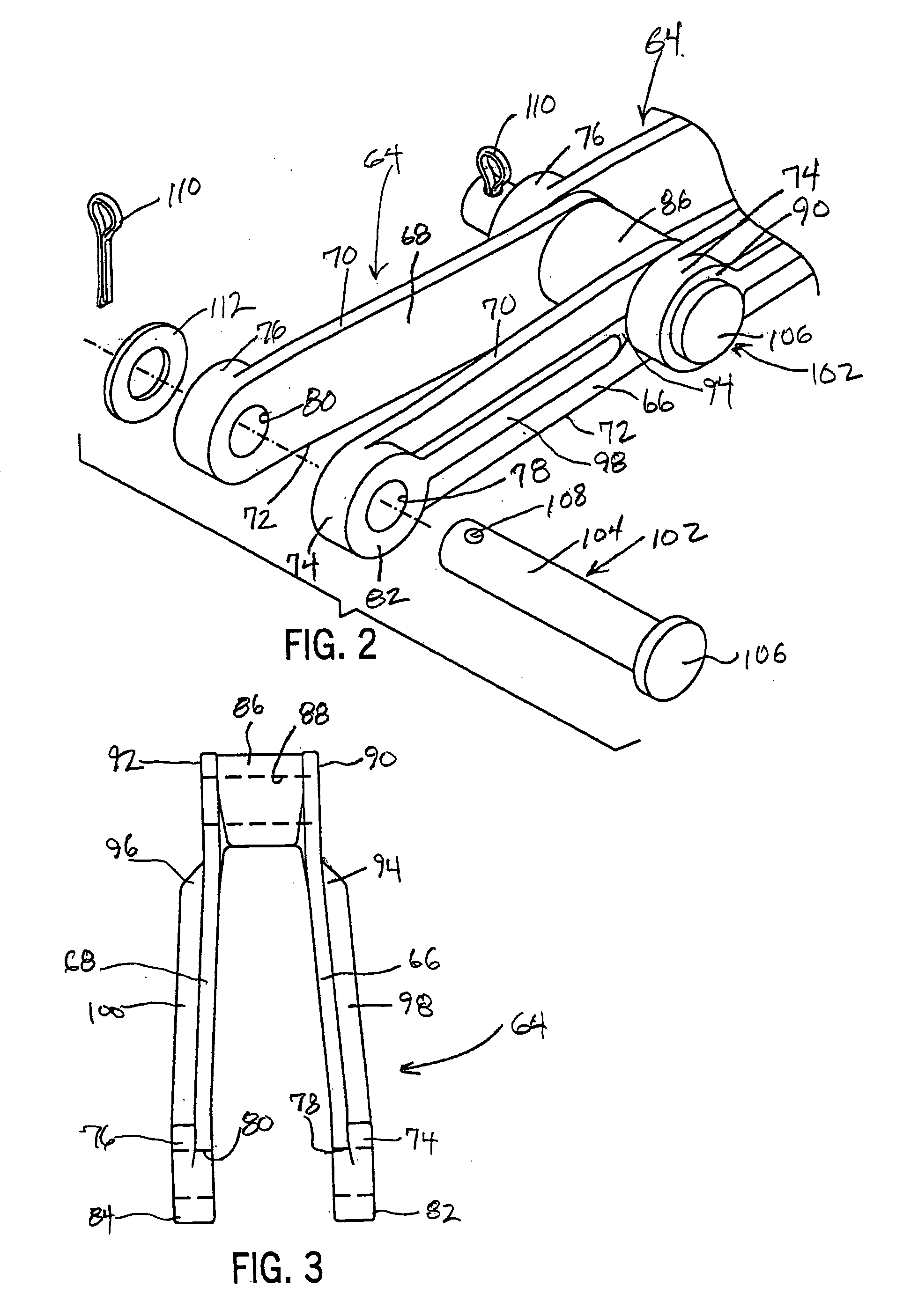

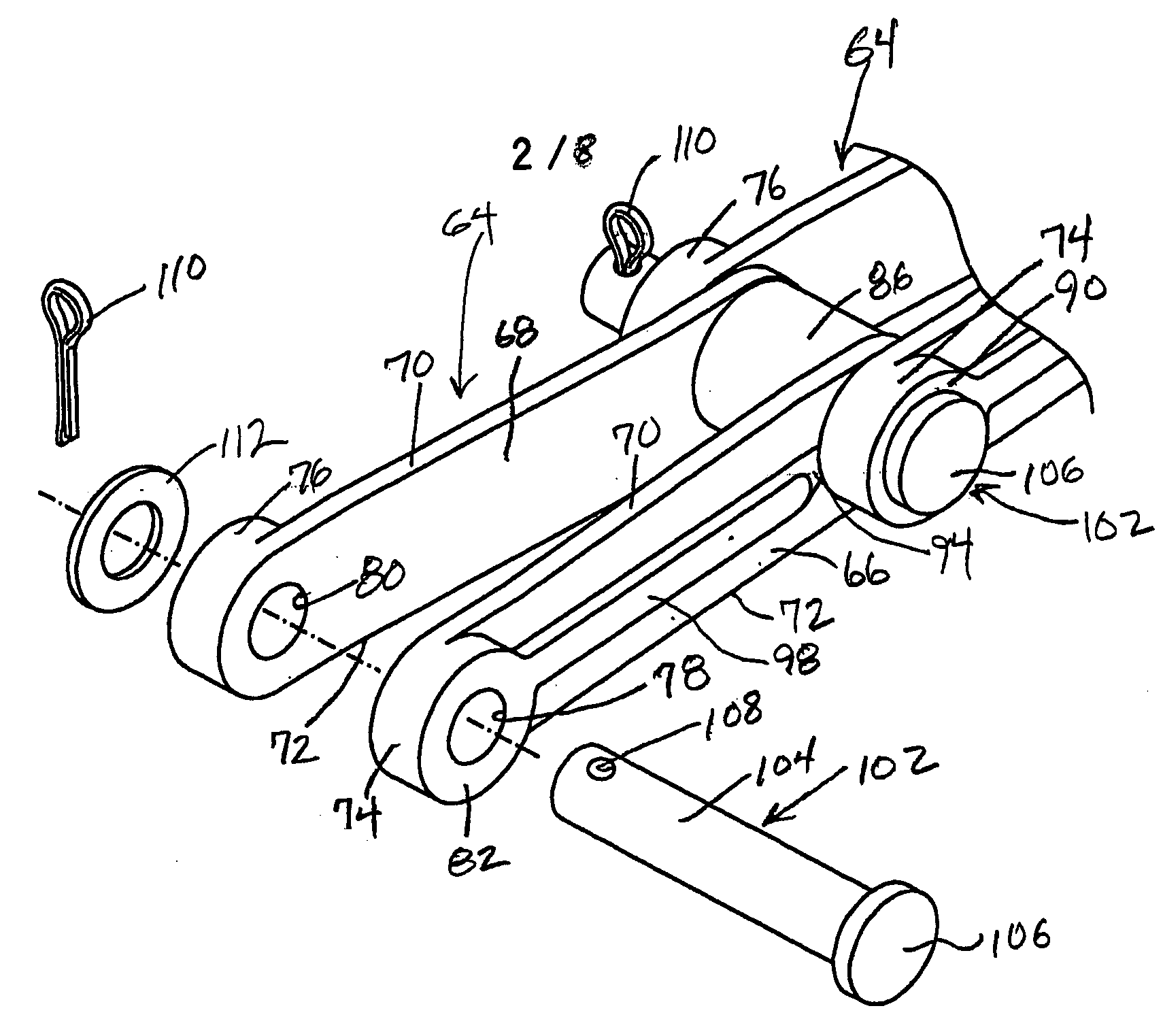

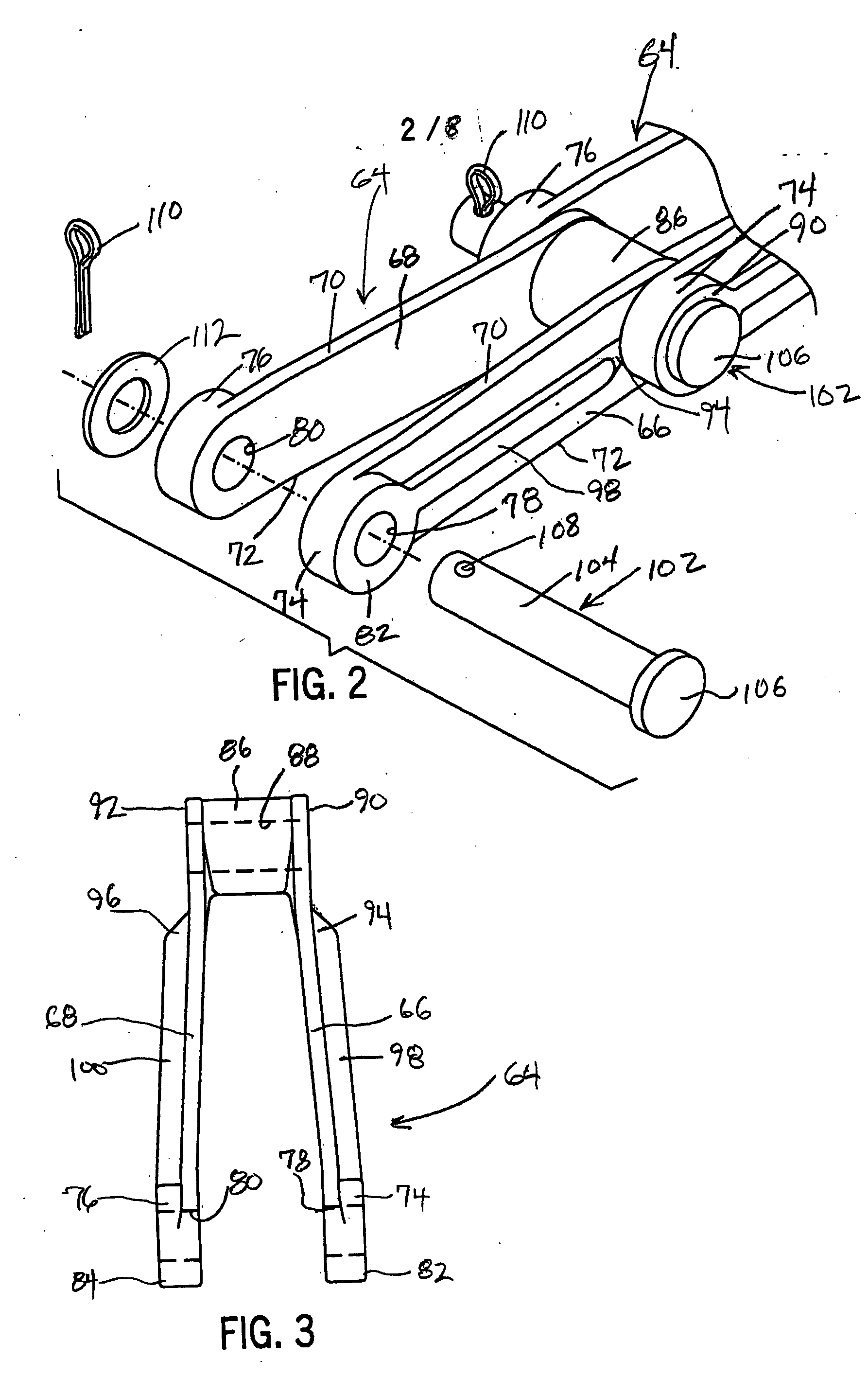

Investment cast, stainless steel chain link and casting process therefor

ActiveUS20070107412A1Reduce tensionEliminate wear and tearFoundry mouldsSedimentation separationFree rotationInvestment casting

An investment cast, stainless steel chain link is provided for chains used in water and wastewater treatment. The chain link comprises a pair of spaced apart, elongated sidebars having forward ends and rearward ends. The forward ends are spread apart and are provided with outwardly and laterally extending bosses having transverse boss pin bores coaxially aligned with each other. The rearward ends are interconnected by a cylindrical barrel having a barrel pin bore extending through each of the sidebars. The sidebars are formed with outwardly and laterally projecting reinforcing ribs extending between the bosses and the barrel pin bore along a substantial length of the sidebars. A freely rotatable chain pin is inserted through aligned boss and barrel pin bores from either end thereof for interconnecting first and second pairs of sidebars. An arrangement is provided for preventing the lateral dislodgement of the chain pin from the sidebars.

Owner:HUMCKE MICHAEL W +1

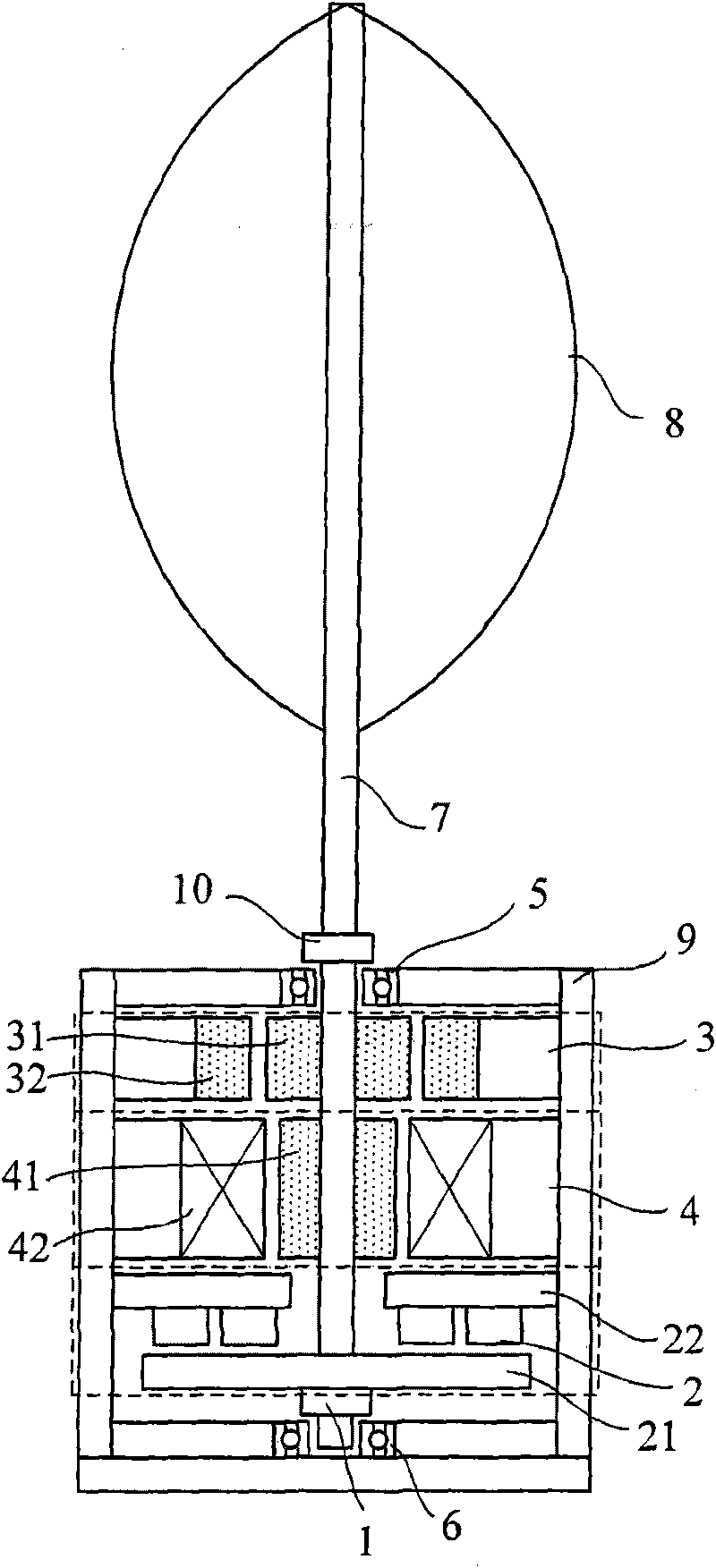

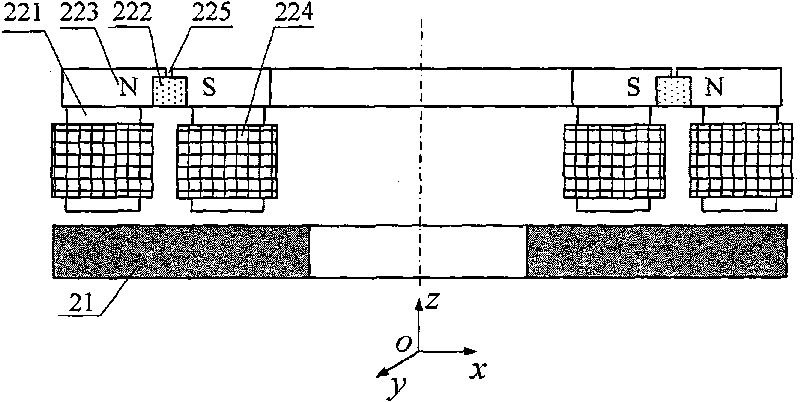

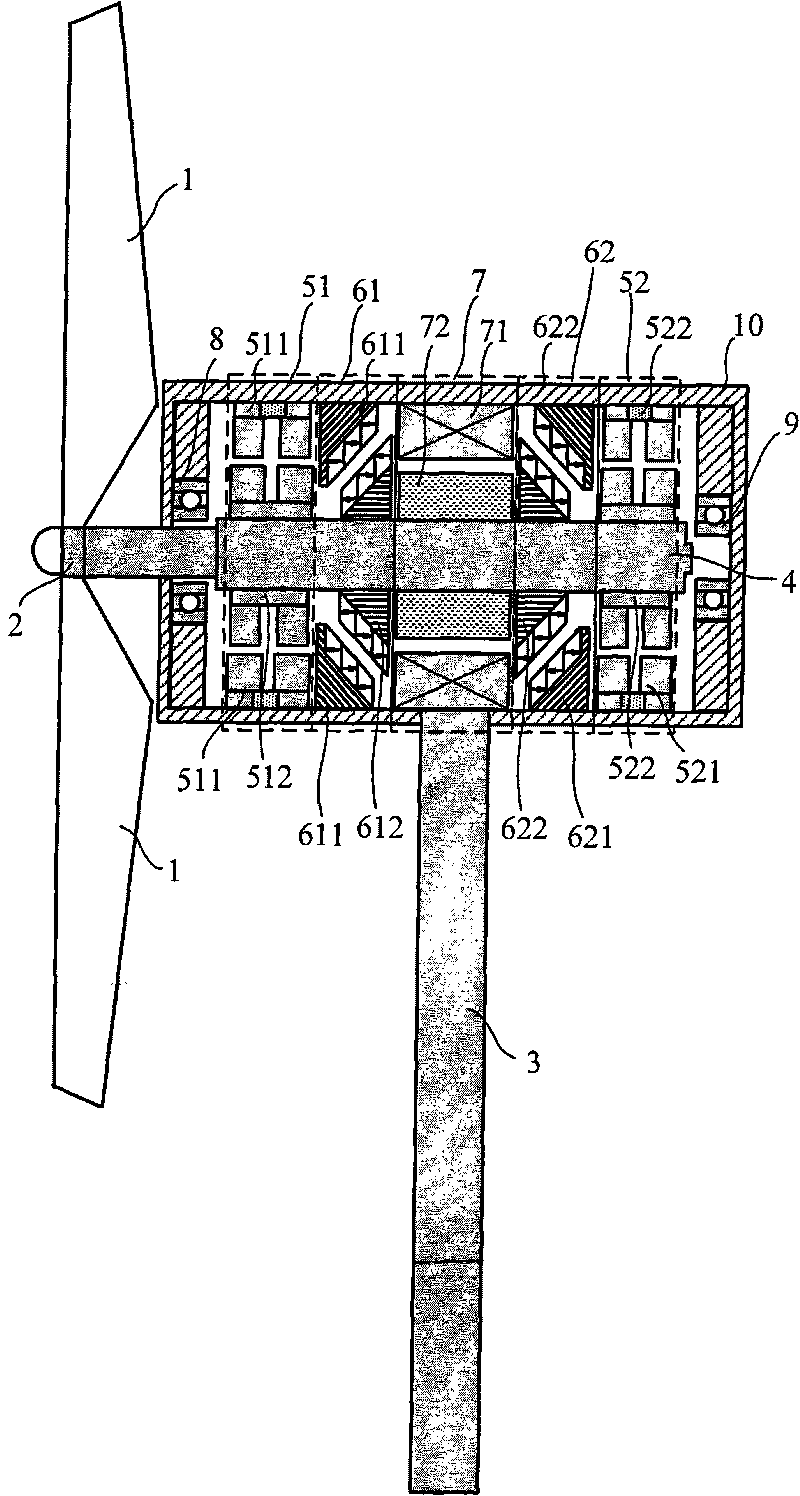

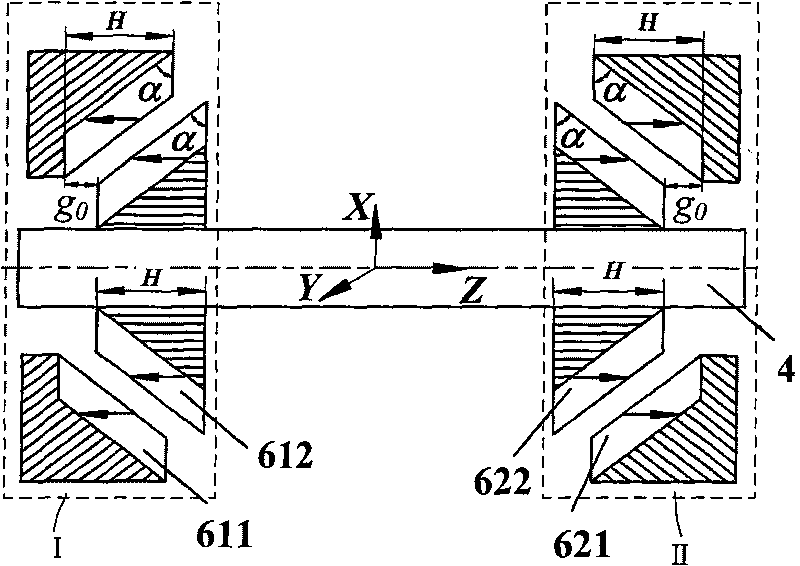

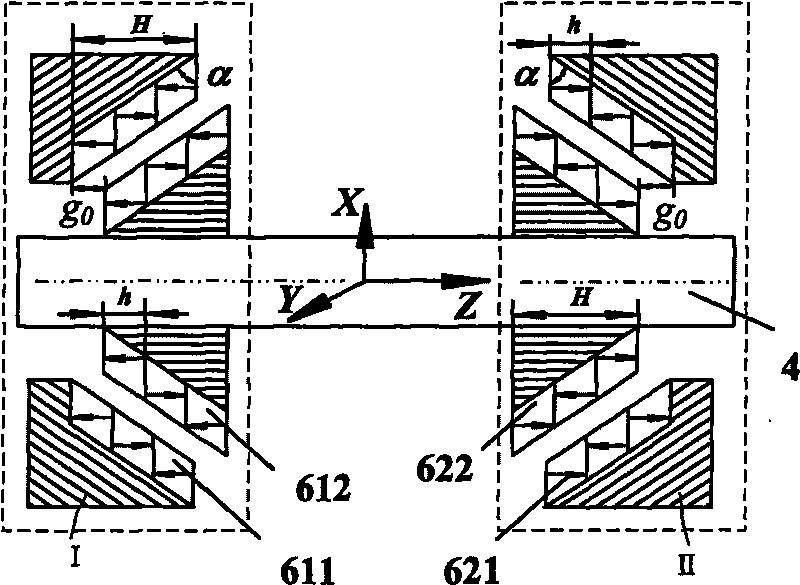

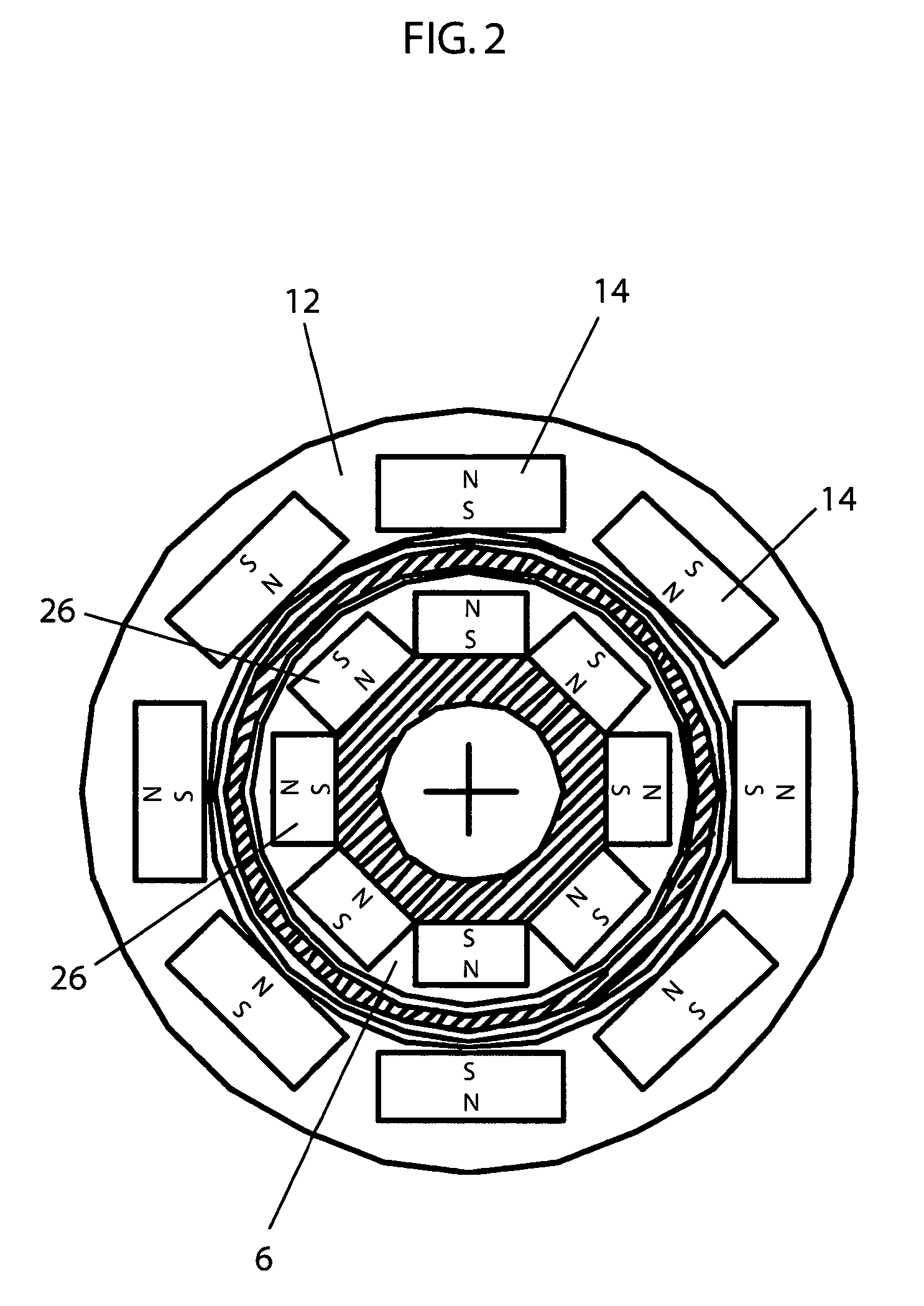

Vertical shaft maglev wind power generator

ActiveCN101761454ALow start wind speedExtend working hoursShaftsMachines/enginesMagnetic bearingMagnetic poles

A vertical shaft maglev wind power generator is composed of vanes, a rotary shaft, a power generator, a radial magnetic bearing, an axial TDOF magnetic bearing, an upper protection bearing, a lower protection bearing, an upper protection bearing retainer ring and a lower protection bearing retainer ring; the rotational part and the stationary part of the fan are not in mechanical contact, the mechanical friction in the fan is completely eliminated and the FDOF levitation of the fan rotor is realized. The axial magnetic bearing of the fan supplies gravity offset through 4 stator magnetic poles and the effect of a suction disc and performs axial translation and two radial rotational DOF control on the rotor; and the radial magnetic bearing finishes the two radial translation control of the fan rotor. The invention has reasonable layout of the components, completely eliminates the friction problem of the vertical shaft fan bearing, greatly reduces the starting wind speed of the wind power generator and improves the wind energy utilization rate.

Owner:BEIHANG UNIV

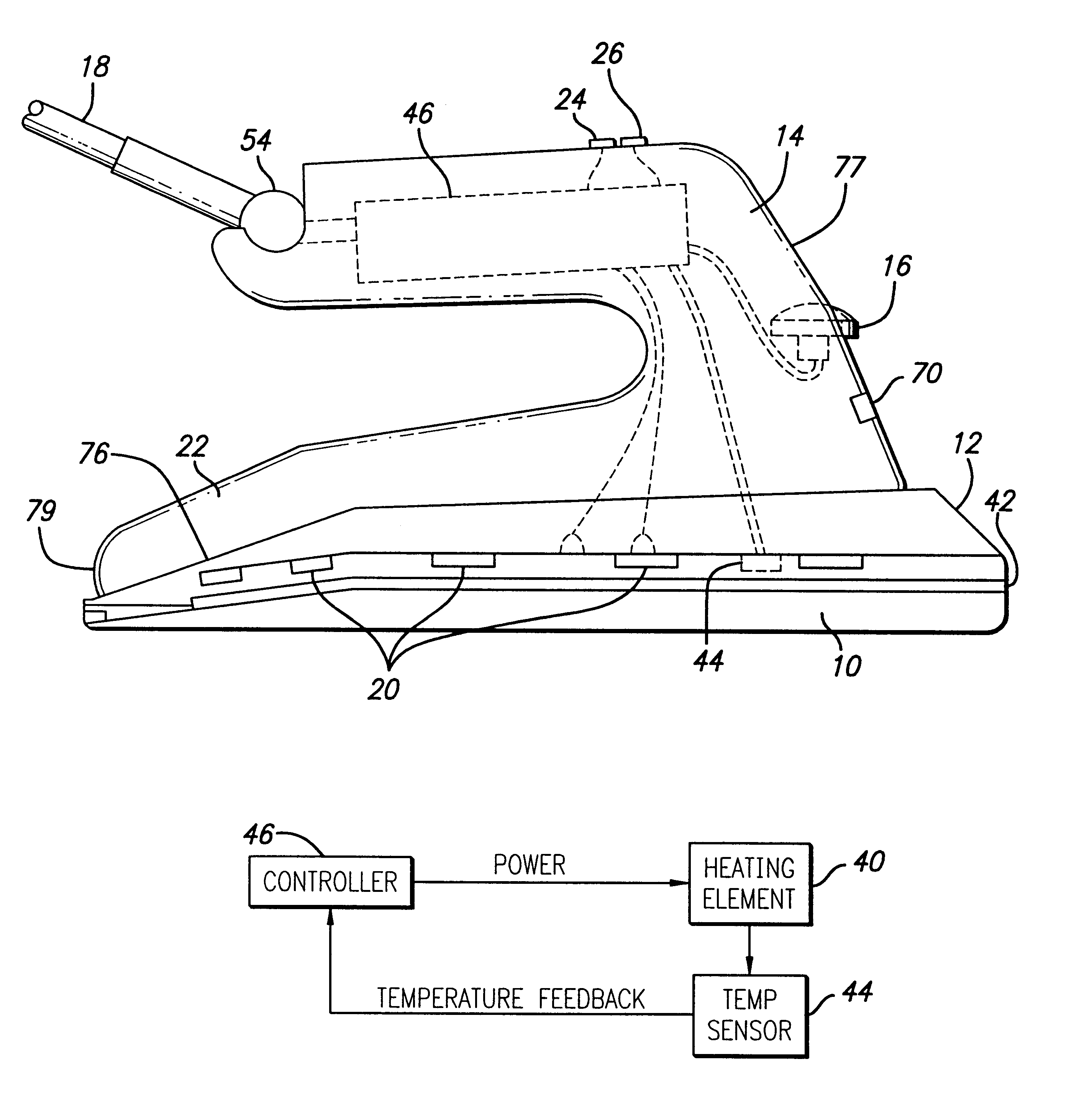

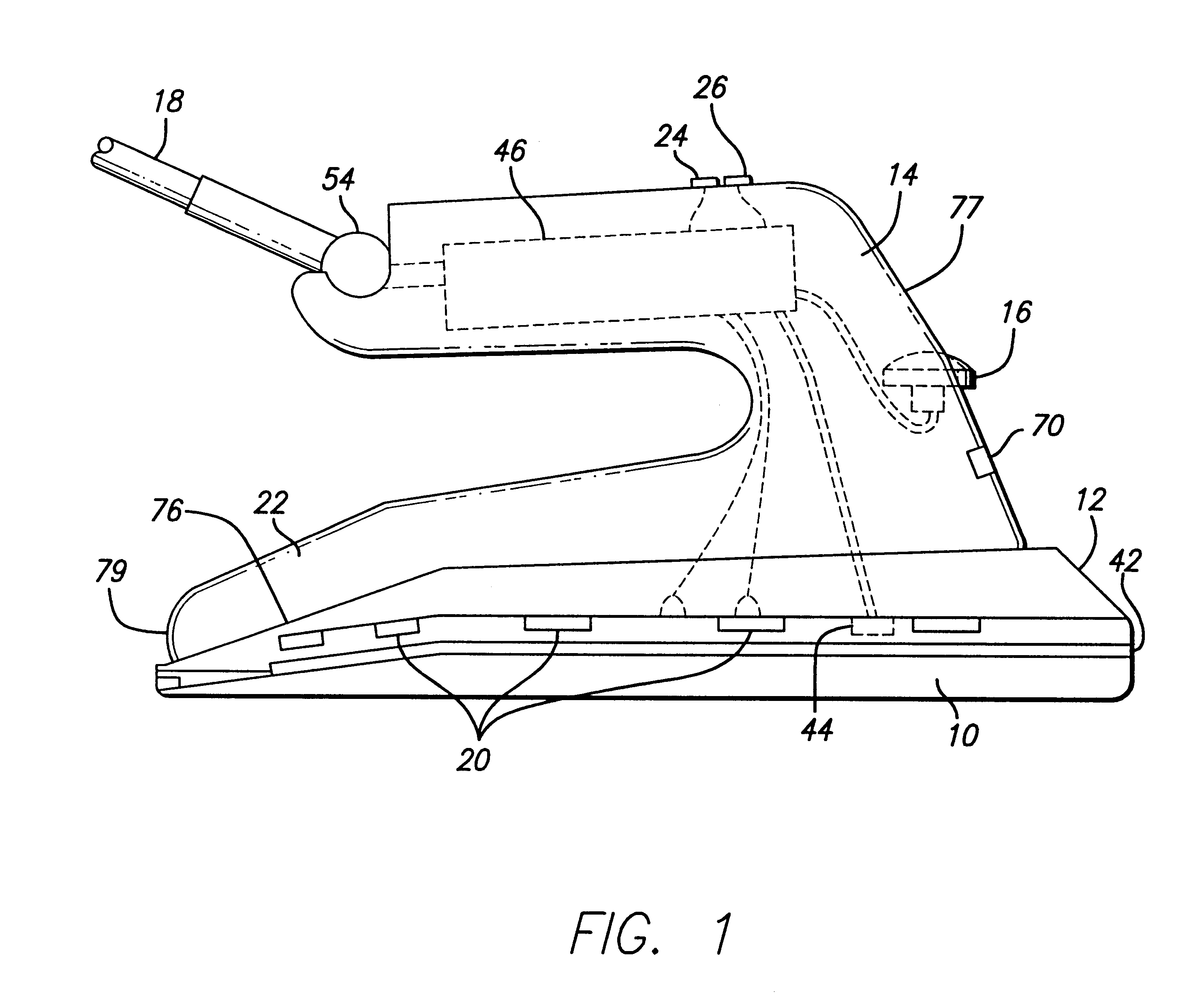

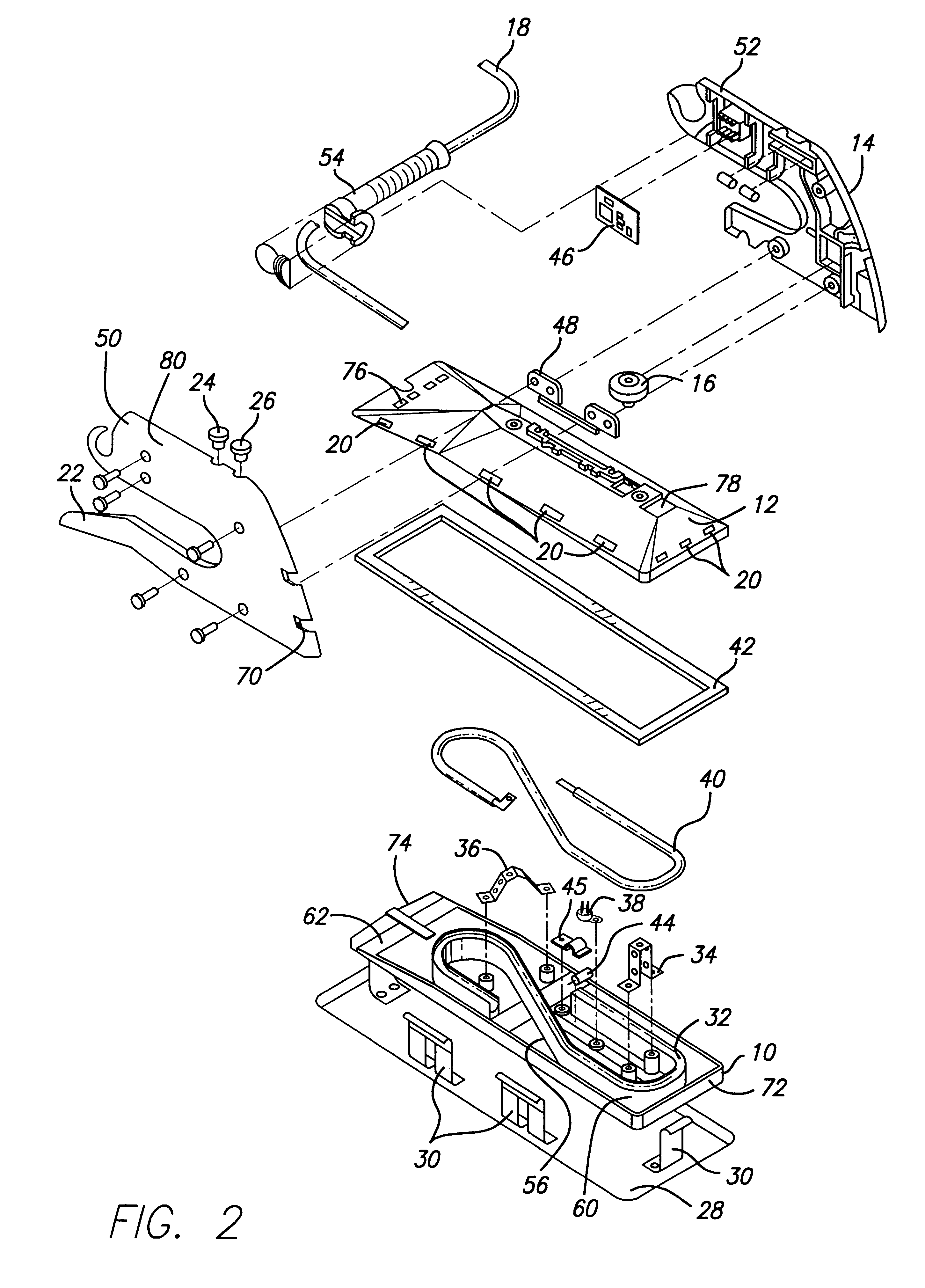

Carpet seaming iron with electronic temperature control

InactiveUS6172335B1Quick to useHeating fastLaminationLamination apparatusPower controllerTemperature control

A carpet seaming iron having an internal electronic temperature control circuit including a solid state temperature sensor, a power controller, and a solid state switching device is disclosed. The iron does not use a thermostat for temperature control. The iron includes a baseplate, an electrically powered heating element, a heat shield, a handle and the internally mounted control circuit. The control circuit includes a means for providing a signal to the power controller corresponding to a desired temperature of the iron. A solid state temperature sensor sends a signal to the power controller corresponding to the baseplate temperature. The power controller controls the switching device so that the amount of power supplied to the heating element is proportional to the difference between the baseplate temperature and the desired temperature. Thus as the baseplate becomes hotter, less power is supplied to the heating element, and the seaming iron maintains a stable and precise temperature.

Owner:GCP APPL TECH INC

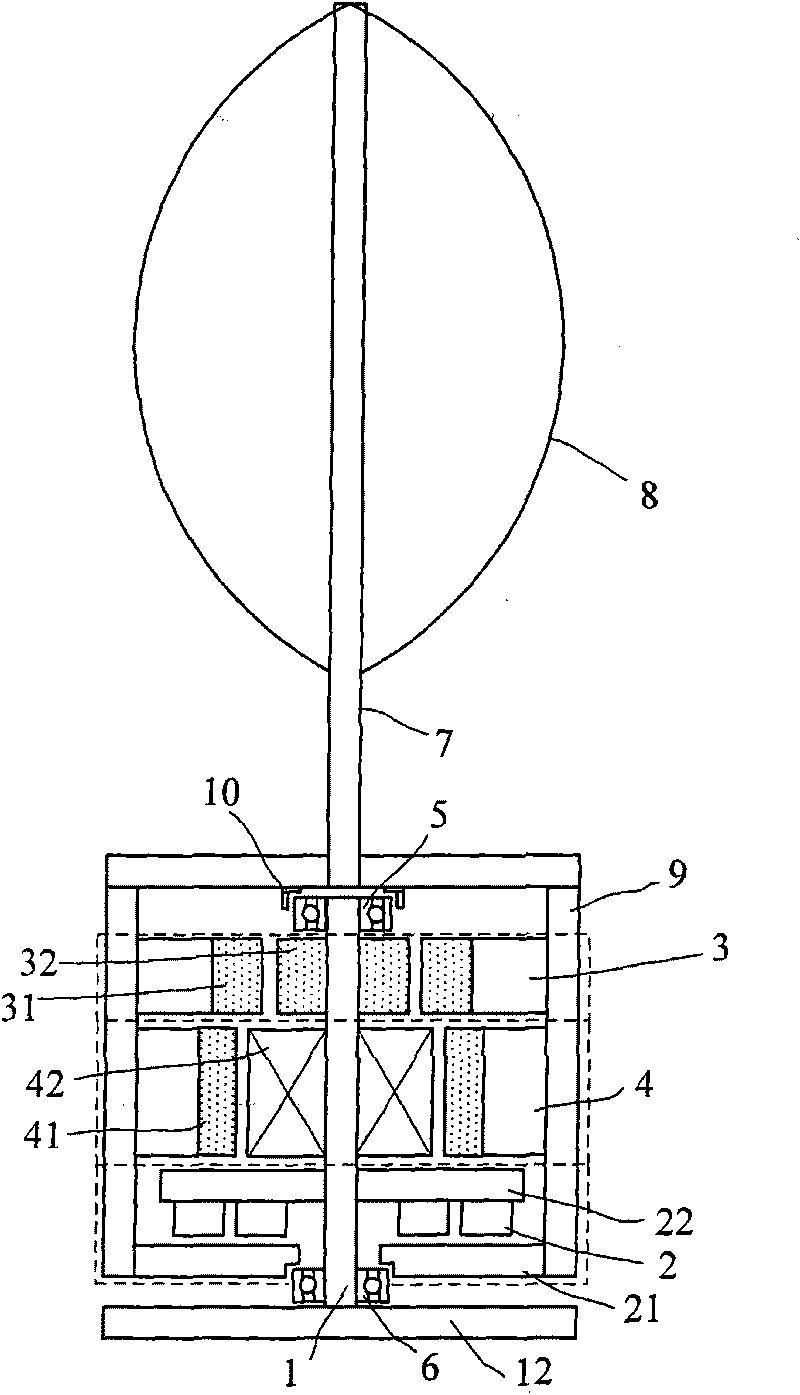

Horizontal shaft magnetic suspension wind driven generator

InactiveCN101701573ARealize full suspension operationReduce maintenanceShaftsWind motor combinationsWind drivenMagnetic bearing

The invention relates to a horizontal shaft magnetic suspension wind driven generator, comprising a stationery part and a rotating part; the stationery part comprises a radial magnetic bearing stator part, an axial magnetic bearing stator part, a generator stator part, a front protective bearing, a rear protective bearing, a stator shell and a blower tower; the rotating part comprises a blade, a hub, a rotating shaft, a radial magnetic bearing rotor part, an axial magnetic bearing rotor part and a generator rotor part; an axial magnetic bearing is composed of a permanent magnet without a control system, a radial magnetic bearing is a permanent magnet bias magnetic bearing, the permanent magnet provides bias flux density, and control force is adjusted by current; the blower rotor realizes five-freedom-degree stable suspension, can completely eliminate the mechanical friction of the rotating part and the stationery part, reduce starting resisting moment and starting wind velocity of the blower and improve the wind energy utilization rate. All components of the invention have rational and compact layout, the maintenance of the blower can be reduced and the service life is prolonged.

Owner:BEIHANG UNIV

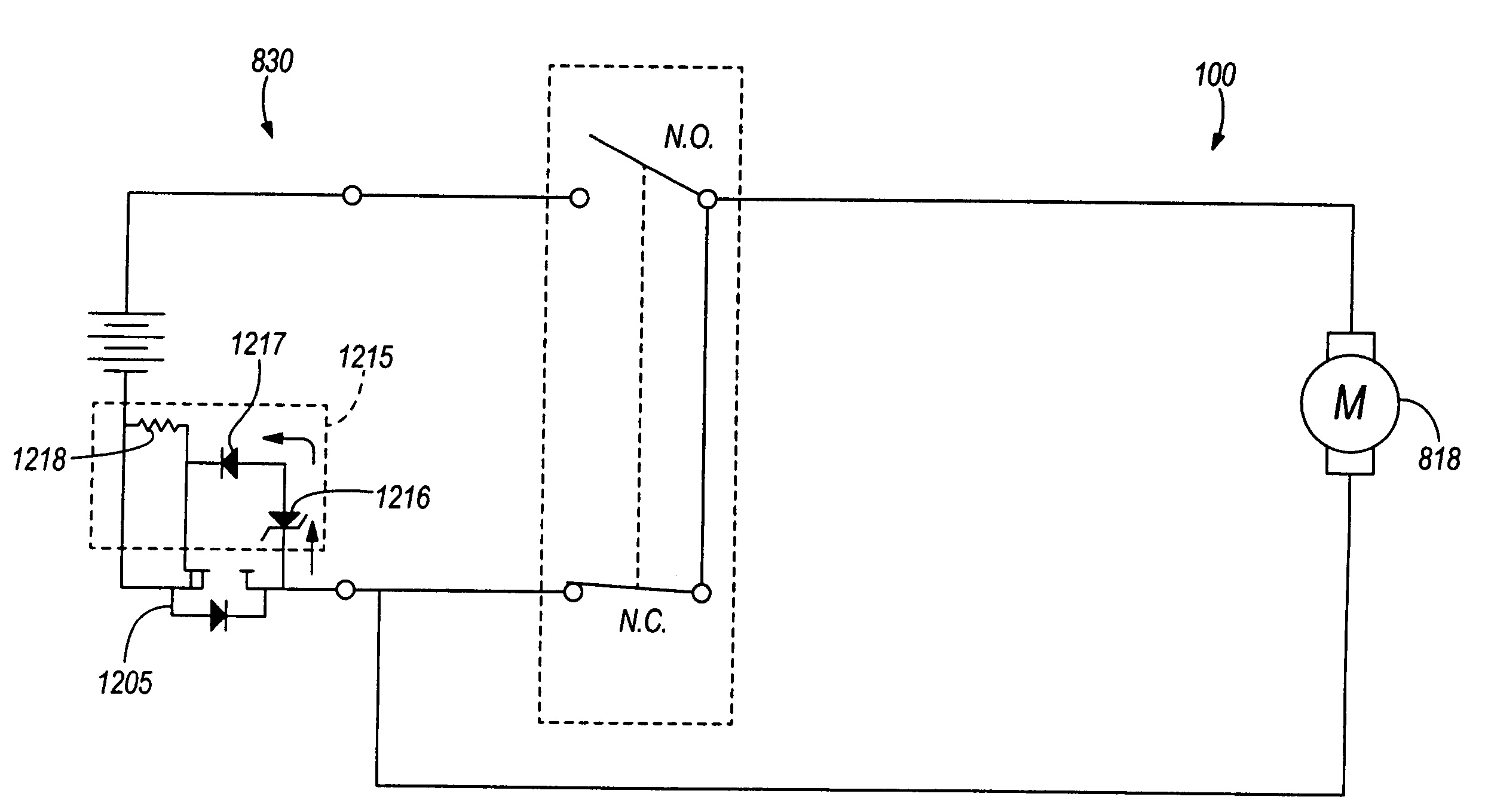

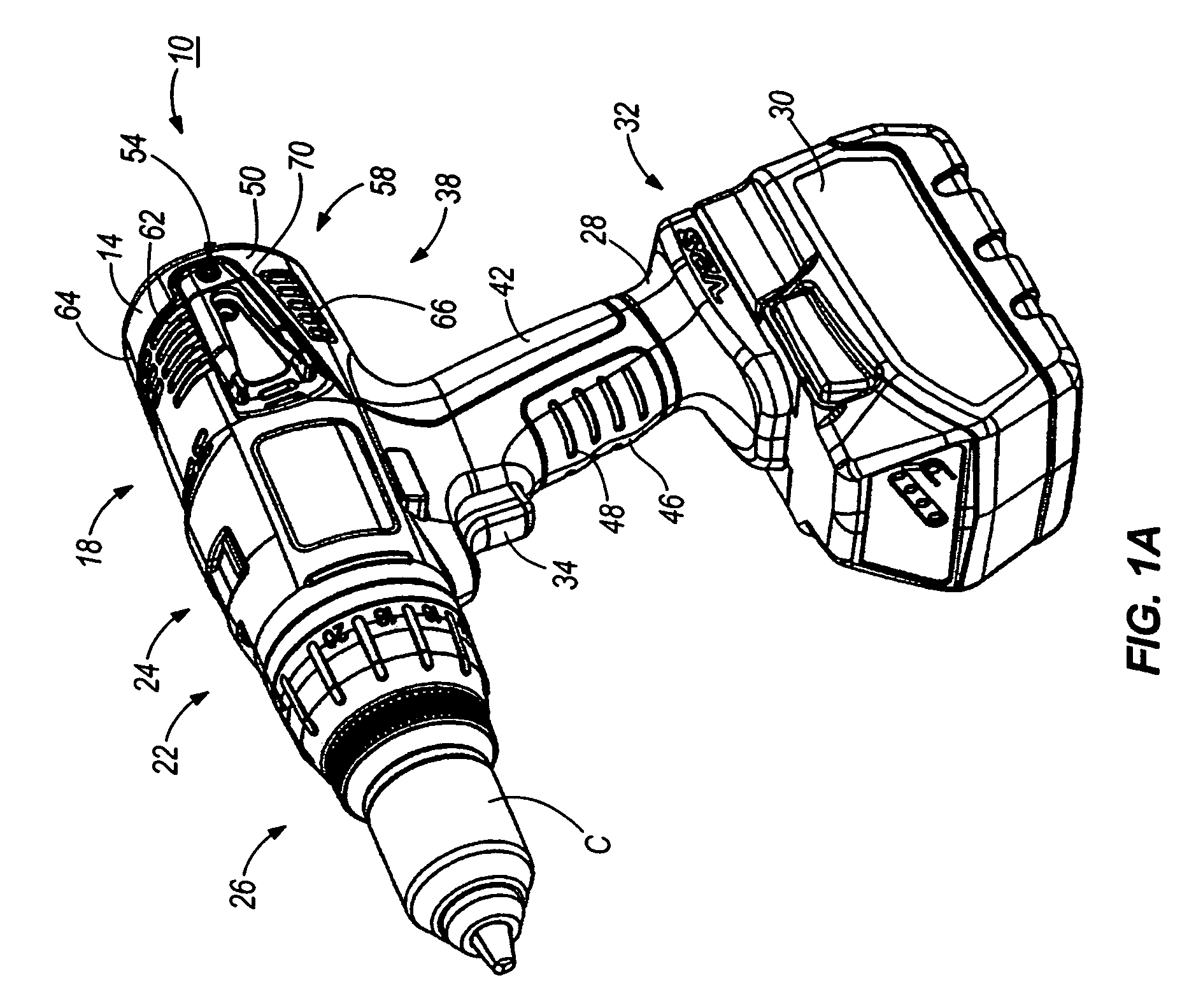

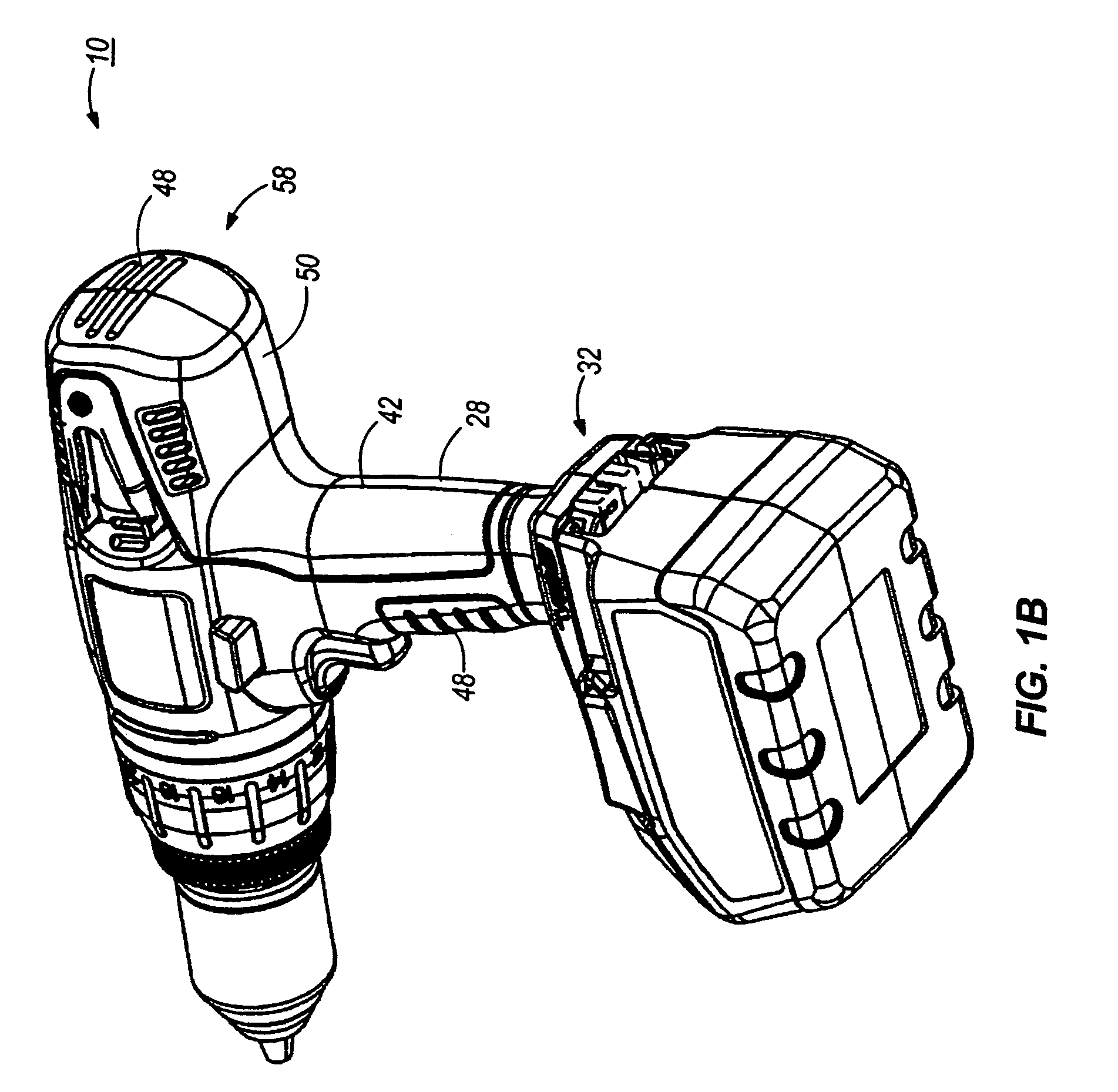

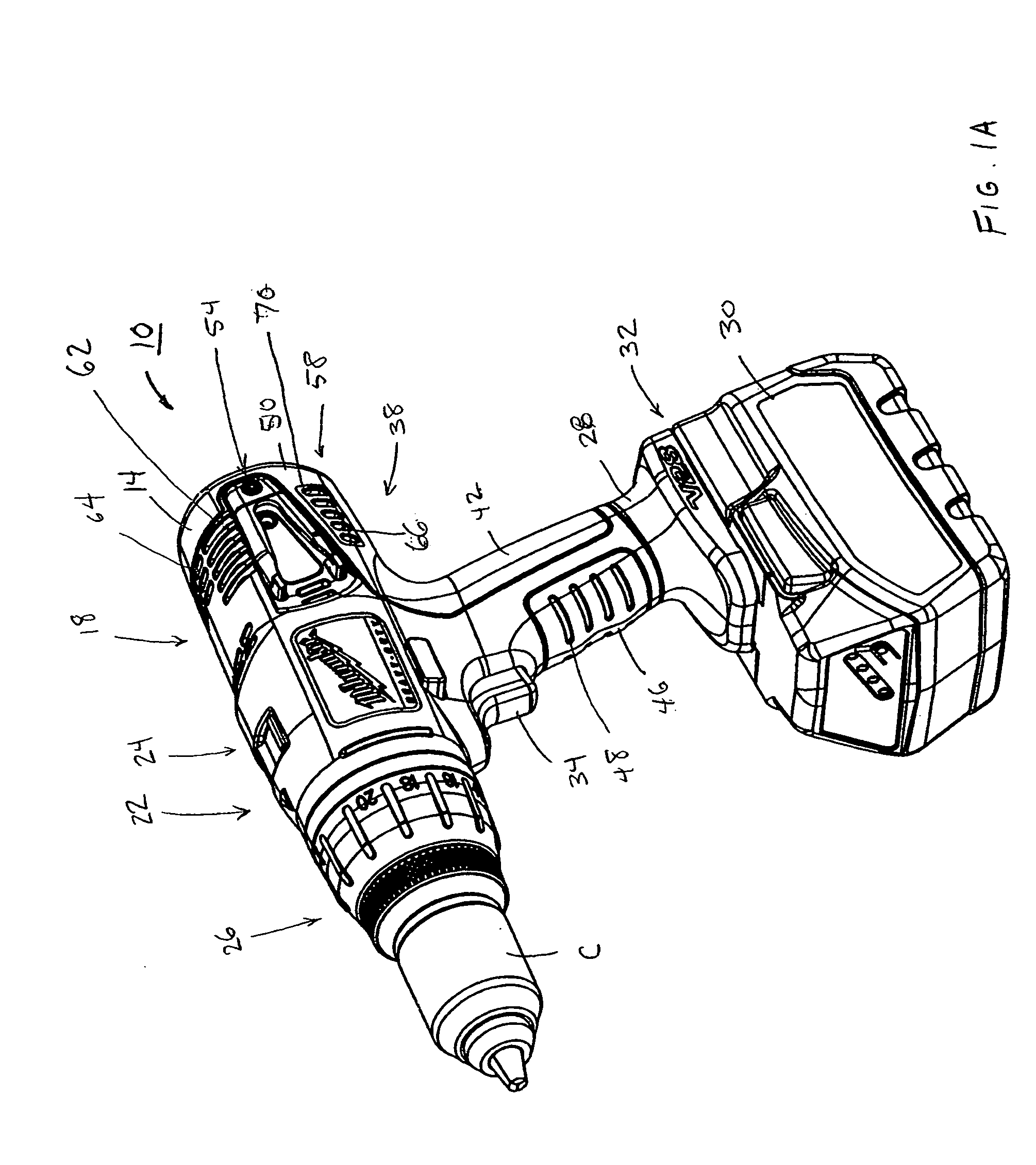

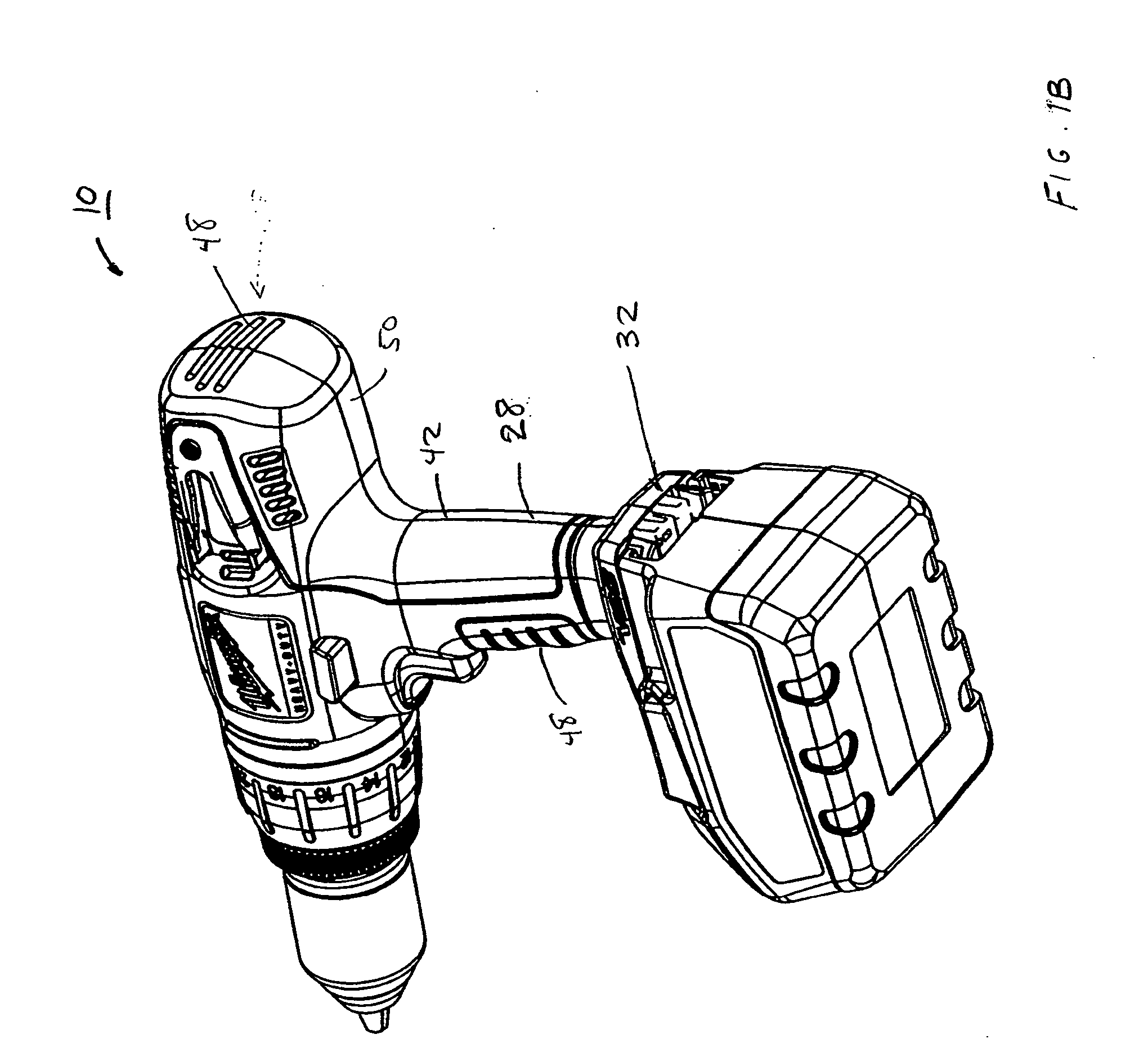

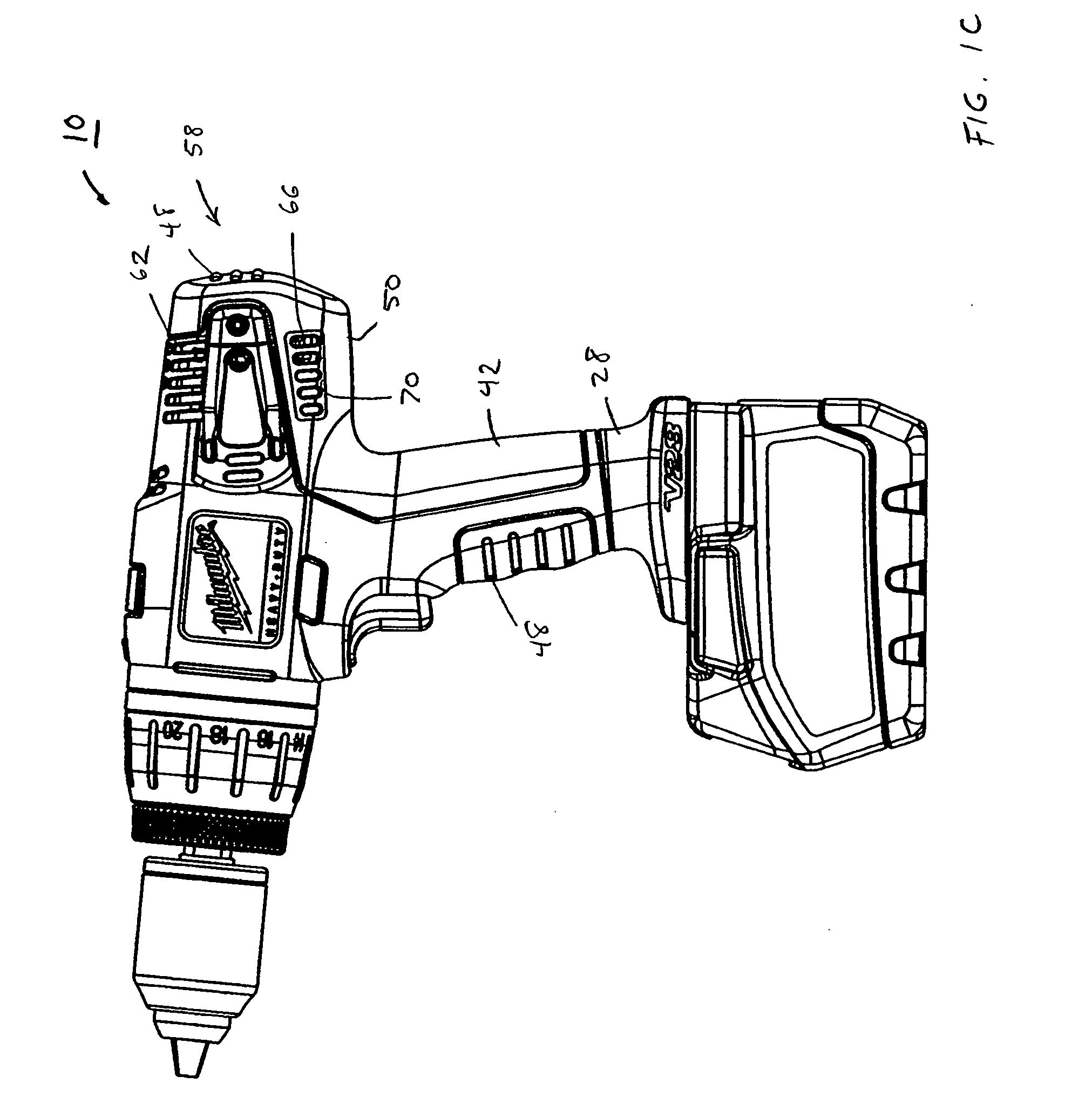

Power tools, battery chargers and batteries

ActiveUS7492125B2Eliminate wear and tearRestrict movementBatteries circuit arrangementsElectric powerEngineeringPower tool

A battery pack for powering a cordless power tool. The battery pack includes at least one battery cell operable to supply a discharge current, a switch operable to control the discharge current and a protection device to protect the switch. The protection device is positioned such that the device absorbs a current traveling in a direction opposite to that of the discharge current supplied from the battery cell.

Owner:MILWAUKEE ELECTRIC TOOL CORP

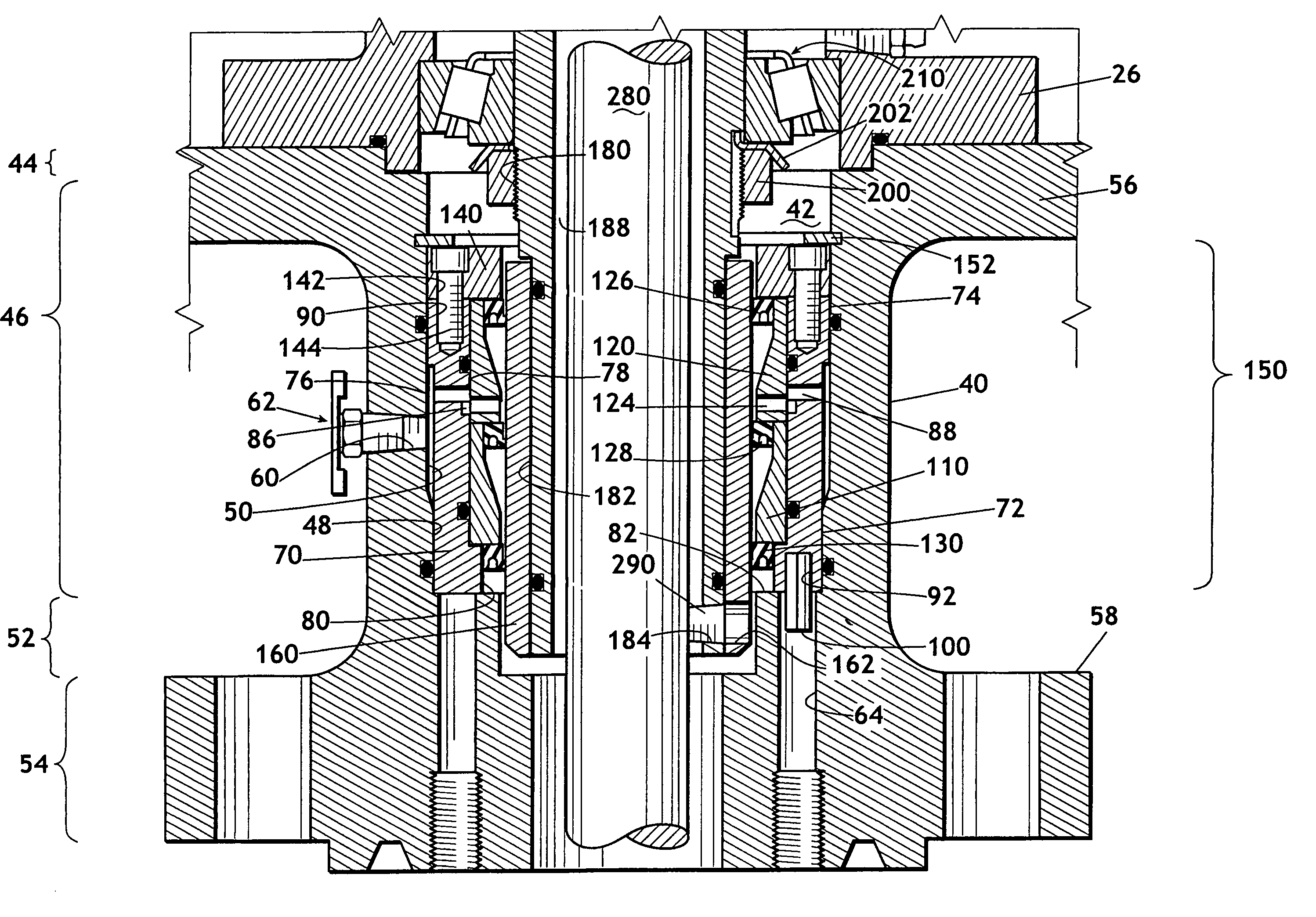

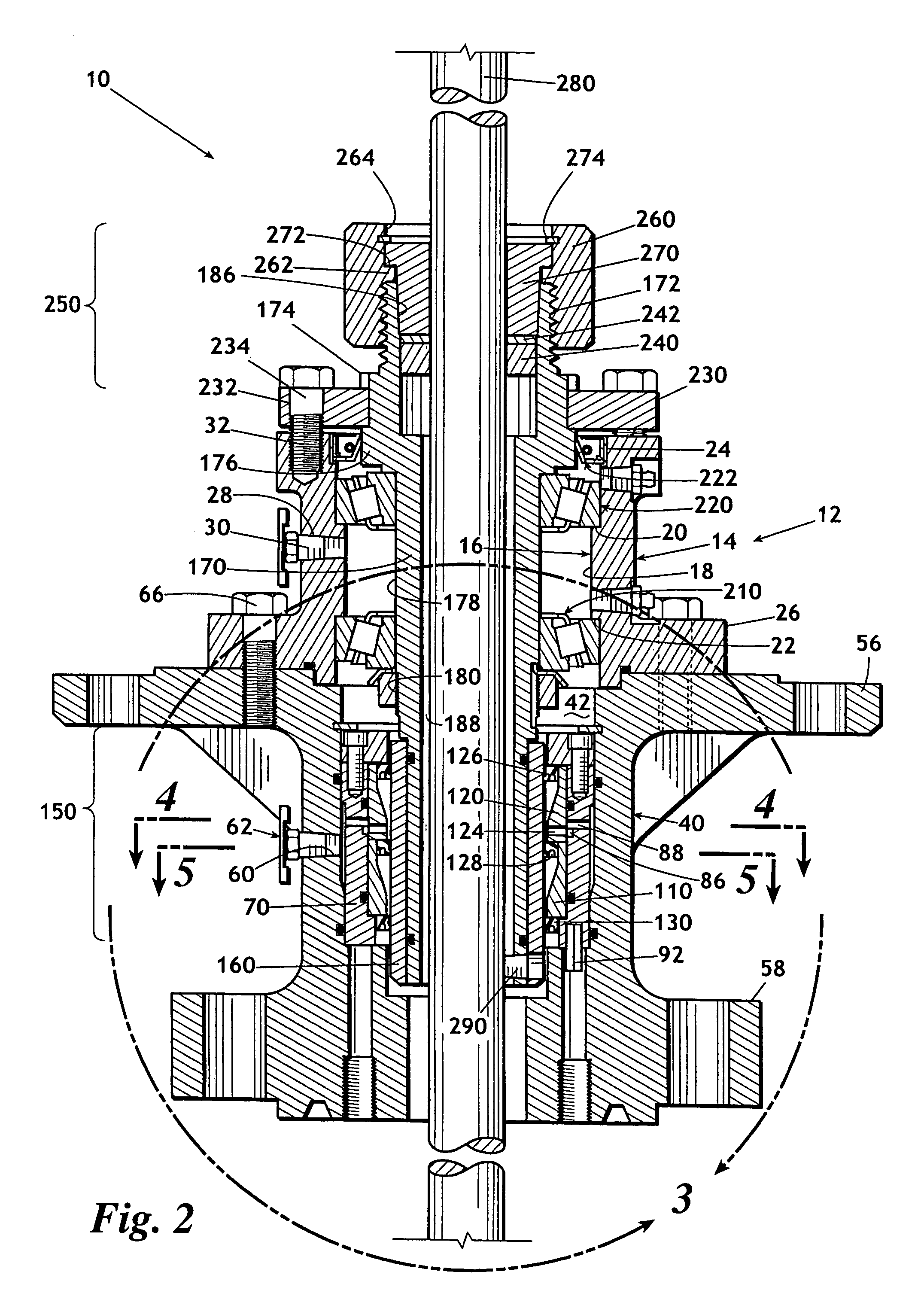

Convertible rotary seal for progressing cavity pump drivehead

ActiveUS7255163B2Eliminate wear and tearDetect failureDrilling rodsFluid removalLocking mechanismEngineering

A convertible rotary seal has a housing for receiving a polish rod. A mandrel is rotatably mounted in the seal housing and surrounds the polish rod. A wear sleeve surrounding the mandrel engages a primary seal. A secondary seal engages the mandrel and polish rod and rotates therewith but may be converted for use as a static seal if necessary. A locking mechanism selectively secures the mandrel in a stationary orientation with respect to the seal housing. Fluid that leaks past the primary seal will be detectible through an external orifice. If a leak in the primary seal is detected via the external port, then the mandrel may be secured in a stationary orientation with respect to the housing and the secondary seal may be reconfigured to operate as a stationary seal until such time as the rotary sealing unit can be overhauled.

Owner:RAVDOS HLDG INC

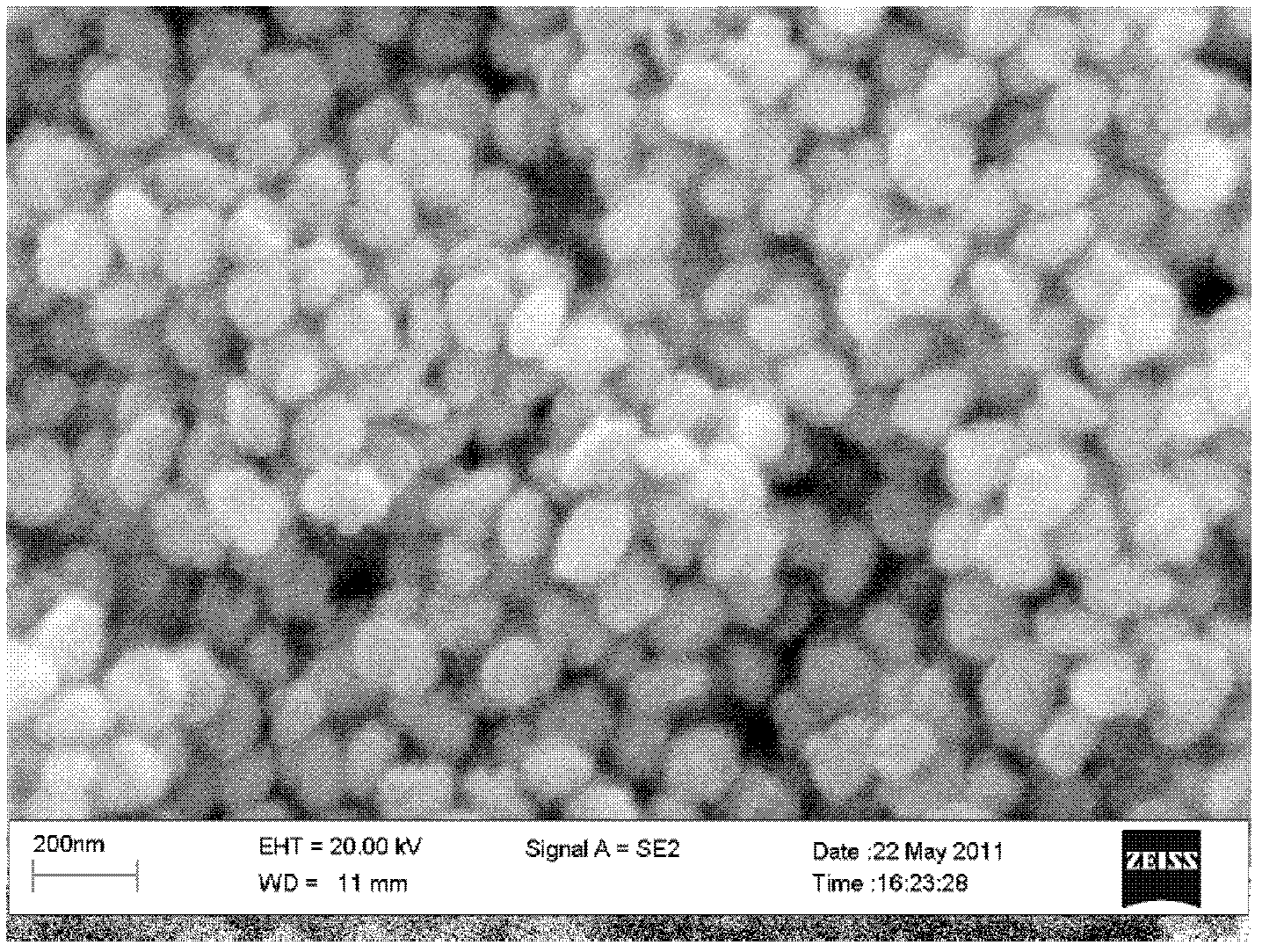

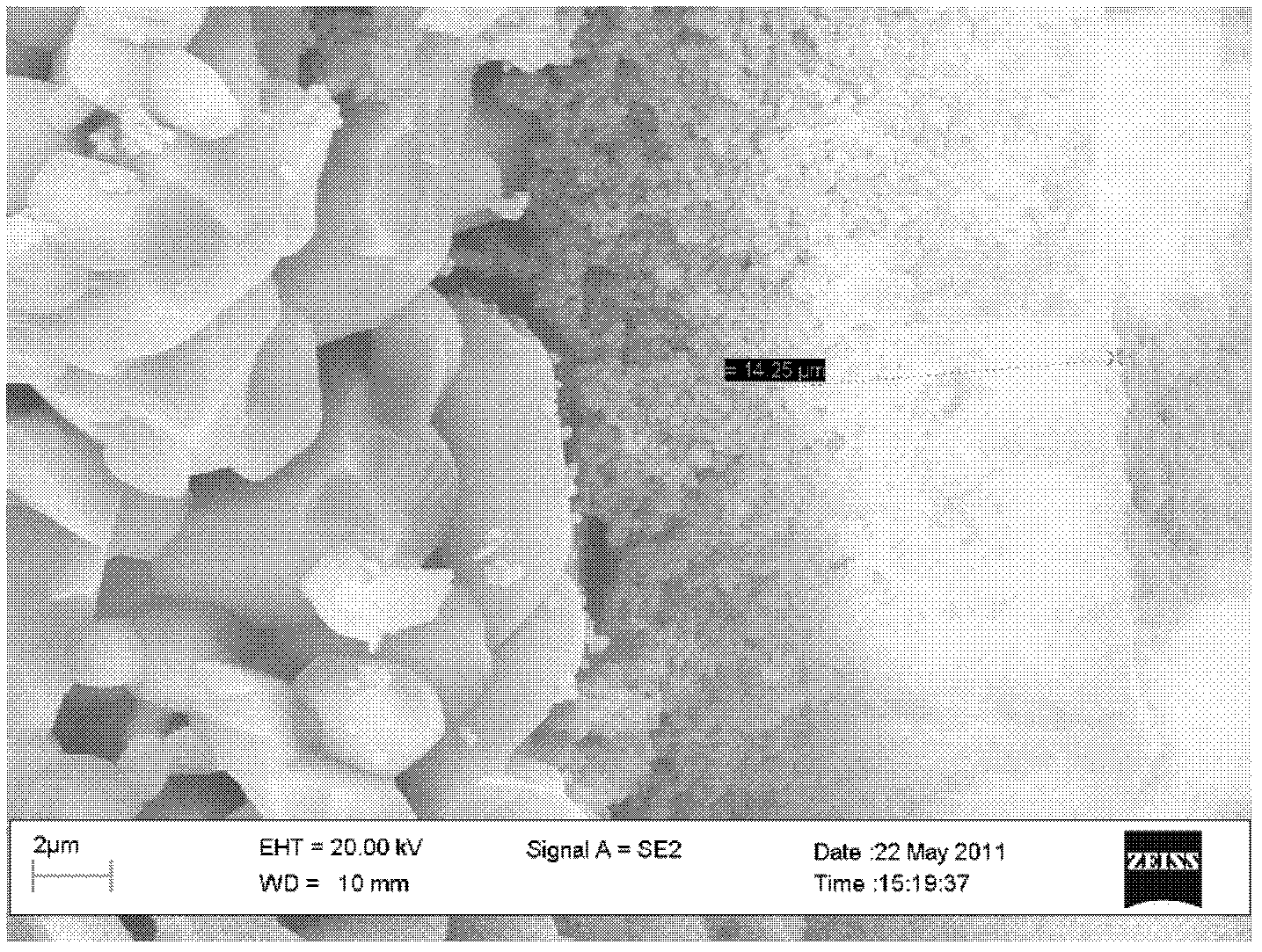

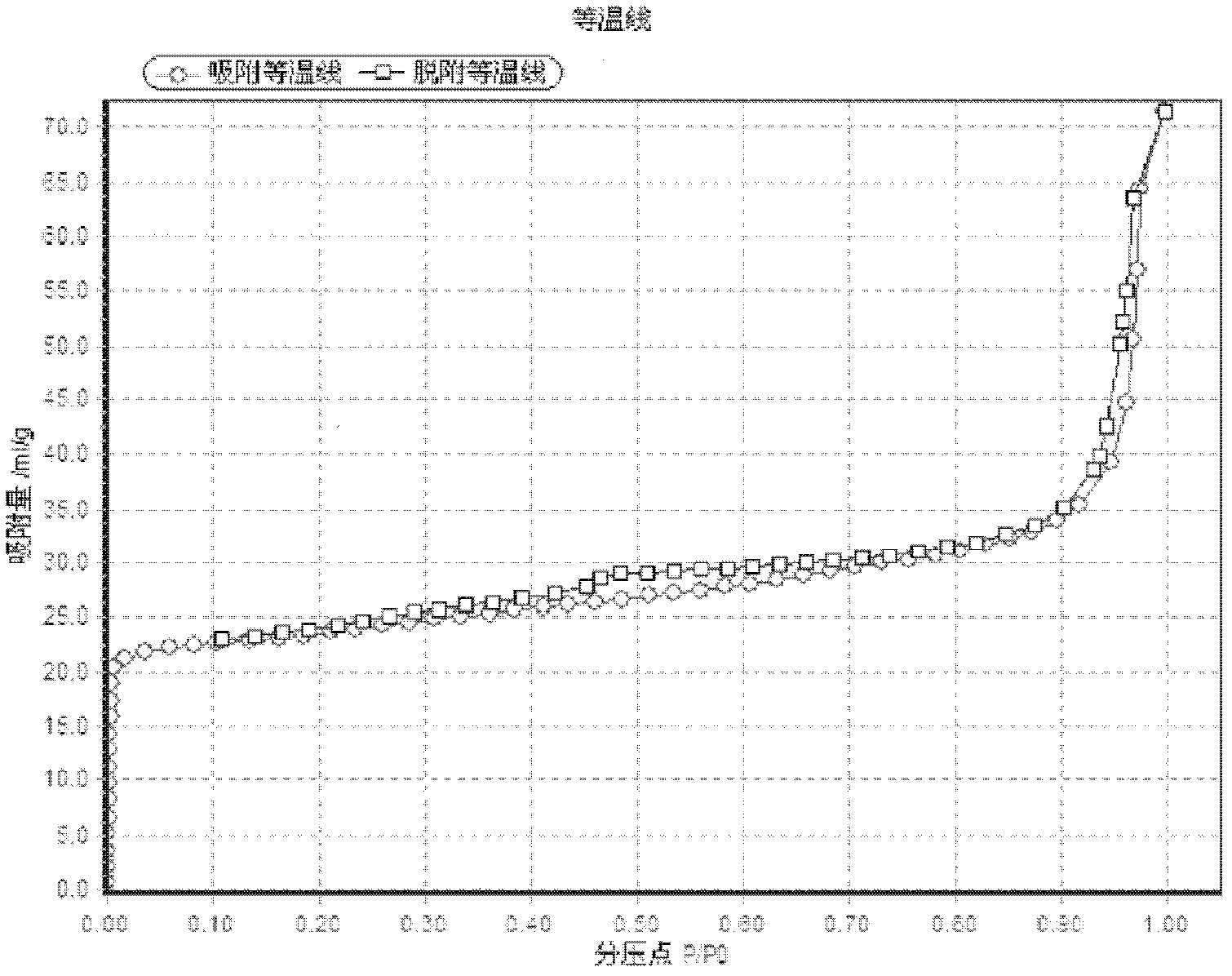

Ultrafine molecular sieve structured catalytic material based on porous silicon carbide carrier and preparation thereof

ActiveCN102716762ACrystal size can be controlledImprove bindingMolecular sieve catalystsMolecular sieveHigh activity

The invention, belonging to the technical field of catalyst and its application, particularly relates to an ultrafine molecular sieve structured catalytic material based on a porous silicon carbide carrier and a preparation method thereof. The material comprises ultrafine molecular sieve crystals as active elements and has a hierarchically porous structure, and the whole ultrafine molecular sieve coating has catalytic activity. The method is characterized by coating a colloidal molecular sieve precursor on the surface of a modified foam silicon carbide carrier, converting the molecular sieve precursor into ultrafine molecular sieve crystals by vapor phase treatment to realize the firm combination between the coating and the carrier. According to the invention, by controlling the synthesis conditions of the colloidal molecular sieve precursor and the method of adding a pore forming agent, the size of the molecular sieve crystals, silica-alumina ratio and intercrystalline porosity can be controlled; a pore structure and the type of the molecular sieve can be designed according to the geometrical structure of a target product; and the capacity of accommodating carbon is raised, the mass transfer capability of the catalyst is reinforced, and the life of catalyst is prolonged while keeping the high activity of the ultrafine molecular sieve and high target product selectivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

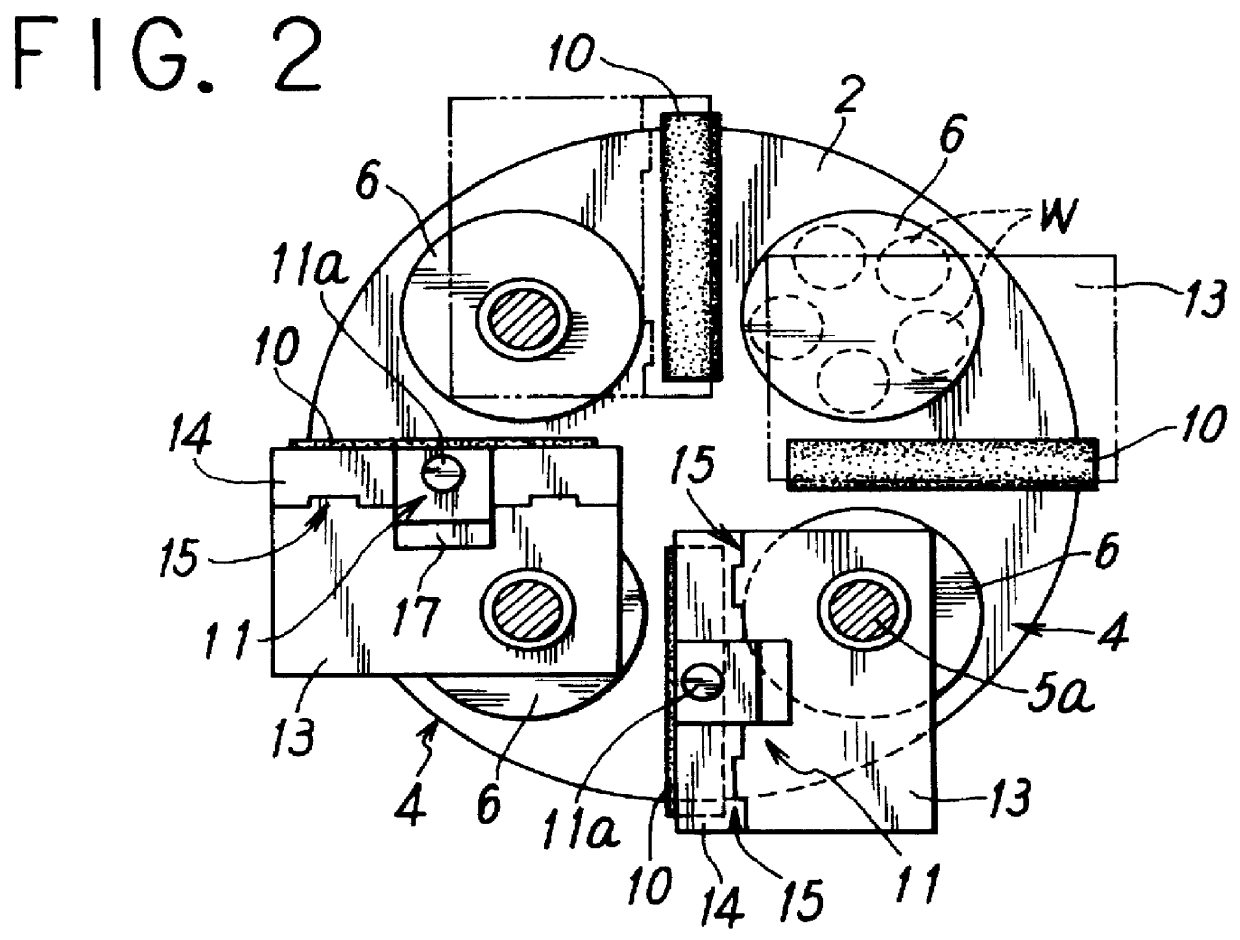

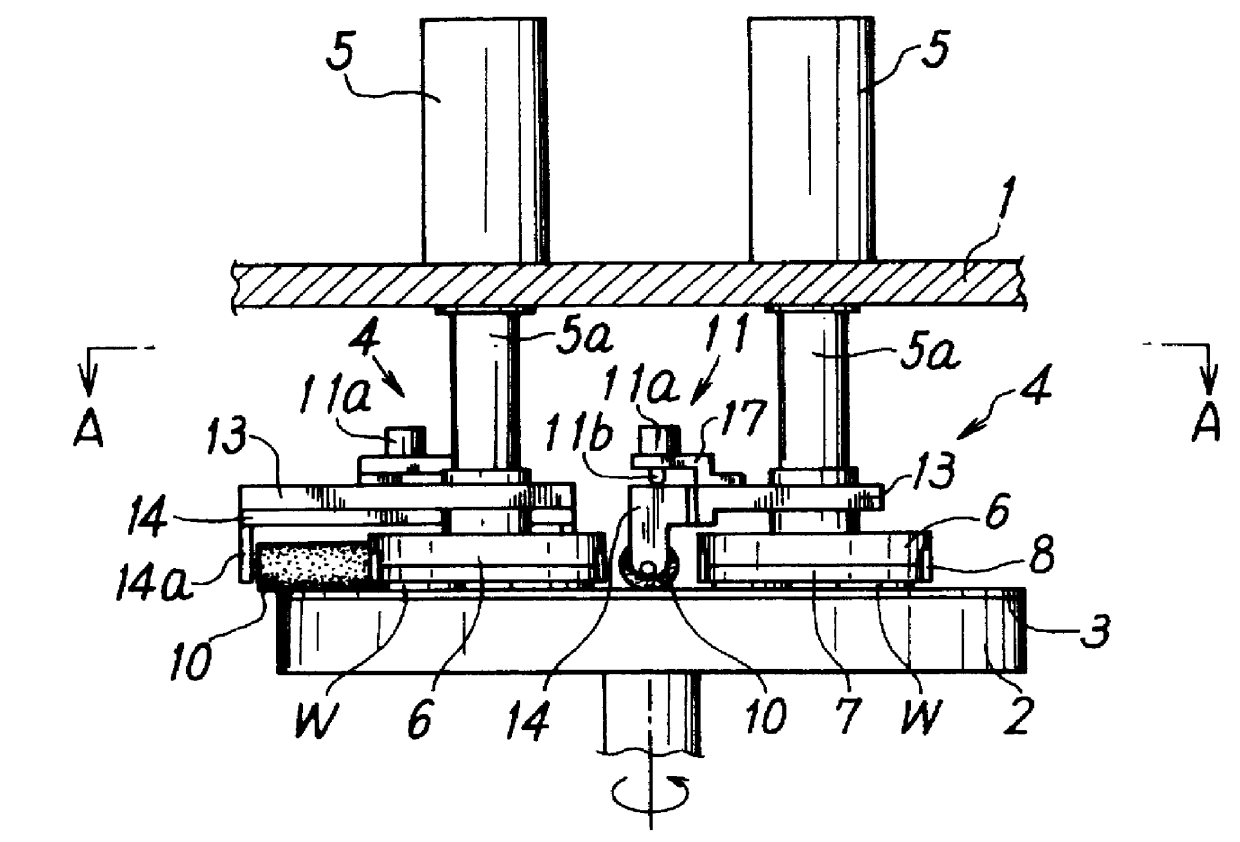

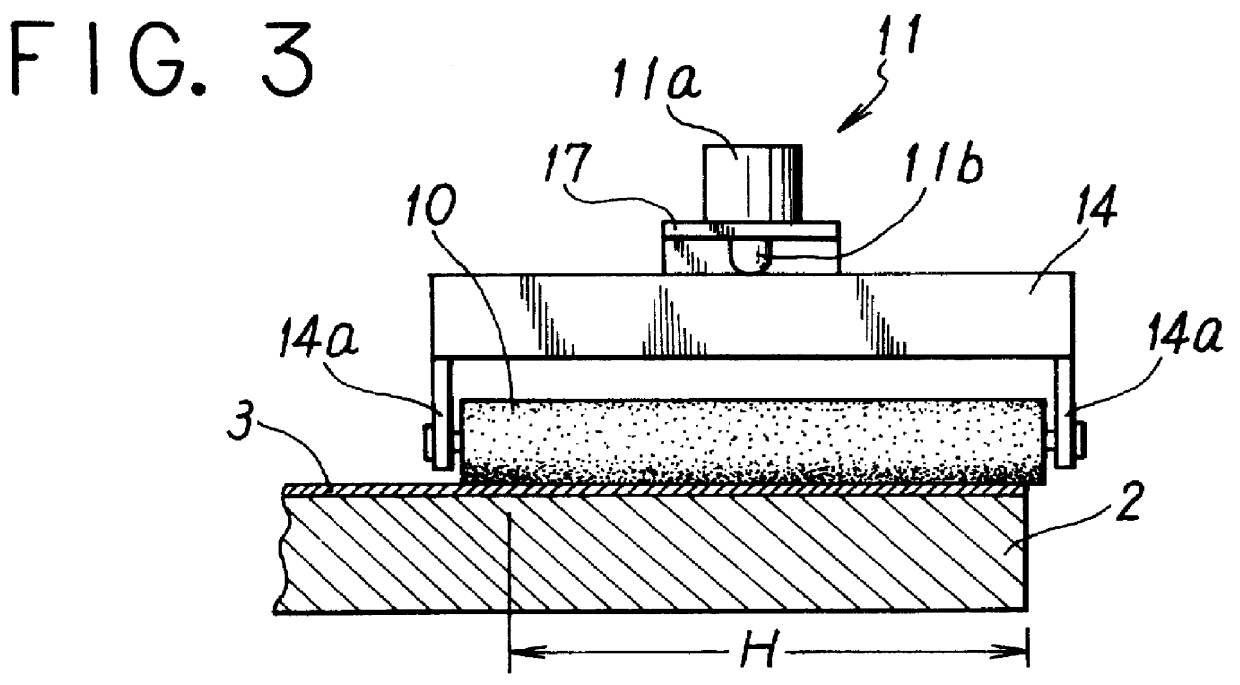

Single side work polishing apparatus

InactiveUS6116997ASuperb enduranceEliminate wear and tearGrinding drivesBelt grinding machinesEngineeringSurface plate

A single side work polishing apparatus rectifies the surface geometry of a polishing pad during the polishing of a work. A correction roller is mounted to a pressure member that pushes a work against a polishing pad held by a rotating surface plate. The correction roller has a length substantially equivalent to the width of the working area of the polishing pad and is arranged along the radial direction of the surface plate. During polishing, the work and the correction roller are pressed against the polishing pad by the pressure member. The correction roller rotates about its longitudinal axis to rectify the polishing pad while the work is being polished.

Owner:SPEEDFAM CO LTD

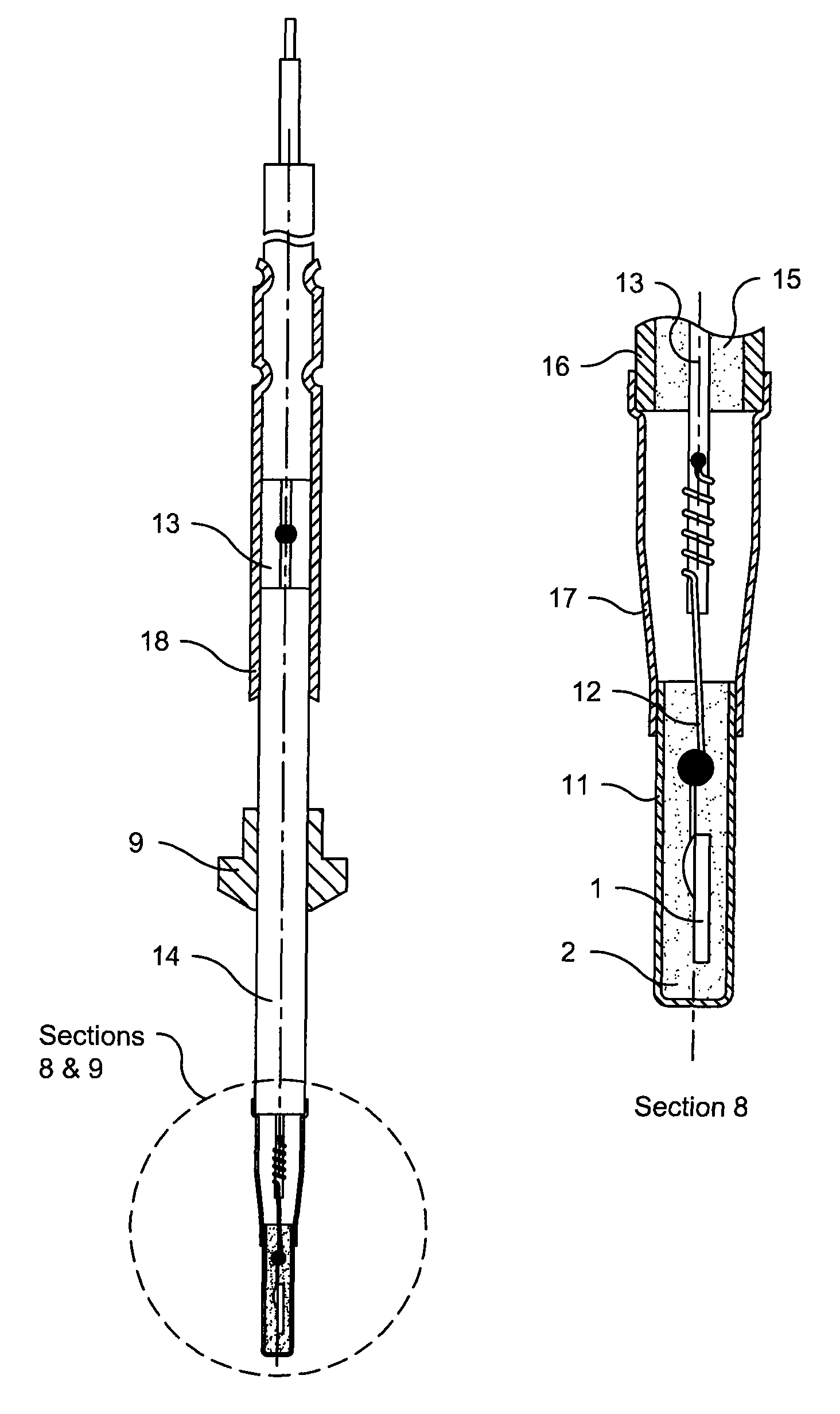

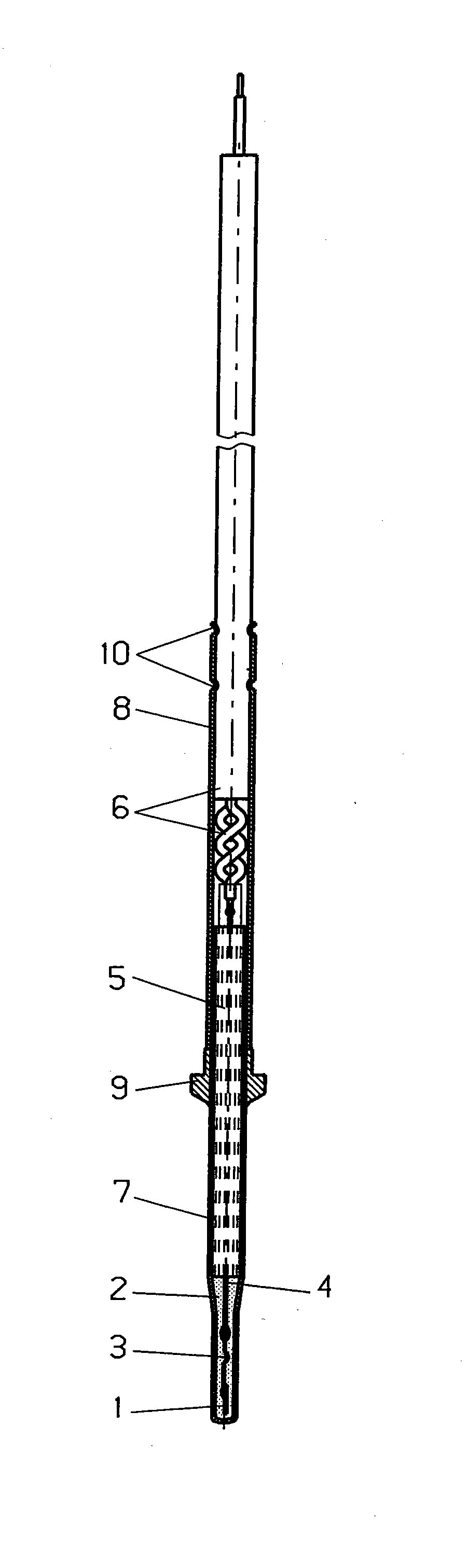

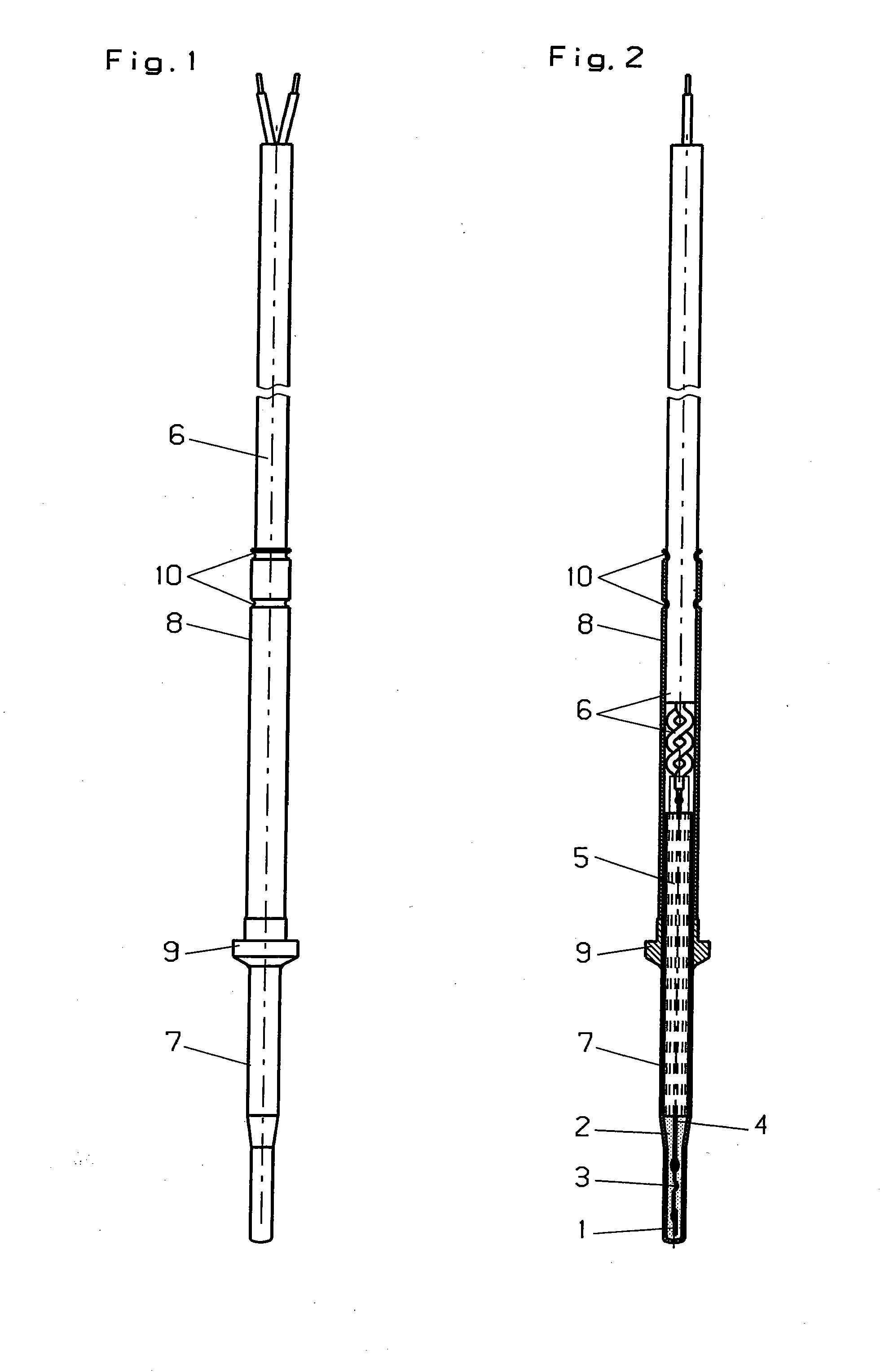

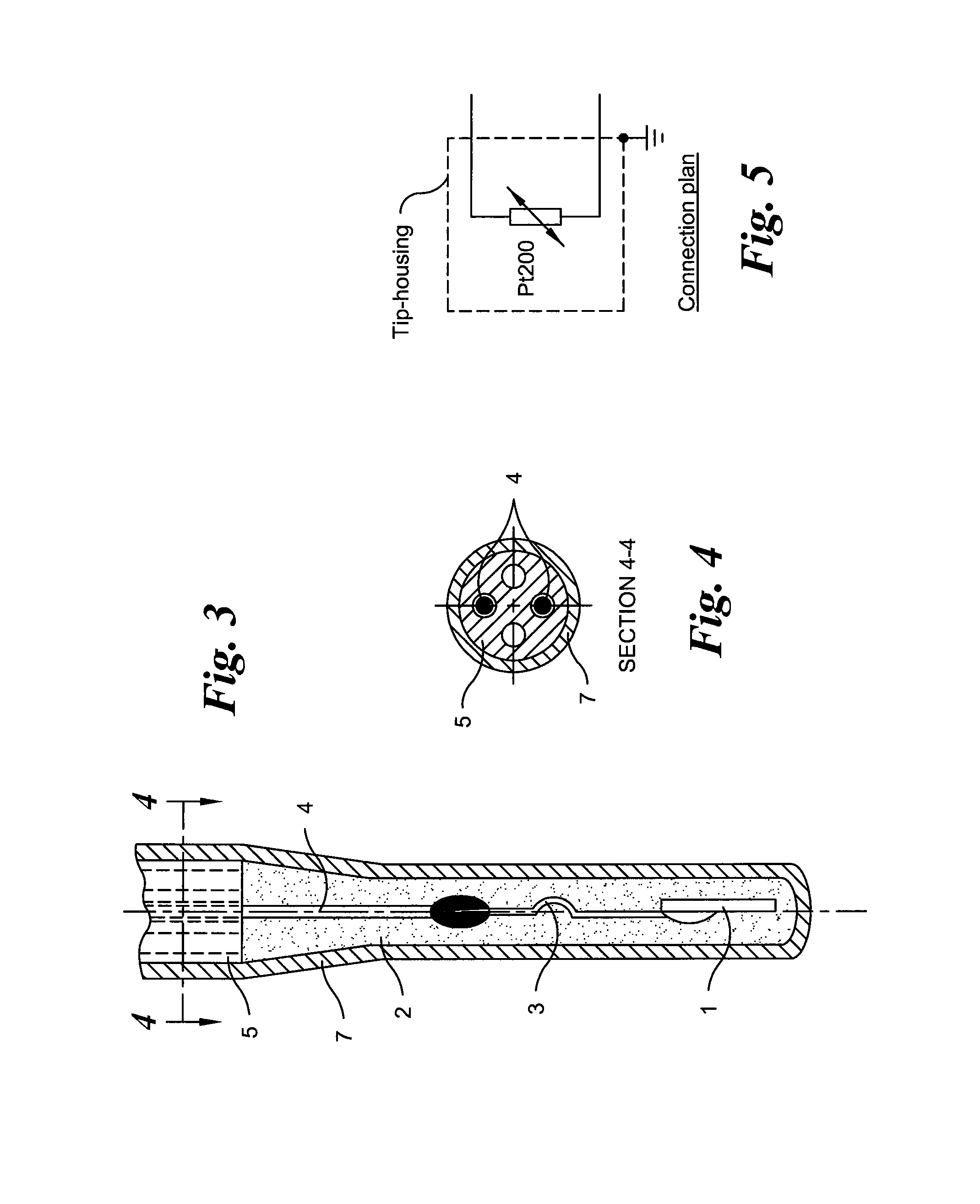

Turbocharger protection device

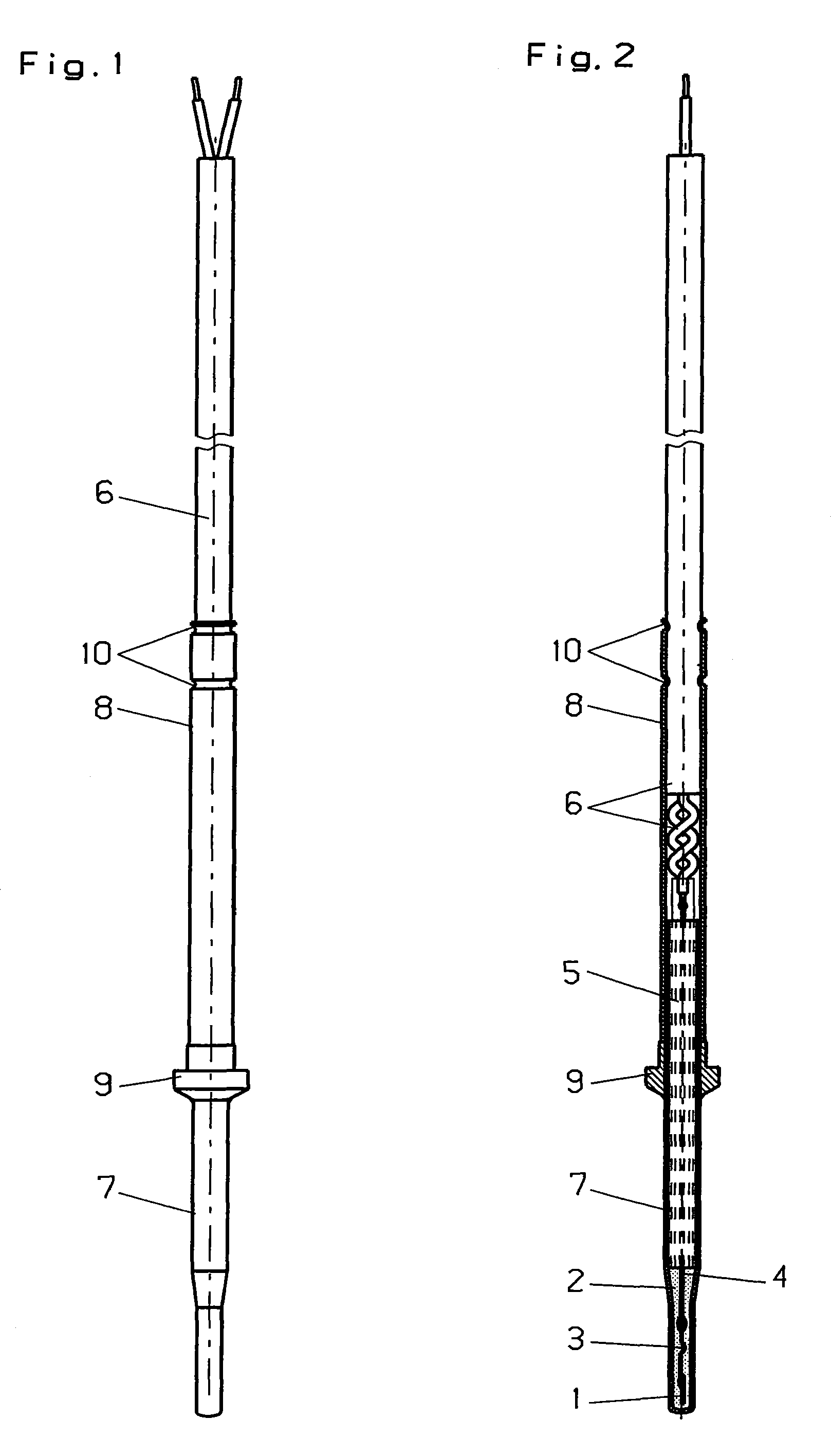

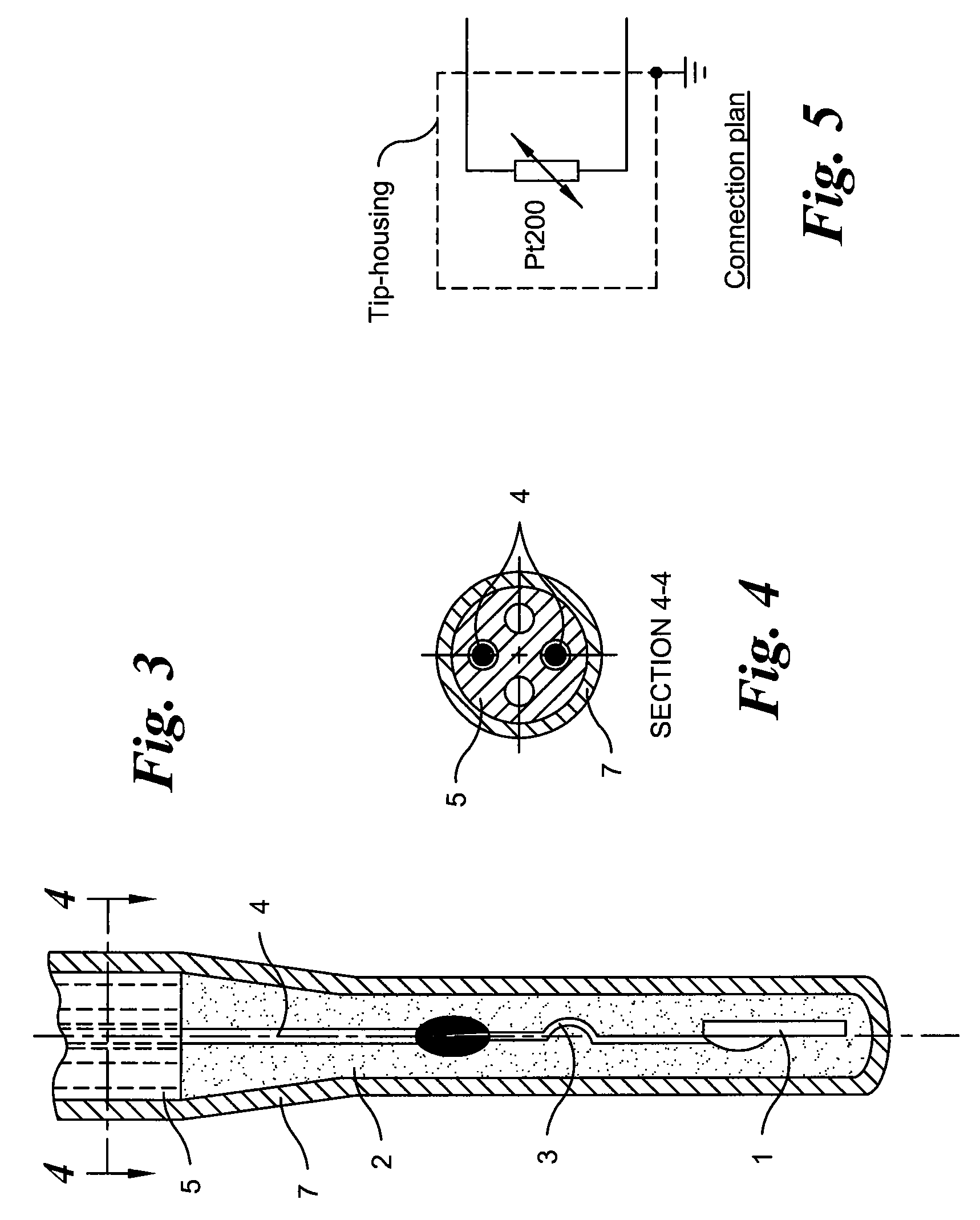

InactiveUS8328419B2Electronic expenseEliminate riskThermometer detailsTemperature measurement in motorsElectrical resistance and conductanceTurbocharger

A temperature sensor, particularly a high-temperature sensor, is provided in which an MI line or a heat-decoupling wire is arranged between the measurement resistor (chip) and the supply-line cable. Springs are stuck on the strands of the MI line, whereby the contacting to the measurement resistor is realized, or the heat-decoupling wire is stretched on one side to the end facing the measurement resistor and is connected elastically on the other end to the supply-line cable.

Owner:HERAEUS NEXENSOS GMBH

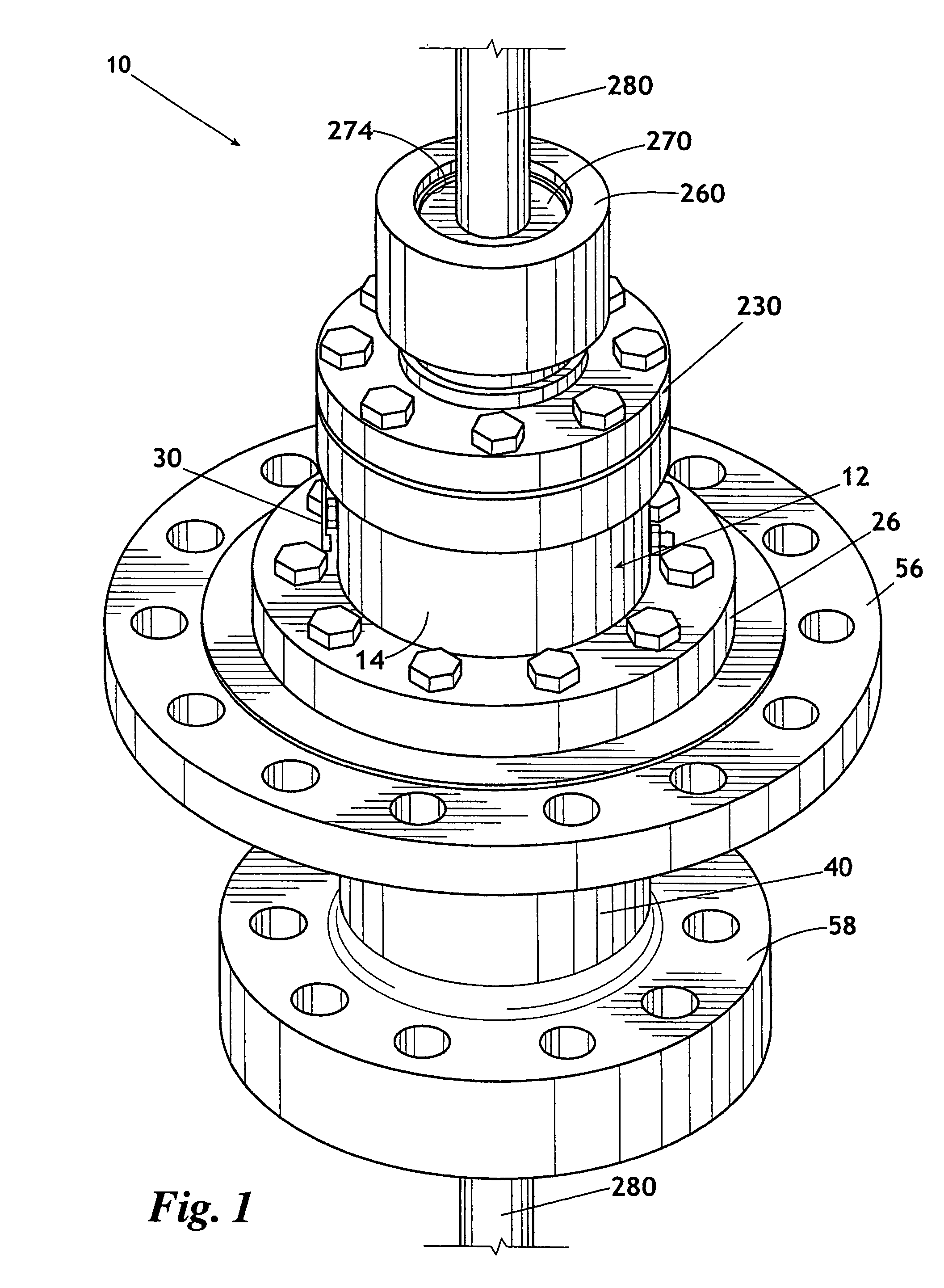

Ultraclean magnetic mixer

ActiveUS7396153B2Eliminate pollutionEliminate wear and tearTransportation and packagingMixer accessoriesThrust bearingMagnetic stirrer

In a magnetically-coupled liquid mixer of the type having a drive mount secured to and extending into a mixing vessel, an external first magnet array adjacent to the drive mount, a stub shaft extending from the drive mount into the vessel and having a first thrust bearing surface, and a driven portion rotatably-mounted on the stub shaft and having a second thrust bearing surface and a second magnet array, the improvement wherein the first and second arrays are positioned with respect to one another such that the first and second thrust bearing surfaces are spaced apart at least in the absence of above-threshold fluid dynamic thrust forces on the driven portion.

Owner:ALFA LAVAL CORP AB

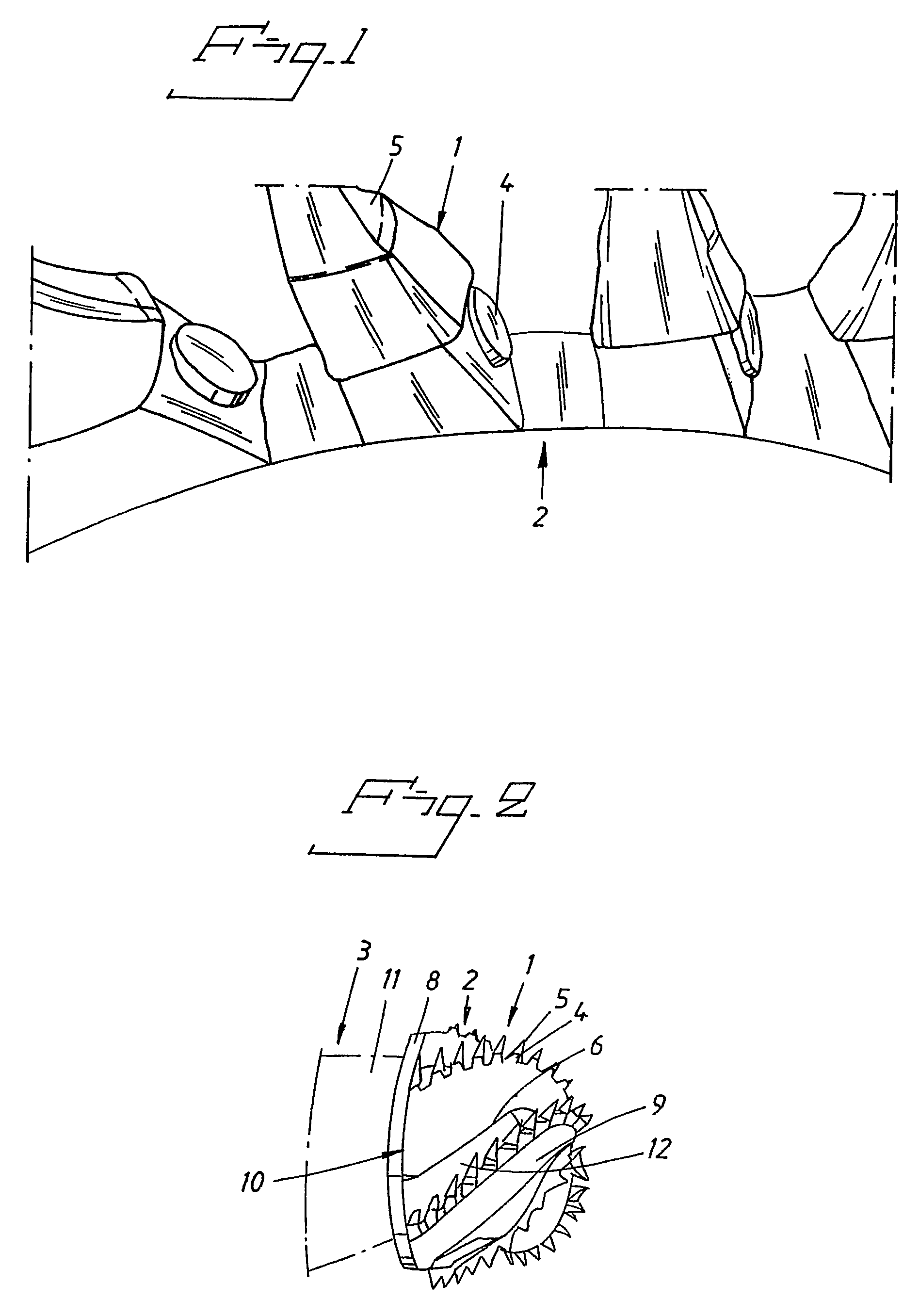

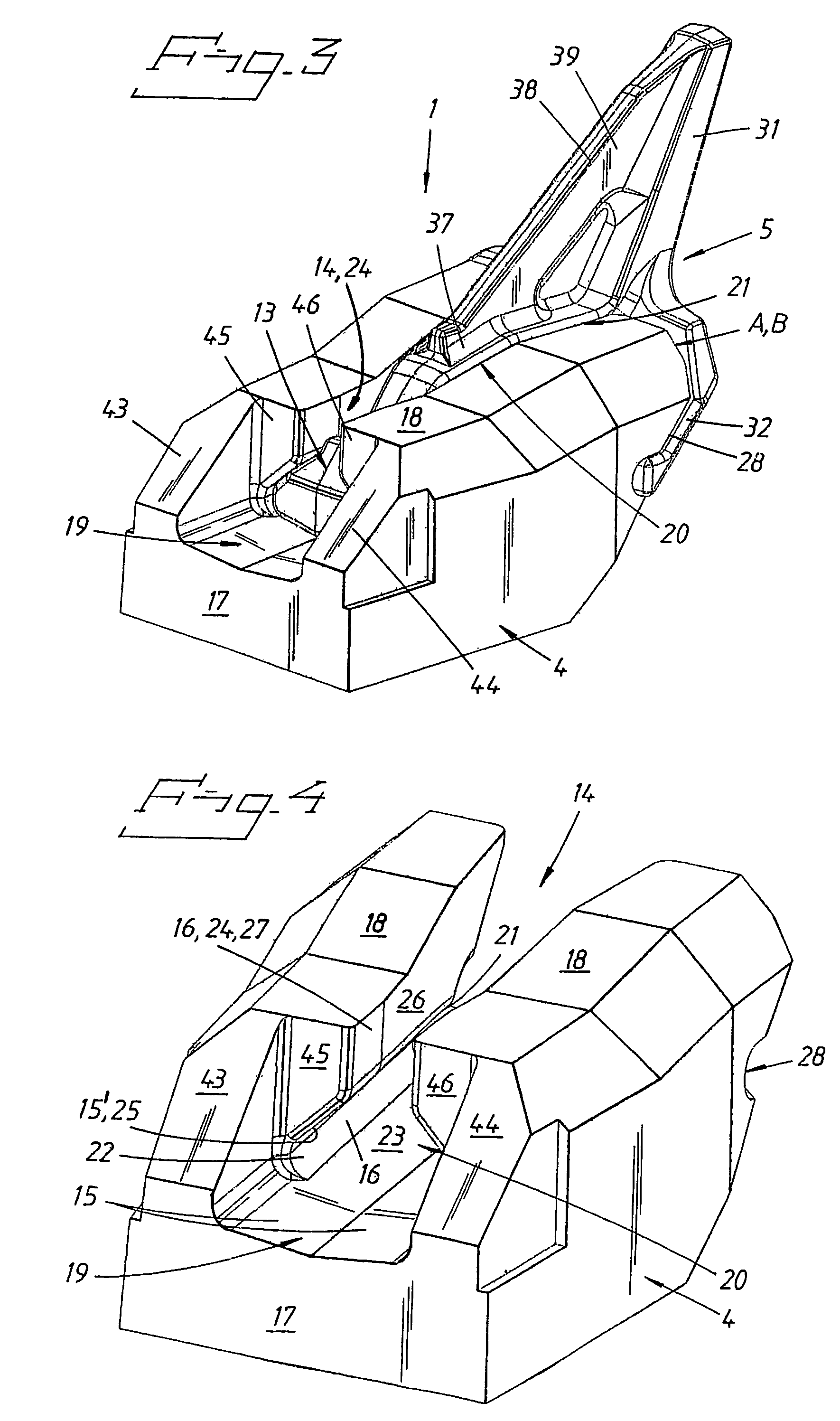

Tooth system

ActiveUS7694443B2Reduce decreaseEliminate wear and tearMechanical machines/dredgersEngineeringAxial symmetry

Owner:COMBI WEAR PARTS AB +1

Investment cast, stainless steel chain link and casting process therefor

ActiveUS20060283168A1Avoid heat concentrationInhibition formationConveyorsSedimentation separationInvestment castingWastewater

An investment cast, stainless steel chain link is provided for chains used in water and wastewater treatment. The chain link comprises a pair of spaced apart, elongated sidebars having forward ends and rearward ends. The forward ends are spread apart and are provided with outwardly and laterally extending bosses having transverse boss pin bores coaxially aligned with each other. The rearward ends are interconnected by a cylindrical barrel having a barrel pin bore extending through each of the sidebars. The sidebars are formed with outwardly and laterally projecting reinforcing ribs-extending between the bosses and the barrel pin bore along a substantial length of the sidebars. A freely rotatable chain pin is inserted through aligned boss and barrel pin bores from either end thereof for interconnecting first and second pairs of sidebars. An arrangement is provided for preventing the lateral dislodgement of the chain pin from the sidebars.

Owner:HUMCKE MICHAEL W +1

Power tools, battery chargers and batteries

ActiveUS20060119318A1Eliminate fretting corrosionEliminate excessive wearBatteries circuit arrangementsElectric powerPower toolBattery cell

A battery pack for powering a cordless power tool. The battery pack includes at least one battery cell operable to supply a discharge current, a switch operable to control the discharge current and a protection device to protect the switch. The protection device is positioned such that the device absorbs a current traveling in a direction opposite to that of the discharge current supplied from the battery cell.

Owner:MILWAUKEE ELECTRIC TOOL CORP

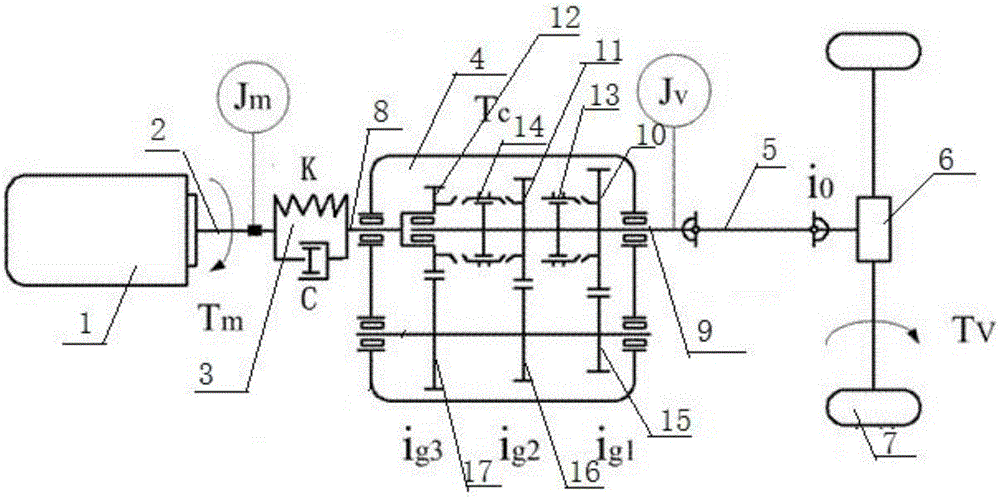

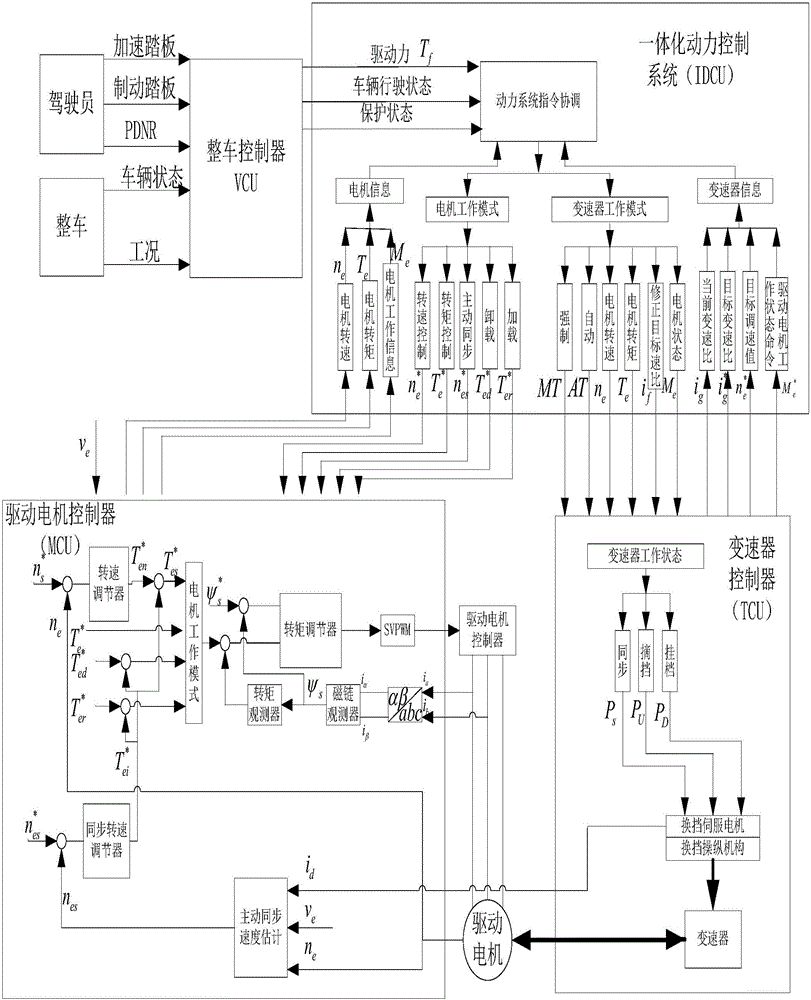

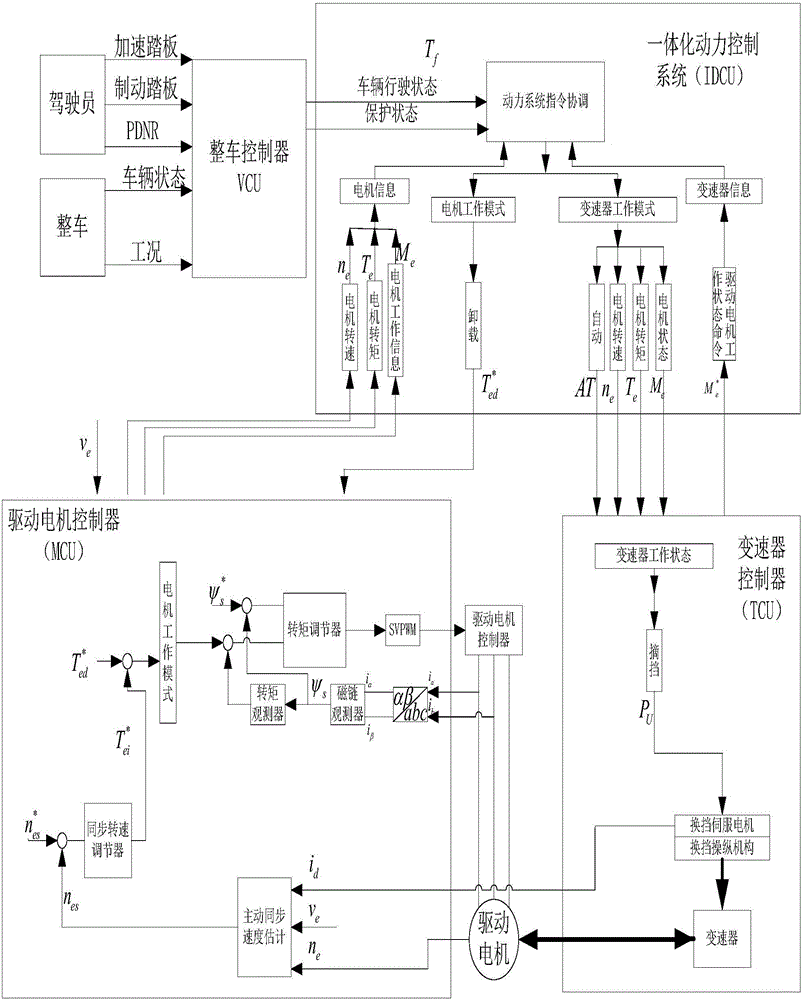

Optimized integrated system with drive motor and automatic transmission and gear shifting control method

ActiveCN106080155AMitigate the cause of loud noiseAvoid damageElectric propulsion mountingControl devicesDrive motorIntegrated systems

The invention provides an optimized integrated system with a drive motor and an automatic transmission and a gear shifting control method. The optimized integrated system comprises the drive motor, an input shaft, a torsional damper, the automatic transmission, a transmission shaft, a main speed reducer and an integrated control unit. An output shaft of the drive motor is connected with one end of the torsional damper through a spline, and the other end of the torsional damper is connected with an input shaft of the automatic transmission through a spline. An output shaft of the automatic transmission is connected with one end of the transmission shaft through a universal joint, and the other end of the transmission shaft is connected with the main speed reducer through a universal joint. The drive motor is directly connected with the automatic transmission through the torsional damper, damage of impact generated in the gear shifting process to the shaft of the drive motor is reduced, and meanwhile, the gear shifting failure rate caused by gear shifting impact is reduced. According to the optimized integrated system, the gear shifting time is shortened, the phenomena of power impact and unsmooth gear shifting are eliminated, equipment abrasion is lowered, and the dynamic performance, the economic performance and the smoothness of an electric automobile are improved.

Owner:金碧波

Hydraulic downhole oil recovery system

InactiveUS20060000616A1Operating efficiency greatDecreased hydraulic efficiencyFluid removalSealing/packingWater basedAbove ground

An improved hydraulic downhole oil recovery system that incorporates an above ground unit and a submersible, reciprocating downhole pump unit. Water-based fluid, rather than hydraulic fluid, is responsible for actuating the reciprocating downhole pump unit. The water-based fluid is transferred through the system using coil, coil tubing. The system further relies upon coil exterior production tubing to provide exceptional advantage in deviated oil wells.

Owner:CRAWFORD JOE

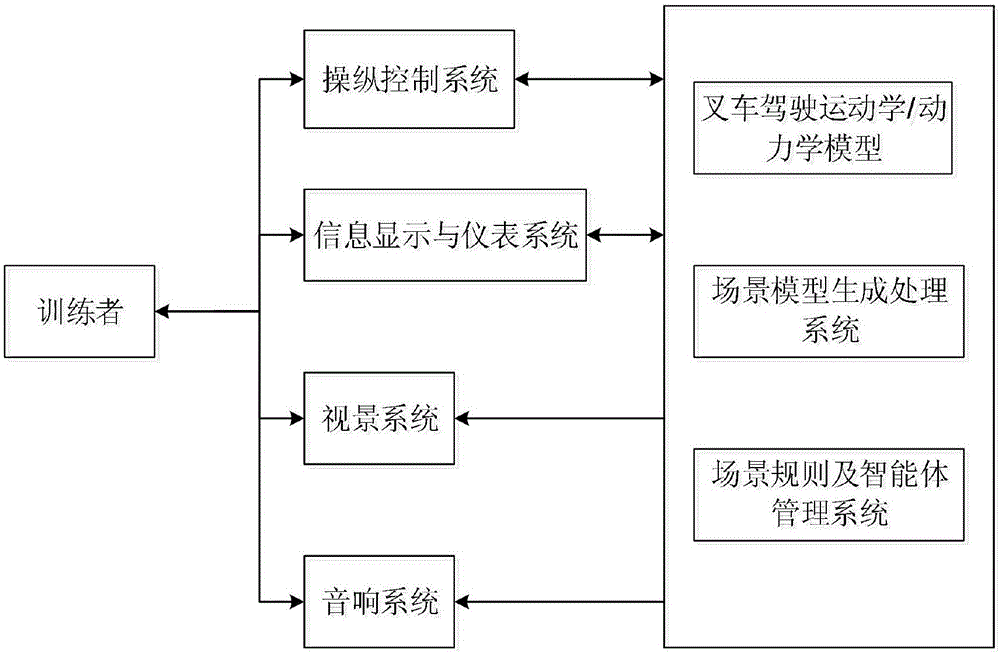

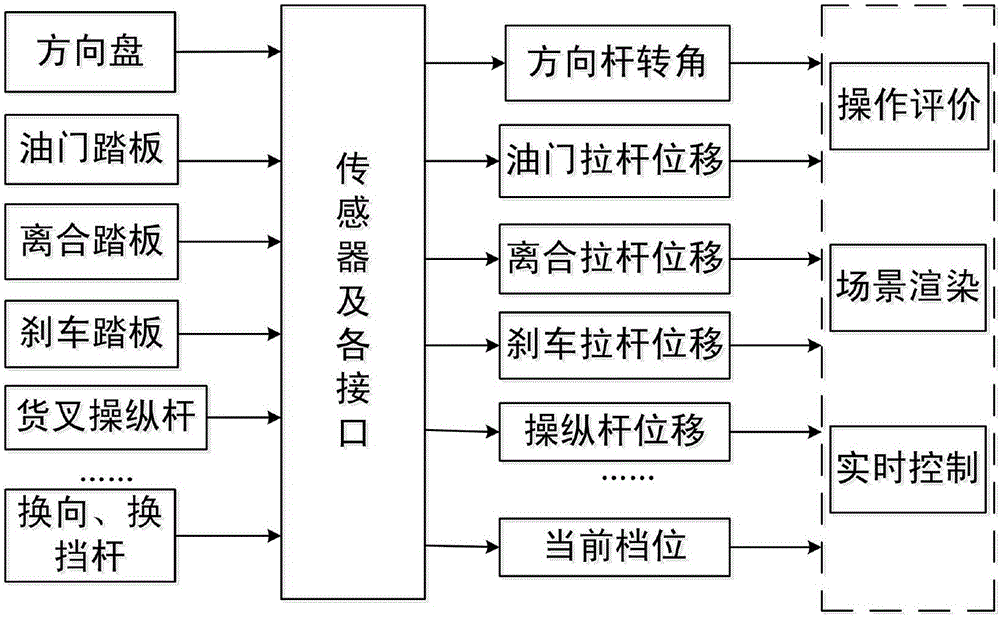

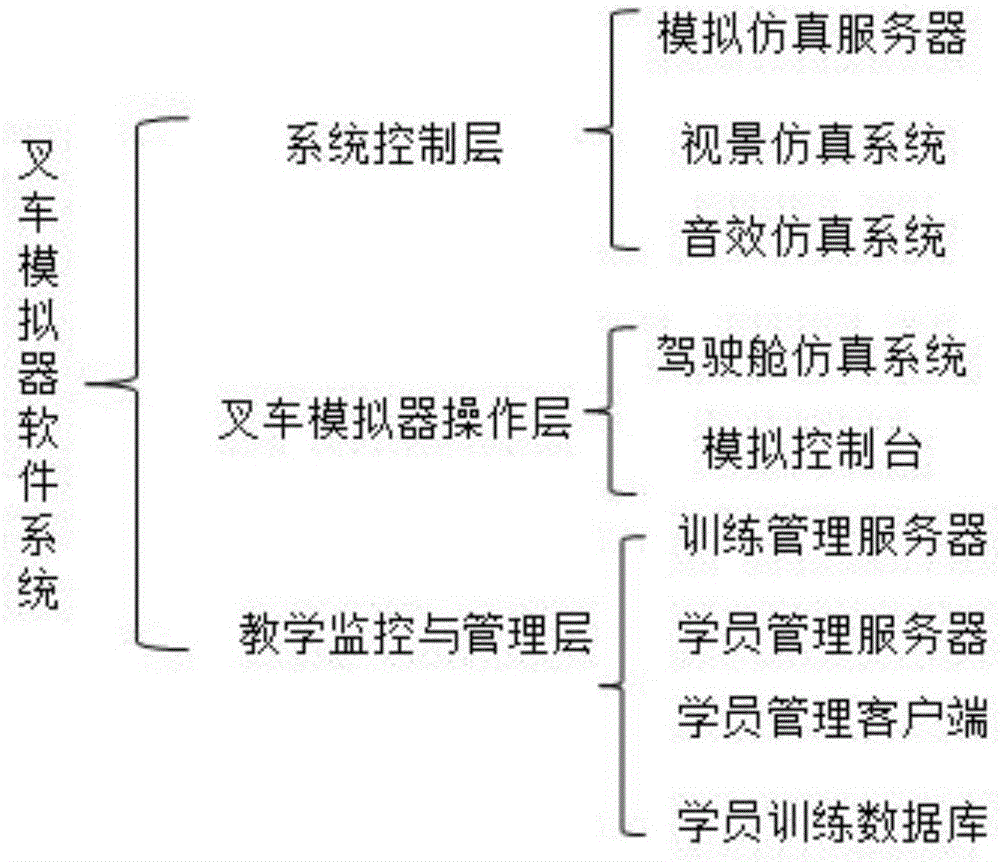

Forklift operation training simulator

InactiveCN106652642ARapid responseAvoid registrationCosmonautic condition simulationsSimulatorsTraining periodSoftware system

The invention relates to a forklift operation training simulator. A main structure of the forklift operation training simulator comprises hardware equipment and a software system. The hardware equipment comprise a simulation cab, an steering control system, an instrument system, a multimedia computer, an audio system, an instructor control panel and the like. The software system comprises an operation platform and is used for real-time working environment animation generation of the computer, dynamic forklift driving simulation, sound simulation, operation evaluation, data management, network control and the like. The forklift operation training simulator has the advantages that a whole training period of a student can be shortened greatly, the student is enabled to finish training tasks in a short time, sudden incidents which rarely happen during practical training can be simulated conveniently, accurate-judging ability, good psychological quality and the ability of handling emergency circumstances correctly of the student can be cultivated, and training quality is improved.

Owner:武汉科码软件有限公司

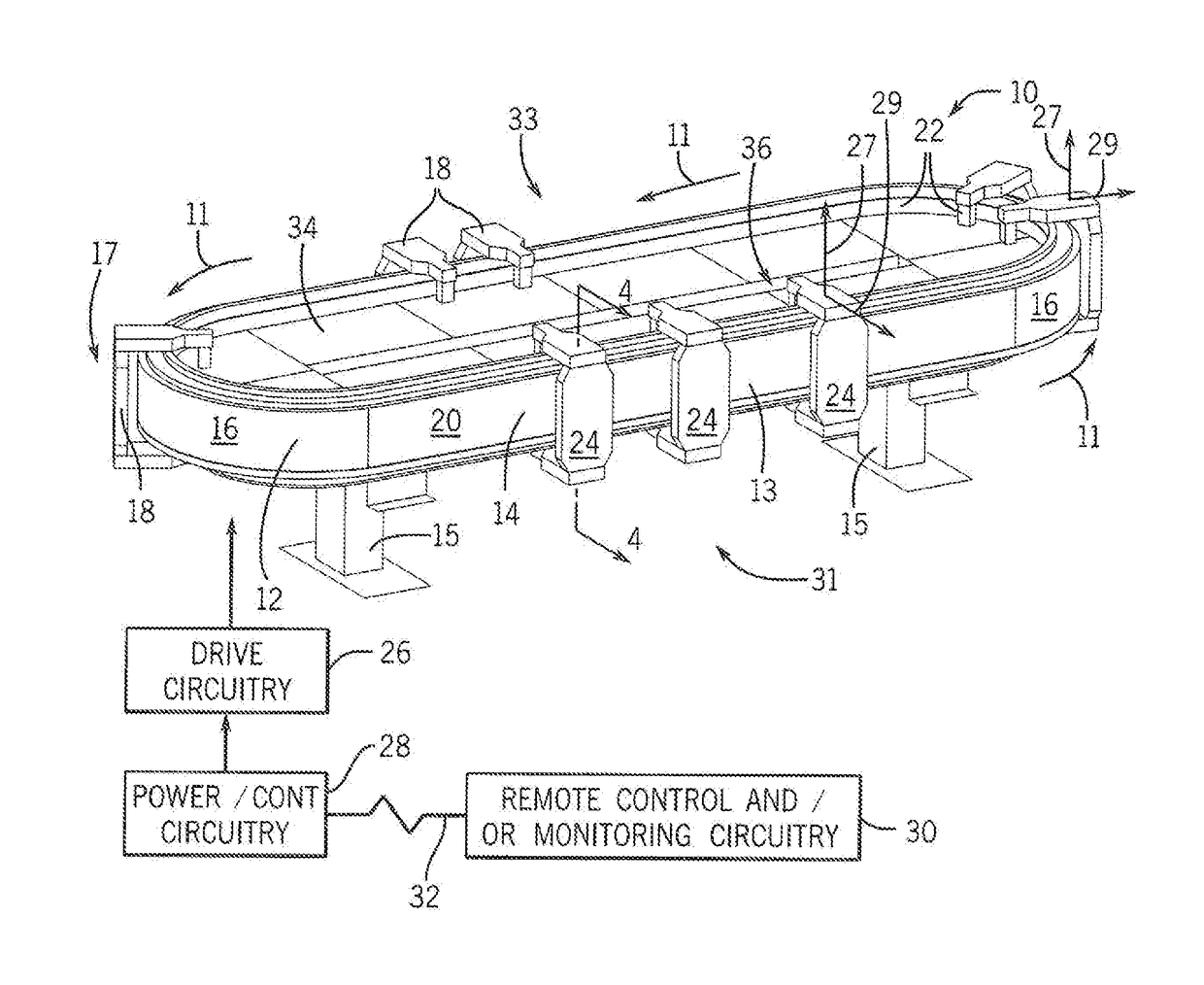

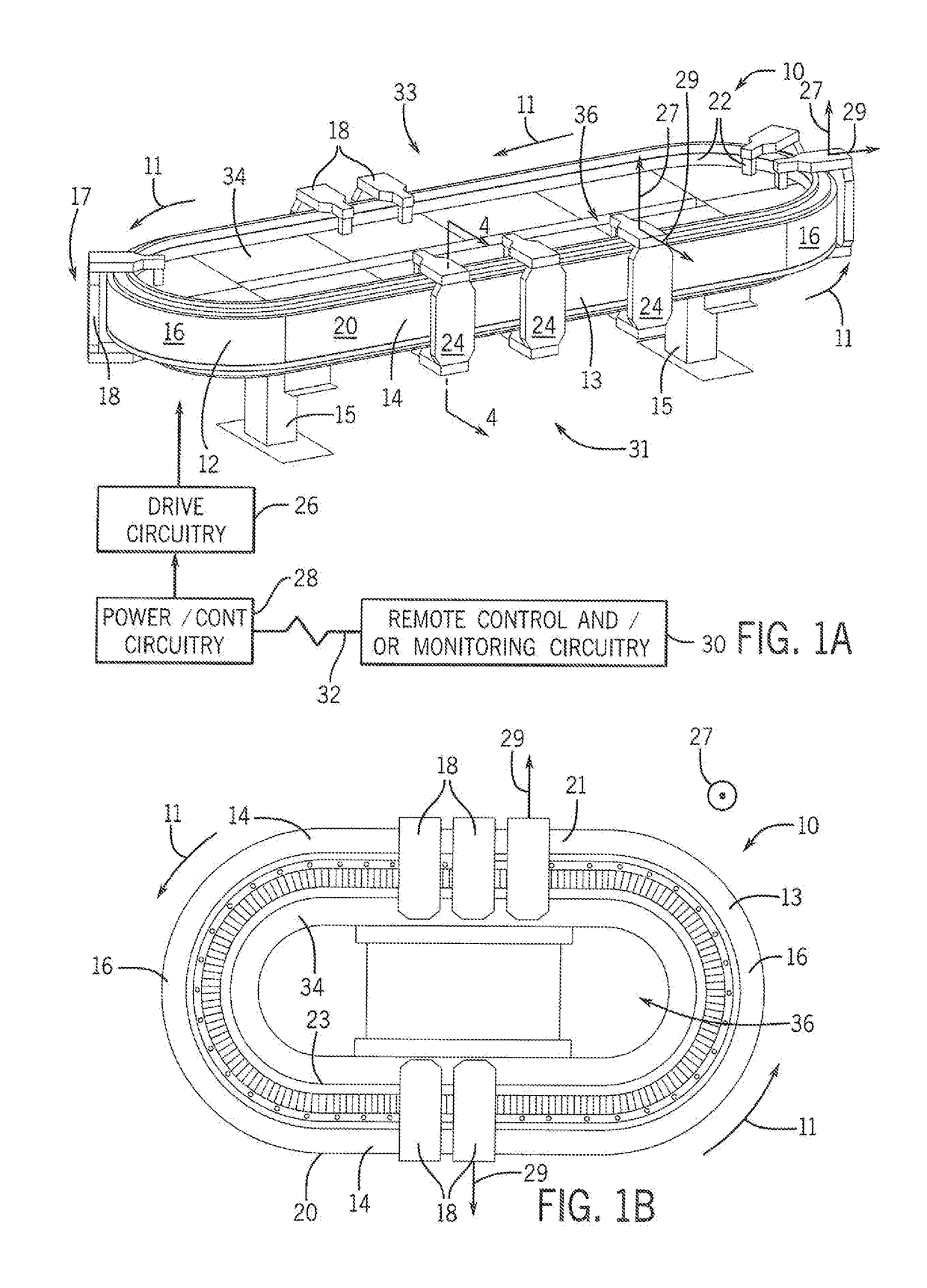

Multi-Rail/Roller Compliance System for Independent Mover Products

A mover system that provides spatially separated rails of the track interacting with pairs of closely spaced opposed wheels of the mover constraining movement of the mover on the track is provided. Each pair of wheels includes standard cylindrical or crowned wheels contacting the opposed parallel sides of standard rectangular rails, retaining the movers on the track in both horizontal and vertical directions normal to a transport direction along the track. The wheels bear loads in a radial direction with respect to axial motion consistent with its naturally positioned strength.

Owner:ROCKWELL AUTOMATION TECH

Turbocharger Protection Device

InactiveUS20100091817A1Electronic expenseEliminate riskThermometer detailsTemperature measurement in motorsTurbochargerEngineering

A temperature sensor, particularly a high-temperature sensor, is provided in which an MI line or a heat-decoupling wire is arranged between the measurement resistor (chip) and the supply-line cable. Springs are stuck on the strands of the MI line, whereby the contacting to the measurement resistor is realized, or the heat-decoupling wire is stretched on one side to the end facing the measurement resistor and is connected elastically on the other end to the supply-line cable.

Owner:HERAEUS NEXENSOS GMBH

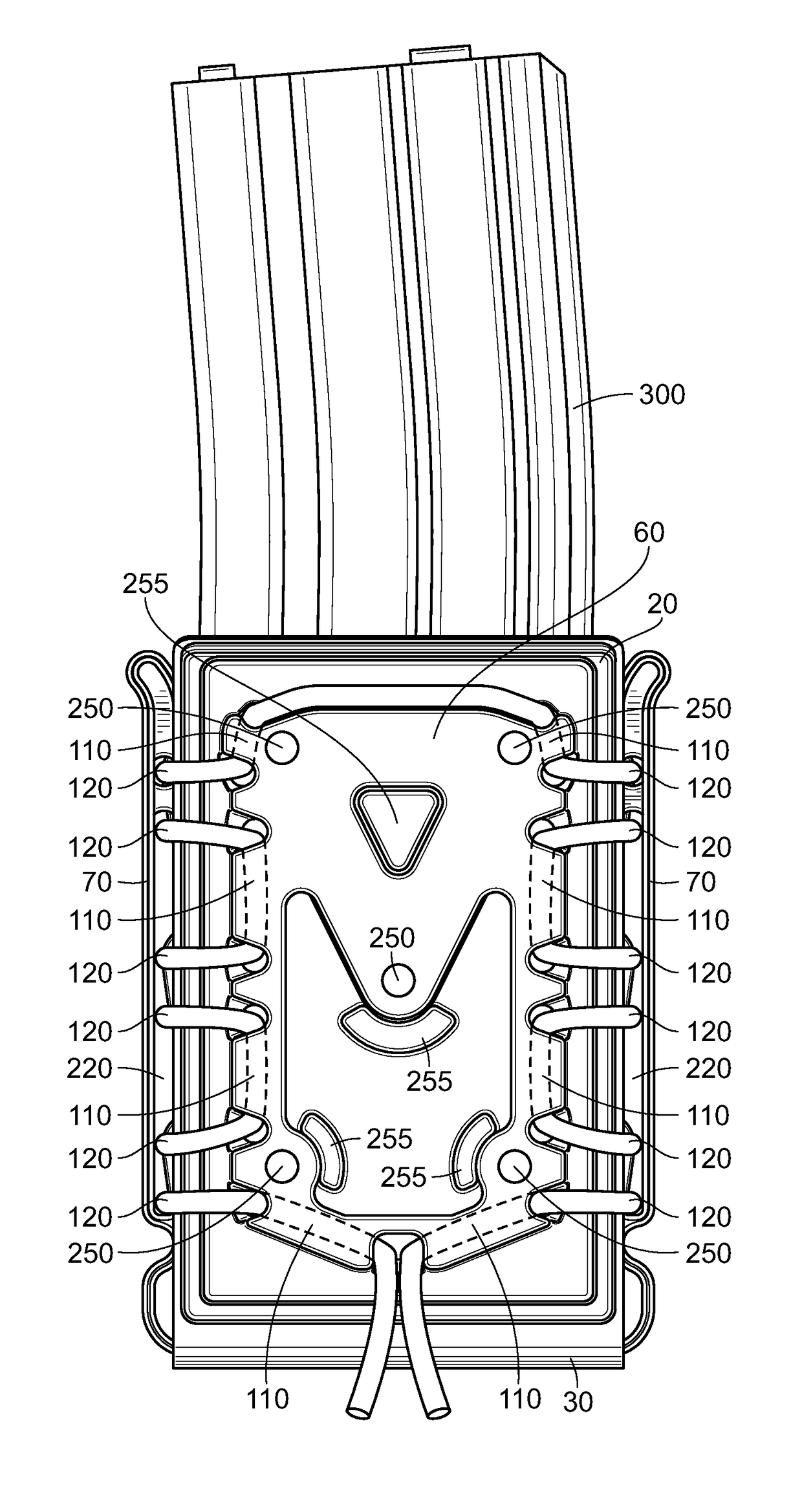

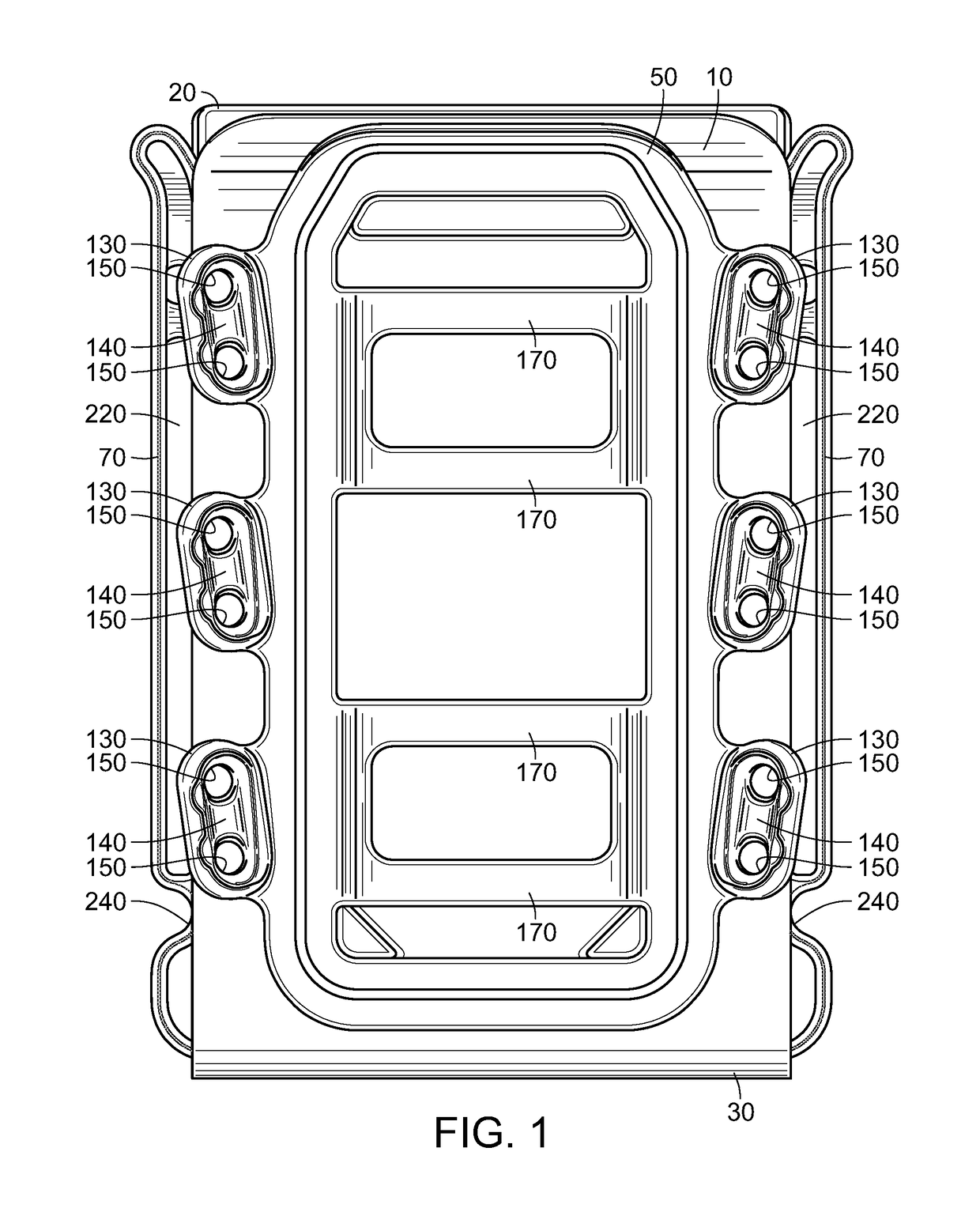

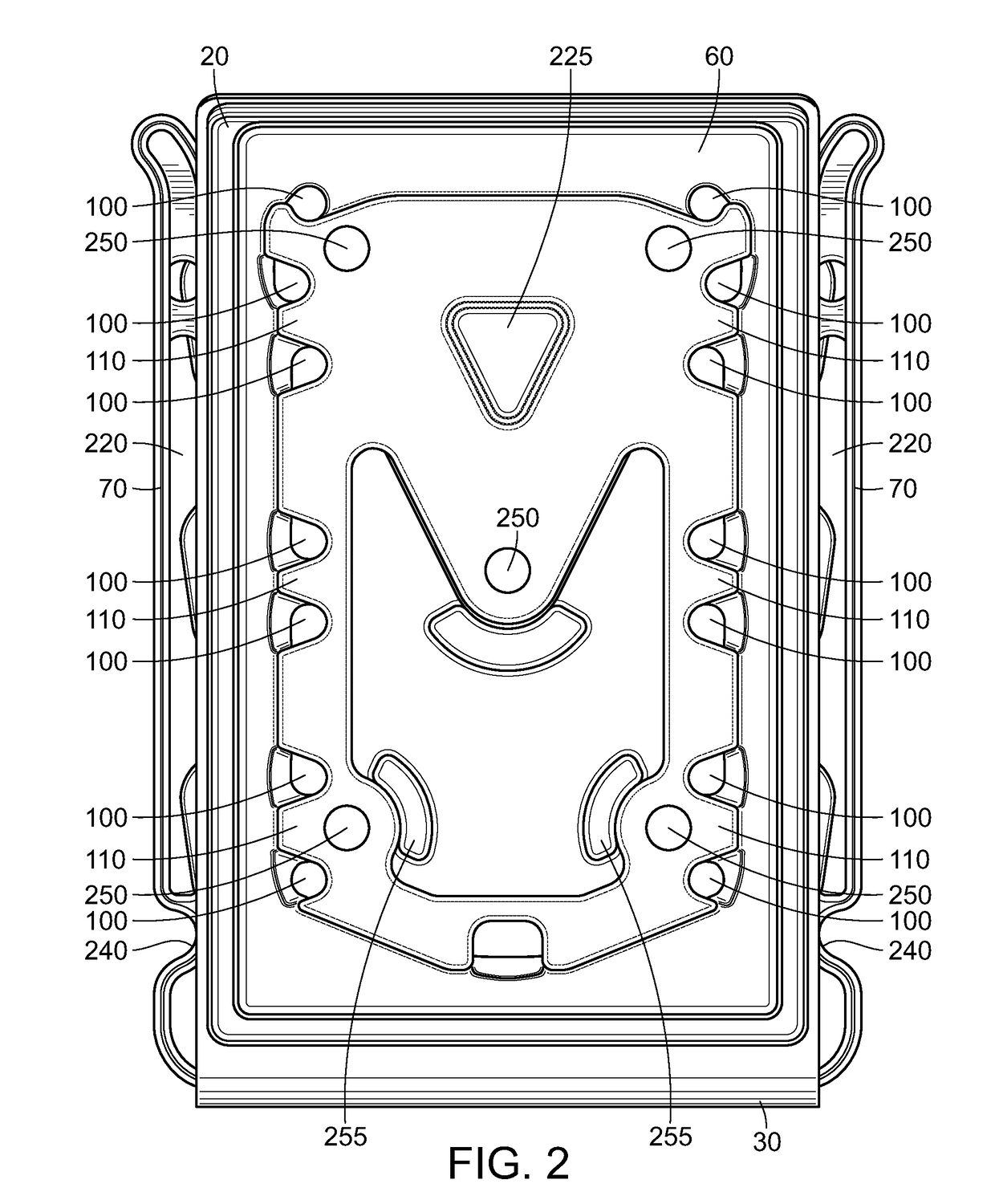

Expandable carry pouch with variable compression

ActiveUS20170099934A1Eliminates unnecessary bulkEliminate weightTravelling carriersHoldersEngineeringExoskeleton

An expandable, variable compression pouch with an exoskeleton construction, which is a hybrid construction that combines a soft, flexible shell with semi-flexible molded outer components on the back, sides, bottom and front of the flexible shell. These molded components form an exoskeleton that provides structural reinforcement where needed without limiting the essential qualities of expansion or contraction or form fit that is essential to achieve the unique features and superior function of the pouch of the present invention.

Owner:EDGE WORKS MFG CO

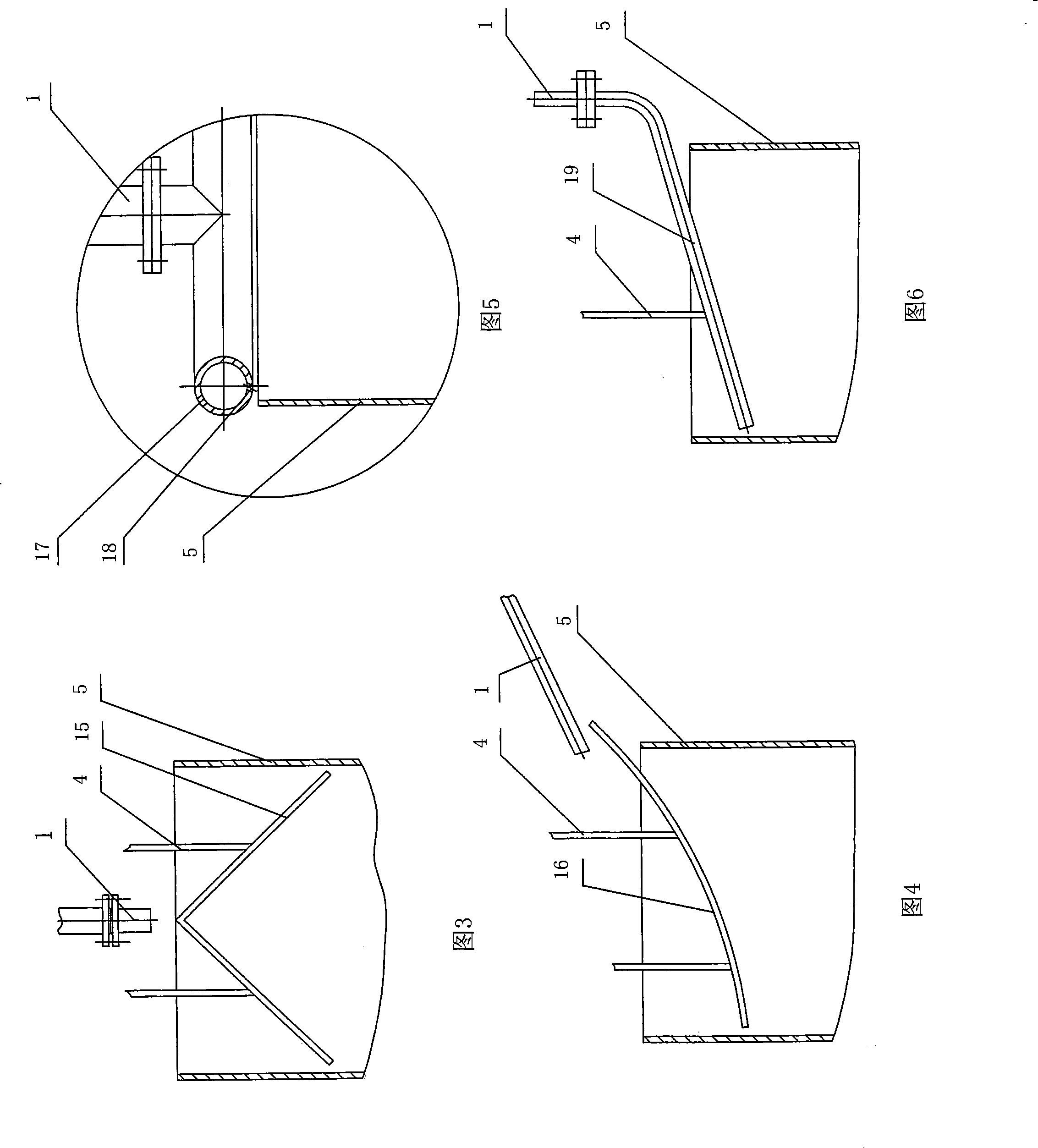

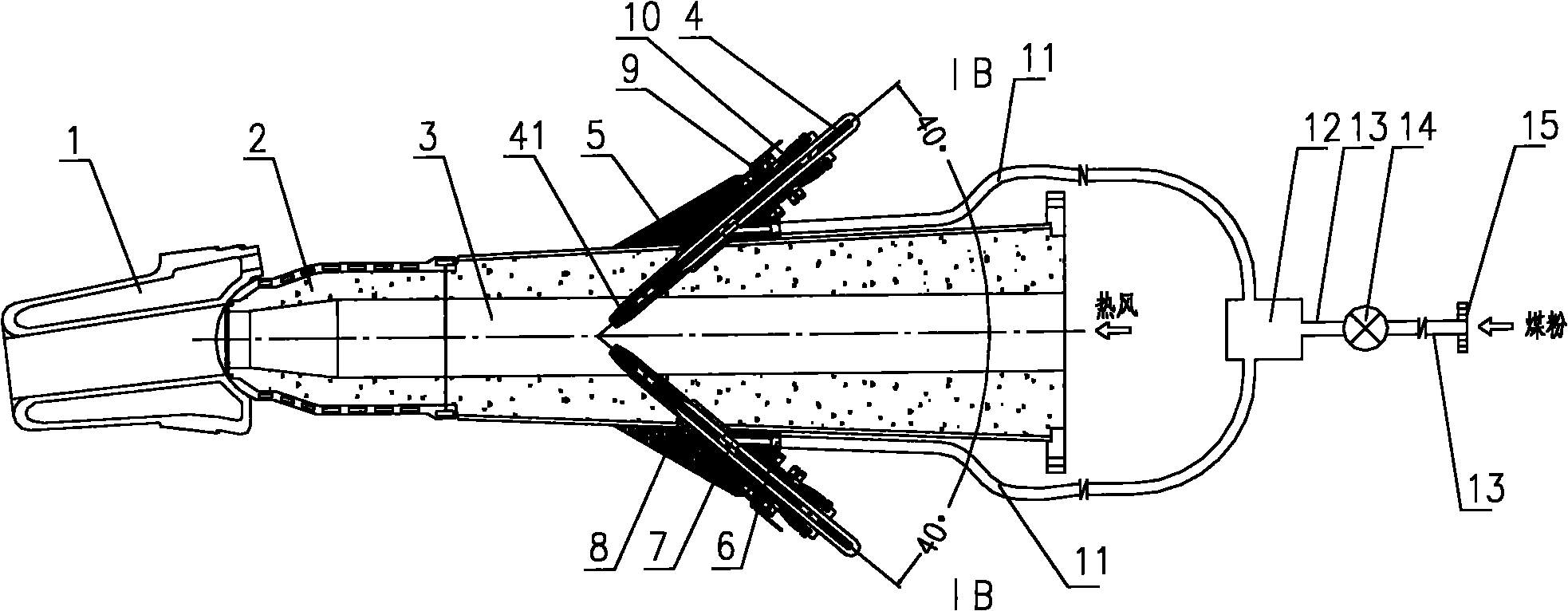

Method and device for blast furnace to blow coal powder

InactiveCN102485913AEnhance heat and mass transferExtended stayTuyeresBlast furnace detailsBall valveNew device

The invention puts forward a method and device for a blast furnace to blow coal powder. Characterized by employment of several short spray guns, a large incidence angle, accurate positioning of spray guns, small heat radiation and long life of blowpipes, and adoption of ceramic nozzles, the new method and new device of the invention aims to eliminate various defects in prior art, such as small coal powder incidence angle, restriction by high speed hot airflow, inadequate mixing with hot air, long length and long service life of spray guns, large heat radiation and short service life of blowpipes, and hard use of oxygen-coal lances, etc. According to the invention, on the blowpipes of each air ports, each short spray gun is inserted into each installation seat, and coal powder blown into a blast furnace enters from blowing inlets positioned on a lateral side of each installation seat, then reaches the inside of each short spray gun through coal spraying holes that are disposed on tube walls of the short spray guns and are over against the blowing inlets, and is finally blown into the furnace through each short spray gun. The device of the invention at least comprises: a blowpipe with a coal powder precombustion function, short spray guns, installation seats, ball valves, locking devices, coal conveying branch pipes, a distributor, a small ball valve, a coal conveying pipe, and an inlet connecting piece.

Owner:张昭贵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com