Patents

Literature

69results about How to "Eliminate wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

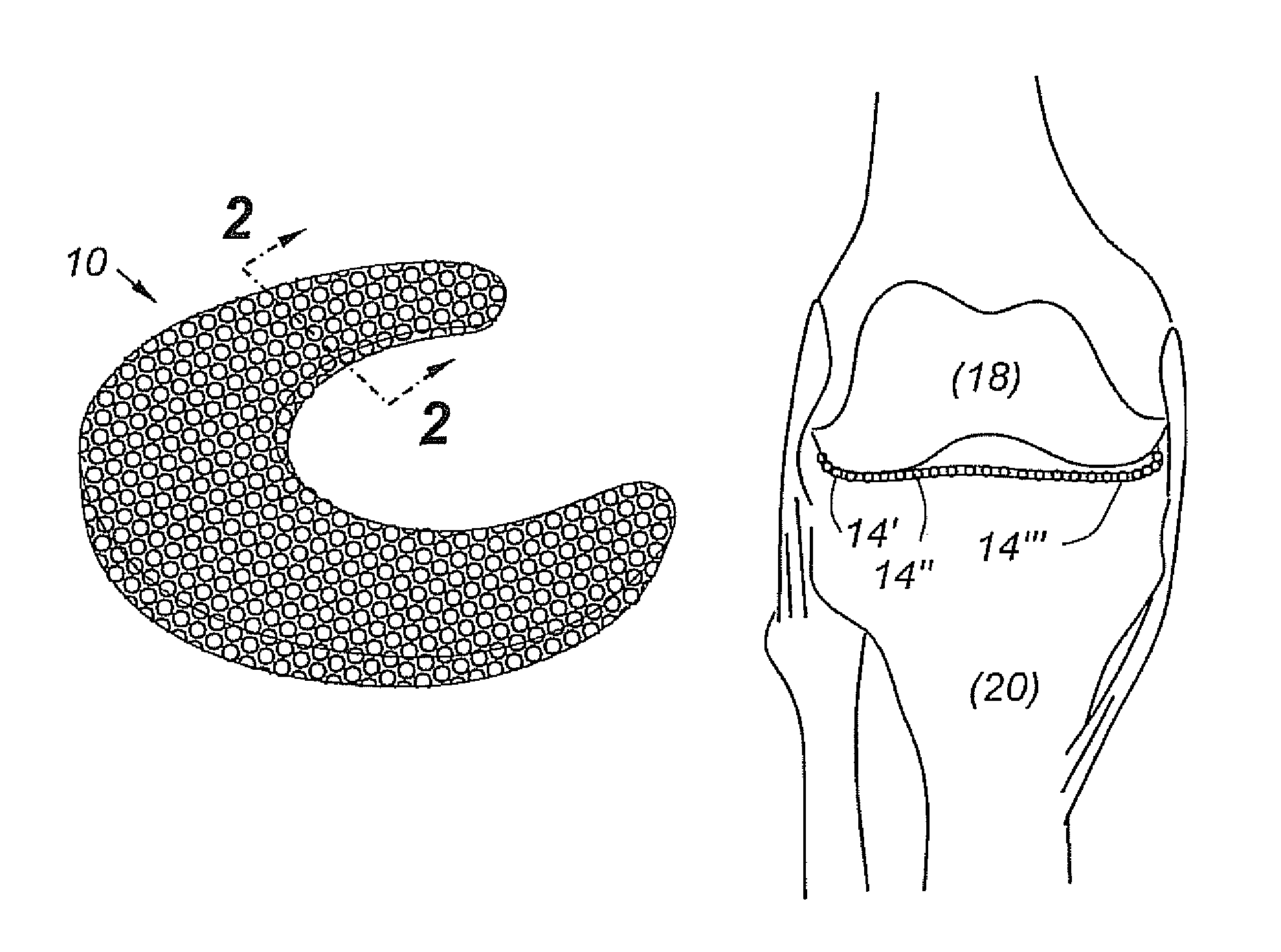

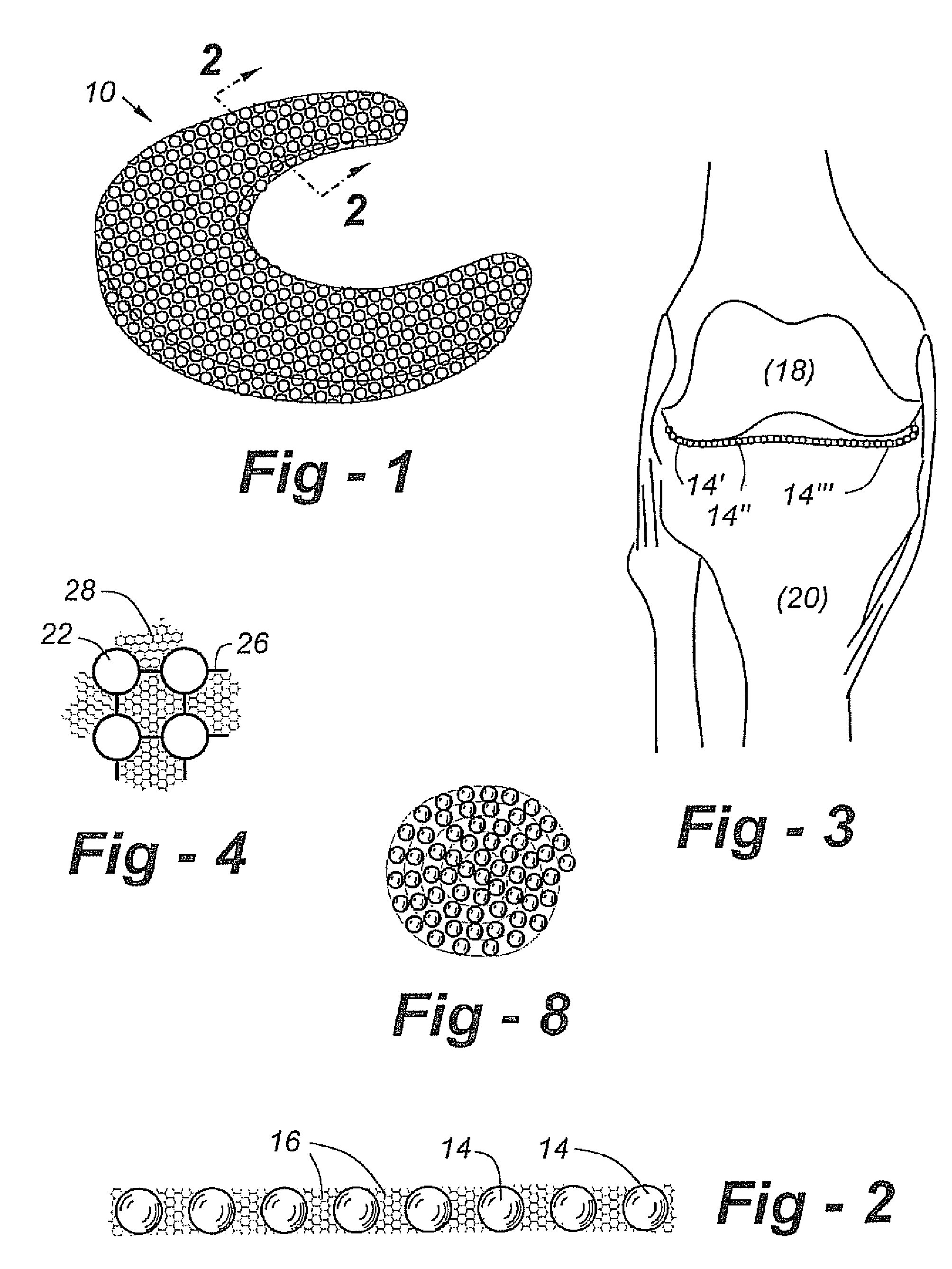

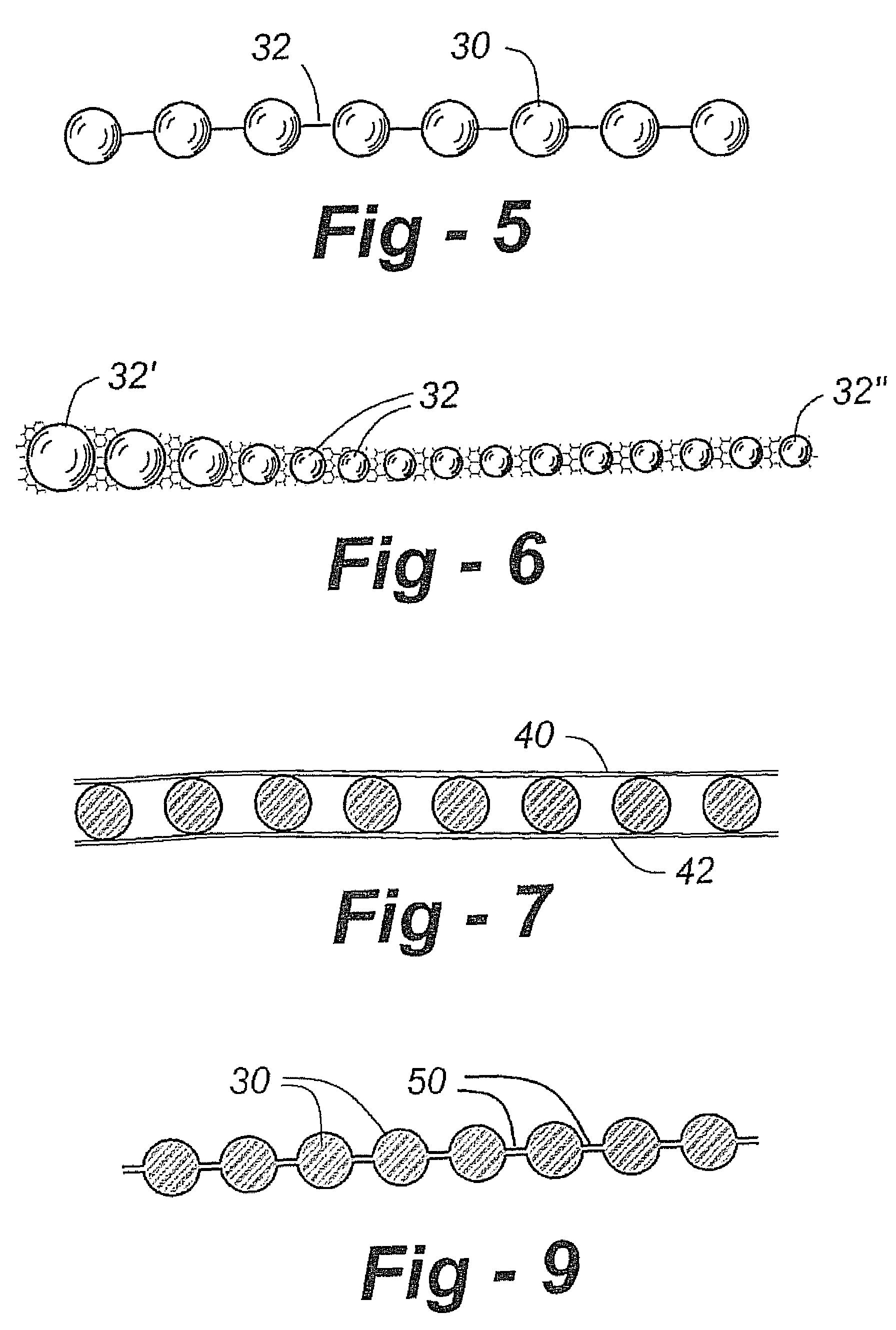

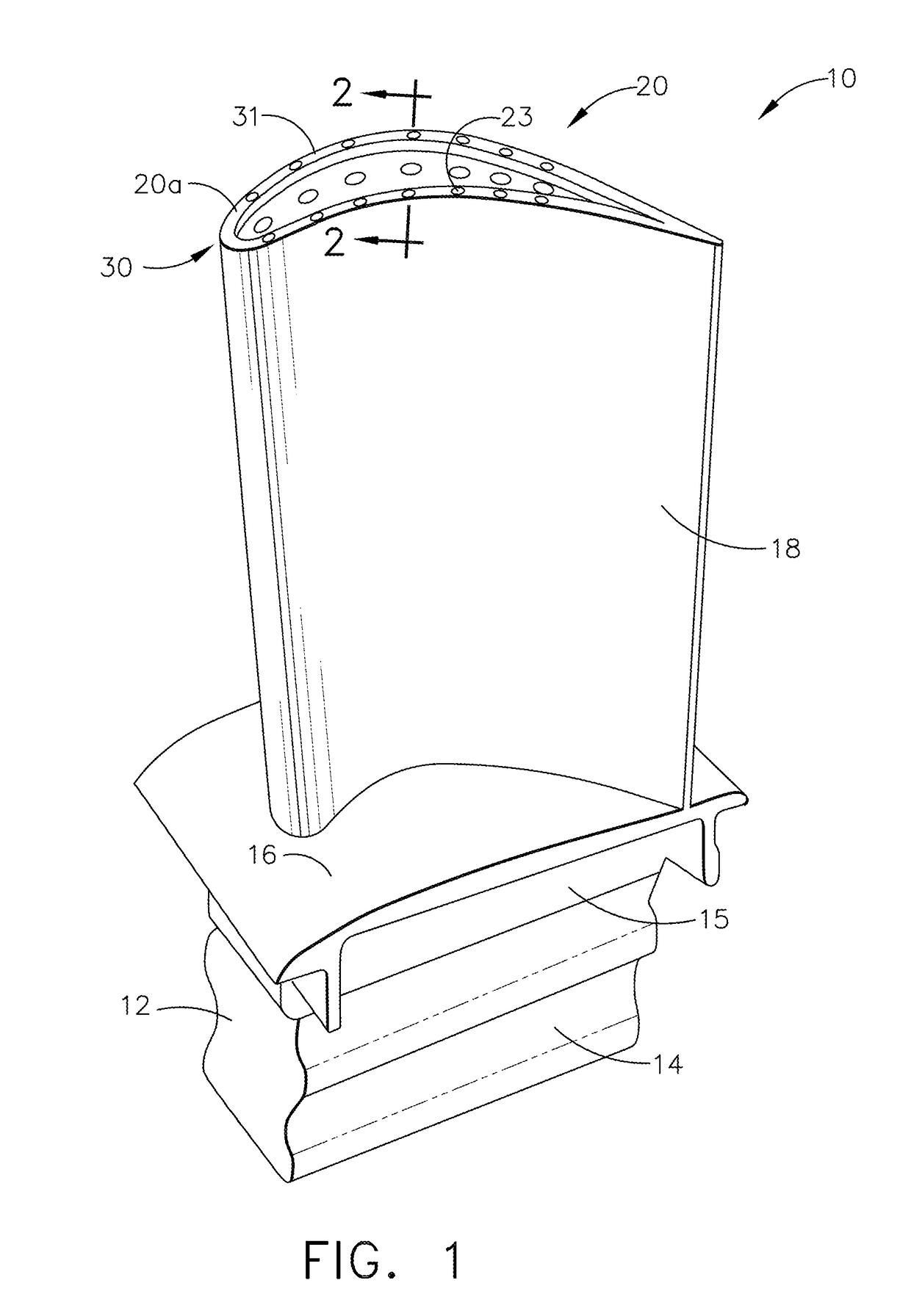

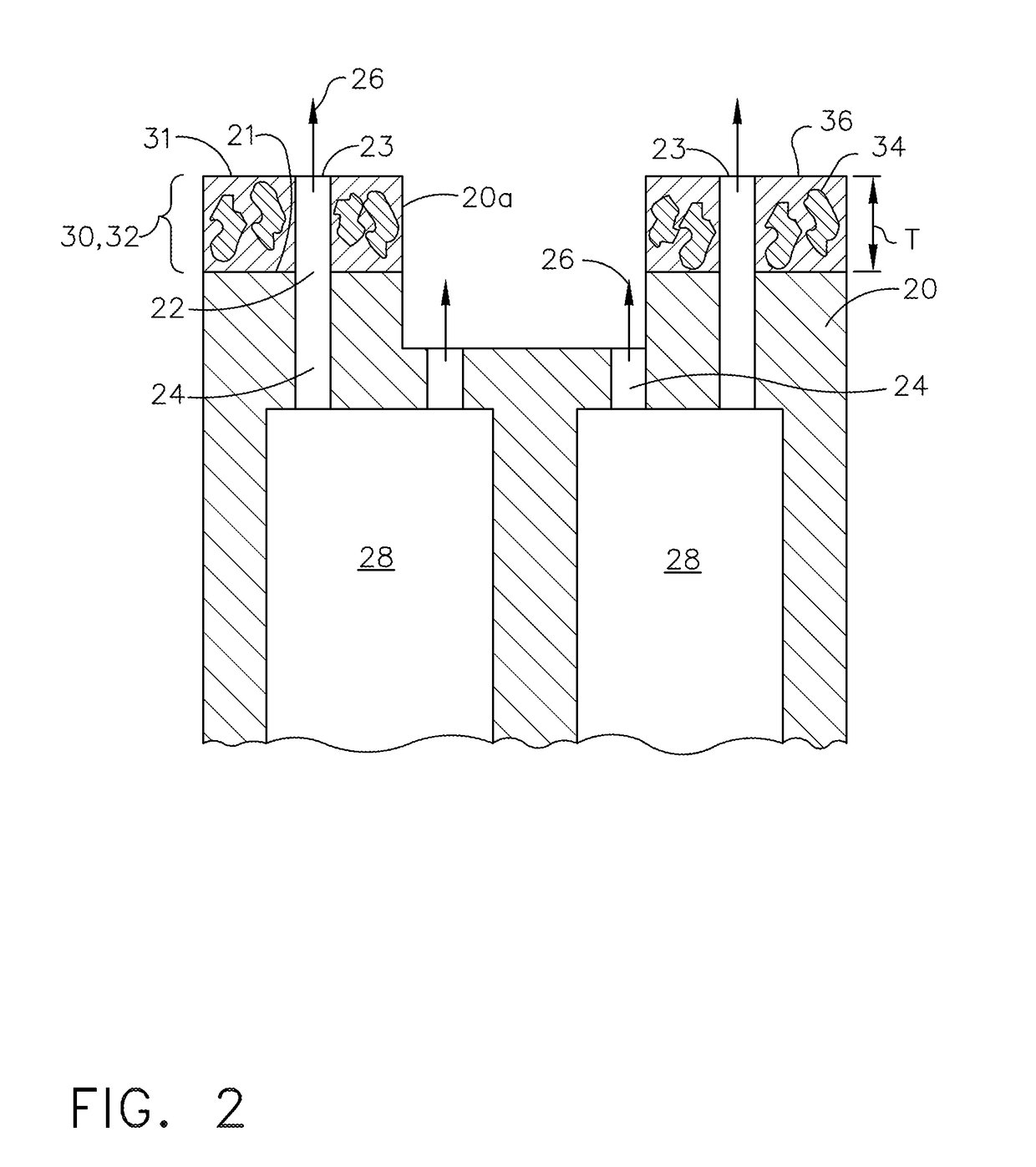

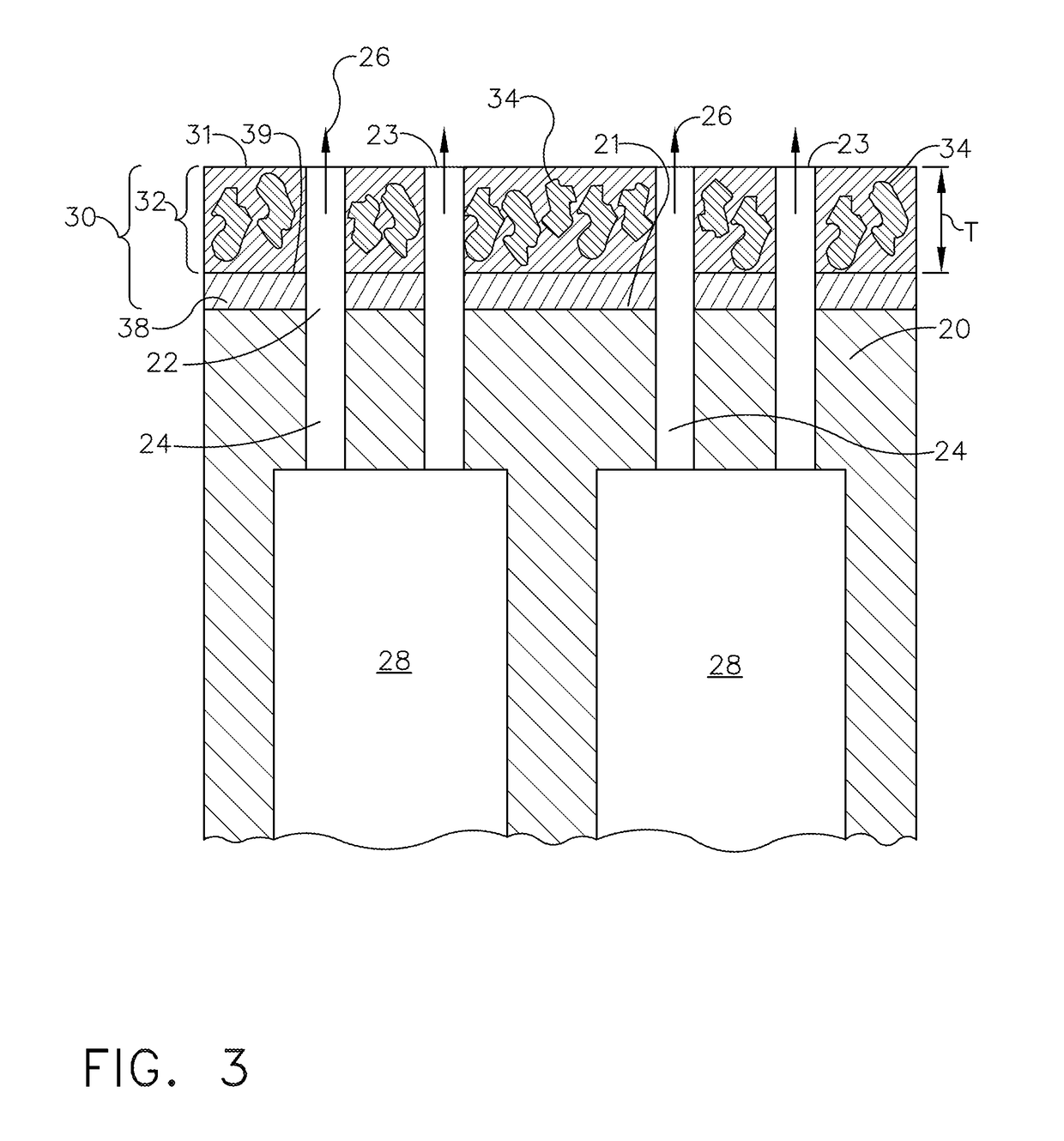

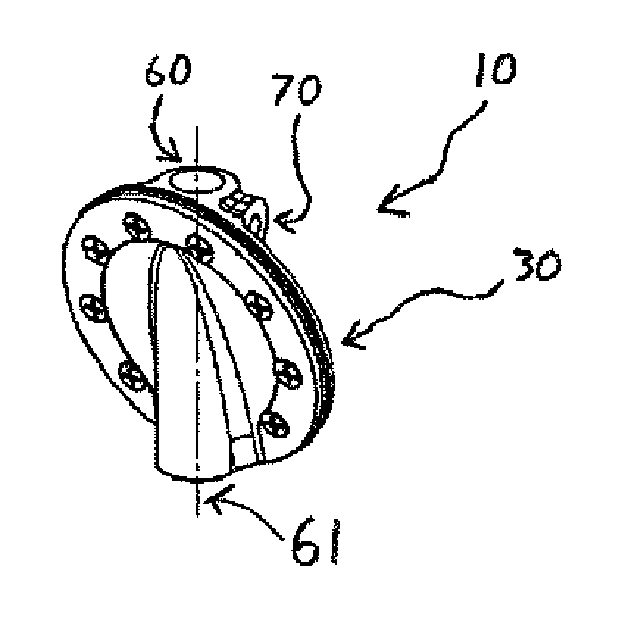

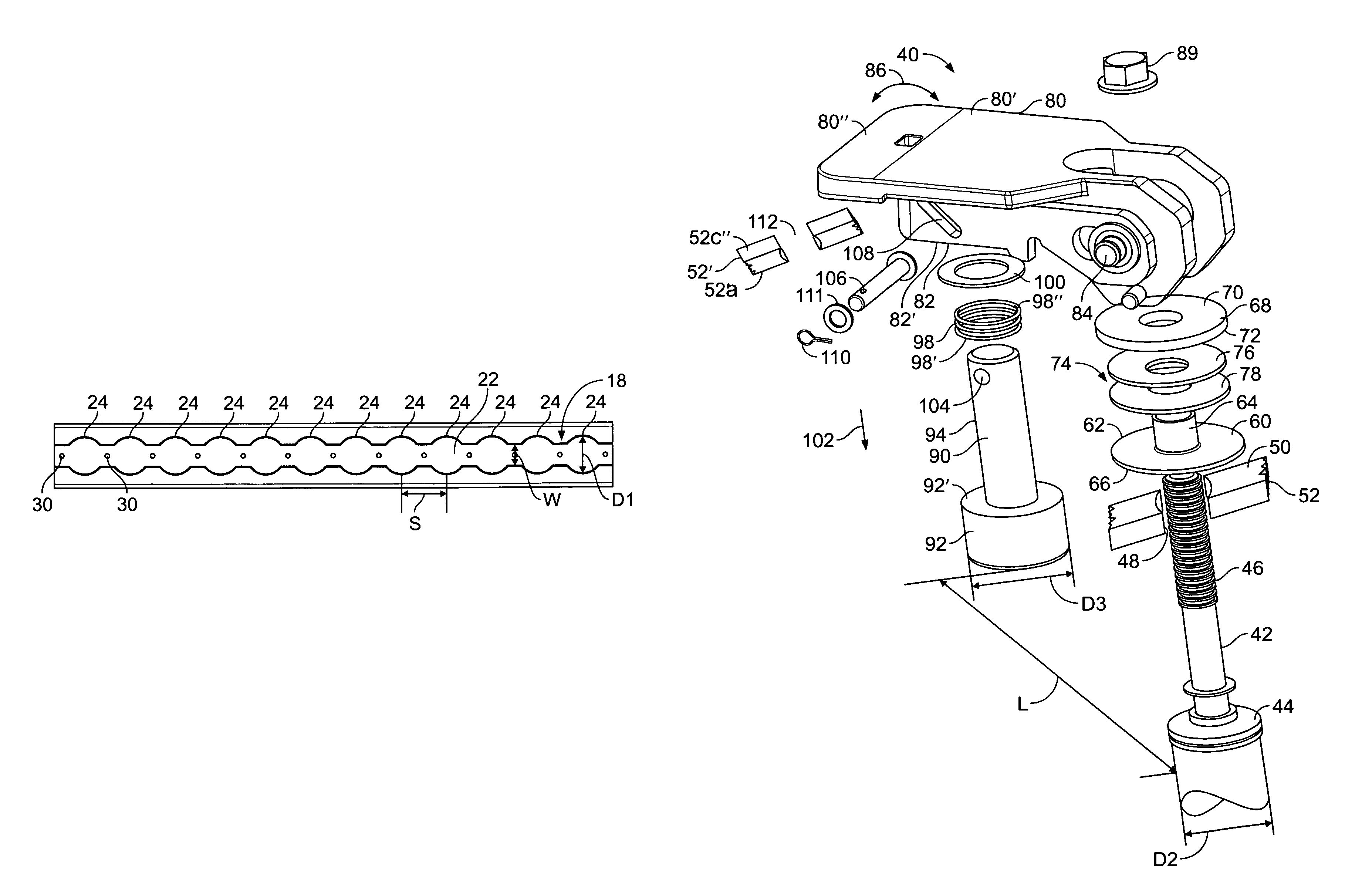

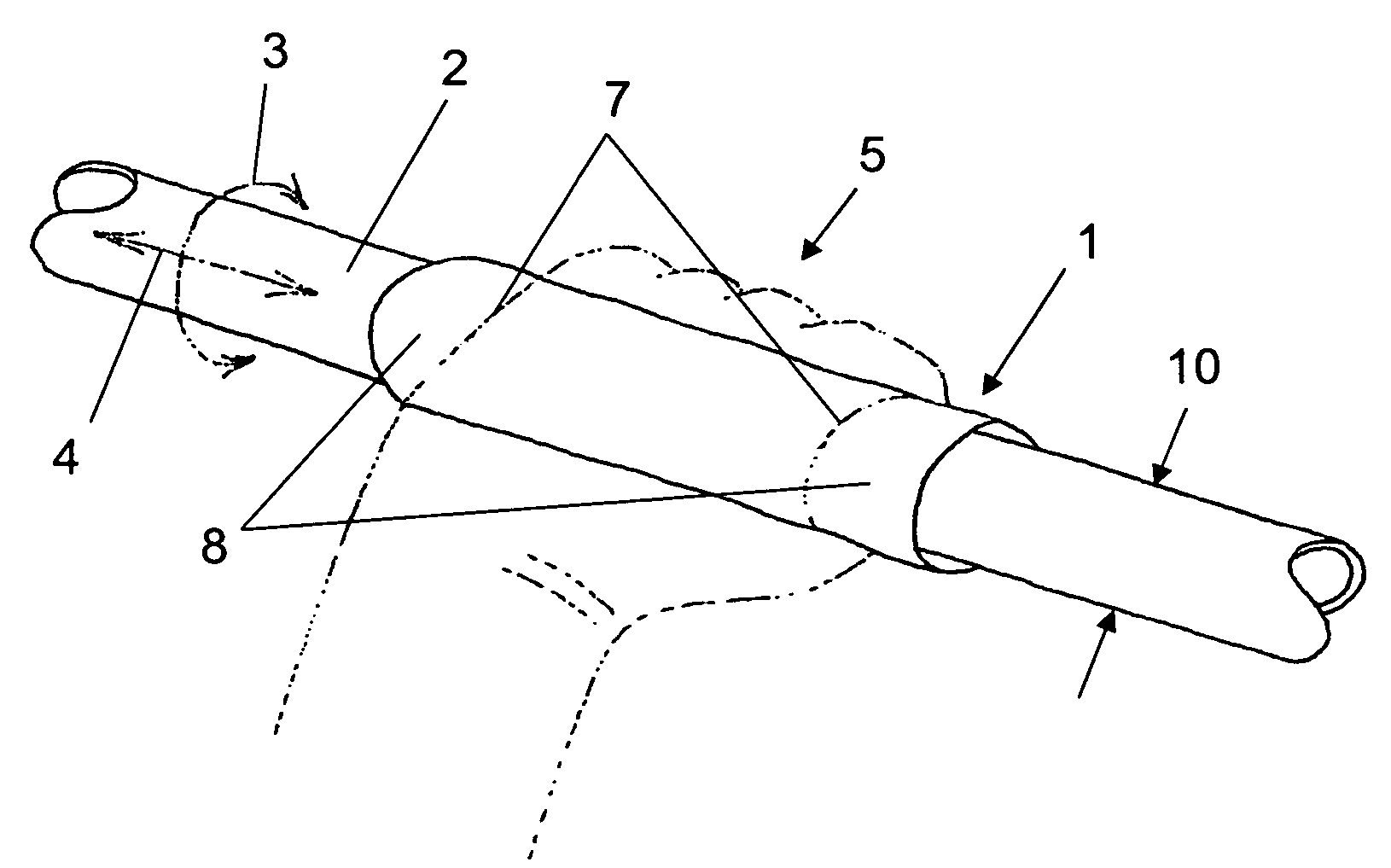

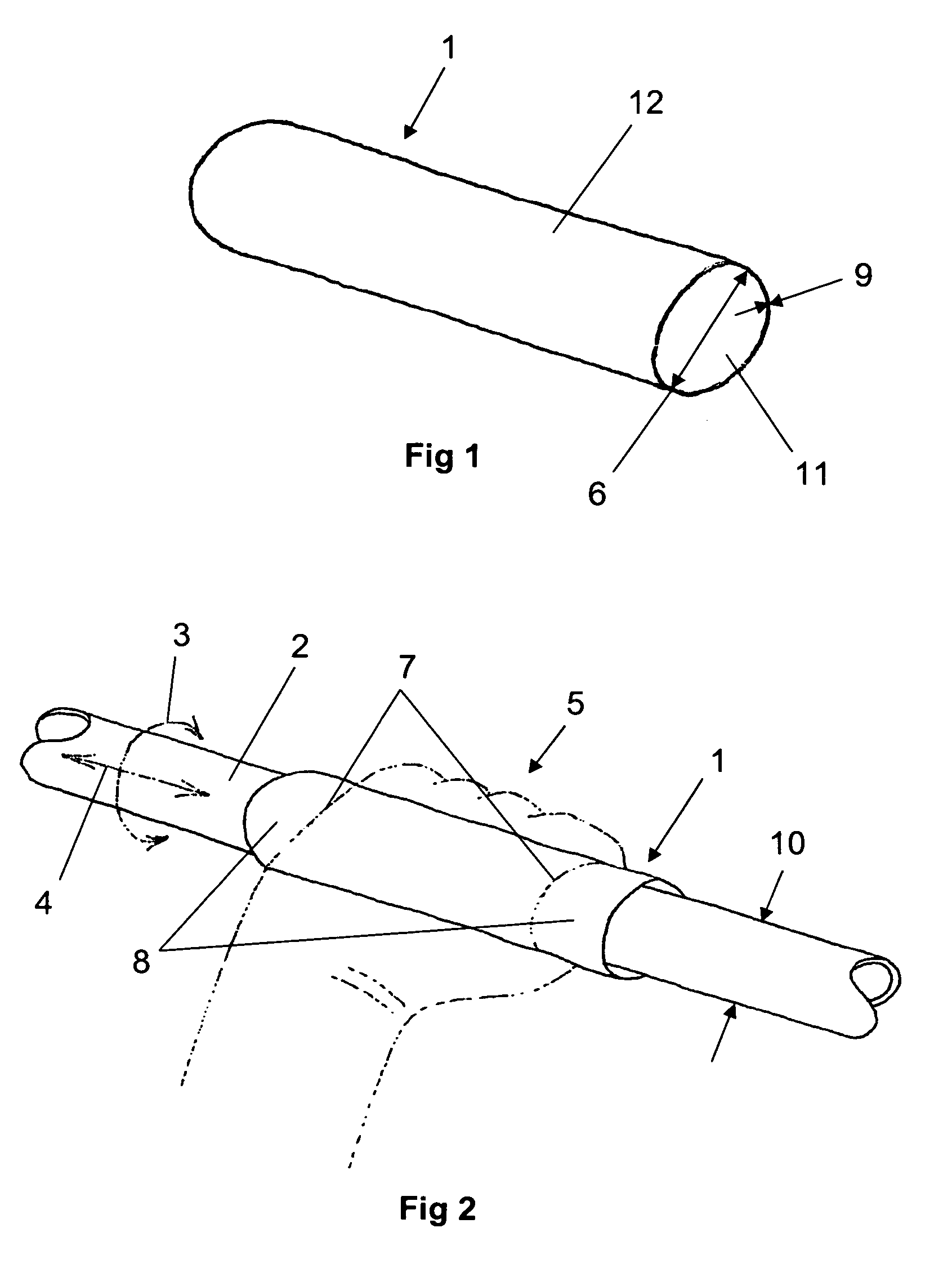

Prosthesis for replacement of cartilage

A cartilage replacement or repair prosthesis comprises a layer of streamlined elastomer elements, preferably in the form of spheres, supported in a matrix material so that the radially opposed surfaces of the spheres are positioned on opposite surfaces of the layer and make contact with the opposed surfaces of the femur and tibia and the forces exerted between these bones extend through the streamlined elements. The matrix material has a substantially lower resistance to deformation than the spheres to control the position of the spheres relative to one another without significantly restraining their load-responsive deformation under forces exerted between the femur and tibia. The layer, with its elastomeric inserts, is sufficiently thin and flexible to allow it to be rolled for arthroscopic insertion into a knee joint.

Owner:SUCCESSOR TRUSTEE OF THE EUGENE RIVIN LIVING TRUST +2

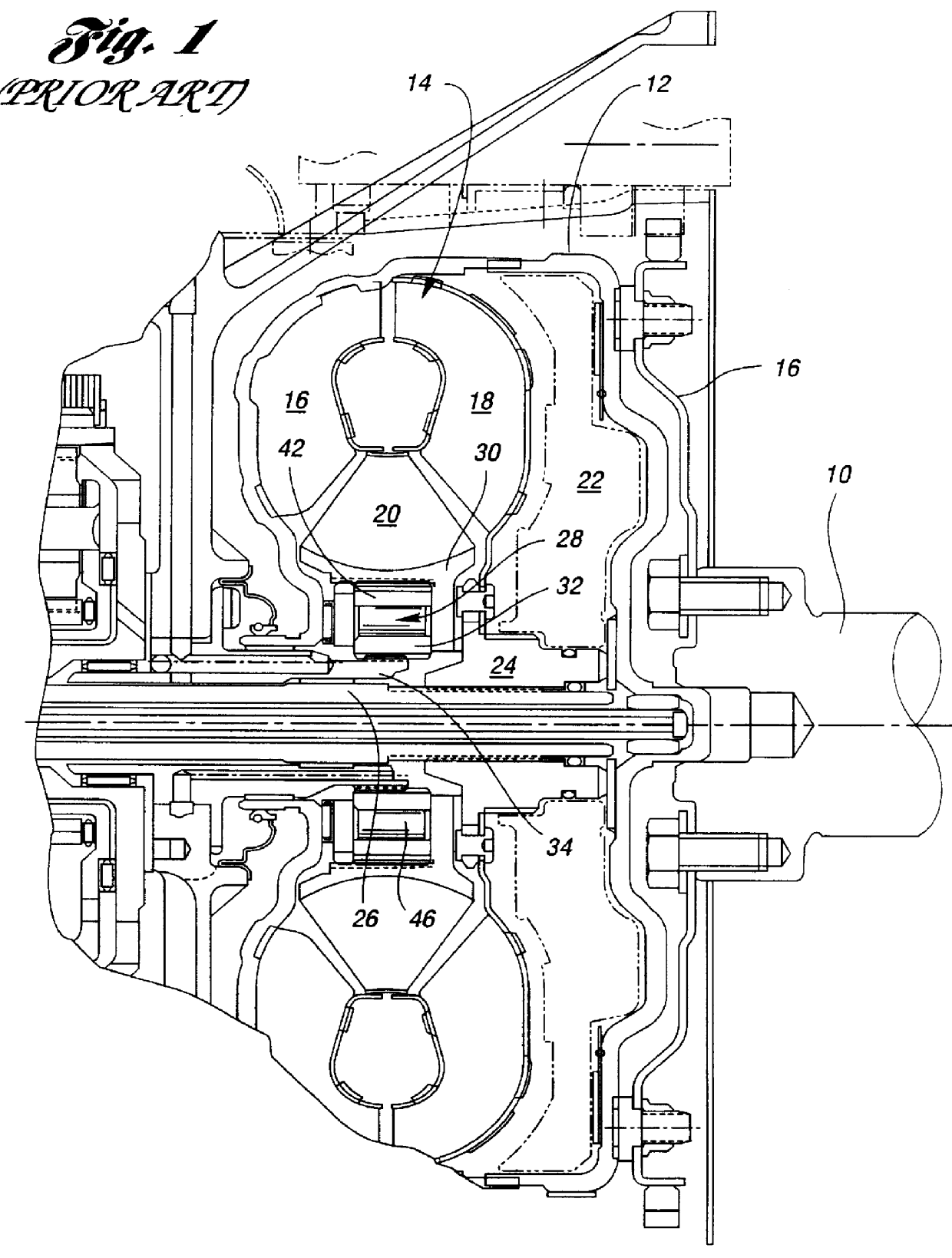

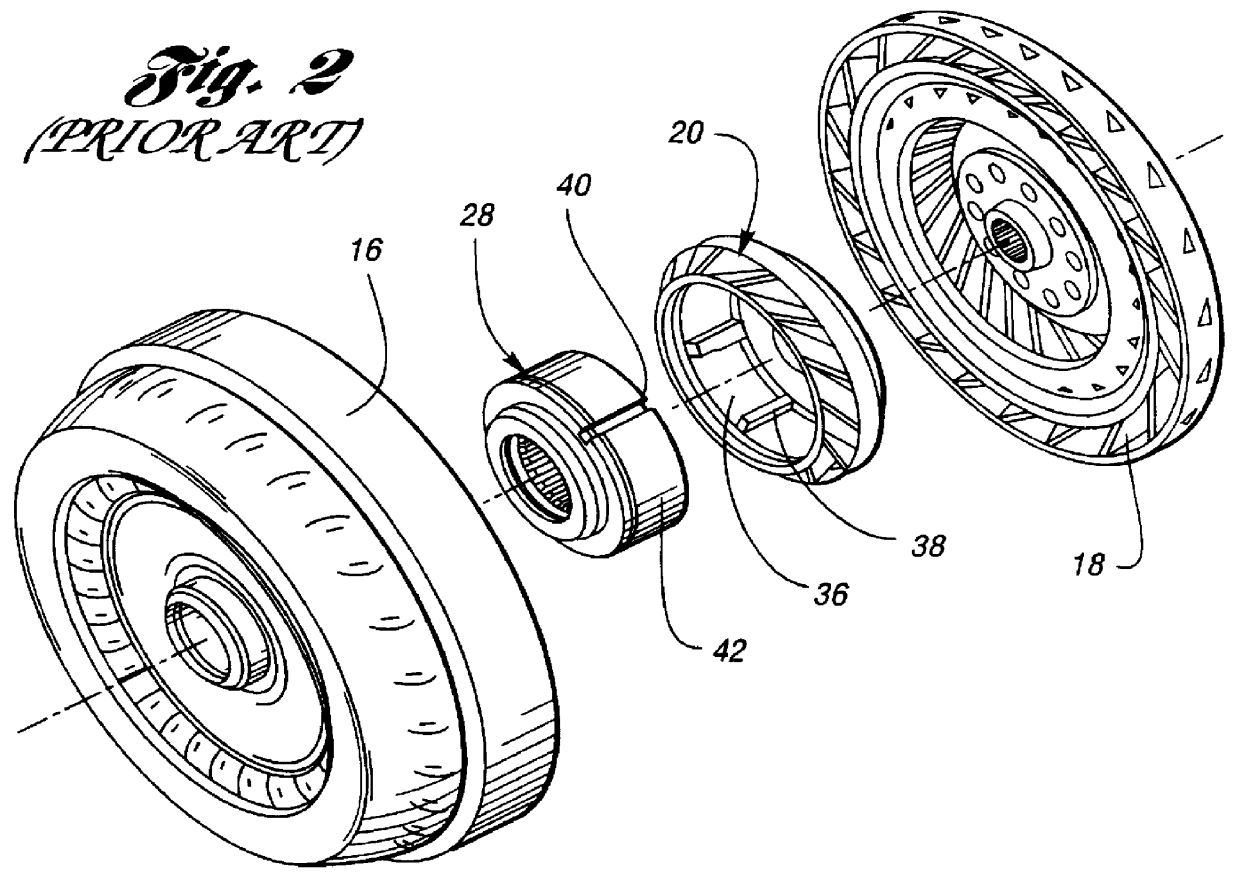

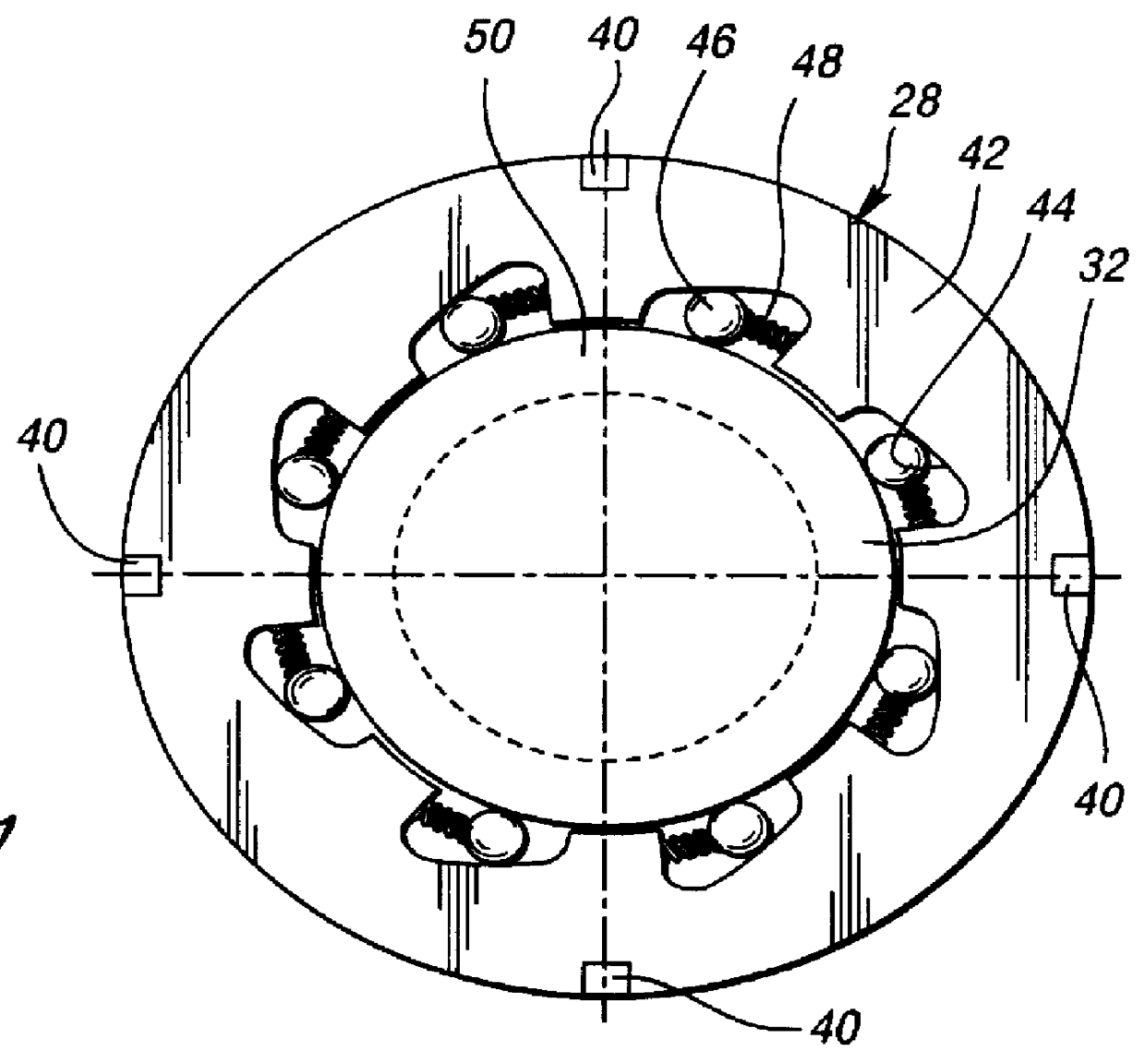

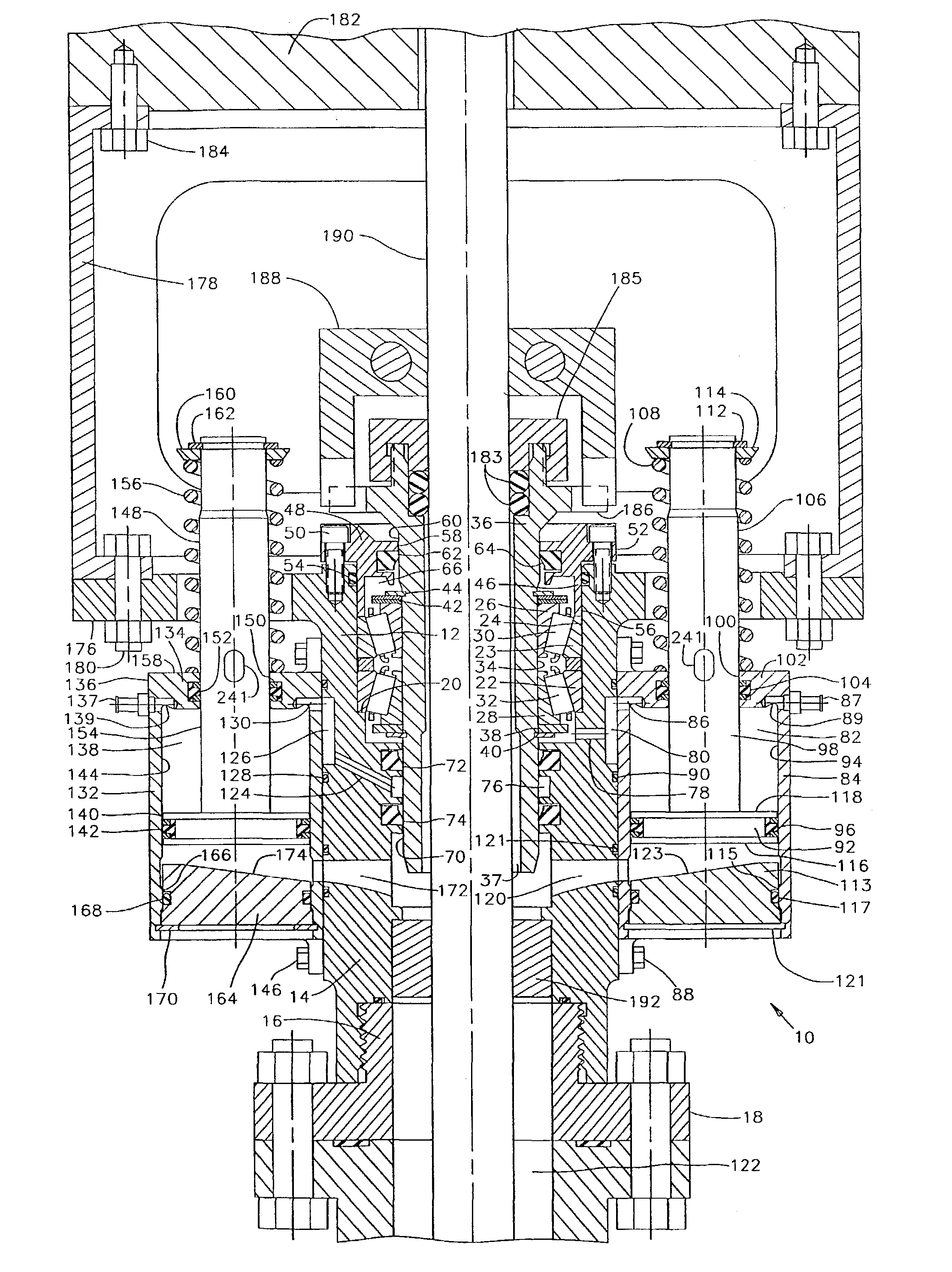

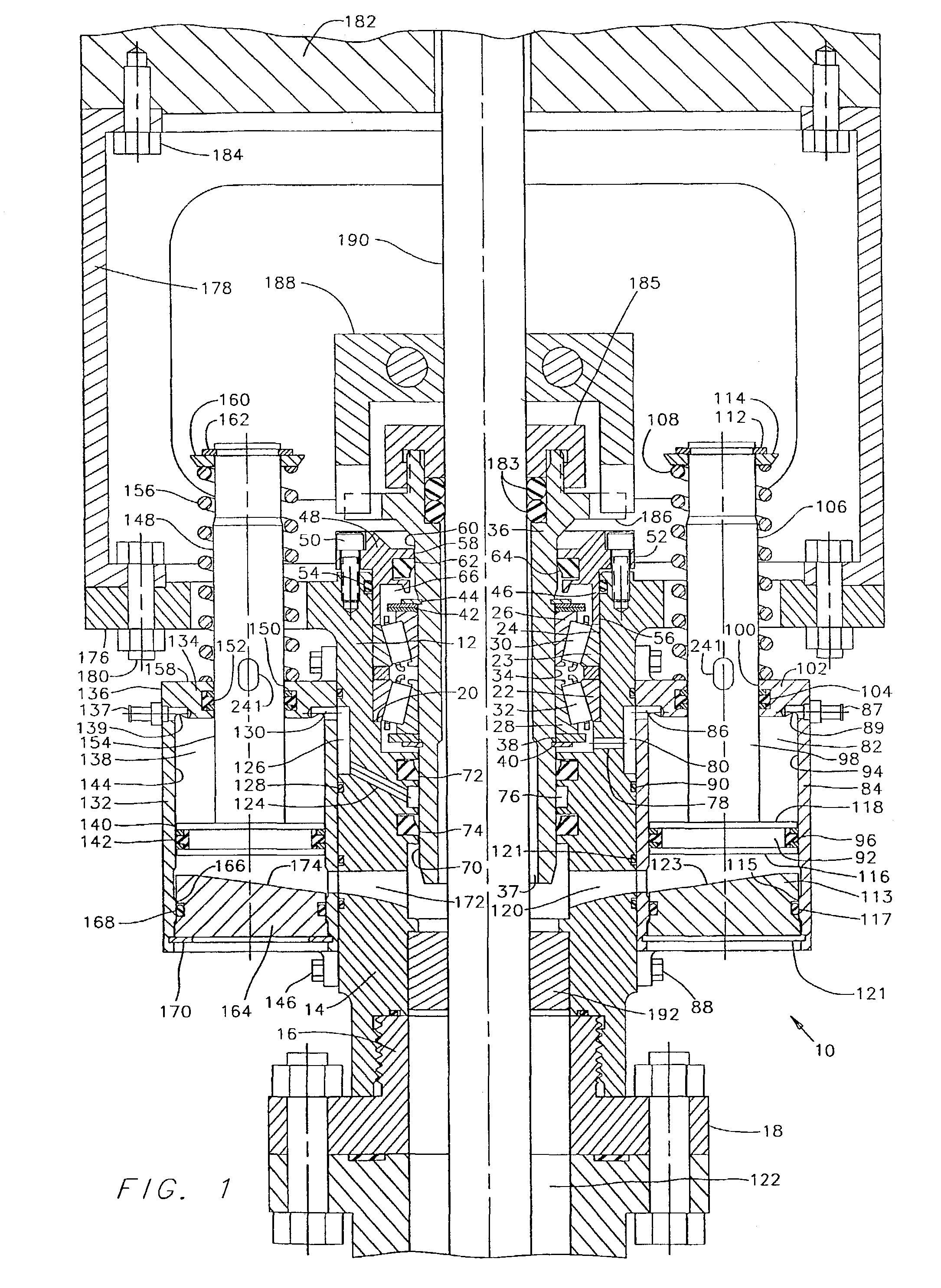

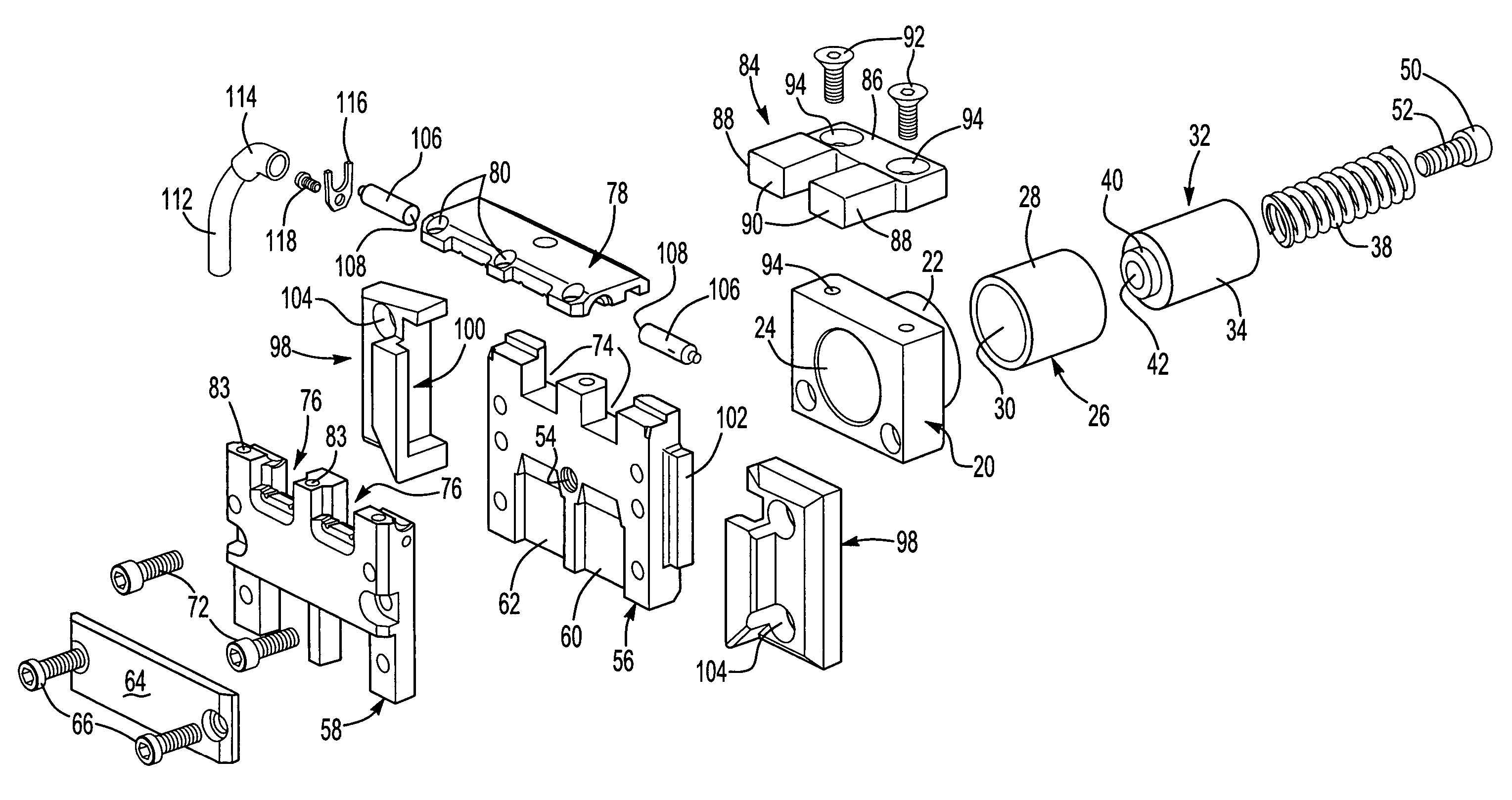

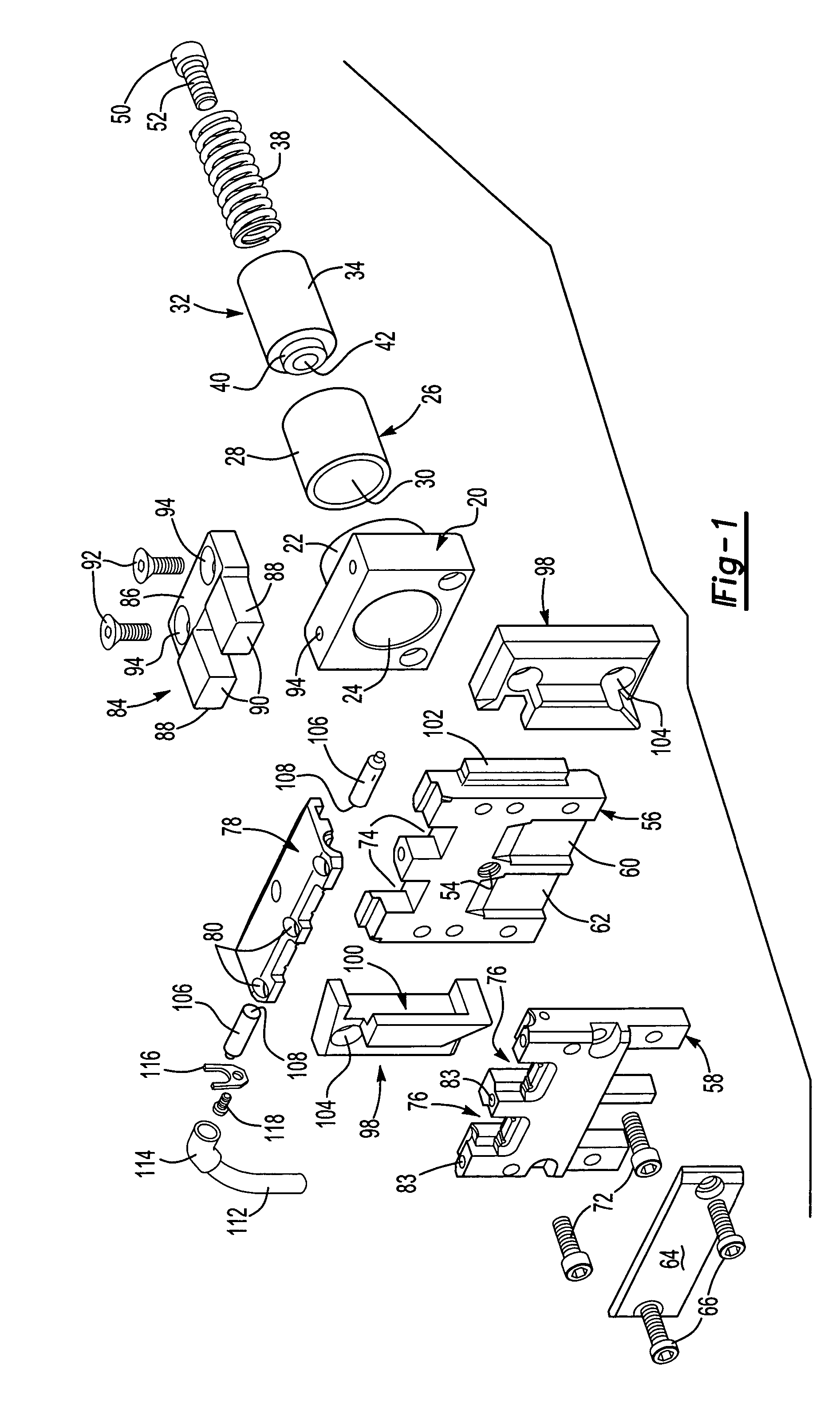

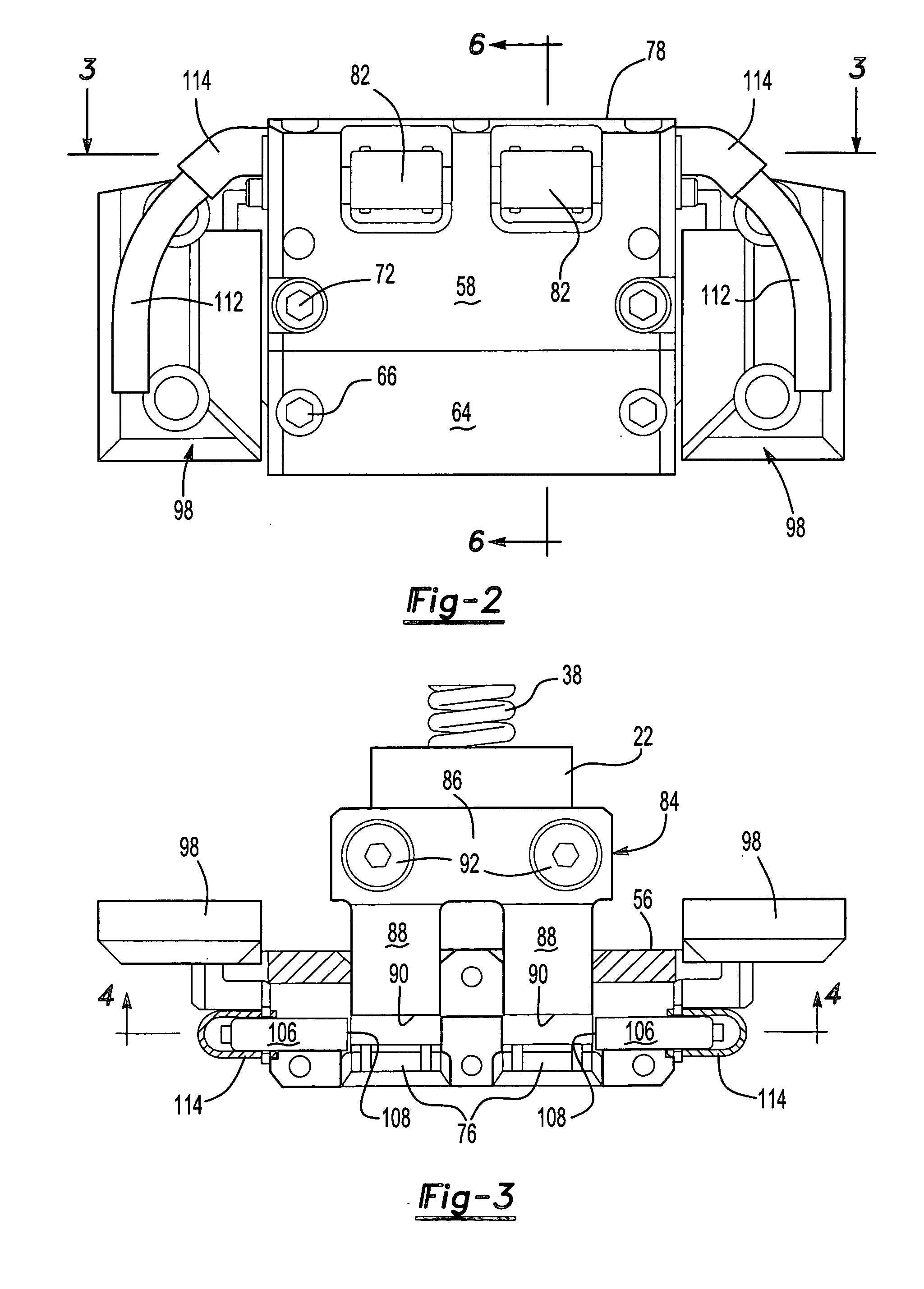

Overrunning coupling assembly

InactiveUS6116394AReduce wearEliminate lubrication control requirementRotary clutchesFriction clutchesCouplingTrunnion

An overrunning coupling assembly includes a notch plate and an annular coupling pocket plate positioned in face-to-face relationship with respect to each other along a common axis. The pocket plate includes strut pockets disposed at angularly spaced positions about the axis. The notch plate includes notch recesses at angularly spaced positions about the common axis and positioned in juxtaposed relationship with respect to the strut pockets. The notch plate includes an inner circumferential rail at a radially inward side of the notch recesses and an outer circumferential rail at a radially outward side of the notch recesses. Torque-transmitting struts are positioned in the strut pockets. Each strut has first and second ears at one edge thereof for enabling pivotal motion of the struts about an ear axis intersecting the ears. The opposite edge of each strut is engageable with one of the notch recesses whereby one-way torque transfer may occur between the plates. Each opposite edge has first and second corners. Each strut pocket is sufficiently enlarged to allow pivotal movement of each strut about a strut axis which is parallel with the common axis, thereby enabling one of the first and second corners to be selectively supported by one of the inner and outer circumferential rails to prevent the struts from slapping against the notch recesses as the notch plate and pocket plate are respectively counterrotated.

Owner:MEANS IND INC

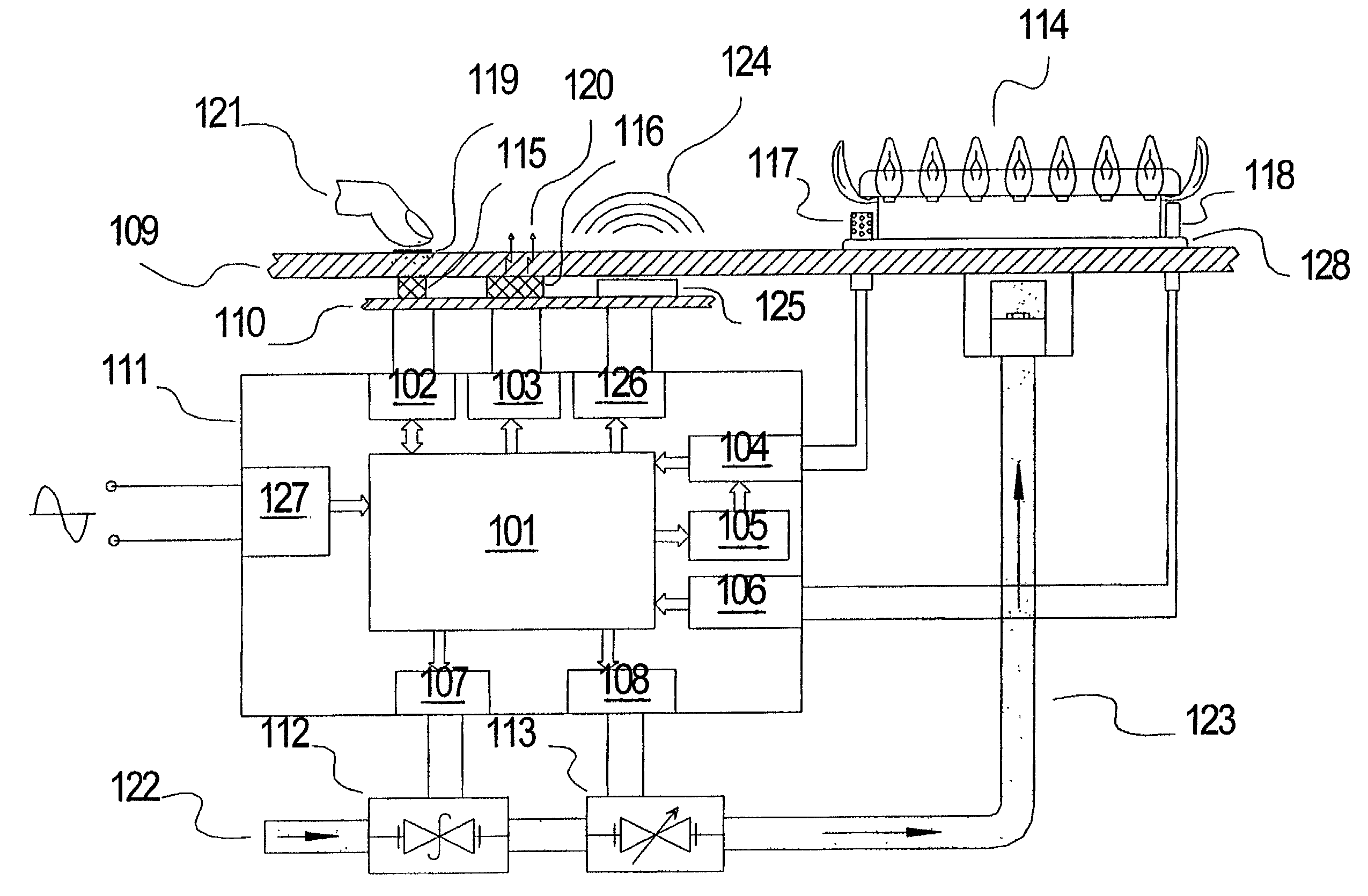

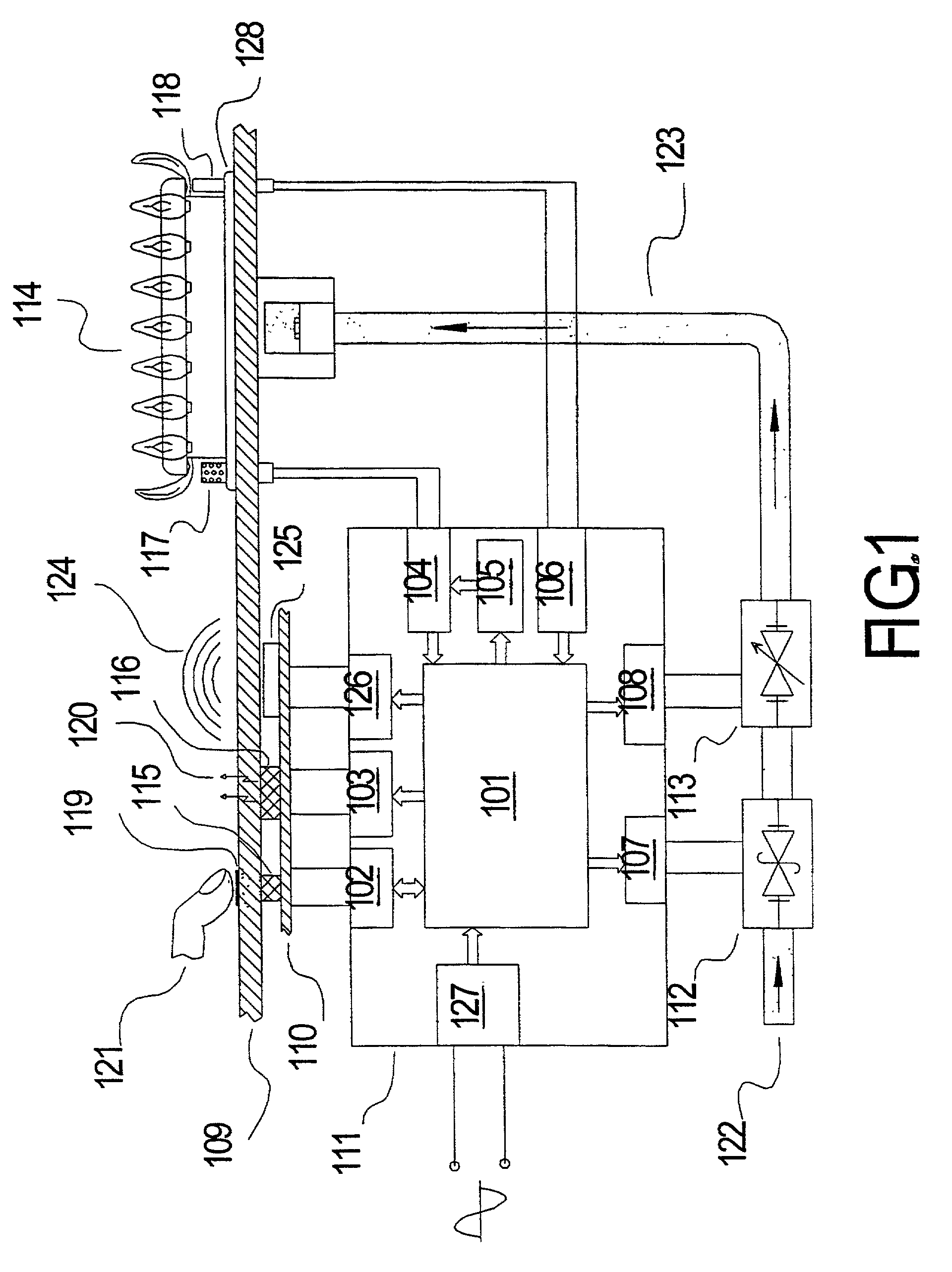

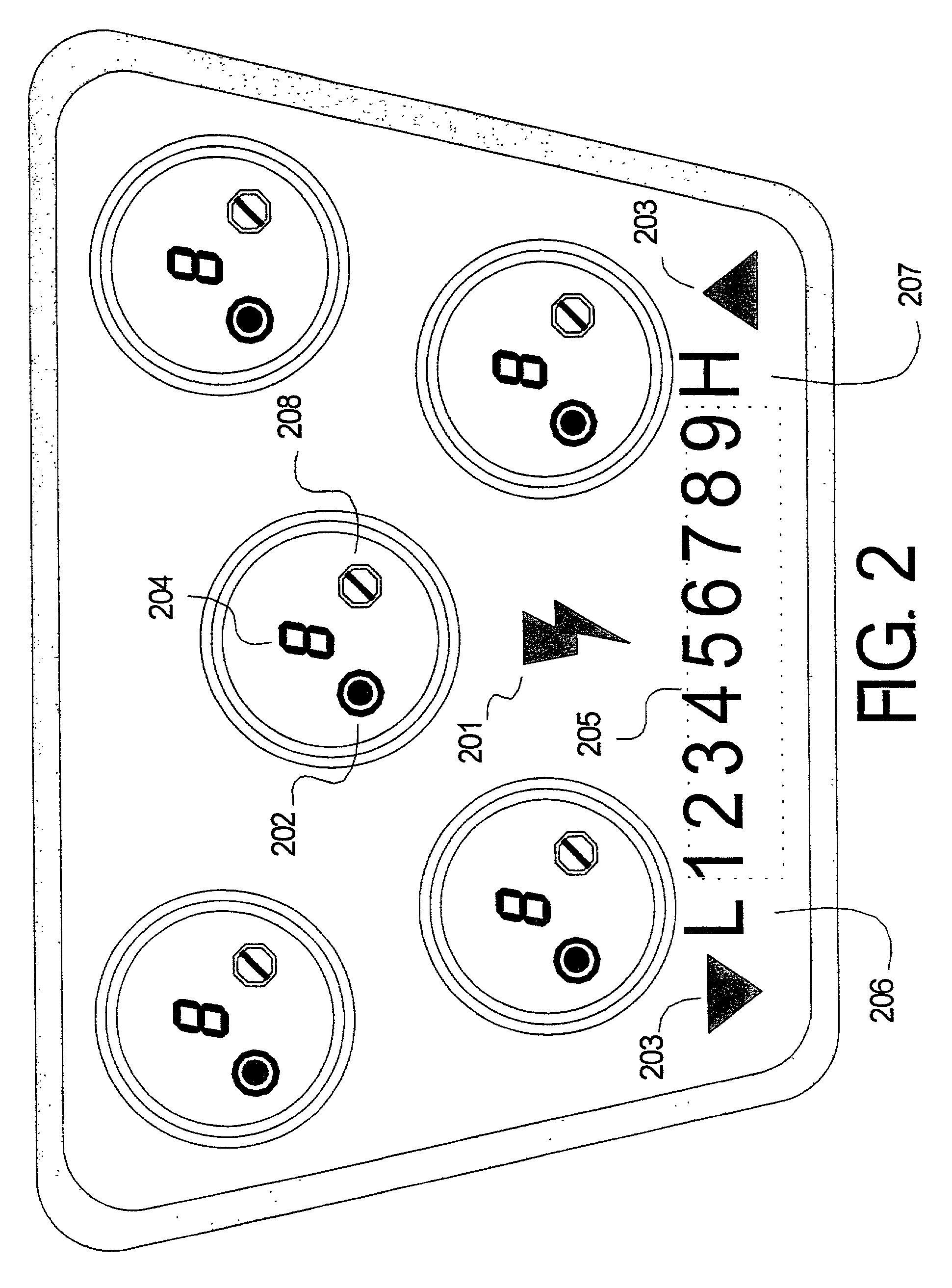

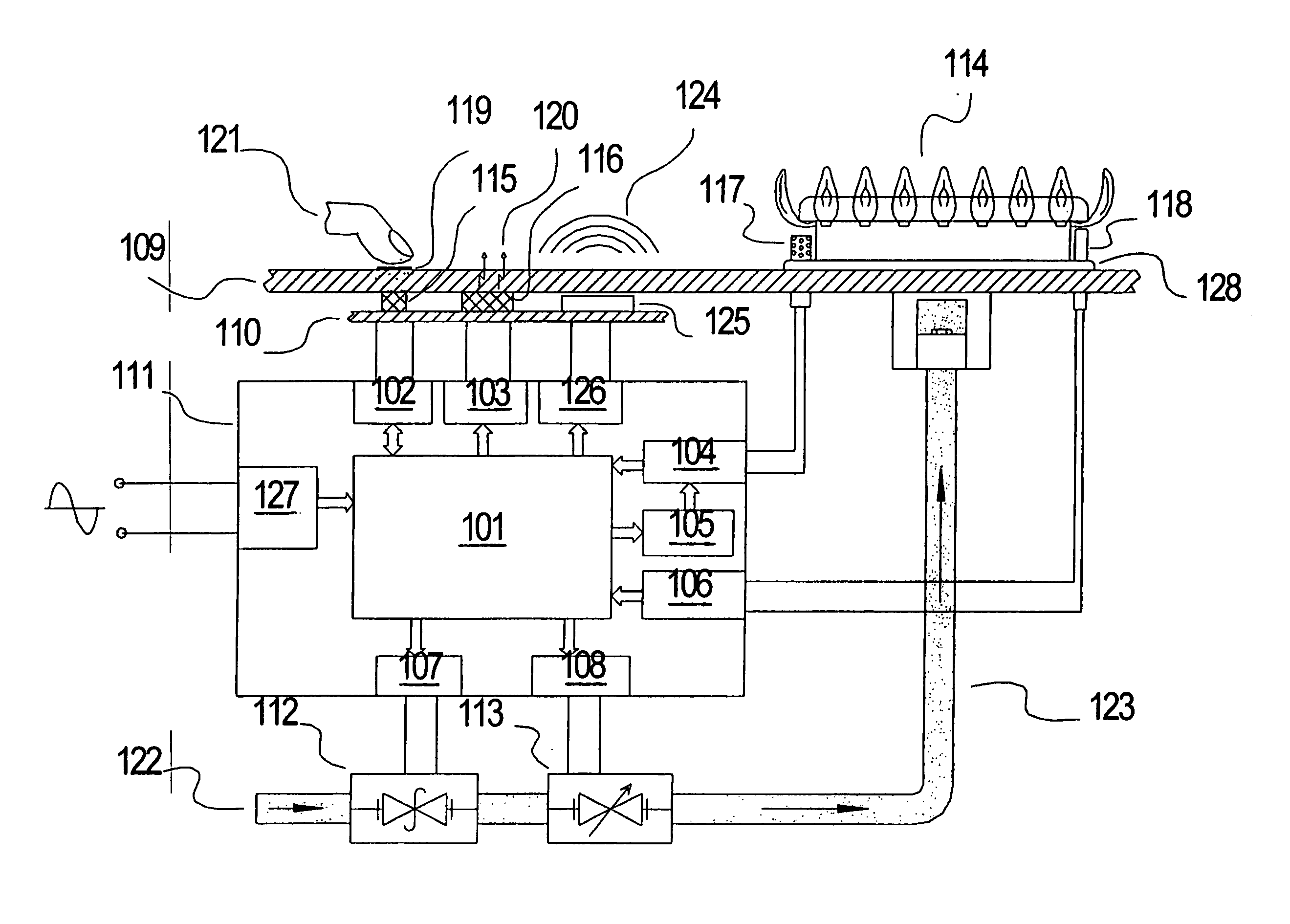

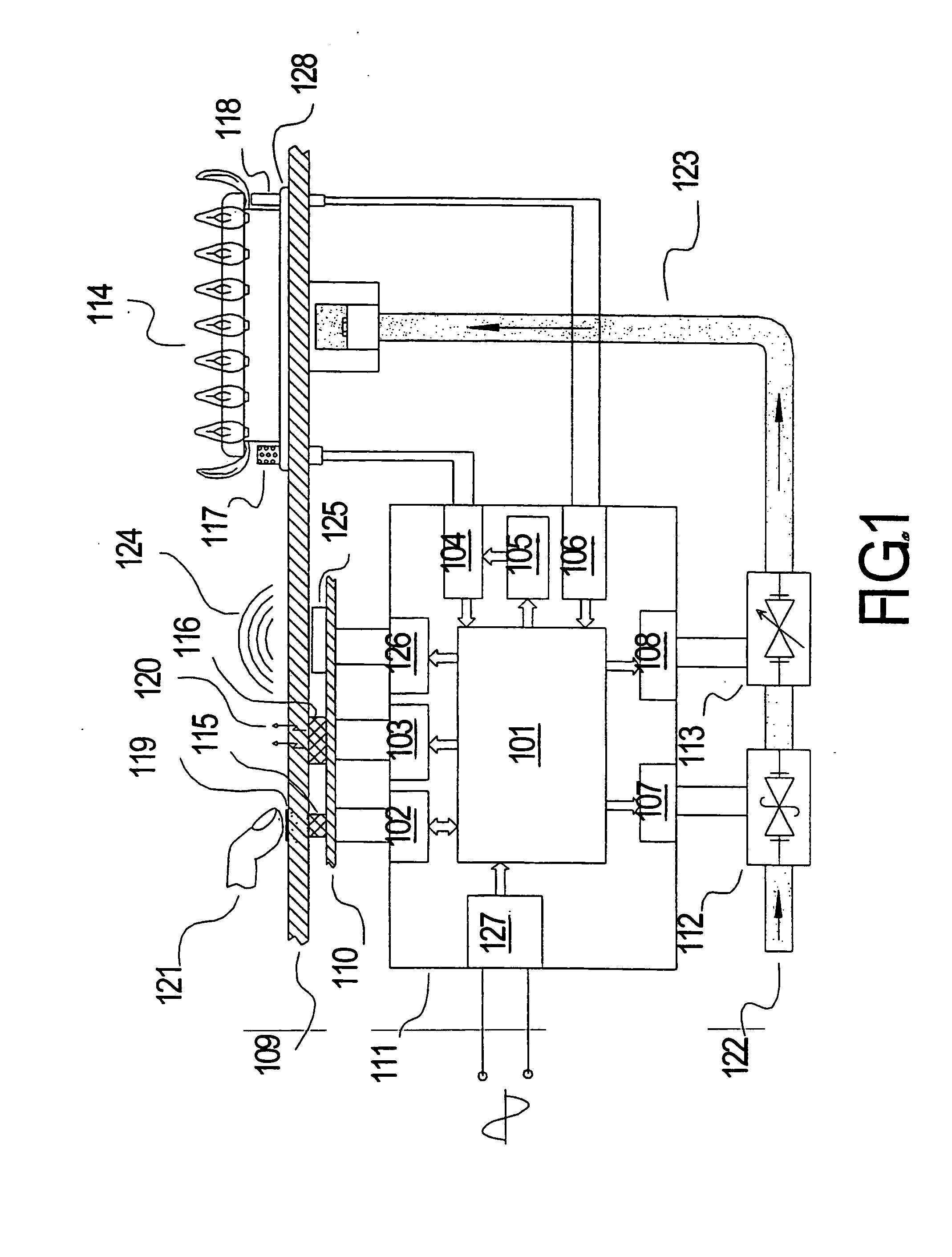

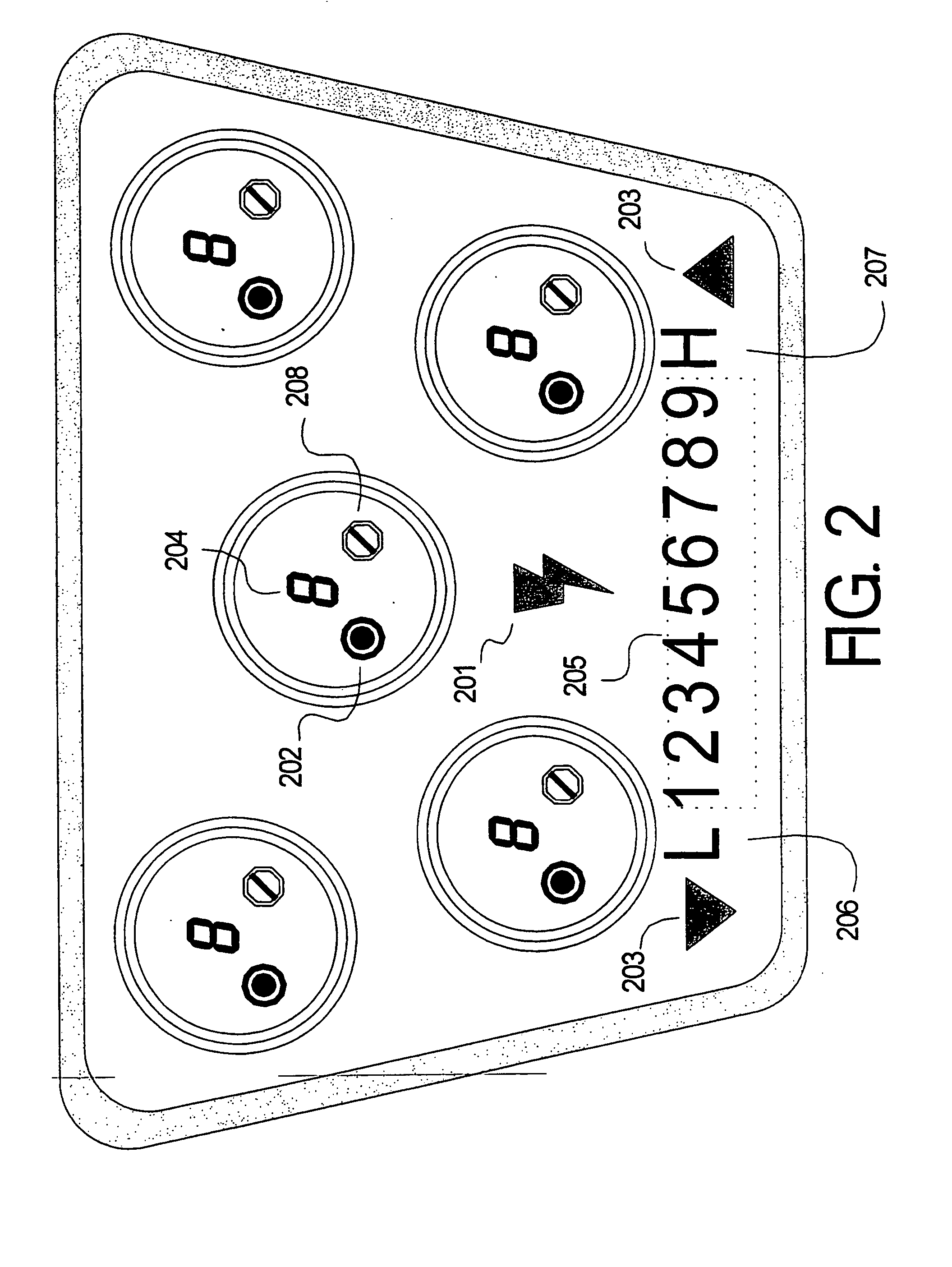

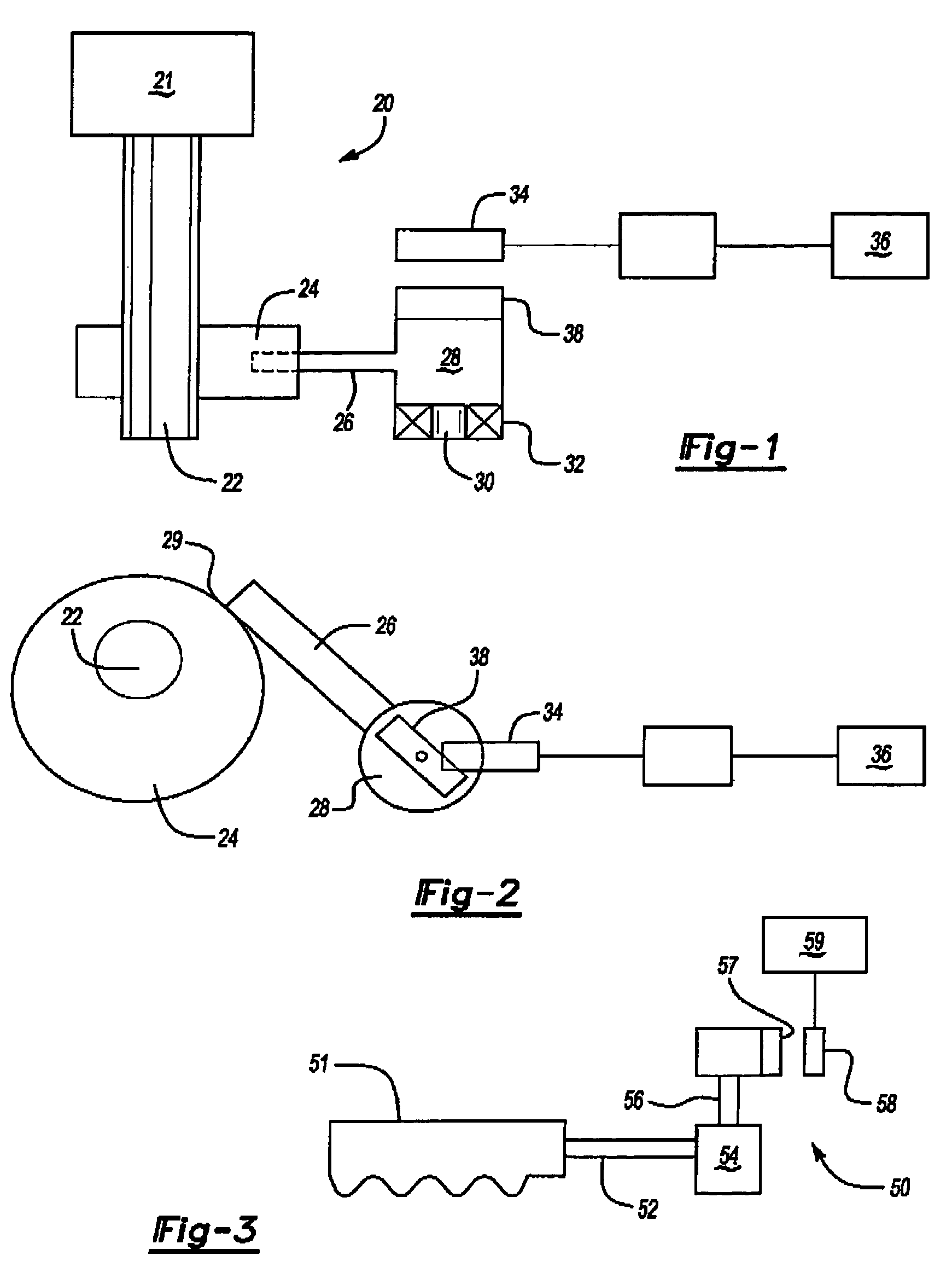

Electronic gas cooktop control with simmer system and method thereof

InactiveUS7255100B2Reduce heating powerHigh outputFuel supply regulationDomestic stoves or rangesControl systemElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

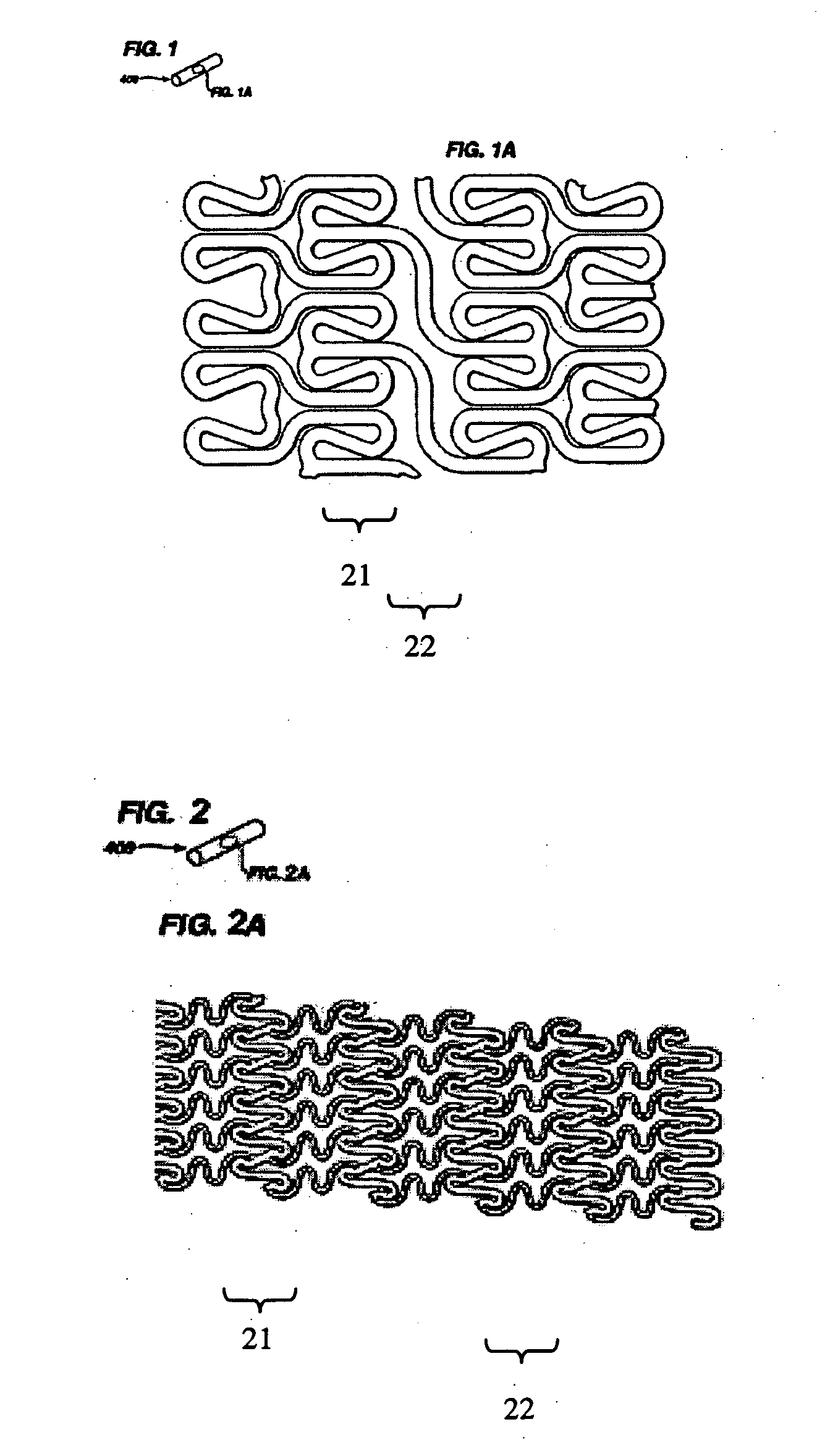

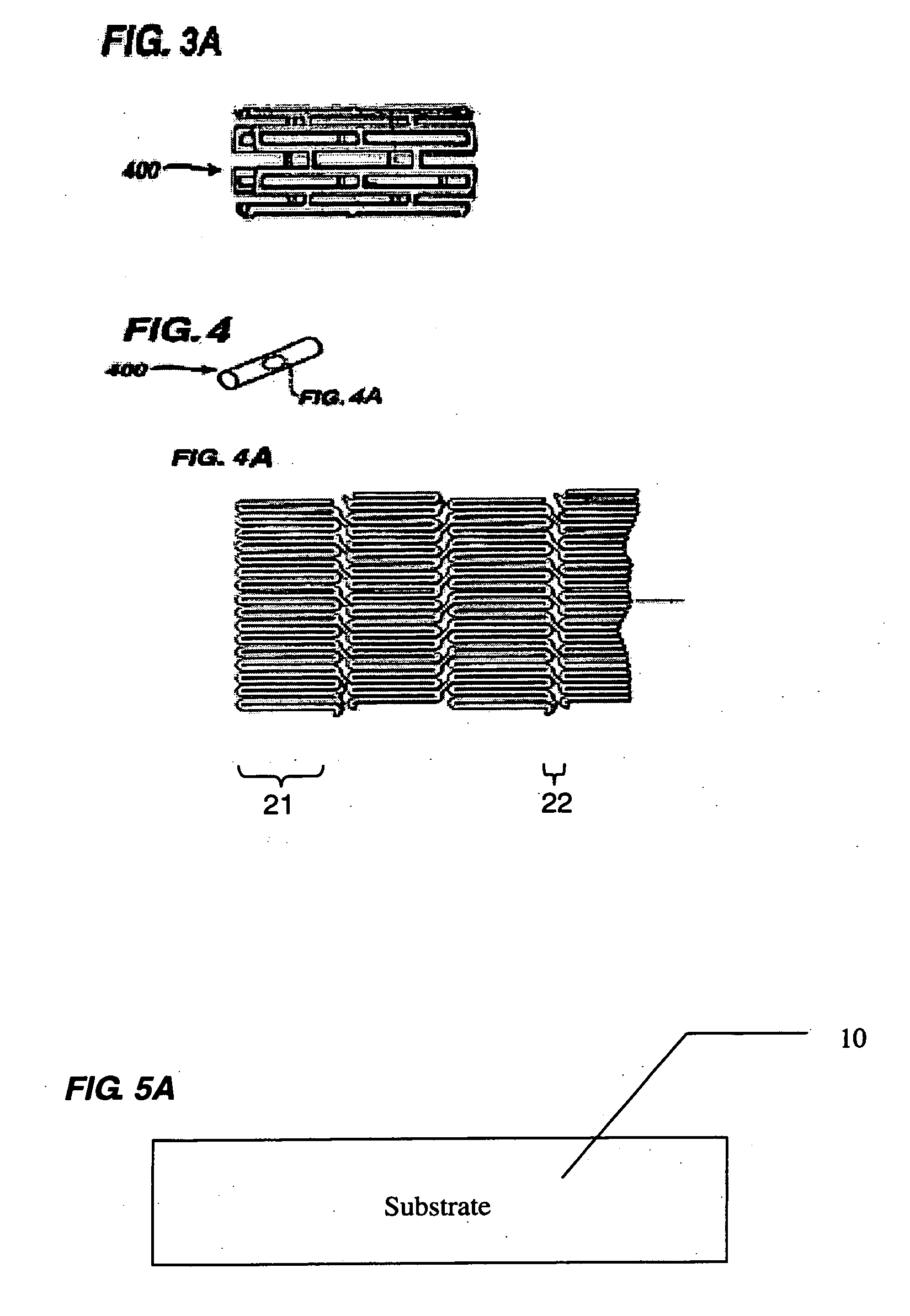

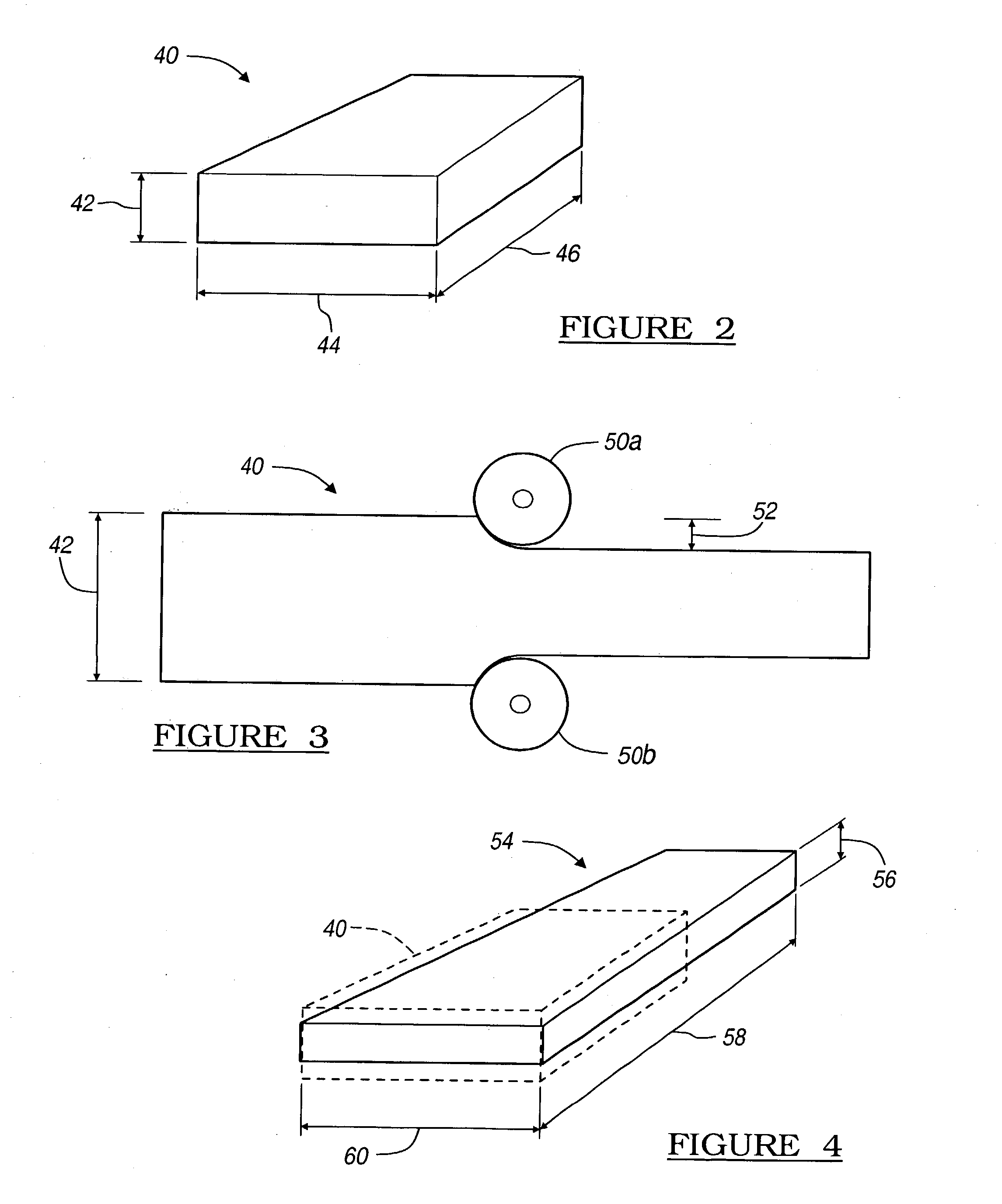

Biodegradable medical devices with enhanced mechanical strength and pharmacological functions

ActiveUS20060264531A1Eliminate riskEliminate wearCosmetic preparationsHalogenated hydrocarbon active ingredientsBiomedical engineeringMedical device

The present invention is directed to a medical device, specifically a prosthesis which utilizes a novel class of blends between biodegradable polymers and bioceramics for medical device applications allowing one to capitalize on the biodegradable nature of these two distinct materials while enhancing the strength of these devices through the addition of various amounts of bioactive ceramic and glasses to biodegradable polymers. The blend may be fabricated into a medical device such as a stent or a distal protection device, and may incorporate various agents to enhance radioapacity and / or pharmacological function. In addition, the blend may be used as a coating to a medical device.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

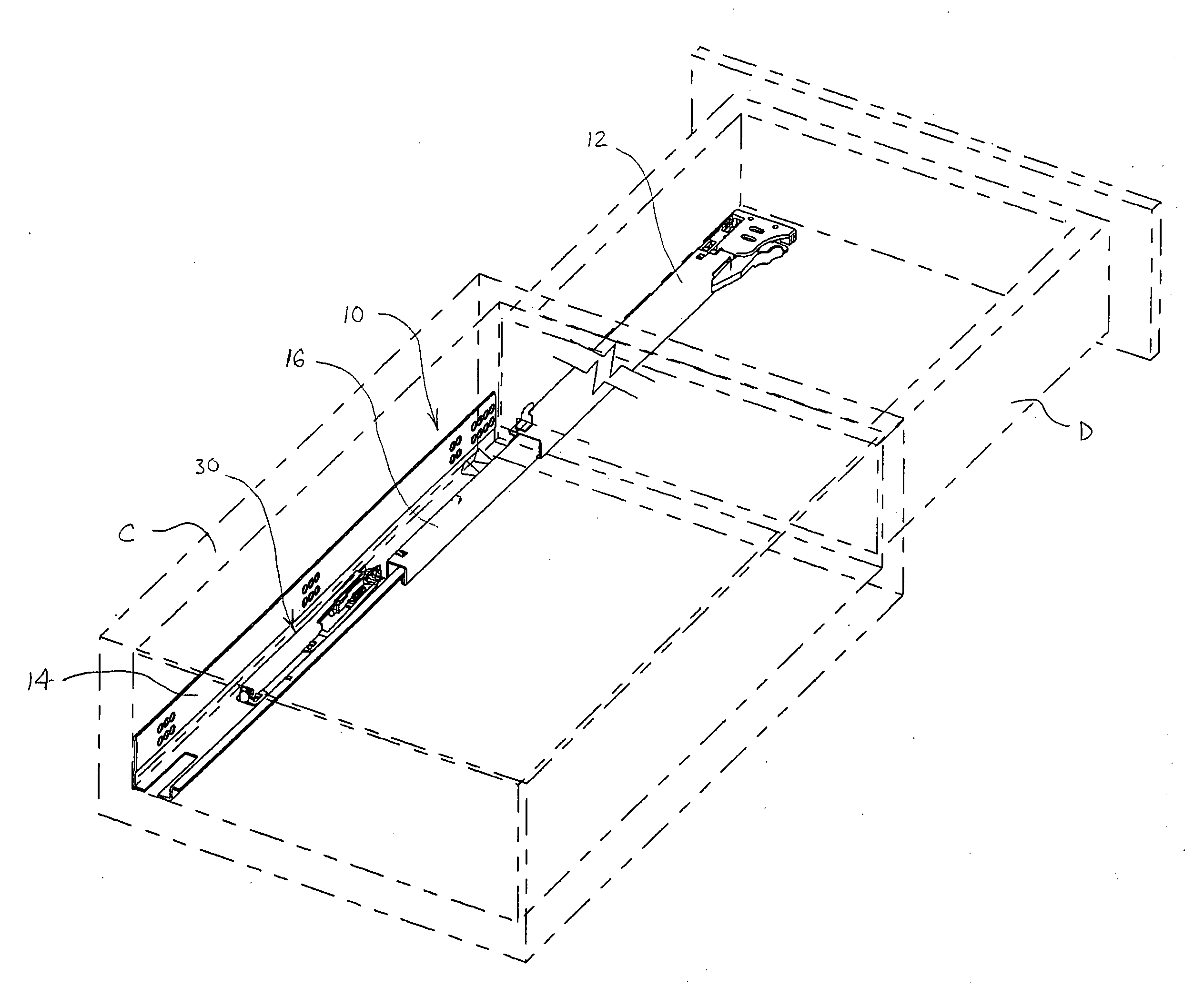

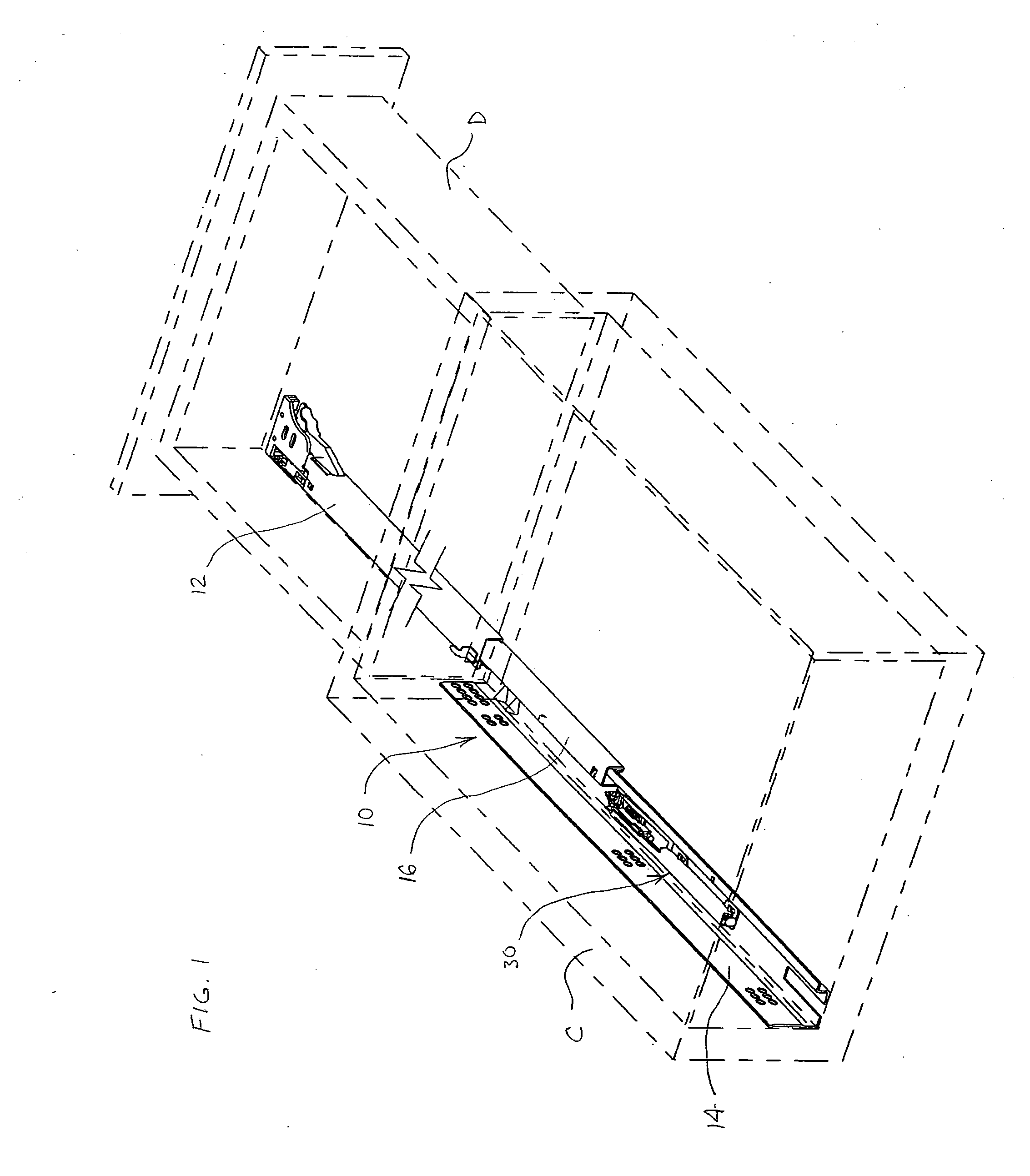

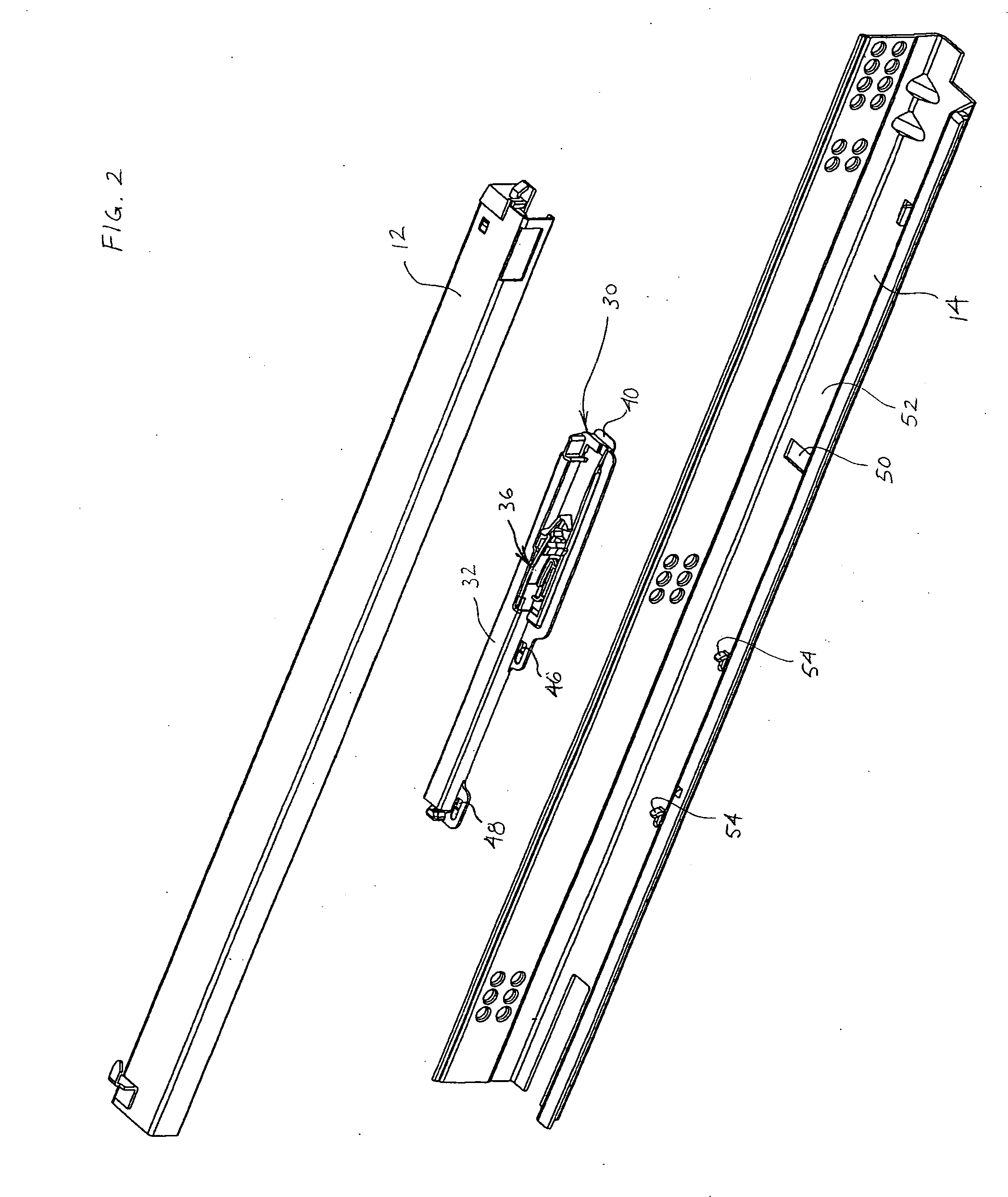

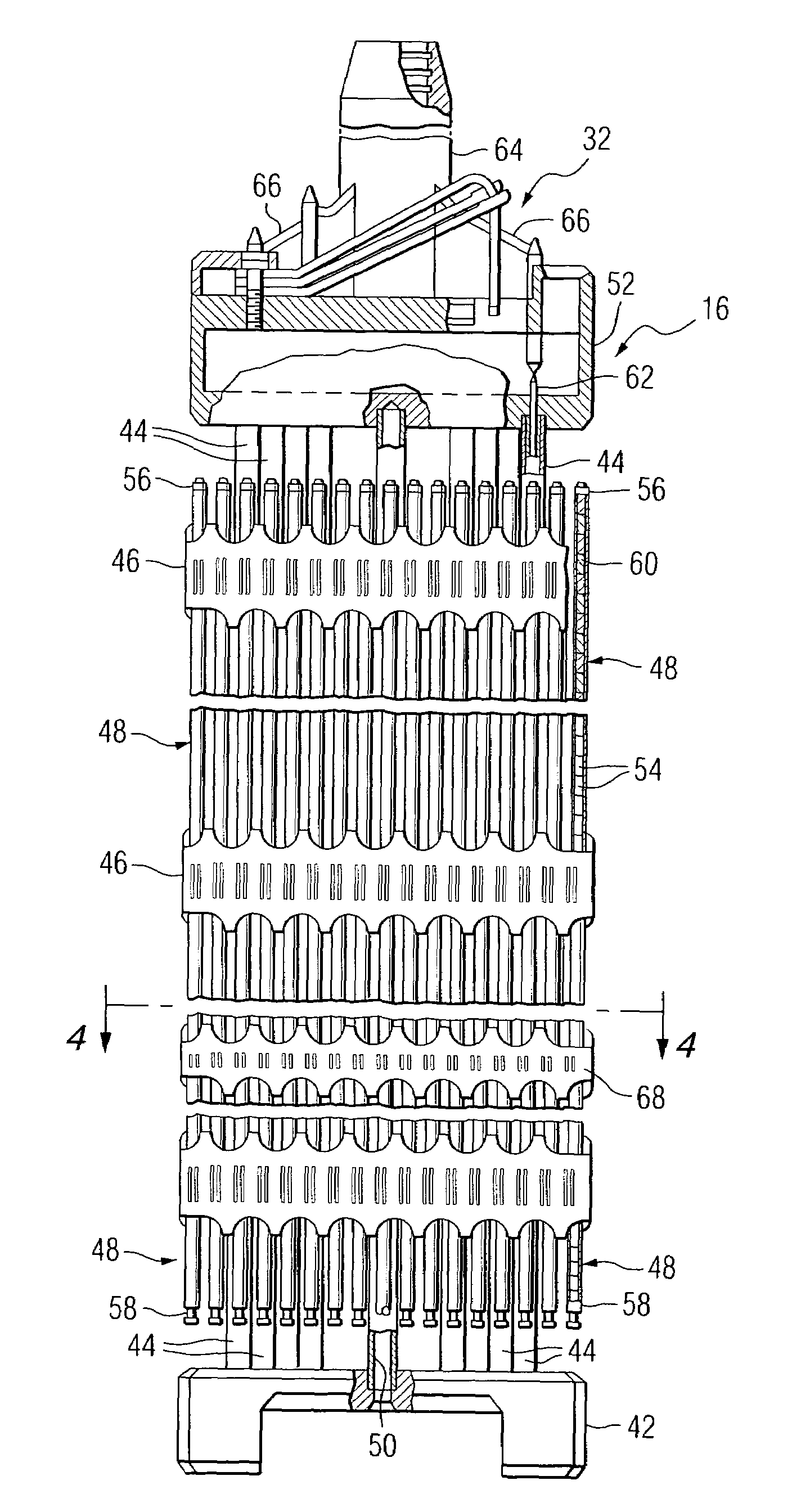

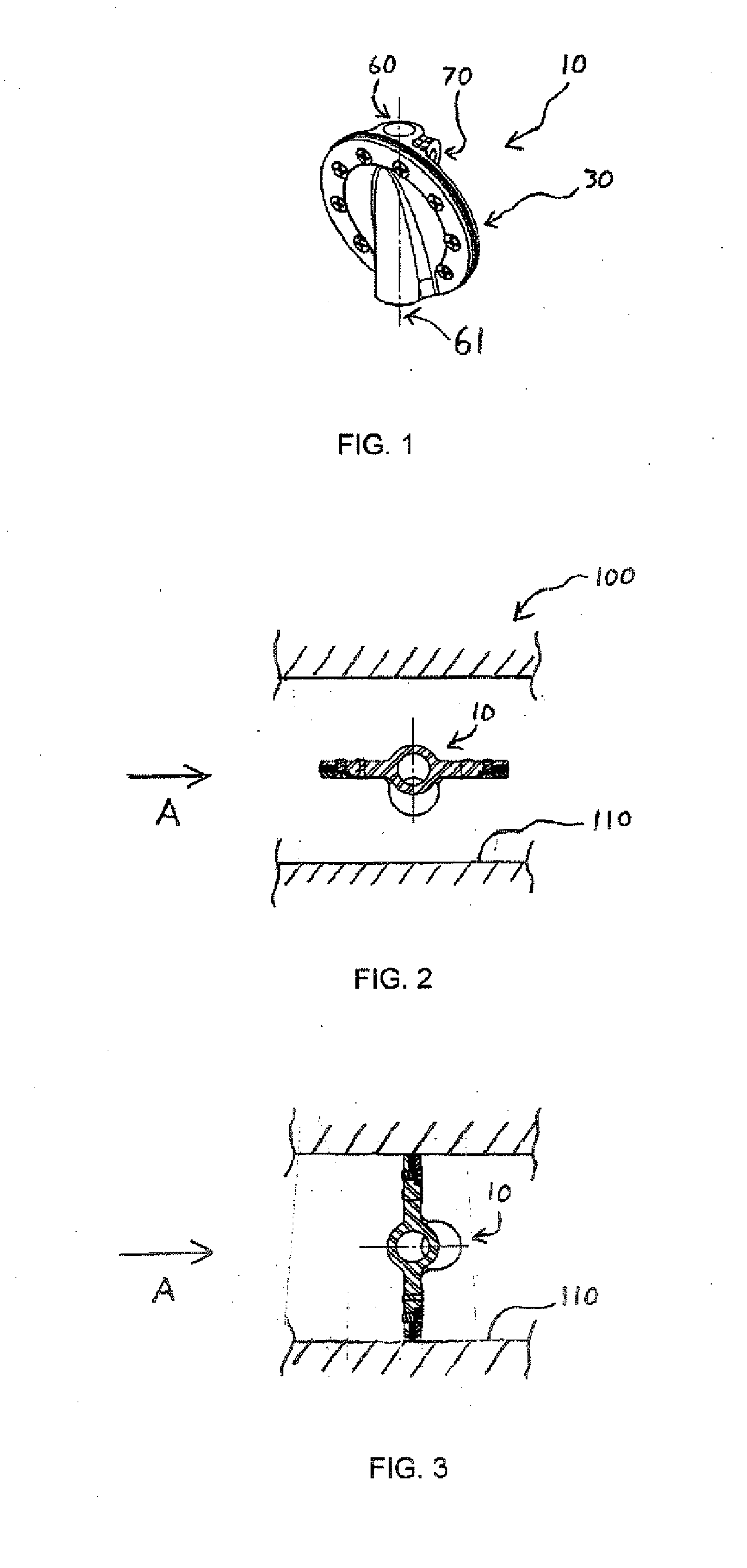

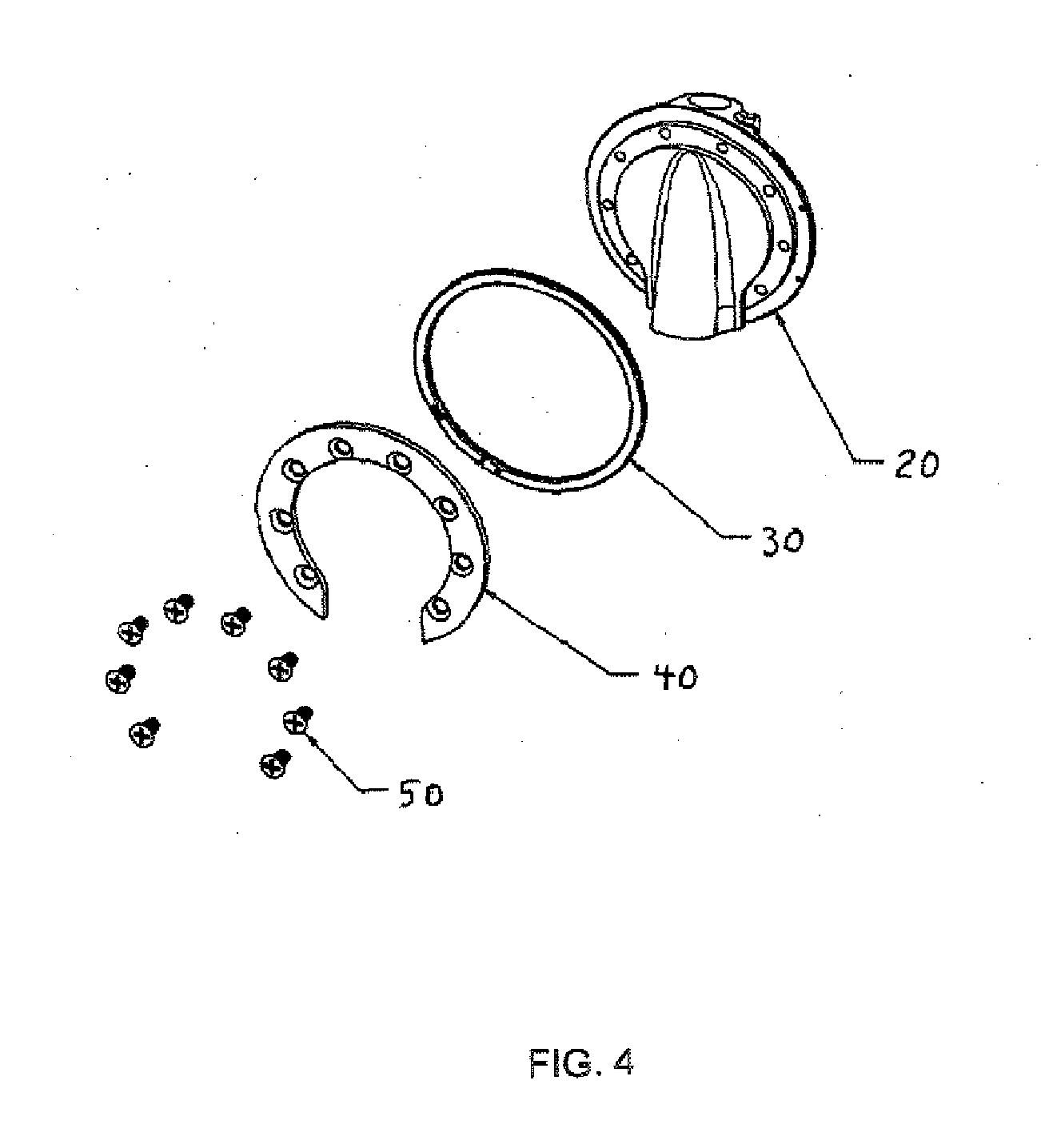

Closing device for drawers

InactiveUS20070046158A1Simple structureSmoother and quieter operationDrawersFittingMechanical engineering

Owner:KNAPE & VOGT MFG

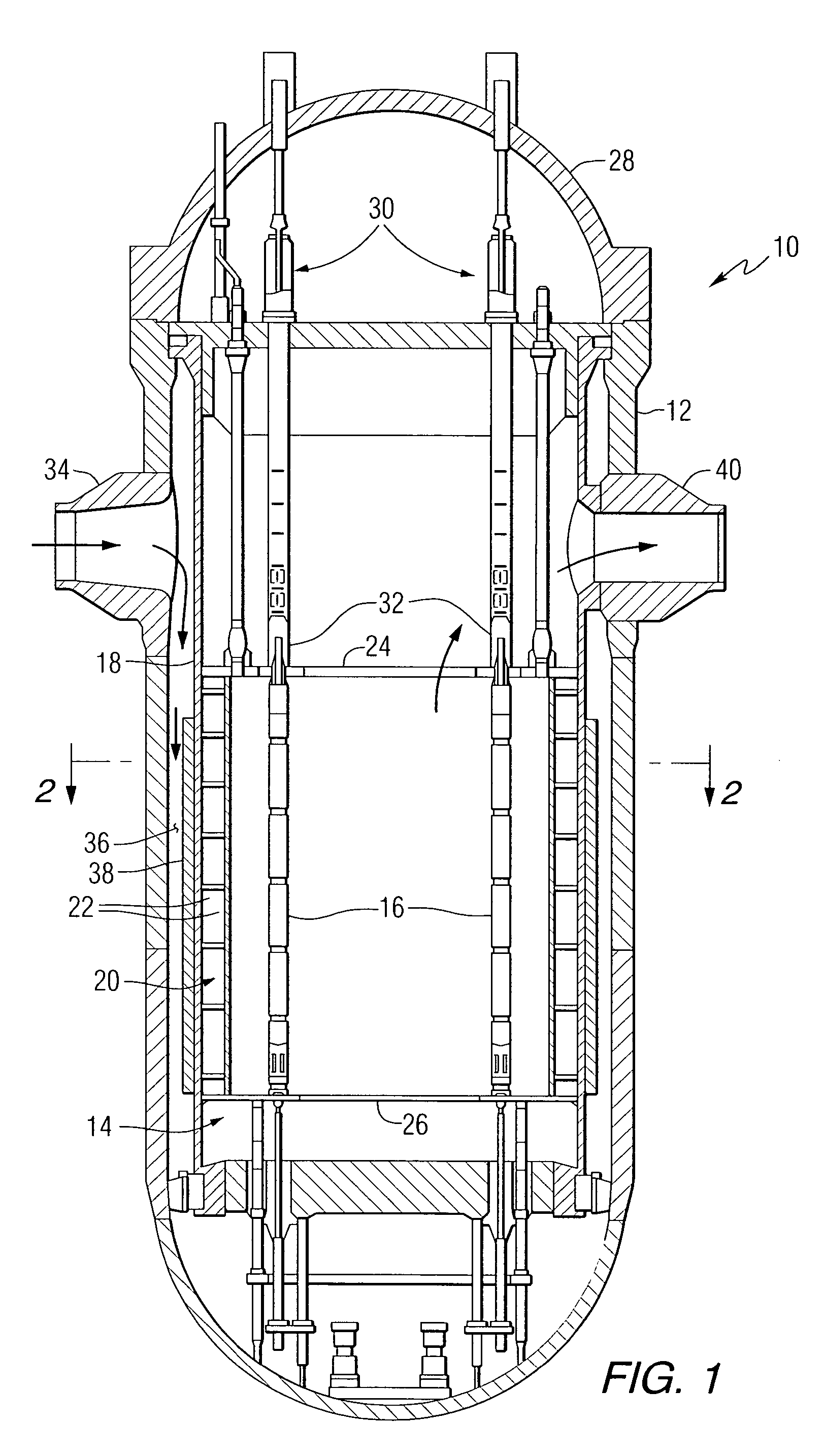

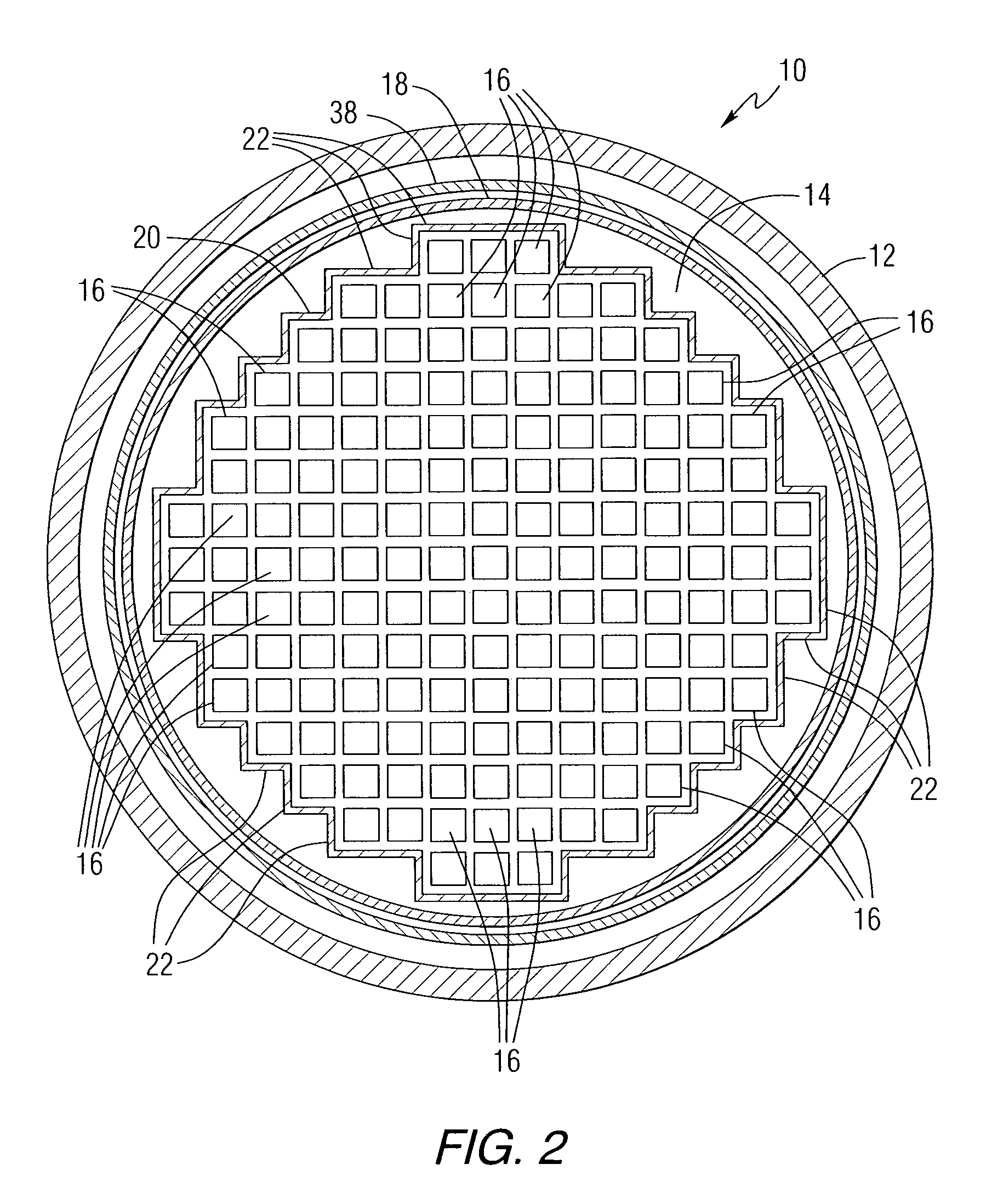

Nuclear reactor fuel assemblies

InactiveUS7085340B2Eliminate wearPrevent “hang-upsNuclear energy generationFuel element assembliesNuclear reactorParallel array

A nuclear fuel assembly having a parallel array of elongated fuel elements supported between an upper and lower nozzle. Main support grids are substantially evenly spaced along the elongated dimension of the assembly to maintain the spacing between fuel elements. A plurality of auxiliary vibration-resistant grids respectively positioned between the main support grids in the middle third elongated dimension of the fuel elements, that are smaller in height and provide a larger fuel element contact area than the main support grids.

Owner:WESTINGHOUSE ELECTRIC CORP

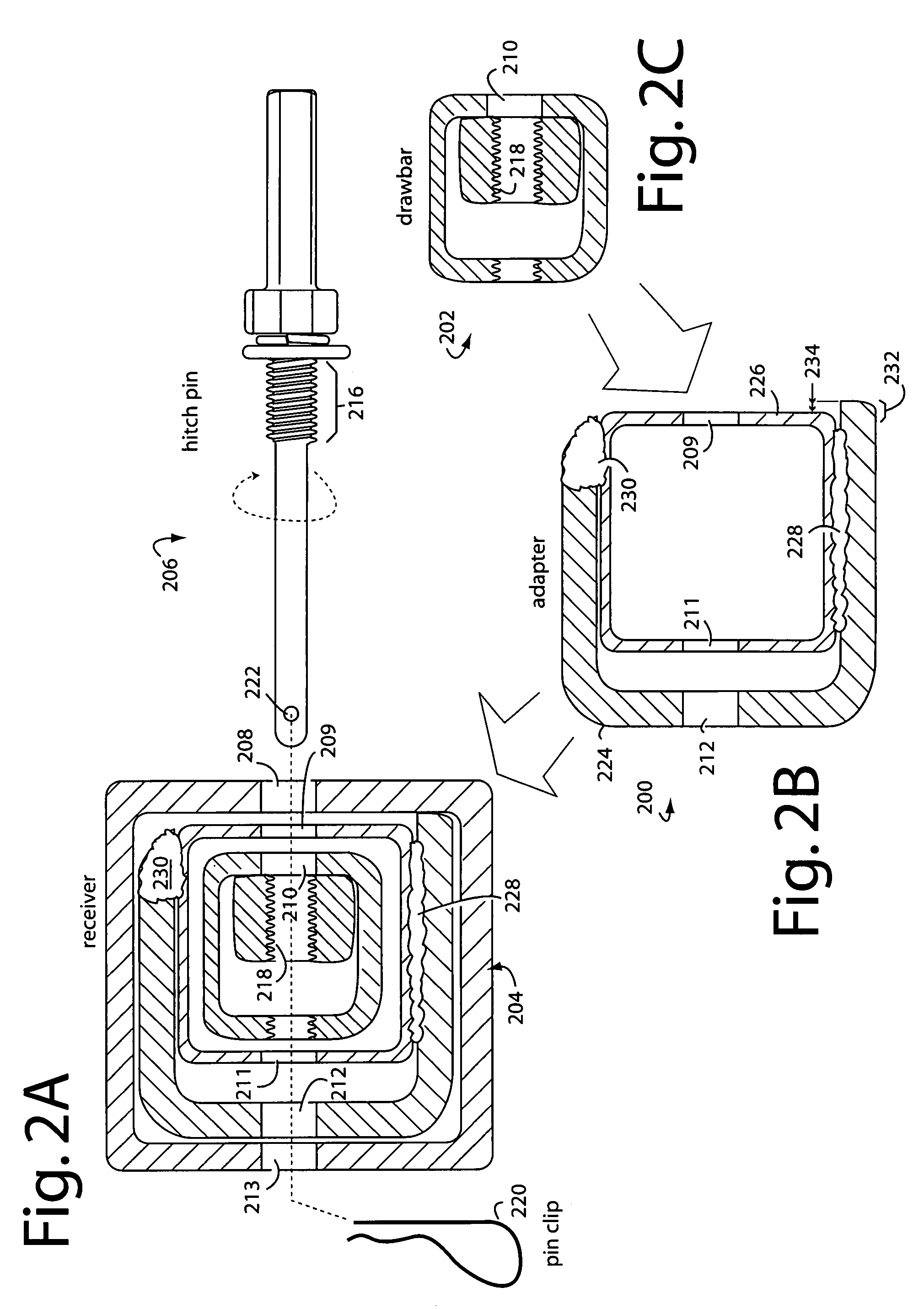

Rotary sealing device

InactiveUS20030205864A1Prolong lifeLong maintenancePiston ringsPositive displacement pump componentsHigh pressureEnhanced service

A contaminant pressure responsive, lubricant pressure amplified or modified rotary seal cartridge for rotary well pumps and other rotary mechanisms. A housing member having a passage subject to contaminant pressure, has a rotary wear sleeve which is supported by bearings and is sealed to the housing by a plurality of spaced seals which define at least one and preferably two or more lubricant chambers for bearing lubrication and for hydrodynamic sealing. Lubricant pressure amplification cylinders are in fluid communication with respective lubricant chambers. Pistons moveable within each of the cylinders define differential surface areas exposed to lubricant and to contaminant pressure. Contaminant pressure acts on the pistons and develops lubricant pressure which is different, preferably higher, but can be lower than contaminant pressure. When lubricant pressure is higher than contaminant pressure it acts directionally toward contaminant pressure or environment pressure to minimize the potential for contaminant intrusion into the lubricant chambers and also enhances the hydrodynamic wedging of the lubricant into the dynamic sealing interface between the seals and the rotary member for enhanced service life of the seals even under high pressure conditions.

Owner:KALSI ENG INC A TEXAS PARTNERSHIP

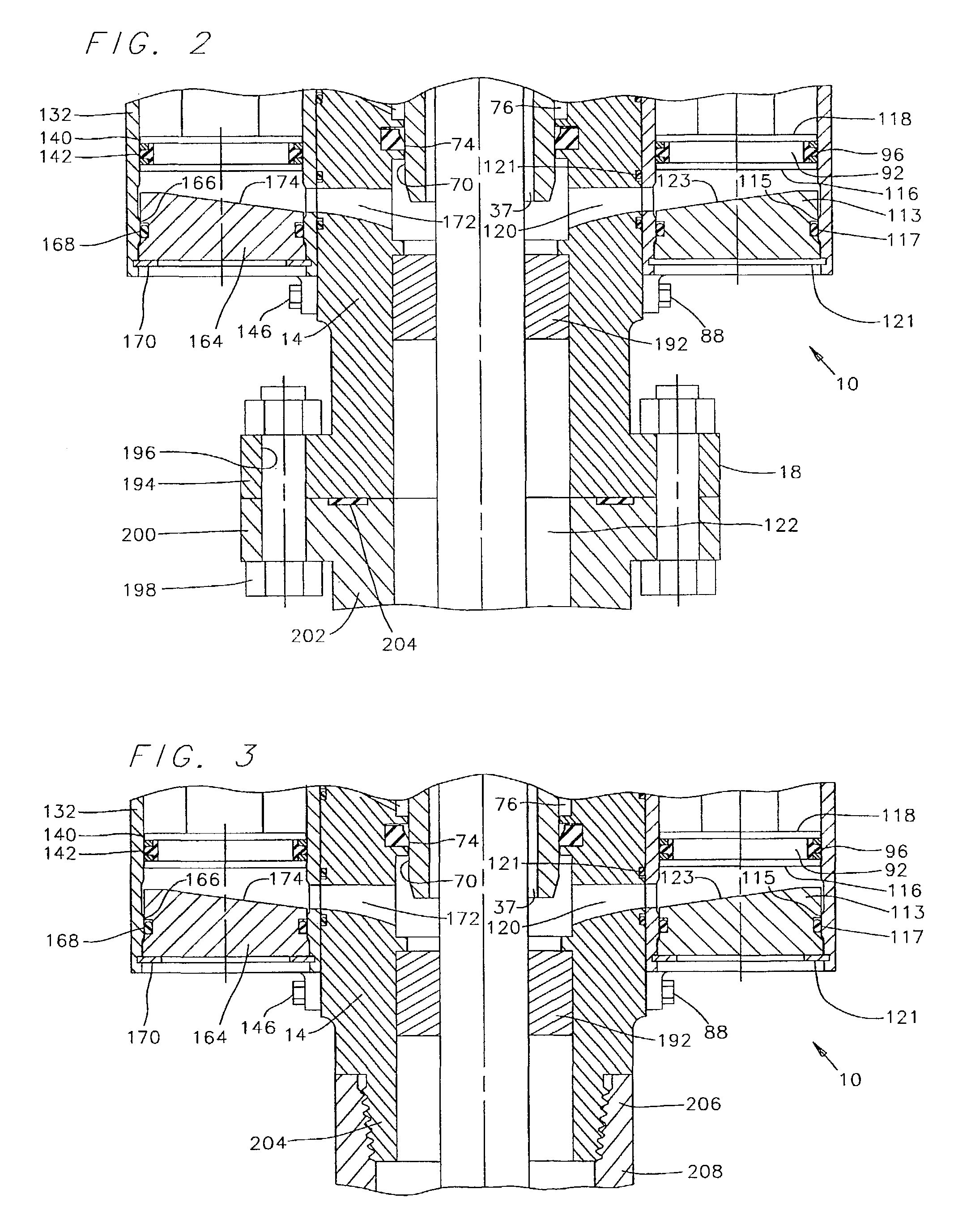

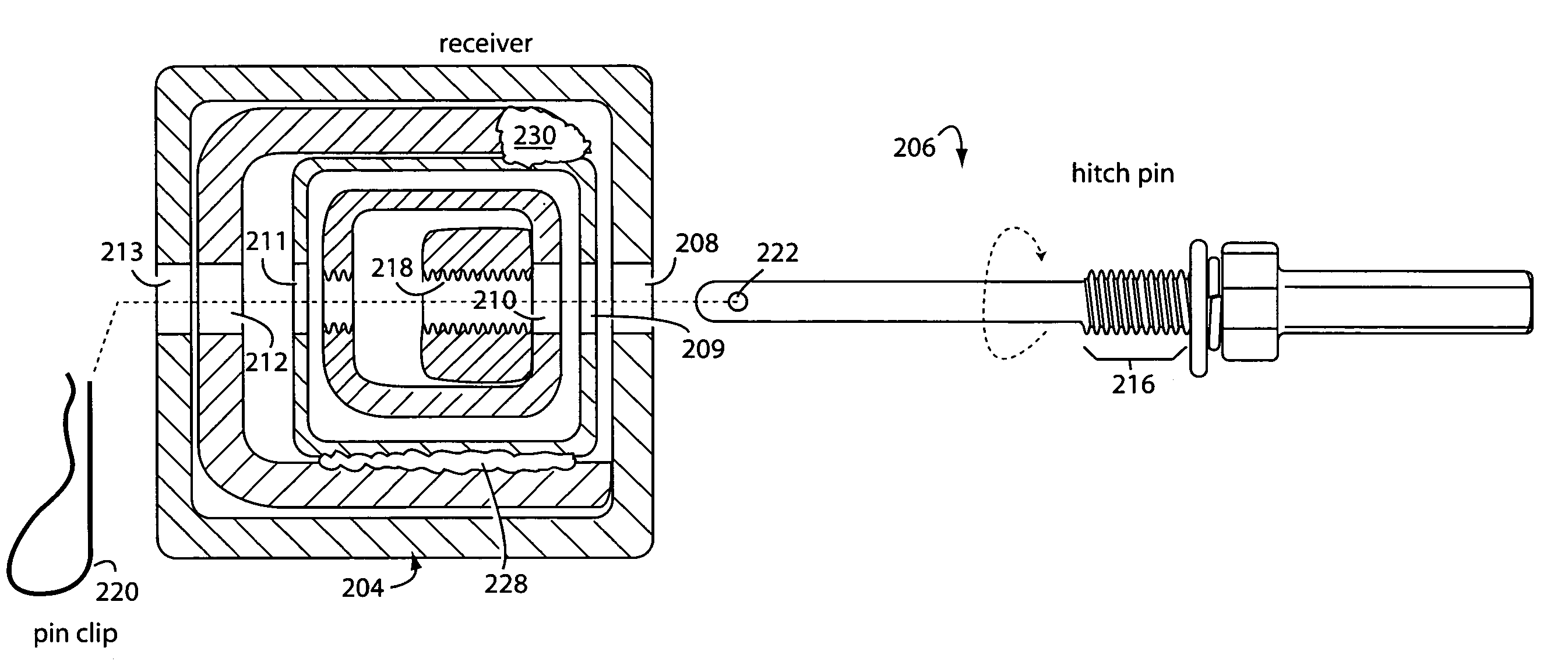

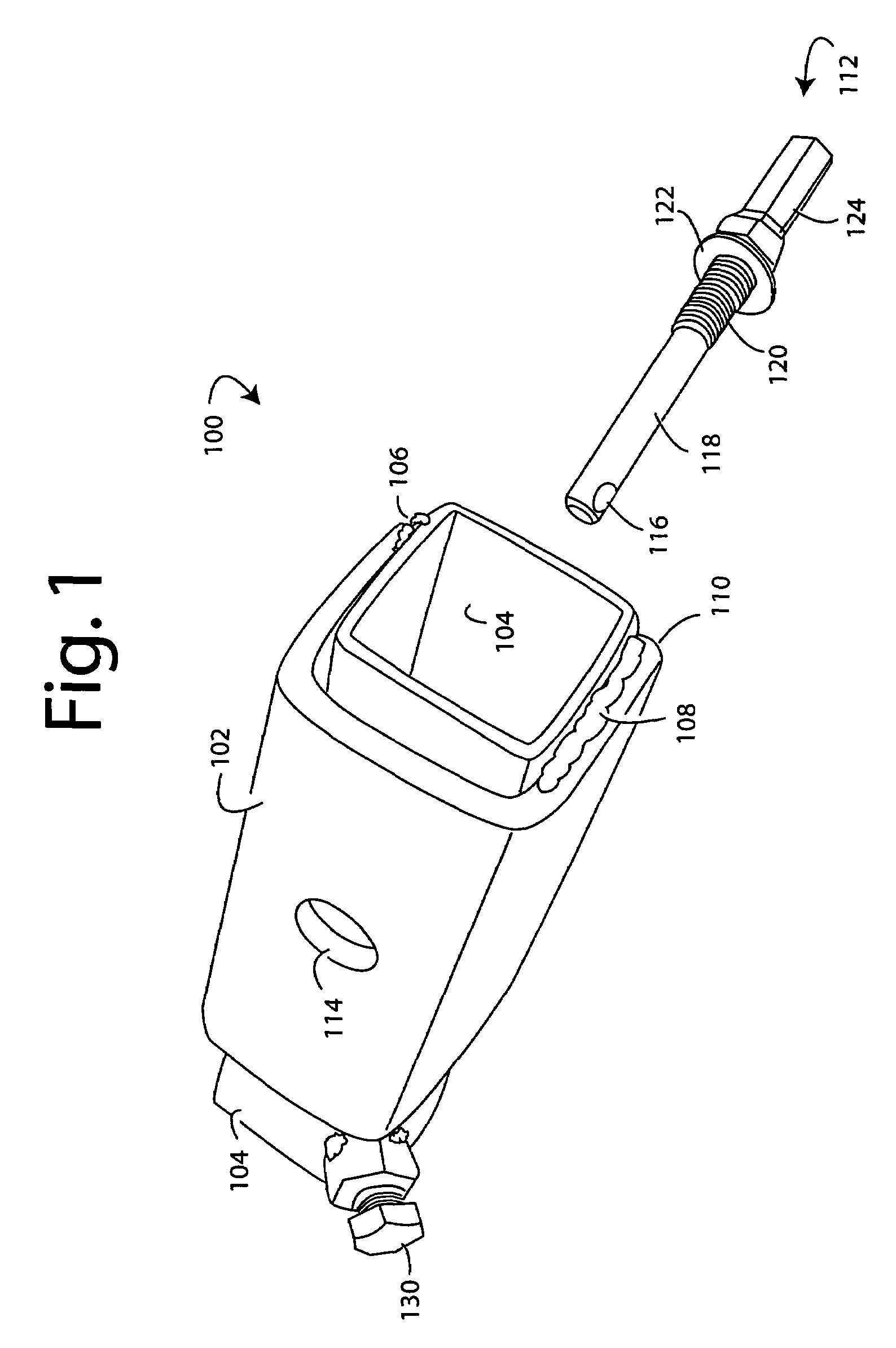

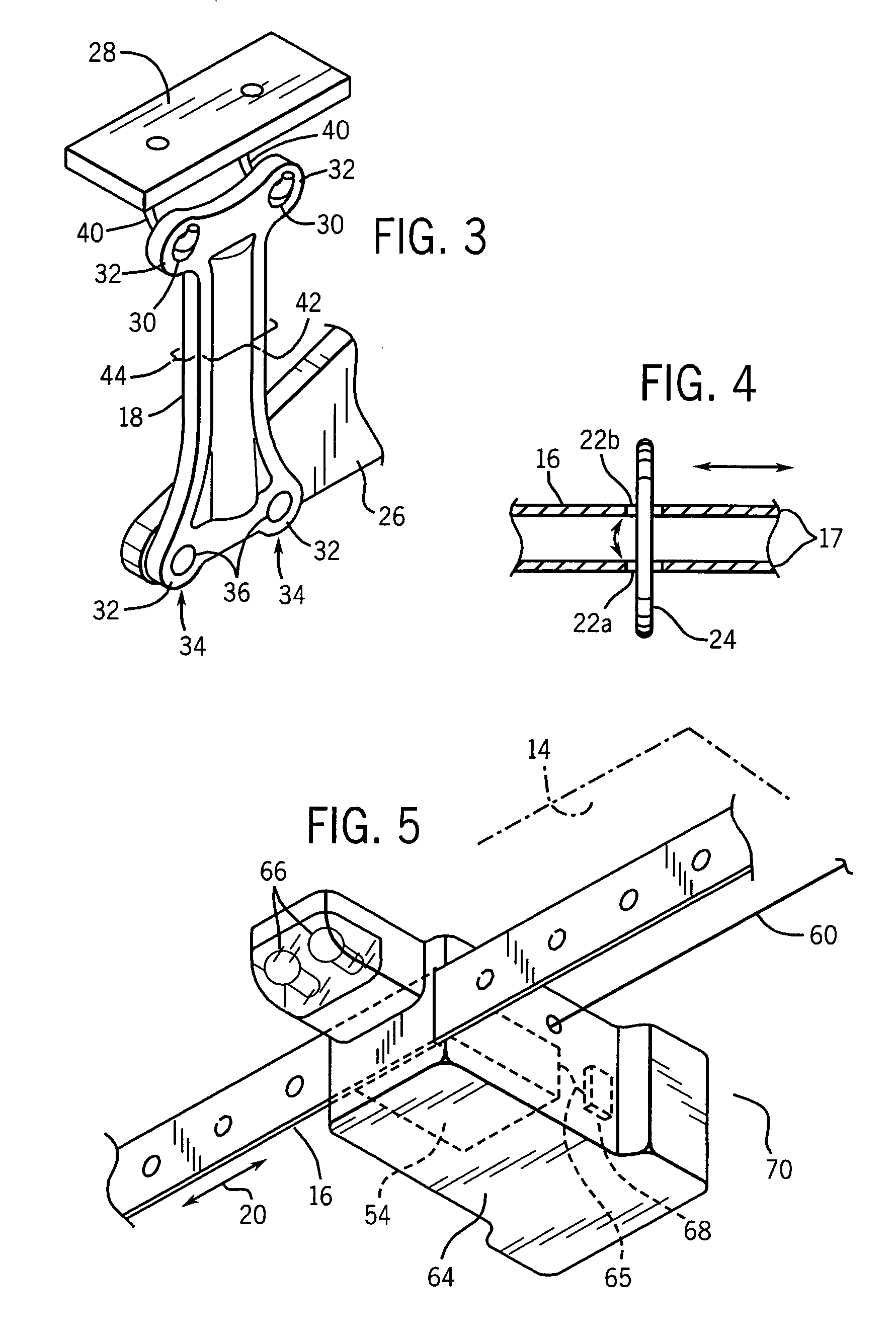

Cam action tightening receiver hitch assembly

InactiveUS7600774B1Eliminate wobble and rattleEliminate relative motionCeilingsScaffold connectionsClass iiiEngineering

A hitch adapter comprises an inner square tube member for receiving Class-II 1.25″ drawbars and an outer U-channel member for plugging into a Class-III 2″ receiver. The inner square tube and outer U-channel members are welded together such that one wall of the inner square tube bridges the gap between the distal edges on opposite legs of the outer U-channel. One such leg of the outer U-channel is longer than the other and is positioned and aligned to protrude about 1 / 16″ beyond the adjacent outer corner of the inner square tube member. Such protrusion nests into the respective inside corner of the particular Class-III 2″ receiver it is mated to. The protrusion provides a camming action to take up any looseness and slack, and thereby eliminate wobble and rattle when installed by a user. A series of hitch pin holes allows a threaded hitch pin to pass through the adapter, a Class-II 1.25″ drawbar and a Class-III 2″ receiver. Threads inside the Class-II 1.25″ drawbar engage the hitch pin threads and provide the user a way to secure the whole assembly.

Owner:SPEER WILLIAM W +1

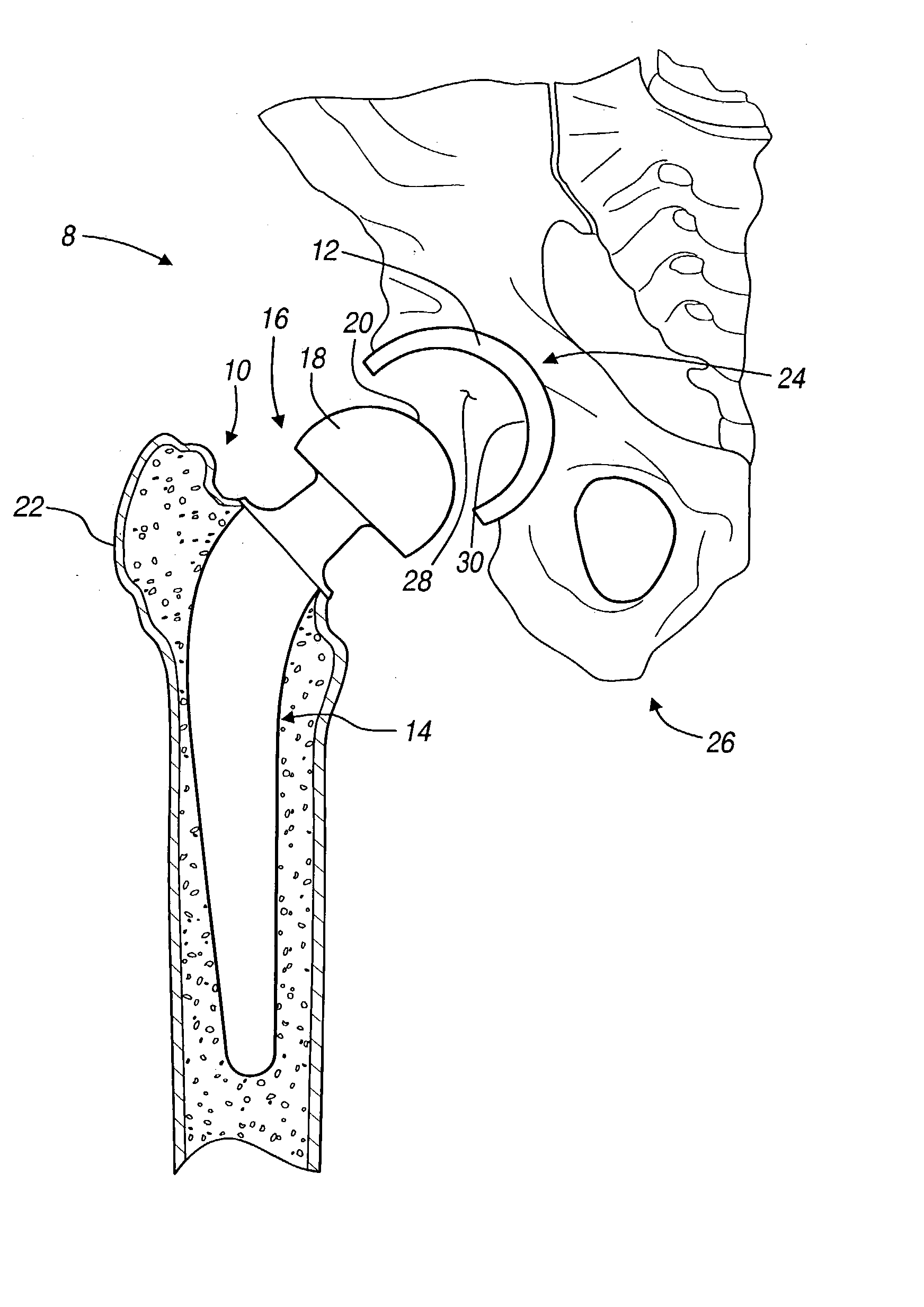

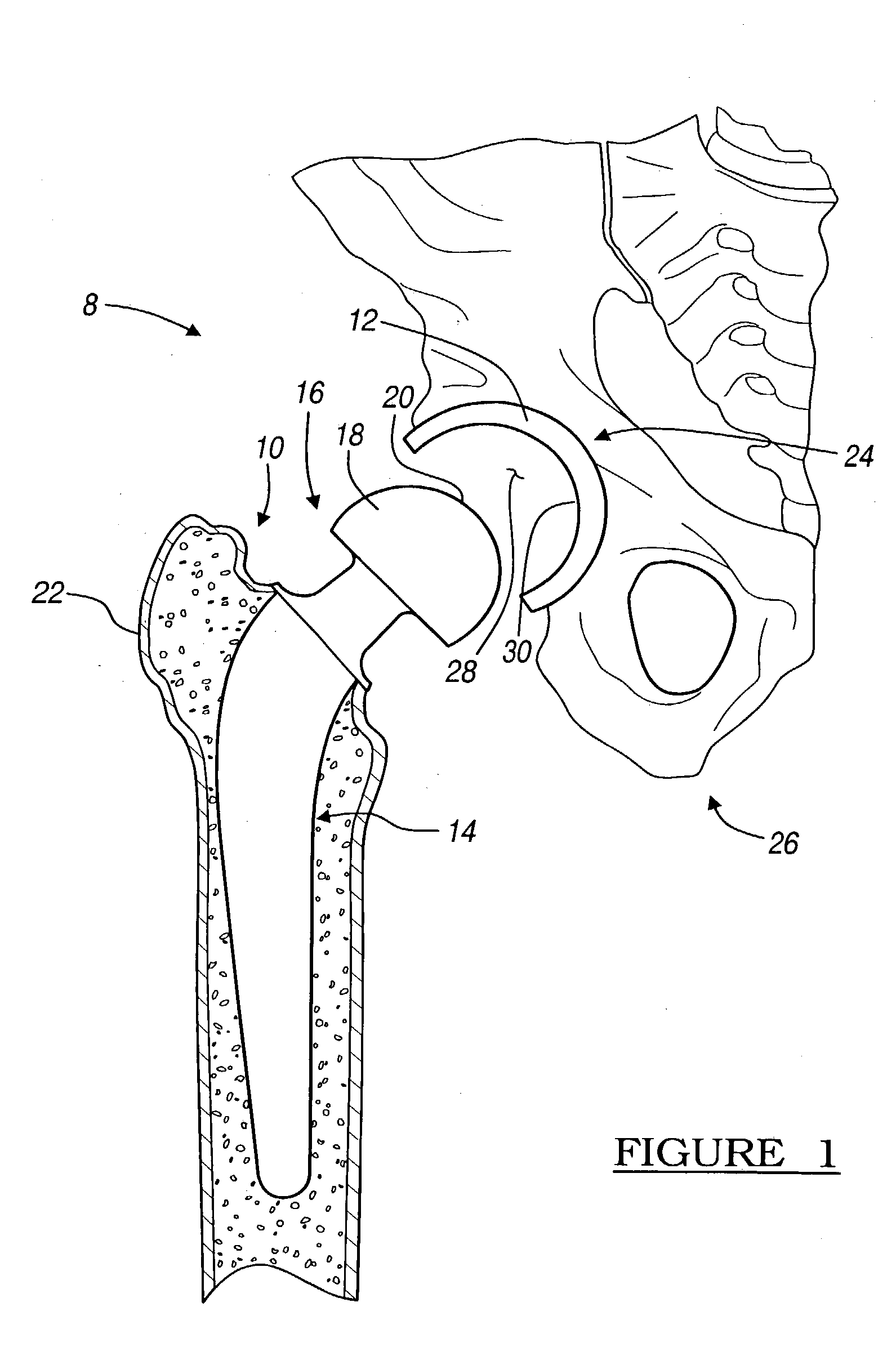

Wear surface for metal-on-metal articulation

InactiveUS20040148033A1Extend your lifeReduce wear debrisBone implantJoint implantsProsthesisSacroiliac joint

A work hardened articulating surface for anatomical prosthetics. Articulating surfaces of prosthetics are work hardened to decrease the wear and increase the longevity of the prosthetic after implantation. The articulating surface can be hardened in any number of ways, for example the articulating surface can be formed from stock material that has been work hardened throughout or the articulating surface can be work hardened prior to final finishing of the prosthetic component. Regardless, the hardened articulating surface reduces wear after implantation while eliminating the need for a separate bearing component.

Owner:BIOMET MFG CORP

Electronic gas cooktop control with simmer system and method thereof

InactiveUS20050089809A9Facilitate maintenanceEliminate needFuel supply regulationDomestic stoves or rangesProcess engineeringElectromagnetic interference

An electronically activated gas cooktop control system, responsive to a touch-sensitive user interface, and capable of providing a predetermined range of cooking and simmer levels of BTU output, has two complementary heating modes of operation A first heating mode of operation is provided to produce a wide selection of simmer levels of BTU output, by electronically sequencing a solenoid-operated modulating gas valve “on” and “off”, at a predetermined level of flame. A second cooking mode of operation is provided by electronically modulating the level of flame, through use of a pulse-width-modulation (PWM) output signal to produce a wide selection of cooking levels of BTU output. An igniter system capable of insuring proper ignition of gas without generating harmful electromagnetic interference is also provided.

Owner:COMPUVALVE +1

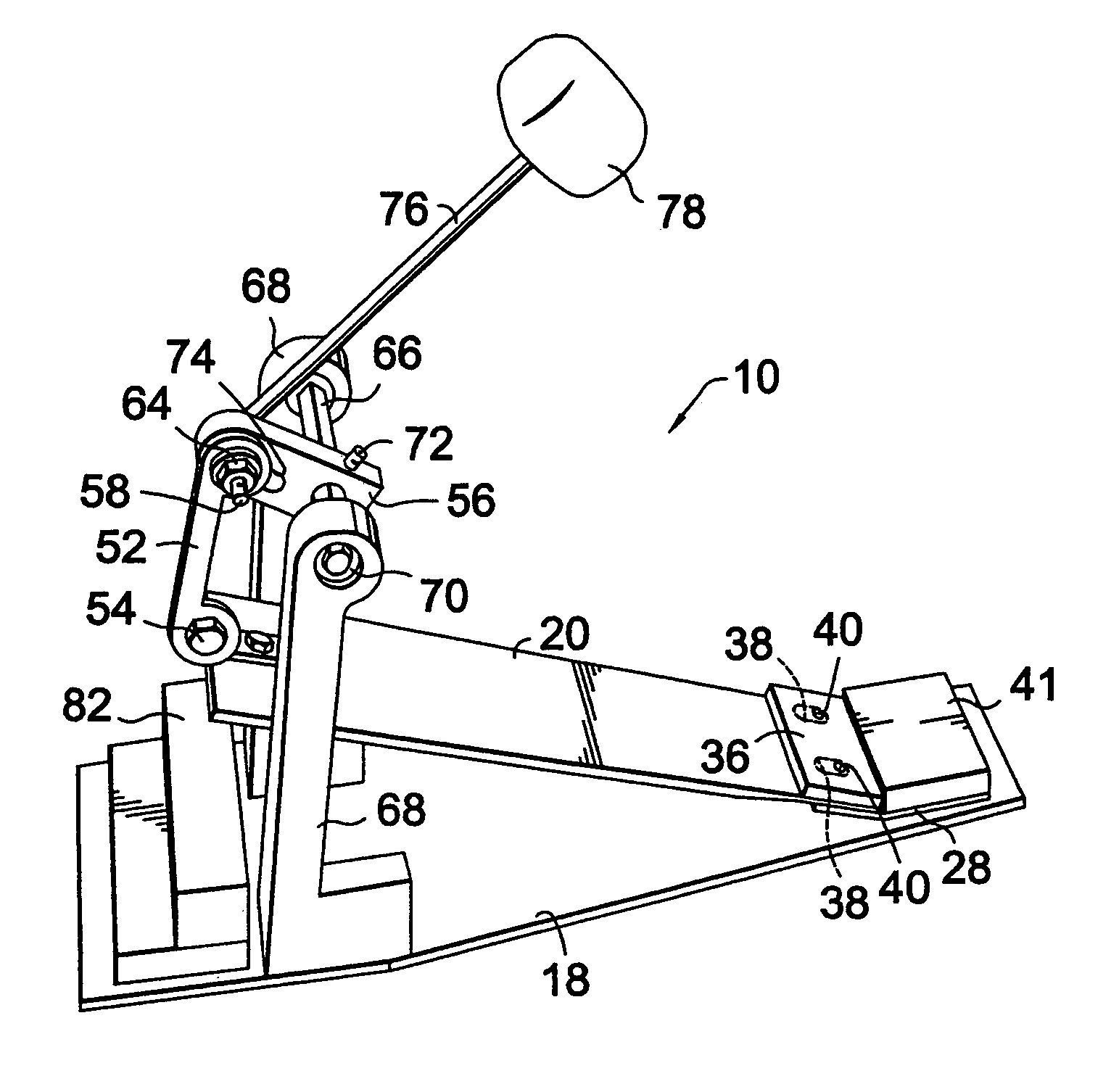

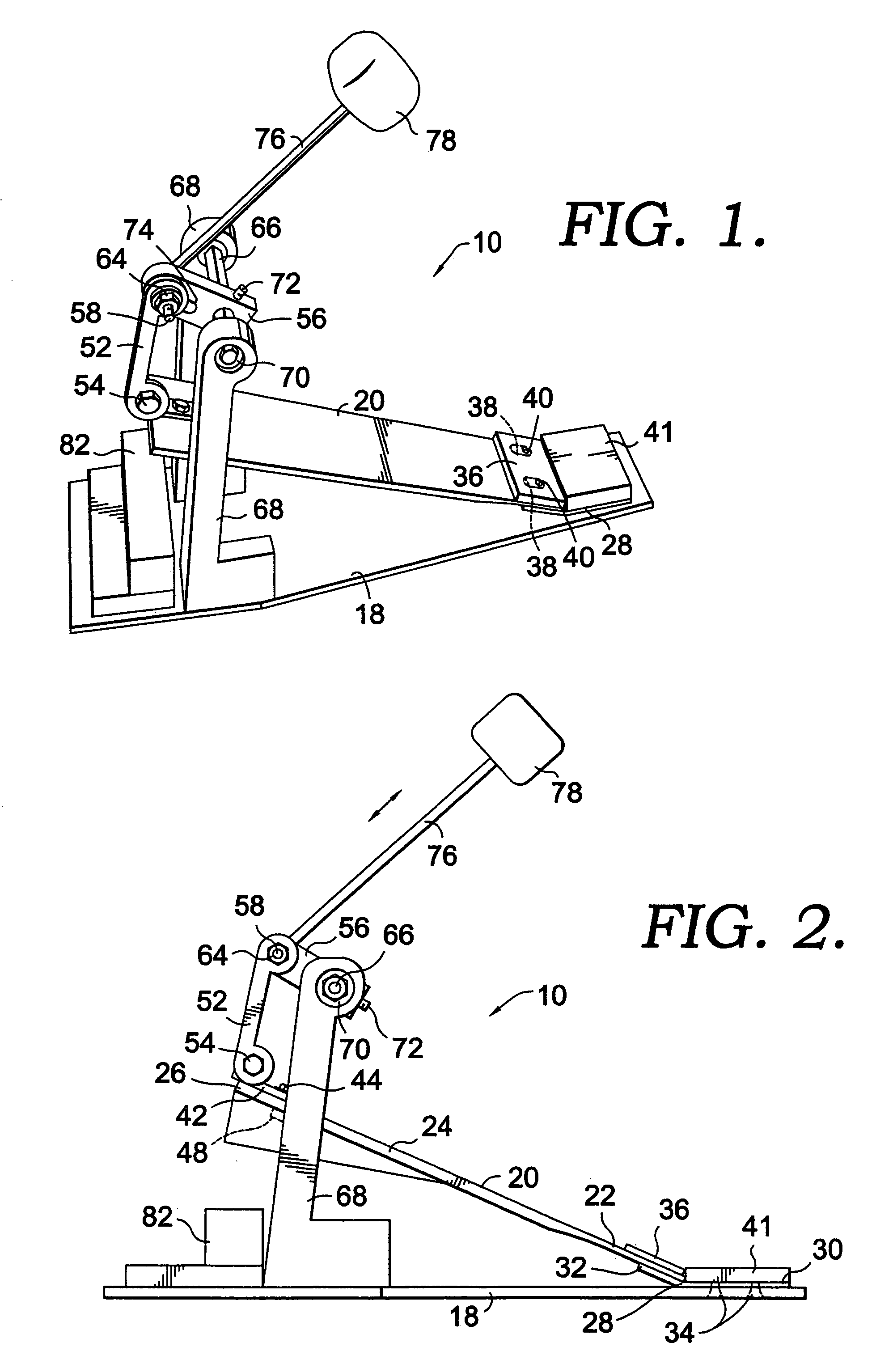

Pedal assembly for musical instruments

InactiveUS7197957B2Eliminate needInherent resiliencyControlling membersMechanical apparatusElastic modulusNormal position

A pedal assembly for a bass drum or high hat cymbals. A flat base plate has a resilient pedal board clamped to it with the pedal board inclined to receive a foot. A beater stick is connected with the toe end of the pedal board by a linkage that drives the beater stick against a bass drum when the pedal is depressed. The resiliency of the pedal board returns it to its normal position when foot pressure is withdrawn. The material of which the pedal board is constructed has a modulus of elasticity between about one million and about six million. A striker pad limits the depression of the pedal board to limit the force that the beater stick can apply to the drum.

Owner:GATZEN ROBERT A

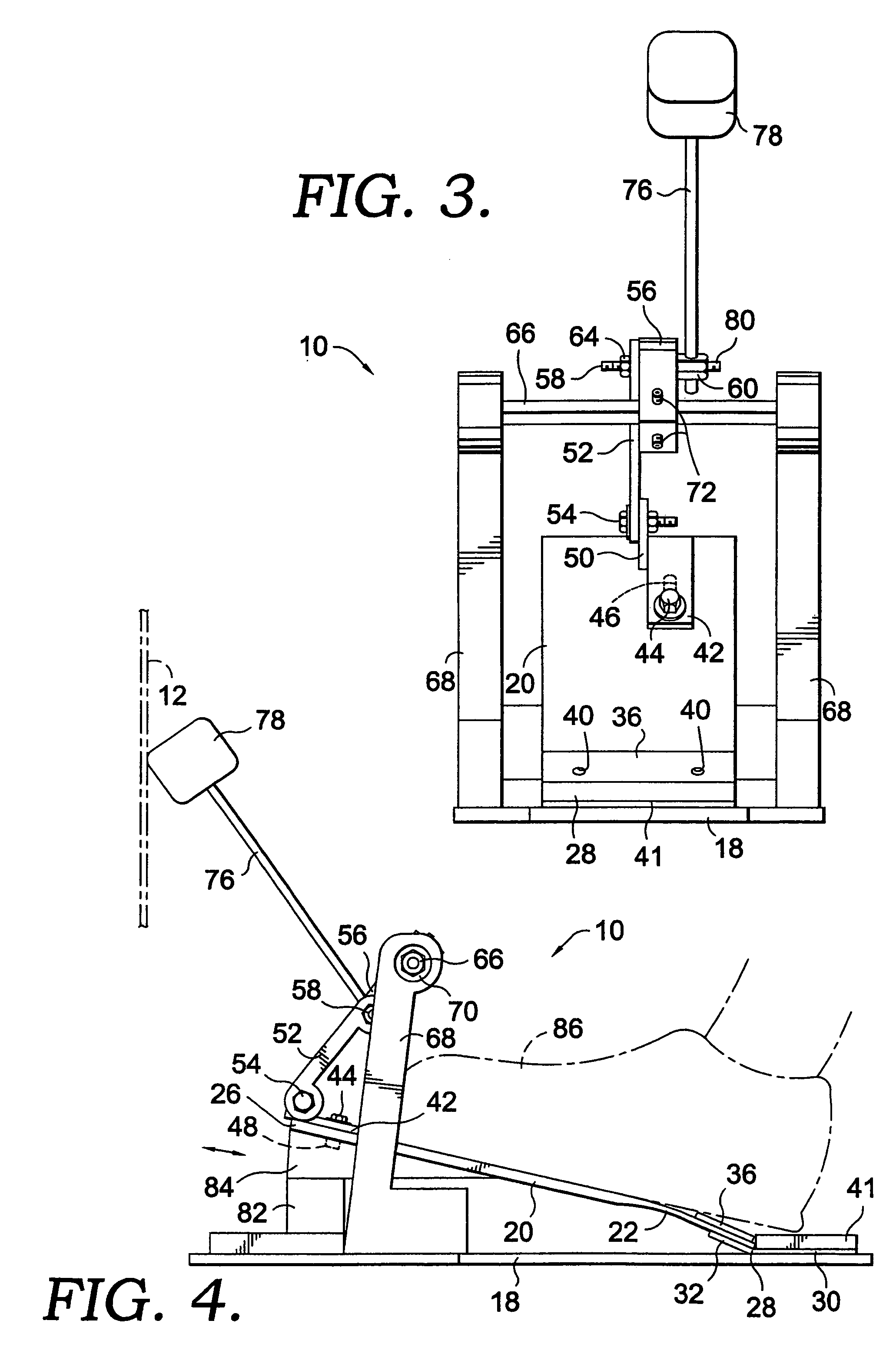

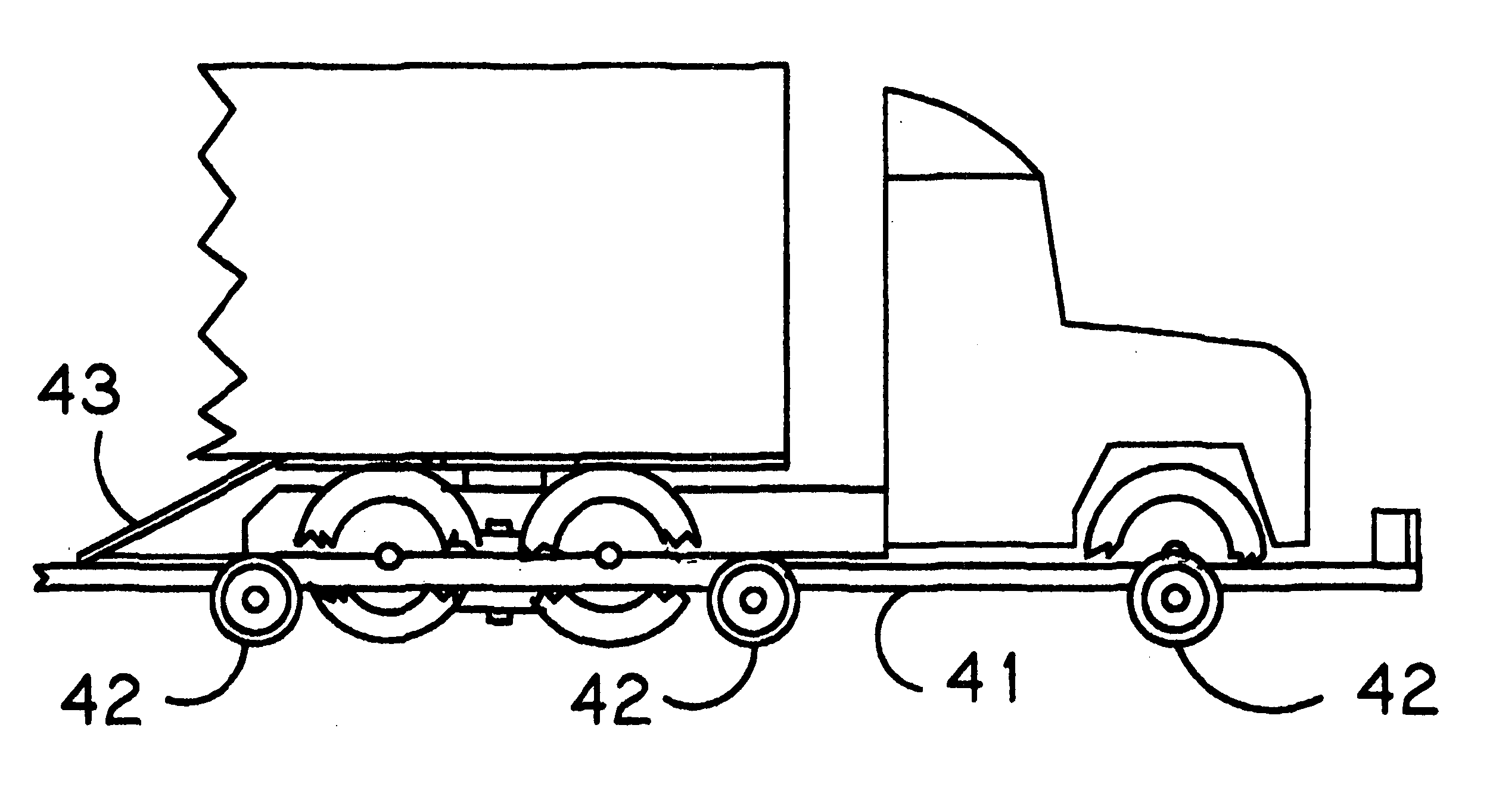

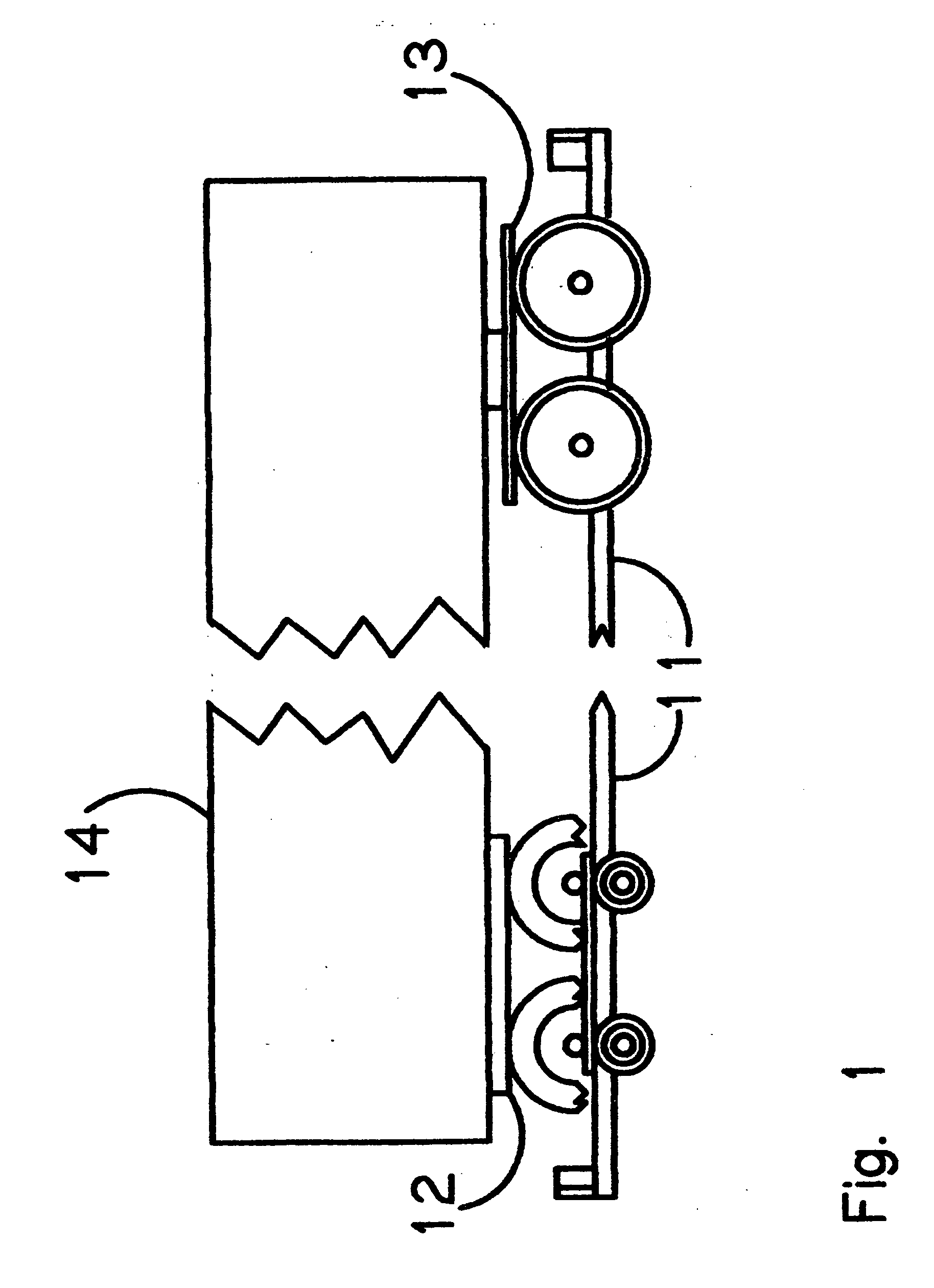

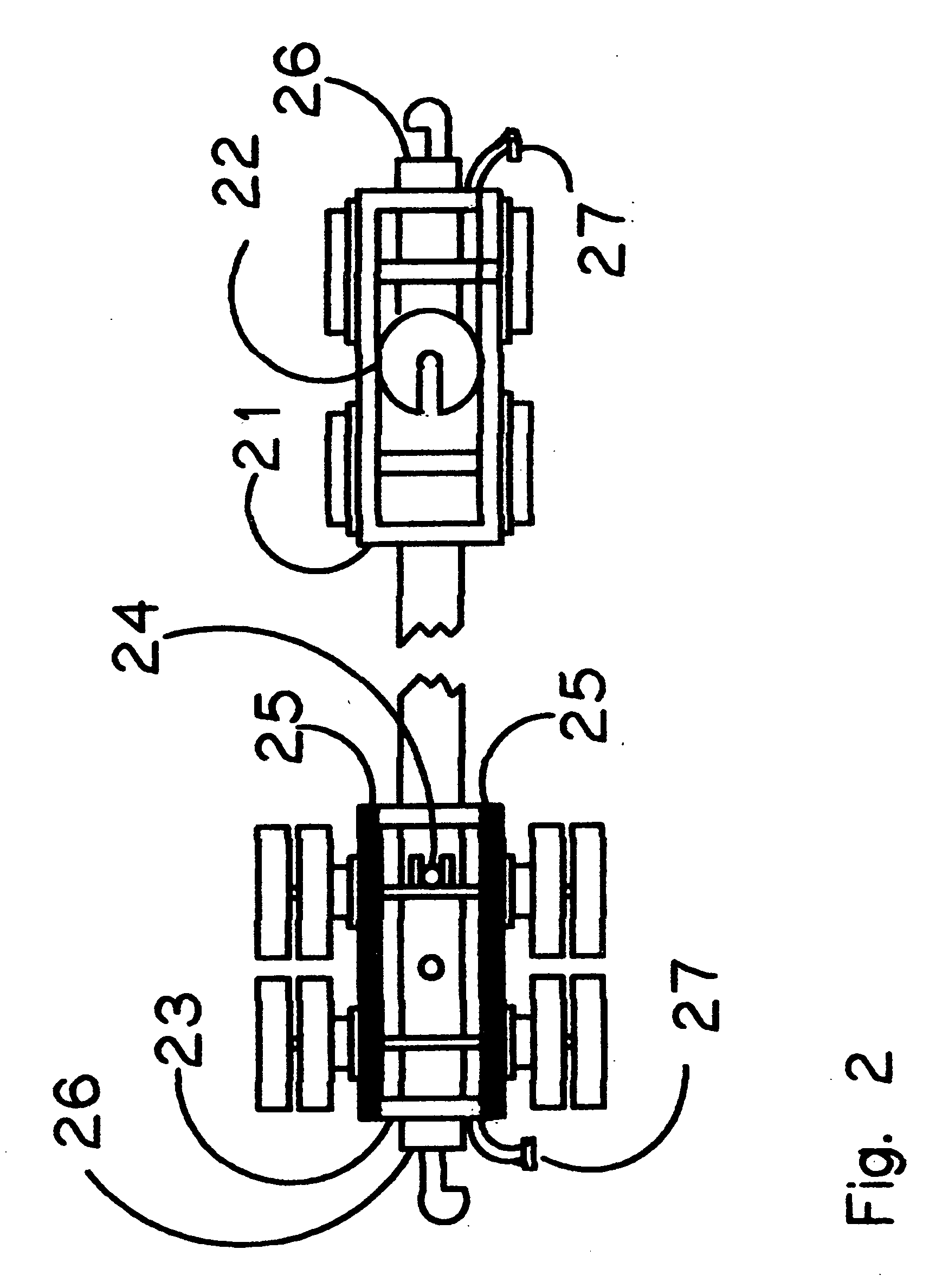

Apparatus and method for intermodal conversion of transport vehicles; rail-to-highway and highway-to-rail

InactiveUS20070089637A1Reduce fuel consumptionExtend delivery timeRail and road vehiclesWagons/vansBogieActuator

This invention is an apparatus and method for reversible intermodal conversion of transport tractors and trailers, highway-to-rail. Trailer add-ons are wheel mount shims and an axle housing draft sill pin receptacle. No add-ons are required for tractors. Highway-to-rail conversion involves securing a rail interface apparatus, consisting of rail carriage assemblies, bogies, and end coupler draft sills beneath each vehicle to align and bear loads-to-rails, and to provide draft load transfer. Staging is on paved grade slightly above rail level. Vehicle conversion is made without loading / unloading mechanized infrastructure, add-on weight, wheel removal, or powered actuators. Full use of inherent vehicle suspension and anti-roll devices is afforded. Draft sills, pneumatic brake lines, and knuckle couplers are employed for train configurations. Draft may be afforded by either a locomotive or a rail converted highway tractor.

Owner:SPROAT WILLIAM HARVEY

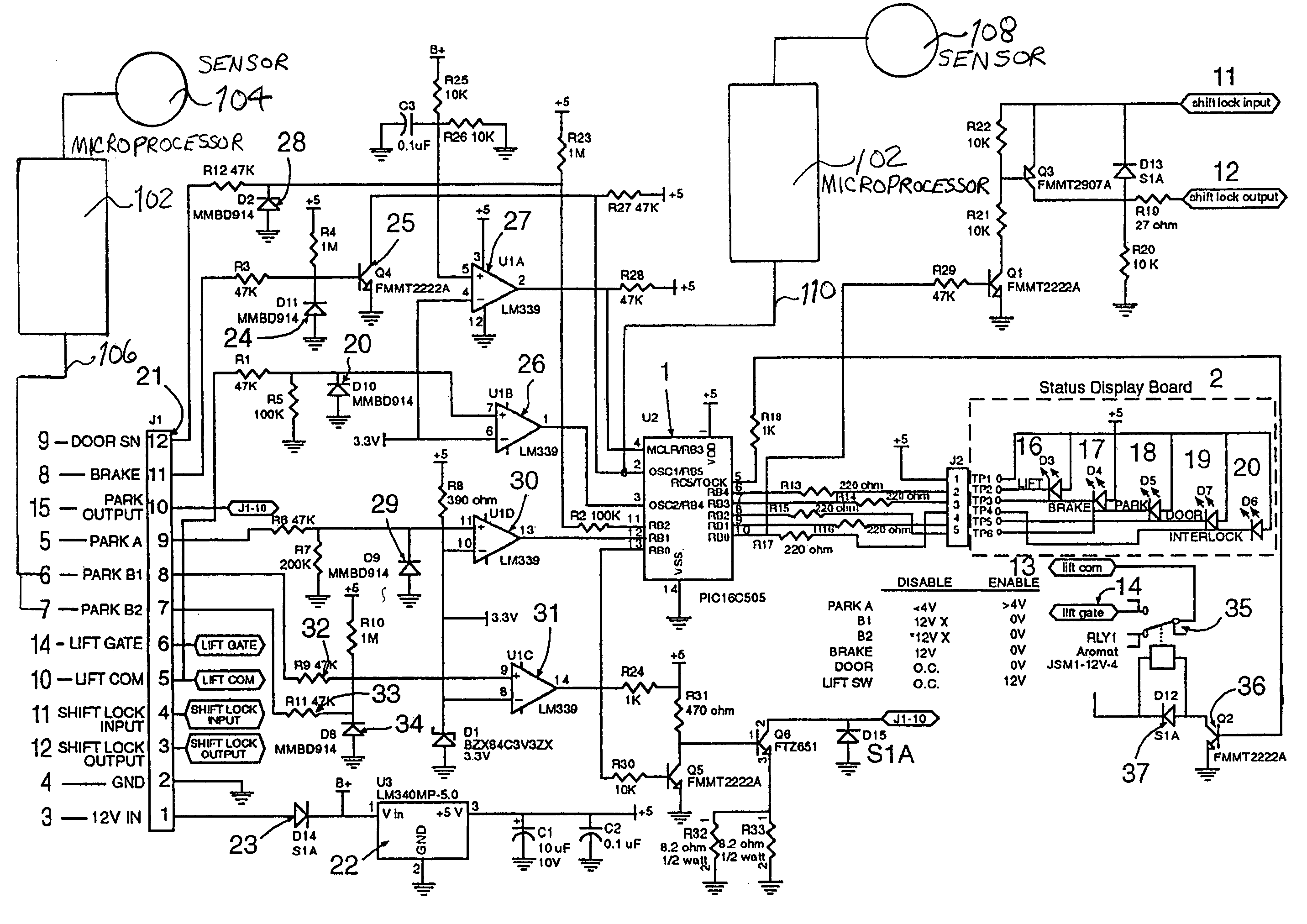

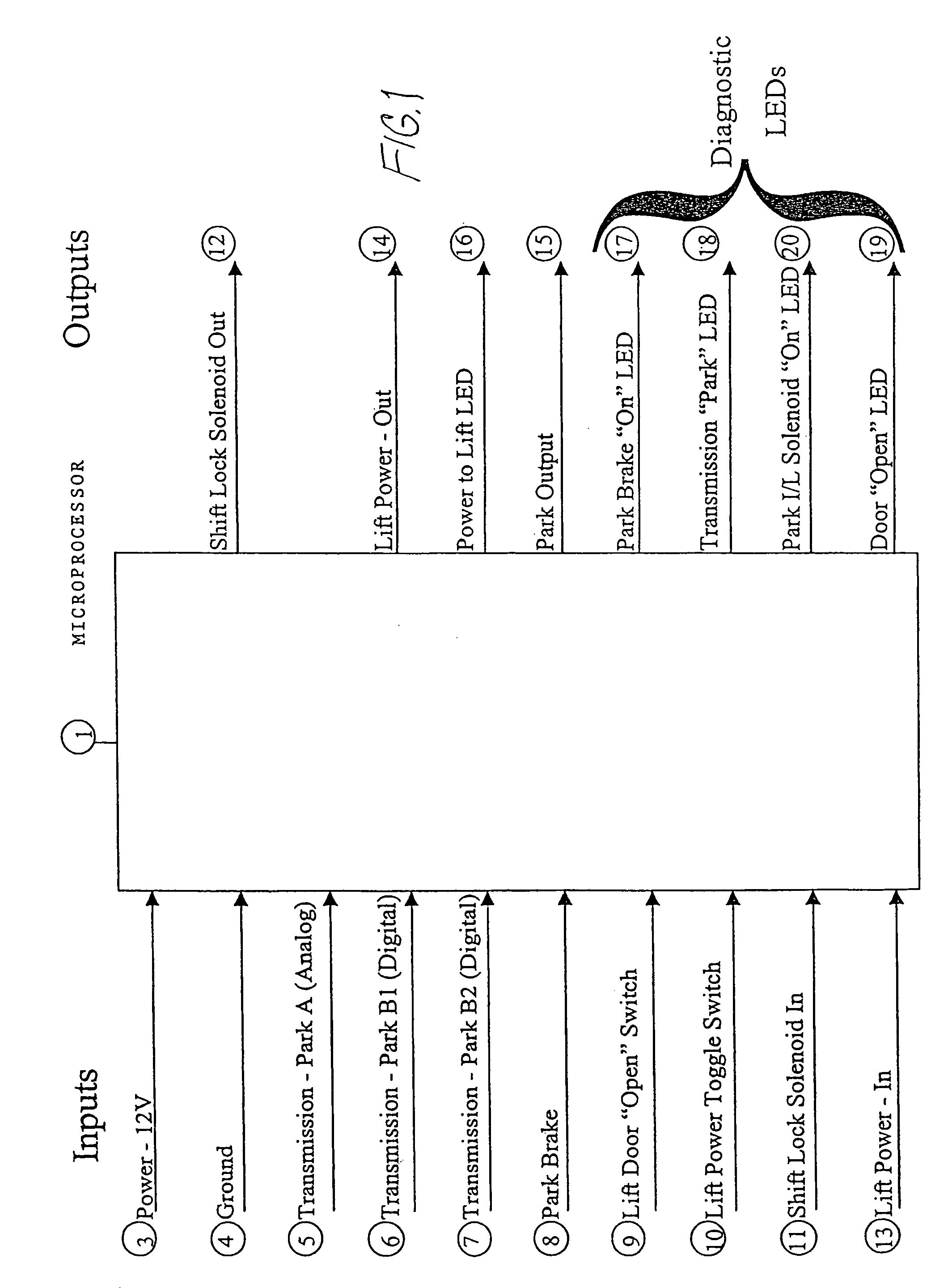

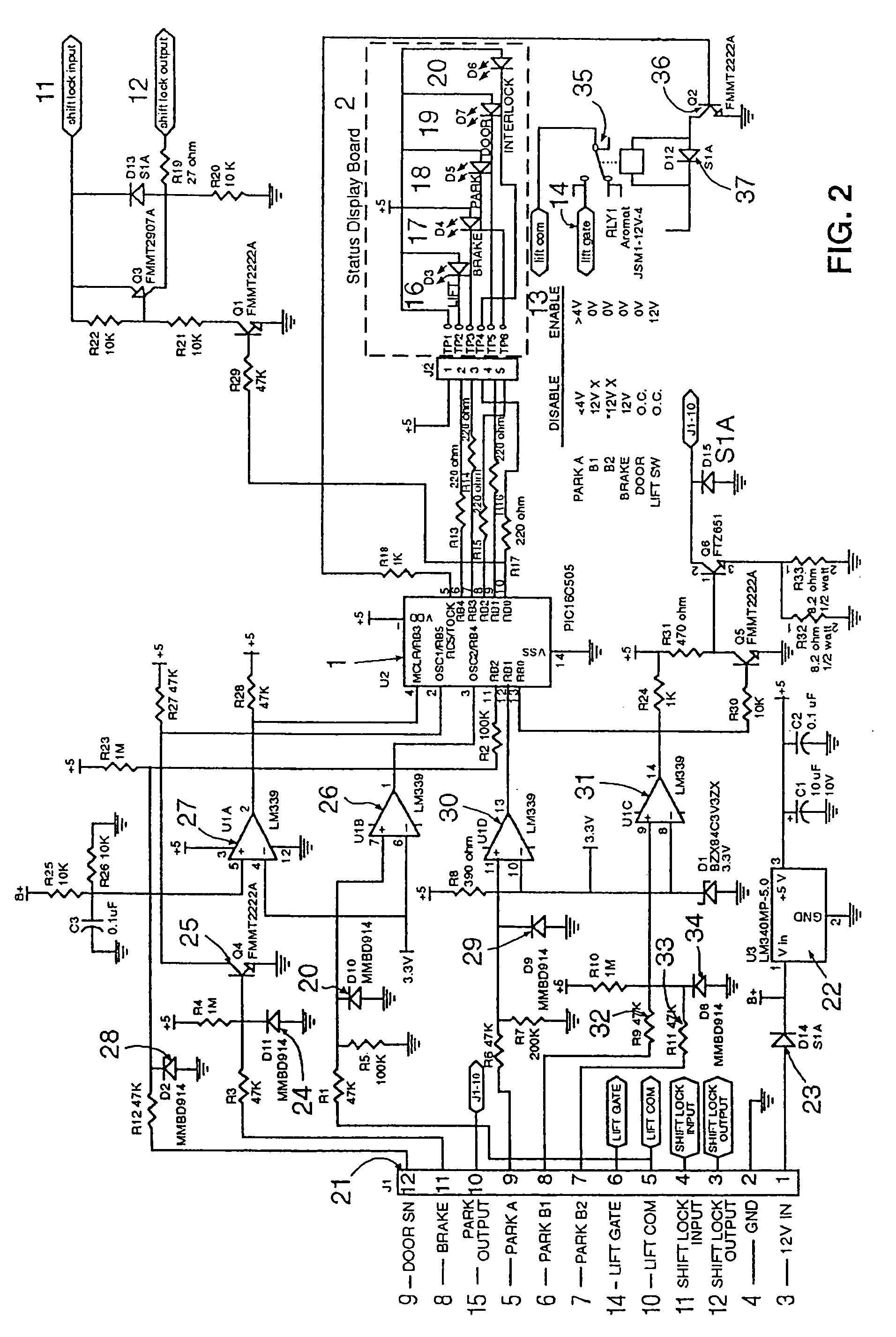

Intelligent lift interlock system

InactiveUS7274980B1Prevent and reduce injuryEliminate wearVehicle with raised loading platformDigital data processing detailsWheelchairControl system

A microprocessor controlled system for ensuring the safe operation of an auxiliary device, such as a wheelchair lift used in conjunction with a vehicle. The microprocessor preferably allows operation of the lift device when one or more parameters are met. These parameters include the following: the vehicle is in “park”, the parking brake is engaged, the vehicle ignition is “on”, the lift power switch is “on”, and the lift door is open. The present invention does not allow the vehicle to be shifted out of park if the lift door is open and / or when the parking brake is “on”.

Owner:INTERMOTIVE

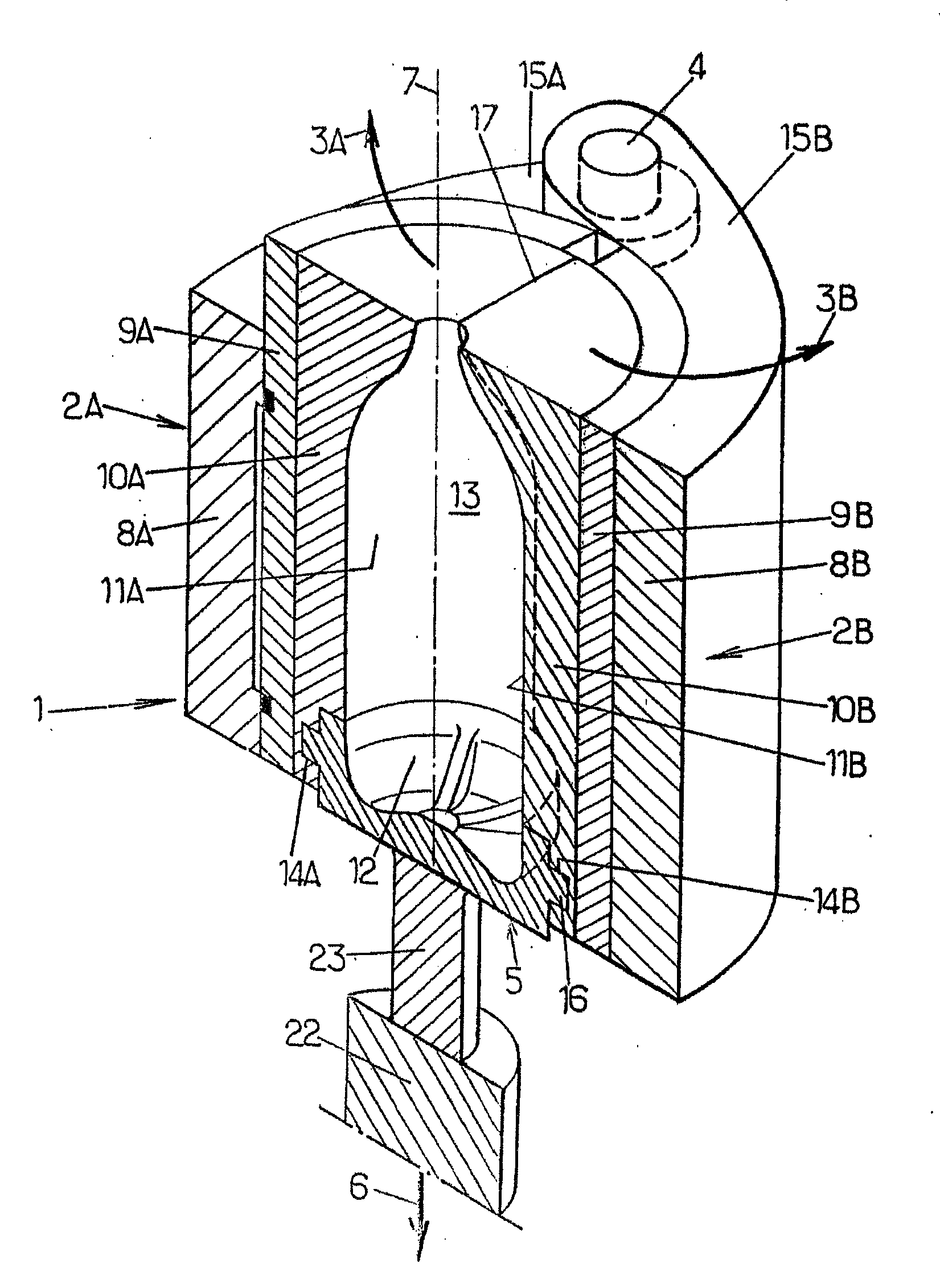

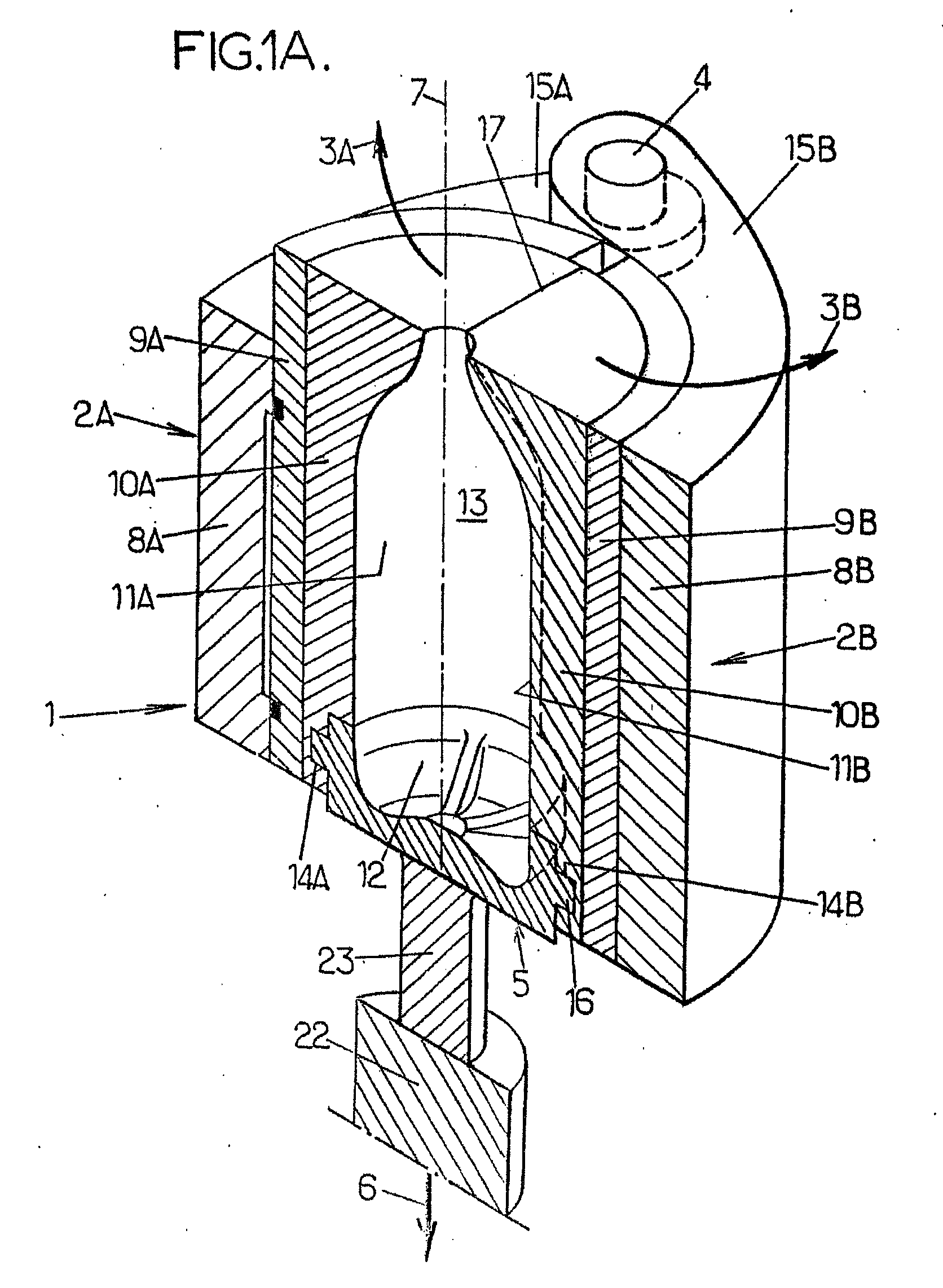

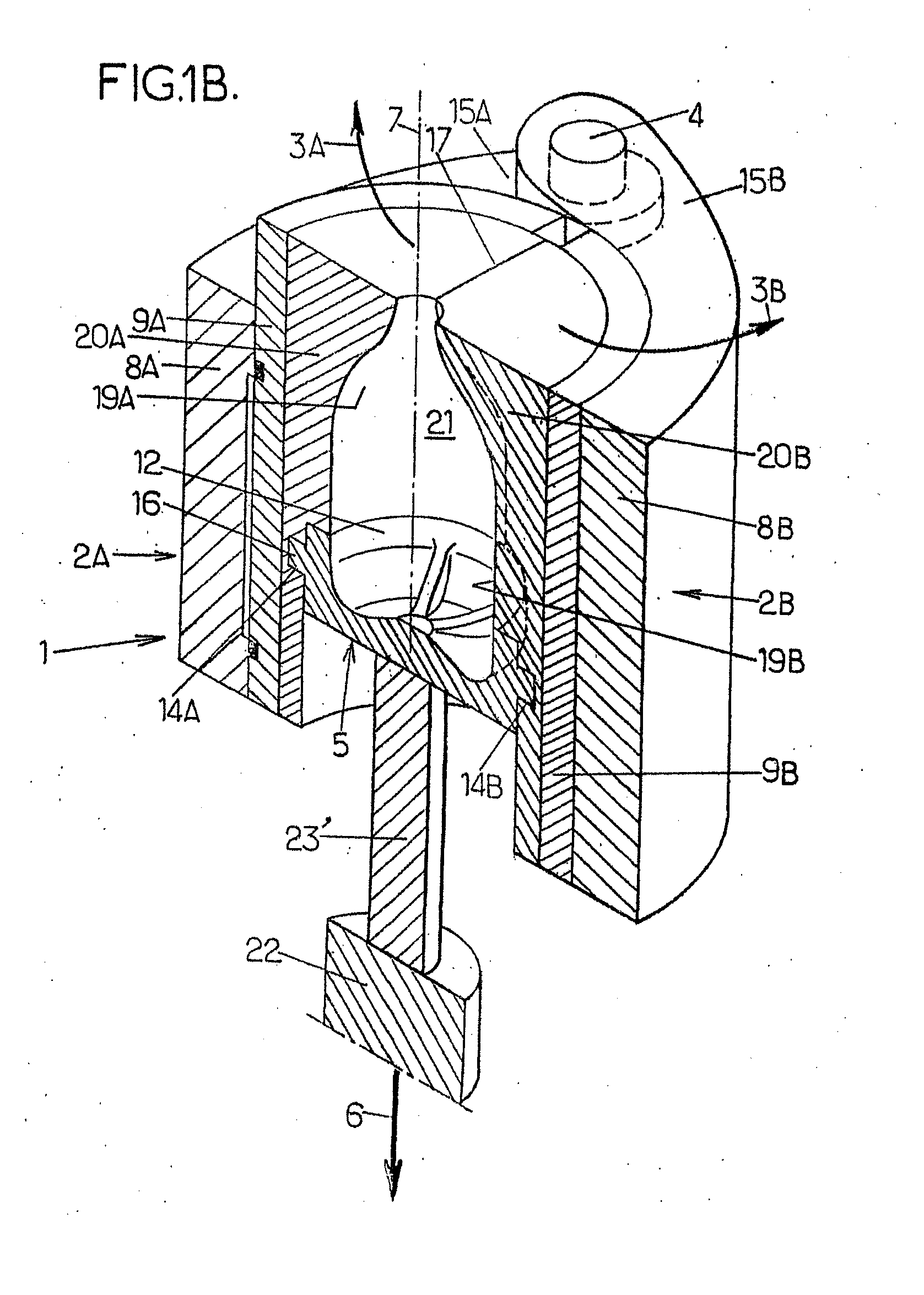

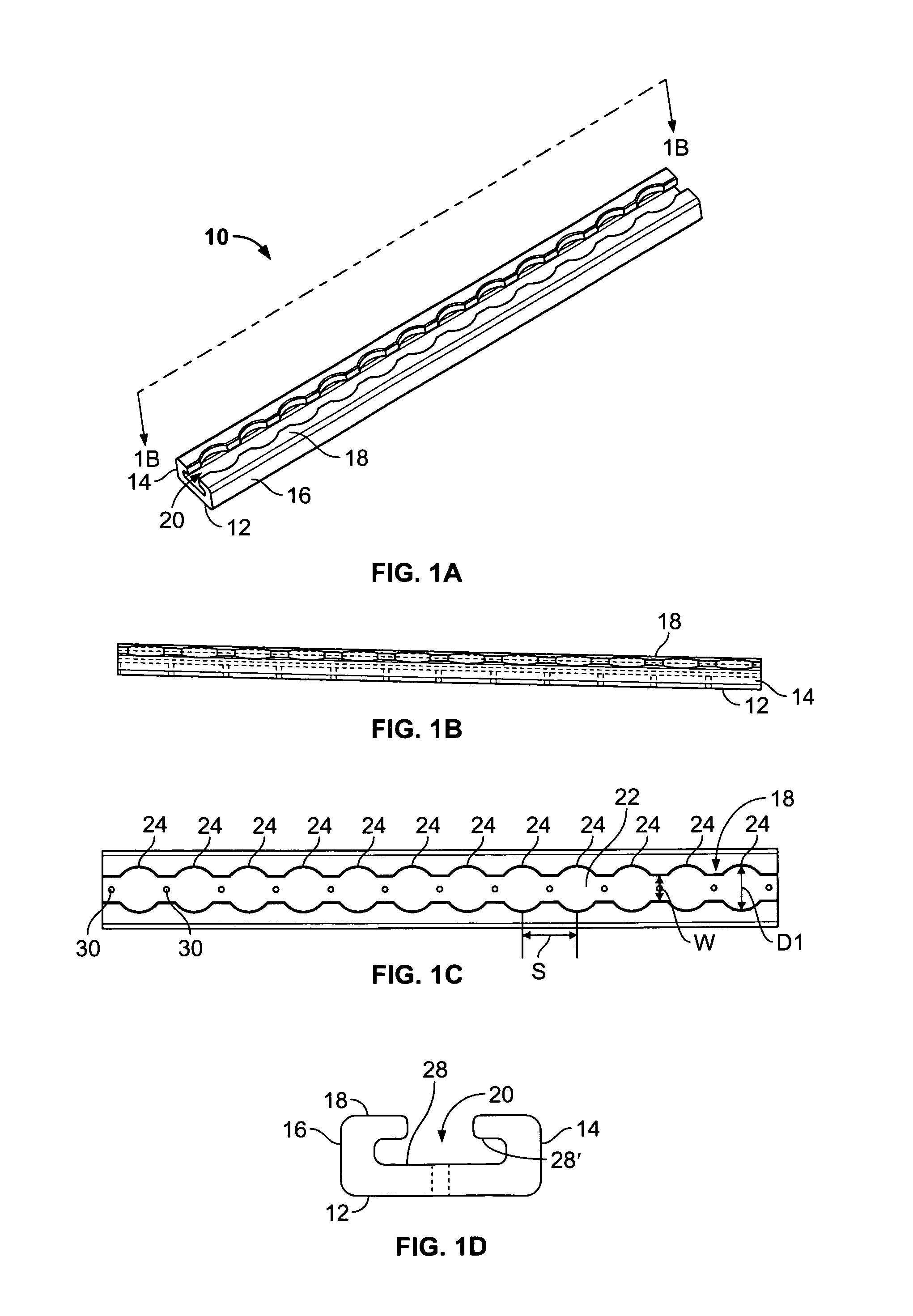

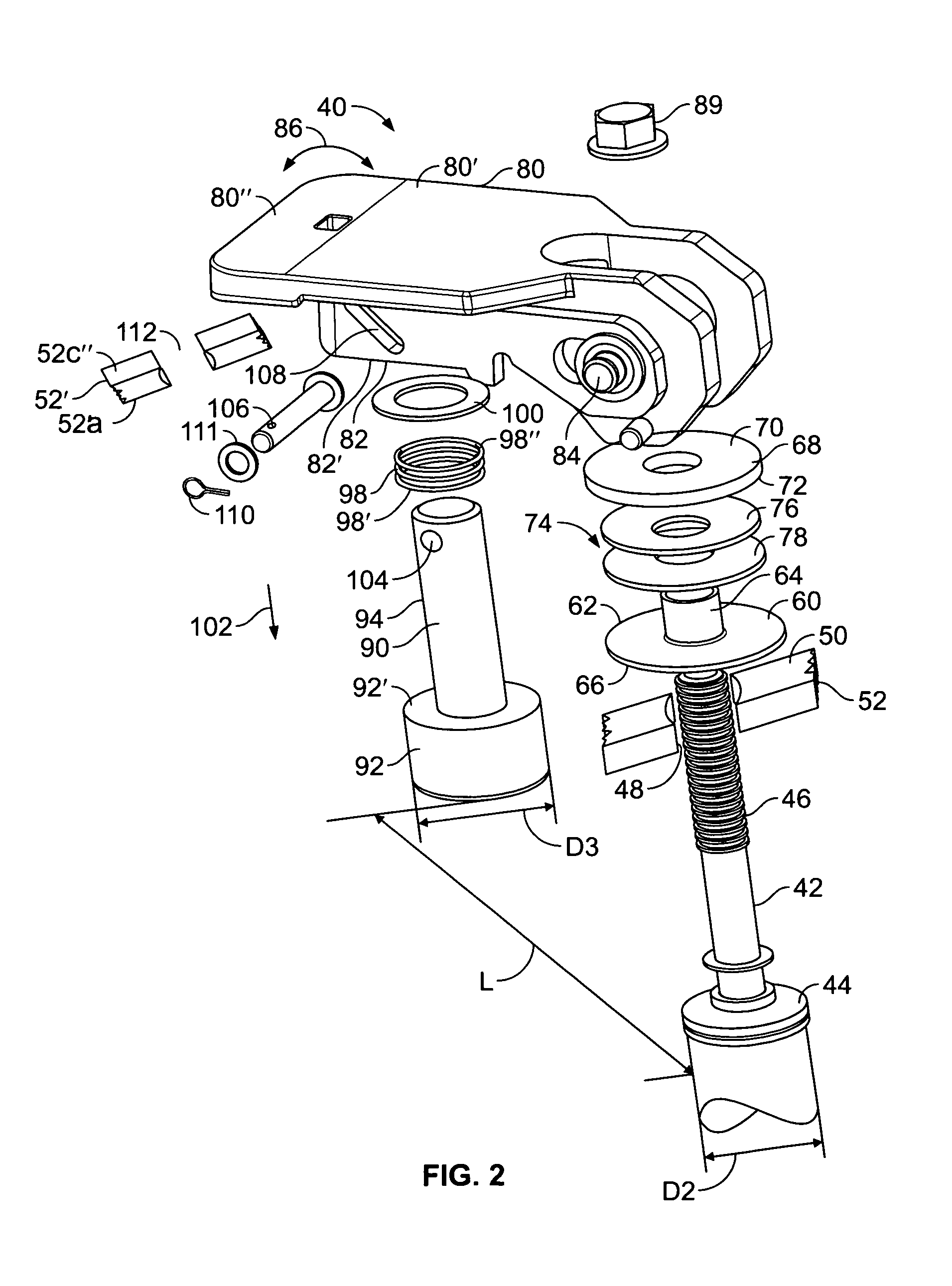

Molding Device with Hight-Adjustable Base for Molding Thermoplastic Containers of Various Heights

InactiveUS20080260884A1Quick and economical adjustmentIncrease the areaConfectionerySweetmeatsBlow moldingAxial displacement

The invention concerns a molding device for making by blow molding or stretch blow molding thermoplastic containers capable of having different heights, comprising a module (1) with two mutually mobile half-molds (2A, 2B) and an axially mobile mold base (5); the mold base is supported by a support (22) with which are associated in operation means for axial displacement; the mold base, and its support (22) are secured by spacing means (24) with adjustable variable heights relative to the height of the molding cavity and provided in the form of threaded means with reverse-pitch double threading; the mold base can thus be positioned axially relative to the height of the molding cavity without modifying the support (22) and / or the displacement means which are operatively associated with it.

Owner:SIDEL PARTICIPATIONS SAS

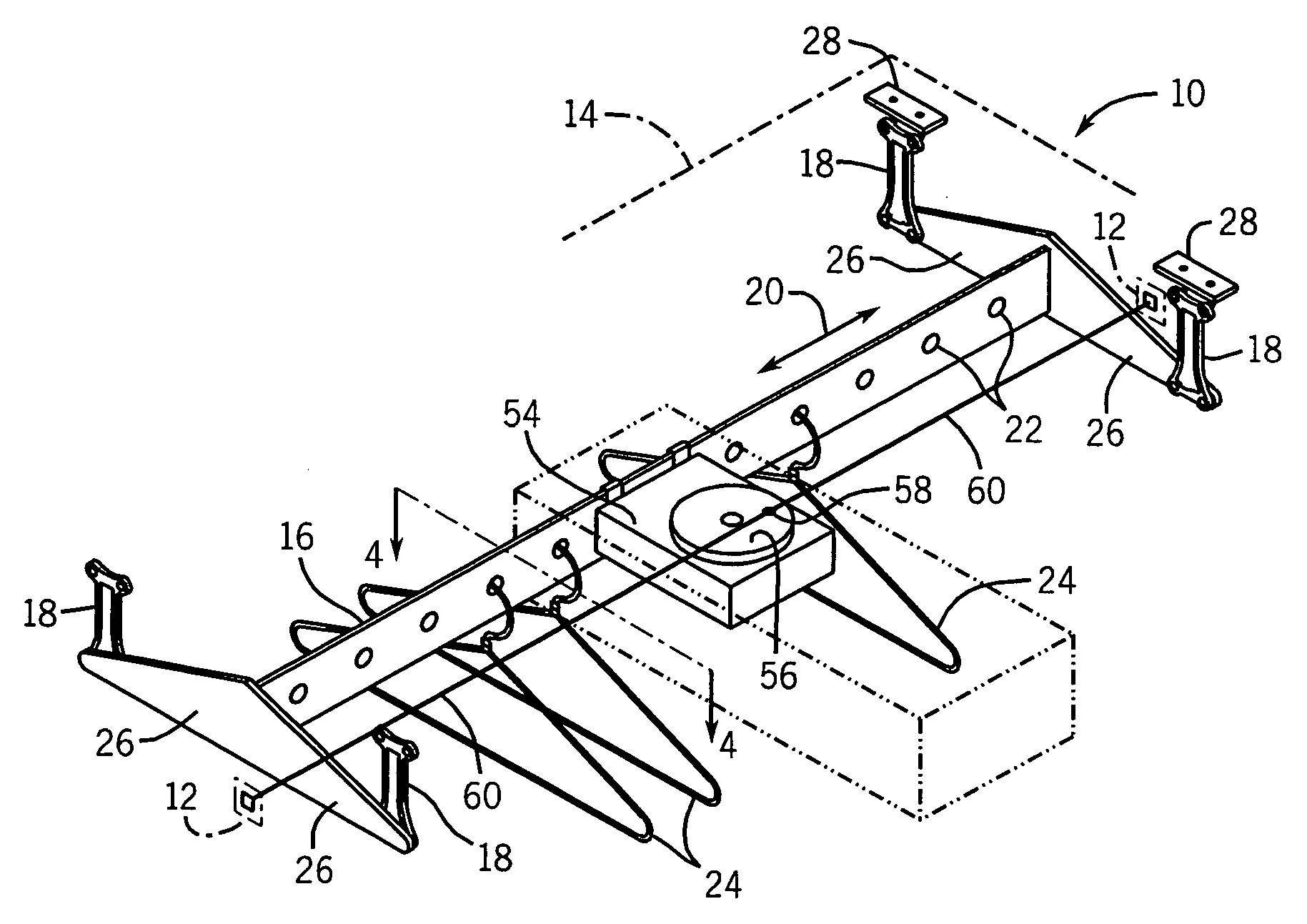

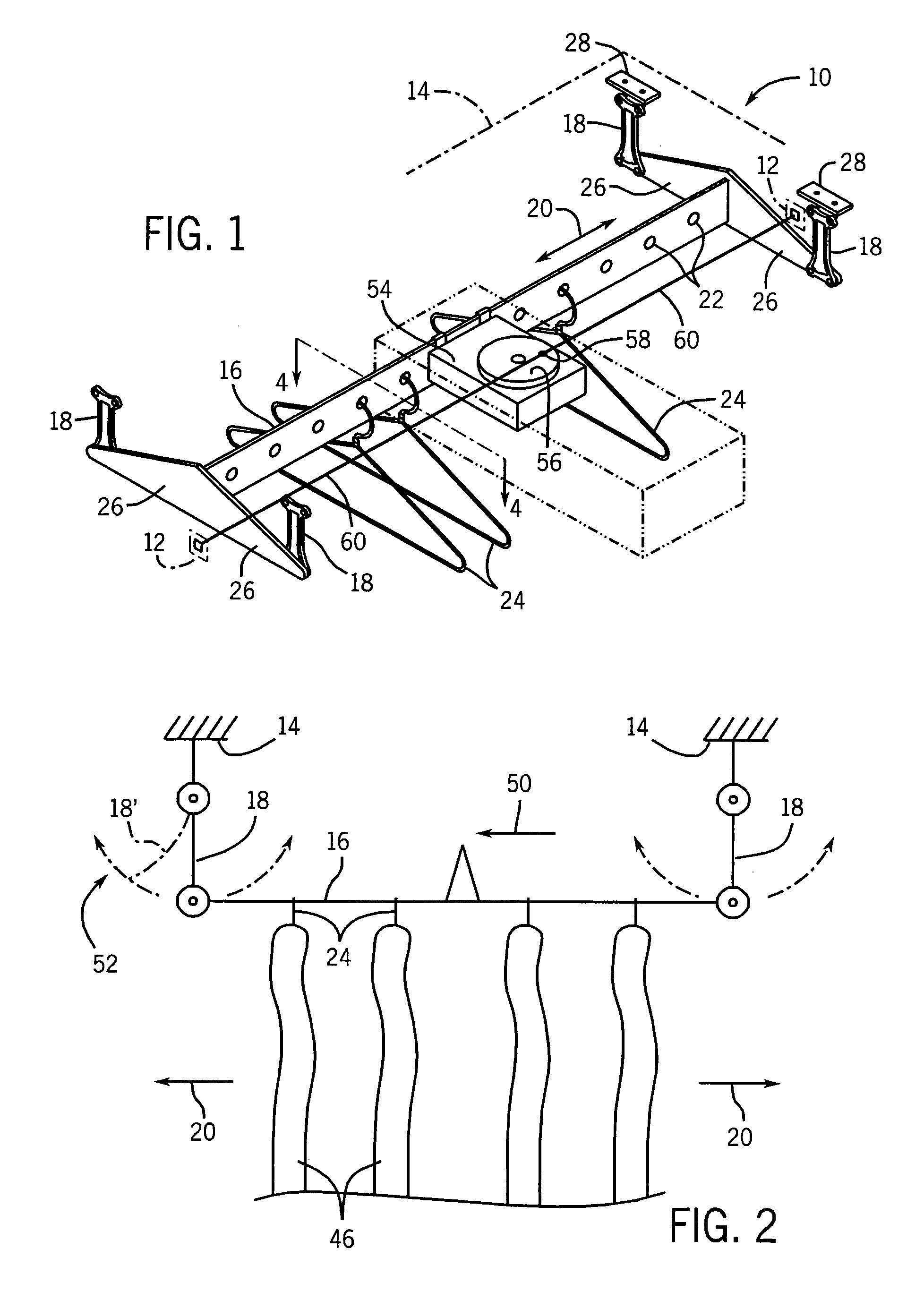

Agitator for removing wrinkles from clothing

An agitator mechanism for a clothes finishing cabinet provides a pendulum mounted hanger bar that may reciprocate under the application of a periodic force by an actuator without rigid connection between the cabinet housing and the hanger bar. Quiet operation is obtained by mounting an actuator motor directly on the hanger bar to be isolated by sound absorbing hanger support materials.

Owner:ILLINOIS TOOL WORKS INC

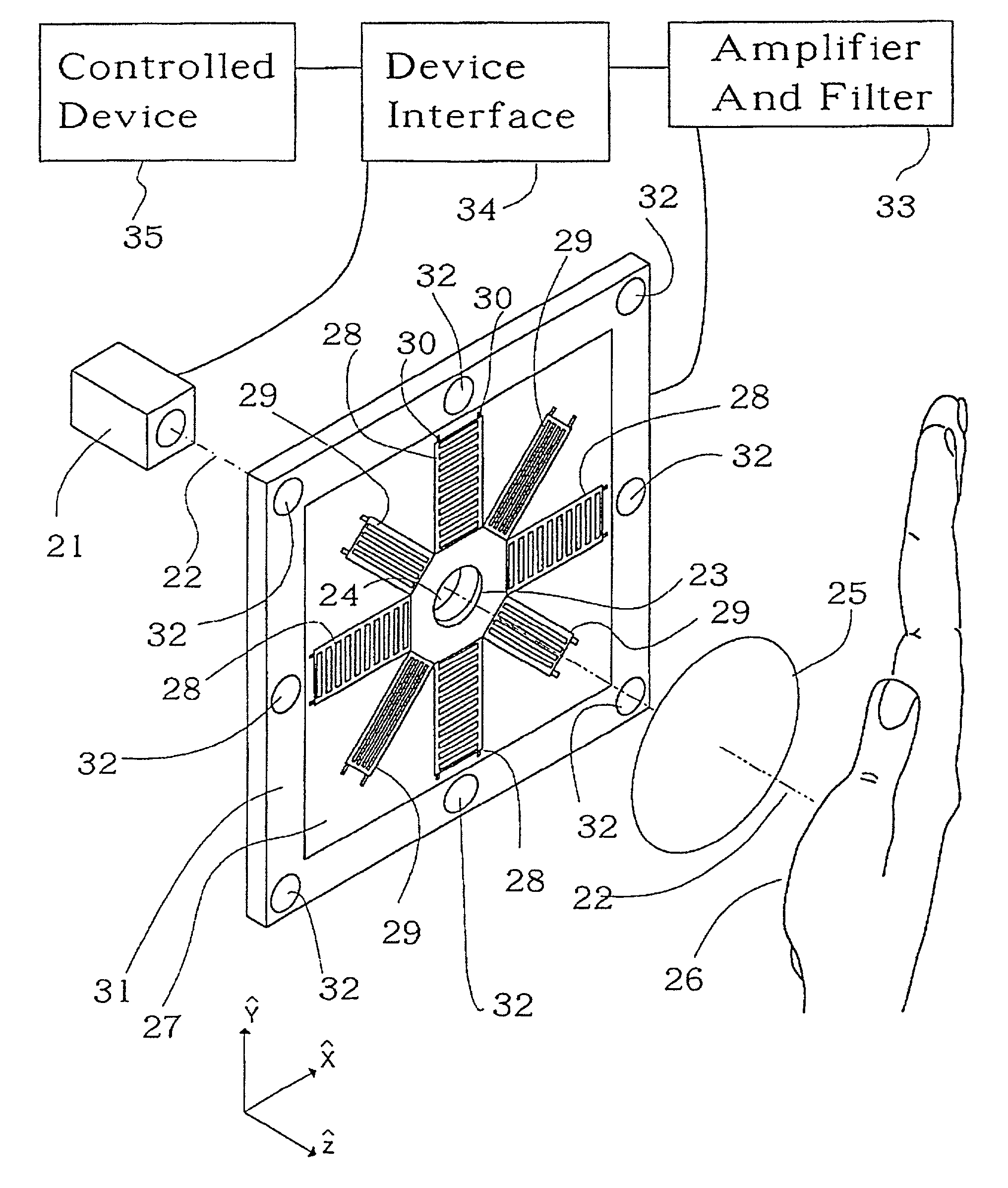

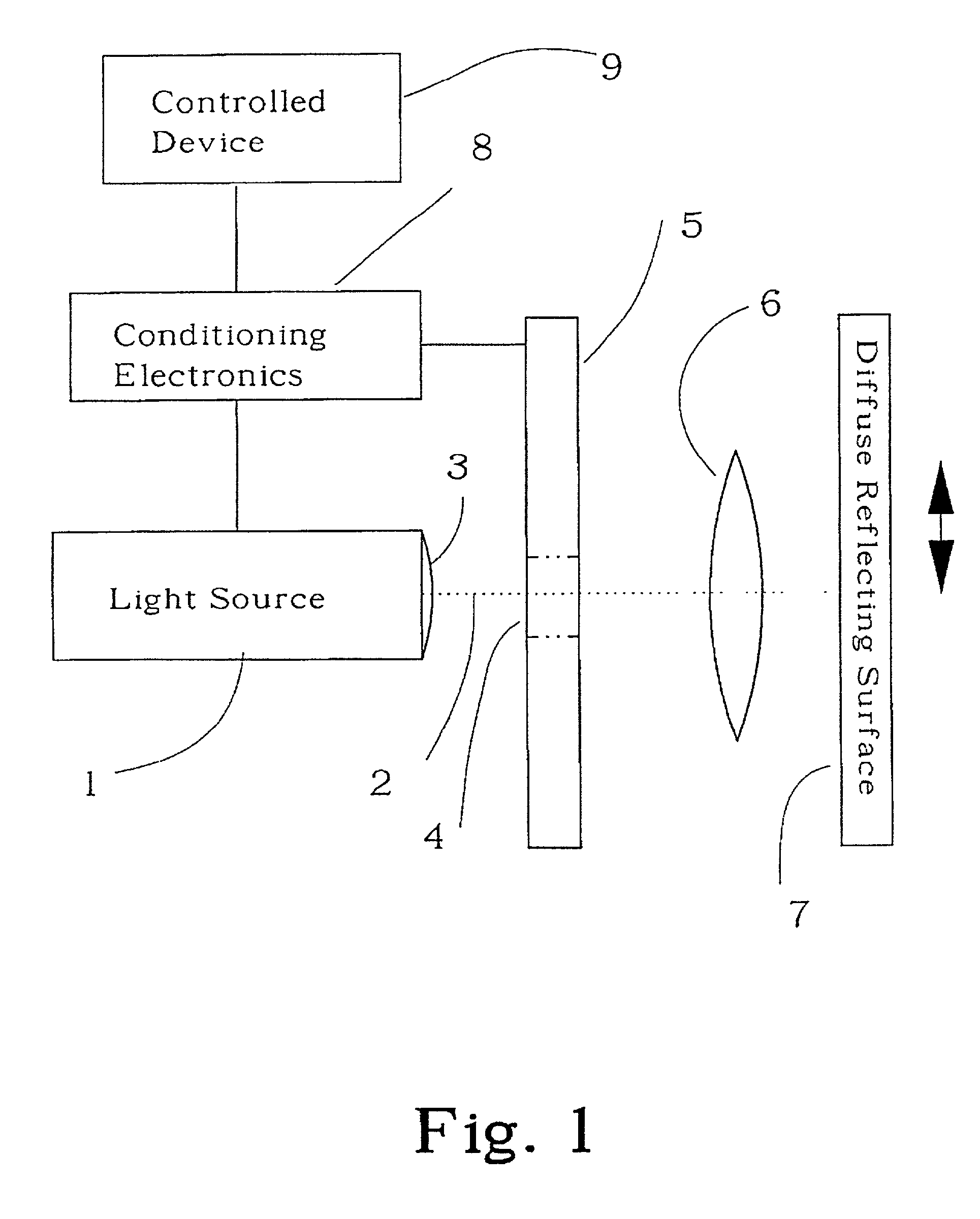

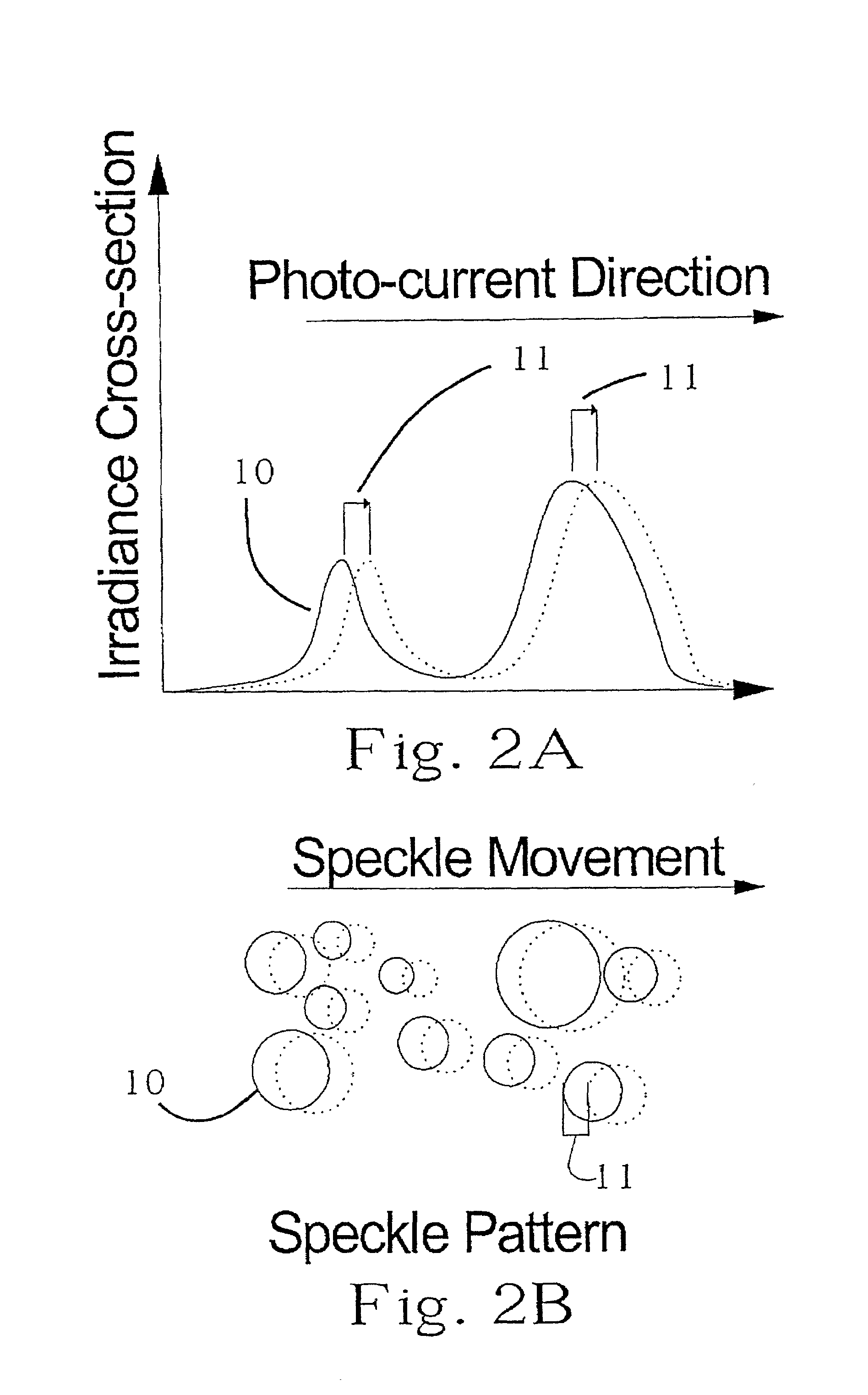

Optically based machine input control device

InactiveUS7002549B2Easy constructionHigh sensitivityInput/output for user-computer interactionCathode-ray tube indicatorsElectronic control systemControl signal

A non-contact optically based apparatus for measuring the motion of a diffusely reflecting surface. The motion measurements and signals derived therefrom are used to provide input control signals to a computer or other electronic control systems requiring a human tactile or other control. The apparatus includes a unique optical sensor which senses both the magnitude and direction of the motion of a surface, relative to the apparatus, by measuring the motion of the pattern generated by illuminating the diffusely reflecting surface with a light source.

Owner:MCCAHON STEPHEN WILLIAM +1

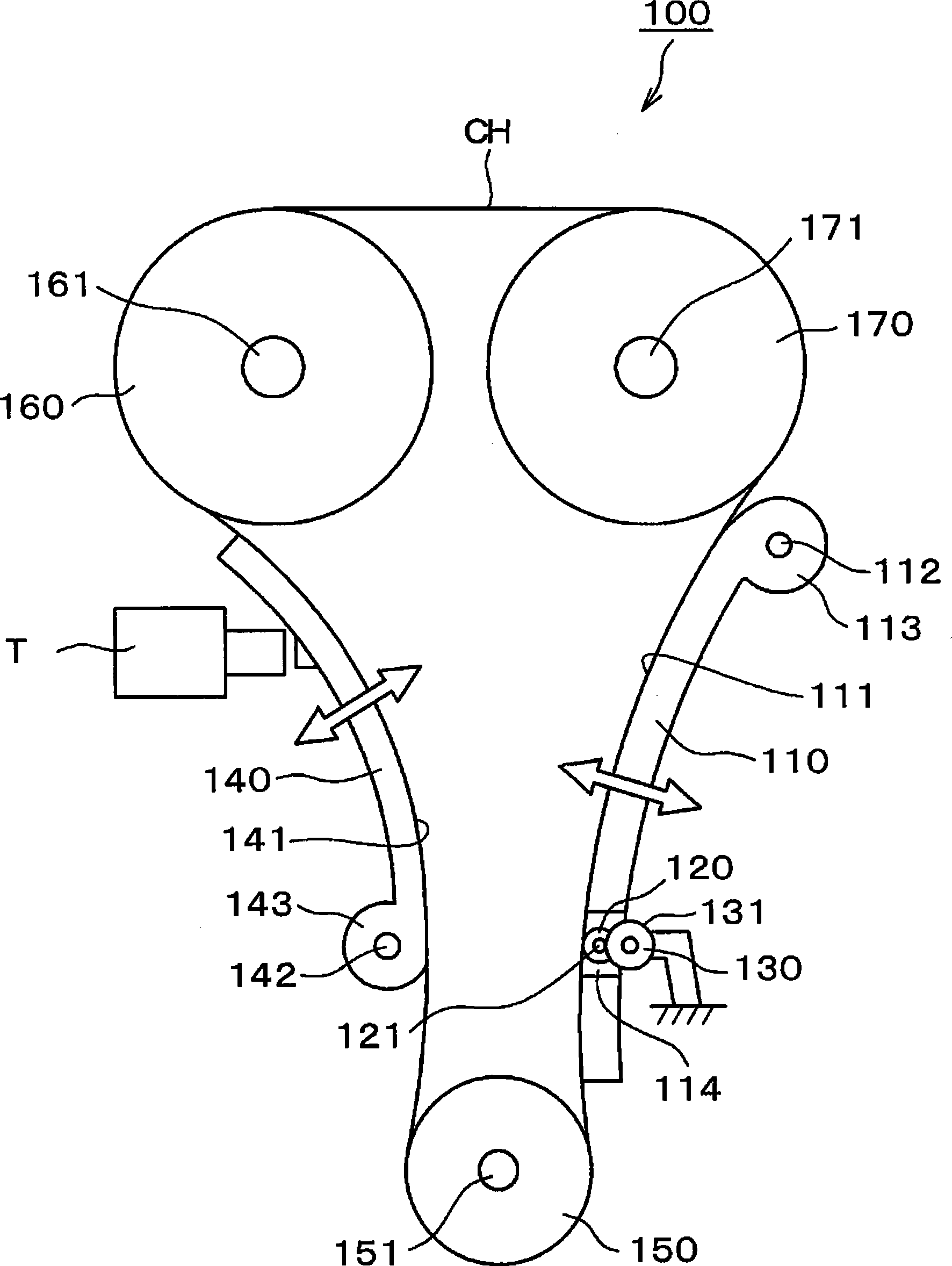

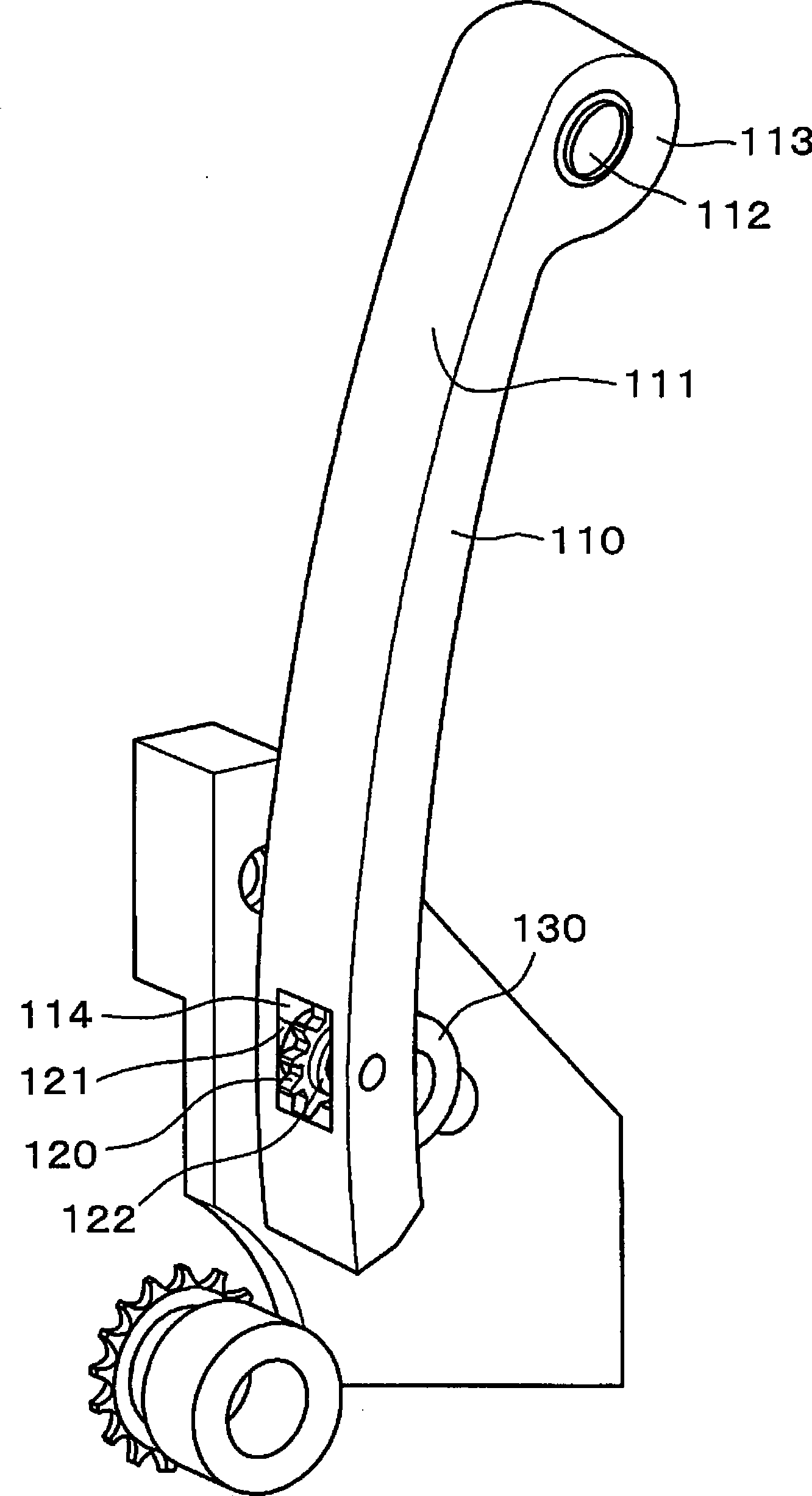

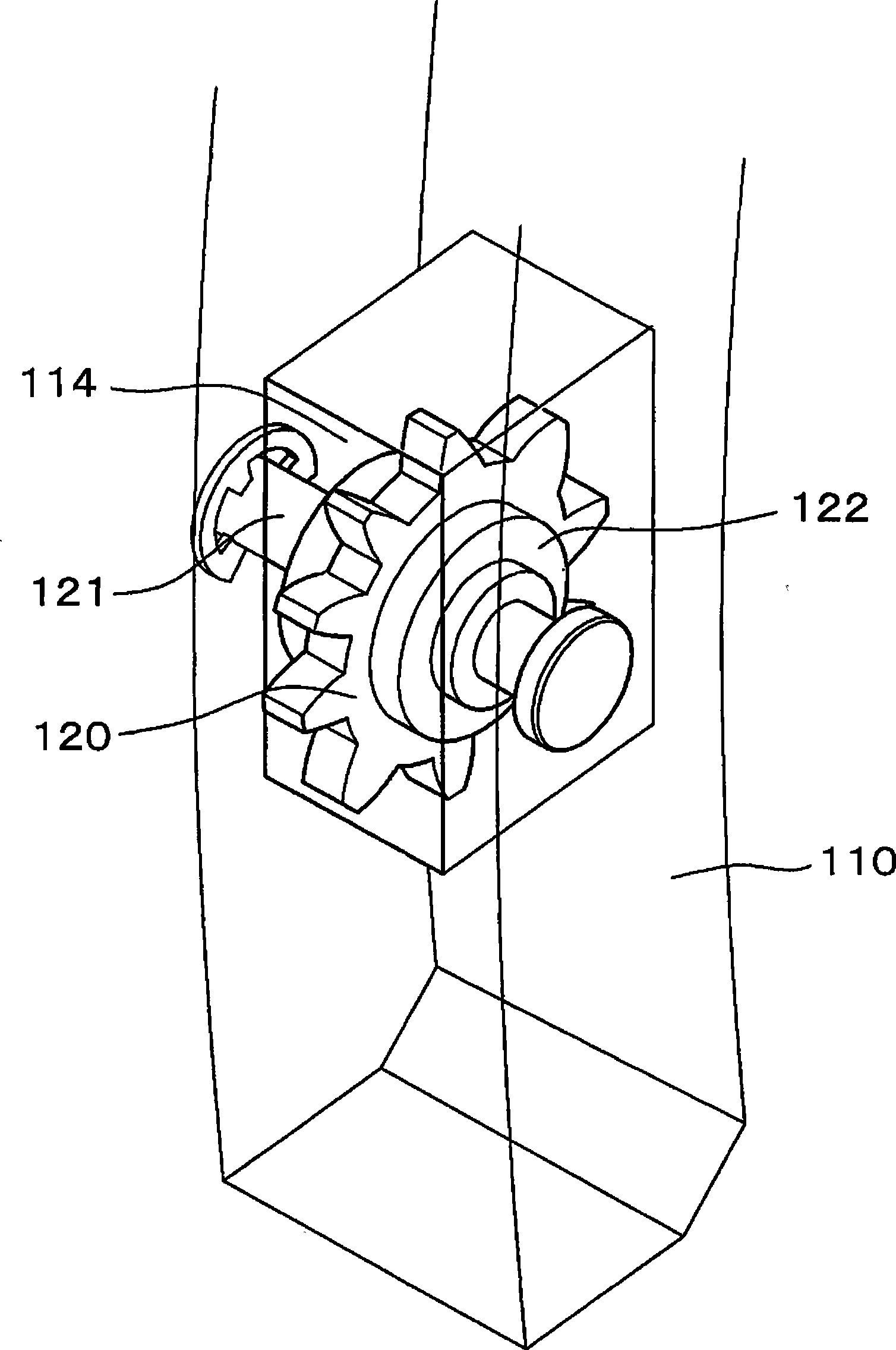

Timing chain drive unit

The invention provides a timing chain drive unit capable of reducing influence of tension changing, and realizing minature lightweighting of chain and increasing system quietness. In an engine timing chain drive(100), chain guiding pieces (110,14) are provided on the looseness side and the tension side of the chain (CH), and the chain guiding piece (110) on the tension side comprises a synchronizing sprocket (120) in fastening-rotation with the chain (CH) and the chain guiding piece (110) is set in synchronized rotation along with tension variation.

Owner:TSUBAKIMOTO CHAIN CO

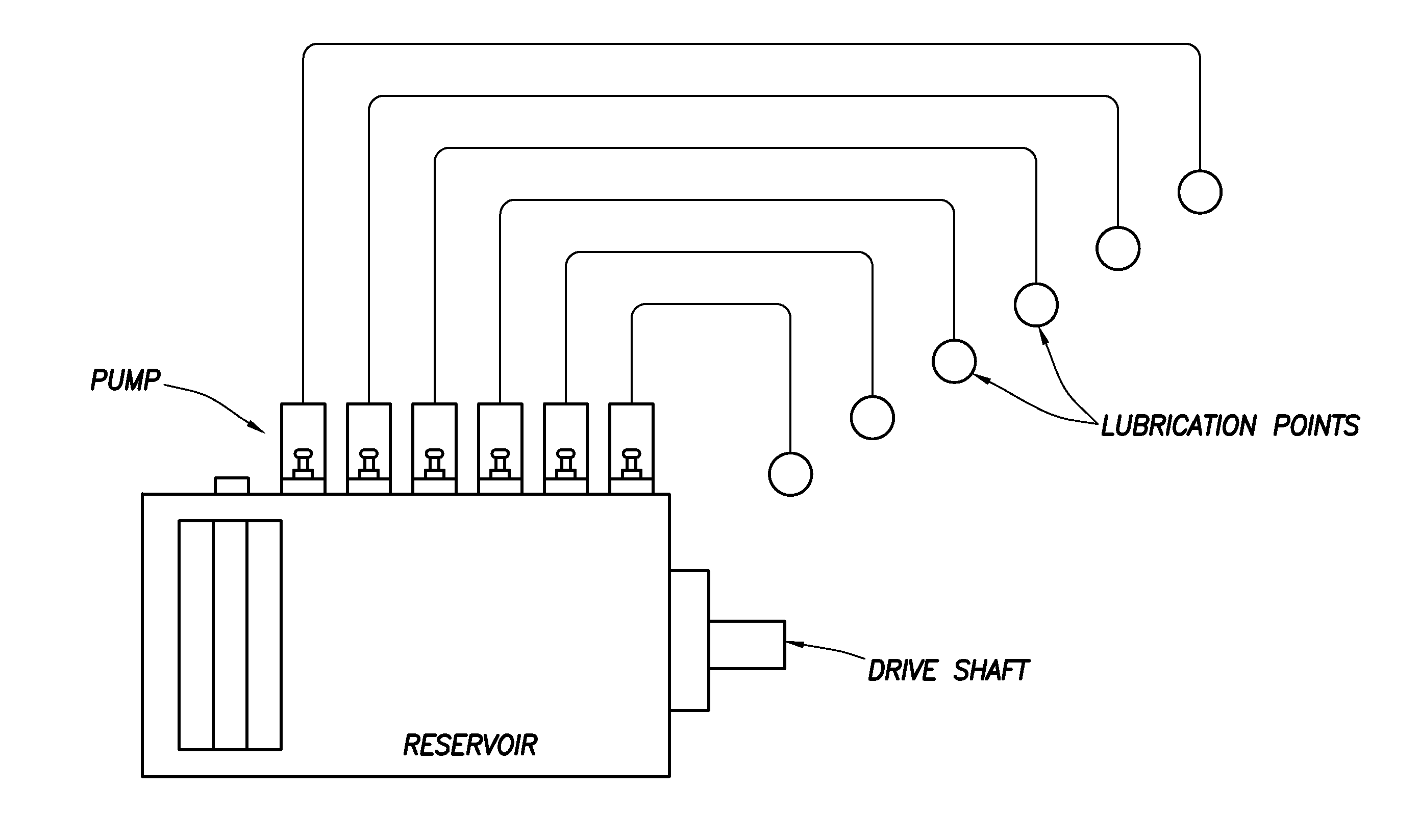

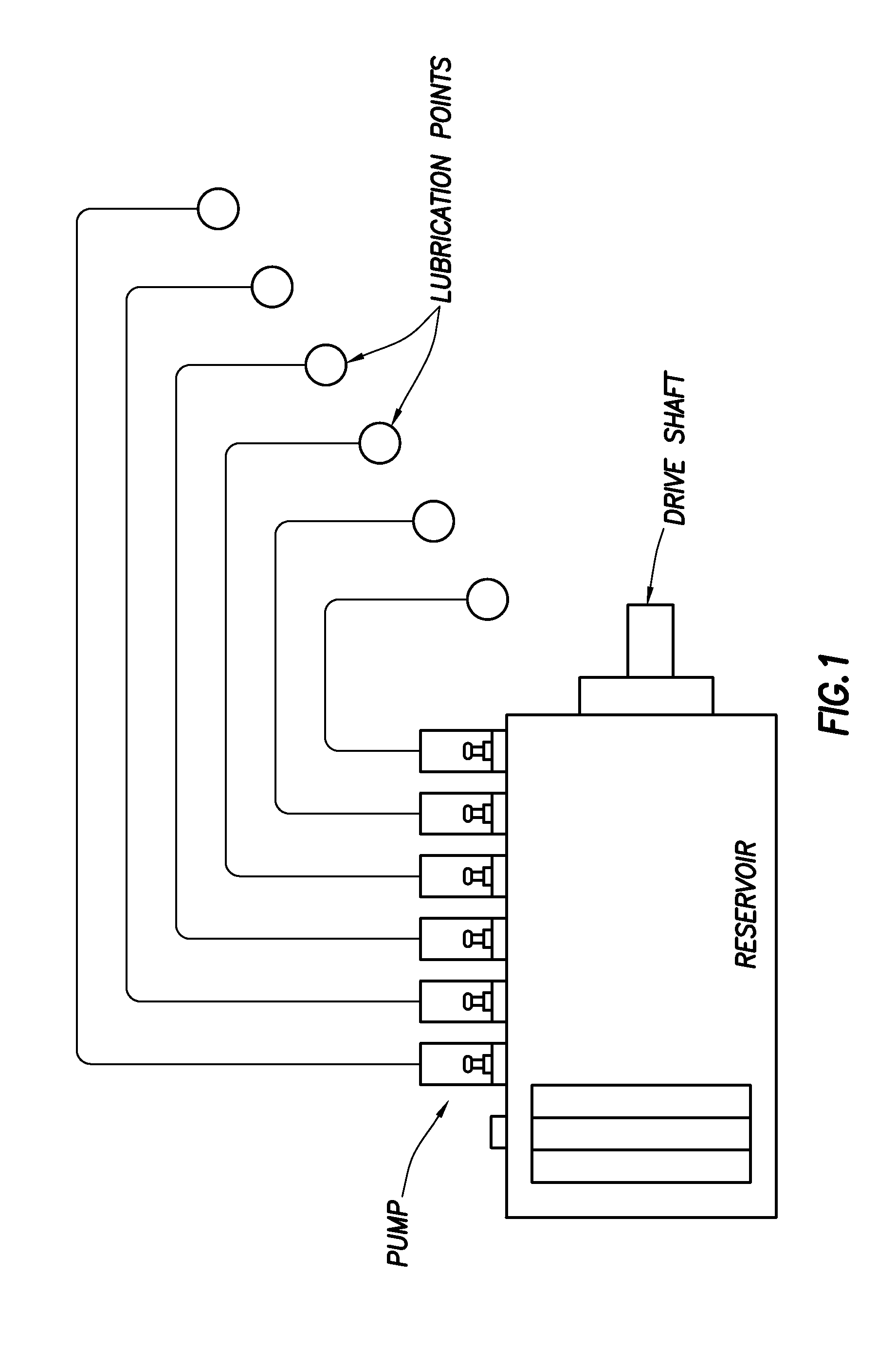

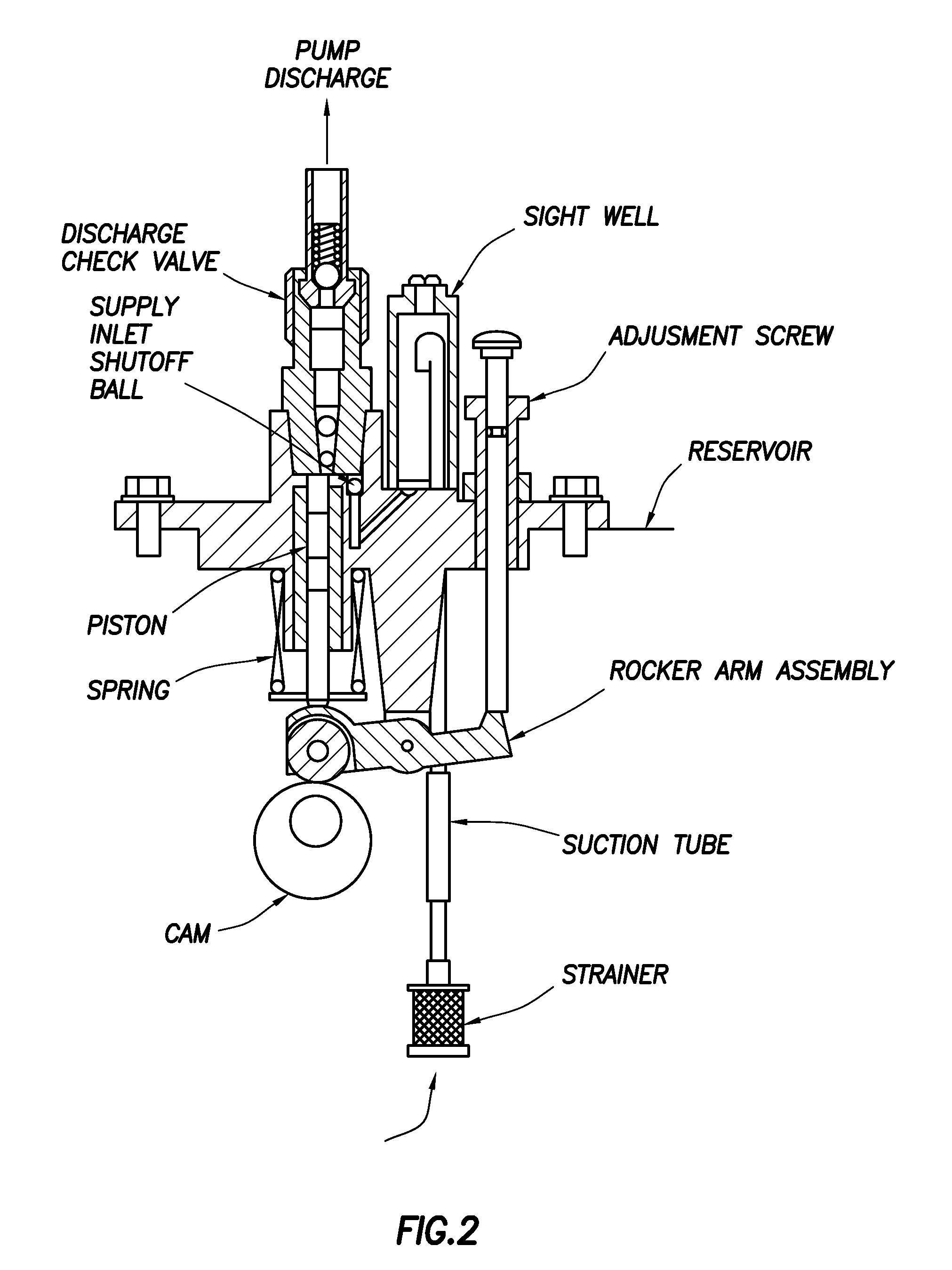

High pressure lubrication system

ActiveUS20110308888A1Accurate monitoringEliminate maintenanceLubricating pumpsMachines/enginesProcess engineeringEngineering

An improved lubrication system for use in connection with high pressure processing and particularly useful for LDPE processing. The lubricating system utilizes flow meters to monitor and control the supply pressure and oil flow to a machine lubrication point. Furthermore, two different types of oil may be used so as to alleviate down time and repair often associated with use of food grade oil as the lubricate for the camshaft and other working components of the lubrication system.

Owner:TF HUDGINS

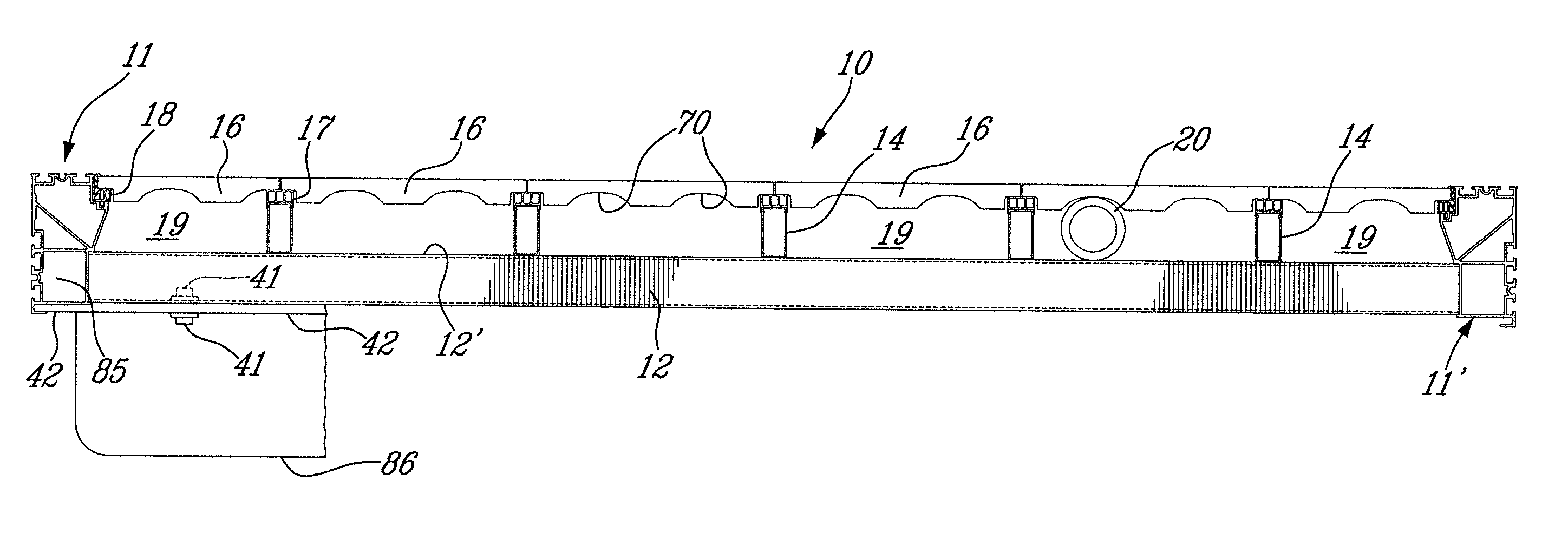

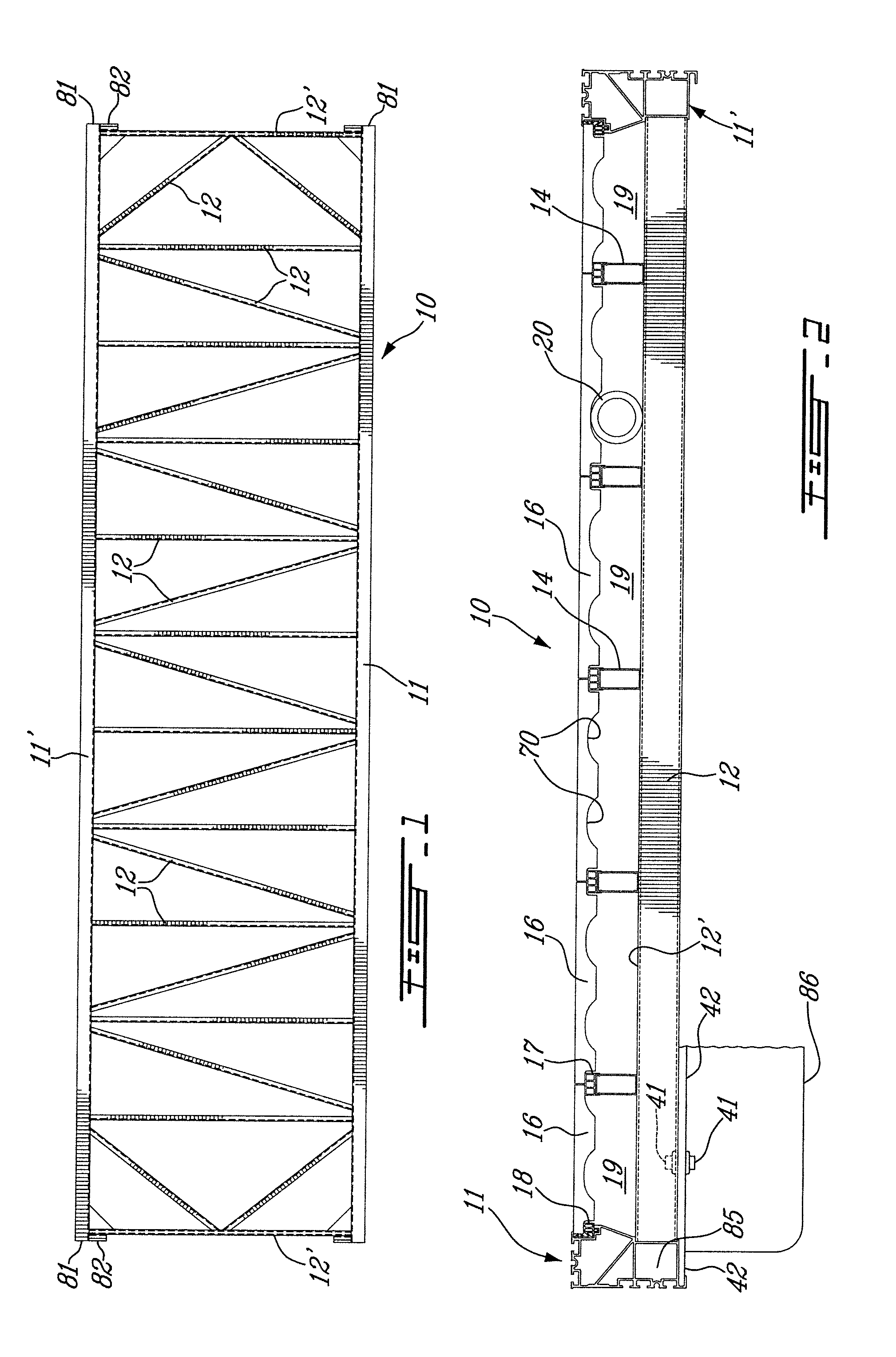

Floating dock structure

InactiveUS7784419B2Remove noiseEliminate wearDry-dockingMarine site engineeringEngineeringMechanical engineering

Owner:MANUFACTURIERS TECHNOMARINE INC TECHNOMARINE MFG

Turbine blade and method of forming blade tip for eliminating turbine blade tip wear in rubbing

ActiveUS20190063250A1Eliminate wearEliminate wear and tearEngine fuctionsBlade accessoriesCoating systemTurbine blade

Coating systems for a cooled turbine blade tip, such as a metal turbine blade tip, are provided. The coating system includes an abrasive layer overlying the surface of the turbine blade tip. One or more buffer layers may additionally be disposed between an outer surface of the blade tip and the abrasive layer. The coated blade tip can be used with a ceramic matrix composite (CMC) shroud coated with an environmental barrier coating (EBC) to provide improved cooling to the tip so as to lengthen oxidation time of the abrasive layer and reduce blade tip wear. Methods are also provided for forming the cooled blade tip and applying the coating system onto the cooled turbine blade tip.

Owner:GENERAL ELECTRIC CO

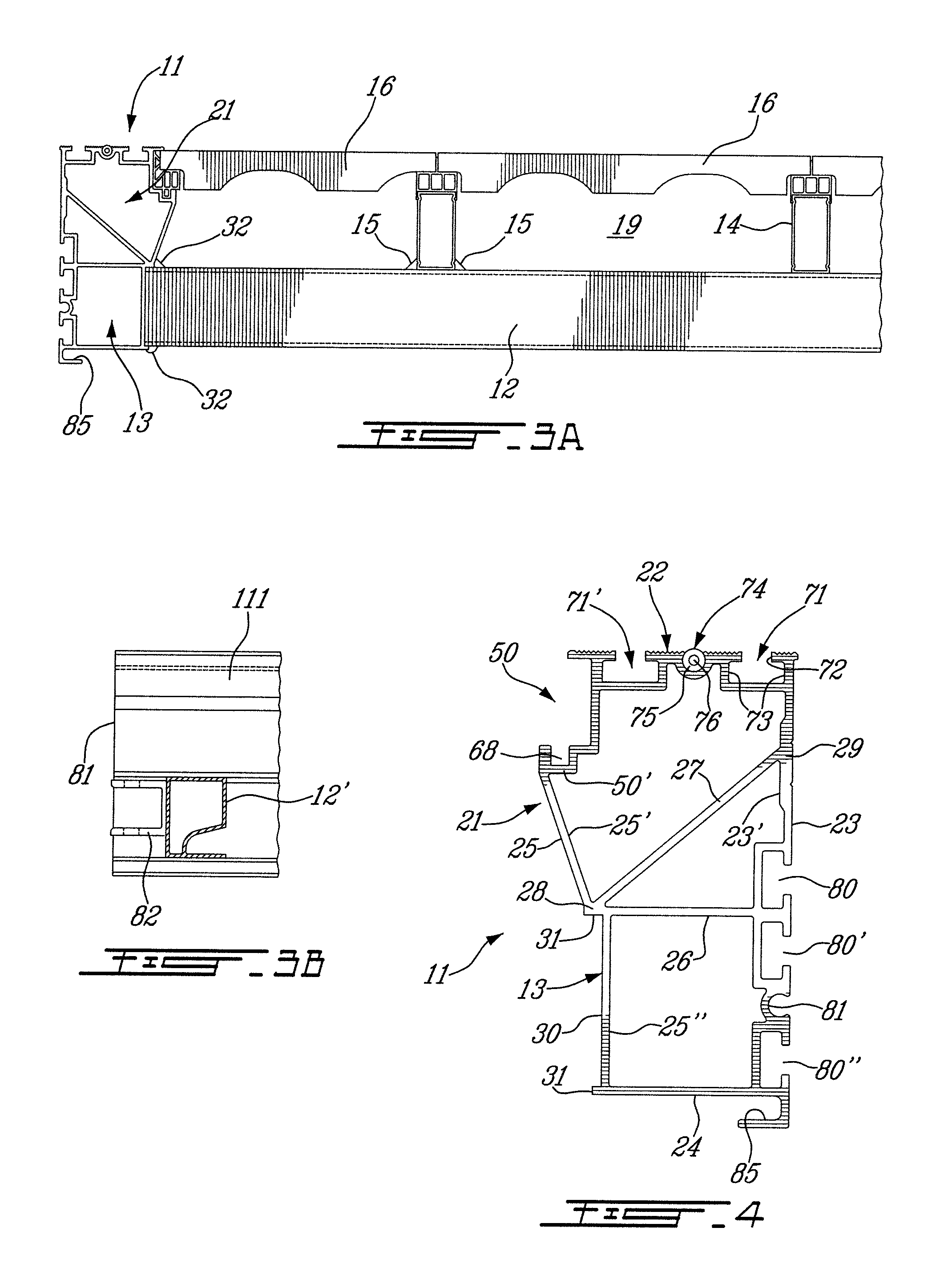

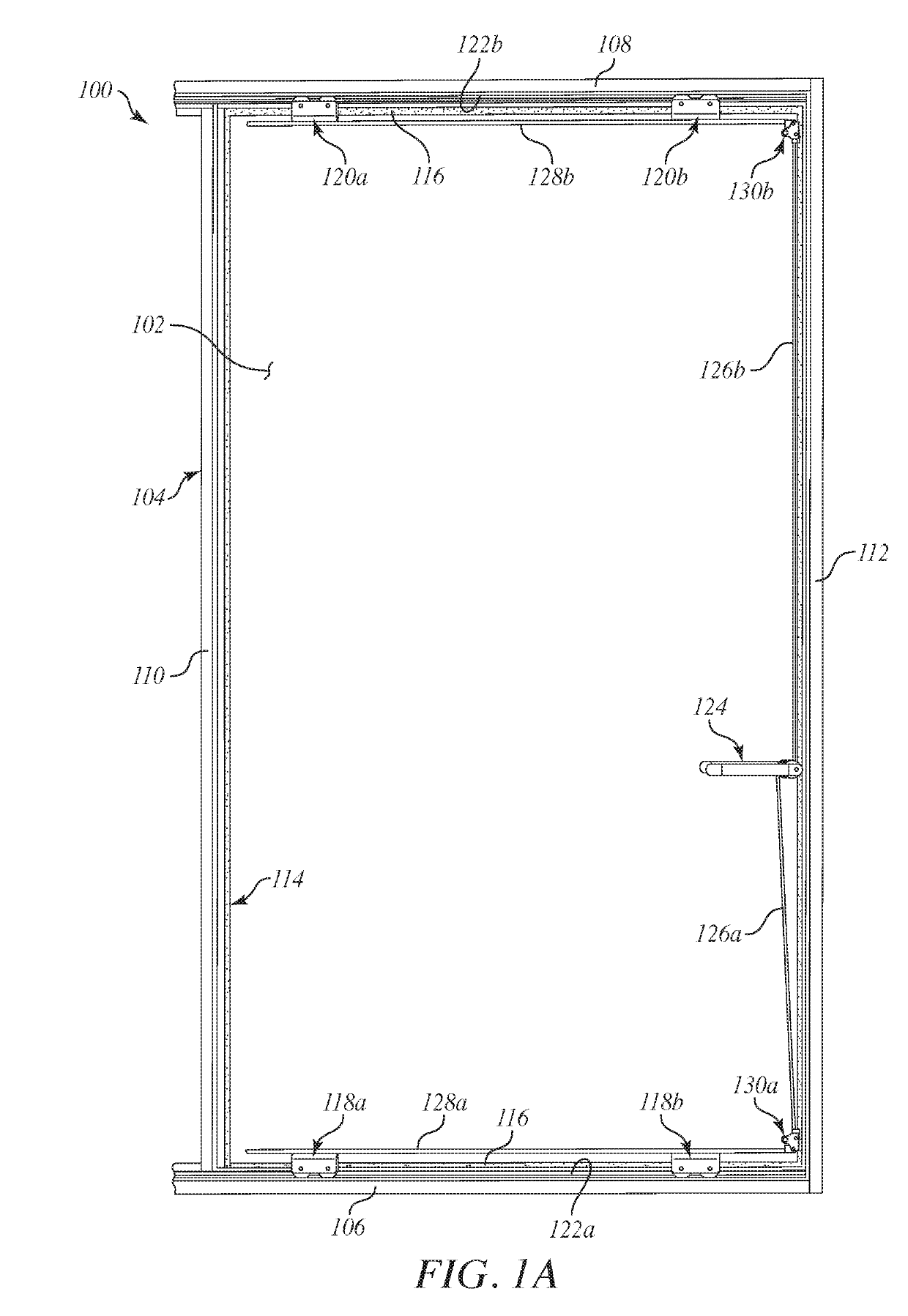

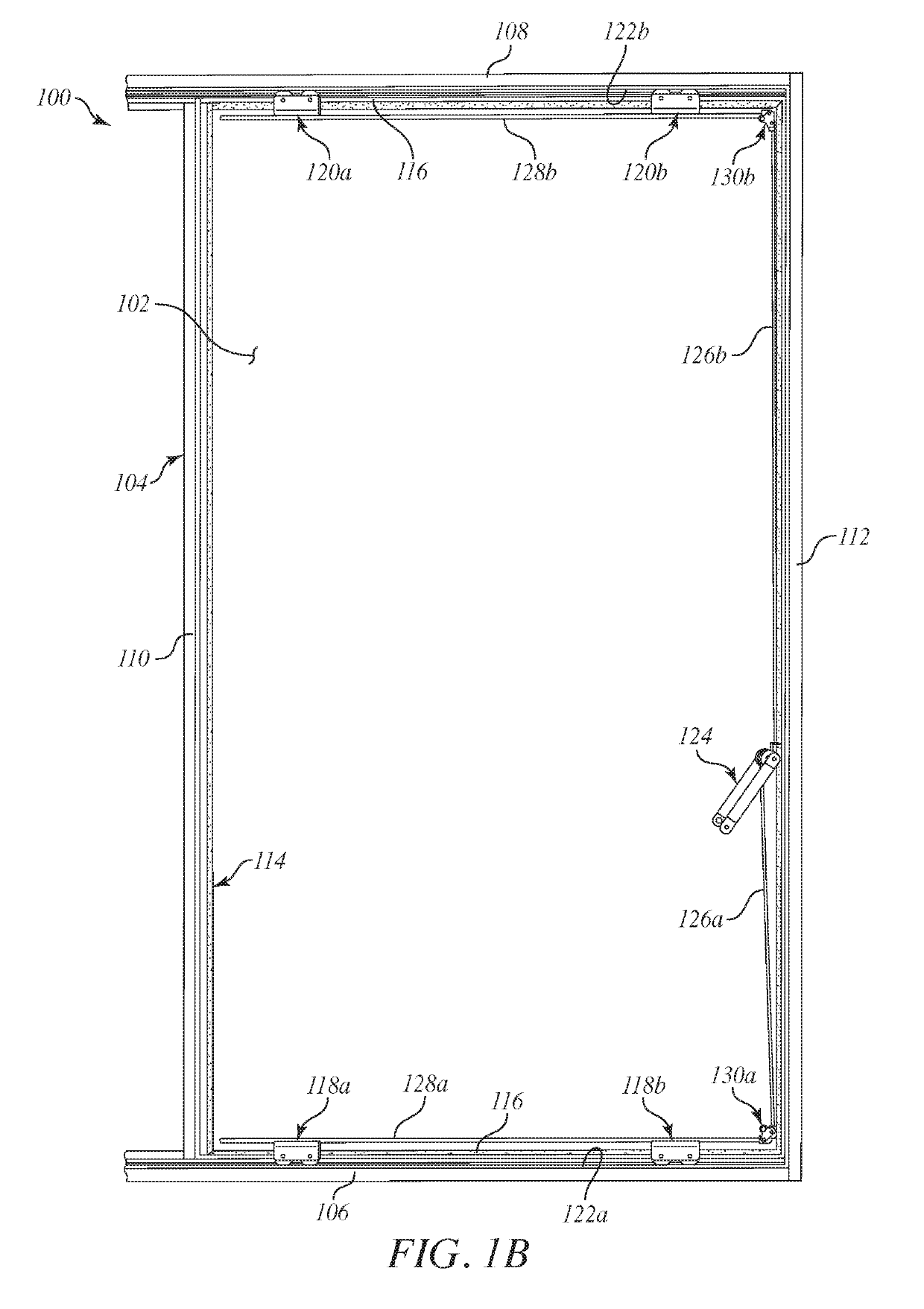

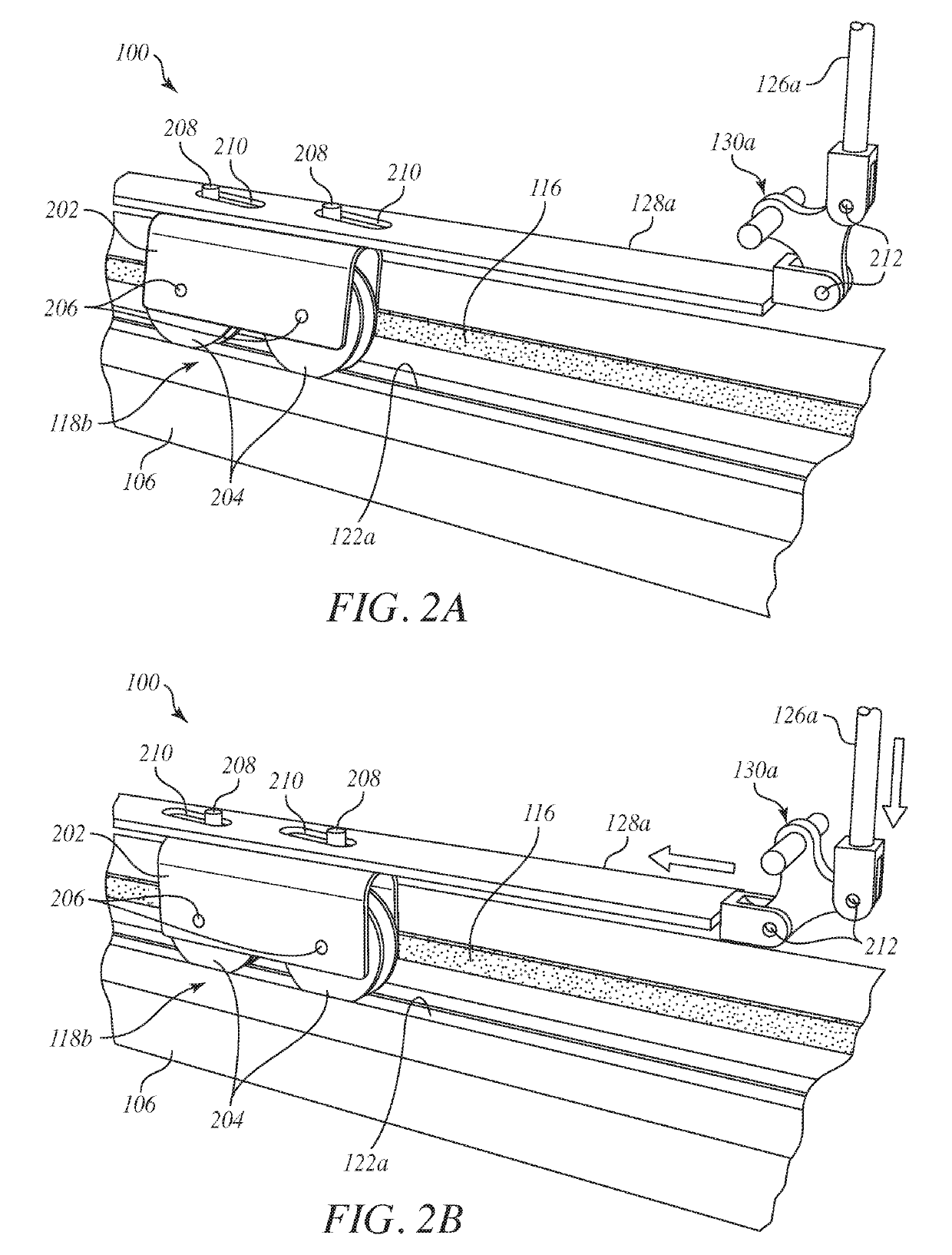

Sliding Door System

A sliding door assembly includes a door panel, a frame that supports the door panel and includes a bottom member with a lower profile and a top member with an upper profile, wherein the lower profile and the upper profile are parallel to one another. A lower sliding assembly is operatively coupled to a bottom of the door panel and engages the lower profile, and an upper sliding assembly is operatively coupled to a top of the door panel and engages the upper profile. A gasket interposes the door panel and a portion of the frame when the door panel is in a sealed position. The door panel is movable between the sealed position, where the gasket creates a sealed interface between the door panel and the frame, and a sliding position, where the door panel is moved laterally relative to the frame while remaining substantially perpendicular to a floor.

Owner:ARCONIC TECH LLC

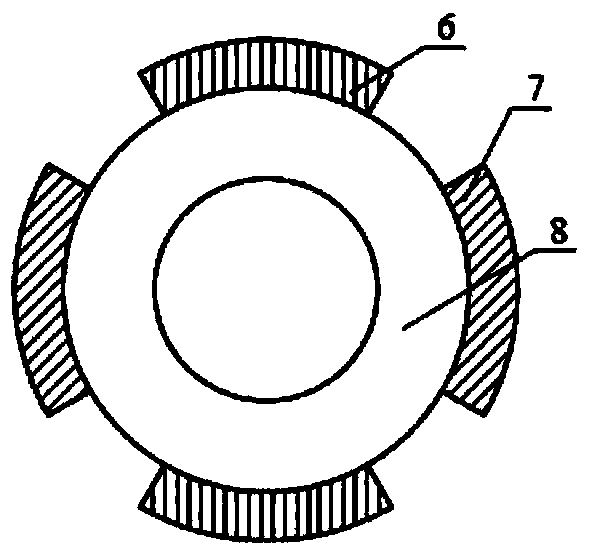

Low friction butterfly ring

ActiveUS20070194265A1Reduce leakageEffectively freely expand and contractLift valveThin material handlingEngineeringButterfly valve

A butterfly valve for controlling the flow of fluid within a bore, including a butterfly and at least one ring extending at least one of substantially and completely around a perimeter of the butterfly and adapted to develop an expansion force in the radial direction when the at least one ring is in a contracted state with respect to the radial direction, wherein the at least one ring is secured to the butterfly in the contracted state and radial expansion due to the developed expansion force of the at least one ring is effectively restrained, wherein the butterfly valve is adapted to operate, when placed in a bore, without friction or substantially without friction between the at least one ring and the bore when the butterfly valve is placed in a closed position within the bore.

Owner:GE AVIATION SYST LLC

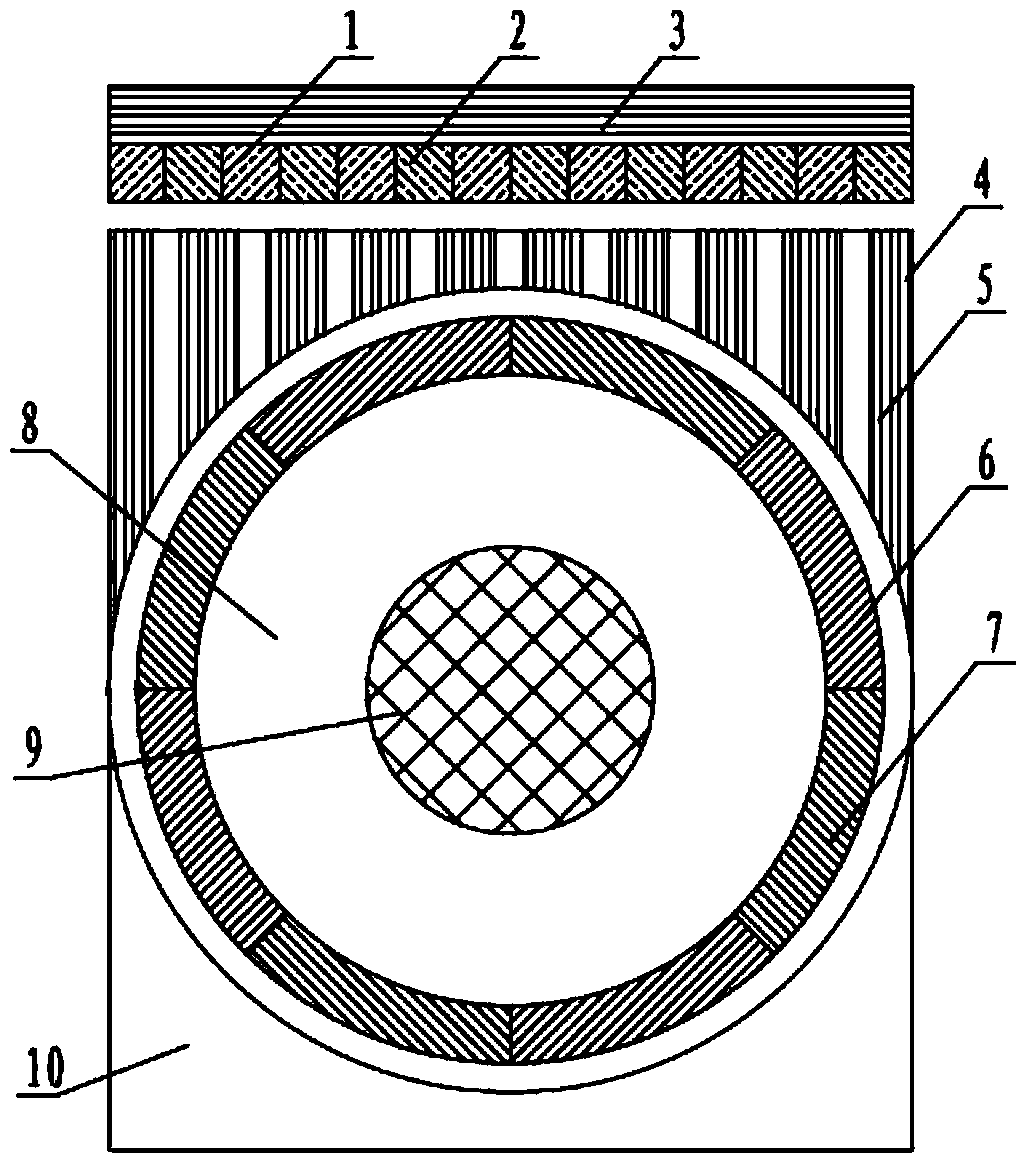

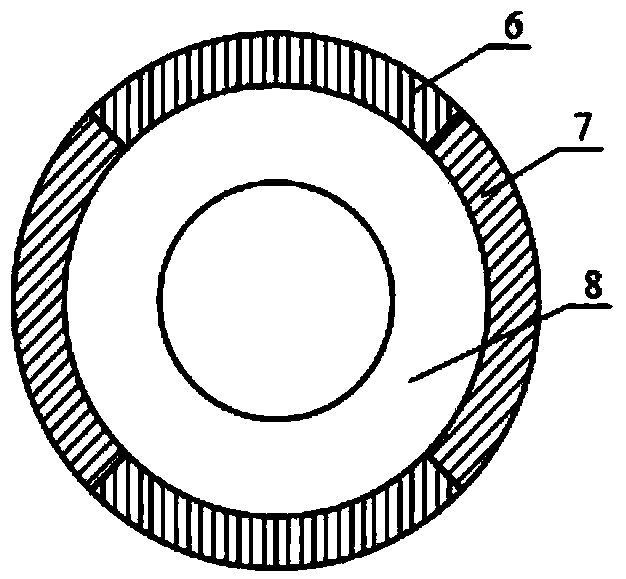

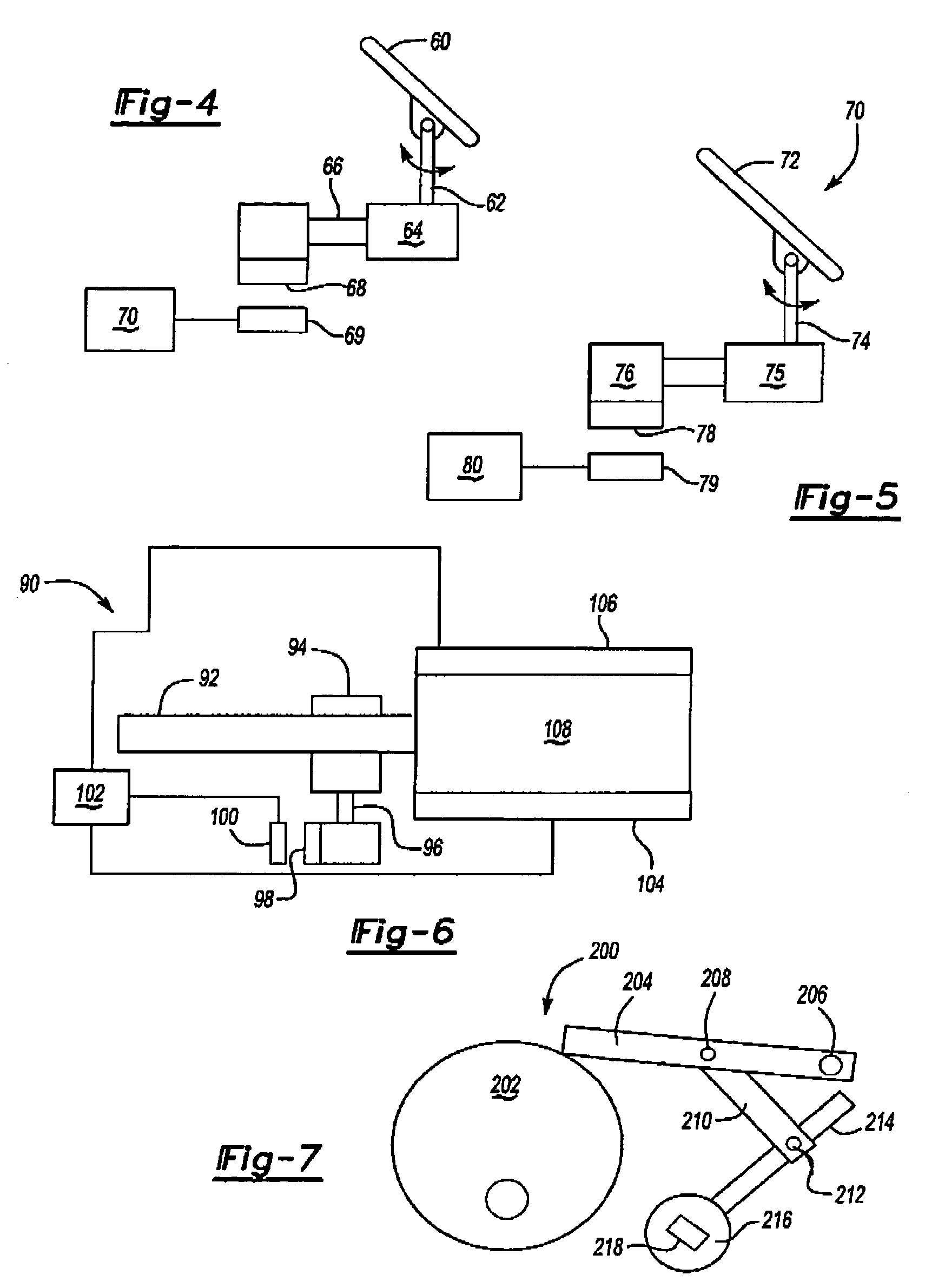

Converter for linear motion and rotary motion

InactiveCN103475185AAchieve conversionAchieve power transmissionPermanent-magnet clutches/brakesLinear motionActive cell

The invention provides a converter for linear motion and rotary motion. The converter for the linear motion and the rotary motion comprises a machine shell (10), a magnetism regulation mechanism which is arranged in the machine shell and is connected with the machine shell, a rotor which is arranged in the magnetism regulation mechanism and an active cell which is arranged outside the magnetism regulation mechanism, wherein an inner air gap is formed between the magnetism regulation mechanism and the rotor, an outer air gap is formed between the magnetism regulation mechanism and the active cell, the rotor is connected with the machine shell (10) through a bearing and rotates freely around the axis, the active cell is connected with the machine shell (10) through a guide rail or an idler wheel and moves in a translational mode along a plane, the magnetism regulation mechanism comprises magnetism regulation blocks (4) and non-magnetic packing media (5), the space between every two adjacent magnetism regulation blocks (4) is filled with the non-magnetic packing media (5), and the magnetism regulation blocks (4) and the non-magnetic packing media (5) are arranged integrally in a staggered mode. The converter for the linear motion and the rotary motion has the advantages of being capable of achieving interconversion between the linear motion and the rotary motion and adjusting the relative speed of the linear motion and the rotary motion, free of contact, low in noise, high in efficiency and the like.

Owner:SOUTHEAST UNIV

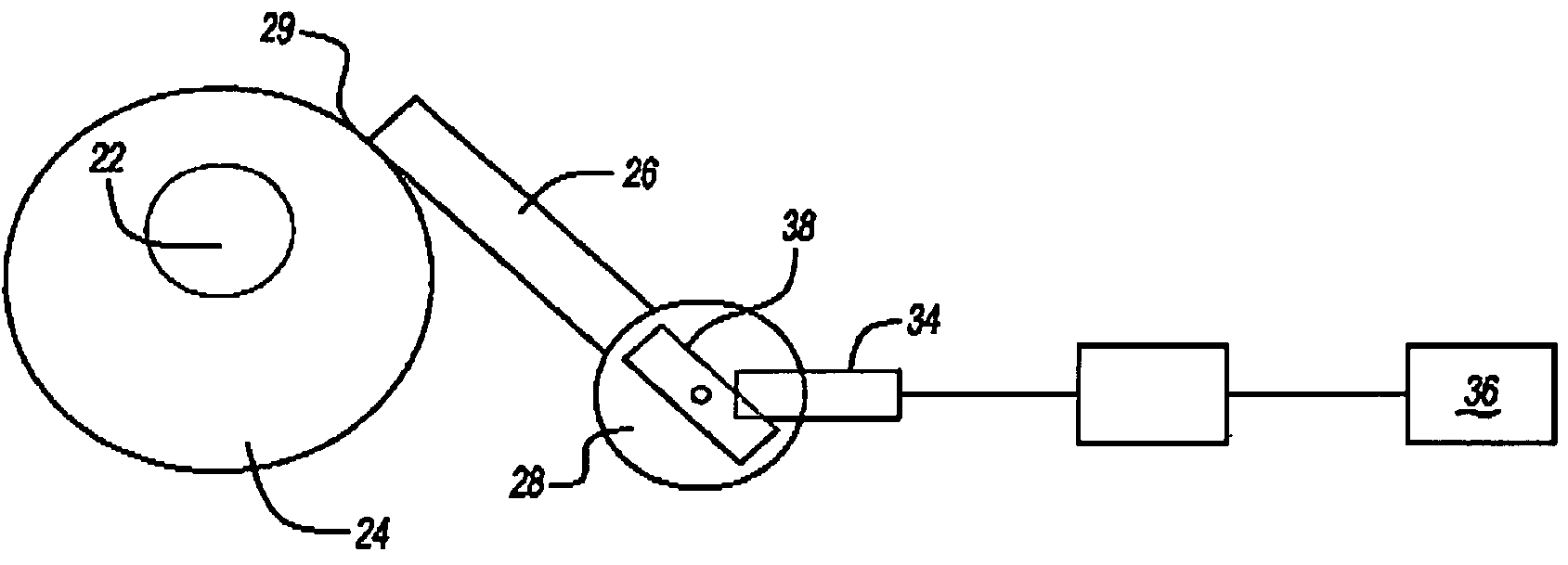

Non-contacting large angle rotary position sensor for rotating shaft

InactiveUS7023200B2Easy to identifyEliminate the problemElectric ignition installationMagnetic-field-controlled resistorsTransducerCam

A rotation sensor provides a control with an indication of shaft position. The sensor utilizes a magnetic connection between a cam follower and a transducer. The magnetic connection eliminates problems in the prior art such as degradation due to wear and corrosion. In particular, a rotating shaft carries a cam. The cam drives a cam follower. As the cam follower moves, a magnet moves. The transducer can sense movement of this magnet. In preferred embodiments, the cam follower is driven to pivot and the magnet is mounted on the pivot point of the cam follower. The present invention is disclosed for use in motorcycle throttle handles, accelerator pedals, brake pedals, and detecting shaft position for valve timing.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Latch arrangement for cargo restraint

ActiveUS8337127B2Easy to installEliminate damageFlexible elementsFreight handlingEngineeringMechanical engineering

Owner:ANCRA INTERNATIONAL CORPORATON

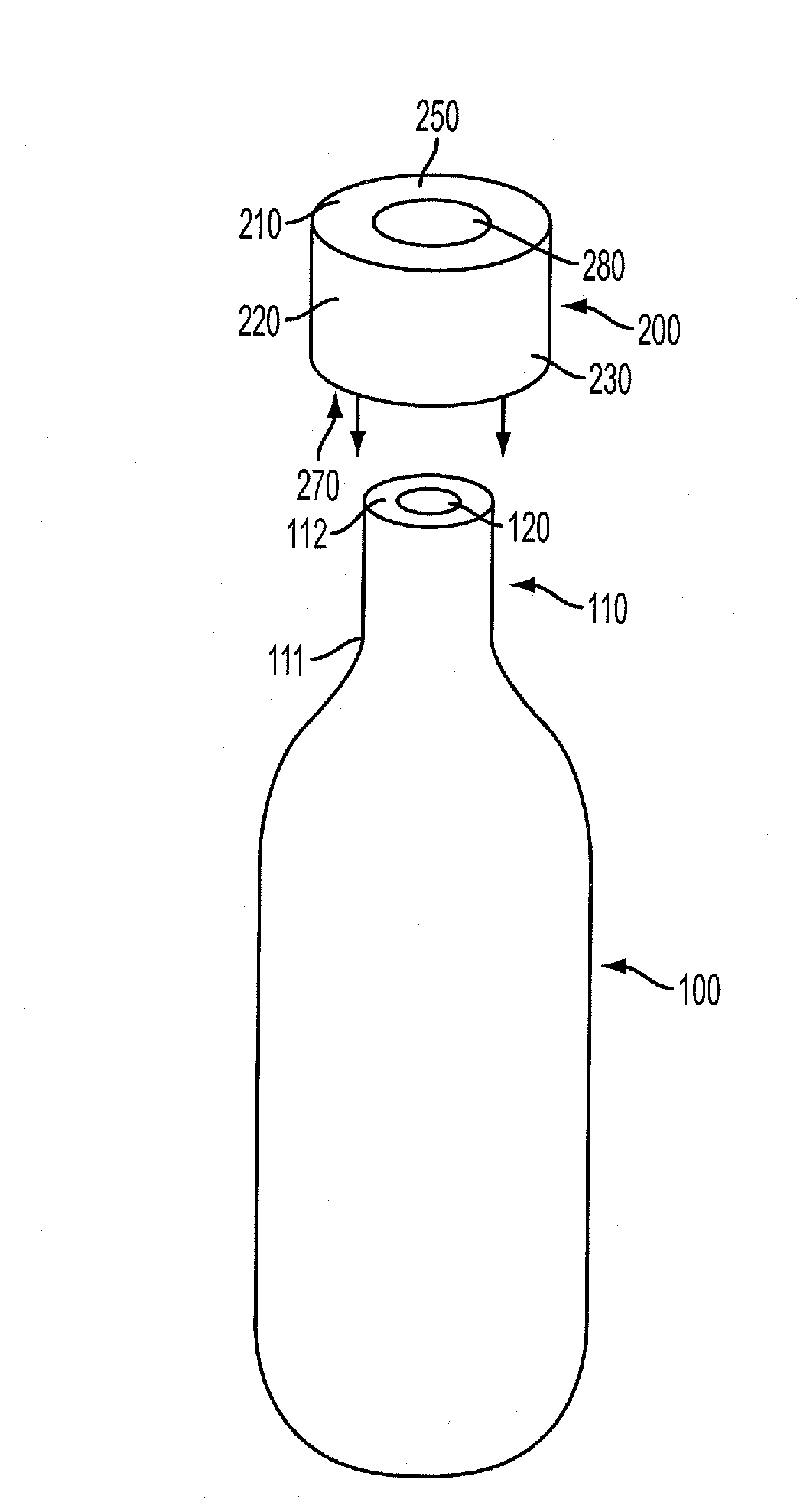

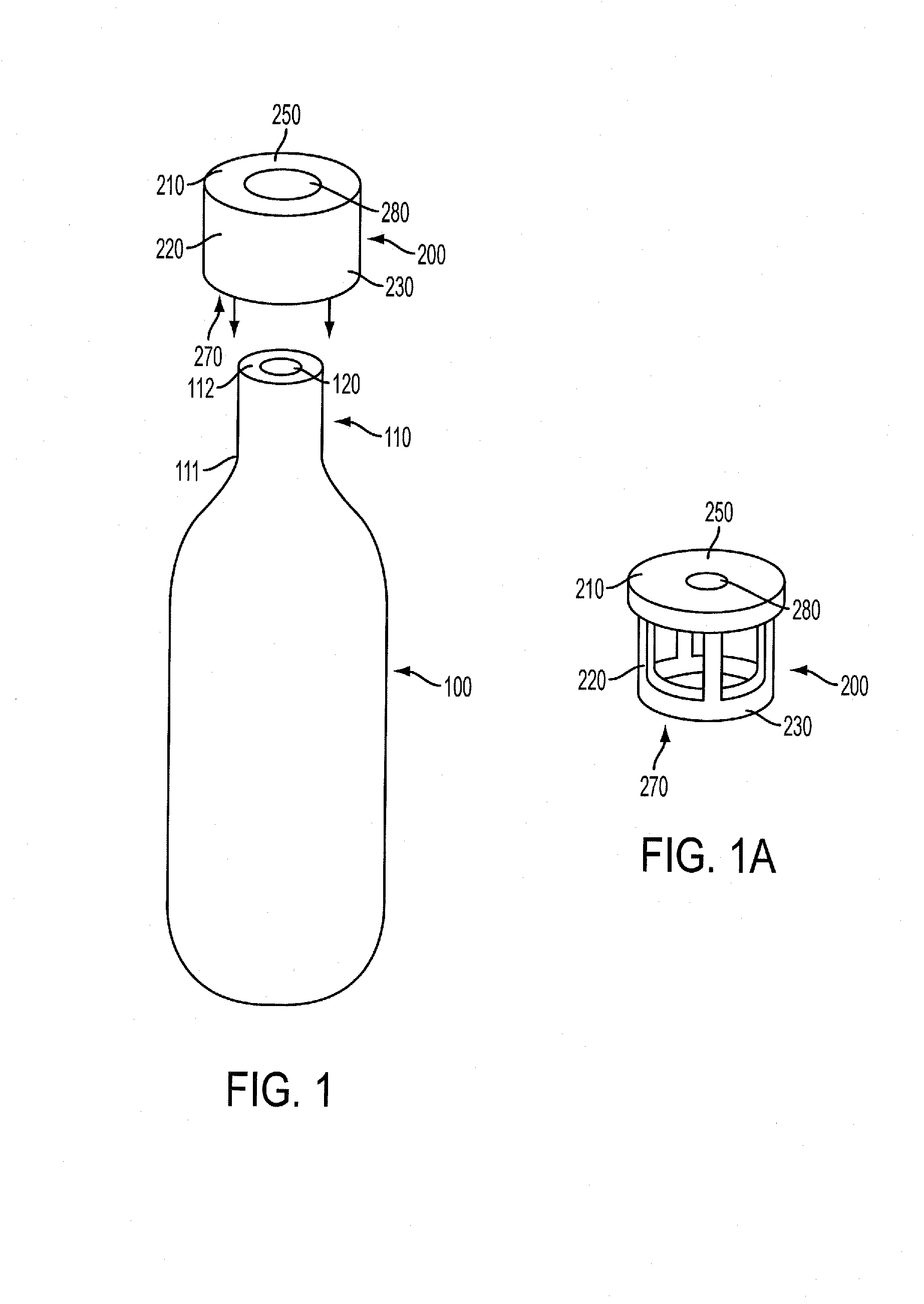

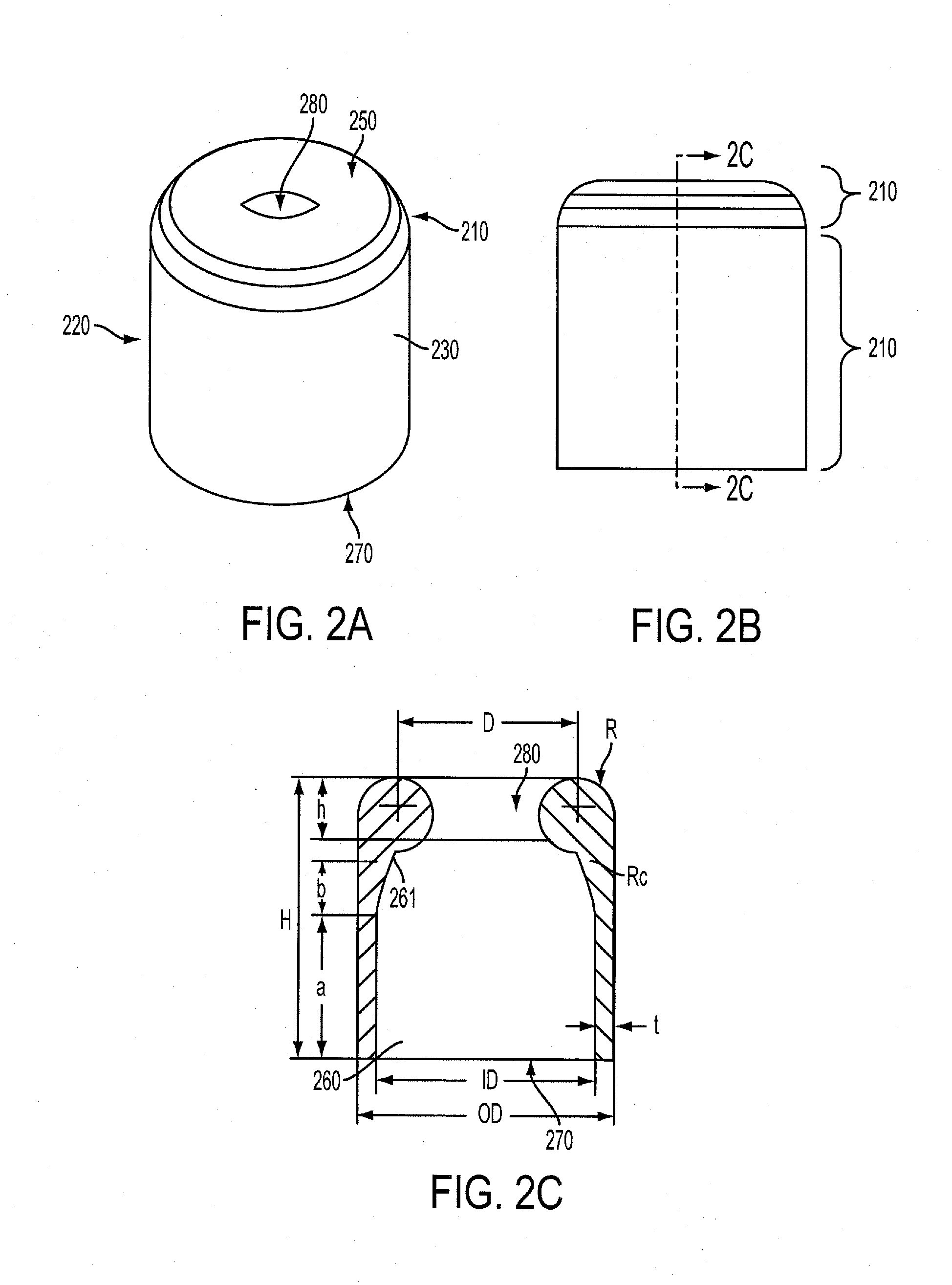

Method and apparatus for gas cylinder sealing

ActiveUS20140042703A1Improve sealingEliminate wearVessel mounting detailsEngine sealsEngineeringGlands secretion

A gasket for a compressed gas cylinder arranged to operate with a gas cylinder having a neck with a top surface around a gas outlet and a side surface extending downwardly from the top surface. The gasket may include an upper portion arranged for positioning on the top surface of the cylinder and for making a seal with the top surface, and a lower portion extending downwardly from the upper portion and around the side surface of the neck of the cylinder, such that the lower portion is arranged to make a seal with the side surface of the gas cylinder. Face and gland seals may be established by the gasket with an opening that receives the gasket and an associated cylinder neck.

Owner:CORAVIN

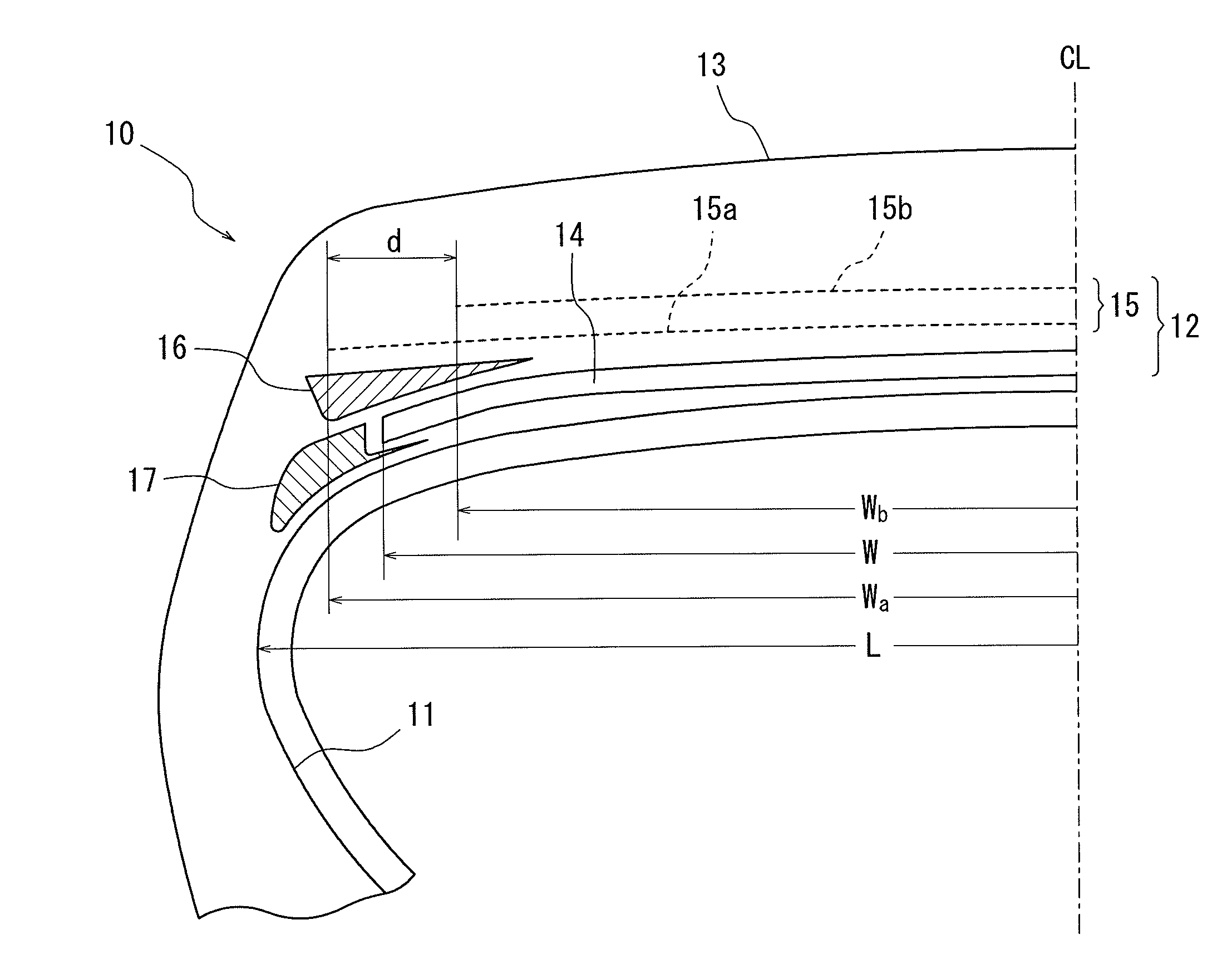

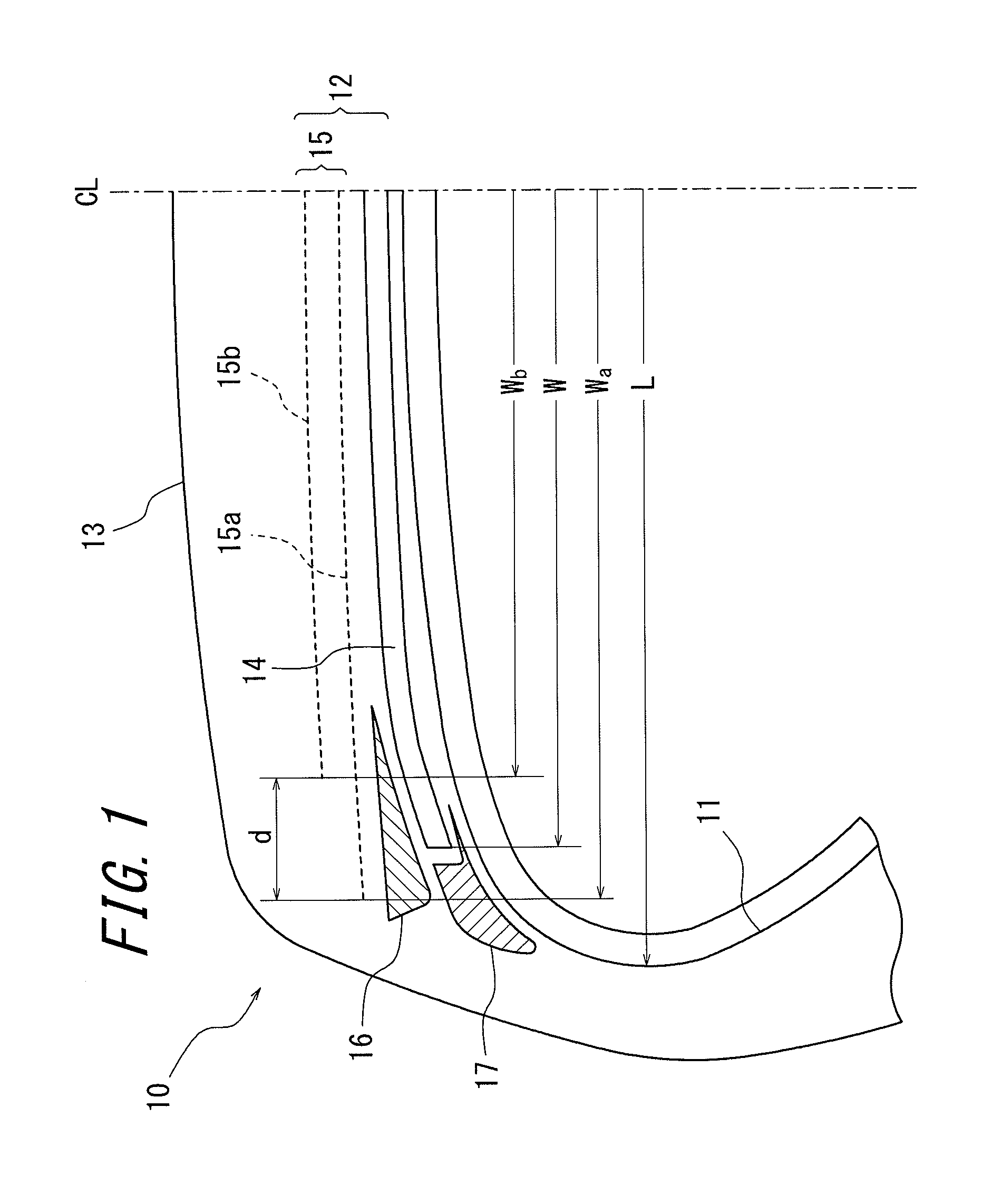

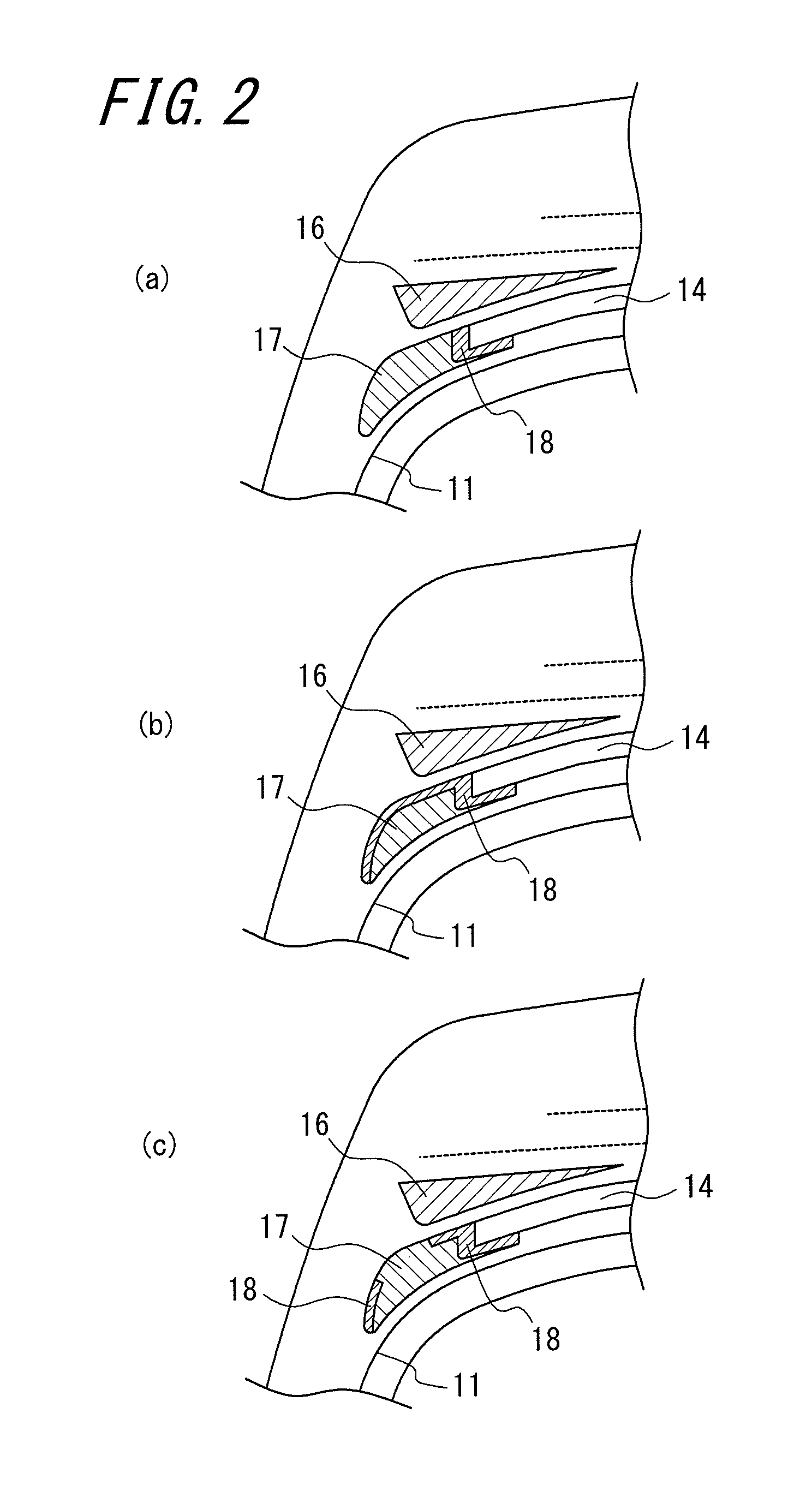

Pneumatic tire

ActiveUS20120216935A1Rolling resistance is deterioratedUneven wearPneumatic tyre reinforcementsWheelsMechanical engineeringElastic modulus

A belt width of an intersecting belt 15a having the maximum belt width is set to 80% or more of the maximum width of a carcass line; a difference in belt widths between the intersecting belt 15a and an intersecting belt 15b is set in the range of 10 mm to 50 mm on one side of the belt in the width direction; the intersecting belt 15a is not narrower than the circumferential belt 14, and the circumferential belt 14 is not narrower than the intersecting belt 15b; and a pneumatic tire according to the present invention has an interposed rubber 16 having a thickness increasing toward the widthwise outer side of the tire to be 3 mm or more, and a side-lower rubber 17 having an elastic modulus less than the elastic modulus of a coating rubber coating the circumferential belt 14.

Owner:BRIDGESTONE CORP

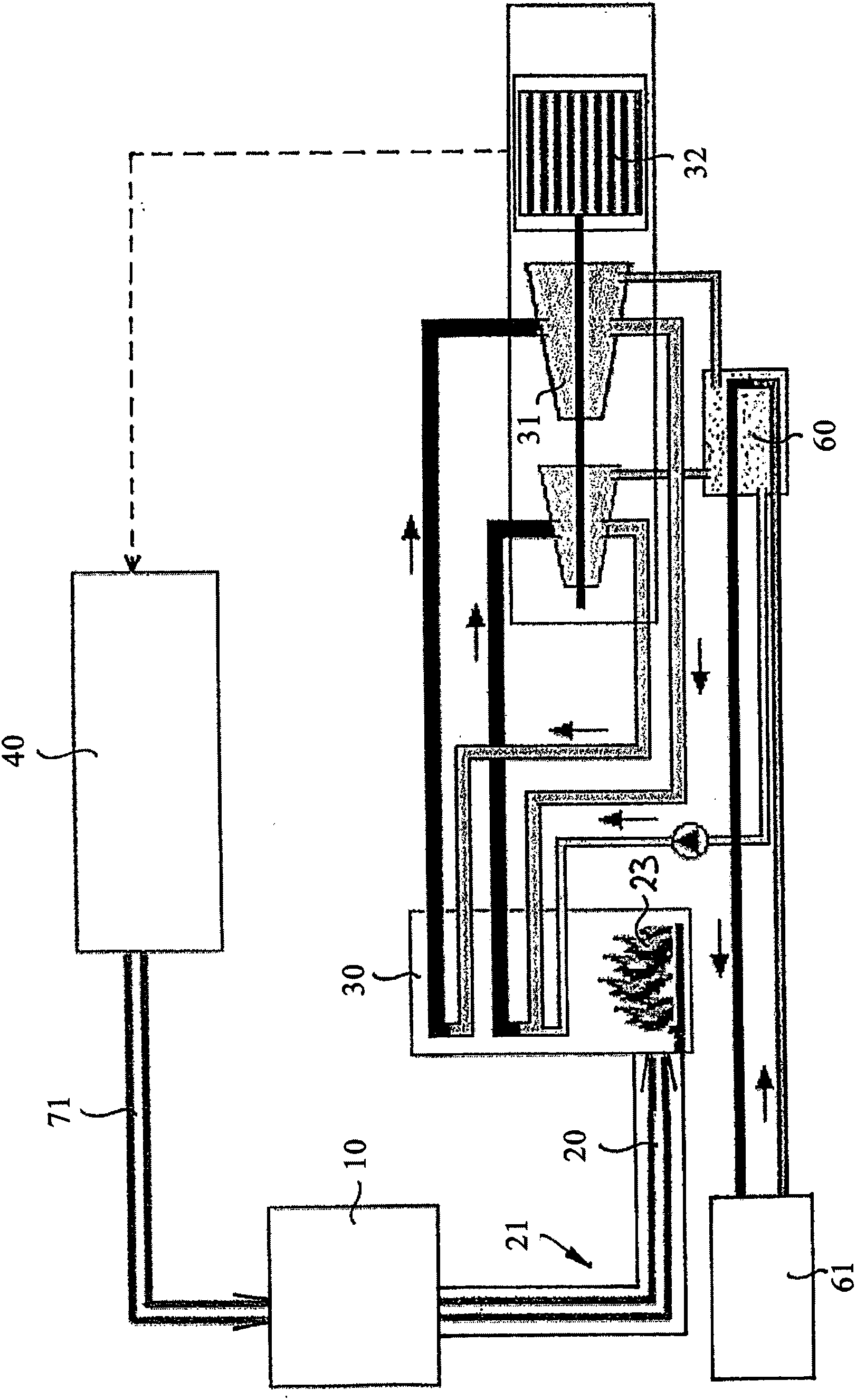

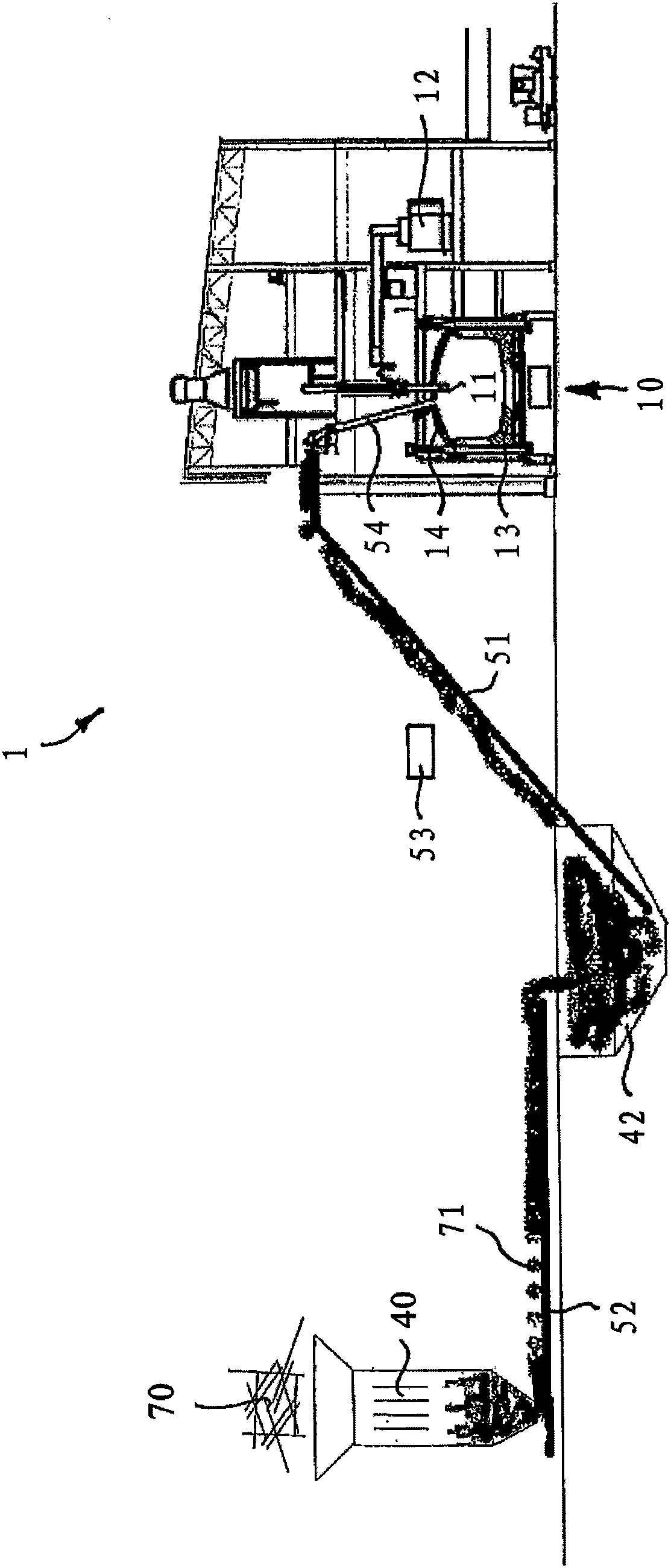

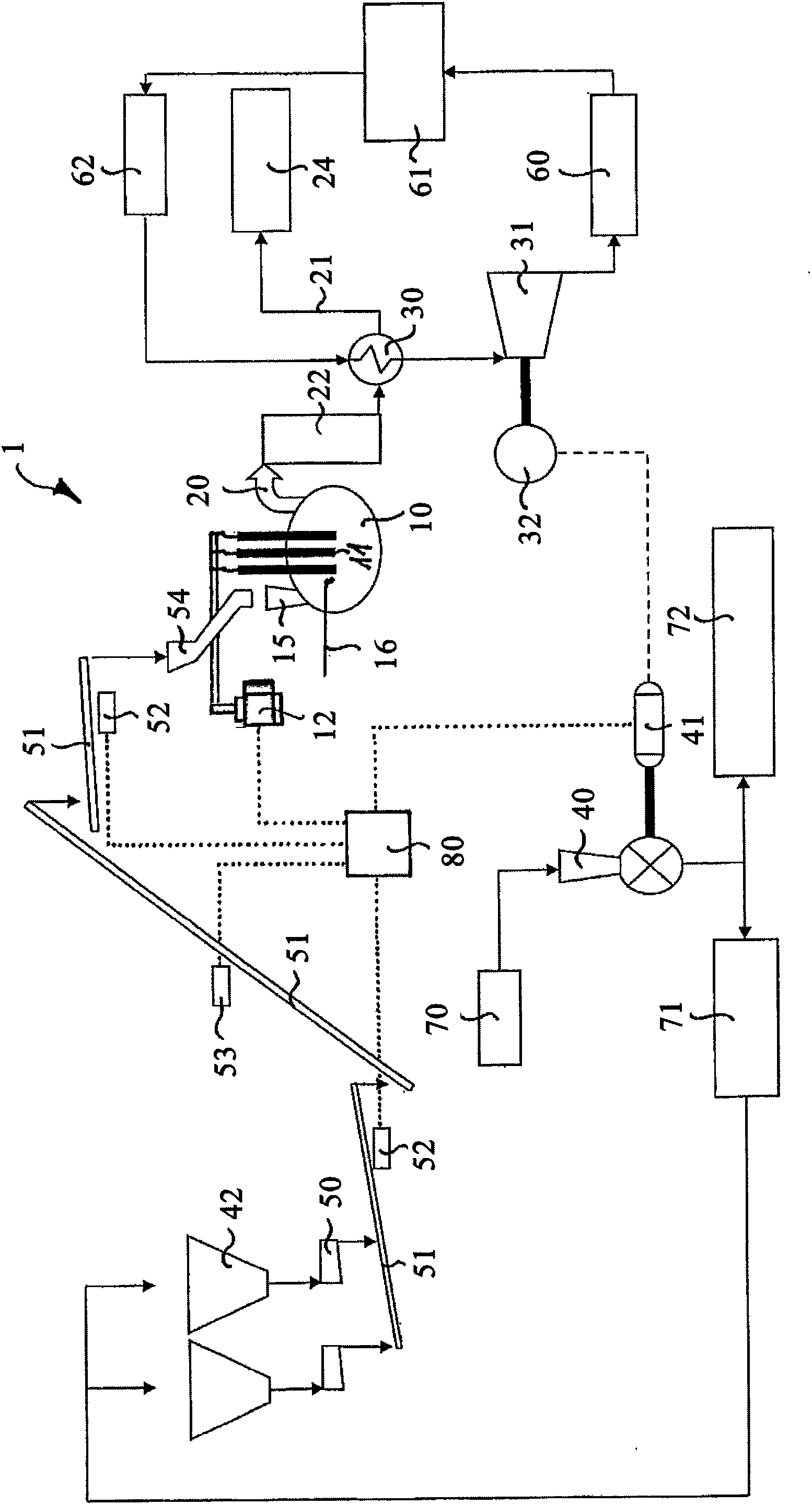

Steel production facility

ActiveCN102439387AIncrease production capacityStable combustionElectric furnaceProcess efficiency improvementElectricityThermal energy

The present invention relates to a steel production facility (1) and a method of uninterrupted or at least cyclical steelmaking in said facility (1), wherein in case of uninterrupted steelmaking at least the first three of the following steps and in case of cyclical steelmaking all five steps will be used: charge materials are molten uninterruptedly or at least cyclically in an electric arc furnace (10); the charge materials like in particular shredded scrap-iron pieces (71) shredded in a shredding-system (40) for shredding discarded iron and / or steel junk (scrap 70), Direct Reduced Iron (DRI) and / or Hot Briquette Iron (HBI) are uninter- ruptedly or at least continuously during a melting process cycle fed into the electric arc furnace (10) by means of conveyance (50, 51,...); a part of liquid steel is uninterruptedly or cyclically discharged from the steel bath of the electric arc furnace (10); from the thermic energy included in the hot process-exhaust (furnace top 20) of the electric arc furnace (10), electric energy is, by means of power generation (30, 31, 32), generated uninterruptedly or at least during a melting process cycle; a shredding-system (40) assigned to the electric arc furnace (10) for shredding discarded iron and / or steel junk (scrap 70) is powered uninterruptedly or at least during a melting process cycle by the electric energy generated from the process exhaust (furnace top 20). The present steel production facility (1), which sets new standards in terms of total energy-balance with regard to productivity and energy saving, consistently continues the trend of the last years.

Owner:拉斐克·布洛斯·道

Fastener installation apparatus

ActiveUS6993831B2Precise alignmentEliminate clippingAutomatic control devicesAssembly machinesReciprocating motionEngineering

The disclosed fastener installation apparatus includes a plurality of spaced parallel feed passages each communicating with a plunger passage in a moveable member and the fixed member includes a plunger assembly having a plurality of spaced parallel legs which reciprocate through the plunger passages to simultaneously install a plurality of fasteners in a panel opposite the plunger passage. In one embodiment, the plunger assembly includes a body portion fixed to the fixed member and a plurality of integral parallel legs and a second embodiment having a plurality of separate spaced parallel plungers. Each plunger passage includes a proximity probe having an end adjacent to, but spaced from the plunger passage eliminating wear or damage to the proximity probes during use.

Owner:PENN AUTOMOTIVE INC

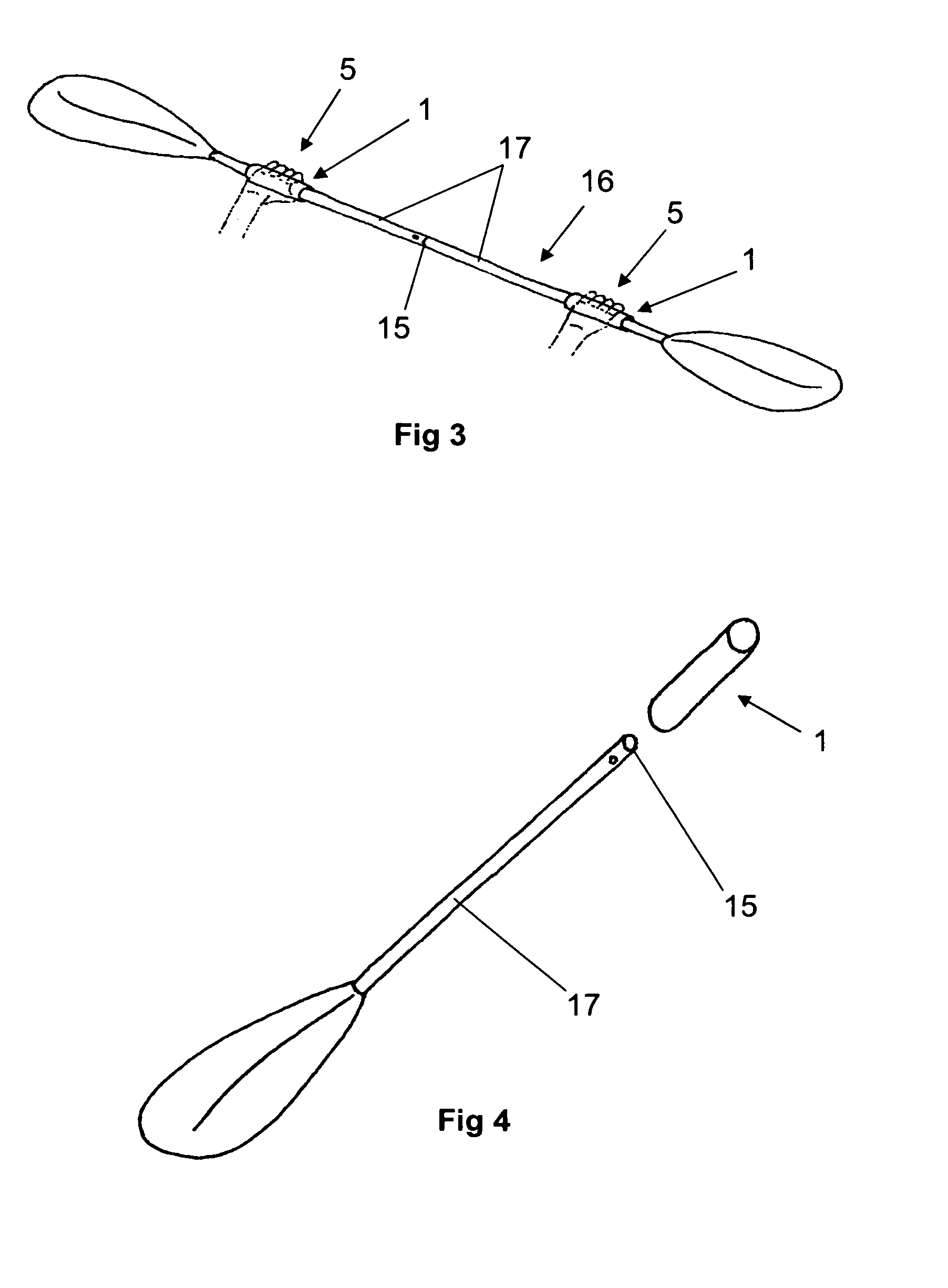

Nonblistering paddle sleeve

InactiveUS20130074288A1Eliminate frictionEliminate wearTravelling carriersHoldersEngineeringMechanical engineering

A pliable tubular paddle hand grip sleeve that reduces friction, motion, chaffing, wear and ultimately blisters to the hand during the normal paddling motion by isolating the motion to the surfaces between the paddle shaft and hand grip sleeve. The sleeve is slipped on to any paddle shaft without any effect to paddle. The sleeve maintains the cross sectional size and all radial and axial contours of any paddle shaft.

Owner:JOHNSON PAUL D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com