Converter for linear motion and rotary motion

A technology of rotary motion and linear motion, applied in the field of power transmission, can solve problems such as low efficiency, limited permanent magnet rack and pinion structure, and low torque density, so as to improve reliability, eliminate wear, increase power density and The effect of energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described.

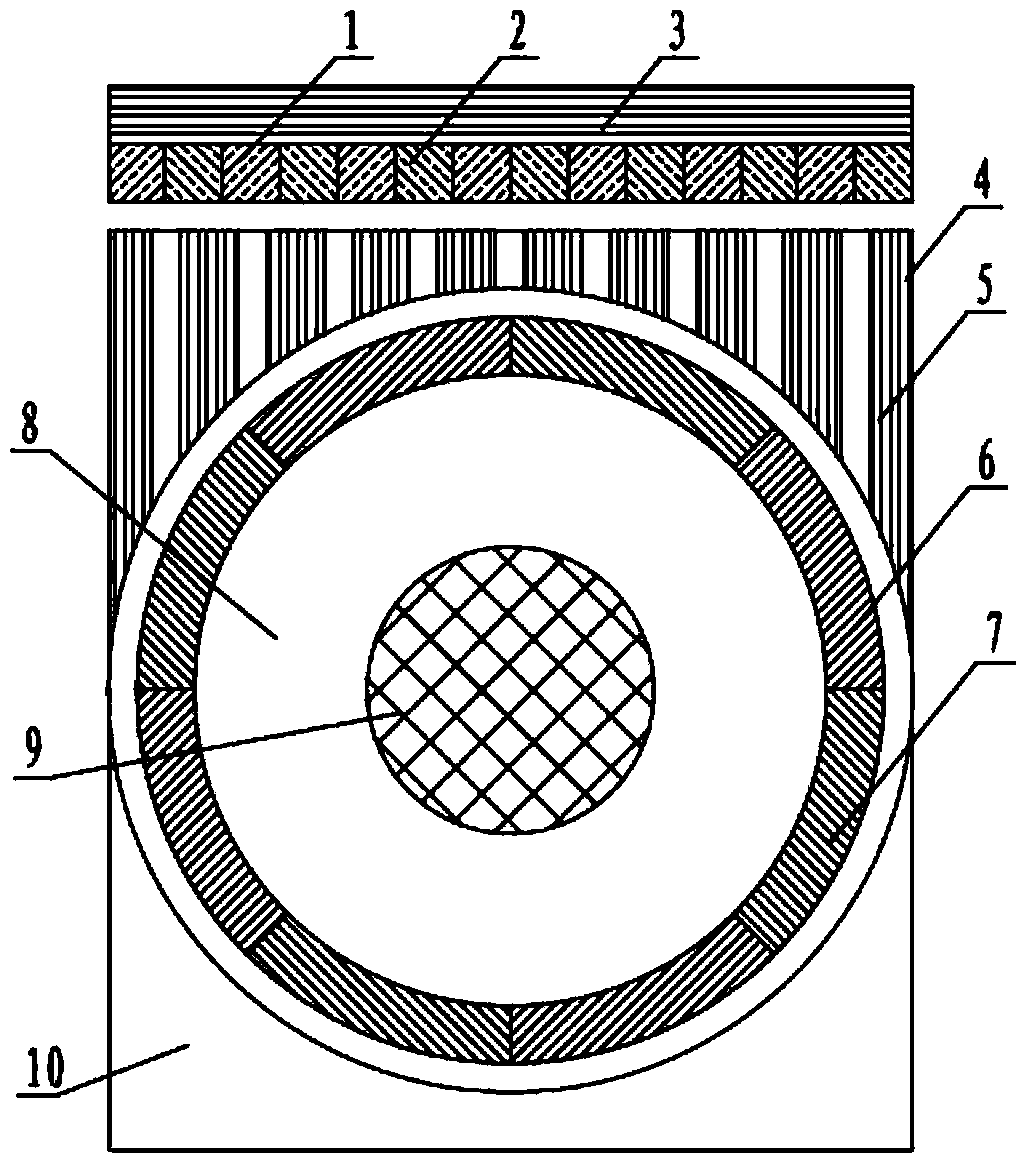

[0030] see figure 1 , the linear motion and rotary motion converter provided by the present invention, the converter includes a casing 10, a magnetic adjustment mechanism placed in the casing 10 and connected to the casing, a rotor arranged in the magnetic adjustment mechanism and a The mover outside the magnetic mechanism; the inner air gap is formed between the magnetic adjustment mechanism and the rotor, and the outer air gap is formed between the magnetic adjustment mechanism and the mover.

[0031] The rotor is connected to the casing 10 through bearings, and freely rotates around the axis. The mover is connected to the casing 10 through guide rails or rollers, and moves in translation along a plane.

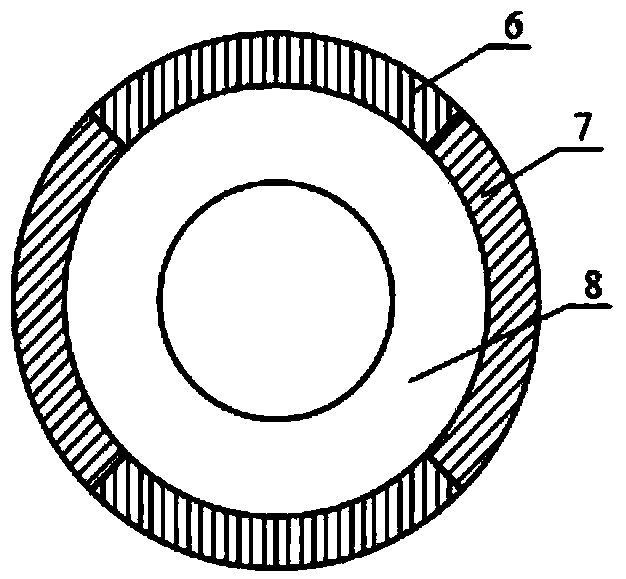

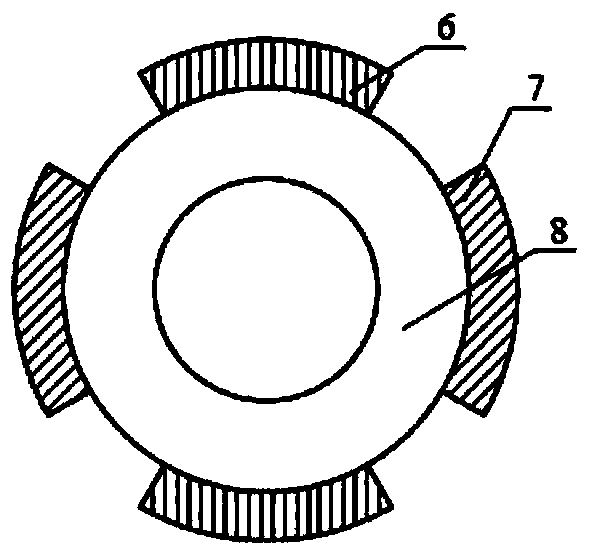

[0032] Wherein, the magnetic adjustment mechanism includes magnetic adjustment blocks 4 and non-magnetic conductive filling medium 5; the non-magnetic conductive filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com