Patents

Literature

105results about How to "Achieve power transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

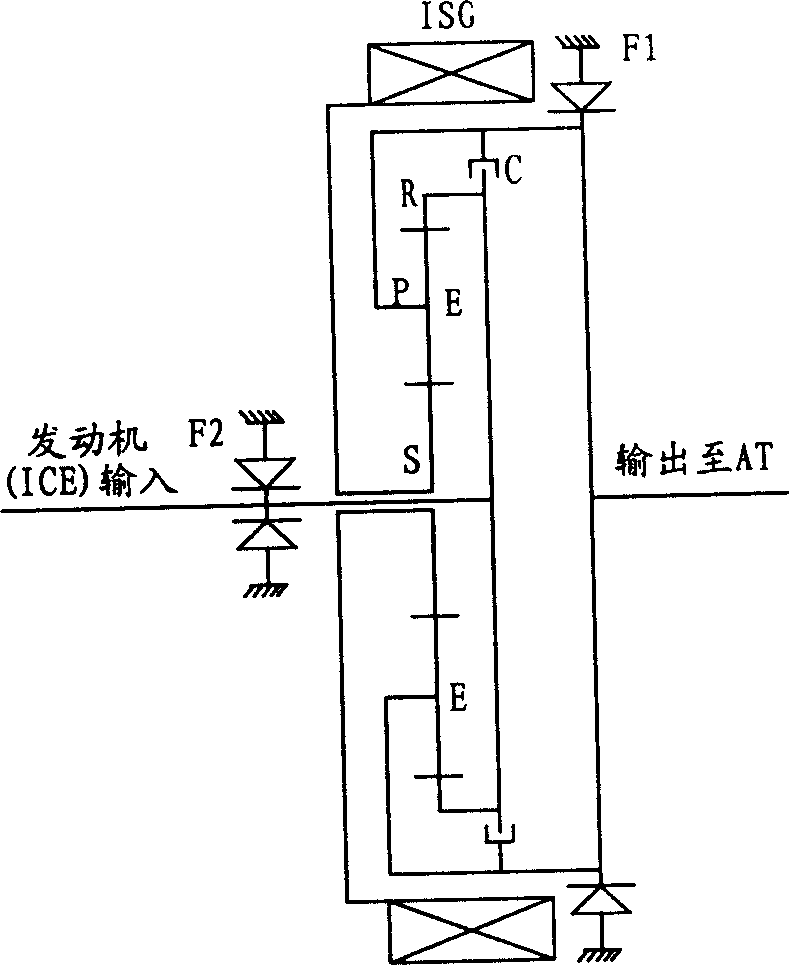

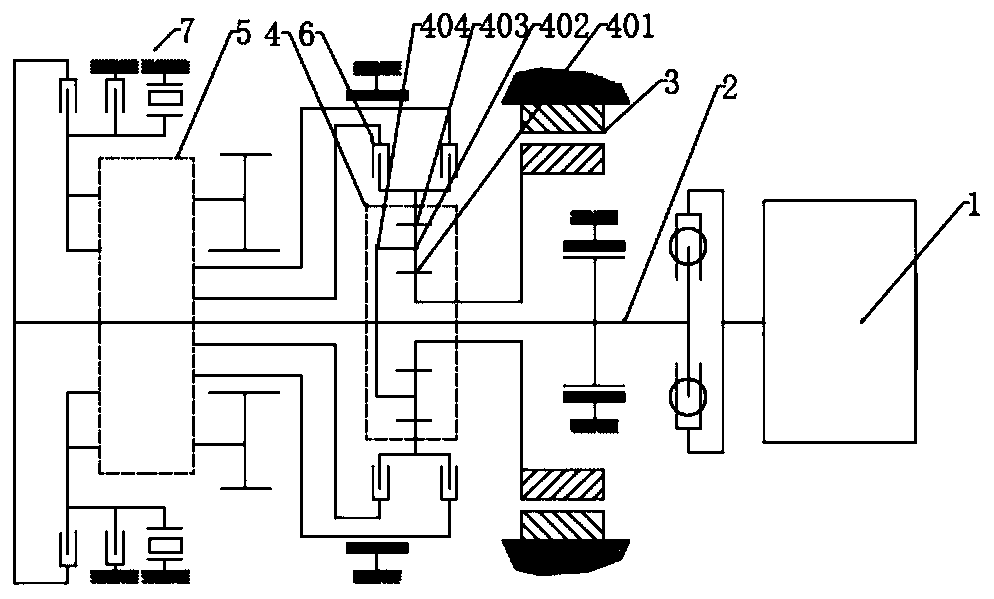

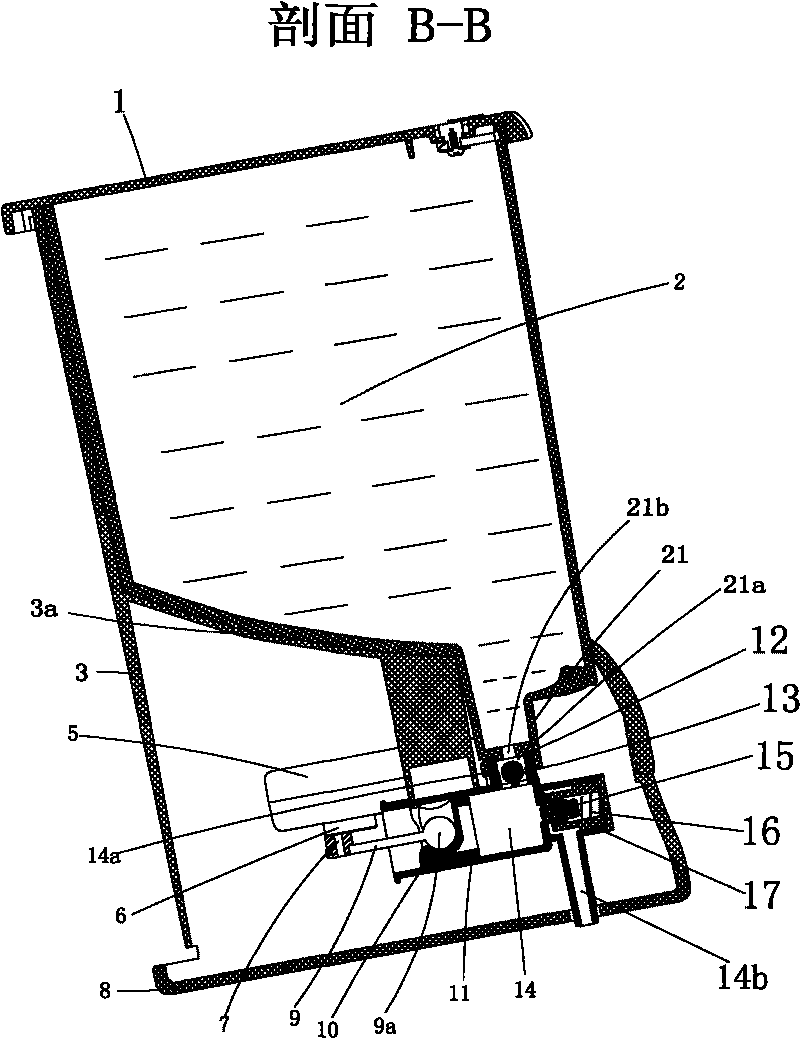

Power driving device for mixed power vehicle

InactiveCN1888483APrevent reversalAchieve power transmissionToothed gearingsGearing controlAutomatic transmissionHybrid electrical vehicle

A power transmission for mixed power vehicles located between an engine and an automatic speed variator consists of a generator, a clutch, a one-way clutch and a planetary gear mechanism consisting of a solar wheel, a planet wheel, a planetary frame and a gear ring. The planet wheel is externally engaged with the solar wheel and internally engaged with the gear ring separately. The output shaft of the engine is connected with the gear ring through a flange, the rotor of the generator is connected with the central shaft of the solar wheel through a spline and the planetary frame is connected with the input shaft of the automatic speed variator through a flange. On the output shafts of the engine and the planetary frame is disposed the one-way clutch separately and between the gear ring and the planetary frame is disposed the clutch.

Owner:TONGJI UNIV

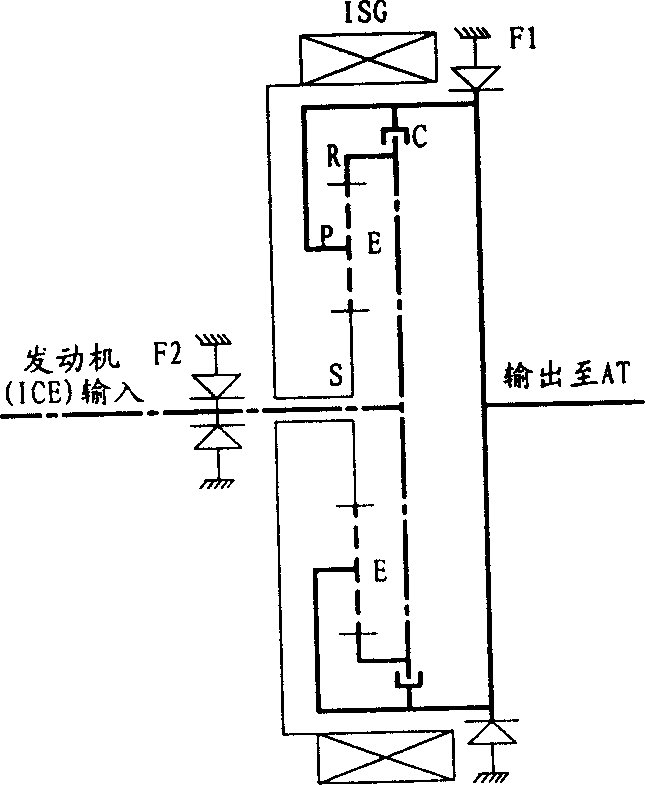

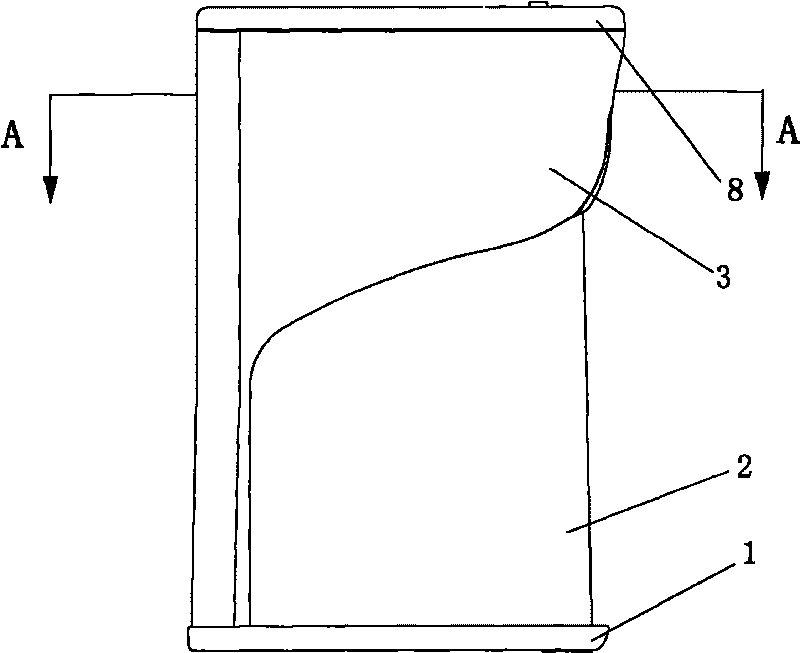

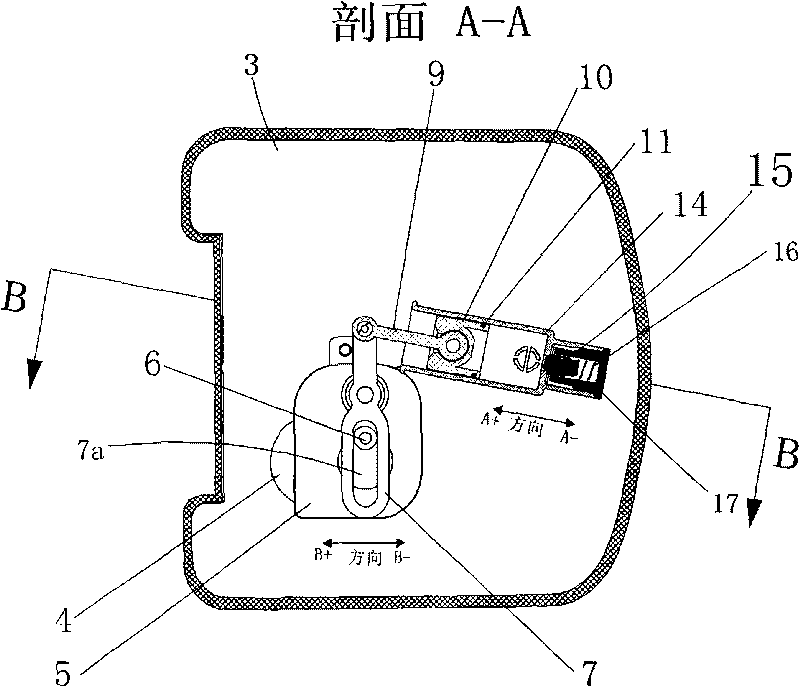

Single-joint water machine fish

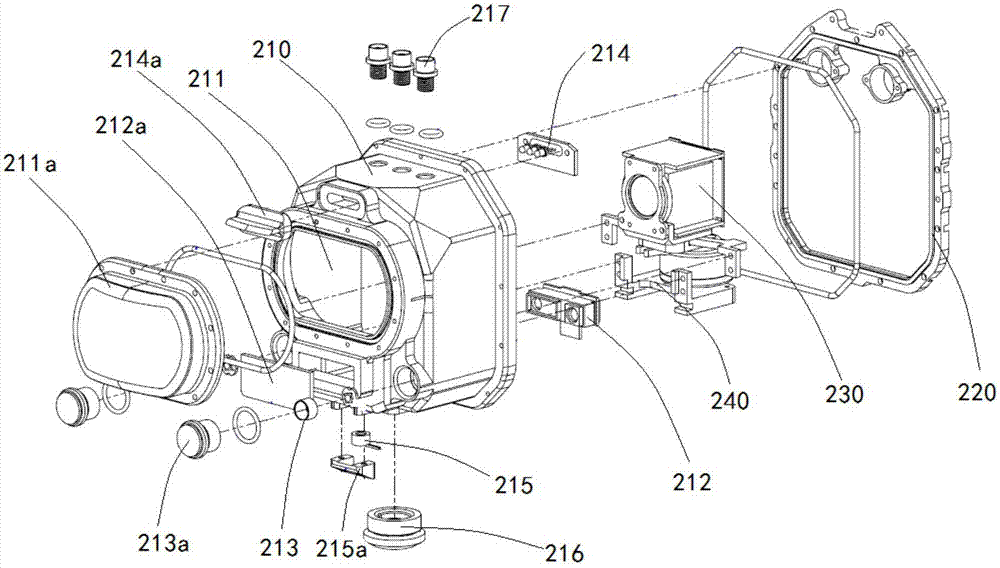

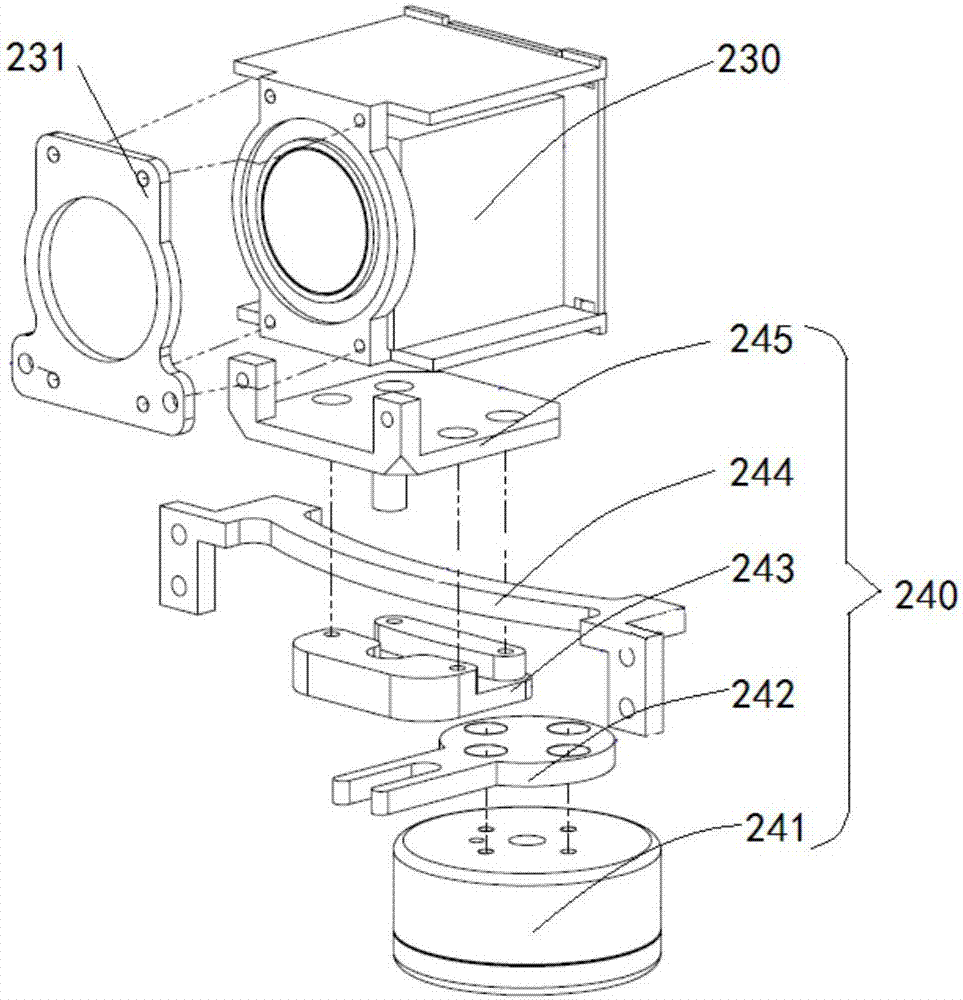

ActiveCN107466280AStable outputRealize underwater camera functionPropulsive elements of non-rotary typeManipulatorUnderwater photographyMarine engineering

The invention relates to a single-joint water machine fish which comprises a shell, a main board cabin, a motion control cabin and a battery cabin; the outer contour of the shell is in a bionic fish shape, one end of the connecting rod is a front shell, and the other end of the front shell is of a bionic fishtail structure, and the front end of the main board cabin is matched and installed with the inner side of the front casing, wherein a lens set is arranged in the main board cabin, an eccentric anti-shake mechanism and a main PCB (printed circuit board), wherein the motion control cabin is connected with the rear end of the main board cabin, a three-axis linkage device and a transmission device are arranged in the motion control cabin, and the battery cabin is arranged below the motion control cabin according to the single-joint water machine fish disclosed by the invention, the special design is adopted for the single-joint water machine fish, the functions of water depth detection, water quality monitoring, underwater photography, underwater exploration, fish school detection, feeding, drug delivery, underwater engineering acceptance and underwater communication, underwater salvage, underwater rescue, seaborne rescue, sea, river, lake bed surveying and mapping, underwater drilling and flaw detection and the like can be realized.

Owner:天长市未名机器人有限责任公司

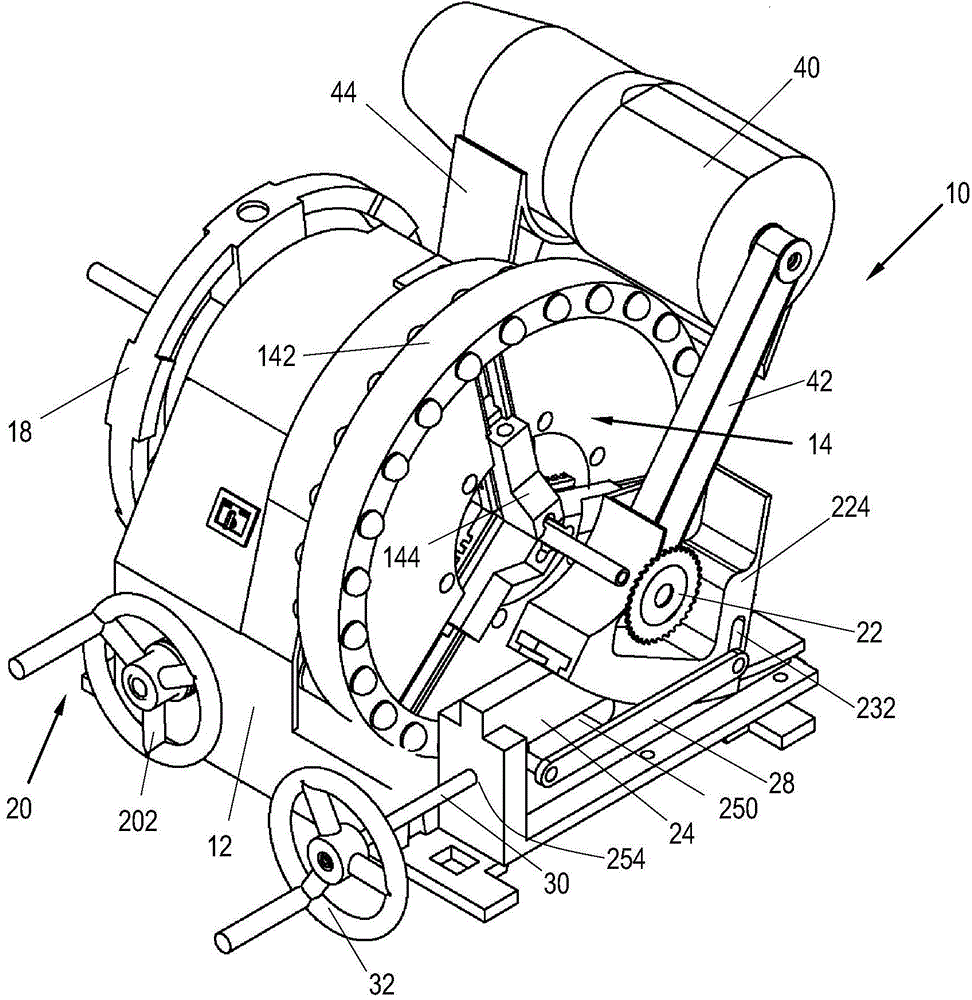

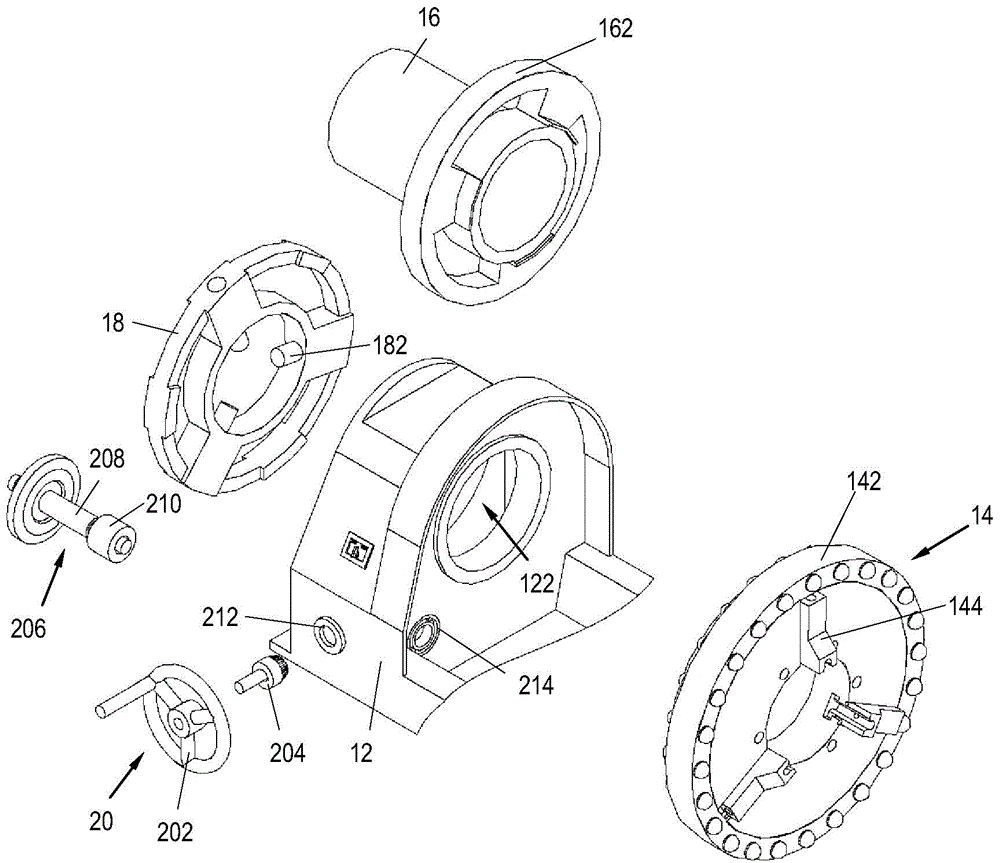

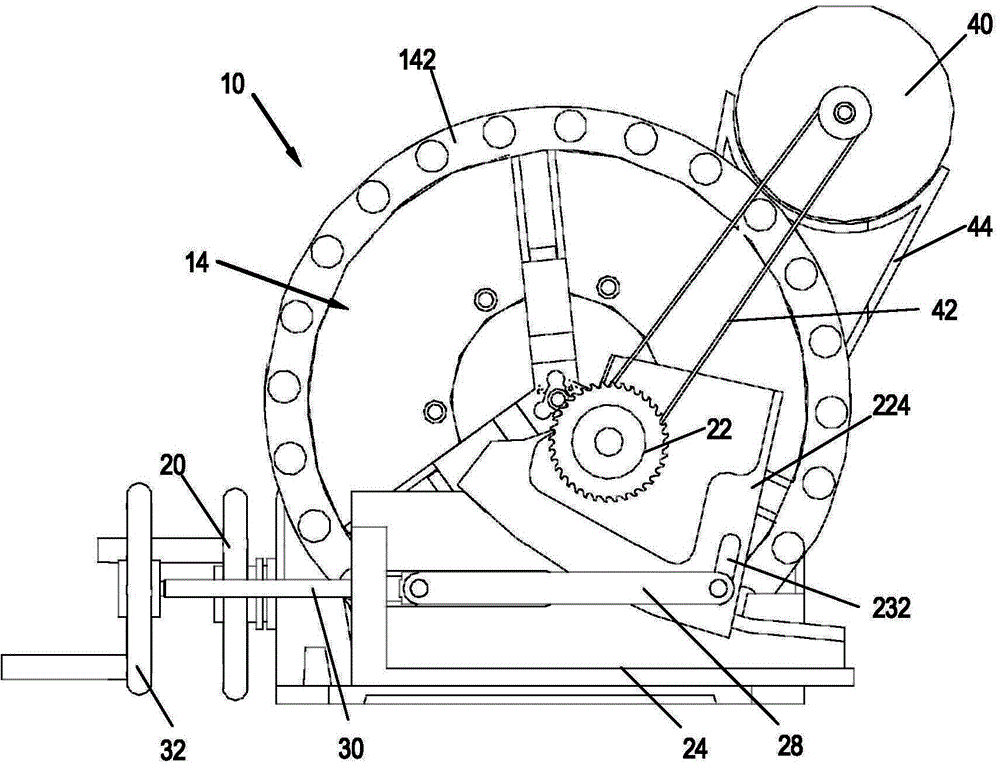

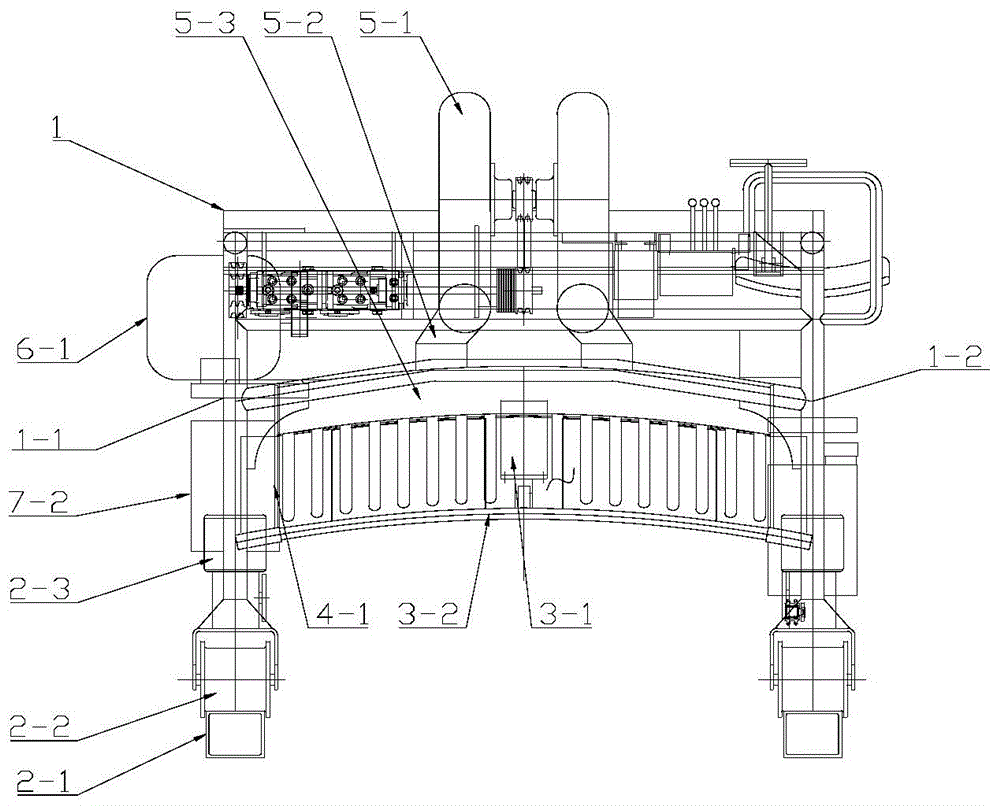

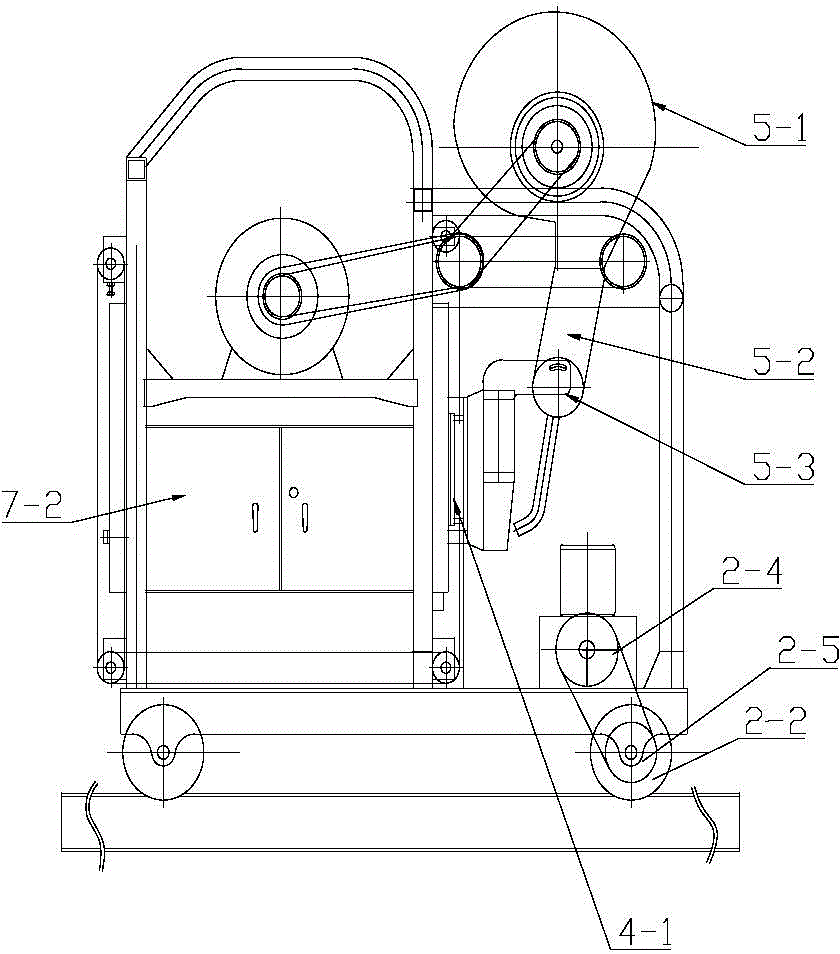

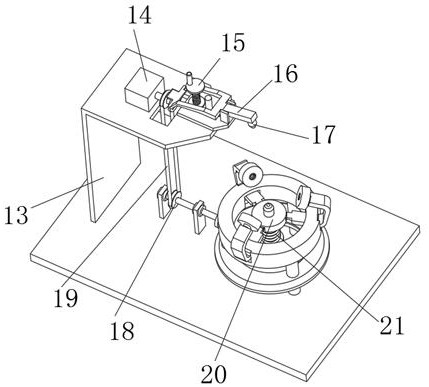

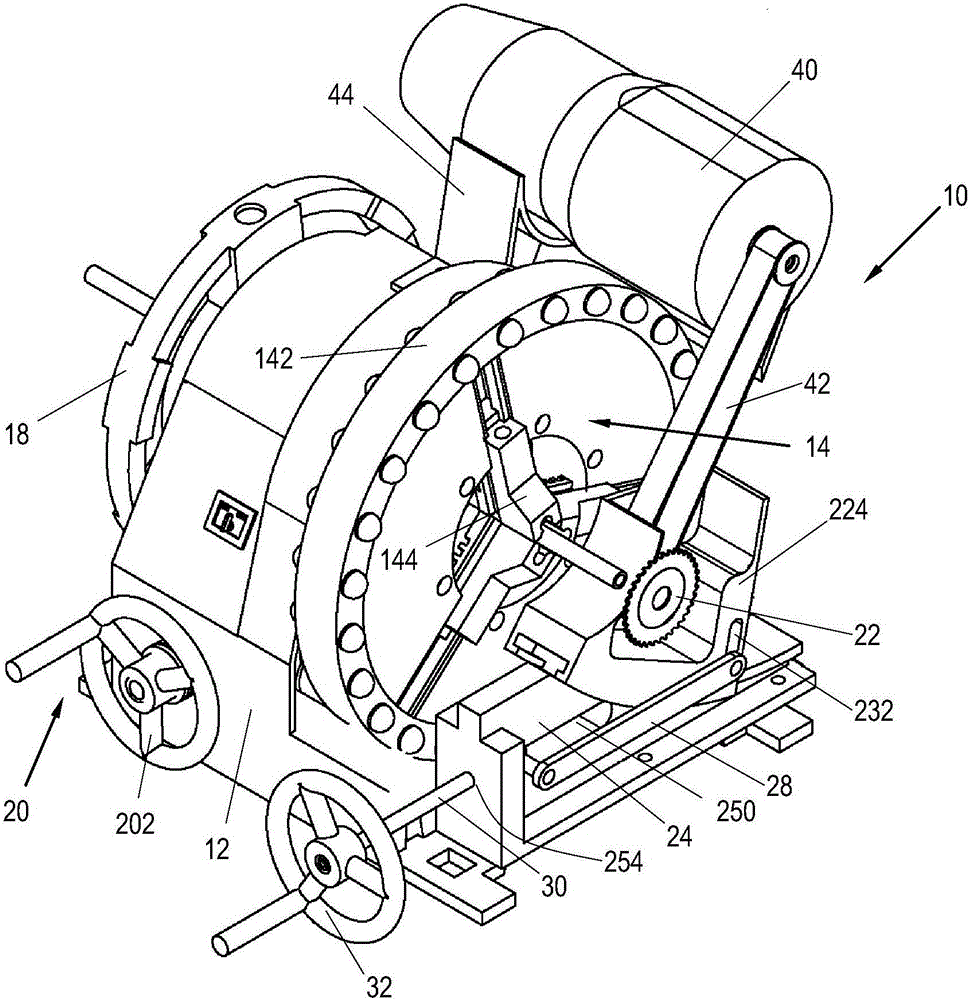

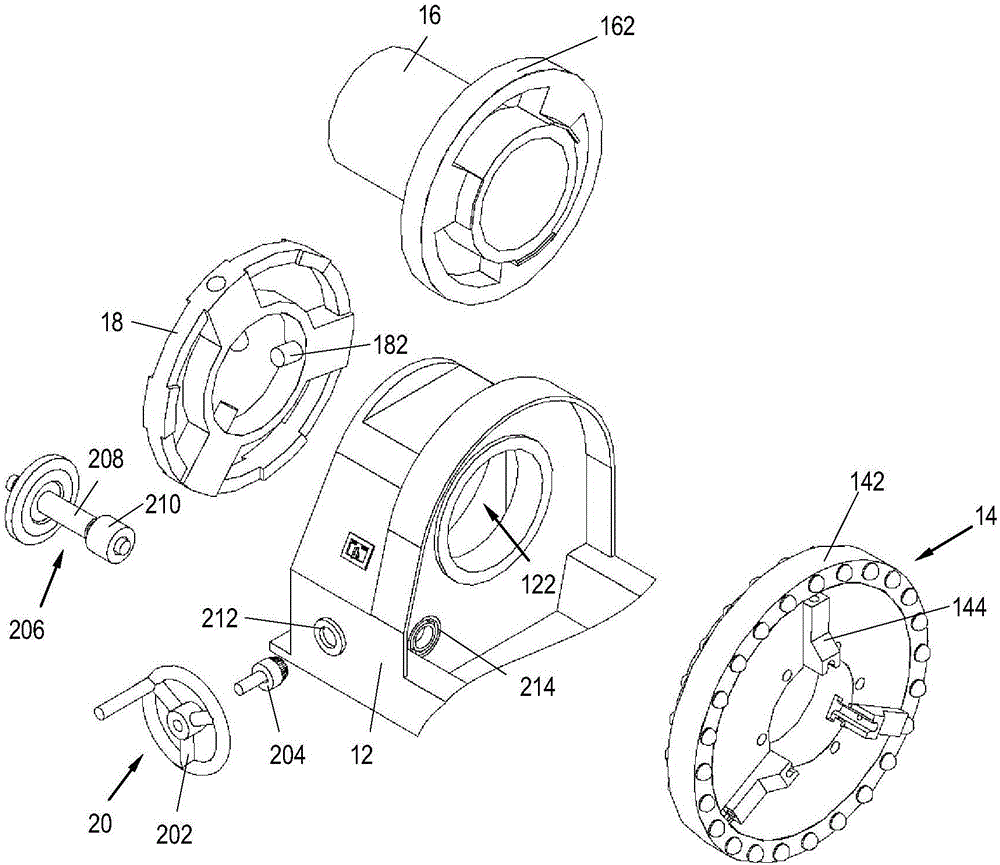

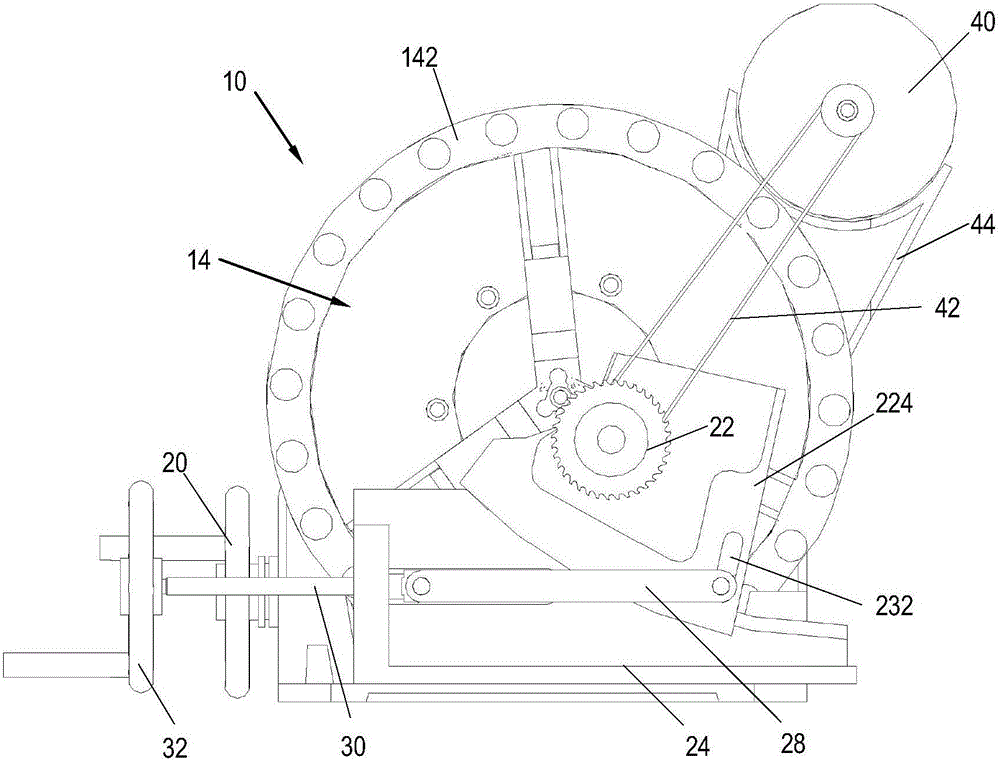

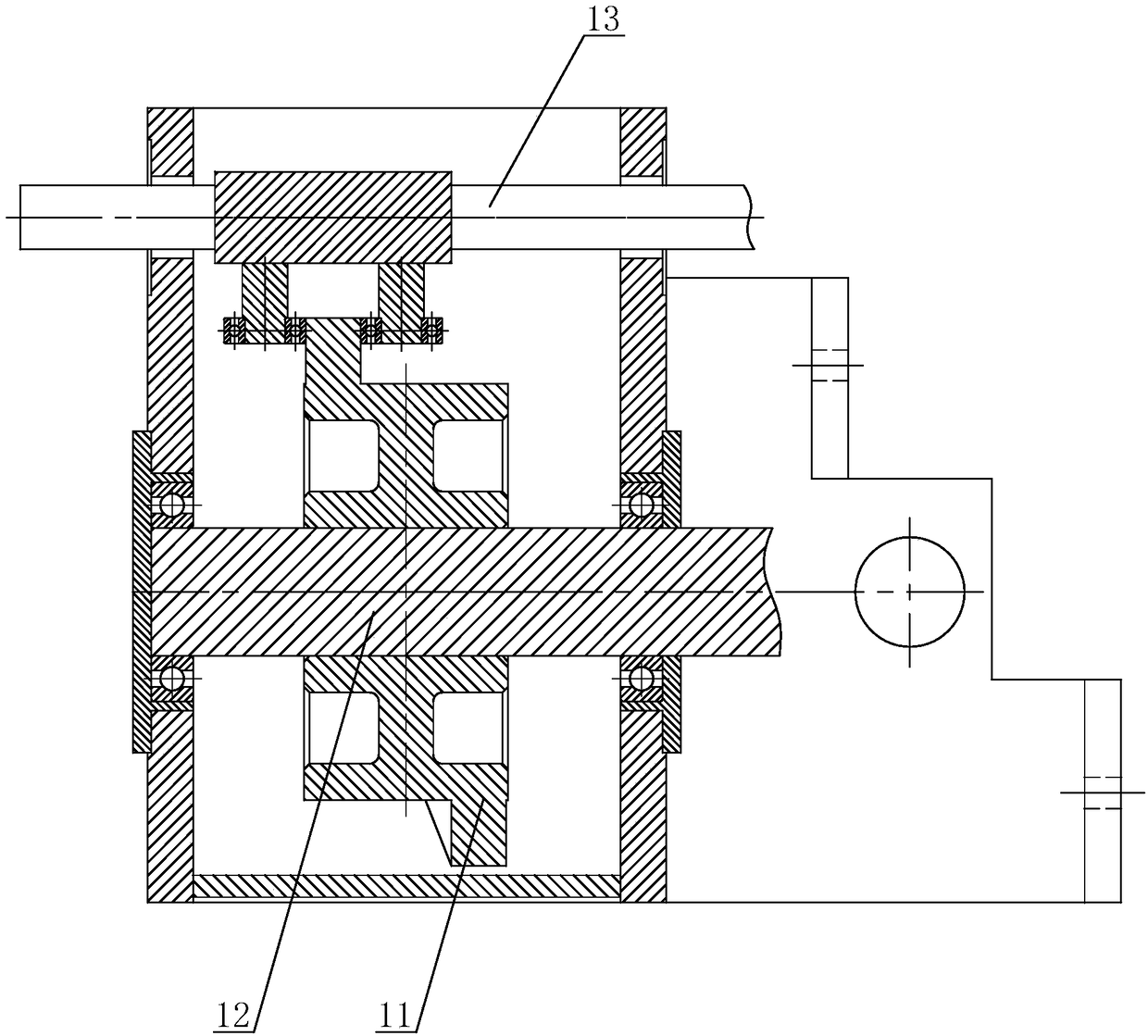

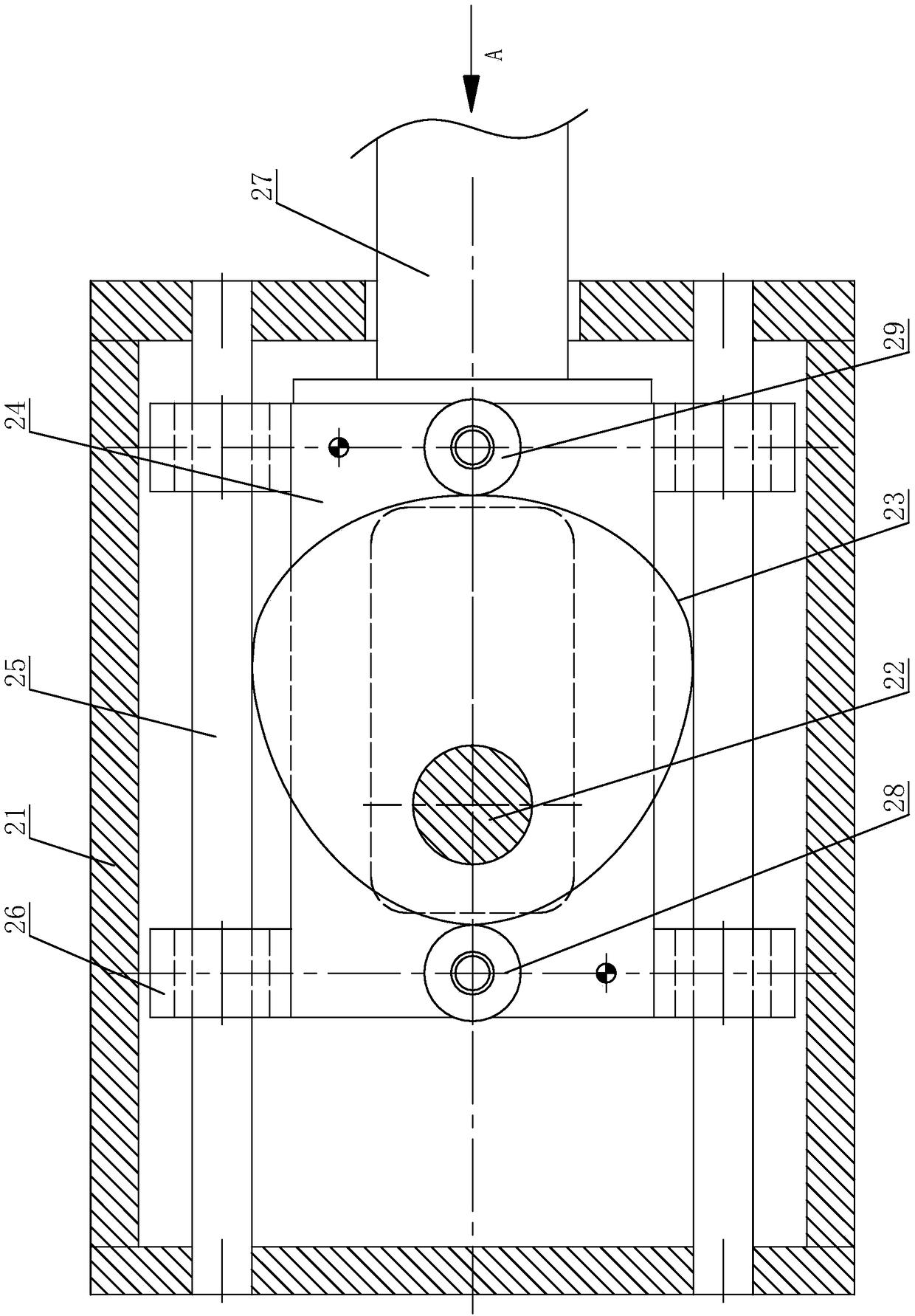

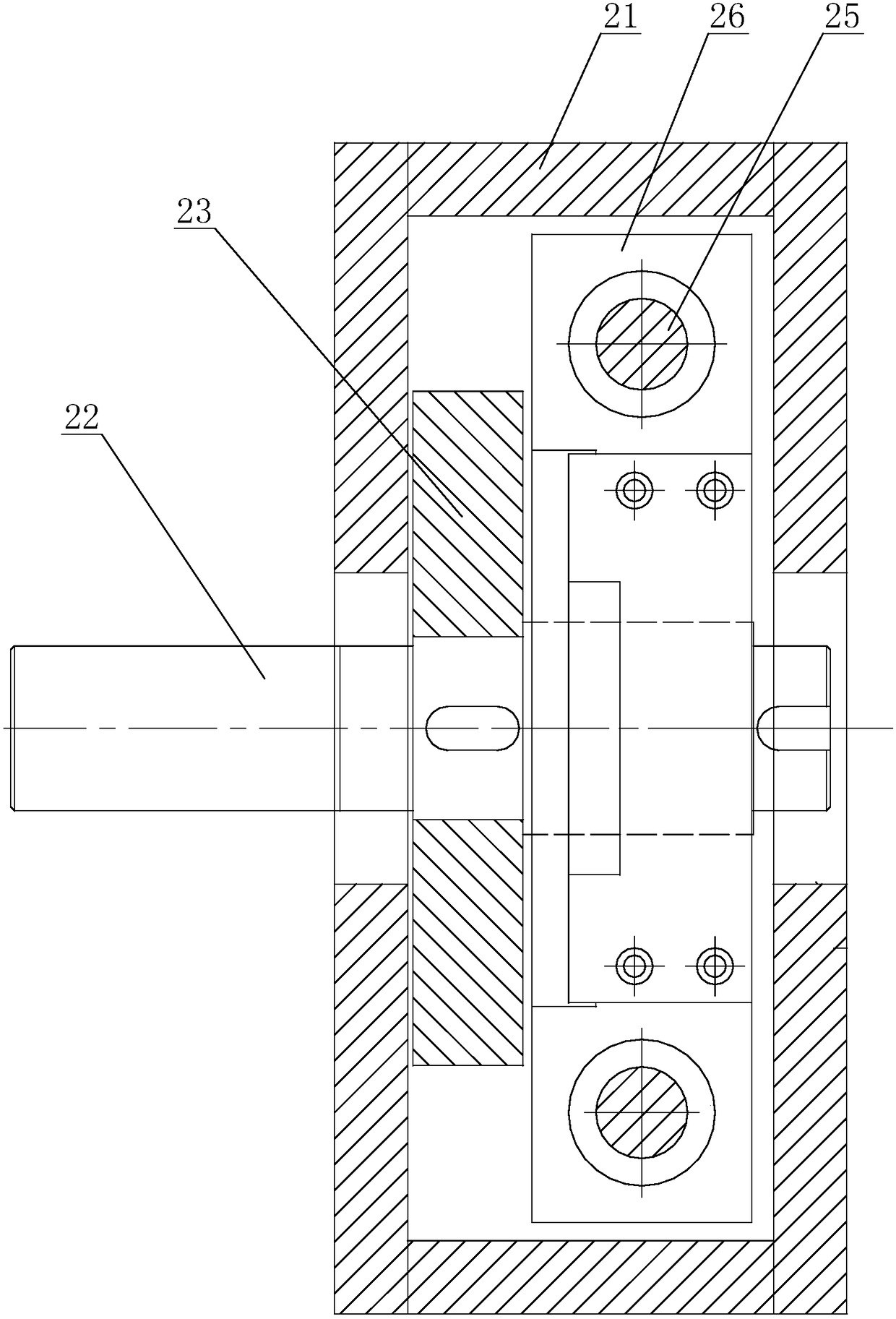

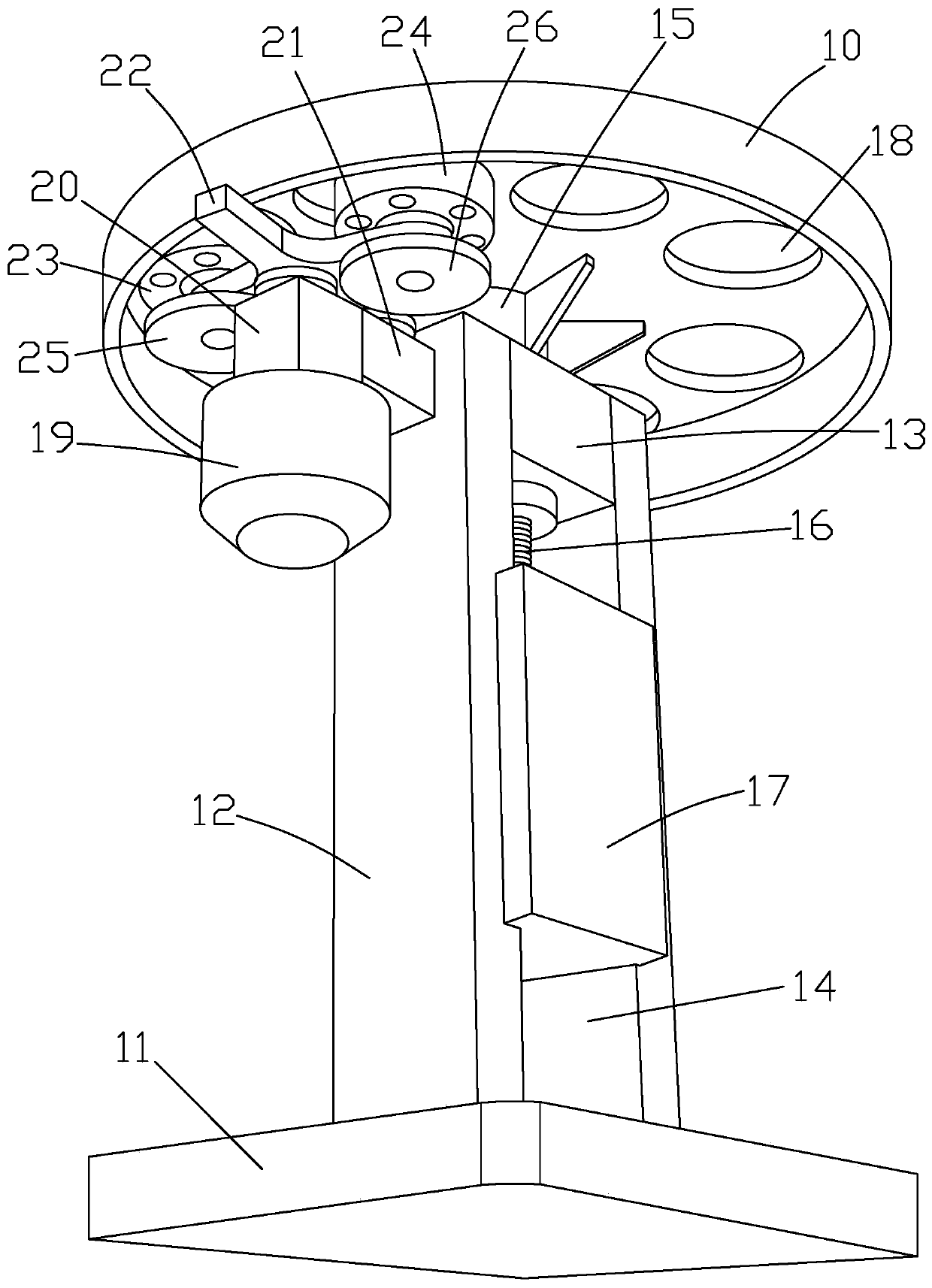

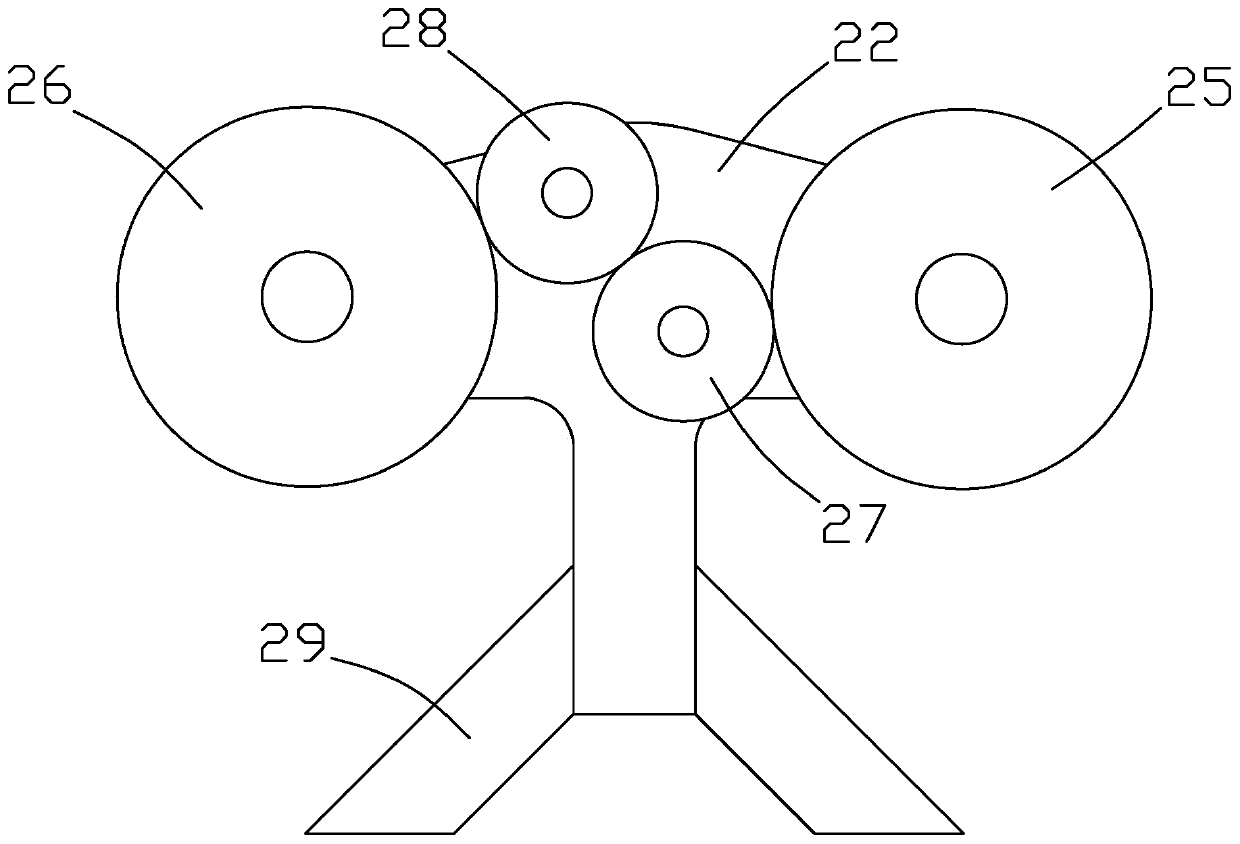

Pipe cutting machine

InactiveCN104551198AImprove cutting accuracyImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a pipe cutting machine. The pipe cutting machine comprises a base, a pipe cutting tool and a motor, wherein the base is provided with a clamping device which is used for clamping a pipe to be cut and can be used for driving the pipe to rotate about the longitudinal axis of the pipe; the pipe cutting tool can move relative to the base; the motor is used for supplying power to the pipe cutting tool; the motor is fixedly arranged on the base; the rotating axis of the motor is parallel to the rotating axis of the pipe cutting tool; the pipe cutting tool can move close to or far away from the pipe to be cut. By adopting the pipe cutting machine disclosed by the invention, the space occupied in the vertical direction can be reduced greatly, so that the application range is enlarged. Moreover, the pipe to be cut is driven to rotate automatically, and the cutting tool does not rotate about the pipe to be cut, so that the operation difficulty of the pipe cutting machine can be lowered, and the use safety is enhanced.

Owner:EMERSON PROFESSIONAL TOOLS SHANGHAI

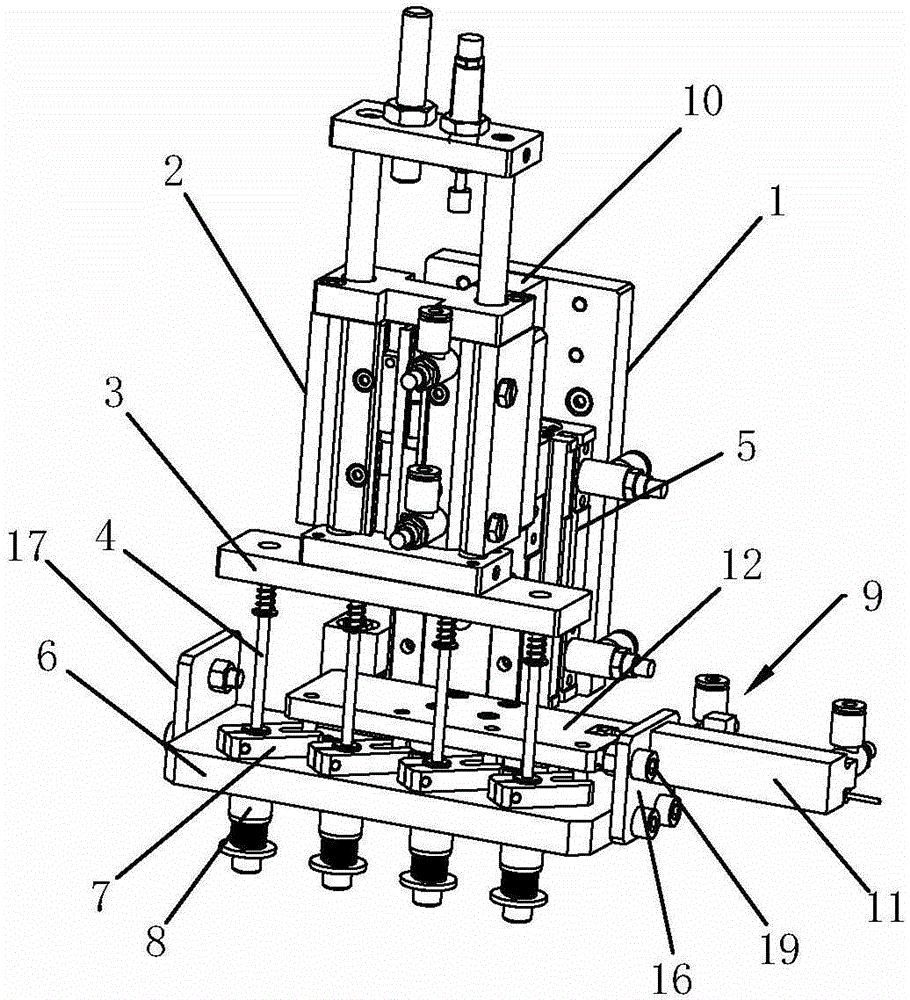

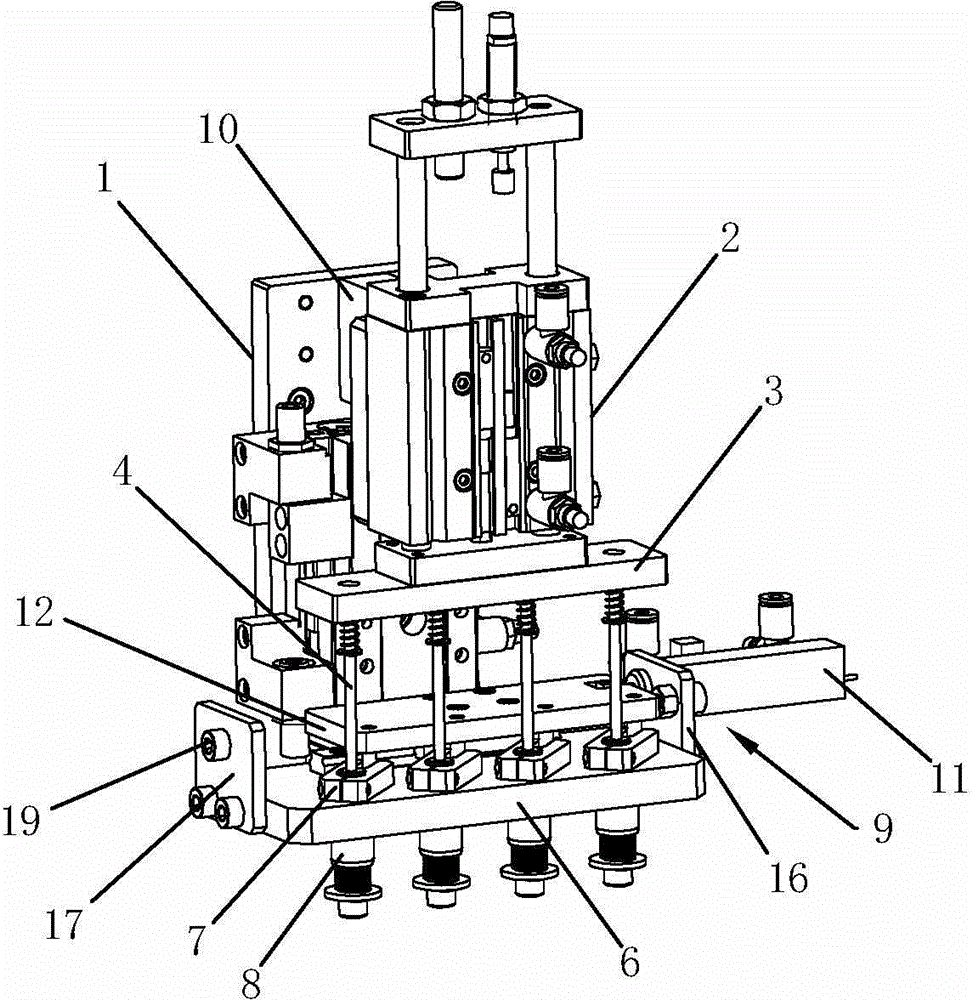

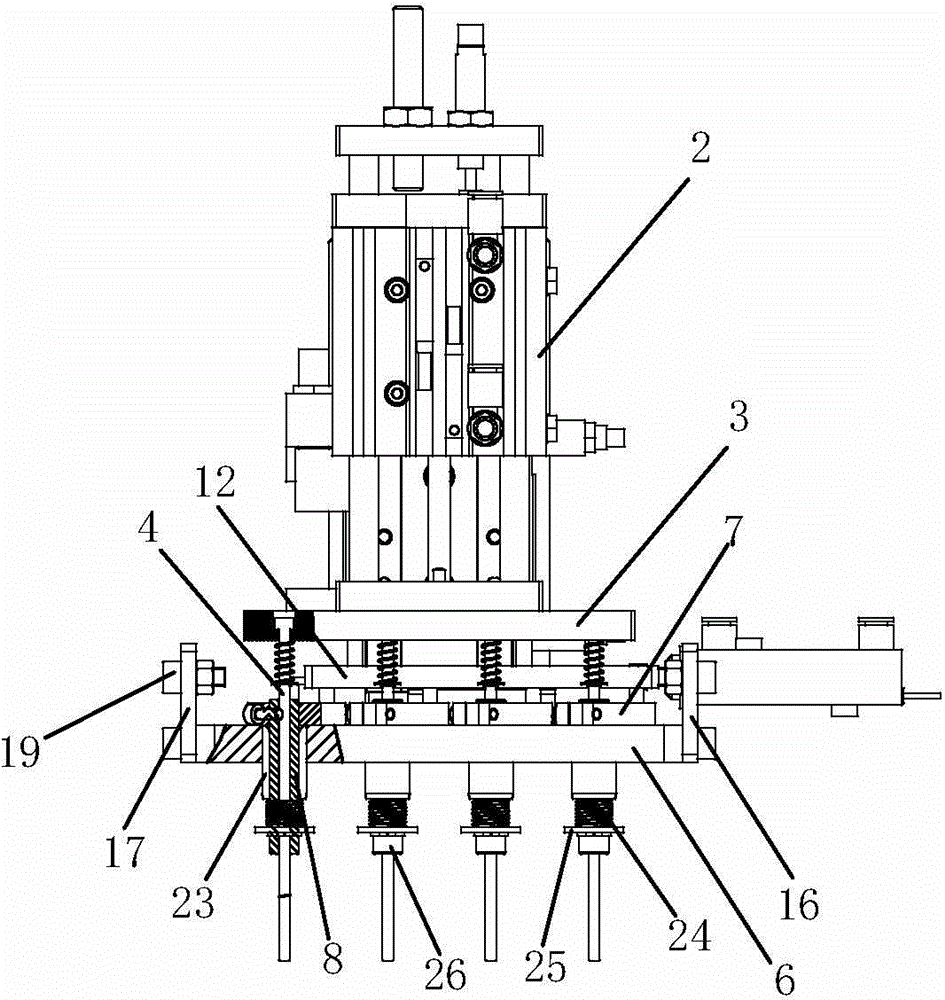

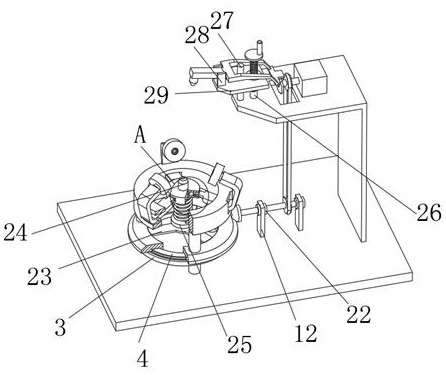

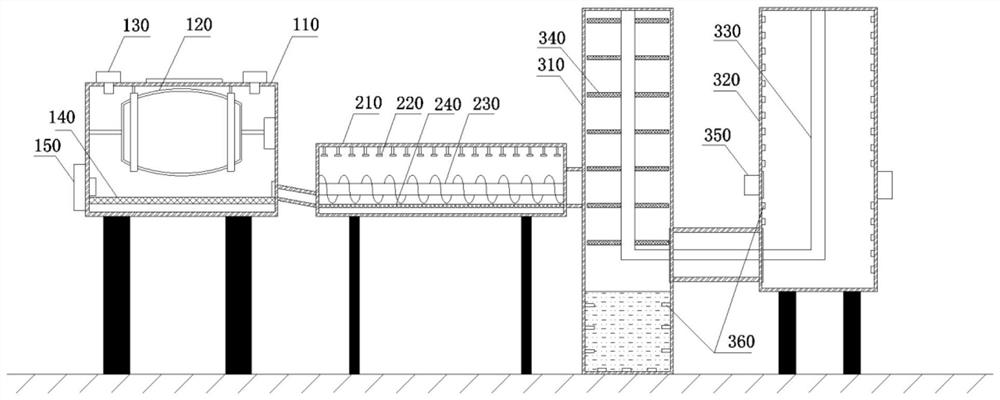

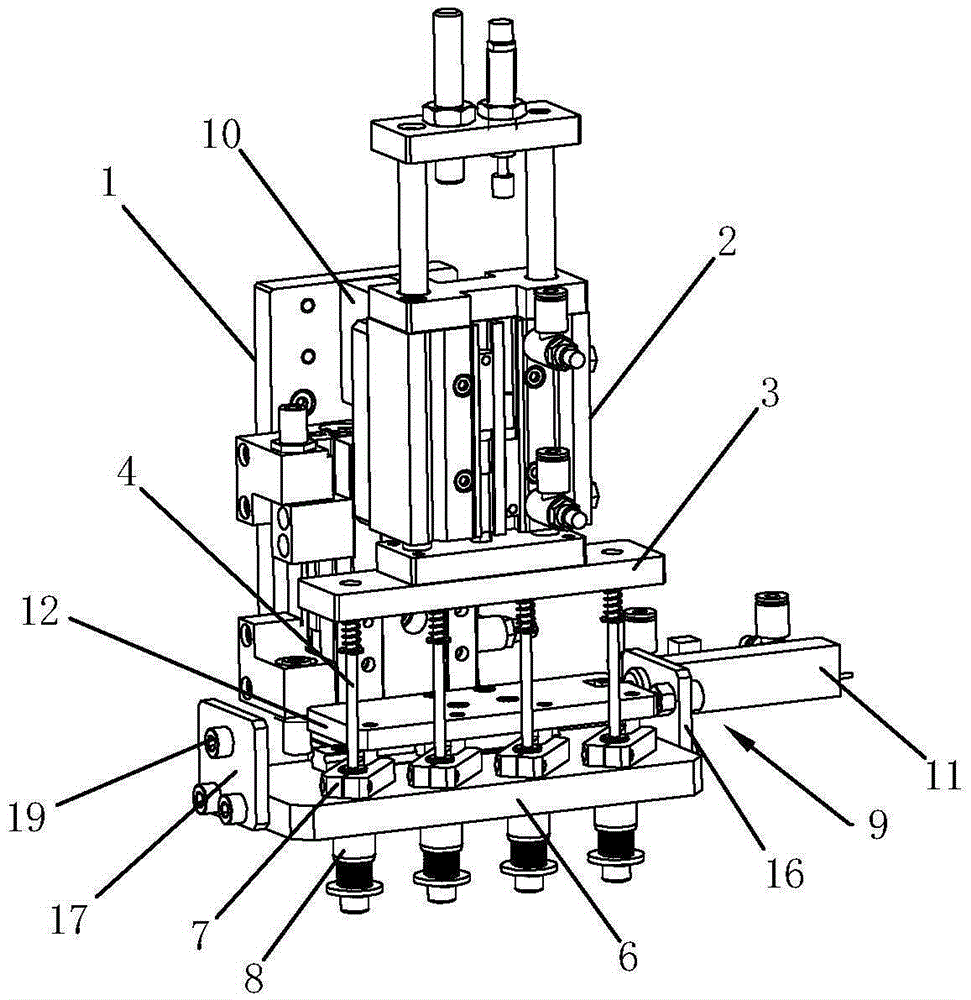

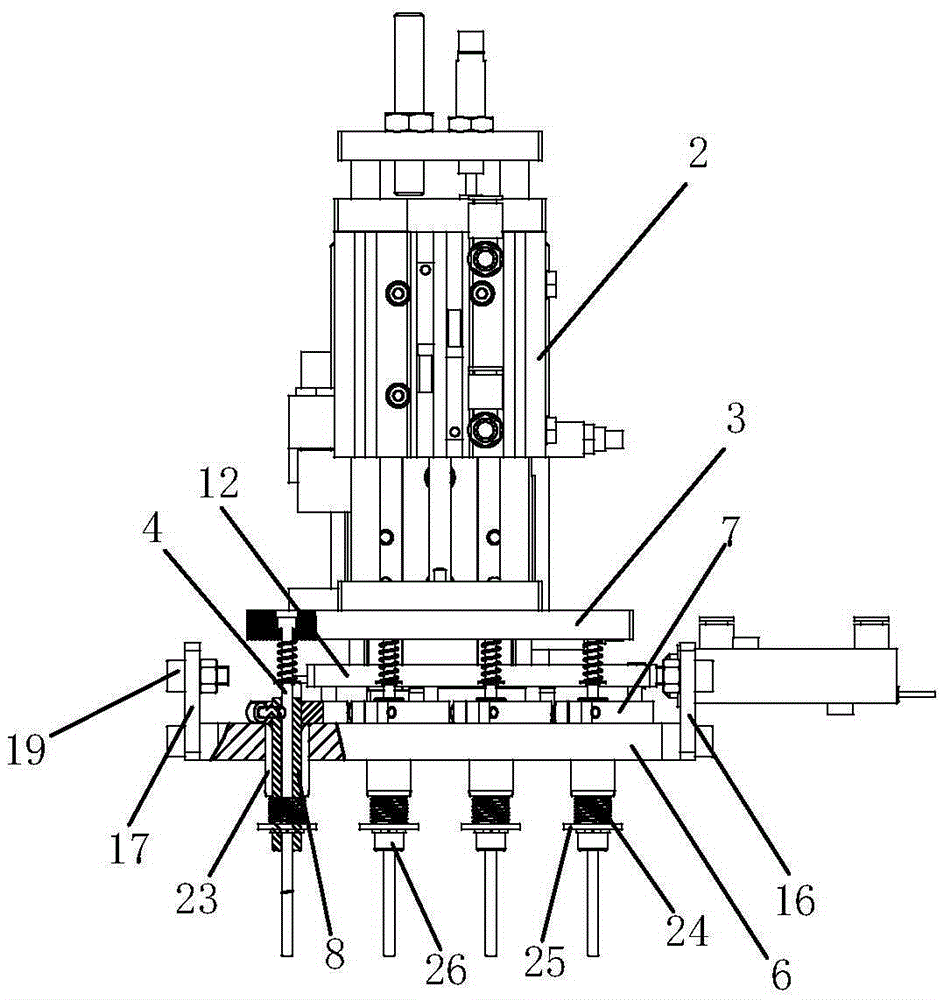

Magnet attraction rotation picking and placing device

ActiveCN104476543ASimple structureImprove adsorption capacityProgramme-controlled manipulatorGripping headsNon magneticMagnet

The invention relates to the technical field of electronic product assembly and provides a magnet attraction rotation picking and placing device. The device comprises a fixing plate. A product fixing mechanism and a product rotation picking and placing mechanism are arranged on the fixing plate. The product fixing mechanism comprises a first air cylinder, a first connection plate and a plurality of non-magnetic ejection rods. The product rotation picking and placing mechanism comprises a picking and placing unit and a rotation unit. The picking and placing unit comprises a second air cylinder, a second connection plate and a plurality of first through holes corresponding to the non-magnetic ejection rods. Corresponding torsion blocks are arranged on the sides of the upper ends of the first through holes close to the first connection plate. Hollow magnet absorption rods for penetrating the non-magnetic ejection rods are arranged in the first through holes, the upper ends of the magnet absorption rods are fixedly connected with the torsion blocks, the lower ends extend to the sides away from the torsion blocks, and the torsion blocks are connected with rotation units controlling the circumference rotation of the torsion blocks, accordingly, a plurality of magnetic products are attracted simultaneously and are put down when rotating to preset angles. According to the device, the structure is simple, power connection is not needed, an air source is used as power, the absorption is firm, and the service life is long.

Owner:GOERTEK INC

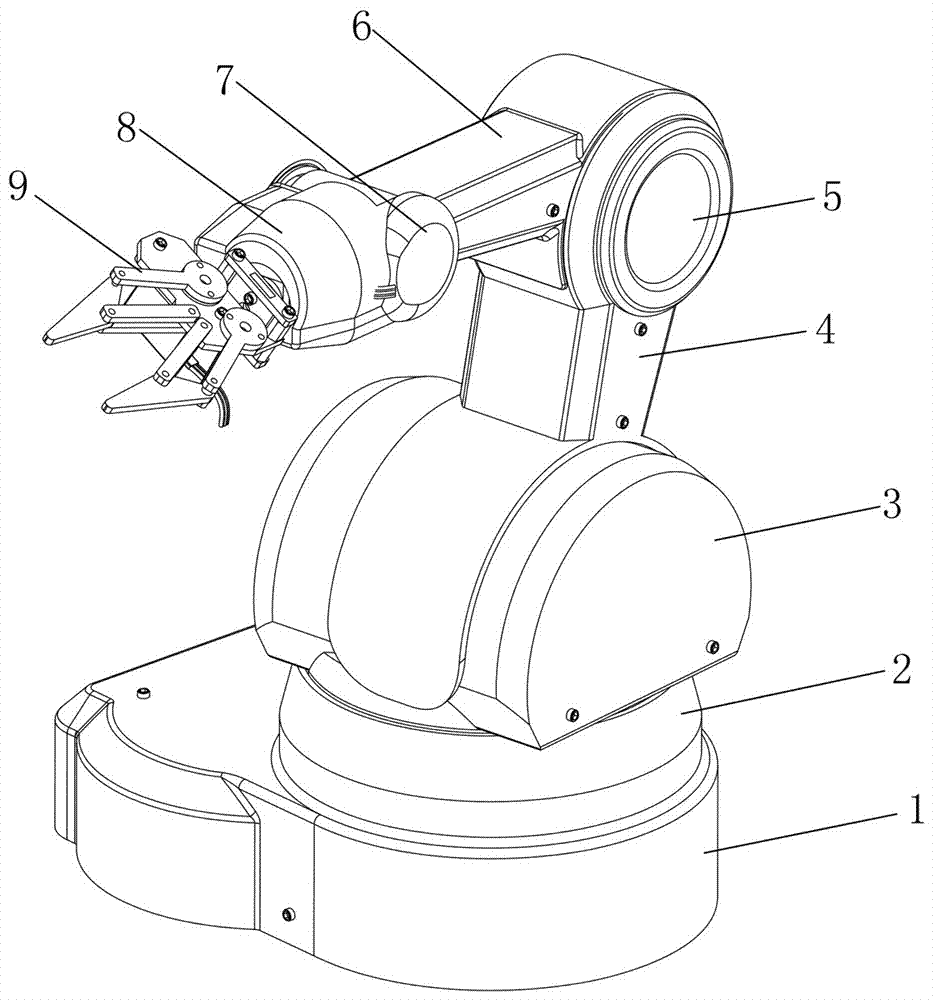

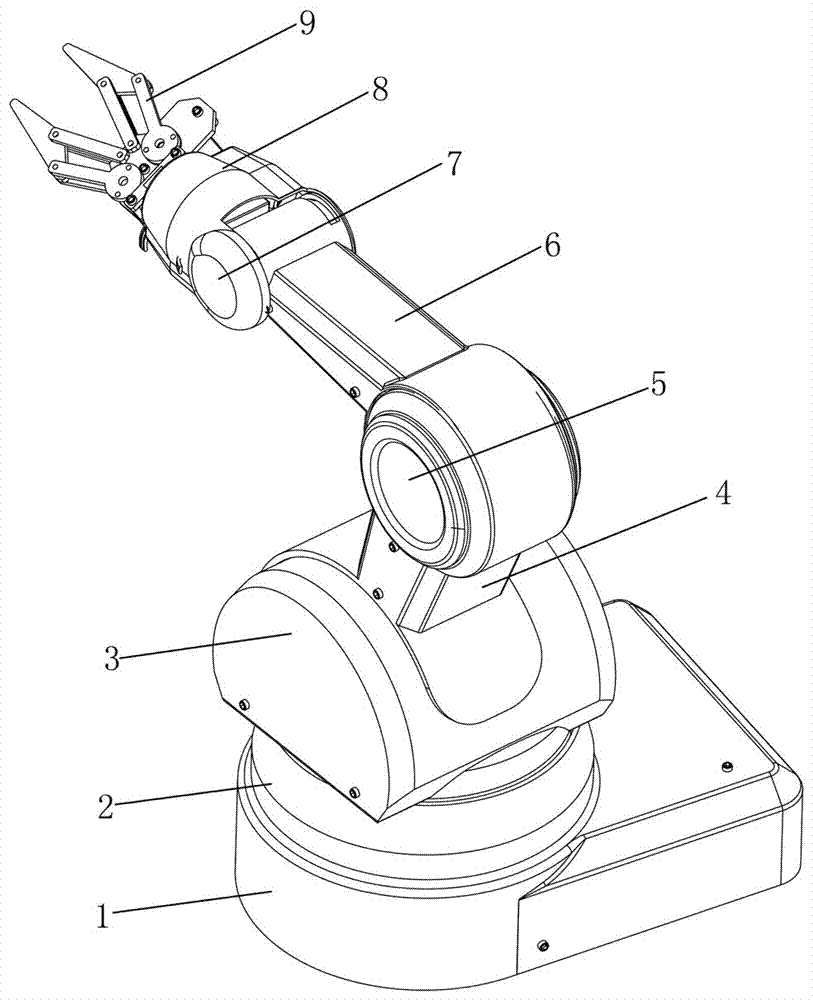

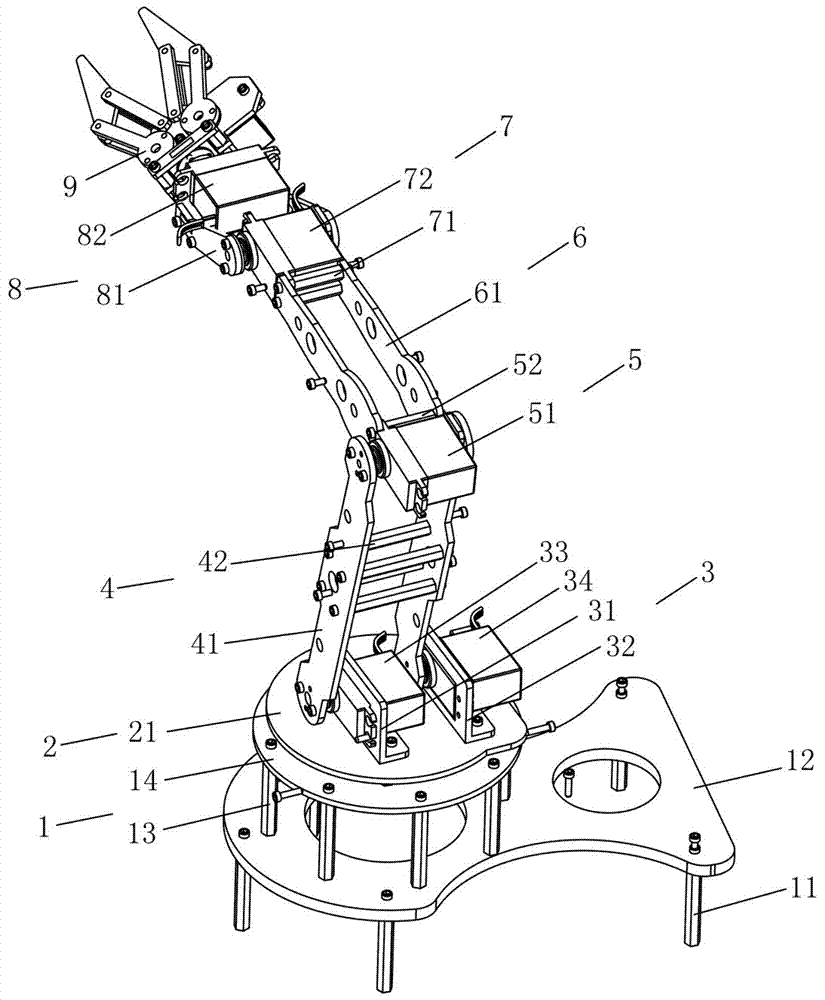

Novel five-degree-of-freedom manipulator

ActiveCN107234610AReduce space occupancyIncrease freedomProgramme-controlled manipulatorGripping headsOccupancy rateEngineering

The invention discloses a novel five-degree-of-freedom manipulator comprising a base, a rotating part, a first connecting part, a first shaft arm, a second connecting part, a second shaft arm, a third connecting part, a third shaft arm and a clamping jaw mechanism; the base is arranged on a horizontal plane, and the rotating part is arranged on the base; the first connecting part is arranged on the rotating part; the lower end of the first shaft arm is rotatably connected to the first connecting part, and the upper end of the first shaft arm is provided with the second connecting part; one end of the first shaft arm is rotatably connected to the first connecting part, and the other end of the first shaft arm is provided with the second connecting part; one end of the second shaft arm is rotatably connected to the second connecting part, and the other end of the second shaft arm is provided with the third connecting part; and one end of the third shaft arm is connected to the third connecting part, and the other end of the third shaft arm is connected with the clamping jaw mechanism. The novel five-degree-of-freedom manipulator is simple in structure, low in space occupancy rate as well as high in degree of freedom, movement stability and precision.

Owner:阳西县精科塑业有限公司

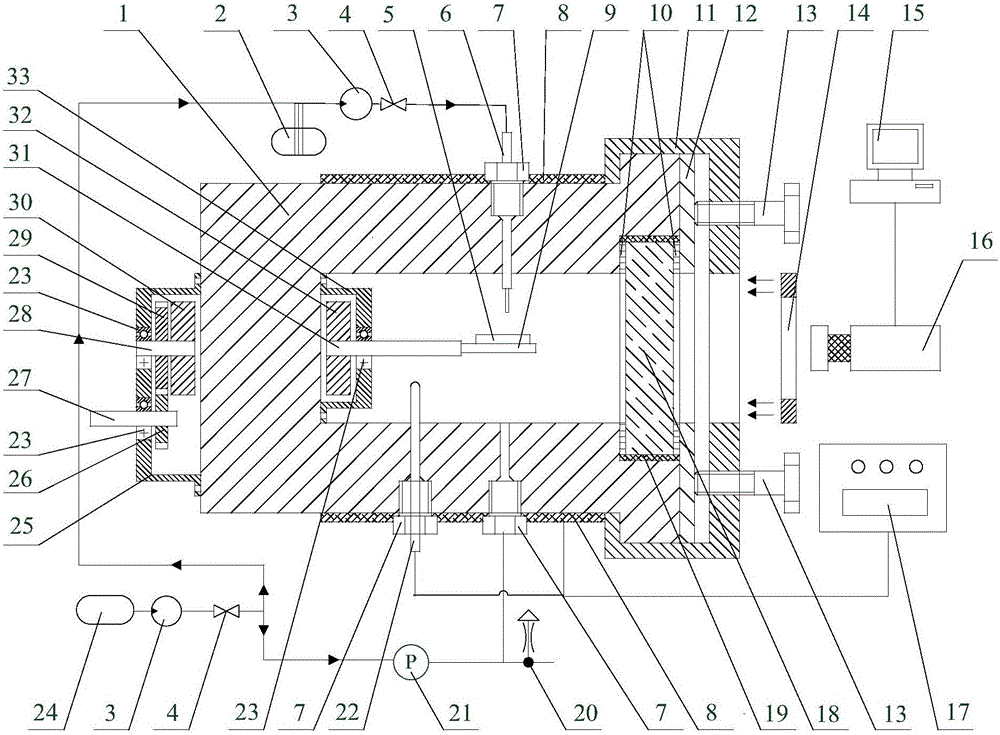

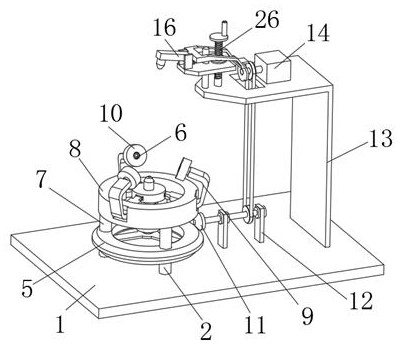

Experimental device for measuring dynamic contact angle under high-temperature and high-pressure environments

InactiveCN106018184AAchieve captureEasy to catchSurface/boundary effectMagnetic tension forceGas cylinder

The invention belongs to the technical field of CO2 geological storage and provides an experimental device for measuring a dynamic contact angle under high-temperature and high-pressure environments. The experimental device comprises a single-opening high-temperature and high-pressure kettle, a solution stirrer, a pump, a valve, a rock sample, an injection needle, a conical-surface connector, a heating belt, a matrix platform, a red copper gasket, a sealing opening ring, a pressing ring, a pressing bolt, an annular optical fiber illumination lamp, a computer, a high-frequency camera, a temperature controller, a sapphire sight glass, a teflon sealing ring, a pressure relief valve, a pressure gauge, a thermocouple, a mini-type rolling bearing, a CO2 gas bottle, an outer cover, gears, a shaft, magnetic bodies and an inner cover. The experimental device is used for controlling a rotary angle of an outer magnetic body through engaging transmission of a small gear and a large gear; an inner magnetic body is driven by magnetic transmission; the inclining angle of the matrix platform is finely adjusted, a liquid drop movement trend and a liquid drop form are accurately captured and the dynamic contact angle is analyzed and measured.

Owner:DALIAN UNIV OF TECH

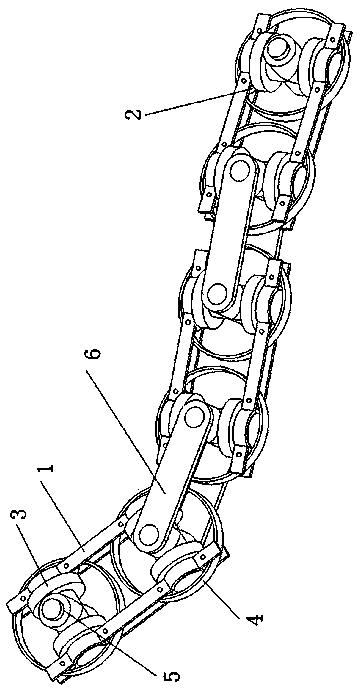

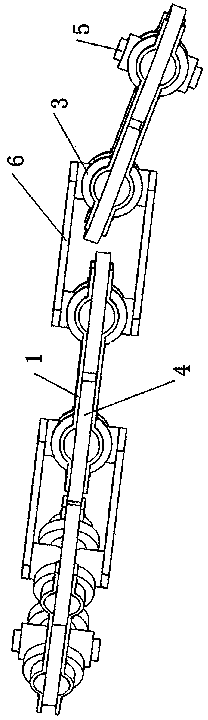

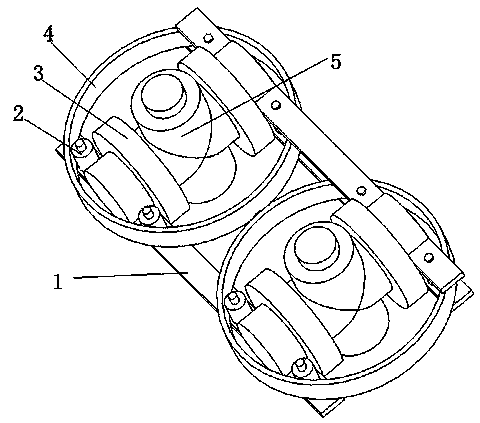

Bearing type universal chain

ActiveCN103939526AAchieve rotationAchieve power transmissionConveyorsChain elementsThree-dimensional spaceCore component

The invention discloses a bearing type universal chain. The bearing type universal chain comprises at least two unit rail links which can rotate relatively and cross shaft connecting pieces used for connecting the adjacent unit rail links. Each unit rail link comprises two walking devices and cross shaft frames which are connected with the two walking devices. The core component of each walking device is a cross shaft, wherein horizontal rotation and vertical rotation can be realized through a longitudinal shaft and a transverse shaft of each cross shaft. The bearing type universal chain has the advantages that each unit rail link is formed through the two cross shafts, the longitudinal shafts of the cross shafts, close to each other, of every two adjacent unit rail links are connected through the corresponding cross shaft connecting piece, rotation of the two adjacent unit rail links in the horizontal direction is realized, the transverse shafts of the two cross shafts of the same unit rail link are connected through the corresponding cross shaft frames, the two ends of each cross shaft frame and the two ends of the corresponding cross shafts are matched in a sleeved mode, relative rotation of the two cross shafts of the same unit rail link in the vertical direction is realized, and power transmission of the chain in three-dimensional space is realized in cooperation with a rail or a tension device at a turning position or a direction-changing position.

Owner:吴慧勇

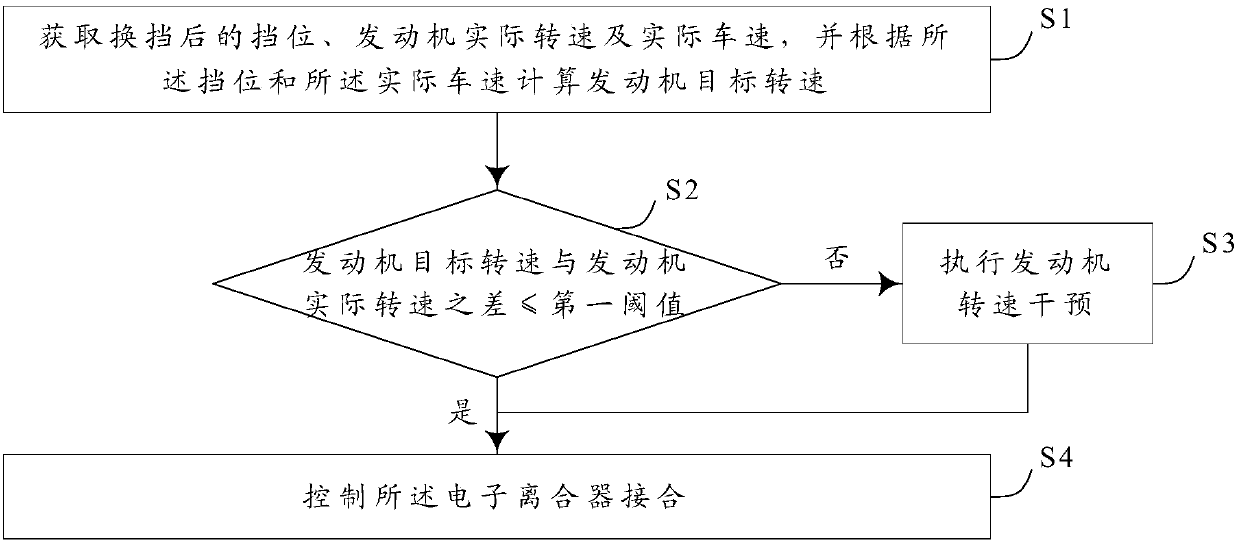

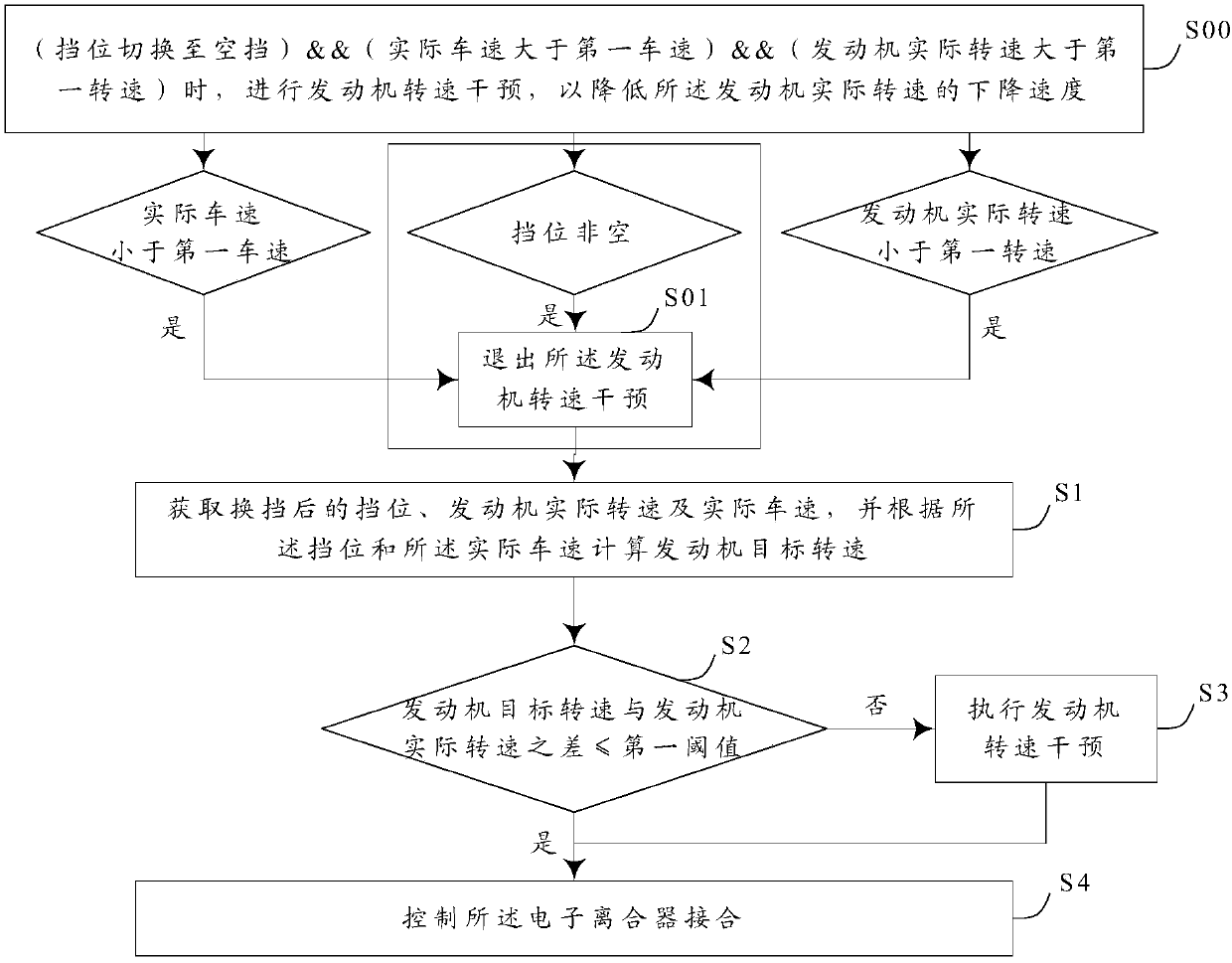

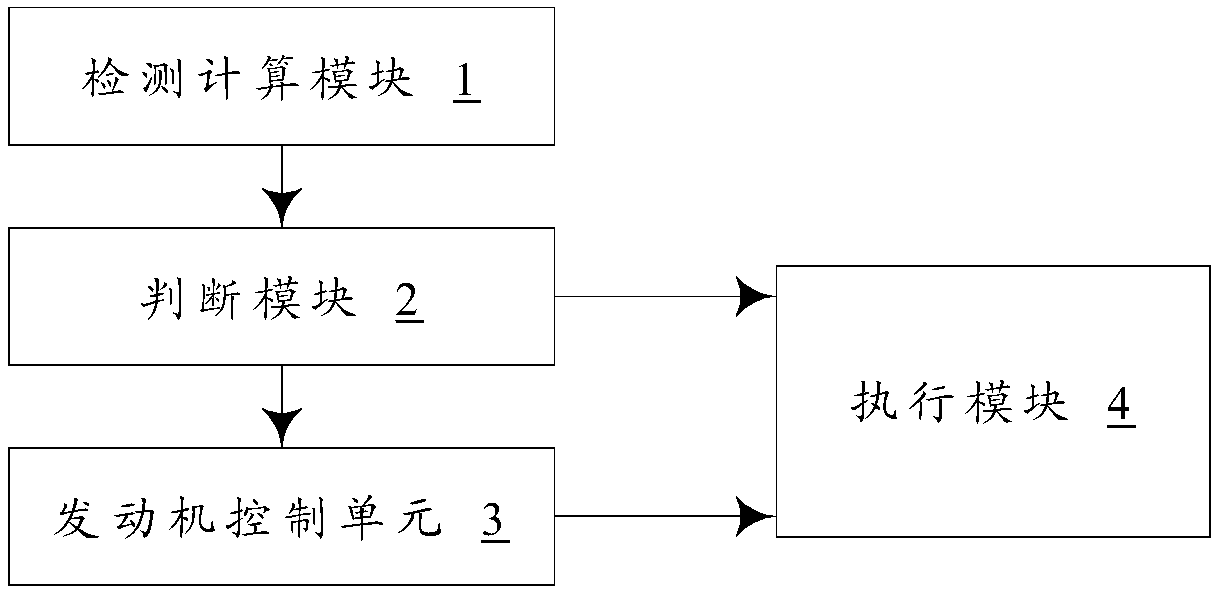

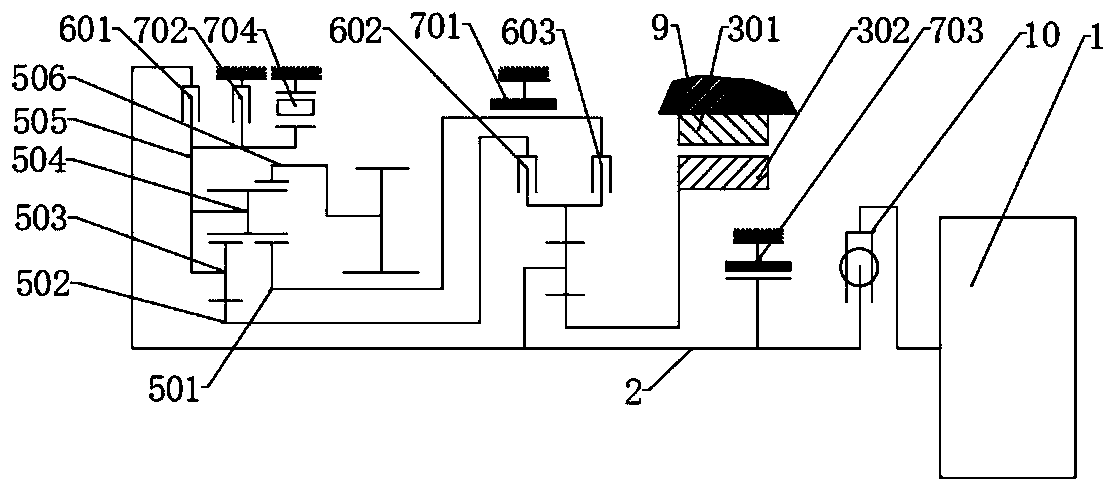

Vehicle and gear shifting control method and system for electronic clutch

The invention discloses a vehicle and a gear shifting control method and system for an electronic clutch. The gear shifting control method for the electronic clutch comprises the following steps thatS1, the gear position obtained after gear shifting as well as the actual rotating speed of an engine and the actual vehicle speed are acquired, and the target rotating speed of the engine is calculated according to the gear position and the actual vehicle speed; S2, the actual rotating speed of the engine is compared with the target rotating speed of the engine, if the difference value between theactual rotating speed of the engine and the target rotating speed of the engine is larger than a first threshold value, S3 is executed, and if the difference value between the actual rotating speed of the engine and the target rotating speed of the engine is smaller than or equal to the first threshold value, S4 is executed; S3, engine rotating speed intervention is performed until the differencevalue between the actual rotating speed of the engine and the target rotating speed of the engine is smaller than or equal to the first threshold value, and then S4 is executed; and S4, the electronic clutch is controlled to be engaged. According to the gear shifting control method for the electronic clutch, the two ends of the electronic clutch can be engaged with a small speed difference in thegear shifting process, and ablation of the electronic clutch is reduced.

Owner:SAIC MOTOR

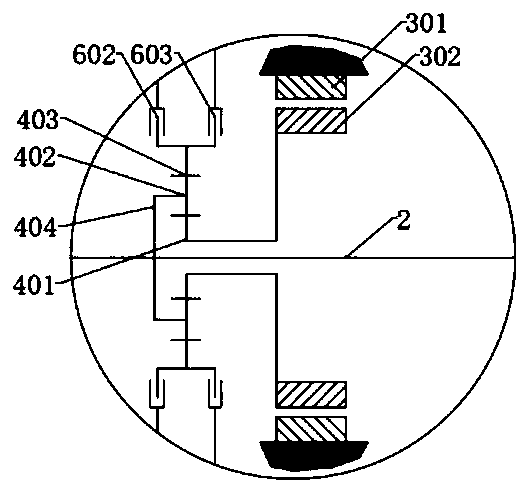

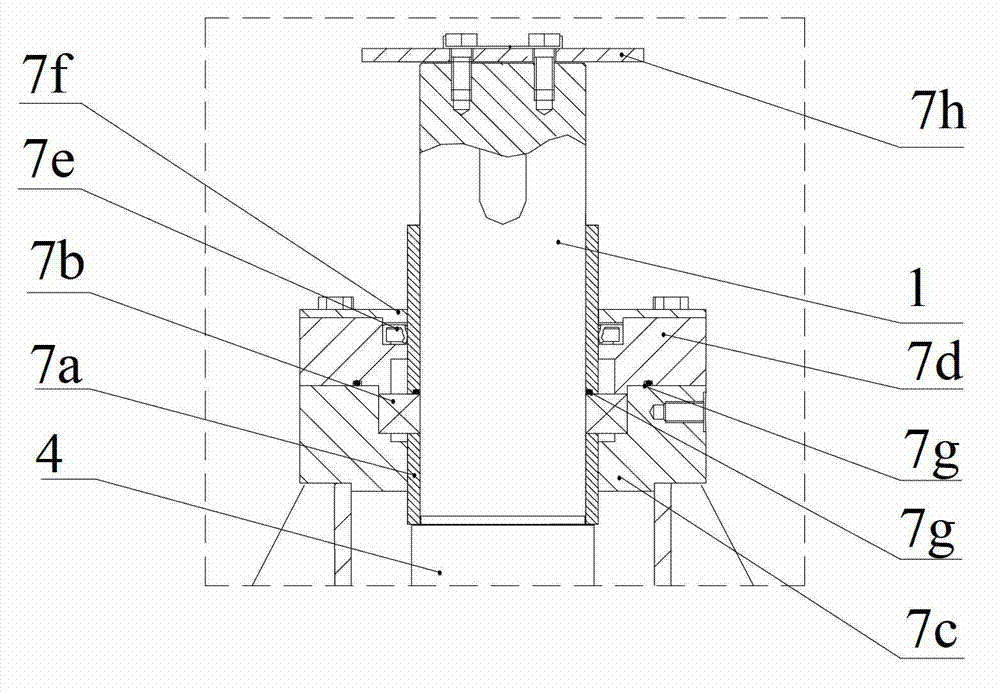

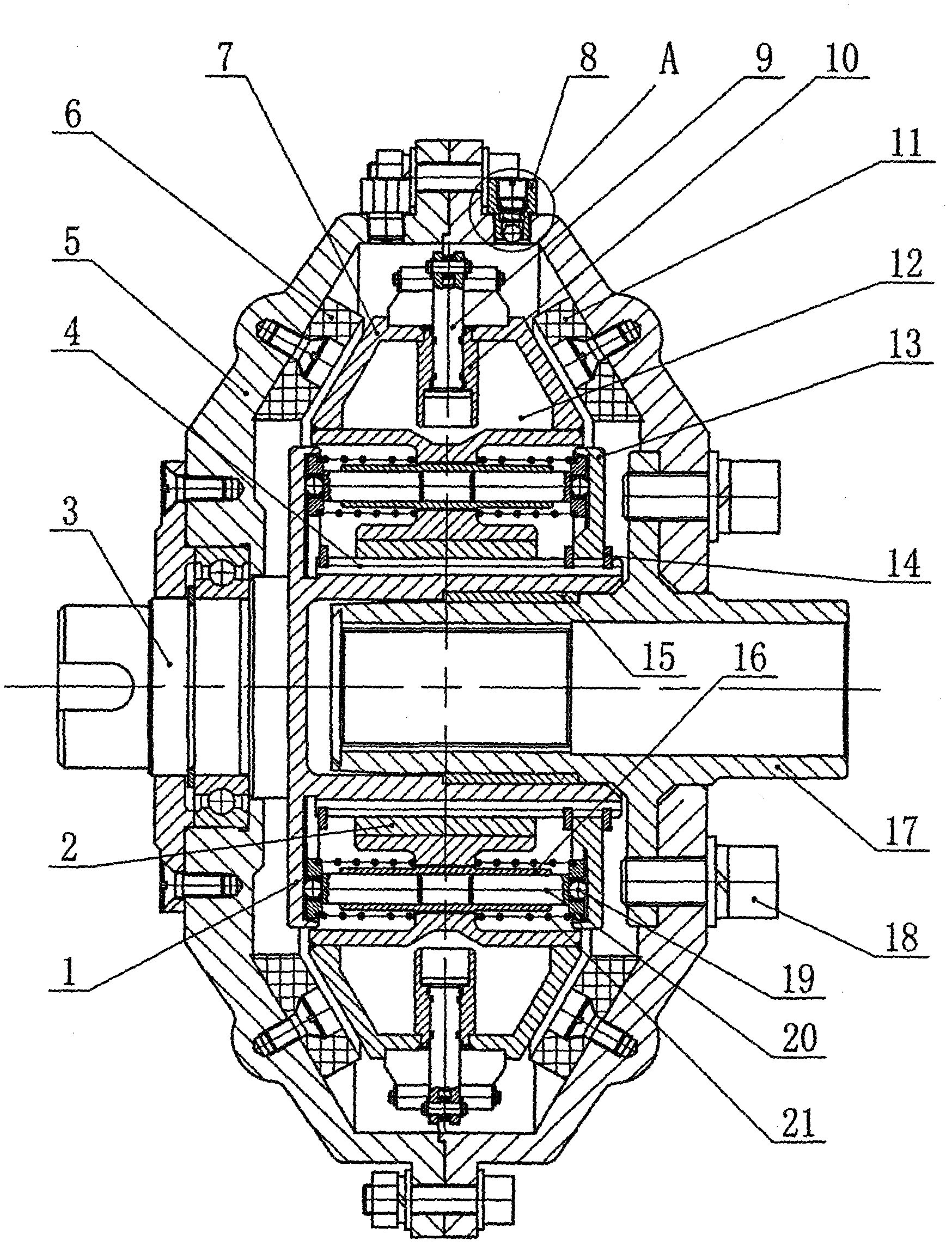

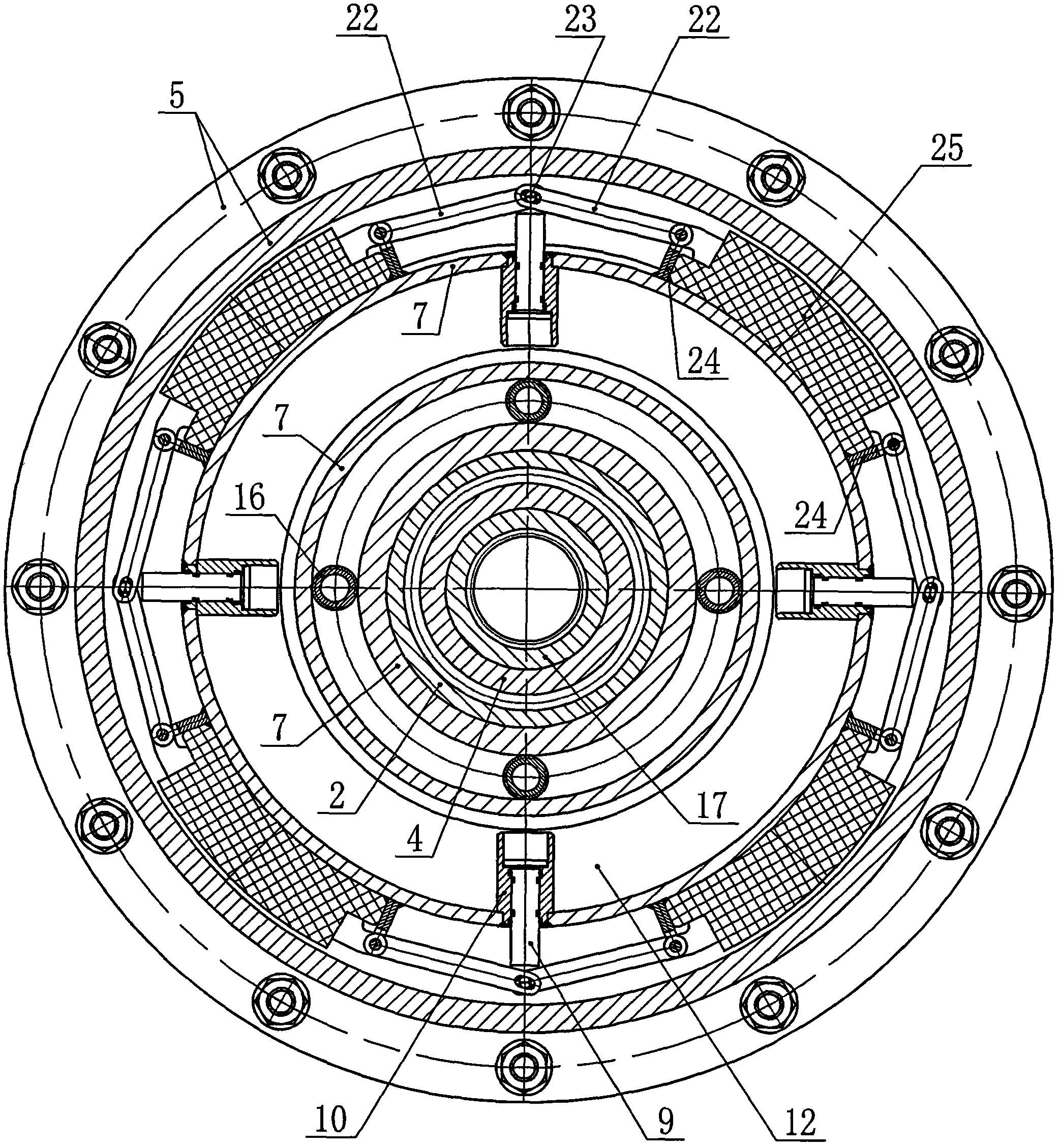

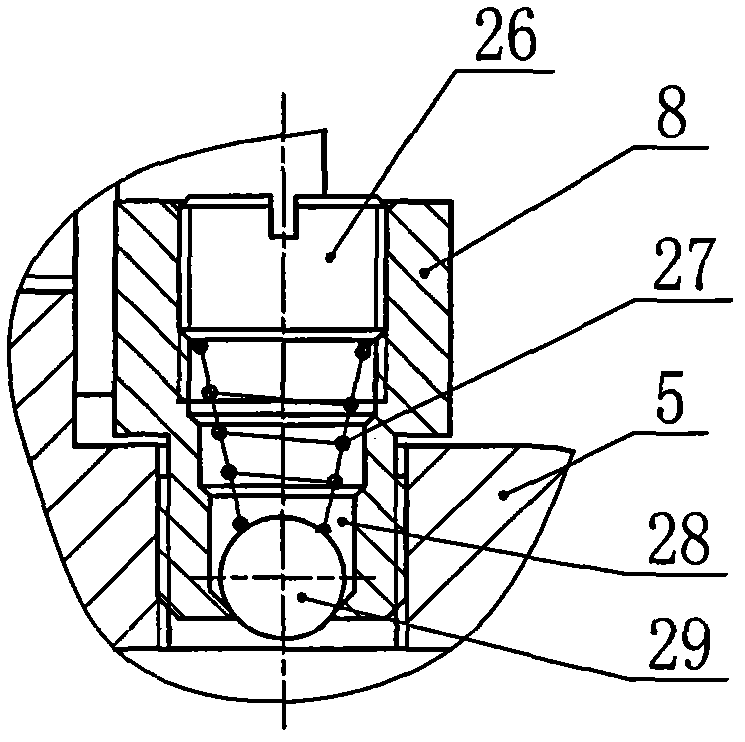

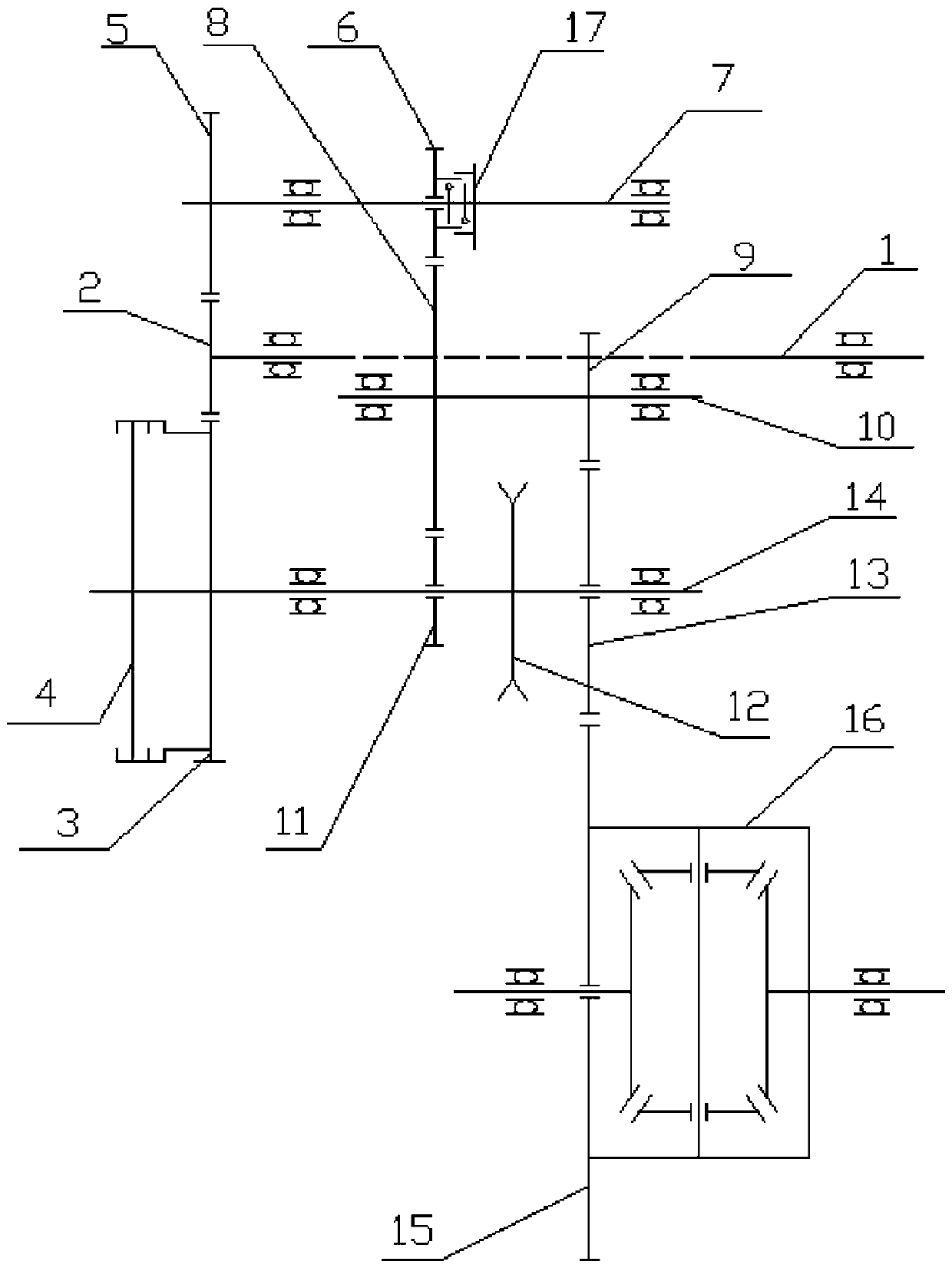

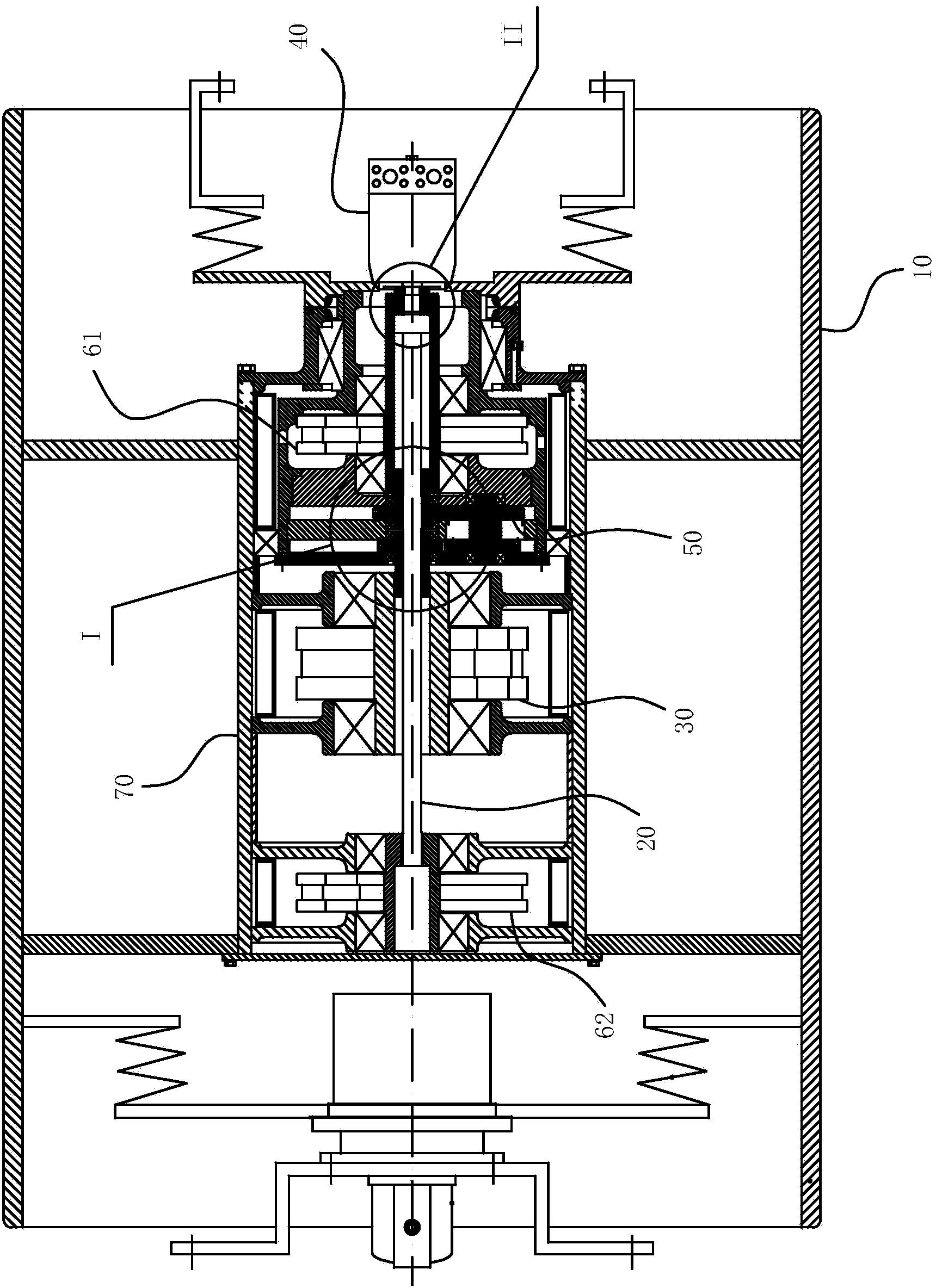

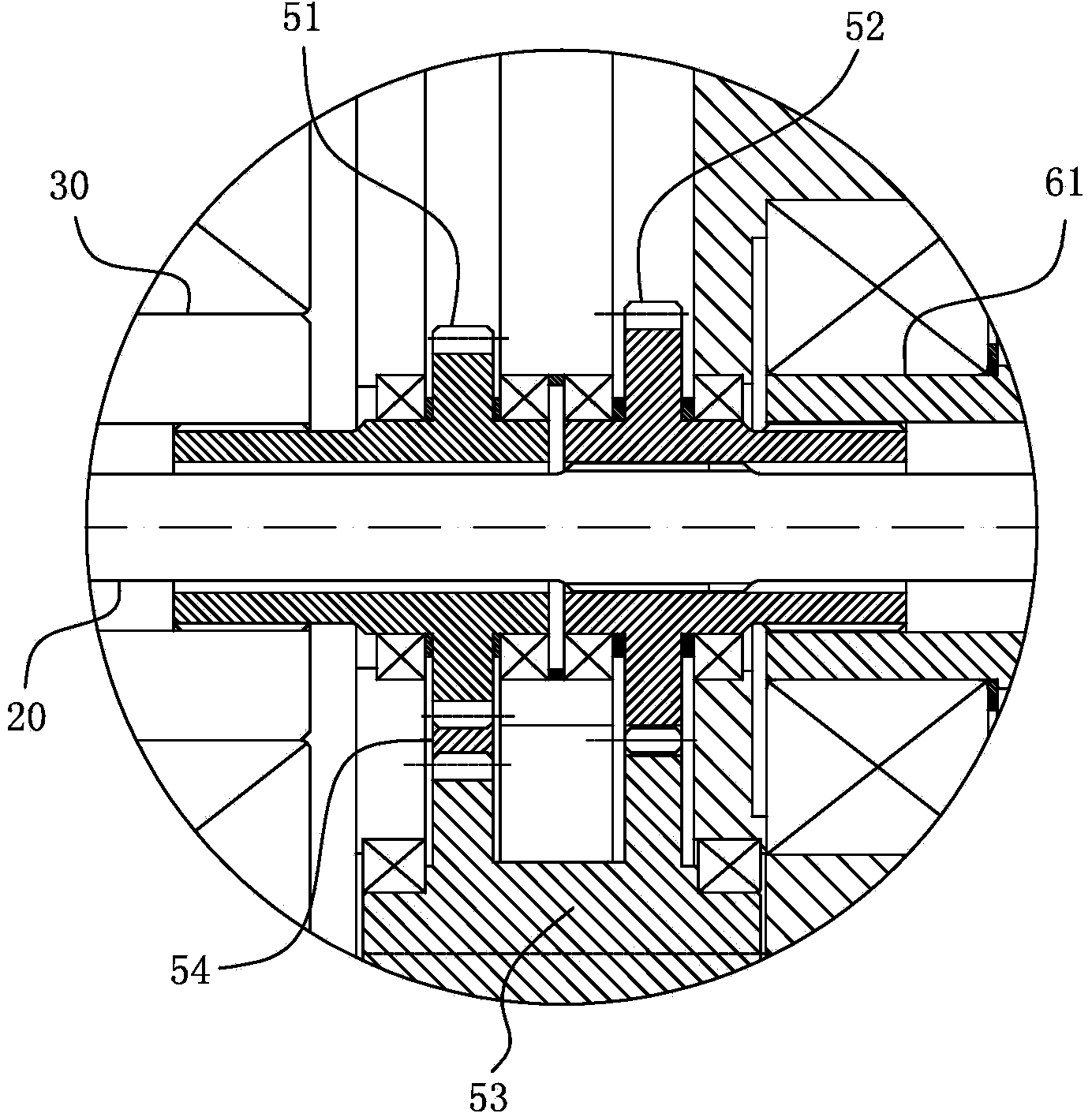

Converter for linear motion and rotary motion

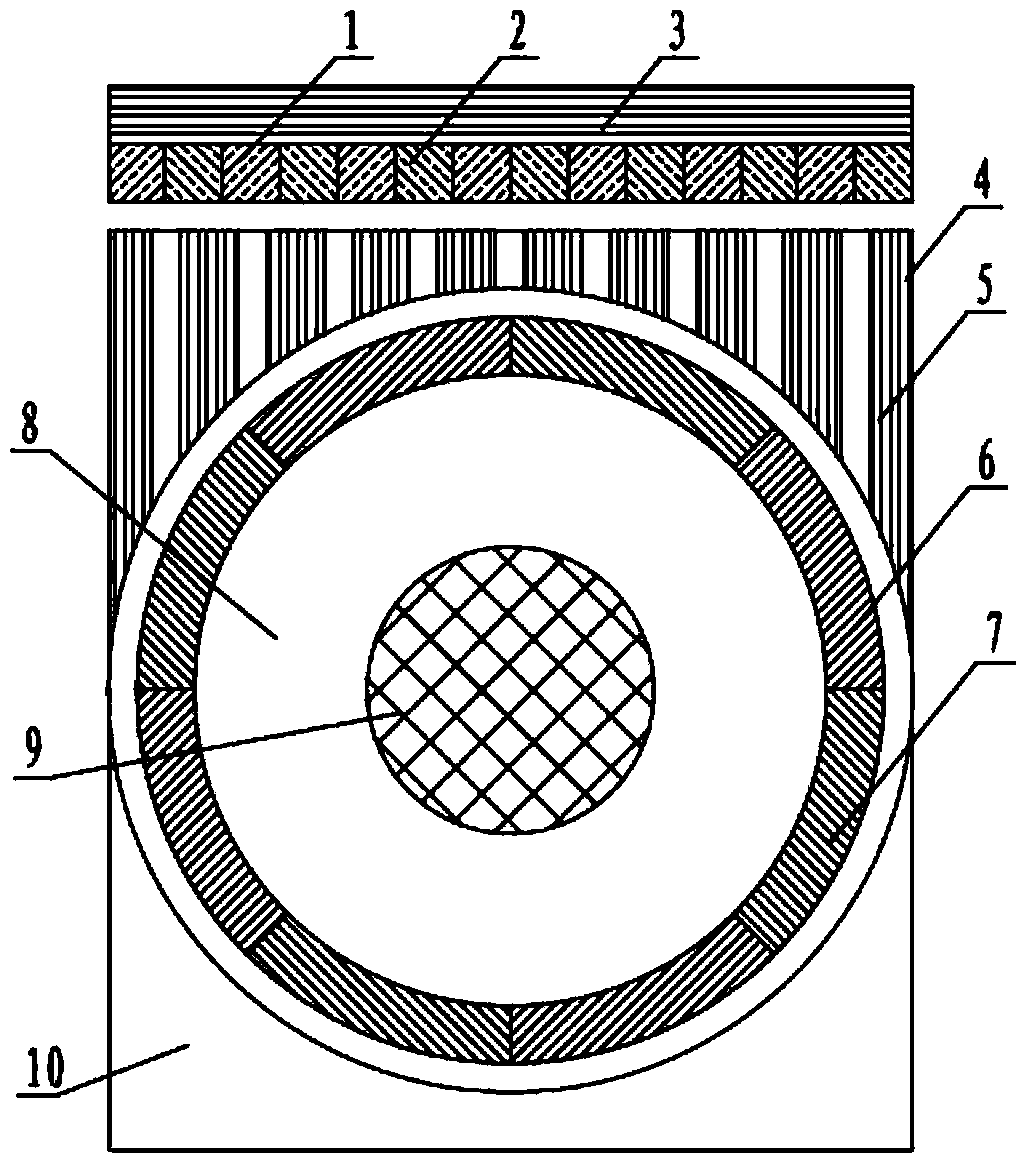

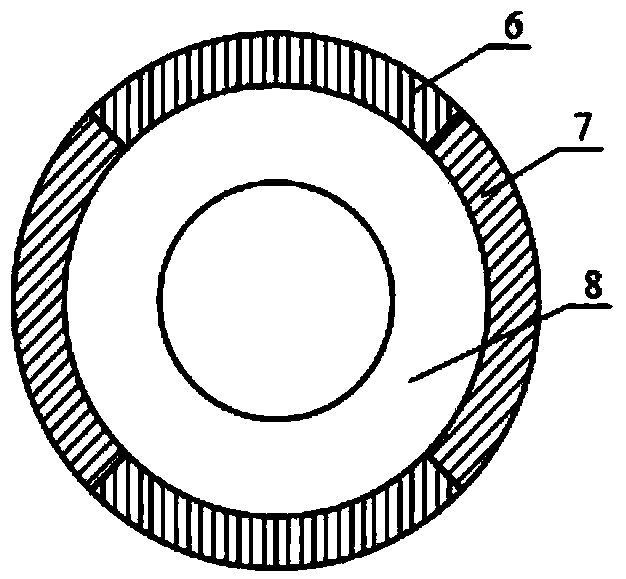

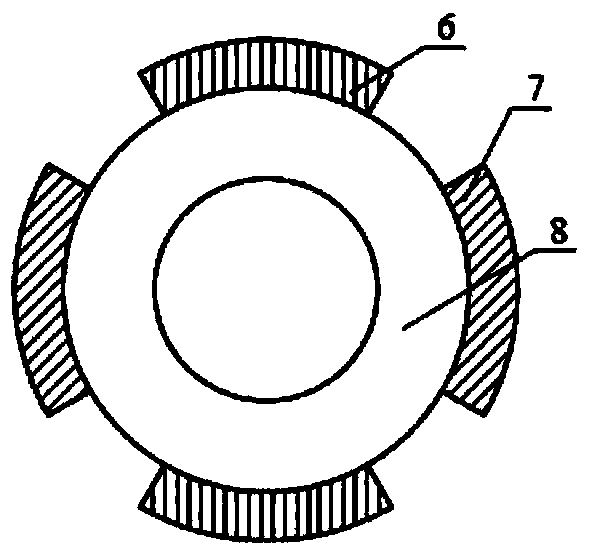

InactiveCN103475185AAchieve conversionAchieve power transmissionPermanent-magnet clutches/brakesLinear motionActive cell

The invention provides a converter for linear motion and rotary motion. The converter for the linear motion and the rotary motion comprises a machine shell (10), a magnetism regulation mechanism which is arranged in the machine shell and is connected with the machine shell, a rotor which is arranged in the magnetism regulation mechanism and an active cell which is arranged outside the magnetism regulation mechanism, wherein an inner air gap is formed between the magnetism regulation mechanism and the rotor, an outer air gap is formed between the magnetism regulation mechanism and the active cell, the rotor is connected with the machine shell (10) through a bearing and rotates freely around the axis, the active cell is connected with the machine shell (10) through a guide rail or an idler wheel and moves in a translational mode along a plane, the magnetism regulation mechanism comprises magnetism regulation blocks (4) and non-magnetic packing media (5), the space between every two adjacent magnetism regulation blocks (4) is filled with the non-magnetic packing media (5), and the magnetism regulation blocks (4) and the non-magnetic packing media (5) are arranged integrally in a staggered mode. The converter for the linear motion and the rotary motion has the advantages of being capable of achieving interconversion between the linear motion and the rotary motion and adjusting the relative speed of the linear motion and the rotary motion, free of contact, low in noise, high in efficiency and the like.

Owner:SOUTHEAST UNIV

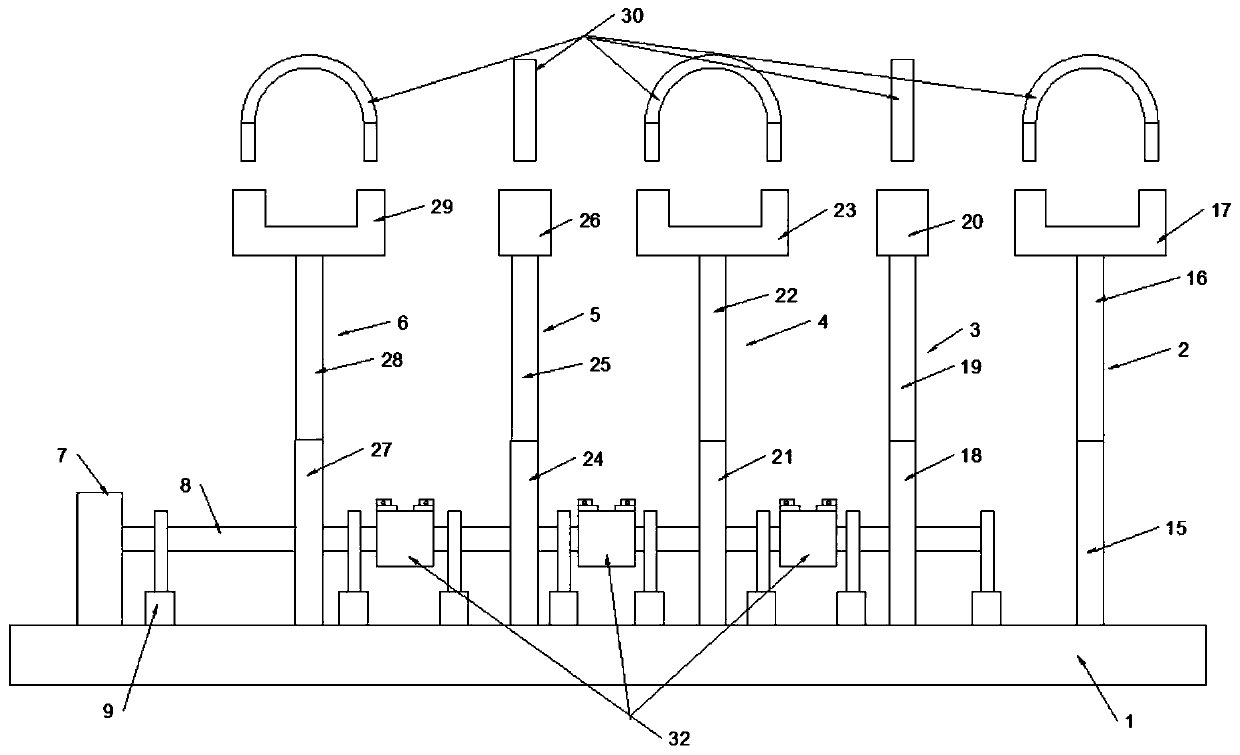

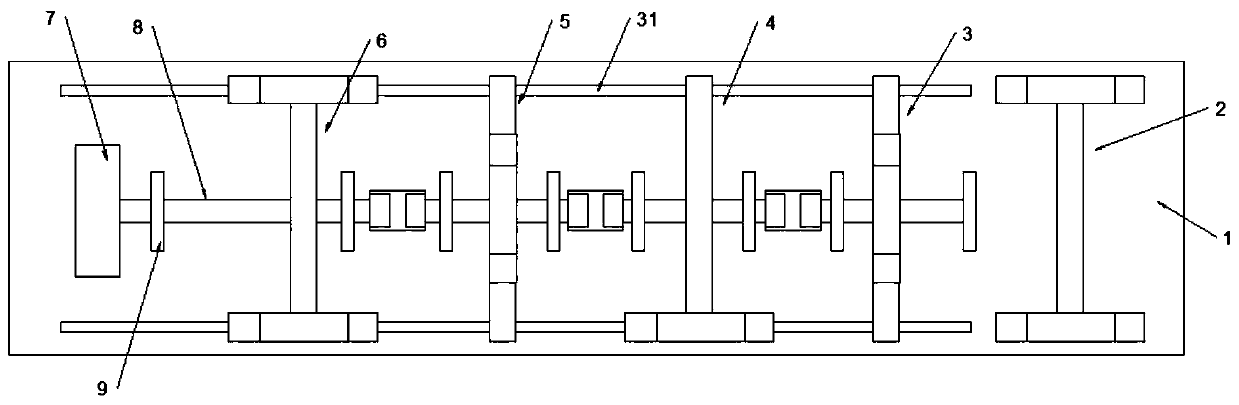

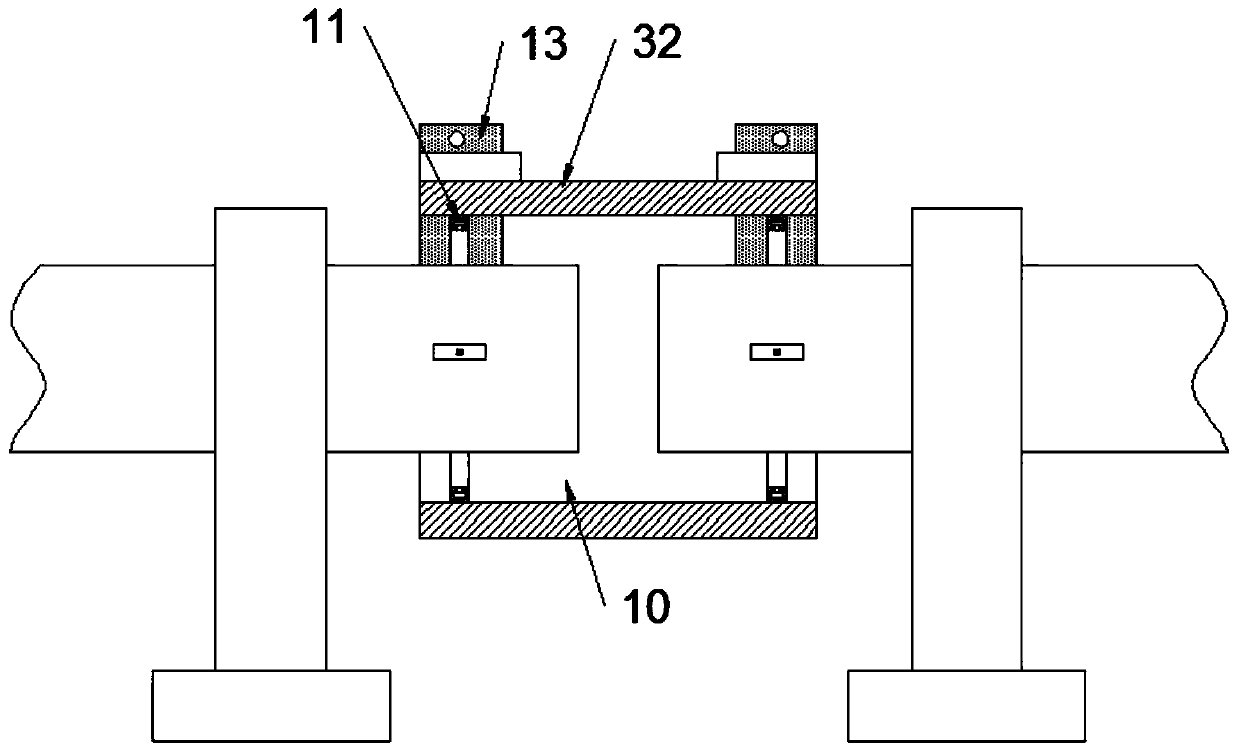

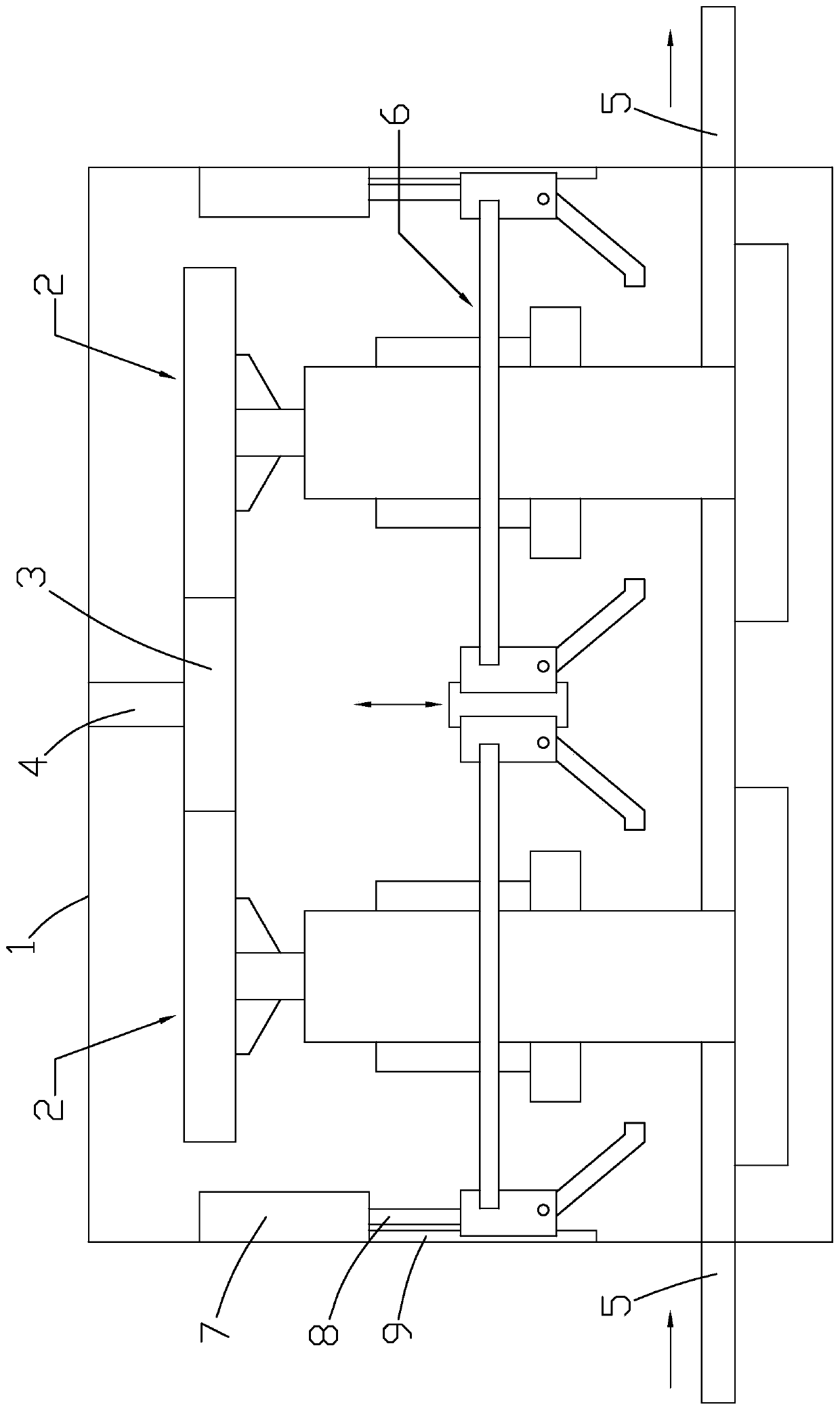

Test bench for tea-picking mechanism of tea garden

ActiveCN104303705AGuaranteed uptimeAccurately adjustable travel speedPicking devicesEngineeringPower output

The invention relates to a test bench for a tea-picking mechanism of a tea garden. The test bench comprises a machine frame, a power source and a traveling mechanism for driving the horizontal movement of the machine frame, wherein the machine frame comprises a left upright column, a right upright column and a crossbeam; a lifting frame and a lifting mechanism are arranged between the left upright column and the right upright column; the lifting mechanism is used for driving the movement of the lifting frame; a mounting port is formed in the front end of the lifting frame; a power output port is formed in the mounting port; a leaf collecting mesh bag which is used for collecting tea leaves picked by the tea-picking mechanism is further arranged on the lifting frame; a fan is arranged on the machine frame; an air supply box body is arranged on the lifting frame; air output by the air supply box body is suitable for blowing the tea leaves picked by the tea-picking mechanism into the leaf collecting mesh bag; the traveling mechanism, the lifting mechanism, the fan and the power output port are driven by a power source respectively. According to the test bench, various factors for influencing the tea-picking quality of a tea-picking machine can be conveniently verified, and the research / development level and the research / development quality of the tea-picking machine are improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Double-cone hydraulic tightening type traction transmission device

InactiveCN102635676ACompact structureLarge transmission rangeFluid gearingsHigh transmissionLoad force

The invention belongs to the technical field of a transmission system, and relates to a traction transmission device, in particular to a double-cone hydraulic tightening type traction transmission device, which comprises an outer friction wheel, an inner friction wheel, one or more than one group of speed control mechanisms and a hydraulic pressing mechanism. When pressure in a hydraulic oil chamber is increased, an inner conical roller and an outer conical roller are respectively matched with a rotating shaft in a sliding way and move inwards along a middle axis, so that the inner friction wheel is contacted with the conical surface of the inner conical roller, and the outer friction wheel is contacted with the conical surface of the outer conical roller. The power transfer function, the stepless speed changing function and the function of loading force control via the friction pair are integrated, and the double-cone hydraulic tightening type traction transmission device has the advantages of simple and compact structure, wide transmission scope, high transmission efficiency, large-scale power transfer, flexible and convenient control and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Iron and steel casting welding slag removal device facilitating welding slag removal

InactiveCN112453802AImprove structural strengthAffect product qualityWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Pinion

The invention discloses an iron and steel casting welding slag removal device facilitating welding slag removal, and relates to the technical field of slag removal devices. The iron and steel castingwelding slag removal device facilitating welding slag removal comprises an operation table, wherein multiple lower stand columns are fixedly connected to the top of the operation table; a base is fixedly connected to the top ends of the multiple lower stand columns; a sliding rail is fixedly connected to the top of the base; a large bevel gear is slidably connected to the top of the sliding rail through a sliding groove; multiple upper stand columns are fixedly connected to the top of the large bevel gear; a supporting disc is fixedly connected to the top ends of the multiple upper stand columns; a clamping part is arranged on the supporting disc; a bevel pinion is engaged with the large bevel gear; a gear shaft is fixedly connected to one side of the bevel pinion; and a power transmissionpart is arranged on the gear shaft. The iron and steel casting welding slag removal device facilitating welding slag removal provided by the invention is reasonable in structure, simple in structureand adjustable in knocking force, the slag removal effect is improved, welding slag does not need to be knocked manually, the labor amount of workers is reduced, and the production speed is increased.

Owner:安徽省含山县伟峰通用配件铸造厂

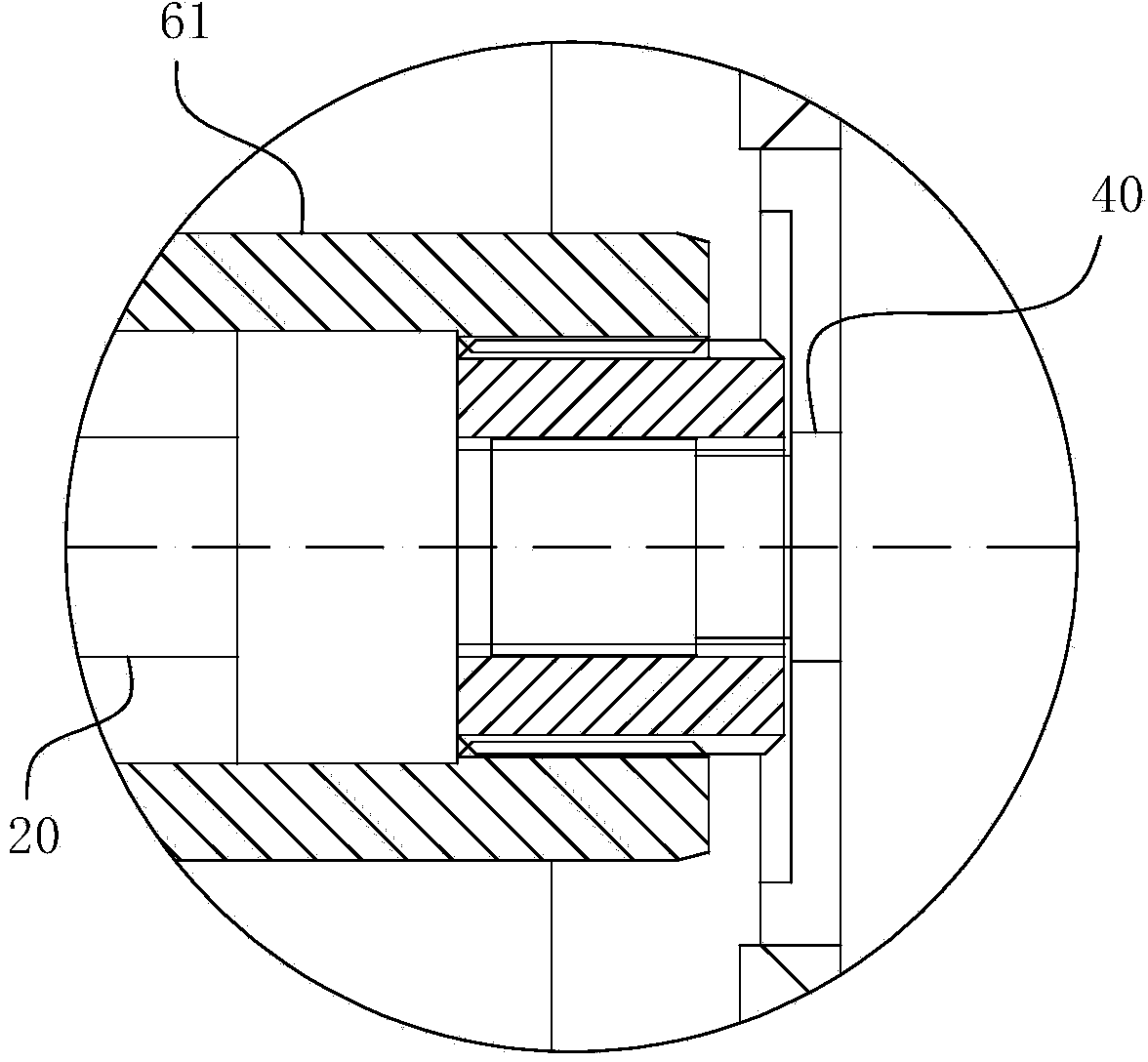

Automobile planetary gear transmission

InactiveCN110281759AAchieve power transmissionAchieve variable speedGas pressure propulsion mountingToothed gearingsEngineeringMechanical engineering

The invention discloses an automobile planetary gear transmission. The automobile planetary gear transmission comprises a split planetary gear set and a compound planetary gear set which are arranged on the same axis. The split planetary gear set comprises a split planetary sun gear, a split planetary ring gear, a split planetary carrier and a plurality of split planetary pinions; the split planetary sun gear is connected to a motor rotor; one end of the split planetary ring gear meshes with the plurality of split planetary pinions and the other end of the split planetary ring gear is separately connected to a second clutch and a third clutch; the plurality of split planetary pinions are supported on the split planetary carrier by bearings; the middle part of the split planetary carrier is connected to a first clutch and a third brake to be a whole through an engine output shaft; and through the engagement or disengagement of a plurality of engagement components and a plurality of braking components, the split planetary gear set and the compound planetary gear set output the rotation of a motor and an engine by speed changing. The automobile planetary gear transmission can reduce the impact of the transmission during gear shifting and improve the comfort of gear shifting.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

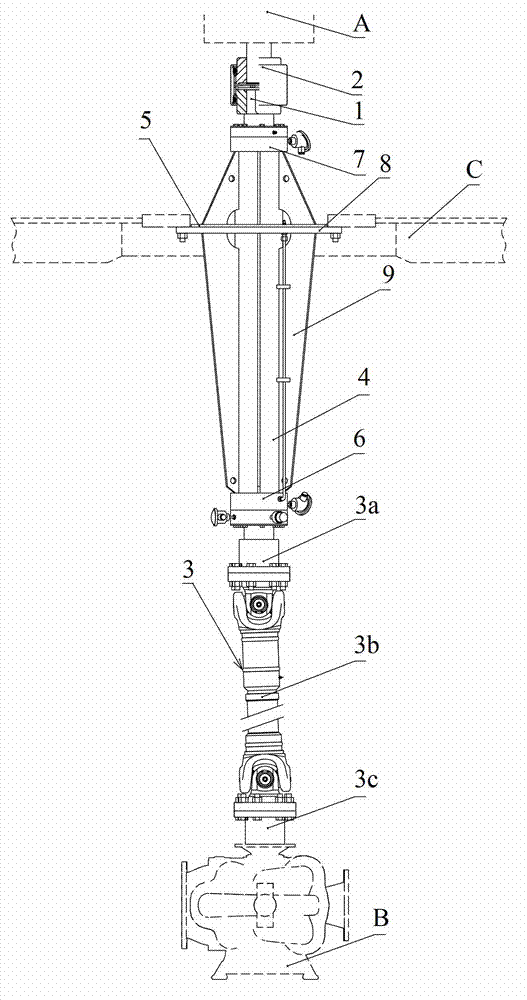

Transmission device

ActiveCN102829164AAchieve power transmissionEffective barrierGear lubrication/coolingDrive shaftEngineering

The invention discloses a transmission device, which belongs to the field of a ship machine. The transmission device comprises a transmission shaft and a sealing component; the sealing component comprises a supporting bushing which is fixed on a separation plate between an engine room and a pump room and a first sealing unit which is arranged on one end of the supporting bushing; the supporting bushing is sleeved on the transmission shaft; the first sealing unit comprises a first bearing, a first bearing seat, a first bearing cover, a first rotary shaft seal and a first sealing cover; the first bearing, the first rotary shaft seal and the first sealing cover are respectively sleeved on the transmission shaft; the first bearing seat is sleeved on the first bearing, and one end of the first bearing seat is connected with one end of the supporting bushing; the first bearing cover is sleeved on the first rotary shaft seal; and one end of the first bearing cover is in sealing connection with the other end of the first bearing seat, and the other end of the first bearing cover is connected with the first sealing cover. Due to the adoption of the transmission device, a turbine motor can be vertically connected with a cargo oil pump.

Owner:WUHAN MARINE MACHINERY PLANT

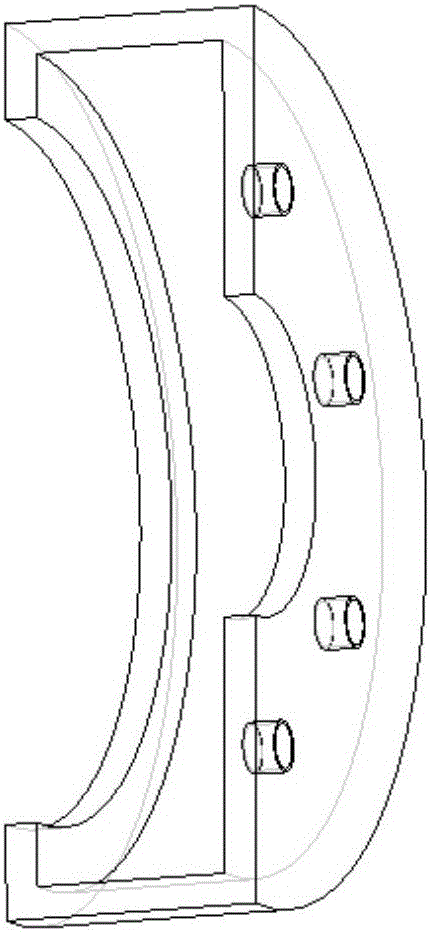

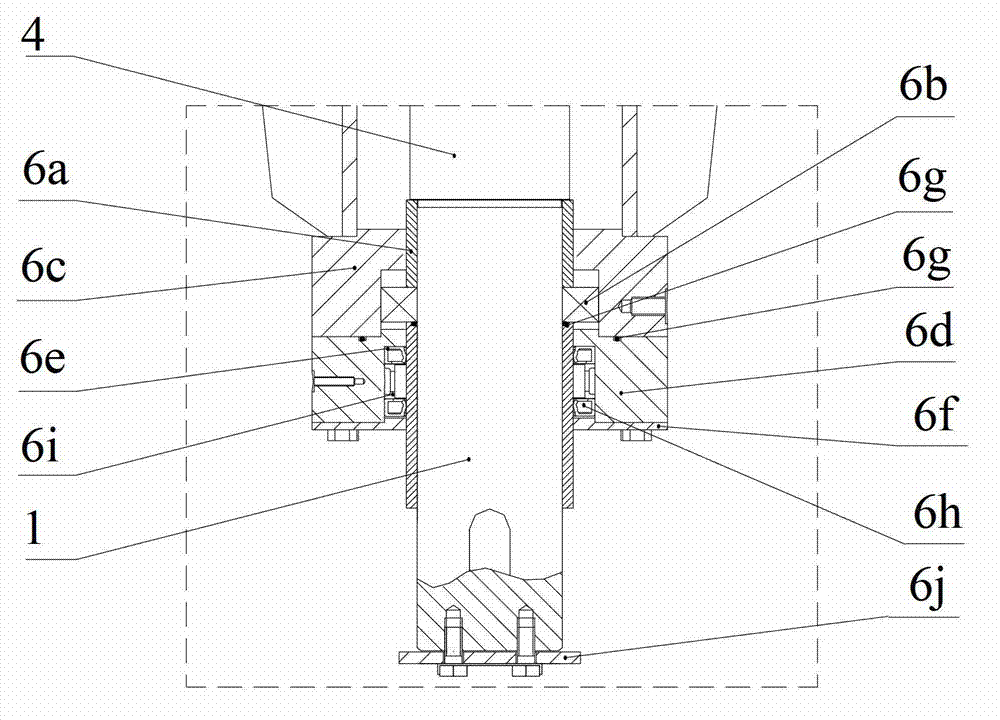

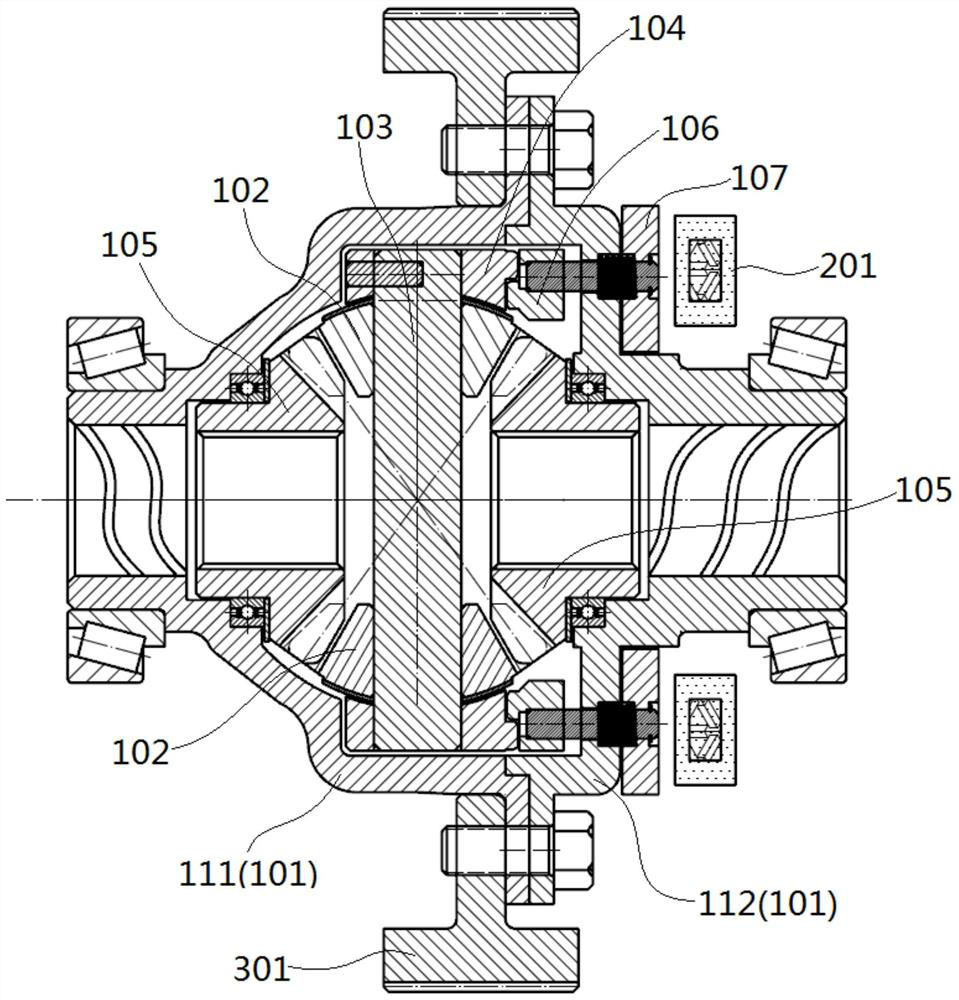

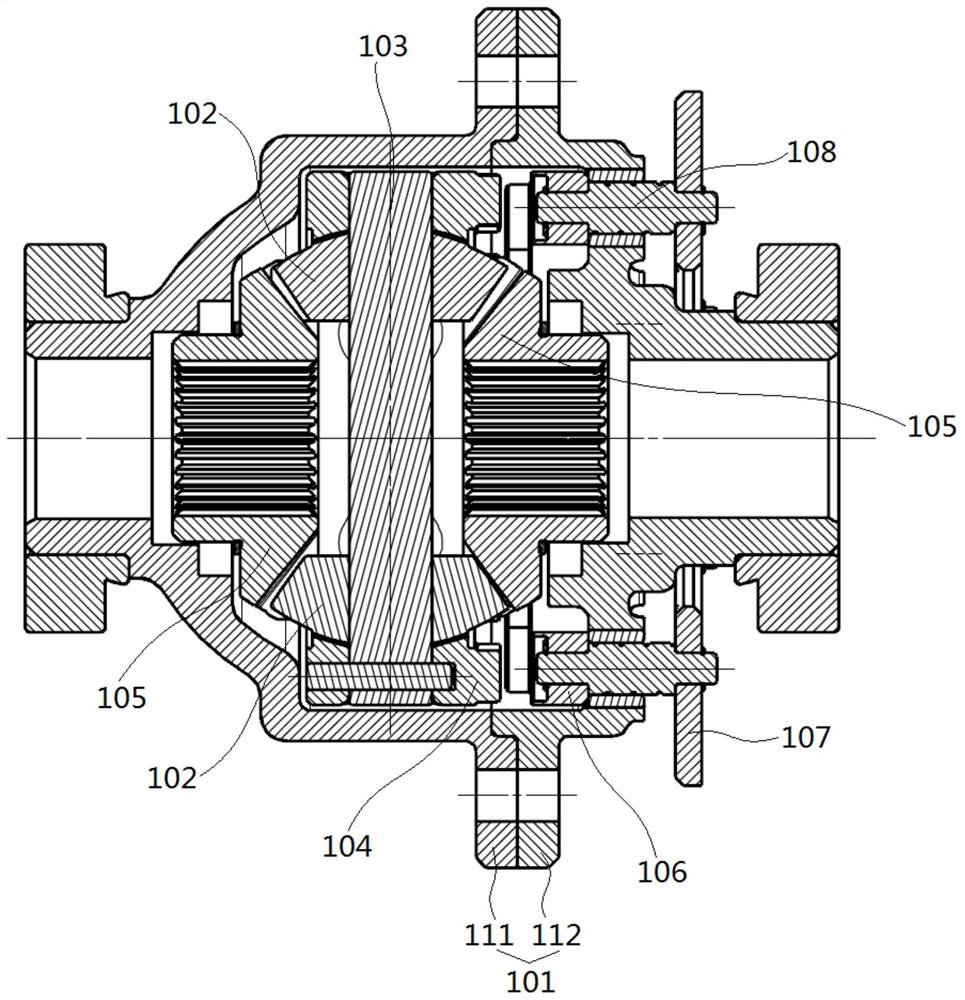

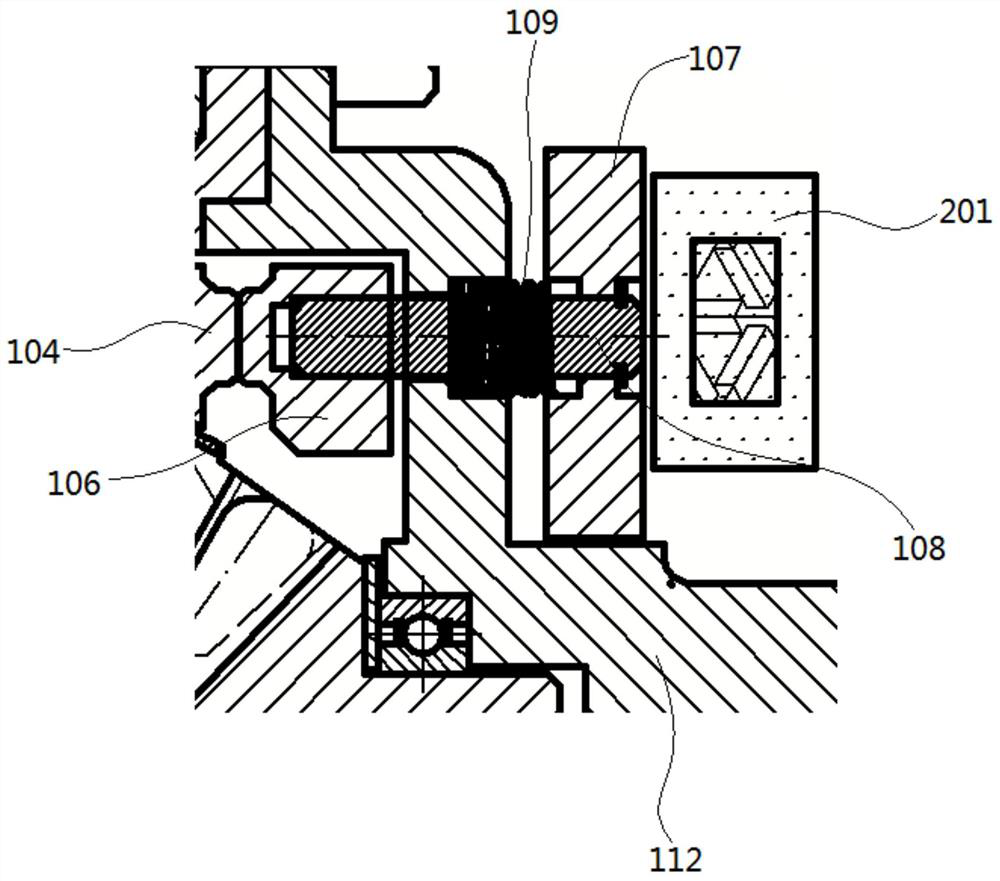

Friction-type coupler

InactiveCN102252047ANo excessive wear and tearAchieve power transmissionSlip couplingFriction clutchesDrive shaftEngineering

The invention relates to a friction-type coupler which comprises a main transmission shaft (3), a friction plate (7), a clutch shell (5), an inner spline connecting sleeve (17) and a device, wherein the device positions the friction plate (7) in axial direction and is subjected to axial spring pressure; when the coupler is started, a friction block (25) is in contact friction with the radial inner surface of the clutch shell (5) under the action of centrifugal force to control the friction between the friction plate (7) and friction rings (6 and11) at the inner side surface of the clutch shell, and power transfer is realized; in overload, the friction plate and the friction rings have friction to cause temperature rise, liquid in an enclosed cavity (12) of the friction plate has temperature rise and expands to force the fraction plate to separate from the friction rings, and then a motor is separated from the load. The friction-type coupler has the advantages of light weight, stable connection, sensitive power transfer, great contact friction force and long-acting effect in use, and the surface temperature of the coupler can be controlled; the over-temperature safety hazard is eliminated thoroughly, and the couple is especially suitable for occasions with the high temperature safety requirement.

Owner:XUZHOU ZHIDIAN ELECTROMECHANICAL EQUIP

Two-stage speed reduction mechanism for speed reducer of pure electric vehicle

The invention relates to a two-stage speed reduction mechanism for a speed reducer of a pure electric vehicle. The two-stage speed reduction mechanism for the speed reducer of the pure electric vehicle comprises a differential mechanism as well as an input shaft, a first auxiliary shaft, a second auxiliary shaft and a middle shaft which are mutually parallel, wherein an input drive gear is fixed to the input shaft; a first driven gear and a one-way overrunning clutch are fixedly arranged in the circumferential direction of the first auxiliary shaft; a second auxiliary shaft clutch and a synchronizer are fixedly arranged in the circumferential direction of the second auxiliary shaft; the first driven gear and a gear of the second auxiliary shaft clutch are co-engaged with the input drive gear; a first drive gear is arranged on the first auxiliary shaft in a manner of slide fit; the first drive gear is connected with the first auxiliary shaft through the one-way overrunning clutch; a reverse gear and an output gear are arranged on the second auxiliary shaft in a manner of slide fit separately; the reverse gear and a second gear are located at the two sides of the synchronizer separately; the second gear is engaged with a differential mechanism input gear of the differential mechanism; a first driven gear and a transmission gear are fixedly arranged on the middle shaft; the firstdriven gear is co-engaged with the first drive gear and the reverse gear; and the transmission gear is engaged with the second gear.

Owner:CHONGQING TSINGSHAN IND

Tea Garden Tea Picking Institution Test Bench

ActiveCN104303705BGuaranteed uptimeAccurately adjustable travel speedPicking devicesEngineeringTea leaf

The invention relates to a test bench for a tea-picking mechanism of a tea garden. The test bench comprises a machine frame, a power source and a traveling mechanism for driving the horizontal movement of the machine frame, wherein the machine frame comprises a left upright column, a right upright column and a crossbeam; a lifting frame and a lifting mechanism are arranged between the left upright column and the right upright column; the lifting mechanism is used for driving the movement of the lifting frame; a mounting port is formed in the front end of the lifting frame; a power output port is formed in the mounting port; a leaf collecting mesh bag which is used for collecting tea leaves picked by the tea-picking mechanism is further arranged on the lifting frame; a fan is arranged on the machine frame; an air supply box body is arranged on the lifting frame; air output by the air supply box body is suitable for blowing the tea leaves picked by the tea-picking mechanism into the leaf collecting mesh bag; the traveling mechanism, the lifting mechanism, the fan and the power output port are driven by a power source respectively. According to the test bench, various factors for influencing the tea-picking quality of a tea-picking machine can be conveniently verified, and the research / development level and the research / development quality of the tea-picking machine are improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

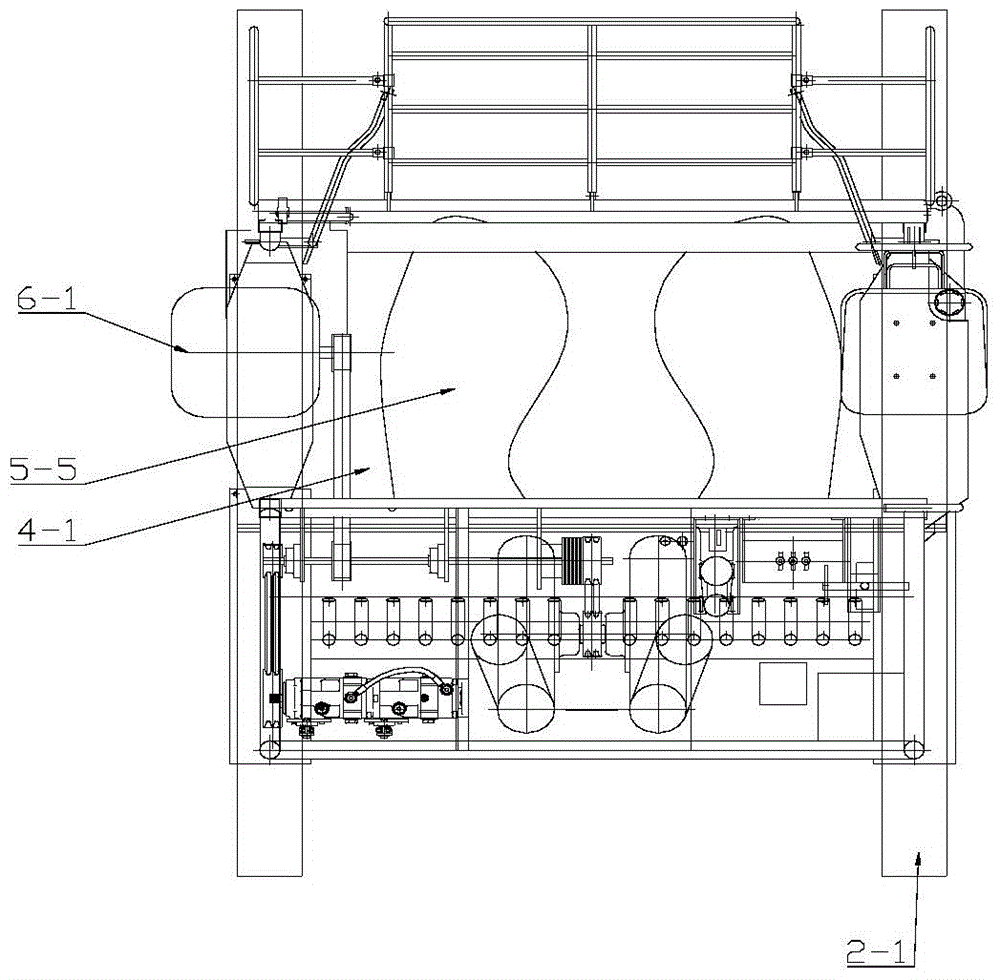

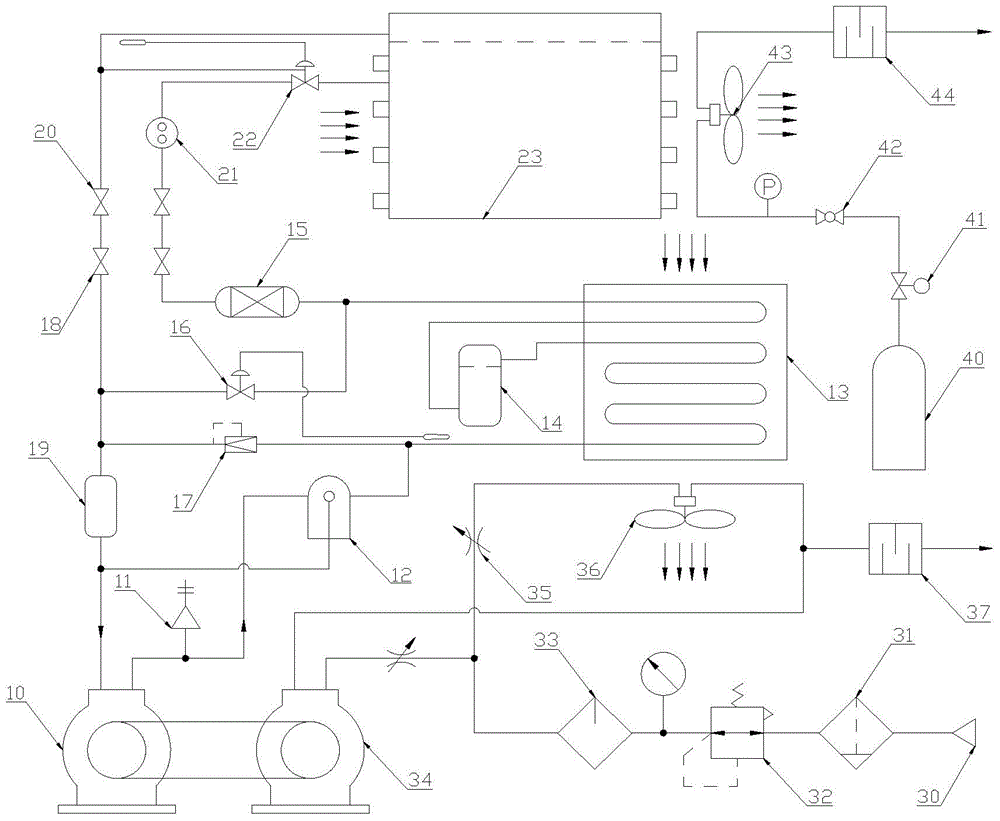

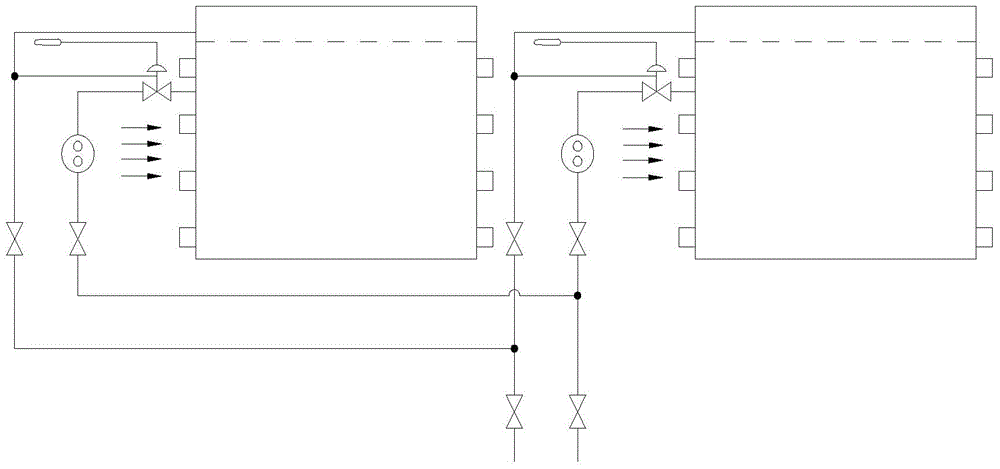

Pneumatic ice storage air conditioning device for downhole rescue

InactiveCN103982965AImprove securityAvoid flashLighting and heating apparatusAir conditioning systemsAutomatic controlAir filter

The invention discloses a pneumatic ice storage air conditioning device for downhole rescue. The pneumatic ice storage air conditioning device comprises a mechanical refrigeration module consisting of a compressor, a safety valve, an oil separator, a condenser, a liquid storage device, a drying filter, a liquid spraying valve, a thermal bypass valve, a gas-liquid separator, a stop valve and the like, an ice storage box module consisting of liquid sight glass, a thermal expansion valve, an ice storage box, a stop valve and the like, a gas path module consisting of a compressed air source, an air filter, a pressure release valve, an atomized lubricator, a pneumatic motor, a flow adjustment valve, a pneumatic condensation fan, a muffler and the like, and a cold release module of a compressed air steel bottle, an adjustment hand valve, a pressure adjuster, a pneumatic fan, a muffler and the like. The pneumatic ice storage air conditioning device for downhole rescue is high in refrigeration efficiency; downhole compressed air is used as an air source, and no power supply is needed in a working process; a refrigeration system adopts a supercooling design; the system can realize continuous running, and a press does not need to be automatically controlled to be switched on and switched off; the compressor is connected with the pneumatic motor through a belt in a transmission manner; the pneumatic ice storage air conditioning device is high in assembling efficiency, and the transmission ratio is controllable.

Owner:合肥天鹅制冷科技有限公司

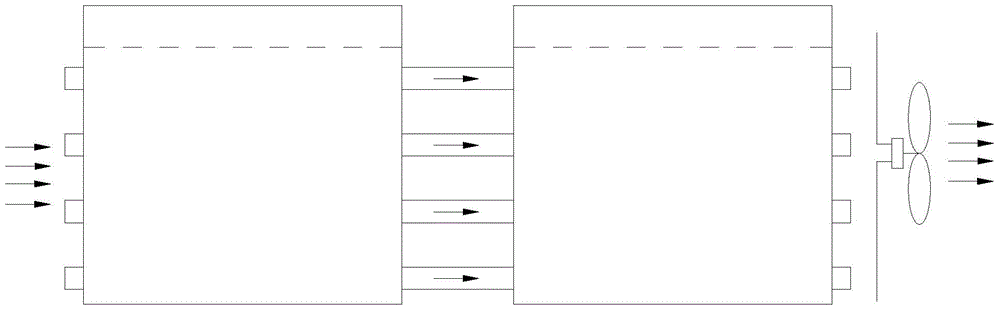

Polygonatum sibiricum red. harvesting and processing production line

ActiveCN111780525AImprove processing efficiencyImprove processing outputDrying gas arrangementsDrying solid materialsProcess engineeringAir blower

The invention discloses a polygonatum sibiricum red. harvesting and processing production line. The polygonatum sibiricum red. harvesting and processing production line involves air-drying equipment,drip washing equipment and steaming and drying equipment, wherein the air-drying equipment comprises an air-drying box body, an air-drying cylinder body, a plurality of hot air blowers, a vibrating screen and an air-drying feeding assembly, the drip washing equipment comprises a drip washing box body, a plurality of drip washing nozzles, a spiral conveyor and a drip washing filter screen, the steaming and drying equipment comprises a steaming box body, a drying box body, a pair of guide rails, a plurality of guide plates and a drying and feeding assembly. Mechanical operation in the whole process from harvesting to rough machining to finish machining can be achieved, the machining efficiency and yield are improved, and the product quality is improved.

Owner:西藏天虹科技股份有限责任公司

A magnetic rotary pick-and-place device

ActiveCN104476543BSimple structureImprove adsorption capacityProgramme-controlled manipulatorGripping headsEngineeringNon magnetic

The invention relates to the technical field of electronic product assembly and provides a magnet attraction rotation picking and placing device. The device comprises a fixing plate. A product fixing mechanism and a product rotation picking and placing mechanism are arranged on the fixing plate. The product fixing mechanism comprises a first air cylinder, a first connection plate and a plurality of non-magnetic ejection rods. The product rotation picking and placing mechanism comprises a picking and placing unit and a rotation unit. The picking and placing unit comprises a second air cylinder, a second connection plate and a plurality of first through holes corresponding to the non-magnetic ejection rods. Corresponding torsion blocks are arranged on the sides of the upper ends of the first through holes close to the first connection plate. Hollow magnet absorption rods for penetrating the non-magnetic ejection rods are arranged in the first through holes, the upper ends of the magnet absorption rods are fixedly connected with the torsion blocks, the lower ends extend to the sides away from the torsion blocks, and the torsion blocks are connected with rotation units controlling the circumference rotation of the torsion blocks, accordingly, a plurality of magnetic products are attracted simultaneously and are put down when rotating to preset angles. According to the device, the structure is simple, power connection is not needed, an air source is used as power, the absorption is firm, and the service life is long.

Owner:GOERTEK INC

Pipe cutting machine

InactiveCN104551198BImprove cutting accuracyImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a pipe cutting machine. The pipe cutting machine comprises a base, a pipe cutting tool and a motor, wherein the base is provided with a clamping device which is used for clamping a pipe to be cut and can be used for driving the pipe to rotate about the longitudinal axis of the pipe; the pipe cutting tool can move relative to the base; the motor is used for supplying power to the pipe cutting tool; the motor is fixedly arranged on the base; the rotating axis of the motor is parallel to the rotating axis of the pipe cutting tool; the pipe cutting tool can move close to or far away from the pipe to be cut. By adopting the pipe cutting machine disclosed by the invention, the space occupied in the vertical direction can be reduced greatly, so that the application range is enlarged. Moreover, the pipe to be cut is driven to rotate automatically, and the cutting tool does not rotate about the pipe to be cut, so that the operation difficulty of the pipe cutting machine can be lowered, and the use safety is enhanced.

Owner:EMERSON PROFESSIONAL TOOLS SHANGHAI

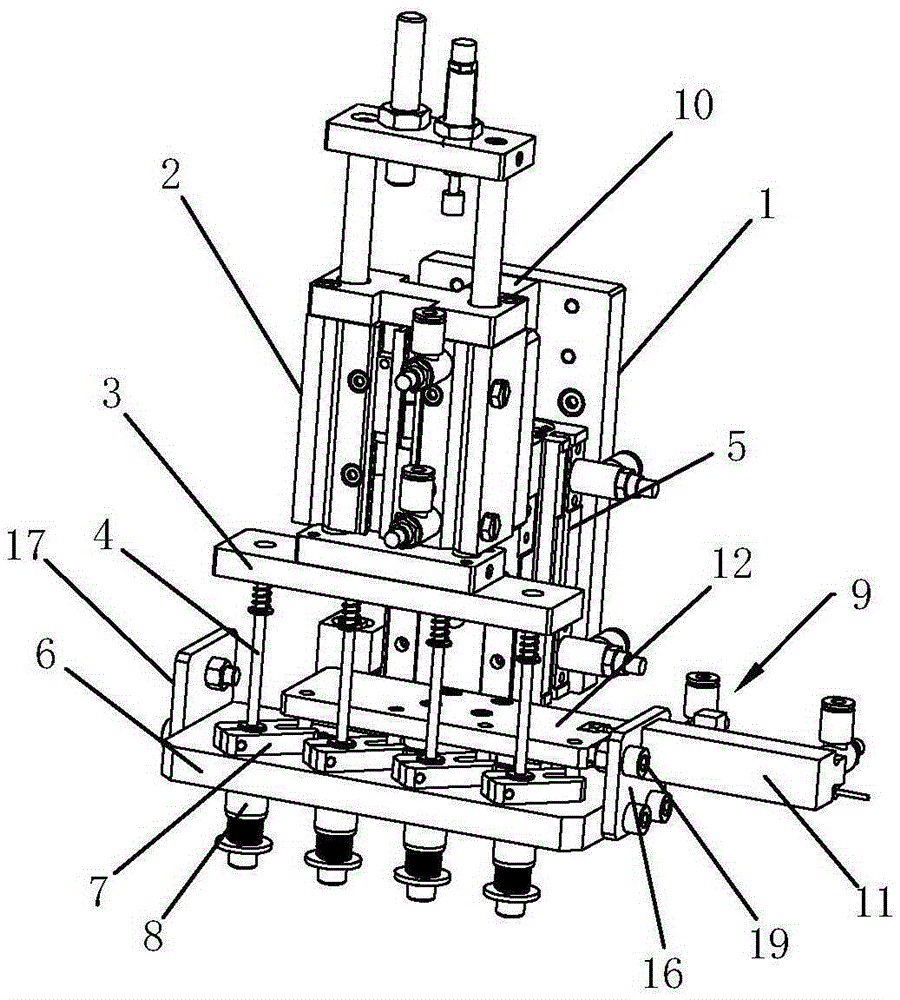

Cam box structure of material transferring mechanism for battery shell stamping

PendingCN108506442ASimple structureReduce volumeCamsMetal-working feeding devicesPunch pressDrive shaft

The invention discloses a cam box structure for a material transferring mechanism for battery shell stamping. The cam box structure comprises a box body, a drive shaft is rotatably connected to the box body, and a cam with a disc-shaped structure is fixedly connected to the drive shaft; the outer edge of the cam is a curved contour, the cam is eccentrically arranged on the drive shaft, and the eccentricity distance is equal to the step distance of a progressive die; the cam is horizontally arranged in a box body, a sliding connection plate is slidably connected in the box body, the sliding connecting plate is horizontally arranged, and the sliding connecting plate is located at the lower part of the cam; a first bearing and a second bearing are arranged on the positions, on both sides of the cam, on the upper end surface of the sliding connecting plate; and when in operation, the curved contour of the cam meshes with one of the first bearing and the second bearing. The cam box structure has the characteristics of small volume and simple structure, the cam box adopting the cam box structure can realize transmission of power between a spindle of a punch press and the cam box only bya vertically arranged transmission shaft, and the structure is greatly optimized.

Owner:无锡市金杨新材料股份有限公司

Vehicle type rear axle and leaf spring subpackaging tool

The invention provides a vehicle type rear axle and leaf spring subpackaging tool. The vehicle type rear axle and leaf spring subpackaging tool comprises a base, a fixed supporting piece, a first movable supporting piece, a second movable supporting piece, a third movable supporting piece and a fourth movable supporting piece, and further comprises a motor, four collinearly-arranged lead screws and the connecting blocks connected between every two adjacent lead screws. A motor shaft of the motor is connected with one ends of the lead screws located at a straight end, the cylindrical containingcavities used for containing the ends of every two adjacent lead screws are formed at the two ends of the connecting block, and an annular sliding groove is coaxially fixed in the cylindrical accommodating cavity; an abutting plate is further fixed to each lead screw, a sliding block capable of sliding in the sliding groove is arranged at the end of the abutting plate, and three sets of through grooves communicating with the cylindrical containing cavity are further formed on the connecting block. The distance between every two adjacent through grooves is the same as the width of the slidingblock, and the limiting plates can be inserted into the through grooves towards the upper cylindrical containing cavity. The vehicle type rear axle and leaf spring subpackaging tool can subpackage various vehicle type rear axles and leaf springs, is simple in structure and lower in processing cost.

Owner:国唐汽车有限公司

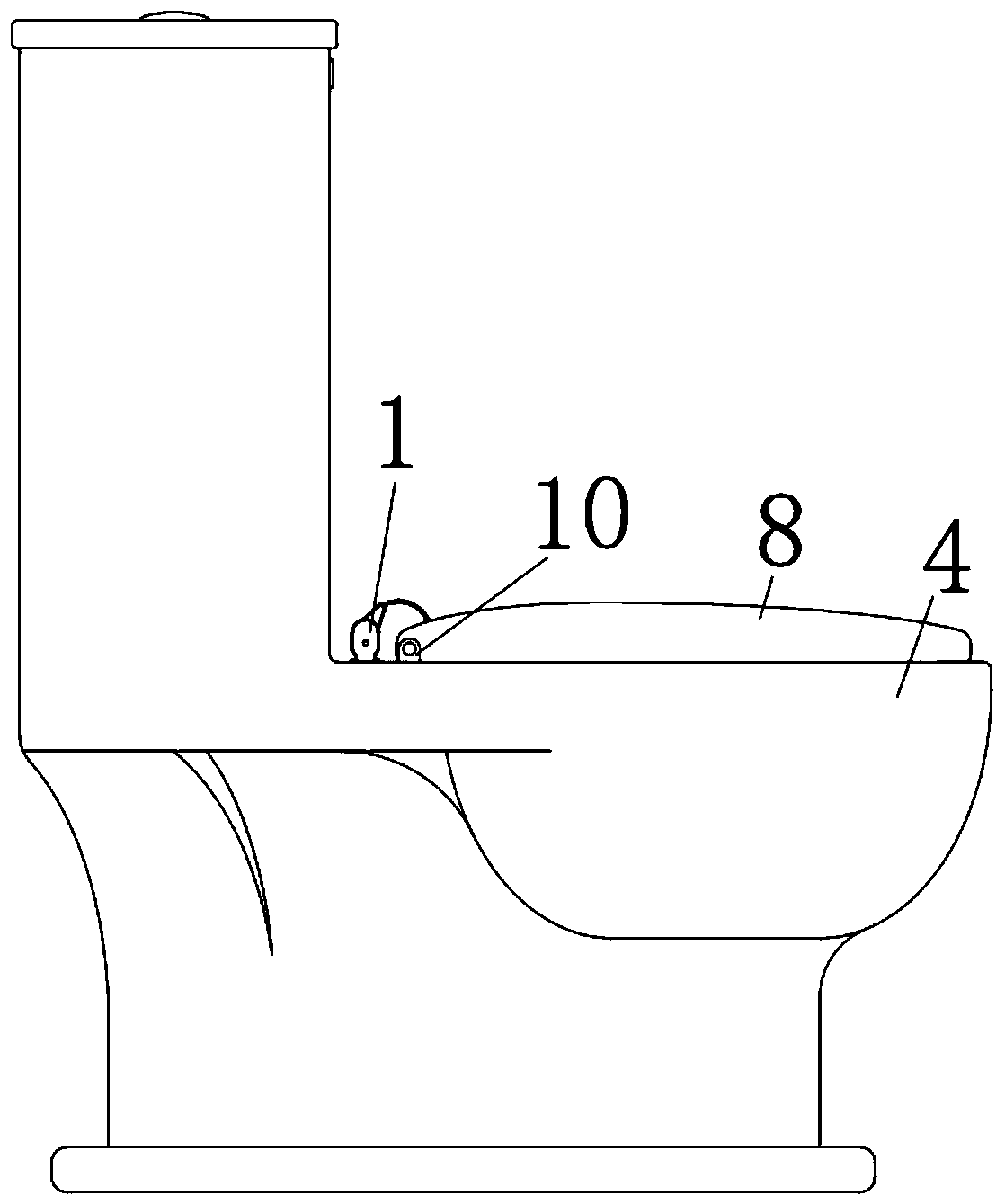

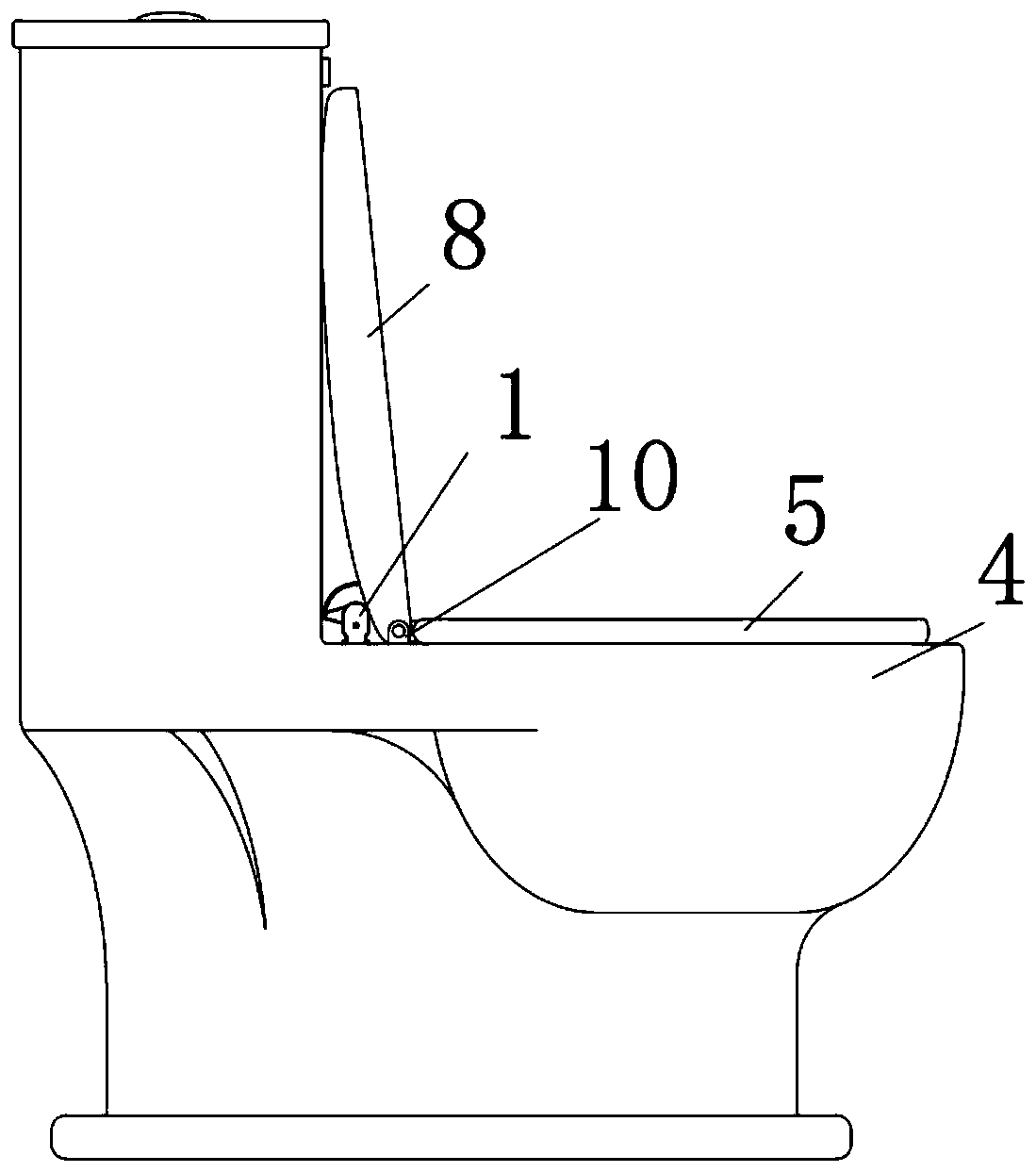

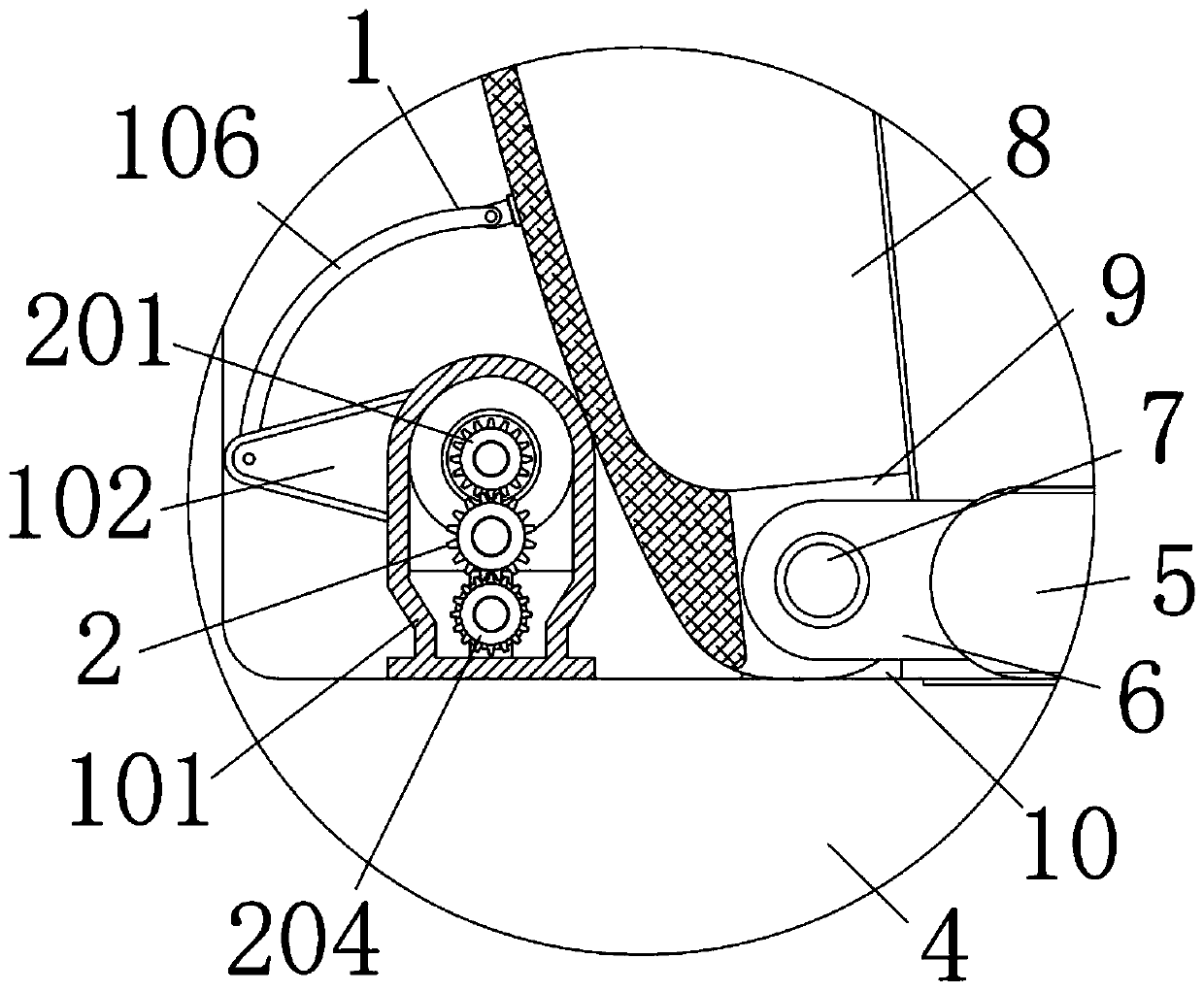

Closestool capable of automatically flushing and closing closestool cover

ActiveCN111287281AAvoid contactImprove hygieneFlushing devicesBathroom coversEngineeringStructural engineering

A closestool capable of automatically flushing and closing a closestool cover comprises an automatic flushing closestool body, the upper surface of the automatic flushing closestool body is covered with a cushion, two rotating shafts are movably connected with a shell through bearings, the left end of a first connecting shaft and the right ends of the rotating shafts are integrally formed, and a wiring hole is formed in the position, close to the right side, of the bottom of the shell. According to the invention, the shell, an eccentric push block, the rotating shaft, the first connecting shaft and the connecting rod are matched; the closestool cover can rotate by taking the third connecting shaft as an axis under the action of the eccentric push block; the connecting rod is dragged to move to enable the closestool cover to move along with the connecting rod, so the closestool cover can be automatically opened and closed, a user is prevented from making contact with the closestool cover, sanitation is improved, the falling speed of the closestool cover during automatic closing is low under the action of the rubber sleeve on the outer wall of the third connecting shaft, and damage caused by too fast falling of the closestool cover is avoided.

Owner:BRAUN (CHINA) SANITARY WARE CO LTD

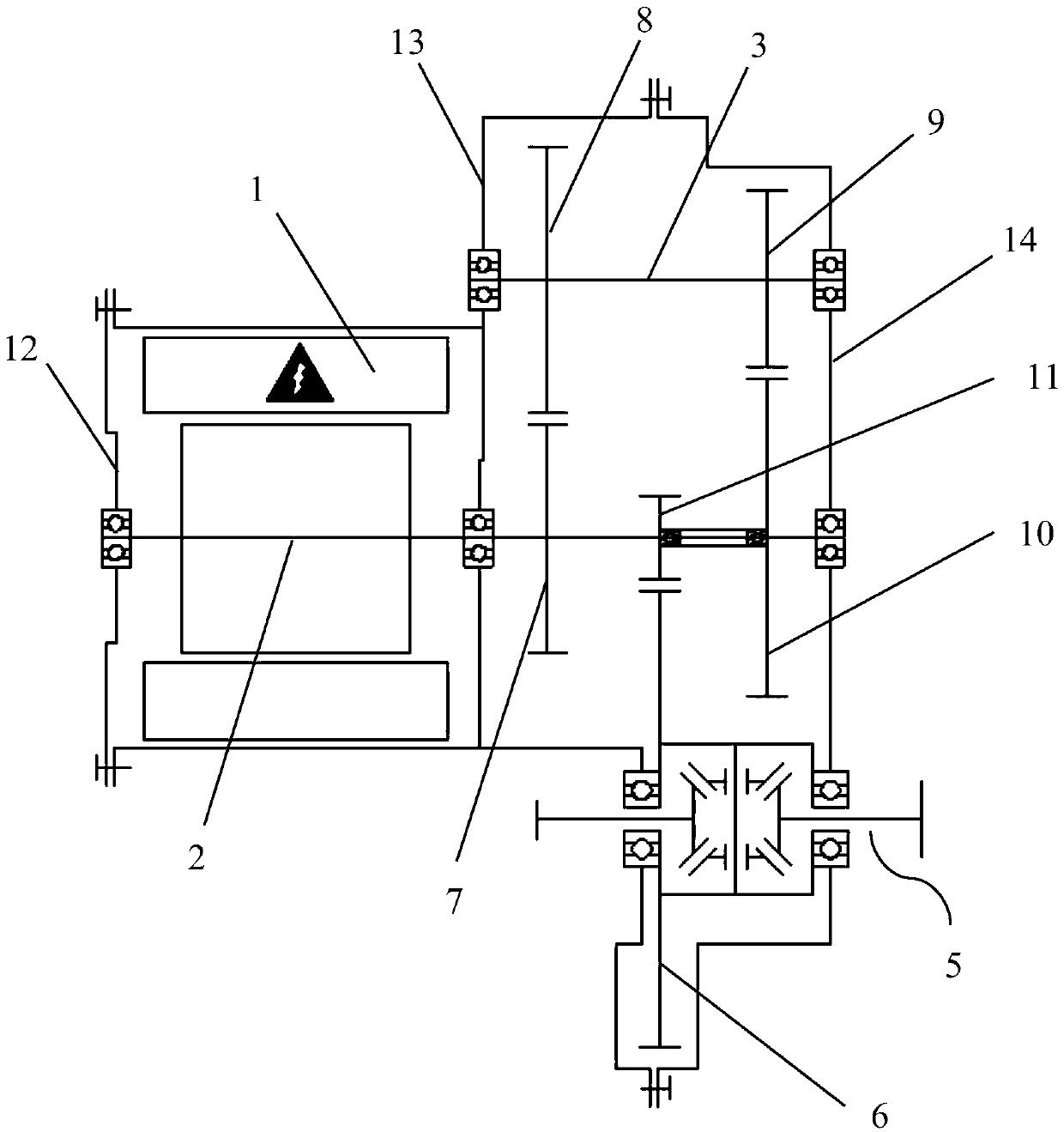

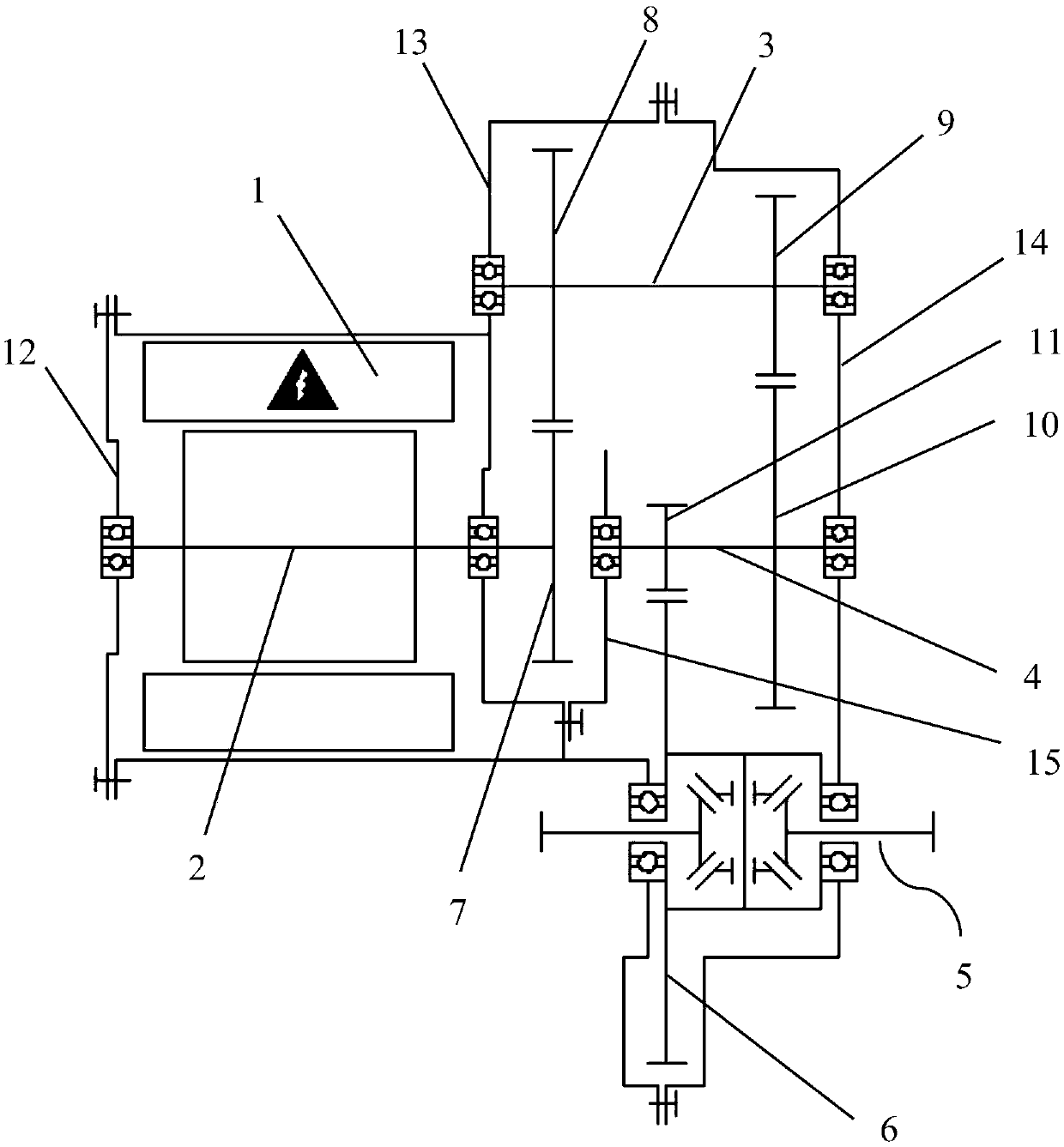

Electric bridge driving system and vehicle

PendingCN110901358ALow costImprove transmission efficiencyElectric propulsion mountingControl devicesGear wheelElectric machinery

The invention relates to an electric bridge driving system and a vehicle. The electric bridge driving system comprises a motor (1), a speed changer, a differential mechanism (5) and a system shell surrounding the electric bridge driving system. The transmission can transmit power of the motor to the differential mechanism (5). The transmission is provided with a motor shaft (2) connected with themotor. The differential mechanism (5) is provided with a driven gear (6) serving as a power input end; wherein the transmission further comprises an intermediate shaft (3) parallel to the motor shaft(2), a first gear (7) is arranged on the motor shaft in an anti-torque manner; a second gear (8) and a third gear (9) are arranged on the intermediate shaft in an anti-torque manner; a fourth gear (10) and a fifth gear (11) which are connected to each other in a rotationally fixed manner are also provided in the transmission, the first gear and the second gear meshing with each other, the third gear and the fourth gear meshing with each other, and the fifth gear and the driven gear meshing with each other, the electric machine and the differential being arranged biased, and the vehicle has thebridge drive system according to the invention.

Owner:SCHAEFFLER TECH AG & CO KG

Automatic liquid supply device

The invention discloses an automatic liquid supply device comprising a base, wherein the upper part of the base is provided with a liquid tank; the lower part of the liquid tank is provided with a liquid outlet mouth; the lower part of the base is provided with a pump body matched with the liquid outlet mouth; an inner cavity of the tail of the pump body is matched with a piston in a sliding way; the tail end of the piston is provided with a link; the lower part of the base is also matched with a motor; the motor is driven by a gearbox and has a lever; the lever is connected with the link and is used for controlling the reciprocating operation of the piston; the power transmission is realized by a lever principle; the automatic liquid supply device has simple structure and stable operation; the lever can achieve the purpose of regulating a linear motion distance by regulating a center distance; the linear motion distance is not limited by an eccentric distance of an eccentric wheel any more; the lever has strong suitability; the regulation of the center distance of the lever is beneficial to reducing power loss; a sealing gasket is configured for completely sealing a space between the pump body and the liquid outlet mouth and enhancing the cleanness of an appliance; a spherical ball rotates flexibly and is difficult to block; and the normal close of the liquid outlet mouth is finally realized by an elastic principle, thereby enhancing the cleanness of a surrounding environment.

Owner:沈海桥

Multifunctional transmission case of agricultural vehicle

InactiveCN104373563AAchieve power transmissionImplement gear changesGearing detailsEngineeringMultiple function

The invention provides a multifunctional transmission case of an agricultural vehicle. The multifunctional transmission case comprises a case body. A power input shaft is arranged in the case body and penetrates through the case body, the input end is connected with a power device, and the output end extends outwards to be connected with a belt pulley so that power can be transmitted outwards. The input shaft is provided with a gear a which is arranged on the input shaft in a non-contact sleeving mode. The input shaft is further fixedly provided with a combination gear which can be meshed with the upper end face of the gear a, the gear a is meshed with a gear b which is arranged on a motor output shaft, and the motor output shaft is parallel to the input shaft. A combination gear hub and a combination gear sleeve are fixedly arranged at the upper portion of the input shaft. A driving power gear c and a driving power gear d are arranged above and below the combination gear hub and the combination gear sleeve respectively. The driving power gear c and the driving power gear d are arranged on the input shaft in a non-contact sleeving mode. The driving power gear c is meshed with a driven power gear e which is arranged on an output shaft parallel to the input shaft, and the output shaft and the motor output shaft are axially arranged on the same straight line.

Owner:CHONGQING XIANYOU TECH DEV

Differential mechanism and automobile transmission system with same

PendingCN113494583AAchieve power transmissionImprove battery lifeGear lubrication/coolingGearing controlGear wheelDriving mode

The invention discloses a differential mechanism and an automobile transmission system with the same. The differential mechanism comprises a shell and two planet gears located in the shell, and further comprises a planet carrier and a driven ring, the planet carrier and the driven ring are located in the shell, and the planet carrier and the driven ring are provided with meshing teeth matched with each other; and the driven ring is connected with the shell and can move relative to the shell to be close to or away from the planet carrier. The two planet gears are fixedly connected with the planet carrier through planet gear shafts; and the differential mechanism further comprises a driving unit, which is used for driving the driven ring to move close to the planet carrier so as to be meshed with the planet carrier or driving the driven ring to move away from the planet carrier so as to be separated from the planet carrier. The differential mechanism is a differential mechanism with a disengaging mechanism. When an automobile is switched from a four-wheel-drive mode to a two-wheel-drive mode, power of a power source is cut off through disengaging of the disengaging mechanism of the differential mechanism, such that only part of the structure of the differential mechanism needs to be driven when wheels rotate and are reversely dragged, rotational inertia is small, and energy consumption is low.

Owner:LIUZHOU WULING MOTORS +1

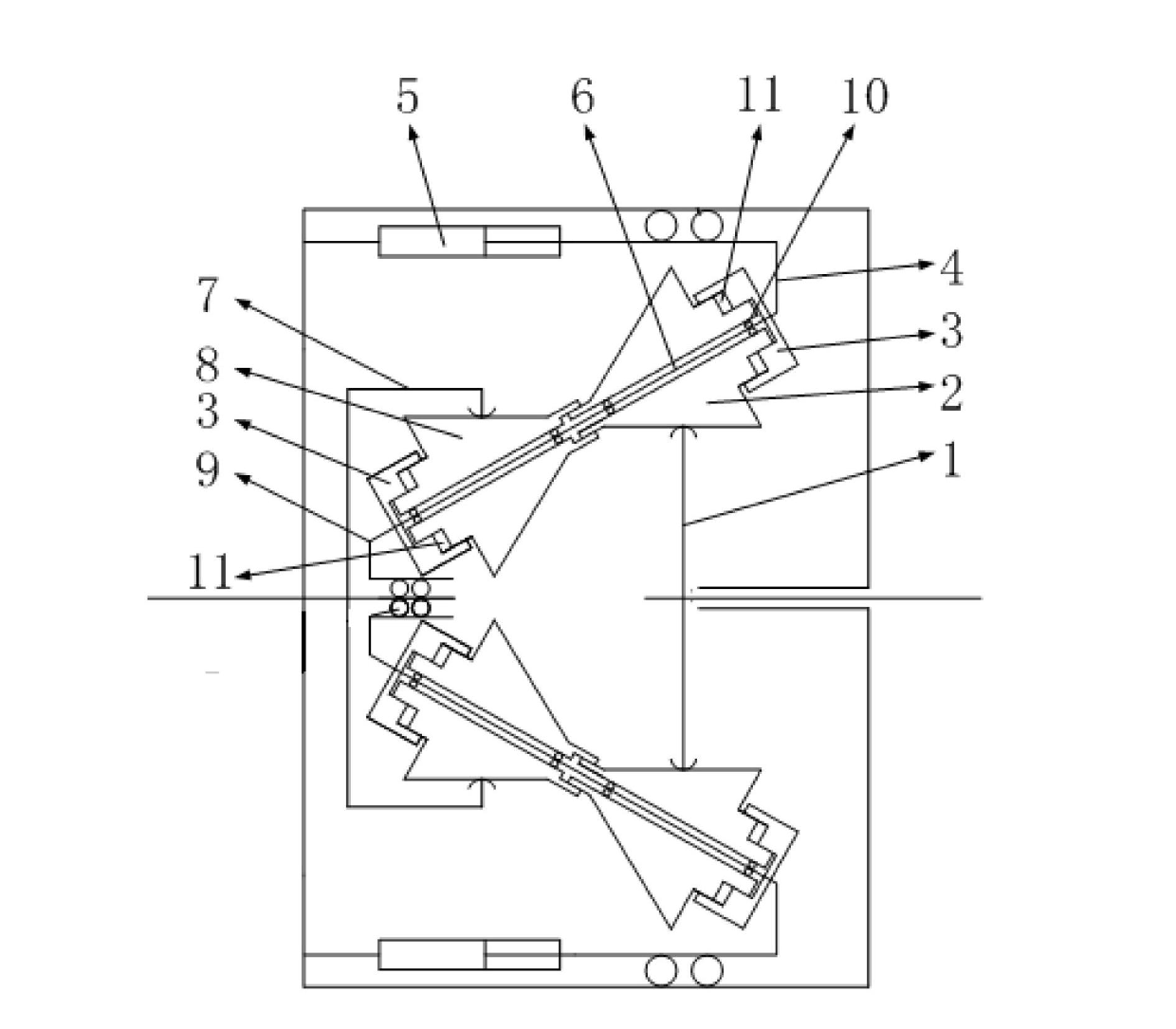

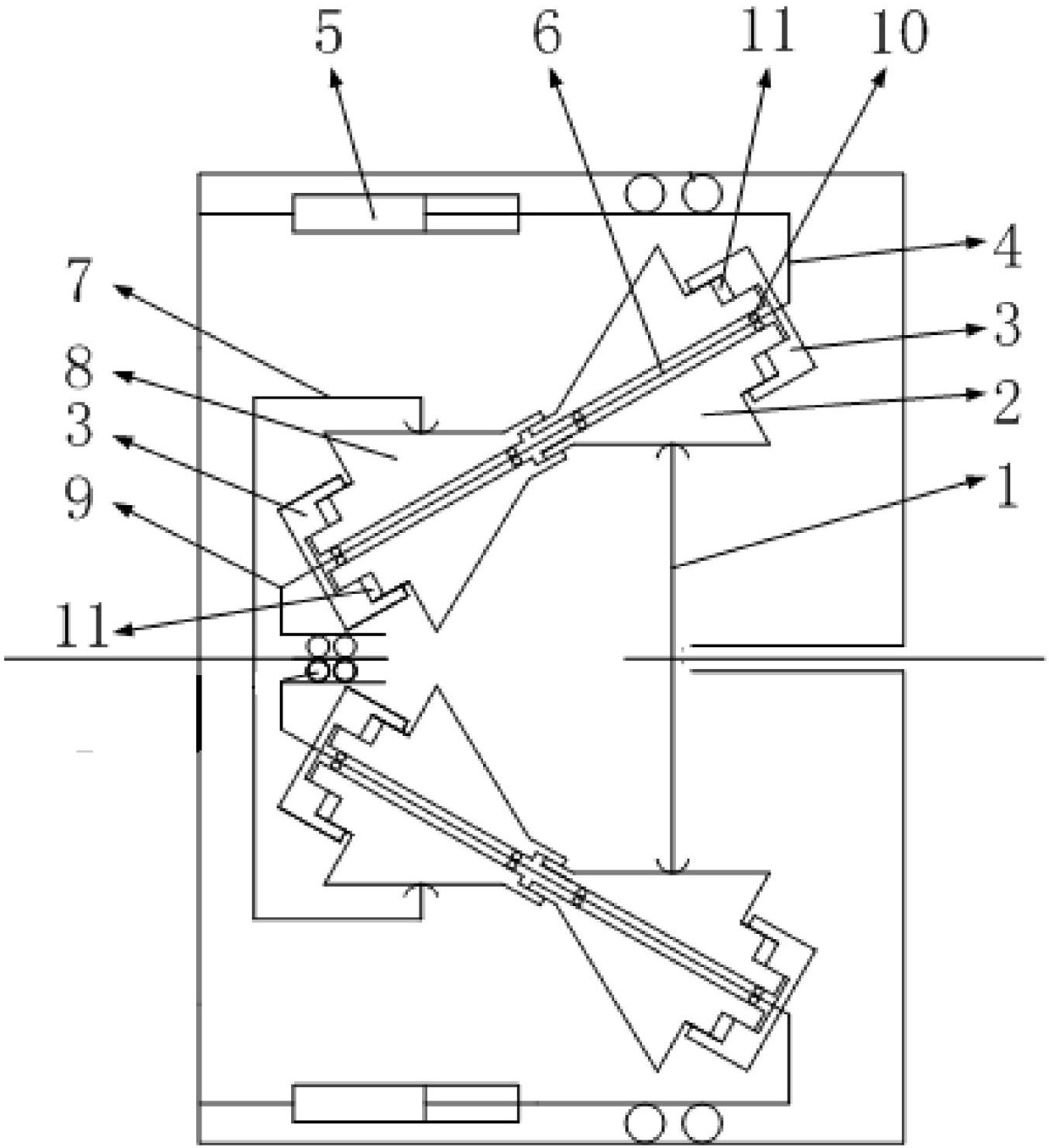

Punching device used for production of pipe molds

ActiveCN110340225AImprove connection strengthImprove connection stabilityShaping toolsHydraulic cylinderPunching

The invention discloses a punching device used for production of pipe molds. The punching device used for production of the pipe molds comprises a box. Two punching mechanisms and a mold positioning mechanism are arranged in the box. The two punching mechanisms are arranged horizontally and are connected through a connecting gear. The connecting gear is connected to the top of the box through a stand column. The mold positioning mechanism is connected to the inner side face of the box in a vertical moving mode through a guide rail. A hydraulic cylinder is arranged on the inner side face of thebox and is located above the guide rail. The hydraulic cylinder is connected with the mold positioning mechanism through a piston rod. The punching device is simple in structure and high in practicability; secondary punching formation of the pipe molds can be achieved, the punching process is simplified, and the punching formation efficiency is improved; and in addition, power transmission between the two punching mechanisms can be achieved, and when the punching mechanism on one side is started, the punching mechanism on the other side can be driven to work, so that continuous production ofthe pipe molds is ensured.

Owner:佛山市顺德区捷壕实业有限公司

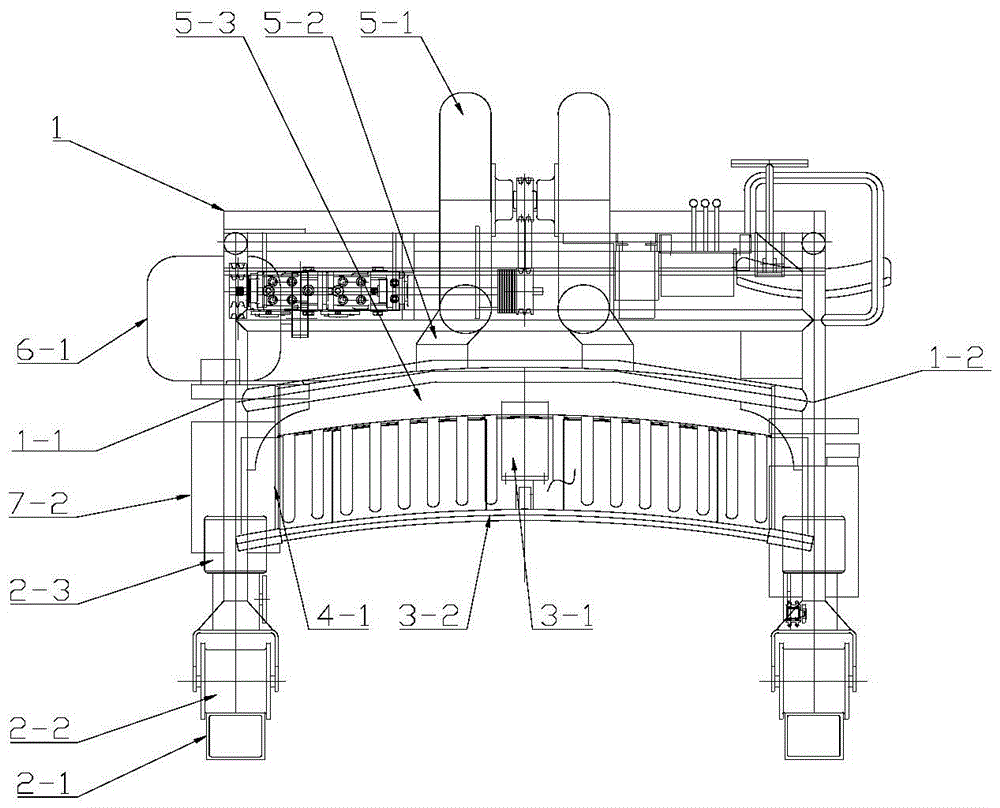

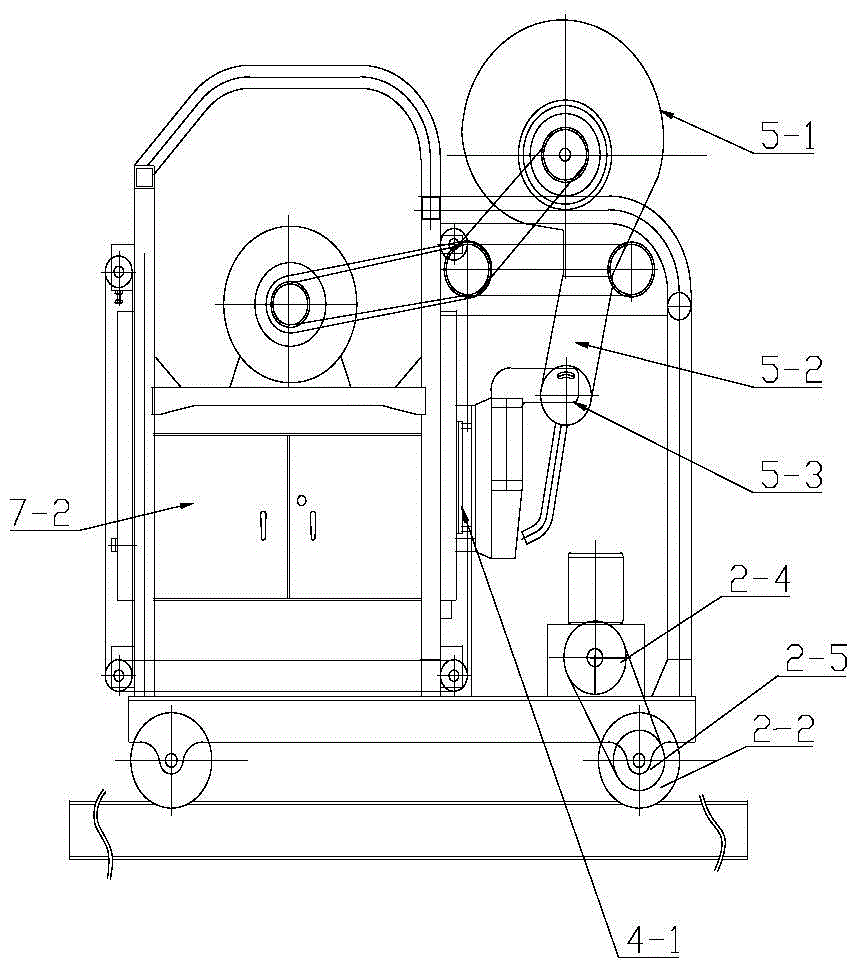

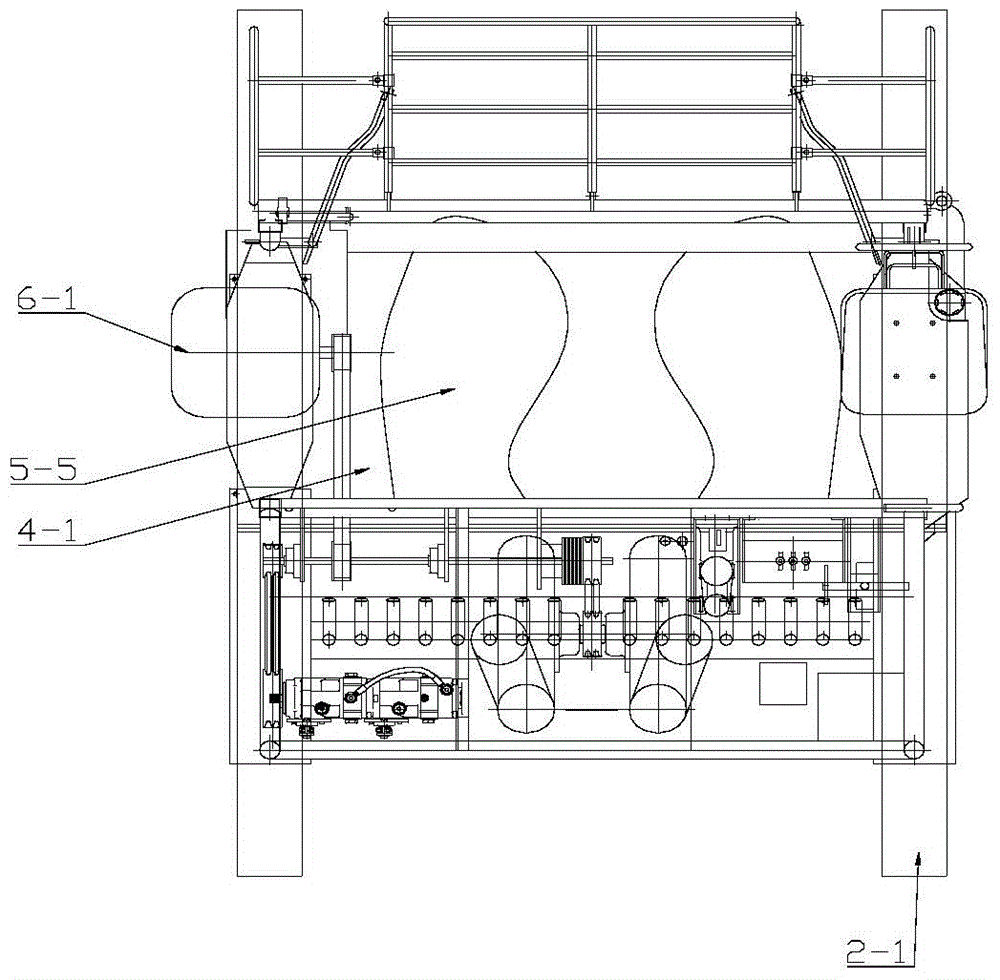

Oriented vibrating wheel system of driving gear box structure of road roller

ActiveCN104005320AReduce impact collision force and frictionExtend overall operating lifeRoads maintainenceOperating lifeBlock group

The invention belongs to the field of road roller equipment and particularly relates to an oriented vibrating wheel system of a driving gear box structure of a road roller. The oriented vibrating wheel system comprises a vibrating wheel, a rotating shaft, a forward eccentric block group and a reverse eccentric block group with the rotating direction opposite to that of the forward eccentric block group, wherein a direction-variable gear set is used for connecting the forward eccentric block group and the reverse eccentric block group, and changing the directions of the forward eccentric block group and the reverse eccentric block group and transferring power between the forward eccentric block group and the reverse eccentric block group; key joint fit with radial activity allowance is adopted between a power output shaft of the direction-variable gear set and a power output shaft of the forward eccentric block group, or between the power output shaft of the direction-variable gear set and a power input shaft of the reverse eccentric block group, or between the power output shaft of the direction-variable gear set and the power output shaft of the forward eccentric block group as well as the power output shaft of the direction-variable gear set and the power input shaft of the reverse eccentric block group. By using the oriented vibrating wheel system, the whole operating life of an inner gear can be effectively prolonged; in addition, influences of motion asynchrony, instant transmission impact and the like caused by small machining and assembling coaxiality errors of all parts and clearances among a plurality of layers of bearings are made up through one or more-layer key joint transmission.

Owner:合肥永安绿地工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com