Automatic liquid supply device

A technology for automatic liquid supply and liquid tank, which is applied in brackets or dispensers, household appliances, sanitary equipment, etc. It can solve the problems of slow liquid flow, unstable speed, and increased viscosity, and achieves not easy to stick and adaptability. Strong, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

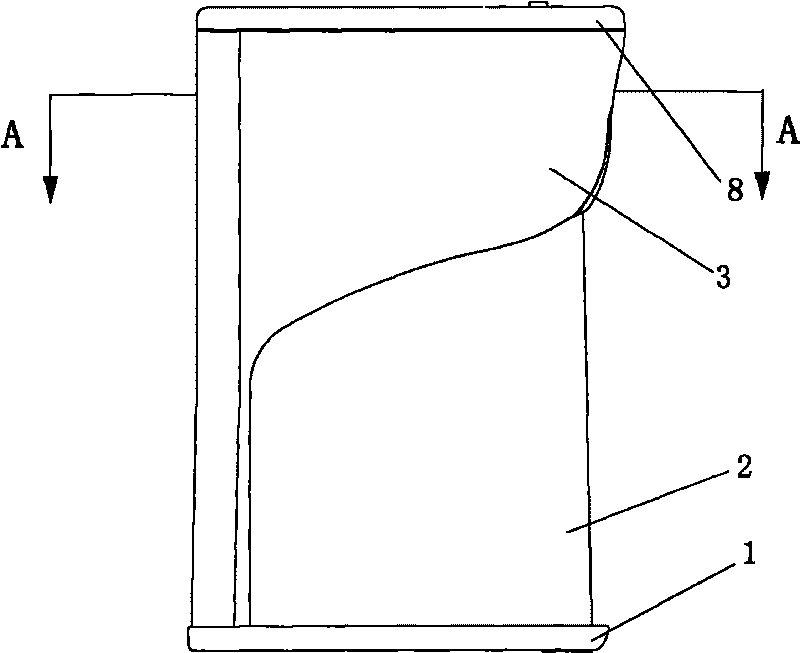

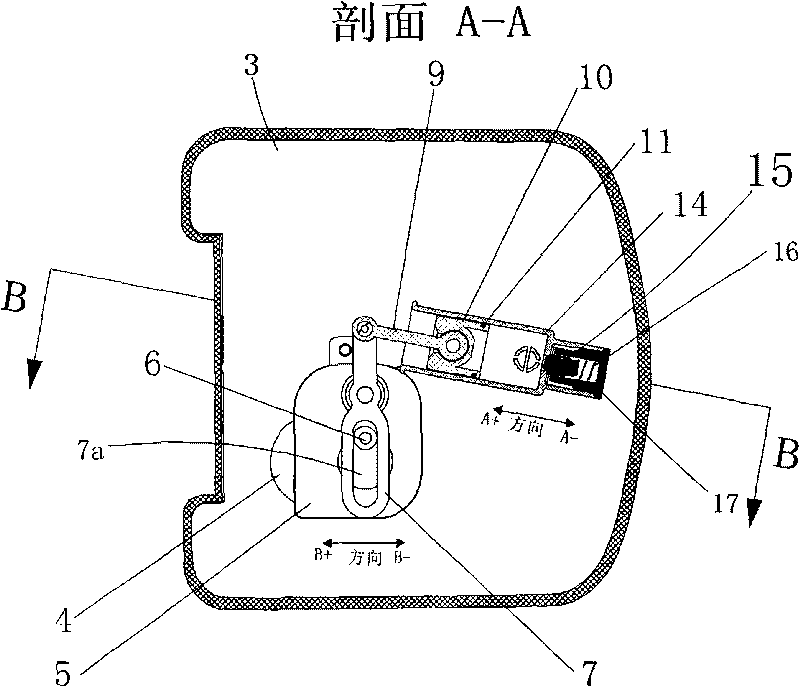

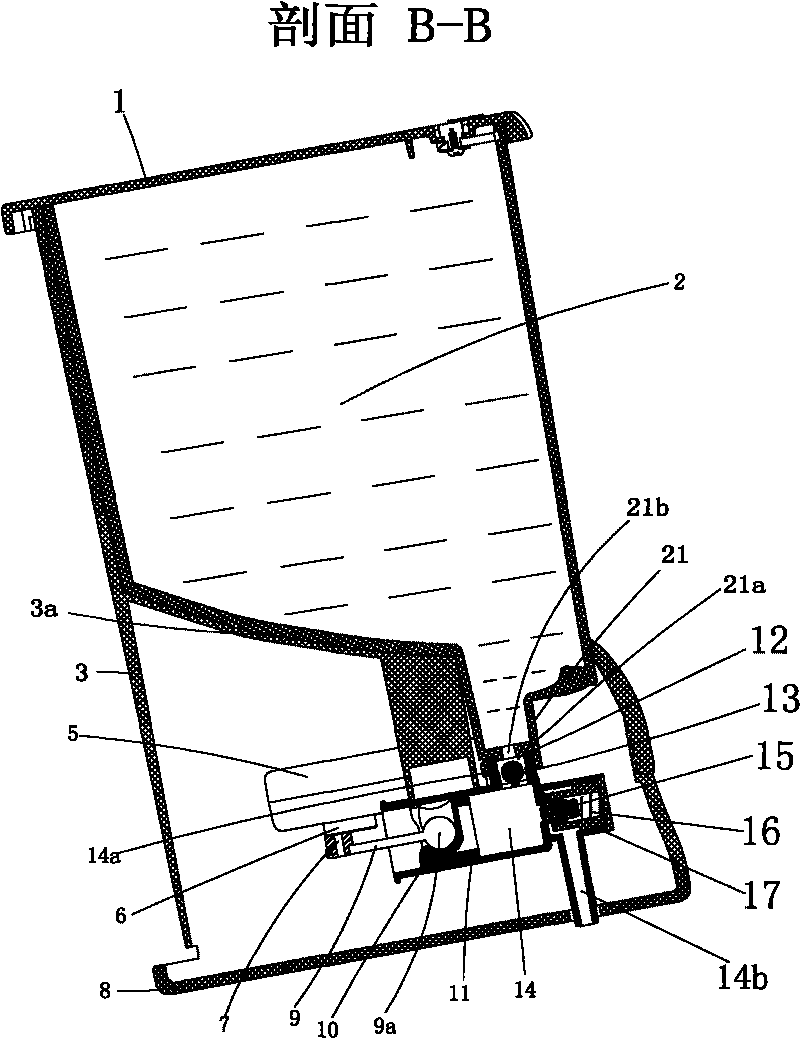

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as Figure 1 to Figure 4 As shown, the symbol numbers are explained as follows: upper cover 1, liquid tank 2, opening 2a, liquid outlet nozzle 21, inner concave hole 21a, liquid outlet hole 21b, base 3, partition plate 3a, concave hole 3b, waist groove 3c , motor 4, gearbox 5, eccentric wheel 6, lever 7, chute 7a, bottom cover 8, perforation 8a, connecting rod 9, ball end 9a, piston 10, sealing ring 11, sealing gasket 12, ball 13, Pump body 14, truncated cone body 14a, liquid outlet pipe 14b, sealing column 15, spring 16, plug 17.

[0024] In the embodiment of the present invention, the automatic liquid supply device includes a base 3, a liquid tank 2 is equipped on the top of the base 3, and a liquid outlet nozzle 21 is equipped on the lower part of the liquid tank 2; a pump body matched with the liquid outlet nozzle 21 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com