Transmission device

A transmission device and transmission shaft technology, applied in the direction of transmission device parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of efficiency loss, leakage to the outside of the cavity, and inability to prevent pump room gas from entering the engine room, etc. Simple, high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

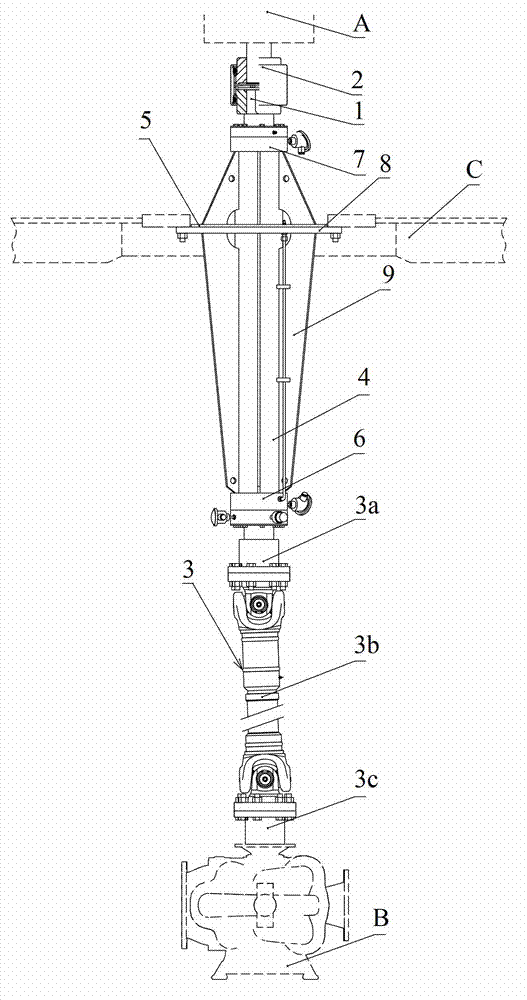

[0026] see figure 1 , The embodiment of the present invention provides a transmission device, which includes: a transmission shaft 1 and a sealing assembly. One end of the drive shaft 1 is provided with a coupling 2 for connecting the drive shaft 1 with the turbine A in the engine room; the other end of the drive shaft 1 is provided with a coupling 2 for connecting the drive shaft 1 with the cargo oil pump B in the pump room. Coupling set 3.

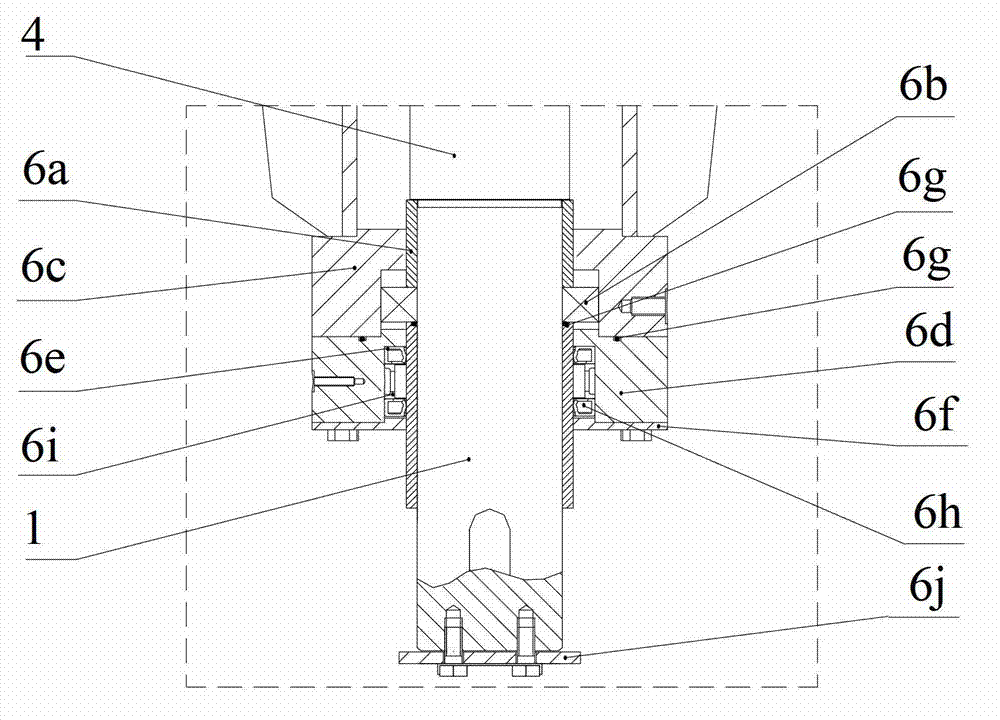

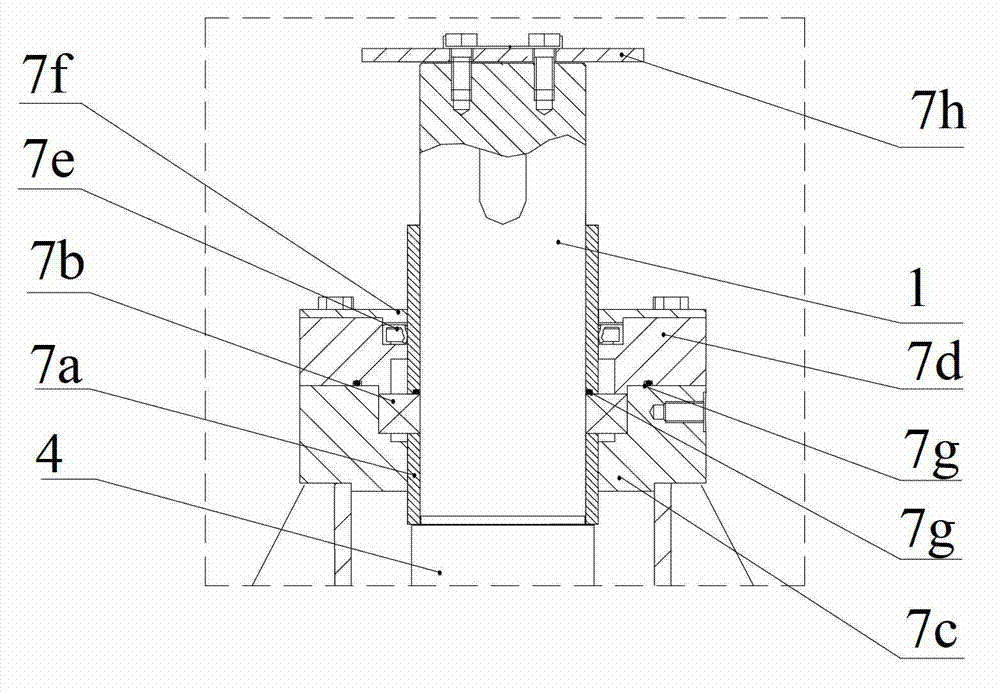

[0027] Wherein, the sealing assembly includes a supporting sleeve 4 for fixing on the partition C between the engine room and the pump room, and a first sealing unit 6 arranged at one end of the supporting sleeve 4 . The supporting sleeve 4 is sleeved on the transmission shaft 1 . see figure 2 , The first sealing unit 6 includes a first bearing 6b, a first bearing seat 6c, a first bearing cover 6d, a first rotary shaft seal 6e and a first sealing cover 6f. The first bearing 6b, the first rotary shaft seal 6e and the first seal cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com