Patents

Literature

11261results about "Gear lubrication/cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

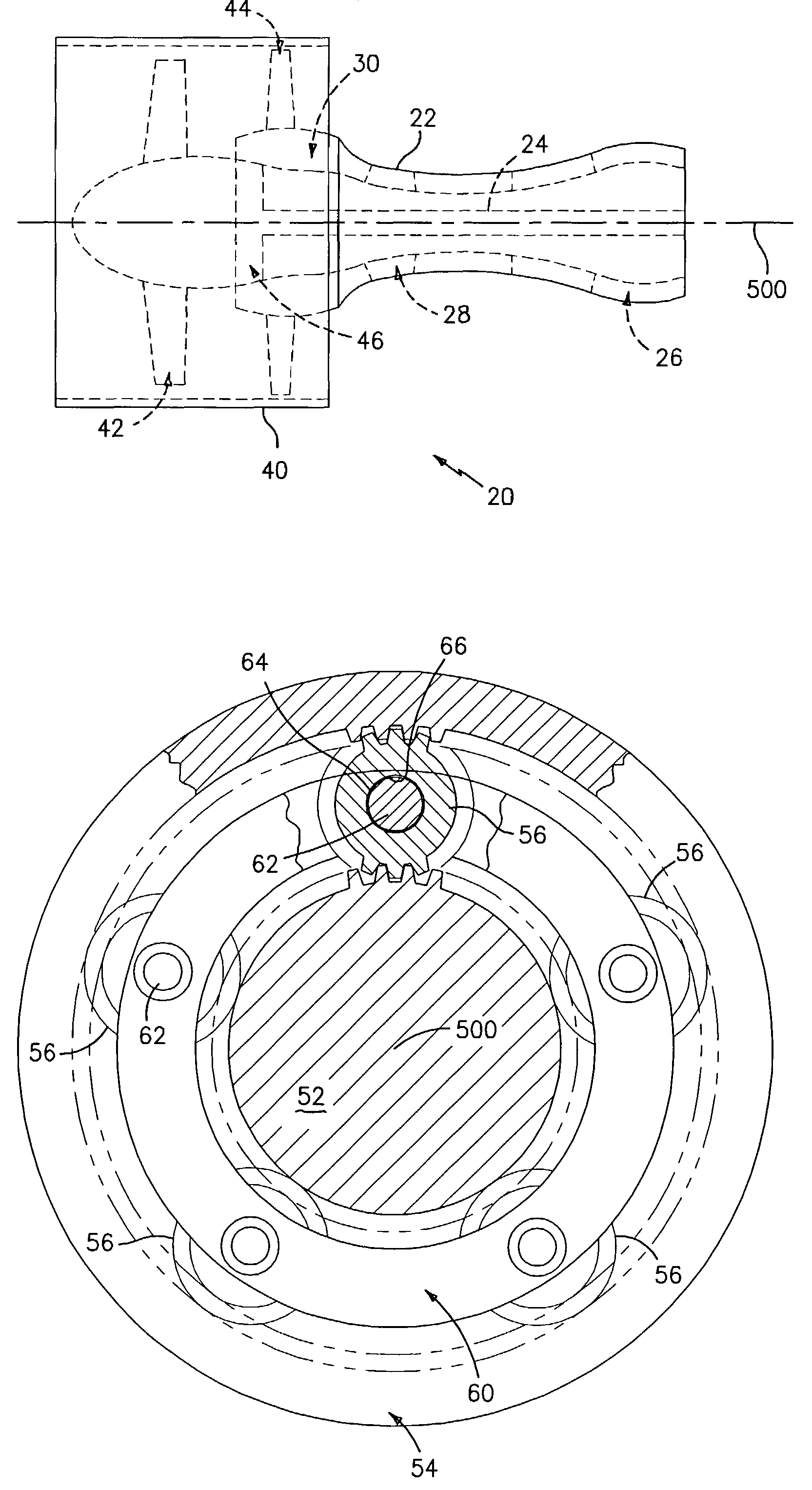

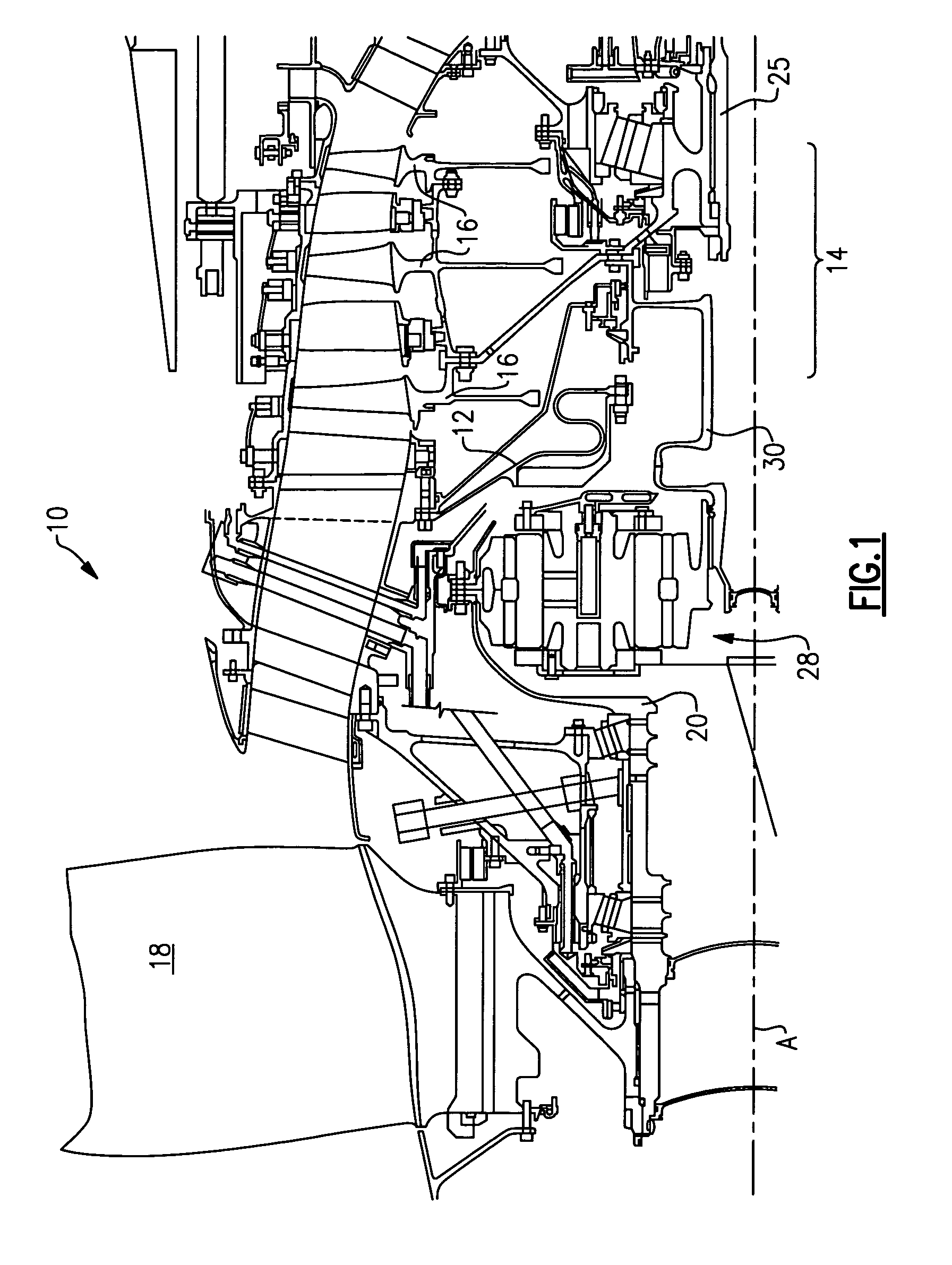

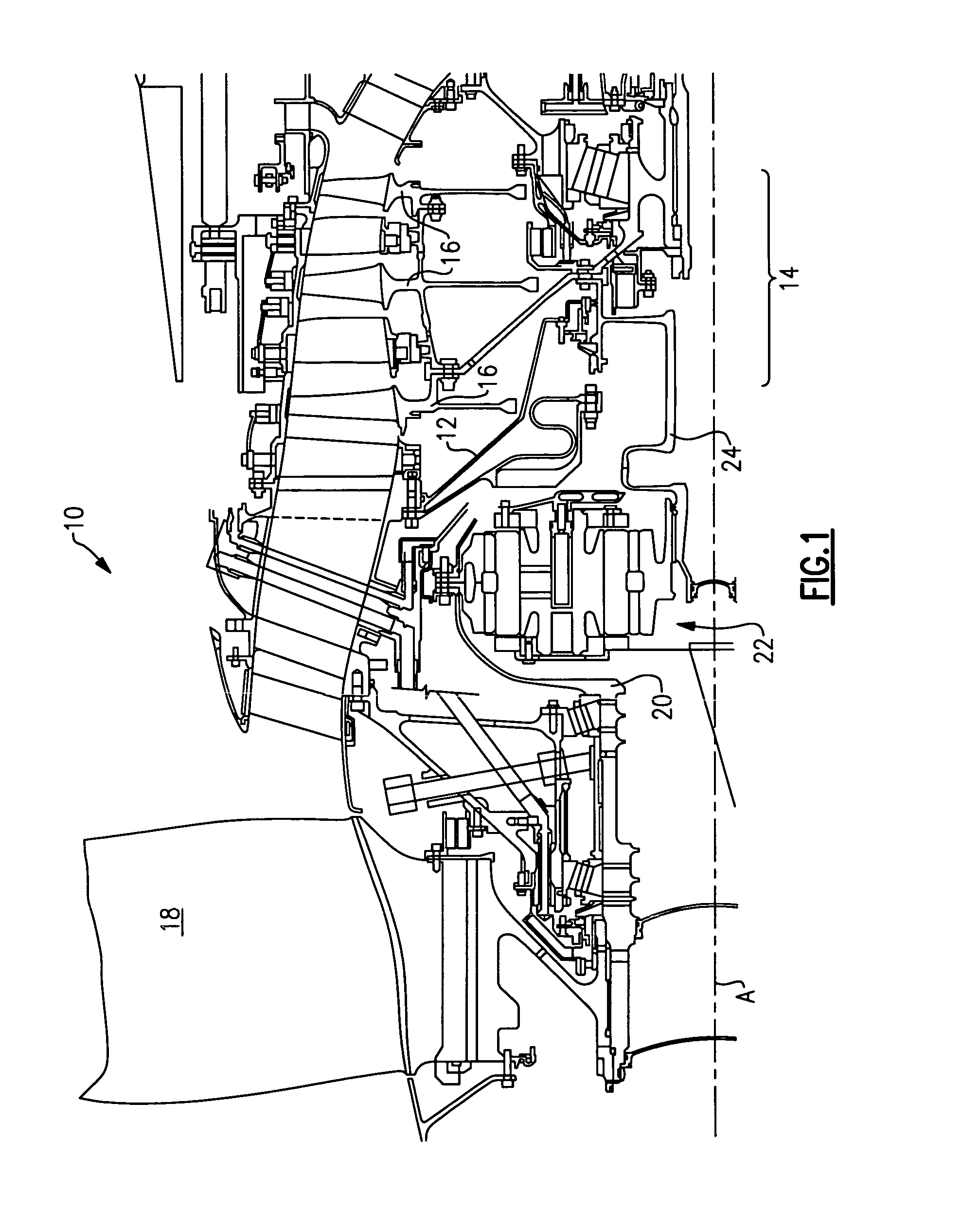

Geartrain coupling for a turbofan engine

Molybdenum disulfide (MoS2) is used as a journal coating for a gearing system. A particular application is the planetary gear system of a geared turbofan engine. Particularly advantageous coatings are deposited via physical vapor deposition (PVD) techniques.

Owner:RAYTHEON TECH CORP

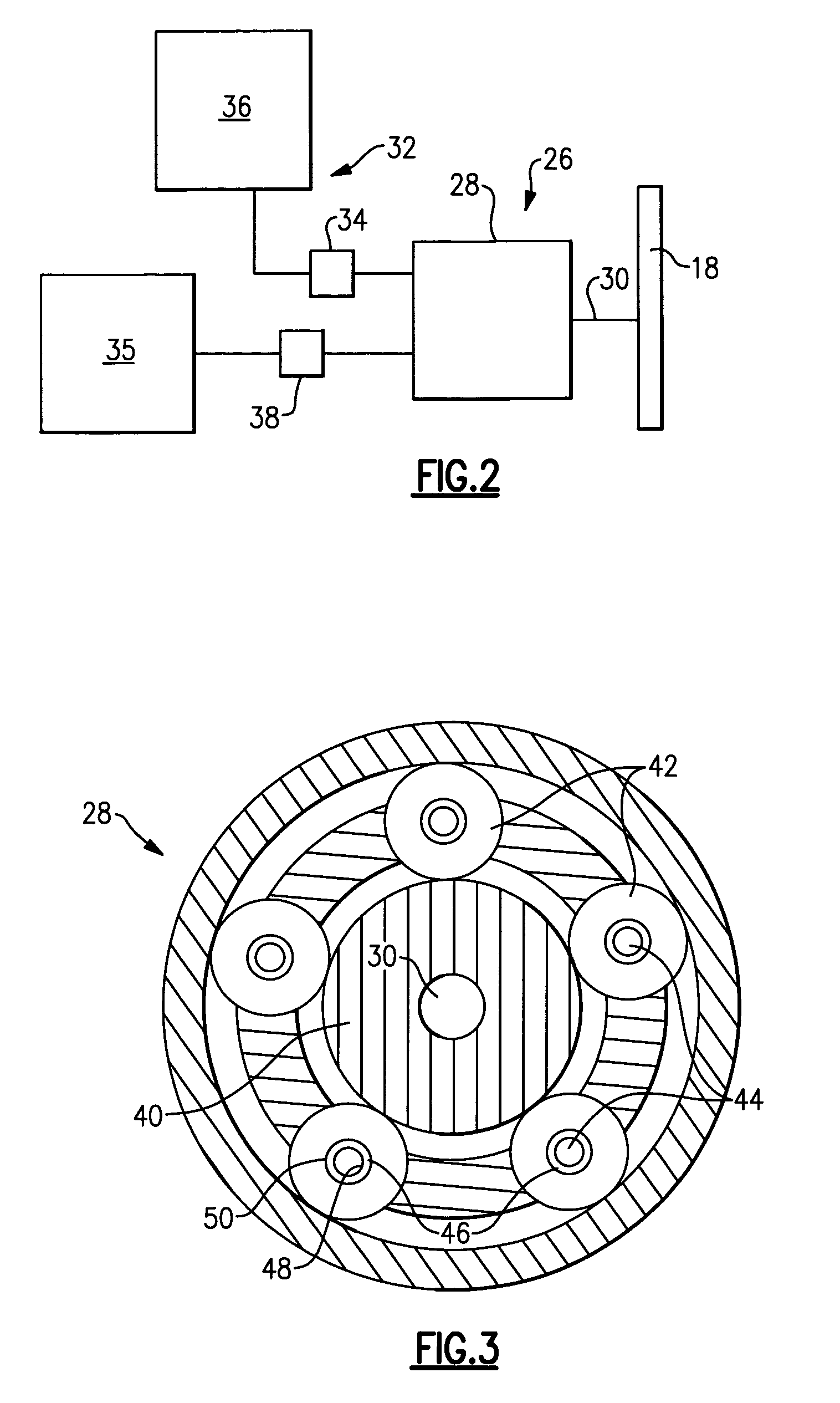

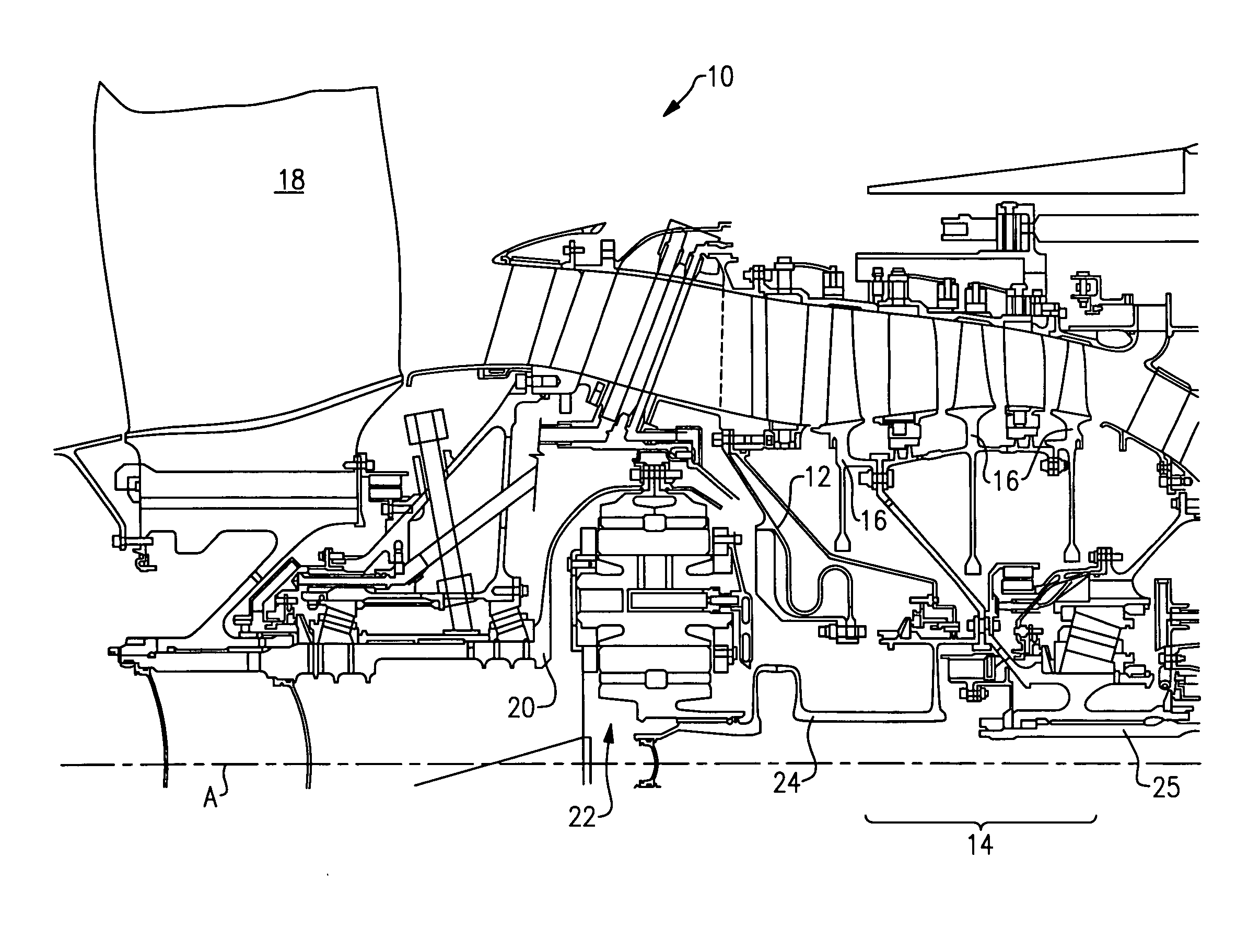

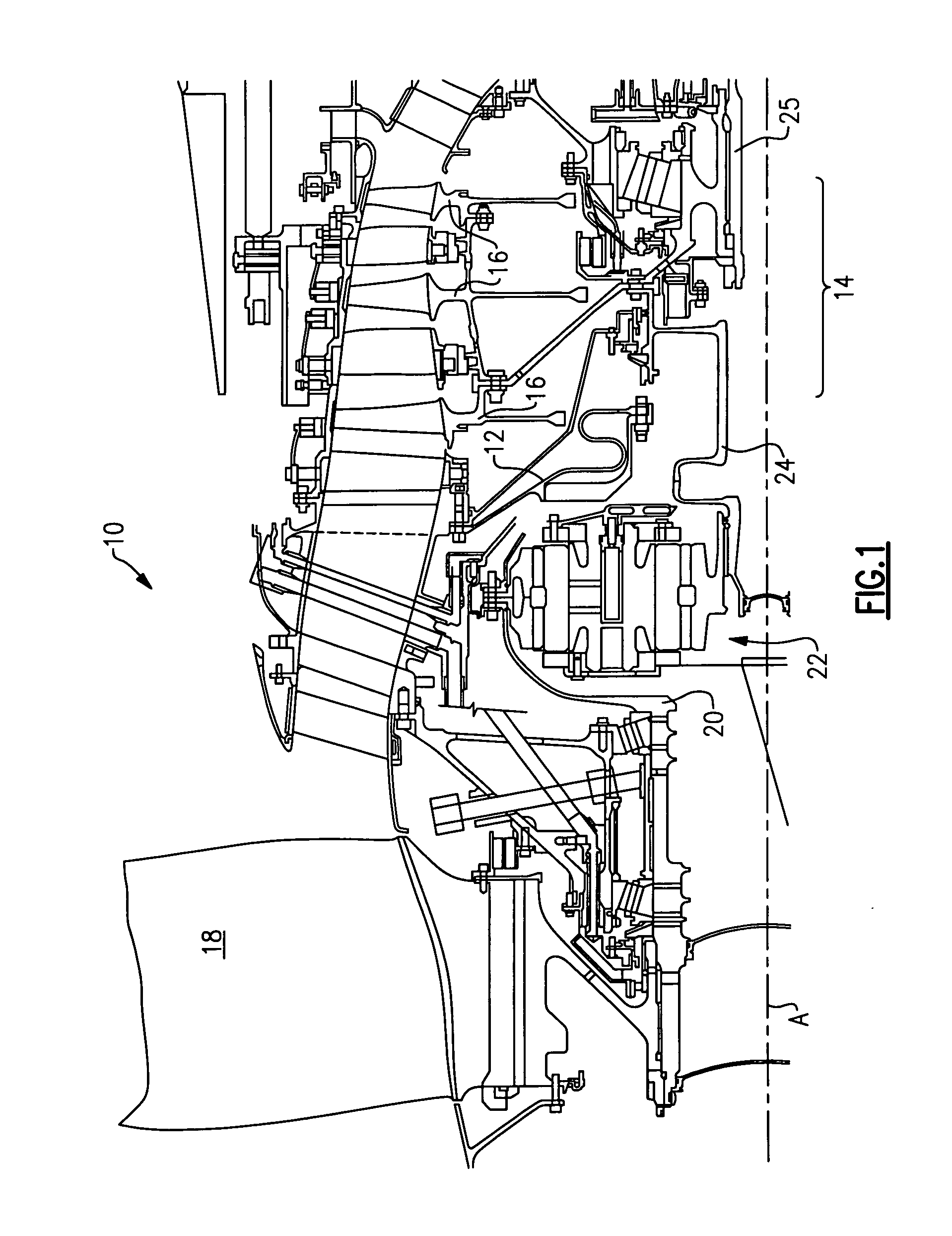

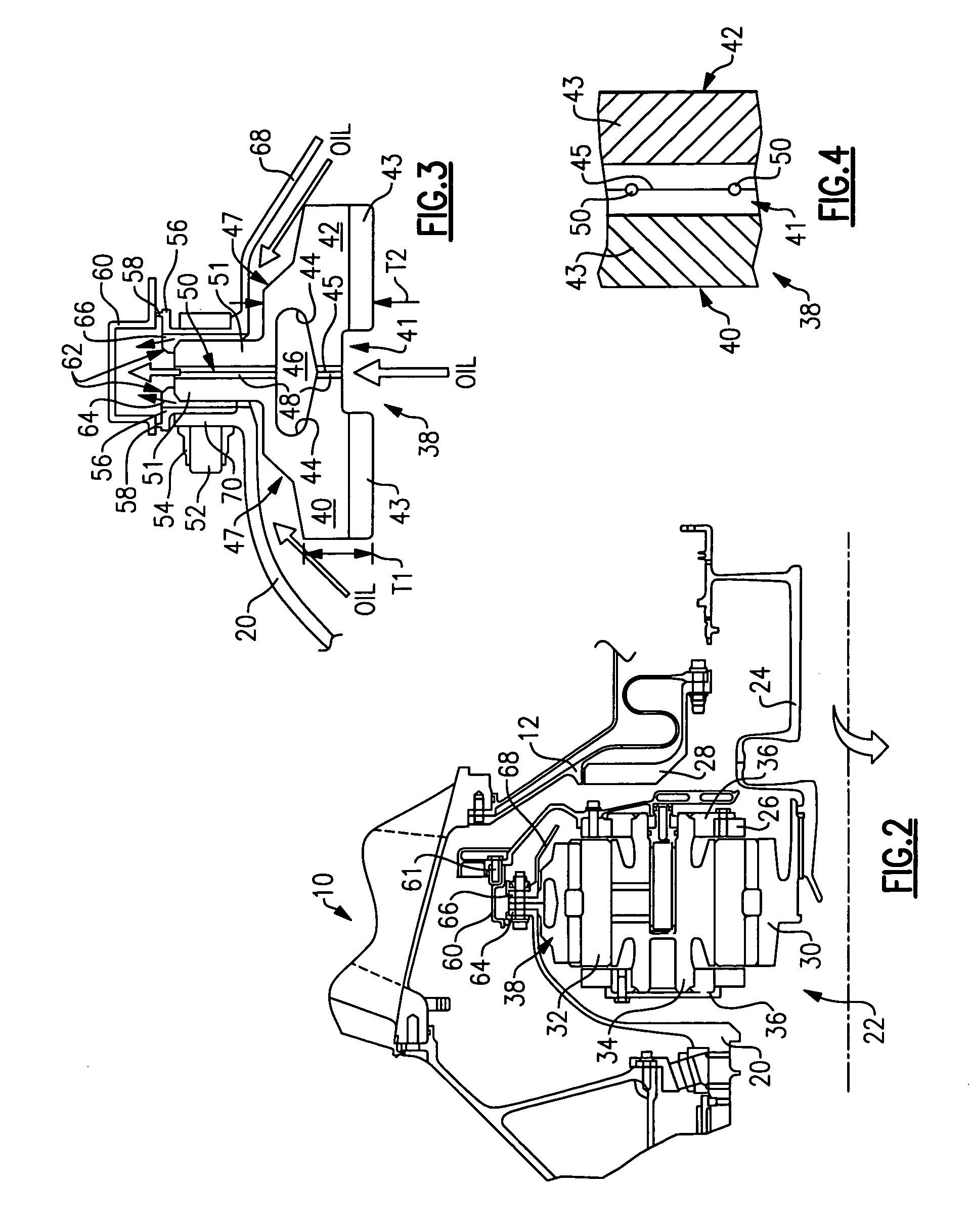

Lubrication of windmilling journal bearings

A support shaft provides lubrication to a journal bearing during windmilling operation of a gear set. A primary oil pump provides oil from an oil supply during driven operation of the fan, and a secondary oil pump provides oil from an internal sump during windmilling operation of the fan. During driven operation of the fan, oil is pumped with the primary oil pump through a primary oil flow path to an outer surface of the support shaft. During windmilling fan operation, oil is pumped from an internal sump with a secondary oil pump through the secondary oil flow path. The secondary oil flow path has a smaller flow capacity, and the secondary oil pump is a smaller capacity pump.

Owner:RTX CORP

Oil baffle for gas turbine fan drive gear system

Owner:RTX CORP

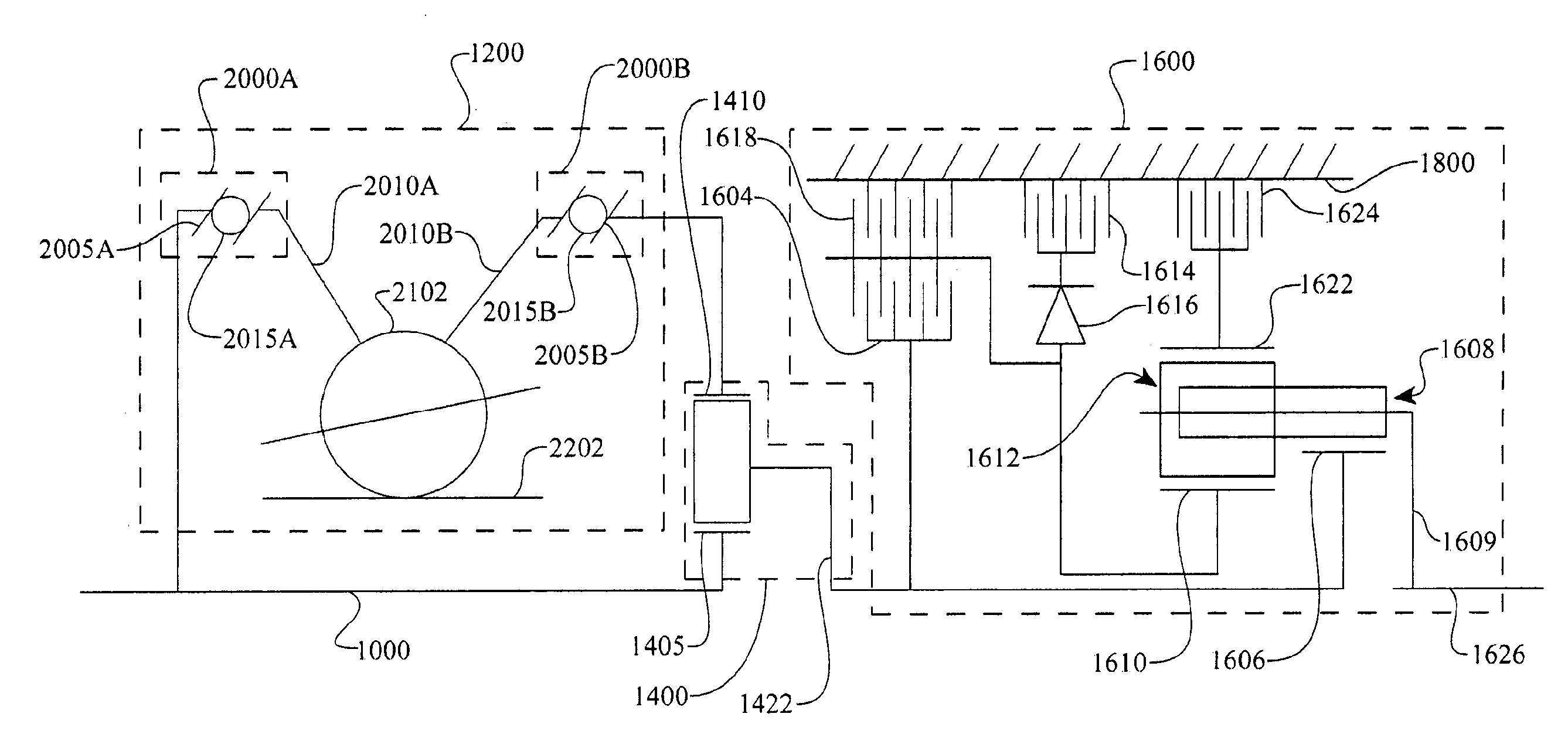

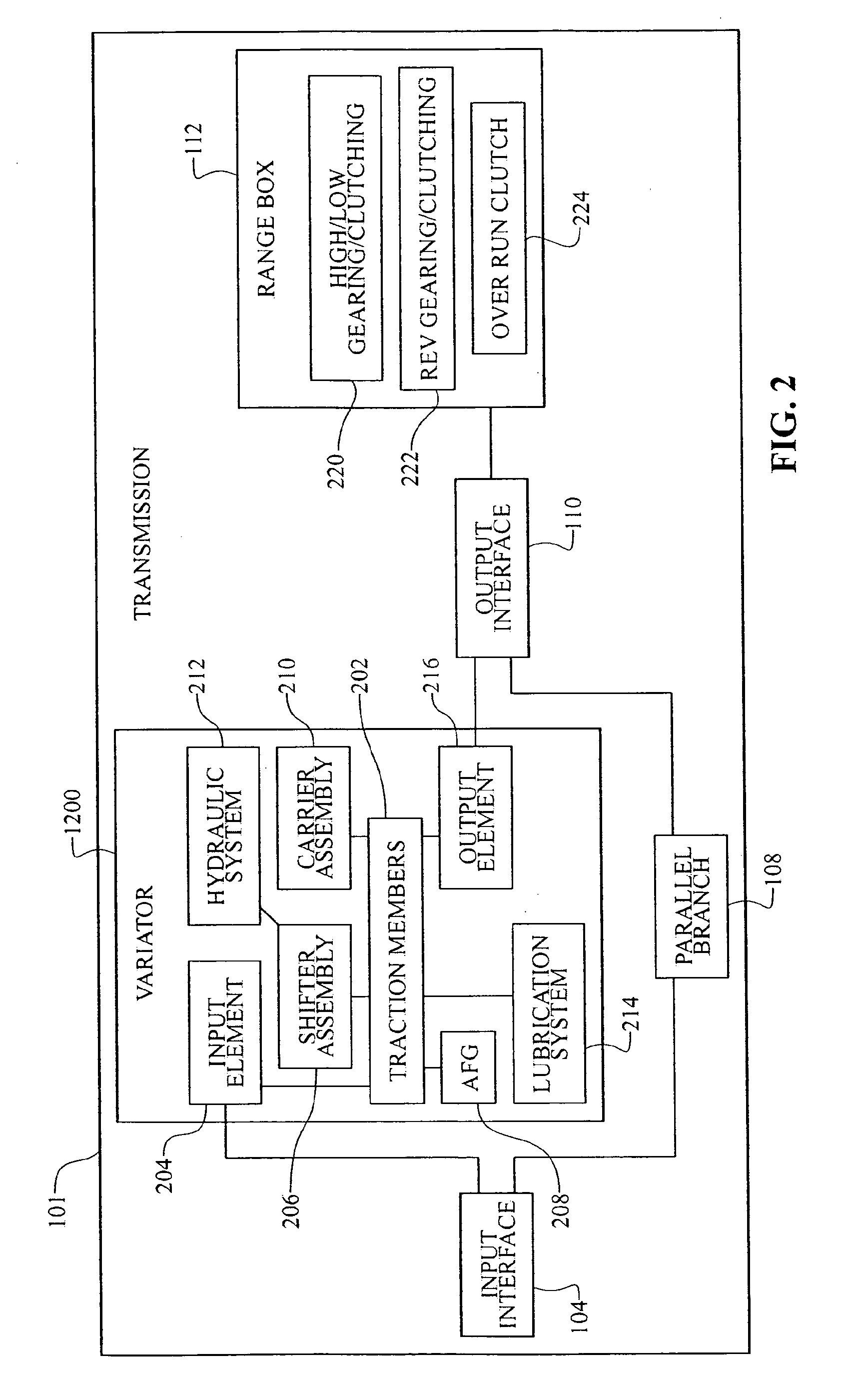

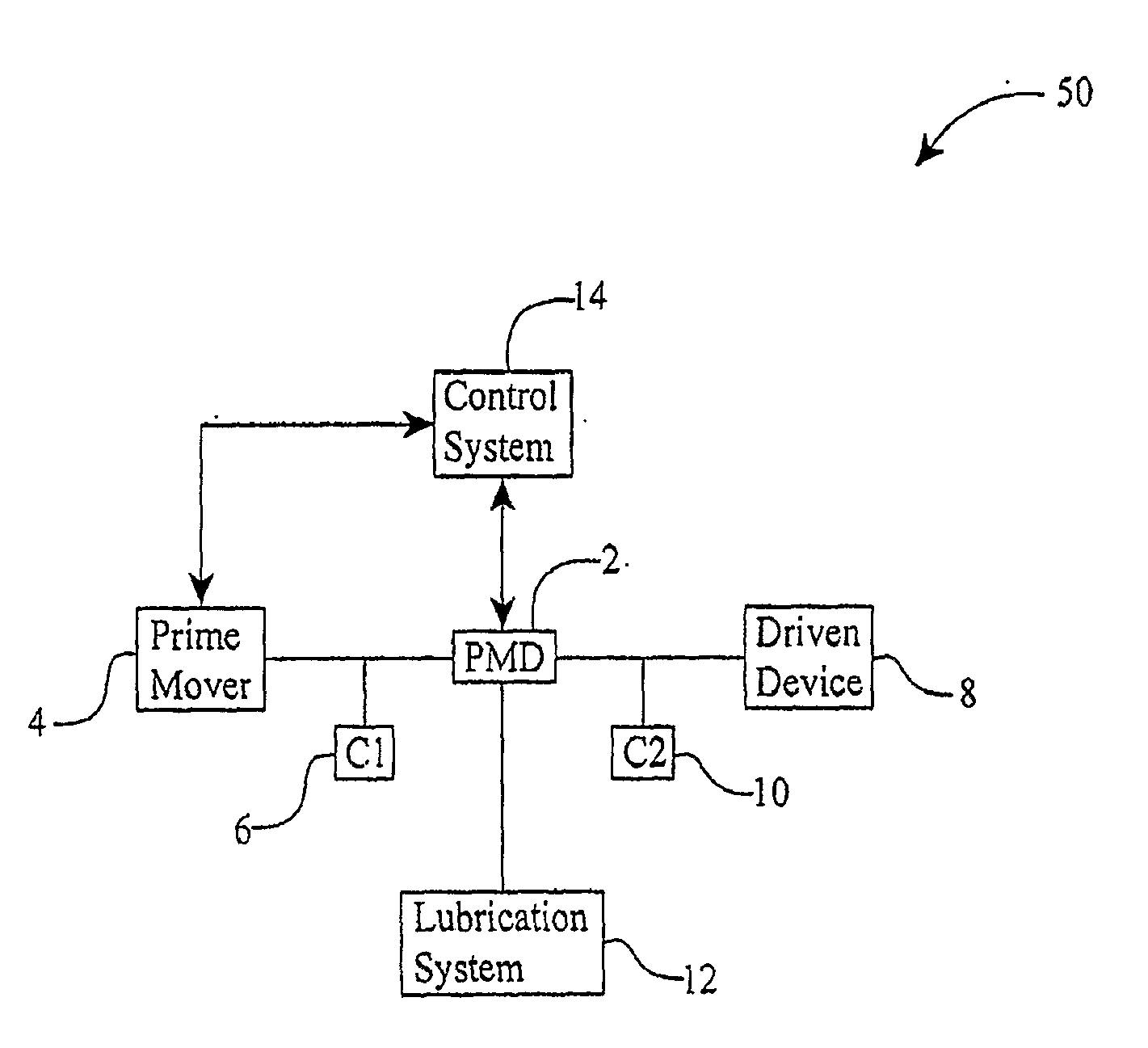

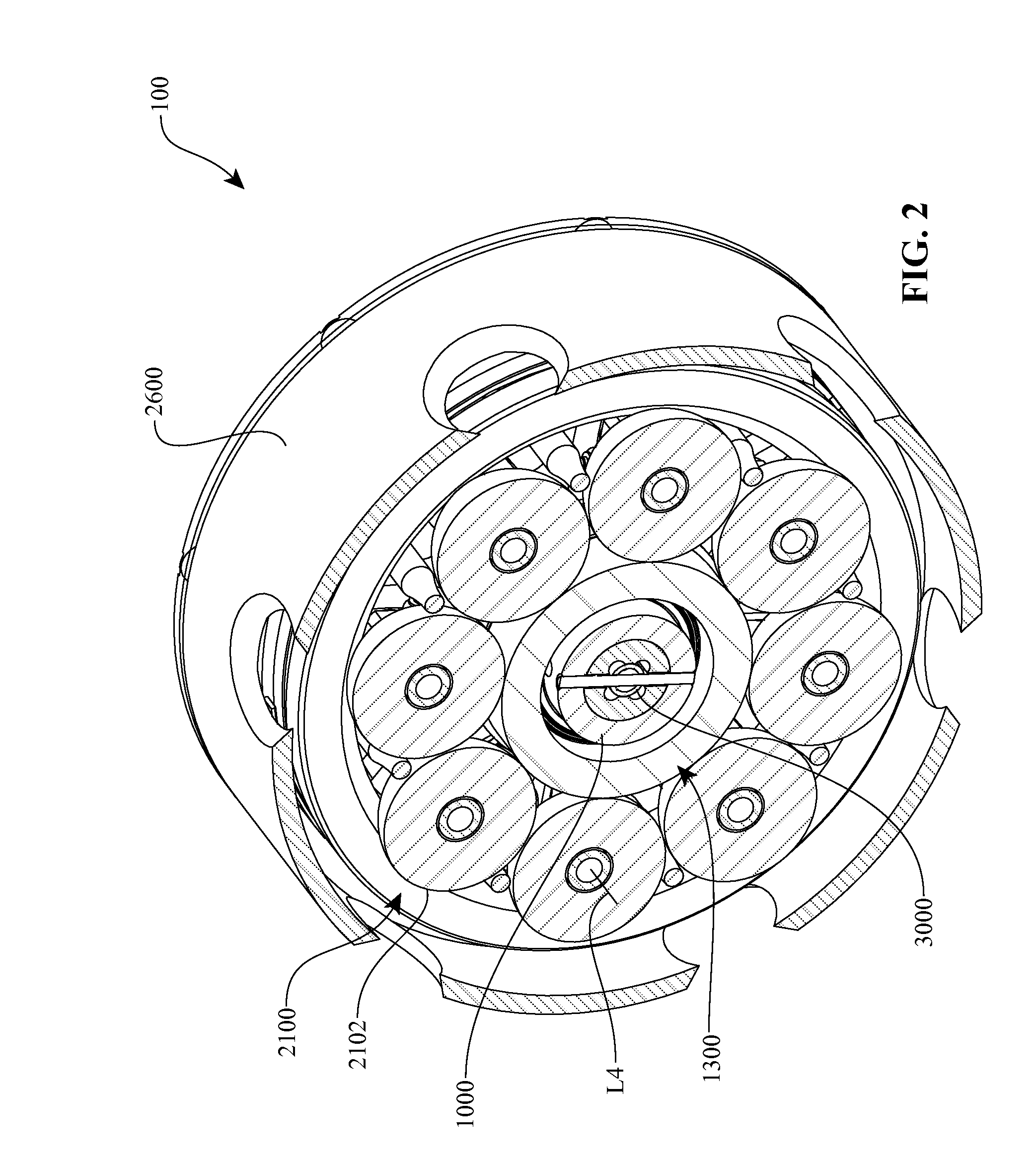

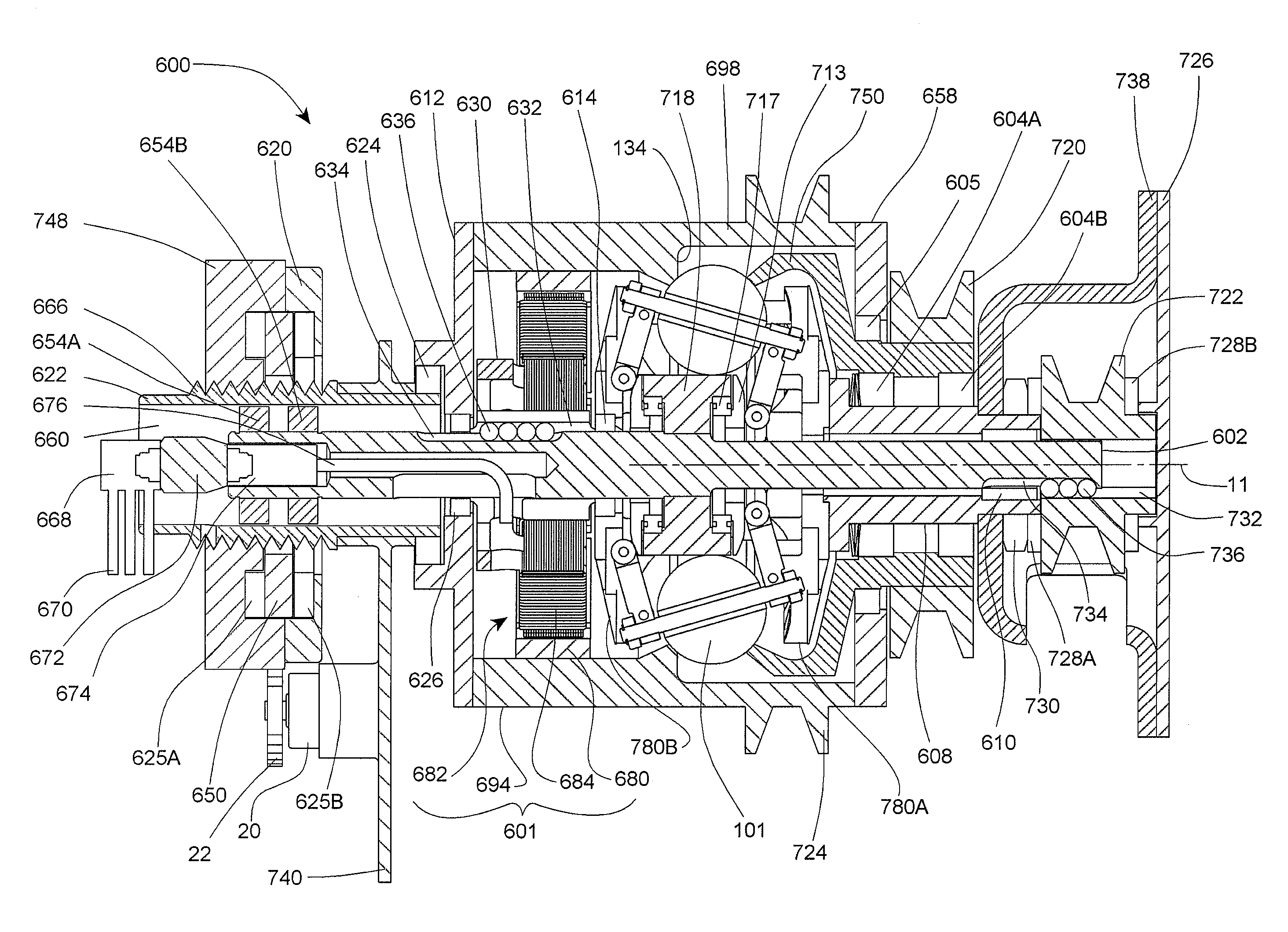

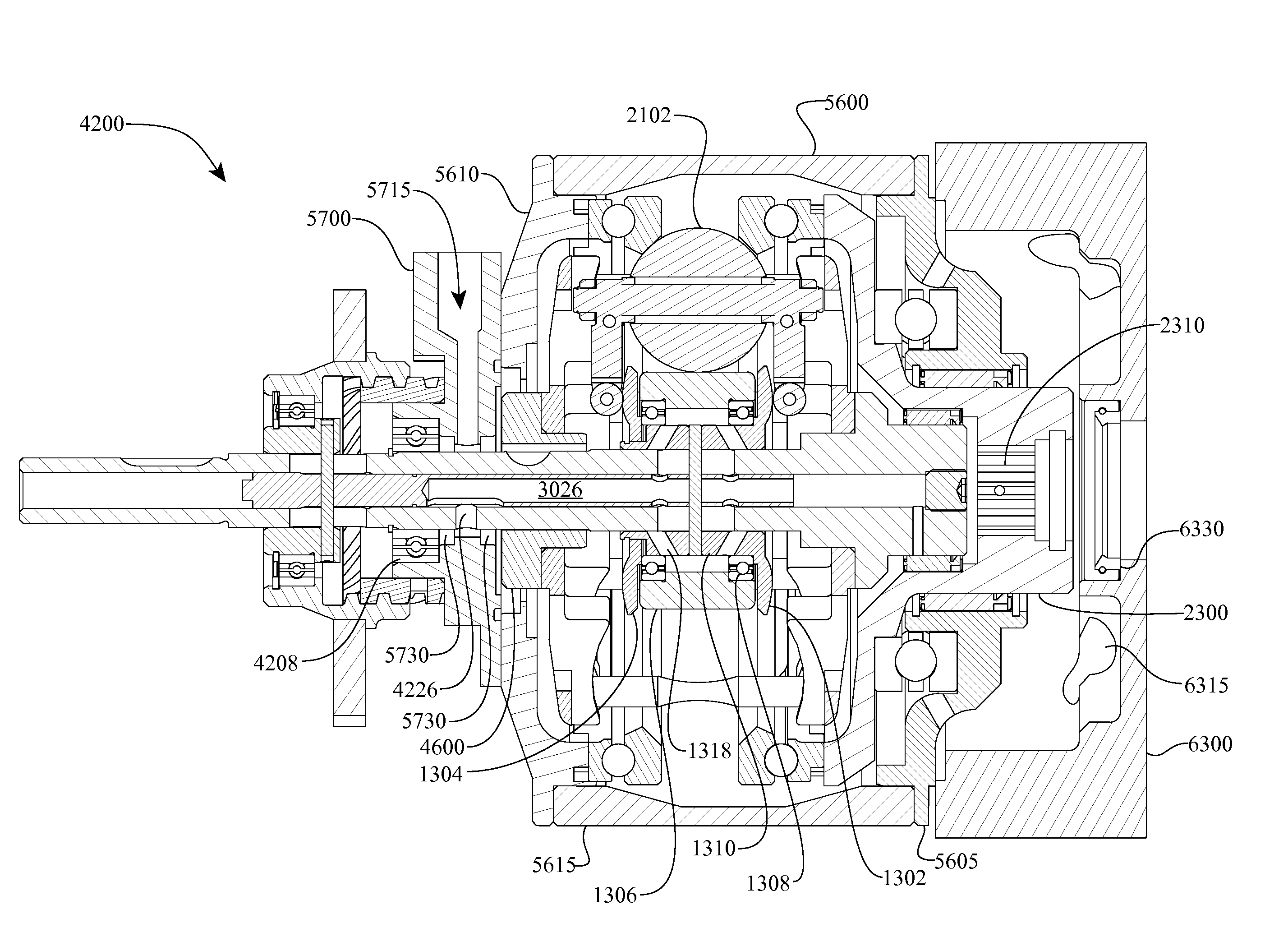

Continuously variable transmissions and methods therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Various inventive shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. Embodiments of a transmission housing and bell housing are adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Various related devices include embodiments of, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies. FIG. 72 shows a torque-split ball-type rolling traction CVT with a ball-type rolling traction variator (1200) and planetary gearset (1400) which is followed by a rangebox (1600).

Owner:FALLBROOK INTPROP COMPANY

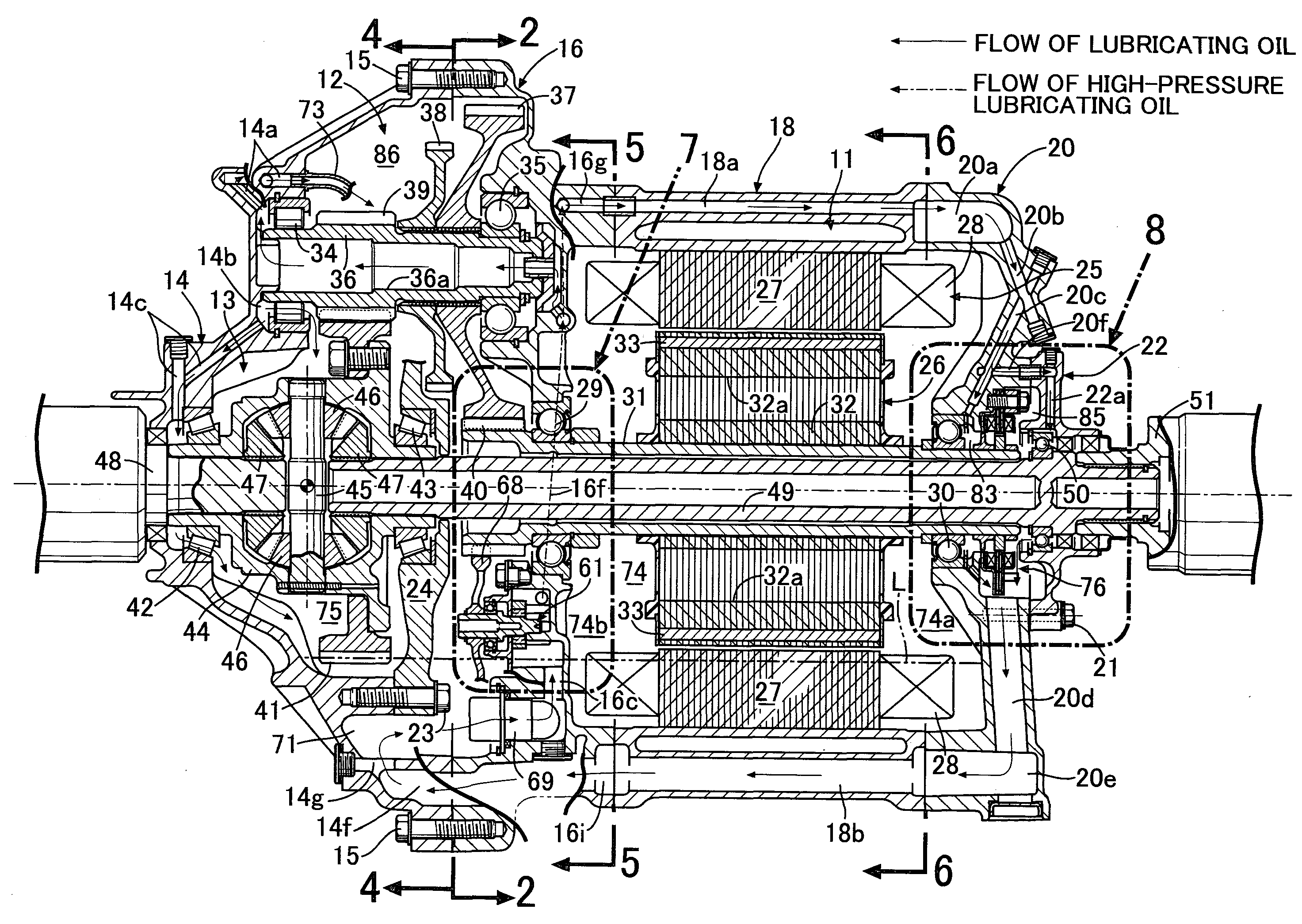

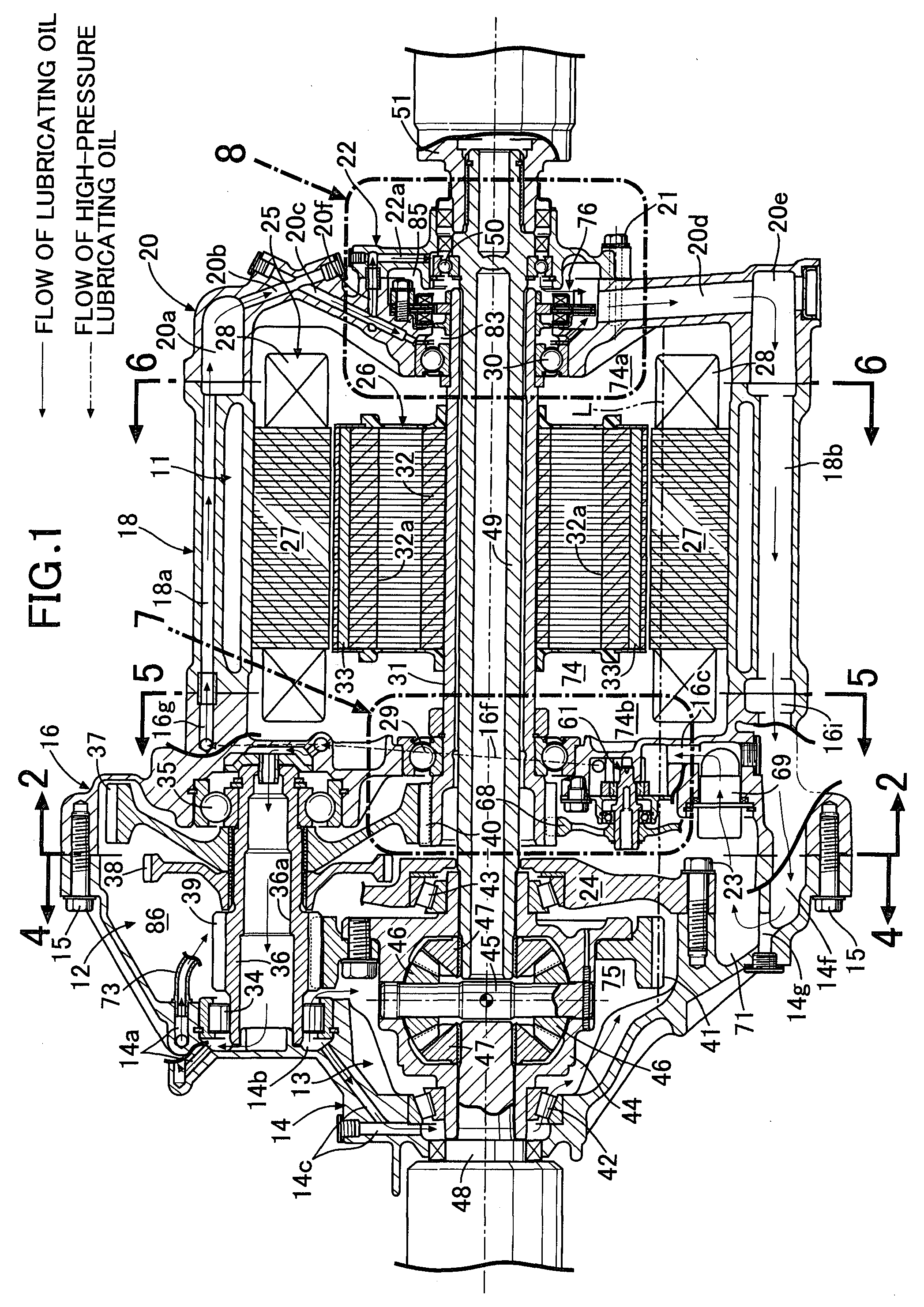

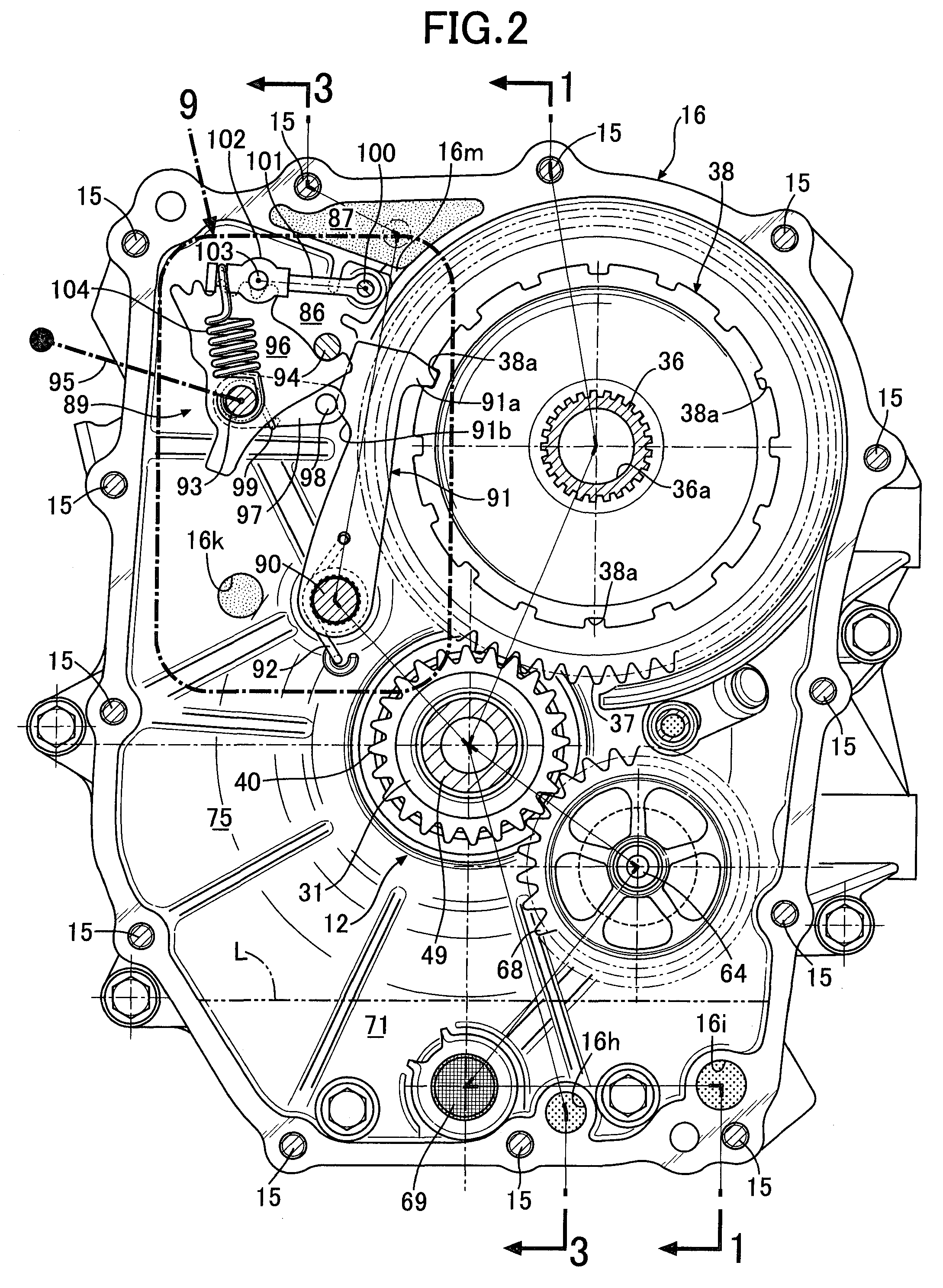

Toroidal type continuoulsy variable transmission

InactiveUS7029418B2Deterioration of hardnessAvoid unnecessary wasteGear lubrication/coolingDynamo-electric brake controlCentre of rotationVariator

A toroidai type continuously variable transmission wherein a rolling member is clamped between rotary members; and wherein a rolling face of rotary members being opposed to each other has a curved face, in which its sectional face along the plane including a center axis of rotation is shaped into an arc, in order to allow said rolling face of said rolling member inclining against the center axis of the rotation of said rotary member, characterized by: an oiling hole formed on the portion on the center side of the rotation in said rolling face of the rotary members being opposed to each other, or on the portion on the center side of the rotation leading to said rolling face; and the oil passage for feeding the lubricating oil to the oiling hole, formed on the center side of the rotation in said rotary member, with being communicated with the oiling hole.

Owner:TOYOTA JIDOSHA KK

Method of operating a wormgear drive at high energy efficiency

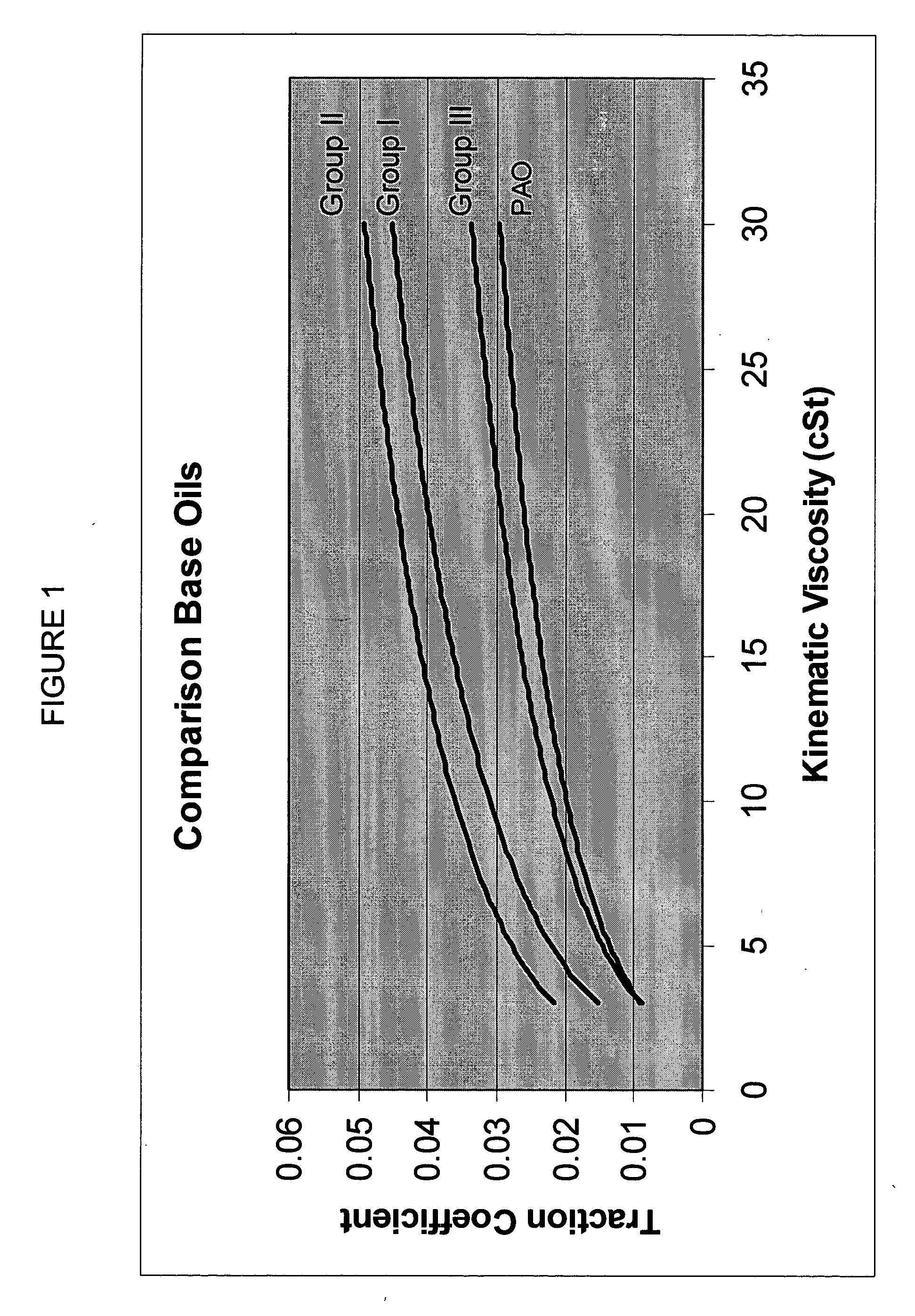

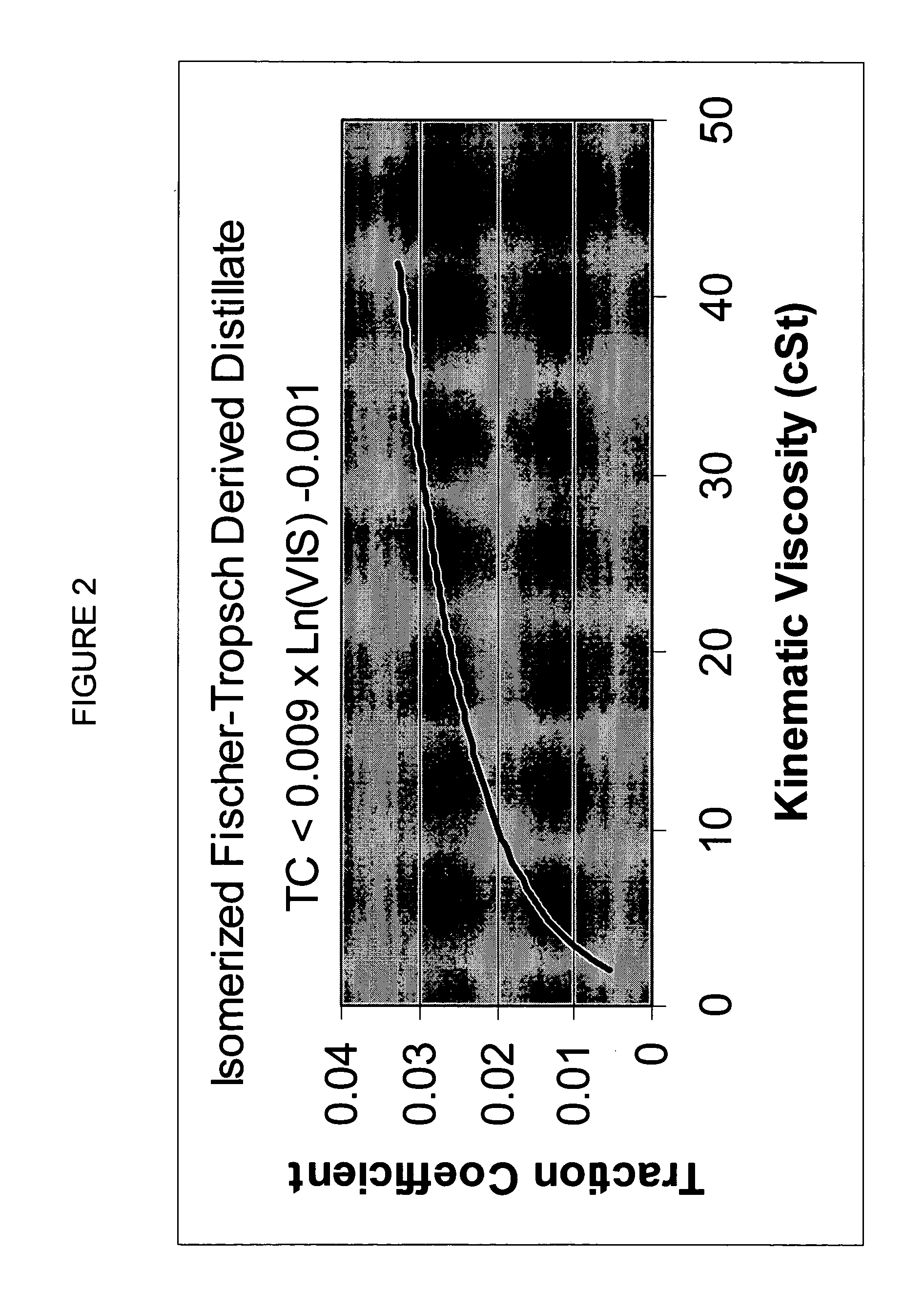

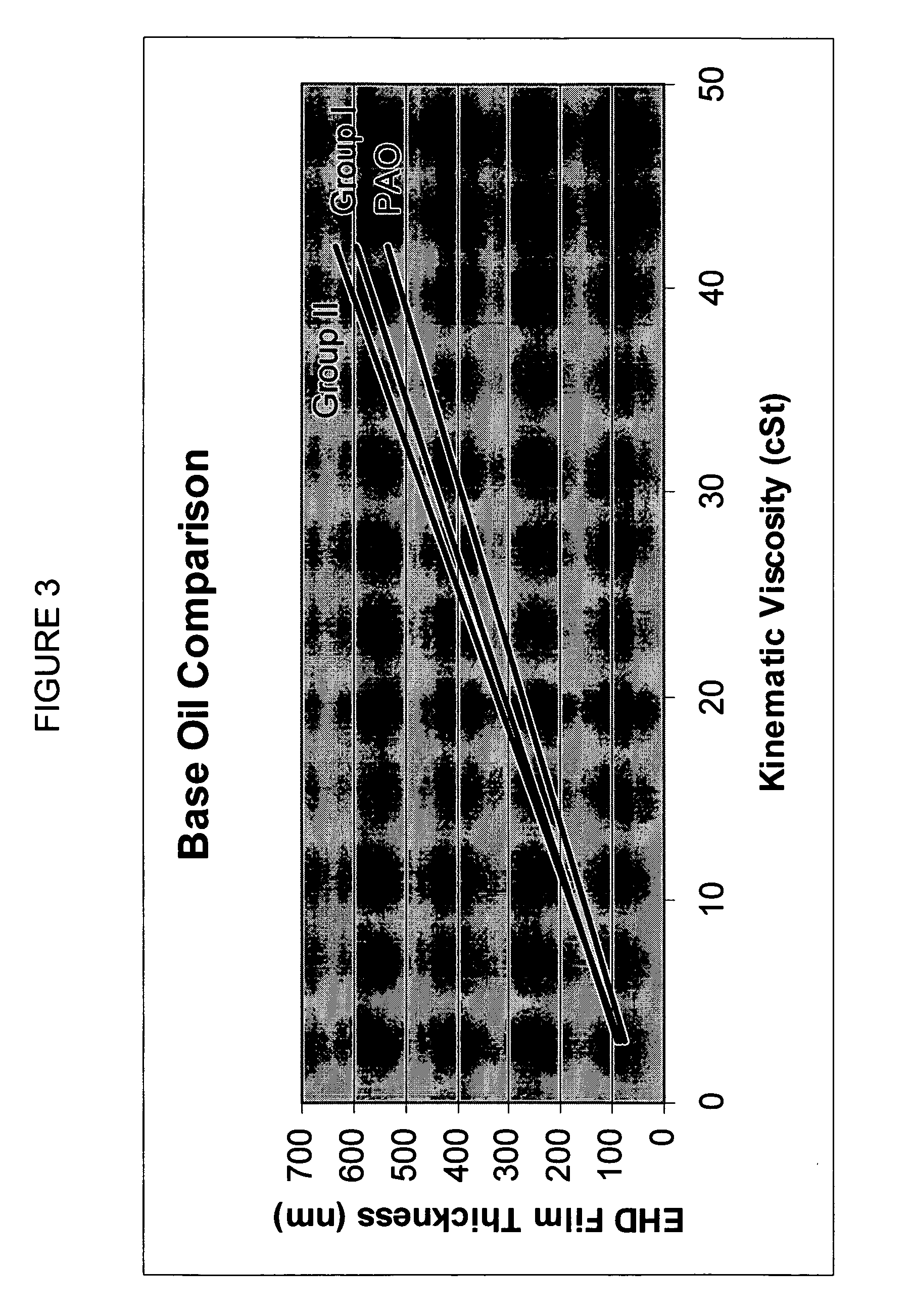

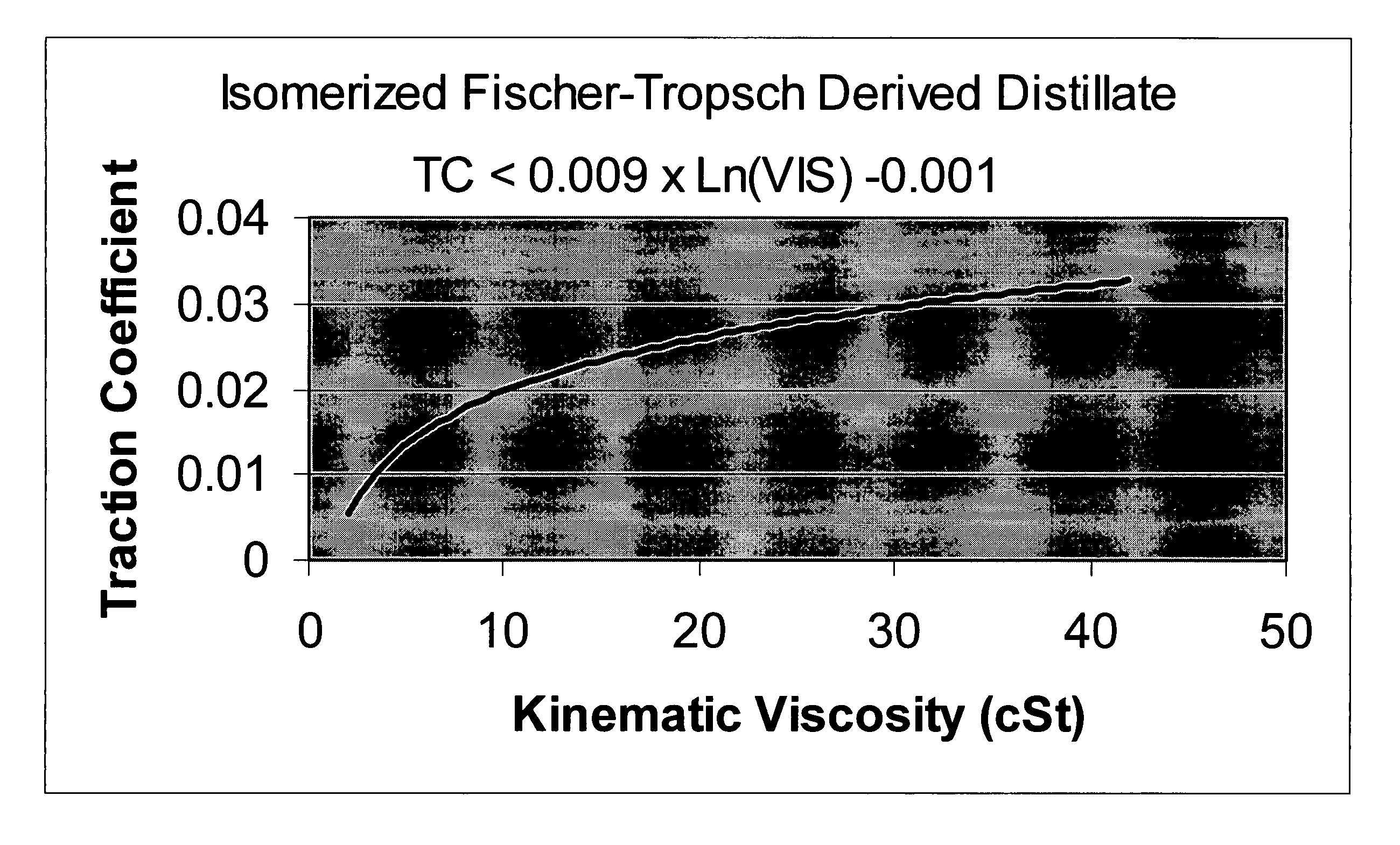

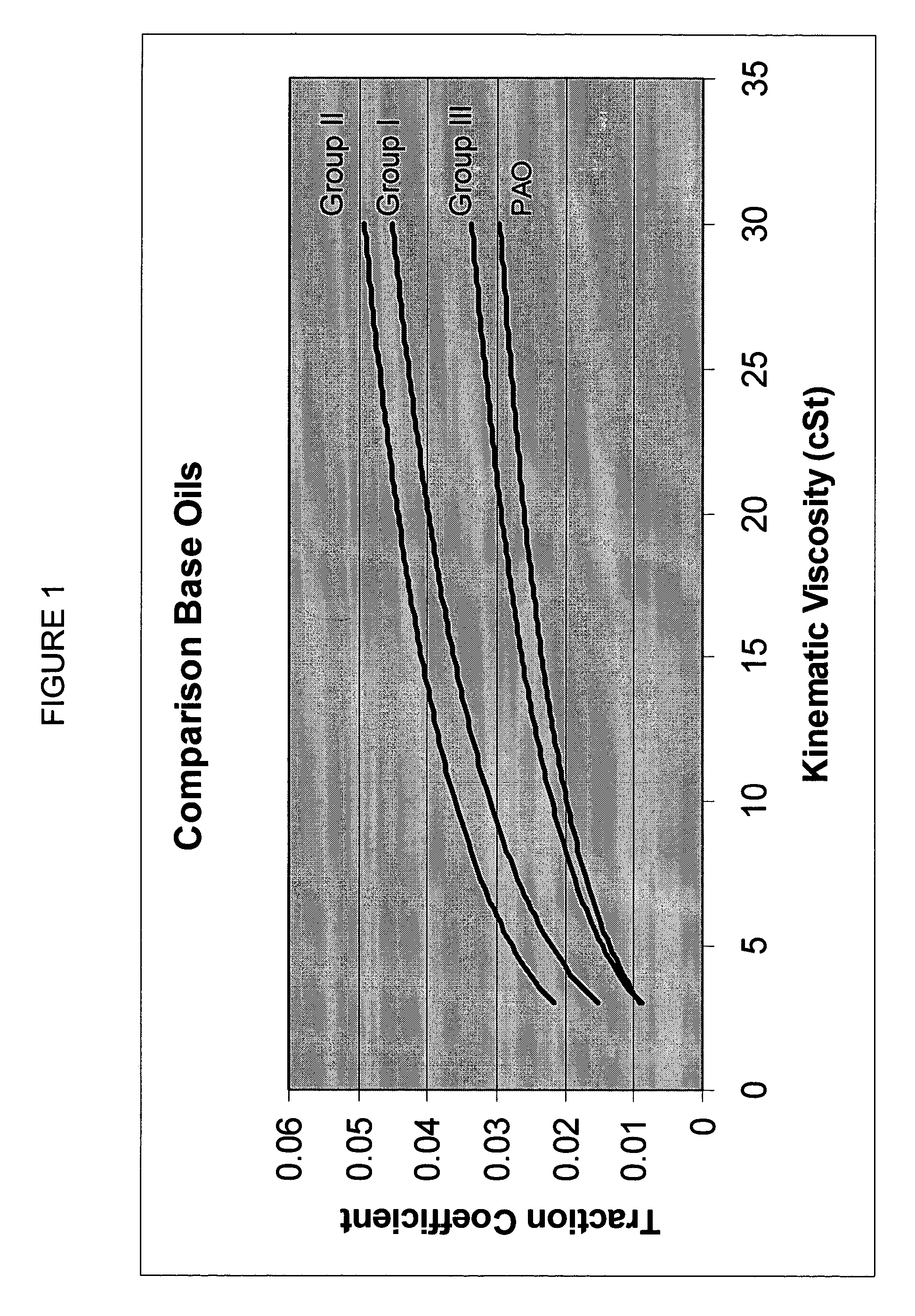

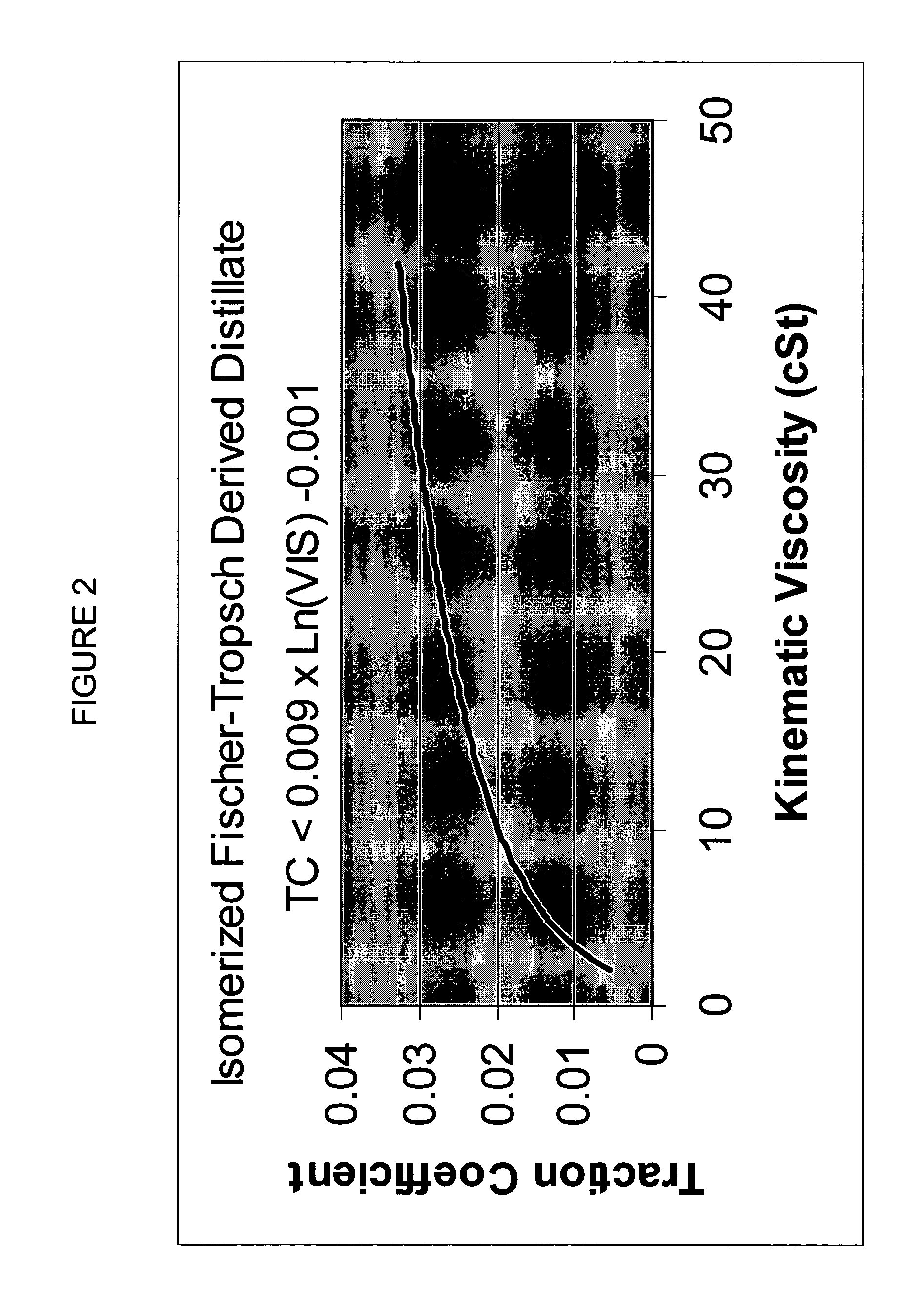

InactiveUS20050241990A1Reducing traction coefficientToothed gearingsGear lubrication/coolingHigh energyBase oil

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

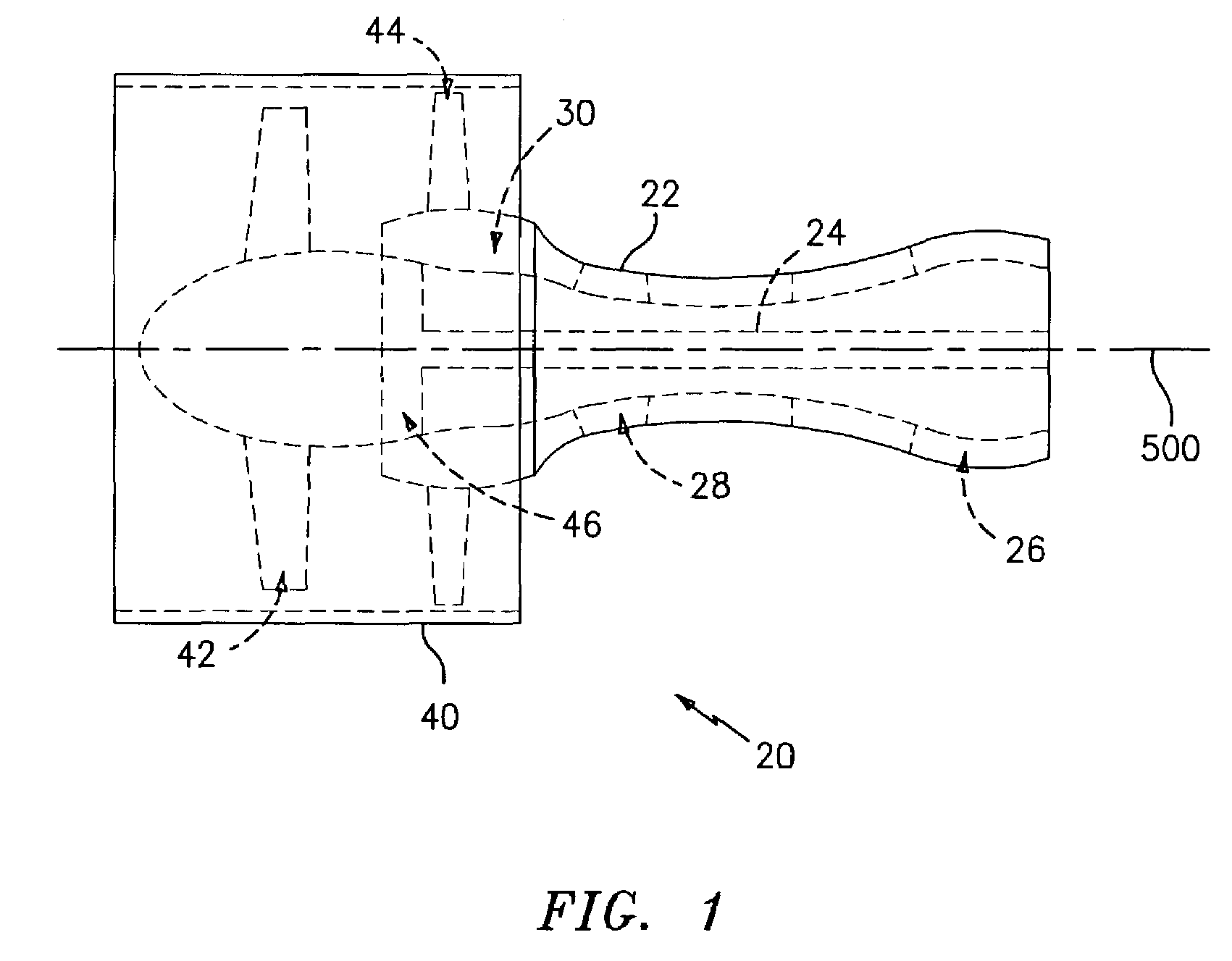

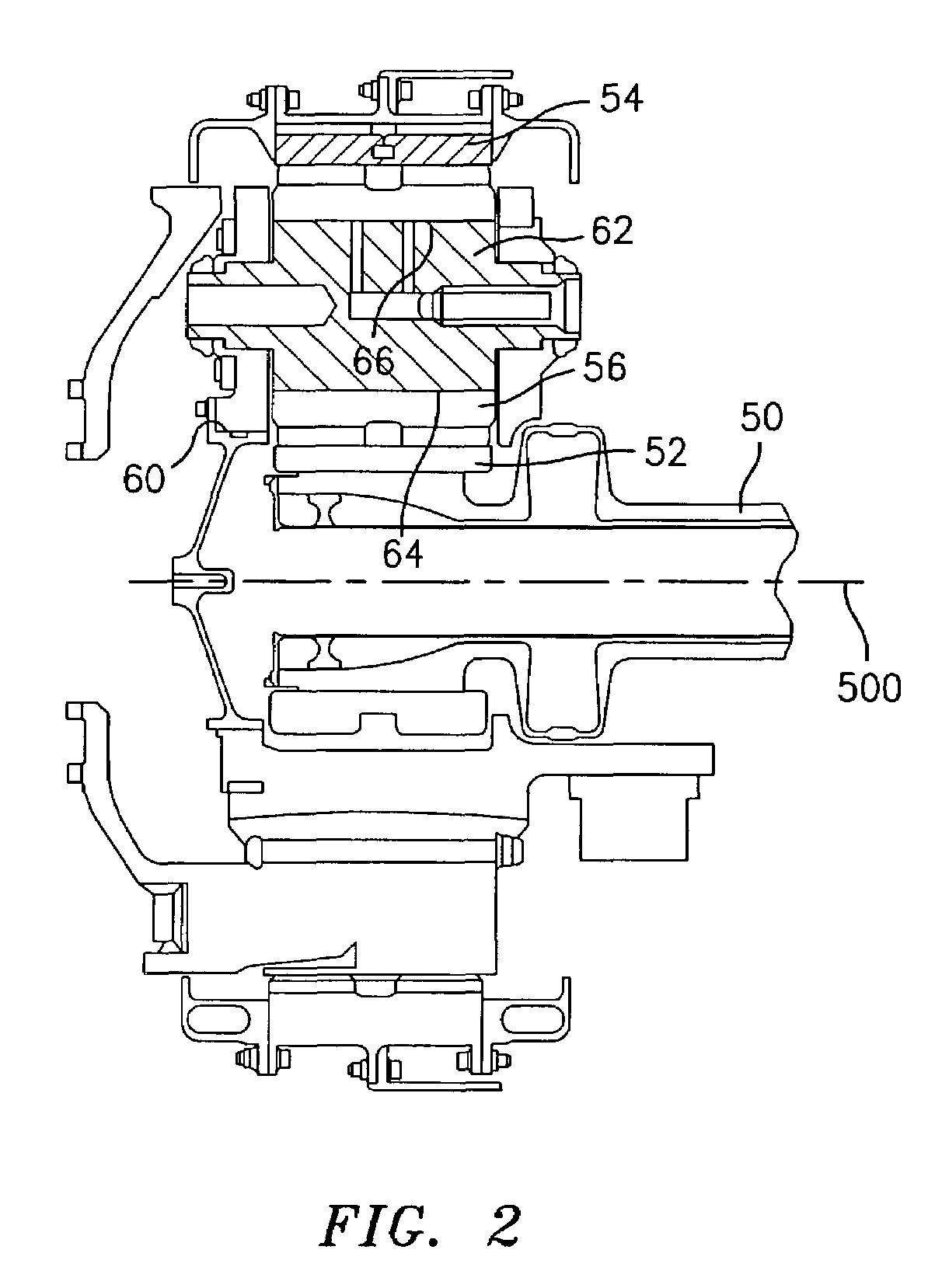

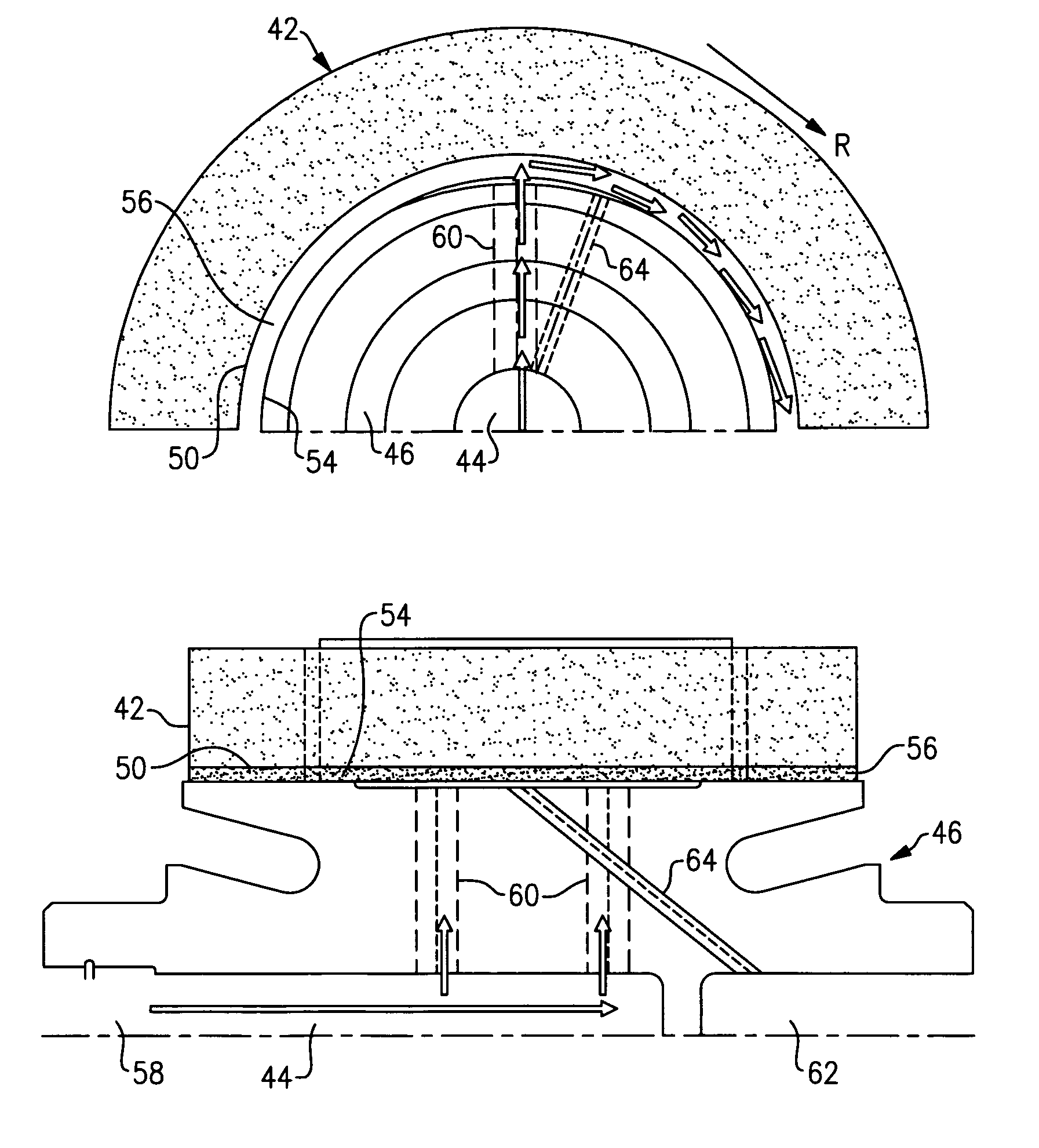

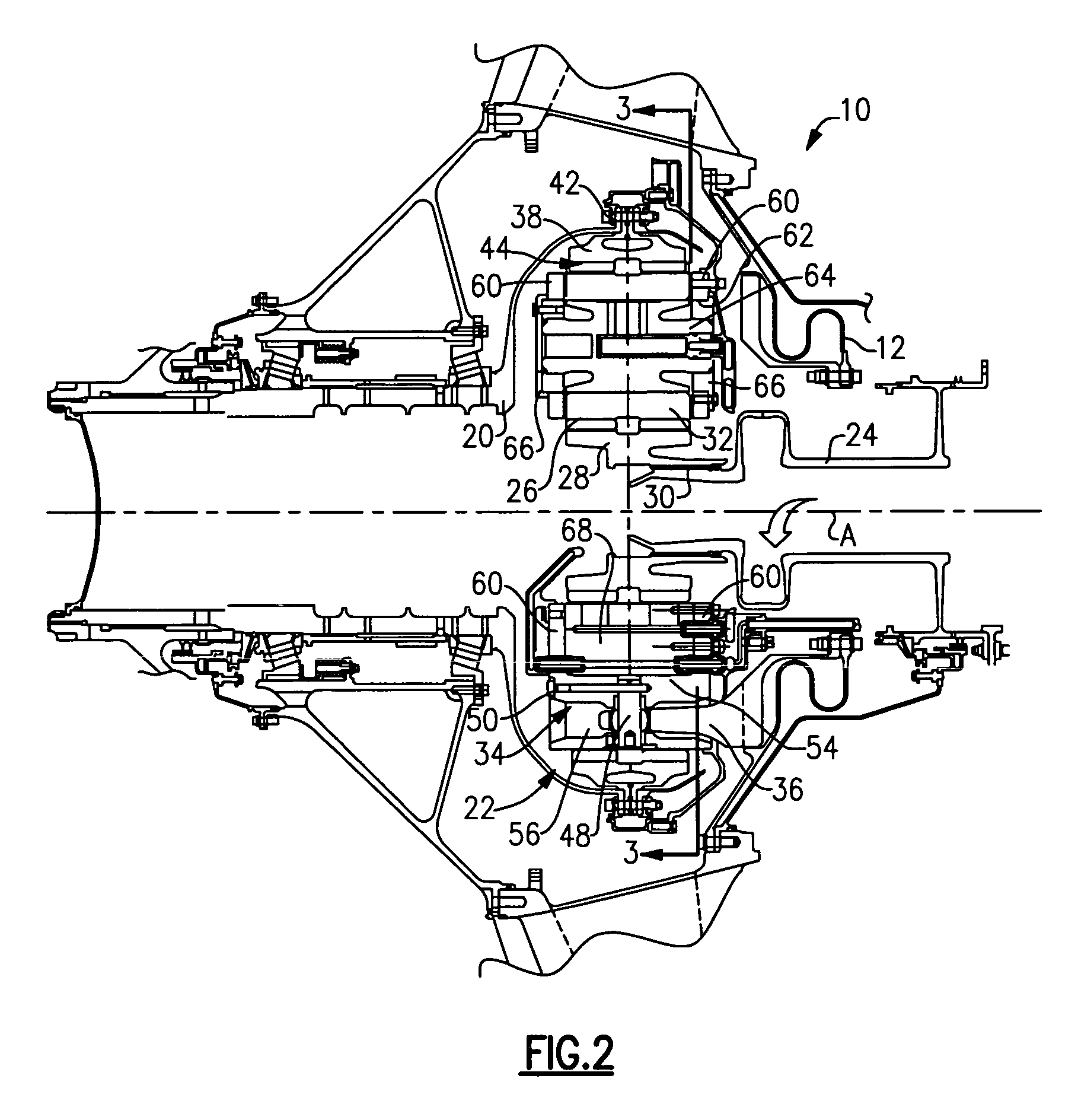

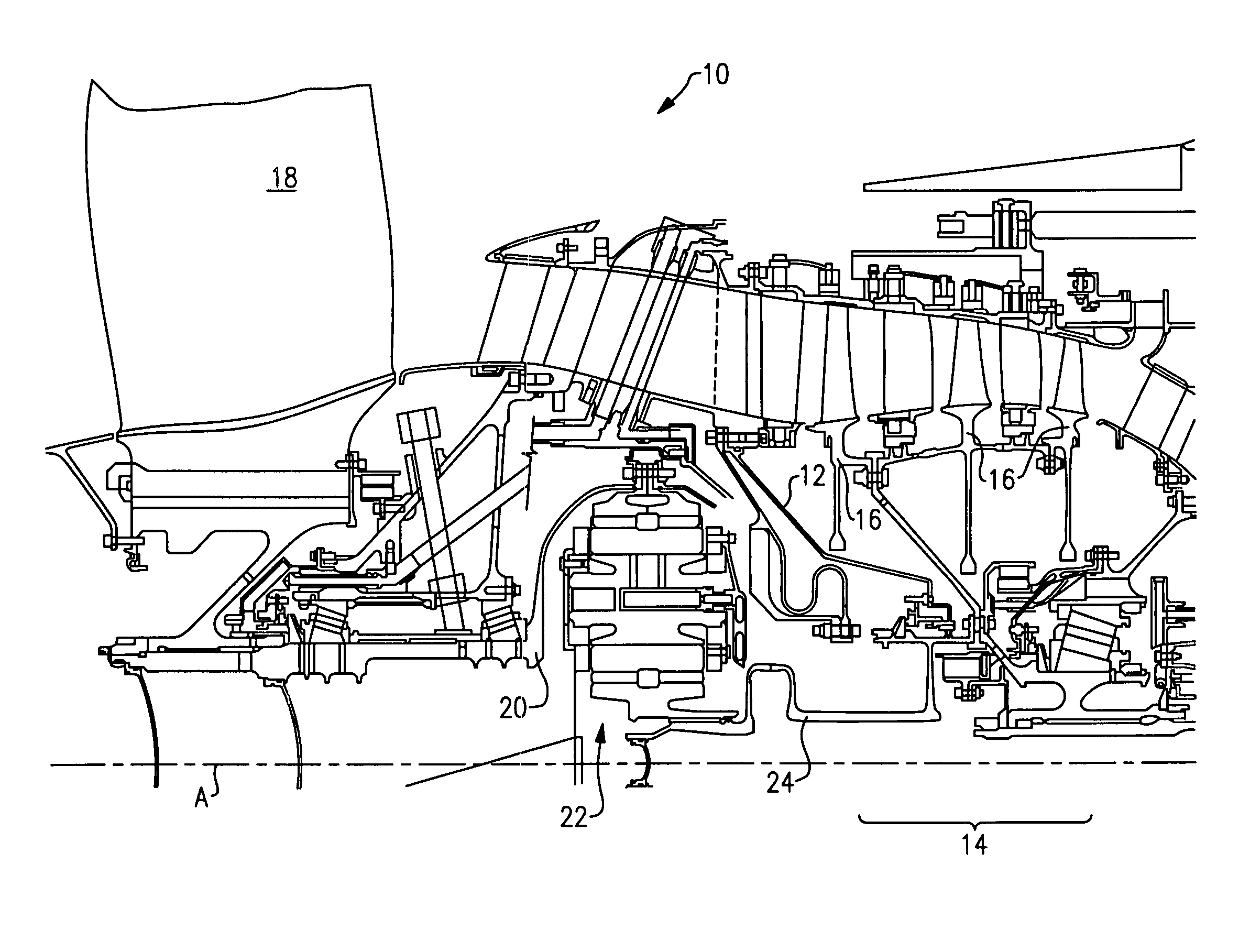

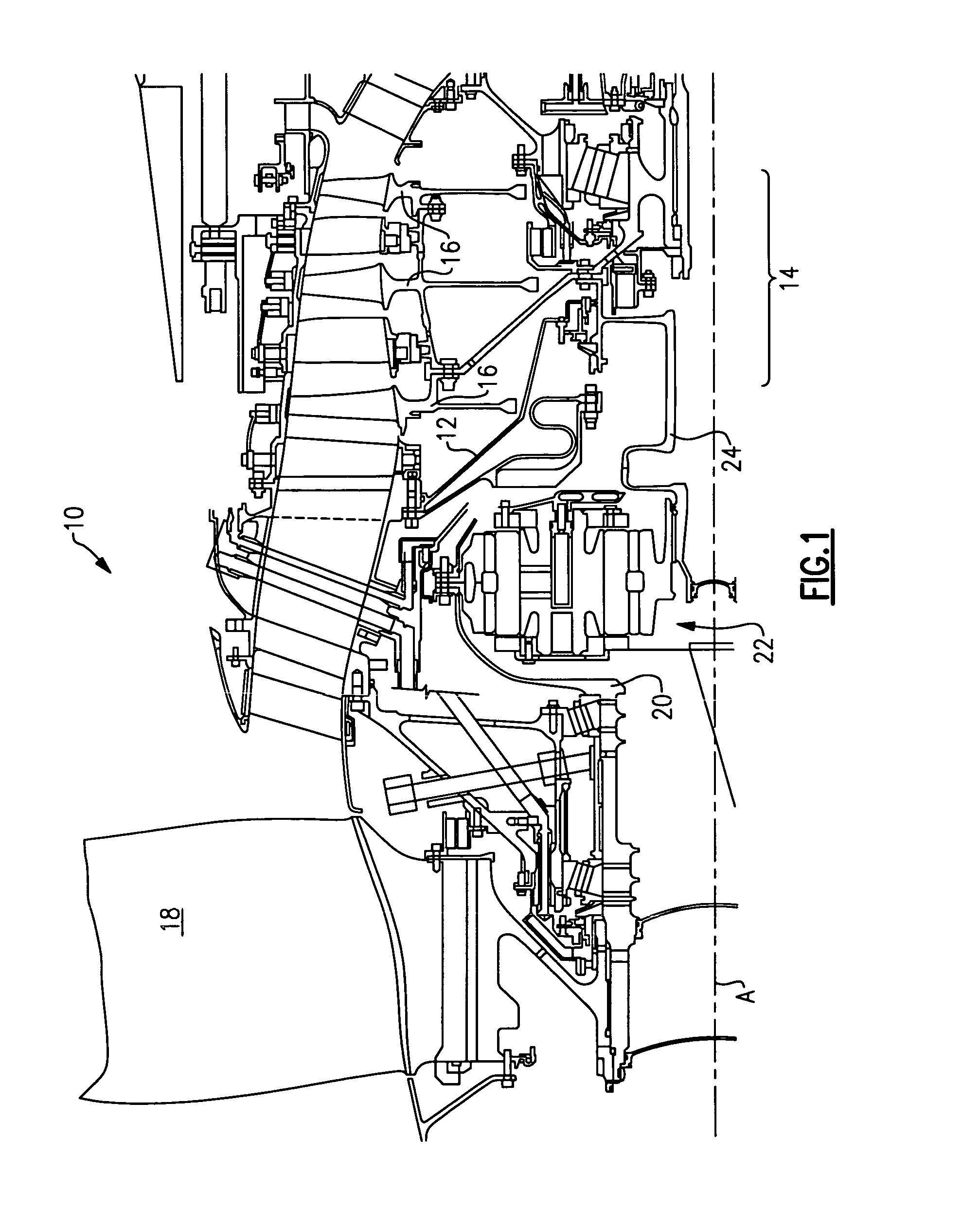

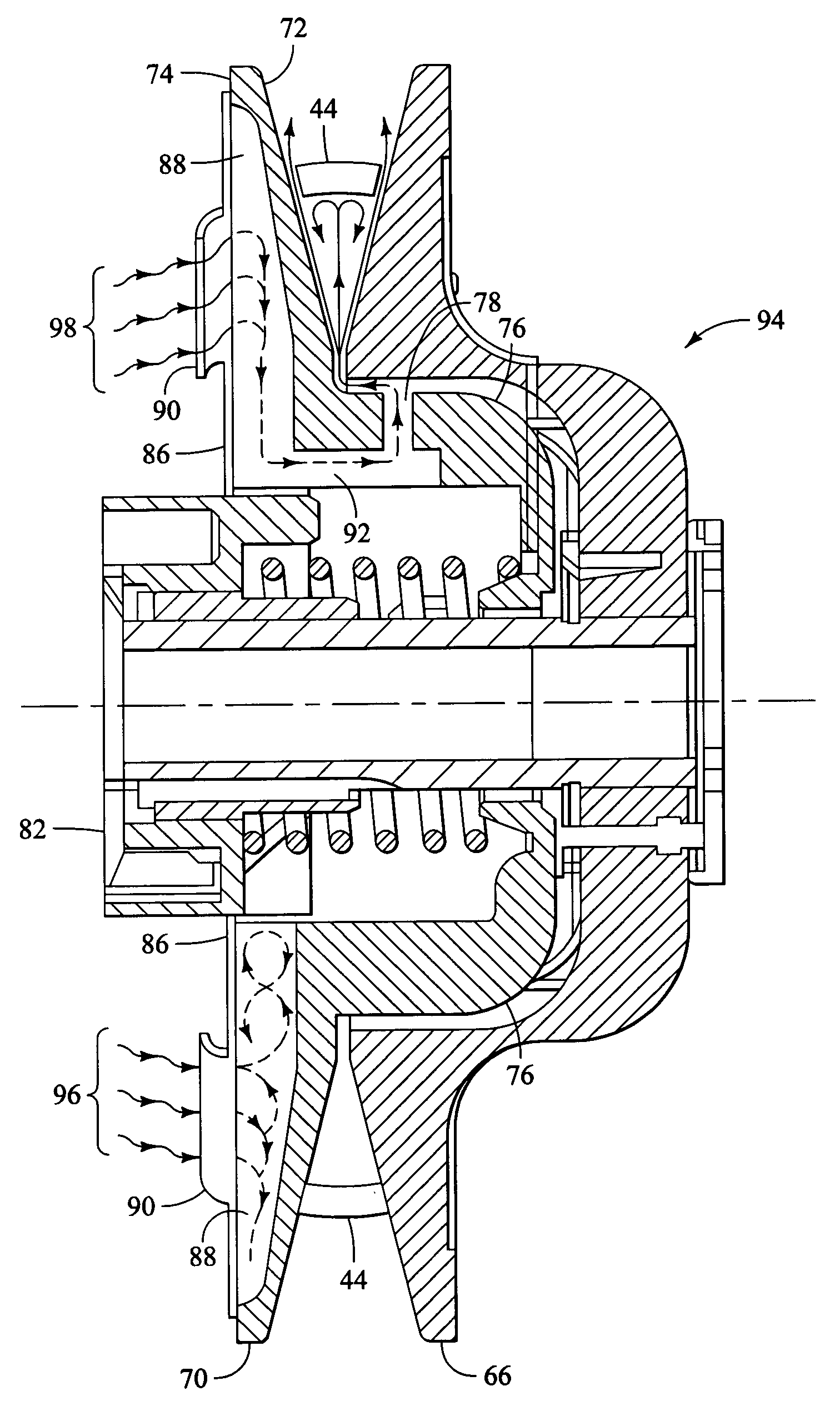

Oil baffle for gas turbine fan drive gear system

A gas turbine engine includes an epicyclic gear train that drives a turbo fan. The epicyclic gear train employs a one-piece carrier in which the spaced side walls are interconnected with circumferentially spaced apart mounts to form a unitary structure. Baffles are secured to the carrier near the mounts and provide lubrication passages that spray oil onto the sun gear and / or intermediate gears arranged between the baffles. The baffles can be constructed from a different material than the carrier since the baffles are not structural components in the gear train.

Owner:RAYTHEON TECH CORP

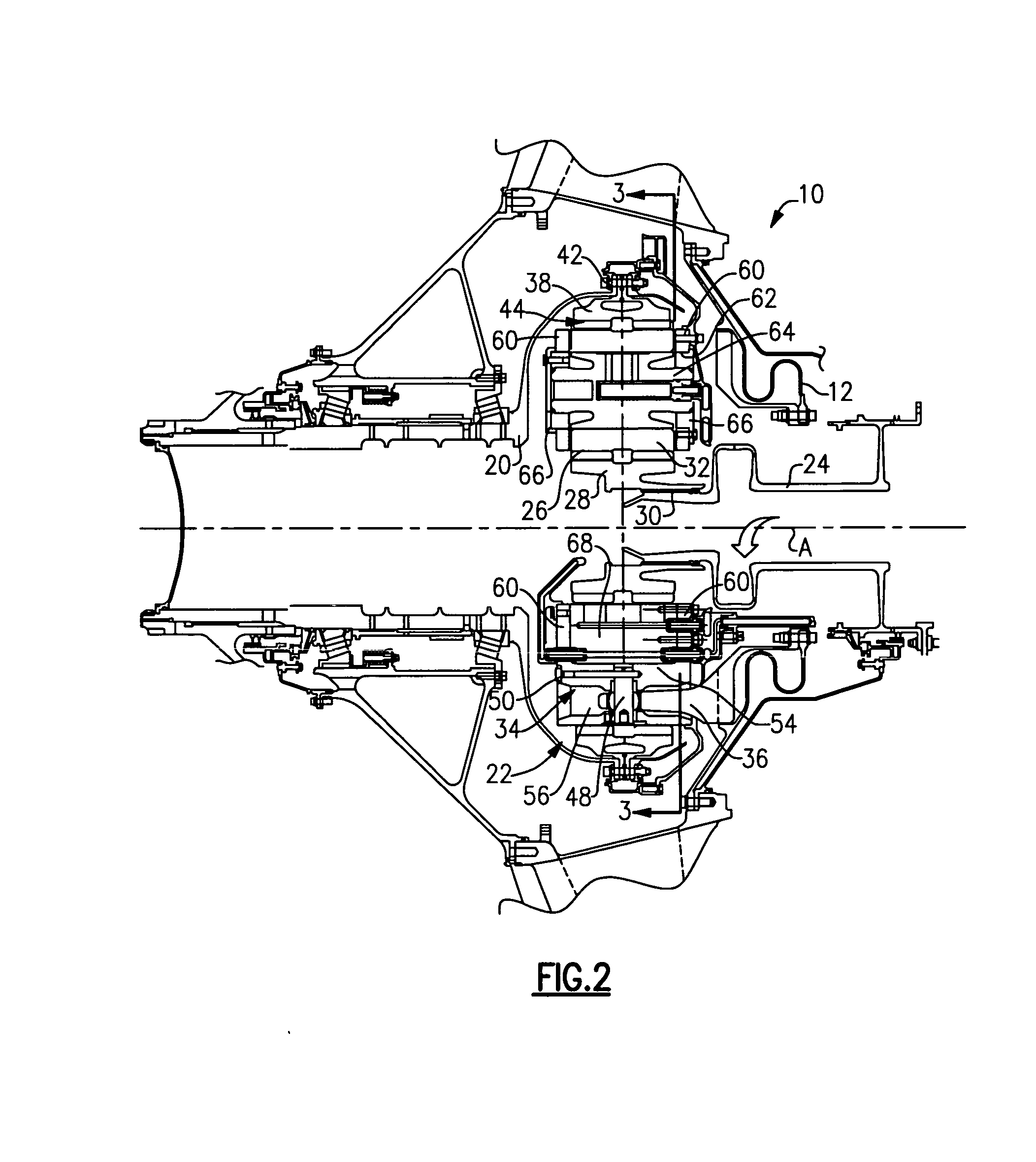

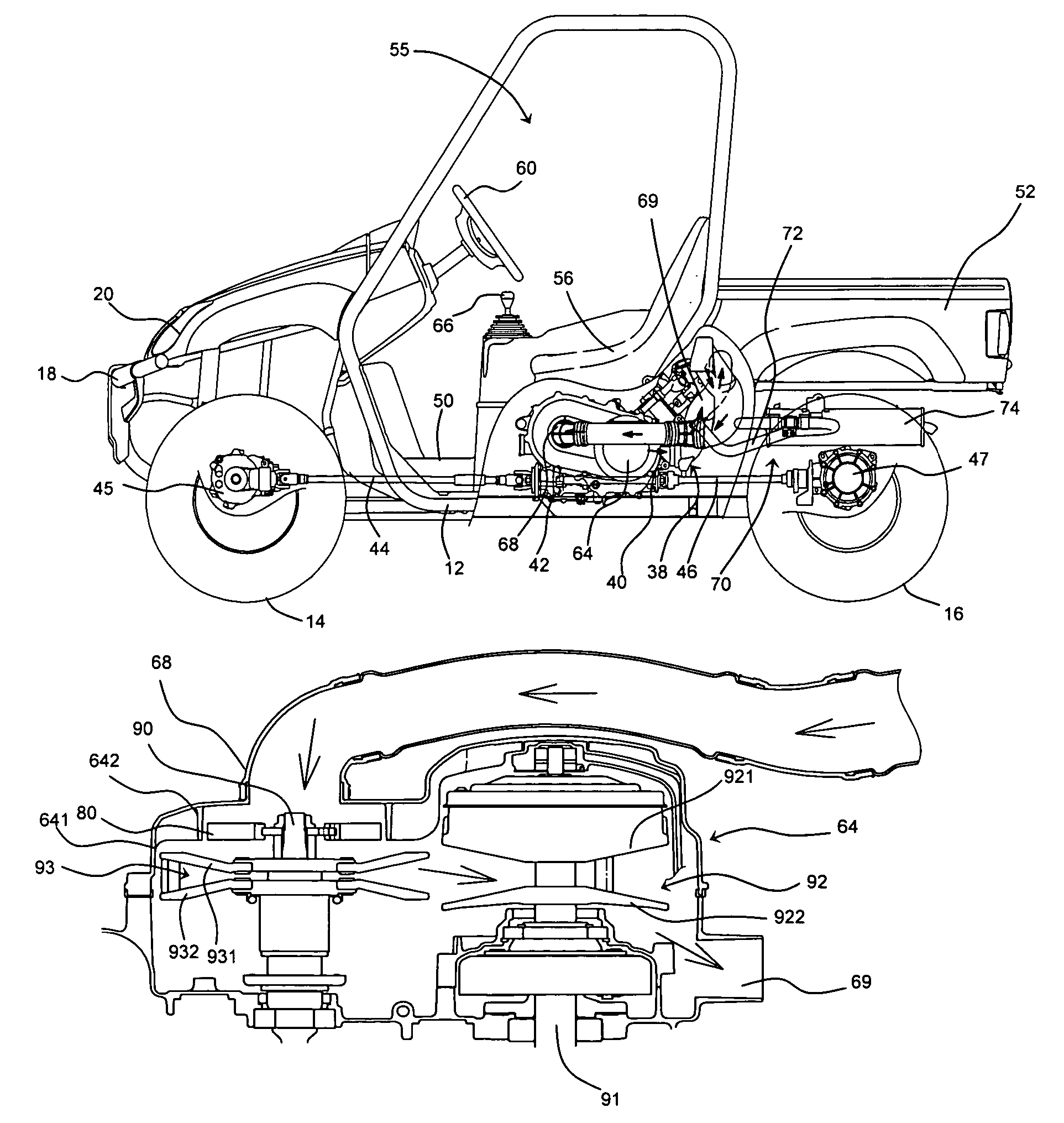

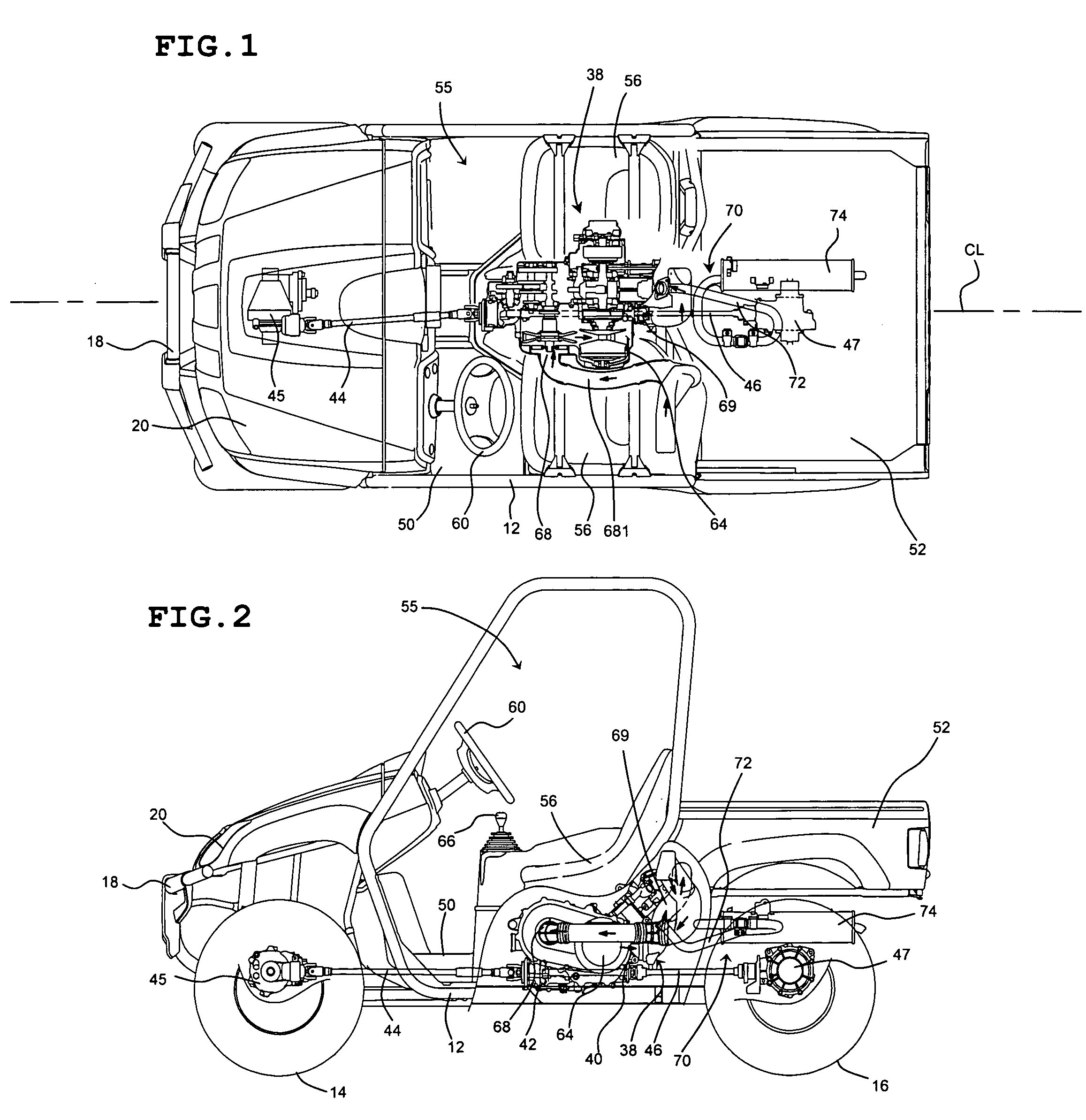

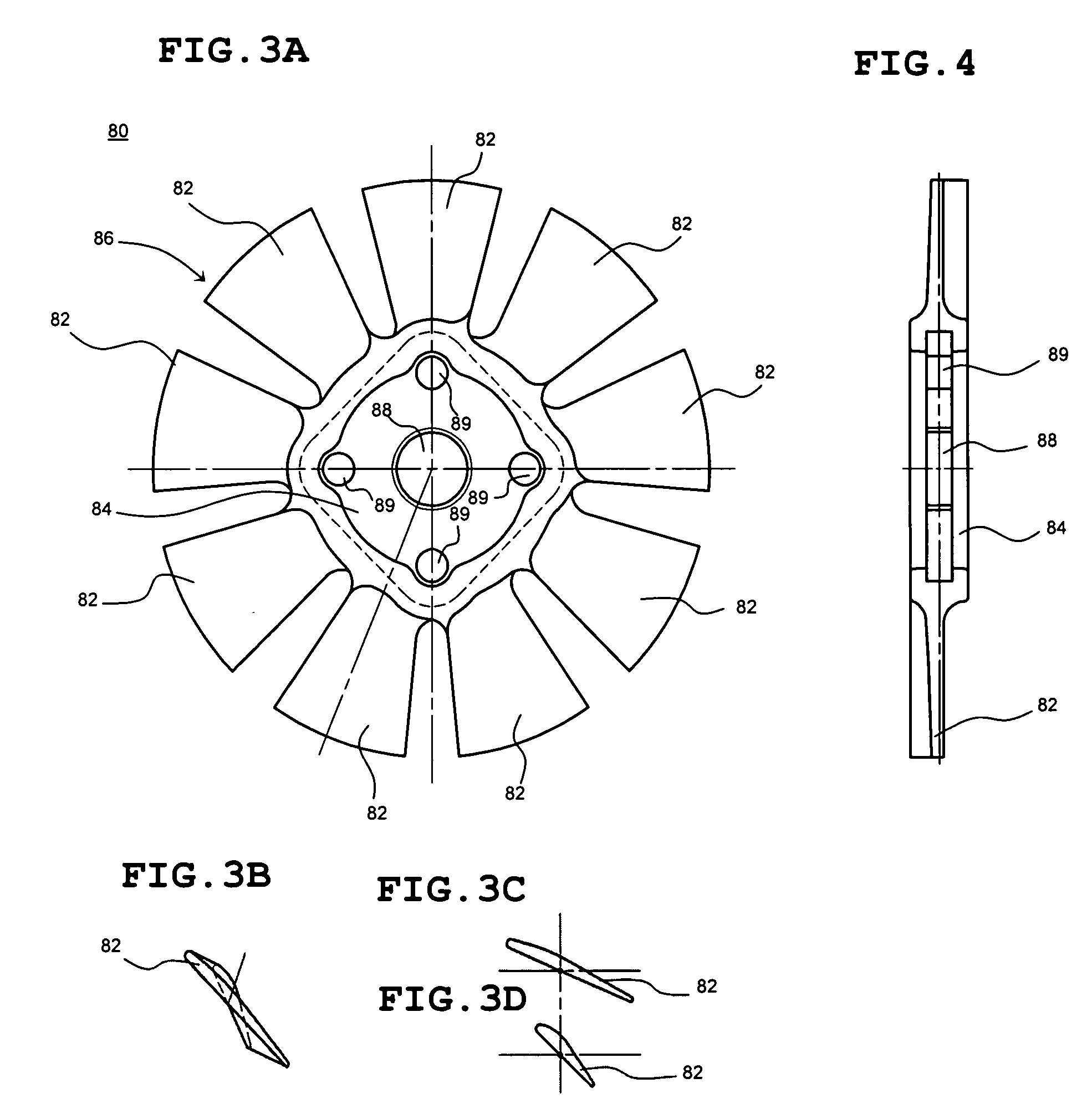

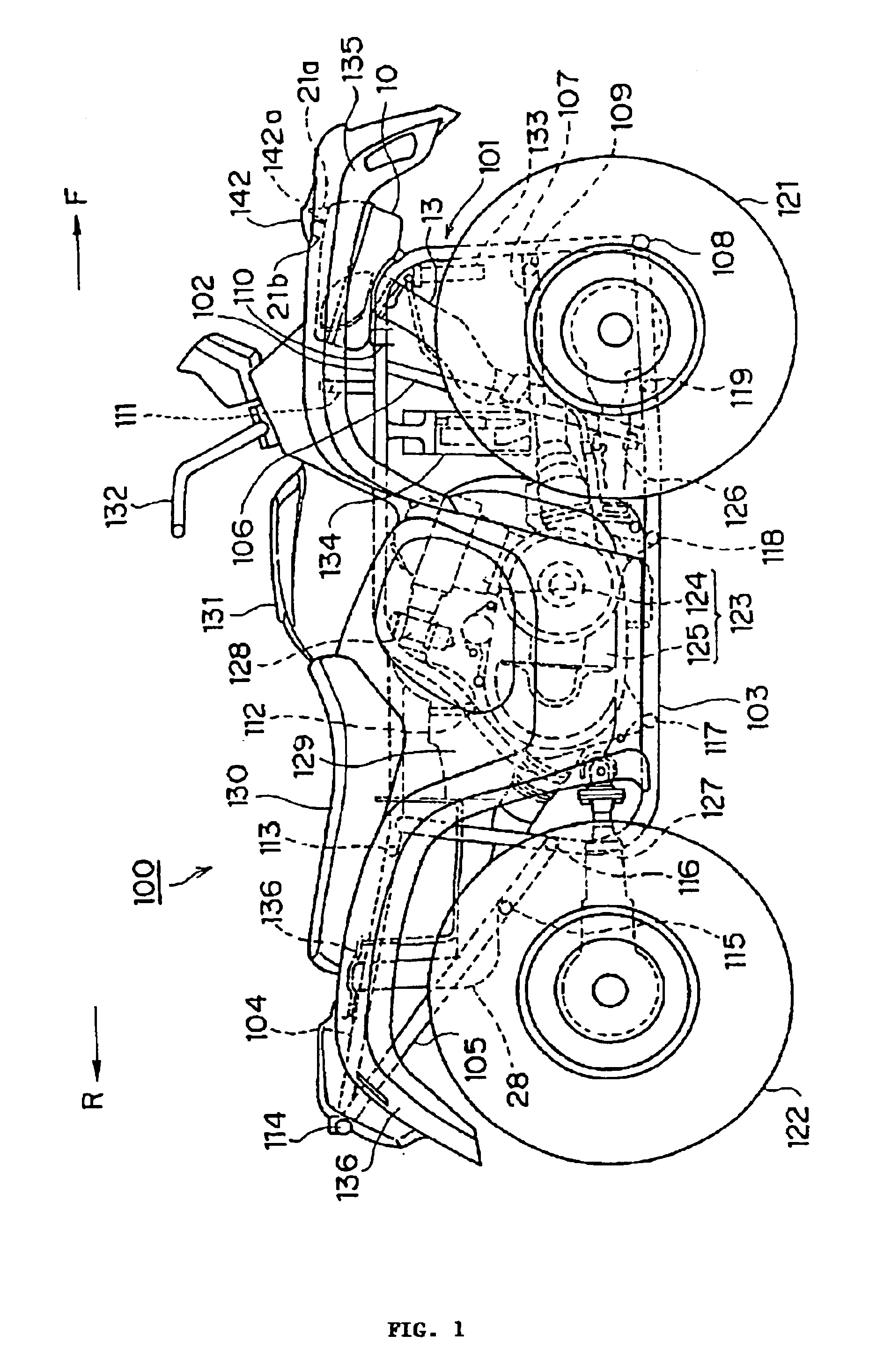

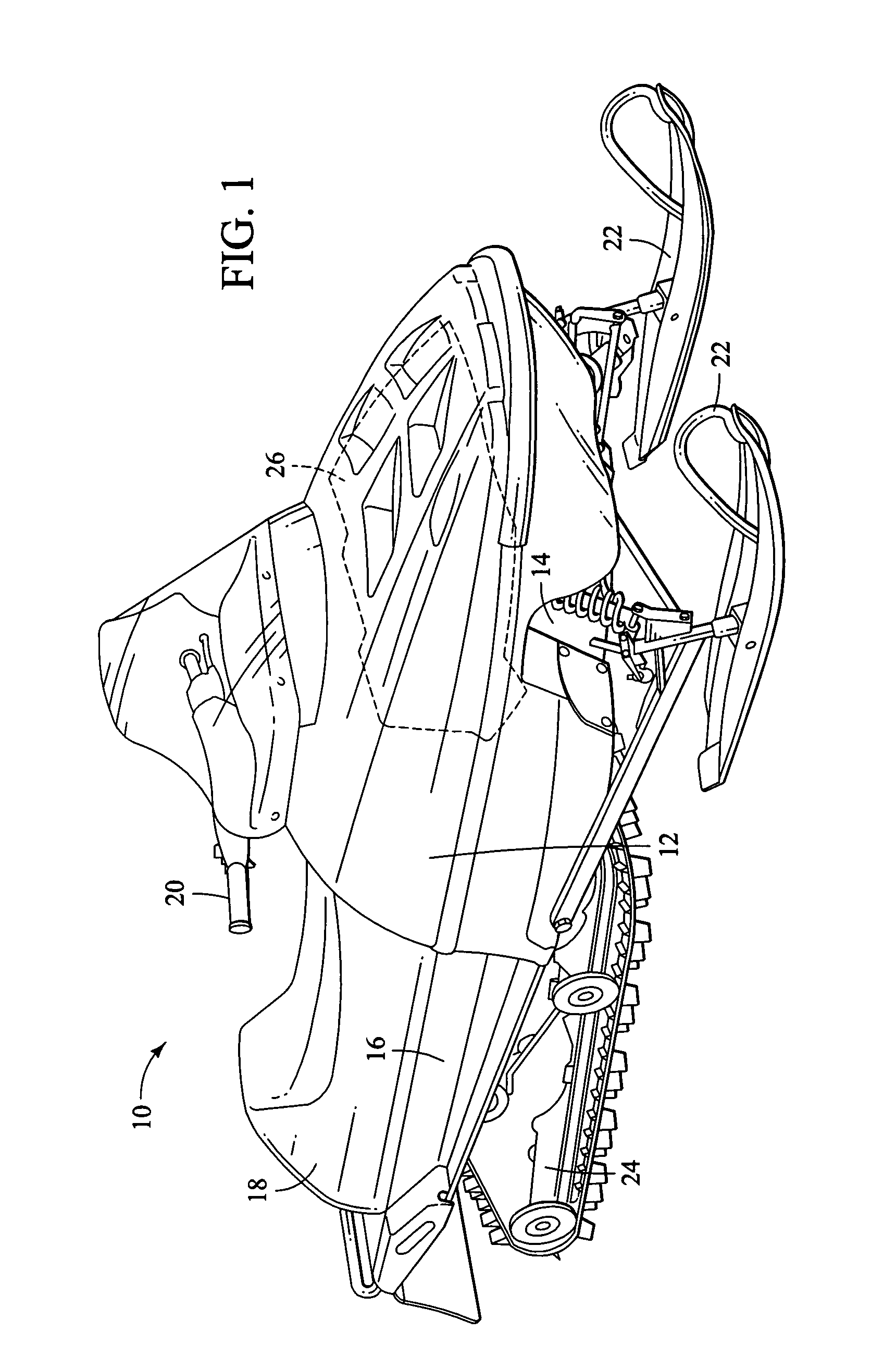

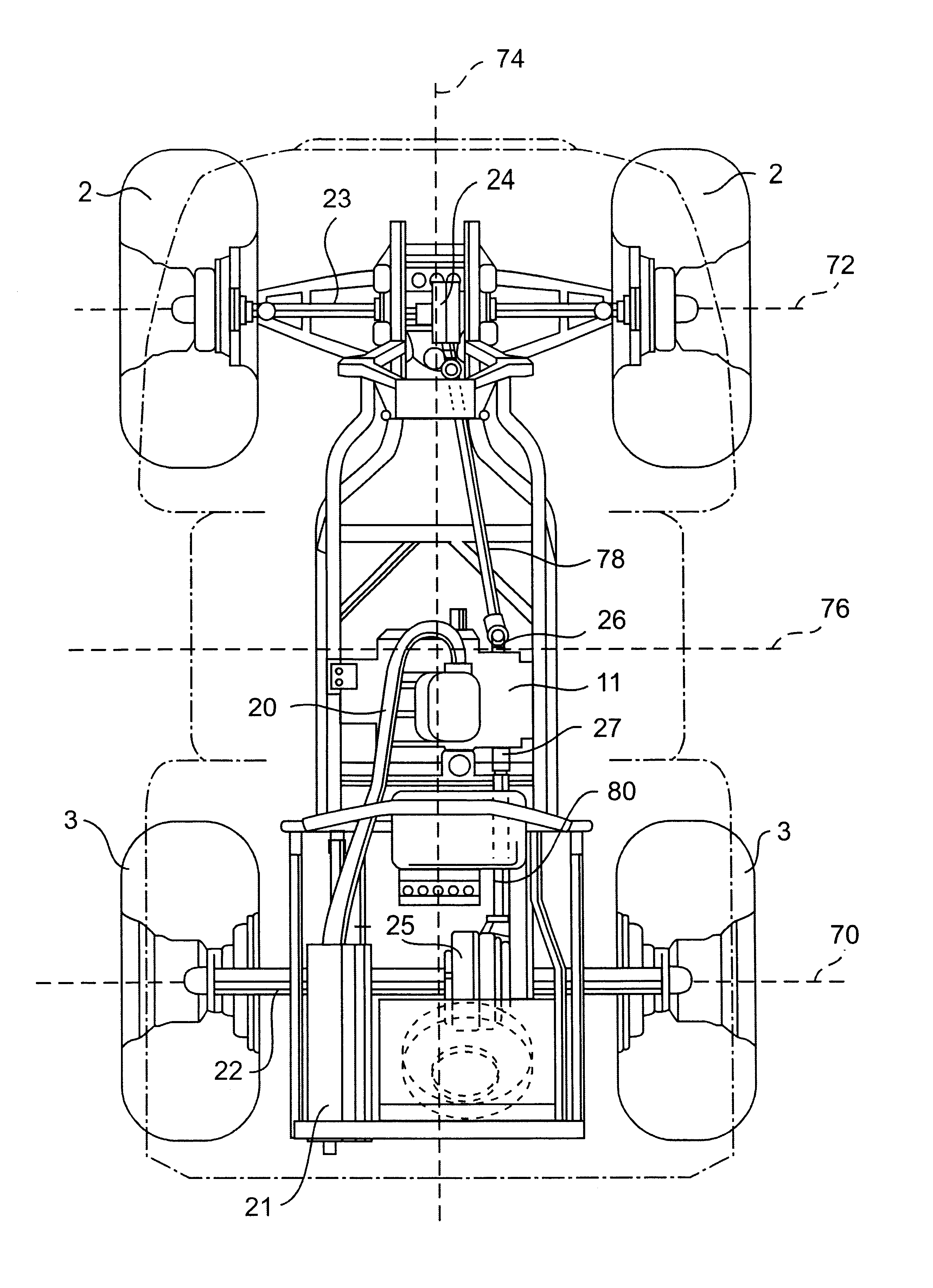

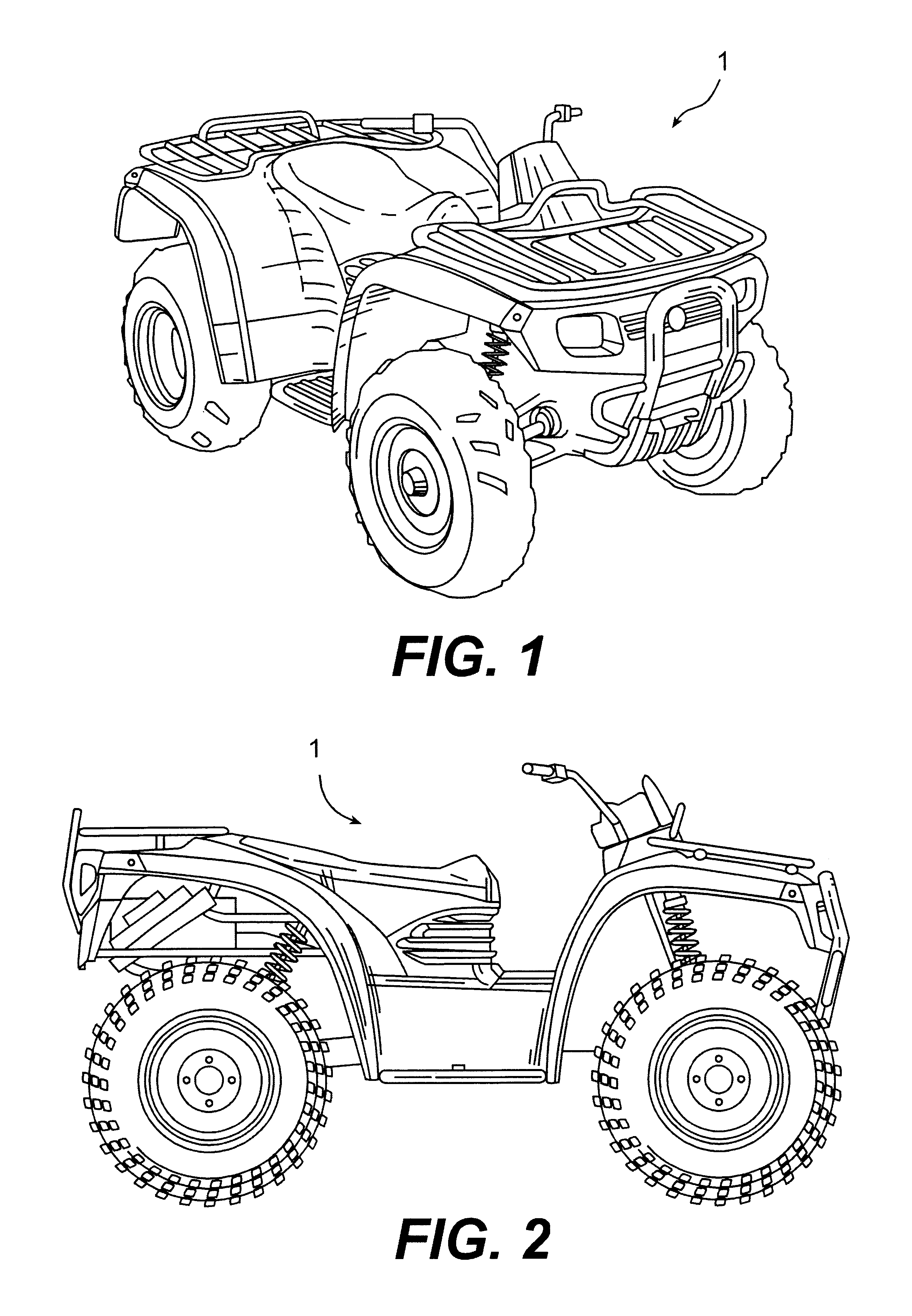

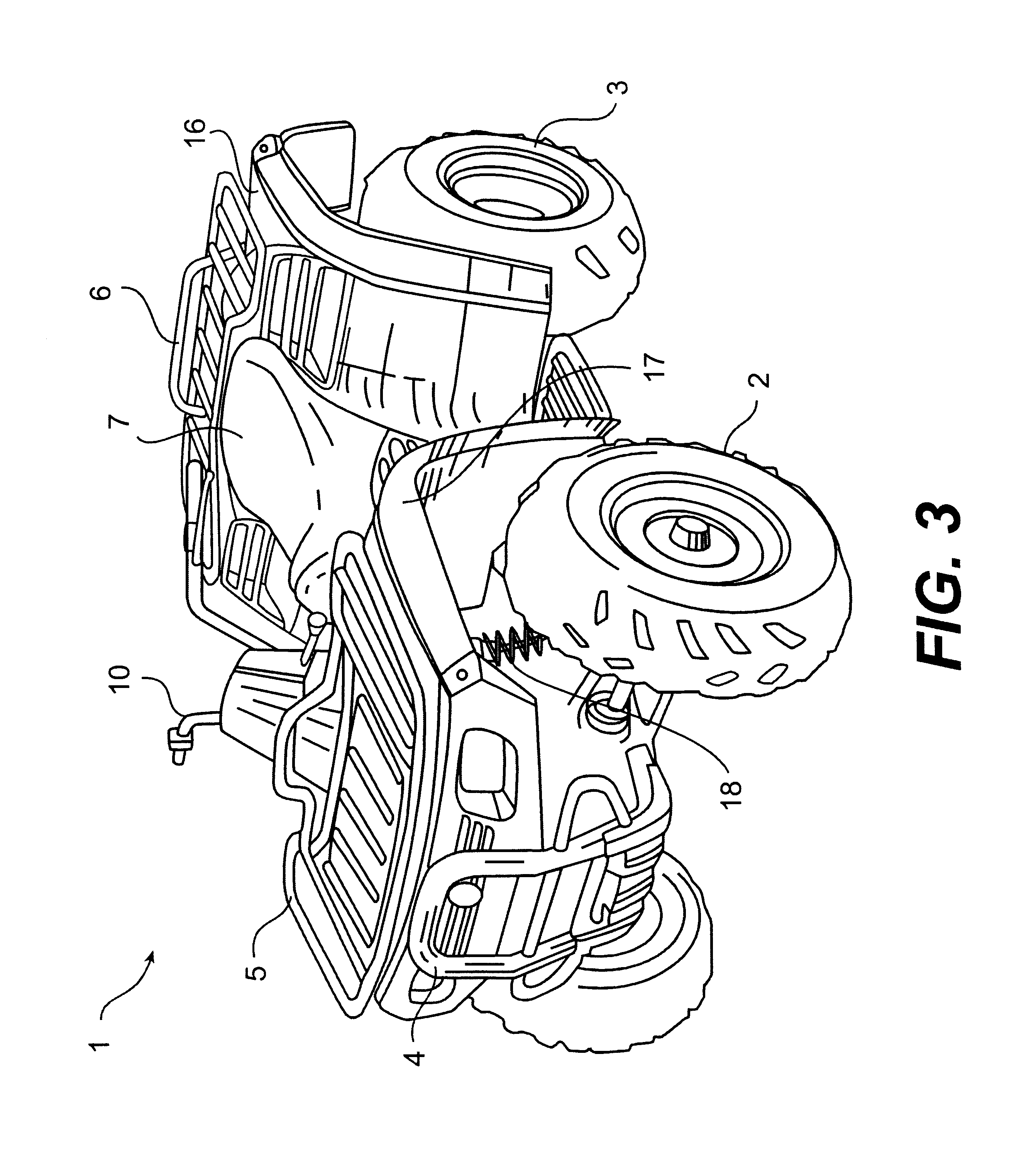

Air inlet for ATV

An all terrain vehicle has a frame assembly. A pair of front wheels and a pair of rear wheels support the frame assembly. A front fender assembly extends over at least a portion of the front wheels. An engine is disposed between the front wheels and the rear wheels. The engine is water-cooled using a radiator and fan combination that is positioned forward of the engine. A belt drive forms a portion of a transmission that transfers power from the engine to at least the rear wheels. The belt drive is air cooled with air that is pulled into the belt drive by fans positioned within a belt case. The air is drawn from an air chamber formed within the front fender assembly. The chamber is positioned vertically higher than the radiator and fan combination and rearward thereof. The air passes between the chamber and the belt case through a duct. The duct extends downward and incorporates a central trap portion. The duct is positioned to lie at least partially within an area that overlaps the fan from a front elevation view. The duct also bends across a central longitudinal plane from inlet to outlet to allow a compact configuration while positioning the duct in protected regions.

Owner:YAMAHA MOTOR CO LTD

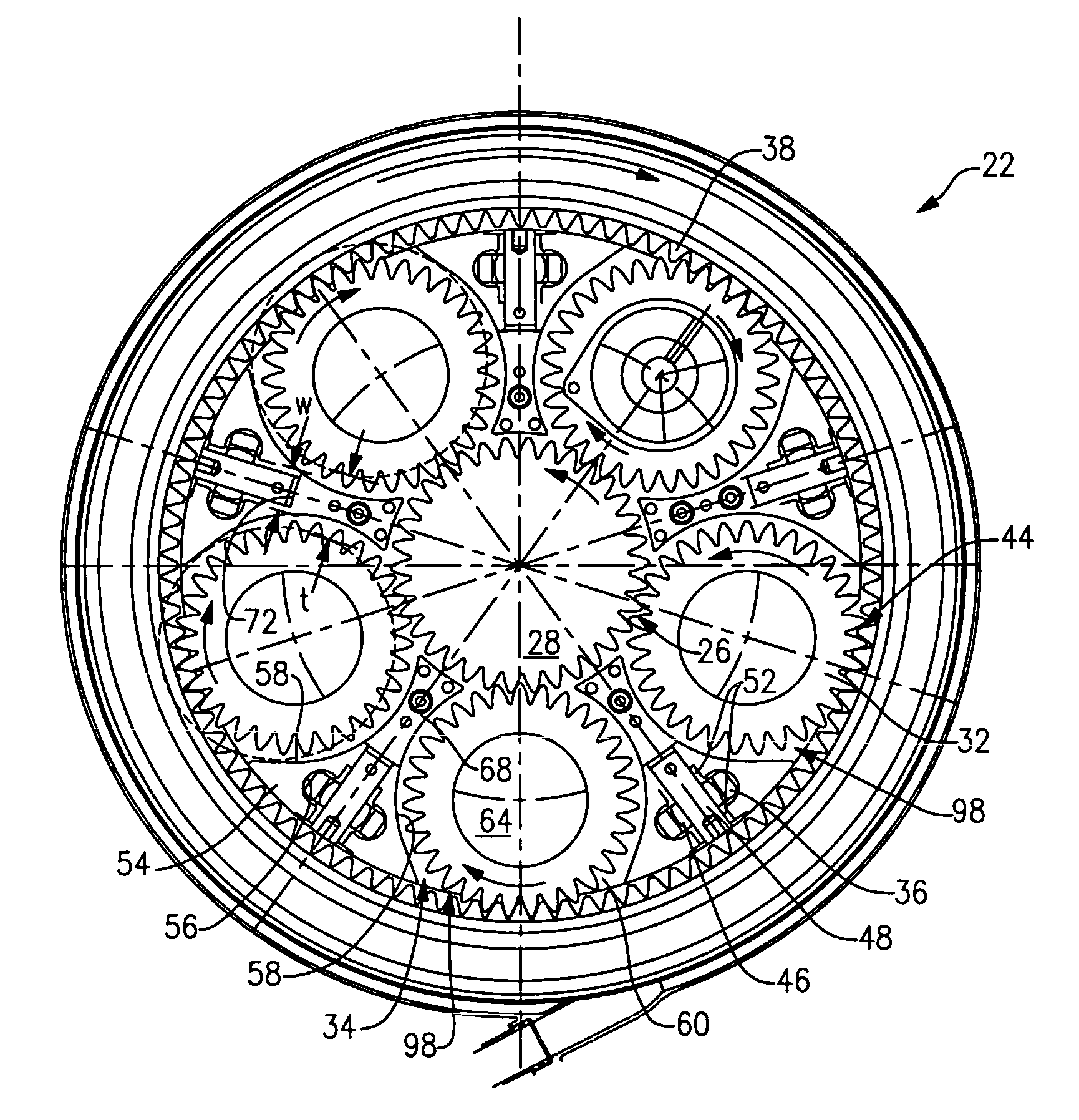

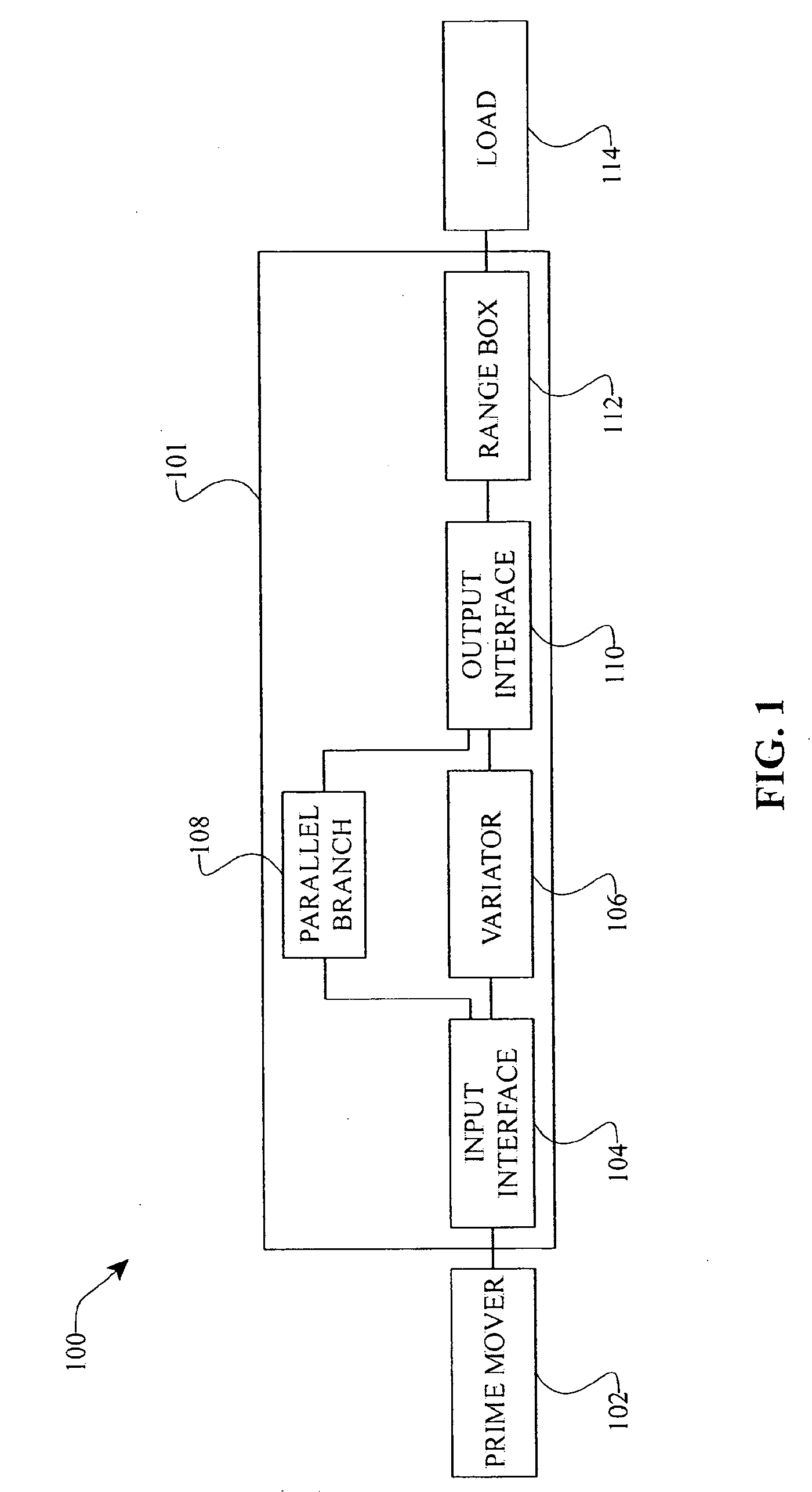

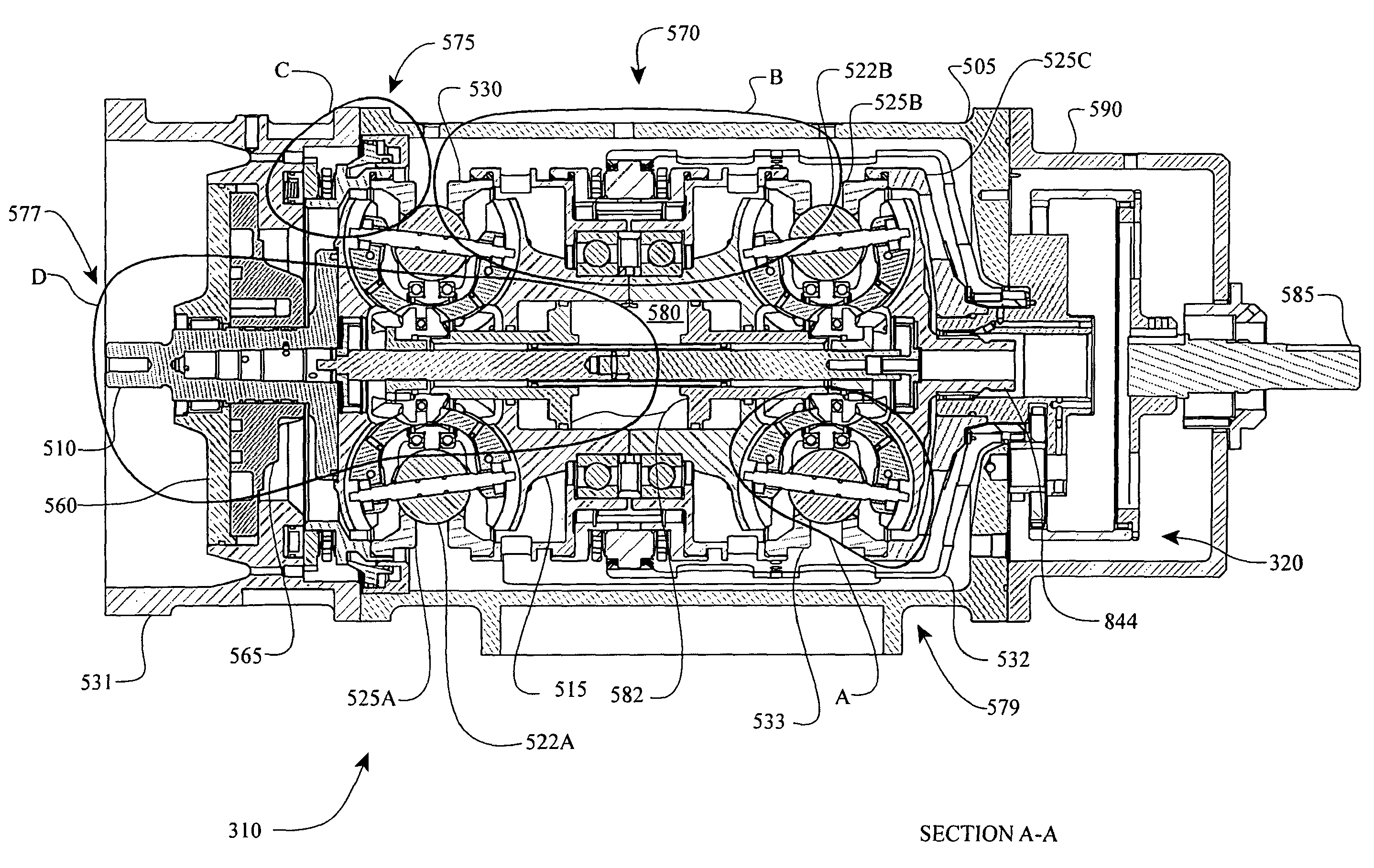

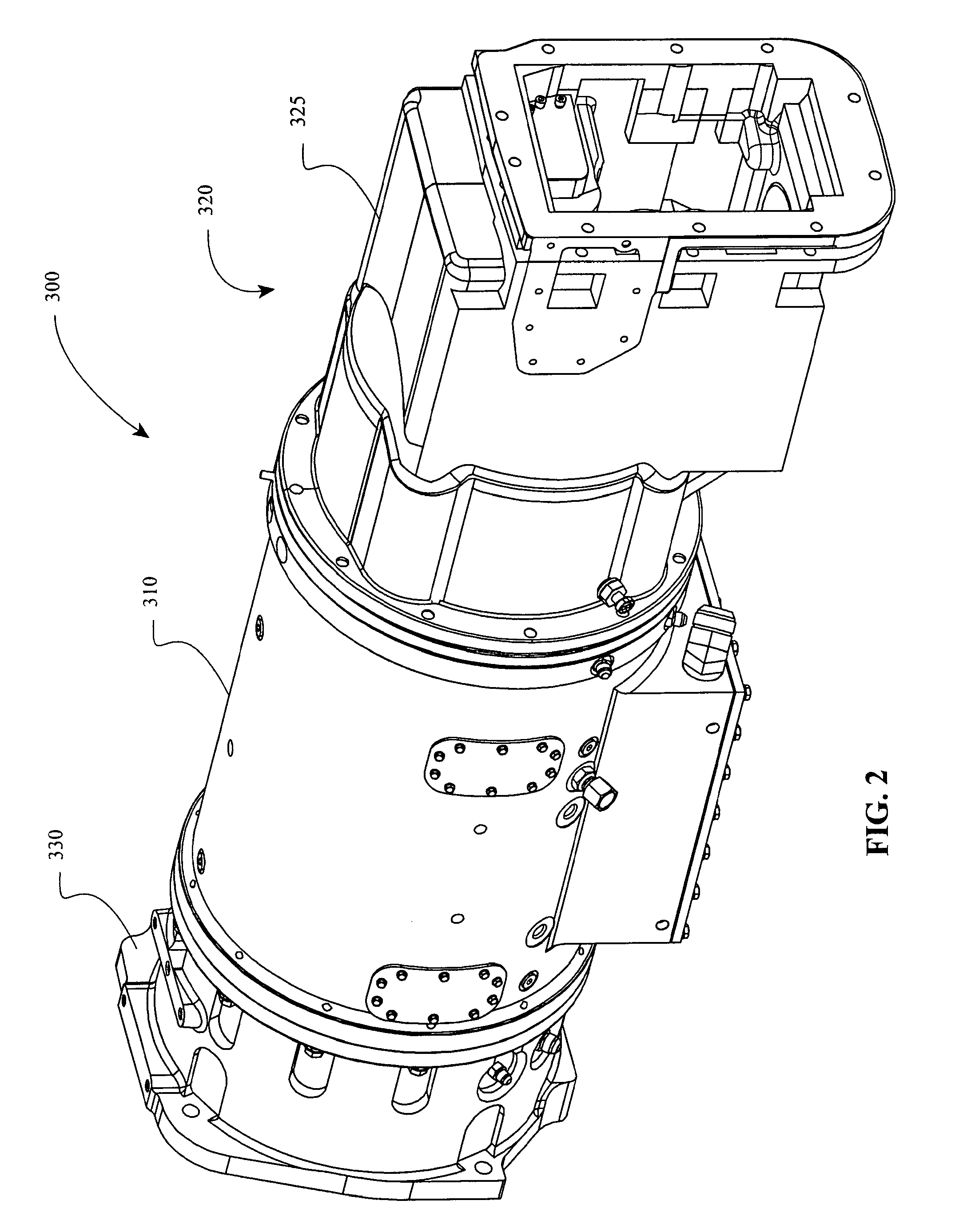

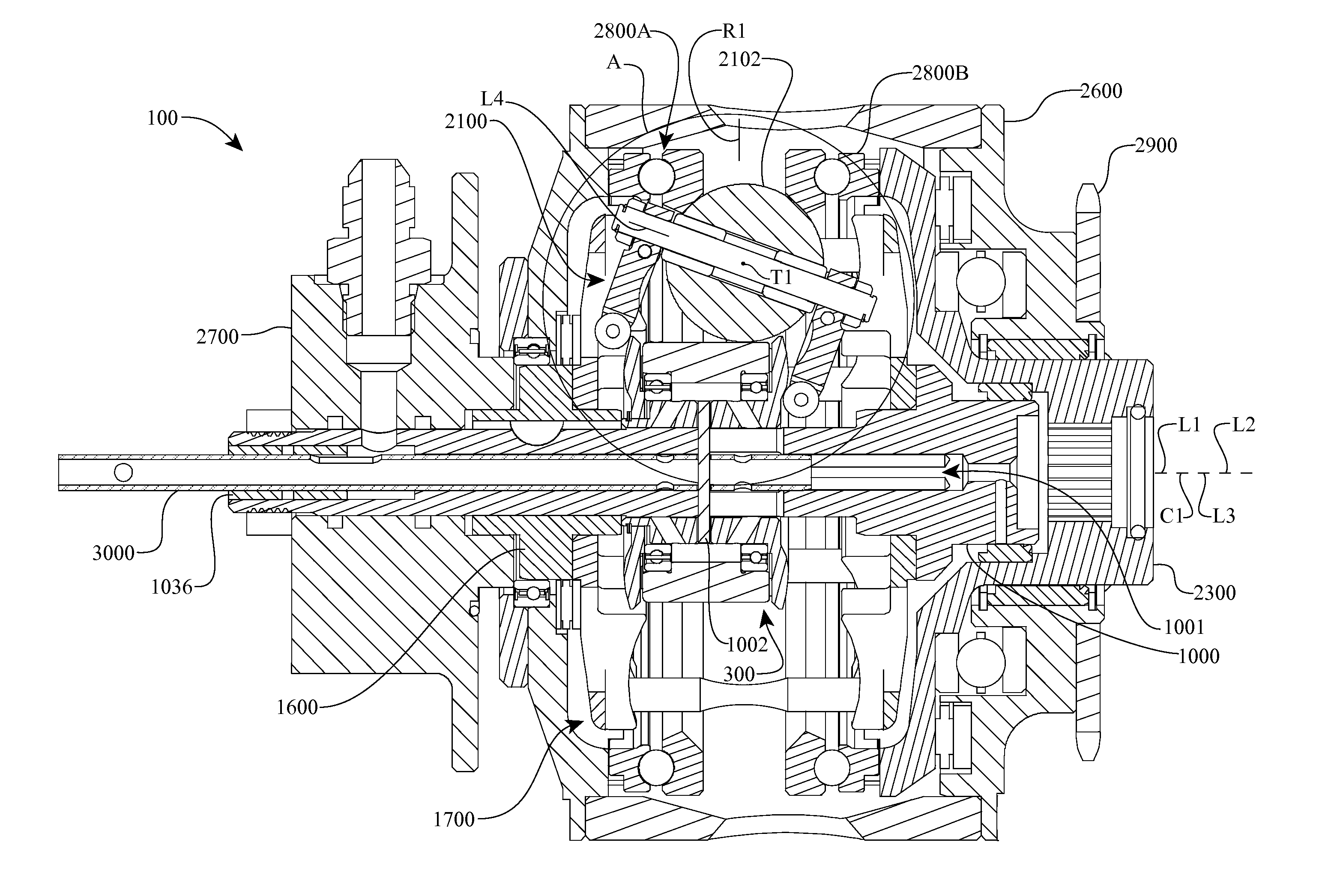

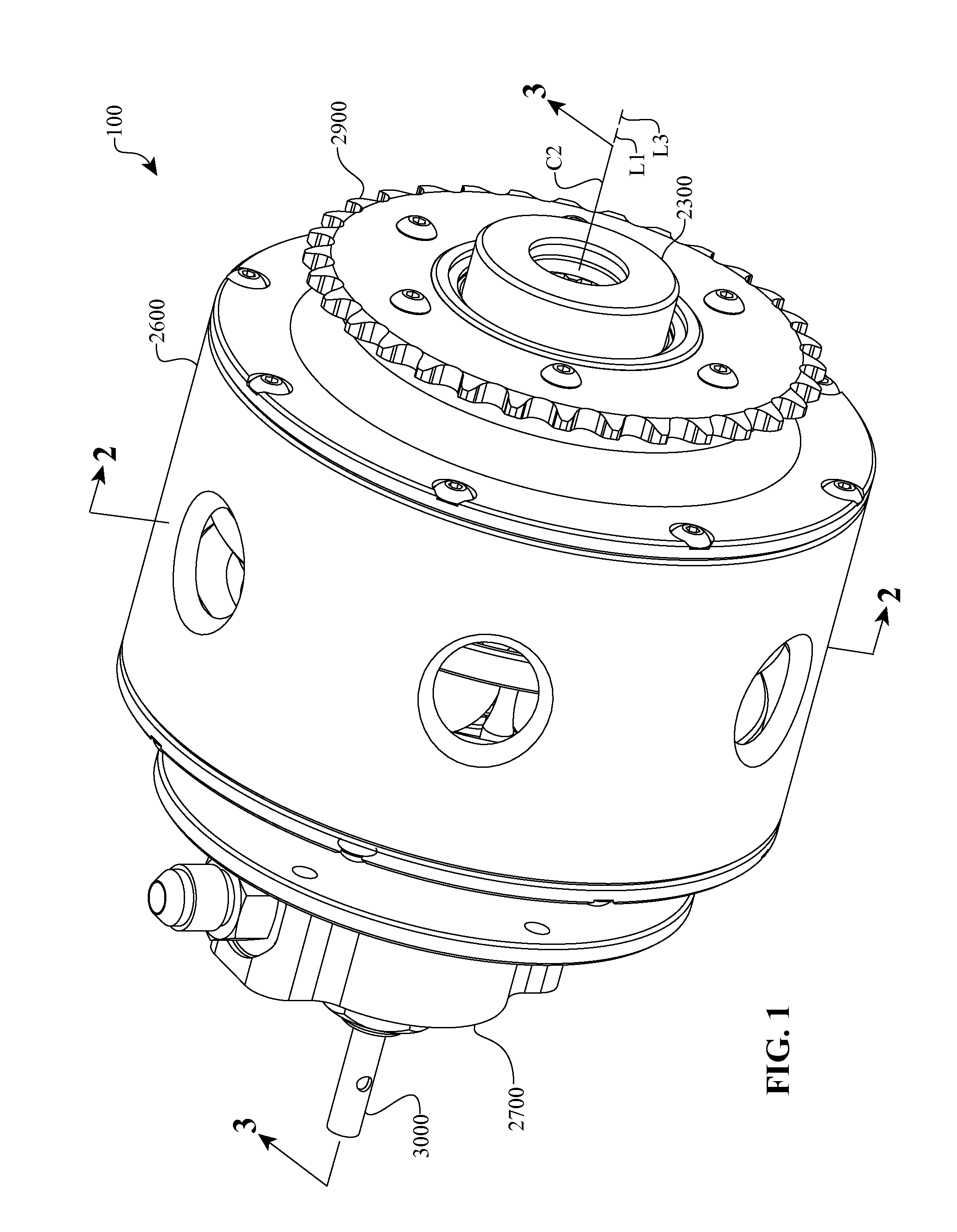

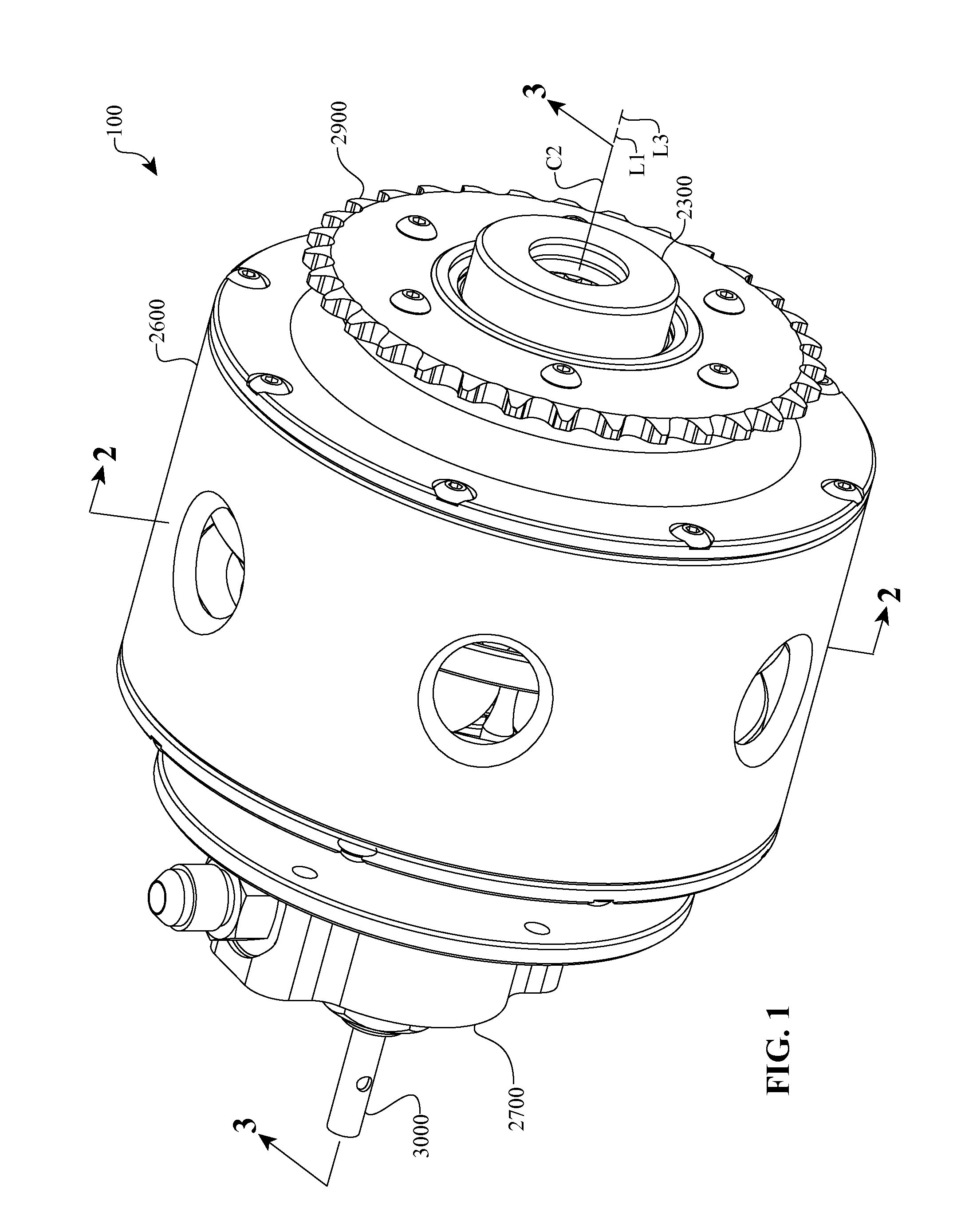

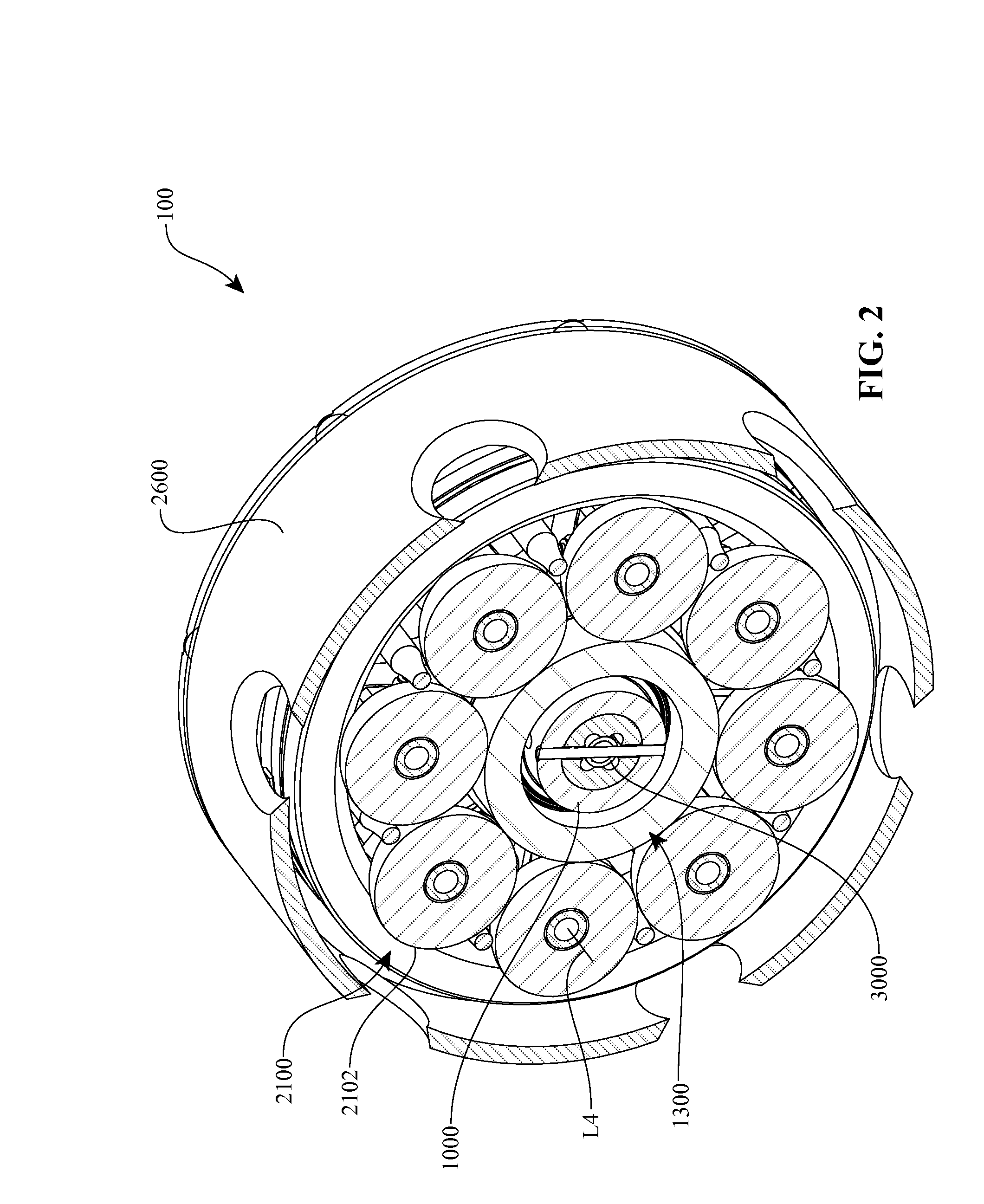

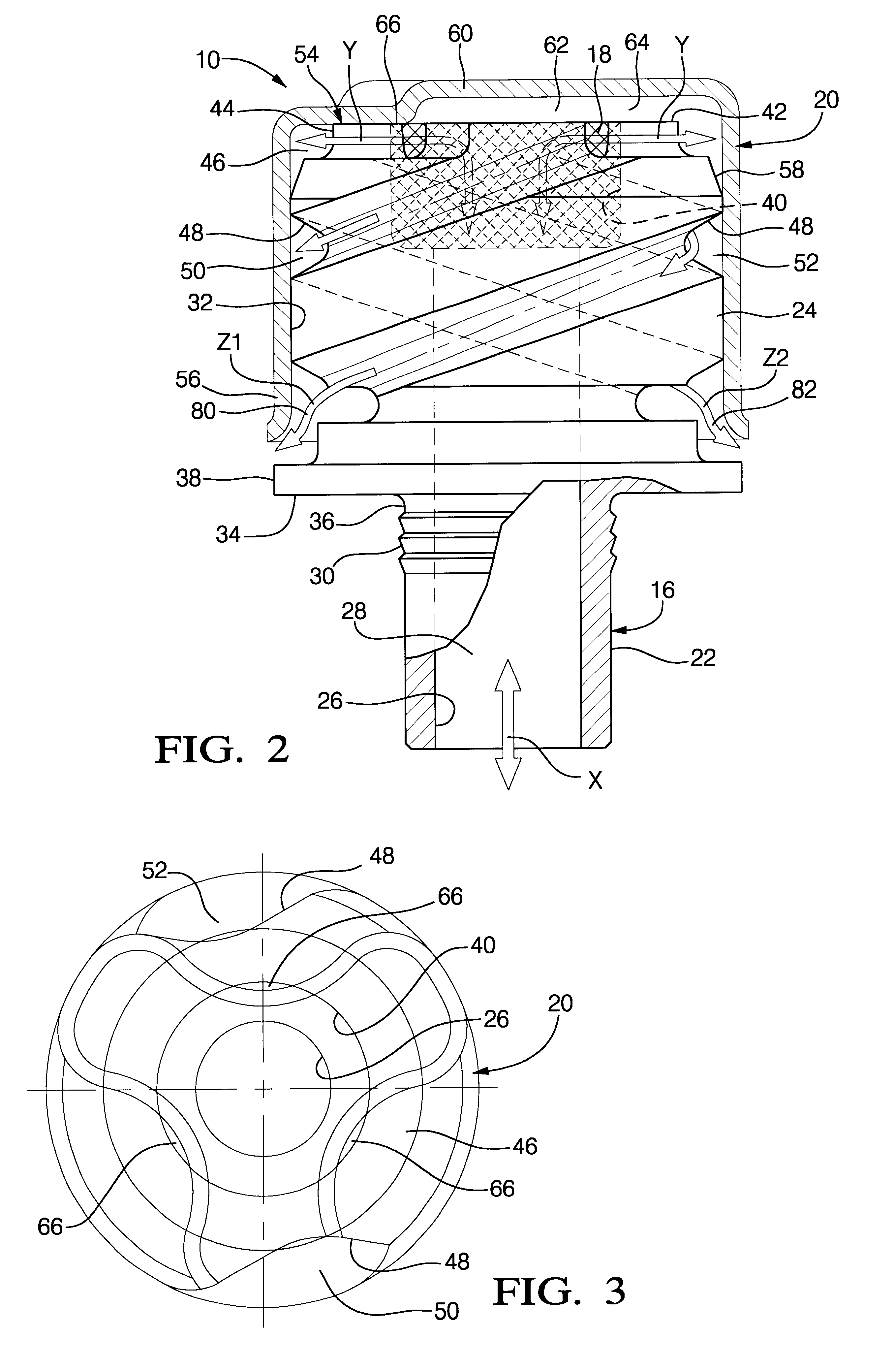

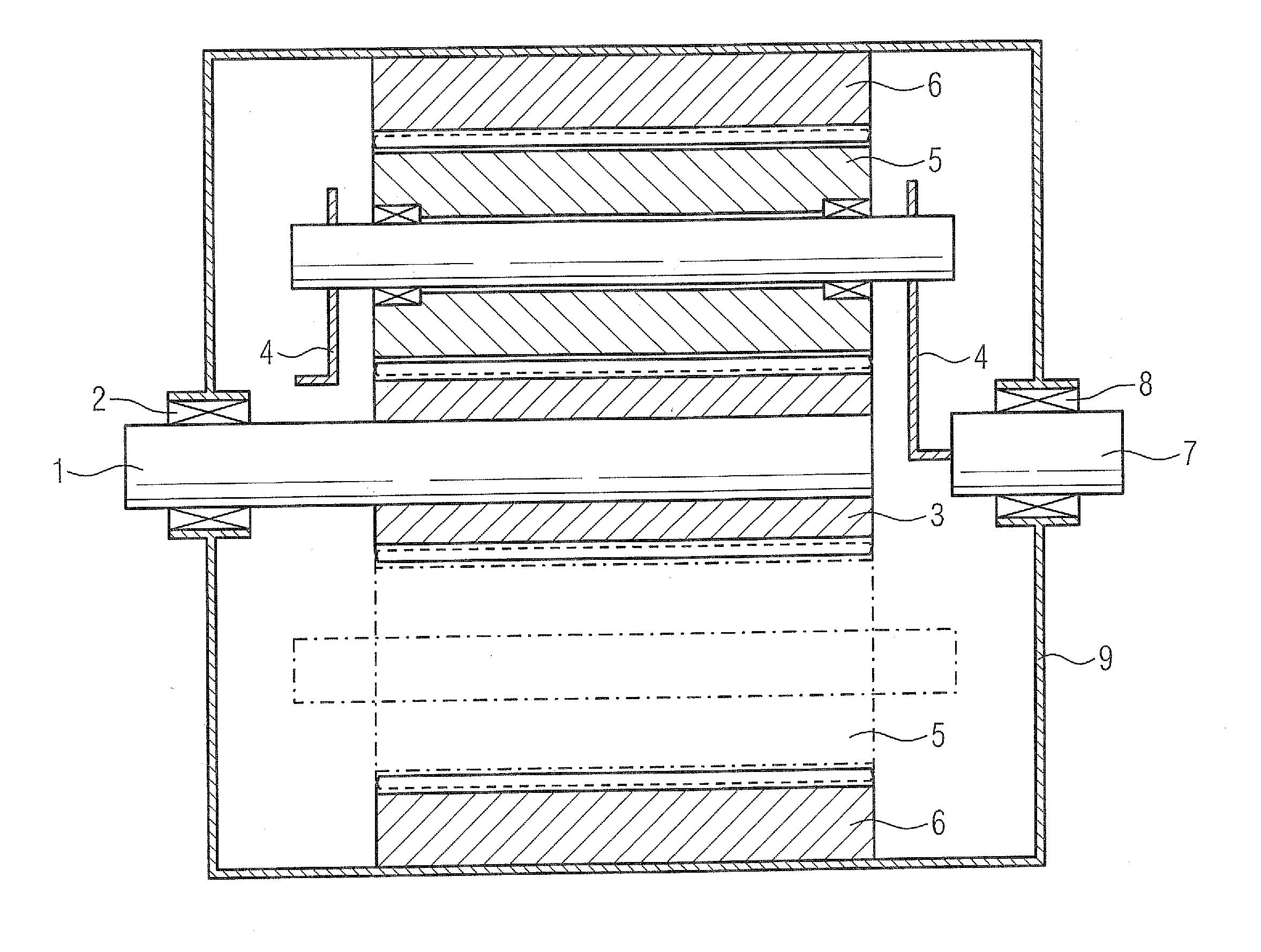

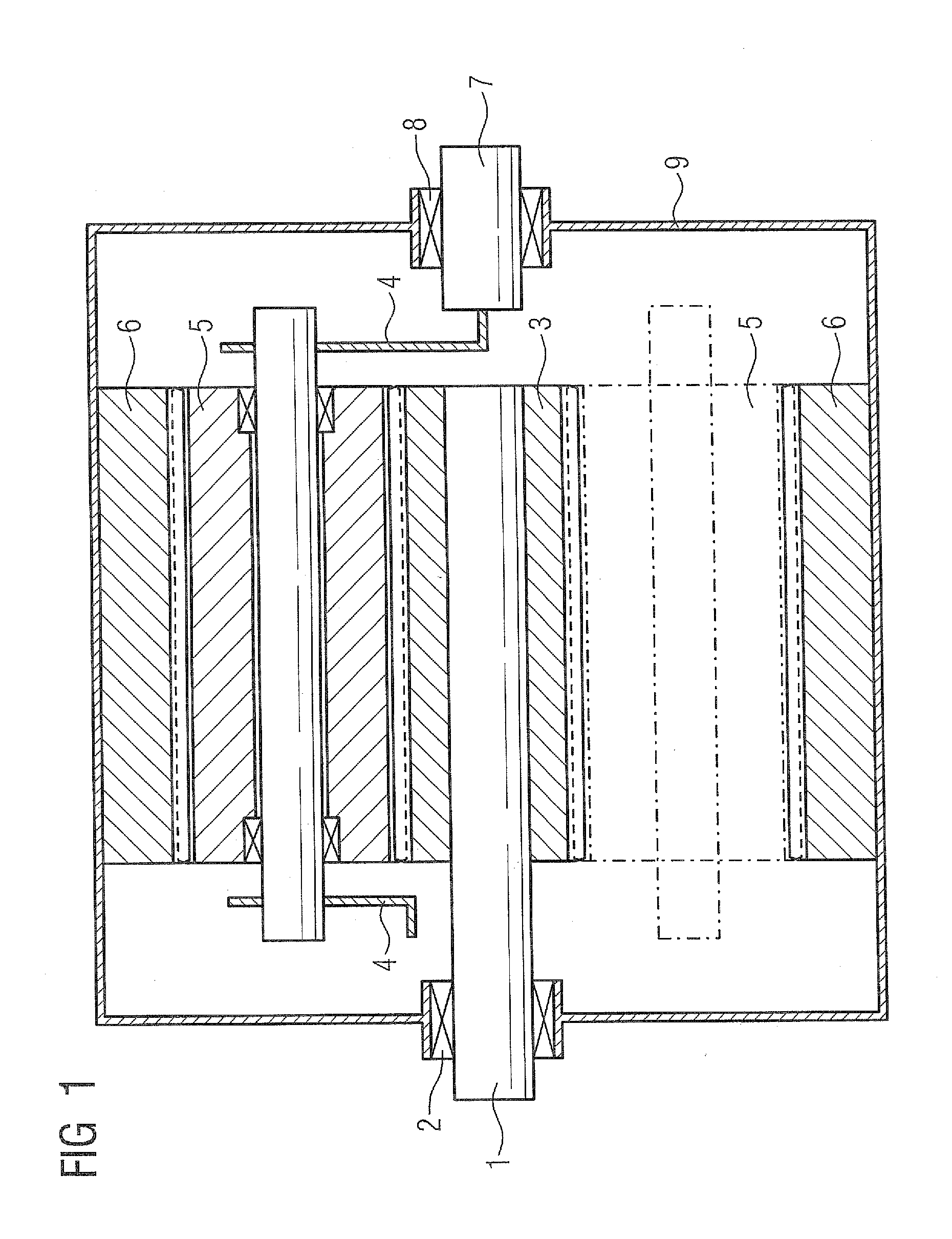

Infinitely variable transmissions, continuously variable transmissions, methods, assemblies, subassemblies, and components therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for infinitely variable transmissions (IVT) having a variator provided with a plurality of tilting spherical planets. In one embodiment, a variator is provided with multiple planet arrays. In another embodiment, a hydraulic system is configured to control the transmission ratio of the IVT. Various inventive idler assemblies and planet-pivot arm assemblies can be used to facilitate adjusting the transmission speed ratio of an IVT. Embodiments of a transmission housing and bell housing are adapted to house components of an IVT and, in some embodiments, to cooperate with other components of the IVT to support operation and / or functionality of the IVT. Various related devices include embodiments of, for example, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, and a rotatable carrier configured to support planet-pivot arm assemblies.

Owner:FALLBROOK INTPROP COMPANY

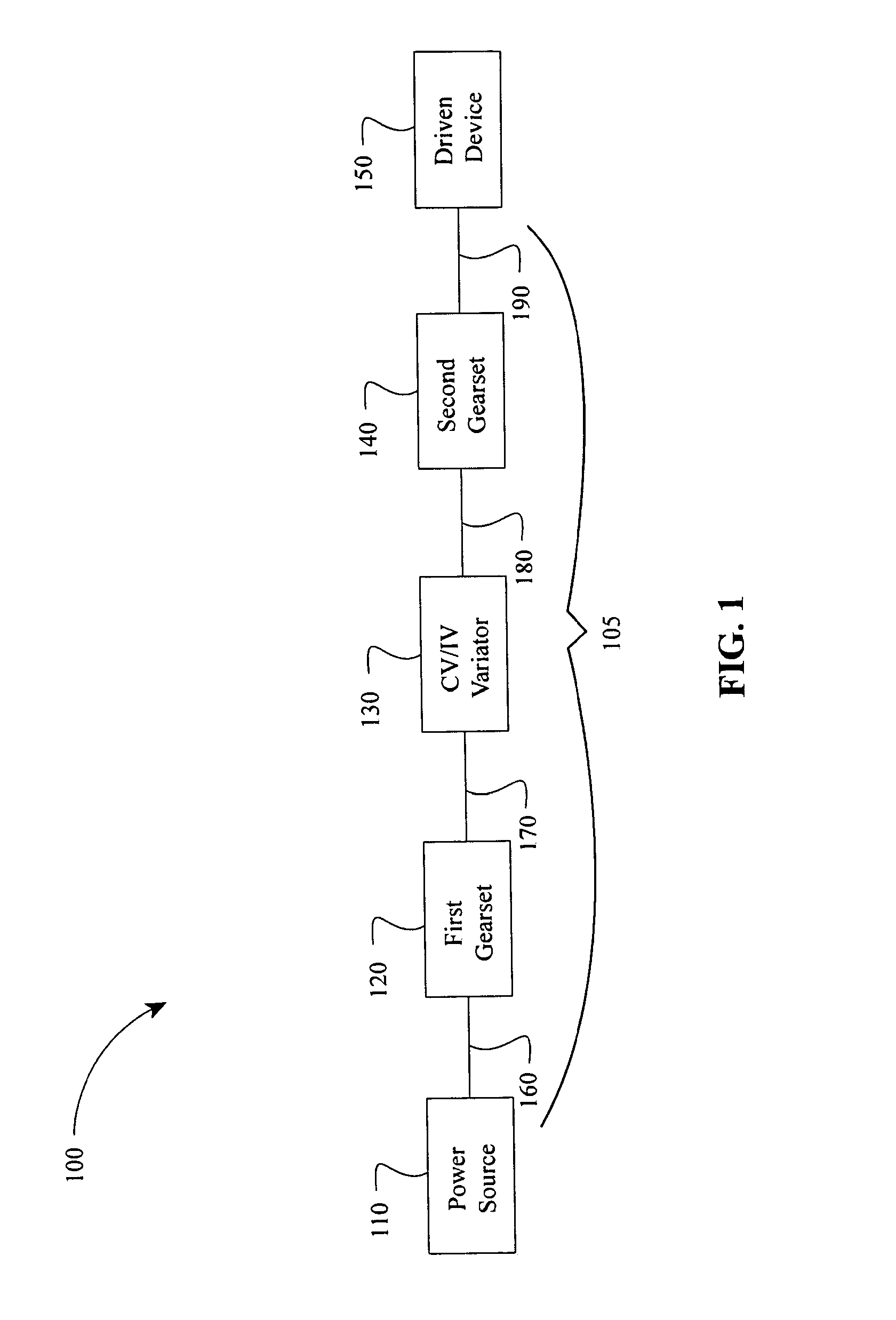

Continuously variable transmission

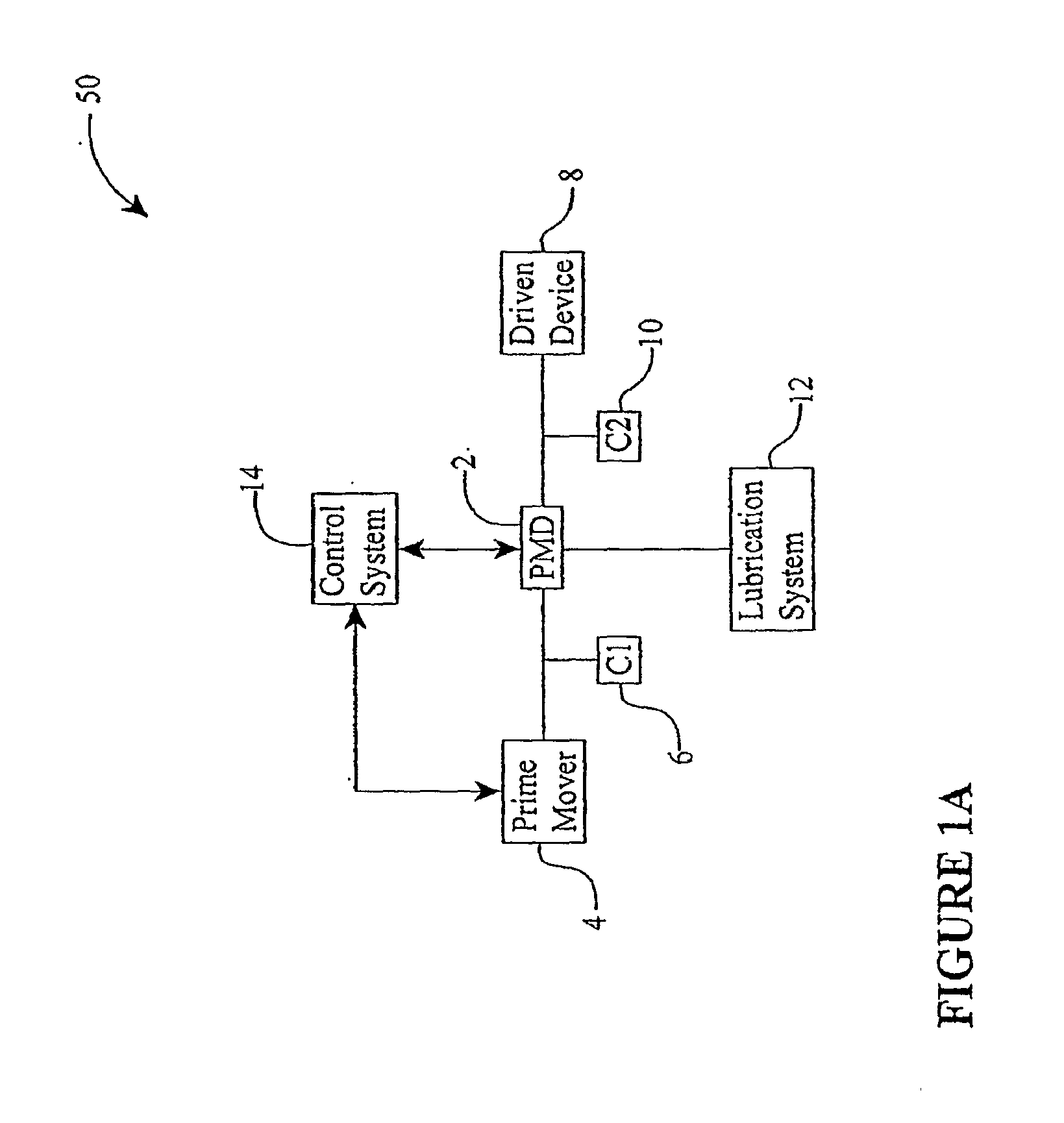

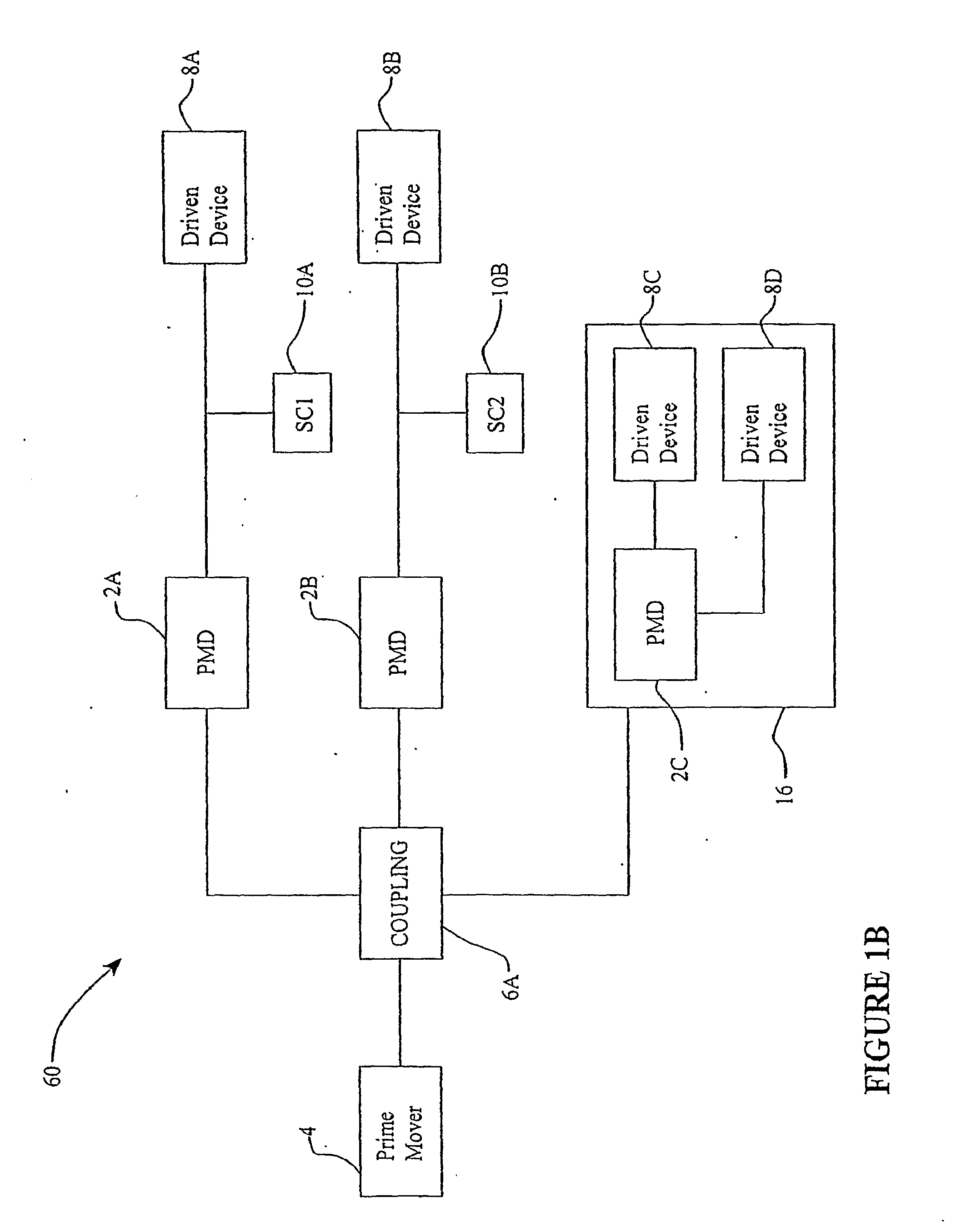

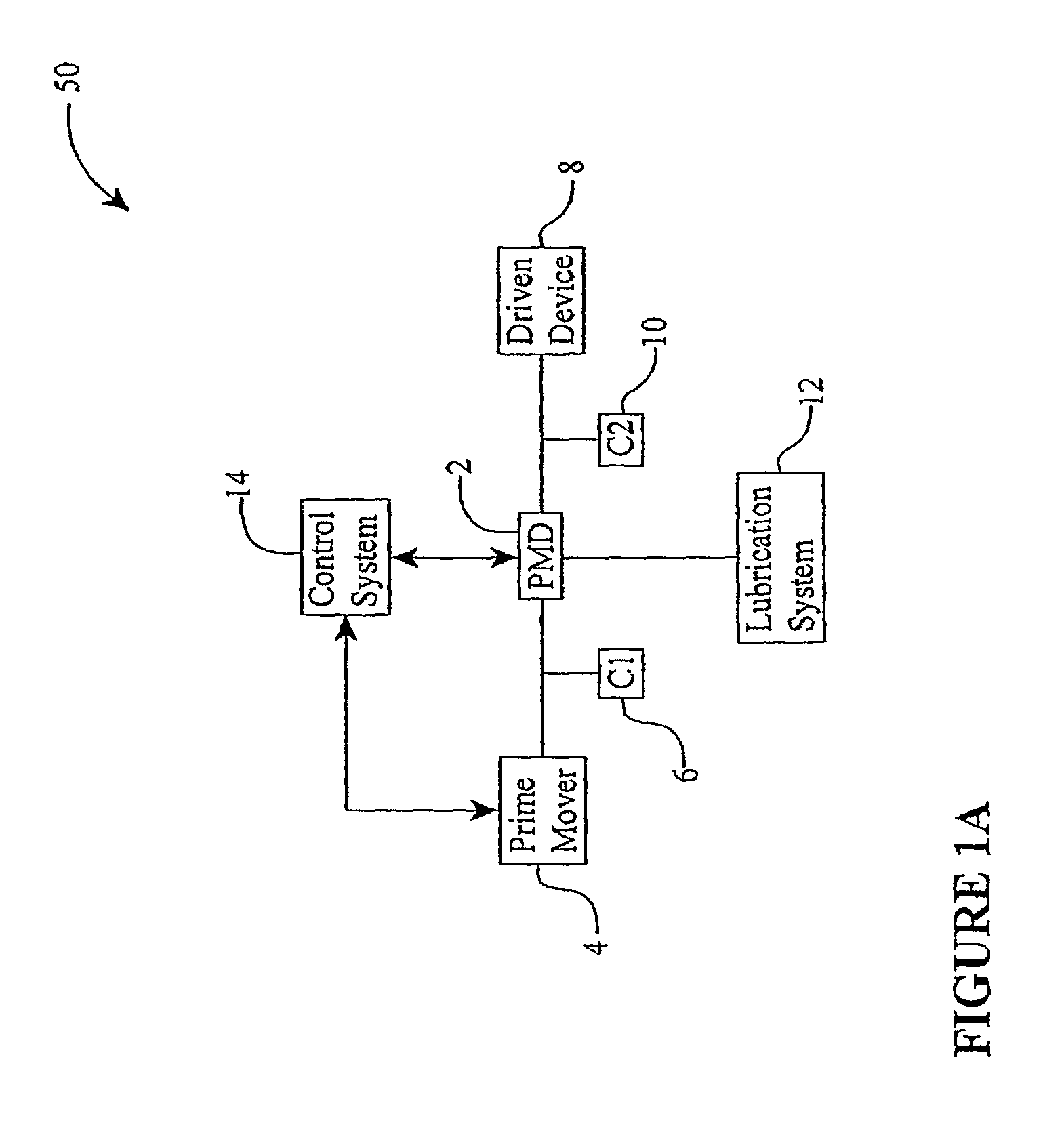

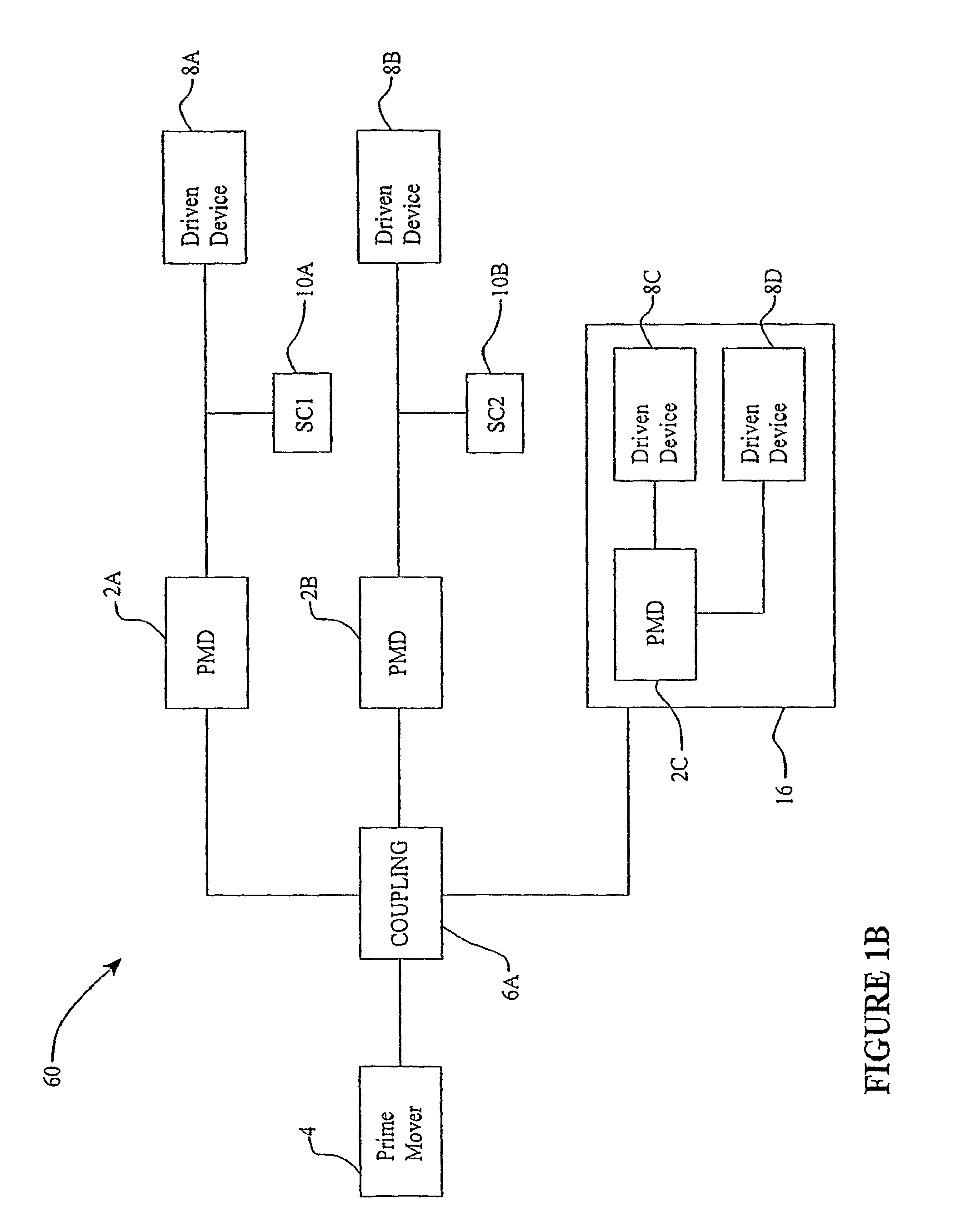

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

Method of operating a wormgear drive at high energy efficiency

InactiveUS7045055B2Reducing traction coefficientGear lubrication/coolingToothed gearingsHigh energyFuel tank

This invention is directed to a method of operating a wormgear drive at high energy efficiency comprising filling an oil reservoir with a wormgear lubricant comprising an isomerized Fischer-Tropsch derived distillate fraction having a low traction coefficient and operating the wormgear drive with the filled oil reservoir at an equilibrium temperature between 20 and 225 degrees C. This invention is also directed to a process for reducing the traction coefficient of a higher-traction coefficient lubricating base oil by blending it with an isomerized Fischer-Tropsch derived distillate fraction. This invention is also directed to a wormgear lubricant comprising an isomerized Fischer-Tropsch distillate fraction and between 2 and 50 weight percent thickener.

Owner:CHEVROU USA INC

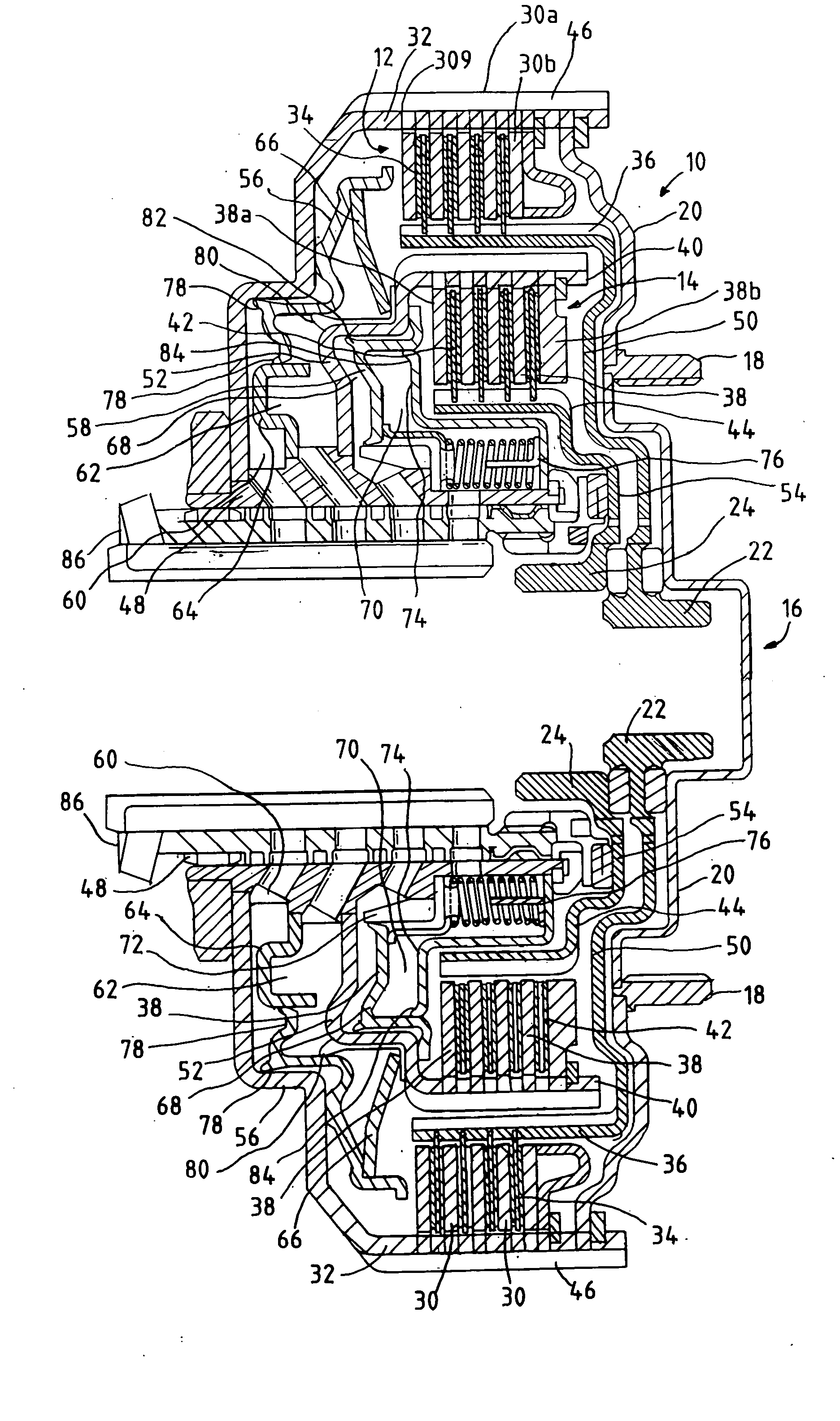

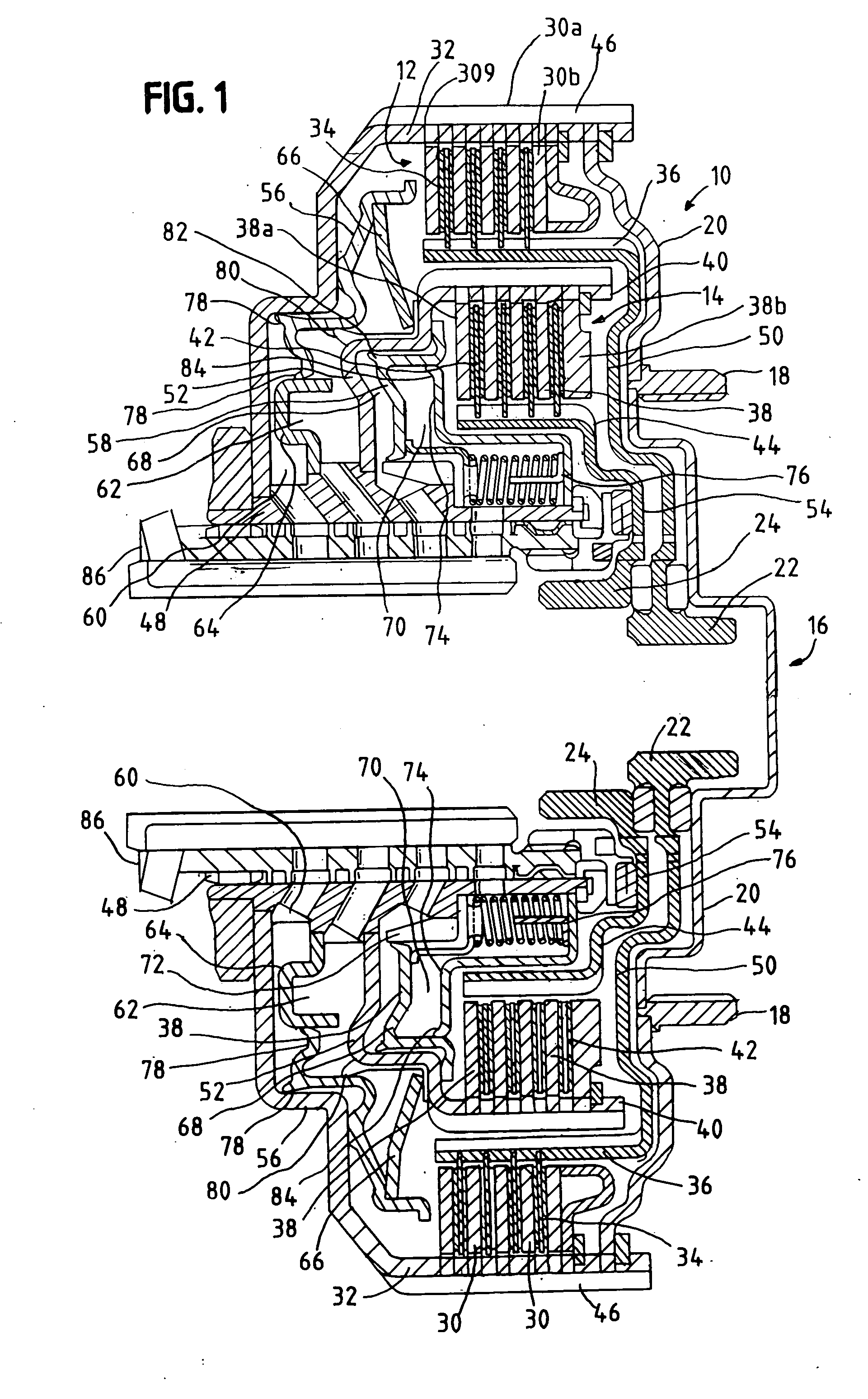

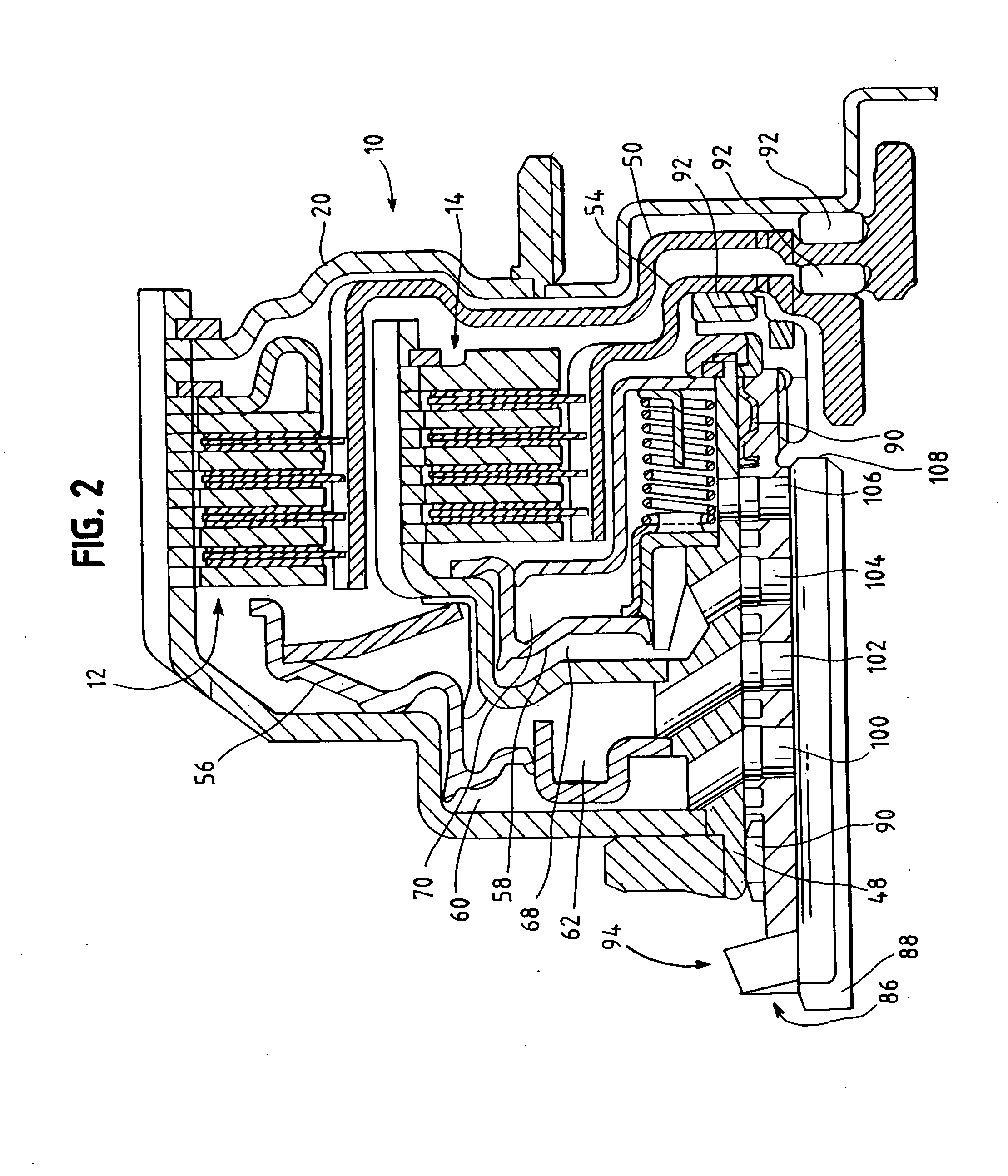

Oil management system for dual clutch transmissions

InactiveUS20050067251A1Solve the lack of balanceReduce flow of fluidFluid actuated clutchesGear lubrication/coolingEngineeringCentrifugal force

The present invention provides an improved fluid management system for dual and other multiple clutch assemblies having fluid-operated pistons and fluid operated balance chambers offsetting the undesired pressures exerted by fluids within the piston chamber induced by centrifugal forces. Among other improvements, the system provides an effective and cost efficient arrangement of fluid supply channels and supply openings capable of maintaining desired fluid levels in the balance chambers under low, otherwise insufficient, flow rate conditions. In another aspect, the system provides a reservoir for the balance chambers under conditions where the fluid flow is stopped or interrupted.

Owner:BORGWARNER INC

Ring gear mounting arrangement with oil scavenge scheme

ActiveUS20080044276A1Reliably rotationally balancedDesired stiffness and resistance to overturning momentsEngine fuctionsBlade accessoriesEngineeringGear train

A turbine engine includes an epicyclic gear train that has a two-piece ring gear. Each portion of the ring gear includes radially outwardly extending flanges that are axially constrained to a turbo fan shaft by bolts secured circumferentially along the flanges. Knife edge seals are secured to the flanges to contain oil expelled through the ring gear into a gutter. The ring gear and turbo fan shaft can be rotationally balanced together.

Owner:RAYTHEON TECH CORP

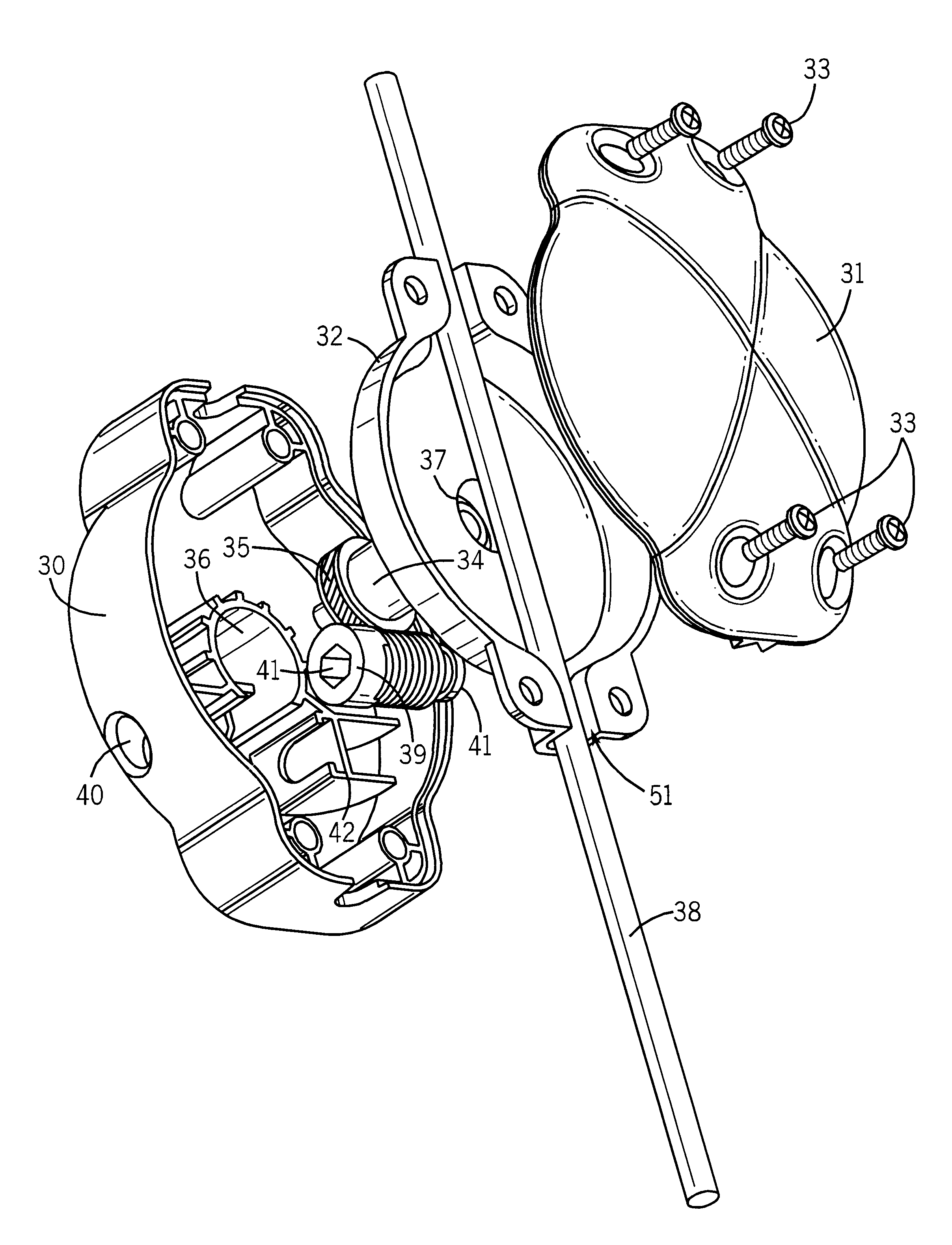

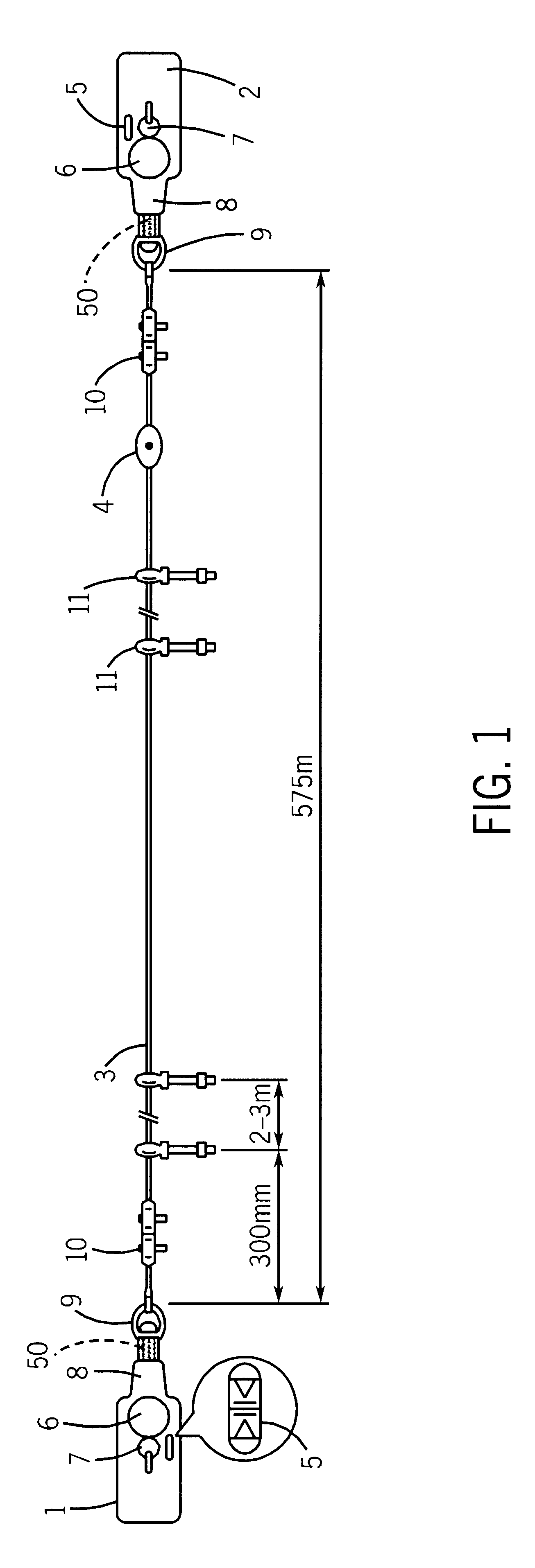

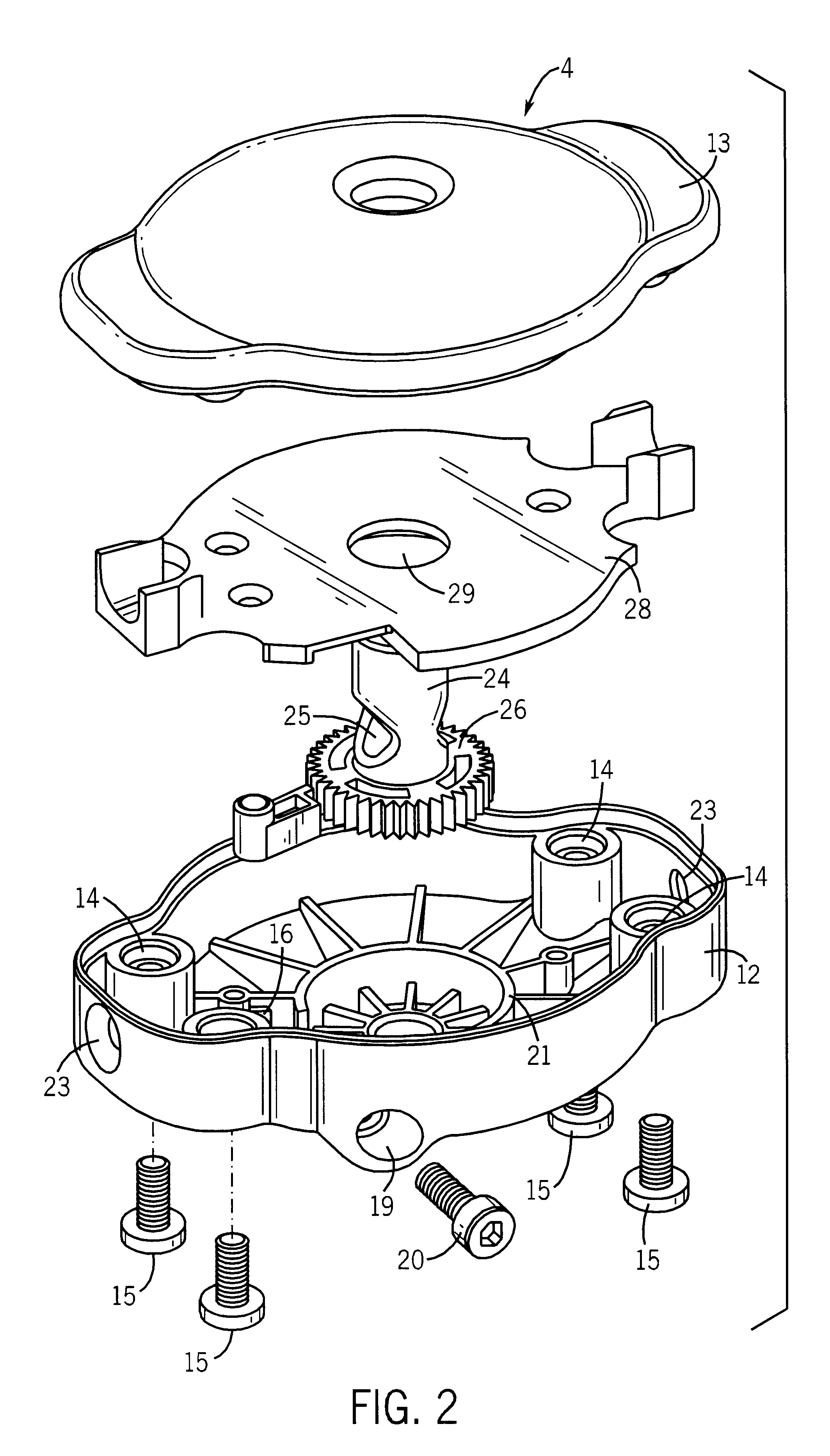

Modified rope tensioner

InactiveUS6705179B1Avoid unwindingQuick effectControlling membersContact mechanismsScrew threadEngineering

A rope tensioner sets the tension of a rope operated switch assembly actuable to switch between first and second conditions on a change in tension of the rope. The tensioner comprises a body, a rotatable member which engages the rope, a shaft for rotating the member relative to the body to adjust tension in the rope by winding the rope around the member, and a lock to lock the member in position relative to the body. The rope opperated switch assembly is much simpler to install than previous assemblies, as the tensioner may be simply threaded or otherwise installed onto the rope without the rope having to be cut.

Owner:ROCKWELL AUTOMATION

Continuously and/or infinitely variable transmissions and methods therefor

An infinitely variable transmission (IVT) having a rotatable input shaft arranged along a longitudinal axis of the transmission. In one embodiment, the input shaft is adapted to supply a lubricant to the interior of the transmission. In some embodiments, a stator assembly is coupled to, and coaxial with, the input shaft. The IVT has a plurality of planets operably coupled to the stator assembly. The planets are arranged angularly about the longitudinal axis of the transmission. In one embodiment, a traction ring is operably coupled to the planets. The IVT is provided with a housing that is operably coupled to the traction ring. The housing is substantially fixed from rotating with the input shaft. The traction ring is substantially fixed from rotating with the input shaft. In some embodiments, the IVT is provided with a lubricant manifold that is configured to supply a lubricant to the input shaft.

Owner:FALLBROOK INTPROP COMPANY

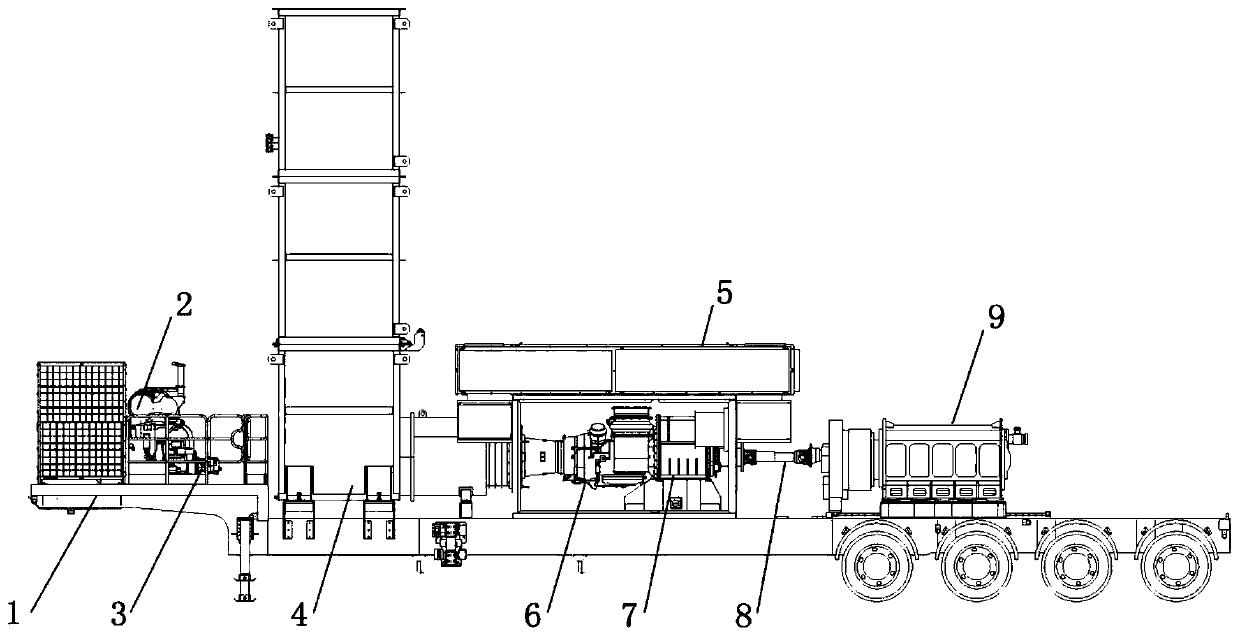

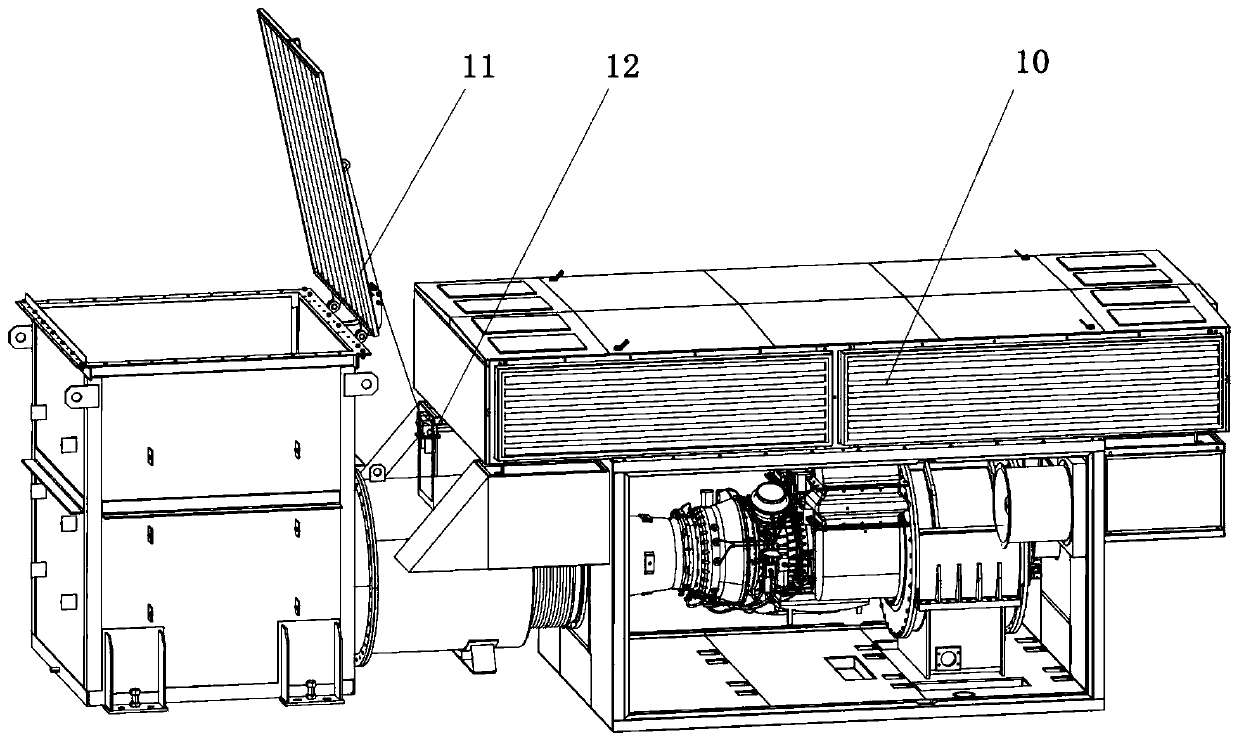

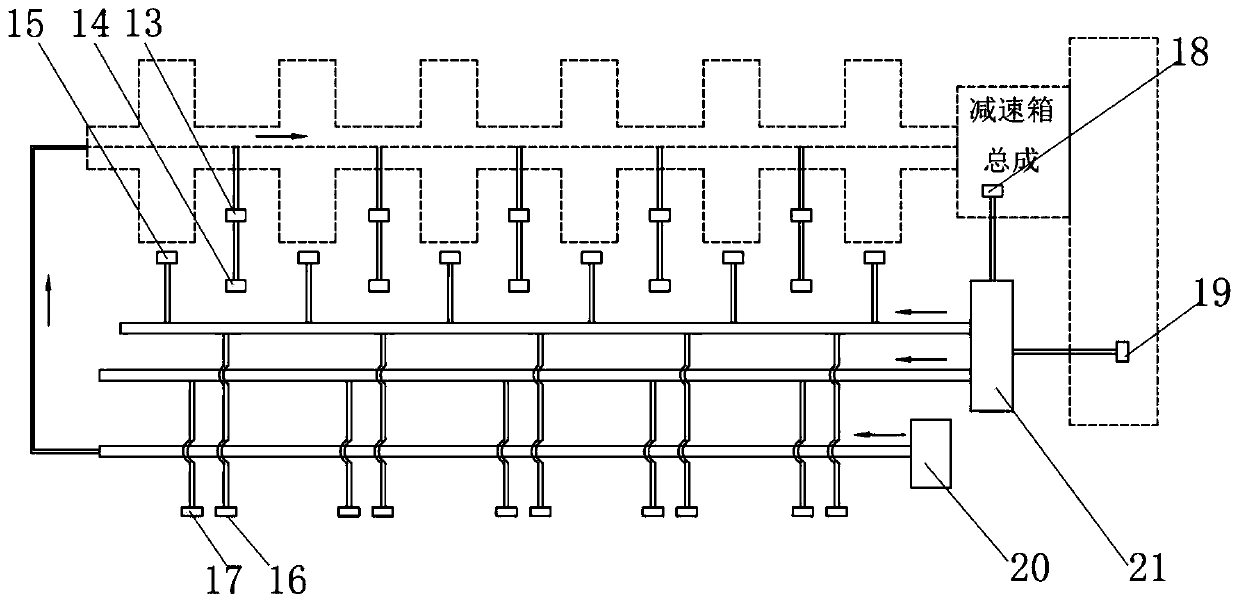

Continuous large-power turbine fracturing equipment

PendingCN111206992AStable and efficient transmissionStable working platformPositive displacement pump componentsGear lubrication/coolingDrive shaftControl engineering

The invention discloses continuous large-power turbine fracturing equipment. The large-power turbine fracturing equipment comprises a turbine engine, a reduction box, a transmission shaft and a plunger pump, wherein the turbine engine and the reduction box are arranged on the same straight line; the reduction box is connected to the plunger pump through a transmission shaft; and an angle of the transmission shaft ranges from 2 degrees to 4 degrees. The continuous large-power turbine fracturing equipment has the beneficial effects that: a chassis T1 material is selected, so that a stable working platform is provided for the equipment; the turbine engine and the reduction box are on the same straight line, the transmission shaft is arranged between the reduction box and the plunger pump, andthe angle of the transmission shaft ranges from 2 degrees to 4 degrees, so that stable and efficient transmission of the turbine engine is guaranteed, and a fault occurrence rate is reduced; a lubricating system driven by an auxiliary power system guarantees that the turbine engine, the reduction box and the plunger pump work under a proper environment; dual lubricating systems guarantee that theplunger pump realizes continuous operation under power of 5000 HP or higher; and the technical means finally can meet continuous large-power operation requirements of the fracturing equipment.

Owner:美国杰瑞国际有限公司

Cooling system for continuous variable transmission of vehicle

InactiveUS20060270503A1Avoid smallImprove cooling effectGearboxesGear lubrication/coolingDrive shaftEngine mount

A vehicle includes a frame assembly, an engine mounted on the frame assembly, and a continuous variable transmission connected to the engine. The continuous variable transmission includes a housing including an air intake duct and an exhaust duct, a drive shaft disposed in the housing, a drive pulley including at least one sheave disposed on the drive shaft, a driven shaft disposed in the housing and spaced from the drive shaft, a driven pulley including at least one sheave disposed on the driven shaft, and a fan disposed on the driven shaft. The fan is disposed between an inner surface of the housing and the driven pulley so as to be spaced from the driven pulley. The air intake duct defines an opening in the housing for providing air from outside the housing into the housing, and the air intake duct is axially aligned with the driven shaft and the fan disposed thereon, such that the air flows directly into the fan and is directed to the driven pulley.

Owner:YAMAHA MOTOR CO LTD +1

Continuously variable transmission

Embodiments are directed to a front end accessory drive (FEAD), subassemblies, and components therefor. Embodiments disclosed cover power modulating devices (PMD) which can be used in a FEAD. In one embodiment, a continuously variable transmission (CVT) is coupled directly to a crankshaft of a prime mover, and the CVT is used to regulate the speed and / or torque delivered to an accessory. A compound drive device includes a motor / generator subassembly cooperating with a CVT subassembly to provide a motor functionality with torque multiplication or division, or alternatively, a generator functionality with torque multiplication or division. In some embodiments, a FEAD includes a PMD having a sun shaft configured to couple to a sun of the PMD and to an electric motor component, such as an electrical armature or an electrical field. In one embodiment, the electrical armature the electrical field are placed concentrically and coaxially and configured to rotate relative to one another in opposite directions.

Owner:FALLBROOK INTPROP COMPANY

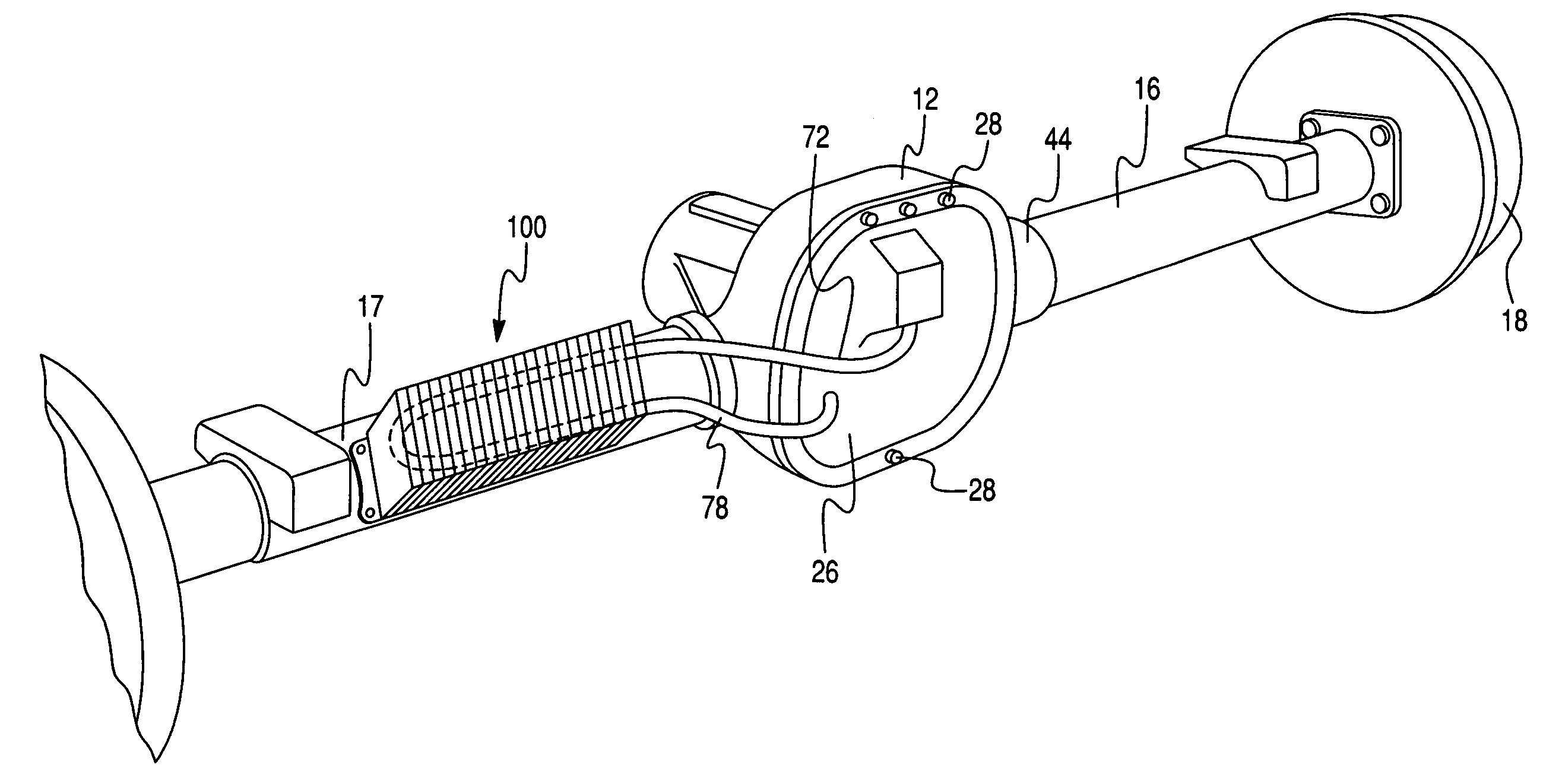

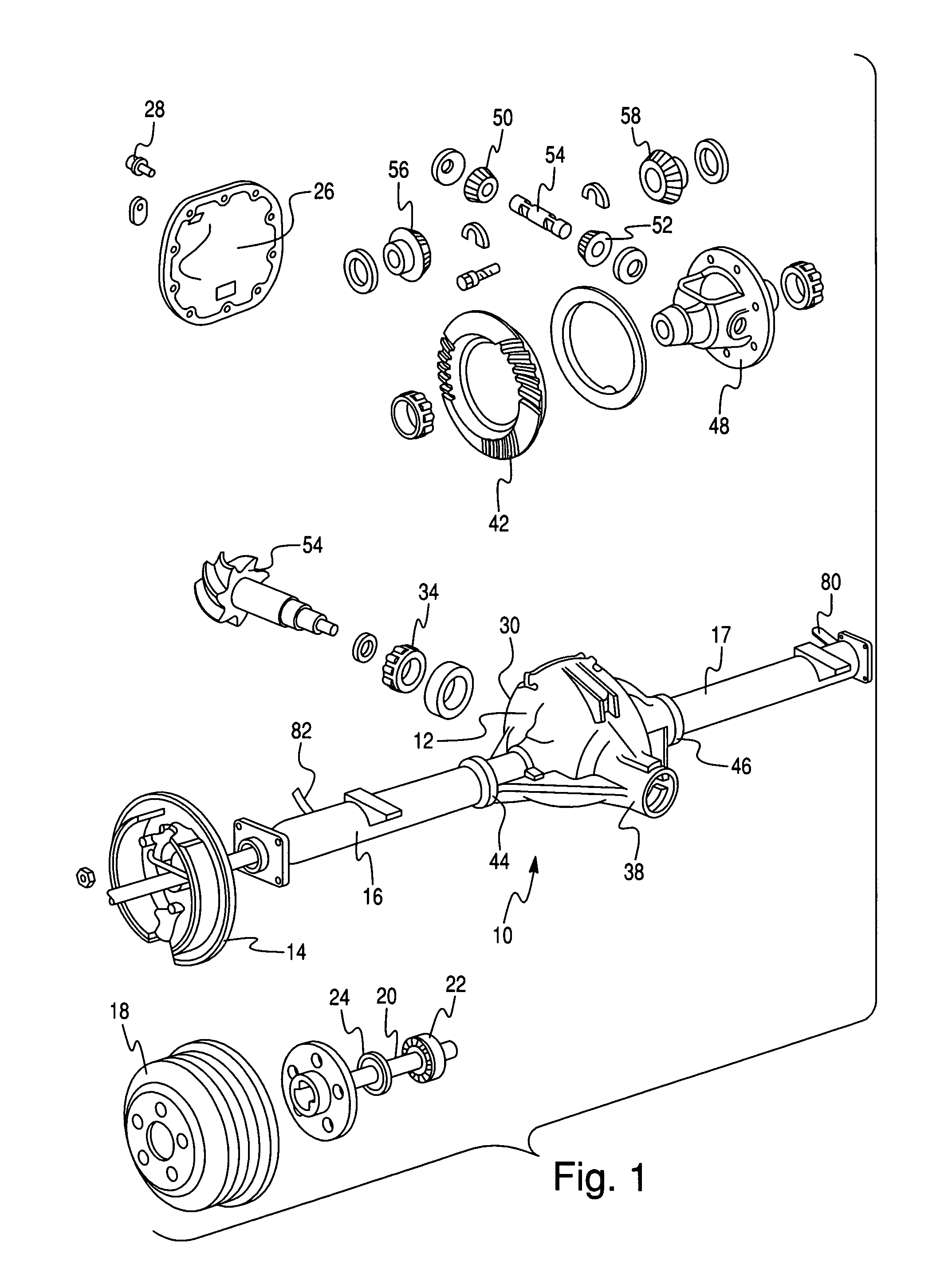

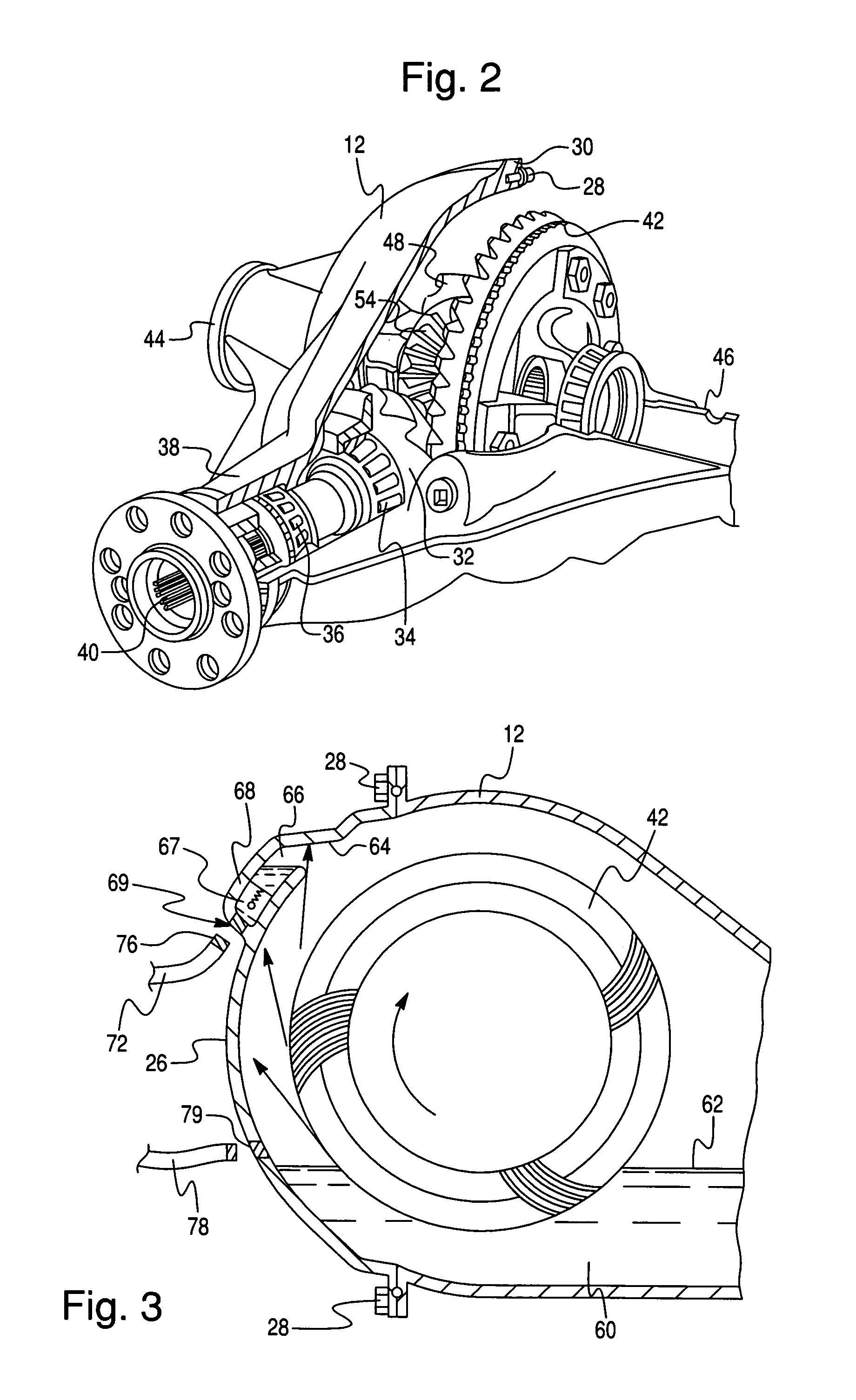

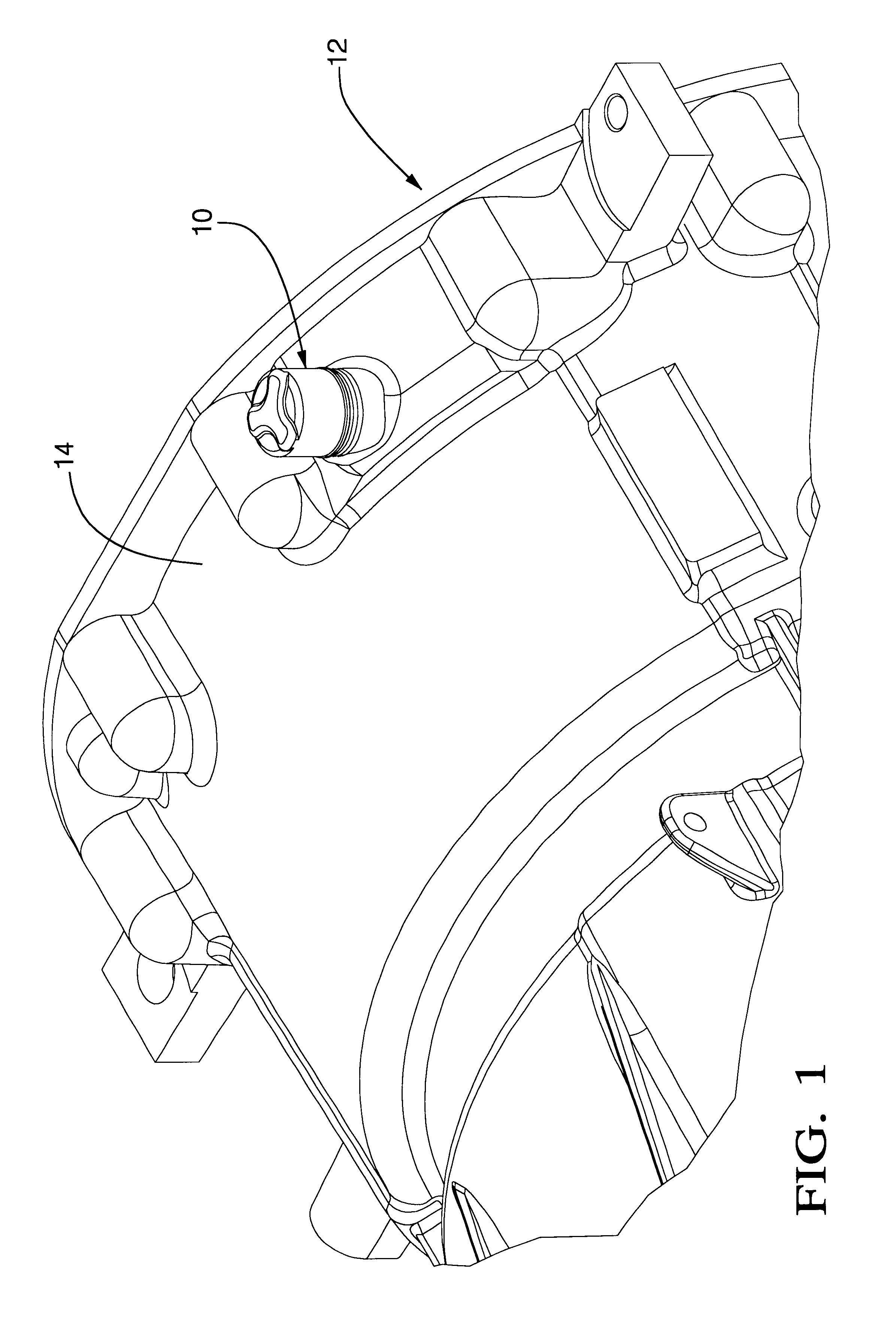

Lubricant cooling system for a motor vehicle axle

In a driven axle assembly (12) for a motor vehicle that includes a differential housing located substantially in the center of the axle and tubes (16, 17) extending laterally from the differential, surrounding axle shafts (20) and opening into a lubricant reservoir (60) in the differential housing, a system for circulating and cooling axle lubricant includes a cover (26) for closing and sealing the housing having a first aperture into the housing where a ring gear rotates through the lubricant reservoir. The aperture in the cover opens to a chamber that holds lubricant carried through the aperture by the rotating ring gear. Conduit (72) connected by a hydraulic fitting to the chamber has its opposite end connected to an oil cooler mounted on the axle tube. Conduit (78) returns the lubricant to the reservoir in the differential housing. Lubricant flows via a gravity feed through the first conduit into the cooler and back to the housing reservoir via the second conduit, effectively cooling the lubricant without the addition of a pump.

Owner:DANA AUTOMOTIVE SYST GRP LLC

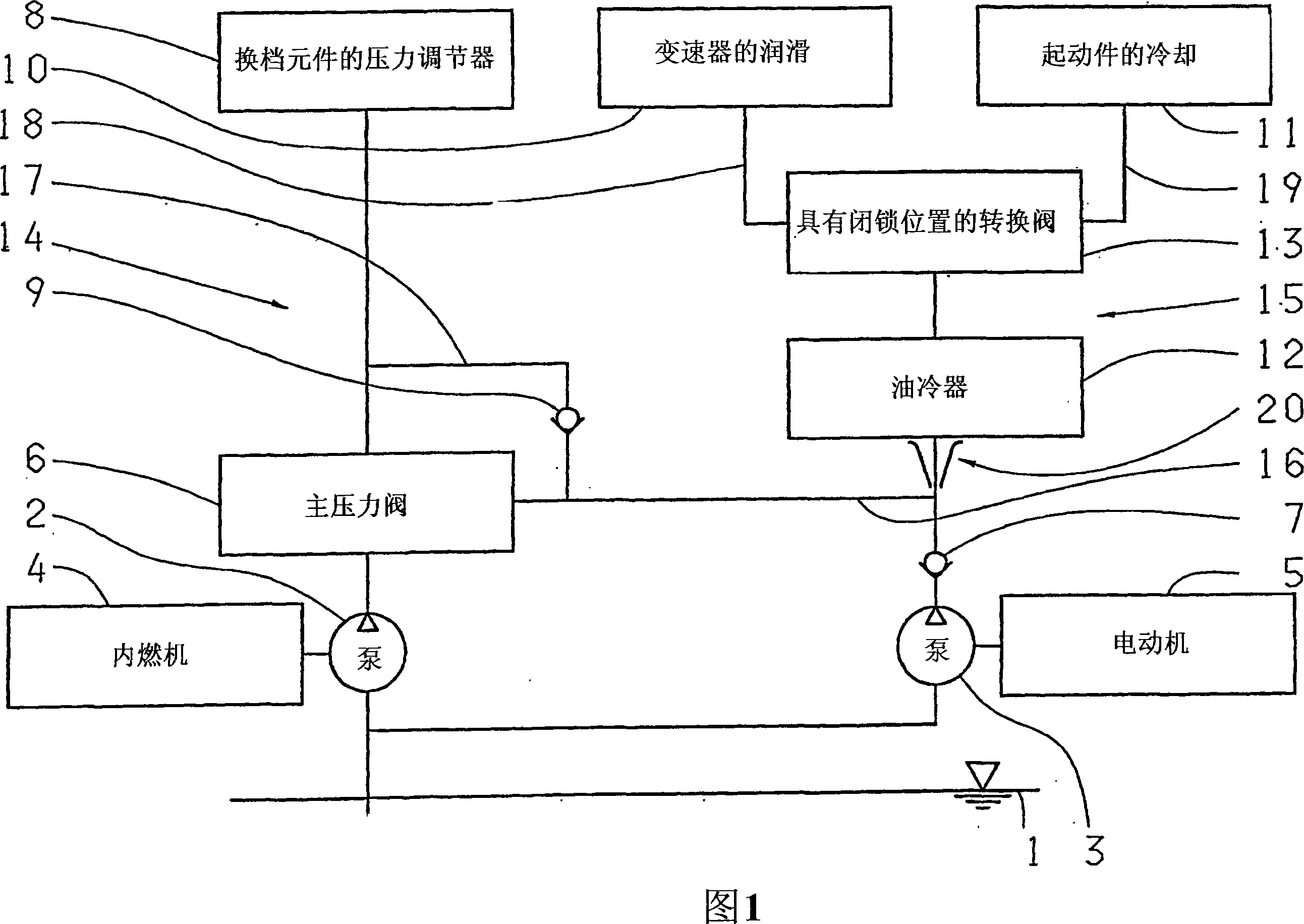

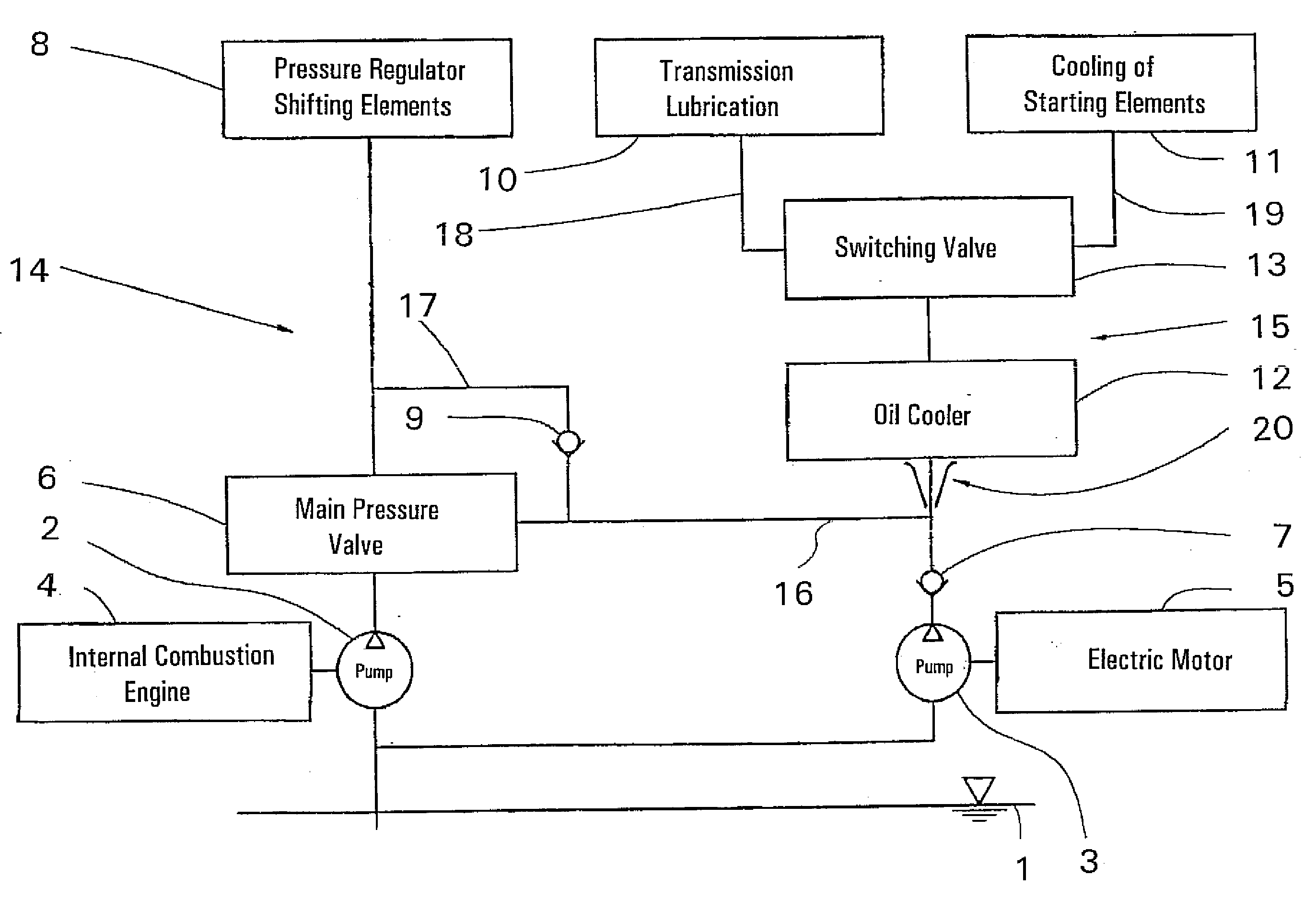

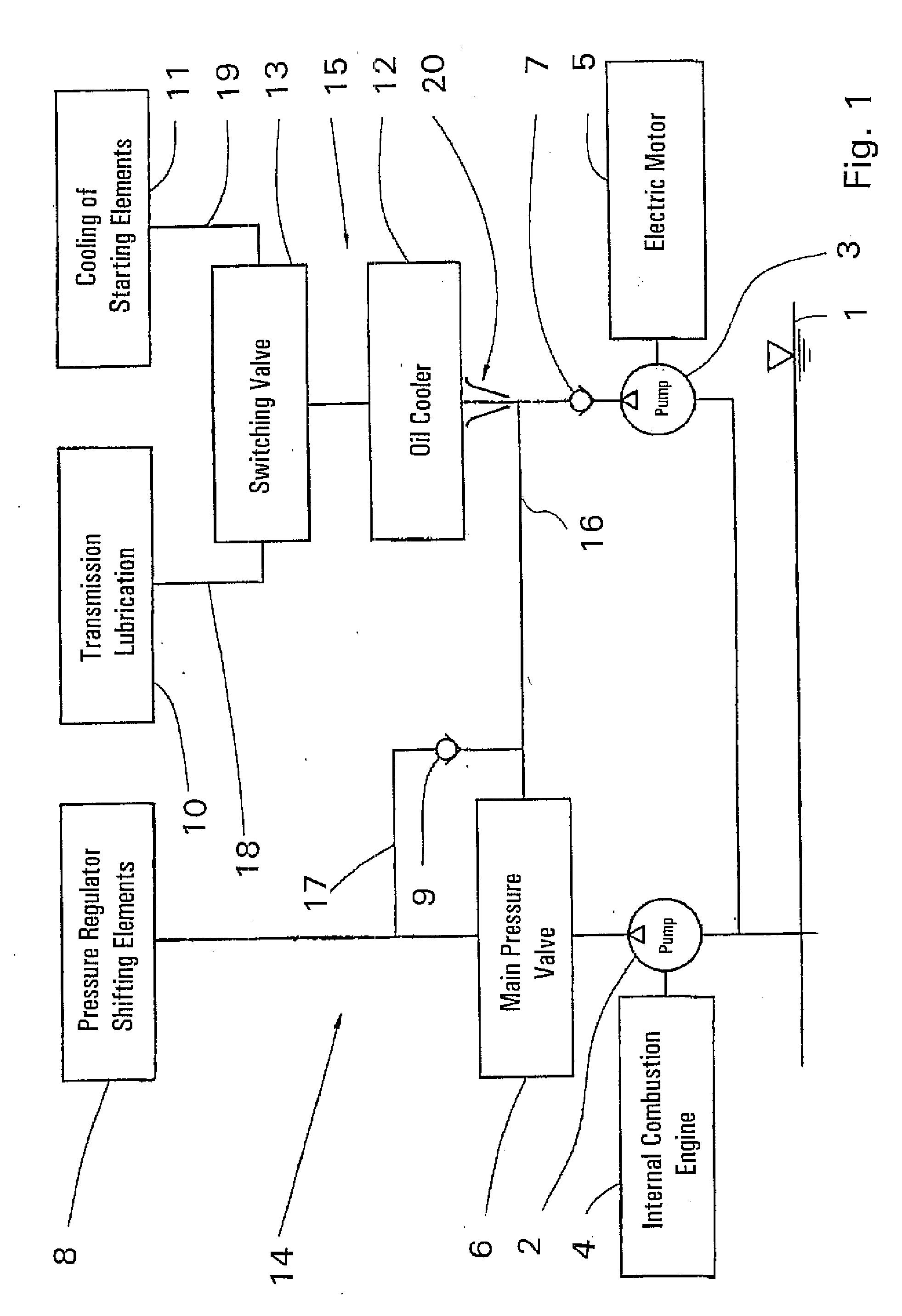

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveCN101147014AAvoid emissionsSave fuelGear lubrication/coolingGearing controlHydraulic control unitAutomatic transmission

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

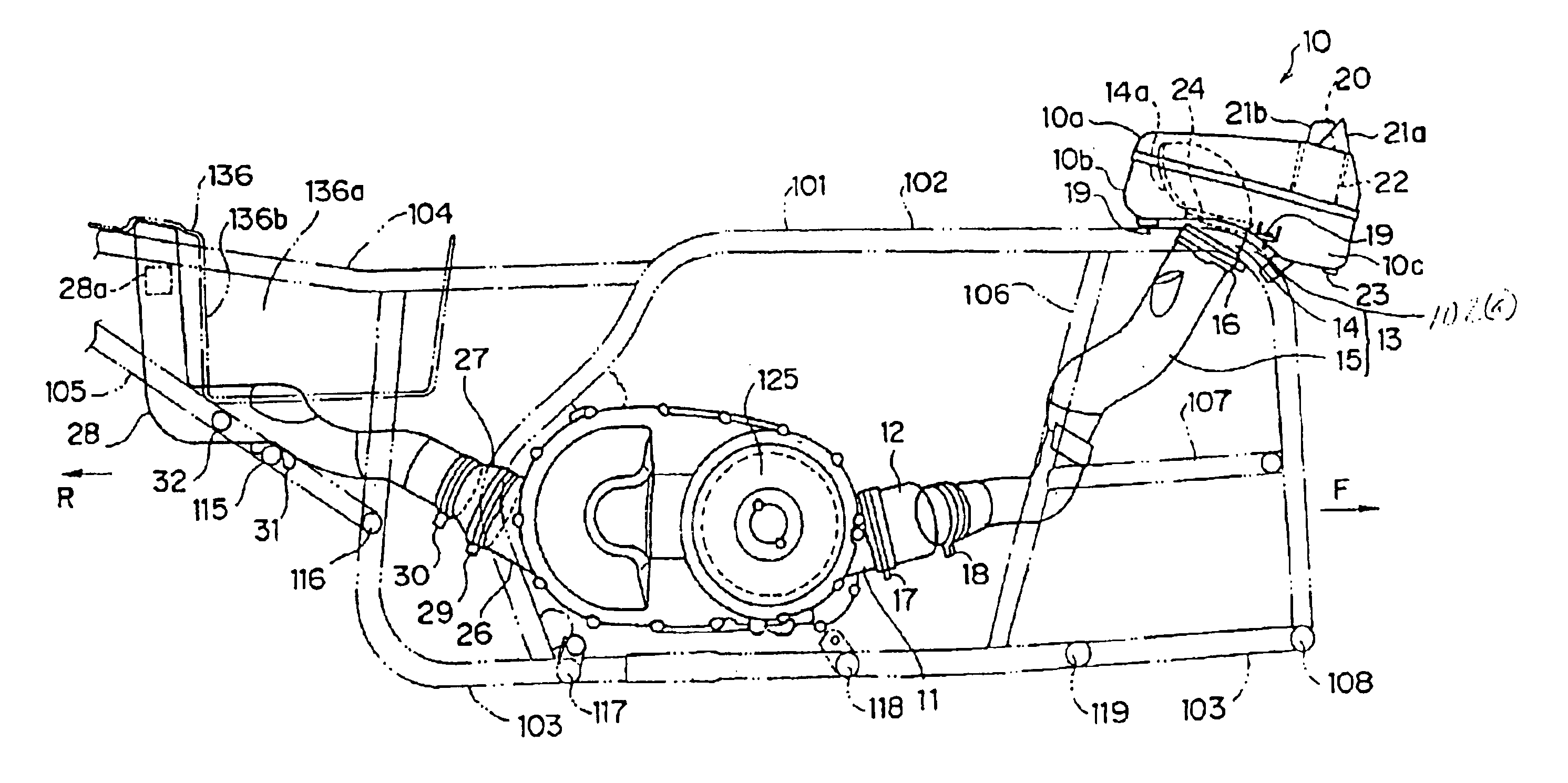

Cooling system for a transmission mechanism

InactiveUS6820708B2Without lowering enduranceAvoid enteringCyclesCycle equipmentsAll terrain vehiclesAerospace engineering

A cooling system for an engine transmission in a saddle type vehicle such as an all-terrain-vehicle. In one embodiment, the cooling system has an induction duct, connected to a belt case that houses a transmission, for inducting cooling air into the belt case. The system further includes a discharge duct connected to the belt case for exhausting the cooling air from the belt case, the discharge duct extending toward a rear fender of the vehicle. In addition, the system has an air exhaust aperture through which the cooling-air exits the discharge duct, the exhaust aperture located at an end of the discharge duct, the discharge duct generally forming an inverted "U" shape as viewed from a rear end of the vehicle, and the air exhaust aperture positioned so that the cooling air exiting the discharge duct does not directly strike the rear fender of the vehicle. The cooling system further has an induction box having a cooling-air induction port that allows the entrance of cooling-air into the induction box, the induction box being generally positioned in the transverse center of the vehicle, and the induction port being opened at a position near the bottom of a front fender of the vehicle.

Owner:SUZUKI MOTOR CORP

Electro-mechanical automatic transmission having dual input shafts

InactiveUS6044719APrevent rollbackImprove efficiencyRoad transportGear lubrication/coolingAutomatic transmissionEngineering

An electro-mechanical automatic transmission is provided including a first input shaft and a second input shaft concentric with the first input shaft. A plurality of drive gears are rotatably mounted to each input shaft and are provided with synchronizer devices for selectively engaging the drive gears to the input shafts. A driver shaft is provided with a plurality of driven gears in meshing engagement with the drive gears. The electro-mechanical automatic transmission is provided with a pair of electro-mechanical clutch actuators for selectively disengaging dual clutches which transmit engine torque to the input shafts, as well as an electro-mechanical shift actuator system which operatively engage the synchronizer devices for selectively engaging the drive gears.

Owner:FCA US

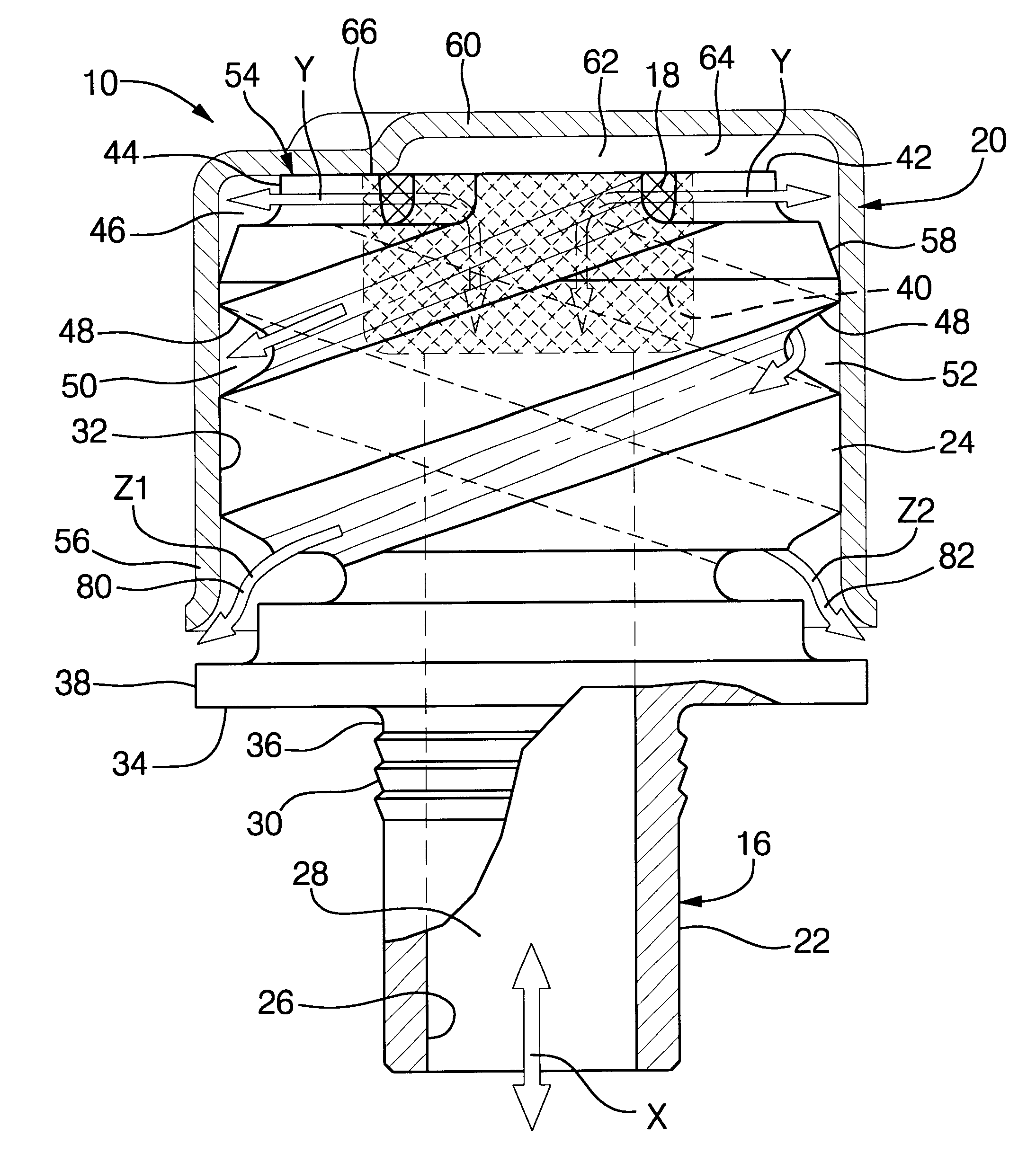

Ventilated clutch having exhaust hub

The invention provides for cooling an endless belt in a continuously variable transmission (CVT). The CVT is comprised of a drive clutch, a driven clutch, and an endless belt disposed about the drive and driven clutches. Both the drive and driven clutches include an axially stationary sheave and an axially movable sheave. A central hub extends from an inner surface of at least one of the sheaves, and further includes at least one bore. The one bore defines an air path extending from an outer face of the hub through the one sheave to the outer face of the one sheave. At least one recessed channel is located on an inner surface of at least one of the sheaves. The one recessed channel defines an air path around a side of the endless belt in contact with the inner face of the one sheave. The invention will cool the belt as it rides about the drive clutch and driven clutches. In addition, the invention will provide at least one reduced-slip sheave surface for the belt in the CVT.

Owner:POLARIS IND INC

Motor-type power device

ActiveUS20090127954A1Suppress stirring resistance of oilEnsure performanceGearboxesGear lubrication/coolingEngineeringCentrifugal force

Due to a centrifugal force in a vehicle width direction due to turning of an automobile, oil in an electric motor housing chamber housing an electric motor and oil in a transmission housing chamber housing a reduction gear and a differential gear flows to-and-fro via oil communication passages that penetrate a partitioning wall. An opening on the transmission housing chamber side of the oil communication passages is spaced from the partitioning wall. Hence, when oil moves from the transmission housing chamber side to the electric motor housing chamber side, it is possible to prevent the oil quantity on the electric motor housing chamber side from increasing excessively and suppress an increase in resistance to oil stirring by a rotor of the electric motor while retaining a constant oil amount on the transmission housing chamber side to ensure lubricating performance for the reduction gear and the differential gear.

Owner:HONDA MOTOR CO LTD

Continuously and/or infinitely variable transmissions and methods therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously or infinitely variable transmissions (C / IVT). In one embodiment, a main axle is adapted to receive a shift rod that cooperates with a shift rod nut to actuate a ratio change in a C / IVT. In another embodiment, a lubricant manifold is adapted to cooperate with the main axle of the C / IVT to supply lubricant to the interior of the C / IVT. Embodiments of a drivetrain housing and housing cover plate are adapted to house components of a C / IVT and, in some embodiments, to cooperate with other components of the C / IVT to support operation and / or functionality of the C / IVT. Shift control interfaces for a C / IVT are disclosed that include, for example, a shift actuation subassembly having a translatable and rotatable shift pin collar. Mechanisms that facilitate shifting of the C / IVT are disclosed that include a shift rod and shift cam adapted to supply lubricant to the interior of the transmission.

Owner:FALLBROOK INTPROP COMPANY

Transmission vent assembly

InactiveUS6447565B1Minimize water ingestionResists ingestionCombination devicesGearboxesAtmospheric airEngineering

A transmission vent assembly includes an apparatus having a central, internal passage extending therethrough. The internal passage has a larger diameter portion defining a pocket. A filter is disposed in the pocket to condense and return fluid to the transmission through the internal passage. The apparatus includes a shoulder adjacent the upper surface and a double lead thread initiating at the shoulder and terminating at a lower end. The assembly further includes a cup-shaped cap, press fittingly disposed over the apparatus. The cap and shoulder define an annular cavity and the cap and the double lead thread define first and second threaded passages. The cap includes an outward impression in the closed end which cooperates with the upper surface of the apparatus to define a connecting passage. Two bi-directional air flow paths extend between the transmission and the atmosphere through the internal passage, connecting air passage, annular air cavity, and each of the two threaded passages.

Owner:ALLISON TRANSMISSION INC

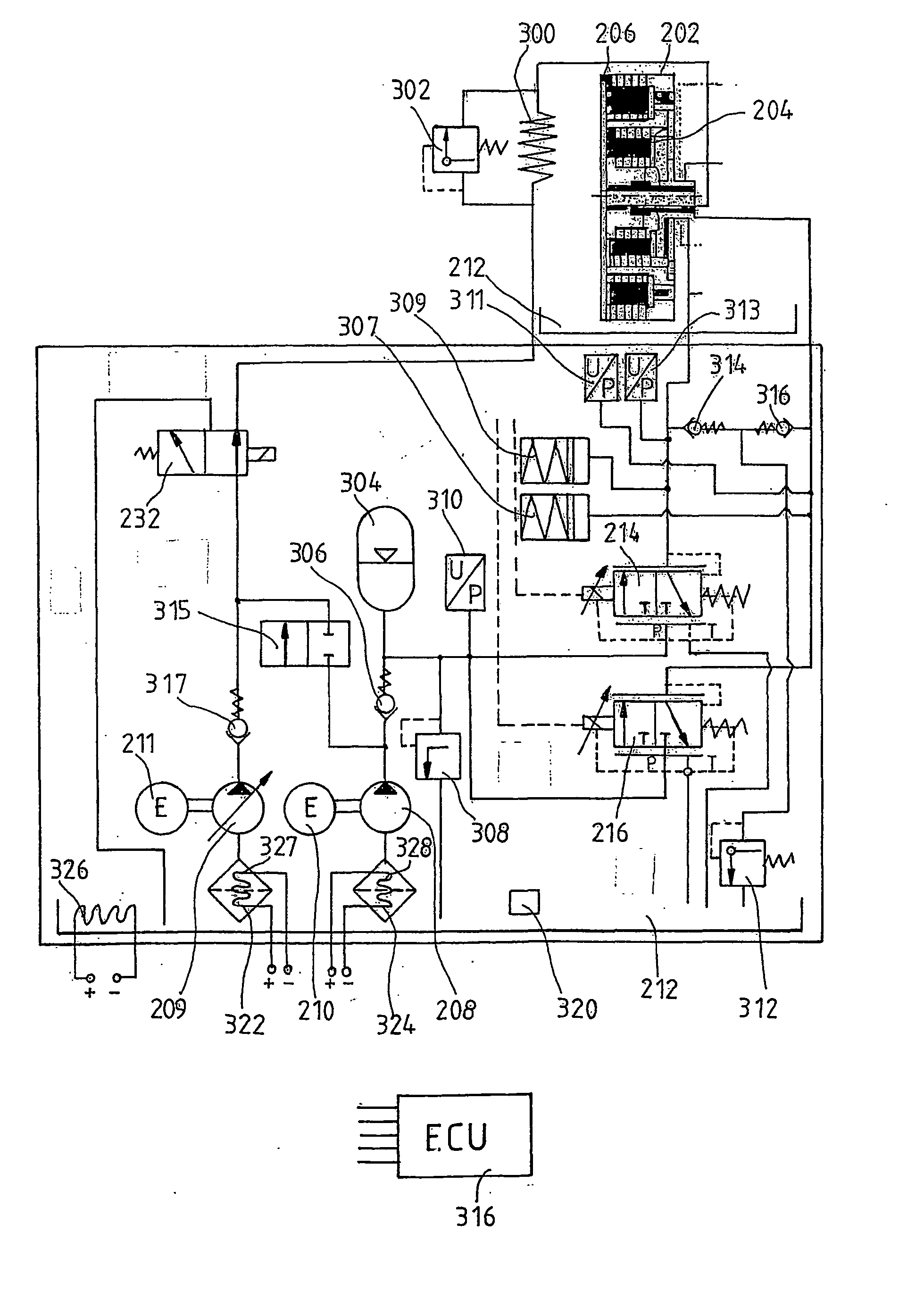

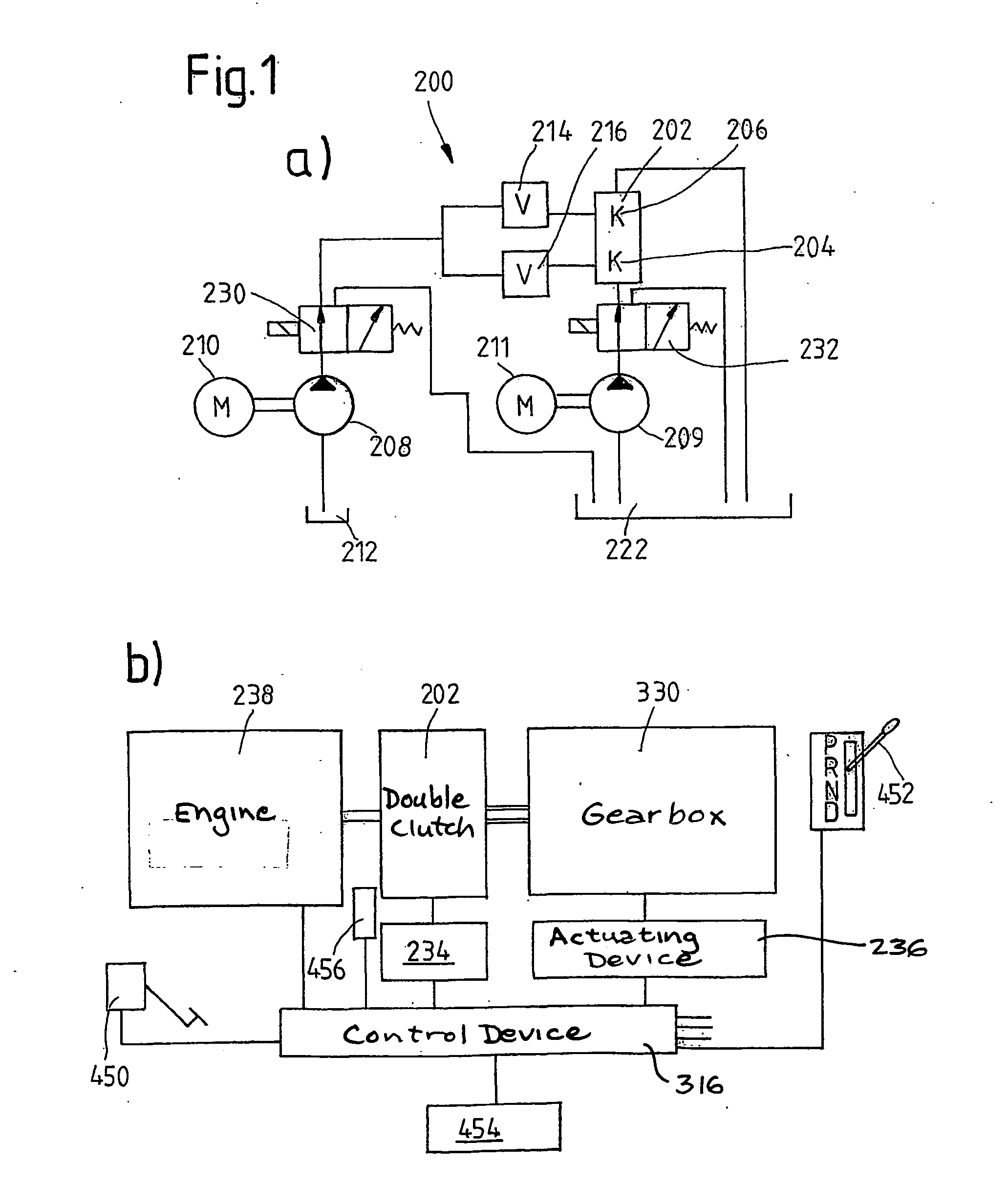

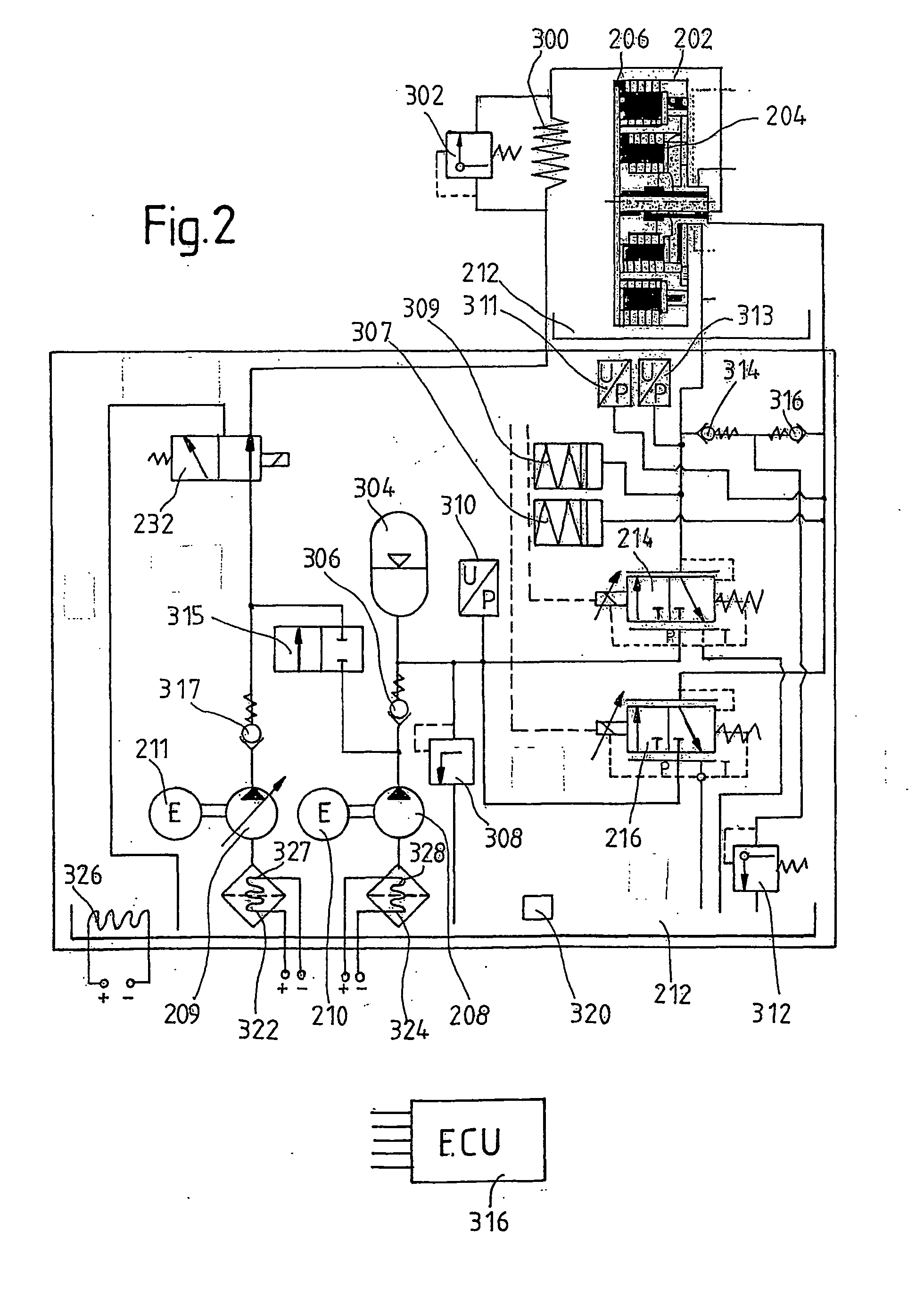

Motor vehicle comprising a drive train having a multiple clutch drive

InactiveUS20040112171A1Easy to participateIncrease engine speedGear lubrication/coolingVehicle sub-unit featuresWorking fluidGear wheel

The invention relates to measures for controlling or reducing drag torque occurring in a multi-plate clutch device (202) due to temperature-related increased viscosity of an operating fluid which is supplied to the plates in operation. The aim of the invention is to enable a motor vehicle to be started or operated even at low temperatures. According to one aspect of the invention, a motor vehicle comprising a drive train is especially provided. Said drive train comprises a drive unit (238), gearbox (330) having a first gearbox input shaft and a second gearbox input shaft, and a clutch (202) having a first clutch device which is associated with the first gearbox input shaft, and a second clutch device which is associated with the second gearbox input shaft, for transferring torque between the drive unit and the gearbox. Said clutch devices are embodied in the form of plate clutches to which an operating fluid can be supplied, especially a cooling oil in order to operate the same. Said gearbox (330) is associated with an actuator device and a control device (316) for controlling the actuator device, the arrangement of which enables the gears associated with the first and second gearbox input shafts to be engaged and disengaged. According to the invention, the control device (316) is designed in such a way that at least one gear is automatically engaged by means of the actuator device (236), as a result of the clutch release of the vehicle.

Owner:VOLKSWAGEN AG +1

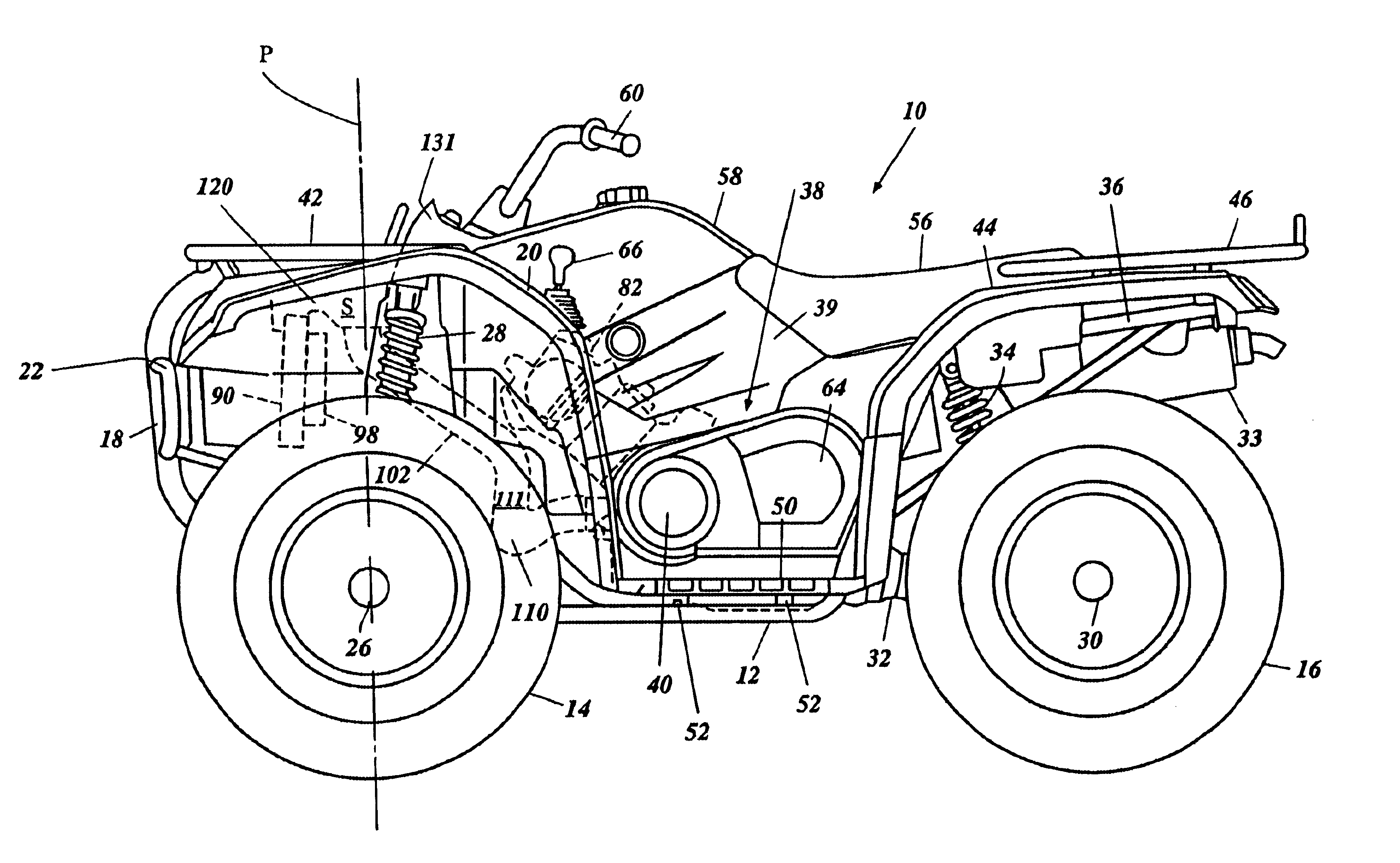

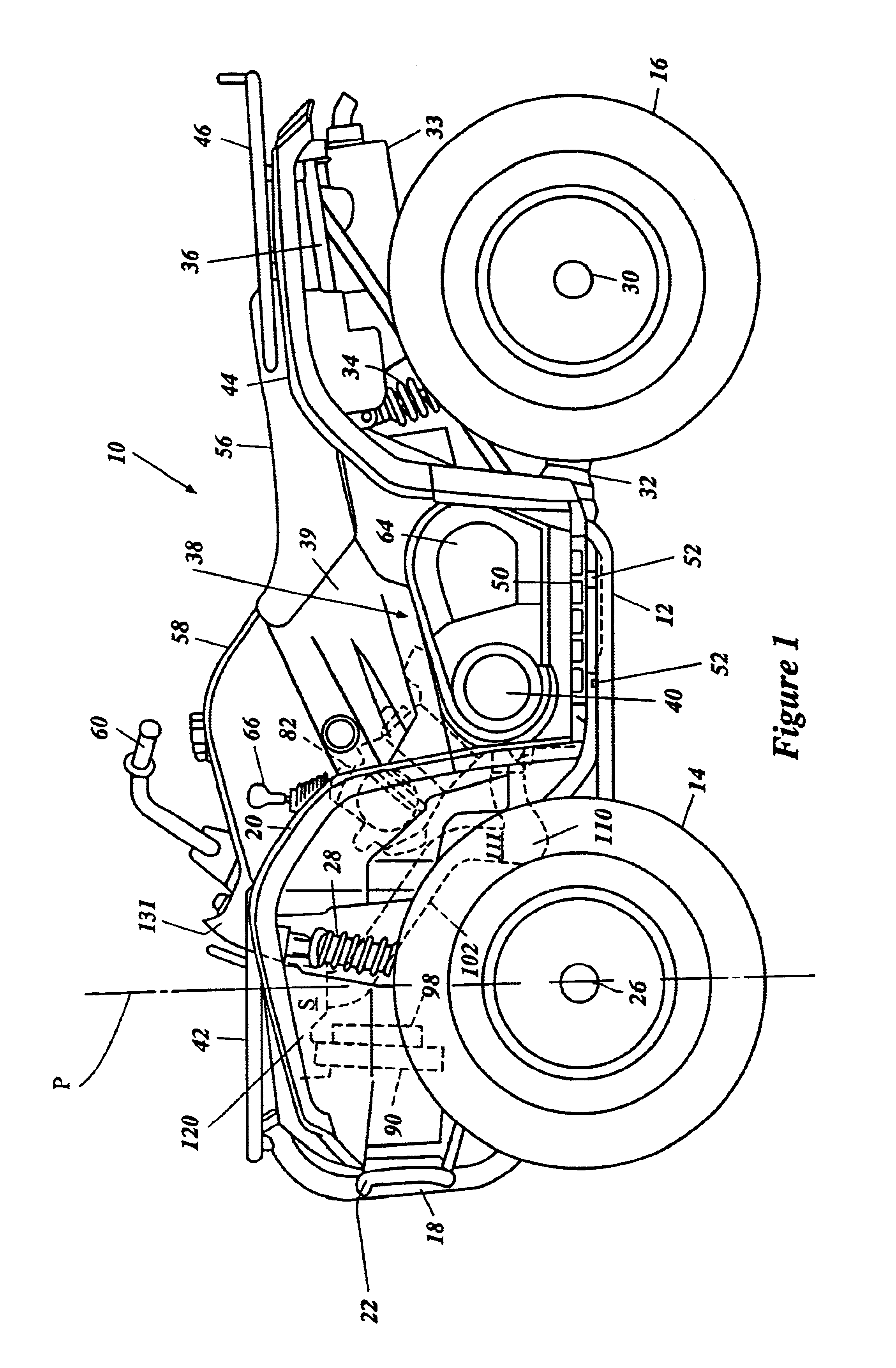

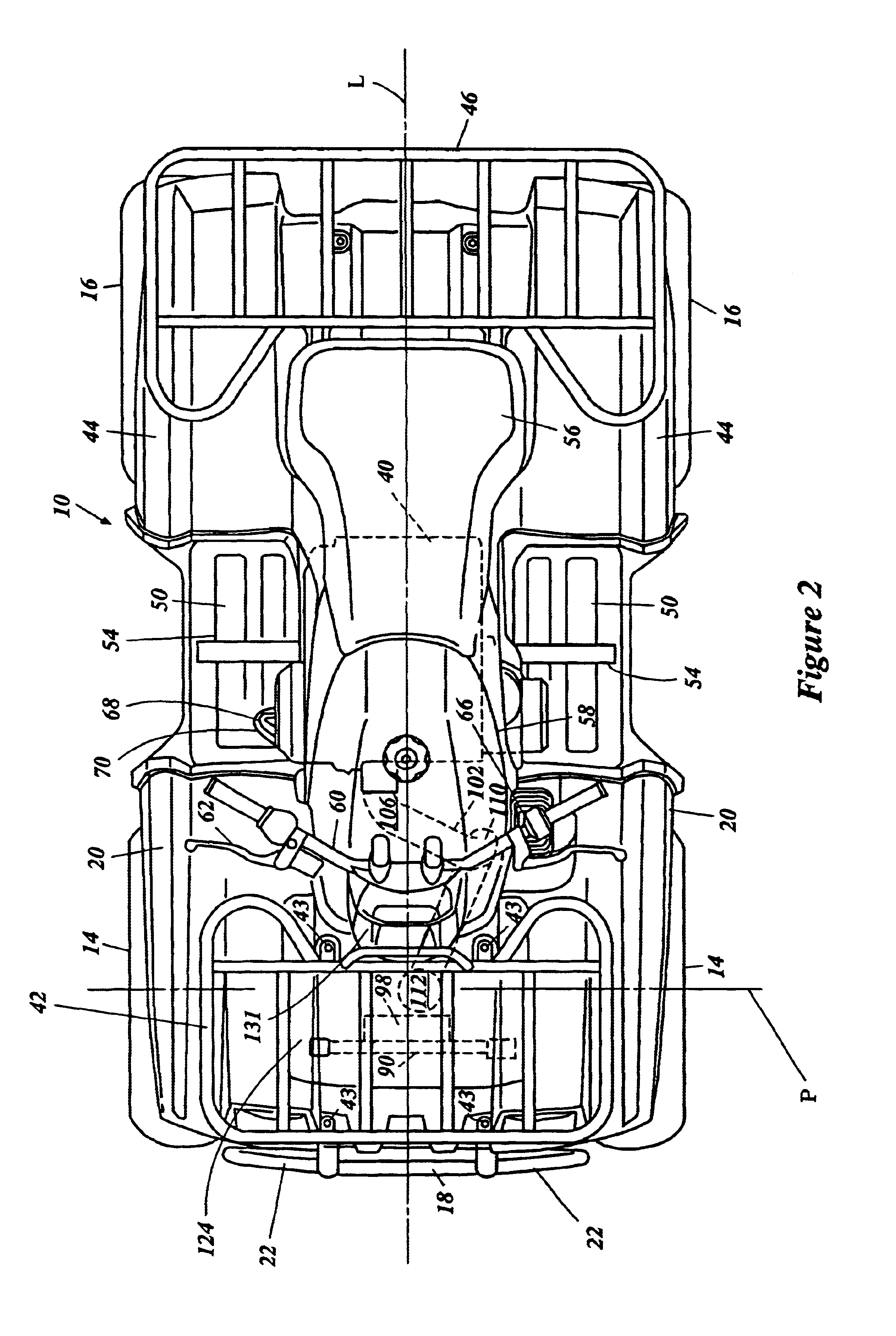

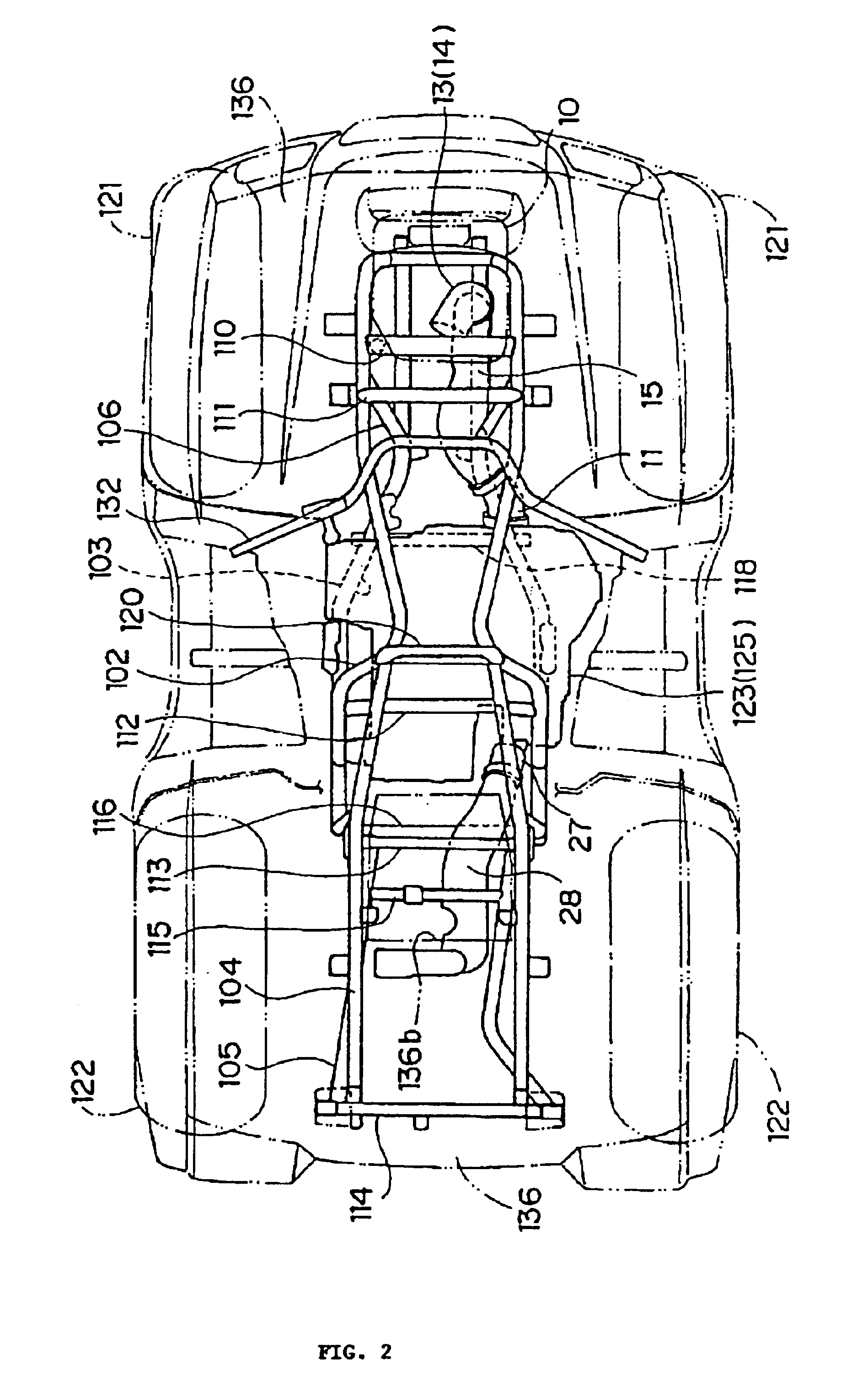

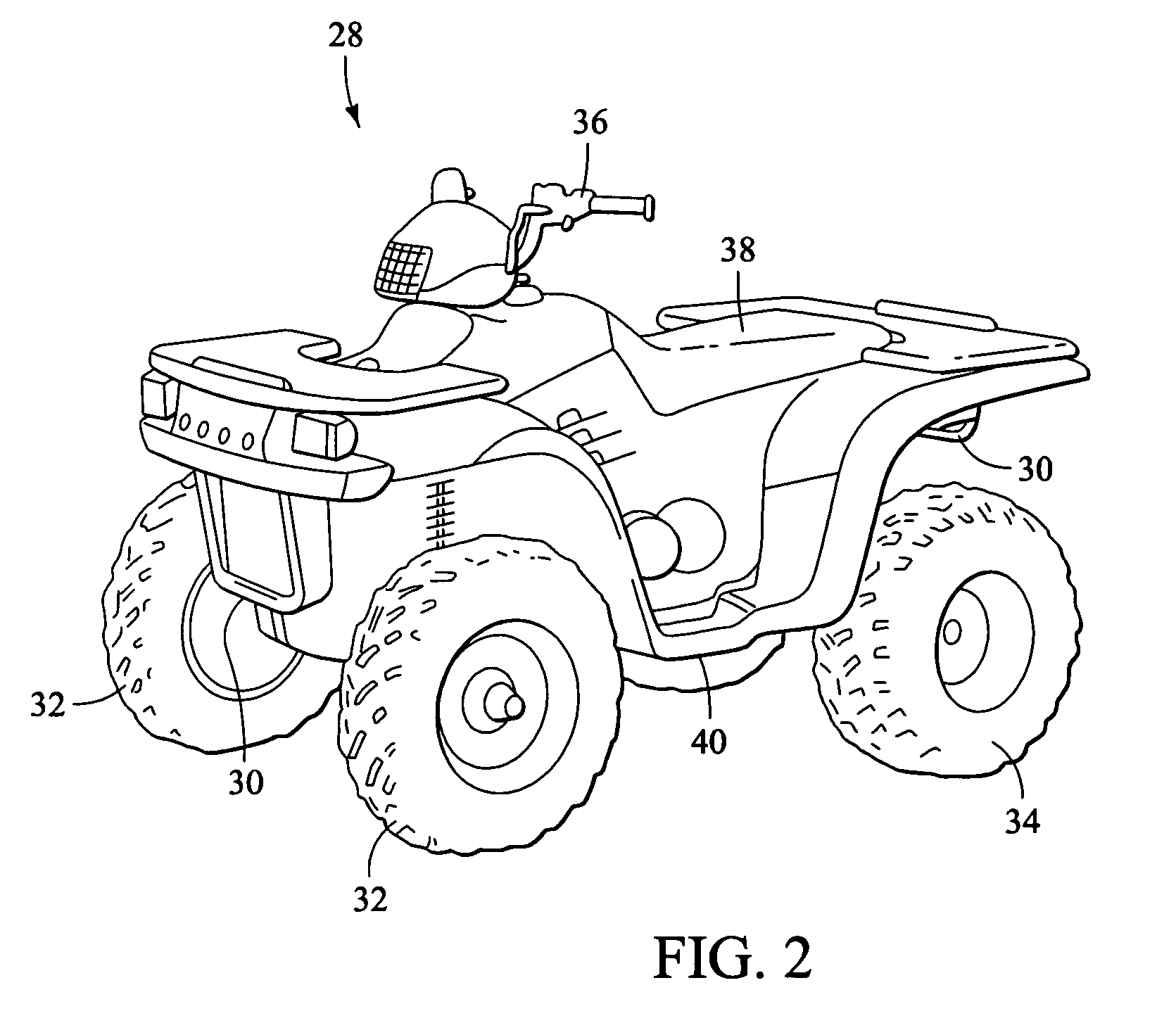

All terrain vehicle with improved motor arrangement

InactiveUS6296073B1Easy to disassembleEasy accessGearboxesGear lubrication/coolingCrankshaftAll terrain vehicle

An all terrain vehicle comprises an engine located under a hingably mounted seat, the seat providing ready access to the engine for maintenance and repair. The engine is placed in the vehicle such that the crankshaft is parallel to the line of travel and the crankshaft is in line with the longitudinal axis of the vehicle. The engine has two output shafts. The front output shaft extends forwardly of the engine to a front differential on the front axle and the rear output shaft extends rearwardly to a rear differential on the rear axle. The front and rear output shafts are in communication with one another by gears which enables different ratios of revolution between-the front and rear axle. The all terrain vehicle is also equipped with a parking gear which locks the two output shafts and prevents rotation with respect to the transmission housing.

Owner:BOMBARDIER RECREATIONAL PROD INC

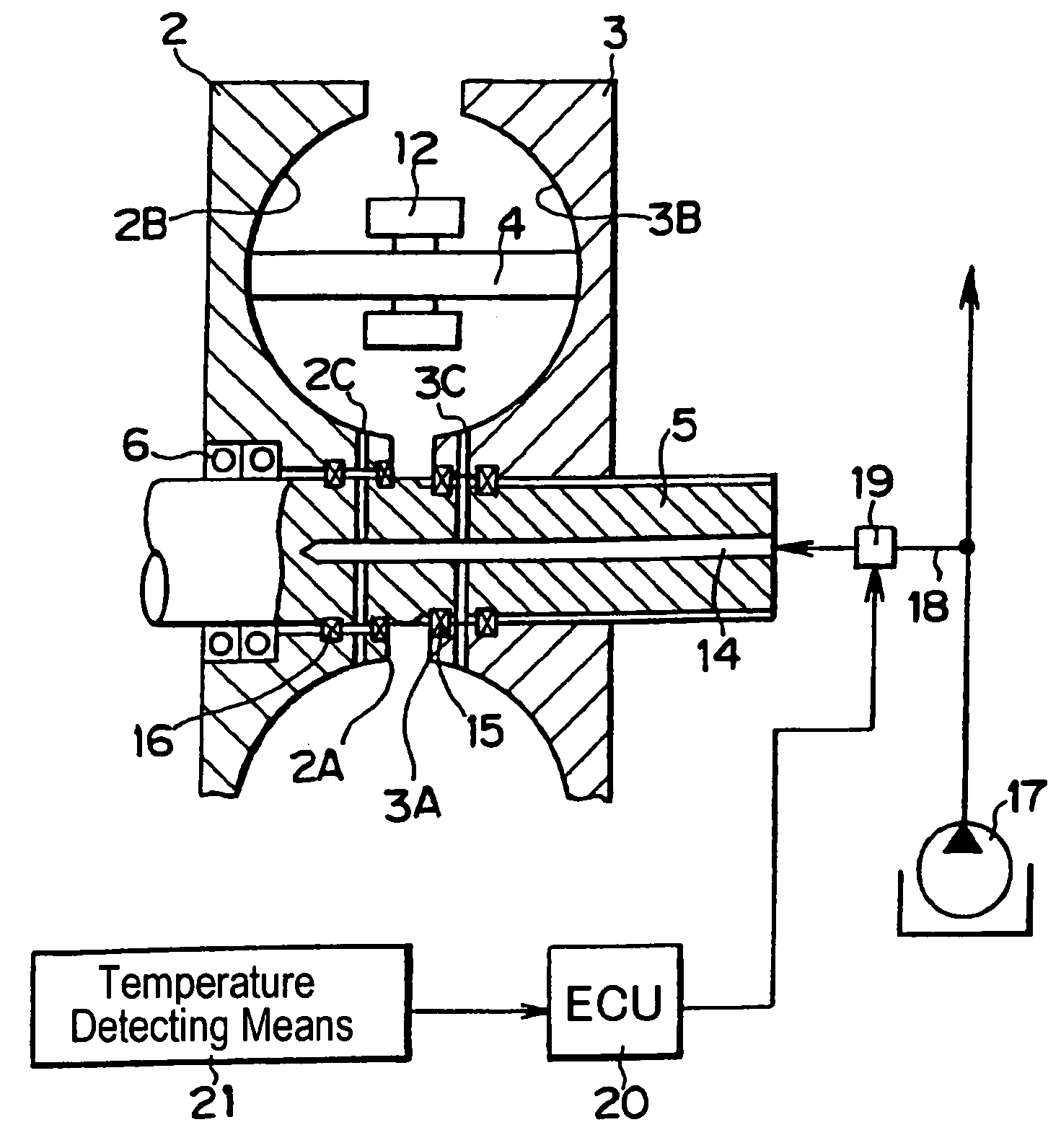

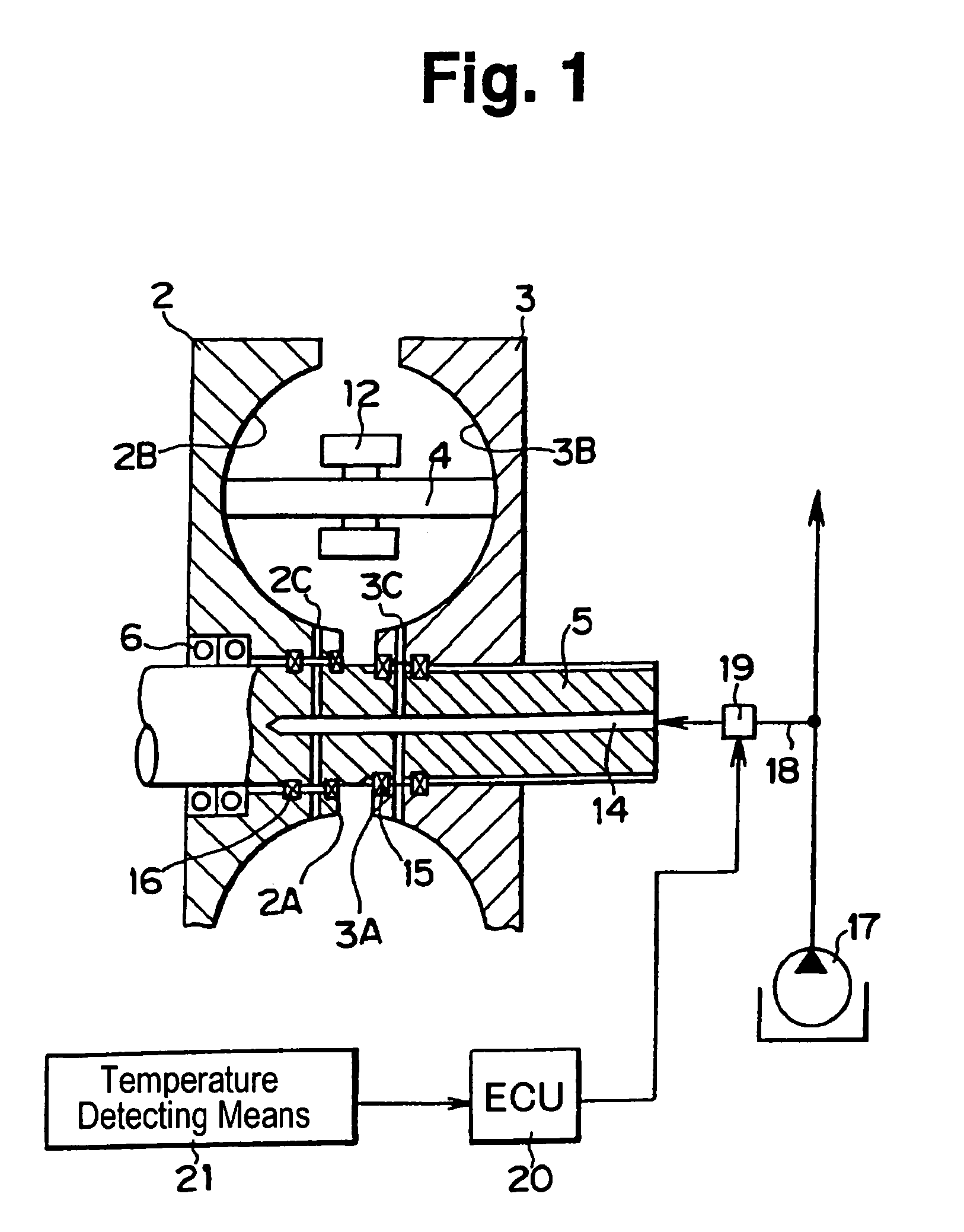

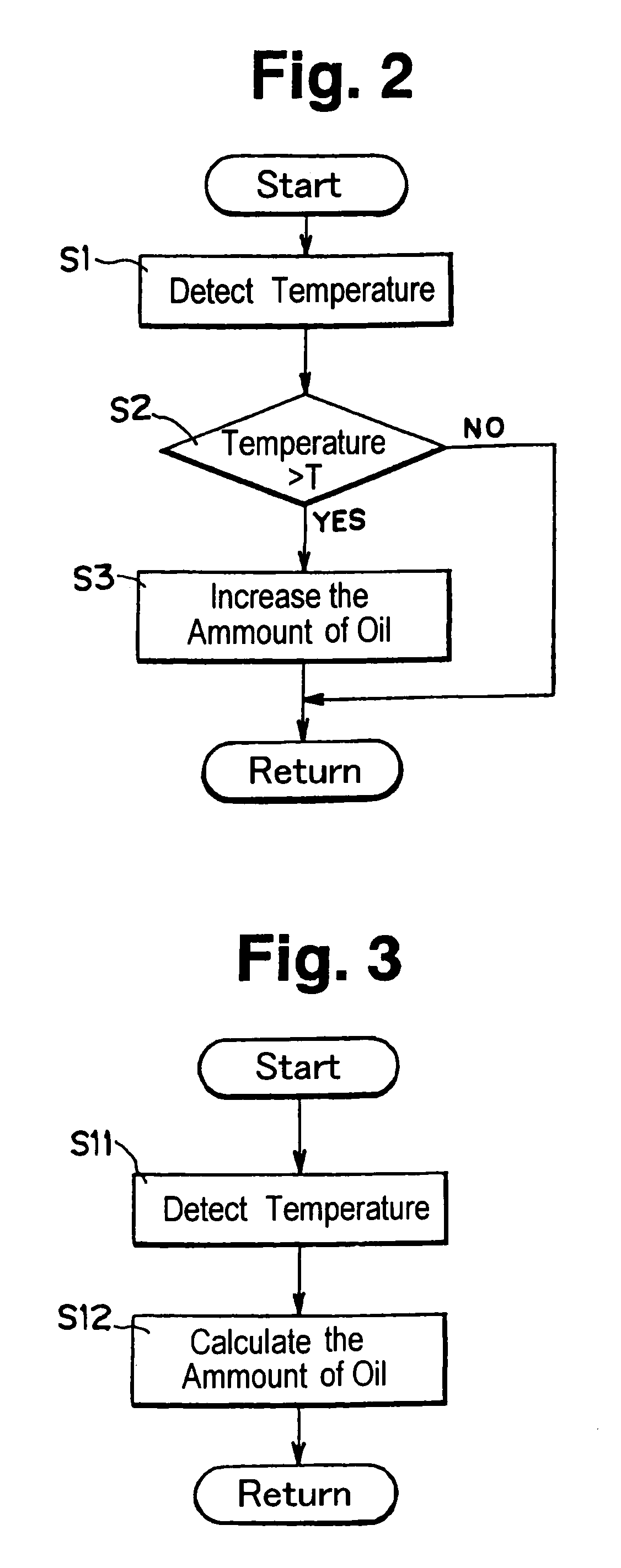

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveUS20090232673A1Avoiding substantial energy lossIncrease productionLiquid coolingGear lubrication/coolingHydraulic control unitElectricity

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

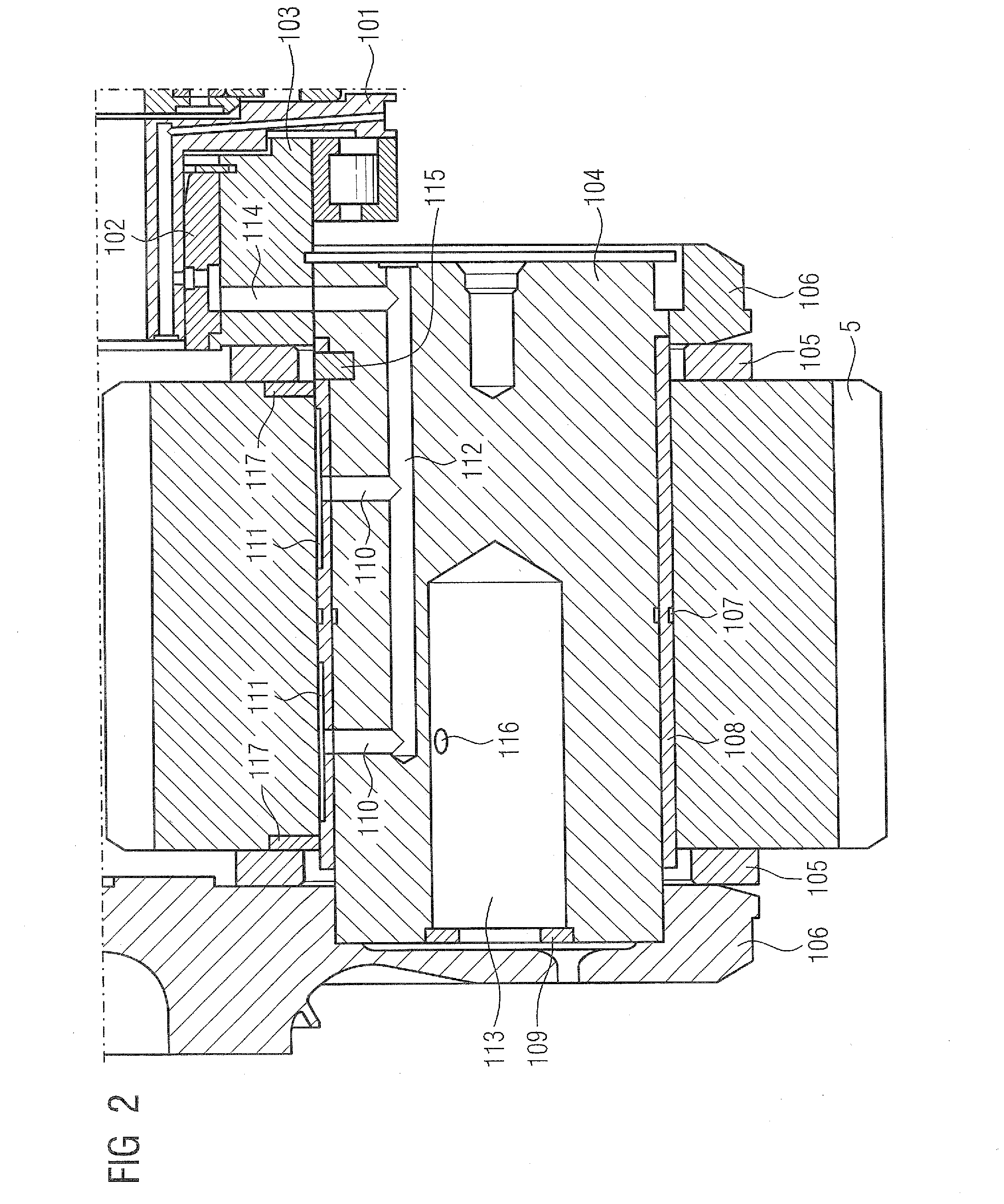

Planetary gear mechanism for a wind power plant

ActiveUS20120108380A1Effective lubricationCost-effective manufacturingEngine fuctionsShaftsEngineeringMechanical engineering

A planetary gear mechanism for a wind power plant includes a sun gear, an internal gear and a planetary carrier with planetary gears supported by radial and axial slide bearings. The radial slide bearings include a sleeve made of a slide bearing material and attached as an inner ring to a planetary gear shaft or mounted as an outer ring in a bore in a planetary gear. An outer bearing ring cooperating with the inner ring is formed by the bore in the planetary gear, or an inner bearing ring cooperating with the outer ring is formed by the planetary gear shaft. A slide bearing material of a first bearing element of the axial slide bearings is applied between a planetary carrier cheek and an end side of a planetary gear. The end side of the planetary gear or the planetary carrier cheek forms a corresponding cooperating second bearing element.

Owner:FLENDER GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com