Patents

Literature

954 results about "Fender" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fender is the American English term for the part of an automobile, motorcycle or other vehicle body that frames a wheel well (the fender underside). Its primary purpose is to prevent sand, mud, rocks, liquids, and other road spray from being thrown into the air by the rotating tire. Fenders are typically rigid and can be damaged by contact with the road surface.

Chip resistant, vibration damping coatings for vehicles

A formulation for covering vehicle panels, such as the inner fenders or floor boards of an automobile, with a chip resistant, vibration damping coating. The formulation includes a blocked polyurethane prepolymer (or a blocked polyisocyanate and a polyol), an epoxy resin, a filler and a plasticizer. A method for forming a chip resistant, vibration damping coating on such a panel including the steps of applying a coating mixture to the panel, the coating mixture including a blocked polyurethane prepolymer (or a blocked polyisocyanate and a polyol) and an epoxy resin, and then heating the panel to form the coating. An improved vehicle panel, wherein the improvement is a polyurethane modified epoxy coating (or a coating which is an interpenetrating network of polyurethane resin and epoxy resin) on the panel.

Owner:ESSEX SPECIALITY PROD INC

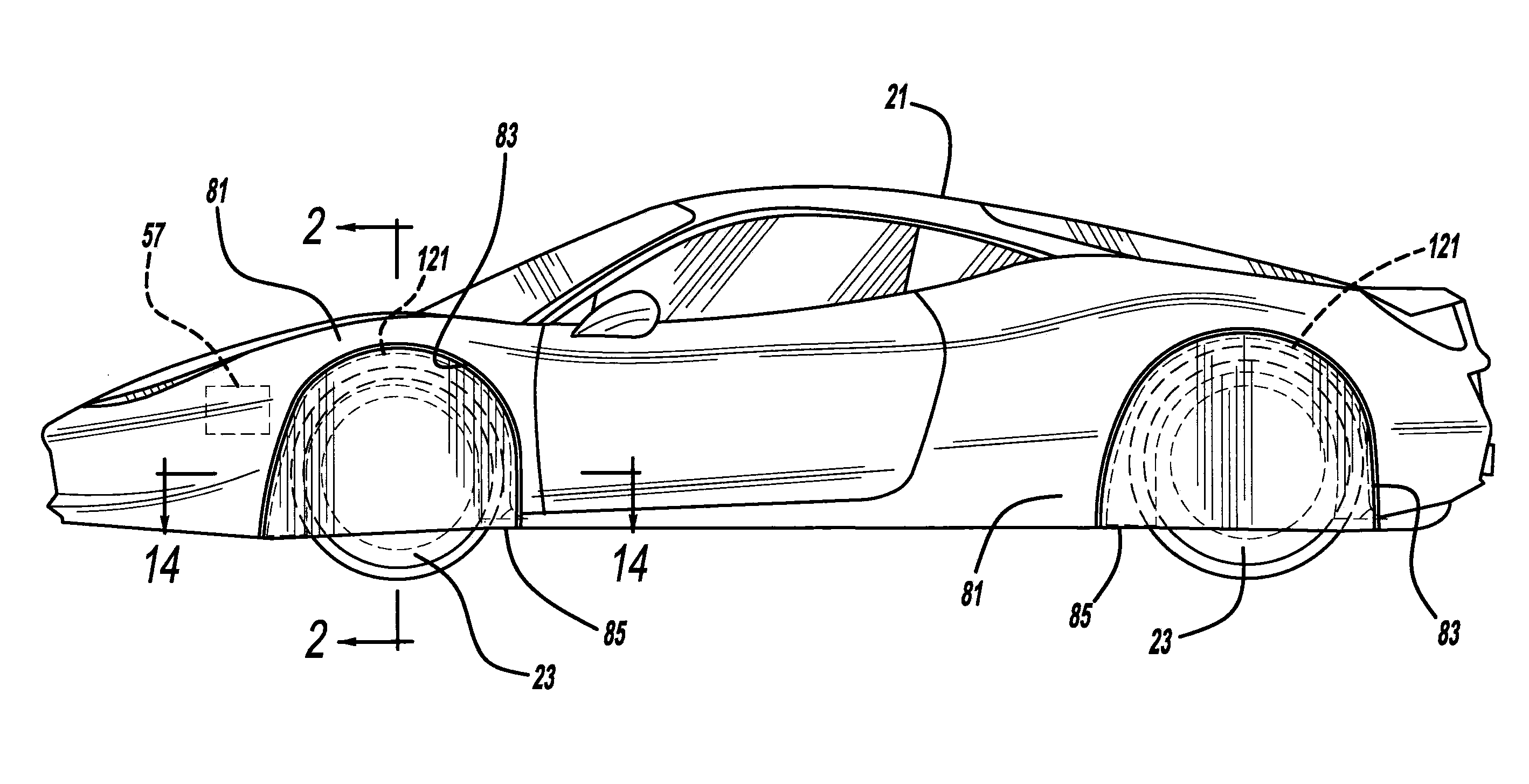

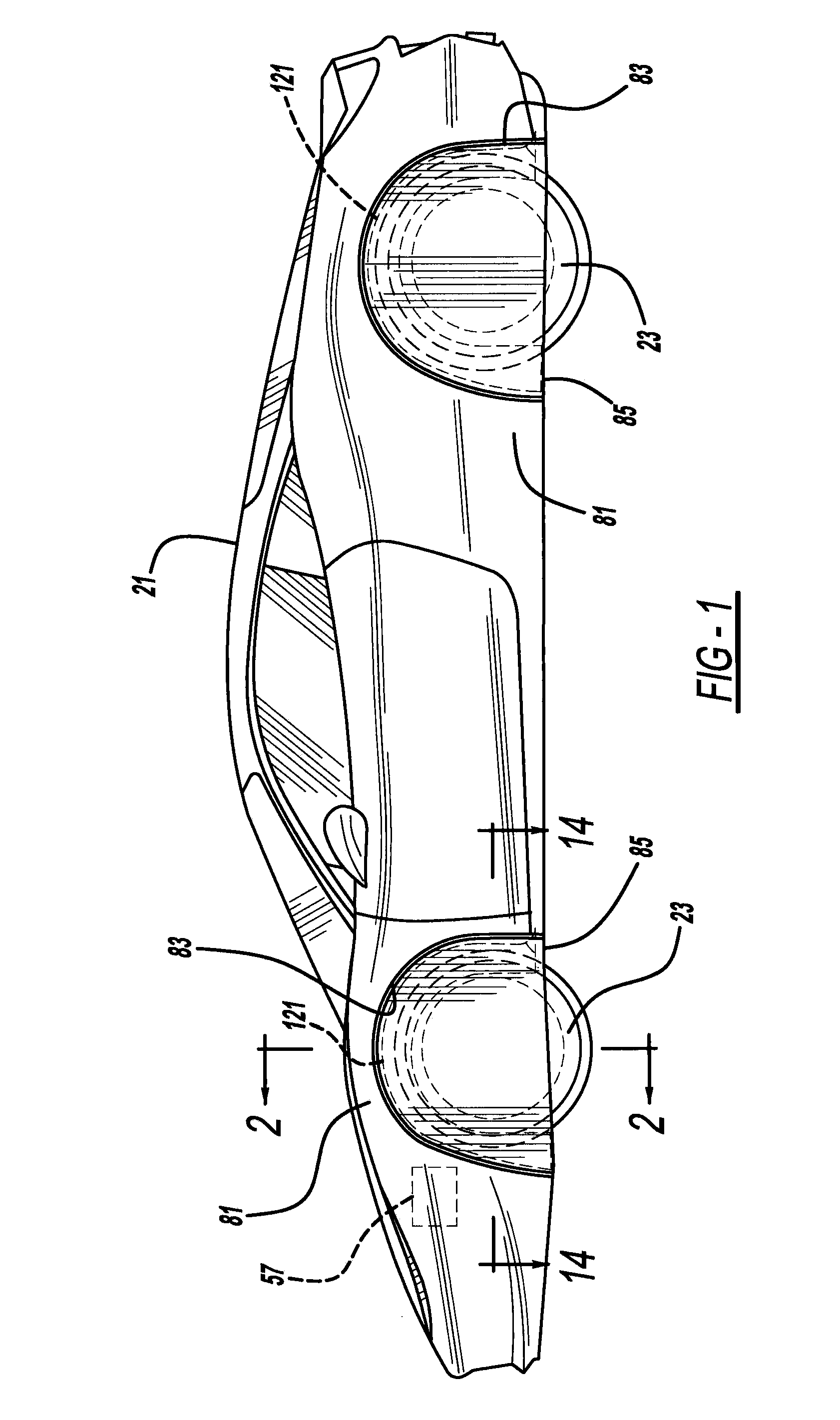

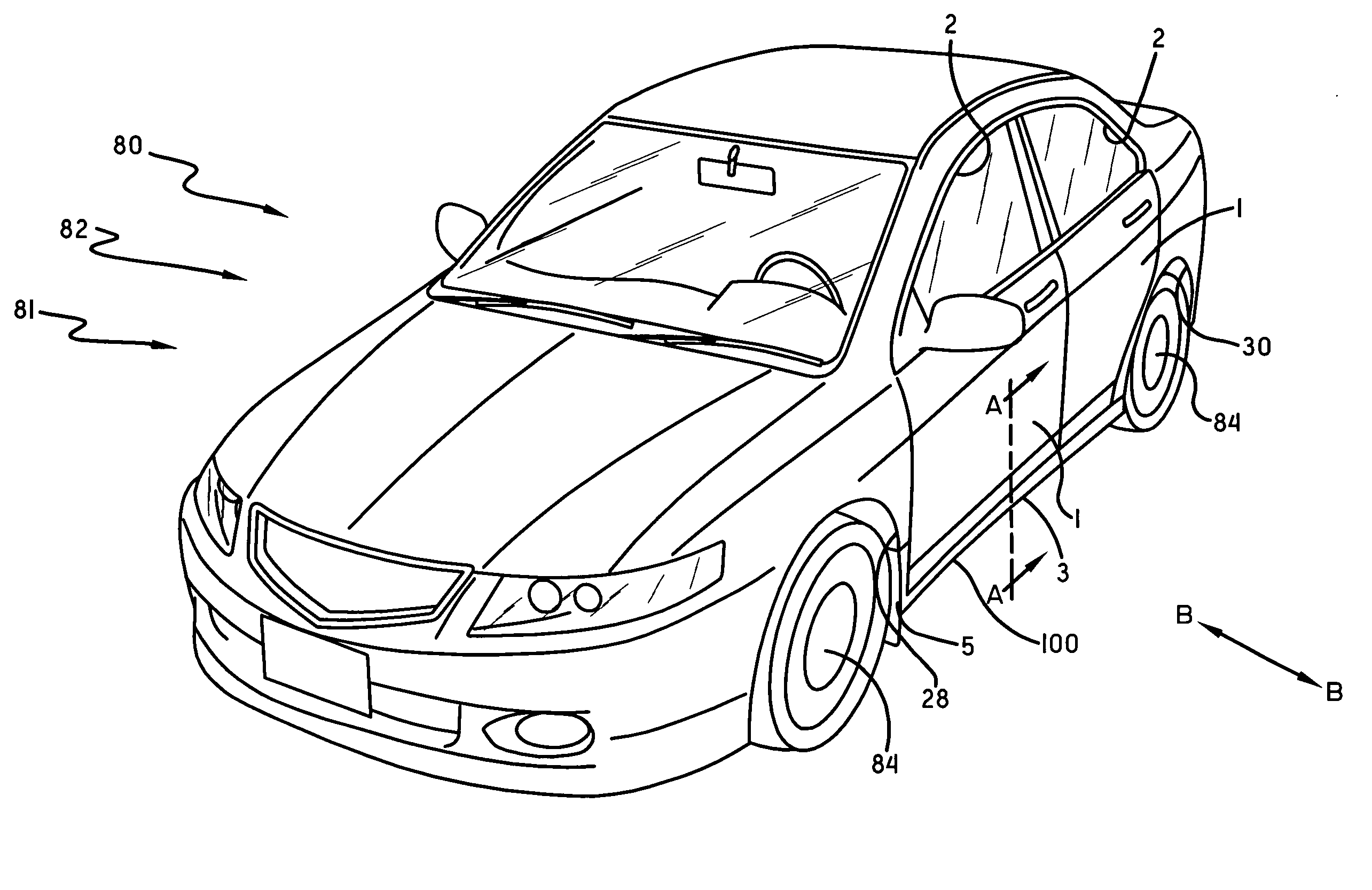

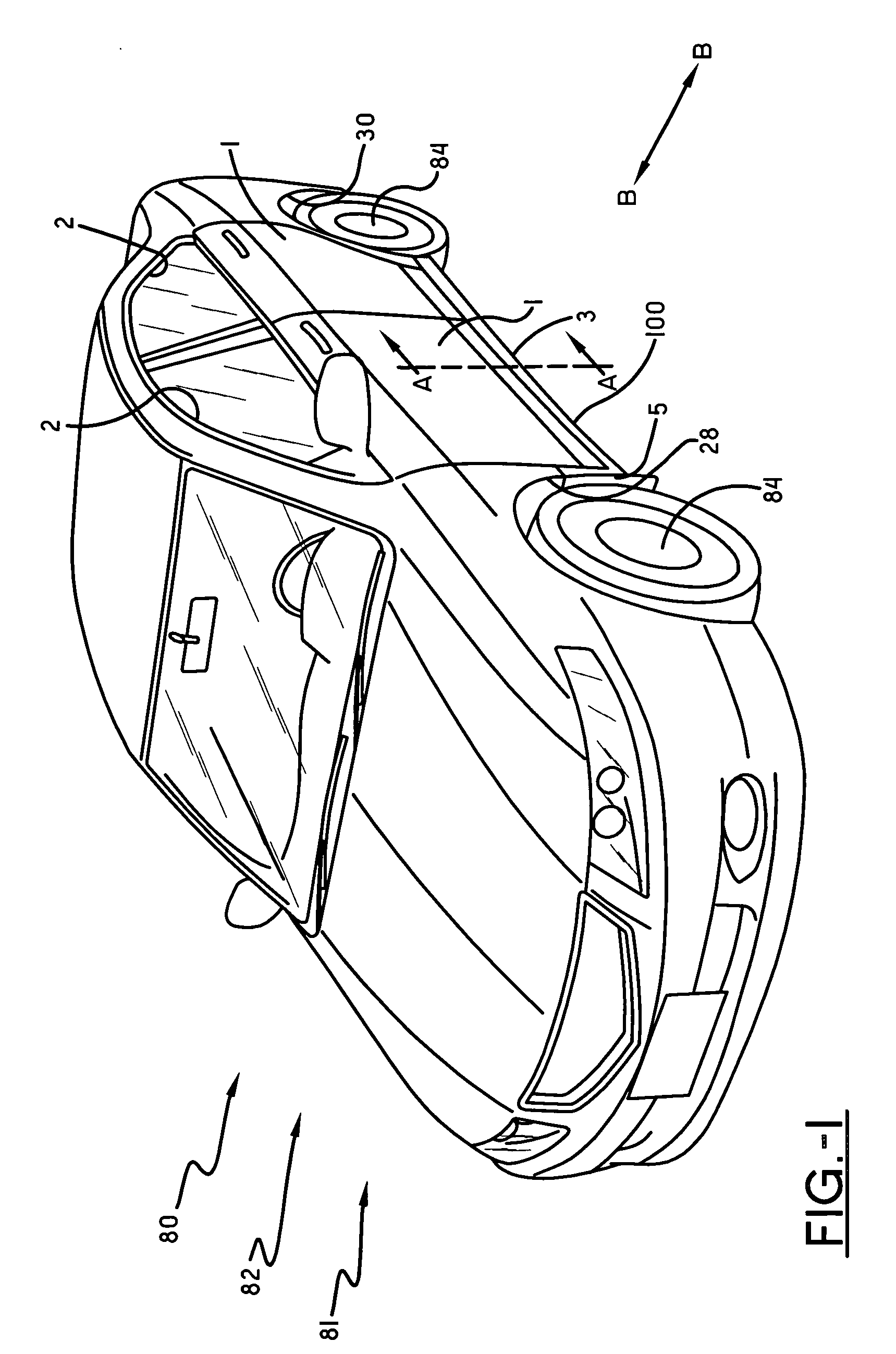

Vehicular wheel cover

InactiveUS20130096781A1Reducing aerodynamic turbulenceReduces circumferential wheel air turbulenceControlling membersMechanical apparatusAutomotive engineeringFender

An automotive vehicle wheel apparatus includes a turnable cover or door for a wheelhouse opening in a fender. In another aspect, a sheath or liner is provided close to at least half of a circumference of a wheel. A further aspect blocks and / or removes circumferential air moving with a wheel.

Owner:APTERA MOTORS

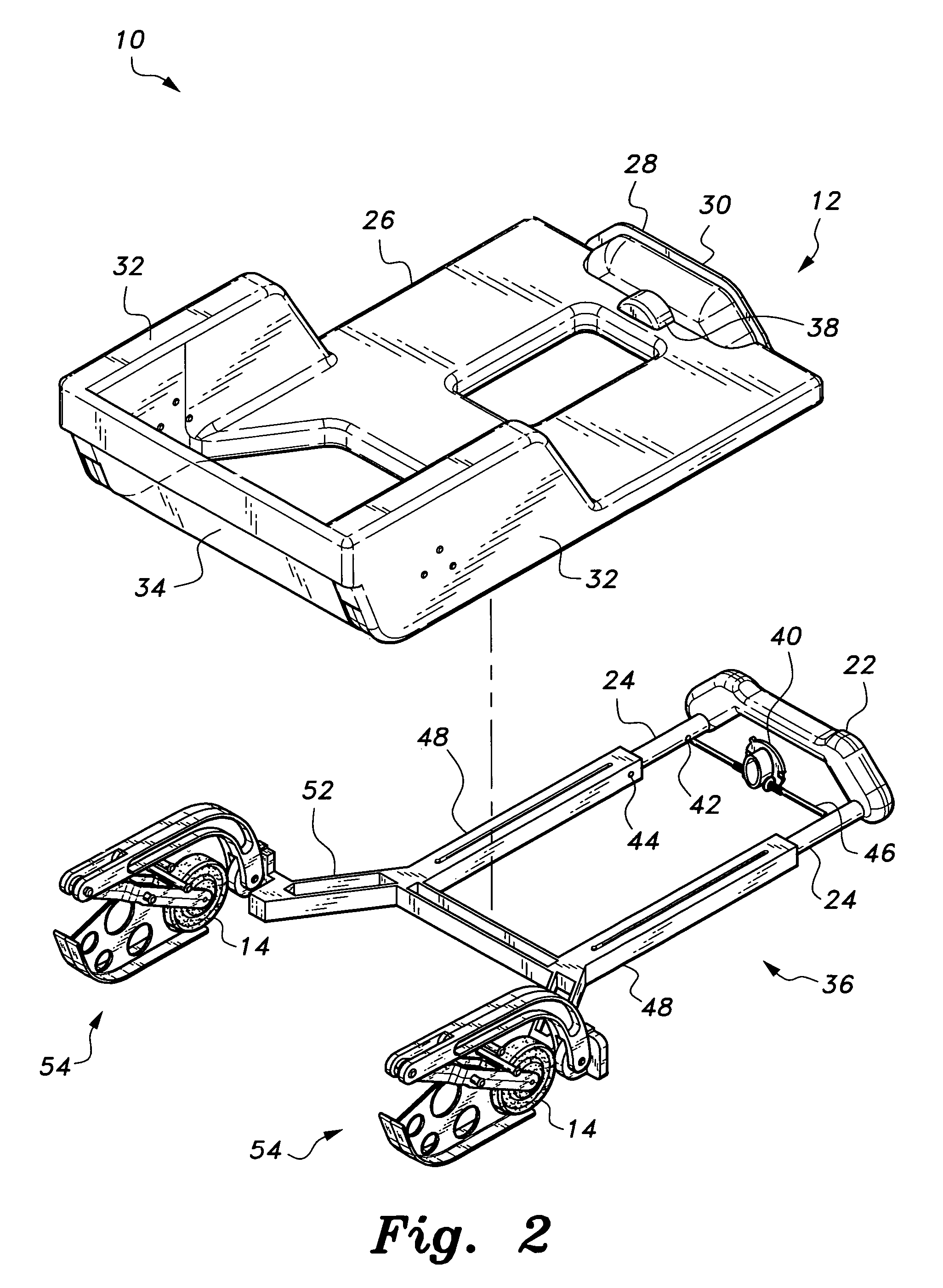

Chassis with retractable wheels

There is a chassis with retractable wheels, wherein the chassis includes a housing. The chassis may also include a chassis sled slidably disposed within the housing. In addition, the chassis may include a pair of lever arms, each said lever arm being disposed in the lower portion of the housing. Furthermore, the chassis includes a pair of mounting wheels, a fender configured to cover the wheels openings in a retracted position, and a web joining the fender to the wheel lever, and having a second end. The chassis with retractable wheels includes a chassis sled, wherein the chassis sled includes an isosceles trapezoid configuration. The chassis sled also includes a pair of receiving members pivotly attached to the first end of the pair of lever arms. The chassis further includes a separation panel attached to the housing configured to conceal the mechanical components of the chassis with retractable wheels.

Owner:RETRAC ENTERPRISES

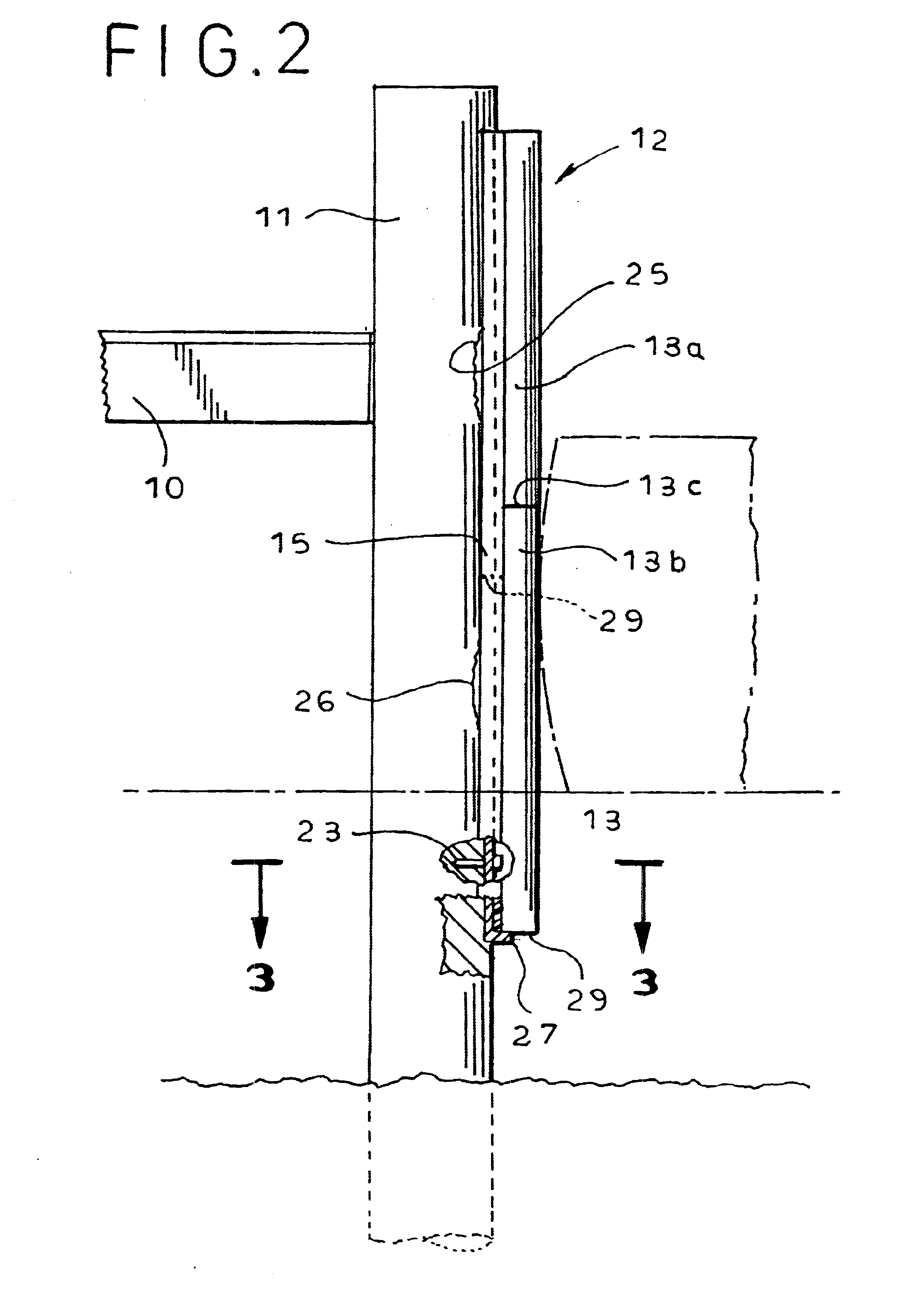

Piling fender

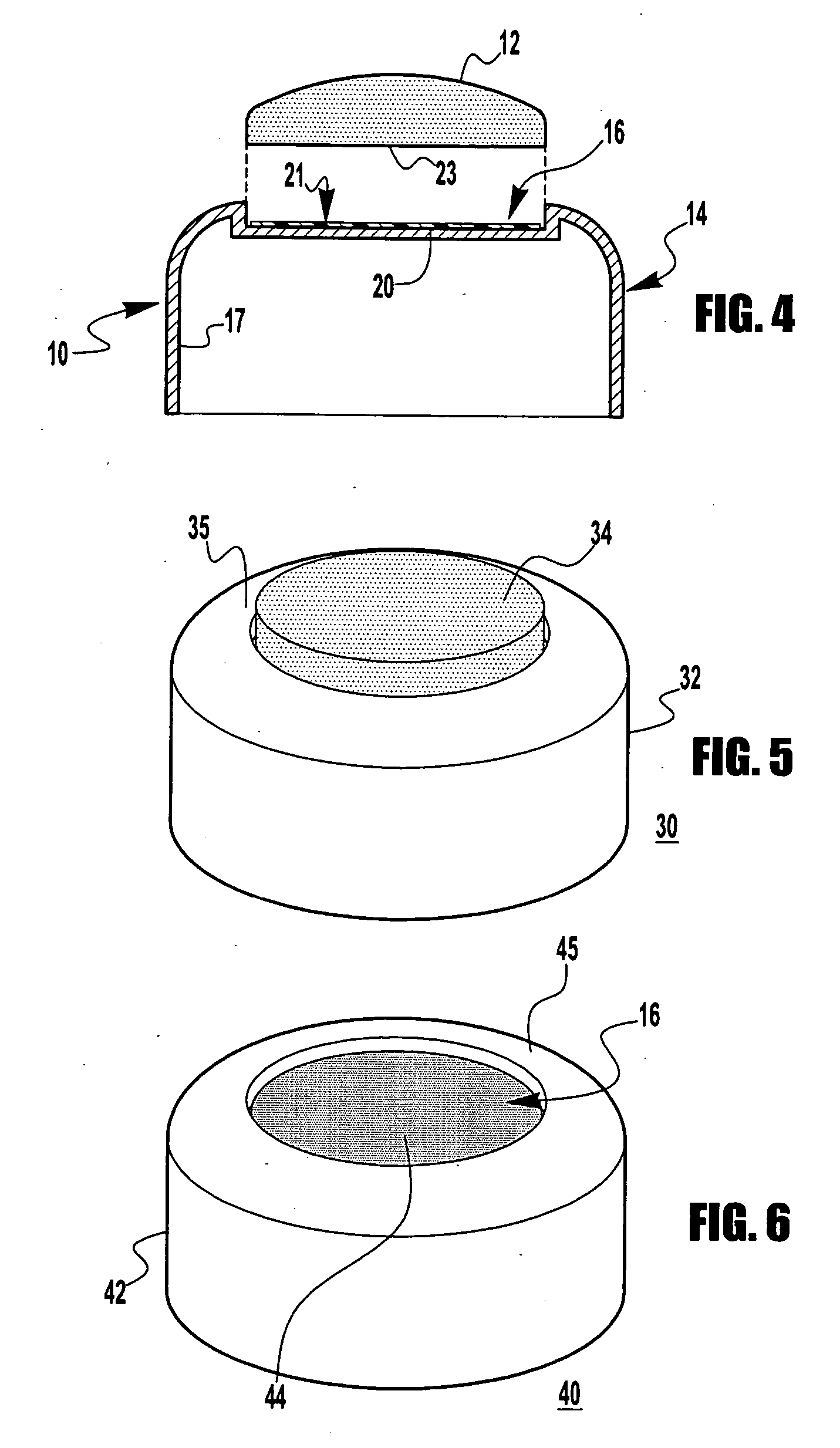

InactiveUS6685395B1Neat and clean and uniform appearanceVessel cleaningClimate change adaptationCushioningEngineering

A dock fender, particularly for attachment to the outer face of a dock piling for cushioning vessels attached to the dock. The fender is of extruded construction, having laterally extending flanges which are conformable to the surface of the pilings. The fender is attached to the piling by lag screws applied to the flanges. Special washers, of rectangular configuration, are provided to underlie the heads of the lag screws. The washers are formed with anti-rotation means such that, after initial proper alignment of the washers with the fender flanges, the washers will retain such orientation during rotational tightening of the lag screws. In one form, the anti-rotation means comprises bent corners of individual washers. In another form, the washers are of a length to engage more than one lag screw.

Owner:PAWLING ENGINEERED PROD

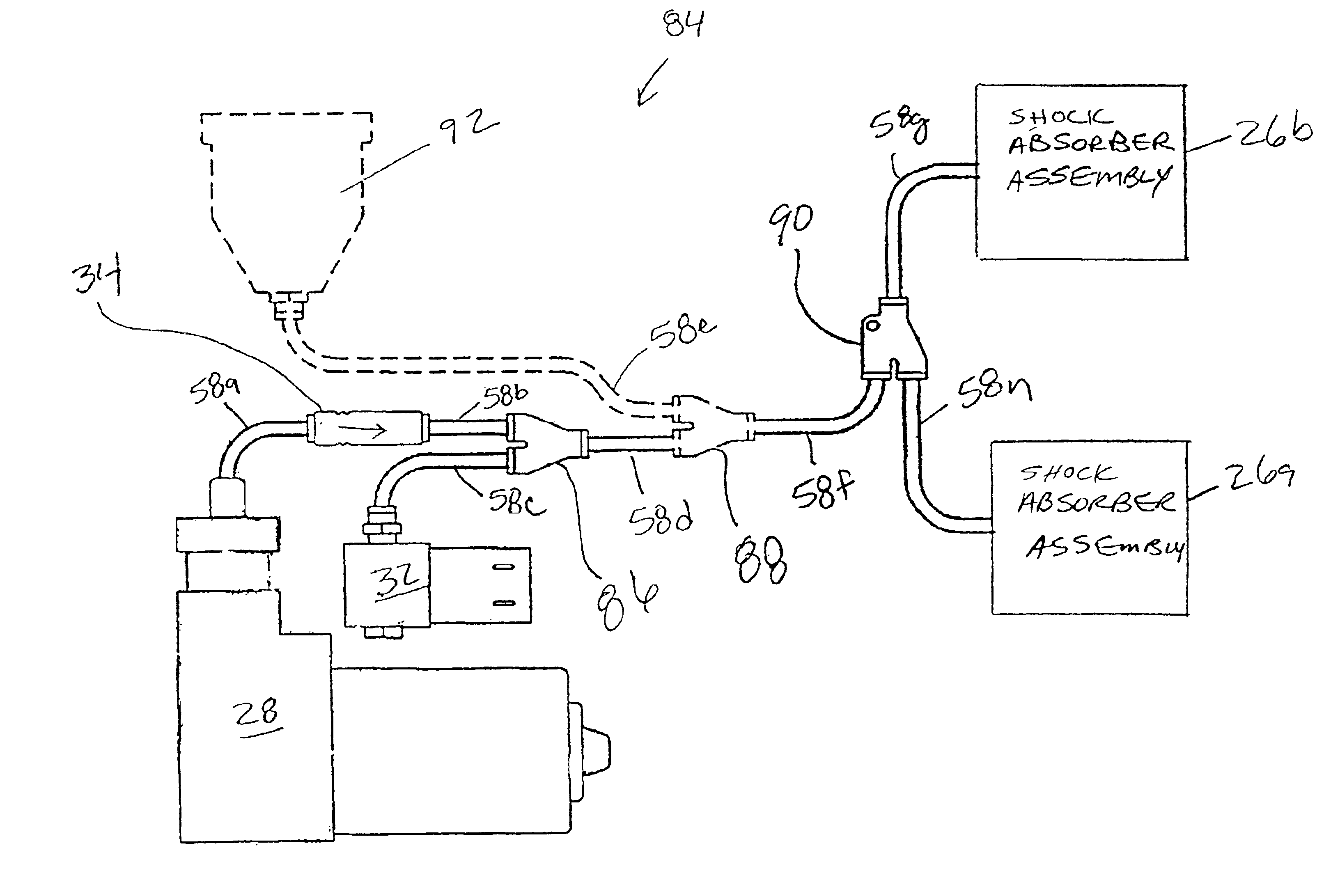

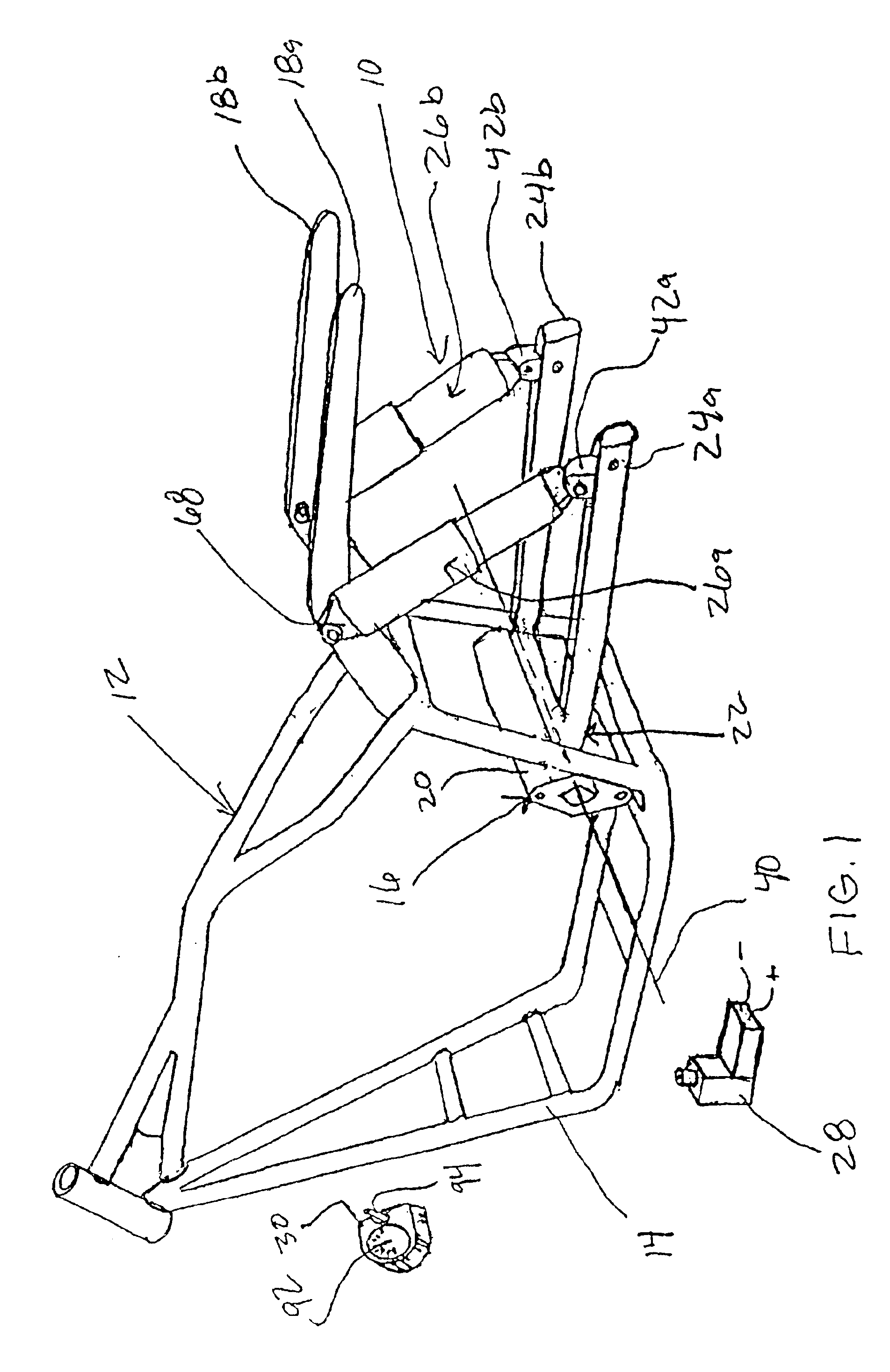

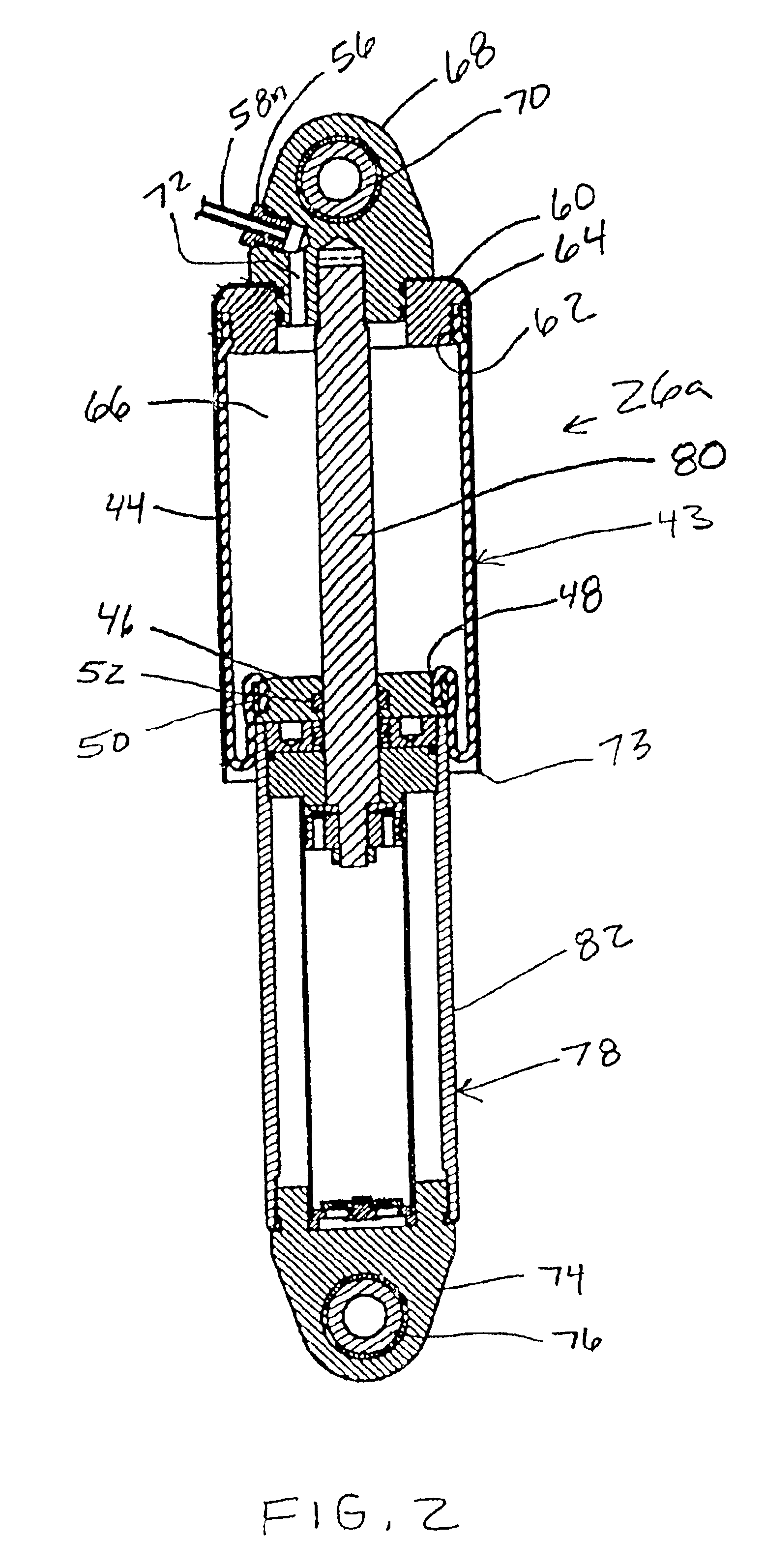

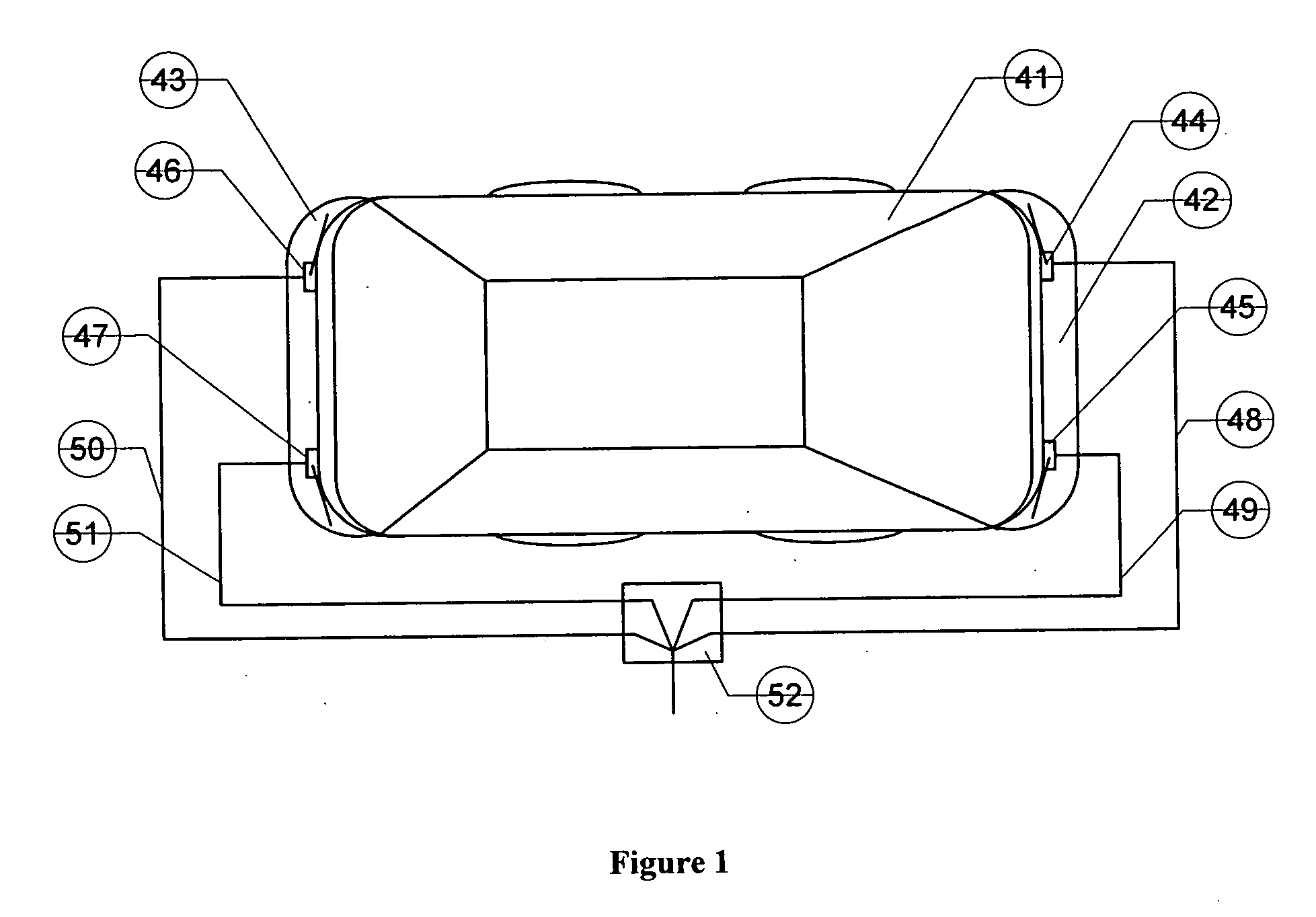

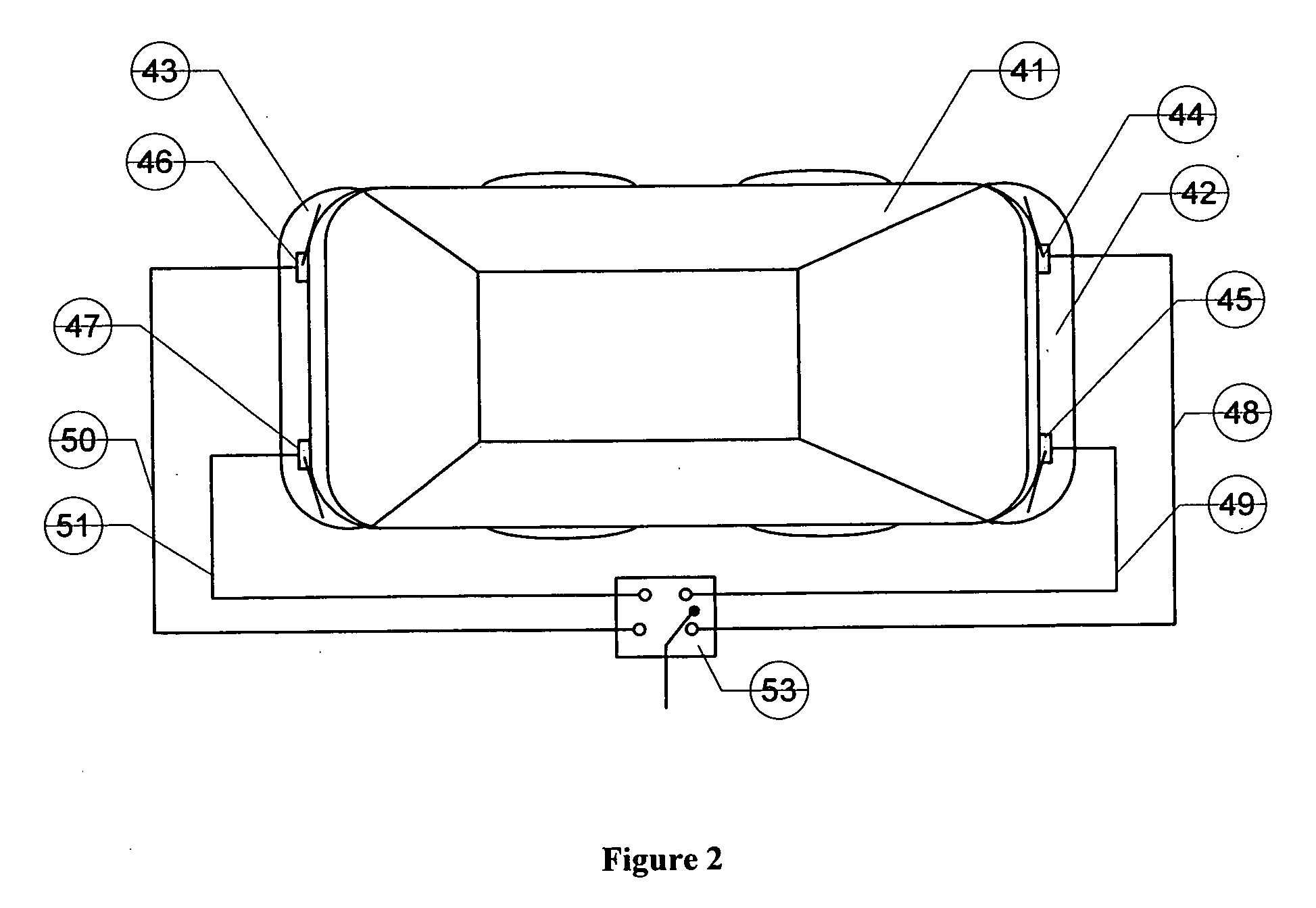

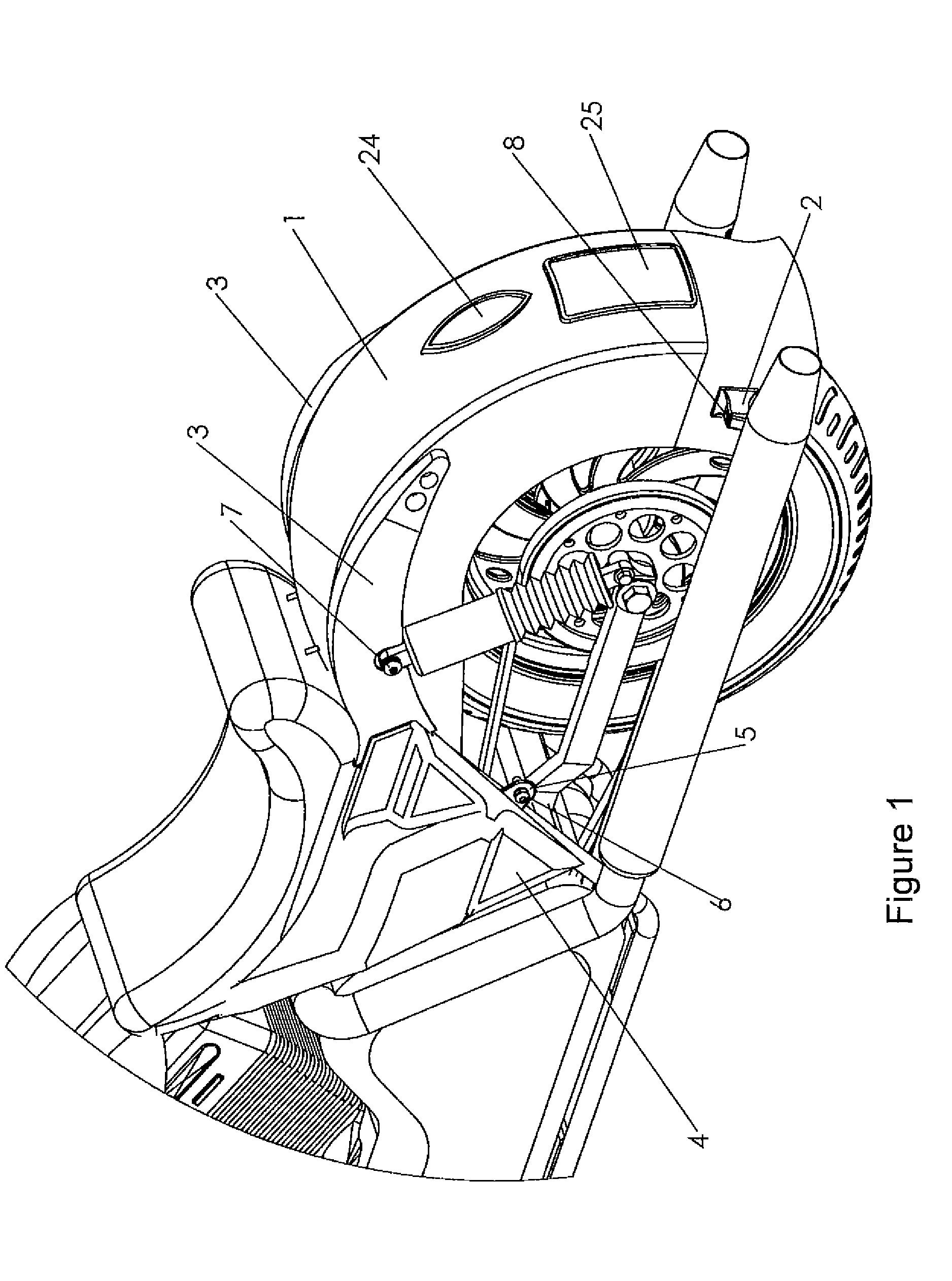

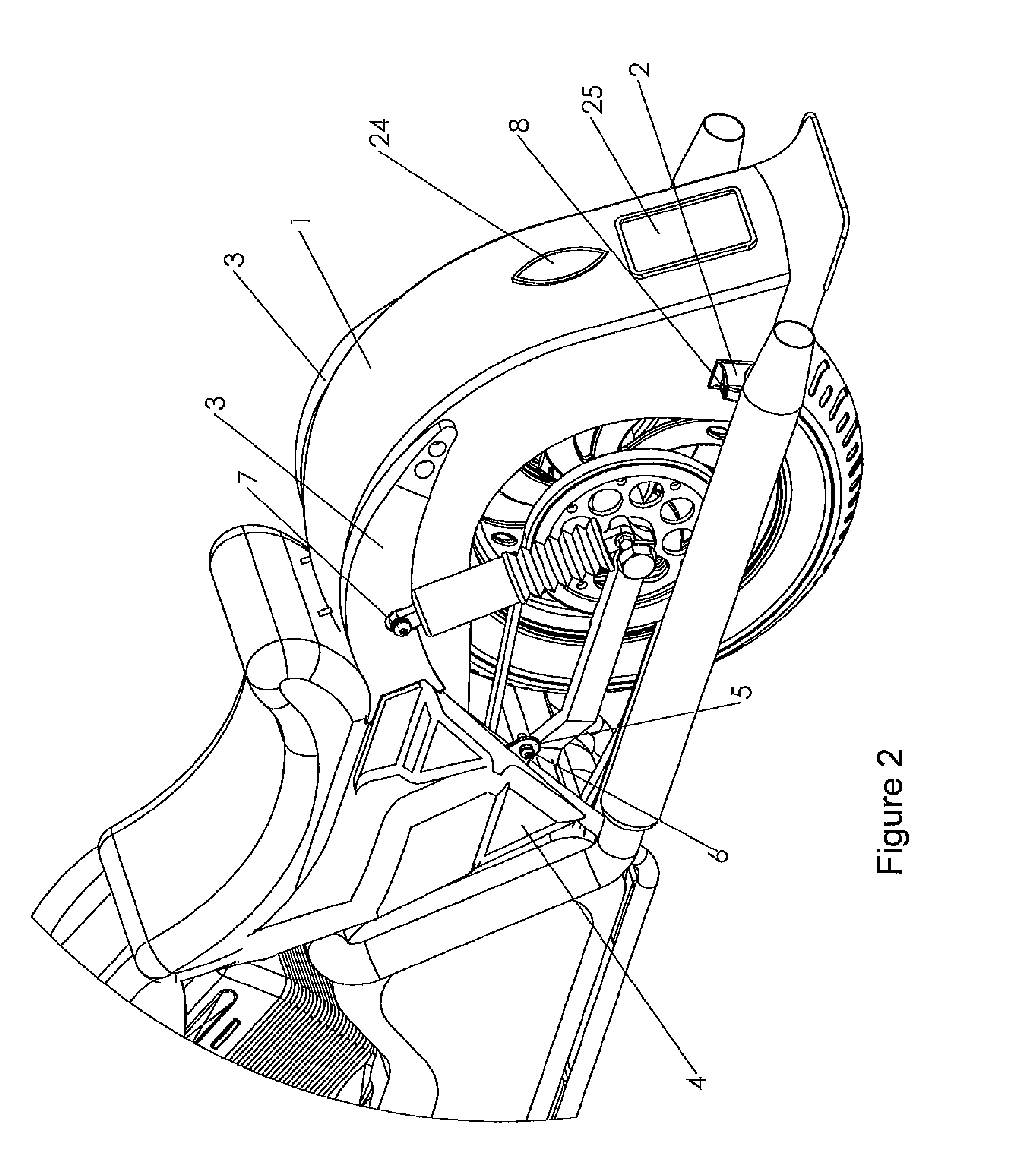

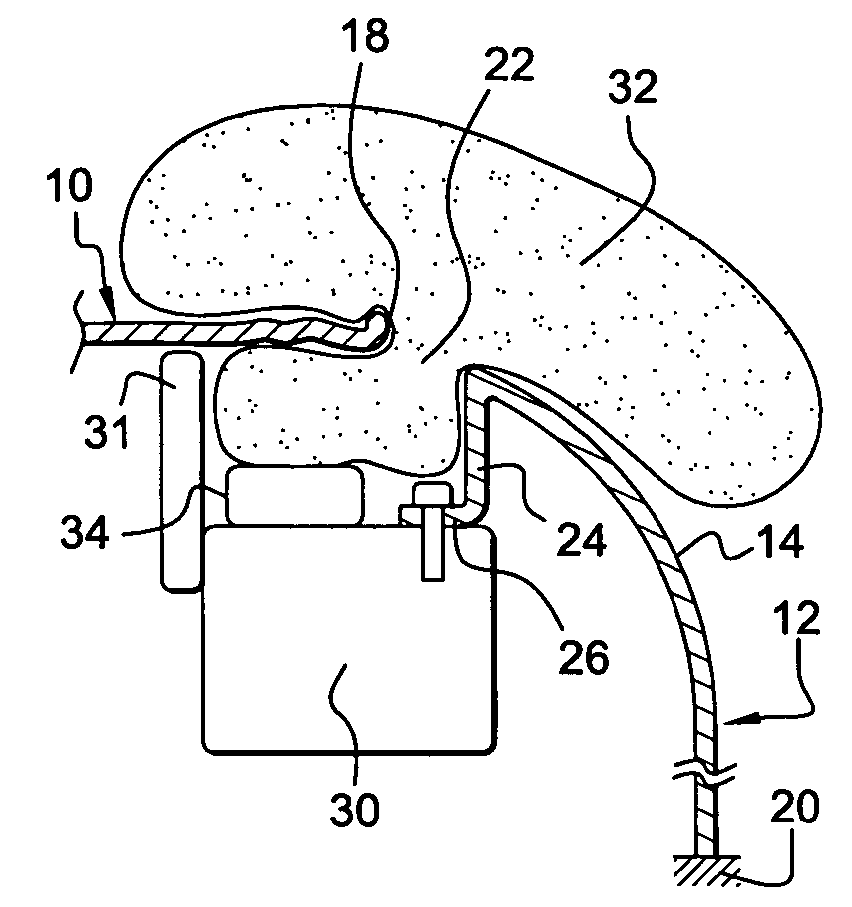

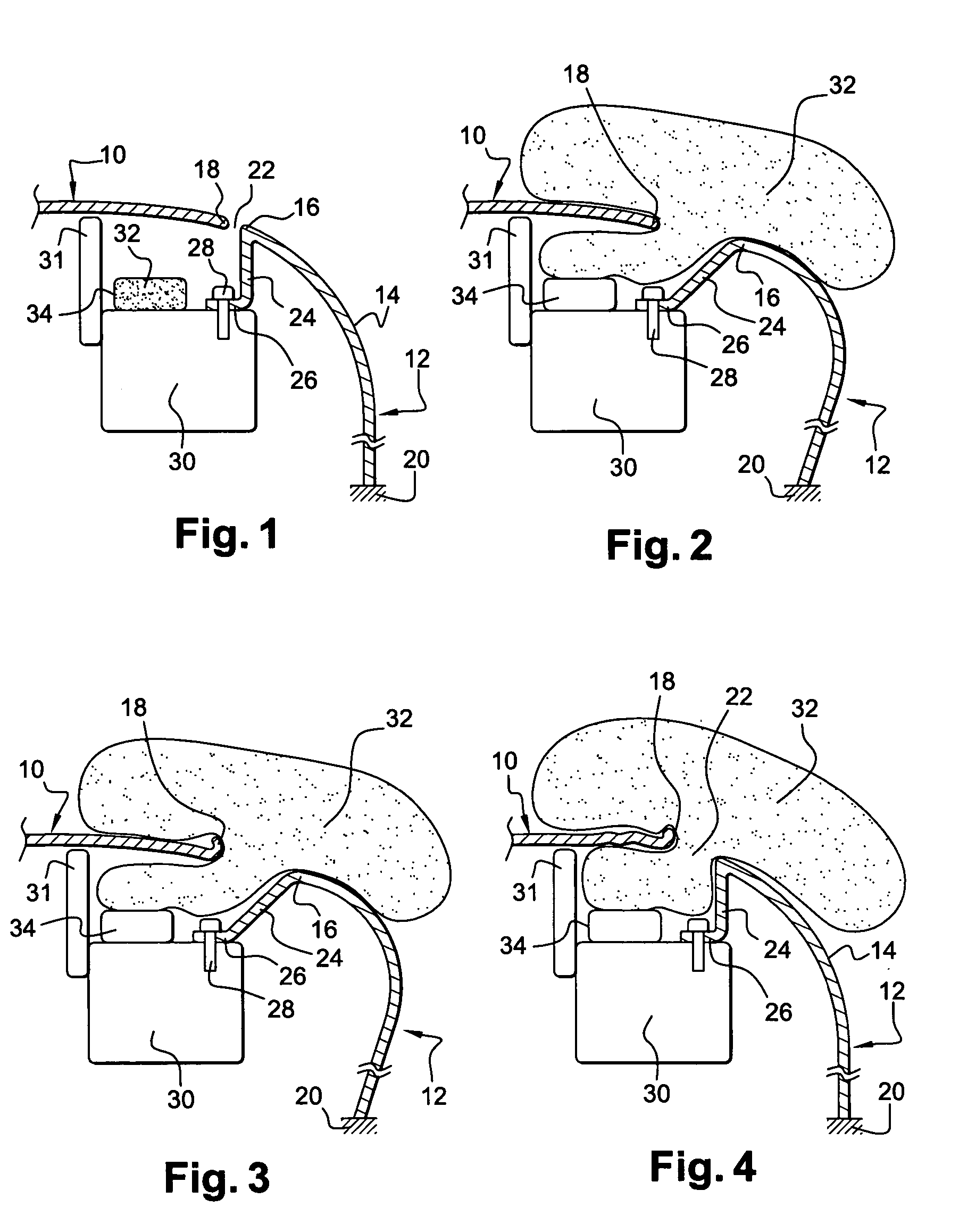

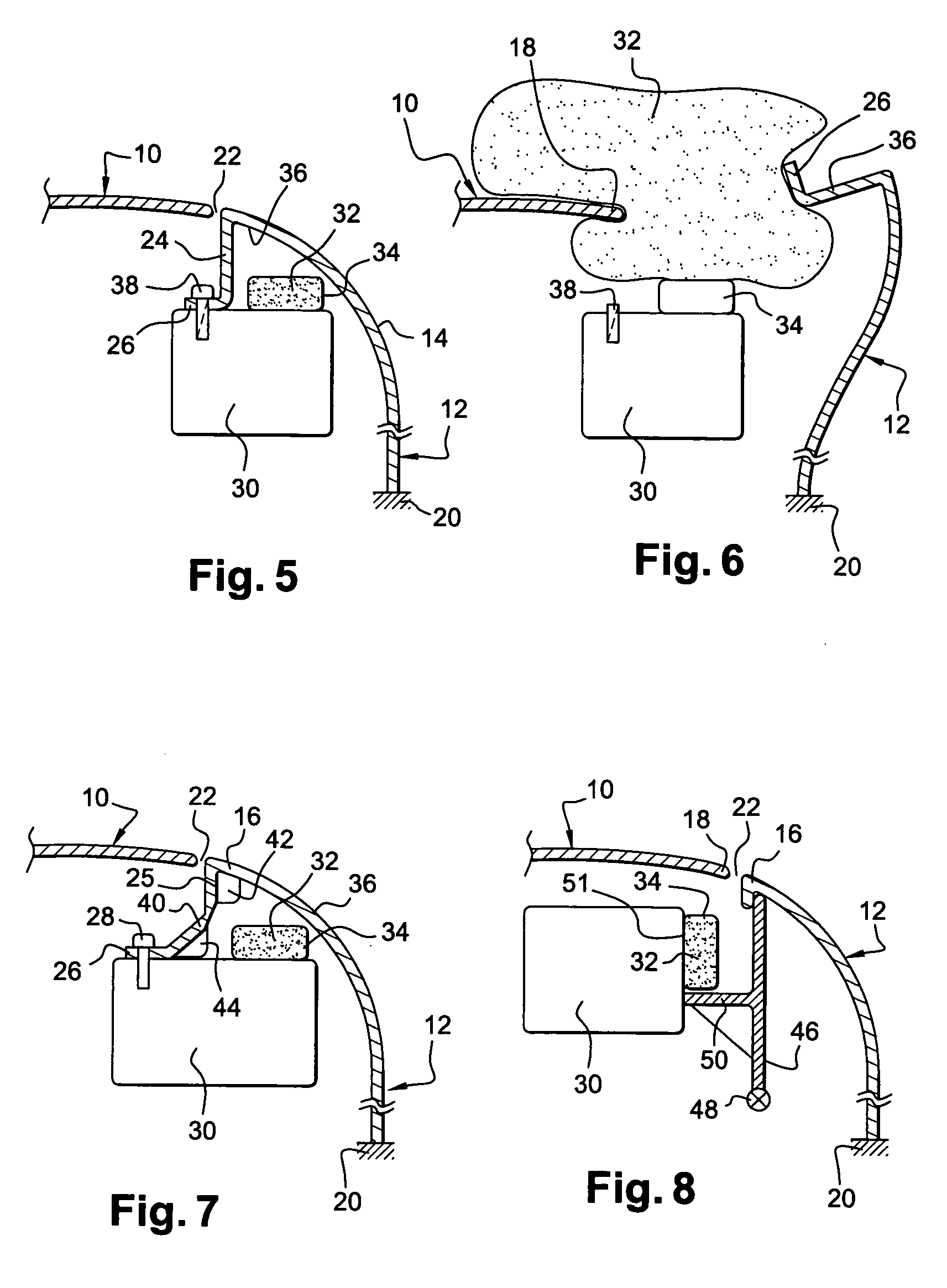

Air-bag suspension system

InactiveUS6905126B1Prevents bottoming-outEasy to replacePassenger cyclesChildren cyclesSolenoid valveOn board

An air-bag suspension system for a motorcycle having a motorcycle main frame, fender struts extending outwardly from the main frame, and a swing arm pivotally mounted to the main frame about a pivot axis. The air-bag suspension system includes shock absorber assemblies each having an air-bag. The air in the air-bags is generated by an on-board compressor and released through a solenoid valve. The air-bag suspension system replaces the standard coil spring hydraulic suspension commonly found on motorcycles and provides a greater range of adjustment, remotely controlled, while the motorcycle is in use. The air-bag suspension system accommodates heavier loads than the stock suspension systems when the air-bags are fully inflated; and when deflated completely, provide an aesthetically pleasing stance. The range of wheel travel provided allows the rider to adjust the suspension to provide the smoothest ride coupled with an increased load capacity or adverse road conditions.

Owner:AFCO PERFORMANCE GRP LLC

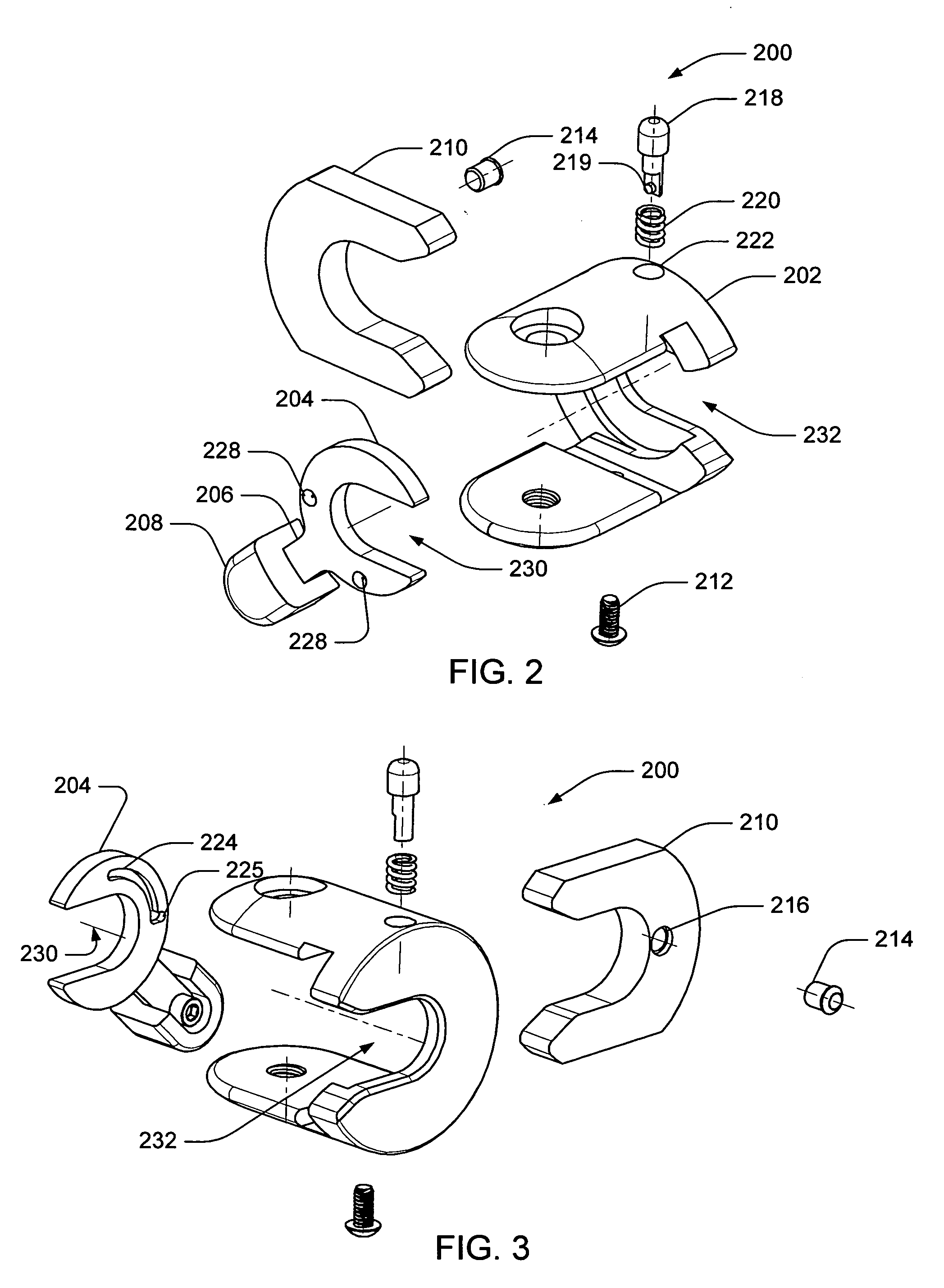

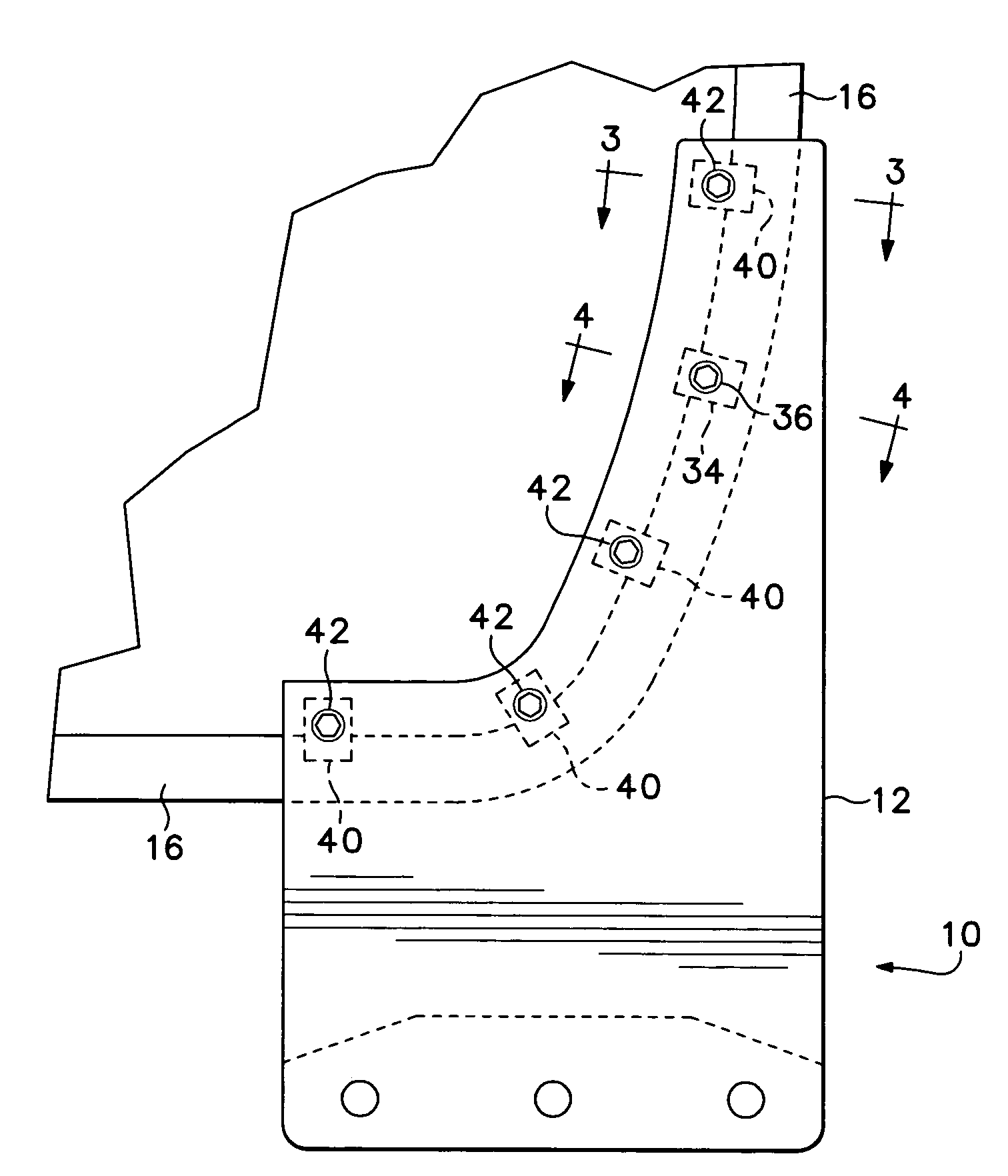

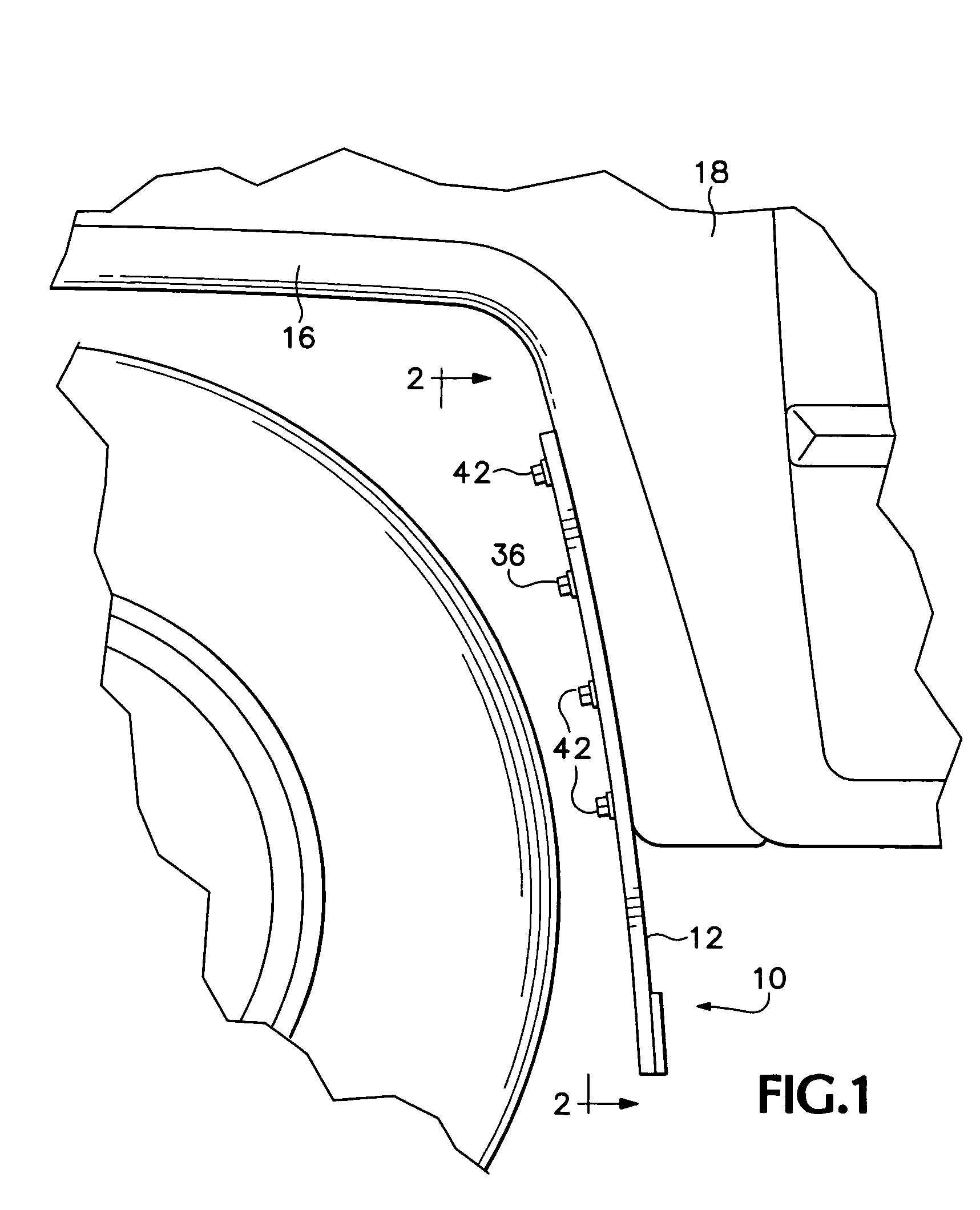

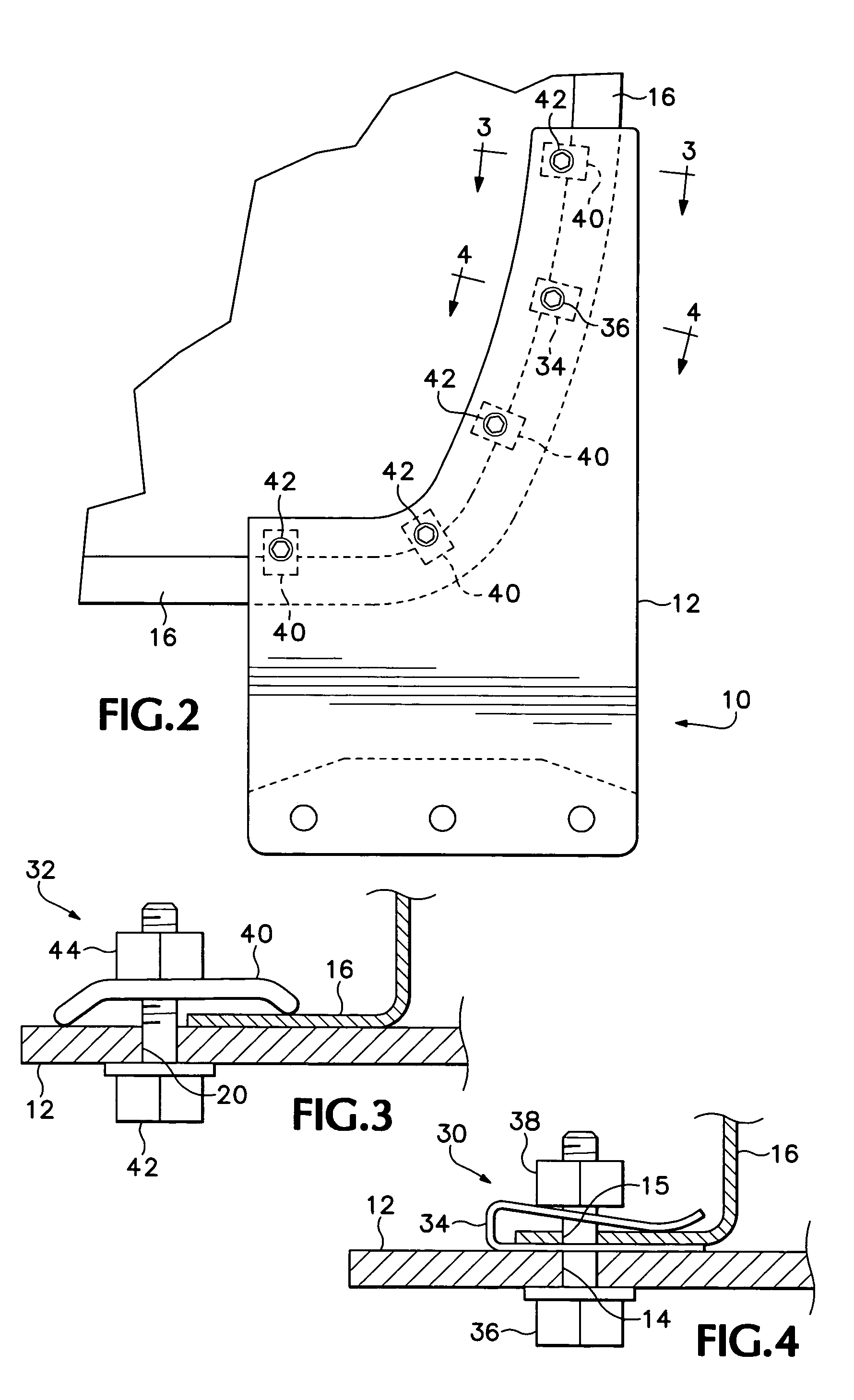

Vehicle mud flap with fender fold clamp

ActiveUS7578527B2Prevent rotationClamp firmlyCarriage/perambulator accessoriesSuperstructure subunitsFenderClassical mechanics

The drilling of new holes into a vehicle fender fold is avoided by providing a mud flap with a rotating clamping member. A clamping arm of the rotating clamping member is rotated from a disengaged position to an engaged position behind the fender fold, and is then drawn forwardly on the threads of an attachment bolt to clamp the fender fold between the rotating clamping member and a stationary clamping member in-molded into the mud flap. A visual indicator may be provided to show whether the rotating clamping member is behind the vehicle fender fold to which the mud flap is to be attached.

Owner:MACNEIL IP

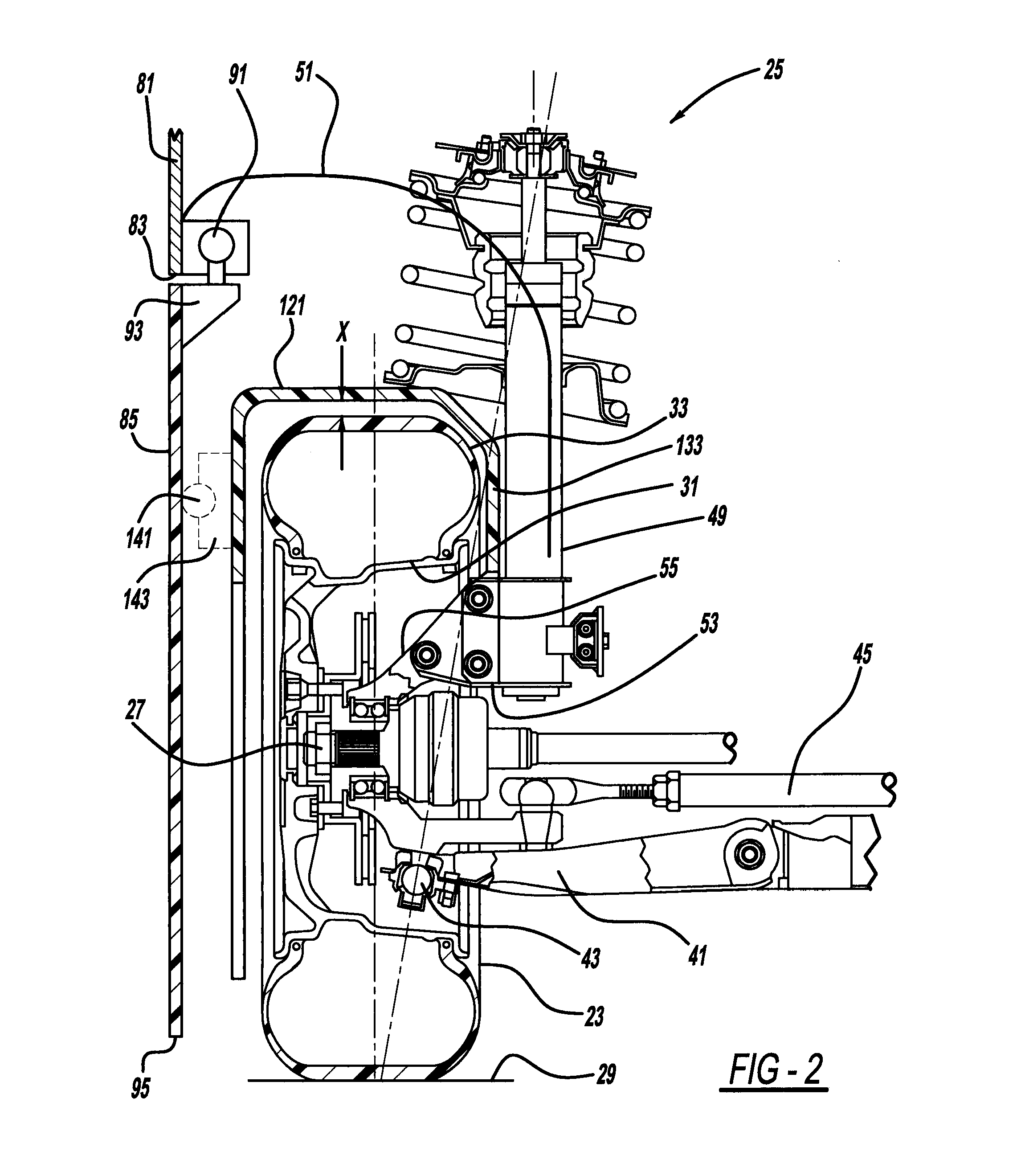

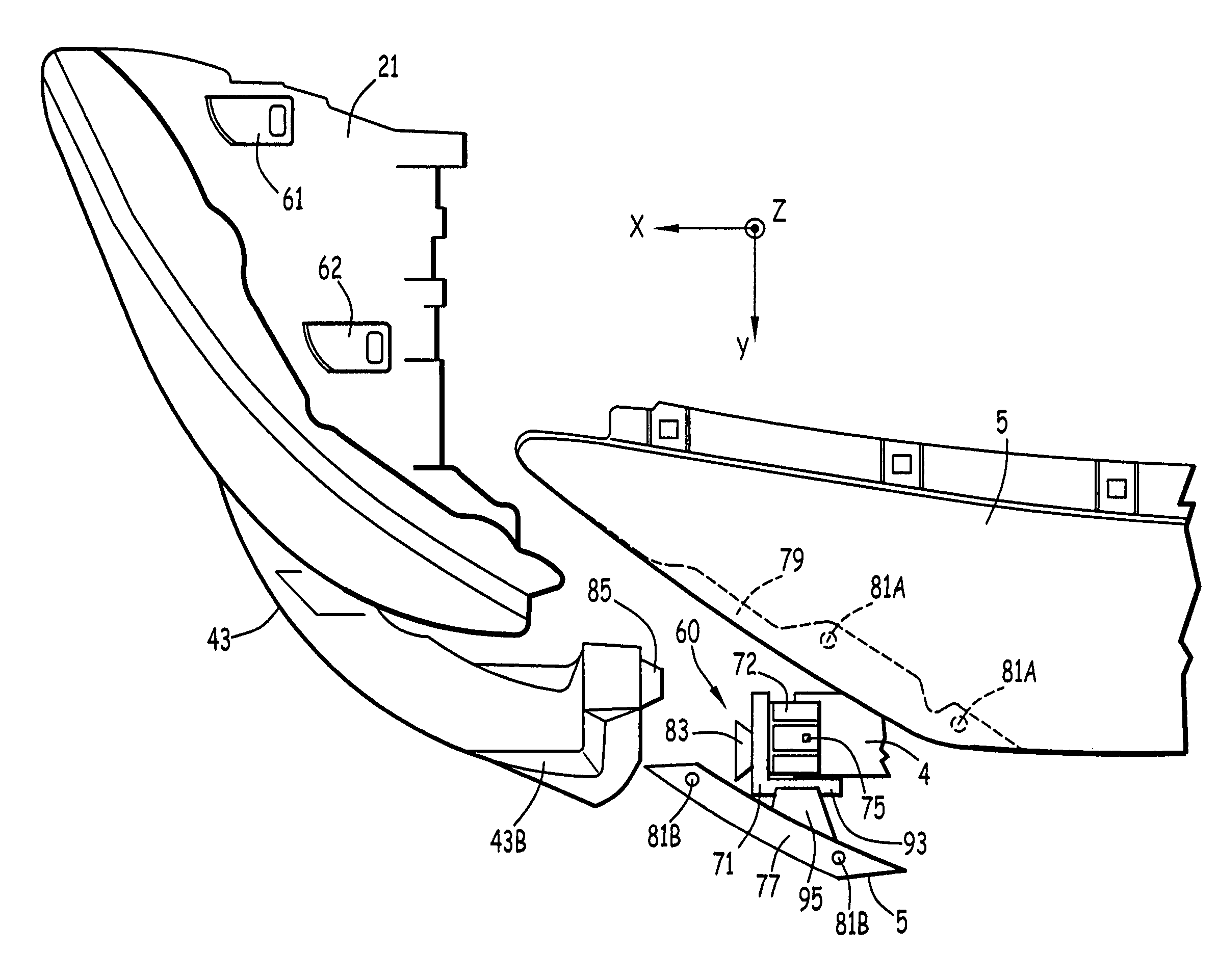

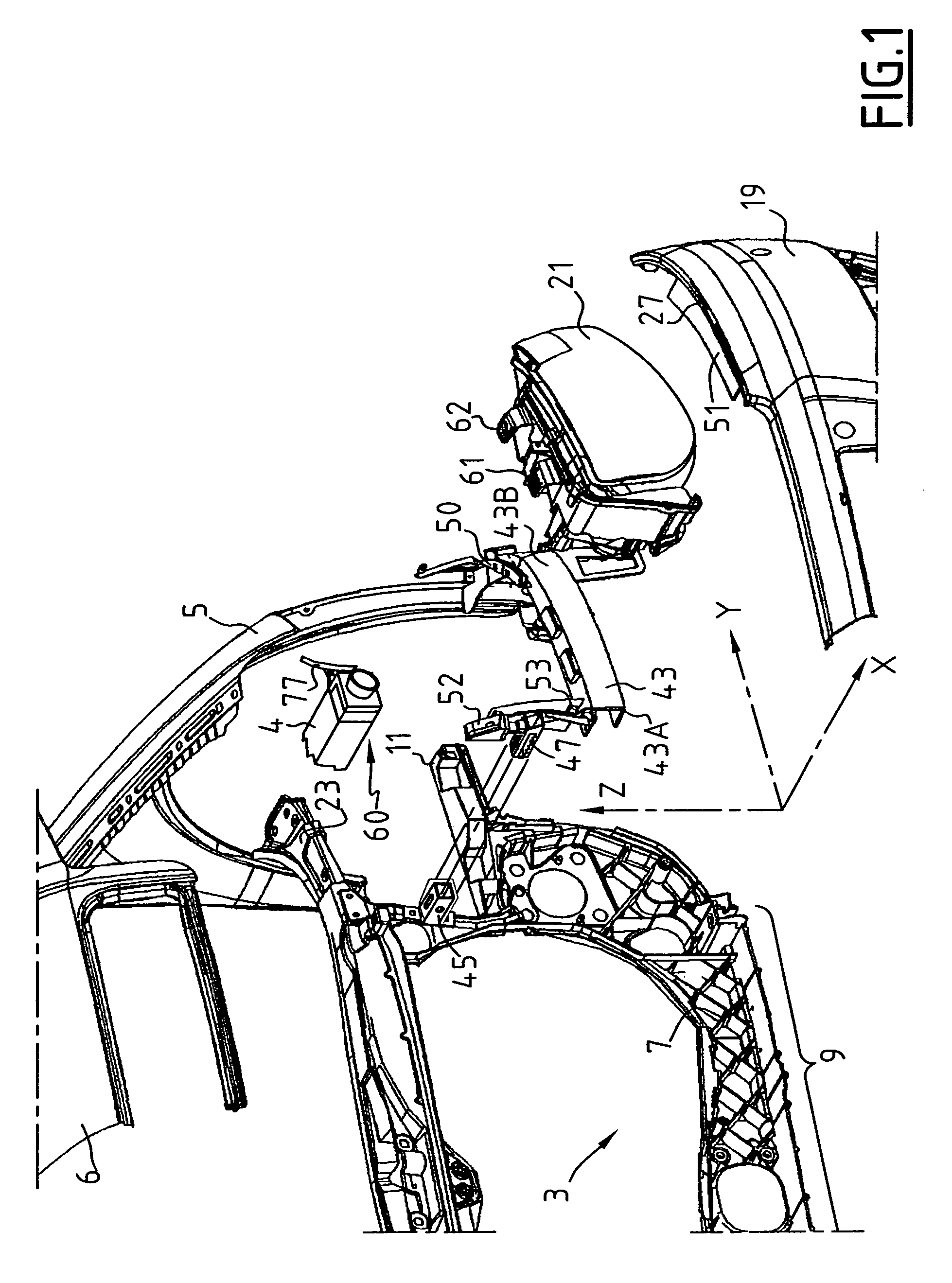

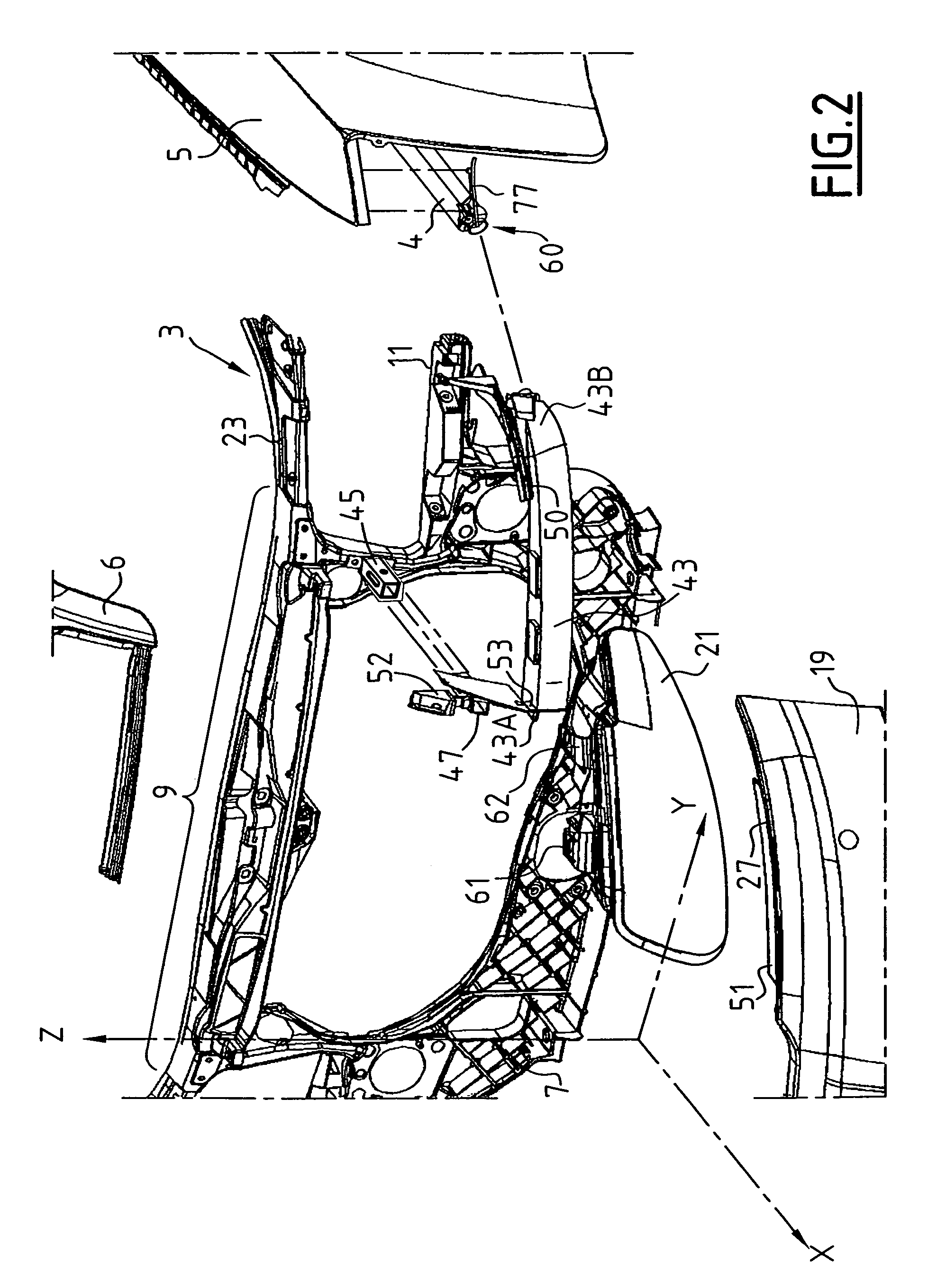

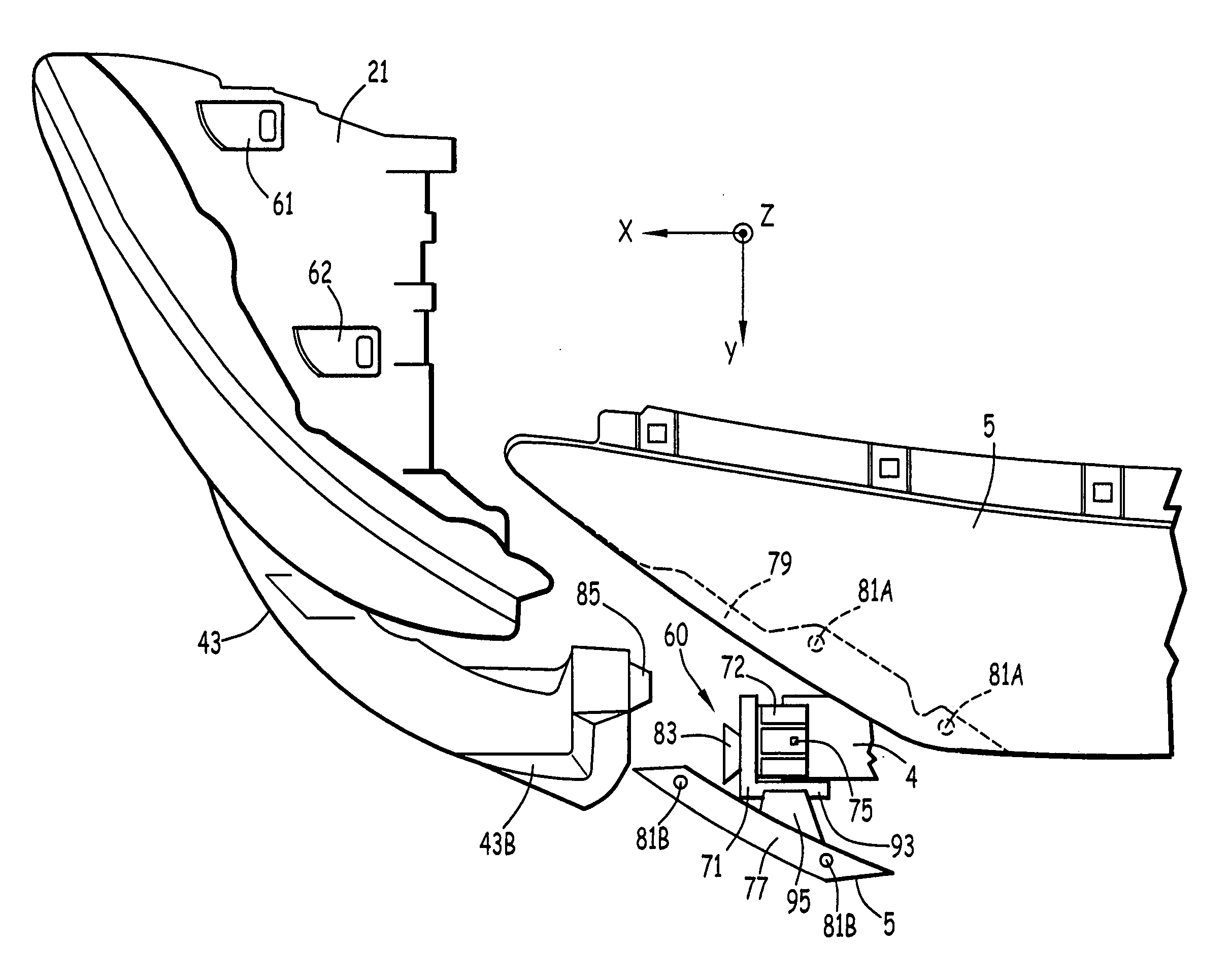

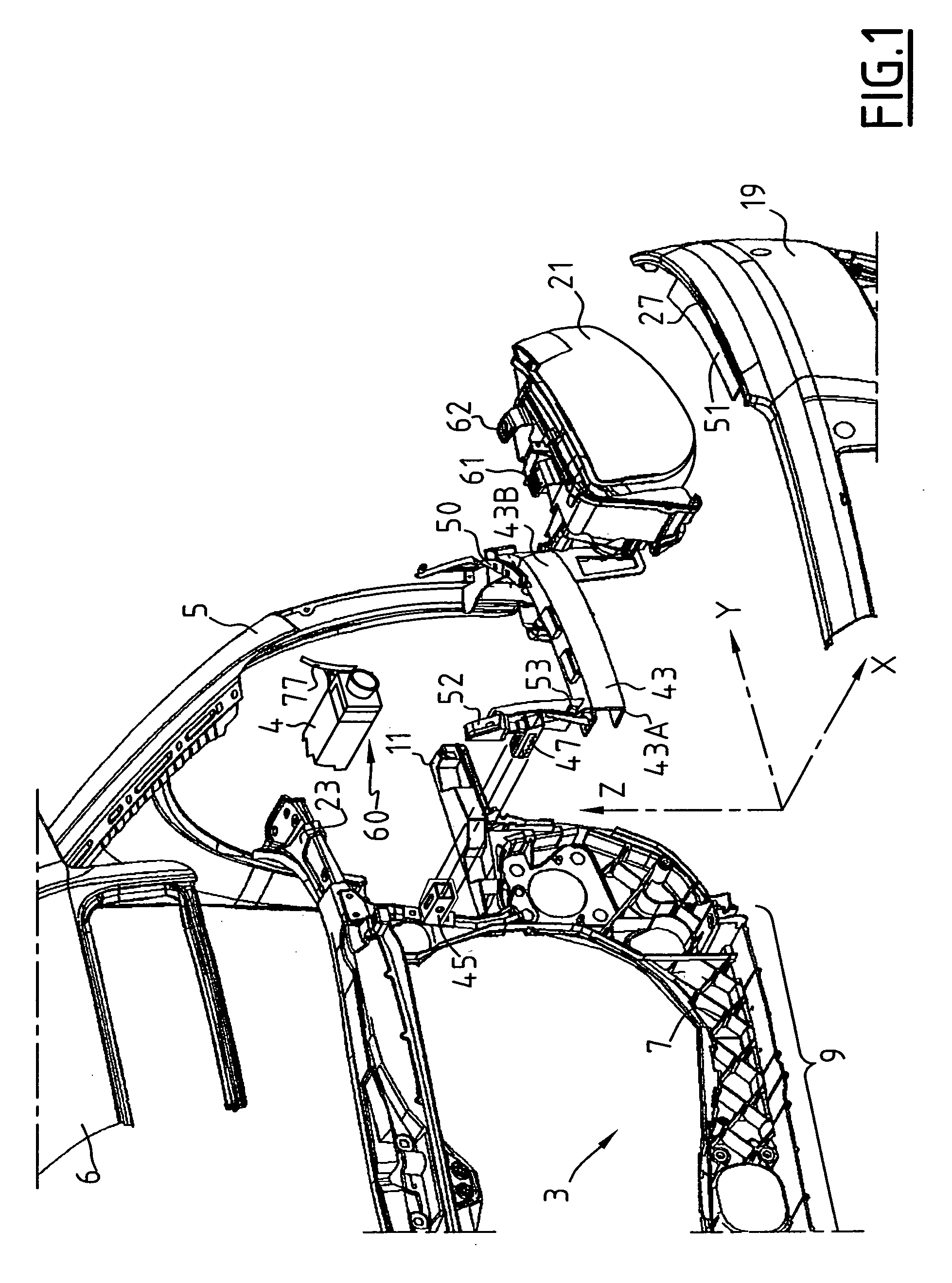

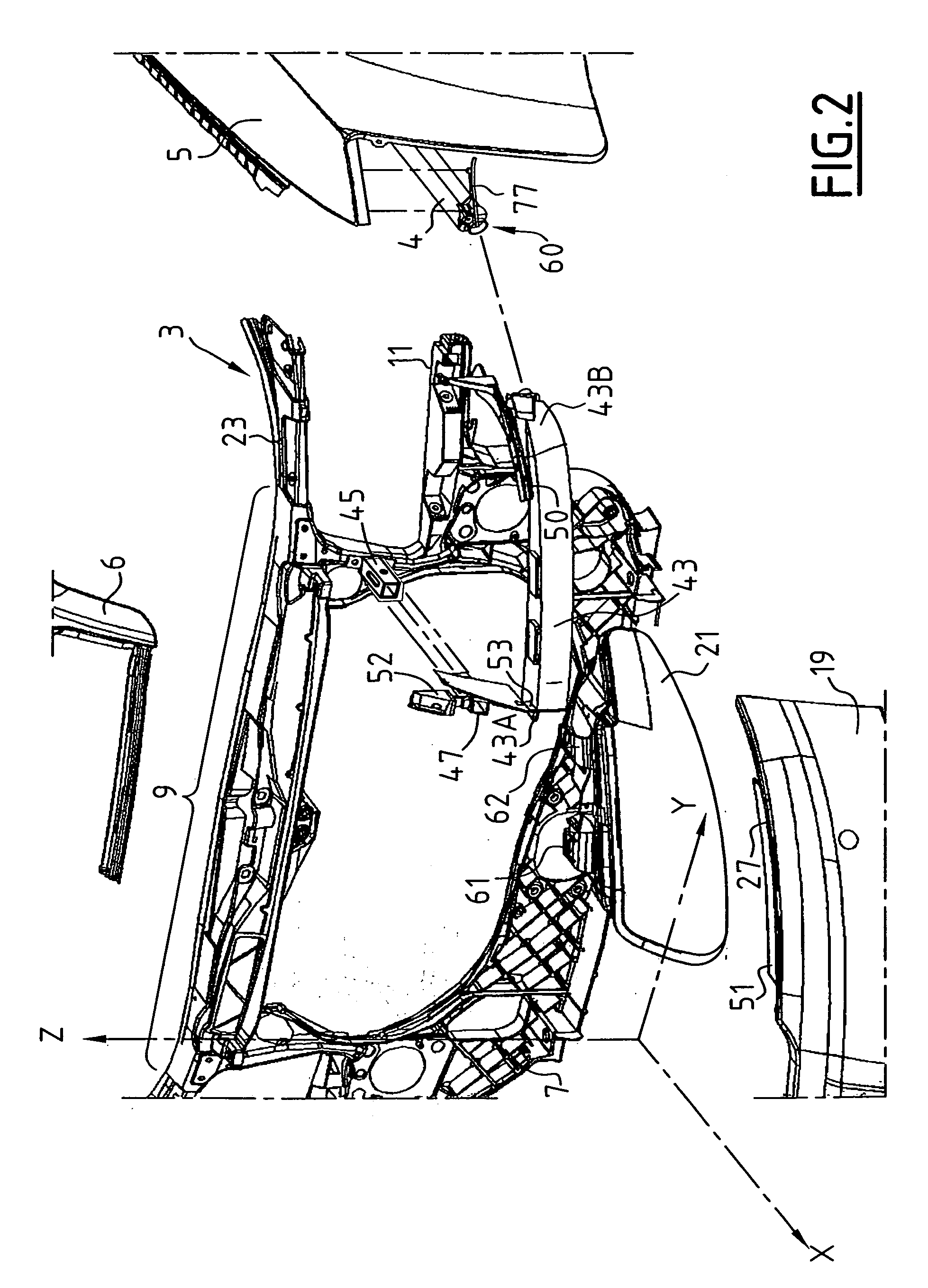

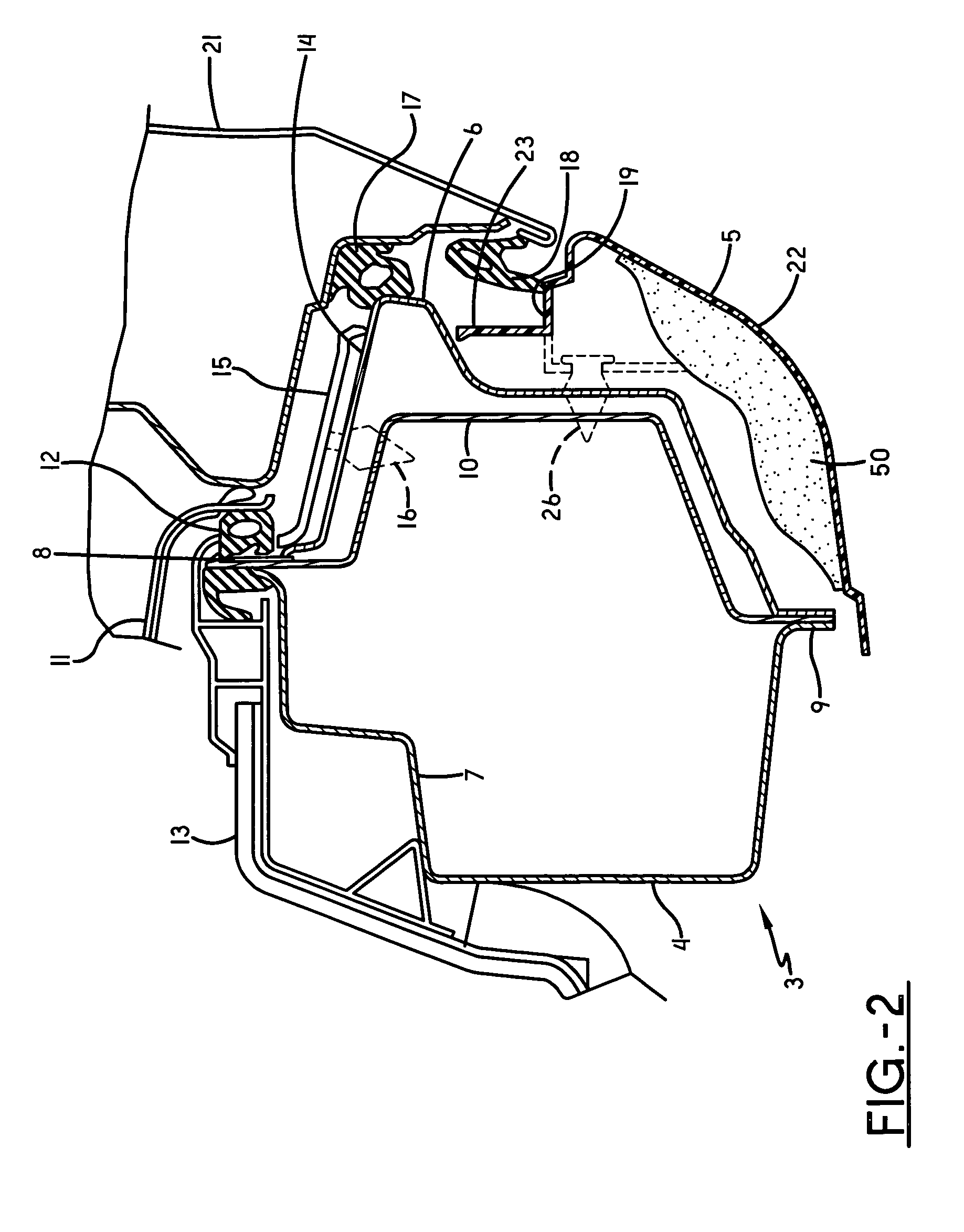

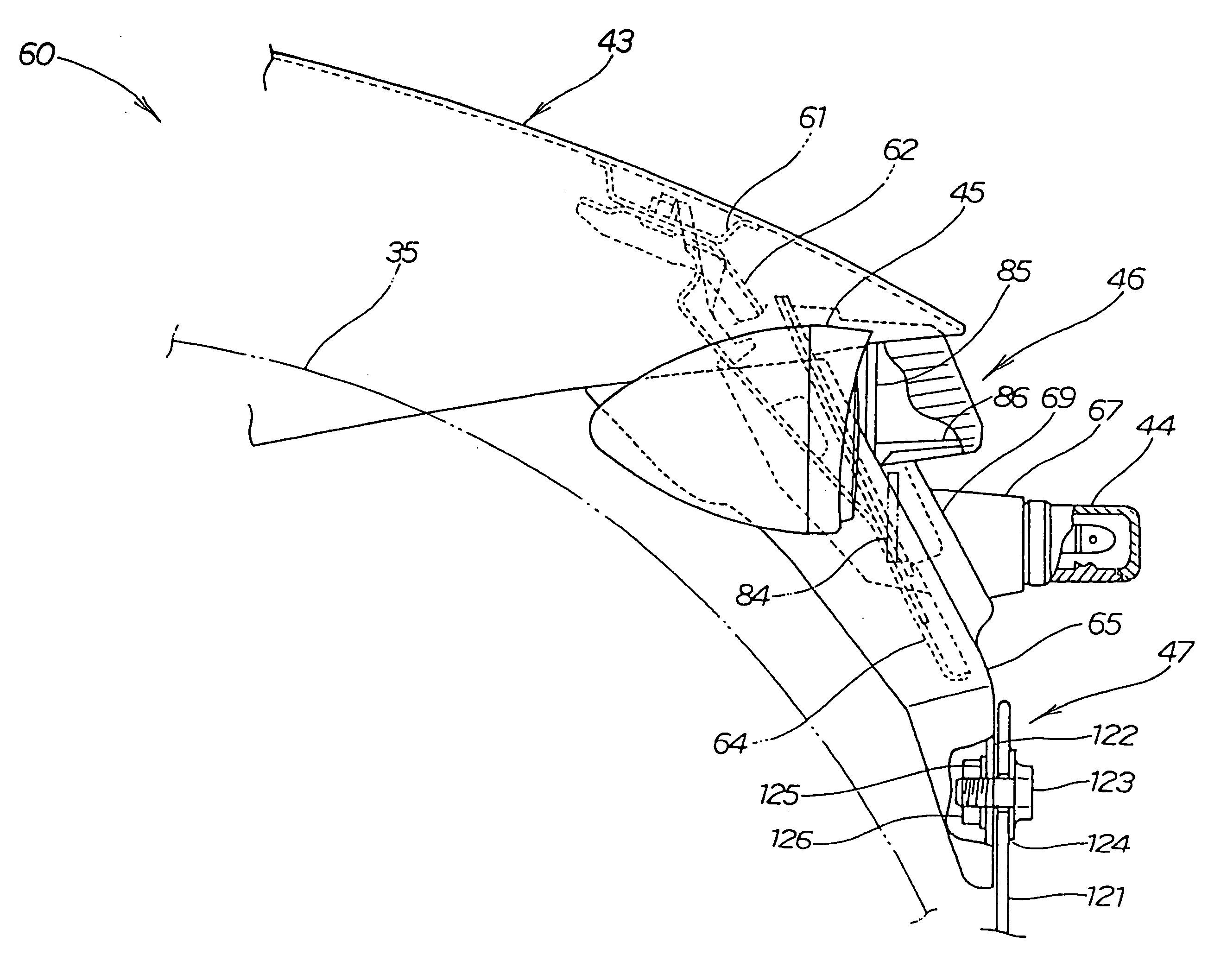

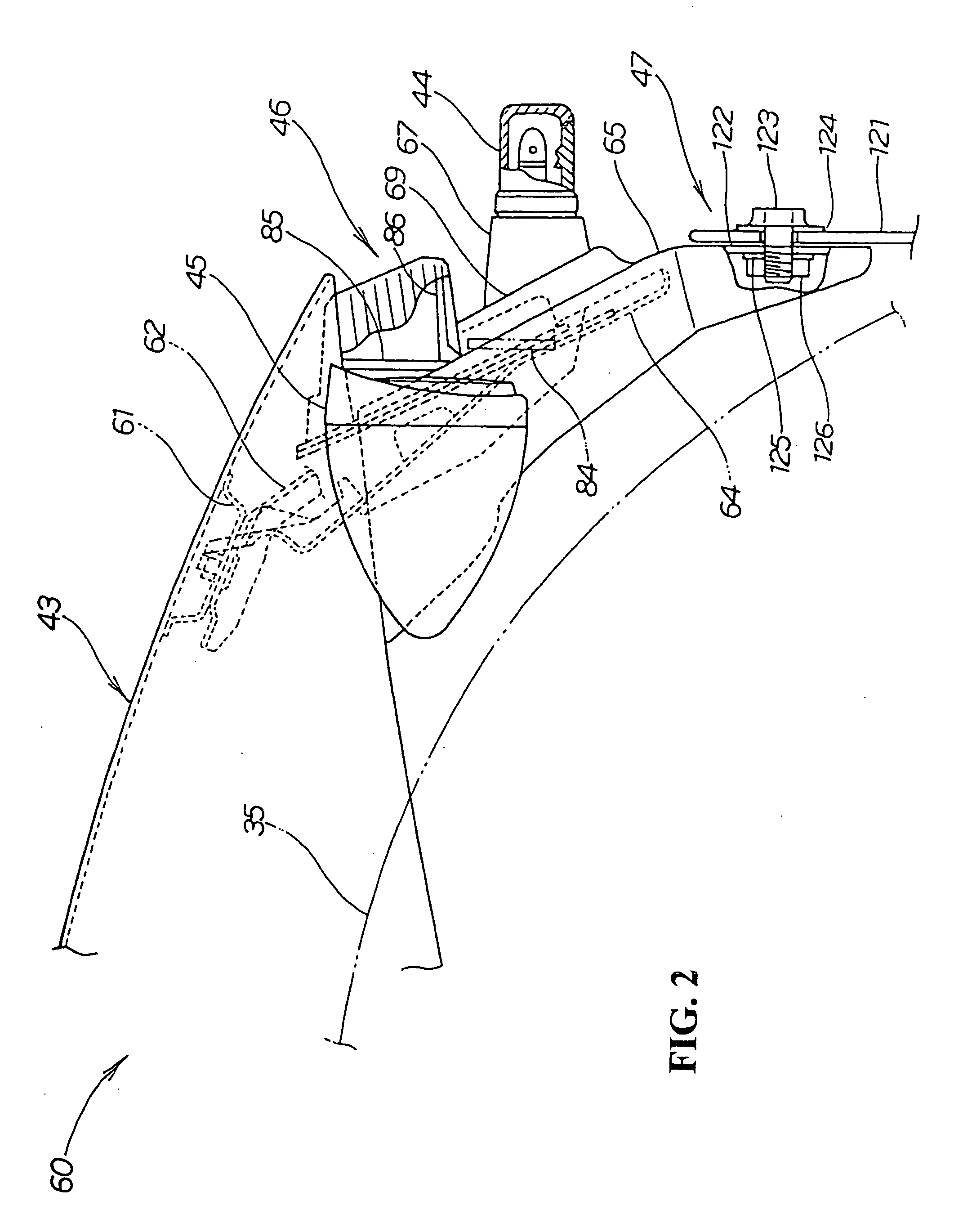

Motor vehicle front portion assembly provided with improved fastening and position-adjustment means, and a motor vehicle including such an assembly

The assembly includes:a front face;a structural front portion (4);a fender front portion (5);a flexible beam (43); anda headlight unit fastened to said beam (43).It further comprises:a centering and guide part (71) fastened to the structural front portion, in a position that can be adjusted, during assembly, along three axes (X, Y, Z);fastening and centering means (83, 85) for fastening the end (43B) of the beam to said part (71) and for centering it thereon; andguide means (93, 95) for guiding the fender front portion (5) on said part (71), providing a sliding connection slidable along one of the three axes (X), making relative adjustment movements possible in order to absorb deformation in said fender front portion. The invention is also relates to a motor vehicle including such an assembly.

Owner:FAURECIA BLOC AVANT

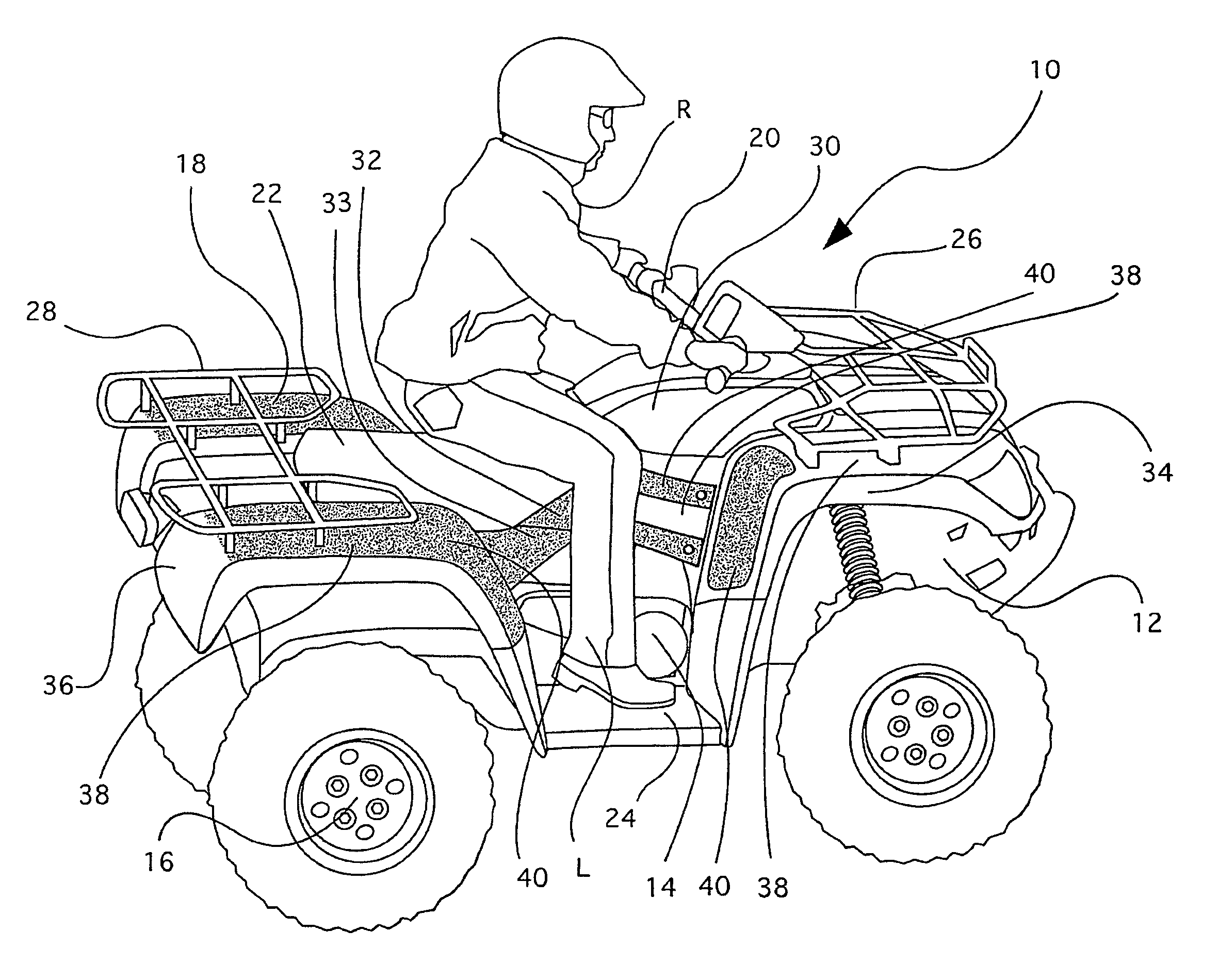

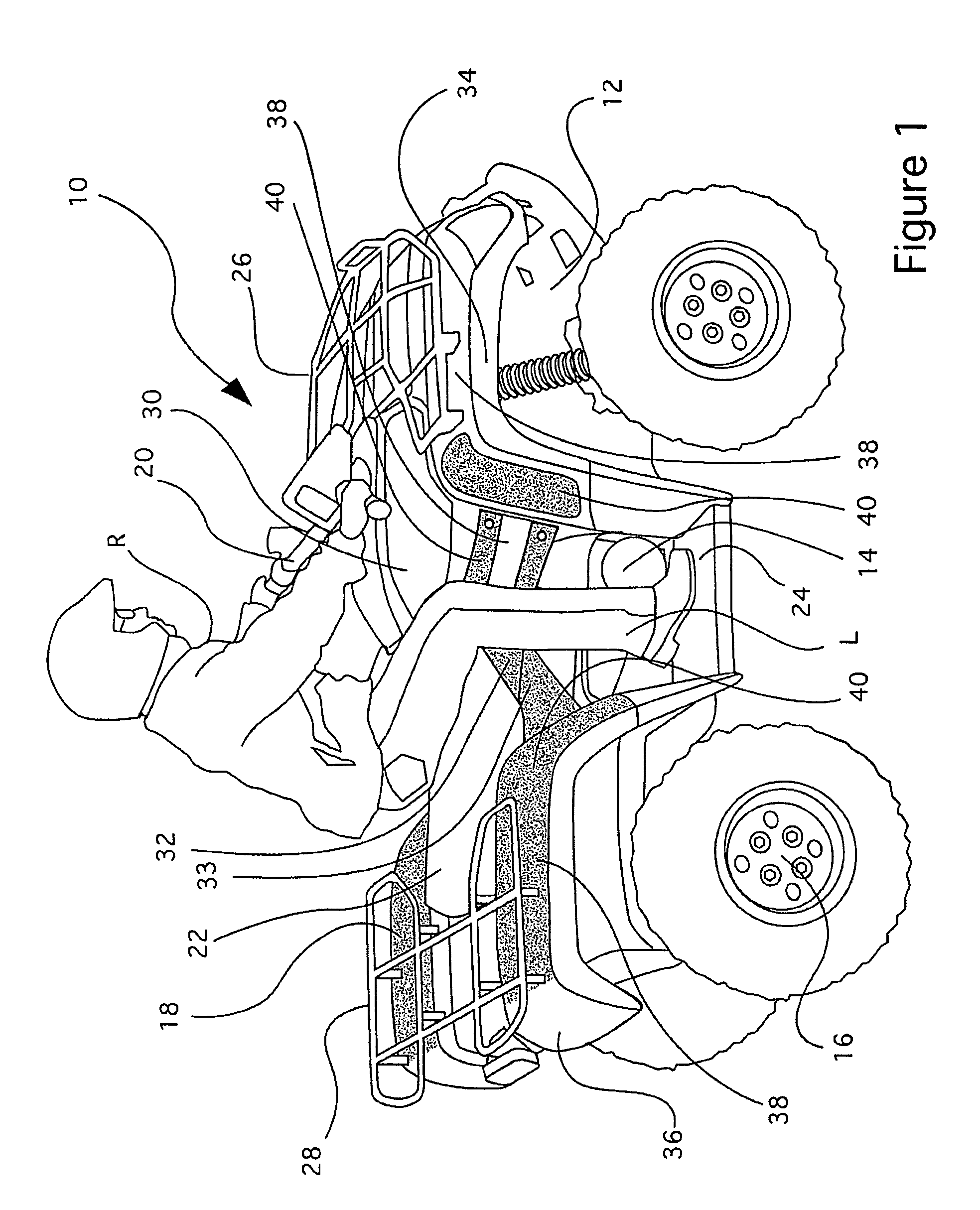

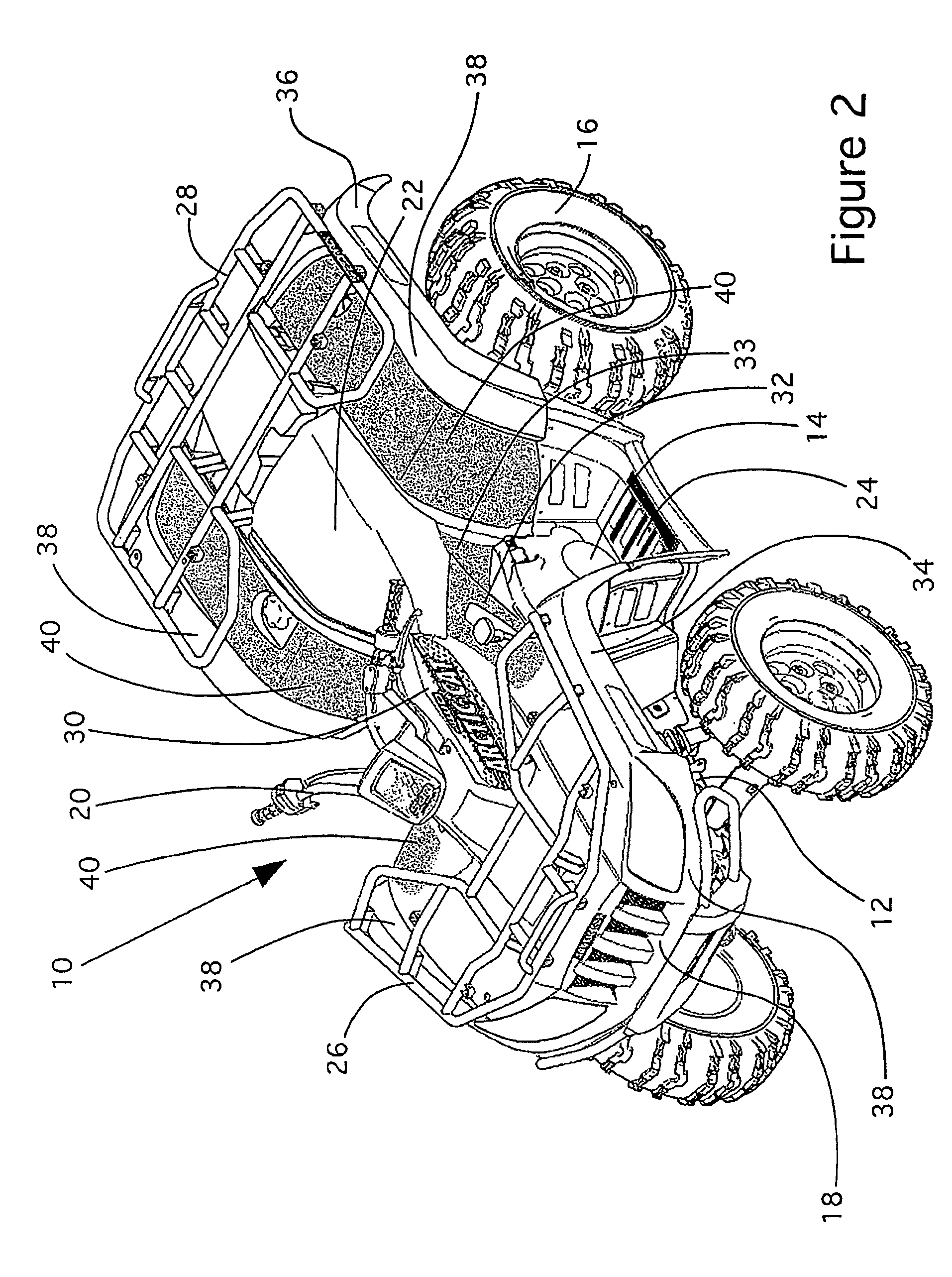

Textured all-terrain vehicle fenders

The present disclosure describes an all terrain straddle-type vehicle for carrying a load including a rider. The vehicle includes a frame, a plurality of wheels, a rear fender, a front fender, and a body panel. The wheels, including front and rear wheels coupled to the frame. The fenders are secured to the frame for covering the wheels. The fenders are formed from a plastic material having a smooth portion and a textured portion thereon. The smooth and textured portions are disposed adjacent to one another and formed integrally on the fender. The textured portion is positioned on the fender in a location of frequent rider or other load contact. The body panel is secured to the frame forward of the rear fender. The body panel includes a textured portion situated in a location of frequent rider contact. A method of manufacturing a fender is also disclosed.

Owner:ARCTIC CAT

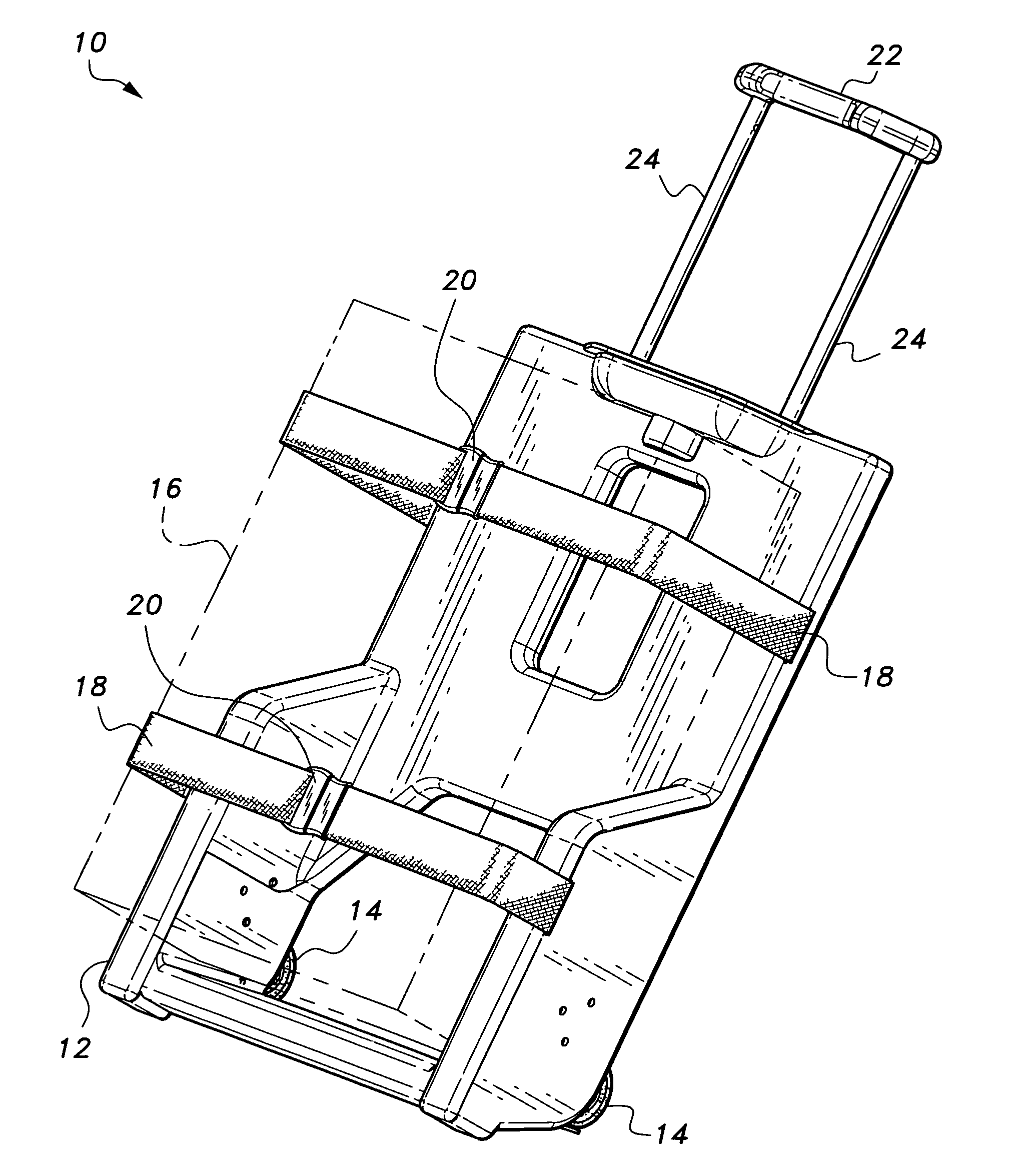

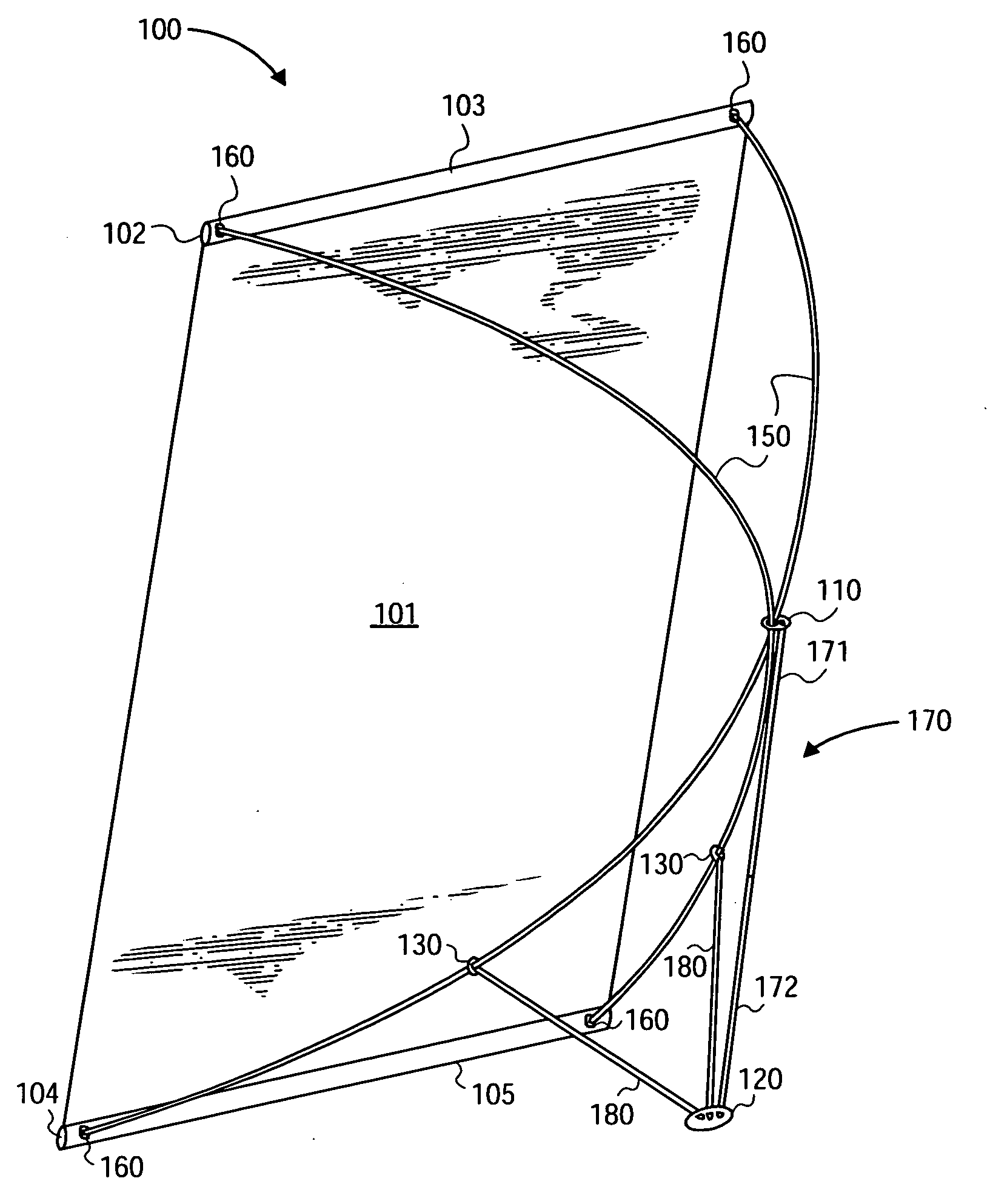

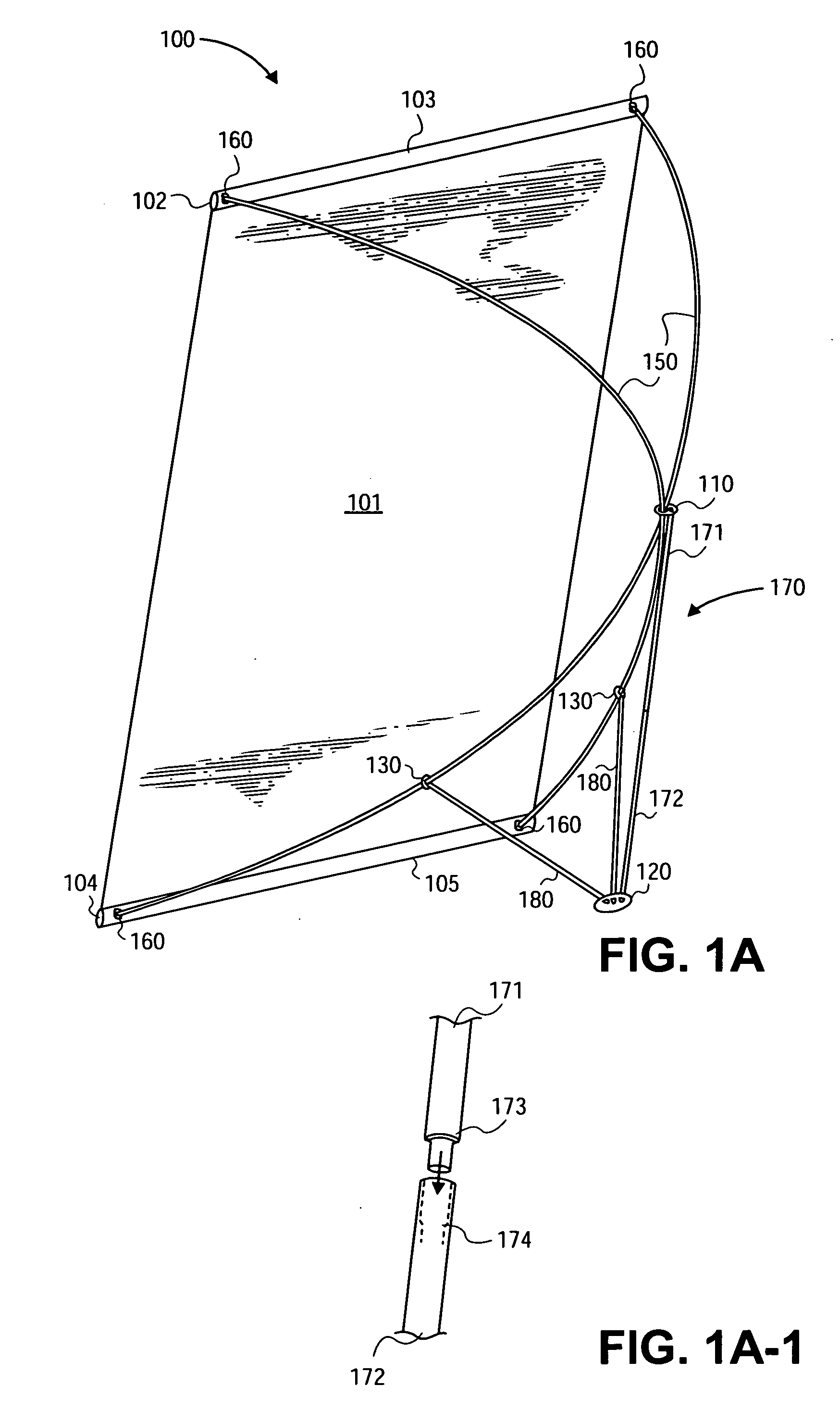

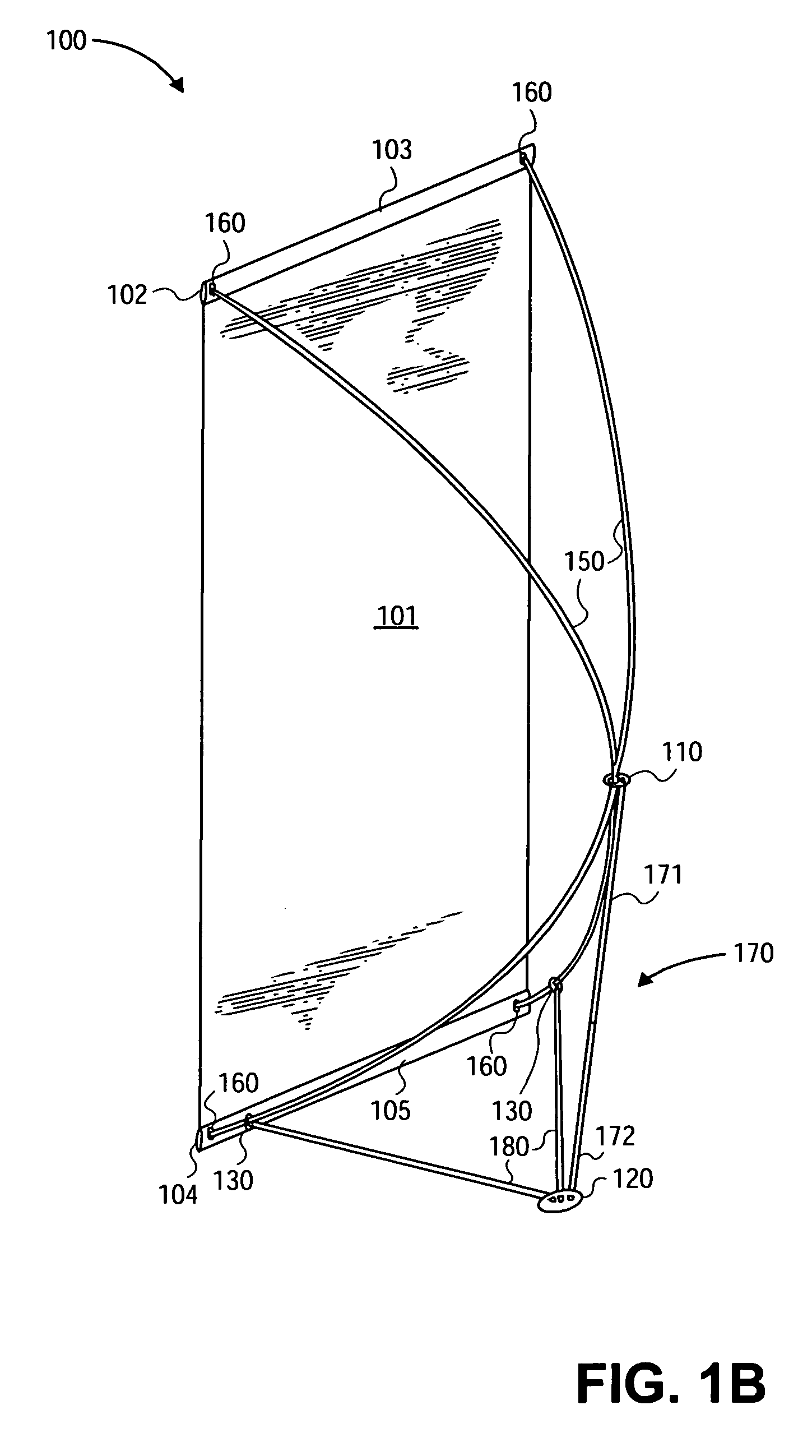

Collapsible display stand

InactiveUS6857607B1Improve adaptabilitySimplified and inexpensiveStands/trestlesKitchen equipmentEngineeringGrommet

A collapsible display stand with a foot-and-bar base is disclosed. The foot-and-bar base provides improved adaptability to uneven surfaces. The foot provides a flexible connection between a vertical support member and two adjustable strut braces. The strut braces have controllable sliding connections to two flexed cross struts. The point of closest approach of the struts may be constrained by a grommet, clamp, sleeve, or motor bracket and maintained a predetermined distance from the foot by a vertical support member. Also disclosed is a simplified, inexpensive apparatus for connecting strut ends to mounting tubes. The simplified apparatus comprises a hole drilled in one side of the mounting tube near each mounting tube end, into which an unadorned strut end may be inserted. The foot, slidable strut brace connectors, and the point-of-closest-approach constraint may be economically made of hard rubber, such as that used in making mud flaps for trucks. The collapsible display stand may be adjusted by hand or, especially for very large embodiments, by motorized point-of-closest-approach and strut brace constraints. The motorized constraints may be remotely controlled. A variation of the display stand, adapted to being mounted on a wall, is also disclosed.

Owner:BURRIS JEFF

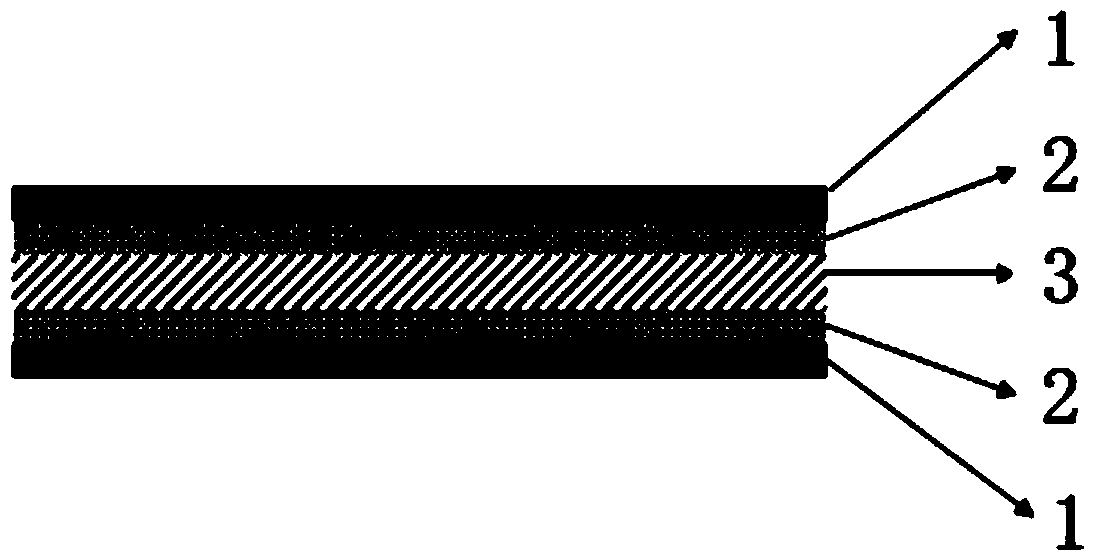

Light, high-toughness strong-sound-absorption thermoplastic composite material for automobile wheel casing fender and fabrication process thereof

ActiveCN103434227AGuaranteed comfortImprove rigiditySynthetic resin layered productsLaminationEthylene-propylene-diene-monomerThermoplastic composites

The invention relates to a light, high-toughness strong-sound-absorption thermoplastic composite material for an automobile wheel casing fender and a fabrication process of the thermoplastic composite material. The thermoplastic composite material is formed by a non-woven fabric, a toughening membrane, an inorganic modified thermoplastic composite material, another toughening membrane and another non-woven fabric which are sequentially overlapped from bottom to top, wherein the inorganic modified thermoplastic composite material takes thermoplastic resin fibers and reinforced fibers as a main body and contains a powdery reinforcing filler. According to the thermoplastic resin composite material for the automobile wheel casing fender, thermoplastic resin reinforced by the reinforced fibers can achieve good rigidity, the toughening membrane can provide excellent impact toughness, the combination of the powdery filler and the fibers can achieve an excellent sound-absorption property, and therefore, the thermoplastic composite material can ensure riding comfort. Besides, the thermoplastic composite material with the scheme has the advantages of simple process, continuous production and controllable toughness, is lower than a PP (Propene Polymer) and EPDM (Ethylene-Propylene-Diene Monomer) system in cost, and can be popularized as a composite material for a new generation of automobile wheel casing fender.

Owner:浙江华江科技股份有限公司

Motor vehicle front portion assembly provided with improved fastening and position-adjustment means, and a motor vehicle including such an assembly

The assembly includes: a front face; a structural front portion (4); a fender front portion (5); a flexible beam (43); a headlight unit fastened to the beam (43); a centering and guide part (71) fastened to the structural front portion, in a position that can be adjusted, during assembly, along three axes (X, Y, Z); fastening and centering elements (83, 85) for fastening the end (43B) of the beam to the part (71) and for centering it thereon; and guide elements (93, 95) for guiding the fender front portion (5) on the part (71), providing a sliding connection slidable along one of the three axes (X), making relative adjustment movements possible in order to absorb deformation in the fender front portion. A motor vehicle including such an assembly is also disclosed.

Owner:FAURECIA BLOC AVANT

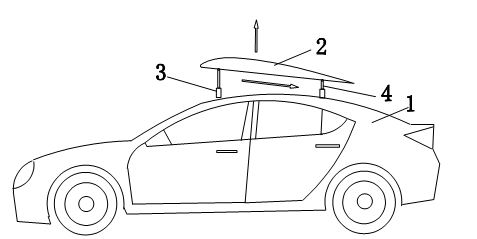

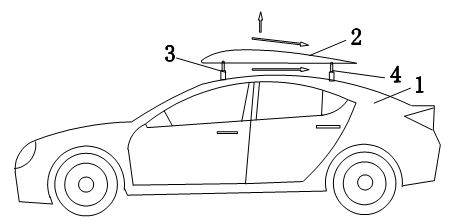

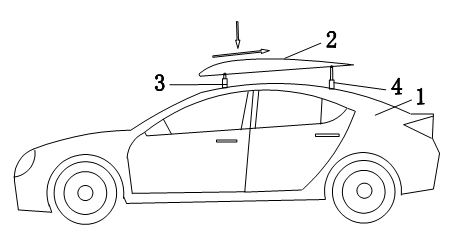

Energy-saving fender for motor vehicle

InactiveCN101947981ARelieve pressureReduce frictional resistanceVehicle body stabilisationFenderEngineering

An energy-saving fender for a motor vehicle is characterized in that a fixed fender (2) is arranged above the top surface of a body (1) of a motor vehicle, wherein space exists between the top surface of the vehicle and the fender; and the fender and the horizontal plane form an elevation angle of 0-20 degrees. The fender has the following beneficial effects: the fender changes the aerodynamic configuration of the motor vehicle, generates extra lift force when the motor vehicle travels at low speed so as to reduce the pressure of the wheels of the motor vehicle on the ground, ensures low frictional resistance between the wheels and the pavement, so that the motor vehicle consumes less energy during travelling, and can ensure the control performance of the vehicle and travelling safety.

Owner:石金成

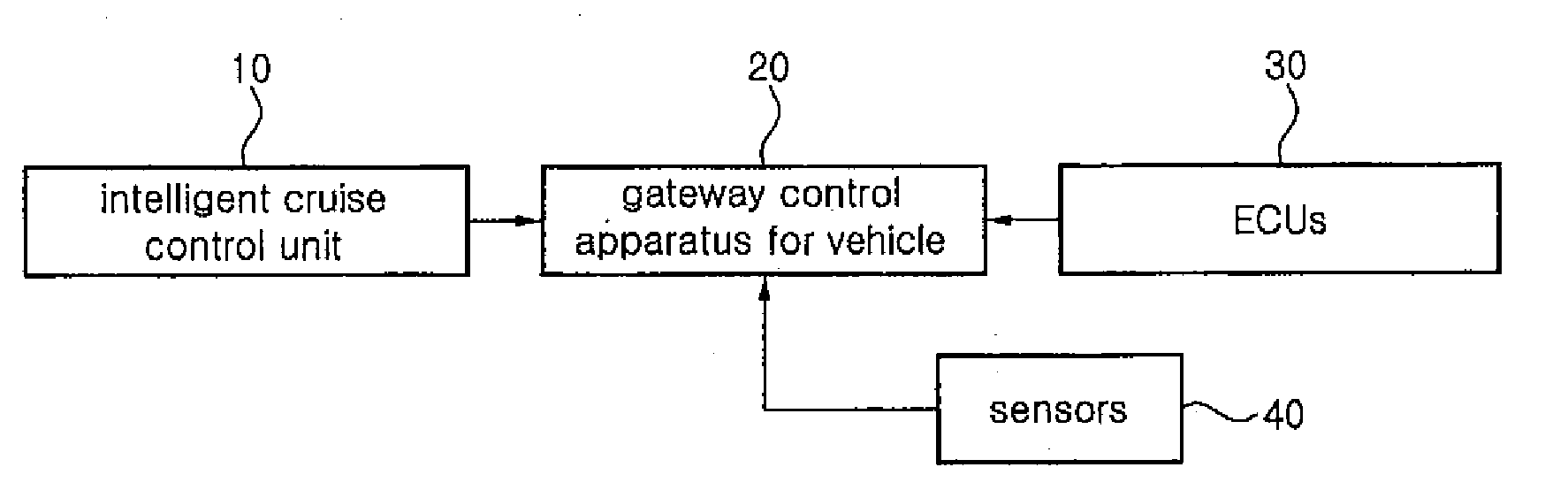

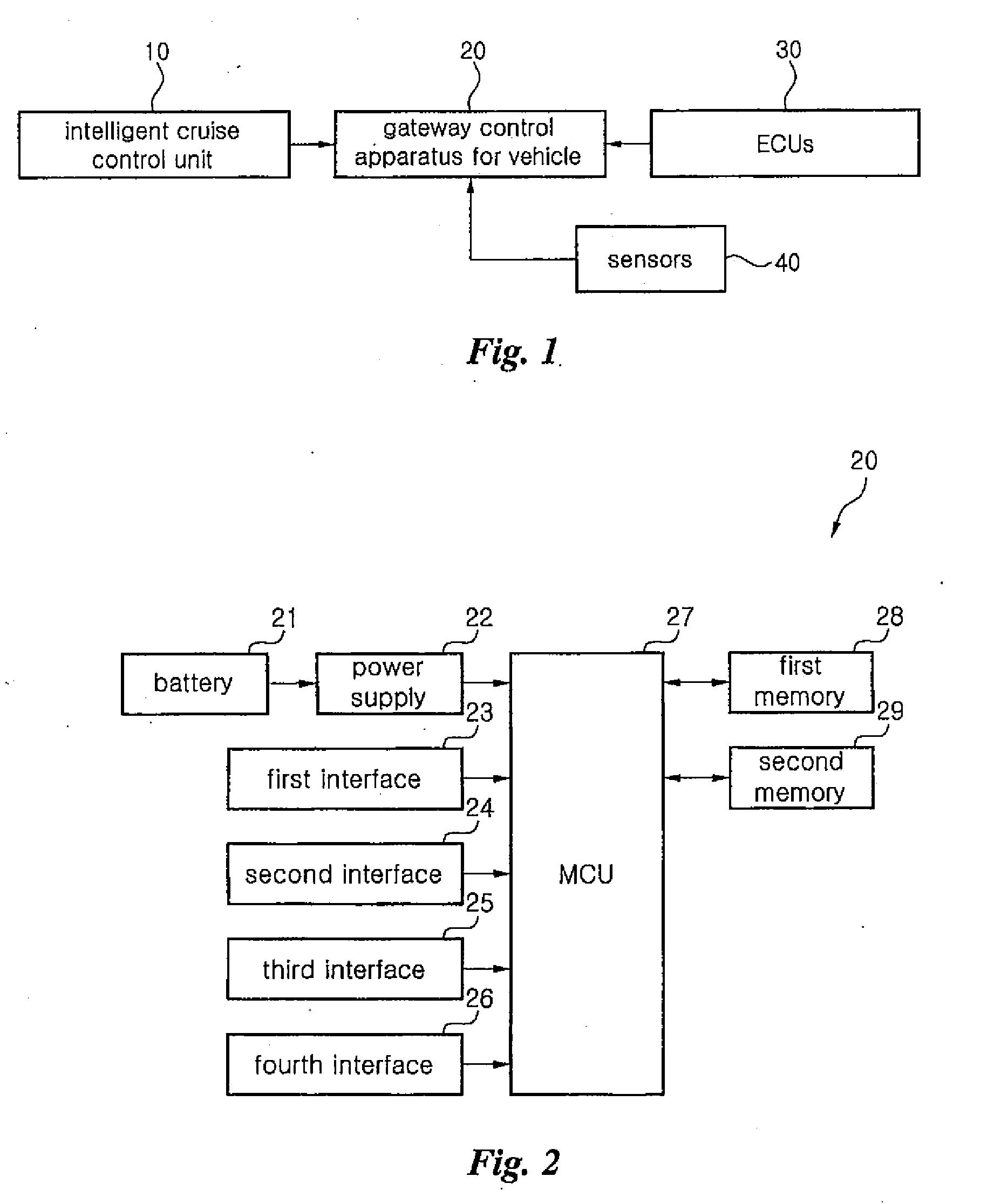

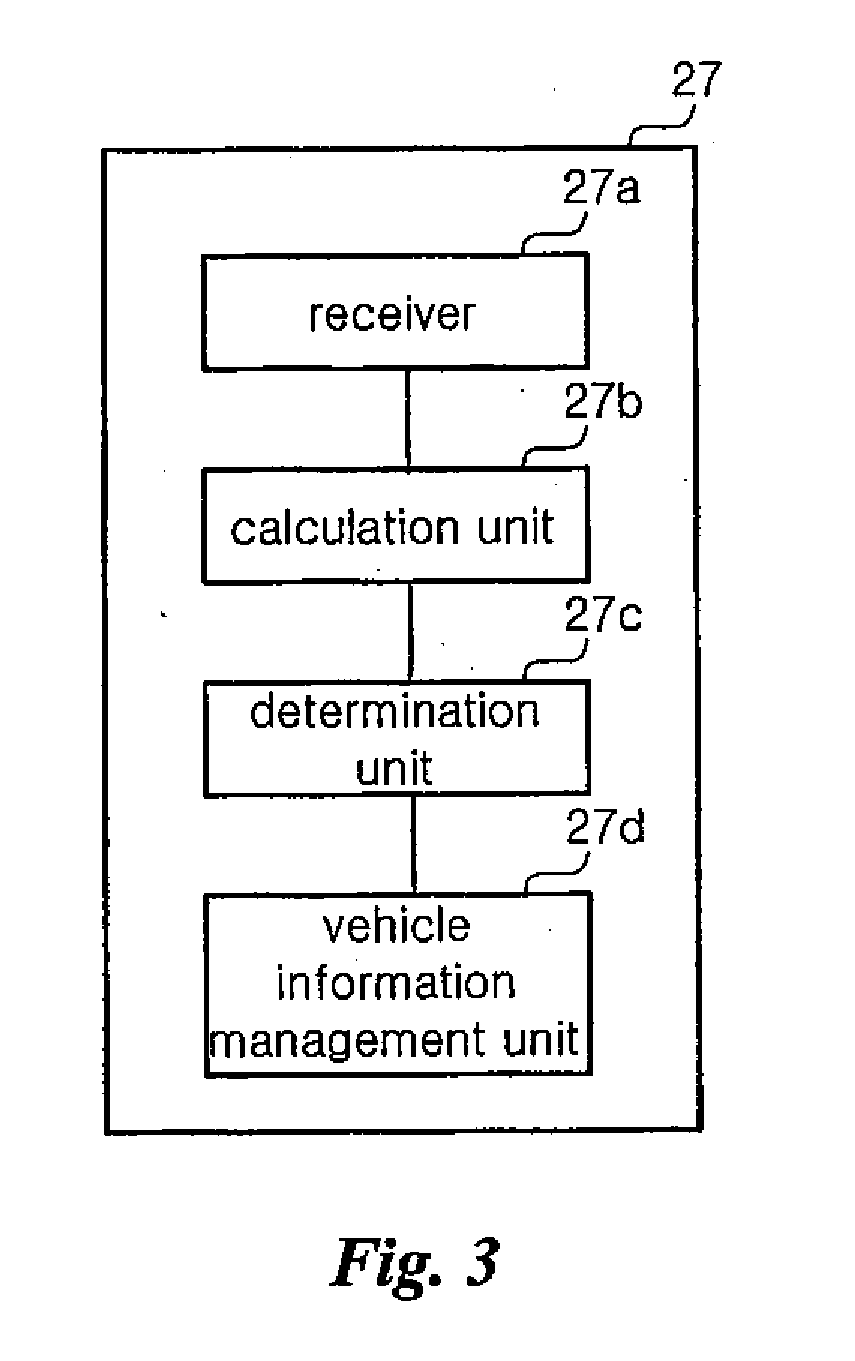

Gateway control apparatus for vehicles and travel information recording method thereof

ActiveUS20100019892A1Vehicle testingArrangements for variable traffic instructionsCruise controlAccidents vehicle

A gateway control apparatus for vehicles includes a receiver configured to receive vehicle state information from vehicle ECUs and a vehicle-to-vehicle distance from an intelligent cruise control unit. The gateway control apparatus also includes a first memory to store the vehicle state information, a calculation unit to calculate a relative velocity and a relative acceleration from the vehicle state information, and to calculate a collision index. A determination unit determines if the collision index exceeds a predetermined value. A vehicle information management unit determines an accident occurrence time point when the collision index exceeds the predetermined value, and allows the first memory to store pre-accident and post-accident vehicle state information. The gateway control apparatus stores the pre-accident and post-accident vehicle state information even in the case of a fender bender or minor collision to use the stored information for post-accident judgment.

Owner:HL KLEMOVE CORP

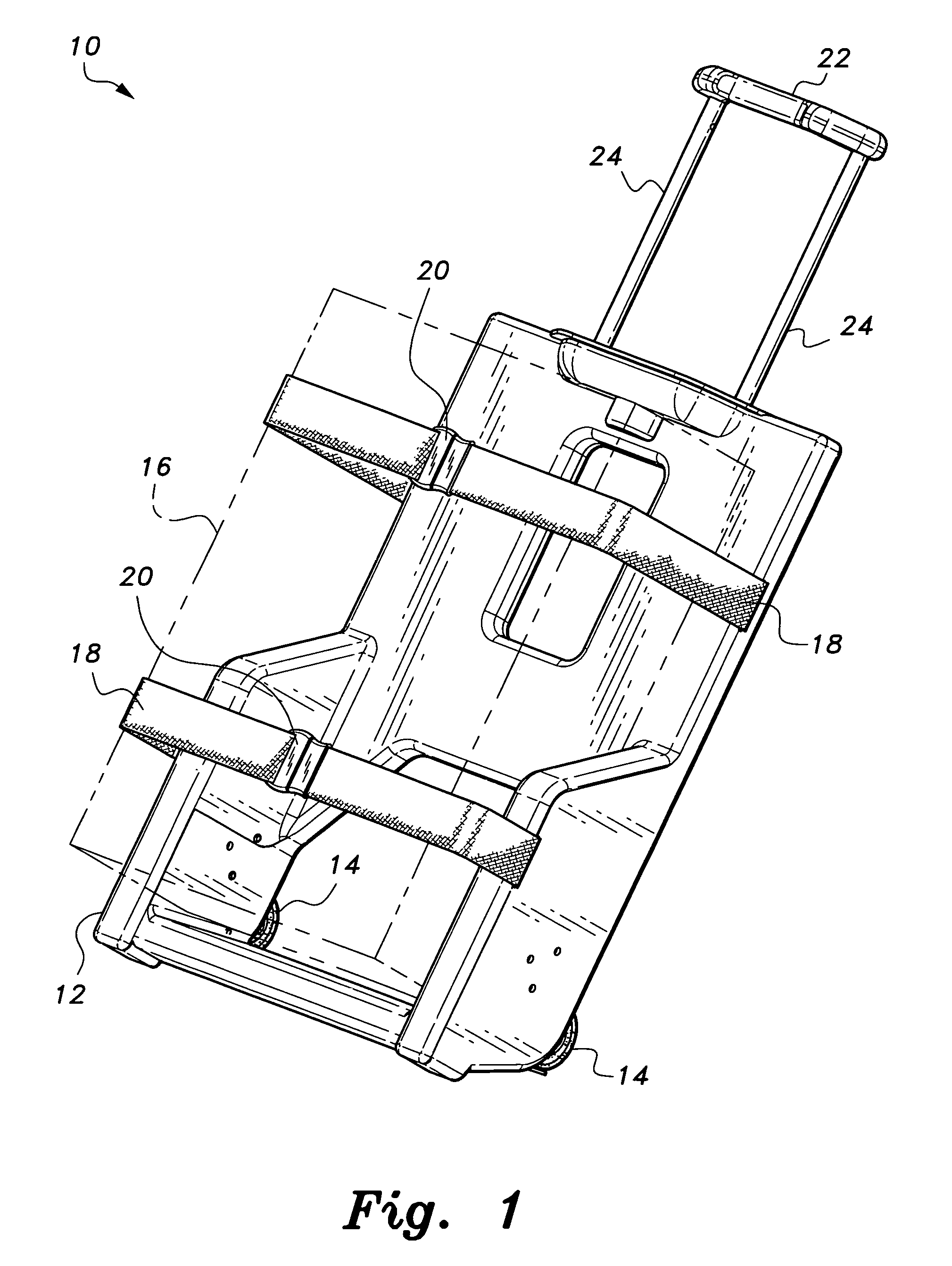

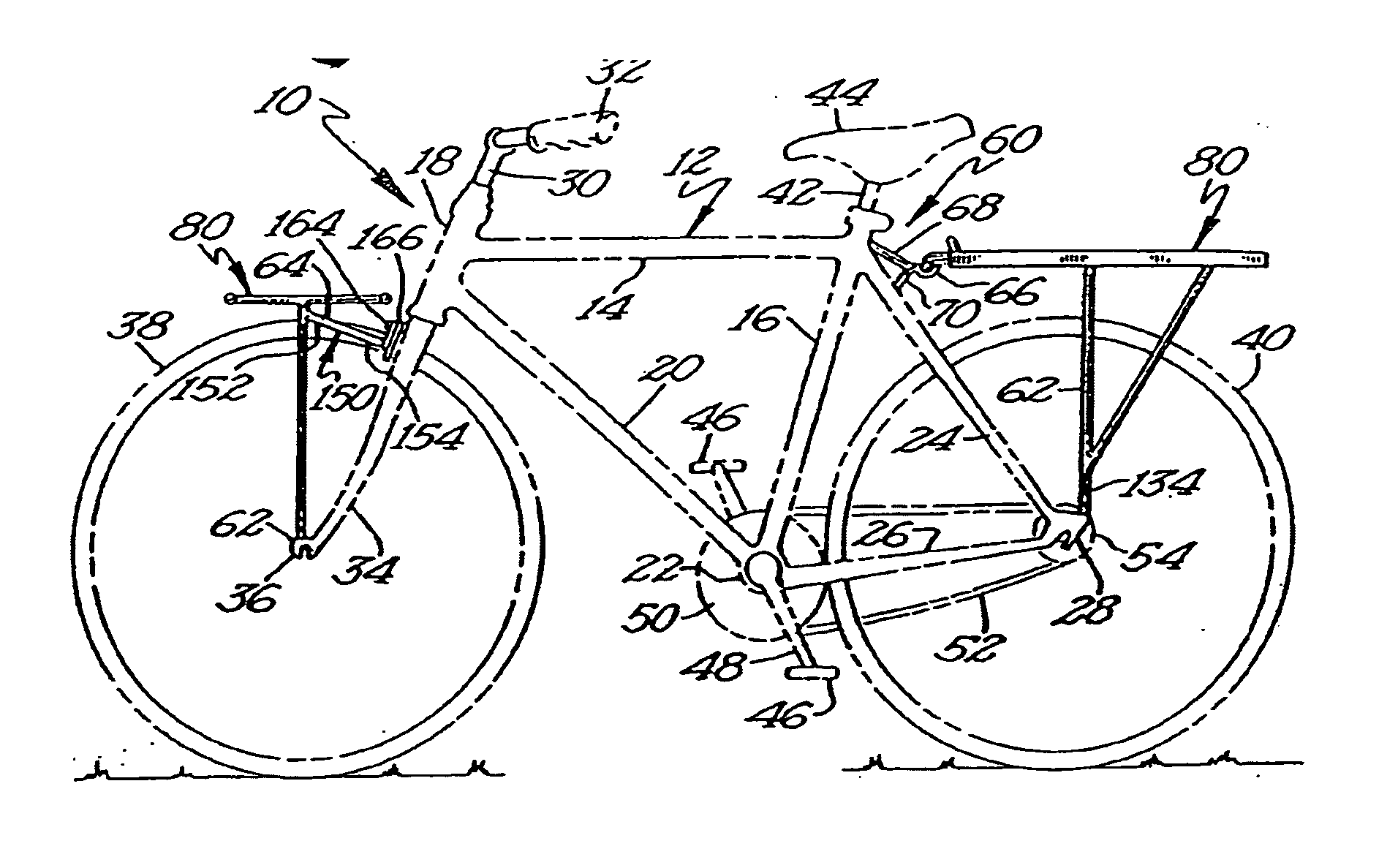

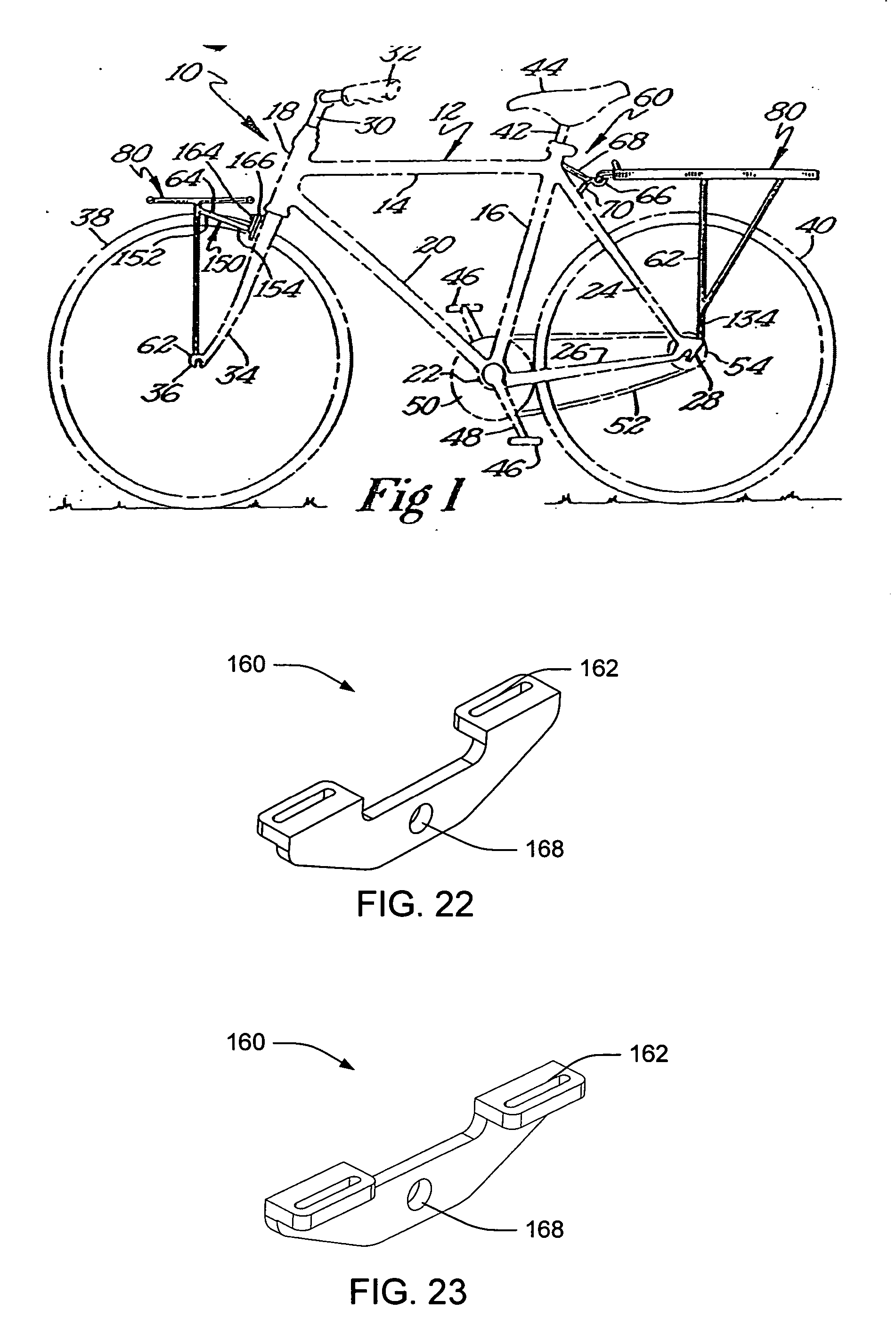

Quick release adapters for bicycle accessory mounting and quick tow mechanism for a bicycle frame

InactiveUS20060076380A1Attachment of simple and easyLuggage carriersSidecarsVehicle frameEngineering

Several versions of quick release adapters for bicycle accessory mounting are disclosed. The quick release adapters include either a thumb screw, a cam lever, or a cam ball pivotally attached to a screw that mates with an accessory leg and screws into a hole in a bicycle dropout. An upper mount for racks or other accessories is also disclosed which attaches to existing fender attachment holes. In addition, a quick tow mechanism for a bicycle frame is disclosed with a perpendicular post and C-shaped base part and a rotor that make attachment of a tow bar very simple and easy for a user.

Owner:TRANSBIKE SYST

Single piece side-sill-garnish and mudguard

InactiveUS20090167010A1Eliminate costReduce tooling costsVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

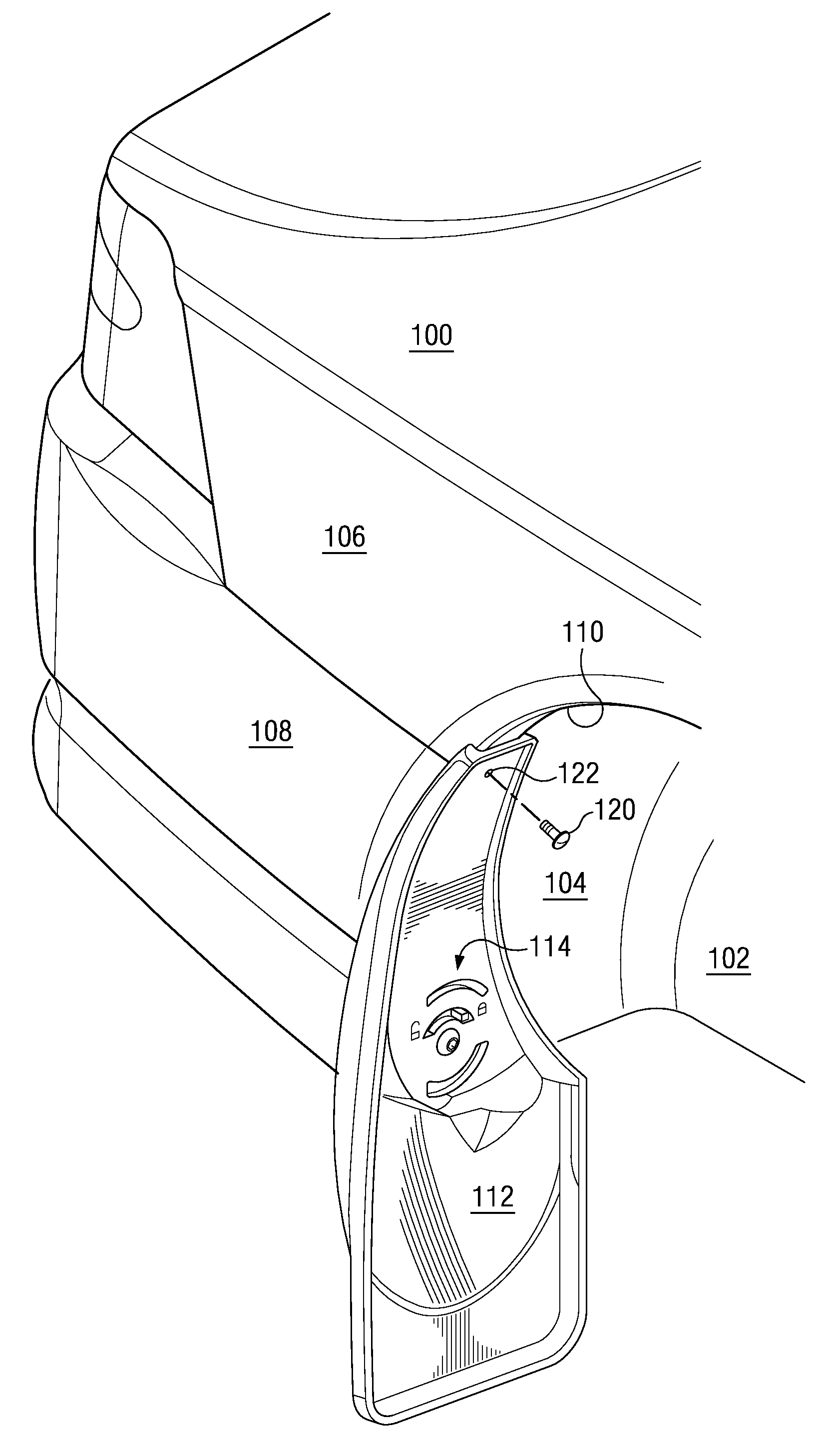

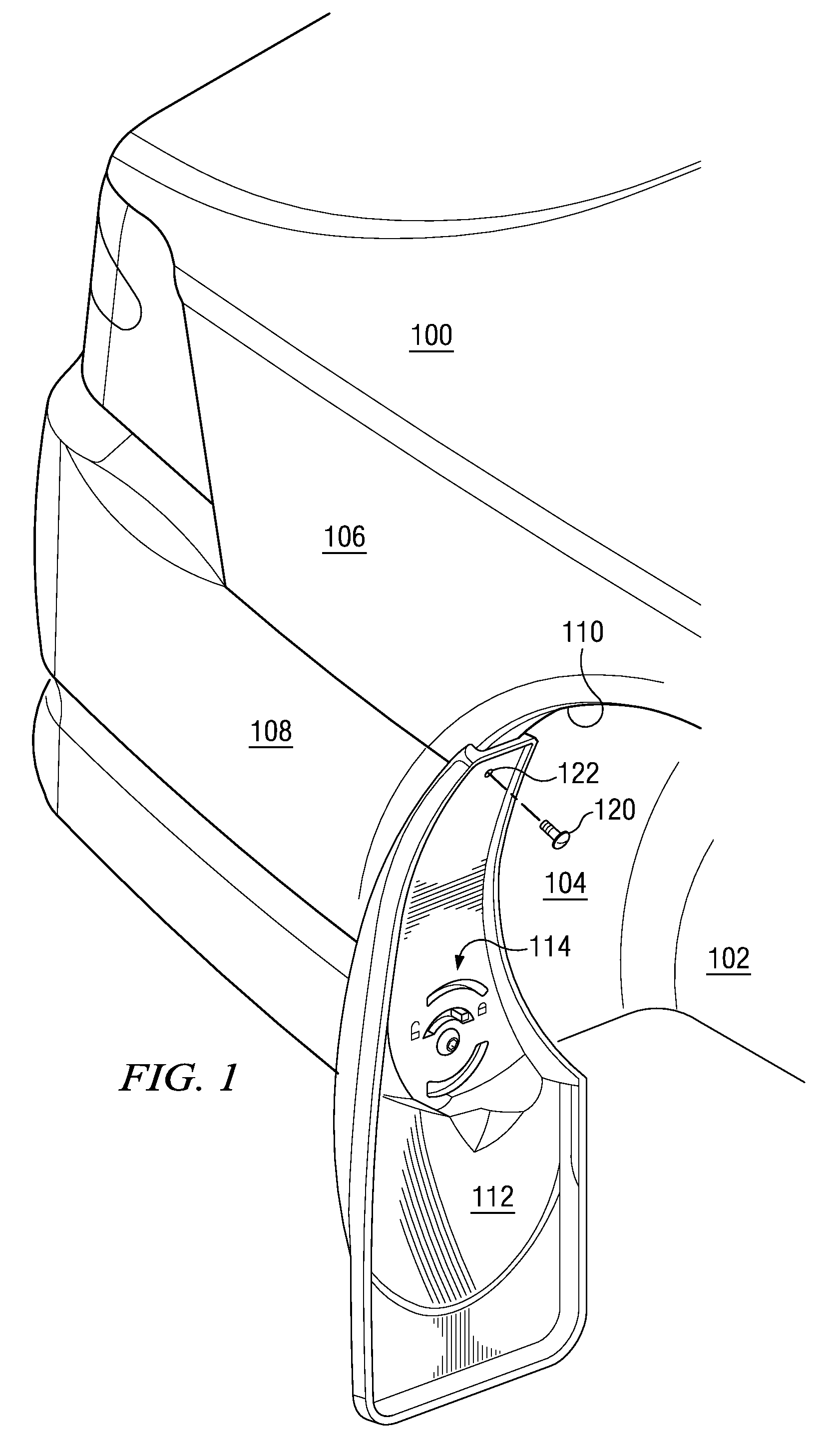

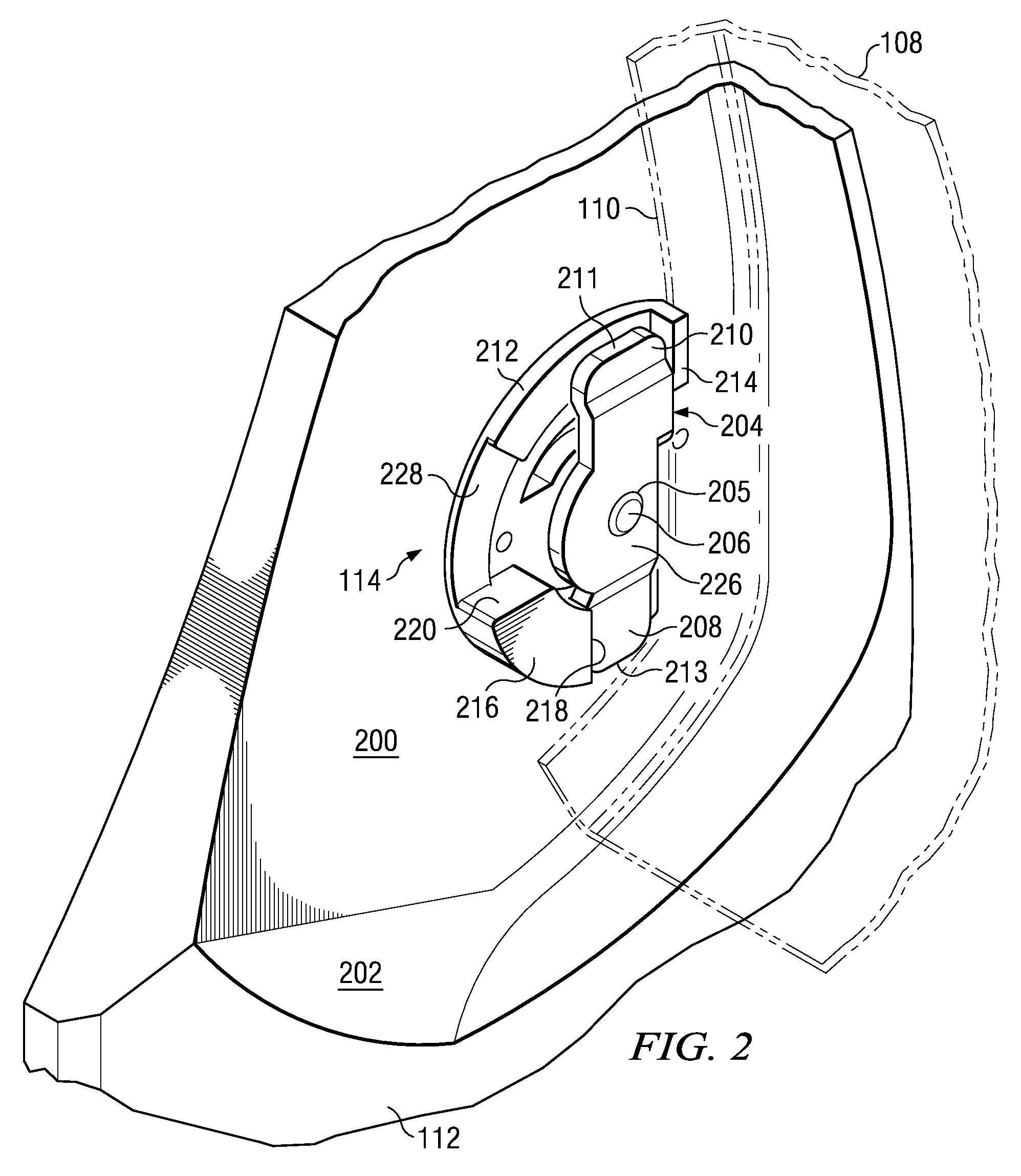

Vehicle concealed antenna

InactiveUS20100225547A1Low costEasy to installAntenna adaptation in movable bodiesElongated active element feedEngineeringRadio system

An antenna assembly for use in a vehicle is provided, whereby the assembly is preferably concealed within a vehicle bumper or non-conductive fender. The assembly includes a flexible antenna radiator directly connected with an output of a tunable matching circuit contained within a housing, whereby the housing further provides a connection means between the input of the matching circuit and a radio system in the vehicle. The matching circuit is tunable by control means provided externally on the housing, enabling the antenna assembly to be easily tuned prior to or during installation. The inventive antenna assembly advantageously provides a low cost antenna with ease of installation, small size, and direct integration with a tunable matching circuit.

Owner:SINCLAIR TECH

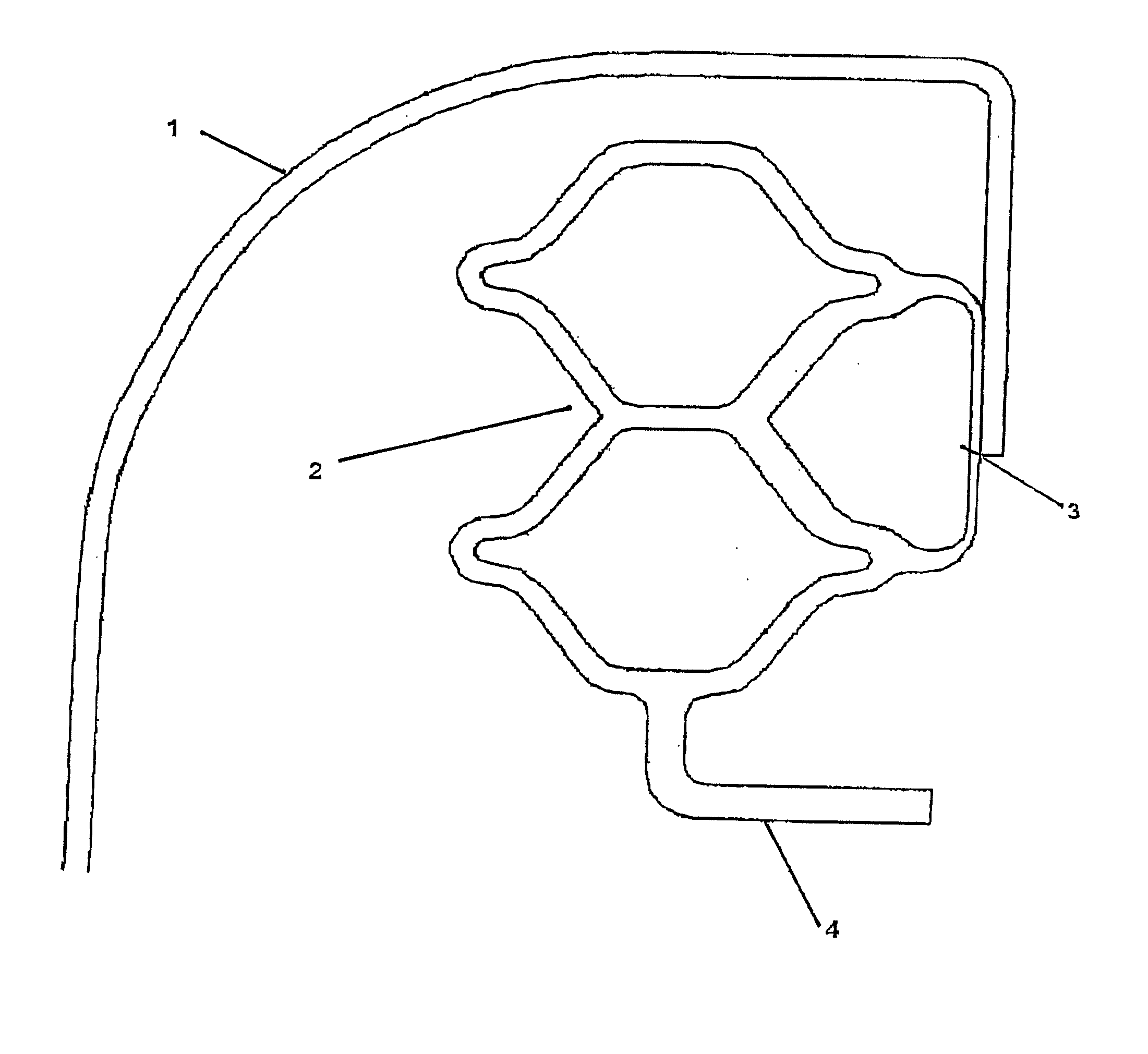

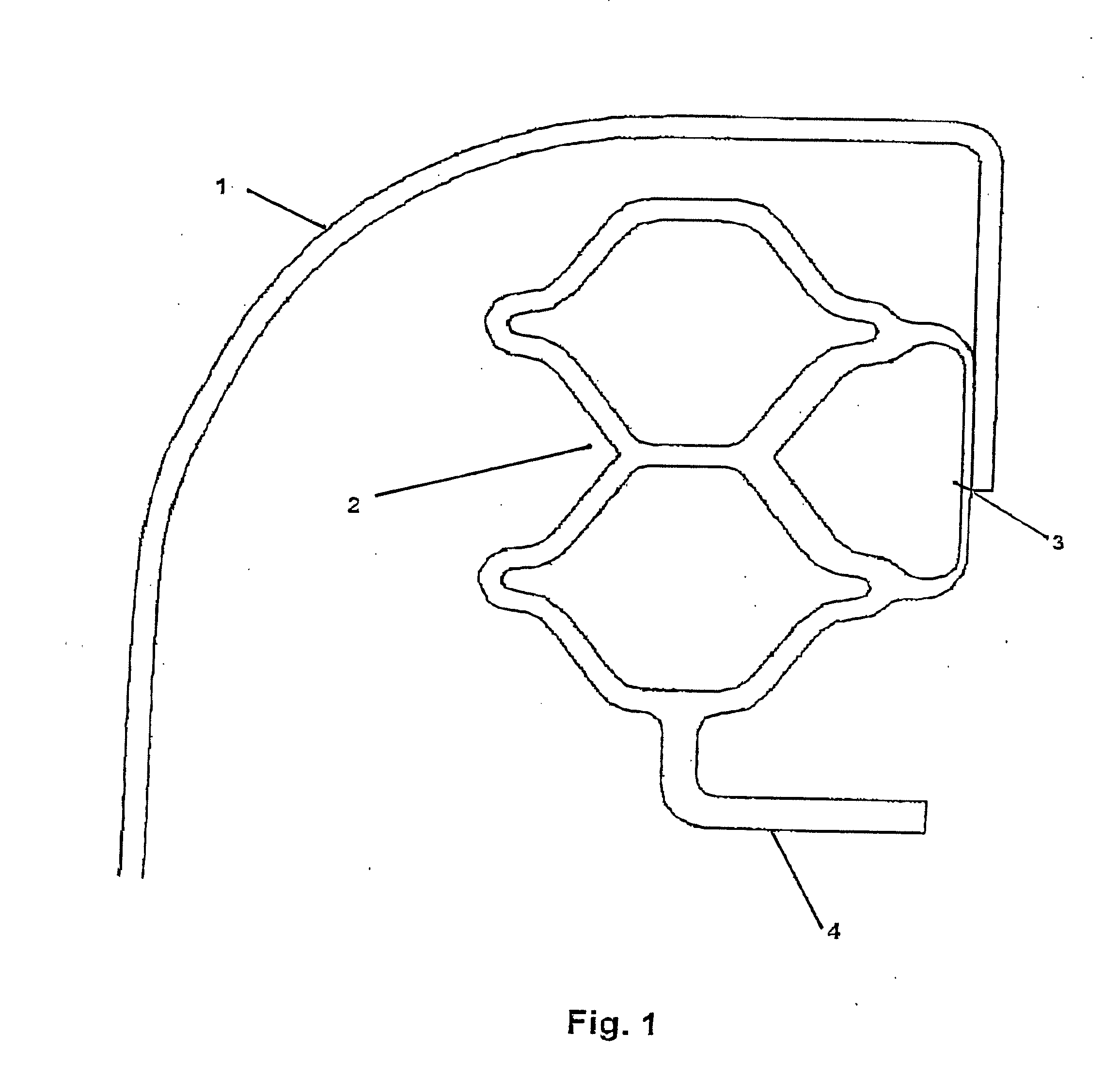

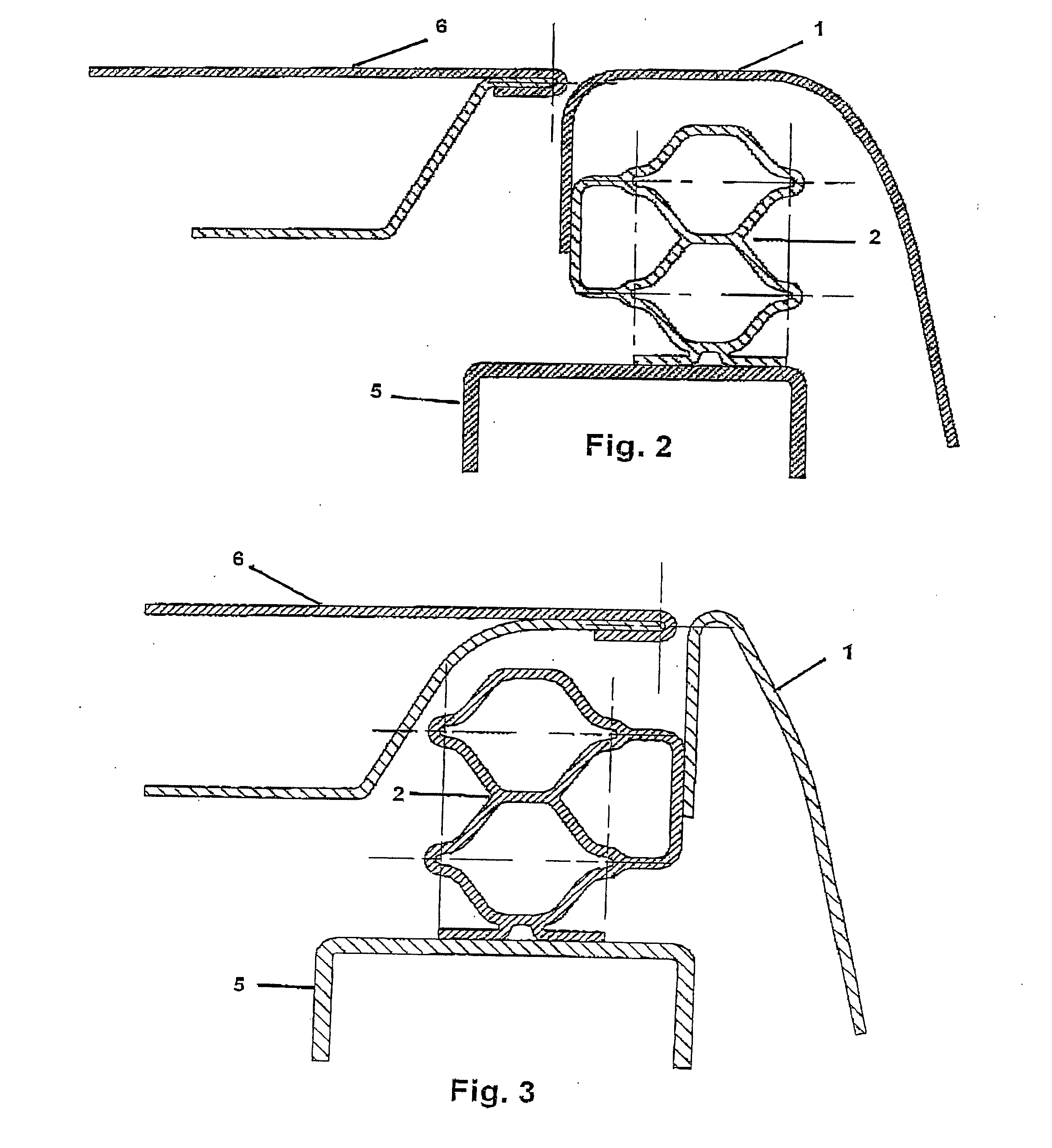

Pedestrian guard for a motor vehicle

InactiveUS20080042454A1Energy be absorbImprove efficiencyVehicle seatsPedestrian/occupant safety arrangementFenderControl theory

A pedestrian guard for a motor vehicle is designed to protect persons in the event of a collision with the motor vehicle. At least one profile section ( 2 ) with a honeycomb cross section is arranged between the component of the motor vehicle against which a person impacts in the event of collision with the motor vehicle, in particular, between the fender ( 1 ) and the component of the motor vehicle ( 5 ) to which the impacted component is connected. The profile section is produced of an aluminum material that is in a soft annealed state.

Owner:ALUTECH

Motorcycle bolt head cover

A cover for bolt heads of motorcycles preferably includes a recessed top and a skirt. In the illustrated and preferred embodiment, the skirt is annular and the recess is circular. The recess is adapted to receive a color matched object, such as a pre-painted insert or a cabochon made from a gemstone, ceramic, glass or plastic. The objects upper surface can be flat, domed, etc. Alternately, the recess is filled with a suitable color matched liquid, such as an epoxy or enamel liquid. In its most preferred forms, the object color matches at least one component of the motorcycle with which it will be used, e.g. the fenders, fuel tank, frame, etc.

Owner:BERGAMONT BRASS WORKS

Mud flap retrofit kit and method of use

A method of installing a mud flap onto a vehicle having a fender which has a contour, so that the mud flap is in a predetermined position. A mud flap installation kit is used. This kit has a mud flap that defines a set of at least three apertures positioned along a curve that parallels the fender contour and a set of flat clips equal in number to the apertures, each flat clip having a bolt and a leaf, defining a leaf aperture. Each flat clip bolt is threaded through a mud flap aperture and a leaf aperture. Then the mud flap is aligned so that each of the apertures is a predetermined distance from the fender, thereby placing the mud flap in the predetermined position. Finally, the flat clips are used to clamp the mud flap to the fender.

Owner:FRIESEN MYRON J

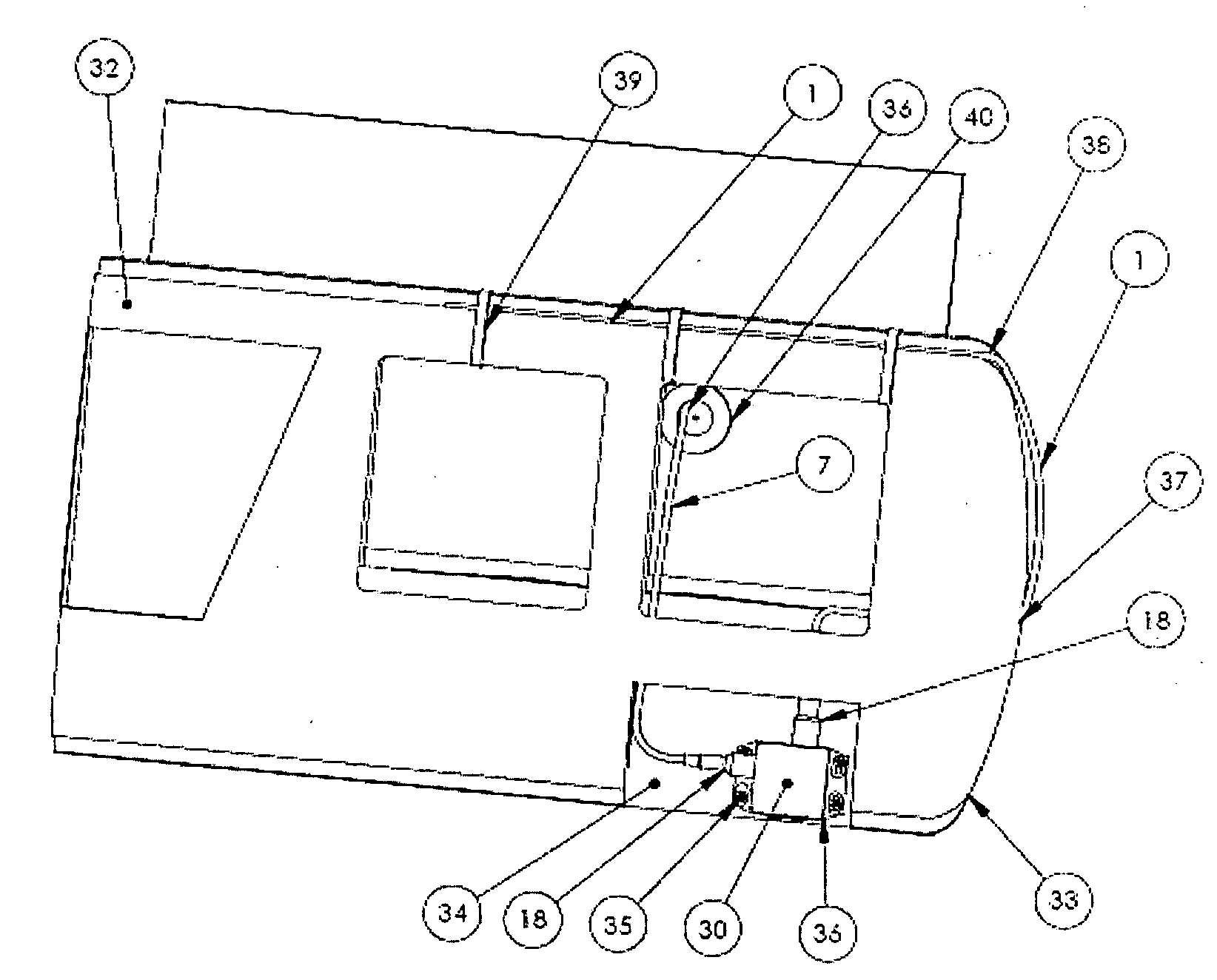

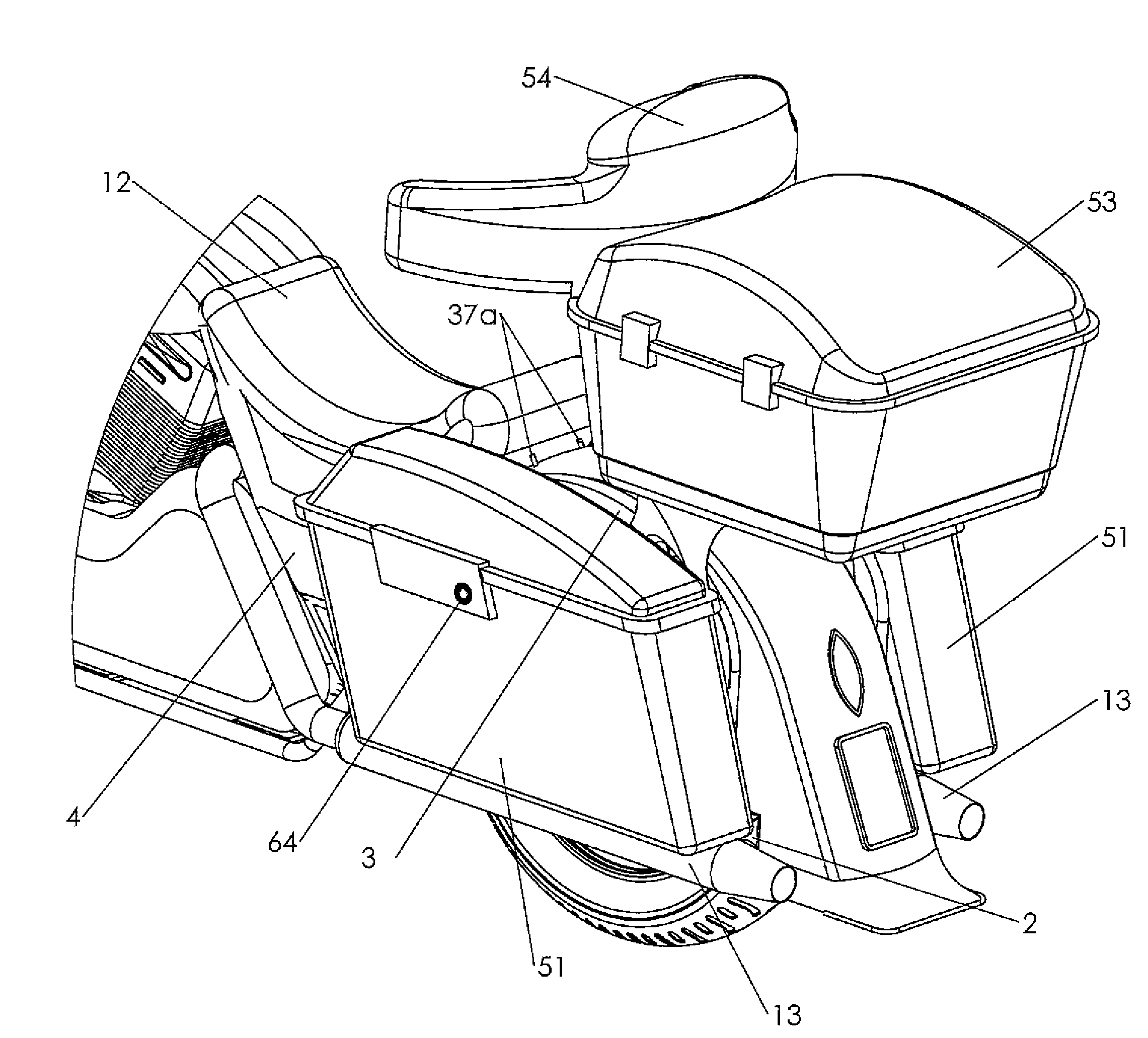

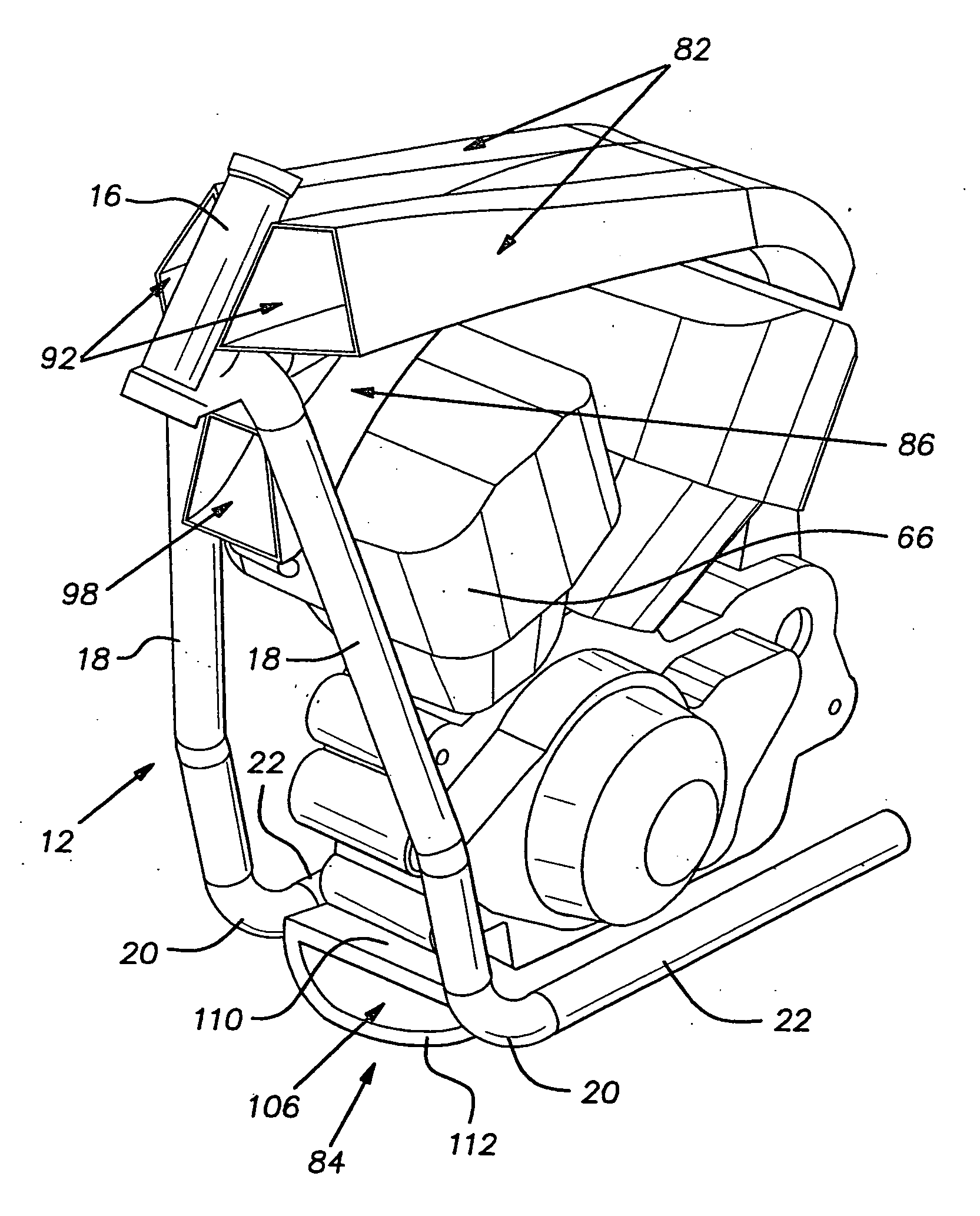

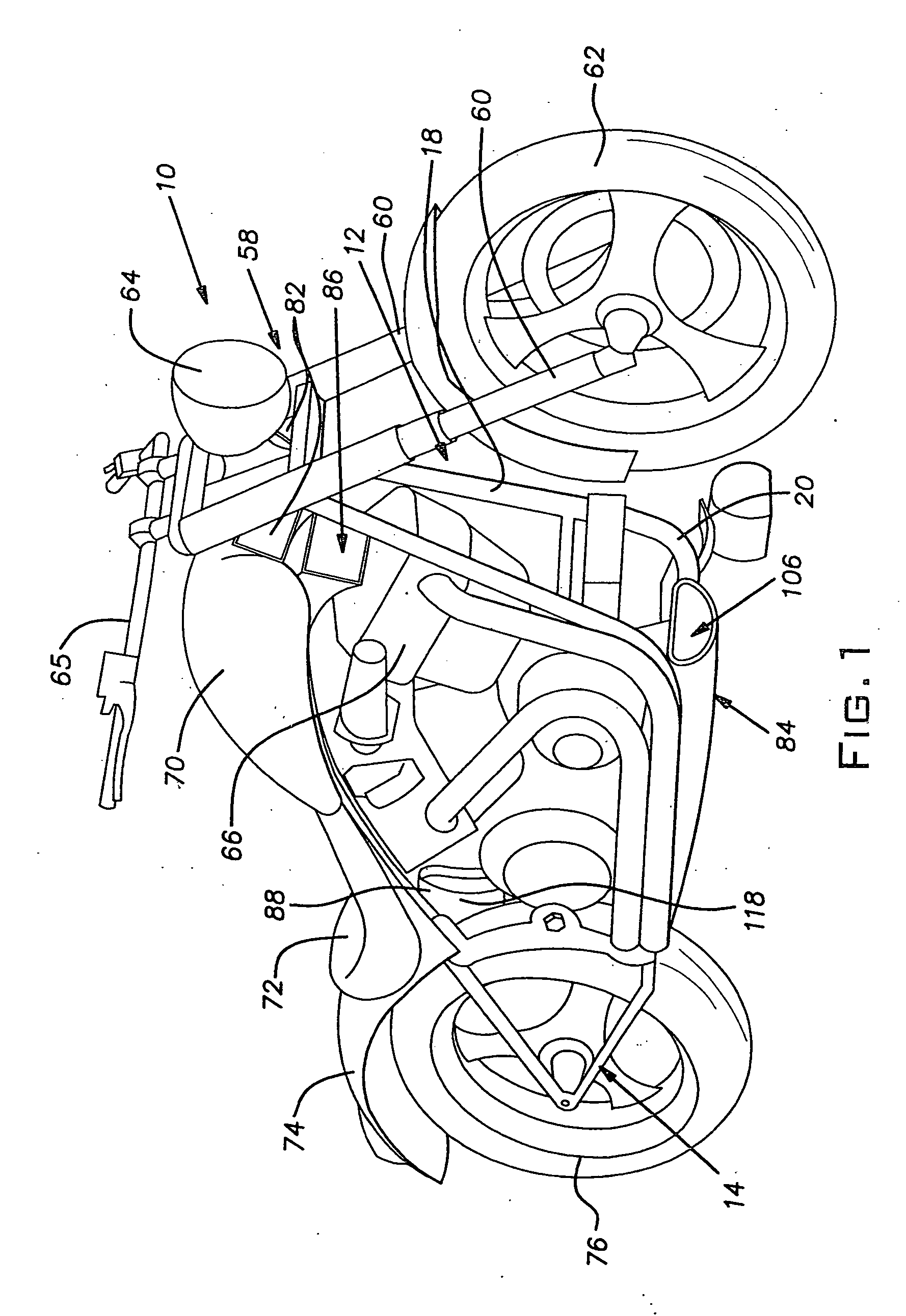

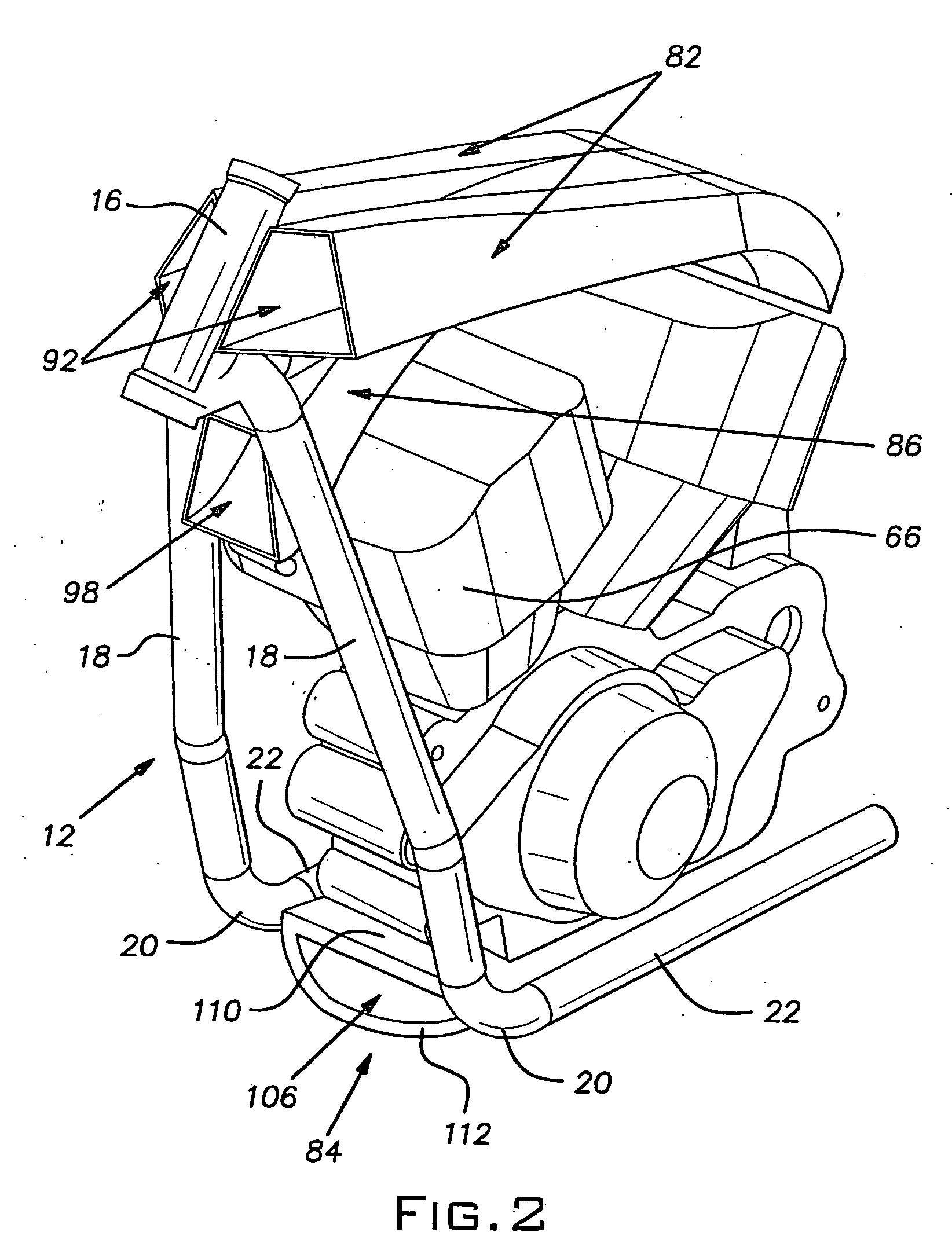

Touring motorcycle modification kit

InactiveUS20080174099A1Prevent removalLuggage carriersSuperstructure subunitsEngineeringBolt connection

A touring motorcycle modification kit comprising: an internal frame, an external frame, and a fender; wherein the fender is situated between the internal and external frames; wherein the internal frame is situated inside of the fender; wherein the internal frame comprises two portions, and wherein the two portions are bolted together; wherein the external frame is mounted on the fender at three frame mounting points; wherein two of the three frame mounting points are located on the exterior of the fender; wherein none of the three frame mounting points is located inside of the fender; wherein the external frame does not bolt to the frame mounting points but is releasably attached to the three frame mounting points; and wherein no tools are required to install or remove the external frame. The present invention can be used with a factory seat, exhaust system, wiring harness, saddle bags and tour pack.

Owner:BROWN PETER L

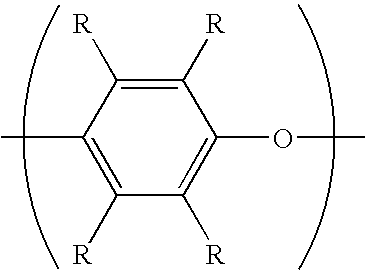

Heat-resistant resin composition

ActiveUS8263697B2Substantial in resin temperatureGood effectSynthetic resin layered productsSpecial tyresPolymer scienceFender

Disclosed is a resin composition comprising an aromatic polyamide having a terminal amino group concentration of 5 to 45 μmoles / g inclusive, polyphenylene ether, a compatibilizing agent for the polyamide and the polyphenylene ether, and a crystal nucleating agent. The composition is extremely useful in an automotive body panel (e.g., an automotive fender), an SMT-compliant component or the like.

Owner:ASAHI KASEI CHEM CORP

Use of a fender and a hood in combination with an air bag, fender retaining and support means, a fender, a fender module, and a hood for a motor vehicle

InactiveUS20050140174A1Increase the protective areaVehicle seatsPedestrian/occupant safety arrangementEngineeringMotorized vehicle

The present invention relates to the use, at the front of a motor vehicle, of a fender and of a hood defining a fender-hood junction leaving predetermined clearance between an edge of the hood and an edge of the fender, in combination with an air bag for deploying to the outside of the vehicle. This use is performed in such a manner that while the air bag is deploying, it deforms the fender and / or the hood in such as a manner as to enlarge the clearance and create a passage between the edge of the hood and the edge of the fender. The invention also relates to retaining means and to a fender support, to a fender, to a fender module, and to a hood for a motor vehicle.

Owner:CO PLASTIC OMNIUM

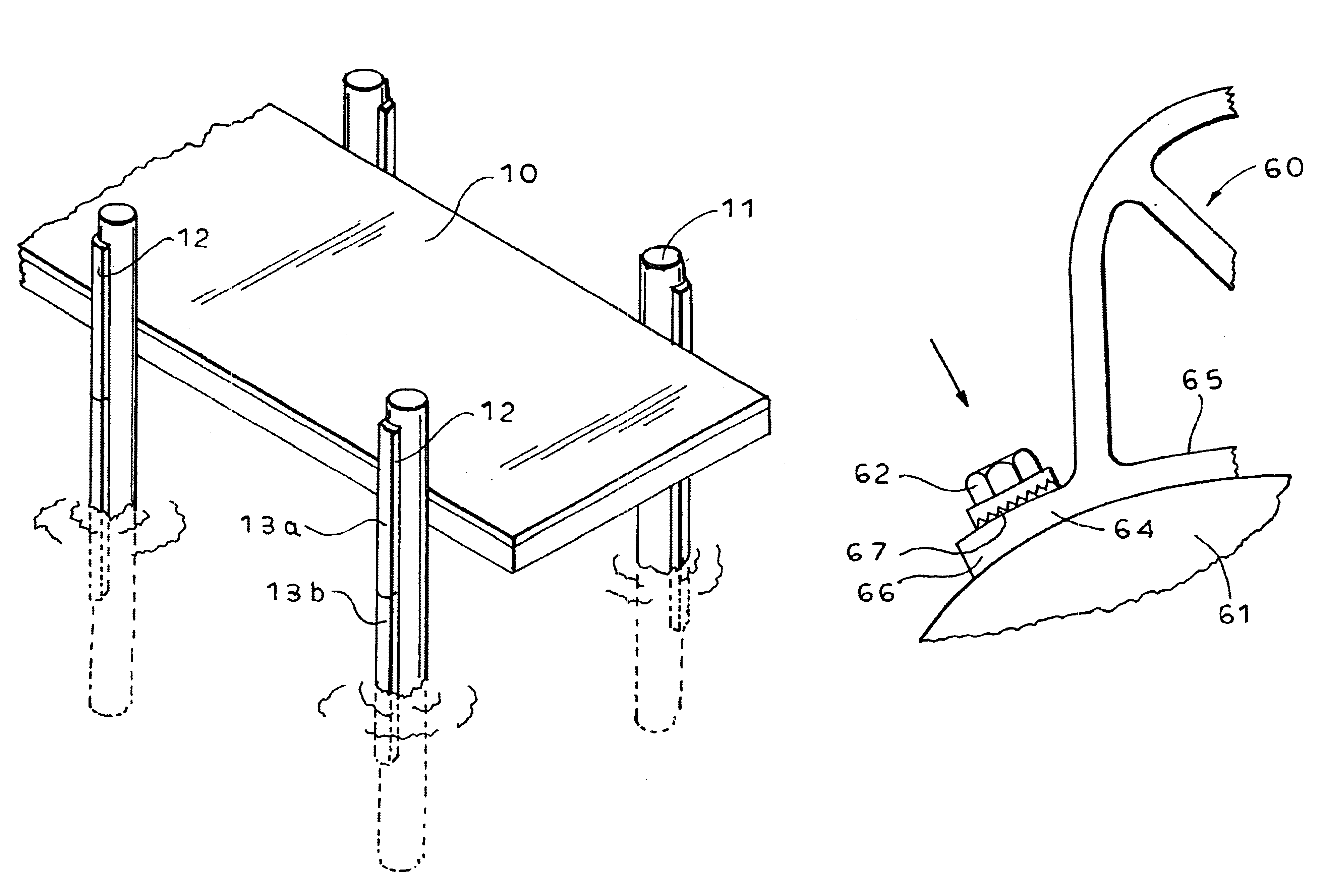

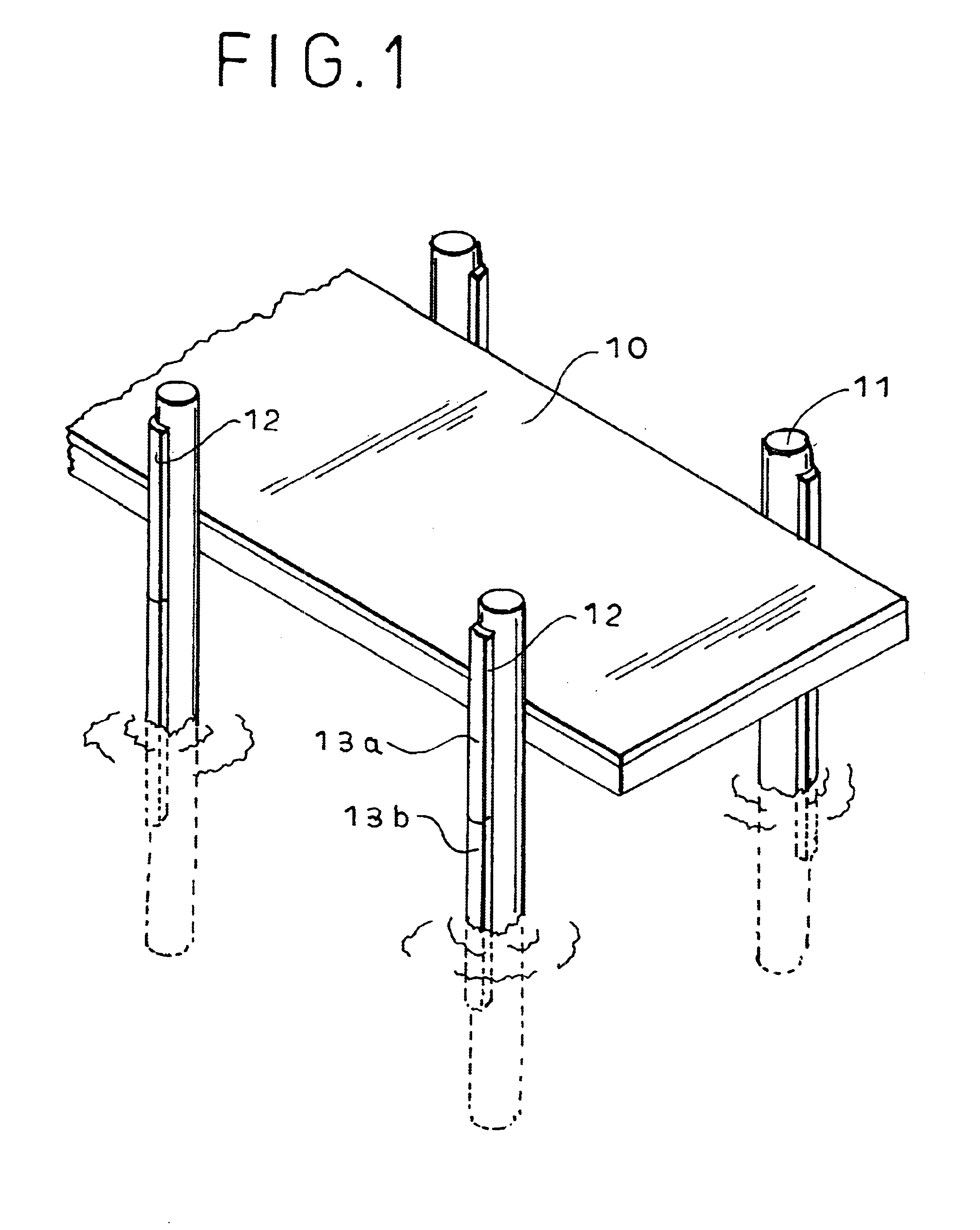

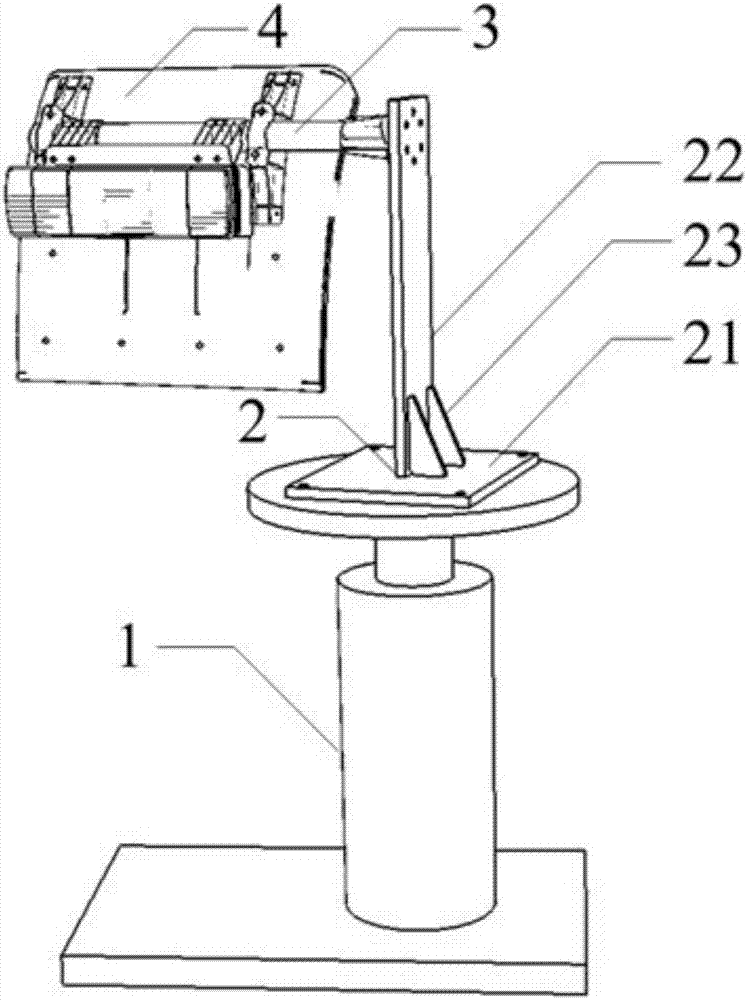

Commercial vehicle mudguard support assembly test stand and endurance test method

InactiveCN106950053AEasy to buildQuick and easy fixture makingVehicle testingMachine part testingCircular discFender

The invention discloses a commercial vehicle fender bracket assembly test bench and a durability test method, which belong to the technical field of performance testing of automobile products, and include a linear actuator, a connecting fixture, a fender bracket and a fender assembly; Wherein, the connecting fixture includes a fixture bottom plate and a bracket connecting vertical plate, and the clamp bottom plate is used for connecting the fixture bottom plate with the top disc of the linear actuator; the bracket connecting vertical plate is connected with one end of the fender bracket; The other end of the fender bracket is fixedly connected with the fender assembly; the structure is simple and compact, has high versatility, saves time and high efficiency, is easy to process, and has high work efficiency. The durability test method described in the present invention aims at strengthening the road load spectrum signal in the test field, and can truly reproduce the vibration state and the vibration state in the vertical direction of the fender bracket assembly in the test room under the actual vehicle working condition by means of simulation iteration. In order to realize the durability performance assessment and test certification of the fender bracket assembly.

Owner:CHINA FIRST AUTOMOBILE

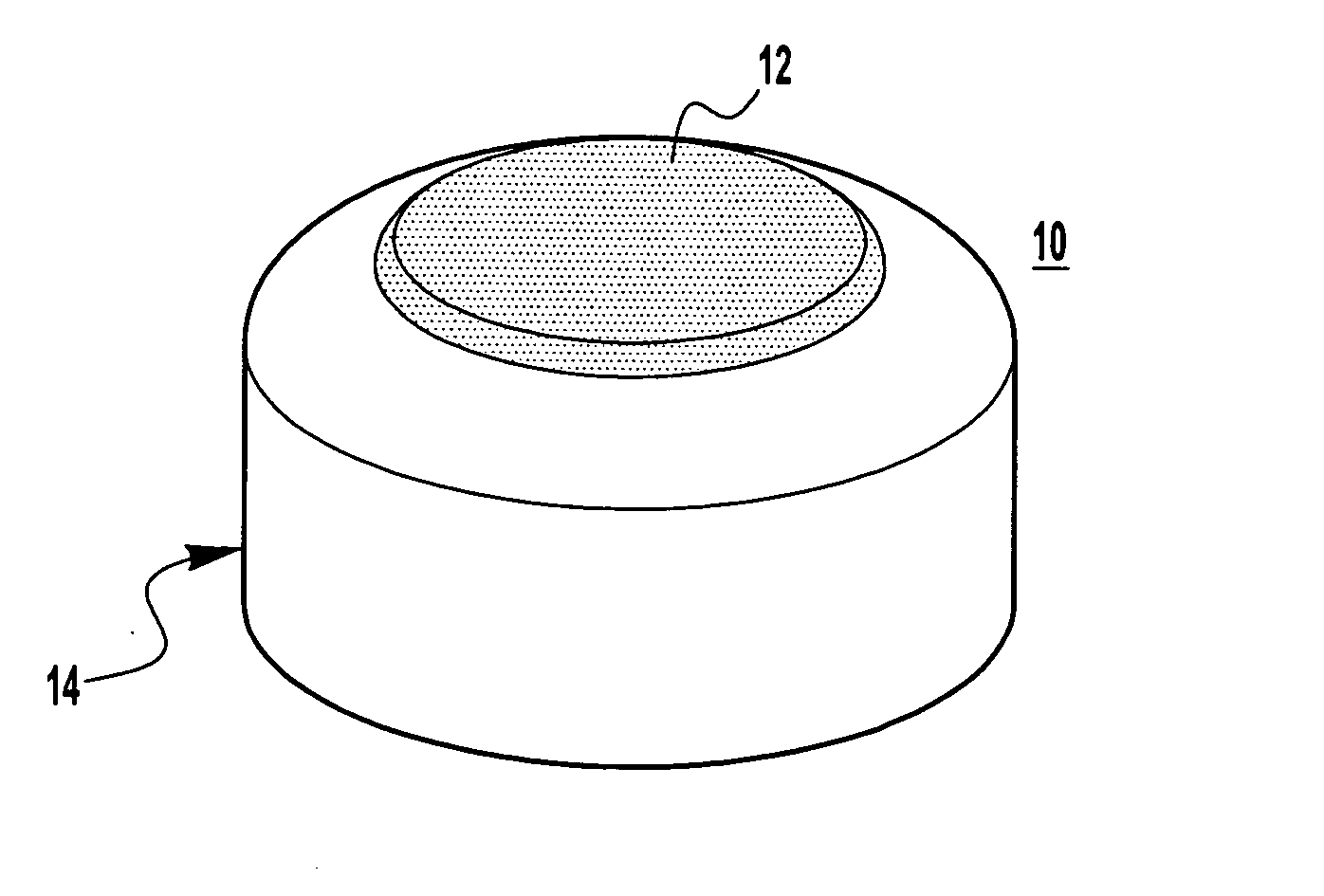

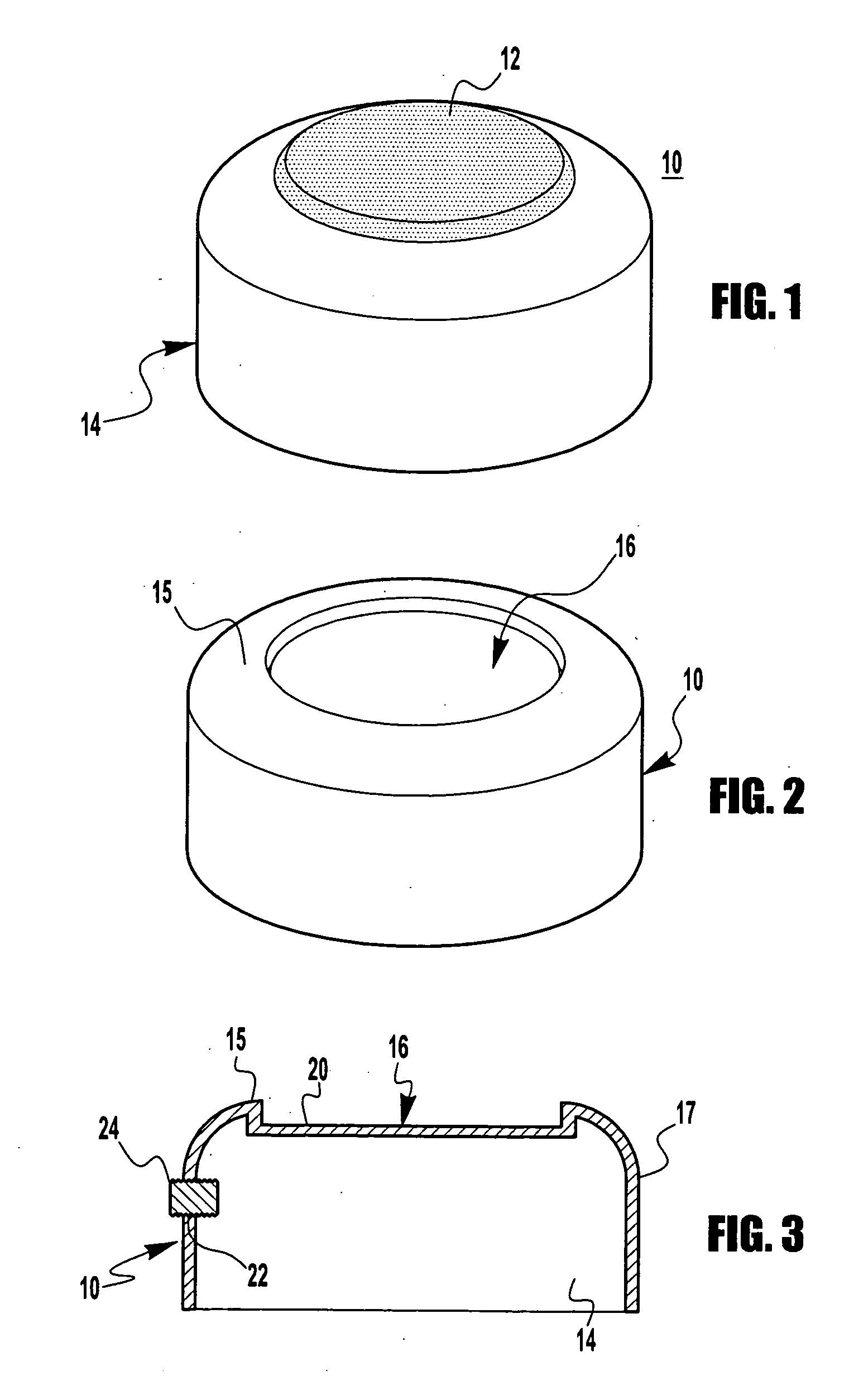

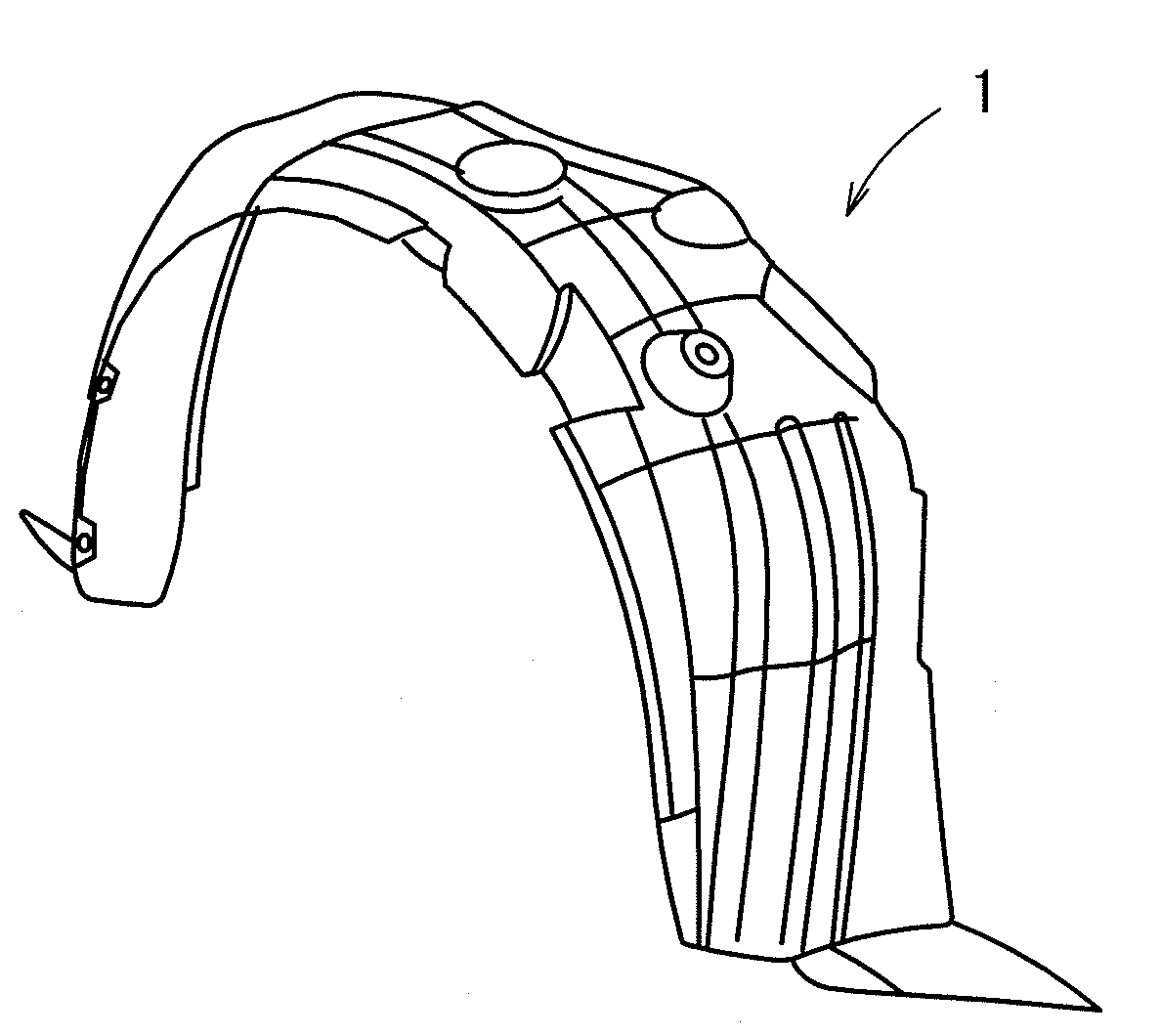

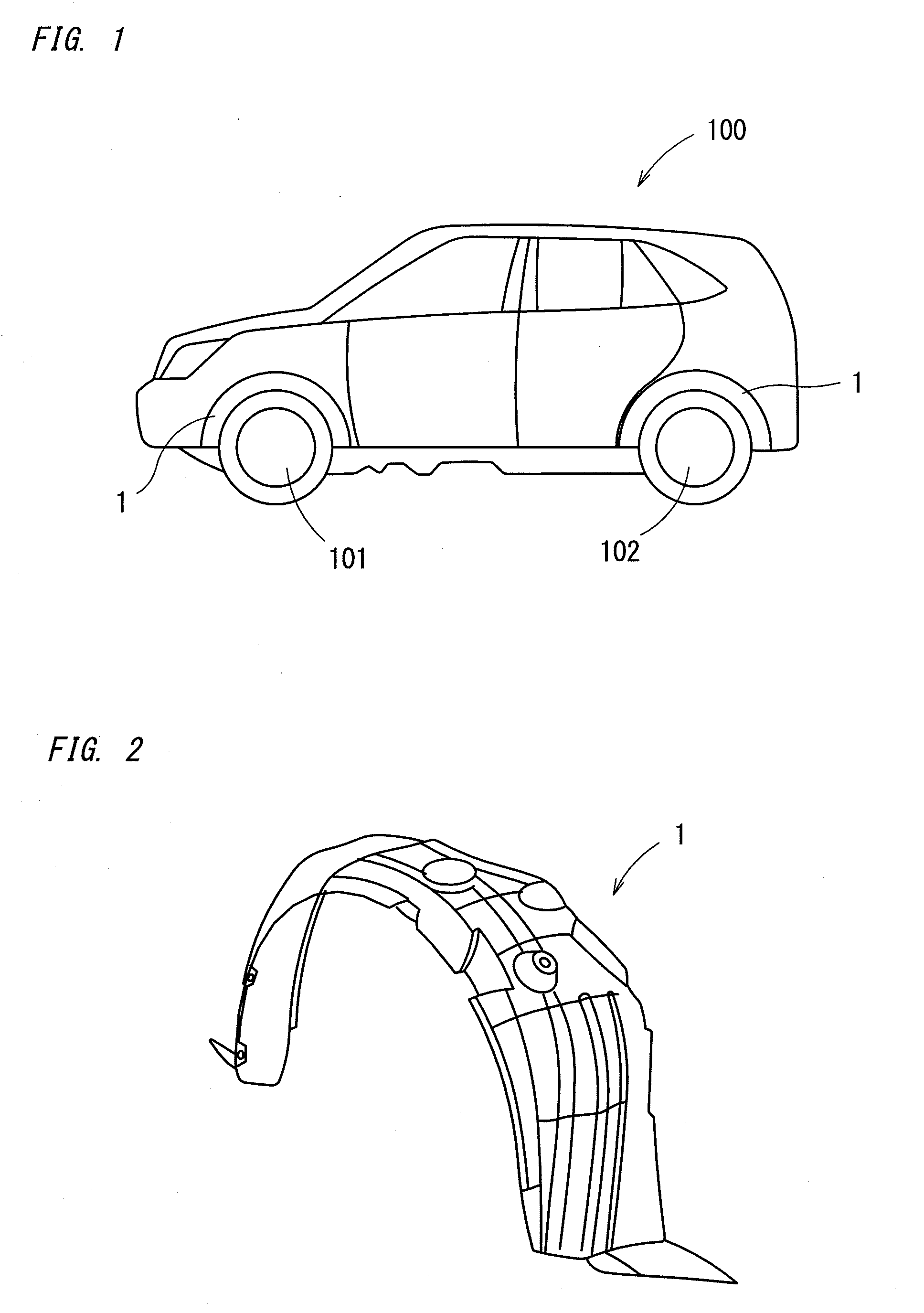

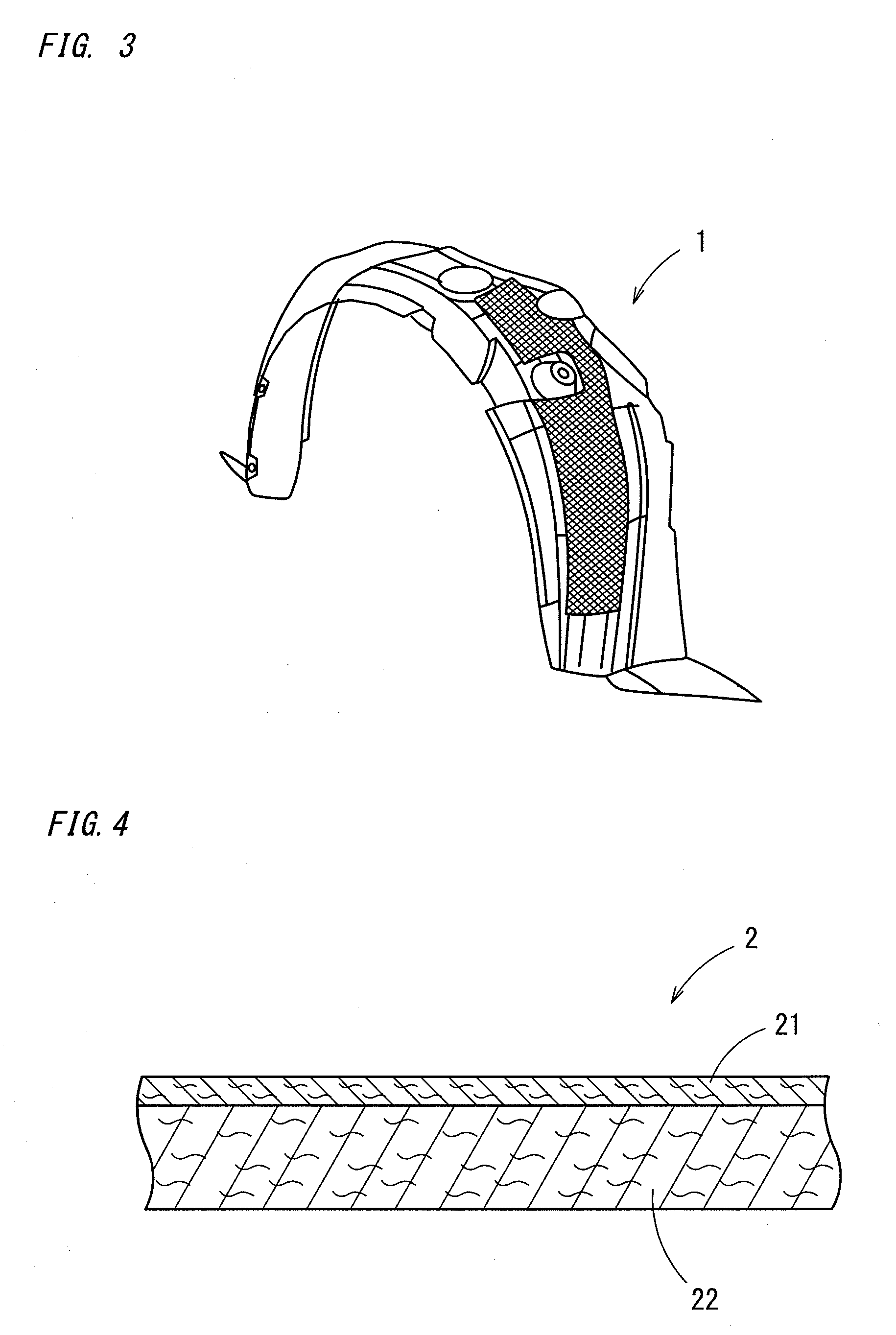

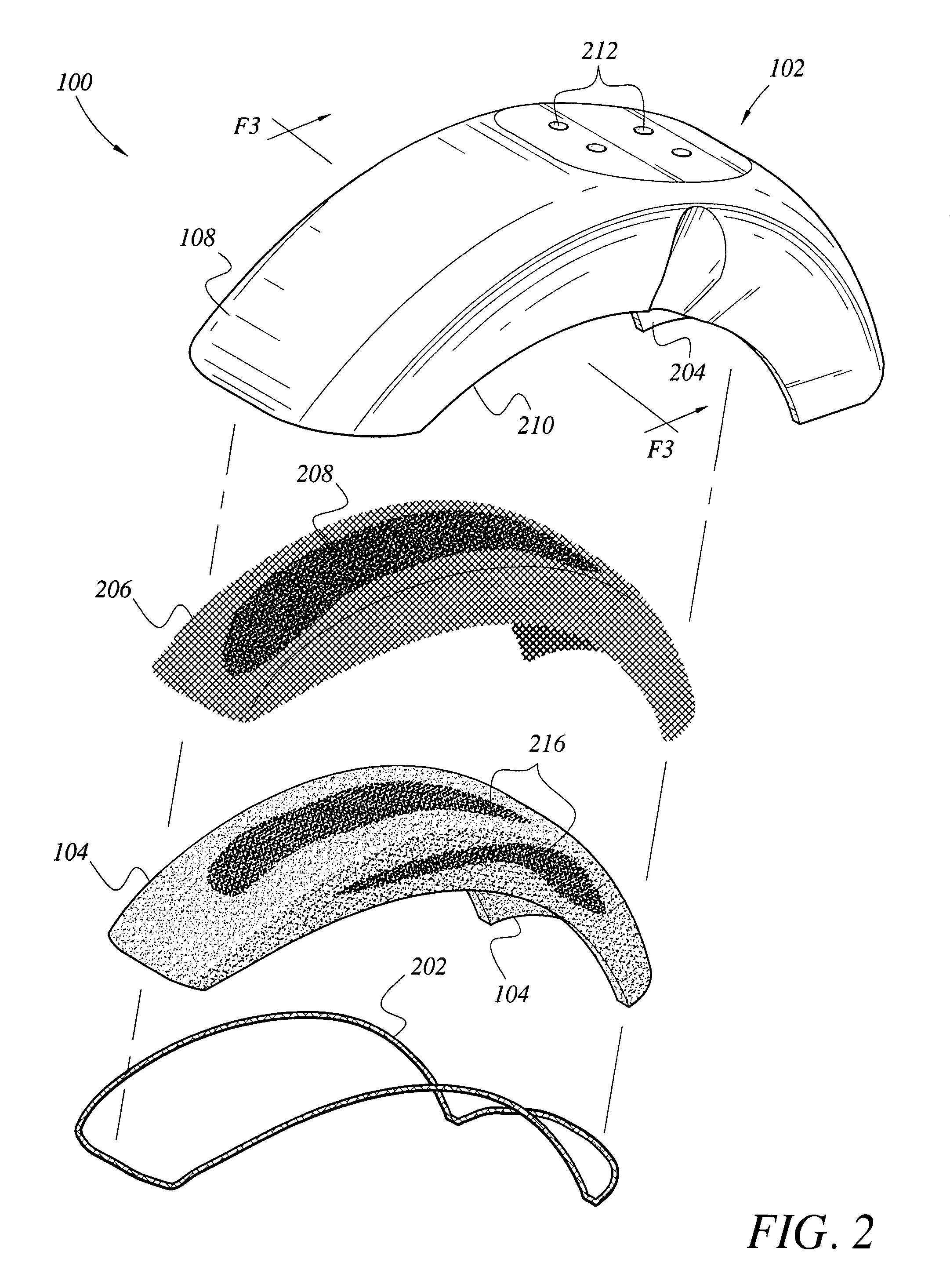

Fender liner and method for producing the same

InactiveUS20090256345A1Improve sound insulationEasy to separateSuperstructure subunitsHigh densityPunching

The present invention provides a fender liner and a method for producing the same that allows reduction of noise caused by collision with pebbles etc. kicked by tires, that has sufficient rigidity, and that allows easier separation of attached ice. The fender liner comprises a low density nonwoven fabric layer, disposed on a side of the outside surface when it is attached to the outside surface, and a high density nonwoven fabric layer, the density of which is 0.6 to 0.9 g / cm3, in a thickness direction. The method comprises: obtaining a compound nonwoven fabric by intertwining and integrating a first and a second nonwoven fabric having predetermined amounts of mass per unit area and thicknesses respectively by a needle punching method; obtaining a nonwoven fabric laminated product for liners by heating the fabric from a side of the first nonwoven fabric layer with simultaneous pressurization; and die forming the product.

Owner:TOYOTA BOSHOKU KK

Tail lamp structure for vehicles

ActiveUS20060077677A1Reduce depthFurther miniaturizationVehicle headlampsLighting support devicesEngineeringLight-emitting diode

In a vehicle that includes a rear fender for covering the upper portion of a rear wheel, a mud guard cover for covering the rear portion of the rear wheel, and a tail lamp arranged around the rear fender and the mud guard cover wherein the tail lamp includes light-emitting diodes as light sources, and includes a light-emitting diode board for placing the light-emitting diodes thereon, a control element board for placing a control element for controlling the light-emitting diodes thereon, a housing for collectively accommodating the light-emitting diode board and the control element board, and a lens for covering the housing and the control element board that is arranged downwardly of the light-emitting diode board.

Owner:HONDA MOTOR CO LTD

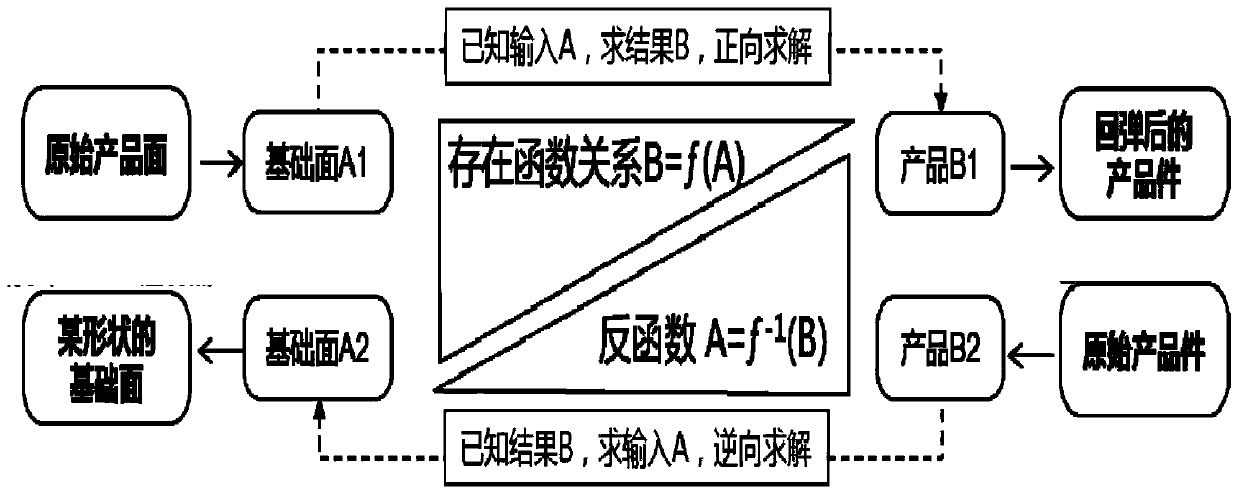

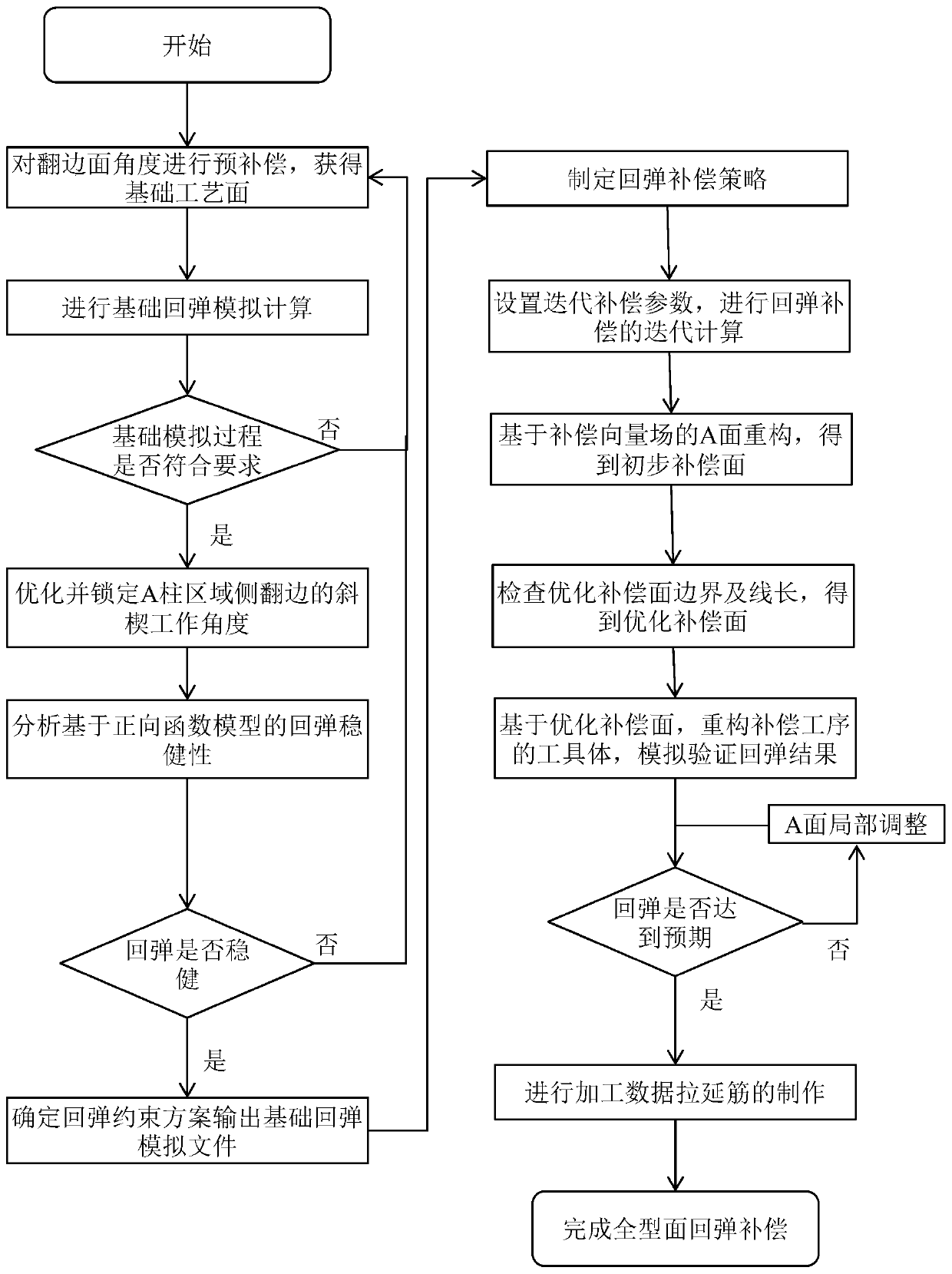

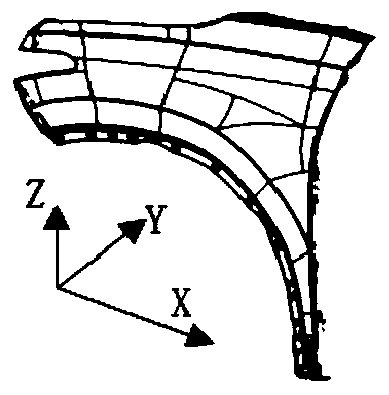

Stamping springback full-profile compensation method for automobile fender

ActiveCN110738005AAchieving RealizabilityAchieve reliabilityGeometric CADDesign optimisation/simulationFenderEngineering

The invention relates to the technical field of stamping die manufacturing, in particular to a stamping springback full-profile compensation method for an automobile fender. The stamping springback full-profile compensation method comprises the following steps: S1, obtaining a basic springback simulation result based on a forward function model; S2, obtaining a full-profile springback compensationstrategy based on a reverse function model; and S3, carrying out reconstruction optimization and simulation verification on the tool body of the compensation process based on a full-profile springback compensation strategy. According to the stamping springback full-profile compensation method for an automobile fender, the design efficiency and precision of fender springback compensation are improved, and the actual part size debugging period is shortened, and the realizability, reliability and accuracy of stamping springback compensation are achieved.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

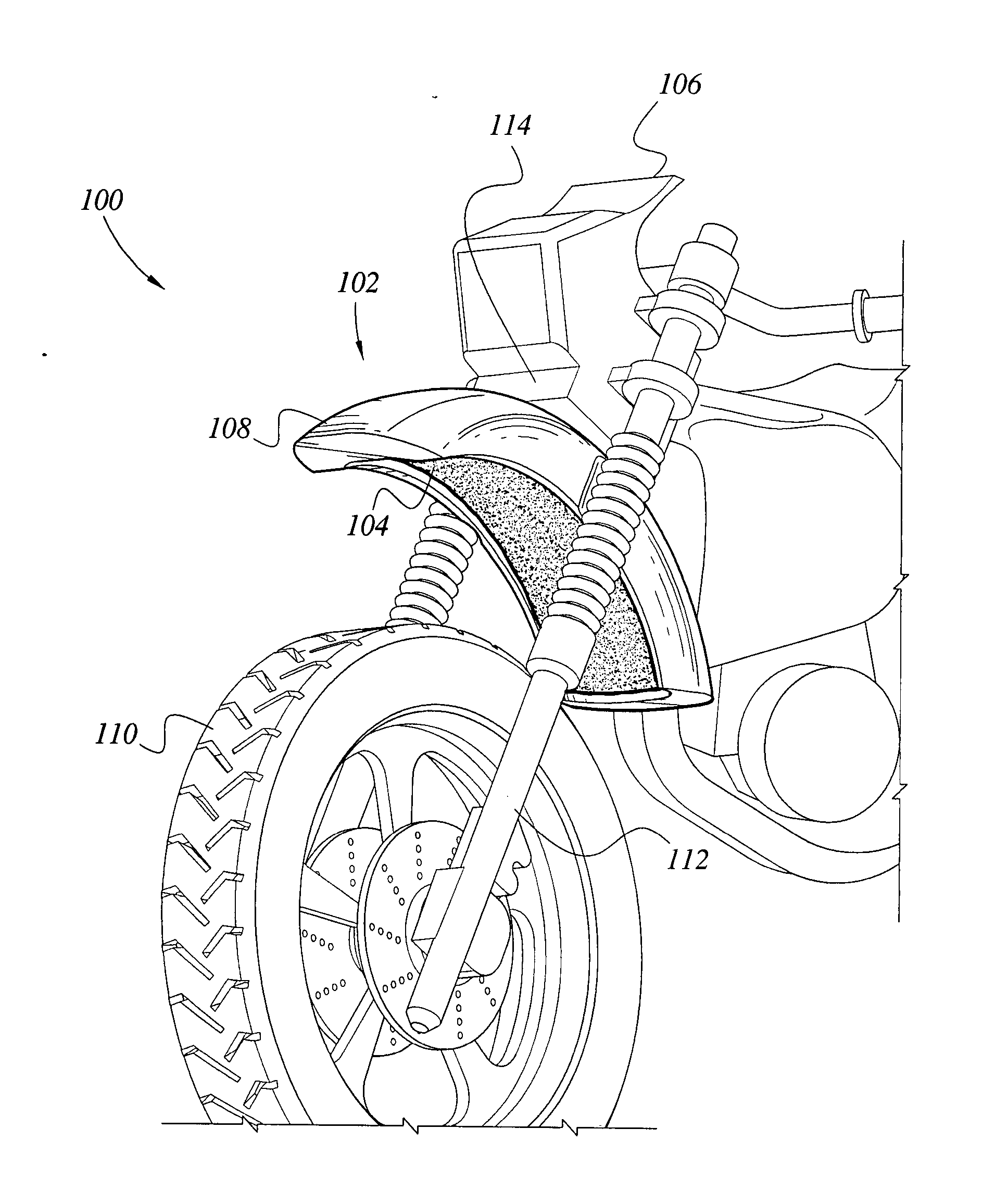

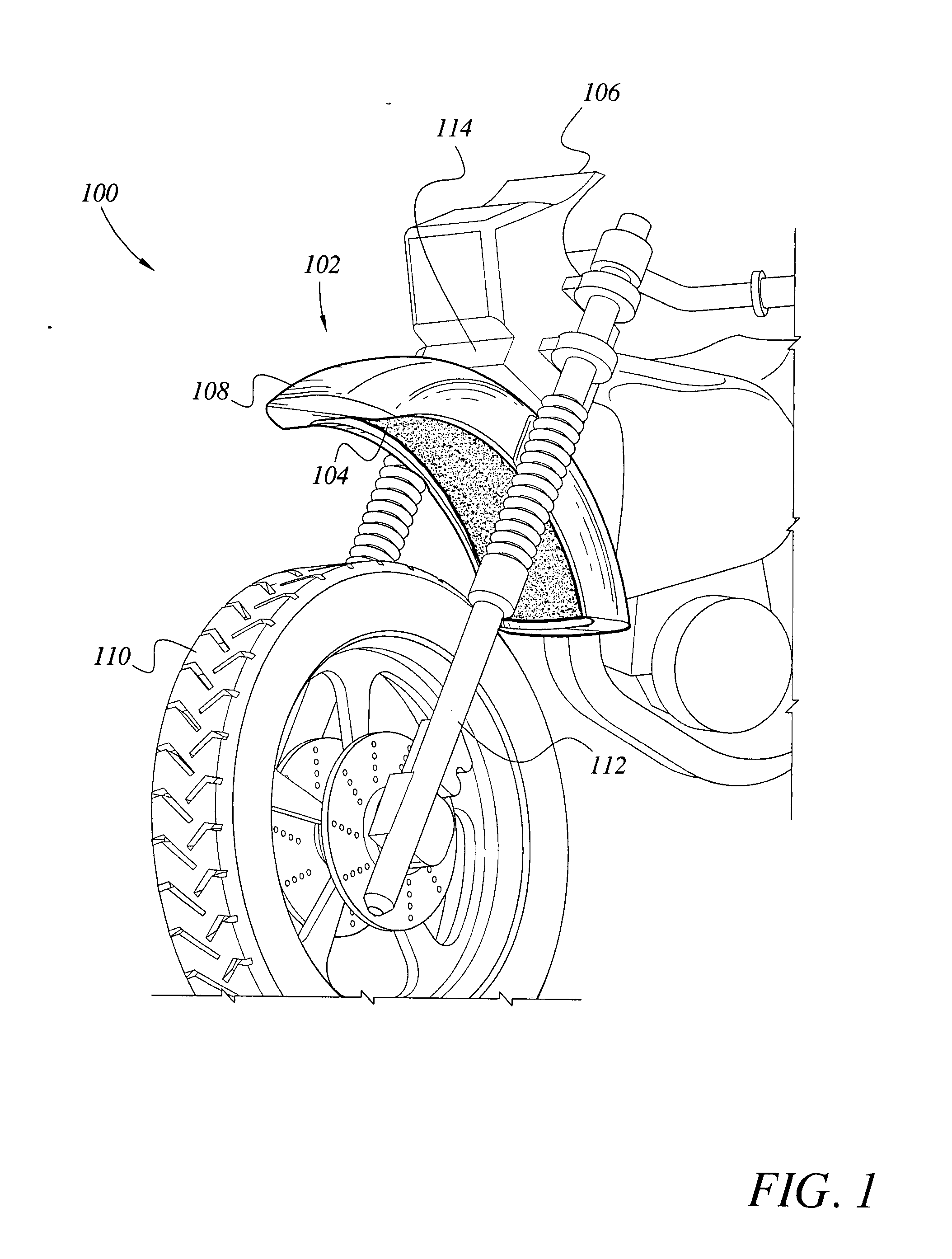

Foam liner and method to prevent accumulation of mud

InactiveUS20070187940A1Reduce weightControl the weight of their vehiclesSuperstructure subunitsMud-guardsSynthetic materialsEngineering

The liner assembly incorporates a liner formed of a synthetic air permeable material adhesively mounted to the underside of an exposed motorcycle fender or to a structure having surfaces susceptible to mud buildup, chipping or other types of damage. The liner is a relatively thin, flexible sheet of air permeable, synthetic material formed to substantially cover the concave portion of an exposed fender. The liner is either directly attached to the structure, or is attached via a double-sided tape, or has a bead of adhesive material disposed around the edge thereof, further securing the liner to the surface of the fender and protecting the edge from fraying and the lining from delaminating. The liner is coated with a wet or dry lubricant to increase its lubricity.

Owner:PRESBY ANTHONY J

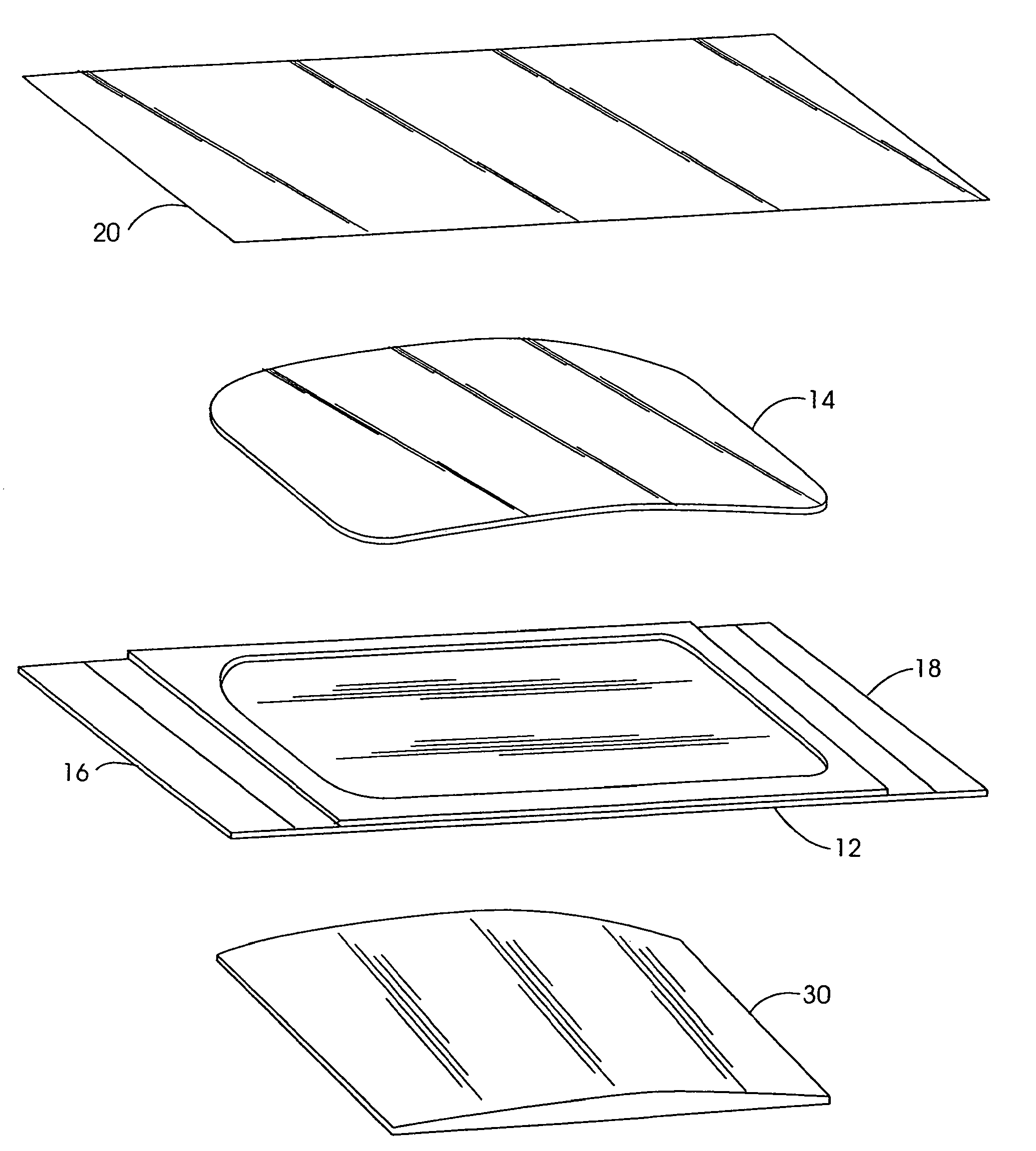

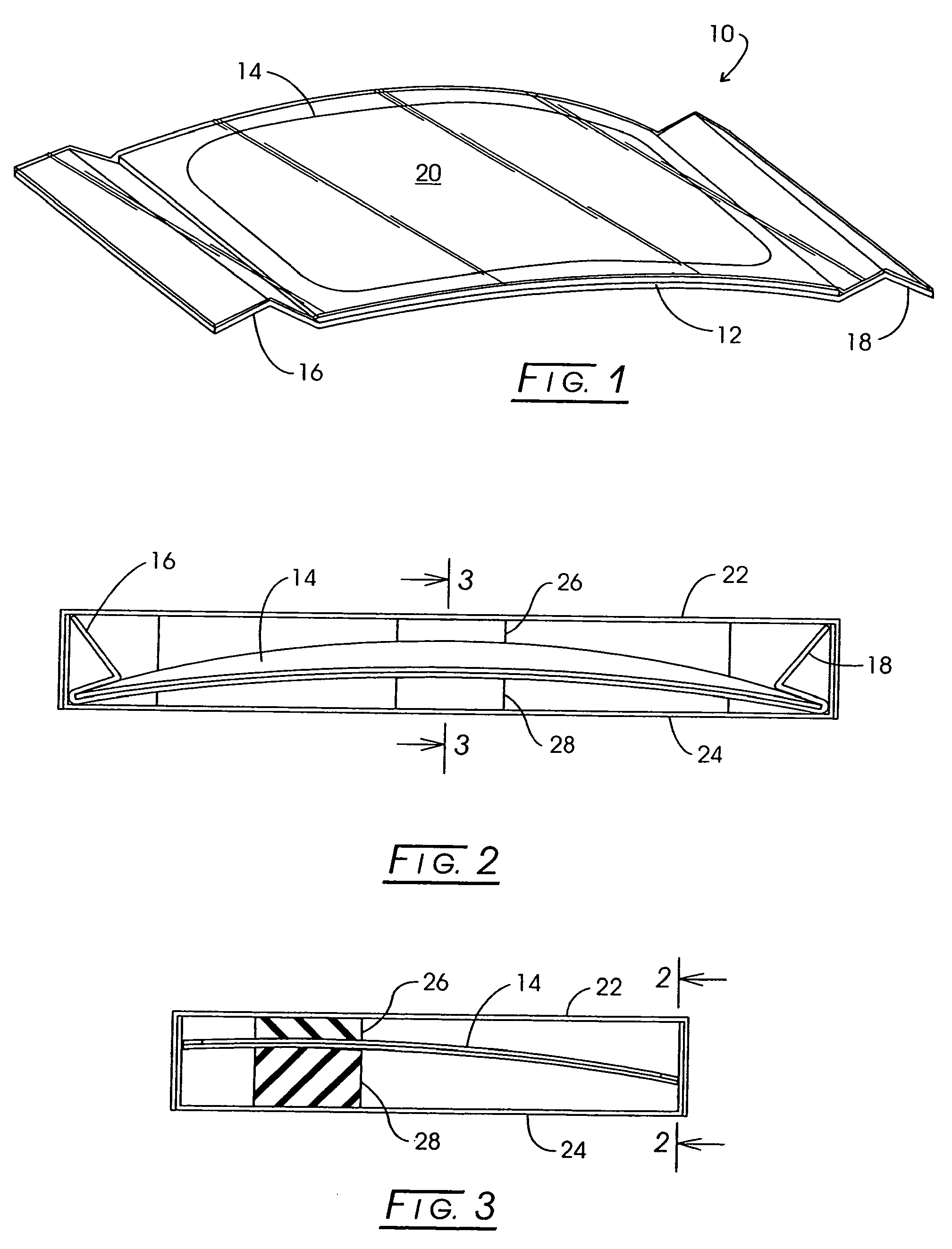

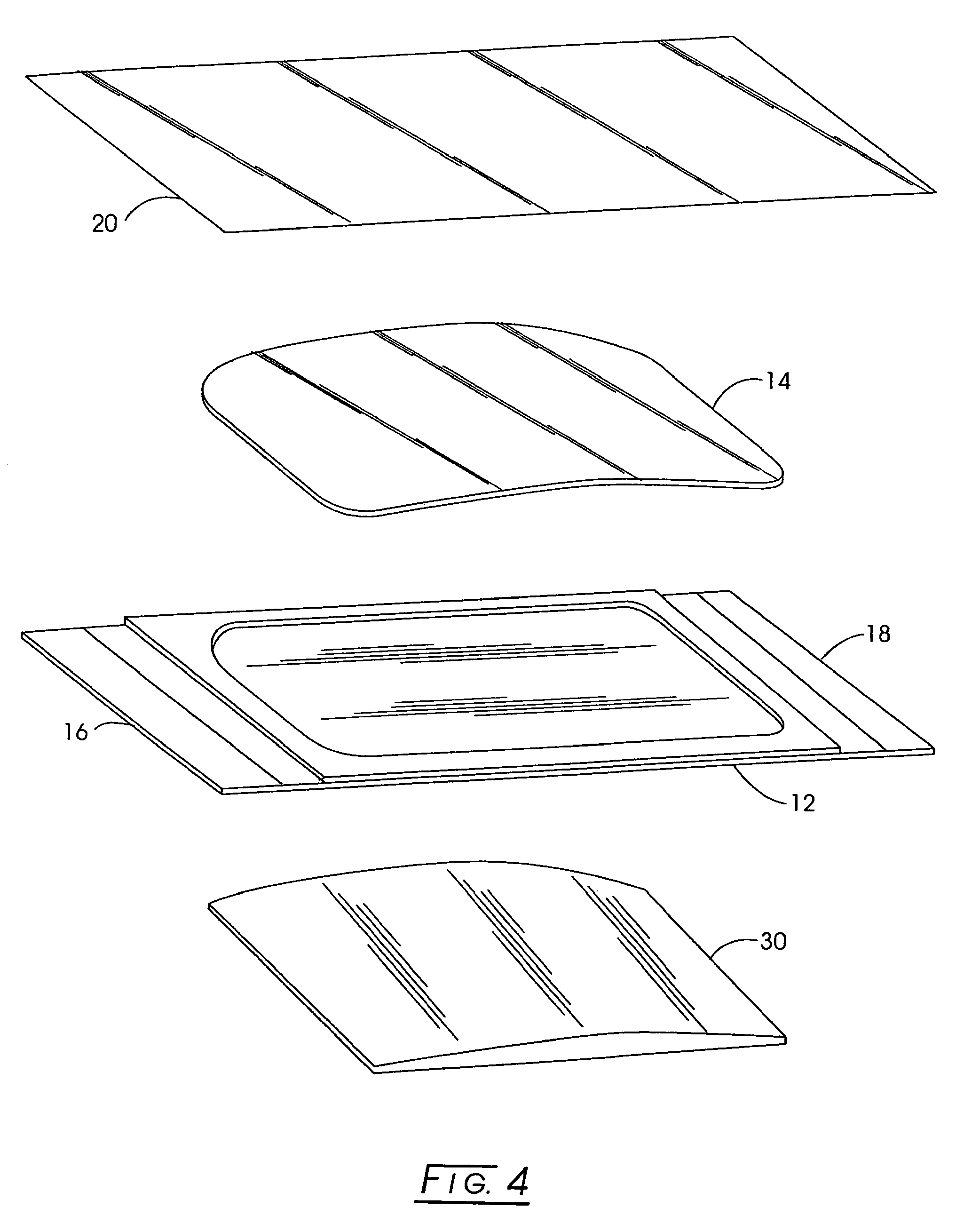

Automobile part shipping system and method

Plies of paperboard are laminated to form a paperboard laminate having a front and a back. An automobile part is placed on the front of the paperboard laminate leaving exposed the front of the paperboard laminate. The automobile part and the exposed paperboard laminate are shrink-wrapped with plastic shrink-wrap material. For automobile window glass, some of the front side plies of the paperboard laminate have been cut out to form a cavity in the configuration of the glass product being packaged. The glass product is disposed in the cavity and a glass product conforming reinforcing block is placed against the backside of the paperboard laminate during the shrink-wrap operation. For automobile fenders, hoods, the paperboard laminate need not be cut out and the sides of the paperboard laminate are folded upwardly to form a carton bottom to which a lid is affixed for shipping.

Owner:DRYIP

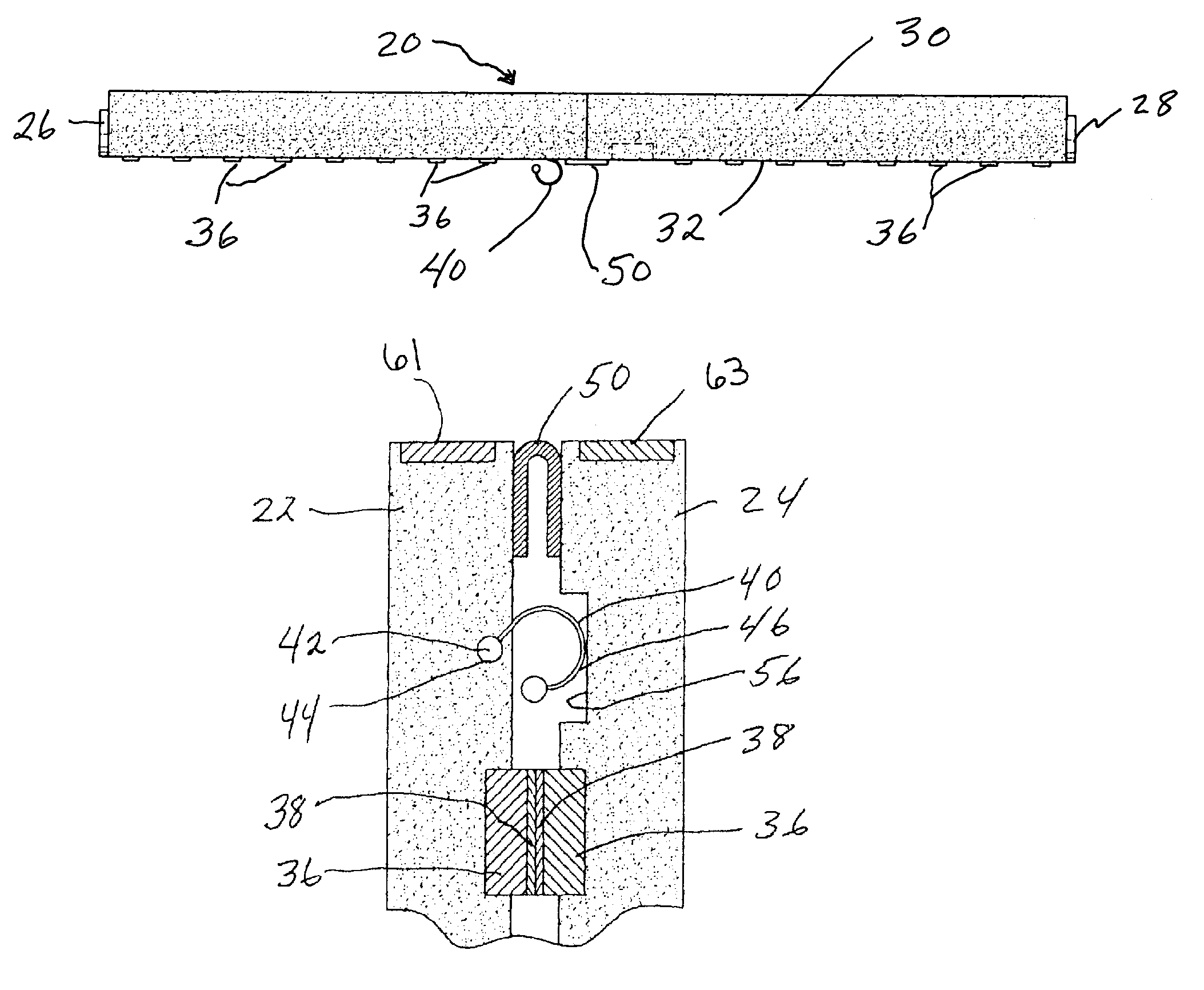

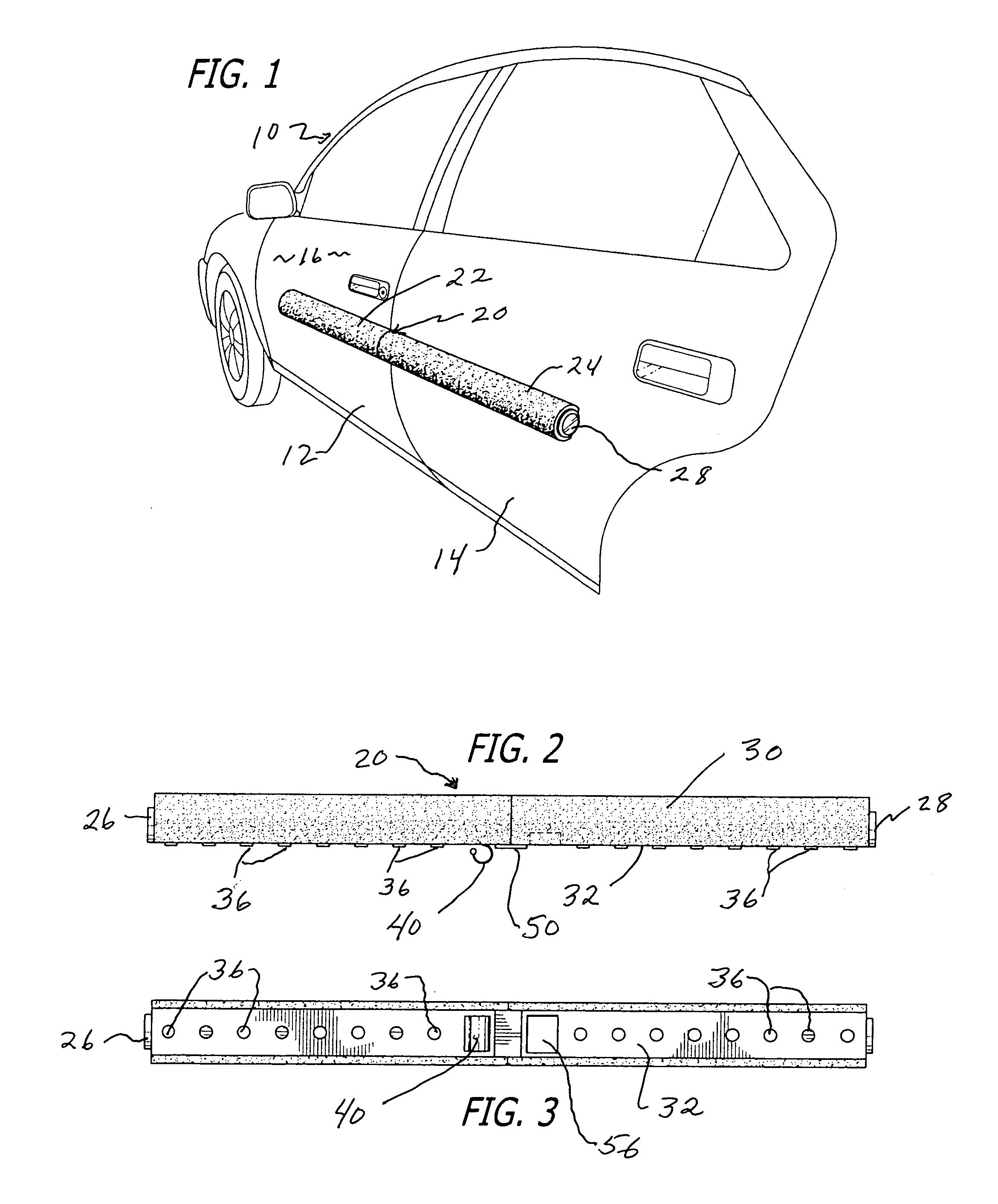

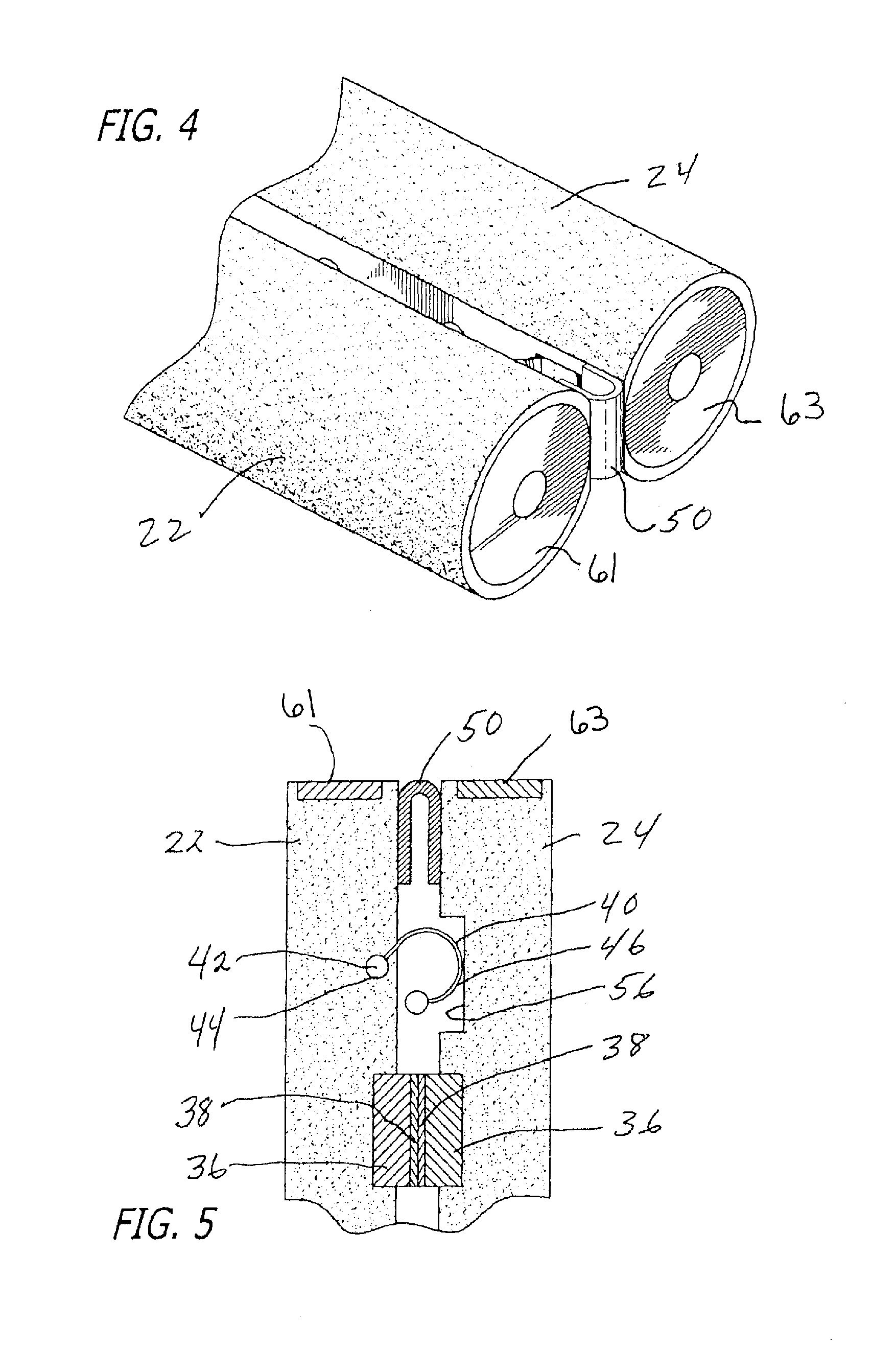

Vehicle door and fender protector

Magnets attach a resilient material protector to the sides of a vehicle. The protector also includes a hook that fits between the vehicle door and the door post to prevent the protector from being removed from the vehicle when the door is locked. The protector has two portions that fold over each other such that the magnets on the respective portions align with each other and secure the portions together in a stowed position. The hook embeds in one portion of the protector and can extend between the vehicle door and its post to secure the protector to the vehicle. A recess opposite the hook in the other portion of the protector receives the hook's free end. The magnets have soft material on their outside to prevent the magnets from scratching the vehicle.

Owner:DEBS PIERRE

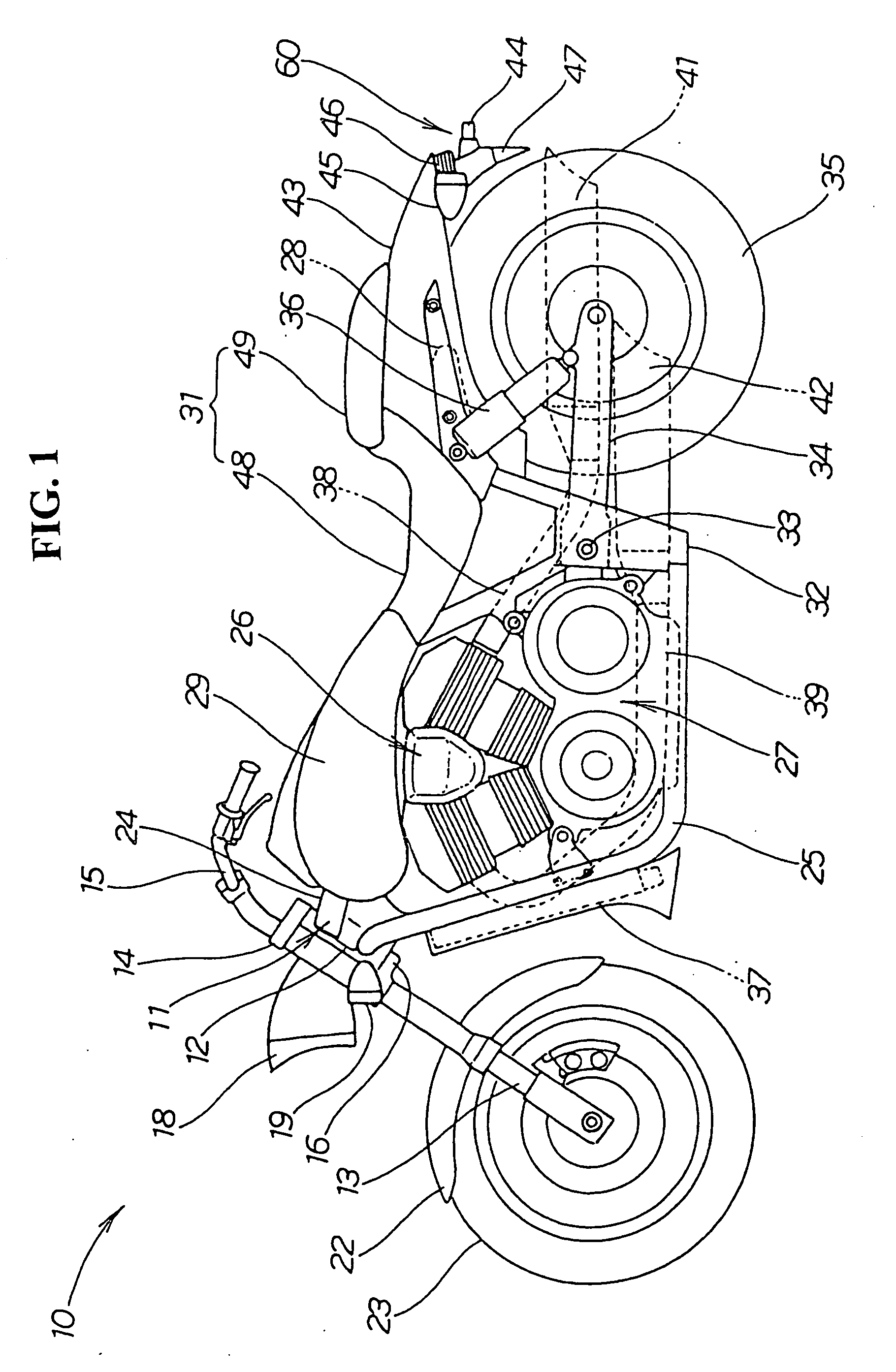

Motorcycle with a rear-mounted radiator

A motorcycle is provided having front and rear wheels. A frame is supported on and connected to the front and rear wheels. The frame includes a rear swing frame pivotally connected to a front frame. A seat and an engine are mounted to the frame. The engine is disposed between the front and rear wheels. A radiator is mounted to the rear swing frame and is disposed between the engine and the rear wheel. A fan assembly is connected to the radiator and is disposed rearward of the radiator. An inner fender is disposed between the radiator and the rear wheel.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com