Light, high-toughness strong-sound-absorption thermoplastic composite material for automobile wheel casing fender and fabrication process thereof

A composite material and thermoplastic technology, which is applied in the field of thermoplastic composite materials for light weight, high toughness, and high sound-absorbing automotive wheel cover guards and its preparation technology, can solve the problems of no sound-absorbing effect and high cost of EPDM, and achieve low cost, The effect of adjustable toughness and excellent impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

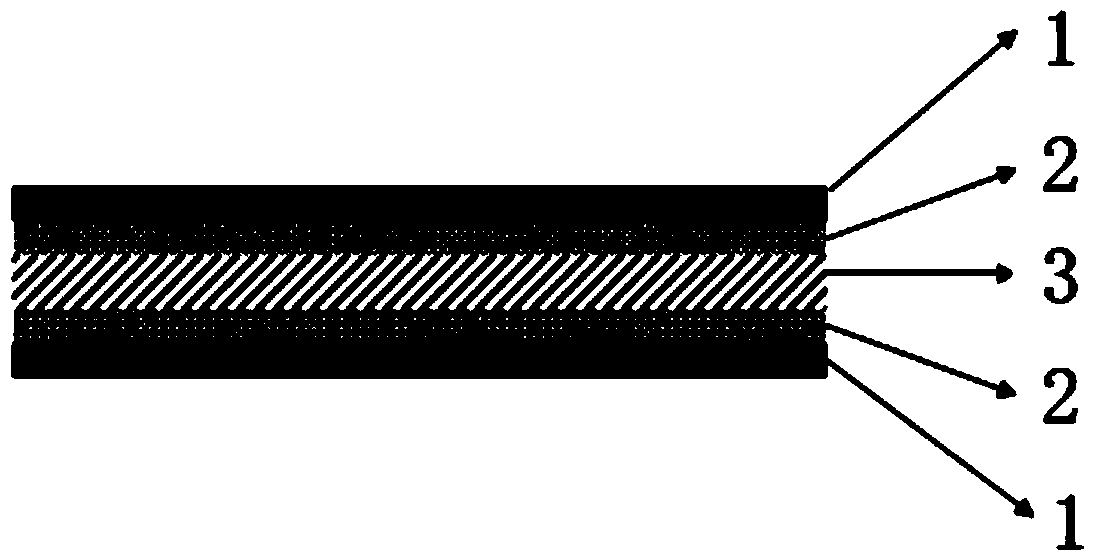

Image

Examples

Embodiment 1

[0028] (1) After the modified PP fiber and glass fiber are opened by a fiber opener, they are cross-laid, and the mass ratio of the two is 6:4, and the aspect ratio of the glass fiber is 500. Sprinkle 5 parts of 500-mesh high-density polyethylene rubber powder through a powder spreader, and then perform double-sided needle punching after rolling and lamination to obtain a composite felt;

[0029] (2) The composite felt is firstly heated by a contact heating device in the form of being sandwiched between upper and lower layers of parallel Teflon belts. The transmission speed is 2m / min, and the temperature is controlled at 170°C. ℃ and then unwind 100g of toughened film and 150g of spunlace PET non-woven fabric at the same time above and below it, and enter the hot-pressing device together with the composite felt, and carry out hot-pressing lamination at 210°C and 5MPa, and hold the pressure for 5s. Among them, the toughened film is a co-extruded film of PE and POE, with a mass ...

Embodiment 2

[0031] (3) After the modified (PP fiber + PA fiber) and (glass fiber + bamboo fiber) are opened by the fiber opener, they are then cross-laid. Among them, the polymer fiber: reinforced fiber is 7:3, and the PP fiber: The PA fiber is 8:2, the glass fiber:bamboo fiber is 8:2, and the aspect ratio of the reinforcing fiber is 1500. Sprinkle 10 parts of 200-mesh carbon black through a powder spreader, and then perform double-sided needle punching after rolling and lamination to obtain a composite felt;

[0032] (4) The composite felt is firstly heated by a contact heating device in the form of being sandwiched between upper and lower layers of parallel Teflon belts. The transmission speed is 5m / min, and the temperature is controlled at 190°C. Then unwind 150g of toughened film and 100g of hot-rolled PET non-woven fabric at the same time above and below it, enter the hot-pressing device together with the composite felt, and carry out hot-pressing lamination at 195°C and 20MPa, and h...

Embodiment 3

[0034] (5) After the modified (PP fiber + PET fiber) and basalt are opened by the fiber opener, they are then cross-laid, in which the polymer fiber: basalt fiber is 8:2, and the PP fiber: PET fiber is 7:3 , The aspect ratio of basalt fiber is 3000. Sprinkle 15 parts of 80-mesh talcum powder through a powder spreading machine, and then perform double-sided needle punching after rolling and lamination to obtain a composite felt;

[0035] The composite felt is firstly heated by a contact heating device in the form of being sandwiched between upper and lower layers of parallel Teflon belts. The transmission speed is 10m / min, and the temperature is controlled at 230°C. Then unwind 250g of toughened film and 50g of spunlace PET non-woven fabric at the same time above and below it, enter the hot-pressing device together with the composite felt, and carry out hot-pressing lamination at 170°C and 50MPa, and hold the pressure for 50s. Among them, the toughened film is a co-extruded fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com