Patents

Literature

96 results about "Dry lubricant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

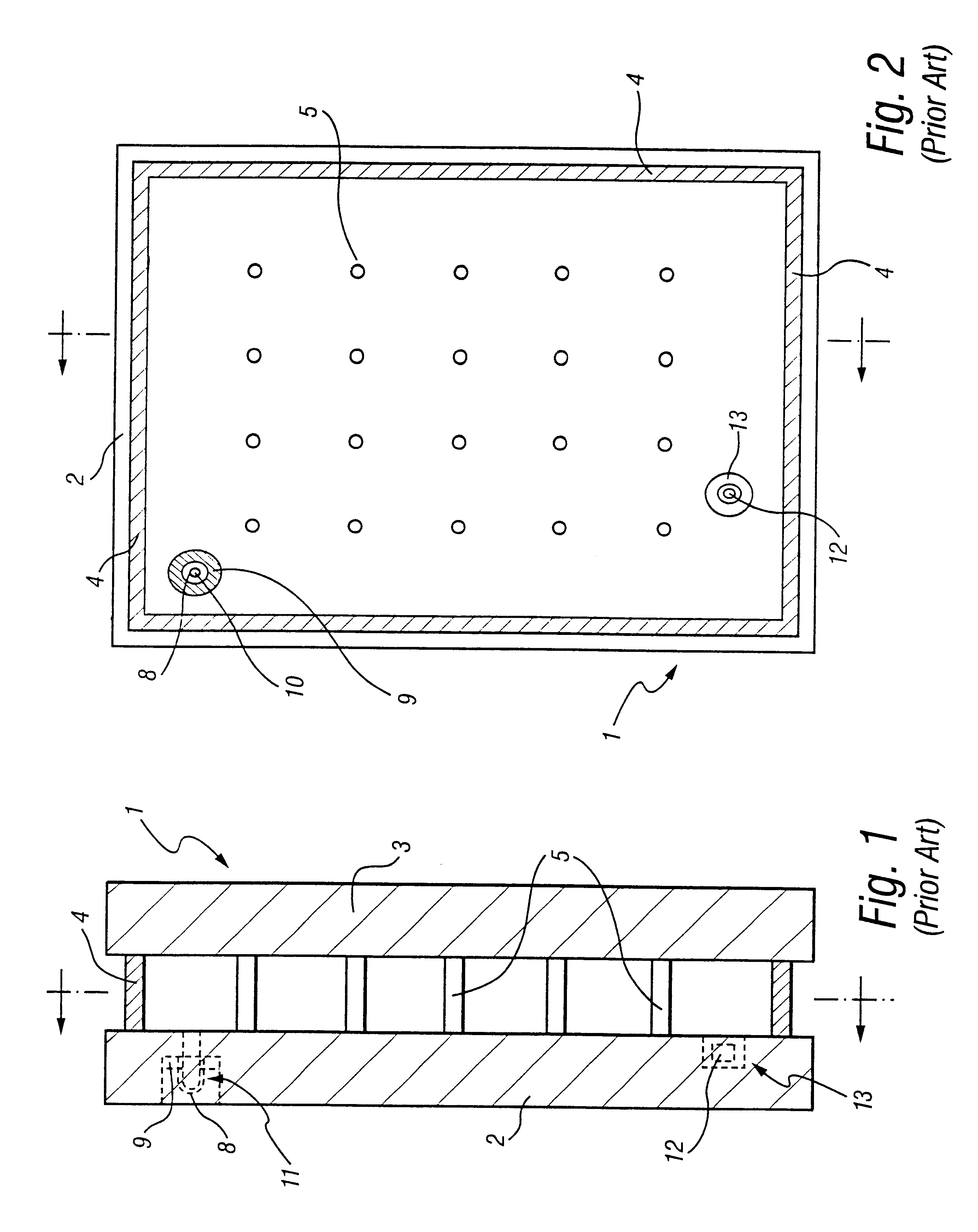

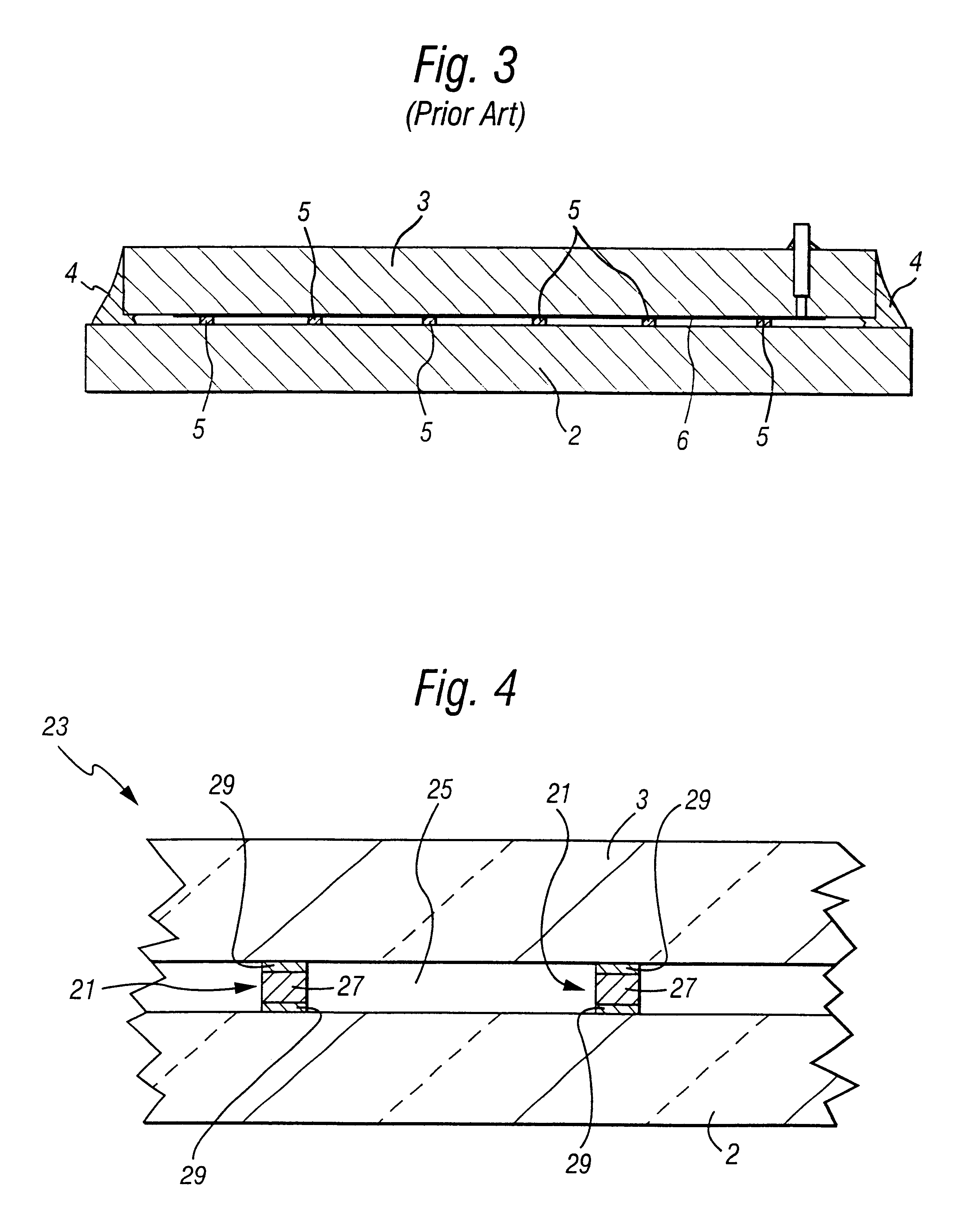

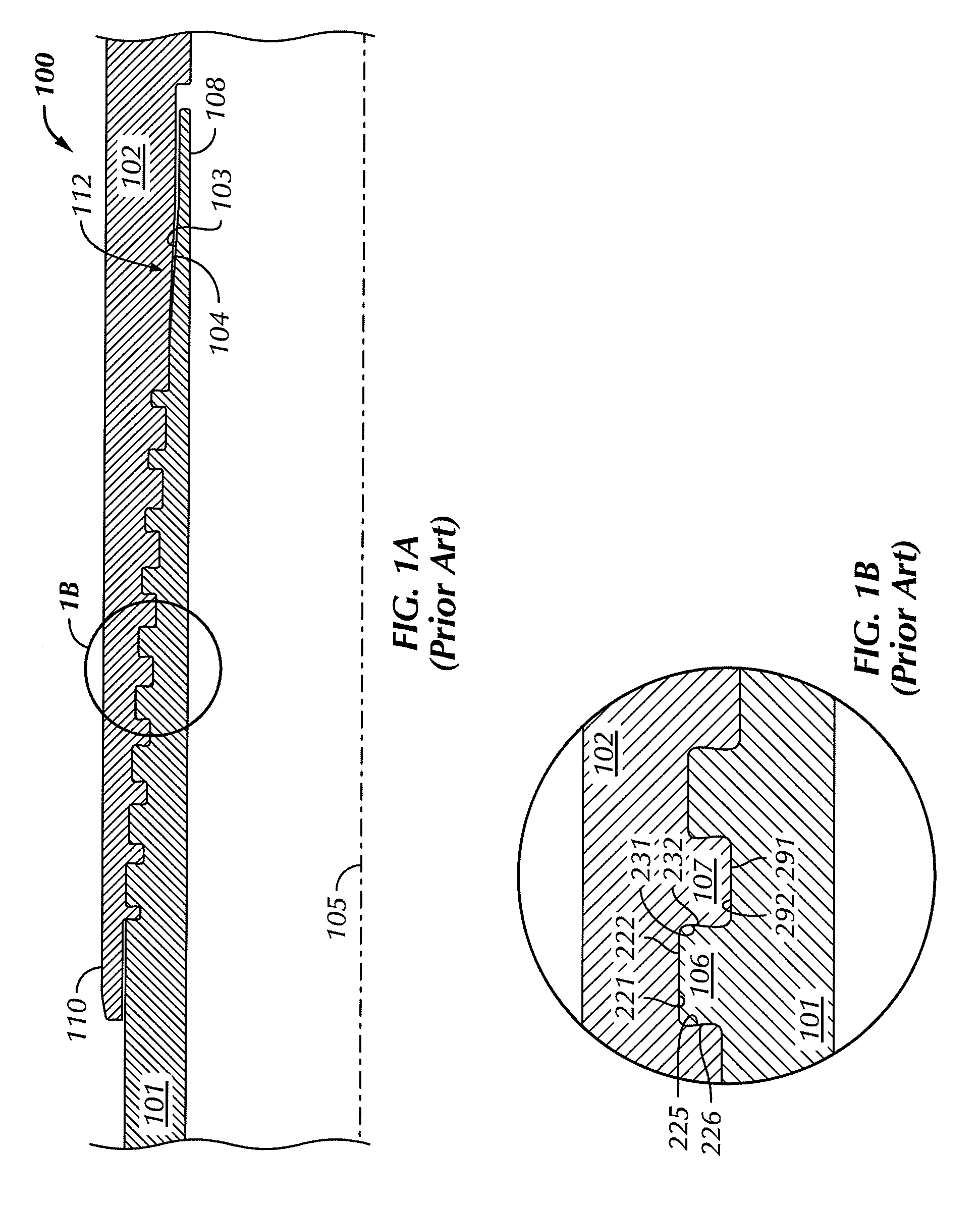

Vacuum IG pillar with lubricating and/or reflective coating

InactiveUS6946171B1Less visibly obtrusiveMinimize cracksClimate change adaptationWindows/door improvementChemical reactionThermal expansion

A vacuum insulating glass (IG) unit is provided with an array of spacers / pillars between opposing glass sheets. At least some of the spacers / pillars are coated on at least one surface thereof with a dry lubricant and / or reflective material such as silver. This coating permits the glass sheet(s) to move relative to one another during thermal expansion while minimizing the degree to which the spacers / pillars scratch or crack the glass during such relative movement. A method of making an exemplary spacer / pillar includes transforming by chemical reaction silver ions on a core into a metallic silver coating thereby resulting in a coated spacer / pillar.

Owner:GUARDIAN GLASS LLC

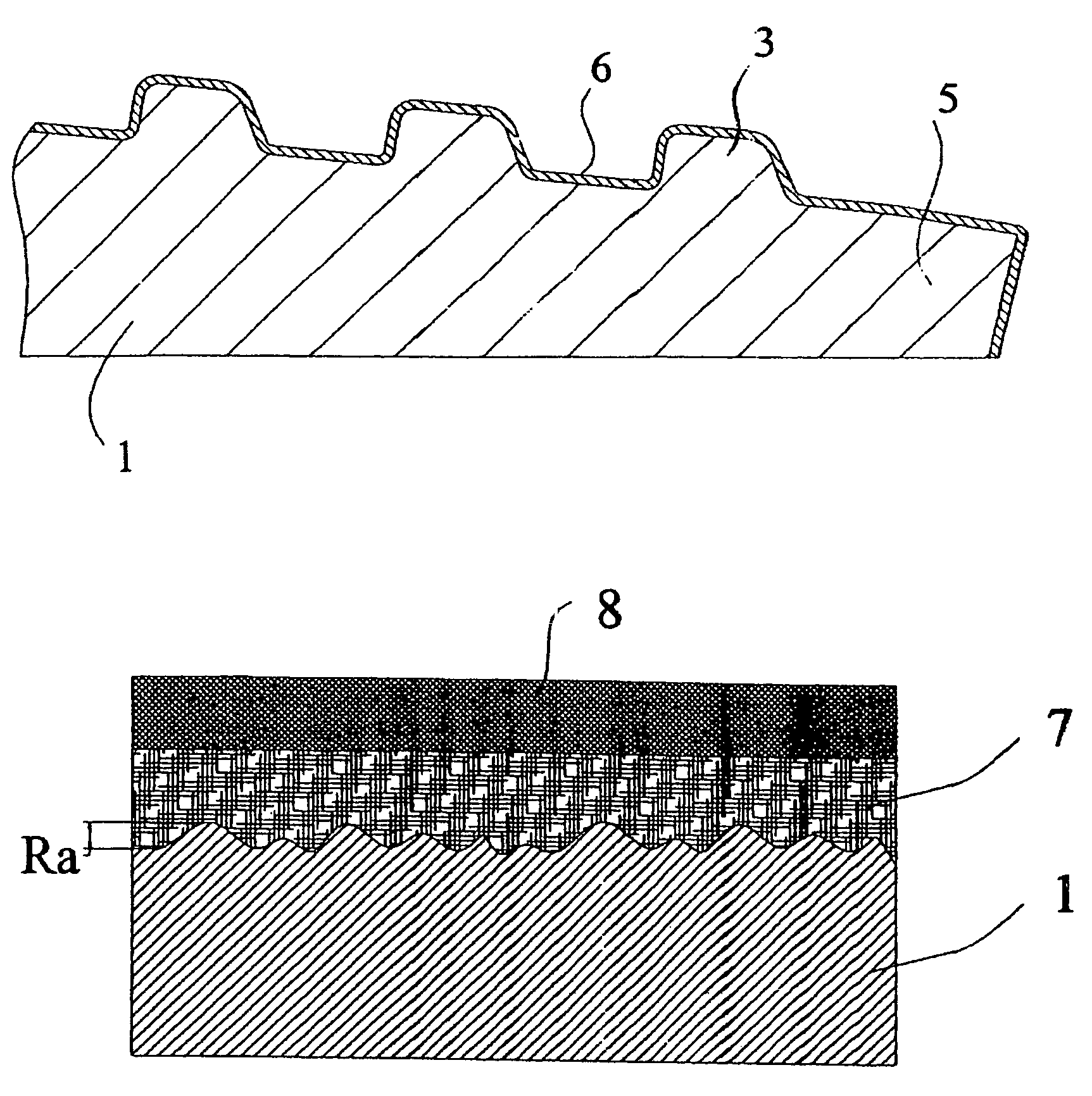

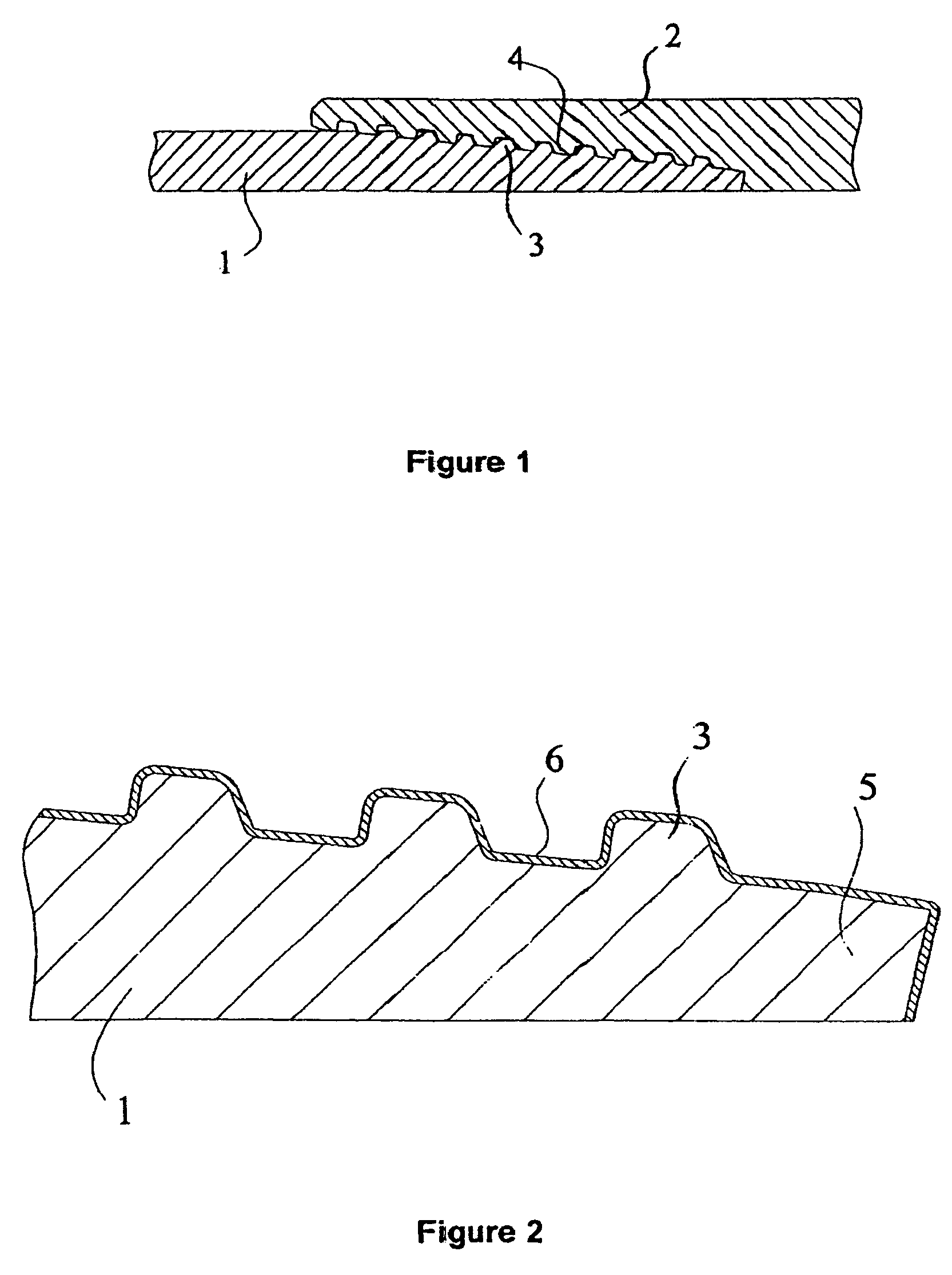

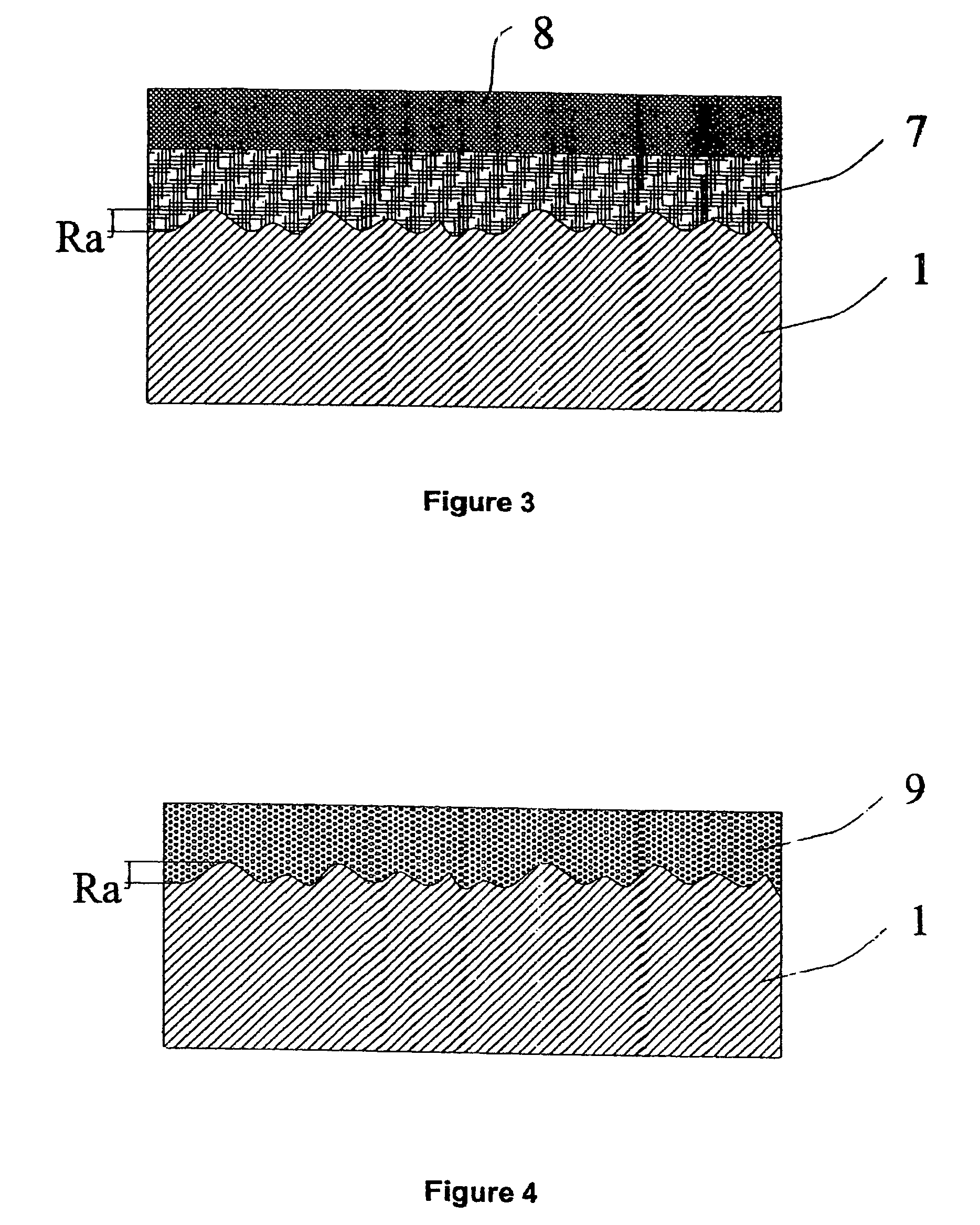

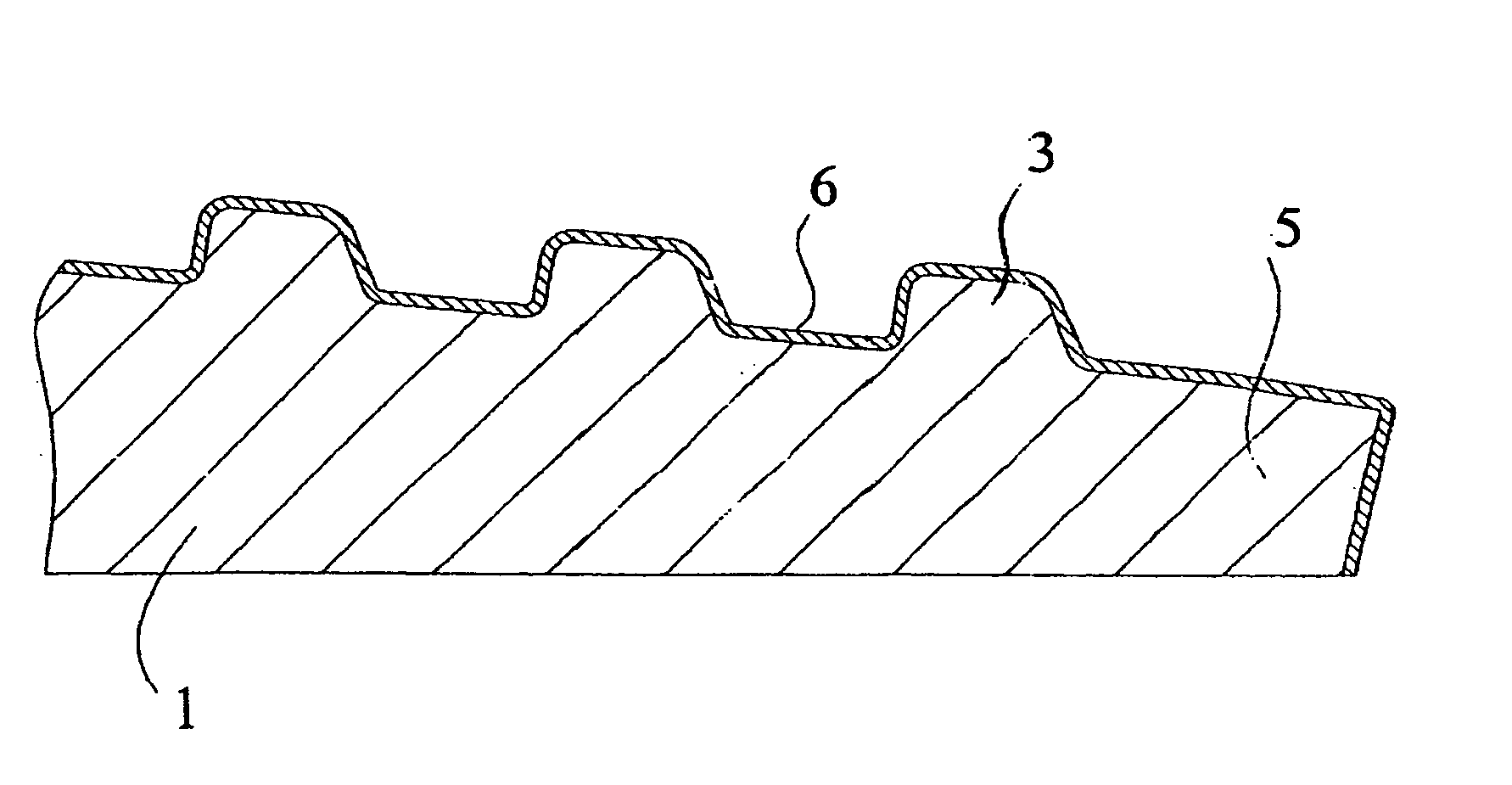

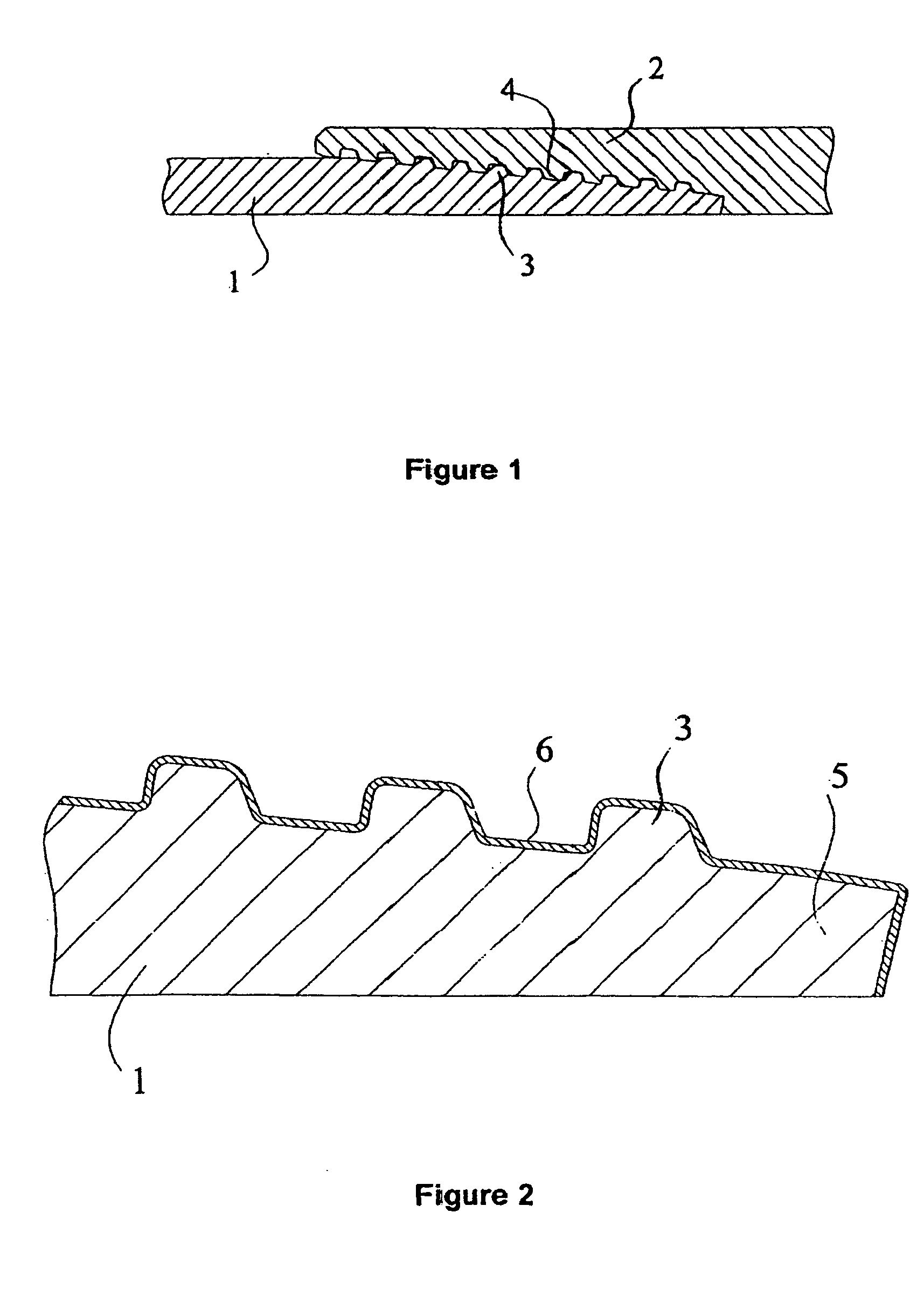

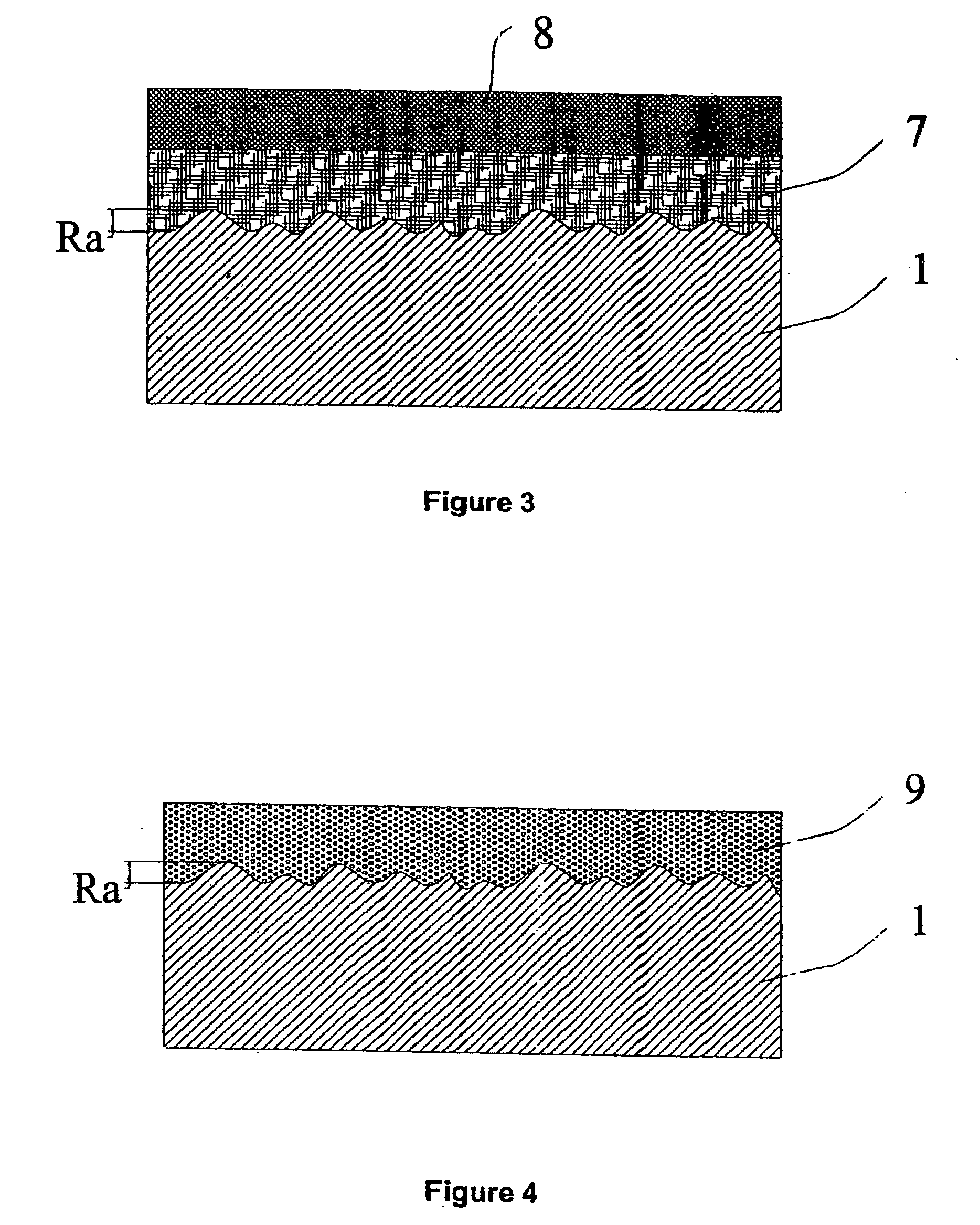

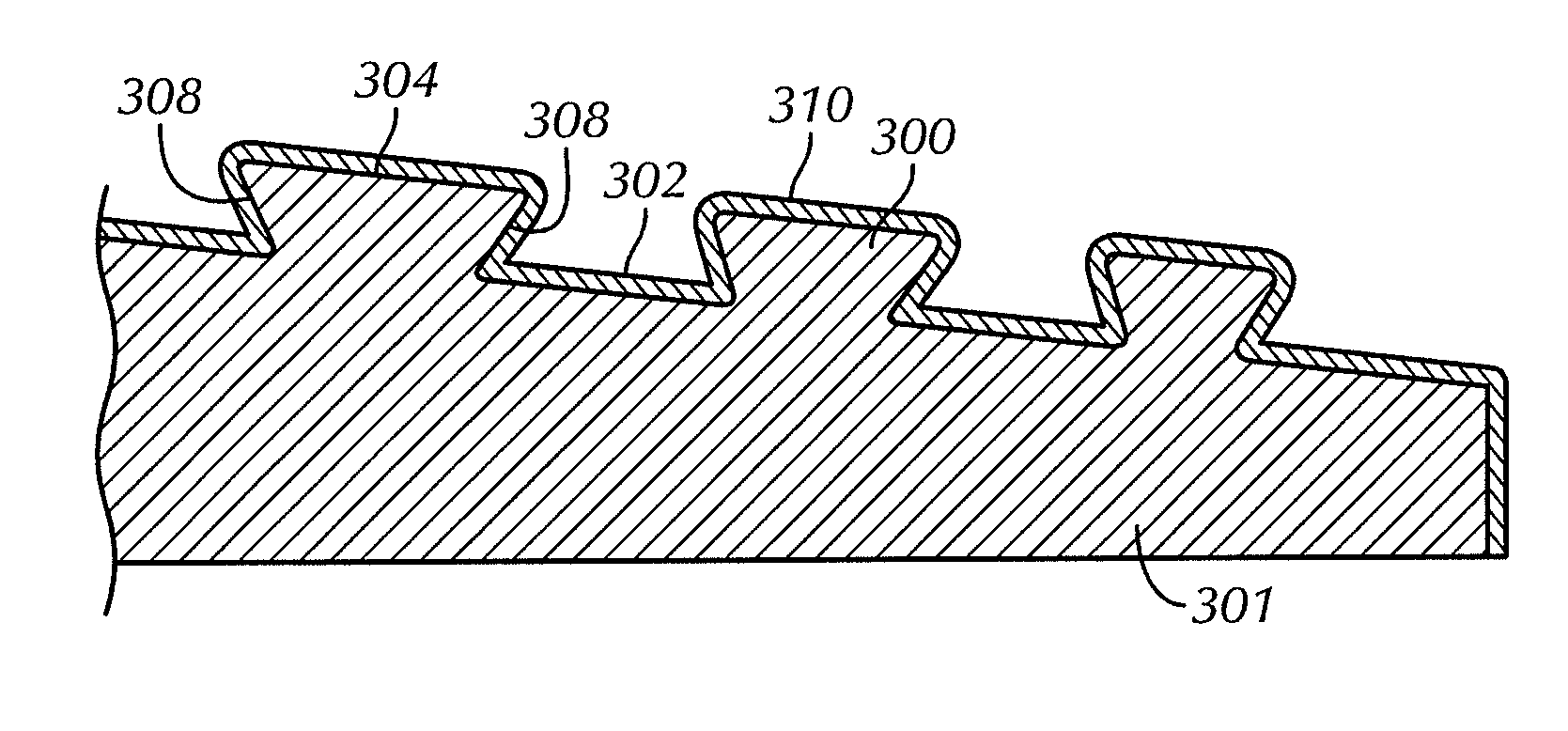

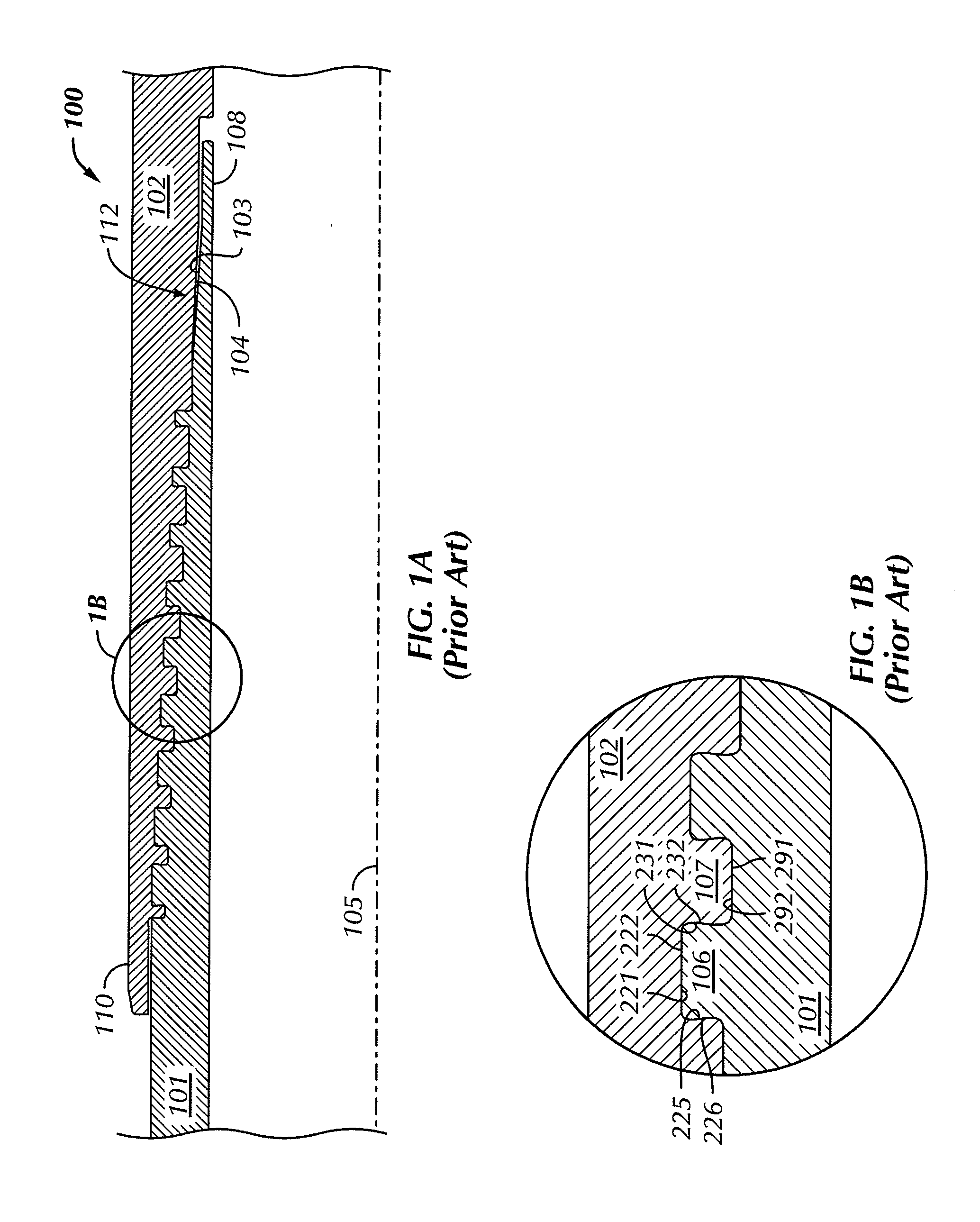

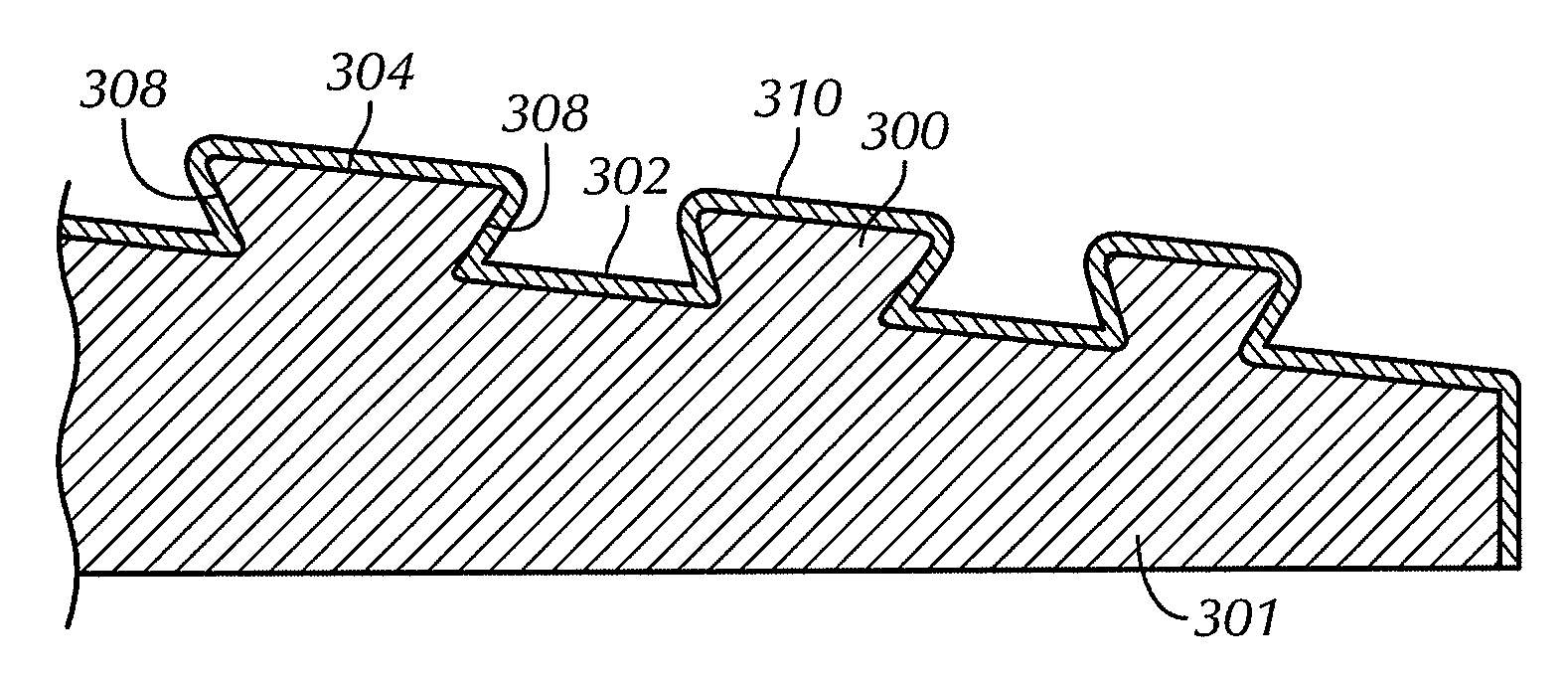

Threaded pipe with surface treatment

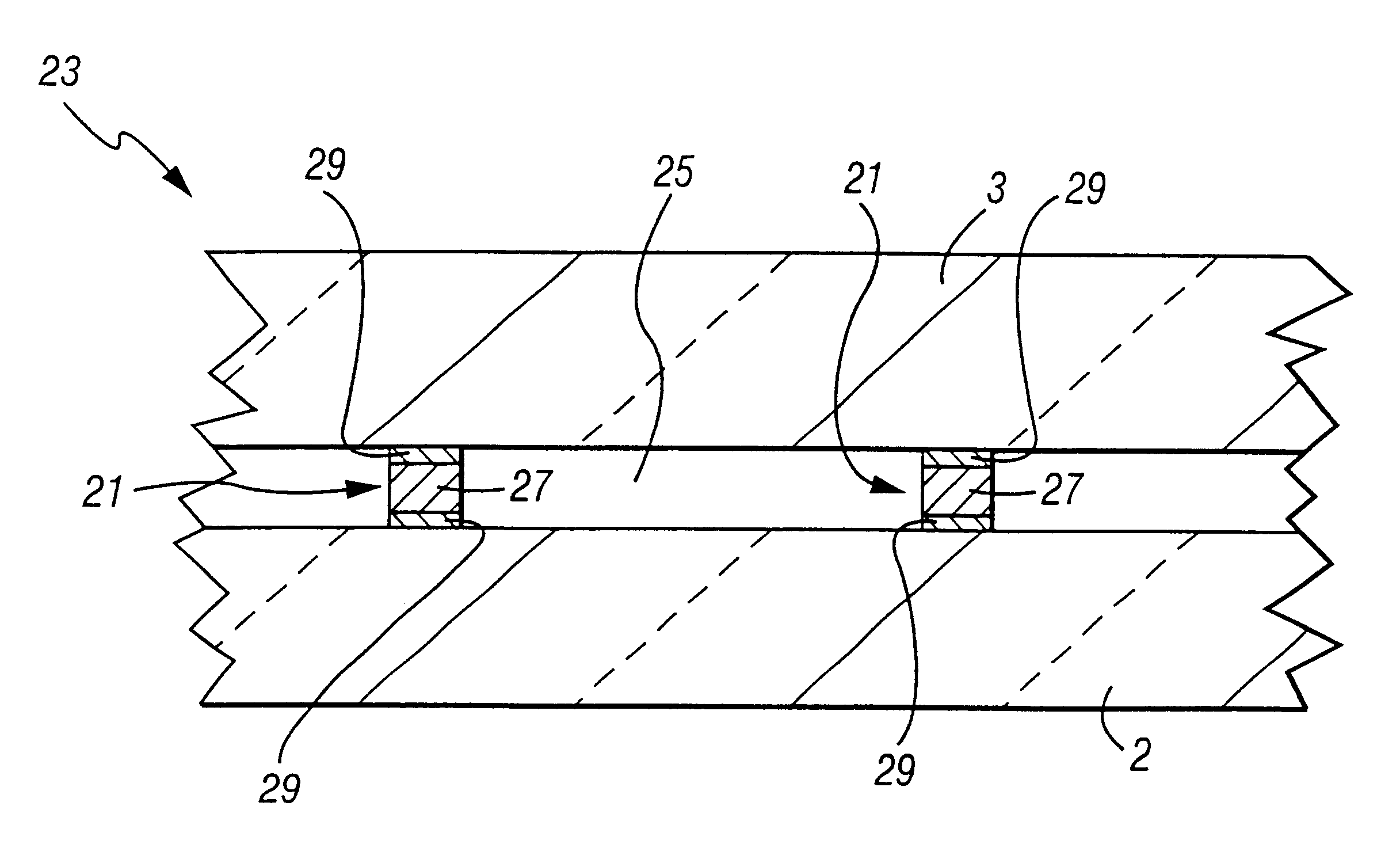

InactiveUS6971681B2Maintain good propertiesIncrease resistanceDrilling rodsPipe elementsThreaded pipeDry lubricant

A threaded metallic pipe for oil extraction industry has a threaded end portion with treated surface in which the metal surface has a roughness (Ra) comprised of 2.0 μm and 6.0 μm, which is covered by a uniform layer (7) of a dry corrosion inhibiting coating and a second uniform layer (8) of dry lubricant coating. Alternatively the layers (8, 9) combined into one uniform layer (9) of a dry corrosion inhibiting coating containing a dispersion of particles of solid lubricant.

Owner:TENARIS CONNECTIONS

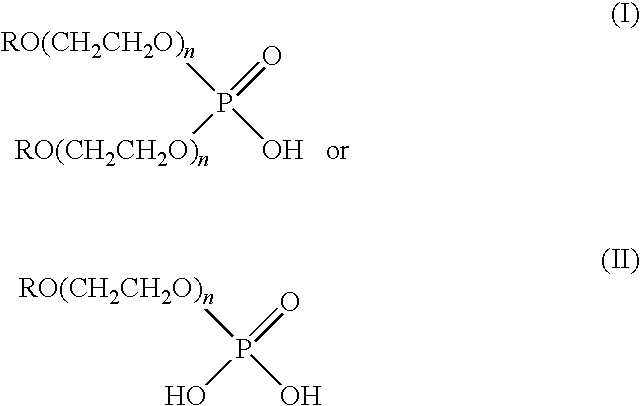

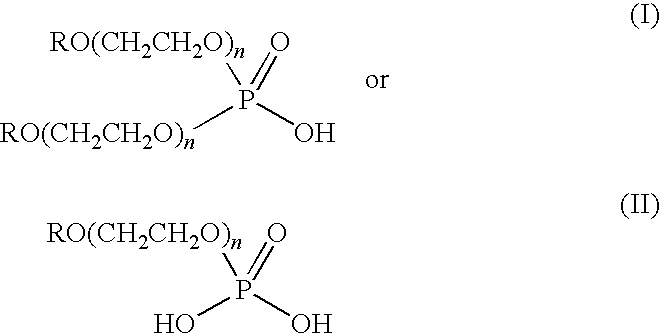

Dry lubricant for conveying containers

ActiveUS20060211583A1Reduce frequencyReduce usageOrganic compound preparationLiquid carbonaceous fuelsEngineeringWater soluble

The passage of a container along a conveyor is lubricated by applying to the container or conveyor a mixture of a water-miscible silicone material and a water-miscible lubricant. The mixture can be applied in relatively low amounts, to provide thin, substantially non-dripping lubricating films. In contrast to dilute aqueous lubricants, the lubricants of the invention provide drier lubrication of the conveyors and containers, a cleaner conveyor line and reduced lubricant usage, thereby reducing waste, cleanup and disposal problems.

Owner:ECOLAB USA INC

Dry lubricant for conveying containers

ActiveUS7741257B2Reduce frequencyReduce usageOrganic compound preparationLiquid carbonaceous fuelsEngineeringDry lubricant

The passage of a container along a conveyor is lubricated by applying to the container or conveyor a mixture of a water-miscible silicone material and a water-miscible lubricant. The mixture can be applied in relatively low amounts, to provide thin, substantially non-dripping lubricating films. In contrast to dilute aqueous lubricants, the lubricants of the invention provide drier lubrication of the conveyors and containers, a cleaner conveyor line and reduced lubricant usage, thereby reducing waste, cleanup and disposal problems.

Owner:ECOLAB USA INC

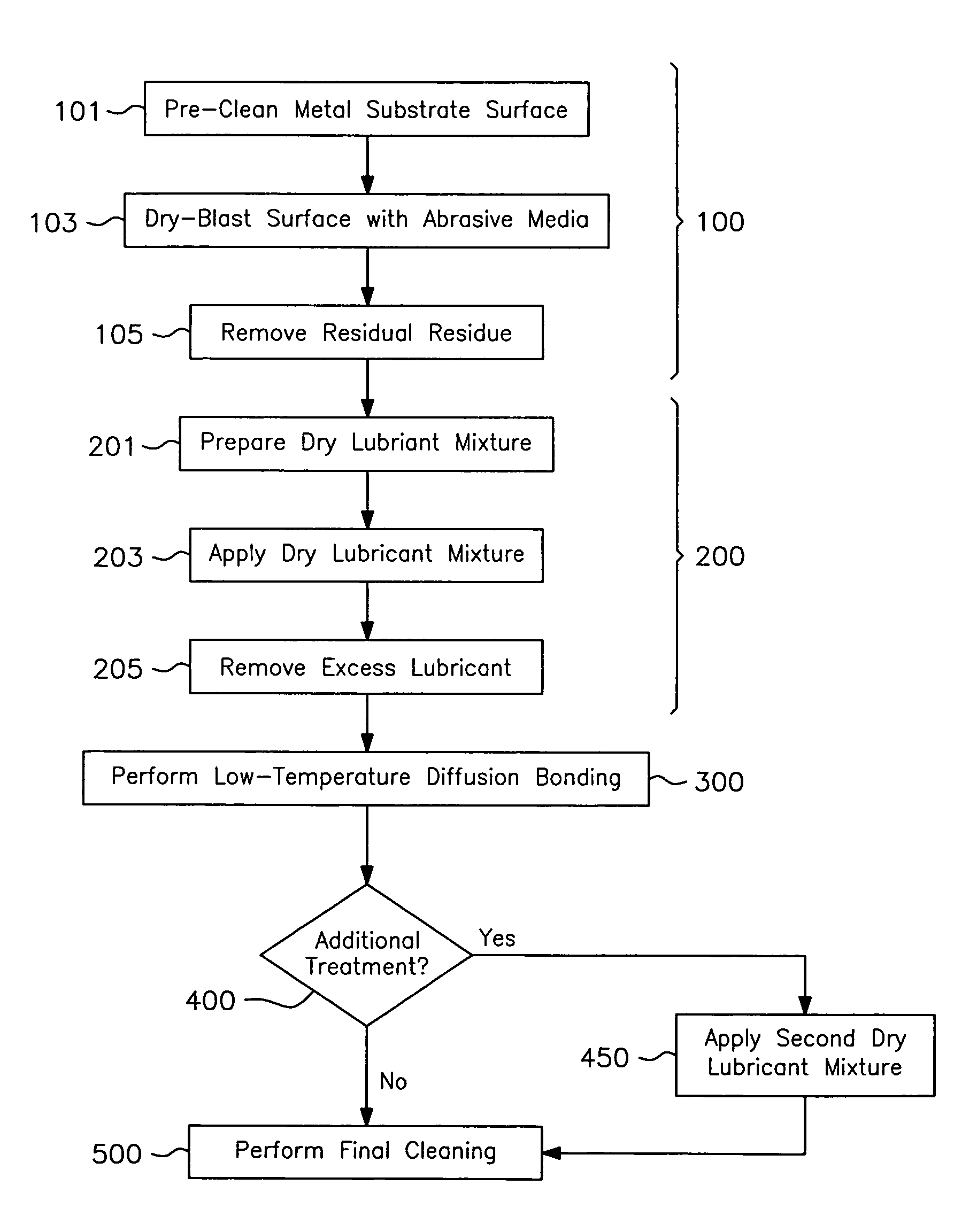

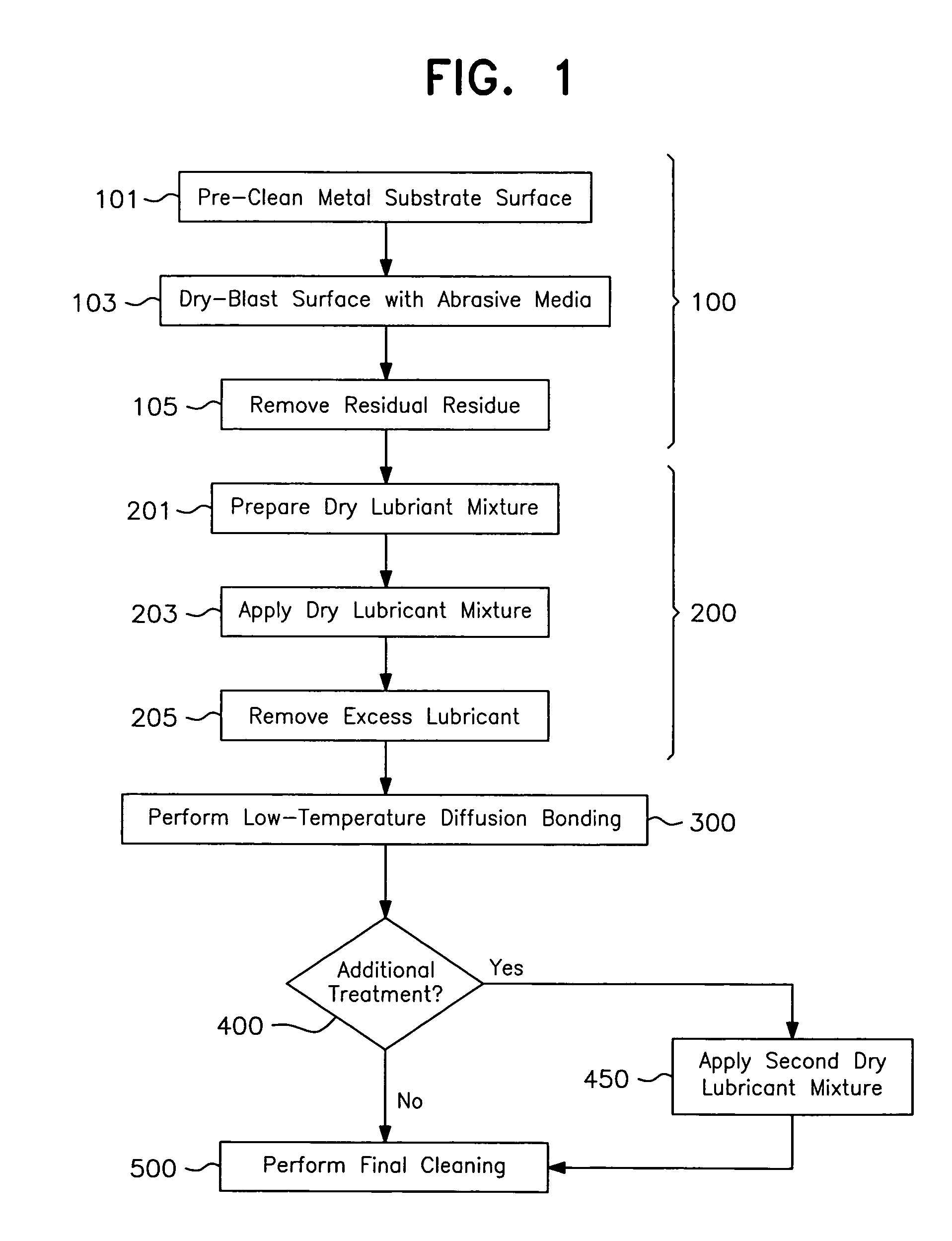

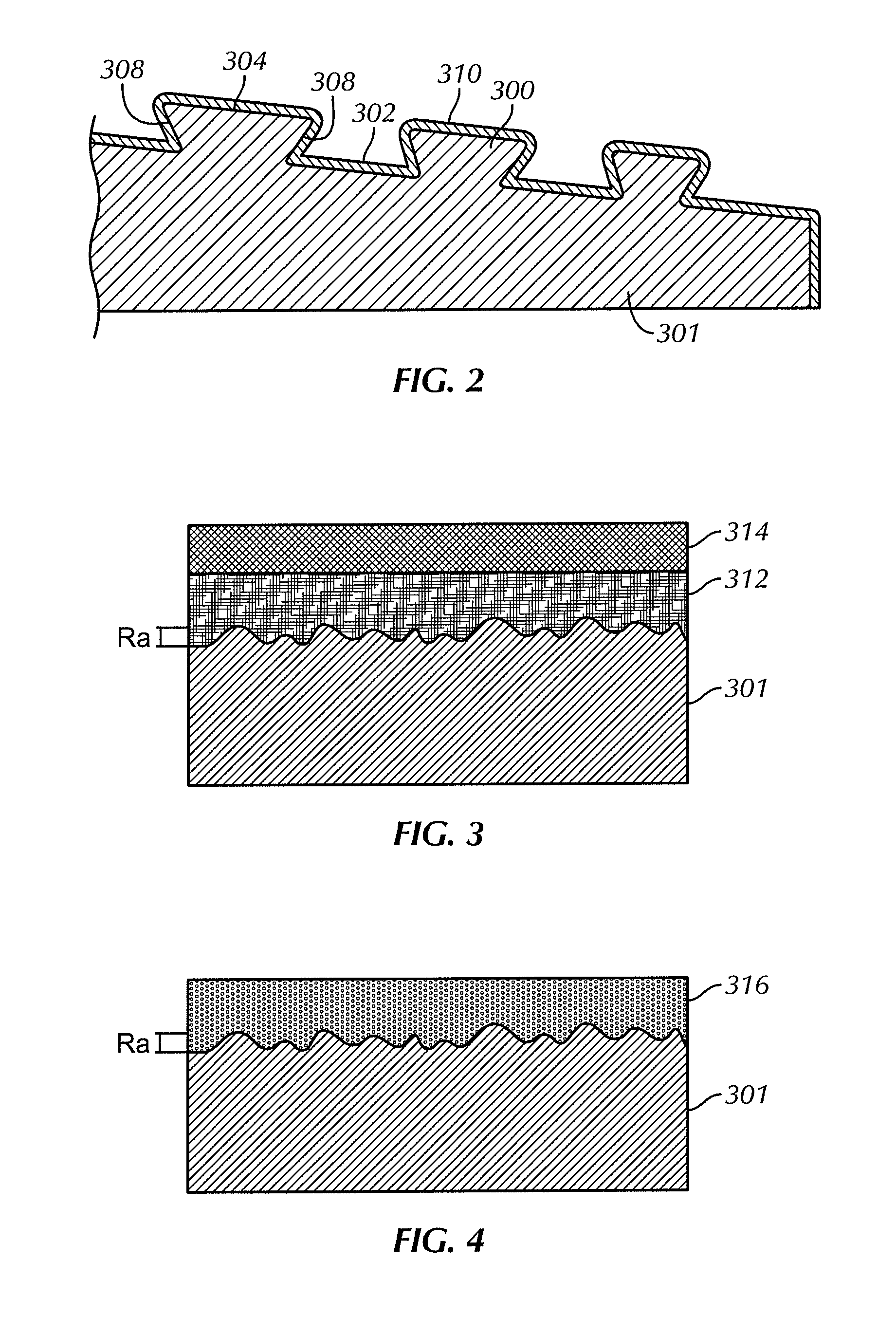

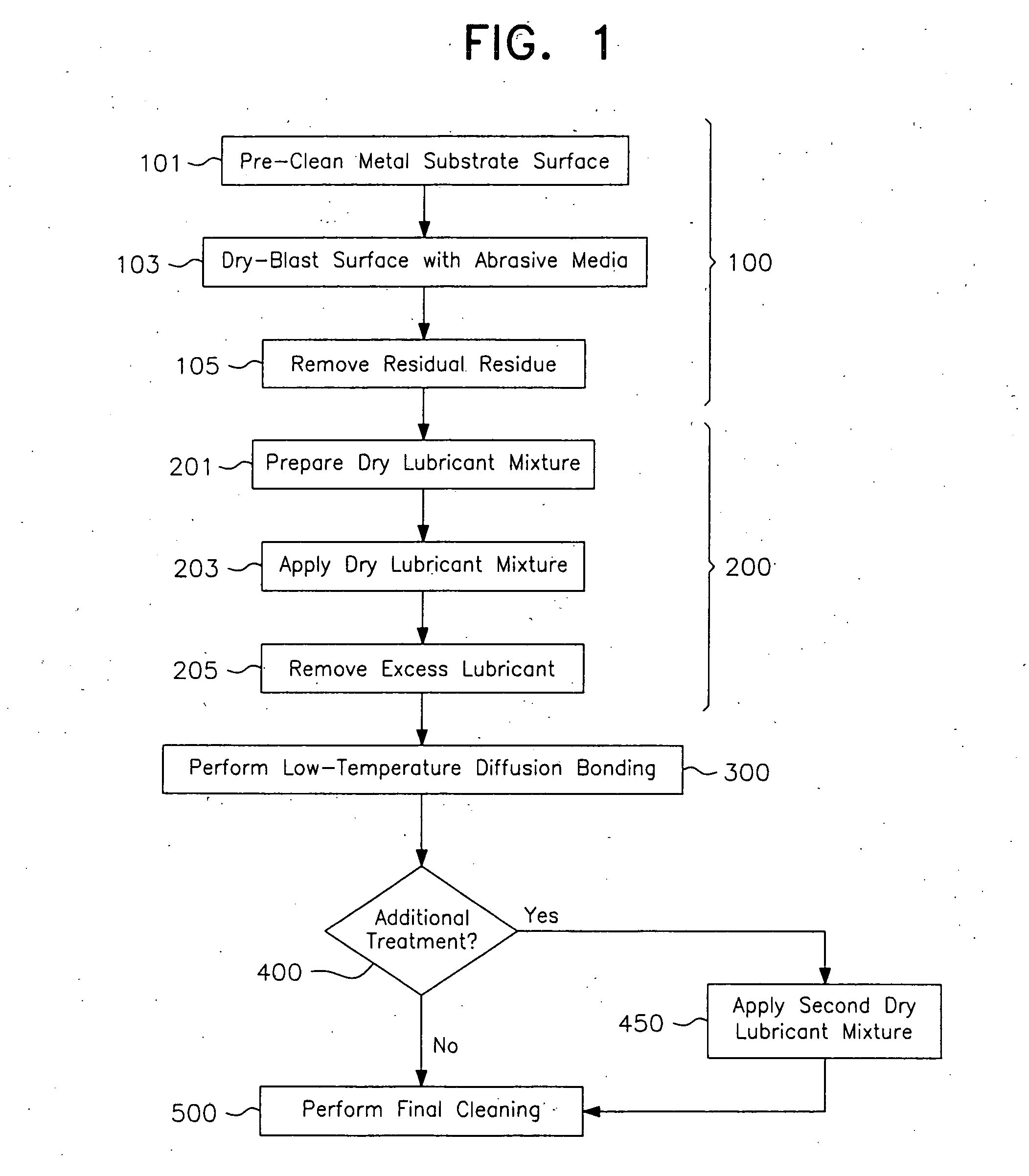

Surface for reduced friction and wear and method of making the same

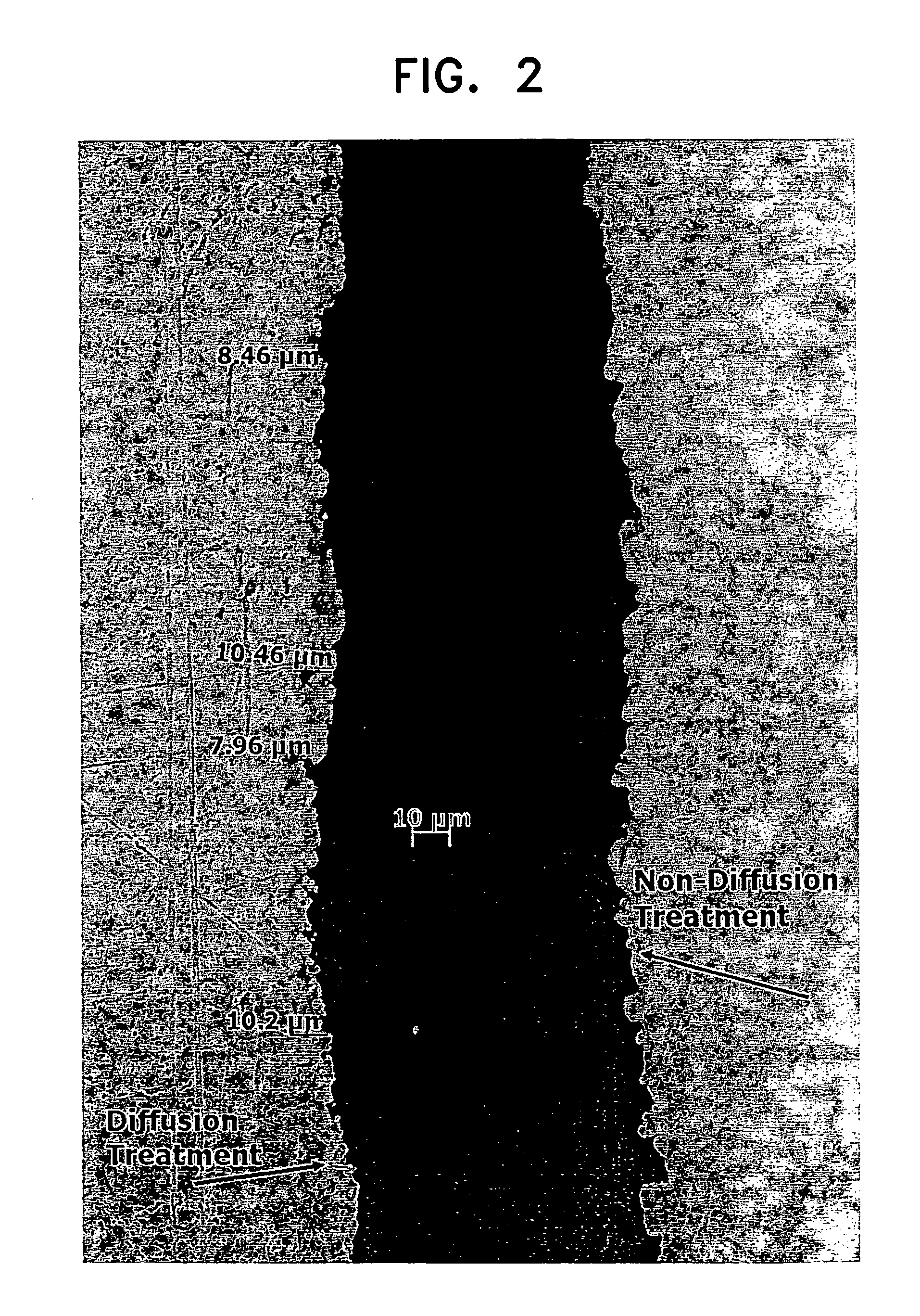

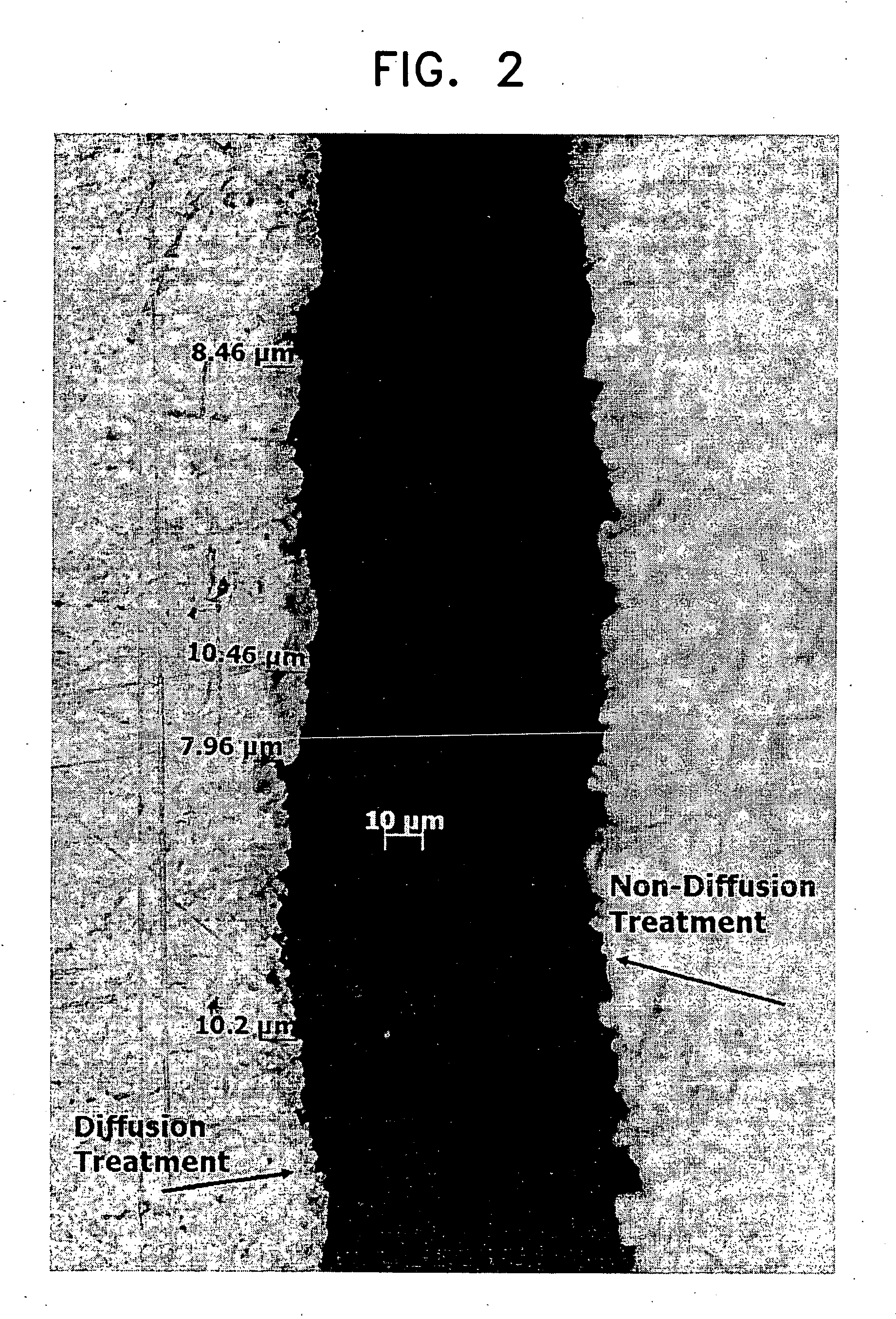

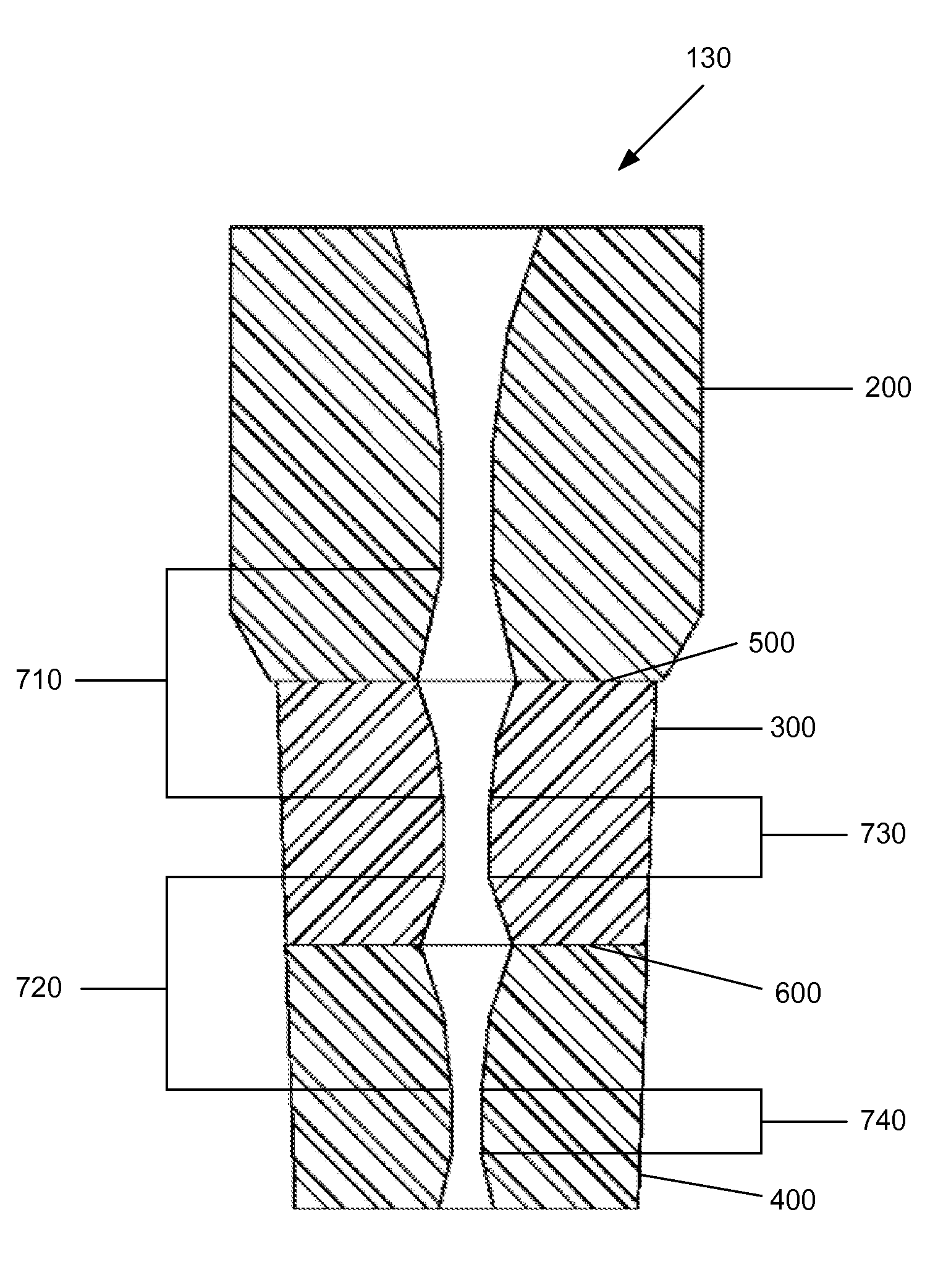

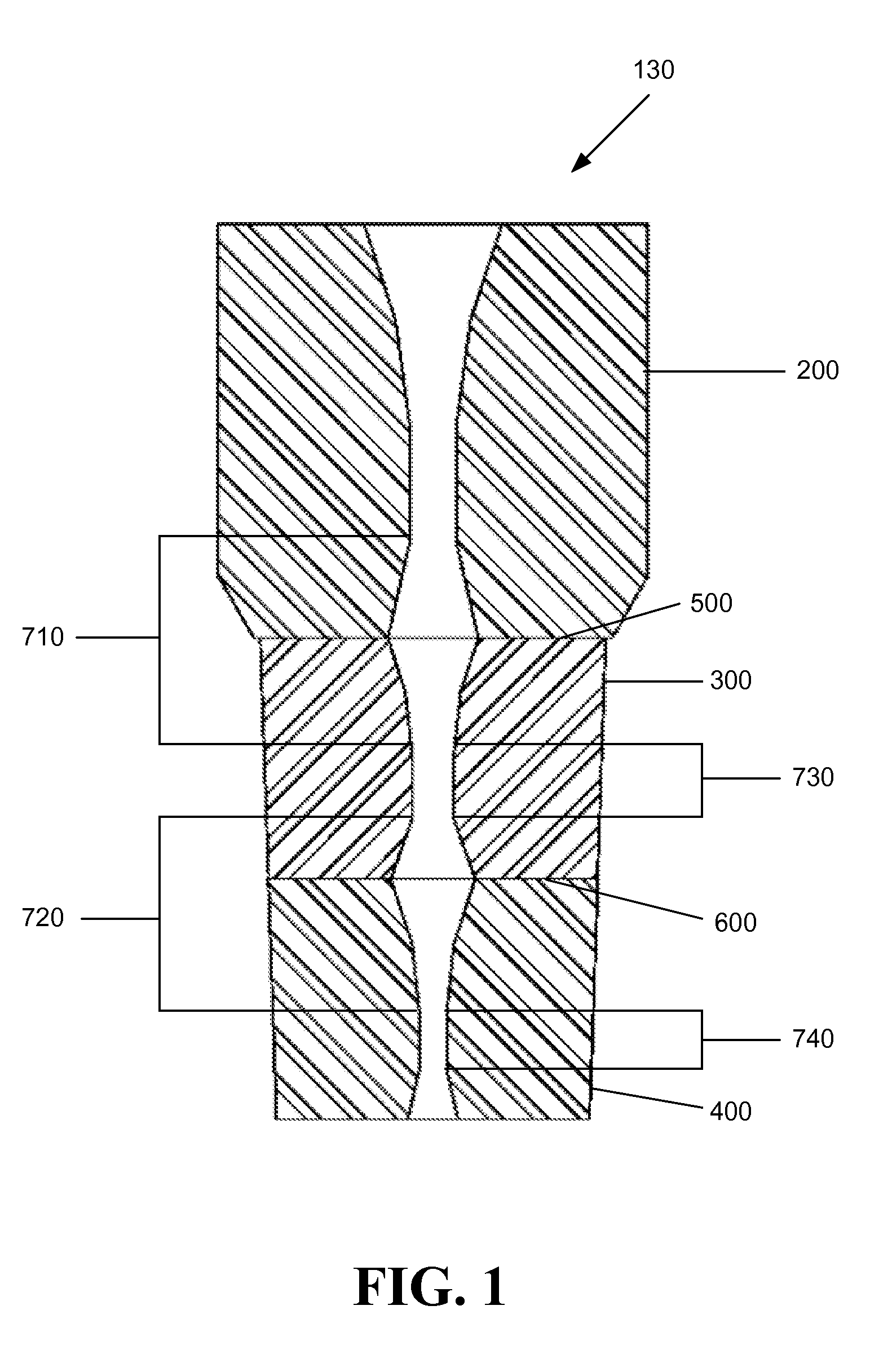

InactiveUS7687112B2Improve performanceFine surfaceLayered productsPretreated surfacesImpact velocityMechanical impact

A process for producing an enhanced friction reducing surface by bonding a dry lubricant to a substrate by way of high velocity mechanical impact and low temperature diffusion bonding, and the friction-reduced surface produced thereby. A process for bonding the dry lubricant by peening and concurrently obtaining a desired dimpling or surface texturizing by appropriate selection of peening particle size and hardness relative to the substrate, as well as impact velocity against the substrate, is also provided.

Owner:KINETITEC CORP

Threaded pipe with surface treatment

A threaded metallic pipe for oil extraction industry has a threaded end portion with treated surface in which the metal surface has a roughness (Ra) comprised of 2.0 mum and 6.0 mum, which is covered by a uniform layer (7) of a dry corrosion inhibiting coating and a second uniform layer (8) of dry lubricant coating. Alternatively the layers (8, 9) combined into one uniform layer (9) of a dry corrosion inhibiting coating containing a dispersion of particles of solid lubricant.

Owner:TENARIS CONNECTIONS

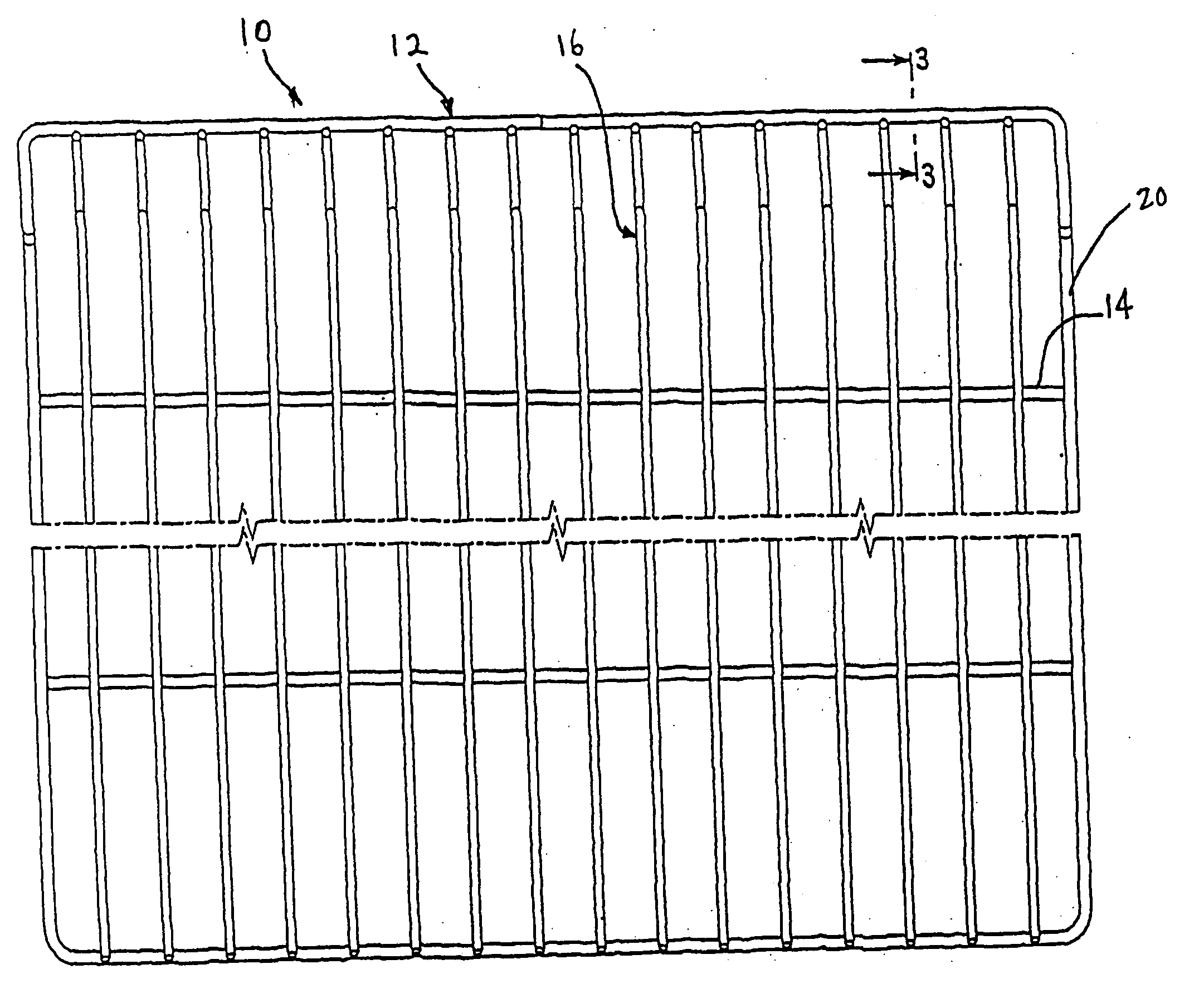

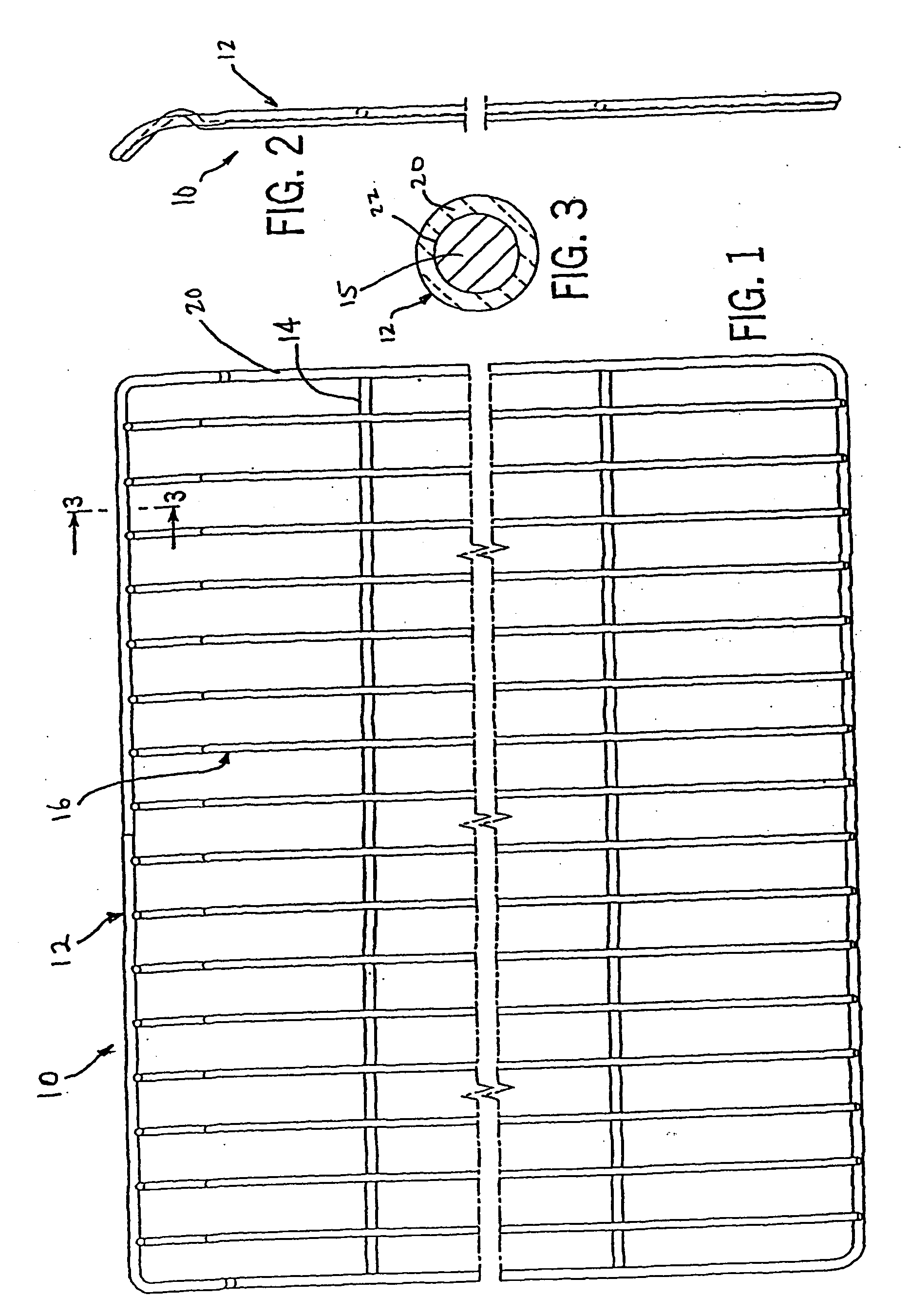

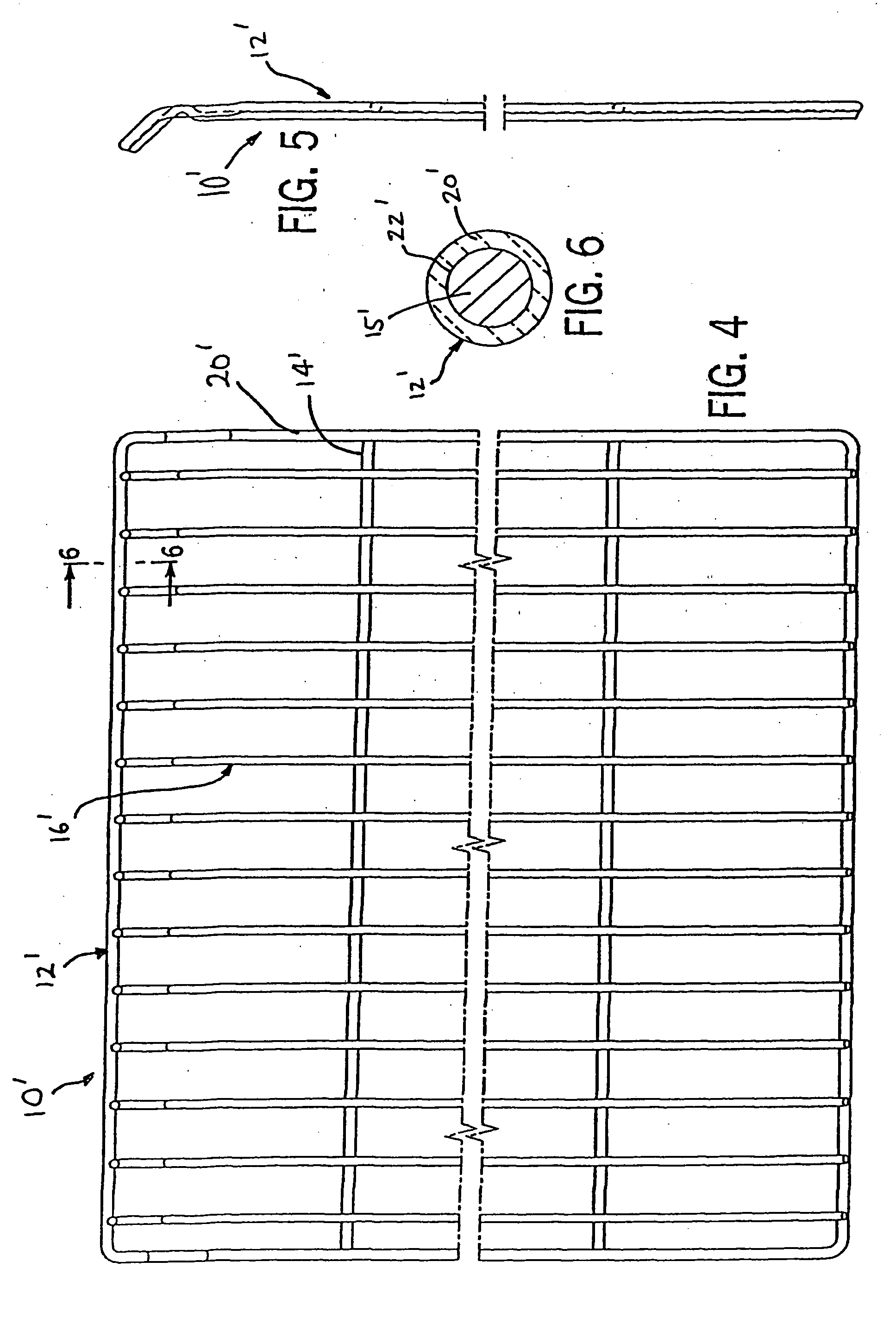

Oven rack having an integral lubricious, dry porcelain surface

InactiveUS20070272231A1Avoid chippingReduce the overall diameterDomestic stoves or rangesStoves/ranges shelves or racksDiamond-like carbonAntimony trioxide

A lubricious porcelain coated steel wire oven rack. The preferred coated steel wire oven rack includes a plurality of elongated steel wire members joined together to form an oven rack having an outer surface. The plurality of elongated steel wire members are made from a cold drawn steel rod material containing from about 80 to about 99.9% by weight of iron, up to about 0.08% by weight of carbon and from about 0.001 to about 0.2% by weight of a carbon stabilizing transition metal, preferably selected from the group consisting of Vanadium, Tantalum, Titanium and Niobium. In a preferred embodiment, the porcelain surface of the oven rack includes a dry lubricant selected from carbon; graphite; boron nitride; cubic boron nitride; molybdenum (IV) sulfide; molybdenum disulfide; molybdenum sulfide; molybdenum (IV) selenide; molybdenum selenide; tungsten (IV) sulfide; tungsten disulfide; tungsten sulfide; silicon nitride (Si3N4); TiN; TiC; TiCN; TiO2; TiAlN; CrN; SiC; diamond-like carbon; tungsten carbide (WC); zirconium oxide (ZrO2); zirconium oxide and 0.1 to 40 weight % aluminum oxide; alumina-zirconia; antimony; antimony oxide; antimony trioxide; and mixtures thereof.

Owner:SSW ADVANCED TECH LLC

High-temperature alloy base self-lubricating composite material and surface pattern treatment method thereof

InactiveCN101078072AExtended service lifeReduce coefficient of frictionBearing componentsLaser beam welding apparatusSurface patternSuperalloy

A kind of high temperature alloy group self-lubricating compound material and the method to pattern surface of it. The components and the mass percent of them are as following: Ni: 28.8-56.8%, Fe: 10.0-30.0%, Cr: 7.2-14.2%, W: 5.0- 15.0%, C: 3.0-6.0%, Si: 0.8%-1.2%, MoS2: 5.0%-15.0%. The method to pattern it' s surface contains the following steps: The surface of the nickel chromium alloy group self-lubricating compound material sample after being hot pressed and mould will be polished. A gammaray laser will be used to corrase micropore on the surface, the focus of the focusing lens will be adjusted to 40-60mm, the facula diameter at the focus is 0.15- 0.20mm, the impulse duration will be adjusted to 450-500ns, the laser bean will process micropore according to ring shape from outside to inside. The surface after being corrased and polished will be lubricated by daubing the fat of solid layered dry lubricant. The alloy group material not only owns high mechanical strength but also owns high temperature self-lubricating ability. The coefficient of friction can be decreased, the application life can be prolonged, and low attrition abrasion in wide temperature range can also be realized by patterning the surface.

Owner:NANJING UNIV OF SCI & TECH

Solvent-free polyurethane sofa leather and preparation method thereof

The invention discloses solvent-free polyurethane sofa leather. The solvent-free polyurethane sofa leather comprises a surface layer and a foaming layer, wherein both the surface layer and the foaming layer are prepared from two-component polyurethane resin; the two-component polyurethane resin is prepared from a component A and a component B; the component A adopts solvent-free hydroxyl mixture resin; the component B adopts isocyanate; dosages of the component A and the component B are counted by OH and NCO, and the mass ratio of OH: NCO of the component A and the component B is 2:(1 to 1.6); the component A comprises the following components in parts by mass: 100 parts of solvent-free hydroxyl mixture resin, 0.1 to 0.3 part of a defoaming agent, 0.1 to 0.5 part of a thickening agent, 0.2 to 0.5 part of a flatting agent, 0.05 to 0.1 part of an organosilicon dry lubricant, 0.05 to 0.2 part of a drying agent, 0.1 to 0.3 part of a cross-linking agent, and 0.8 to 3.5 parts of solvent-free color paste. Meanwhile, the invention further discloses a preparation method of the solvent-free polyurethane sofa leather. The solvent-free polyurethane sofa leather is scientific and simple, pollution-free, low in energy consumption, investment saving, and excellent in product quality.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

Sealing member having internal lubricant additives

A sealing member for use in an electrophotographic image forming device according to one example embodiment includes a molded body formed of an elastomer material and internal lubricant additives. The lubricant additives include at least about 20% by weight of the molded body. The lubricant additives include a wet lubricant, a dry lubricant and rounded beads.

Owner:LEXMARK INT INC

Method of lubricating a conveyor belt

InactiveUS20100009879A1Improve the lubrication effectReduce frictionCleaningLiquid carbonaceous fuelsEngineeringDry lubricant

The present invention relates to a method of lubricating a conveyor belt, wherein a lubricant concentrate containing at least 0.1 wt-% of at least one free fatty acid and at least one corrosion inhibitor is employed as a dry lubricant in a dry lubrication process.

Owner:JOHNSONDIVERSEY INC

Spherical pellet formulations

A process for preparing spherical pellets comprising (a) a water-soluble active ingredient soluble, freely soluble or very soluble in water; and in particular having a water-solubility of ≧0.5 g / ml; (b) a spheronizing agent; (c) a dry lubricant, said method comprising preparing a mixture of the active ingredient, the spheronising agent, the dry lubricant; and an amount of water which is less than 5%, w / w relative to the total weight of the mixture; extruding said mixture to obtain an extrudate; and spheronising the extrudate to form spherical pellets. The invention further concerns pellets obtained by this process and sustained release oral dosage forms containing said pellets.

Owner:STRONG BRIAN +2

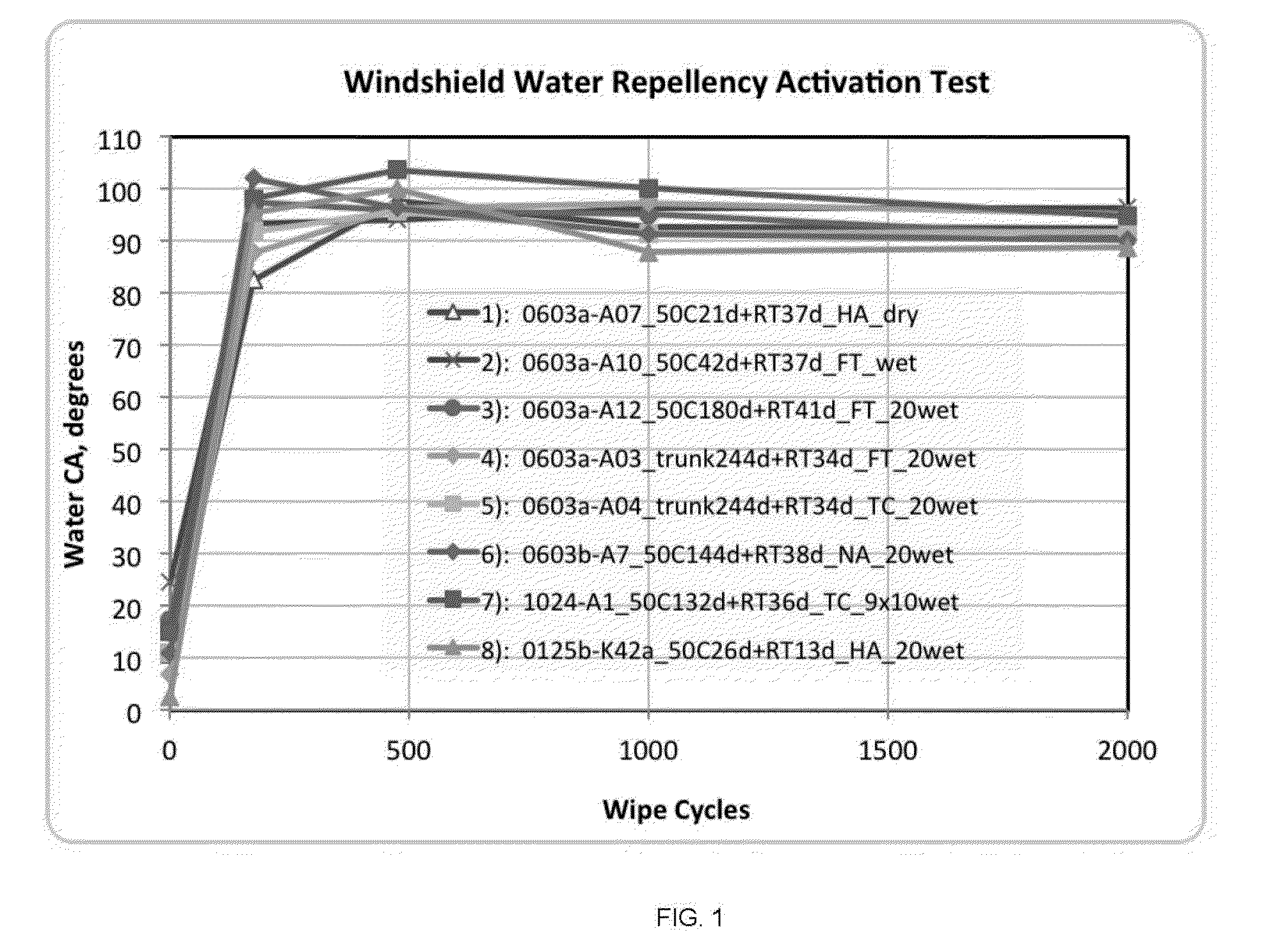

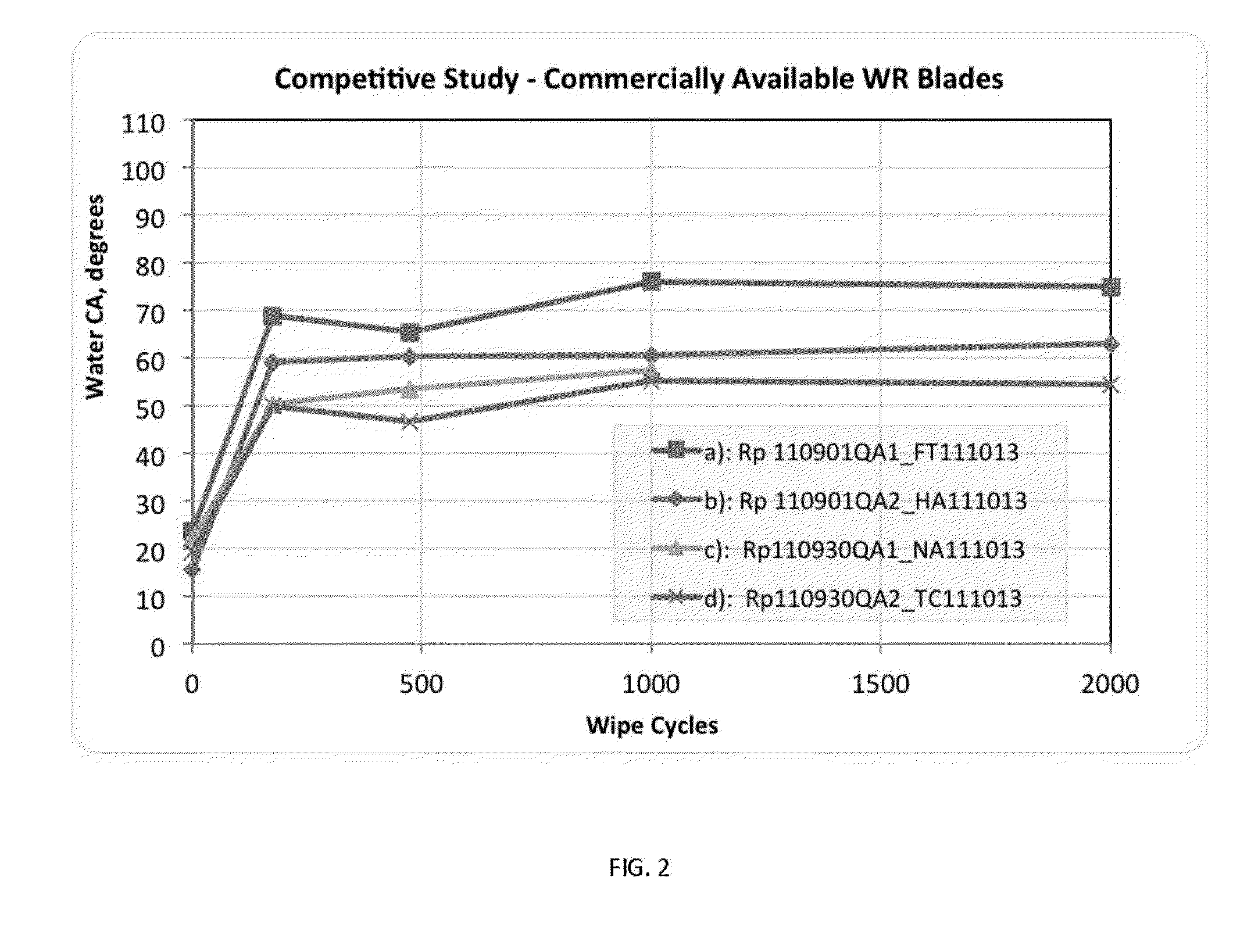

Applicator with hydrophobic coating transferable to contacting surface

A coating composition for imparting a hydrophobic film on a target surface is provided that, includes an oil of a silicone oil or a fluoropolymer oil or a combination thereof, a resin, and a dry lubricant. A solvent is present to form a solution of the oil and resin. A coating is imparted to an applicator that in turn can transfer the coating as a hydrophobic film. The coating composition is stable and able to impart hydrophobic film even after storage for several weeks at elevated temperature. The coating composition does so through the exclusion of synthetic waxes especially including silicone waxes. A kit is also provided that includes a wiper blade having the above coating composition applied along with instructions for the securement of the wiper blade to a vehicle to impart the hydrophobic film to a vehicle windshield contacted by the wiper blade.

Owner:ILLINOIS TOOL WORKS INC

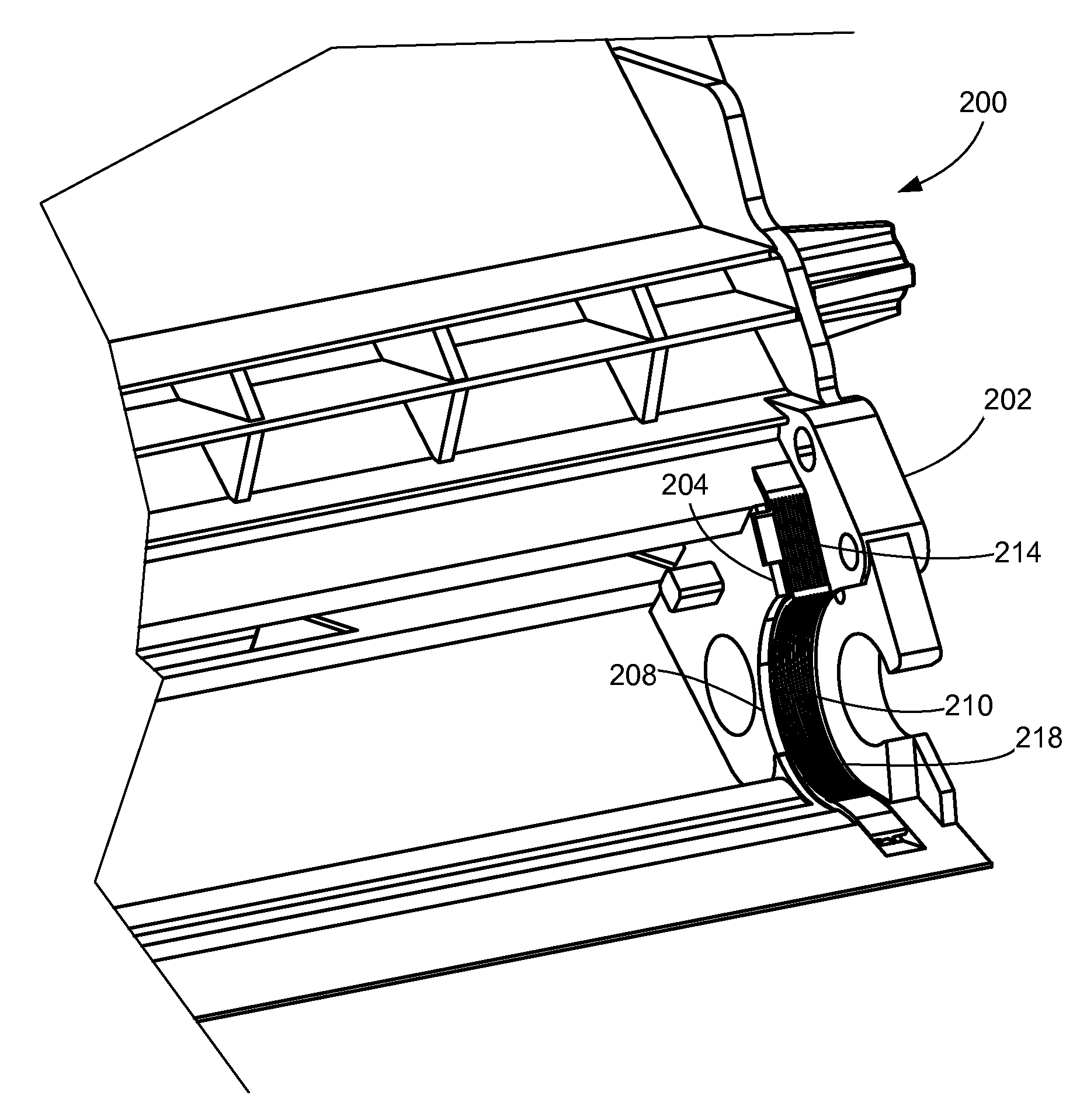

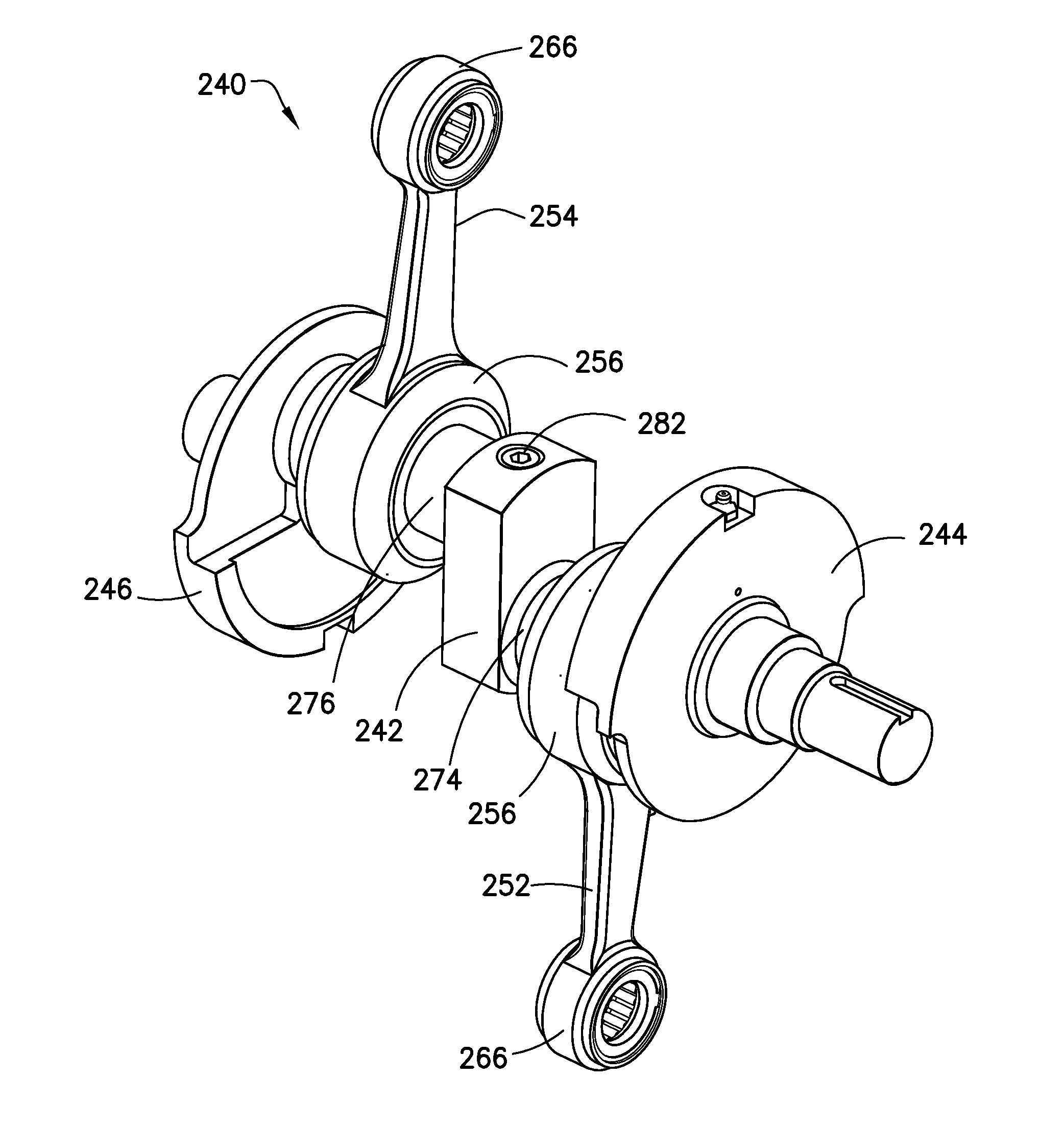

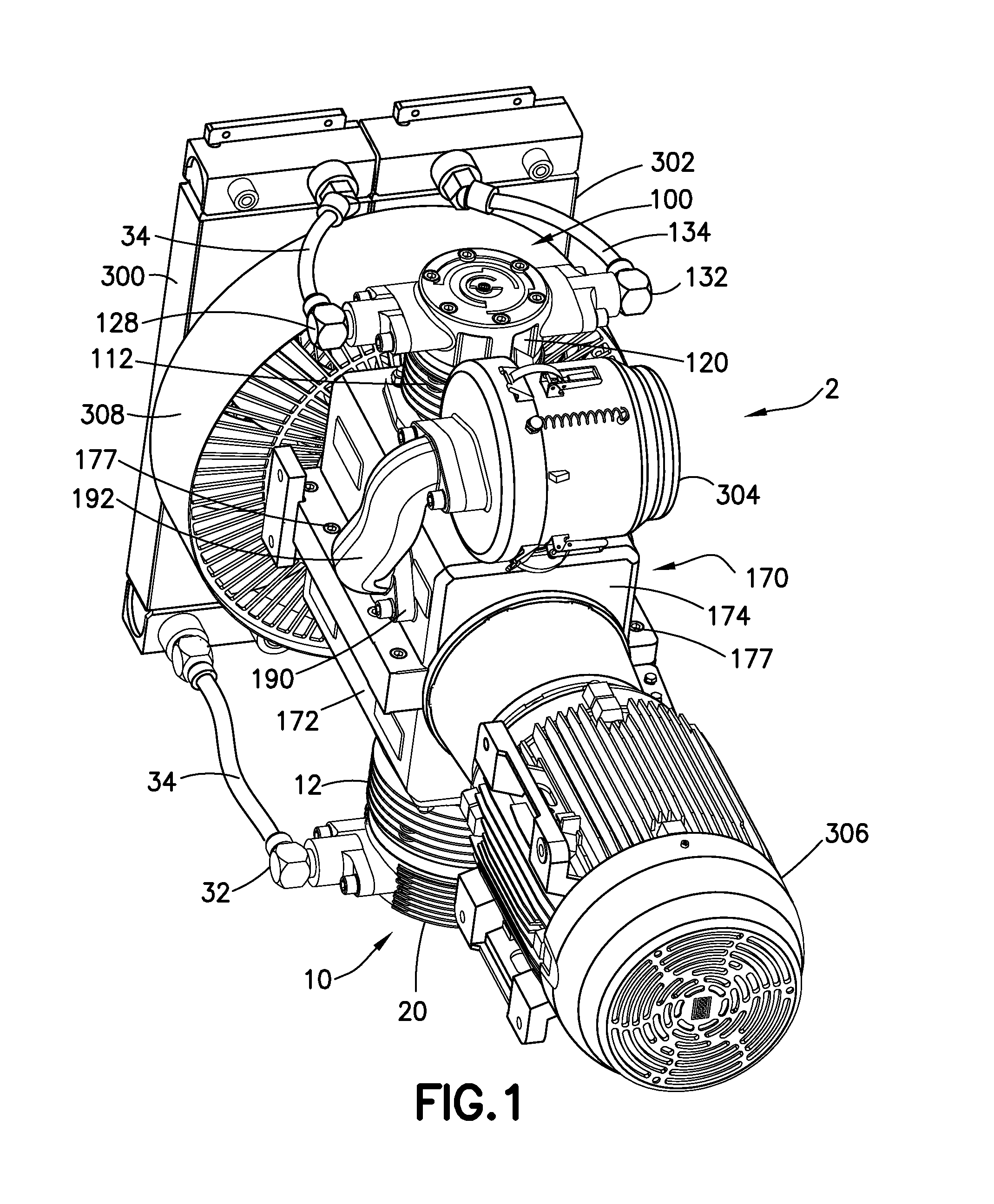

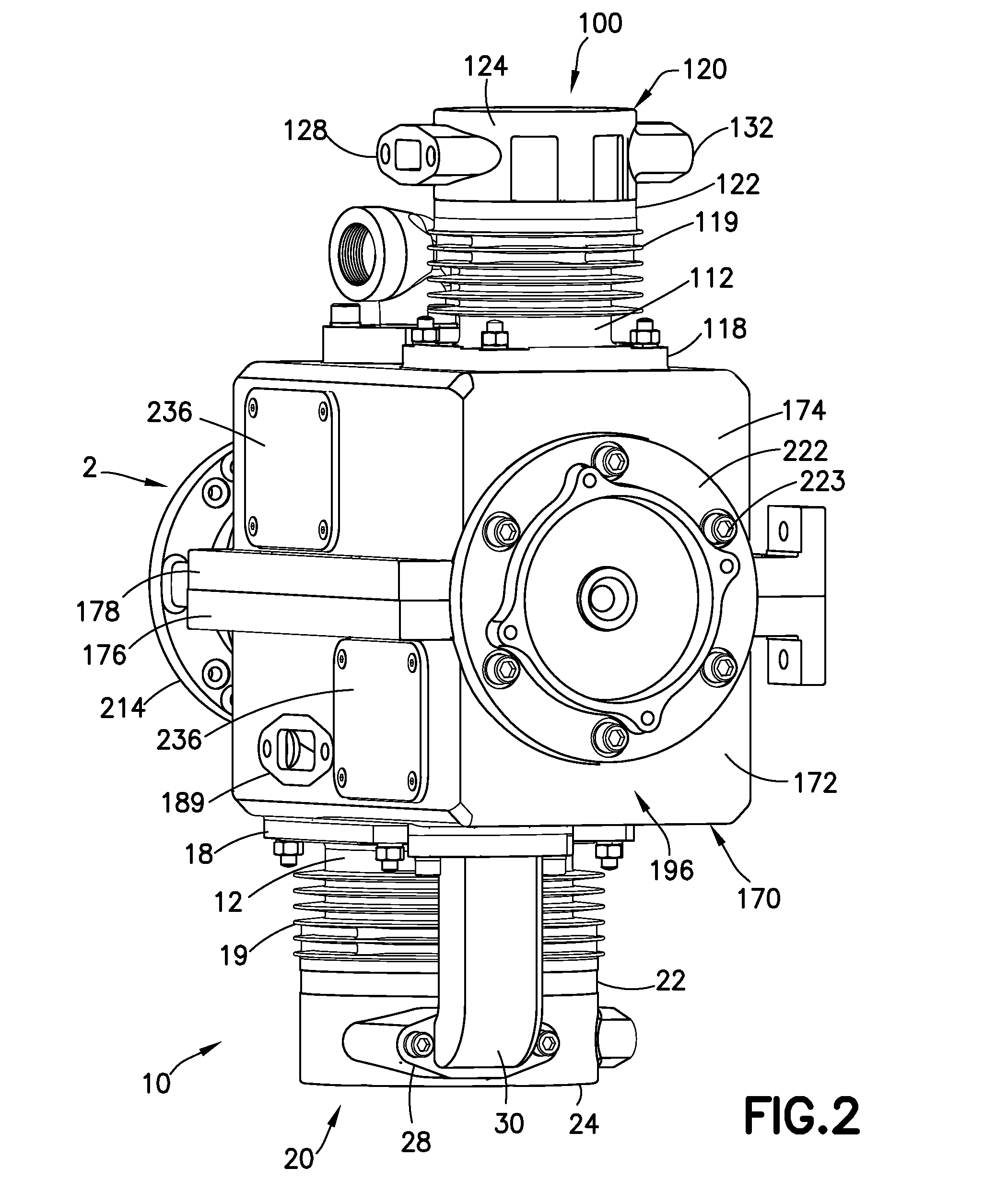

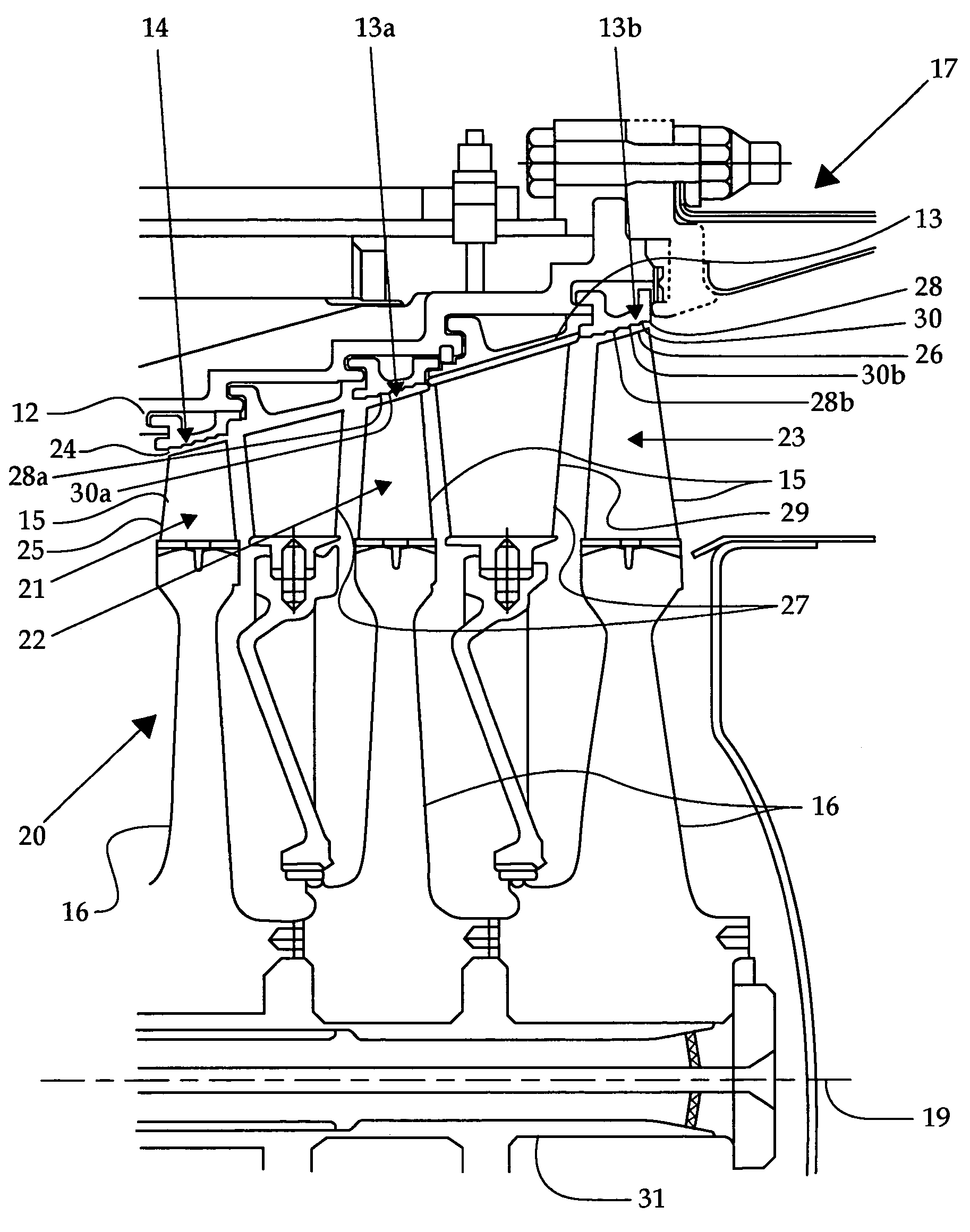

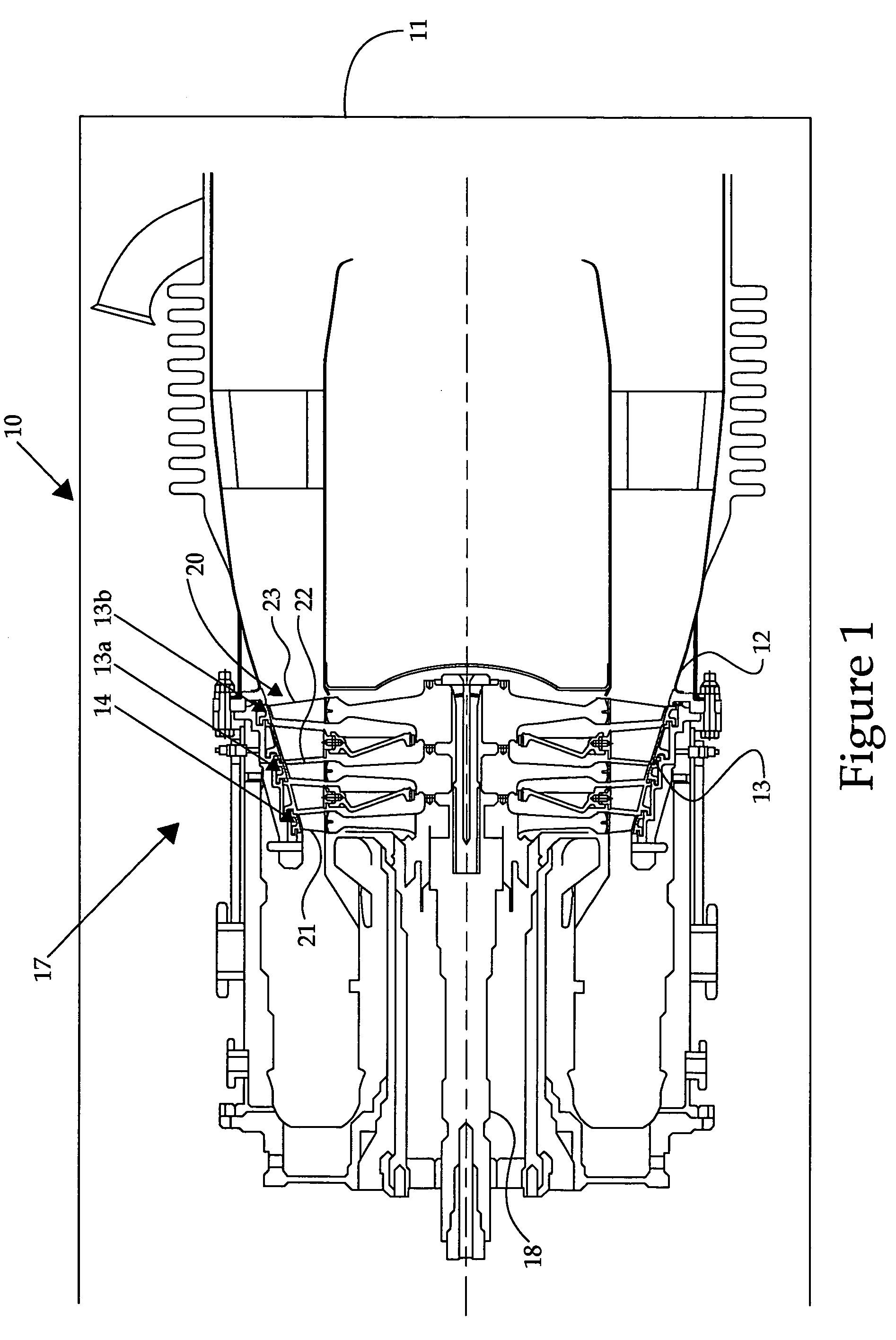

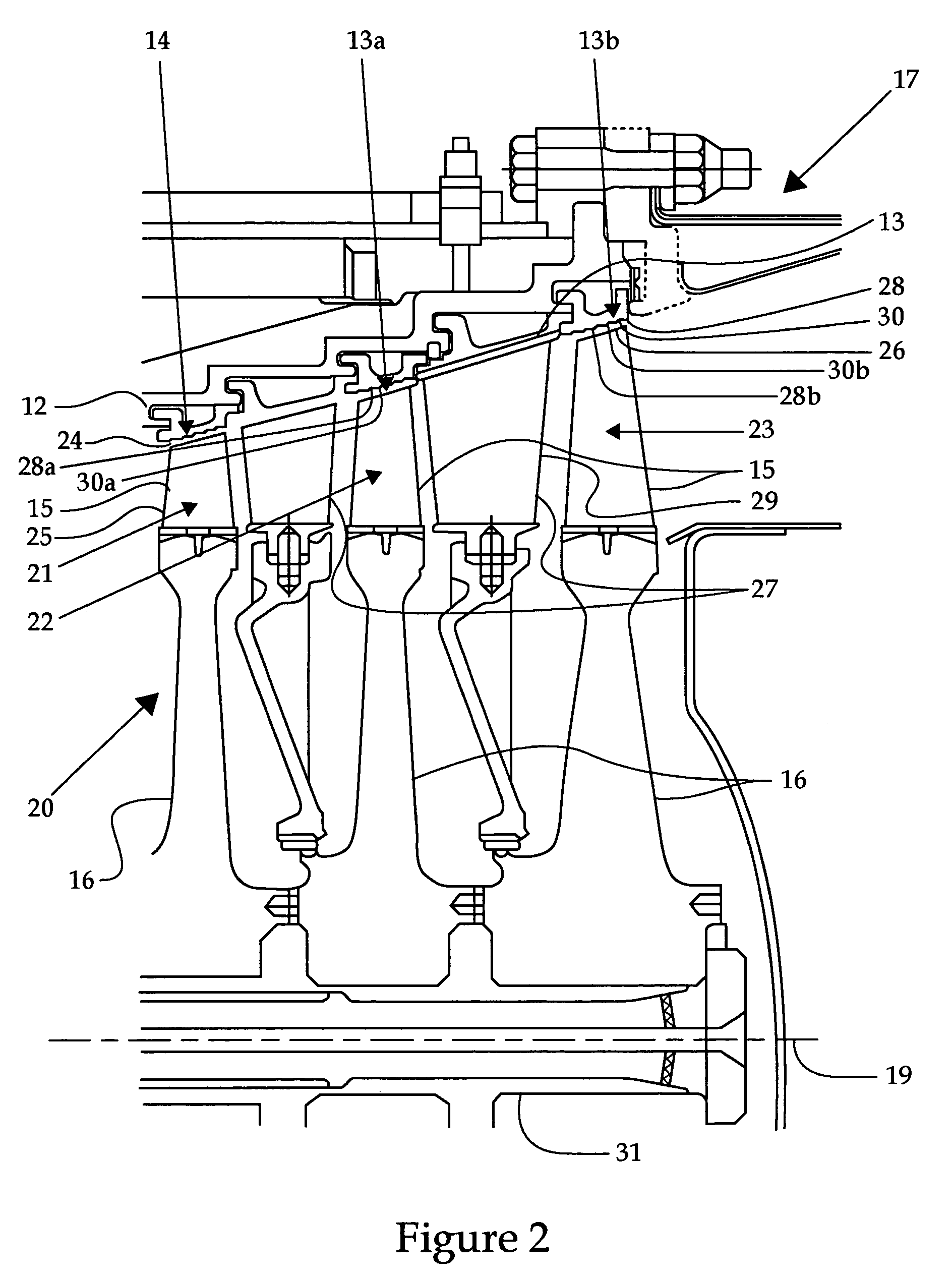

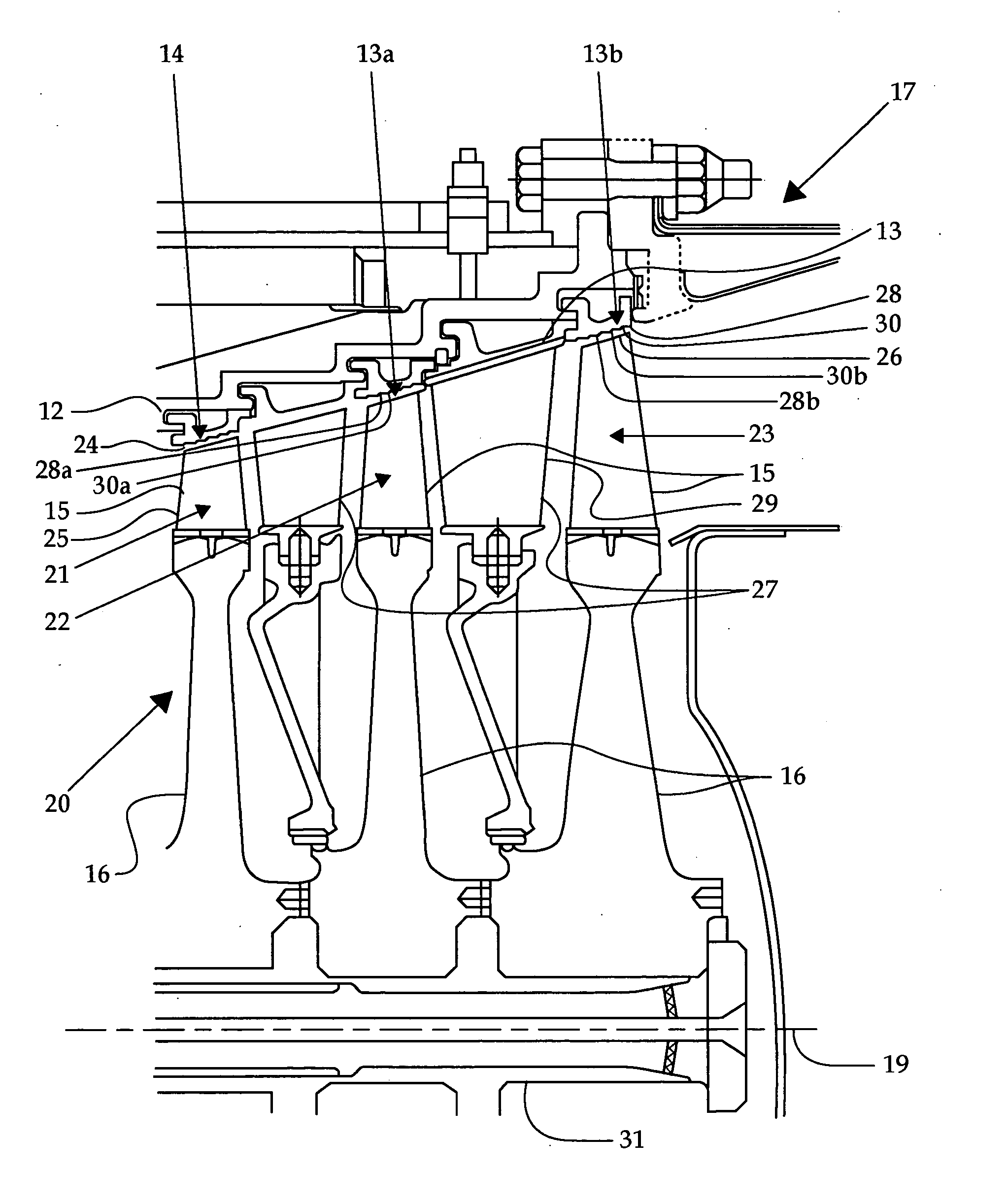

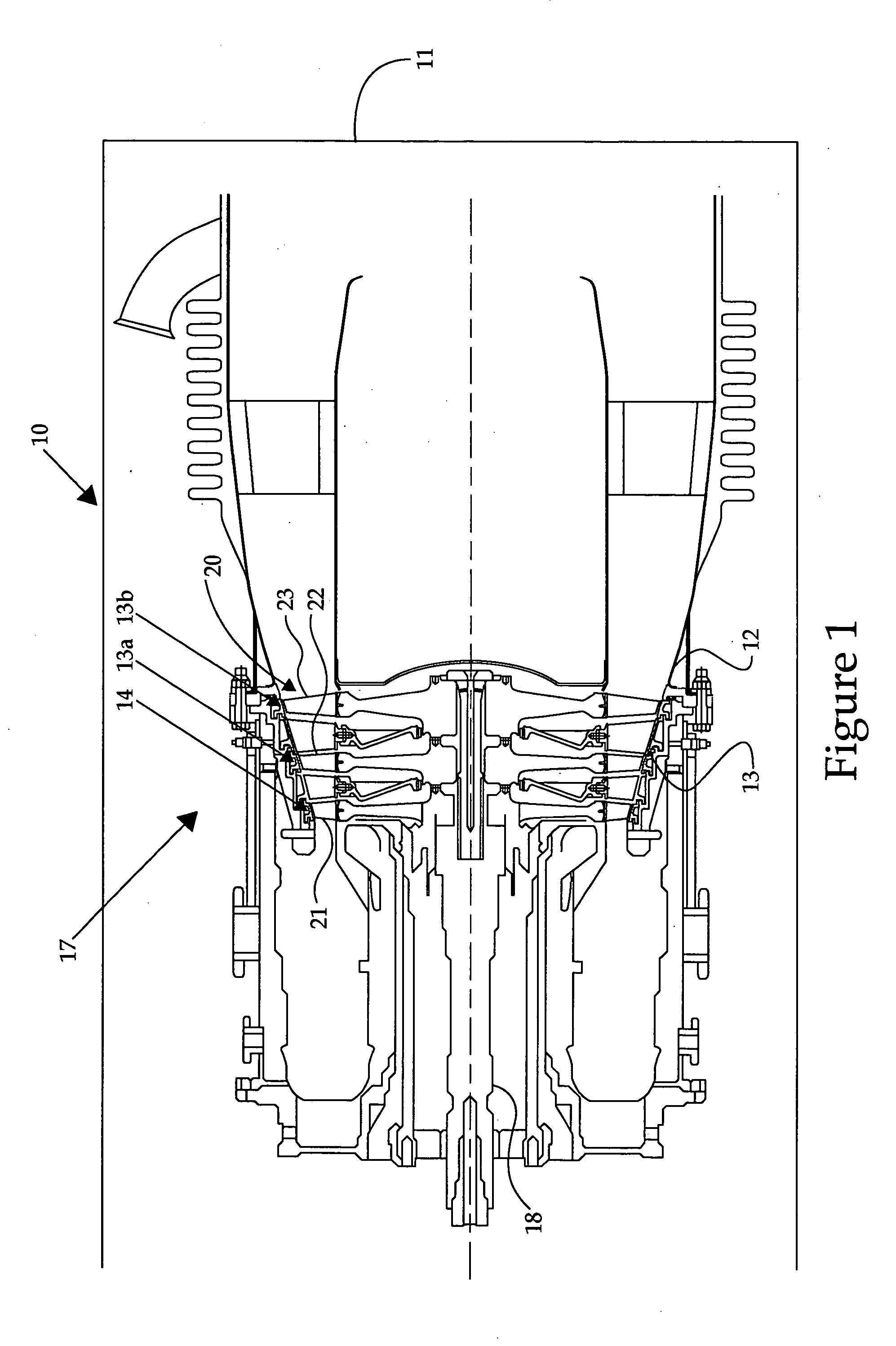

Oil-free air compressor for rail vehicles with air ventilation

An oil-free compressor for a rail vehicle includes a multi-piece compressor housing, a first piston cylinder supported in a first opening in the compressor housing, a second piston cylinder supported in a second opening in the compressor housing, a multi-piece crankshaft assembly supported by the compressor housing, and an optionally filtering air plenum in fluid communication with the compressor housing interior to provide a volume of air to the compressor housing interior. The crankshaft assembly is linked to pistons of the first and second piston cylinders by respective connecting rods. The connecting rods connect to a wrist pin associated with each of the pistons, and the wrist pins are respectively supported by a dry lubricant bushing to the associated piston. The compressor housing may have a first housing portion and a second housing portion forming respective halves of the compressor housing.

Owner:WABTEC HLDG CORP

Wedge threads with a solid lubricant coating

A tubular connection includes a pin member having external wedge threads configured to engage a box member having corresponding internal wedge threads, and a solid lubricant coating applied on at least one of the internal and external wedge threads wherein the solid lubricant coating comprises a first uniform layer of a dry corrosion inhibiting coating made of an epoxy resin containing particles of zinc and a second uniform layer of a dry lubricant coating covering the first uniform layer.

Owner:HYDRIL CO

Cable lubricant

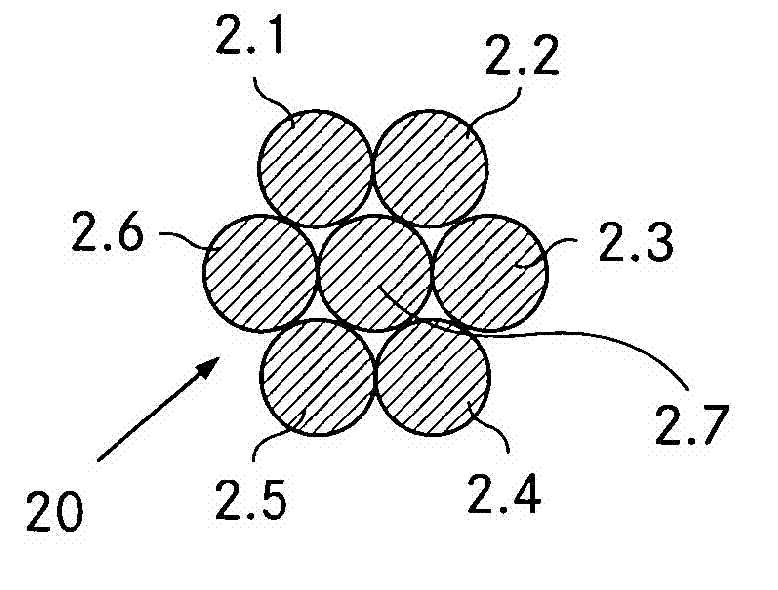

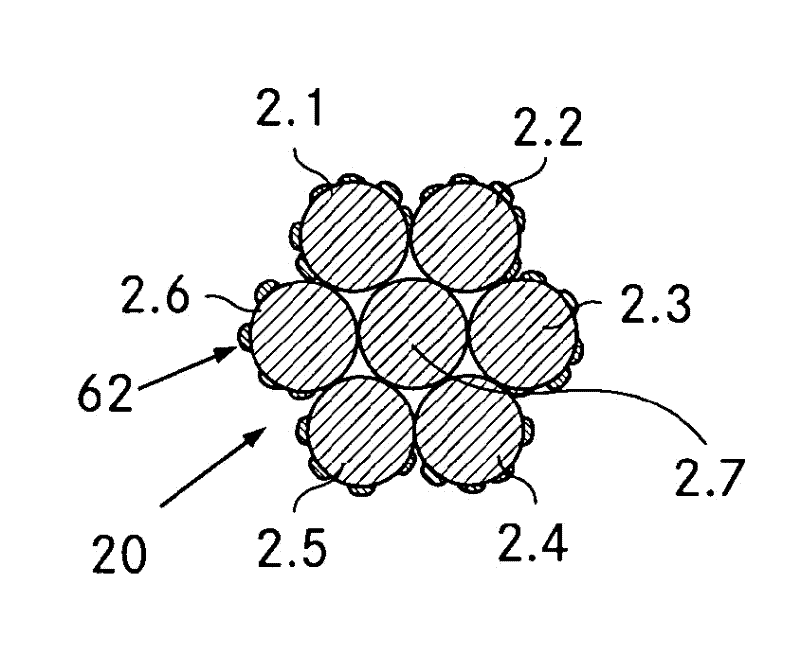

A dry lubricant (50) for flexible traction members (10), in particular wire cables and / or stranded ropes for static and / or dynamic loads, is characterized in that a major percentage of the dry lubricant (50) consists of a polymer material. Furthermore, in a method for manufacturing a flexible traction member (12) made up of multiple tension-proof elements (1.1, 1.2,..., 1.7, 20), in particular wires and / or strands and / or ropes, a dry lubricant (50) is applied to the tension-proof elements (1.1, 1.2,..., 1.7, 20) before the latter are joined together, said dry lubricant (50) being sprayed onto the tension-proof elements (1.1, 1.2,..., 1.7, 20) in a fluid state.

Owner:布鲁格钢缆公司

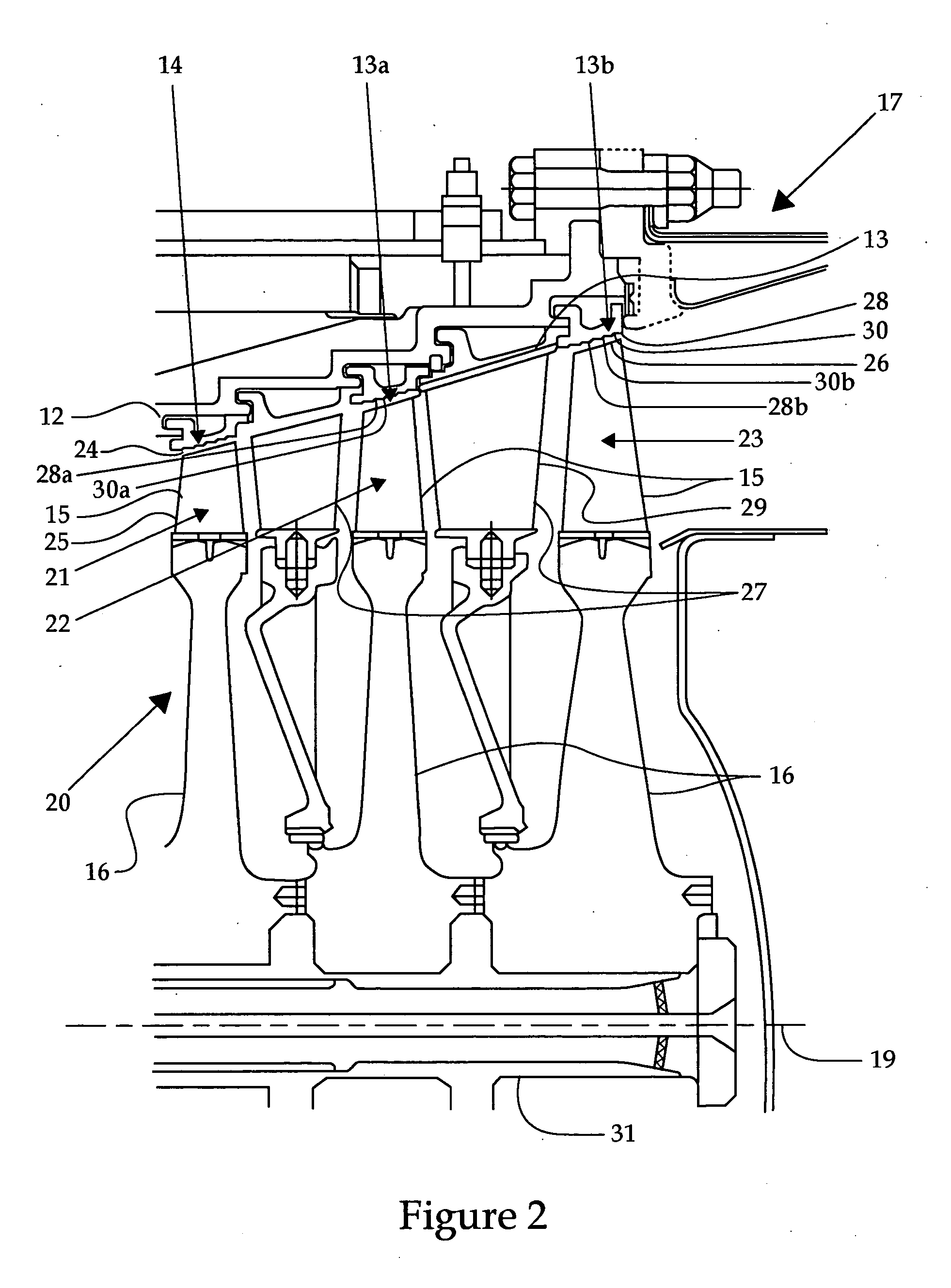

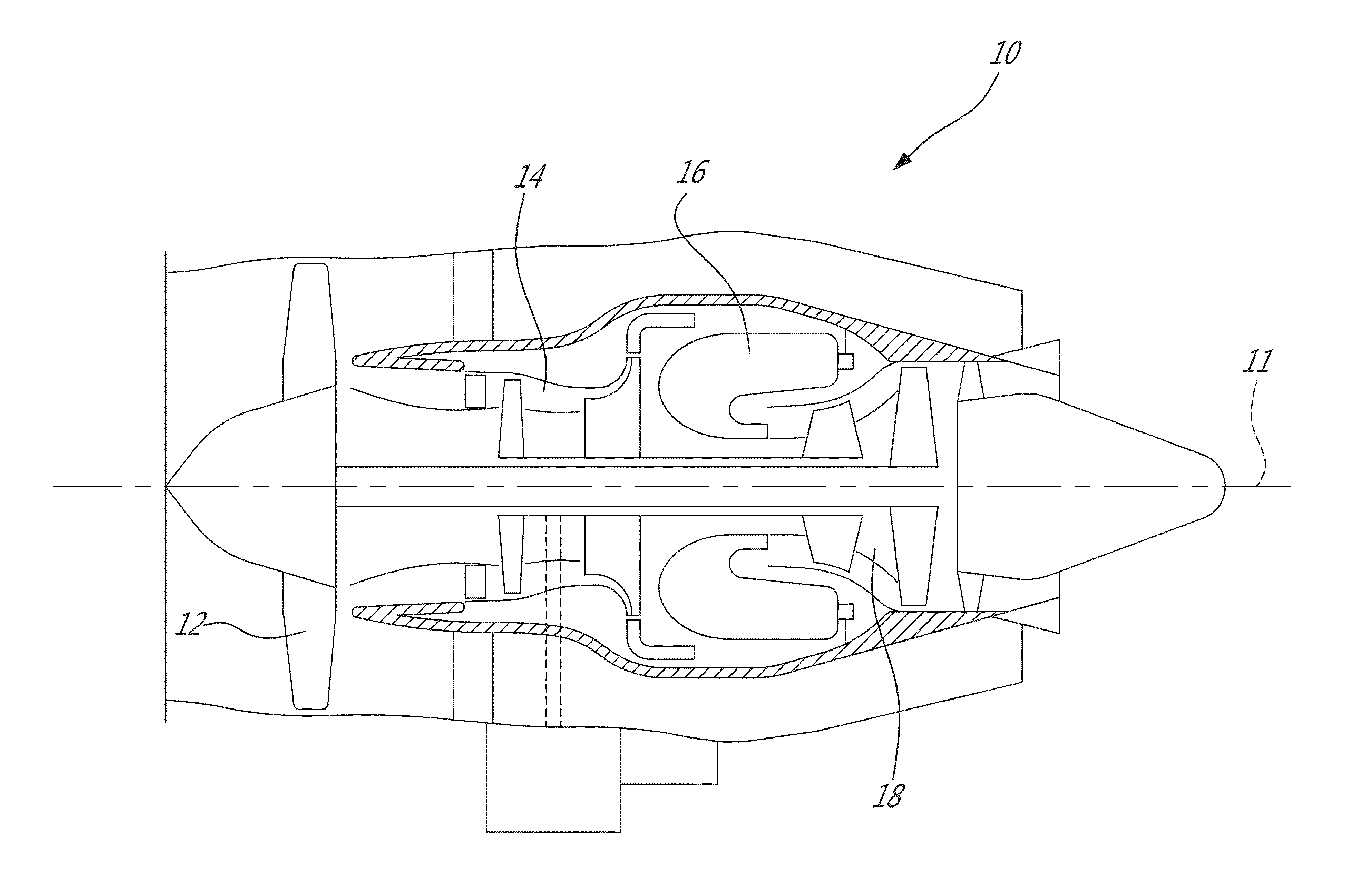

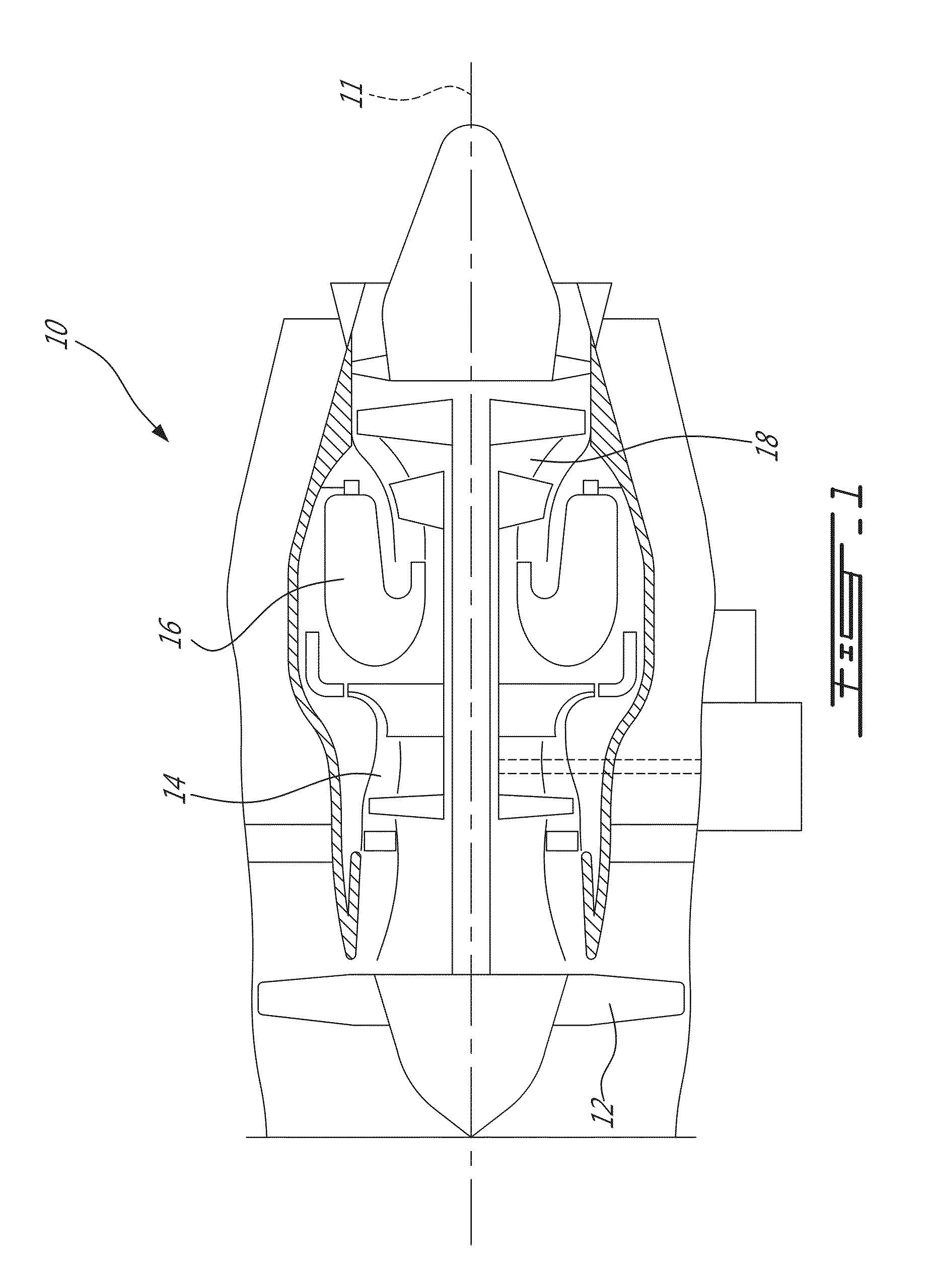

Low-mid turbine temperature abradable coating

In order to minimize a clearance between a turbine and its housing, and thus, improve the efficiency of a turbine engine, an abradable coating can be applied to an inner surface of the turbine housing. However, there are no known abradable coatings that can be applied to a housing that is subjected to temperatures between 950–1500° F. for extended periods of time. The apparatus of the present disclosure includes a housing including a 950–1500° F. section in which at least one rotating blade row is positioned. The rotating blades and the 950–1500° F. section each includes a surface being comprised of a relatively non-abradable material. The surface of the housing comprised of the relatively non-abradable material is covered by a 950–1500° F. relatively abradable coating that includes a metallic matrix and at least one of a thermoplastic and dry lubricant. The metallic matrix is 55–85% of the coating by volume.

Owner:SOLAR TURBINES

Low-mid turbine temperature abradable coating

In order to minimize a clearance between a turbine and its housing, and thus, improve the efficiency of a turbine engine, an abradable coating can be applied to an inner surface of the turbine housing. However, there are no known abradable coatings that can be applied to a housing that is subjected to temperatures between 950-1500° F. for extended periods of time. The apparatus of the present disclosure includes a housing including a 950-1500° F. section in which at least one rotating blade row is positioned. The rotating blades and the 950-1500° F. section each includes a surface being comprised of a relatively non-abradable material. The surface of the housing comprised of the relatively non-abradable material is covered by a 950-1500° F. relatively abradable coating that includes a metallic matrix and at least one of a thermoplastic and dry lubricant. The metallic matrix is 55-85% of the coating by volume.

Owner:SOLAR TURBINES

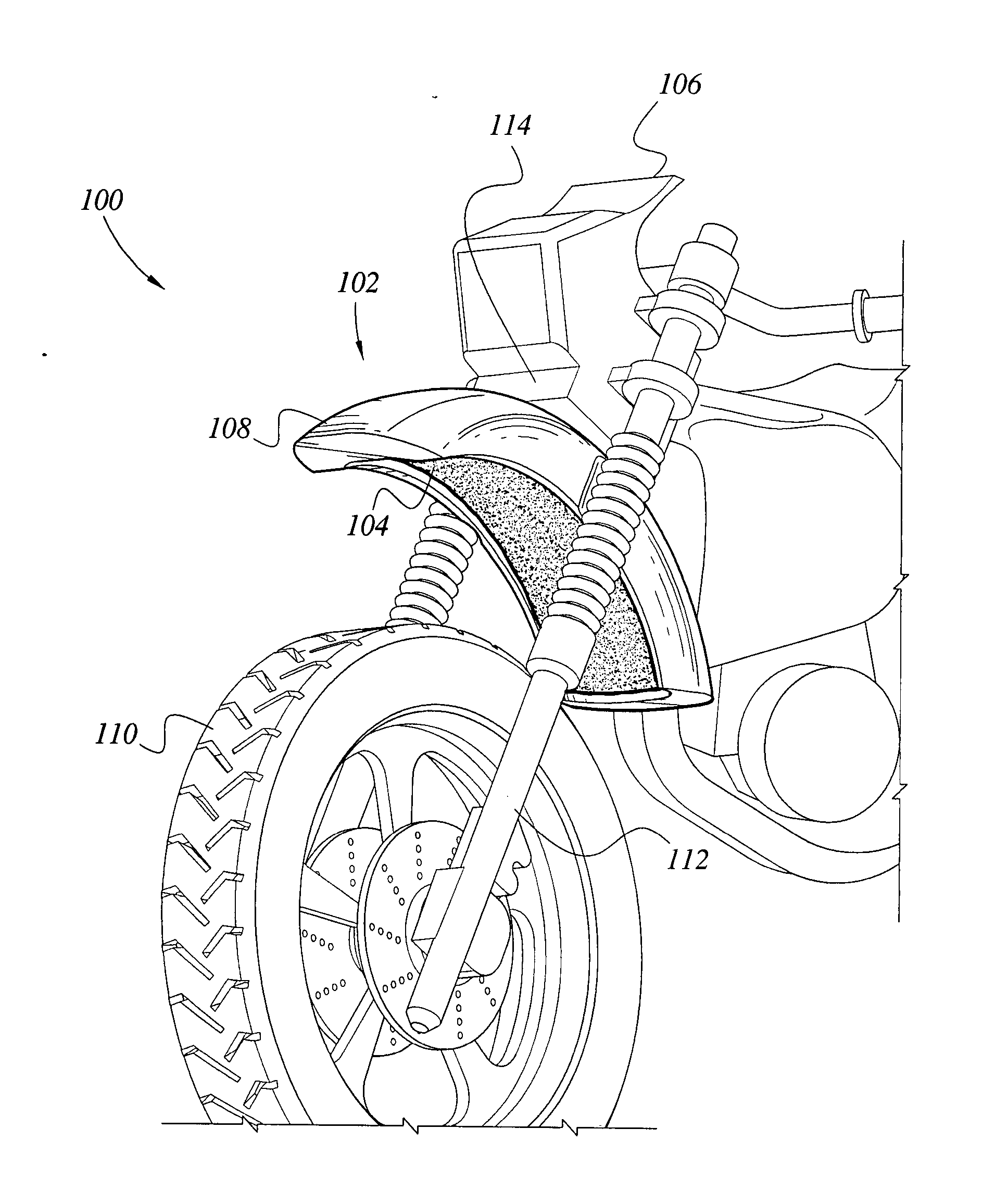

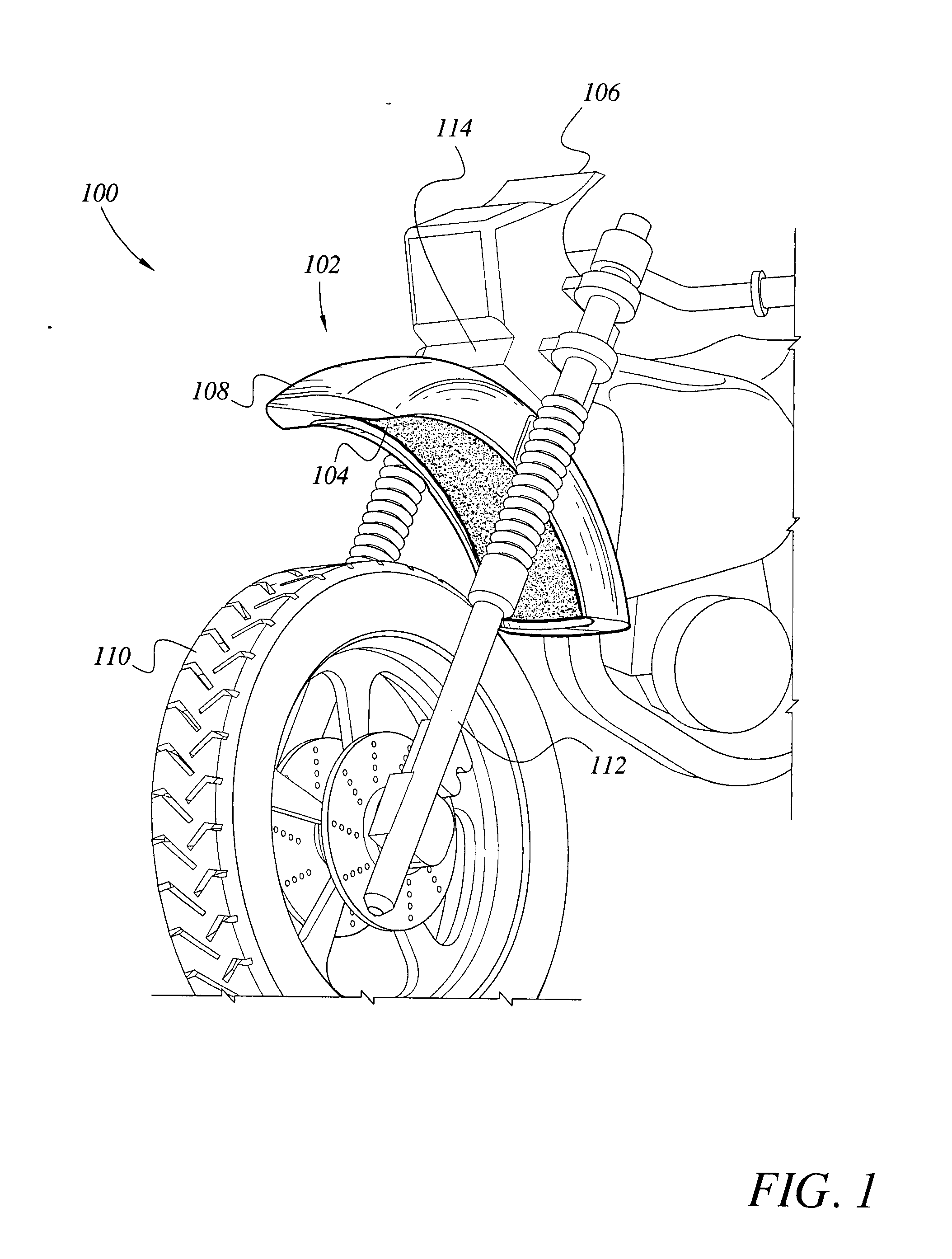

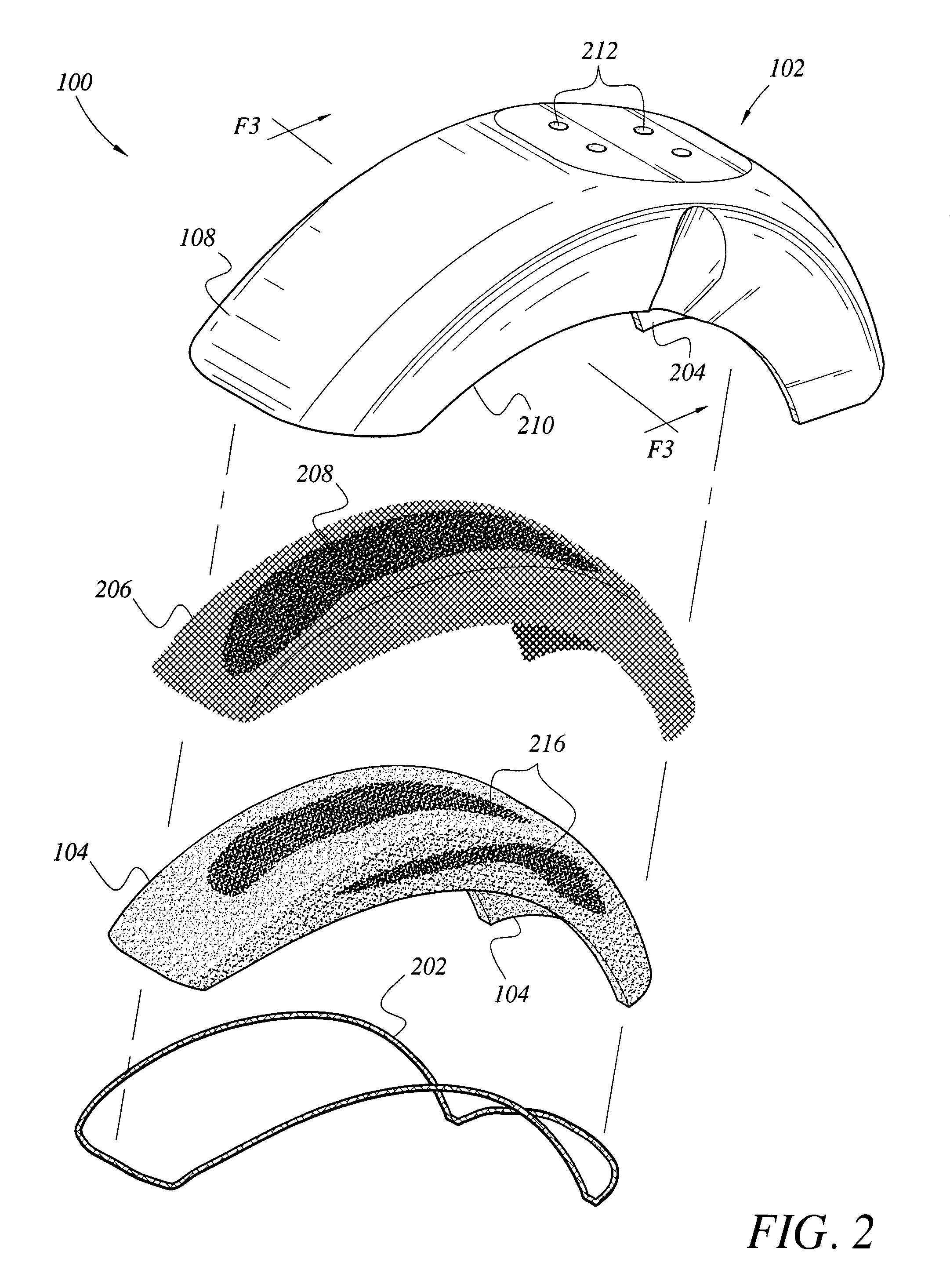

Foam liner and method to prevent accumulation of mud

InactiveUS20070187940A1Reduce weightControl the weight of their vehiclesSuperstructure subunitsMud-guardsSynthetic materialsEngineering

The liner assembly incorporates a liner formed of a synthetic air permeable material adhesively mounted to the underside of an exposed motorcycle fender or to a structure having surfaces susceptible to mud buildup, chipping or other types of damage. The liner is a relatively thin, flexible sheet of air permeable, synthetic material formed to substantially cover the concave portion of an exposed fender. The liner is either directly attached to the structure, or is attached via a double-sided tape, or has a bead of adhesive material disposed around the edge thereof, further securing the liner to the surface of the fender and protecting the edge from fraying and the lining from delaminating. The liner is coated with a wet or dry lubricant to increase its lubricity.

Owner:PRESBY ANTHONY J

Wedge threads with a solid lubricant coating

A tubular connection includes a pin member having external wedge threads configured to engage a box member having corresponding internal wedge threads, and a solid lubricant coating applied on at least one of the internal and external wedge threads wherein the solid lubricant coating comprises a first uniform layer of a dry corrosion inhibiting coating made of an epoxy resin containing particles of zinc and a second uniform layer of a dry lubricant coating covering the first uniform layer.

Owner:HYDRIL CO

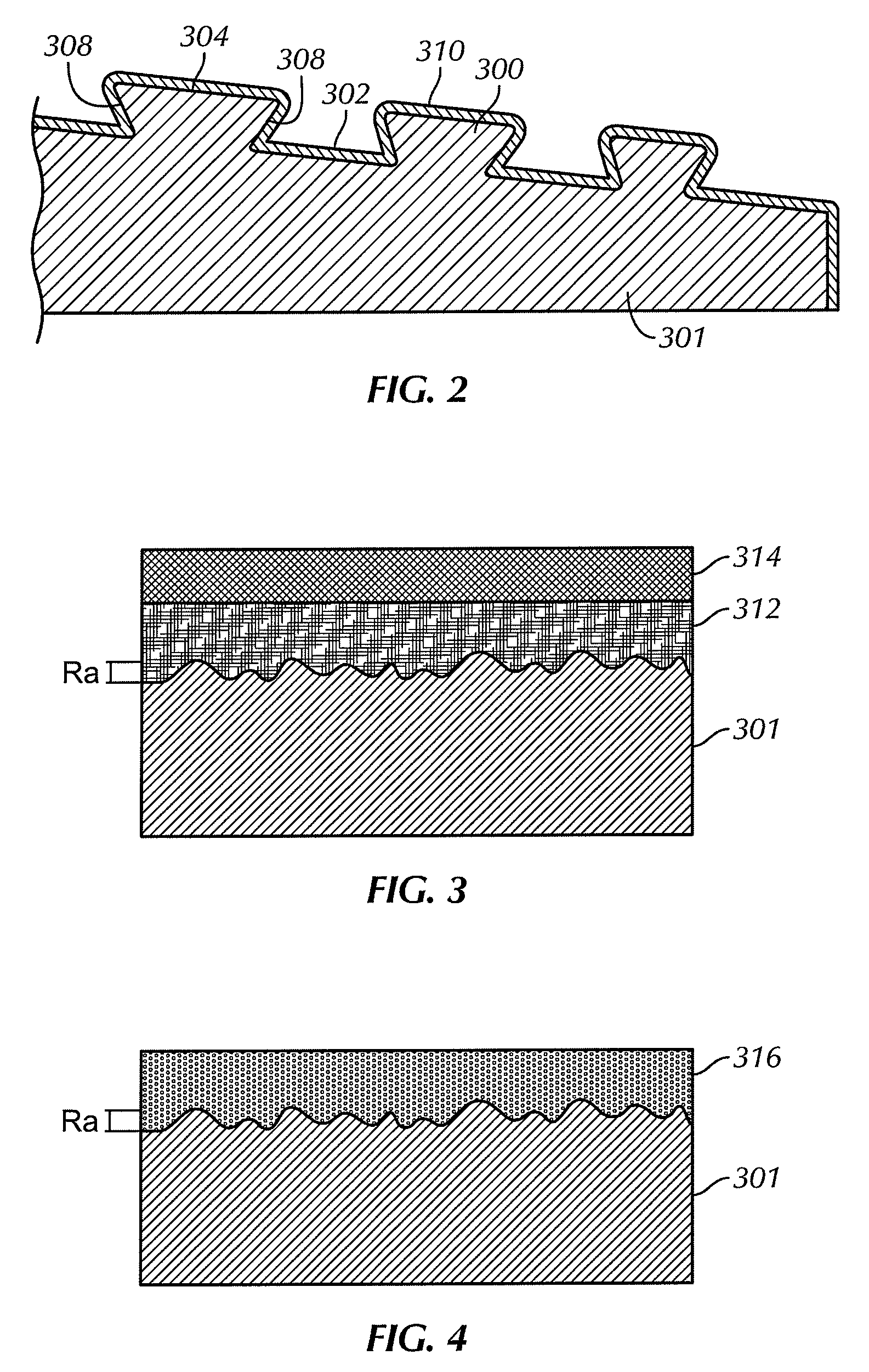

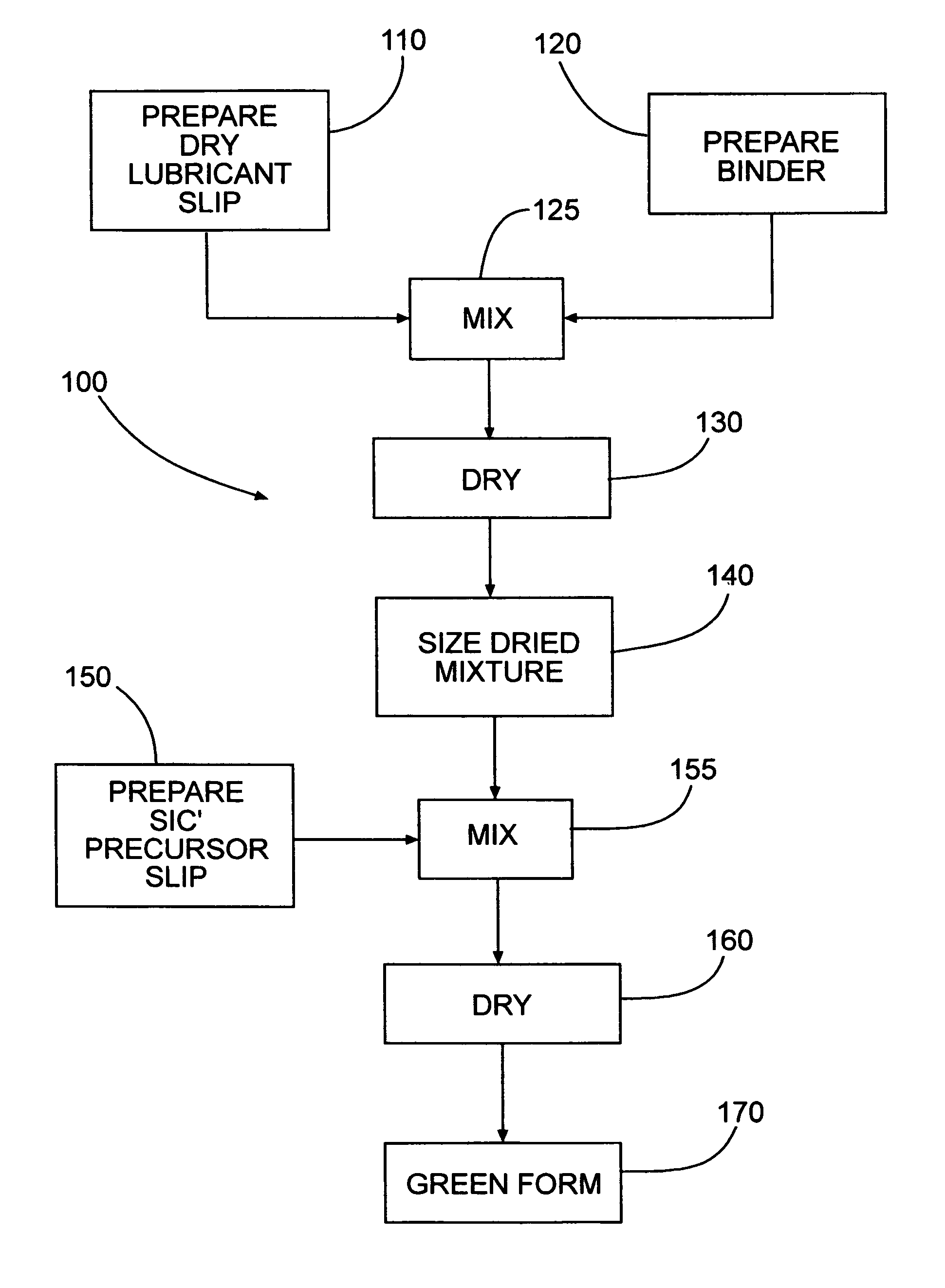

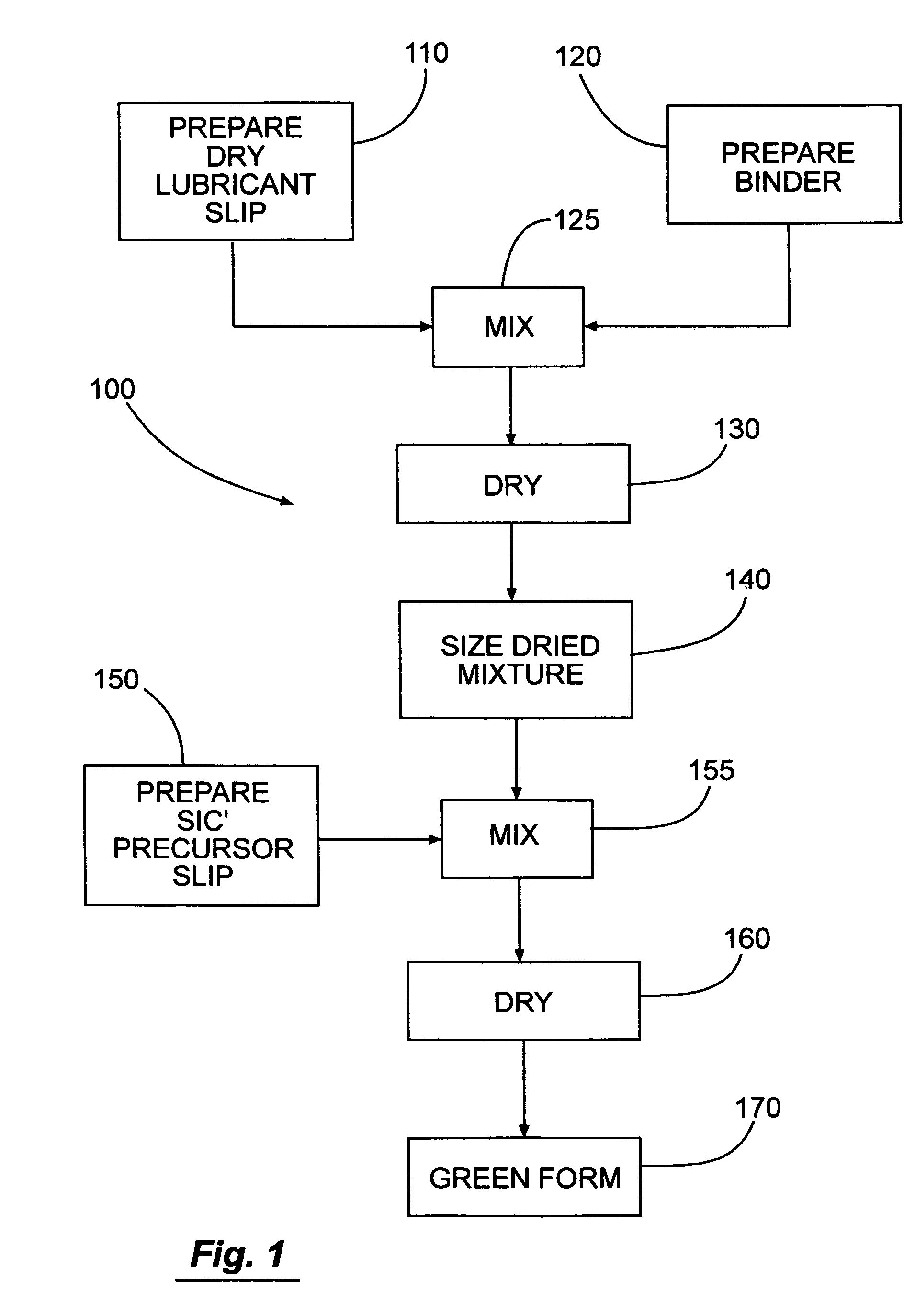

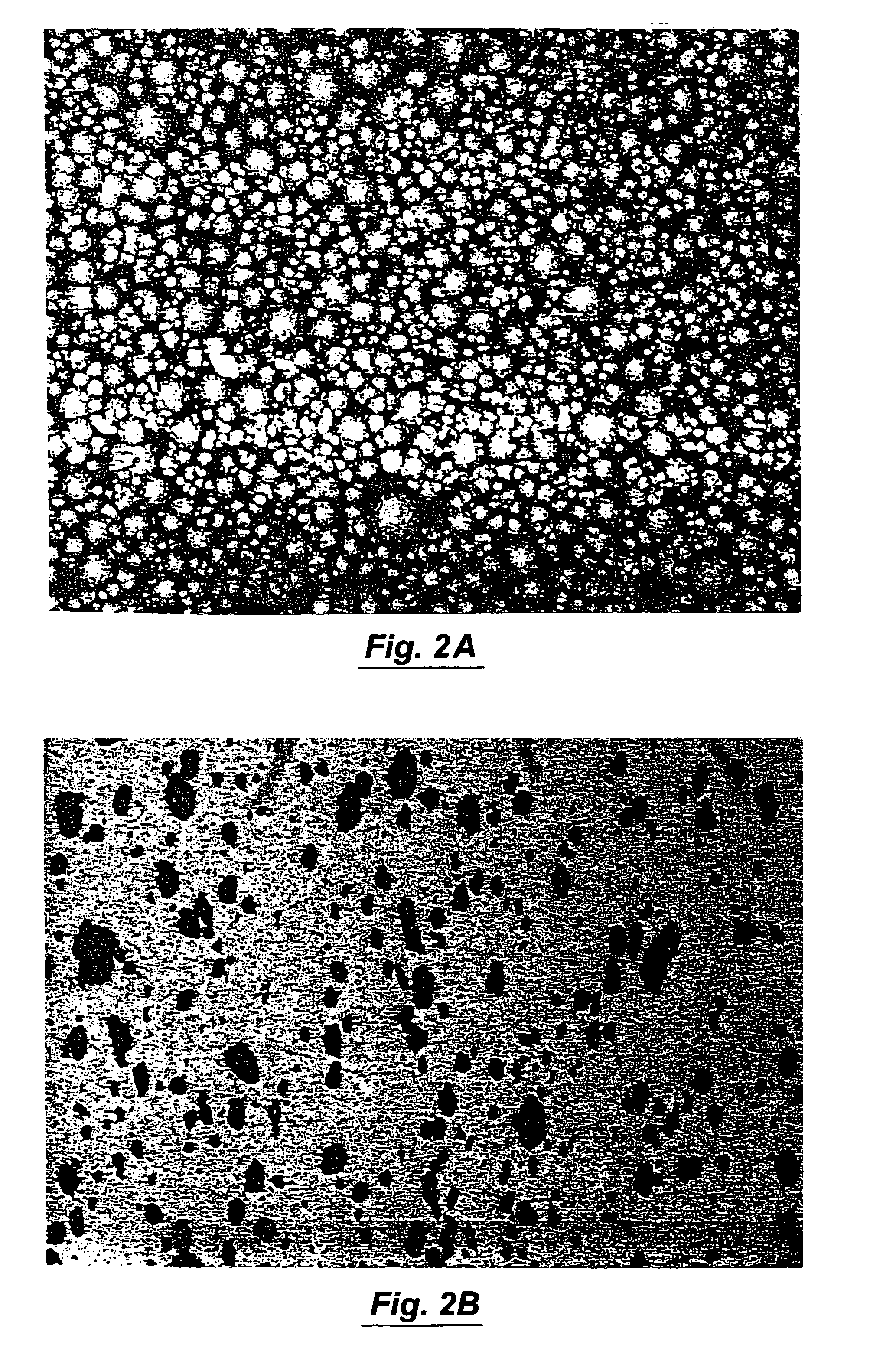

Graphite loaded silicon carbide and methods for making

InactiveUS7015165B2Degree of lubricitySimple preparation processCeramic shaping apparatusClaywaresGraphiteSlurry

The invention provides exemplary silicon carbide ceramic bodies and processes for making such ceramic bodies. In one embodiment, a raw batch for producing a ceramic body includes a silicon carbide slurry and agglomerates of particles defining a dry lubricant mixture. The mixture includes a binder and a dry lubricant such as graphite, with a majority of the agglomerates having a shape that is generally spherical.

Owner:COORSTEK INC

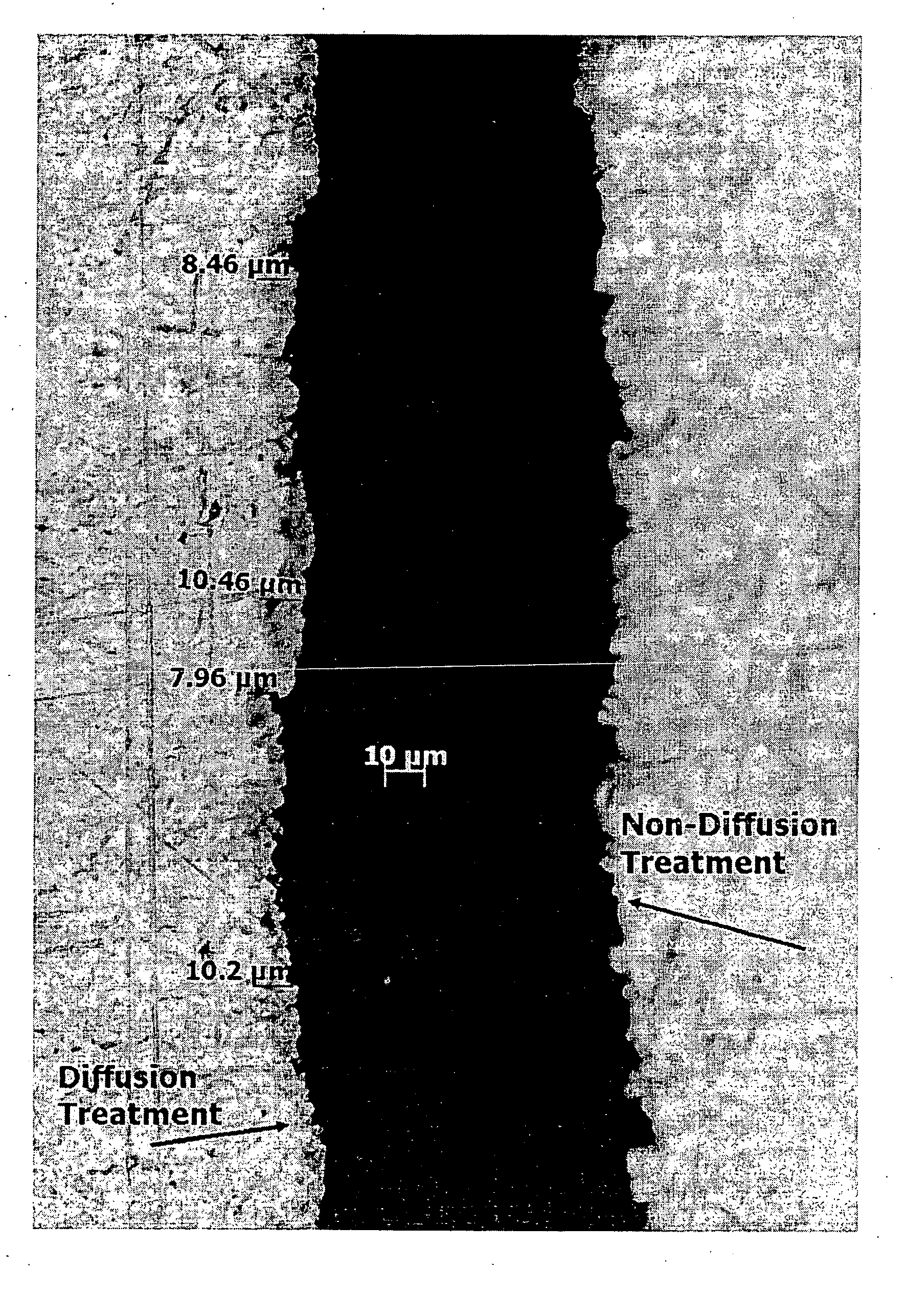

Enhanced friction reducing surface and method of making the same

InactiveUS20070134468A1Deep penetrationReduce frictionRecord information storageSolid state diffusion coatingBond energyMechanical impact

A process for producing an enhanced friction reducing surface by bonding a dry lubricant to a substrate by way of high velocity mechanical impact and low temperature diffusion bonding, and the friction-reduced surface produced thereby. Kinetic energy produced from the mechanical impact drives the lubricant against the surface of the substrate, forming a metallurgical bond between the lubricant and the substrate surface. Performance of a subsequent low temperature solid state diffusion bonding step at less than half the melting point of the substrate causes, in combination with the stored bond energy, causes the lubricant to penetrate into the sub-surface of the substrate. The resulting substrate, modified at the sub-surface level but without any loss of metallurgical characteristics, demonstrates significantly improved wear and friction-reducing characteristics.

Owner:KINETITEC CORP

Wiper blade for windscreen wiper and method for producing the same

InactiveUS20060046047A1Reduce energy consumptionReduce air resistanceSynthetic resin layered productsPretreated surfacesEngineeringPolypropylene

A wiper blade, especially for a windshield wiper, is proposed, which is provided at least from area to area with a friction-reducing coating formed by a lubricating varnish. The lubricating varnish contains a polyurethane, a siloxane and, as dry lubricant, graphite, polytetrafluoroethylene, polypropylene and / or molybdenum.

Owner:ROBERT BOSCH GMBH

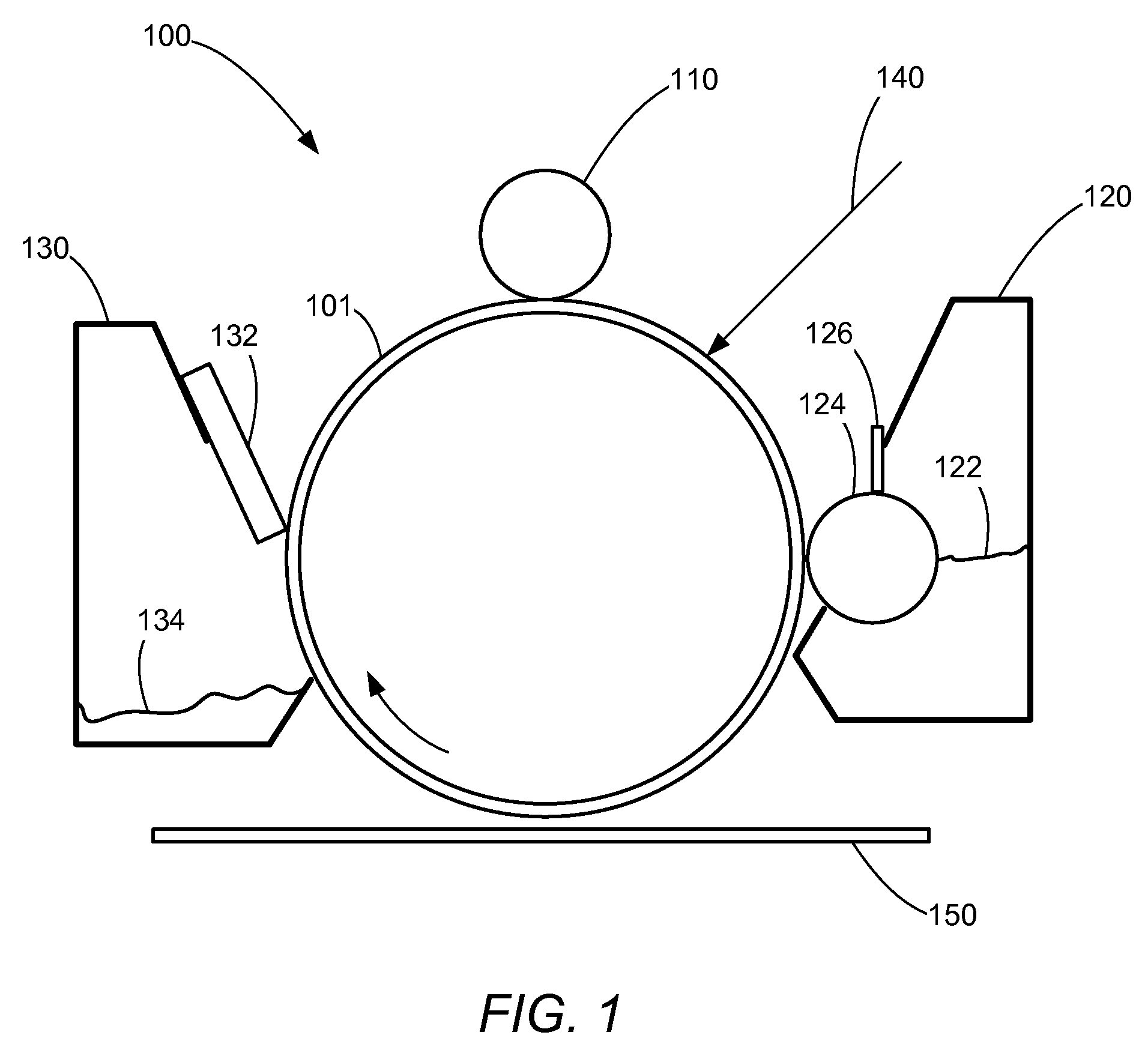

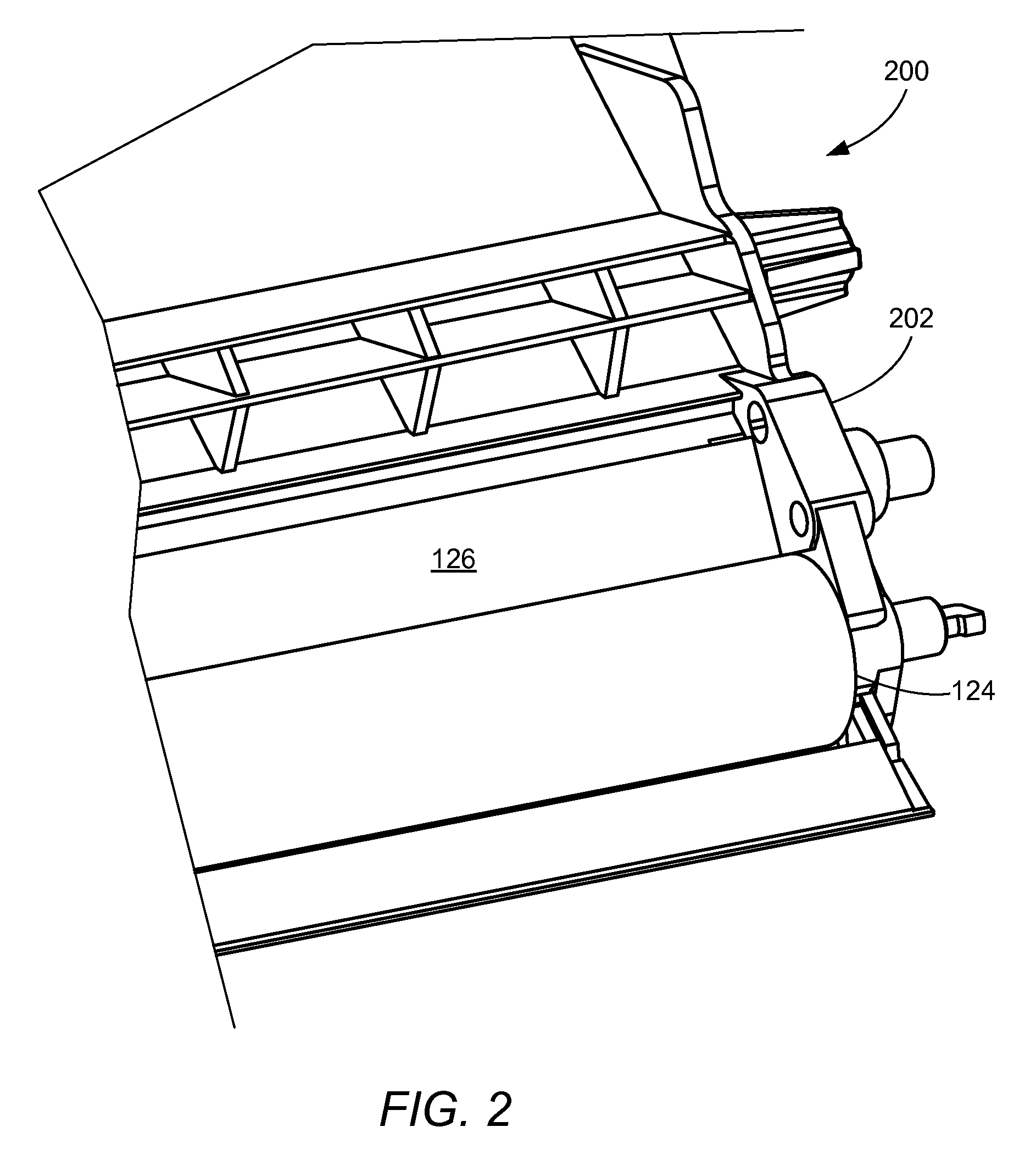

Torsional wire treatment drawing system

Owner:TYL THOMAS WILSON

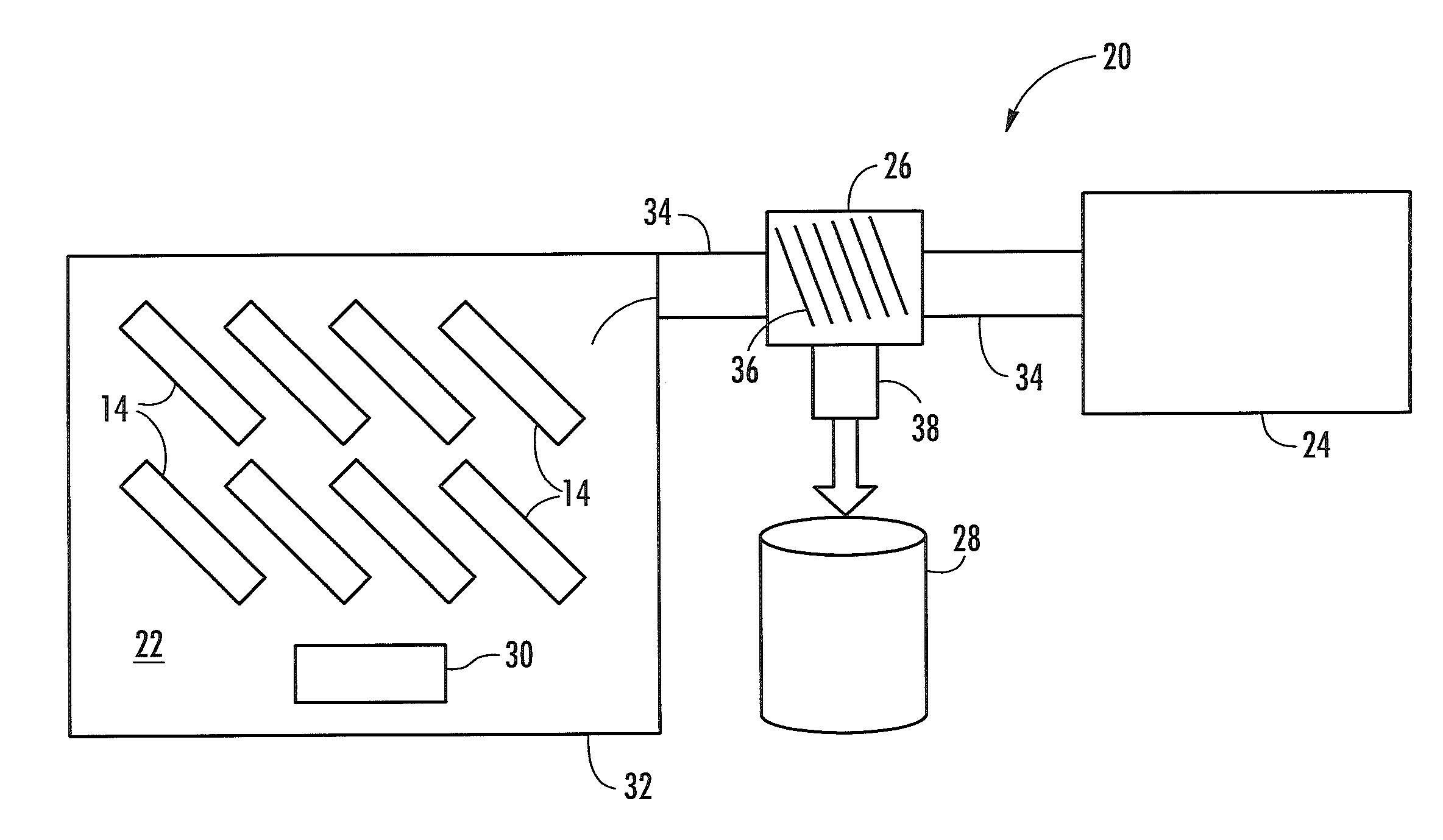

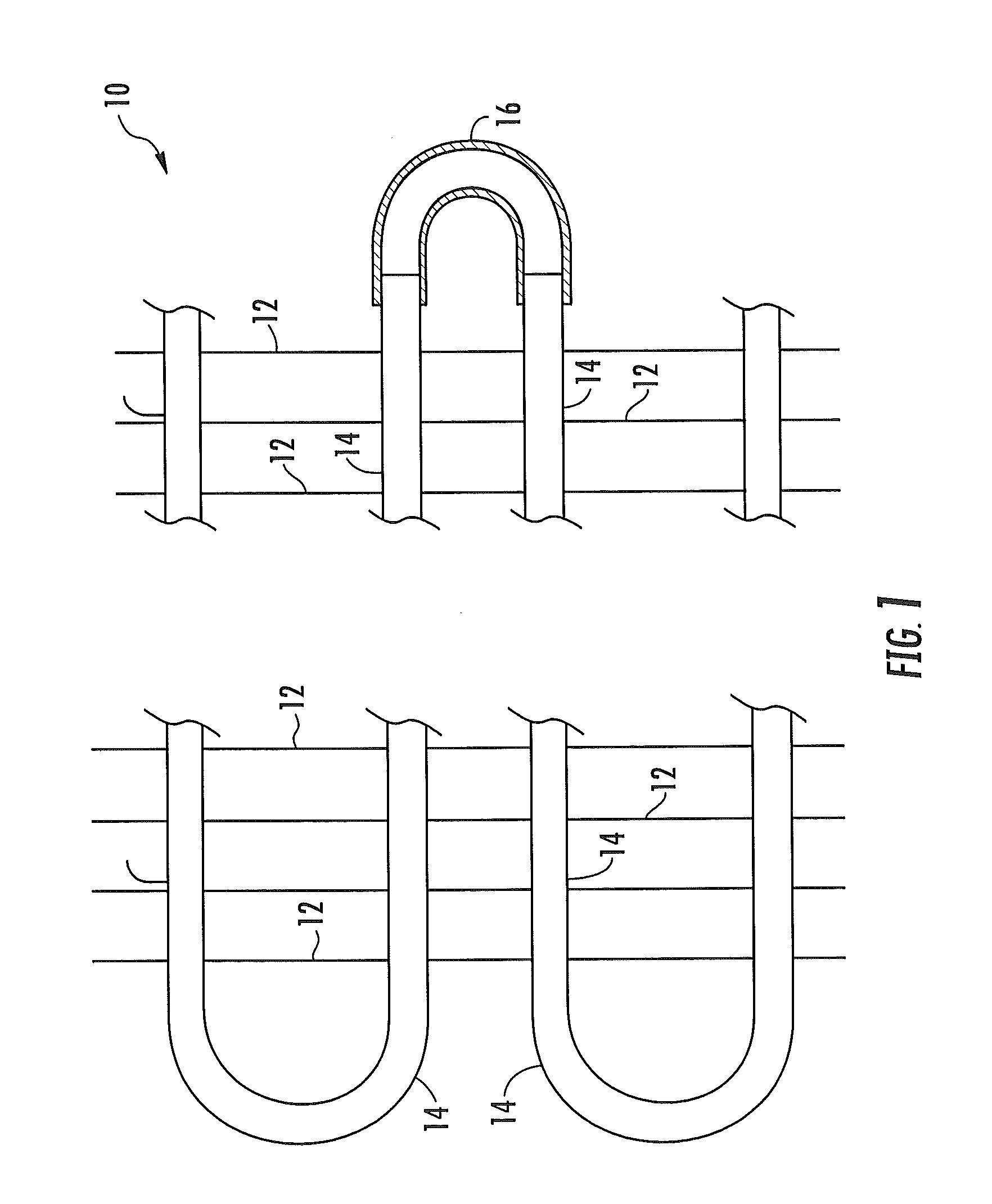

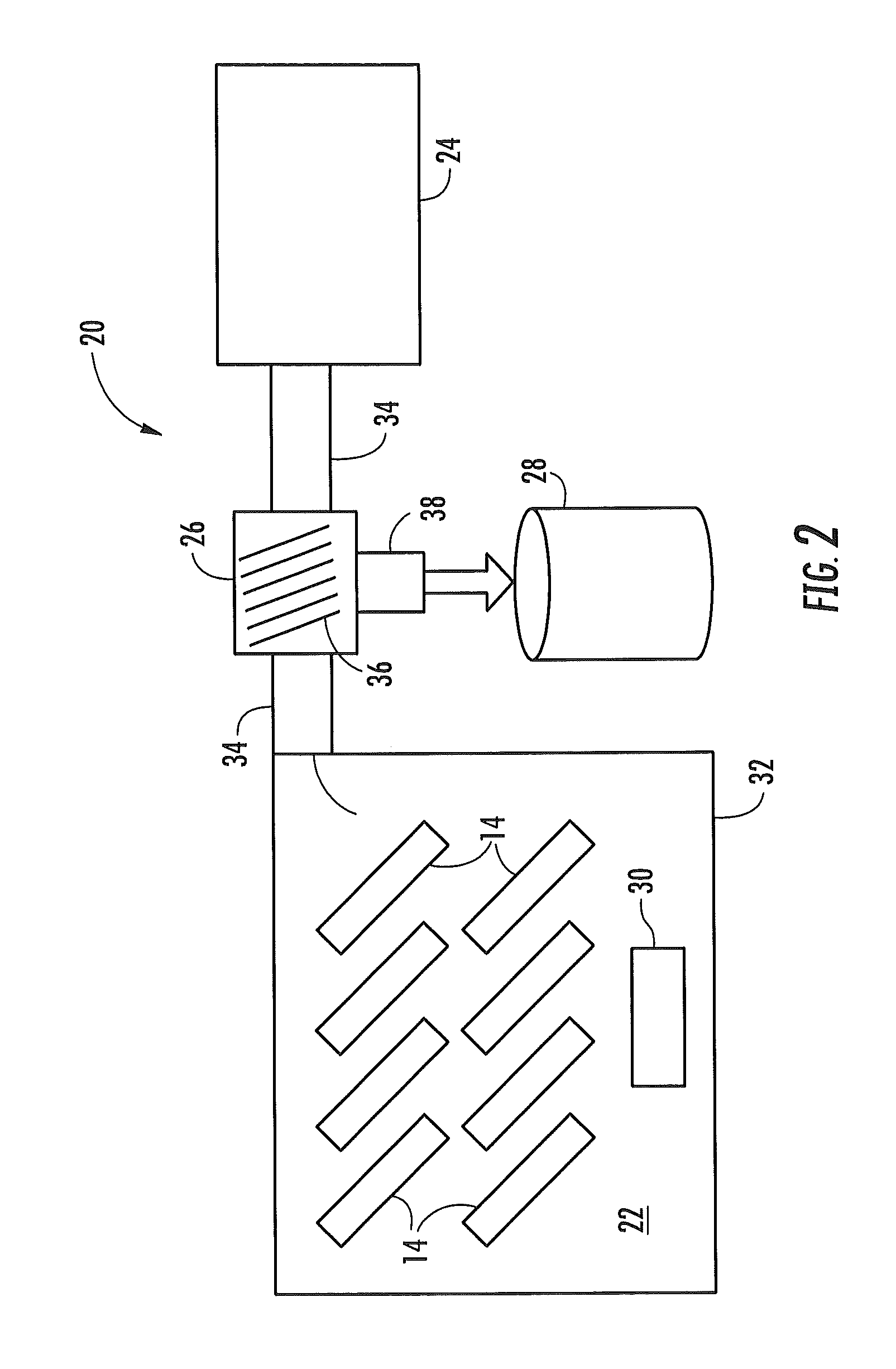

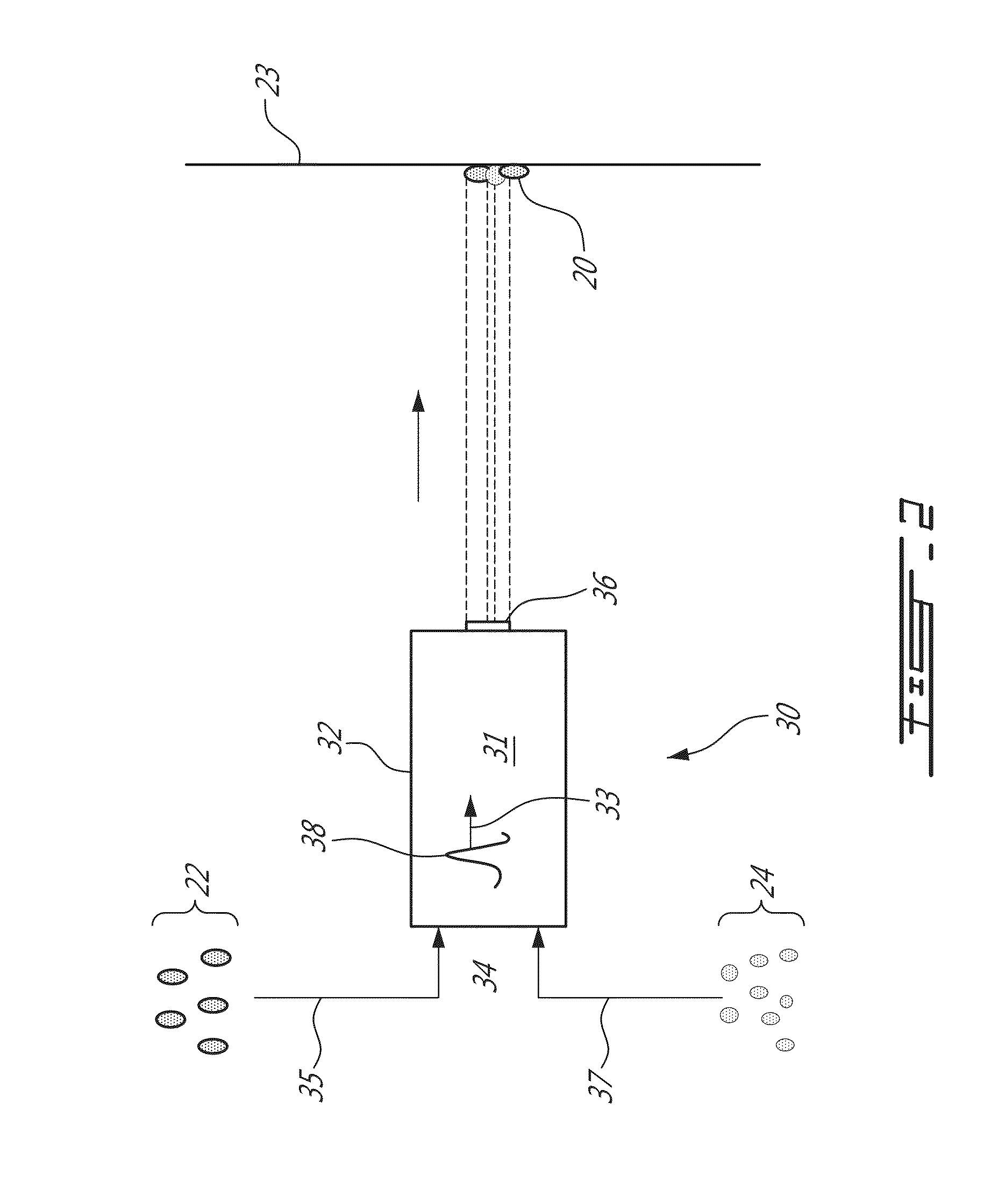

Vacuum Drying Of Heat Exchanger Tubes

InactiveUS20130205614A1Safe removalDrying solid materials with heatDrying solid materials without heatSolvent vaporRadiant heater

A method and an apparatus are disclosed for removing a solvent from a solvent wetted surface of a heat exchange tube. The method includes placing the heat exchange tube in a vacuum chamber, evacuating the vacuum chamber to a lower pressure at which the solvent boils to a vapor, and reclaiming the solvent vapor. The method may include heating the heat exchange tube within the vacuum chamber to a temperature of at least room temperature, but below the solvent's flash point temperature. The apparatus includes a vacuum chamber, a vacuum pump for evacuating the vacuum chamber and a solvent reclaimer for recovering solvent vapor. The apparatus may also include an infrared heater, a radiant heater or other non-flame heater. The method and apparatus may be used for removing solvent from a heat exchange tube having an inside surface wetted with a solvent carrying a dry lubricant.

Owner:CARRIER CORP

Emulsion-type lubricant and its application in medical rubber product

An emulsion-type lubricant and its application in medical rubber products are disclosed. The said lubricant including oil-in-water O / W-type one, water-in-oil W / O-type one and composite one is prepared from oily liquid matrix of organosilicon and water-base lubricant. The said water-base lubricant contains one or more of water, ethanediol, propanediol, glycerine, etc. The said oil-base contains oily liquid of organosilicon. Its advantage is high lubricating performance.

Owner:GUANGZHOU WANFANGJIAN MEDICINE

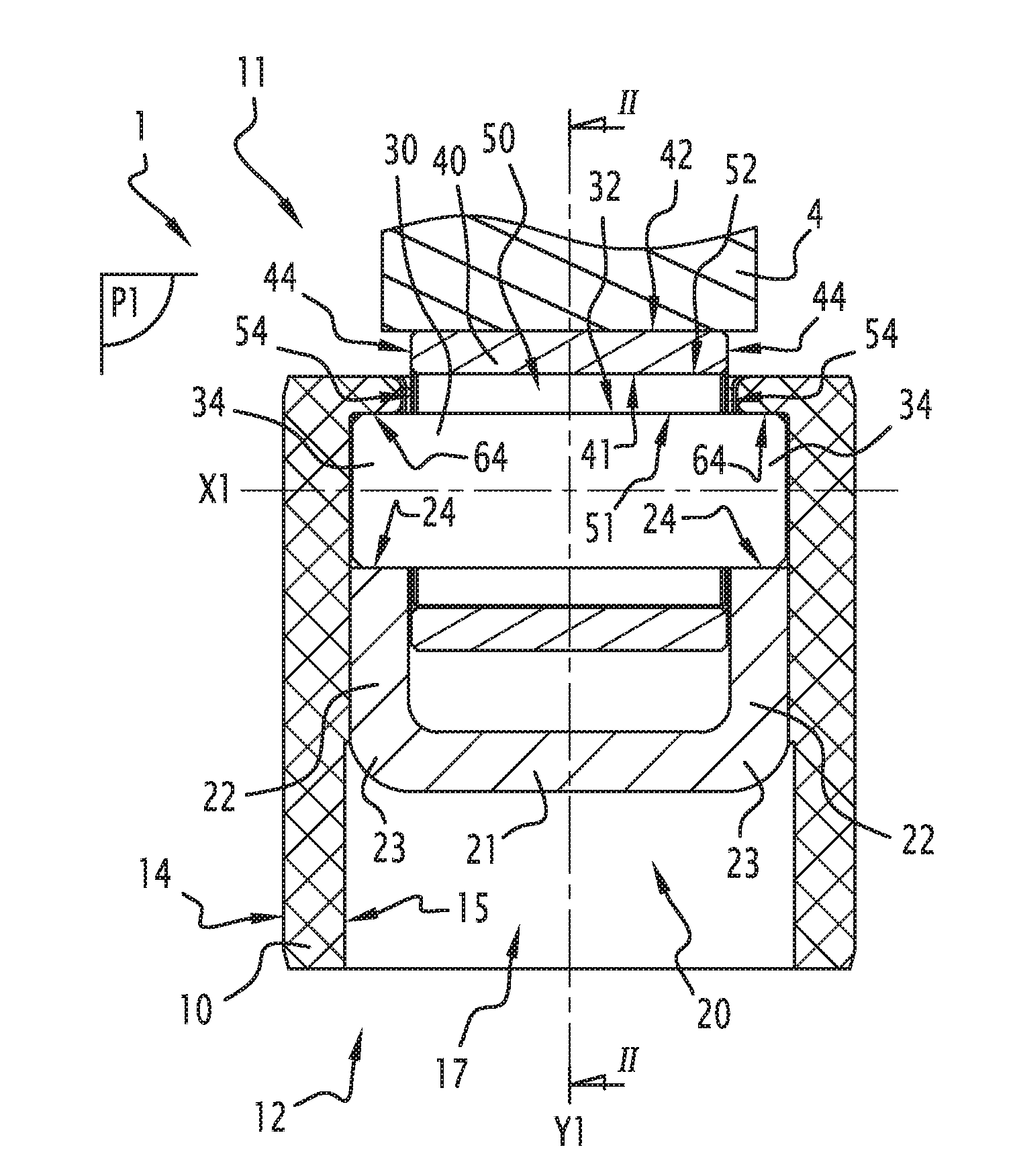

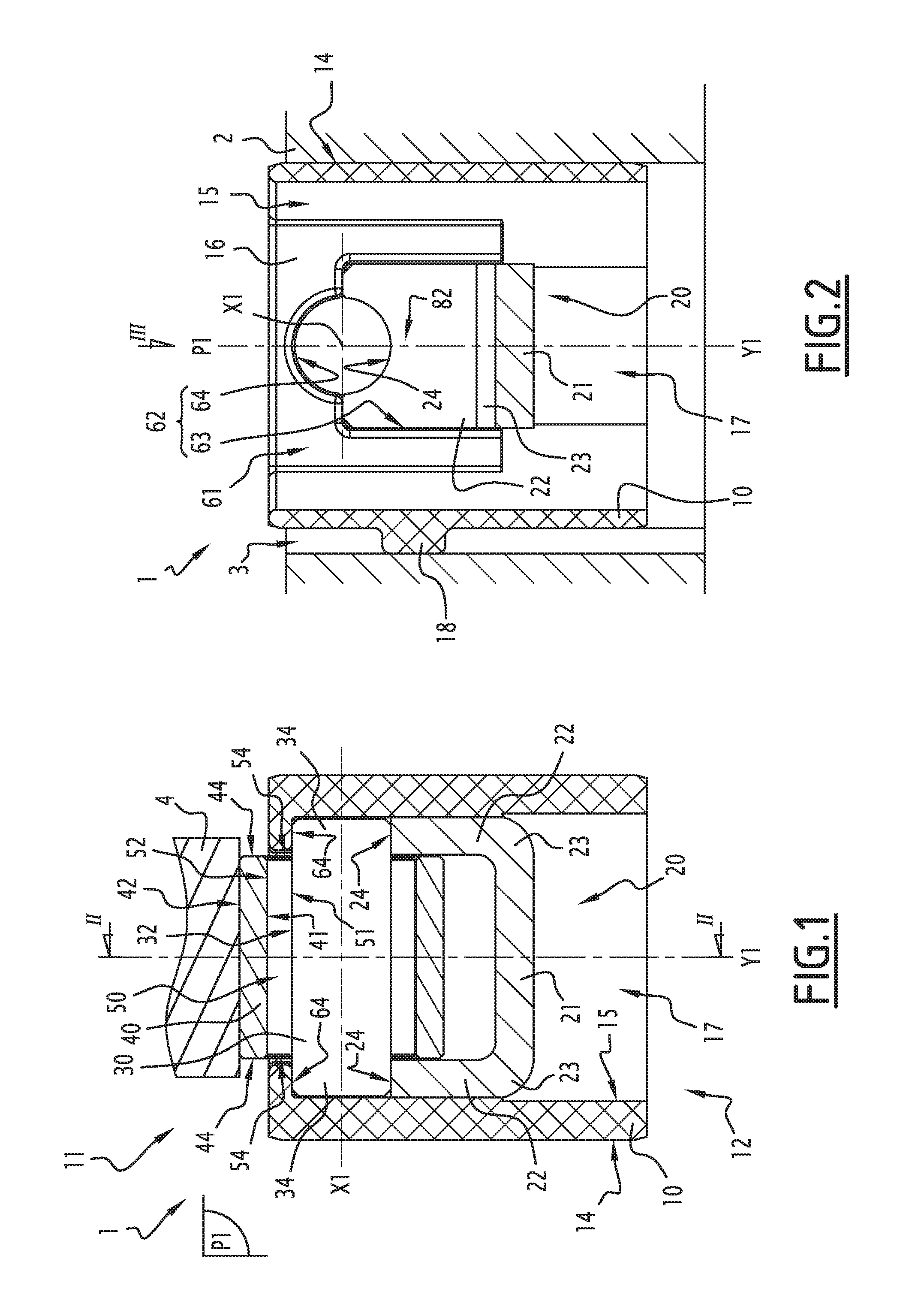

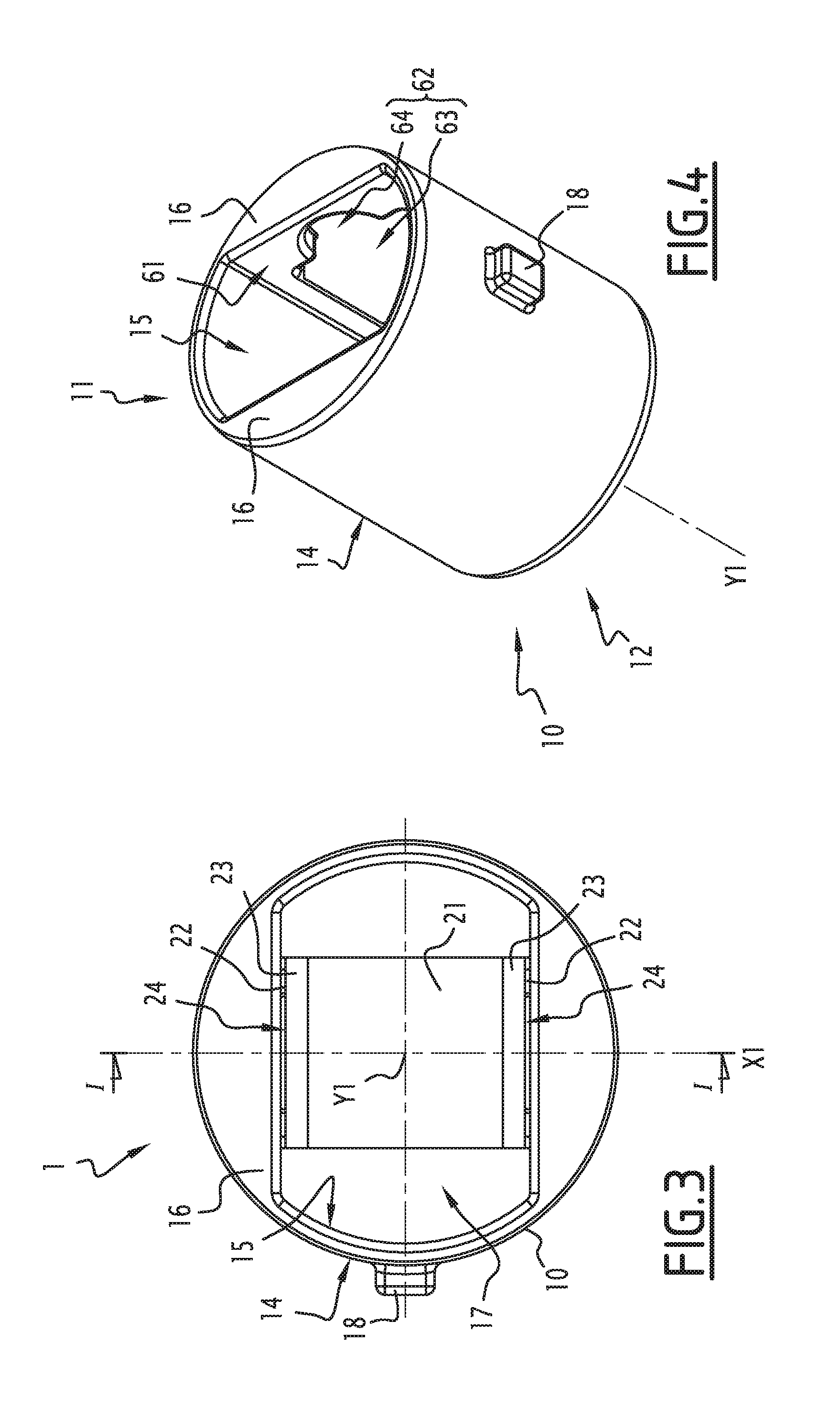

Cam follower, injection pump and valve actuator comprising such a cam follower, and manufacturing method

ActiveUS20160312665A1Prevent rotationReduce wearValve arrangementsCam-followersTransverse axisMobile vehicle

The invention concerns a cam follower providing a tappet having a cylindrical outer surface centered on a longitudinal axis (Y1) and adapted to slide in a housing surrounding the tappet, a pin extending between two opposite ends along a transverse axis (X1) perpendicular to the longitudinal axis, and a roller element movable in rotation relative to the pin around the transverse axis and adapted to roll on a cam. The tappet is made of a composite material integrating at least one dry lubricant released at the cylindrical outer surface when the cam follower is in operation. The invention also concerns a valve actuator for a motor vehicle, providing such a cam follower. The invention also concerns a method for manufacturing such a cam follower.

Owner:AB SKF

Environment-friendly type high-performance PU synthetic leather and its preparation method

InactiveCN1966578ASolve serious environmental problemsPlay a role in sterilizationTextiles and paperPlasticizerMoisture absorption

The invention relates to a kind of environment-friendly high performance PU synthetic leather which belongs to burn-retarding synthetic leather domain. The invention uses the aquosity polyurethane as the material, the phosphide fire-fast plasticizer as the retardant; it also contains the accessories such as modifier and dispersing agent; the invention has solved the serious environment-protection problem in leather producing and the eight poisonous and toxic elements in the synthetic leather has satisfied the European standards. By adding organosilicon dry lubricant prescription in the invention, the leather has many effects such as clean, dry, lubricate, sterilization, mould proof, water proof, moisture absorption proof and separation proof; it has more notable dermis simulating effect.

Owner:JIANGSU GUOXIN SYNTHETIC LEATHER

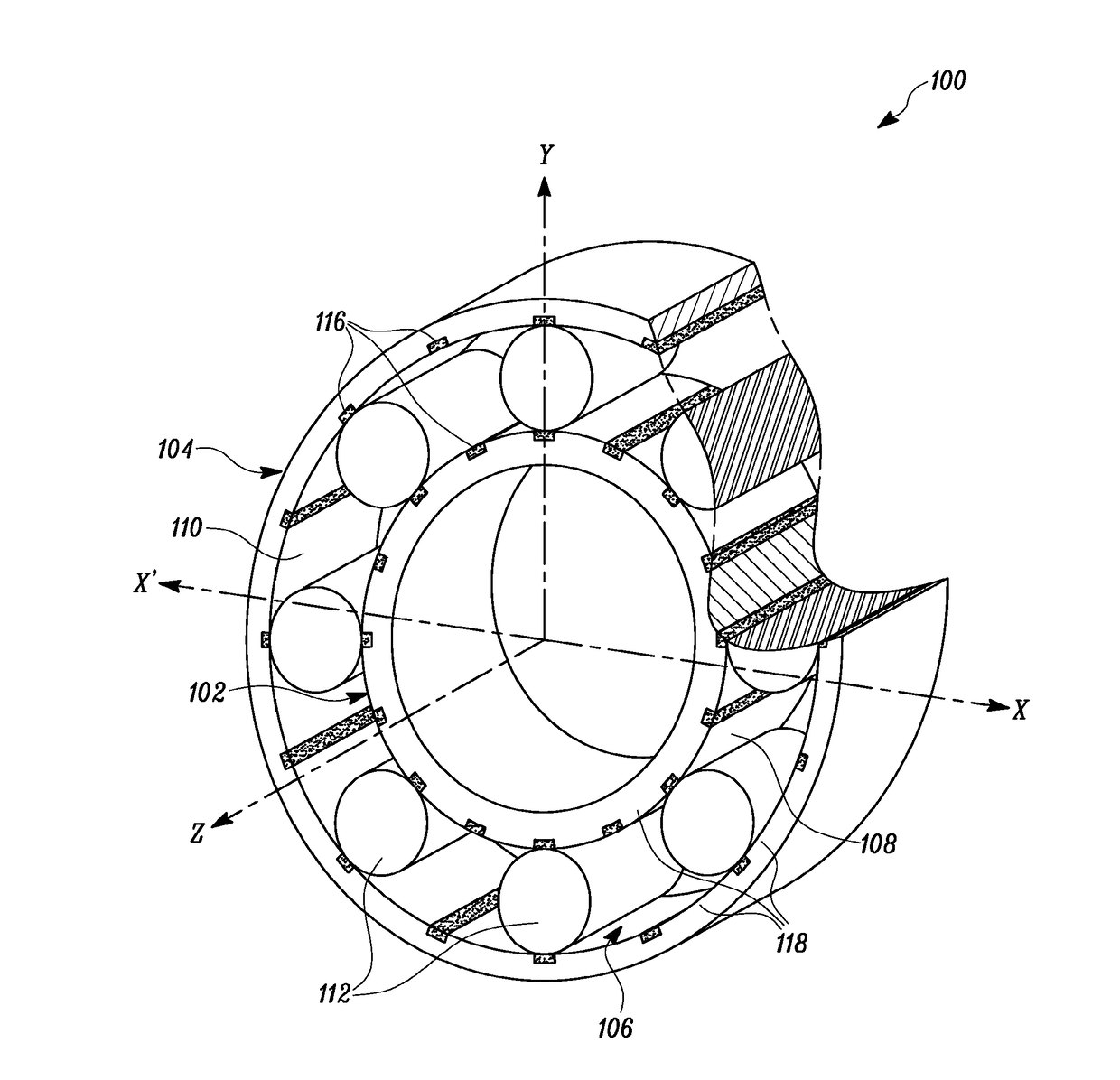

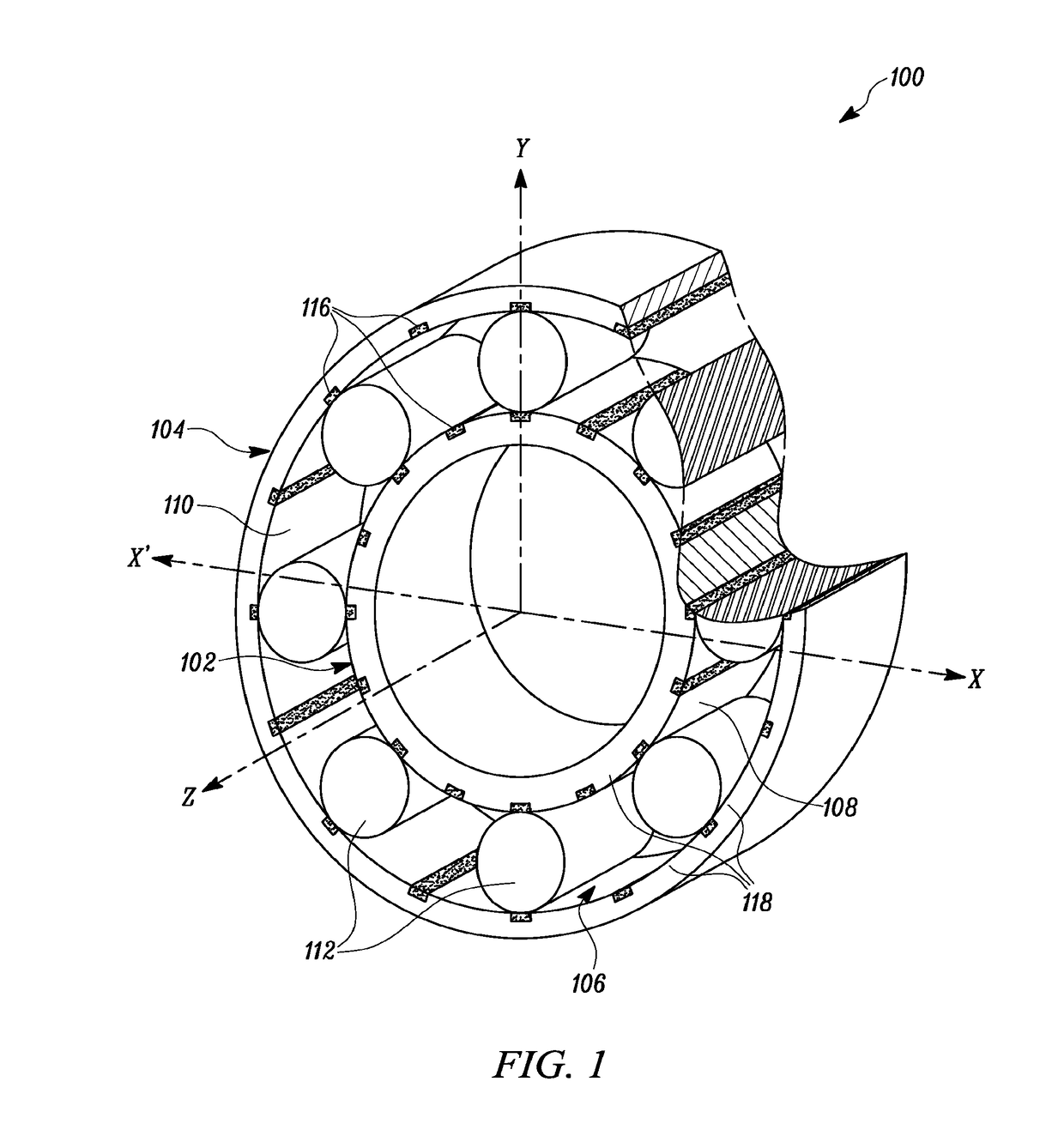

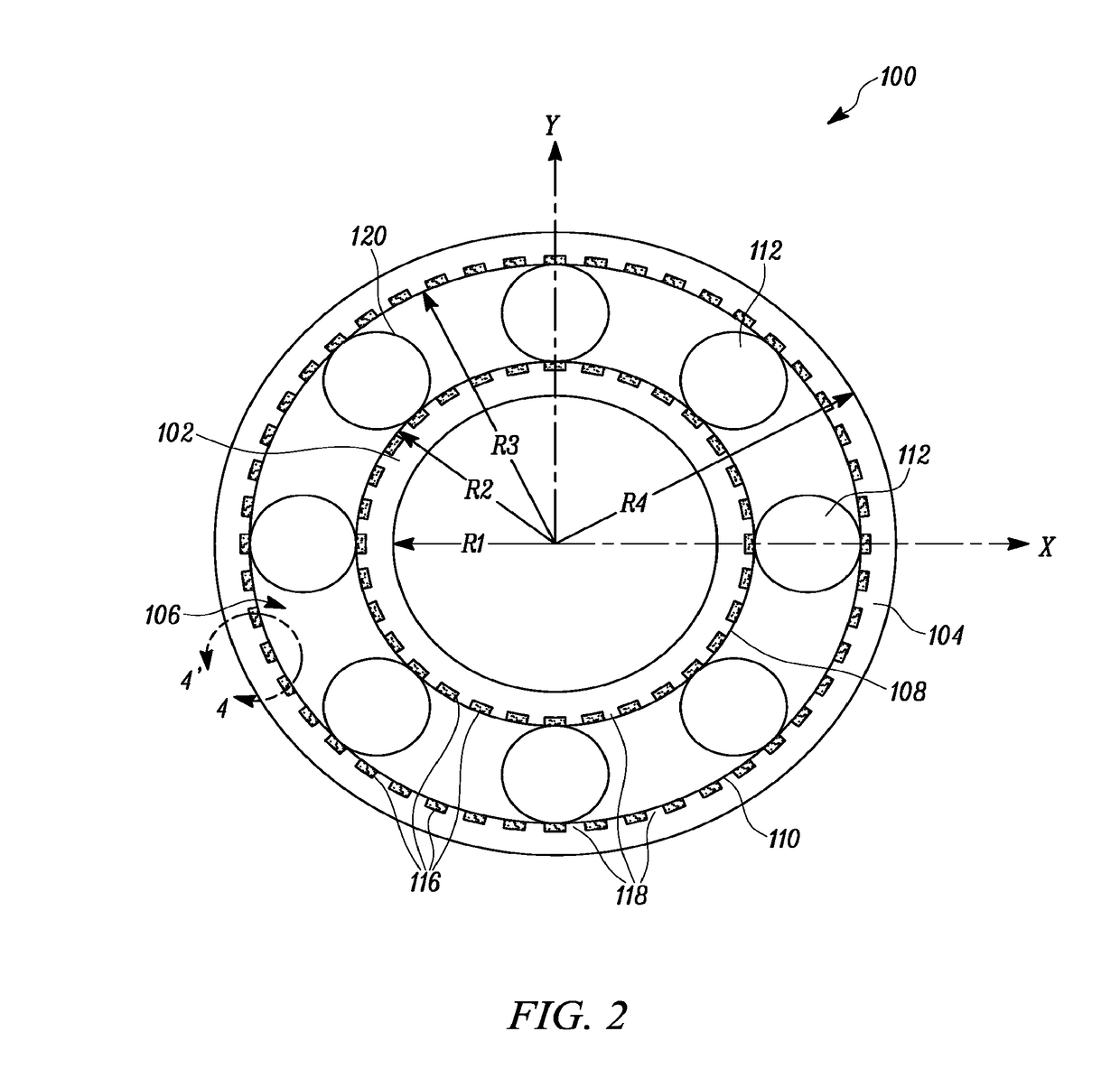

Self-lubricating roller bearing and methods of making and using self-lubricating roller bearing

InactiveUS20170298990A1Additive manufacturing apparatusRoller bearingsRolling-element bearingEngineering

A self-lubricating roller bearing is provided. The roller bearing includes an inner race, an outer race, and a plurality of rollers between the inner and outer races. Each of the inner race and the outer race includes a bearing surface for contact with the rollers. The bearing surface of one or more of the inner race, the outer race, and the rollers has one or more laser hardened areas and one or more non-laser hardened areas arranged in a predetermined pattern. The one or more non-laser hardened areas create dry lubricant for the roller bearing upon wear thereof.

Owner:CATERPILLAR INC

Method of forming an abradable coating for a gas turbine engine

InactiveUS20150239010A1Reducing interparticle spacingEnhanced particle densityPretreated surfacesLeakage preventionTrappingEngineering

A method of forming an abradable coating on a gas turbine engine component comprising, in sequence: placing dry lubricant particles and trapping particles in a channel having a spraying end and containing a gas; causing at least one shockwave in the gas to travel in the channel toward the spraying end, the at least one shockwave causing the dry lubricant particles and the trapping particles to travel in the channel with it, the at least one shockwave reducing interparticle spacing and increasing particles density; directing a resulting flow of the dry lubricant particles and the trapping particles from the spraying end at a supersonic velocity to impact the component; and then plastically deforming the trapping particles upon impacting the component with the resulting flow thereby trapping the dry lubricant particles with the deformed trapping particles onto the component to provide the abradable coating.

Owner:PRATT & WHITNEY CANADA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com