Patents

Literature

4302 results about "Tungsten carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through a process called sintering for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry.

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

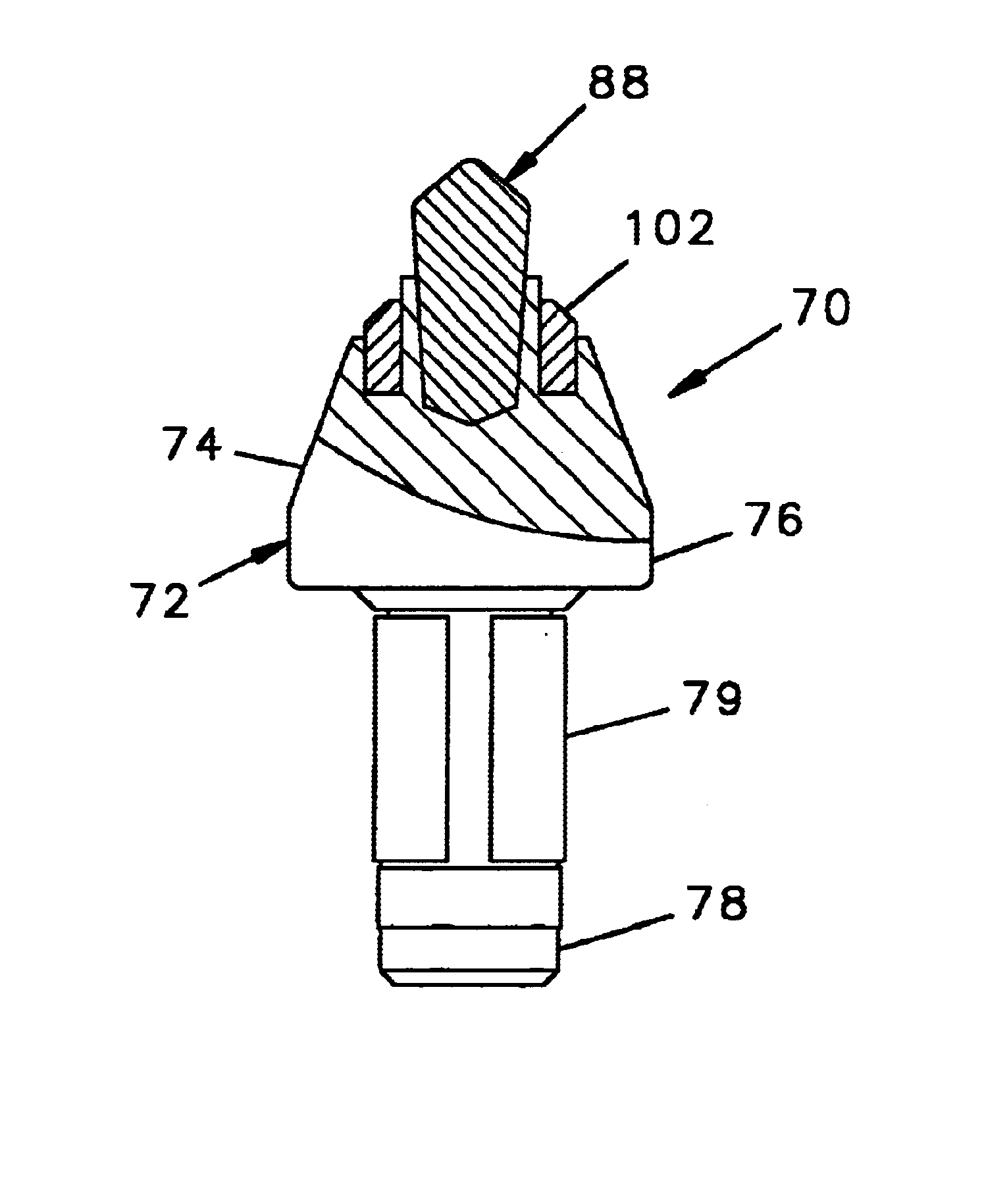

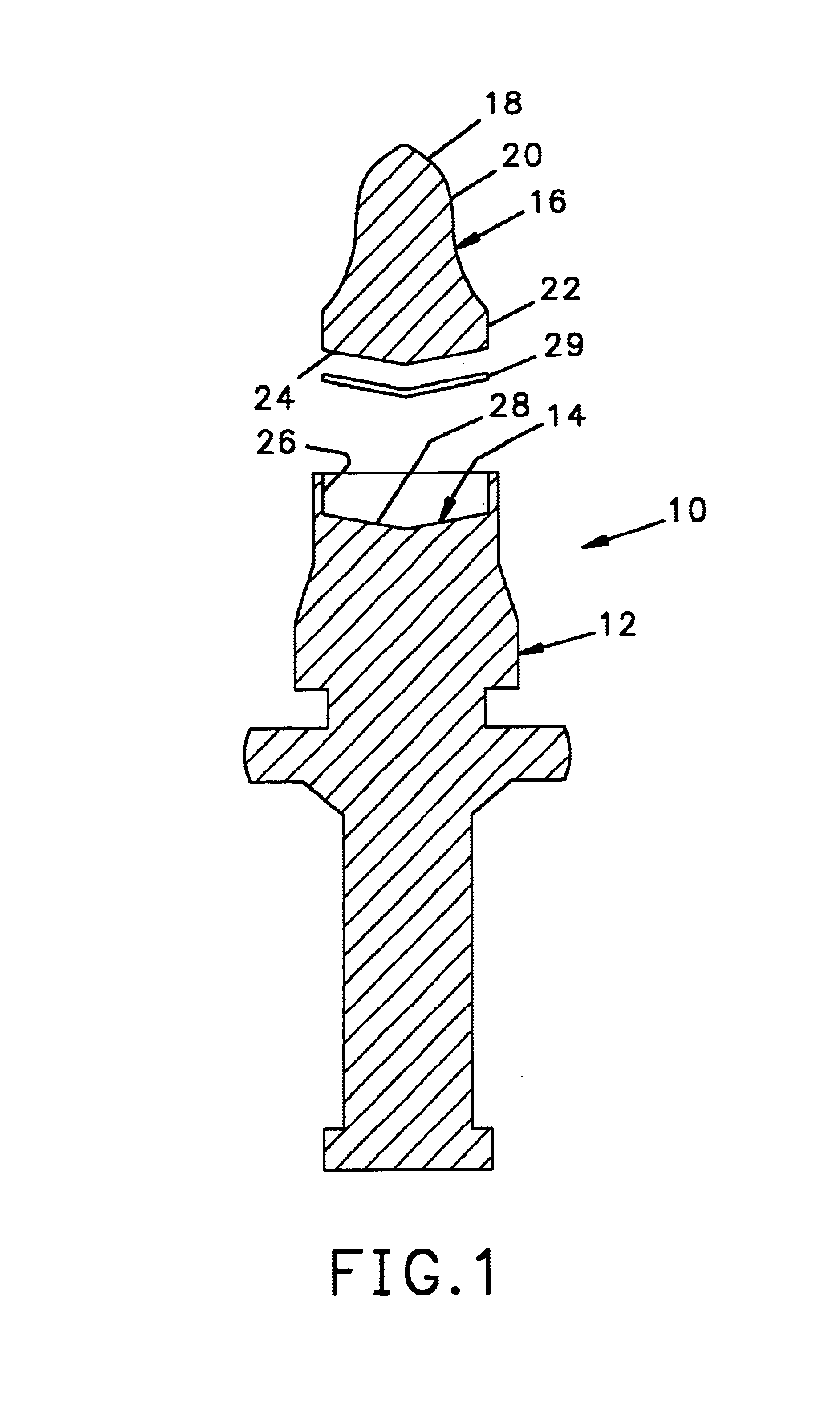

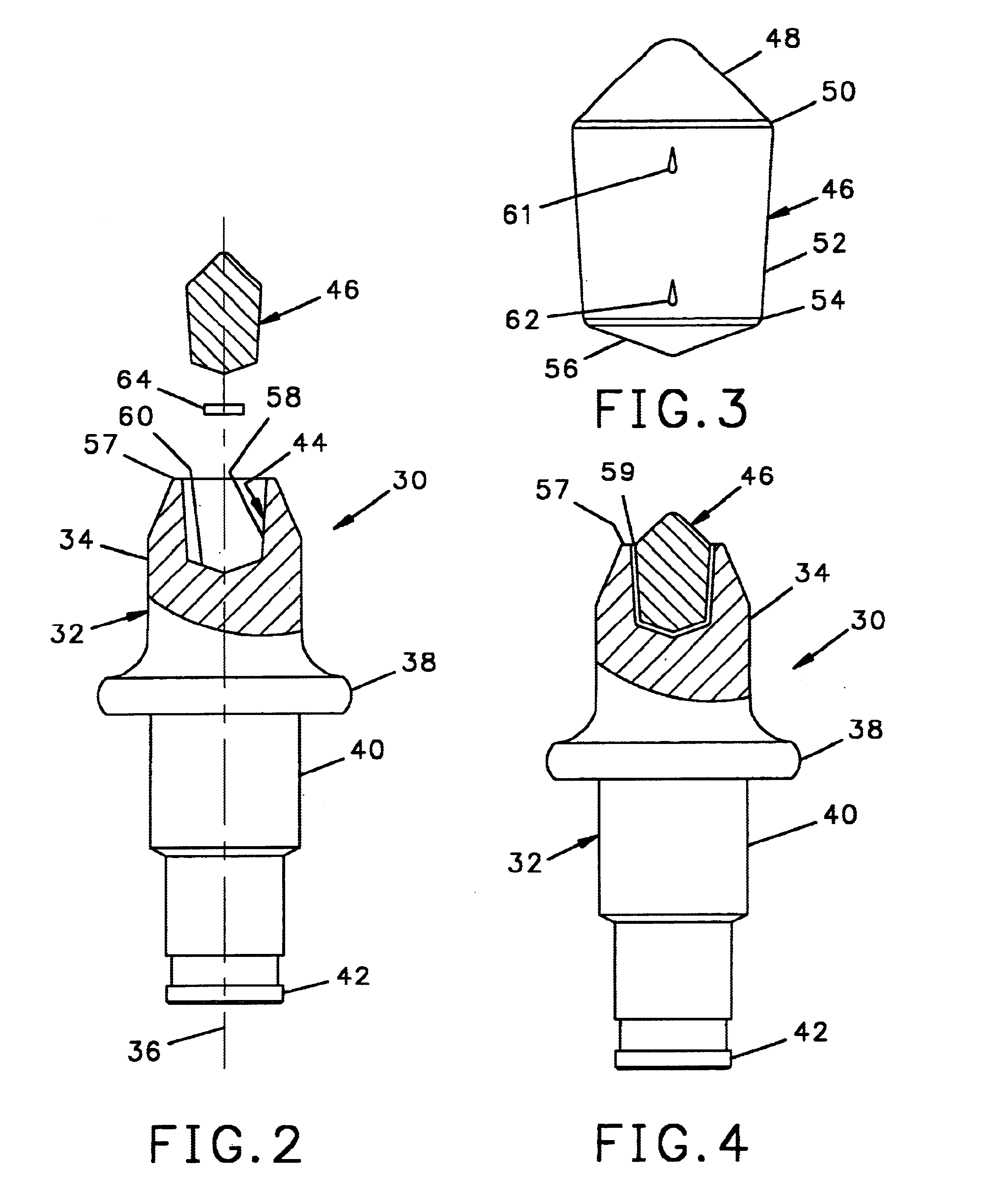

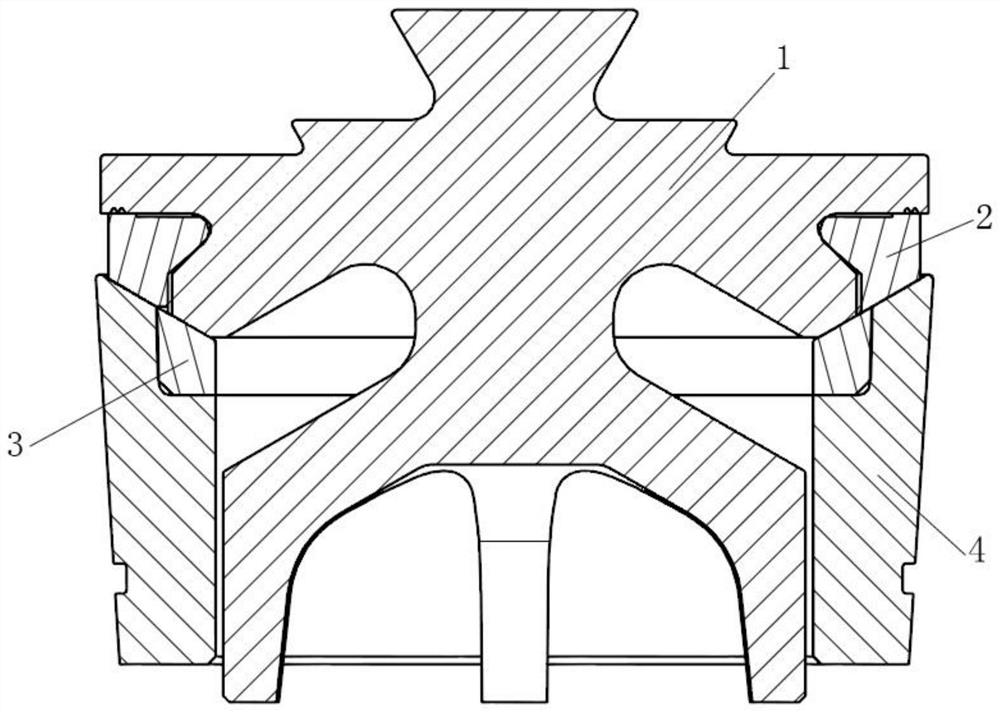

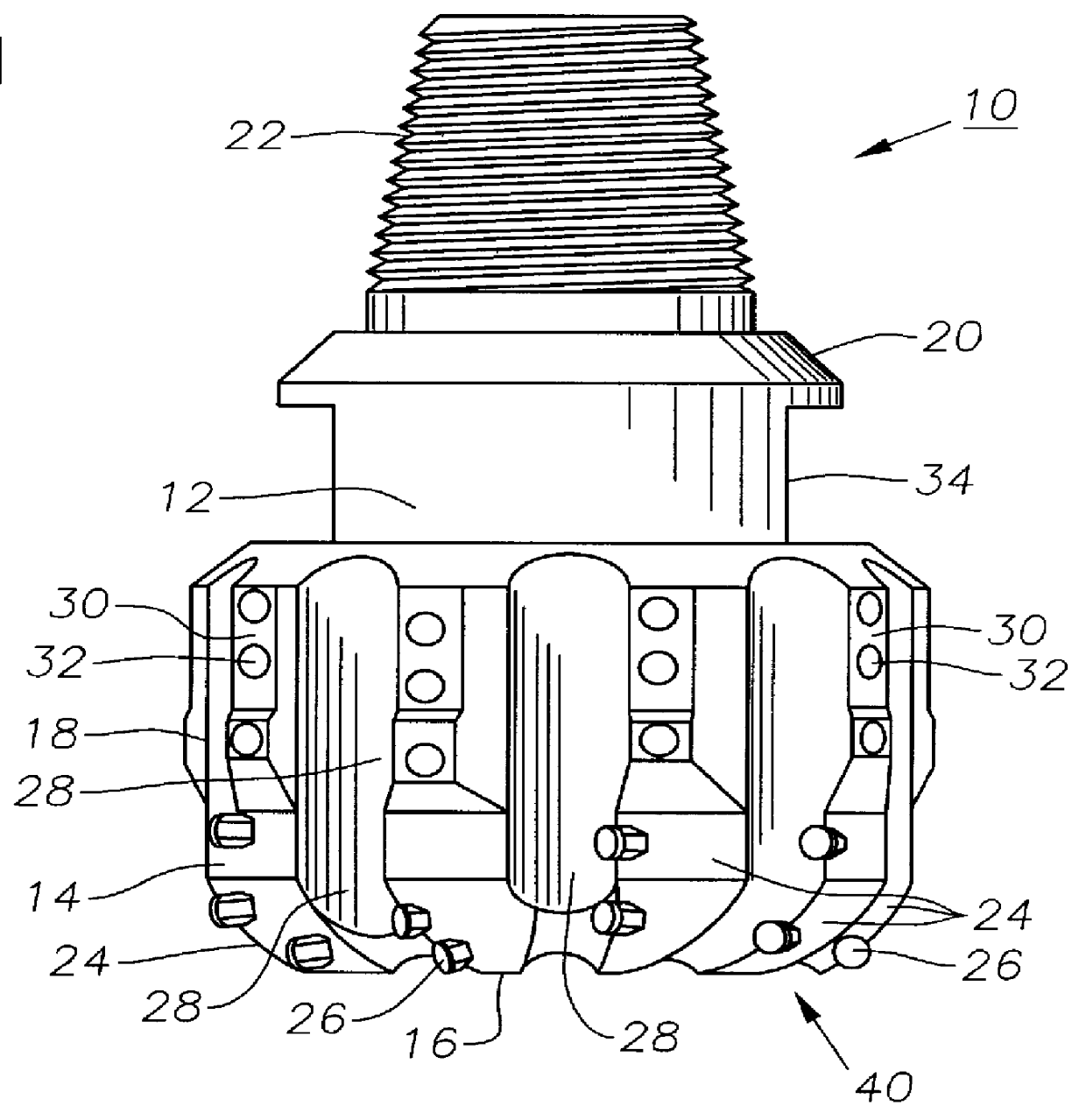

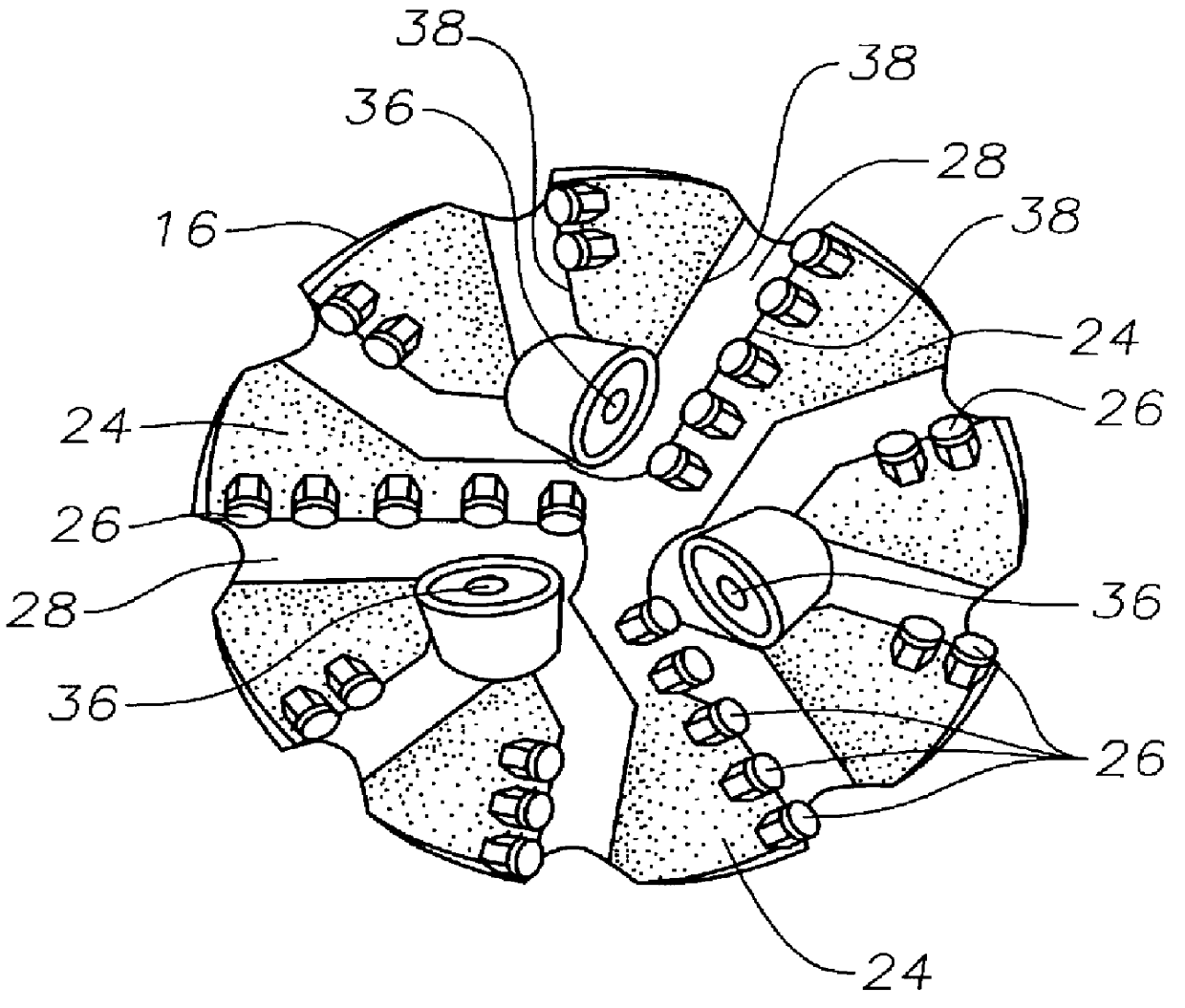

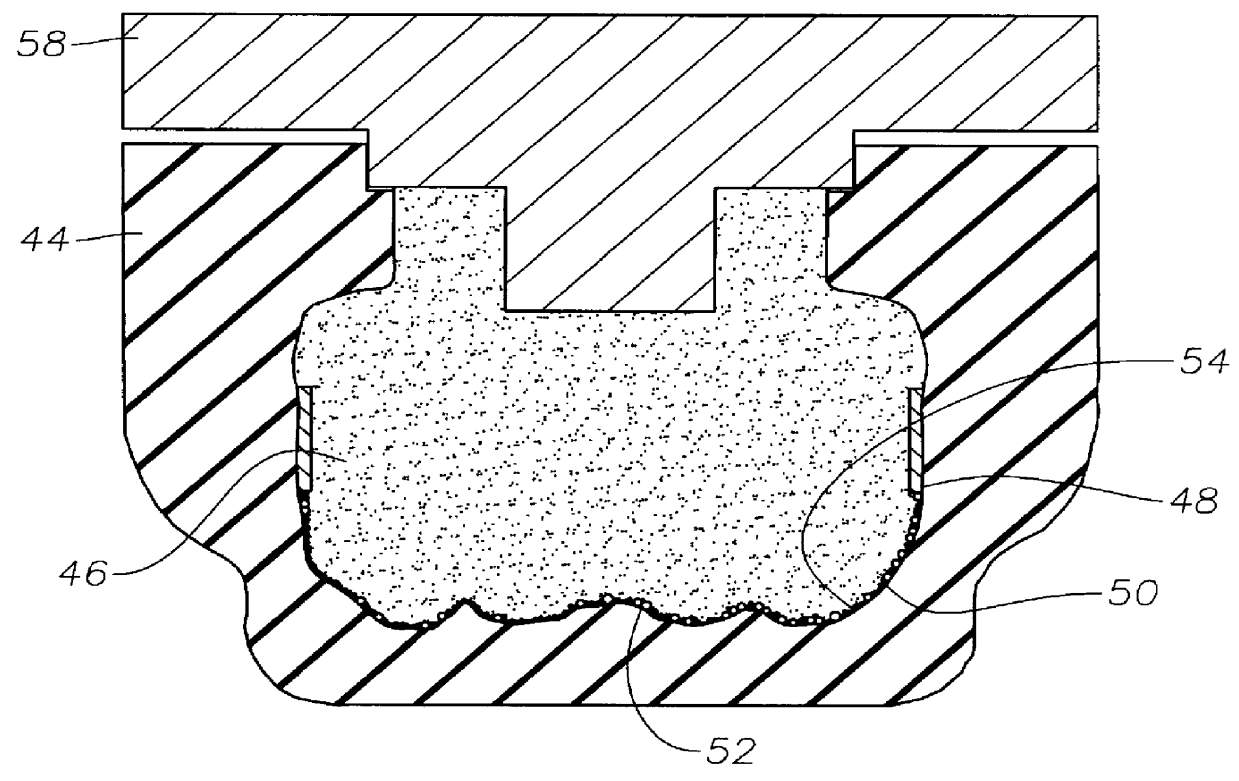

Cutting tool with hardened tip having a tapered base

InactiveUS6739327B2Improved cutting tipReduce harmSlitting machinesFine working devicesEngineeringMechanical engineering

A cutting tool has a centrally located tungsten carbide insert brazed into a seat at the forward end of the tool. The seat has a circular mouth and rearward of the mouth is a frustoconical inner wall. At the bottom of the seat is a transverse surface. A tungsten carbide insert is brazed into the seat and the base of the insert is complementary in shape to the seat. A second annular insert may also be brazed into a complementary shaped annular seat that surrounds the centrally located seat.

Owner:THE SOLLAMI COMPANY

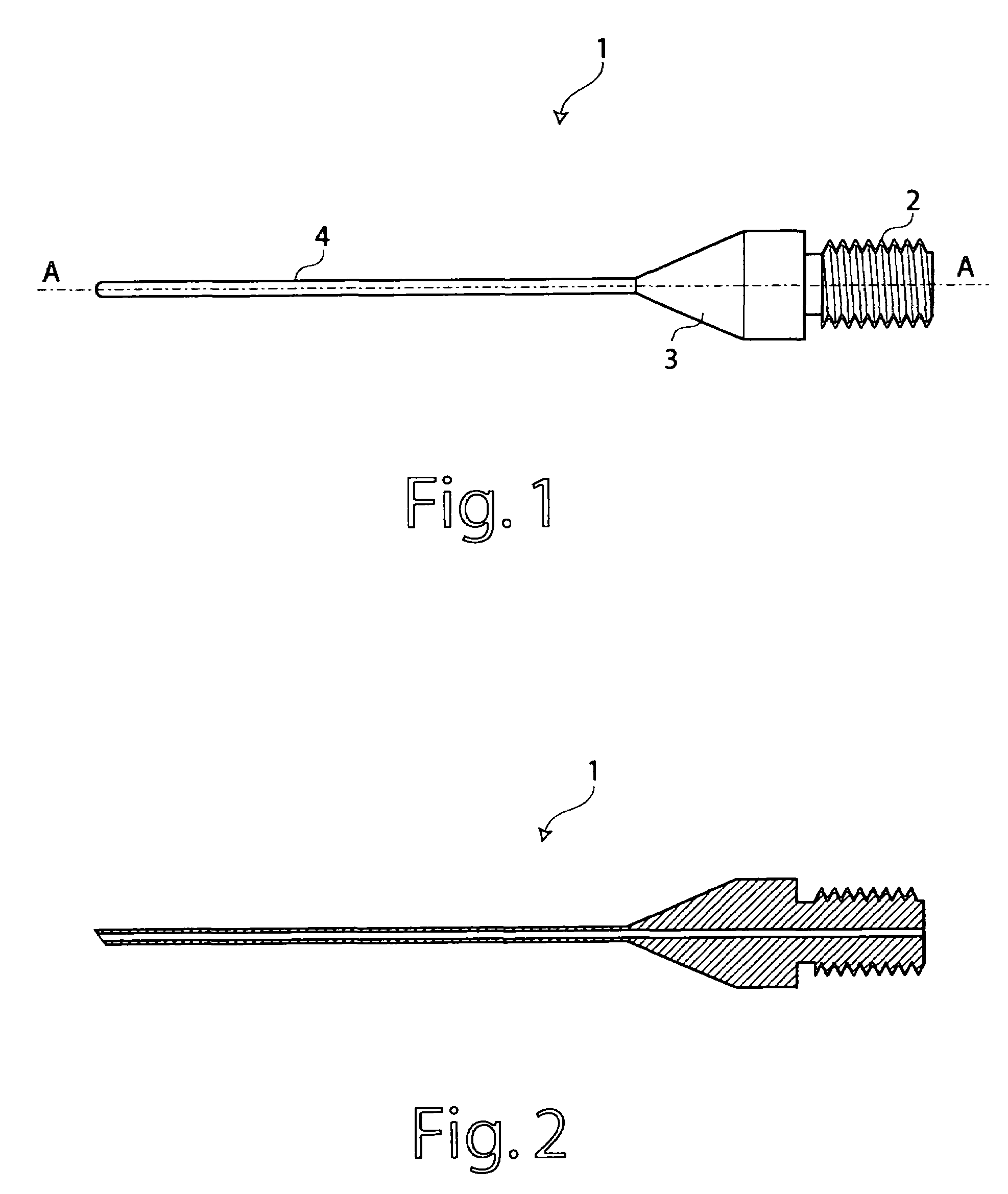

Emulsificated tip for oculistic surgery, particularly for phacoemulsification of cataract

InactiveUS7018389B2Improve adhesionEye surgerySurgical instrument detailsPhacoemulsificationSurgical department

The invention concerns an improved tip (1) for oculistic surgery, particularly for the removal of cataract, having a proximal joint end (2) and a distal end (4), contacting the crystalline during the surgical intervention, wherein the distal end (4) contacting a corneal or sclera tissue is coated with an anti-friction treatment, based on carbon and tungsten carbide.

Owner:OPTIKON 2000

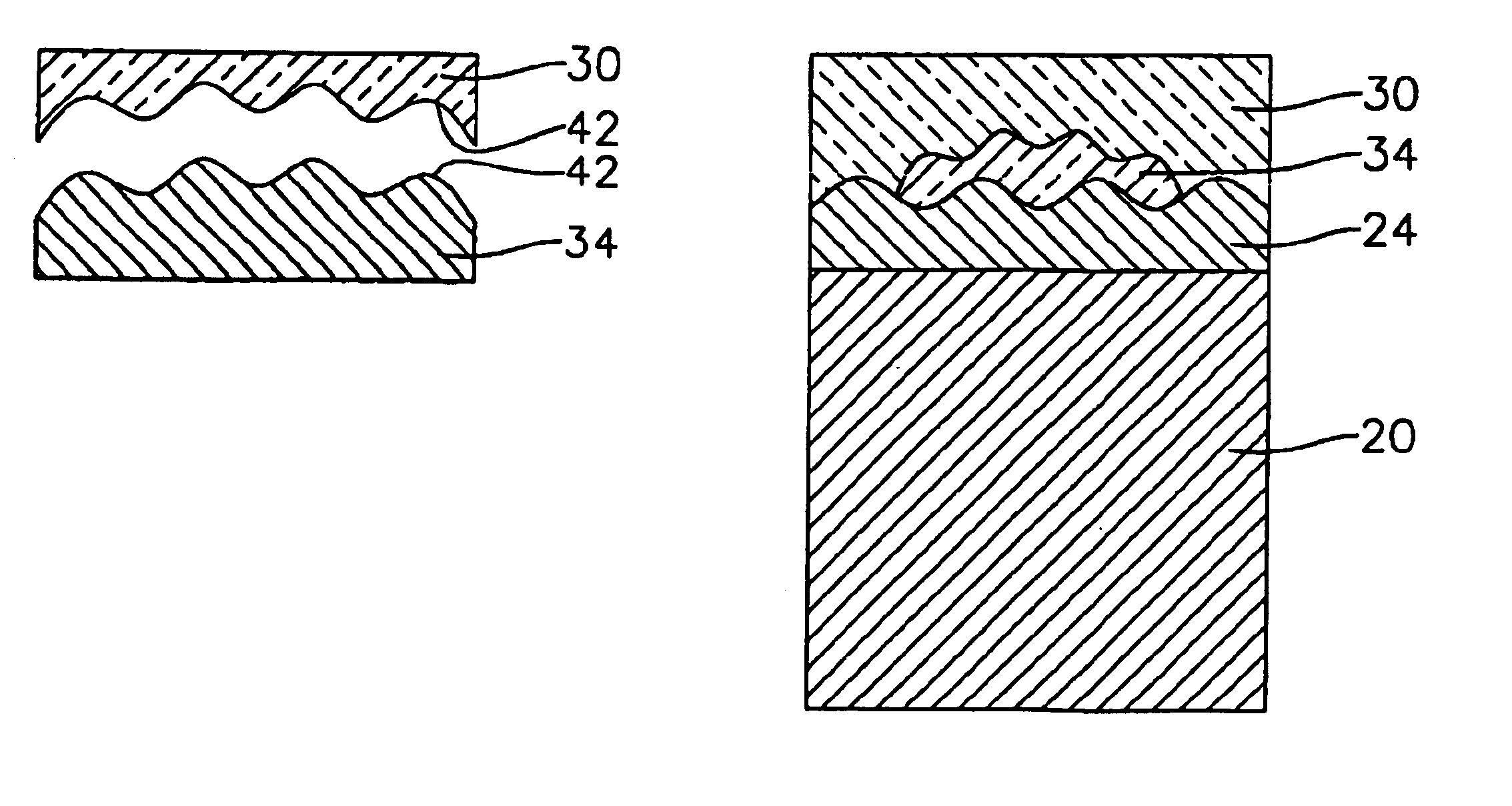

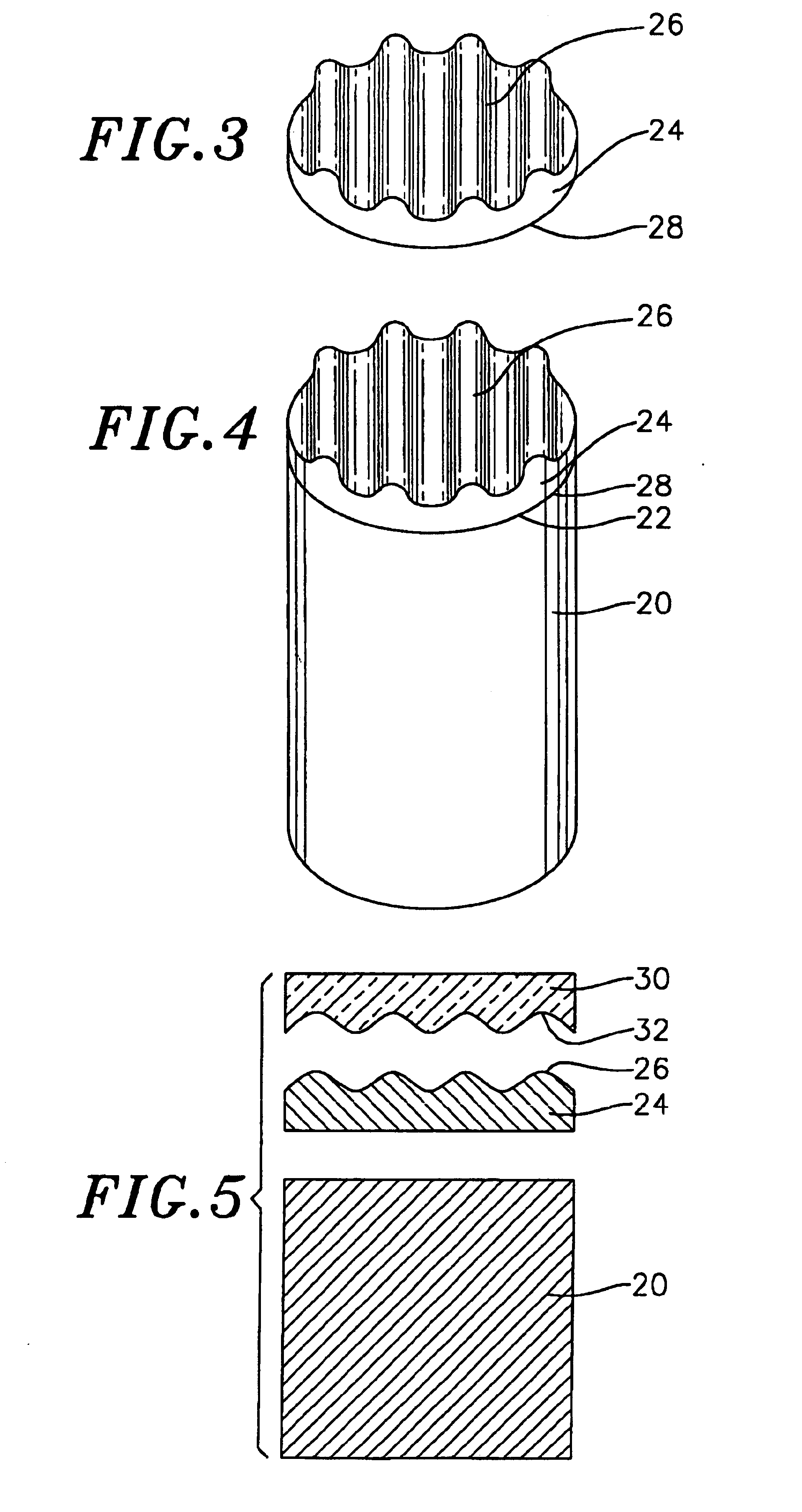

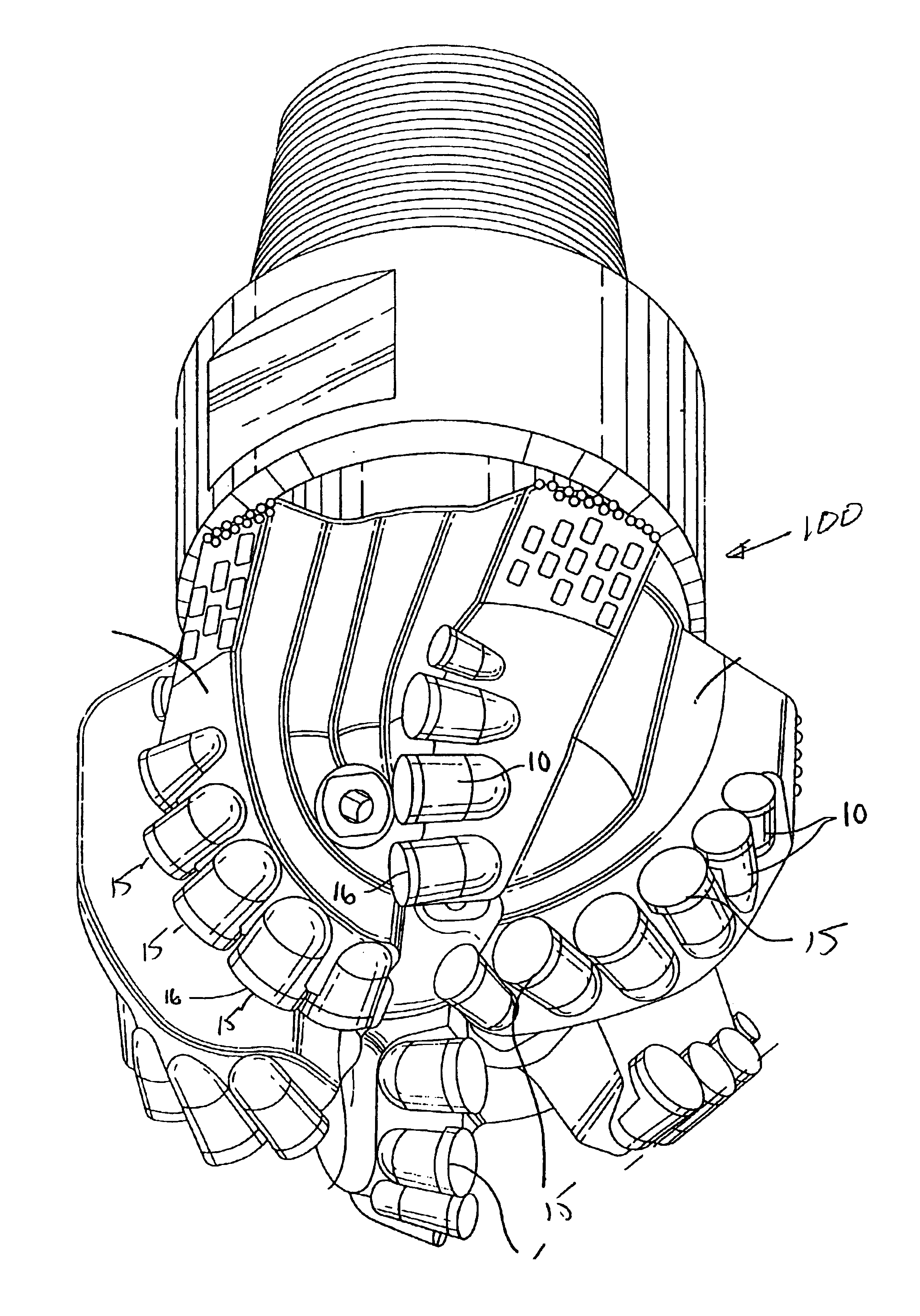

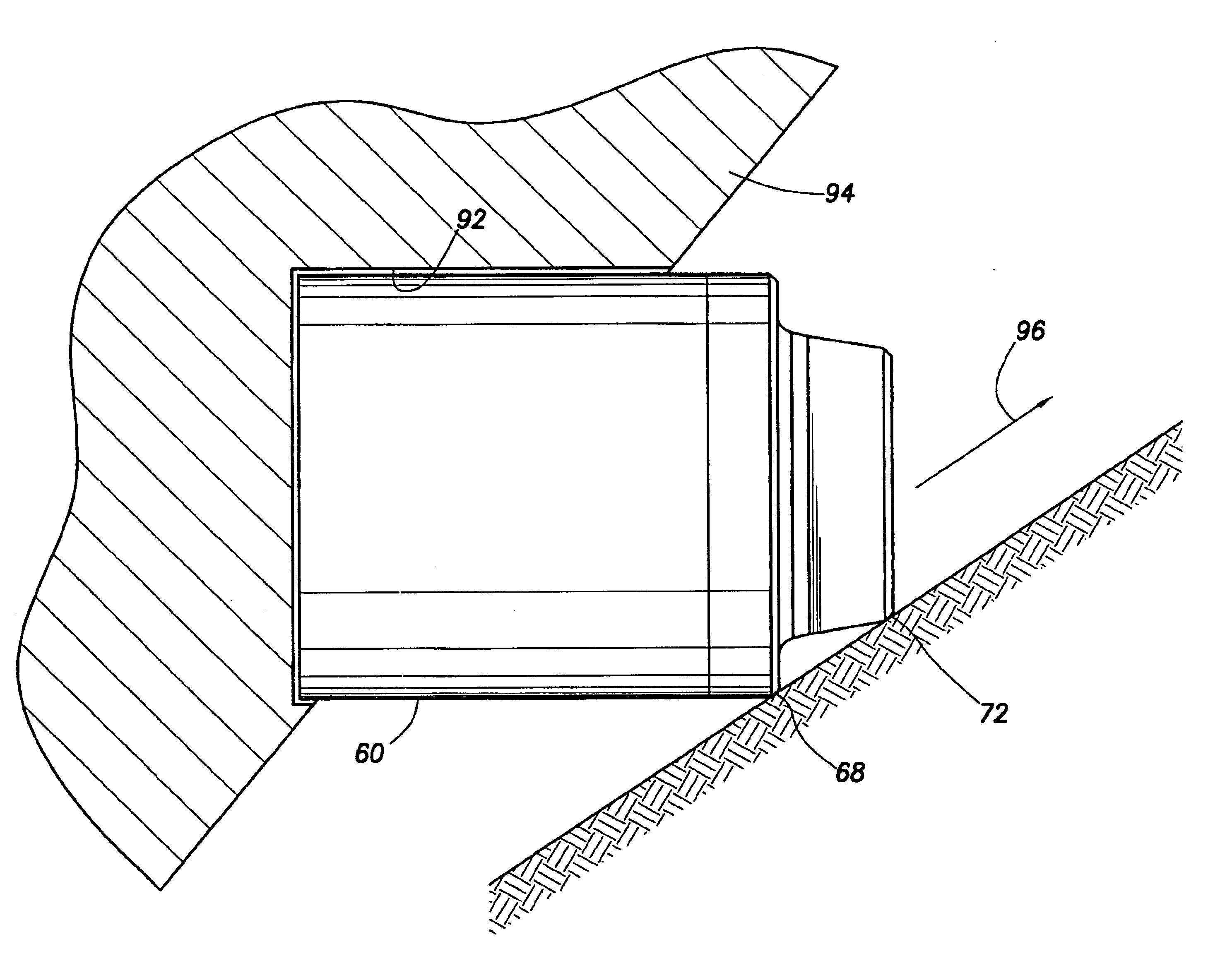

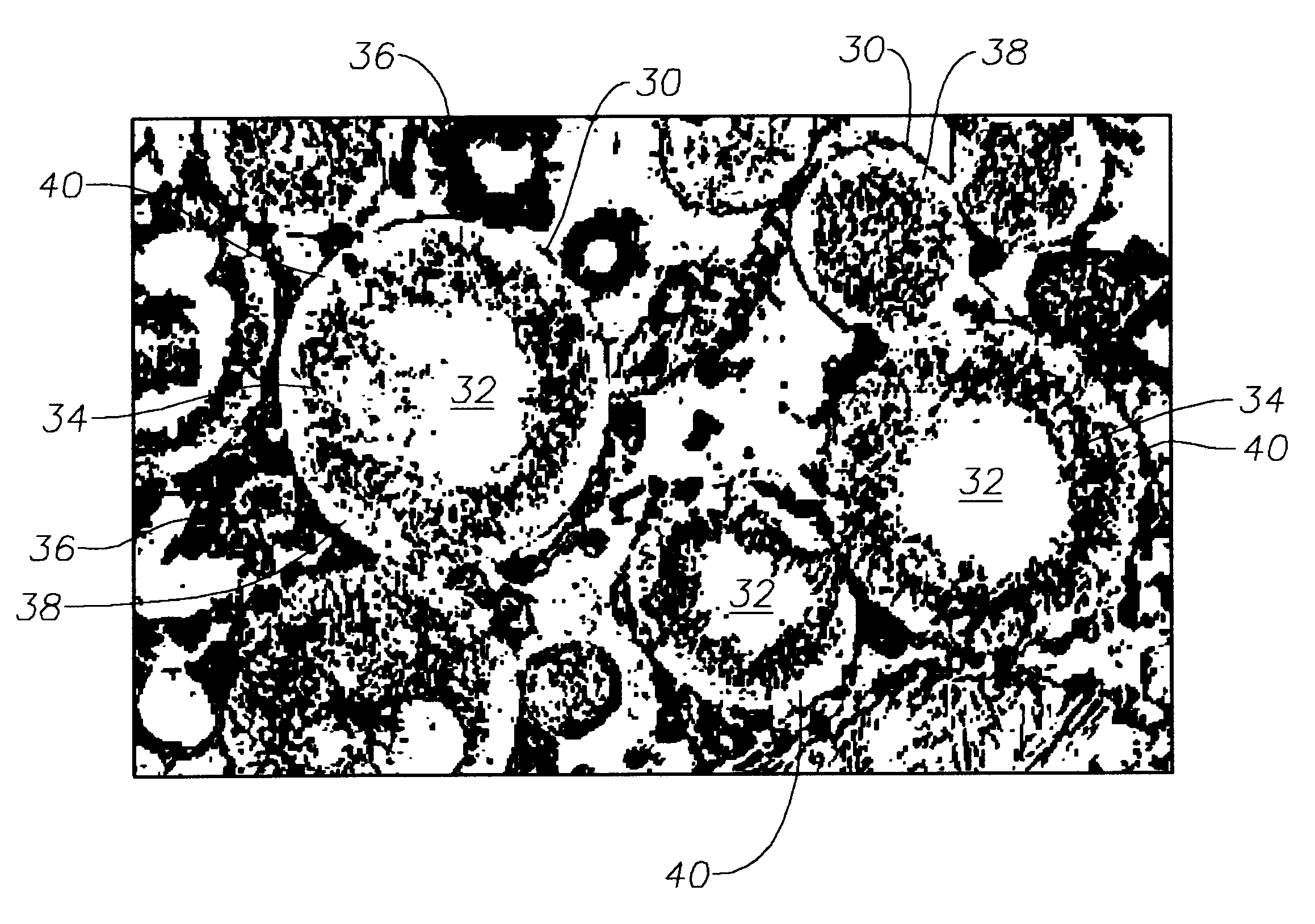

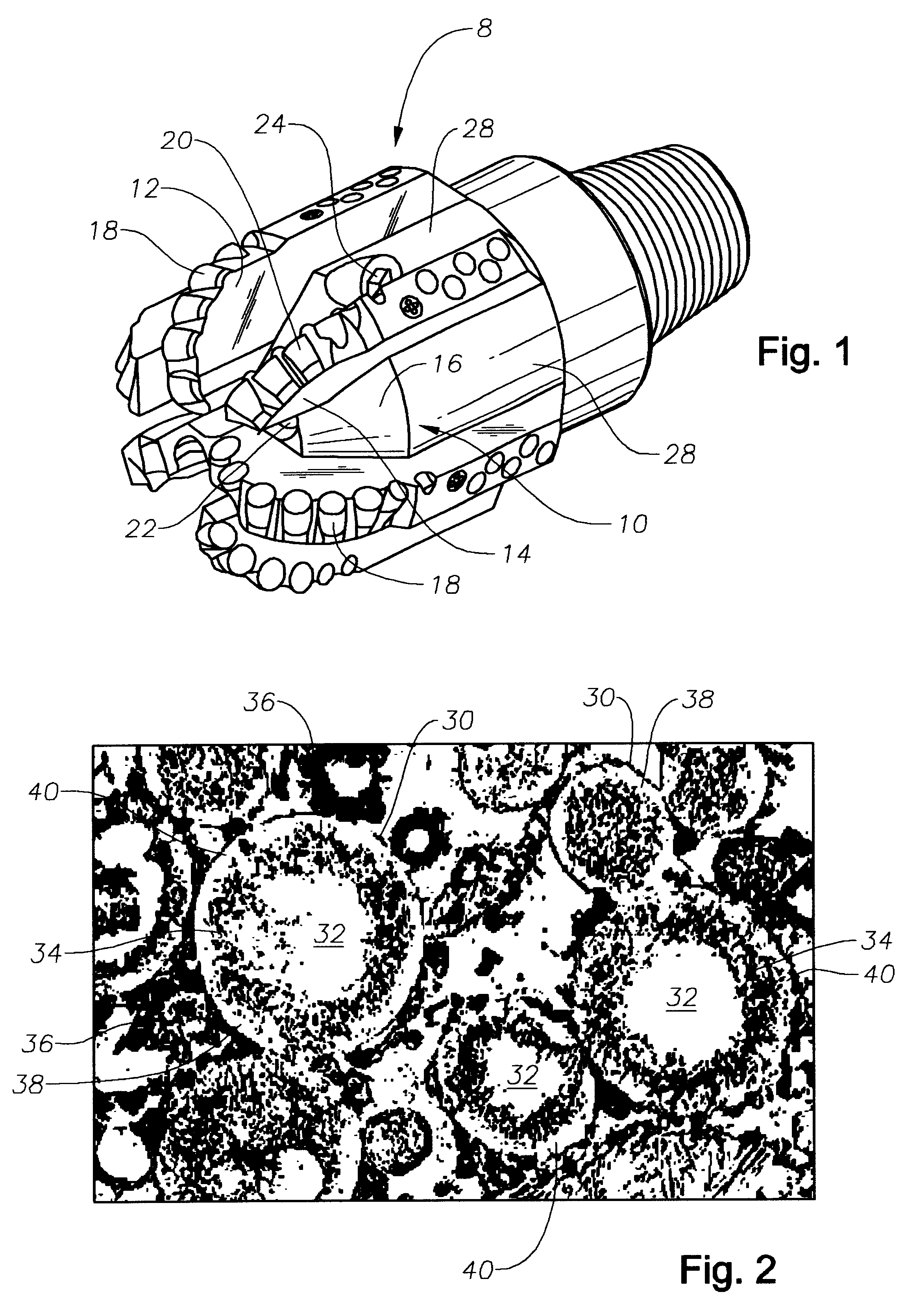

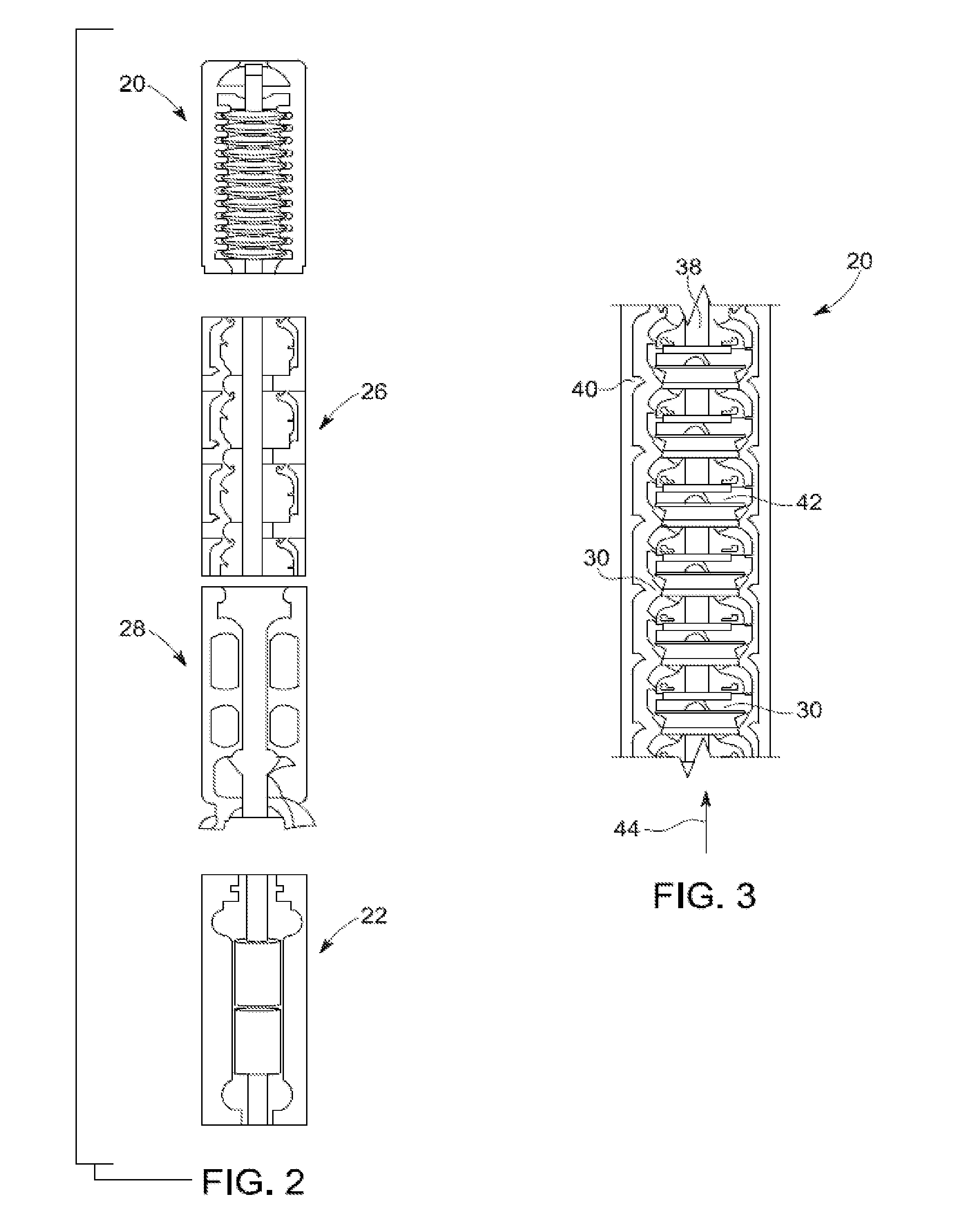

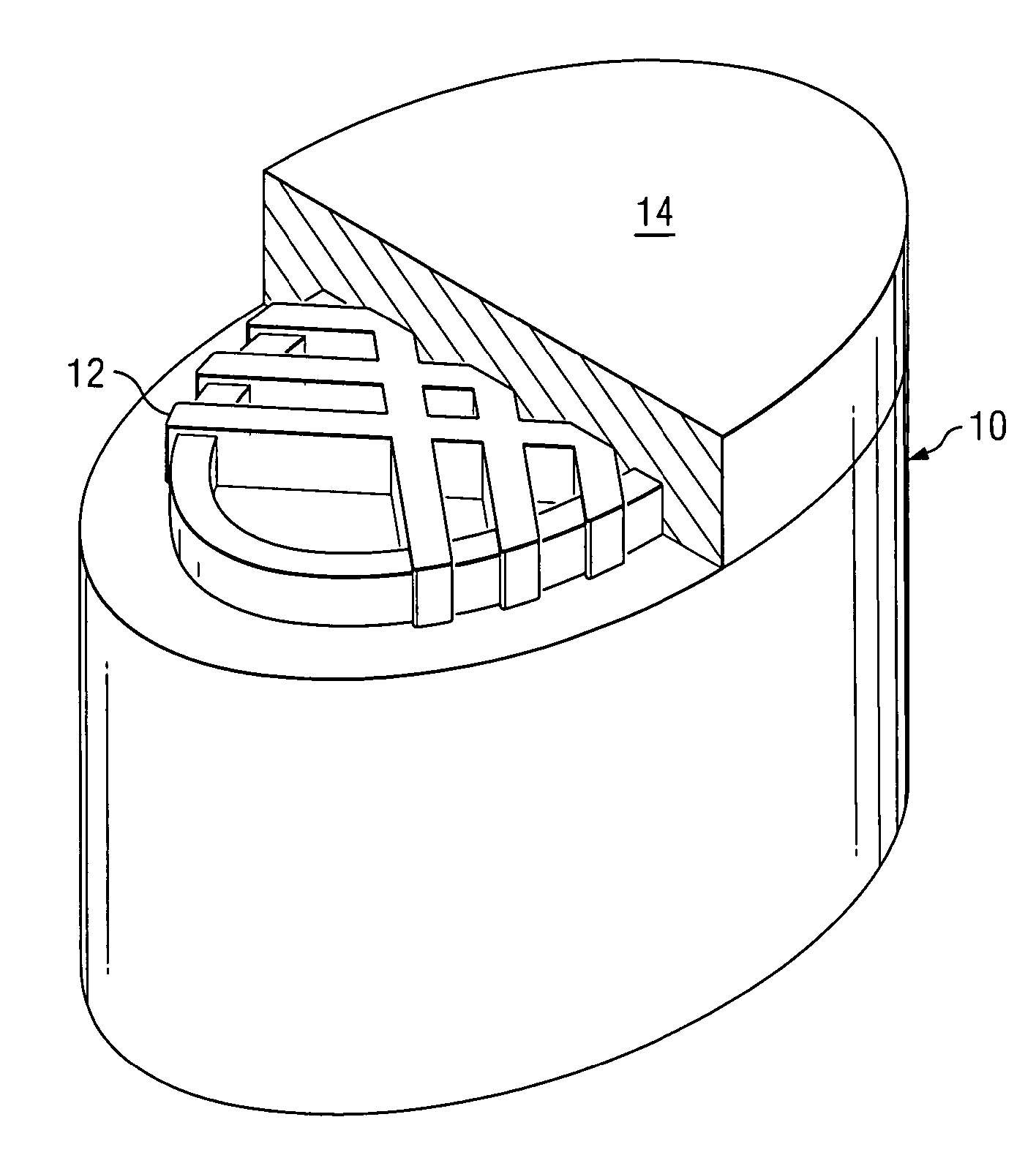

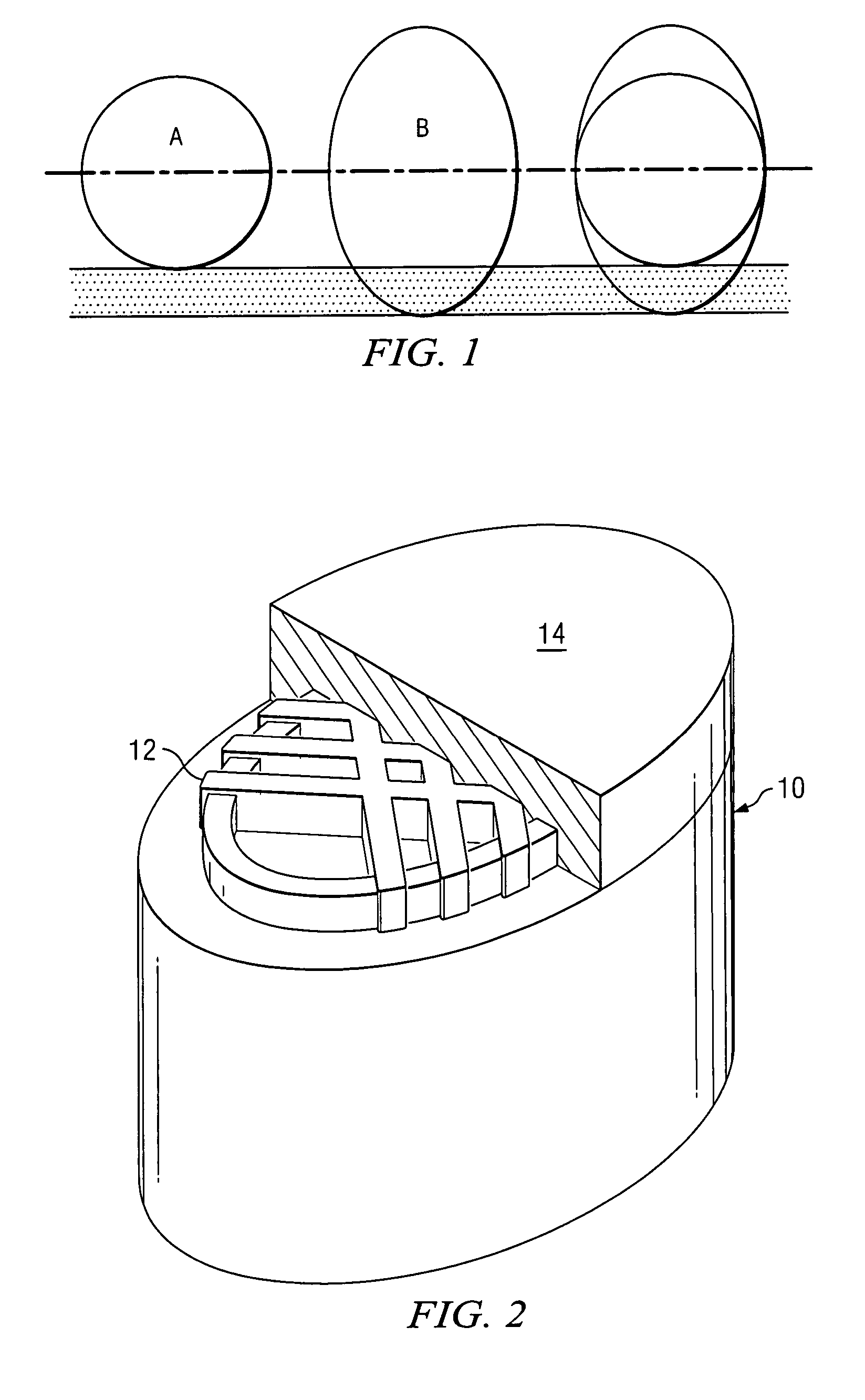

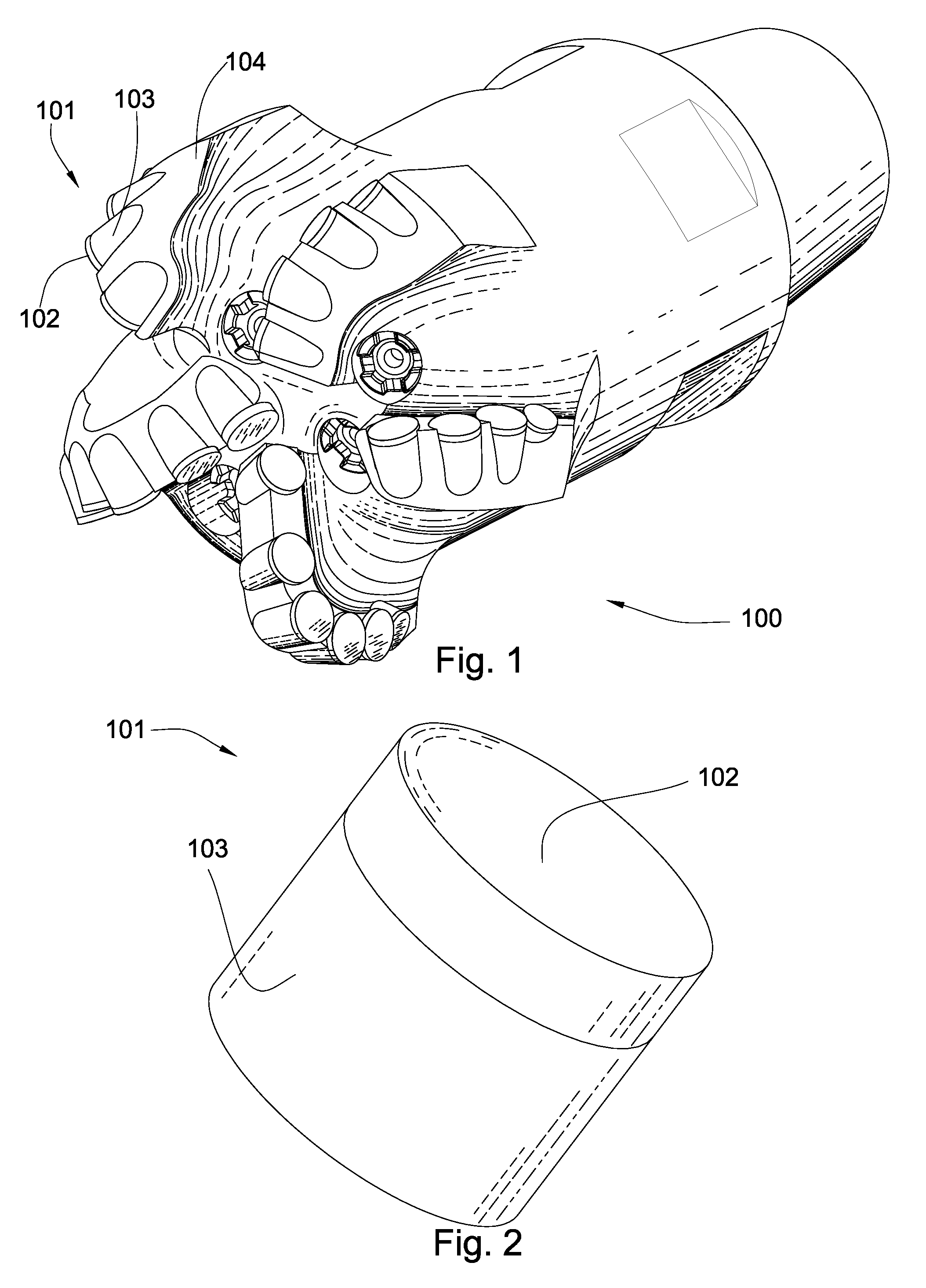

Cutting element having a substrate, a transition layer and an ultra hard material layer

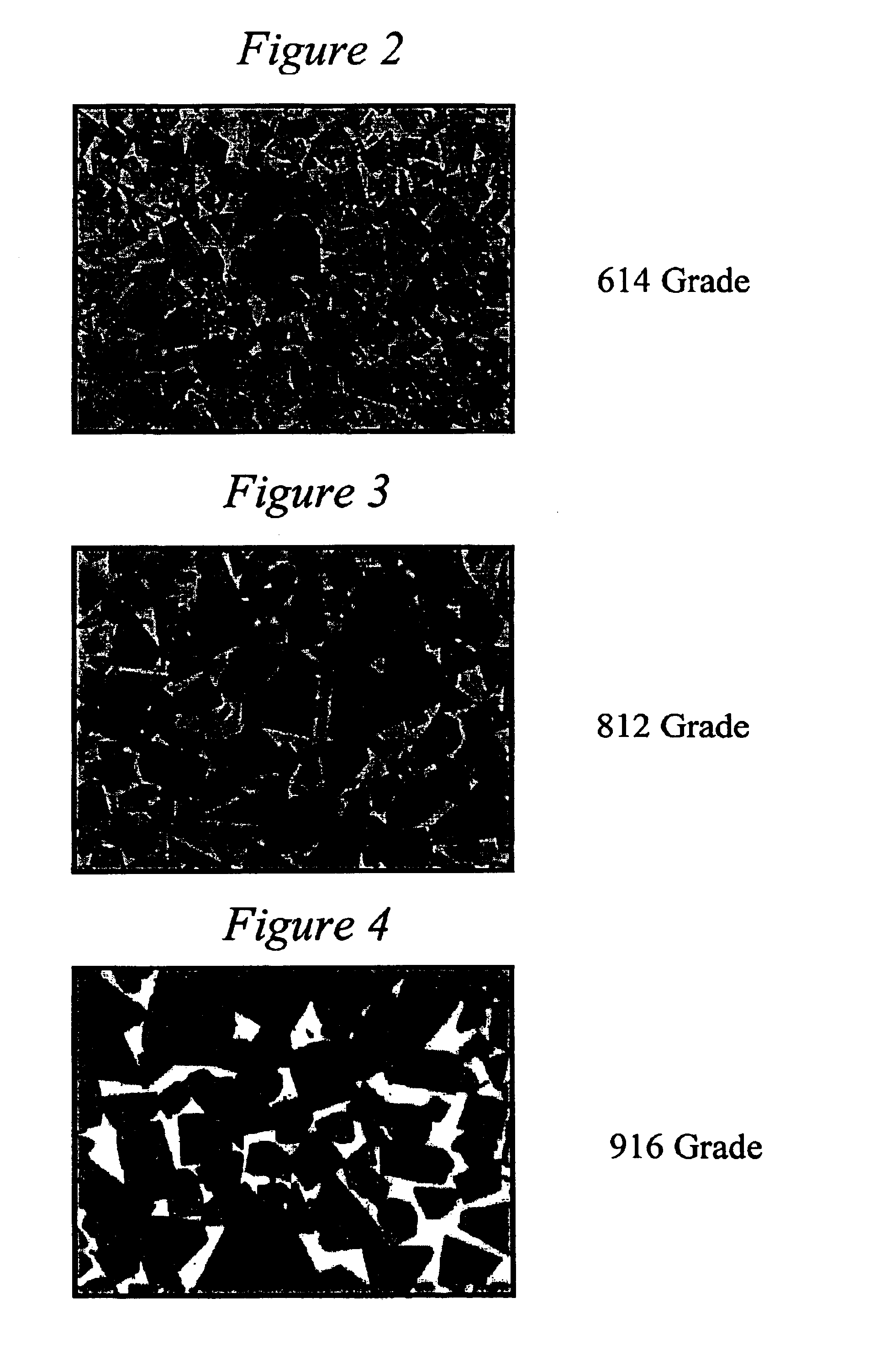

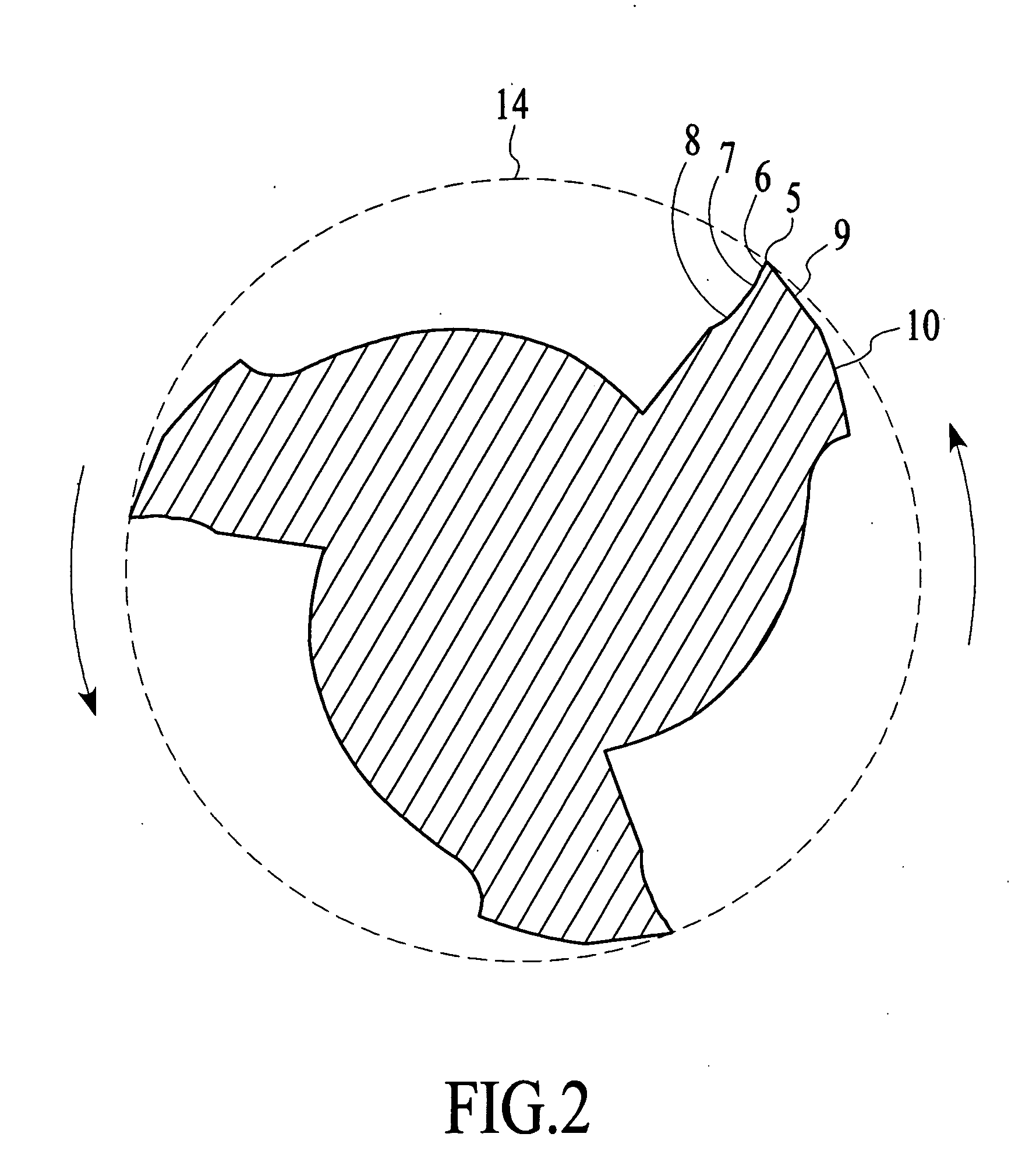

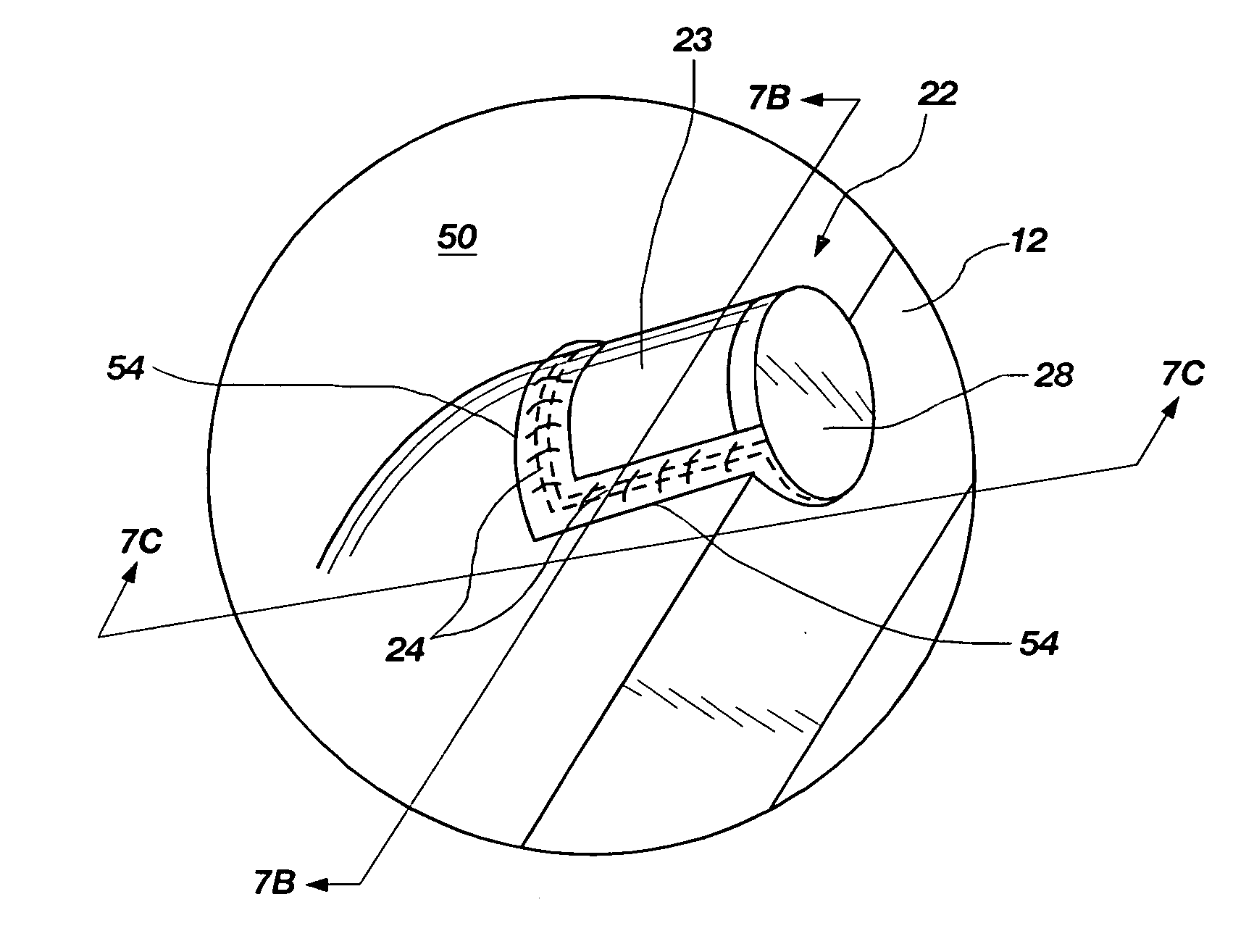

A non-uniform interface is formed between a polycrystalline ultra hard material layer and a cemented tungsten carbide substrate, or a polycrystalline ultra hard material layer and a transition layer, or a transition layer and a substrate of a cutting element. A first sheet made from an intermediate material is formed and embossed on one face forming a non-uniform pattern raised in relief on the face. The embossed sheet is placed on a face of a presintered substrate. An ultra hard material sheet is formed and embossed, forming a non-uniform face complementary to the non-uniform face on the sheet of intermediate material. The ultra hard material sheet is placed over the intermediate material sheet so that the complementary faces are adjacent to each other. The assembly of substrate and sheets is sintered in a HPHT process. The sintering process causes the first sheet to become integral with the substrate and results in a substrate having a non-uniform cutting face onto which is bonded a polycrystalline ultra hard material layer. Embossed transition material sheets may be employed between the ultra hard material sheet and the first sheet to form transition layers with uniform or non-uniform interfaces.

Owner:SMITH INT INC

Polycrystalline diamond carbide composites

InactiveUS20070193782A1Improve fracture toughnessEasy to useDrill bitsOther chemical processesPolycrystalline diamondCarbide

Owner:SMITH INT INC

Long-service-life split type valve seat

PendingCN111664087AExtended service lifeHigh hardnessPositive displacement pump componentsLiquid fuel engine componentsWorking pressureStructural engineering

The invention discloses a long-service-life split type valve seat. The long-service-life split type valve seat comprises linings and bases. The linings are embedded into the outlet ends of the bases.The linings are matched with a valve body for use. Each lining is a tungsten carbide alloy. The long-service-life split type valve seat has the beneficial effects that the valve seat is composed of the linings and the bases, the linings are made of a hard alloy material, the hardness, the strength, the wear resistance and the corrosion resistance of the linings are improved, and the service life of the valve seat is greatly prolonged; the valve seat is of a split structure, once abrasion occurs, only the linings or the bases need to be replaced, integral replacement is not needed, maintenanceis convenient, the time and labor are saved, and meanwhile the production cost of an oil and gas field is reduced; the appropriate diameter sizes of the linings can be selected according to the working pressure, the conveying medium, the degree of abrasion of the valve body to the valve seat and the like in actual working conditions, and the application range is wide; the linings and the bases arein various shapes and can be combined according to actual working condition requirements, and the applicability is high.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

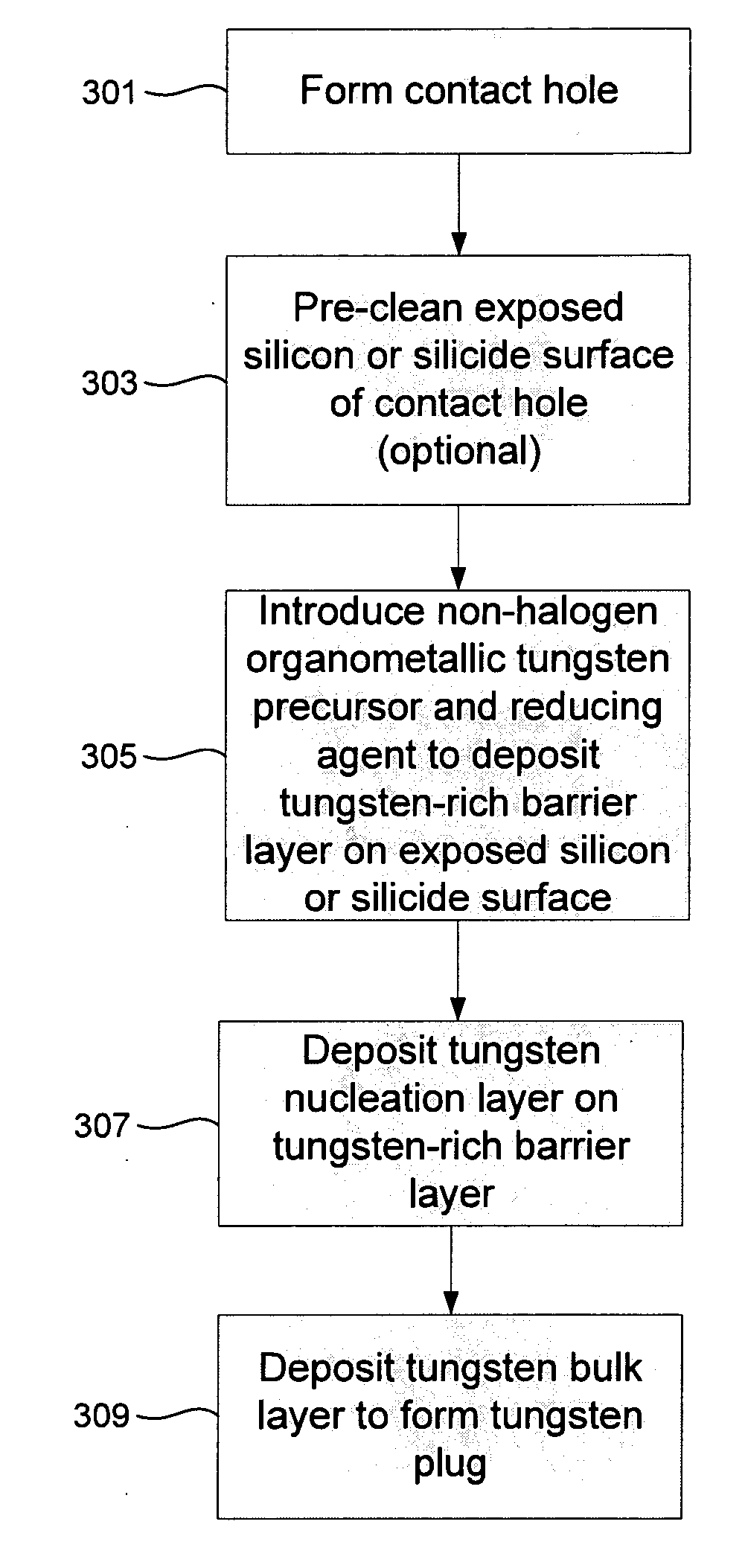

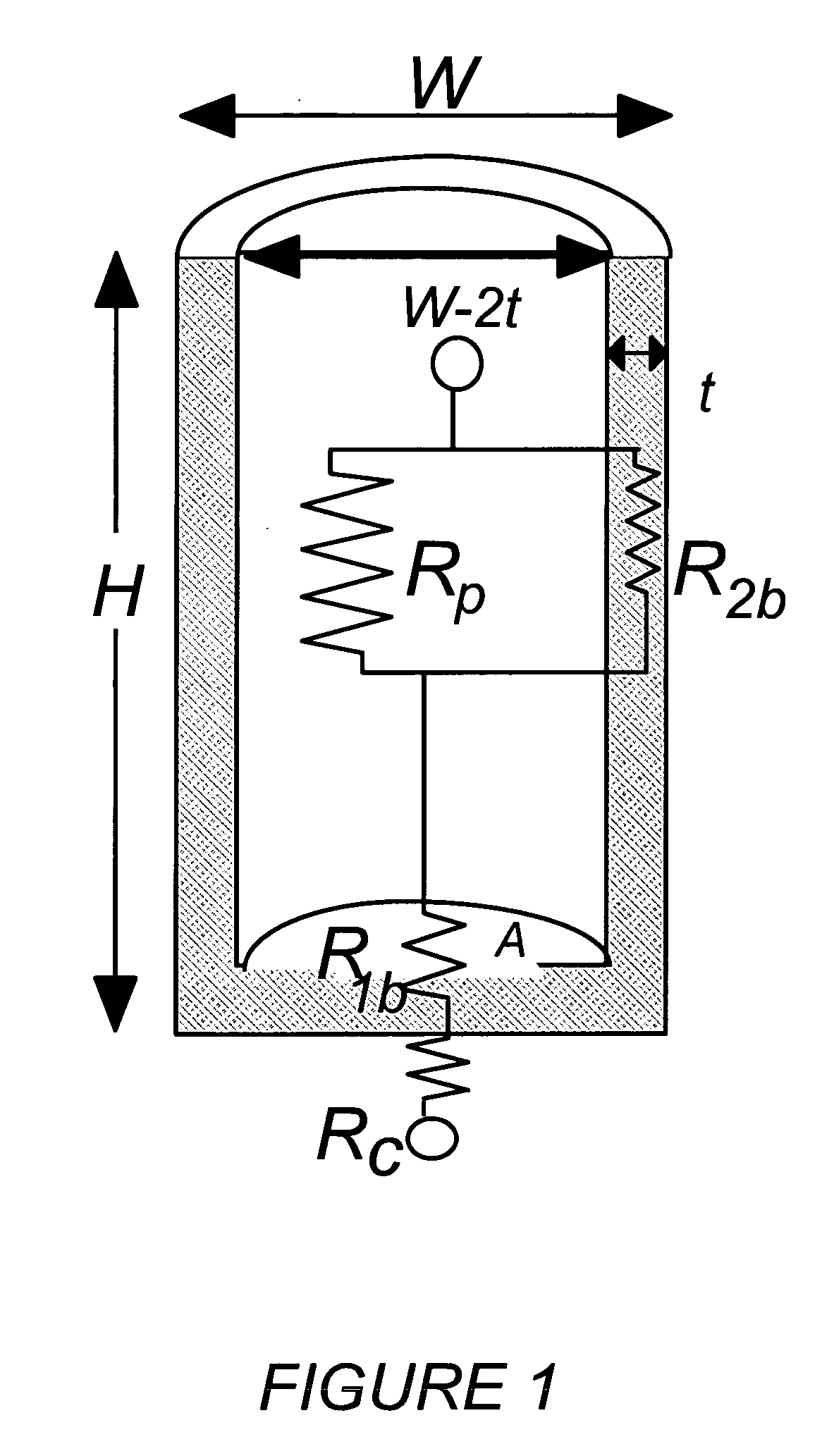

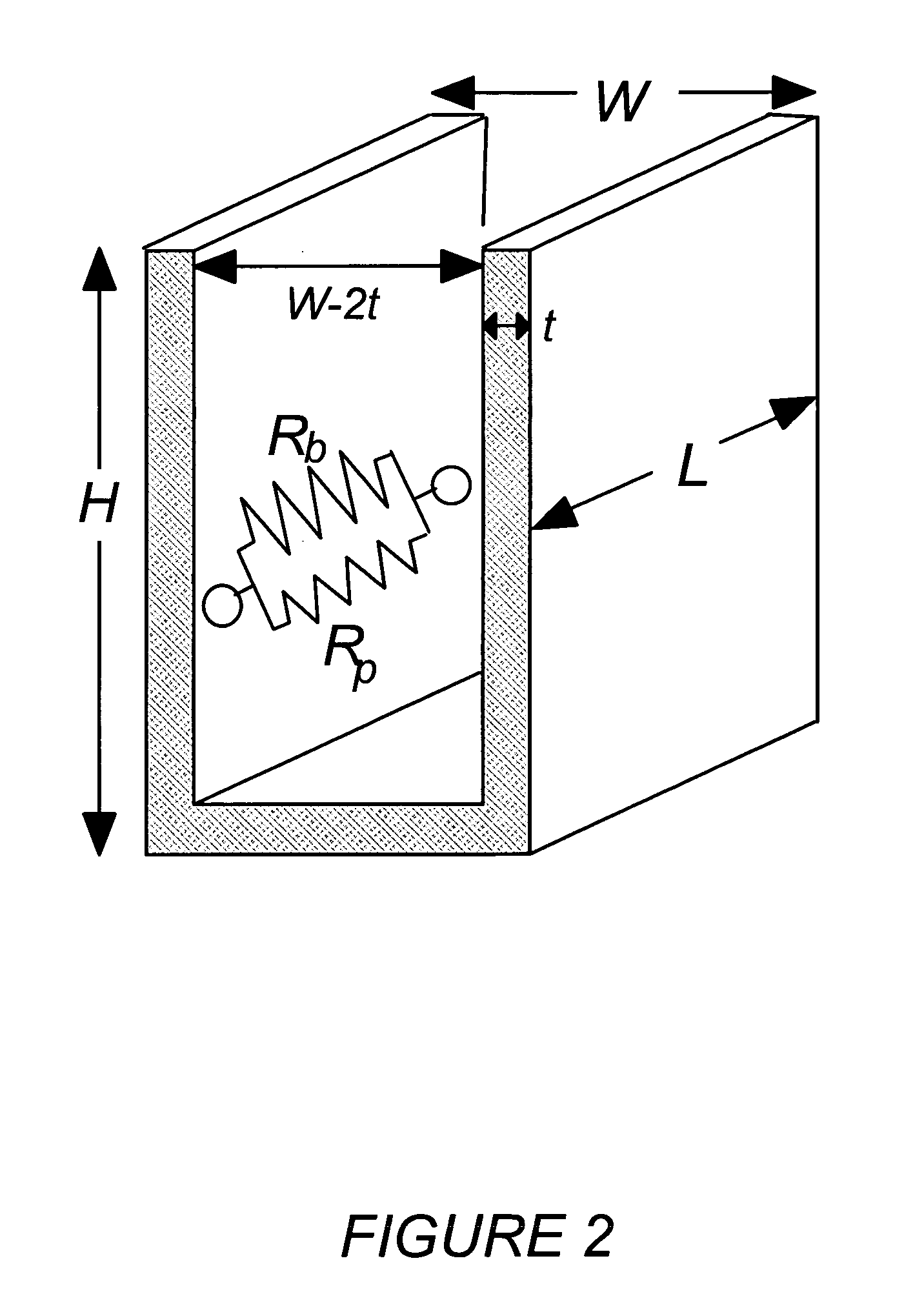

Methods for forming all tungsten contacts and lines

InactiveUS20090163025A1Improve adhesionGood baseSemiconductor/solid-state device detailsSolid-state devicesBit lineNucleation

Novel low-resistivity tungsten film stack schemes and methods for depositing them are provided. The film stacks include a mixed tungsten / tungsten-containing compound (e.g., WC) layer as a base for deposition of tungsten nucleation and / or bulk layers. According to various embodiments, these tungsten rich layers may be used as barrier and / or adhesion layers in tungsten contact metallization and bitlines. Deposition of the tungsten-rich layers involves exposing the substrate to a halogen-free organometallic tungsten precursor. The mixed tungsten / tungsten carbide layer is a thin, low resistivity film with excellent adhesion and a good base for subsequent tungsten plug or line formation.

Owner:NOVELLUS SYSTEMS

Stepped polycrystalline diamond compact insert

InactiveUS6904984B1Reduces rock strengthLess riskDrill bitsConstructionsPolycrystalline diamondEngineering

The present invention addresses this need in the art by providing a cutter insert comprising a plug section and a cutter pedestal. The cutter insert is preferably formed of tungsten carbide, except for two exterior surfaces covered with PDC. The plug section may be circular or oval in cross section perpendicular to the axis of the insert. The plug section and the pedestal each defines a shoulder which is coated with a PDC layer. In this way, two cutting surfaces are applied to the formation, enhancing the cutting ability of the insert.

Owner:GEN ELECTRIC CAPITAL

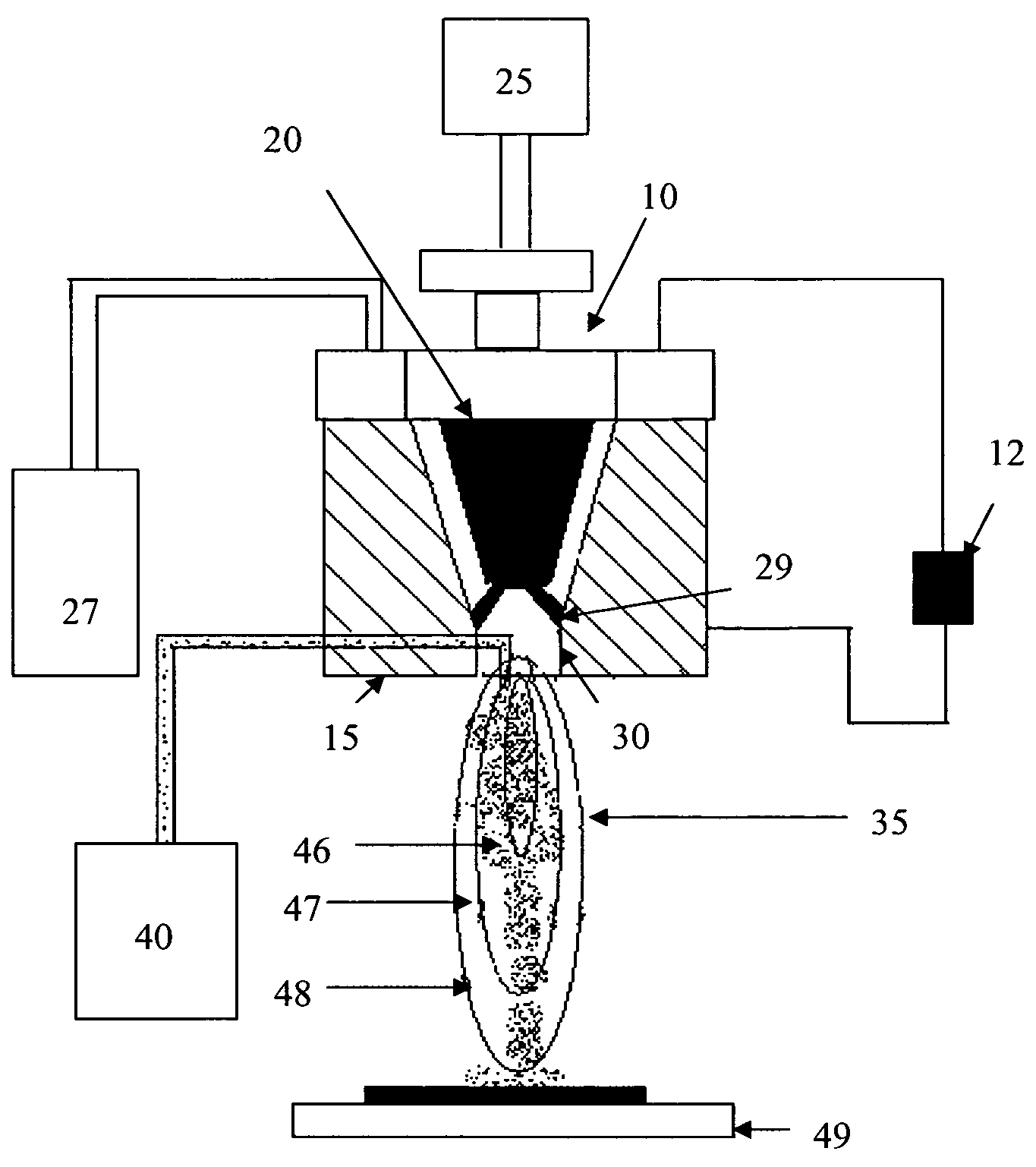

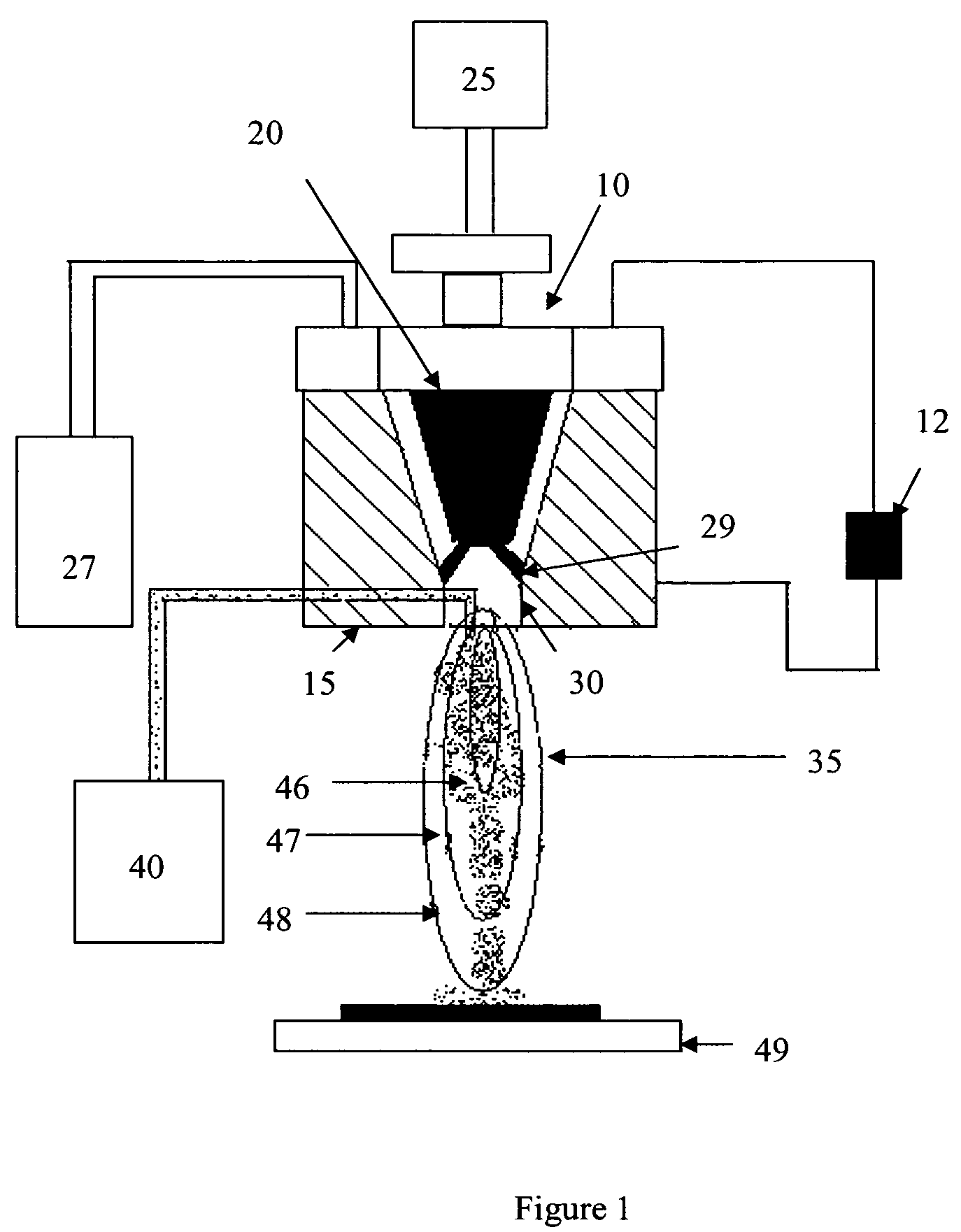

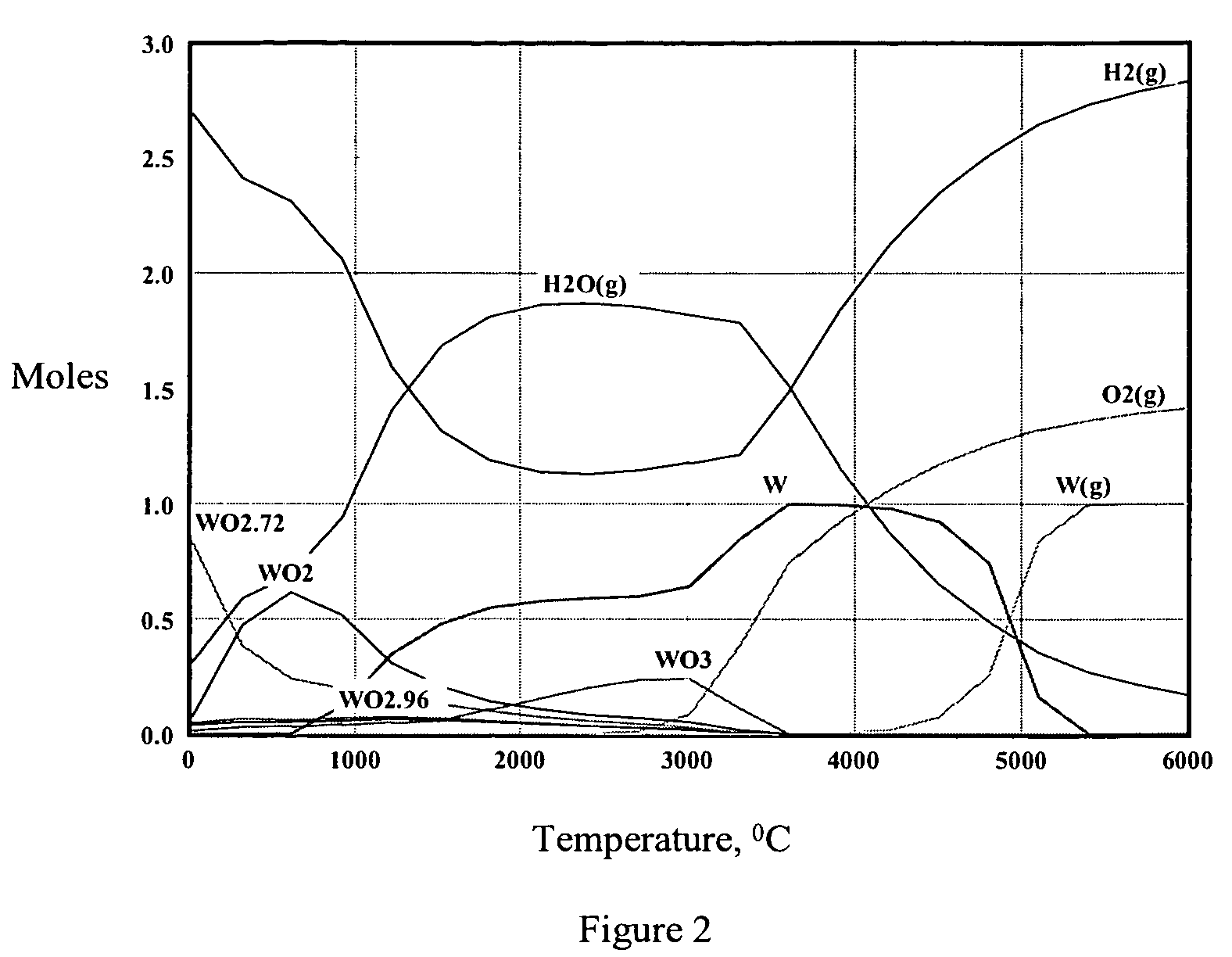

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

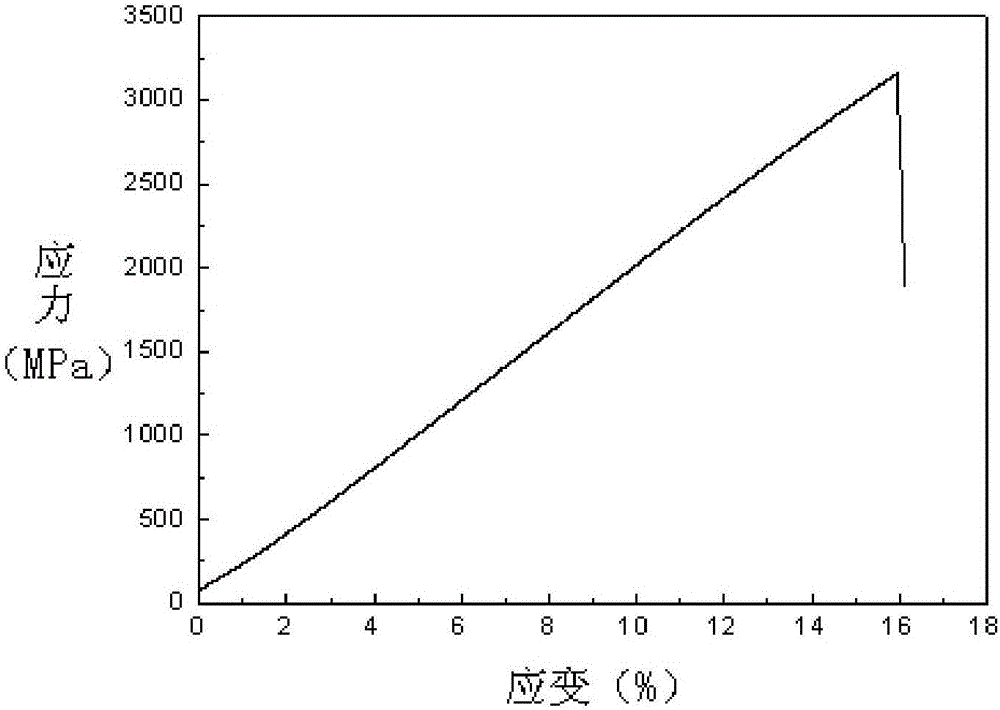

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

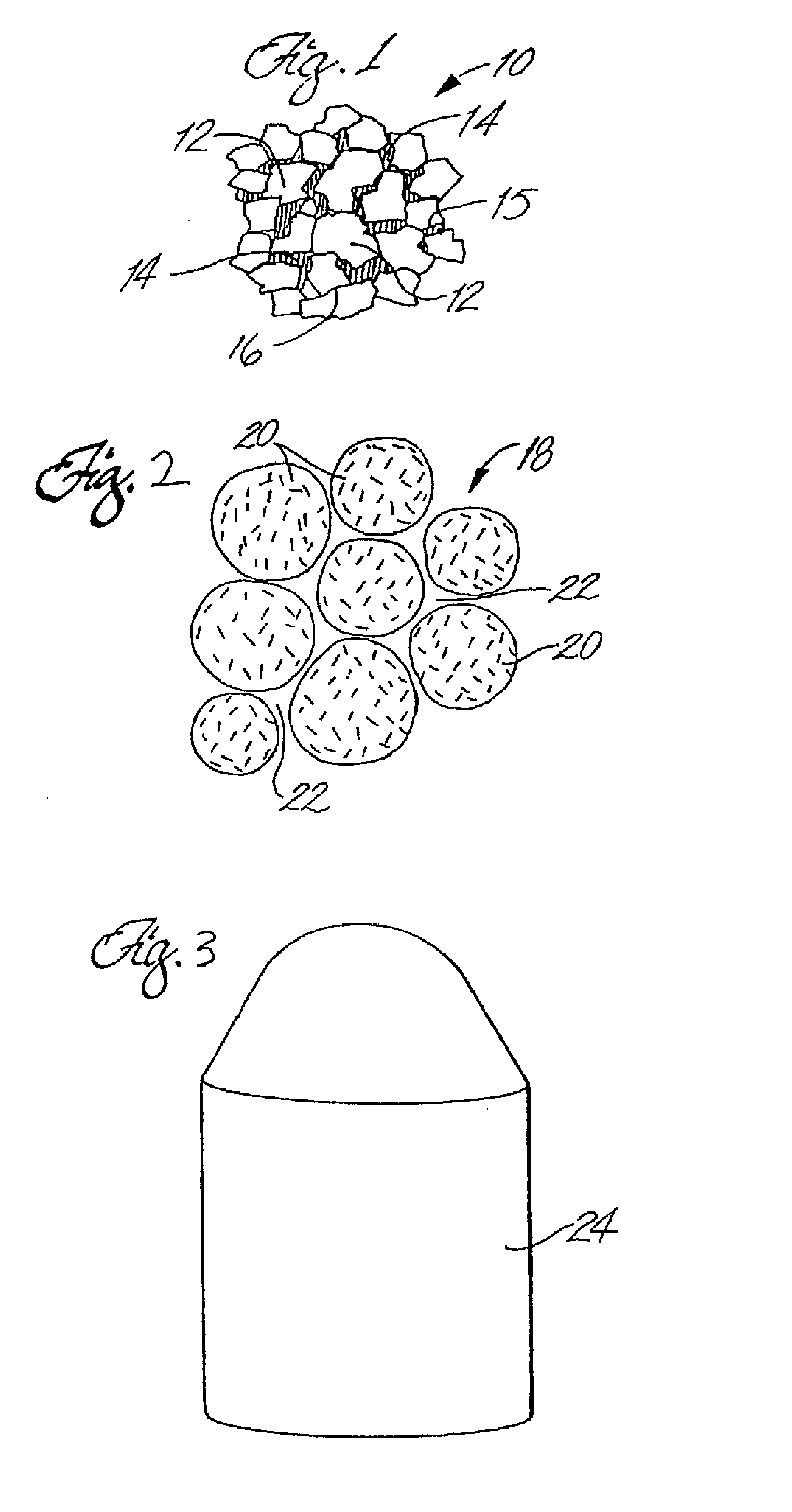

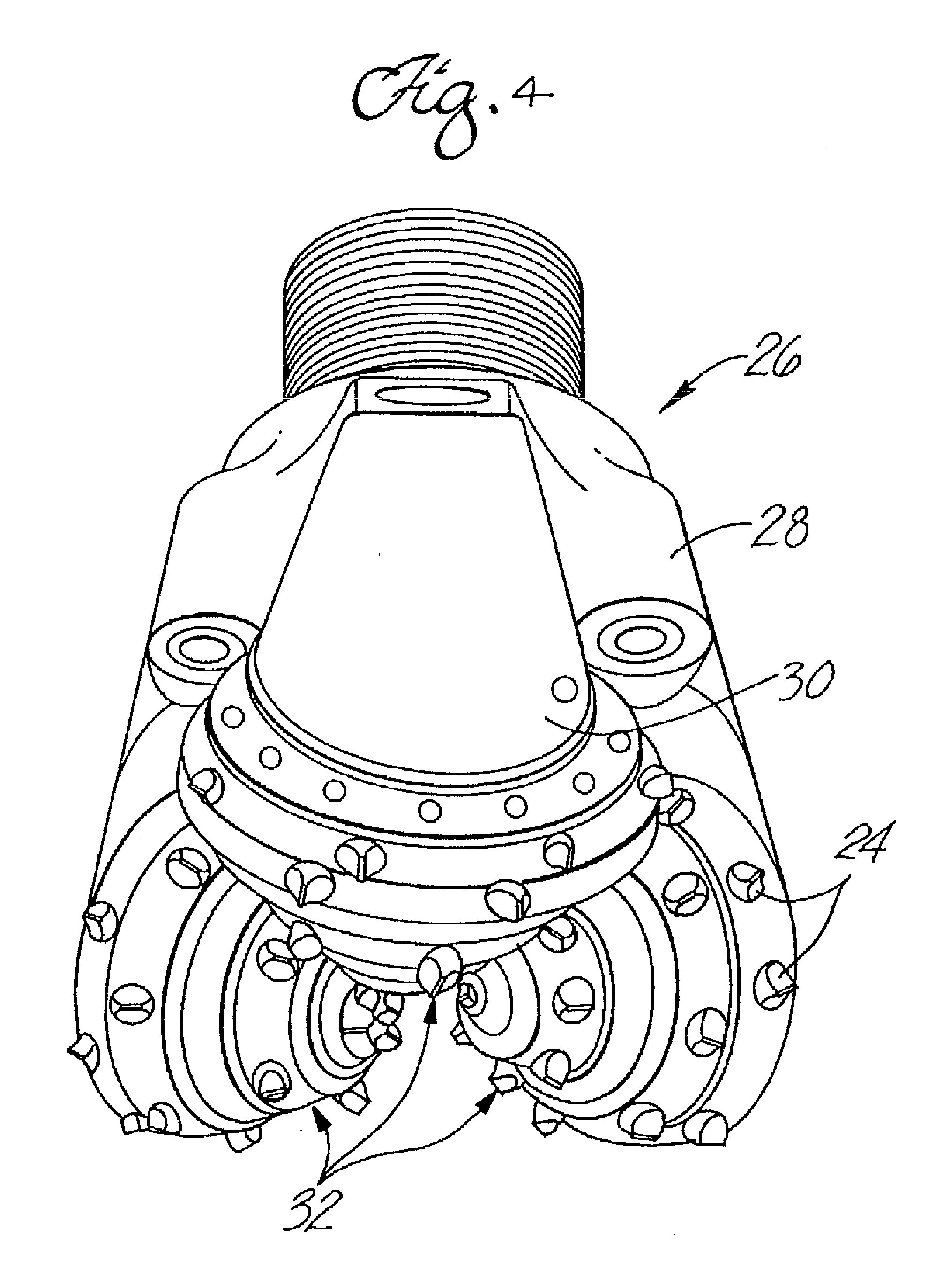

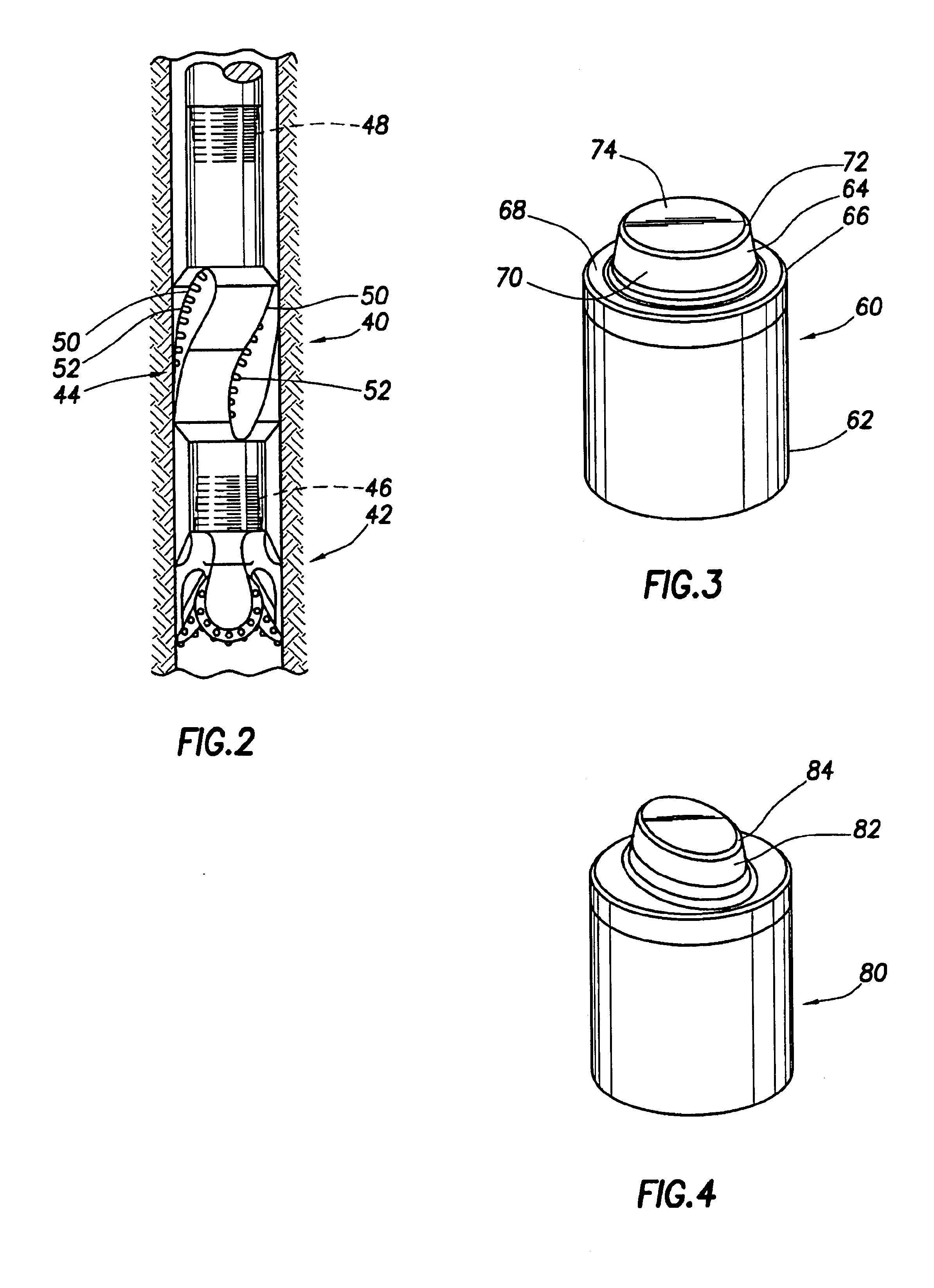

Wear resistant drill bit

InactiveUS6454028B1Improve wear resistanceHigh densityDrill bitsTransportation and packagingWear resistantSpherical shaped

A wear resistant drill bit of the matrix bodied type has a bit body comprising a tungsten carbide material bound with a binder material, wherein the tungsten carbide material includes at least some tungsten carbide particles of generally spherical shape. The tungsten carbide material includes particles having a relatively hard central core and a softer skin. The skin includes a large proportion of a high temperature phase of tungsten carbide.

Owner:CAMCO INT

High-strength, high-toughness matrix bit bodies

A new composition for forming a matrix body which includes spherical sintered tungsten carbide and an infiltration binder including one or more metals or alloys is disclosed. In some embodiments, the composition may include a Group VIIIB metal selected from one of Ni, Co, Fe, and alloys thereof. Moreover, the composition may also include cast tungsten carbide. In addition, the composition may also include carburized tungsten carbide.

Owner:SMITH INT INC

Abrasive-bladed cutting wheel

Owner:SHIN ETSU CHEM IND CO LTD

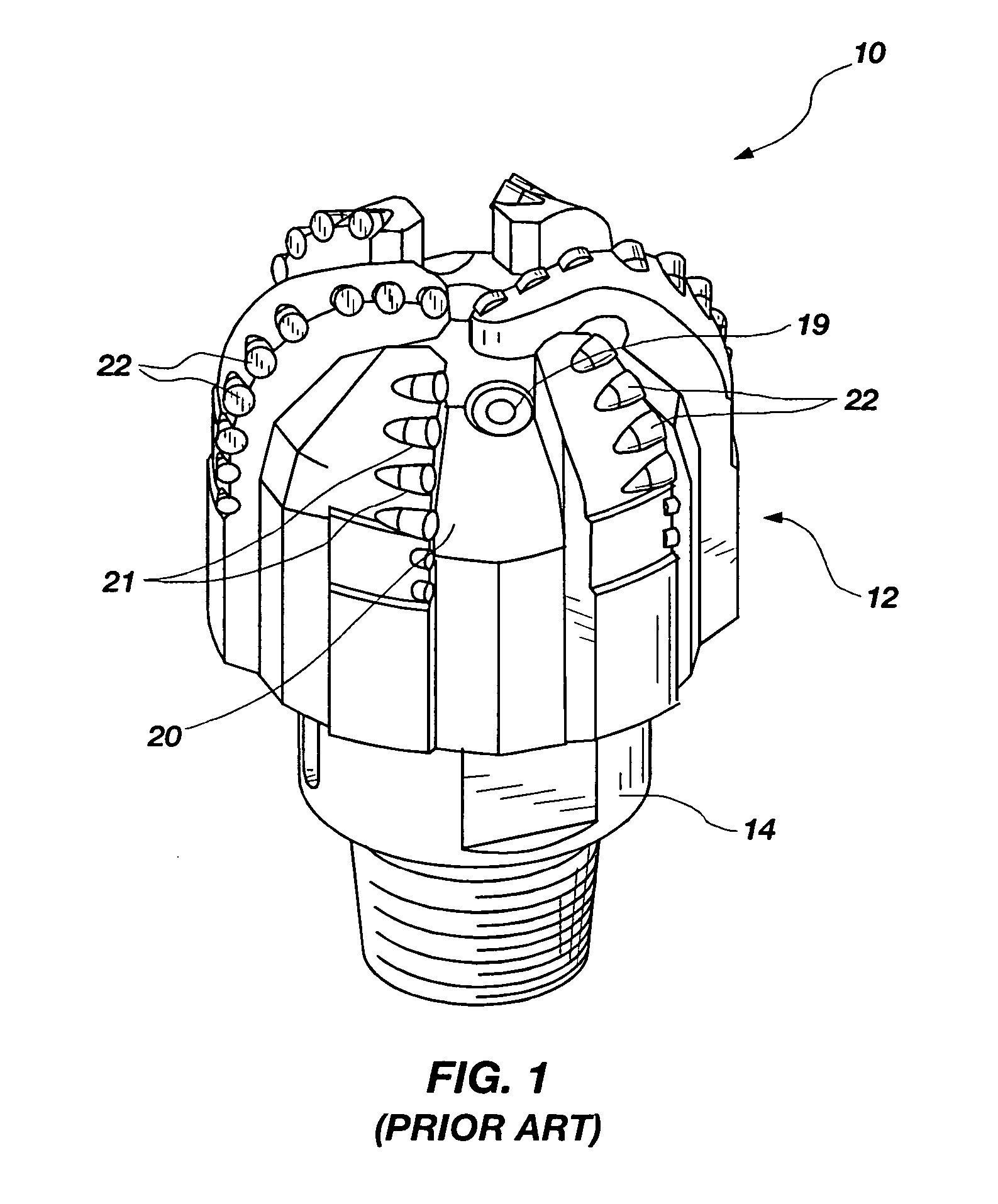

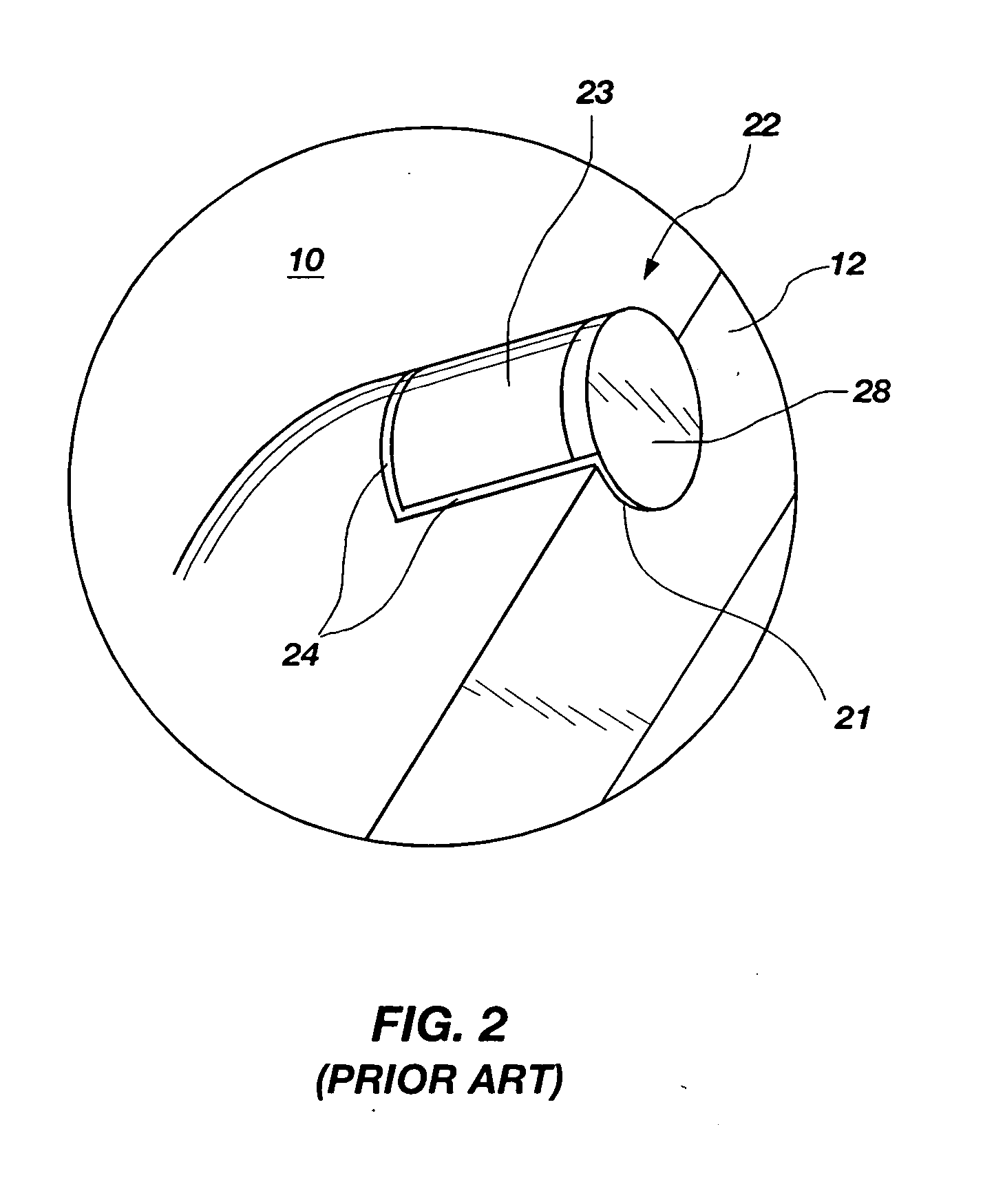

Fixed cutter drill bits with thin, integrally formed wear and erosion resistant surfaces

A fixed-cutter drill bit for boring through earth has a body made predominately of high strength steel with thin erosion and abrasion resistant surfaces integrally formed in the steel in areas likely to encounter abrasive or erosive conditions. The drill bit may be formed by a rapid solid state densification (RSSDPM) process. The drill bit combines the high strength of conventional steel bits with design freedom and hardness equal to or greater than conventional matrix bits. Due to the manner in which the hard particles, such as tungsten carbide, are integrally held in a steel matrix, aggressive fluid hydraulics may be employed with the drill bit without unduly limiting the performance of the drill bit.

Owner:REEDHYCALOG LP

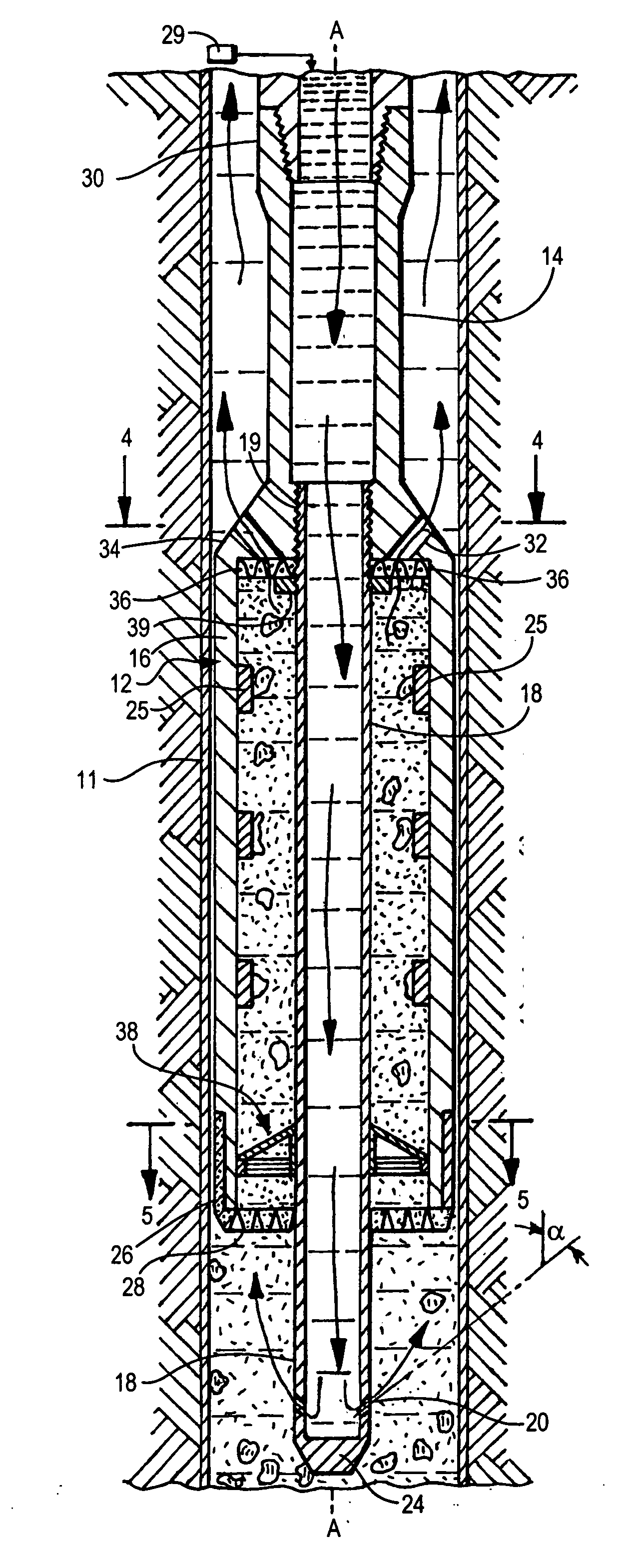

Tool for recovering junk and debris from a wellbore of a well

A downhole tool incorporates a junk catcher with full body casing drift. It is made of an inner tubular member that conveys the hydraulic power or circulating fluid to rearward and outward facing jet nozzles for directly flushing downhole junks in front of the tool (if encountered) into a junk collecting barrel equipped with individual magnets to retain magnetically attractive metal junks. The barrel is made of high grade steel material with outer diameter matching the full drift of wellbore casing. The front, or the lower end of the outer body is addressed with tungsten carbide cutters to effectively handle metal junks in case of milling action is required. The back, or upper end of the barrel has return flow ports equipped with a filter screen to retain small, medium and large size junks while fluid is pumped through the tool.

Owner:SAUDI ARABIAN OIL CO

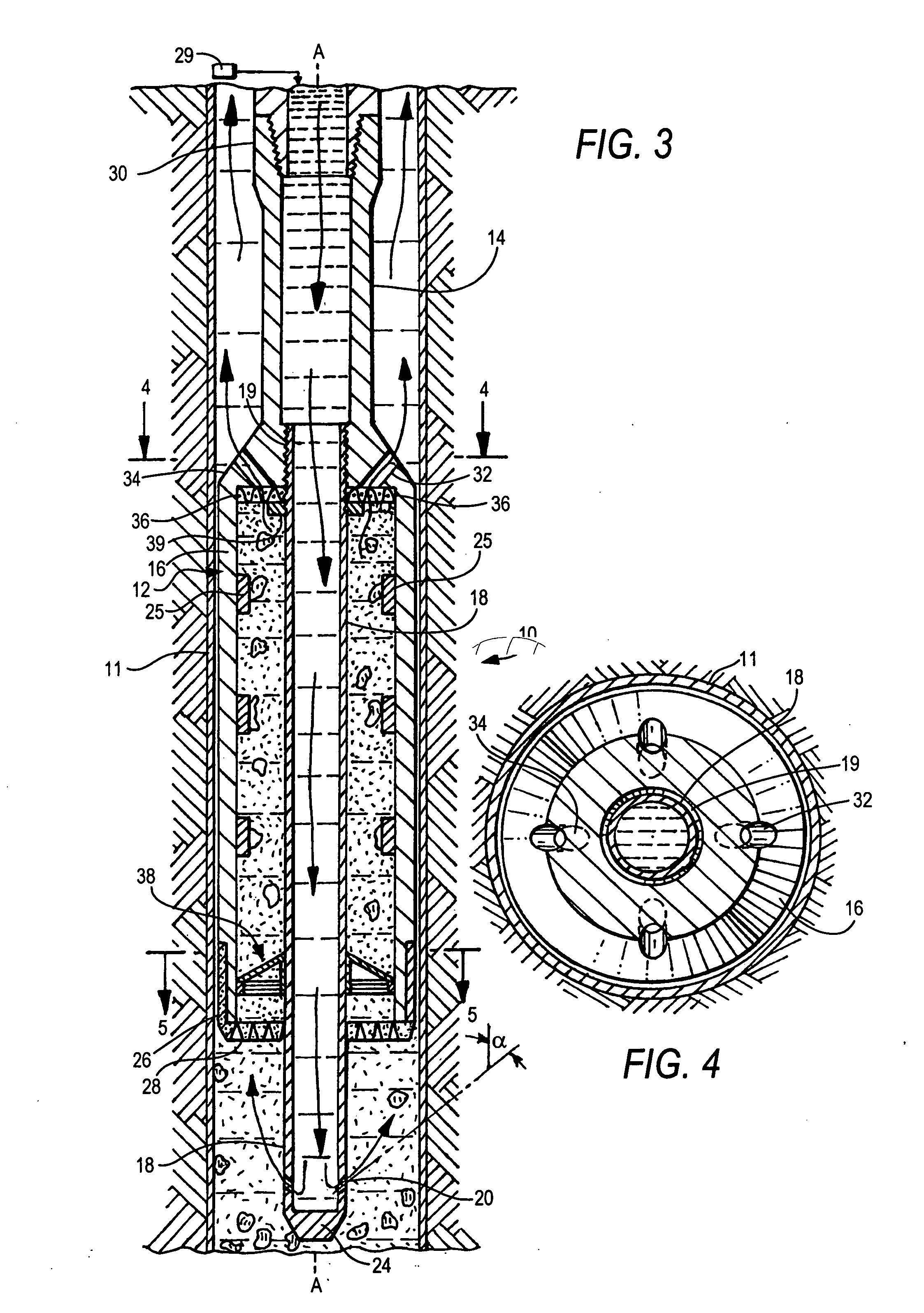

End mill

InactiveUS20060067797A1Aggressive and deep cutLess forceMilling cuttersWorkpiecesUltra fineEngineering

An end mill with a peripheral margin which increases in width from the terminal end of the tool to the shank portion of the tool. The end mill also has a tooth face made up of three tooth-face walls The depth of the tool face gradually decreases from the terminal end to the shank portion of the tool. The end mill also has an end cutting face which includes a flat, narrow land at the outmost region of the end cutting end. The end mill has chip breakers with rounded peripheral corners. The end mill can be made up of ultra-fine micro grain tungsten carbide with a cobalt content which varies throughout the length of the tool.

Owner:CALAMIA GUY ALLEN

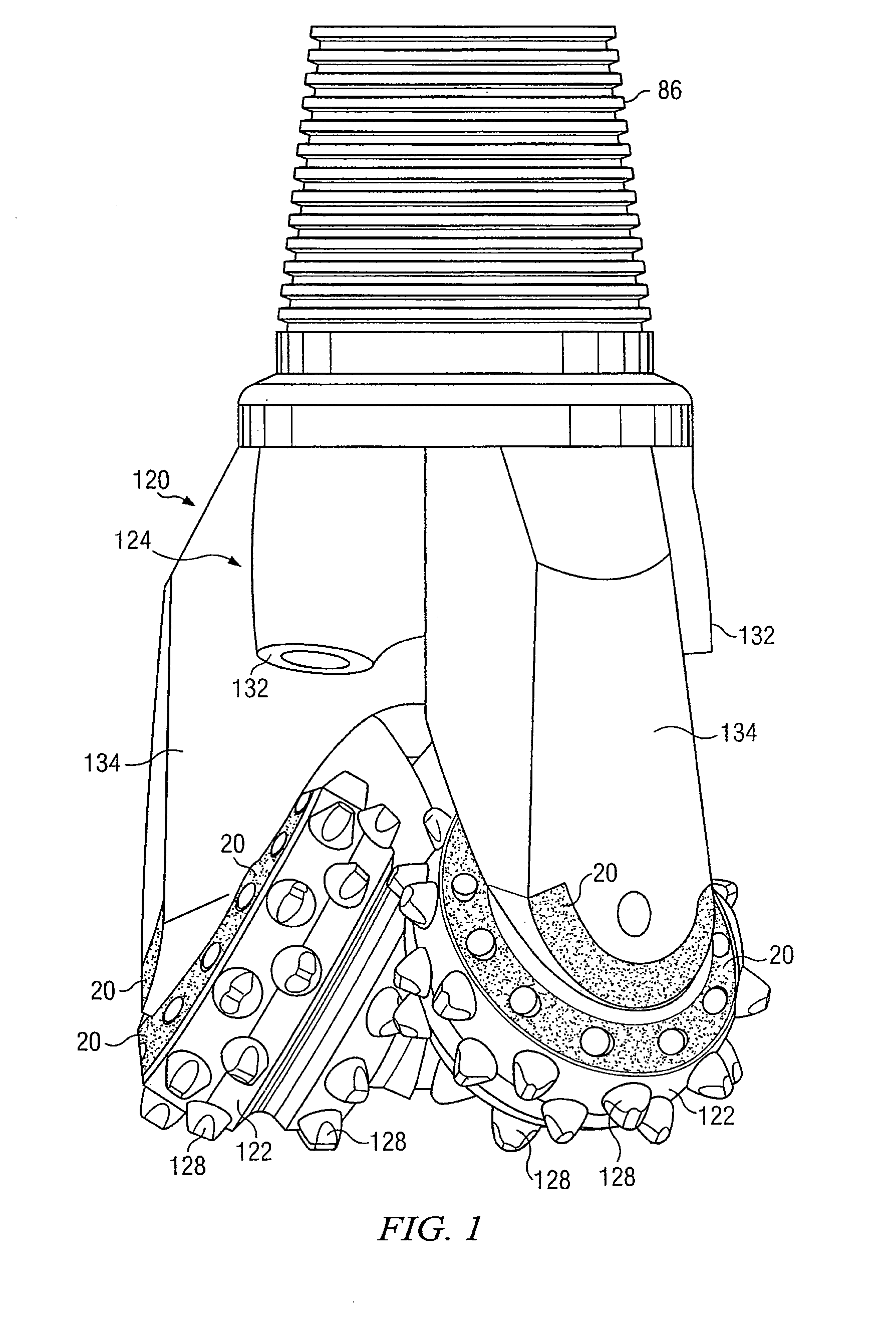

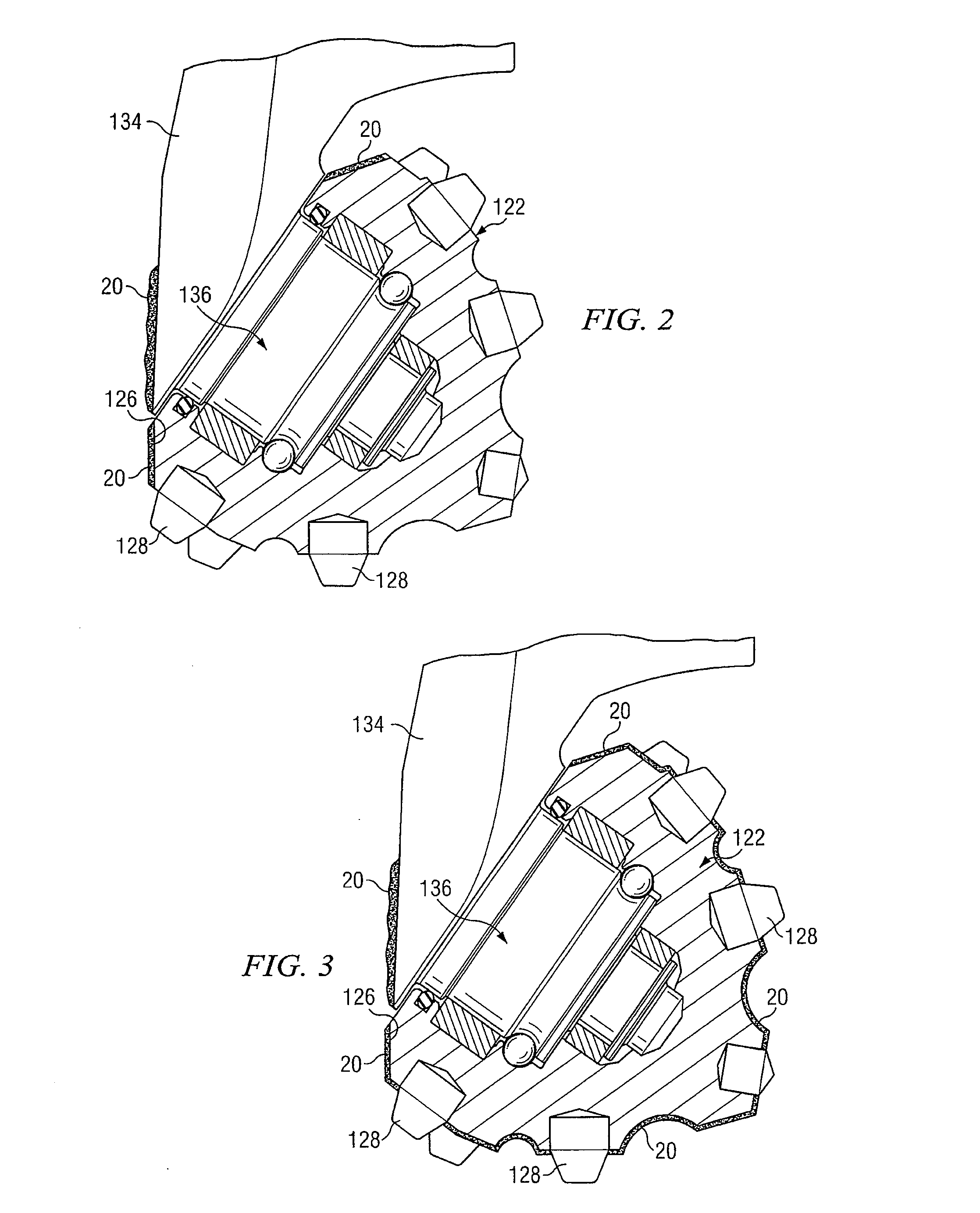

Composite materials including nickel-based matrix materials and hard particles, tools including such materials, and methods of using such materials

An abrasive wear-resistant material includes a matrix and sintered and cast tungsten carbide granules. A device for use in drilling subterranean formations includes a first structure secured to a second structure with a bonding material. An abrasive wear-resistant material covers the bonding material. The first structure may include a drill bit body and the second structure may include a cutting element. A method for applying an abrasive wear-resistant material to a drill bit includes providing a bit, mixing sintered and cast tungsten carbide granules in a matrix material to provide a pre-application material, heating the pre-application material to melt the matrix material, applying the pre-application material to the bit, and solidifying the material. A method for securing a cutting element to a bit body includes providing an abrasive wear-resistant material to a surface of a drill bit that covers a brazing alloy disposed between the cutting element and the bit body.

Owner:BAKER HUGHES INC

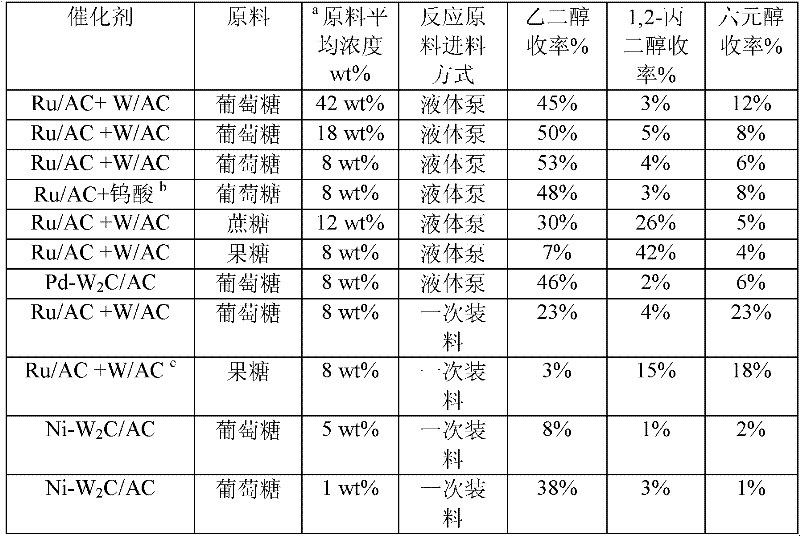

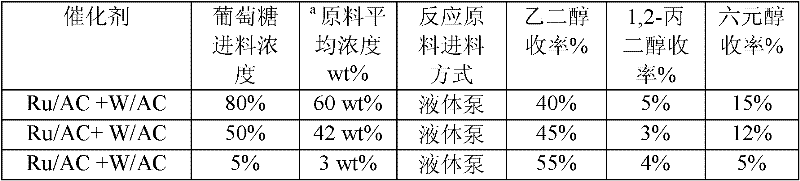

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

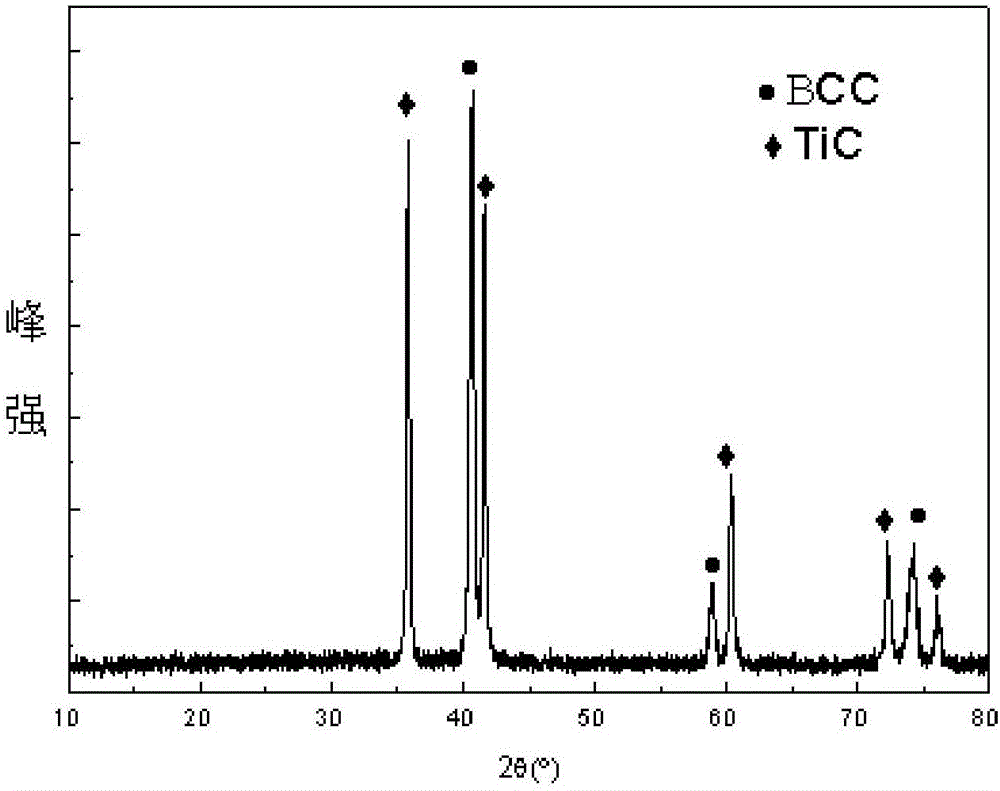

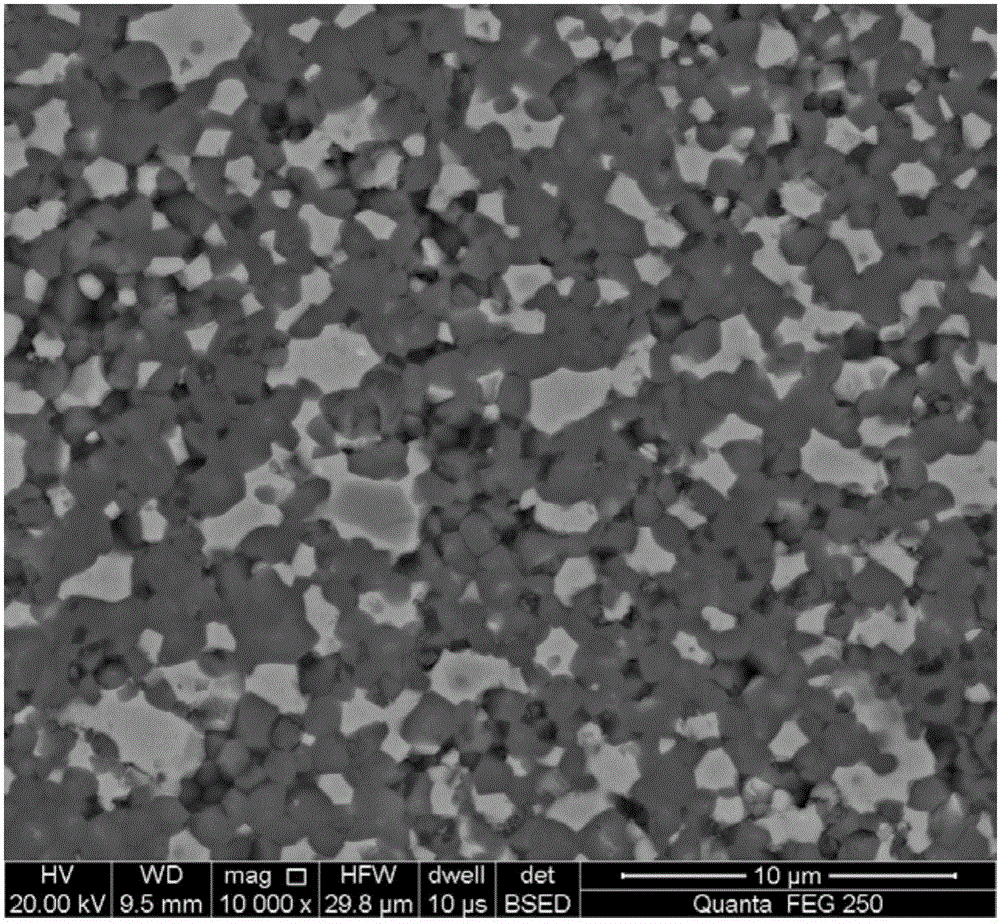

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

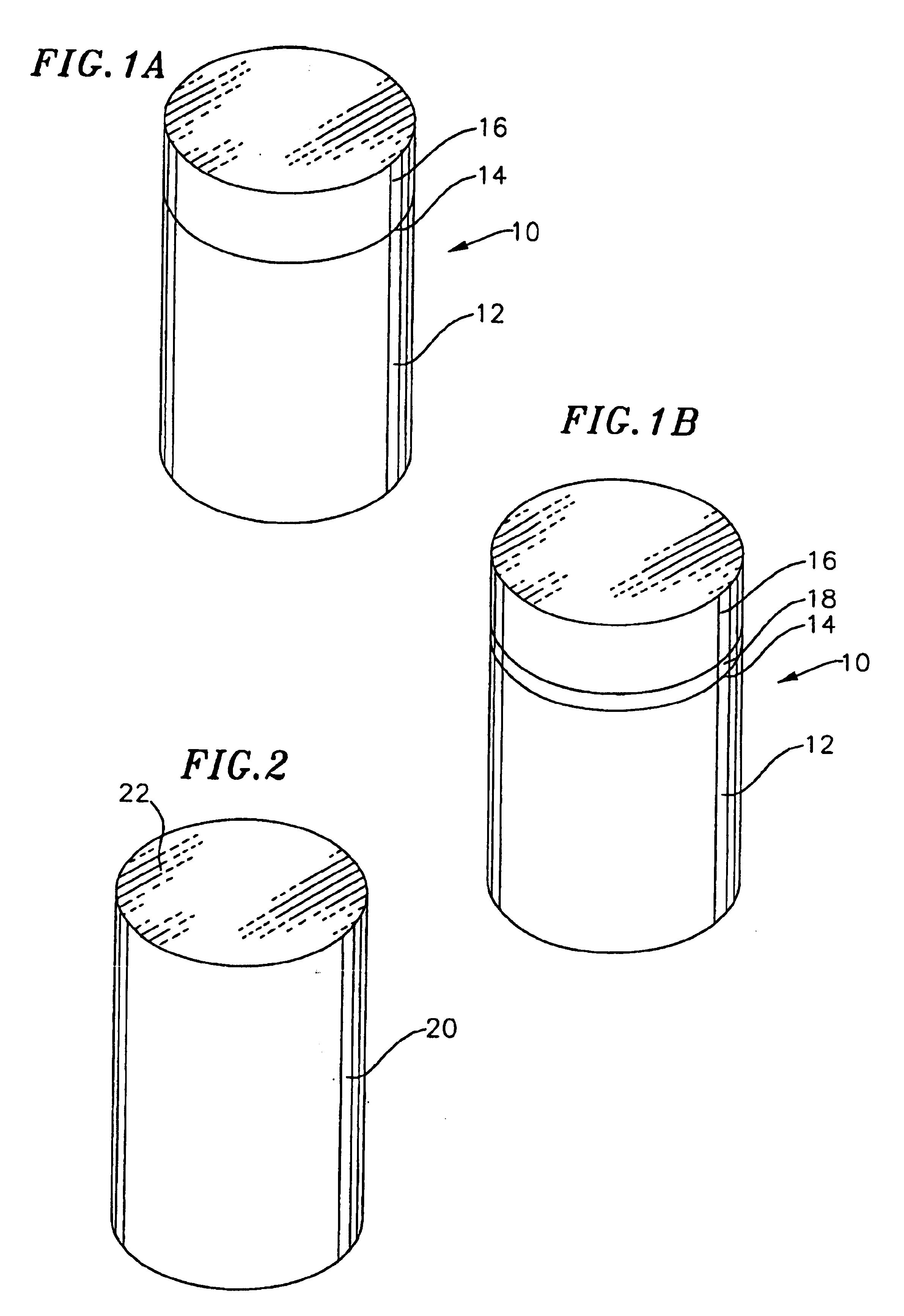

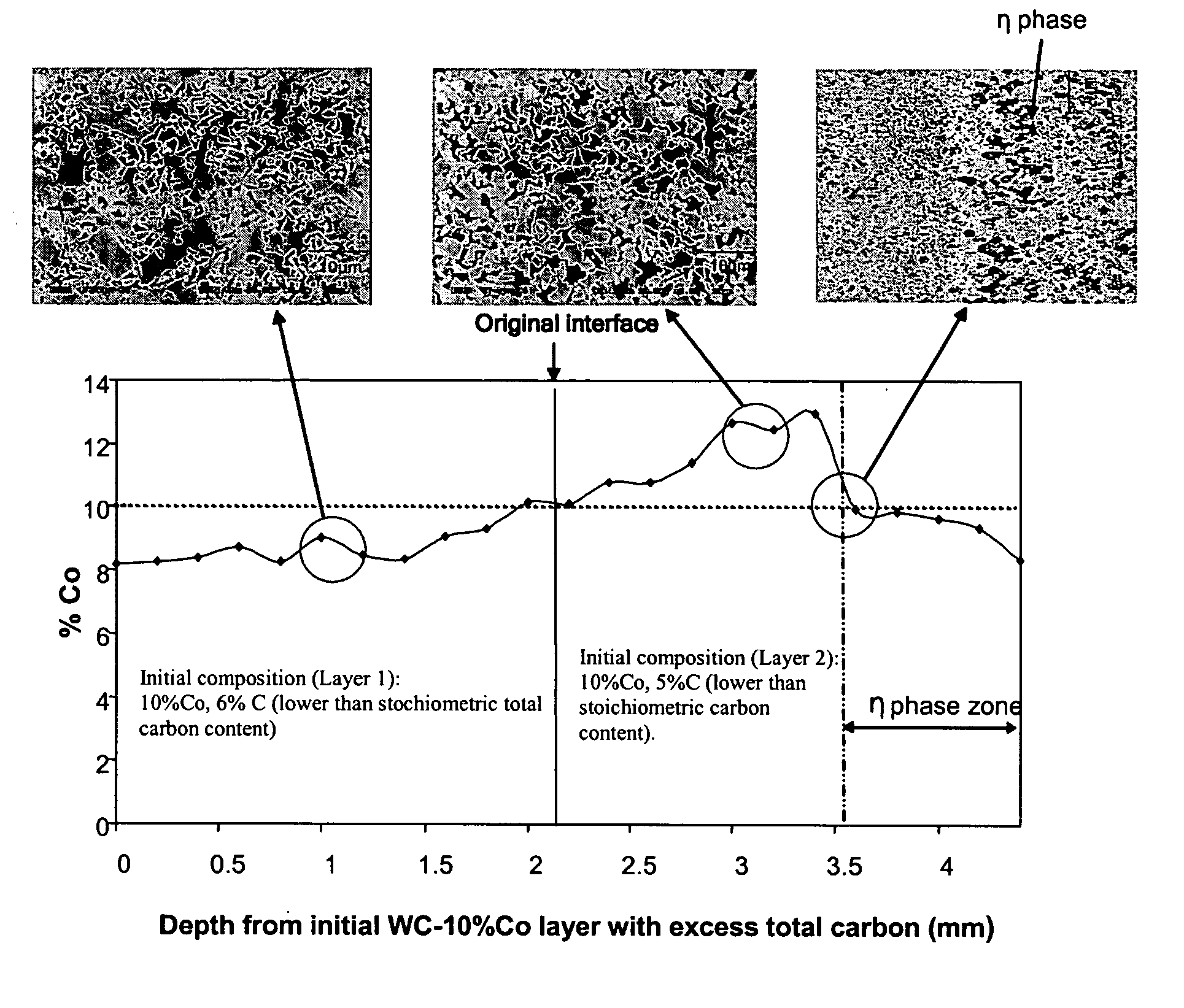

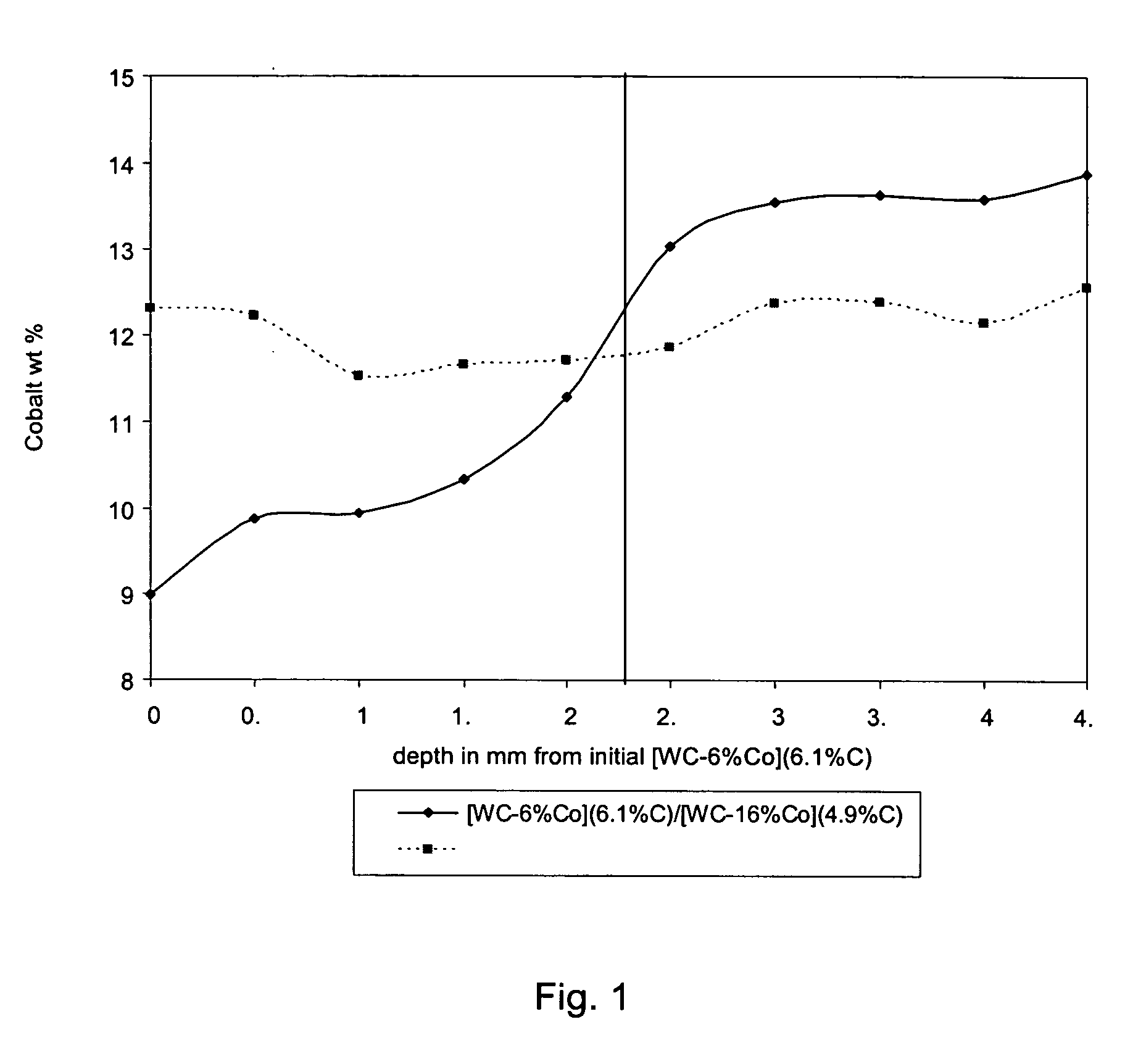

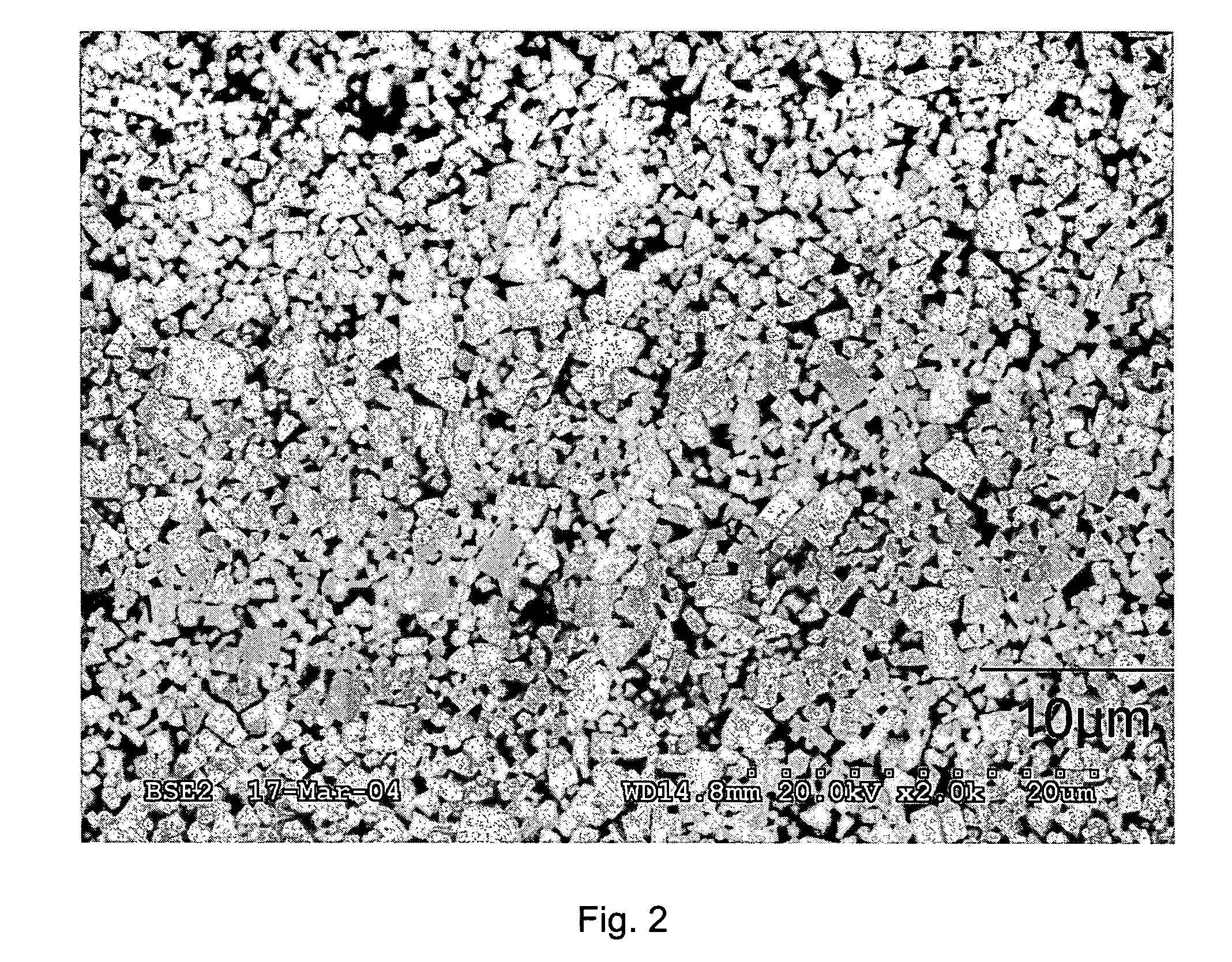

Functionally graded cemented tungsten carbide

The present invention is a method for producing functionally graded materials that contain a hard phase that is embedded in a metal matrix phase. The material have a continuous gradient of a matrix metal phase. An example of these types of materials include functionally graded cemented tungsten carbide (the hard phase) that has a continuous gradient of cobalt (the matrix metal) from one reference position, for example, one surface of a part, to another reference position, for example, the opposite surface of the part or within the part. The functionally graded materials are sintered via a liquid phase sintering (LPS) technique. In order to achieve the desired continuous gradient of the matrix metal, an initial gradient of one of the chemical elements of the hard phase is designed and built into the part prior to liquid phase sintering. The exact gradient of the composition material elements that will be required depends on factors such as the desired final matrix metal gradient, the dimension of the part to be made, and the sintering time and temperature.

Owner:UNIV OF UTAH RES FOUND

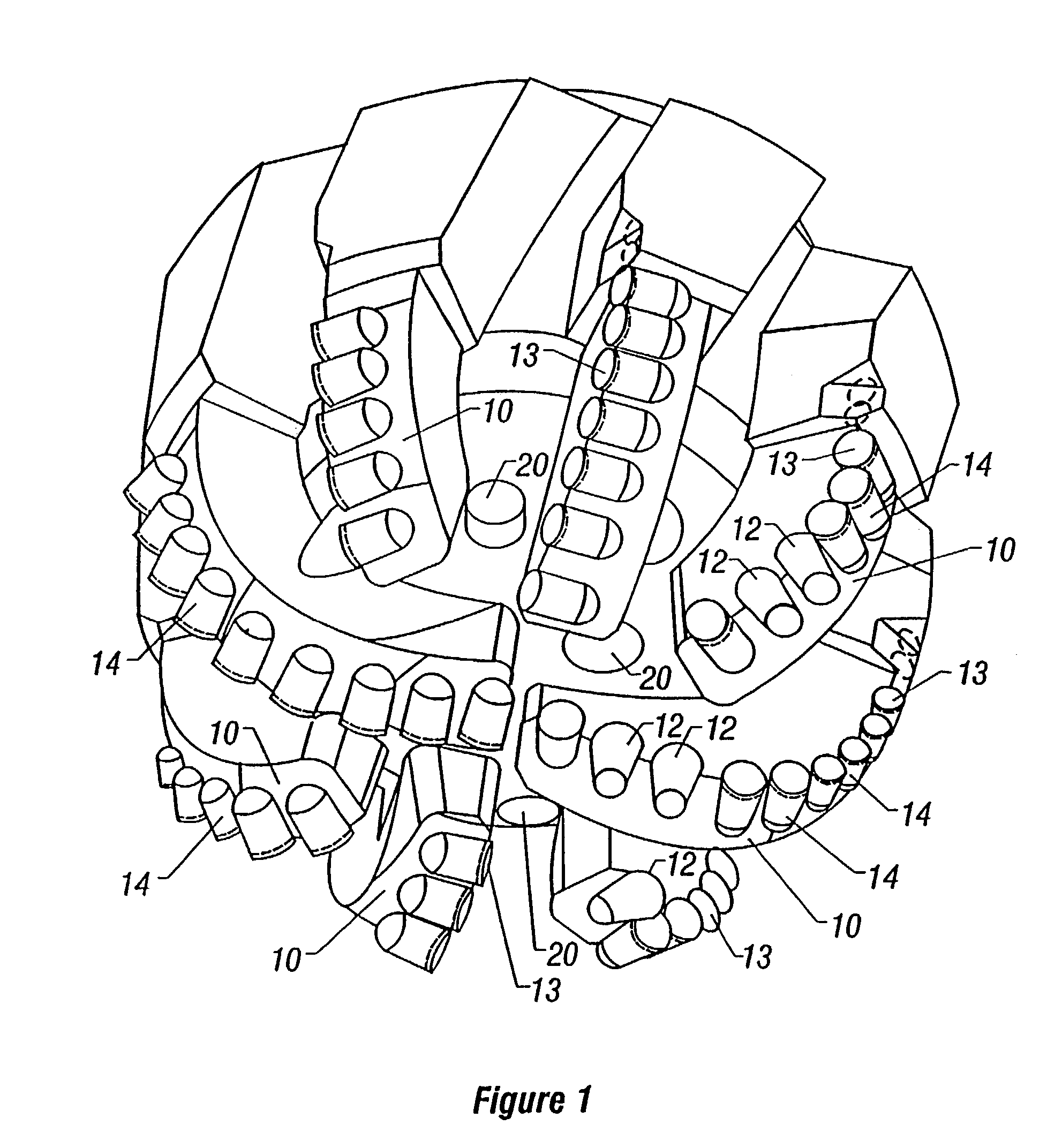

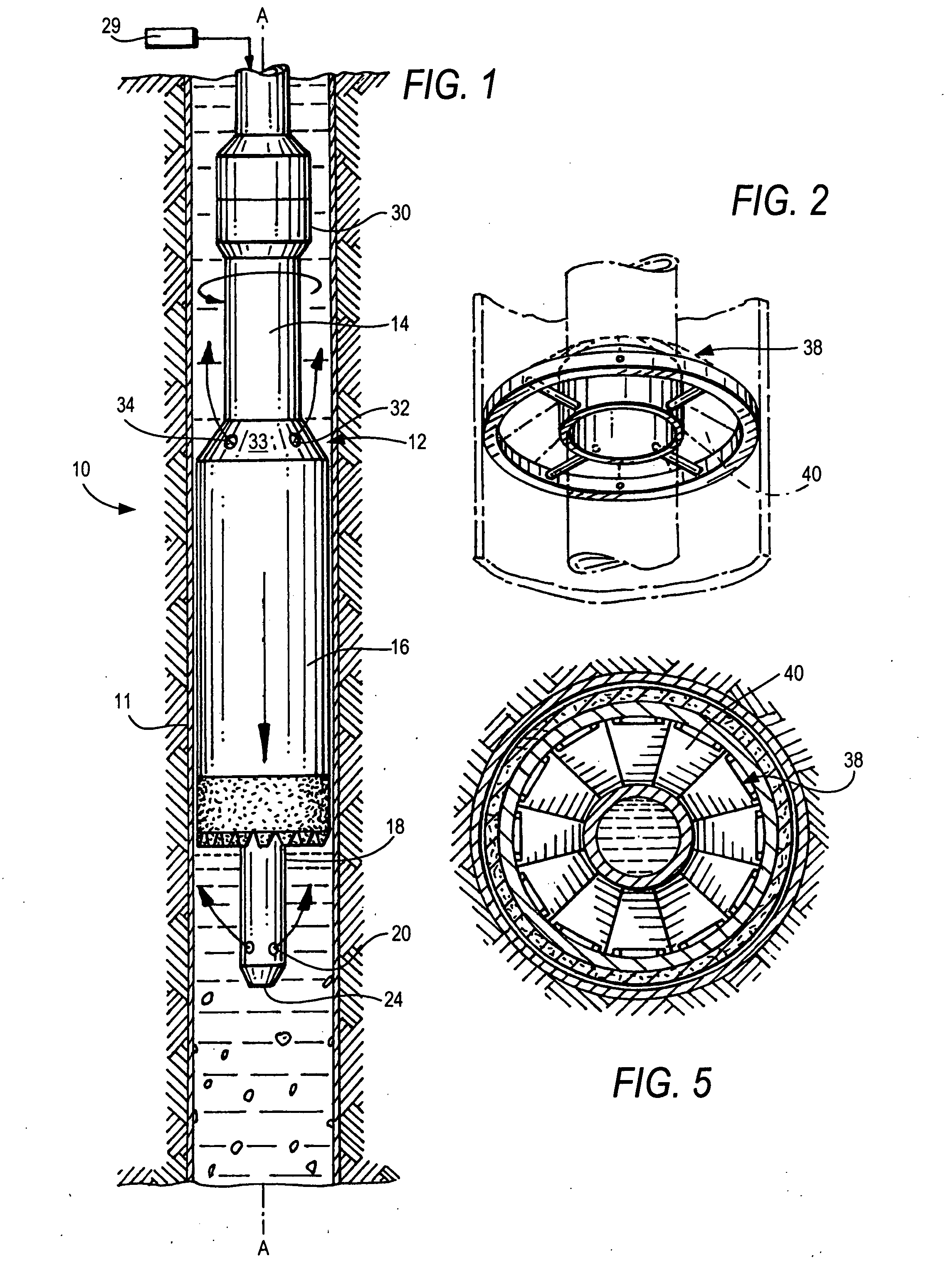

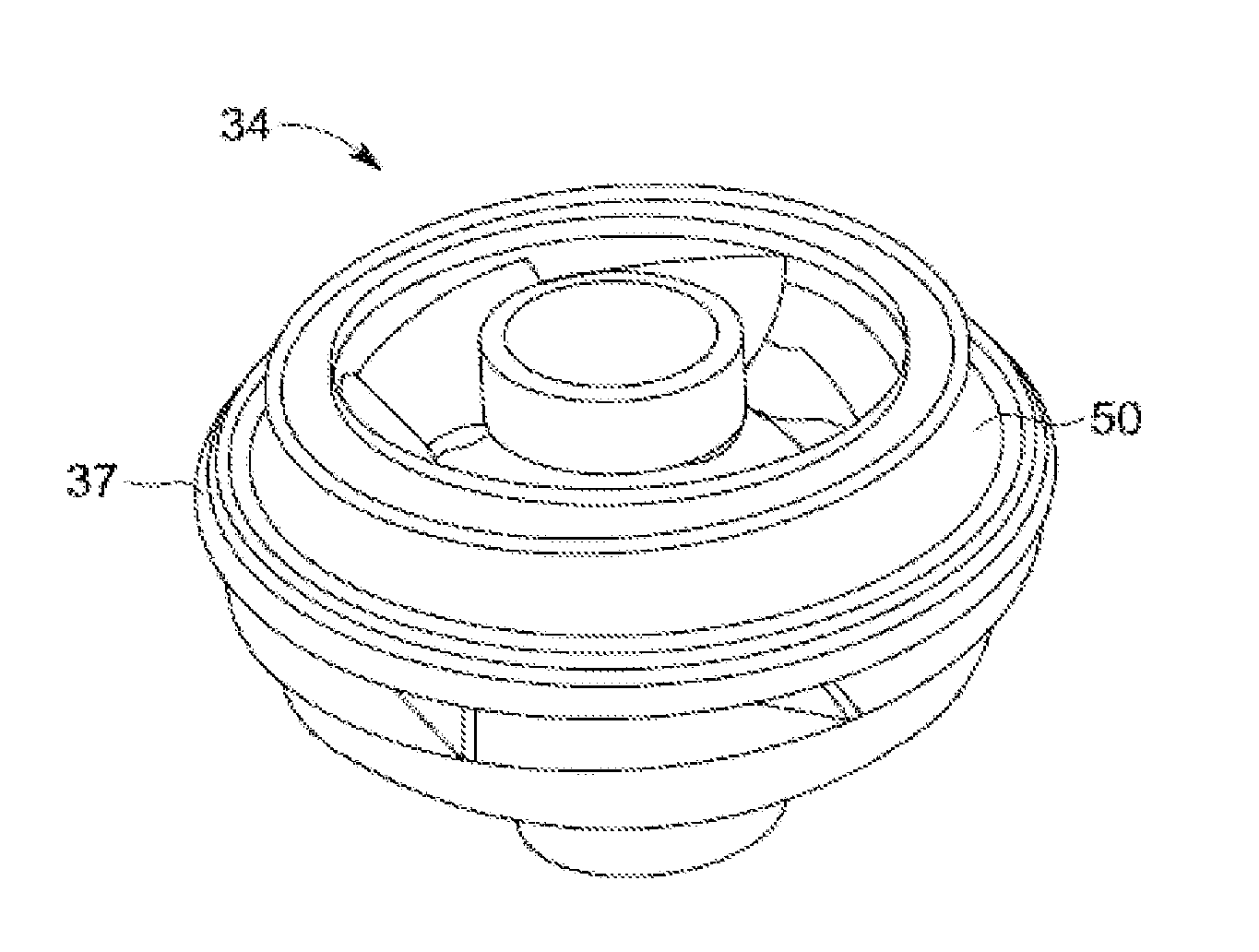

Electrical submersible pump and pump system including additively manufactured structures and method of manufacture

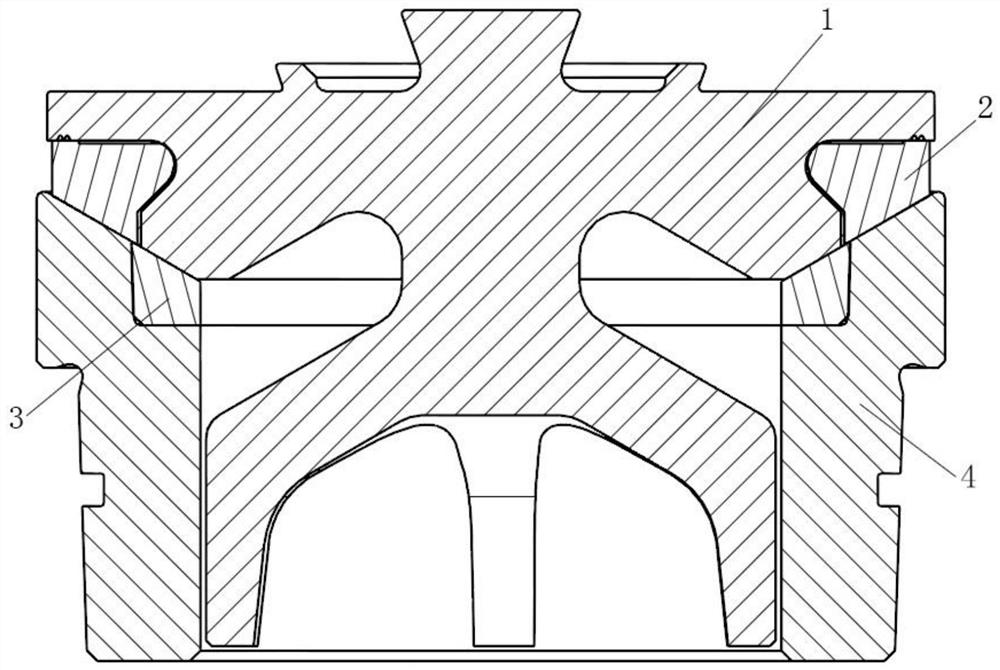

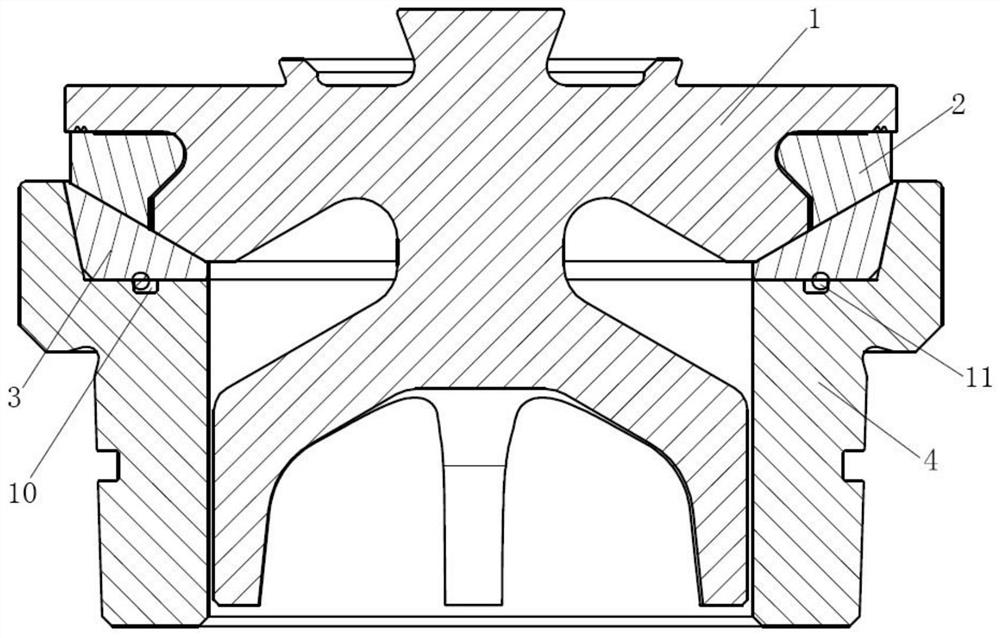

An electric submersible pump and pump system including additively manufactures structures and method of manufacture are disclosed. The pump system including the electric submersible pump and an electric motor configured to operate the electric submersible pump. The electric submersible pump including a housing, at least one impeller and at least one diffuser disposed within the housing in cooperative engagement. The housing, the at least one impeller, and the at least one diffuser defining an internal volume configured to receive a fluid. At least one of the at least one impeller and the at least one diffuser configured as a monolithic additively manufactured structure comprised of a metal matrix composite. Also provided is an electric submersible pump including an impeller and a diffuser, wherein at least one of the impeller and the diffuser is configured as a monolithic additively manufactured structure comprised of a tungsten carbide (WC) dispersed in a metal matrix.

Owner:GENERAL ELECTRIC CO

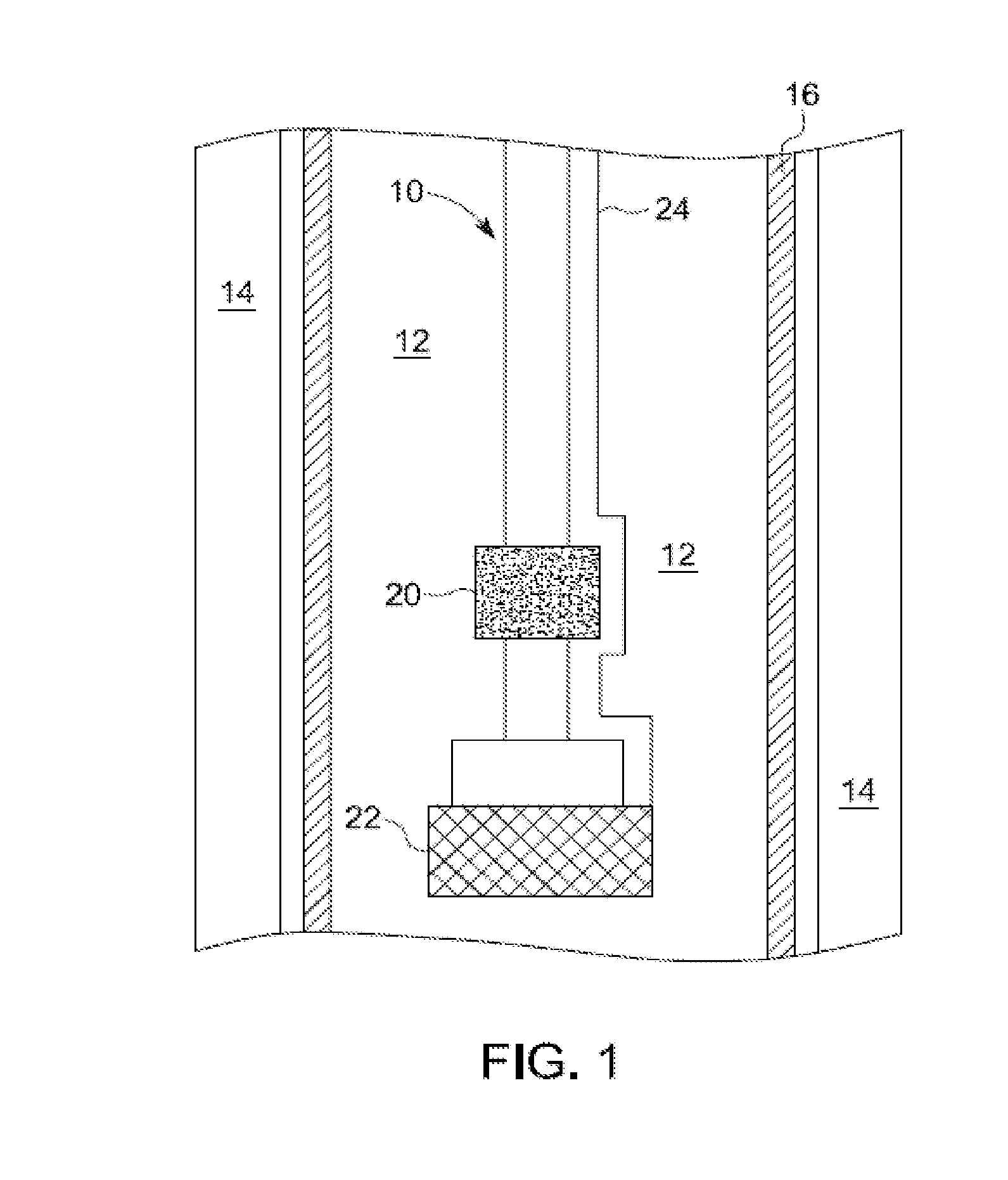

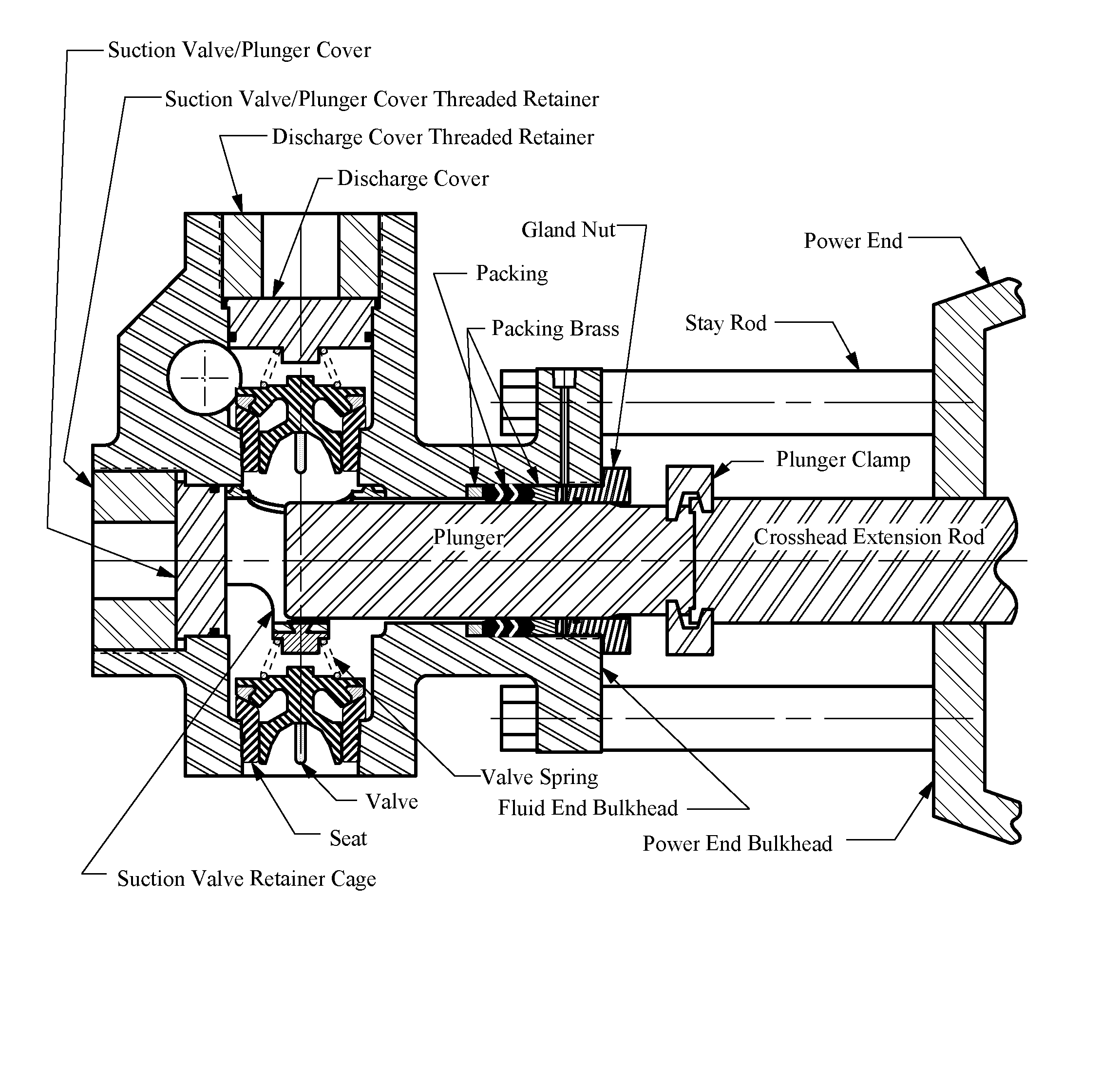

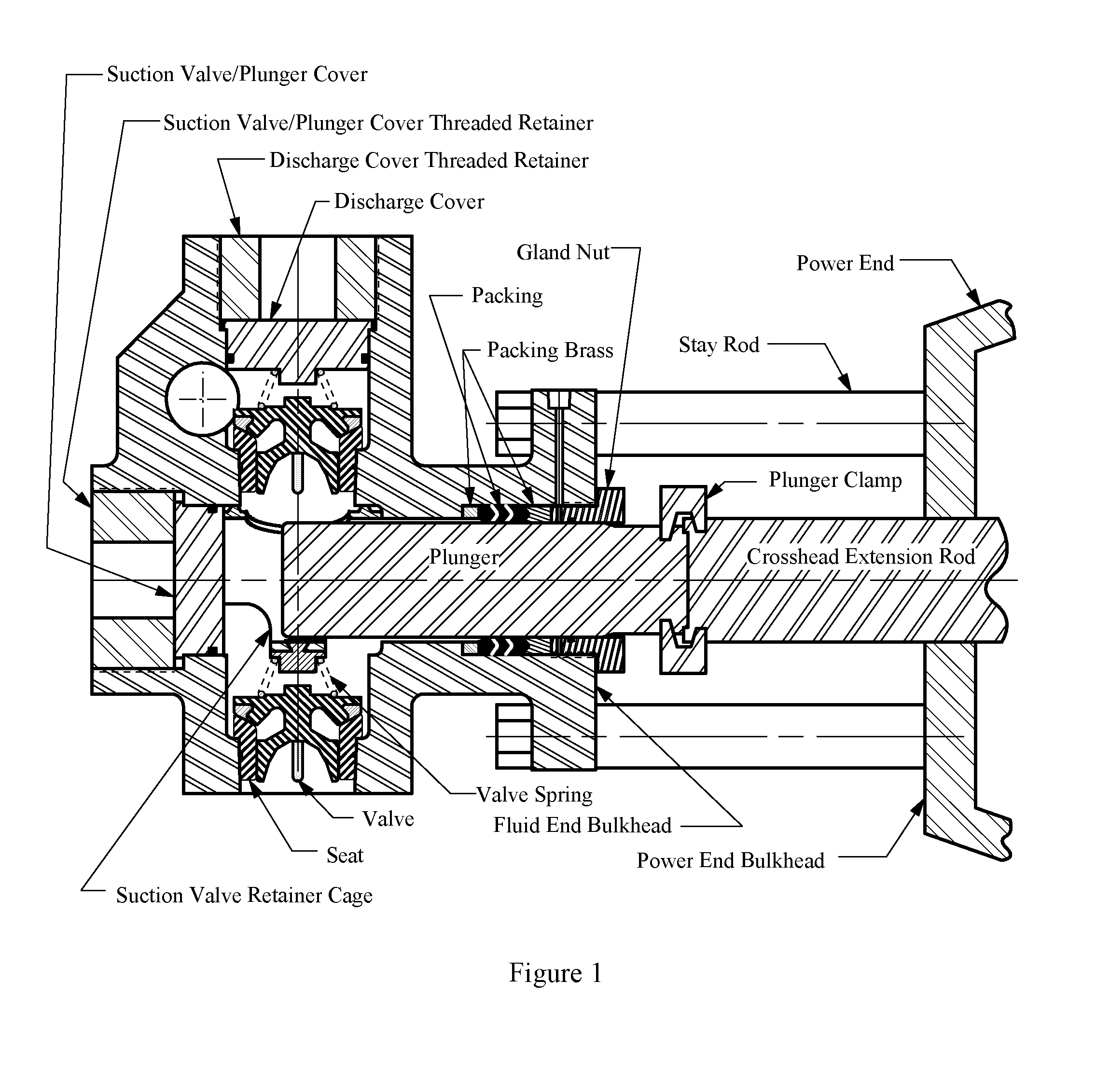

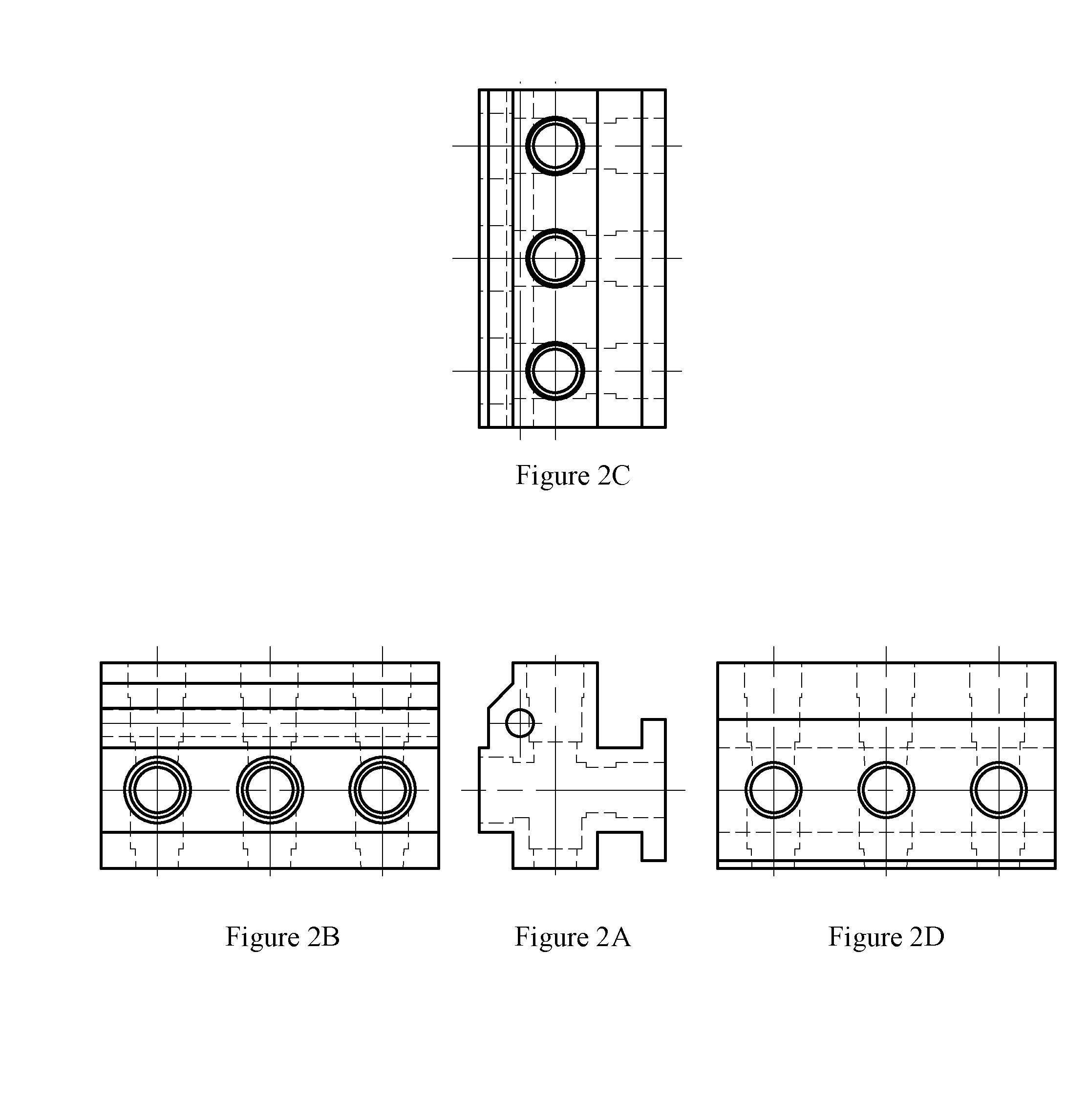

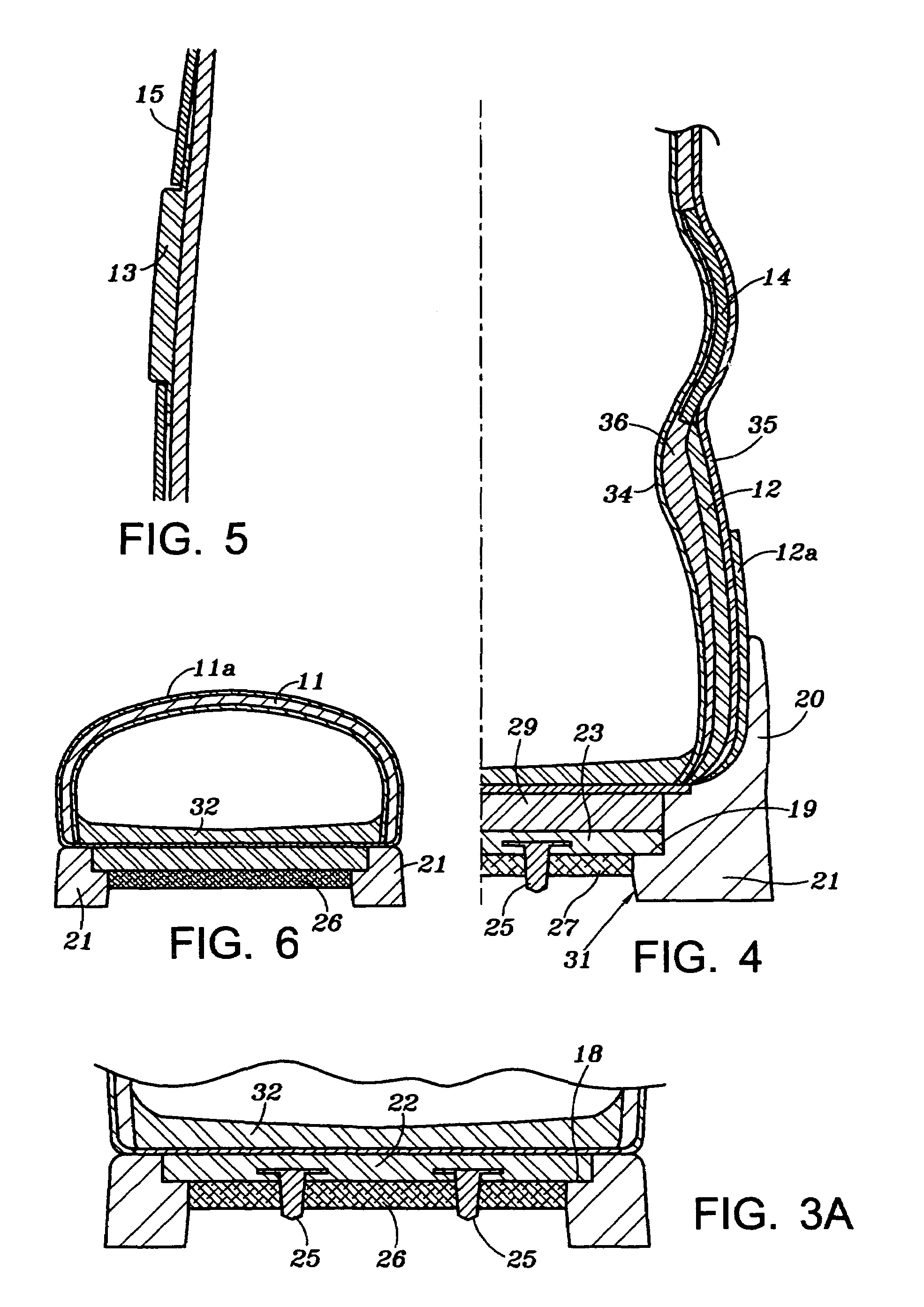

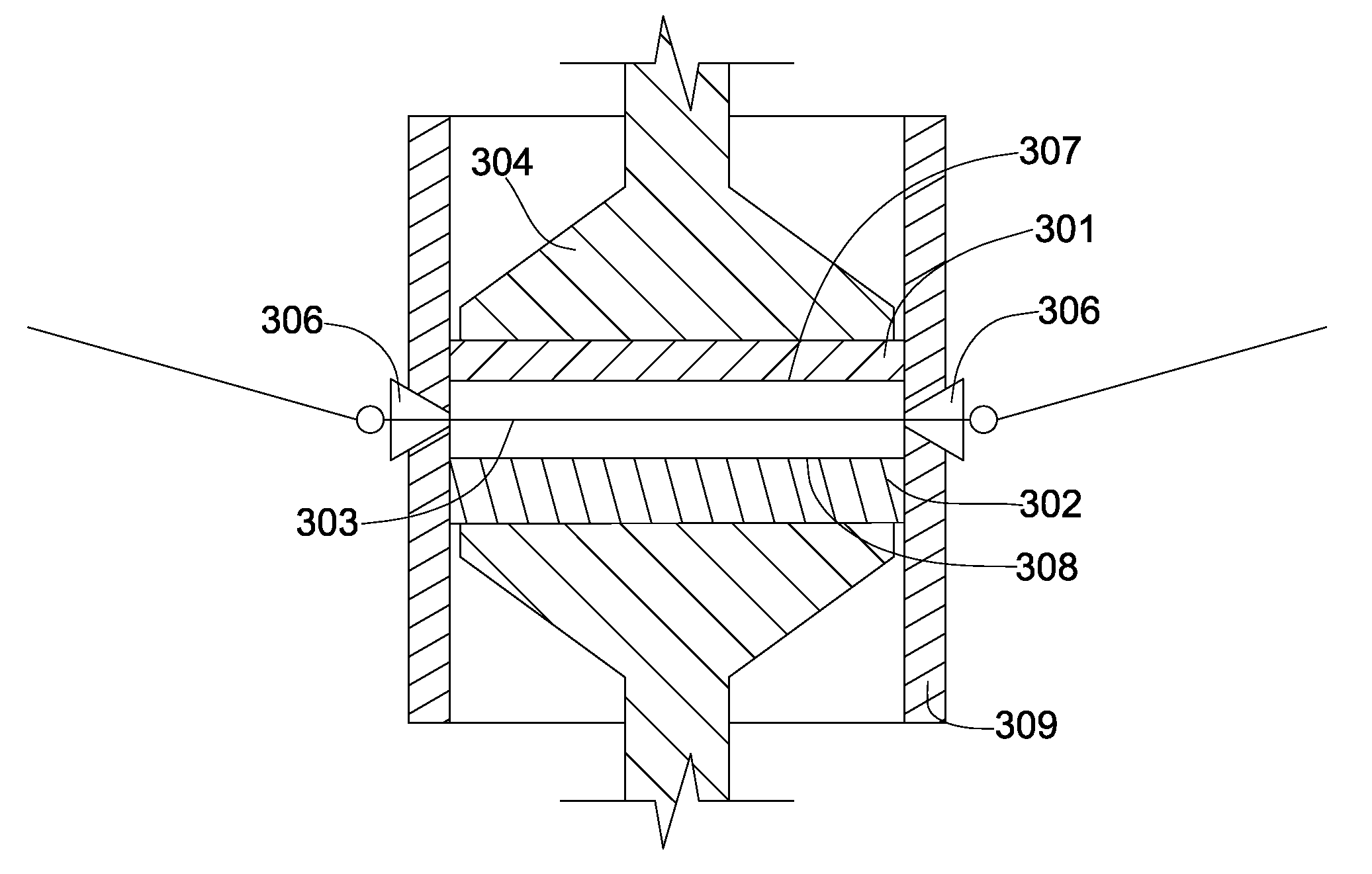

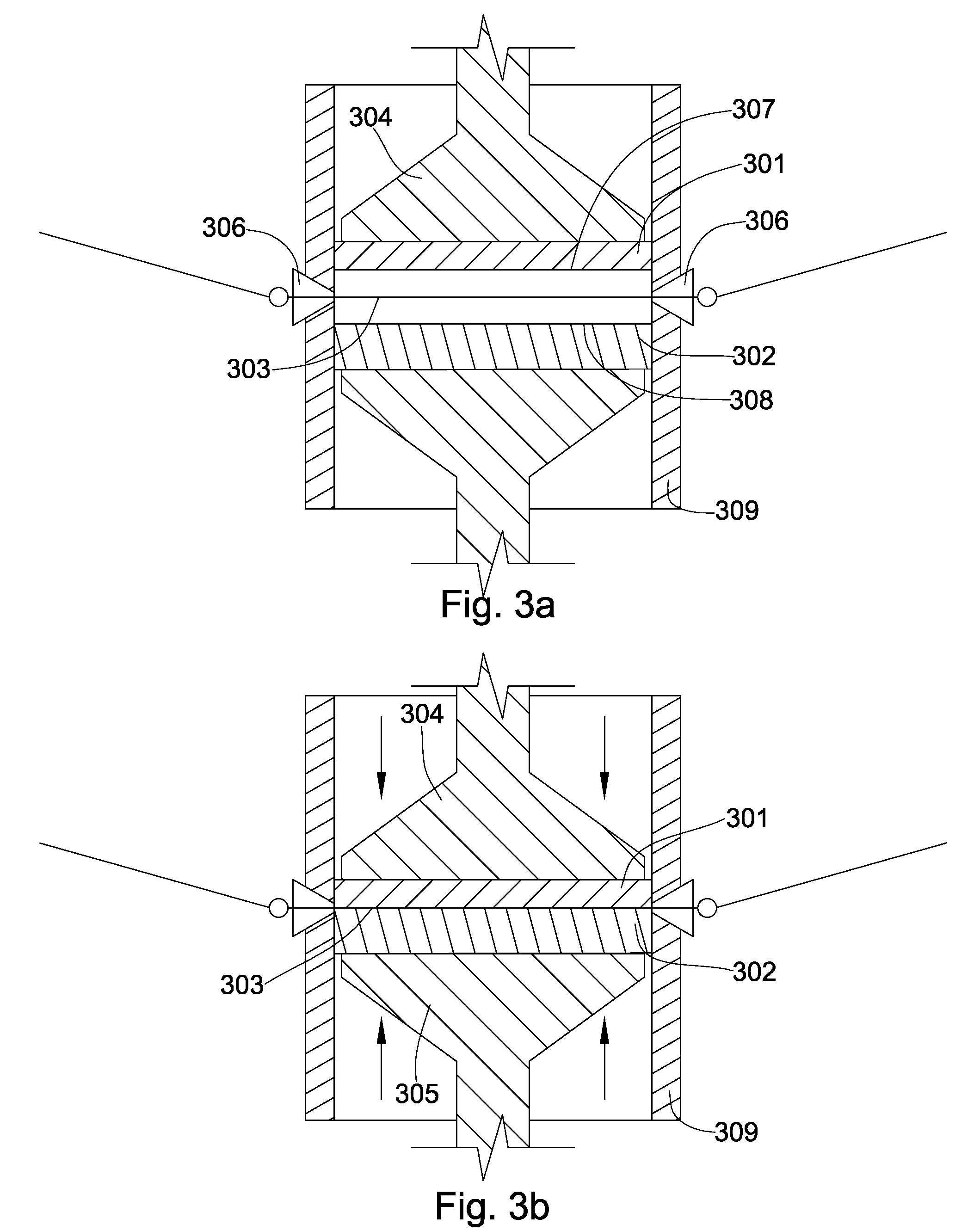

Fluid end with carbide valve seat and adhesive dampening interface

ActiveUS9435454B2Avoid fracturesApply evenlyPositive displacement pump componentsCheck valvesInterference fitCarbide

Owner:ALTIS INVESTMENTS LLC

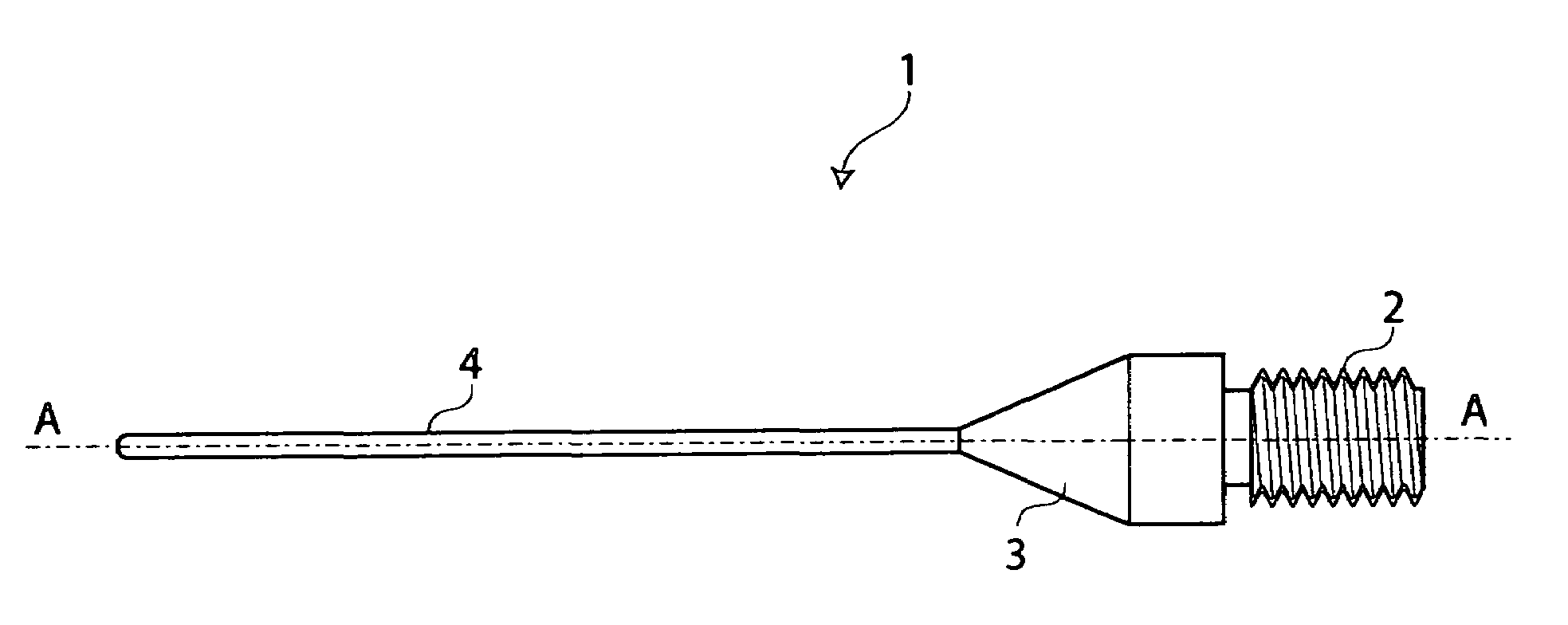

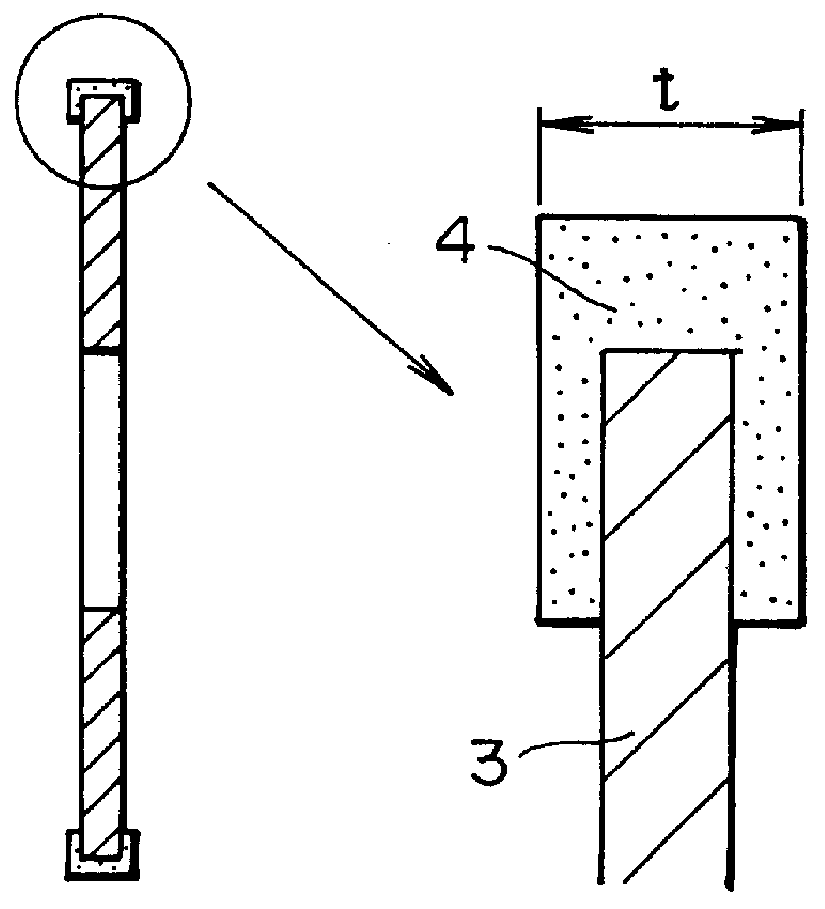

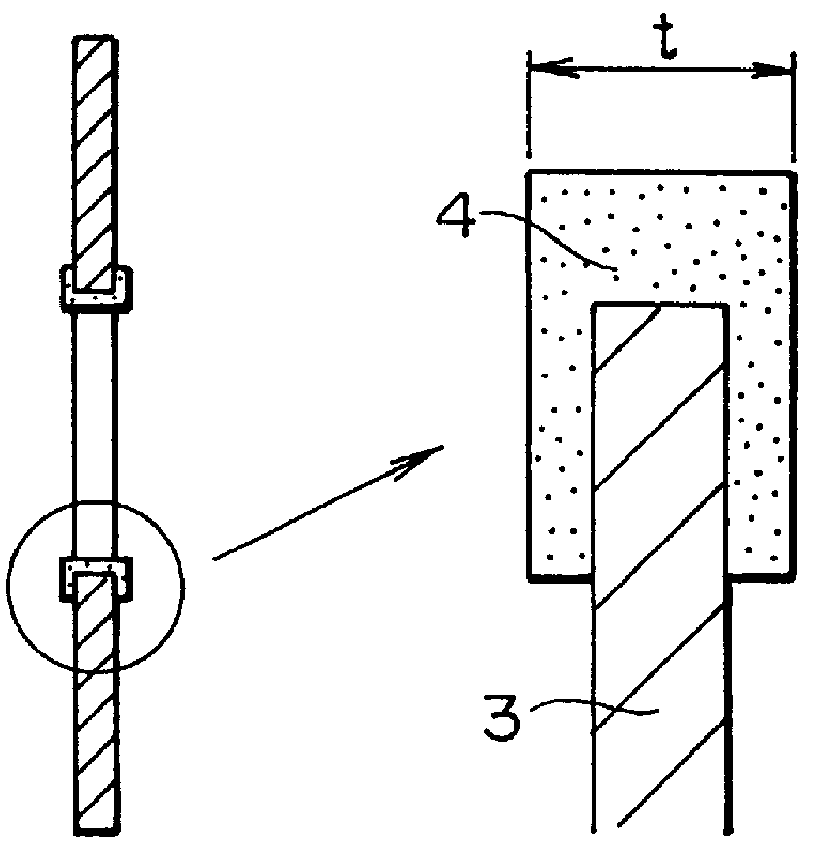

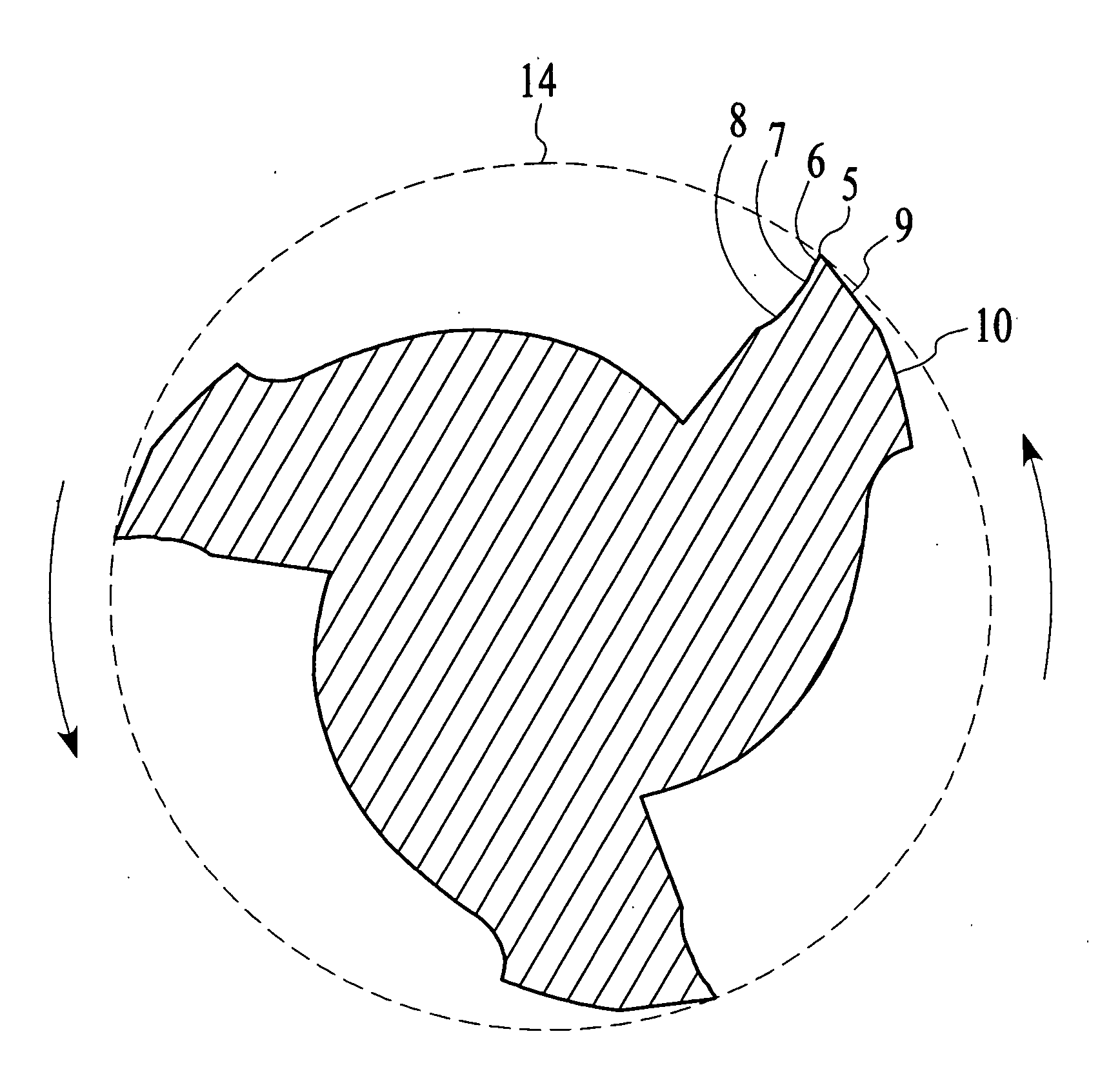

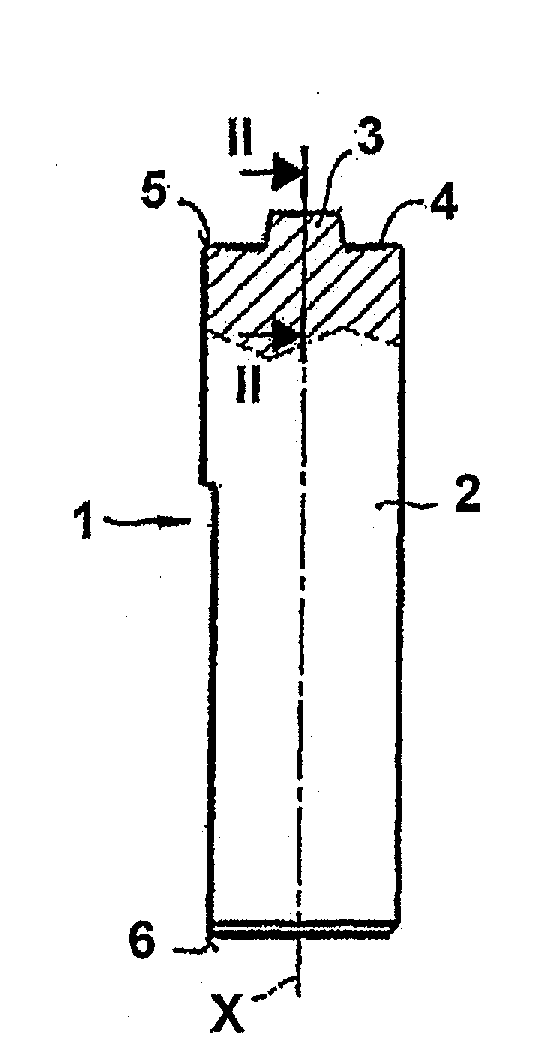

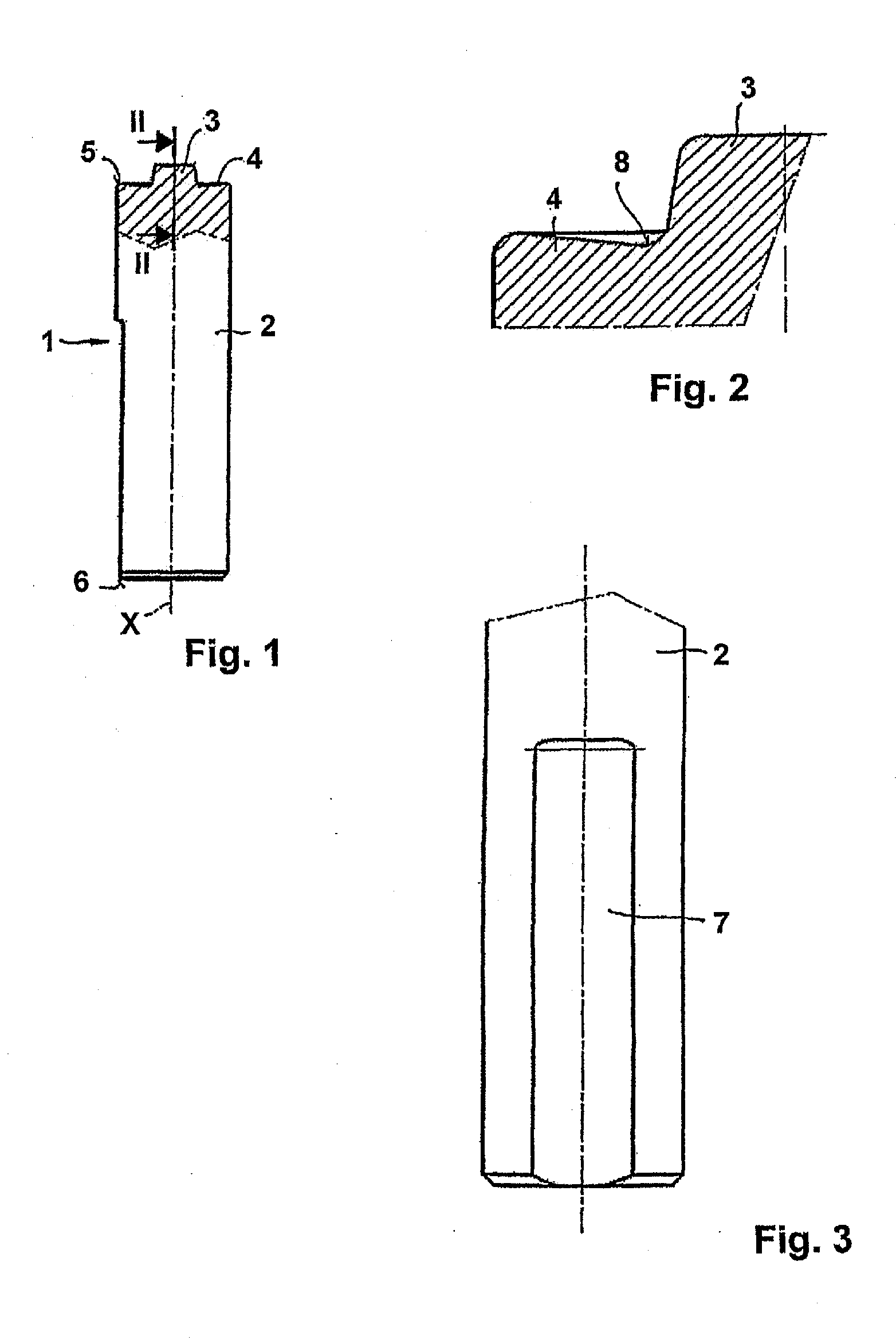

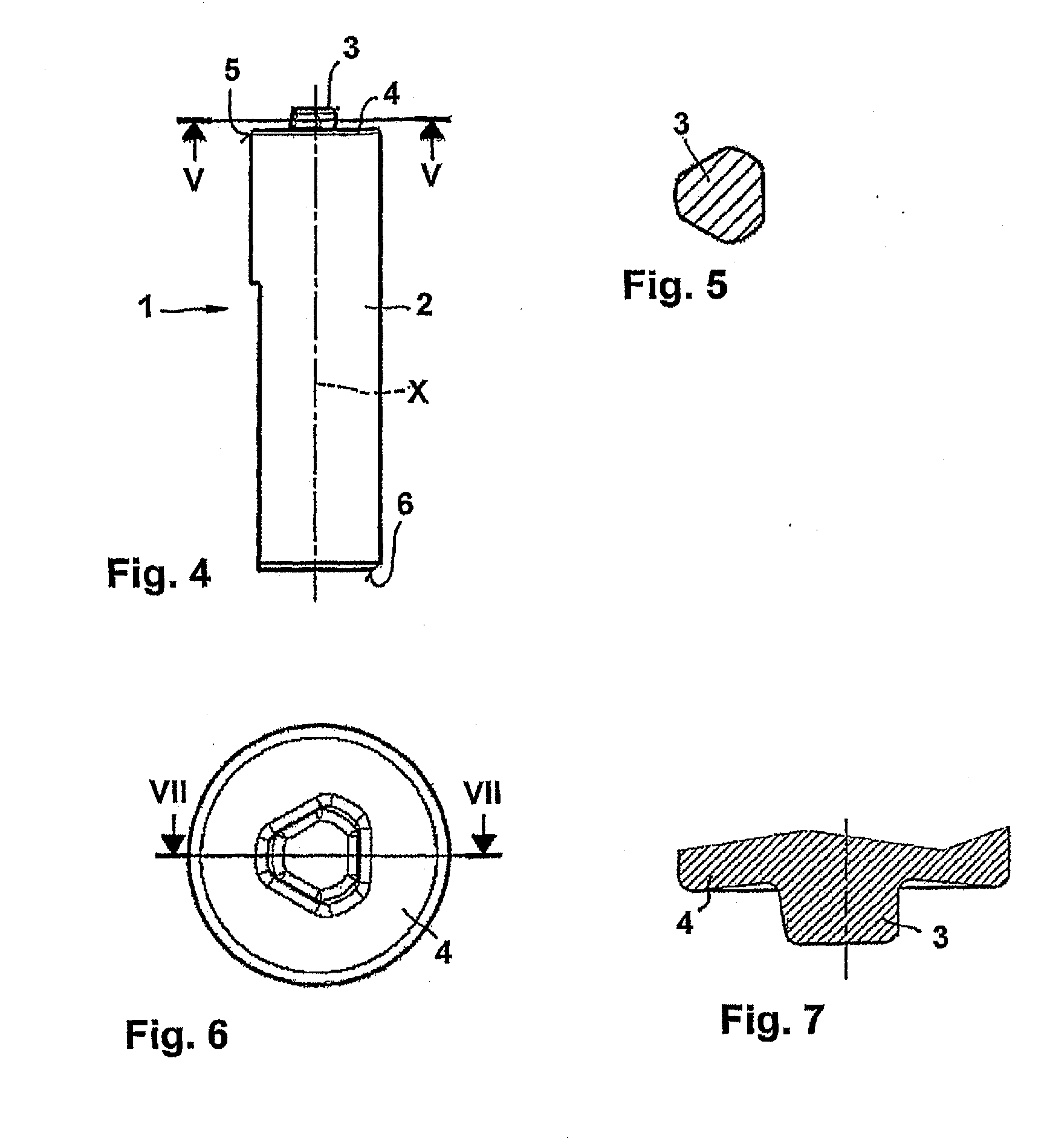

Friction stir welding tool

InactiveUS20100258612A1Easy to useReduce sensitivityWelding/cutting auxillary devicesAuxillary welding devicesHard metalTitanium carbide

The invention relates to a friction stir welding tool (1) with an essentially cylindrical shank (2), which has a peg (3) with a smaller diameter projecting on one end (5) starting from a shoulder region (4) of the shank (2). According to the invention it is provided in order to create a friction stir welding tool (1) for welding steel, that the friction stir welding tool (1), at least in the region of the peg (3) and in the shoulder region (4), is made of a hard metal containing 80% by weight to 98% by weight tungsten carbide with an average grain size of more than 1 μm and up to 20% by weight cobalt as well as optionally a total of up to 18% by weight titanium carbide, tantalum carbide, niobium carbide and / or mixed carbides thereof and at least in one of the referenced regions has a coating of one or more layers.

Owner:BOEHLERIT GMBH & CO KG

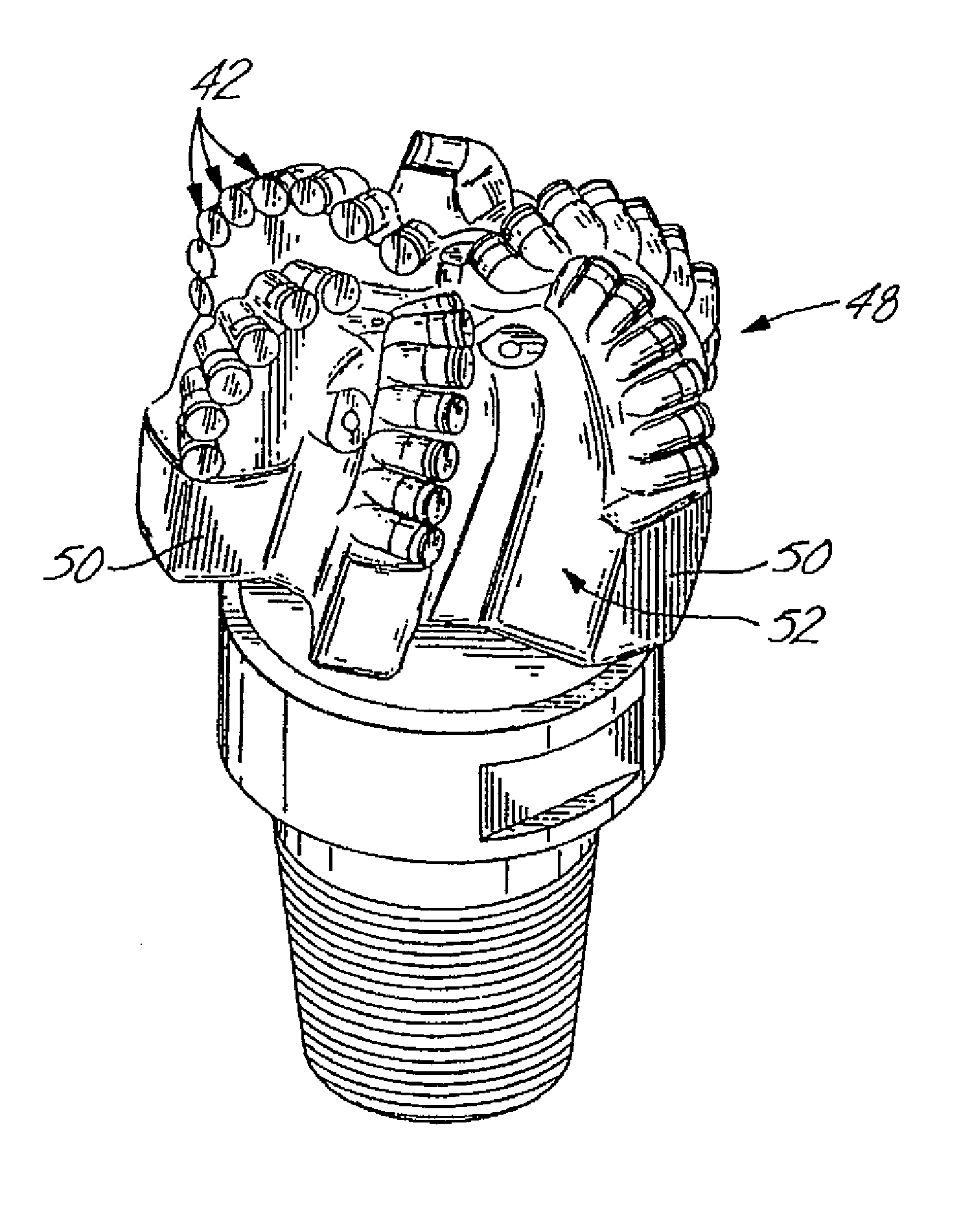

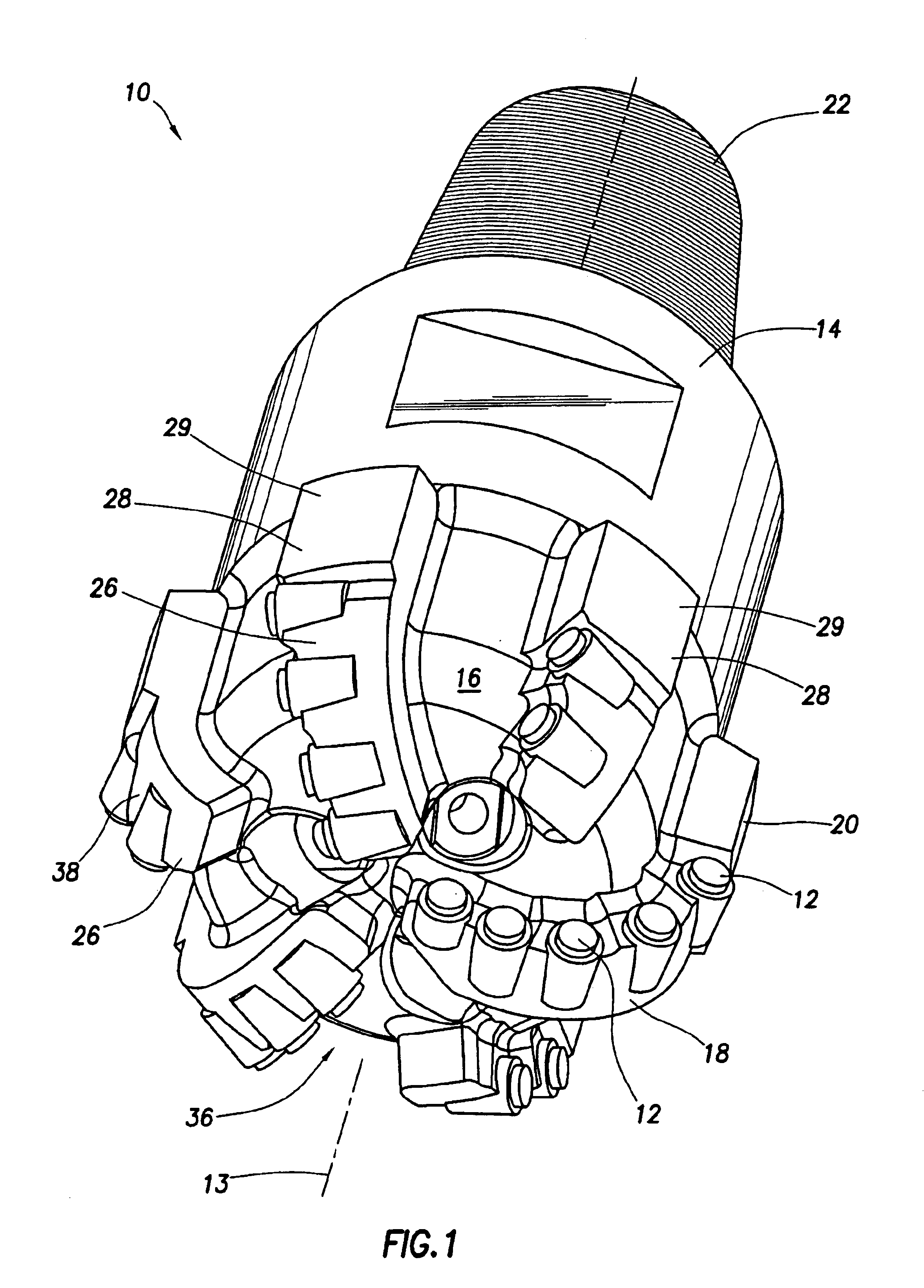

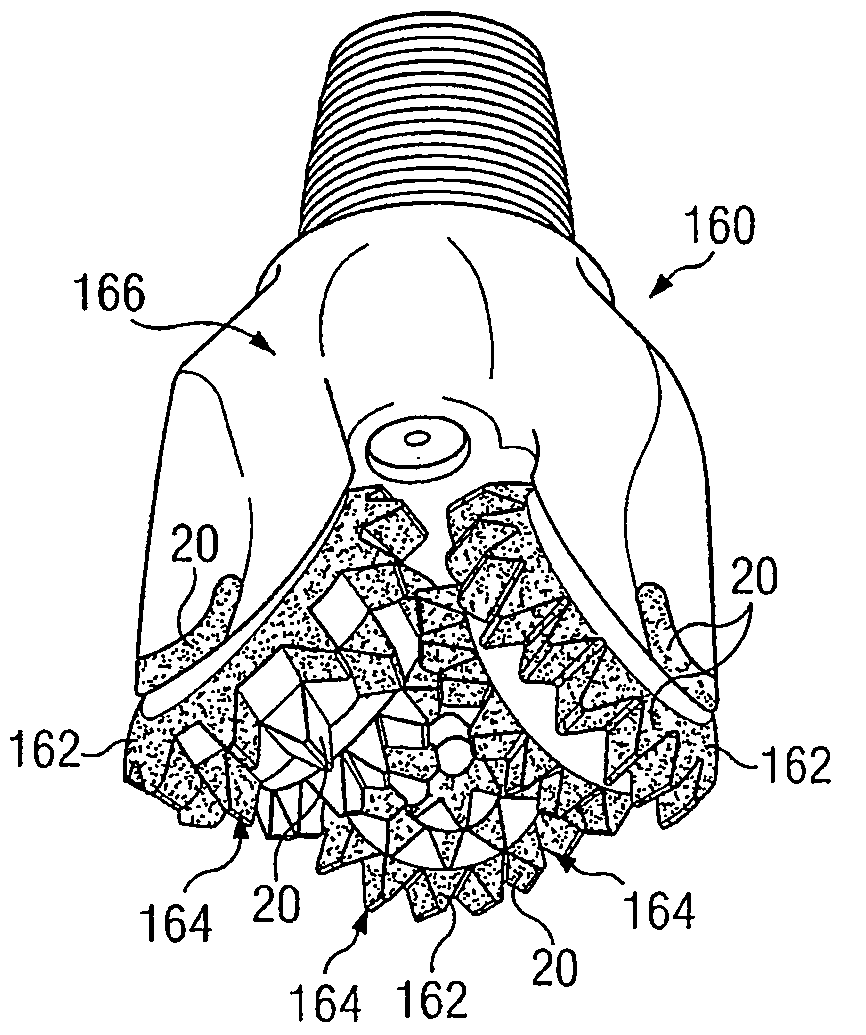

Drill bits and other downhole tools with hardfacing having tungsten carbide pellets and other hard materials

ActiveUS20100101866A1Improve performanceEasy to wearLiquid surface applicatorsDrill bitsCase hardeningSpherical shaped

A hardfacing is provided to protect surfaces of drill bits and other downhole tools. The hardfacing may include tungsten carbide particles or pellets formed with an optimum weight percentage of binding material and dispersed within and bonded to a matrix deposit. The tungsten carbide particles may be formed by sintering or other appropriate techniques. The tungsten carbide particles may have generally spherical shapes, partially spherical shapes or non-spherical shapes.

Owner:HALLIBURTON ENERGY SERVICES INC

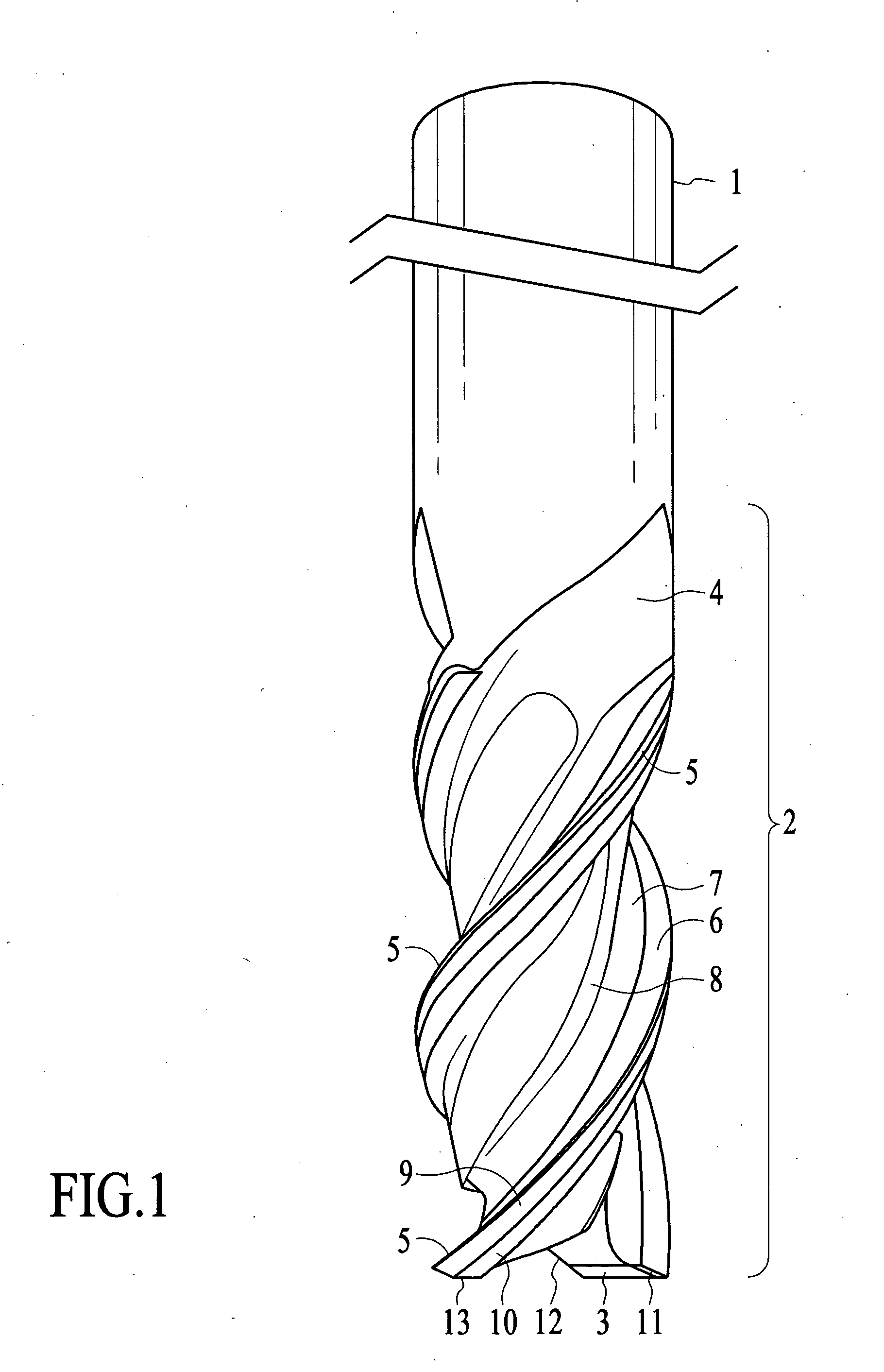

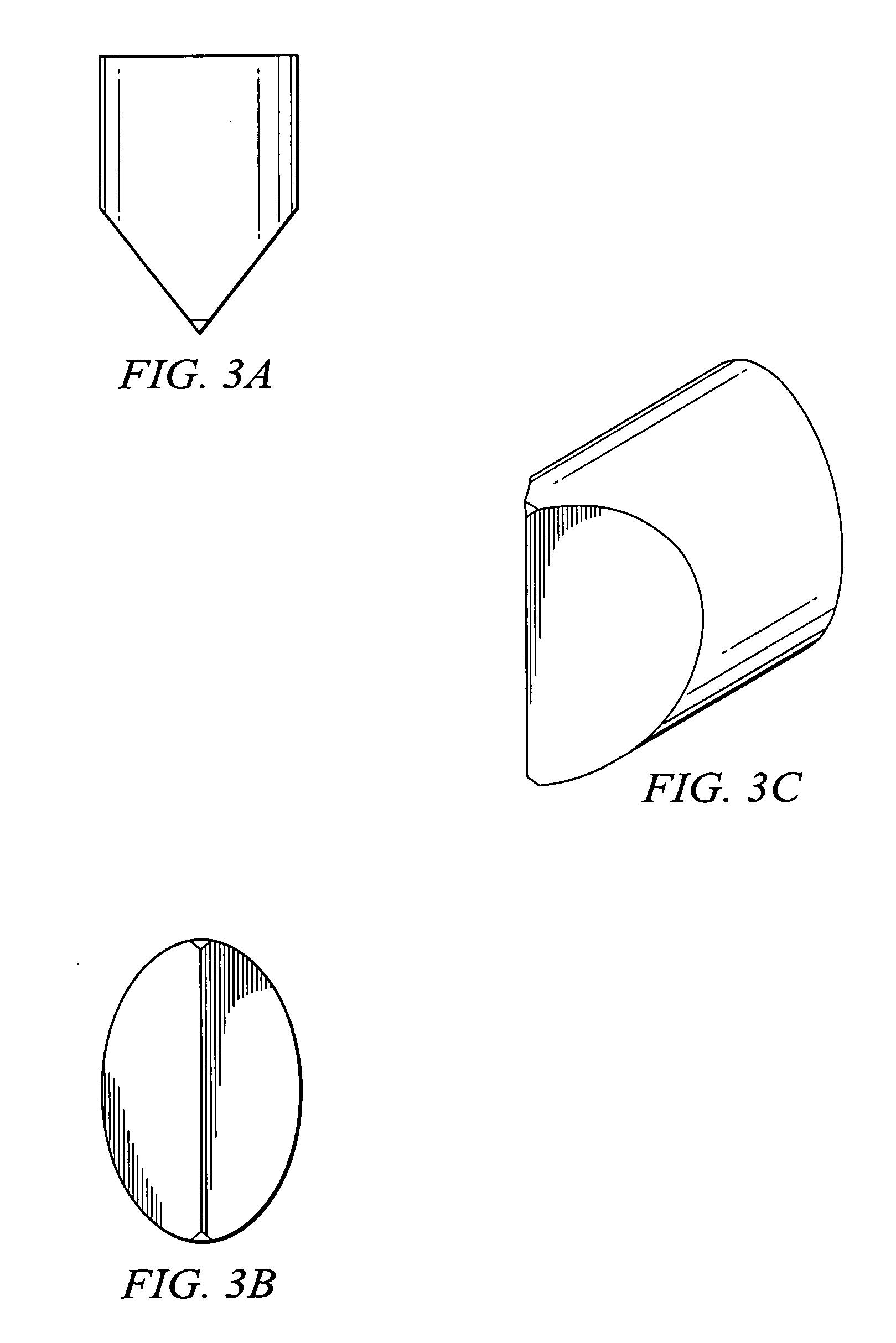

PDC cutter for high compressive strength and highly abrasive formations

InactiveUS20070235230A1Reduce wearReduce crackingDrill bitsConstructionsCompressive strengthUltimate tensile strength

A PDC cutter utilizes the combination of an elliptical shape with higher thermal resistance obtained through leaching to provide a cutter which is more effective than a cutter using either concept alone. The PDC cutter includes a tungsten carbide portion with protrusions extending from a surface thereof in a pattern. The diamond volume is mounted to the surface wherein the protrusions allow for the diamond volume to be larger about a perimeter edge of the cutter and smaller / shallower in a center region of the cutter. The protrusions providing surfaces for the diamond layer (table) to bond to the underlying tungsten carbide portion. With this configuration, diamond volume is maximized around the edge of the cutter.

Owner:VAREL INT IND

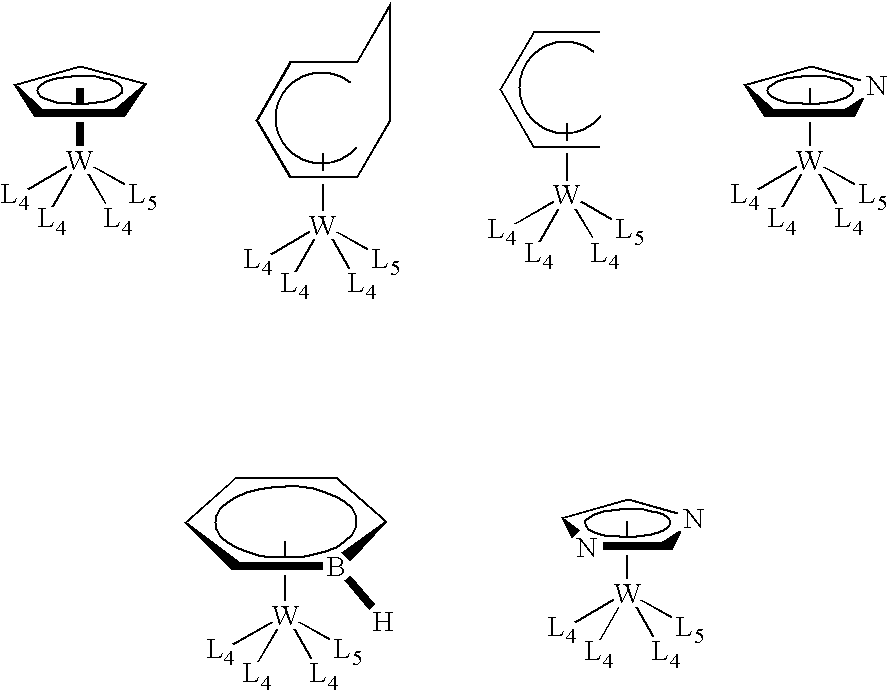

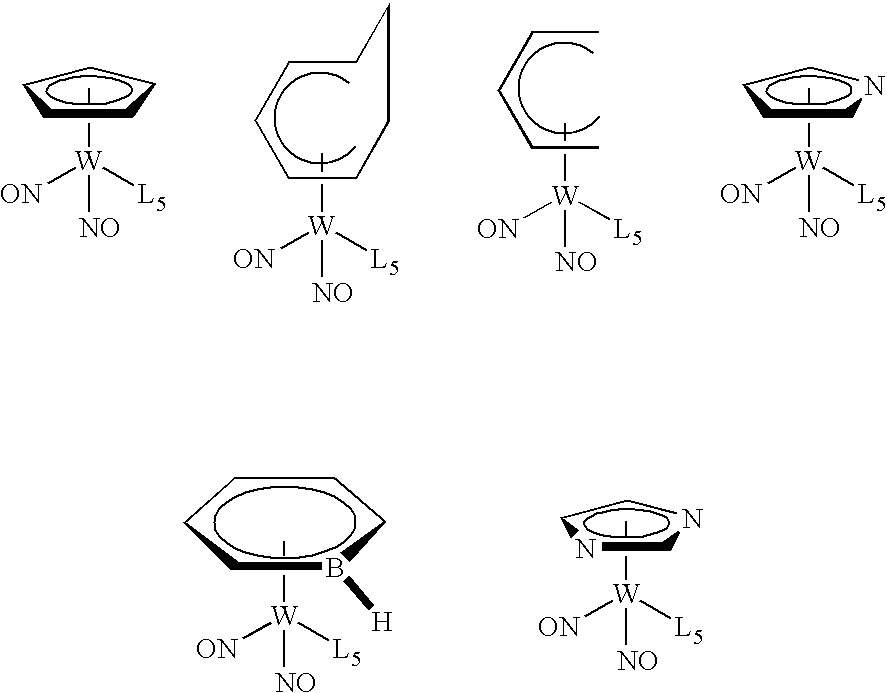

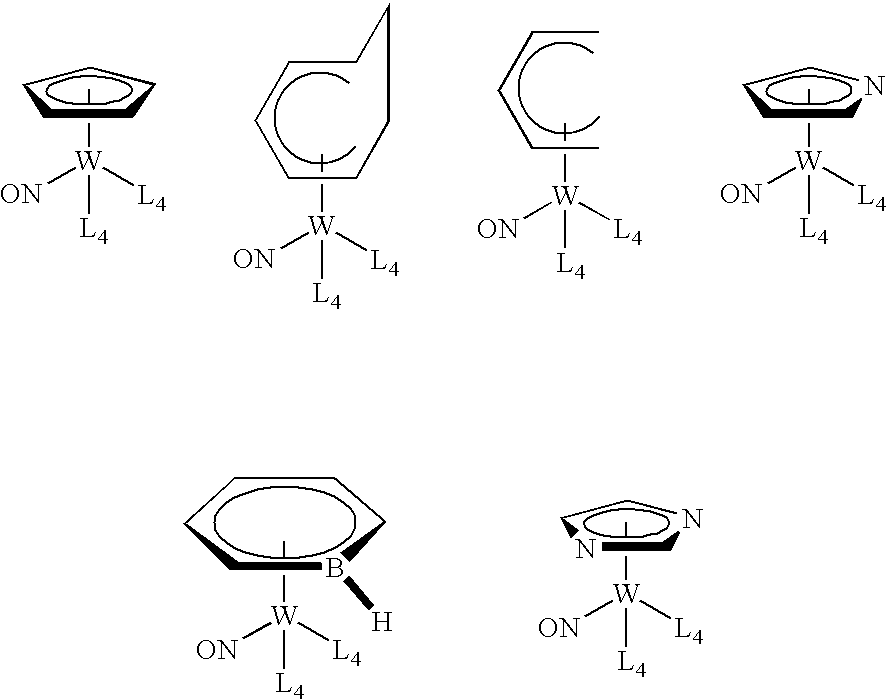

Organometallic compounds, processes for the preparation thereof and methods of use thereof

ActiveUS20080081127A1Improve responseReduce usageGroup 5/15 element organic compoundsSolid-state devicesIntegrated circuit manufacturingElectron donor

This invention relates to organometallic compounds represented by the formula (L1)yM(L2)z-y wherein M is a Group 5 metal or a Group 6 metal, L1 is a substituted or unsubstituted anionic 6 electron donor ligand, L2 is the same or different and is (i) a substituted or unsubstituted anionic 2 electron donor ligand, (ii) a substituted or unsubstituted cationic 2 electron donor ligand, or (iii) a substituted or unsubstituted neutral 2 electron donor ligand; y is an integer of 1, and z is the valence of M; and wherein the sum of the oxidation number of M and the electric charges of L1 and L2 is equal to 0.; a process for producing the organometallic compounds; and a method for depositing a metal and / or metal carbide / nitride layer, e.g., a tungsten, tungsten nitride, tungsten carbide, or tungsten carbonitride layer, on a substrate by the thermal or plasma enhanced dissociation of the organometallic precursor compounds, e.g., by CVD or ALD techniques. The metal and / or metal carbide layer is useful as a liner or barrier layer for conducting metals and high dielectric constant materials in integrated circuit manufacturing.

Owner:PRAXAIR TECH INC

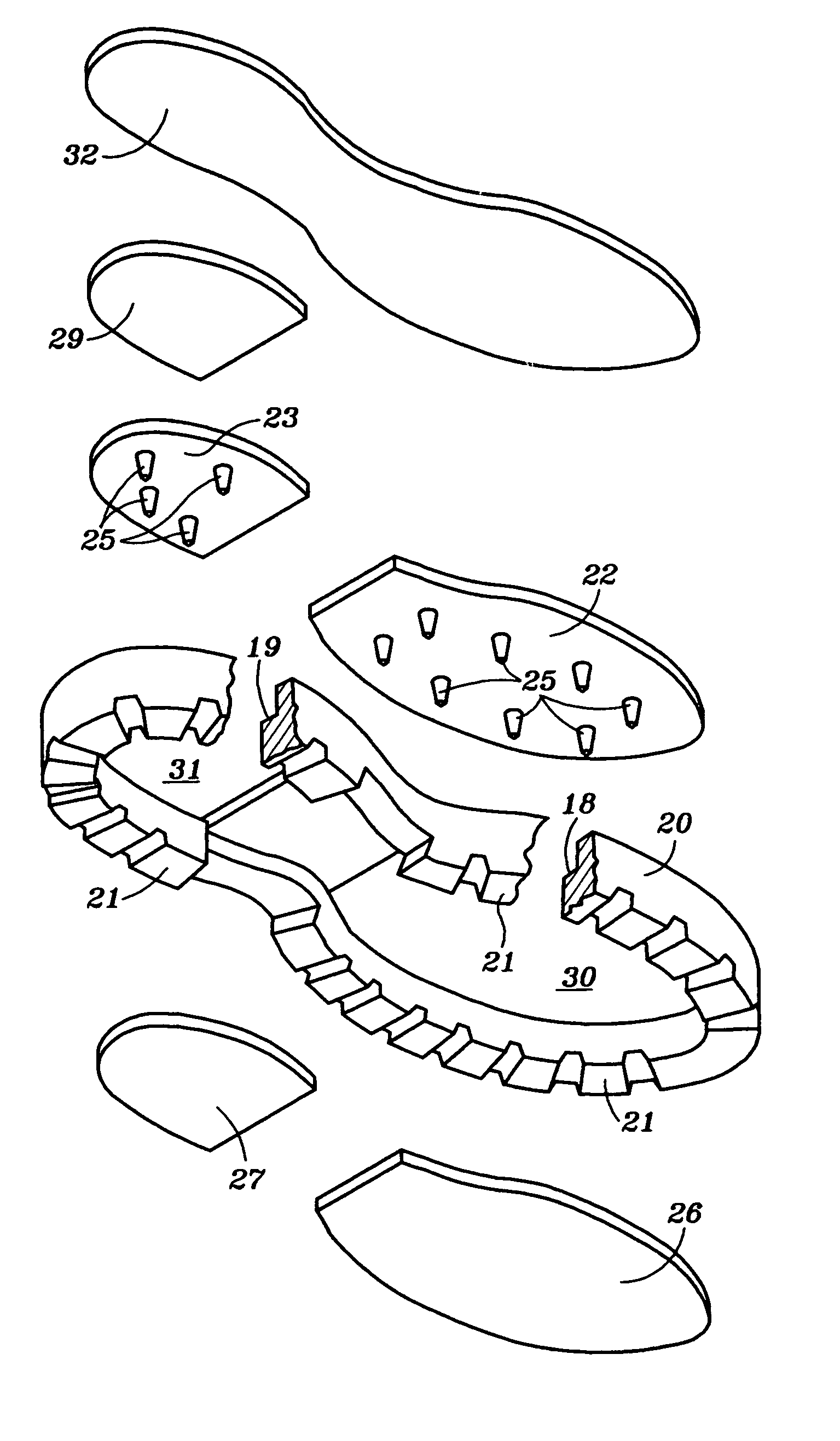

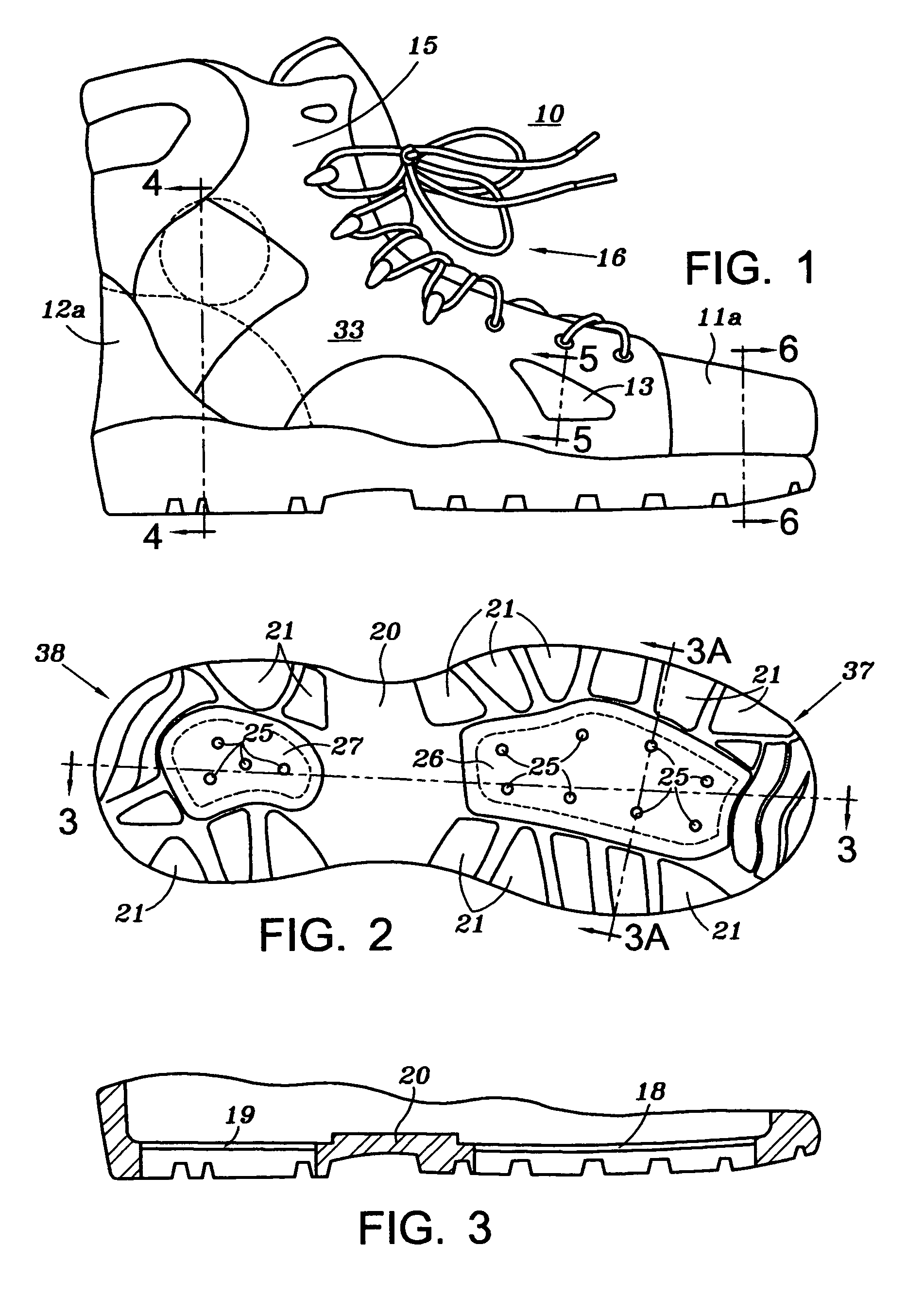

Field and stream boot

A field and stream boot for traversing rivers, lakes and stream beds, as well as, outdoor trails which includes; an upper construction with a hard heel, a hard toe, an ankle cup, and a metatarsus rigid panel that provide foot protection from outdoor or underwater terrain and obstacles; and an outsole construction where the outsole has peripheral intermittent tread surrounding a heel array of tungsten carbide spikes overlain with felt with the spike protruding through the felt but not below the peripheral intermittent tread, and surrounding a forefoot array of tungsten carbide spikes overlain with felt with the spikes protruding through the felt but not below the peripheral intermittent tread. The tread may be in the form of lugs, cleats or other gripping ribs or ridges.

Owner:MYERS ROBERT J

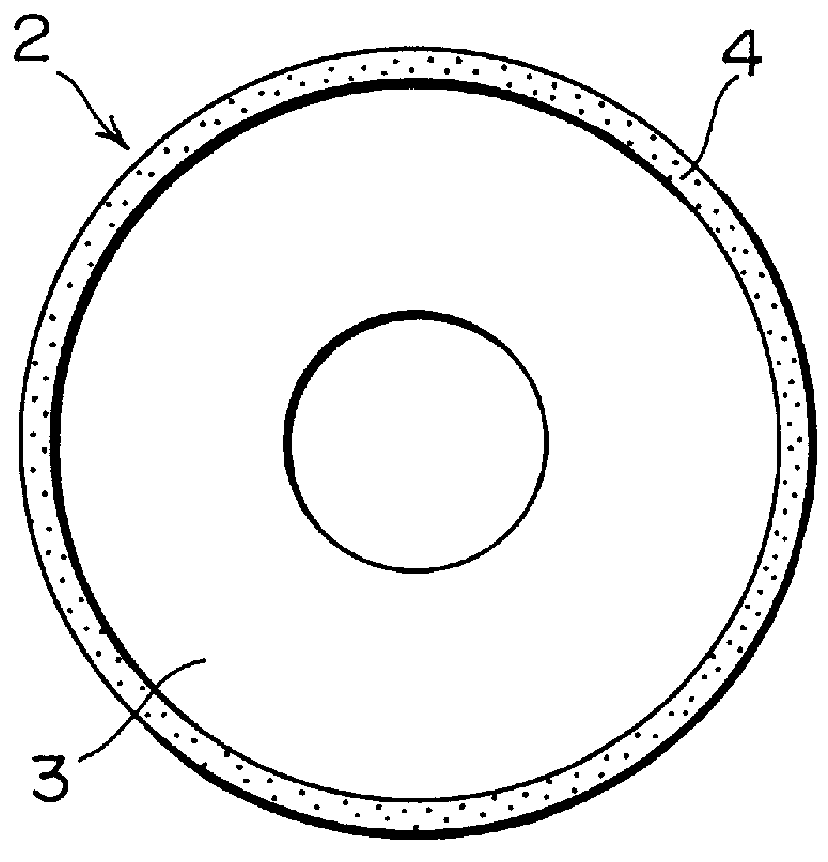

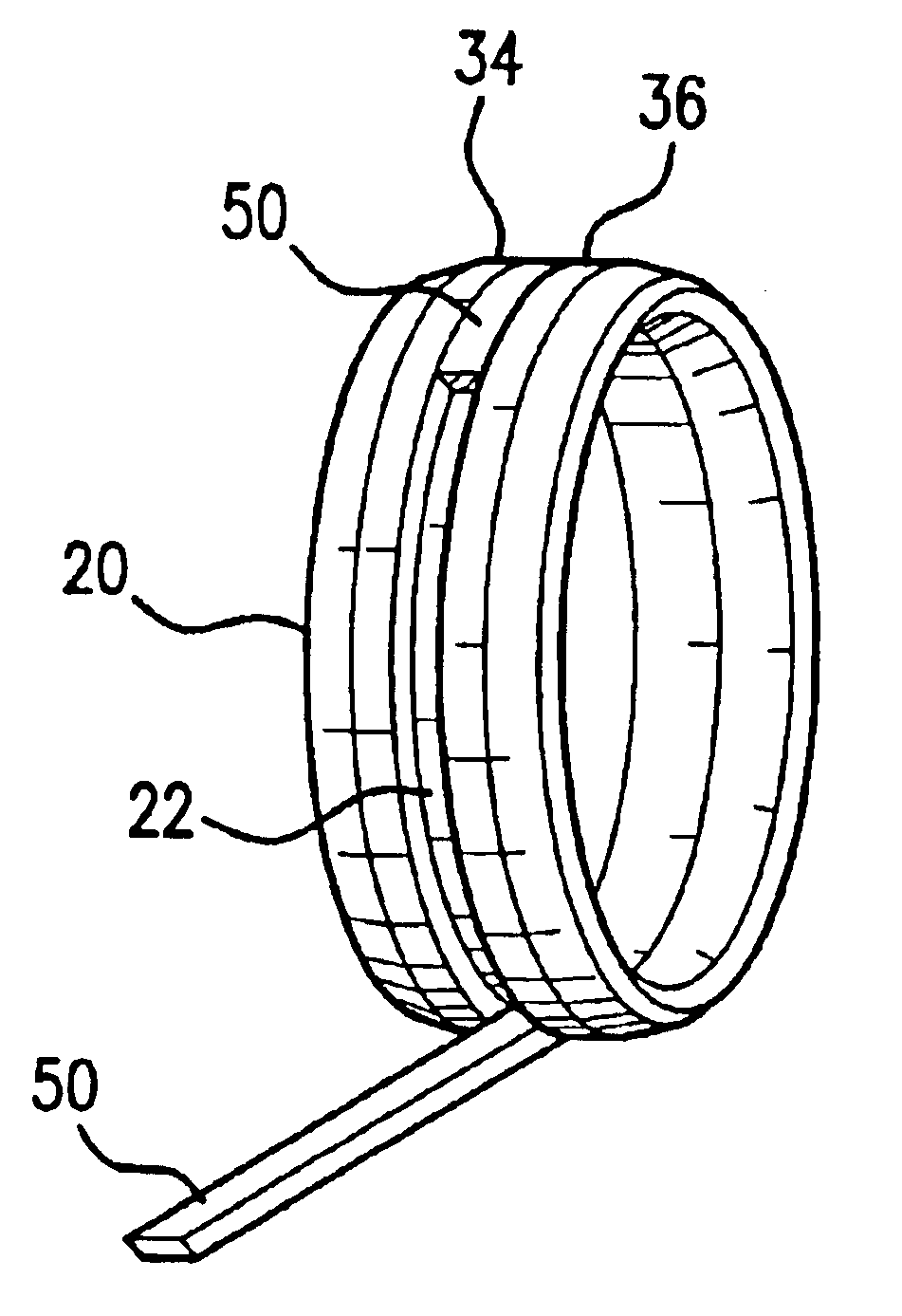

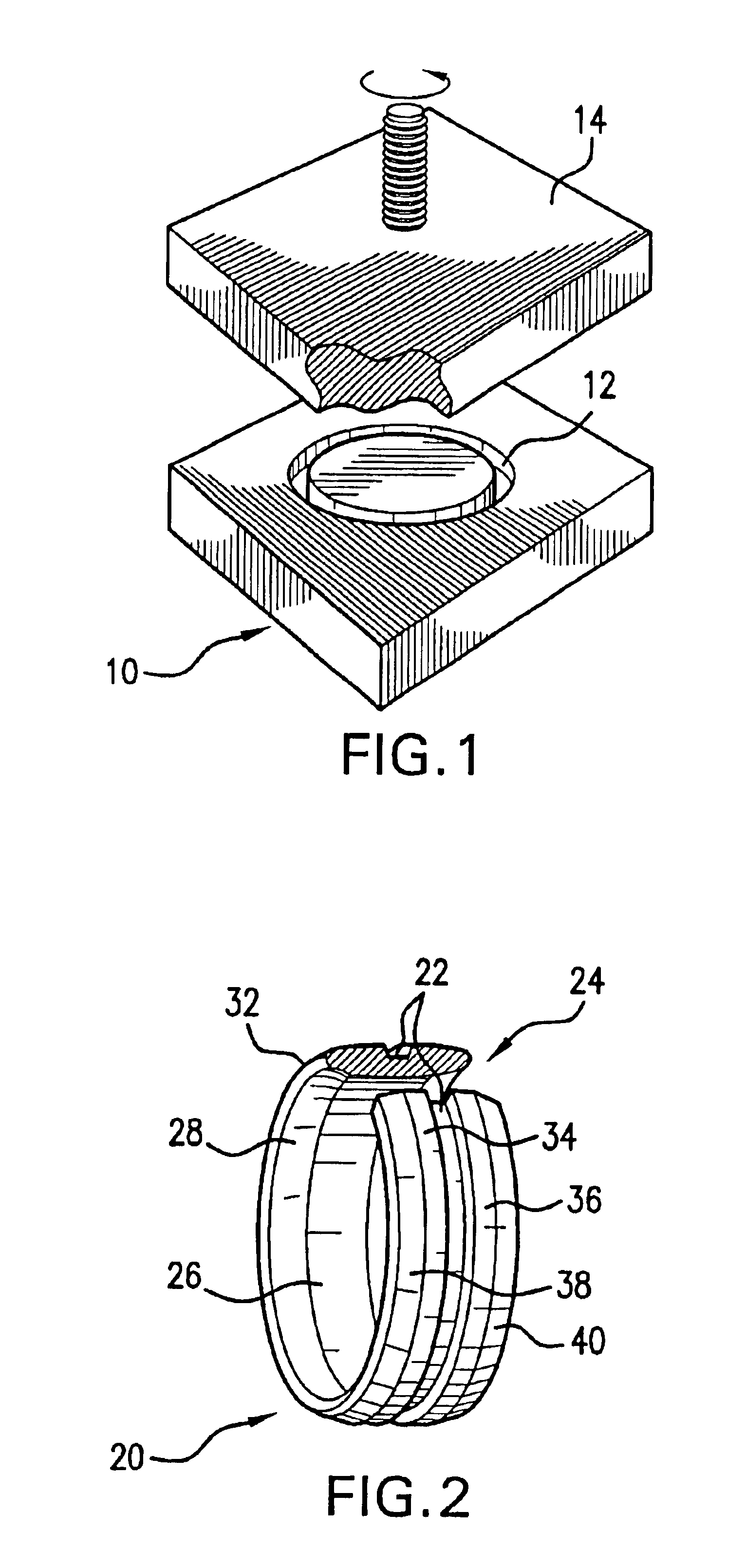

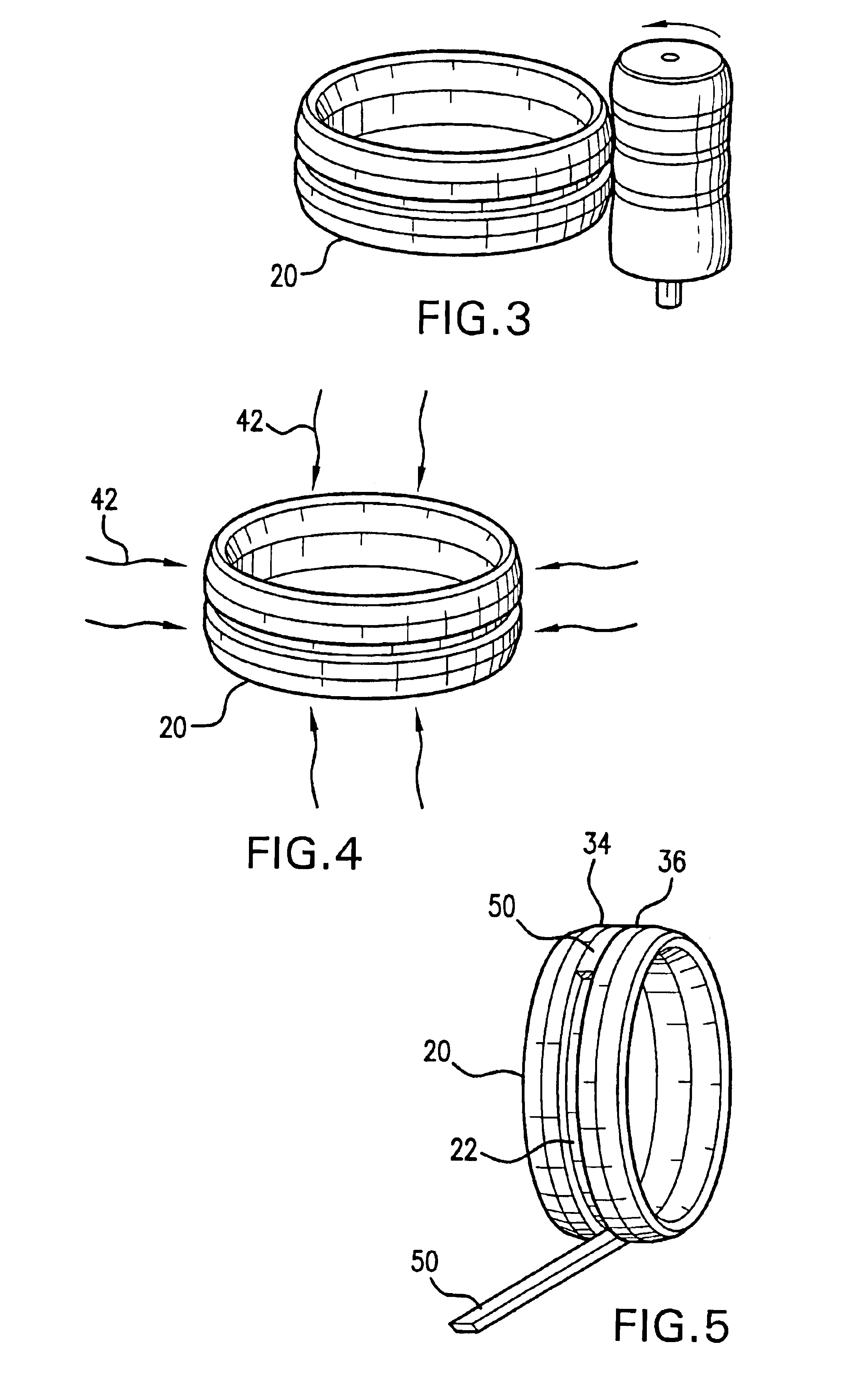

Jewelry ring and method of manufacturing same

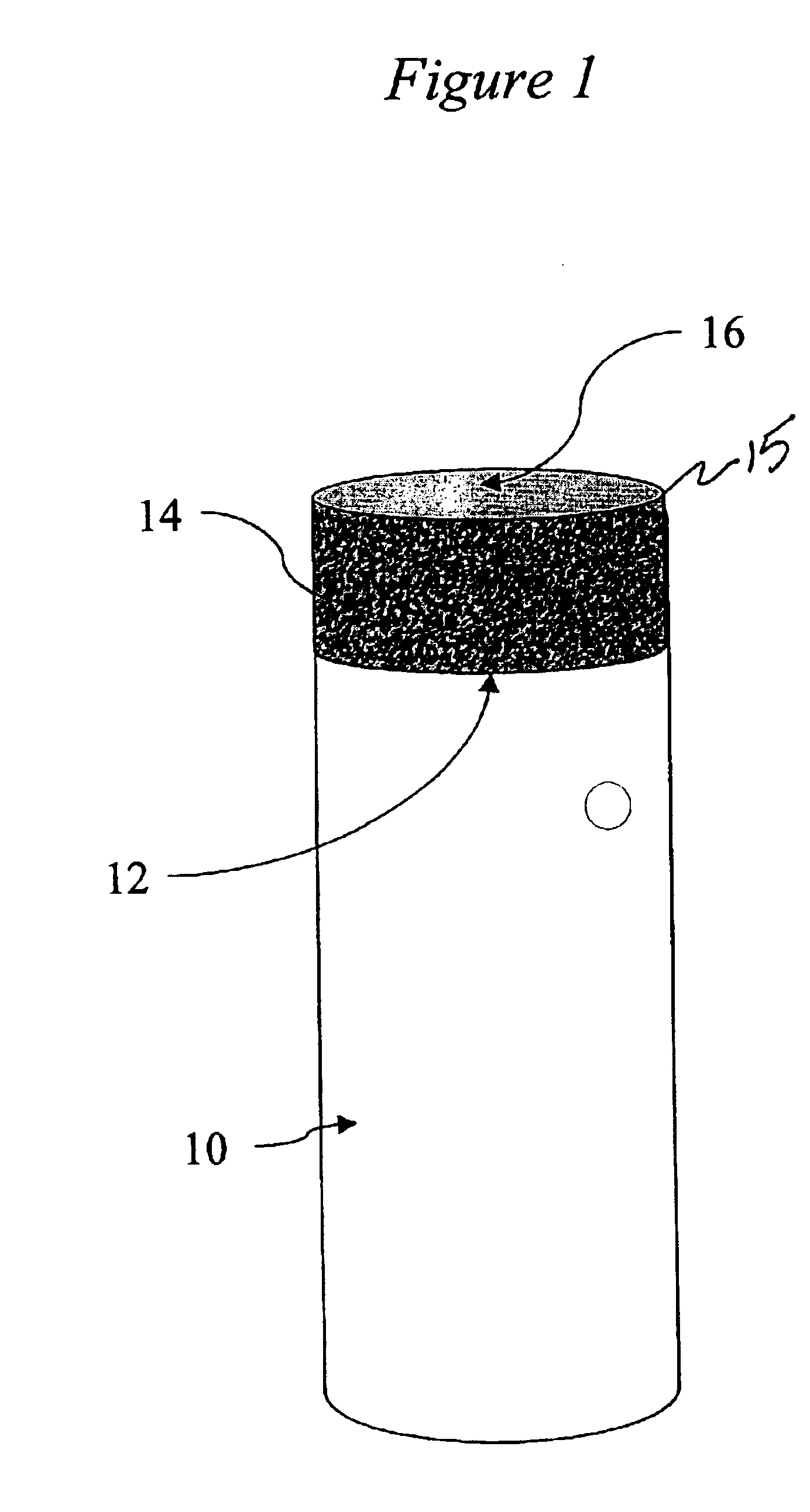

Methods are provided of making annular, tungsten-carbide jewelry articles including finger rings, bracelets, earrings, body jewelry, and the like. Advantageously, the methods include providing a tungsten-carbide based annular jewelry article having a desired surface profile and including an annular band that includes providing a mixture of two or more powdered materials of at least 50 weight percent to about 90 weight percent tungsten carbide to form the annular band of the article into a pressure mold having a cavity of predetermined annular configuration and sized formed therein, the size of the mold being greater than the final size of the annular band, compressing the powdered material mixture at a pressure sufficient to form an annular blank, and sintering the annular blank at a temperature sufficient to form the tungsten-carbide based annular jewelry article so as to be long wearing and virtually indestructible during normal use thereof.

Owner:WEST TRENT

Bonded Assembly Having Low Residual Stress

InactiveUS20100326740A1Heating fastImprove impact performanceDrill bitsLamination ancillary operationsPolycrystalline diamondCobalt

In one aspect of the present invention, a method for forming a bonded assembly comprises providing a first and second portion of the assembly; preparing a mating surface on each portion that conforms substantially to the mating surface of the other portion; rapidly heating a bonding material while substantially heating no more than a thin surface zone adjacent each mating surface, and rapidly assembling the two portions in such a manner as to confine a fraction of the bonding material between the mating surfaces. The first portion may comprise polycrystalline diamond or thermally stable polycrystalline diamond; the second portion may comprise cobalt-cemented tungsten carbide. The assembly may comprise a tool for high-impact applications.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com