Patents

Literature

81results about How to "Reduce distillation energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

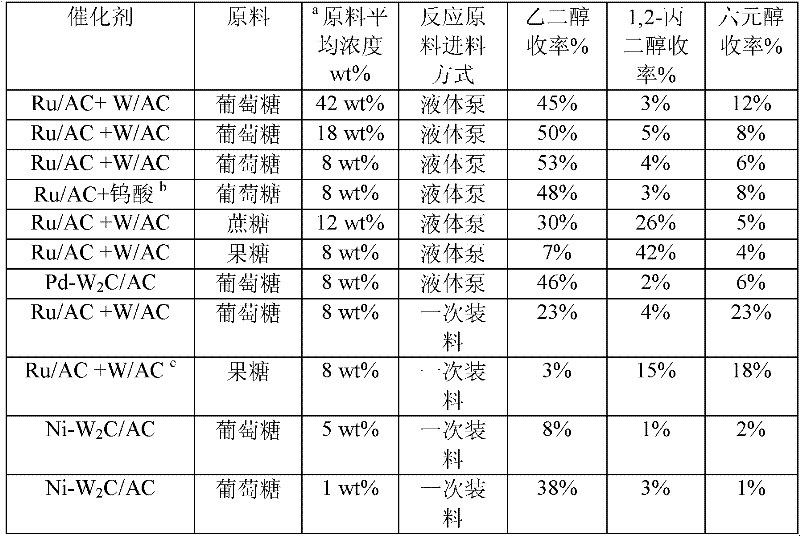

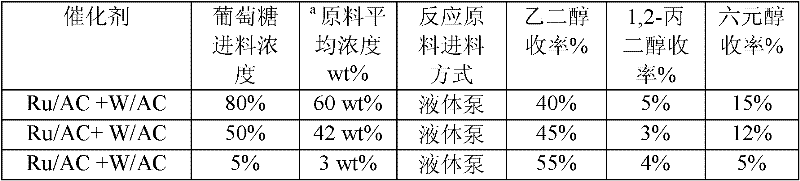

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

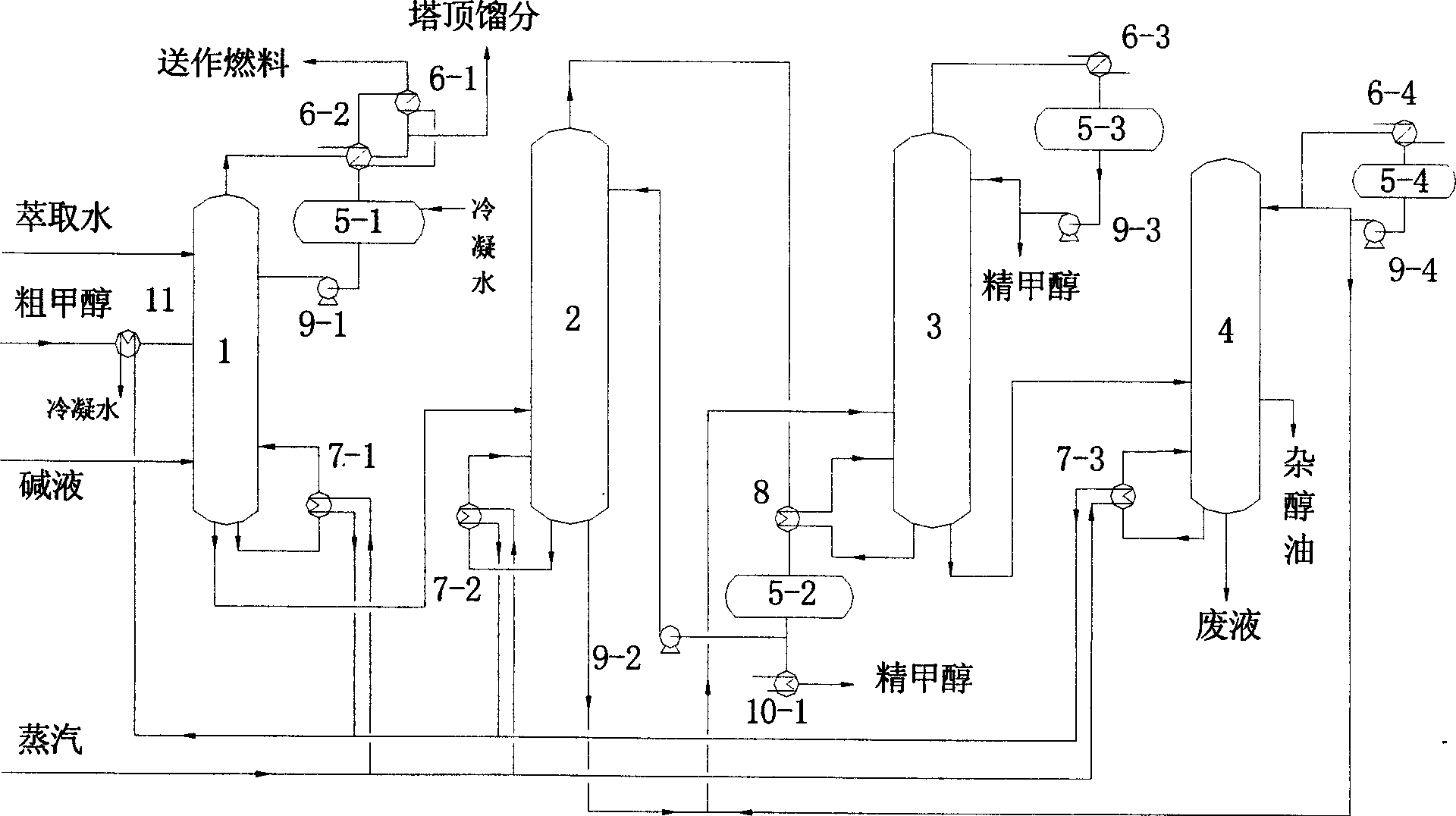

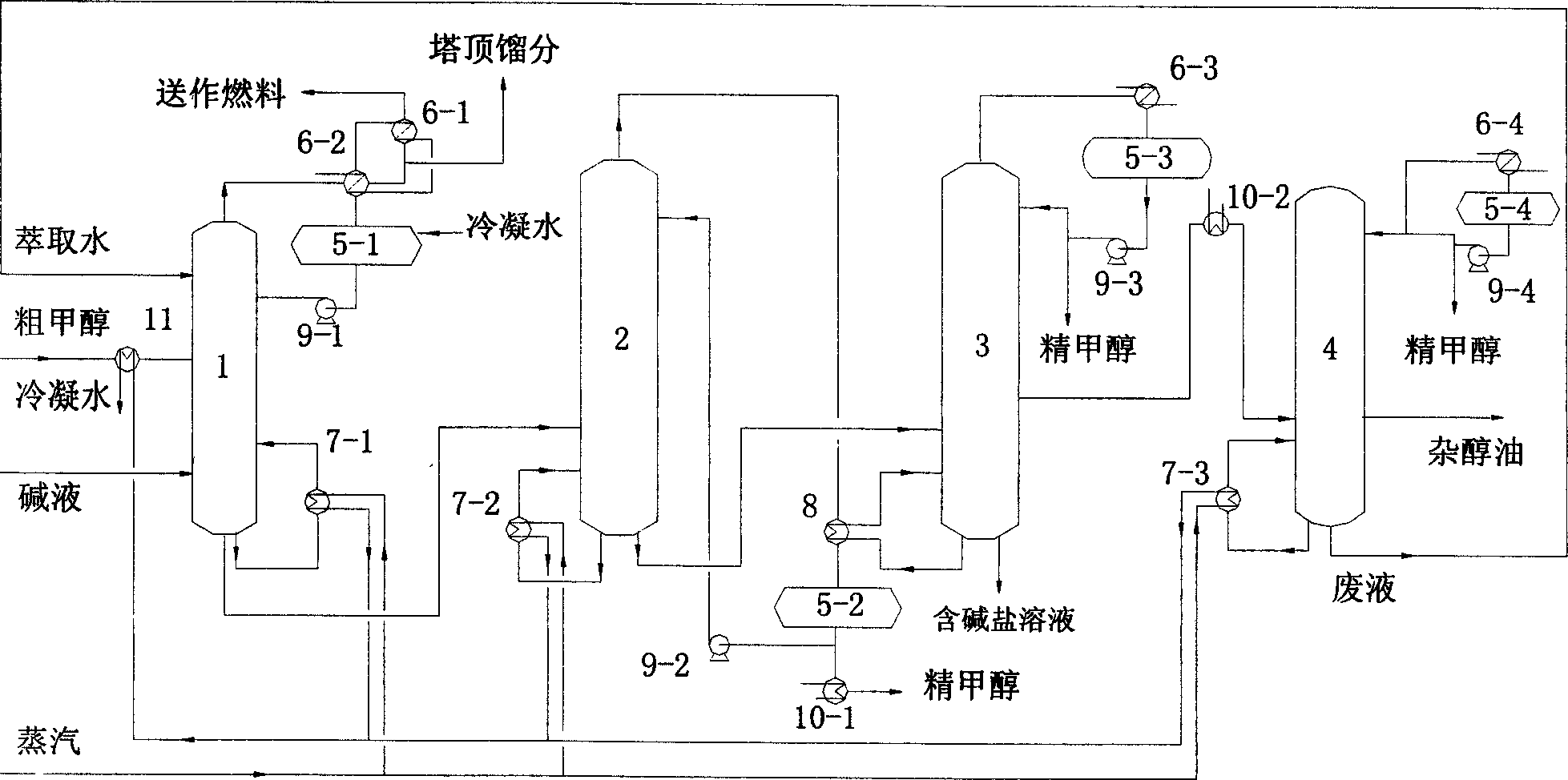

Double-efficient energy-saving and water-saving rectifying system and process for methanol

InactiveCN1817836AReduce distillation energy consumptionSave extraction waterOrganic compound preparationChemical industryWater savingDual effect

A methanol dual-effect rectification energy and water saving system and process are disclosed. The system consists of crude methanol pre-heater, pre-rectification tower, methanol pre-heater, pressurizing tower, normal-pressure tower, re-boiler, condensing re-boiler and methanol recovering tower. The side producing pipe of normal-pressure tower is connected to cooler, which is connected with feed port of recovering tower, the bottom of normal-pressure tower is connected to solution containing alkaline salt producing pipe, side line of recovering tower is connected with potato spirit producing pipe, and effluent blow-off pipe on bottom of tower is communicated with extracting pipe of pre-rectification tower. It has less consumption and saves extracting water.

Owner:TIANJIN UNIV

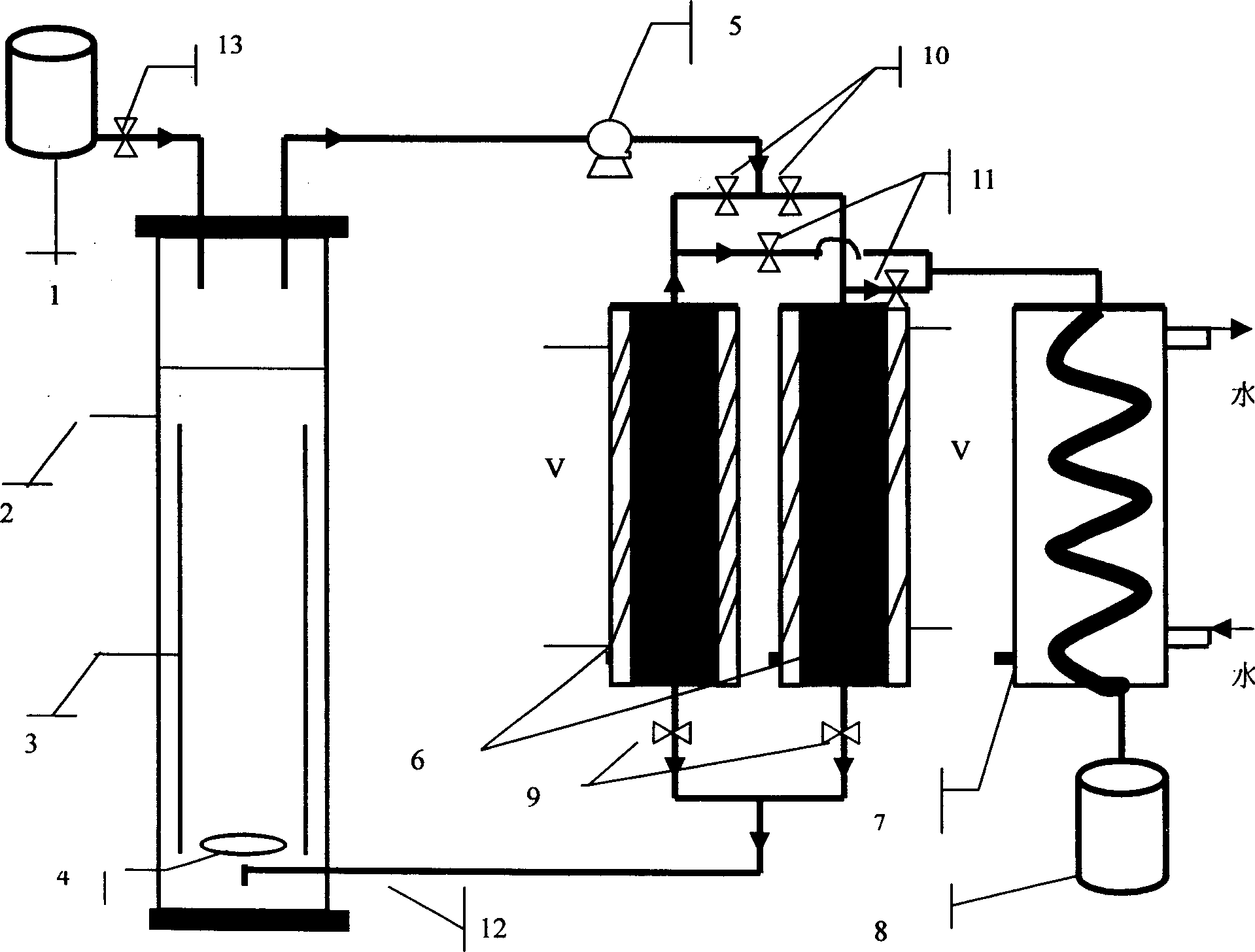

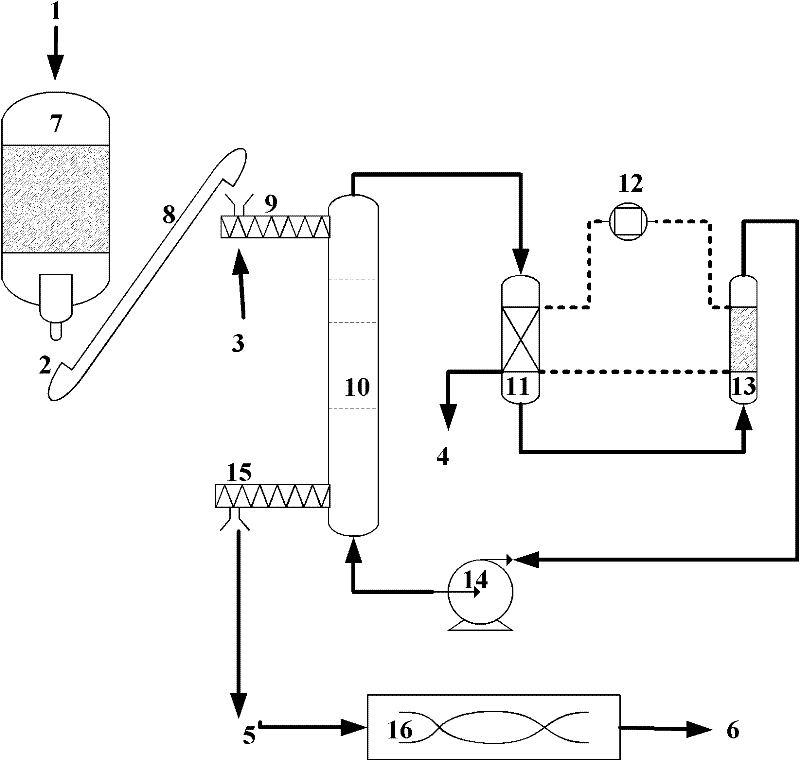

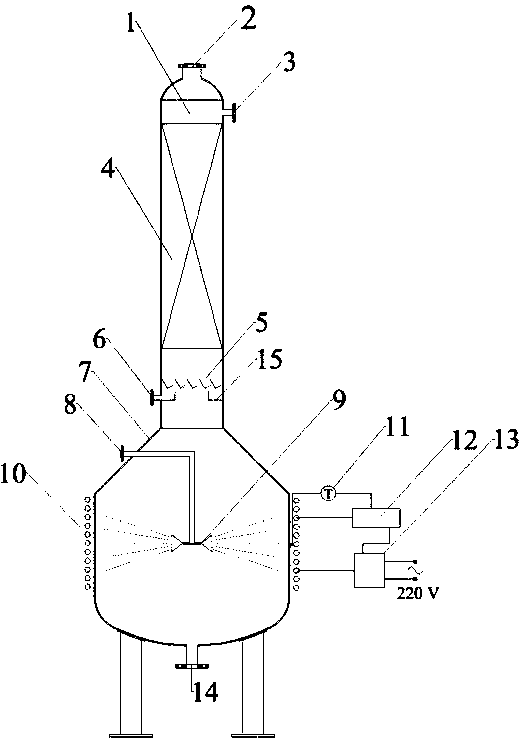

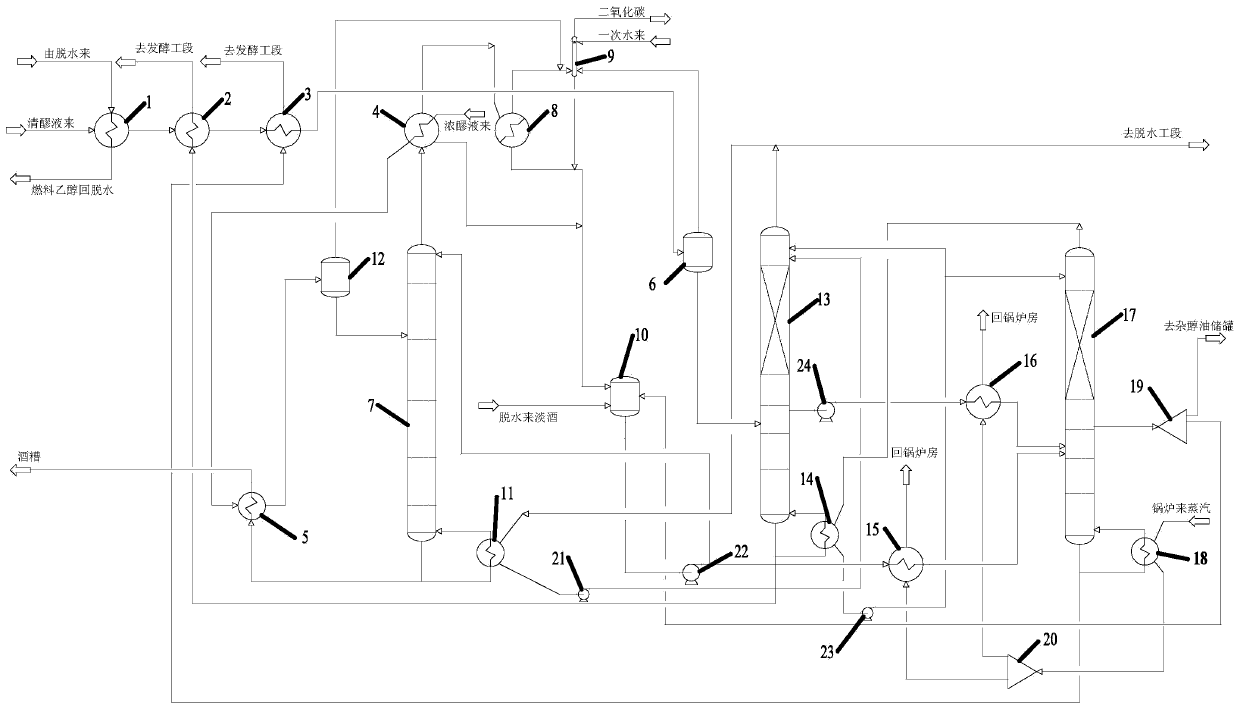

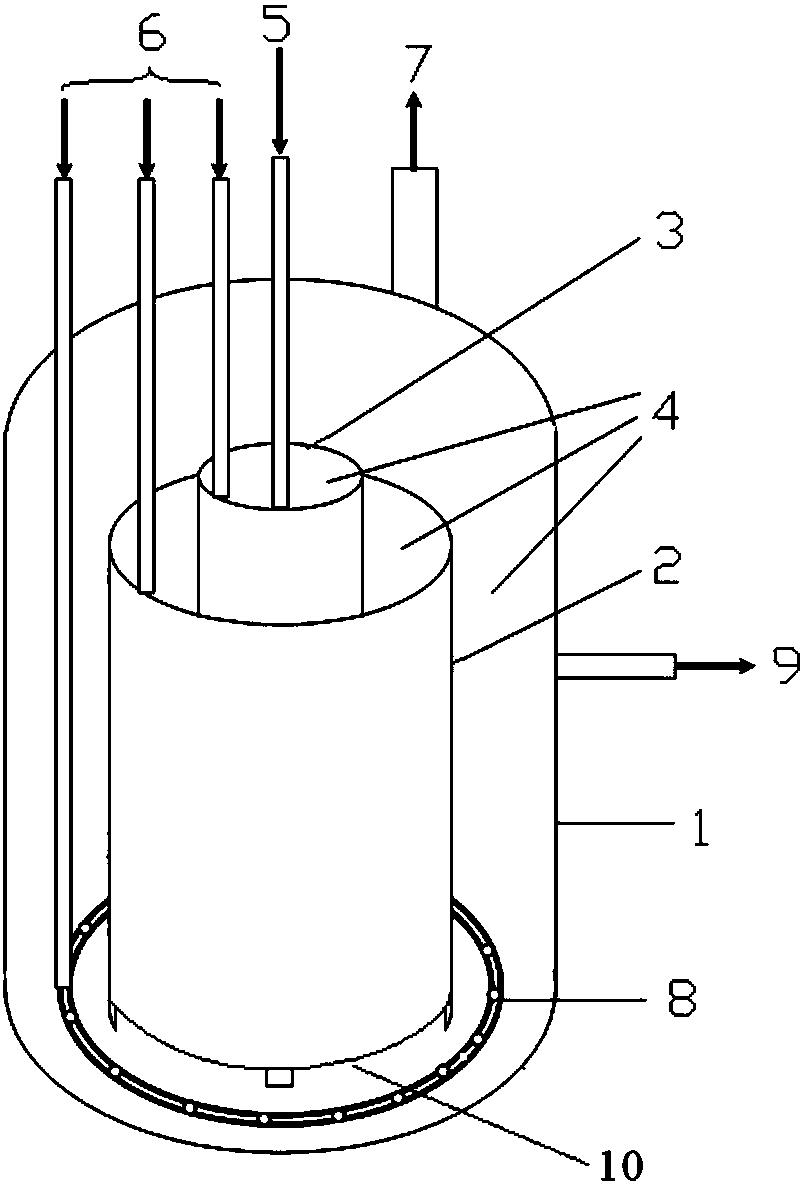

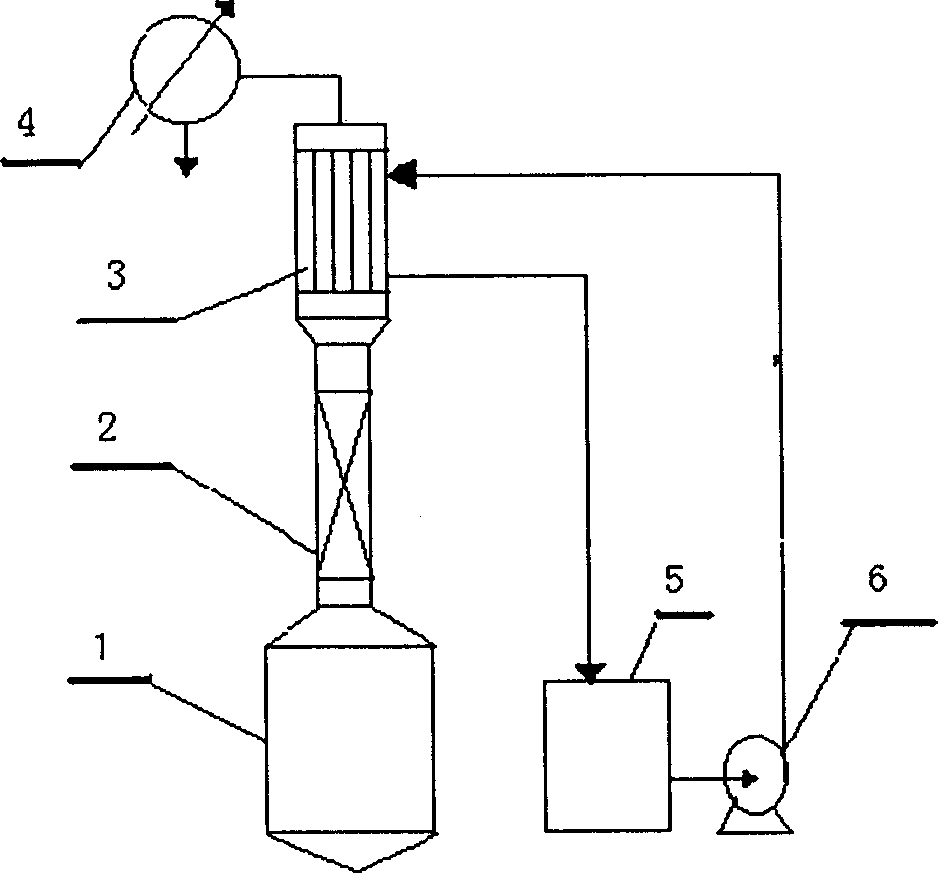

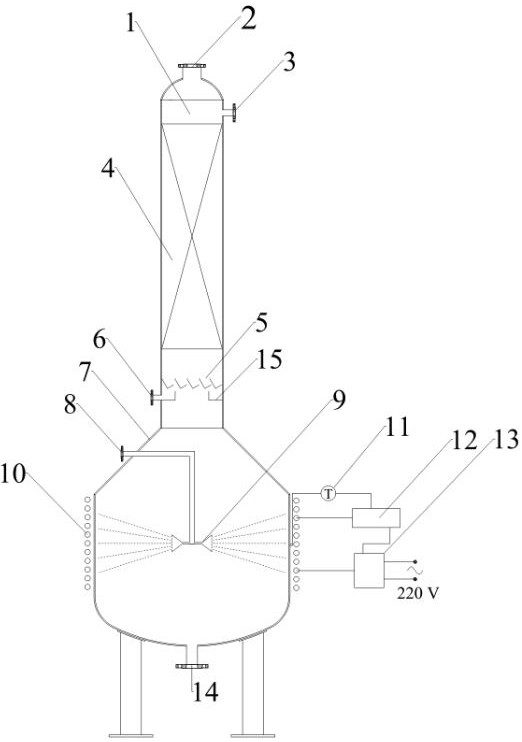

Alcohol preparing airlift fermentation and separation coupling technological process and special equipment

InactiveCN1403579ASave cycle compressorHigh activityBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol productionProduct gas

The present invention belongs to the technology of fermenting alcohol production, and is especially alcohol preparing airlift fermentation and separation coupling technological process and special equipment. The equipment is one airlift alcohol fermenting reactor, which includes one tank, one inner circulating guide tube concentrically set inside the tank, one gas distributor below the guide tube, and one active carbon adsorbing and desorbing unit comprising condensator and two parallelly connected adsorbing active carbon towers. The airlift alcohol bioreactor is maintained in a 4000-8000 Pa vacuum with a water ring pump; the two parallelly connected adsorbing active carbon towers are used to adsorb and desorb the pumped mixed gas alternately; and the condensator is used to collect the desorbed alcohol.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

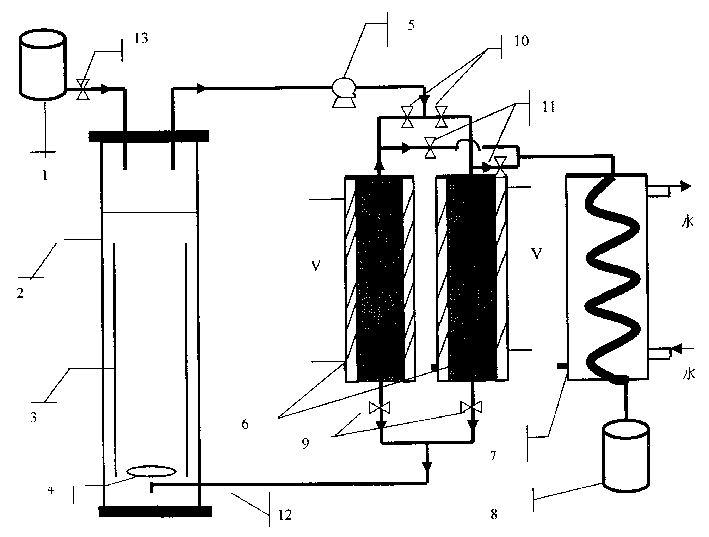

Method for preparing absolute ethyl alcohol from furfural residue

InactiveCN101413017ALarge amount of resourcesLow priceMicroorganism based processesFermentationFiberAlcohol

The invention provides a method for preparing absolute ethyl alcohol by furfural residues. A furfural residue cellulose raw material is adopted, lignin is separated, and then the absolute ethyl alcohol is obtained through synchronous diastatic fermentation and pervaporation coupling separation of alcohol, then distillation, pervaporation dehydration and rectification. The method has the advantages that the method organically combines the prior mature rectification technology with a modern advanced separation technology to improve the production efficiency when high fiber raw materials are used to prepare the absolute ethyl alcohol.

Owner:BEIJING FORESTRY UNIVERSITY

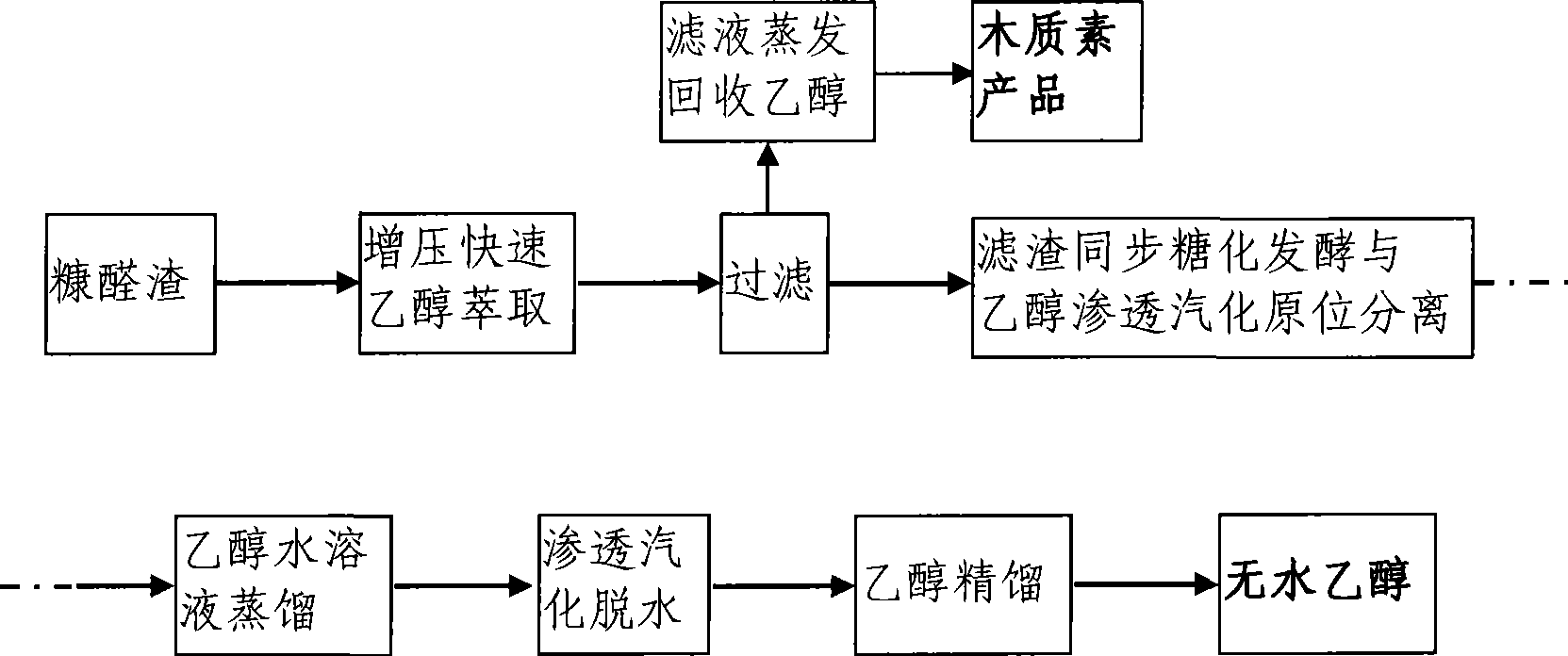

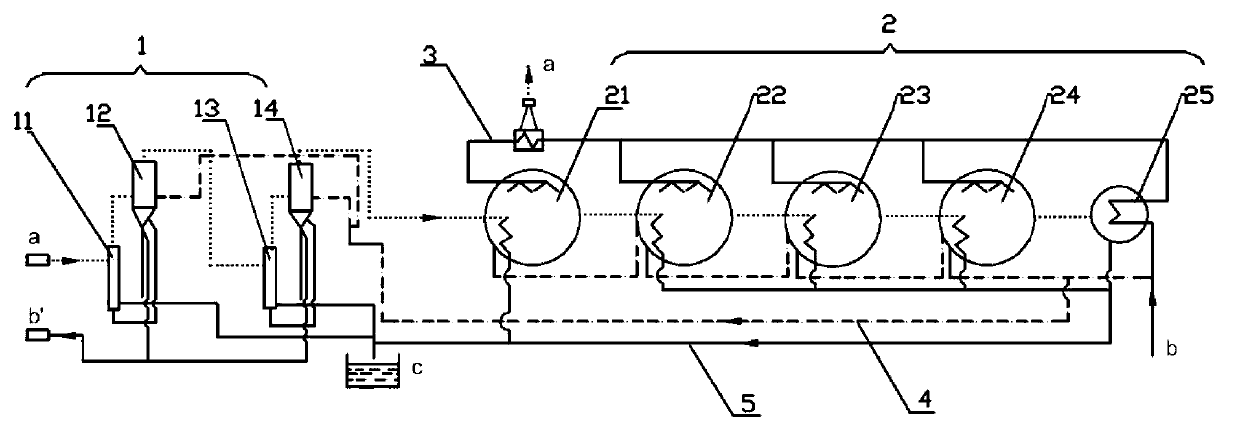

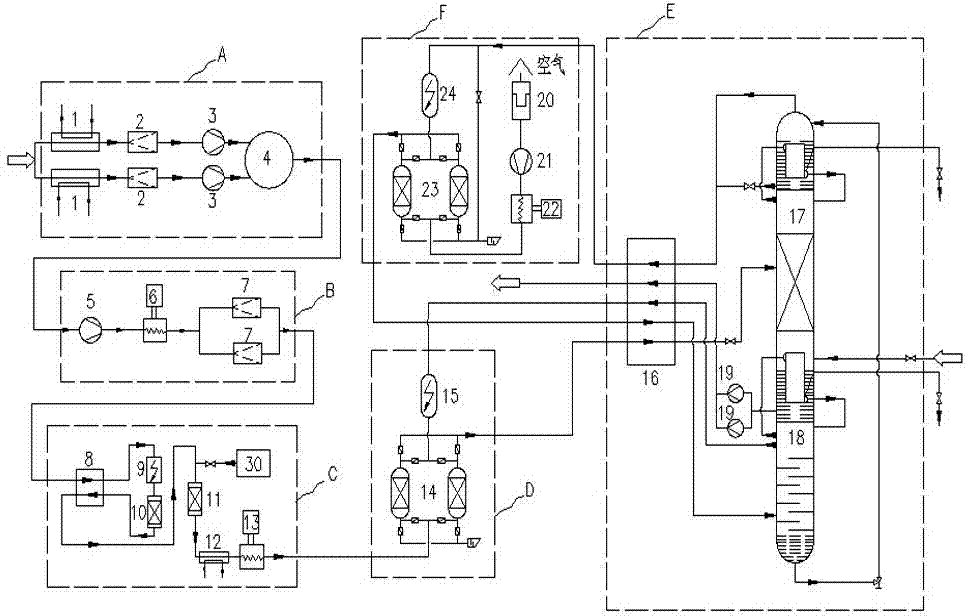

Method and device for purifying and recycling emitted argon in preparation process of monocrystalline silicon

ActiveCN103373716AHigh recovery rateImprove reliabilityNitrogen purification/separationNoble gas compoundsAlkaneAutomatic control

The invention relates to a method and device for purifying and recycling emitted argon in a preparation process of monocrystalline silicon. The method comprises the following steps of: collecting crude argon emitted by a monocrystalline silicon furnace and then carrying out compression oil removal treatment, removing carbon monoxide and alkane by adopting a catalytic oxidation method, removing oxygen by adopting a hydrogenation oxygen removing method, removing carbon dioxide and water by adopting an adsorption method, and removing nitrogen and hydrogen by adopting a high-low pressure dual-tower low-temperature distillation method to finally obtain pure compressed argon which can be directly conveyed to the monocrystalline silicon furnace for being recycled. The device comprises a crude argon collecting and pretreating system for carrying out crude oil filtration on the crude argon emitted by the monocrystalline silicon furnace, a compression oil removing system for filtering refine oil, a catalytic reaction system for removing carbon monoxide, alkane and oxygen components, a crude argon purifying system for removing the carbon dioxide and the water, a low-temperature distillation system for removing the nitrogen and hydrogen components, an air treating system for providing a raw material air source for a process of preparing the nitrogen by the low-temperature distillation system, and an automatic control system for controlling the whole set of device. The method and device can realize that a large quantity of protection argon in the monocrystalline silicon industry is recovered and recycled.

Owner:HANGZHOU HANGYANG

Method for producing ethanol by continuous solid state fermentation of restaurant-kitchen garbage

InactiveCN102174591AImplement preprocessingImprove degradation rateBiological substance pretreatmentsLiquid production bioreactorsDigestionHeat pump

The invention discloses a method for producing ethanol by continuous solid state fermentation of restaurant-kitchen garbage. The method comprises the following basic steps of: (1) performing steam explosion pretreatment on the restaurant-kitchen garbage; (2) adding saccharification enzyme, cellulase and active dry yeast into the treated raw materials; (3) continuously delivering the raw materials to a reactor under set conditions to perform continuous ethanol fermentation and extraction; and (4) automatically discharging the fermentation residue out of the reactor, and drying the fermentation residue in a continuous dryer to form an organic fertilizer. The wastewater treatment problem in the production is avoided by adopting a solid state fermentation process, the treatment efficiency of the garbage is improved by adopting a continuous production process, and heat energy produced in the fermentation process is fully utilized for extraction of the ethanol through a coupled heat pump system so as to reduce the energy consumption and reduce the production cost of the ethanol. The organic fertilizer can be obtained besides the ethanol in the production process, wastes and new pollutants are totally not produced in the production process, and full digestion and full utilization of the restaurant-kitchen garbage are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing butanol by continuous solid state fermentation of restaurant-kitchen garbage

InactiveCN102174595AImplement preprocessingImprove degradation rateBioreactor/fermenter combinationsBiological substance pretreatmentsSolventCulture mediums

The invention discloses a method for producing butanol by continuous solid state fermentation of restaurant-kitchen garbage. The method comprises the following basic steps of: (1) performing liquid-solid separation on the restaurant-kitchen garbage by using a centrifugal dehydrator; (2) performing steam explosion pretreatment on the dehydrated restaurant-kitchen garbage; (3) adding saccharification enzyme into the treated restaurant-kitchen garbage according to the weight, and delivering the cellulase to a continuous solid state fermentation reactor; (4) continuously inoculating the cultured clostridium acetobutylicum seed solution to a culture medium; (5) continuously delivering the raw materials to the reactor under set conditions to perform continuous butanol fermentation and extraction; (6) rectifying the condensed solvent to obtain pure products of acetone, ethanol and butanol; and (7) further drying the fermentation residue through a continuous dryer till the water content is less than 14 percent to prepare an organic fertilizer. By adopting the continuous solid state fermentation process, wastewater treatment is avoided, the treatment efficiency is increased, the energy consumption is reduced, and the production cost of the butanol is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

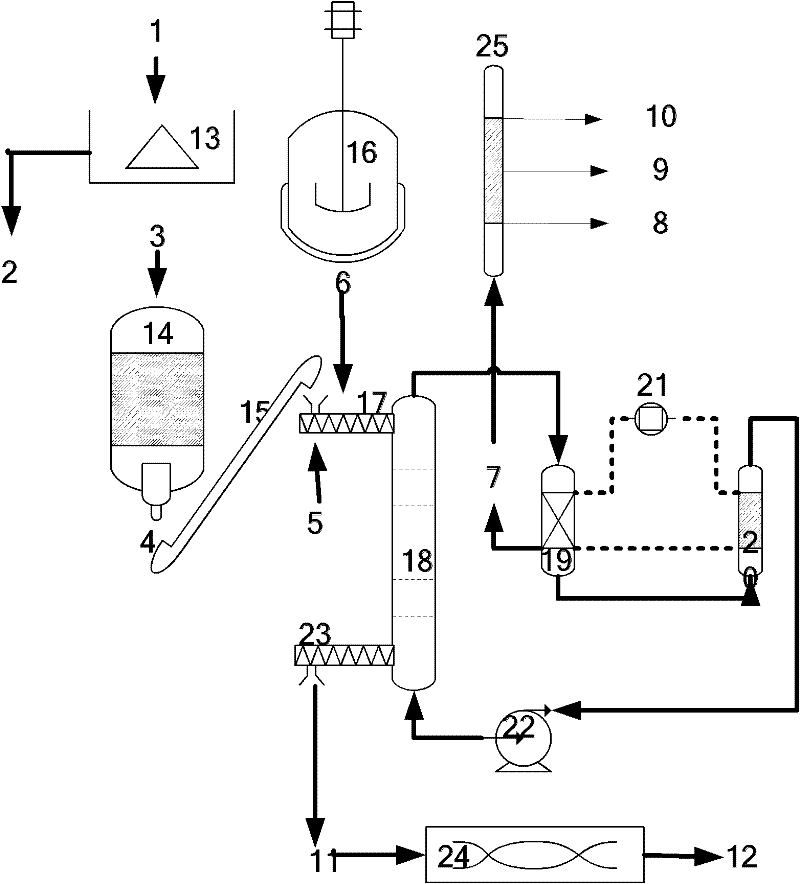

Efficient energy-saving process for continuously processing dihydromyrcenol

ActiveCN101684065AThe replacement process is continuousIncrease mass transfer rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryIntegrated systems

The invention discloses an efficient energy-saving new process for continuously synthesizing dihydromyrcenol, which is a new technology for synthesizing the dihydromyrcenol by using an integrated system consisting of a reinforcing jet reaction device, a phase separator and a continuous rectification device. A catalyst complementing and replacing system is also arranged in the process flow. The process has simple process flow and high conversion rate, can improve the hydration reaction rate of dihydromyrcene by 1 to 3 times compared with a fixed bed reaction under the same condition, and savesthe energy consumption as high as about 50 percent.

Owner:厦门中坤化学有限公司 +1

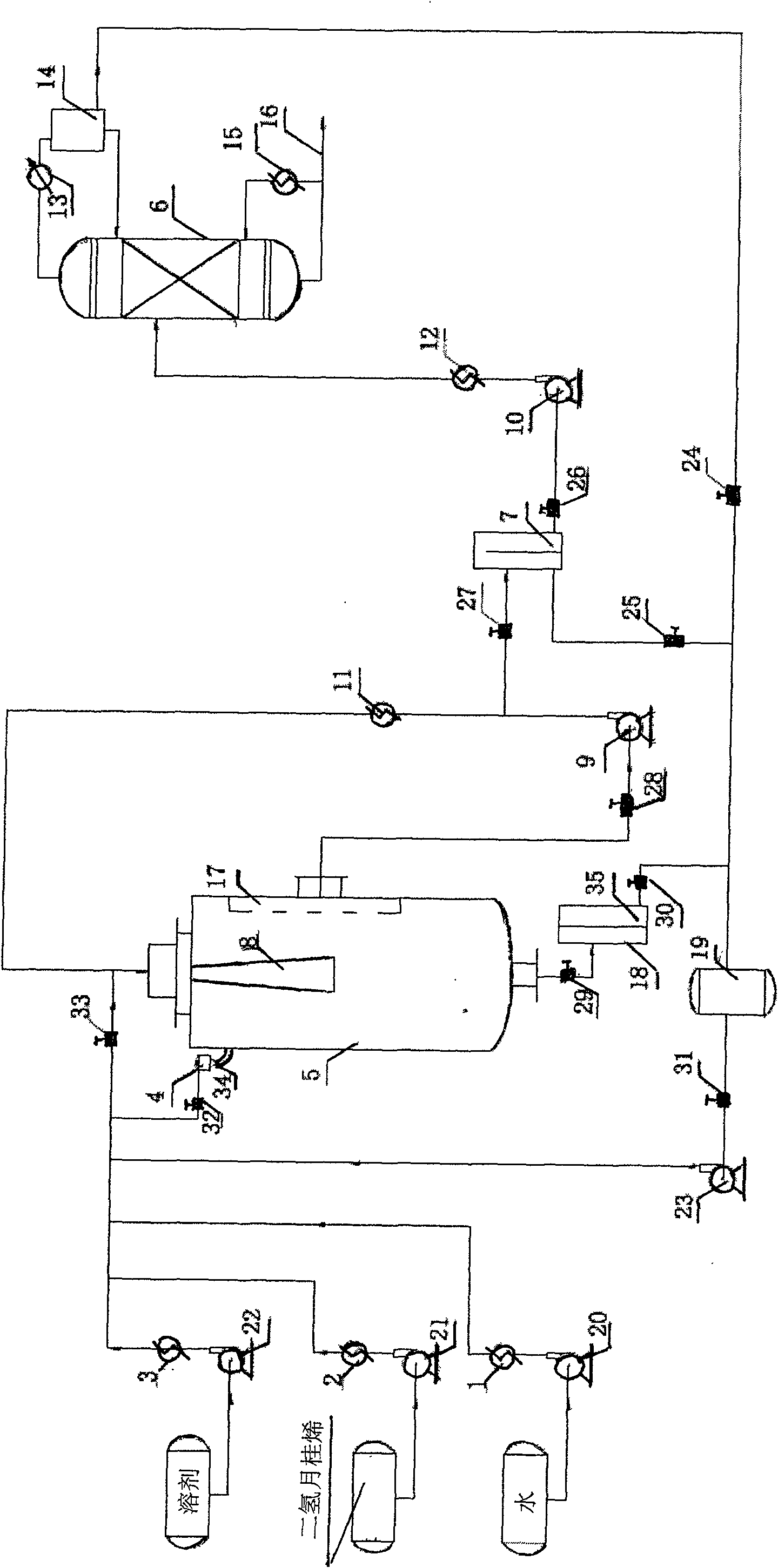

Absorption process for directly preparing dimethyl ether and methanol water solution from synthetic raw material gas

InactiveCN1351986ALow running costReduce distillation energy consumptionEther preparation from oxiranesSyngasMethanol water

The present invention puts forward an absorption process for preparing dimethyl ether-methanol water solutino from synthetic feed gas. The process includes synthesis of dimethyl ether, separation and absorption of dimethyl ether from synthetic gas and fractionation of dimethyl ether-contained solution of prepare high purity dimethyl ether. The process features that synthetic gas is first cooled to -20 to 10 deg.C and condensed to separated partial dimethyl ether and then absorbed with water solution of methanol to absorb un-condensed dimethyl ether, and the water solution containing dimethyl ether and methanol is fractioned to produce dimethyl ether product with concentration over 99.5 wt%. Methanol may be reused to lower production cost.

Owner:WUHUAN ENG

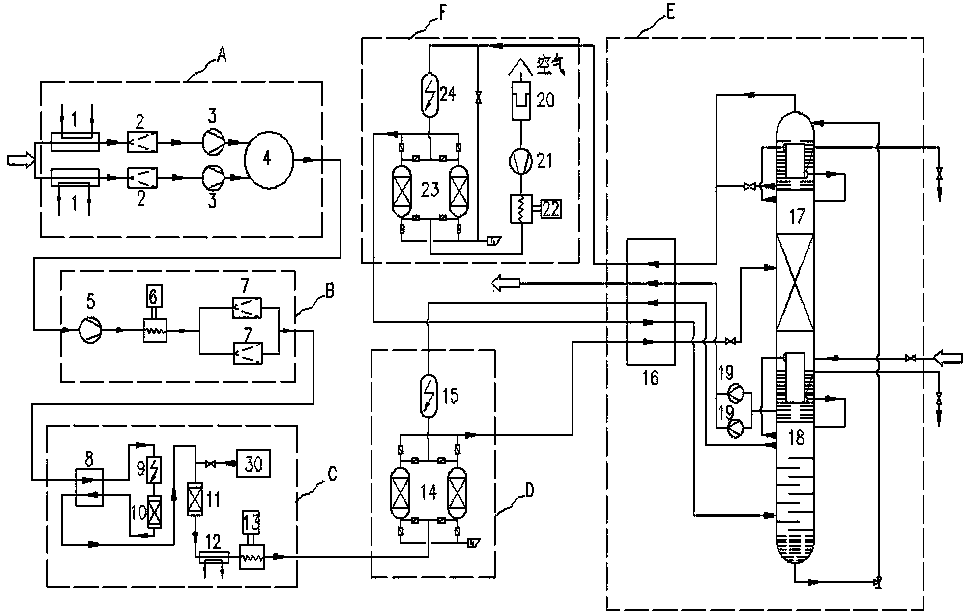

Method for solid state fermentation of ethanol through steam explosion of cassava and comprehensive utilization of cassava

InactiveCN101768606ASolve the need to consume a lot of energy for cassava crushingSolve the cooking of starchClimate change adaptationBiofuelsNutritive valuesDistillation

The invention discloses a method for solid state fermentation of ethanol through steam explosion of cassava and comprehensive utilization of the cassava. In the method, the steam explosion technology is applied to the pretreatment of the cassava. On one hand, under the action of high-temperature water vapor of the steam explosion pretreatment, cyanogenetic glycoside in the cassava raw material is converted into volatile hydrocyanic acid for volatilization, the toxic action of the cyanide in the cassava product is removed, and the utilization ratio of the follow-up resource is improved; on the other hand, the cassava after the steam explosion pretreatment can be directly fermented to produce the ethanol, and the energy consumption for crushing the cassava and stewing and liquefying the starch is greatly reduced. The cassava is subjected to solid fermentation, so that the water content in the fermenting mash is greatly reduced. Therefore, the ethanol concentration in the fermenting mash is increased, the distillation energy consumption is reduced, subsequent wastewater treatment is reduced, the problems that the alcohol dregs obtained by the traditional fermentation process have large water content, low nutritive value and difficult utilization are solved, the production cost is reduced, and the method is favorable for the comprehensive utilization of the cassava.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

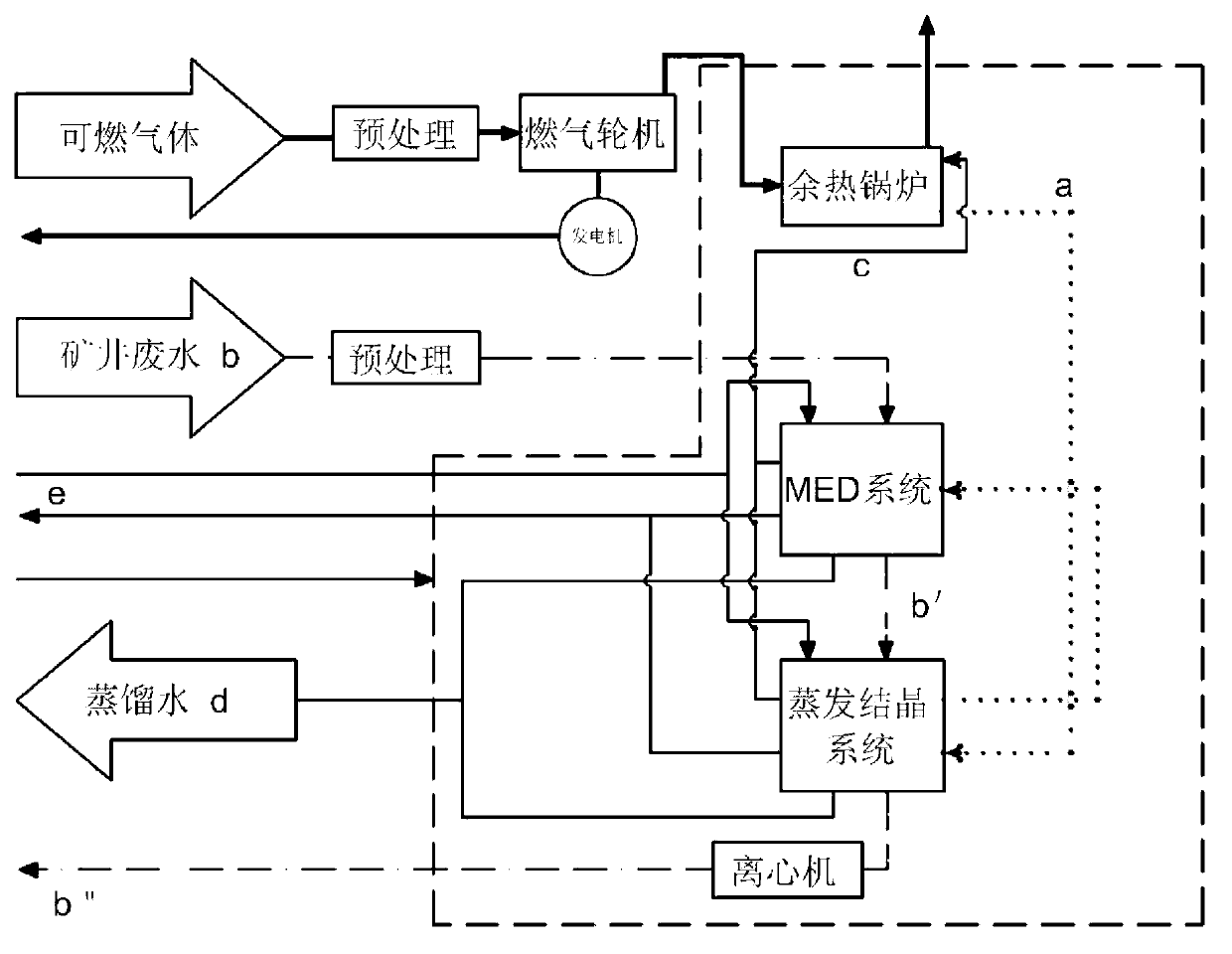

Wastewater zero-discharge treatment system

ActiveCN102992427ARealize multiple reuseReduce distillation energy consumptionWater/sewage treatment by heatingMultiple-effect evaporationMulti effectGas turbines

The invention provides a wastewater zero-discharge treatment system, which is composed of a waste-gas waste-heat utilization system, a low-temperature multi-effect horizontal pipe distillation system and an evaporative crystallization system, wherein the low-temperature multi-effect horizontal pipe distillation system is a MED (Multi-Effect Distillation) system; the waste-gas waste-heat utilization system comprises a combustion gas turbine capable of combusting gas to discharge high-temperature smoke, and a waste-heat boiler making use of the waste heat of the high-temperature smoke so as to obtain high-temperature steam; the low-temperature multi-effect horizontal pipe distillation system comprises a low-temperature multi-effect evaporator and a condenser; and the evaporation crystallization system comprises a stand-pipe falling-film evaporator making use of the high-temperature steam to purify wastewater and a drying device. The wastewater zero-discharge treatment system disclosed by the invention has the beneficial effects that low-grade energy can be used as a heating source to realize multiple reutilization of heat, so that distillation consumption is reduced greatly; and the concentration of brackish water is realized, so that crystallized salt is separated from distilled water and the zero discharge of the brackish water is realized.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

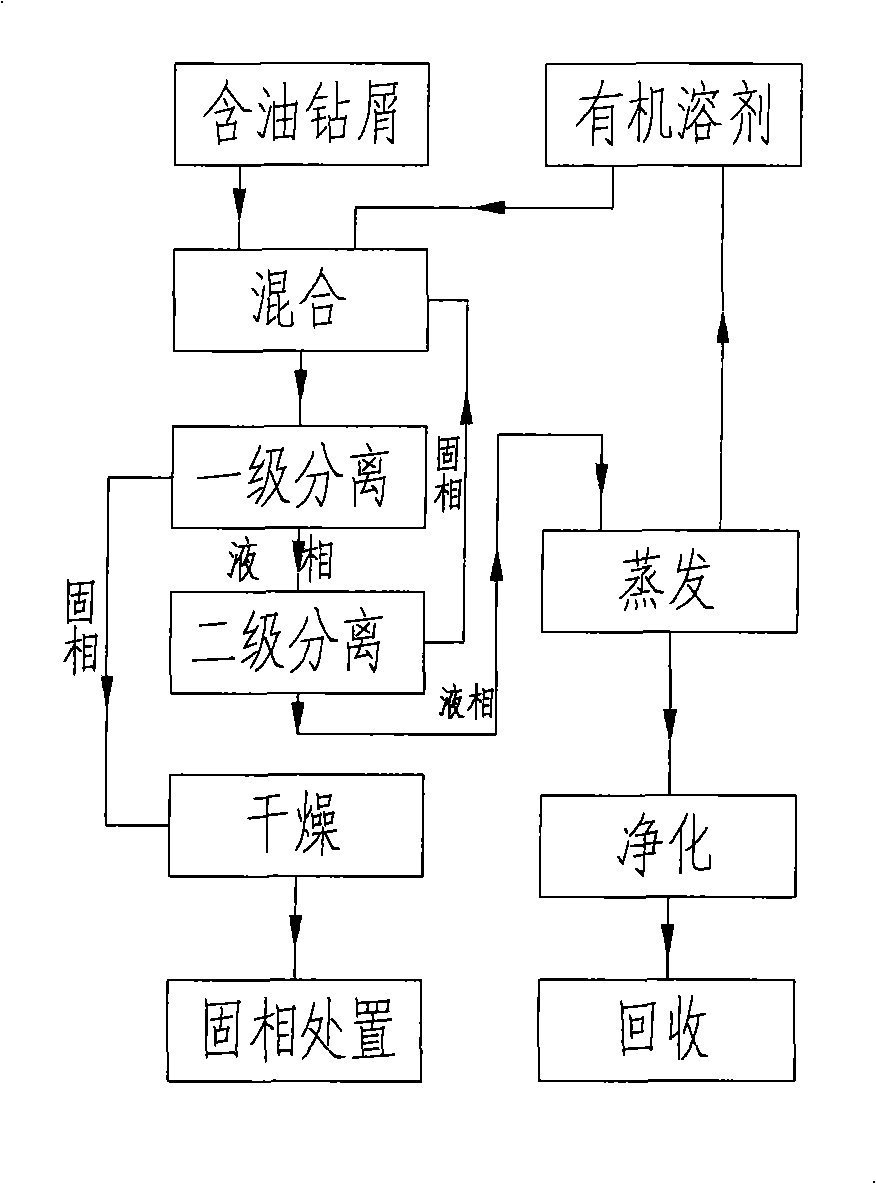

Method for removing oil-containing drill cuttings and oil component in oil polluted soil

InactiveCN101269380AReduce dosageReduce usageContaminated soil reclamationSolventComponents of crude oil

The invention discloses a method for removing oil in drill cuttings containing oil and soil contaminated from oil. The method includes the following steps: an organic solvent and drill cuttings containing oil or soil contaminated from oil are mixed in a mixer according to the weight ratio of 0.2:2; the mixture is sent into a drainer for one-step liquid-solid separation so as to get one-step solid phase materials and one-step liquid phase materials; the one-step liquid phase materials are sent to a centrifuge for second-stage liquid-solid separation so as to get second-stage solid phase materials and second-stage liquid phase materials; the one-step solid phase materials are sent to a drier for drying and solid phase disposition; the second-stage solid phase materials are sent to the mixer; the second-stage liquid phase materials are sent to a solvent evaporator; the organic solvent is separated and sent to the mixer for recycling; the oil-base drilling fluid separated by the evaporator is cleaned and decolored. The method provided by the invention reaches the purpose of pollution-free processing of soil contaminated from oil or drill cuttings containing oil, besides, the oil can be recycled, thereby increasing the economic benefits.

Owner:TIANJIN DEV ZONE LANDUN OILFIELD SERVICE

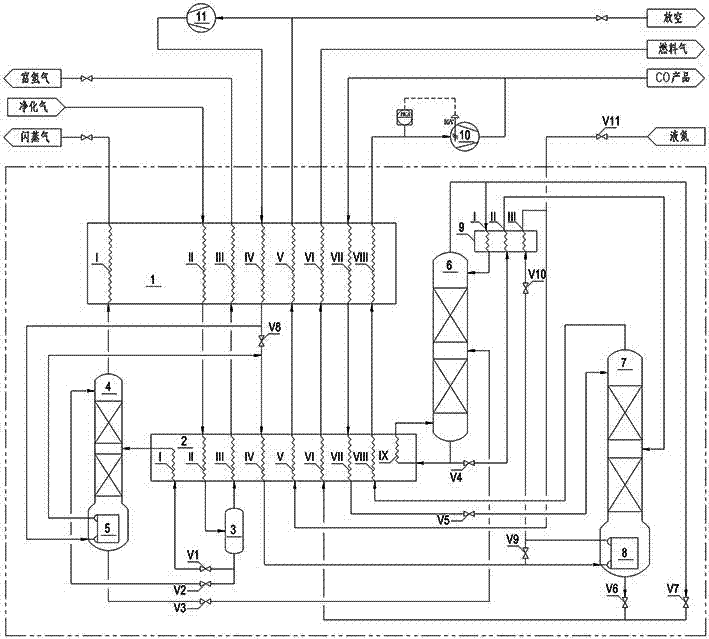

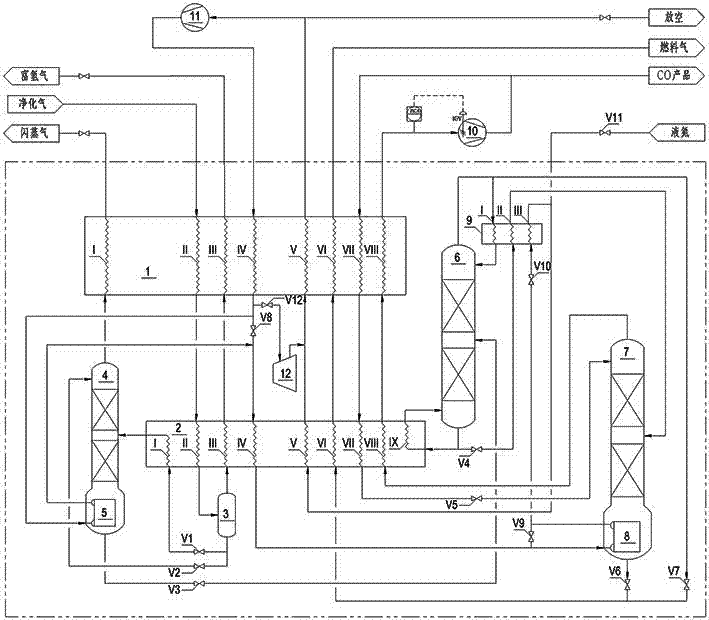

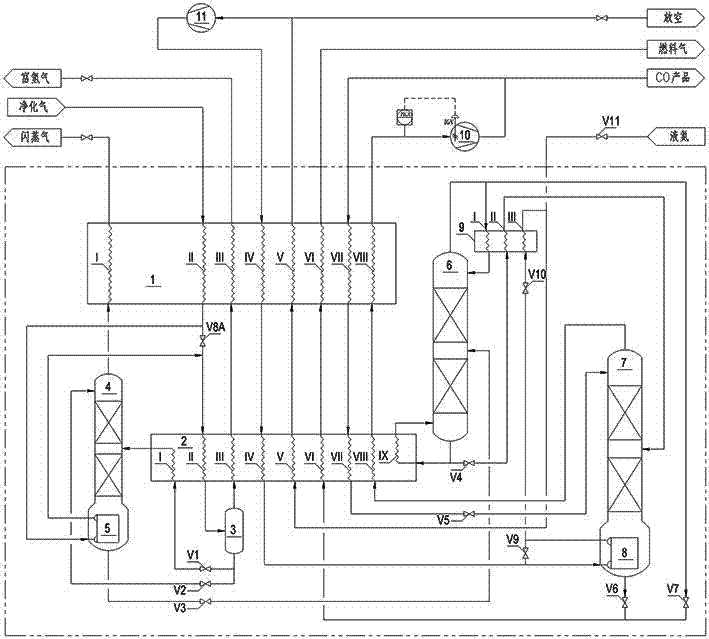

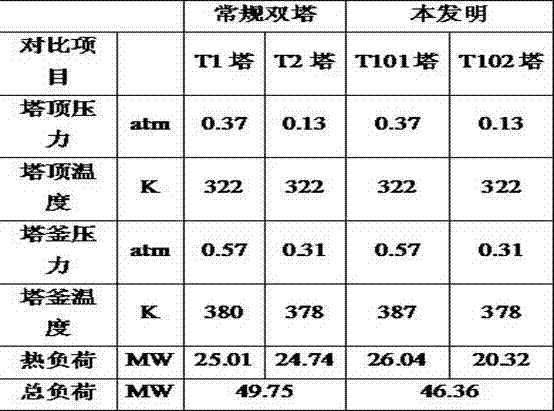

CO cryogenic separation system using double circulation and separation method thereof

ActiveCN107328166AReduce distillation energy consumptionReduce energy consumptionSolidificationLiquefactionGas compressorNitrogen cycle

The invention discloses a CO cryogenic separation system using double circulation. The CO cryogenic separation system comprises main heat exchangers, a low-temperature separator, a hydrogen stripping tower, a denitriding tower, a demethanizer, a CO compressor and a circulation nitrogen compressor. The invention further discloses a separation method of the CO cryogenic separation system using double circulation. The method includes the processing steps of heat transfer, dehydrogenation, denitrification, demethanation, CO compression cycle, nitrogen compression refrigeration cycle and the like. The CO cryogenic separation system using double circulation and the separation method thereof have the beneficial effects that the double-circulation process of CO compression and nitrogen compression is adopted, and the dual advantages that rectification energy consumption of CO compression cycle is low and compression energy consumption and investment of nitrogen cycle are low are given into play. A heat source of a rectifying tower evaporator and a cold source of a condenser are optimized, and rectification loads can be controlled reliably and stably. Starting and purifying time of the device can further be shortened, and the evacuation amount at the starting stage is decreased. Energy consumption is low, the starting speed is high, the investment can be reduced, and the quantity of emissions is small. The general trend of energy saving and cost reduction are met, and the economic benefits and environmental protection benefits are good.

Owner:四川蜀道装备科技股份有限公司

Multiple-component lateral line thermal coupling rectification method

ActiveCN102641604AReduce distillation energy consumptionChemical industryDistillation purification/separationMultiple componentLateral line

The invention relates to a multiple-component lateral line thermal coupling rectification method. A lateral line connection is added between two rectification towers, so that the rectification energy consumption can be greatly reduced. At least two rectification towers are adopted in the method, raw materials enter the first rectification tower, light components are rectified out on the top of the first tower, and intermediate components and heavy components are rectified out in a tower kettle and used as feeding materials for the second tower. An intermediate component and heavy component mixture containing a small amount of light components is extracted at the lateral line of the first tower, and the intermediate component content of the lateral line is obviously higher than the intermediate component content in the flow of the tower kettle, so that the back mixing degree of the intermediate components is reduced; the mixture is used as the newly added material for the second tower; and a feeding tower plate is positioned above the original feeding position. Compared with the conventional rectification method, the method has the advantage of obvious energy-saving effect. The method can be universally applied to the rectification separation process of the three-component, four-component or multi-component mixture.

Owner:CHINA PETROLEUM & CHEM CORP +1

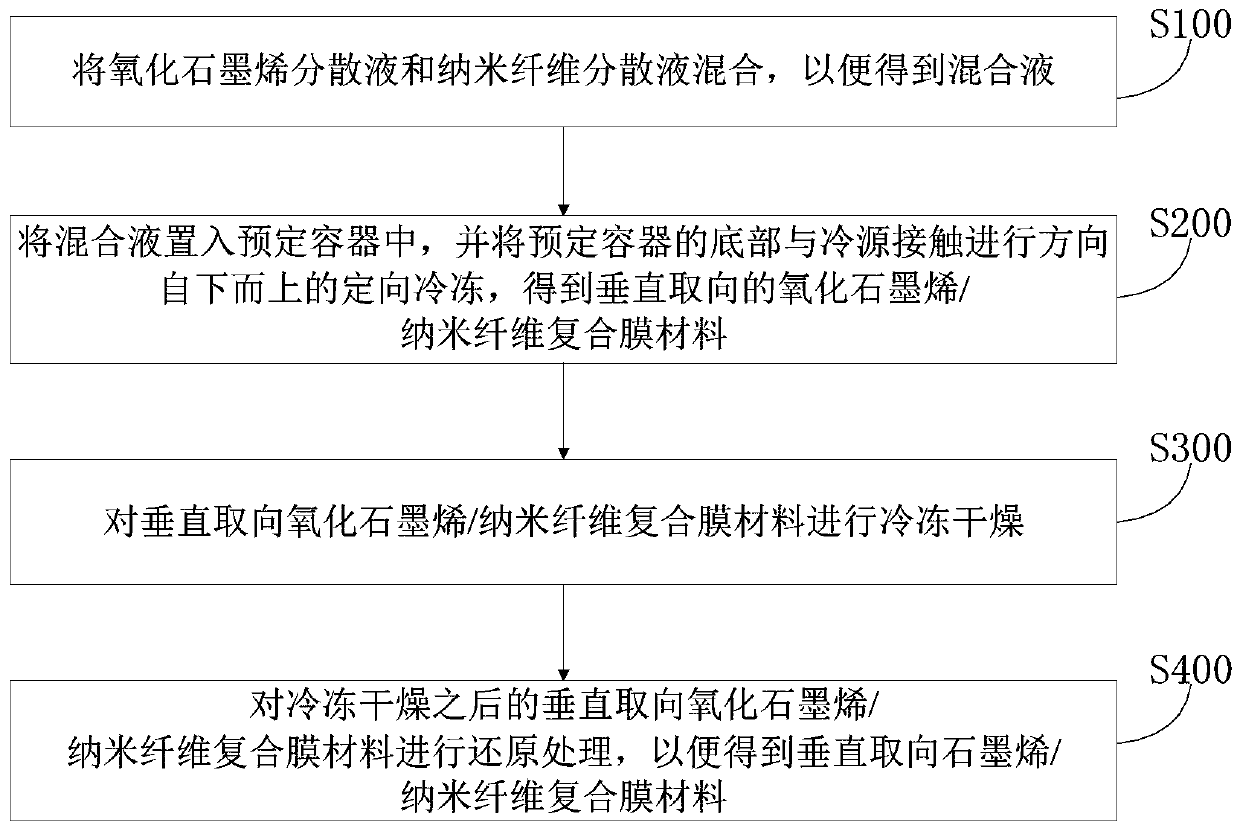

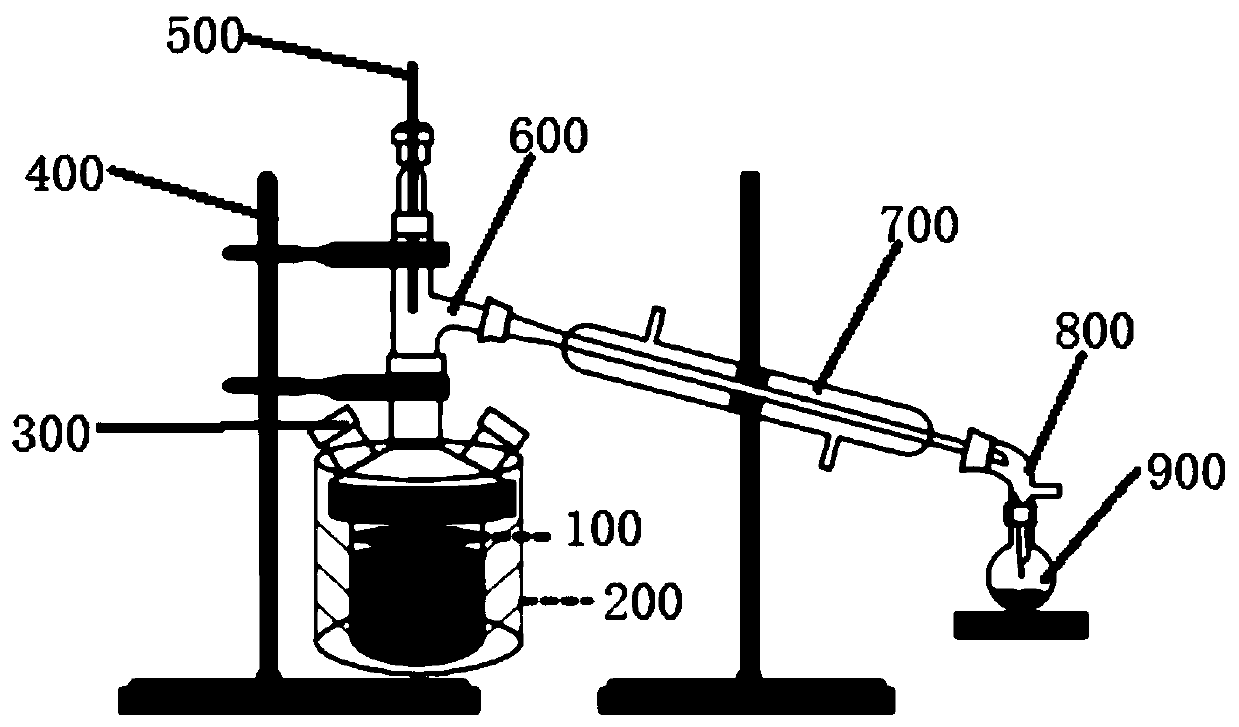

Vertically-oriented graphene/nanofiber composite membrane material and preparation method and application thereof

ActiveCN110773003AImprove distillation efficiencyReduce distillation energy consumptionDistillationFiberNanofiber

The invention provides a vertically-oriented graphene / nanofiber composite membrane material and a preparation method and application thereof. The vertically-oriented graphene / nano-fiber composite membrane material comprises: graphene, which is provided with vertically-oriented channels arranged in an array; and nanofibers, which shuttle back and forth in the graphene and the channels. Therefore, when the composite membrane material is used as a distillation medium, distillation efficiency can be effectively improved, distillation energy consumption is reduced, and distillation time is shortened; moreover, due to the introduction of the nanofibers, the composite membrane material has excellent mechanical properties, so the composite membrane material can be compressed, bent and stretched without its structure not damaged, and thus, the composite membrane material maintains relatively high distillation efficiency for a long time.

Owner:TSINGHUA UNIV

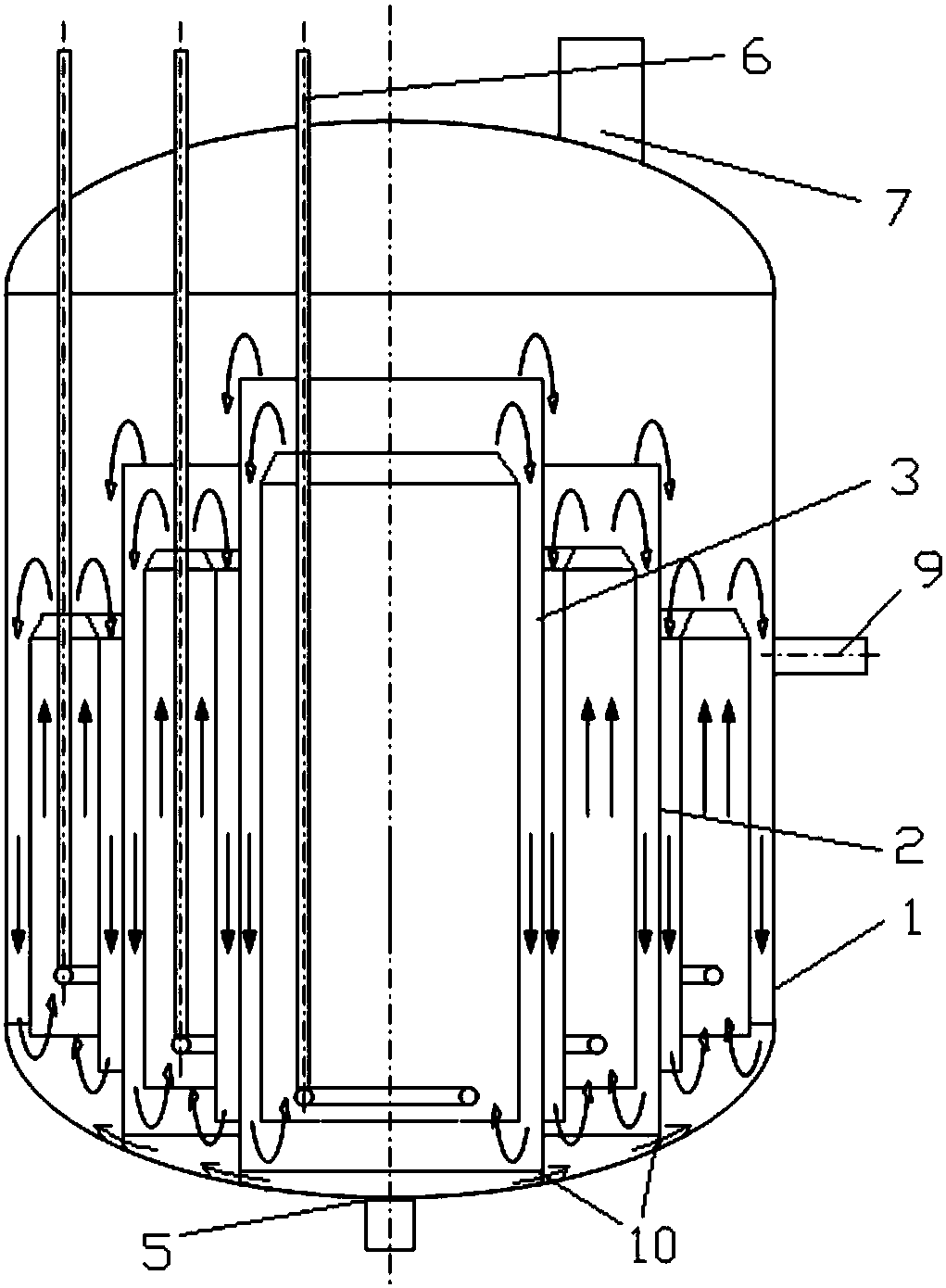

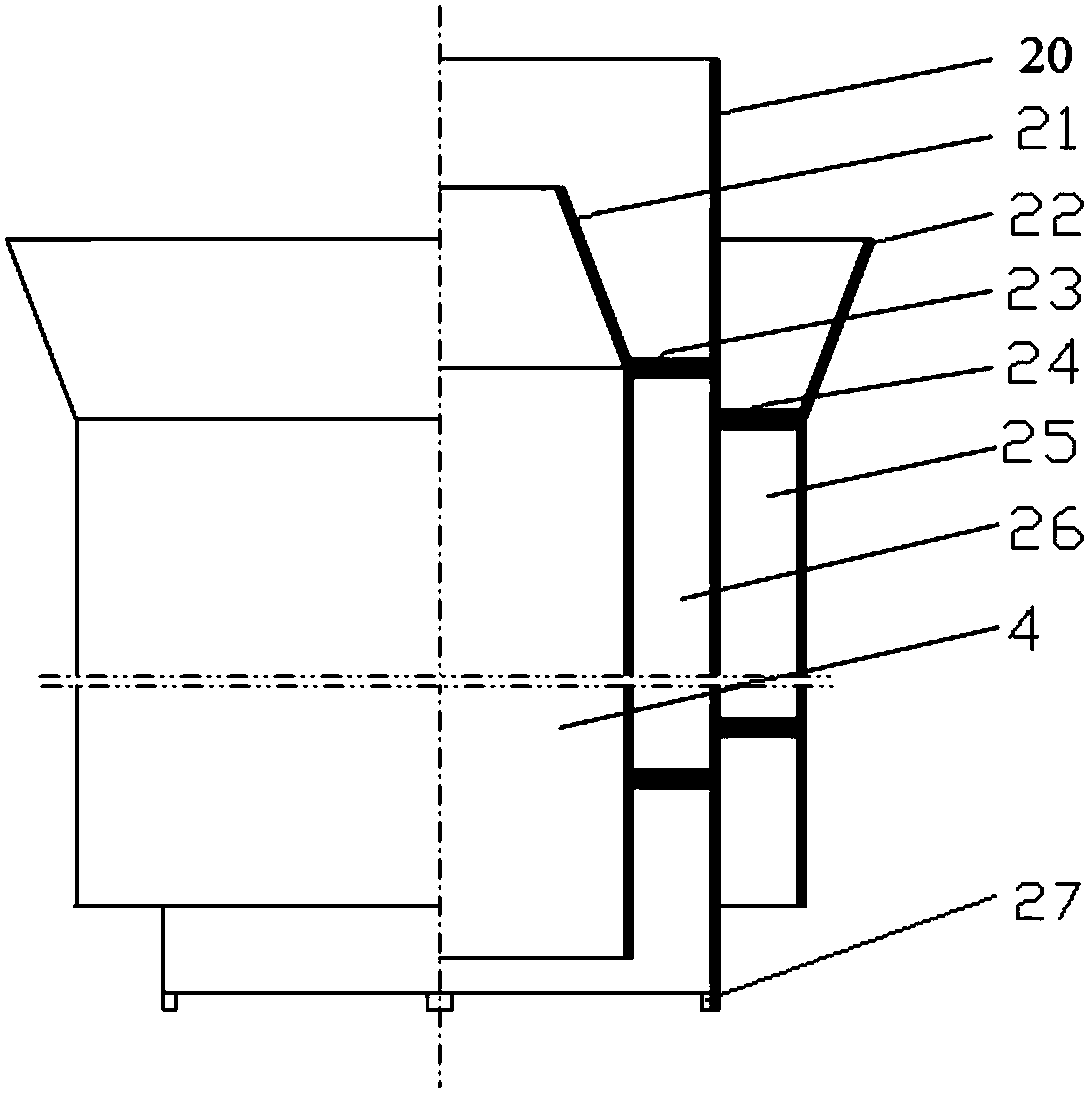

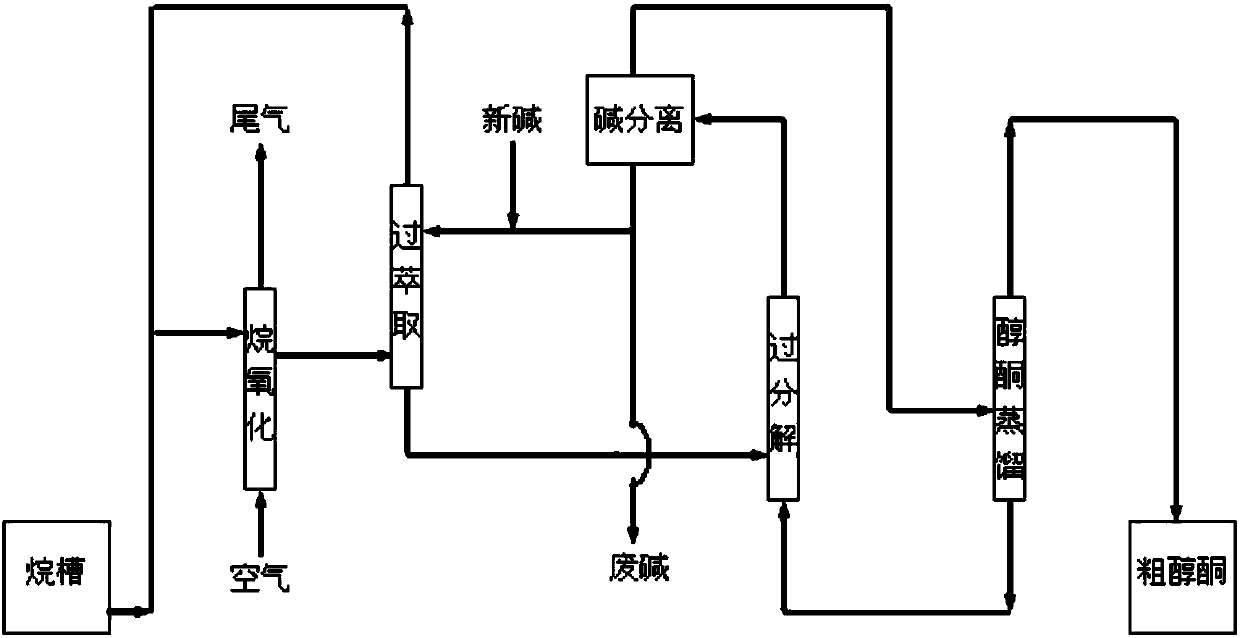

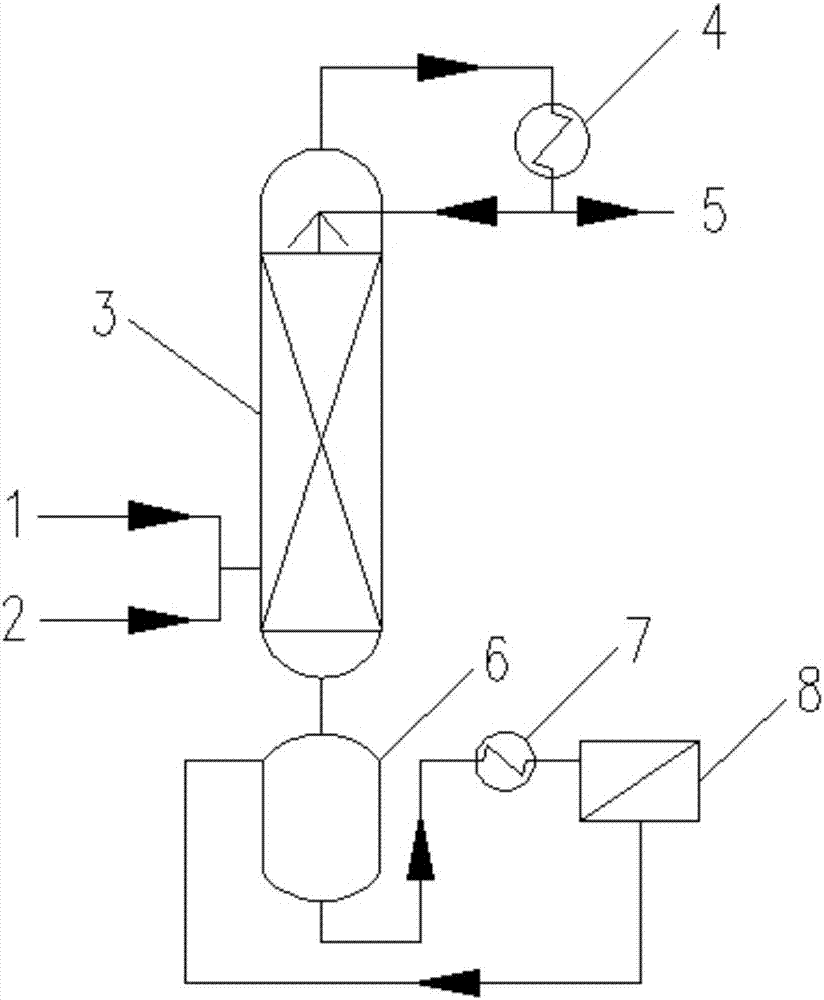

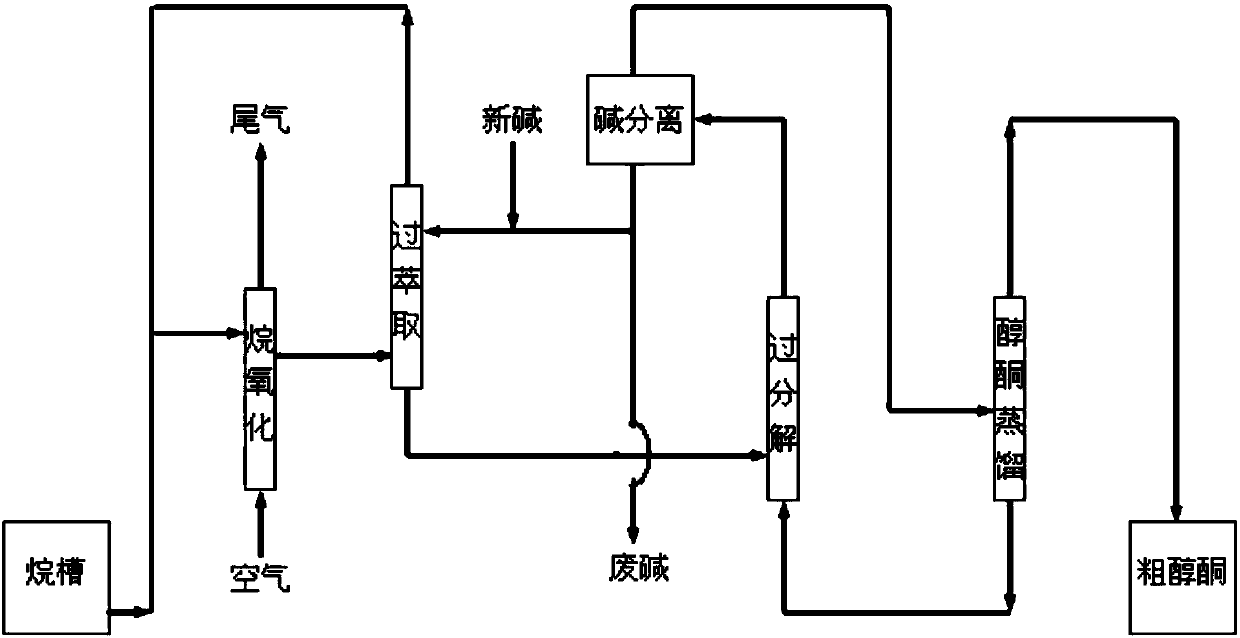

Method for preparing cyclohexanol and cyclohexanone based on multi-layer annular flow guide cylinder bubbling reactor

ActiveCN107778131AAvoid backmixingReduce backmixingOxygen-containing compound preparationLiquid-gas reaction as foam/aerosol/bubblesCyclohexanoneDistillation

The invention discloses a method for preparing cyclohexanol and cyclohexanone based on a multi-layer annular flow guide cylinder bubbling reactor. The method comprises the following steps: in a multi-layer annular flow guide cylinder bubbling reactor, oxidizing cyclohexane with an oxygen-containing gas to generate a cyclohexyl hydroperoxide-containing oxidation liquid, extracting an oxidation liquid with a strong base solution so as to obtain a cyclohexyl hydroperoxide-containing alkali water phase and a cyclohexane organic phase, performing a decomposition reaction on the cyclohexyl hydroperoxide-containing alkali water phase in the presence of a high-melting point solvent, performing sedimentation separation on a decomposition liquid, distilling the cyclohexane organic phase so as to obtain a mixture of cyclohexanol and cyclohexanone, and feeding back the extracted cyclohexane solution to the cyclohexane oxidation reaction process. By adopting the method, the oxidation selectivity and the reaction efficiency of the cyclohexane can be greatly improved, and the cyclohexane distillation energy consumption can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for performing thick mash alcohol fermentation by using cassava dregs and fresh cassava

InactiveCN101899477AImprove equipment utilizationReduce labor productivityFermentationChemistryStarch production

The invention relates to a method for performing thick mash alcohol fermentation by using cassava dregs and fresh cassava. The method comprises the following steps of: pulping the cassava dregs, adding liquifying enzyme, regulating the pH value, heating to liquefy, filtering, and repeating the technical processes until solid matters of the liquefied filter liquor account for 22 to 25 weight percent; and using the filter liquor as grinding solution for the fresh cassava, making the initial total sugar concentration of the grinded pulp reaches 22.5-24.5 (g / 100ml), and liquefying, sterilizing, saccharifying, performing thick mash fermentation and other processes, and finally obtaining maturely fermented raw spirit with the alcohol of 12.5 percent (v / v) or more. The method effectively improves the initial total sugar concentration in cassava alcohol fermentation, and solves the problems of high feed liquid viscosity, poor liquidity, low mass transfer efficiency and difficult continuous production in the thick mash fermentation process, not full utilization of the cassava dregs produced in the cassava starch production process, and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Rectification tower capable of rapidly heating and vaporizing material

ActiveCN109011676AImprove thermal efficiencyUniform temperatureFractional distillationTemperature controlLiquid layer

The invention discloses a rectification tower capable of rapidly heating and vaporizing a material. The rectification tower comprises a rectification tower body, a tower bottom heating vessel and an atomizer arranged in the tower bottom heating kettle, the rectification tower body is provided with a tower top rising gas port and a tower top return port, and the rectification tower body is filled with a packing; the tower bottom heating kettle is provided with a feed inlet and a kettle bottom discharge outlet, an electromagnetic coil is arranged around the outer wall of the tower bottom heatingkettle, and two ends of the electromagnetic coil are connected with a temperature control circuit system; and the atomizer is connected with a feed inlet pipeline of the tower bottom heating kettle,and jet orifices are arranged at the side parts of the atomizer. The rectification tower is especially suitable for rectification separation of high-boiling point heat-sensitive materials, atomizes the material during rectification, and makes atomized liquid drops in direct contact with a heating surface without generating a liquid layer thickness in order to realize high-vacuum vaporization of the material; and the heating and vaporizing are carried out in the form of liquid drops, so the heat exchange efficiency is high, rapid heating and vaporizing of the material are achieved, the residence time of the material on the high temperature surface is shortened, and the material is prevented from denaturing and coking.

Owner:ZHEJIANG UNIV OF TECH

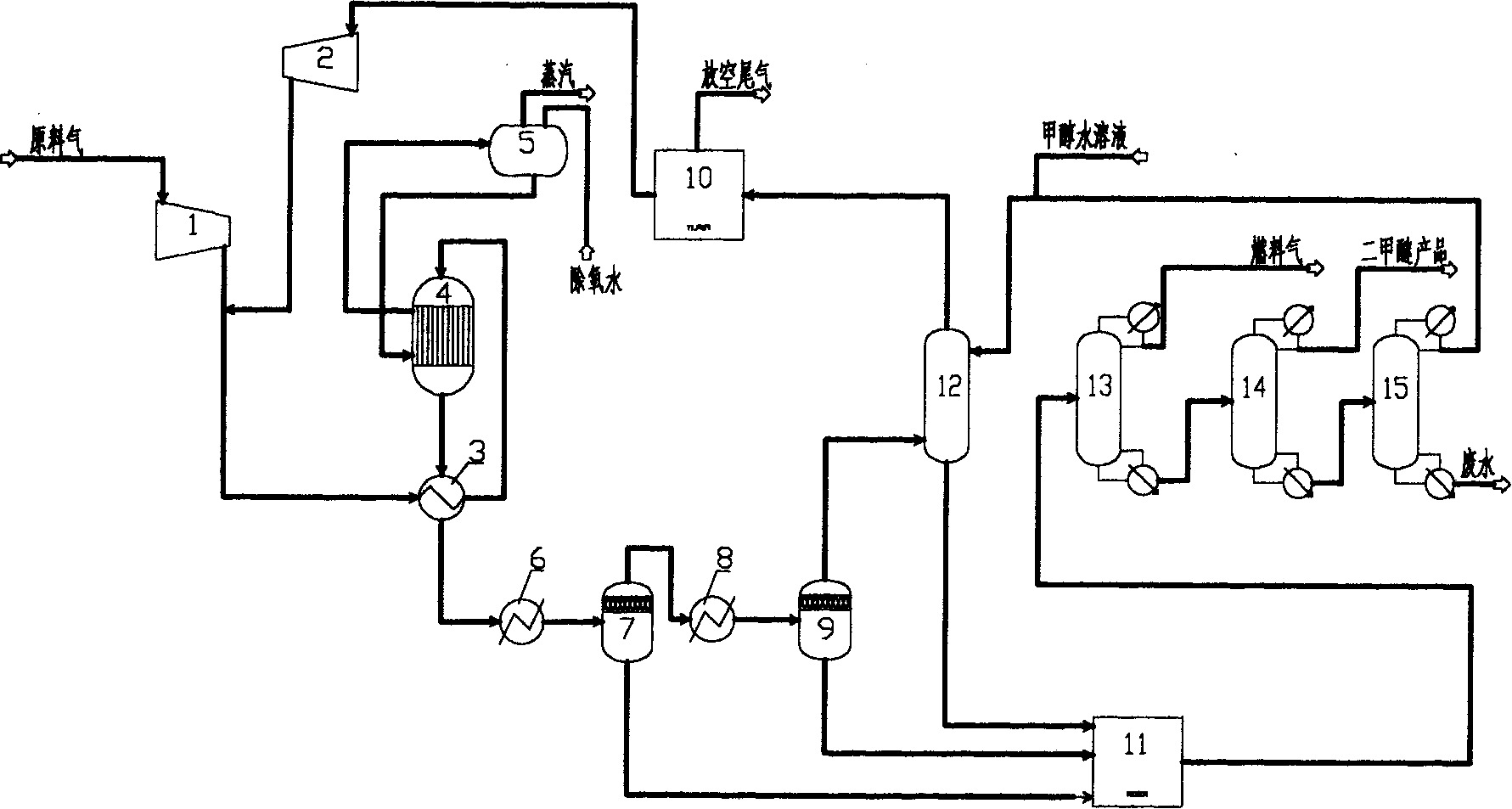

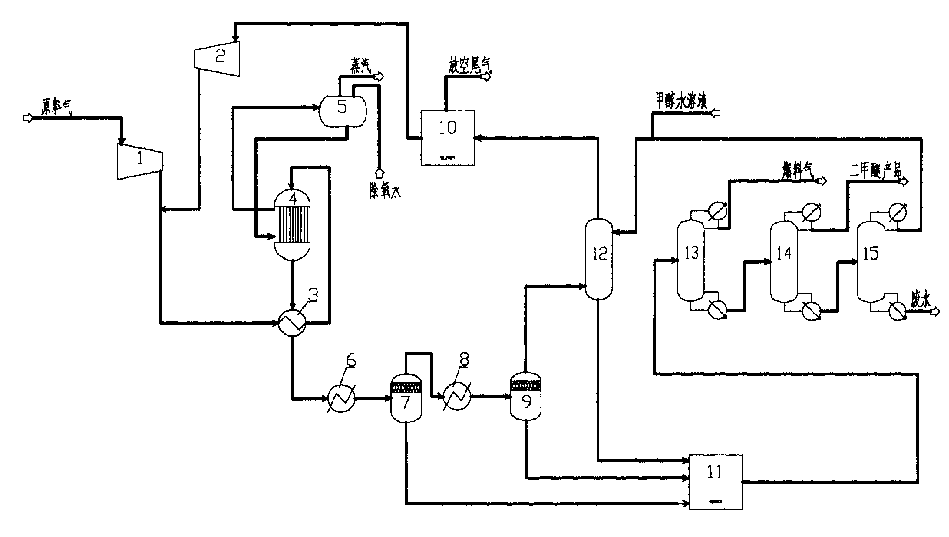

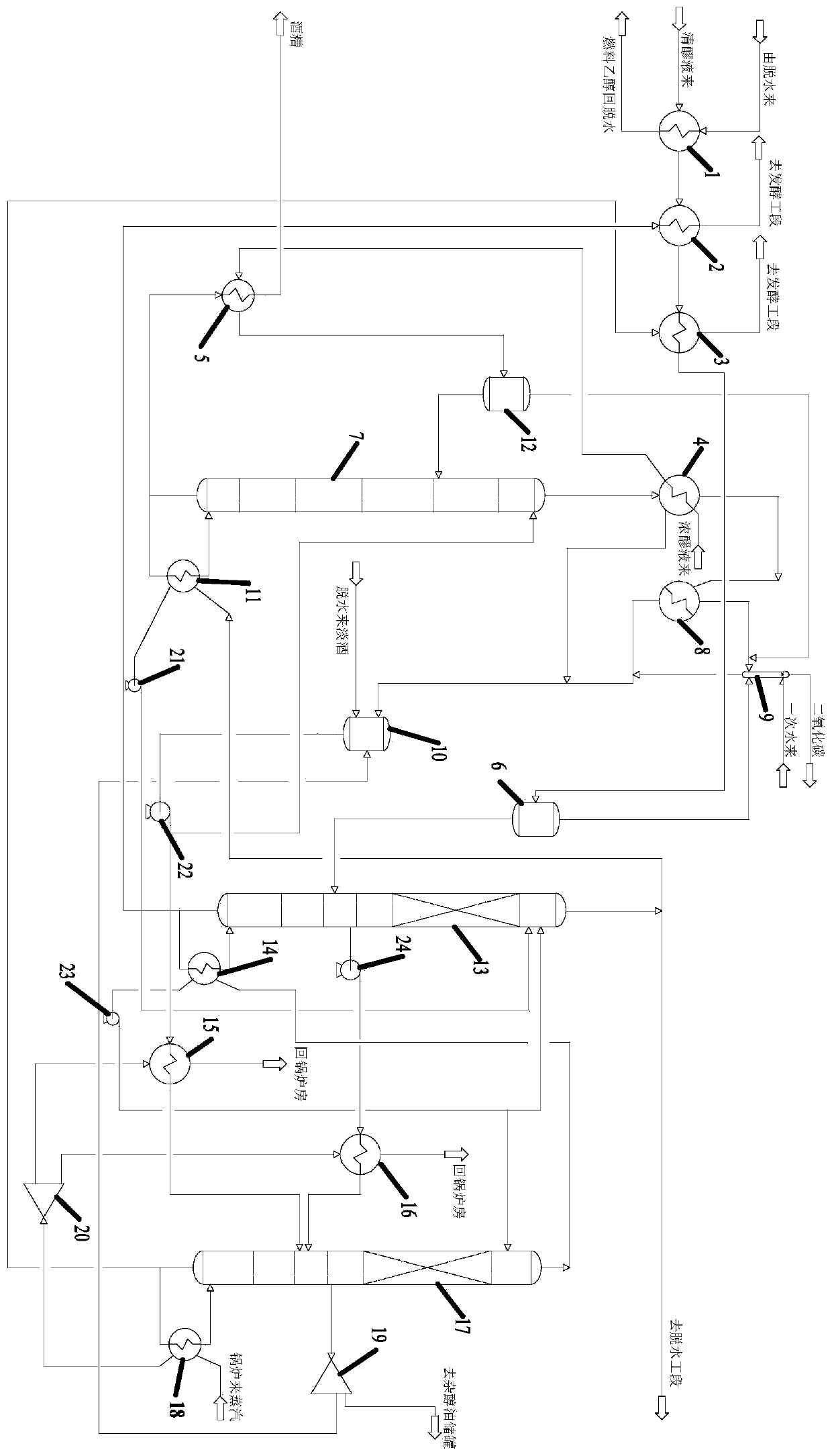

Energy-saving distillation system for preparing ethanol from carbon monoxide and distillation method thereof

PendingCN109908616AEfficient use ofReduce distillation energy consumptionOrganic compound preparationChemical industryChemistryReboiler

The invention discloses an energy-saving distillation system for preparing ethanol from carbon monoxide and a distillation method thereof. The energy-saving distillation system comprises a crude distillation tower I, a composite tower comprising a crude distillation tower II / a rectification tower II, a rectification tower I, as well as a reboiler, a condenser, a heat exchanger, a storage tank, a vacuum pump, a transfer pump and the like which are matched with the rectification tower I, wherein a boiler is used to steam, and the rectification tower I is heated by the reboiler; alcohol vapor atthe tower top of the rectification tower I is supplied to the composite tower for heating; alcohol vapor at the tower top of the composite tower is supplied to the crude distillation tower I for heating; alcohol vapor at the tower top of the crude distillation tower I serves as fermentation thick mash for first-stage preheating; vinasse at the bottom of the crude distillation tower I serves as thick mash for second-stage preheating. By the adoption of a reasonable distillation thermal coupling technology and a three-stage differential pressure distillation technology, the energy-saving distillation system can fully couple usable energy in alcohol production, so that the distillation energy consumption is reduced by about 20% when being compared with that of conventional distillation; the distillation method is simple; energy between the towers is ensured to be fully and effectively used; the energy consumption is low; the production cost is significantly reduced.

Owner:CHINA LIGHT IND XIAN DESIGN ENG

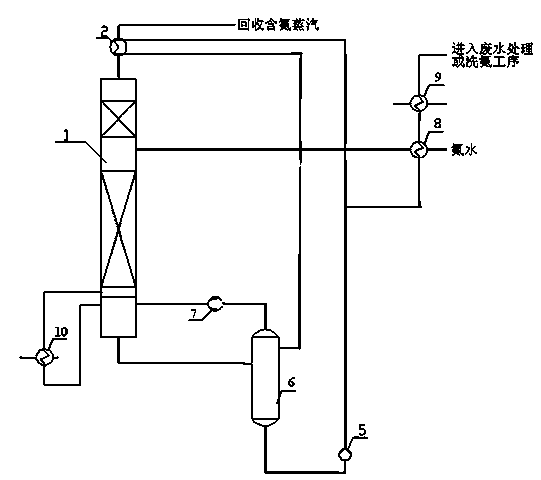

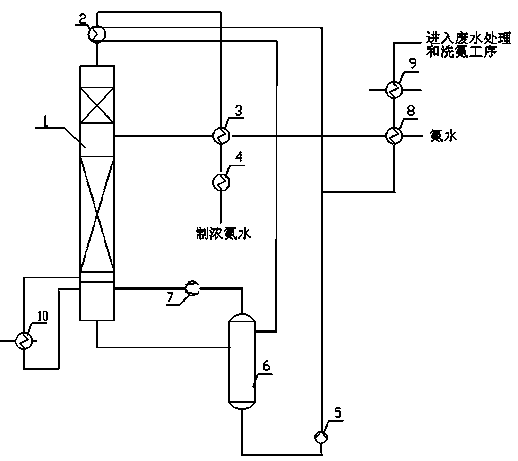

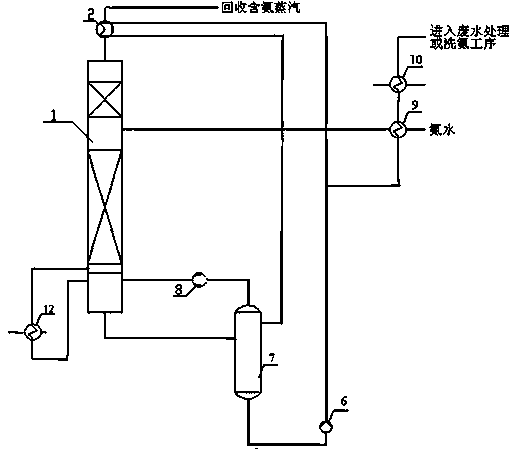

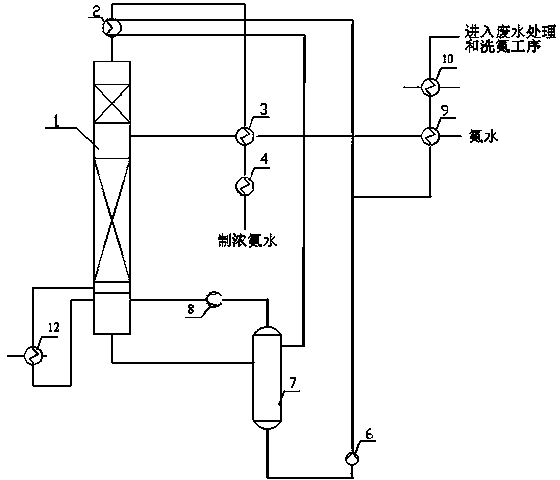

Novel heat pump distillation deamination energy-saving process

ActiveCN104058475AIncrease profitReduce distillation energy consumptionWater/sewage treatment by heatingWater/sewage treatment by degassingDistillationWastewater

The invention provides a novel heat pump distillation deamination energy-saving process. The process comprises the steps of A, carrying out distillation deamination on ammonia water sent from the outsides of a boundary region in an ammonia distillation tower, sending ammonia distillation wastewater at the bottom of the ammonia distillation tower to a flash tower, and carrying out flash distillation in the flash tower; B, sending flash steam generated by the flash distillation into a compressor, and compressing the flash steam by the compressor to do work; and C, sending steam output by the compressor into the bottom in the ammonia distillation tower, forming rising steam needed by distillation with evaporated ammonia distillation wastewater, transferring mass and heat with an ammonia countercurrent decreased from the upper part of the tower to finish the distillation process, carrying out heat exchange on a part of ammonia distillation wastewater after flash distillation and ammonia-containing steam exhausted from the top part of the ammonia distillation tower, recovering the heat of the ammonia-containing steam, returning the ammonia distillation wastewater to the flash tower, carrying out heat exchange on the rest of the ammonia distillation wastewater after flash distillation and the ammonia water which enters the ammonia distillation tower, recovering the heat, water cooling the ammonia distillation wastewater to 35-45 DEG C, then introducing the wastewater into a treating procedure or an ammonia washing procedure. The novel heat pump distillation deamination energy-saving process is a novel deamination distillation process which is simple in the process flow, little in the investment and high in the energy-saving efficiency of 70 percent.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

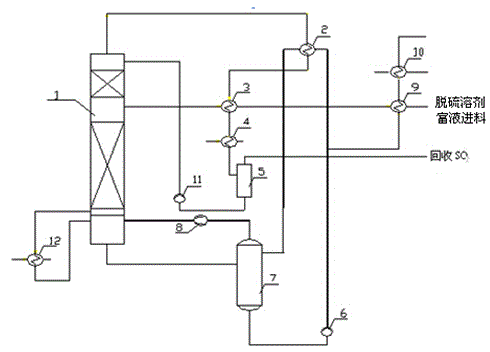

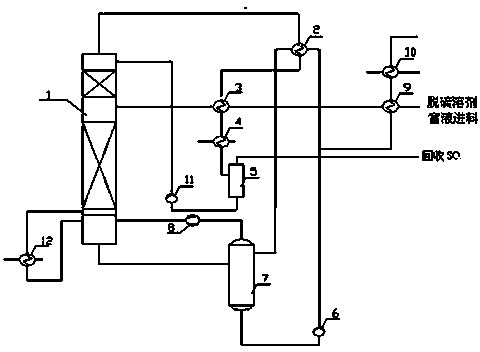

Novel heat pump distillation energy saving process for desulfurization solvent in regenerable flue gas desulfurization

ActiveCN104083885AIncrease profitReduce distillation energy consumptionDispersed particle separationWater/sewage treatment by heatingFractionating columnSolvent

The invention provides a novel heat pump distillation energy saving process for a desulfurization solvent in regenerable flue gas desulfurization. The novel heat pump distillation energy-saving process comprises the following steps that A, SO2 is separated from a pregnant solution of an SO2-containing desulfuration solvent at a desulfuration section in a distillation tower through distillation, and a barren liquor at the bottom of the distillation tower is sent to a flash tower, and is flashed in the flash tower; B, flashing steam generated by the flashing is sent to a compressor, and is compressed by using a compressor to act; and C, steam output from the compressor is sent to the bottom in the distillation tower, and forms raising steam required by the distillation together with vaporized water, the raising steam and the pregnant solution falling from the upper part of the distillation tower reversely flow for performing mass and heat transfer to complete the distillation process, part of flashed barren liquor and the steam discharged from the top of the distillation tower are exchanged with heat, and the barren liquor returns to the flashing tower after the steam heat is recycled, the left flashed barrel liquor and the desulfurization solvent pregnant solution entering the distillation tower are exchanged with the heat, and cooled to 40-55 DEG C through water cooling after the heat of the barren liquor is recycled so as to be sent to a desulfurization section for being recycled. When the distillation is performed by adopting the heat pump distillation process, energy can be saved more than 70 percent in comparison with that of a conventional distillation method.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of hydroxylamine sulfate

ActiveCN106946234AImprove conversion rateHigh yieldChemical industryHydroxylamineFiltrationHydroxylamine sulfate

The invention belongs to the field of chemical engineering and relates to a preparation method of hydroxylamine sulfate. In the preparation method, sulfuric acid and ketoxime are employed as raw materials for producing the hydroxylamine sulfate in a reactive rectification system. The preparation method includes the steps of: (1) adding a sulfuric acid solution and ketoxime to the reactive rectification system to perform reactive rectification; (2) successively withdrawing a distillate from the column top of the reactive rectification system, when concentration of the hydroxylamine sulfate in the reaction liquid reaches 2-8.5 mol / L, performing crystallization and filtration at the same time; and (3) reducing the temperature of the reaction liquid and performing crystallization and filtration. The method for producing the hydroxylamine sulfate is greatly reduced in production energy consumption and achieves zero-emission of process wastewater.

Owner:BEIJING UNIV OF CHEM TECH

Method and device for purifying and recycling emitted argon in preparation process of monocrystalline silicon

ActiveCN103373716BHigh recovery rateImprove reliabilityNitrogen purification/separationNoble gas compoundsAlkaneAutomatic control

The invention relates to a method and device for purifying and recycling emitted argon in a preparation process of monocrystalline silicon. The method comprises the following steps of: collecting crude argon emitted by a monocrystalline silicon furnace and then carrying out compression oil removal treatment, removing carbon monoxide and alkane by adopting a catalytic oxidation method, removing oxygen by adopting a hydrogenation oxygen removing method, removing carbon dioxide and water by adopting an adsorption method, and removing nitrogen and hydrogen by adopting a high-low pressure dual-tower low-temperature distillation method to finally obtain pure compressed argon which can be directly conveyed to the monocrystalline silicon furnace for being recycled. The device comprises a crude argon collecting and pretreating system for carrying out crude oil filtration on the crude argon emitted by the monocrystalline silicon furnace, a compression oil removing system for filtering refine oil, a catalytic reaction system for removing carbon monoxide, alkane and oxygen components, a crude argon purifying system for removing the carbon dioxide and the water, a low-temperature distillation system for removing the nitrogen and hydrogen components, an air treating system for providing a raw material air source for a process of preparing the nitrogen by the low-temperature distillation system, and an automatic control system for controlling the whole set of device. The method and device can realize that a large quantity of protection argon in the monocrystalline silicon industry is recovered and recycled.

Owner:HANGZHOU HANGYANG

Method for preparing cyclohexanol and cyclohexanone based on multi-layer guide cylinder bubbling reactor

ActiveCN107778132AImprove circulation rateImprove oxidation reaction efficiencyOrganic compound preparationOxygen compounds purification/separationCyclohexanoneDistillation

The invention discloses a method for preparing cyclohexanol and cyclohexanone based on a multi-layer guide cylinder bubbling reactor. The method comprises the following steps: in a multi-layer guide cylinder bubbling reactor, oxidizing cyclohexane with an oxygen-containing gas to generate a cyclohexyl hydroperoxide-containing oxidation liquid, extracting an oxidation liquid with a strong base solution so as to obtain a cyclohexyl hydroperoxide-containing alkali water phase and a cyclohexane organic phase, performing a decomposition reaction on the cyclohexyl hydroperoxide-containing alkali water phase in the presence of a high-melting point solvent, performing sedimentation separation on a decomposition liquid, distilling the cyclohexane organic phase so as to obtain a mixture of cyclohexanol and cyclohexanone, and feeding back the extracted cyclohexane solution to the cyclohexane oxidation reaction process. By adopting the method, the oxidation selectivity and the reaction efficiencyof the cyclohexane can be greatly improved, and the cyclohexane distillation energy consumption can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

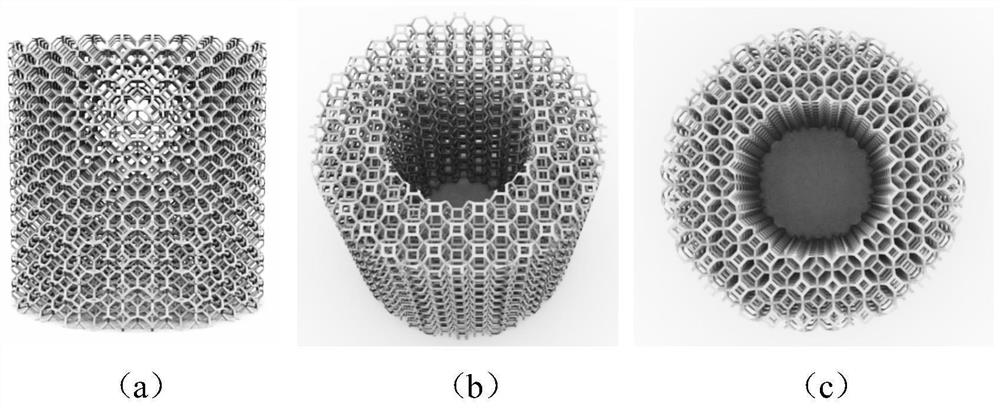

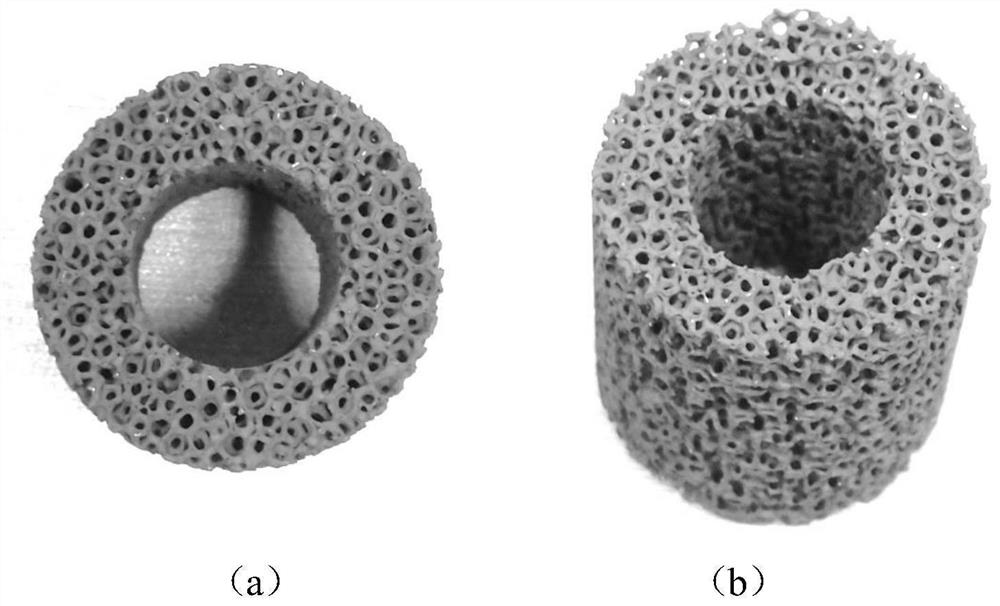

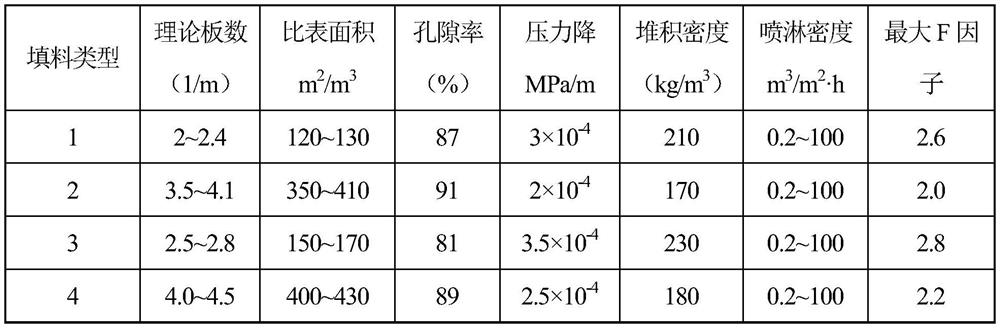

Silicon carbide random filler with porous structure, and preparation method thereof

The invention mainly relates to the field of chemical fillers, and especially to a silicon carbide random filler with a porous structure, and a preparation method thereof. The random filler is made of silicon carbide and is porous in structure. The filler mainly comprises, by mass, 70-100% of silicon carbide, 0-15% of carbon, 0-30% of silicon and 0-10% of silicon dioxide. The filler has the following characteristics: 1, the filler has better corrosion resistance than a common oxide ceramic filler, and can work in corrosive environments of sulfuric acid, nitric acid, hydrochloric acid, hydrofluoric acid and the like for a long time; 2, the filler can be provided with a three-dimensional communicated pore structure, and pores can be of a regular tetrakaidecahedron-like foamed structure and can also be of a quadrangle or a hexagon or the like; and 3, the random silicon carbide filler has developed pores, large specific surface area and small density, and the rectification efficiency is superior to that of the common ceramic filler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Novel energy-saving distillation technology of heat pump

ActiveCN104056461AIncrease profitReduce distillation energy consumptionFlash distillationFractional distillationProcess engineeringWater cooling

The invention provides a novel energy-saving distillation technology of a heat pump, aiming at reducing the device energy consumption of distillation of the heat pump and simplifying the process. The technology comprises the following steps: A. conveying a kettle solution at the bottom of a distillation column to a flash column, and performing flashing in the flash column; B. introducing flashing steam generated by flashing into a compressor, and carrying out compression on the flashing steam for acting by the compressor; C. introducing steam output by the compressor to the bottom in the distillation column, forming rising steam required for distillation by the steam output by the compressor and a vaporized kettle solution, and transferring mass and heat between the rising steam and a liquid declining from the upper part of the distillation column in a backflow mode to complete the distillation process; exchanging heat between partial kettle solution subjected to flashing with steam discharged from the top of the distillation column, and returning to the flash column after recycling heat of the steam; and exchanging heat of the residual kettle solution subjected to flashing with a material liquid entering the distillation column, and carrying out water cooling and recycling after recycling the heat of the kettle solution. The novel distillation technology provided by the invention is simple in technological process, low in investment and high in energy saving efficiency, and can save more than 70% of energy compared with a traditional distillation method.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing levulinic acid from steam explosion produced straw short fiber by adding polymerization inhibitor and performing solid acid catalysis

InactiveCN102675086ASmall granularityLarge specific surface areaOrganic compound preparationChemical recyclingFiberChemical industry

The invention discloses a method for preparing levulinic acid from steam explosion produced straw short fiber by adding polymerization inhibitor and performing solid acid catalysis. The method comprises the steps of using the straw short fiber which is produced by the steam explosion, performing hydrolysis to the straw short fiber tissue by using solid acid catalyst instead of liquid acid to obtain intermediate products such as hexose and the like, then dehydrating the hexose to obtain hydroxymethyl furfural, and finally performing ring opening and hydration to hydroxymethyl furfural to obtain the levulinic acid. The polymerization inhibitor of p-hydroxyanisole is added after optimization of conditions and pre-enzymolysis. The yield of levulinic acid reaches 25.2%, and the yield is 68.7 % of the theoretical yield. The reaction condition of the method is mild, and the catalyst shows high activity. The product does not contain inorganic acid, so that the product does not produce a lot of waste residue and corrode equipment. The catalyst can be separated from raw materials and the product easily, and accords with today's chemical industry green development direction. And also, the whole straw is no longer low-value used. Instead, the long fiber and the short fiber of the straw are separated to carry out stratified multistage directional transformation to achieve the diversification of straw products and high-value utilization of resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

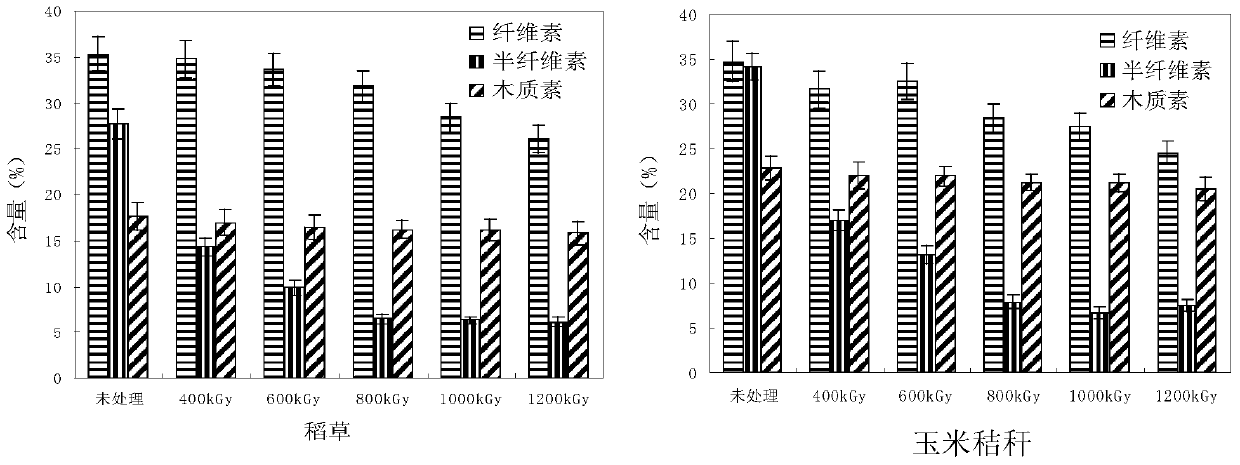

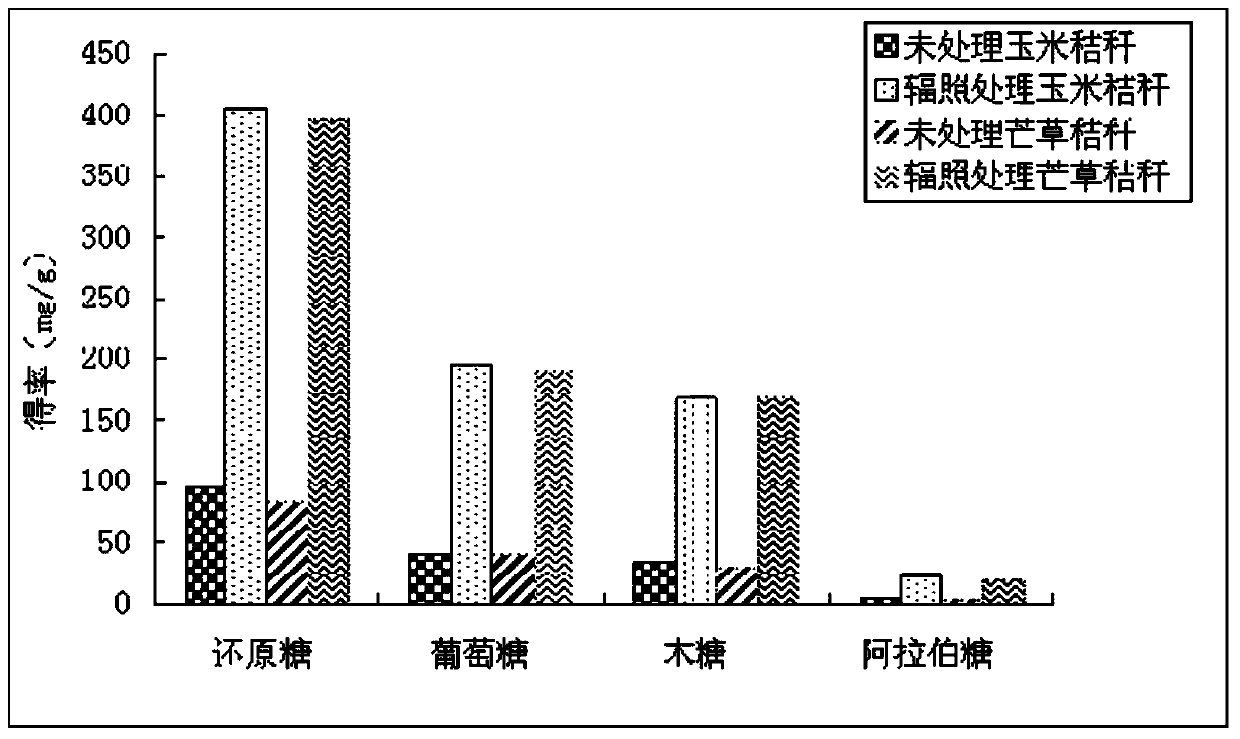

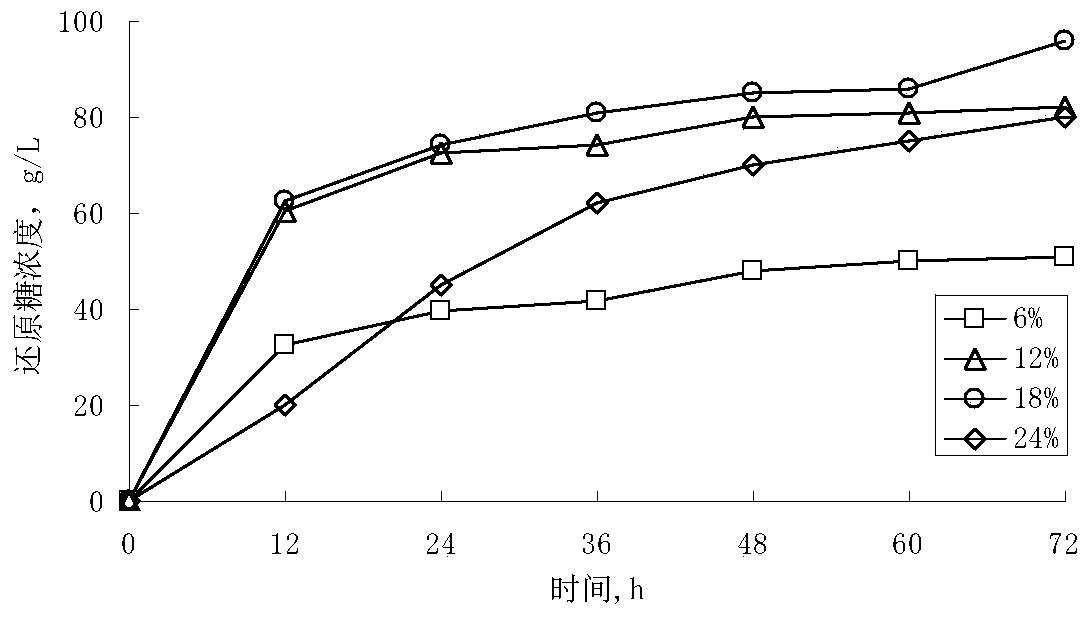

A method of irradiation pretreatment and batch feeding to realize enzymatic hydrolysis of lignocellulose with high substrate concentration

The invention discloses a method for realizing enzymatic hydrolysis of lignocellulose with high substrate concentration through irradiation pretreatment and feeding in batches. It uses the lignocellulosic raw material pretreated by high-dose ray irradiation as the substrate, and adopts the strategy of feeding in batches and adding cellulase in batches to increase the substrate concentration in the enzymatic hydrolysis system, so as to obtain high-concentration reducing sugar. Hydrolyzate. The advantage of the present invention is that the ray irradiation pretreatment technology has the advantages of simple operation, clean and pollution-free, can be carried out under normal temperature and pressure, no material loss, and remarkable effect, and adopts the strategy of feeding in batches to greatly improve the enzymatic hydrolysis system. The concentration of the substrate in the medium can make the concentration of the treated substrate reach 36%. While increasing the concentration of the enzymatic hydrolysis raw material, a high concentration of reducing sugar can be obtained. The high concentration of reducing sugar in the obtained enzymatic hydrolyzate can reach more than 200g / L, which has reached the advanced level at home and abroad. Level. The obtaining of high-concentration reducing sugar enzyme hydrolyzate of lignocellulose can improve the high-concentration ethanol fermentation in the later stage and reduce the energy consumption of ethanol distillation, thereby reducing the production cost of fiber fuel ethanol.

Owner:HUNAN AGRICULTURAL UNIV

Flow-control-free intermittent fine distillation method and apparatus

Owner:GUANGXI UNIV

A rectification tower that can realize rapid temperature rise and vaporization of materials

ActiveCN109011676BImprove thermal efficiencyUniform temperatureFractional distillationLiquid layerTemperature control

The invention discloses a rectification tower capable of realizing rapid temperature rise and vaporization of materials, which comprises a rectification tower body, a tower bottom heating kettle and an atomizer arranged inside the tower bottom heating kettle, and the rectification tower body is provided with a tower top The gas-rising port and the top reflux port, the interior of the rectification tower body are provided with fillers; the heating tank at the bottom of the tower is provided with a feed inlet and a discharge port at the bottom of the tank, and an electromagnetic coil is wound on the outer wall of the heating tank at the bottom of the tower. The two ends are connected with a temperature control circuit system; the atomizer is connected with the feed inlet pipeline on the heating tank at the bottom of the tower, and the side of the atomizer is provided with a spray port. The rectification tower of the present invention is especially suitable for rectification and separation of high-boiling point and heat-sensitive materials. During rectification, the materials are atomized, and the atomized liquid droplets are in direct contact with the heating surface, without generating a liquid layer thickness, and realizing high-vacuum vaporization of the materials. ;At the same time, it is heated and vaporized in the form of droplets, with high heat exchange efficiency, which can realize rapid heating and vaporization of materials, reduce the residence time of materials on high-temperature surfaces, and prevent denaturation and coking of materials.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com